An apparatus for building a three-dimensional article and a method for building a three-dimensional article

A technology of equipment and products, applied in the field of equipment for building three-dimensional products, can solve the problems of complicated production process, messy powder spraying system, and inability to reuse waste materials, etc., and achieve the effect of improving the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

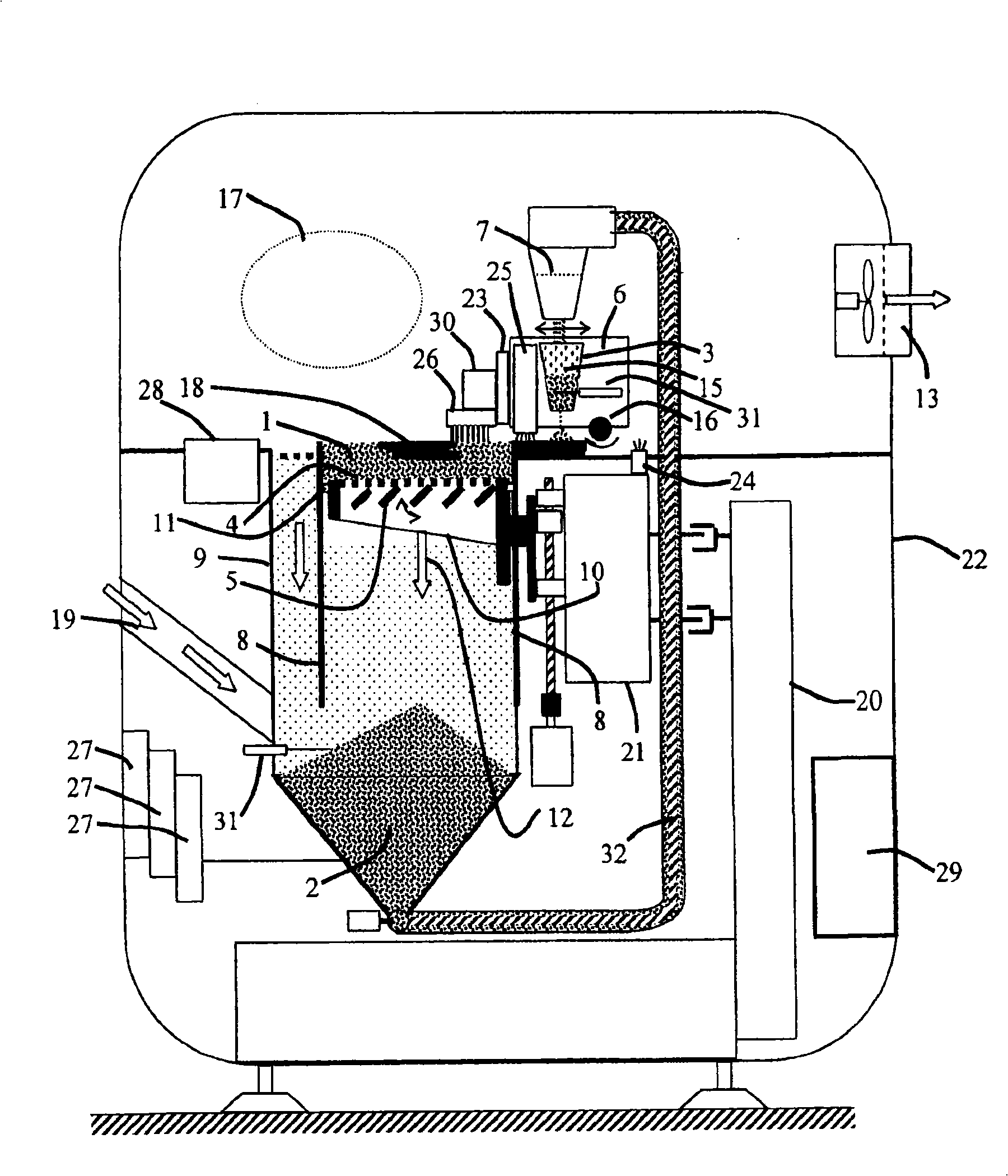

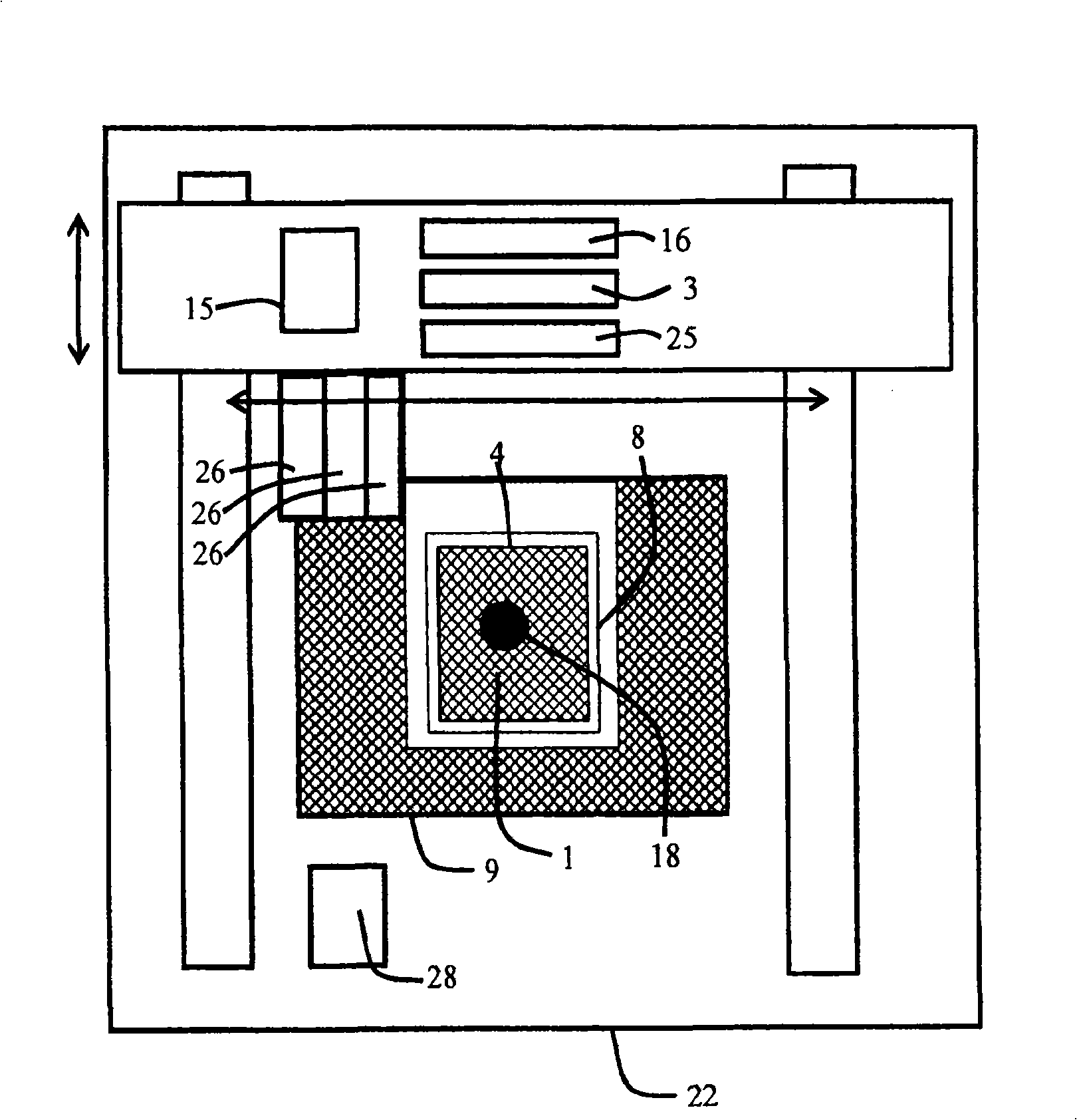

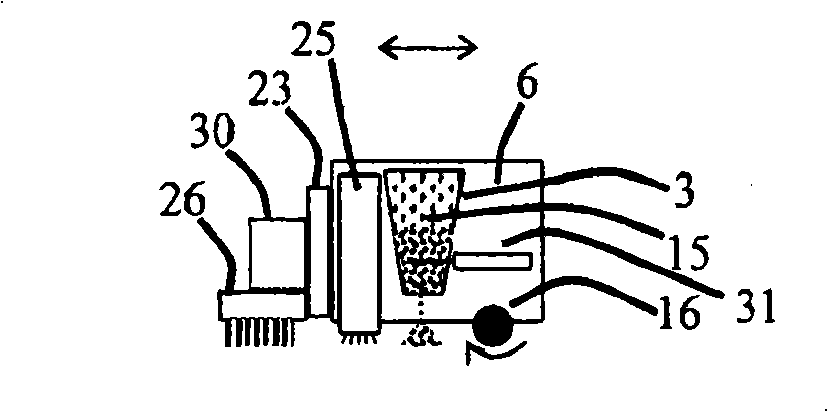

[0143] exist figure 1 with 2 Among them, the powder conveying system includes: a reservoir for conveying powder material 2; a powder conveying system 32 leading to a filter screen 7, which leads to a powder dosing device 3; a spraying system, which includes a 1 roller 16. The building chamber 1 comprises an inner wall 8 and an outer wall 9, a building platform 10 which is movable along the inner wall of the building chamber, eg by means of a piston. The building platform consists of an upper part comprising a grid and a lower part comprising a collapsible baffle.

[0144] The device also includes an adhesive reservoir 27 connected to the printhead reservoir 30 for delivering liquid reagents applied by the printhead 26 to the respective powder layers. At least 75% of the space formed between the upper part of the inner and outer walls of the build chamber 1 comprises direct contact with the powder recovery system whereby, via the upper (top) boundary of the build chamber 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com