Patents

Literature

80results about How to "Fast liquid absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioabsorbable hemostatic gauze

InactiveUS20070104769A1Improved performance characteristicsImprove liquid absorption capacityOrganic active ingredientsBiocideCelluloseWater soluble polysaccharides

Bioabsorbable, water-soluble hemostatic cellulose based gauze matrix structures are described, including one or more species of chitosan, etherized cellulose, nonionic surfactant, water-soluble polysaccharide hydrocolloid and / or gum. Approximately 85% to 95% deacetylated decrystallized chitosan, present in an amount from about 2% to about 15% by weight, is found to be particularly advantageous. Favorable properties are found related to rapid stoppage of bleeding and bioabsorbability, among other properties.

Owner:LIFESCI PLUS

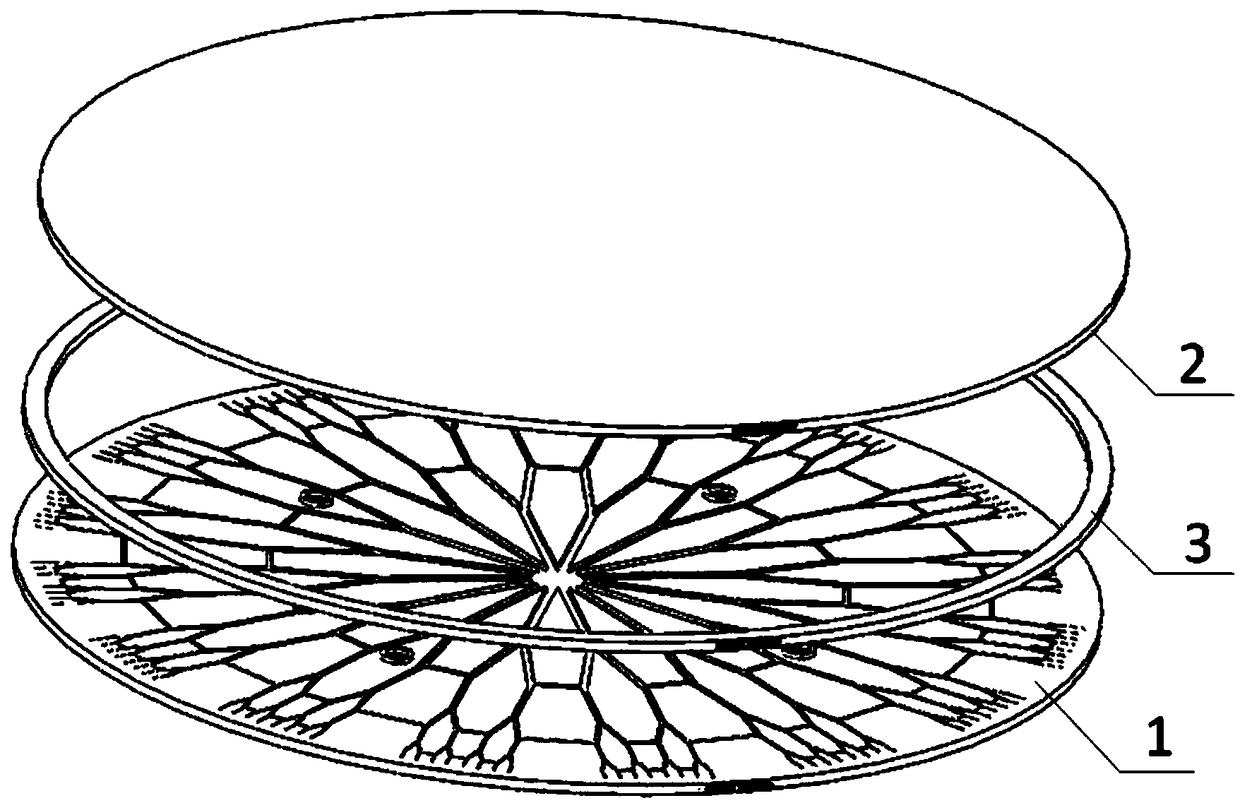

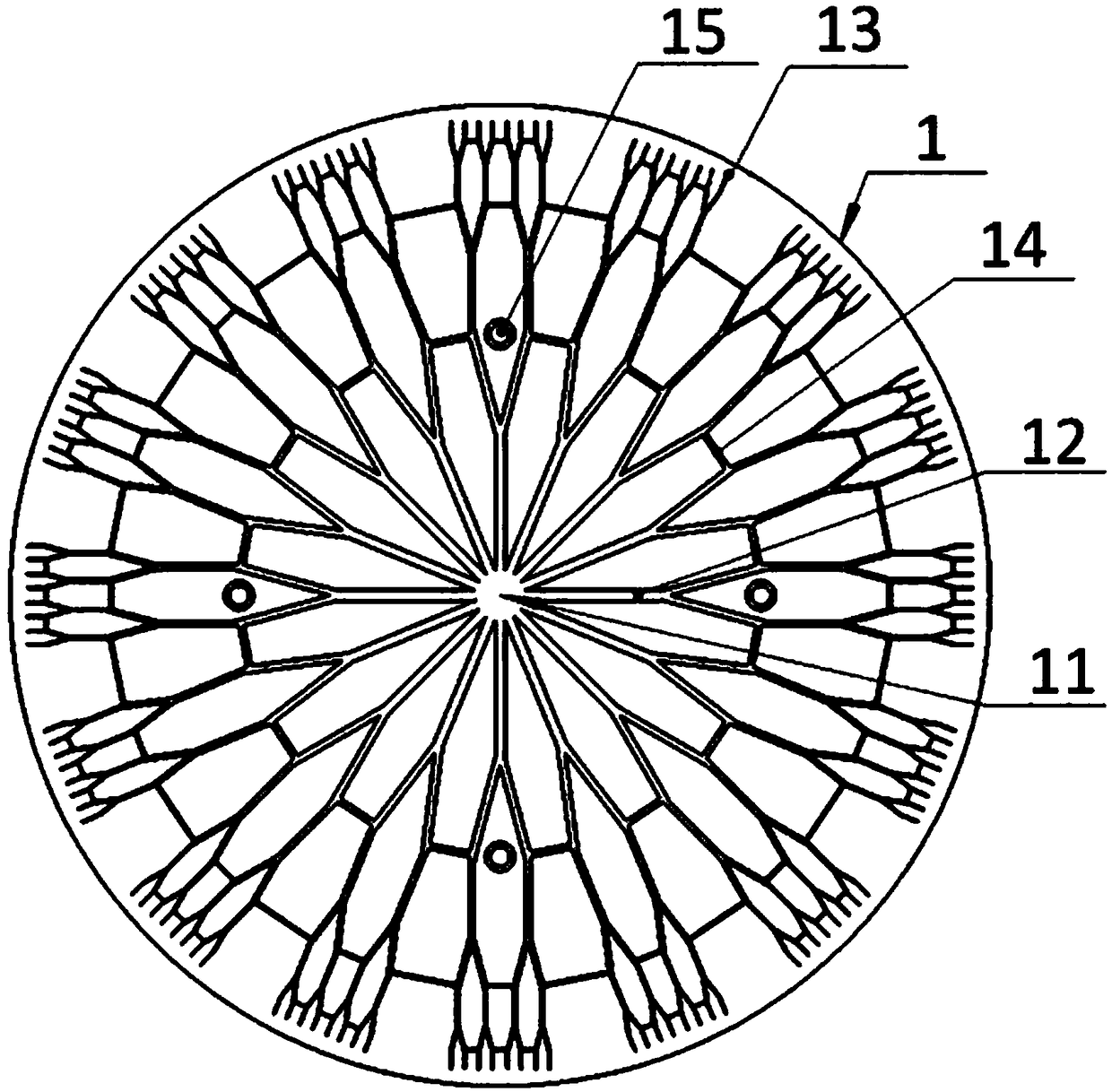

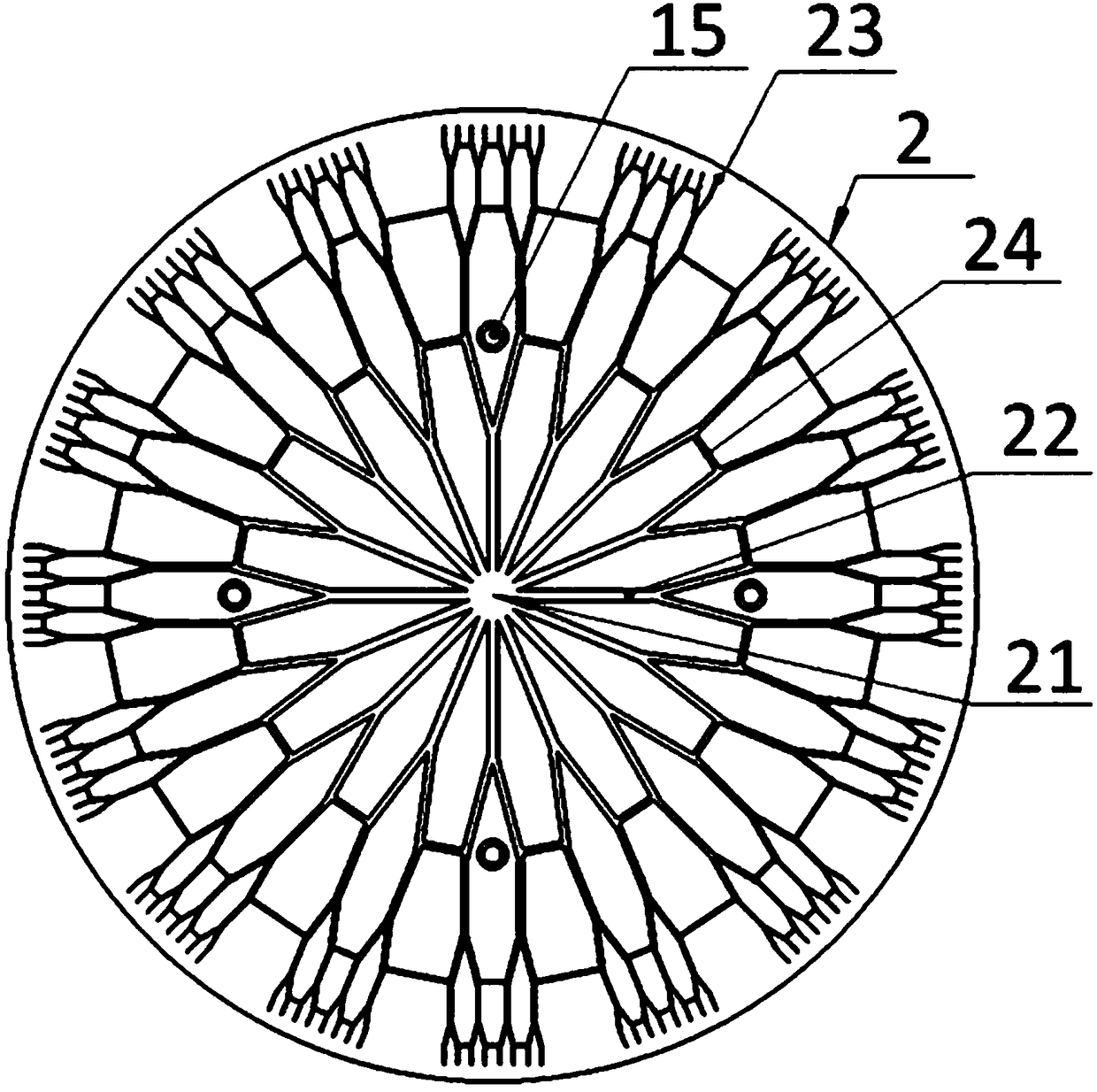

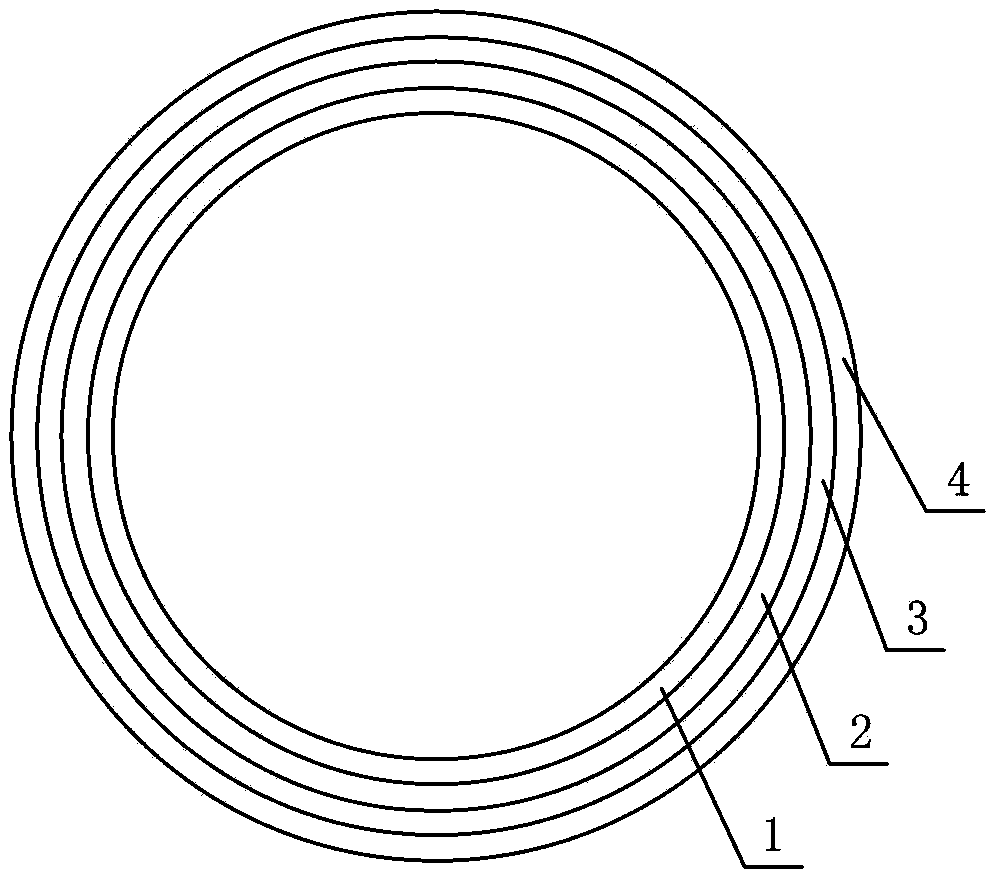

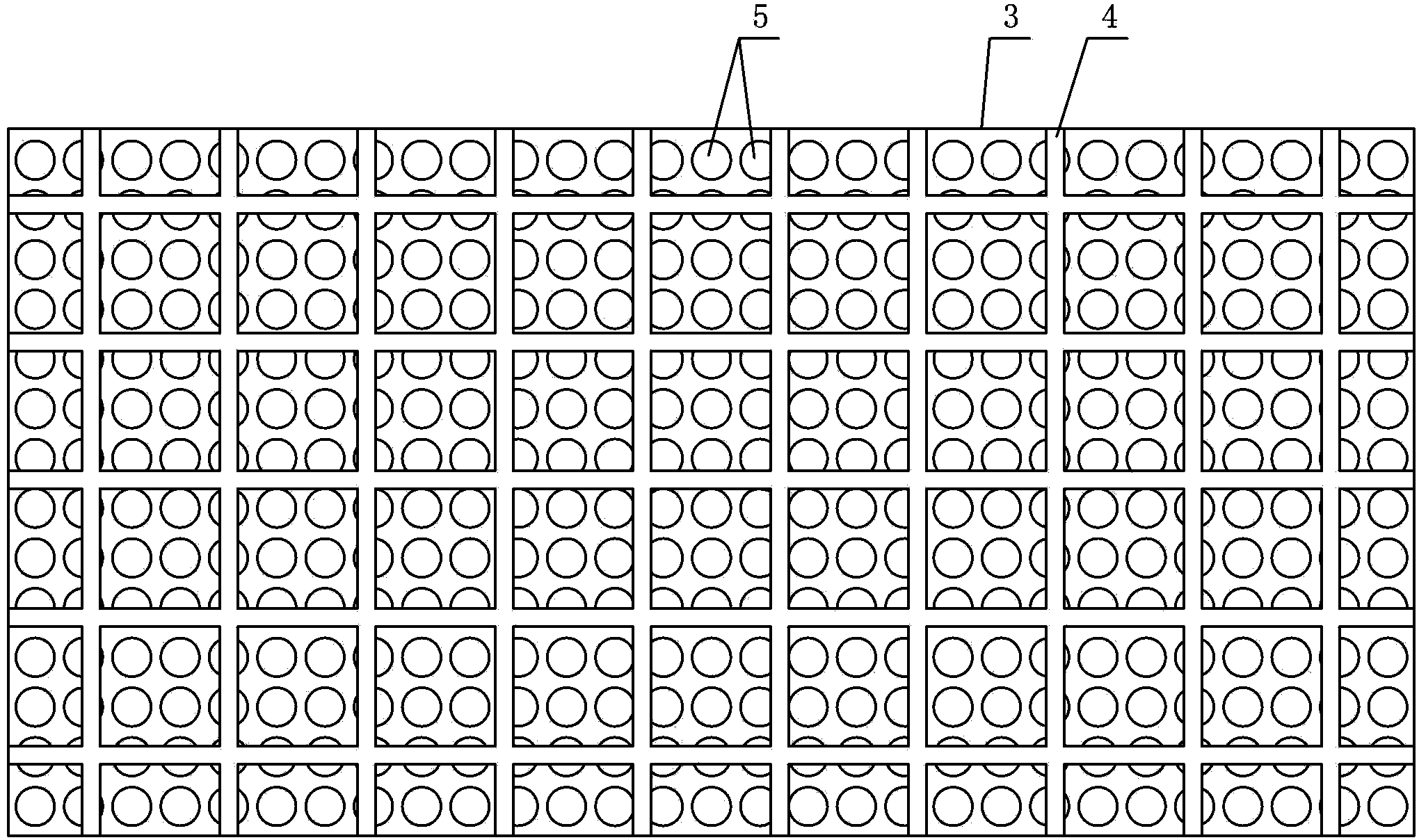

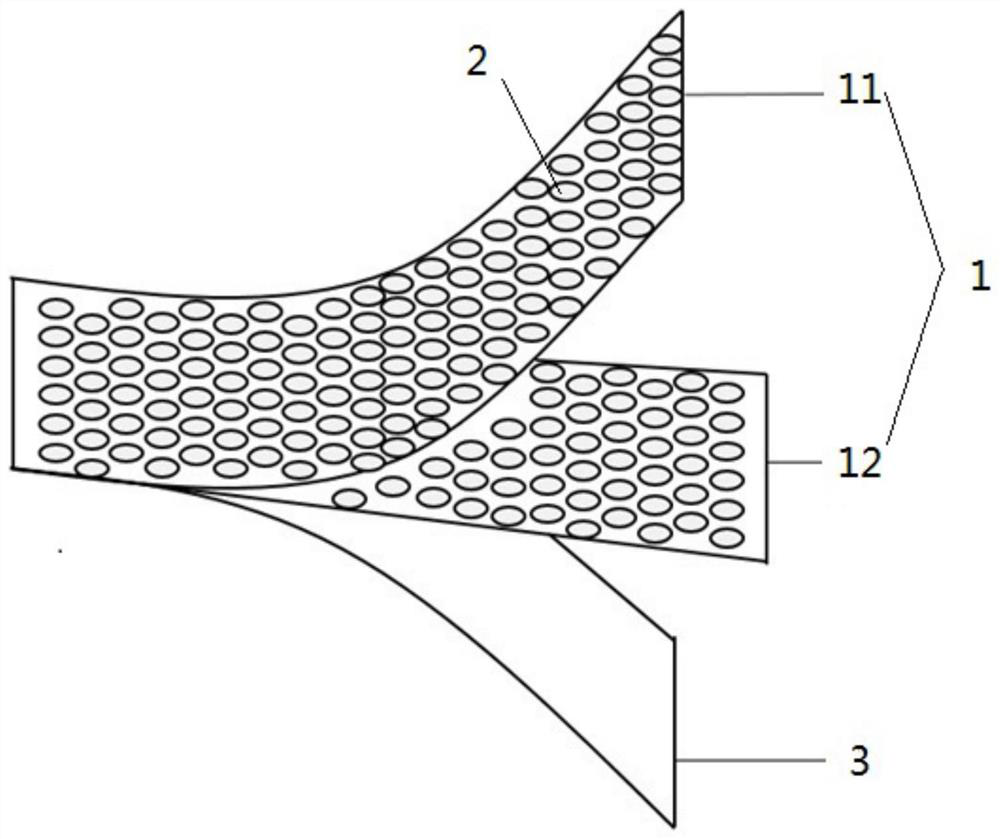

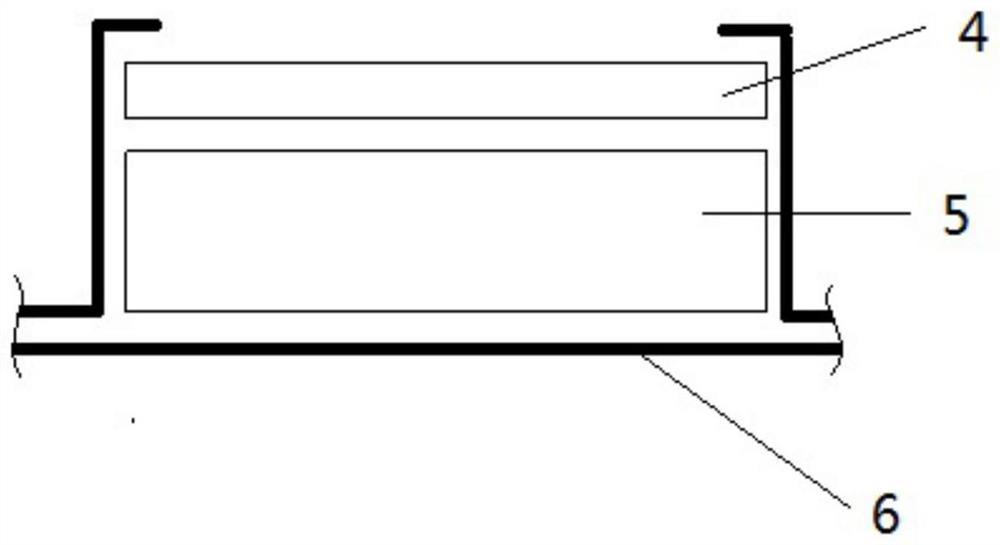

Soaking plate

PendingCN108444324AEnhanced capillary actionFast liquid absorptionIndirect heat exchangersMain channelEvaporation

The invention discloses a soaking plate comprising an evaporation plate, a condensation plate and a connecting plate. The evaporation plate directly faces the condensation plate. The connecting plateis used for connecting the evaporation plate with the condensation plate so as to form a closed cavity, and the closed cavity is filled with a working medium. The evaporation plate is provided with channels for conveying the working medium, and the channels are distributed in the circumferential direction of the evaporation plate and are divergent from the center to the edge of the evaporation plate. According to the soaking plate, the evaporation plate and the condensation plate are provided with bionic vein polygon micro-channel structures, the wall faces of the channels of the evaporation plate and the periphery of support columns are covered with lyophilic liquid sucking cores, thus the wall faces have lyophilic performance, capillary performance of the channel liquid sucking cores isimproved, and liquid sucking speed of the channel liquid sucking cores is increased. The wall faces of the channels of the evaporation plate and the periphery of the support columns are covered with lyophilic materials, liquid spreading is achieved progressively from the edge to the center of the condensation plate, the downward circulation speed of the working medium in main channels is increased, a working medium backflow path is shortened, working medium backflow speed is increased, and heat dissipation benefits are increased.

Owner:GUANGDONG UNIV OF TECH

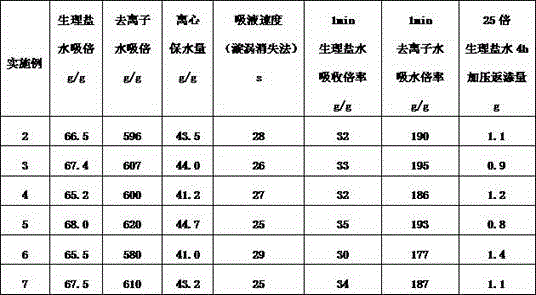

Preparation method of super absorbent resin with high return permeability resistance

ActiveCN106750475AImprove uniformityIncrease surface areaAbsorbent padsLight irradiationFoaming agent

The invention relates to a preparation method of super absorbent resin with high return permeability resistance. The method comprises the following steps: neutralizing an acrylic acid aqueous solution by using alkali, adding a composite initiator, a crosslinking agent and a foaming agent, and performing polymerization reaction under UV light irradiation; cutting up and pelleting hydrogel after polymerization, adding a gel cutting aid in the cut-up process, drying and pulverizing to obtain primary granules of super absorbent resin; and spray-coating the surfaces of the primary granules with surface crosslinking liquid, and performing reaction at high temperature to obtain a final product of the super absorbent resin. The super absorbent resin prepared by the method has the characteristics of high absorbing rate, high absorbing speed, high water-retaining property, excellent return permeability resistance and the like.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD

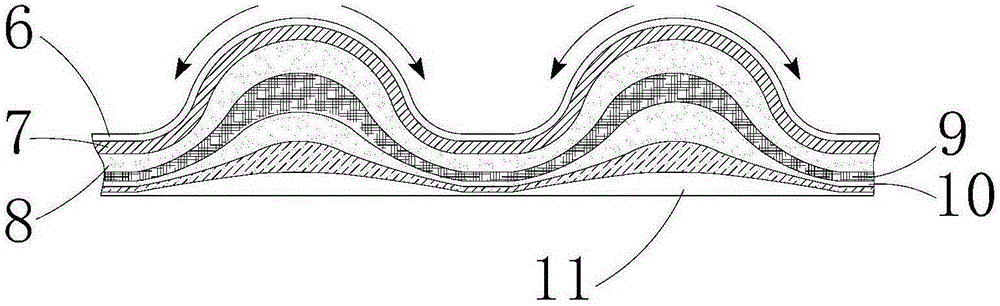

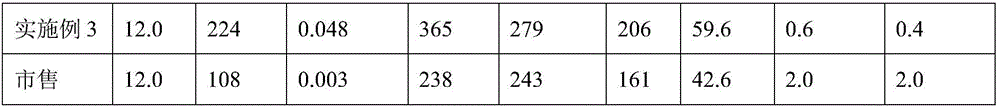

Absorption product with core of double-layer structure and manufacturing method of absorption product

The invention belongs to the field of personal hygienic products, and discloses an absorption product with a core of a double-layer structure and a manufacturing method of the absorption product. The absorption product comprises a fluid permeability surface layer, a non-fluid-permeability bottom layer and the absorption core between the fluid permeability surface layer and the non-fluid-permeability bottom layer, wherein the absorption core comprises an upper layer and a lower layer; the upper layer is a double-combed and double-formed fluffy sheet; the fluffy sheet of the upper layer is divided into a dense surface and a fluffy surface; the lower layer of the absorption core is a dense sheet; the fluffy surface of the fluffy sheet and the dense sheet of the lower layer are bonded together; macromolecule water-absorbing particles or fibers of the absorption core are evenly distributed between the fluffy surface and the dense sheet of the lower layer. The absorption product has the advantages of being capable of rapidly absorbing liquid and diffusing liquid, good in air permeability and good in closed-fit performance.

Owner:湖南倍健卫生用品有限公司

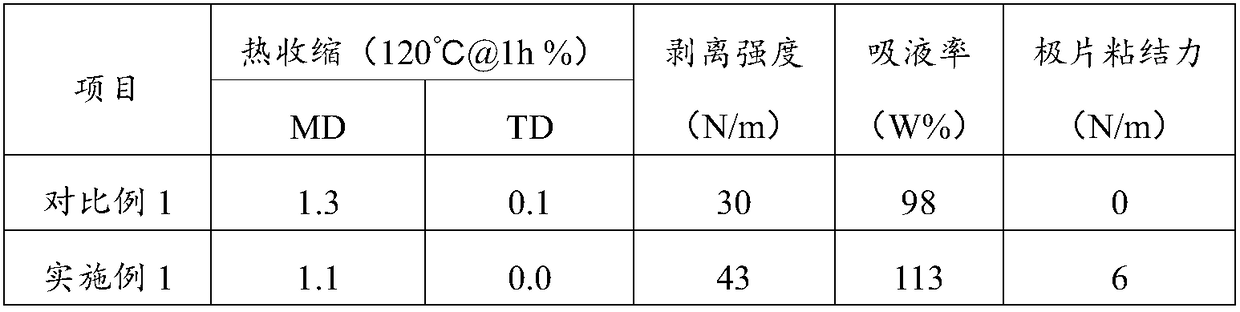

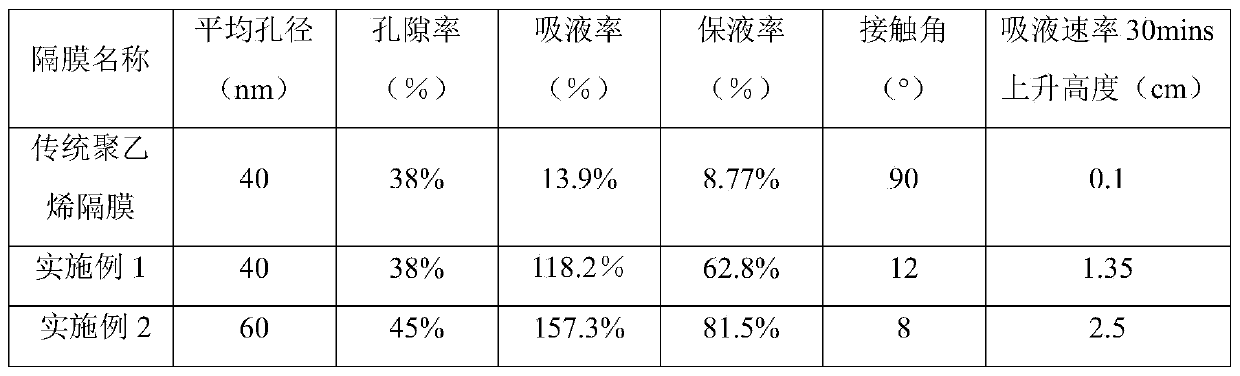

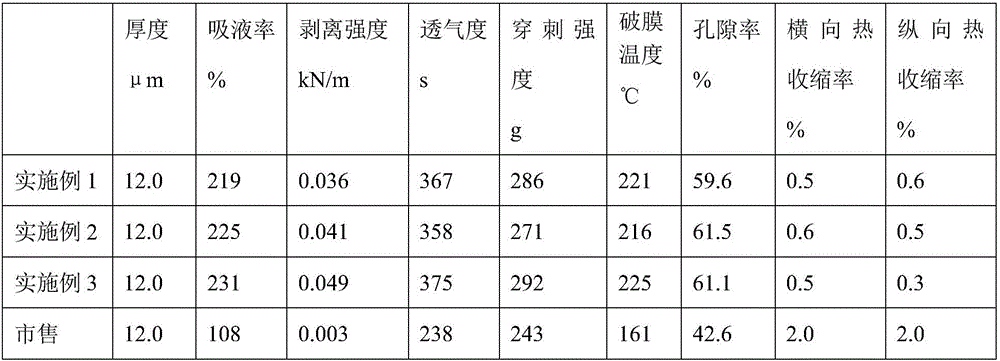

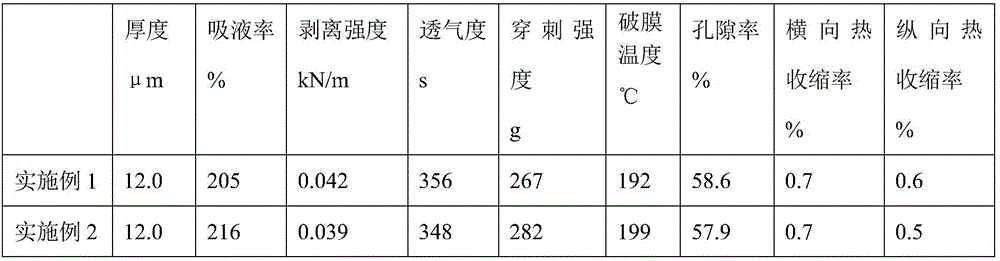

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Lithium ion battery and combination electrode used for the same and production method thereof

ActiveCN101246958AGood compatibilityGood diaphragm wettingElectrode manufacturing processesSecondary cellsSolubilityHydrophilic monomer

The present invention relates to compound electrode slices applied in lithium ion battery and producing method thereof, which belongs to fields of battery production, in order to provide a new septum and cathode two-in-one electrode slices. The provided compound electrode slices is polymer colloid latex initiated, grafted and copolymerized by 1-5 portion initiator in aqueous solution containing 100 portion water-solubility polymer by 30-500 portion hydrophobic monomer and 0-200 portion hydrophilic monomer. Counted as that the solid content in the polymer colloid latex is 100%, the inorganic filler of 0-100% and the plasticizer of 20-100% are added, and the slurry is coated on the carbon cathode slice which is obtained by drying. The electrode slices has good heat stability and electrochemistry stability, super water absorptivity and rapid water absorption speed, and keeps higher water absorptivity in whole circle service life period. The battery has credible safety and circle service life, and the present invention provides a new thinking for lithium ion battery fields.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

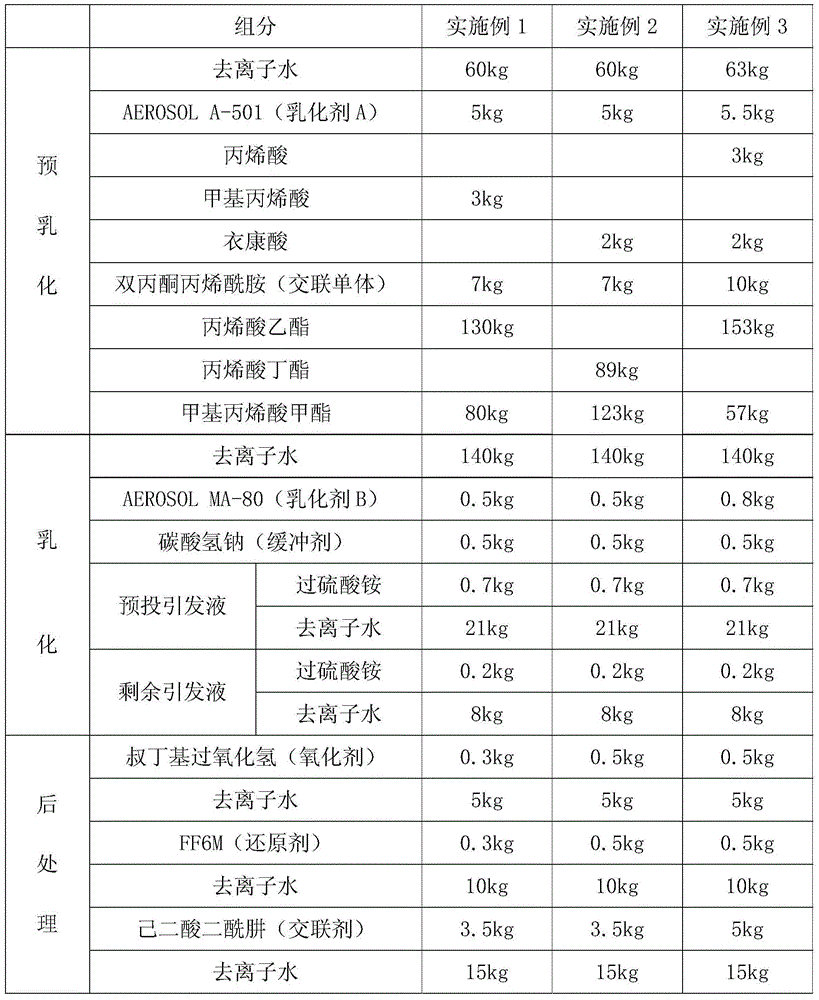

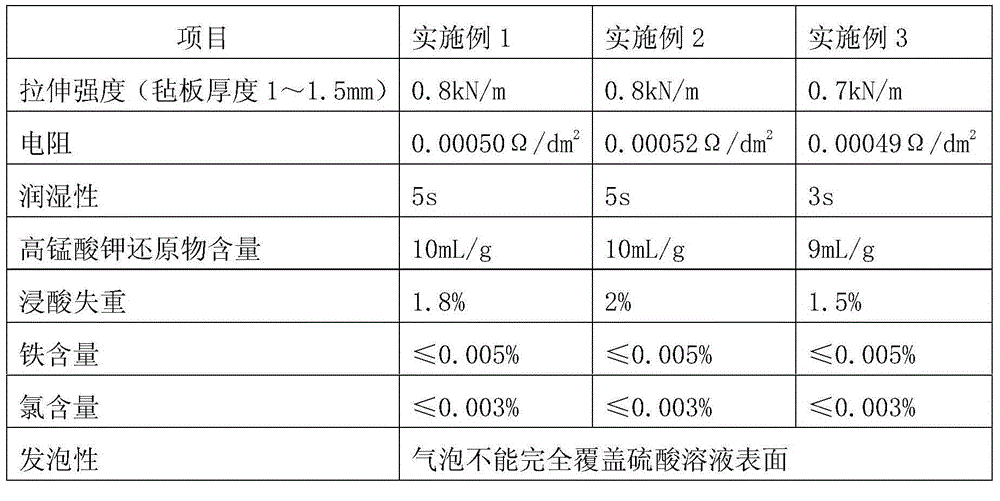

Self-crosslinking acrylate emulsion and preparation method thereof

ActiveCN103554349AImprove performanceIncrease surface areaEster polymer adhesivesFunctional monomerPotassium

The invention discloses self-crosslinking acrylate emulsion and a preparation method thereof. The self-crosslinking acrylate emulsion is prepared from (methyl) acrylate monomer, a functional monomer, a crosslinking monomer, a crosslinking agent, an emulsifying agent A, an emulsifying agent B, a buffering agent, an initiator, an oxidizer, a reducer and deionized water, wherein the reducer is an FF6M macromolecule polymerization novel reducer produced by a Bruegmann company in Germany, the emulsifying agent A is an emulsifying agent AEROSOL A-501 produced by a Cytel company in America, and the emulsifying agent B is an emulsifying agent AEROSOL MA-80 produced by the Cytel company in America; the preparation method of the self-crosslinking acrylate emulsion comprises pre-emulsification, emulsification and post treatment. A superfine glass fiber separating plate made by adopting the self-crosslinking acrylate emulsion is low in potassium hypermanganate reduzate content, high in liquid absorption speed, high in amount of absorbed liquid and excellent in performance.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Paper diaper capable of rapidly absorbing liquid and keeping dry

InactiveCN105232235AAbsorbent dryReasonable structureAbsorbent padsBandagesCompression moldingPulp and paper industry

The invention discloses a paper diaper capable of rapidly absorbing liquid and keeping dry. The paper diaper comprises a diaper main body, an elastic front waistline and an elastic rear waistline, wherein an absorbent core is longitudinally arranged in the middle of the diaper main body, and the absorbent core is manufactured by compression molding; a plurality of diversion bumps are distributed on the absorbent core; a long diversion slot is longitudinally pressed in the center of the absorbent core; the absorbent core is composed of a surface non-woven fabric layer, a diversion layer, a first high molecular water absorbent layer, a wood pulp layer, a second high molecular water absorbent layer and an anti-leakage bottom film, and the weight ratio of the first high molecular water absorbent layer to the second high molecular water absorbent layer is (3.5-4.5) to 1; the elastic front waistline is arranged at the longitudinal front end of the diaper main body; and the elastic rear waistline is arranged at the longitudinal rear end of the diaper main body. The paper diaper capable of rapidly absorbing liquid and keeping dry disclosed by the invention is reasonable in structure, high in liquid absorption speed and relatively good in thermal-wet comfort property, and the paper diaper is capable of greatly reducing a contact area between the core of the paper diaper and baby's skin and is capable of enhancing comfort thereof.

Owner:ZHEJIANG YOUQUAN CARE PROD TECH CO LTD

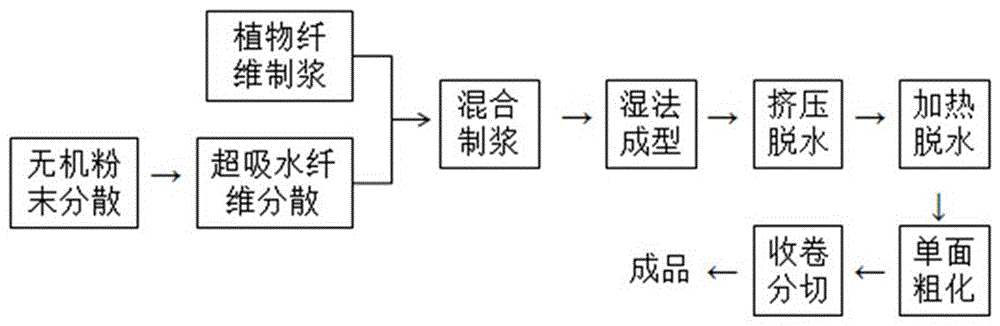

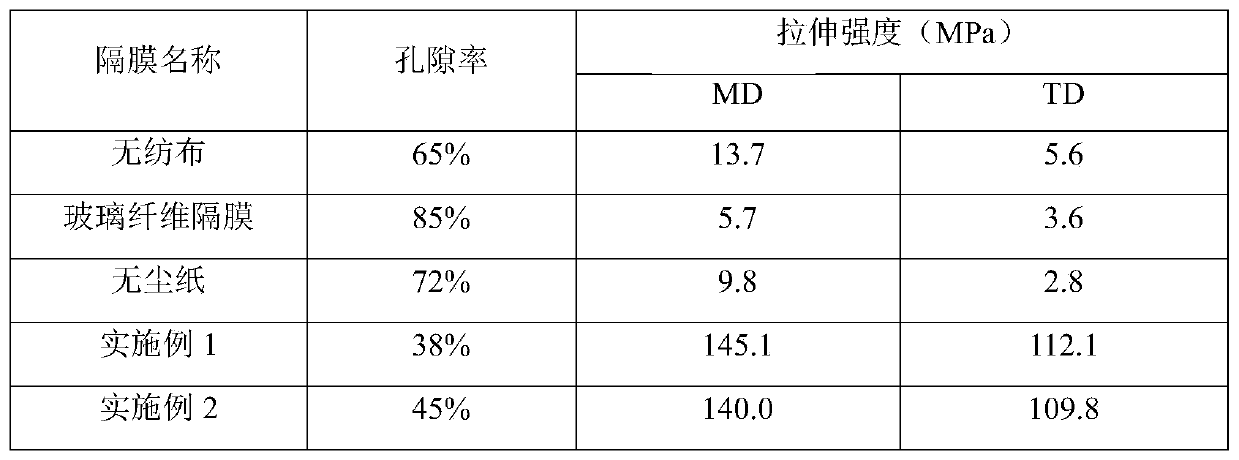

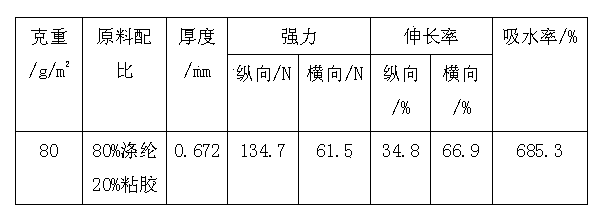

Battery, capacitor diaphragm and preparation method of battery and capacitor diaphragm

InactiveCN105870383ASoft natureImprove toughnessHybrid capacitor separatorsCell component detailsCapacitancePorosity

The invention relates to a battery, a capacitor diaphragm and a preparation method of the battery and the capacitor diaphragm. The diaphragm is prepared from, by weight, 65% to 75% of sulfite wood pulp, 10% to 20% of superabsorbent fibers (SAF), 5% to 30% of attapulgite mineral powder, 0.3% to 0.8% of chitosan, 3% of synthetic fibers and 1.2% to 1.7% of hydrogen storage material ZnO2. The preparation method of the battery and the capacitor diaphragm comprises the step that the finished product is prepared through the steps of plant fiber pulping, inorganic powder dispersing, superabsorbent fiber dispersing, mixed pulping, wet forming, extruding dehydration, heating dehydration, single-face coarsening, rolling and splitting and the like. The defects that in the existing process and technology, the aperture and porosity of a super capacitor diaphragm of a battery are hard to control, the electrolyte retention rate is low, proton passing resistance is large, the gluing process is hard to control, and single-face coarsening of the diaphragm cannot be achieved are overcome, and according to the battery, the capacitor diaphragm and the preparation method of the battery and the capacitor diaphragm, the liquid retention rate is high, gas permeability is good, the physical property is high, internal resistance is low, and the process and technology are more advanced.

Owner:王温珏

Rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

ActiveCN108306013ATake advantage ofHigh tap densityFinal product manufactureElectrode carriers/collectorsManganateCarbon nanotube

The invention discloses a rapidly discharged / charged high power lithium ion battery and a manufacturing method thereof. The positive current collector comprises an aluminum foil and a conductive coating. The negative current collector comprises a copper foil and a conductive coating. The diaphragm is a PE material, which is bidirectionally and synchronously stretched, and ceramic oxide is paintedon the surface of the PE material. The anode paste comprises following components in parts by weight: 10 to 35 parts of lithium cobaltate, lithium nickelate, lithium manganate, lithium iron phosphate,lithium manganese phosphate, lithium iron manganese phosphate, or lithium vanadium phosphate, 62 to 81 parts of nickel cobalt lithium manganate, 1 to 3 parts of Ketjen black or carbon nanotube, and 1to 3 parts of graphene or Super-P and modified 1,3-polyvinylidene fluoride. The cathode paste comprises following components in parts by weight: 55 to 75 parts of artificial graphite or meso-phase carbon micro beads, 20.5 to 36 parts of soft carbon or hard carbon, 1 to 2 parts of CMC, 2 to 4 parts of Super-P, and 1.5 to 3 parts of styrene butadiene rubber SBR or polystyrene-acrylate. The providedlithium ion battery can continuously discharge or charge (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90%or more of 1C capacity.

Owner:FENGFAN

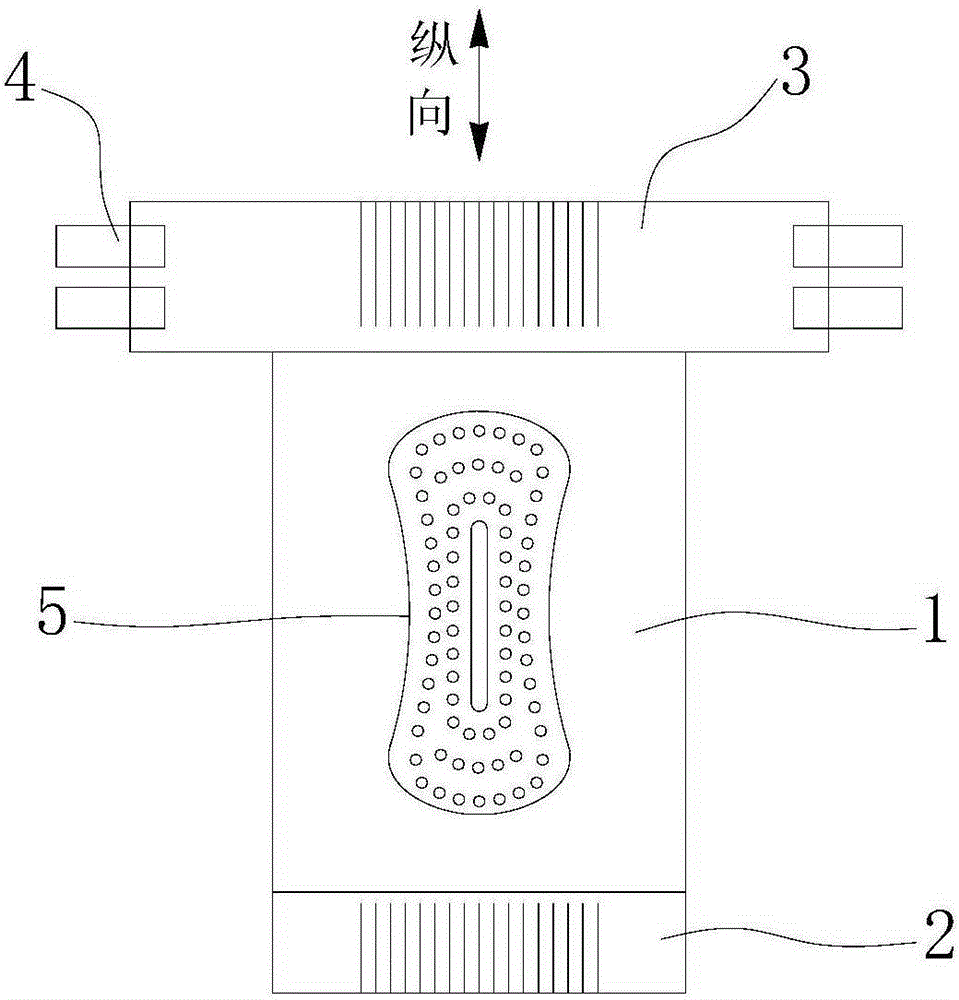

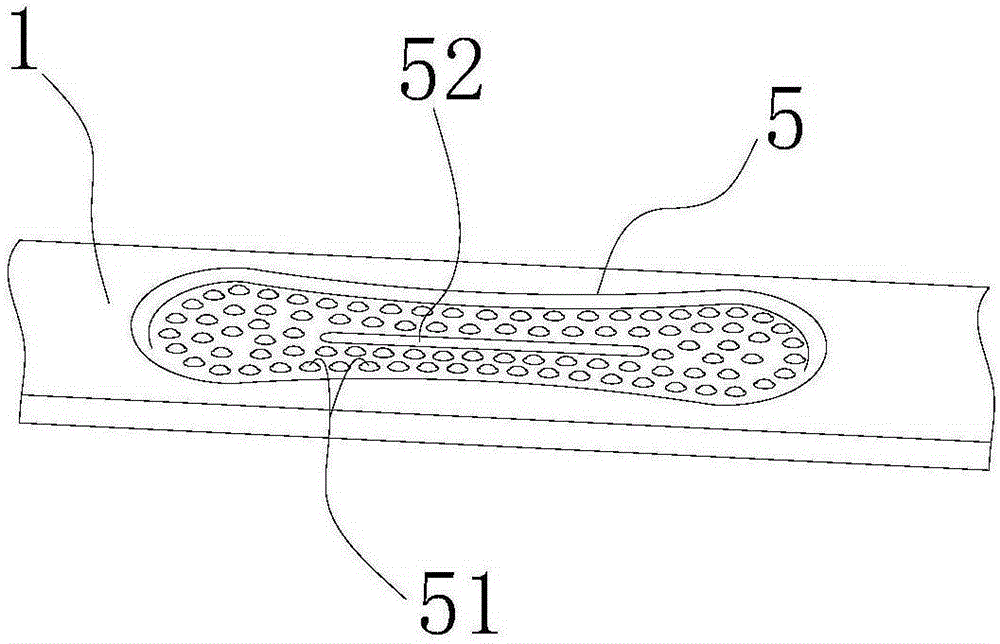

Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

InactiveCN107904787AFluffy goodExcellent suction speedNon-woven fabricsBandagesReverse osmosisEngineering

The invention discloses a spun-bonded non-woven fabric for a diaper diversion layer and a production technology of the fabric. The non-woven fabric comprises an absorption core which is formed by coarse denier fiber, the direction of the coarse denier fiber is the longitudinal direction, the pattern of the coarse denier fiber is the strip pattern, the pattern of the absorption core is the patternof the character 'yi', and the pattern direction of the absorption core is consistent with the fiber direction. Compared with the prior art, the fabric has the advantages that a hot wind non-woven fabric can be replaced, the production speed of the spun-bonded non-woven fabric is higher than that of the hot wind short fiber, the cost is low, and the effect is good; the coarse denier product is good in diversion effect, diffusion is accelerated, the diffusion length is increased, and the amount of reverse osmosis is lowered; compared with ordinary hot wind non-woven fabrics and other products,the fluffiness is better, and the liquid absorbing speed is higher.

Owner:山东恒鹏卫生用品有限公司

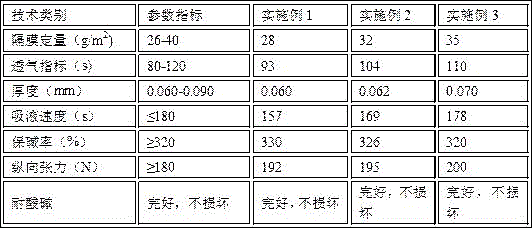

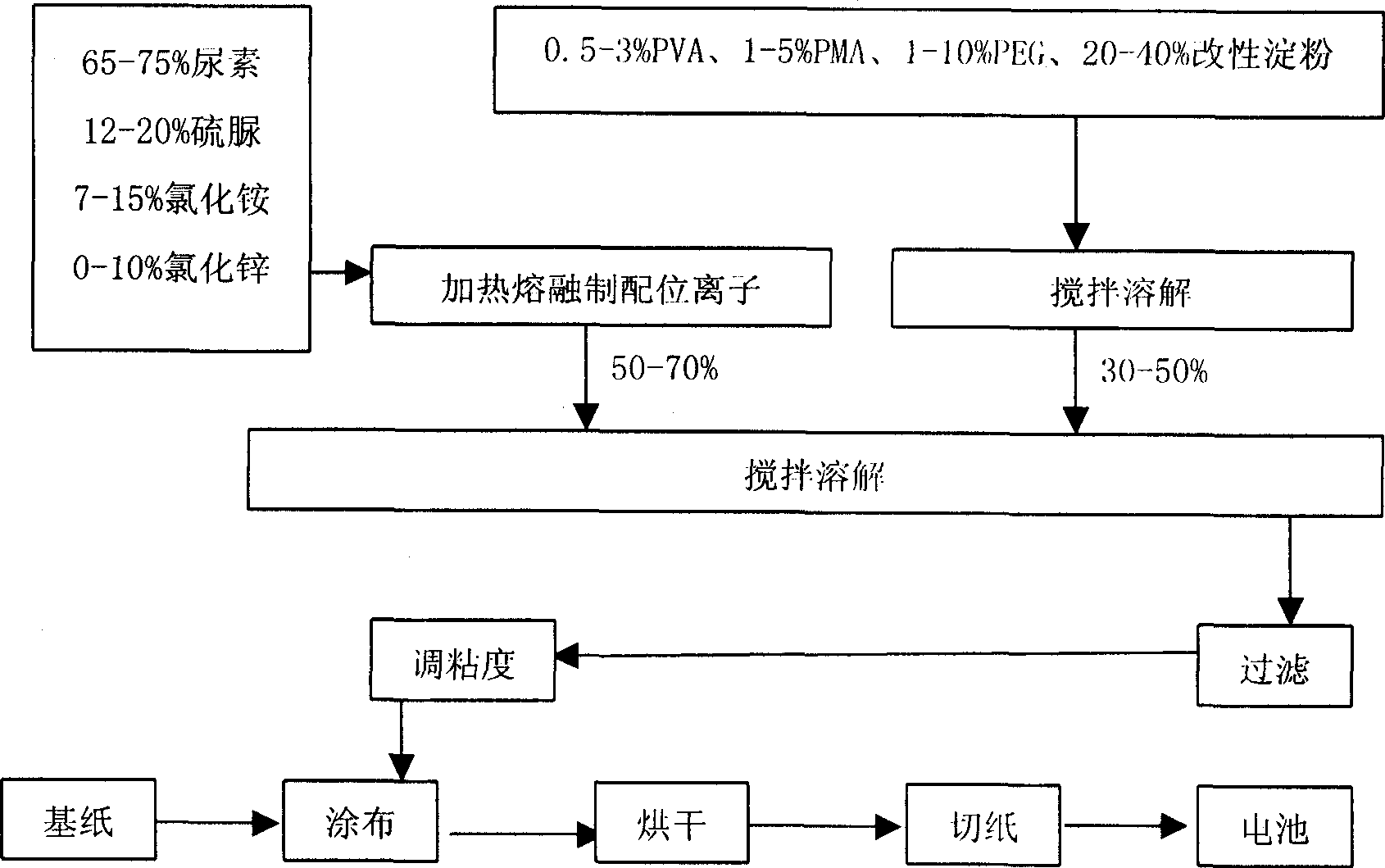

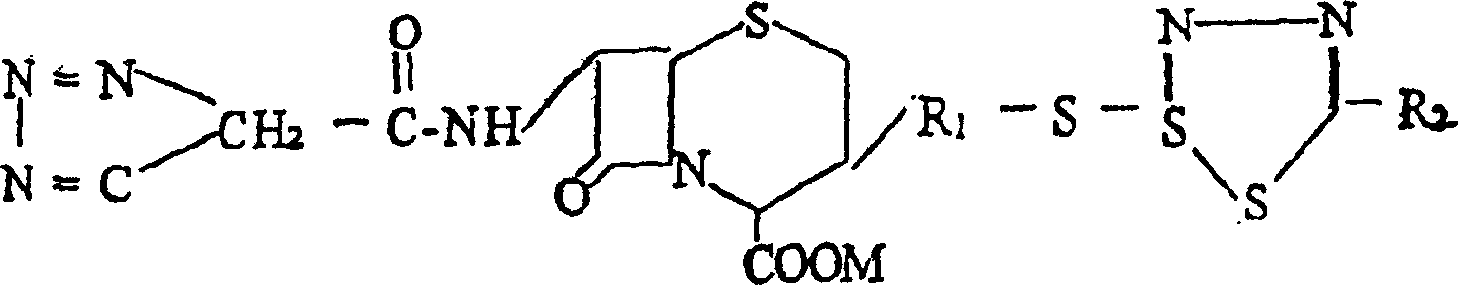

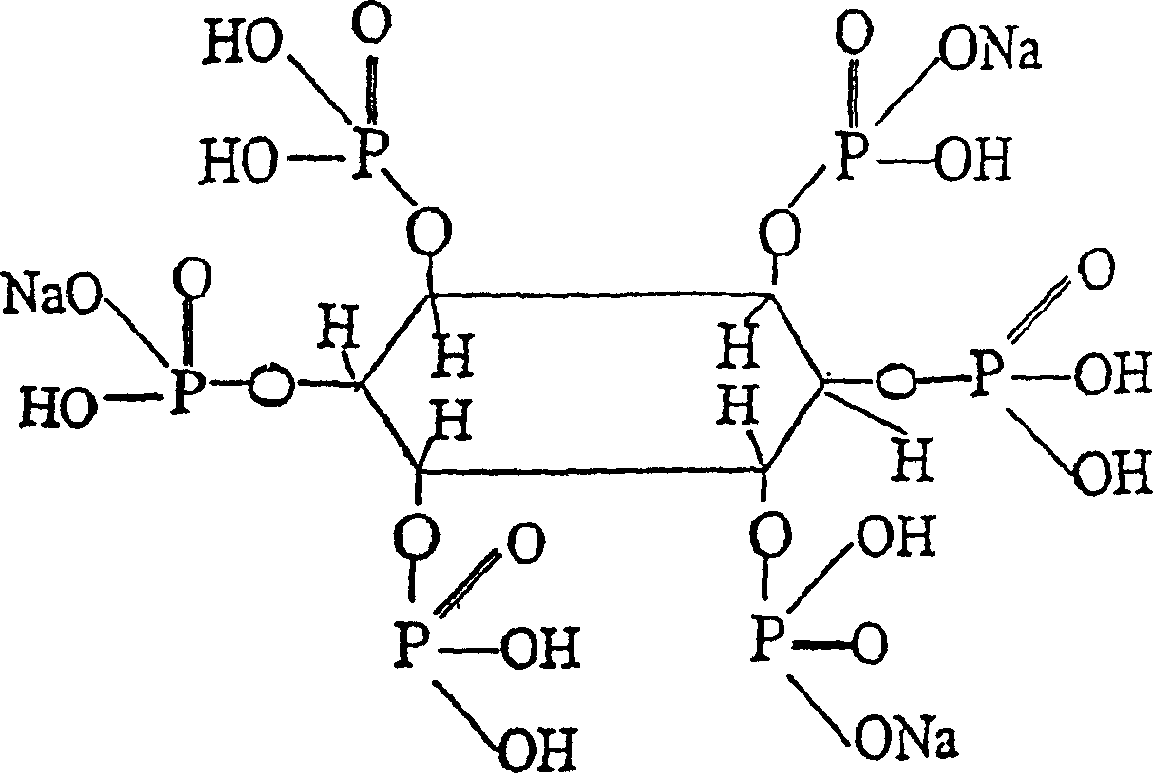

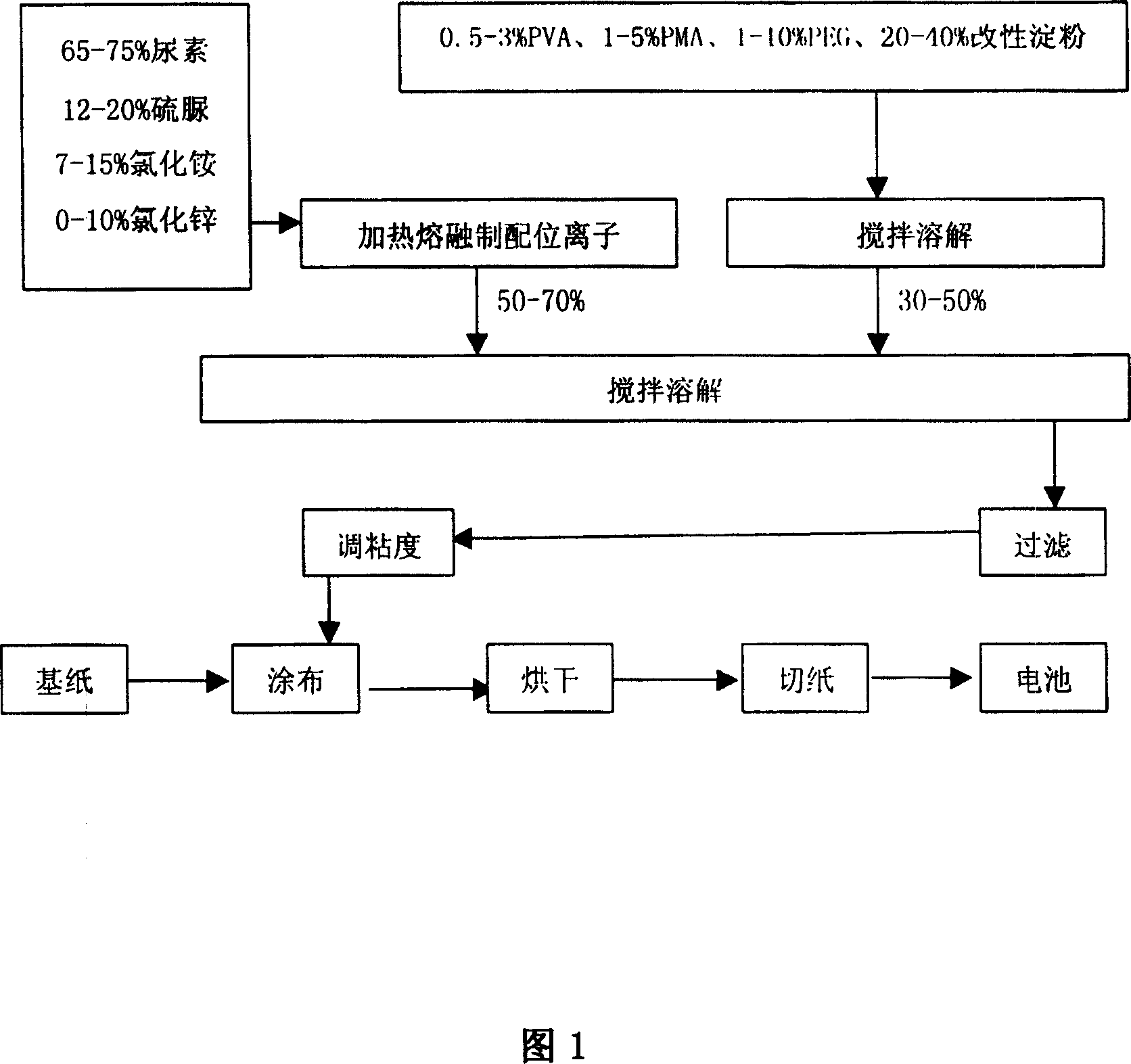

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1673455ALower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Water-based metal ion secondary battery diaphragm, and preparation method and application thereof

InactiveCN110364664AImprove wettabilityImprove liquid retention capacitySecondary cellsCell component detailsWater basedPolymer

The invention discloses a water-based metal ion secondary battery diaphragm, and a preparation method and application thereof, and belongs to the technical field of lithium battery diaphragms. The water-based metal ion secondary battery diaphragm comprises a porous base membrane; the surface of the porous base membrane is coated with a hydrophobic coating; the surface of the hydrophobic coating isgrafted with a hydrophilic coating; the hydrophilic coating is grafted on the surface of the hydrophobic coating through a laser radiation surface grafting method; the wavelength of a light beam forradiation is 9.1-10.6 [mu]m; and the radiation duration is 100-500 ns, preferably 100-200 ns. By adopting the technical scheme provided by the invention, the wettability and the liquid retention of the diaphragm can be effectively improved on the basis of keeping the original excellent physical properties, conductivity and cycle performance of the polymer diaphragm, so that the use requirements ofthe water-based metal ion secondary battery diaphragm are met.

Owner:安徽金力新能源有限公司

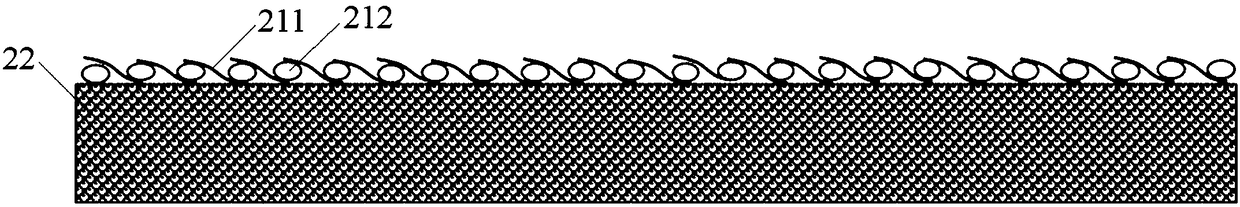

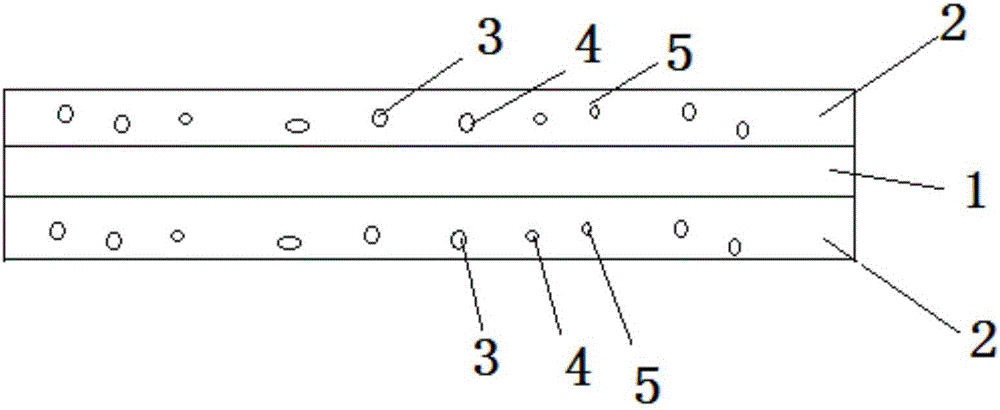

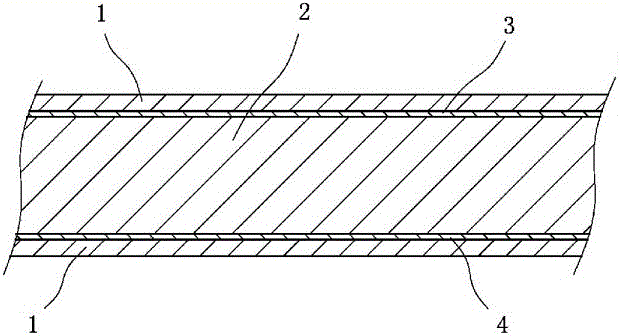

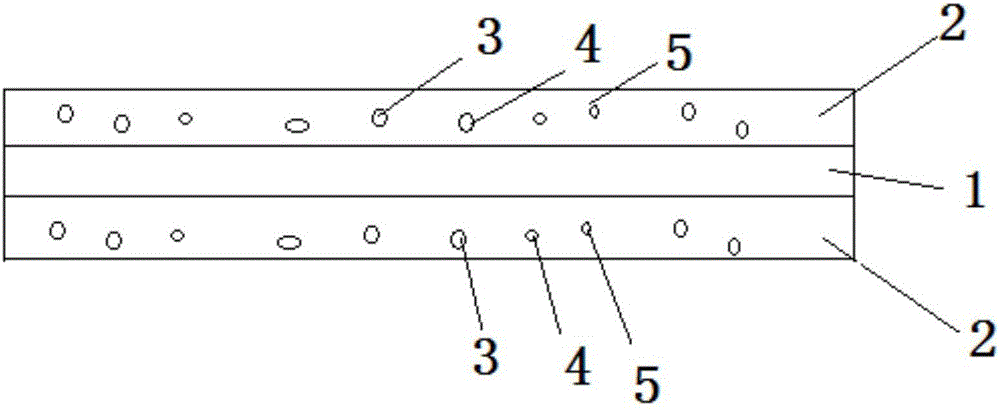

Consumer battery diaphragm high in safety

The invention provides a consumer battery diaphragm high in safety. The consumer battery diaphragm high in safety comprises a base layer (1) and modified layers (2) arranged on the surfaces of the base layer (1). The base layer (1) is made of hydrophilic PET non-woven fabric filled with a high-molecular polymer. Each modified layer (2) comprises a polypropylene material matrix (3), porous alumina superfine powder (4), ceramic particles (5) and phase-change microspheres (5), wherein the porous alumina superfine powder (4), the ceramic particles (5) and the phase-change microspheres (5) are dispersed in the polypropylene material matrix (3). The battery diaphragm is simple in process, high in liquid absorption amount, large in surface area, high in porosity, small in aperture, high in chemical purity and safe to use and has few harmful impurities.

Owner:华富(江苏)锂电新技术有限公司 +1

Cathode paste of rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

InactiveCN108305989AHigh tap densityIncrease compaction densityElectrode manufacturing processesSecondary cellsPolystyreneSodium-ion battery

The invention discloses a cathode paste of a rapidly discharged / charged high power lithium ion battery. The cathode paste comprises following components in parts by weight: 55 to 75 parts of active substance C, 20.5 to 36 parts of active substance D, 1 to 2 parts of thickening agent, 2 to 4 parts of conductive agent C, and 1.5 to 3 parts of binder B; wherein the active substance C is artificial graphite or meso-phase carbon micro beads; the active substance D is soft carbon or hard carbon; the conductive agent C is Super-P; the thickening agent is sodium carboxymethyl cellulose CMC; and the binder B is styrene butadiene rubber SBR or polystyrene-acrylate. The provided lithium ion battery can be rapidly charged and discharged, has high power and a long service life, and can be continuouslydischarged or charged (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90% or more of 1C capacity. Compared with a conventional power type lithium ion battery, the charge performance is improved by 20% or more, and the discharge performance is improved by 10% or more.

Owner:FENGFAN

Three-dimensional jacquard weave bulging cover

InactiveCN103352328AImprove the three-dimensional effectSoft touchNeedling machinesMoisture absorptionEngineering

The invention discloses a three-dimensional jacquard weave bulging cover, and belongs to the technical field of spunlace non-woven fabric production equipment. The three-dimensional jacquard weave bulging cover comprises a supporting cover, a lining mesh, a mesh cover and a grid nickel mesh, wherein the supporting cover, the lining mesh, the mesh cover and the grid nickel mesh are sequentially and fixedly arranged from inside to outside. A plurality of mesh holes are formed in the mesh cover. Spunlace non-woven fabric produced through the three-dimensional jacquard weave bulging cover has three-dimensional effect, and is soft in hand feel, good in hydrophilic property and moisture absorption performance and high in liquid absorbing speed.

Owner:ZHEJIANG HEZHONG NONWOVEN

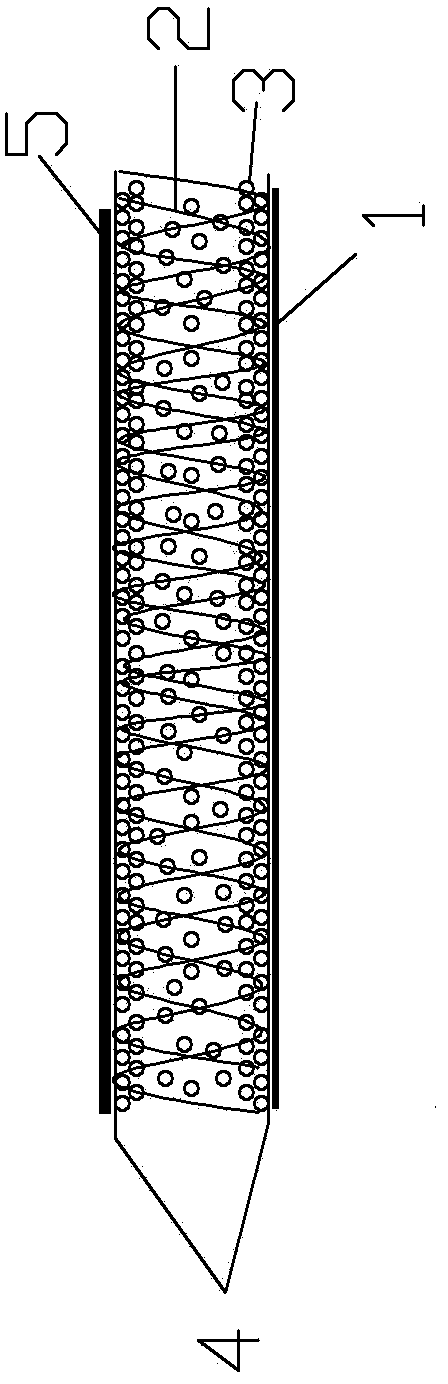

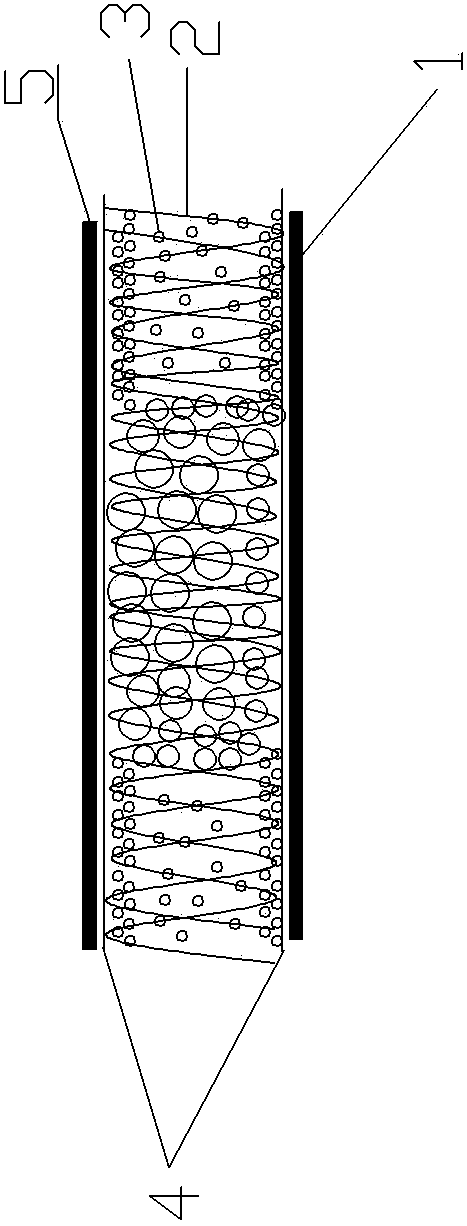

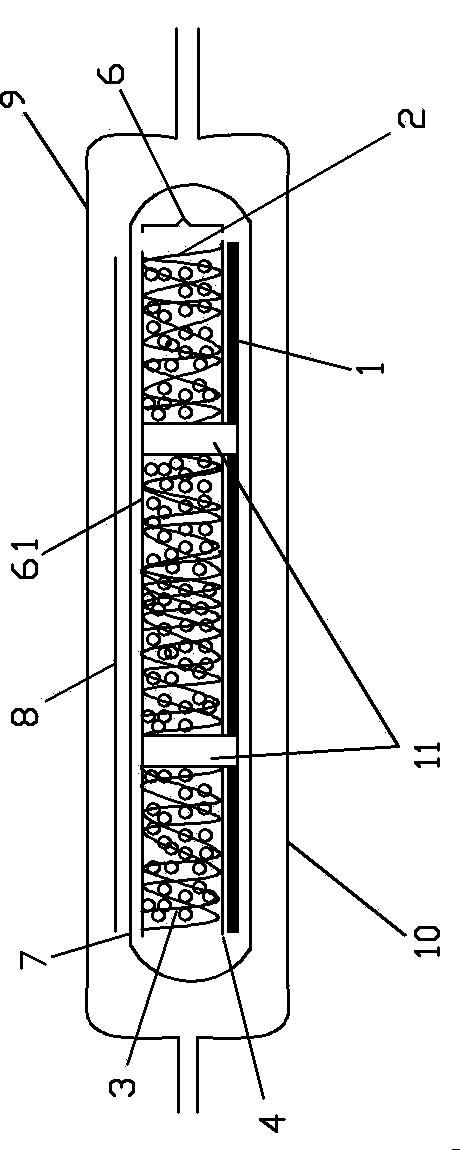

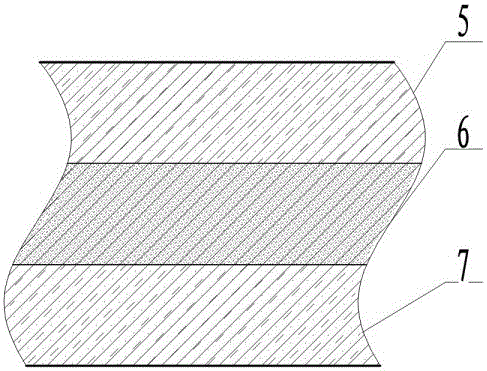

Storage battery partition plate and pregnant solution type storage battery

PendingCN106340606AIncrease liquid absorptionFast liquid absorptionFinal product manufactureCell component detailsFiber structureOxygen compound

The invention discloses a storage battery partition plate and a pregnant solution type storage battery. The partition plate is of a multi-component fiber structure and is formed by processing glass fibers and hydrophobic PE fibers of various diameters and lengths. The PE fiber content of an upper layer and a lower layer of the vertical section structure of the partition plate is the same and is lower than that of an intermediate interlayer. A bag type structure partition plate is adopted for the pregnant solution type storage battery. The storage battery partition plate can have the advantages that a PE partition plate and an AGM partition plate are small in pore diameter and low in resistance and easily made into a bag type, and it can be guaranteed that the pregnant solution type storage battery has good low temperature discharge performance, oxygen compound efficiency and cost performance.

Owner:SHANDONG SACRED SUN POWER SOURCES

Fiberglass membrane of lead-acid battery

InactiveCN105789535AIncrease liquid absorptionFast liquid absorptionCell component detailsChemical purityChemistry

The invention provides a fiberglass membrane of a lead-acid battery. The fiberglass membrane comprises a fiberglass and polyvinyl alcohol fiber composite layer, polymer and water-soluble resin composite layers arranged on two surfaces of the fiberglass and polyvinyl alcohol fiber composite layer, and nano-particle coatings arranged on the outer surfaces of the polymer and water-soluble resin composite layers. According to the fiberglass membrane of the lead-acid battery, the fiberglass membrane is applied to the production of battery membrane paper, the produced battery membrane paper has better performance than the common battery membrane paper, such as larger liquid absorption amount, higher liquid absorption speed and better hydrophily, and keeps high liquid absorption rate during the whole life; meanwhile, the fiberglass membrane has the advantages of large superficial area, high porosity, small pore diameter, high chemical purity, fewer detrimental impurities, excellent acid resistance and oxidation resistance and small resistance.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Preparation method of foaming type magnesium polyacrylate imbibition resin

InactiveCN1908058AIncrease surface areaImprove drynessAbsorbent padsBandagesPotassium persulfateNitrourea

the invention discloses a preparing method of foaming magnesium polyacrylate imbibition resin, which comprises the following steps: adopting 63-72% acrylic emulsion and 27-36% magnesium hydroxide as raw material; adding compound 0.2-0.5% foamer, 0.04-0.09% crosslinking agent and 0.4-0.8% potassium persulphate; neutralizing; crosslinking; squeezing; drying; breaking; foaming; metering; packing. the compound foamer is composed of benzene disulfonate hydrazide and nitrourea and the compound crosslinking agent is composed of epichlorohydrin and methylene diacrylamide.

Owner:FUJIAN NORMAL UNIV

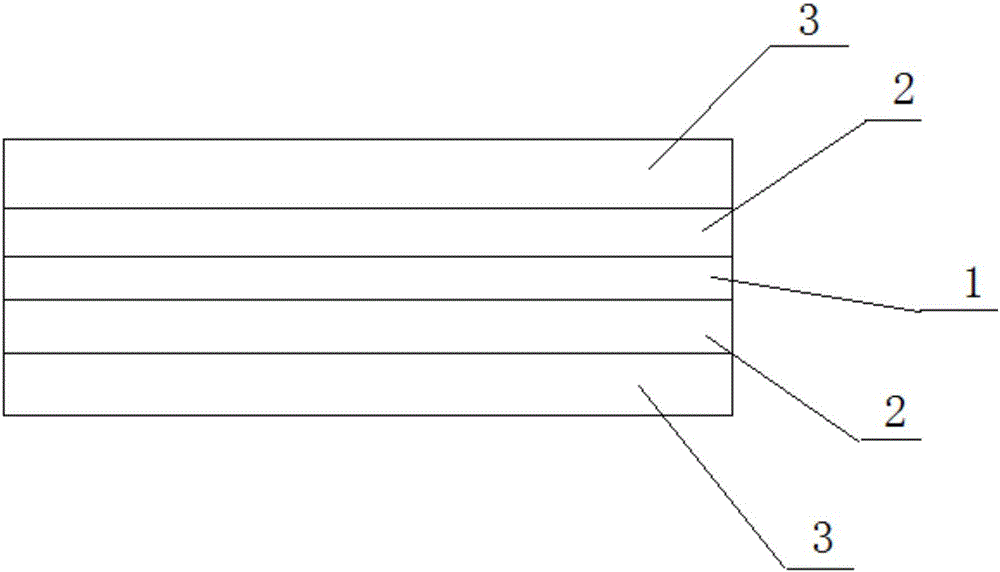

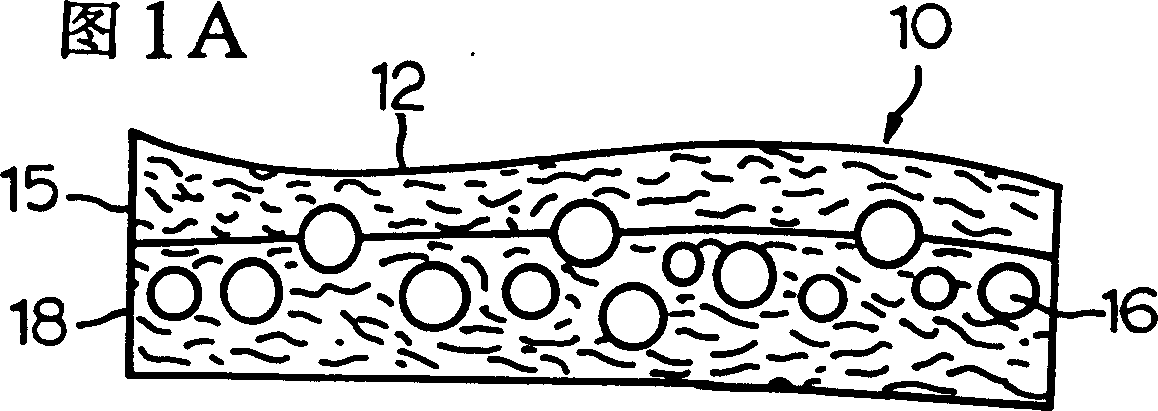

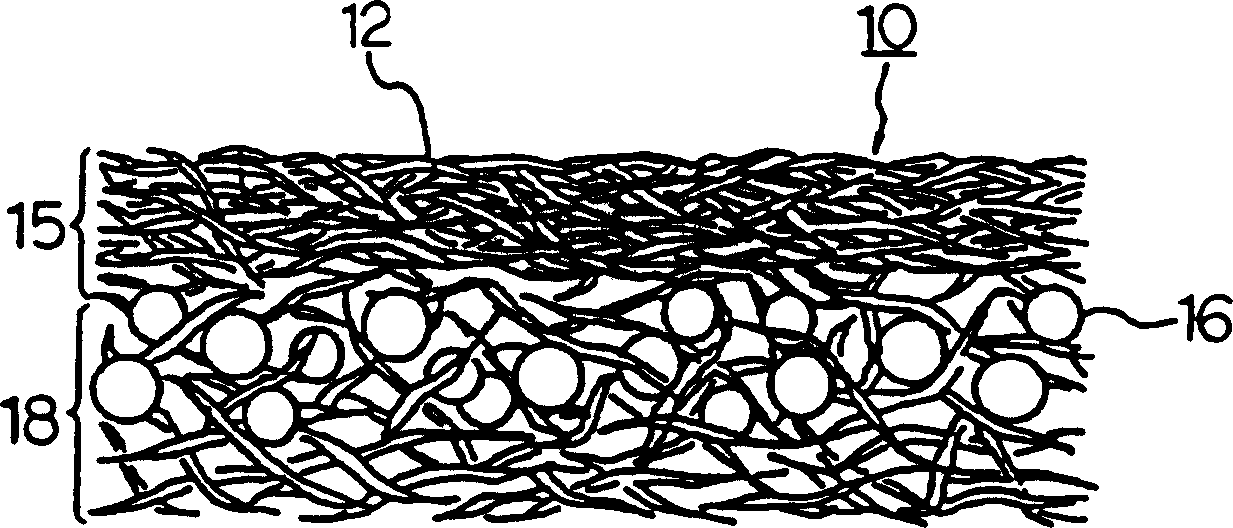

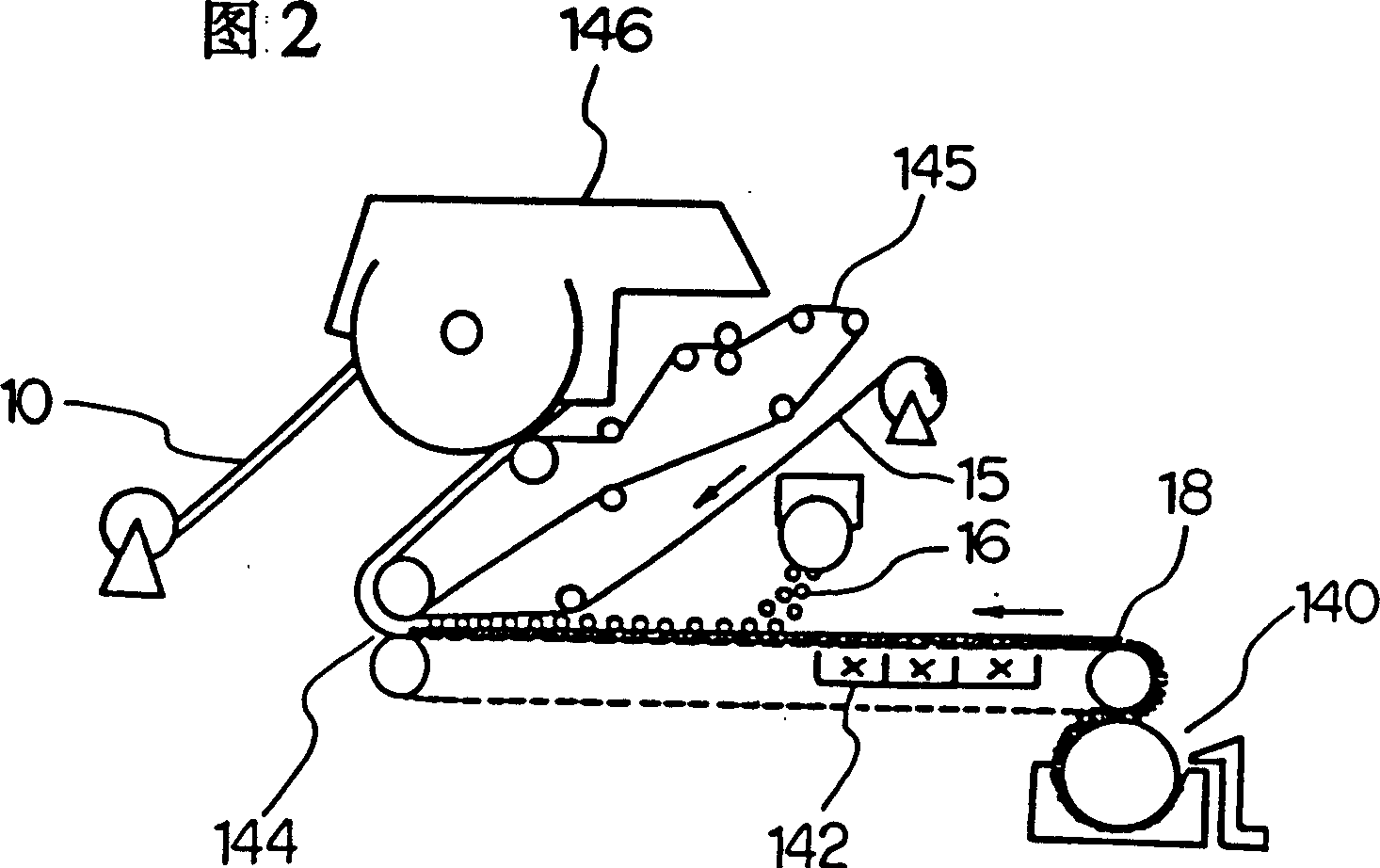

Absorbent sheet, process for producing the same, and absorbent article using the same

InactiveCN1130174CPromote absorptionExcellent absorption speedNon-fibrous pulp additionSpecial paperFiberPolymer science

The absorbent sheet comprising at least hydrophilic fibers and thermally fusible bonding fibers or a strengthening assistant, and a superabsorbent polymer is characterized in that the superabsorbent polymer is not present on an absorbent surface of the absorbent sheet for absorbing liquid but distributed inside the absorbent sheet, and is adhered and fixed to the hyrophilic fibers constituting the absorbent sheet, the superabsorbent polymer is spread at an amount of 5 to 300 g per 1 m2 of the absorbent sheet and the absorbent sheet has thickness of 0.3 to 1.5 mm.

Owner:KAO CORP

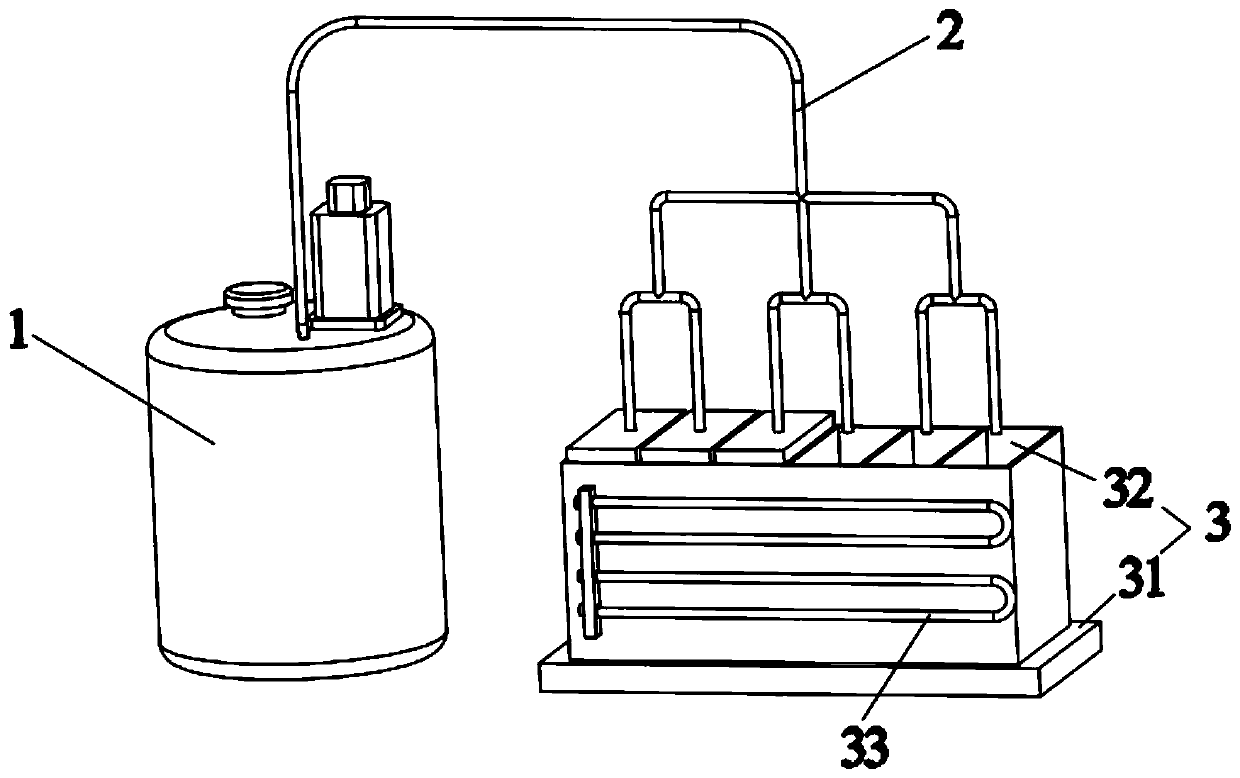

Liquid injection device and method of lithium ion battery

PendingCN110021733AImprove efficiencyImprove stabilitySecondary cellsCell component detailsLiquid storage tankEngineering

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a liquid injection device of a lithium ion battery. The liquid injection device comprises a liquid storage tank, a liquid injection pipe and a fixture, wherein the liquid storage tank communicates with the liquid injection pipe, the liquid injection pipe is arranged on the fixture, the liquid storagetank comprises an outer tank wall layer and an inner tank wall layer, a closed first cavity is formed between the outer tank wall layer and the inner tank wall layer, and a first heating body is arranged in the first cavity. By the first heating body, the liquid storage tank and an electrolyte can be heated, the viscosity of the electrolyte is reduced, and the liquid injection efficiency and theimmersion efficiency of a battery cell are improved; and moreover, the heating stability and consistency of the liquid storage tank also can be improved, and influence on uniform heating of the liquidstorage tank and the electrolyte due to overheat is prevented. Moreover, the invention also discloses a liquid injection method of the lithium ion battery.

Owner:东莞天予天正新能源科技有限公司

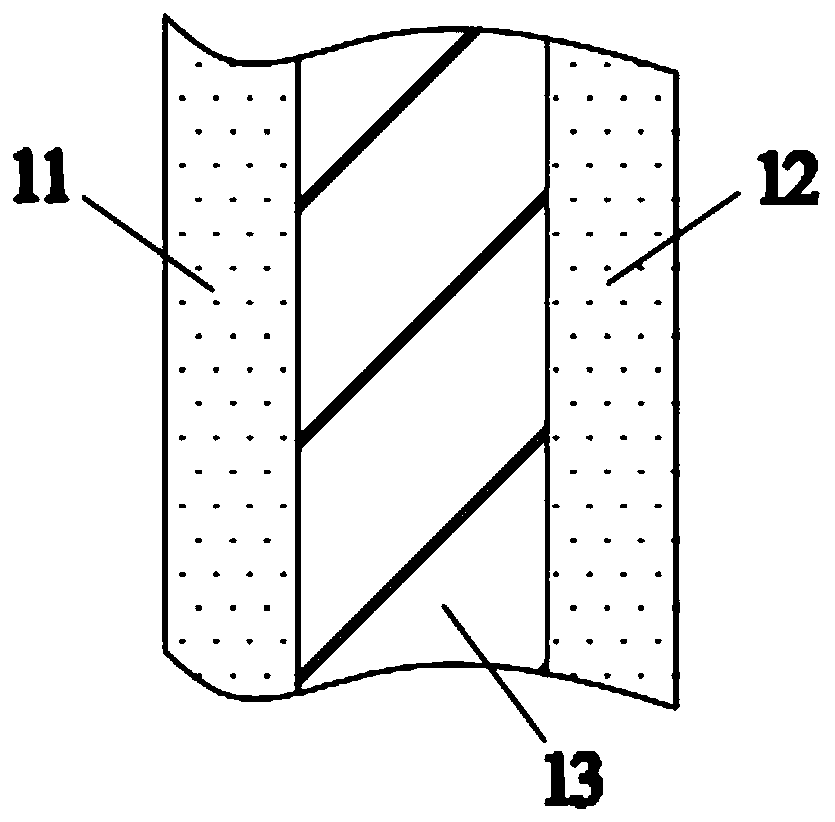

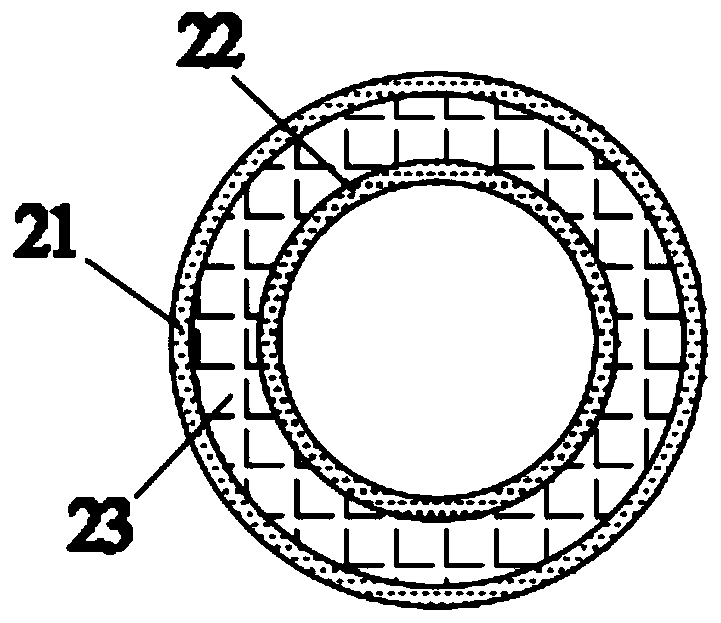

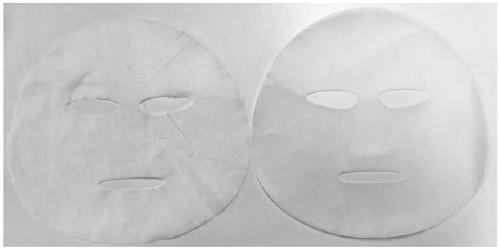

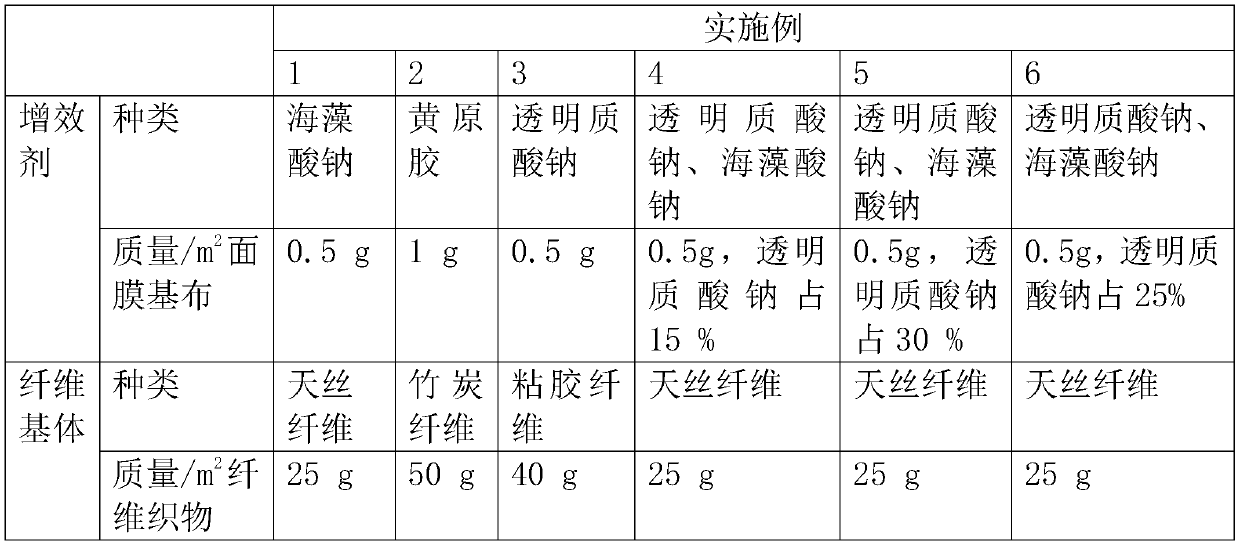

Mask base cloth, preparation method thereof and mask containing mask base cloth

InactiveCN111593477AModerate mechanical propertiesHigh liquid absorptionCosmetic preparationsToilet preparationsCellulosePolymer science

The invention relates to a mask base cloth, a preparation method thereof and a mask containing the mask base cloth. The mask base cloth comprises a fiber matrix, a synergist is attached to the fiber matrix, and the synergist is selected from at least one of collagen, xanthan gum, sodium hyaluronate, hydroxyethyl cellulose, alginate and alginate. According to the invention, the proper synergist isselected, and forms a coating layer on fiber filaments forming the fiber matrix, so that the fiber matrix keeps proper mechanical properties and deformation and wrinkles are effectively reduced. At the same time, the inventor also found that the mask base cloth of the invention has the following advantages that the mechanical properties are good and the deformation rate is low; the liquid absorption rate and the liquid absorption speed are high and the water locking ability is high; the mask base cloth is smooth, soft and skin-friendly; the transparency is high; lasting moisturizing is promoted; and the effect of mask application is improved.

Owner:科丝曼(广州)有限公司

Preparation method of hydrogel dressing containing honey

InactiveCN108404202AFast liquid absorptionIncrease liquid absorptionBandagesCurative effectUltraviolet lights

The invention discloses a preparation method of hydrogel dressing containing honey. The preparation method comprises the steps: evenly mixing a gel stock solution with honey according to a certain proportion, adding a photoinitiator, pouring mixed liquid into a mould to be formed and curing through ultraviolet light to obtain a gel sheet. The hydrogel dressing containing honey disclosed by the invention can quicken a liquid absorption speed of hydrogel, can improve a liquid absorption amount of the hydrogel and can make the hydrogel have a good treating effect on infected wounds.

Owner:ROOSIN MEDICAL CO LTD

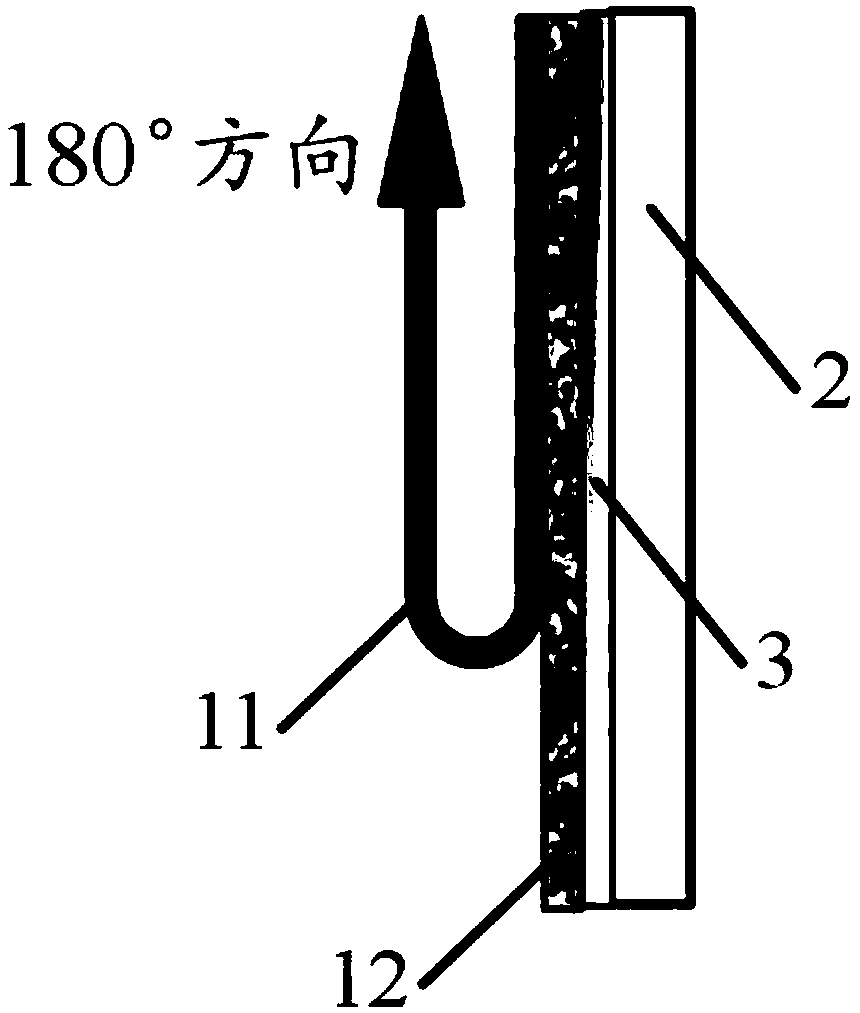

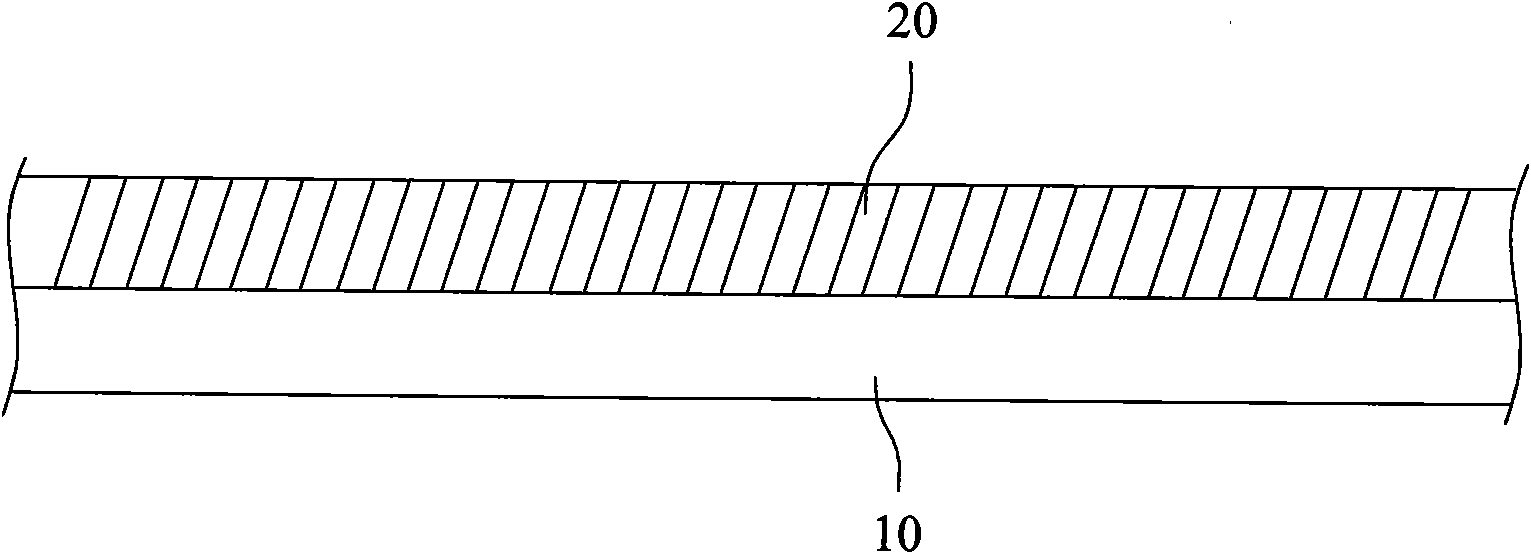

Consumer battery diaphragm

The invention provides a consumer battery diaphragm. The consumer battery diaphragm comprises a base layer (1) and a modification layer (2) arranged on the surface of the base layer (1), wherein the base layer (1) is a glass fiber and polyvinyl alcohol fiber composite layer; the modification layer (2) comprises a polypropylene material matrix (3) as well as porous alumina ultrafine powder (4), ceramic particles (5) and phase change microspheres (5) which are dispersed in the polypropylene material matrix (3). The battery diaphragm has the advantages of simple process, high liquid absorption amount, great surface area, high porosity, small aperture, high chemical purity, fewer harmful impurities and safety in use.

Owner:华富(江苏)锂电新技术有限公司 +1

Method for testing imbibing capability of leakage-proof plugging agent while drilling

InactiveCN102998199AFast liquid absorptionImprove test accuracyWeighing by absorbing componentChemistryQuick Test

The invention discloses a method for testing imbibing capability of a leakage-proof plugging agent while drilling. The method comprises the steps of (a) purifying and drying the leakage-proof plugging agent while drilling for future use; (b) weighing W1 g of the dried leakage-proof plugging agent while drilling and putting the dried leakage-proof plugging agent into a reaction container; (c) adding a liquid to be imbibed; (d) weighing an imbibed gel weight W2 after imbibing is saturated; and (e) calculating an imbibing rate of the leakage-proof plugging agent while drilling through a formula. With the adoption of the method, the imbibing capability of the leakage-proof plugging agent while drilling can be rapidly tested; the test precision is high, and the test steps are simple; and the test cost is greatly reduced.

Owner:莫俊龙

High-salt-tolerance high-water-absorption resin, preparation method and applications thereof

ActiveCN110746541AImprove liquid absorption capacityImprove salt toleranceAbsorbent padsBandagesFoaming agentOrganosolv

The invention discloses high-salt-tolerance high-water-absorption resin, a preparation method and applications thereof. The preparation method comprises: S1, dissolving an alkaline compound in deionized water, and adding an acrylic monomer and an acrylamide monomer solution to obtain a neutralization solution; S2, adding chitosan into an acetic acid solution, sequentially adding an initiator, n-dodecyl mercaptan, the neutralization solution, a cross-linking agent and a foaming agent, and carrying out a polymerization reaction; S3, adding ethanol to precipitate the product, carrying out suctionfiltration, carrying out vacuum drying on the obtained precipitate filter cake, and crushing to obtain resin particles; and S4, mixing the resin particles and tricalcium phosphate powder, soaking inan organic solvent dissolved with titanium dioxide, drying, and spraying with a surface cross-linking solution. According to the invention, the high-salt-tolerance high-water-absorption resin can be used for disposable paper diapers, and has advantages of high absorption rate, high liquid absorption speed, excellent water retention performance and excellent salt resistance.

Owner:深圳市乐闵科技有限公司

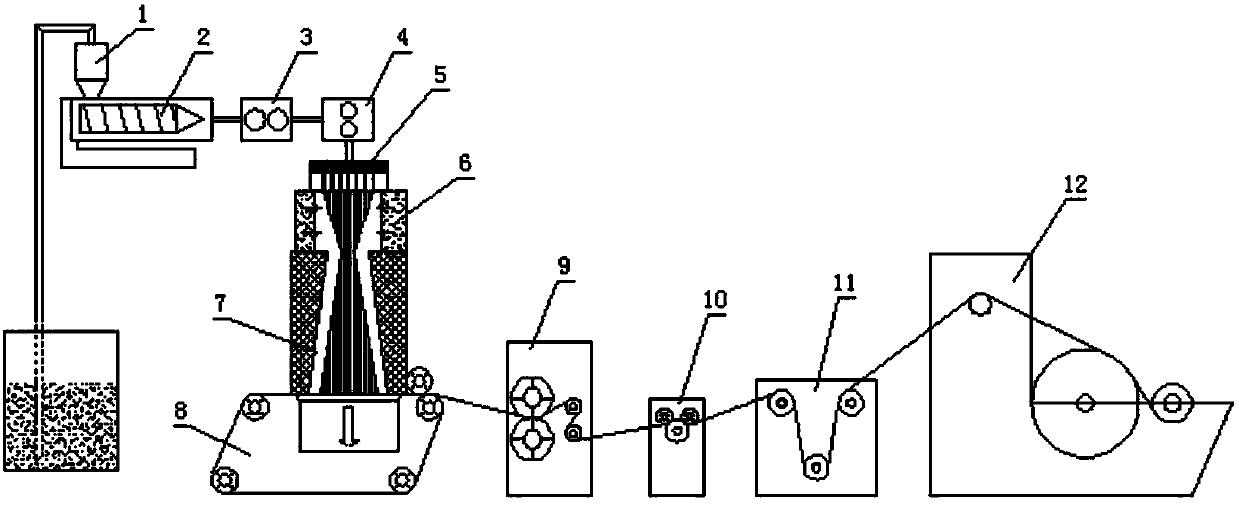

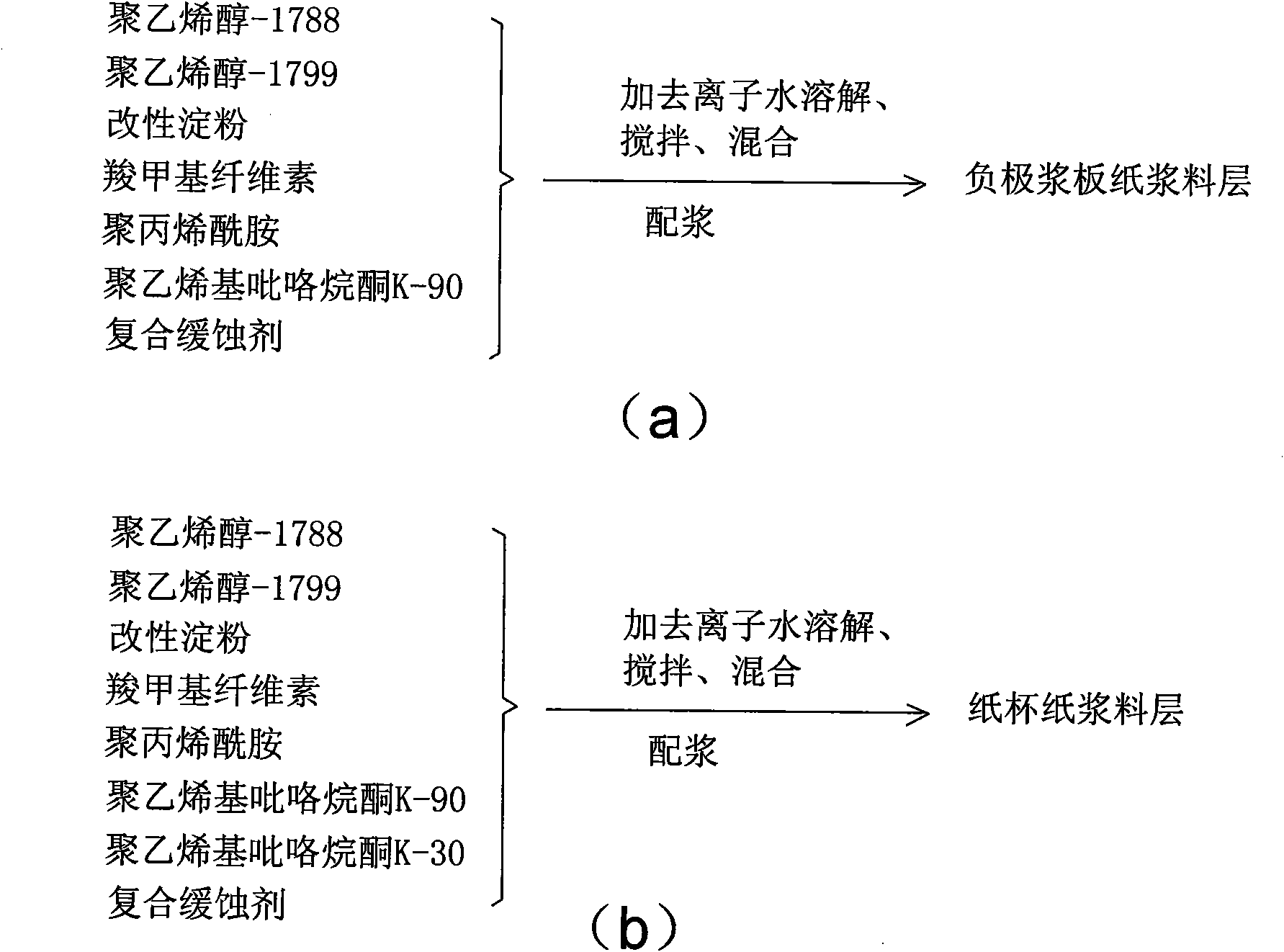

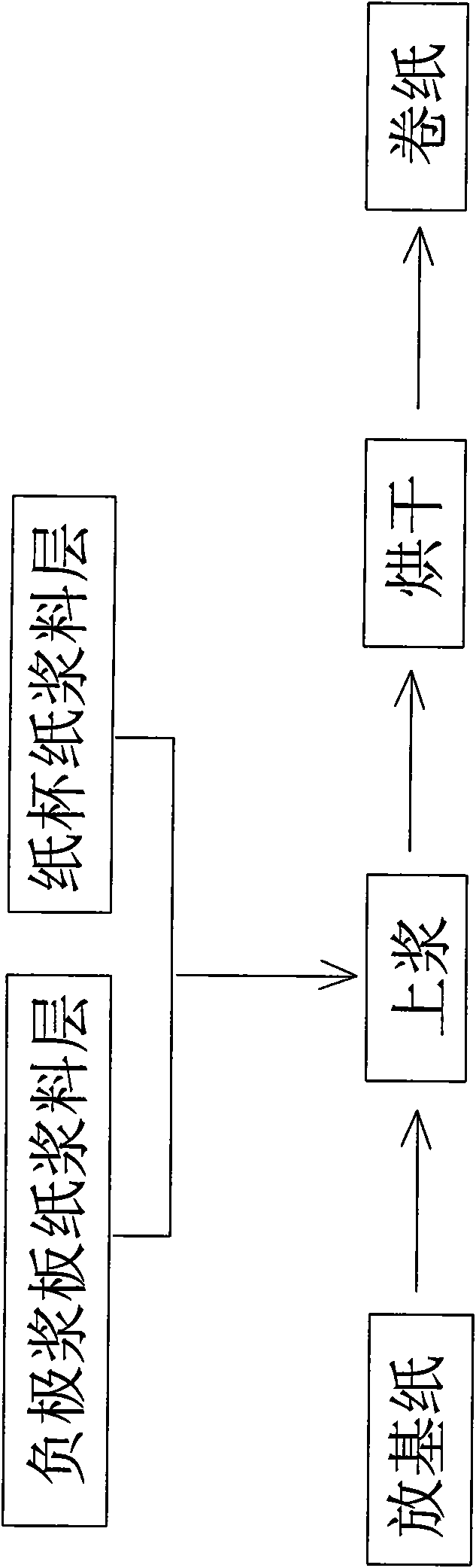

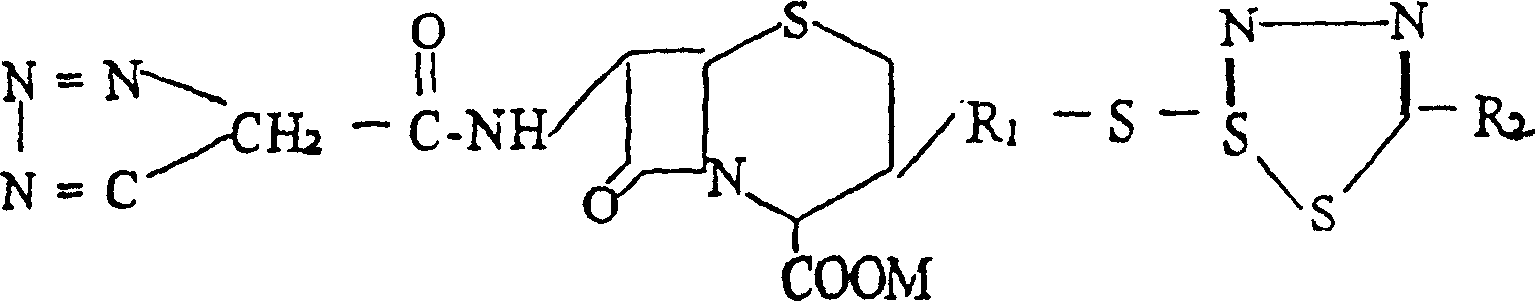

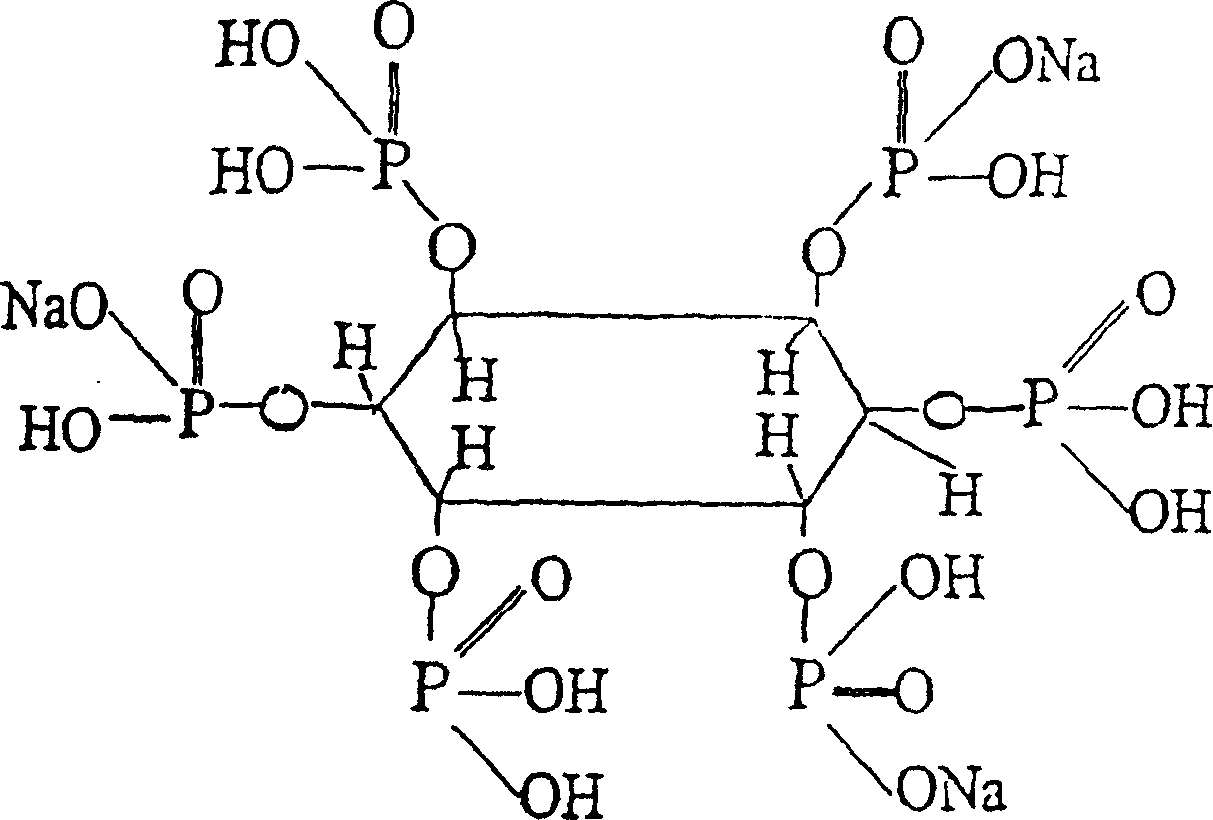

Coated paper for stacked battery and preparation method thereof

InactiveCN101671975AClose contactReduce storage timePaper coatingPaper/cardboardPolyvinyl alcoholManganese

The invention provides coated paper for a stacked battery and a preparation method thereof, wherein, the coated paper comprises base paper and a coating layer coated at the front of the base paper, i.e. single-side coating; and the coating layer is composed of modified starch, polyacrylamide, polyvinyl alcohol, a composite corrosion inhibitor, polyvinyl pyrrolidone and the like. The coated paper for the stacked battery is composed of negative pulp board paper and cup paper (i.e. carbon-clad paper), wherein, the negative pulp board paper has good liquid keeping performance and high isolation performance; and the cup paper has large liquid absorption amount and fast liquid absorption speed, thus meeting the electrical property requirement of high open circuit voltage and low short-circuit current for the stacked zinc-manganese dry cell. The coated paper can meet the industrial production requirement of the stacked battery.

Owner:GUANGDONG ZHAOQING MINGZHU PAPER

Pure cotton spunlace composite fabric as well as preparation method and application thereof

PendingCN112779666ASuction speed hindranceSuction speed is fastAbsorbent padsNon-woven fabricsPolymer scienceCotton fibre

The invention discloses a preparation method of a pure cotton spunlace composite fabric. The method comprises the following steps of preparing a surface layer from water-repellent cotton fibers, performing spunlace compounding on the pre-wetted surface layer and a structural layer to obtain a water-repellent all-cotton composite surface layer, preparing meshes in the water-repellent all-cotton composite surface layer by adopting a punching process, compounding the structural layer and a flow guide layer, and enabling the flow guide layer to cover the meshes in the water-repellent all-cotton composite surface layer, so that the pure cotton spunlace composite fabric is obtained. The water-repellent cotton fibers are creatively adopted to manufacture the water-repellent pure cotton surface layer, and after the water-repellent pure cotton surface layer and the structural layer are subjected to spunlace compounding, the water-repellent all-cotton composite surface layer with higher strength can be obtained, and the meshes with clearer edges are formed, so that it is guaranteed that the liquid absorption speed of the surface layer is not hindered by edge fibers of the meshes; and in addition, after the water-repellent all-cotton composite surface layer and the flow guide layer are compounded, the liquid absorption speed of the surface layer can be increased through the flow guide layer, and meanwhile the situation of glue leakage of the meshes of the surface layer can be effectively prevented.

Owner:WINNER MEDICAL CO LTD +1

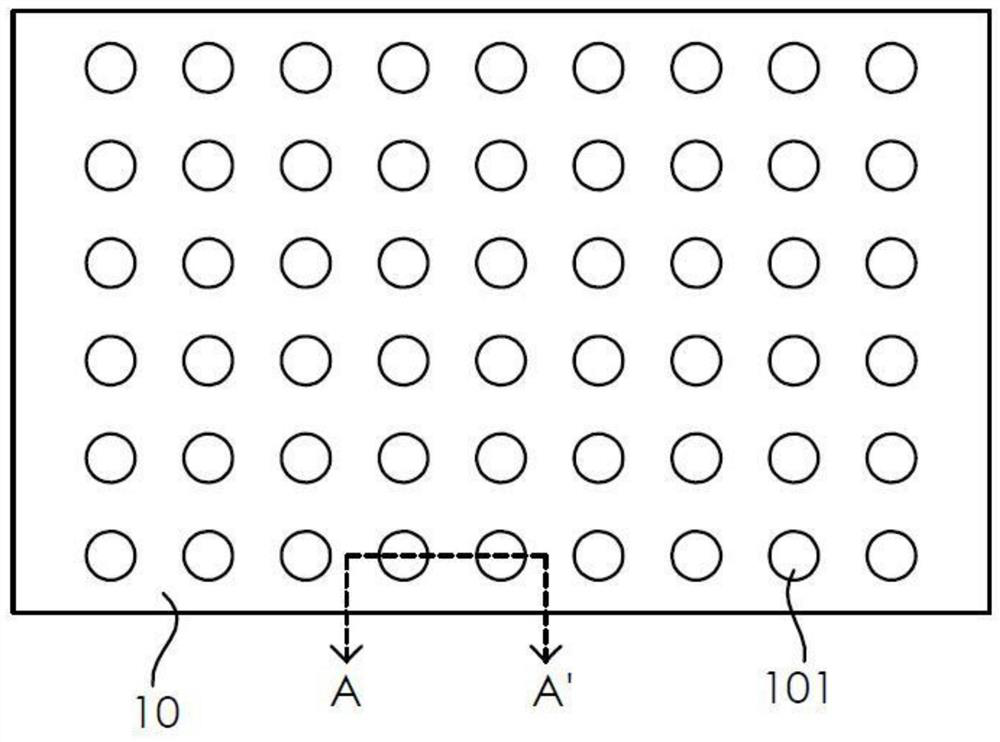

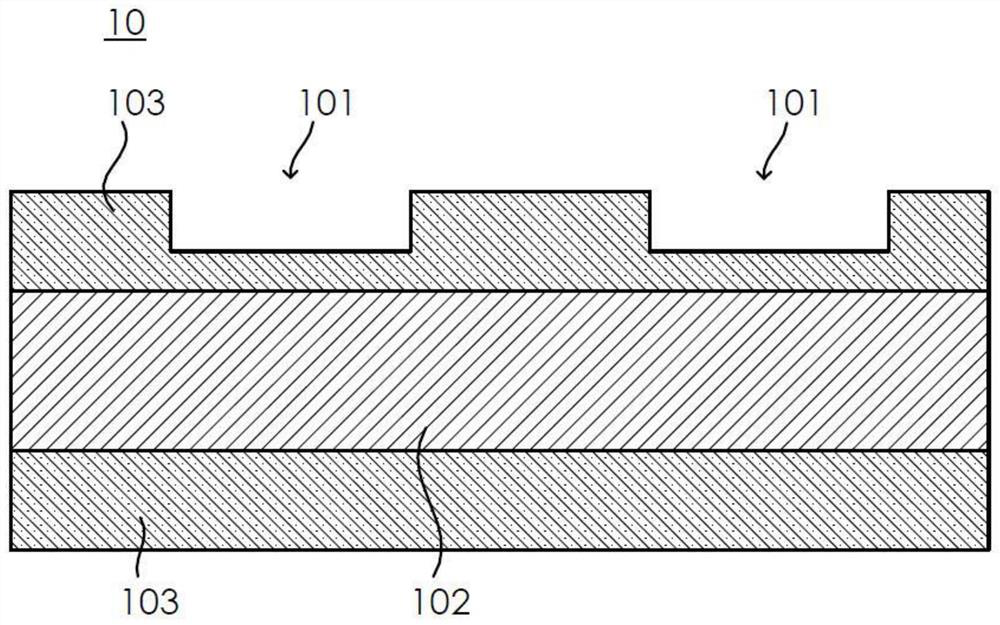

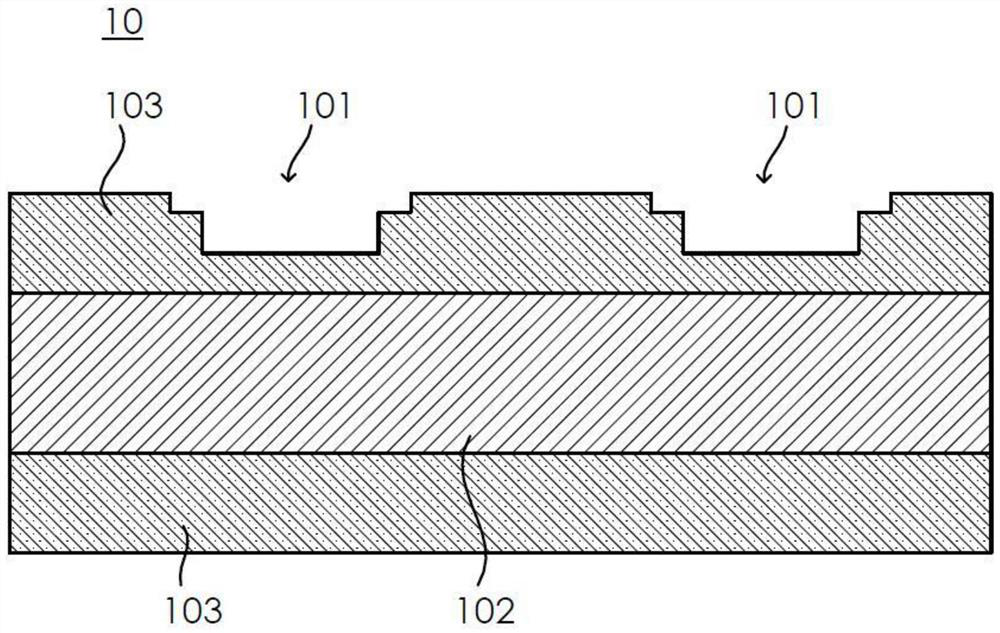

Positive plate, manufacturing method thereof and battery

InactiveCN113285052AFast liquid absorptionSlow down the rate of polarizationFinal product manufactureNon-aqueous electrolyte accumulator electrodesStructural engineeringPositive current

The embodiment of the invention discloses a positive plate, a manufacturing method thereof and a battery. The positive plate comprises a positive current collector and a coating arranged on the surface of the positive current collector, the surface of the coating of the positive plate is provided with at least four concave parts, the at least four concave parts are arranged in a two-dimensional array form, and the depth of the concave parts is smaller than the thickness of the coating. According to the embodiment of the invention, the charging and discharging performance of the battery in a low-temperature environment can be improved.

Owner:FPR CONNECTIVITY TECH INC

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1321244CLower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com