Piezoelectric driving-based crawling actuator and working method thereof

A technology of piezoelectric drive and working method, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Fast speed and other issues, to achieve the effect of small size, large load and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

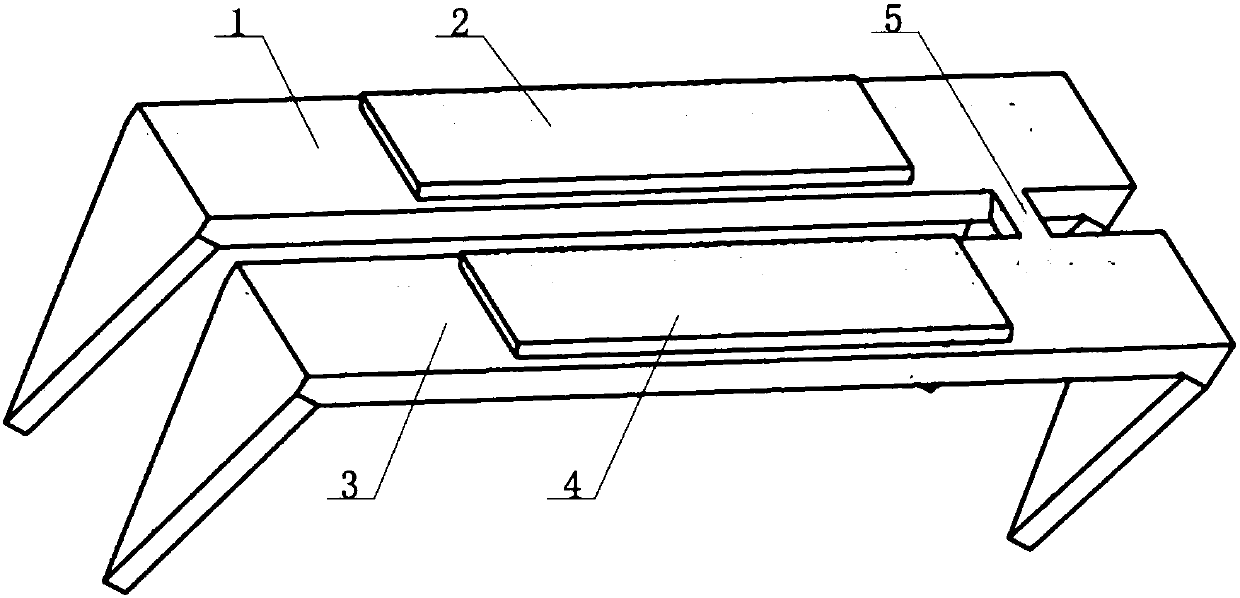

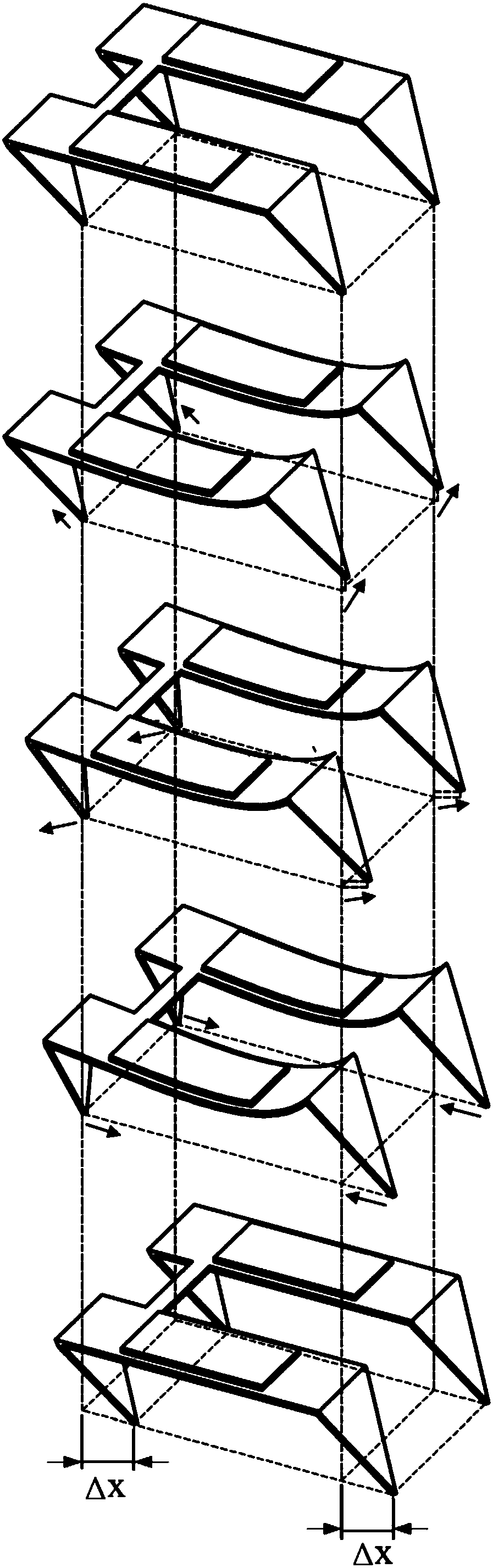

[0031] The creeping actuator based on piezoelectric drive includes: a first phosphor bronze substrate 1 , a first piezoelectric ceramic sheet 2 , a second phosphor bronze substrate 3 , a second piezoelectric ceramic sheet 4 , and a connecting rod 5 .

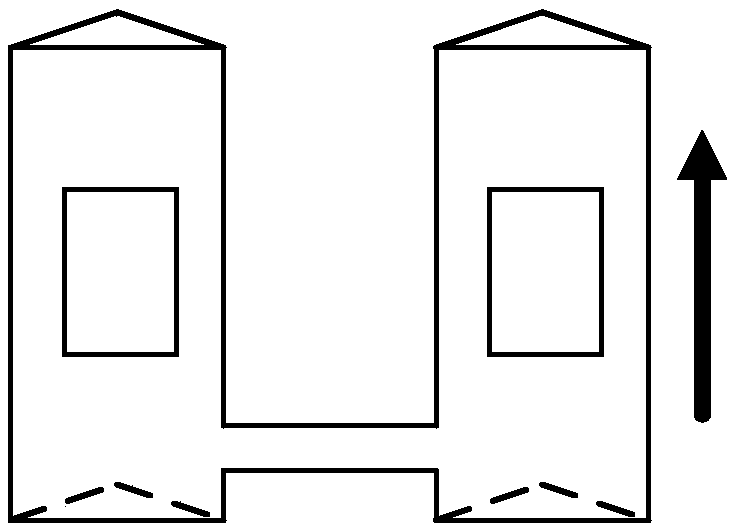

[0032] The first phosphor bronze substrate 1 and the second phosphor bronze substrate 3, the shape and size of the first piezoelectric ceramic sheet 2 and the second piezoelectric ceramic sheet 4 are all the same, the first piezoelectric ceramic sheet 2 and the second piezoelectric ceramic sheet 4 is a rectangle. Both ends of the first phosphor bronze base body 1 and the second phosphor bronze base body 3 are provided with legs, and the shape of the legs is an equilateral triangle.

[0033] A first pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com