Liquid discharge device and discharge method

A technology of liquid and liquid supply, applied in the direction of liquid injection device, injection device, spray conveying, etc., can solve the problem of changing the mixing ratio design without precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

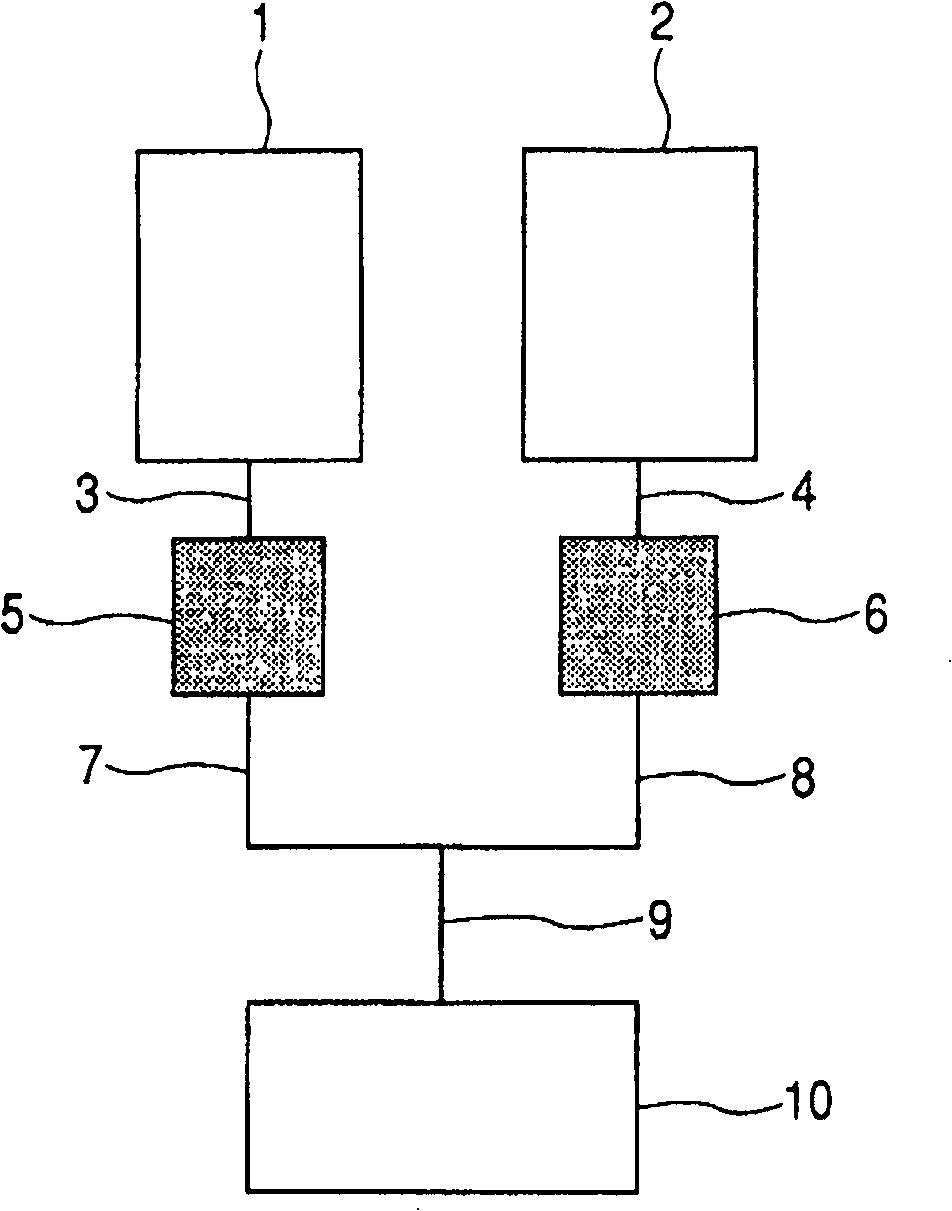

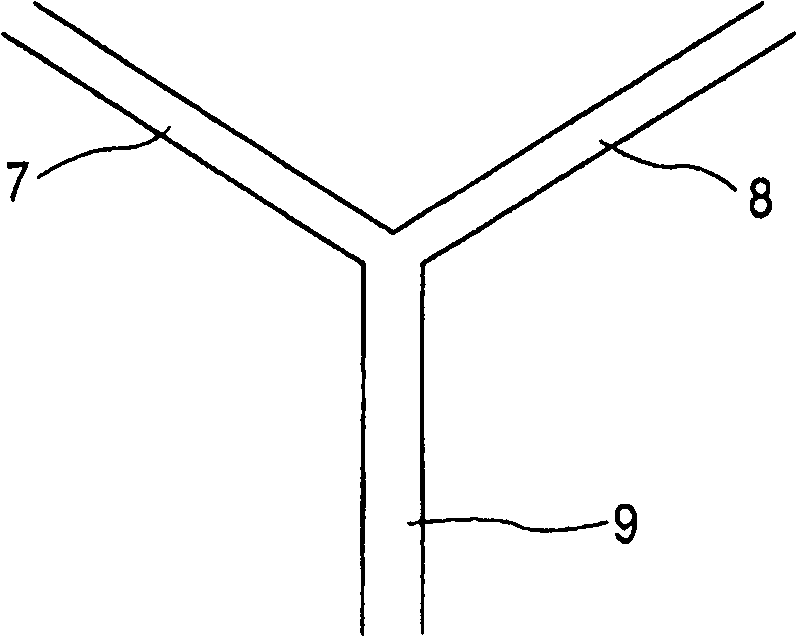

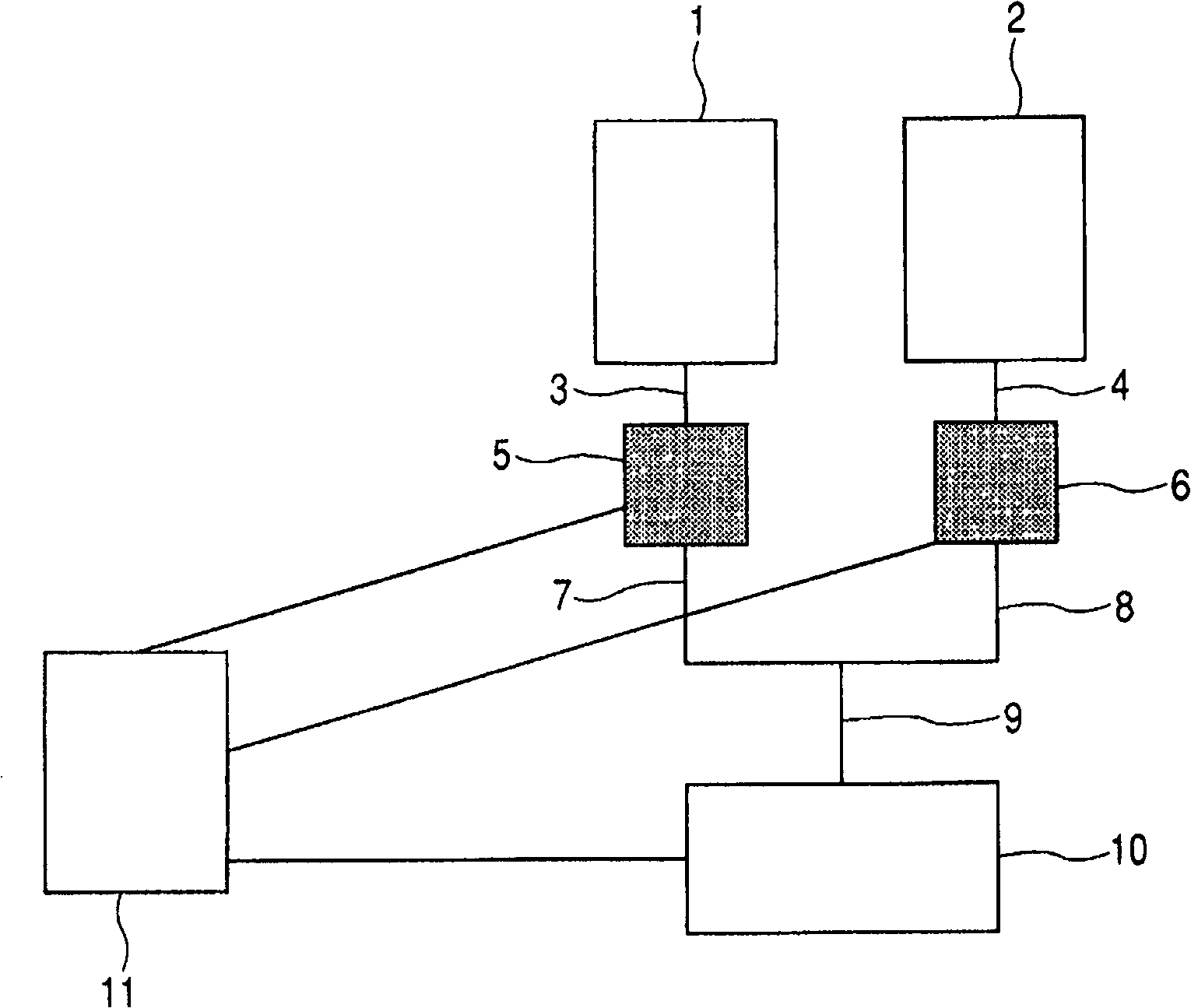

Method used

Image

Examples

example 1

[0064] Storage parts 1 and 2 were filled with solution A and solution B described below, respectively. In addition, piezoelectric pumps are used in the liquid supply parts 5 and 6, respectively. This pump is limited to delivering 50 microliters of liquid when the pump is actuated at 50 Hz for one second. For the actual actuation of the pumps, the frequencies of the pumps for solutions A and B were set to 40 Hz and 10 Hz, respectively, and activated simultaneously for one second to deliver 4 microliters of solution A and 1 microliter of solution B, respectively.

[0065] Solution A: 4mg / ml insulin in water

[0066] Solution B: 20mg / ml lauryl sarcosine aqueous solution

[0067] The ejection unit 10 used had 400 nozzles with a nozzle diameter of 3 micrometers. The mixed liquid was atomized for one second, and then atomized again at intervals of 4 seconds, whereby a total of 50 atomizations were performed. For repeated atomization, liquid supply and liquid supply are appropria...

example 2

[0081] In Example 1, the substance in solution B was changed to arginine, the pump setting was changed to 40 Hz, and the amount of liquid to be delivered was changed to 4 microliters. Since both liquid supply components have the same drive frequency, the liquid supply components are controlled such that their actuation timings are staggered. In addition, after storage of solutions A and B at 30°C for two months, the same evaluation was carried out by nebulization as in Example 1. It turned out that all 50 atomization trials were successful. Furthermore, in terms of the concentration ratio of the liquids to be mixed and supplied, a ratio of 0.08 was obtained.

example 3 to example 5

[0083] In Example 2, the liquid contents were changed to those shown in Table 1, and then evaluated in the same manner as in Example 2. The results obtained are shown in Table 1. That is, it was found that the mixing ratio can be precisely controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com