Patents

Literature

42results about How to "Good light curing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

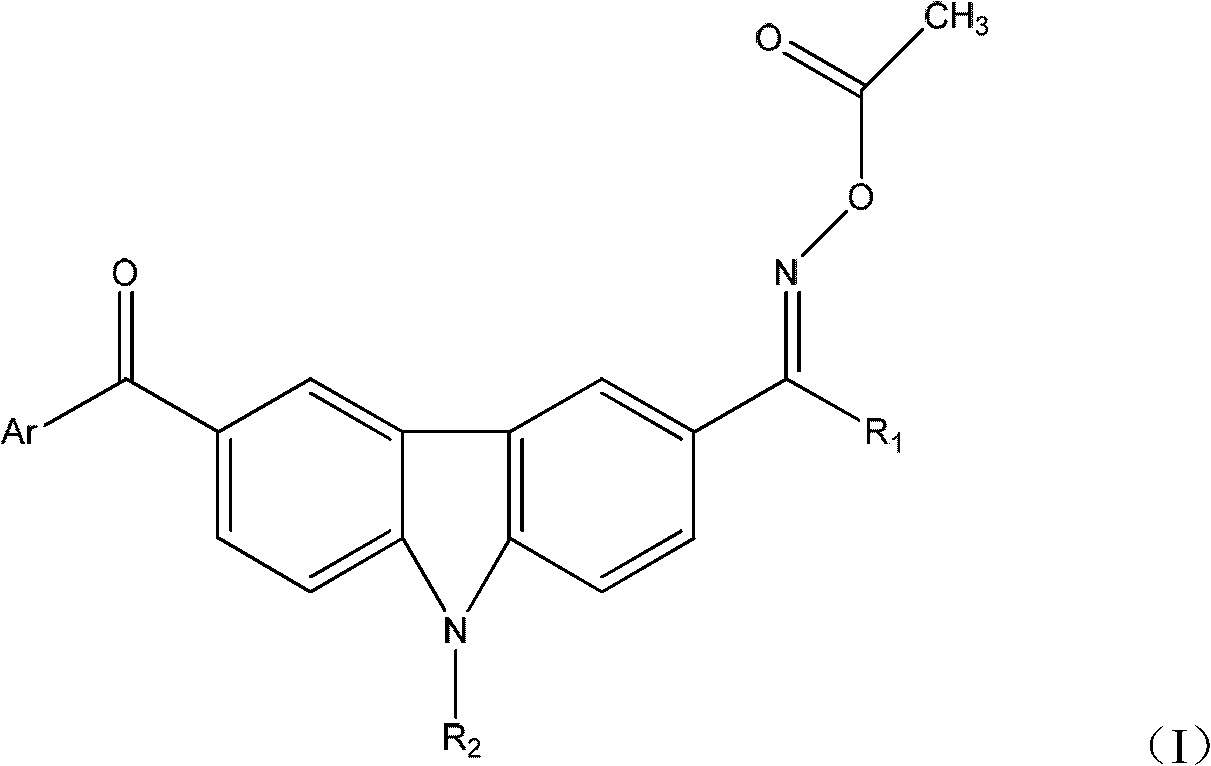

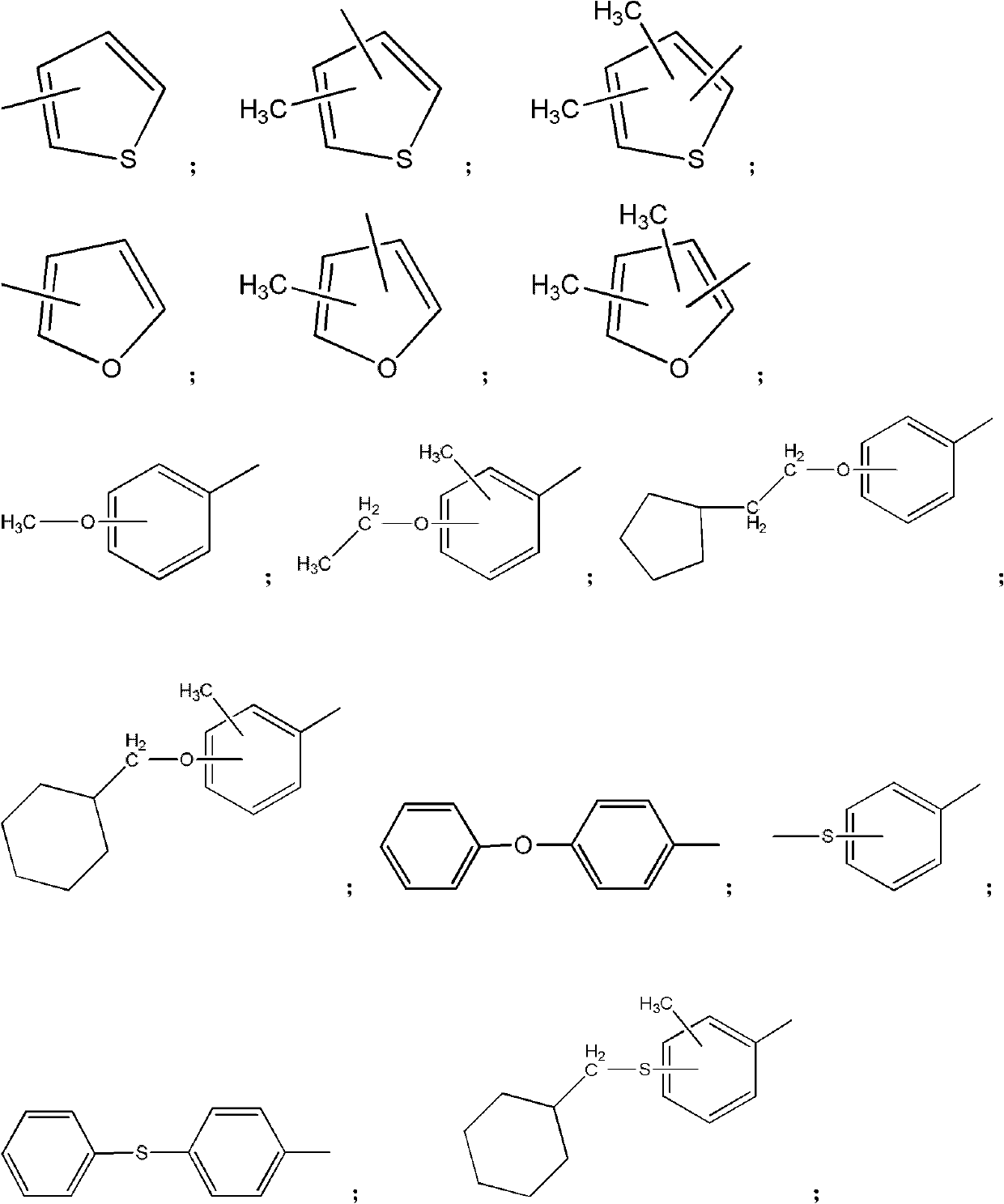

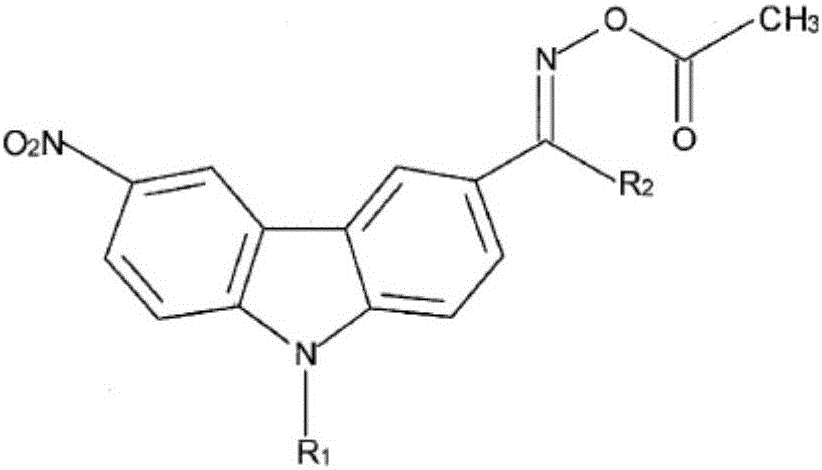

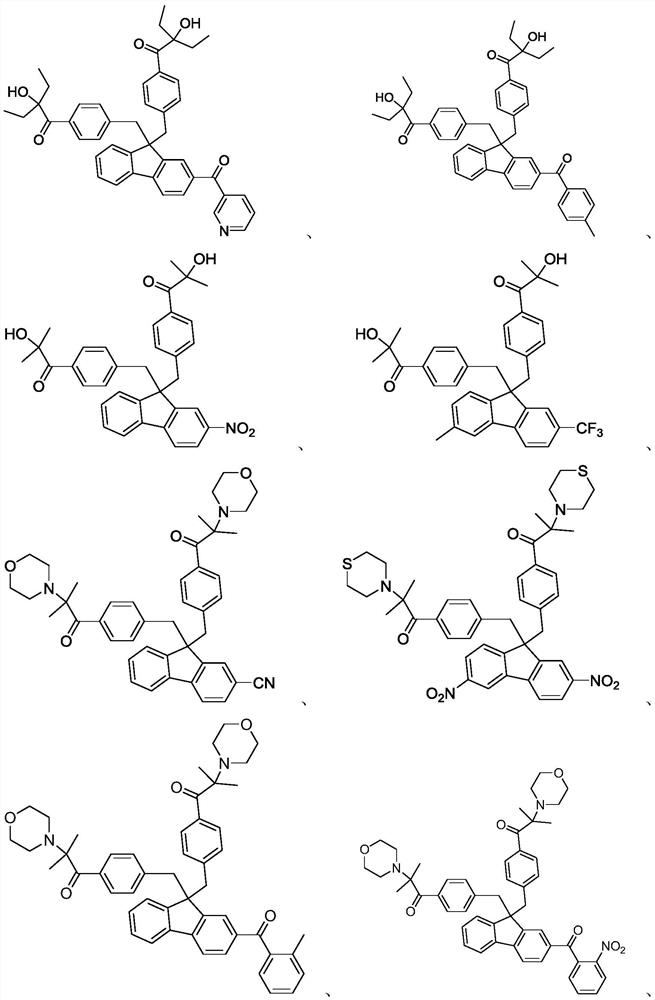

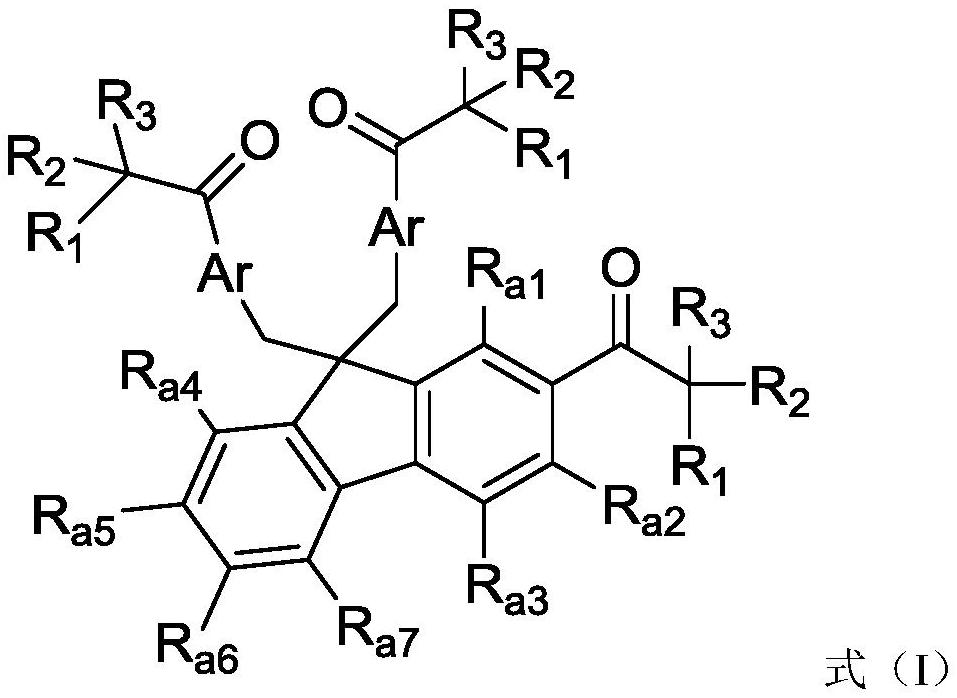

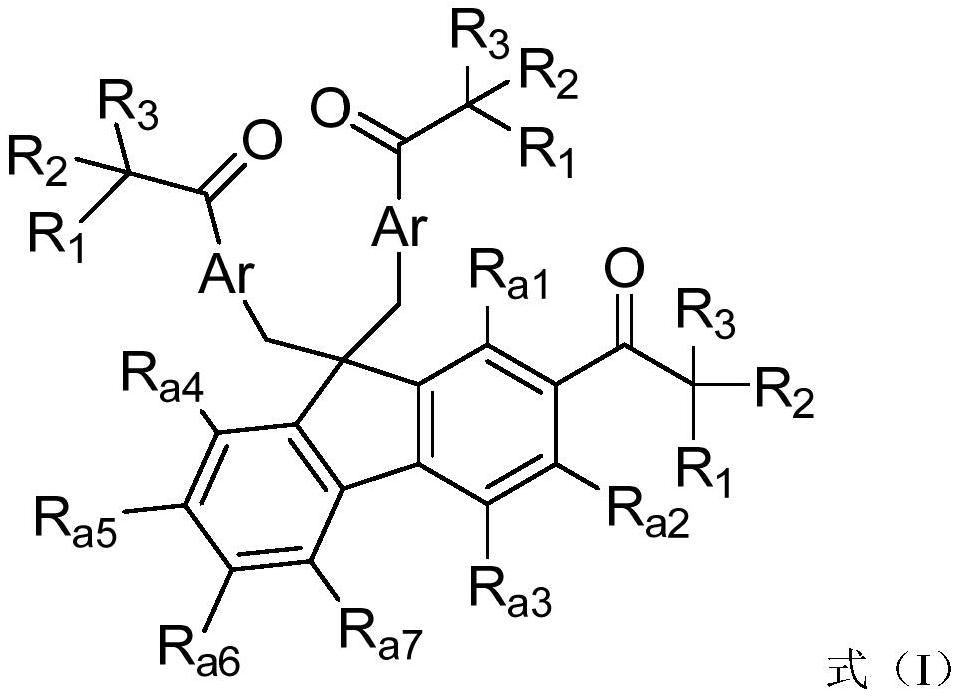

Pyrazole oxime ester photoinitiator with high photosensibility, preparation method and application thereof

ActiveCN102020727AImprove applicabilityHigh photosensitivityOrganic chemistryPhotosensitive materials for photomechanical apparatusColor gelPhotoinitiator

The invention relates to a pyrazole oxime ester photoinitiator with a chemical formula (I). The photoinitiator has excellent application performance and extremely high photographic performance, can greatly improve the photocuring performance when being applied to photosensitive compositions and remarkably improve the production efficiency of the photosensitive compositions in the application fields, such as the preparation of color filters, and the like. The invention also relates to a preparation method of the pyrazole oxime ester photoinitiator and the application of the pyrazole oxime ester photoinitiator to the photosensitive compositions.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD

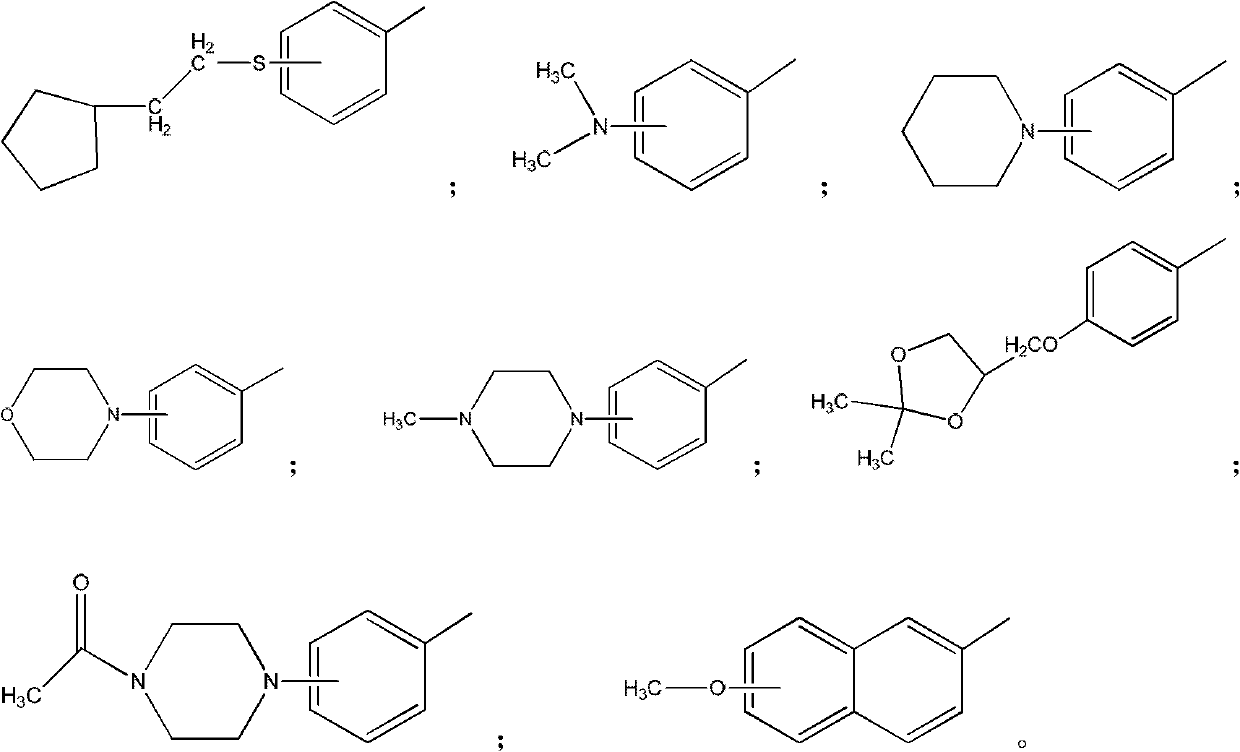

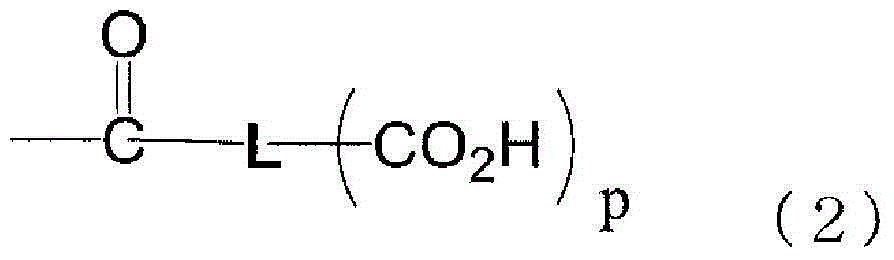

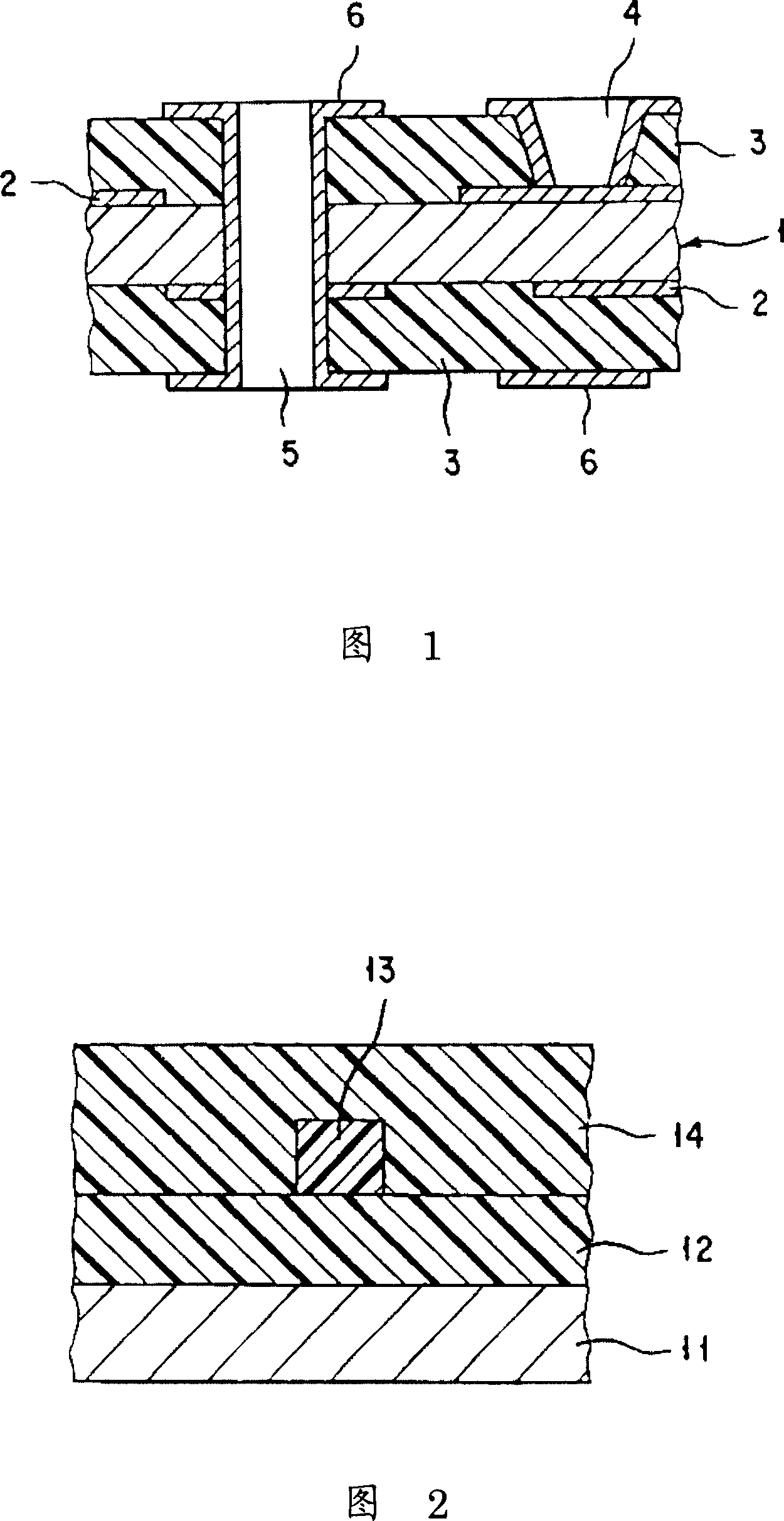

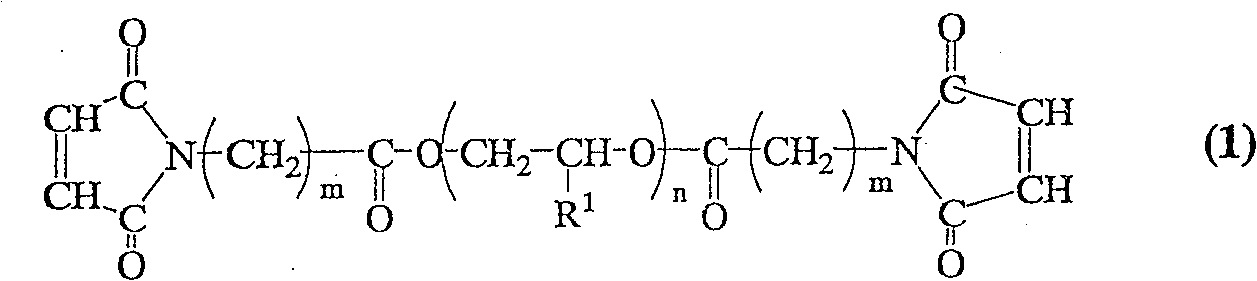

Photosensitive resin composition and cured substance for insulating film

ActiveCN104062849AGood dimensional stabilityImprove patiencePhotosensitive materials for photomechanical apparatusPolymer chemistryChemical resistance

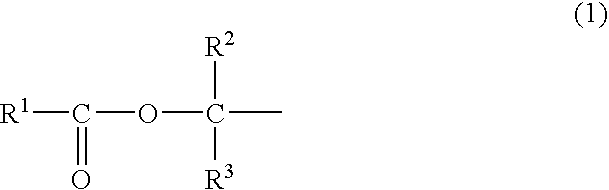

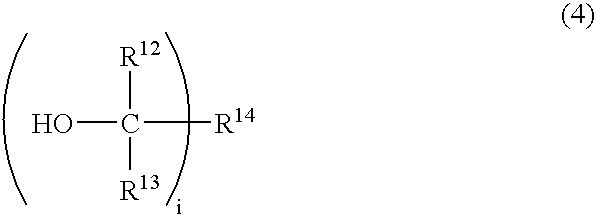

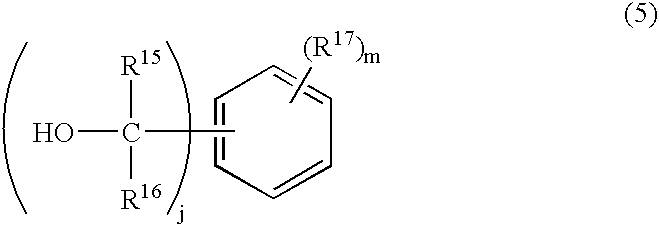

The invention provides a photosensitive resin composition for an insulating film. The photosensitive resin composition is advantaged by high sensitivity, high resolution, high reliability and excellent chemical resistance, and is applicable to a permanent insulating film without increasing the supplementation of photopolymerization initiators. The photosensitive resin composition for the insulating film is characterized in that as the necessary composition, the photosensitive resin composition comprises (i) alkali soluble resin with hydroxyl and a polymerizable unsaturated group in one molecule shown by the general formula (1) below, (ii) a photopolymerizable monomer with at least an alkene-attribute unsaturated bond, (iii) a photopolymerizable initiator and (iv) an epoxy composition.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

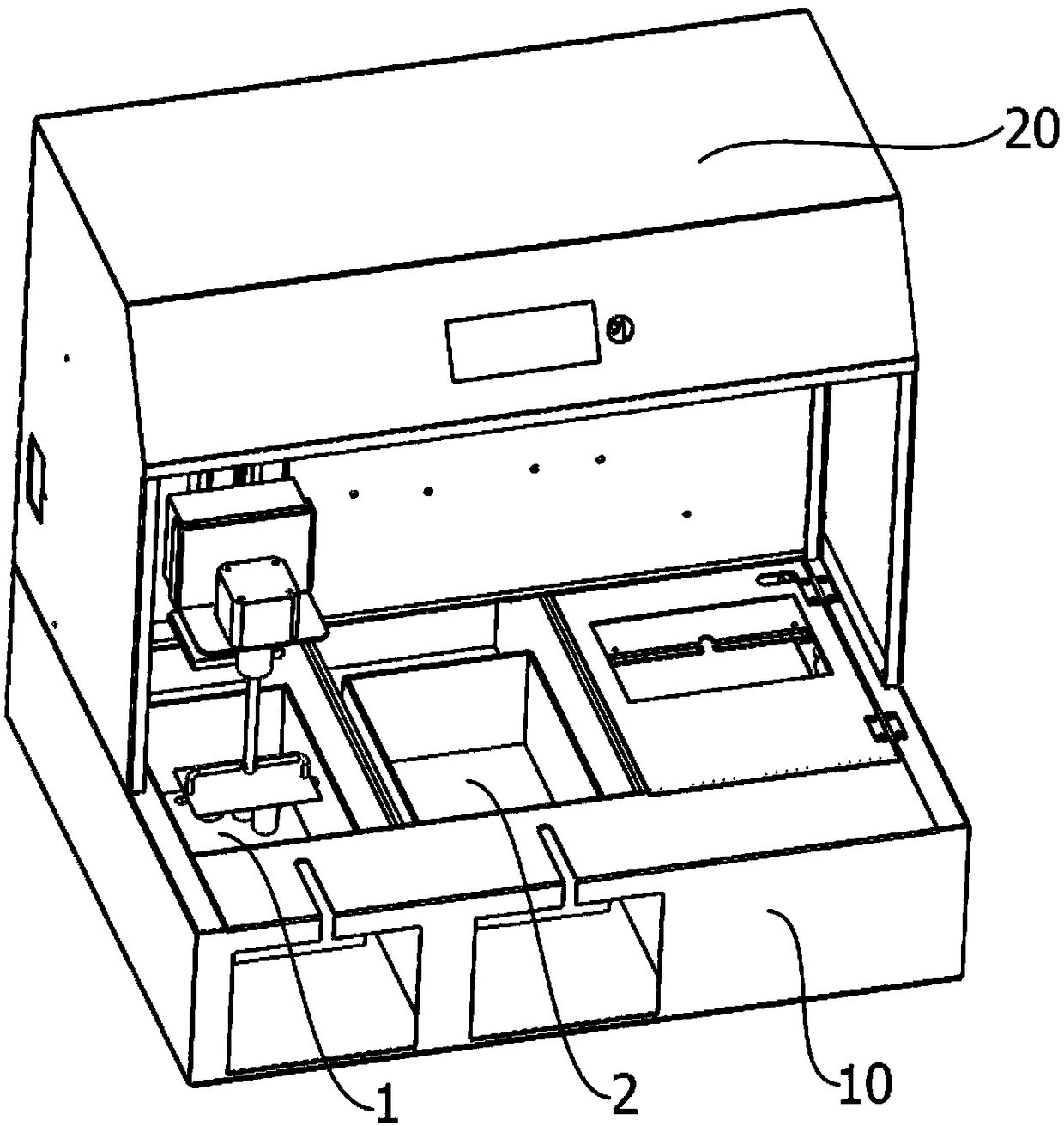

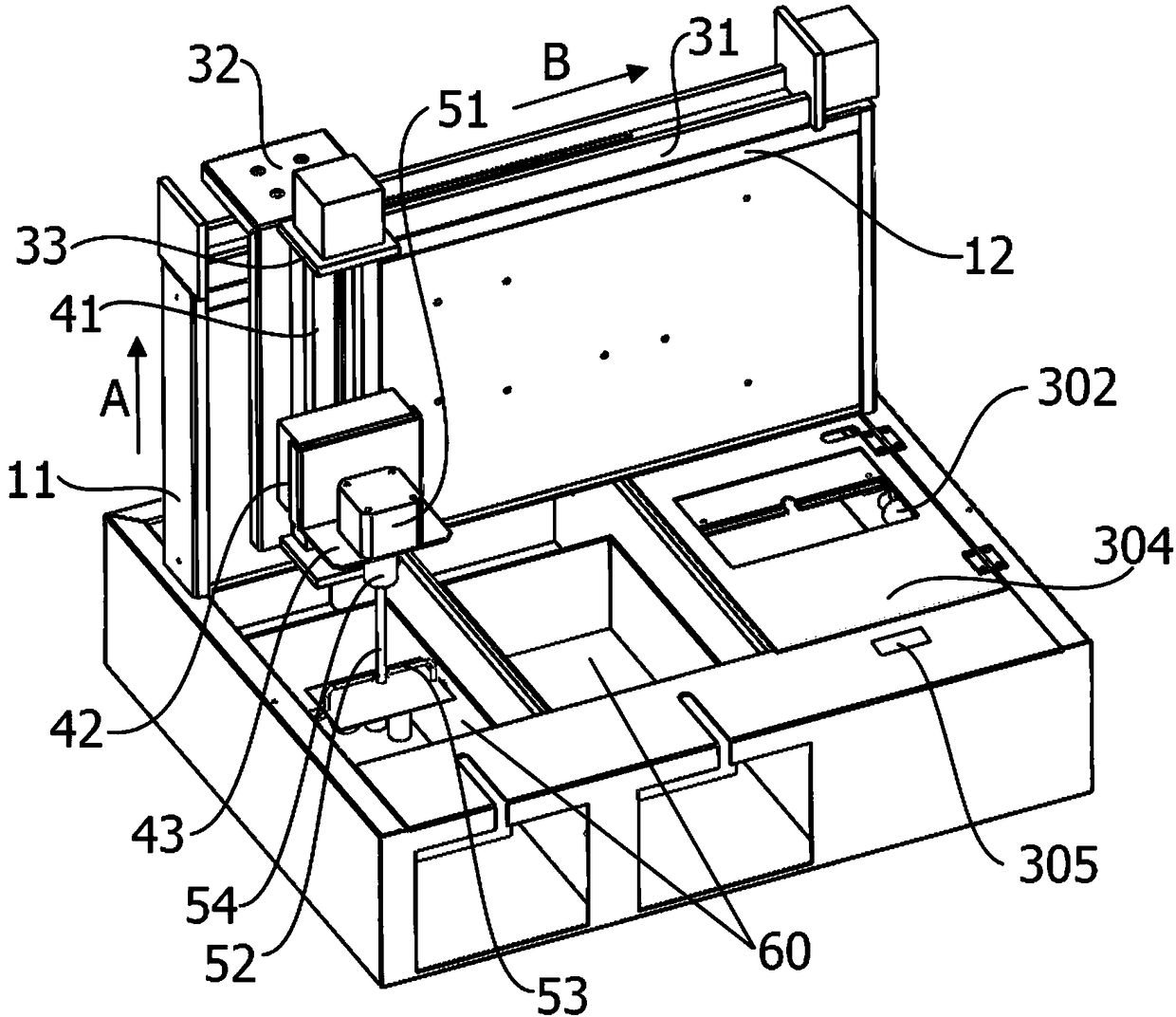

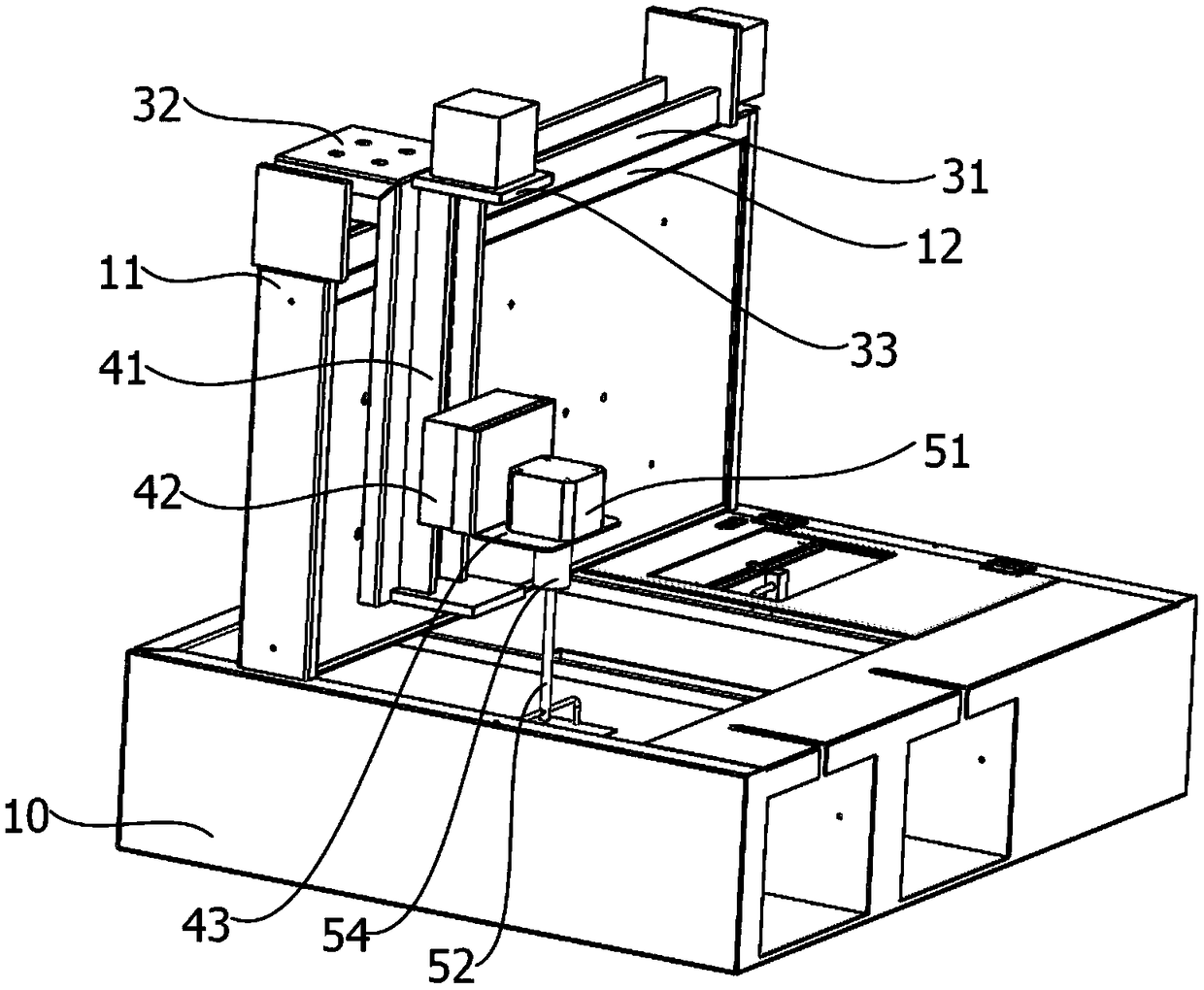

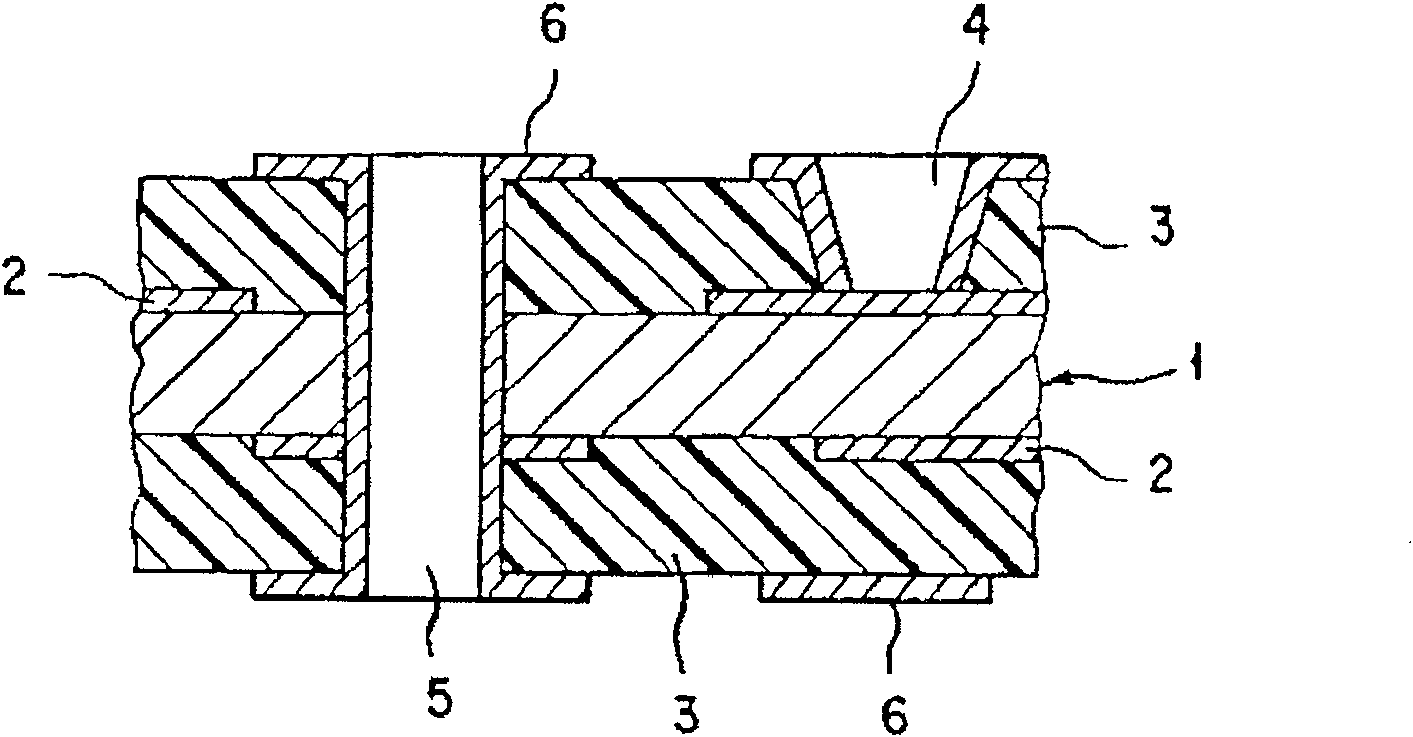

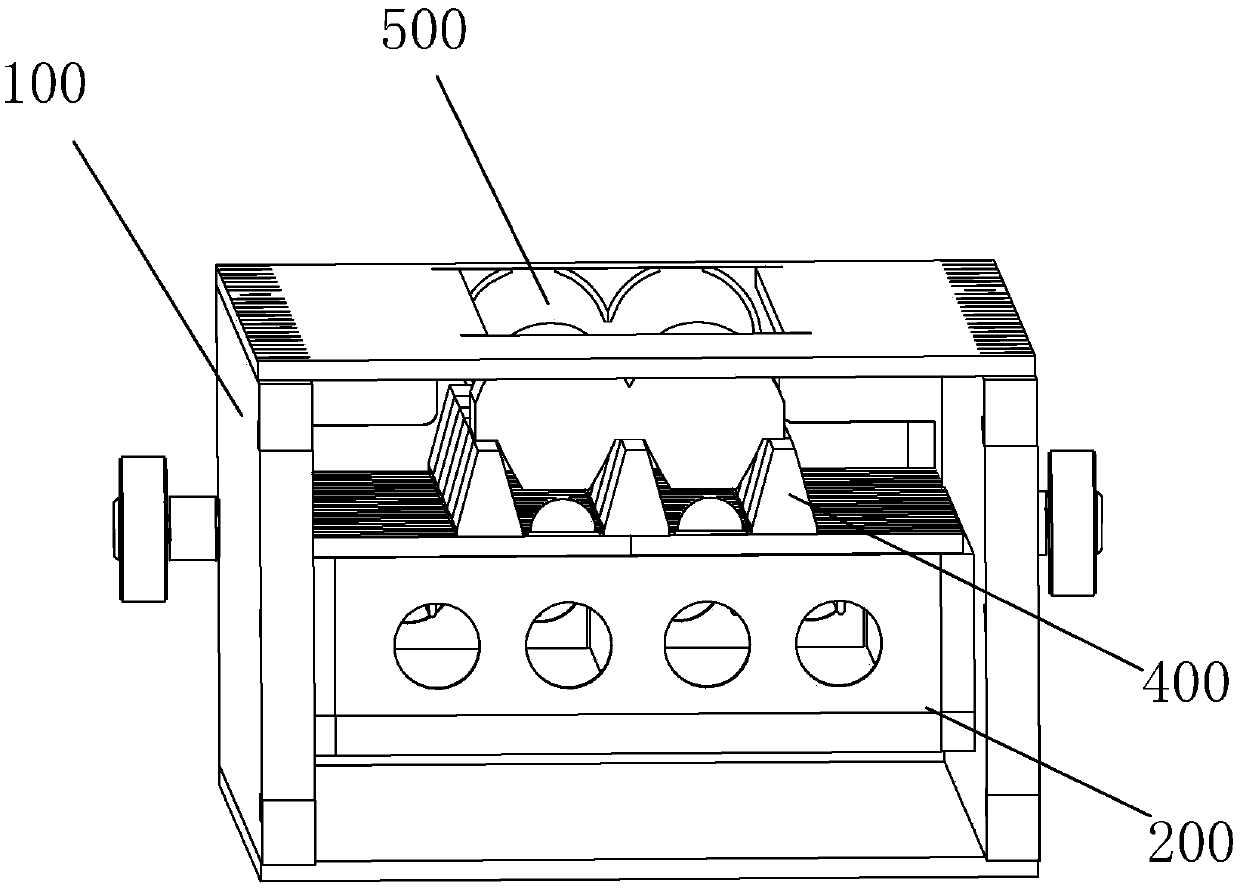

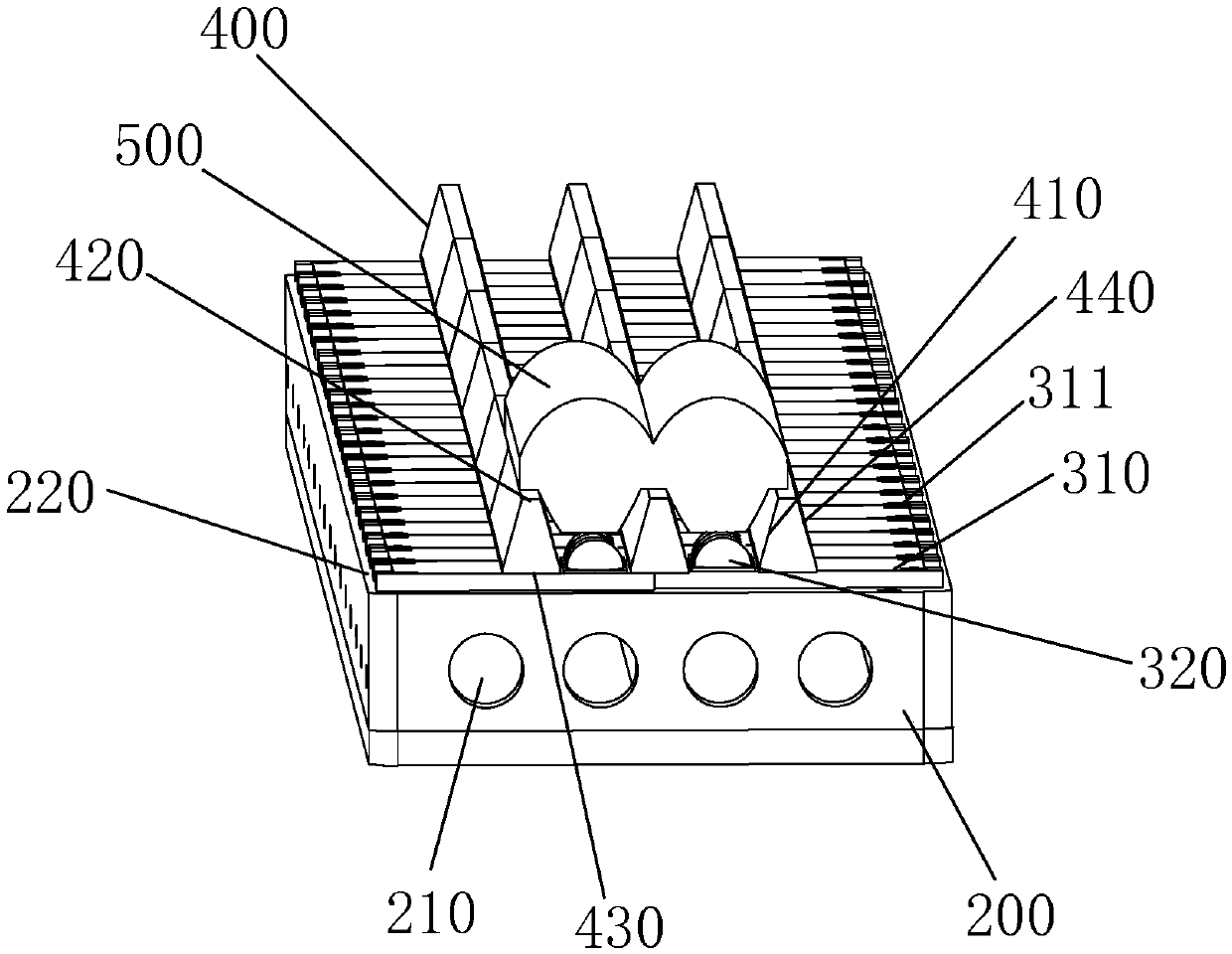

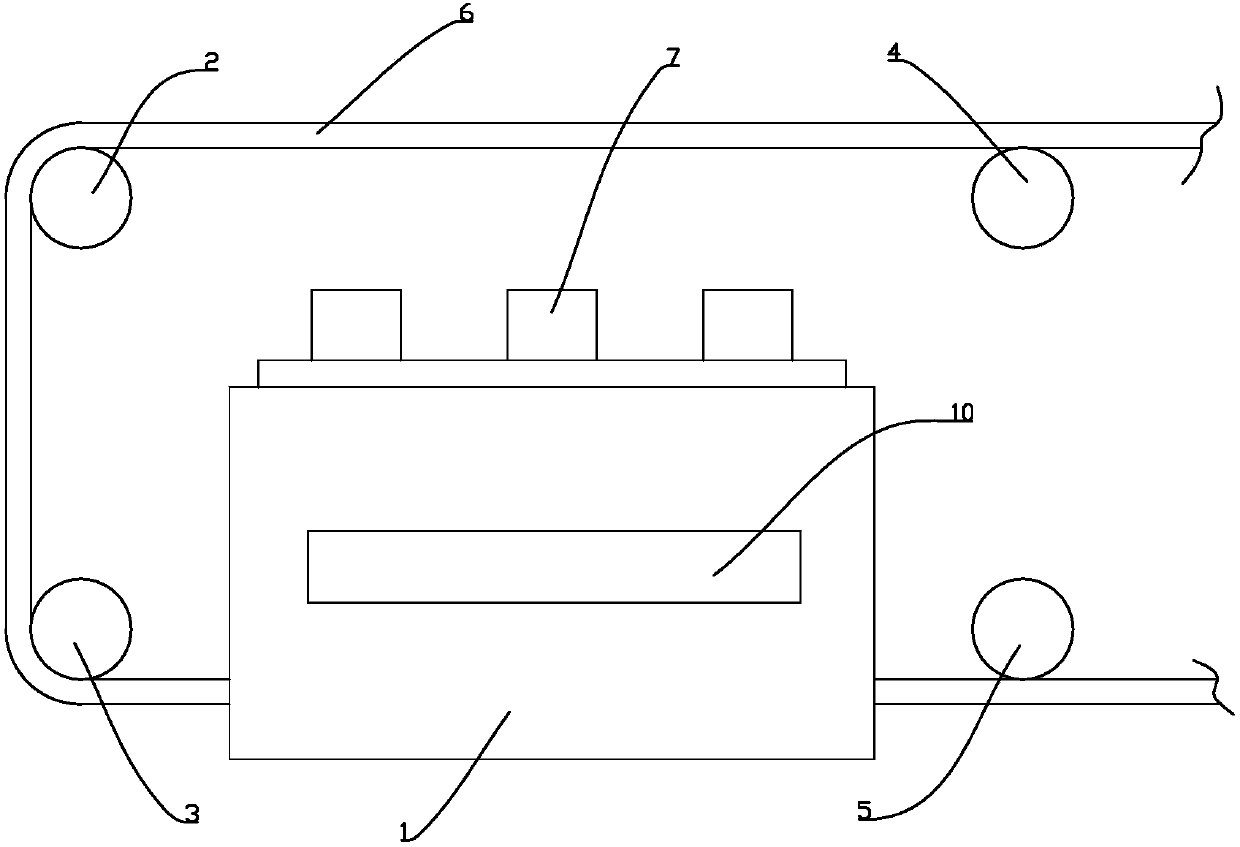

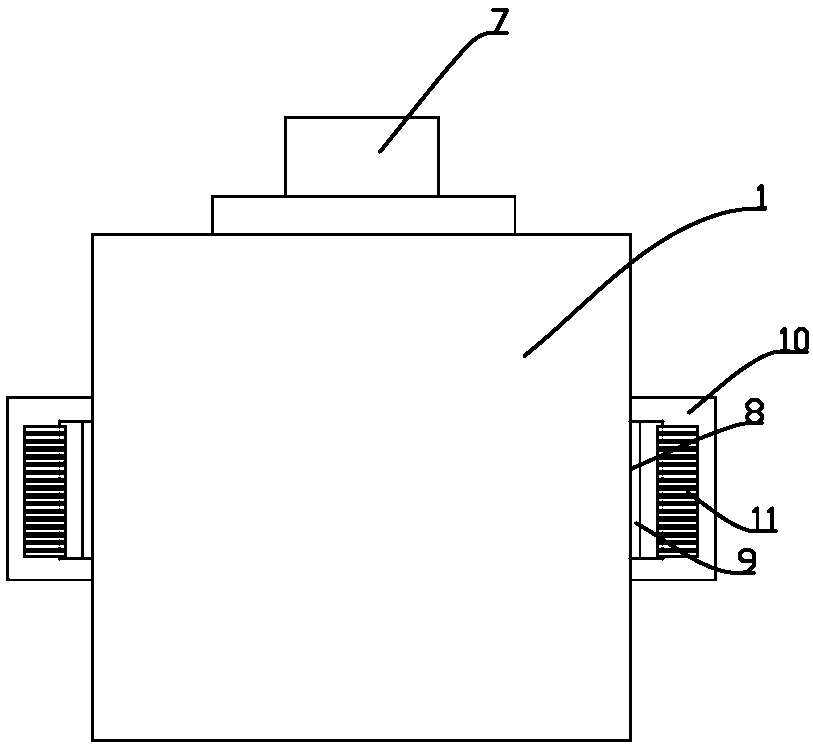

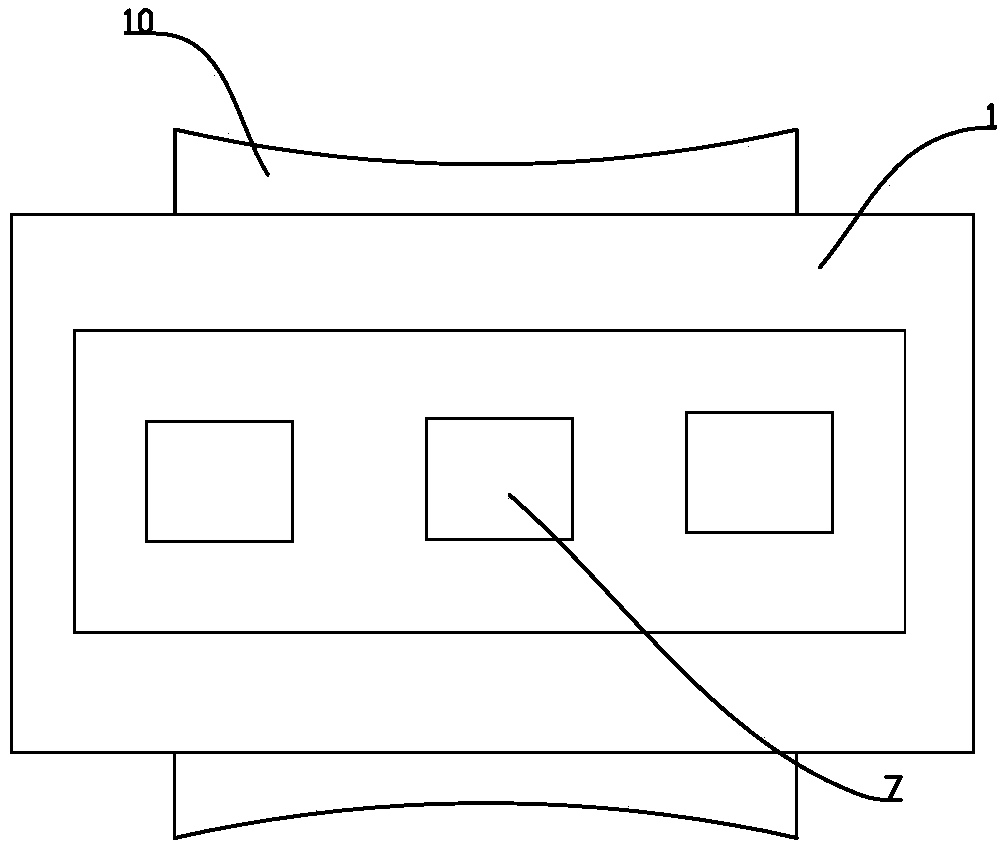

3D (three-dimensional) printing post-processing equipment

PendingCN108568969AGood light curing effectHigh degree of automationAdditive manufacturing apparatusManufacturing recycling3d printUltraviolet lights

The invention provides 3D (three-dimensional) printing post-processing equipment. A first sliding rail parallel to a beam is fixedly arranged on the beam of a base box body; a first sliding block is in sliding connection with the first sliding rail; the first sliding block is connected with a second sliding rail by a first fixed plate; the second sliding rail is arranged in parallel to an uprightcolumn; a second sliding block is in sliding connection with the second sliding rail; a motor is arranged on a second fixed plate; the motor is in transmission connection with a rotating shaft parallel to the second sliding rail; by respective movement of the first and second sliding blocks on the first and second sliding rails, movement of a processed object in the horizontal and vertical directions is implemented; by transverse movement of the first sliding block, switching of a receiving room, a cleaning room and a curing room can be completed, so that an automation degree is improved; theprocessed object is driven by the second sliding block and the motor to conduct the vertical and rotating motion, so that a cleaning effect is improved; a fan for cooling and dissipating heat is arranged in the curing room, and a reflector is arranged in the curing room to reflect emergent ultraviolet light into the curing room, so that a light curing irradiation effect on the processed object isimproved.

Owner:GUANGZHOU VIVID PRINT MATERIAL

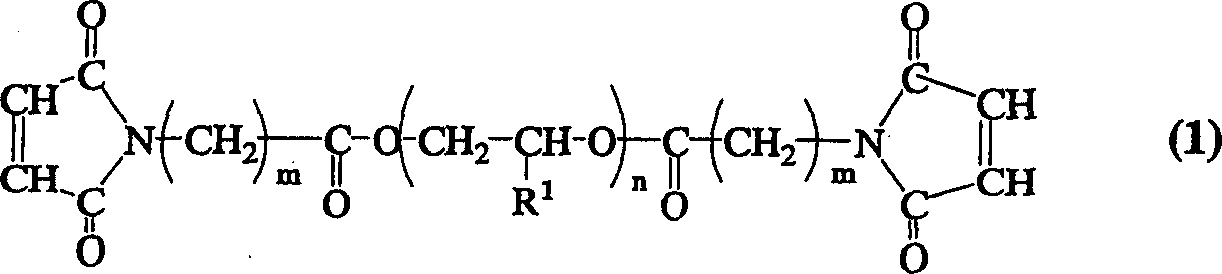

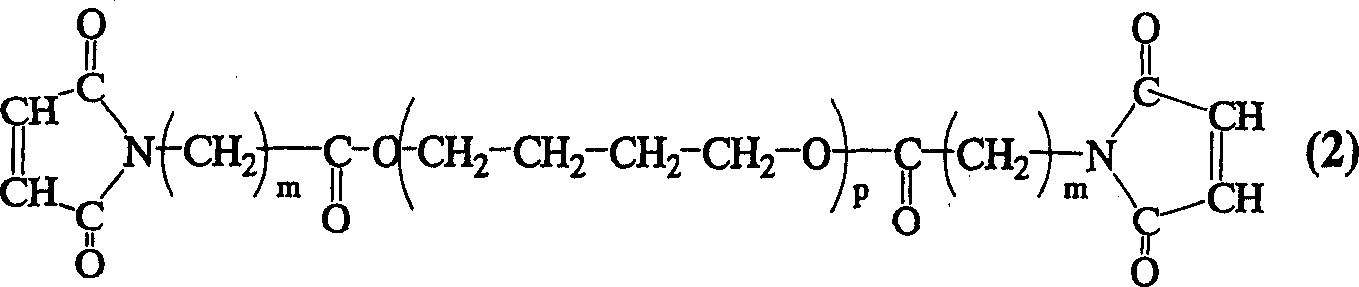

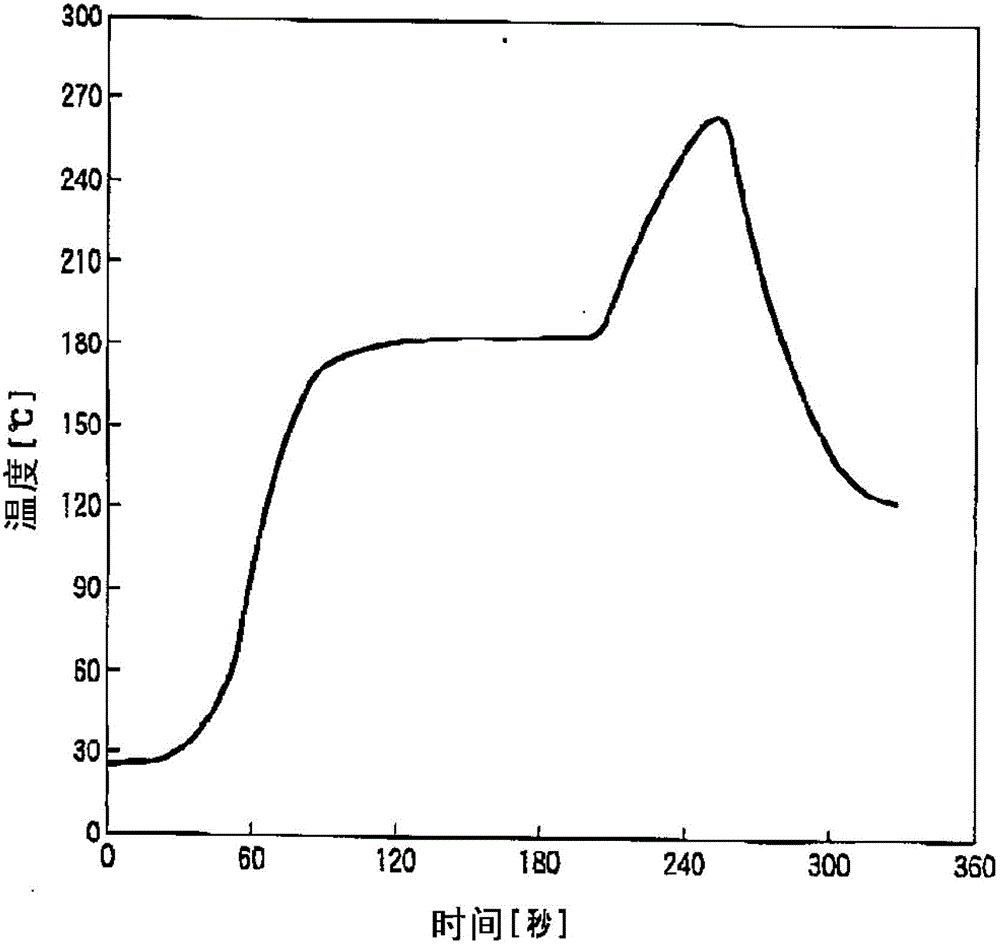

Photocurable/thermosetting resin composition and cured product thereof

ActiveCN1984938AEfficient use ofGood light curing effectOptical waveguide light guidePhotosensitive materials for photomechanical apparatusCarboxyl radicalCyclic ether

Disclosed is a photocurable / thermosetting resin composition wherein the volatile component is reduced by using no or less photopolymerization initiator. This photocurable / thermosetting resin composition can be cured by relatively small amount of ultraviolet irradiation and can be developed with an aqueous alkaline solution. This composition contains a carboxyl group-containing photosensitive resin (A), a maleimide derivative (B), a compound (C) having two or more epoxy groups and / or oxetanyl groups in one molecule, and a radically polymerizable compound (D) having a cyclic ether group or a morpholino group.

Owner:TAIYO HLDG CO LTD

Photocurable resin composition

InactiveUS20070004816A1Good light curing effectHigh strength3-dimensional image productionCompound (substance)Photoinitiator

The invention relates to a radiation curable composition comprising (A) a component comprising a carboxyl group that may dissociate in the presence of an acid, (B) a cationically polymerizable compound, and (C) a cationic photoinitiator.

Owner:DSM IP ASSETS BV

Photocurable/thermosetting resin composition and cured product thereof

ActiveCN100569825CGood light curing effectReduce usageOptical waveguide light guidePhotosensitive materials for photomechanical apparatusCarboxyl radicalUV curing

Owner:TAIYO HLDG CO LTD

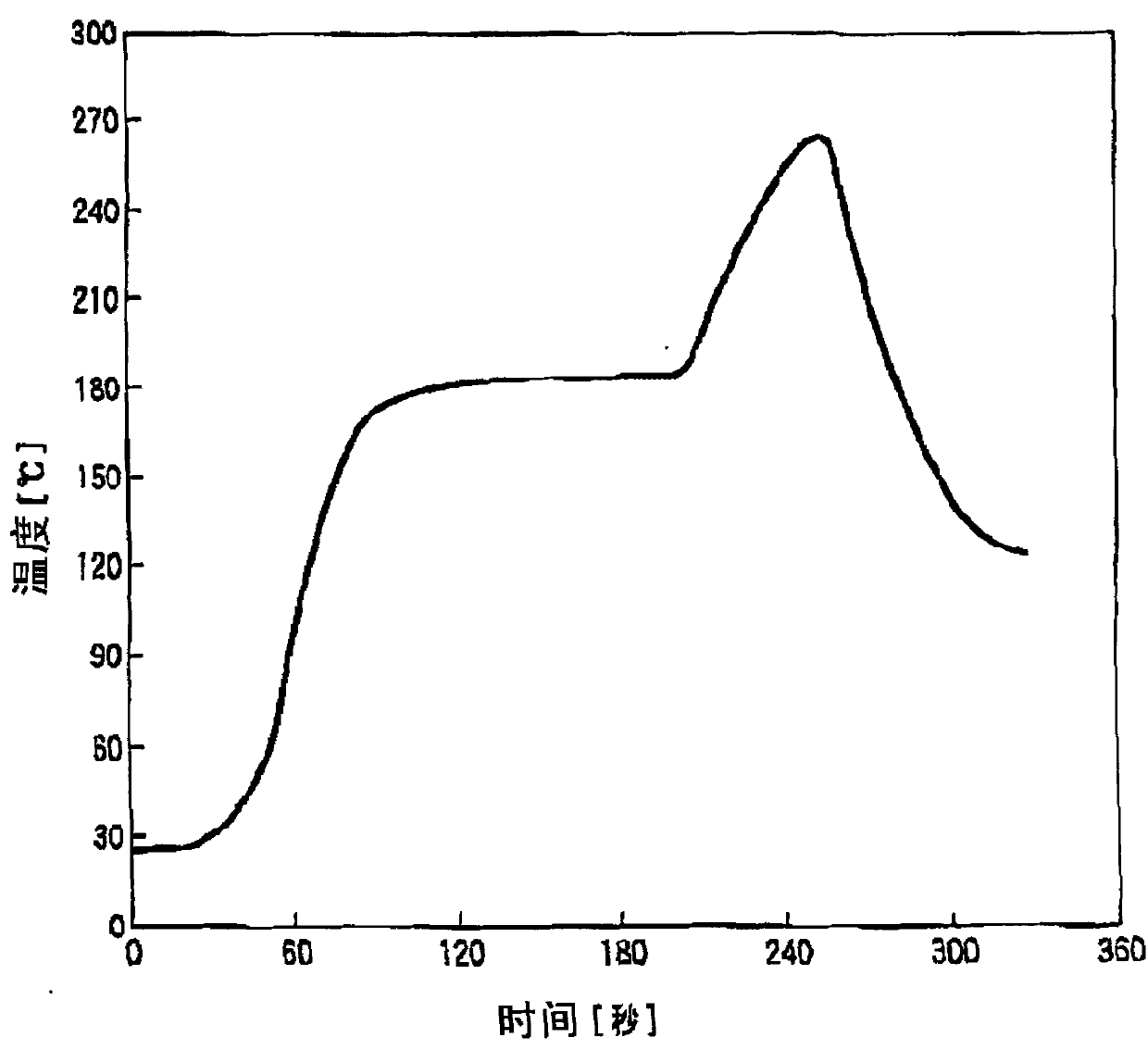

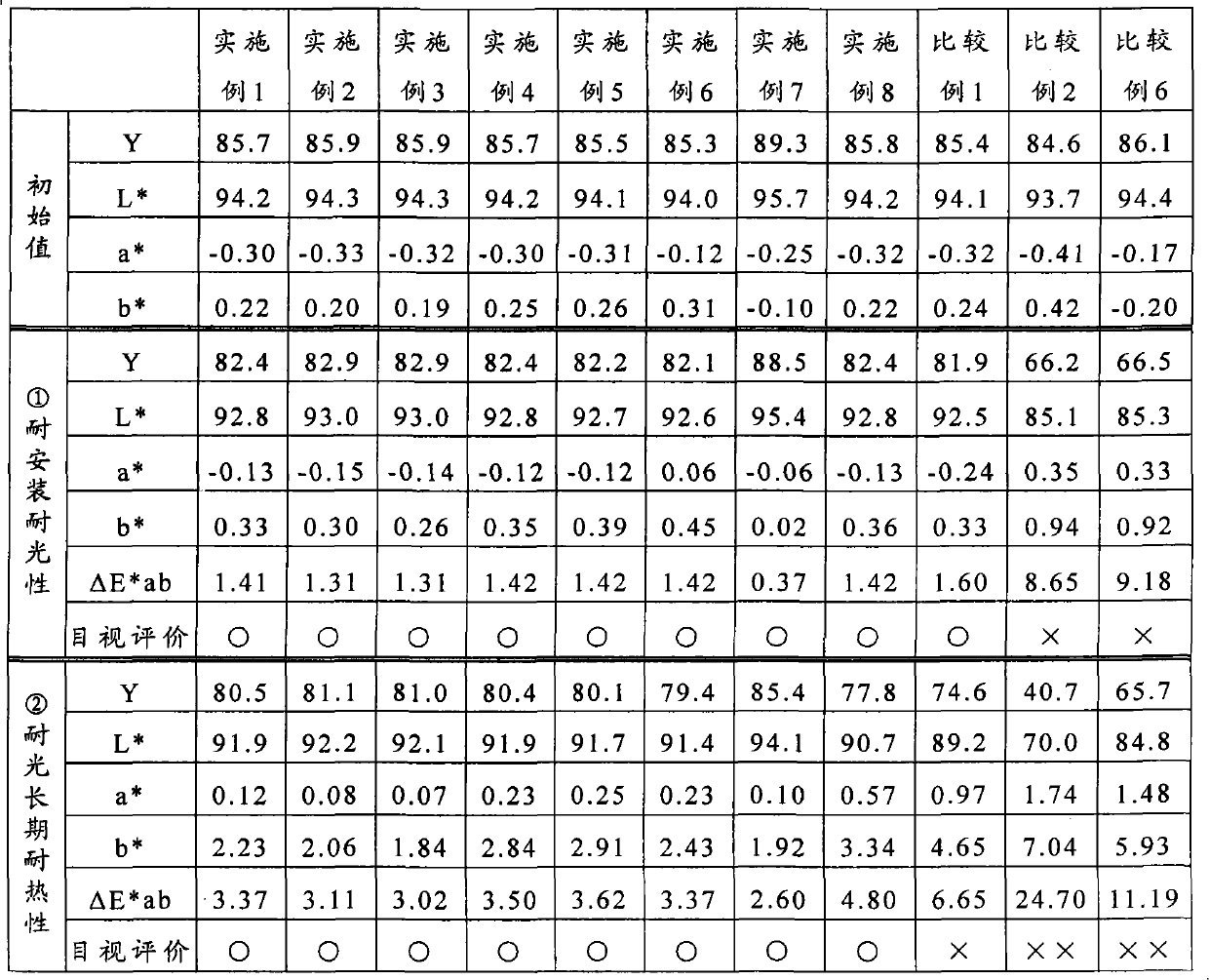

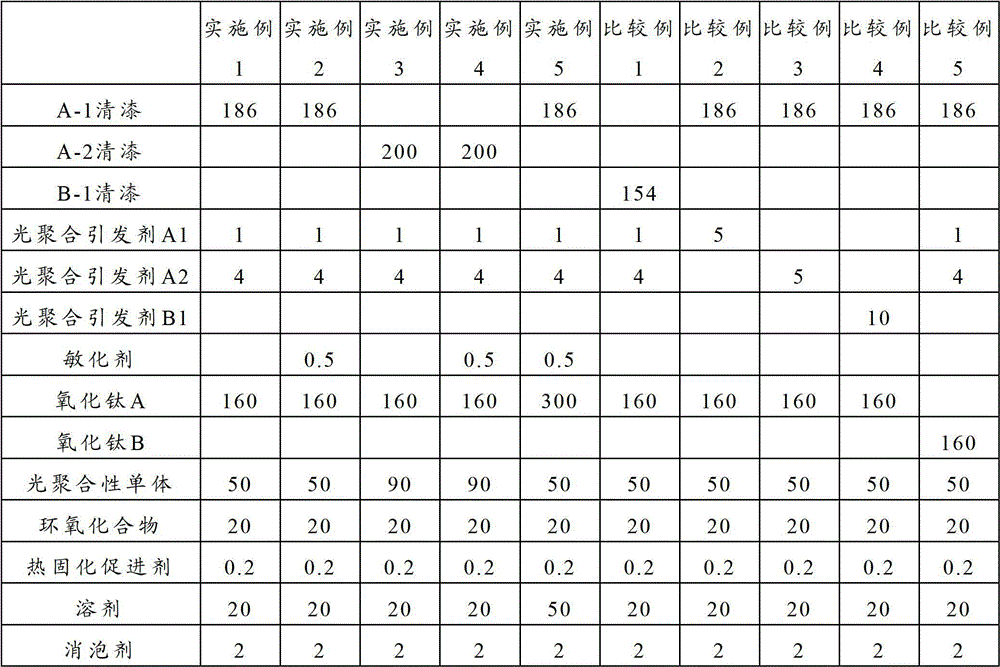

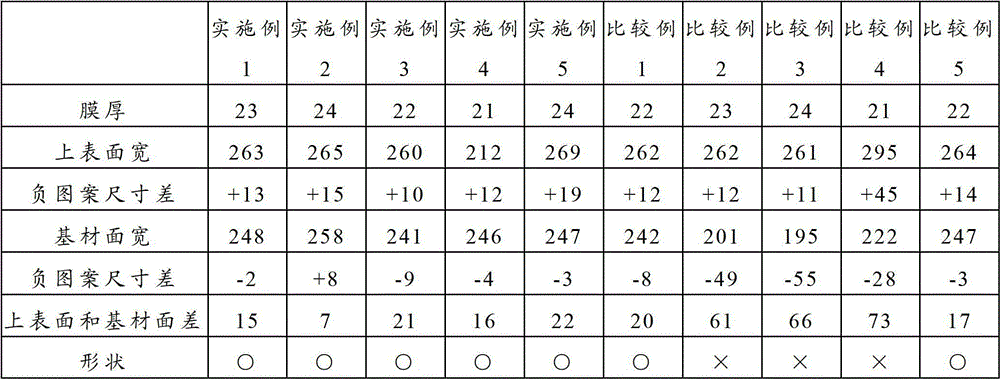

Solder resist composition and printed circuit board

InactiveCN102004394AImprove reflectivityHigh resolutionRadiation applicationsPhotosensitive materials for photomechanical apparatusResistAcyl group

The invention provides a solder resist composition and a printed circuit board, concretely a solder resist composition with high reflectivity and high resolution capable of preventing the reflectivity from being reduced due to discoloration deterioration and a printed circuit board obtained by forming a solder film using the solder resist composition. The solder resist composition comprises: (A) carboxyl-containing resin without aromatic ring; (B) bi-acyl phosphine oxide type light polymerization initiator; (C) monoacyl phophine oxide type light polymerization initiator; (D) light polymerization monomer; (E) rutile type titanium oxide; (F) epoxide; (G) organic solvent; and (H) antioxidant.

Owner:TAIYO HLDG CO LTD

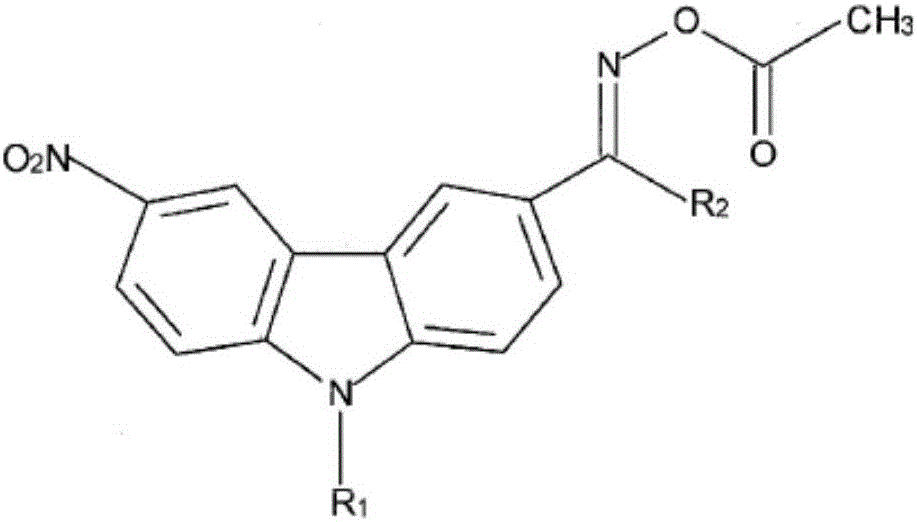

Pyrazole oxime ester photoinitiator with high photosensibility, preparation method and application thereof

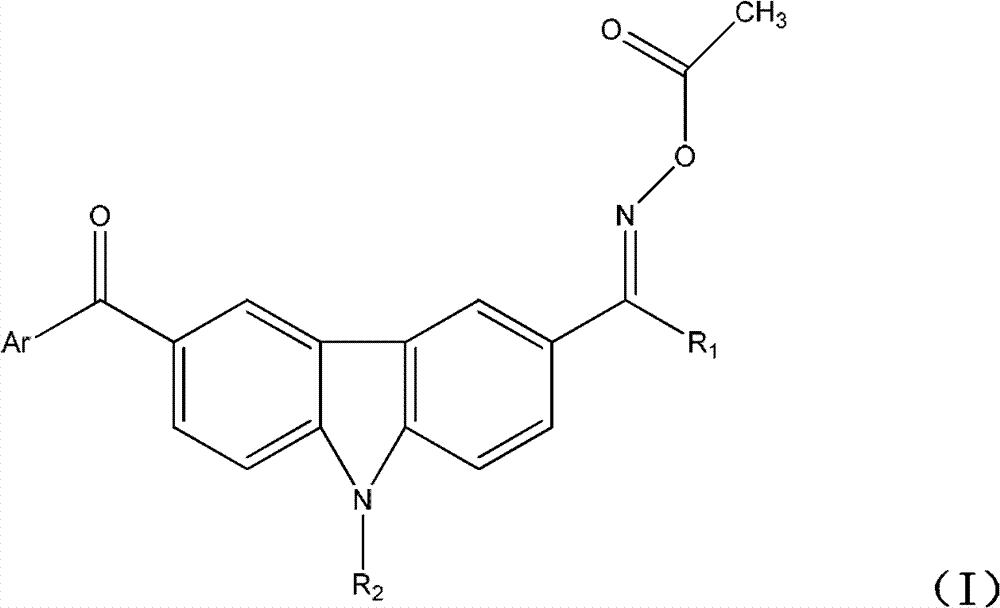

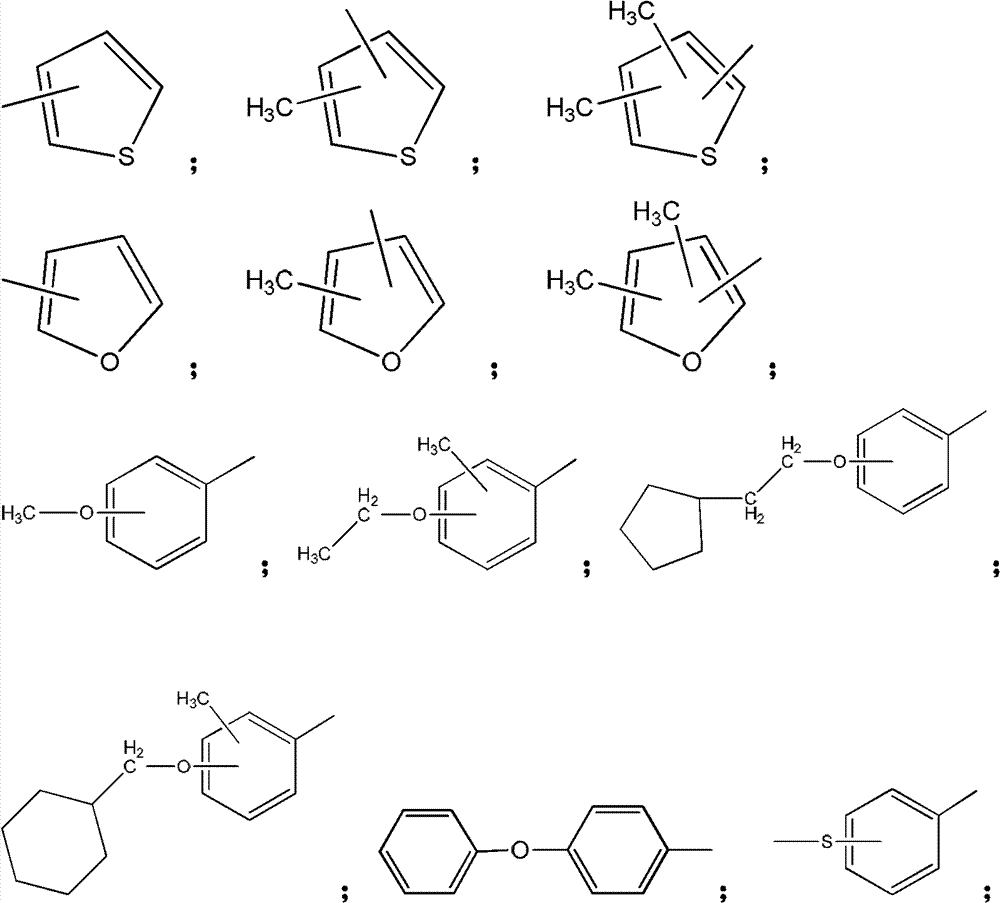

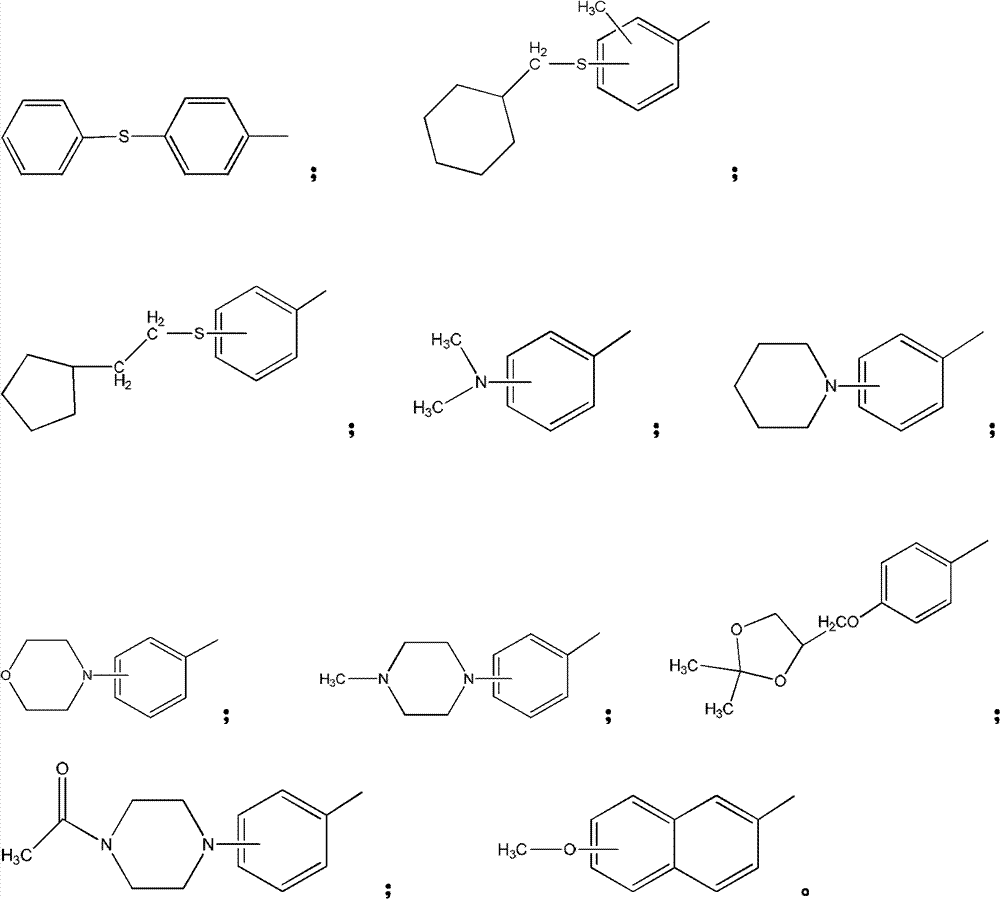

ActiveCN102020727BImprove applicabilityIncrease photosensitivityOrganic chemistryPhotomechanical apparatusCarbazoleColor gel

A carbazole oxime ester-type photoinitiator represented by the following structural formula (I) is disclosed. The photoinitiator has excellent properties in application, especially high photosensibility. The photoinitiator can greatly improve the photocuring properties of photopolymers when applying on them, thus can significantly increase the productivity of photosensitive compositions in application fields such as preparing color filter. The preparation method of the carbazole oxime ester-type photoinitiator and its use in photosensitive composition are also disclosed.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD

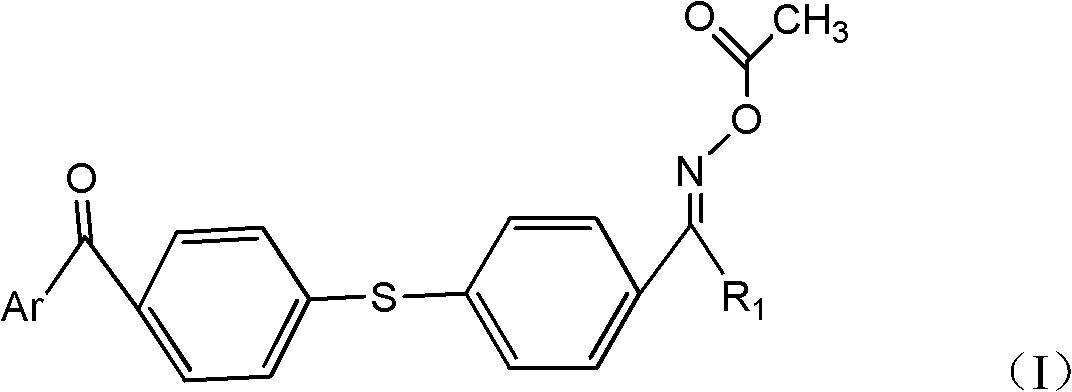

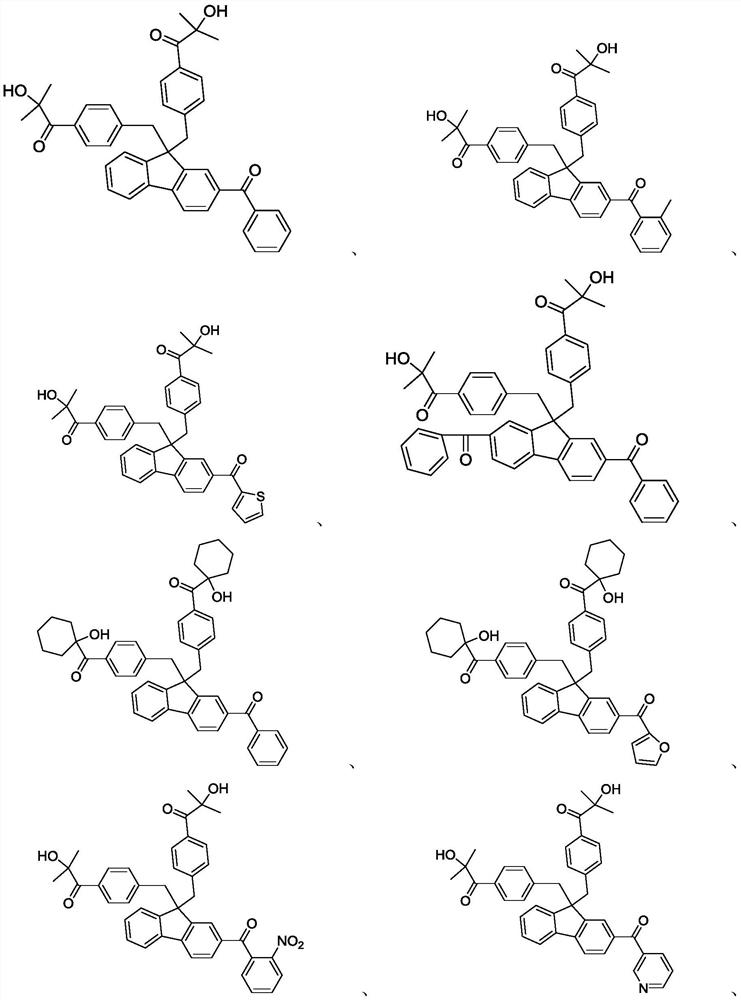

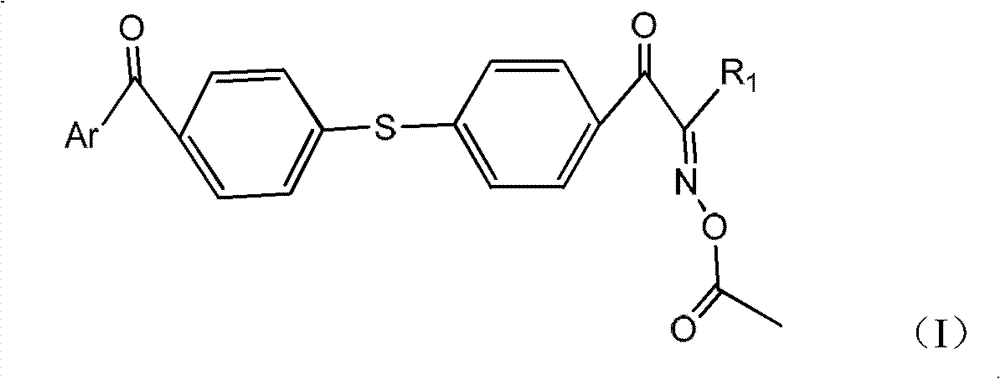

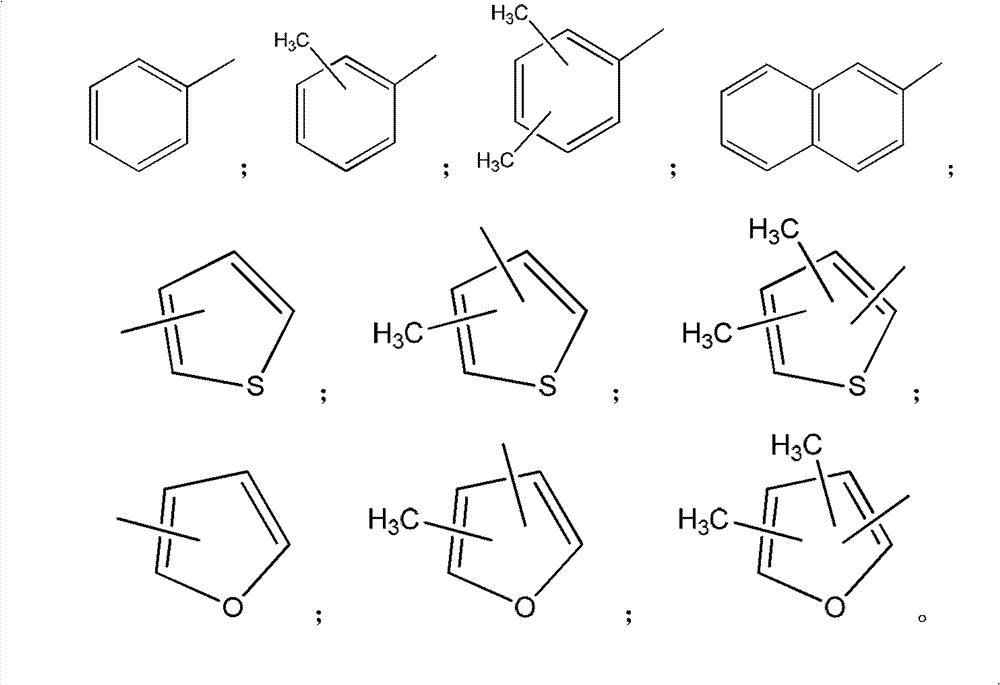

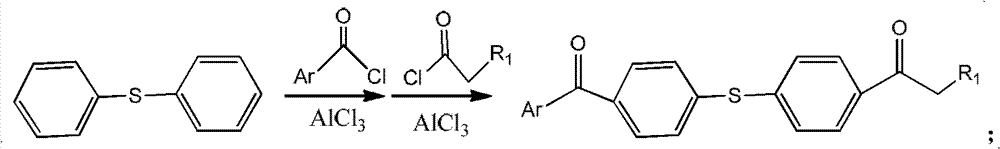

Photoinitiator of diphenyl sulfide oxime esters as well as preparation method and application thereof

ActiveCN102492060BImprove applicabilityGood application effectPhotosensitive materials for photomechanical apparatusSulfide preparationChemical structureColor gel

The invention relates to a photoinitiator of diphenyl sulfide oxime esters. The photoinitiator has a chemical structure shown as a formula (1) in the specifications, is excellent in application performance, high in photosensibility, free of yellowing and good in dissolubility, and has the advantages of greatly increasing a photo-curing performance when applied to photosensitive compositions and obviously increasing the performance and production efficiency in the photosensitive composition application field, such as preparation of color filters. The invention further relates to a preparation method of the photoinitiator and application of the photoinitiator to the photosensitive compositions.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD

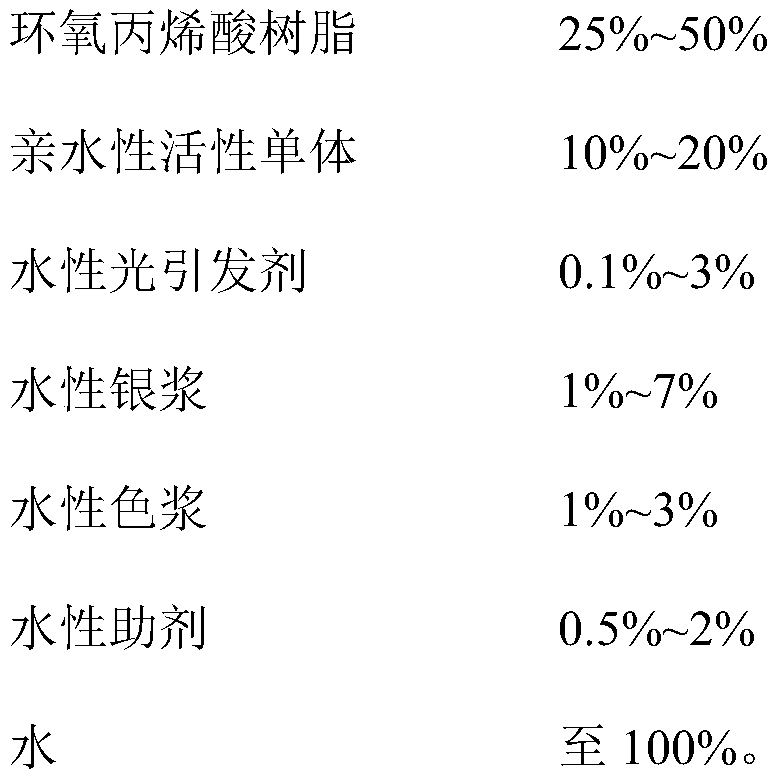

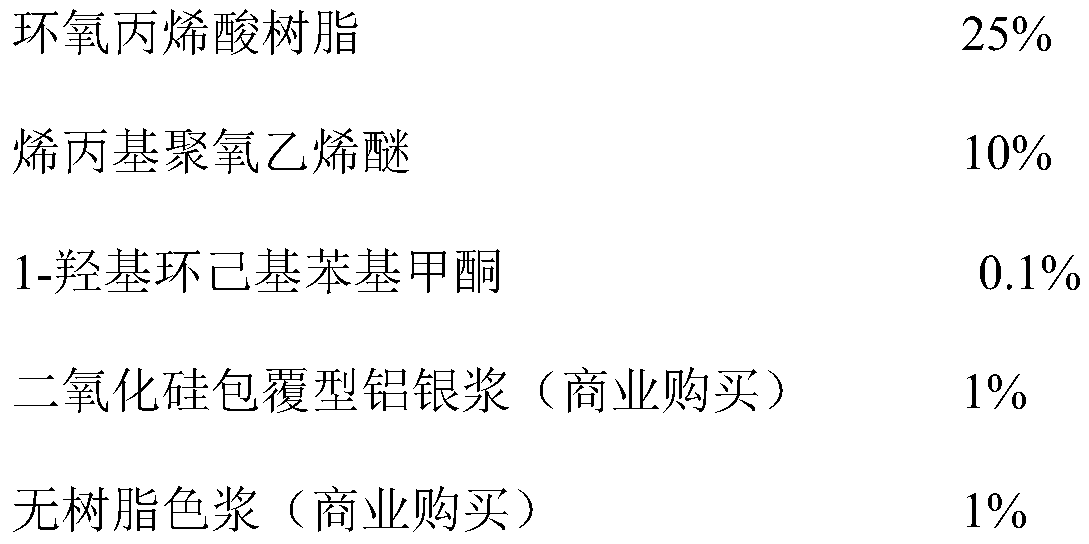

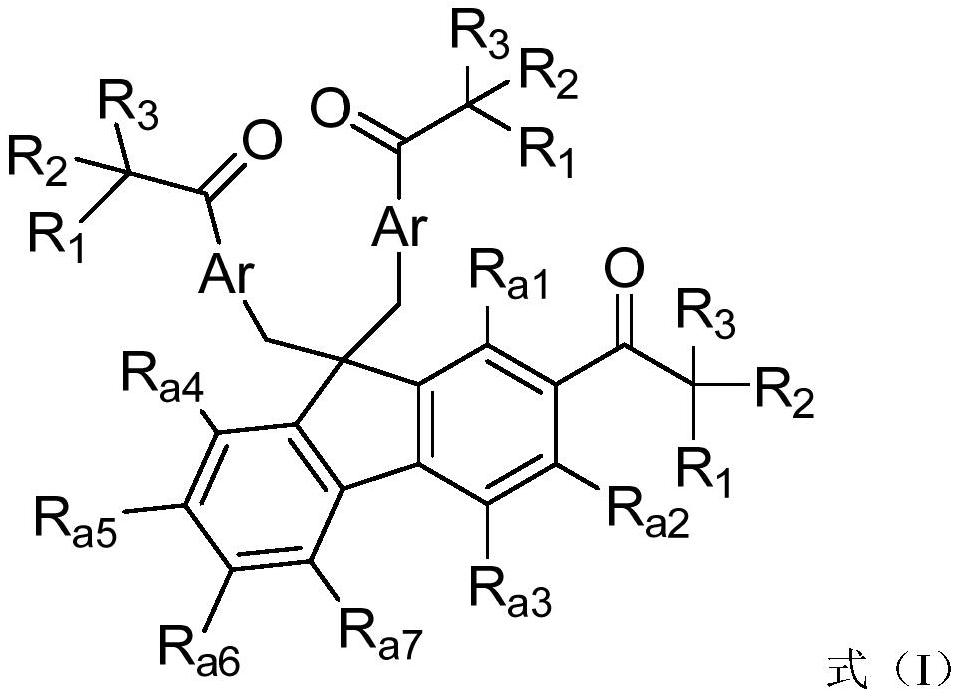

Water-based one-coating UV-cured epoxy acrylate coating and preparation method thereof

ActiveCN111253837AFast curingFully cross-linked and curedPolyether coatingsEpoxy resin coatingsSilver pastePolymer science

The invention belongs to the technical field of coatings, and discloses a water-based one-coating UV-cured epoxy acrylate coating and a preparation method thereof. The coating comprises the followingcomponents in percentage by mass: 25%-50% of epoxy acrylic resin, 10%-20% of a hydrophilic active monomer, 0.1%-3% of a water-based photoinitiator, 1%-7% of water-based silver paste, 1%-3% of water-based color paste, 0.5%-2% of a water-based additive and the balance of water, totaling 100%. By adopting a specific catalyst and a polymerization inhibitor, a paint film can be quickly cured at one time, and the cross-linking curing of the paint film is more sufficient; and a specific hydrophilic functional monomer is adopted, so that the stability of the water-based paint is further improved.

Owner:GUANGDONG RITOP FINE CHEM

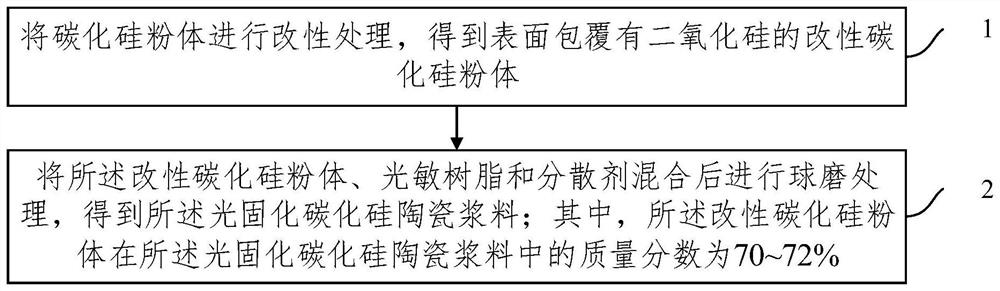

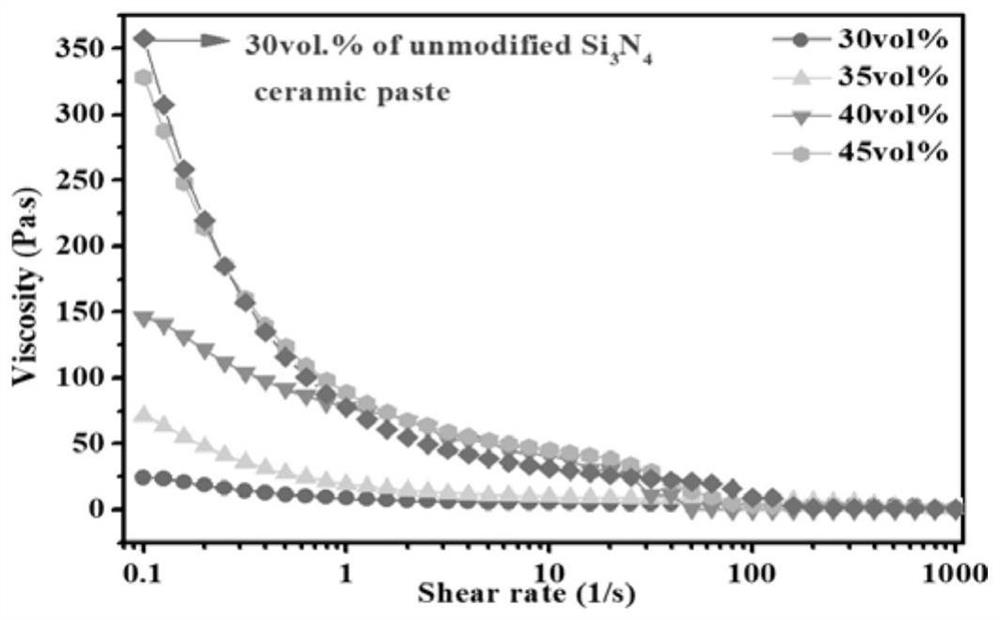

Photo-cured silicon carbide ceramic slurry as well as preparation method and application thereof

The invention provides light-cured silicon carbide ceramic slurry and a preparation method and application thereof, and the preparation method comprises the following steps: (1) carrying out modification treatment on silicon carbide powder to obtain modified silicon carbide powder coated with silicon dioxide on the surface; and (2) mixing the modified silicon carbide powder, photosensitive resin and a dispersing agent, and carrying out ball milling treatment to obtain the light-cured silicon carbide ceramic slurry, wherein the mass fraction of the modified silicon carbide powder in the light-cured silicon carbide ceramic slurry is 70-72%. The prepared photocuring silicon carbide ceramic slurry is good in fluidity and high in curing capacity, 3D printing of a high-solid-content silicon carbide ceramic green body is achieved, and a guarantee is provided for the mechanical property of the silicon carbide ceramic green body after degreasing and sintering. The method realizes printing of silicon carbide with a complex structure, and has the advantages of high forming precision, high speed and capability of manufacturing a silicon carbide ceramic component with a complex shape without a mold.

Owner:SHENZHEN POLYTECHNIC

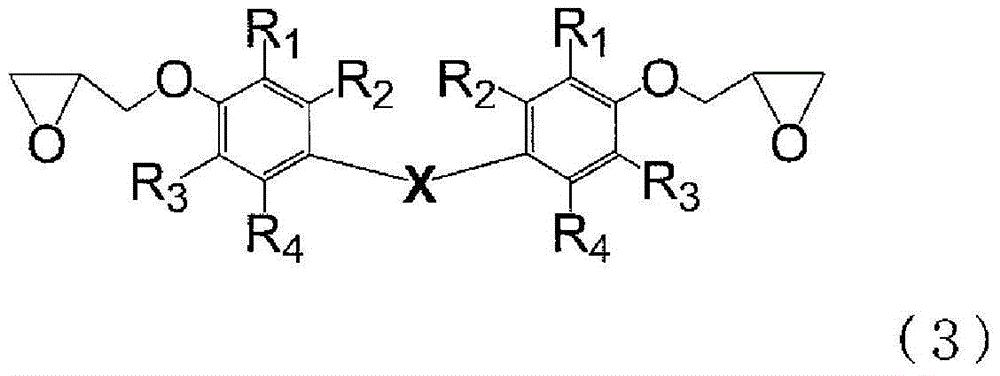

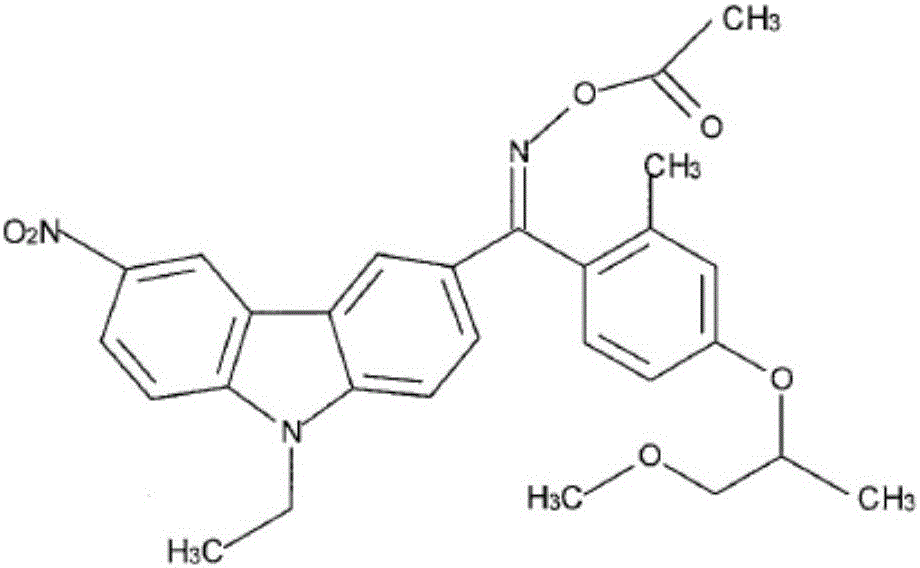

Photosensitive resin composition

InactiveCN106814539AShorten the exposure processHigh sensitivityPhotosensitive materials for photomechanical apparatusEpoxyPhenyl group

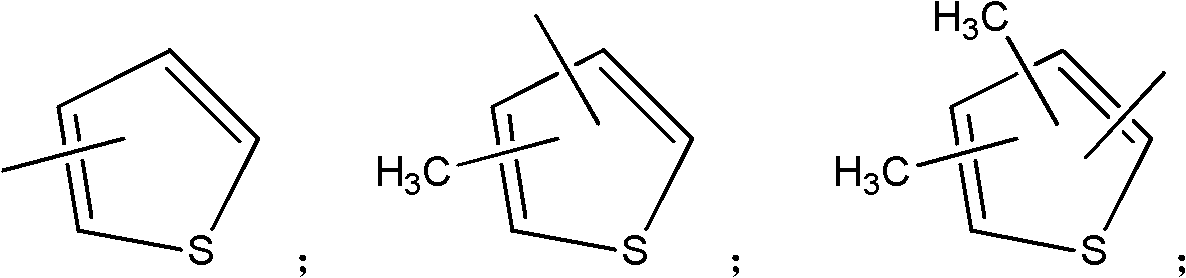

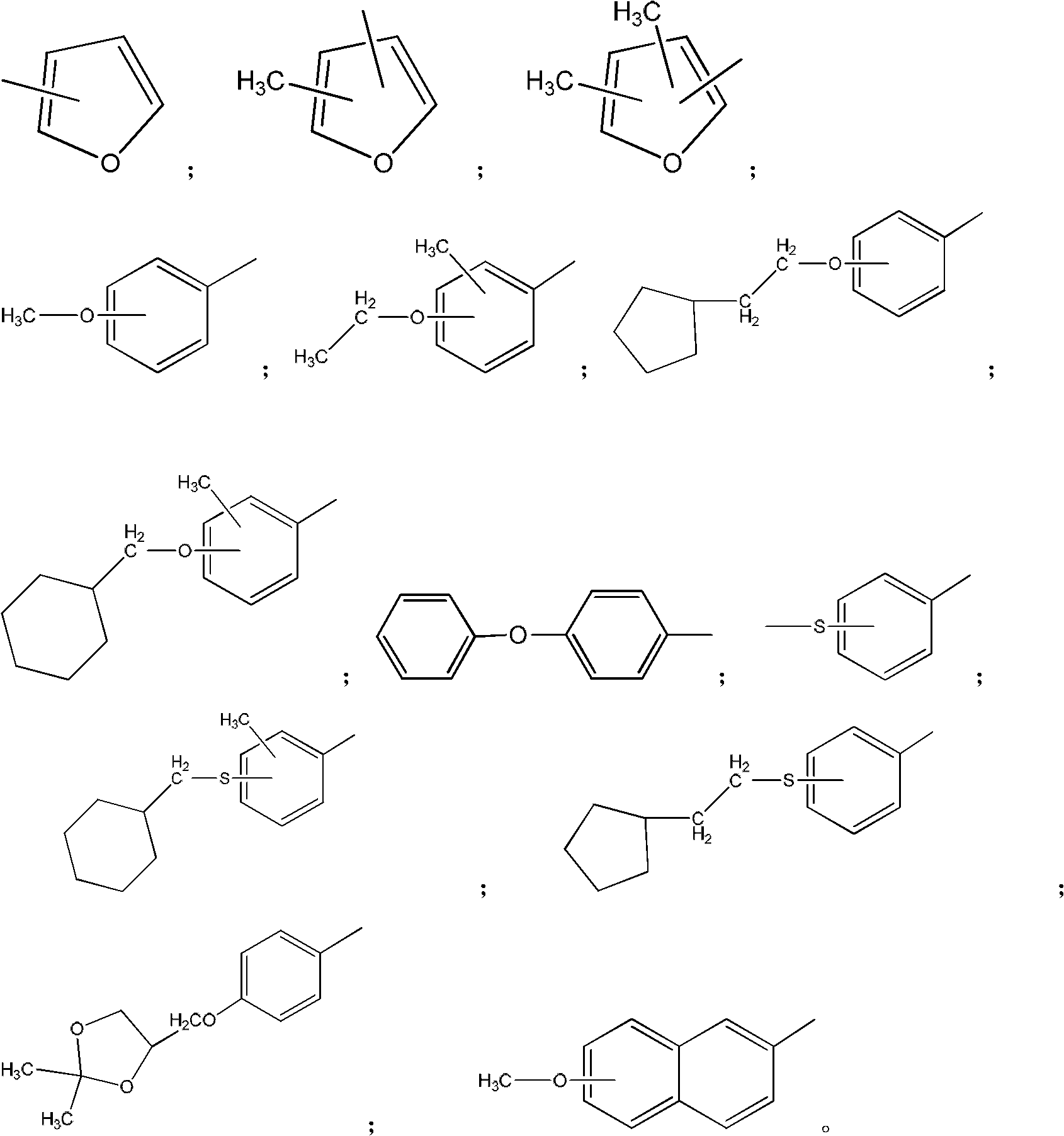

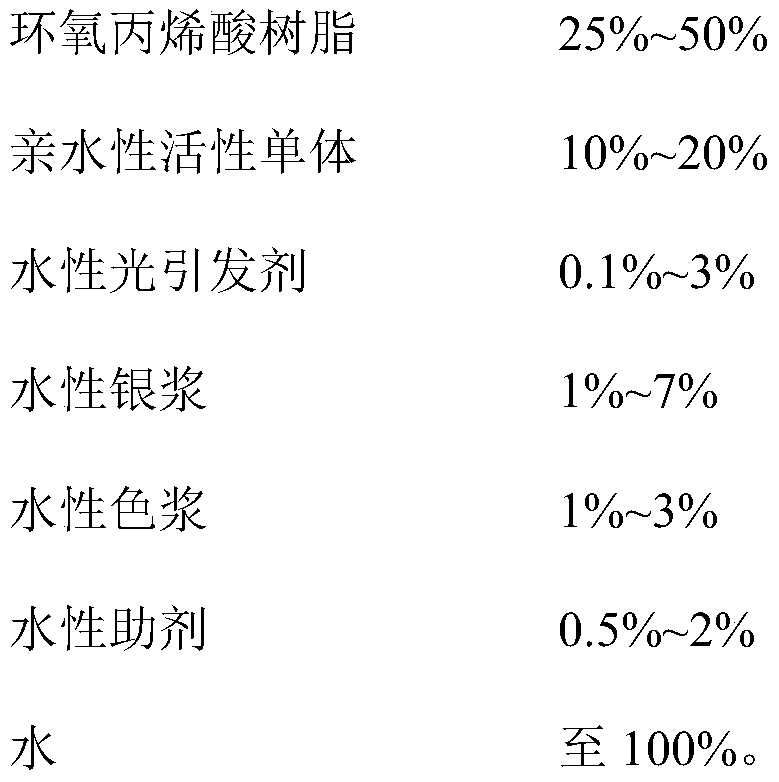

The invention aims to provides a photosensitive resin composition. The basic characteristics such as electrical insulation property are not destroyed. The photosensitive resin composition is exposed by a direct scanning device, the inner of the coating has a photo curing property and good sensitivity, the linear shape deterioration of a cured object is avoided, and excellent resolution is obtained. The photosensitive resin composition comprises (A) carboxyl containing photosensitive resin, (B) a polymerization initiator, (C) epoxy compounds, and (D) a coloring agent. The (B) polymerization initiator is represented by a formula, wherein in the formula, R1 represents H, a C1-C17 alkyl group, or a C1-C17 alkoxyl group, and R2 represents a phenyl group substituted by at least one of a phenyl group, a C1-C5 alkyl group, -O-CmH2m-CH3-, and -O-CnH2n-CpH2p-CH3, wherein m, n, and p all represent an integer from 1 to 5.

Owner:TAMURA KK

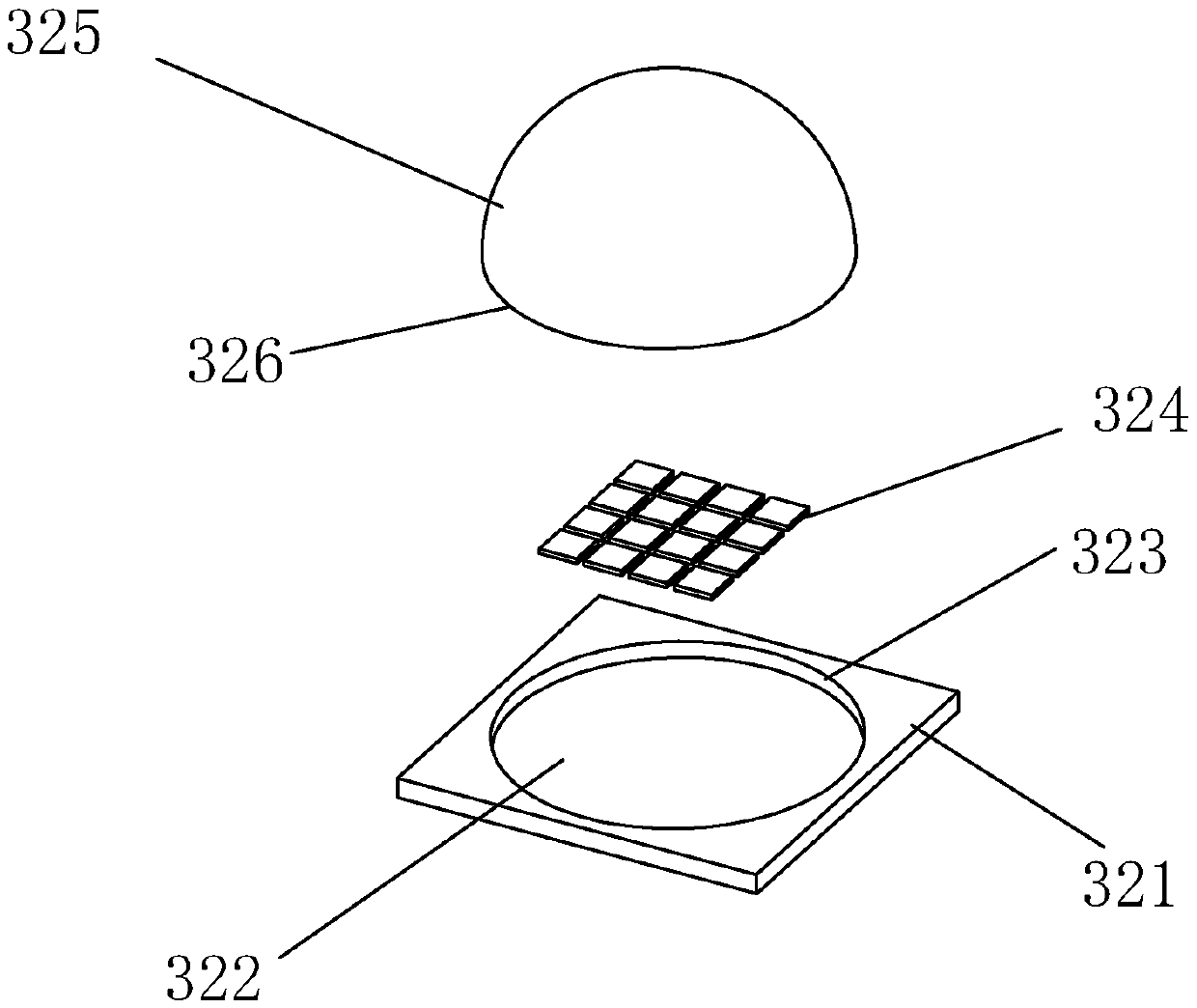

Optical mechanism

PendingCN109591448AGood light curing effectIncrease productivityPrinting press partsOptical powerEngineering

The invention relates to the technical field of photo-curing, in particular to an optical mechanism for offset printing light curing. The optical mechanism comprises a shell, a heat dissipation device, a light source assembly and a first optical lens, wherein the heat dissipation device is arranged in the shell, the light source assembly comprises LED lamp beads and a first substrate for bearing the LED lamp beads, the first optical lens is arranged right front of the LED lamp bead, so that light rays emitted by the LED lamp beads are converged; the heat dissipation device is propped against the substrate, and the LED lamp beads comprise a plurality of chips. A quartz glass sheet or a cylindrical quartz glass rod of a flat plate adopted by a traditional UV-LED light source is changed intoa special-shaped quartz glass, the LED lamp beads packaged in the 16 PCS purple light chips are combined and closely arranged, so that the light source UV energy and the optical power density are greatly improved, the light curing effect and the production efficiency are improved.

Owner:深圳市瑞丰光电紫光技术有限公司

Optical hot-pressing film

ActiveCN106753006AGood viscosity increasing effectImprove stabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAntioxidantUnsaturated polyester

The invention discloses an optical hot-pressing film. The optical hot-pressing film comprises a base material and glue which is positioned on the base material; the optical hot-pressing film is obtained by coating the base material with the glue; the glue comprises the following raw materials in parts by weight: 31 to 52 parts of EVA hot-melt adhesive, 1 to 6 parts of terpene resin, 0 to 6 parts of rosin resin, 2 to 9 parts of dicyclopentadiene resin, 0 to 3 parts of isophthalic unsaturated polyester resin, 3 to 6 parts of diphenyl propane epoxy resin, 9 to 16 parts of a photoinitiator, 2 to 8 parts of an antioxidant, 12 to 26 parts of cashew nut shell oil-modified amine hardener, and 8 to 12 parts of optical curing monomers. According to the optical hot-pressing film, the production cost of an optical adhesive is greatly reduced; the optical hot-pressing film has excellent reworking property; moreover, a hot-melt pressure-sensitive adhesive has excellent optical performance.

Owner:NANJING HUIXIN PHOTOELECTRIC MATERIAL

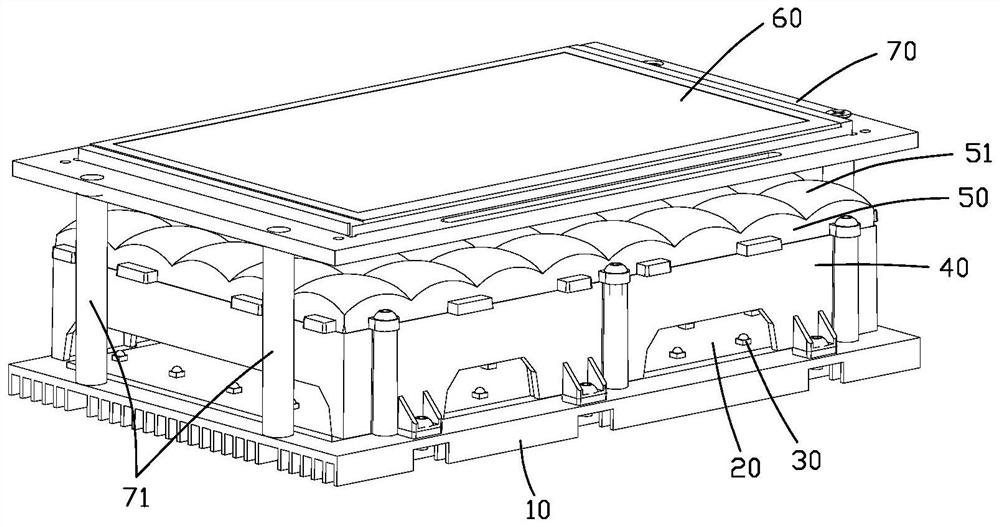

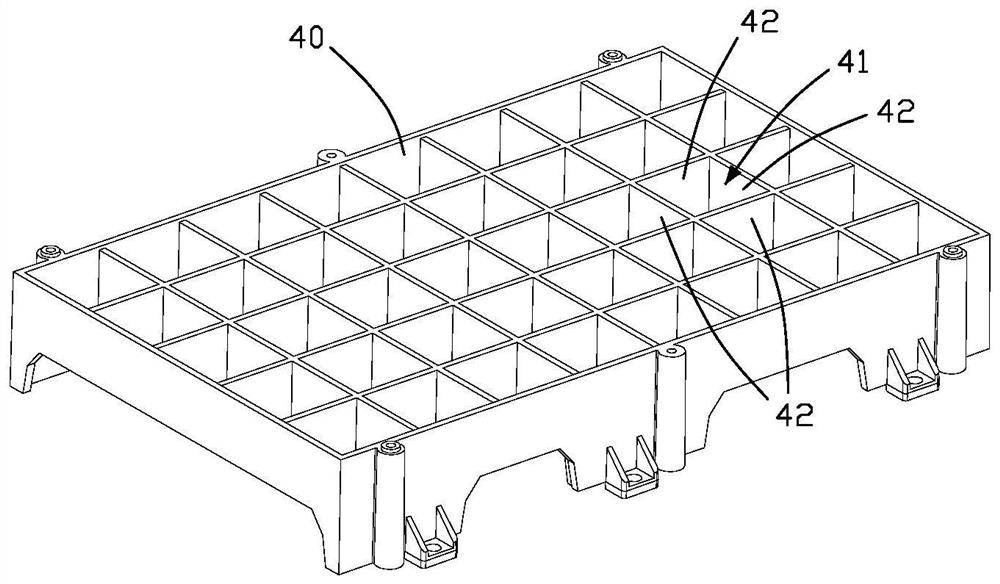

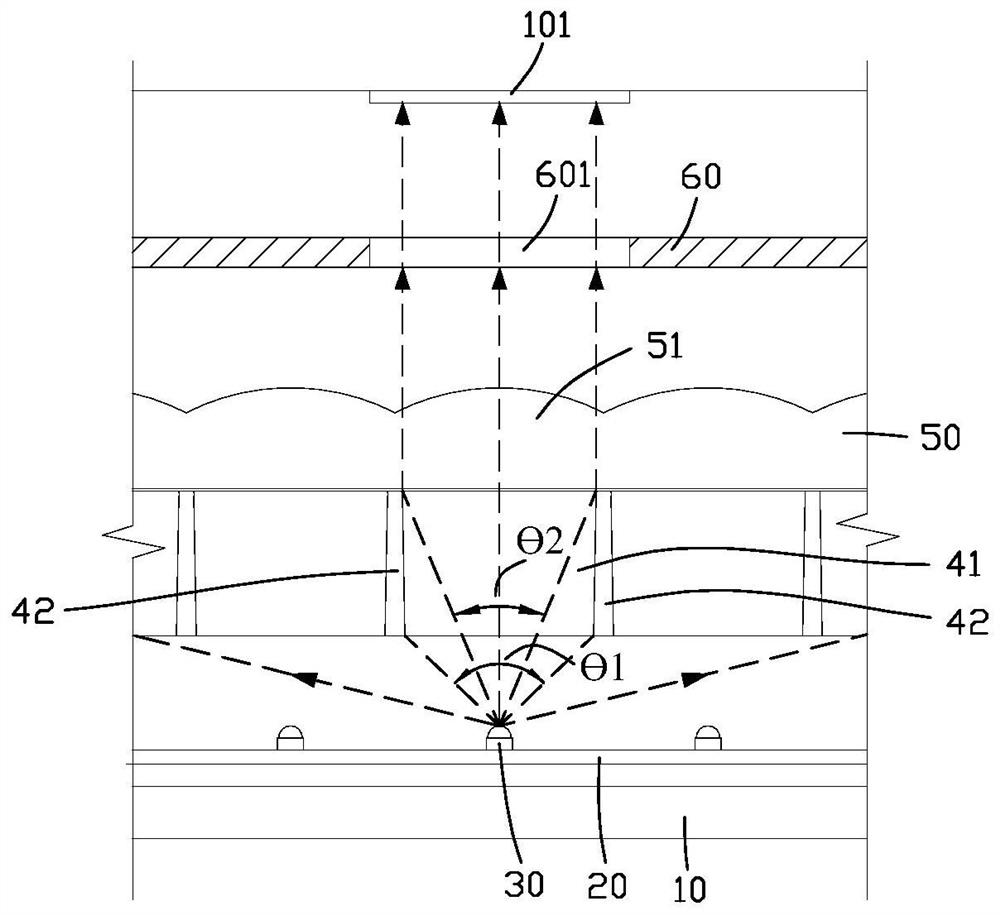

Photocuring 3D printer light machine, printer and light-emitting display method

PendingCN113290860AImprove uniformityGood light curing effectManufacturing irradiation arrangements3D object support structuresDot matrixComputer printing

The invention relates to a photocuring 3D printer. The photocuring 3D printer comprises a plurality of light-emitting sources, a grid plate, a lens and an LCD liquid crystal light-transmitting screen, wherein the multiple light-emitting sources are uniformly arranged and emit scattered light rays simultaneously; the grid plate is located above the light-emitting sources, a vertical light channel is formed in the position, corresponding to the position over one light-emitting source, of the grid plate, the light-emitting sources are located in the center of the light channel, and the light channel is defined by vertical light-proof side walls limiting light reflection; the lens is located above a light guide part, and a condensing lens unit is formed at the position, corresponding to the position over one light channel, of the lens; and the LCD liquid crystal light-transmitting screen is positioned above the lens, and the LCD liquid crystal light-transmitting screen is provided with a pixel dot matrix. According to the photocuring 3D printer, the control requirement for the light sources is simplified, the light uniformity is improved, and the product curing effect is improved.

Owner:SHENZHEN PENGJI PHOTOELECTRICITY CO LTD

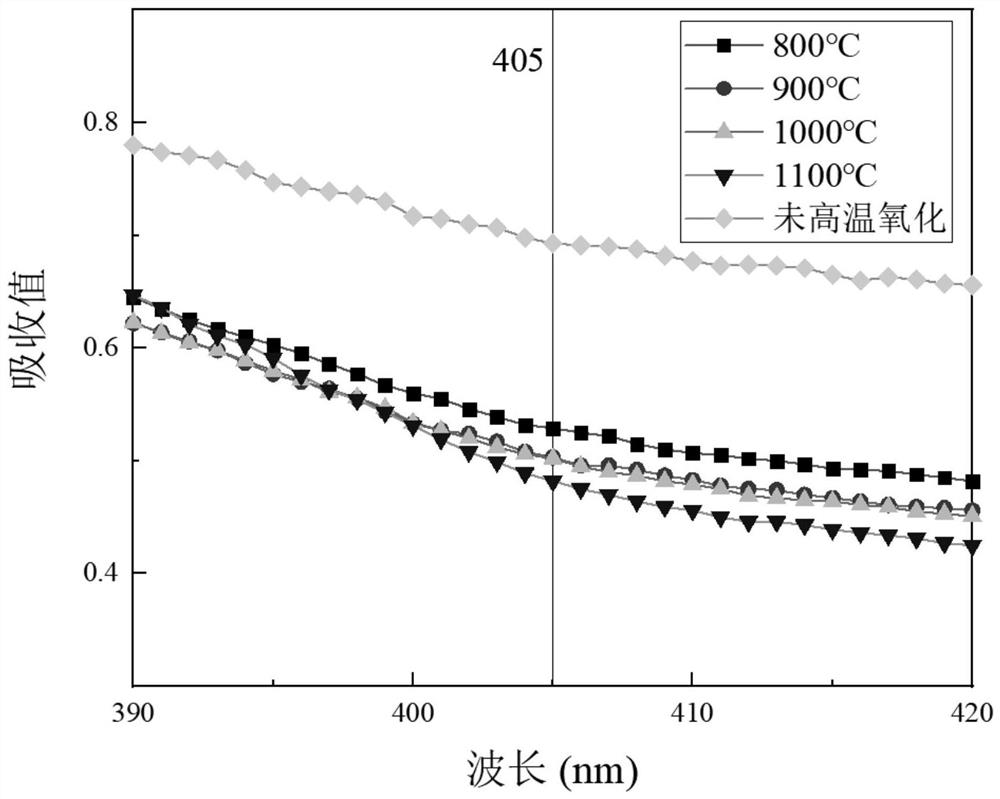

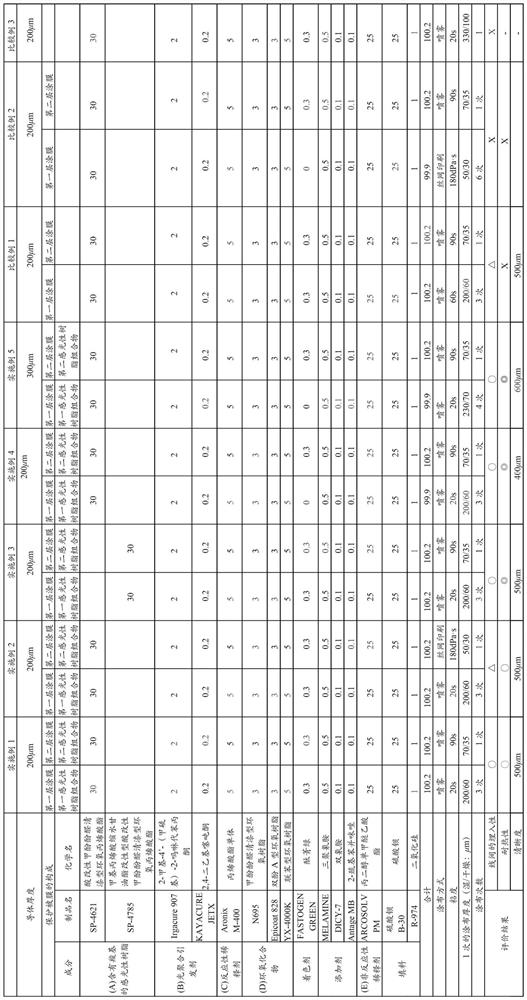

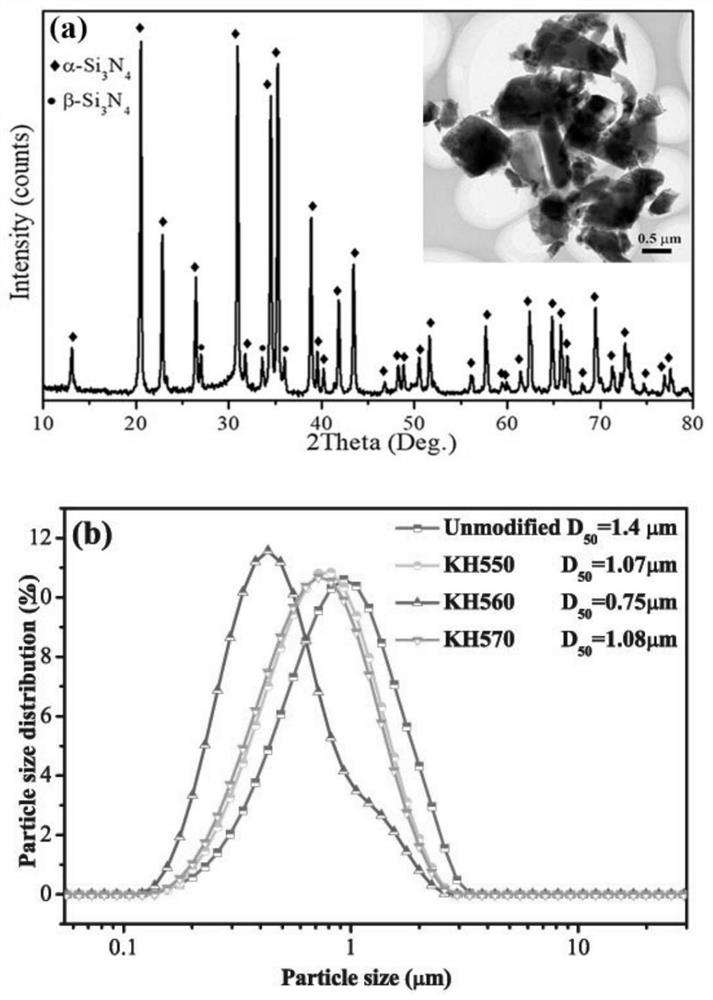

Silicon carbide reinforced silicon nitride ceramic and preparation method thereof

ActiveCN113548903AEasy to operateImprove light curing abilityIncreasing energy efficiencyCarbide siliconSilica fume

The invention discloses silicon carbide reinforced silicon nitride ceramic and a preparation method thereof, and relates to the technical field of ceramic materials. According to the preparation method, the silicon powder is subjected to heating surface oxidation treatment, so that a SiO2 layer with relatively low absorbance and refractive index is formed on the surface of the silicon powder, the introduced oxygen content is removed through carbon thermal reduction, and meanwhile, the silicon carbide phase reinforced silicon nitride ceramic is generated. The silicon nitride ceramic prepared by taking the silicon powder as the raw material through a reaction sintering method has the characteristic of low shrinkage distortion, and the preparation of the silicon carbide reinforced silicon nitride ceramic with a complex shape can be realized by matching with a photocuring molding technology.

Owner:GUANGDONG UNIV OF TECH

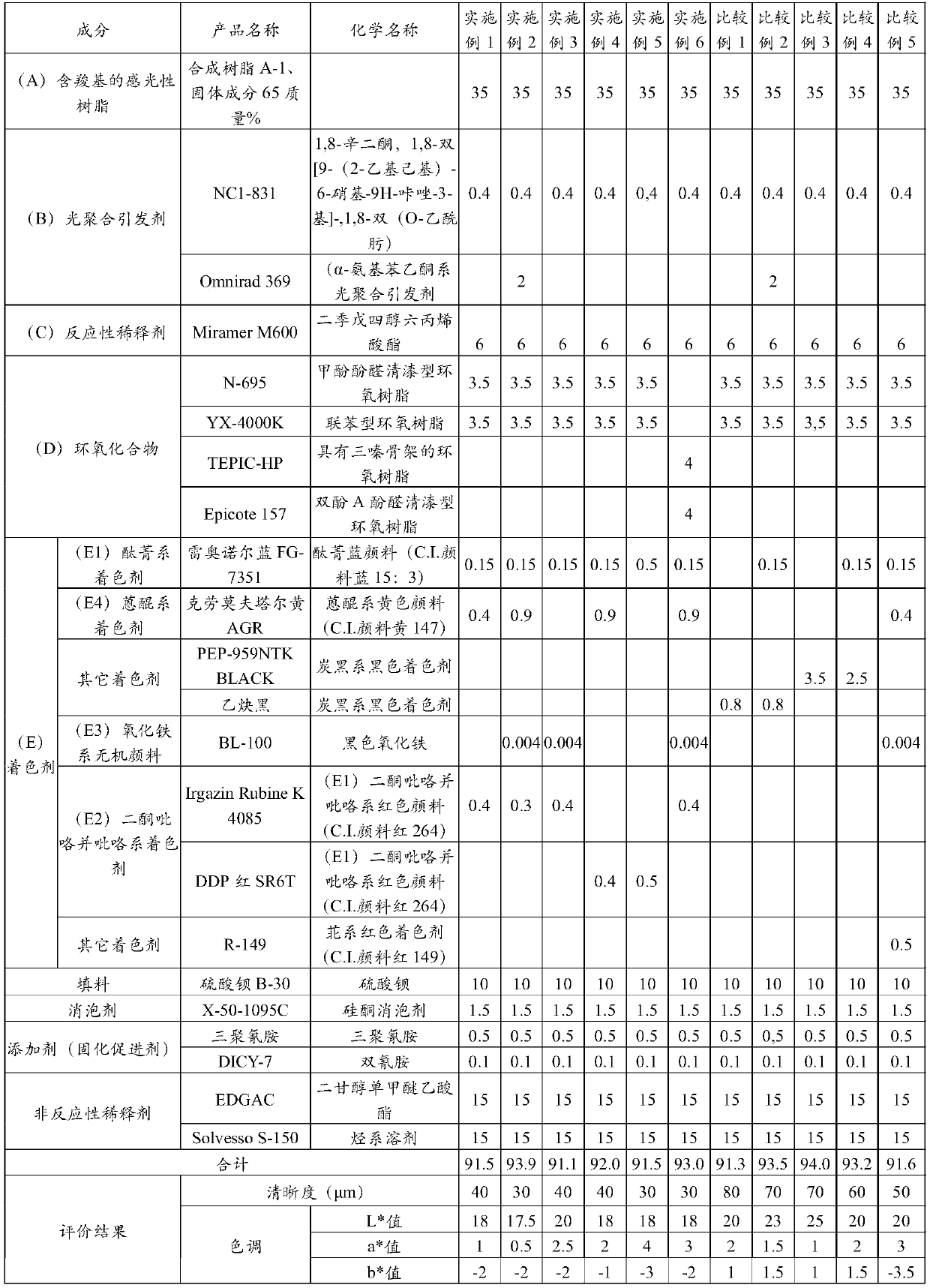

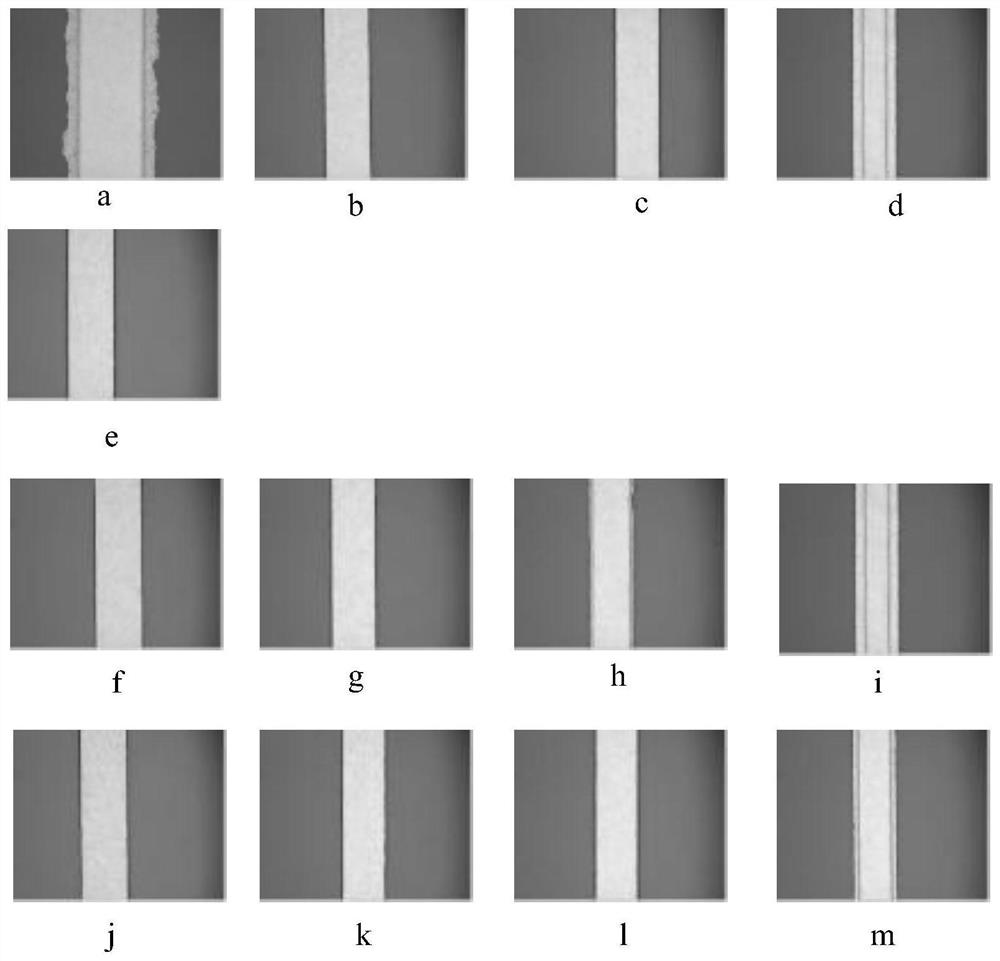

Black photosensitive resin composition

PendingCN111381441AImprove clarityGood blacknessPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationDiketonePolymer science

The present invention provides a black photosensitive resin composition which has excellent clarity and excellent blackness, thereby having high covering power. The black photosensitive resin composition contains (A) a carboxyl group-containing photosensitive resin, (B) a photopolymerization initiator, (C) a reactive diluent, (D) an epoxy compound, and (E) a colorant, wherein the (E) colorant contains (E1) a phthalocyanine colorant and (E2) a diketopyrrolopyrrole colorant.

Owner:TAMURA KK

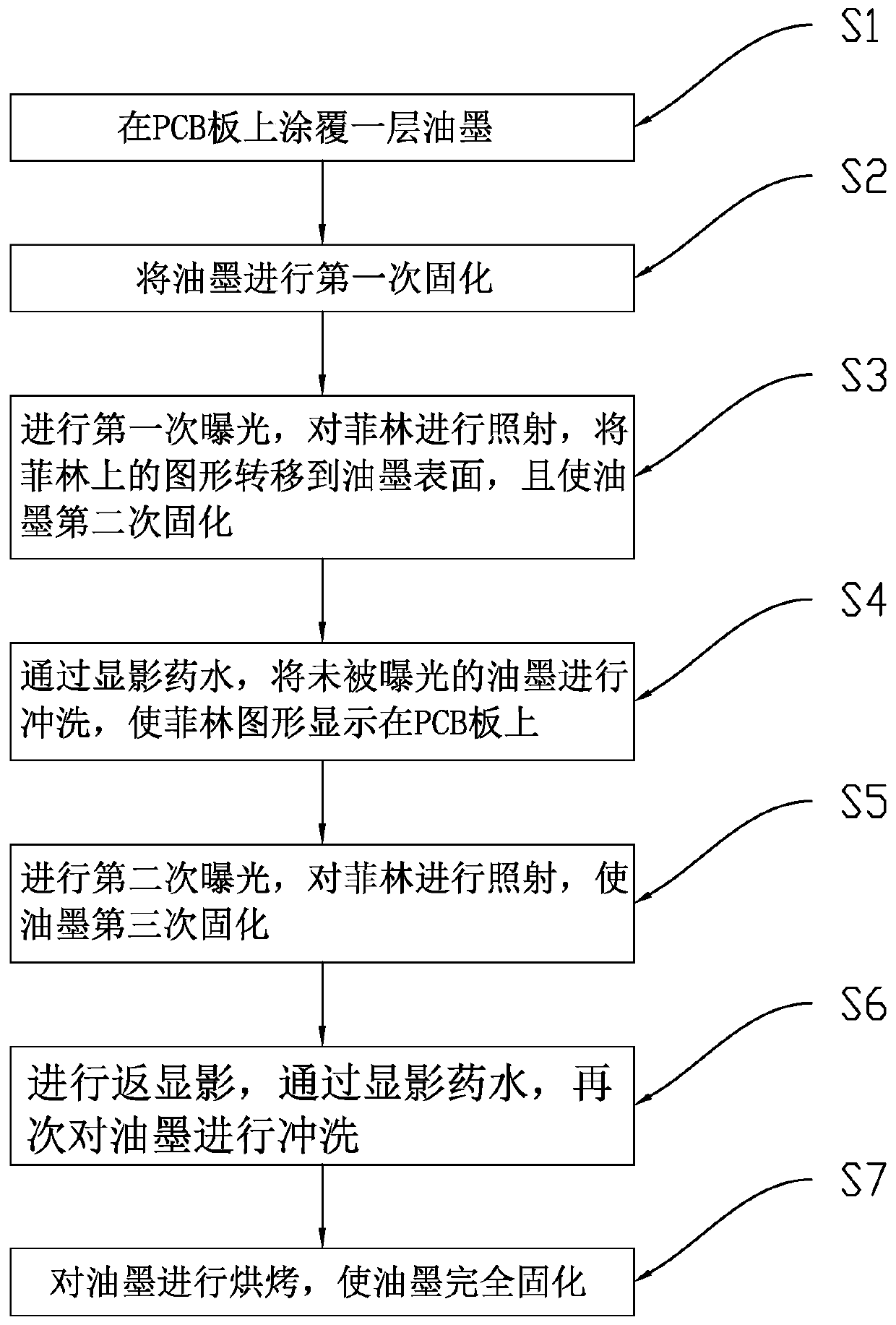

Anti-welding method for small aperture through holes

InactiveCN110475435AGood light curing effectGuaranteed Alignment AccuracyPrinted circuit dryingConductive pattern polishing/cleaningResistEngineering

The invention relates to an anti-welding method for small aperture through holes. The method includes the following steps: S1, coating a layer of printing ink on a PCB; S2, performing first curing onthe printing ink; S3, performing first exposure, performing irradiation on a film, transferring a pattern on the film to the surface of the printing ink, and performing second curing on the printing ink; S4, performing washing on unexposed printing ink through a developer so that the film pattern can be displayed on the PCB; S5, performing second exposure, performing irradiation on the film, and performing third curing on the printing ink; S6, performing reverse development, and performing washing on the printing ink again; and S7, performing baking on the printing ink to make the printing inkcompletely cured. Through the first exposure and the second exposure, light curing effects can be increased; reverse development and through holes washing can be performed, so that solder resist bridge and alignment accuracy can be guaranteed to meet quality requirements, the printing ink in holes can be cleaned, risks brought by backwash or repairing can be avoided, and the method is suitable for the making of the through holes with all apertures and spacing.

Owner:江西景旺精密电路有限公司

Liquid resin composition for production of optical waveguide, optical waveguide produced by using the liquid resin composition, and production method of the optical waveguide

ActiveUS8901196B2Improve mobilityHigh curing sensitivityCladded optical fibrePhotomechanical apparatusMeth-Liquid state

Owner:NITTO DENKO CORP

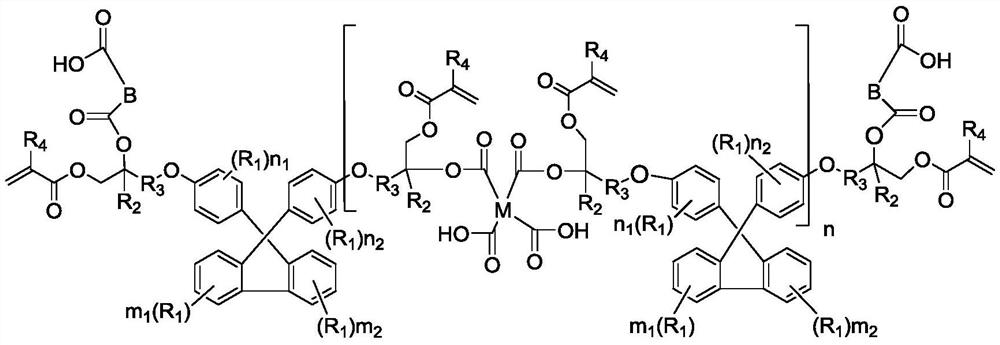

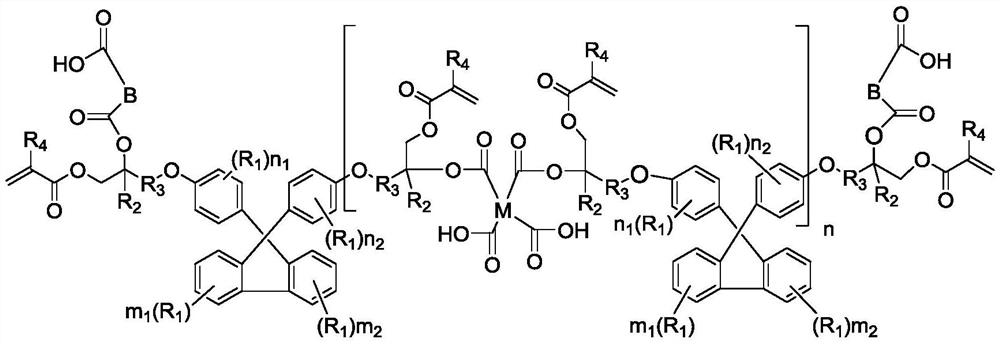

Photosensitive resin composition and photoresist

PendingCN112578632ALow acid valueGood light curing effectPhotosensitive materials for photomechanical apparatusPolymer scienceOrganic chemistry

The invention provides a photosensitive resin composition and a photoresist. The photosensitive resin composition comprises resin, and the resin comprises at least two kinds of photosensitive resin, wherein the two kinds of photosensitive resin independently have the structure shown in the structural formula I, one kind of photosensitive resin is high-molecular-weight photosensitive resin, the weight-average molecular weight of the photosensitive resin is 6,300-7,800, and the weight-average molecular weight of the photosensitive resin is 5,000-5,500; the structural formula I is shown in the specification, and the photosensitive resin with the structural formula I has the photocuring performance, wherein the adhesiveness to a substrate, the alkali solvent resistance and the solvent resistance are high; and the two photosensitive resins with the advantages are compounded, so the molecular weight of each photosensitive resin is further controlled; the resolution and the adhesive force canbe improved by utilizing the high molecular weight photosensitivity, and the developability is improved and the residual film rate is reduced by utilizing the low molecular weight photosensitive resin, so a black matrix with high sensitivity and uniform CD can be prepared.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +2

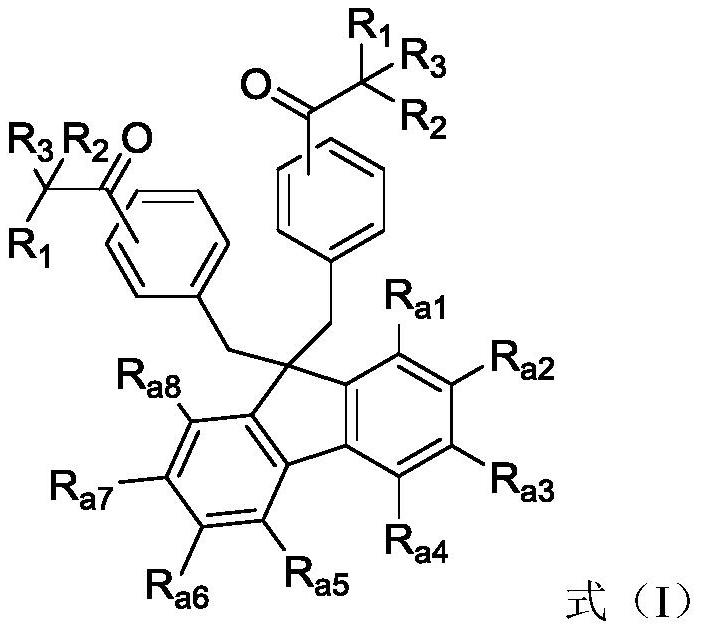

Fluorene photoinitiator, preparation method thereof, photocuring composition containing fluorene photoinitiator and application of fluorene photoinitiator in field of photocuring

ActiveCN112010997AImprove sensibilityNot easy to migrateOrganic compound preparationPhotomechanical apparatusBenzophenonePhotoinitiator

The invention provides a fluorene photoinitiator, a preparation method thereof, a photocuring composition containing the fluorene photoinitiator and application of the fluorene photoinitiator in the field of photocuring. The fluorene photoinitiator has a structure shown as a formula (I), wherein R3 is selected from photoactive groups. A benzophenone alkyl substituent group is introduced to a No.9carbon atom position of a fluorene structure, and fragments formed by the initiator still have high stability and photocuring effect after initiation reaction; meanwhile, the introduction of the photoactive group R3 can improve the light absorption efficiency of the photoinitiator so that the improvement of the sensitivity of the photoinitiator is facilitated. In addition, due to the fact that thephotoinitiator is large in component and light in color, the photoinitiator further has the advantages of being not prone to migration and excellent in yellowing resistance, and therefore the photoinitiator further has the advantages of being almost free of VOC emission, low in smell and excellent in yellowing resistance.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD +1

Novel ink photocuring device

InactiveCN107552355ASatisfy light curing requirementsGood light curing effectPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a novel ink photocuring device. The novel ink photocuring device comprises a rack and a curing furnace, wherein an UV lamp pipe is arranged in the curing furnace; a charge portand a discharge port are formed in the left side and the right side of the curing furnace; the rack is provided with an upper left roll and a lower left roll at the left side of the curing furnace inthe vertical direction, and provided with an upper right roll and a lower right roll at the right side of the curing furnace; a conveying belt is arranged on the upper left roll, the lower left roll,the upper right roll and the lower right roll; the conveying belt sequentially passes through the lower right roll, the curing furnace, the lower left roll, the upper left roll and the upper right roll; a low-voltage halogen lamp is arranged at the top of the outer side of the curing furnace; the upper right roll and the upper left roll are both located above the low-voltage halogen lamp in the vertical direction; exhaust ports are formed in the front side and the rear side of the curing furnace separately; an exhaust fan is arranged on each exhaust port; the curing furnace is provided with alight barrier at the outer side of each exhaust port; and each light barrier is in an arc shape with a middle part sunken towards the corresponding exhaust port. According to the novel ink photocuring device disclosed by the invention, secondary photocuring is carried out through the low-voltage halogen lamp above the curing furnace, so that the photocuring effect can be effectively improved; andmeanwhile, rapid and stable heat dissipation is realized by virtue of the exhaust fans.

Owner:ZHEJIANG WELLVAST PACKING PRINTING PRODS

Fluorene initiator, photocurable composition containing same, and application thereof

PendingCN112409295AHigh light curing effectHigh sensitivityOrganic chemistryComposite materialPhotoinitiator

The invention provides a fluorene initiator, a photocurable composition containing the same and an application of the fluorene initiator and the photocurable composition. The fluorene photoinitiator has a structure as shown in a formula (I). According to the photoinitiator, one or more alkyl ketone substituents are introduced to a fluorene structure, and two aryl ketone substituents are introducedto a No.9 carbon atom, so that fragments formed by the initiator still have relatively high stability and photocuring effect after initiation of an initiation reaction; meanwhile, due to the introduction of a plurality of photoactive groups R3, the number of free radicals generated by the photoinitiator per unit mass can be increased, and the sensitivity of the photoinitiator can be improved. Inaddition, due to the fact that the photoinitiator is large in molecular weight and light in color, the photoinitiator further has the advantages of being not prone to migration and excellent in yellowing resistance, and therefore the photoinitiator further has the advantages of being almost free of VOC emission, low in smell and excellent in yellowing resistance.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS +1

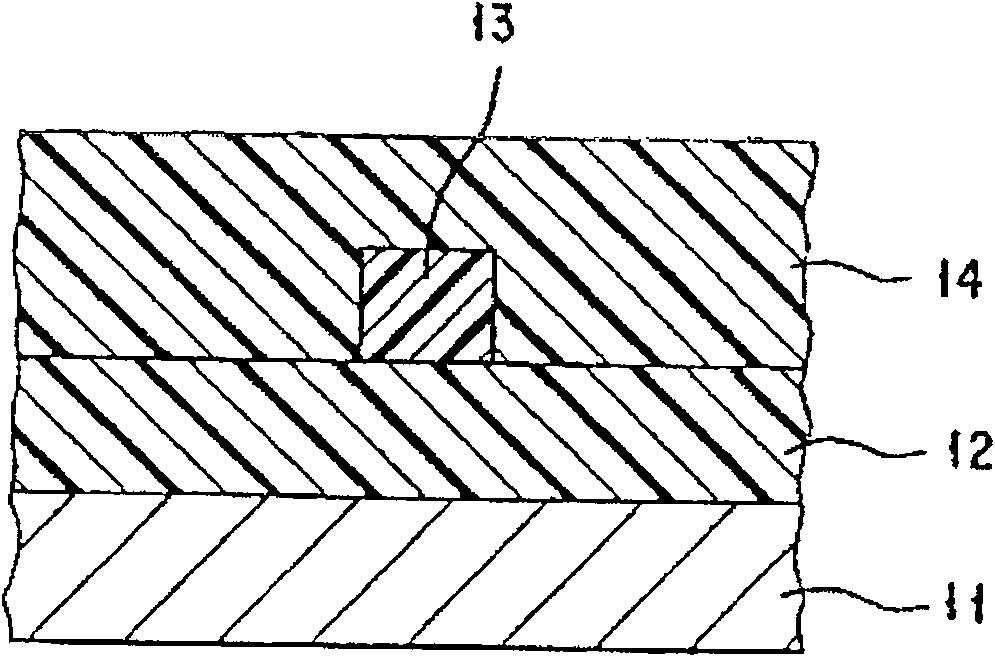

Method for manufacturing wiring board having protective film

PendingCN112020235AAvoid it happening againReduce gapNon-metallic protective coating applicationElectrical conductorHeat resistance

The present invention provides a method for manufacturing a wiring board having a protective film, by which voids can be prevented from being generated in the protective film and excellent heat resistance can be imparted to the protective film. The manufacturing method of the wiring board having the protective film comprises the following steps: a first coating film formation step, wherein a firstphotosensitive resin composition is sprayed on a wiring board having a substrate and a conductor provided on the substrate to form a first coating film, the viscosity of the first photosensitive resin composition is 10-50 seconds when measured by a rock field cup, and the film thickness of the first coating film after drying is less than or equal to the thickness of the conductor; a second coating film formation step, wherein a second photosensitive resin composition having a viscosity higher than that of the first photosensitive resin composition is applied to the surface of the first coating film to form a second coating film, and the sum of the film thickness of the first coating film after drying and the film thickness of the second coating film after drying is greater than the thickness of the conductor.

Owner:TAMURA KK

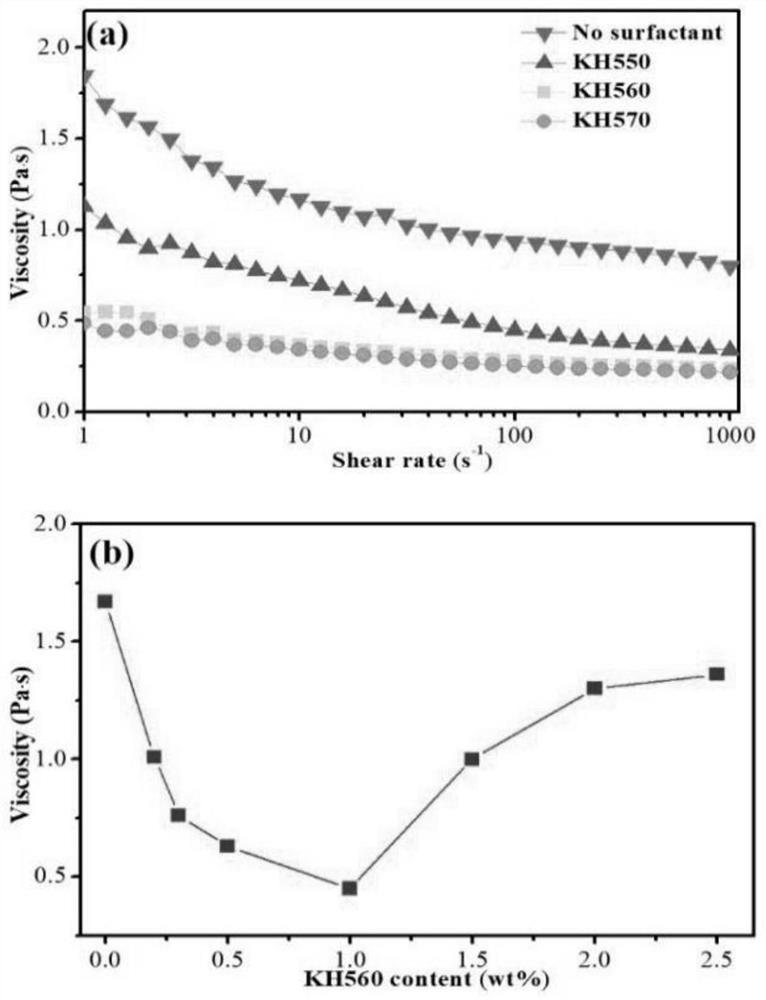

Preparation method of gradient layered structure silicon nitride ceramic

PendingCN113620717AReduce the refractive index differenceLow wettabilityHigh densityRefractive index

The invention discloses a preparation method of a gradient layered structure silicon nitride ceramic, the preparation method comprises the following steps: firstly, screening out a surface modifier capable of effectively reducing the refractive index difference of silicon nitride ceramic particles, and increasing the curing depth of the surface modifier; the applicant reveals a photocuring forming mechanism of the modified silicon nitride ceramic slurry by comparing rheological properties, dynamic stability, wettability and photocuring properties of the silicon nitride ceramic slurry before and after modification. By utilizing the mechanism, the rheological property, the dynamic stability, the wettability and the photocuring property of the silicon nitride ceramic slurry are improved, and the silicon nitride ceramic with high density, hardness and fracture toughness can be prepared.

Owner:萍乡旭材科技有限公司

Diphenyl sulfide ketone oxime ester photoinitiator as well as preparation method and application thereof

ActiveCN102492059BImprove applicabilityIncrease photosensitivityPhotosensitive materials for photomechanical apparatusSulfide preparationChemical structureKetone

The invention relates to a diphenyl sulfide ketone oxime ester photoinitiator which has a chemical structure as shown in a formula (I). The photoinitiator has excellent application performance, also has ultra-high photosensitive property when being applied to a photosensitive composition, particularly shows high photosensitive activity under the excitation of an LED (Light-emitting Diode) light source, is remarkably superior to the existing photoinitiator and embodies huge advantages in energy consumption, light source stability and operation safety. The invention also relates to a preparation method of the photoinitiator and an application of the photoinitiator to the photosensitive combination.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD

A two-component tile grout

Owner:广东美佳康新材料有限公司

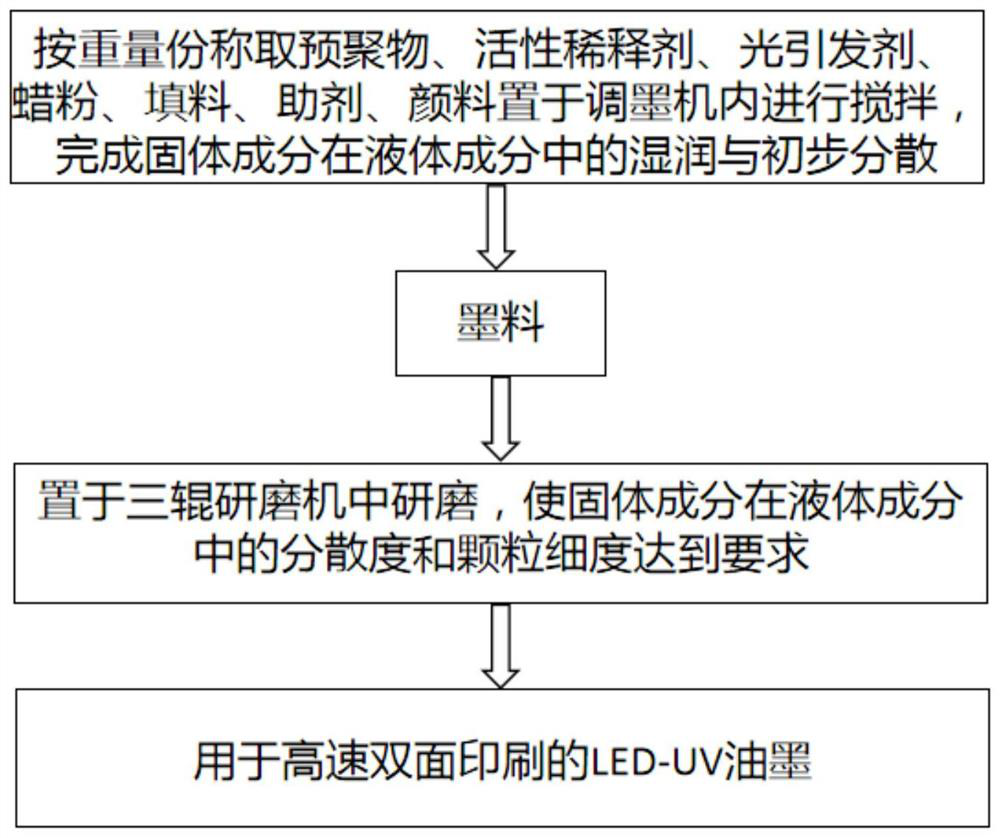

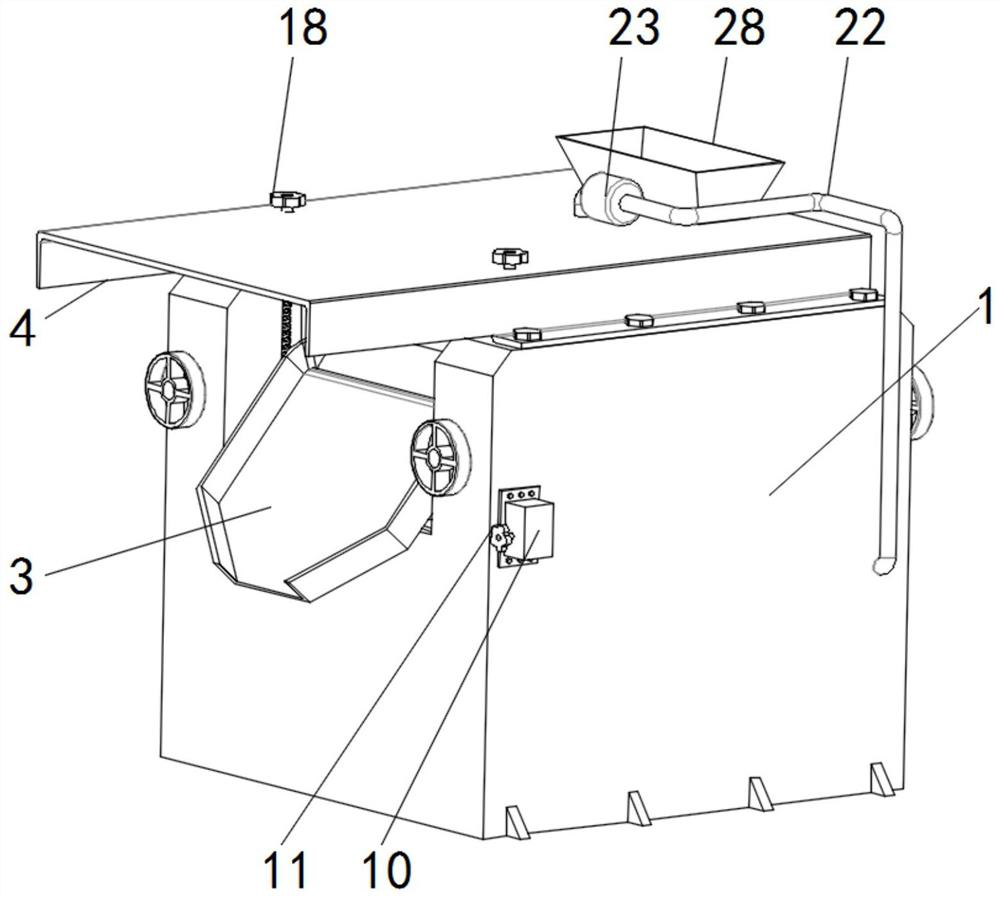

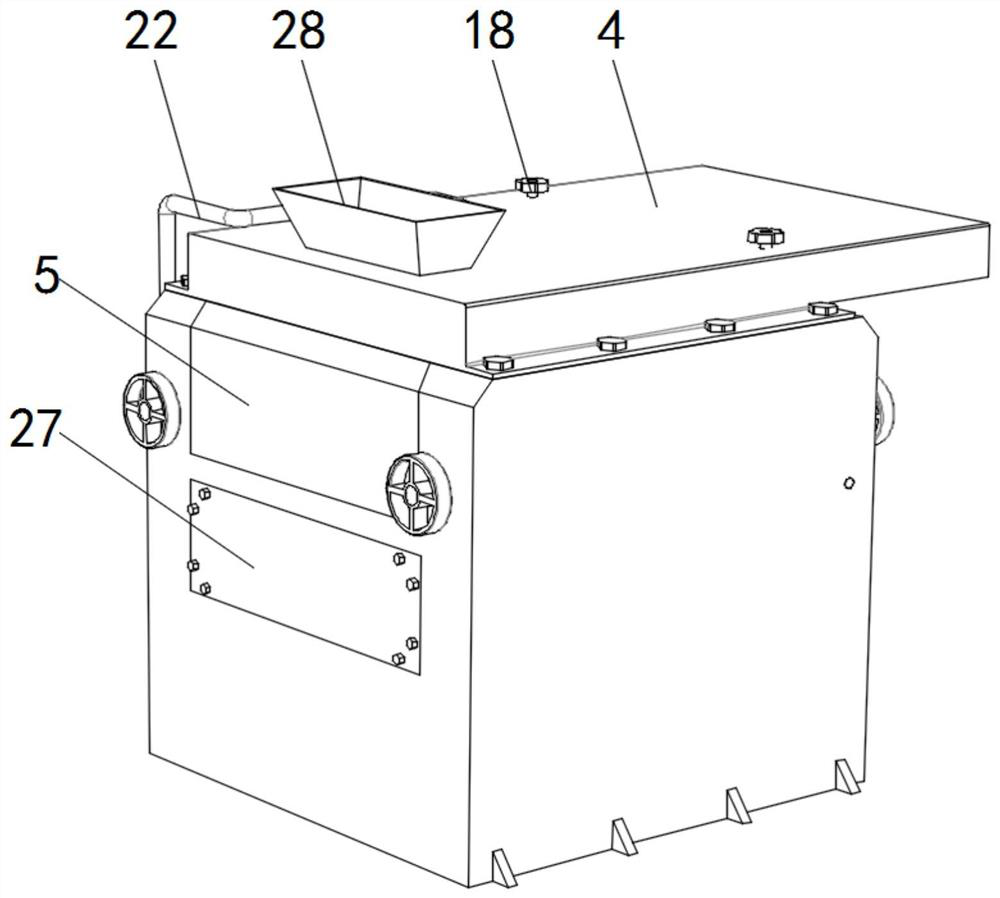

LED-UV ink for high-speed double-sided printing and preparation method thereof

PendingCN113604104AExtended service lifeGood light curing effectInksGrain treatmentsComposite materialPhotoinitiator

The invention discloses LED-UV ink for high-speed double-sided printing and a preparation method thereof. The LED-UV ink is prepared from the following raw materials: a prepolymer, a reactive diluent, a photoinitiator, a pigment, a filler, wax powder and an auxiliary agent. The prepared LED-UV ink can be rapidly cured in an LED-UV curing system, a cured ink film layer is high in glossiness and good in wear resistance, the ink does not contain volatile substances and is safe and environmentally friendly, and the printing efficiency and the printing quality are greatly improved.

Owner:深圳松本新材料科技有限公司

Solder resist composition and printed wiring board

ActiveCN102722083AImprove reflectivityHigh resolutionPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationResistOrganic solvent

A high reflective / high definition solder composition and a printed circuit board using thereof are provided secure the excellent patterning ability by light and resolving potency. A high reflective / high definition solder composition contains a carboxyl containing resin without an aromatic ring, bisacylphosphine oxide based photopolymerization initiator, a mono-acylphosphineoxide based photopolymerization initiator, a photo-polymerizable monomer, a rutile-type titanium oxide, and an organic solvent. The carboxyl containing resin without the aromatic ring is a copolymer resin having a carboxyl group obtained by reacting a (meth) acrylic copolymer resin containing the carboxyl group, and a compound with an ethylenically unsaturated group.

Owner:TAIYO HLDG CO LTD

Method for improving binding force between outer layer conductive pattern and ink of thick copper plate

InactiveCN114615823AImprove high temperature resistanceImprove heat resistanceInksNon-metallic protective coating applicationHeat stabilityEngineering

The invention relates to the field of circuit board printing, and aims to solve the problems that the binding force between the existing PCB ink and an outer layer conductive pattern of a thick copper plate is poor, so that the ink is easy to fall off, a circuit cannot be effectively protected finally, a large amount of heat is released in the use process of a PCB, the PCB ink is damaged by heating, and the service life of the PCB is prolonged. According to the method for improving the binding force between the outer layer conductive pattern of the thick copper plate and the printing ink, the binding force between the outer layer conductive pattern of the thick copper plate and the printing ink can be obviously improved by using binding glue, meanwhile, the high temperature resistance of the binding glue is good, and the circuit cannot be effectively protected. The modified light-cured resin can separate the thick copper plate from the printing ink, so that a coating formed by the printing ink is prevented from being damaged under the heating condition, the thermal stability of a product is ensured, and the thermal stability of the product is further ensured as the modified light-cured resin has better heat resistance.

Owner:CHANGZHOU AOHONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com