Tin phosphorus bronze band and preparation method thereof

A technology of tin-phosphorus bronze strip and tin-phosphorus bronze, which is applied in the field of tin-phosphorus bronze strip and its preparation, can solve the problems of strength and hardness reduction, cracking, and prone to bulging of vapor chambers, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

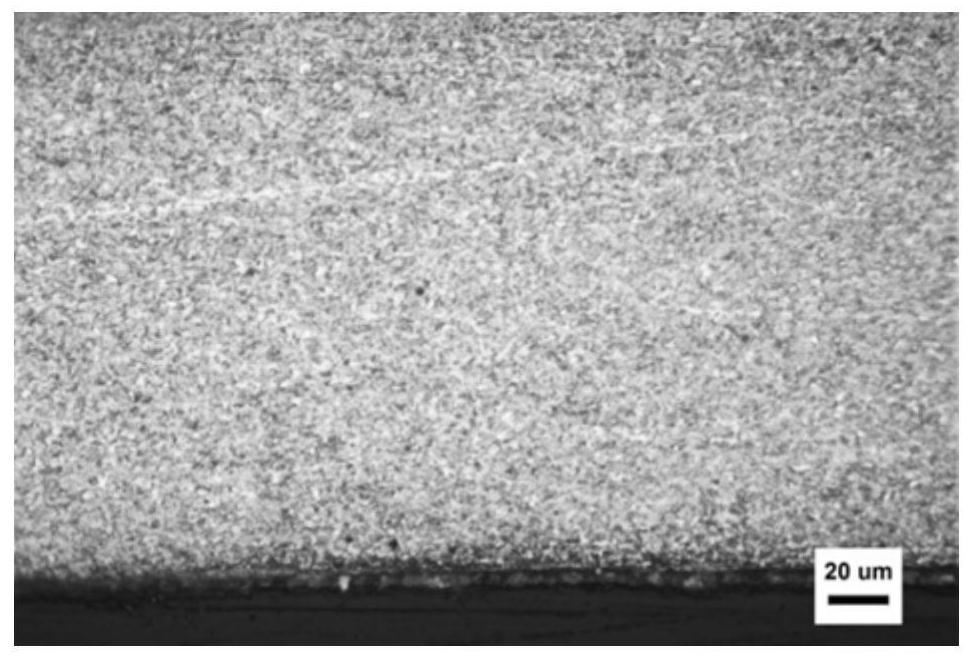

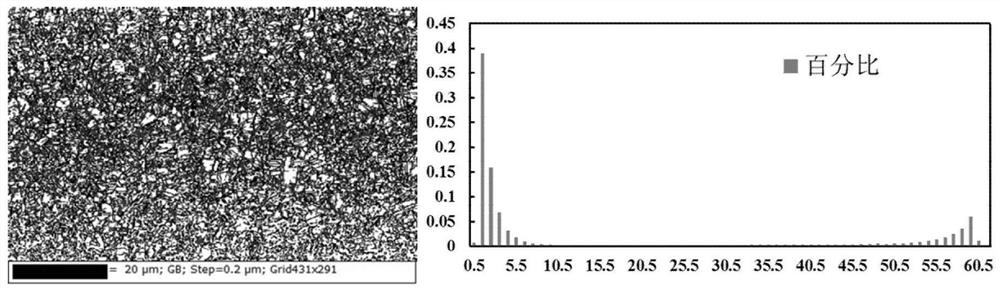

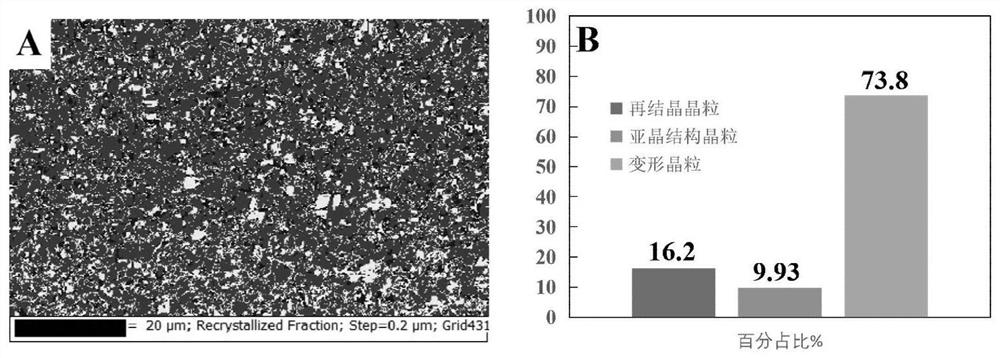

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] Select 15 examples and 6 comparison examples. The alloy composition of the examples and comparison examples is as shown in Table 1. The examples are prepared according to the process flow of the tin phosphor bronze strip of the present invention. The preparation process is: smelting→casting→homogenizing annealing→ Face milling→rough rolling→intermediate annealing→pickling→intermediate rolling→first air cushion furnace annealing→finish rolling→second air cushion furnace annealing→finished product rolling→low temperature annealing→stretch bending straightening, the specific process is:

[0030] (1) Melting: Feed materials in the order of copper, iron, nickel, and tin. After all of them are melted, add phosphor-bronze master alloy with a composition requirement of 50% mass, and perform slag removal, and then cover and bake on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com