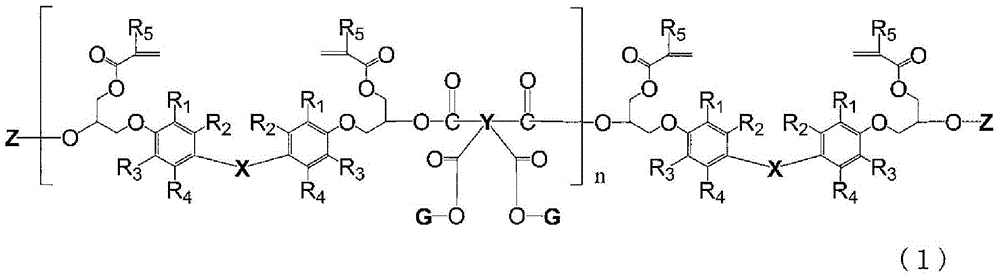

Photosensitive resin composition and cured substance for insulating film

A technology of photosensitive resin and insulating film, which is applied in the direction of photosensitive materials used in optomechanical equipment, optics, optomechanical equipment, etc. It can solve the problems that the proportion of polymerizable unsaturated bonds does not increase, and the crosslinking density cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

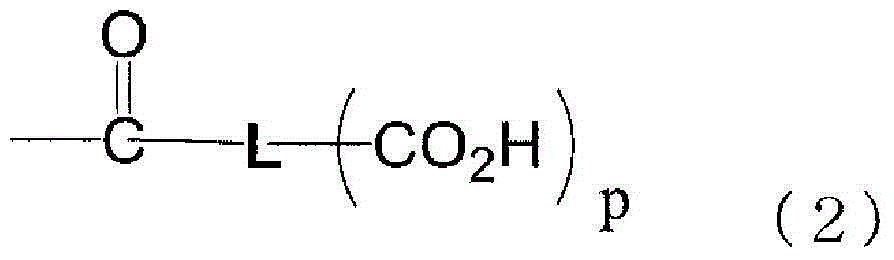

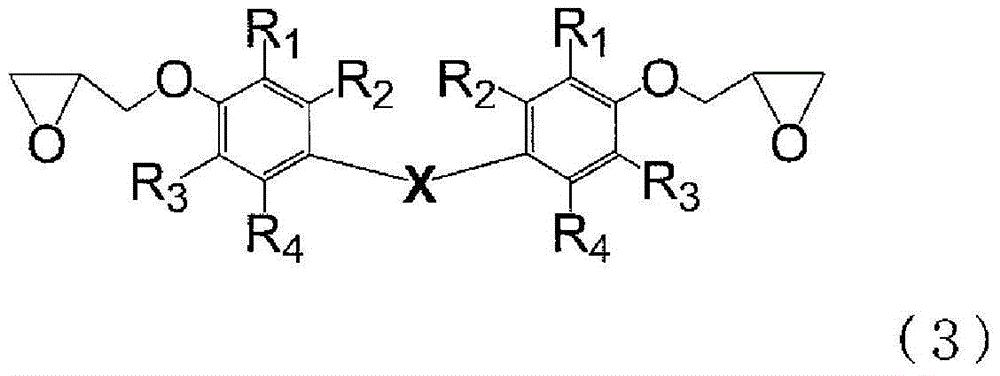

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0101] Add 600.0g (0.49mol) of 50% PGMEA solution of FHPA [(A) component], 72.8g (0.25mol) BPDA [(B) component], 39.6g PGMEA and 1.30 g of TPP was stirred under heating at 120 to 125° C. for 2 hours, and further heated and stirred at 70 to 75° C. for 6 hours to obtain a reaction product (a). The solid content concentration of the obtained reaction product (a) was 52.4 wt%, the acid value of the resin was 78.0 mgKOH / g, and the molecular weight (Mw) was 3400.

[0102] Next, 73.9 g (0.52 mol) of GMA [component (C)] was added to this reaction product (a), and it stirred at 80 degreeC for 8 hours, and made it react. Furthermore, 156.7 g (1.0 mol) of THPA [component (D)] was put into a flask, it stirred at 80 degreeC for 7 hours, and the alkali-soluble resin (i)-1 was synthesize|combined. The obtained alkali-soluble resin had a solid content of 62.0 wt %, an acid value of 112 mgKOH / g, and a molecular weight (Mw) of 3,700. In addition, the names and compounding ratios of the compon...

Synthetic example 2

[0104] Alkali-soluble resin (i)-2 was obtained in the same manner as in Synthesis Example 1, except that the feed amount of THPA [(D) component] in Synthesis Example 1 was changed to 118.7 g (0.78 mol).

Synthetic example 3

[0106] Add 600.0g (0.49mol) of 50% PGMEA solution of FHPA [(A) component], 96.0g (0.33mol) BPDA [(B) component], 4.36g PGMEA and 1.02 g of TEAB was stirred under heating at 120 to 125° C. for 2 hours, and further heated and stirred at 60 to 65° C. for 8 hours to obtain a reaction product (b). The obtained reaction product (b) had a solid content concentration of 57.8 wt %, an acid value of 91.6 mgKOH / g, and a molecular weight (Mw) of 8,800.

[0107] Next, 93.8 g (0.66 mol) of GMA [component (C)] was added to this reaction product (b), and it stirred at 80 degreeC for 24 hours, and made it react. Furthermore, 153.7 g (1.0 mol) of THPA [component (D)] and 153.7 g of PGMEA were added to the flask, and it stirred at 80 degreeC for 24 hours, and the alkali-soluble resin (i)-3 was synthesize|combined. The obtained alkali-soluble resin had a solid content concentration of 59.2 wt %, an acid value of 127 mgKOH / g, and a molecular weight (Mw) of 6,800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com