Consumer battery diaphragm high in safety

A battery separator and consumer technology, applied in the field of battery materials, can solve the problems of affecting the battery cycle life, poor air permeability of the polyolefin separator, unable to meet the fast charging and discharging of the battery, etc., and achieves low oxidation resistance and hydrophilicity. Good, small aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

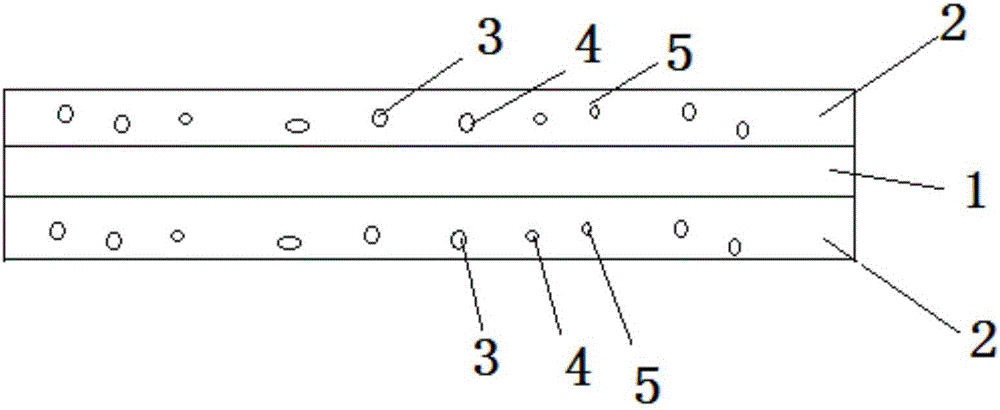

[0020] High-safety consumer battery separators, see figure 1 ,include

[0021] Base layer 1, said base layer 1 is a hydrophilic PET non-woven fabric filled with high molecular polymer;

[0022] The modified layer 2 provided on the surface of the base layer 1; the modified layer 2 includes a polypropylene material matrix 3 and porous alumina ultrafine powder 4, ceramic particles 5 and phase change microspheres 5 dispersed in the polypropylene material matrix 3 ;

[0023] The phase change microspheres 5 are made of the following components by weight: 40 parts of chlorinated paraffin, 2 parts of glyceryl monostearate, 1 part of sodium dodecylbenzene sulfonate, and ethylene terephthalate 12 parts of ester, 4 parts of 2-acrylamido-2-methylpropanesulfonic acid, 6 parts of dimethylaminoethyl acrylate, 1 part of terephthalic acid, 3 parts of graphite, 2 parts of silicon dioxide, sulfuric acid decahydrate 20 parts of sodium, 10 parts of ammonium sulfate, 10 parts of sodium bisulfate, 3 par...

Embodiment 2

[0032] High-safety consumer battery separators, see figure 1 ,include

[0033] Base layer 1, said base layer 1 is a hydrophilic PET non-woven fabric filled with high molecular polymer;

[0034] The modified layer 2 provided on the surface of the base layer 1; the modified layer 2 includes a polypropylene material matrix 3 and porous alumina ultrafine powder 4, ceramic particles 5 and phase change microspheres 5 dispersed in the polypropylene material matrix 3 ;

[0035] The phase change microspheres 5 are made of the following components by weight: 60 parts of chlorinated paraffin, 1 part of glyceryl monostearate, 3 parts of sodium dodecylbenzene sulfonate, and ethylene terephthalate 8 parts of ester, 6 parts of 2-acrylamido-2-methylpropanesulfonic acid, 4 parts of dimethylaminoethyl acrylate, 3 parts of terephthalic acid, 1 part of graphite, 4 parts of silicon dioxide, sulfuric acid decahydrate 40 parts of sodium, 20 parts of ammonium sulfate, 5 parts of sodium bisulfate, 1 part ...

Embodiment 3

[0044] Consumer battery separator with high safety, see figure 1 ,include

[0045] Base layer 1, said base layer 1 is a hydrophilic PET non-woven fabric filled with high molecular polymer;

[0046] The modified layer 2 provided on the surface of the base layer 1; the modified layer 2 includes a polypropylene material matrix 3 and porous alumina ultrafine powder 4, ceramic particles 5 and phase change microspheres 5 dispersed in the polypropylene material matrix 3 ;

[0047] The phase change microspheres 5 are made of the following components by weight: 50 parts of chlorinated paraffin, 1.5 parts of glyceryl monostearate, 2 parts of sodium dodecylbenzene sulfonate, and ethylene terephthalate 10 parts of ester, 5 parts of 2-acrylamido-2-methylpropanesulfonic acid, 5 parts of dimethylaminoethyl acrylate, 2 parts of terephthalic acid, 2 parts of graphite, 3 parts of silicon dioxide, sulfuric acid decahydrate 30 parts of sodium, 15 parts of ammonium sulfate, 8 parts of sodium bisulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com