Method and system for reusing residual powder from an installation for the rapid prototyping of three-dimensional objects

A generative manufacturing, powder technology, applied in the direction of manufacturing tools, additive manufacturing, manufacturing aids, etc., can solve problems such as the impact of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method and a system for reusing surplus powder from a device for the generative manufacture of three-dimensional objects are described below by means of figures.

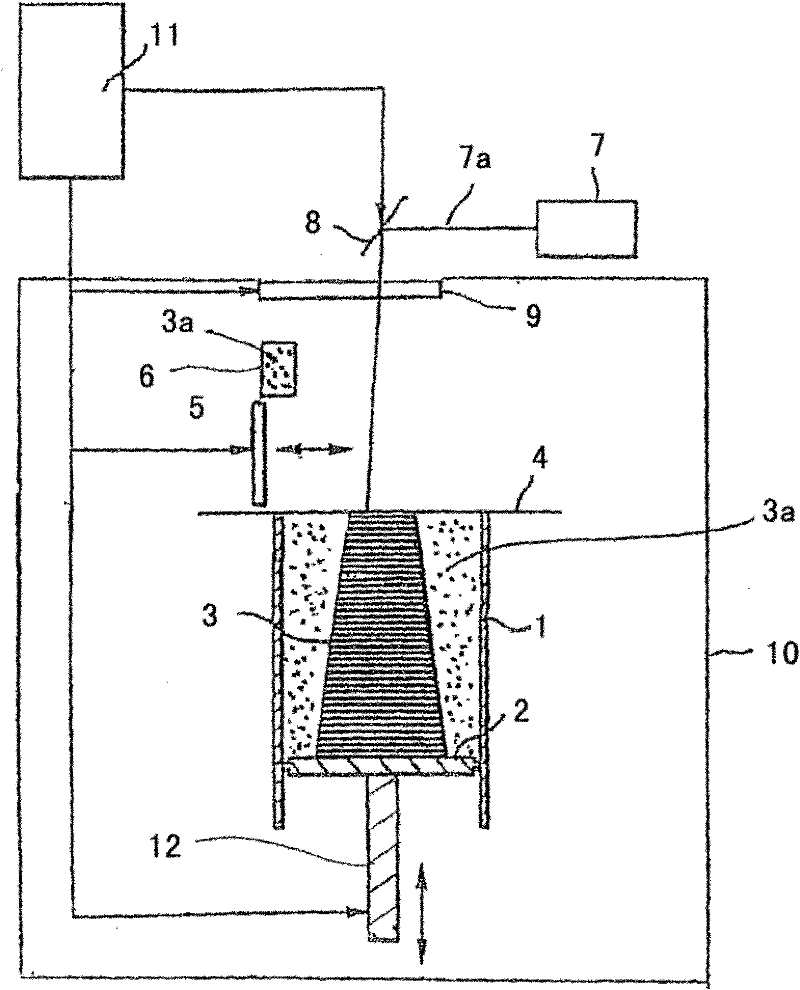

[0018] figure 1 A schematic diagram of a production device according to the invention for producing a three-dimensional object 3 is shown, which is designed as a laser sintering device in the exemplary embodiment.

[0019] The laser sintering system has an upwardly open frame 1 which includes a vertically movable plate 2 situated therein, which supports a three-dimensional object 3 to be produced. Frame 1 and plate 2 internally define a fabrication space. The plate 2 is connected to a lifting mechanism 12 which moves the plate in the vertical direction so that the respective layers of the objects 3 to be consolidated lie in a working plane 4 .

[0020] Although this is figure 1 Not shown, a metallic base plate can be manually placed on the plate and fixed or screwed if necessary. Such a substrate is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com