Patents

Literature

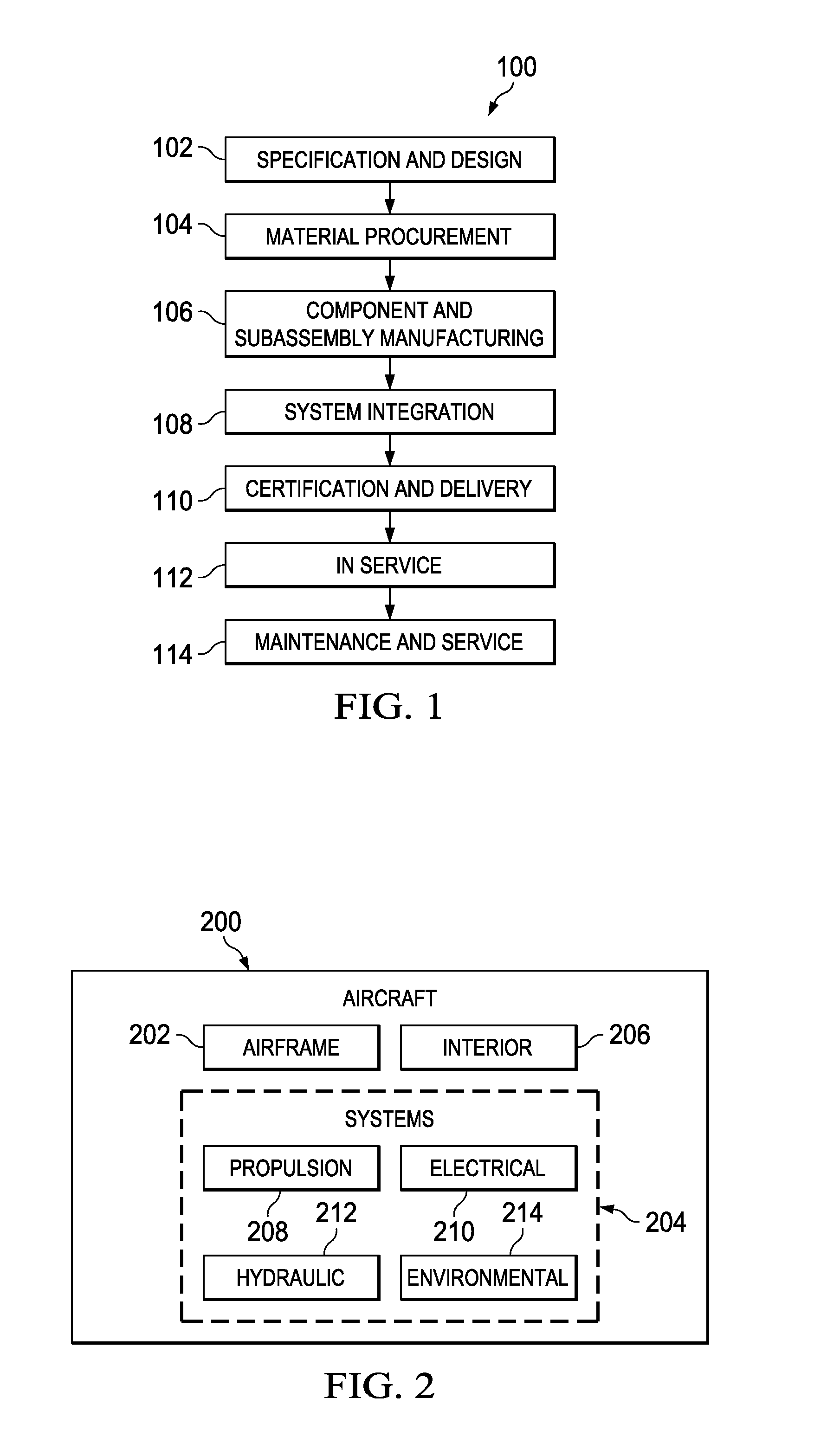

619results about "Manufacturing recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

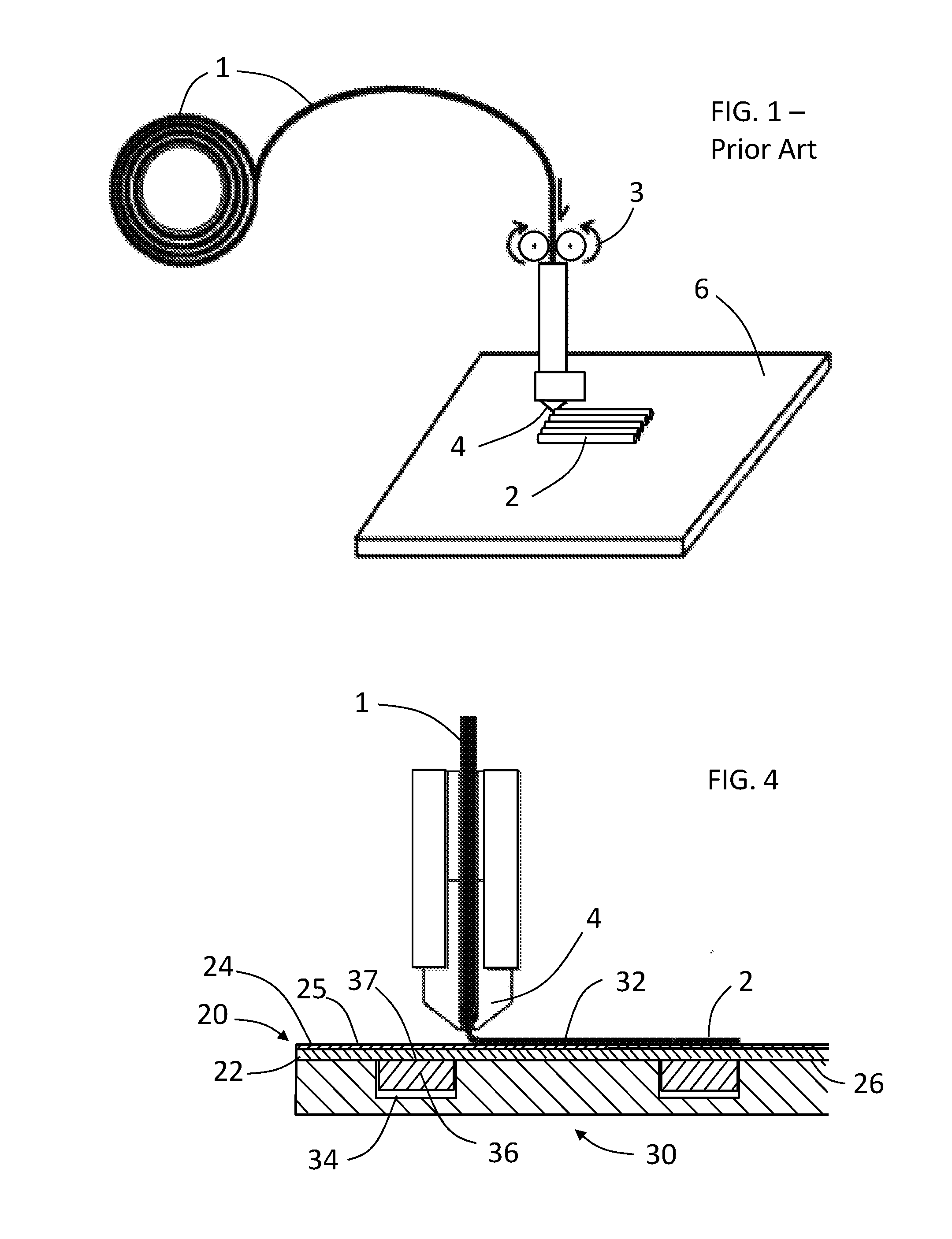

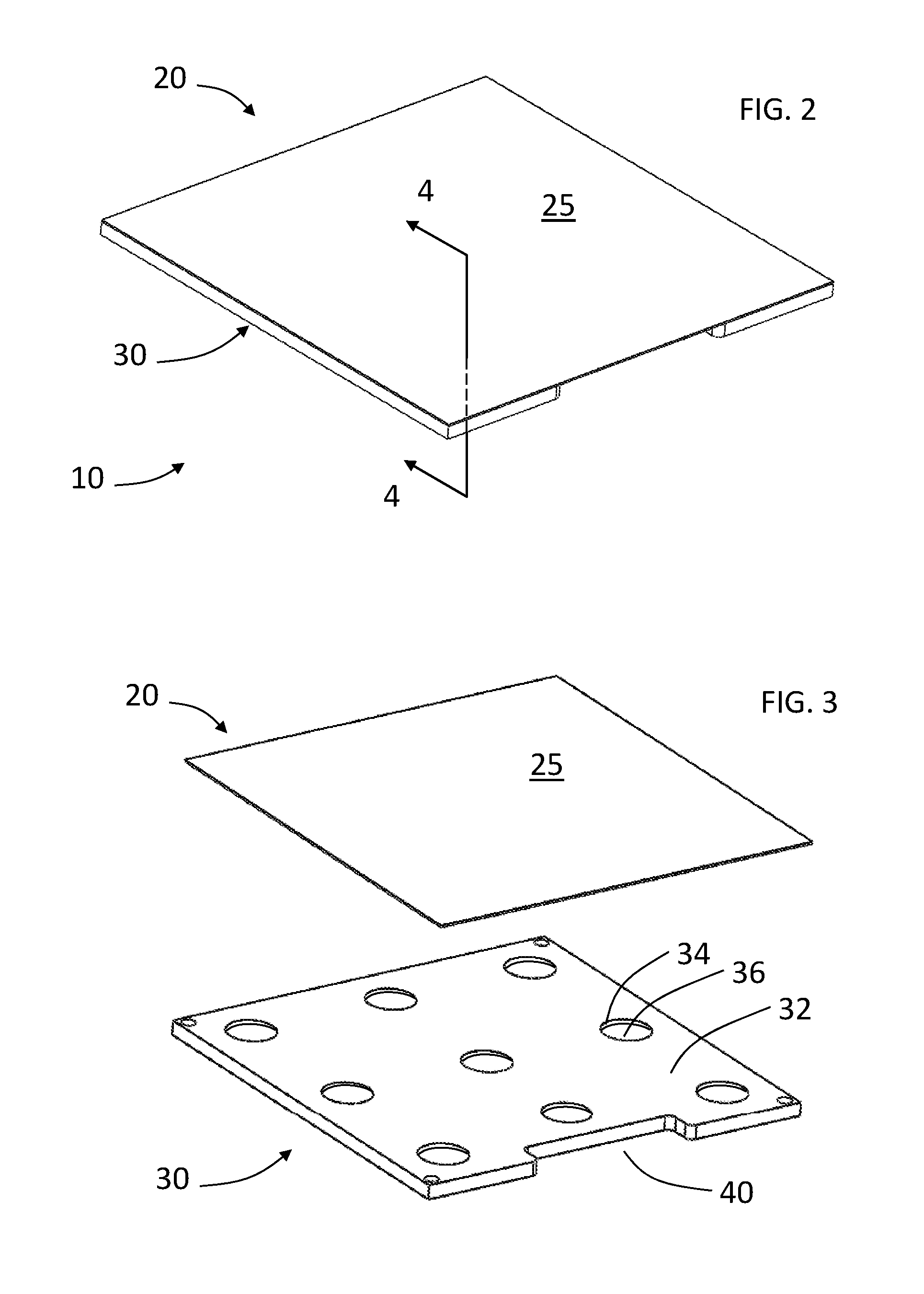

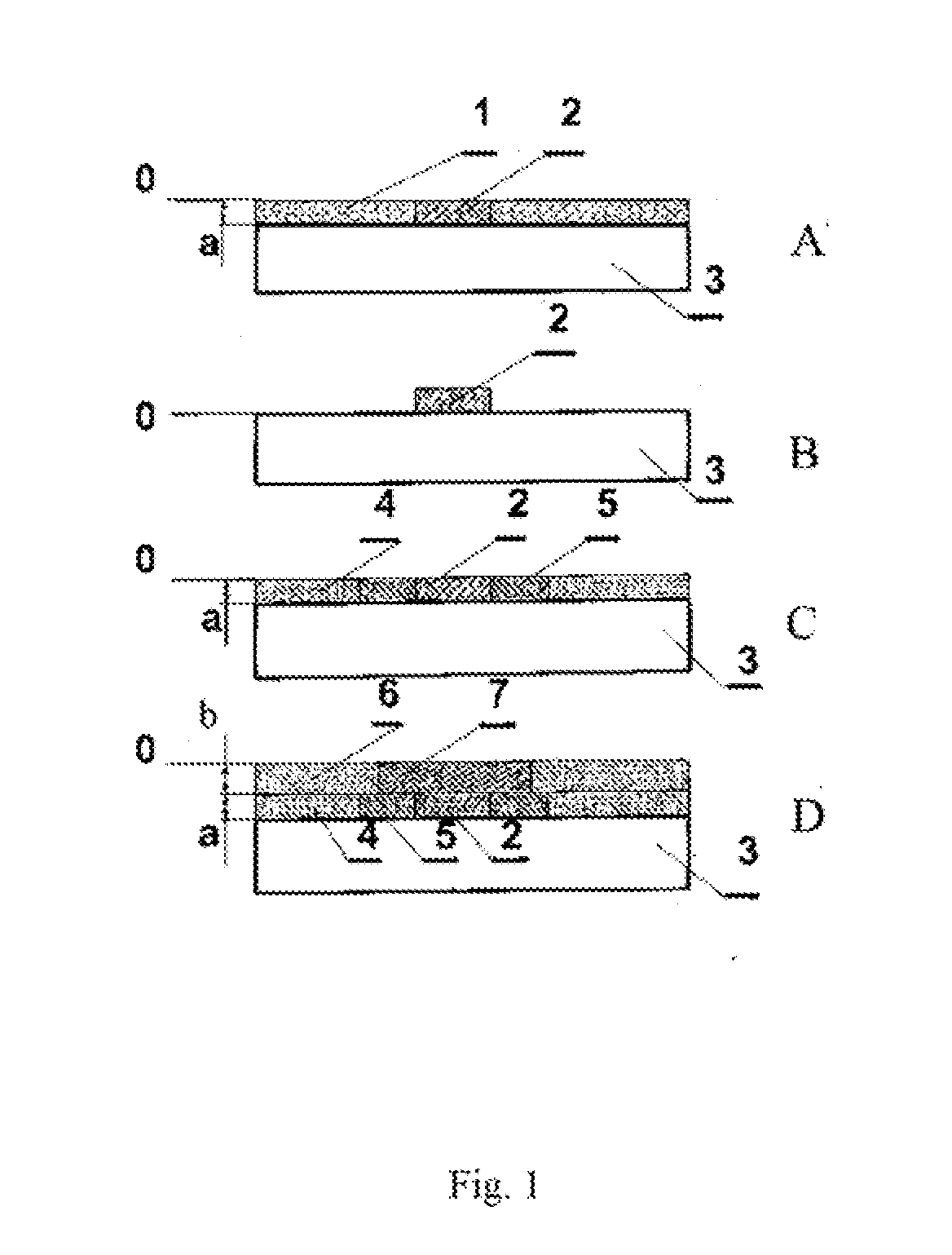

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

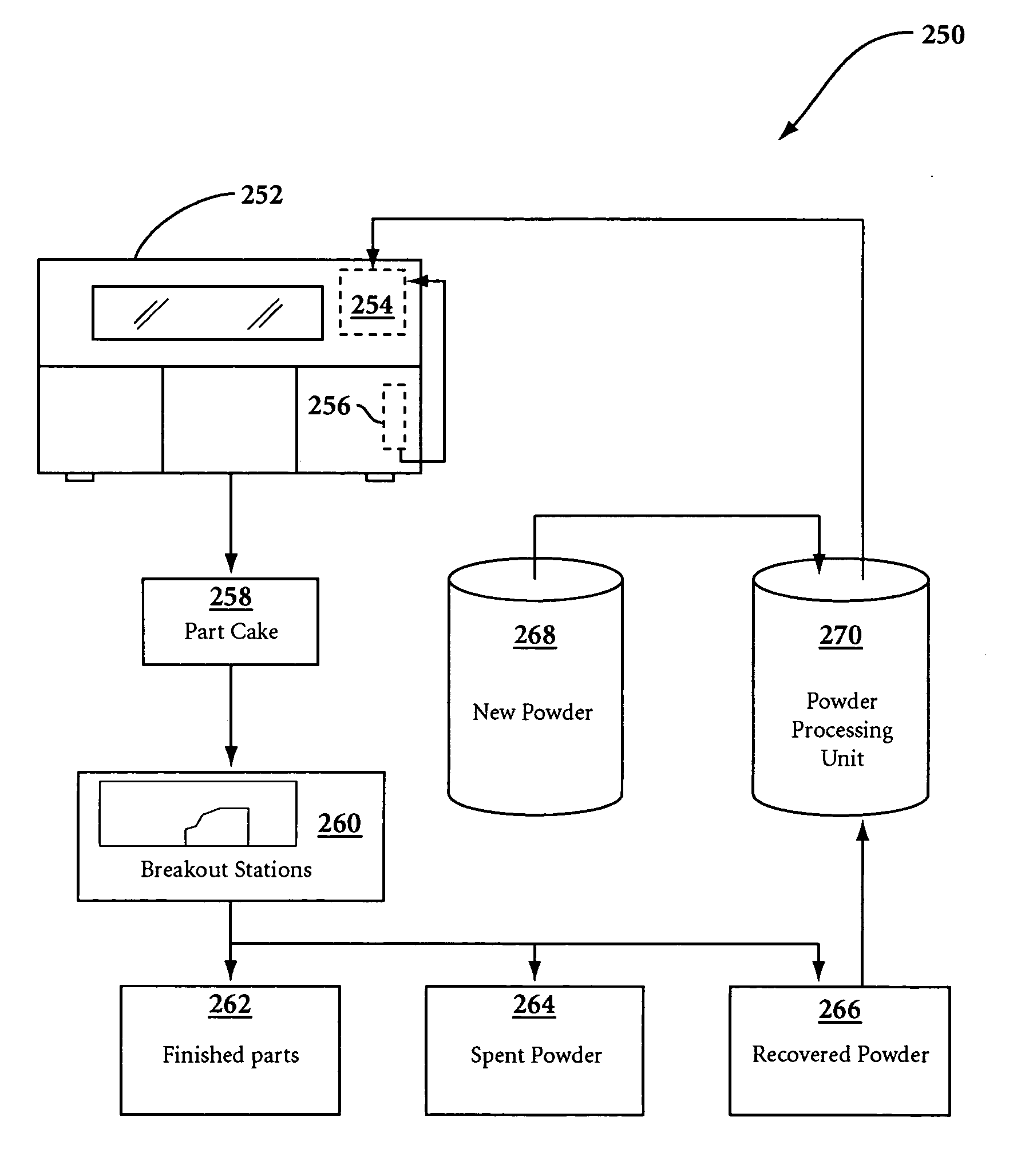

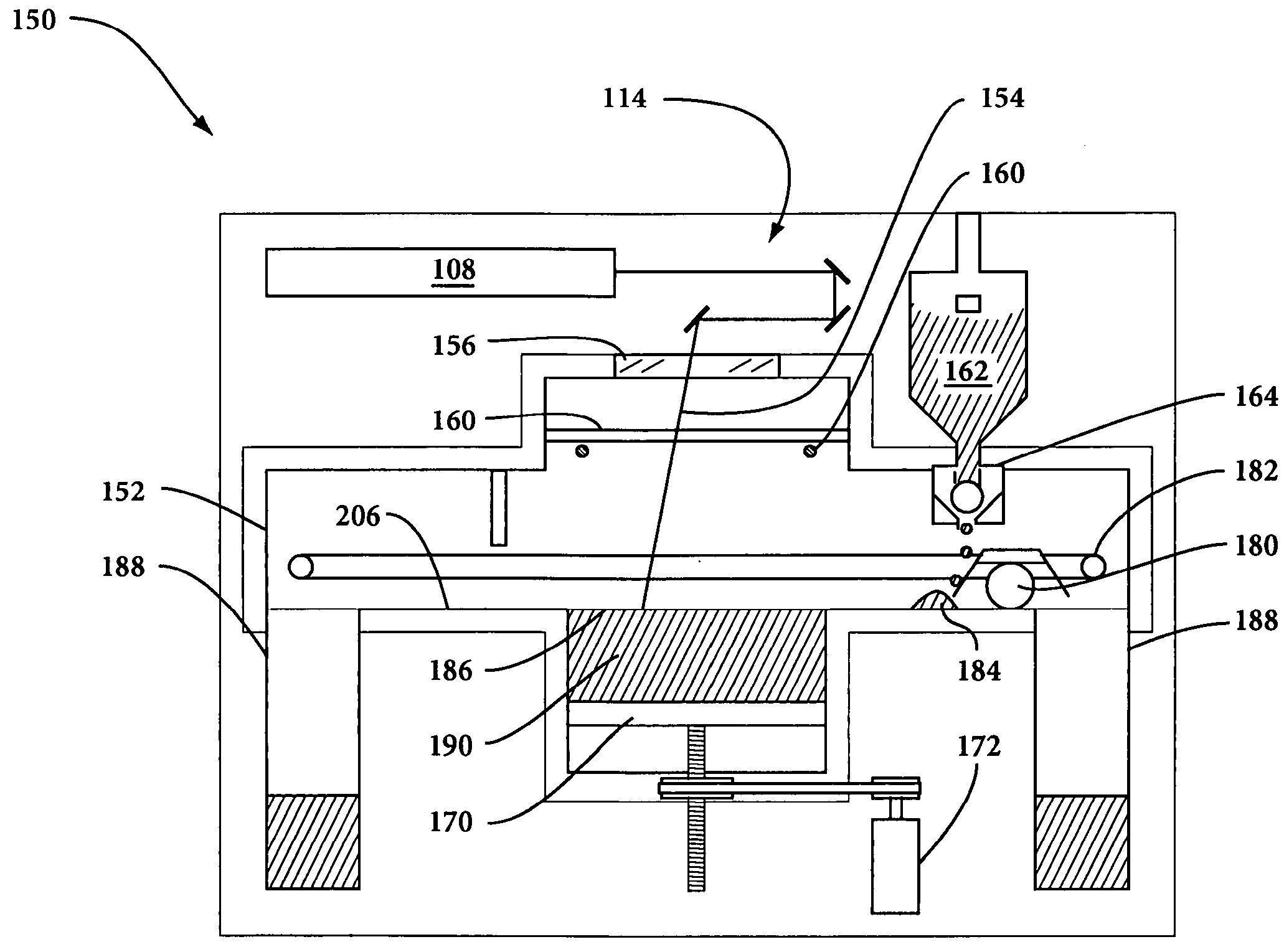

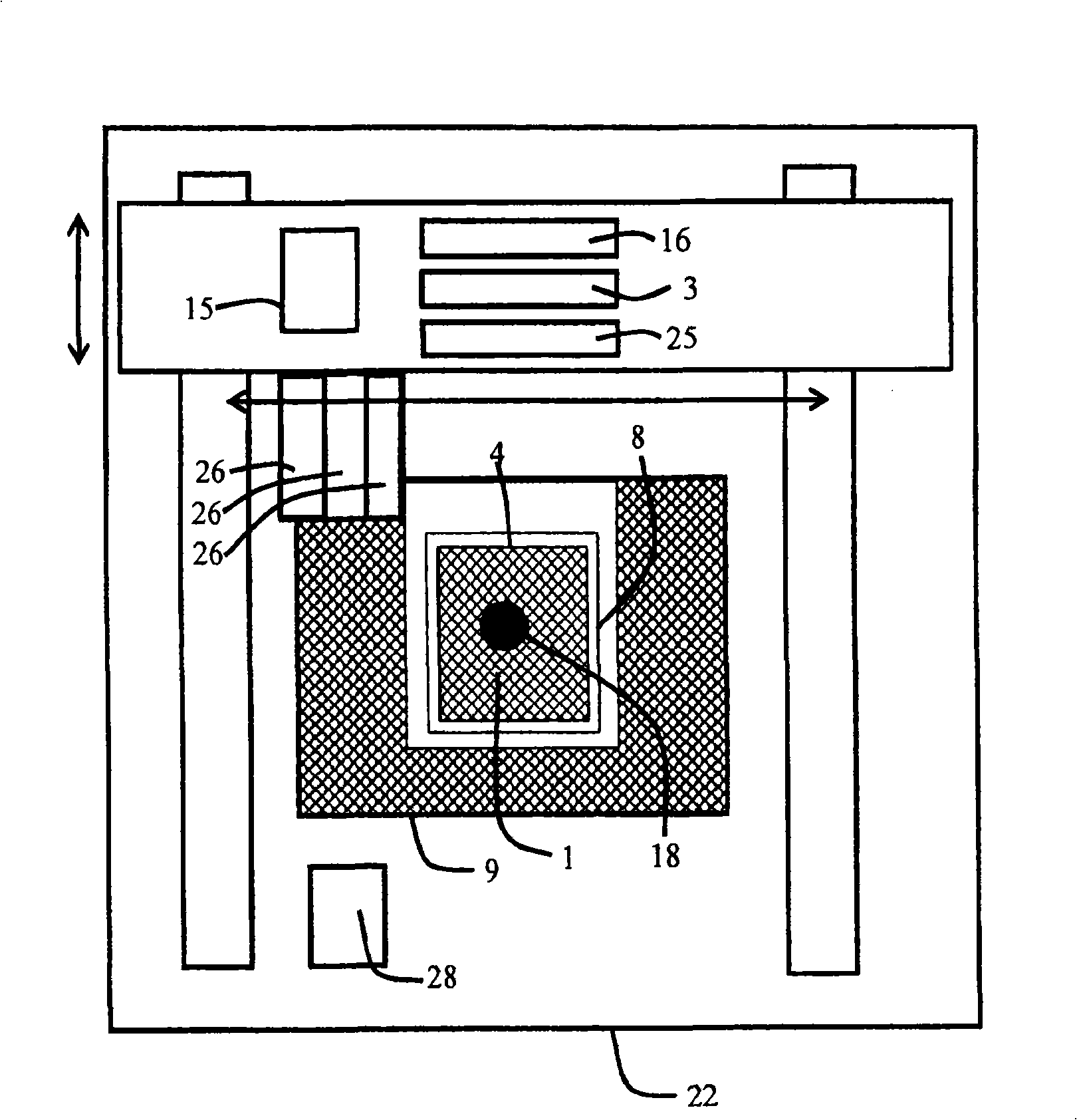

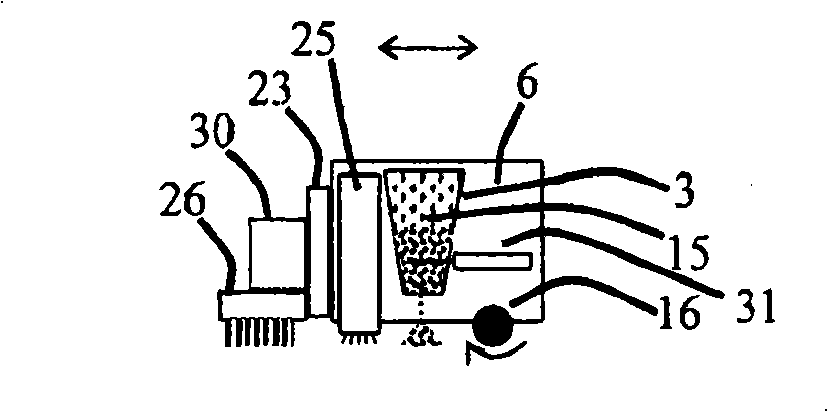

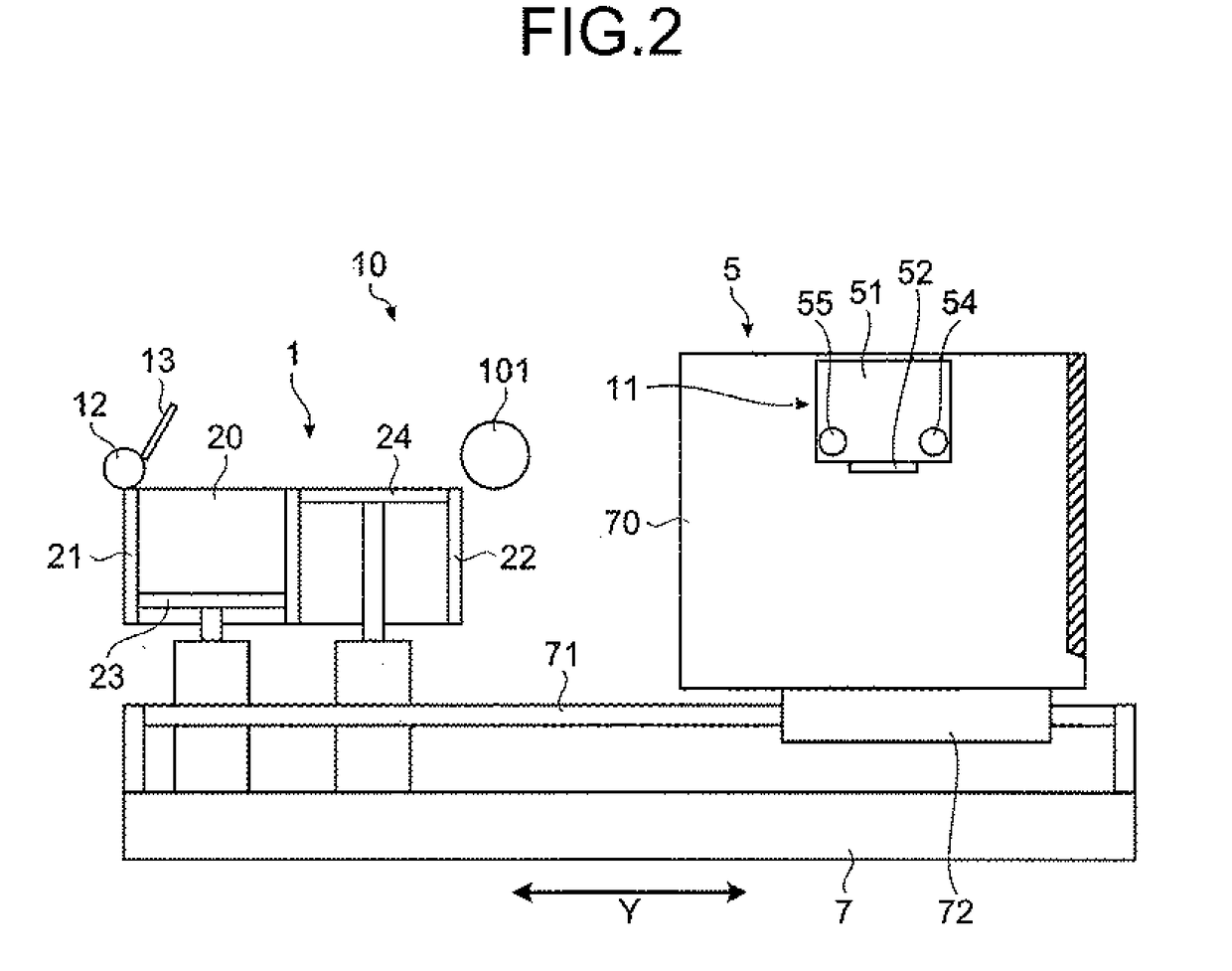

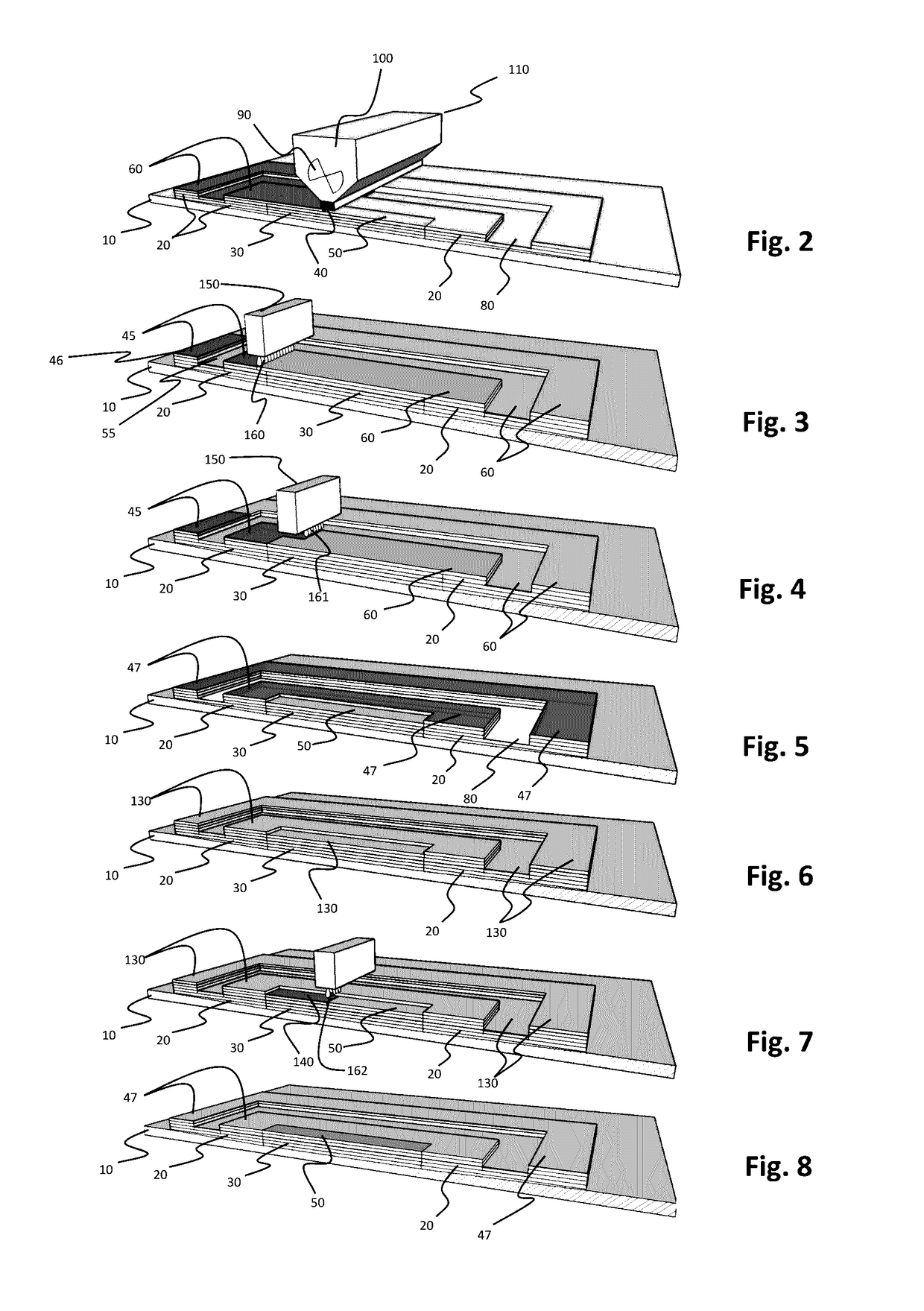

Apparatus and methods for handling materials in a 3-D printer

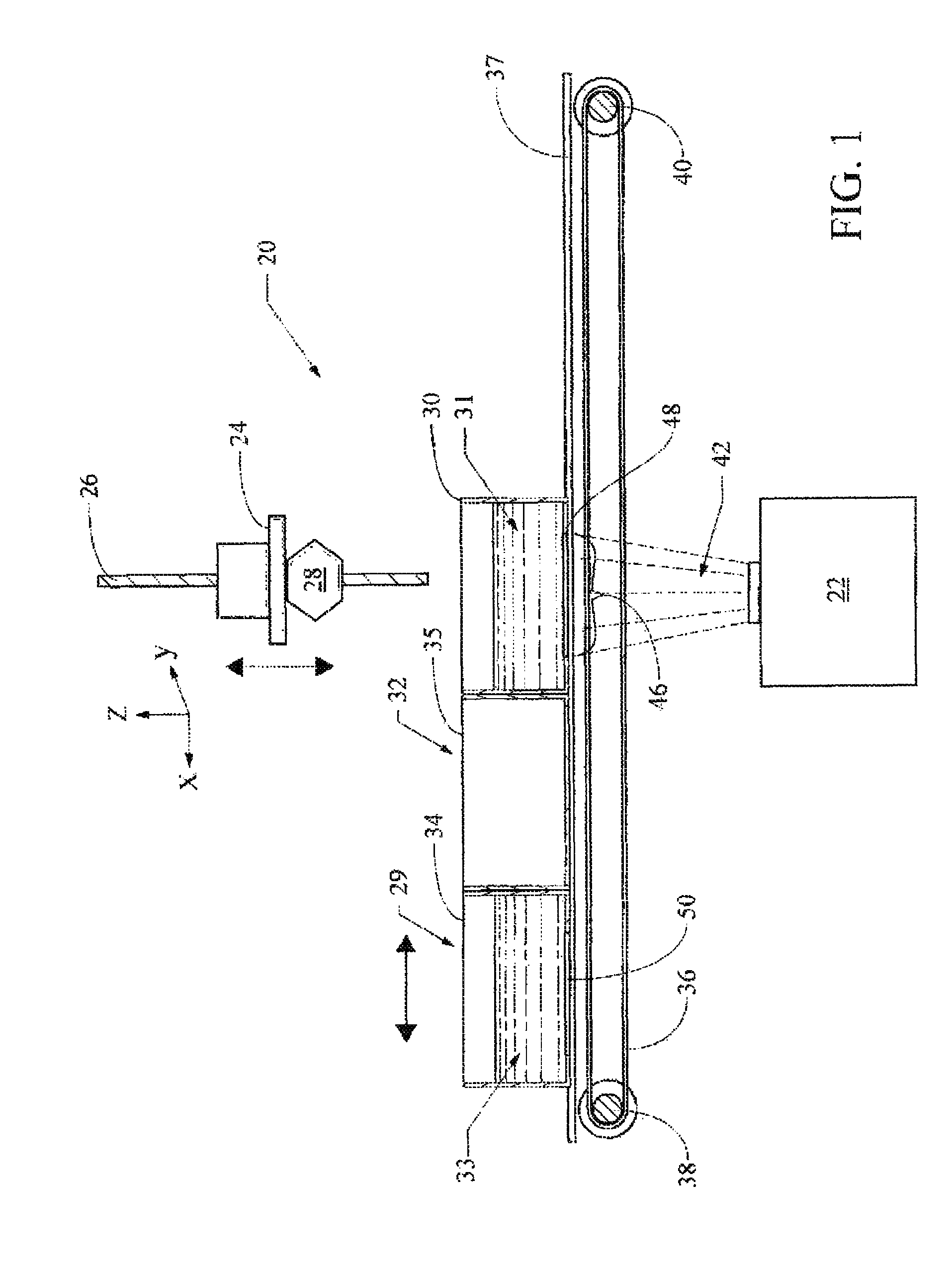

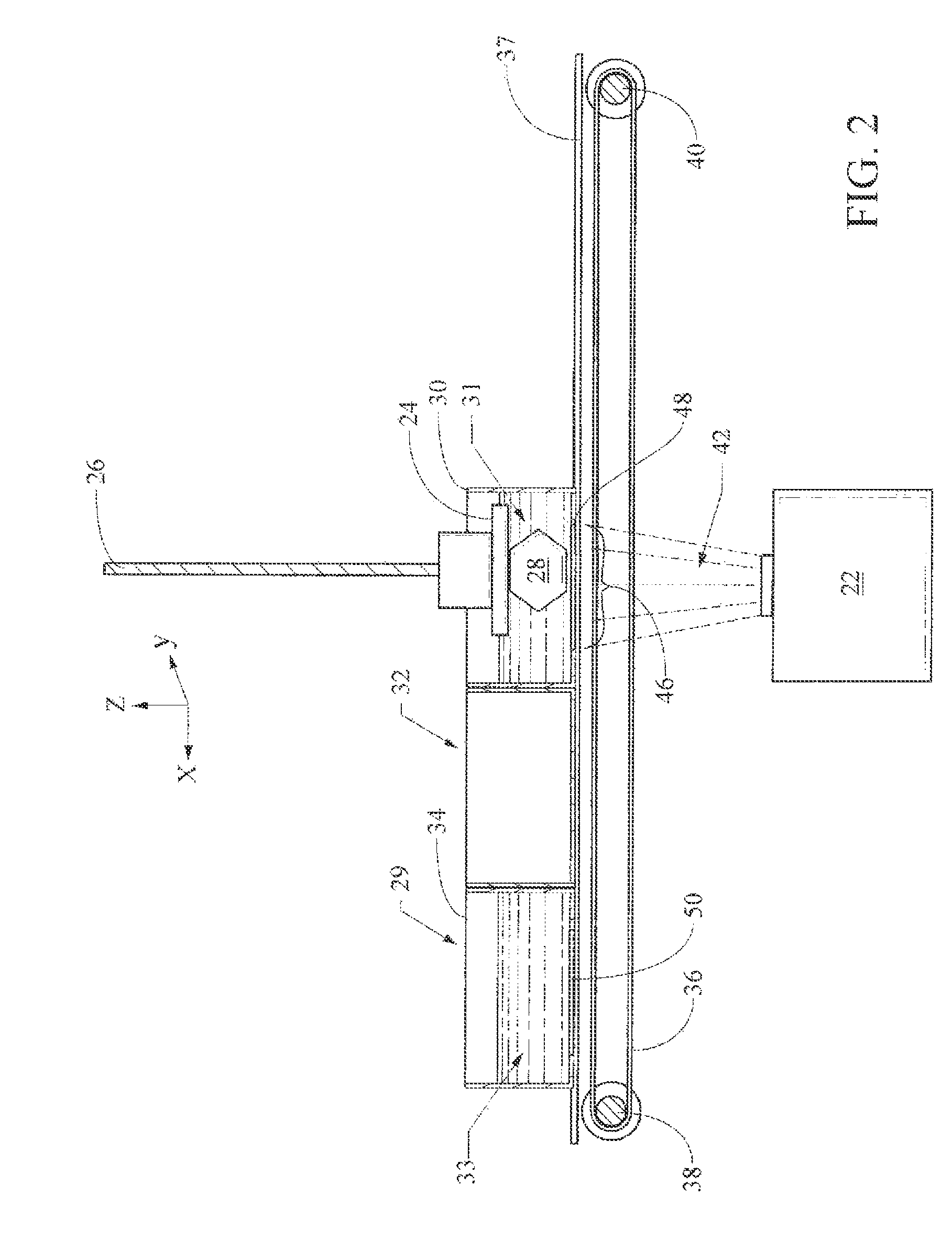

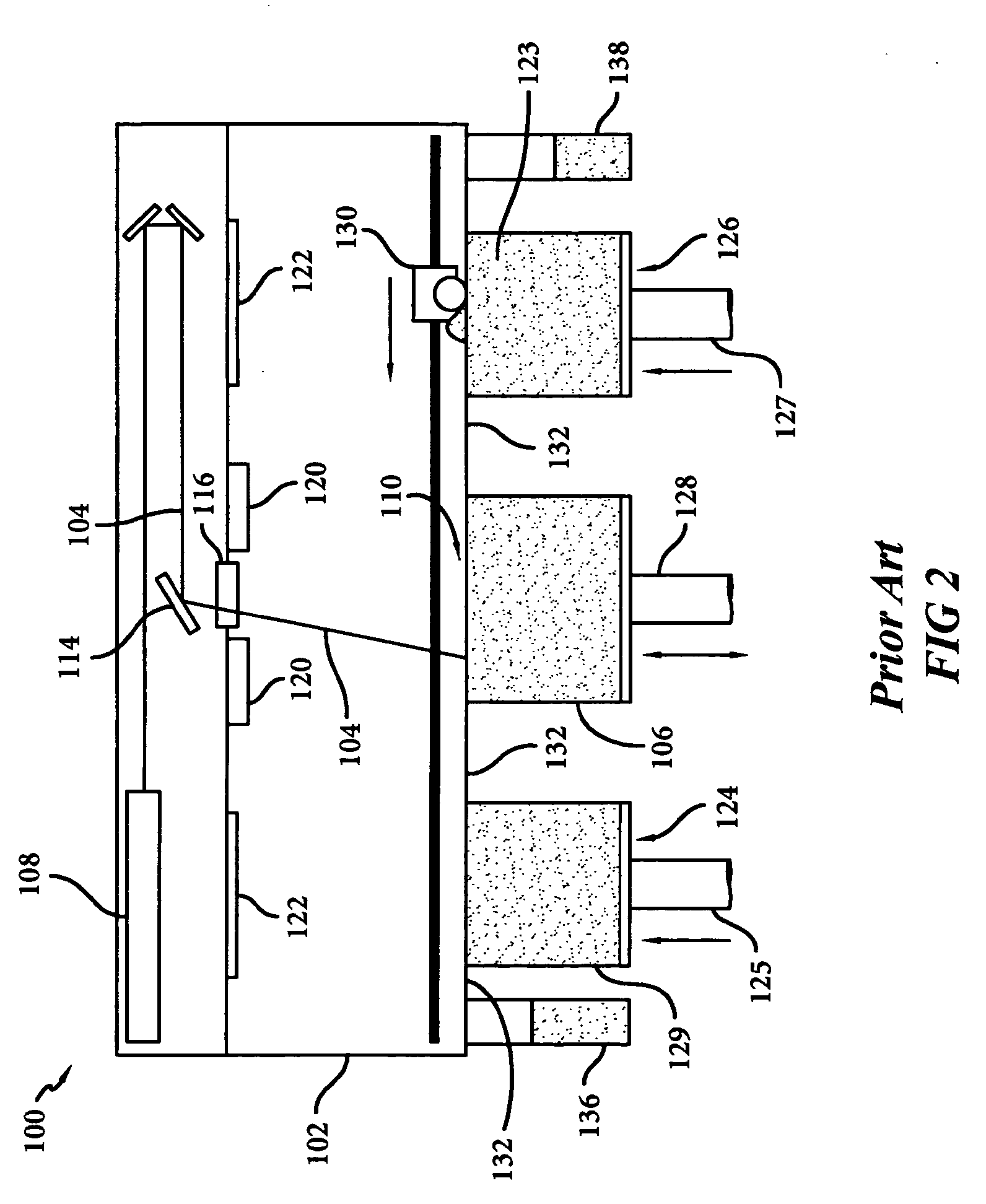

ActiveUS20080006334A1Improve efficiencyProcess uneconomicalLiquid surface applicatorsPowdered material dispensingComputer printing3d printer

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

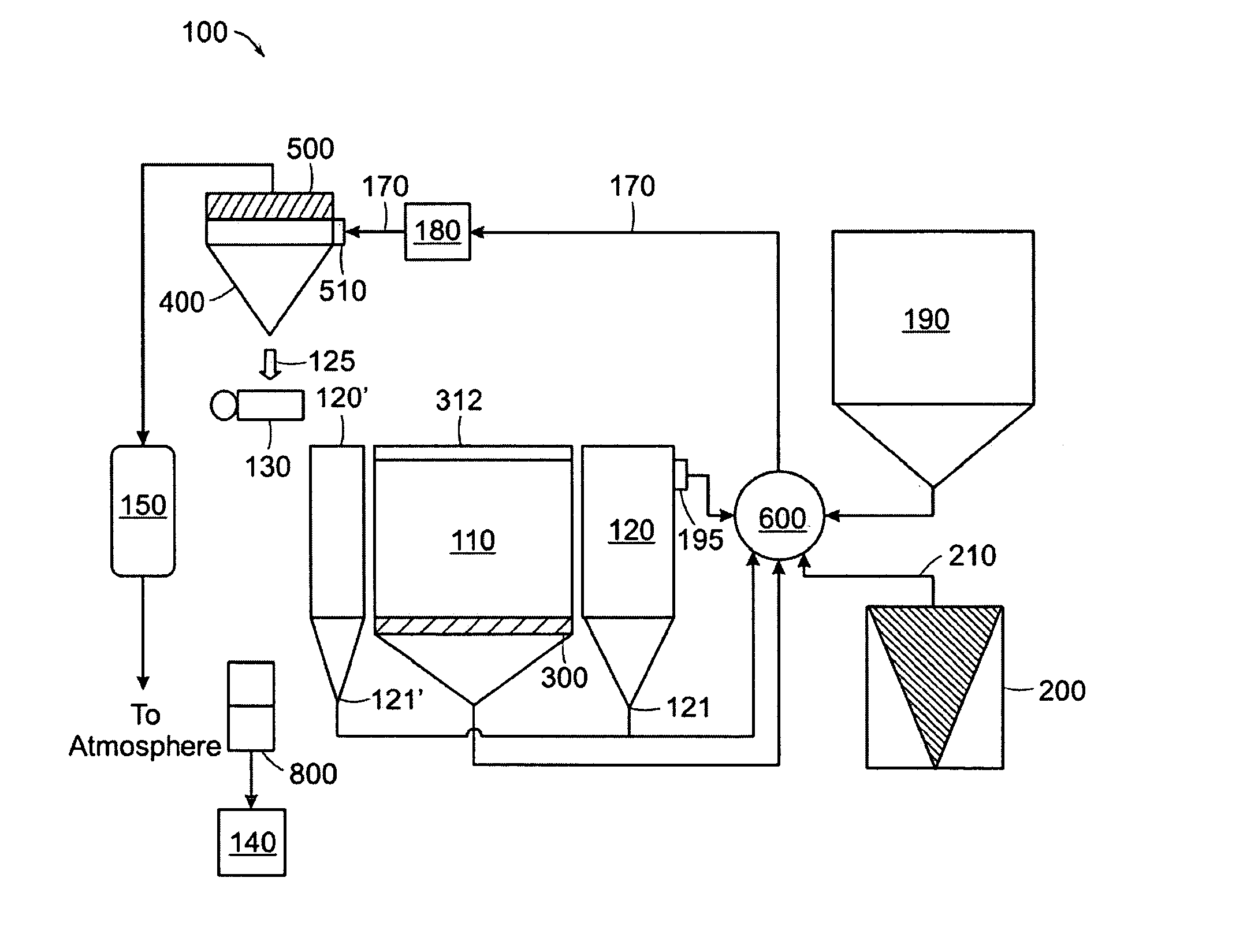

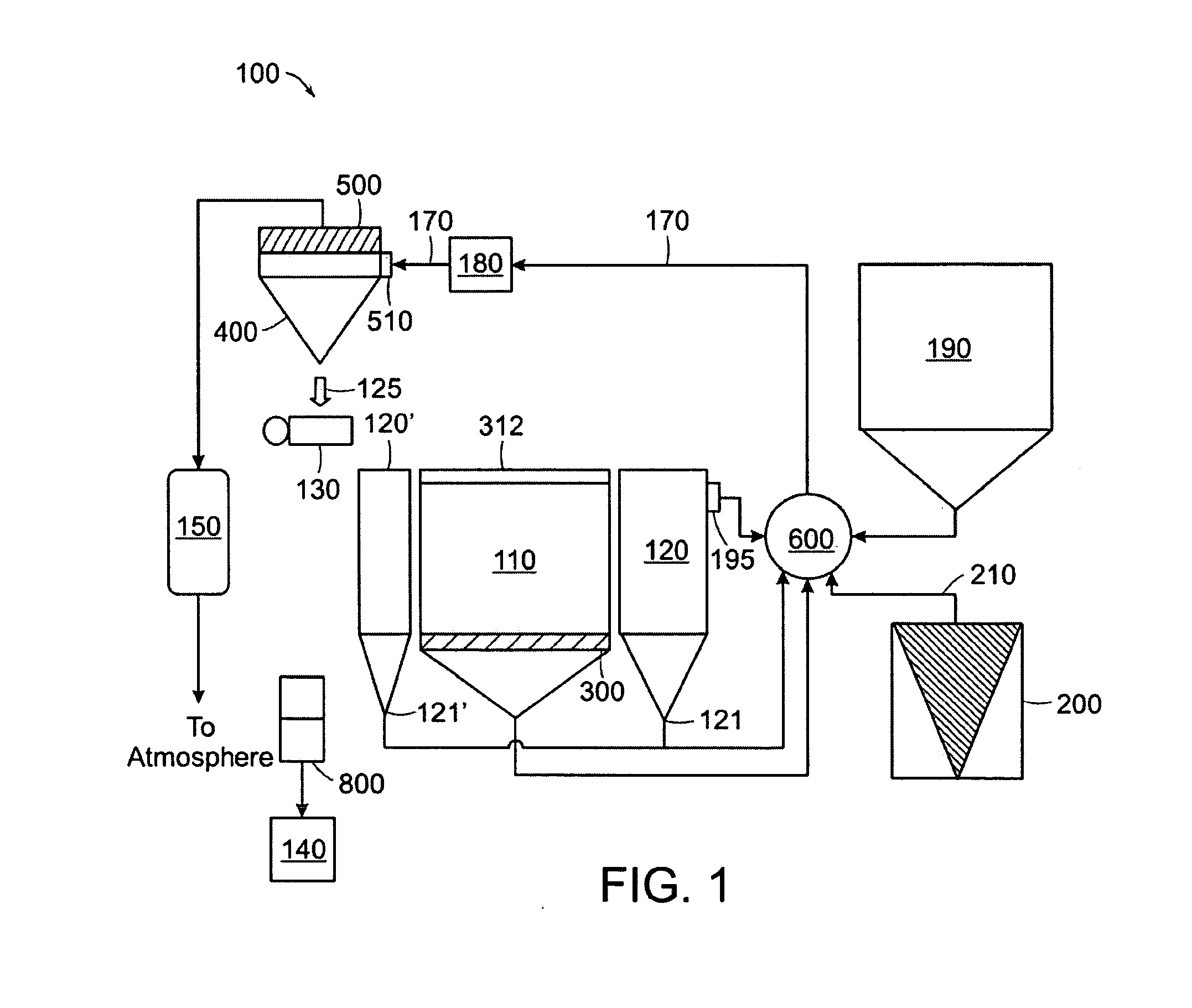

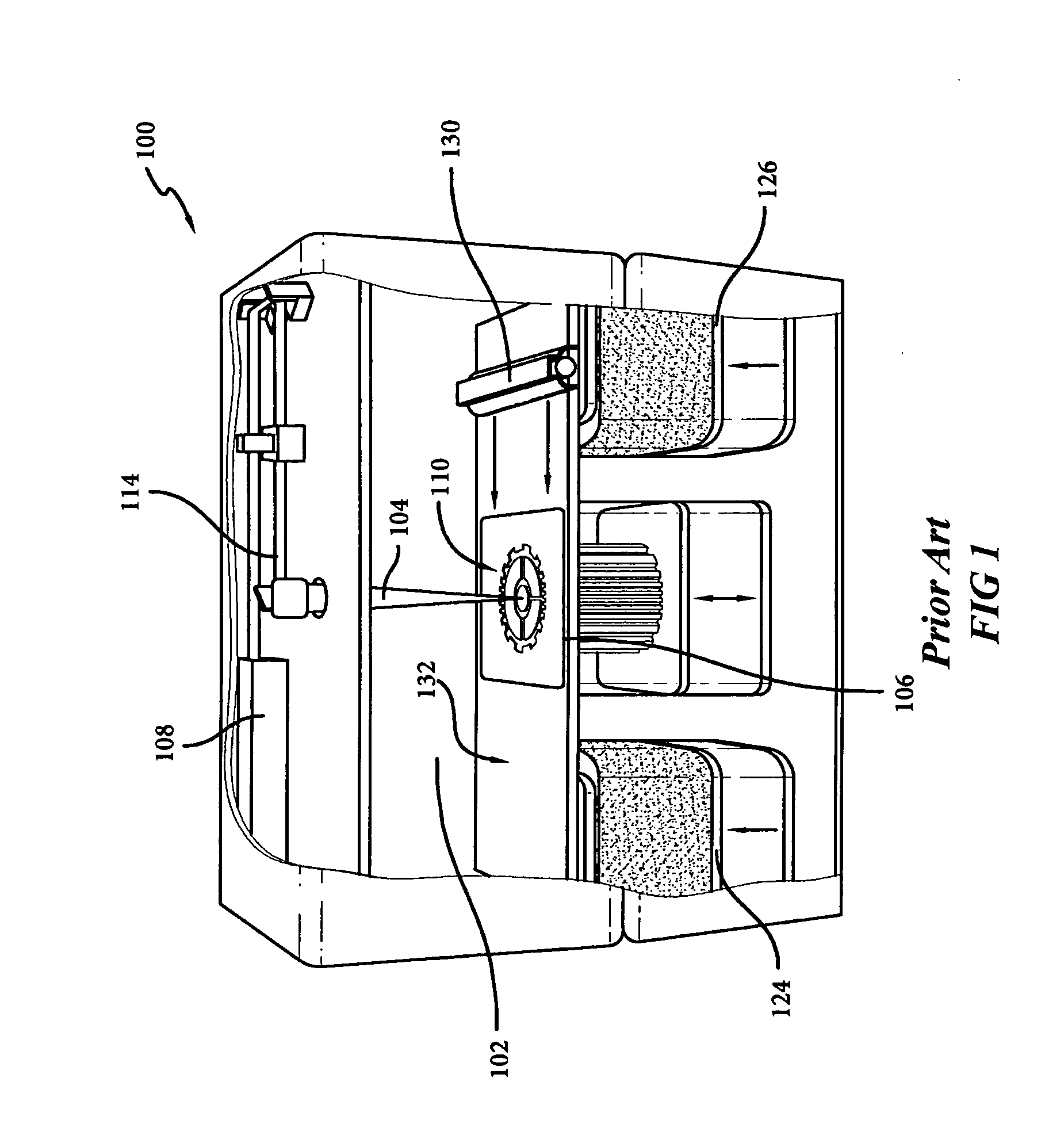

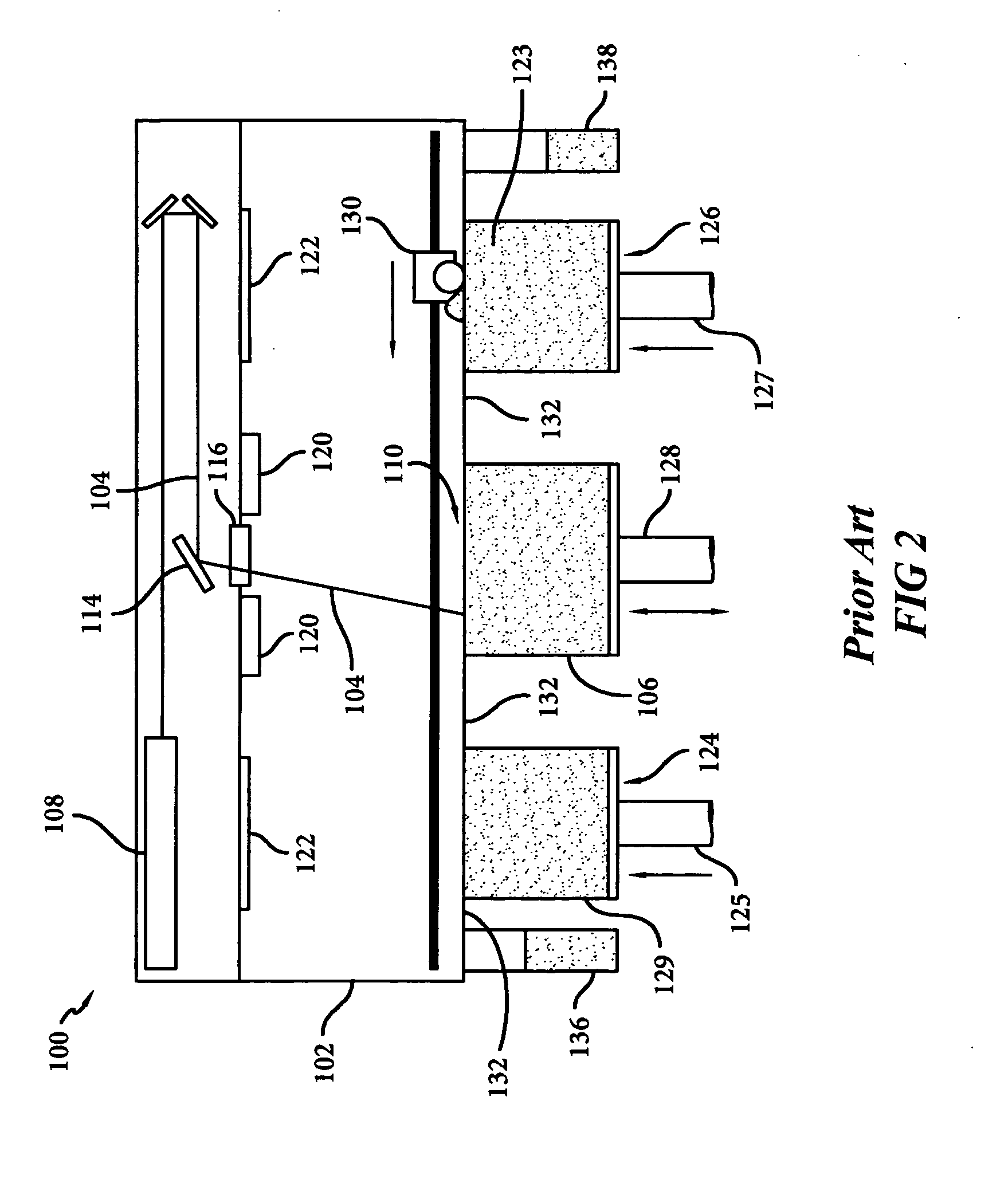

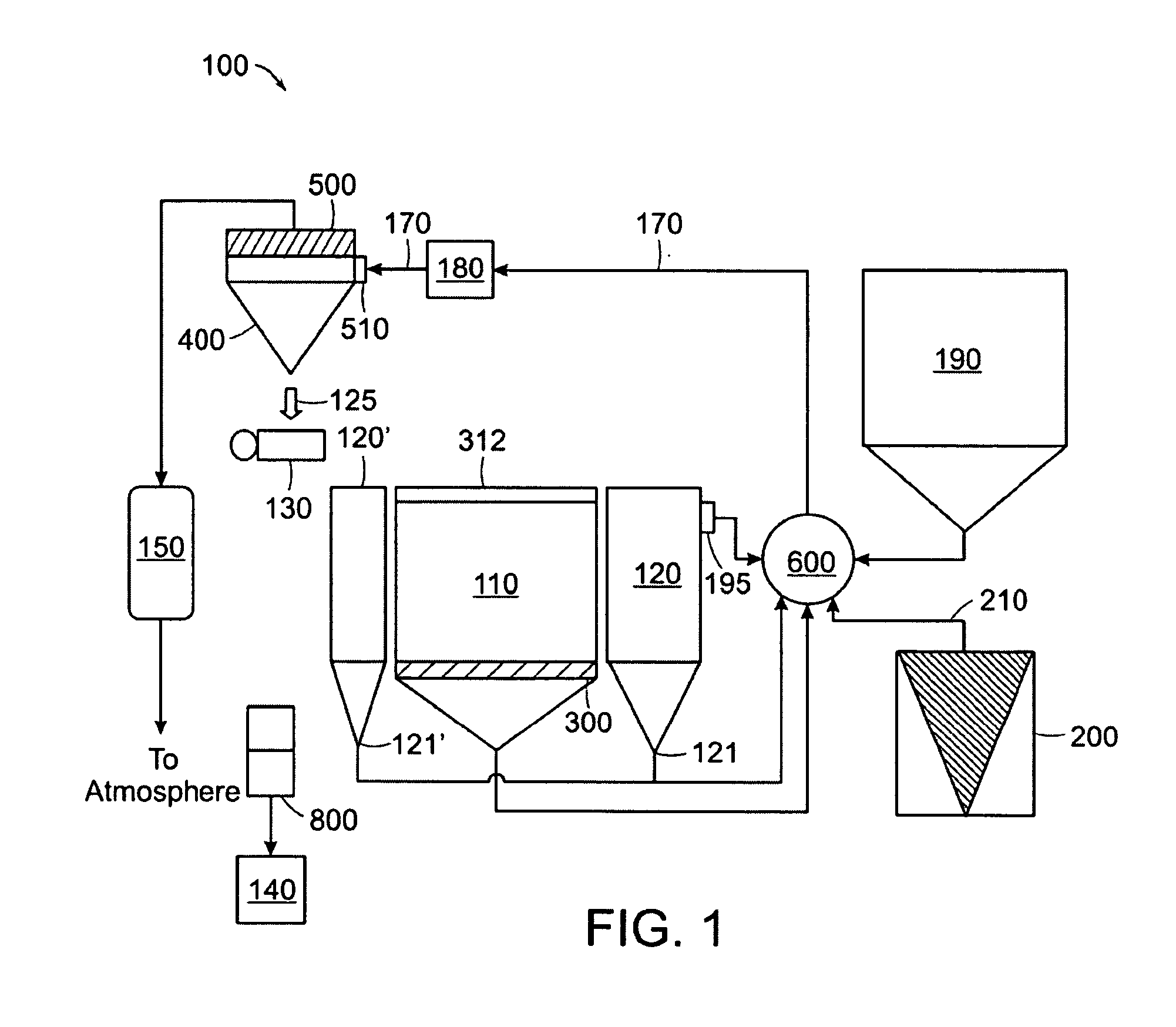

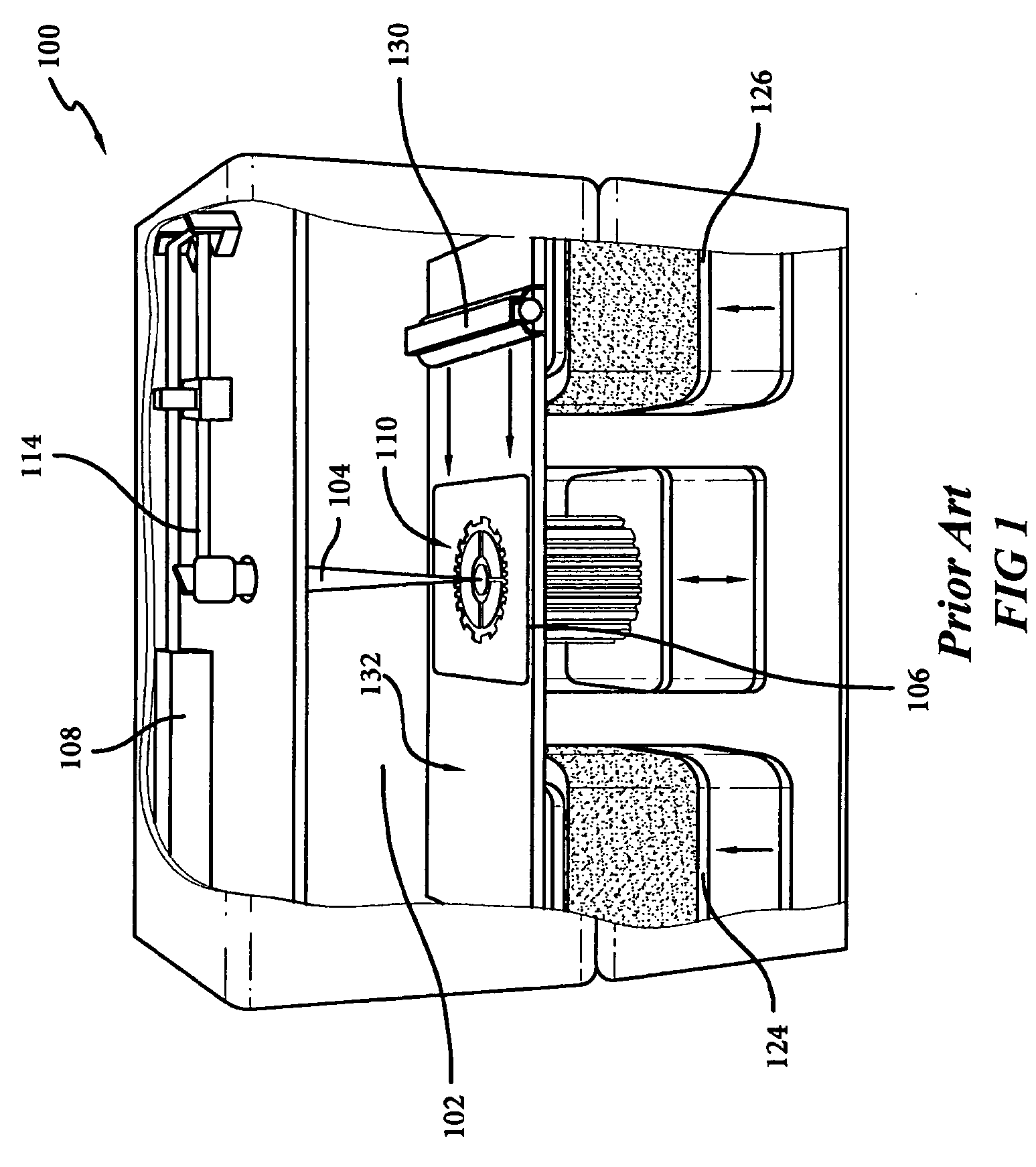

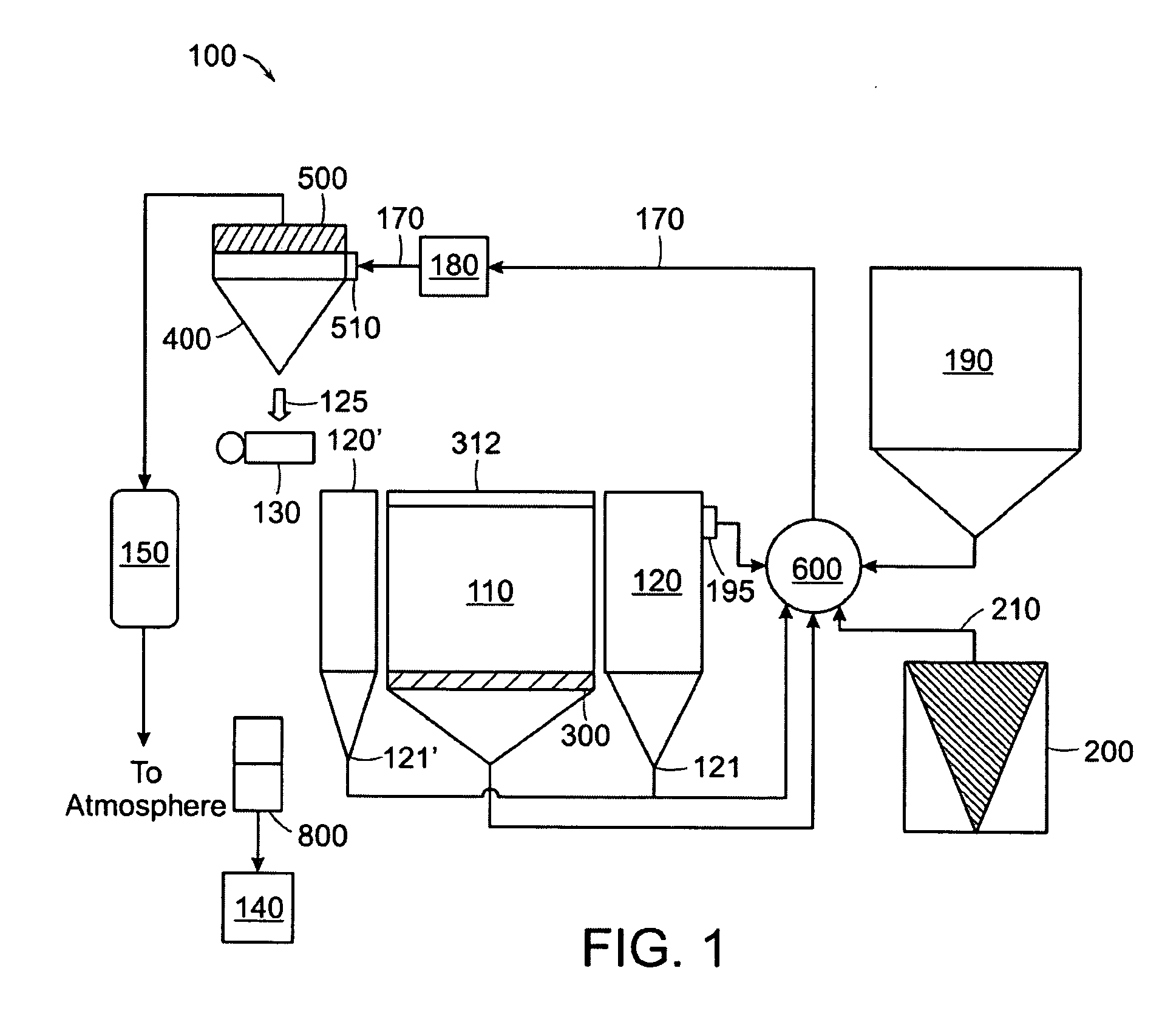

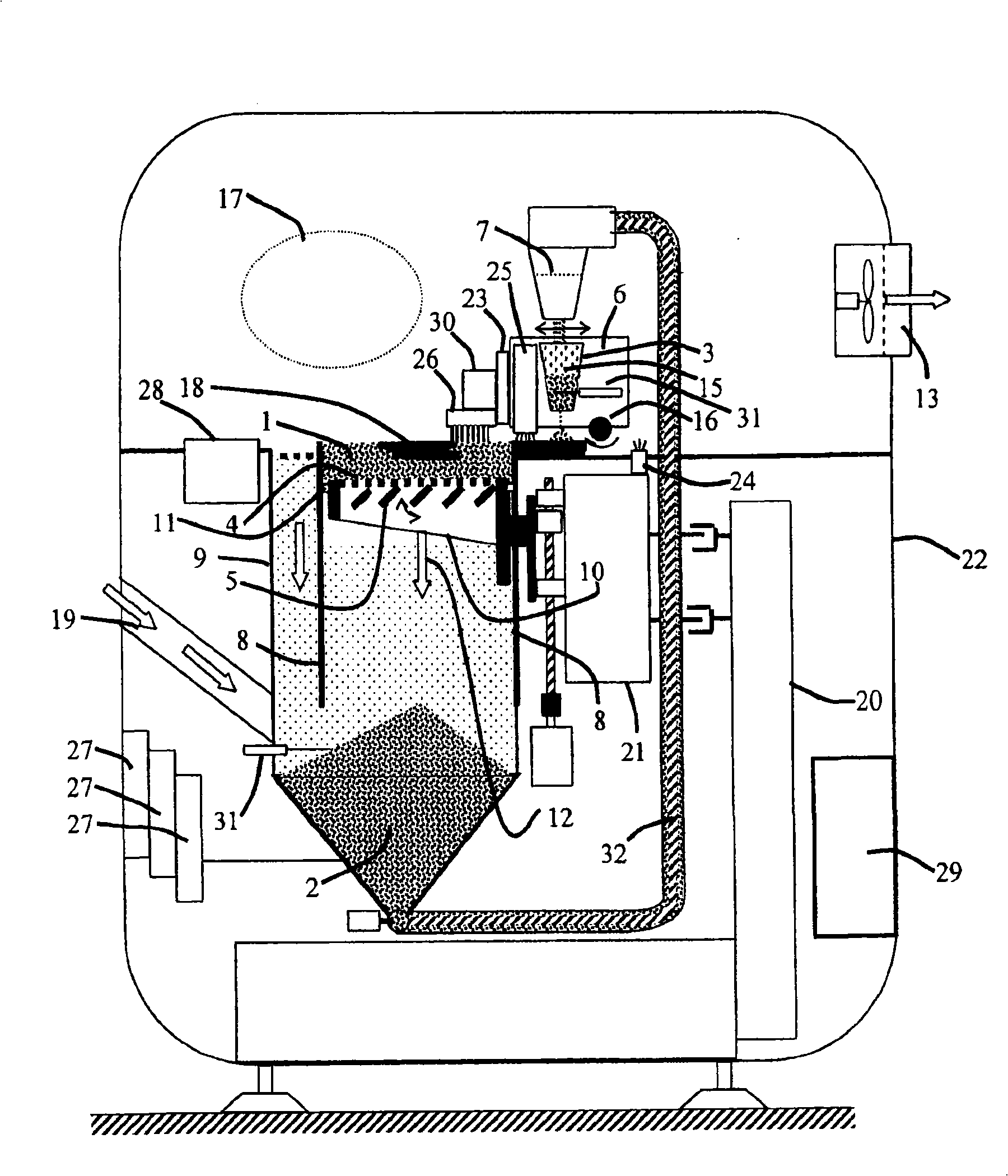

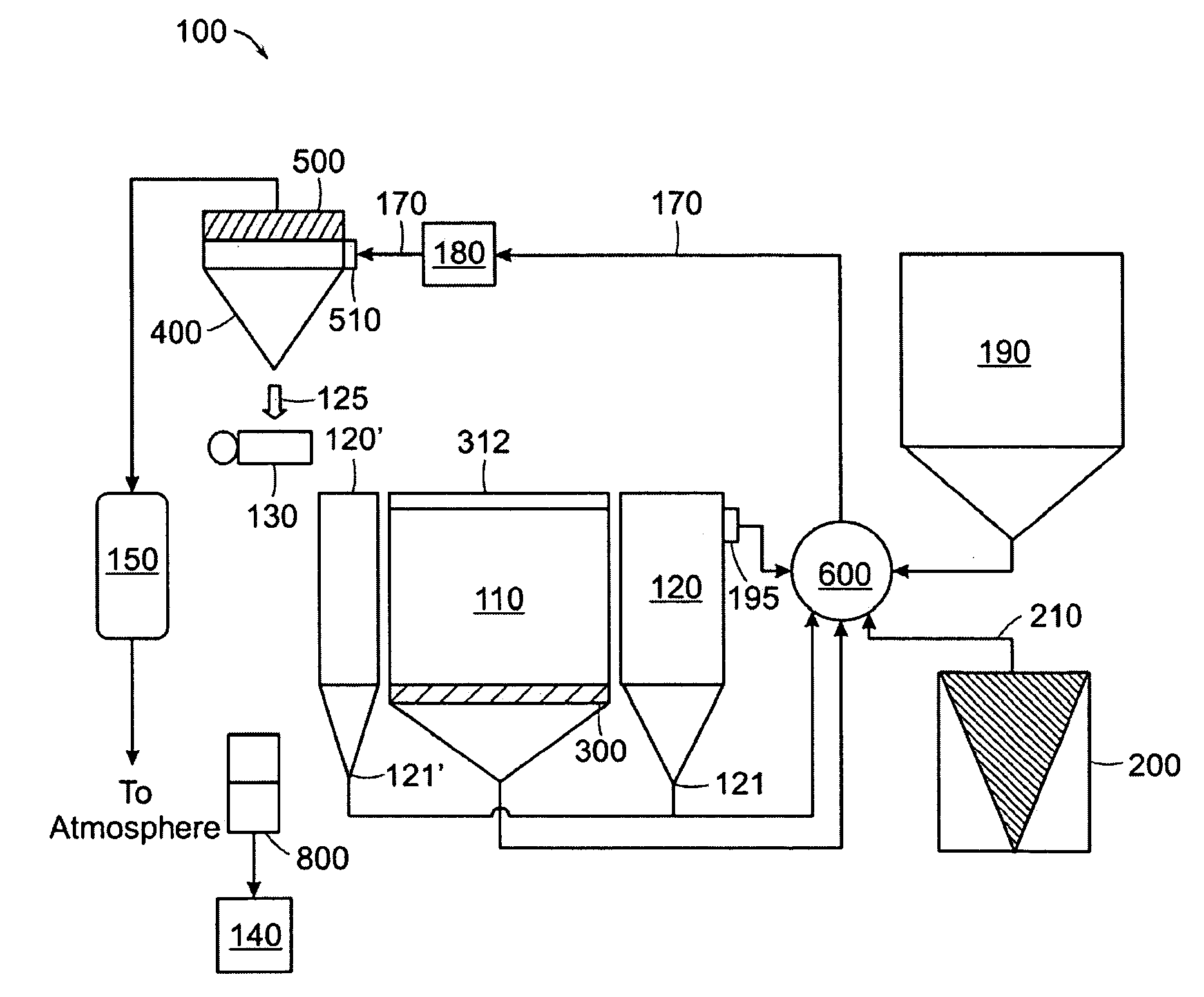

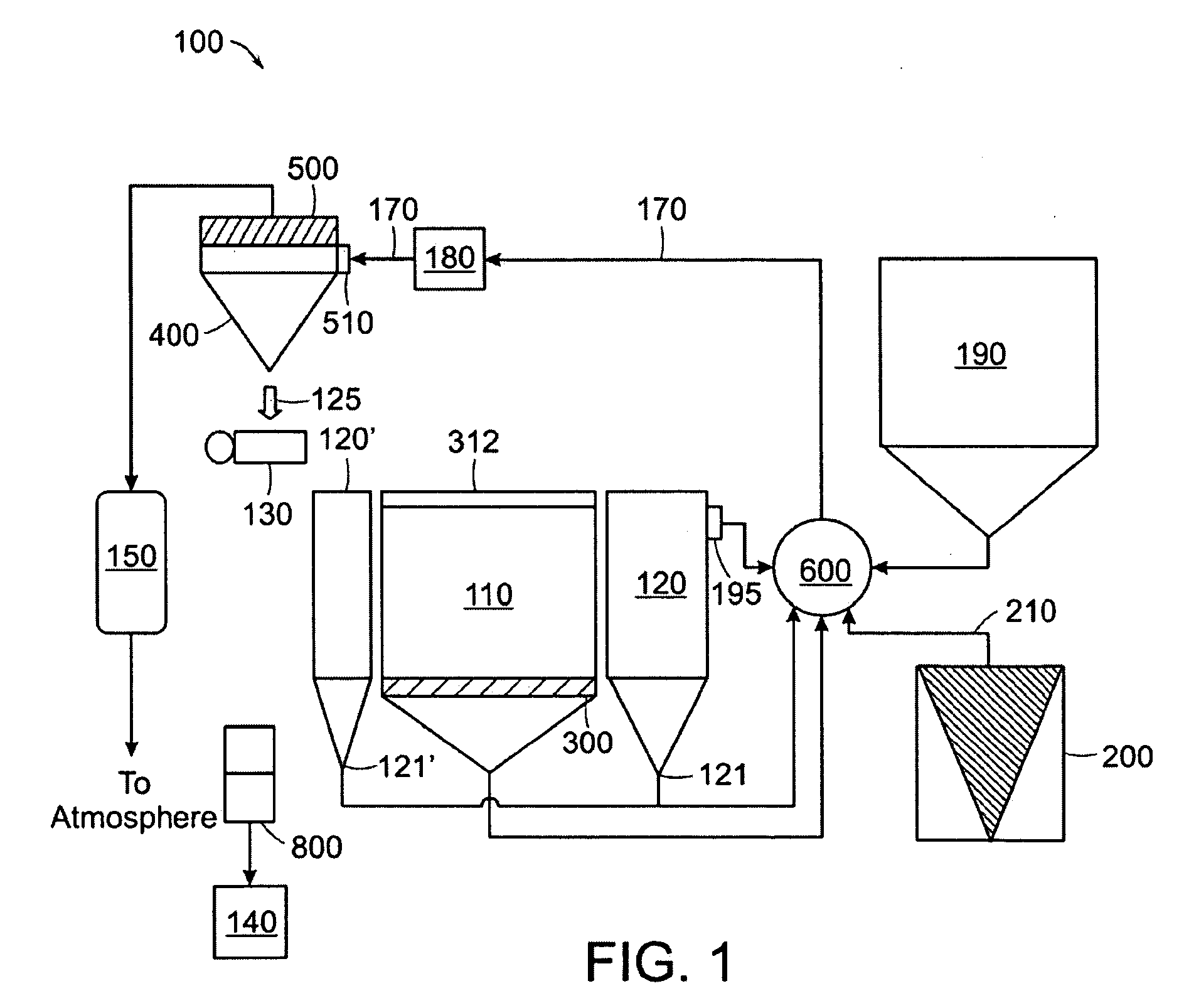

Laser sintering powder recycle system

InactiveUS20060214335A1Reduce powder lossGood blendingFlow mixersTransportation and packagingMetallurgyLaser

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

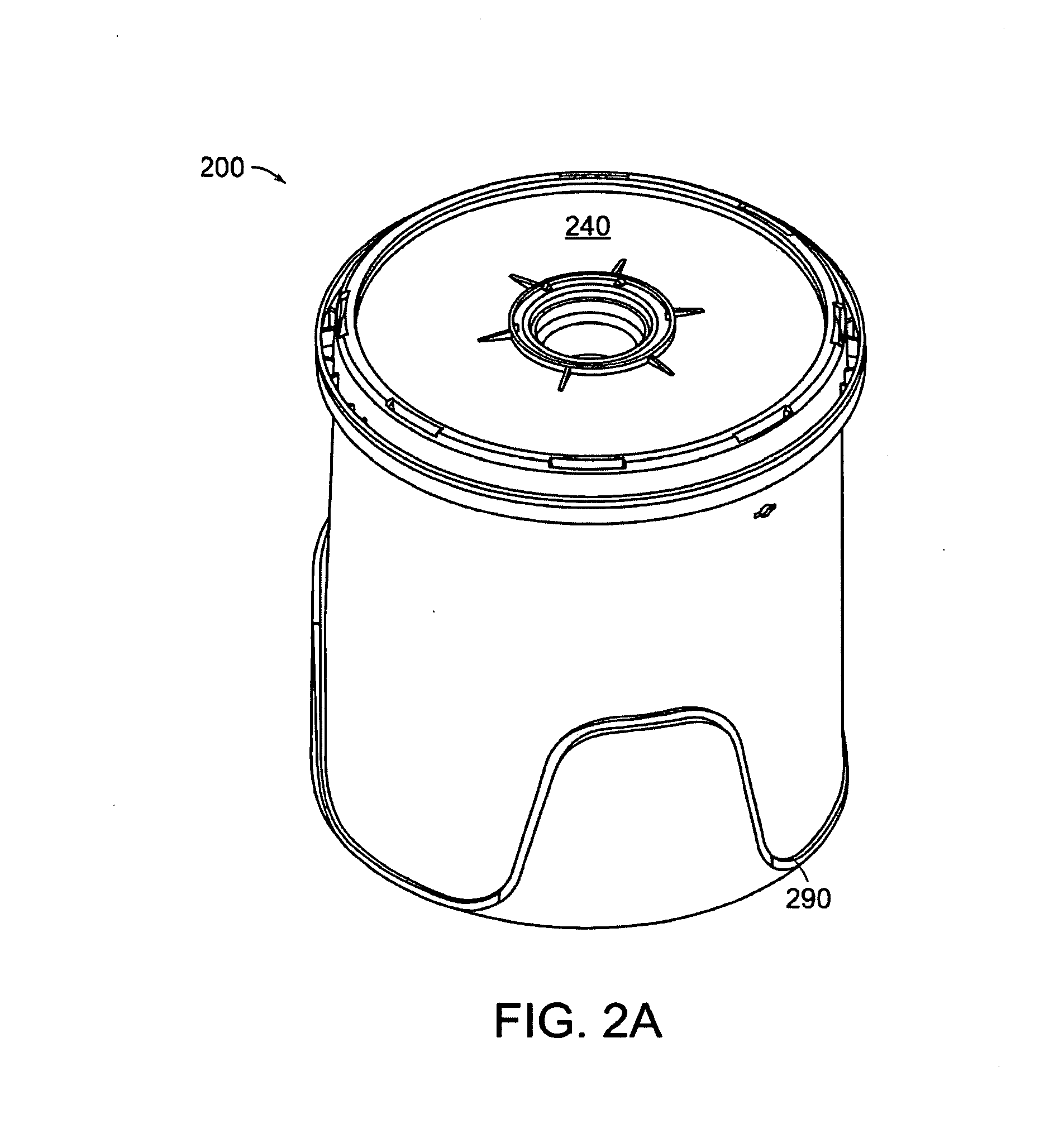

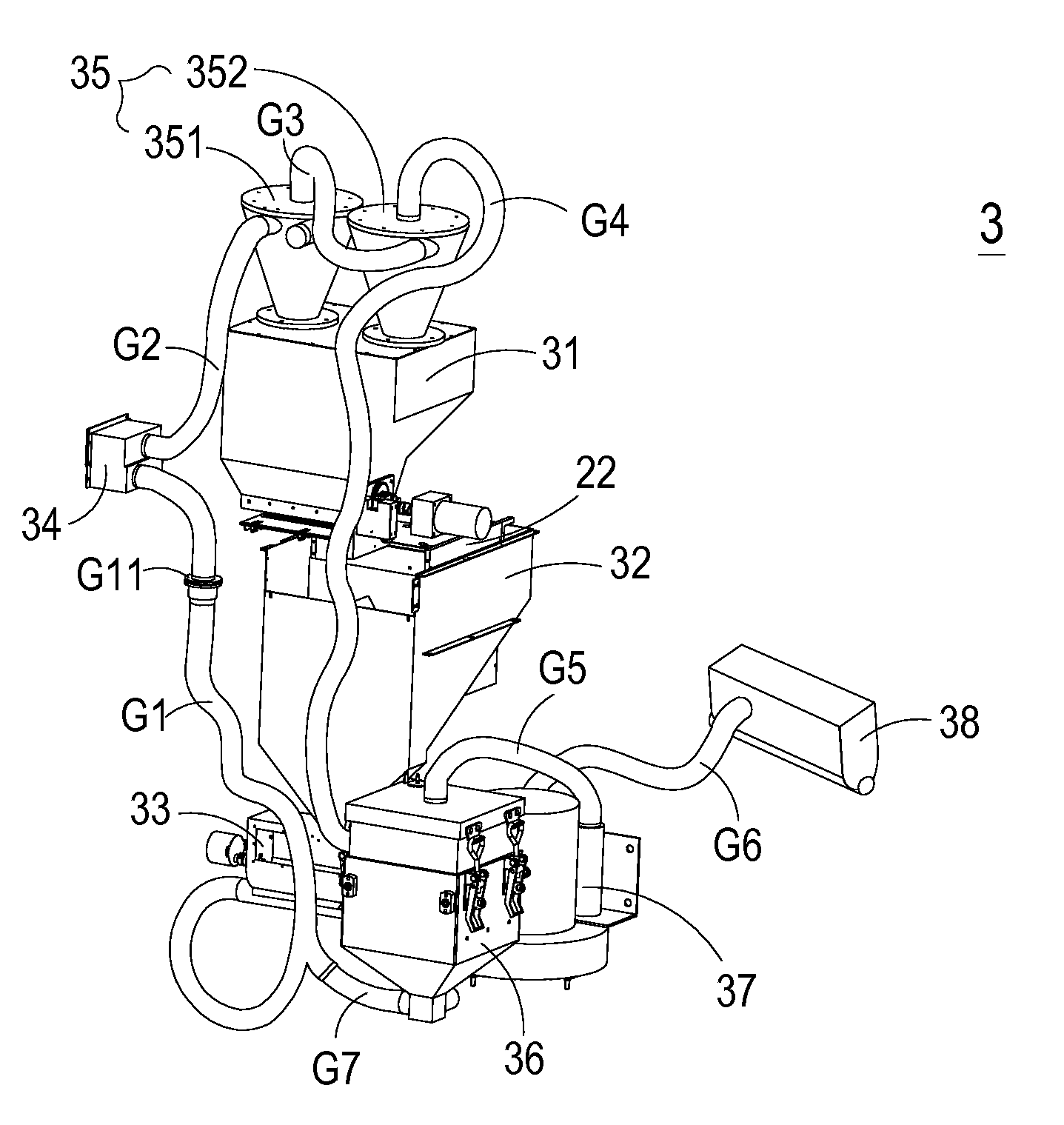

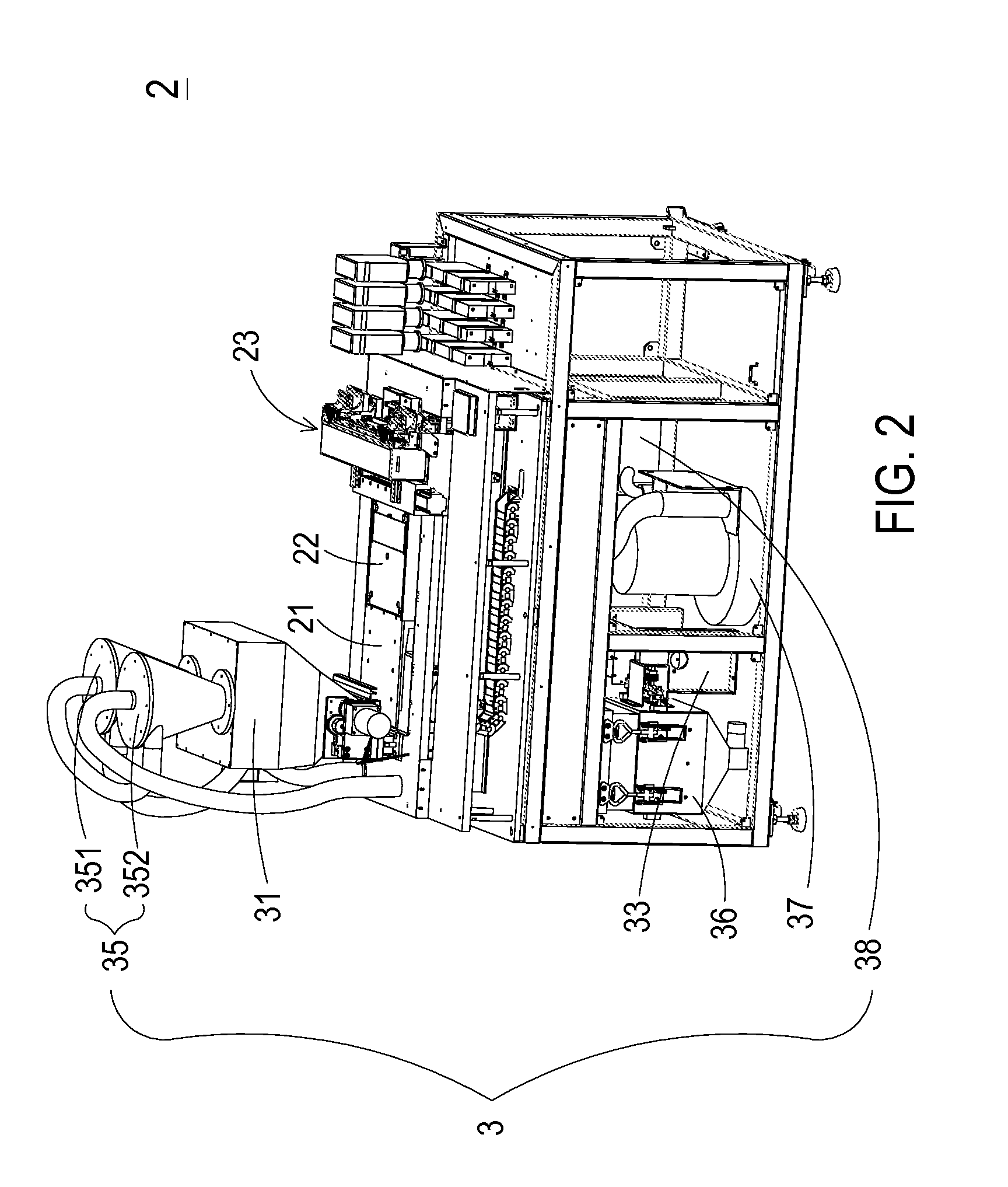

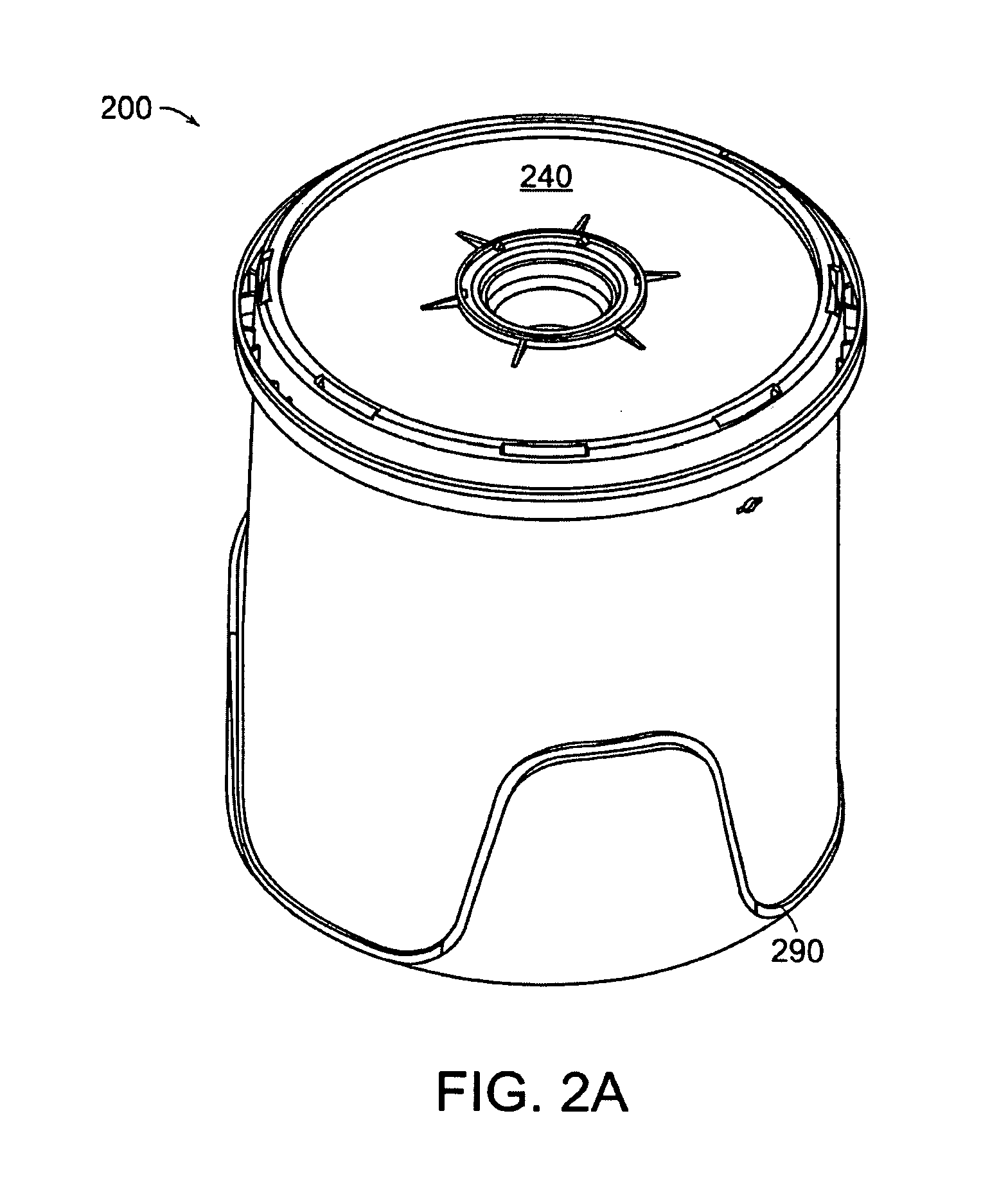

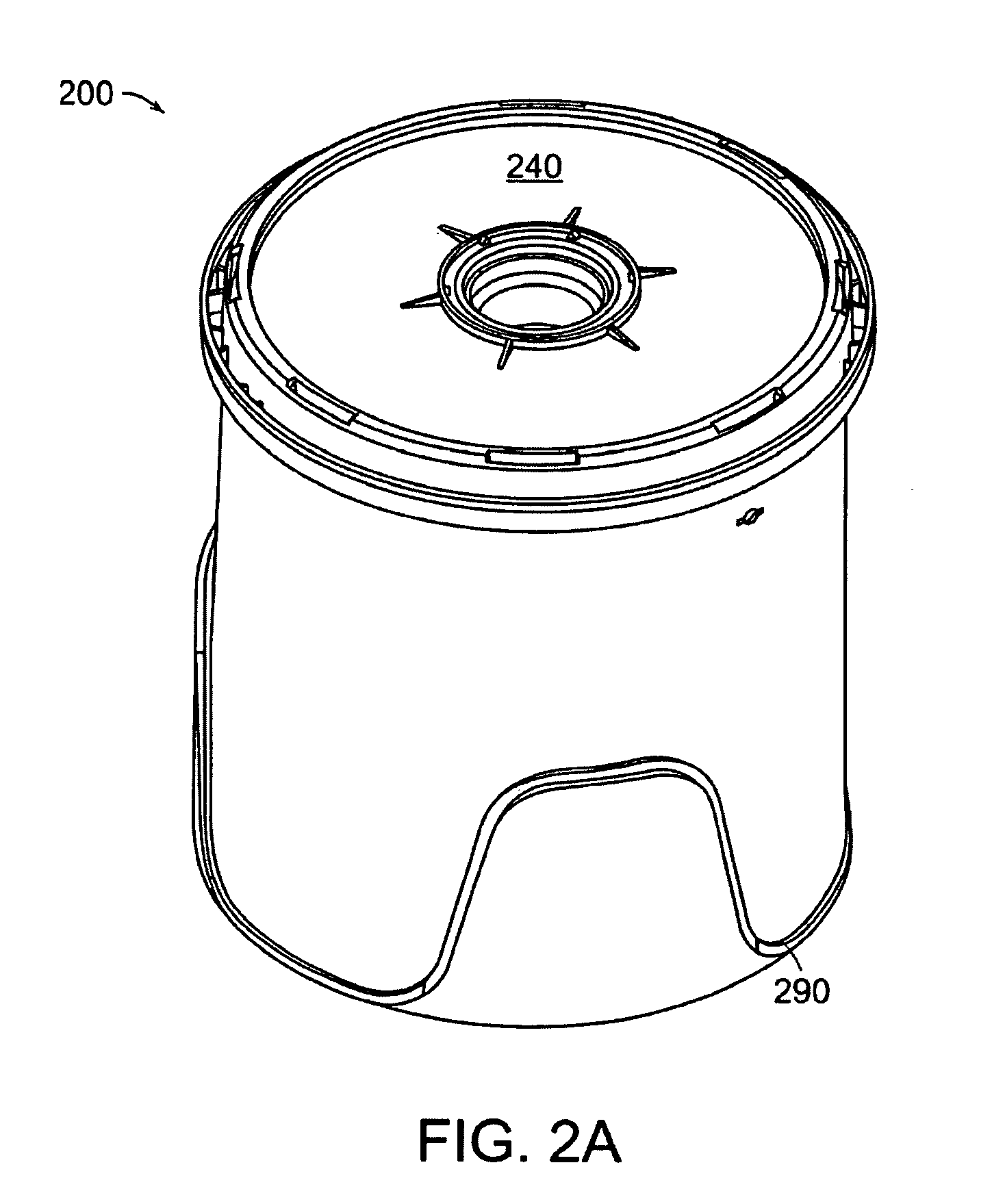

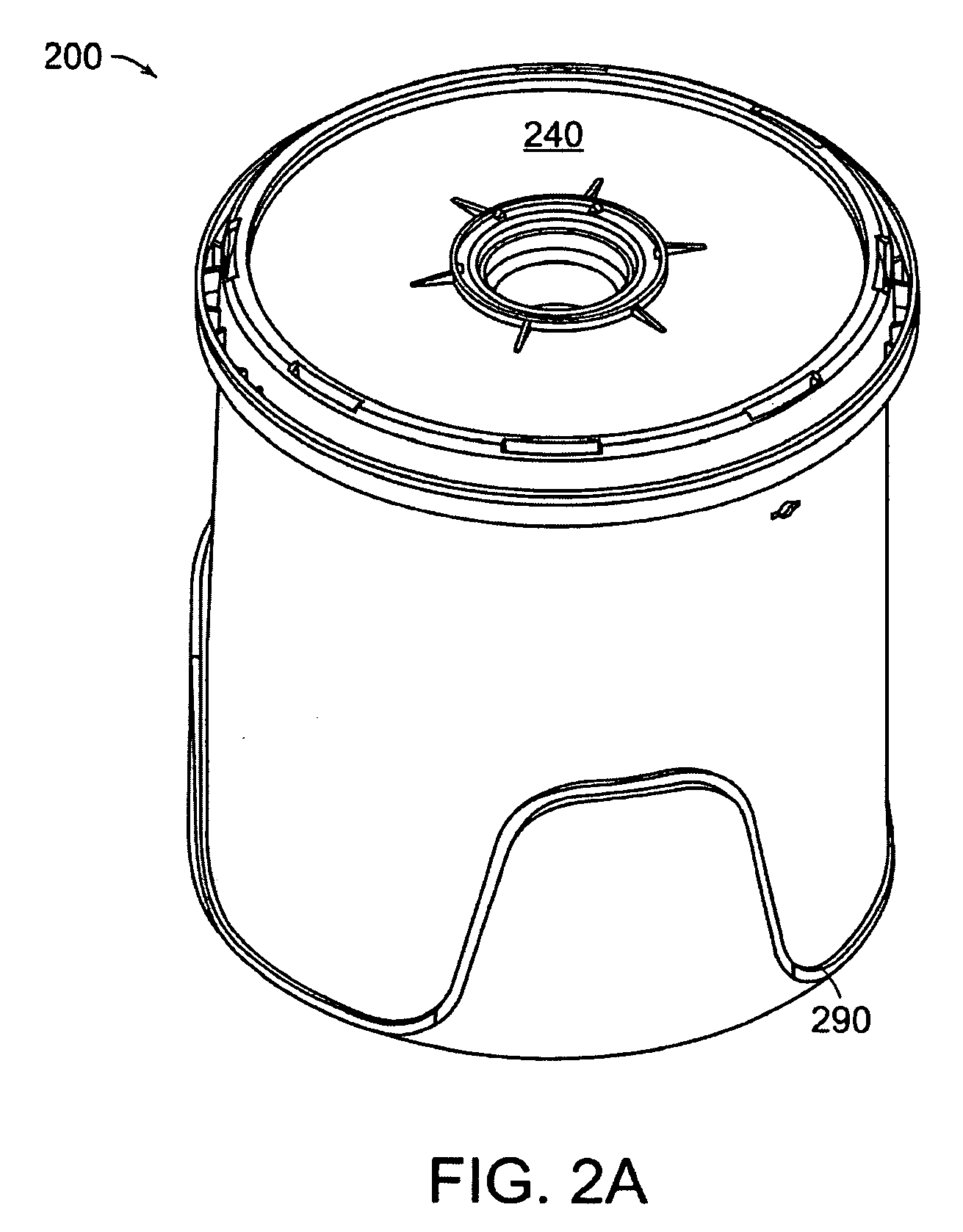

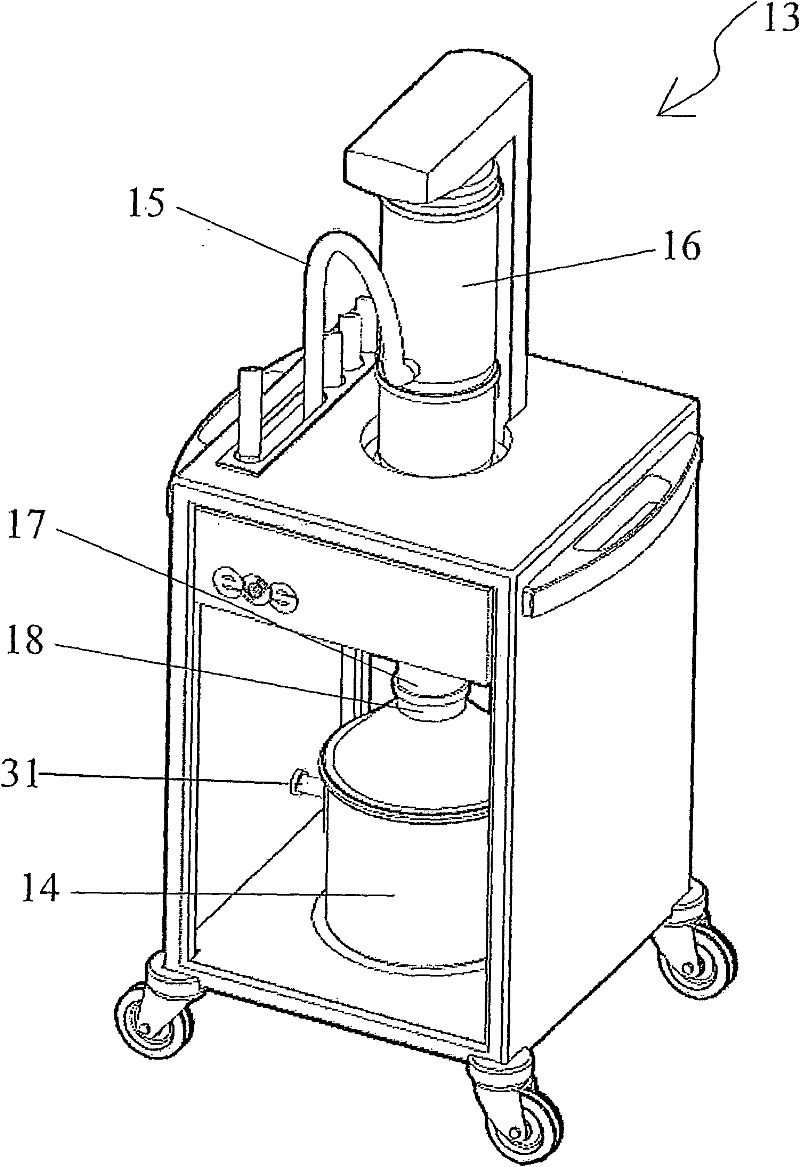

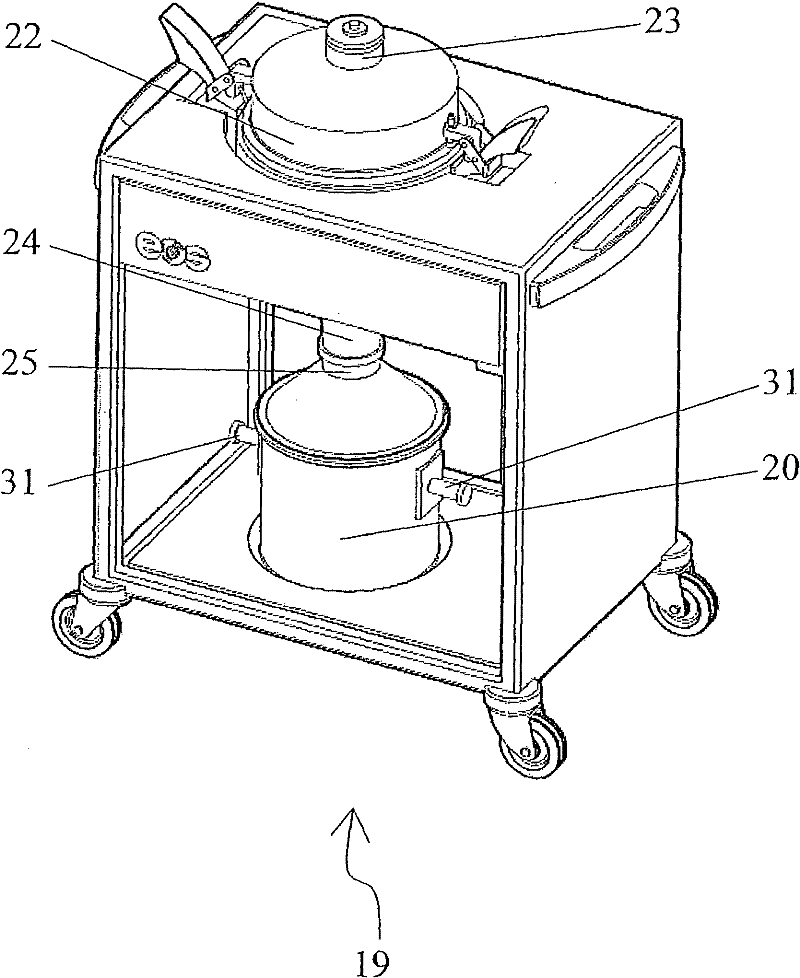

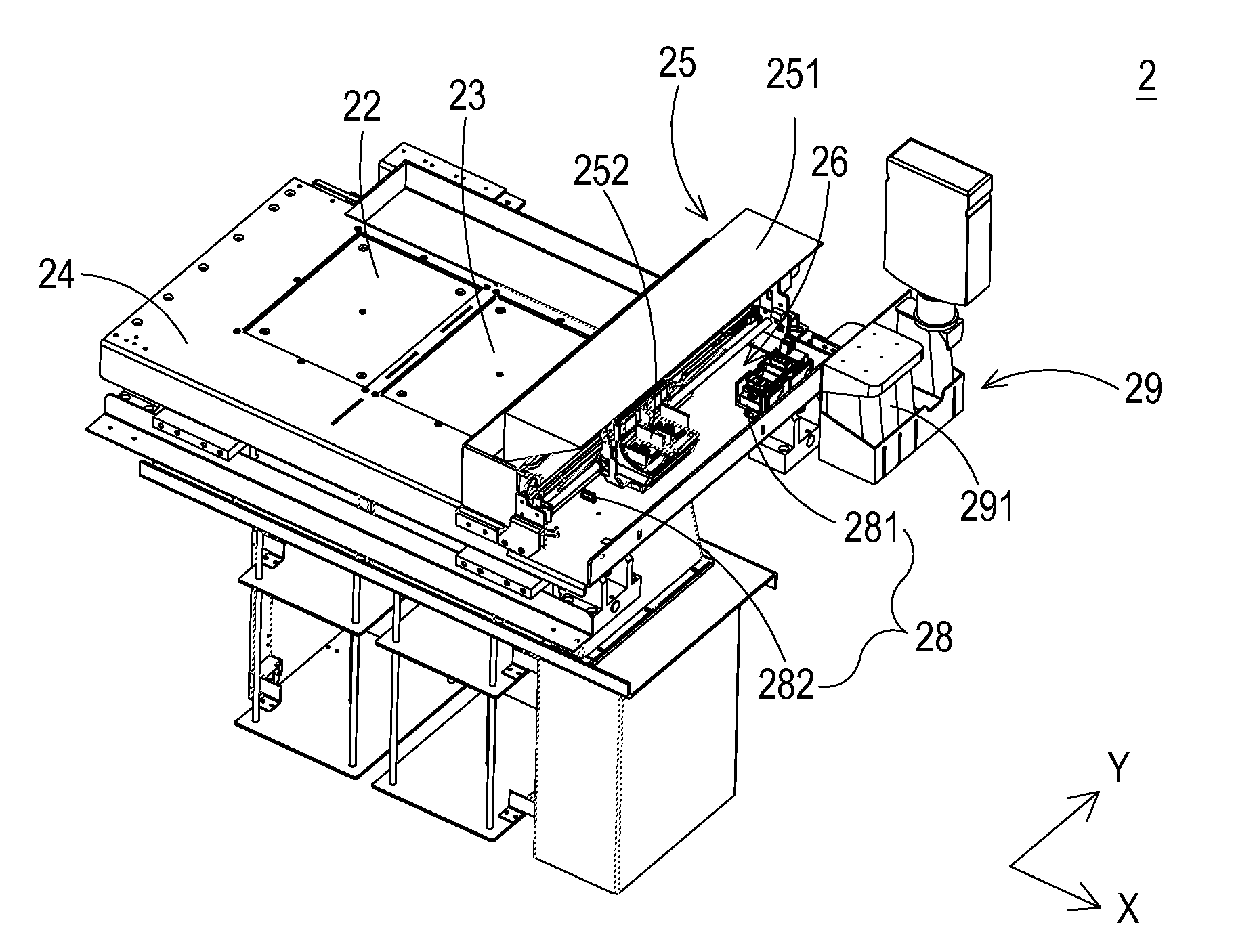

Powder recycling system

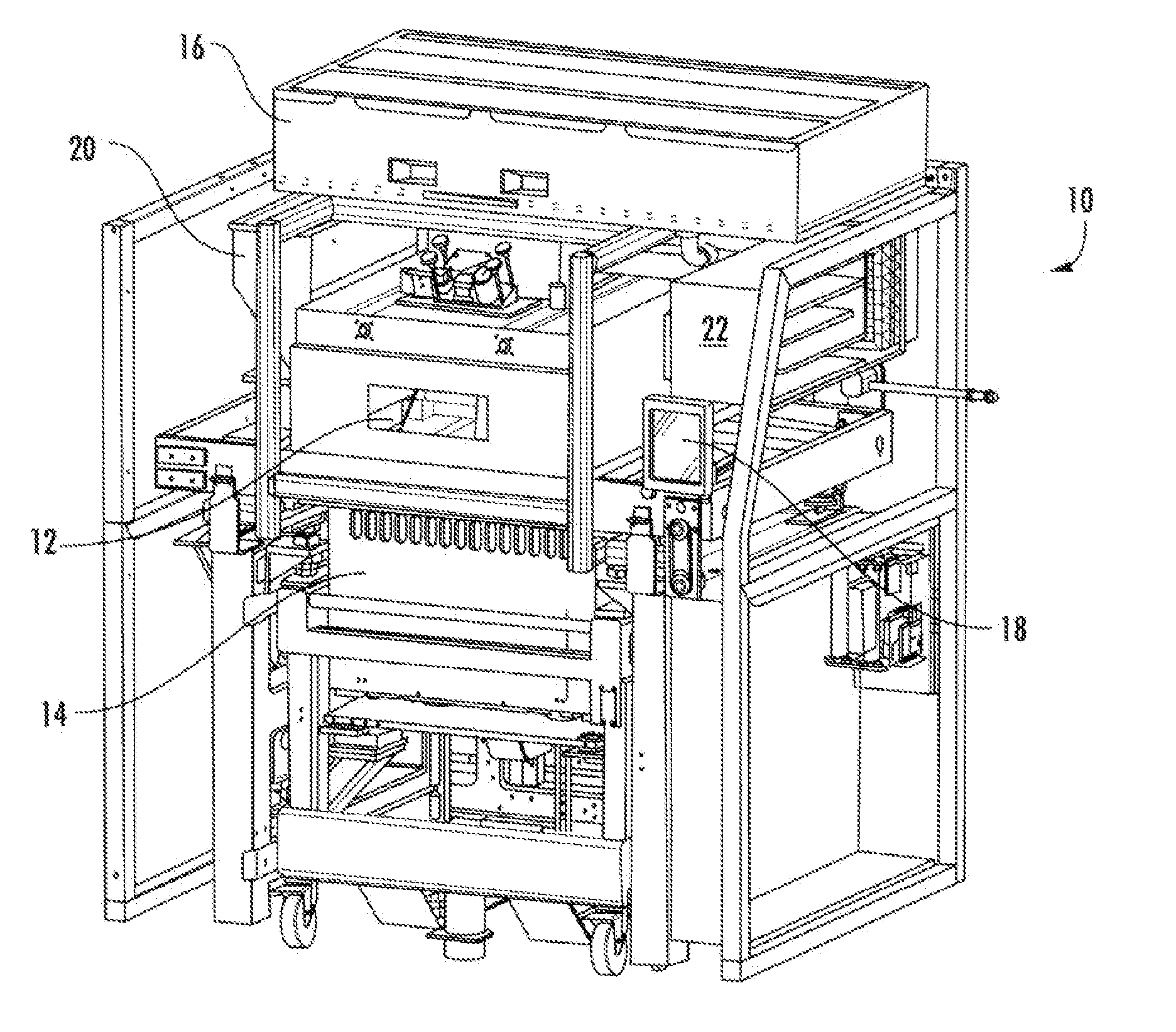

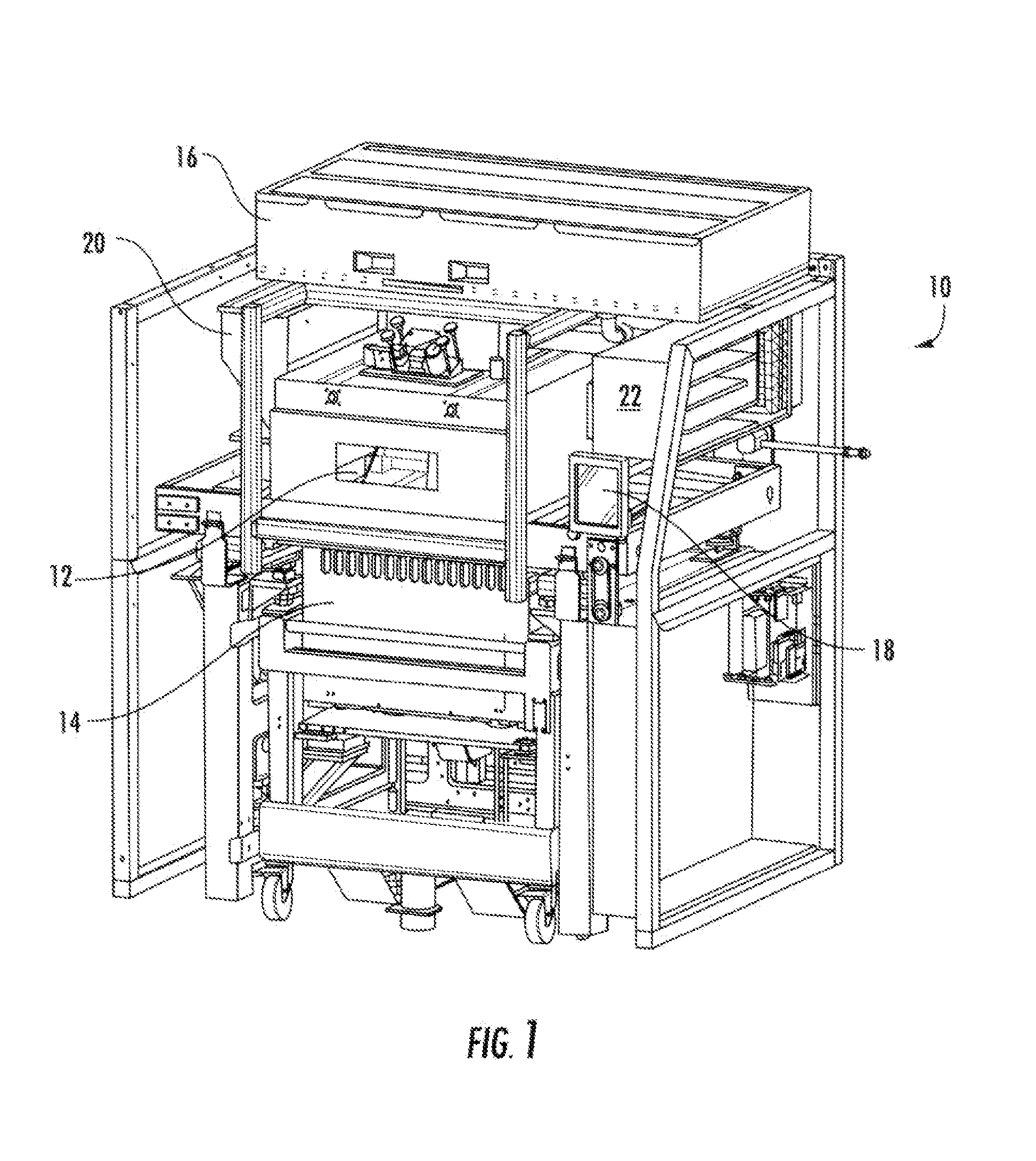

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

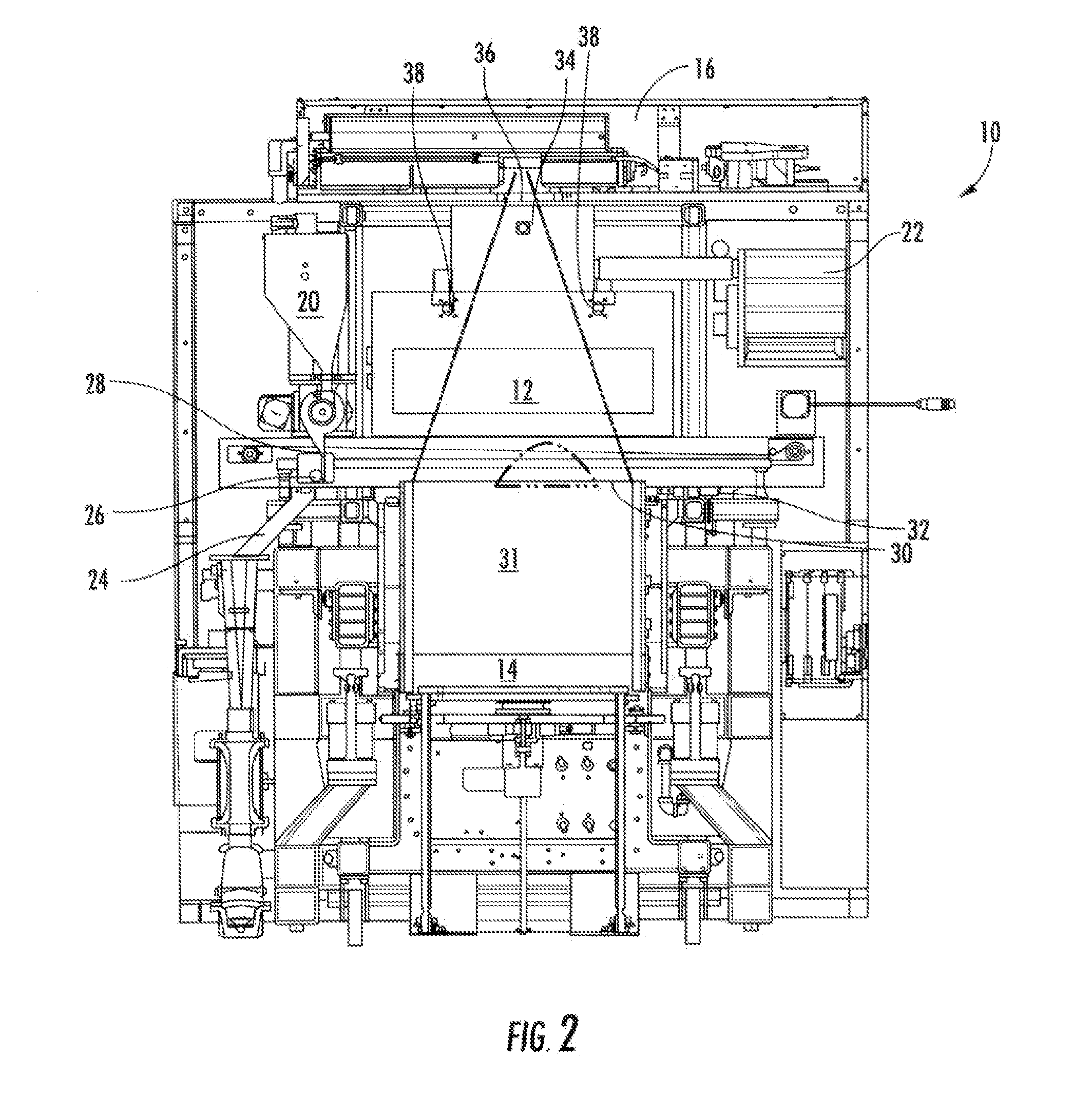

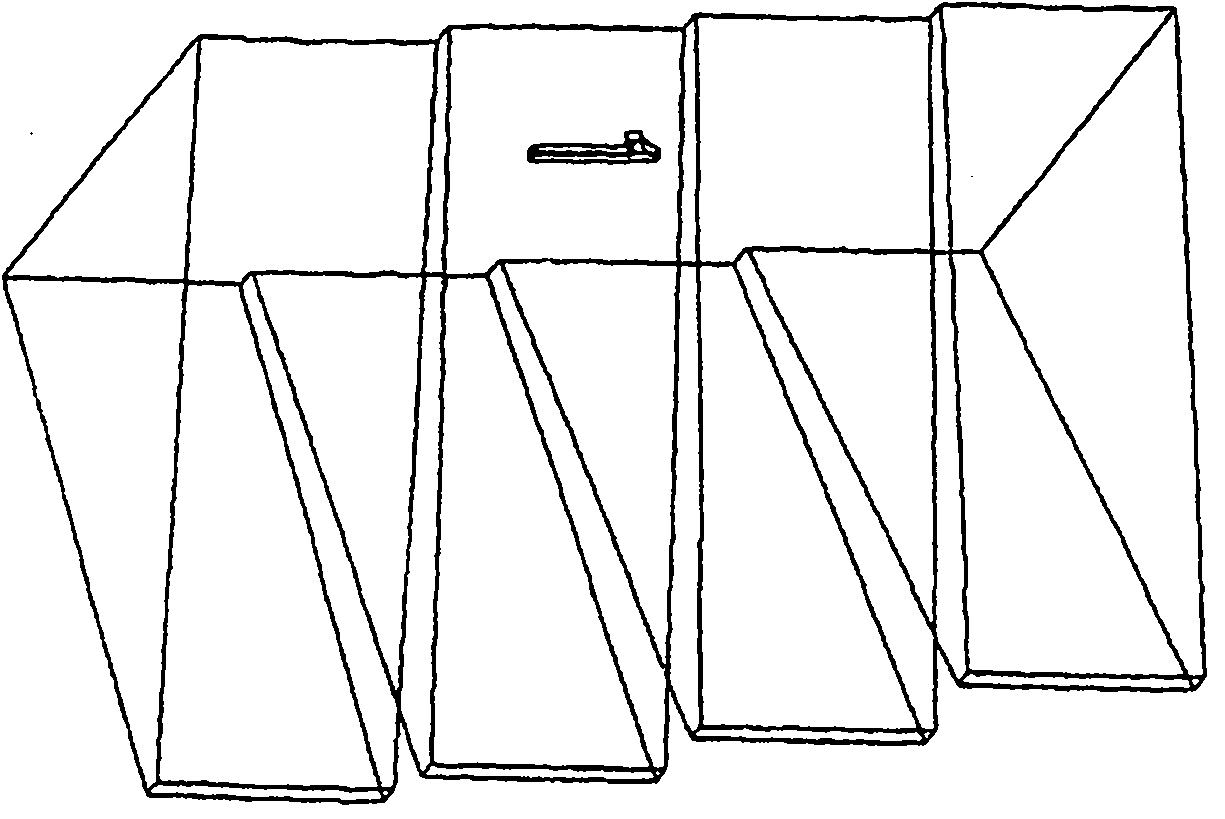

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

Apparatus and methods for handling materials in a 3-D printer

InactiveUS20080047628A1Improve efficiencyProcess uneconomicalAdditive manufacturing apparatusSolid material3d printerBiomedical engineering

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

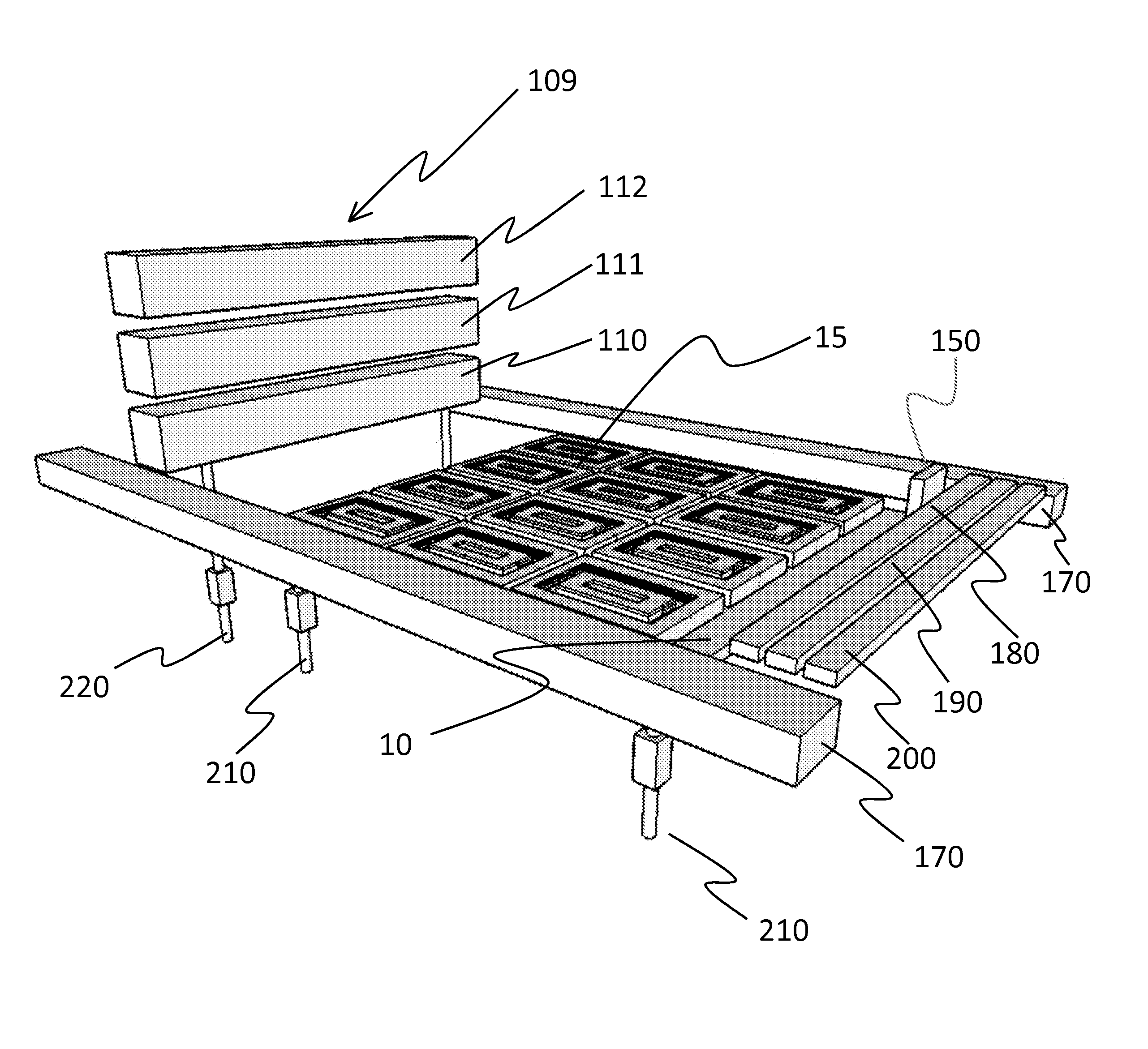

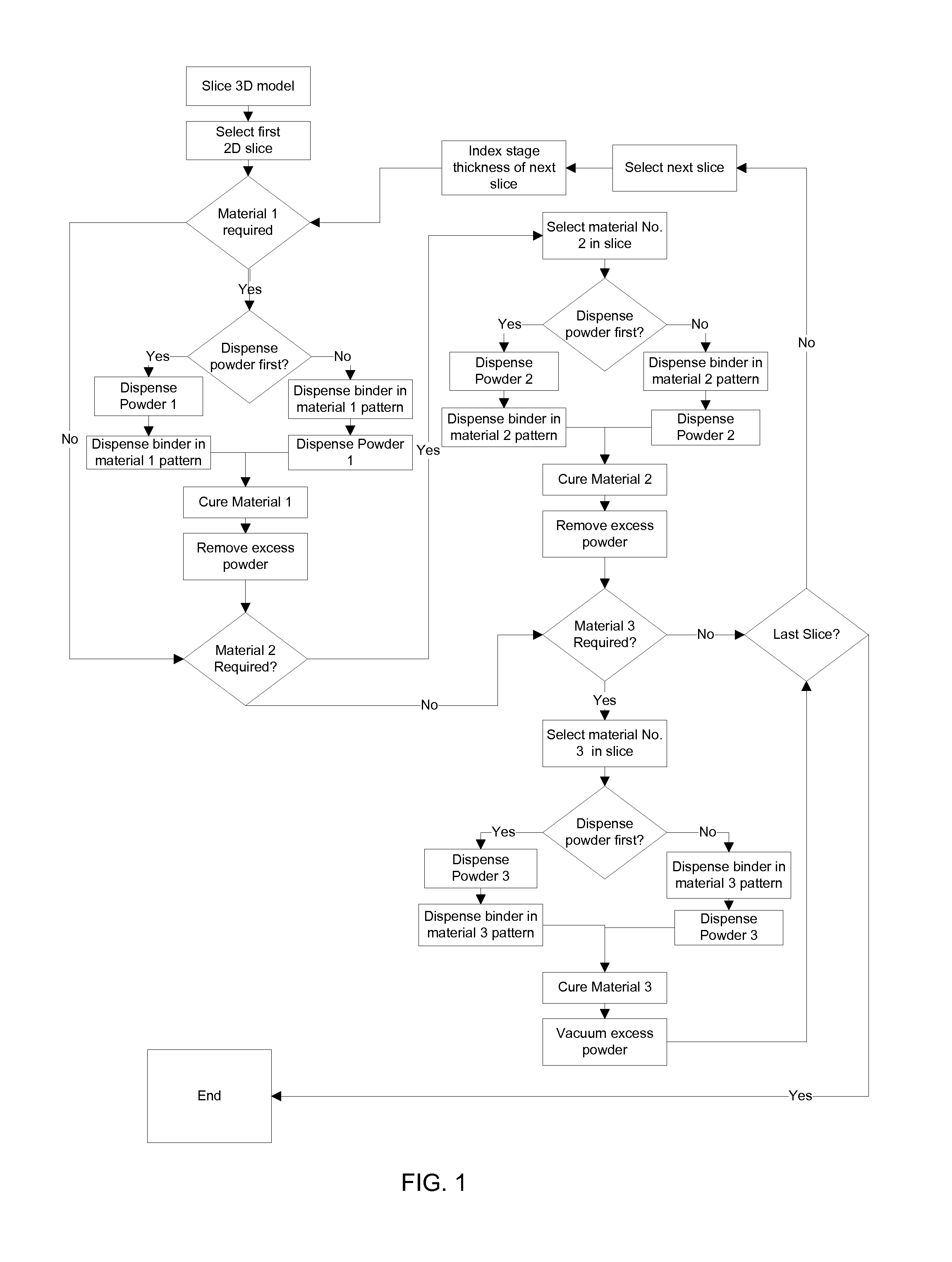

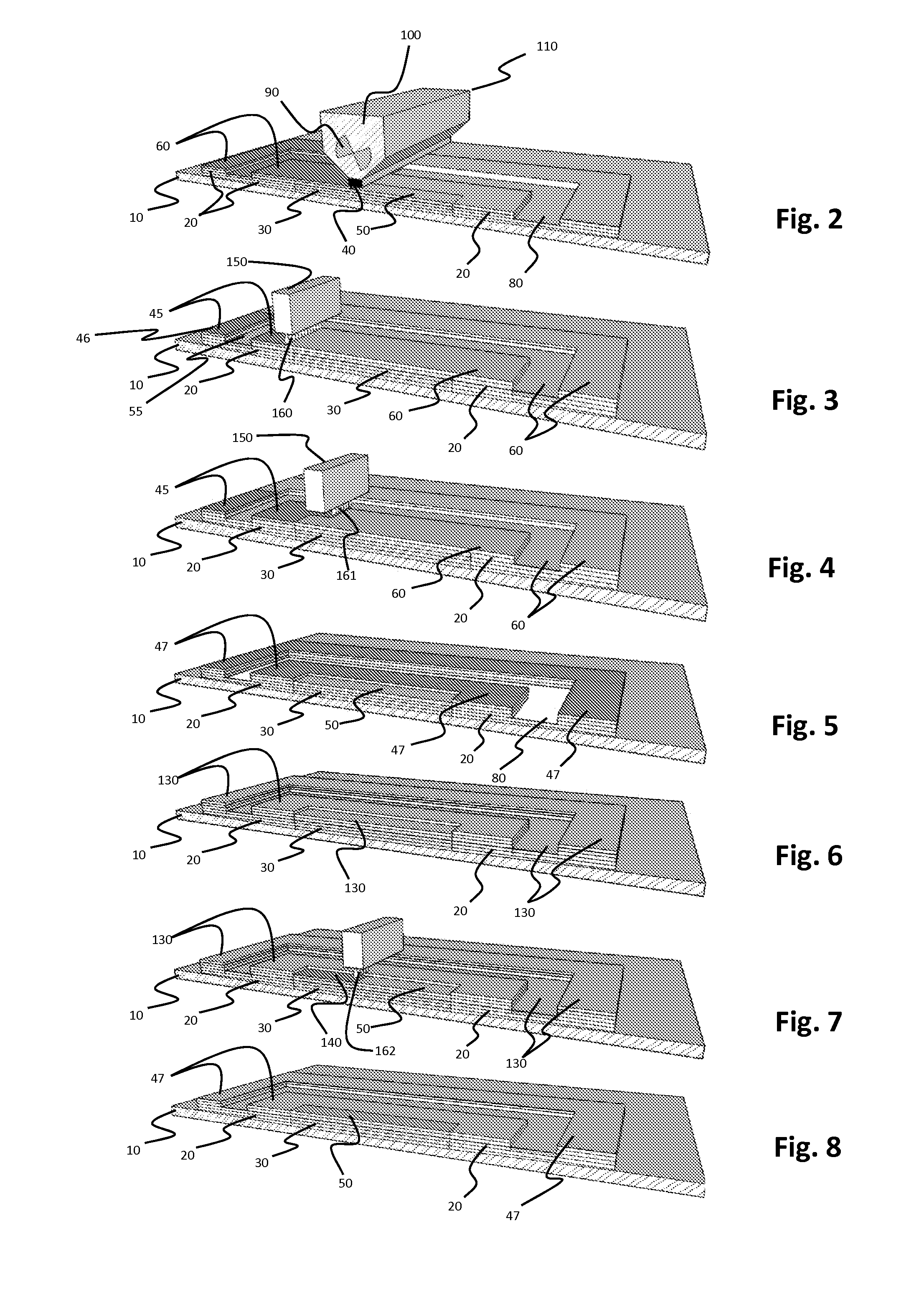

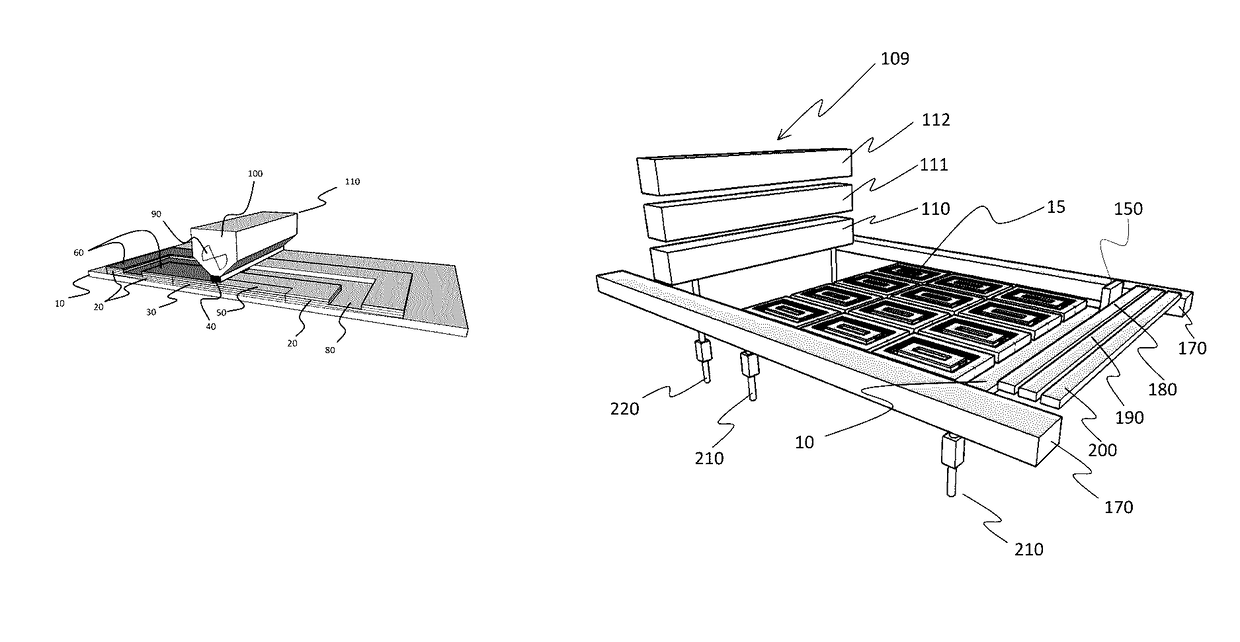

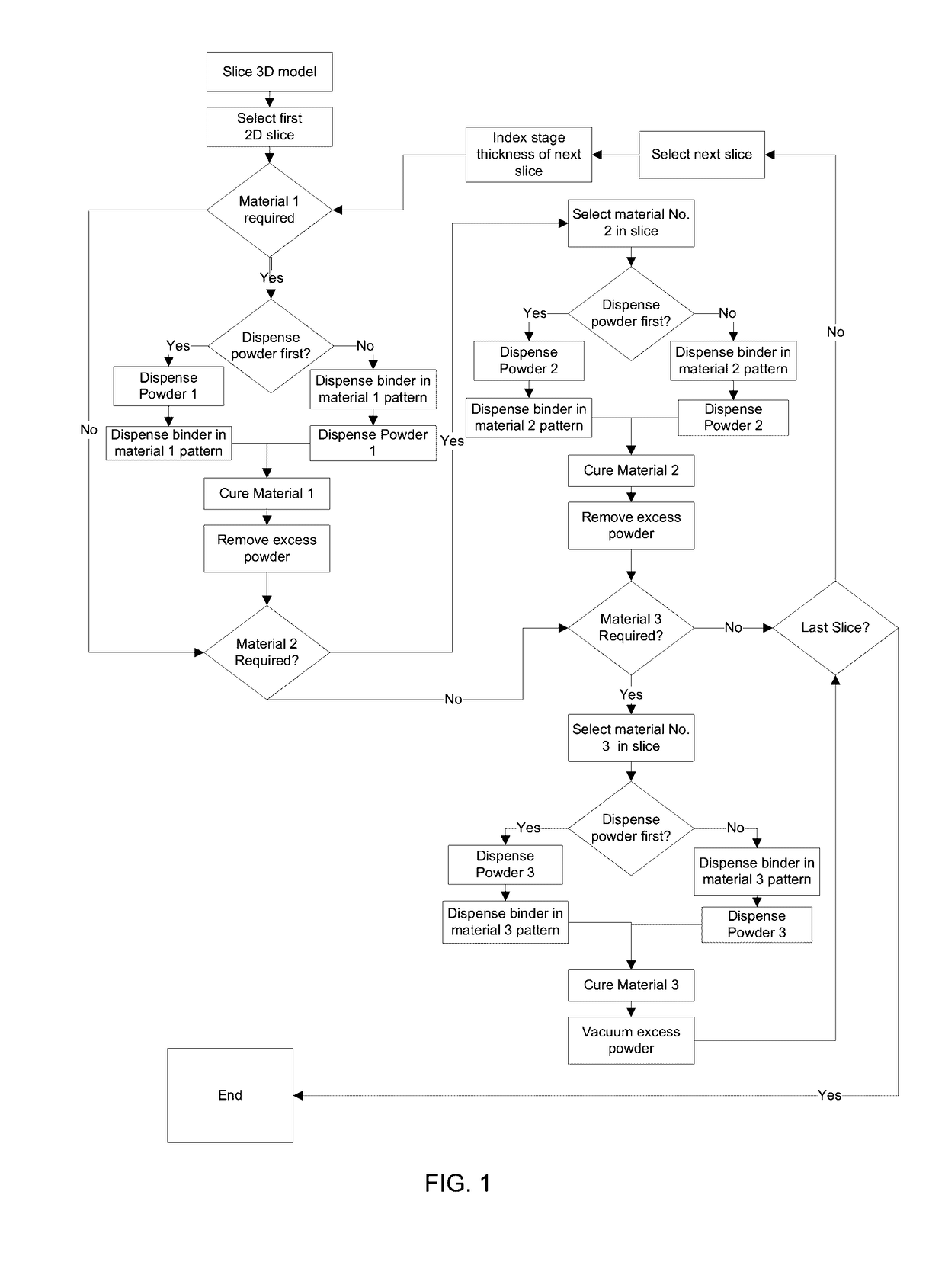

Multi-material three dimensional printer

A layer of a first powder is dispensed in a layer over a build plate. Binder is then selectively applied to hold portions of the layer of first powder together. Unbound first powder is then removed. A second powder is then dispensed in a layer over the build plate and portions of the bound first powder above the build plate. Binder is then selectively applied to hold portions of the second powder together. Unbound second powder is then removed. A third or more different powders can be similarly dispensed and bound to complete a multi-material layer. The process is then be repeated on a next subsequent layer. A curing radiation source can accelerate binding of powder together. Voids can be formed in portions of the layers by dispensing a fugitive material in portions of each multi-material layer. Mechanisms for implementing the printing process are also disclosed.

Owner:EOPLEX

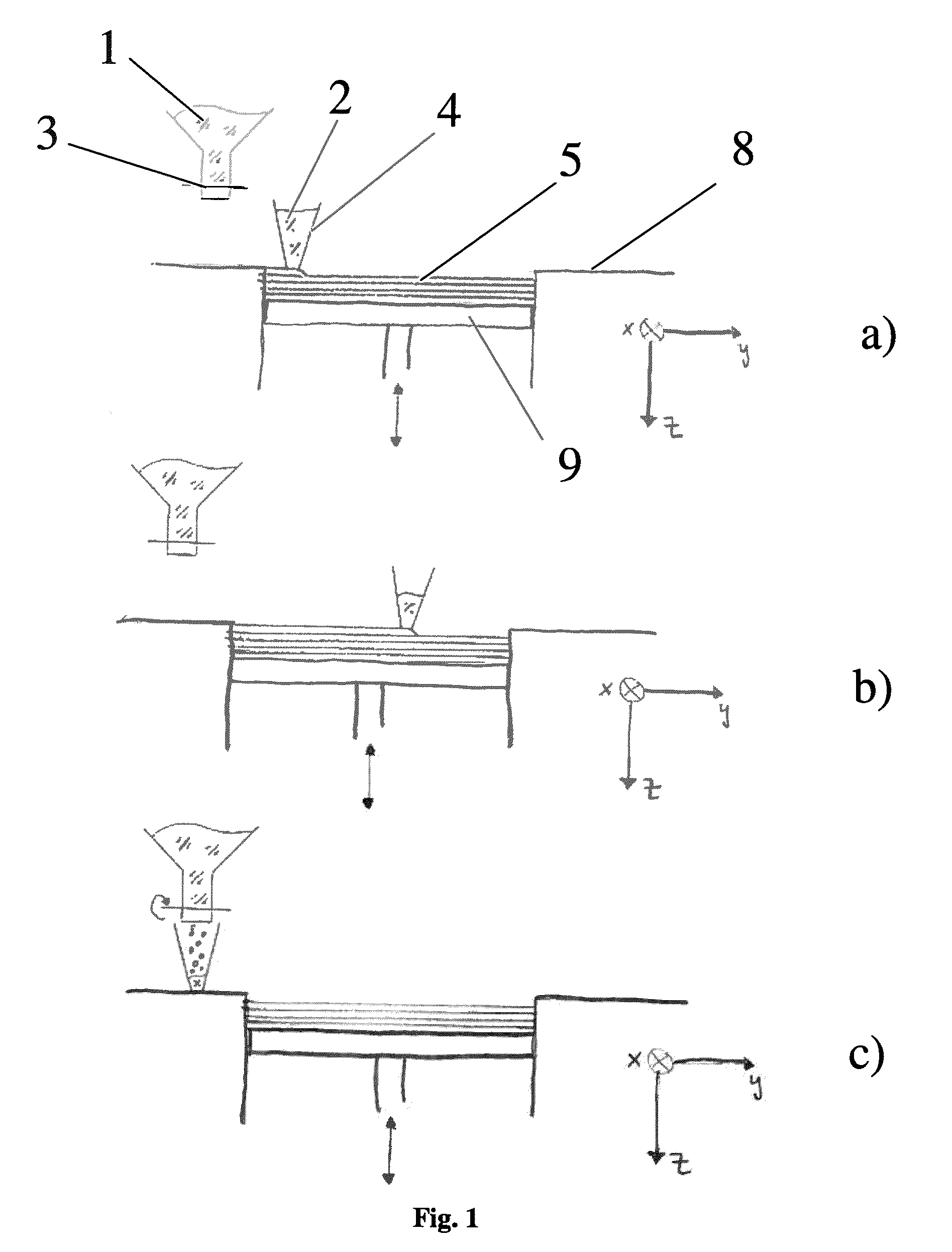

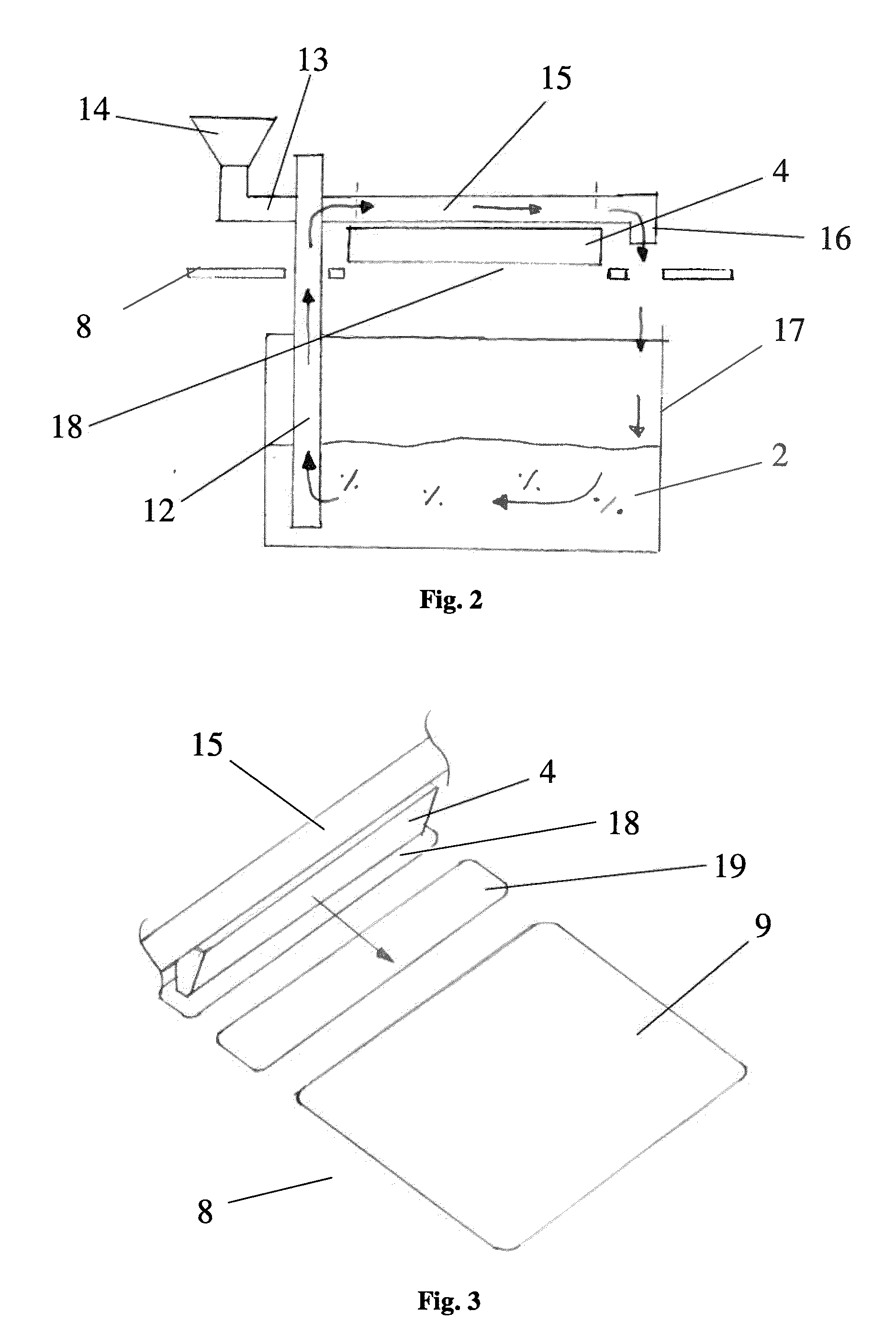

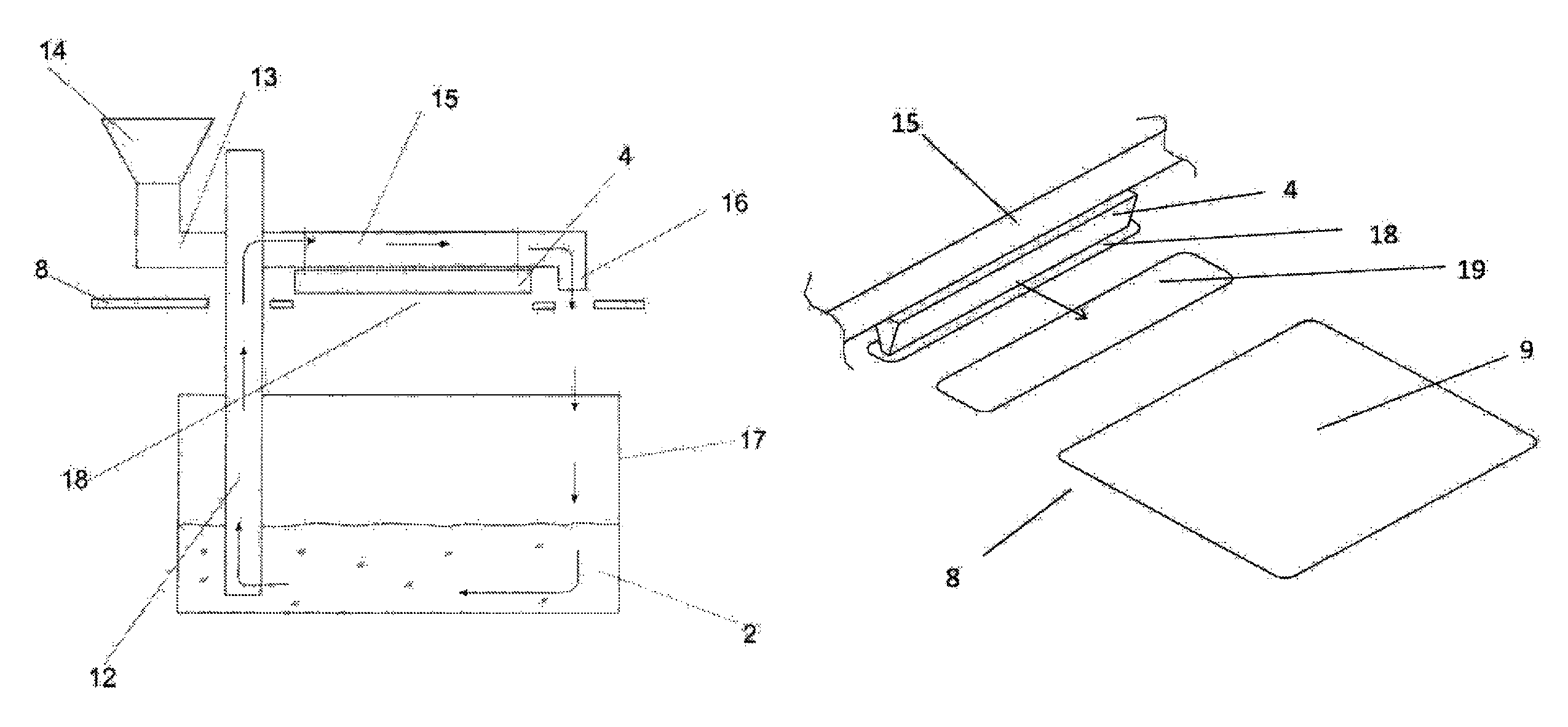

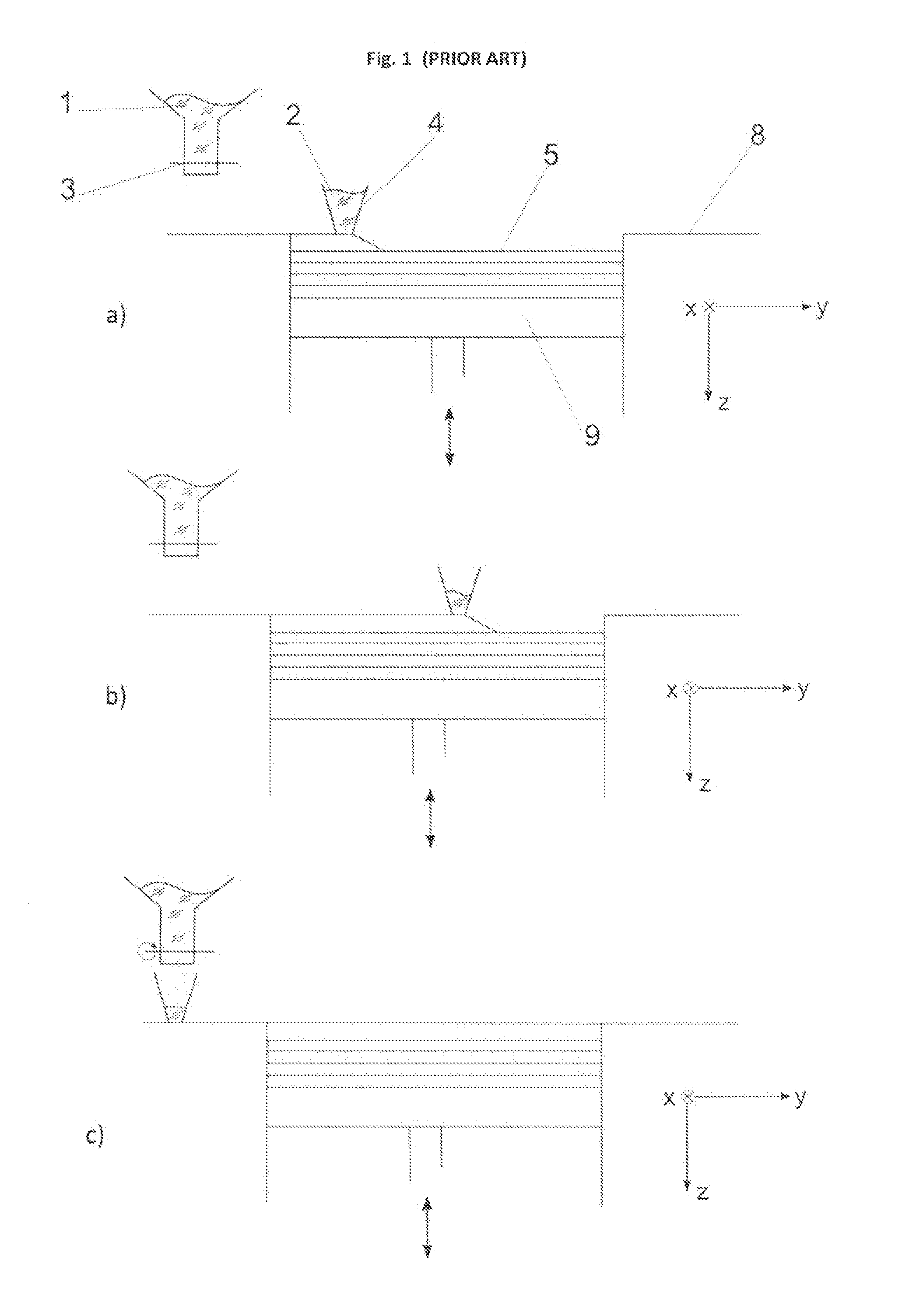

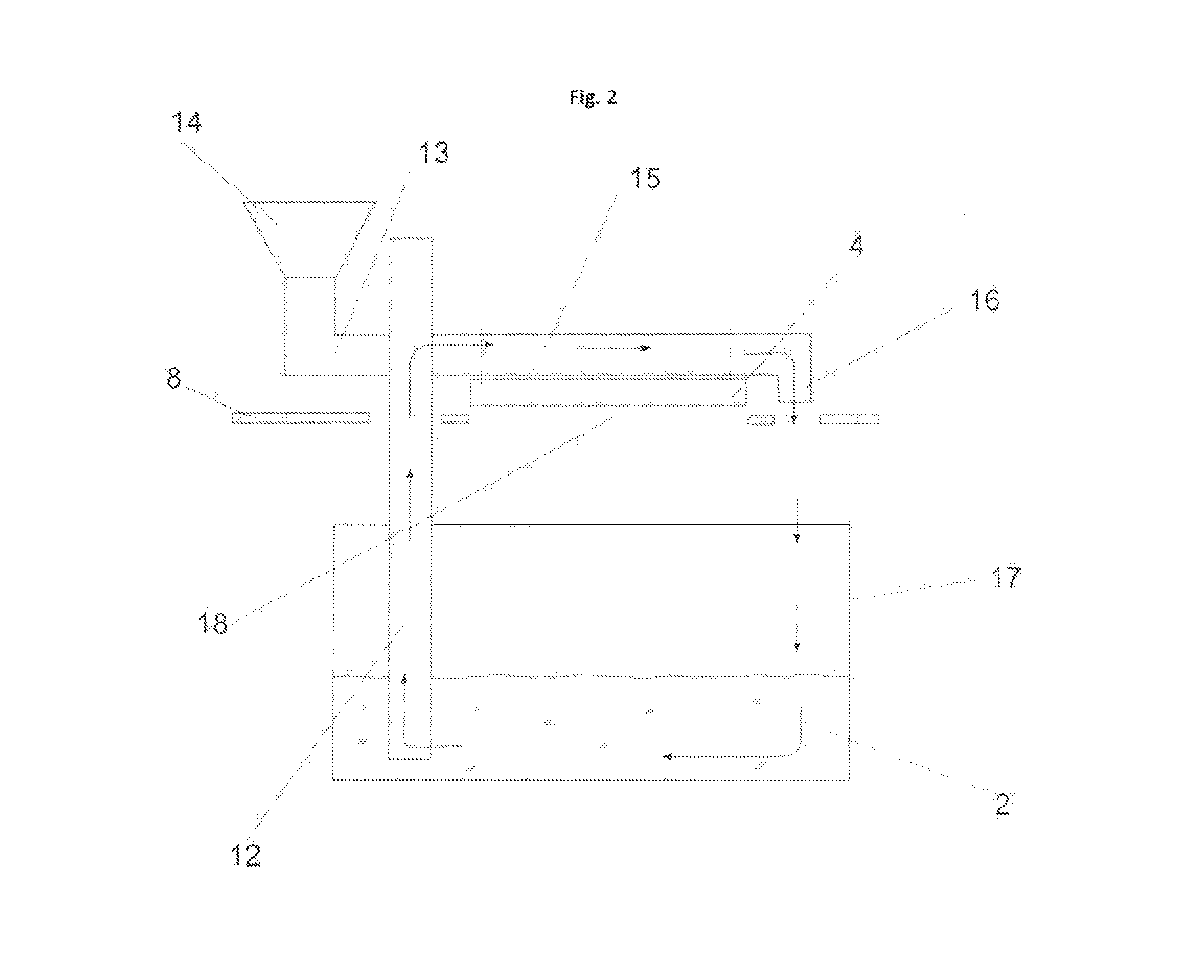

Method and device for conveying particulate material during the layer-wise production of patterns

ActiveUS20100272519A1Evenly filledAdditive manufacturing apparatusLiquid surface applicatorsEngineeringMechanical engineering

The present invention relates to a method for conveying particulate material during the manufacture of patterns in layers, wherein powder is conveyed out of a reservoir into a spreader unit and, if applicable, excess powder fed to the spreader unit is again conveyed back into the reservoir and wherein this conveying takes place in a closed conveying circuit.

Owner:VOXELJET AG

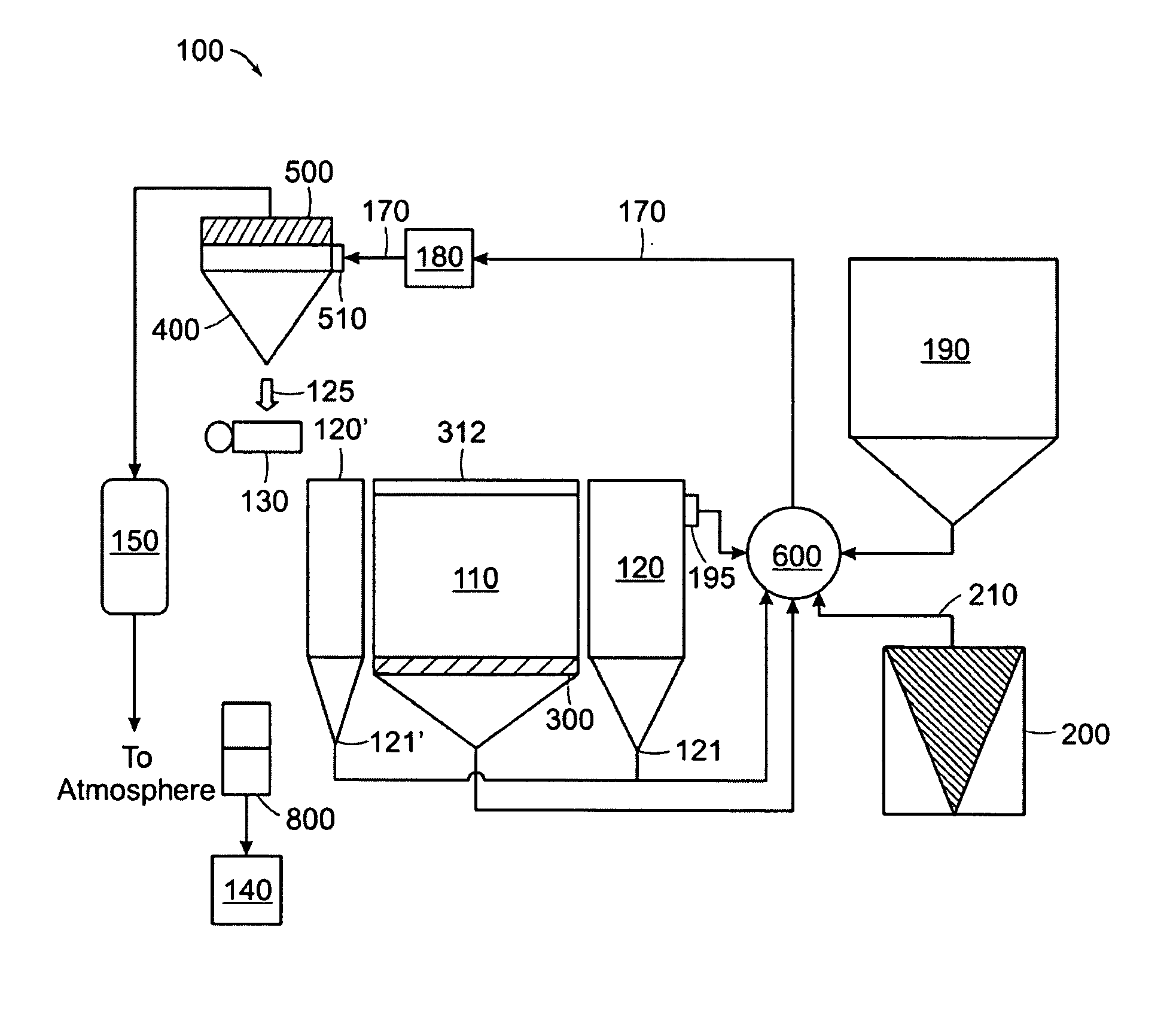

Selective Laser Sintering Powder Recycle System

ActiveUS20090169664A1Good blendingReduce powder lossFlow mixersTransportation and packagingSelective laser sinteringMetallurgy

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

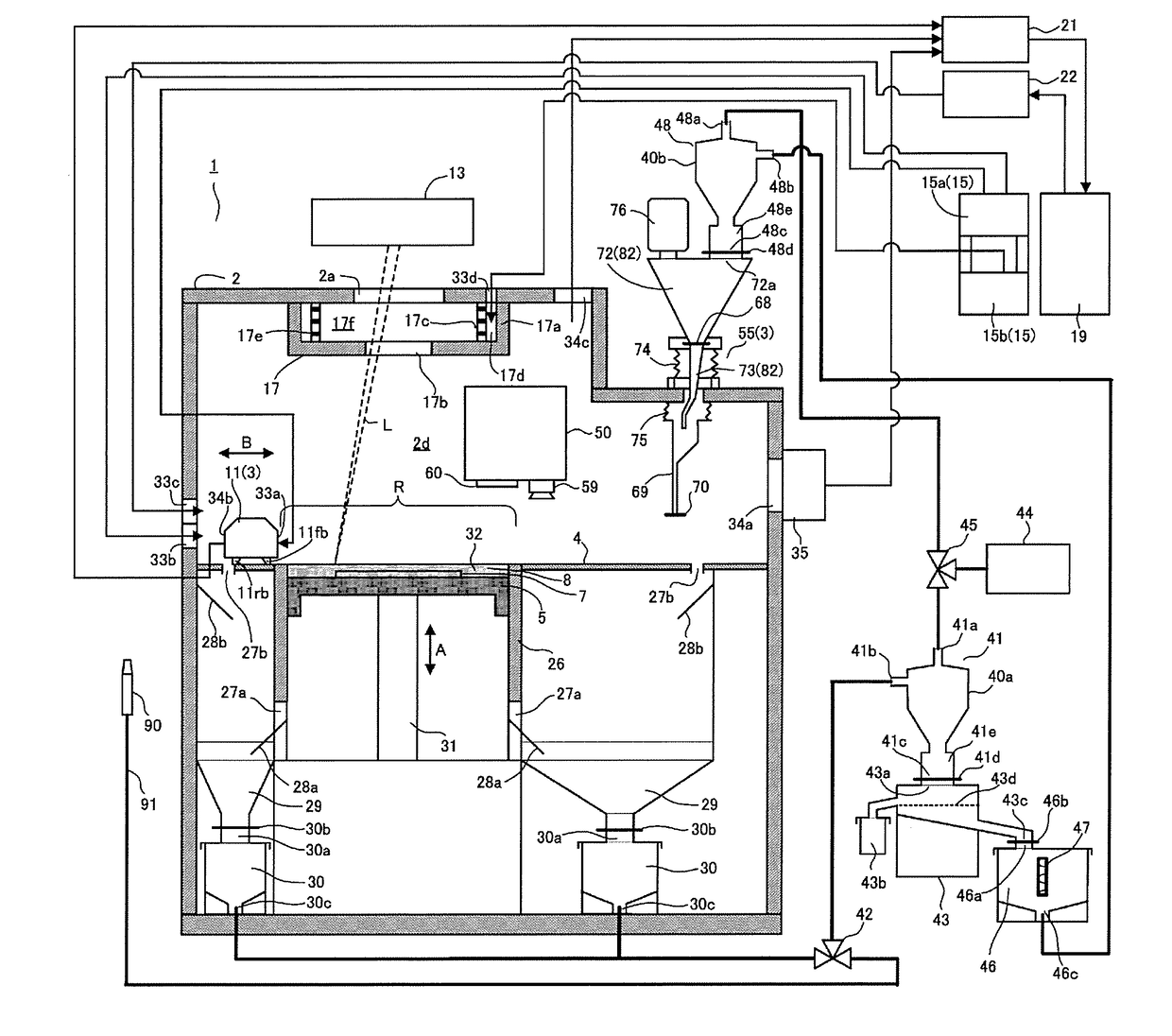

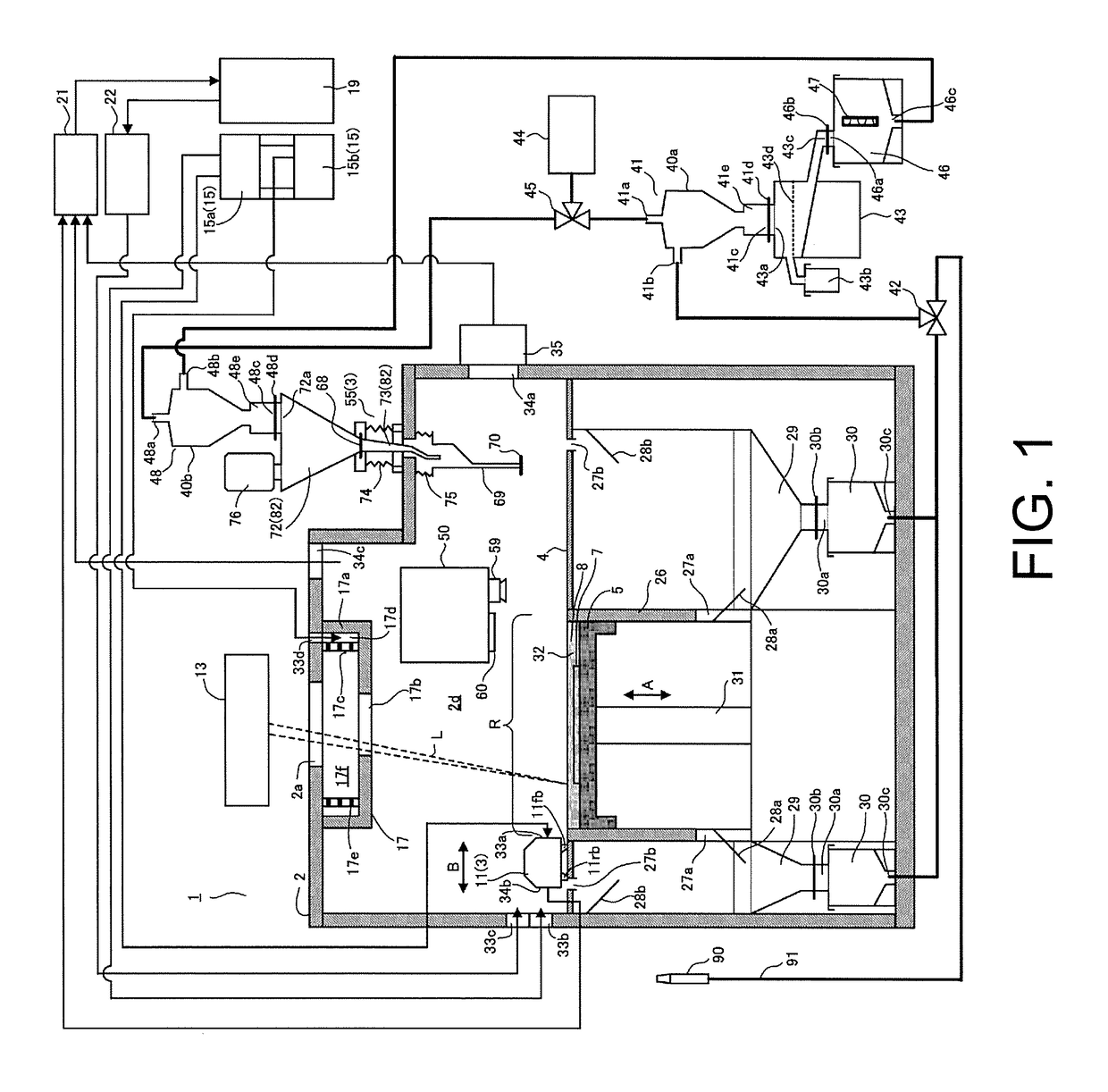

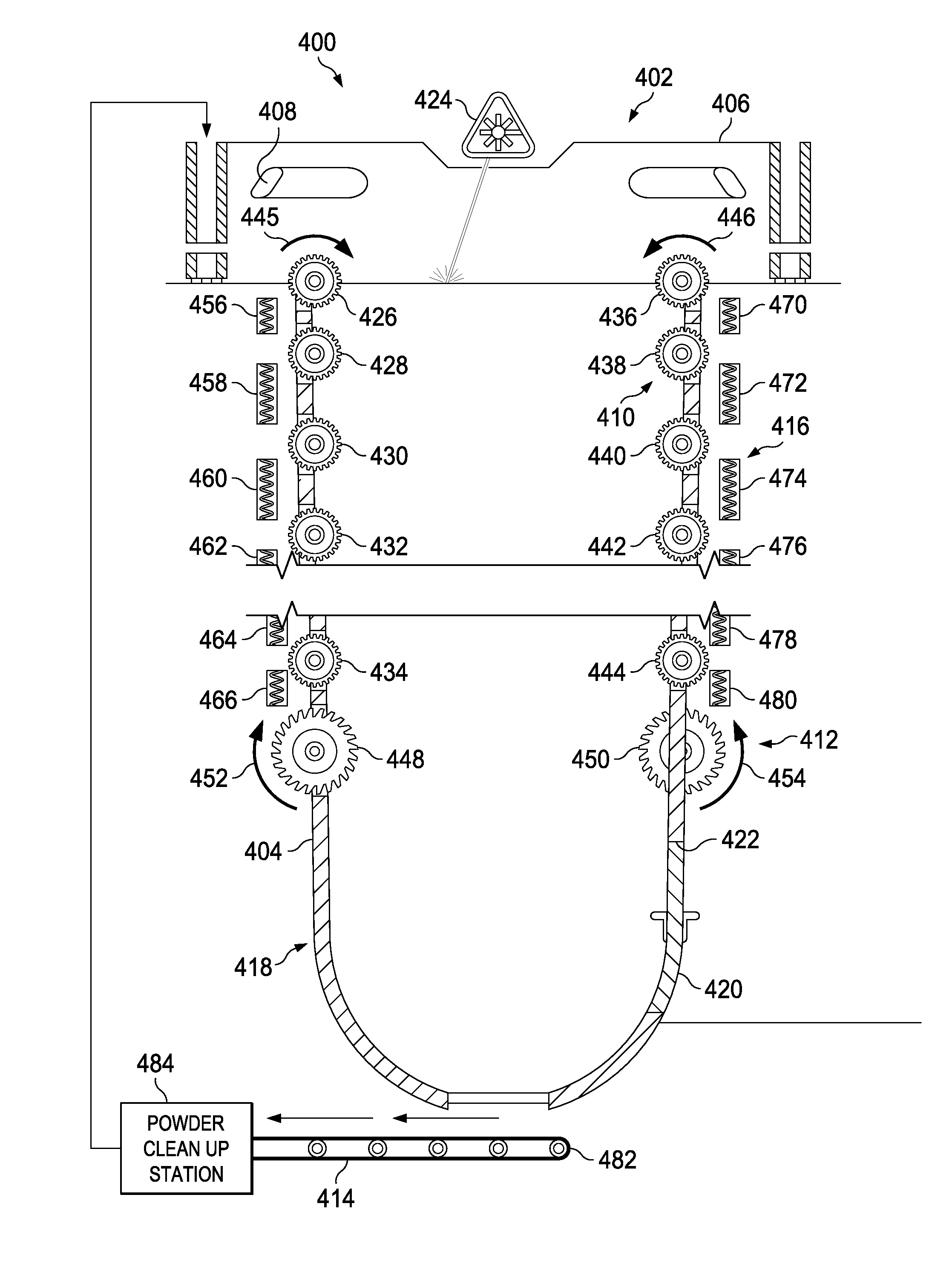

Three-dimensional printer

ActiveUS20170348771A1Form evenlyLong automationManufacturing enclosuresManufacturing material handlingMaterial supplyRetaining wall

A three-dimensional printer (1) includes a material supply device (3) that supplies material powder to a table which is movable vertically, a powder retaining wall (26) that surrounds the table and retains the material powder, a material-recovery bucket (30) that accommodates excess material powder and impurities discharged from the powder retaining wall, an impurity removing device (43) that removes the impurities from the material powder, and a material drying device (47) that dries the material powder. The material powder from which the impurities have been removed and which has been dried is returned and recycled to the material supply device.

Owner:SODICK CO LTD

Method for producing three-dimensional objects from powders and device for implementing same

InactiveUS20160339639A1Possible to obtainManufacturing platforms/substratesIncreasing energy efficiencyMulti materialMaterials science

The invention is a method and device for producing three-dimensional objects, having a gradient of properties and multi-material objects, from powders. A method involves the selection of powders of various materials according to diameter, the successive application of layers of powder of a given thickness during the vertical displacement of a piston of a device build chamber with an object to be sintered, and the programmed selective sintering / melting of a given area in the plane of each layer. After sintering, piston is raised, unsintered powder is removed from a layer. The piston is then returned, and a layer of powder having a different diameter and being of a dissimilar material is applied and selectively sintered. When the object-sintering process is finished, the unsintered powder is removed from the build chamber, and the powders are separated according to diameter. The separated powders are returned to feed containers of device for re-use.

Owner:CHIVEL JURY ALEKSANDROVICH

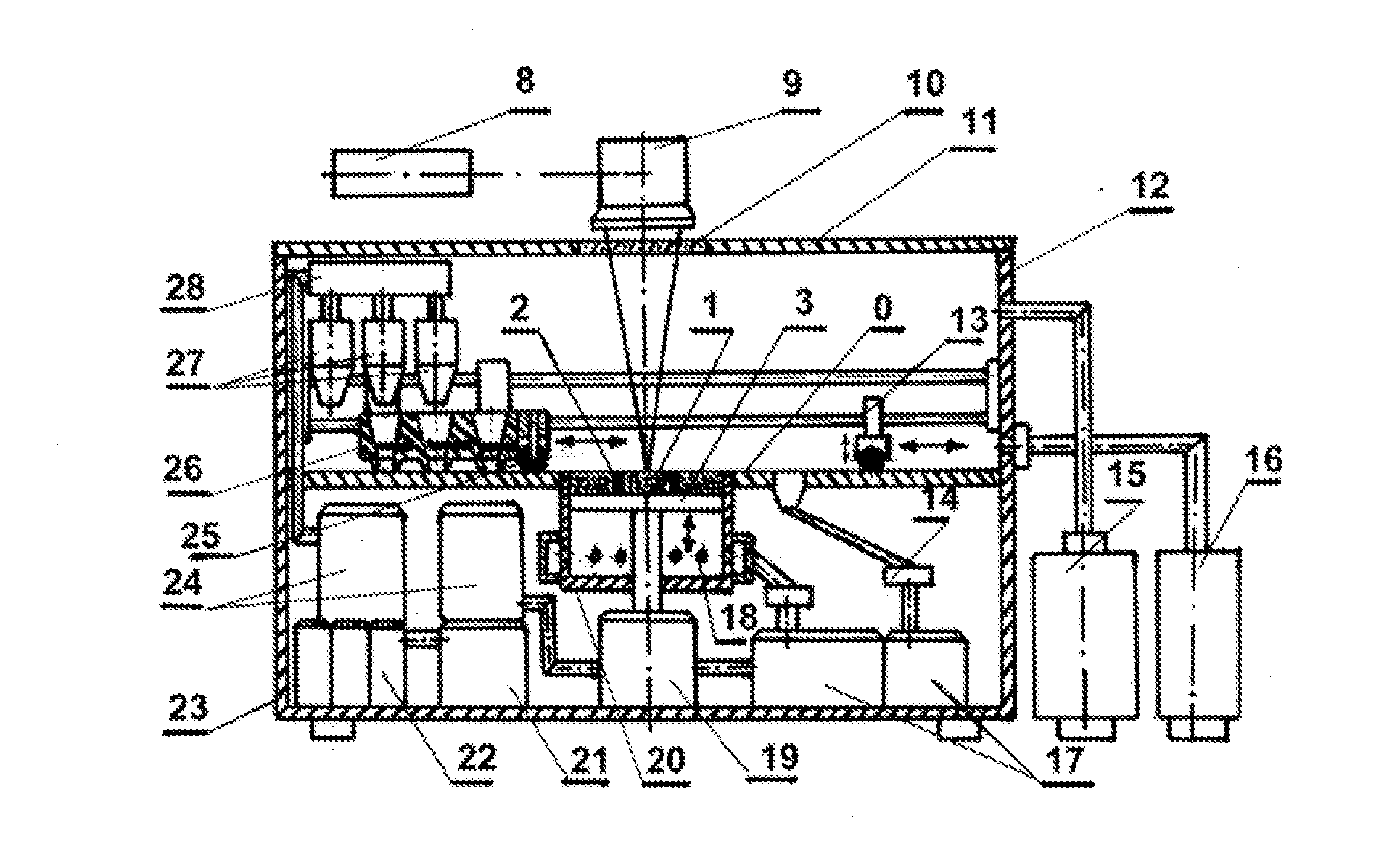

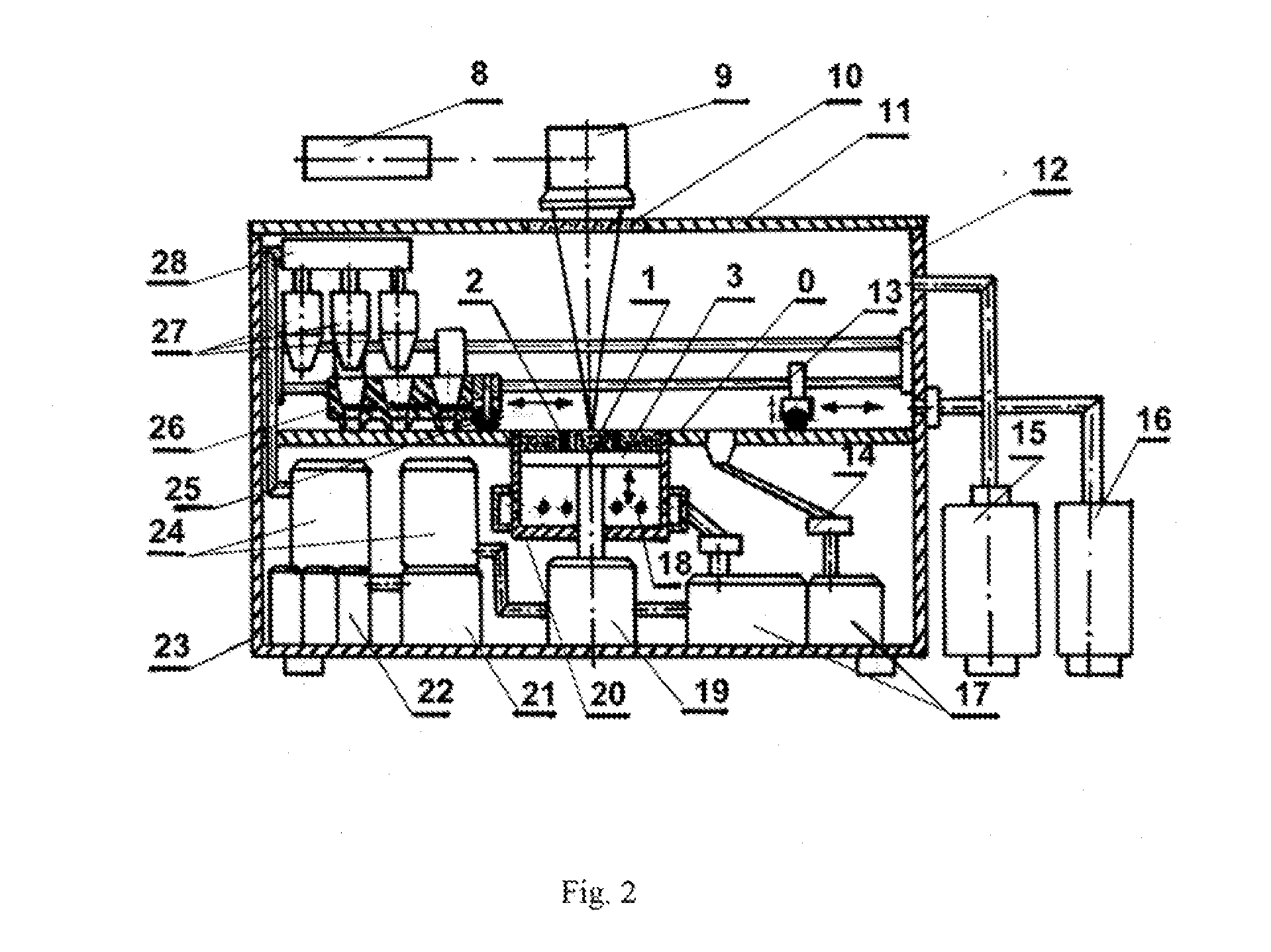

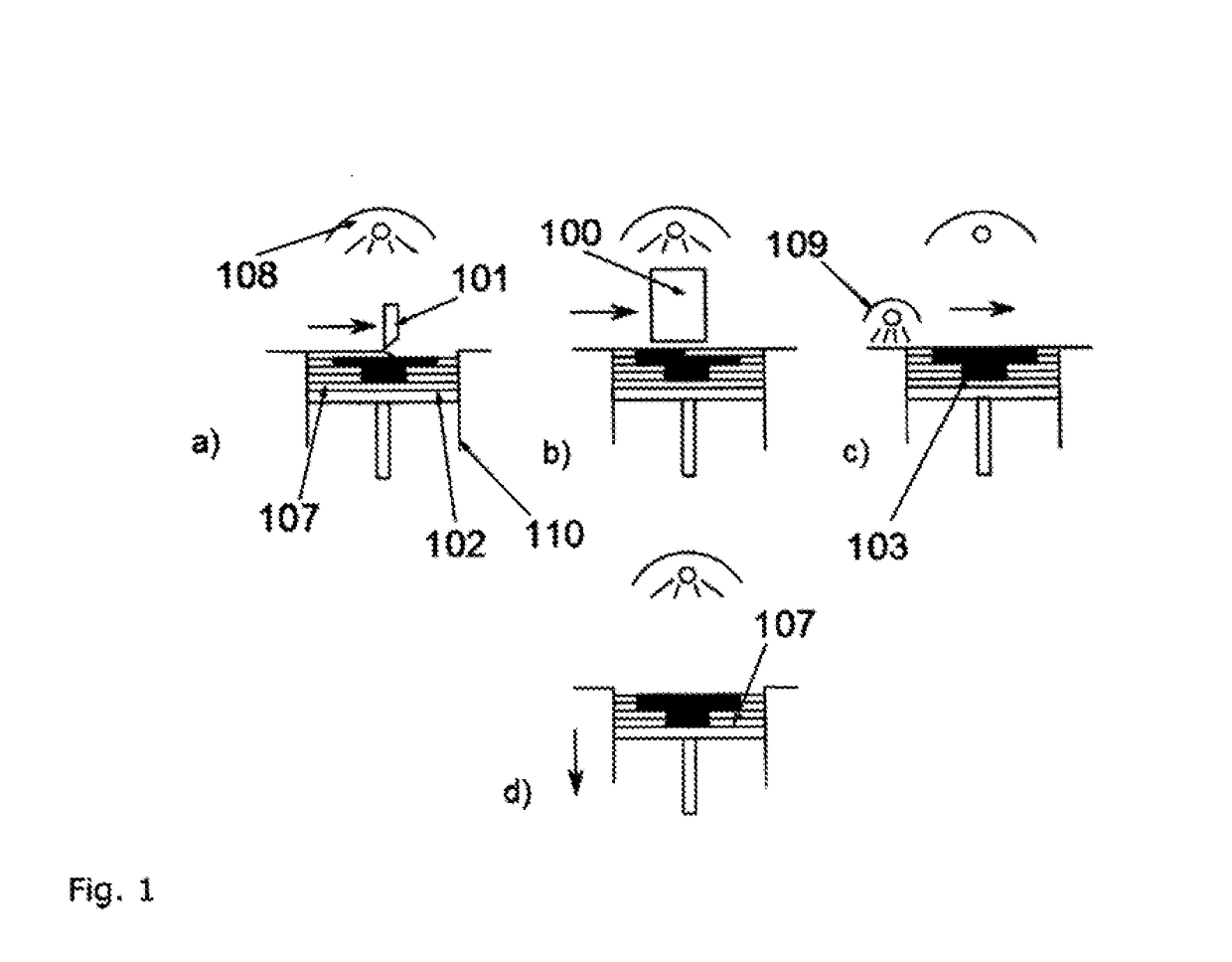

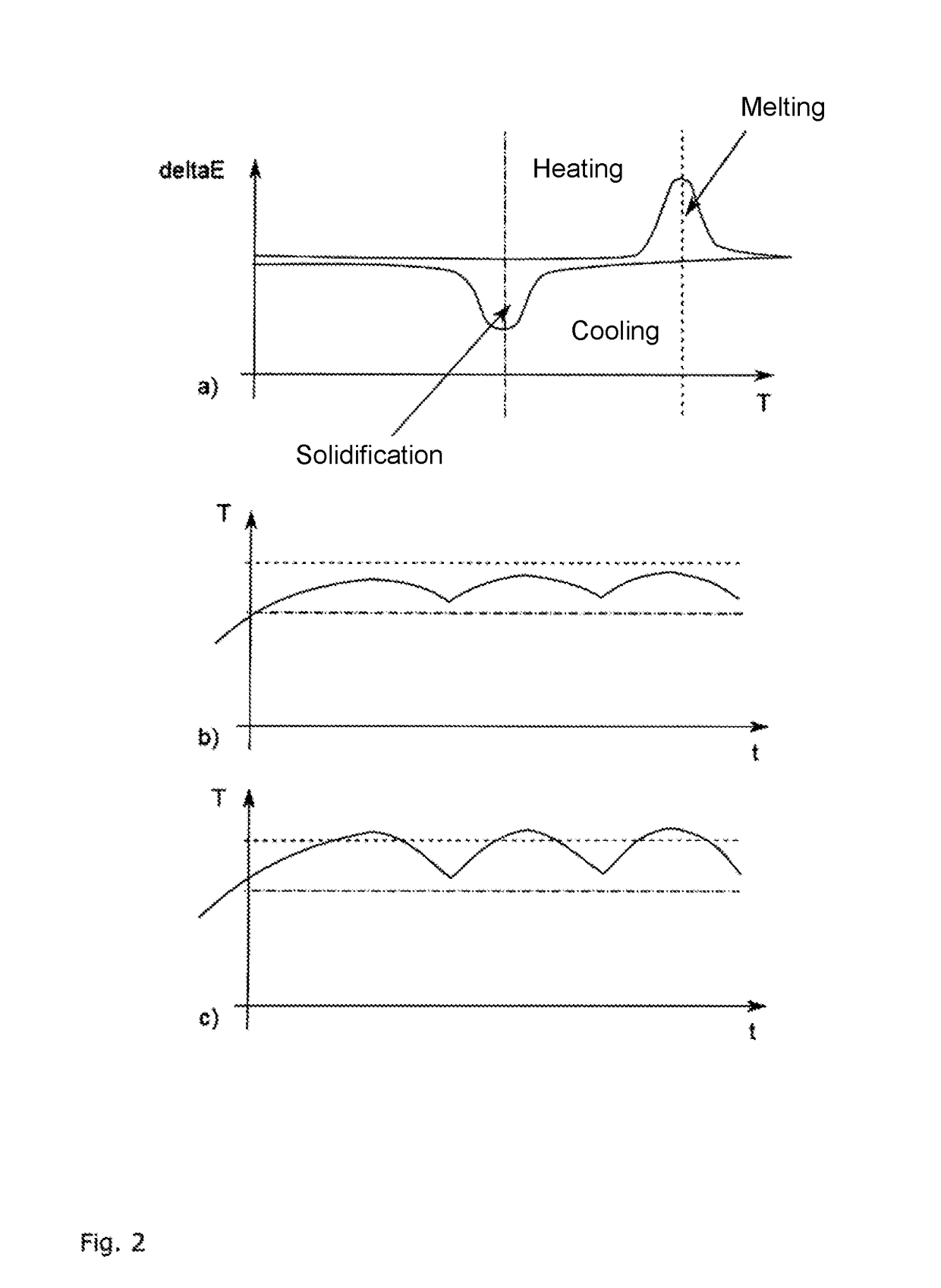

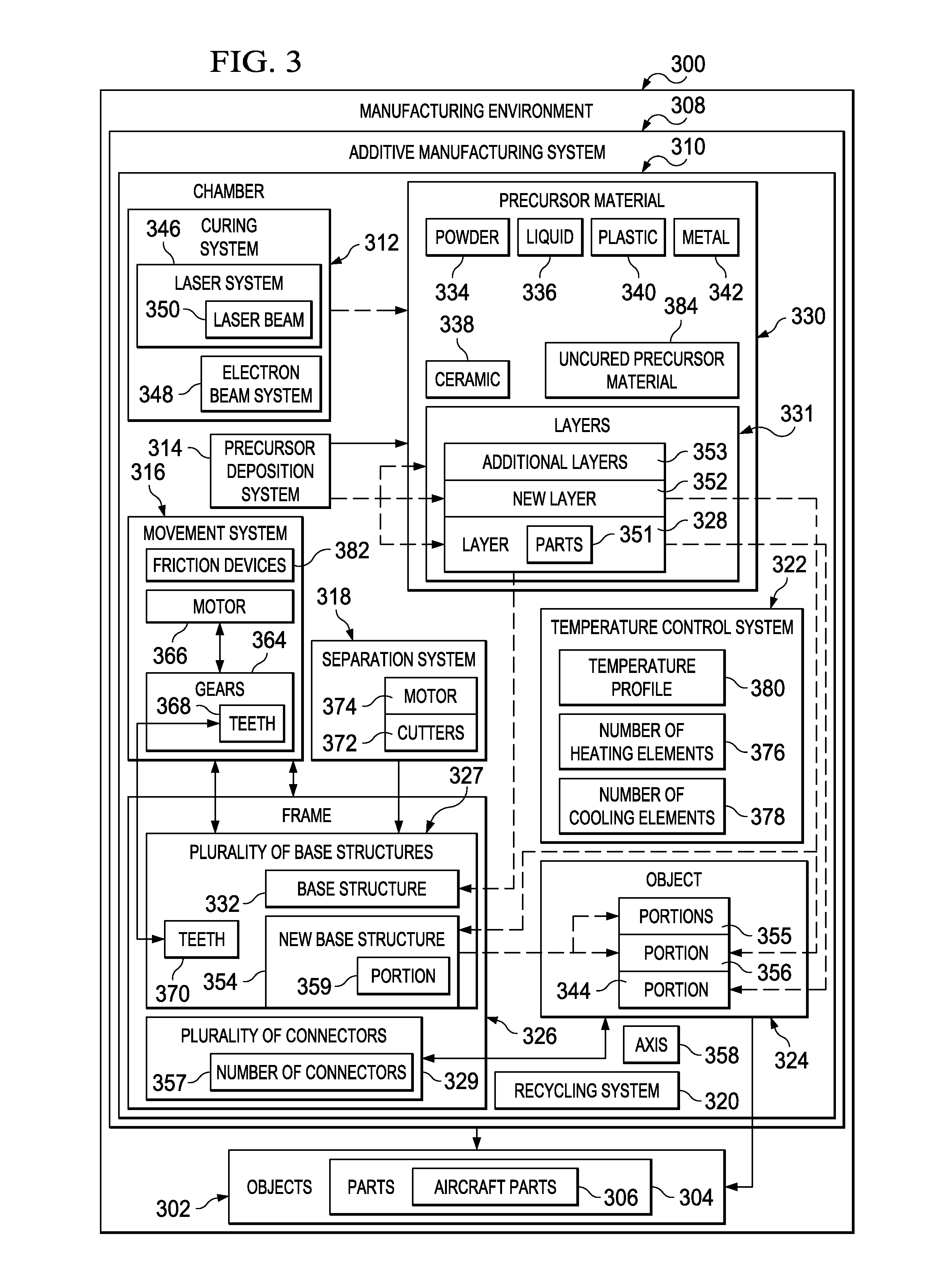

Method and device for producing 3D moulded parts by means of a layer construction technique

ActiveUS20170355137A1High boiling pointAdjustable temperatureManufacturing heating elementsManufacturing recyclingMaterials scienceThree dimensional model

The invention relates to a method and an apparatus for producing three-dimensional models by layering in a high-speed sintering process.

Owner:VOXELJET AG

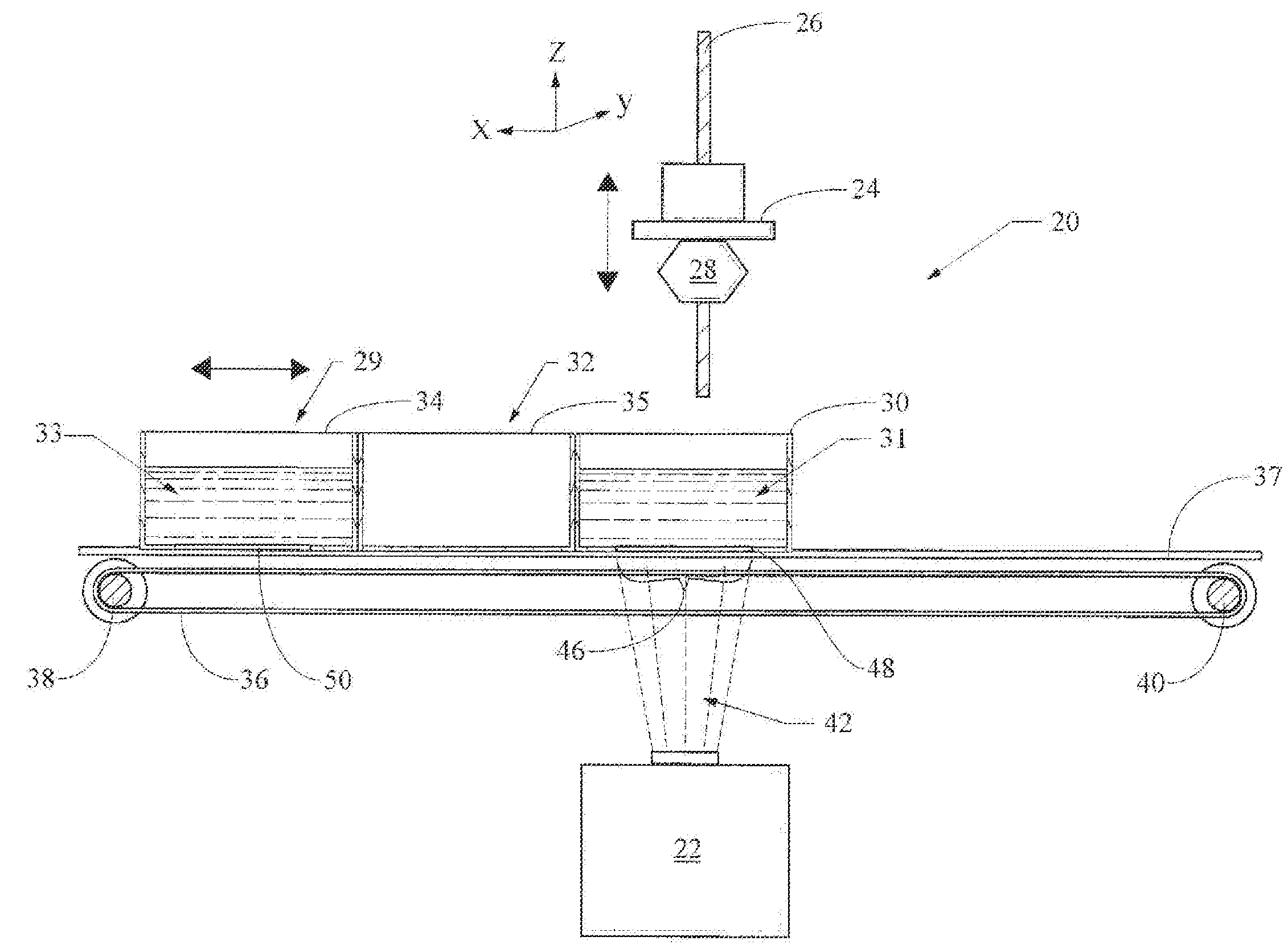

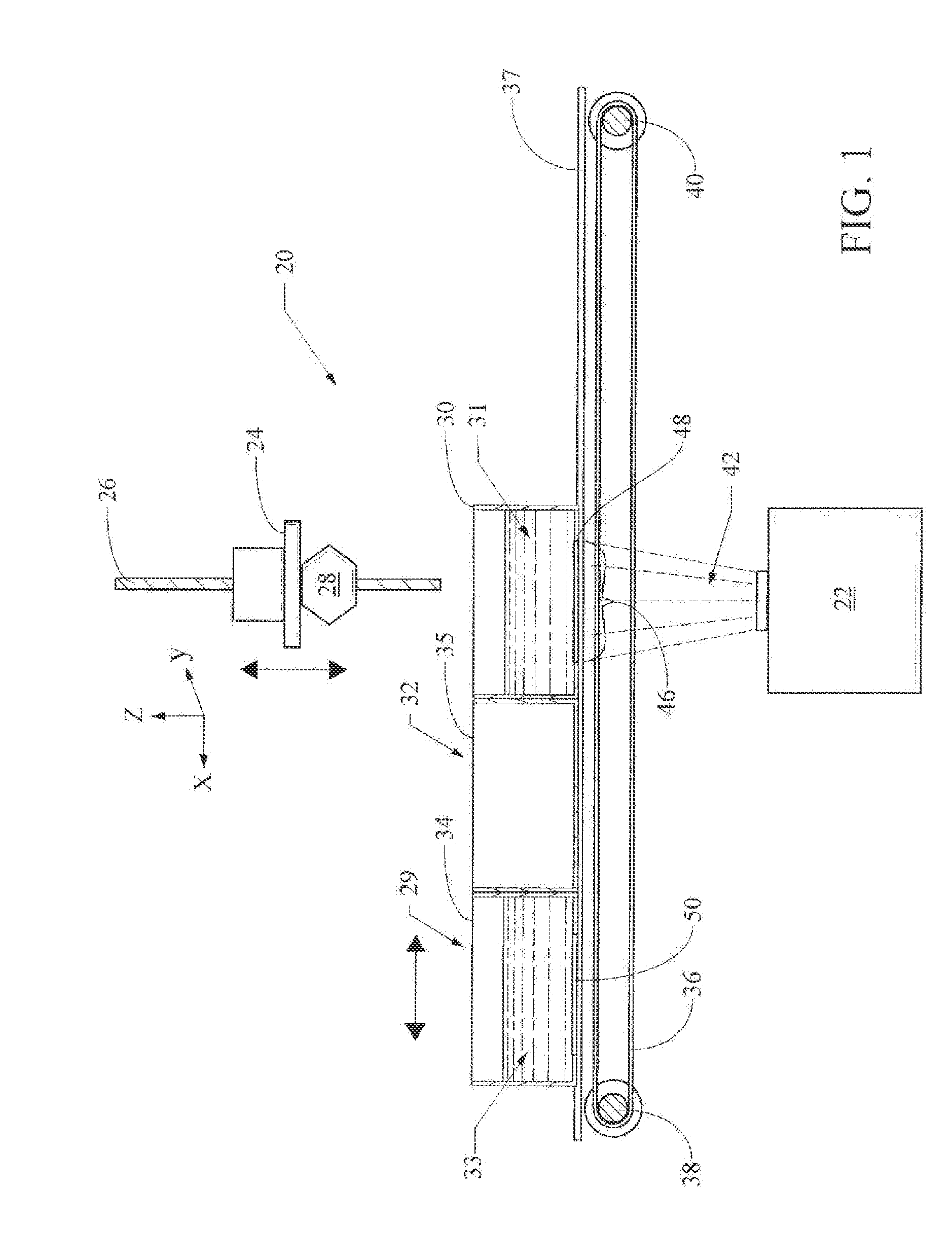

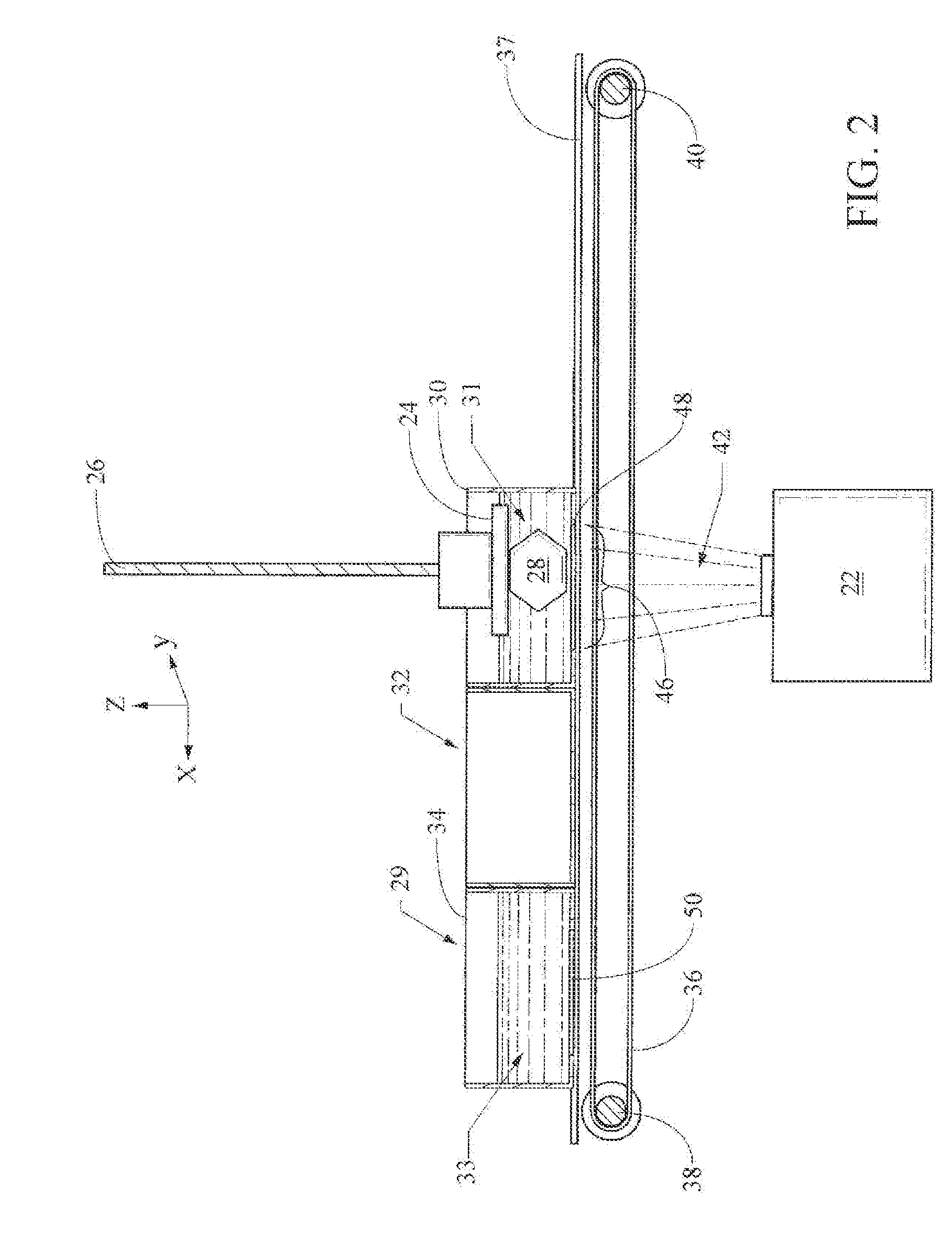

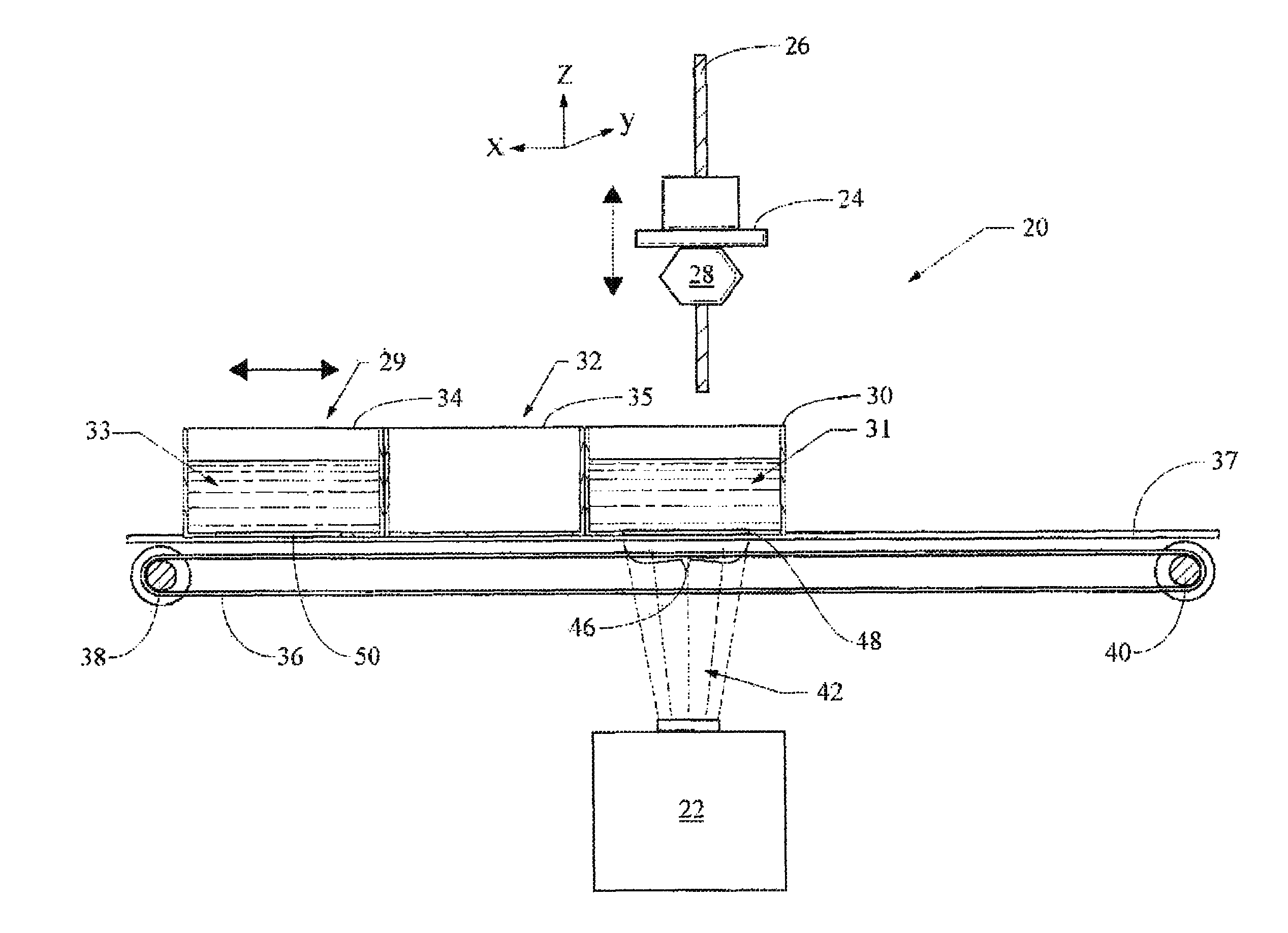

Apparatus and methods for handling materials in a 3-D printer

ActiveUS20080060330A1Improve efficiencyProcess uneconomicalAdditive manufacturing apparatusDispersed particle filtration3d printerBiomedical engineering

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

An apparatus for building a three-dimensional article and a method for building a three-dimensional article

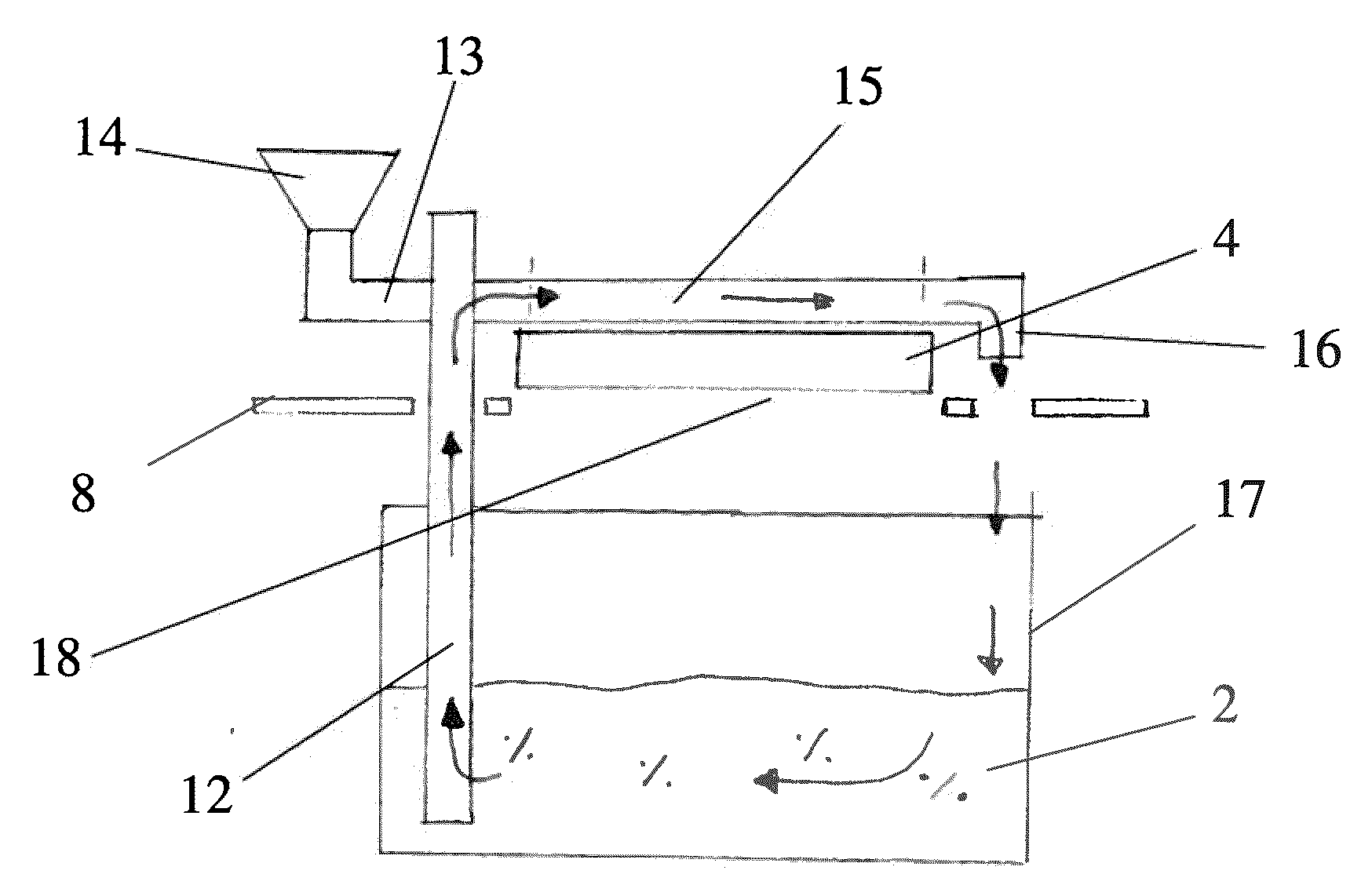

InactiveCN101326046AEasy to produceFull circulationManufacturing recycling3D object support structuresBiomedical engineeringDelivery system

The invention provides an apparatus for building a three-dimensional article in sequential cross-sectional layers, which apparatus comprises: a powder delivery system comprising one or more reservoirs for delivering a powder (2) and a powder spreading system (16); a printing system (26) for delivering a liquid; a build chamber (1) comprising an outer wall (5), an inner wall (8) and a build platform (10) which is movable along the inner wall of the build chamber; and a powder recovery system; wherein the building chamber comprises a space defined by the upper portion between the inner wall and the outer wall of the building chamber and this space is in communication with the powder recovery system and / or the build platform is capable of releasing unused powder (directly) from the build chamber in a downward direction into the powder recovery system. The invention further provides a method building a three-dimensional article wherein use is made of said apparatus.

Owner:PTS SOFTVEHAR BV +4

Method and device for conveying particulate material during the layer-wise production of patterns

ActiveUS8727672B2Evenly filledLiquid surface applicatorsAdditive manufacturing apparatusEngineeringMechanical engineering

Owner:VOXELJET AG

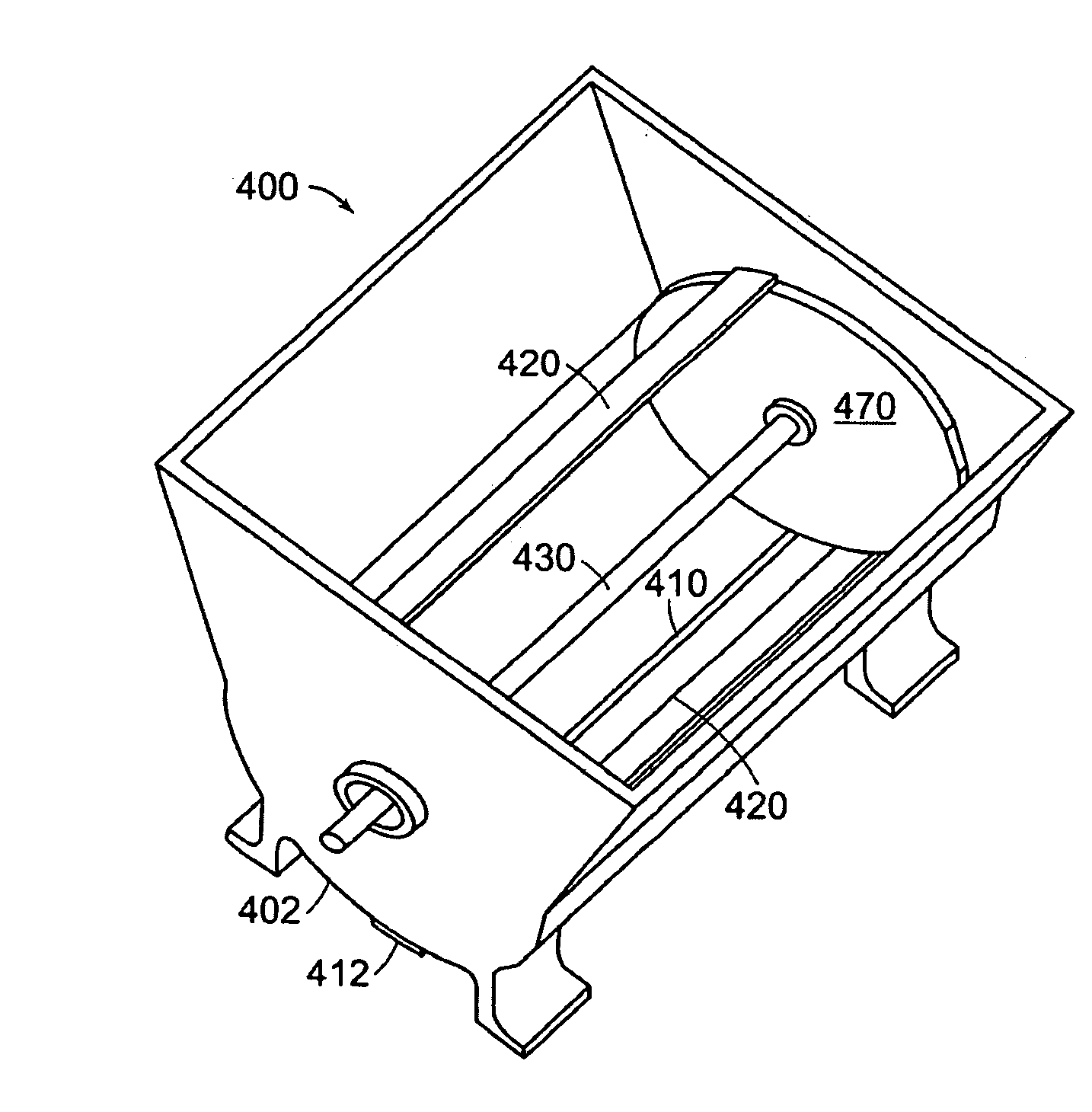

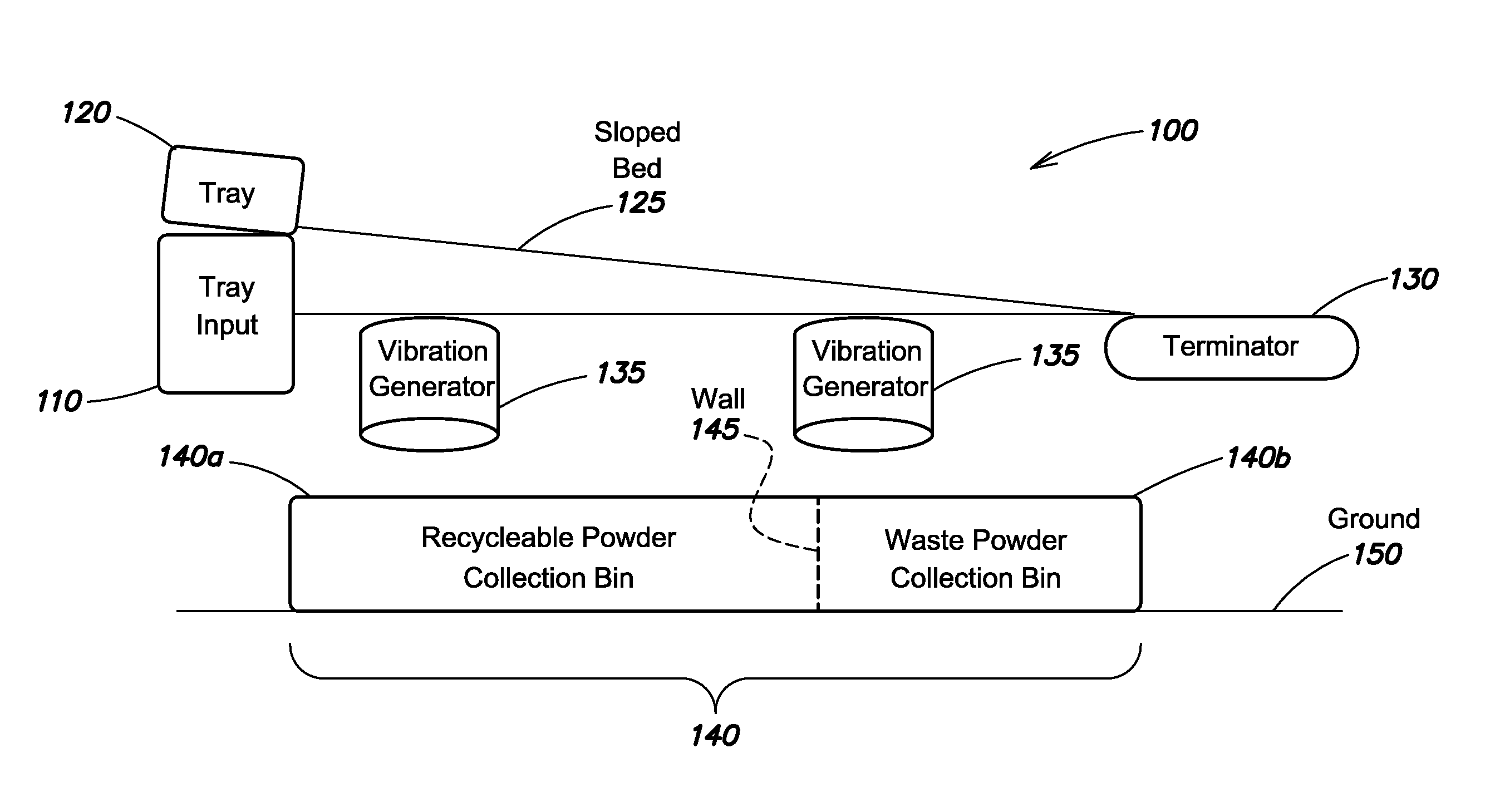

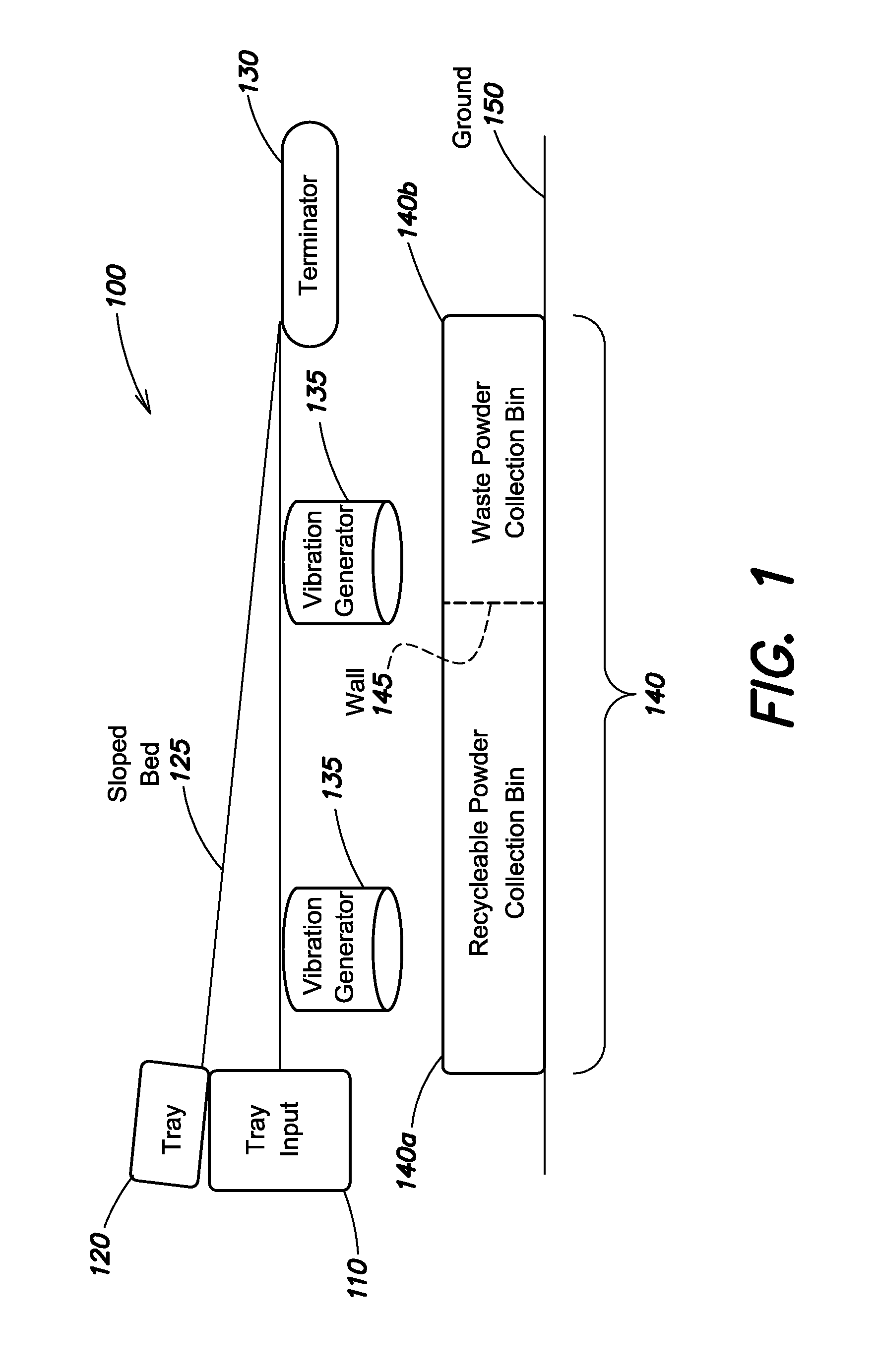

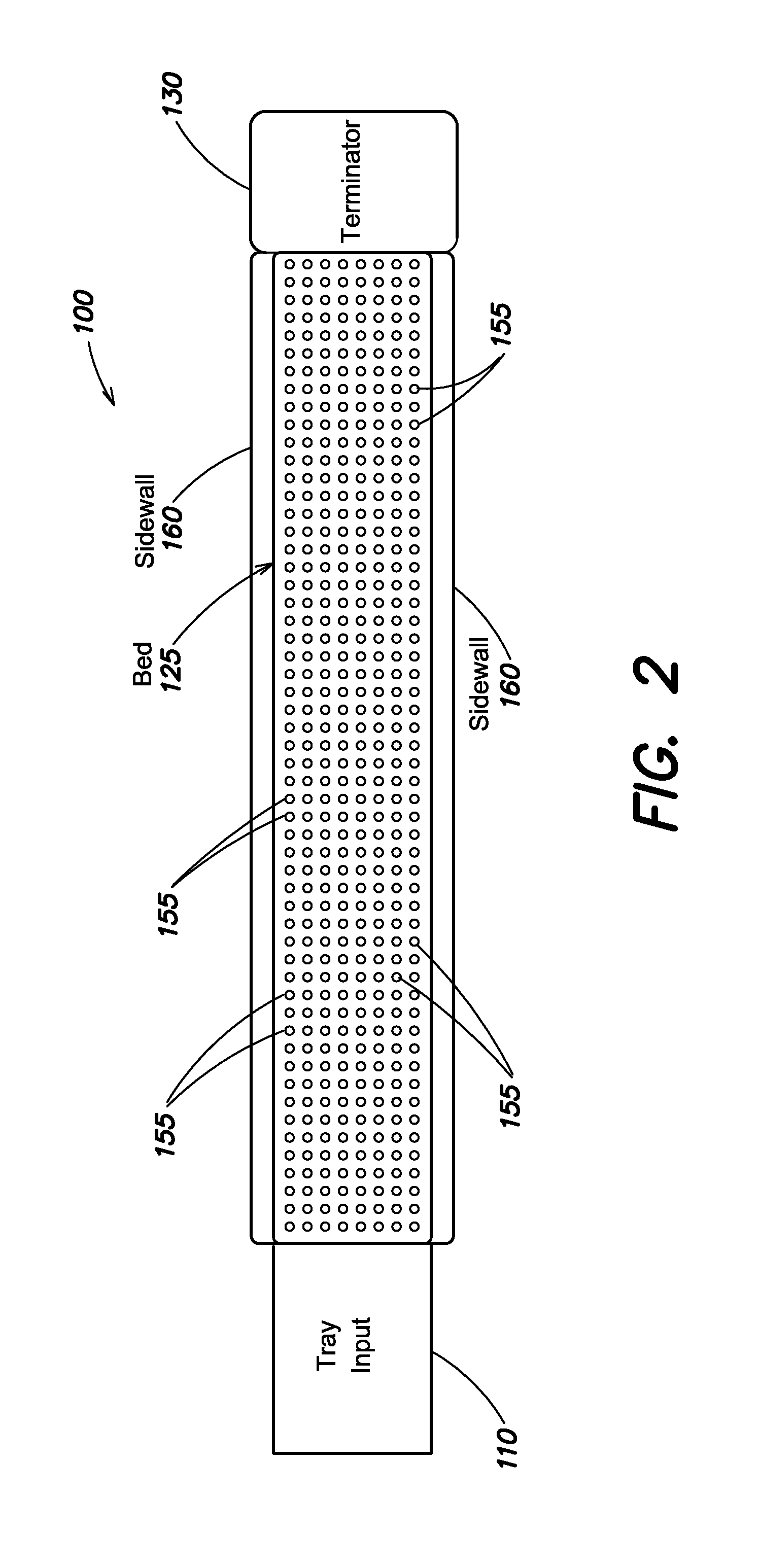

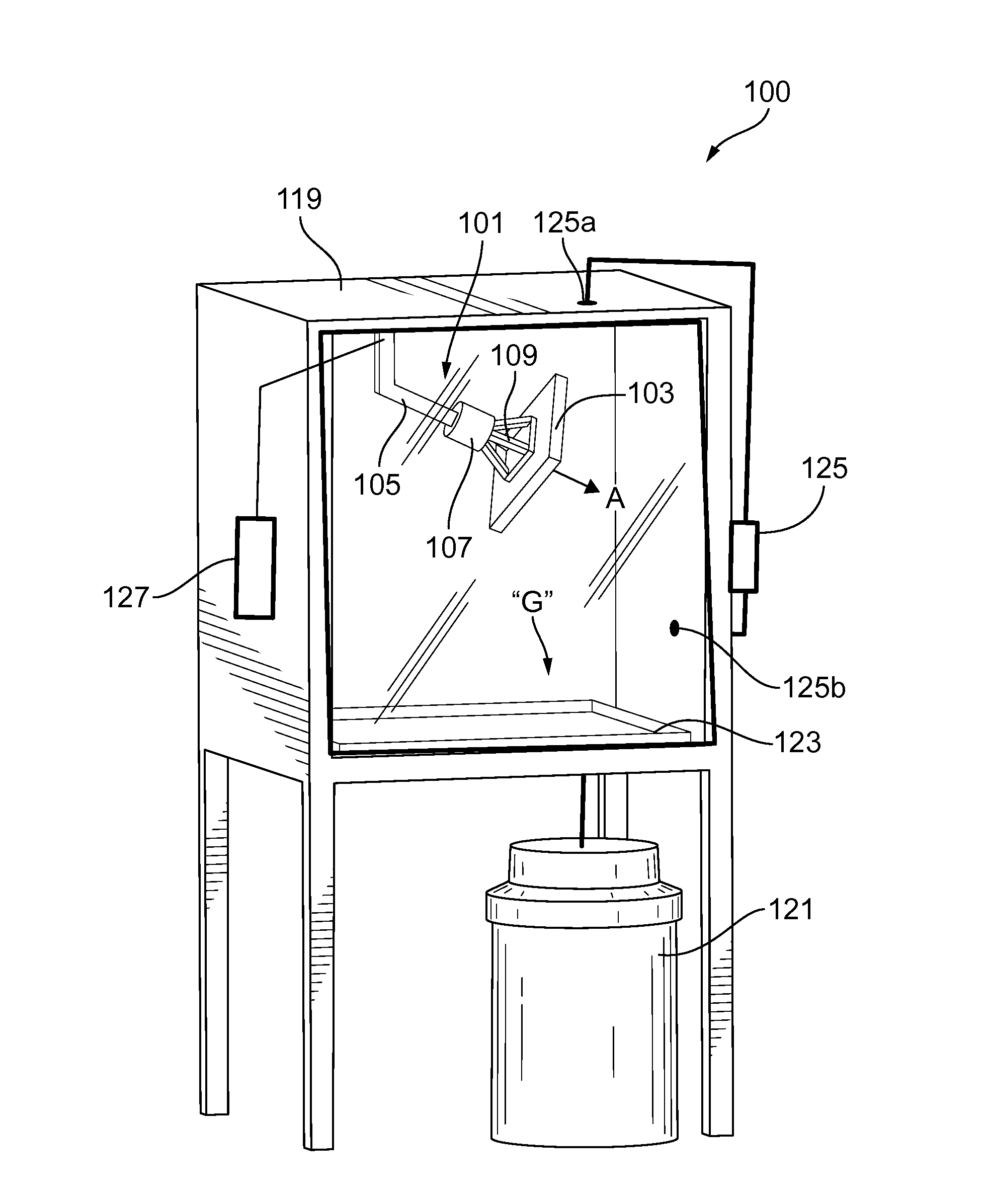

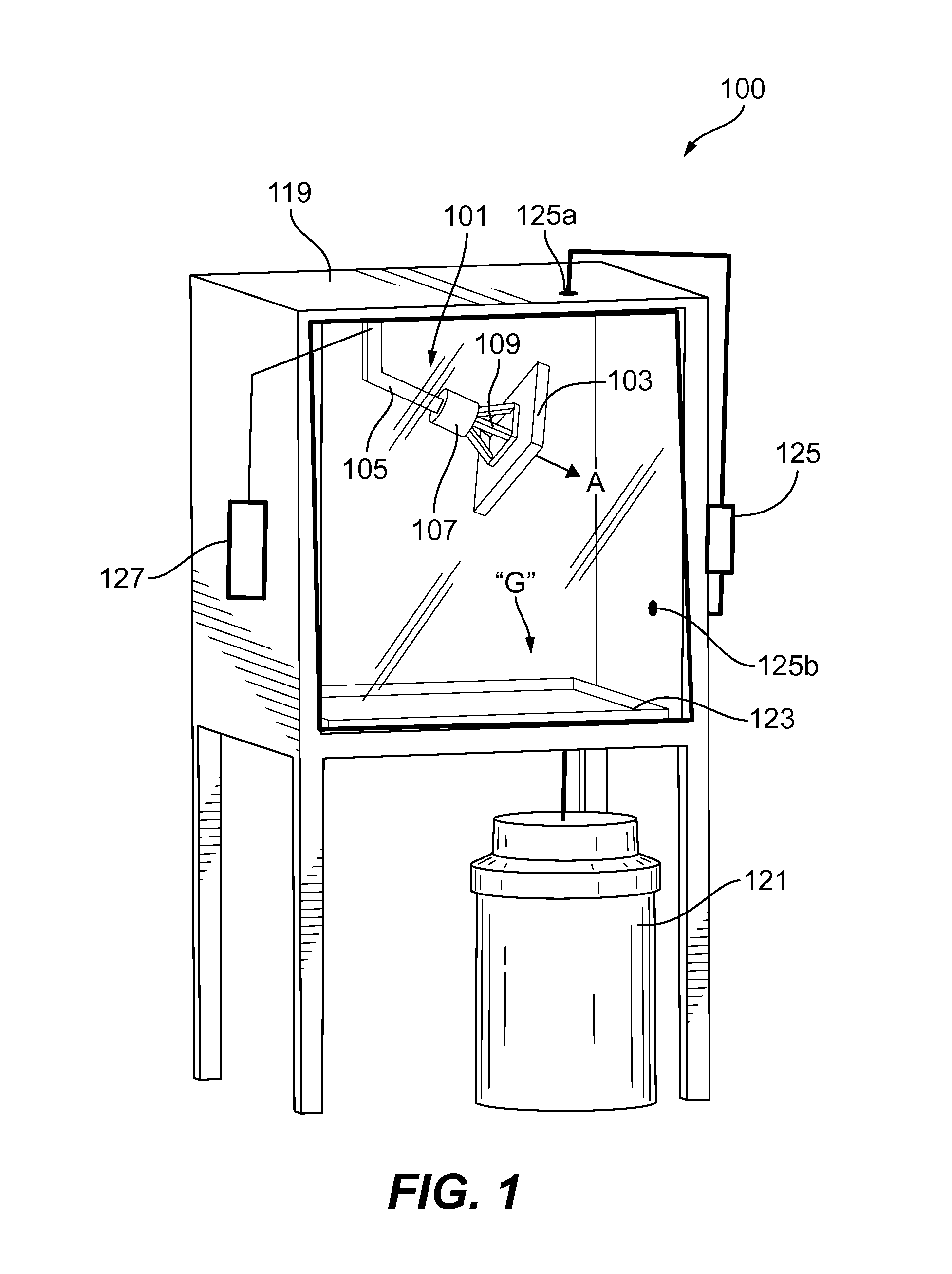

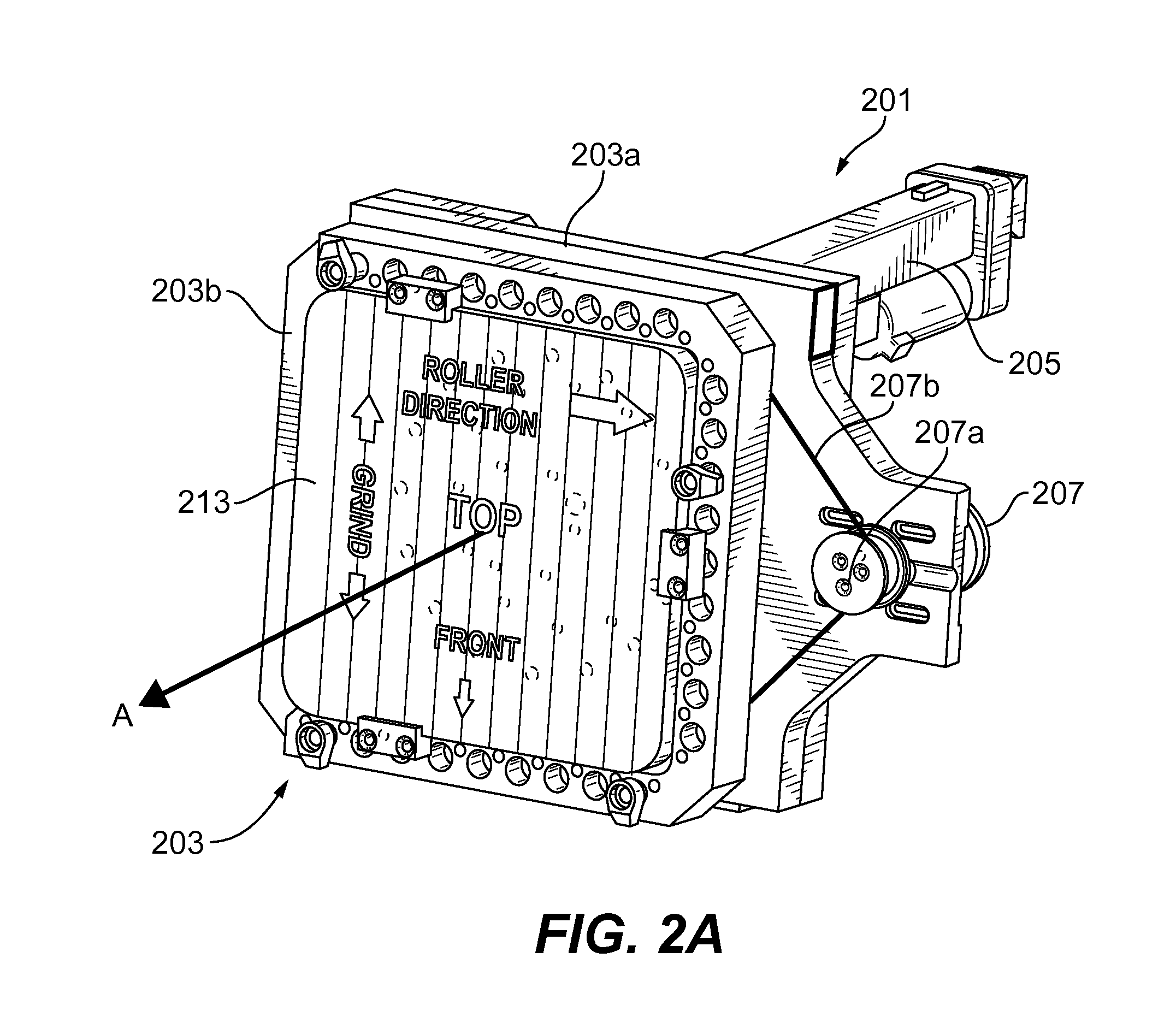

Processing of three dimensional printed parts

A system for post-print processing of 3D printed parts includes an automated breakout system for separating 3D printed parts from printing media in a tray and a vibratory media cleaning system for removing printing media from the 3D printed parts. The automated breakout system includes a tray input mechanism, a bed including a first end disposed adjacent the tray input mechanism, the bed including one or more passageways configured to pass printing media through the bed, a vibration generator coupled to the bed and configured to vibrate the bed, and a part terminator disposed adjacent a second end of the bed. The vibratory media cleaning system include a vibratory bin, a vibration generator coupled to the vibratory bin and configured to vibrate the vibratory bin, an automated parts loader configured to introduce 3D printed parts to be cleaned into the bin, and an automated parts removal mechanism.

Owner:SHAPEWAYS

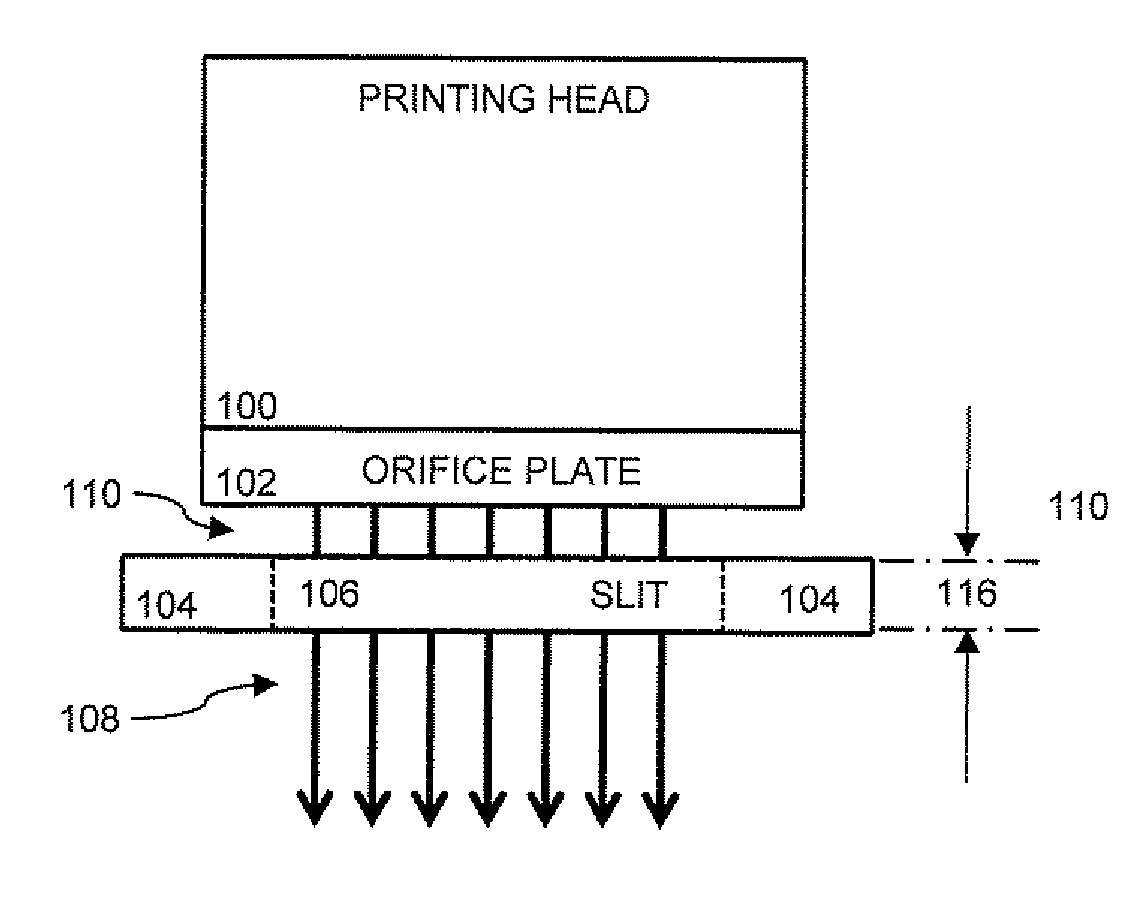

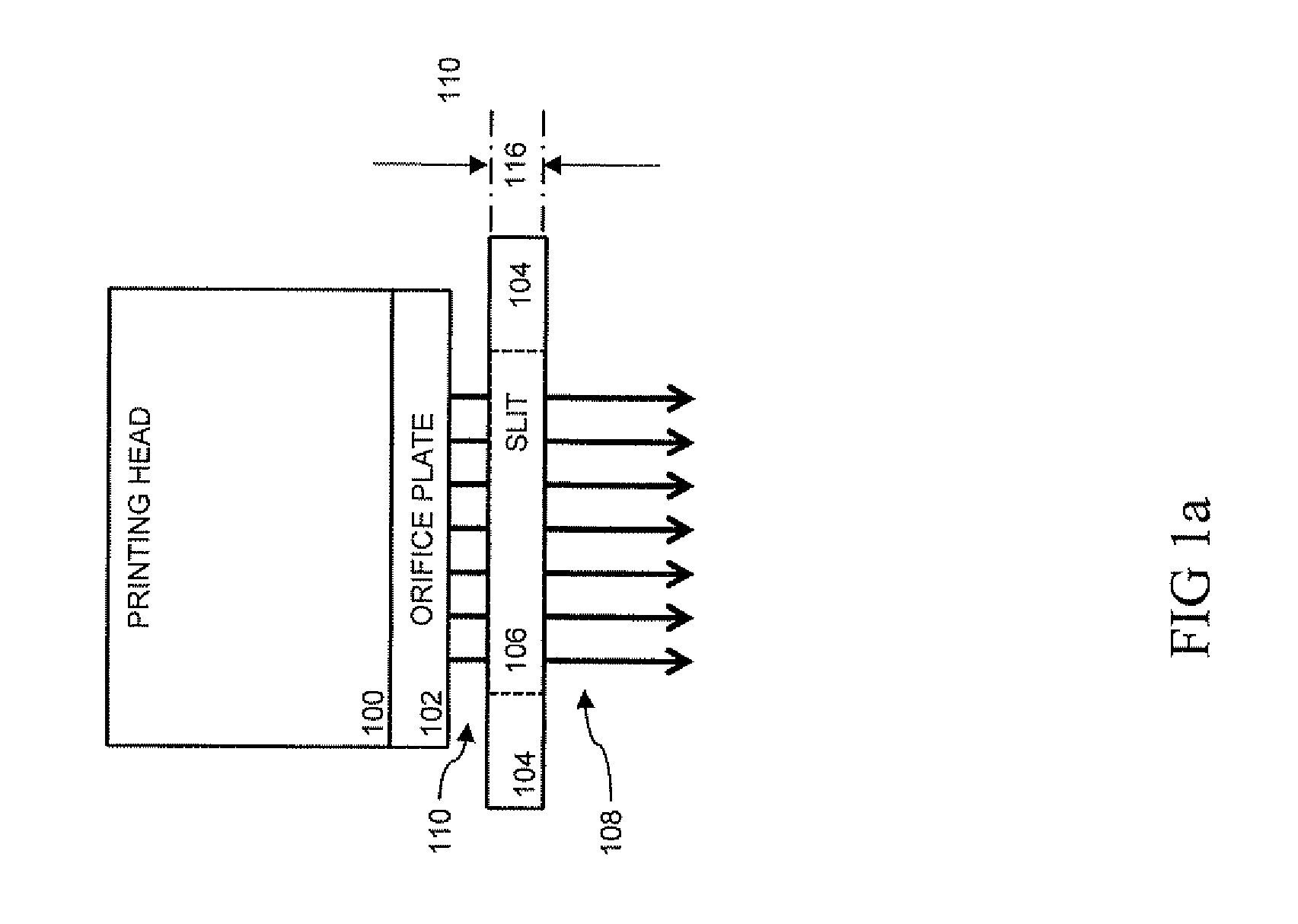

Printing system with self-purge, sediment prevention and fumes removal arrangements

A printing head assembly with integrated purge mechanism is disclosed. The printing head assembly comprises: (a) a liquid dispensing head comprising one or more dispensing nozzles enclosed in a nozzle plate, driven by at least first and second pressures, and (b) a shielding mask including an opening in front of the one or more nozzles, wherein the opening being configured such that when printing liquid is dispensed from the head driven by the first pressure, the liquid being dispensed in pulses through the opening in the shielding mask, and (ii) when purge printing liquid is dispensed from the head driven by the second pressure the liquid being drawn to a capillary gap formed between the shielding mask and the nozzle plate thereby removing the purge printing liquid from the nearby nozzles.

Owner:XJET

Apparatus and methods for handling materials in a 3-D printer

ActiveUS20080006958A1Improve efficiencyProcess uneconomicalLiquid fillingCeramic shaping apparatus3d printerBiomedical engineering

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

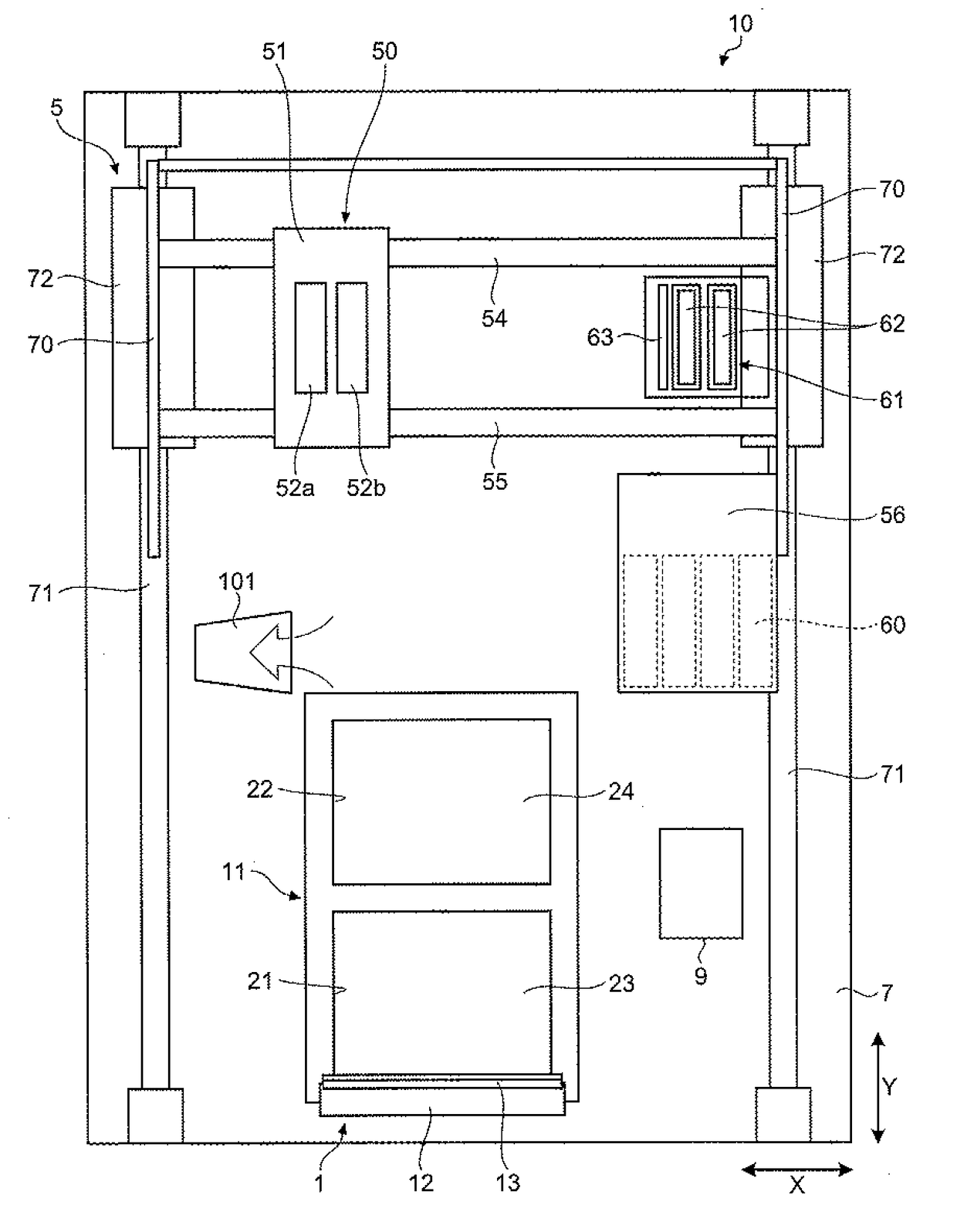

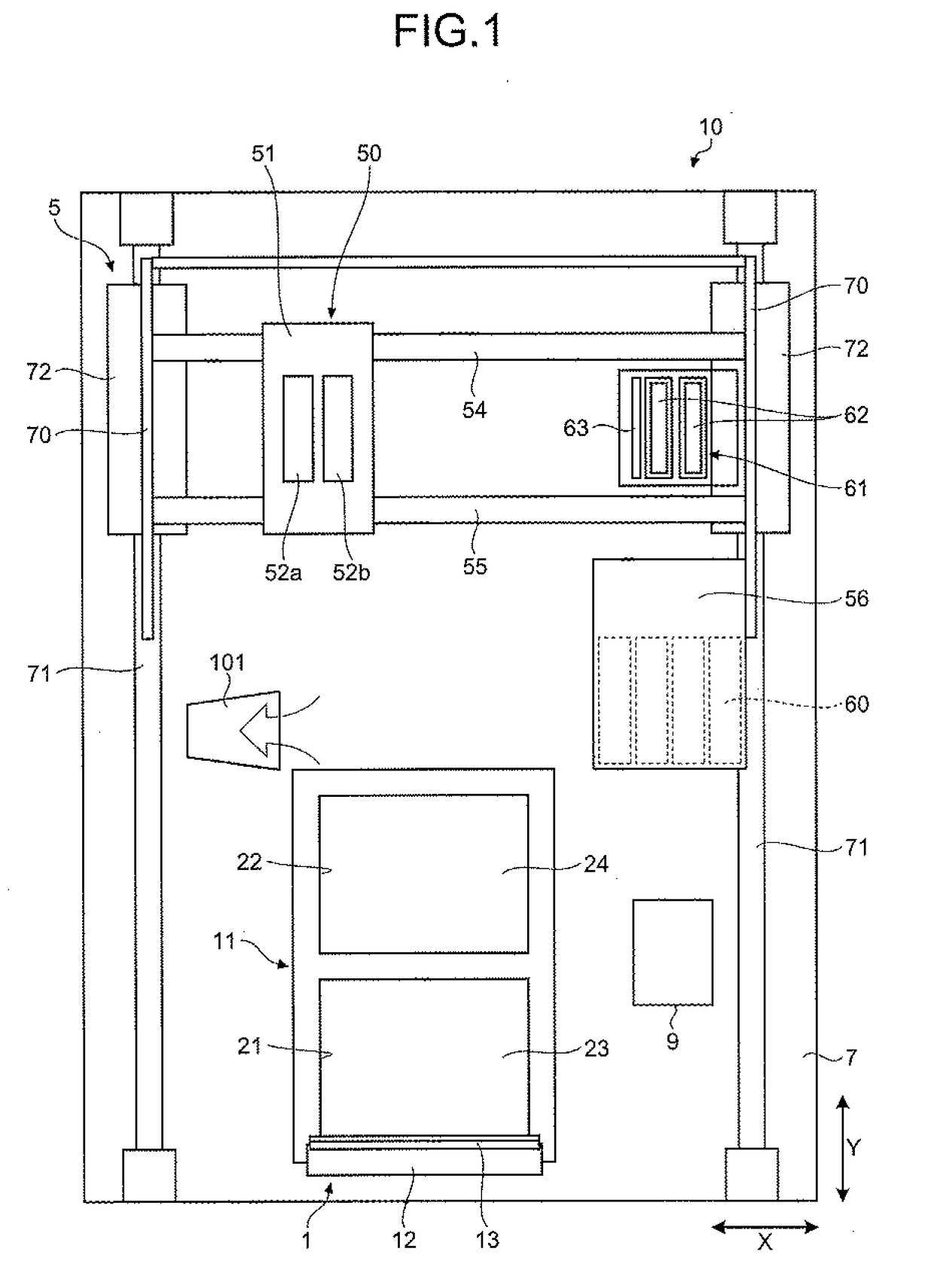

Three-dimensional shaping apparatus and three-dimensional shaping system

ActiveUS20170144374A1Additive manufacturing apparatusManufacturing recyclingEngineeringThree dimensional shape

A three-dimensional shaping apparatus includes: a shaping chamber configured to hold powder; a leveler configured to move from a first position to a second position in a first direction on a top surface of the powder held in the shaping chamber to flatten the top surface of the powder; an ejector configured to eject a shaping liquid to the flattened top surface of the powder held in the shaping chamber; and a suction mechanism including a suction inlet arranged close to the second position of the shaping chamber.

Owner:RICOH KK

Continuous Linear Production in a Selective Laser Sintering System

ActiveUS20120067501A1Reduce gas flowMechanical working/deformation3D object support structuresSelective laser sinteringLinearity

Owner:THE BOEING CO

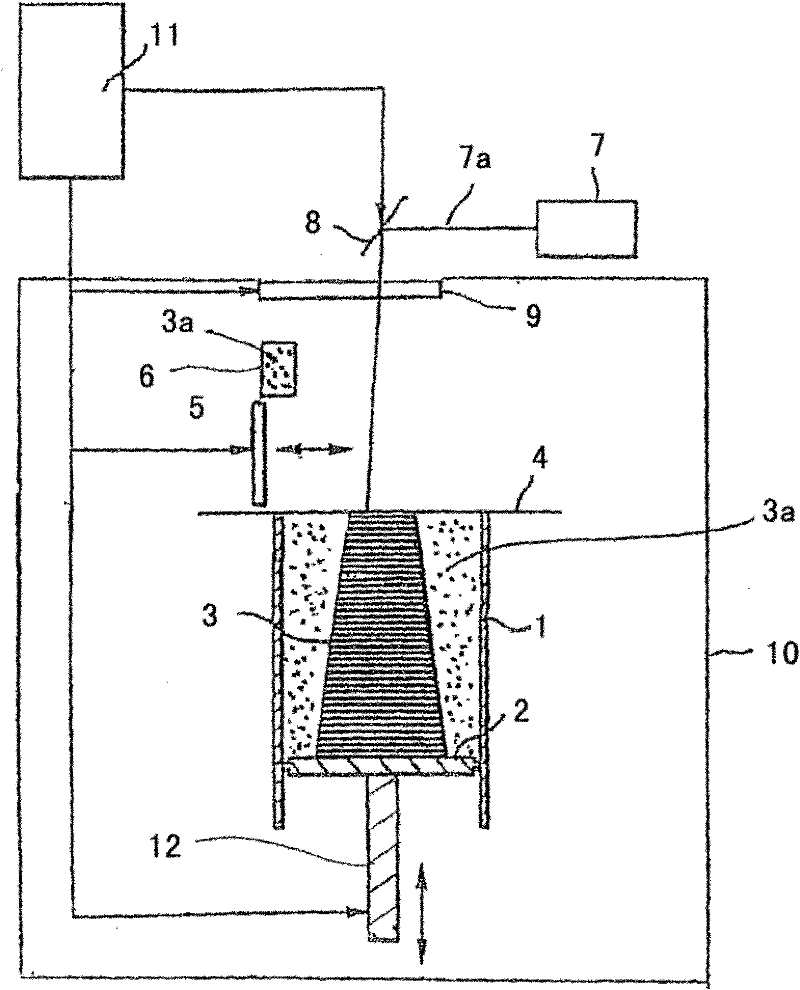

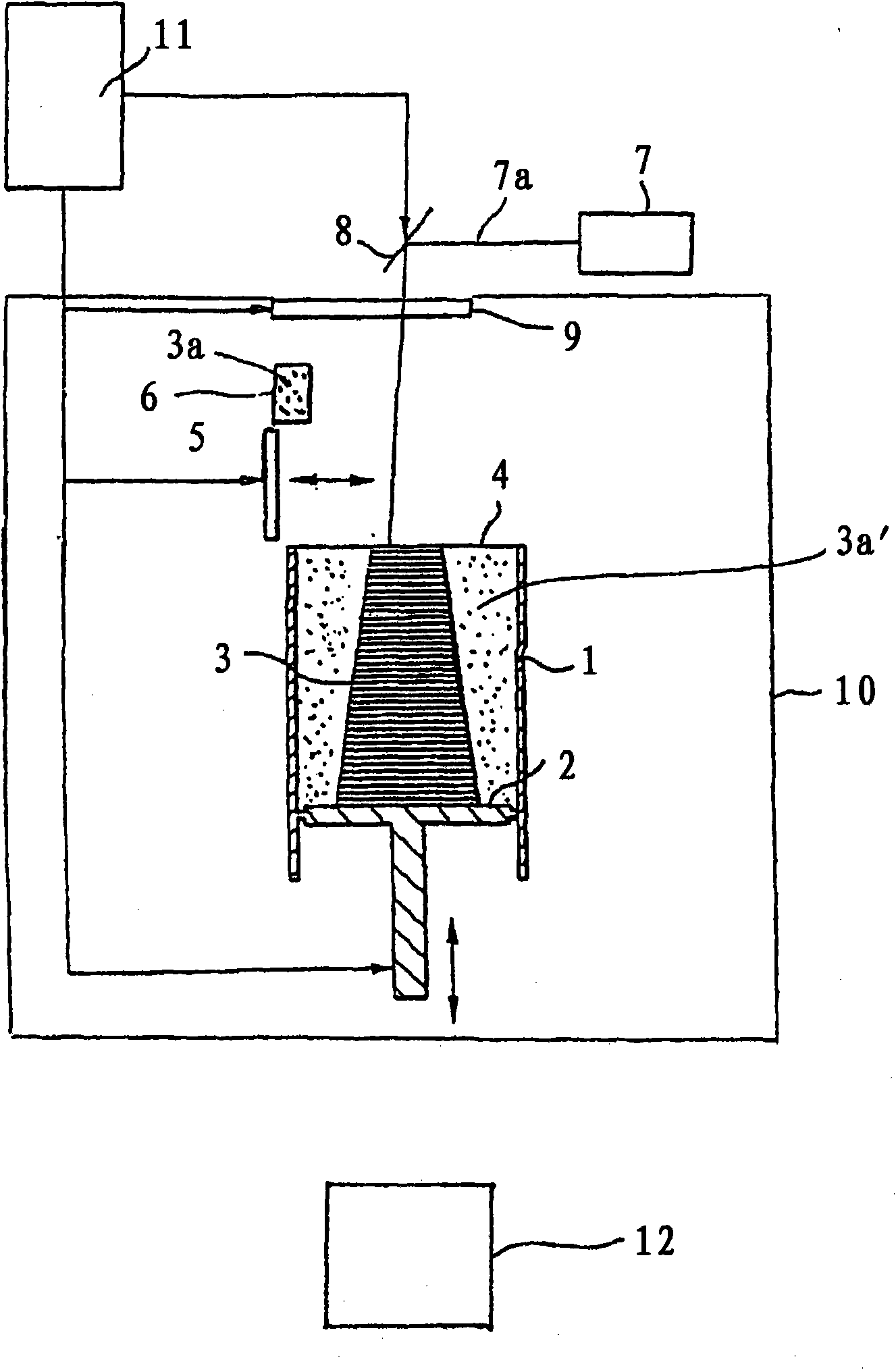

Method and system for reusing residual powder from an installation for the rapid prototyping of three-dimensional objects

The invention relates to a method and a system for reusing residual powder from an installation for the rapid prototyping of three-dimensional objects (3), including the steps of sieving the residual powder (3a) or for mixing the residual powder (3a) with fresh powder. The method is characterized by adding the step of modifying a property of the resulting powder.

Owner:EOS ELECTRO OPTICAL SYST

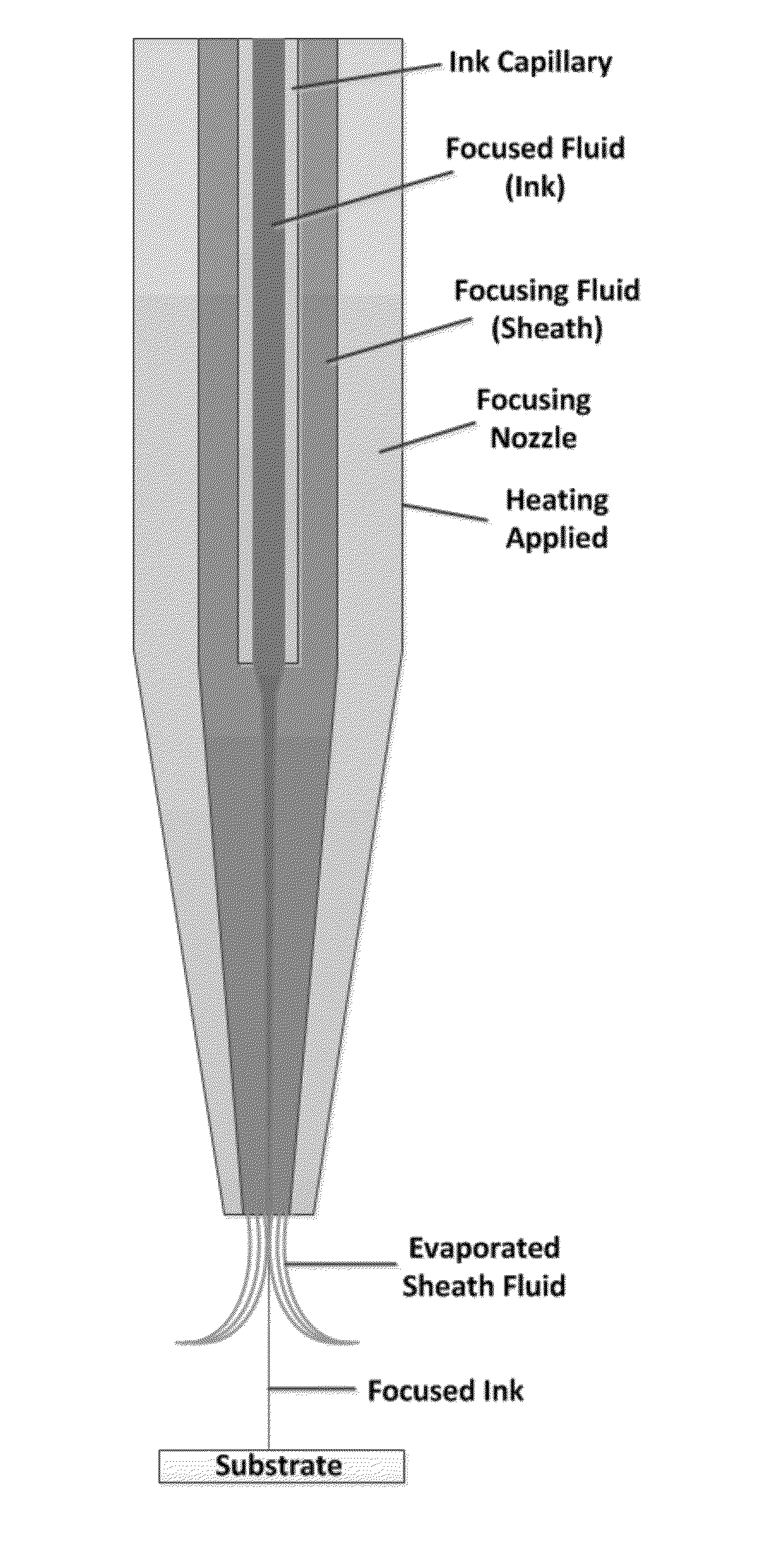

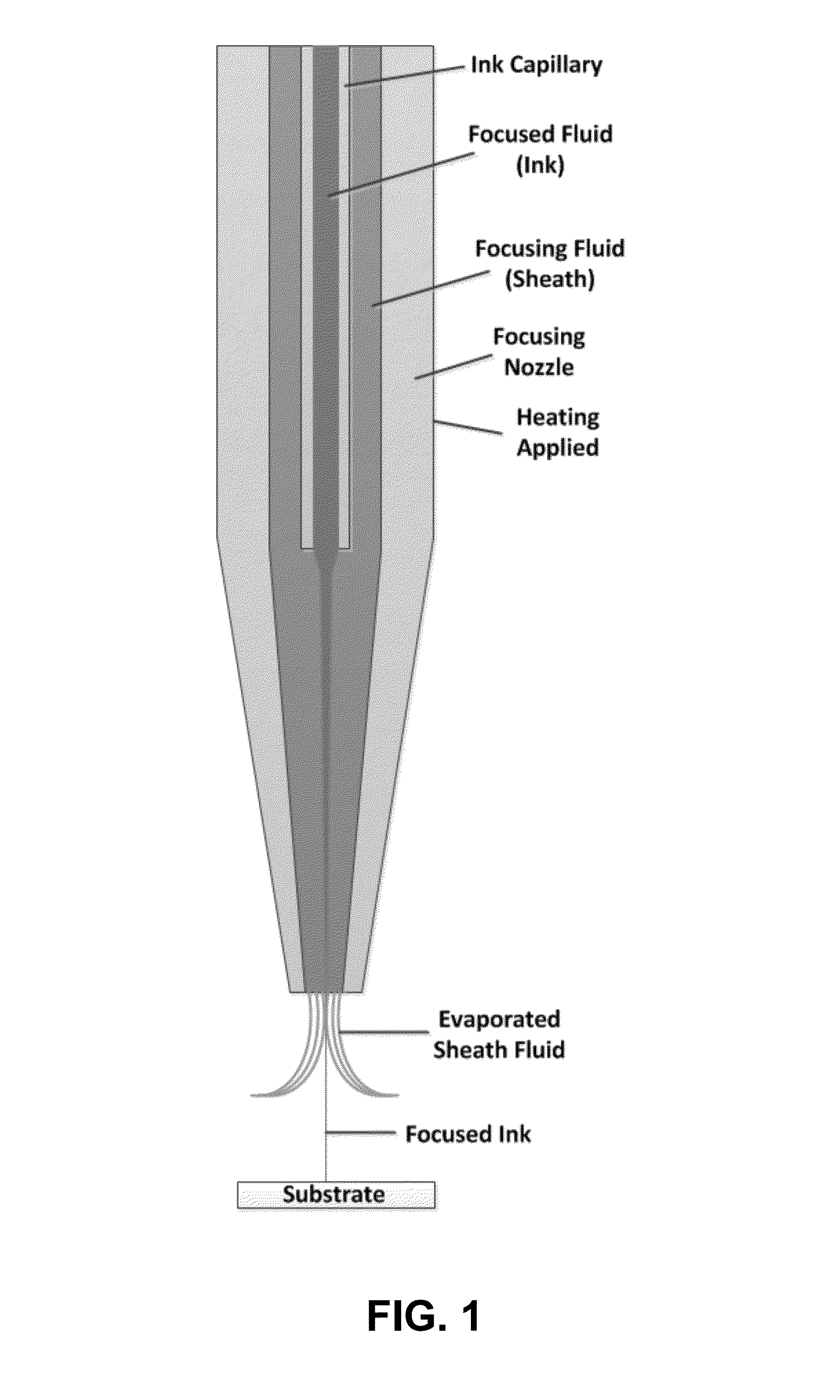

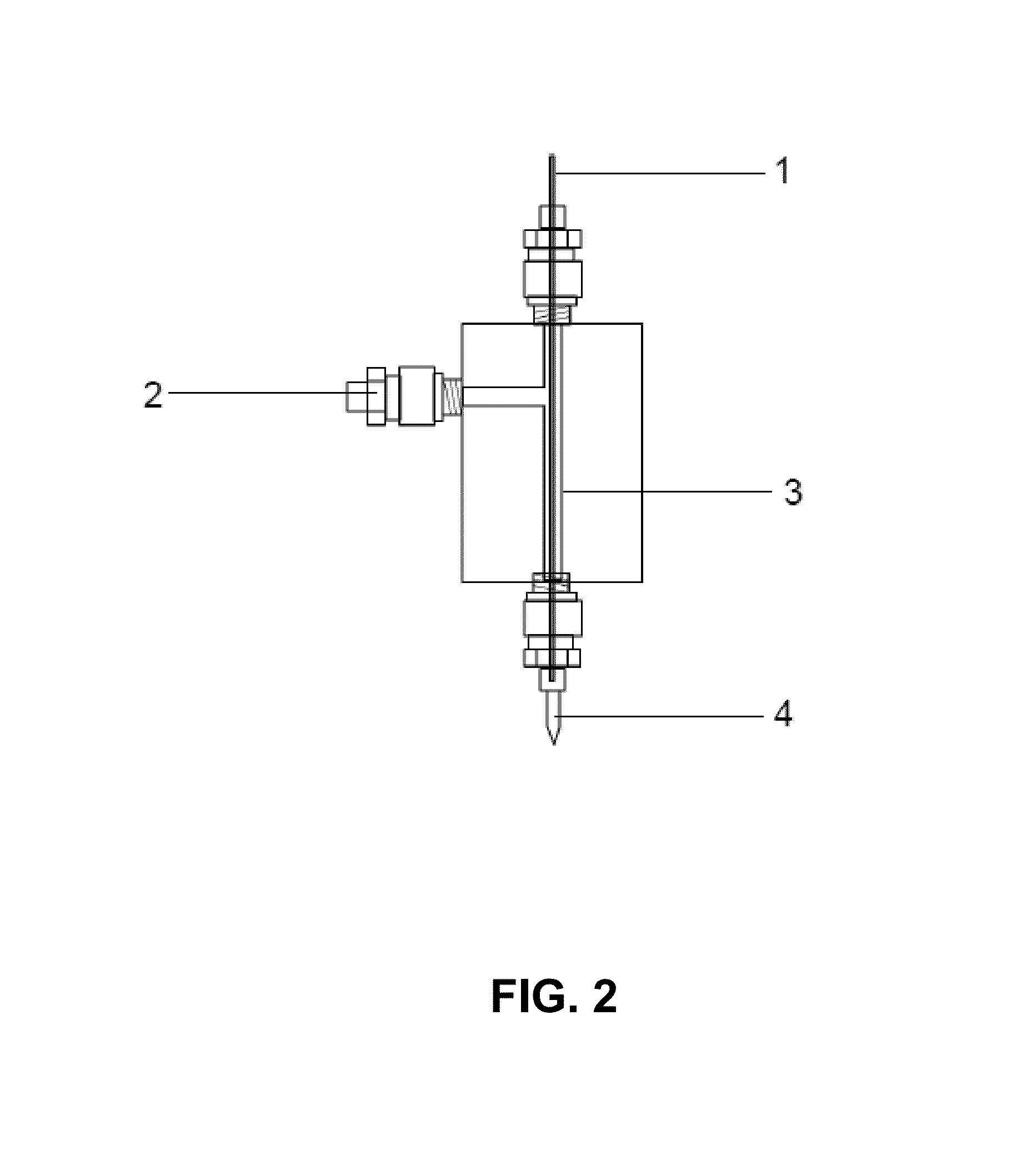

Two-Fluid Hydrodynamic Printing

ActiveUS20160129634A1Manufacturing platforms/substratesFilament/thread formingEngineeringPrinted electronics

Hydrodynamic focusing of two fluid steams provides a novel micro printing technology for printed electronics and other high performance applications.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Systems and methods for post additive manufacturing processing

ActiveUS20170036401A1Additive manufacturing apparatusIncreasing energy efficiencyEngineeringActuator

A system for removing powder from an additively manufactured article includes a powder removal mechanism. The powder removal mechanism can include a build plate holder configured to hold a build plate at a distal end thereof. The powder removal mechanism can also include a first actuator that is configured to angle the build plate holder relative to gravity and a second actuator that is configured to rotate the build plate holder about a central axis of the build plate holder.

Owner:COLLINS ENGINE NOZZLES INC

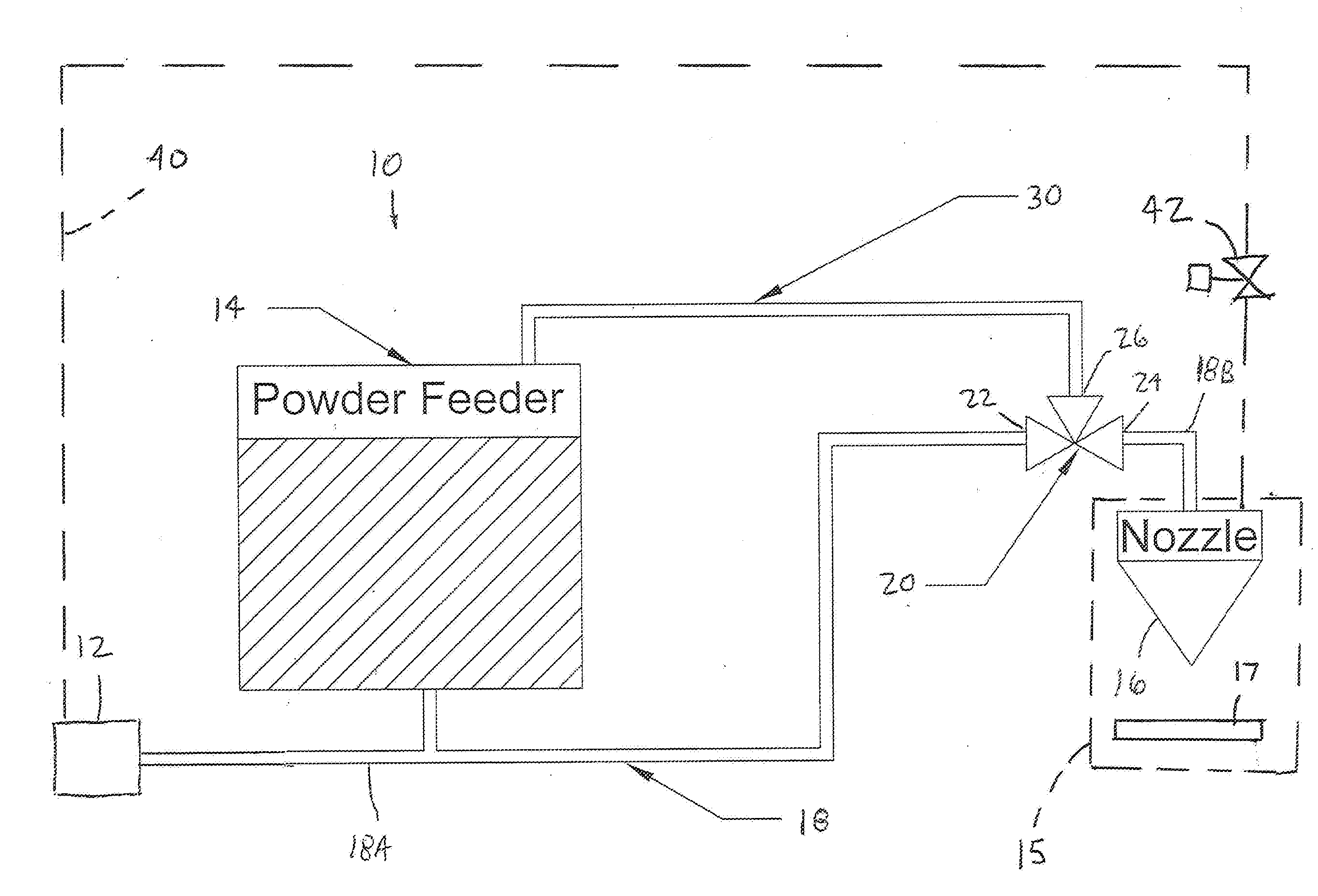

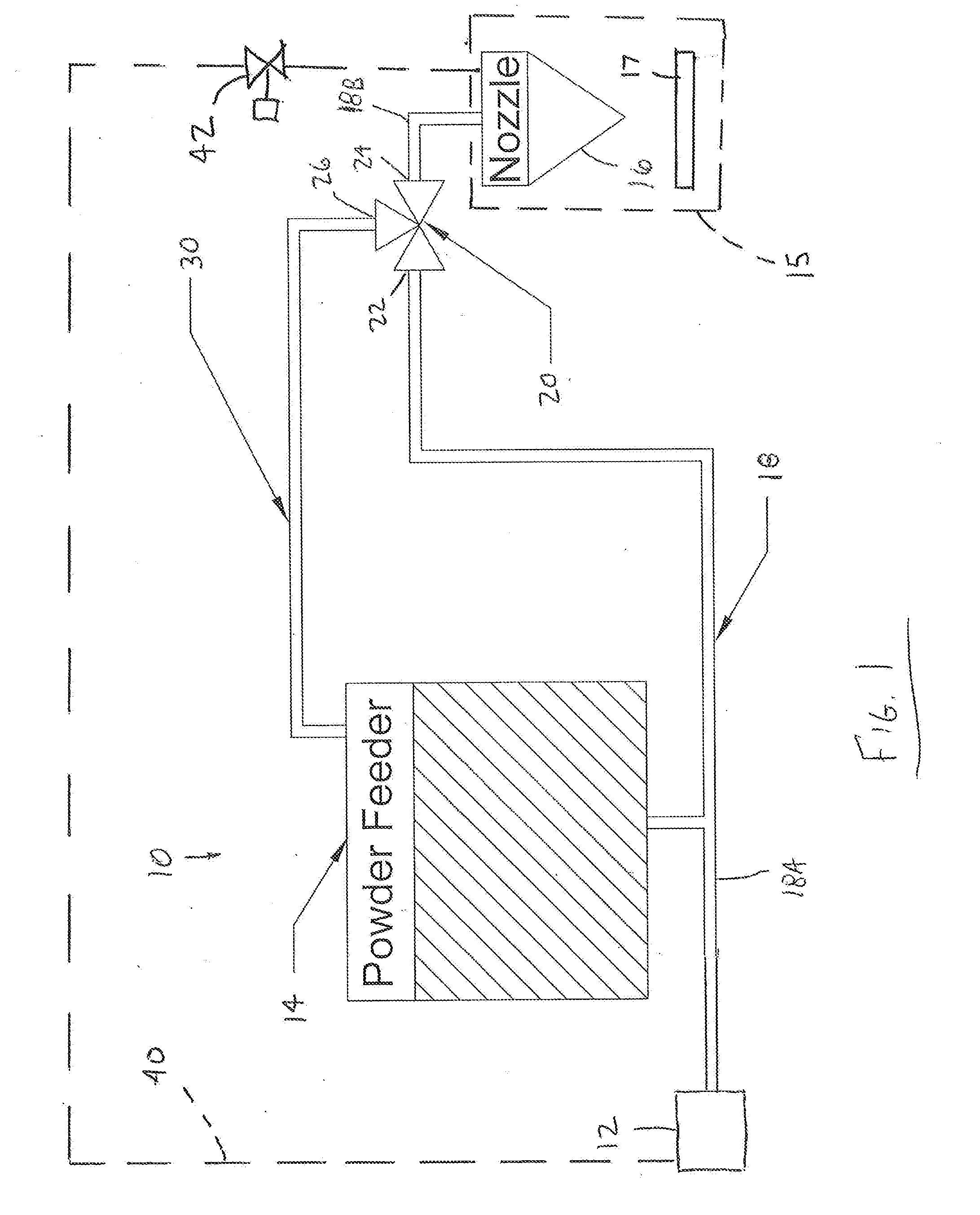

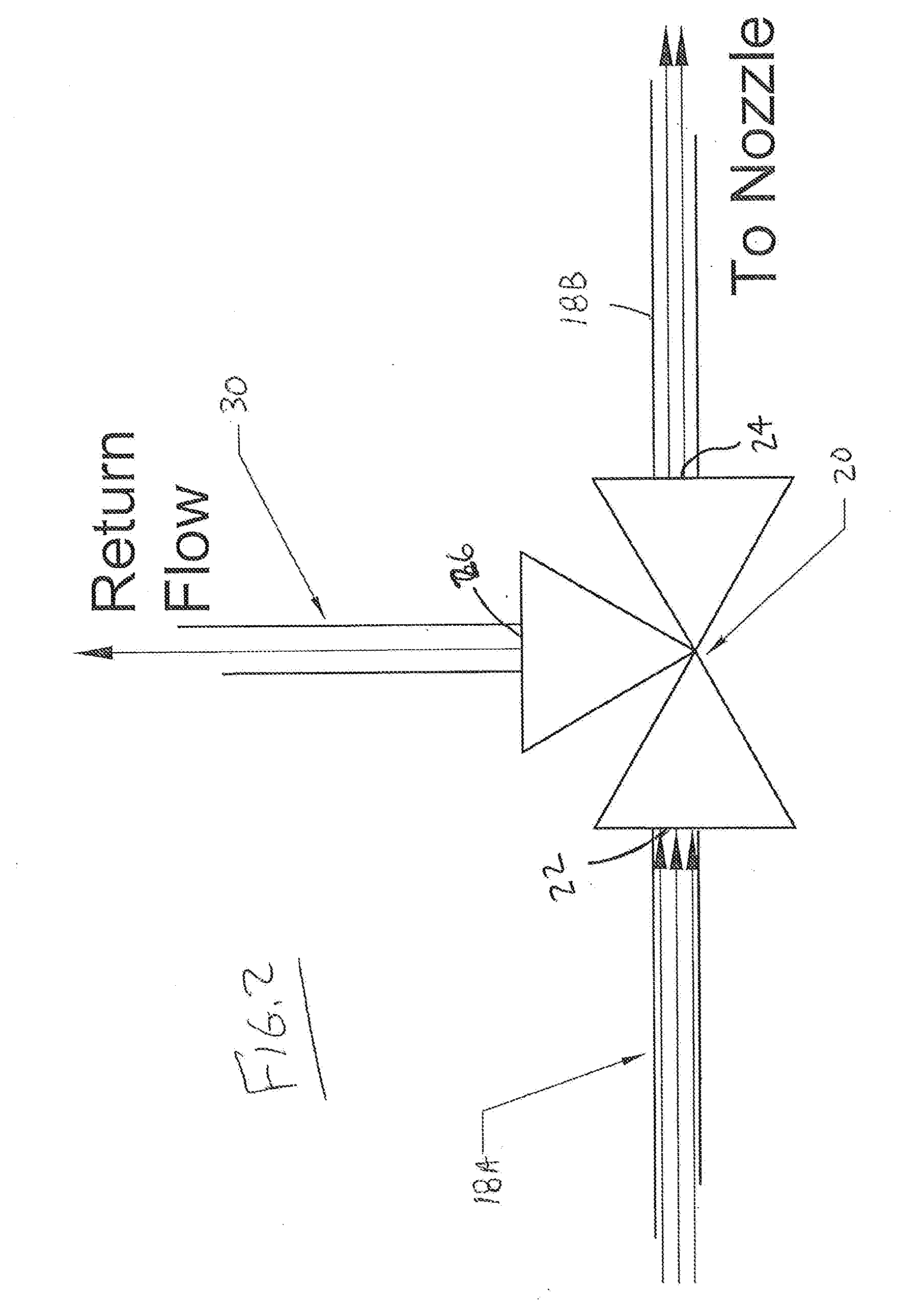

Powder Delivery Systems and Methods for Additive Manufacturing Apparatus

ActiveUS20170028631A1Additive manufacturing apparatusIncreasing energy efficiencySpray nozzleControl valves

A powder delivery system for use in an additive manufacturing device includes a powder control valve configured to selectively divert at least a portion of an input fluid flow to a return line while a remainder of the input flow is delivered to a delivery nozzle. In some embodiments, the powder delivery valve may be modulated to alter the percentage of input flow diverted to the return line. Alternatively, the powder delivery valve may be either fully open or closed. In each embodiment, the powder delivery valve permits rapid changes in the amount of powder delivered to the nozzle.

Owner:DMG MORI SEIKI USA

Multi-material three dimensional printer

Owner:EOPLEX

Method and device for the layered production of a three-dimensional object from a powdery material

ActiveCN101842222AGood environmental compatibilityEconomic treatmentAdditive manufacturing apparatusPlastic recyclingElectromagnetic radiationMaterials science

The invention relates to a method for producing a three-dimensional object by selectively compacting layers of a powdery material (3a) in the areas corresponding to the cross-section of the object (3) in the respective layer, by applying electromagnetic radiation (7a). The powder used is a plastic powder, preferably polyamide. After the production of the object, the non-compacted powder (3a') is subjected to a water or vapour treatment at a higher temperature, is subsequently dried and then is used again to produce a new object.

Owner:EOS ELECTRO OPTICAL SYST

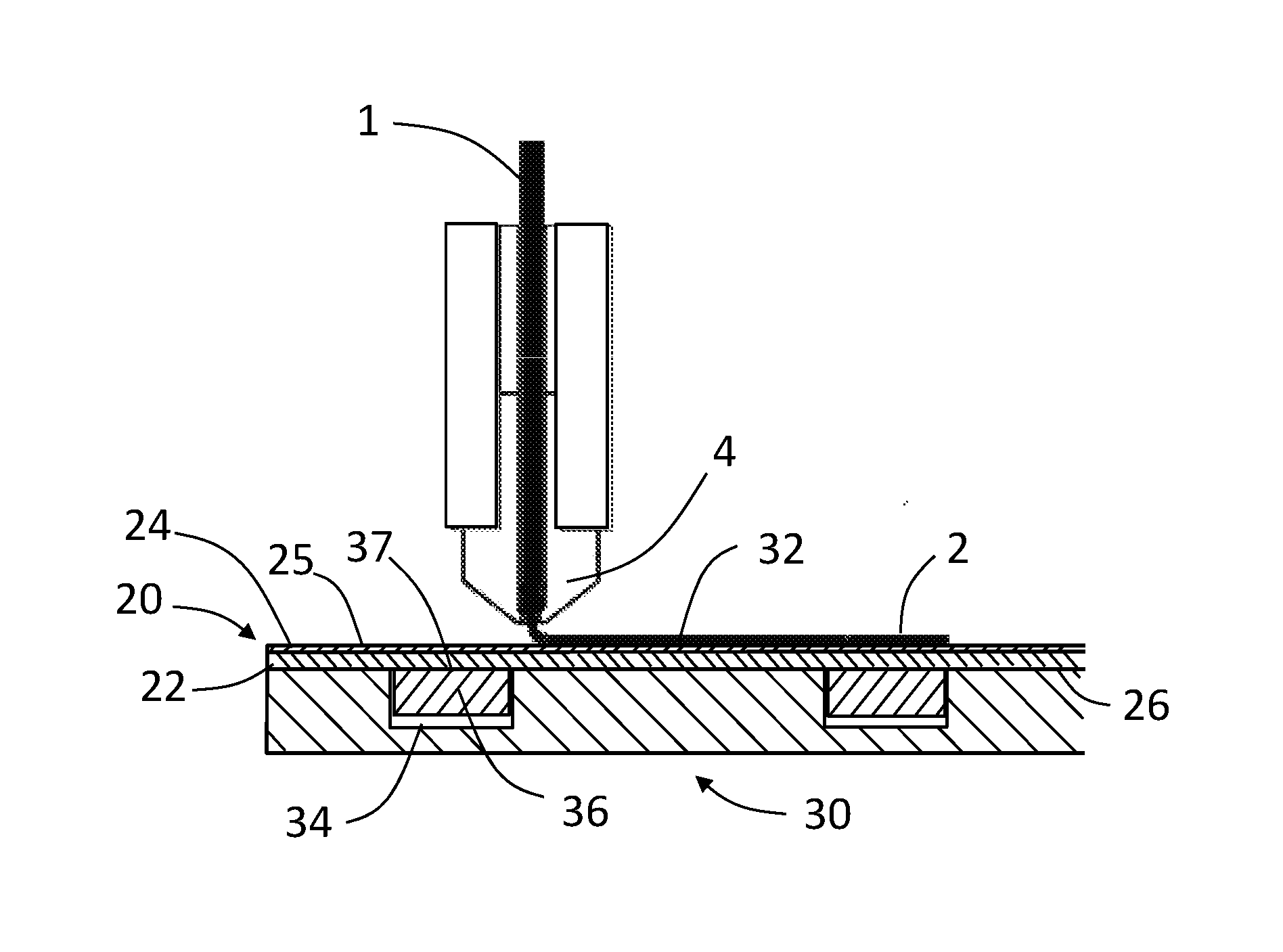

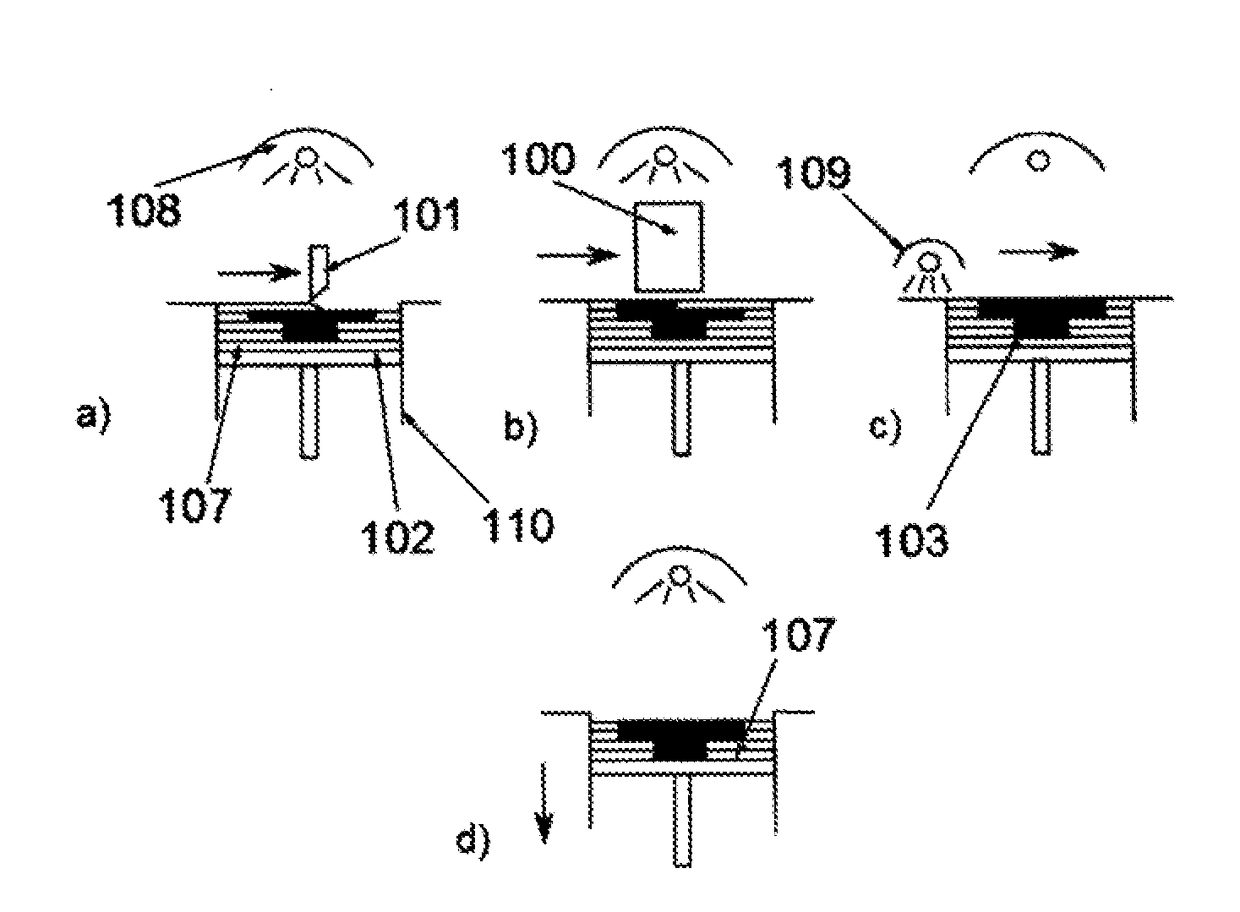

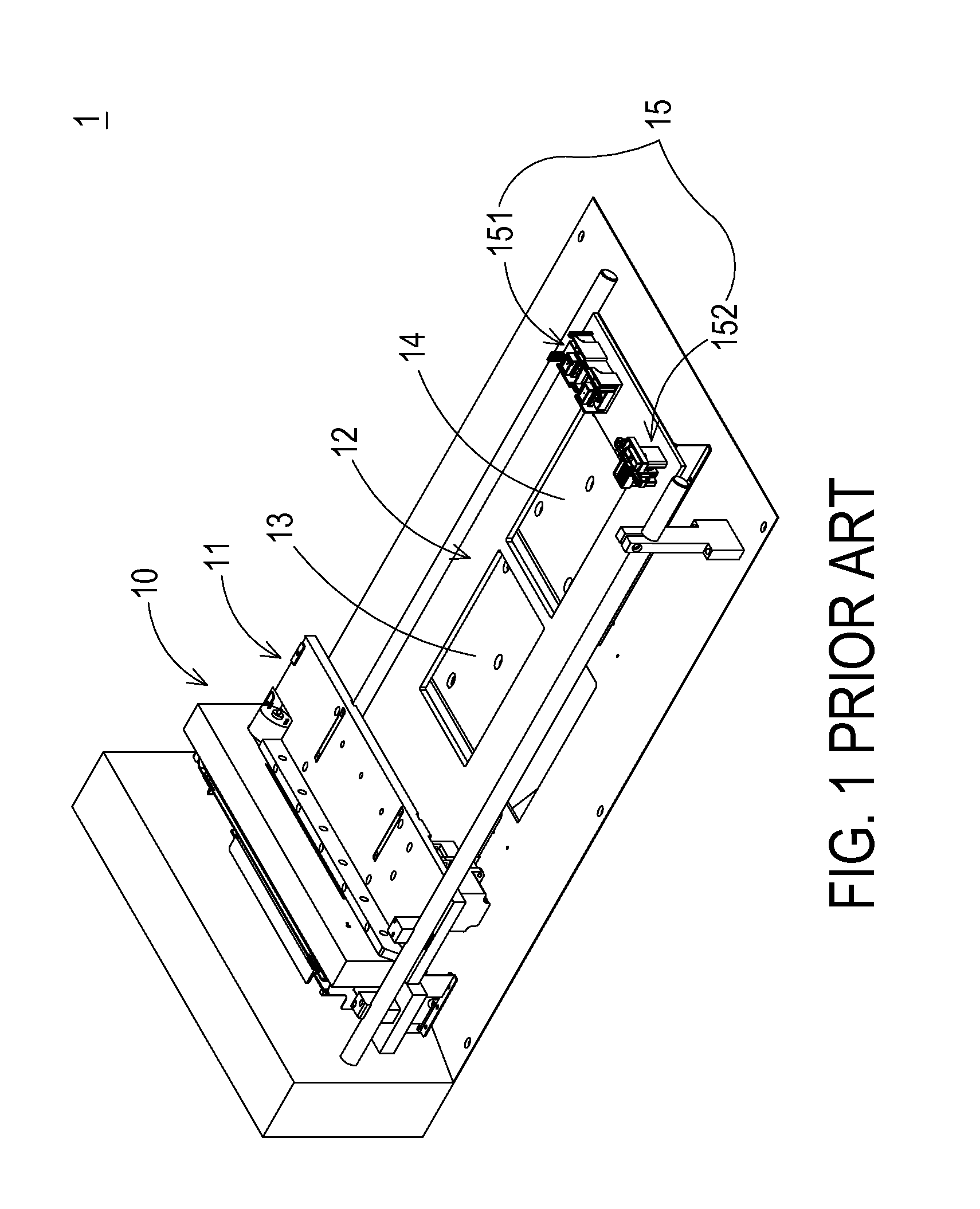

Rapid prototyping apparatus for producing three-dimensional ceramic object

ActiveUS20150231832A1Quality improvementHigh speedCeramic shaping apparatusManufacturing recyclingArchitectural engineeringRapid prototyping

A rapid prototyping apparatus includes a construction platform, a movable platform, a printing module, a cleaning and maintenance module, a construction material spreading element, a heater and a heat shield. A construction chamber is formed in the construction platform. The movable platform and the construction platform are movable relative to each other. The printing module is installed on the movable platform, and includes at least one printhead unit. The cleaning and maintenance module is installed on the movable platform. The construction material spreading element is installed on the movable platform for spreading a ceramic construction material to the construction chamber. After the ceramic construction material is spread in the construction chamber, the construction material is heated by the heater. After the printhead unit performs a printing operation, the printhead unit is cleaned and maintained by the cleaning and maintenance module.

Owner:MICROJET TECH

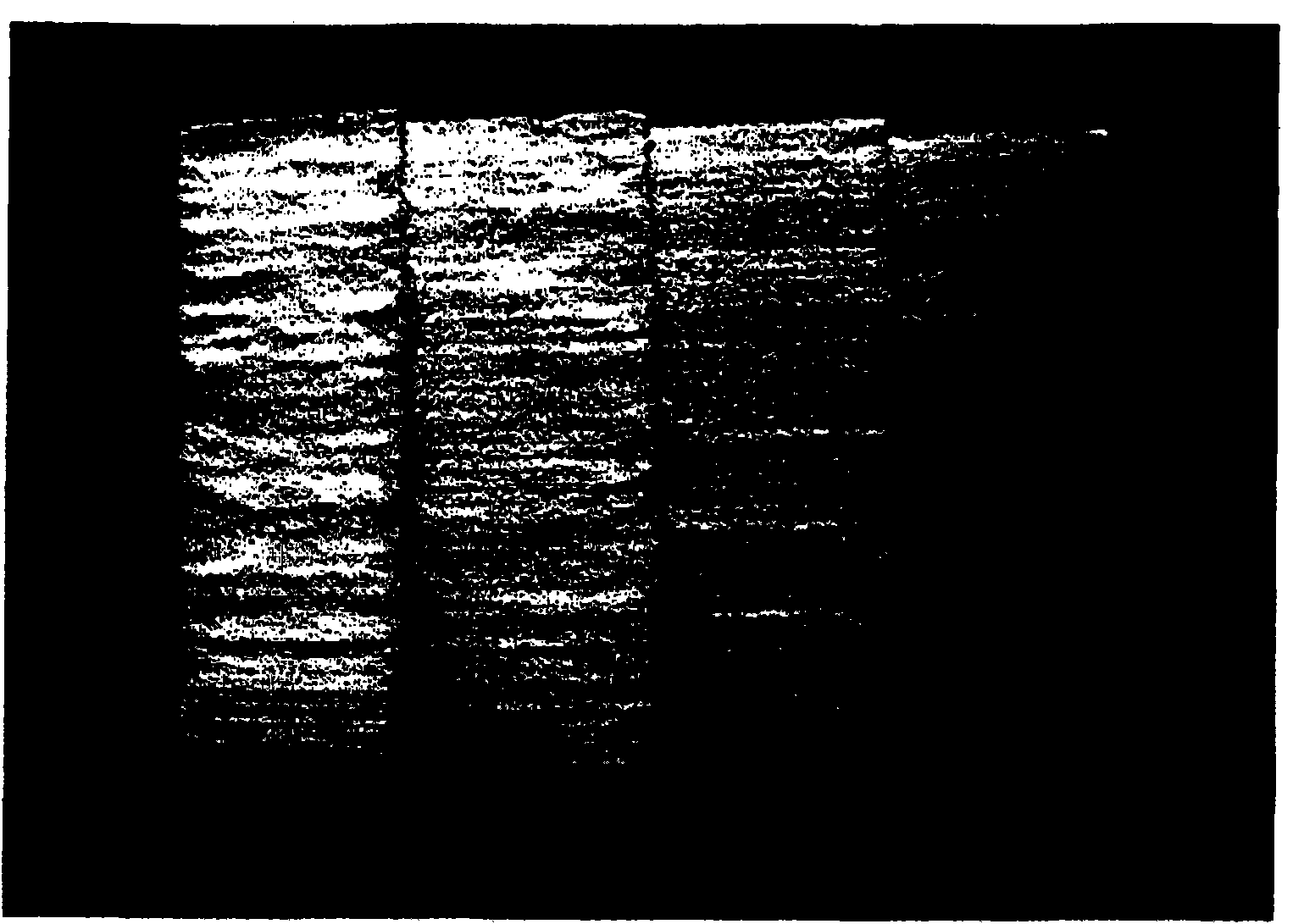

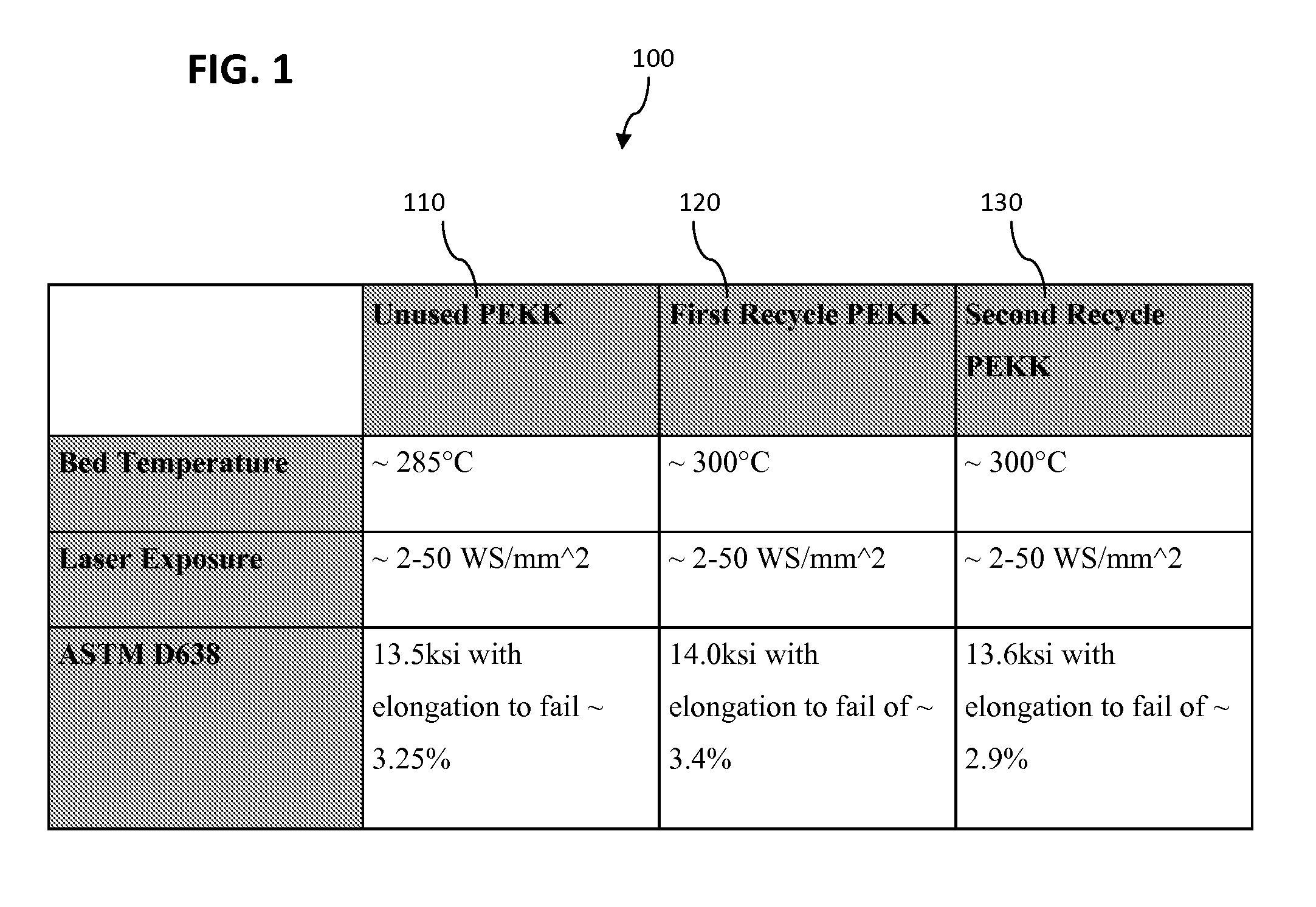

Method for processing paek and articles manufactured from the same

ActiveUS20130217838A1Additive manufacturing apparatusManufacturing recyclingIn planeSelective laser sintering

A process for manufacturing a three-dimensional object from a powder by selective sintering the powder using electromagnetic radiation. The powder comprises recycled PAEK. In one embodiment, the powder comprises recycled PEKK. In one embodiment, the powder comprises first recycle PEKK and second recycle PEKK. In one embodiment, the powder consists essentially of recycled PEKK. The process may include the step of maintaining a bed of a selective laser sintering machine at approximately 300 degrees Celsius and applying a layer of the powder to the bed. The average in-plane tensile strength of the three-dimensional object is greater than that of a three-dimension object manufactured by selective sintering using a powder comprising an unused PEKK powder.

Owner:HEXCEL

Popular searches

Cleaning using gases Processes with additional operations Acid polymer adhesives Additive manufacturing with liquids Epoxy resin adhesives Hydrocarbon polymer adhesives Conjugated diene hydrocarbon adhesives Applying layer means Conjugated diene hydrocarbon coatings Manufacturing environment conditioning

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com