Patents

Literature

134results about How to "Low antioxidant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant ceramic matrix composite material and preparation method thereof

The invention relates to an ultra-high temperature resistant ceramic-based composite and a preparation method, which adopts carbon or boron nitride fabric cloth as reinforcing phases, ceramic powders of high melting point or high-temperature resistant metal powders as the stuffing, and carbon / silicon carbide as the base. Through the blending and ball milling of the adhesives and the powder stuffing, the sizing agent thus acquired is coated on the reinforcing phase fabric cloth, and then overlapping, molding, cross-bonding, high-temperature pyrolysis, and repeated densification are carried out in preparing the composite. The ultra-high temperature resistant ceramic composite has the advantages of excellent thermal shock resistance, low density, and low ablating rate under ultra-high temperature.

Owner:NAT UNIV OF DEFENSE TECH

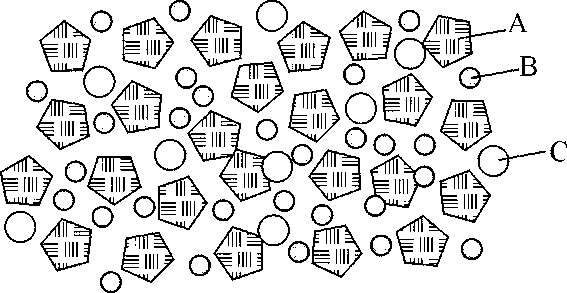

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

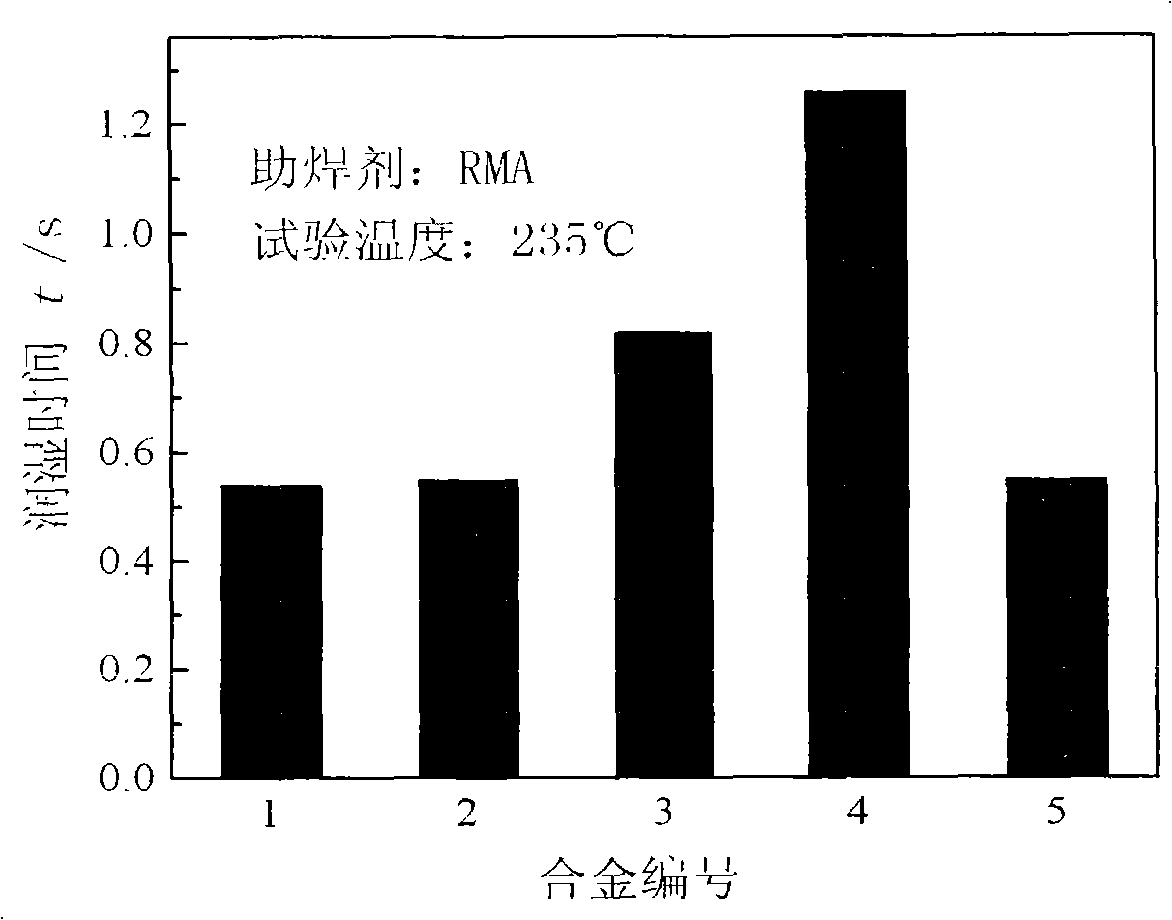

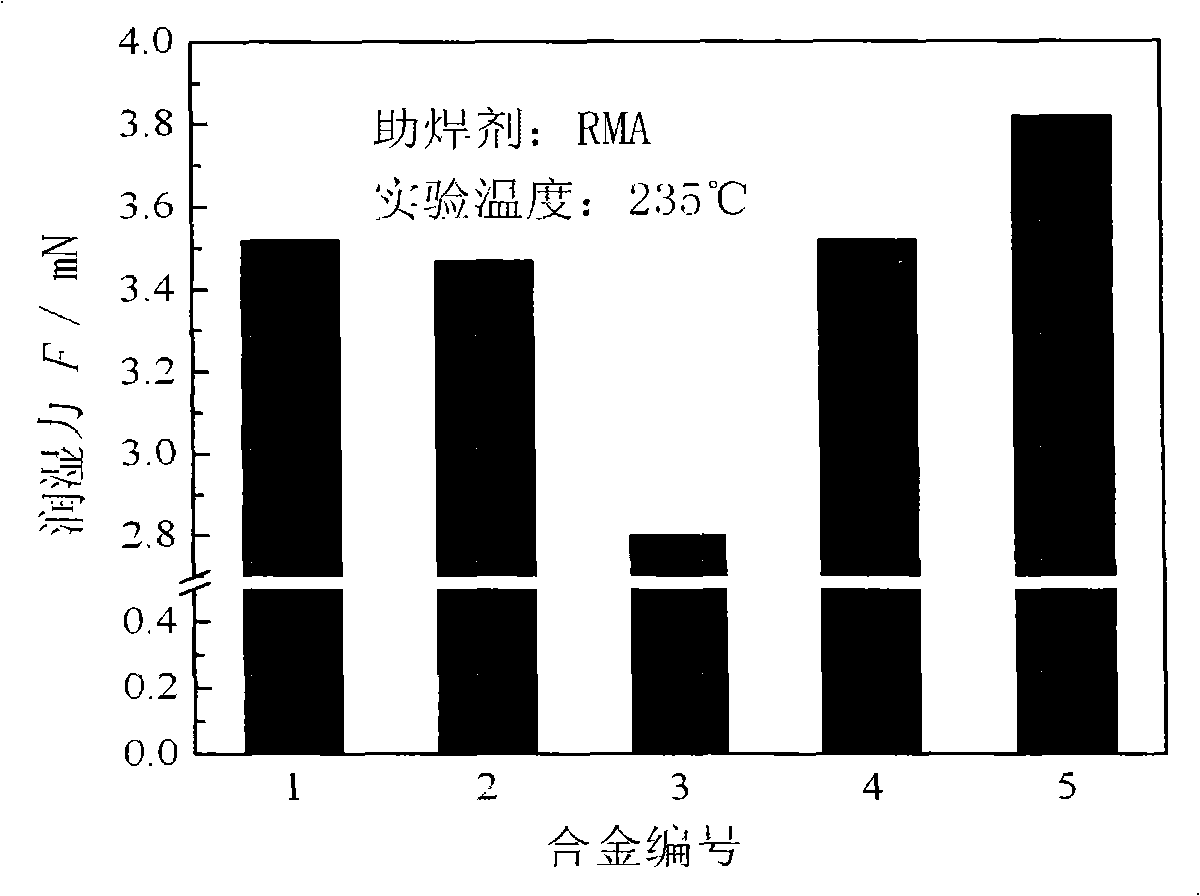

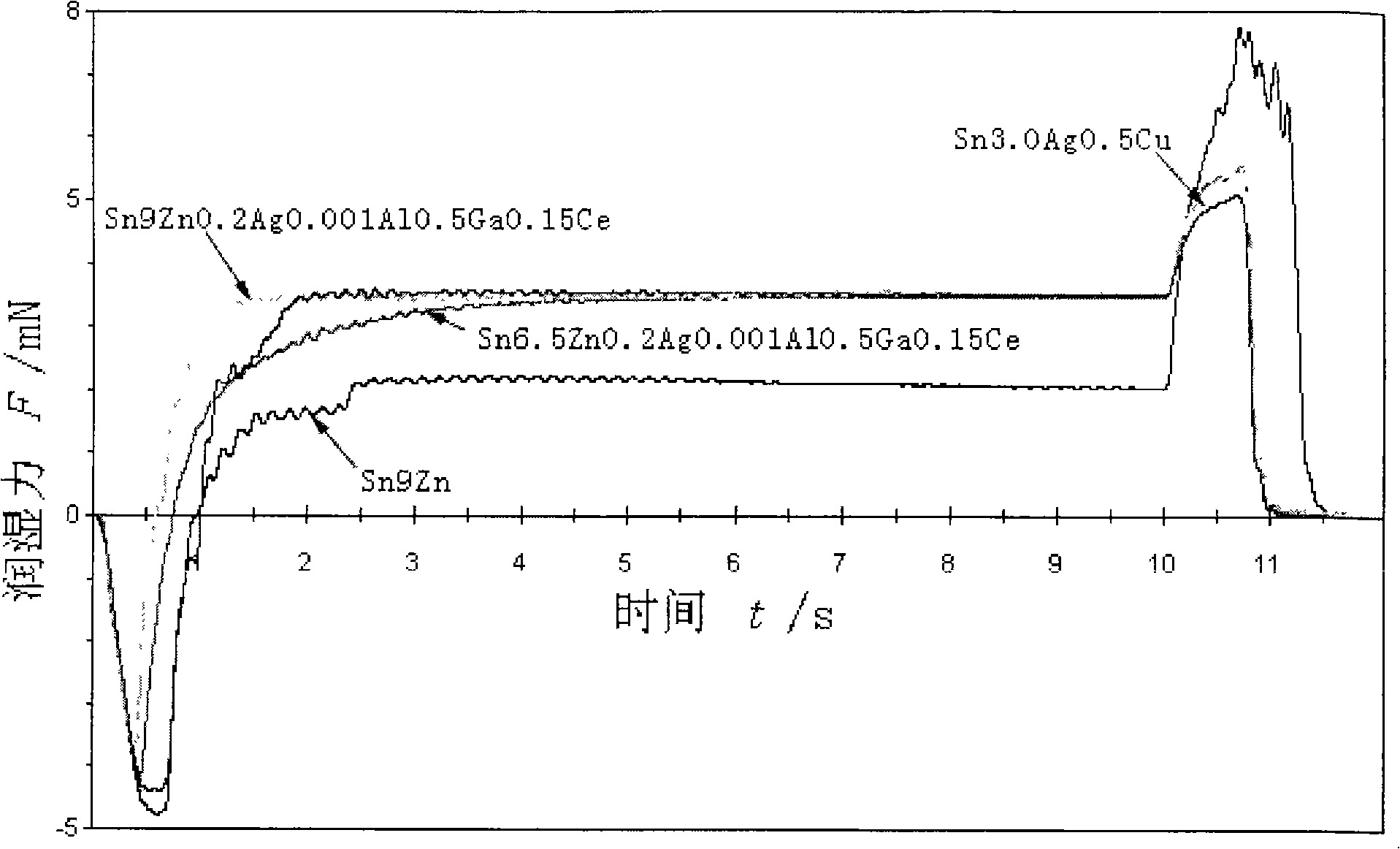

Sn-Zn-Ga-Ce leadless brazing filler metal

InactiveCN101269446AReduce oxidationImprove wettabilityWelding/cutting media/materialsSoldering mediaSilver plateCerium

The invention relates to Sn-Zn-Ga-Ce lead-free brazing filler metal, which belongs to a metal material and a braze welding material of the metallurgic field. The chemical constitution according to a mass percentage is as follows: 5 to 10 percent of zinc, 0.05 to 3 percent of gallium, 0.001 to 0.5 percent of cerium, 0.01 to 3 percent of silver, 0.001 to 0.5 percent of aluminum, and rest percent of tin. Market sold tin ingot, zinc ingot metal, gallium, silver ingot (or silver plate), aluminum ingot and metal cerium are in a mixture ratio according to requirements; when smelting, optimization screened and determined covering agentia is added or inactive gas protection is adopted for smelting and casting, so as to get a bar. Through extruding and drawing, the brazing filler metal silk material is gained (scaling powder can also be added so as to make flux-cored brace welding wire). With the adoption of a powder manufacturing apparatus, new brazing filler metal can be made to a graininess (the graininess size is between 0.106 mm (140 mu) to 0.0380 mm (400 mu)) so as to be used for BGA packaging or made to the soldering paste for use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

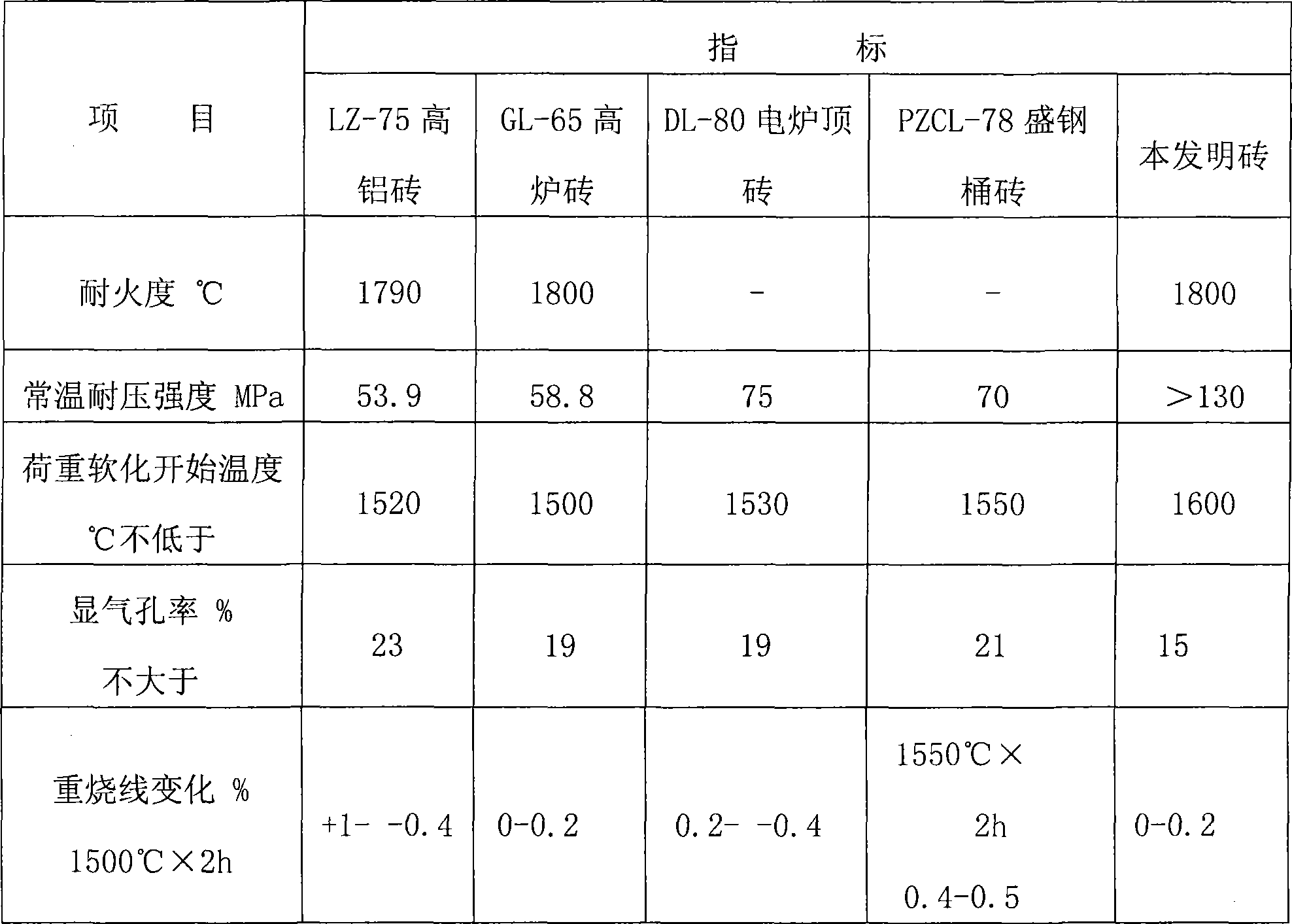

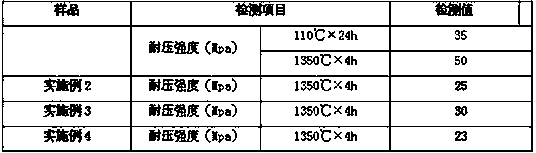

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

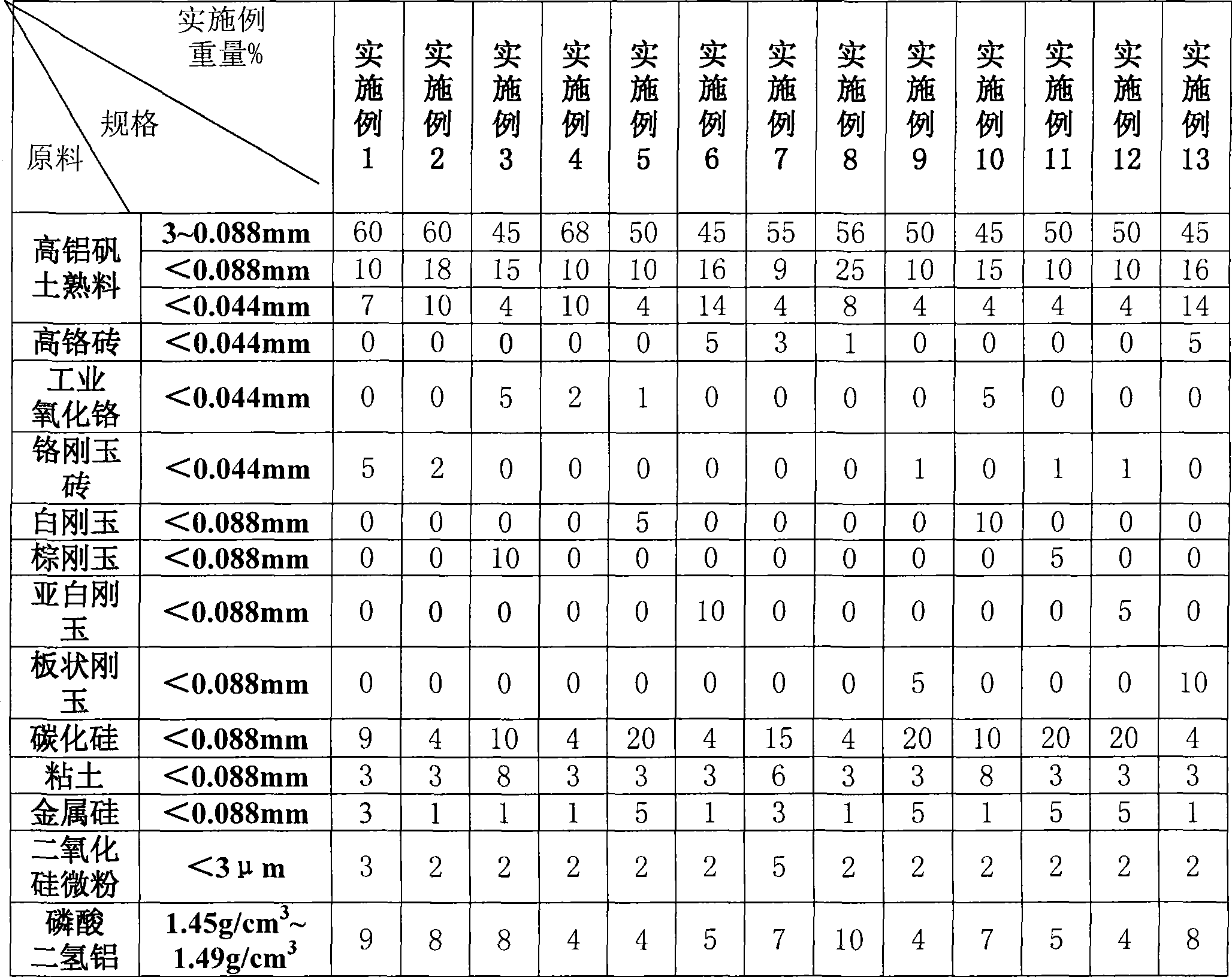

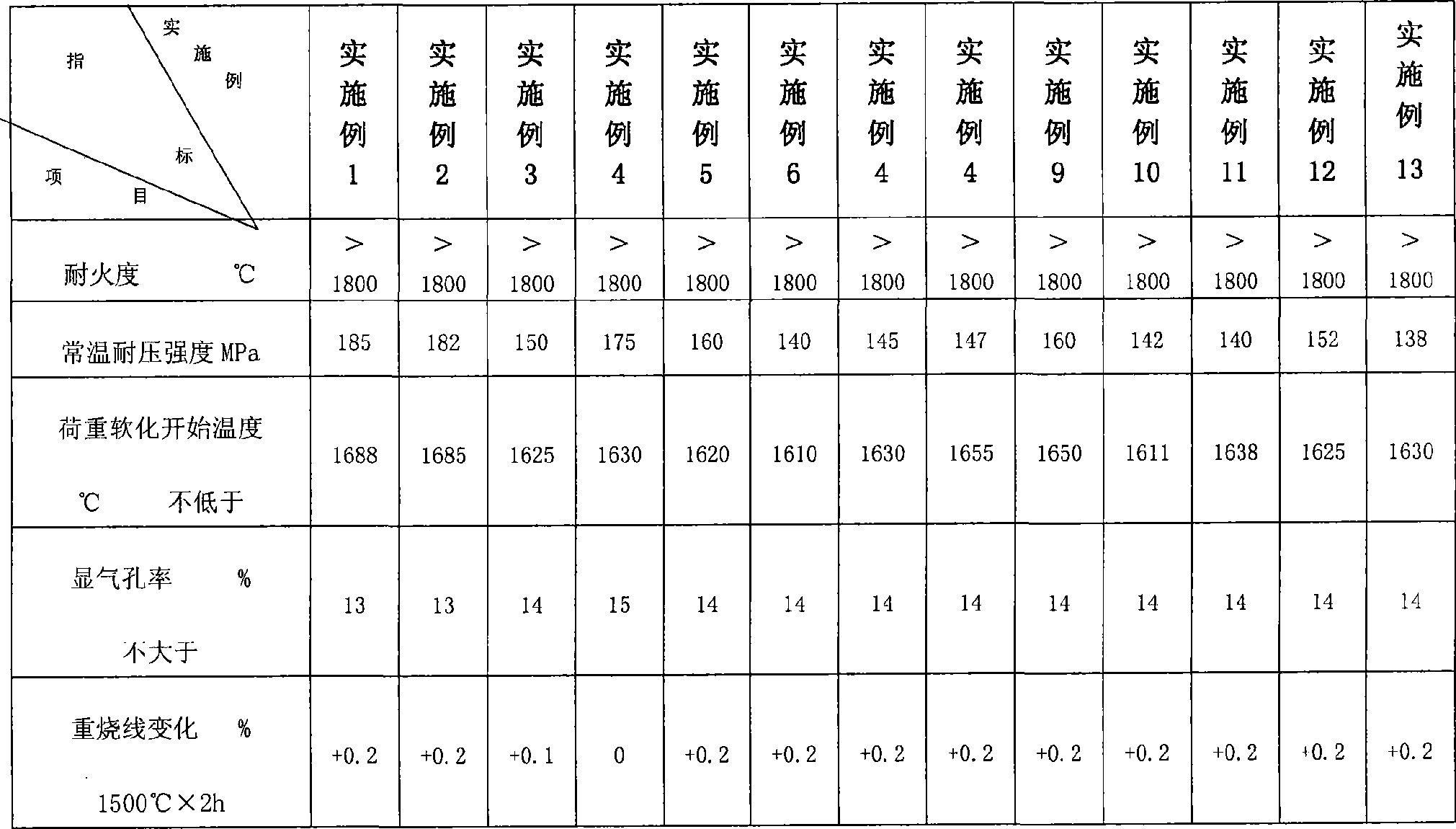

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

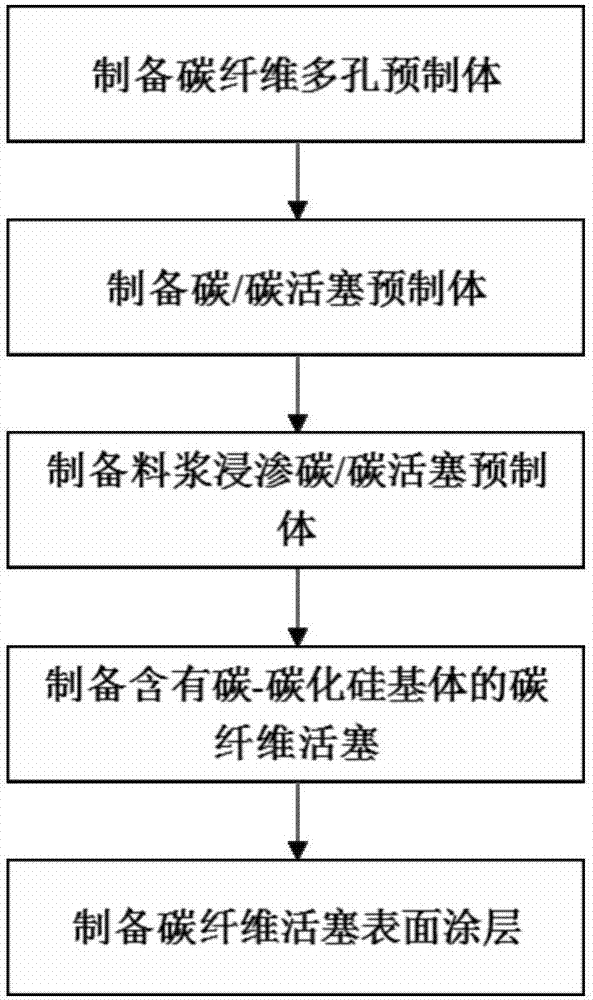

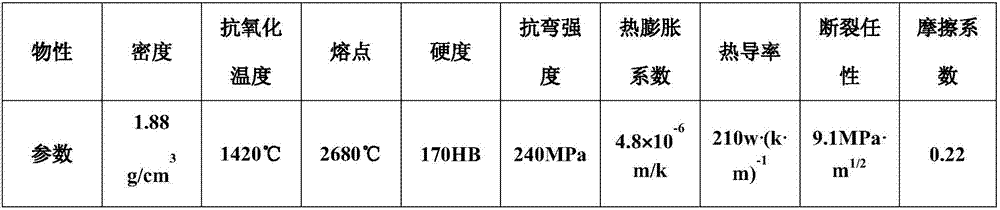

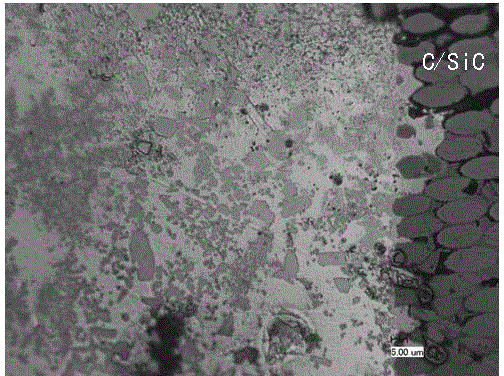

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

Silicon nitride fiber reinforced silicon dioxide ceramic based composite and preparation method and application thereof

ActiveCN107188591AHigh preparation temperatureLow dielectric constantRadiating element housingsFiberCarrying capacity

The invention discloses a silicon nitride fiber reinforced silicon dioxide ceramic based composite and a preparation method and application of the silicon nitride fiber reinforced silicon dioxide ceramic based composite. The silicon nitride fiber reinforced silicon dioxide ceramic based composite comprises an Si3N4 fiber prefabricate and an SiO2 ceramic base, and the SiO2 ceramic base is evenly put in holes of the Si3N4 fiber prefabricate. The preparation method comprises the following steps: (1) removing a binder from the Si3N4 fiber prefabricate in the vacuum or inertia atmosphere; (2) preparing an Si3N4 / SiO2 composite intermediate through the processes of impregnating in vacuum, drying a gel and sintering; and (3) decarbonizing thermally in the aerobic environment. The composite has the advantages of high temperature resistance, ablation resistance, scouring resistance, excellent oxidation resistance, strong carrying capacity and excellent dielectric property, and has an excellent application value in the field of high temperature wave transmitting material; and the preparation method is simple in process and relatively low in cost and is suitable for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

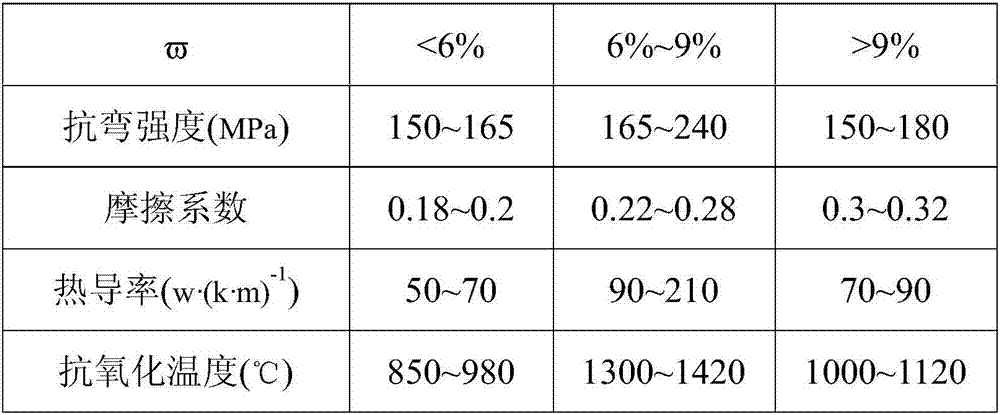

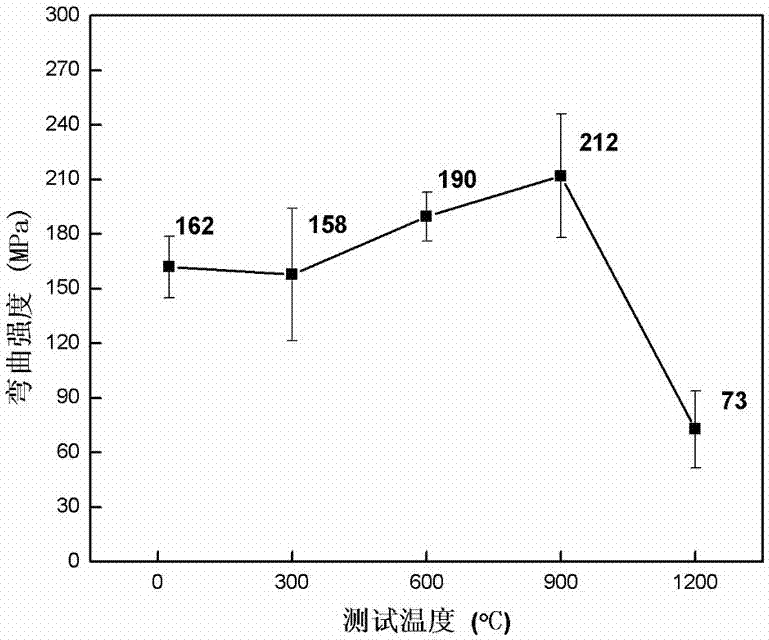

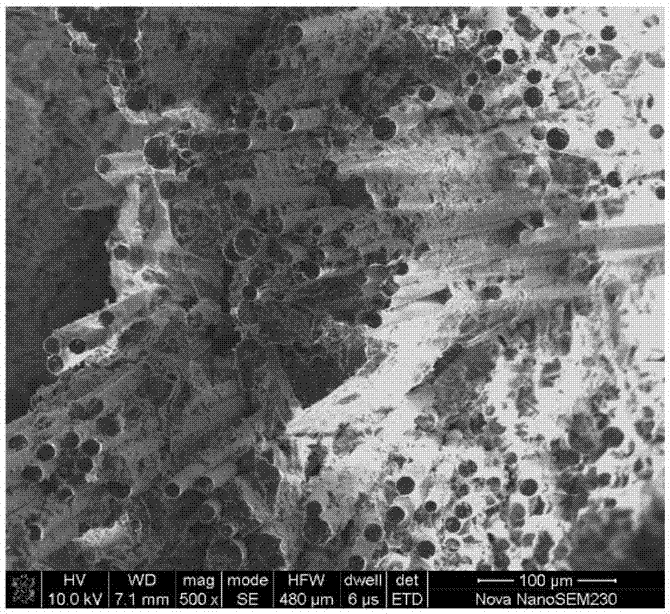

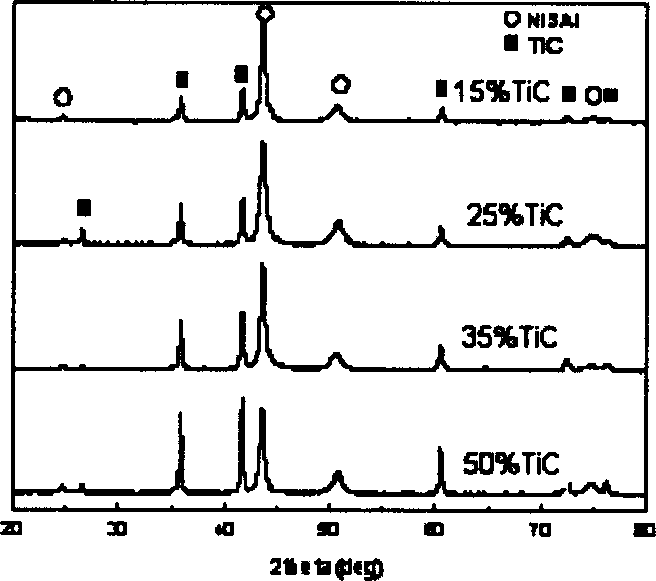

Method for preparing TiC/Ni3Al intermetallic compound based surface composite coating

The invention relates the Cast-SHS preparation technology used for TiC / Ni3Al surface composite coating. The technology comprises the following steps: using Ni, Al, Ti, C powders as raw material, mixing them in proper proportion, pressing them to form precast block, drying, stick organic binding agent on the mould wall; preheating mould, pouring molten steel, and forming the TiC / Ni3Al intermetallic compound surface composite coating on the surface of steel. By adjusting the powder composition, intermetallic compound surface composite coatings which contain different ceramic enhancement phase contents can be obtained. The method possesses the advantages of simple technology, low cost, strong binding force and good combination property.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

Biological enzyme preparation and preparing method thereof

InactiveCN103651663AImprove qualityImprove featuresPre-baking dough treatmentFood preparationProteaseSieve

The invention relates to a biological enzyme preparation. The biological enzyme preparation comprises, by weight, 1.2-1.5 parts of dextranase, 2.5-8 parts of amylase, 1-5.3 parts of lipase, 1.8-4.5 parts of protease, 1.5-3.8 parts of oxidase, 0.8-1.6 parts of glutamine transaminase, 0.5-1.2 parts of phytase, 1.5-5.0 parts of emulgator, 1.0-5.0 parts of water retention agents and 0.5-3.5 parts of flour gluten fortifier. By means of the biological enzyme preparation, the dough performance can be adjusted obviously, the bread size is increased, the bread stiffness is obviously improved, and the bread softness is improved. A preparing method of the biological enzyme preparation includes the steps of weighing the above raw materials by weight to be stirred and evenly mixed, passing through an 80-mesh sieve, further stirring and even mixing until the raw materials are completely and evenly mixed, and obtaining the biological enzyme preparation.

Owner:ZHONGSHAN NAIDE BIOTECH

Modified high-purity magnesium aluminate spinel composite brick and preparation method thereof

The invention belongs to the technical field of a high-grade refractory matter for metallurgy, coloring, glass and cement kilns, and preparation thereof, and particularly relates to a modified high-purity magnesium aluminate spinel composite brick and a preparation method thereof. Aggregate is prepared from the following raw materials in parts by weight: 65 to 80 parts of high-purity magnesia and 15 to 35 parts of high-purity magnesium aluminate spinel; powder materials are prepared from the following raw materials in parts by weight: 1 to 5 parts of fused magnesia powder, 1 to 5 parts of fused magnesia-alumina spinel, 1 to 3 parts of fused magnesia-alumina spinel micro powder, 1 to 3 parts of desilicication zirconia, 1 to 3 parts of titanium oxide, 0.1 to 0.5 part of sintering agents, 1 to 3 parts of active aluminum oxide micro powder and 3 to 4 parts of combining agents. The modified high-purity magnesium aluminate spinel composite brick has the advantages that the purity is high; the density is great; the strength is high; the high-temperature thermal shock stability is good; the corrosion resistant performance is high; the molten metal resistant and antioxidation capability is high; no harmful gas is exhausted; green refractory material standards are conformed. The preparation method is simple; the cost is low; no carbon and no chrome are discharged; no pollution occurs; practical applicability is realized.

Owner:大石桥市中建镁砖有限公司

Ultraviolet ray and infrared ray adsorption blue transparent glass

The invention relates to ultraviolet ray and infrared ray adsorption blue transparent glass, which is formed by that Fe2O3 and CeO2 are added in dry SiO2 and other auxiliary materials, and then the glass is directly fired under the high-temperature melting and low-temperature annealing processes, and the glass is blue and transparent; Visible light transmittance of the glass with 2mm is more than 70 percent, the transmittance of the ultraviolet rays with 200nm-390nm can be reduced to 10-7, the transmittance of the infrared rays with 780nm-1300nm is reduced to 10-6, and the transmittance of the infrared rays with 1300nm-2000nm is reduced to 10-5. The ultraviolet ray and infrared ray adsorption blue transparent glass has low cost, can completely achieve the technical data of vacuum coated glass with Europe and America technology, which is applied to eyesight protection glass products, and can thoroughly overcome the low oxidation resistance, ageing resistance and friction resistance of the vacuum coated glass and is mainly applied to the eyesight protection glass products such as arc welding mask lens, spectacle lens, computer screens, television screens and the like.

Owner:蔡绪忠 +5

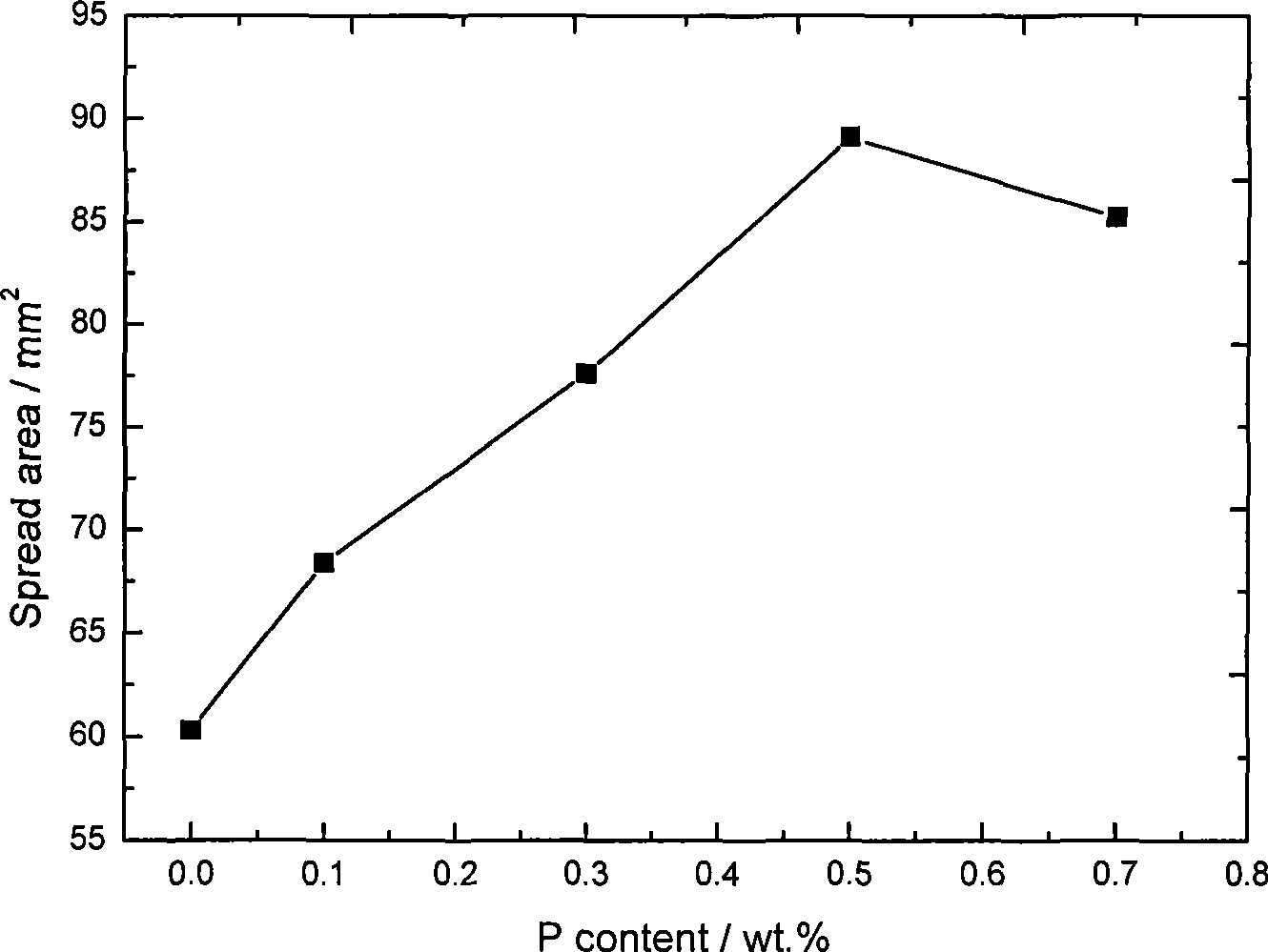

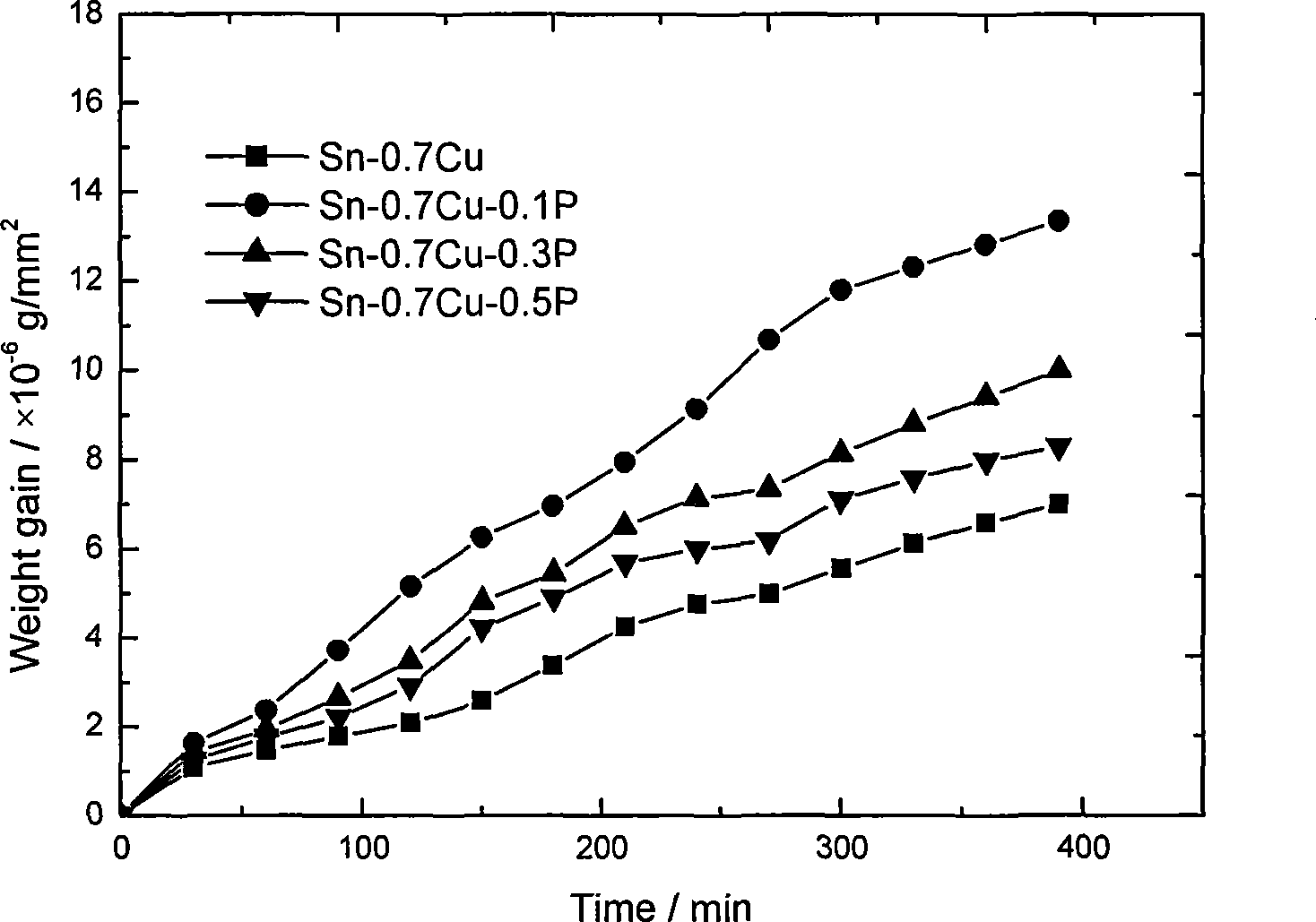

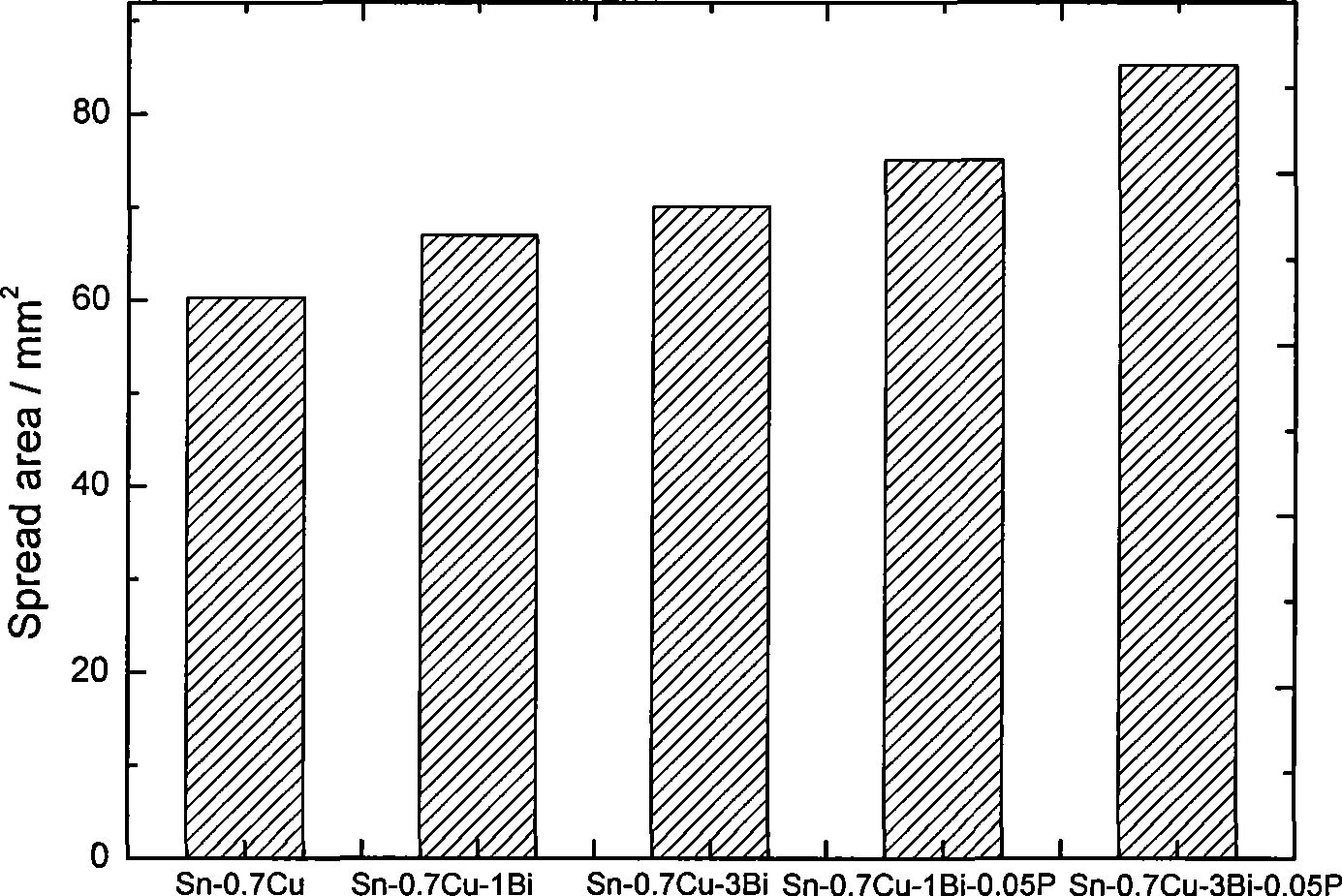

Sn-Cu base leadless solder alloy and preparation method

InactiveCN101381826AImprove wettabilitySmall mechanical propertiesMechanical propertyMaterials science

The invention relates to tin-copper-based lead-free solder alloy and a preparation method thereof. The compositions in mass percentage of the alloy are 0.1 to 1.5 percent of copper, 0.001 to 1 percent of phosphor, 0 to 6 percent of bismuth, 0 to 3 percent of zinc, and the balance being tin. The preparation method comprises the following steps: 3 to 8 percent of the phosphor and 92 to 97 percent of the tin are weighed at first and placed into a graphite crucible; the mixture is covered with protective molten salt and subjected to heat preservation for 30 to 60 minutes at a temperature of between 400 and 550 DEG C; after uniform stirring, casting is performed and tin-copper intermediate alloy is obtained; the tin-copper intermediate alloy is weighed according to the fact that the phosphor occupies 0.001 to 1 percent as calculated by the total mass of 100 percent, and 0.1 to 1.5 percent of the copper, 0 to 6 percent of the bismuth, 0 to 3 percent of the zinc and residual tin are weighed and placed into the graphite crucible; the mixture is covered with the protective molten salt and subjected to heat preservation for 40 to 80 minutes at a temperature of between 450 and 550 DEG C; and after uniform stirring, the mixture is cast into ingots. The preparation method has simple preparation technique and is easy to operate; and the product of the tin-copper-based lead-free solder alloy has the advantages of good wettability, low melting point, good mechanical property, good antioxidation, low cost and so on.

Owner:NANCHANG UNIV

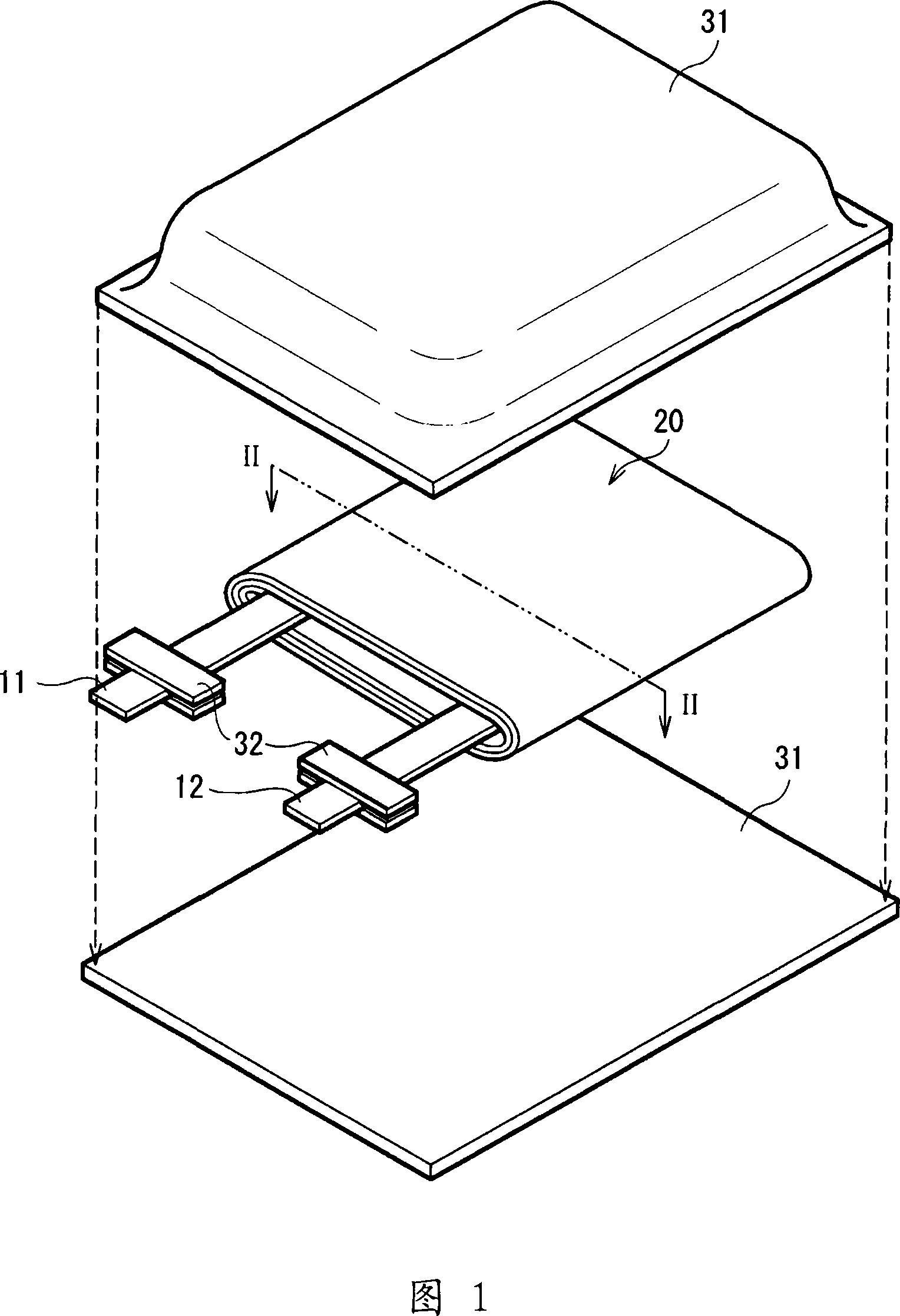

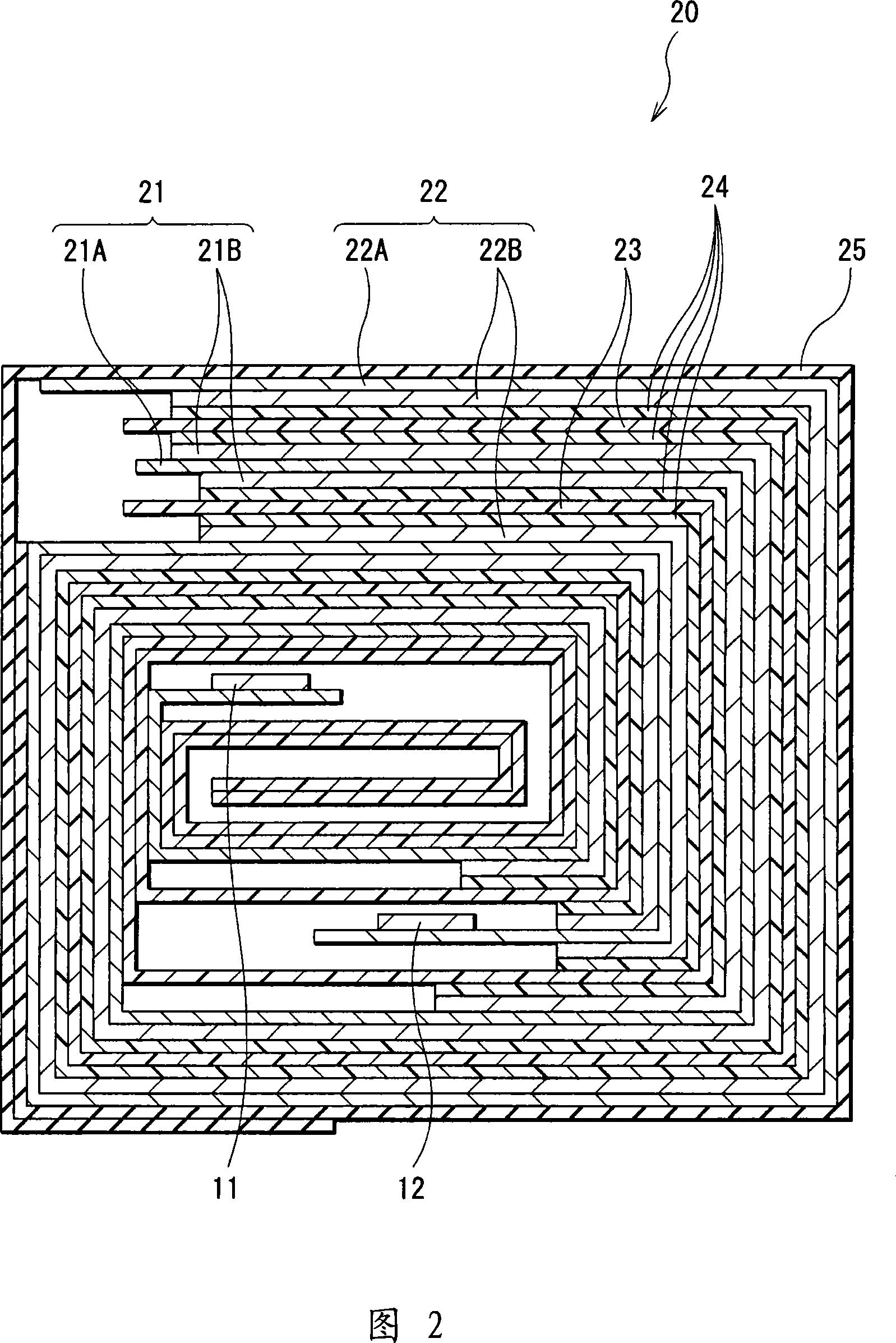

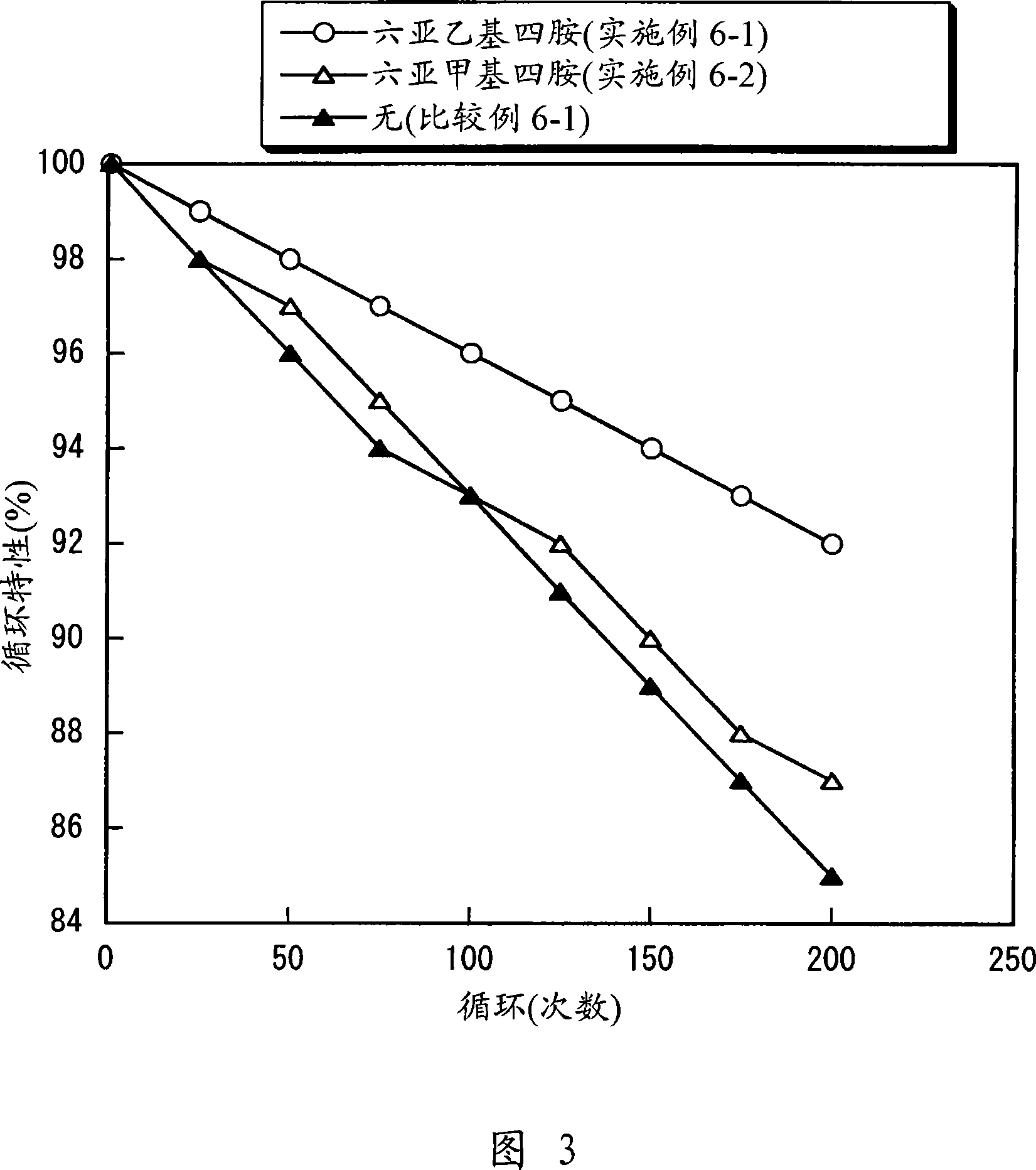

Electrolyte solution and battery

ActiveCN101124695AGood effectPrevent decomposition reactionOrganic electrolyte cellsActive material electrodesDischarge efficiencyHydrofluoric acid

Disclosed is an electrolyte solution which enables to improve battery characteristics such as battery swelling and charge / discharge efficiency. Also disclosed is a battery using such an electrolyte solution. Specifically disclosed is a battery wherein a positive electrode (21) and a negative electrode (22) are arranged in layers via an electrolyte layer (24). The electrolyte layer (24) is a gel containing an electrolyte solution and a polymer compound, and the electrolyte solution contains a compound having a proton-collecting function such as hexamethylenetetramine or hexaethylenetetramine. Consequently, a free acid such as hydrofluoric acid can be captured, thereby suppressing decomposition reaction of the electrolyte.

Owner:MURATA MFG CO LTD

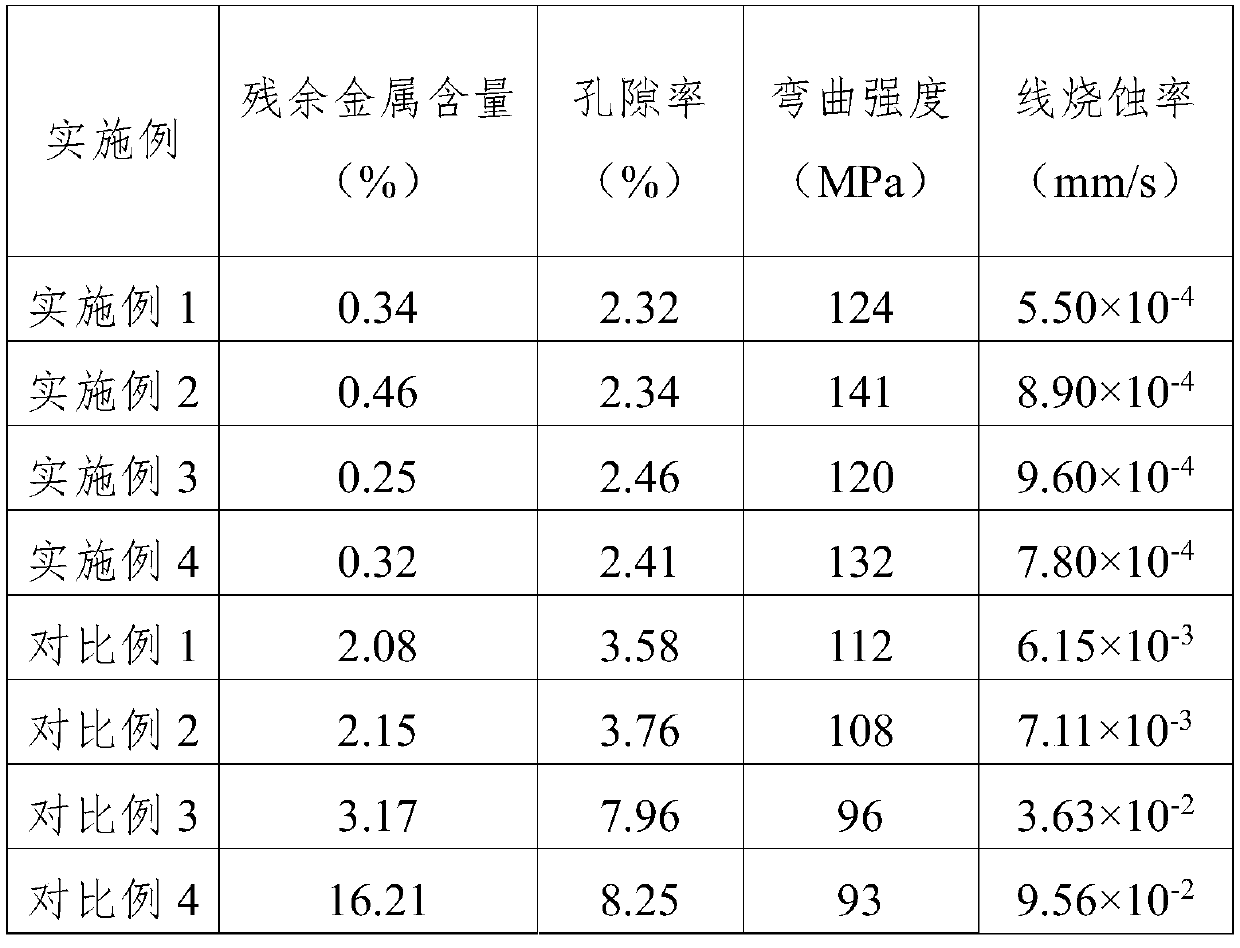

Carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and preparation method thereof

ActiveCN111099911ALow cost of preparationImprove anti-ablation performanceCarbide siliconZirconium carbide

The invention relates to a carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and a preparation method thereof. The method comprises the following steps: (1) depositing a pyrolytic carbon matrix on the surface of carbon fibers contained in a carbon fiber preform to obtain a modified carbon fiber preform; (2) preparing a mixed resin solution of silicon powder, zirconium powder, graphite powder and phenolic resin in a mass ratio of (1-3): (4-6): 5: 100; (3) impregnating the modified carbon fiber preform with the mixed resin solution, and then sequentially carrying out curing and carbonization reactions on the impregnated modified carbon fiber preform, wherein the carbonization reaction is carried out in an inert atmosphere, the temperature of the carbonization reaction is 1650-1750 DEG C, and the time is 0.5-2 hours; and (4) repeating the step (3) at least once to obtain the composite material. According to the invention, silicon carbide and zirconium carbide can be uniformly distributed in the composite material, the content of free metals is reduced, and the oxidation resistance and ablation resistance of the material are improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

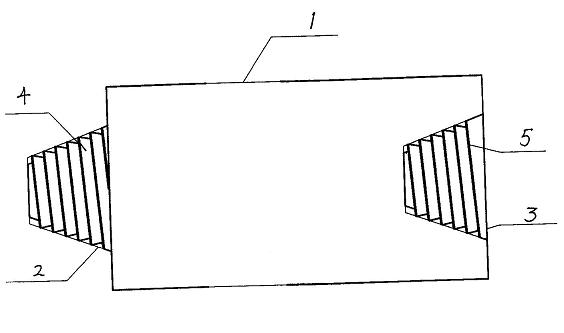

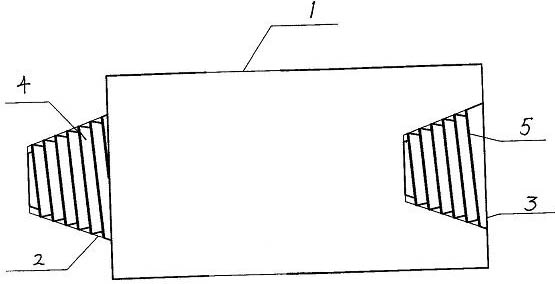

ZrSiCN nano-composite gradient coating cutter and preparation process thereof

InactiveCN105063554AReduce coefficient of frictionLow antioxidantVacuum evaporation coatingSputtering coatingManufacturing technologyMedium frequency

The invention belongs to the technical field of fabrication of mechanical cutting tools and particularly relates to a ZrSiCN nano-composite gradient coating cutter and a preparation process thereof. The ZrSiCN nano-composite gradient coating cutter is fabricated by the aid of multi-arc ion plating and a medium frequency magnetron sputtering deposition coating film method; a ZrSiCN nano-composite gradient layer is designed on the surface of the cutter; a Zr and ZrSiC transition layer is arranged between the ZrSiCN nano-composite gradient layer and a cutter substrate. The ZrSiCN nano-composite gradient coating is high in hardness and oxidation resistance and low in friction coefficient, and during cutting, cuttings adhesion, friction, cutting force, cutting temperature and cutter wear can be reduced and the service life of the cutter can be prolonged. The ZrSiCN nano-composite gradient coating cutter is widely applicable to dry cutting and cutting of hard-to-machine materials.

Owner:SHANDONG UNIV

Special carbon electrode for smelting of titanium slag and preparation method thereof

InactiveCN101983002AHigh resistivityLow high resistivityElectric discharge heatingCooking & bakingPetroleum coke

The invention belongs to the technical field of carbon electrodes and discloses a special carbon electrode for smelting of titanium slag and a preparation method thereof. The preparation method is mainly technically characterized by screening solid raw materials comprising electrically calcined coal, petroleum coke and graphite scrap after calcination, proportioning the materials by an electronic proportioning system, then adding into a mixing and kneading pot, stirring and dry-mixing, then adding coal asphalt, mixing and kneading, and further molding, baking and machining for producing a special carbon electrode finished product for smelting of the titanium slag. The special carbon electrode for the smelting of the titanium slag has the advantages of no asphalt volatile matters, high volume density, low ash content and good oxidation resistance; and the the special carbon electrode is used for replacing a self-baking electrode, thus flue gas volatile matters emitted during baking is avoided, the power consumption during the baking process of the self-baking electrode is saved, energy conservation and environmental friendliness are realized, the installation is simple and convenient, the accidents of soft breakage and hard breakage of the electrode caused by careless operation are avoided, and the safety is greatly improved.

Owner:JIZHOU CHANGAN ELECTRODE

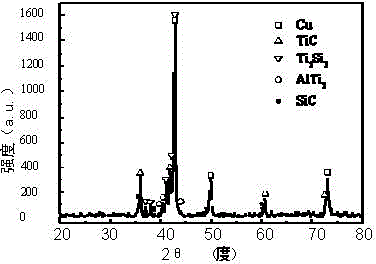

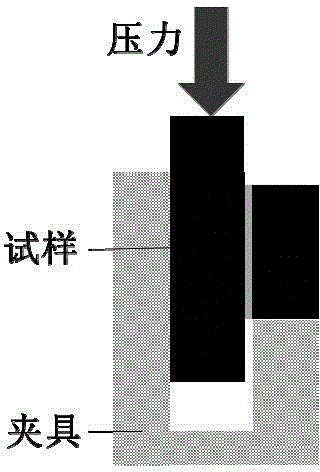

Brazing filler metal for SiC base composite material connection

ActiveCN105014257ALow costReduced corrosion resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesAl powderMetallurgy

The invention relates to brazing filler metal for SiC base composite material connection. The brazing filler metal comprises brazing filler metal powder composed of Cu powder, Ti powder and / or TiH2 powder and Al powder. The brazing filler metal powder comprises 1-10wt% of Al, 4-18wt% of Ti and / or TiH2 and the balanced Cu.

Owner:嘉兴睿创新材料有限公司

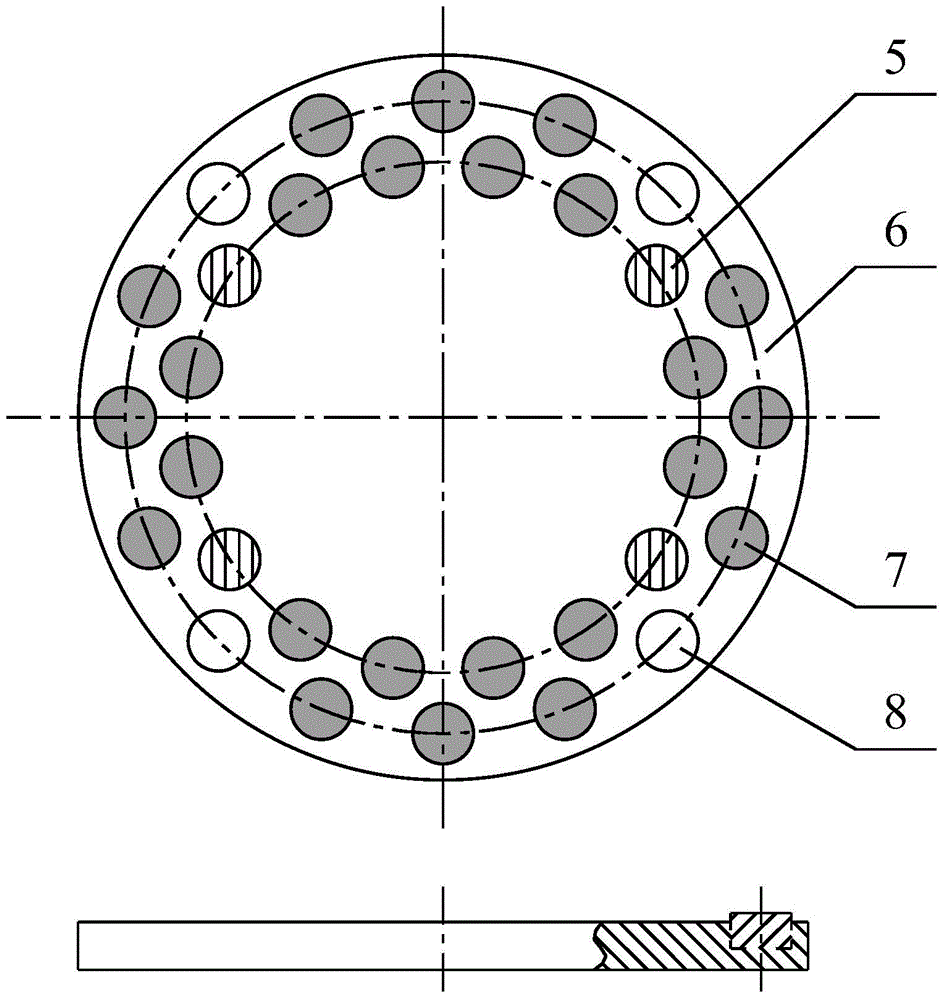

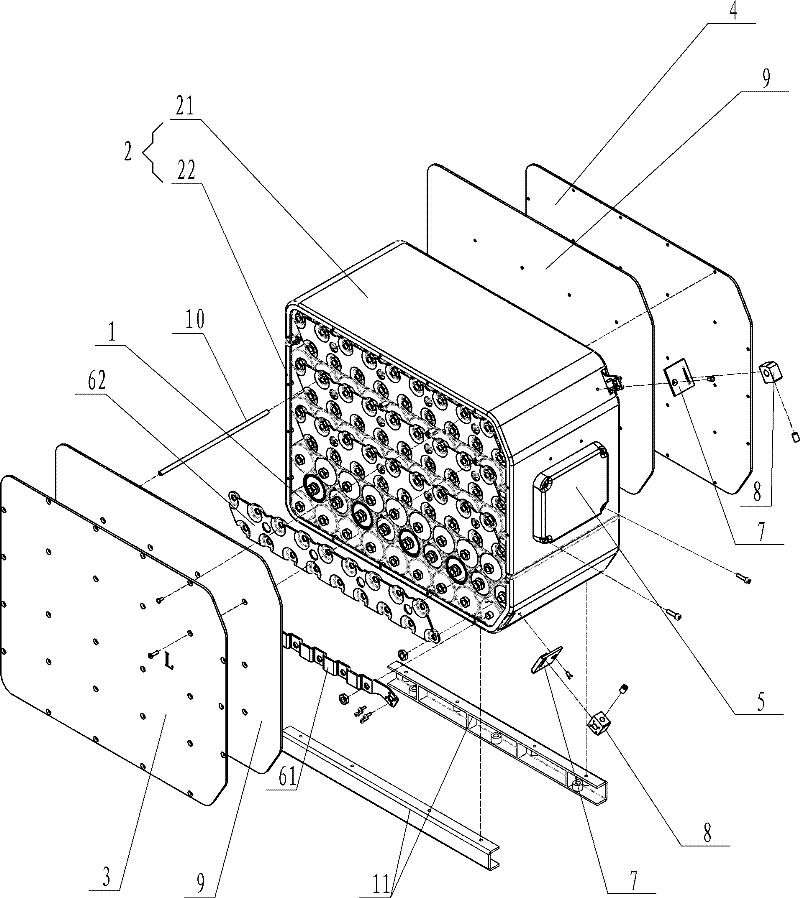

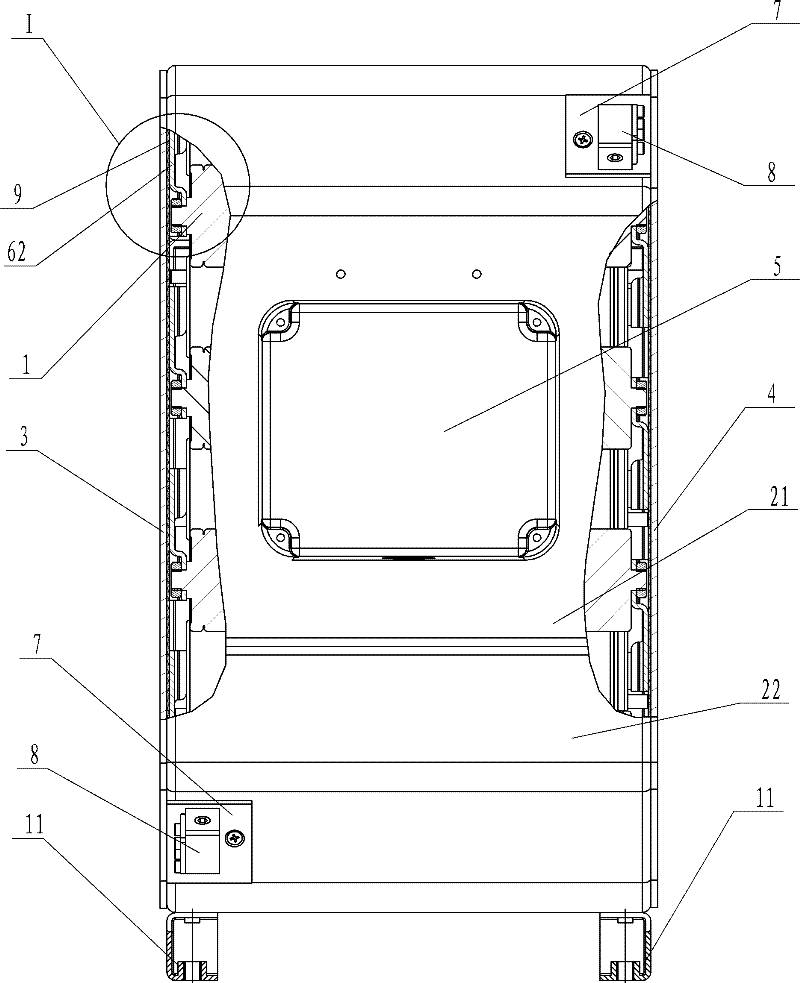

Totally-enclosed battery box

InactiveCN102651463AImprove cooling effectReduce weightSecondary cellsCell component detailsHeat conductingEngineering

The invention discloses a totally-enclosed battery box which is high in safety, excellent in radiation effect, explosion-proof effect and flame retardant effect. The battery box comprises a box body, a battery pack and a battery management module (5), wherein the box body comprises a box frame (2), a left cover plate (3) and a right cover plate (4), and the battery pack is formed by connecting a plurality of cylindrical monomer batteries through conductive plates (61, 62) in regular rules; left and right surfaces of the battery pack are covered with heat-conducting silicon sheets (9), and the left cover plate (3) and the right cover plate (4) are respectively fixedly connected with left and right surfaces of the box frame (2) through pressing the heat-conducting silicon sheets (9); and inner walls of the box frame (2), the left cover plate (3) and the right cover plate (4) are plated with a high-heat conducting ceramic material. The totally-enclosed battery box is applicable to providing power supply for electric vehicles.

Owner:覃美莲

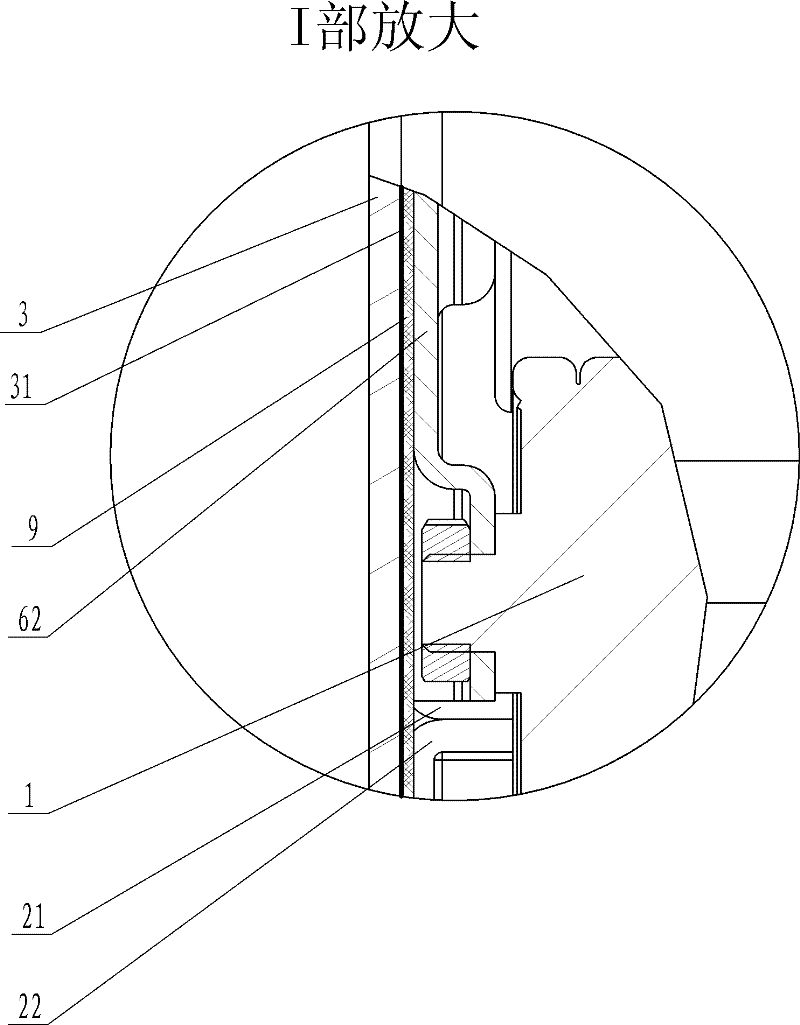

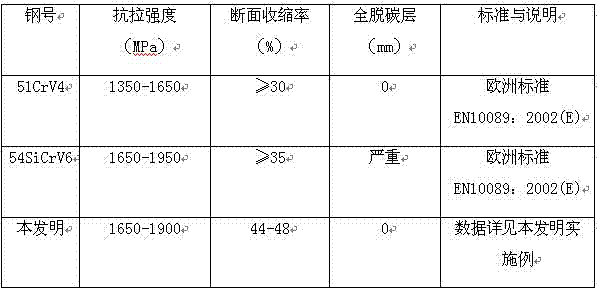

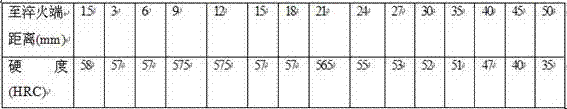

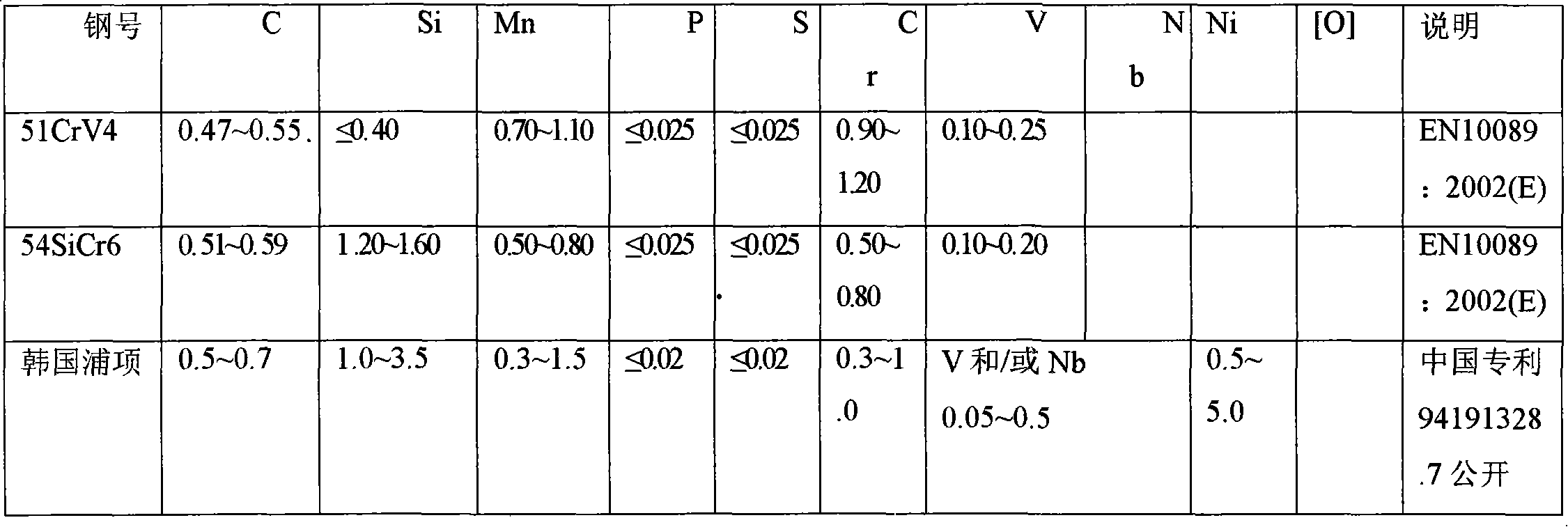

Novel high-strength LPD50 spring steel

ActiveCN107267864ALow antioxidantHigh strengthQuenching devicesLow internal friction springsManufacturing technologyHigh intensity

The invention discloses novel high-strength LPD50 spring steel, and belongs to the field of high-strength spring steel for thermal pressure machining purposes and manufacturing technologies. The novel high-strength LPD50 spring steel is characterized in that the novel high-strength LPD50 spring steel comprises the following components, by mass percent, 0.47-0.53% of C, 0.15-0.35% of Si, 0.75-1.10% of Mn, 0.90-1.20% of Cr, 0.05-0.10% of V, 0.02-0.10% of Nb, 0.15-0.25% of Mo, less than or equal to 0.25% of Cu, less than or equal to 0.25% of Ni, less than or equal to 0.02% of P, less than or equal to 0.015% of S and the balance Fe and unavoidable impurities. The novel high-strength LPD50 spring steel has the excellent characteristics of low carbon removed amount, high strength, high plasticity and toughness, low alloy content and low cost, and can meet the requirements on high stress, high fatigue property, high processing property and high reliability from lightweight flat springs.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

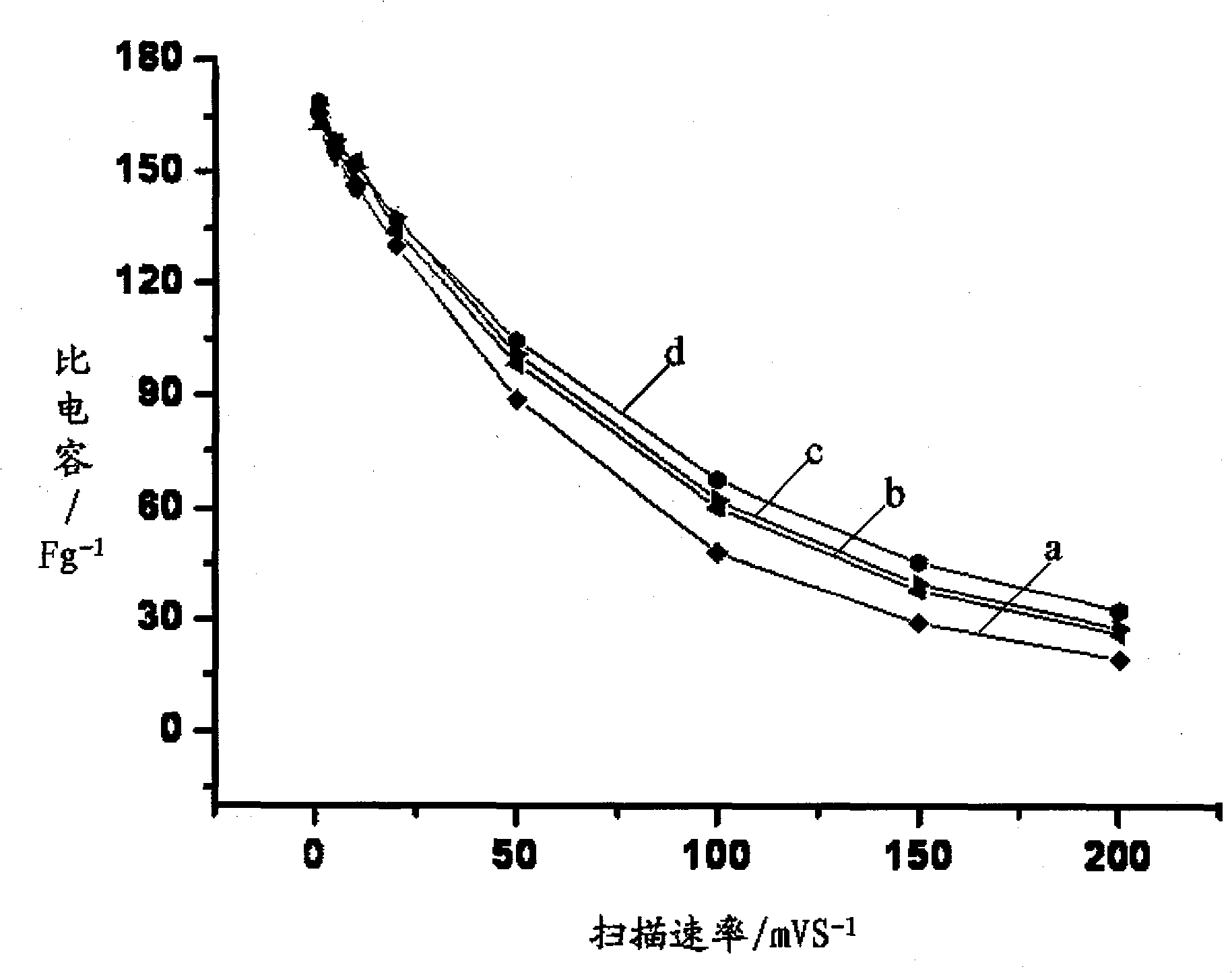

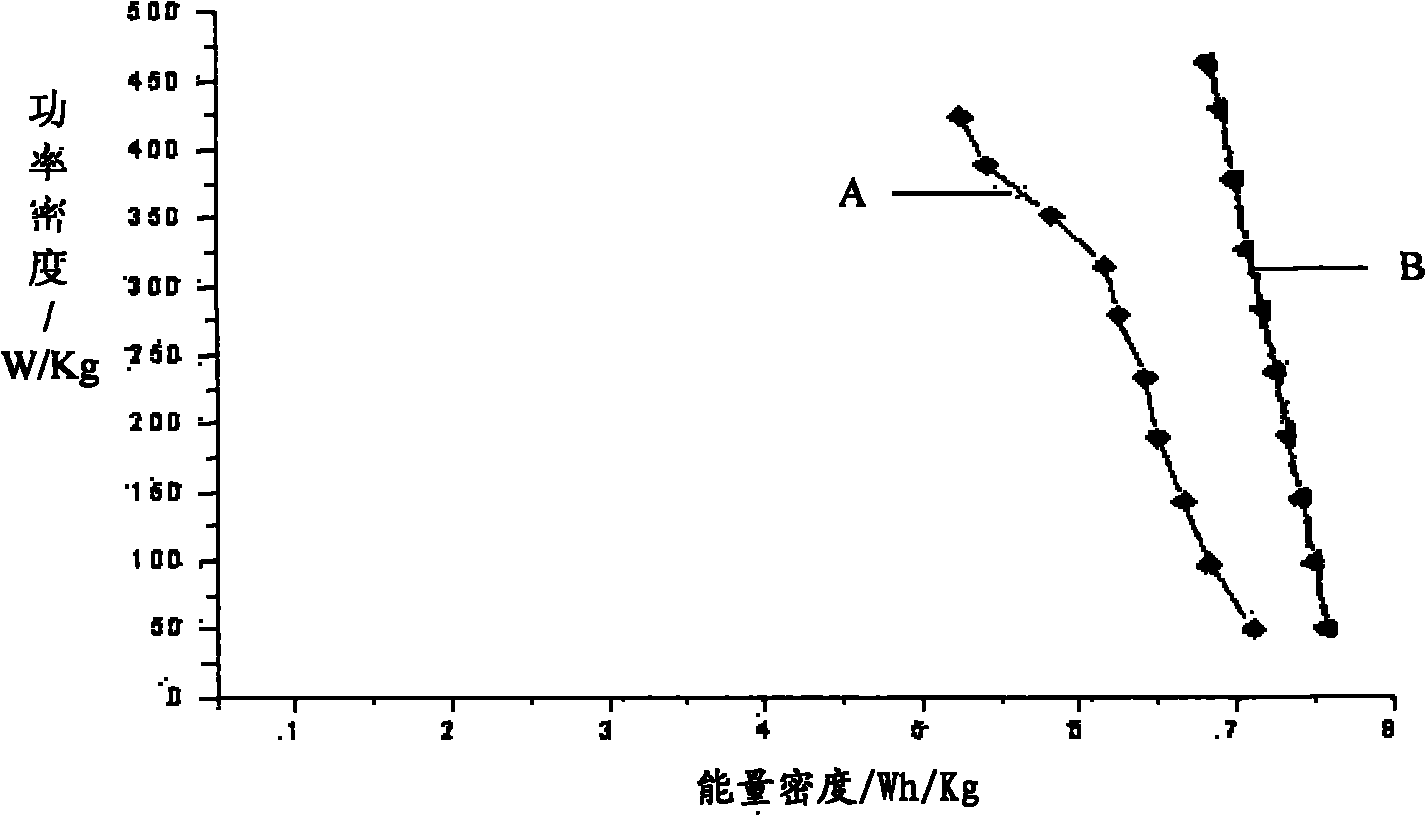

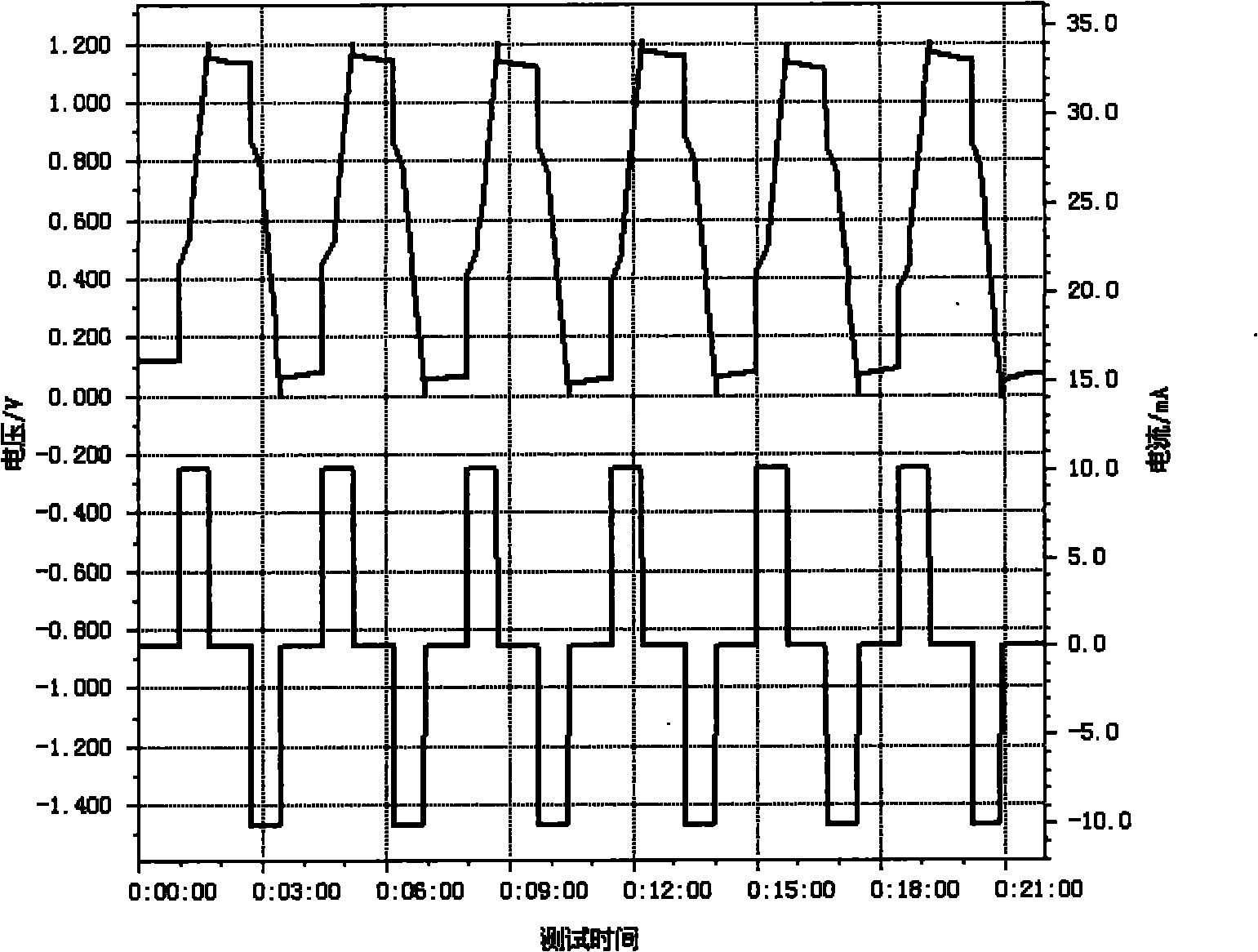

Electrolyte for super capacitor and super capacitor

InactiveCN101840784AImprove ionic conductivityNot easy to precipitateLiquid electrolytic capacitorsHigh concentrationElectrochemical window

The invention provides an electrolyte for a super capacitor. In the electrolyte, a solvent is water, and a solute is 2 to 6M sodium perchlorate. The invention also provides the super capacitor, which comprises an anode, a cathode, a diaphragm between the anode and the cathode, and the electrolyte, wherein the electrolyte is 2 to 6M aqueous solution of sodium perchlorate. The aqueous solution of sodium perchlorate with high concentration has high ionic conductivity, the sodium perchlorate is difficult to separate out at a low temperature, and the aqueous solution of sodium perchlorate has low freezing point and can adapt to a low-temperature work environment; and the aqueous solution of sodium perchlorate has wide electrochemical window and good electrochemical properties at the same time. The super capacitor provided by the invention has high ionic conductivity, the capacity is slowly attenuated during charge and discharge, and the energy density and power density are high; and in addition, the electrolyte and the super capacitor provided by the invention have the advantages of simple preparation process, low cost of raw materials, convenient operation and reduction in production cost and using cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

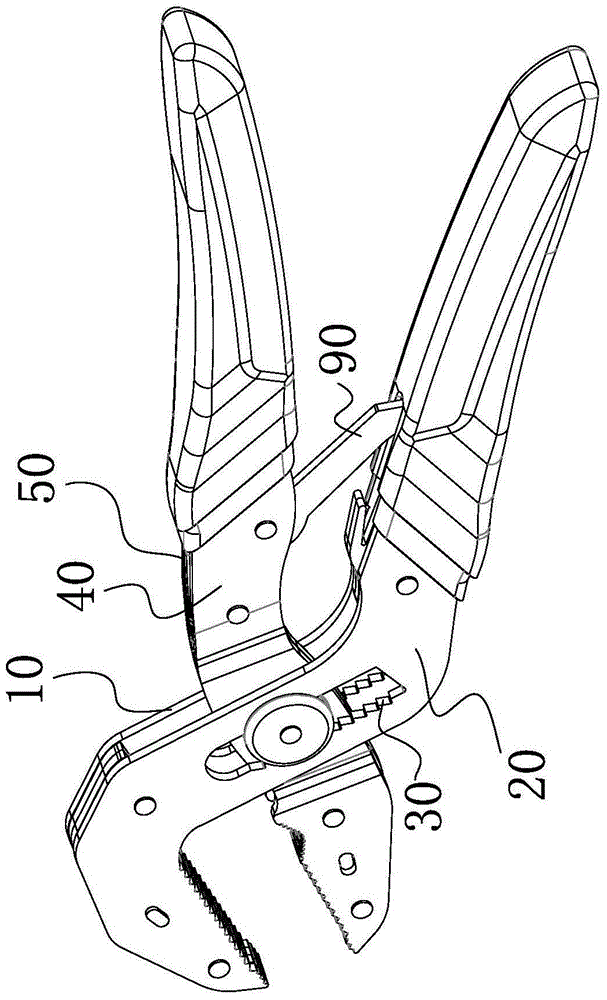

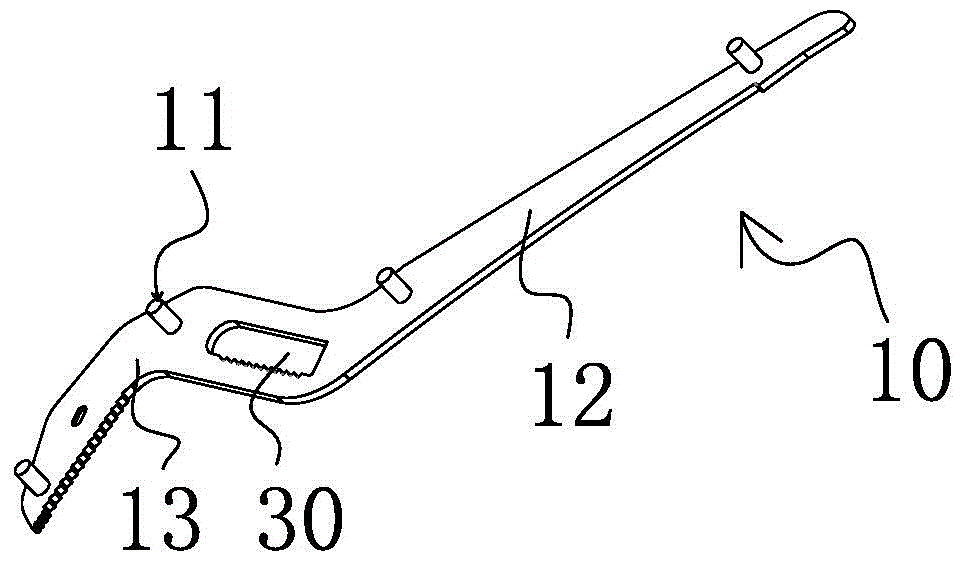

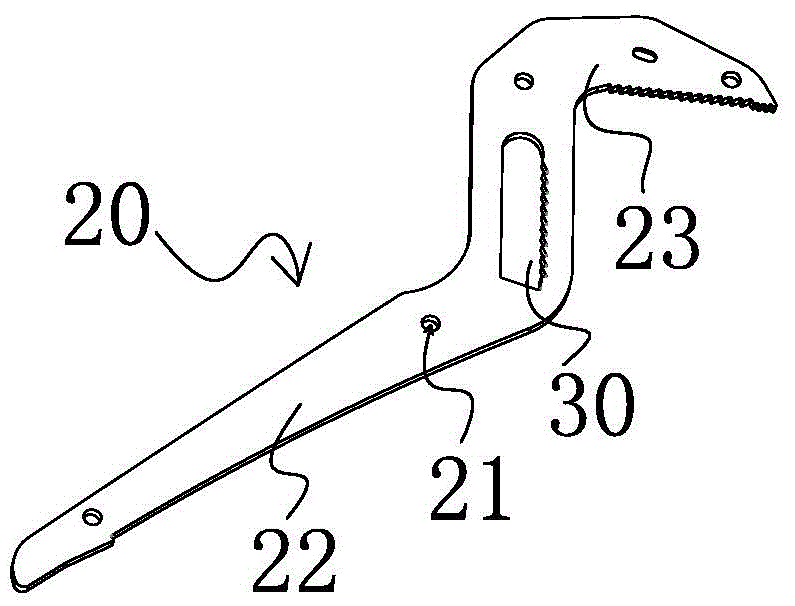

Water pump pliers

The invention provides water pump pliers. The water pump pliers comprise a first fixed pliers arm, a second fixed pliers arm, a first movable pliers arm, a second movable pliers arm, a first clamping part, a second clamping part, a limiting rod and a connecting rod, wherein the first fixed pliers arm and the second fixed pliers arm are fixedly connected to from a fixed pliers arm assembly, the first movable pliers arm and the second movable pliers arm are hinged to the space between the first fixed pliers arm and the second fixed pliers arm through a sliding piece, through grooves are formed in the middle of the first fixed pliers arm and in the middle of the second fixed pliers arm respectively, the two ends of the sliding piece are movably installed in the two through grooves respectively, the limiting rod is arranged between the first fixed pliers arm and the second fixed pliers arm, a sliding groove is formed in the limiting rod, one end of the connecting rod is installed on the first fixed pliers arm, and the other end of the connecting rod is installed on the movable pliers arms. According to the water pump pliers, both the first clamping part and the second clamping part are made of rare earth permanent magnetic materials, are magnetic and can attract each other, in this way, a part is clamped by a pliers head, the clamping force is increased, operation is convenient, and working efficiency is improved; the water pump pliers are simple in structure, detachable and high in safety performance.

Owner:NINGBO YINZHOU YONGJIA ELECTRICAL TOOLS

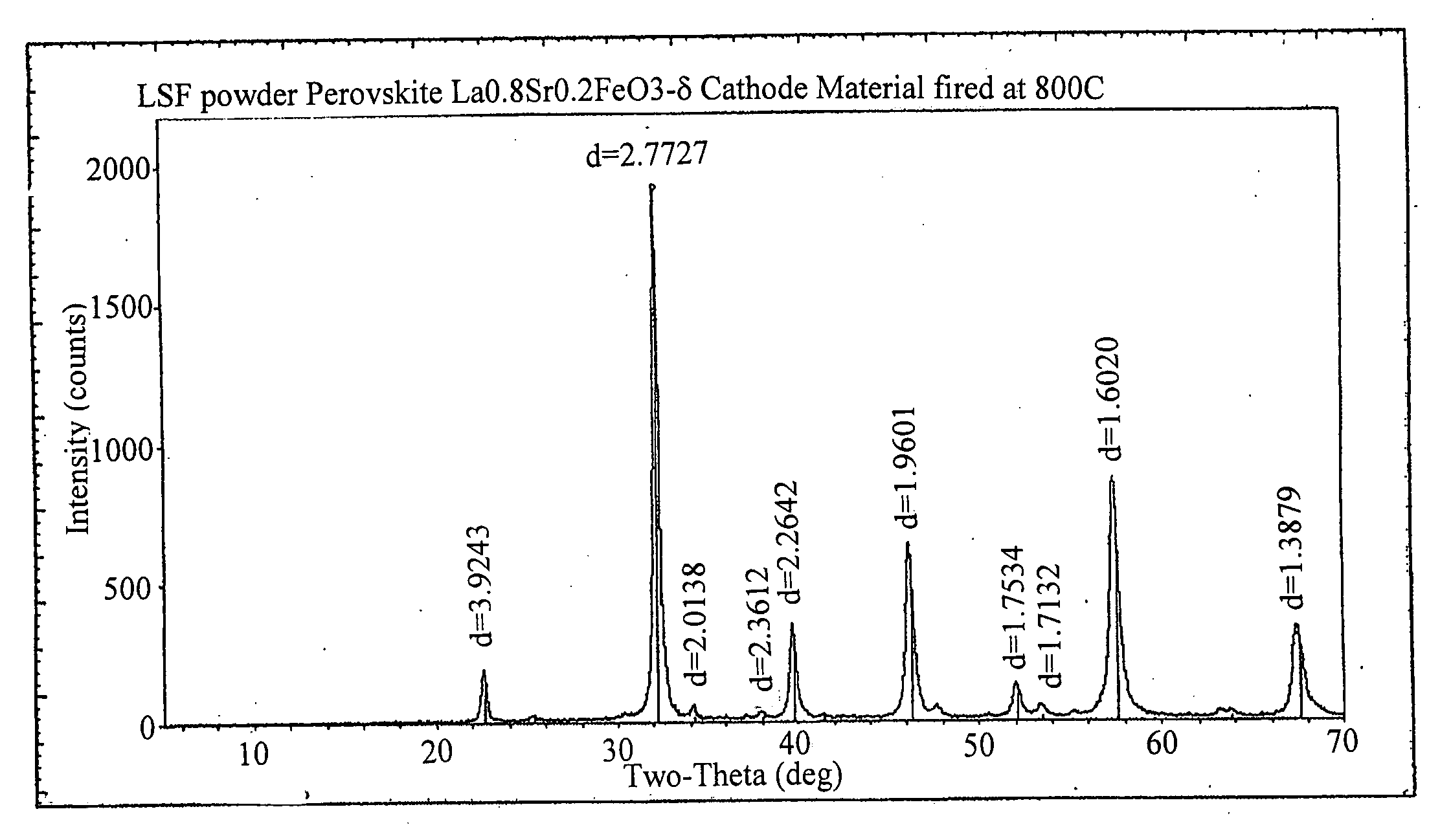

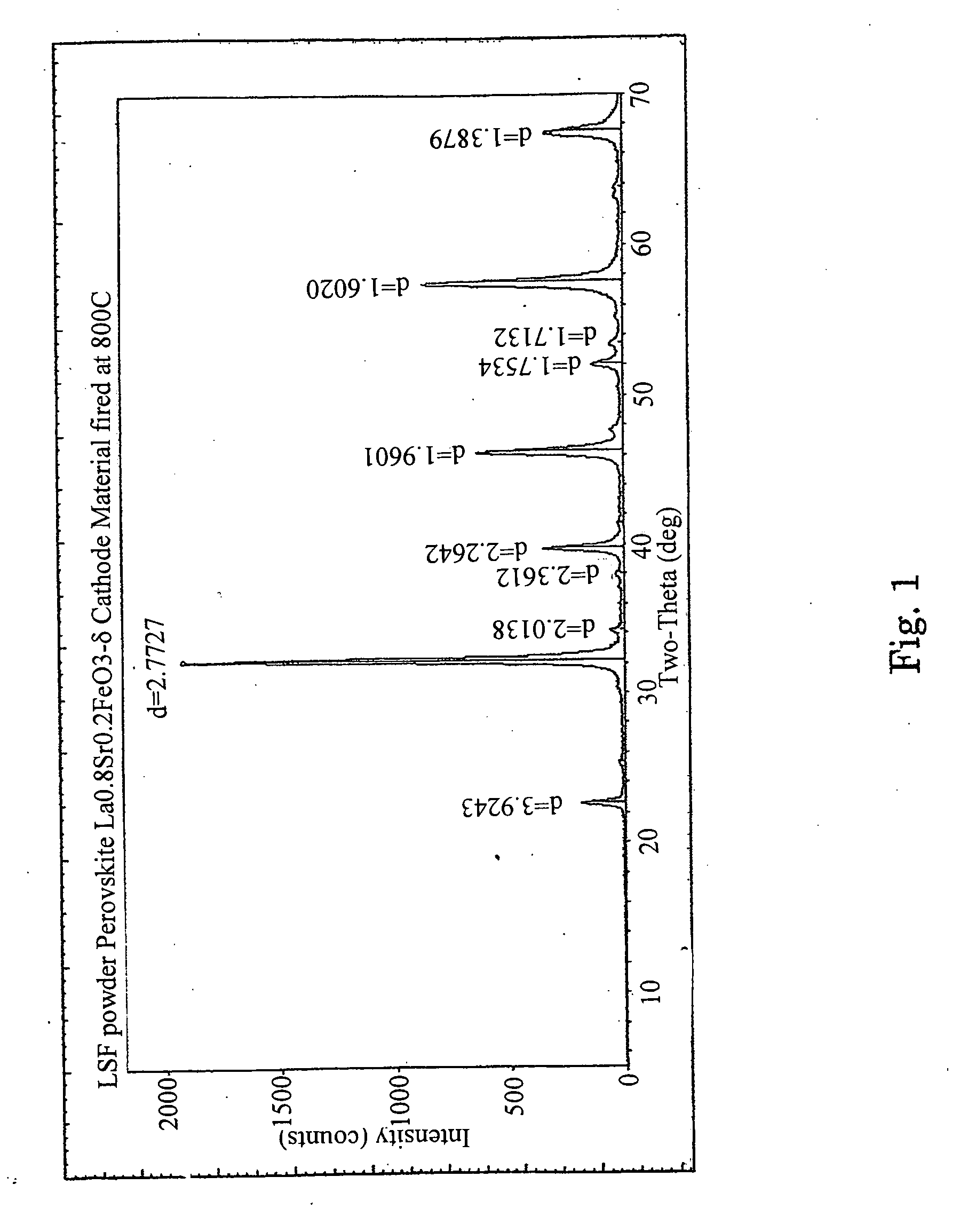

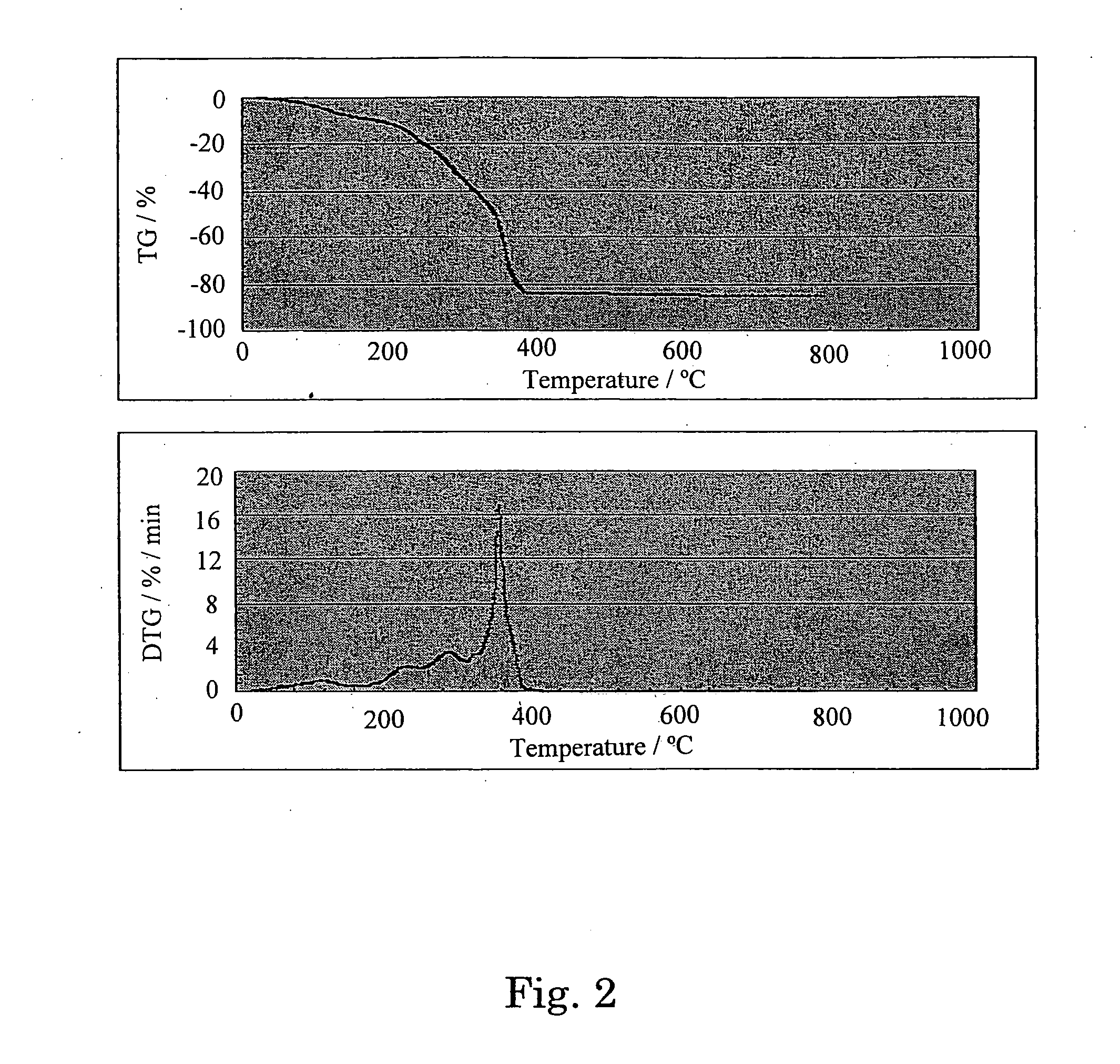

Sol-gel derived high performance catalyst thin films for sensors, oxygen separation devices, and solid oxide fuel cells

InactiveUS20090297923A1Improve performanceReduce decompositionFinal product manufactureCell electrodesFuel cellsComposite cathode

A method of forming a sol-gel derived catalyst thin film on an electrolyte substrate includes forming a cathode precursor sol and / or composite cathode slurry, depositing the cathode precursor sol or slurry on the electrolyte and drying the deposited film to form a green film, and heating the green film to form a sol-gel derived catalyst thin film. An electrochemical cell such as a solid oxide fuel cell can include the sol-gel derived catalyst thin film.

Owner:CORNING INC

Method for preparing graphene foam material from furfural acetone formaldehyde resin, graphene foam material and application of graphene foam material

The invention discloses a method for preparing a graphene foam material from furfural acetone formaldehyde resin. The method includes the steps that curing molding is conducted on furfural acetone formaldehyde resin by adding non-carbon-atom matter which can be easily removed at a high temperature, then high-temperature carbonization and graphitization are conducted in an inert gas environment, and thus the novel super-power graphene foam material with a hexagonal or pentagonal two-dimensional or three-dimensional polyhedral crystal net structure is formed. The obtained material is a carbon foam material with excellent performance, has the prominent properties of low thermal expansivity, high porosity and pore uniformity, good stability, high temperature resistance, corrosion resistance, good oxidation resistance, small density, light weight, processibility and the like, and the advantages of high thermal conductivity, high melting point, large specific heat, good electric conductivity and excellent shielding performance, and is wide in application range and long in service life. Besides, low-cost and large-batch production of the material can be achieved through the preparation method, no pollution is generated in the preparation or use process, and batch application of the graphene foam material is achieved.

Owner:杨佳伟

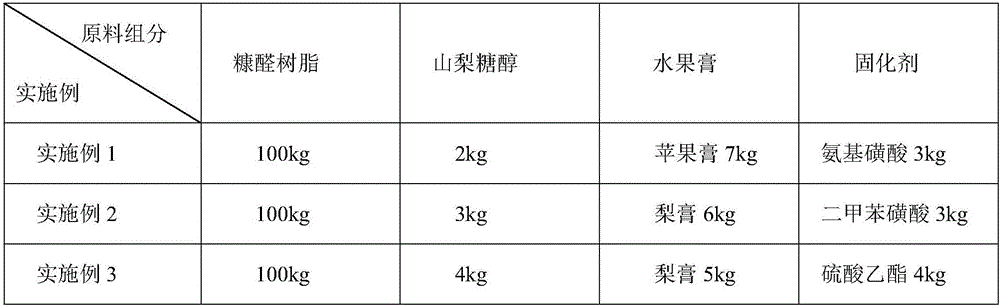

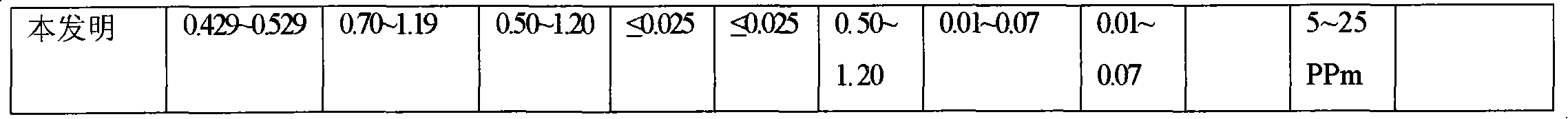

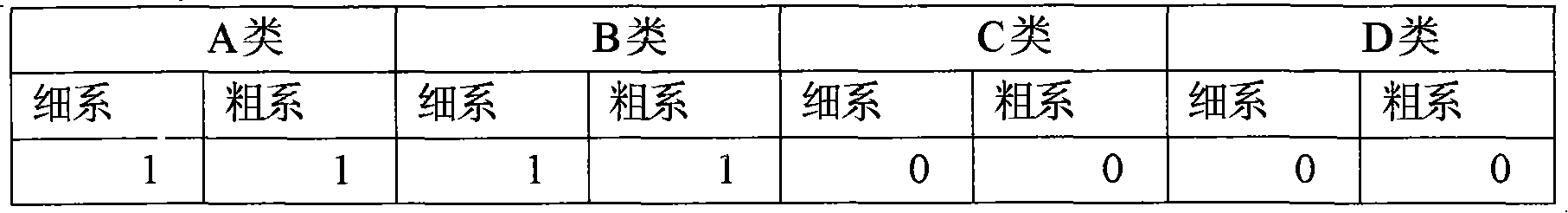

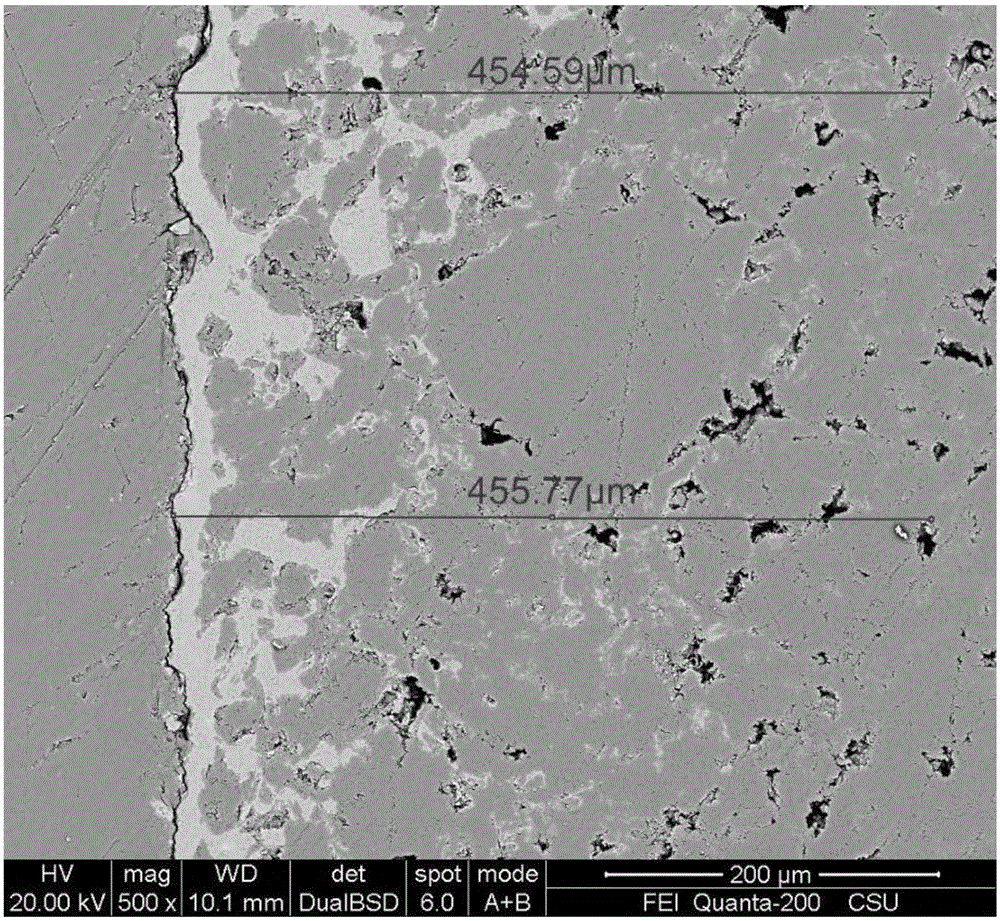

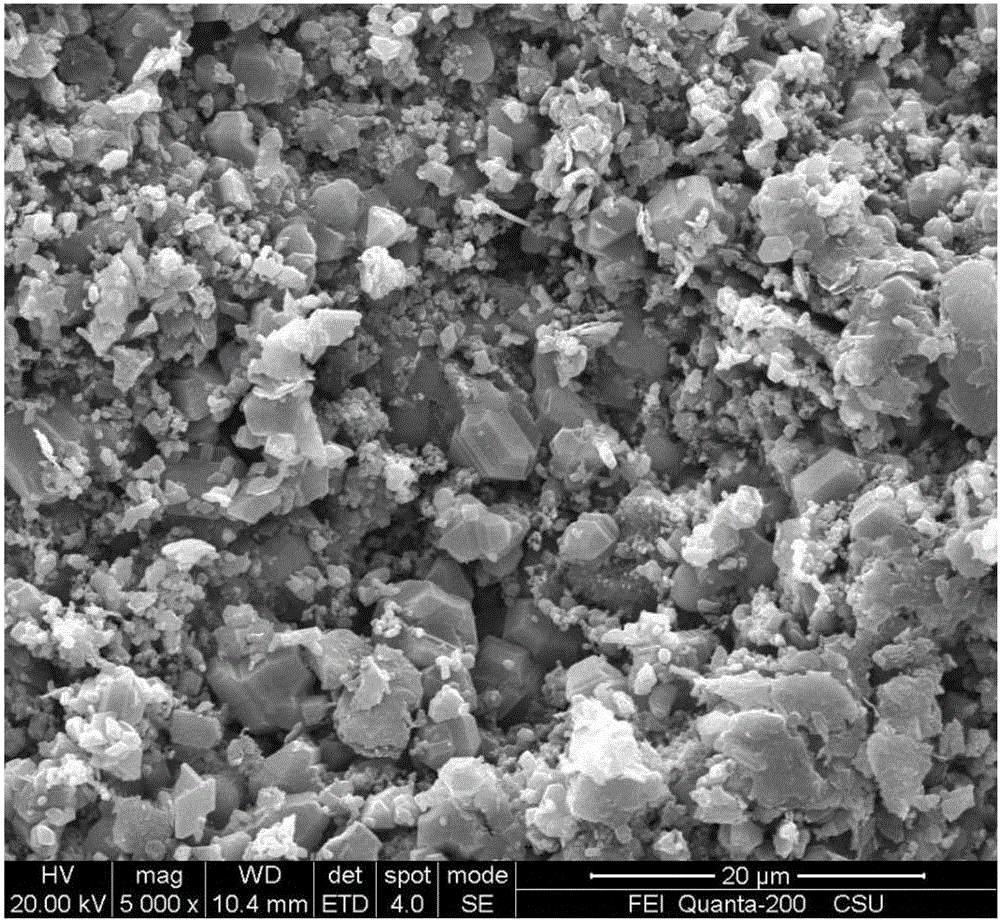

Big-wire diameter suspension helical spring material and preparation method thereof

InactiveCN101619418ALow antioxidantLow decarbonization effectFurnace typesHeat treatment furnacesAlloyHigh intensity

The invention relates to a big-wire diameter suspension helical spring material, which comprises the following chemical components in percentage by weight: 0.429 to 0.529 percent of C, 0.70 to 1.19 percent of Si, 0.50 to 1.20 percent of Mn, 0.50 to 1.20 percent of Cr, 0.01 to 0.07 percent of V, 0.01 to 0.07 percent of Nb, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 5 to 25ppm of O, and the balance of Fe and inevitable impurities. The big-wire diameter suspension helical spring material has technical properties of low decarburization, high strength and high plasticity, has a low alloy content and is a good material for making a helical spring of a suspension having a big wire diameter of a medium or heavy vehicle and also for making a suspension helical spring of a car, a vehicle torsion bar spring and a stock stabilizer, and also a good material used for making a high-strength spring steel wire and an oil tempering spring steel wire.

Owner:孙心红

Graphite material with SiC doped layer and preparation method of graphite material

The invention discloses a graphite material with a SiC doped layer and a preparation method of the graphite material. The preparation method of the graphite material with the SiC doped layer comprises the following step: by taking mixed powder of silicon-containing powder and boron nitride as a silicon source, performing liquid-phase siliconing sintering on a graphite material, thereby obtaining the graphite material with the SiC doped layer. The graphite material with the SiC doped layer prepared by using the method comprises a graphite substrate and the SiC doped layer on the surface of the graphite substrate, the SiC doped layer is well combined with the graphite substrate without thermal mismatch, the graphite material is good in oxidation and corrosion resistance and relatively low in cost, and a small amount of silicon is adhered to the surface of the graphite material.

Owner:NAT UNIV OF DEFENSE TECH

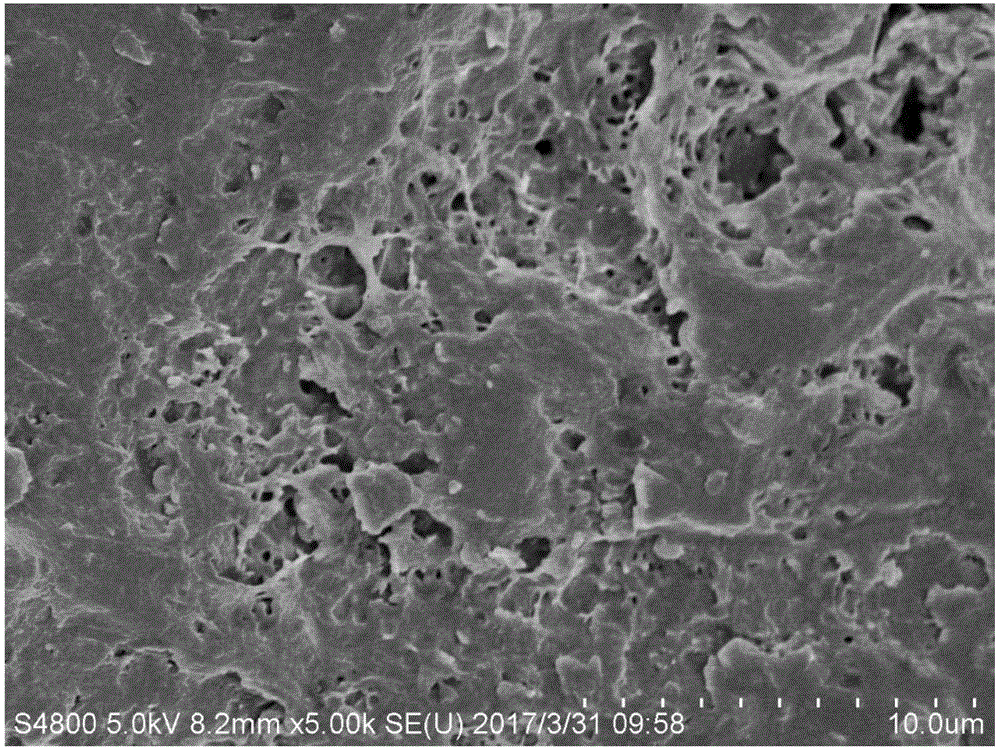

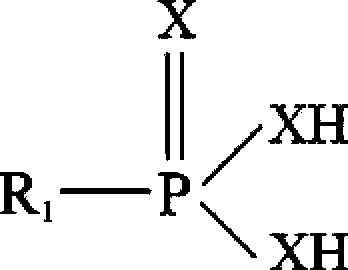

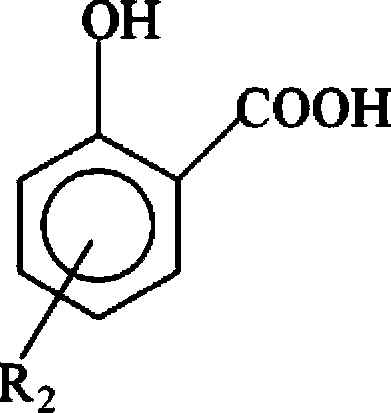

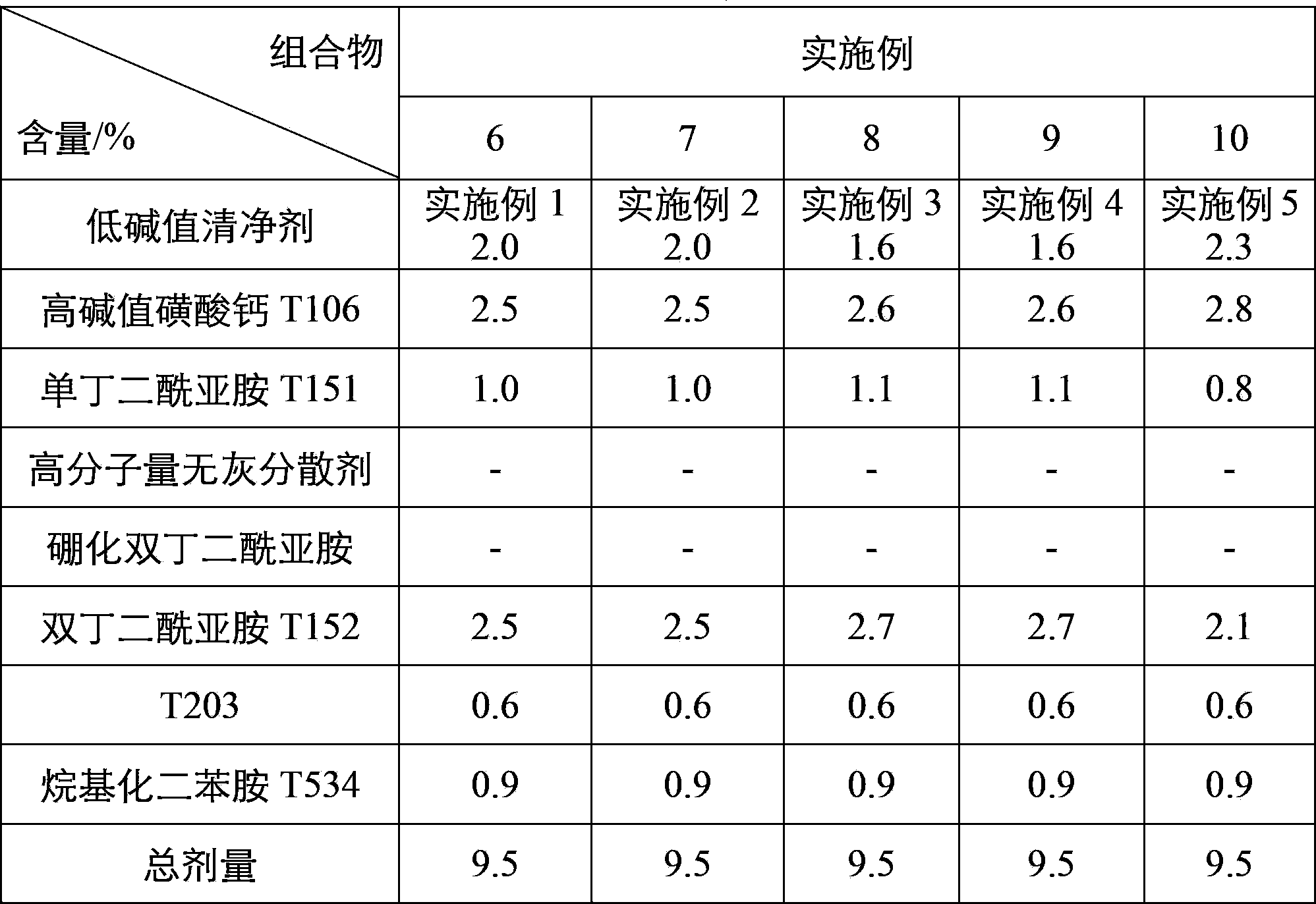

Internal combustion engine lubricating oil composition

The invention provides an internal combustion engine lubricating oil composition which comprises(A)a low-alkaline-value clearing agent which is 0.1-6.0 percent of the total mass of the composition, (B) a high-alkaline-value clearing agent which is 0.1-8.0 percent of the total mass of the composition, (C) a dispersing agent which is 0.1-8.0 percent of the total mass of the composition, (D) an antioxidant which is 0.1-3.0 percent of the total mass of the composition and (E) lubricating basic oil which is used as a main component of the composition, wherein a preparation method for the low-alkaline-value clearing agent comprises the following steps: simultaneously or sequentially performing saponification on organic sulfur phosphonic acid, oxides of alkaline metals and / or alkaline-earth metals, water, alkylsalicylate and inorganic acid and / or an aromatic carboxylic acid accelerator, and collecting products. The internal combustion engine lubricating oil composition disclosed by the invention is relatively low in phosphorous content, relatively high in high-temperature detergency, oxidation resistance, and abrasion resistance and relatively low in metal corrosivity, and can meet the performance requirements of an API CF-4 15W / 40 diesel engine oil and requirements of environment-friendly emission.

Owner:CHINA PETROLEUM & CHEM CORP +1

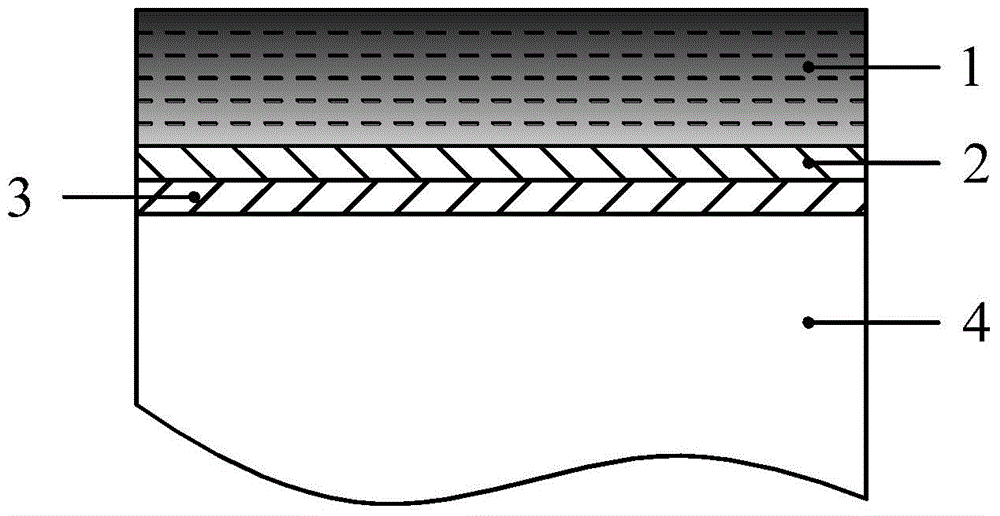

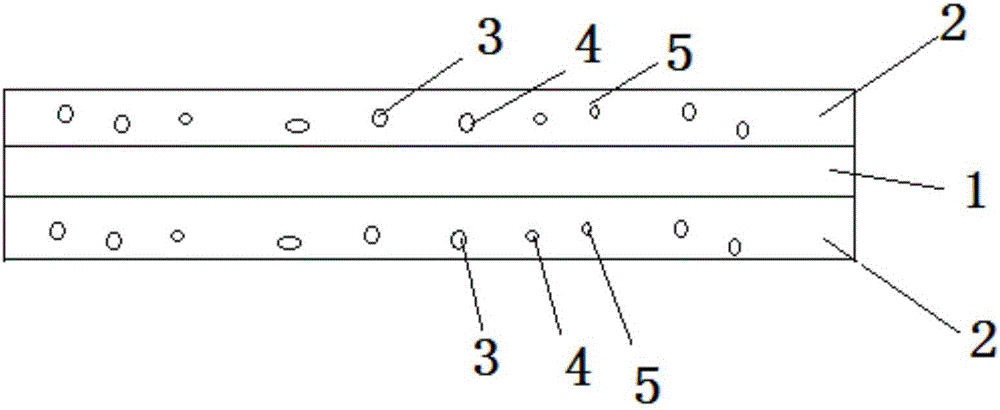

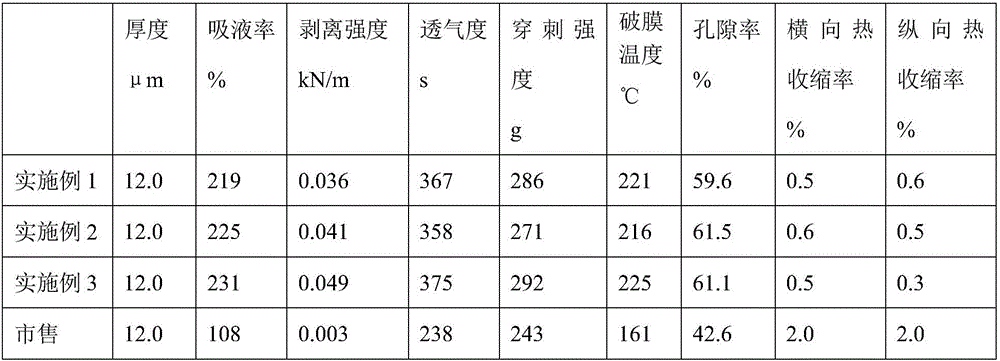

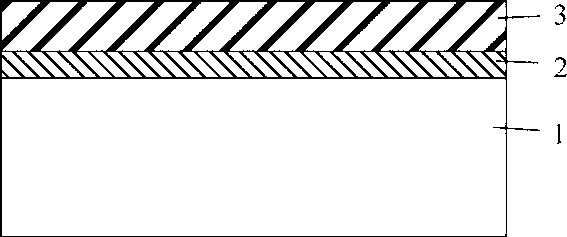

Consumer battery diaphragm high in safety

The invention provides a consumer battery diaphragm high in safety. The consumer battery diaphragm high in safety comprises a base layer (1) and modified layers (2) arranged on the surfaces of the base layer (1). The base layer (1) is made of hydrophilic PET non-woven fabric filled with a high-molecular polymer. Each modified layer (2) comprises a polypropylene material matrix (3), porous alumina superfine powder (4), ceramic particles (5) and phase-change microspheres (5), wherein the porous alumina superfine powder (4), the ceramic particles (5) and the phase-change microspheres (5) are dispersed in the polypropylene material matrix (3). The battery diaphragm is simple in process, high in liquid absorption amount, large in surface area, high in porosity, small in aperture, high in chemical purity and safe to use and has few harmful impurities.

Owner:华富(江苏)锂电新技术有限公司 +1

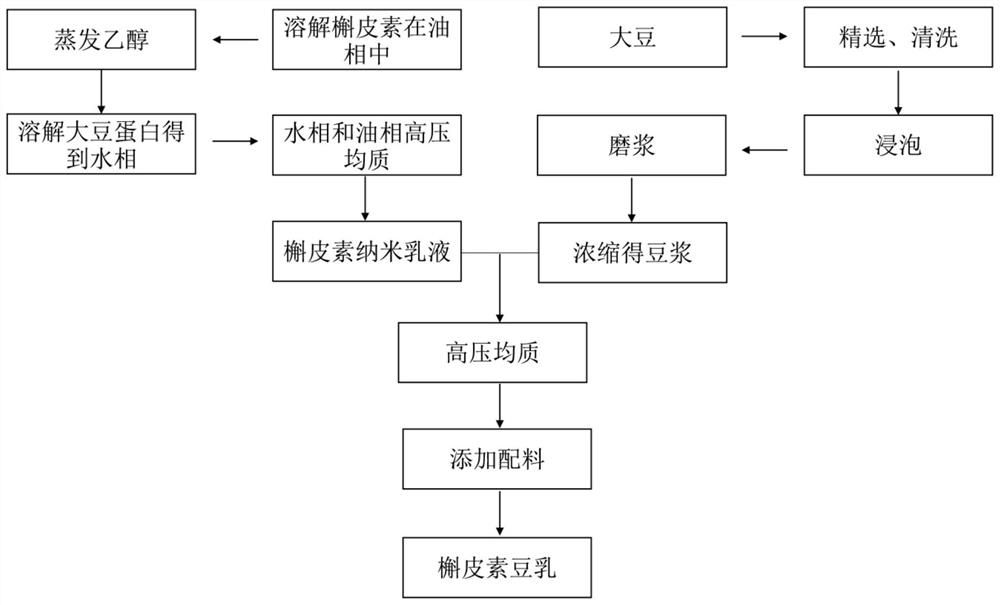

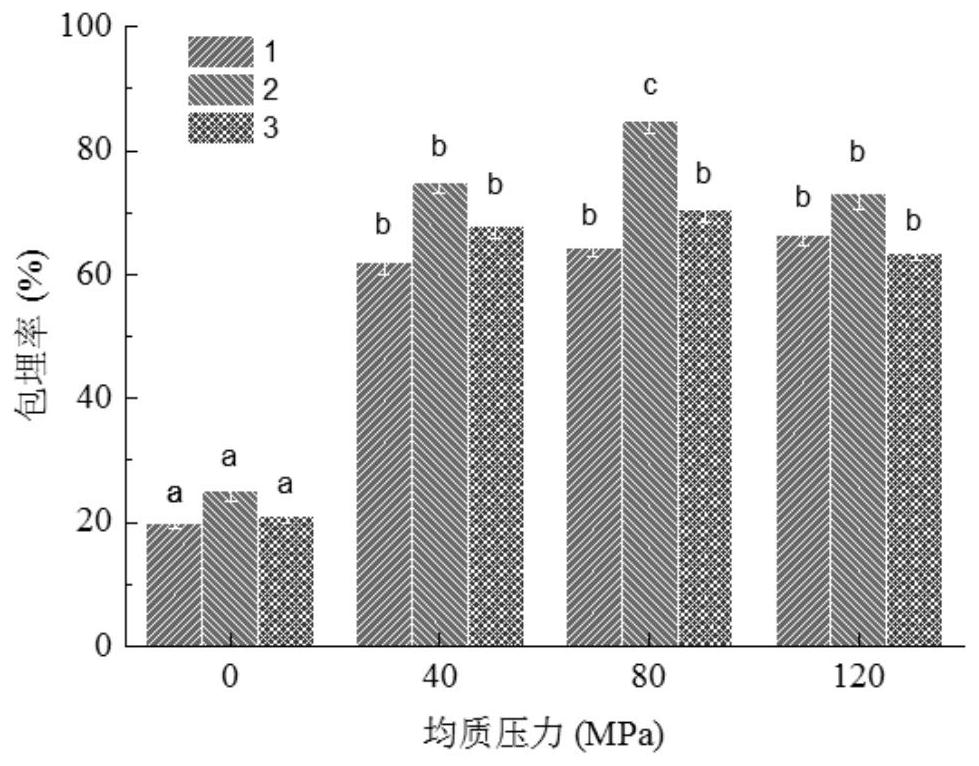

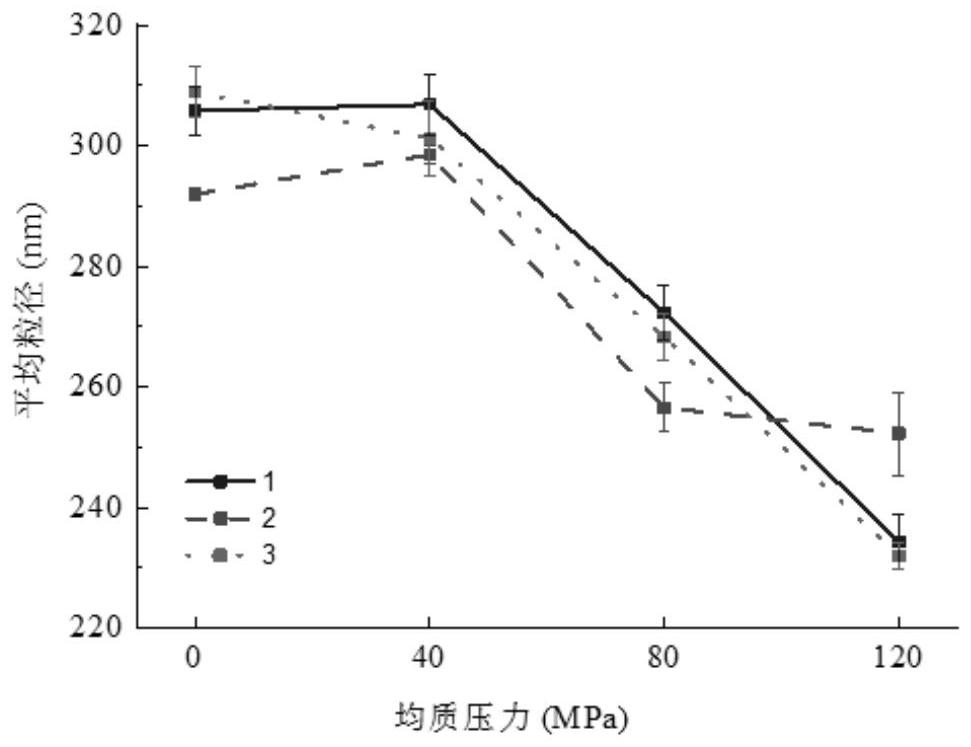

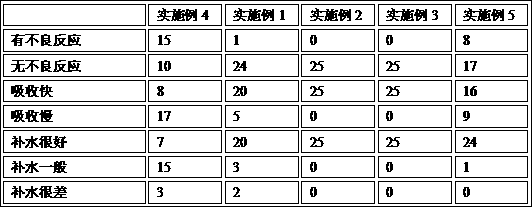

Preparation method of quercetin soybean milk

PendingCN111642567ALarge particle sizeSmall particle sizeMilk substitutesBiotechnologyOrganic chemistry

The invention discloses a preparation method of quercetin soybean milk, belongs to the technical field of soybean milk processing, and solves the problems of precipitation, oxidative degradation and the like caused by adding quercetin into soybean milk in the prior art. The quercetin is embedded in a nano-emulsion and then added into the soybean milk, the quercetin nano-emulsion and the soybean milk are mixed through a high-pressure homogenization technology, and finally the uniform and stable quercetin soybean milk is obtained. While the quercetin nano-emulsion and the soybean milk are mixedby utilizing the pressure and the cavity effect of a high-pressure homogenizer, the particle size of the soybean milk can be reduced, the taste of the soybean milk is improved, and the absorption of the soybean milk in the human body is promoted.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Smearing type hydro lifting needle without additive and preparation method of smearing type hydro lifting needle

InactiveCN107898689AAvoid allergiesImprove playbackCosmetic preparationsToilet preparationsALPHA-ARBUTINAdditive ingredient

The invention discloses a smearing type hydro lifting needle without an additive and a preparation method of the smearing type hydro lifting needle. The smearing type hydro lifting needle comprises the following main ingredients: thermal spring water, a bio-saccharide gum-1, alpha-arbutin, glycoprotein, glutamic acid, valine, threonine, butanediol, 3-o-ethyl ascorbic acid, sodium hyaluronate, polypropylene glycol-26, p-hydroxyacetophenone, a saussurea involucrata extract, oligopeptide-1, a peony root extract, deer bone collagen, 1,2-hexanediol, a sambucus nigra fruit extract, fullerene, a kiwifruit extract, an xanthan gum and EDTA (Ethylene Diamine Tetraacetic Acid) disodium, the various components are mutually synergic through proper matching of the ingredients, and with the scientific preparation method, the smearing type hydro lifting needle having multiple effects of resisting oxidation, whitening, moisturizing, causing low allergy and repairing is prepared.

Owner:达威控股有限公司

Thermal-state repair spray coating and preparation method thereof

The invention belongs to the technical field of spray coating, and particularly relates to thermal-state repair spray coating for quickly repairing a working lining in a thermal state and a preparation method of the thermal-state repair spray coating. The thermal-state repair spray coating is prepared from the following components in percentage by weight: 70-76% of brown aluminium oxide, 4.5-5.5%of Guangxi white mud, 4.5-5.5% of pure calcium aluminate 70 cement, 1.5-2.5% of boric acid, 4.5-5.5% of silicon metal, 1.5-2.5% of aluminum metal and 7-9% of silicon carbide. According to the thermal-state repair spray coating, in the thermal state, the conditions of severe local erosion, peeling or local damage occurring in the use process of the working lining are quickly repaired, a prepared finished product is good in bonding, high in strength and long in service life.

Owner:河南恒耐尔耐火材料有限公司

Composite coating material for metal surface and application thereof

ActiveCN102757671ALower sintering temperatureReduce manufacturing costLiquid surface applicatorsCell component detailsAdhesiveSpray coating

The invention provides a composite coating material being capable of being densified by being sintered at low temperature and used for protecting metals from being oxidized in various high-temperature devices and especially used for coating metal parts of SOFC (Solid Oxide Fuel Cells). The composite coating material contains at least two oxide components in percentage by weight: 40%-90% of conductive composite oxides (component A) and 10%-60% of single oxides of transition metals (component B); and besides, the composite coating material also contains 0.01%-10% of the transition metals (component C). In the invention, the composite coating material is mixed with a solvent, an organic adhesive and other additives, then slurry is coated on the metal parts through methods, such as brush coating, spray coating, dip coating, and the like, and the metal parts are dried and then sintered at the low temperature of 700-900 DEG C to form a protective coating. The preparation method has the advantages of simple process, low sintering temperature, easy industrial production, and the like; and the formed protective coating has good conductive property, high temperature stability and oxidation resistance and high combinability with a metal base body and can effectively prevent the Cr from dispersing out of the metal parts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com