Heat pipe and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

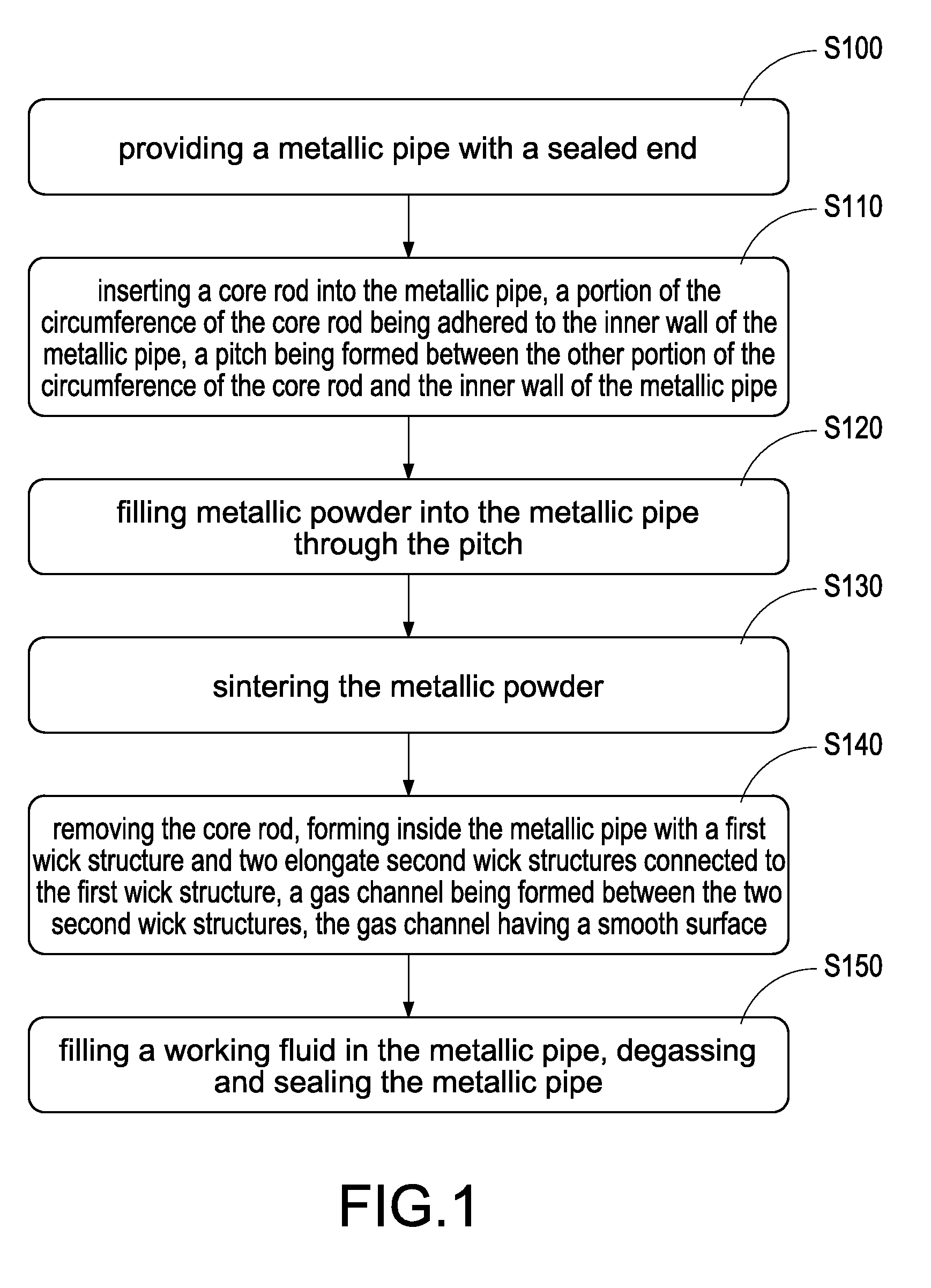

[0031]The characteristics and technical contents of the present invention will be explained in more detail with reference to the accompanying drawings. However, the drawings are illustrative only but not used to limit the present invention.

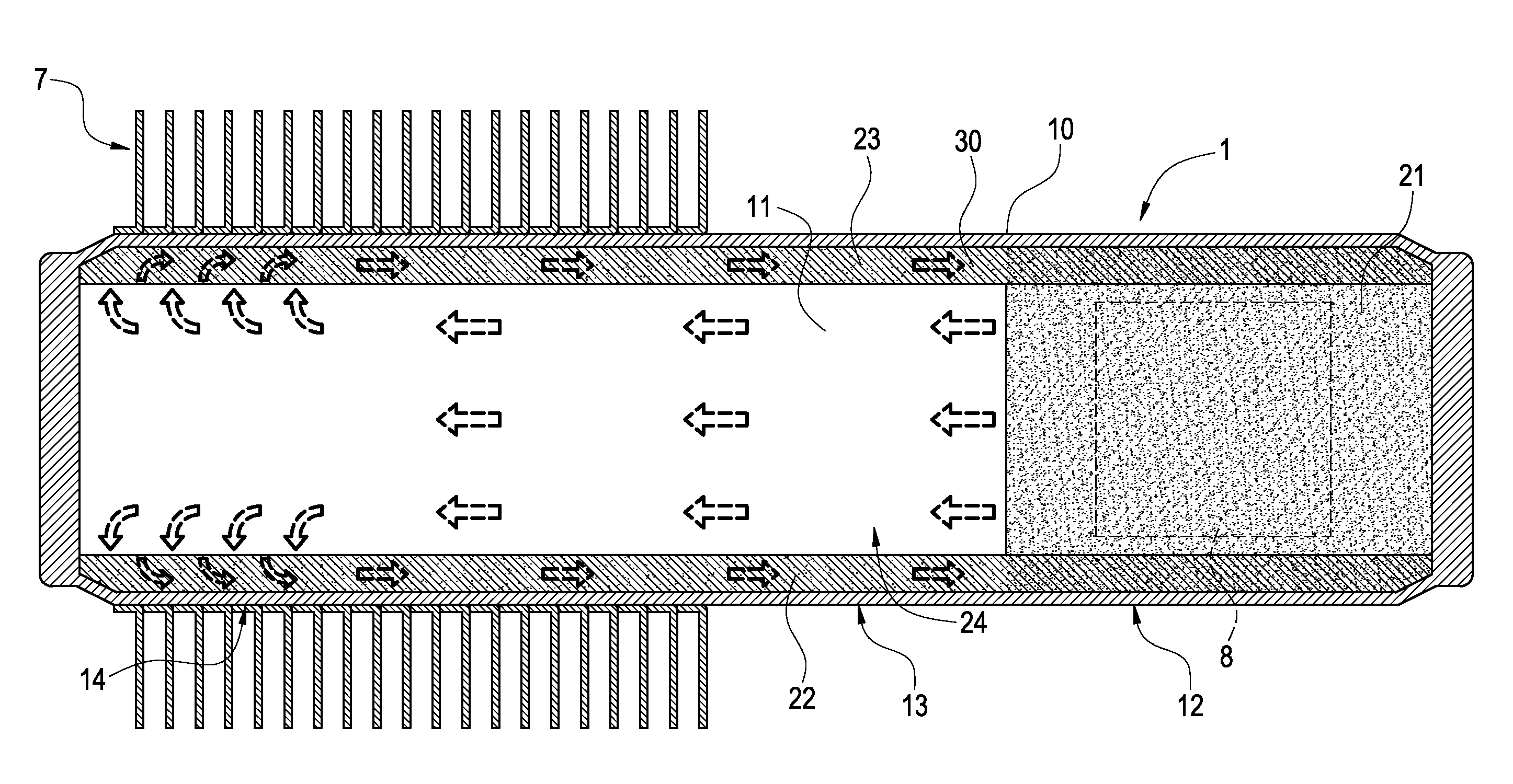

[0032]Please refer to FIG. 7. The present invention provides a heat pipe 1, which includes a metallic pipe 10, a wick structure 20 and a working fluid 30.

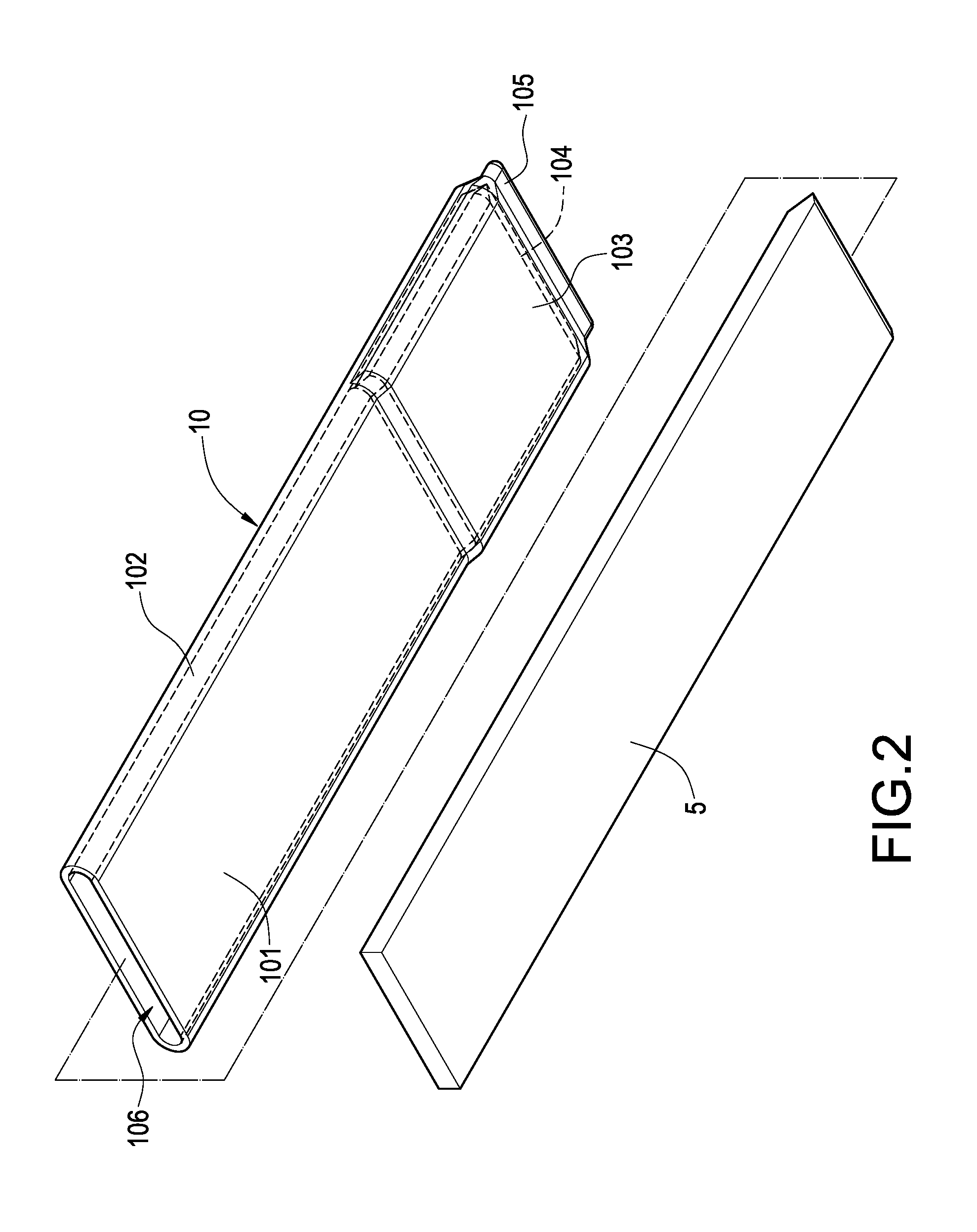

[0033]The metallic pipe 10 is pre-formed to have a flat profile. The cross section of the metallic pipe 10 is enclosed by two flat plates101 and two curved plates 102 (FIG. 5). The interior of the metallic pipe 10 has a sealed chamber 11 that is formed into an evaporating section 12, an adiabatic section 13 and a condensed section 14 along the lengthwise direction of the metallic pipe 10. The outer surface of the lower flat plate 101 of the evaporating section 12 protrudes to form a protrusion 103 (FIG. 4). The interior of the protrusion 103 is formed with a trough 104.

[0034]The wick structure 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com