Circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder

A circulating fluidized bed and fluorite powder technology, which is applied in the field of circulating fluidized bed technology, can solve the problems of excessive dispersant entrainment and difficulty in separation, and achieve the goal of inhibiting particle agglomeration and wall sticking, low conversion rate and high degree of wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

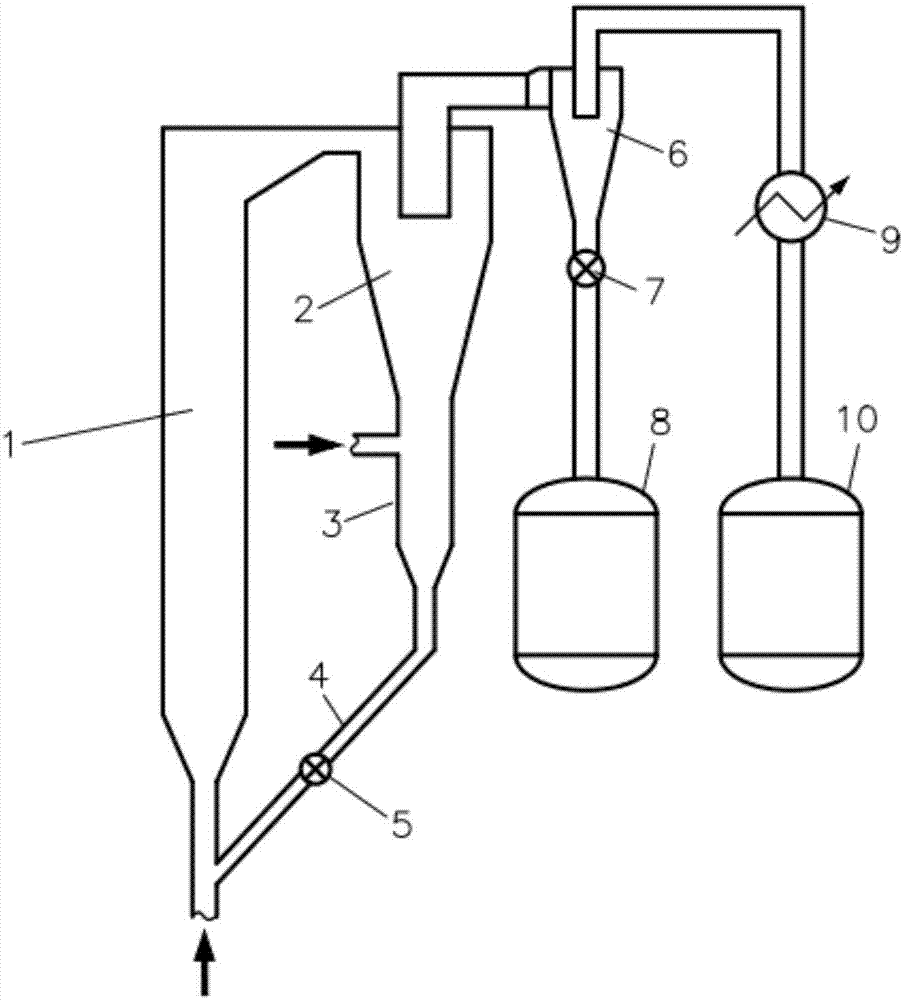

Embodiment 1

[0035] The mixed gas of sulfur trioxide, water vapor and HF with a molar ratio of 1:1:1.5 is used as the raw material gas, preheated to 300 degrees Celsius, at 10.0m 3 / h gas velocity enters the reactor inlet pipe, mixes with circulating solids and enters the reactor for reaction. The reactor operates at a temperature of 350 degrees Celsius and a pressure of 1.2 bar. The output reaction product with incompletely reacted solid enters the circulation part, and enters a cyclone separator to separate incompletely reacted solid particles with larger particle size. The pressure drop of the primary cyclone separator is 0.05bar. Sinking solids enter the solids settling section, while gases and smaller solid particles with high conversion rates enter the solids separation section. The solid entering the solid settling section enters the inlet pipe through the lower inclined pipe and the control valve on it, mixes with the reaction gas and circulates back to the reactor. The length o...

Embodiment 2

[0039] Sulfuric acid vapor with a mass fraction of 98% and HF gas are mixed at a molar ratio of 1:1.5 as raw material gas, preheated to 350 degrees Celsius, and 8.0m 3 / h gas velocity enters the reactor inlet pipe, mixes with circulating solids and enters the reactor for reaction. The reactor operates at a temperature of 350 degrees Celsius and a pressure of 0.95 bar. Micro-negative pressure can reduce the chance of leakage of dangerous reactants and products. The reaction product with incompletely reacted solids produced by the reactor enters the circulation part, and the incompletely reacted solid particles with larger particle sizes are separated by the primary cyclone separator. The pressure drop of the primary cyclone separator is 0.05 bar. Sinking solids enter the solids settling section, while gases and smaller solid particles with high conversion rates enter the solids separation section. The solid entering the solid settling section enters the inlet pipe through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com