Internal combustion engine lubricating oil composition

A lubricating oil composition and composition technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of hidden dangers in the use of boronized ashless, high phosphorus content, coexistence of detergency and easy precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

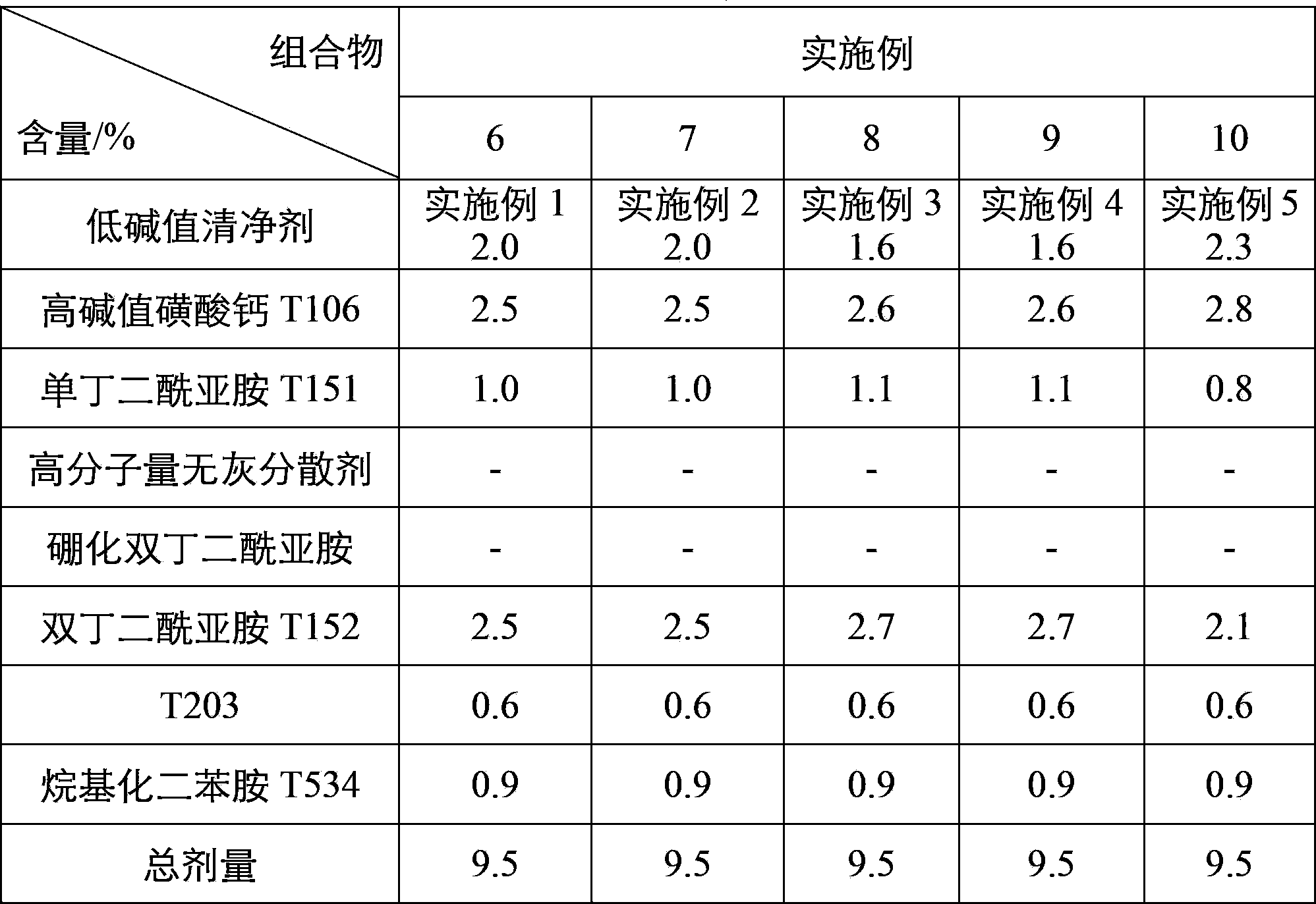

Examples

preparation example Construction

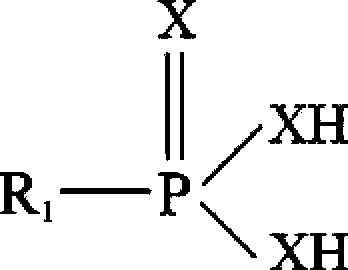

[0082] Preparation of organothiophosphonic acid A

[0083] Add 1000 grams of polyisobutylene with a number average molecular weight of 1000 in a three-necked flask equipped with electric stirring, add P 2 S 5 168 grams, gradually heat up from room temperature to 210°C, the heating rate is 30°C / hour, and react at a constant temperature of 210°C for 12 hours. At this time, the material gradually changes from colorless to brown, and 8.5 grams of water vapor is introduced for reaction and post-treatment . The obtained polyisobutylenethiophosphonic acid had a sulfur content of 5.2% and a phosphorus content of 2.2%, which was recorded as organothiophosphonic acid A.

[0084] Preparation of organothiophosphonic acid B

[0085] Add 1000 grams of polyisobutylene with a number average molecular weight of 2300 in a three-necked flask equipped with electric stirring, add P 2 S 5 158 grams, gradually warming up from room temperature to 225 ° C, heating rate 30 ° C / hour, 12 hours a...

Embodiment 1

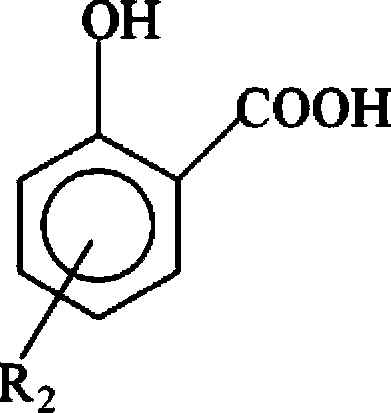

[0087] In Example 1, the molar ratio of the raw material organic thiophosphonic acid A to alkyl salicylic acid was 1:1.5, and the saponification reaction was carried out by adding the raw materials at one time.

[0088] Add 60 grams of organothiophosphonic acid A (molecular weight=1112, 0.054mol) and 62.72 grams (0.081mol) of alkyl salicylic acid in the 500ml three-necked flask that temperature control system and electric stirring are installed, add 120ml n-heptane again, stir 5 minutes, then add 8.9 grams of calcium oxide (0.159mol), add 5 grams of water (0.278mol), 2.2 grams of 98% benzoic acid, heat up to 95 ° C and react for 6.5 hours. At this time, the material turned into a brown liquid. Add 85 Gram 150SN diluting oil, then distill out water, material is cooled to 50 ℃, is centrifugal 30 minutes on the centrifuge of 2000rpm in rotating speed, distills after removing the slag, obtains low alkali value cleaning agent Ca-1, and its alkali value is 78.7mgKOH / g, The sulfur co...

Embodiment 2

[0090] In Example 1, the molar ratio of the raw material organic thiophosphonic acid A to alkyl salicylic acid was 1:1.5, and the saponification reaction was carried out by adding the raw material twice.

[0091] In the 500ml there-necked flask that temperature control system and electric stirring are installed, add organothiophosphonic acid A60 gram (molecular weight is 1112, 0.054mol), then add No. 200 solvent gasoline of 100ml, stir 5 minutes, then add 4.6 grams of calcium oxide ( 0.082mol), add 3 grams of water (0.167mol), stir for 25 minutes, heat up to 95°C for 3 hours, and the material turns into a brown liquid. Then add 62.72 grams of alkyl salicylic acid (0.081mol) and react for 15 minutes, then add 4.3 grams of calcium oxide (0.077mol), 2 grams of water (0.111mol), 2.2 grams of benzoic acid, control the reaction temperature to be 95 ° C, and react 3 hour, add 85 grams of 150SN diluent oil after the reaction, then distill out the water, cool the material to 50°C, cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com