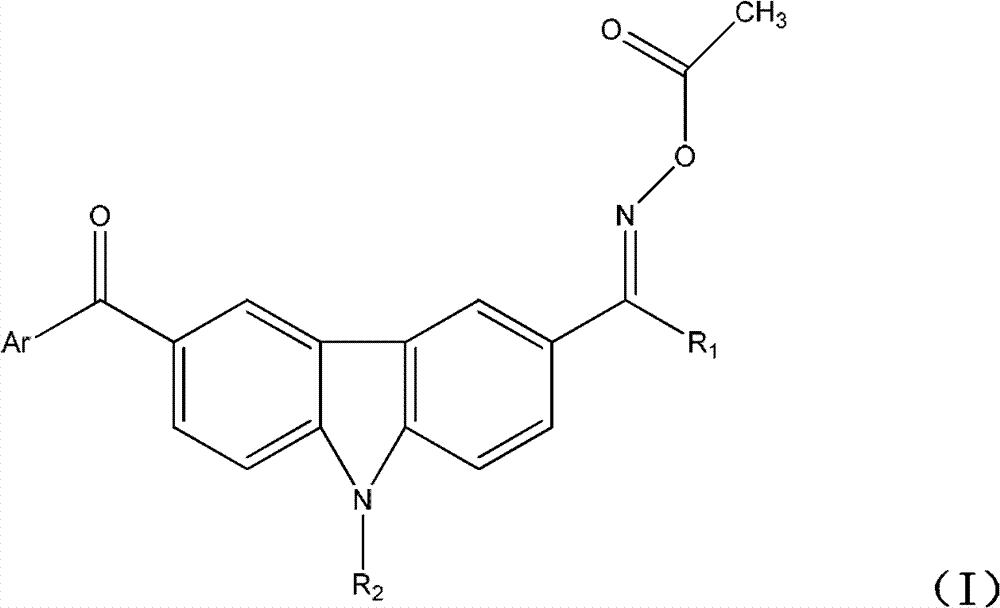

Pyrazole oxime ester photoinitiator with high photosensibility, preparation method and application thereof

A technology of photoinitiator and carbazole oxime, applied in the field of photoinitiator, can solve the problem of not being able to meet the needs of high-end color filters and LED applications, and achieve the effect of improving photocuring performance, excellent application performance and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

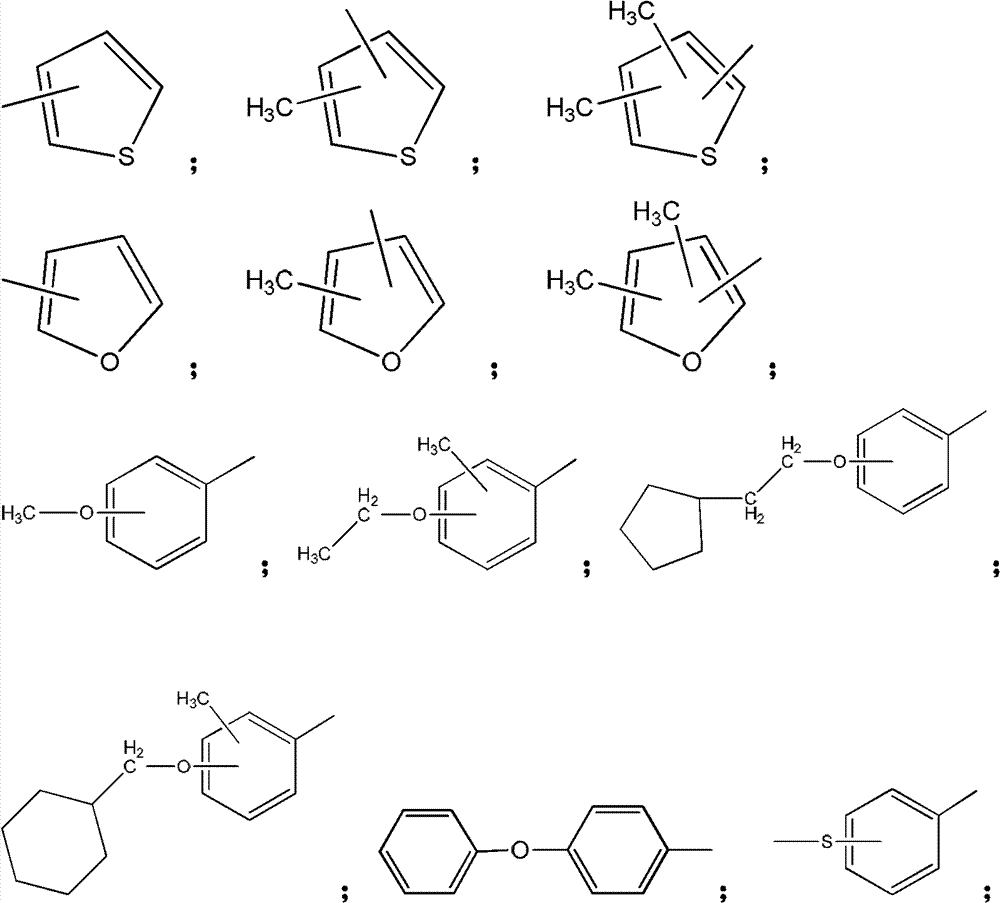

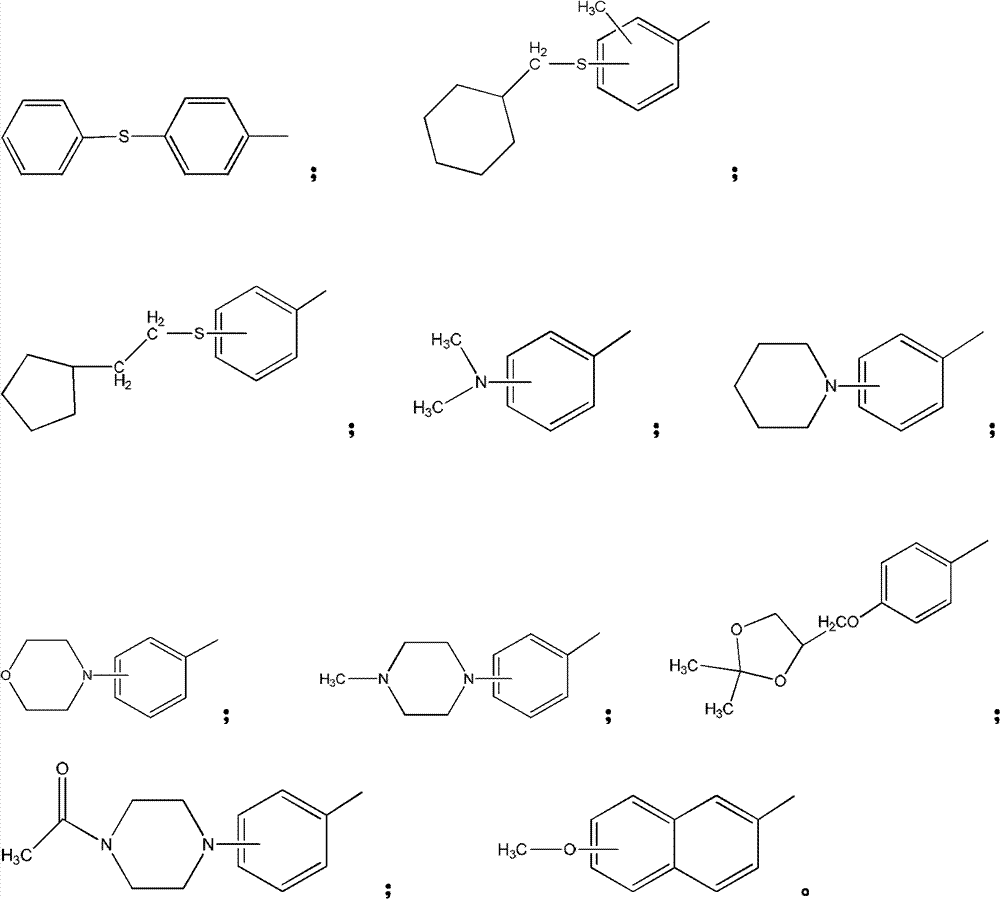

Method used

Image

Examples

Embodiment 1

[0033] Preparation of 1-[6-(2-thiophenoyl)-9-ethylcarbazol-3-yl]-(3-cyclopentylacetone)-1-oxime acetate as shown in the following formula

[0034]

[0035] Step 1: Preparation of 9-ethylcarbazole

[0036]

[0037] Put 20g of carbazole, 0.8g of tetraethylammonium bromide, and 100mL of toluene into a 250mL four-necked flask. Under stirring, add 70g of the 50% NaOH aqueous solution that is now prepared, dropwise add 15.6g of bromoethane, drop it for about 30min, and then Heating to reflux for 6h. Cool to room temperature, separate to remove the water layer, wash the material liquid layer 3 times, anhydrous MgSO 4 Dry, filter with suction, concentrate under reduced pressure to remove the solvent, and recrystallize the residue with absolute ethanol to obtain 33.5 g of white needle-like crystals with a yield of 72.0% and a relative purity of 99.0%.

[0038] Step 2: Preparation of 3-(3-cyclopentylpropionyl)-6-(2-thienoyl)-9-ethylcarbazole

[0039]

[0040] Drop into 30g 9...

Embodiment 2--12

[0053] Referring to the method shown in Example 1, the compounds of Examples 2--12 were prepared from corresponding acylating reagents, corresponding aldehydes or ketones. target compounds and their 1 H-NMR data are listed in Table 1.

[0054] Table 1

[0055]

[0056]

[0057]

[0058]

[0059]

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com