Patents

Literature

490 results about "Clearing Agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Any substance that is administered to facilitate the removal of another substance.

Cluster clearing agents

InactiveUS6908903B1Rapid and efficient complexationImprove efficiencyBiocideNanomedicineClearing AgentHepatic clearance

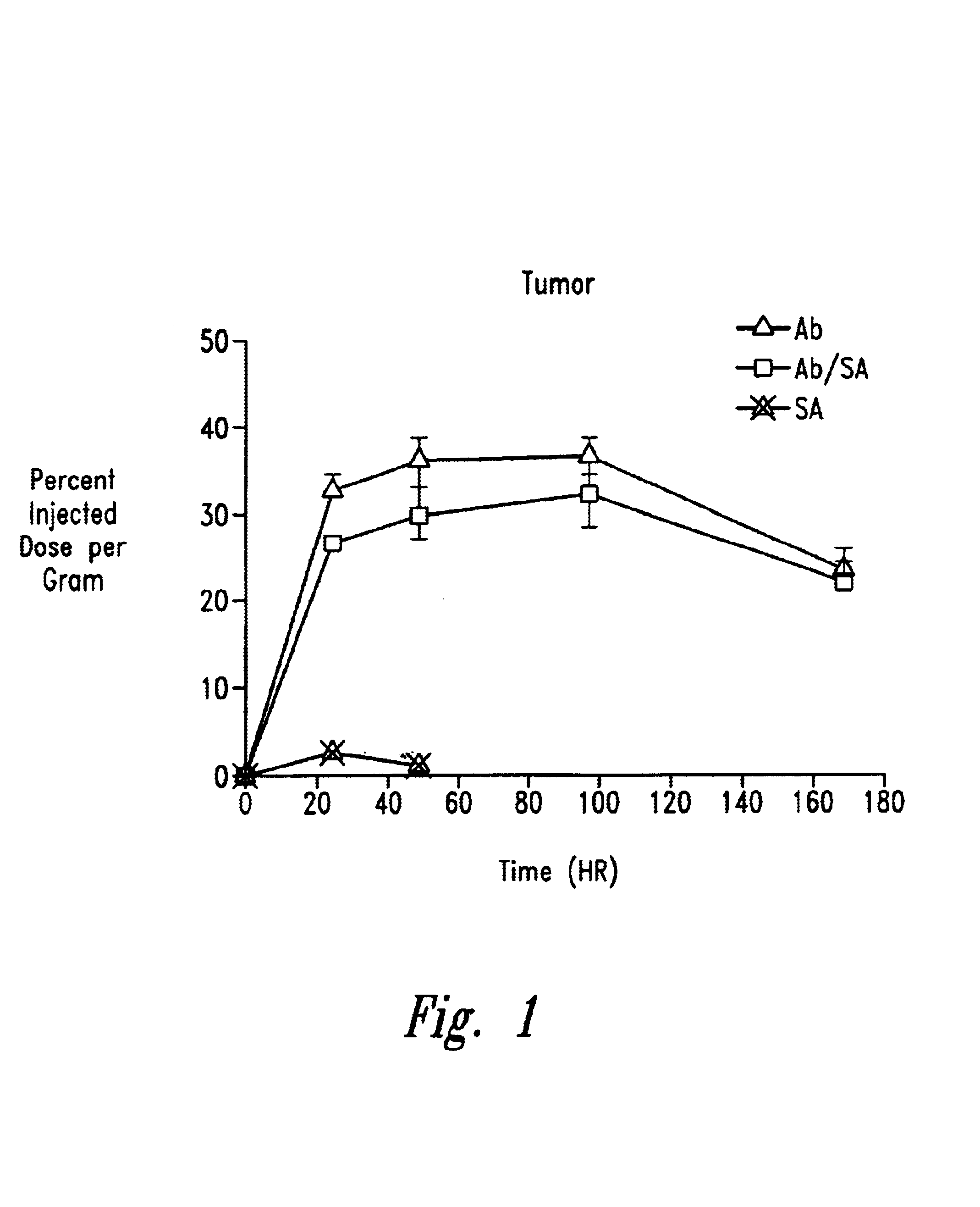

Cluster clearing agents (CCAs) and the use thereof are discussed. CCAs are composed of a hepatic clearance directing moiety which directs the biodistribution of a CCA-containing construct to hepatic clearance; and a binding moiety which mediates binding of the CCA to a compound for which rapid hepatic clearance is desired.

Owner:ALETHEON PHARMA

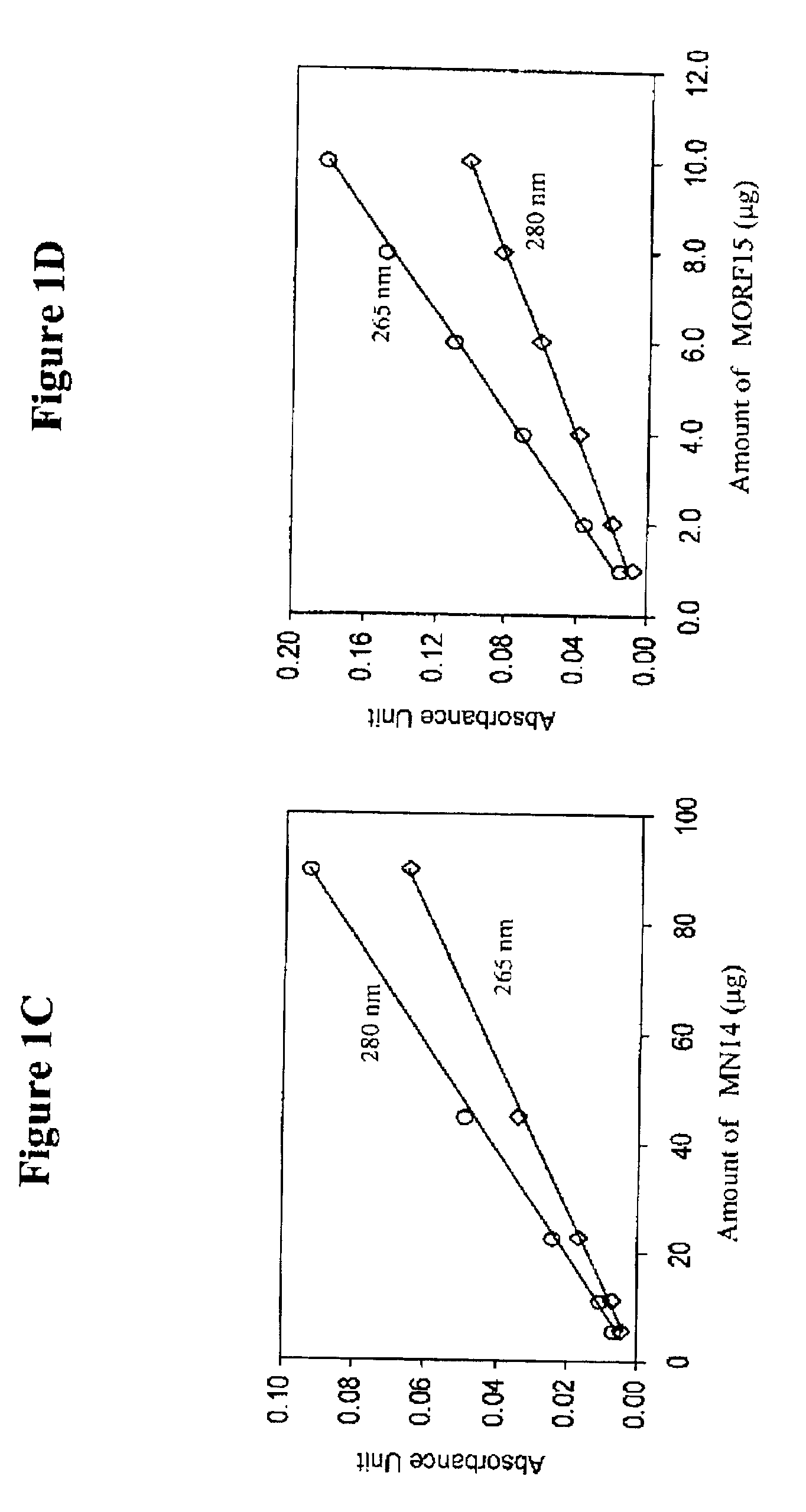

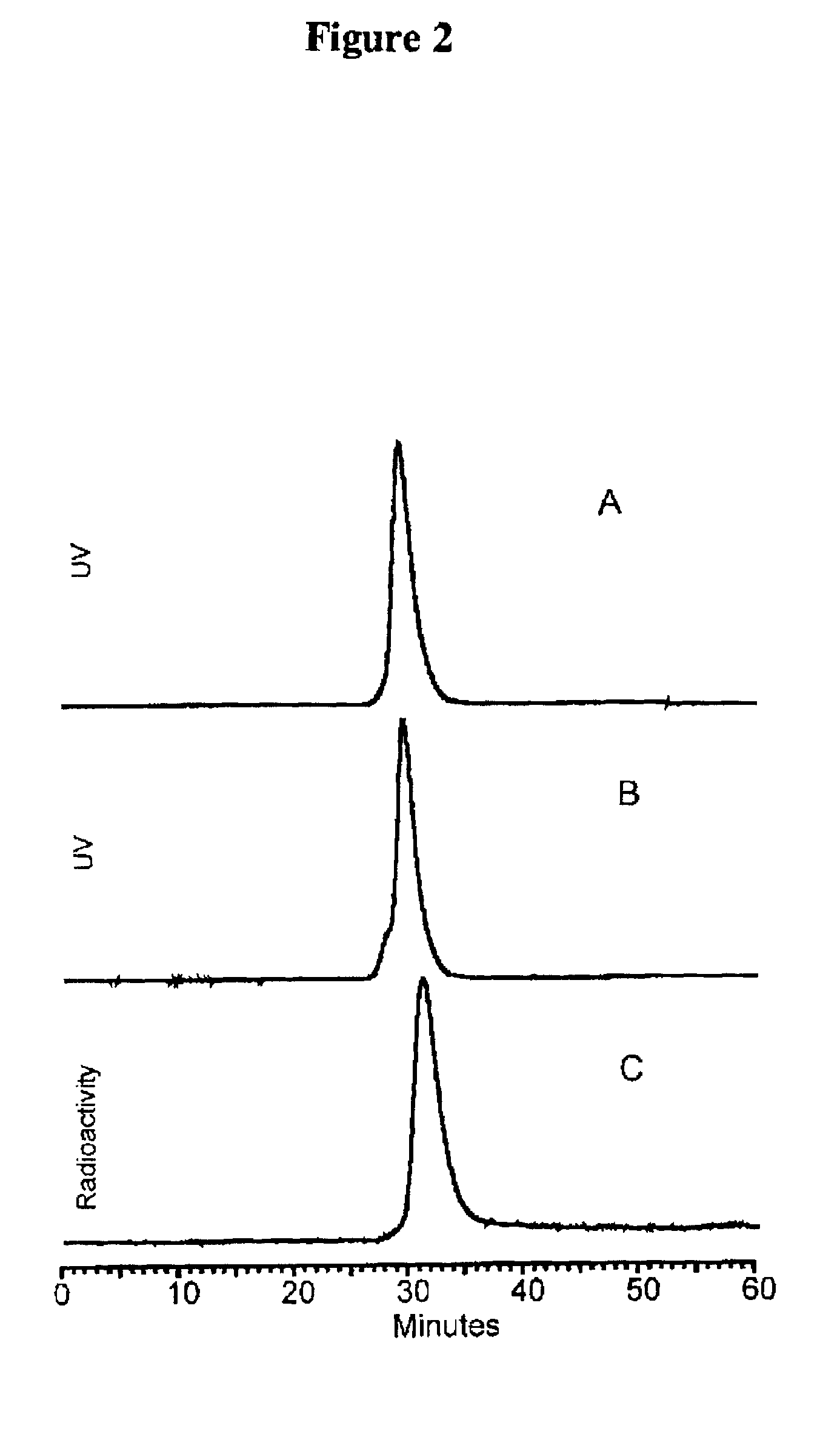

Morpholino imaging and therapy

InactiveUS6899864B2Strong specificityImprove stabilityUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsOligomerDiagnostic agent

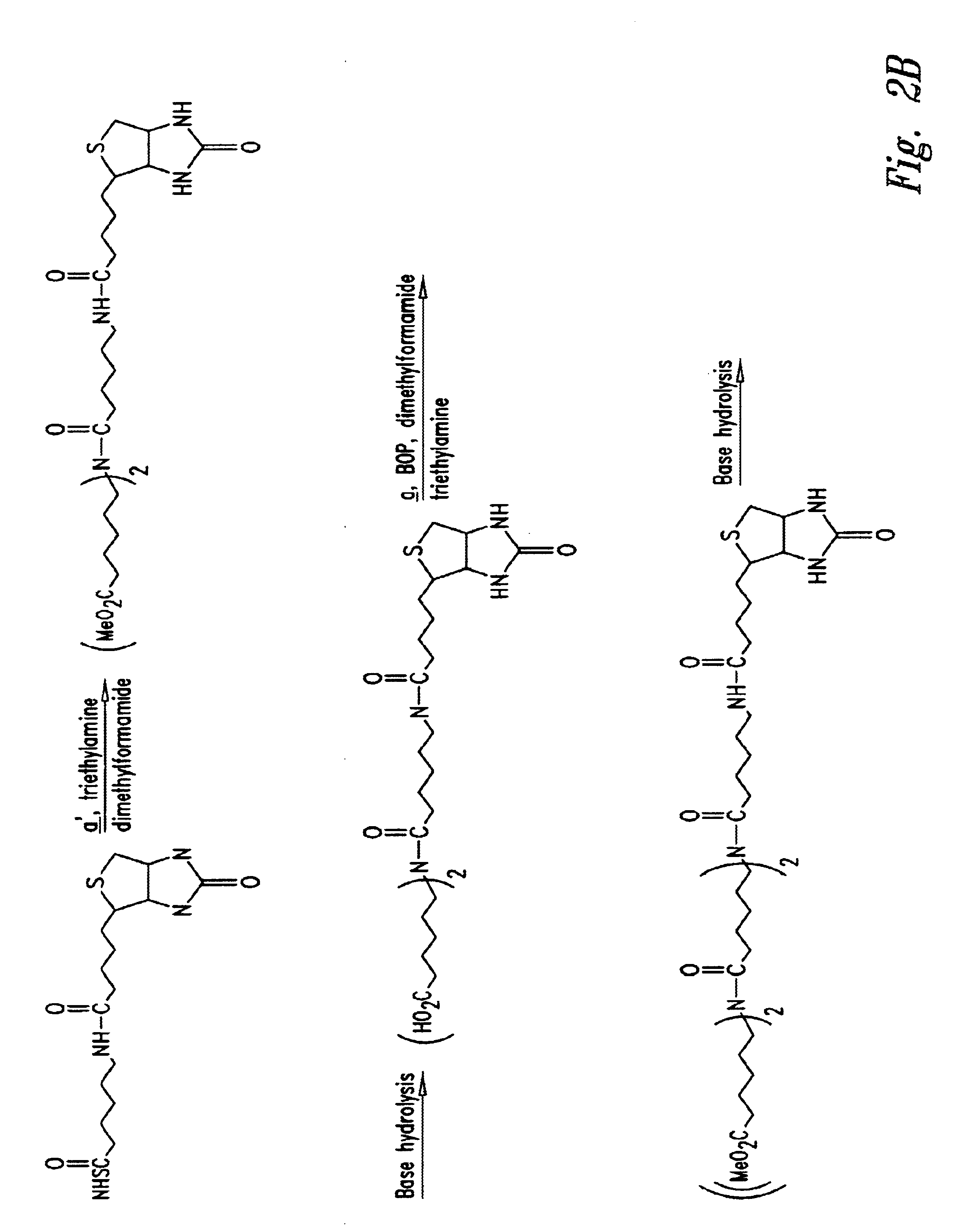

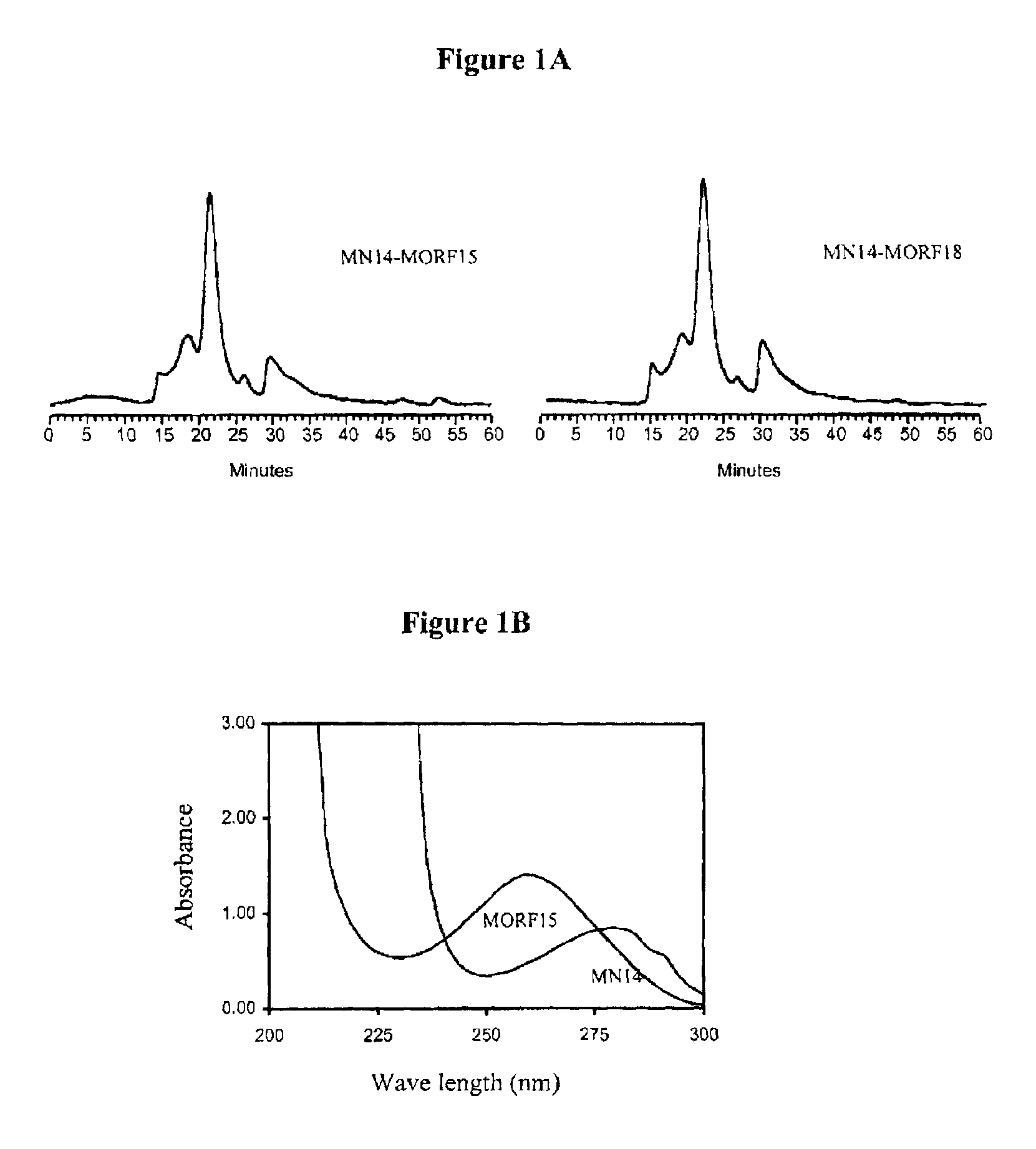

The present invention provides a kit and a method for targeting of a diagnostic or therapeutic agent to a target site in a mammal having a pathological condition. The kit comprises, in separate containers, (a) a first conjugate comprising a targeting moiety and a Morpholino oligomer, wherein the targeting moiety selectively binds to a primary, target-specific binding site of the target site or to a substance produced by or associated with the target site; (b) optionally, a clearing agent; and (c) a second conjugate comprising a complementary Morpholino oligomer and a diagnostic agent or therapeutic agent. The method comprises administering (a), optionally (b), and (c) to a mammal.

Owner:UNIV OF MASSACHUSETTS

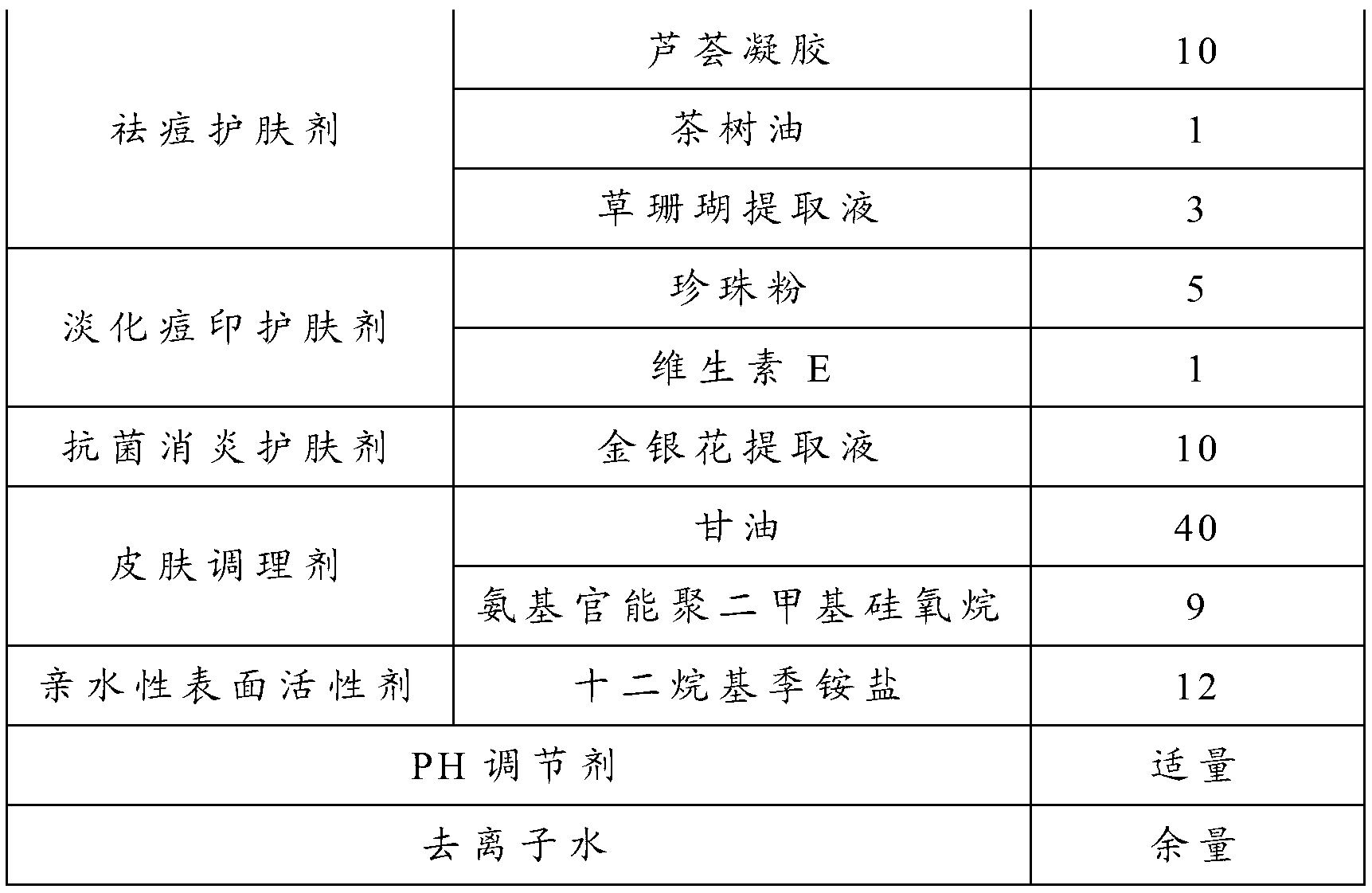

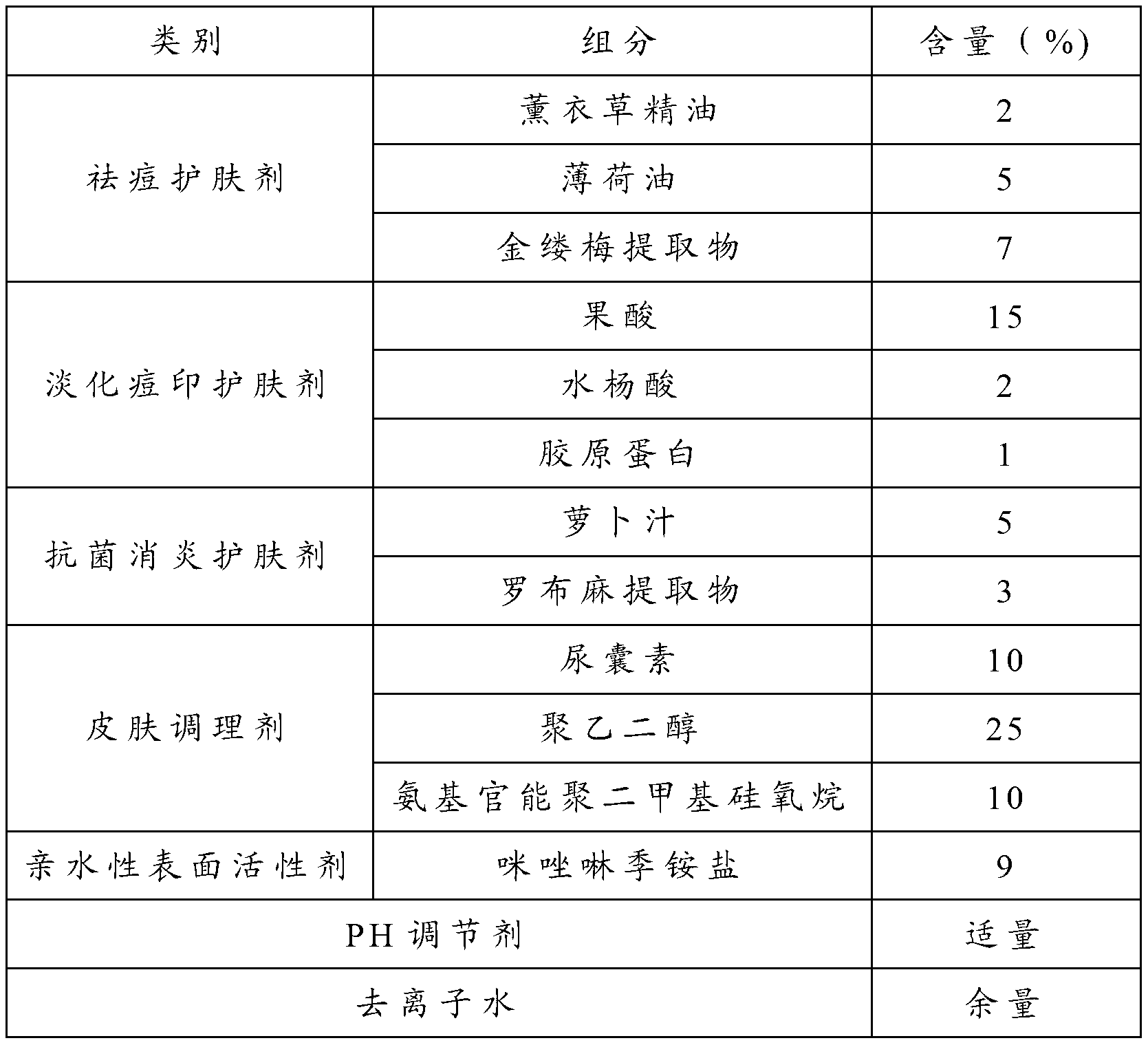

Acne-removing and skin-clearing composition and tissue applying same

InactiveCN103169641AHas the function of deperspiration and moisture absorptionEasy to carryCosmetic preparationsToilet preparationsMedicineClearing Agent

The invention provides an acne-removing and skin-clearing composition comprising an acne-removing agent containing at least one natural component, a skin-clearing agent containing at least one natural component, and an antibacterial and anti-inflammatory agent containing at least one natural component, wherein the mass ratio of the acne-removing agent to the skin-clearing agent to the antibacterial and anti-inflammatory agent is (0.1-60):(0.1-60):(0.01-30). The invention further provides a tissue applying the acne-removing and skin-clearing composition. The tissue disclosed by the invention not only has a sweat-removing and humidity-absorption function, but also can improve a skin condition of a user and has the functions of removing acnes, clearing acne scars and removing pimples.

Owner:GOLD HONG YE PAPER

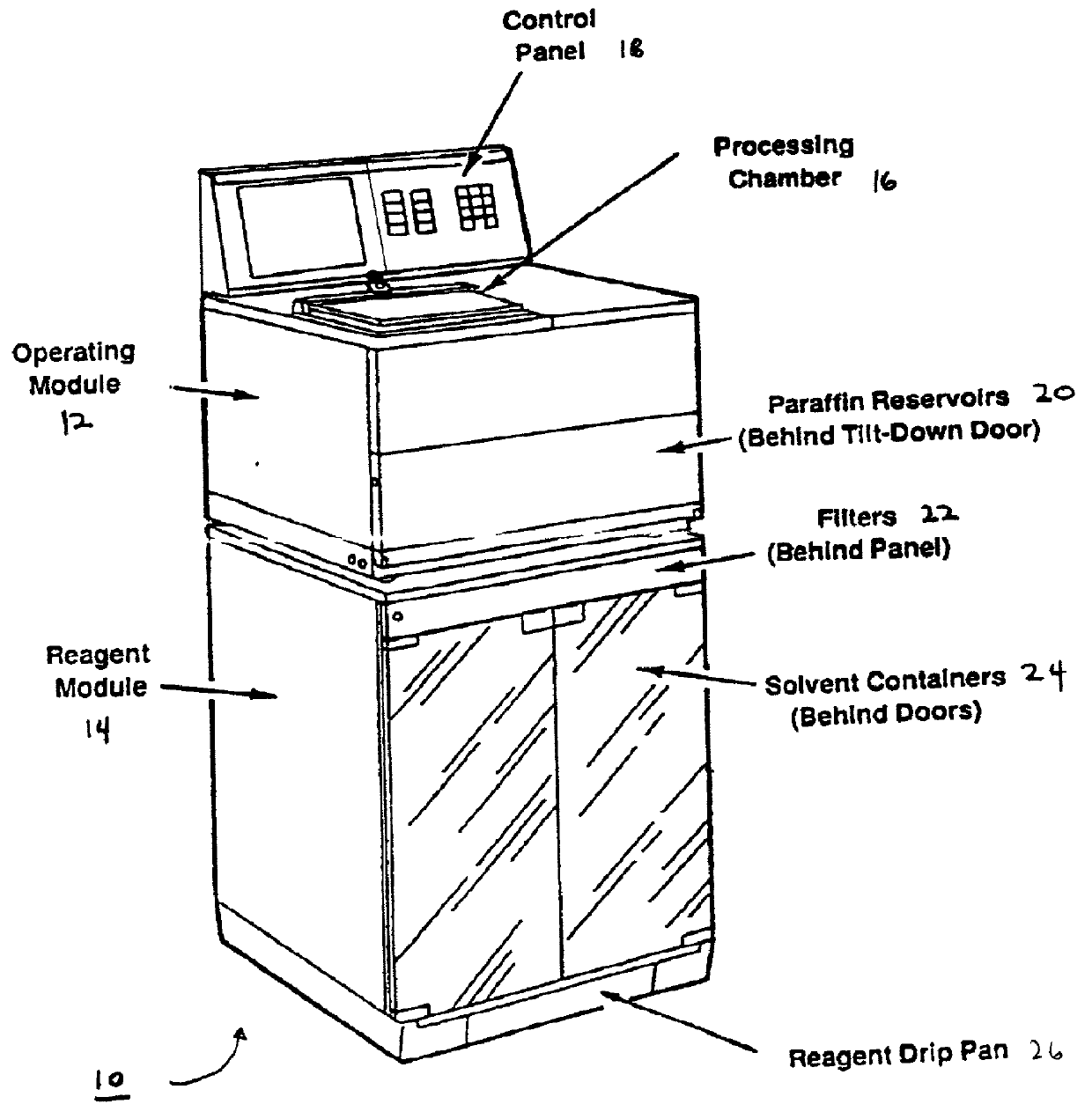

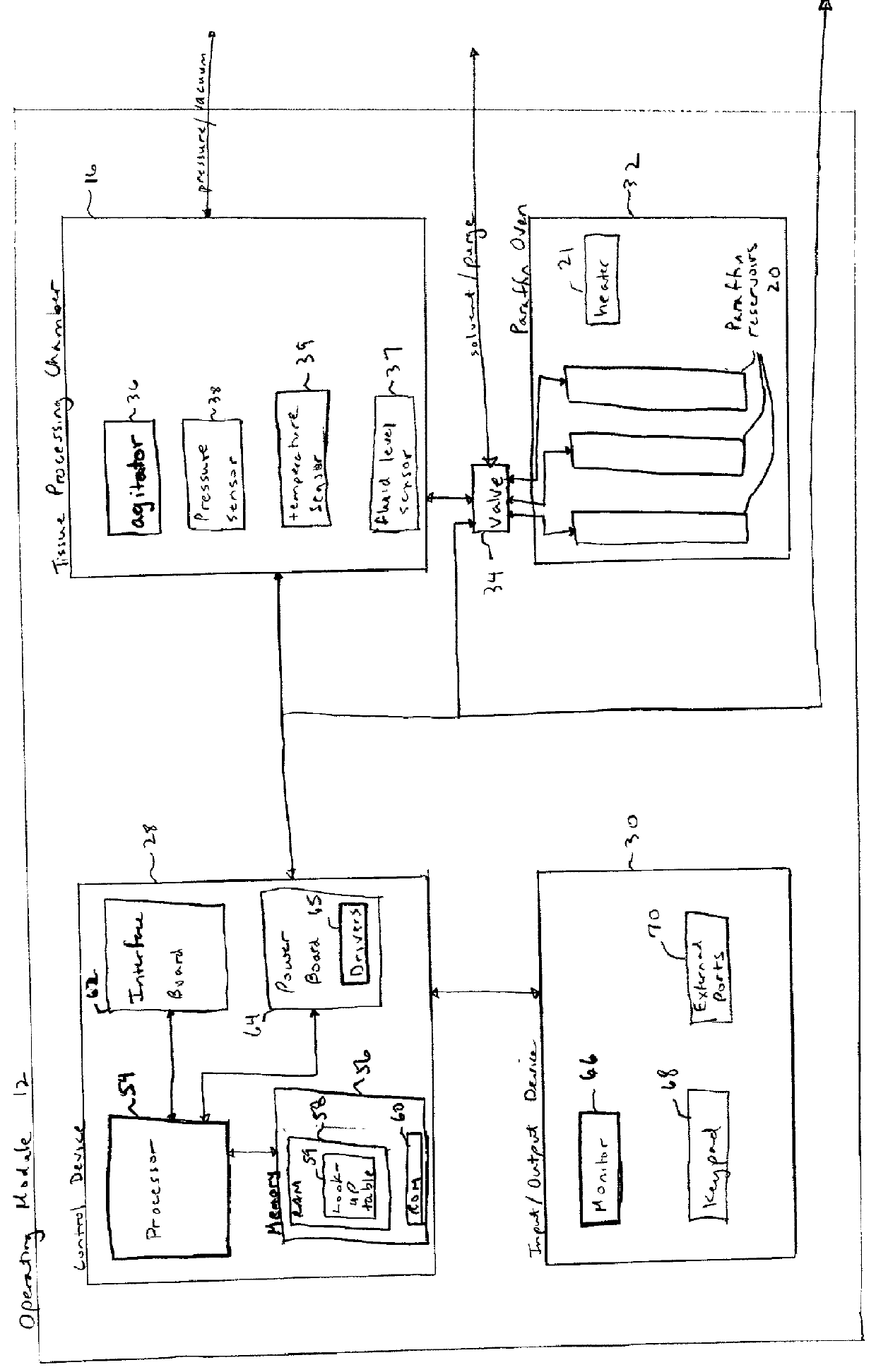

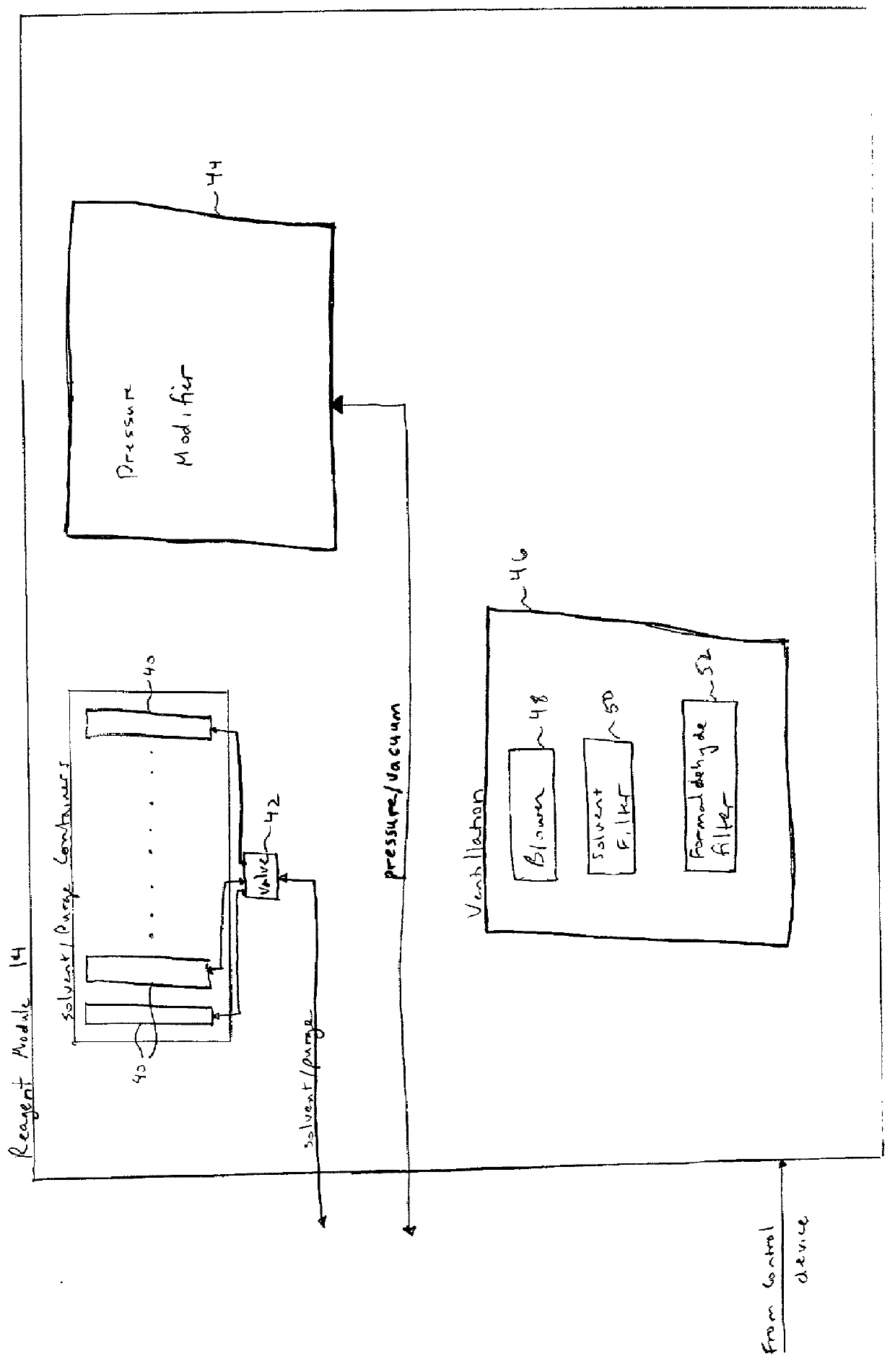

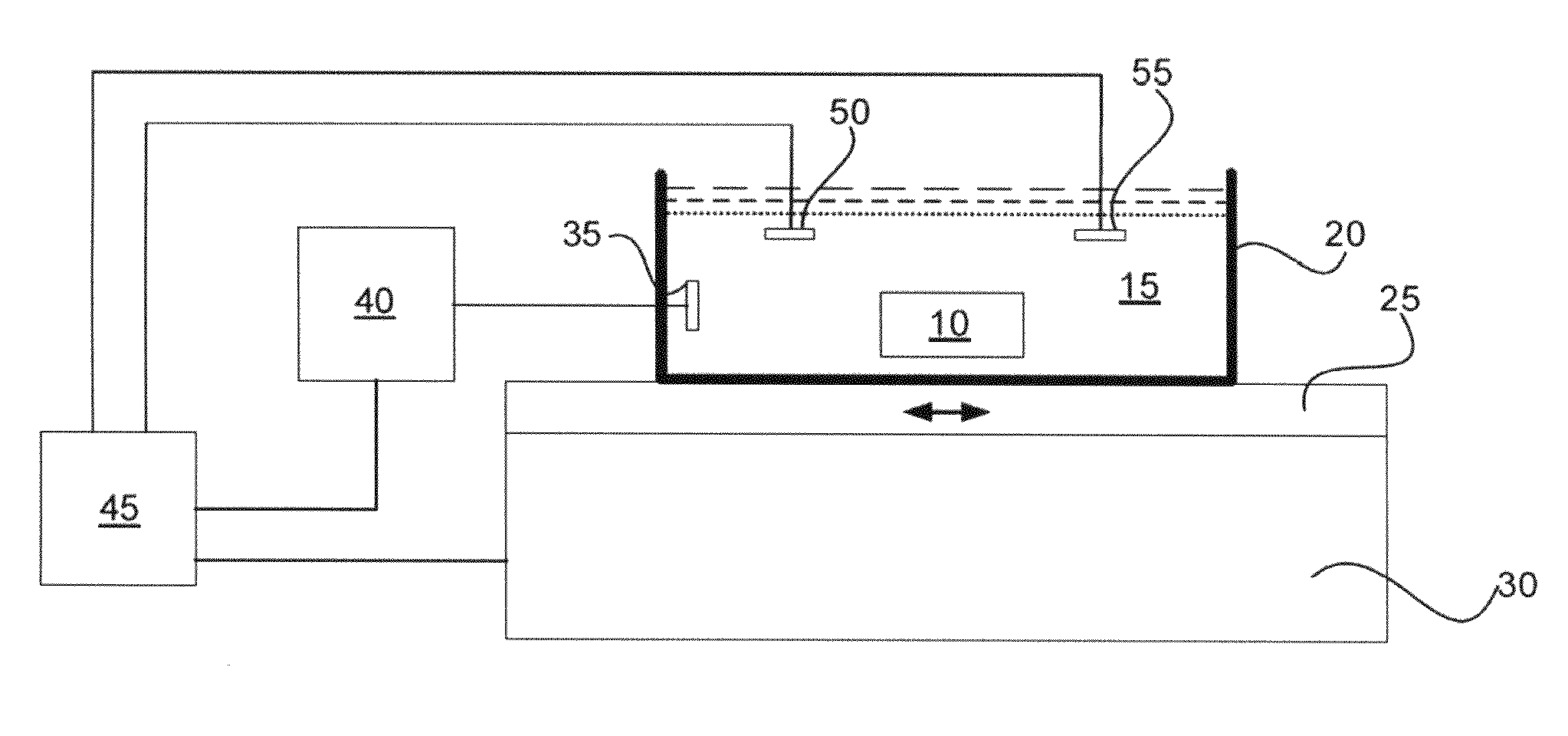

Method and apparatus for automated reprocessing of tissue samples

InactiveUS20010055799A1Bioreactor/fermenter combinationsBiological substance pretreatmentsTissue sampleClearing Agent

A method and apparatus of automatically reprocessing a specimen for microscopic examination is disclosed. Processing of a specimen for microscopic examination involves fixation of the specimen and preparation of the embedded specimen from the fixed specimen. There are instances where, once a specimen has been processed, it is necessary to reprocess the specimen due to contamination of reagents during processing or inadequate fixation. The system automatically reprocesses a specimen by removing residual embedding material from the specimen with a clearing agent, removing the clearing agent with a dehydrating agent, and removing the dehydrating agent with an aqueous fluid.

Owner:VENTANA MEDICAL SYST INC

Extreme-pressure abrasion-resistant open gear oil

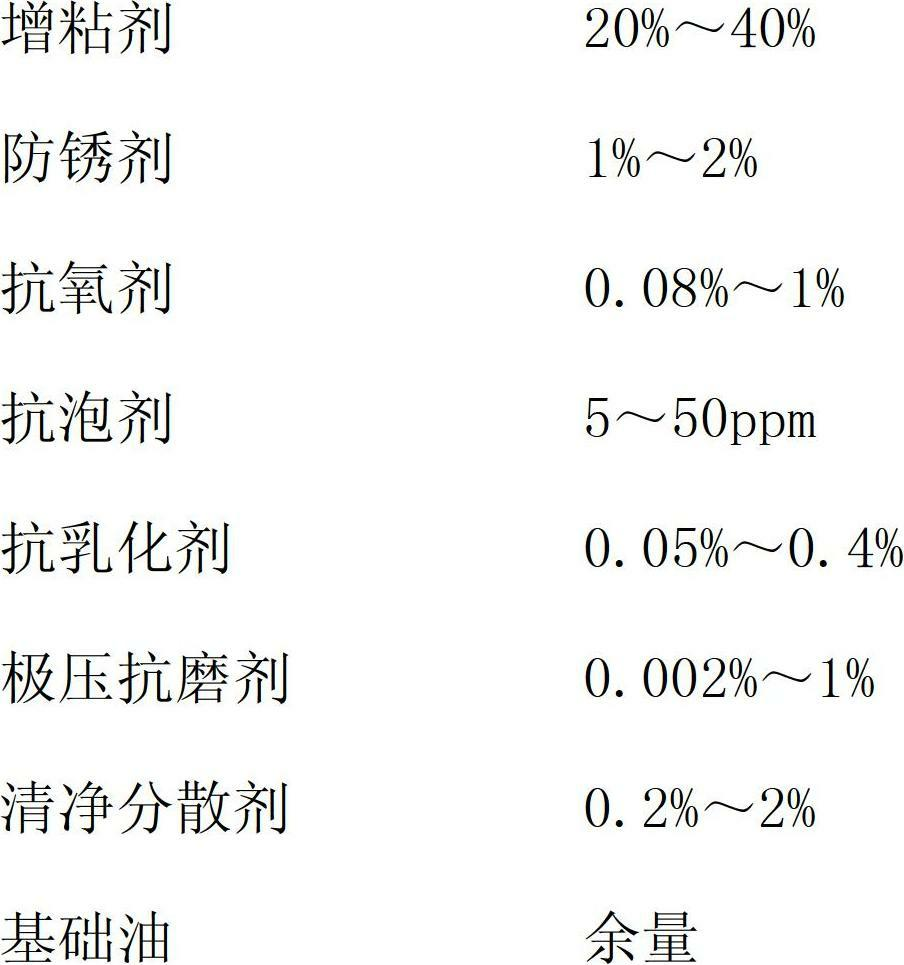

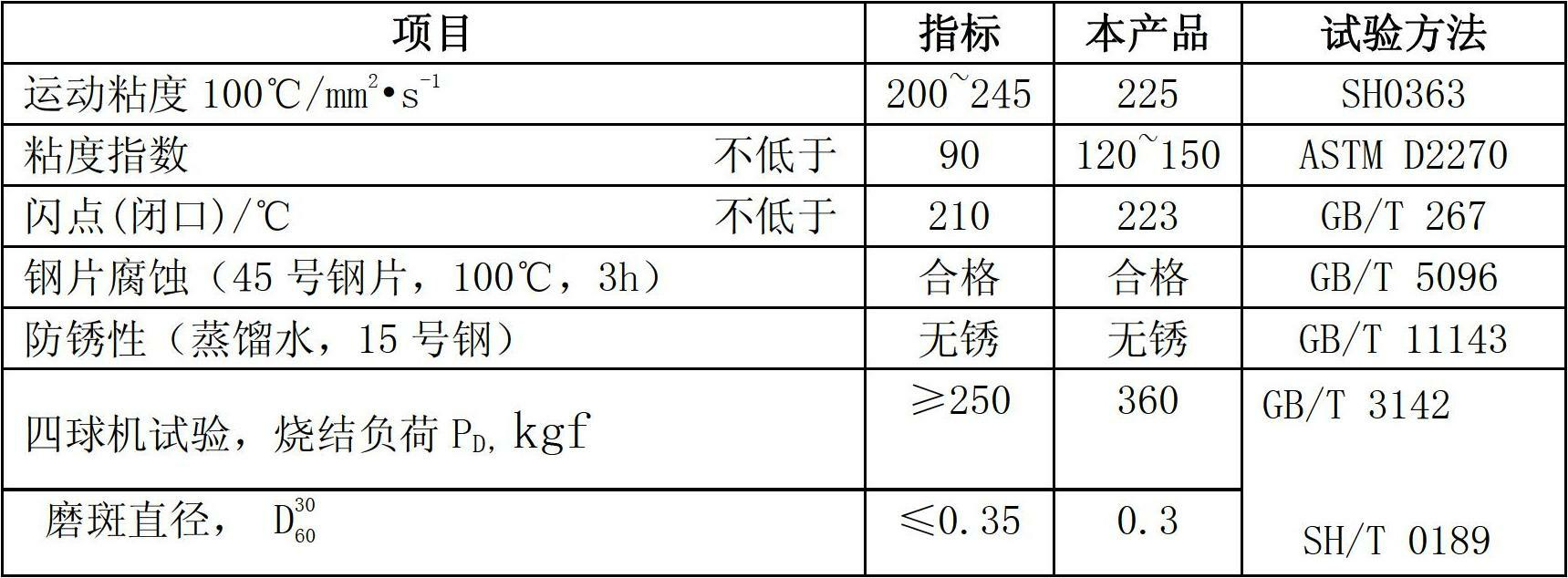

ActiveCN102690702ASolve the problem of clogged equipmentGood extreme pressure and anti-wear propertiesAdditivesFoaming agentAdhesive

The invention discloses extreme-pressure abrasion-resistant open gear oil which is prepared from the following components by weight: 20-40% of tackifier, 1-2% of rust inhibitor, 0.08-1% of antioxygen, 5-50ppm of anti-foaming agent, 0.05-0.4% of demulsifying agent, 0.002-1% of extreme-pressure abrasion-resistant agent, 0.2-2% of purification dispersant and the balance being base oil, wherein the extreme-pressure abrasion-resistant agent refers to nanometer grapheme. By adding the nanometer grapheme to serve as the extreme-pressure abrasion-resistant agent, the extreme-pressure abrasion resistance of the gear oil is improved, an abrasion-resistant effect is remarkable and the abrasion loss can be reduced by 52%; by utilizing effective adhesive, clearing agent, antirust corrosion-resistant additive and the antioxygen, the adhesion, viscosity-temperature characteristic and antioxidant rust resistance of the oil are ensured; and by adding the dispersant, the problem of blockage caused by poor dispersibility of the nanometer grapheme which serves as a solid extreme-pressure agent is solved.

Owner:上海福岛新材料科技有限公司

Methods and compositions for treatment of human immunodeficiency virus infection with conjugated antibodies or antibody fragments

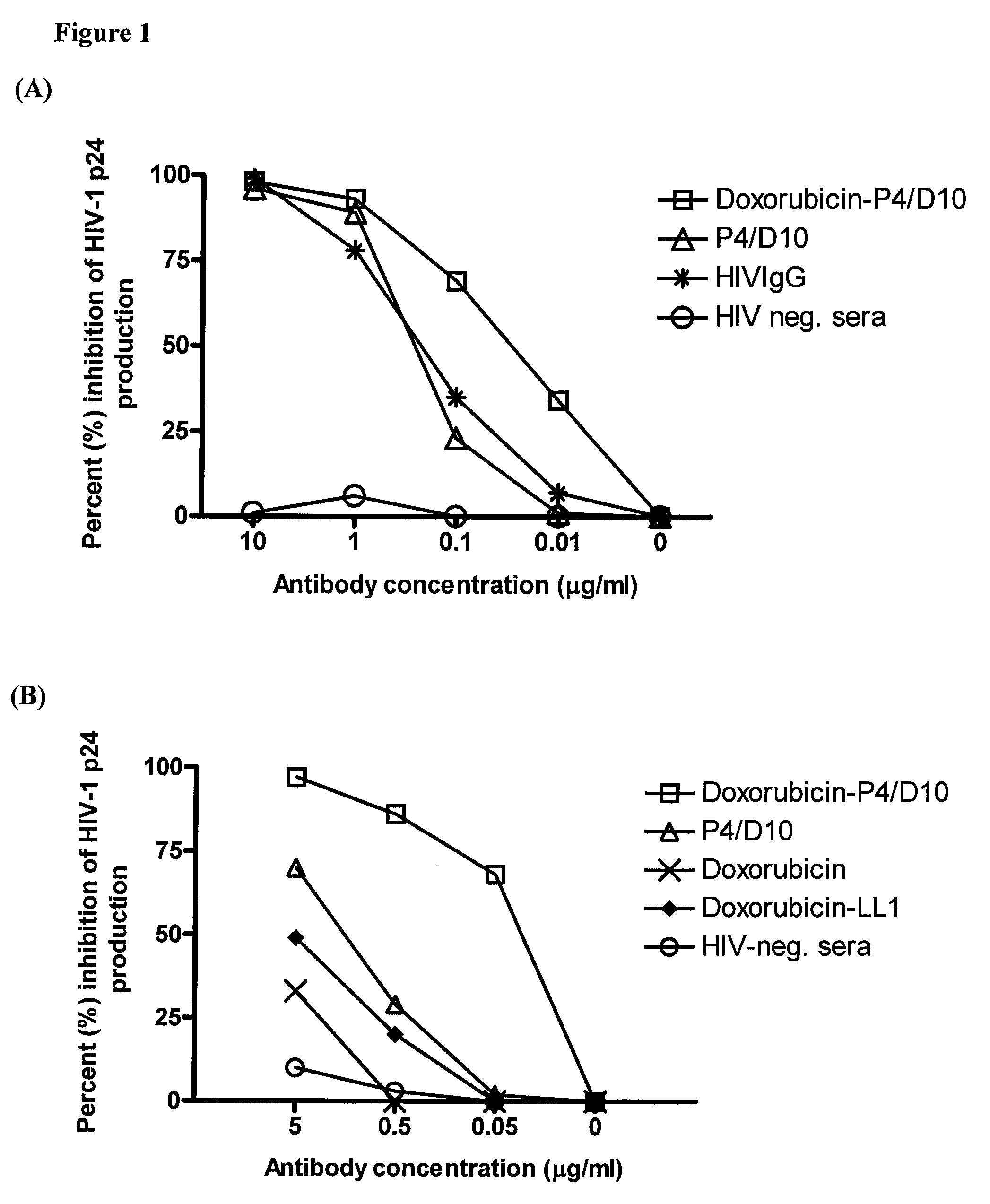

ActiveUS8333971B2Avoid infectionReduce eliminateOrganic active ingredientsAntiviralsDiagnostic agentBinding site

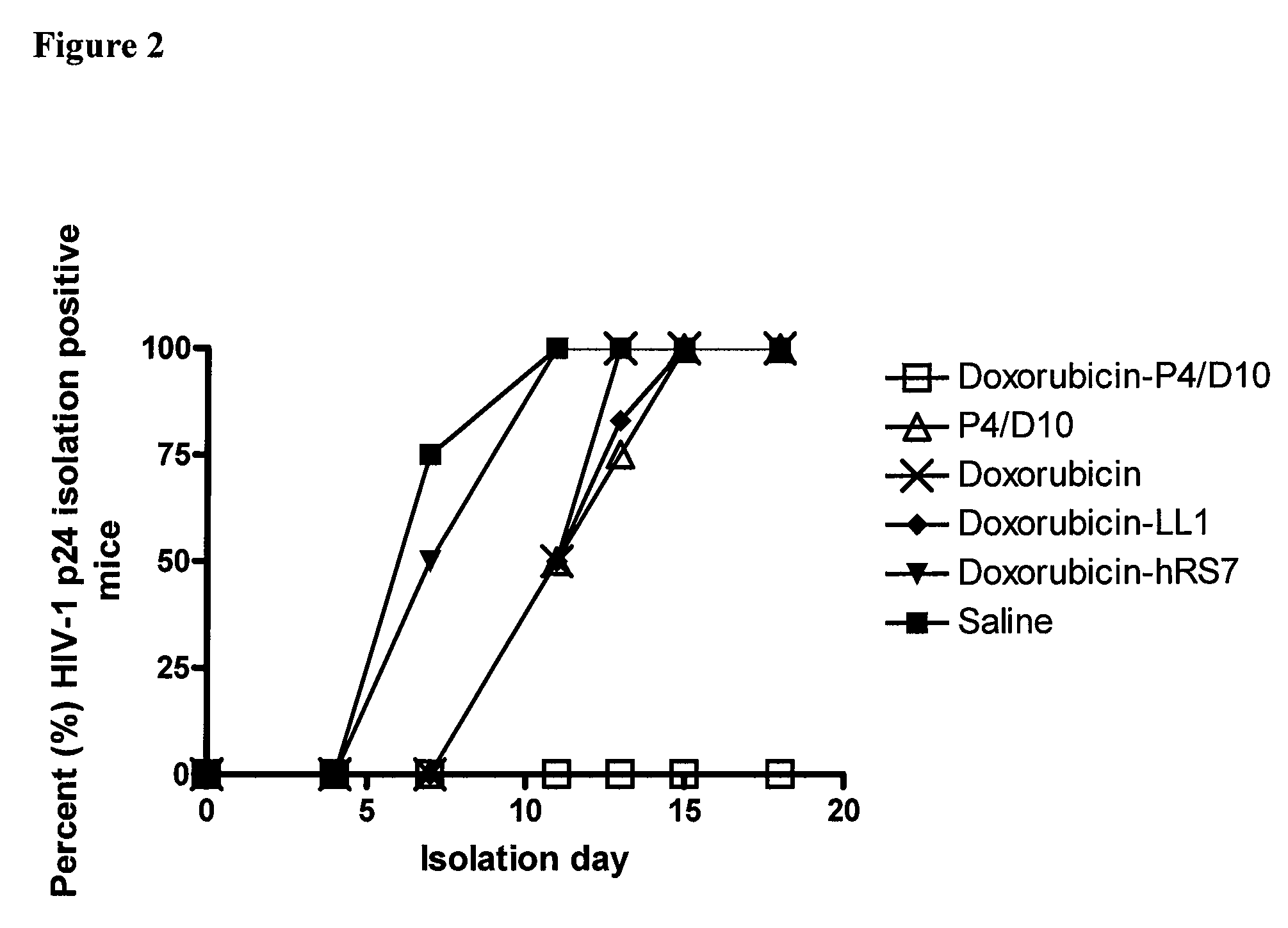

The present invention concerns methods and compositions for treatment of HIV infection in a subject. The compositions may comprise a targeting molecule against an HIV antigen, such as an anti-HIV antibody or antibody fragment. The anti-HIV antibody or fragment may be conjugated to a variety of cytotoxic agents, such as doxorubicin. In a preferred embodiment, the antibody or fragment is P4 / D10. Other embodiments may concern methods of imaging, detection or diagnosis of HIV infection in a subject using an anti-HIV antibody or fragment conjugated to a diagnostic agent. In alternative embodiments, a bispecific antibody with at least one binding site for an HIV antigen and at least one binding site for a carrier molecule may be administered, optionally followed by a clearing agent, followed by administration of a carrier molecule conjugated to a therapeutic agent.

Owner:IMMUNOMEDICS INC

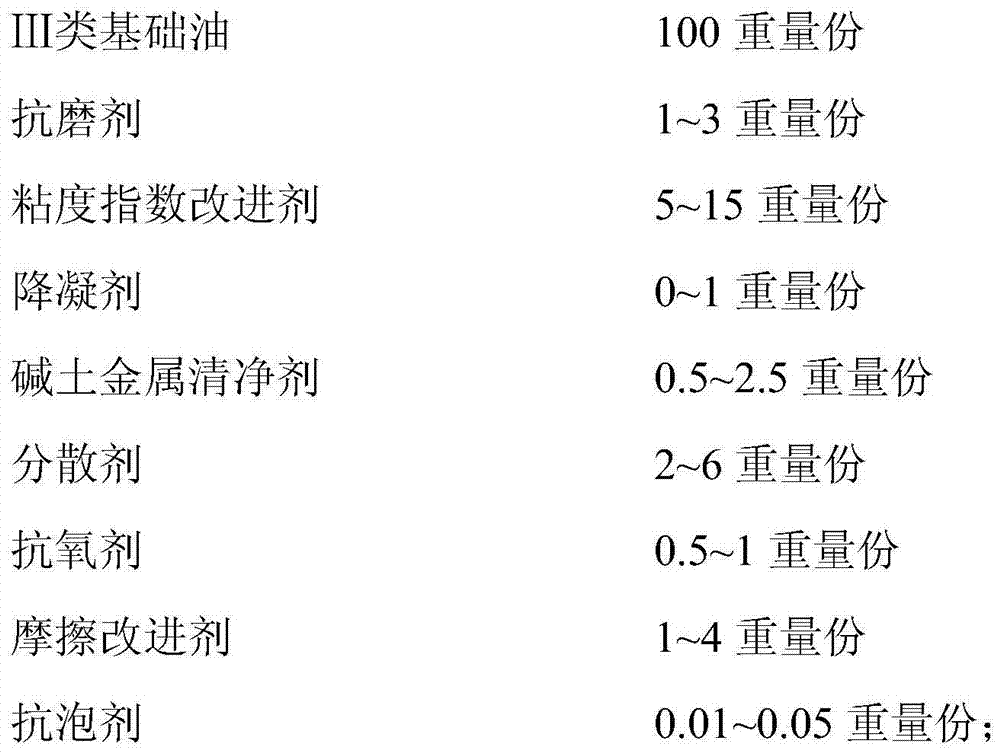

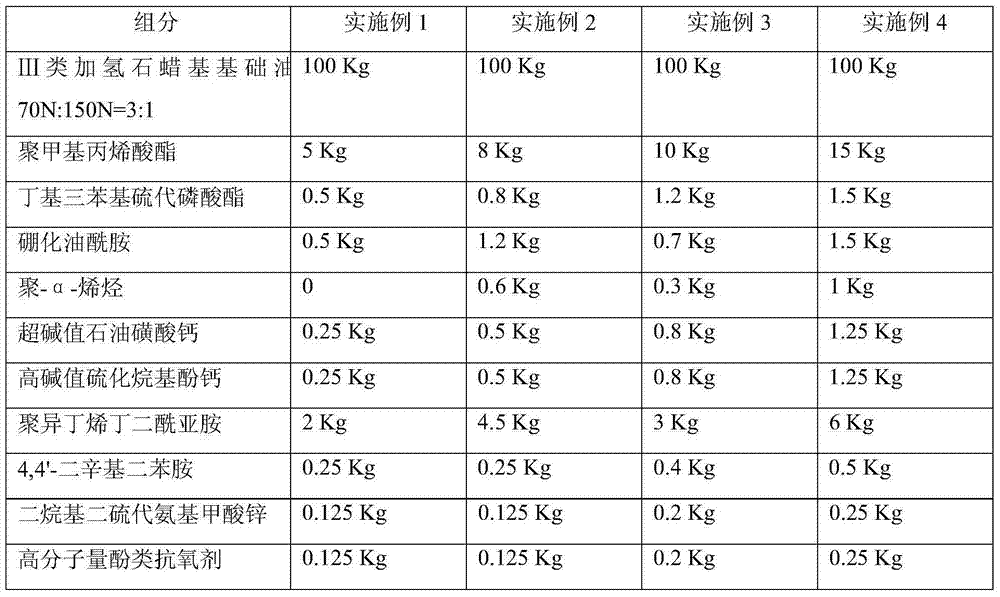

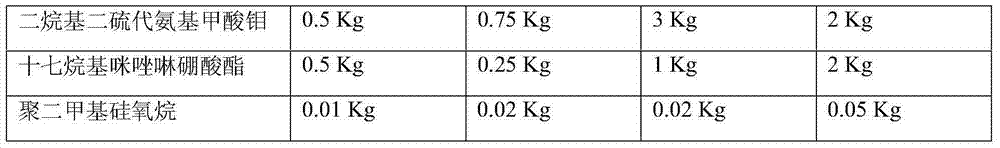

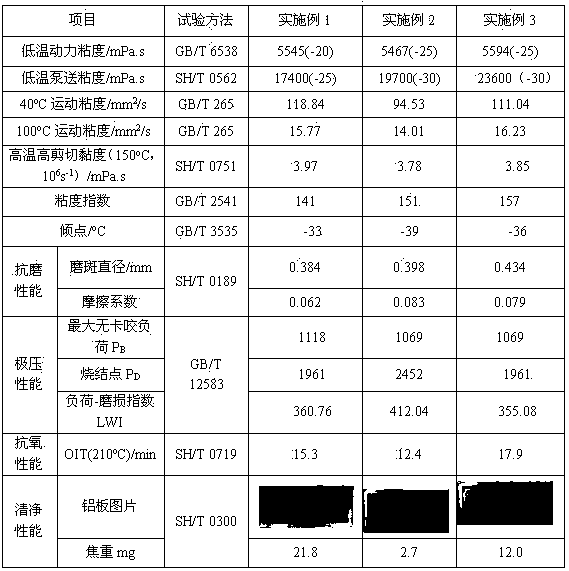

Automobile continuously variable transmission fluid and preparation method thereof

The invention discloses an automobile continuously variable transmission fluid and a preparation method thereof. The automobile continuously variable transmission fluid comprises the following components: 100 parts by weight of class III base oil, 1-3 parts by weight of antiwear agent, 5-15 parts by weight of viscosity index improver, 0-1 part by weight of pour point depressant, 0.5-2.5 parts by weight of alkaline earth clearing agent, 2-6 parts by weight of dispersant, 0.5-1 part by weight of antioxidant, 1-4 parts by weight of friction modifier and 0.01-0.05 part by weight of anti-foaming agent. According to the invention, the chosen additives are optimally combined together to obtain the CVTF, and the obtained CVTF has excellent comprehensive properties; the CVTF is excellent in viscosity index, oxidation stability, shear stability, wearing quality and cryogenic property, and more critically, large in torque, high in traction coefficient and high in transmission efficiency; and consequently, the use requirements of B-CVT and T-CVT can be met simultaneously.

Owner:GUANGZHOU MECHANICAL ENG RES INST

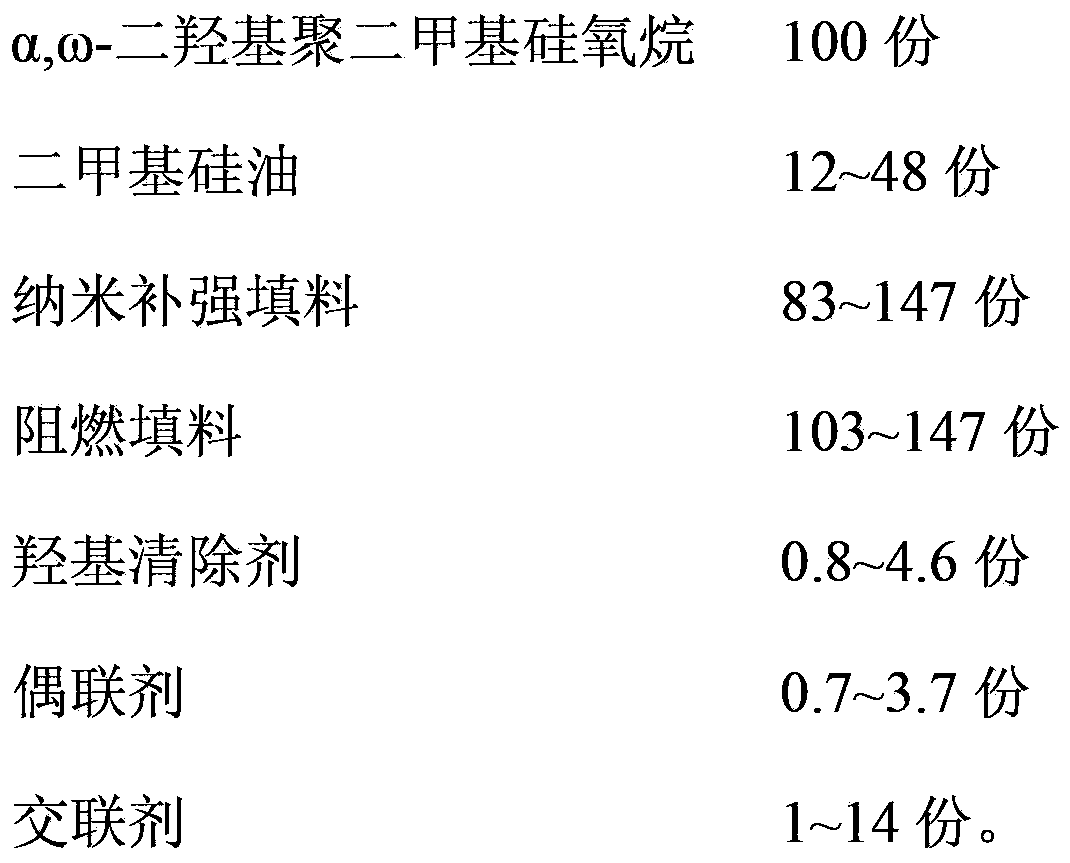

Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

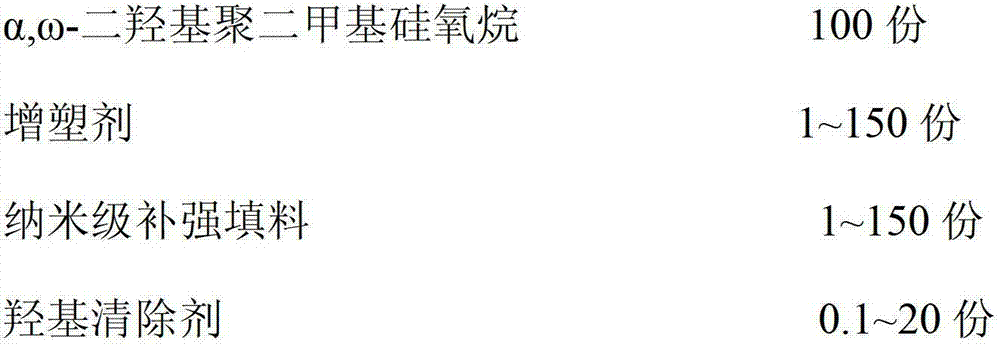

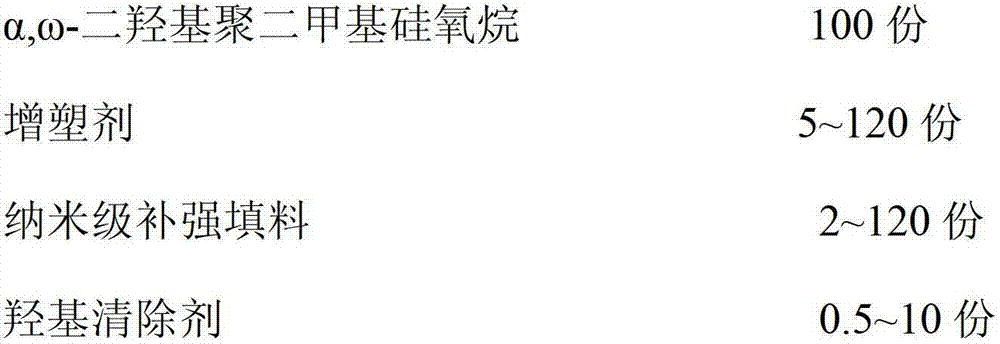

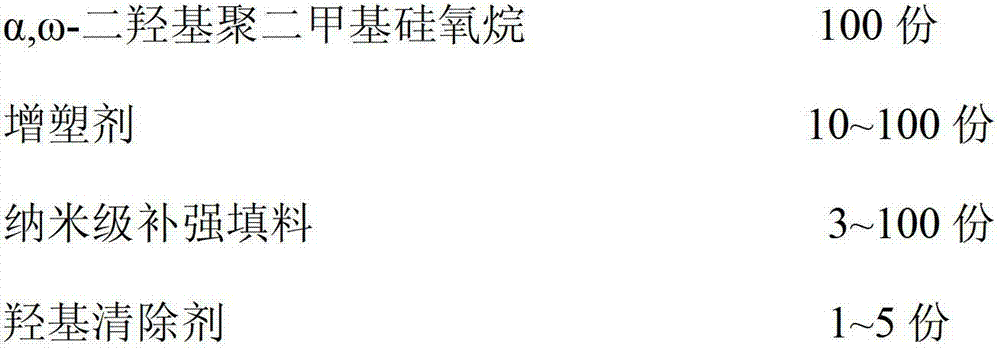

InactiveCN102757759AGood physical propertiesLong storage periodNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention relates to a single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber. A ground mass comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 1-150 parts of plasticizer, 1-150 parts of nano level reinforced filler and 0.1-20 parts of hydroxyl clearing agent; and the single-component catalytic dealcoholized RTV silicone rubber comprises the following components in parts by weight: 100 parts of ground mass, 0.1-30 parts of crosslinking agent and 0.1-8 parts of coupling agent. The invention also relates to a preparation method of the single-component catalytic dealcoholized RTV silicone rubber, and the method comprises the following steps of: dewatering and blending the alpha, omega-dyhydroxyl polydimethylsiloxane, the plasticizer, the nano level reinforced filler and the hydroxyl clearing agent to obtain the ground mass; taking the ground mass, vacuumizing, stirring, adding the crosslinking agent, vacuumizing and stirring; and adding the coupling agent, vacuumizing and stirring to obtain the single-component catalytic dealcoholized RTV silicone rubber. The method provided by the invention has the advantages that a nano material is adopted as the filler, the plasticizer is added, so that the single-component catalytic dealcoholized RTV silicone rubber has better physical properties; and the nano filler is treated by adopting the silane, thus the storage life of a sealant is prolonged.

Owner:兆舜科技(广东)有限公司

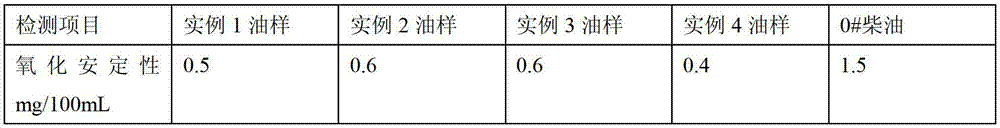

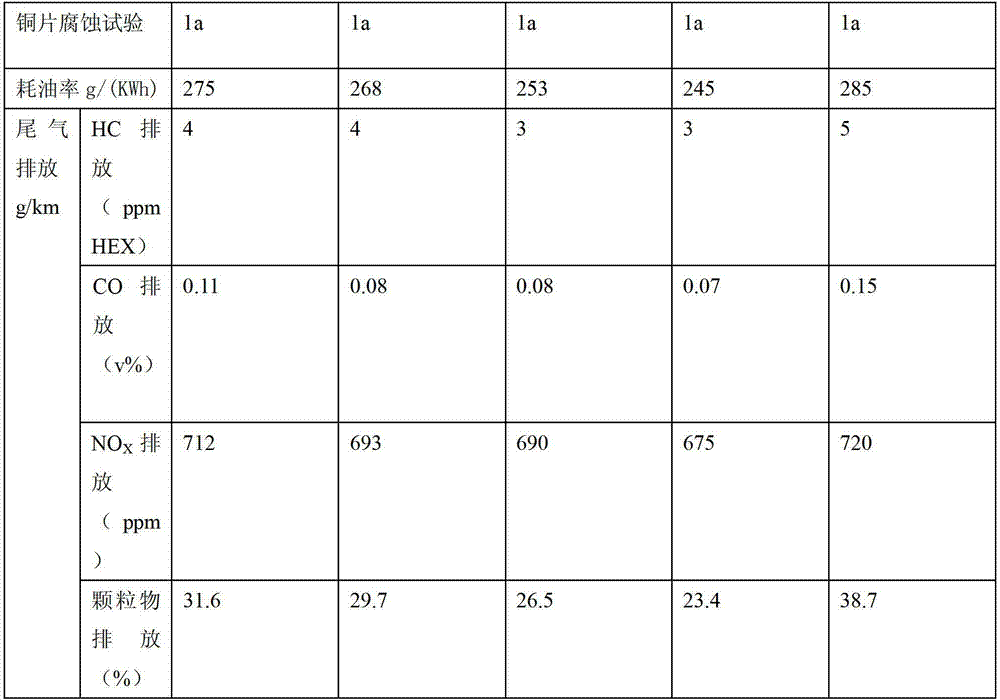

Diesel composite additive

ActiveCN103194282AImprove detergencyImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesChemical industryAntioxidant

The invention relates to the technical field of chemical industry and relates to a multifunctional diesel composite additive capable of reducing the oil consumption and reducing the pollution of the exhaust emission. The diesel composite additive is mainly formed by uniformly mixing a clearing agent, a smoke abatement combustion improver, a cetane number improver, a pour point reducer, an antioxidant, a metal corrosion inhibitor and a cosolvent. The diesel composite additive can improve the clearness, the low-temperature mobility, oxidation resistance and corrosion resistance of the diesel, also can improve the combustion performance of the fuel, can reduce the oil consumption and can reduce the pollution of the exhaust emission.

Owner:山东京博众诚清洁能源有限公司

Universal type synthetic gasoline-diesel lubrication oil and preparation method thereof

ActiveCN104498144AHigh viscosity indexImprove the lubrication effectBase-materialsGasolineClearing Agent

The invention belongs to the technical field of development and manufacture of petrochemical products and in particular relates to universal type synthetic gasoline-diesel lubrication oil and a preparation method thereof. The lubrication oil comprises the following raw materials in parts by weight: 0.01-30 parts of synthetic ester base oil, 0.01-90 parts of mineral oil, 0.01-90 parts of olefin synthesis oil PAO, 5.0-10.0 parts of a viscosity modifier, 3-10.0 parts of a clearing agent, 1.0-5.0 parts of a dispersing agent, 0.5-3.0 parts of an oxidation and corrosion inhibitor, 1.0-3.0 parts of a pour point depressant, 0.5-3.0 parts of FK303 and 0.0001-0.01 part of a defoaming agent. The preparation method of the lubrication oil comprises the following steps: step one, adding synthetic ester base oil, the mineral oil and the olefin synthesis oil PAO in a mixing kettle, and stirring at 80-90 DEG C for 1 hour; step two, adding the viscosity modifier into the mixing kettle in the step one, and continuing to stir at 80-90 DEG C for 3 hours; adding the clearing agent, the dispersing agent, the oxidation and corrosion inhibitor, the pour point depressant, FK303 and the defoaming agent into the mixing kettle and continuing to stir at 80-90 DEG C for 1-2 hours to obtain the lubrication oil. The universal type synthetic gasoline-diesel lubrication oil is mainly used in the application field of motor vehicle lubricating oil.

Owner:XINJIANG FUKE OIL PROD CO LTD

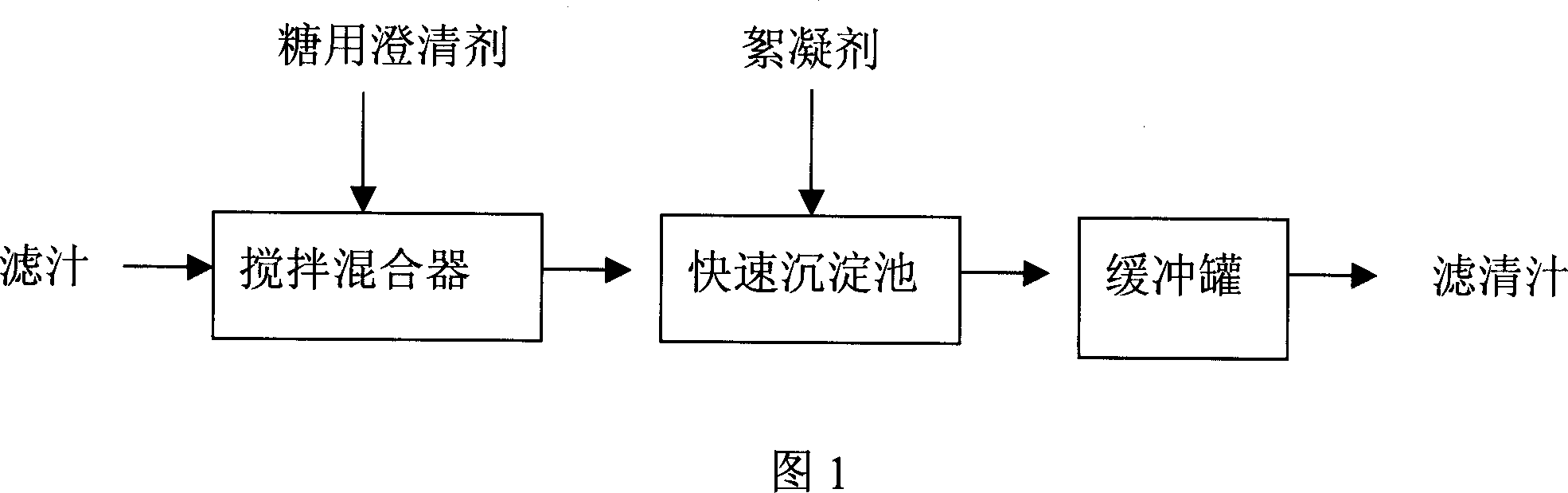

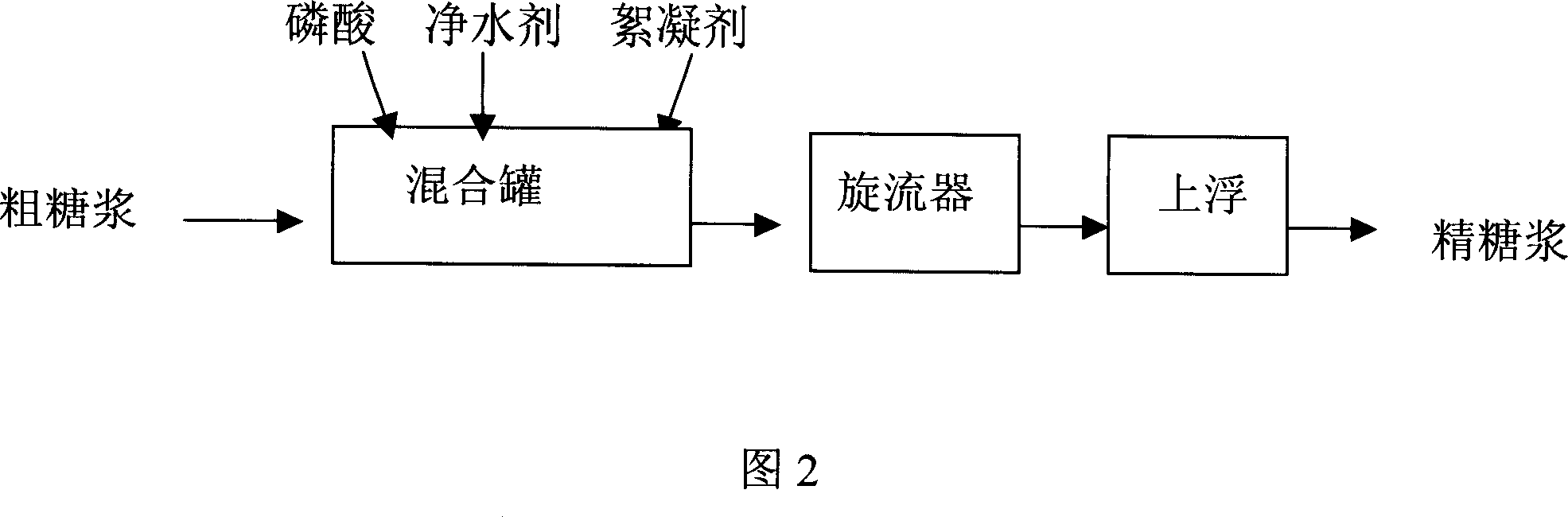

Composite type clearing agent in use for refining sugar, and preparation method

InactiveCN1958811AExtensive local contact condensationIncrease profitSugar juice purificationUltra fineAmmonium chloride mixture

This invention relates to a composite clarification agent used in sugar production. The composite clarification agent is composed of: polymerized AlCl3, organic polymeric materials (including chitosan, chitosan quaternary ammonium salt and dimethyl diallyl ammonium chloride), and ultra-fine powder (including perlitic powder, diatomite and clay) at a ratio of (45-90) :( 1-10) :( 5-50). The composite clarification agent has high electrical neutralization and bridge linkage performances, and has such advantages as low cost, rapid solid-liquid separation and no toxicity. The composite clarification agent is suitable for clarifying mixed juice, filtrate and syrupy in sugar production. The method has such advantages as abundant raw materials, simple process and easy operation.

Owner:GUANGZHOU SUGARCANE IND RES INST

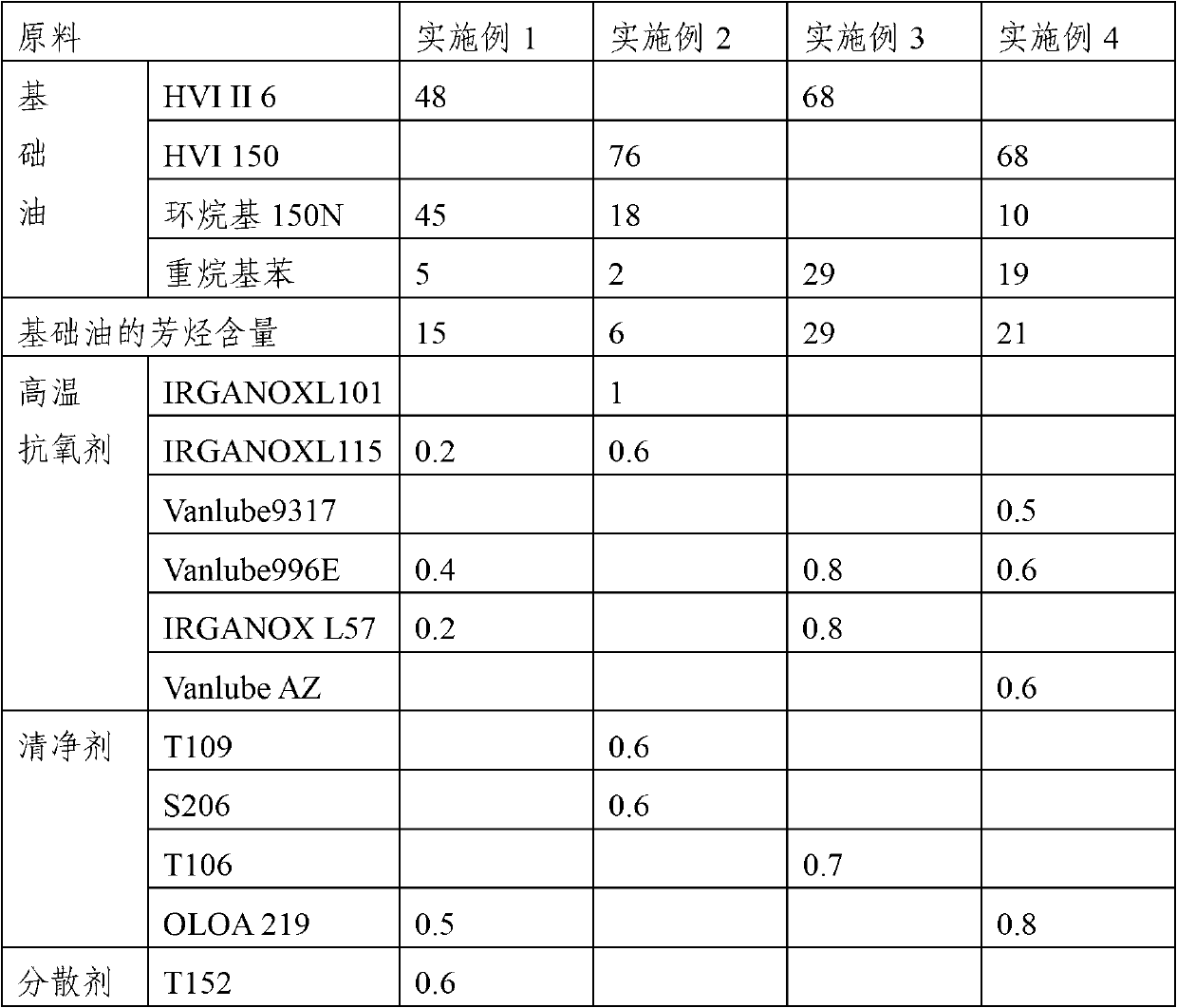

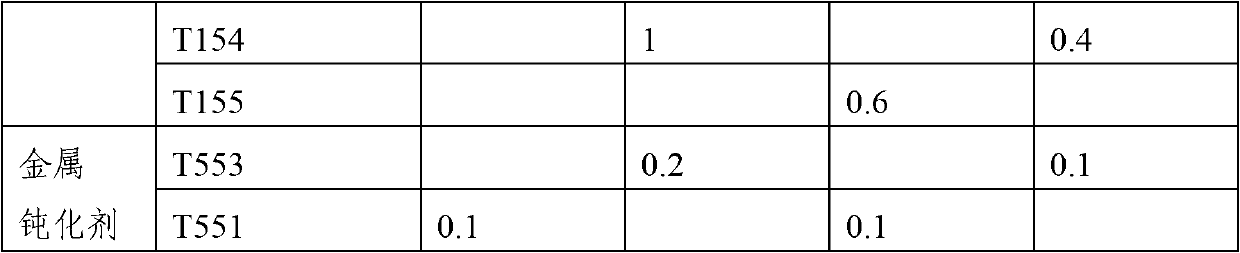

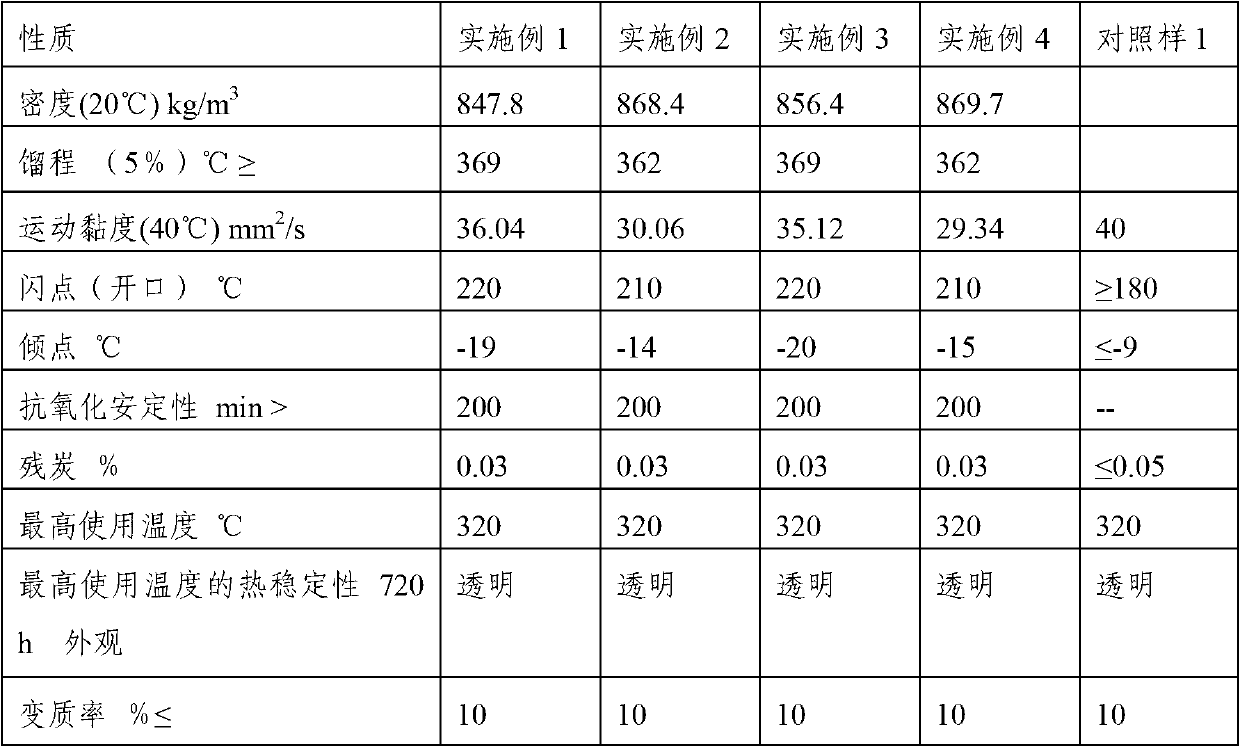

High-temperature heat transfer oil composition

ActiveCN103305192AImprove thermal stabilityImprove heat transfer performanceHeat-exchange elementsBiochemical engineeringAntioxidant

The invention provides a high-temperature heat transfer oil composition which consists of the following components in percentage by weight: 95-98% of base oil, 0.01-2.0% of high-temperature antioxidant, 0.01-2.0% of clearing agent, 0.01-1.0% of dispersing agent and 0.01-0.5% of metal deactivator, wherein the base oil is one or more of HVI base oil, naphthenic-base base oil and alkylbenzene. The high-temperature heat transfer oil composition dominated by mineral-oil base oil, provided by the invention, has the advantages of good thermal stability, good heat transfer effect, no toxicity, low cost, easiness in realizing industrial production and the like; and the maximum service temperature is up to 320 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of clear mulberry juice drink

The invention discloses a preparation method of a clear mulberry juice drink, which comprises the following steps: selecting and cleaning fresh mulberries, crushing, juicing, clearing, filtering, batching, filtering, deaerating and sterilizing. The clear mulberry juice drink prepared by the method adopts the procedures of firstly adding pectase and then adding bentonite and gelatin to clear mulberry juice during the preparation, the pectase can firstly decompose the pectin in the juice, lower the juice viscosity and avoid the interference of the bentonite and the gelatin to the clearing effect of the pectase when clearing agents are added simultaneously; the latterly added bentonite and the latterly added gelatin enable anions and cations in the mulberry to be electrically neutralized, thereby leading molecules to be changed into macromolecules to be coagulated and settled down so that the clearing effect is more ideal and the product is more transparent and glossy (the transmittance reaches more 80 percent) without settlement and has creamy mouthfeel; moreover, the clearing procedure of the natural juice can be rapidly complete under normal temperature and the natural juice has simple process and can realize industrialized production.

Owner:ZHEJIANG PHARMA COLLEGE

Aluminum alloy for wheel hub and preparation method thereof, and aluminum alloy wheel hub

The invention discloses an aluminum alloy for a wheel hub and a preparation method thereof, and an aluminum alloy wheel hub. The preparation method comprises the following steps: a, melting an aluminum ingot so as to prepare a primary aluminum liquid; b, mixing a slag-clearing agent with the primary aluminum liquid, and discharging molten slag so as to prepare a second-stage aluminum liquid; c, mixing a refining agent with the second-stage aluminum liquid in the presence of nitrogen and then carrying out standing and slagging so as to prepare a third-stage aluminum liquid; d, mixing a refiner and a modifier with the third-stage aluminum liquid so as to prepare a fourth-stage aluminum liquid; E, spreading the slag-clearing agent onto the surface of the fourth-stage aluminum liquid to clear slag so as to prepare a fifth-stage aluminum liquid; and f, spreading the slag-clearing agent on the surface of the fifth-stage aluminum liquid, and carrying out degassing treatment so as to prepare the aluminum alloy for the wheel hub. According to the invention, the contents of hydrogen and impurities in the aluminum alloy for the wheel hub are low, so the aluminum alloy for the wheel hub has excellent fluidity and shrinkage during solidification; therefore, the surface of the aluminum alloy wheel hub prepared from the aluminum alloy used for the wheel hub is free of pin holes and slag holes.

Owner:WUHU HUANGYAN IND

Peptide clearing agents

InactiveUS20130053543A1Easy to removeReduce molecular weightPeptide sourcesNanomedicineDipeptideReactive site

A peptide clearing agent is provided for clearance of a conjugate of an enzyme and a binding molecule which binds specifically at a target location from a non-target location in a subject. The peptide clearing agent binds the active site of the enzyme. The peptide also binds to the asialoglycoprotein receptor expressed by hepatic cells to facilitate clearance through the liver. The peptide may be glycosylated to facilitate clearance through the liver by binding to hepatic cells expressing an asialoglyco-protein receptor. Typically, the peptide prevents or inhibits enzyme activity upon binding to the enzyme and is not substantially modified by the enzyme activity. The peptide may be based upon the dipeptide amino-naphthoic acid (ANA)-glutamate (GIu) and may comprise the amino acid sequence serine (Ser)-Alanine (Ala)-amino-naphthoic acid (ANA)-glutamate (GIu). In such cases, the enzyme of interest is typically CPG2.

Owner:MOLOGIC LTD

Lubricant composition for gas engine

ActiveCN102690709AImprove antioxidant capacityImprove wear resistanceAdditivesAlkaline earth metalAntioxidant

The invention relates to a lubricant composition for a gas engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.8% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a dispersant, C) one or more sulfurized alkaline earth metal alkyl phenolate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, F) one or more metal deactivators and G) a main amount of lubricating base oil. The lubricant composition for a gas engine adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a gas engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

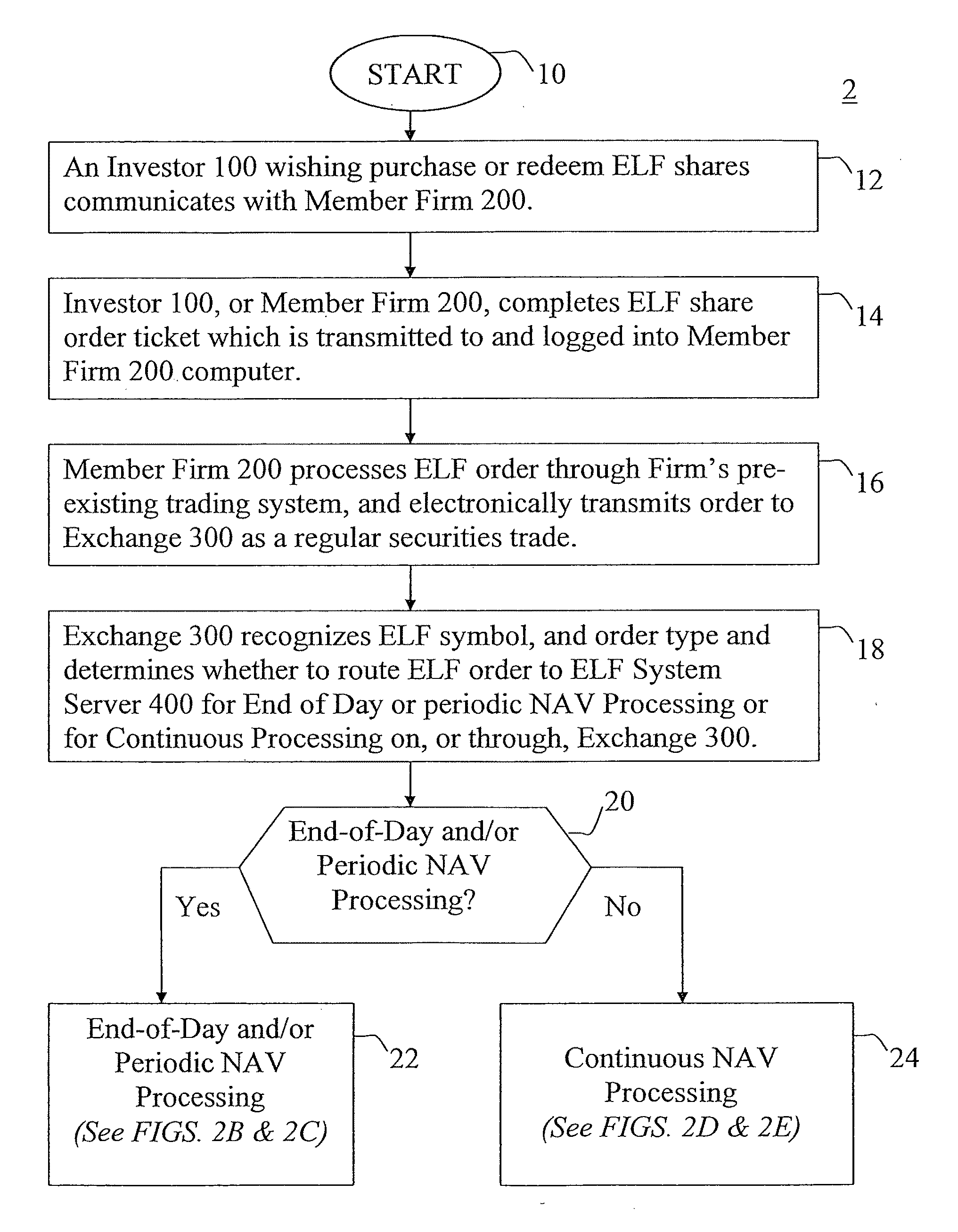

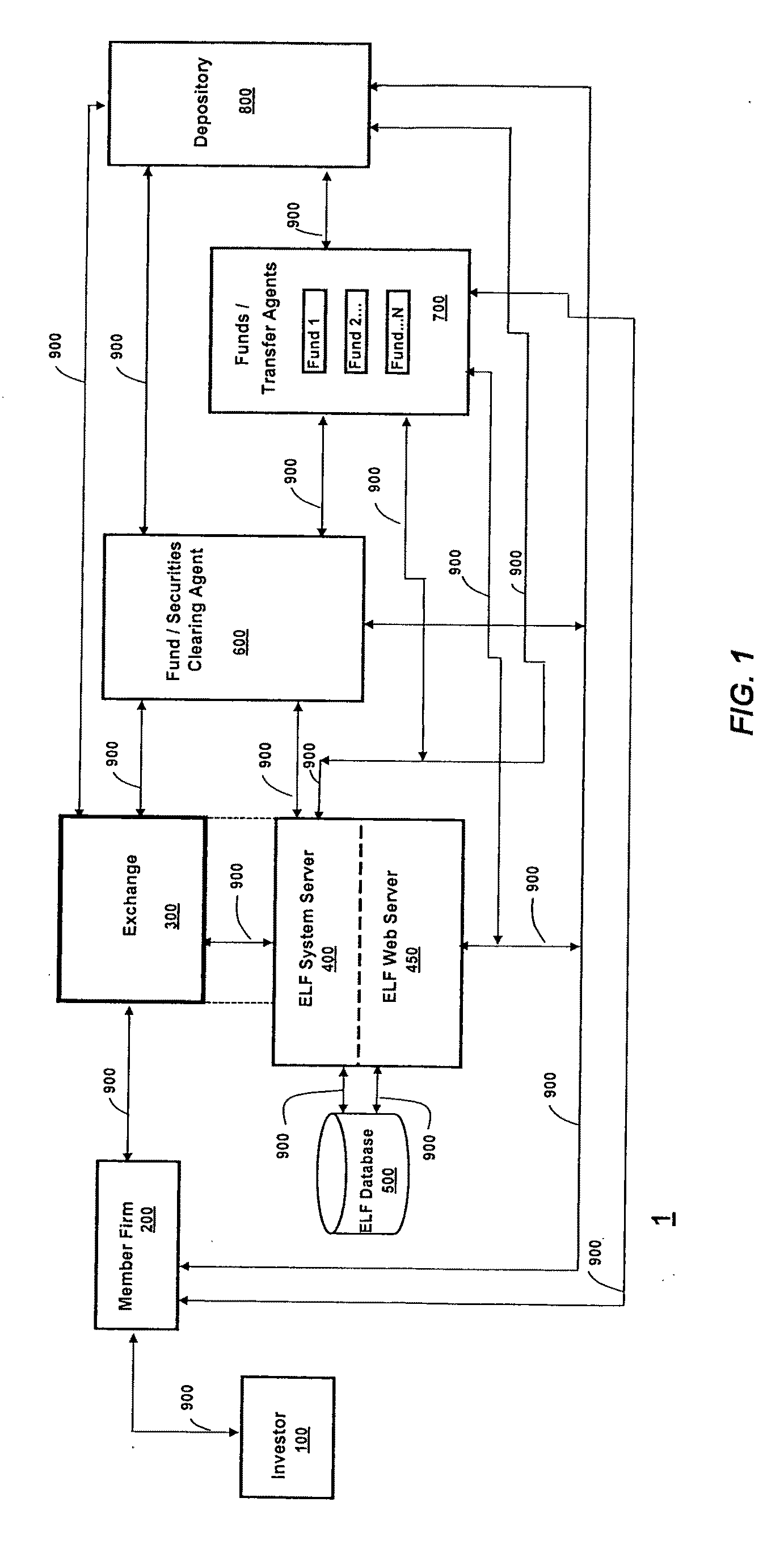

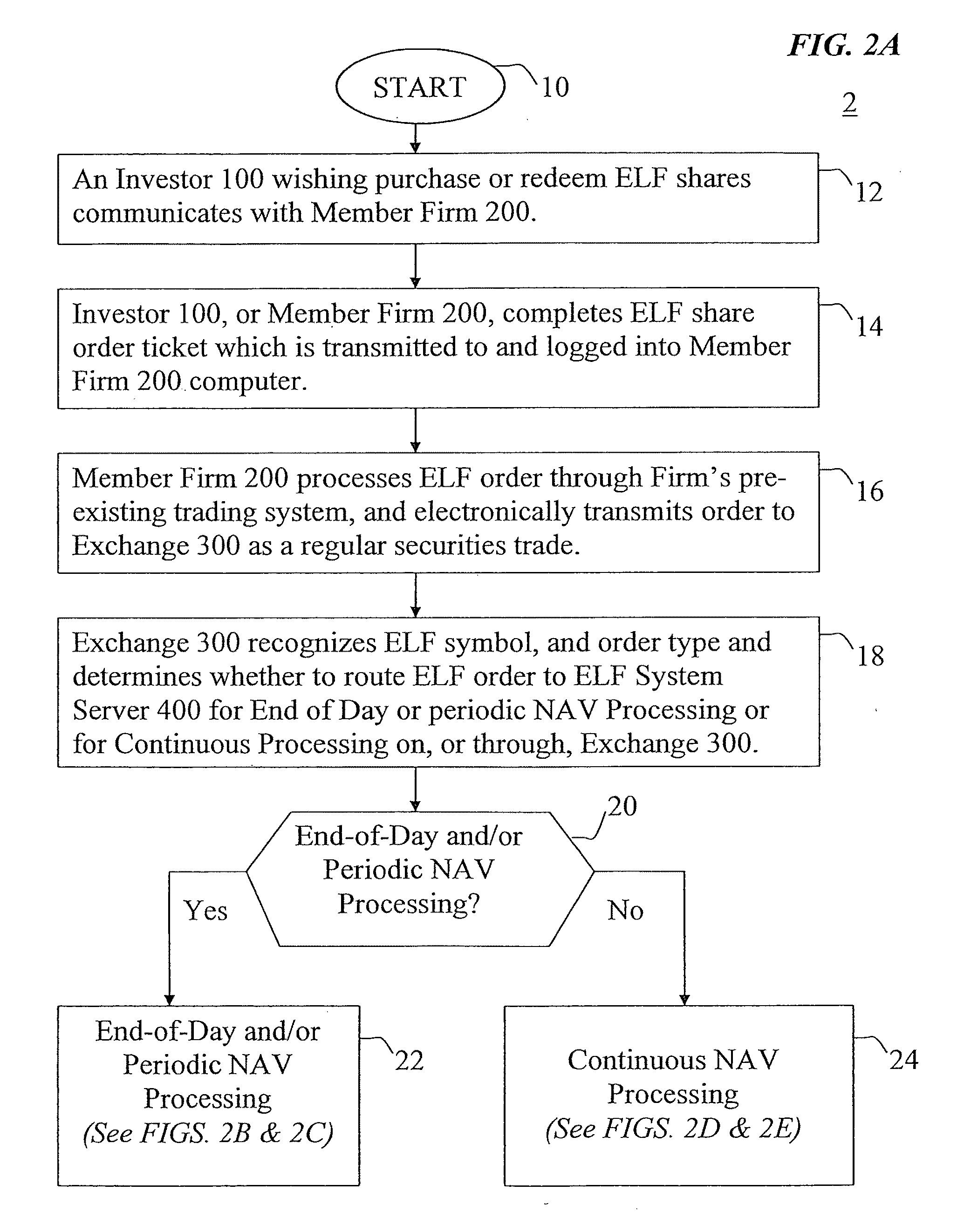

System and methods for processing open-end mutual fund purchase and redemption orders at centralized securities exchanges and other securities trading and processing platforms

InactiveUS20100057608A1Efficiently and uniformlyReduce chargeFinanceMultiple digital computer combinationsPaymentClearing Agent

A system for processing traditional open-end mutual fund purchase and redemption orders at a server at designated Exchange(s) for receiving order messages from at least one of a plurality of Brokers and Member Firms, the server having at least one processor and memory for storing routines operable to process individual or aggregated order messages, preferably based on a prioritized set of business rules, and / or match the purchase and redemption orders, reformat the orders, and transmit the reformatted orders to at least one of a plurality of Fund / Securities Clearing Agents, Funds / Transfer Agents and Depositaries for confirmation, and clearing and settlement of issuance and redemption orders for mutual fund shares, as well as payment of mutual fund dividends.

Owner:MACPHERSON JAMES

Combustion assisting agent with aeration combustion-supporting and coal saving function

The invention offer strong oxygen combustion supporting synergy coal saving combustion adjuvant. Its main technique feature is proportioning the following each preparation by weight part ratio according to coal quality: strong oxidant: potassium permanganate, potassium chlorate, potassium nitrate, hydrogen peroxide, hexamethylene tetramine, potassium perchlorate; strong catalyst: manganese dioxide, magnesia; scale remover: calcium oxide dolomite fines, calcium carbonate; fume clearing agent: sodium carbonate, active magnesia, light magnesium oxide; desulfurizer: alumina, magnesium silicate, barium nitrate; leavening agent: industry using sodium chloride; diatomite: pumice, boric sludge; ferric oxide is very fit for low grade coal. The advantages of the invention are that it can make low grade coal burn fully, increase thermal efficiency, save energy, no pollution; and it can save fund for corporation; it can save 100-250 thousand yuan per ten thousand ton coal; and the coal saving rate can reach 15-25%.

Owner:迟万斌

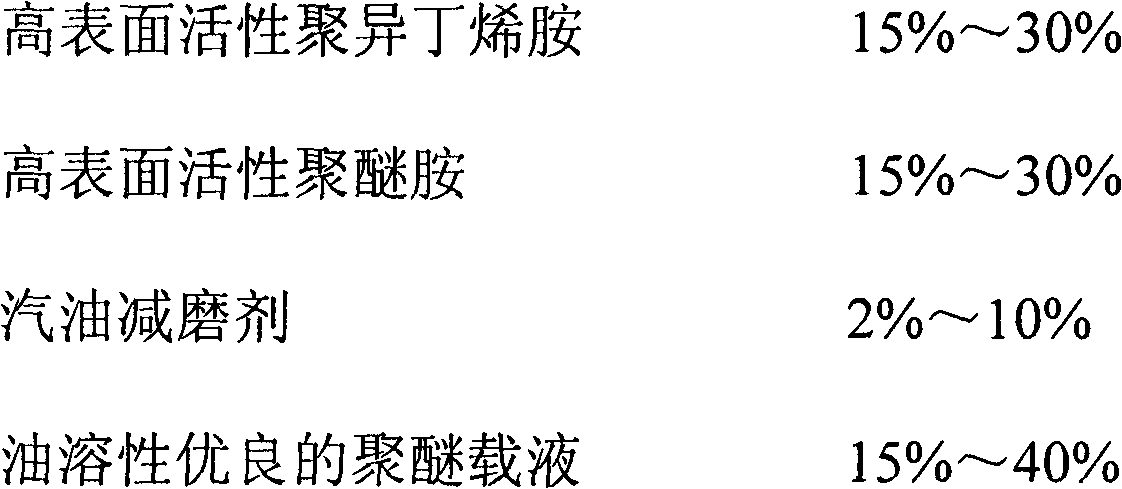

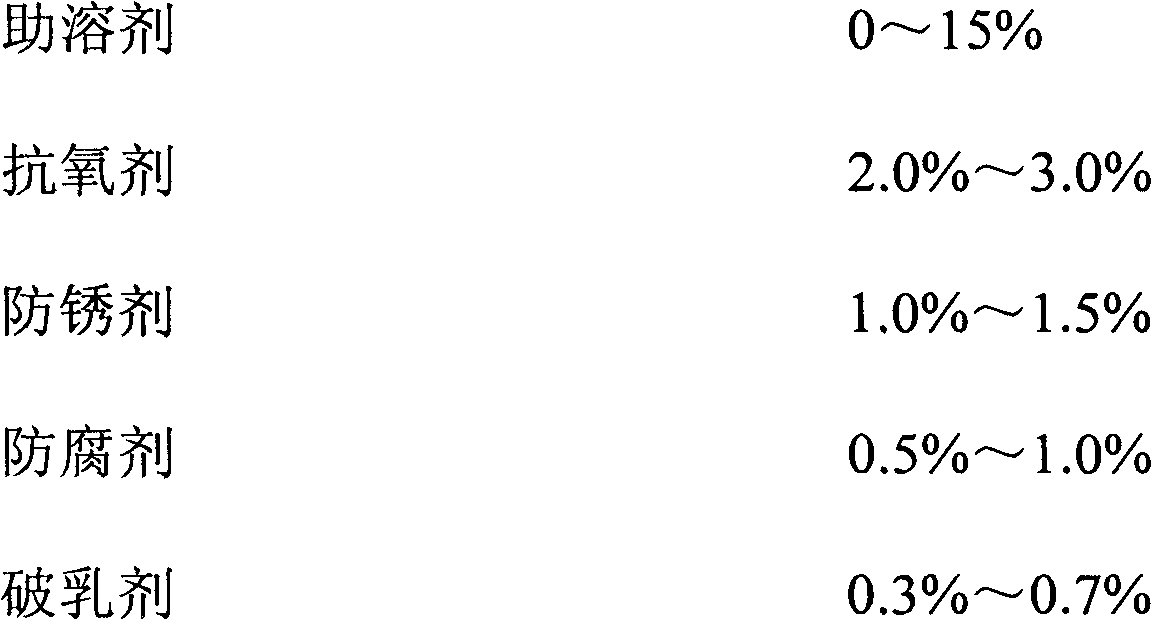

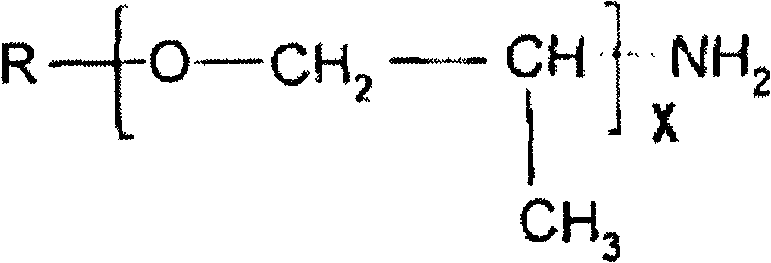

Gasoline additive capable of remarkably reducing precipitate in gasoline engine combustion chamber

InactiveCN103666605AReduced drop rateDecrease increaseLiquid carbonaceous fuelsSolubilityCombustion chamber

The invention relates to a gasoline additive capable of remarkably reducing the precipitate in a gasoline engine combustion chamber. The gasoline additive comprises PIBA with high surface activity, polyether amine, gasoline anti-friction composition, polyether carrier liquid with excellent oil solubility, antioxidant, antirust agent, preservative and emulsion breaker. The weight percentages of the components are as follows: 15 to 30 percent of PIBA, 15 to 30 percent of polyether amine, 2 to 10 percent of gasoline anti-friction composition, 15 to 40 percent of polyether carrier liquid and 20 to 40 percent of cosolventk and other functional agent. When 220 to 550 ppm of the gasoline additive is added into the gasoline for the car sold in the market, the accumulated carbon in an oil nozzle and an air inlet valve can be washed, the precipitate in the gasoline engine combustion chamber can be obviously reduced, the mechanical friction loss can be reduced, and the power can be enhanced. The increment of the precipitate of the car gasoline containing the gasoline clearing agent in the combustion chamber can be reduced by more than 50 percent, the running noise of the machine can be effectively lowered, the power can be obviously enhanced, and an energy-saving and emission-reducing effect can be realized.

Owner:济南道宽环保科技有限公司 +2

Gasoline engine lubricating coil composition and preparation method thereof

InactiveCN107760419AReduce usageGive full play to the synergistic effectLubricant compositionChemical compositionBoron containing

The invention discloses a gasoline engine lubricating coil composition and a preparation method thereof. The gasoline engine lubricating coil composition comprises the following components in percentby weight: (A) 0.1 to 6.0 percent of an ashless dispersing agent, (B) 0.1 to 8.0 percent of a clearing agent, (C) 0.01 to 1.5 percent of oil-soluble or dispersible oil stability boron-containing compound, (D) 0.003 to 0.5 percent of oil-soluble or dispersible oil stability molybdenum-containing compound, (E) 0.02 to 3.2 percent of zinc dialkyl dithiophosphate, (F) 0.01 to 3.0 percent of an antioxidant and (G) lubricating oil base oil with a main amount, wherein the boron molybdenum mass ratio of the component (C) to the component (D) ranges from 1:5 to 10:1. The blended gasoline engine oil composition contains all of the boron-containing compound, the molybdenum-containing compound and the zinc dialkyl dithiophosphate, completely exerts the synergistic effect between the additives, improves the anti-oxidation property, the anti-wear and friction-reducing properties and the extreme pressure property of the lubricating oil composition and reduces the ash content and the thionazin contentof the lubricating oil composition.

Owner:江西福安路润滑材料有限公司 +1

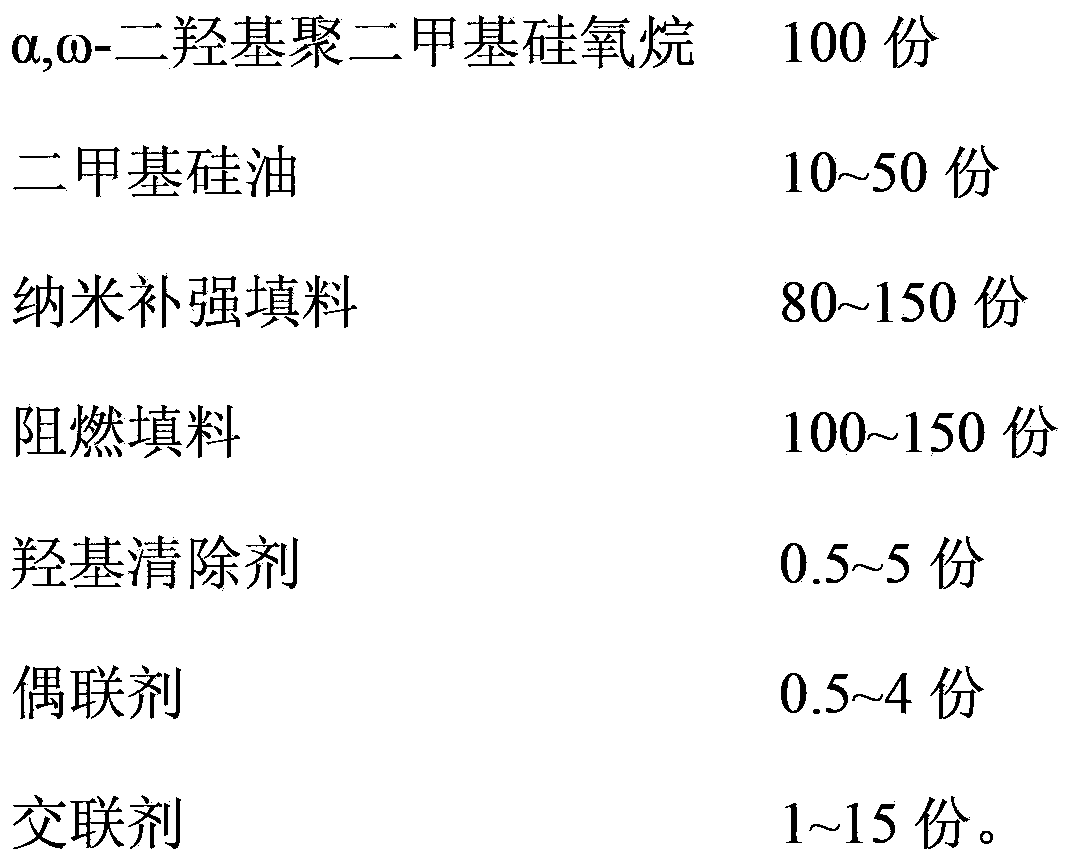

Single-component dealcoholization-type flame-retardant room temperature vulcanized (RTV) silicone rubber sealant and preparation method thereof

ActiveCN103396757AImprove heat resistanceImprove thixotropyNon-macromolecular adhesive additivesOther chemical processesCross-linkPolymer science

The invention relates to a single-component dealcoholization-type flame-retardant room temperature vulcanized (RTV) silicone rubber sealant and a preparation method thereof. A base material is obtained by dewatering and blending of 100 parts by mass of alpha, omega-dihydroxyl polydimethylsiloxane, 10-50 parts by mass of dimethicone, 80-150 parts by mass of a nanometer reinforced filler, 100-150 parts by mass of a flame-retardant filler and 0.5-5 parts by mass of a hydroxyl clearing agent in a power mixer at the temperature of 120-150 DEG C with the vacuum degree of 0.09-0.1 MPa for 60-240 min; and at the normal temperature, the base material is vacuumized to the vacuum degree of 0.09-0.1MPa, after 10 min of stirring, 1-15 parts by mass of a cross-linking agent is added, after 15 min-30 min of stirring under the vacuum condition, 0.5-4 parts by mass of a coupling agent is added, and after 10 min-30min of stirring under the vacuum condition, the base material can be packaged into a finished product.

Owner:兆舜科技(广东)有限公司

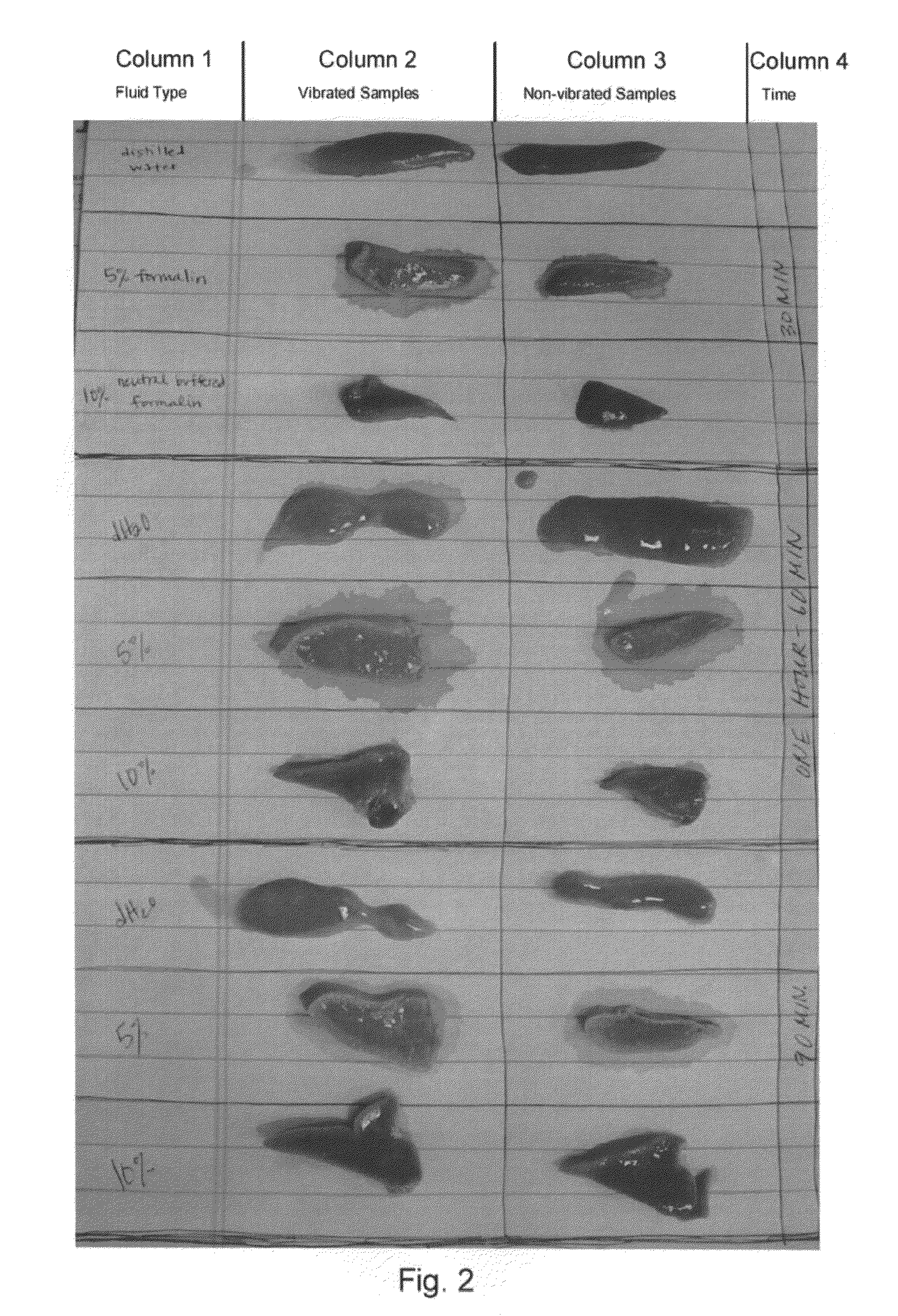

Methods for accelerating tissue processing

InactiveUS20100144002A1Effective diffusionPreparing sample for investigationElectrical/wave energy microorganism treatmentTissue sampleClearing Agent

Systems and methods for accelerating tissue processing by treating tissue samples and one or more tissue processing agents with infrasonic vibrations are discussed. Some non-limiting examples of tissue processing agents include a tissue fixative, dehydrating agent, clearing agent, impregnating agent, embedding agent, tissue stain, enzyme, or another chemical that diffuses into the tissue sample when the sample is being preserved or prepared for microscopic examination. The infrasonic vibrations can have a frequency from about 10 to about 600 Hz. The infrasonic vibrations can have an amplitude that is sufficiently high, when combined with the frequency, to induce turbulent mixing of the processing agent and accelerate tissue processing. The tissue sample may optionally be vibrated with ultrasonic vibrations. The ultrasonic vibrations can have a frequency and amplitude that are sufficiently high to induce turbulent mixing of the processing agent and to accelerate tissue processing.

Owner:DONNDELINGER THOMAS M

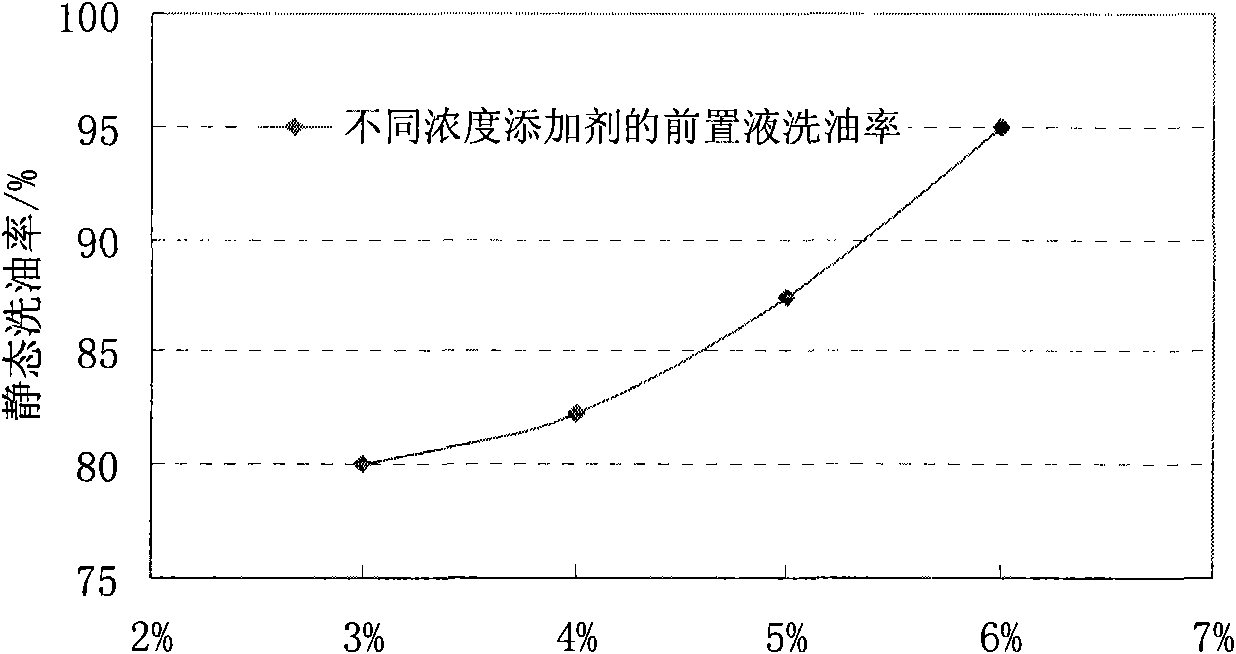

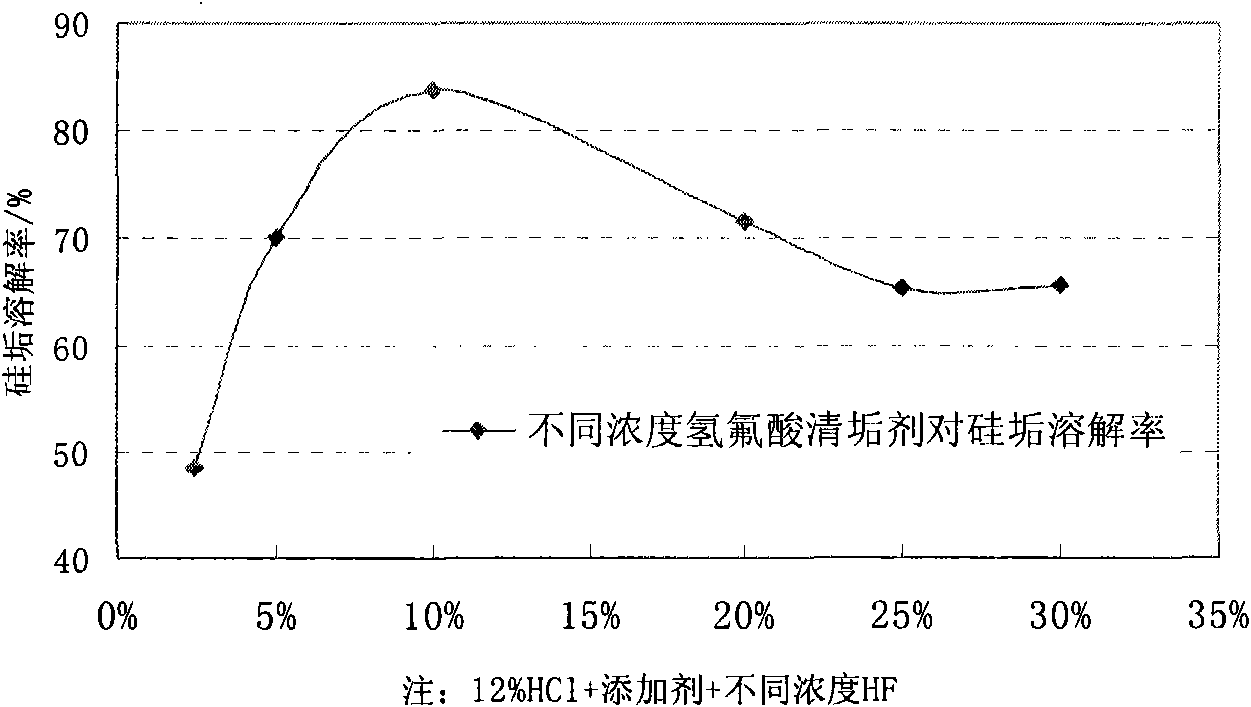

Silicate scale clearing agent for ternary combination flooding extraction well

The invention discloses a silicate scale clearing agent for a ternary combination flooding extraction well. The silicate scale clearing agent consists of prepad fluid and scale clearing main agent. The prepad fluid consists of 6% of additive (SYQ-II) and the balance of water. The additive (SYQ-II) consists of sodium dodecyl benzene sulfonate (ABS), nonyl phenol polyethenoxy ether (OP10) and ethylene glycol monobutyl ether with the ratio of 3:1:2. The scale clearing main agent consists of 12% of hydrochloric acid, 10% of hydrofluoric acid, 2% of glacial acetic acid, 0.2% of citric acid, 0.5% indoor-synthesized imidazoline type corrosion inhibitor (YC-II) and the balance of water. The scale clearing agent achieves a silicate scale clearing rate up to 80%, and can effectively clear silicate scale at an oil well pump cylinder, a rod pipe and other positions and prolong the pump examination period of the extraction well.

Owner:PETROCHINA CO LTD +1

Aircraft engine cleansing agent and preparing method thereof

InactiveCN105969545AEnhanced removal of salt stainsLift oilInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsClearing AgentEngineering

The invention relates to the technical field of engine cleansing agents, in particular to an aircraft engine cleansing agent and a preparing method thereof. The aircraft engine cleansing agent has the advantages of fasting dissolving deposited carbon, dust dirt, oil contamination and salt marsh at normal temperature and normal pressure and being noncorrosive, high in stability, not prone to deterioration and free of pollution. The aircraft engine cleansing agent is prepared from, by weight, a deposit carbon cleansing agent, a clearing agent and corrosion inhibitor. The clearing agent is prepared from, by weight, lauryl sodium sulfate, fatty alcohol polyoxyethylene ether, alkylolamide, span and deionized water; the corrosion inhibitor is organic. The preparing method of the aircraft engine cleansing agent includes the following steps that the deposit carbon cleansing agent is weighed and added into a reaction still to be heated to 40-60 DEG C; the clearing agent is weighed, added into the reaction still and fully stirred for 15-20 min; the corrosion inhibitor is heated to 50-70 DEG C, added into the reaction still and stirred uniformly; the reaction still is sealed and stands for 2 h to obtain the finished aircraft engine cleansing agent product.

Owner:北京科宇泰技术开发有限公司

Alpha or beta emitters attached to fragments in radioimmunotherapy

InactiveUS6667024B1Minimizing damageGood tumor uptakeOrganic active ingredientsAntinoxious agentsAntigen Binding FragmentBinding site

The present invention relates to radioimmunoconjugates useful in targeted radioimmunotherapy and methods of treating a patient using radioimmunoconjugates. The radioimmunoconjugates of the present invention comprise an alpha- or beta-emitting radioisotope and a binding site linked to or on an antigen-binding fragment of an antibody which specifically binds to a tumor-associated antigen. The methods of treating a patient can include administering one or more clearing agents to the patient in conjunction with the radioimmunoconjugate of the present invention, as well as subsequently grafting bone-marrow or autologous stem-cells to the patient.

Owner:CENT FOR MOLECULAR BIOLOGY & MEDICINE

Method for manufacturing nano-sized Fe3O4

The present invention is preparing process of nano ferroferric oxide or superfine ferroferric oxide particle, and belongs to the field of nano material preparing technology in radiochemistry. The radiochemical process adopts ferric trichloride as iron particle source, ammonia water as precipitant, IPA as oxidizing free clearing agent in aqua, hydrophilic surfactant PVA for controlling crystal kernel growing speed and particle size, and electron accelerator to produce electron beam for irradiation treatment, and the solution after being irradiated is washed, centrifugally separated and stoved to obtain black nano ferroferric oxide powder. The present invention has simple technological process, short production period, no pollution, and high safety. The prepared nano ferroferric oxide has very low magnetic saturation strength and very small coercive force and is one excellent kind of supermagnetic material and soft magnetic material.

Owner:SHANGHAI UNIV

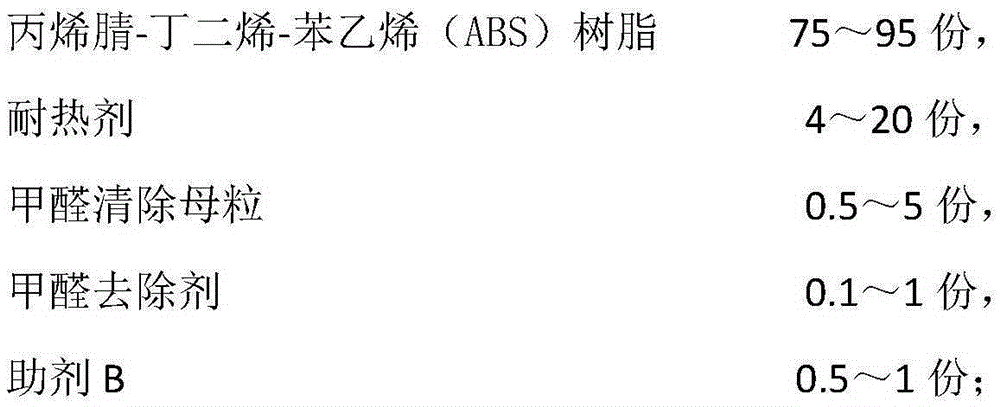

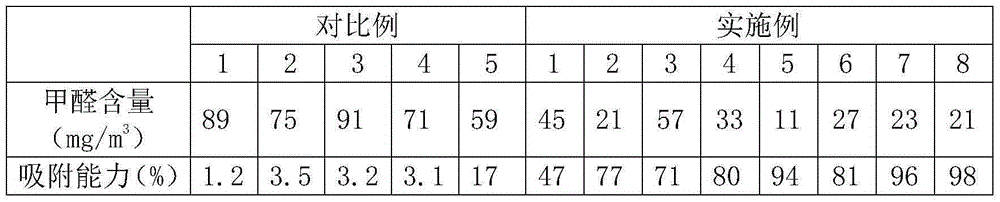

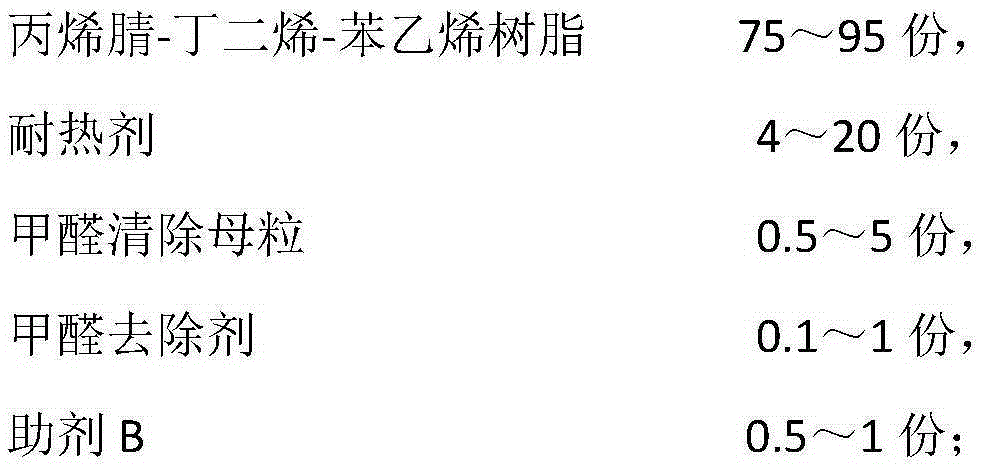

Self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and preparation method thereof

ActiveCN105385097AReduce formaldehyde contentFormaldehyde content suppressionClearing AgentAcrylonitrile butadiene styrene

The invention discloses a self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and a preparation method thereof. The material is prepared from, by weight, 75-95 parts of ABS resin, 4-20 parts of heat resistant agent, 0.5-5 parts of formaldehyde clearing master batches, 0.1-1 part of formaldehyde clearing agent and 0.5-1 part of other auxiliaries. During preparation, the ABS resin, the heat resistant agent and other auxiliaries are mixed and fed through a main feeding port of a twin-screw extruder; the formaldehyde clearing master batches and the formaldehyde clearing agent are fed through the rear section of the extruder, and the material can be obtained through extruding and granulating. Thanks to the method, the content of formaldehyde in granules can be reduced by 40%, the content of formaldehyde in sealed space is reduced by 50% or above, and the content of other volatile organic compounds is reduced by 10% to 20% at the same time, so that the effects of controlling emission of material formaldehyde for a long time and inhibiting the content of formaldehyde in space are achieved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Nano borate engine oil

InactiveCN105400577AReasonable formula designReasonable designAdditivesN dimethylformamideAntioxidant

The invention discloses nano borate engine oil and belongs to the technical field of engine oil formulas. The nano borate engine oil is prepared from API II type base oil, a molybdenised abrasion-resistant and energy-saving agent, alkylphenol, cetyl calcium borate, nano cerium borate, a defoaming agent, a clearing agent, N,N-dimethylformamide, an ashless dispersing agent, hydroxy stearate, dimeticone, sulfonate, a succinimide dispersing agent, talcum powder, amine antioxidant, ethylene glycol butyl ether, a viscosity index improver, molybdenum disulfide, graphite powder, mono-succinimide, sorbitan monooleate, petroleum ether, chloroform, friction modifier sulfurized isobutylene, dodecenylsuccinic acid and phosphite ester. The nano borate engine oil is good in dynamic property, capable of saving energy, environmentally friendly, low in friction coefficient, small in ash content and long in service life.

Owner:烟台狮王石化工业有限公司

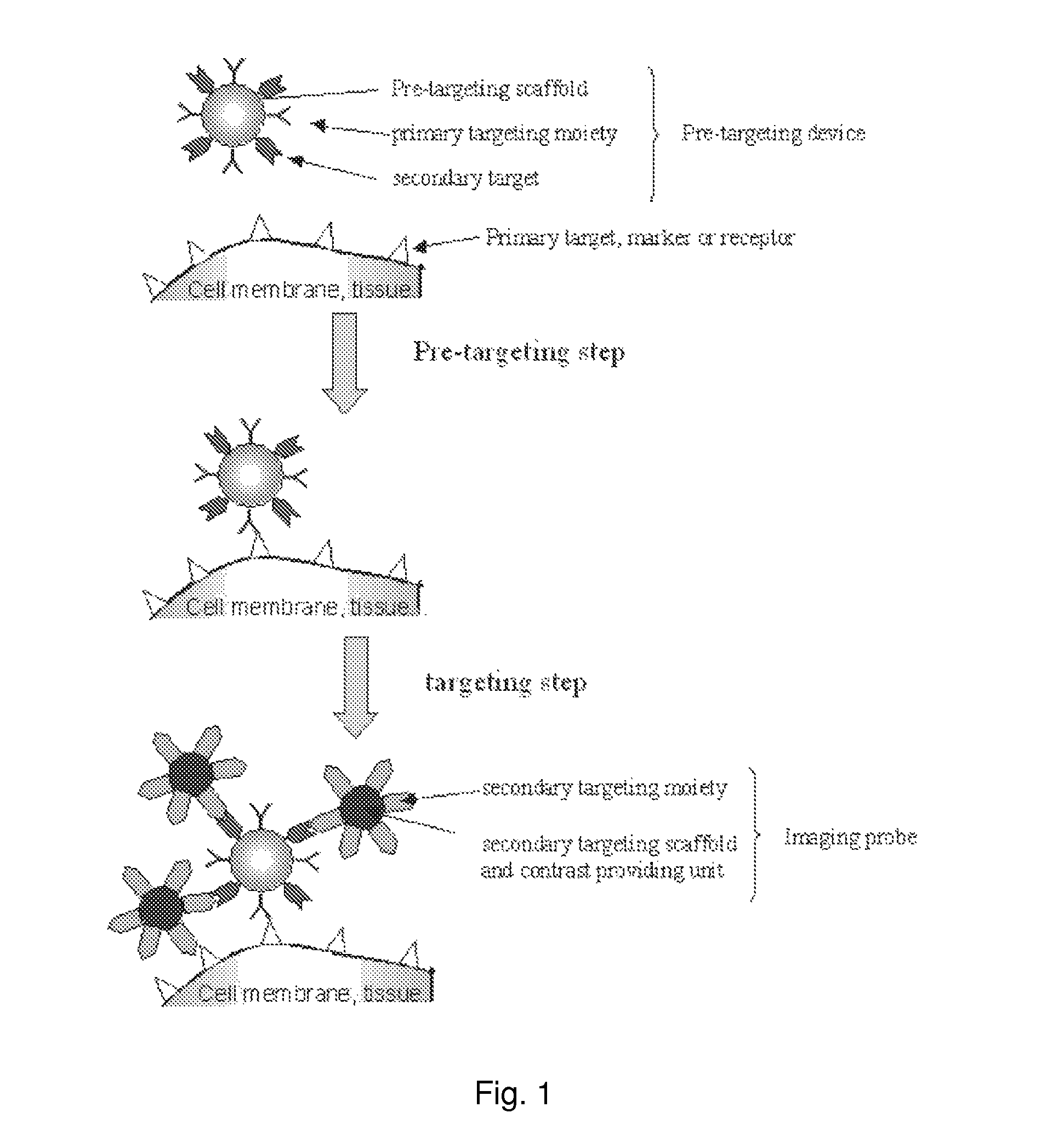

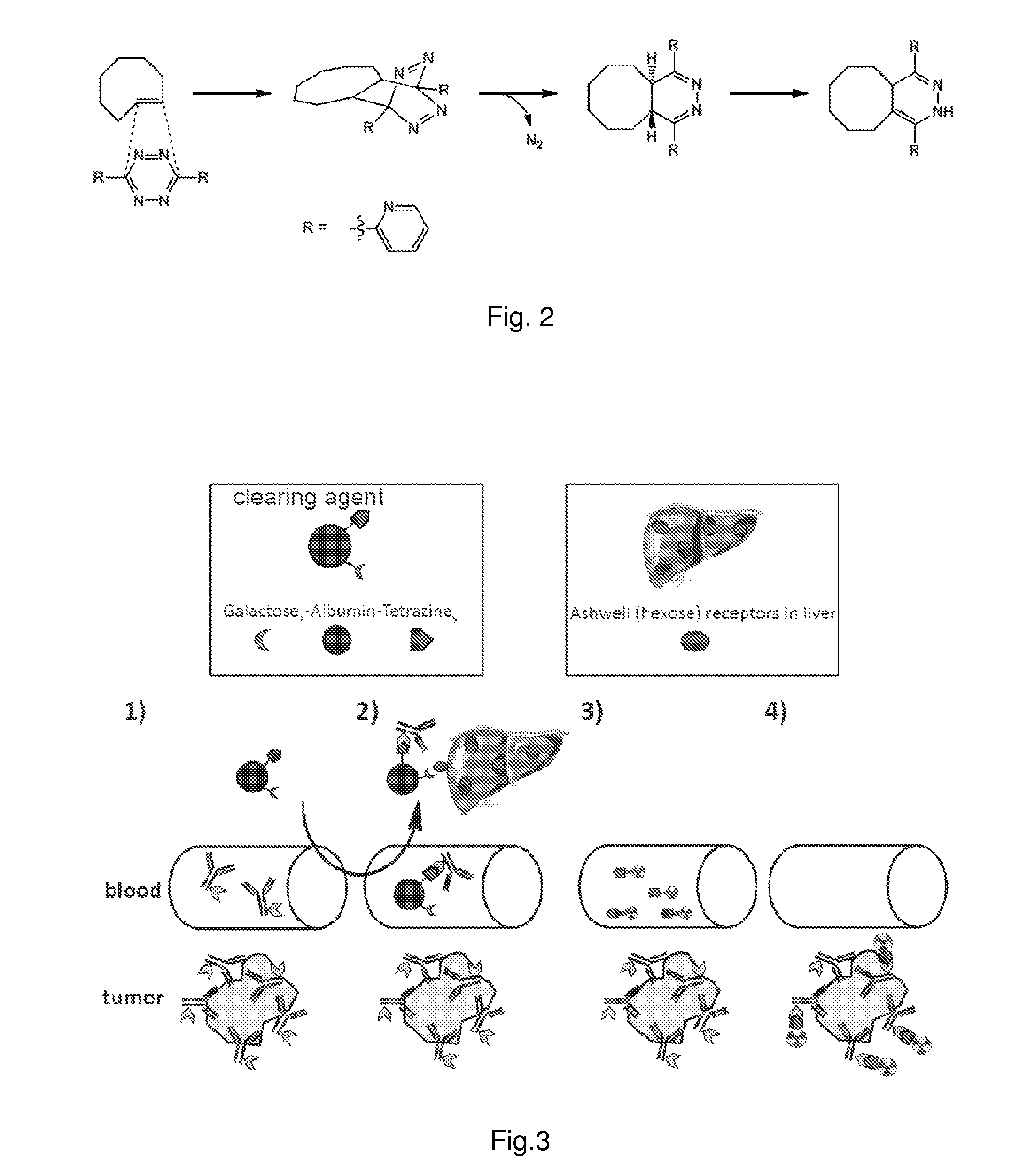

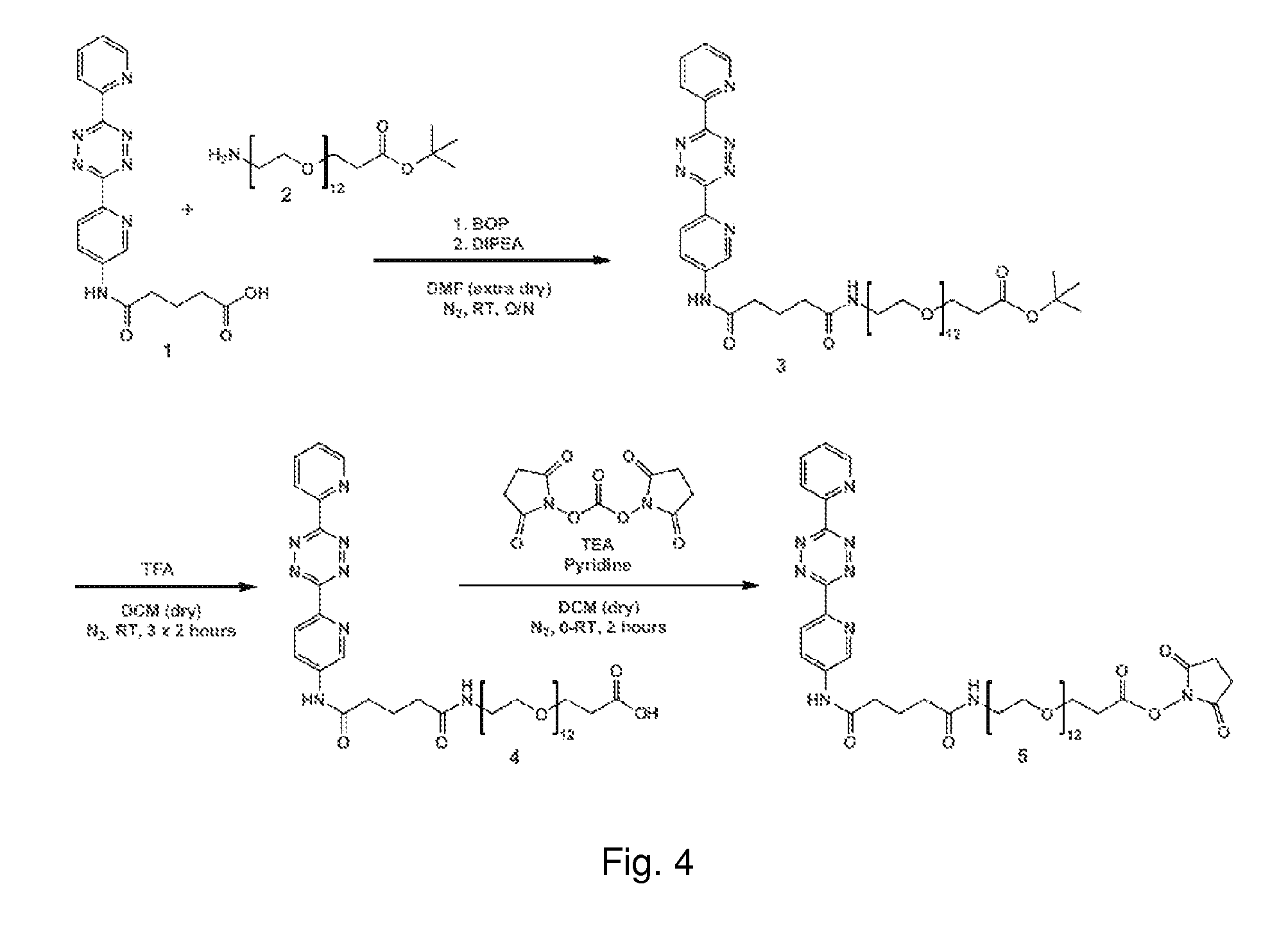

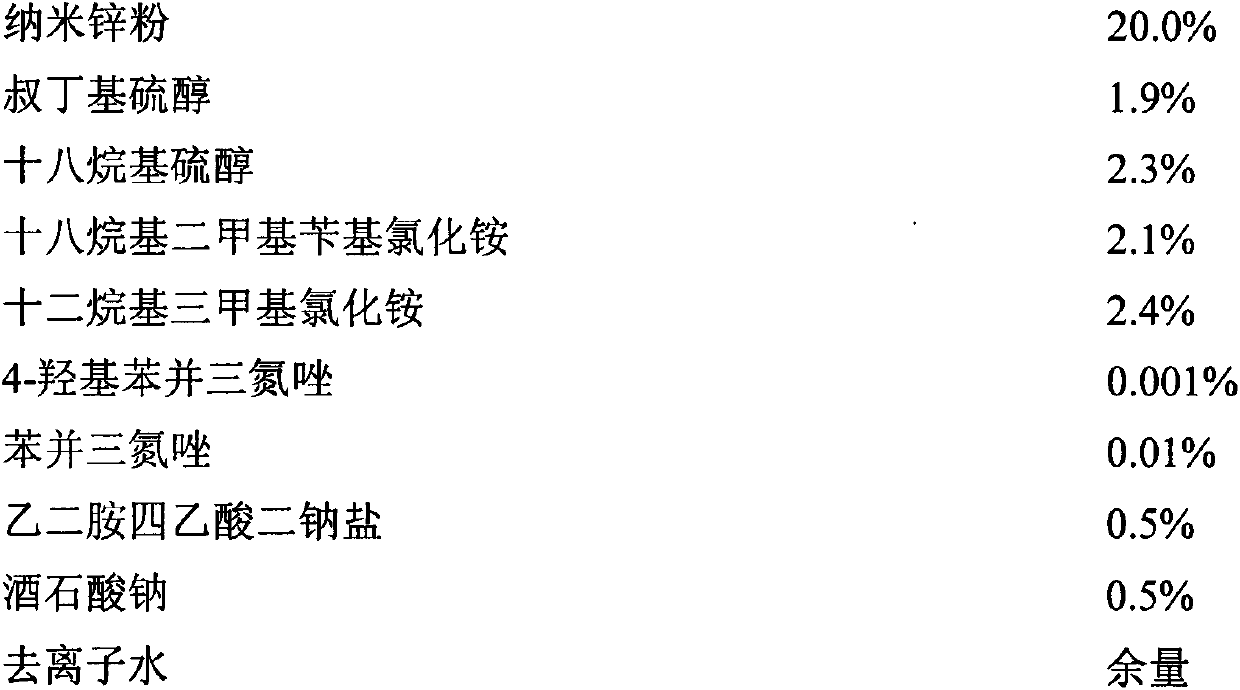

Agents for clearing biomolecules from circulation

Described is a method, and a combination of agents for used therein, by which an agent administered to a subject can be rapidly cleared from circulation. This is achieved by providing an Administration Agent (e.g. a probe for pretargeting) with a reactive group and providing a Clearing Agent with another reactive group, said reactive groups forming a bio-orthogonally reactive pair. Preferably, the reactive pair comprises a cyclooctene or cyclooctyn as one reactant, and a diene as the other reactant. The method and combination can be used for the removal of any bindable molecule from circulation, such as an excess of a pre-targeting probe in the course of a pre-targeting method, a targeting or imaging agent delivered, or the removal of any biomolecule already present in circulation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

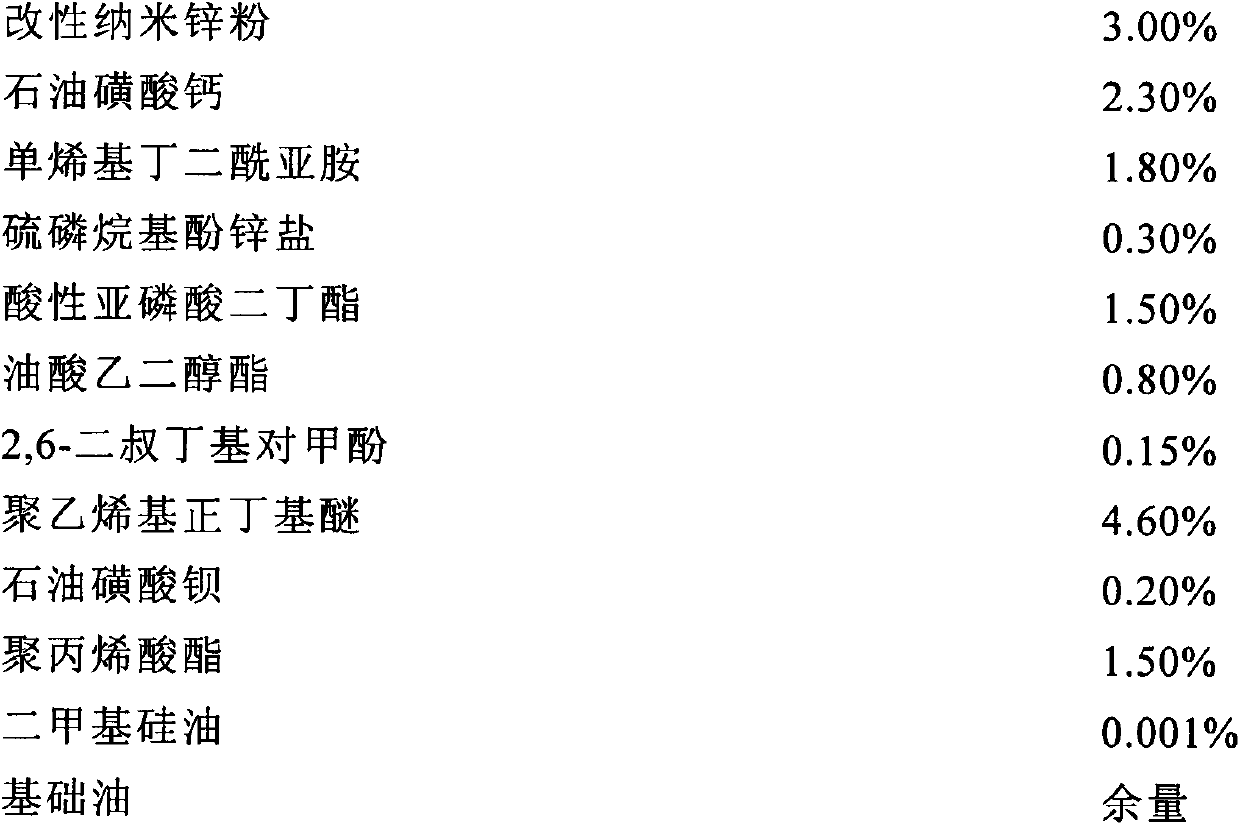

Lubricating oil added with modified nano-Zn powder and ionic liquid and preparation method of lubricating oil

InactiveCN103756754AAdditivesPigment treatment with non-polymer organic compoundsIonic liquidElectric power

The invention discloses lubricating oil added with modified nano-Zn powder and an ionic liquid, and a preparation method of the lubricating oil. According to the method, the lubricating oil composition is prepared by compositing base oil, a clearing agent, a dispersing agent, a preservative, an extreme pressure anti-wear reagent, an oiliness agent, antioxygen, a viscosity index improver, an antirust agent, a pour point reducer, an anti-foaming agent, the ionic liquid and the modified nano-Zn powder. The production process is simple and feasible, the equipment investment is low, the energy consumption is low, no environmental pollution is caused, and the method is favorable for popularization and application. The lubricating oil added with the modified nano-Zn powder and the ionic liquid can be widely applied in the industrial fields like the mechanical industry, the automobile industry, precise instruments, the electric power industry, the metallurgical industry, the mould making and applying industry, the iron and steel industry, the machine tool industry and the like, and has extensive application prospects.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com