Patents

Literature

182 results about "Morpholino" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

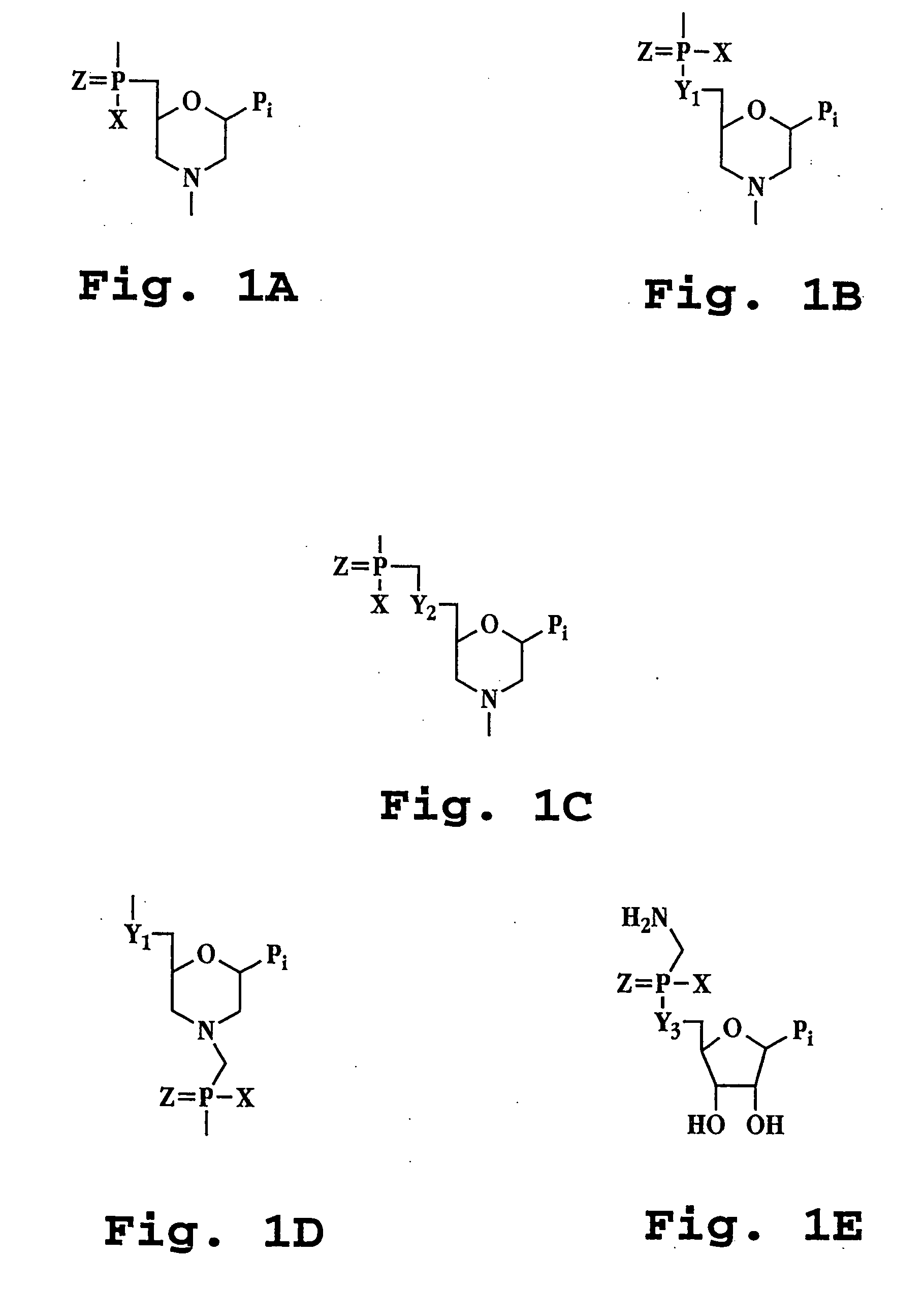

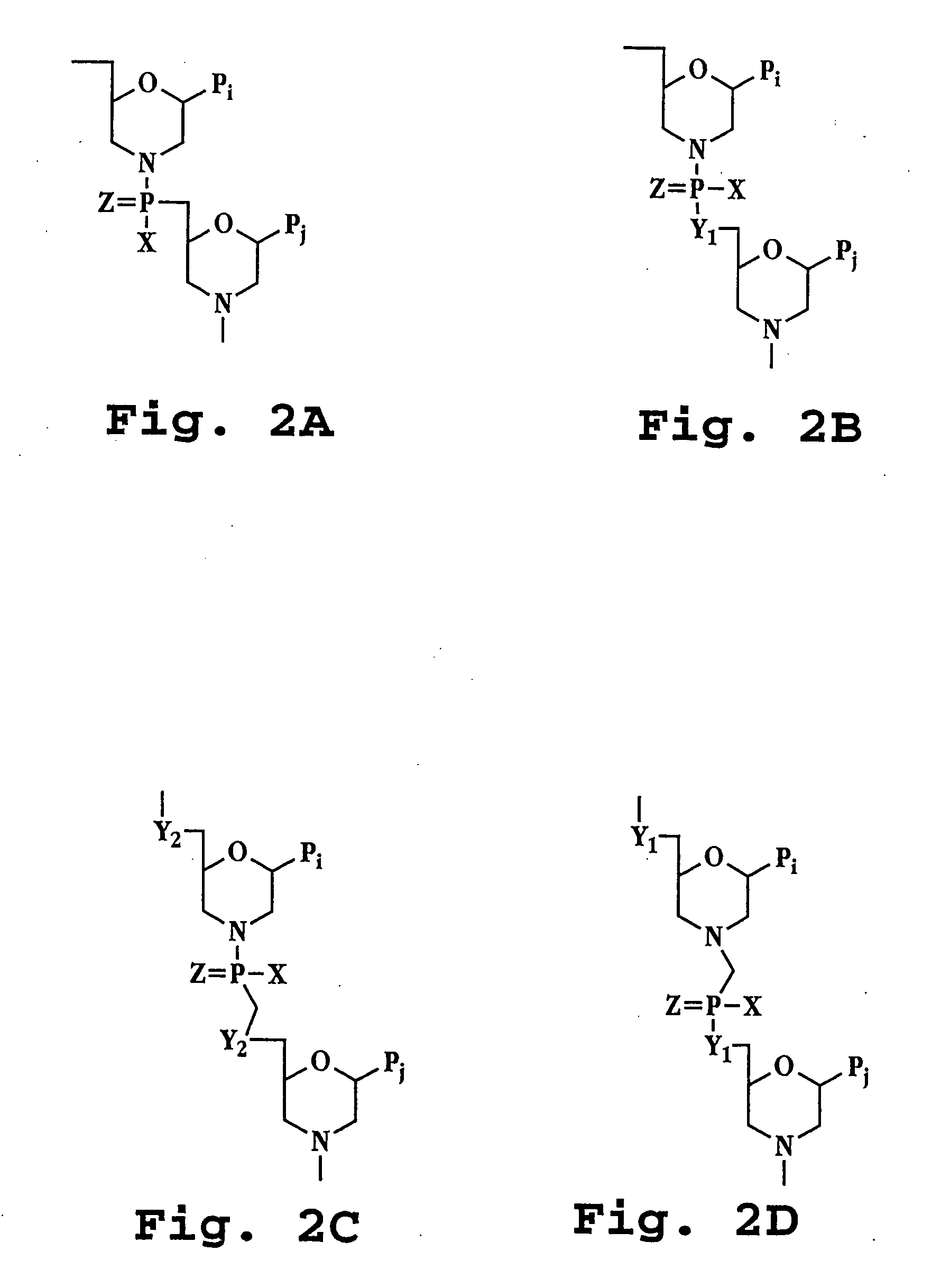

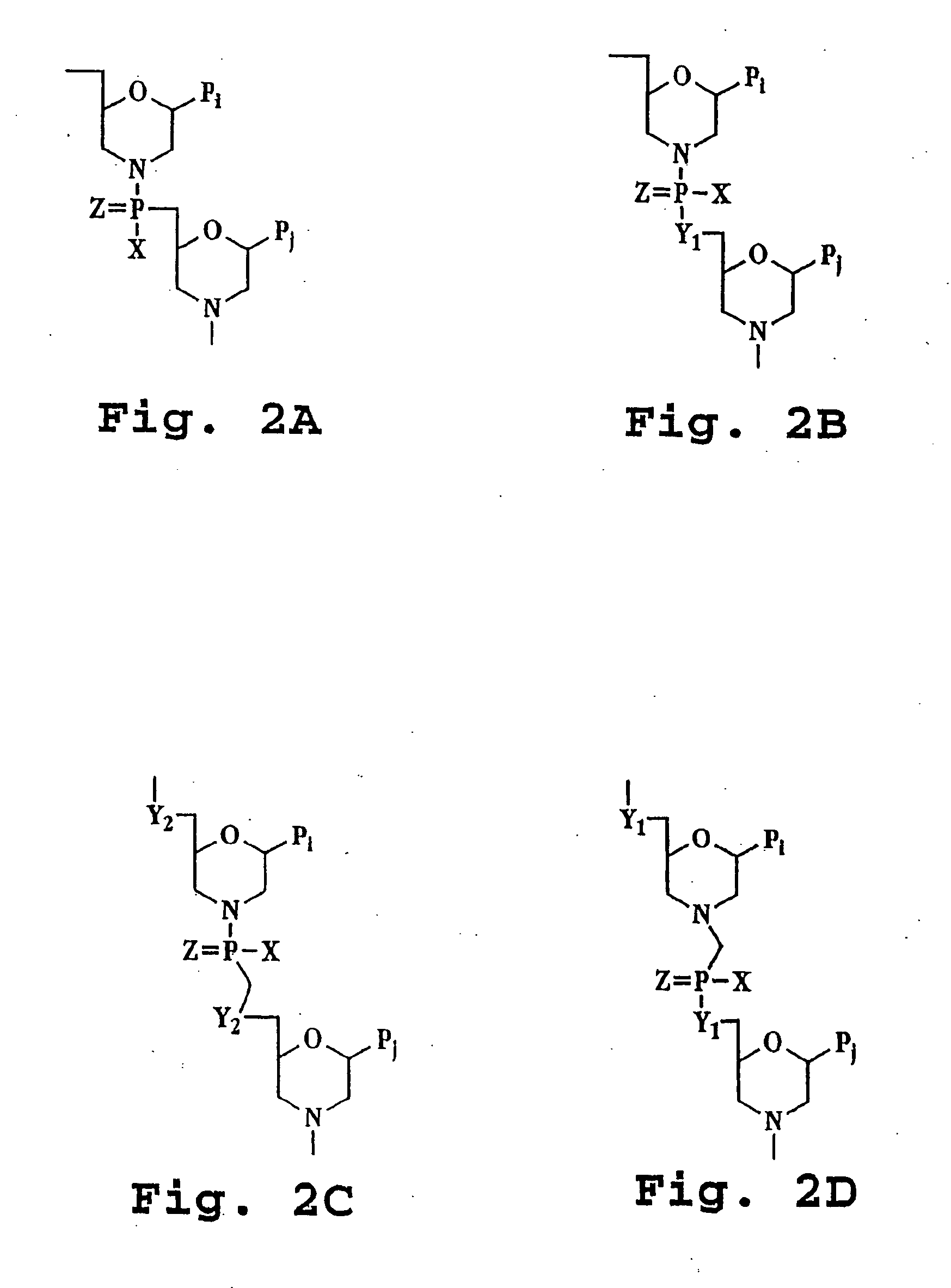

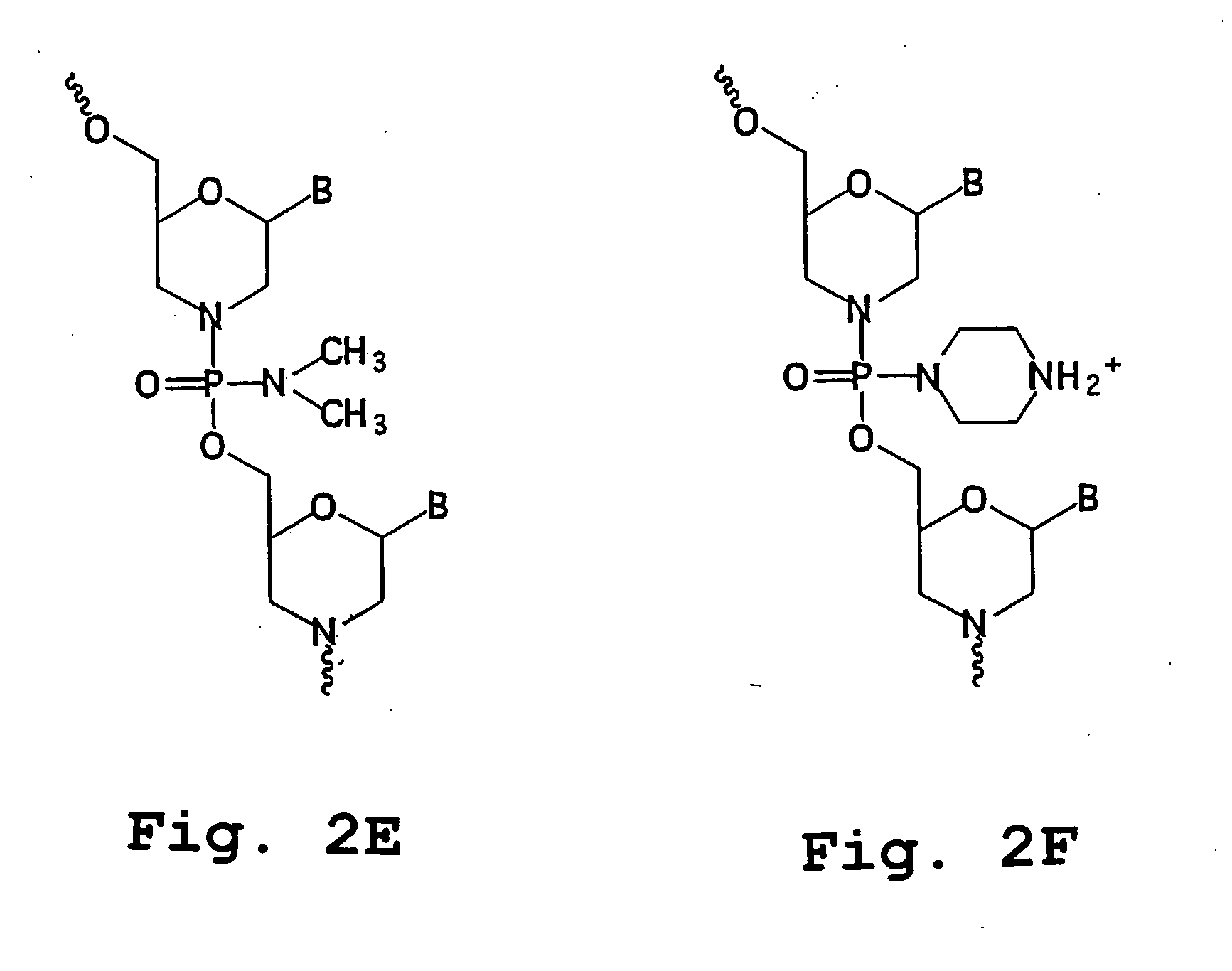

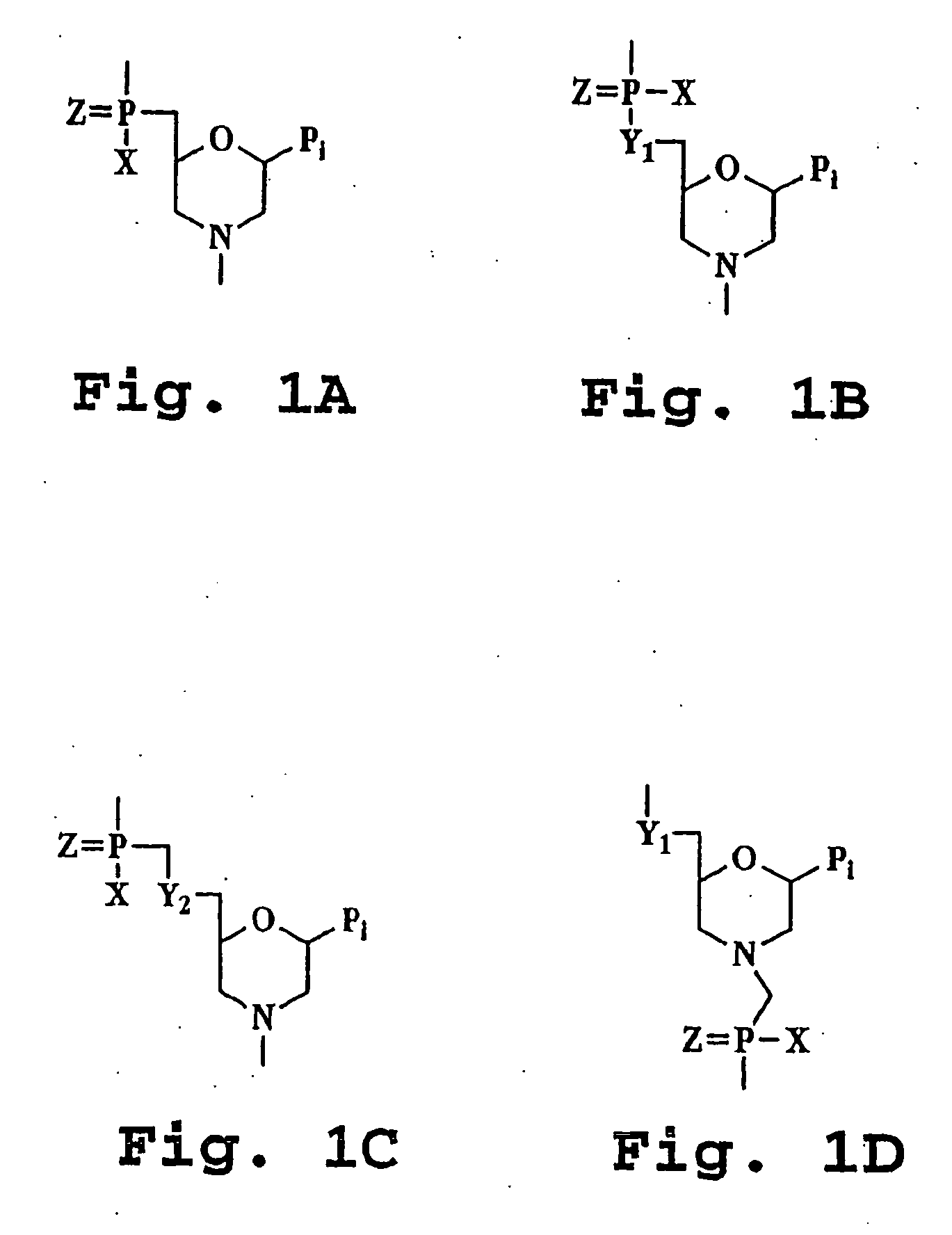

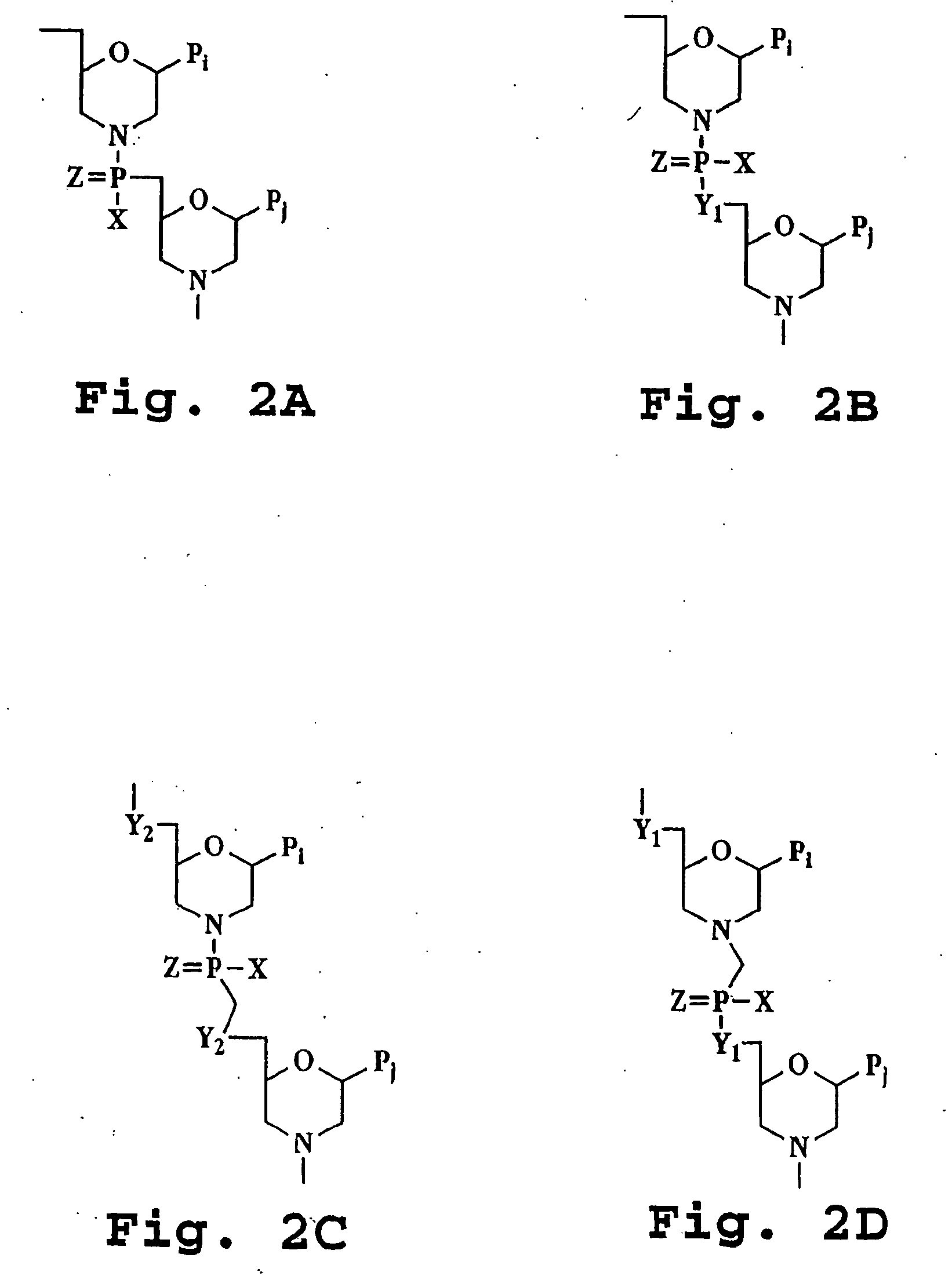

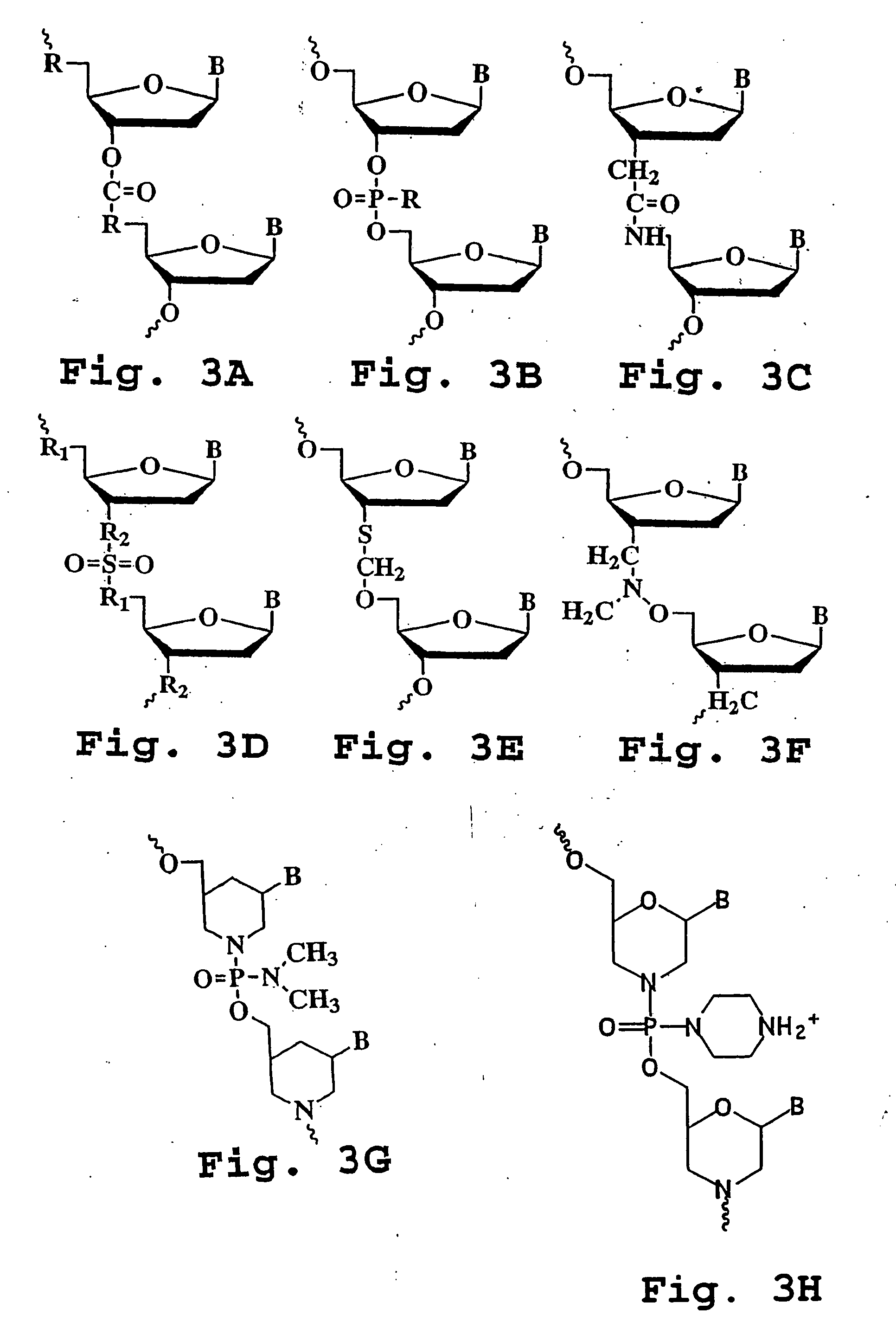

A Morpholino, also known as a Morpholino oligomer and as a phosphorodiamidate Morpholino oligomer (PMO), is a type of oligomer molecule (colloquially, an oligo) used in molecular biology to modify gene expression. Its molecular structure has DNA bases attached to a backbone of methylenemorpholine rings linked through phosphorodiamidate groups. Morpholinos block access of other molecules to small (~25 base) specific sequences of the base-pairing surfaces of ribonucleic acid (RNA). Morpholinos are used as research tools for reverse genetics by knocking down gene function.

Antisense restenosis composition and method

Owner:SAREPTA THERAPEUTICS INC

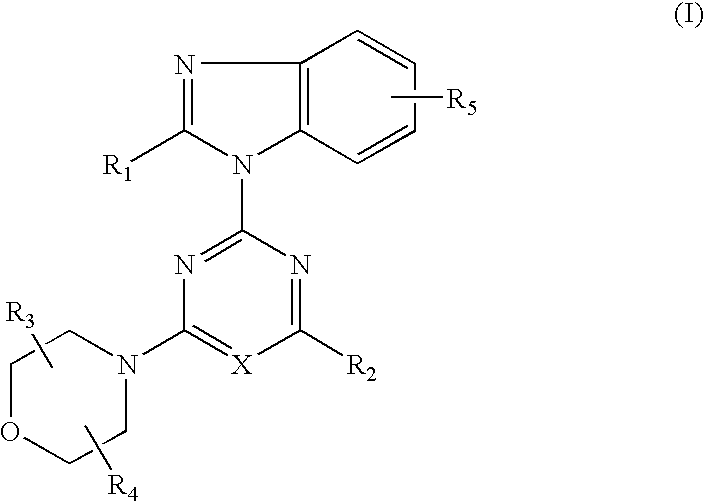

Heterocyclic compound and antitumor agent containing the same as active ingredient

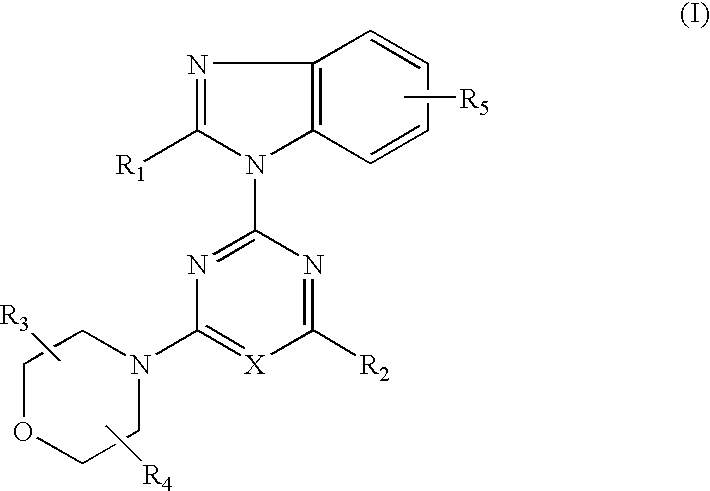

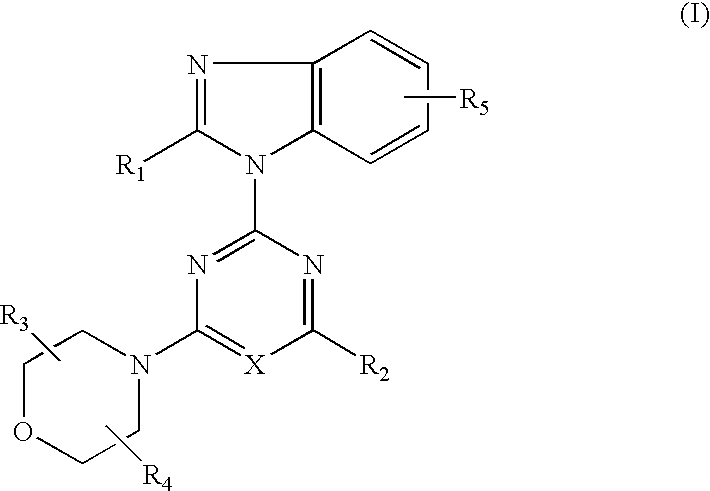

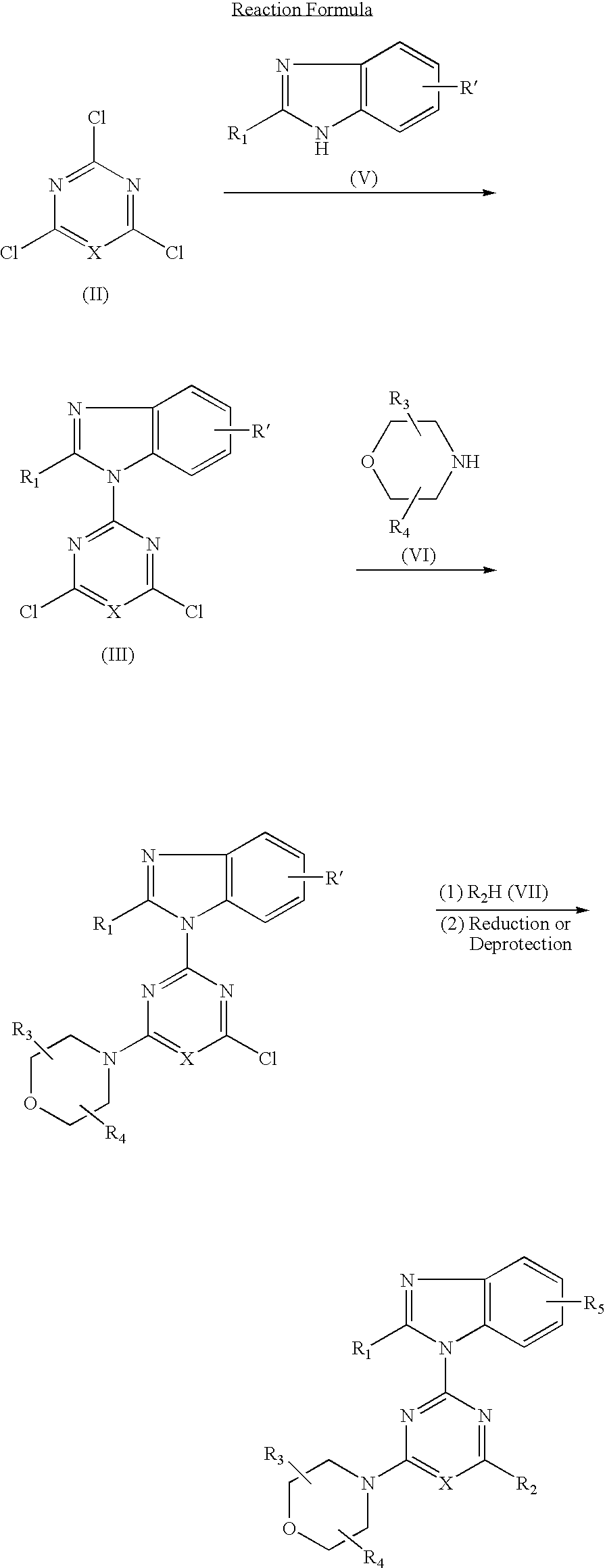

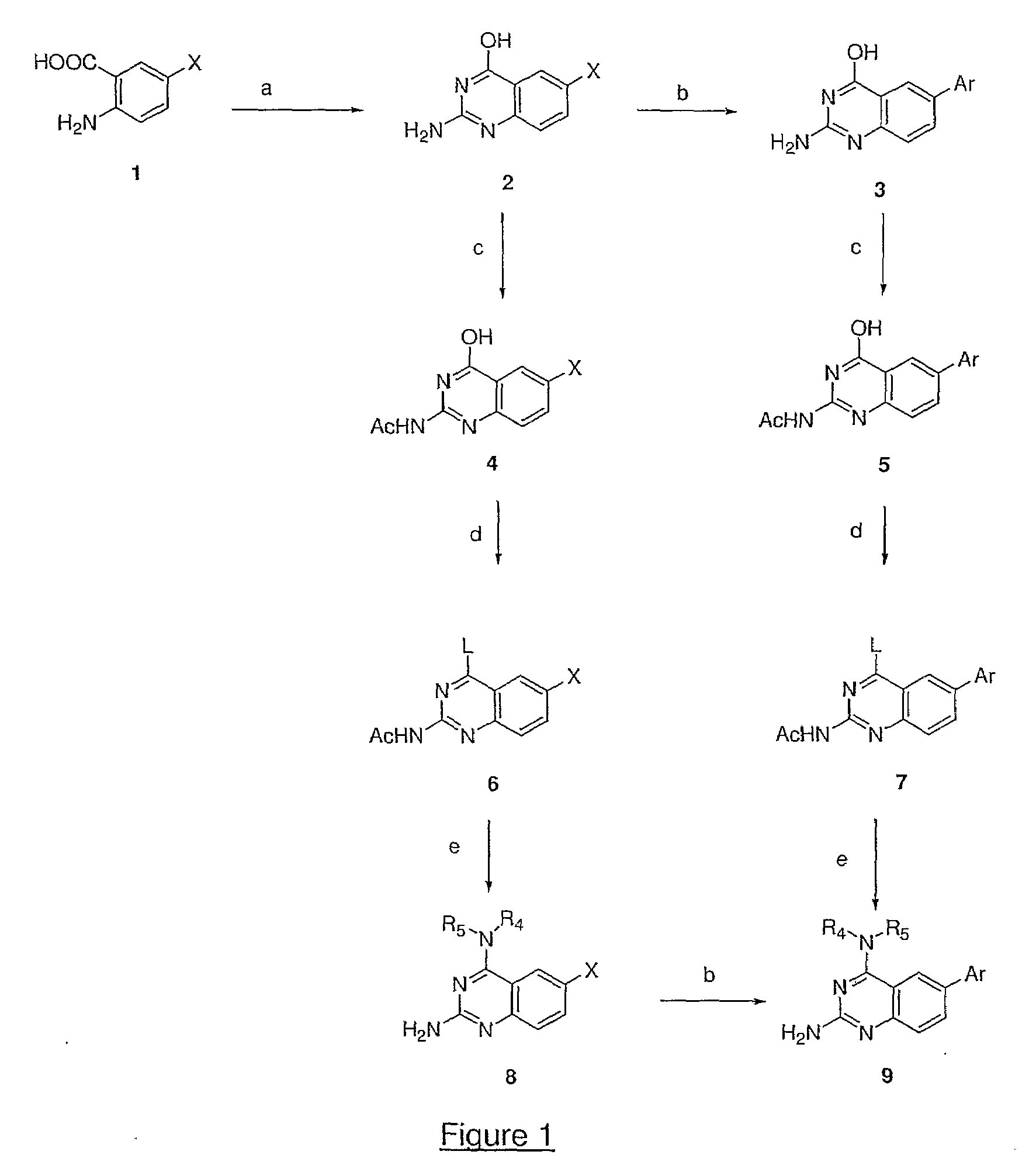

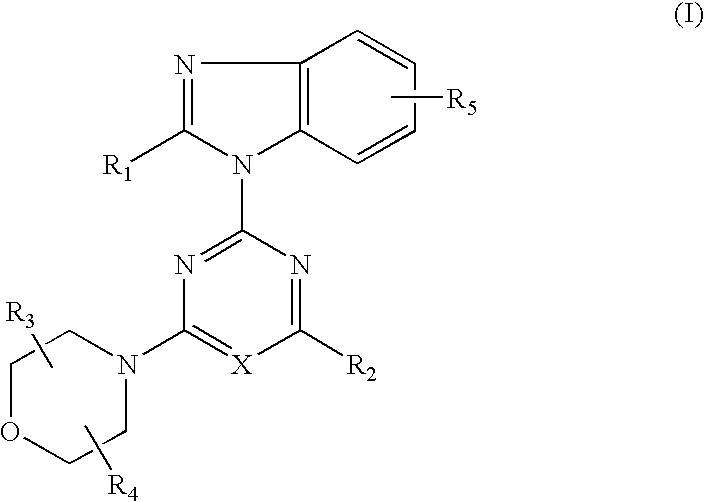

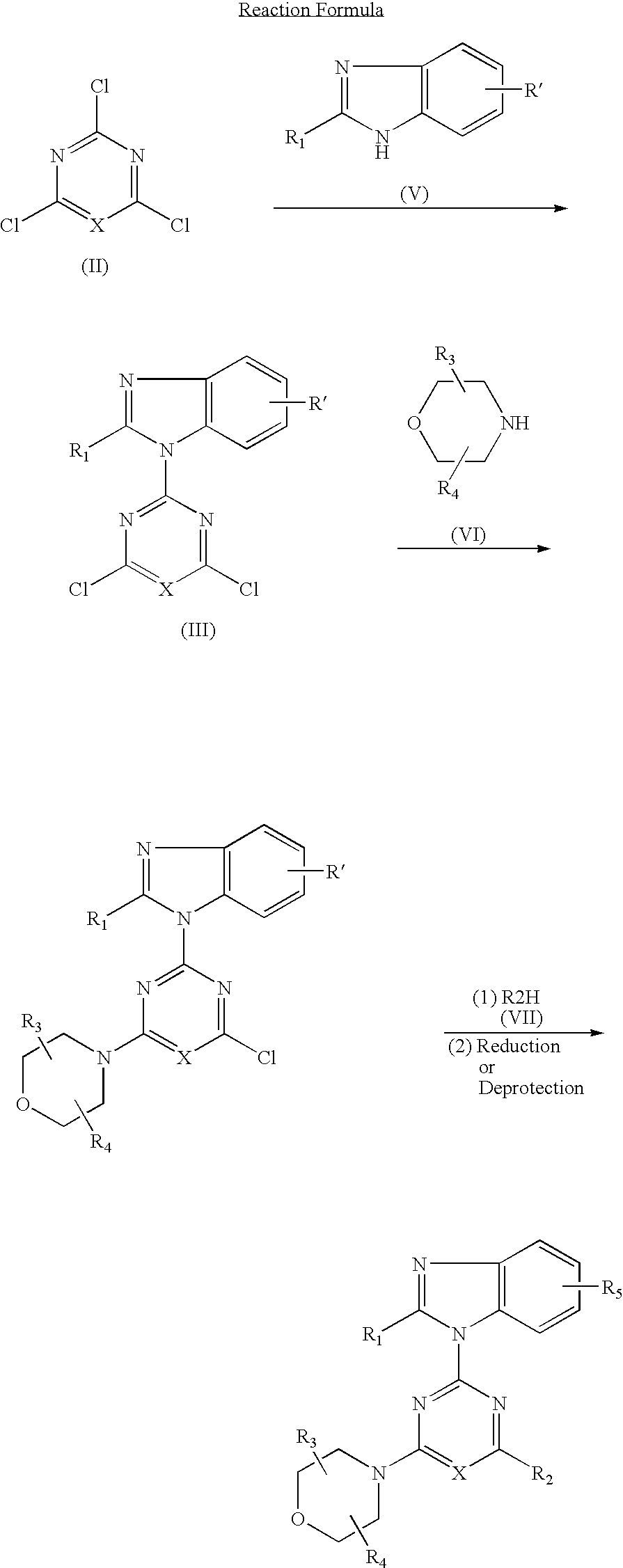

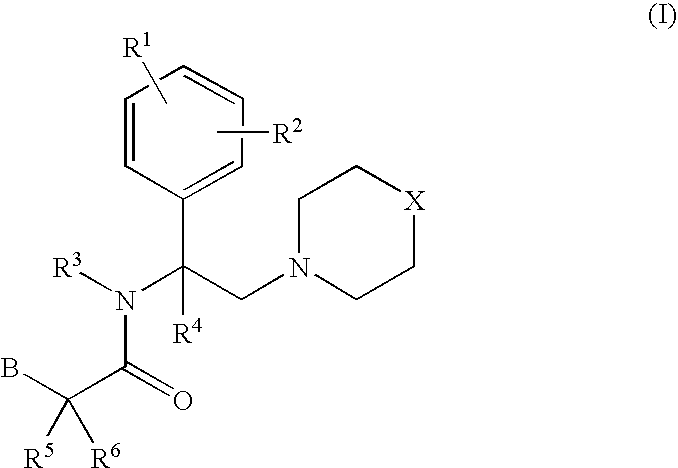

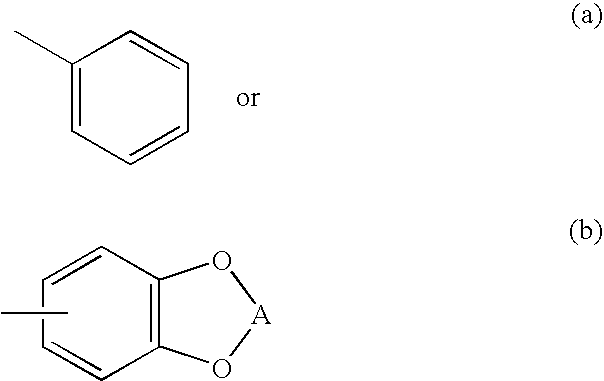

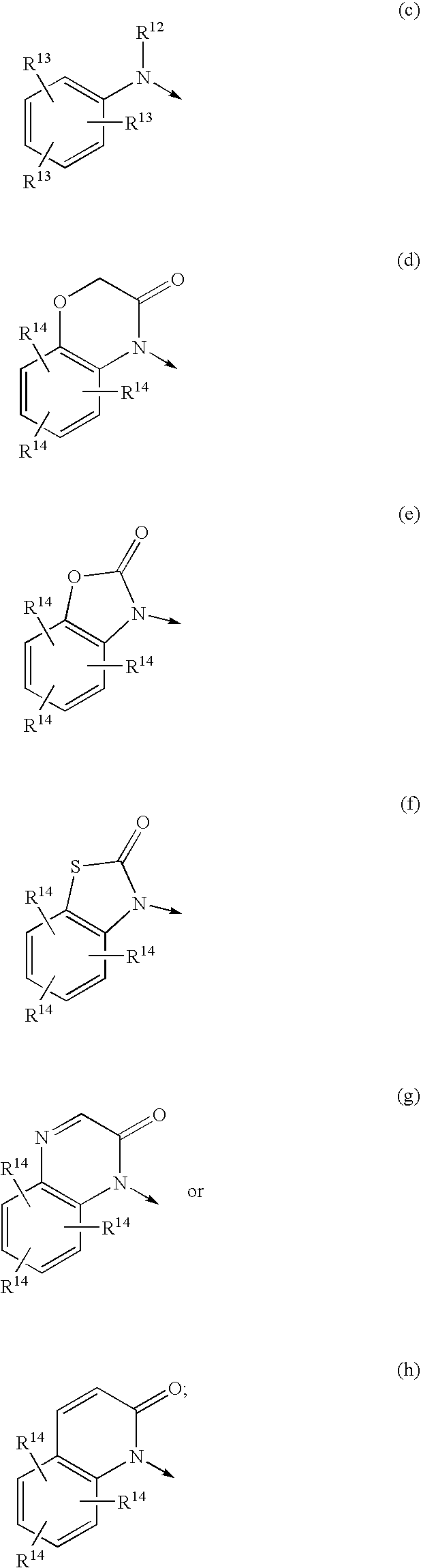

The present invention relates to heterocyclic compounds represented by the formula I or pharmaceutically acceptable salts thereof and antitumor agents containing the heterocyclic compounds as effective components:wherein X represents nitrogen atom or CH; R1 represents CHnF3-n (wherein n is 1 or 2), hydroxy C1–C6 alkyl, NHR6 [wherein R6 represents hydrogen atom or COR (wherein R represents hydrogen atom, C1–C6 alkyl or C1–C6 alkoxy)]; R2 represents morpholino (which may be substituted with one to four C1–C6 alkyl), thiomorpholino, piperidino, pyrrolidinyl (which may be substituted with hydroxy C1–C6 alkyl), oxazolidinyl (which may be substituted with one or two C1–C6 alkyl) or tetrahydro-1,4-thiazin-1-oxo-4-yl; R3 and R4 each represent hydrogen atom or C1–C6 alkyl; and R5 represents hydrogen atom, amino or hydroxyl.

Owner:OHARA PHARMA

Antibacterial antisense oligonucleotide and method

ActiveUS20100234281A1Simple designEasy to testAntibacterial agentsOrganic active ingredientsArginineMorpholine

A method for enhancing, by at least 10 fold, the antibacterial activity of an antisense oligonucleotide composed of morpholino subunits linked by phosphorus-containing intersubunit linkages. The method includes one or both of: conjugating an arginine-rich carrier to a 3′ or 5′ end of the oligonucleotide and modifying the oligonucleotide to contain 20%-50% intersubunit linkages that are positively charged at physiological pH. Also disclosed is an antisense oligonucleotide having enhanced antibacterial activity by virtue of one or both modifications.

Owner:SAREPTA THERAPEUTICS INC

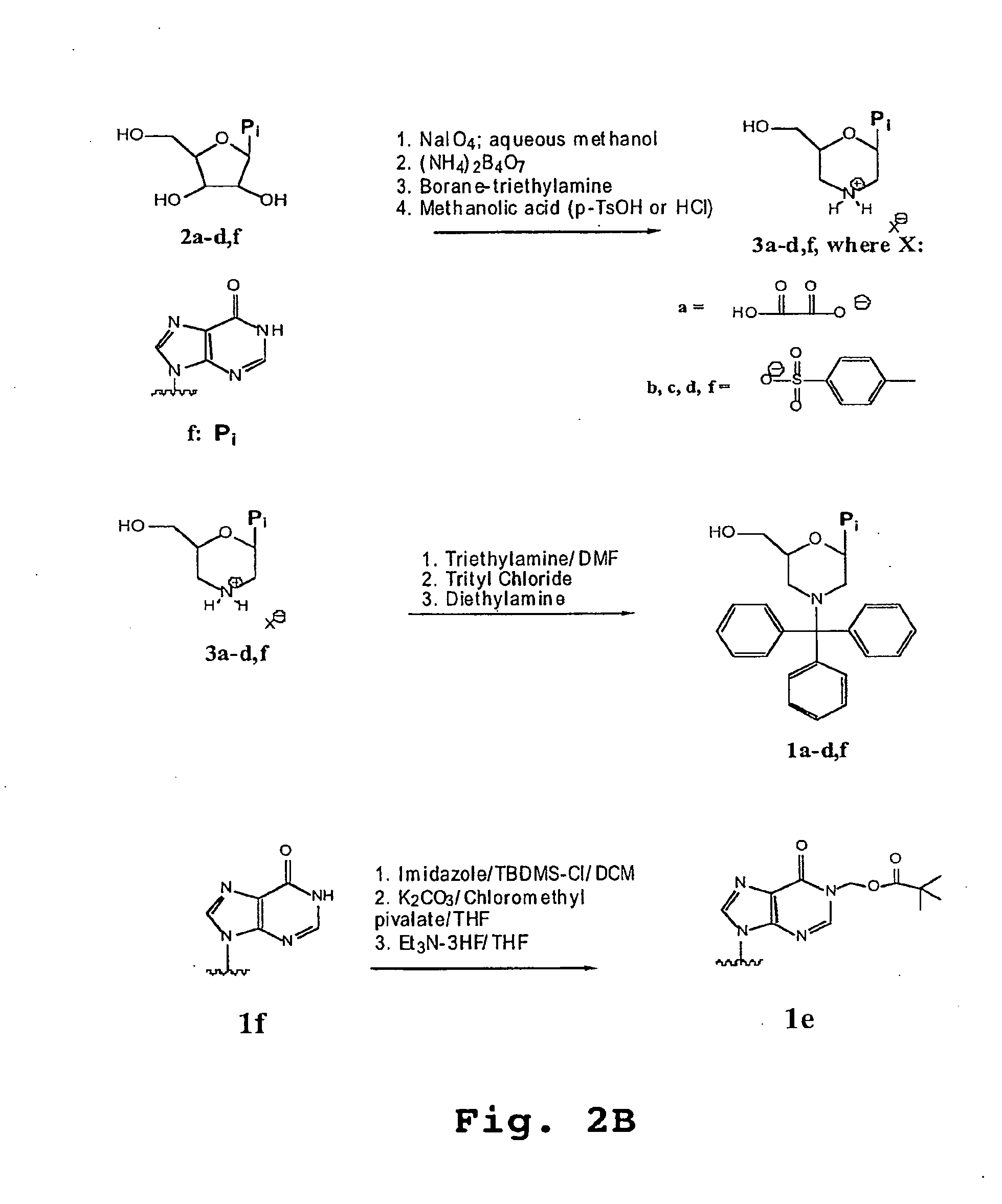

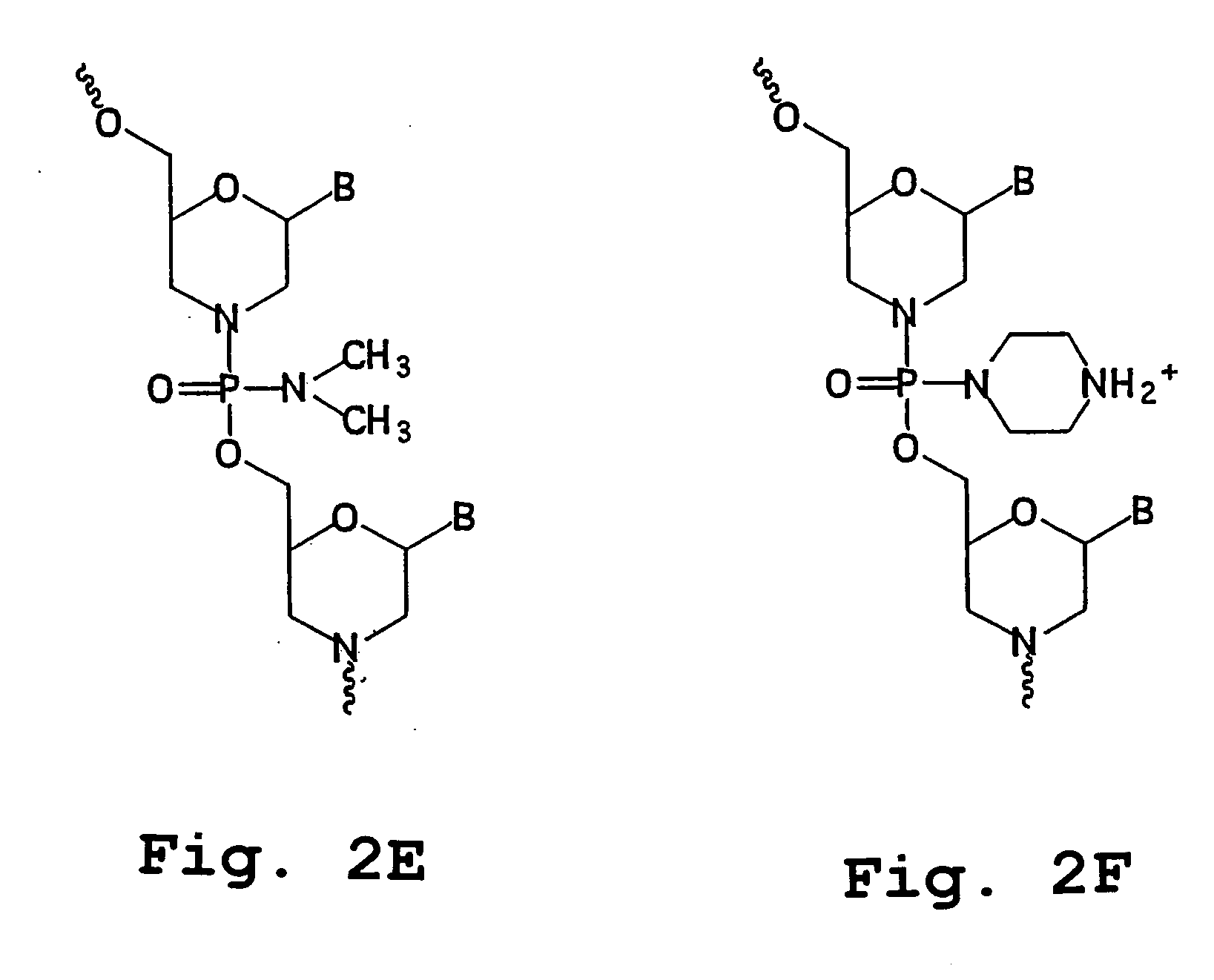

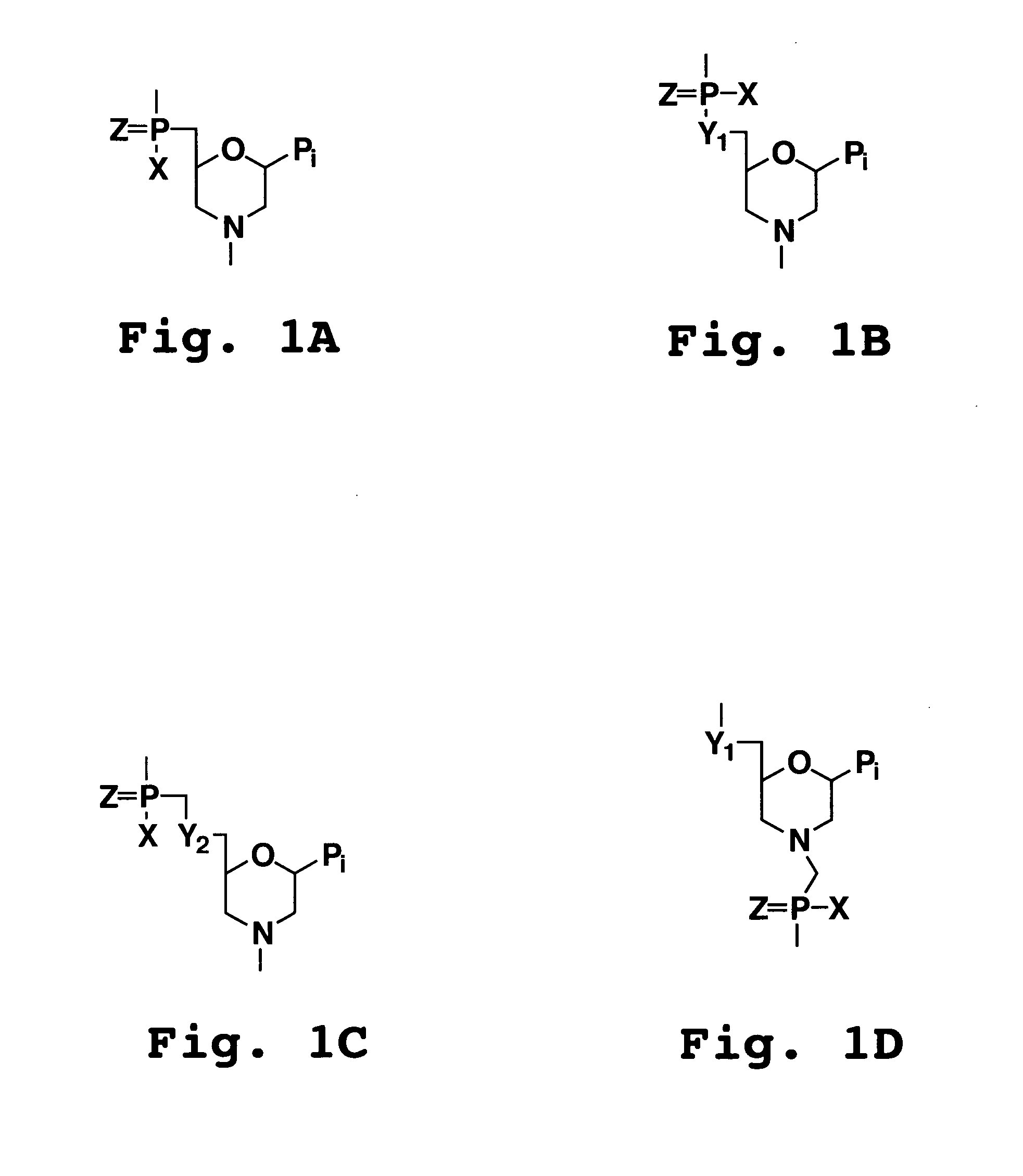

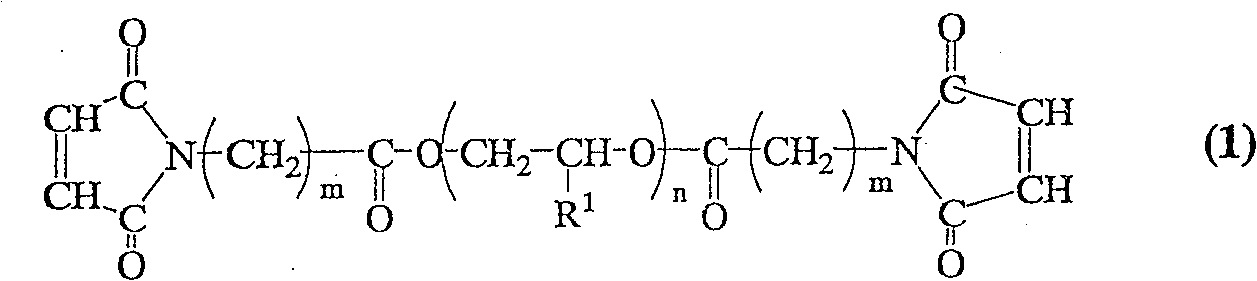

Morpholino Nucleic Acid Derivatives

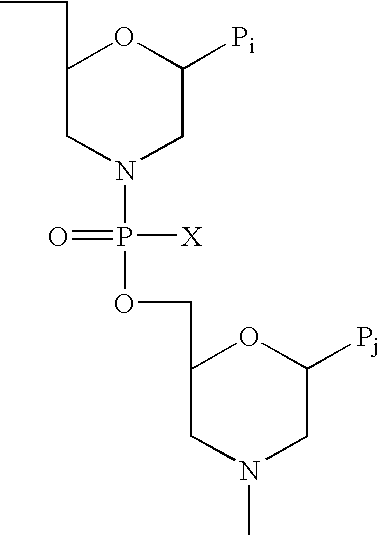

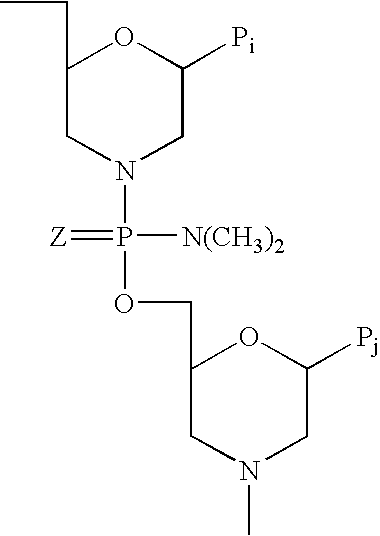

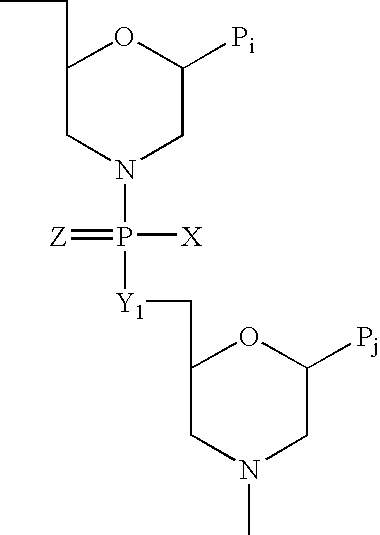

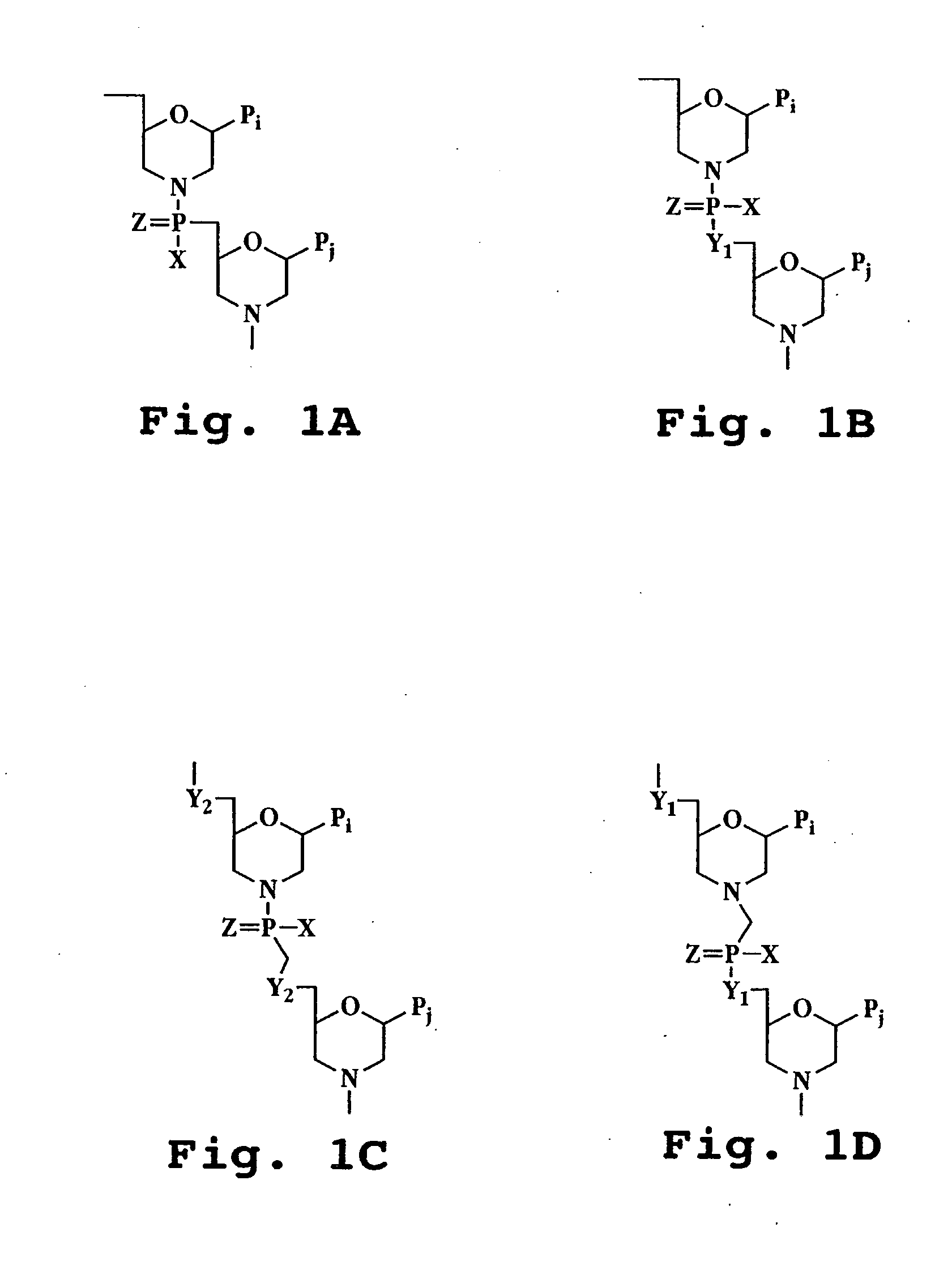

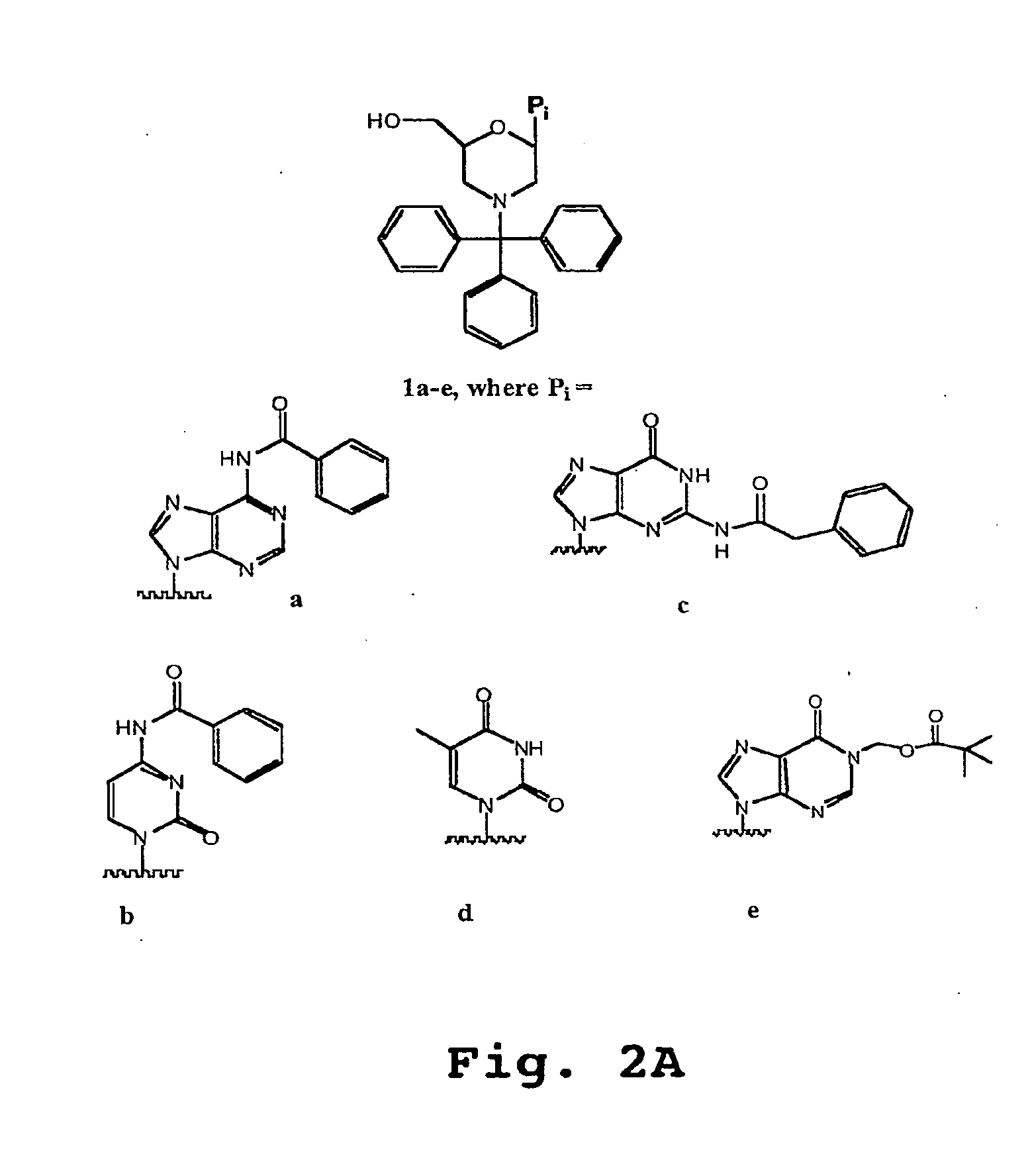

The present invention provides a useful morpholino nucleic acid derivative for synthesizing a morpholino nucleic acid oligomer. The present invention provides a compound represented by the following general formula (1) or a salt thereof.Here, R1 represents hydrogen, trityl and so on.R2 represents an amide or an imine.R3 represents a hydroxy group which may be protected by trialkylsilyl and so on, or a group represented by the following general formula (5):(wherein X represents O or S, Y represents dialkylamino or alkoxy, and Z represents chlorine).

Owner:NIPPON SHINYAKU CO LTD

Antisense restenosis composition and method

InactiveUS20070265215A1Reduce riskOrganic active ingredientsBiocideStart codonPercent Diameter Stenosis

The present invention provides an improved method for reducing the risk or severity of restenosis following cardiac angioplasty. The method includes administering to a target vessel region, a morpholino antisense compound having a phosphorus-containing backbone linkages, and spanning the start codon of a human c-myc mRNA. Also disclosed are novel antisense compounds and compositions, and a method for assaying the effectiveness of antisense delivery and uptake to a target vessel region.

Owner:AVI BIOPHARMA

Antisense composition and method for treating muscle atrophy

A method and compound for treating skeletal muscle mass deficiency in a human subject are disclosed. The composition is an oligomer of morpholino subunits and phosphorus-containing intersubunit linkages joining a morpholino nitrogen of one subunit to a 5′ exocyclic carbon of an adjacent subunit, contains between 10-40 nucleotide bases, has a base sequence effective to hybridize to an expression-sensitive region of processed or preprocessed human myostatin RNA transcript, identified, in its processed form, by SEQ ID NO:6, and is capable of uptake by target muscle cells in the subject. In practicing the method, the compound is administered in an amount and at a dosage schedule to produce an overall reduction in the level of serum myostatin measured in the patient, and preferably to bring the myostatin level within the a range determined for normal, healthy individuals.

Owner:AVI BIOPHARMA

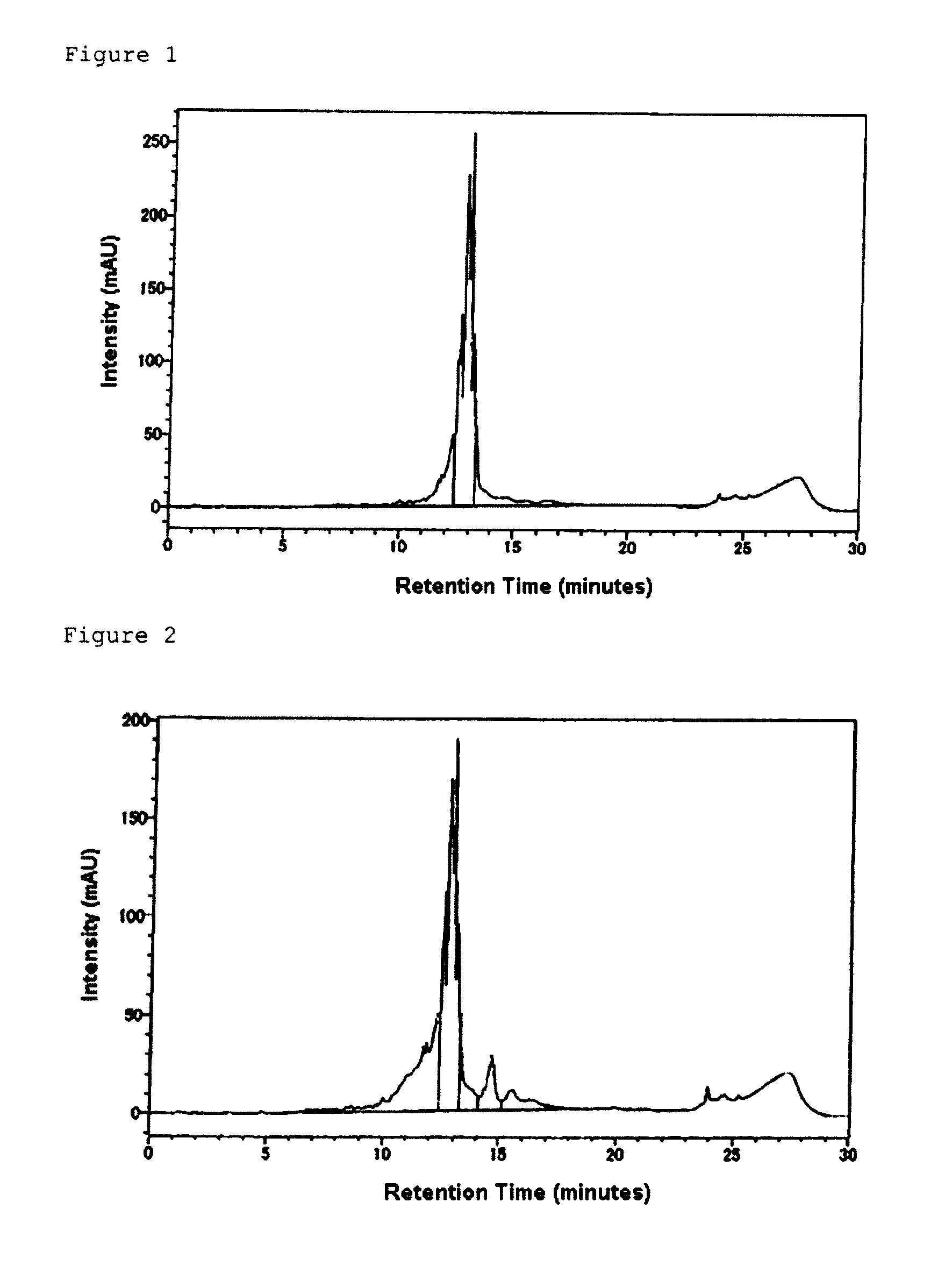

Process for the preparation of compositions for modulating a kinase cascade and methods of use thereof

The invention relates to compositions comprising 2-(5-(4-(2-morpholinoethoxy)phenyl)pyridin-2-yl)-N-benzylacetamide and its mesylate and dihydrochloride salts. More specifically, the invention provides an efficient process for the synthesis of 2-(5-(4-(2-morpholinoethoxy)phenyl)pyridin-2-yl)-N-benzylacetamide and its mesylate and dihydrochloride salts and methods for modulating one or more components of a kinase cascade using the compositions of the invention.

Owner:ATNX SPV LLC

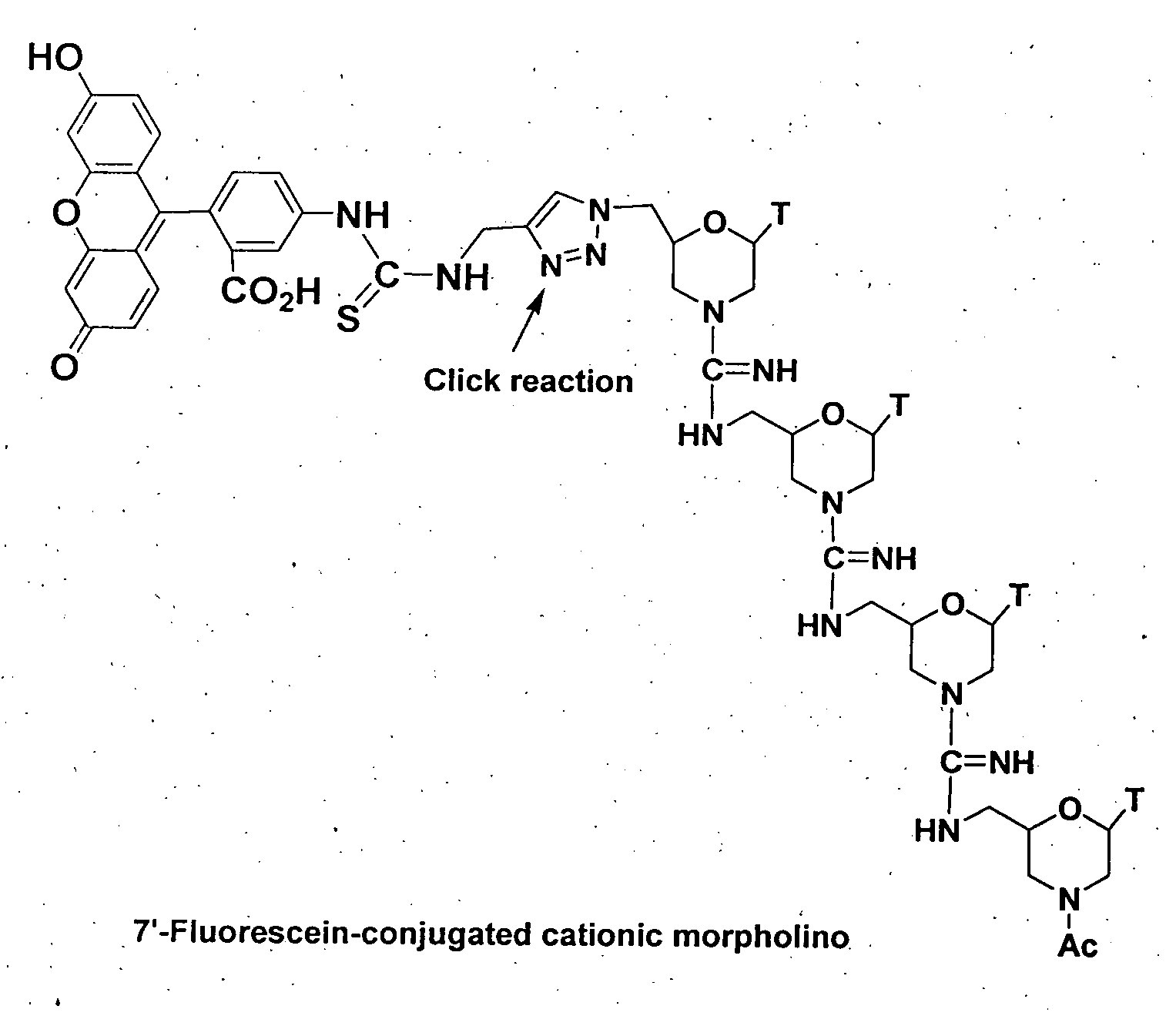

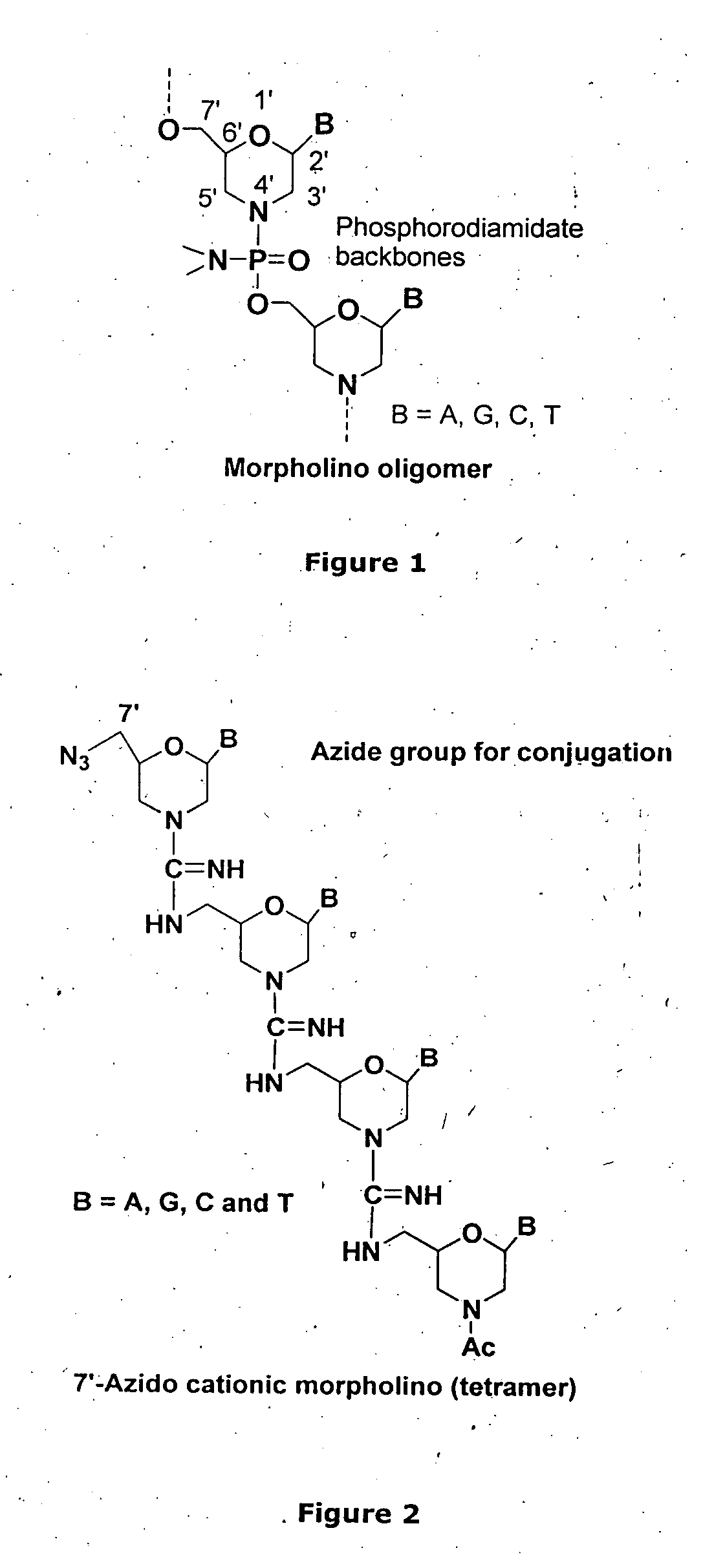

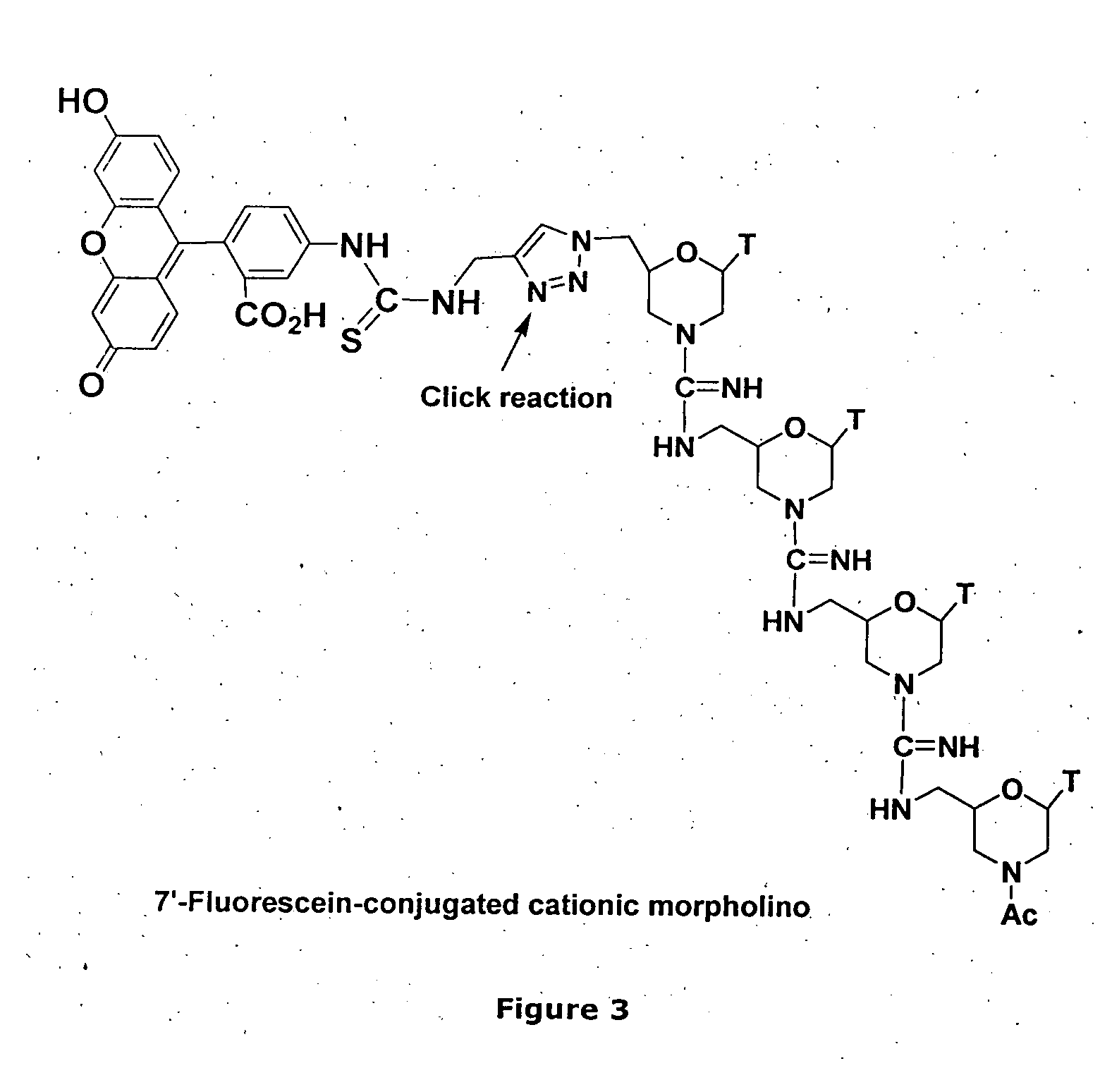

Morpholino-based antisense agent

ActiveUS20120296087A1High activityHigh selectivitySilicon organic compoundsActivity regulationOligomerRegulation of gene expression

Morpholino-based oligomers suitable as antisense agent comprising modifications of phosphorodiamidate backbone or modification with 5-substituted pyrimidines of morpholino compound that is soluble in culture medium and sufficient for cell penetration thereby eliminating the need for injecting into the cells. Monomers comprising the said oligomers and its method of manufacture, method of manufacture of the said oligomers and its dye, flurophore, drug, biomolecule conjugate wherein the said oligomers find different end use but not limited to regulation of gene expression, tissue culture with improved transfection efficiency and related studies on cellular transfection.

Owner:INDIAN ASSOC FOR THE CULTIVATION OF SCI

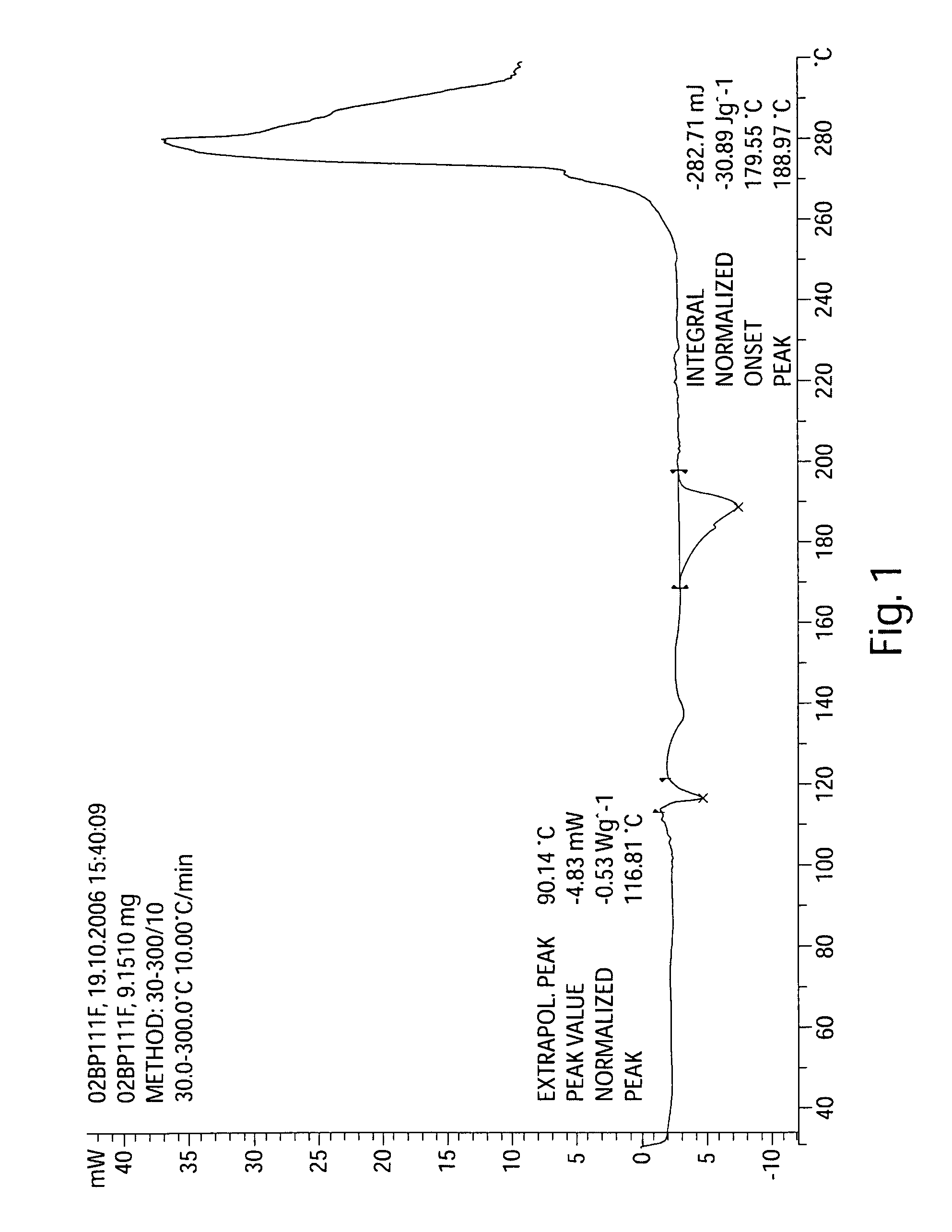

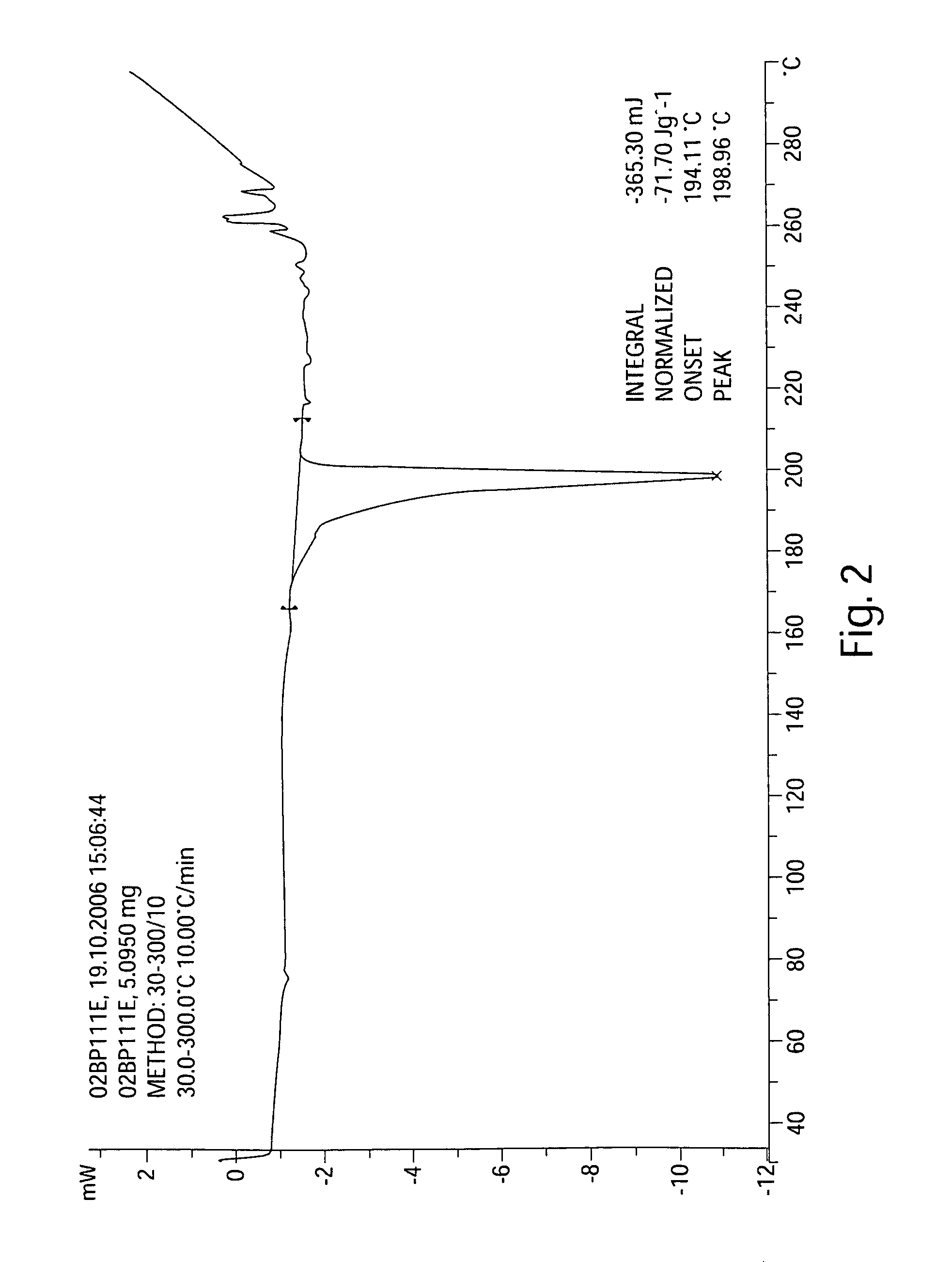

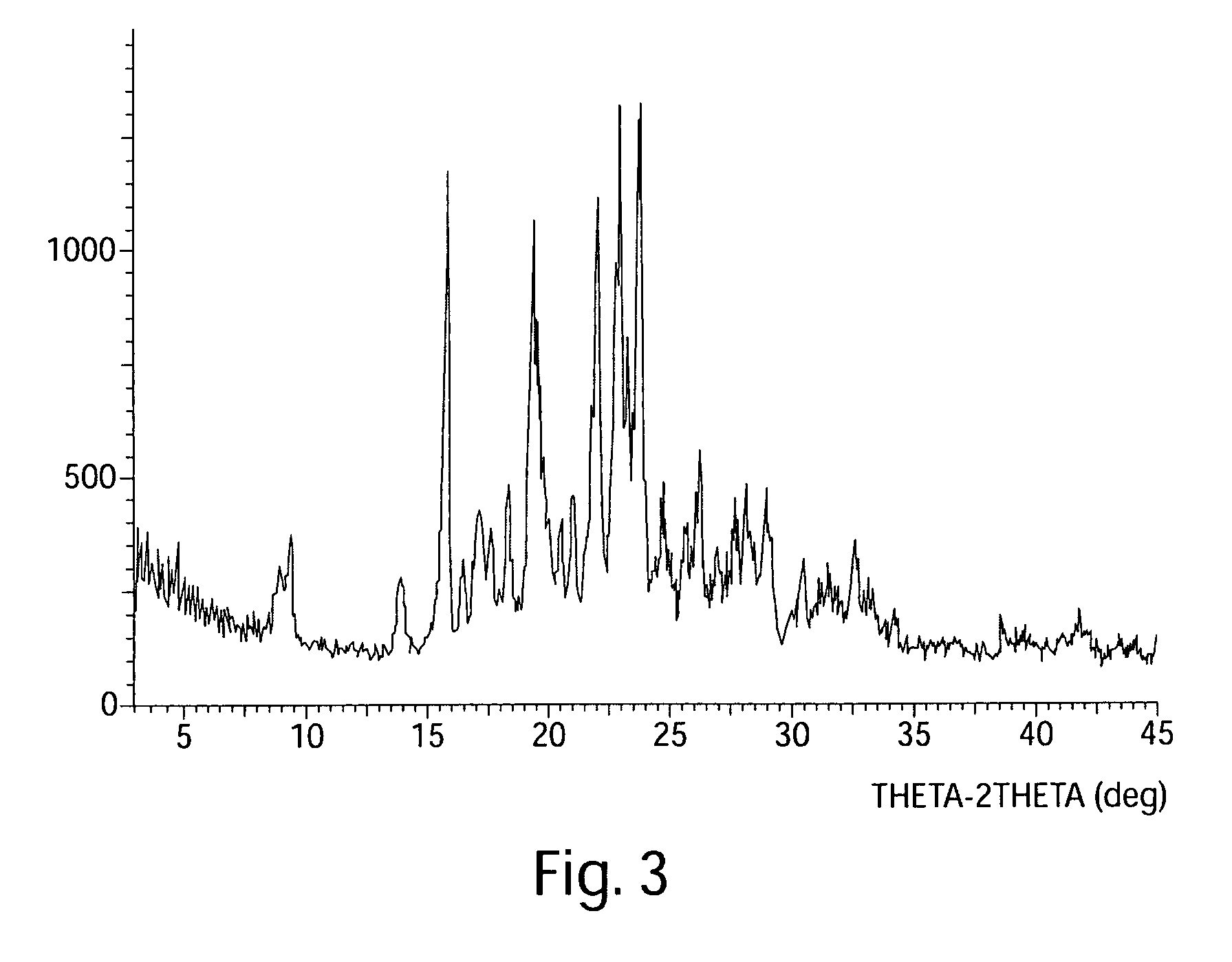

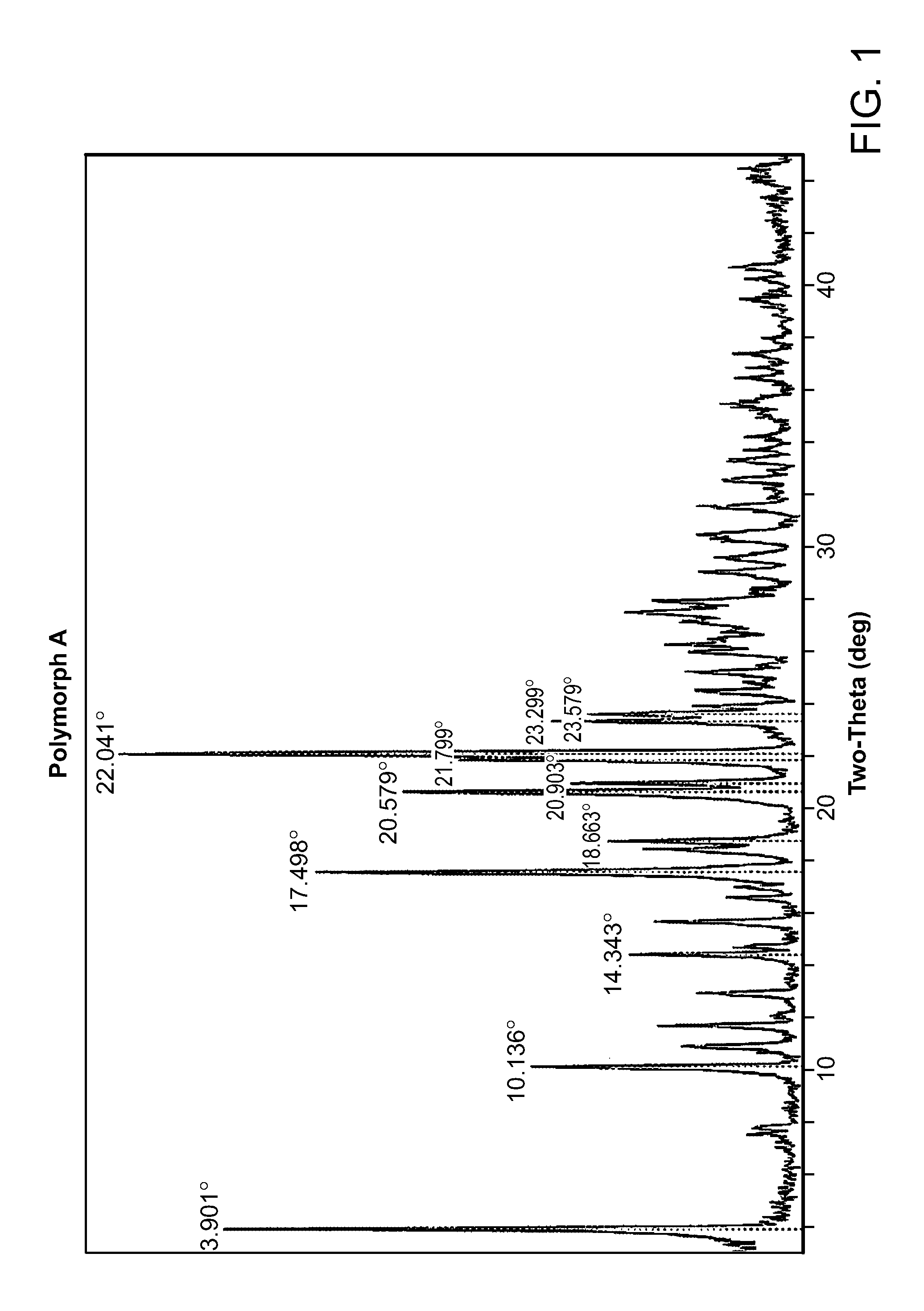

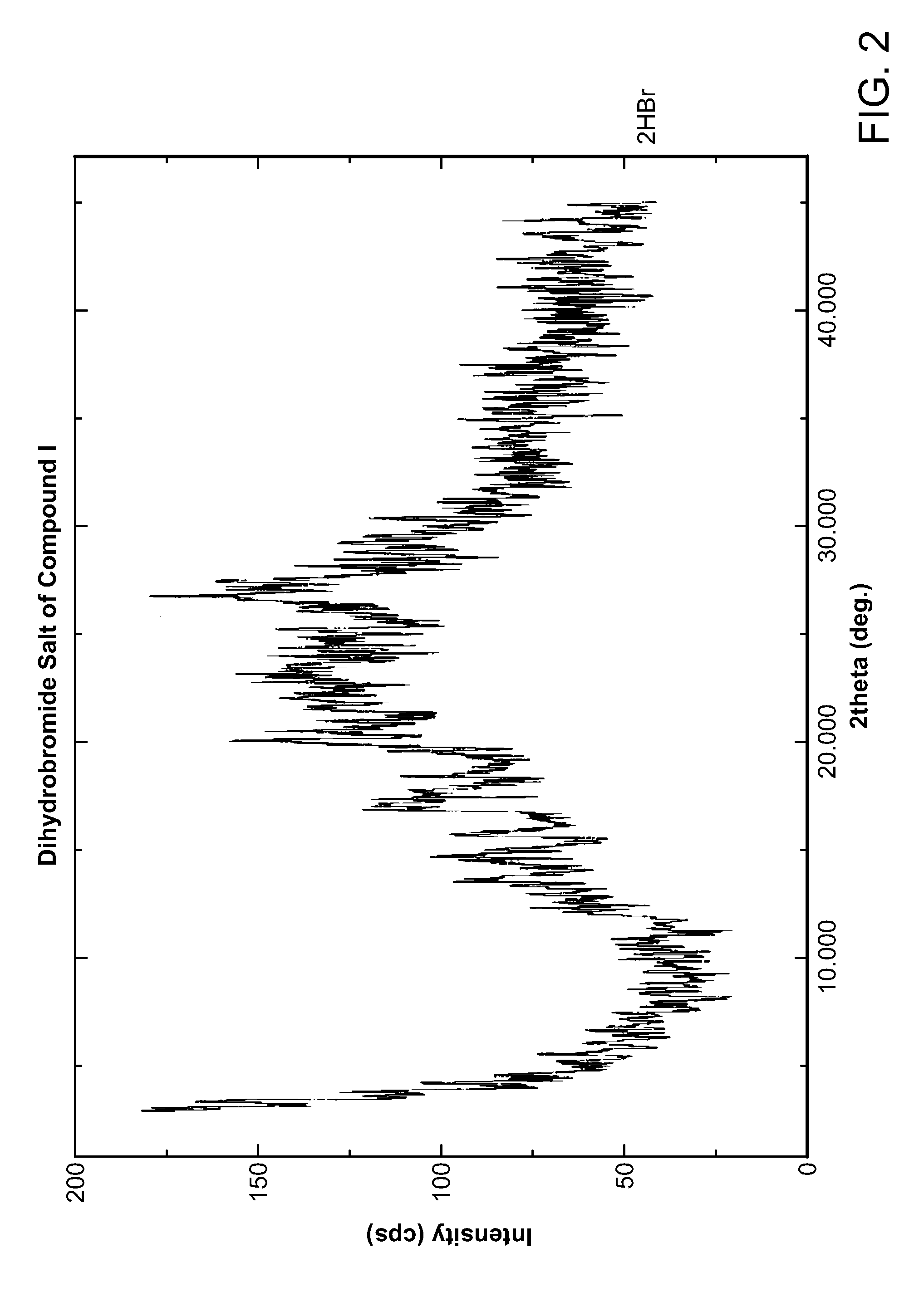

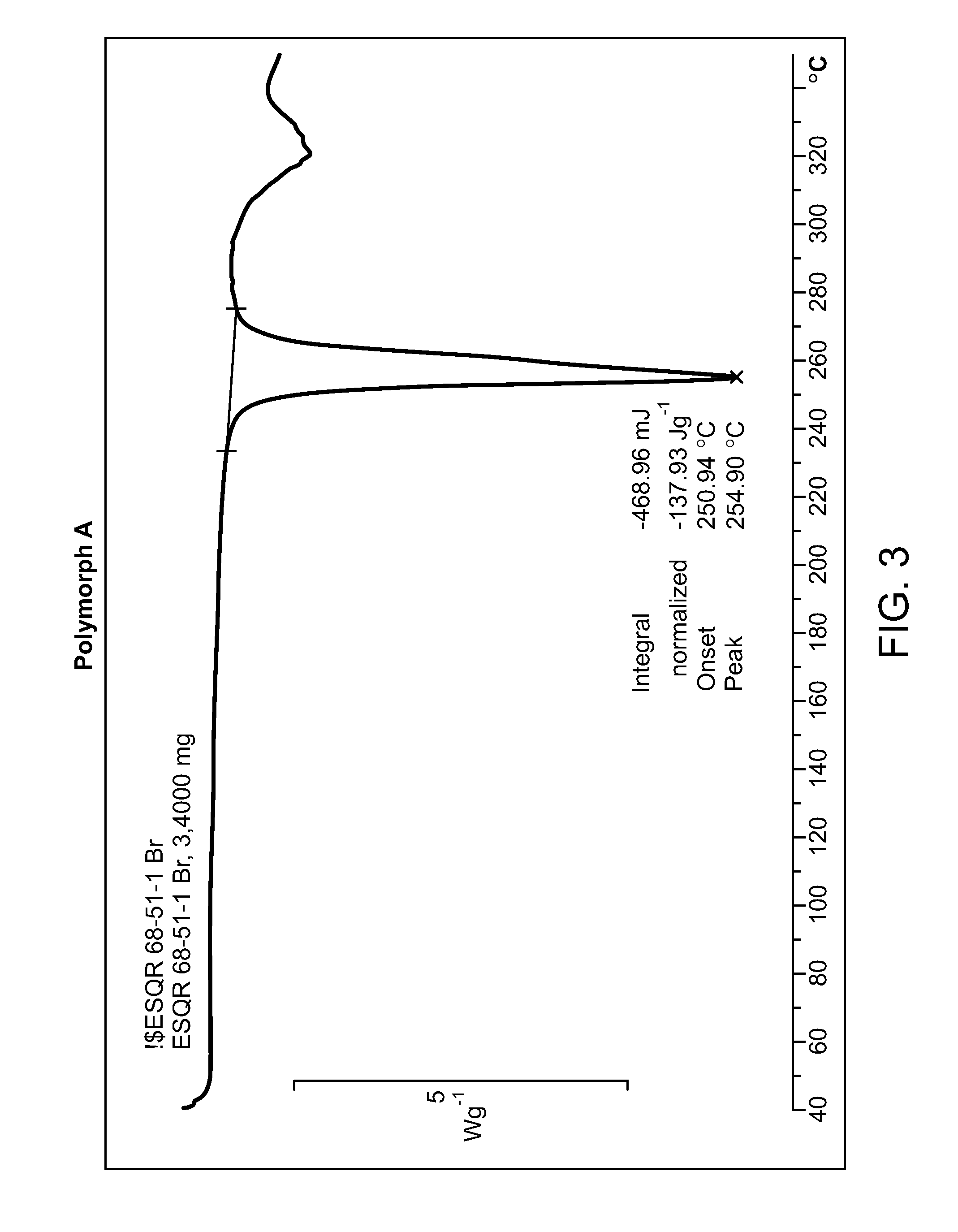

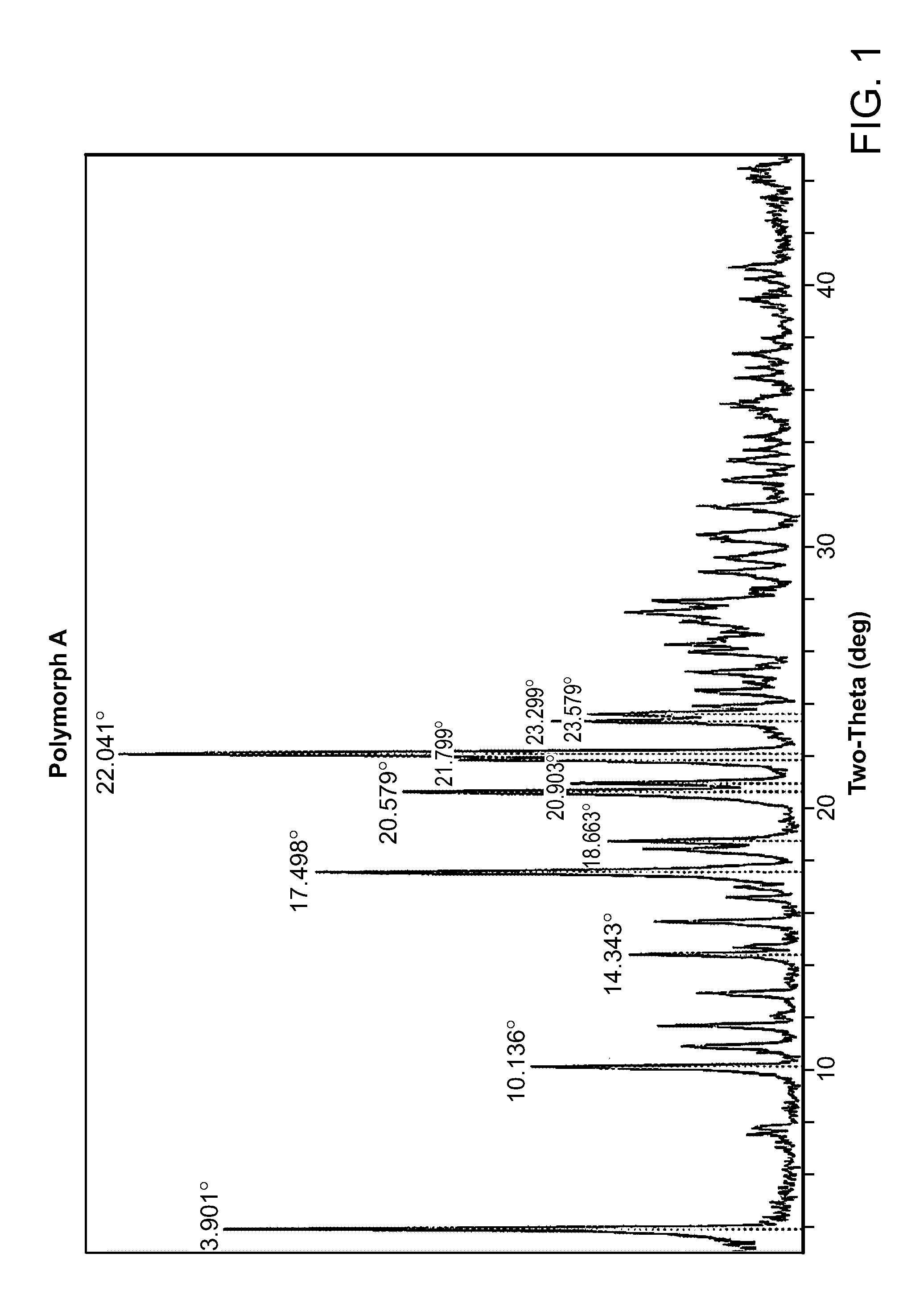

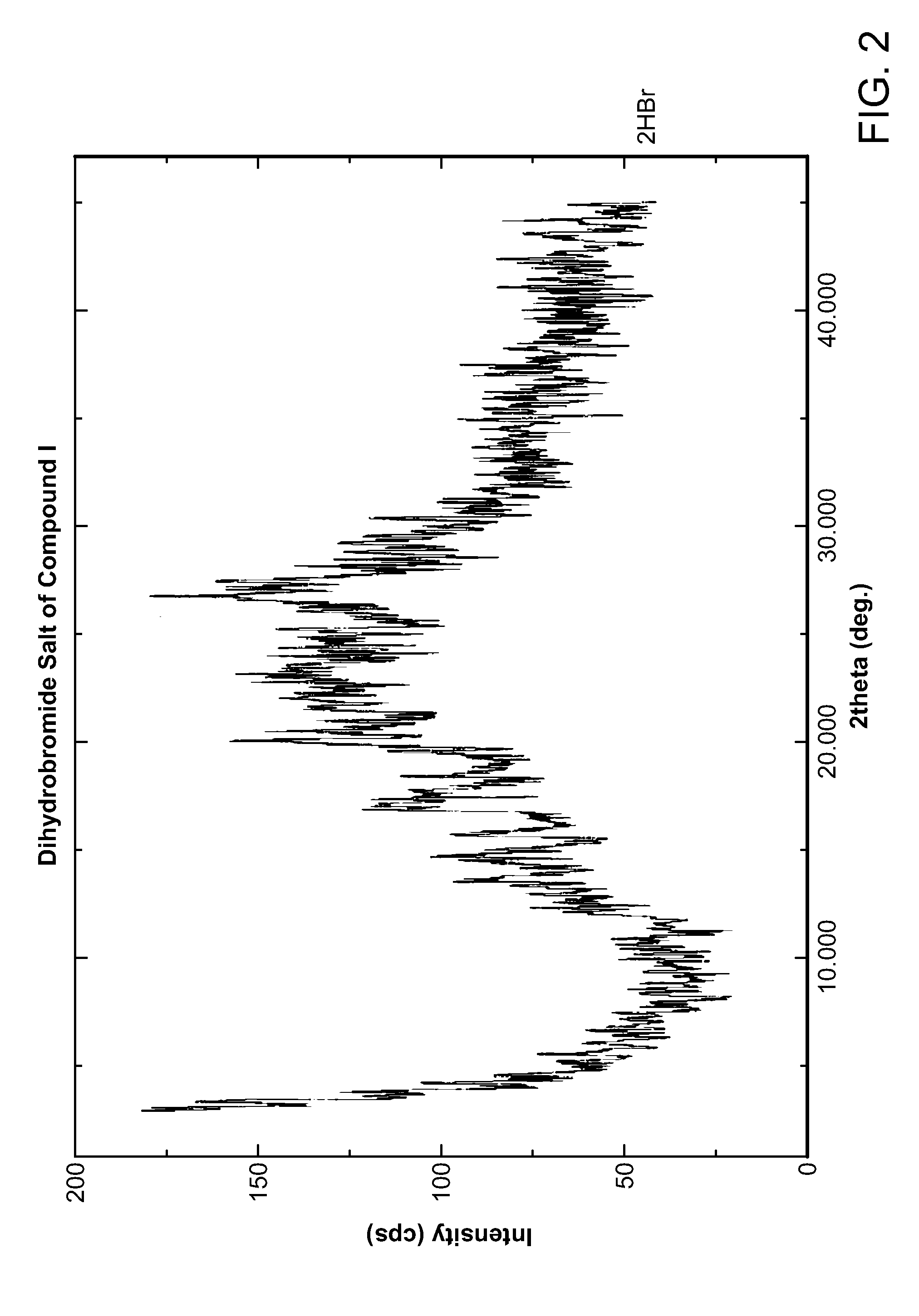

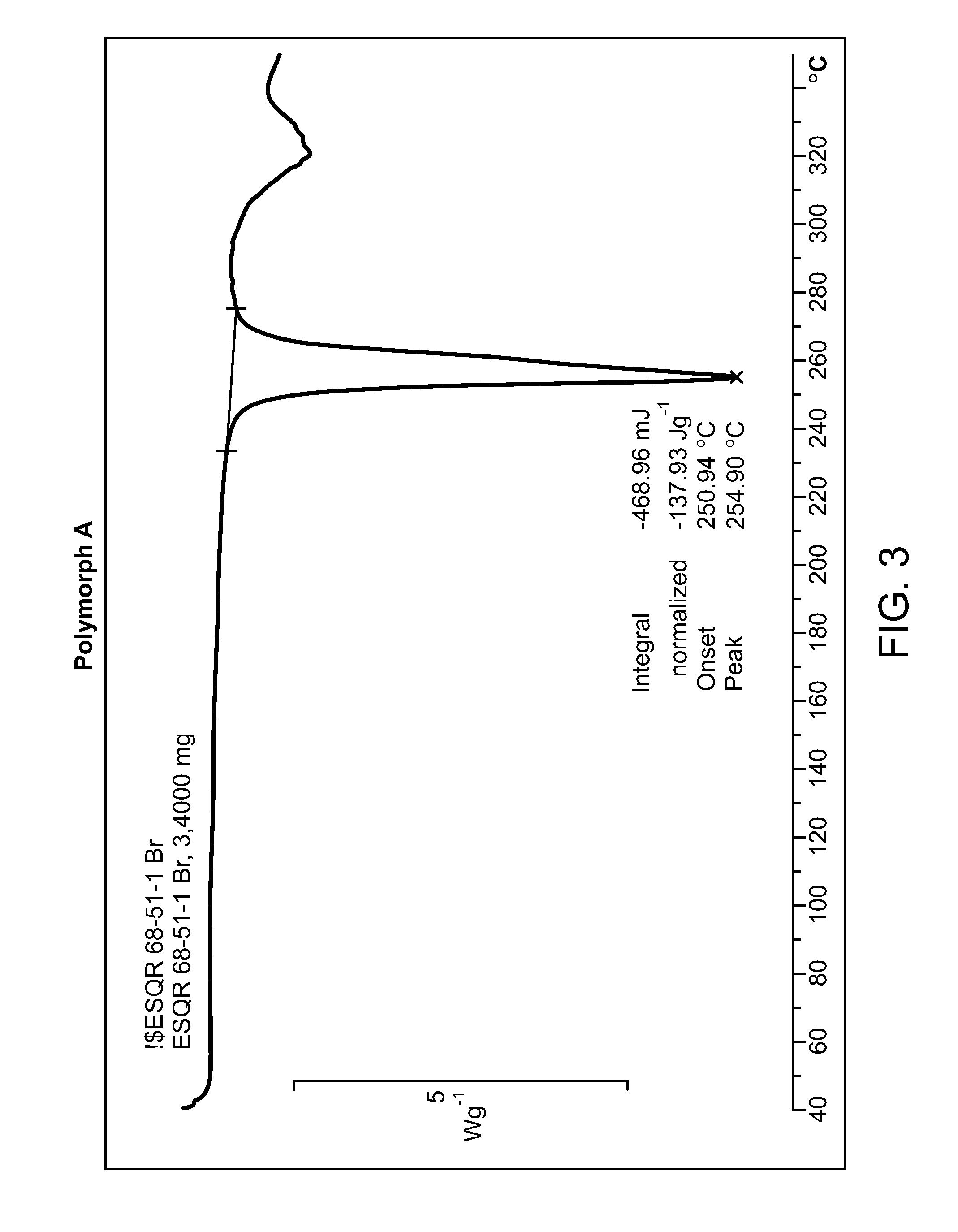

Salt form of a human histone methyltransferase EZH2 inhibitor

Provided herein is N-((4,6-dimethyl-2-oxo-1,2-dihydropyridin-3-yl)methyl)-5-(ethyl(tetrahydro-2H-pyran-4-yl)amino)-4-methyl-4′-(morpholinomethyl)-[1,1′-biphenyl]-3-carboxamide hydrobromide. Also provided herein is a particular polymorph form of this compound.

Owner:EISIA R&D MANAGEMENT CO LTD +1

Morpholino nucleic acid derivatives

The present invention provides a useful morpholino nucleic acid derivative for synthesizing a morpholino nucleic acid oligomer. The present invention provides a compound represented by the following general formula (1) or a salt thereof.Here, R1 represents hydrogen, trityl and so on.R2 represents an amide or an imine.R3 represents a hydroxy group which may be protected by trialkylsilyl and so on, or a group represented by the following general formula (5):(wherein X represents O or S, Y represents dialkylamino or alkoxy, and Z represents chlorine).

Owner:NIPPON SHINYAKU CO LTD

Antisense restenosis composition and method

InactiveUS20060269587A1Reduce riskReduce severityBiocideHydroxy compound active ingredientsMorpholineBackbone chain

The present invention provides an improved method for reducing the risk or severity of restenosis following cardiac angioplasty. The method includes administering to a target vessel region, a morpholino antisense compound having uncharged phosphorus-containing backbone linkages, and spanning the start codon of a human c-myc mRNA. Also disclosed are novel antisense compounds and compositions, and a method for assaying the effectiveness of antisense delivery and uptake to a target vessel region.

Owner:AVI BIOPHARMA

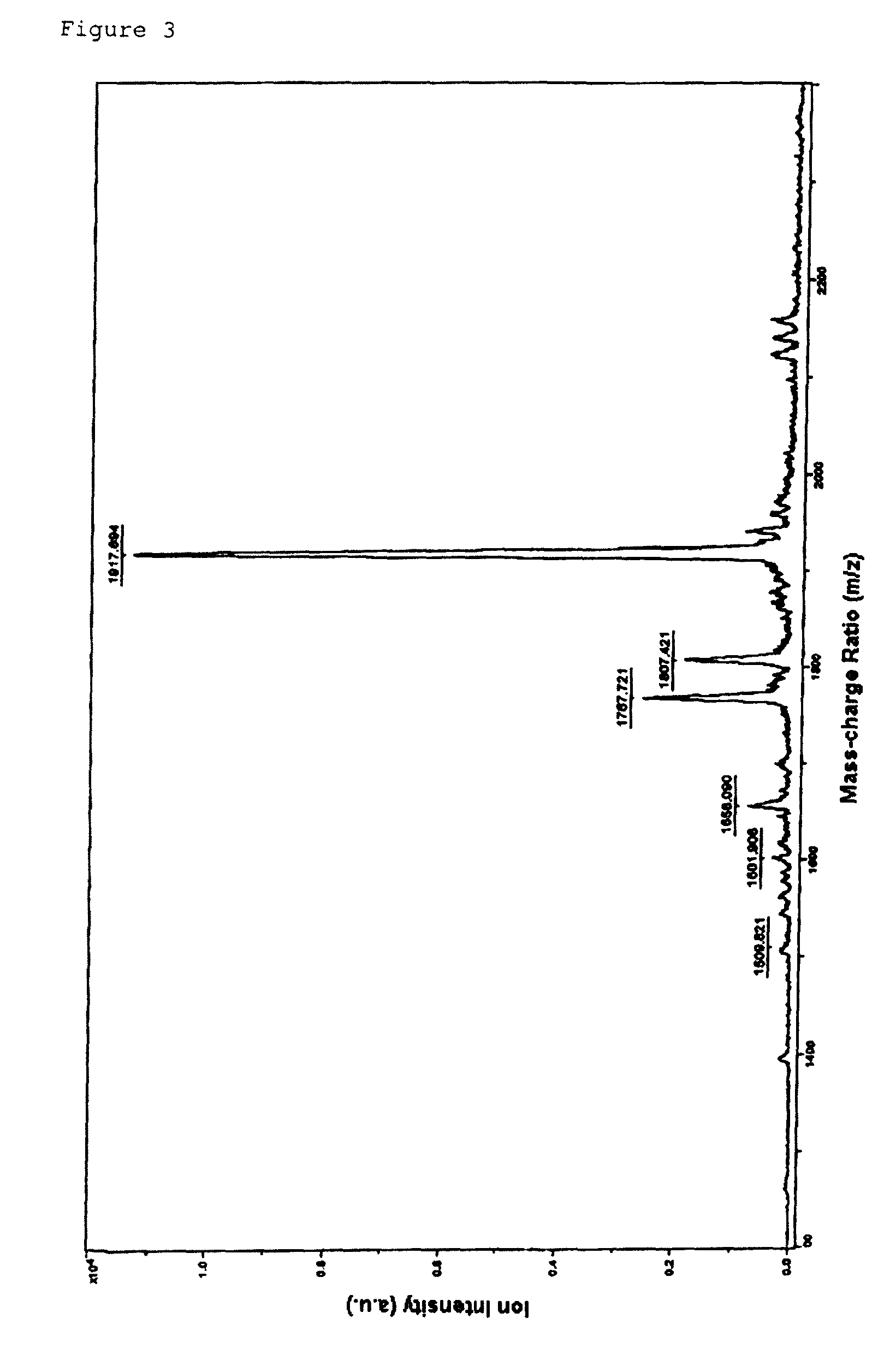

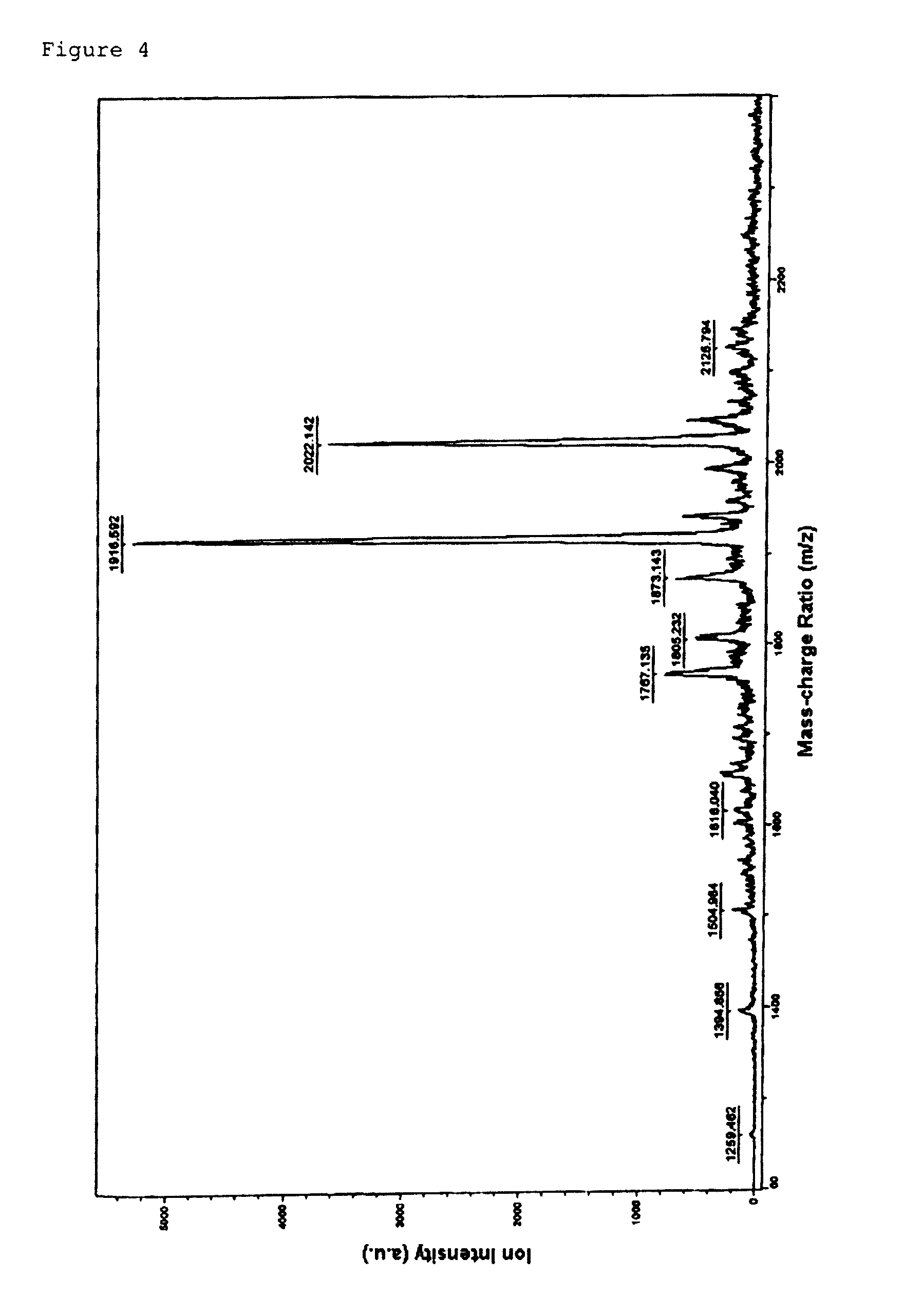

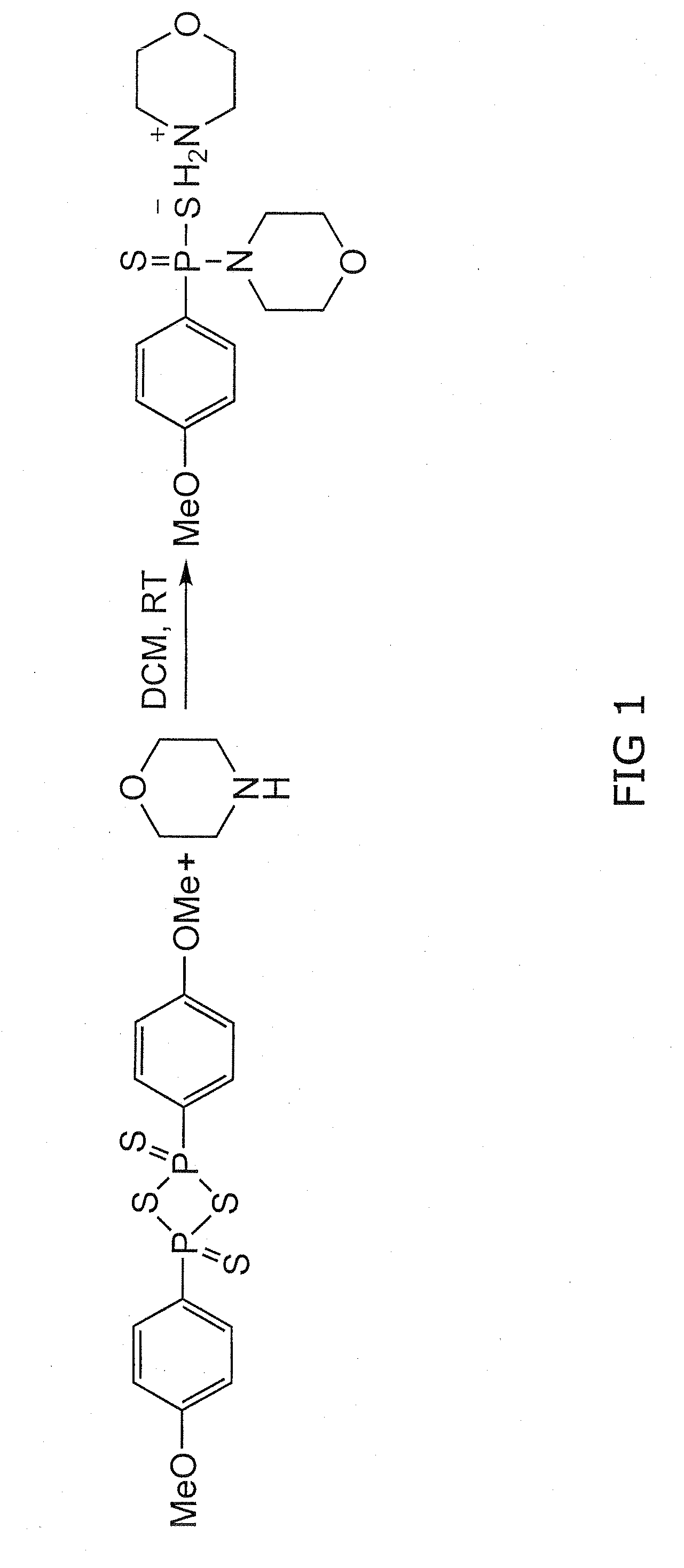

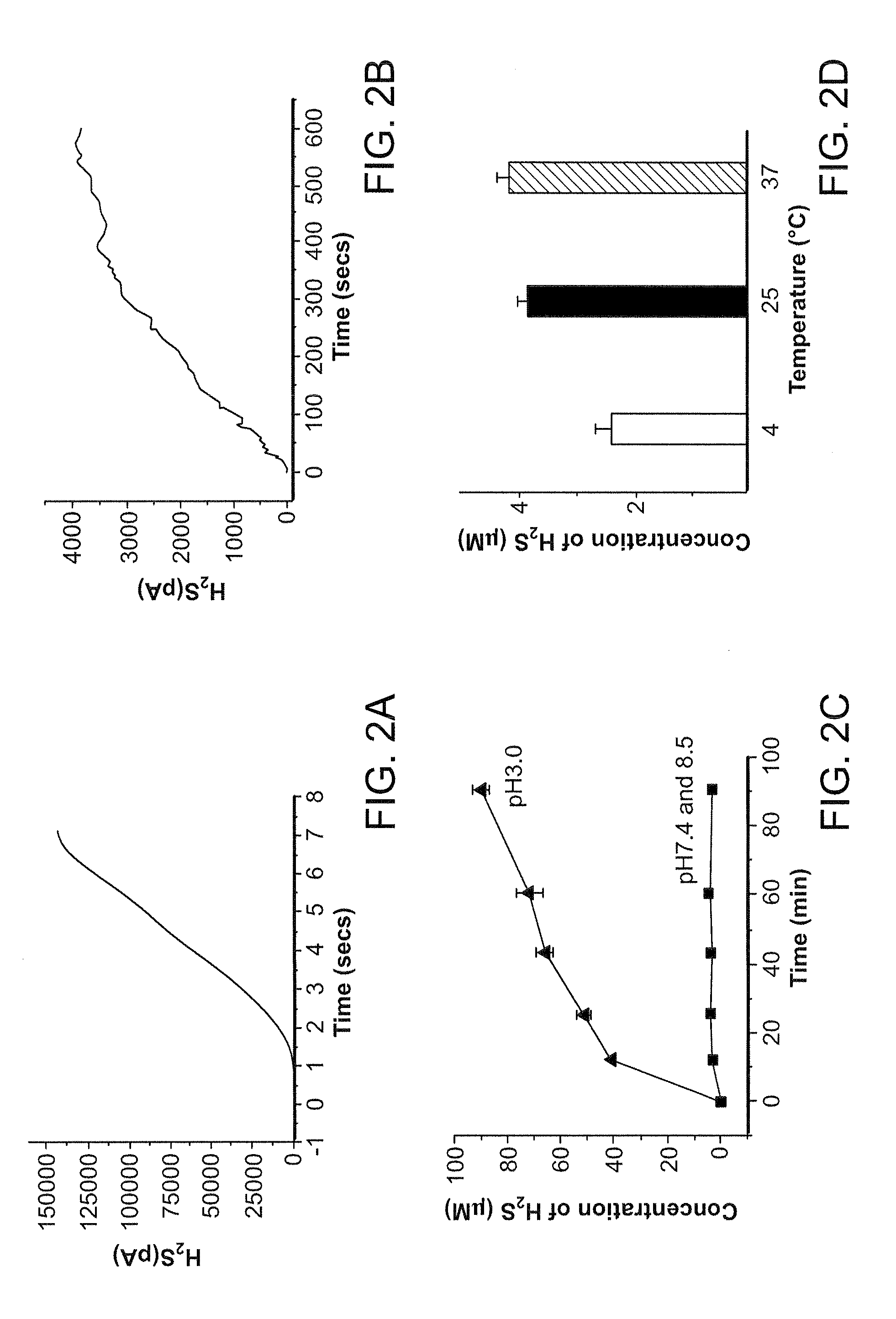

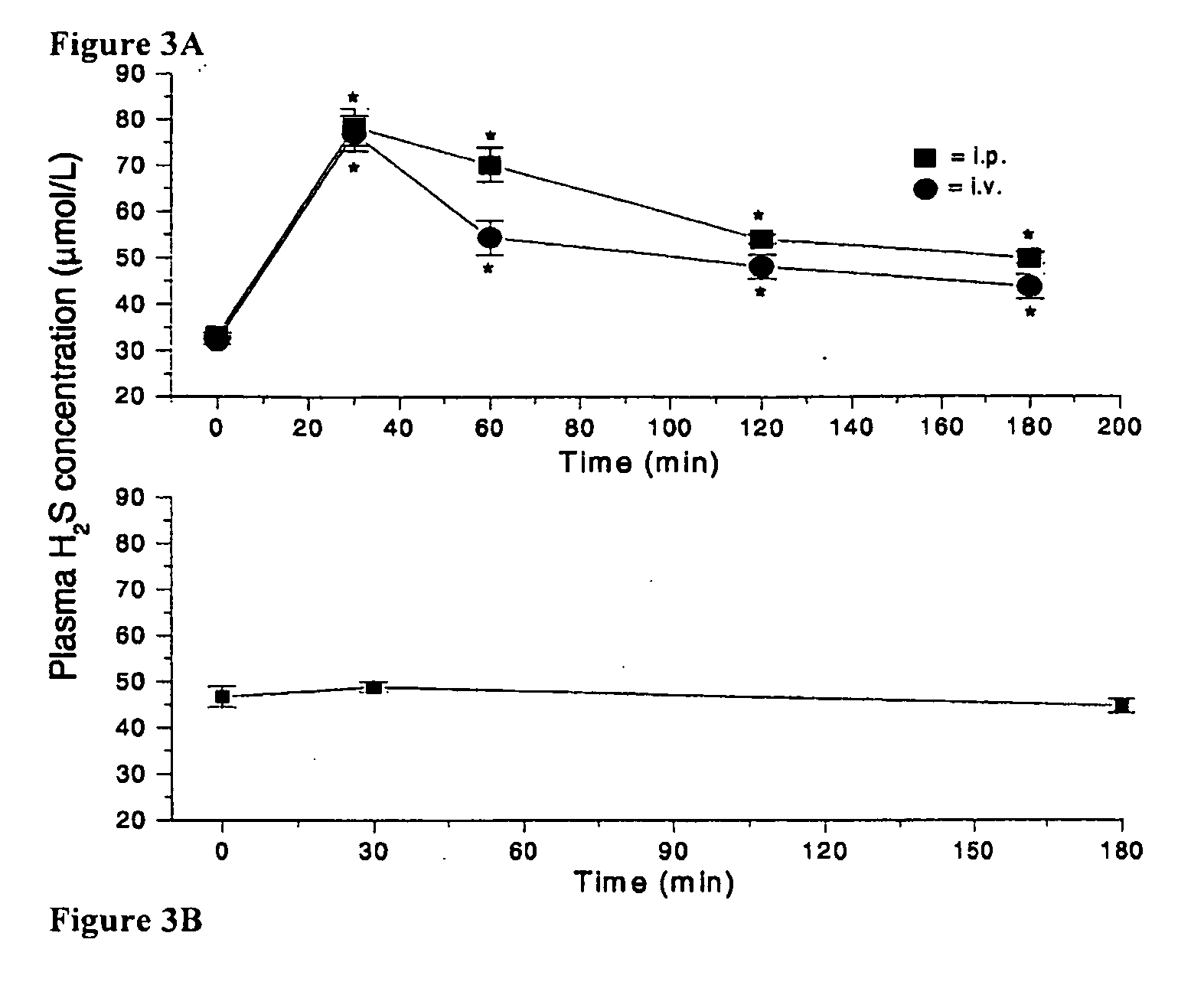

Morpholin-4-ium 4 methoxyphenyl (morpholino) phosphinodithioate (gyy4137) as a novel vasodilator agent

InactiveUS20100273743A1Lower blood pressureBiocidePhosphorous compound active ingredientsPharmaceutical medicineStructural formula

The invention is directed to a method of administering hydrogen sulfide (H2S) slowly and sustainably to an individual in need thereof comprising administering an effective amount of a compound represented by the following structural formula:or a pharmaceutically acceptable salt thereof.

Owner:NAT UNIV OF SINGAPORE

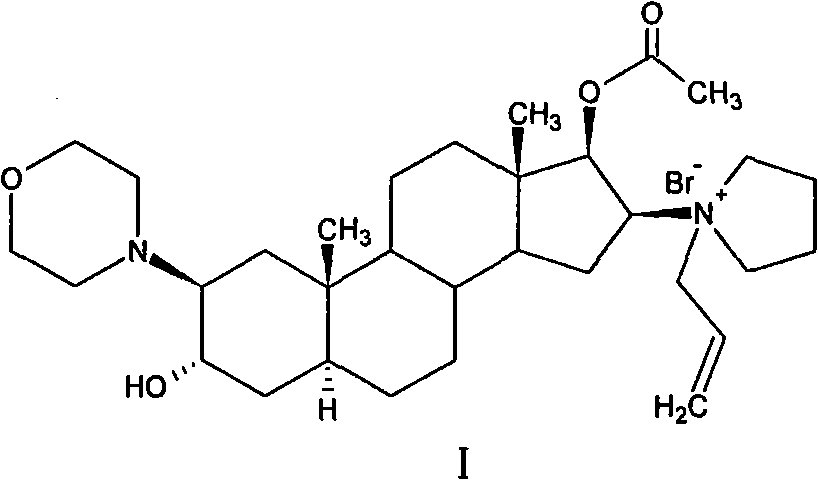

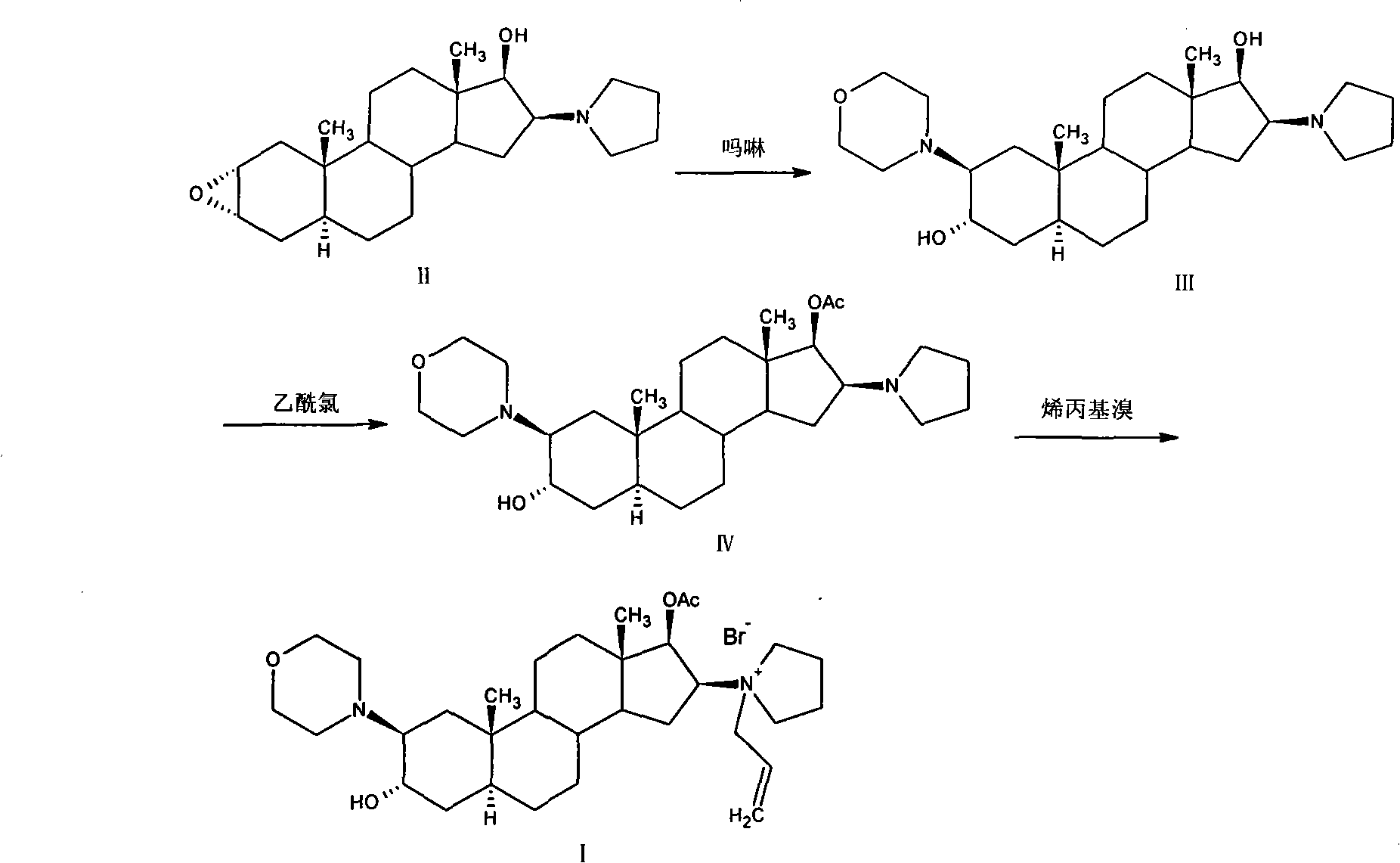

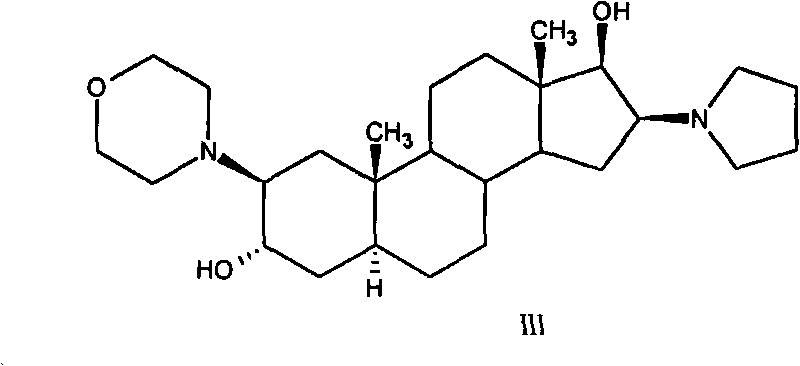

High-purity (2 beta, 3 alpha, 5 alpha, 16 beta, 17 beta)-2-(4-morpholinyl)-16-(1-pyrrolidinyl)-androstane-3,17-diol or composition thereof and preparation method thereof

The invention relates to a high-purity (2 beta, 3 alpha, 5 alpha, 16 beta, 17 beta)-2-(4- morpholinyl)-16-(1-pyrrolidinyl)-androstane-3,17-diol or a composition thereof, a preparation method thereof (a compound shown in a formula III) or a composition thereof and application thereof to preparing rocuronium (a compound shown in a formula I). The method has good effect, low cost, high quality and simple and convenient operation and is suitable for large-scale industrial production; and the obtained product has high purity and stable properties.

Owner:重庆凯林制药有限公司 +1

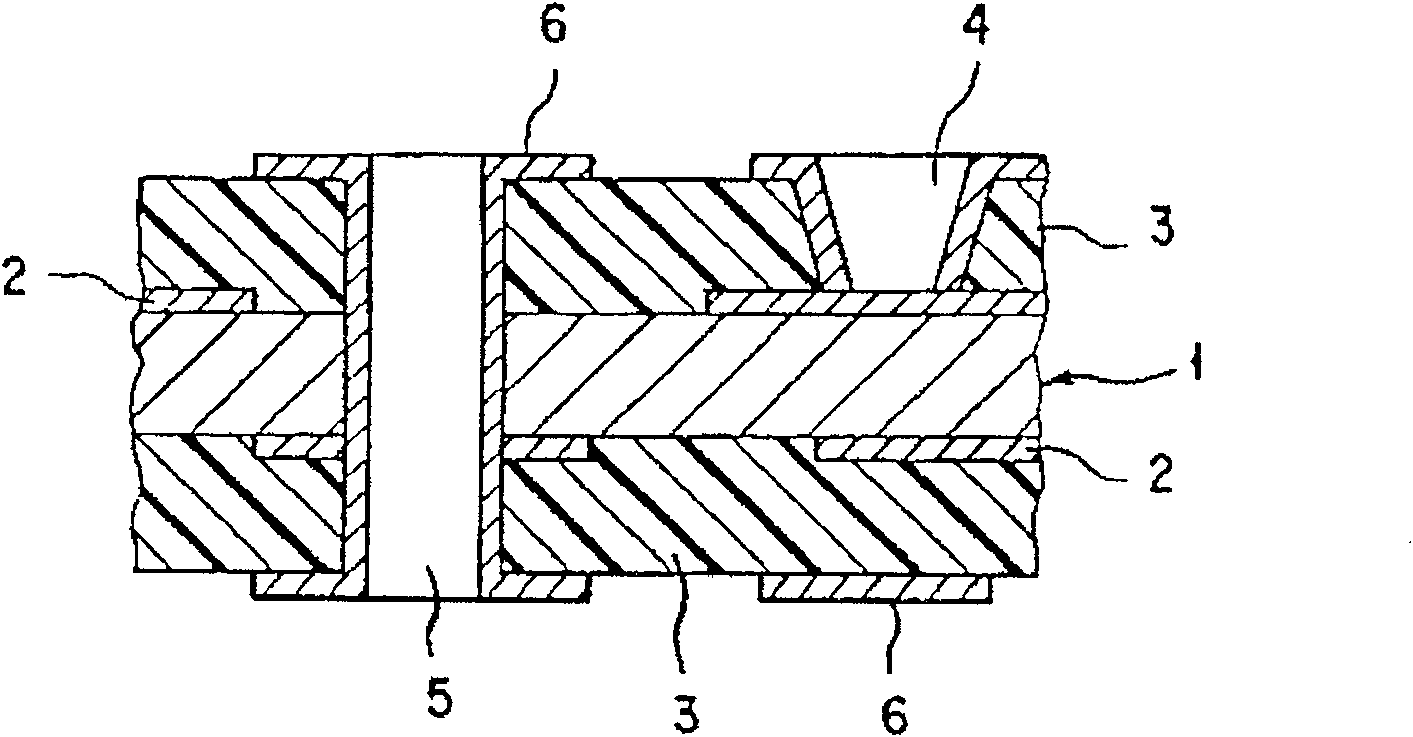

Copper chemical mechanical polishing solutions using sulfonated amphiprotic agents

InactiveUS20050037936A1Simple compositionOther chemical processesSurface-active detergent compositionsSlurry3-aminopropanesulfonic acid

A family of slurries useful in modifying exposed surfaces of wafers for semiconductor fabrication are provided along with methods of modifying exposed surfaces of wafers for semiconductor fabrication utilizing such a family of working slurries, and semiconductor wafers. The slurries of the invention are a solution of initial components, the components comprising: a sulfonated zwitterion selected from 2-(N-Morpholino)ethanesulfonic acid, (3-[N-Morpholino])propanesulfonic acid, 2-[(2-Amino-2-oxoethyl)amino]ethanesulfonic acid, Piperazine-N, N′-bis(2-ethanesulfonic acid), 3-(N-Morpholino)-2-hydroxypropanesulfonic acid, N ,N-Bis(2-hydroxyethyl)-2-aminoethanesulfonic acid, 3-(N-Morpholino)propanesulfonic acid, N-(2-Hydroxyethyl)piperazine-N′-(2-ethanesulfonic acid), N-Tris(hydroxymethyl)methyl-2 aminoethanesulfonic acid, 3-[N ,N-Bis(2-hydroxyethyl)amino]-2-hydroxypropanesulfonic acid, 3-[N -Tris(hydroxymethyl)methylamino)-2-hydroxypropanesulfonic acid, N-(2-hydroxyethyl)piperazine-N′-(2-hydroxypropanesulfonic acid), Piperazine-N ,N′-bis(2-hydroxypropanesulfonic acid), N-(2-Hydroxyethyl)piperazine-N′-(3-propanesulfonic acid), N-Tris(hydroxymethyl)methyl-3-aminopropanesulfonic acid, 3-[(1,1-Dimethy 1-2-hydroxyethyl)amino]-2-hydroxypropanesulfonic, acid, 2-(N-Cyclohexylamino)ethanesulfonic acid, 3-(Cyclohexylamino)-2-hydroxy-I-propanesulfonic acid, 2-Amino-2-methyl-I-propanol, 3-(Cyclohexylamino)-1-propanesulfonic acid, an oxidizing agent; optionally, a passivating agent; optionally a chelating agent, optionally abrasive particles, optionally a surfactant, optionally a secondary buffering agent and water. The method of the invention comprises the steps of: a) providing a wafer comprising a first material having a surface etched to form a pattern and a second material deposited over the surface of the first material; b) contacting the second material of the wafer with abrasive in the presence of the working slurry; and c) relatively moving the wafer or polishing pad or both while the second material is in contact with the slurry and abrasive particles until an exposed surface of the wafer is planar and comprises at least one area of exposed first material and one area of exposed second material.

Owner:ARKEMA INC

Salt form of a human histone methyltransferase ezh2 inhibitor

ActiveUS20150065503A1Inhibits histone methyltransferase activityOrganic active ingredientsOrganic chemistry methodsHydrobromideMorpholine

Provided herein is N-((4,6-dimethyl-2-oxo-1,2-dihydropyridin-3-yl)methyl)-5-(ethyl(tetrahydro-2H-pyran-4-yl)amino)-4-methyl-4′-(morpholinomethyl)-[1,1′-biphenyl]-3-carboxamide hydrobromide. Also provided herein is a particular polymorph form of this compound.

Owner:EISIA R&D MANAGEMENT CO LTD +1

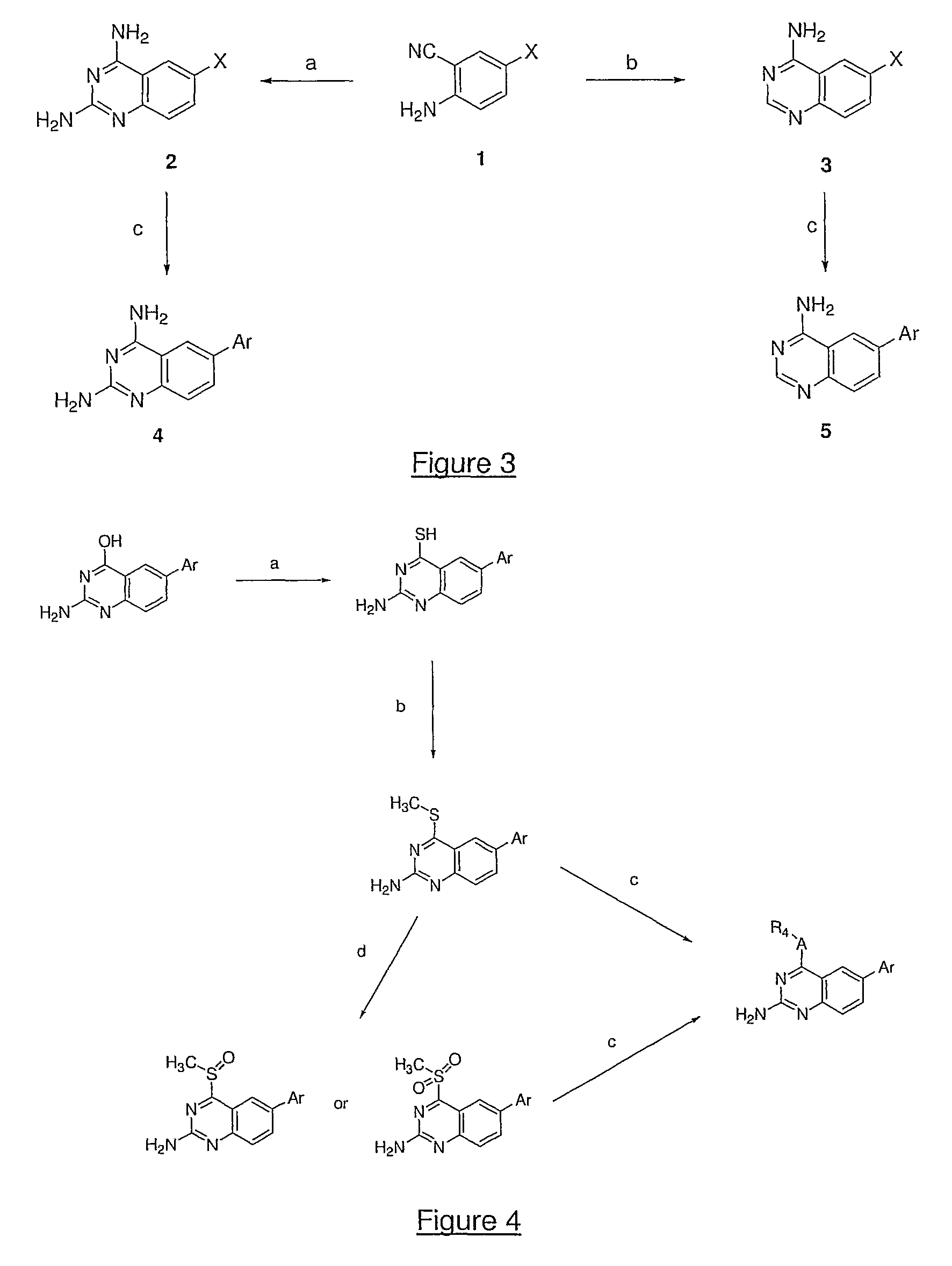

4,6-di- and 2,4,6-trisubstituted quinazoline derivatives useful for treating viral infections

Owner:GILEAD SCI INC

Hair treatment agents containing 4-morpholino-methyl-substituted silicone(s) and conditioning agent(s)

Owner:HENKEL KGAA

Heterocyclic compound and antitumor agent containing the same as effective ingredient

Owner:ZENYAKU KOGYO KK

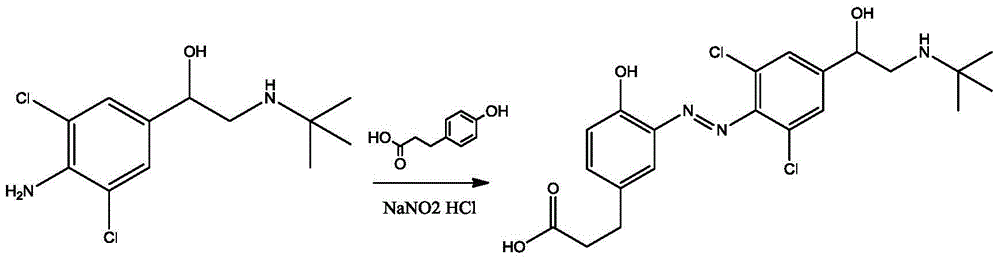

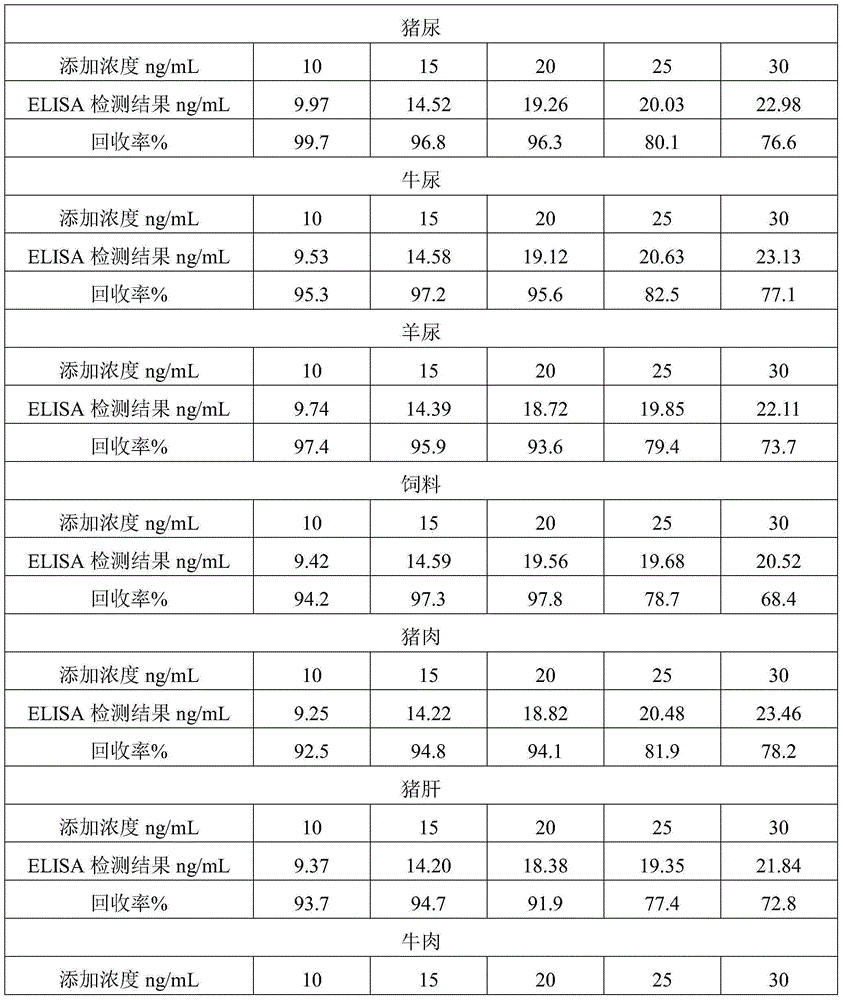

Clenbuterol immunomagnetic bead separation and enrichment kit and application thereof

The invention relates to a clenbuterol immunomagnetic bead separation and enrichment kit. The clenbuterol immunomagnetic bead separation and enrichment kit comprises a magnetic bead which is coupled to a clenbuterol monoclonal antibody, reconstitution fluid and a magnet, wherein the magnetic bead which is coupled to the clenbuterol monoclonal antibody is formed by mixing and dissolving the clenbuterol monoclonal antibody and the magnetic bead in 2-(N-morpholino) ethanesulfonic acid monohydrate in a coupling way according to a mass ratio of 1:(500 to 1000); the clenbuterol monoclonal antibody is obtained by taking a coupling substance obtained from clenbuterol haptin and bovine serum albumin as an immunogen to immune Balb / c mice; the clenbuterol haptin is obtained by carrying out diazo-reaction on clenbuterol and P-hydroxybenzene propanoic acid and bringing a carboxyl spacer arm on amino. The invention also relates to a sample preprocessing method for separating the clenbuterol by adopting the clenbuterol immunomagnetic bead separation and enrichment kit. According to the sample preprocessing method disclosed by the invention, higher specificity, higher recovery rate and higher accuracy on the clenbuterol are obtained, sample preprocessing steps are simplified, and various and a mass of organic solvents can be prevented from being used during a sample preprocessing procedure.

Owner:BEIJING KWINBON BIOTECH

Method and antisense compound for potentiating anti-cancer agents

InactiveUS20050113328A1Increase lethalityEnhance lethality/doseOrganic active ingredientsBiocideCancer cellAnticarcinogen

A method and compound for enhancing the lethality of an anti-cancer therapy, such as radiation, chemotherapy, or TRAIL protein, are disclosed. The compound is composed of morpholino subunits joined by phosphorodiamidate linkages, and has a targeting sequence that is complementary to an AUG start, IRES, or splice-donor region of the transcript for human X-linked inhibitor of apoptosis protein (XIAP). The method includes exposing cancer cells to the compound.

Owner:AVI BIOPHARMA

Modification method for animal skin collagen

InactiveCN101314058AGive full play to efficiencyModification process is simpleSurgeryProsthesisGenipinFreeze-drying

The invention discloses a method for modifying a collagen body of animal skin, which is characterized in that: 100 weight portions of collagen body material is taken and is added into 800 to 2,000 weight portions of 40 to 80v / v percent alcohol solution of 2-N-morpholino ethanesulfonic acid (MES) with a concentration between 20 and 70mmol / L and a pH value between 5.0 and 6.0 or a phosphate buffer solution (PBS) with the pH value between 5.0 and 6.0, the mixture is oscillated for 15 to 60min, then is respectively added with 2 to 30 weight portions of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) and N-hydroxysuccinimide (NHS), is oscillated for 4 to 24h at room temperature to produce a collagen body modification material; or 100 weight portions of the collagen body material is taken, is added into 800 to 2,000 weight portions of the phosphate buffer solution (PBS) with the pH value between 6.0 and 8.0, is oscillated for 15 to 60min, then is added with 3 to 15 weight portions of genipin, and is oscillated for 10 to 24h at a temperature of between 20 and 40 DEG C to produce the collagen body modification material; then a monobasic sodium phosphate solution with the concentration of 0.1mol / L, the phosphate buffer solution with the pH value between 7.2 and 7.4 and double distilled water are orderly used to repeatedly clean the collagen body modification material, each cleaning time is not less than 60min, the cleaning time of each cleaning solution is not less than 3h, and the total cleaning time reaches more than 24h; and finally a modified collagen body material is produced by freeze drying.

Owner:JIANGYIN BENXIANG BIOTECHOLOGY

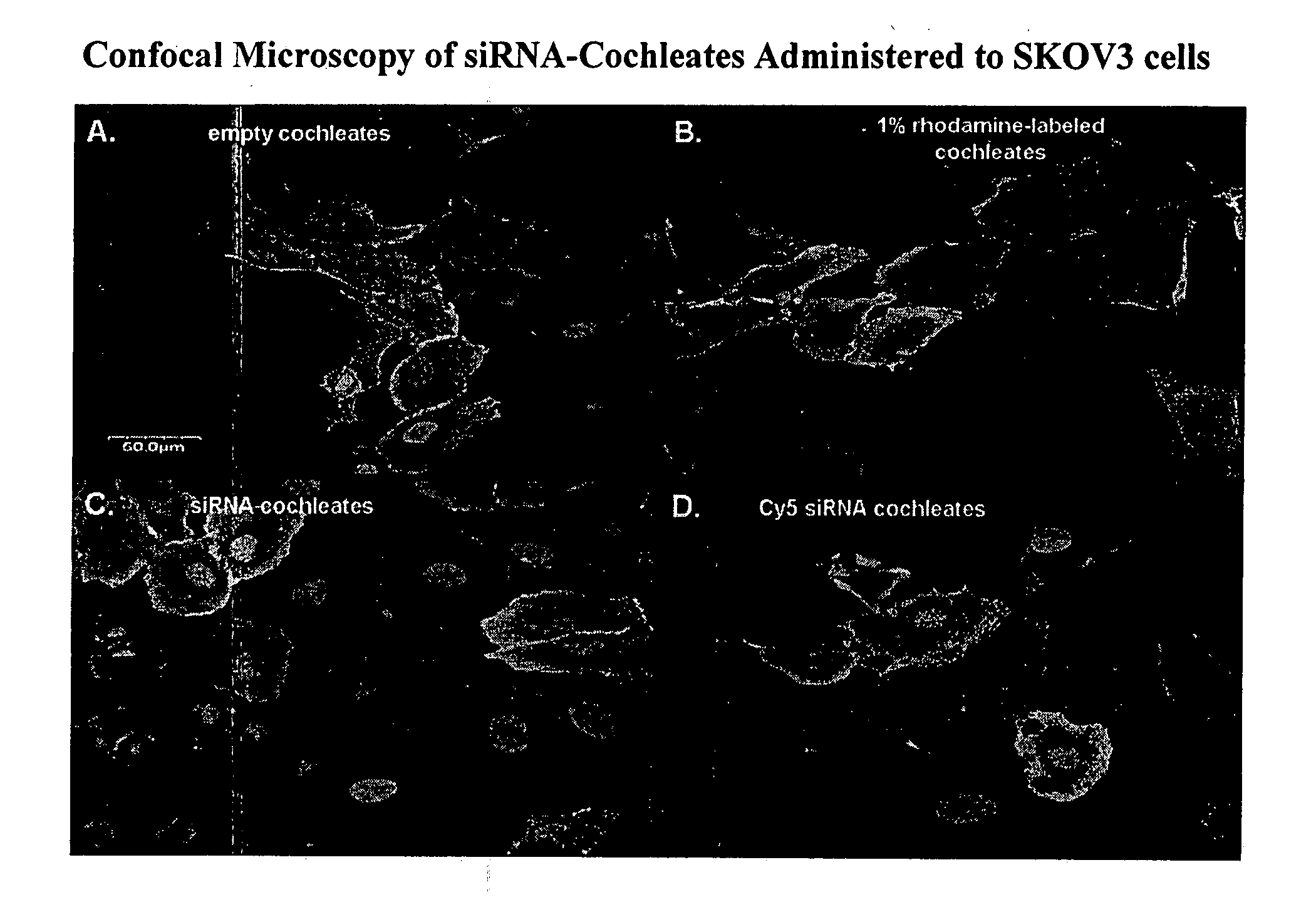

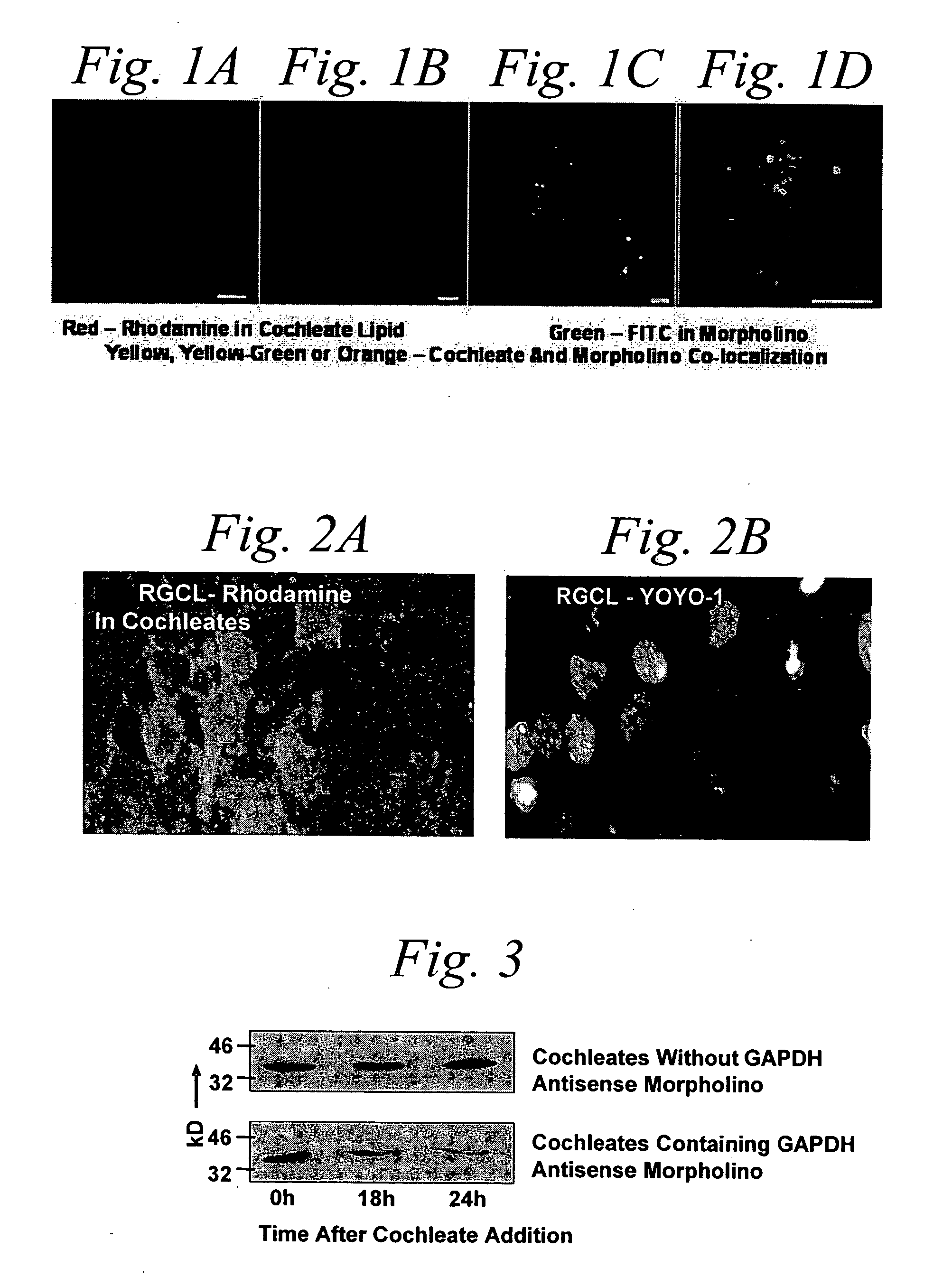

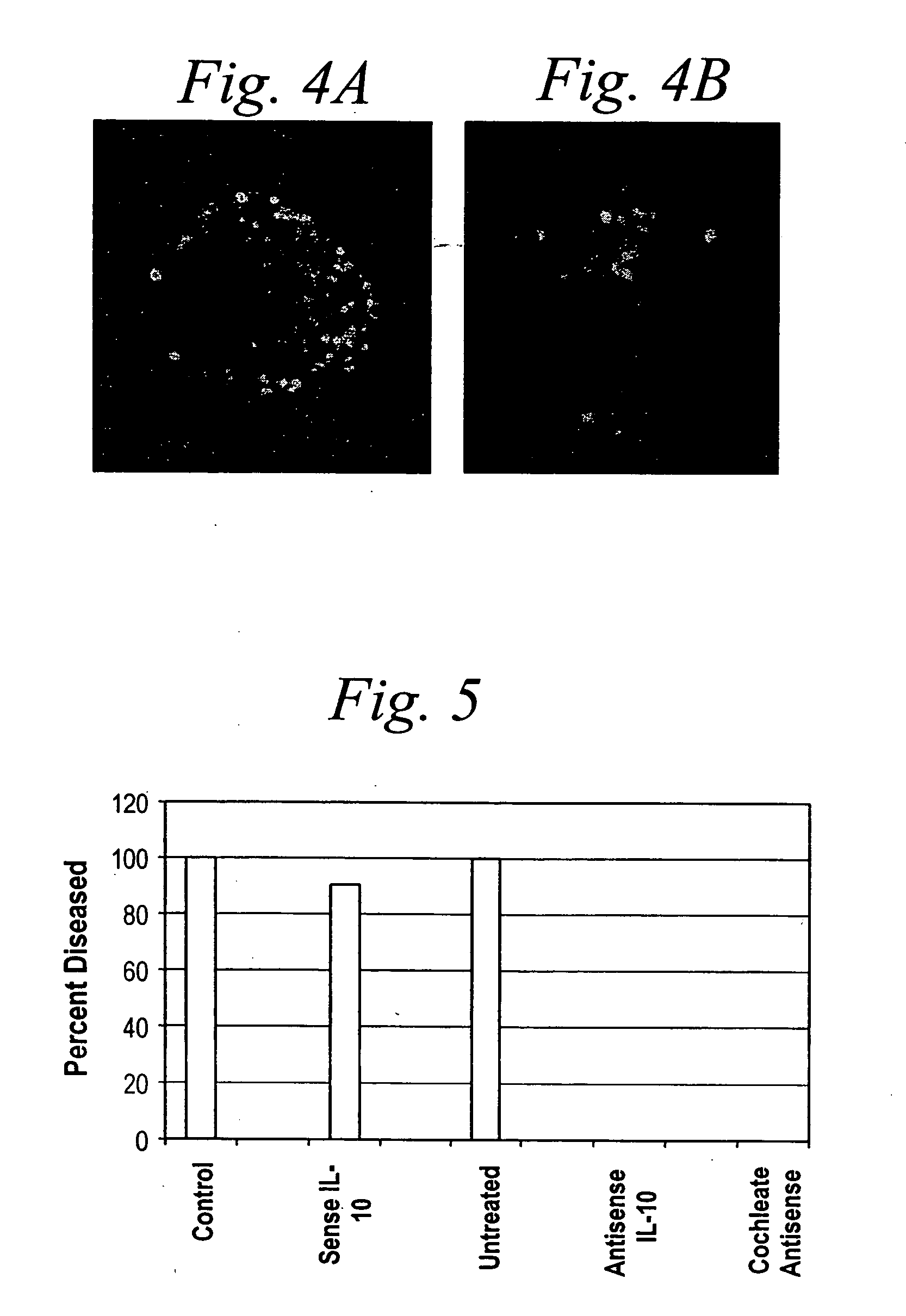

Cochleate compositions directed against expression of proteins

InactiveUS20080009457A1Quick and efficientRetain efficacyAntibacterial agentsOrganic active ingredientsMorpholino OligosMolecular biology

Disclosed herein are novel siRNA-cochleate and morpholino-cochleate compositions. Also disclosed are methods of making and using siRNA-cochleate and morpholino-cochleate compositions.

Owner:BIODELIVERY SCI +1

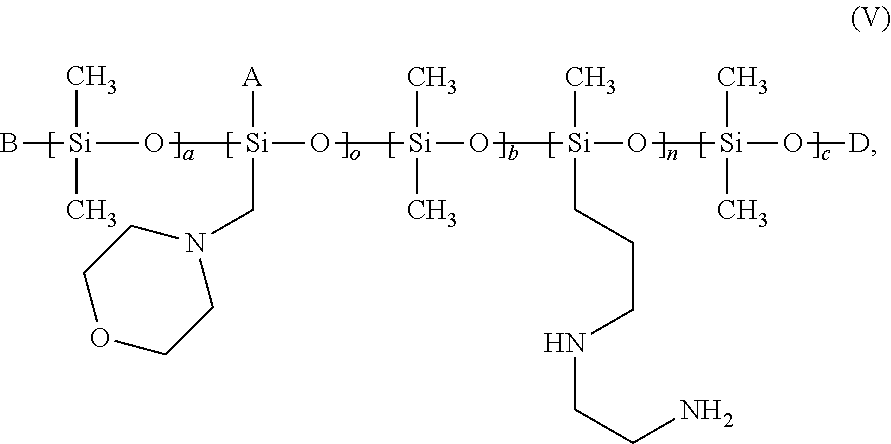

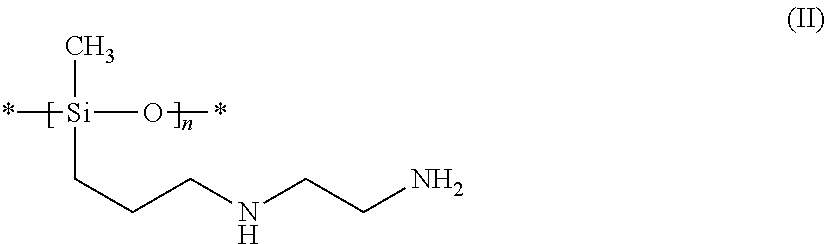

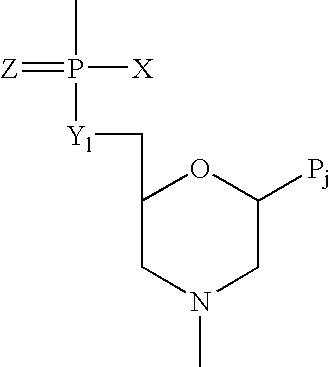

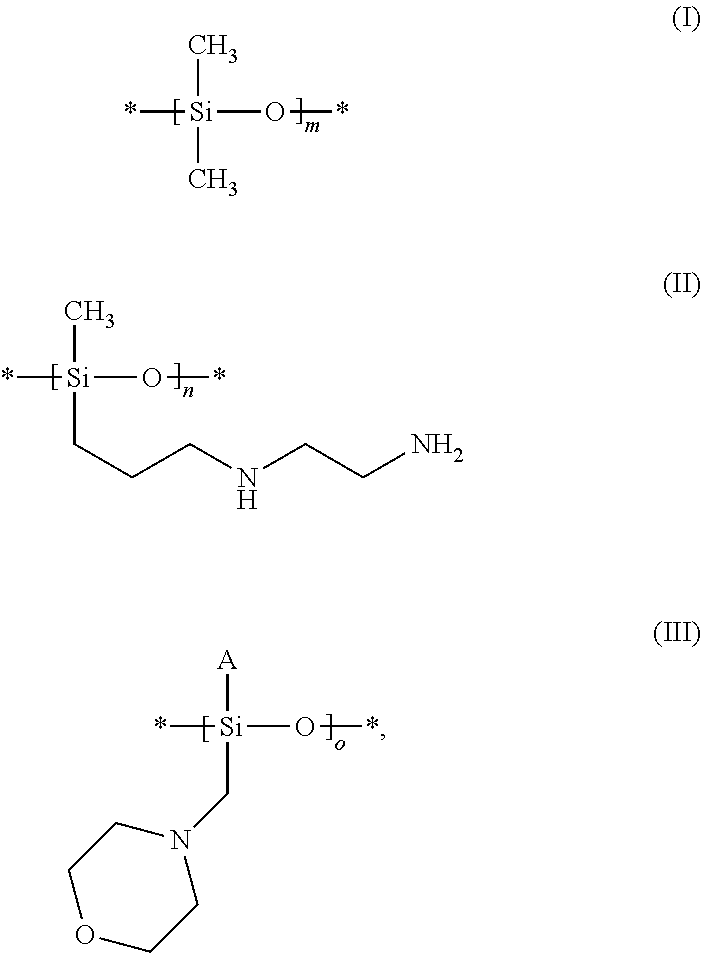

Pretreatment agents for keratin fibers comprising 4-morpholino-methyl-substituted silicone(s)

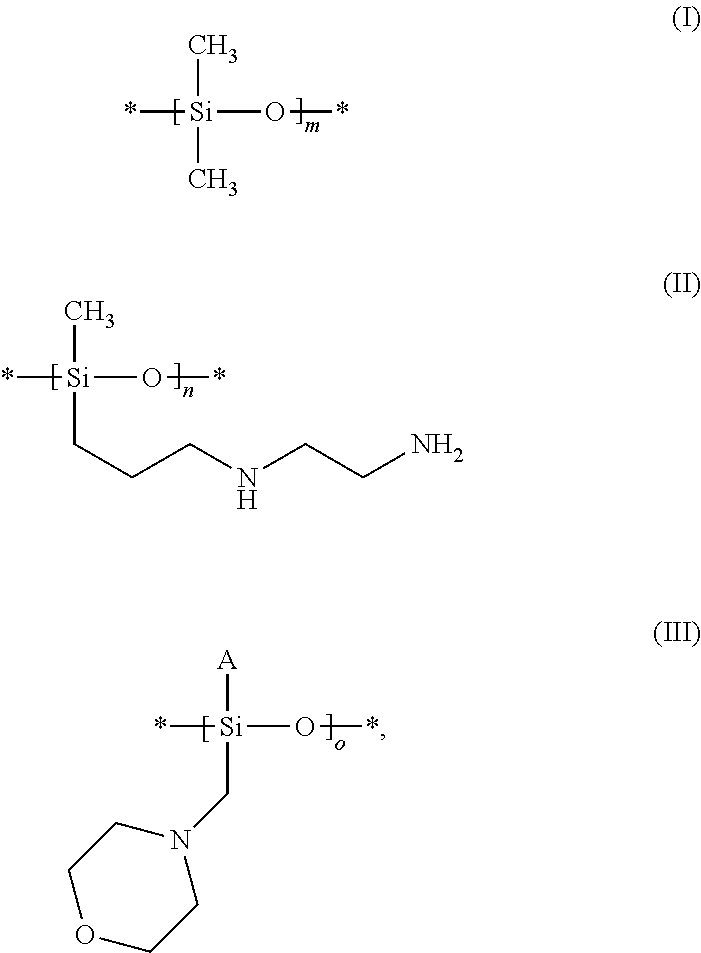

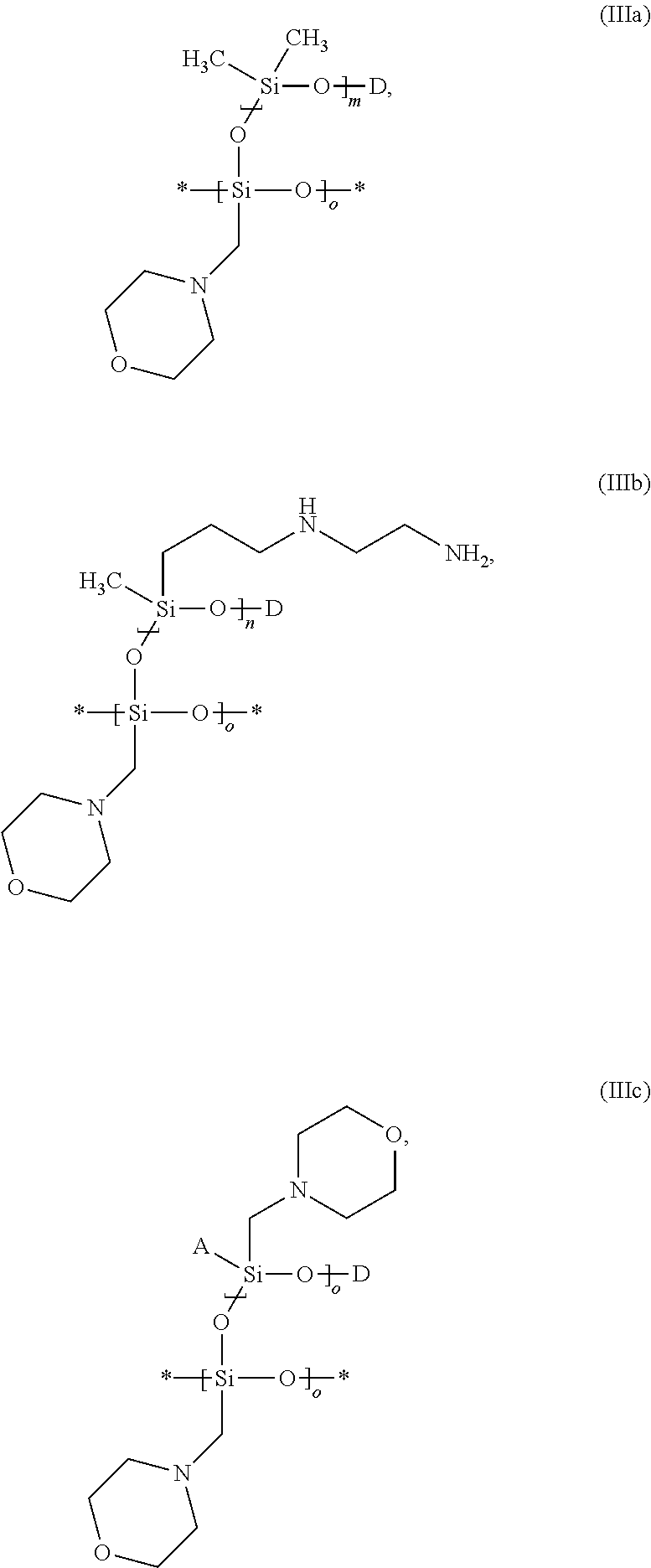

The invention relates to pretreatment agents for keratin fibers, which include, based on its weight, 0.00001 to 10 wt. % of at least one 4-morpholino-methyl-substituted silicone, which includes in each case at least one of the structural units of the formulae (I), (II) and (III) described herein, wherein * represents a bond to one of the structural units (I), (II) or (III) or an end group B (Si-bound) or D (O-bound); B represents a group —OH, —O—Si(CH3)3, —O—Si(CH3)2OH, —O—Si(CH3)2OCH3; D represents a group —H; —Si(CH3)3, —Si(CH3)2OH, —Si(CH3)2OCH3; A represents an O-bound structural unit (I), (II) or (III) or a O-bound oligomeric or polymeric radical including structural units of the formulae (I), (II) or (III) or half of a connecting O atom to a structural unit (III) or represents —OH; n, m and o represent whole numbers between 1 and 1000 and include at least 50 wt. % of water.

Owner:HENKEL KGAA

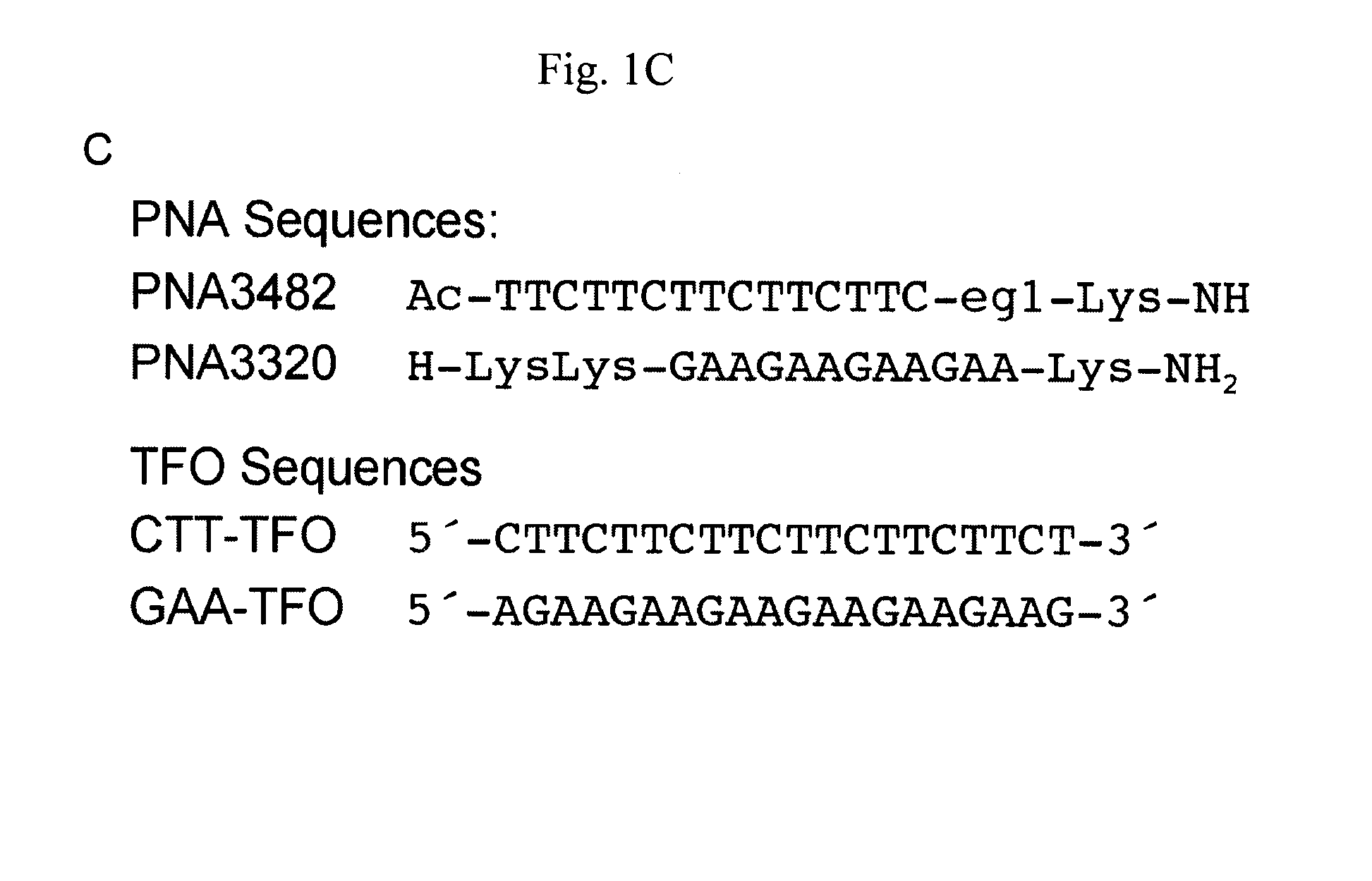

Diagnosis and treatment of friedreich's ataxia

ActiveUS20140128455A1Increased target affinityImproved strand displacementOrganic active ingredientsNervous disorderNucleotideNucleic acid sequencing

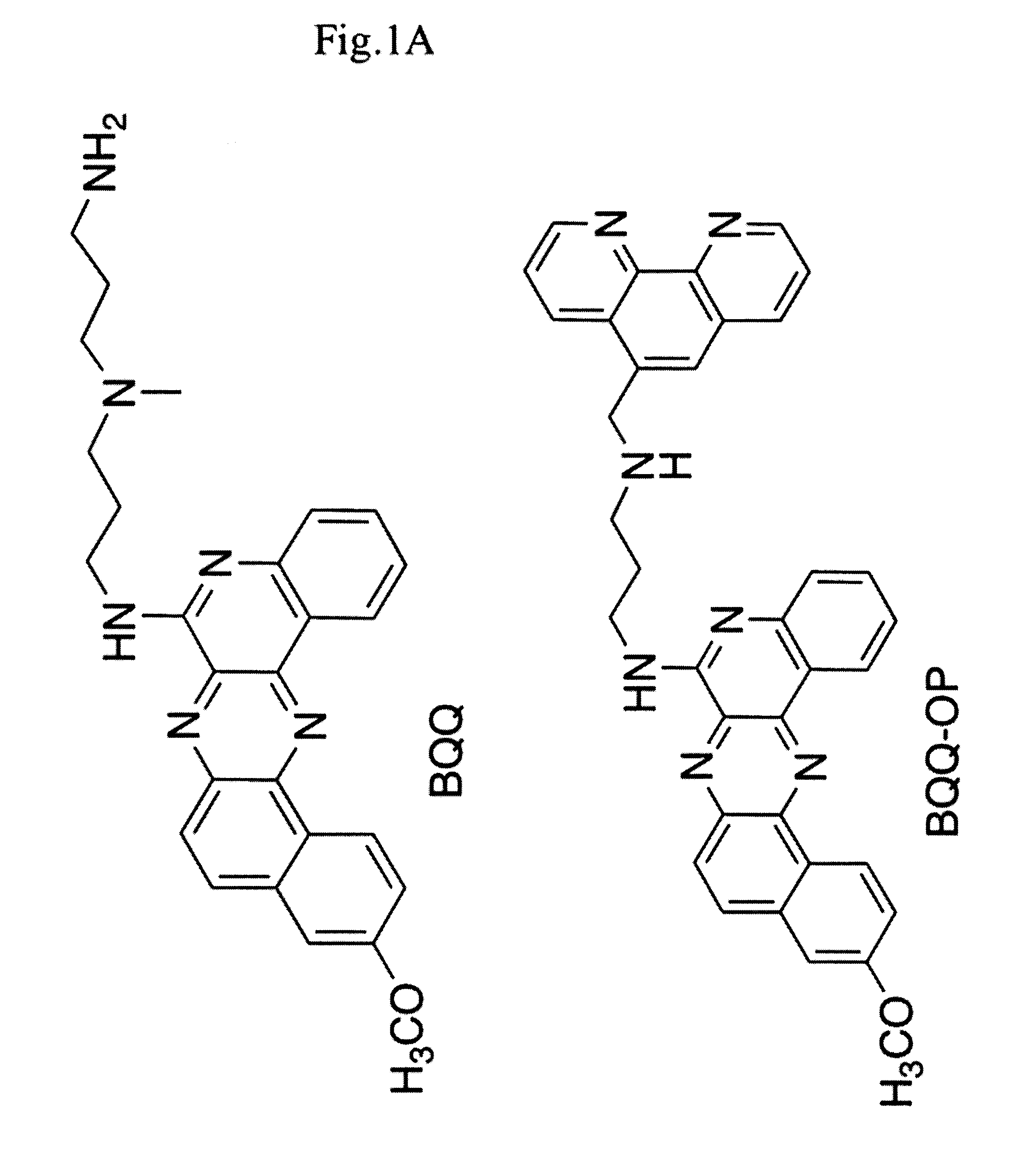

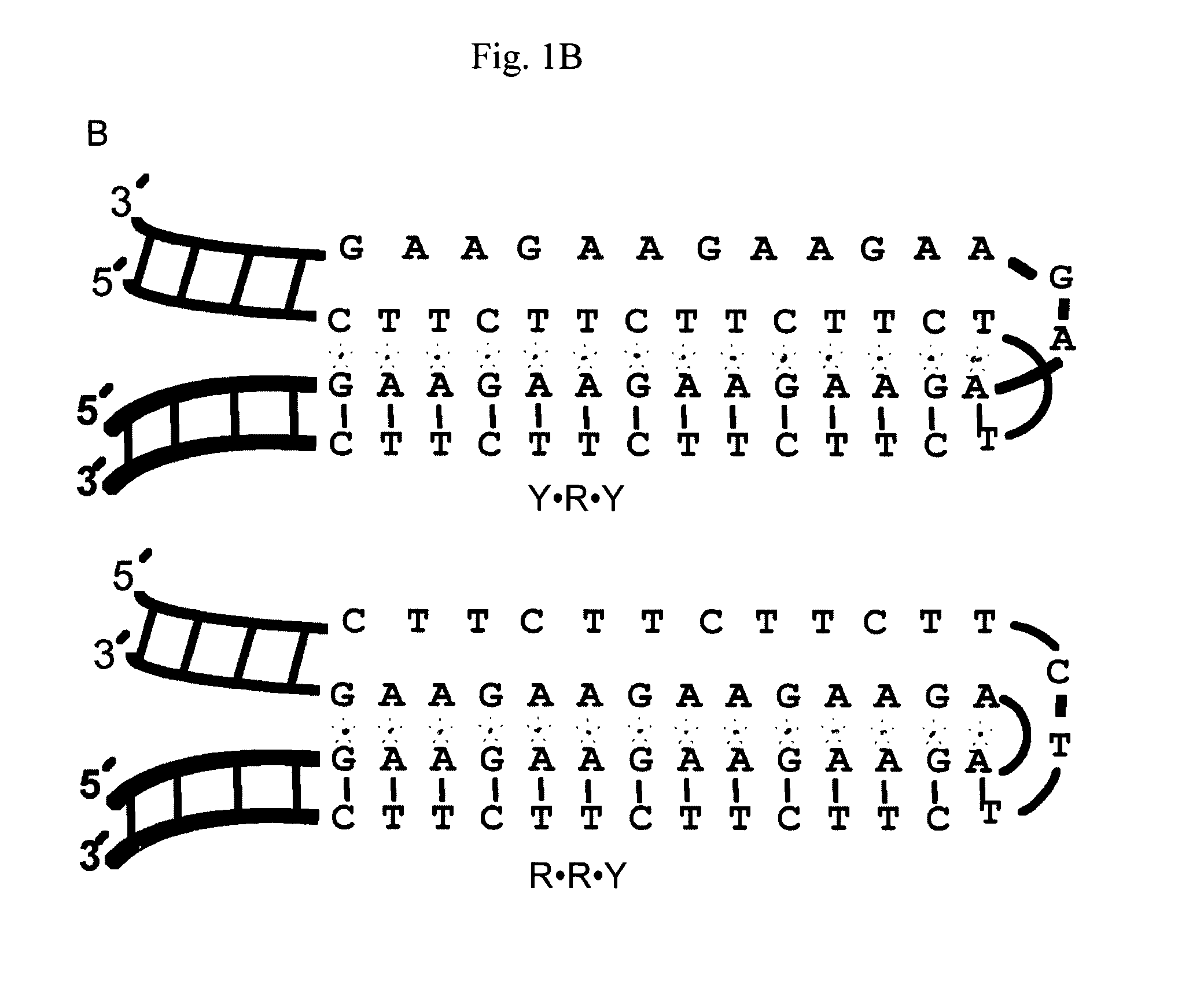

The present invention is directed to oligonucleotides based on peptide nucleic acid oligonucleotide or an equivalent oligonucleotide analogue, such as morpholino or a locked nucleic acid sequences and the use of such oligonucleotides for the dissociation of higher order structures, including triplex-helix DNA structures, in repeated sequences of DNA in Friedreich's ataxia. The dissociation of such structures may be used in the diagnosis and / or treatment of Friedreich's ataxia. Consequently, the present invention is also directed to a method for diagnosing Friedreich's ataxia and the use of peptide nucleic acid oligonucleotide or an equivalent oligonucleotide analogue, such as morpholino or a locked nucleic acid sequences in the treatment of Friedreich's ataxia. Preferably, the oligonucleotides comprise a sequence selected from the group consisting of (GAA)n, (CTT)n, (JTT)n or a mixed (JTT / CTT)n sequence.

Owner:ZAIN LUQMAN RULA

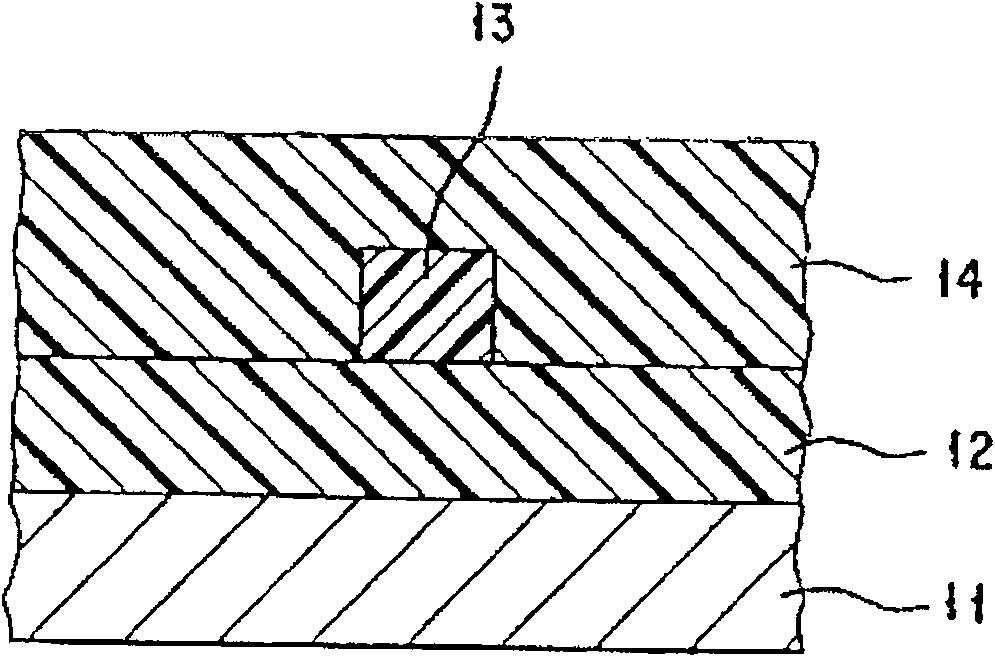

Photocurable/thermosetting resin composition and cured product thereof

ActiveCN100569825CGood light curing effectReduce usageOptical waveguide light guidePhotosensitive materials for photomechanical apparatusCarboxyl radicalUV curing

Owner:TAIYO HLDG CO LTD

Method and antisense composition for selective inhibition of HIV infection in hematopoietic cells

The invention provides antisense antiviral compounds and methods of their use in inhibition of growth of human immunodeficiency virus-1 (HOV-1), as in treatment of a viral infection. The antisense antiviral compounds have morpholino subunits linked by uncharged phosphorodiamidate linkages interspersed with cationic phosphorodiamidate linkages. An exemplary embodiment of the invention provides an antisense compound directed to the HIV Vif gene, causing the production of defective HIV- 1 virions in an infected individual.

Owner:AVI BIOPHARMA

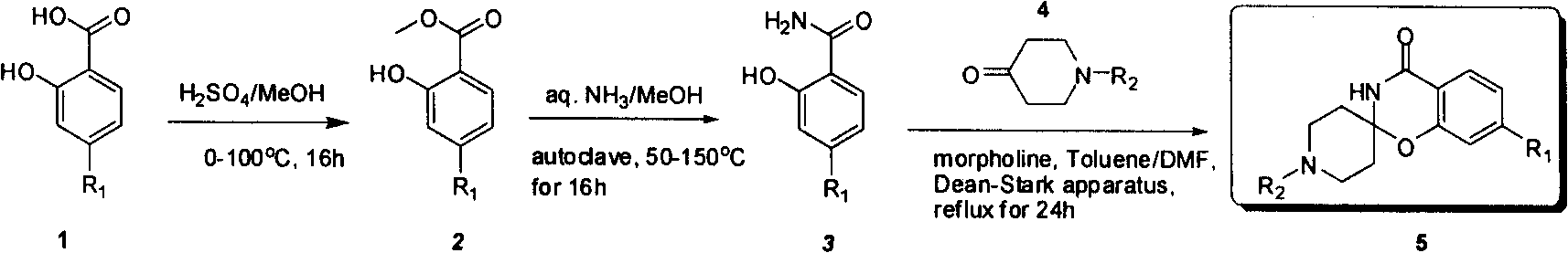

Industrial compounding method of mule (benzo (e) (1,3) oxazine-2, 4'-piperidine)-4(3H)-ketonic

ActiveCN101550143AReasonable choice of reaction processReaction is easy to controlOrganic chemistryState of artBenzene

Owner:上海药明康德新药开发有限公司 +1

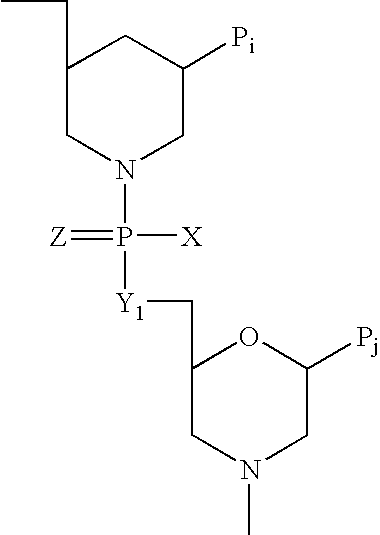

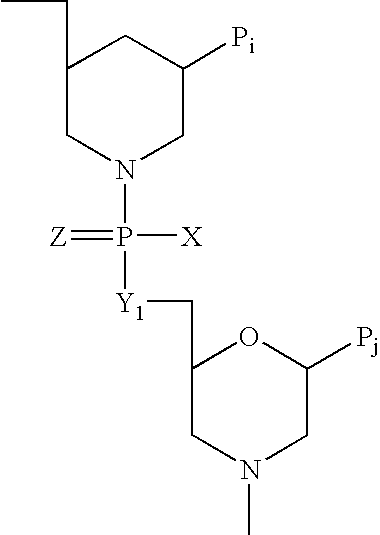

Morpholinyl and pyrrolidinyl analogs

Owner:GLAXO SMITHKLINE LLC

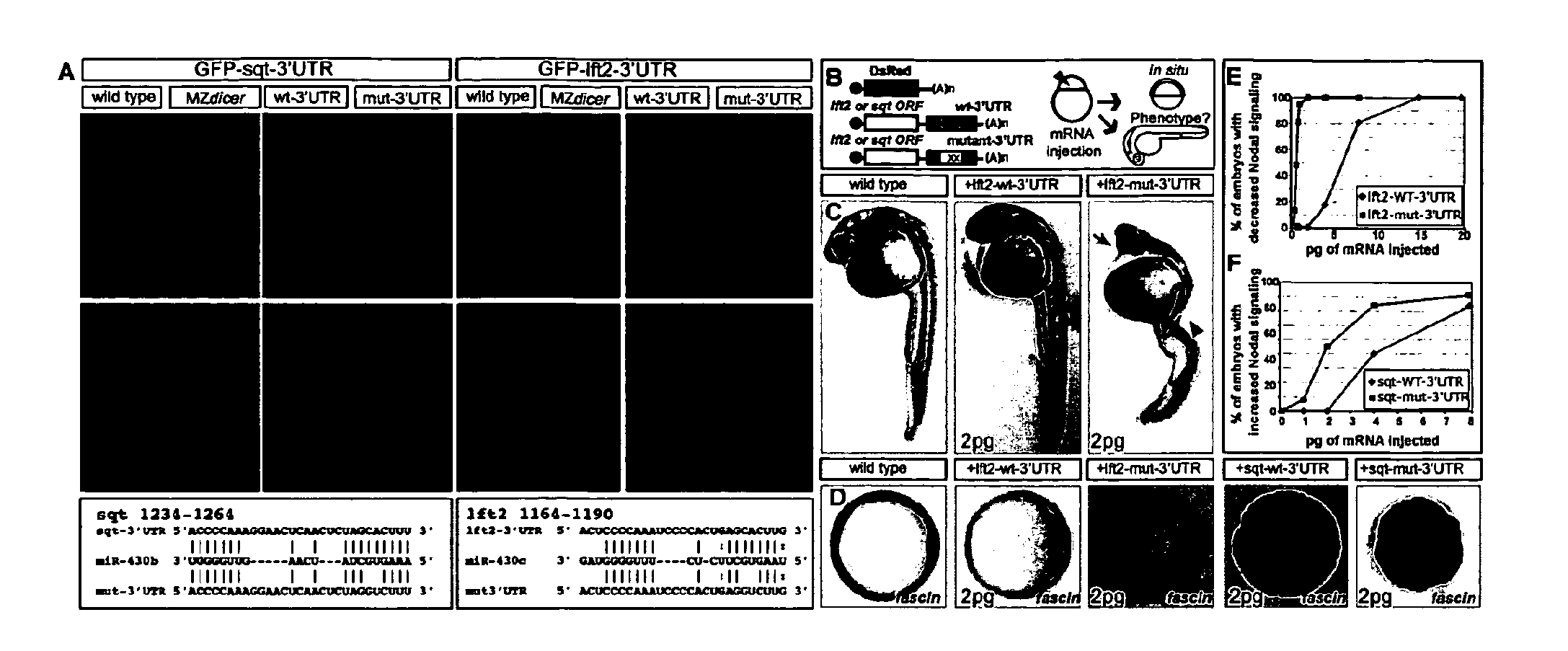

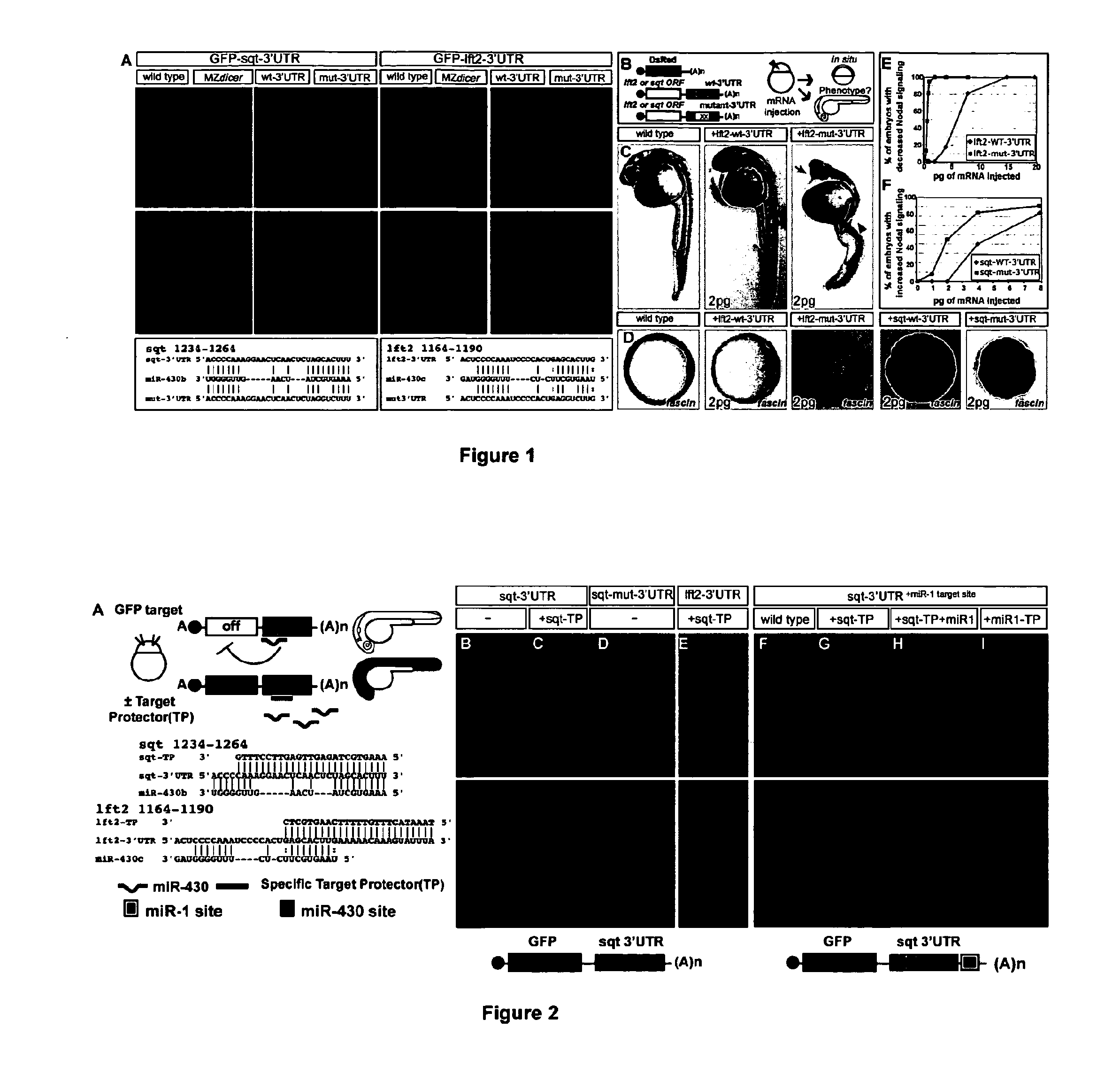

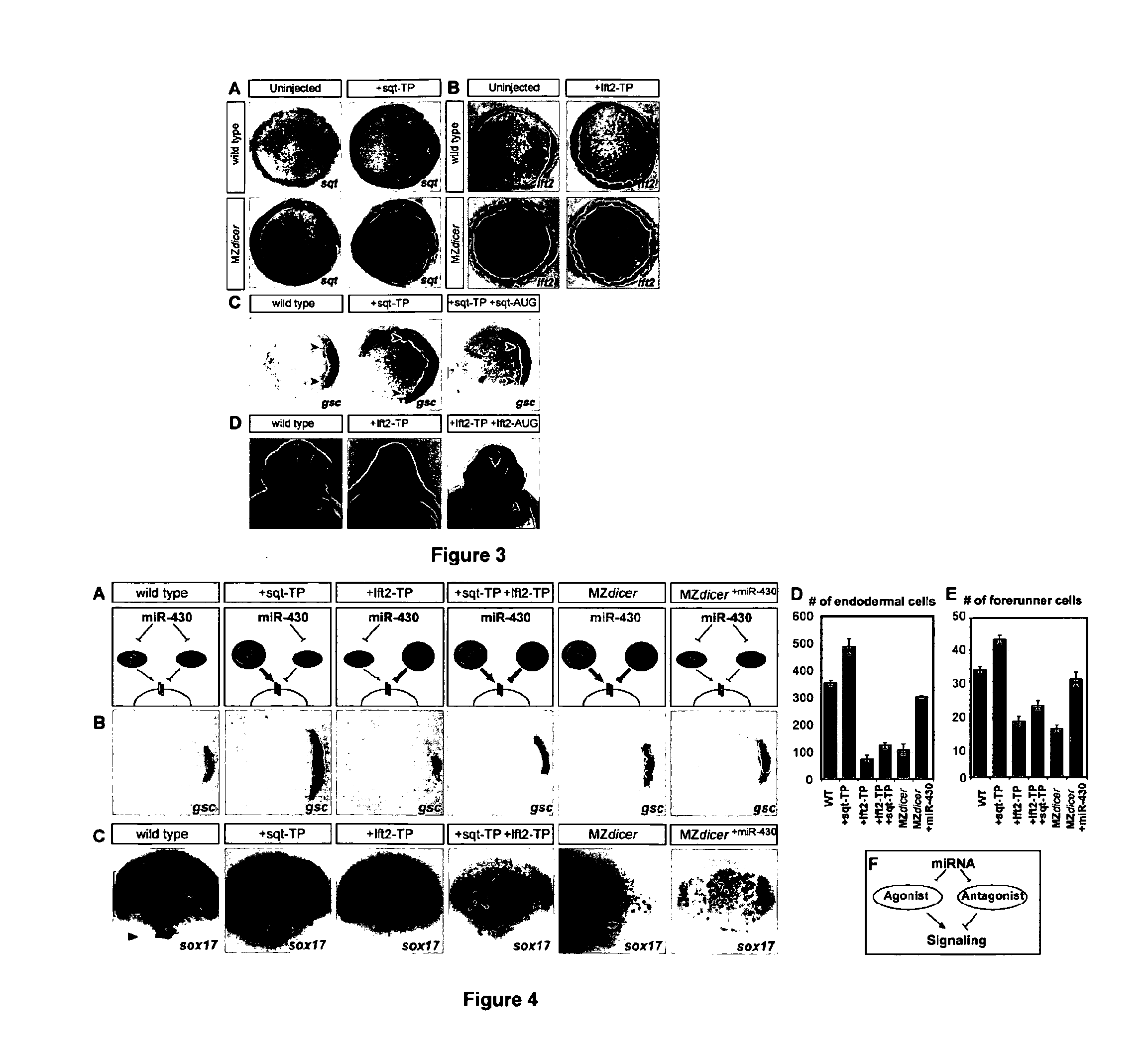

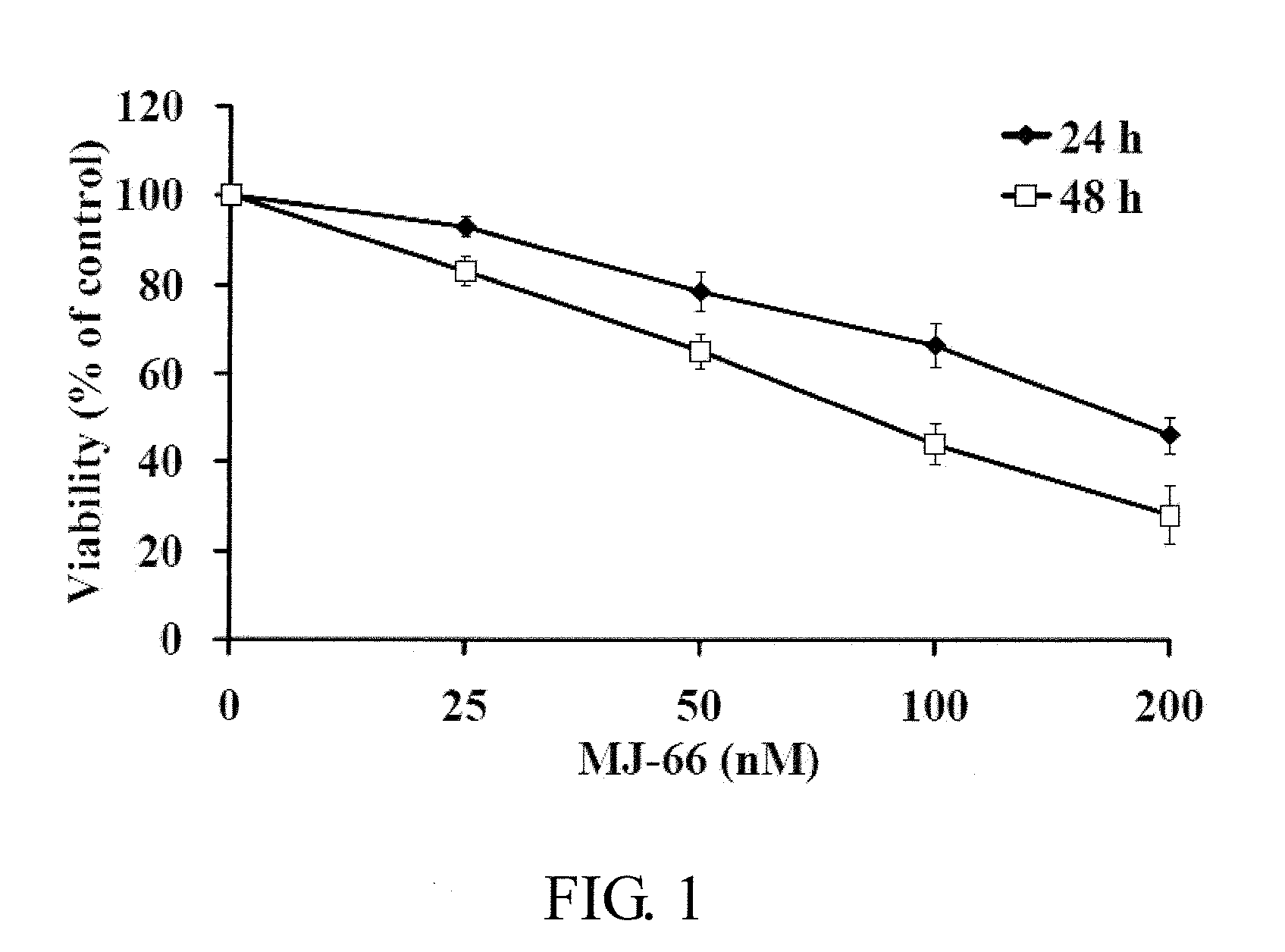

Methods of increasing gene expression through RNA protection

InactiveUS20110009466A1Increase gene expressionHigh expressionOrganic active ingredientsTissue cultureTarget mrnaHuman patient

This invention relates to the use of one or more RNA target protectors to inhibit the binding of an RNA, e.g., small RNA, to a target RNA (e.g., a target mRNA), thus increasing the stability of the target RNA and its function (e.g., increasing the gene expression of the gene corresponding to a target mRNA). An RNA target protector may be, for example, an oligonucleotide, e.g., a morpholino, or a small molecule. The invention further relates to the treatment of a human patient in need thereof with one or more RNA target protectors.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

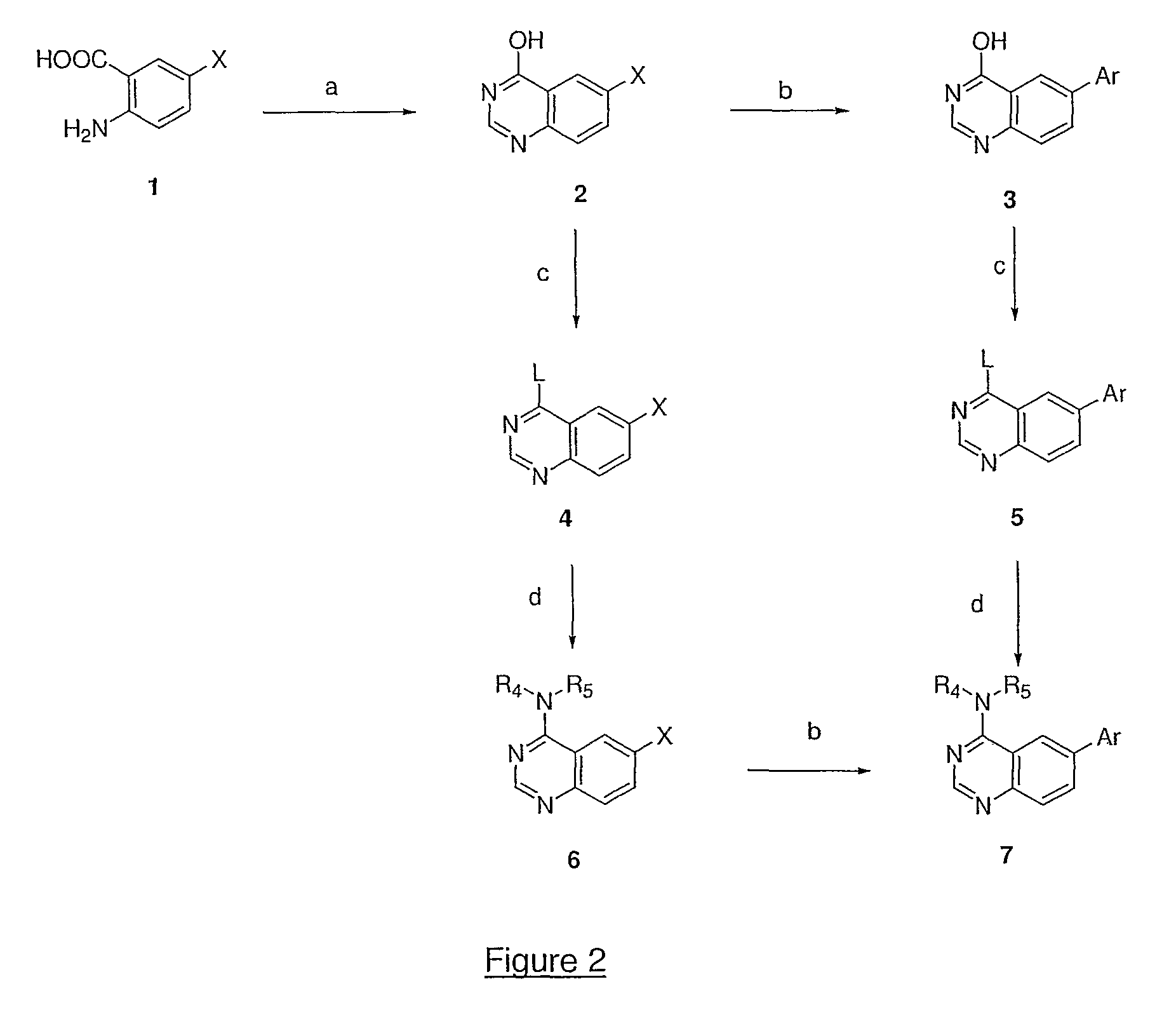

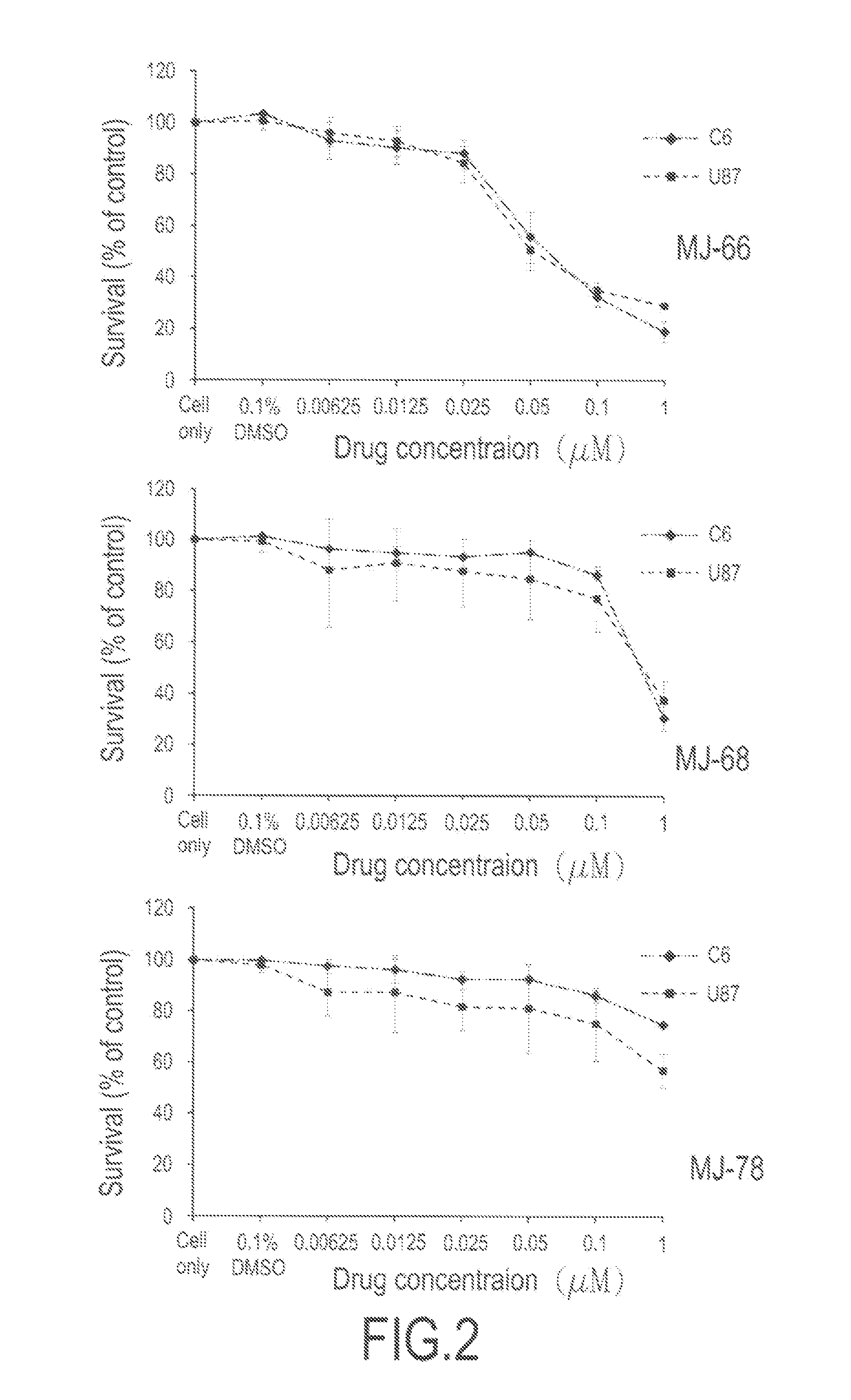

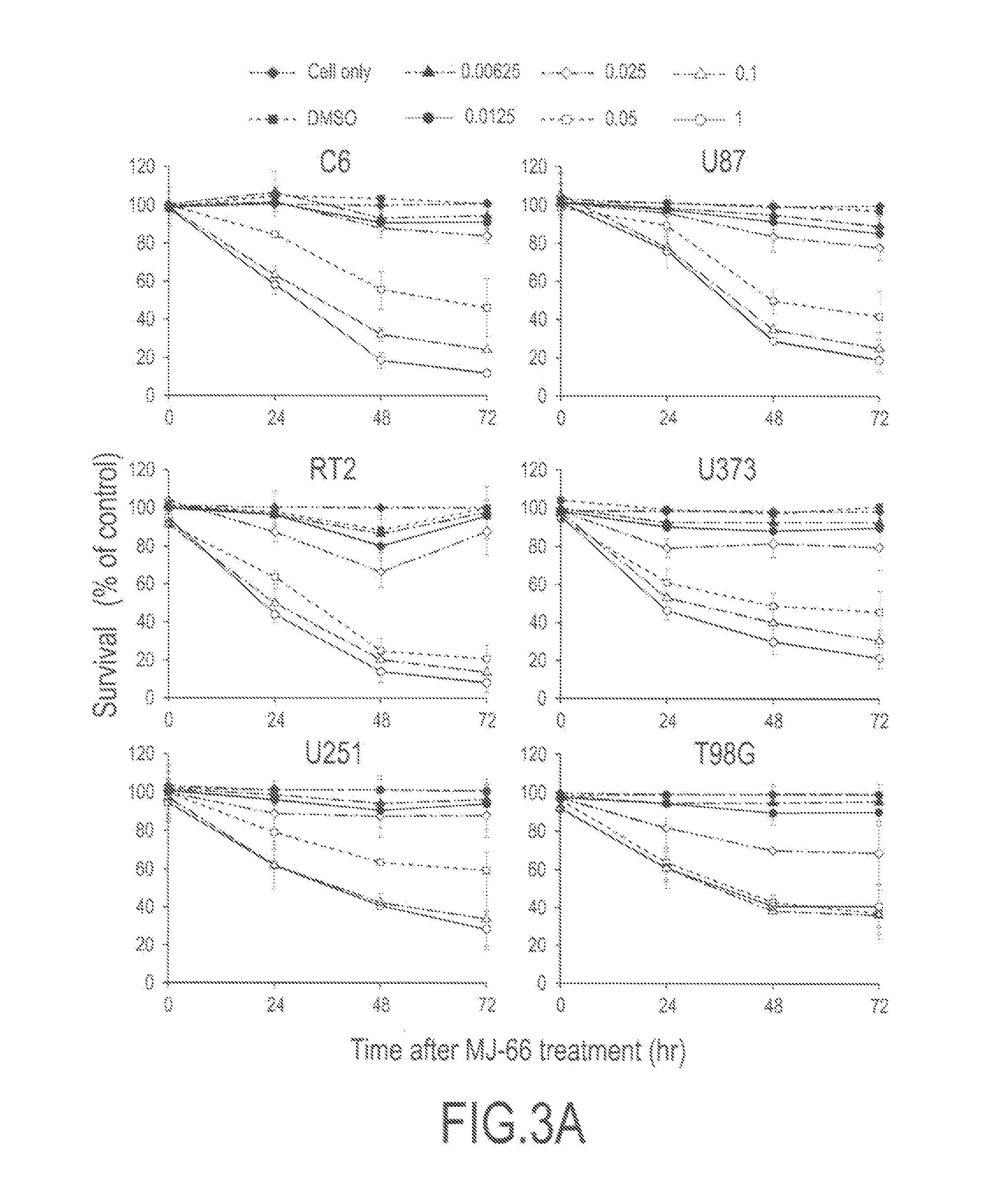

2-Aryl-4-Quinazolinones And Their Pharmaceutical Compositions

Provided is a compound of the formula I or a pharmaceutically acceptable salt, solvate or stereoisomer thereof:wherein Ar representsR5, R6, R7, R8, R1′, R2′, R3′, R4′, R5′, R6′, R7′, R8′ independently represent H, OH, F, Cl, Br, C1 to C6 alkyl group, C1 to C6 alkoxy group, C2 to C6 alkenyl group, C2 to C6 alkenoxy group, C2 to C6 alkynyl group, C2 to C6 alkynoxy group, amine group, mono- or di-substituted amino group, cyclic C1 to C5 alkylamino group, imidazolyl group, morpholino group, piperazinyl group, optionally substituted with one or more hydroxy or halo; and X represents NH, O or S. The present invention also provides a composition comprising the compound of formula I. The compound and the composition in accordance with the present invention are effective on treating or alleviating a disease or disorder, such as malignant glioma.

Owner:CHINA MEDICAL UNIVERSITY(TW)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com