Patents

Literature

66results about How to "Reduced tool wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

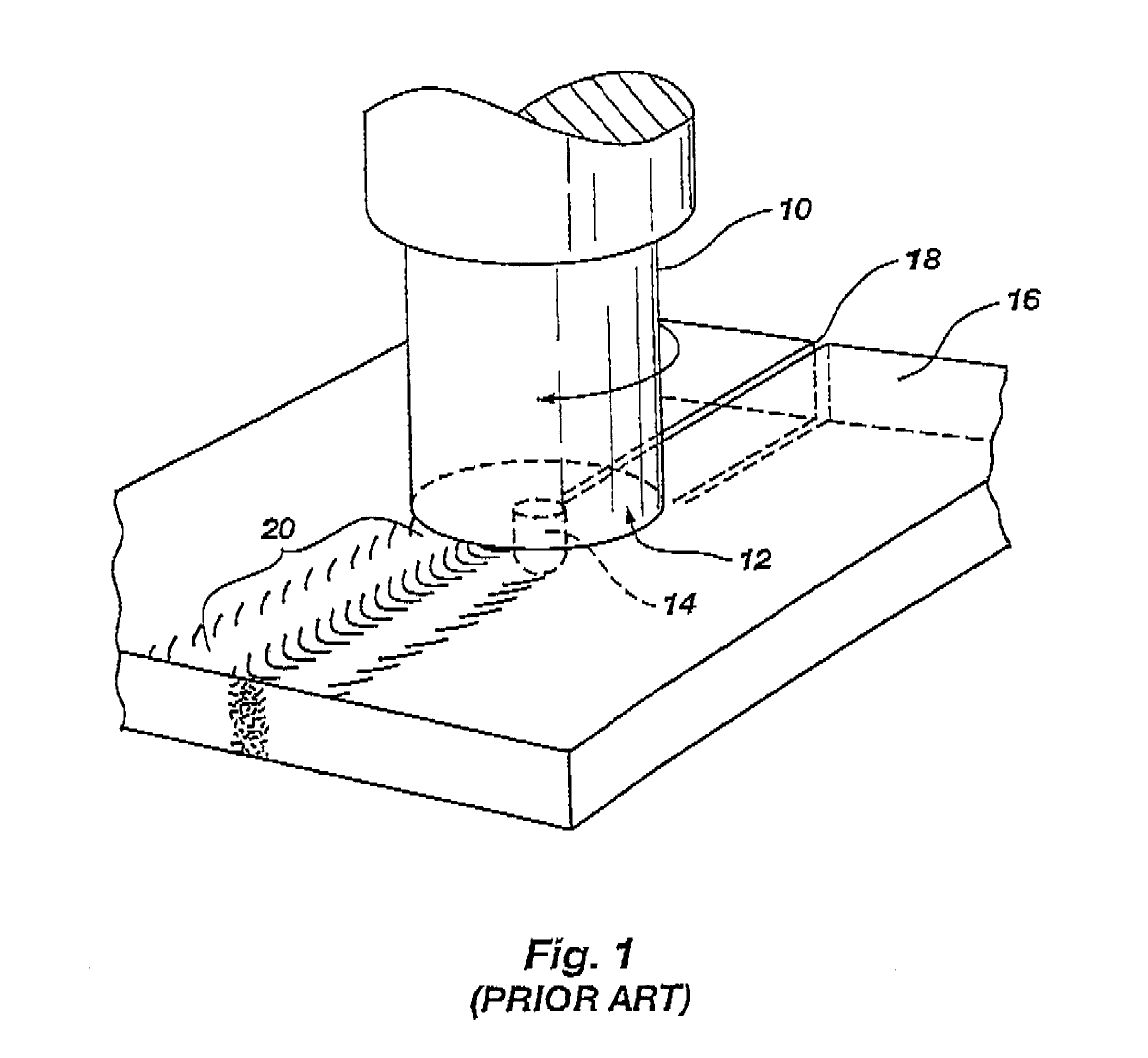

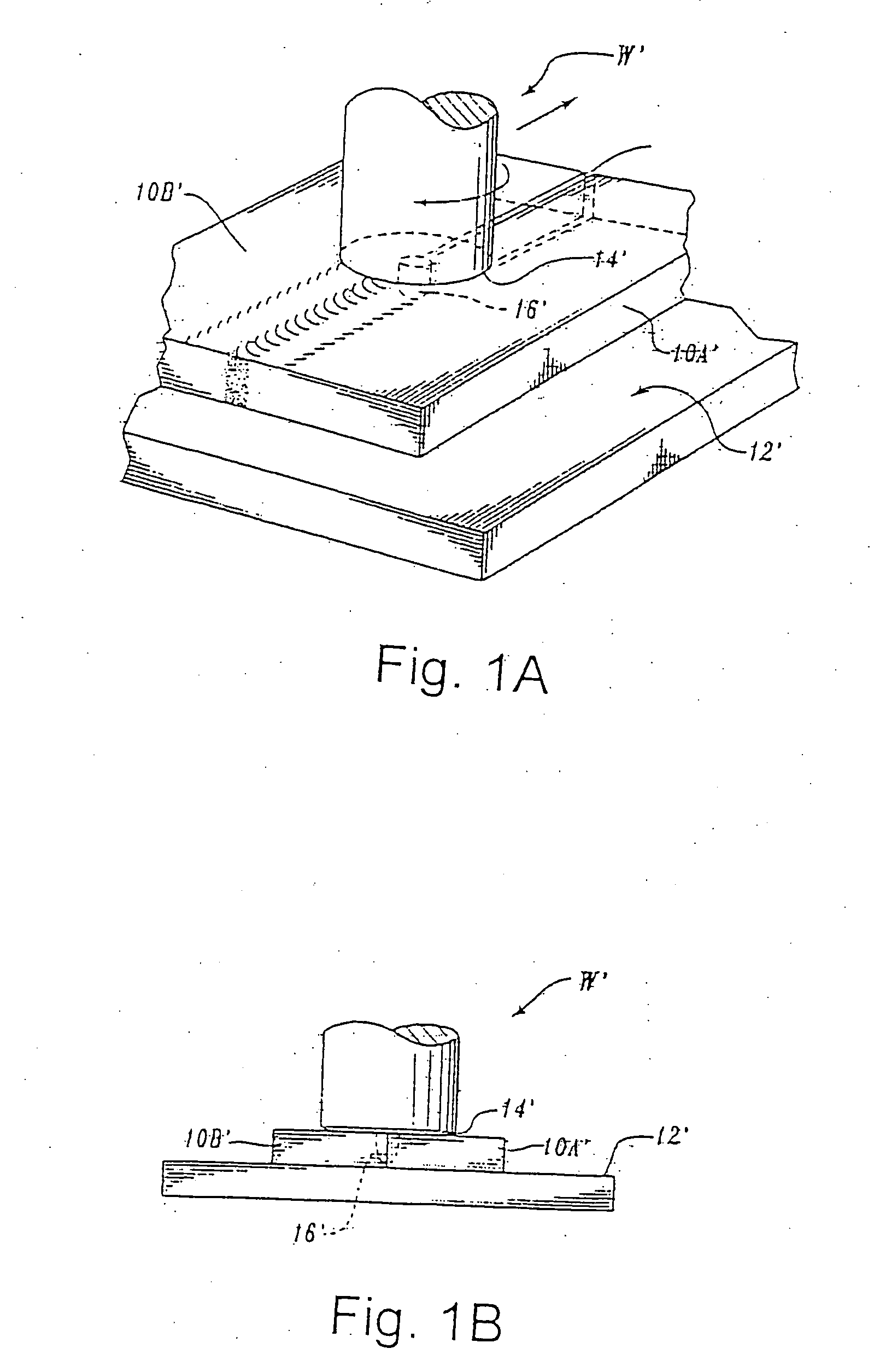

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

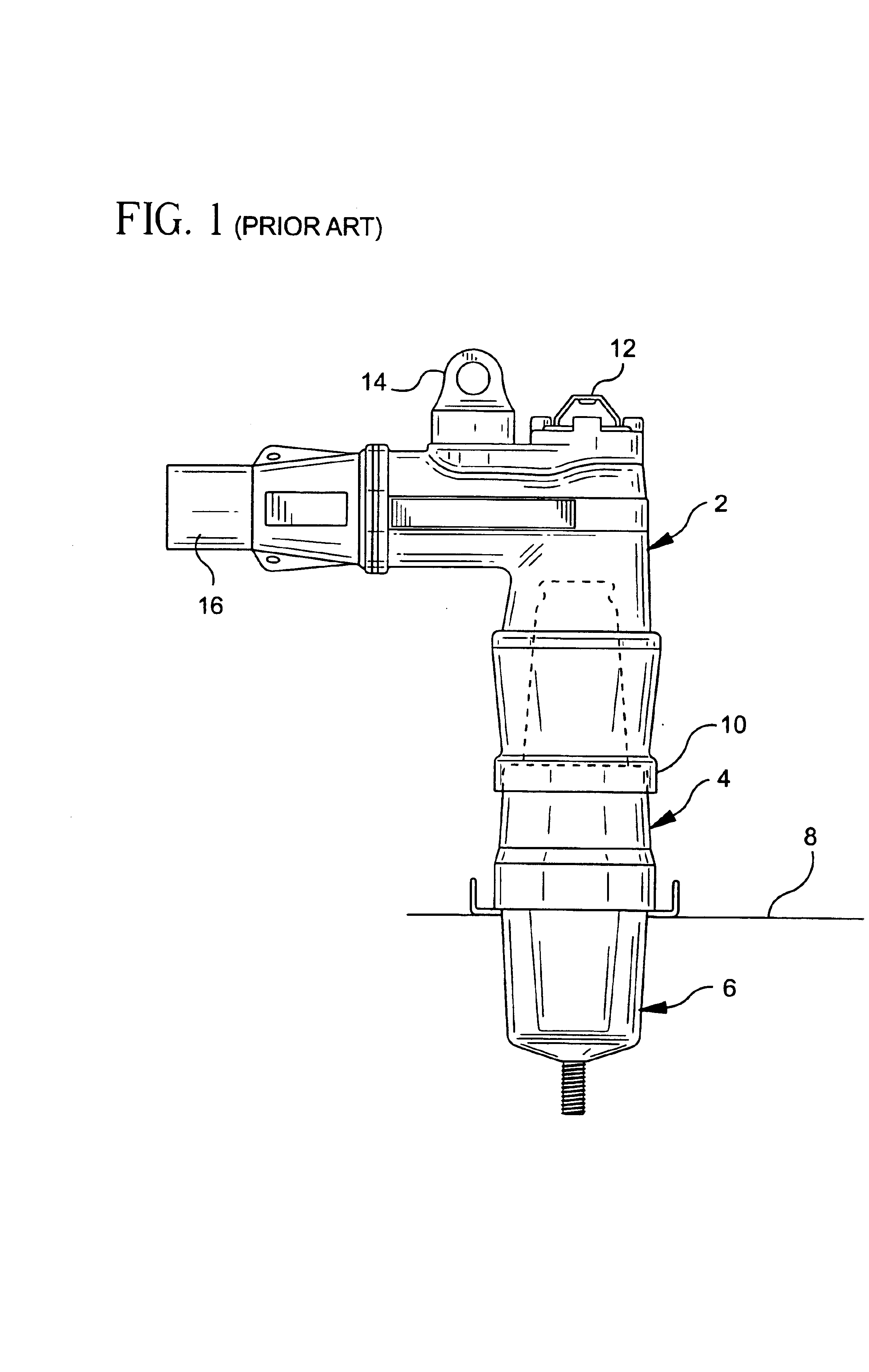

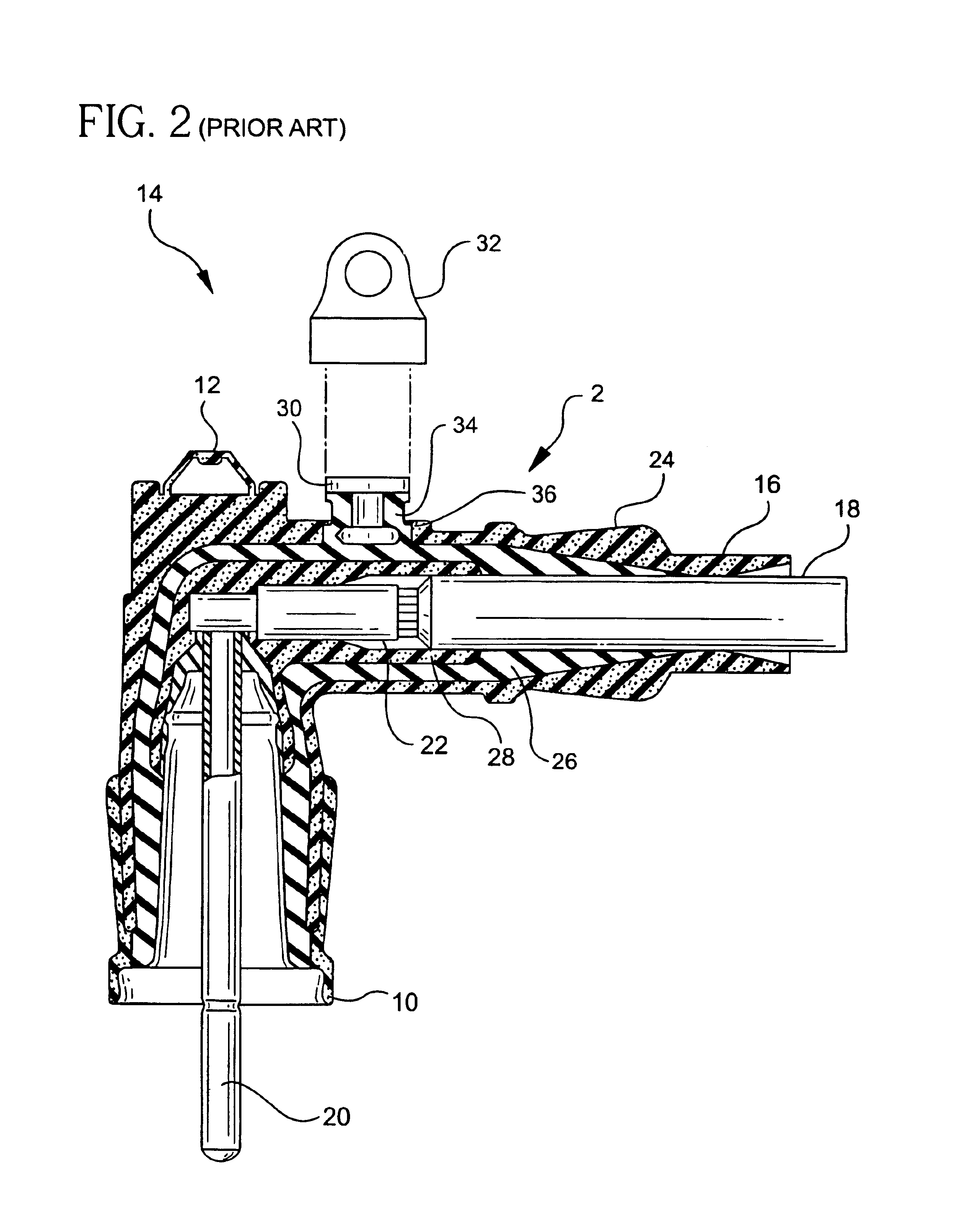

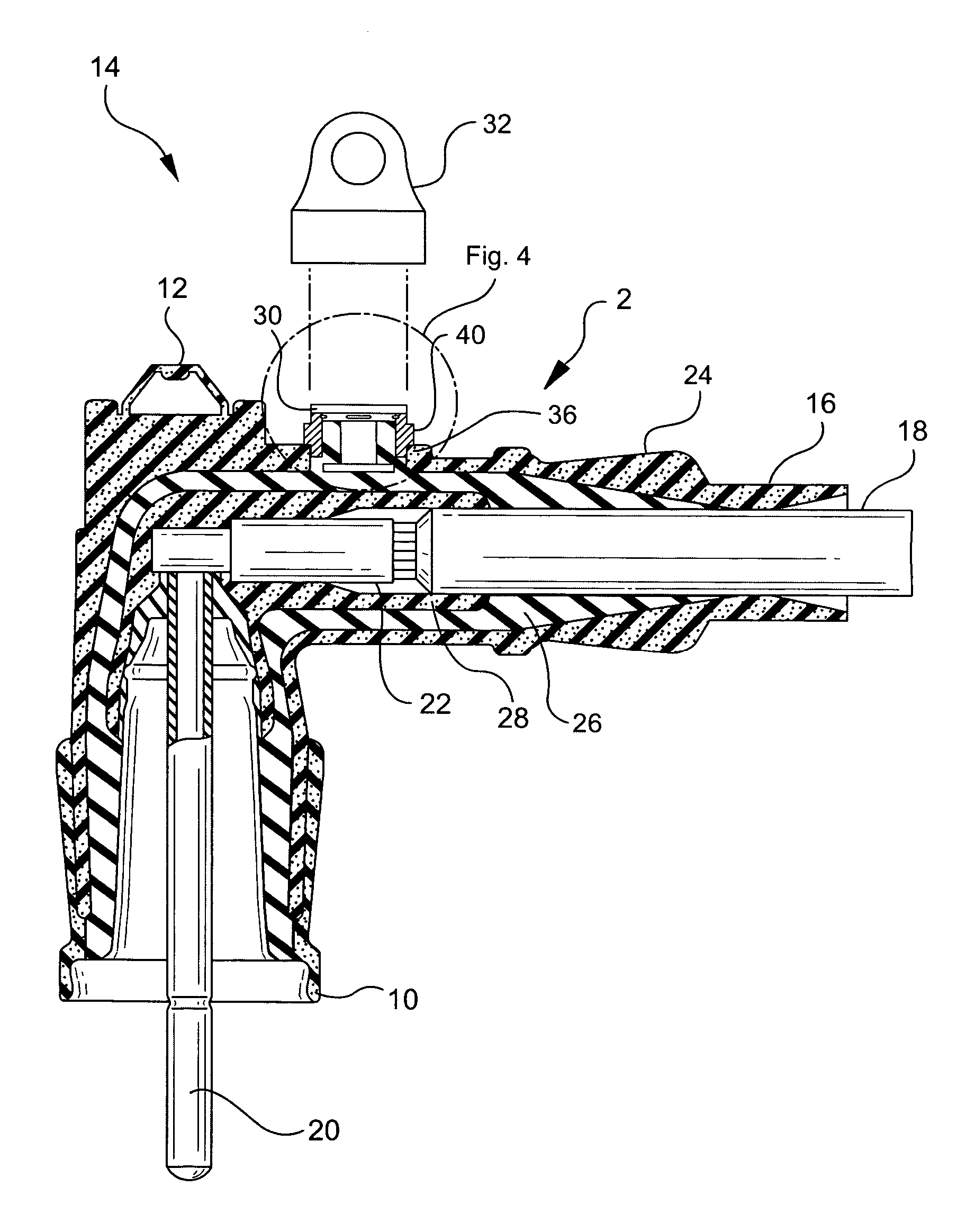

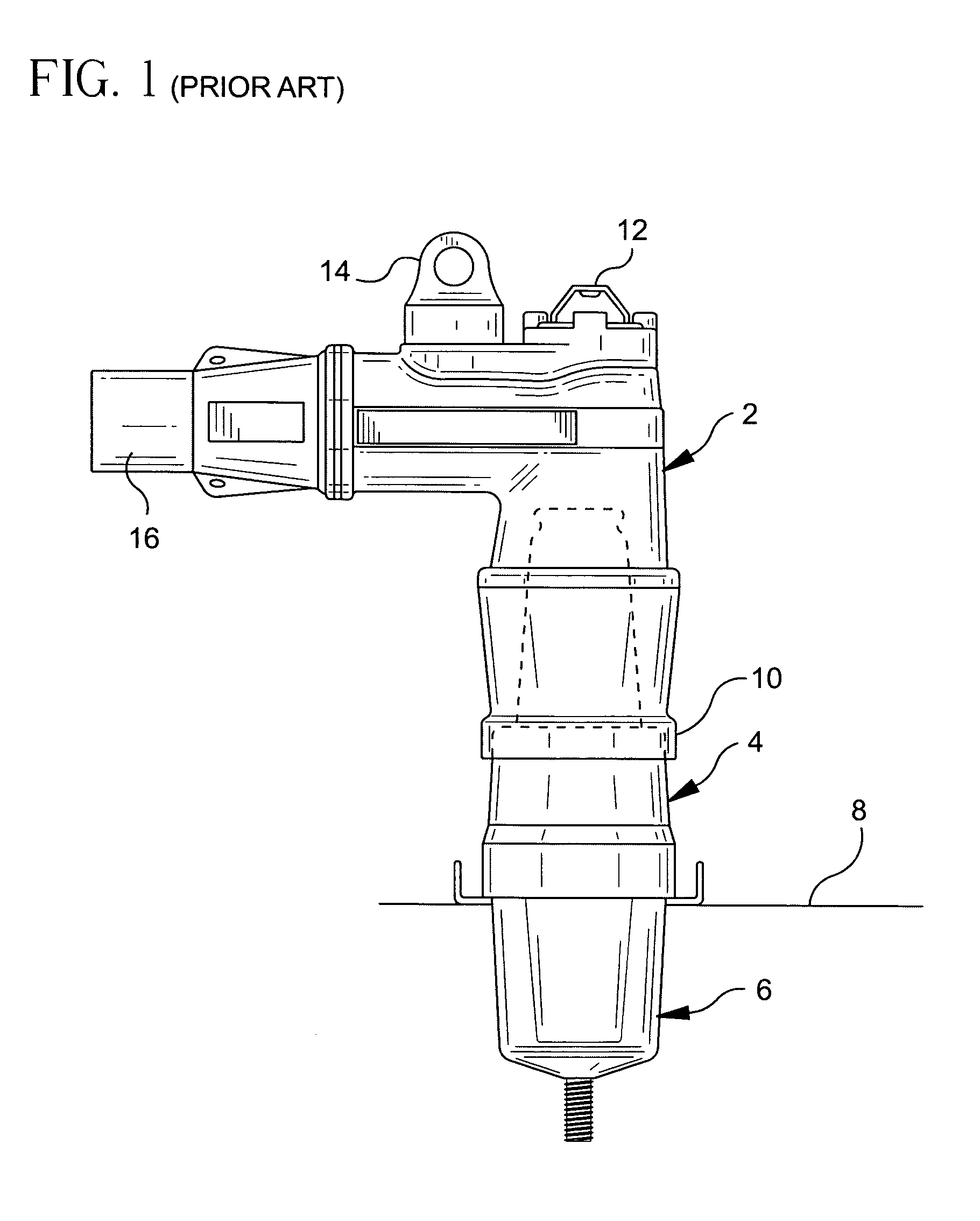

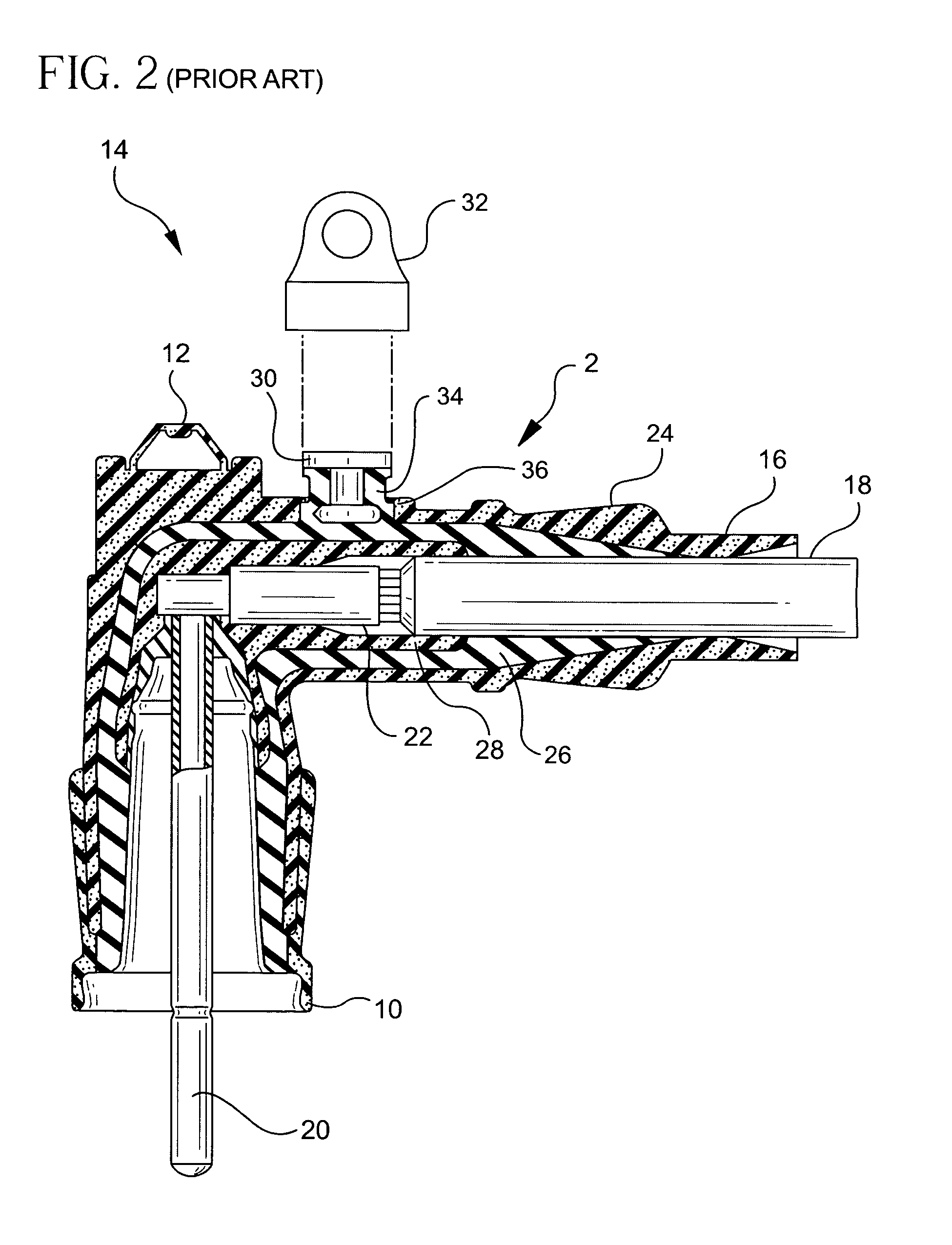

Electrical connector with voltage detection point insulation shield

ActiveUS6843685B1Reduce frictionReduces wear and cleanRelieving strain on wire connectionCouplings bases/casesCapacitive couplingThermoplastic

Owner:THOMAS & BETTS INT INC

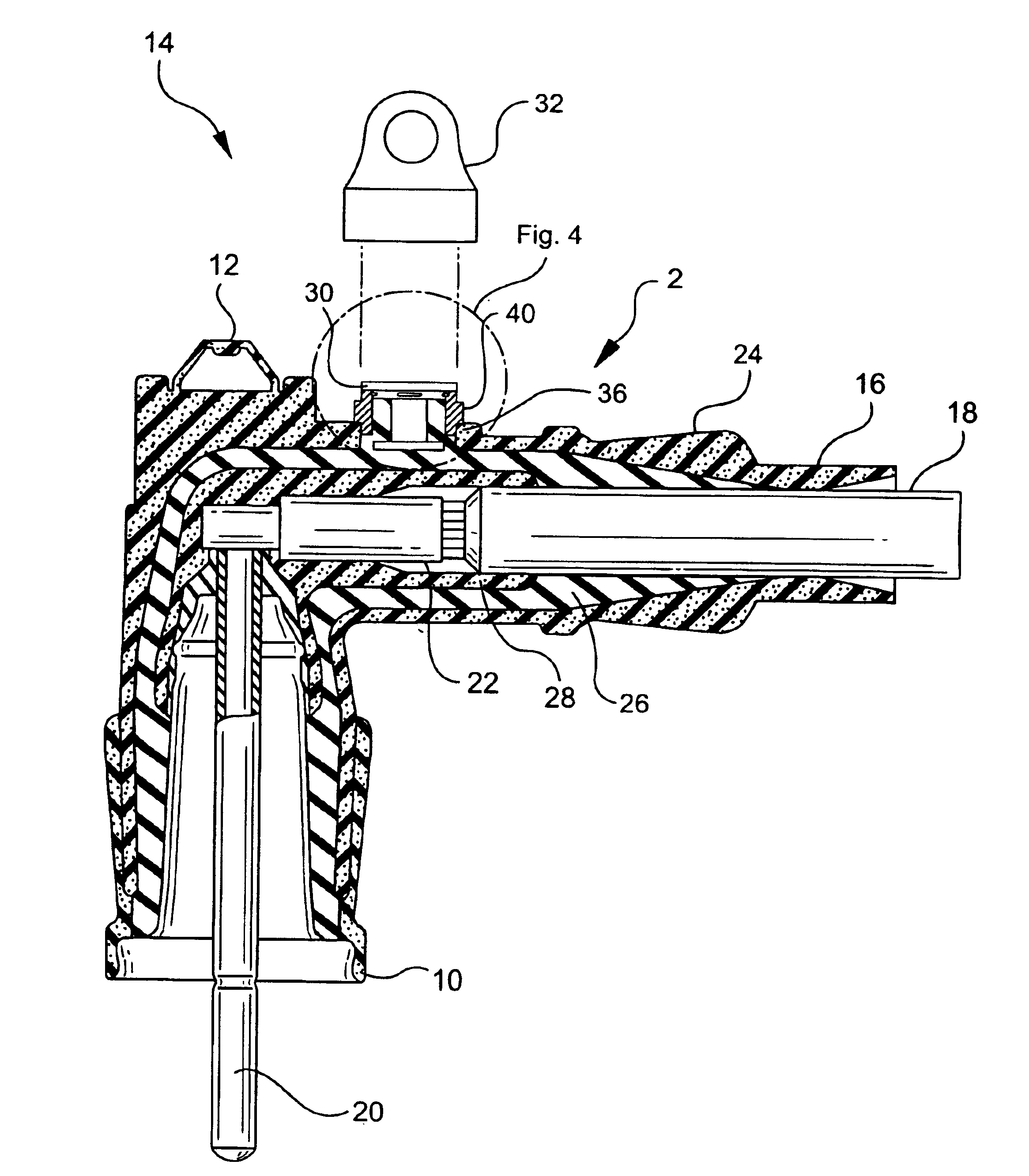

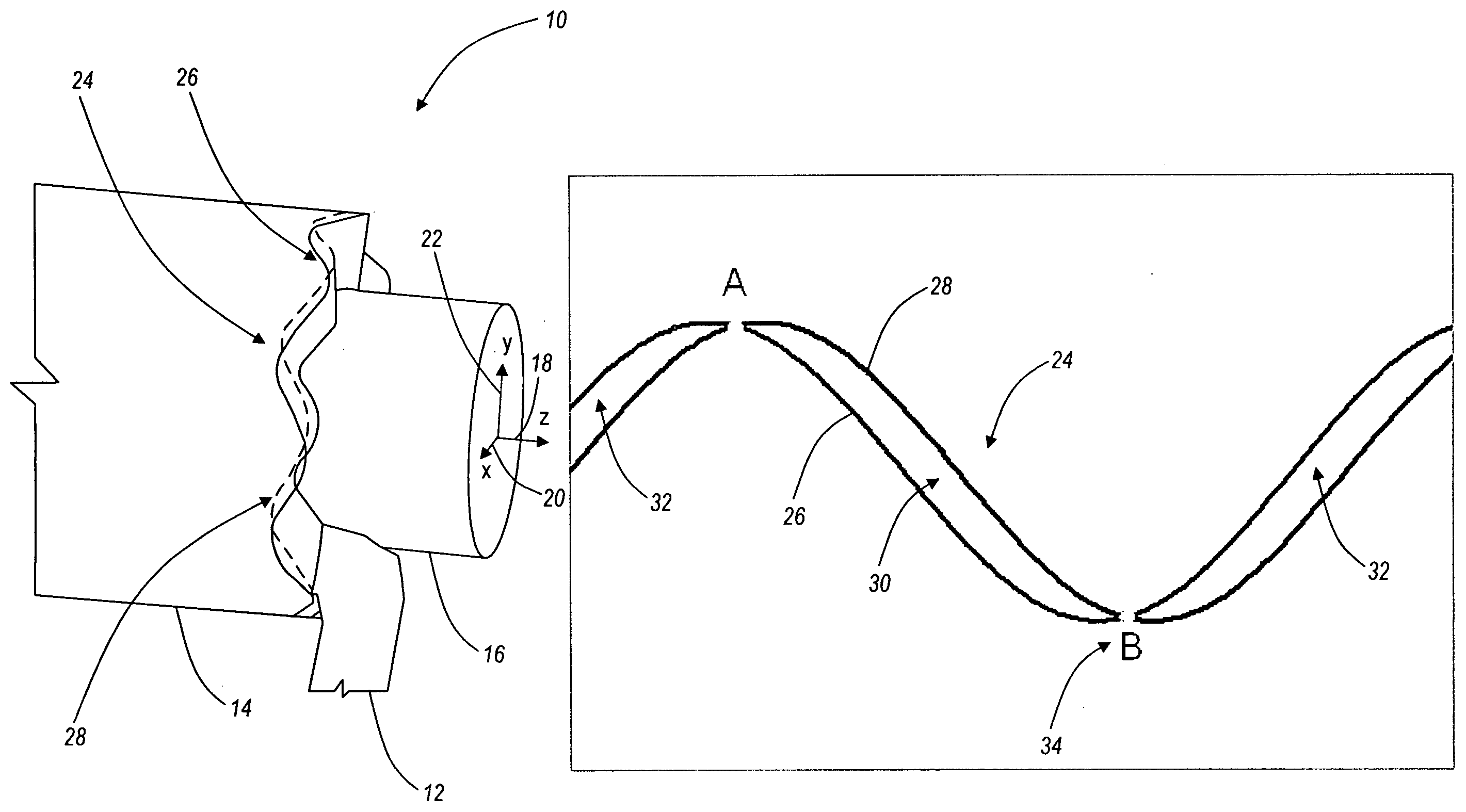

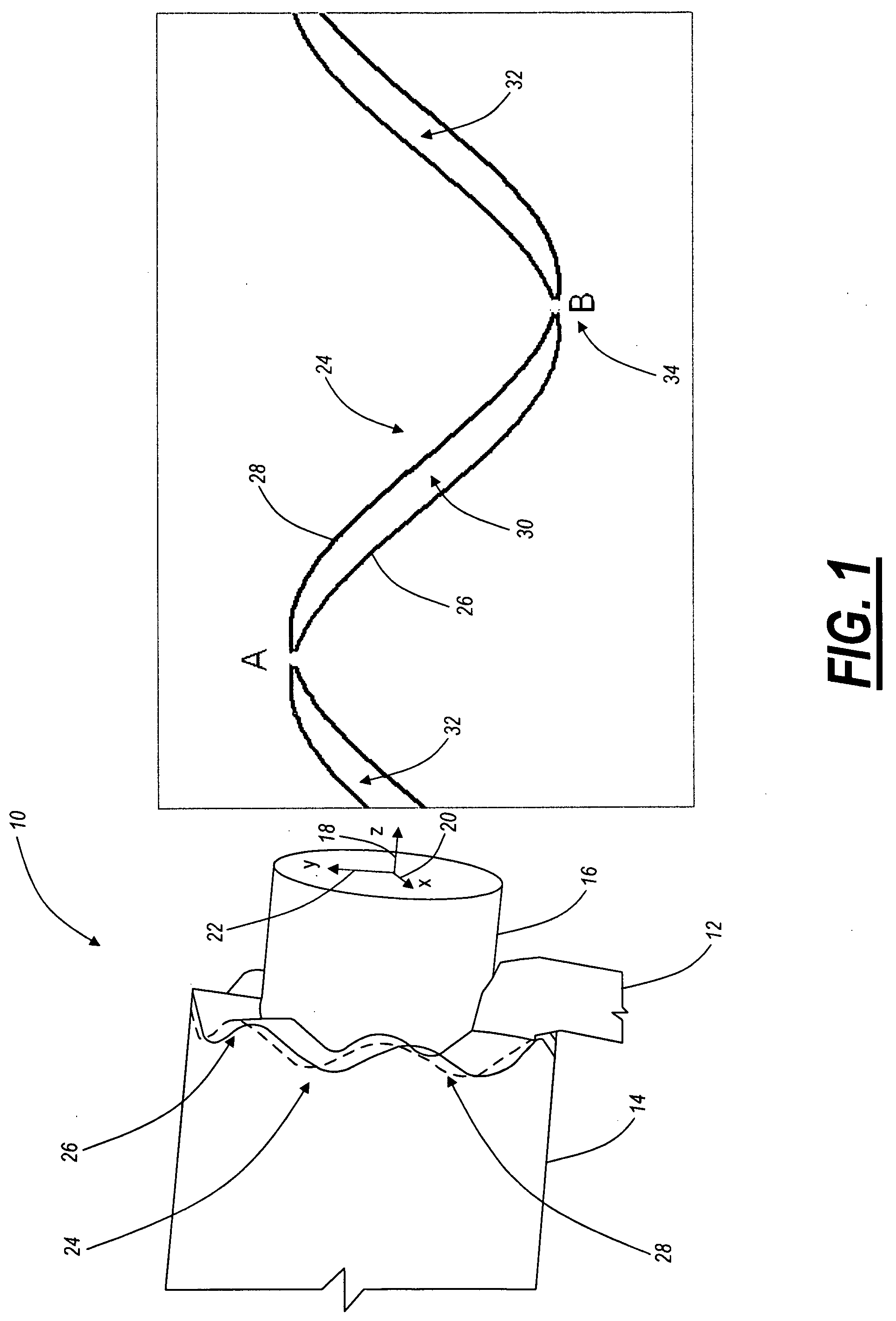

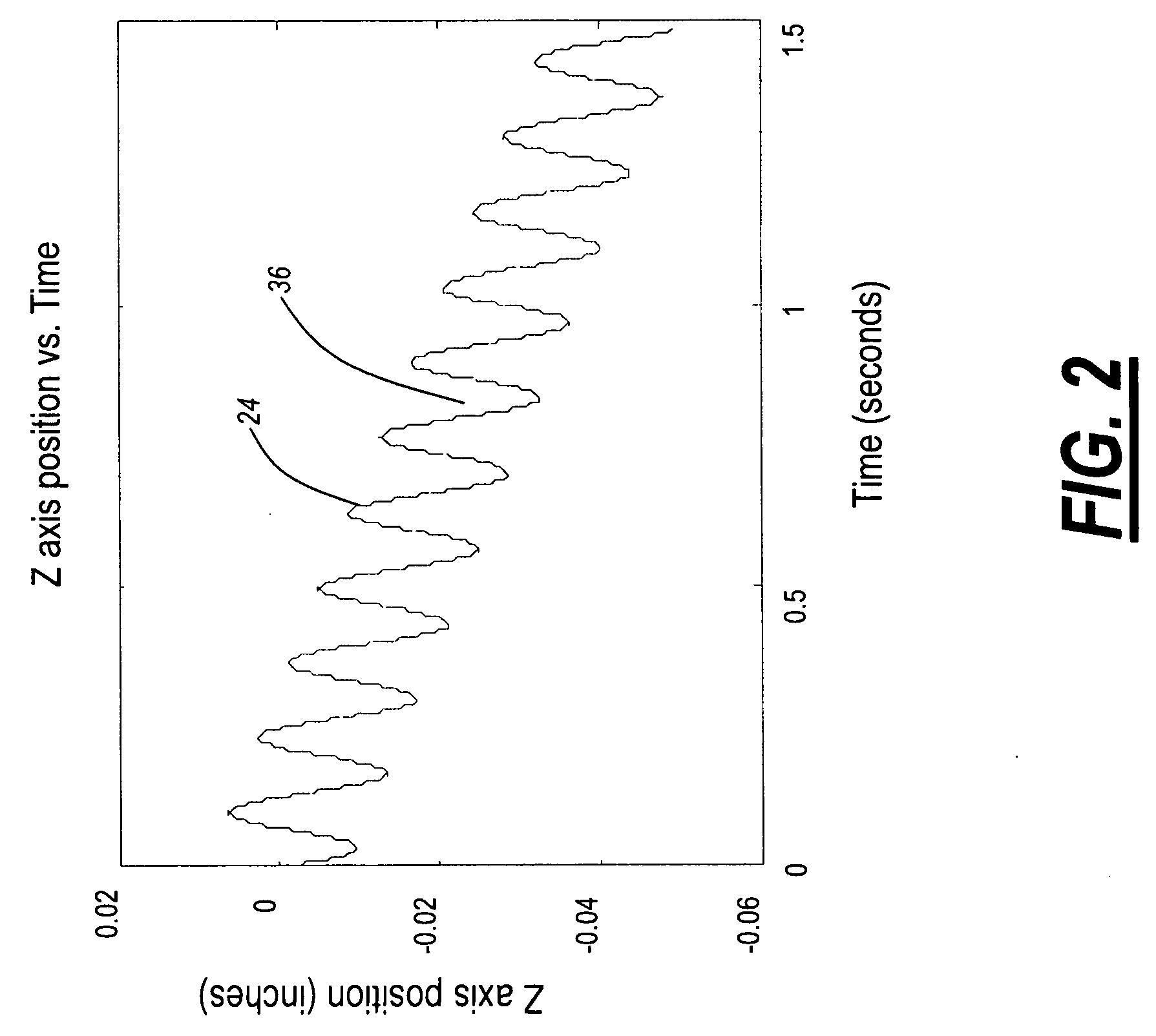

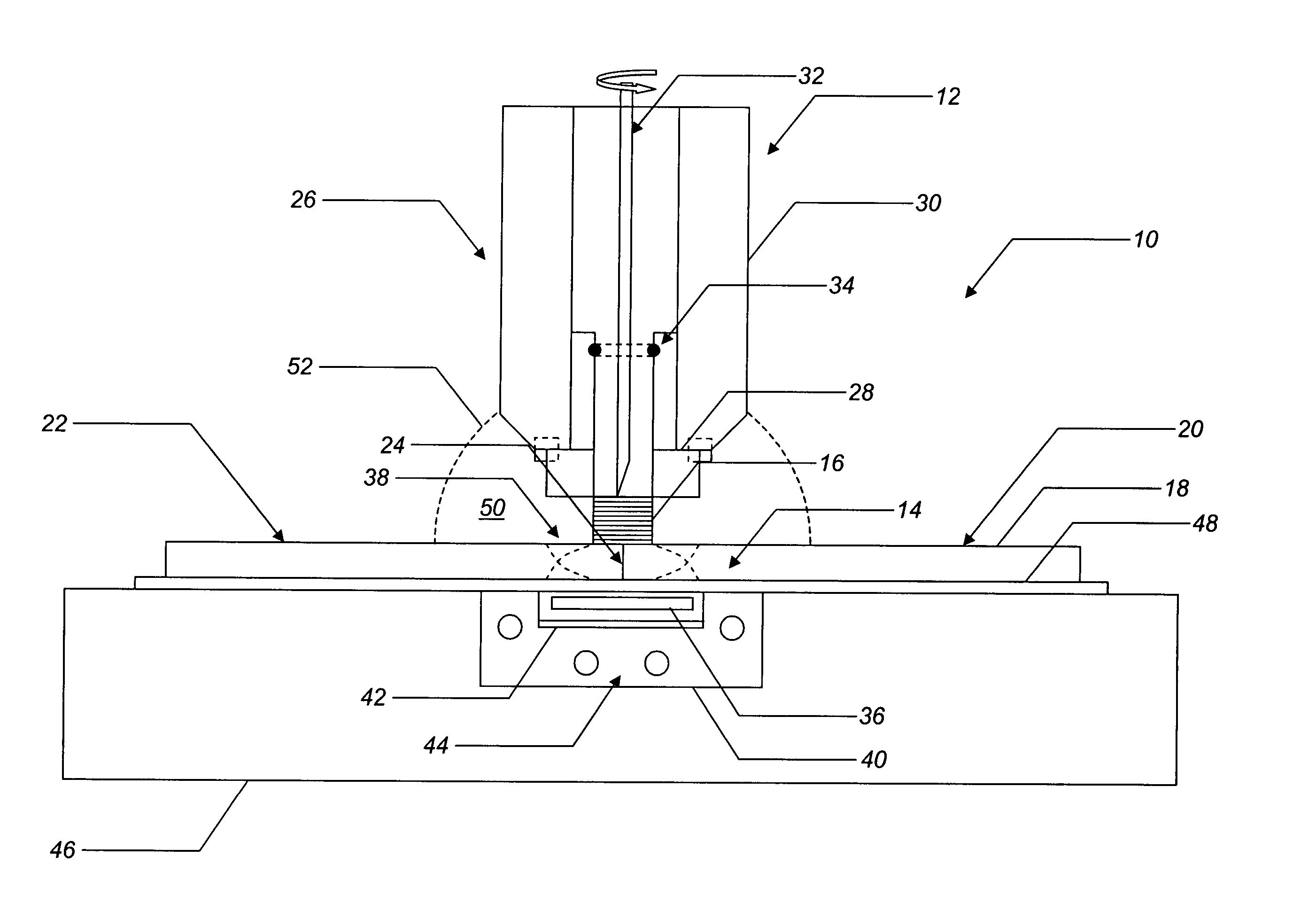

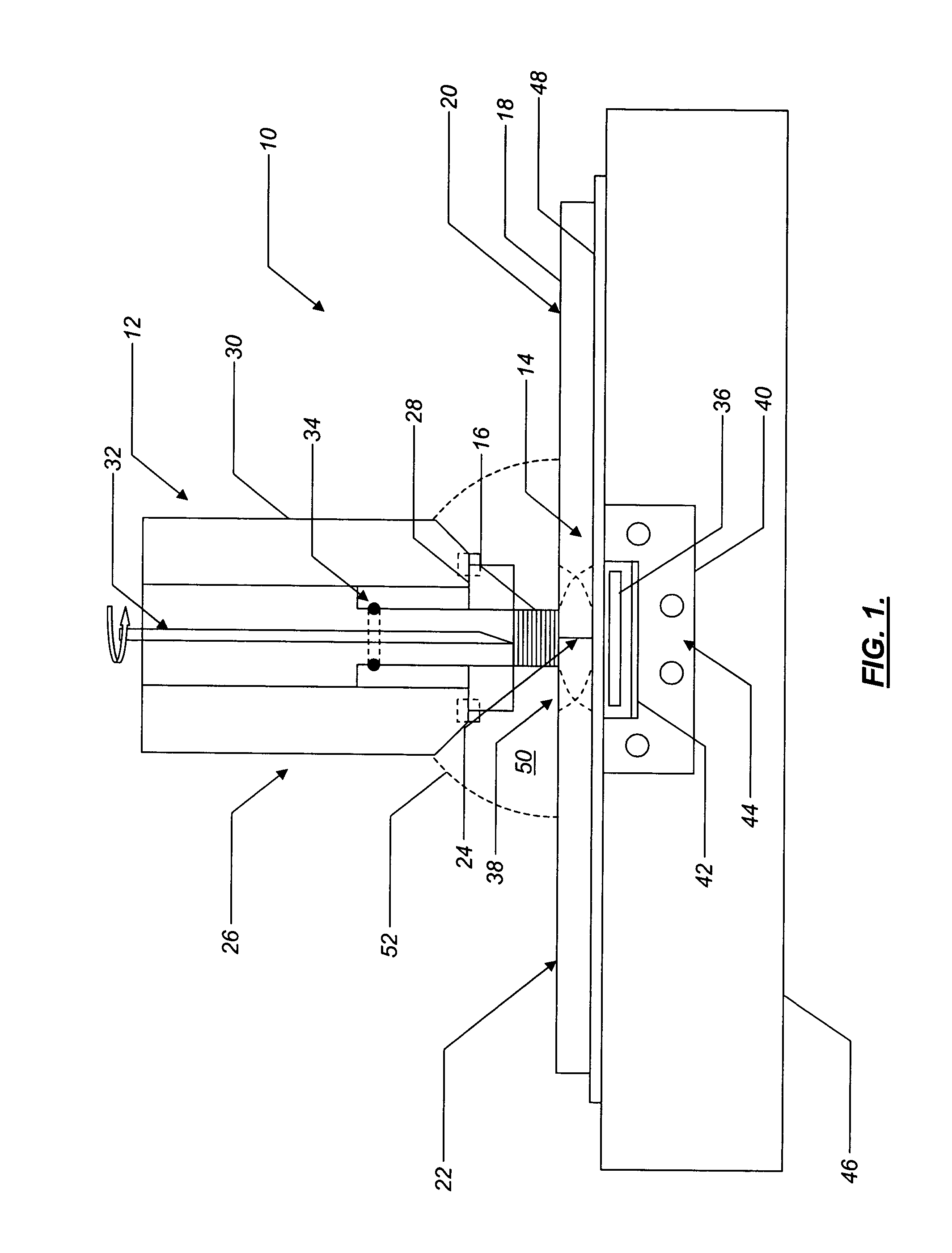

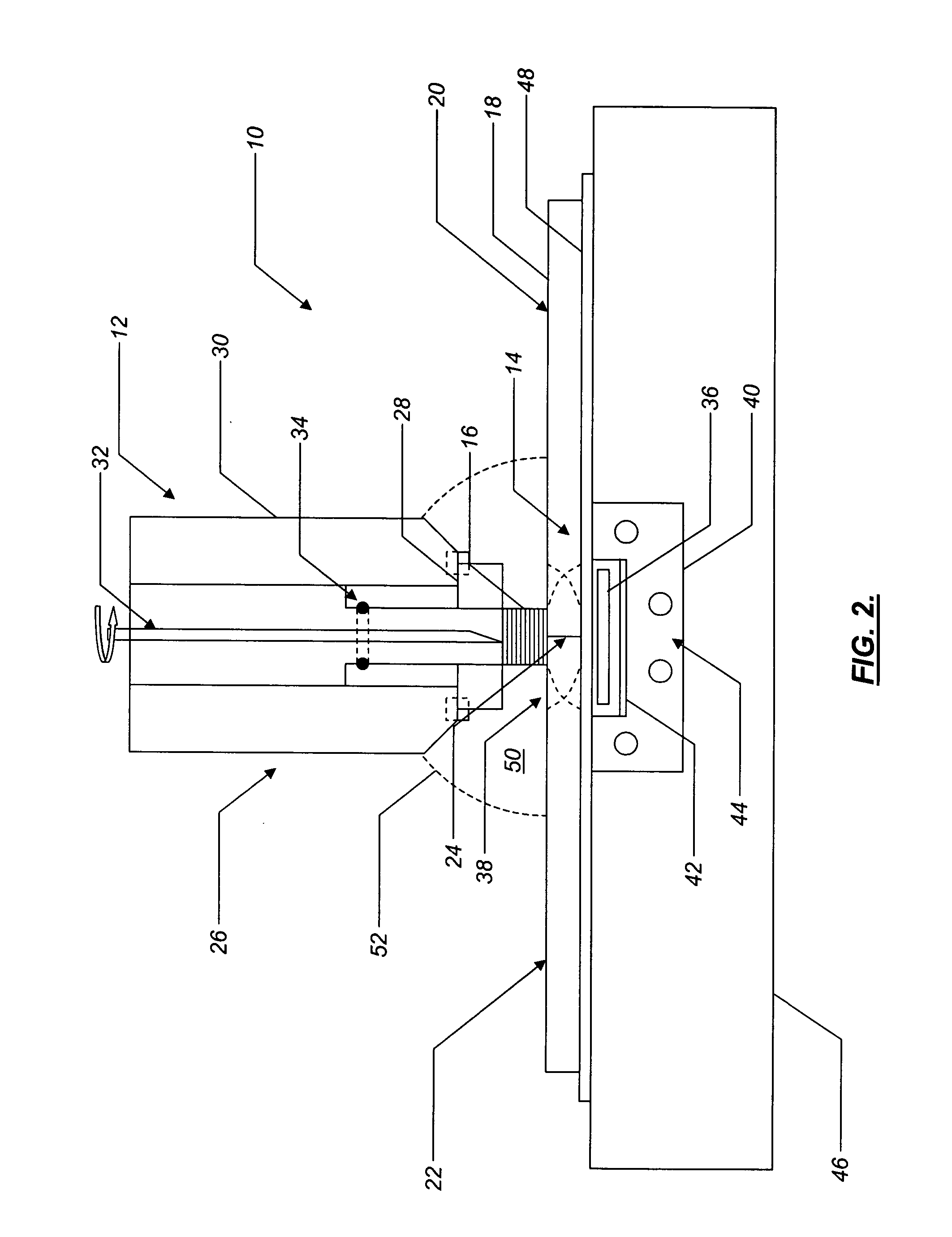

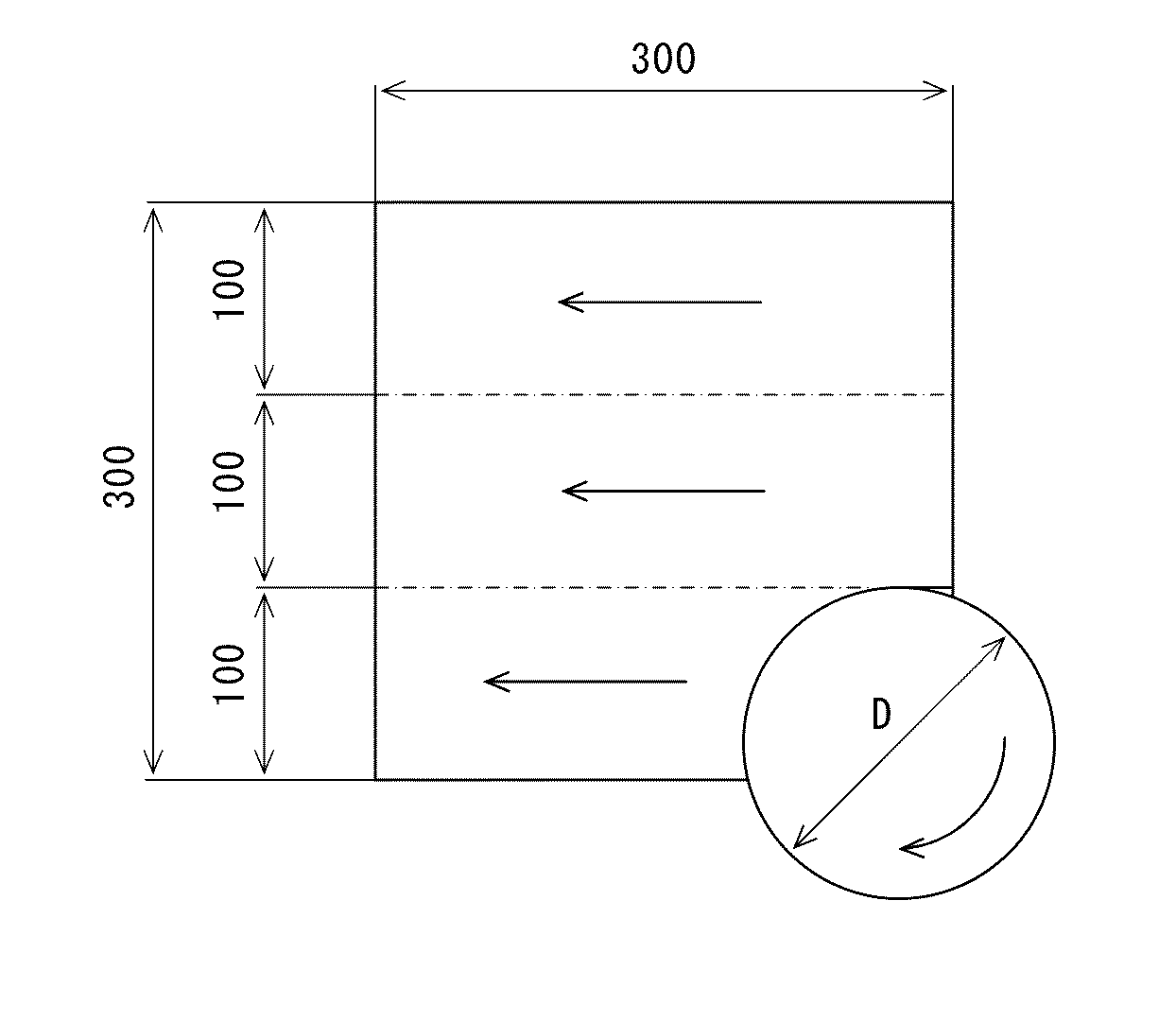

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

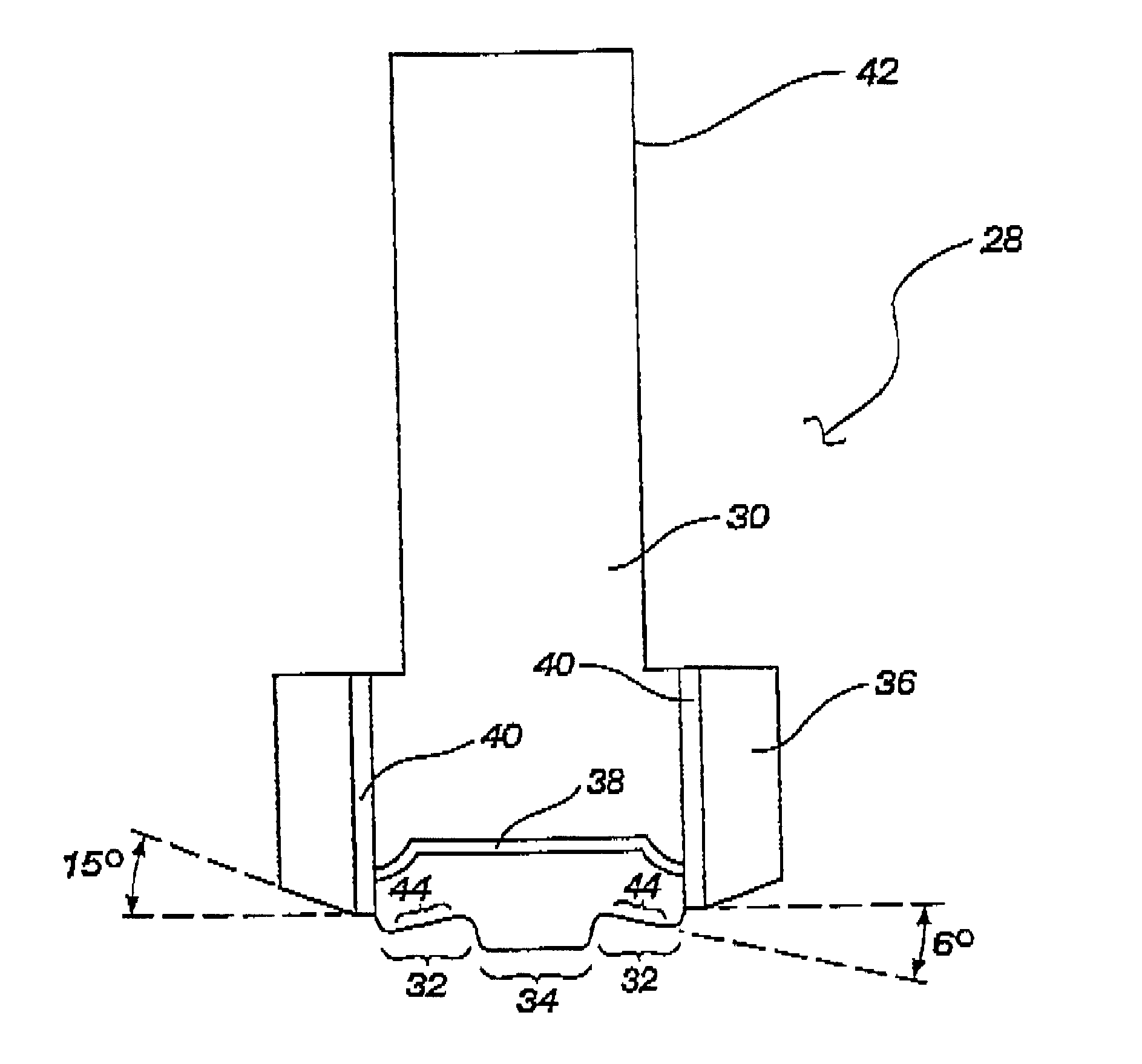

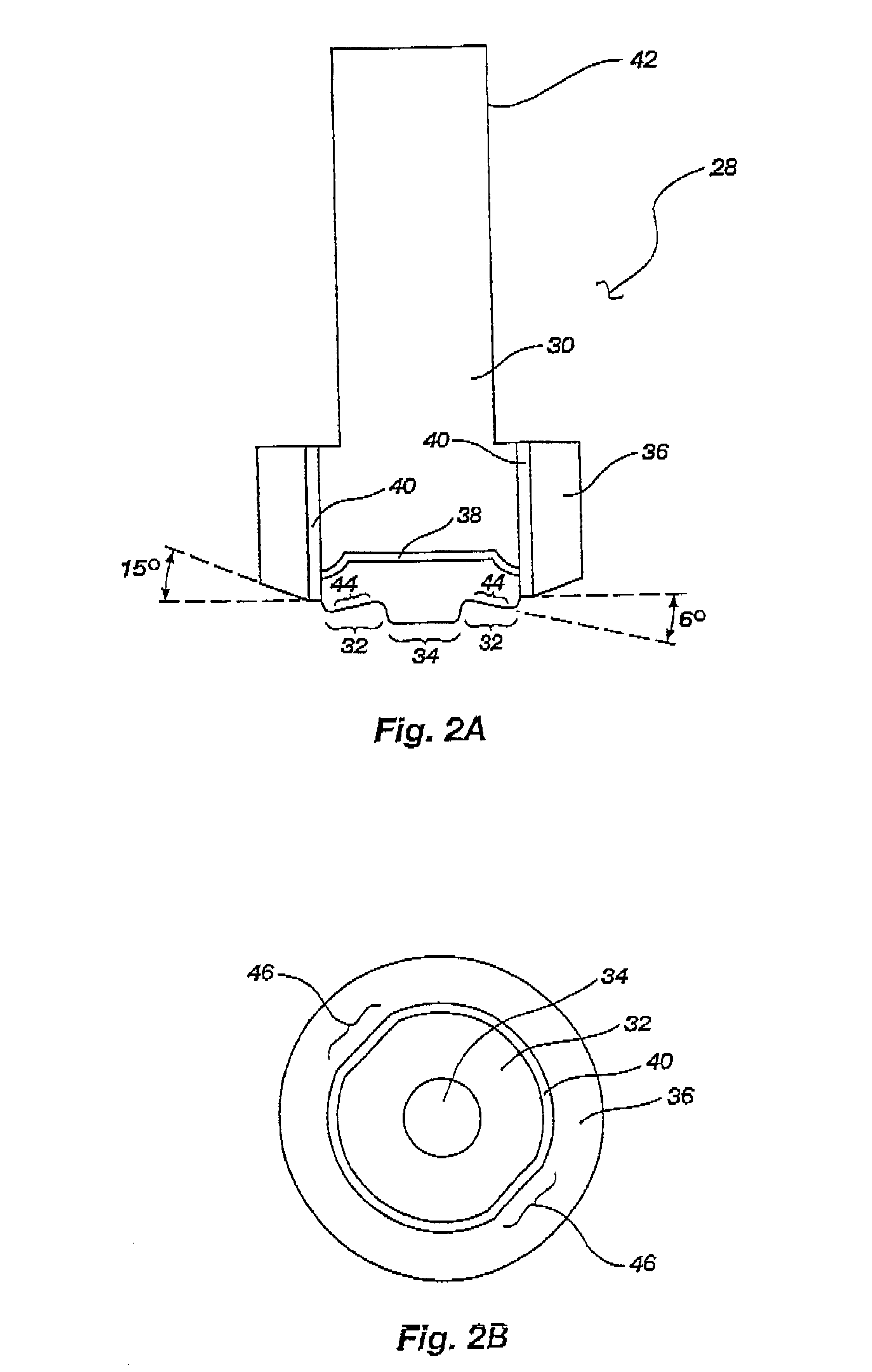

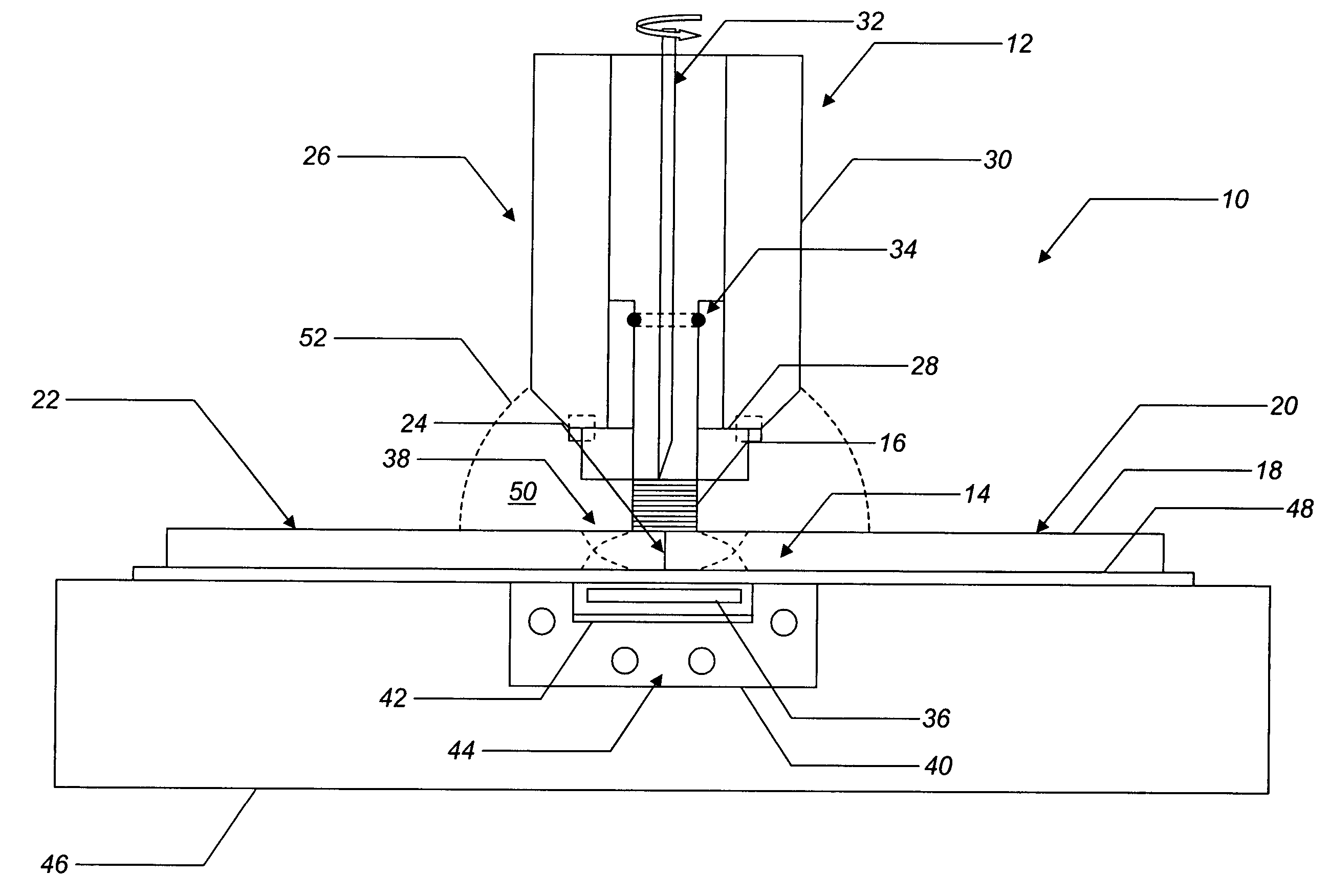

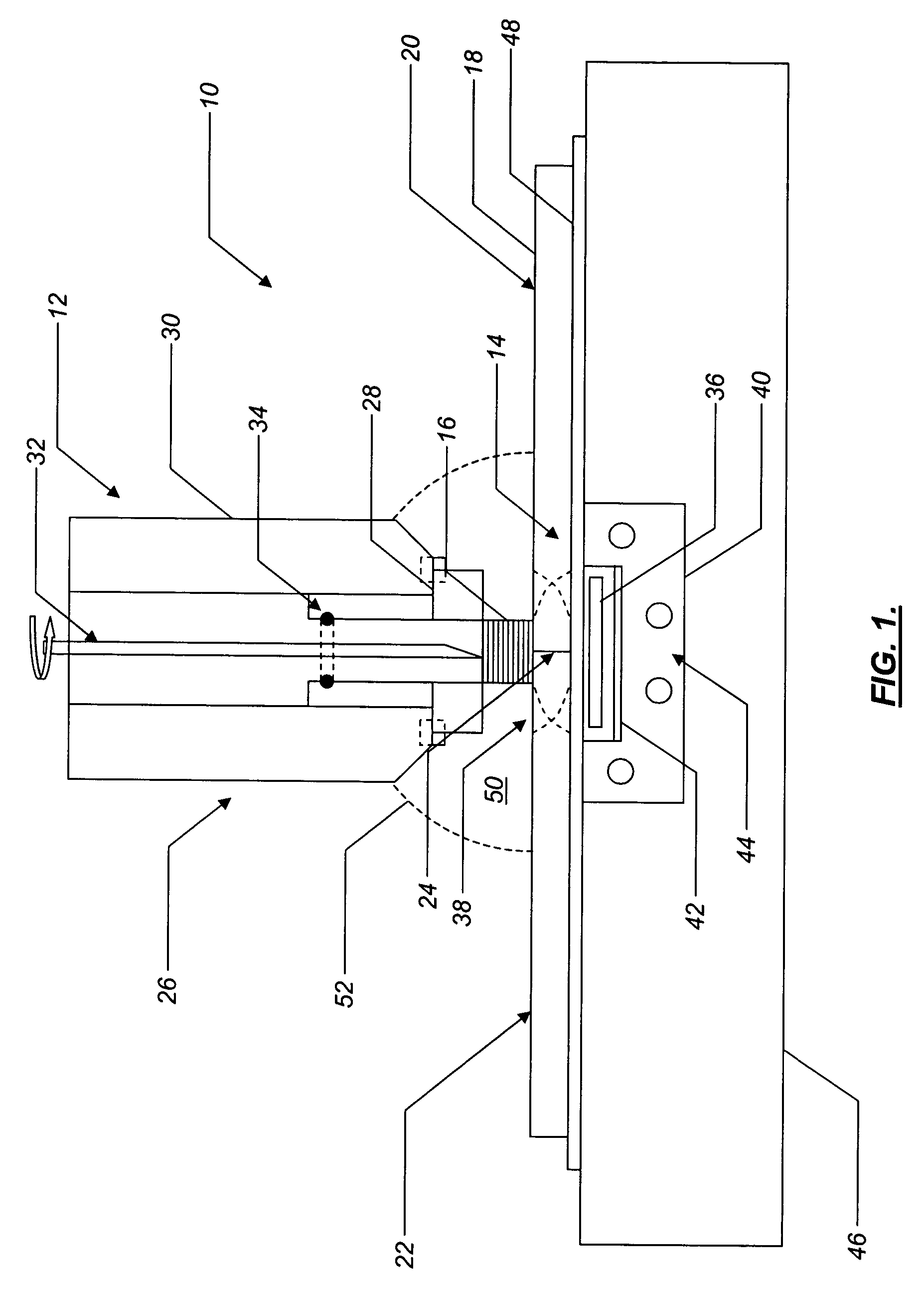

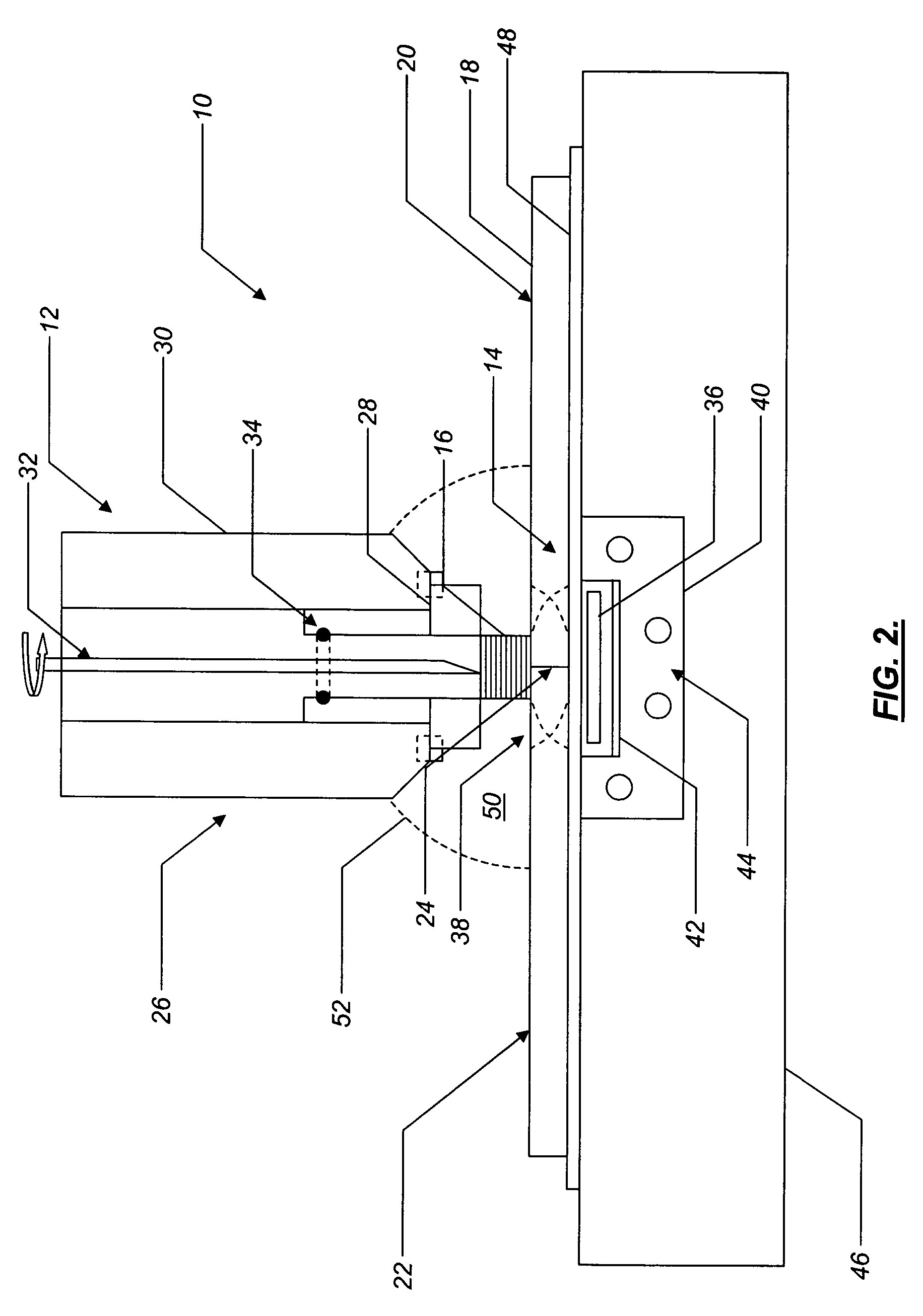

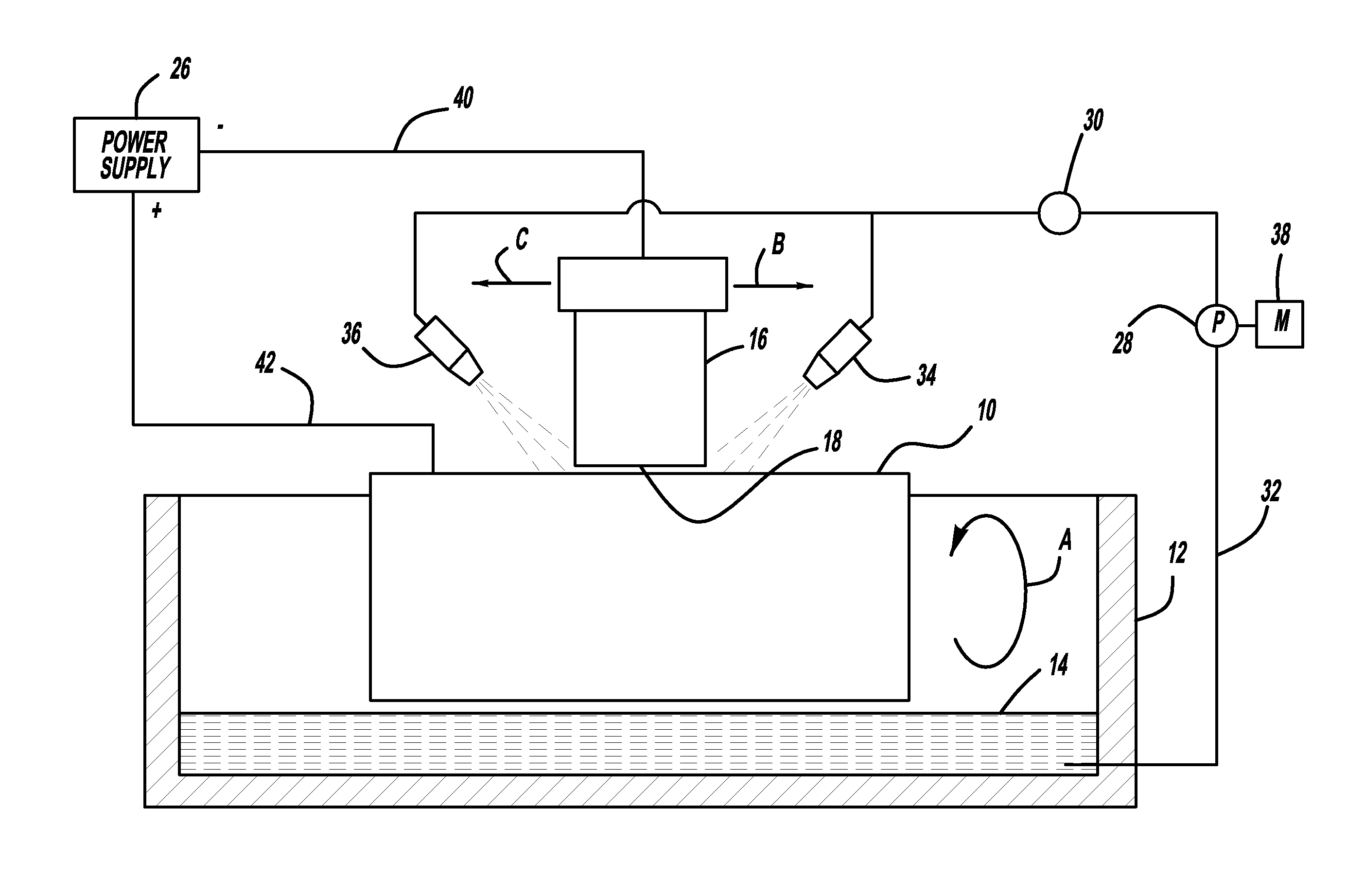

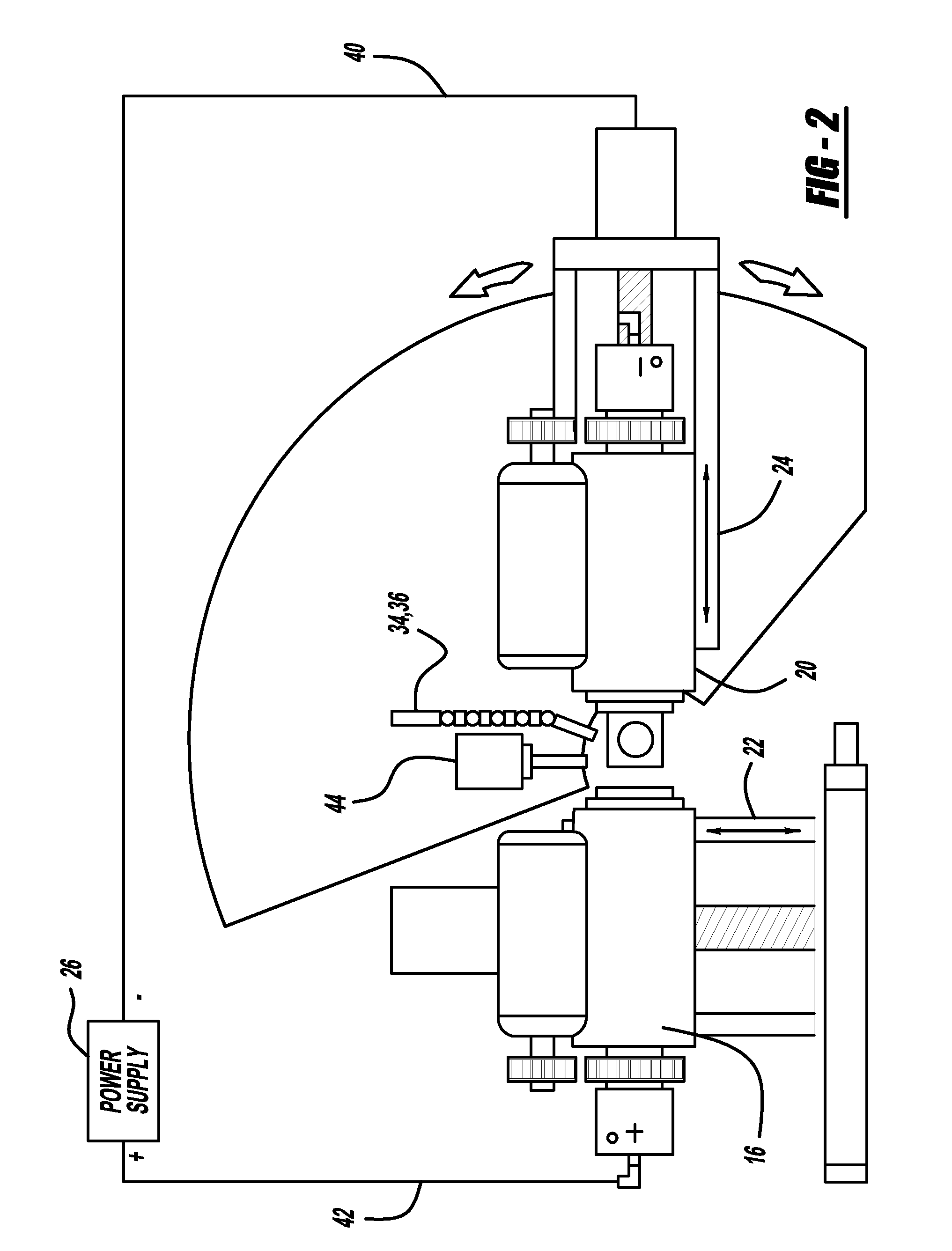

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

Method for forming an electrical connector with voltage detection point insulation shield

ActiveUS7150098B2Reduce frictionReduce irregularitiesContact member manufacturingRelieving strain on wire connectionThermoplasticElectrical conductor

In a method for forming an electrical cable connector having a voltage detection test point, an insulative shield is first molded from a thermoplastic and a conductive voltage detection test point terminal is inserted within the plastic insulative shield. After the pre-assembled insulative plastic shield and test point terminal are positioned adjacent the opening of the conductive outer shield, and after the conductive outer shield and an internal conductor are positioned within a mold cavity, an inner insulative housing is molded within the conductive outer shield and around the internal conductor.

Owner:THOMAS & BETTS INT INC

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS7121448B2Improve integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

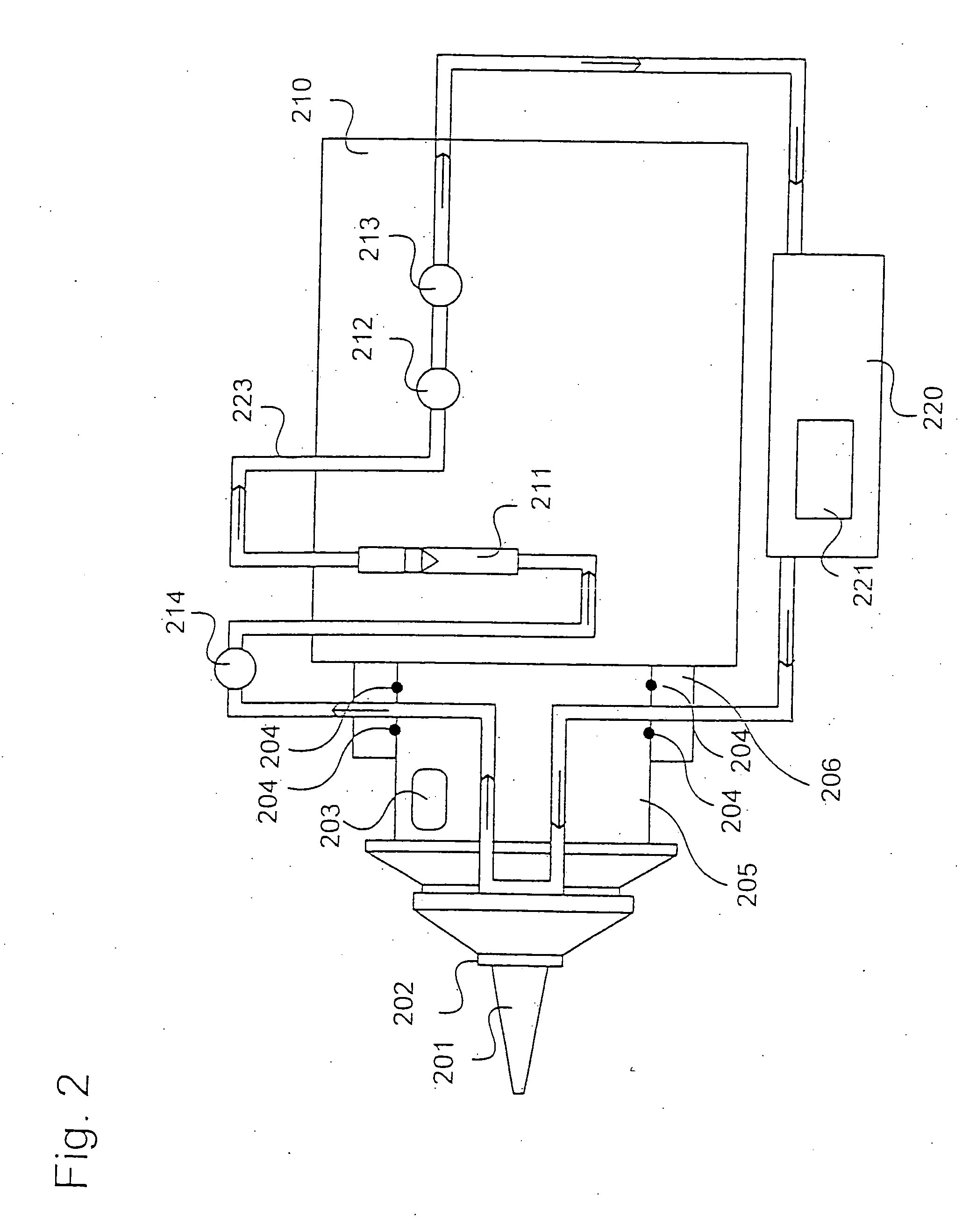

Method for friction stir welding

InactiveUS20050006438A1Improve welding qualityAvoid overall overheatingHigh frequency current welding apparatusNon-electric welding apparatusTemperature controlEngineering

The invention relates to a method of friction stir welding in which use is made of a rotating friction stir welding tool, said tool having a probe, the method comprises, (a) temperature control of the tool during welding of a workpiece of hard to weld materials by passing a temperature controlling coolant through one or more channels in the tool in order to control the temperature of the probe, thereby removing excessive heat from the tool and from the area of the workpiece being welded, (b) said coolant having a predetermined first temperature upon entering the tool, (c) measuring a second predetermined temperature indicative of the tool probe temperature, and (d) controlling the welding process such that the tool probe is kept essentially at a predetermined tool probe temperature. The invention also relates to a combination for performing the method.

Owner:ANDERSSON CLAES GORAN +1

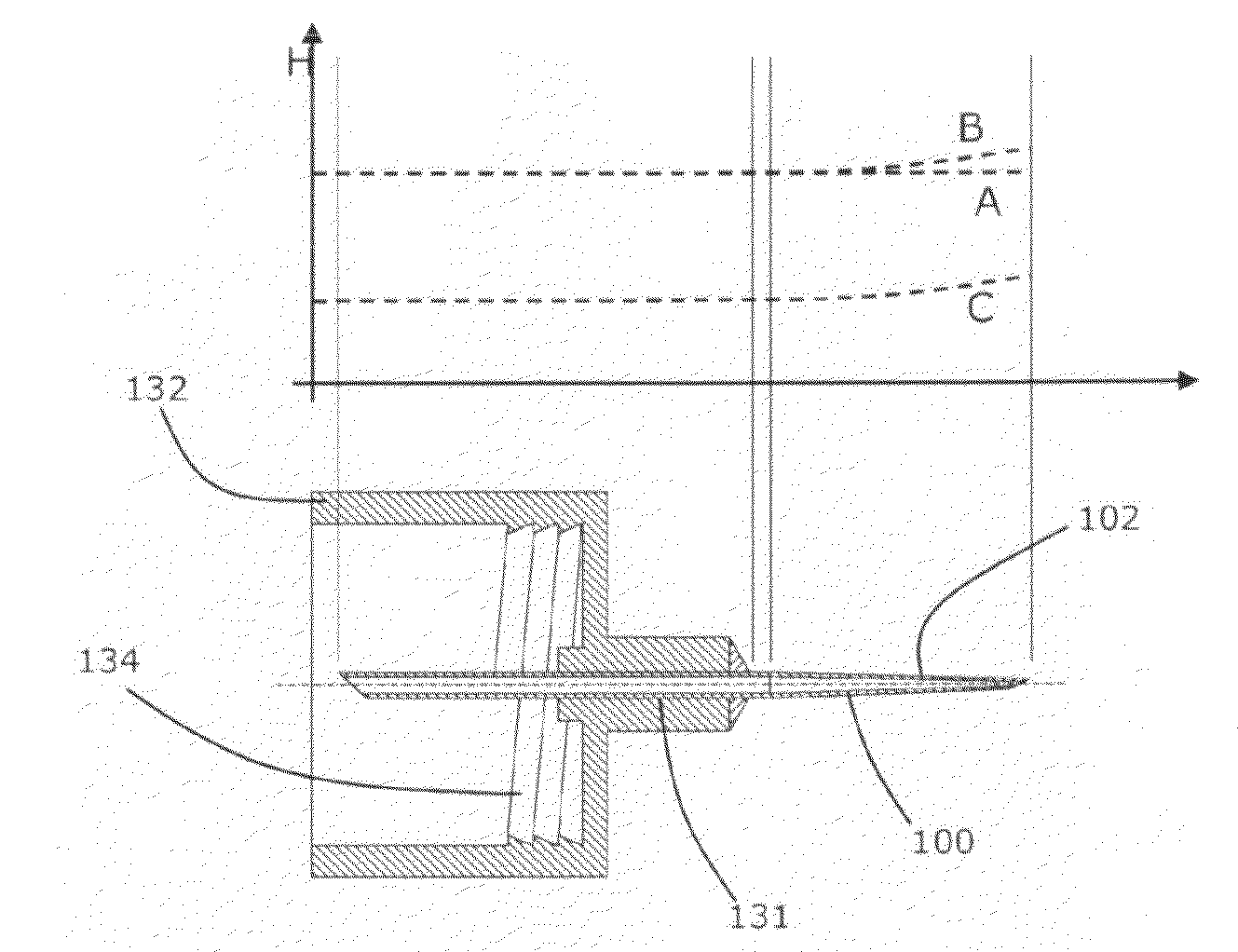

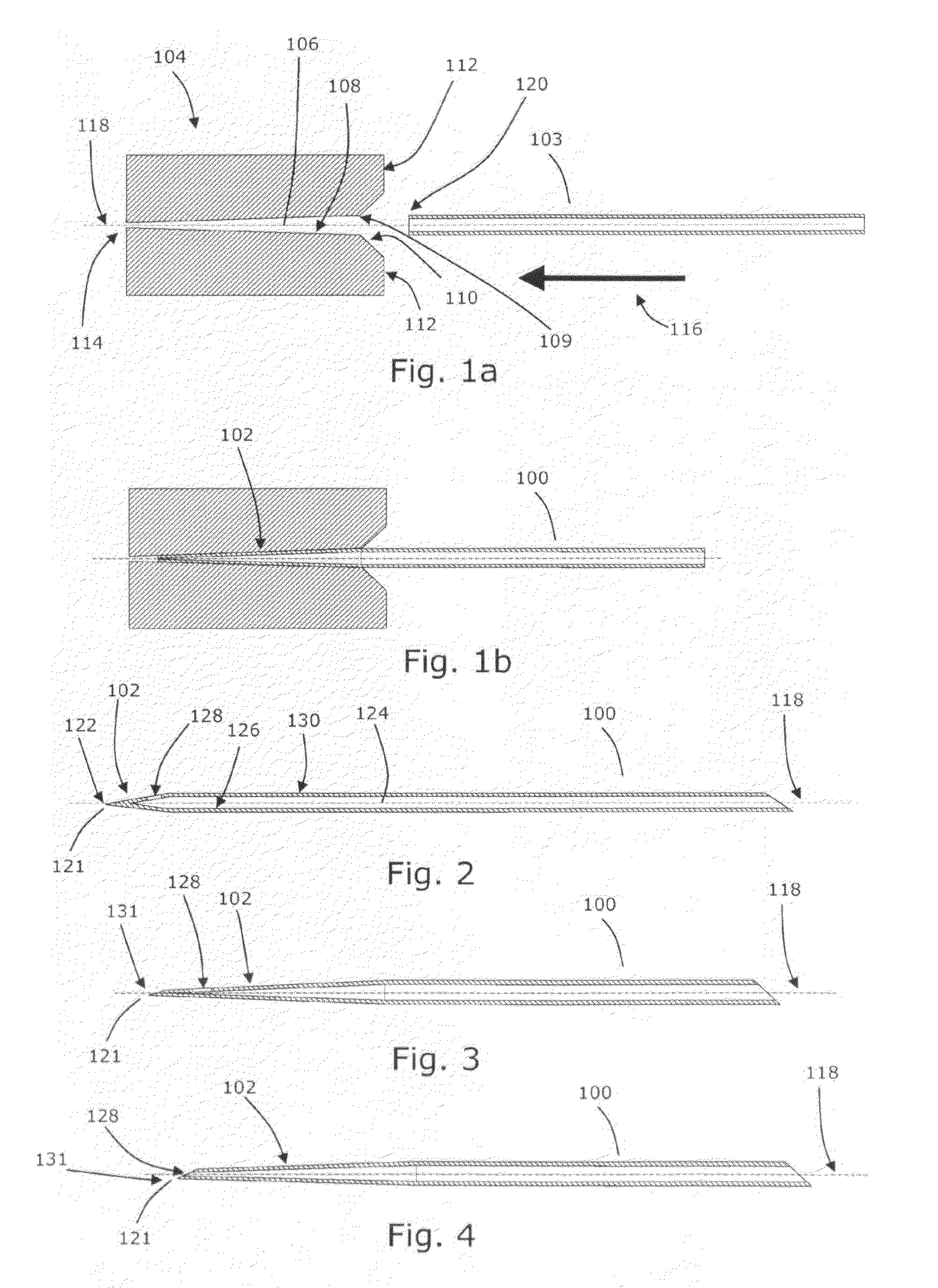

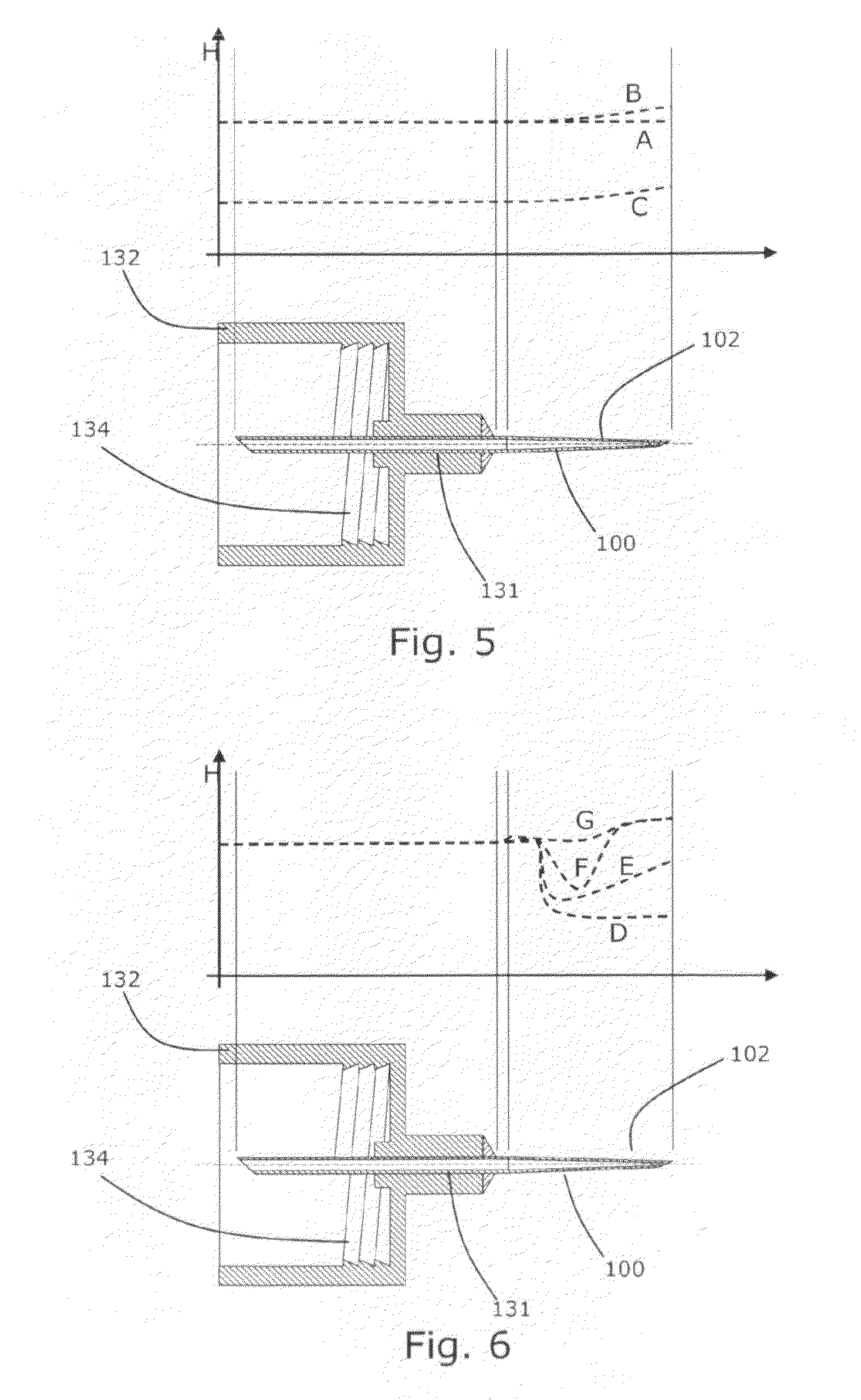

Cannula For An Injection Device, The Cannula Having A Tapered End, And A Method For Manufacturing the Same

InactiveUS20090163877A1Reduce partRelieve pressureInfusion syringesInfusion needlesBiological bodyHardness

A cannula (100) for an injection device, the cannula defining a tapered end part termination (102) in a distal end for insertion into the tissue of a living being, wherein the hardness of the cannula decreases in the direction of the distal end. A tool (104) for providing a tapered portion of a cannula, the tool defining a tapered cavity (106). A method of manufacturing a cannula defining a tapered end part, by forcing a distal end of an tubular element into a tapered cavity of a tool.

Owner:NOVO NORDISK AS

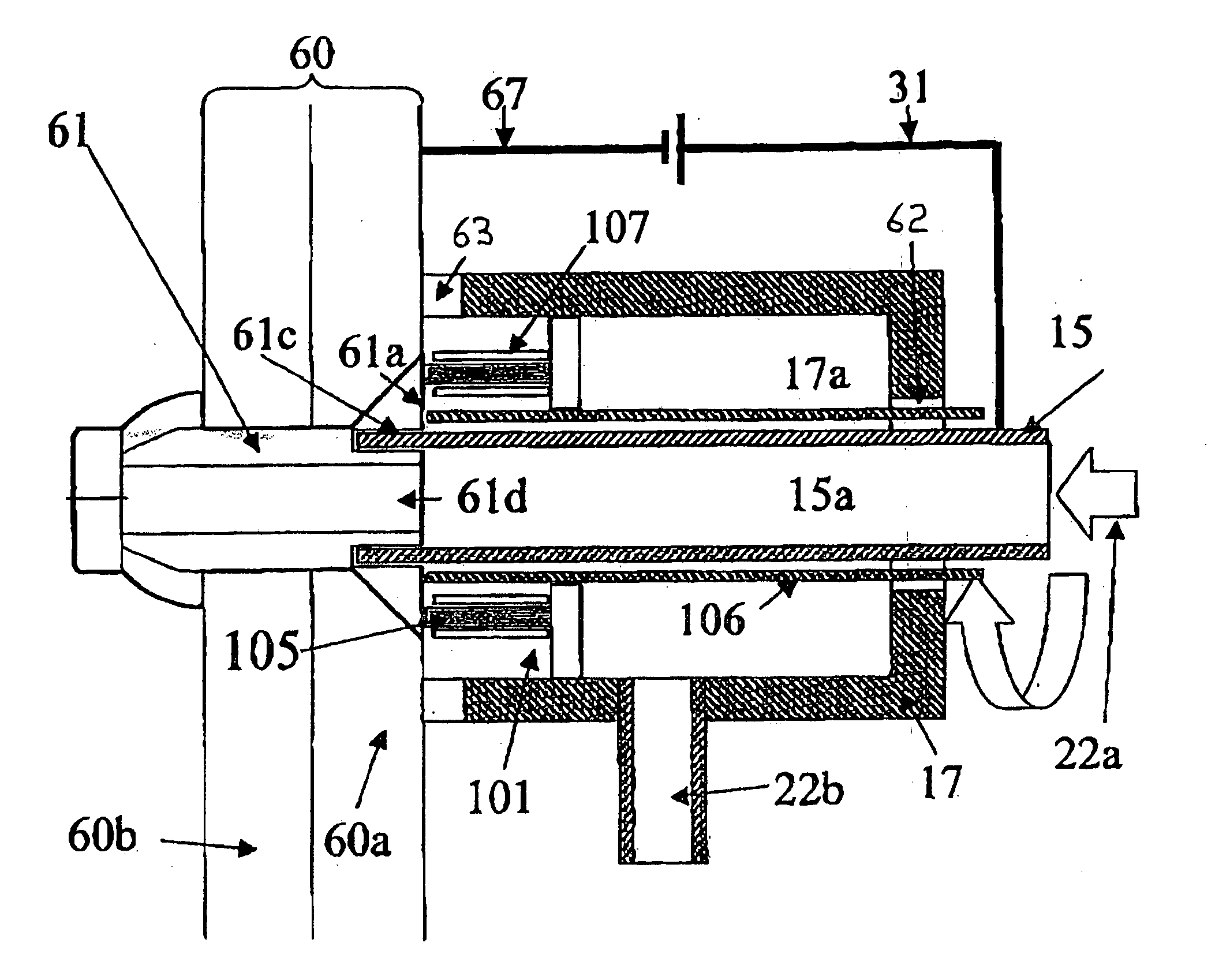

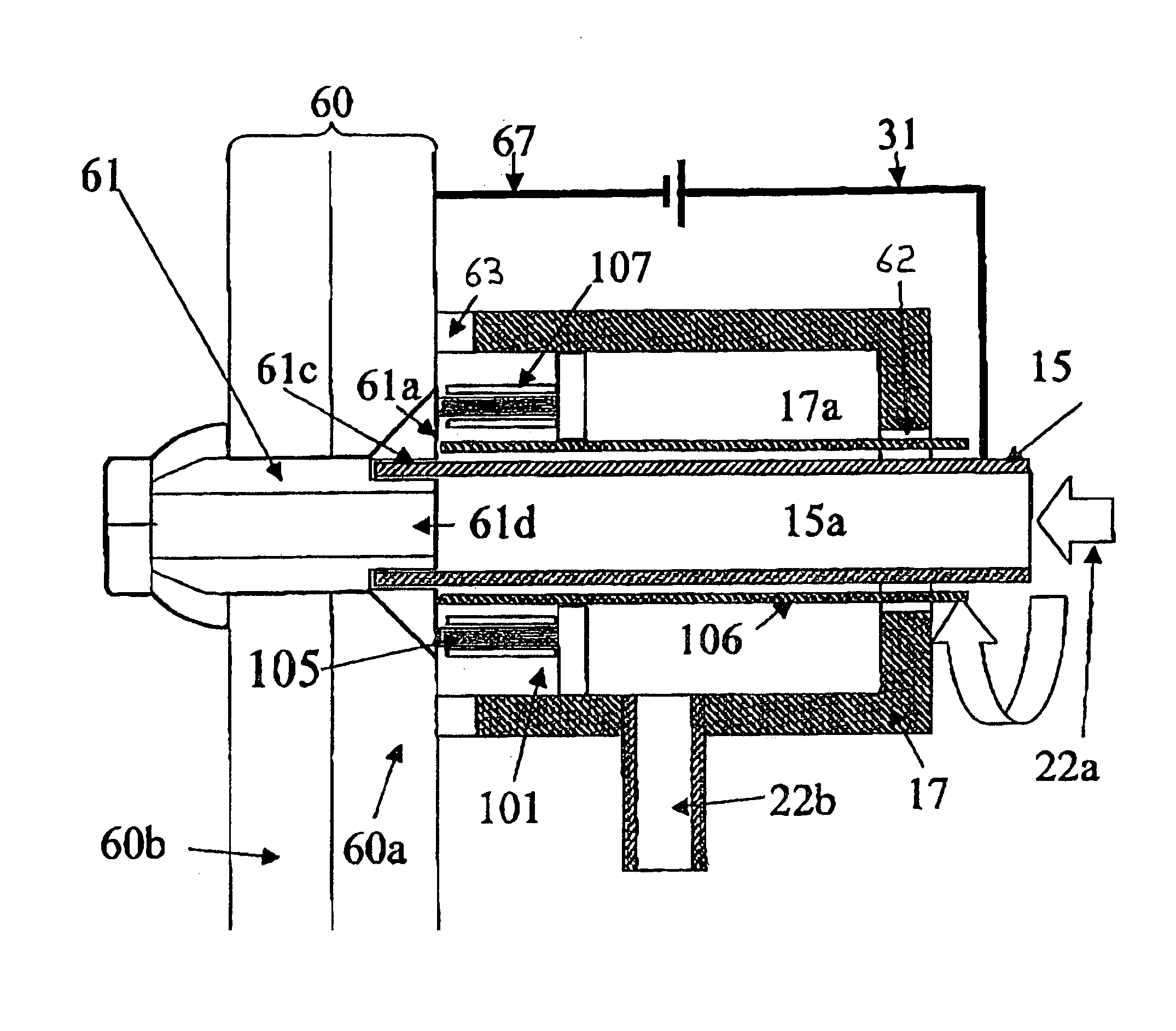

Erosion apparatus for the shaping machining of a metallic structural component or a metallic insert element in a structural component as well as an erosion method

ActiveUS20050184030A1Reduce processing timeReduced tool wearElectrode vibration holdersElectric circuitsElectricityElectrical connection

Apparatus and method for erosion machining a structure comprising one of a metallic structural component, a metallic insert element, and a connecting element, by way of erosion. The apparatus includes an eroding head including an electrode, a power supply, and a control device. The power supply and the control device produce an erosion current. A grounding device is arranged in an area of the eroding head and includes at least one contact element. When the eroding head is arranged to perform erosion machining, the at least one contact element contacts and forms an electrical connection with a surface of the structure, whereby an eroding electric circuit is formed via the electrode and the structure. The method includes arranging the erosion head in an area of the connecting element, sealing, with a seal, a flushing cage to the structural component, contacting a portion the connecting element with the electrode; and electrically connecting the at least one contact element and another portion of the connecting element. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

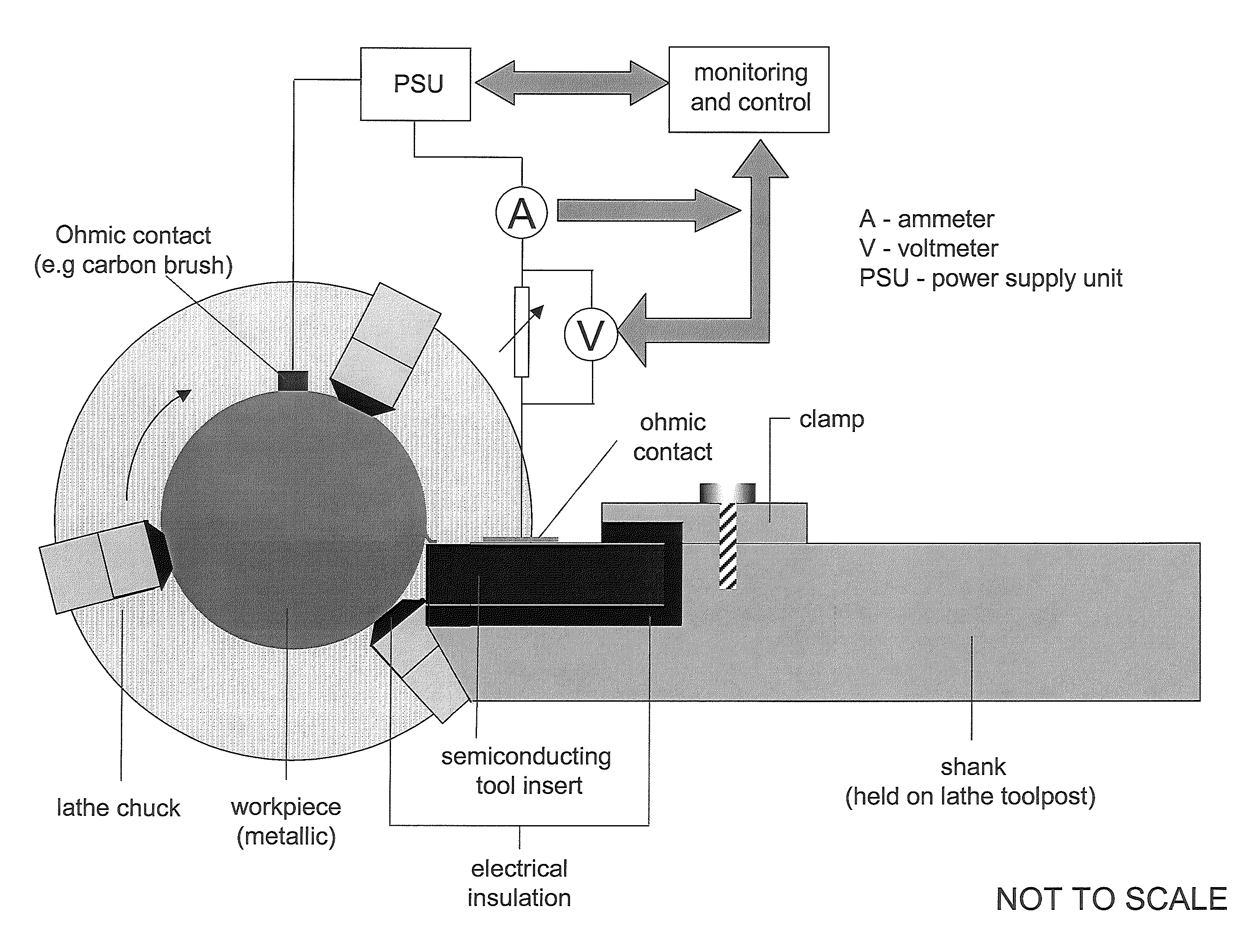

Electrolytic microfinishing of metallic workpieces

The invention is an electrolytic microfinishing process which utilizes a conductive tool as a cathode and a conductive workpiece as an anode both connected to a power supply. Electrolytic fluid is pumped between the tool and workpiece, creating a decomposition of the workpiece surface allowing the surface of the workpiece to be removed or wiped away by the interaction of the flowing electrolyte and rotation of the tool without generating any heat at a rate significantly faster than any other known machining process. The tool has no contact with the workpiece and accordingly, requires very low clamping loads to hold the workpiece in the spindle during the finishing operation. Due to the low clamping loads, the distortion of the workpiece is completely eliminated. Modulating the power supply during the work cycle allows the use of a single tool for both roughing and finishing as a continuous cycle to significantly provide surface finishes previously unobtainable.

Owner:THIELENHAUS MICROFINISH

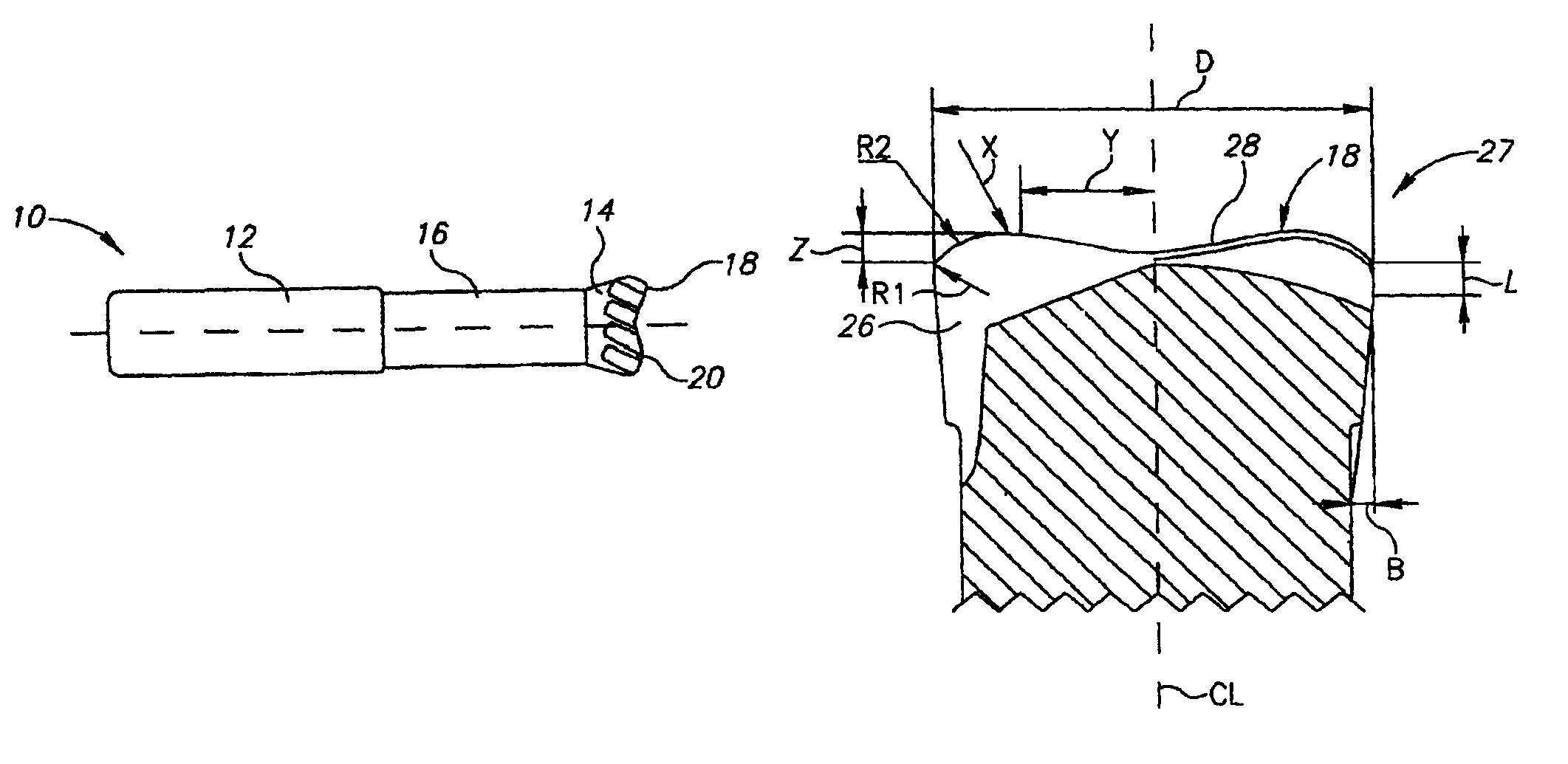

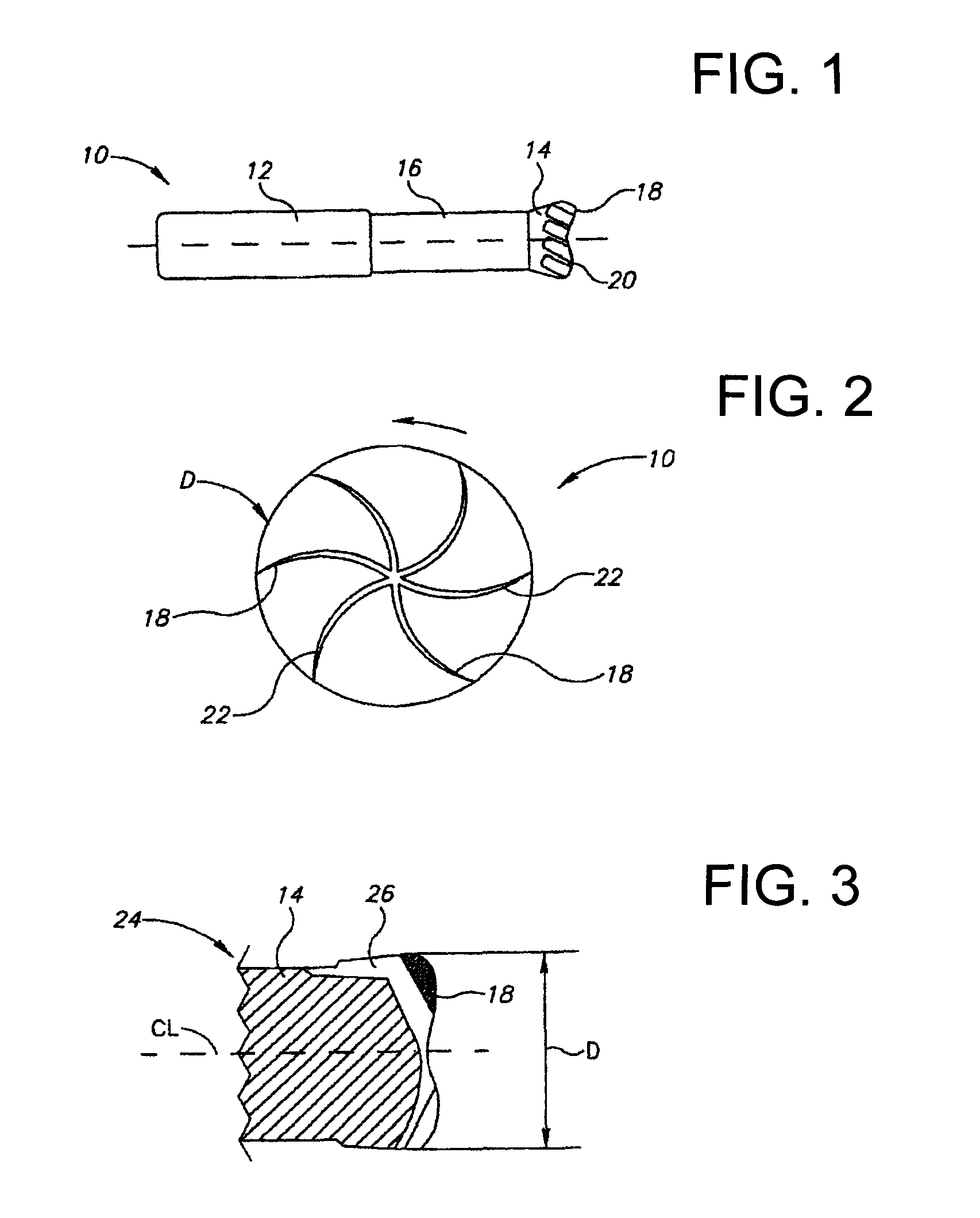

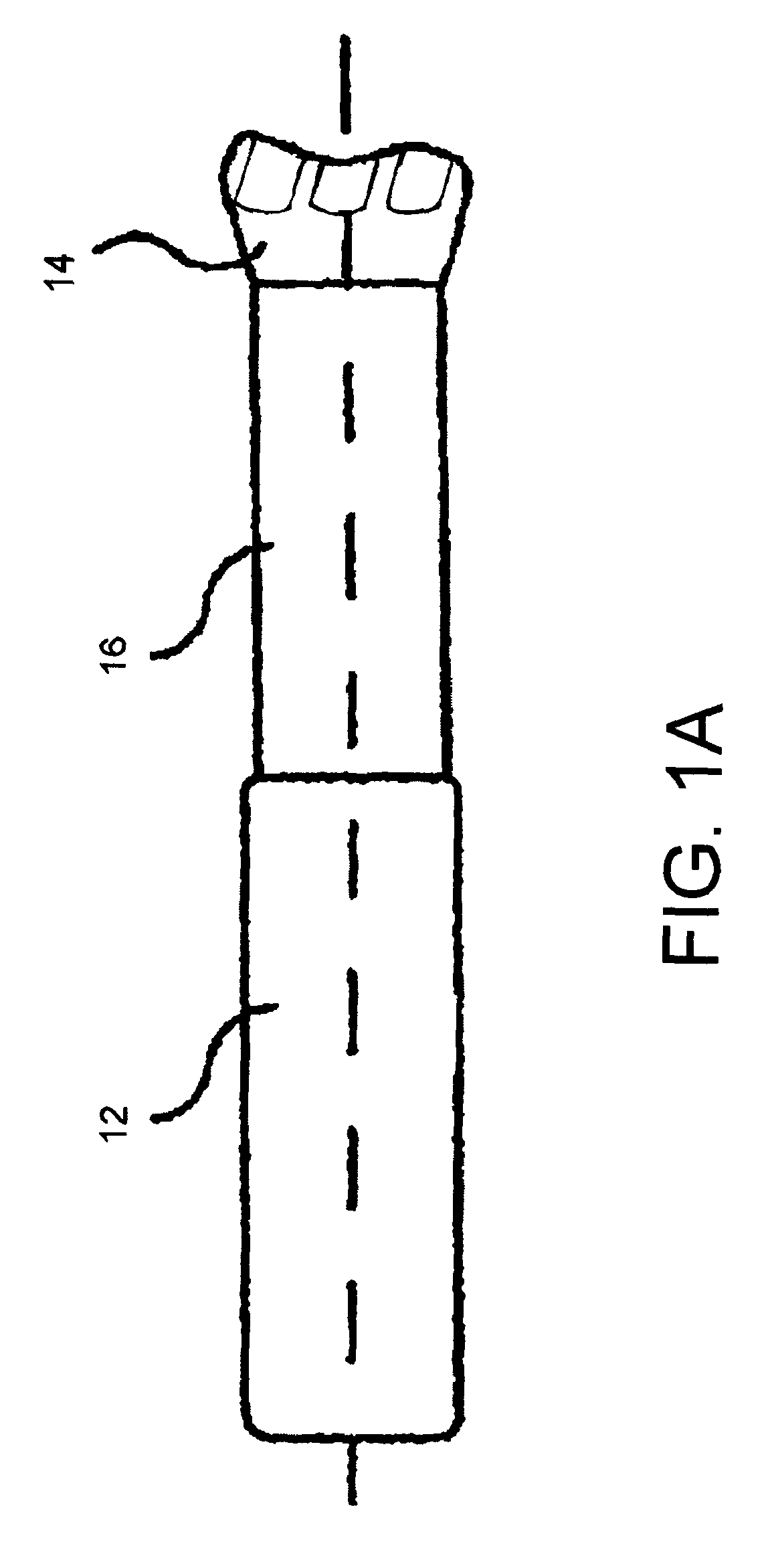

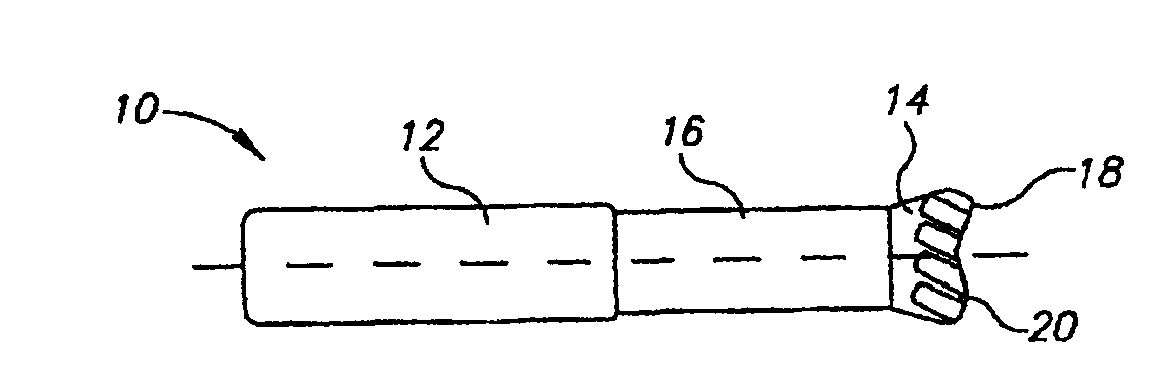

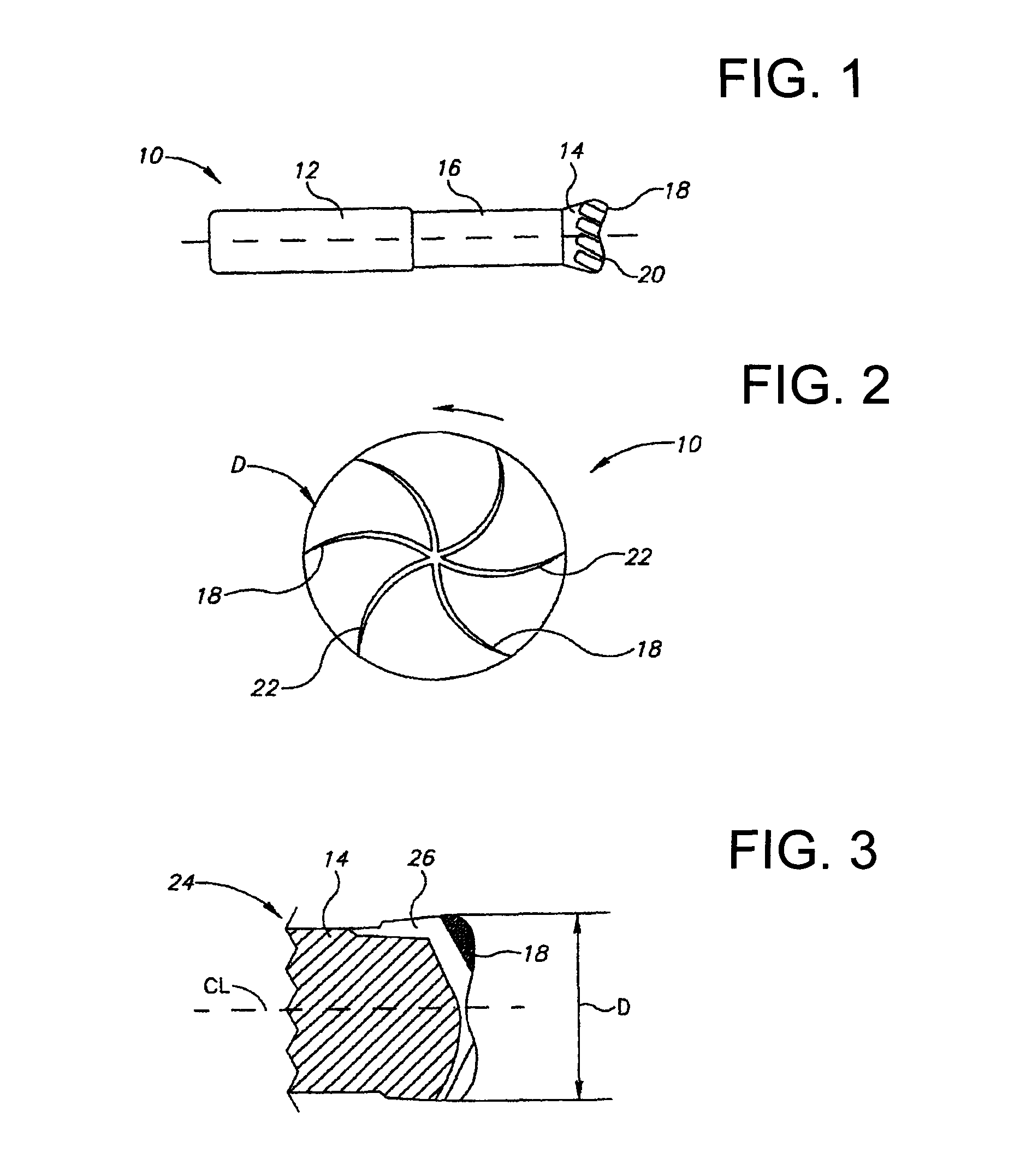

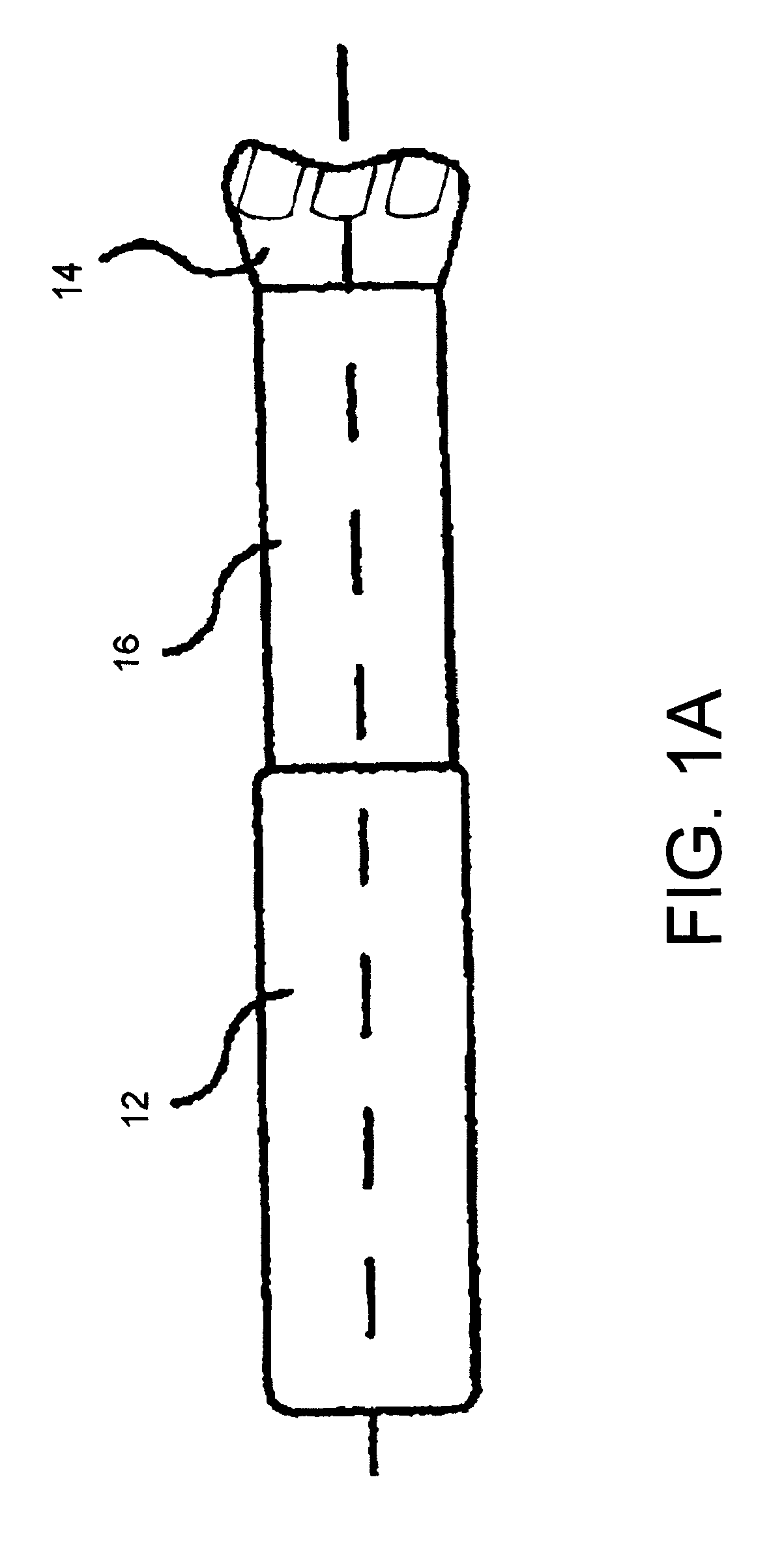

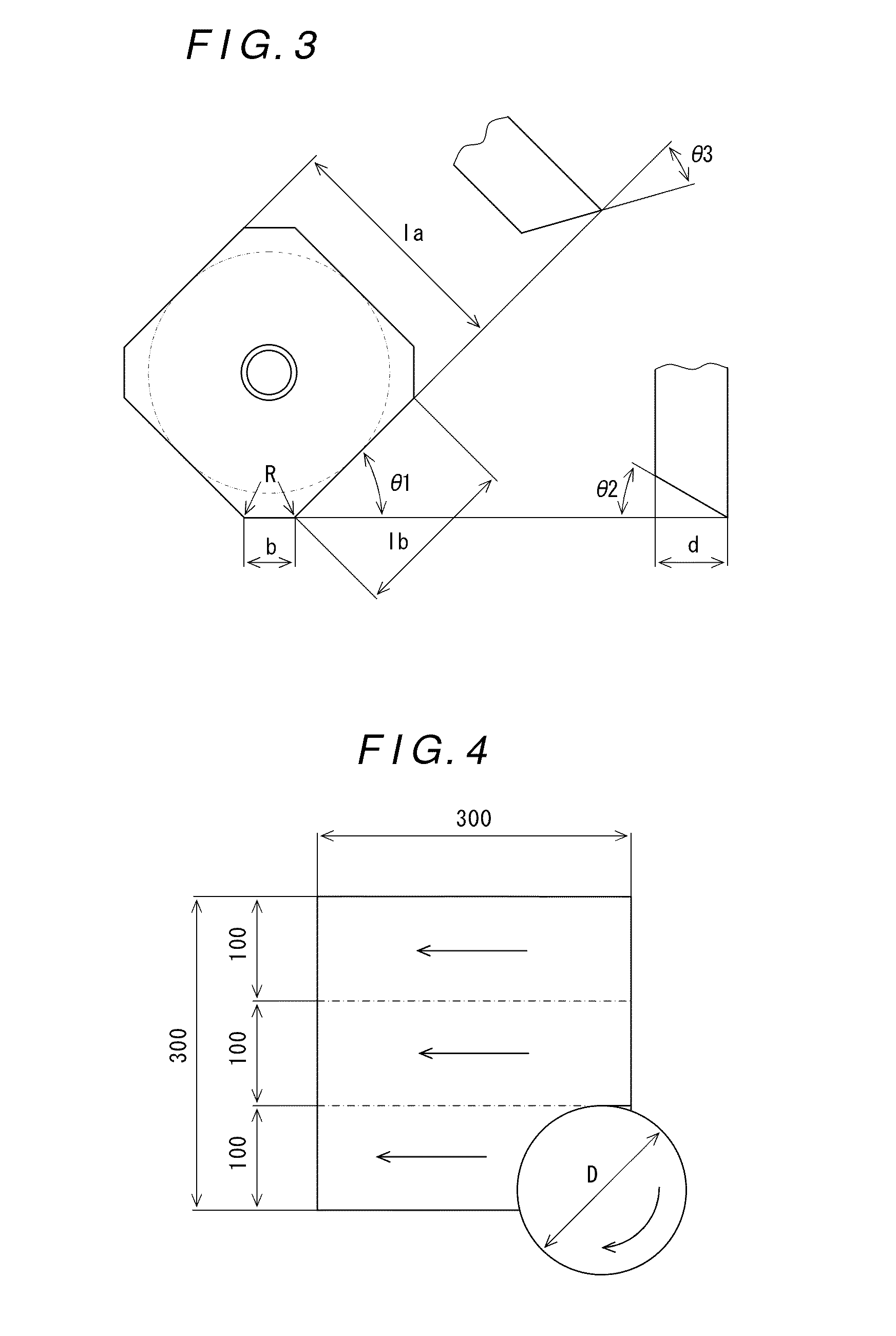

Face milling cutter

ActiveUS8807882B2Increase ratingsRemove restrictionsTool workpiece connectionMilling cuttersMilling cutterMechanical engineering

A face milling cutter has a shank portion adjoining a cutting portion. The cutting portion terminates in a plurality of cutting edges extending in a radial direction from a central axis of the face milling cutter. The cutting edges are convexly curved at least along a part of their length. A portion of the cutting edges proximate the central axis is nearer in an axial direction to the shank portion than a point, X, on the cutting edges that is farthest away from the shank portion. A distance Y, between the point, X, and the central axis is between 20% and 40% of a diameter, D, of the face milling cutter, and a central portion extends the distance, Y, and has a radius of curvature of about 110% of the diameter, D.

Owner:HANITA METAL WORKS

Face milling cutter

ActiveUS20090252564A1Minimize tool breakageImprove wear resistanceTool workpiece connectionMilling cuttersMilling cutterTrademark

A face milling cutter. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:HANITA METAL WORKS

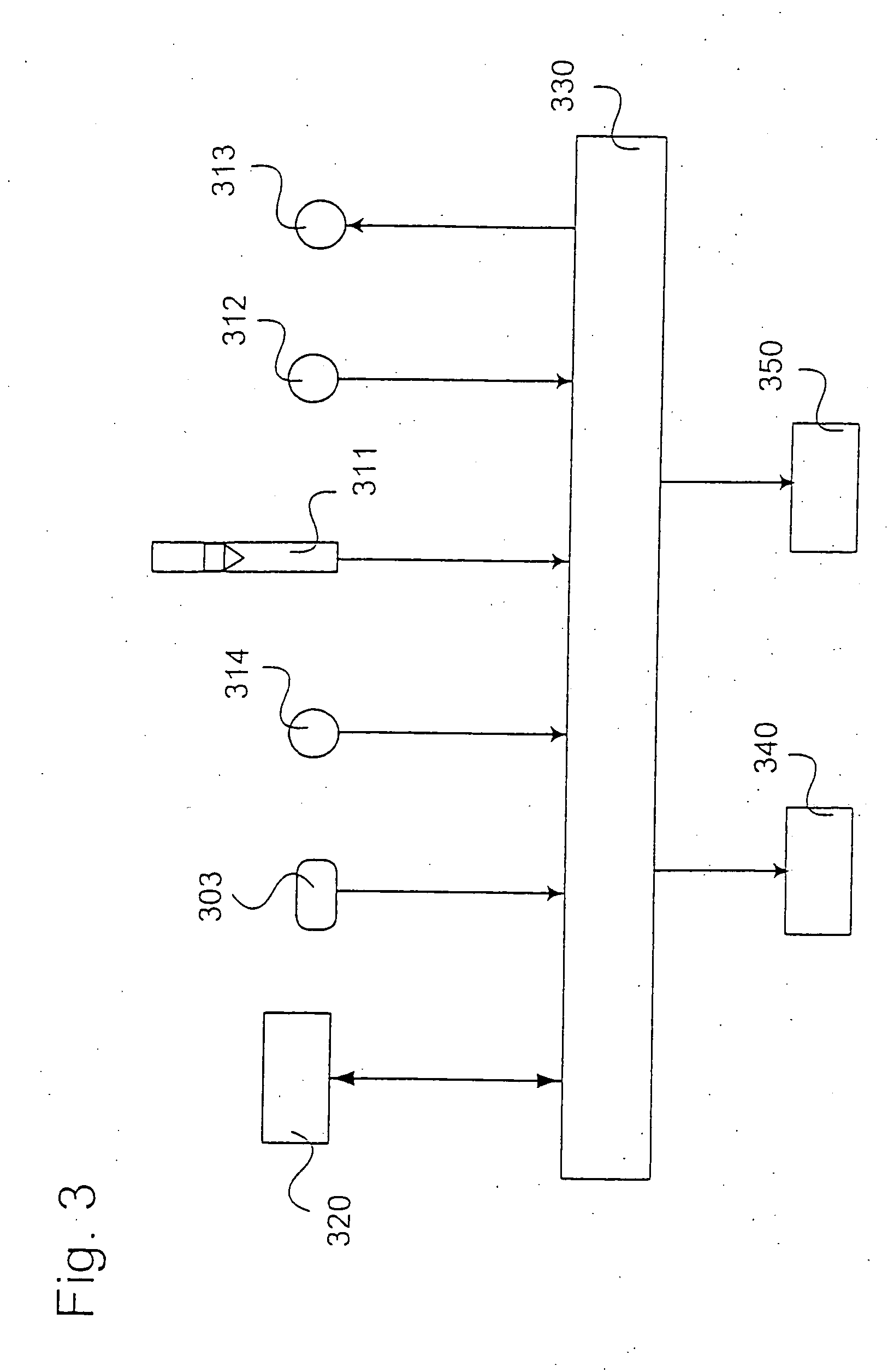

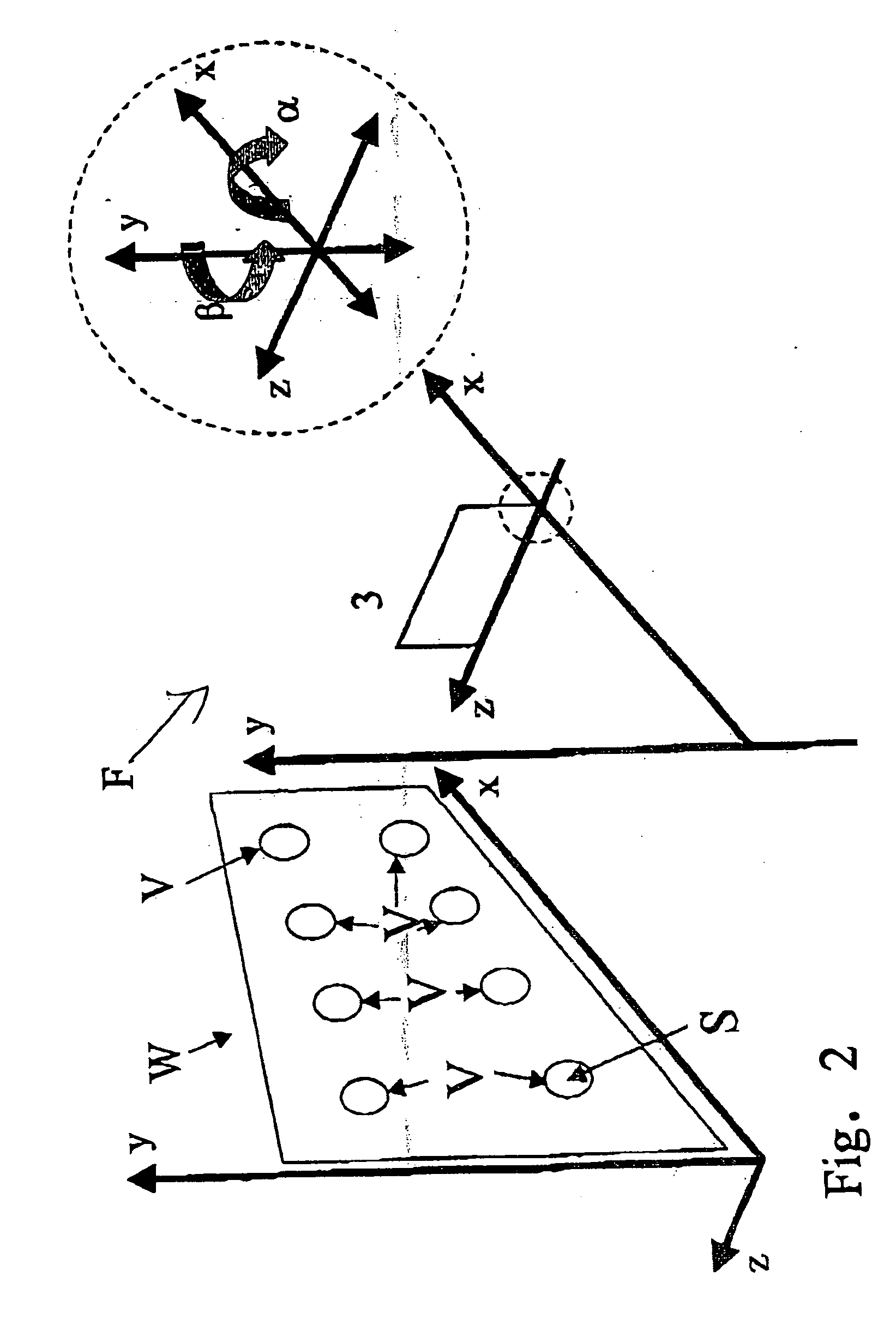

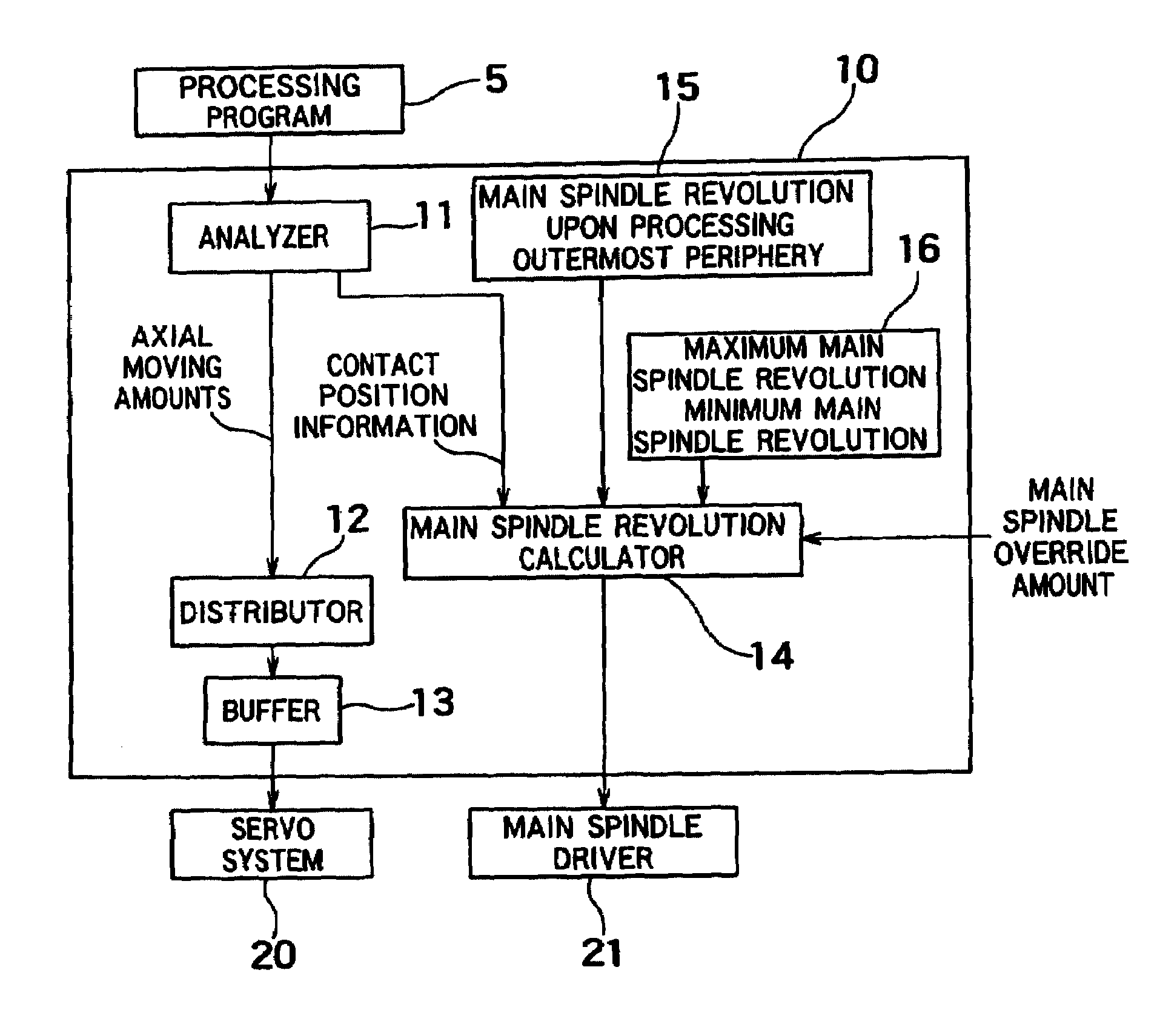

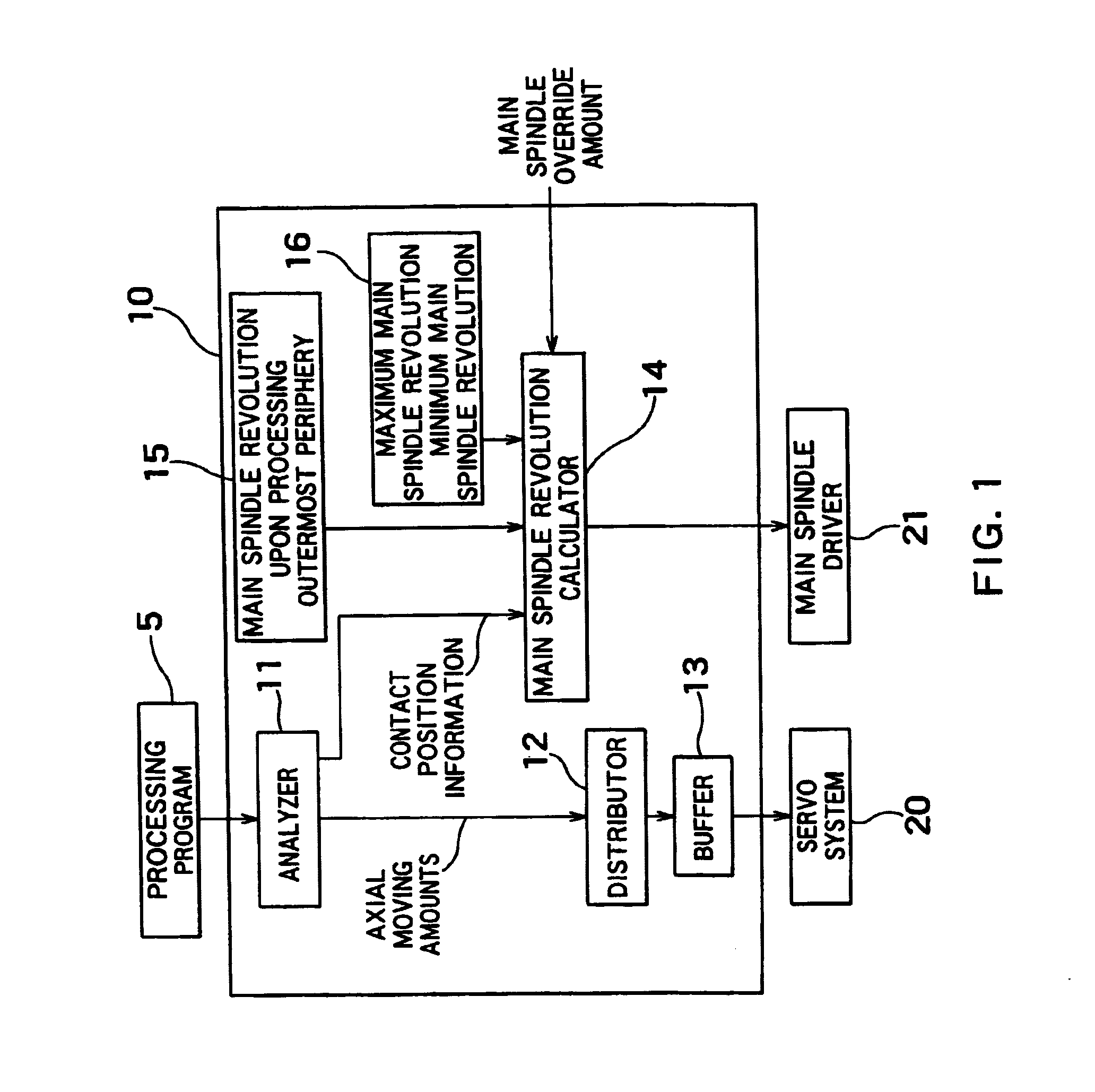

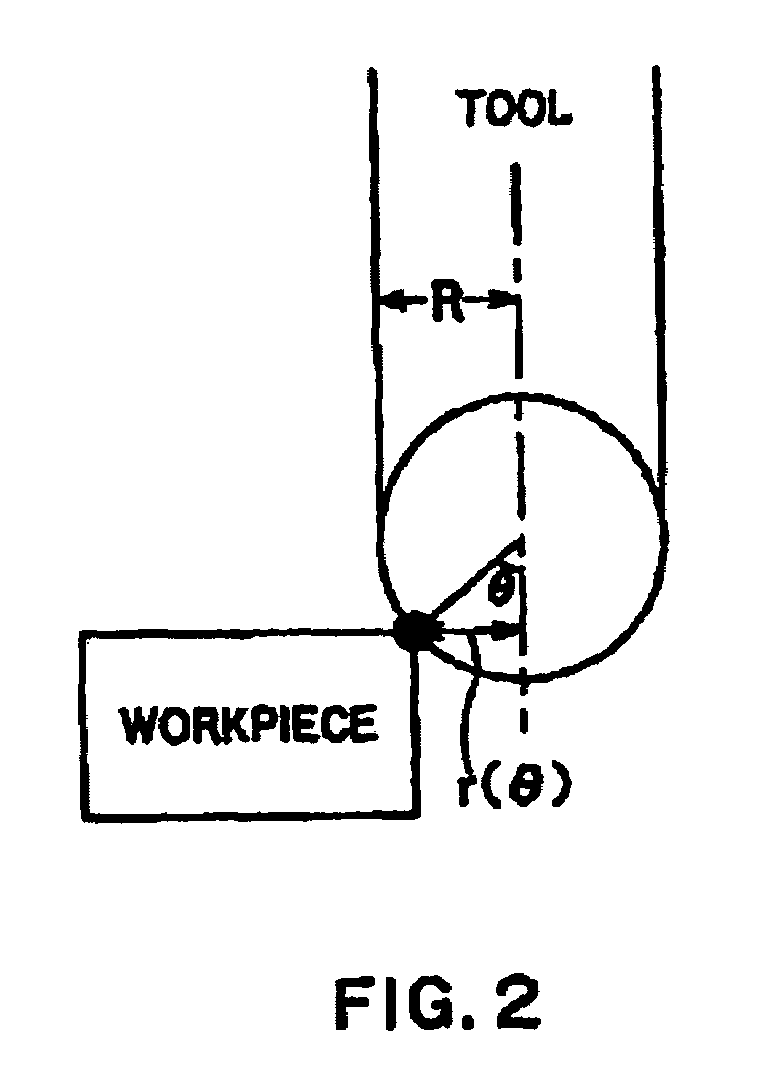

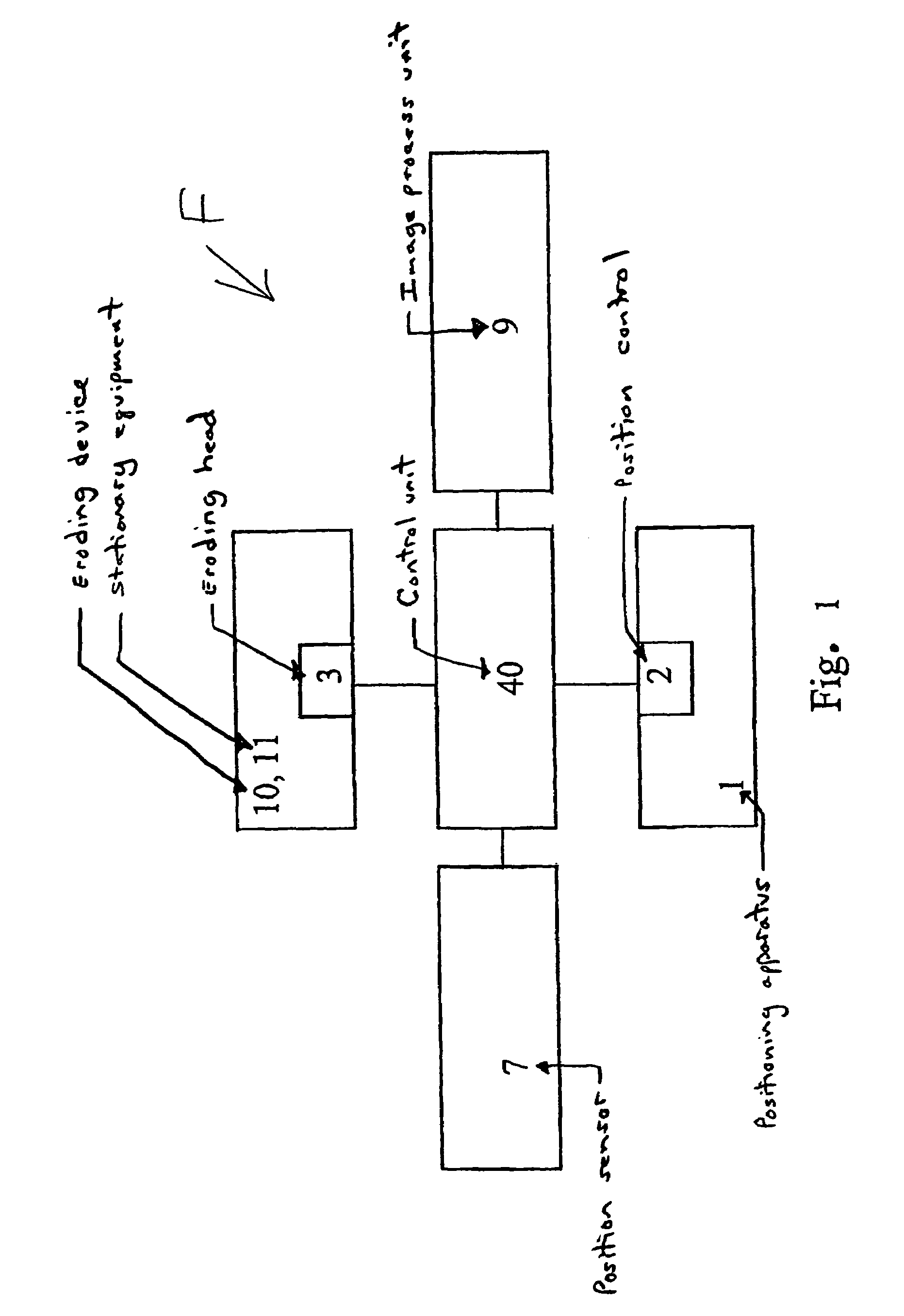

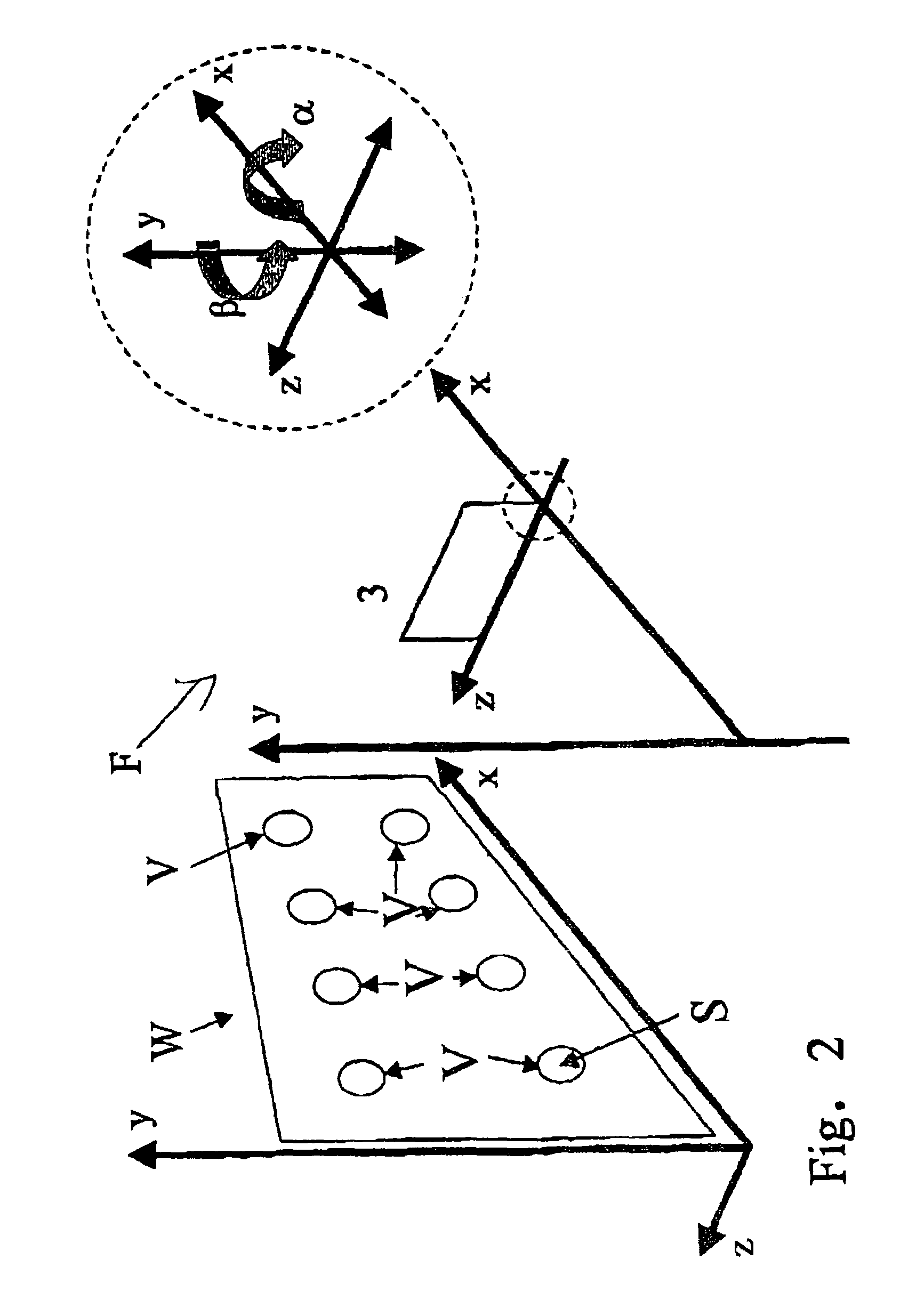

Numerical control apparatus and CAM system

InactiveUS6999843B2Reliably optimumReduced tool wearAutomatic control devicesComputer controlNumerical controlContact position

Upon analyzing a processing program (5) in an analyzer (11, 31), a numerical control apparatus extracts information about a contact position between a tool and a workpiece, and based on the information, it calculates a main spindle revolution instruction value in a main spindle revolution calculator 14, 38). In a CAM system, information about the contact position between the tool and the workpiece to be supplied to the numerical control apparatus is calculated and added to the processing program.

Owner:TOSHIBA MASCH CO LTD

Antimicrobial metal working fluids

ActiveUS7595288B2Reduced tool wearWork fasterBiocideLiquid carbonaceous fuelsMetal working fluidMetal working

Owner:HENKEL KGAA

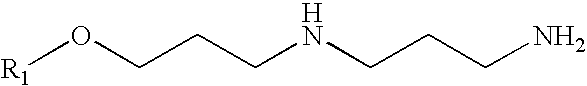

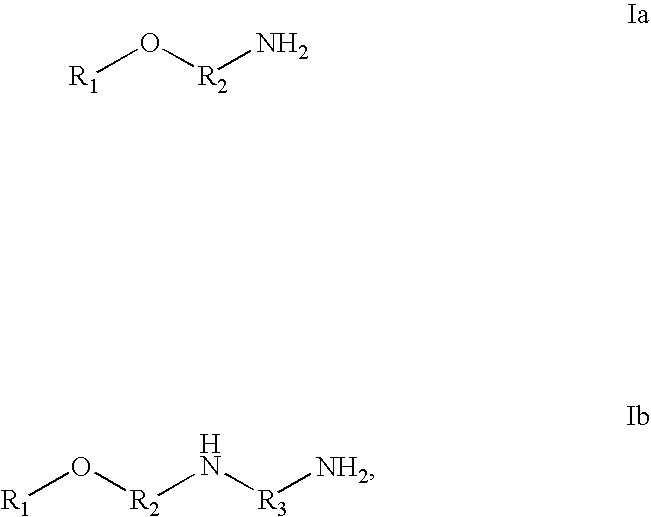

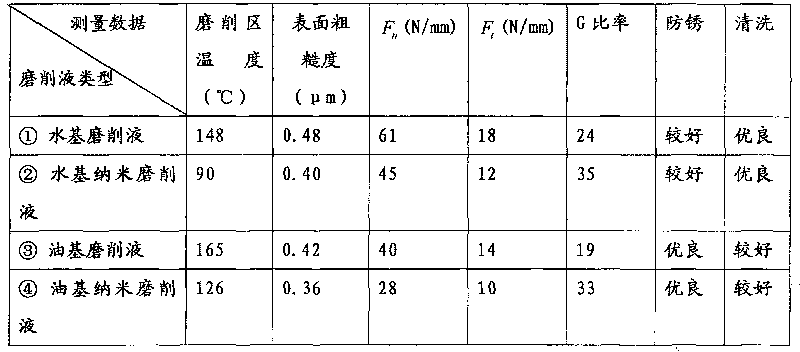

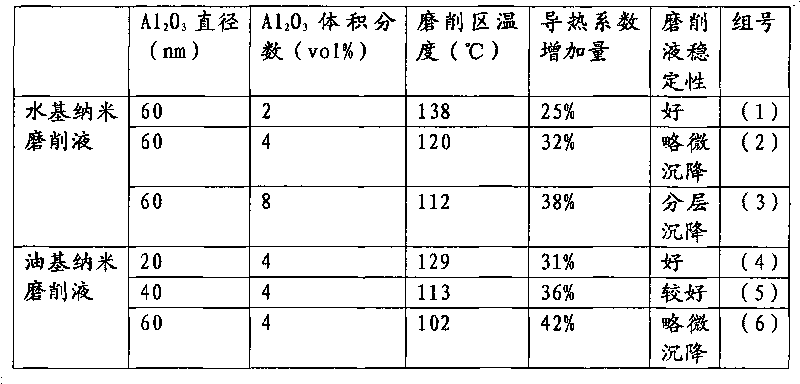

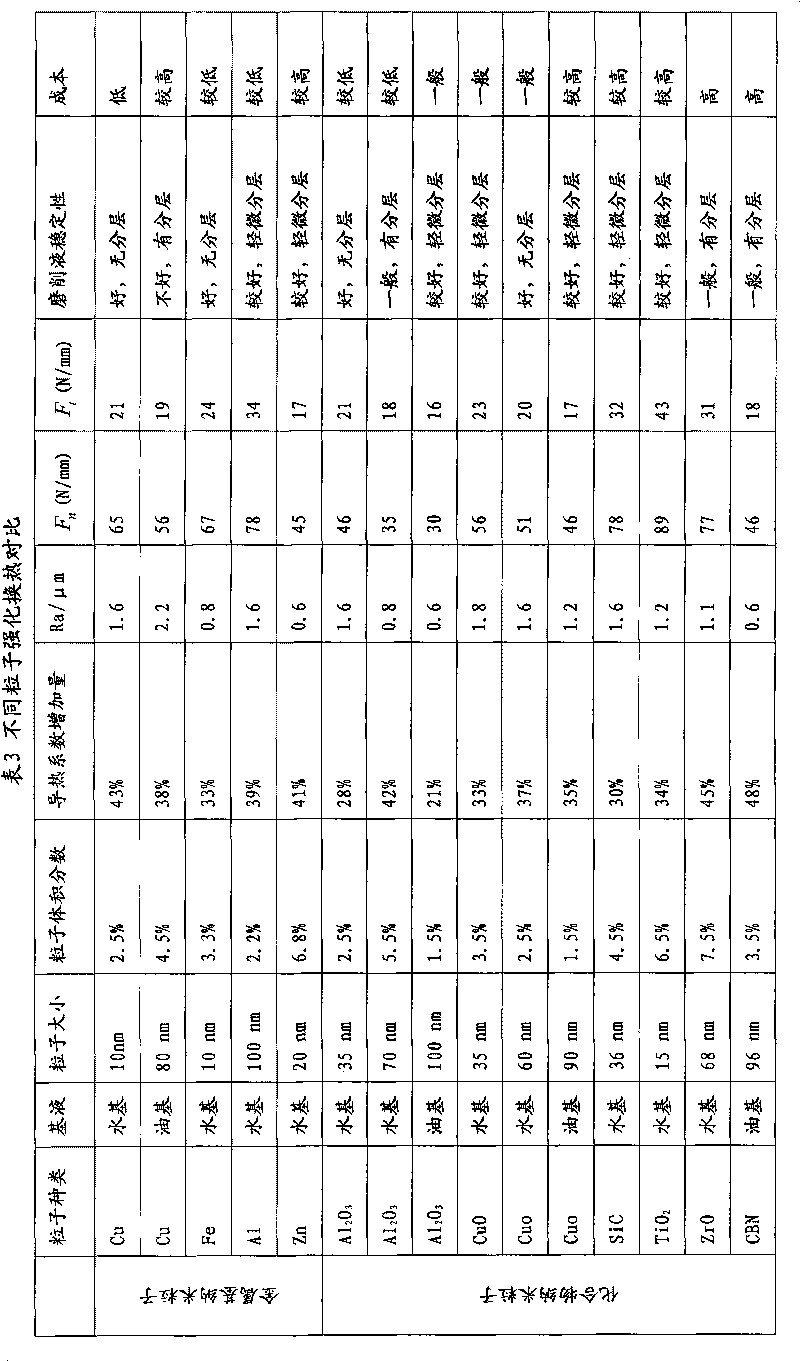

Nanometer grinding process and nanometer grinding liquid

InactiveCN101760285AReduced tool wearImproved processing quality and economic benefitsAdditivesNanometreSolid matter

The invention belongs to a machining method and a material, in particular to a nanometer grinding process and nanometer grinding liquid. In the nanometer grinding process, the nanoscale particles of solid matter are added into the grinding process; the nanometer grinding liquid is formed by mixing the nanoscale particles of solid matter and fluidic grinding liquid. The invention has the following beneficial effect: compared with the existing water-base or oil-base grinding liquid, the nanometer grinding liquid has greatly lowered indexes, such as grinding zone temperature, surface roughness, grinding resistance, grinding tool loss and the like; machining quality and economic benefit are obviously improved, and thus the invention has higher application value and market prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method and apparatus for erosion machining with an electrical contact element

ActiveUS7019245B2Reduce processing timeReduced tool wearElectrode vibration holdersElectric circuitsElectricityElectrical connection

Apparatus and method for erosion machining a structure comprising one of a metallic structural component, a metallic insert element, and a connecting element, by way of erosion. The apparatus includes an eroding head including an electrode, a power supply, and a control device. The power supply and the control device produce an erosion current. A grounding device is arranged in an area of the eroding head and includes at least one contact element. When the eroding head is arranged to perform erosion machining, the at least one contact element contacts and forms an electrical connection with a surface of the structure, whereby an eroding electric circuit is formed via the electrode and the structure. The method includes arranging the erosion head in an area of the connecting element, sealing, with a seal, a flushing cage to the structural component, contacting a portion the connecting element with the electrode; and electrically connecting the at least one contact element and another portion of the connecting element. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

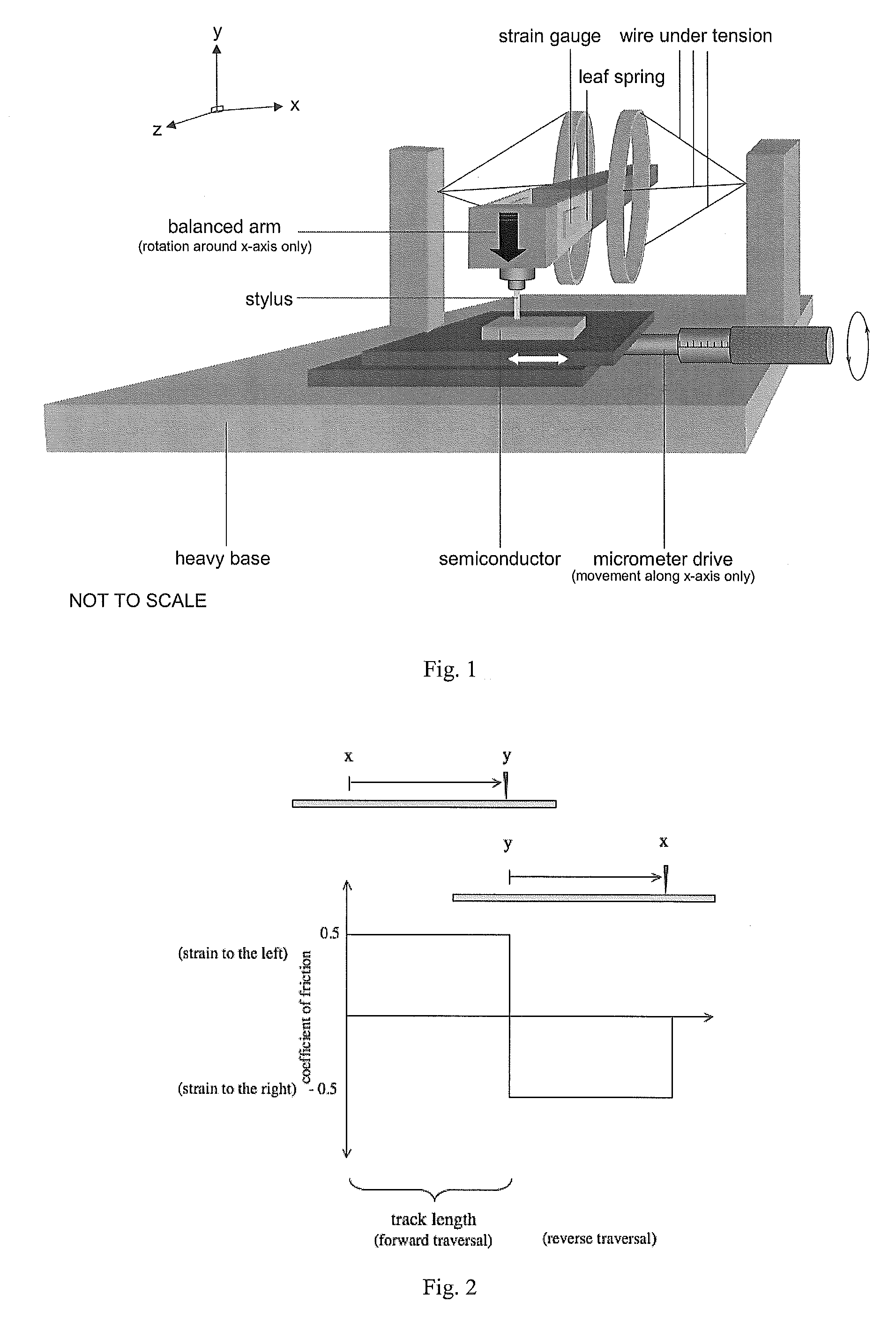

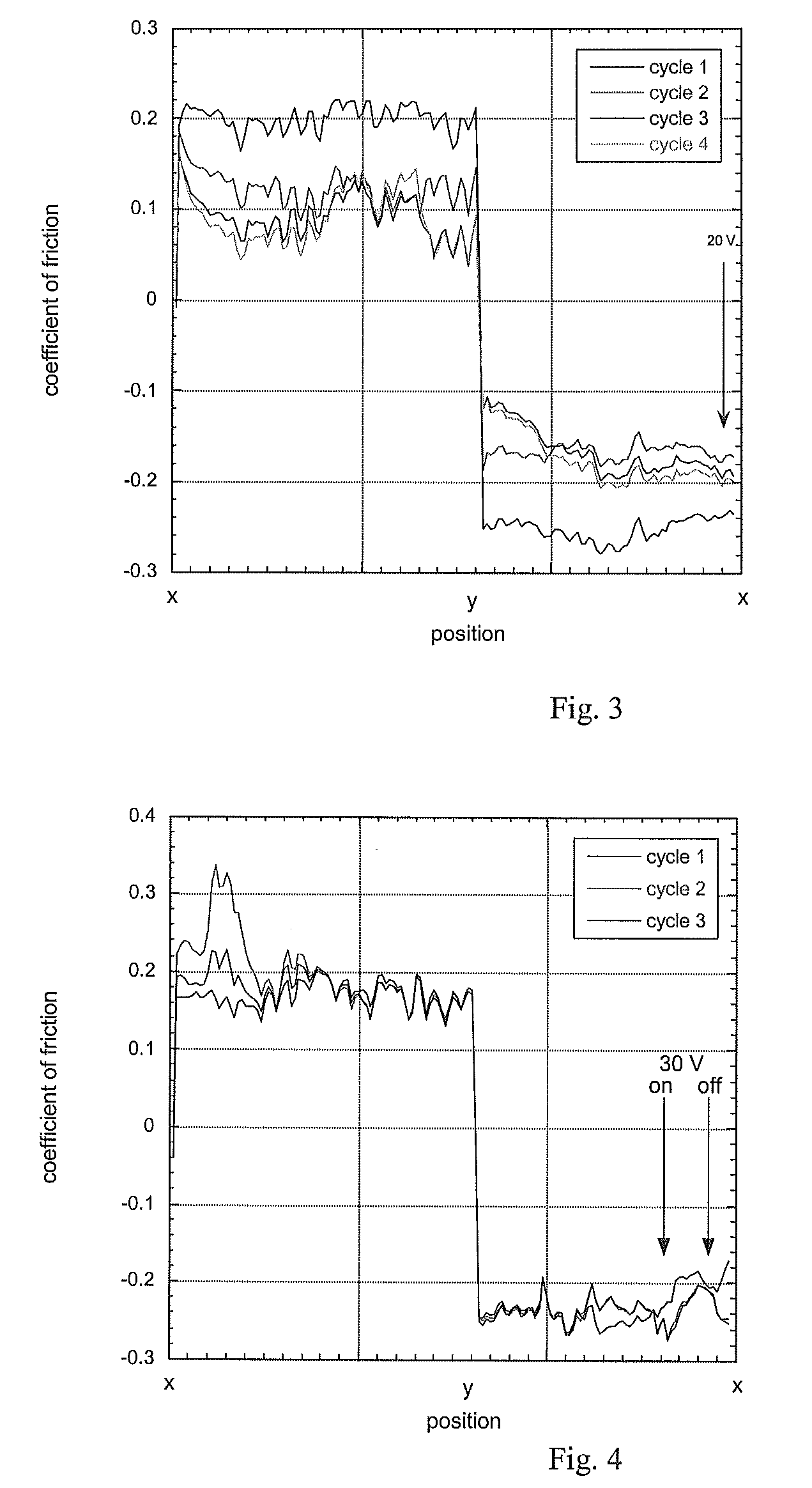

Friction Control in Apparatus Having Wide Bandgap Semiconductors

InactiveUS20090108266A1Friction controlReduce frictionEdge grinding machinesLapping machinesBroadbandEngineering

Apparatus comprising, in use, a wide bandgap semiconductor, a conductor which is moveable relative to the semiconductor and means for applying a potential across the junction between a conductor and semiconductor to control the friction generated by the relative movement between the semiconductor and the conductor. A method of controlling friction between a wide bandgap semiconductor and conductor which are moveable relative to each other comprising applying a potential across the junction between the semiconductor and the conductor.

Owner:HIRD JONATHAN +3

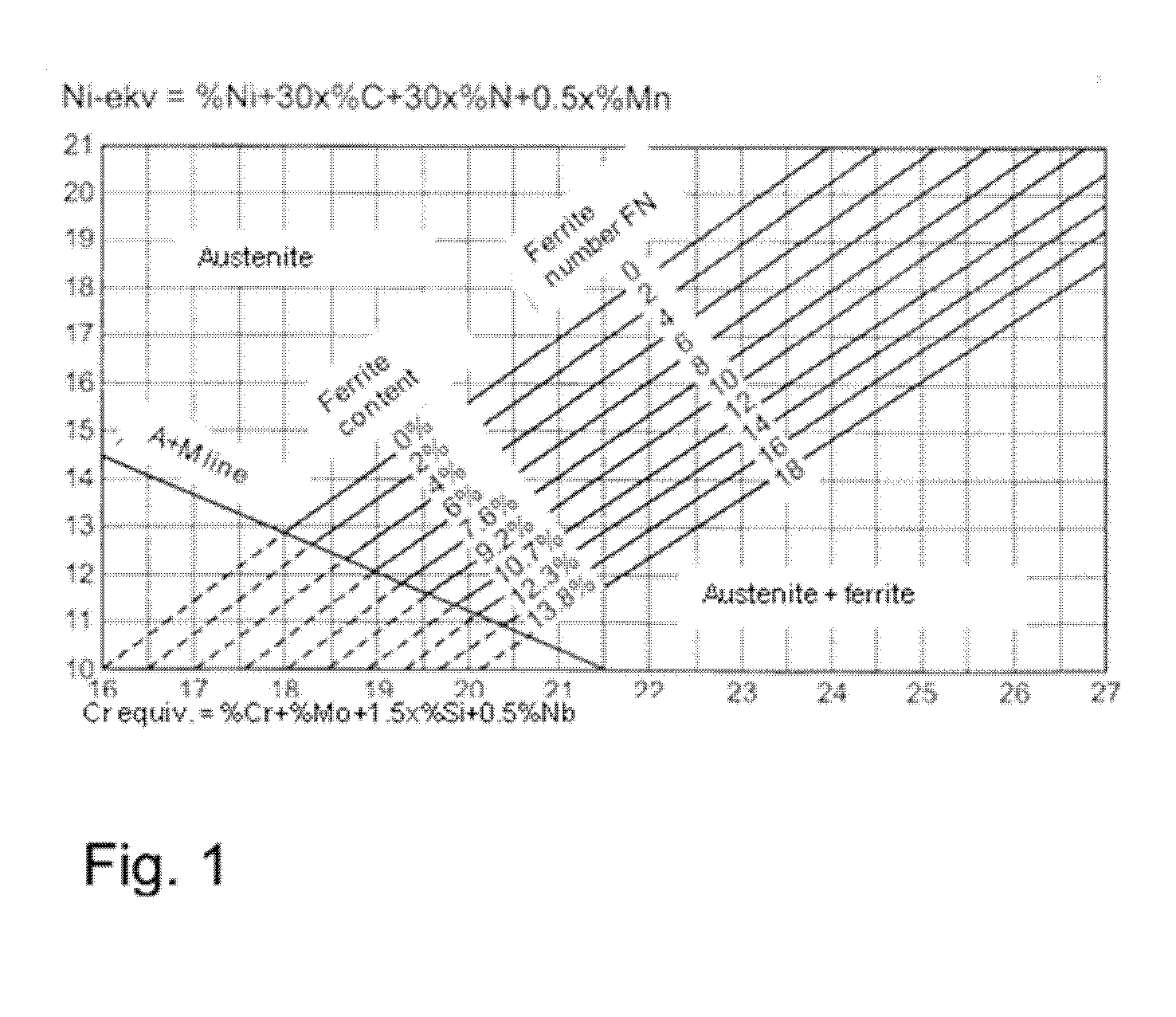

Austenitic stainless steel product and a method for manufacturing same

ActiveUS20140338800A1High yield strengthGood preservation of toughnessIncreasing energy efficiencyFurnace typesSS - Stainless steelUltimate tensile strength

A steel product, such as a strip, plate, sheet, bar or wire, manufactured from austenitic stainless steel. A steel product, wherein: a—the average grain size of the recrystallized austenitic structure of said product is at most 6 , b—less than 50% of the structure of said product is non-recrystallized austenite c—the yield strength (Rpo.2) is at least 350 MPa, d—the tensile strength (Rm) is at least 600 MPa, and e—the uniform elongation (Ag) of said product is at least 5%, depending on the strength. The invention also relates to a method.

Owner:SOLU STAINLESS OY

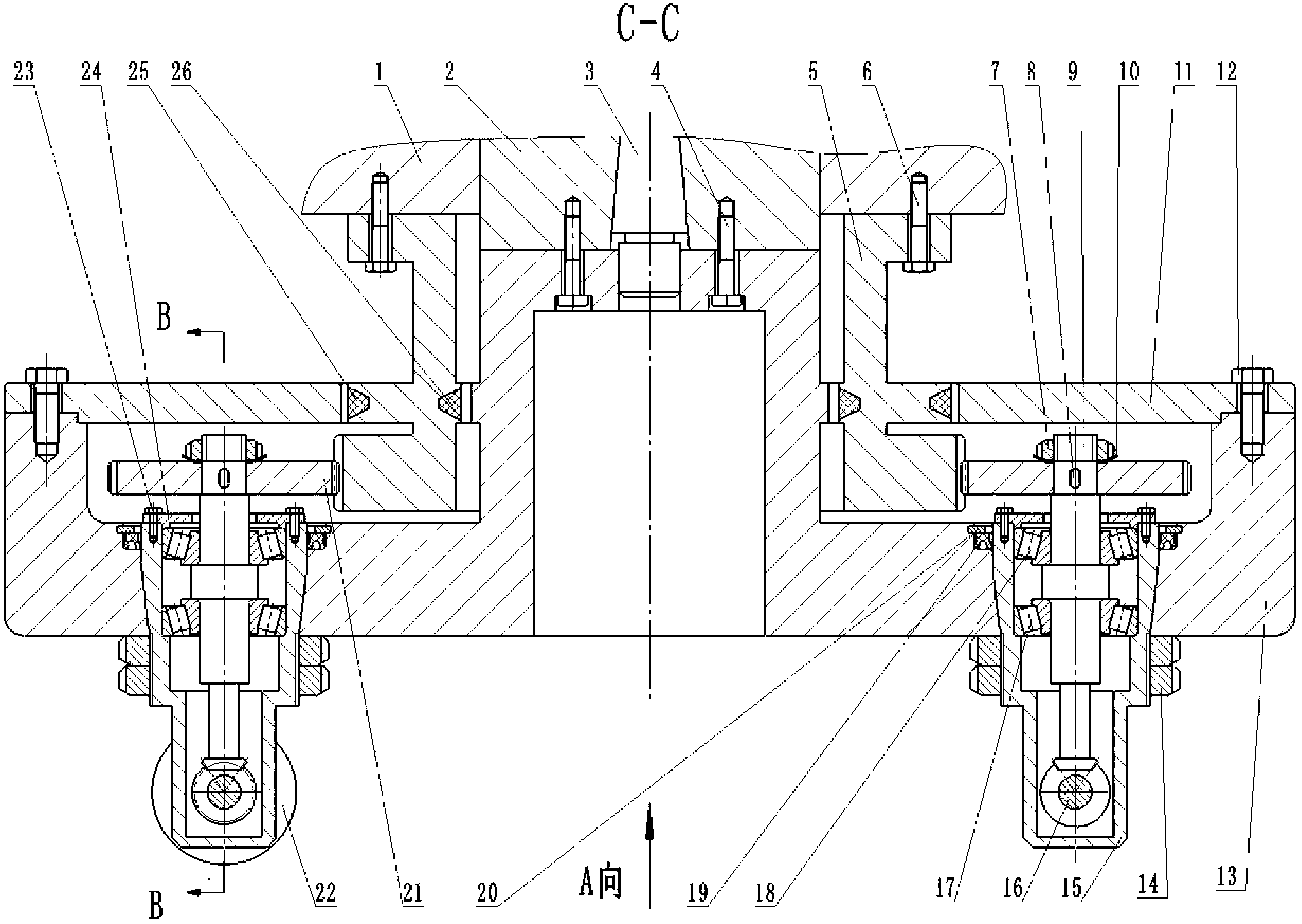

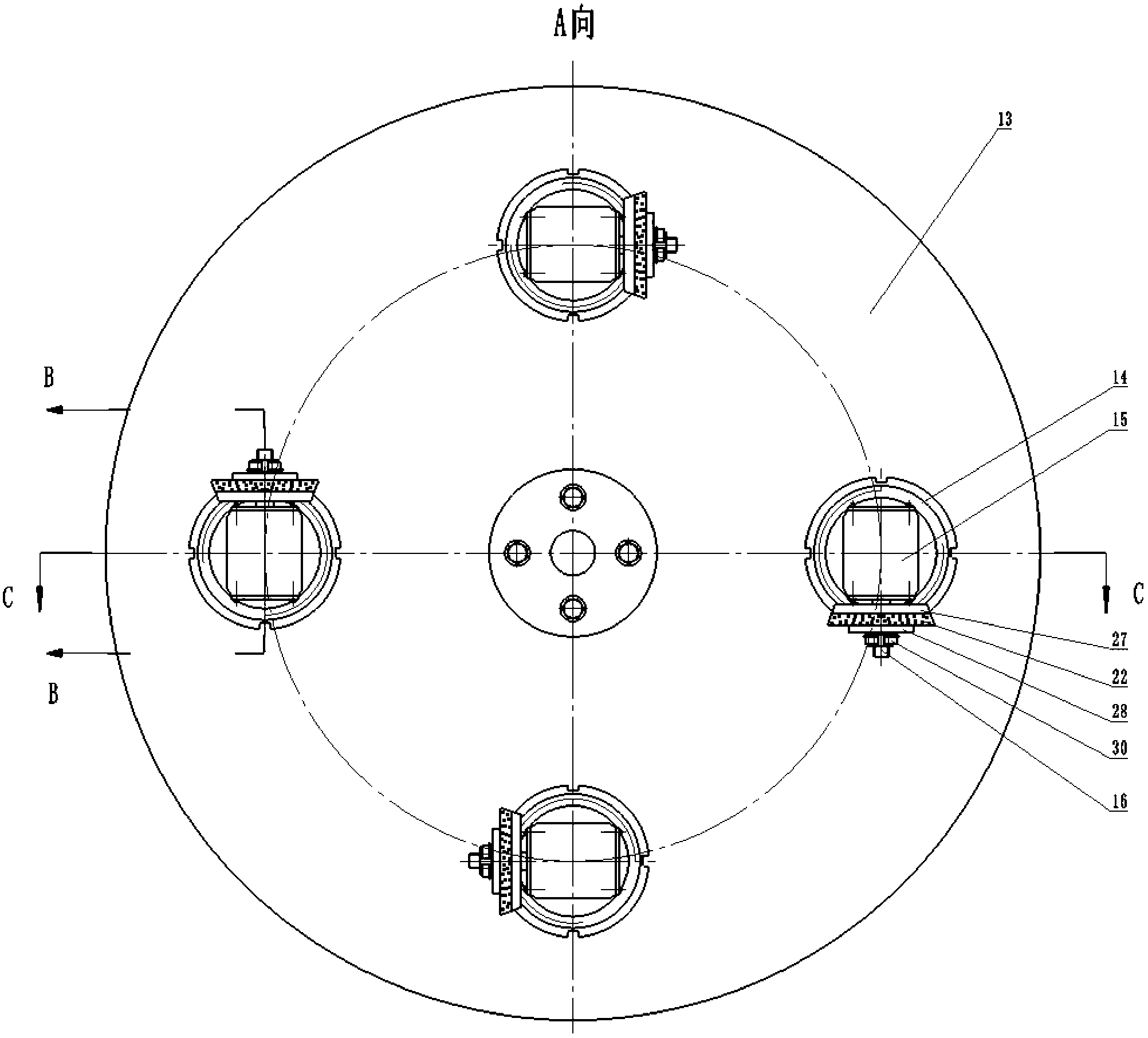

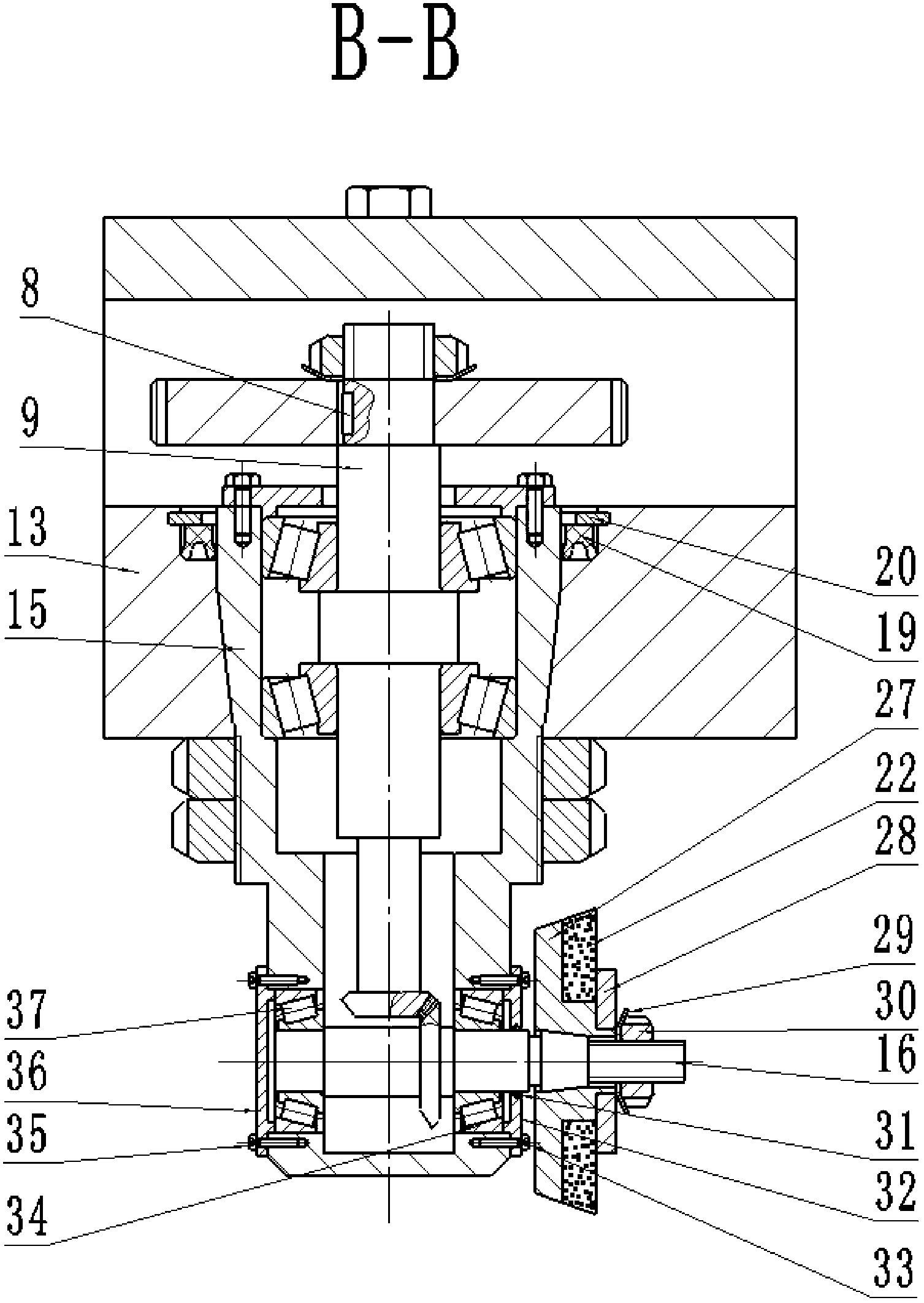

Special milling cutter made of difficult-to-process material

InactiveCN103071842AReduced tool wearExtend tool lifeMilling cuttersMilling equipment detailsEngineeringMachine tool

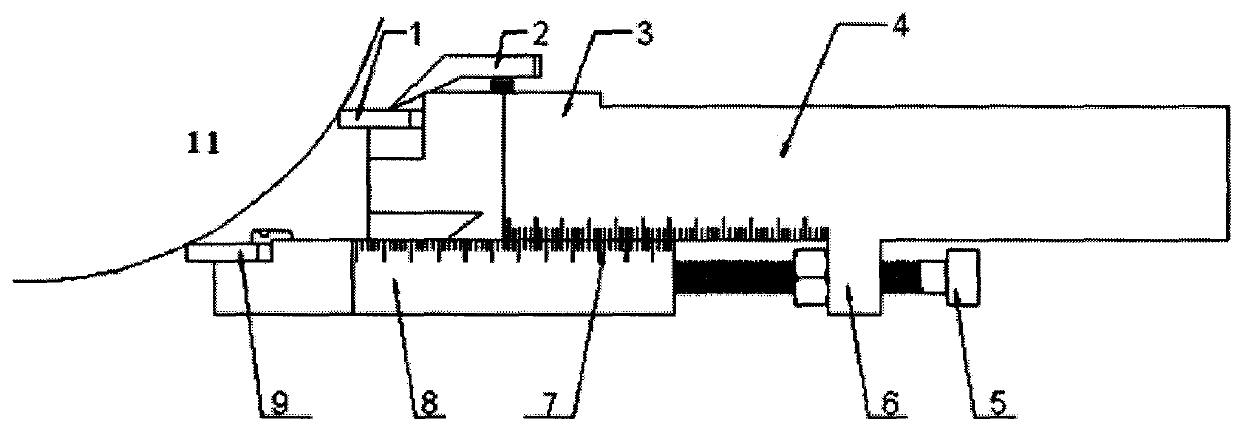

The invention relates to a special milling cutter made of a difficult-to-process material and belongs to the technical field of machining. The special milling cutter comprises a machine tool spindle box, a machine tool rotating spindle, a milling cutter positioning mandrel, a plurality of tightening screws, a center wheel frame, a plurality of wheel frame bolts, a cutter disc, a center wheel frame outer oil seal, a center wheel frame inner oil seal, an upper cover plate, a plurality of upper cover plate bolts and a plurality of planet wheels. The plurality of planet wheels are arranged on the horizontal circumference taking a machine tool rotating spindle axis as a rotating center at equal intervals. While carrying out feed movement along with the cutter disc, a circular blade of each plane wheel rotates around a self axis to finish processing of a workpiece. The special milling cutter made of the difficult-to-process material has the advantages that the abrasion of the cutter can be effectively reduced, the service life of the cutter is improved, and the cutting speed and the processing efficiency are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rivet Setting Method and System

A method is provided for self-pierce riveting which reduces a setting force required for setting the rivets. For this purpose, a clamping force produced by a clamping device is substituted by the force produced by a rivet on a punch. The clamping force varies within a known magnitude, whereas the setting force is reduced by 20%.

Owner:BAYERISCHE MOTOREN WERKE AG

Tool For The Cutting Machining Of Workpieces And Process For Coating Substrate Bodies

ActiveUS20140169891A1Reduced tool wearExtended service lifeMilling cuttersVacuum evaporation coatingSputteringLayer thickness

The invention relates to a tool having at least one layer of TixAl1-xN, where 0.2 ≦x≦0.8, which is composed of a plurality of laminar plies to give an overall layer thickness of 0.01 μm to 3 μm and which has crystallites having a size of ≦10 nm. To produce such a layer, by magnetron sputtering in an N2 atmosphere, Ti and Al are respectively released from separately arranged cathode targets, wherein the tool is moved past the cathode repeatedly at a speed which is such that in each case only a nanocrystalline layer forms upon this movement.

Owner:KENNAMETAL INC

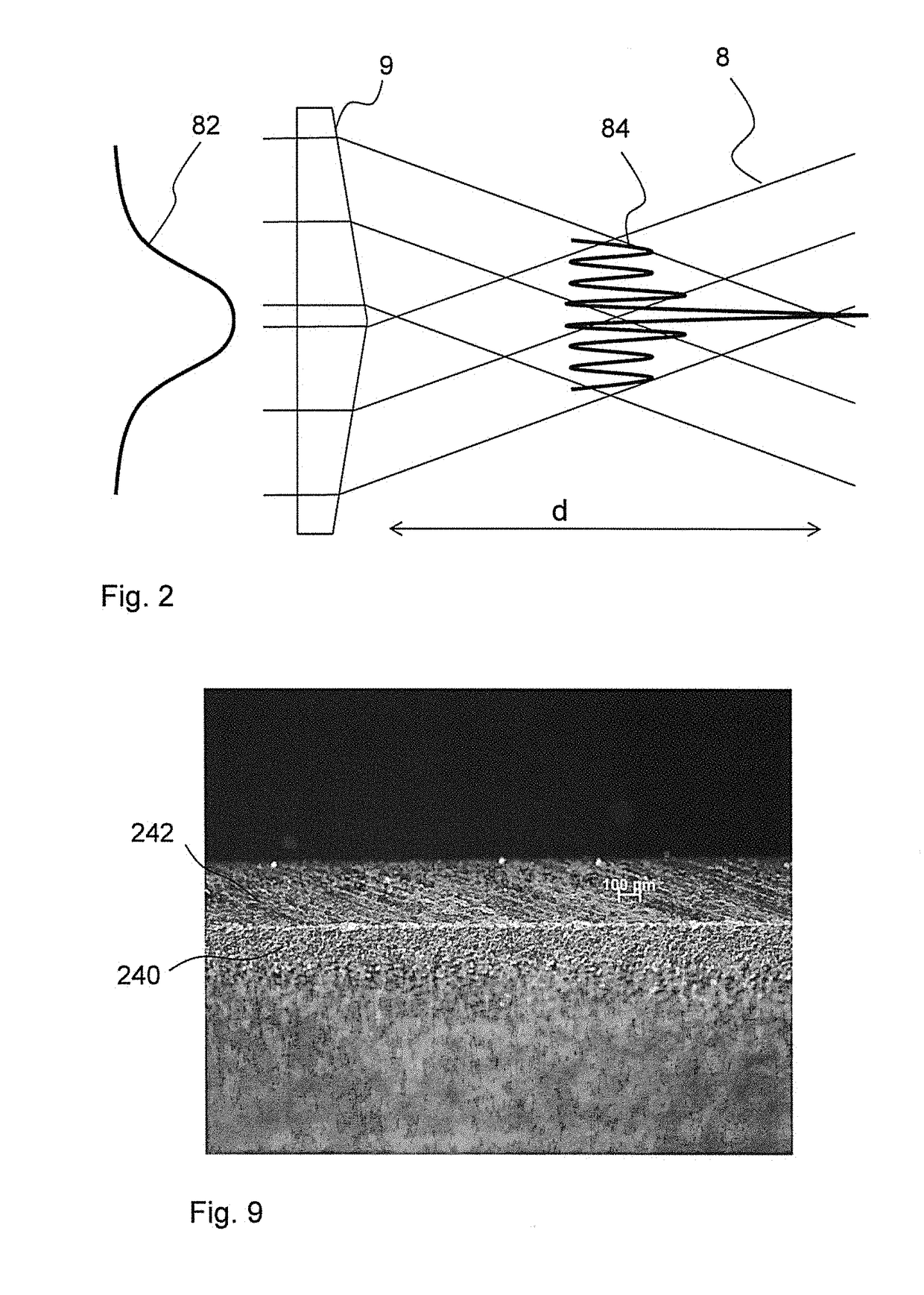

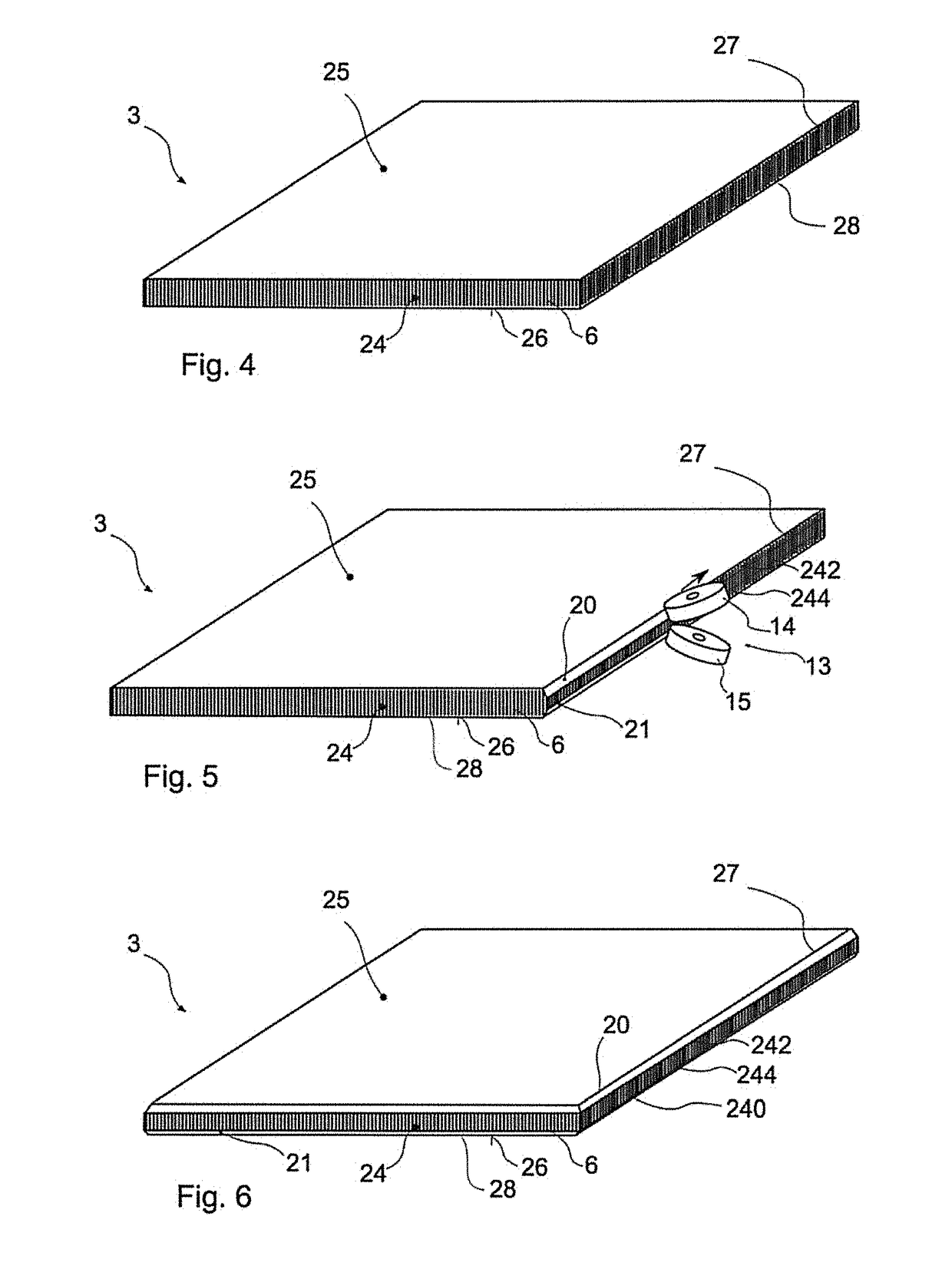

Method for machining the edges of glass elements and glass element machined according to the method

ActiveUS20180370840A1Precise definitionLess materialAbrasion apparatusGlass severing apparatusFlat glassEdge surface

A method for the production of glass or glass ceramic elements from flat glass or glass ceramic parts is provided where the edges of the glass or glass ceramic elements are treated by a combination of two processes. The flat glass or glass ceramic element with an edge surface connecting the two side surfaces is produced. The edge surface has at least one first elongated, strip-shaped edge region and at least one second elongated strip-shaped edge region, which are formed by a ground edge. The edge regions extend in the longitudinal direction along the edge surface and along the side surfaces. The first edge region has elongated parallel filamentary damages that are parallel and adjacent to one another and, in particular, spaced apart equidistantly, in the longitudinal direction thereof extending transversely to the side surfaces and along the surface of the first edge region.

Owner:SCHOTT AG

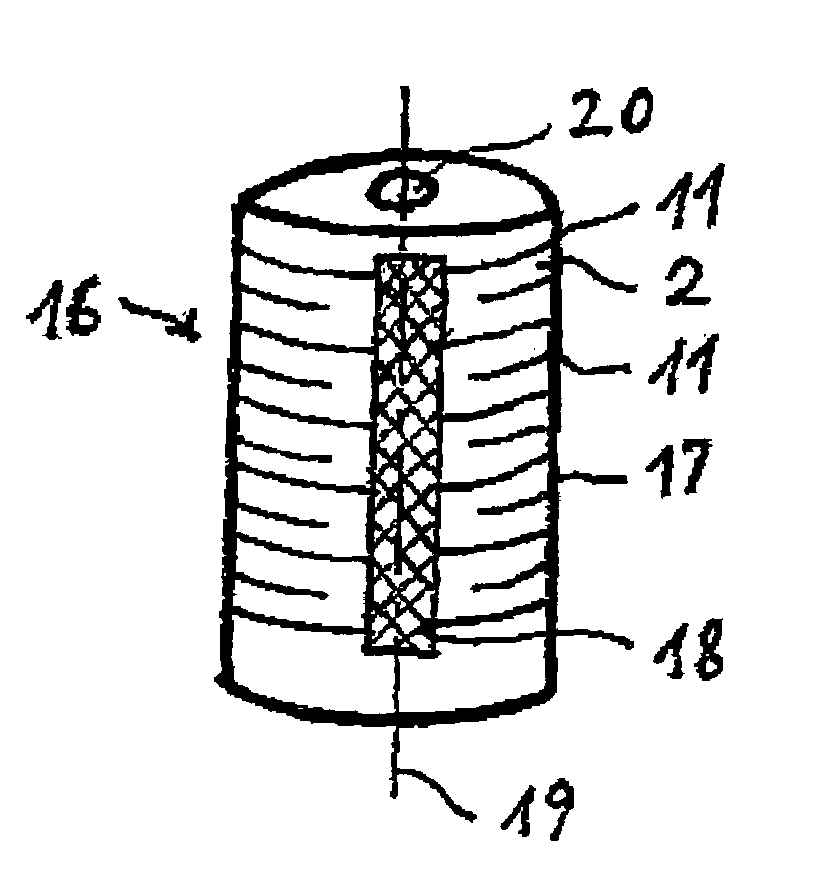

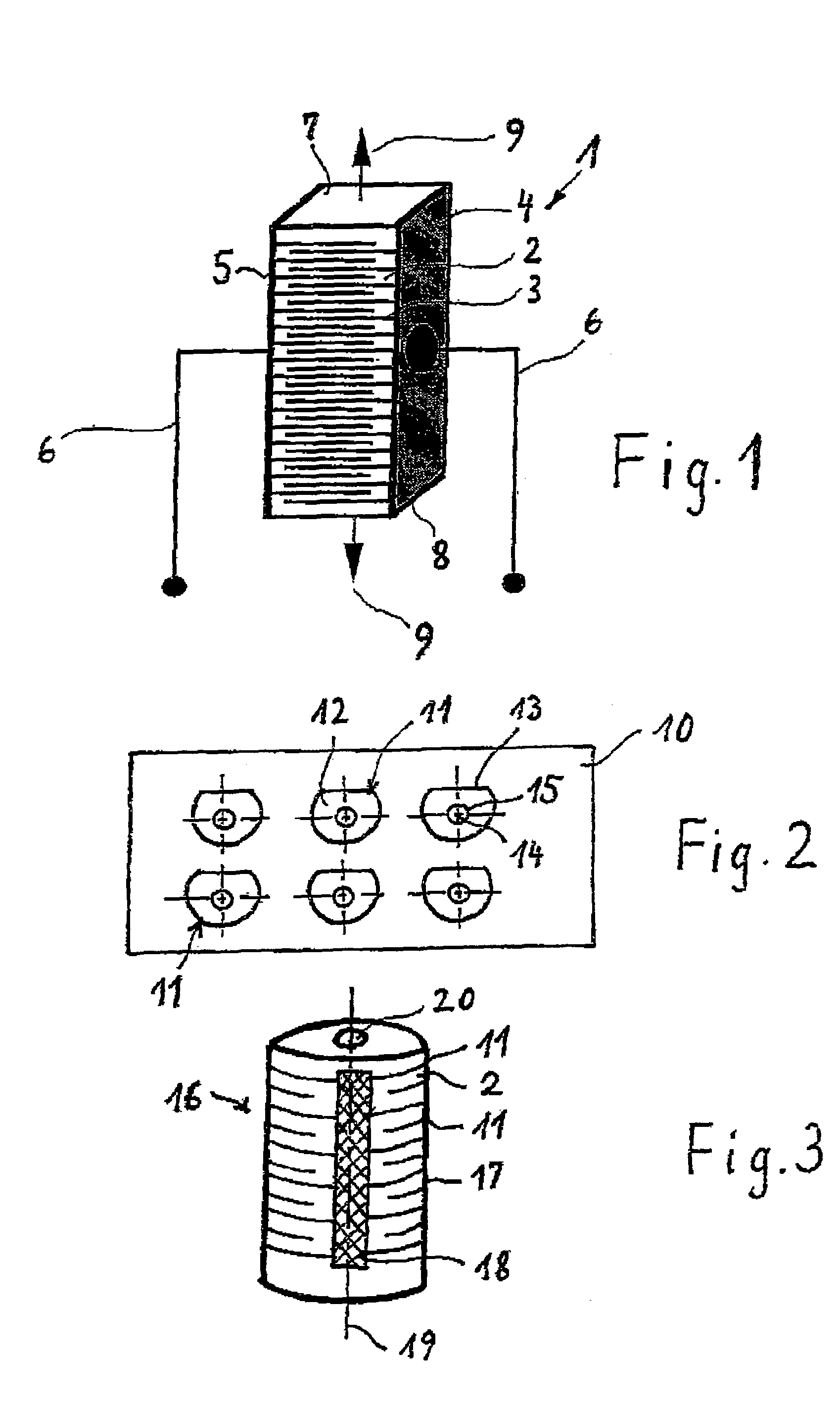

Process for the manufacture of piezoceramic multilayer actuators

InactiveUS7309397B2Improve machinabilityHigh strengthPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsActuatorBiomedical engineering

A block of stacked green films provided with internal electrodes is laminated, at least one actuator is separated from the block, the actuator obtains its shape by means of a machining operation, is then sintered, and the sinter skin produced by the sintering is used as an insulating layer. The sinter skin is abraded at the points where the internal electrodes are connected to the external electrodes.

Owner:CERAMTEC

Torque Transmission Device Useful as a Fixed Constant Velocity Ball Joint Constructed as an Opposed Track Joint and Method for Producing Such a Joint

InactiveUS20090176586A1Fast and efficient productionHigh hardnessClutchesYielding couplingJoint componentTorque transmission

A torque transmitting device, such as a fixed constant velocity ball joint as a counter track joint and a method for producing such a joint, in which the curvatures of the bases of the joint tracks deviate in their axial course from the curvatures of the ball contact lines. The method is characterized in that the joint component is brought to an increased hardness by a hardening process prior to the formation of the longitudinal profile of the component, and a diffusion layer is partially or completely removed in the region of the longitudinally profiled structure.

Owner:NEUMAYER TEKFOR HLDG GMBH

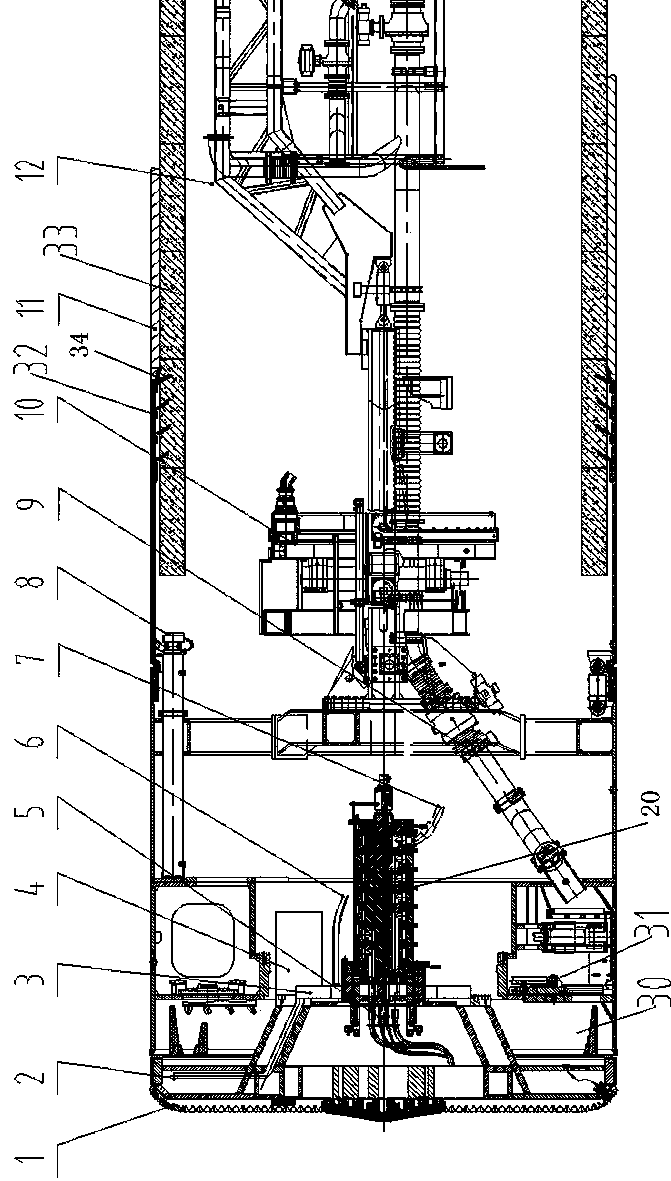

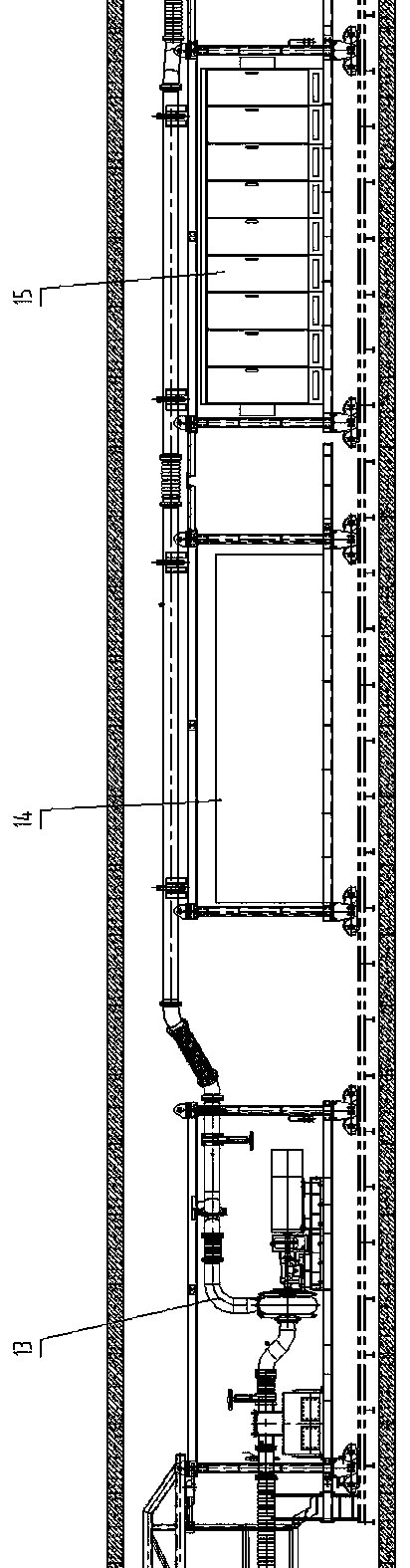

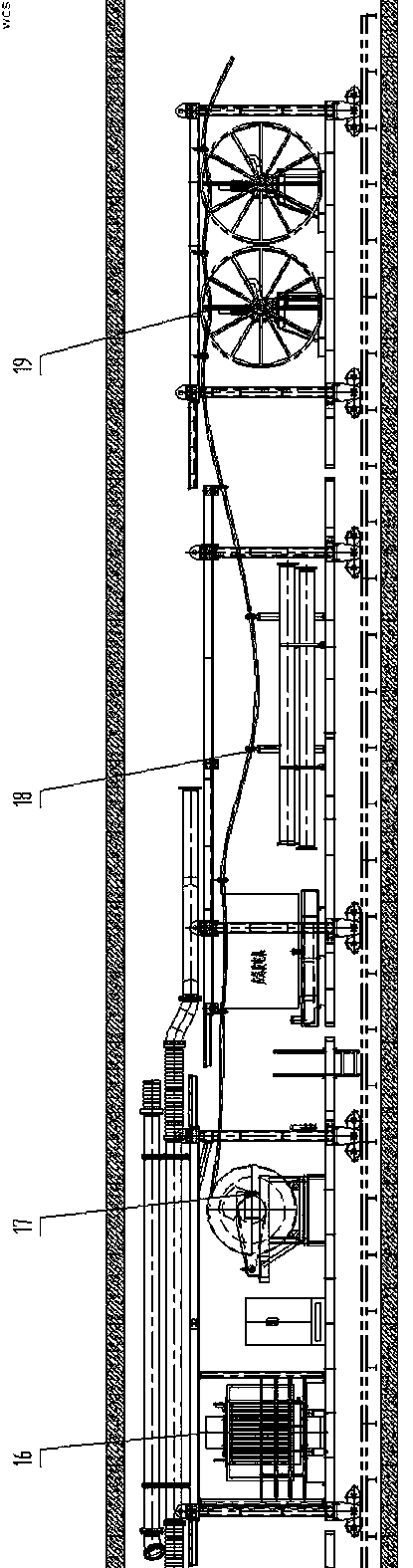

High-voltage pulse discharge-mechanical combined rock-breaking full-section tunneling machine

ActiveCN109488316AImprove rock breaking efficiencyReduced tool wearTunnelsTunnel engineeringHigh voltage pulse

The invention discloses a high-voltage pulse discharge-mechanical combined rock-breaking full-section tunneling machine, and solves the problems of slow tunneling speed, fast tool wear and the like byadopting a prior mechanical breaking working mode in tunnel engineering. The tunneling machine comprises a tunneling machine main machine, wherein a cutter head and cutter system is arranged on the tunneling machine main machine, and an electrode is arranged on the cutter head and cutter system. The tunneling machine designs a novel electrode scraper with high-voltage pulse discharge and a scraping capability; the electrode of a high-voltage pulse discharge control system is coupled with other mechanical cutters such as a hob and the like, so that the rock breaking efficiency is improved, andthe wear of the cutter is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

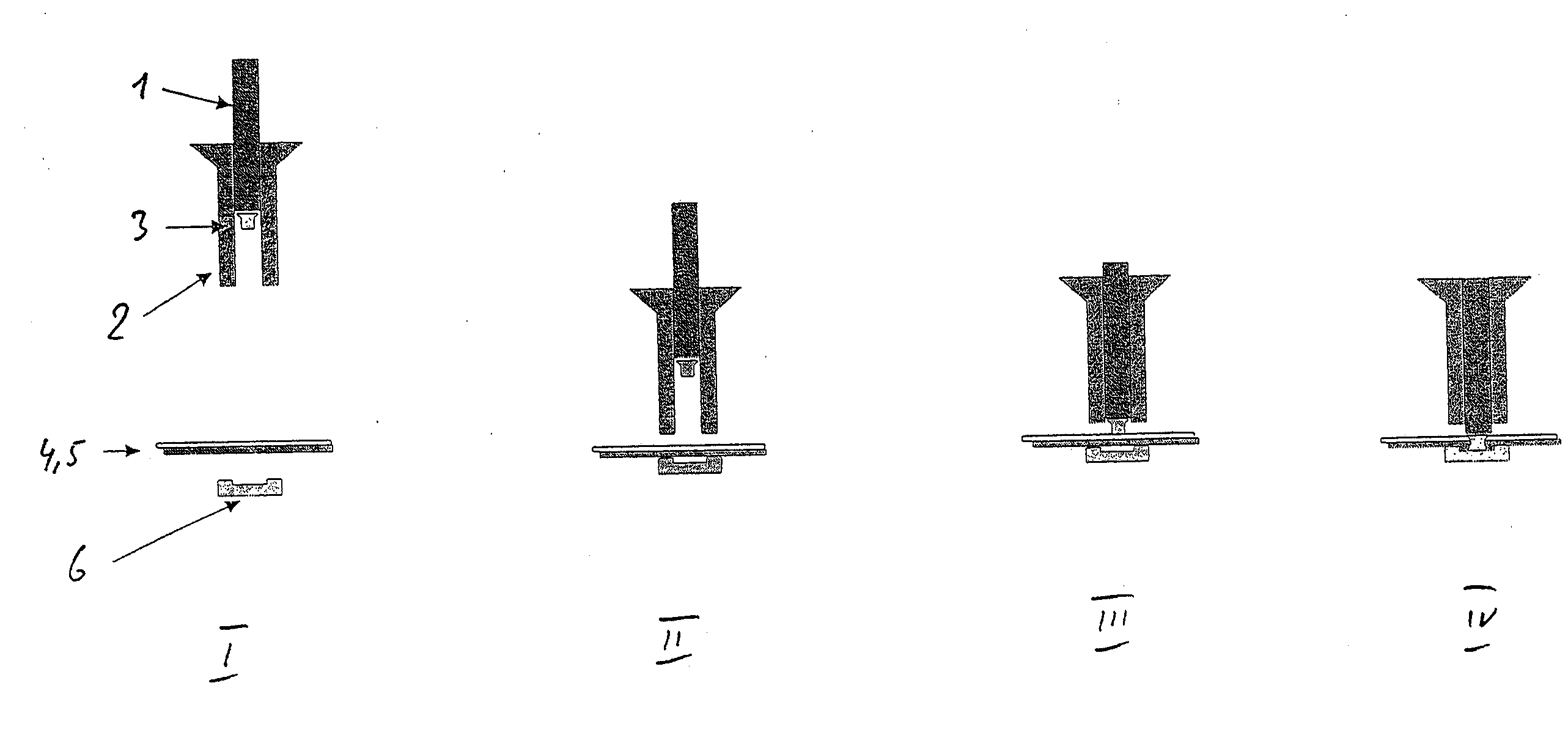

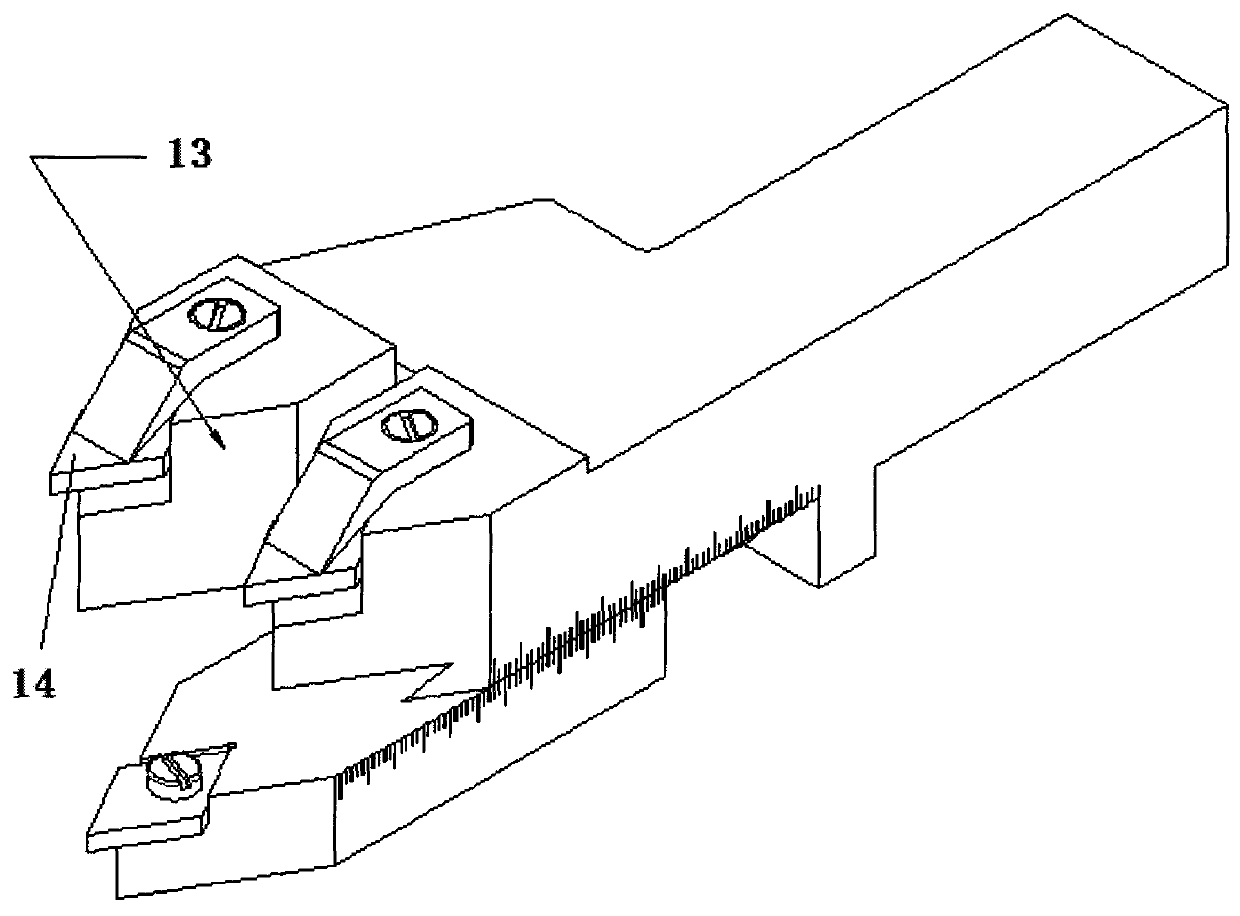

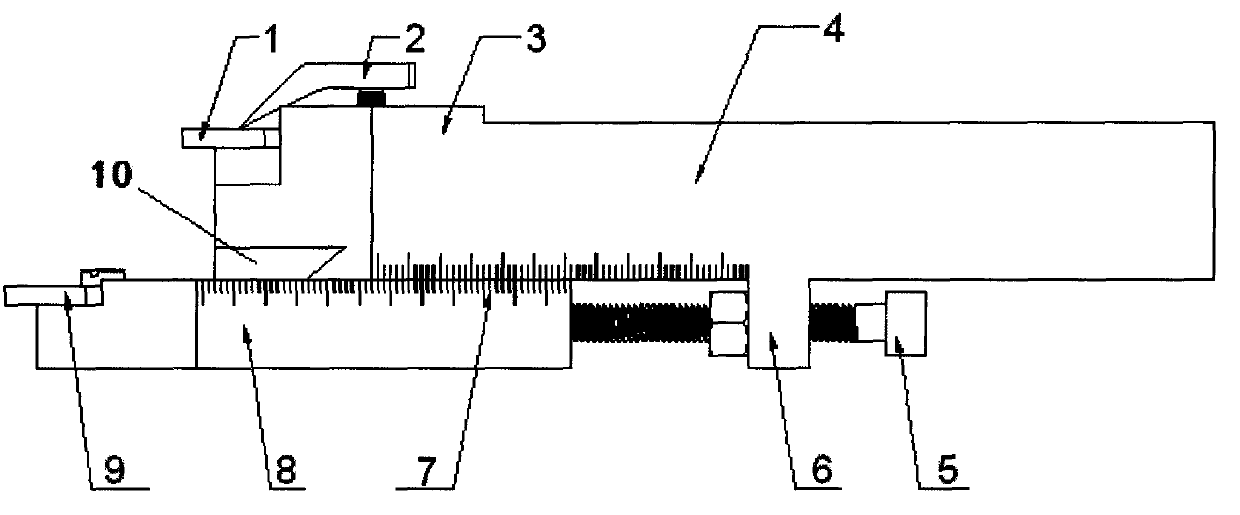

Integrated deburring finish machining turning method and cutter

The invention relates to an integrated deburring finish machining turning method and a cutter and belongs to the field of mechanical machining. The integrated deburring finish machining turning method is characterized in that only one cutter is used, and deburring cutting and finish machining are conducted automatically during rough machining of turning. The cutter is provided with three cutting heads and can install three blades. A cutter point of a cutting blade (1) and a cutter point of a deburring blade (9) are both on an arc with a workpiece axis as a circular center and turning radius as the radius. Simultaneously, a main cutting edge of the cutting blade and a main cutting edge of the deburring blade are coincided with a bus of a surface to be machined. A cutting head (3) is parallel to a finish machining cutting head (13), and after the blades are installed, a connecting line of two blade cutter points is parallel to the workpiece axis. When the cutting blade (1) cuts a workpiece, burrs of the surface to be machined are exactly scraped off by the deburring blade (9), and protrusions of a machined surface are just scraped off by a finish machining blade (14).

Owner:NANJING AGRICULTURAL UNIVERSITY

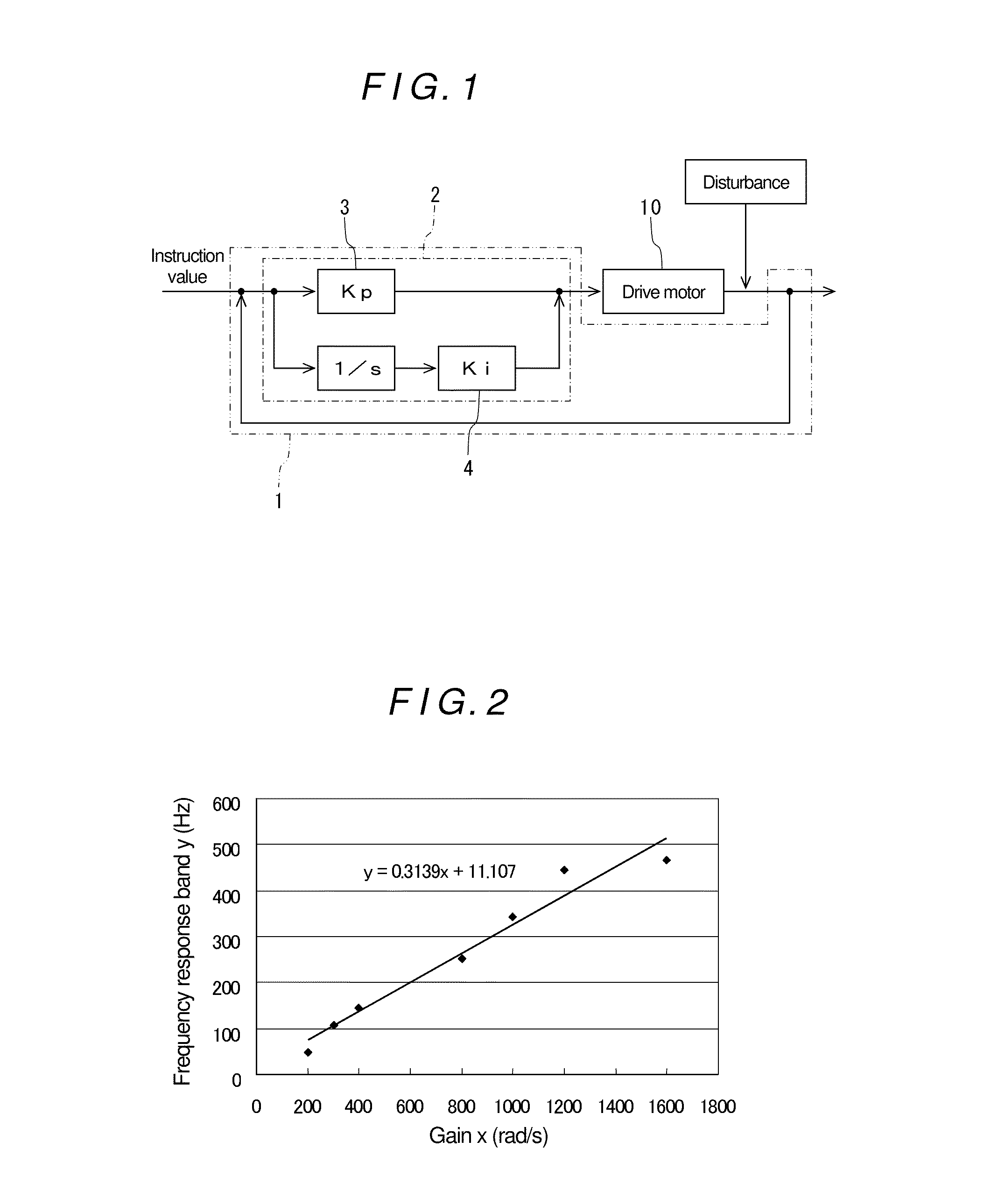

Method of Machining Workpiece with Machine Tool

ActiveUS20130322977A1Improve machine qualityImprove machine efficiencyProgramme controlMilling equipment detailsControl systemDrive motor

A workpiece is machined by setting a frequency response band of a control system for a rotation drive motor or a feed drive motor so that tool abrasion is within a predetermined allowable range. The frequency response band may be adjusted by adjusting a proportional gain and an integral gain. With the workpiece machined by such a process, where the frequency response band maintains tool abrasion within the allowable range, machining quality and efficiency are improved.

Owner:DMG MORI SEIKI CO LTD +1

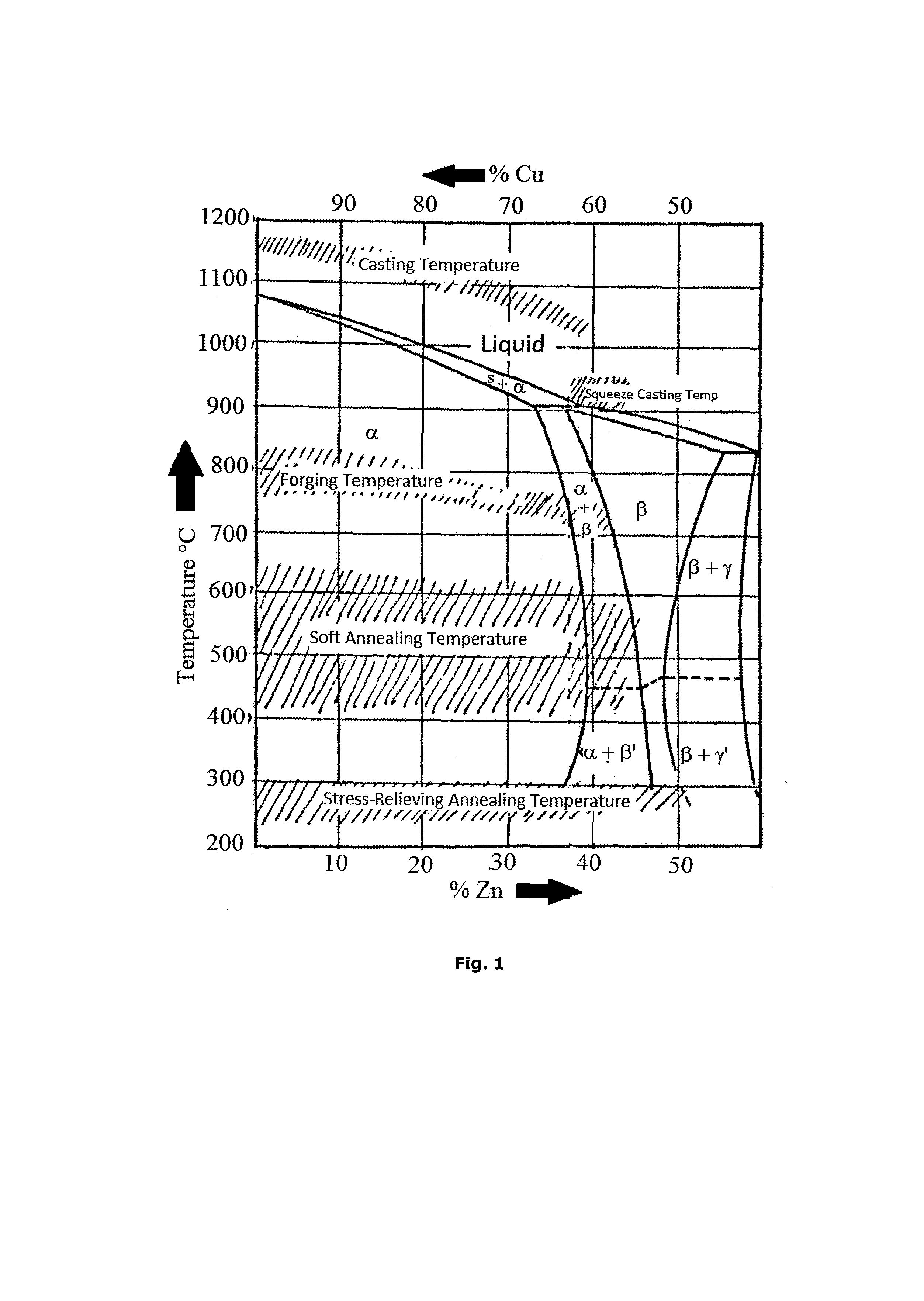

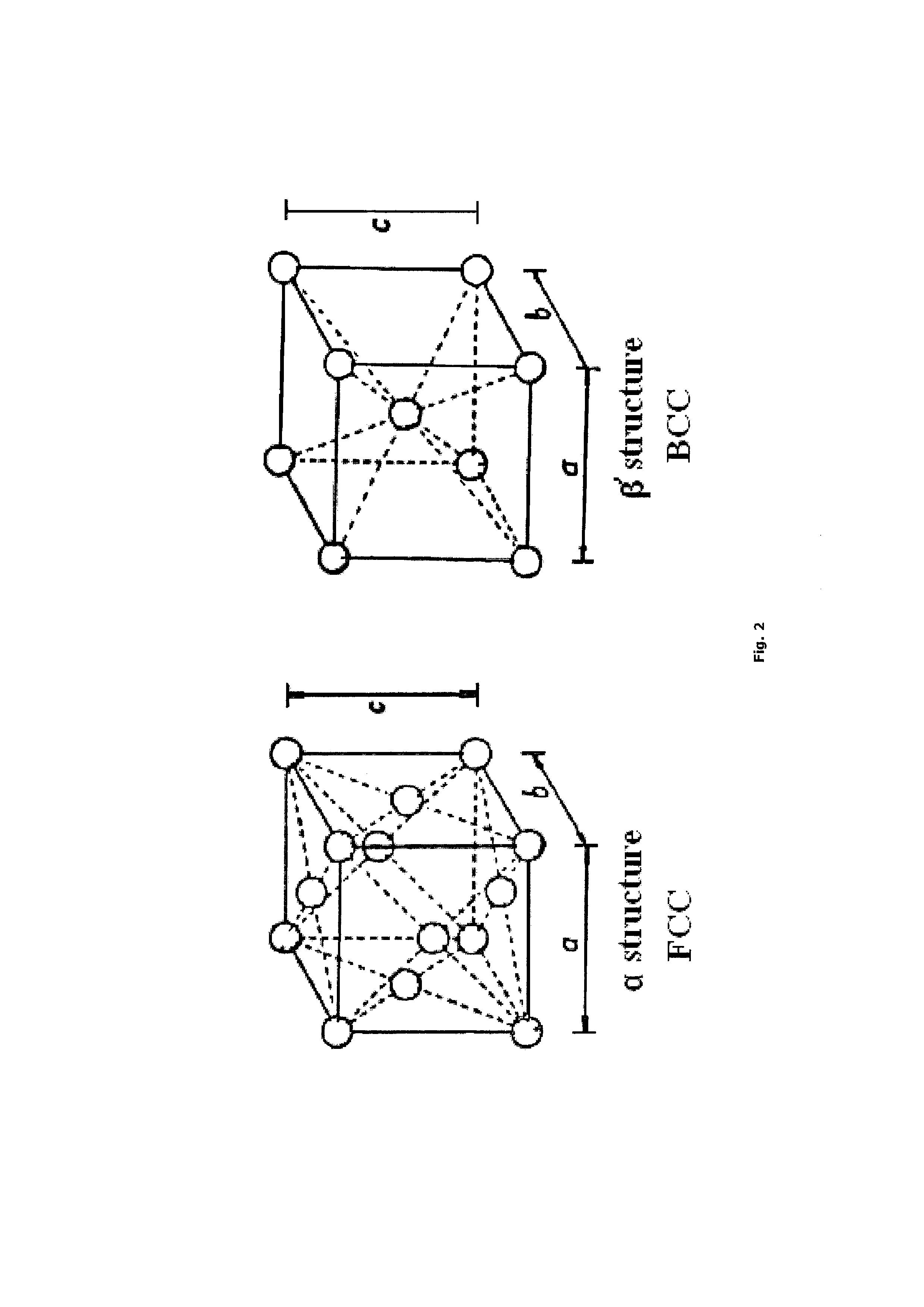

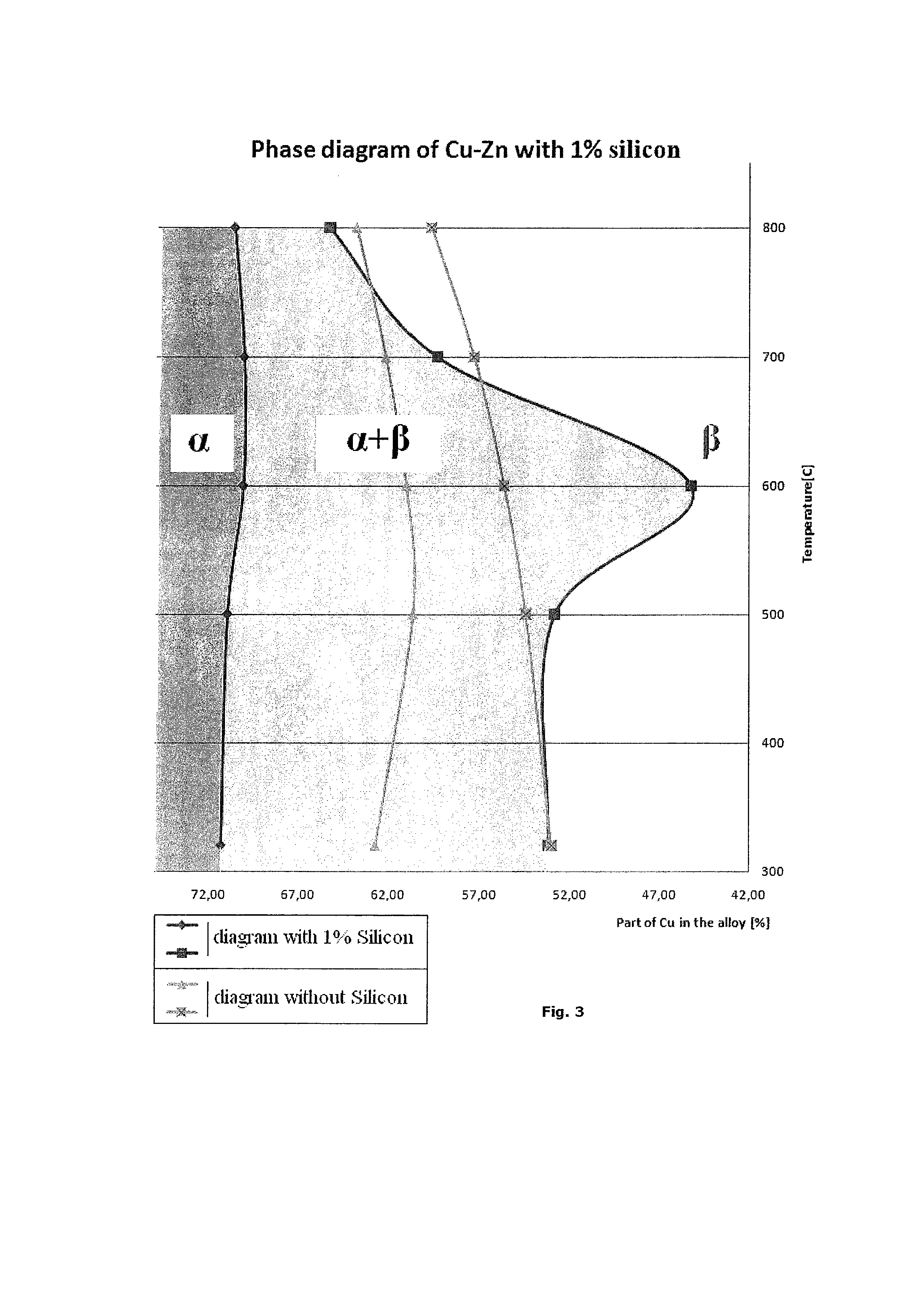

Brass alloy comprising silicon and arsenic and a method of manufacturing thereof

ActiveUS20130177472A1Dezincification resistance and machining abilityReduced tool wearManufacturing convertersAlloySilicon

Owner:RAUFOSS WATER & GAS

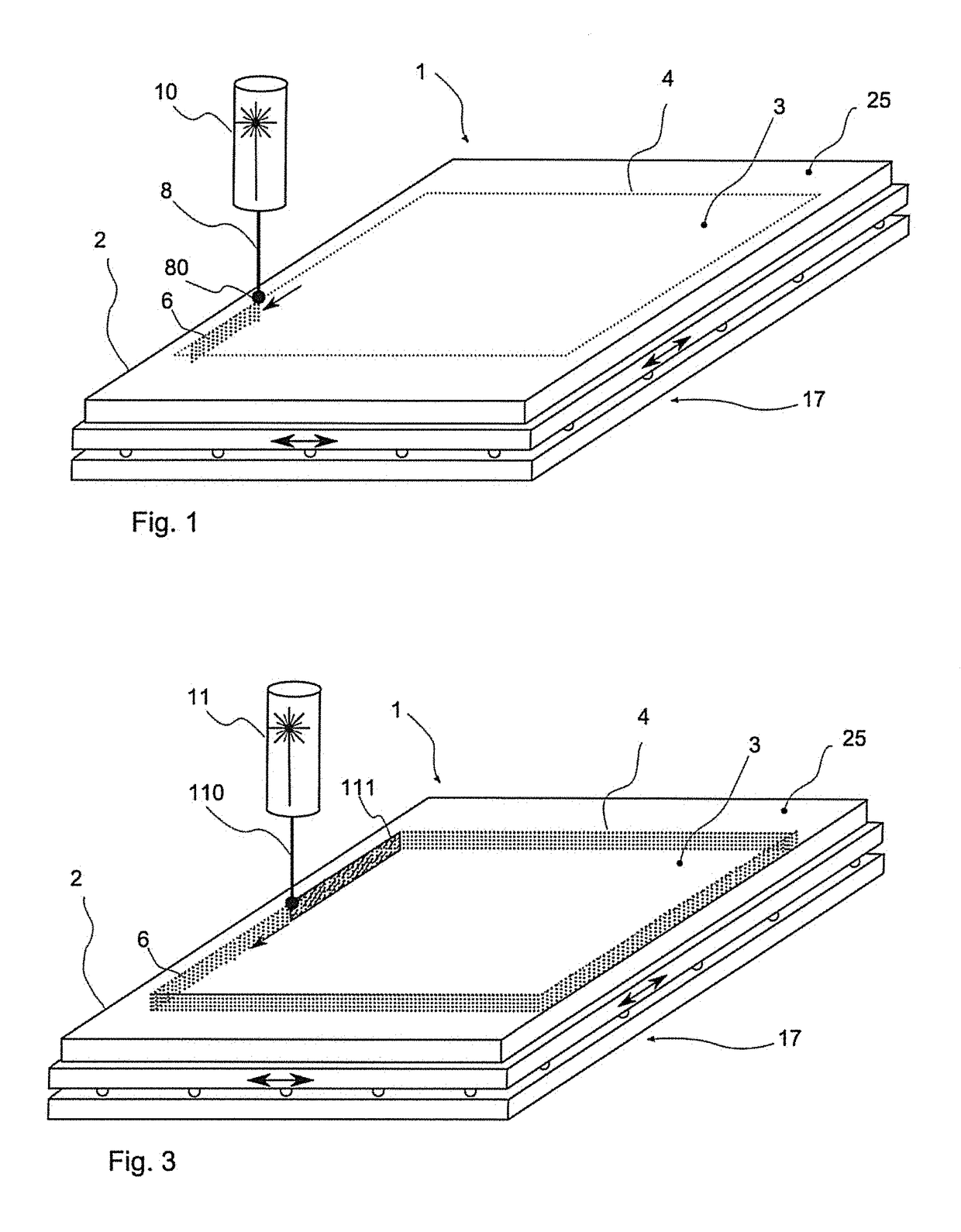

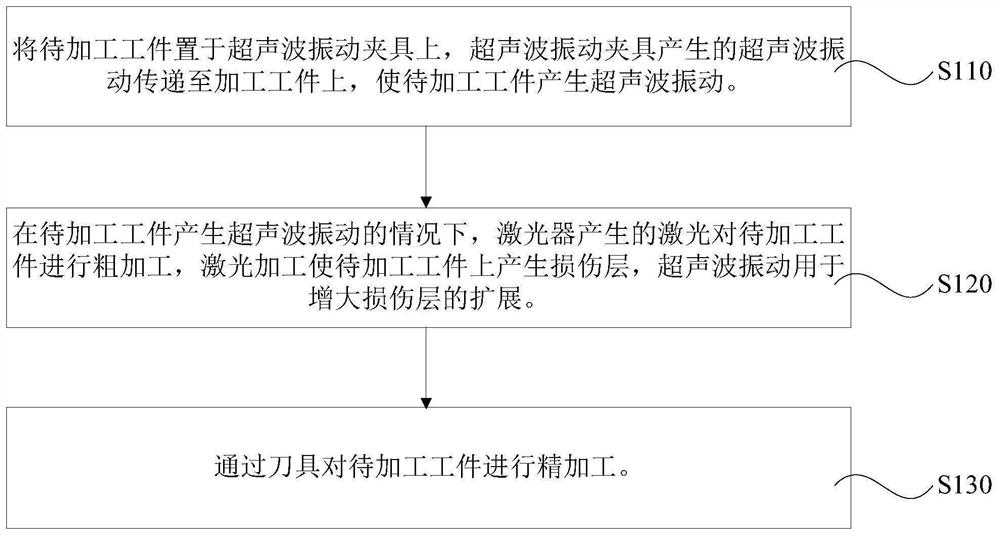

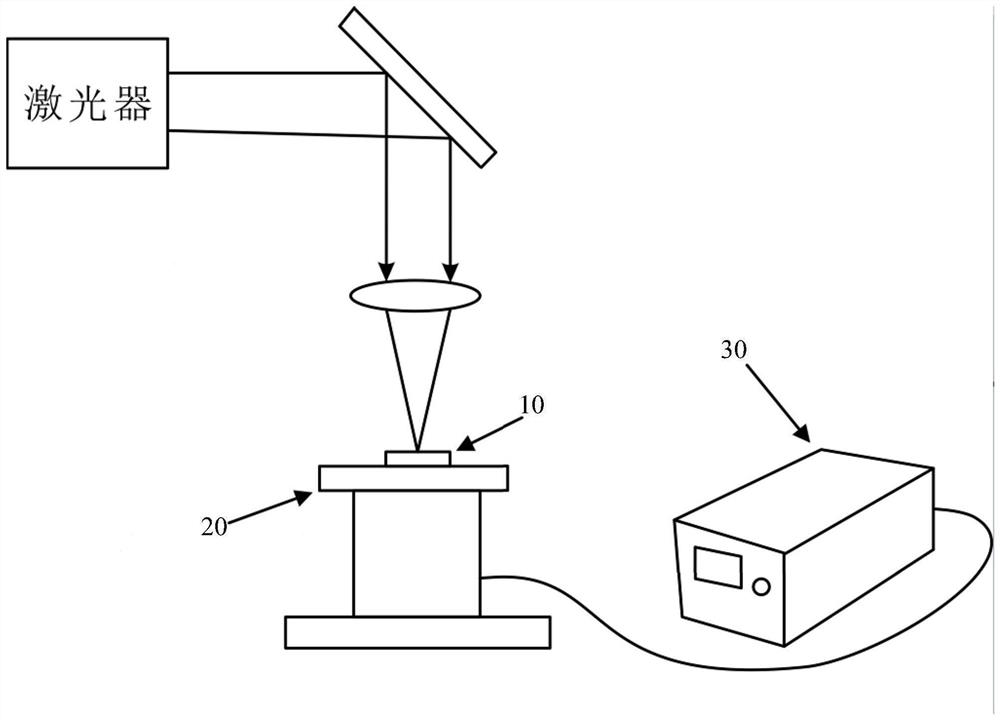

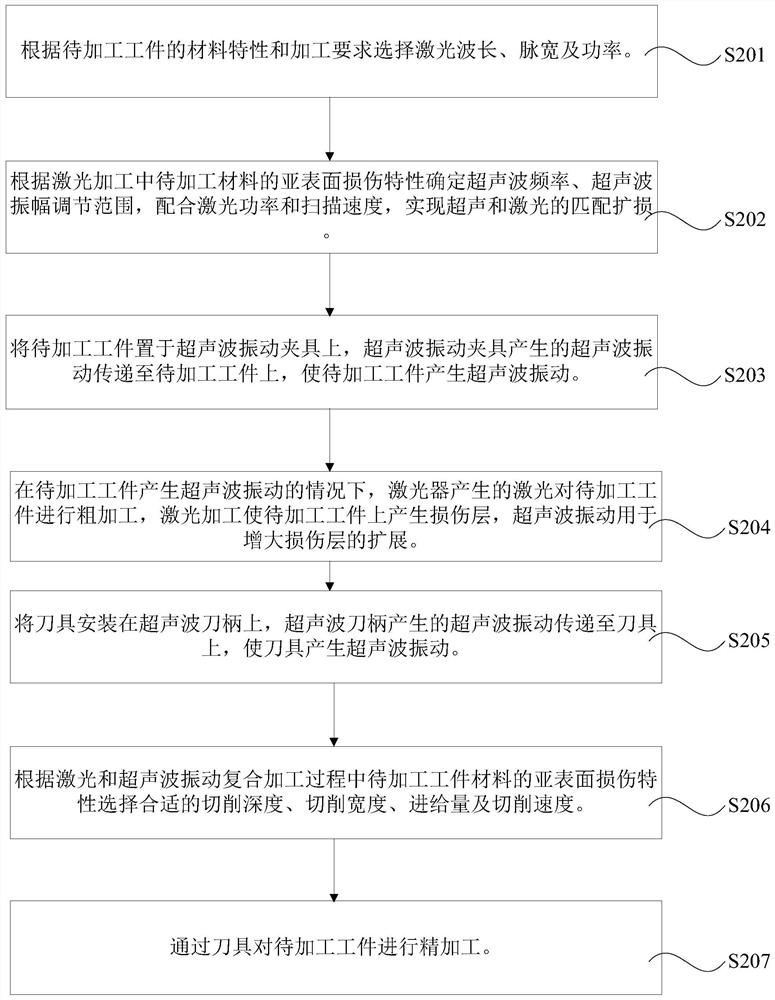

Ultrasound, laser and machine combined machining method, ultrasonic vibration clamp, machine tool and laser device

ActiveCN112548339AIncrease heightStable increase in expansionProcess efficiency improvementLaser beam welding apparatusLaser processingUltrasonic vibration

The invention relates to an ultrasound, laser and machine combined machining method, an ultrasonic vibration clamp, a machine tool and a laser device. Under the condition that a to-be-machined workpiece generates ultrasonic vibration, laser generated by the laser device roughly machines the to-be-machined workpiece, and a damage layer with cracks is generated on the to-be-machined workpiece through laser machining; ultrasonic vibration is used for increasing expansion of the damage layer, and then finish machining is conducted on the to-be-machined workpiece through a cutter. The ultrasonic vibration is beneficial to disengagement of molten drops generated after the laser ablates the to-be-machined workpiece, so that the contact between the to-be-machined workpiece and the laser is increased. The laser ablation effect can cause the surface of the to-be-machined workpiece to generate the damage layer with microcracks, under the action of ultrasonic vibration, after the microcracks are formed, due to the existence of high-frequency vibration, stress in the material is released more completely, the expansion of the microcracks is stably enlarged, and then the expansion of the damage layer is stably expanded; and in this way, removal of the material can be facilitated when the cutter conducts finish machining on the machined workpiece, the cutting force and cutter abrasion are reduced, and the machining efficiency is improved.

Owner:GUANGDONG UNIV OF TECH +2

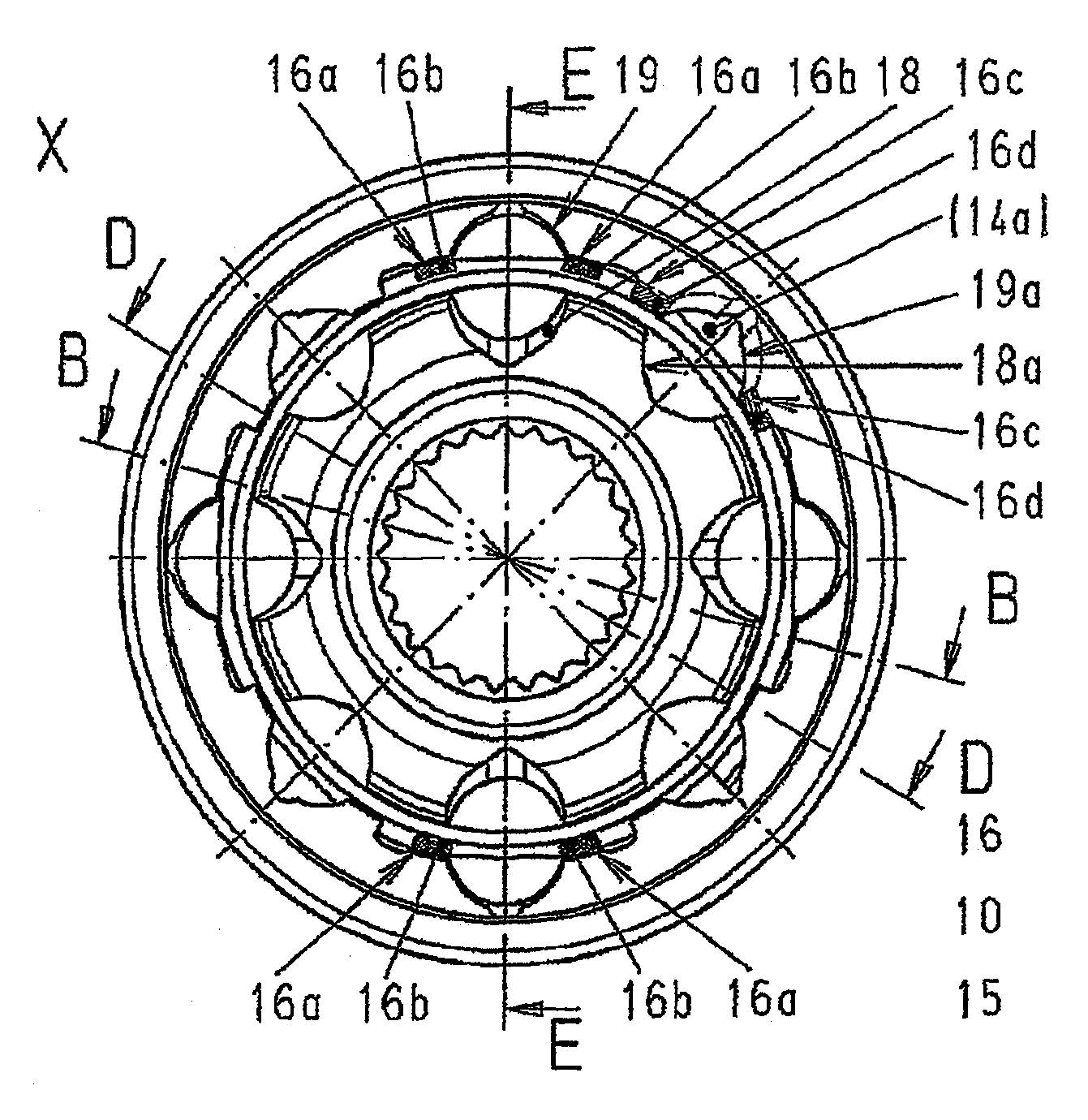

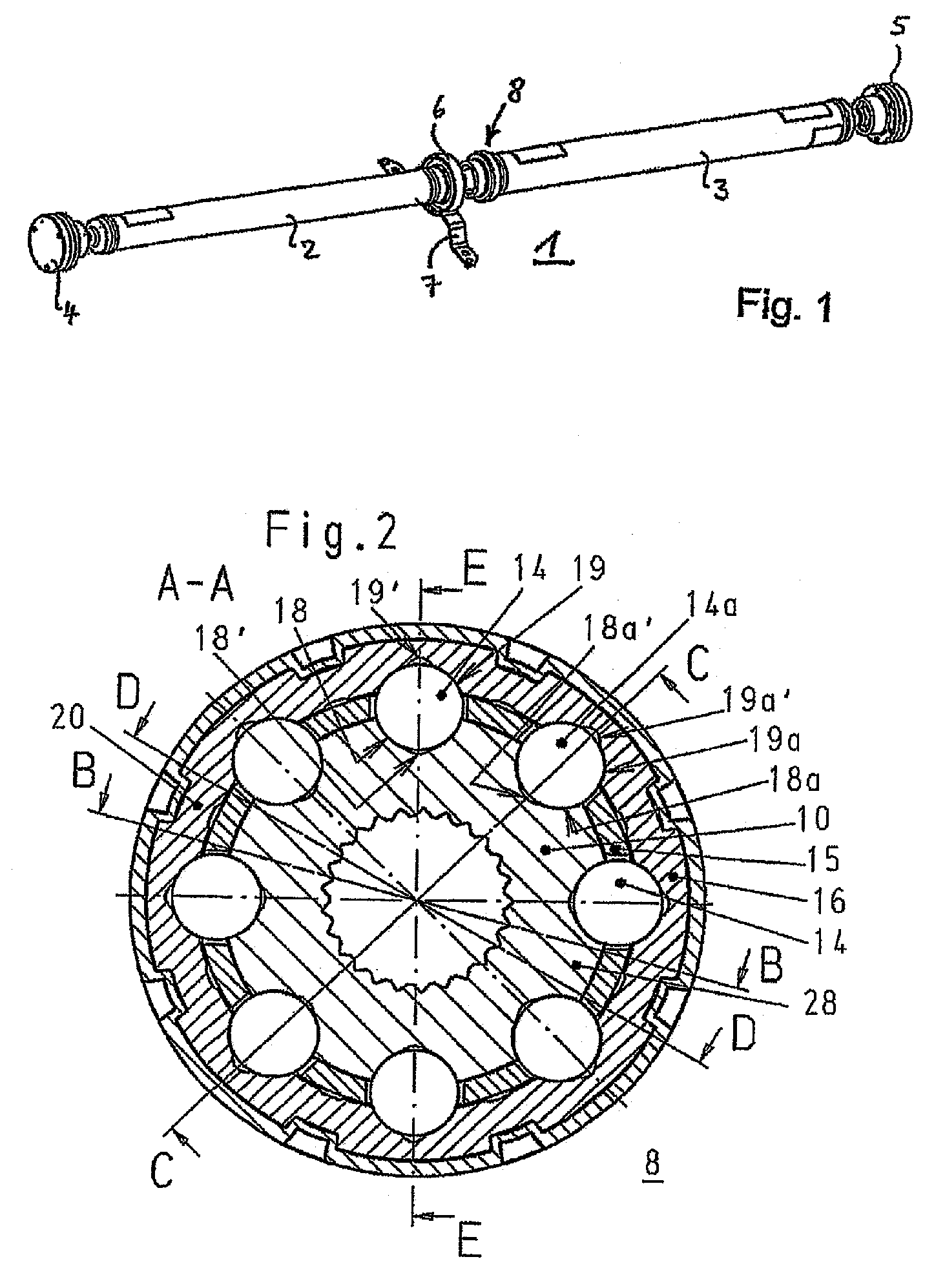

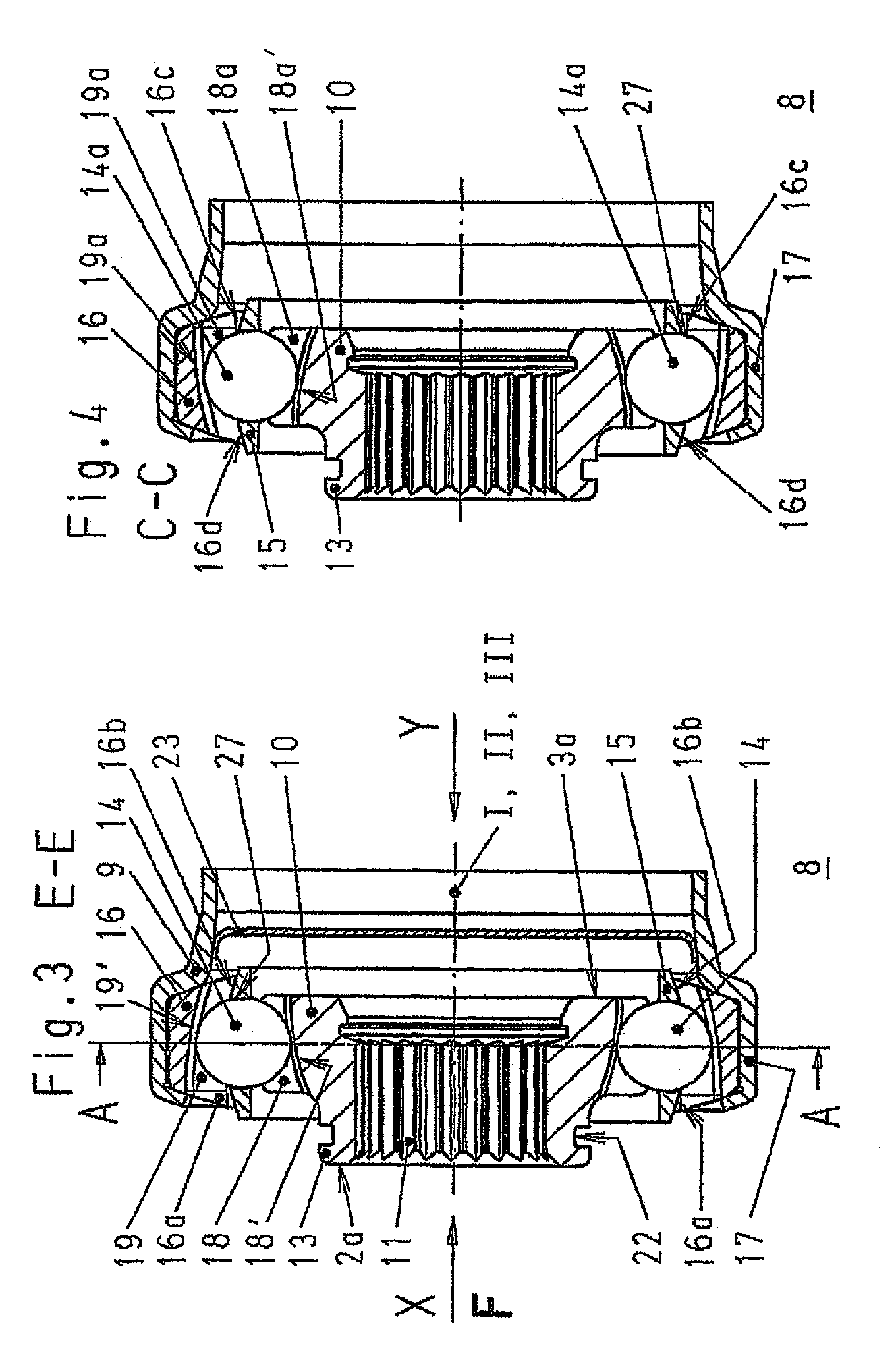

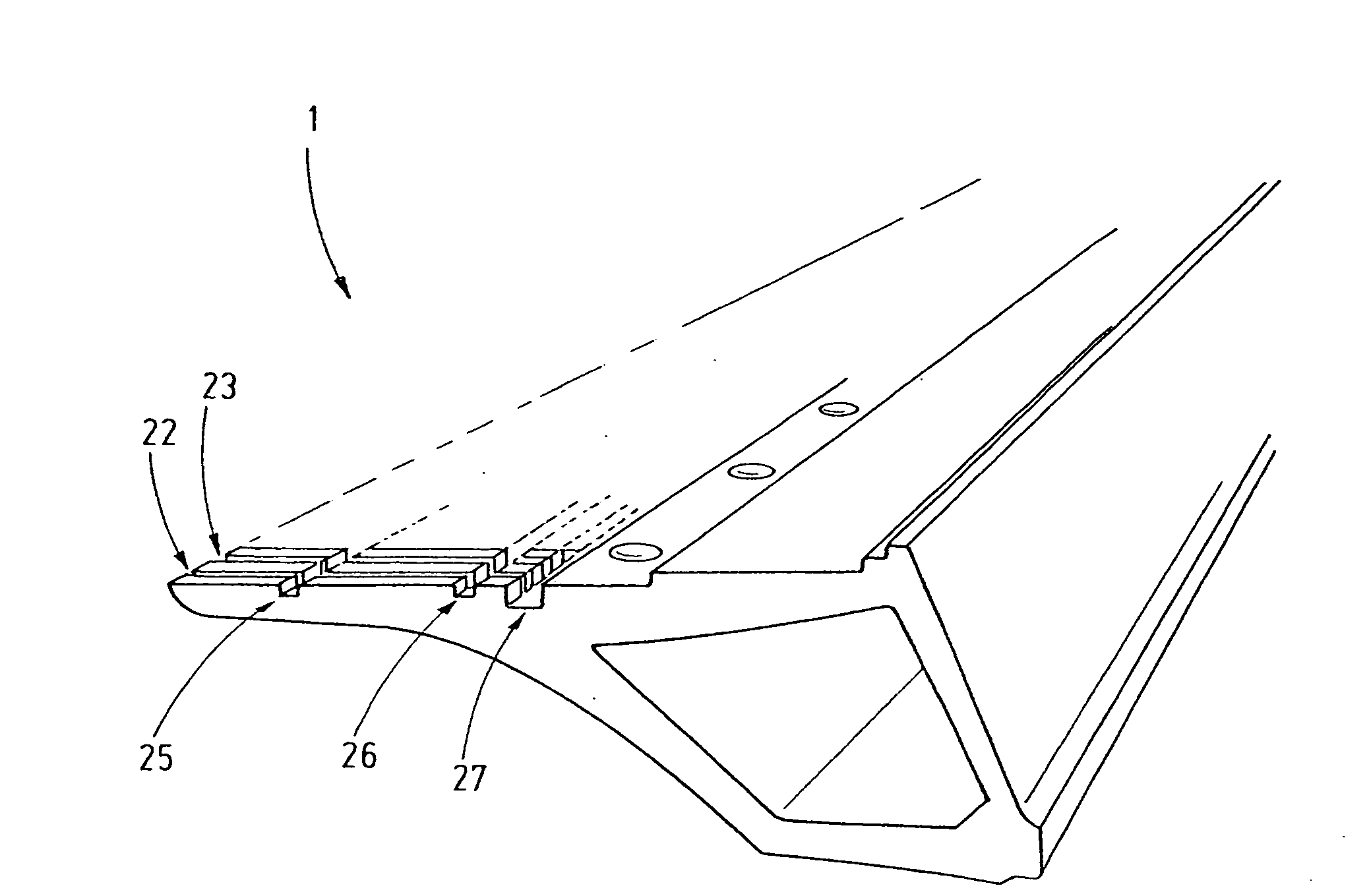

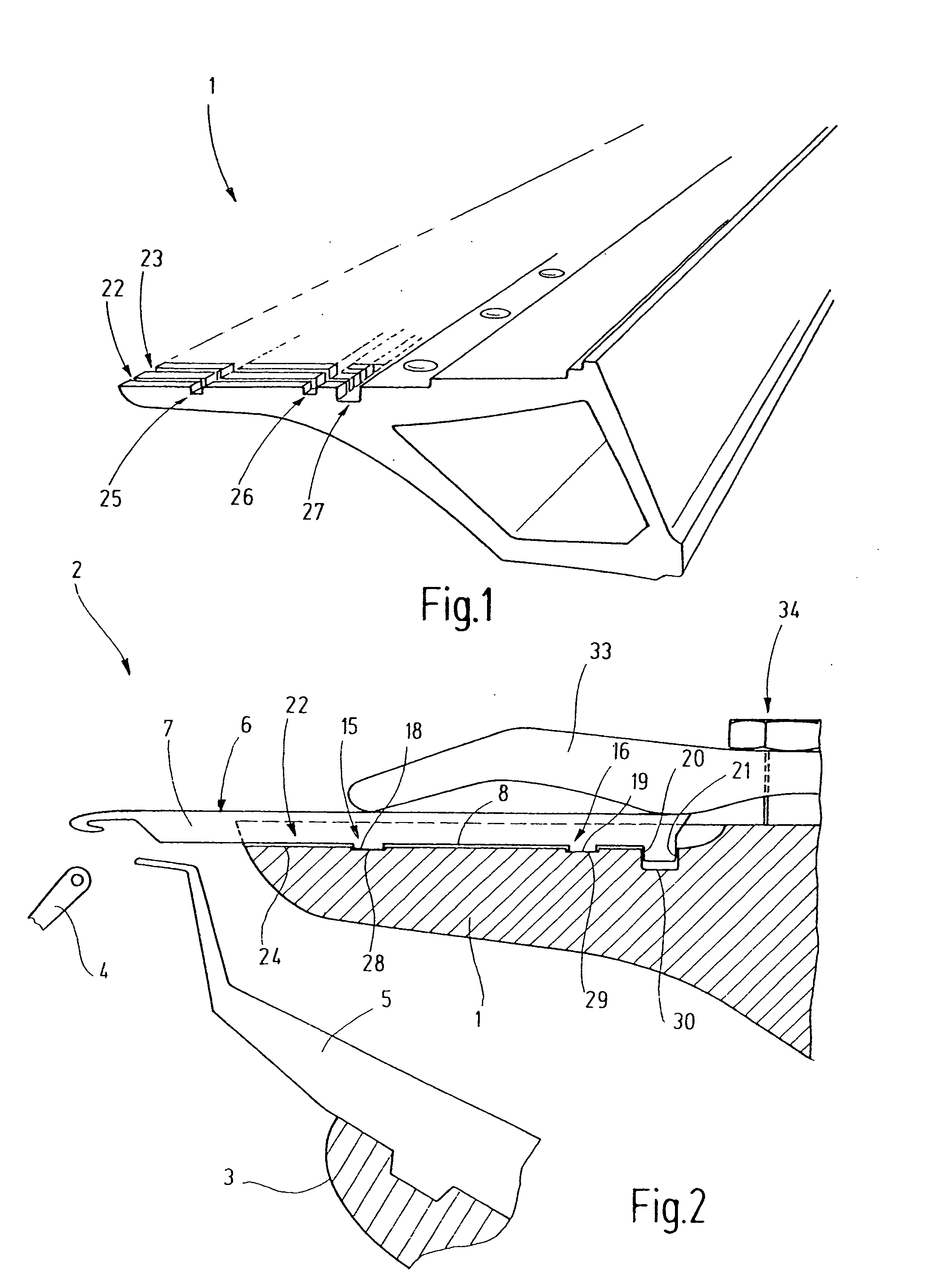

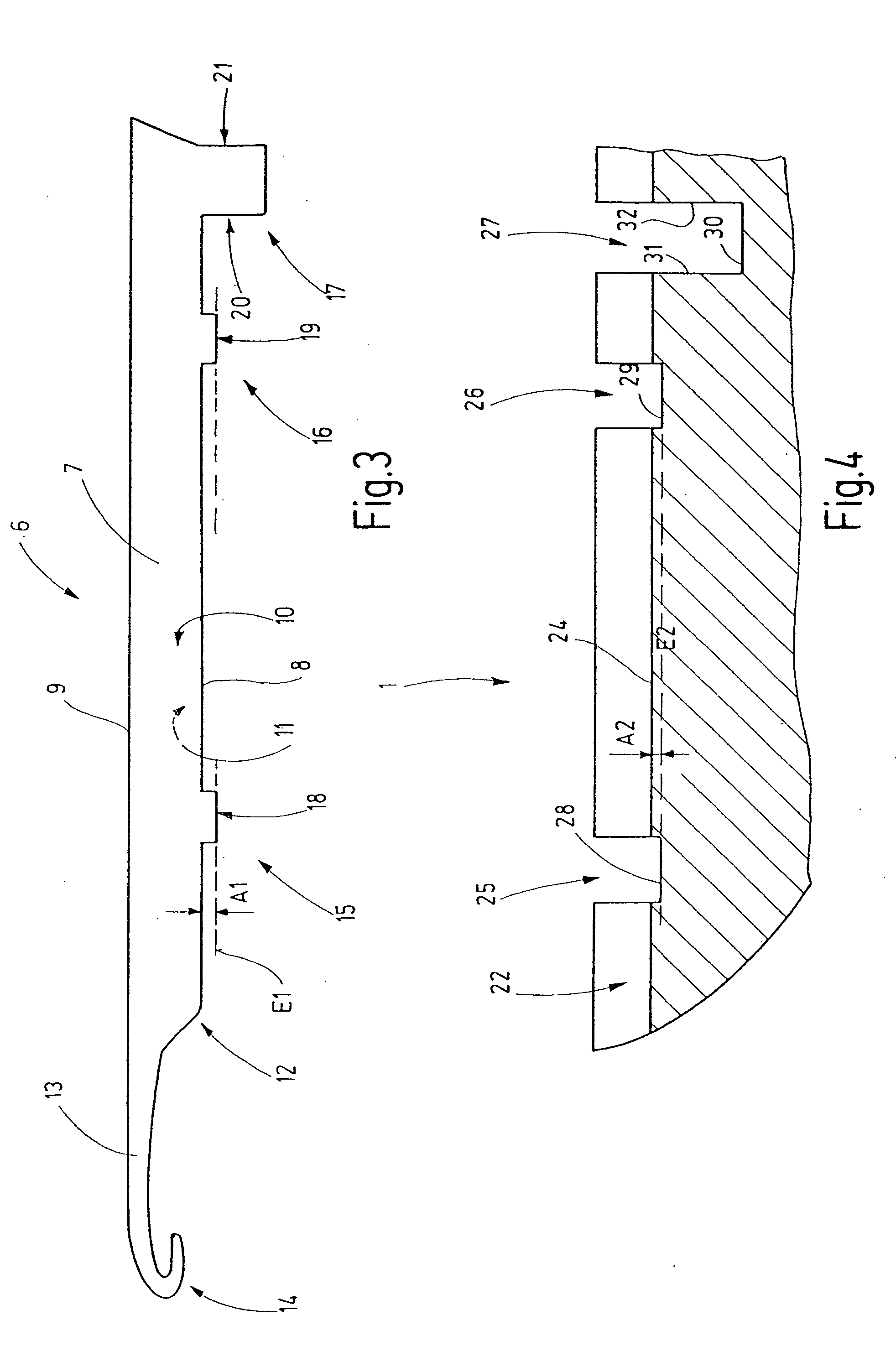

Knitting needle and bar for said needle

ActiveUS20070169518A1Low costReduce effortWeft knittingFlat warp knitting machinesBiomedical engineering

The inventive knitting tools, in particular knitting needles (6), have a body (7) which, for alignment, has on its narrow side projections (15, 16) which have precisely machined abutment surfaces (18, 19) on their end faces. The abutment surfaces (18, 19), can be produced, for example, during a suitable stage of the manufacturing process. One of the projections (15, 16) or an additional projection (17) can be provided with abutment surfaces (20, 21) which are used for longitudinal positioning of the knitting tool. Corresponding grooves (25, 26, 27) in the needle bar (1) are assigned to the projections (15, 16, 17).

Owner:GROZ BECKERT KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com