Special milling cutter made of difficult-to-process material

A difficult-to-machine and milling cutter technology, applied in the field of special milling cutters for difficult-to-machine materials, can solve the problems of limiting cutting speed and processing efficiency, shortening tool life, and tool wear, so as to improve cutting speed and processing efficiency and reduce tool wear , Improve the effect of tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

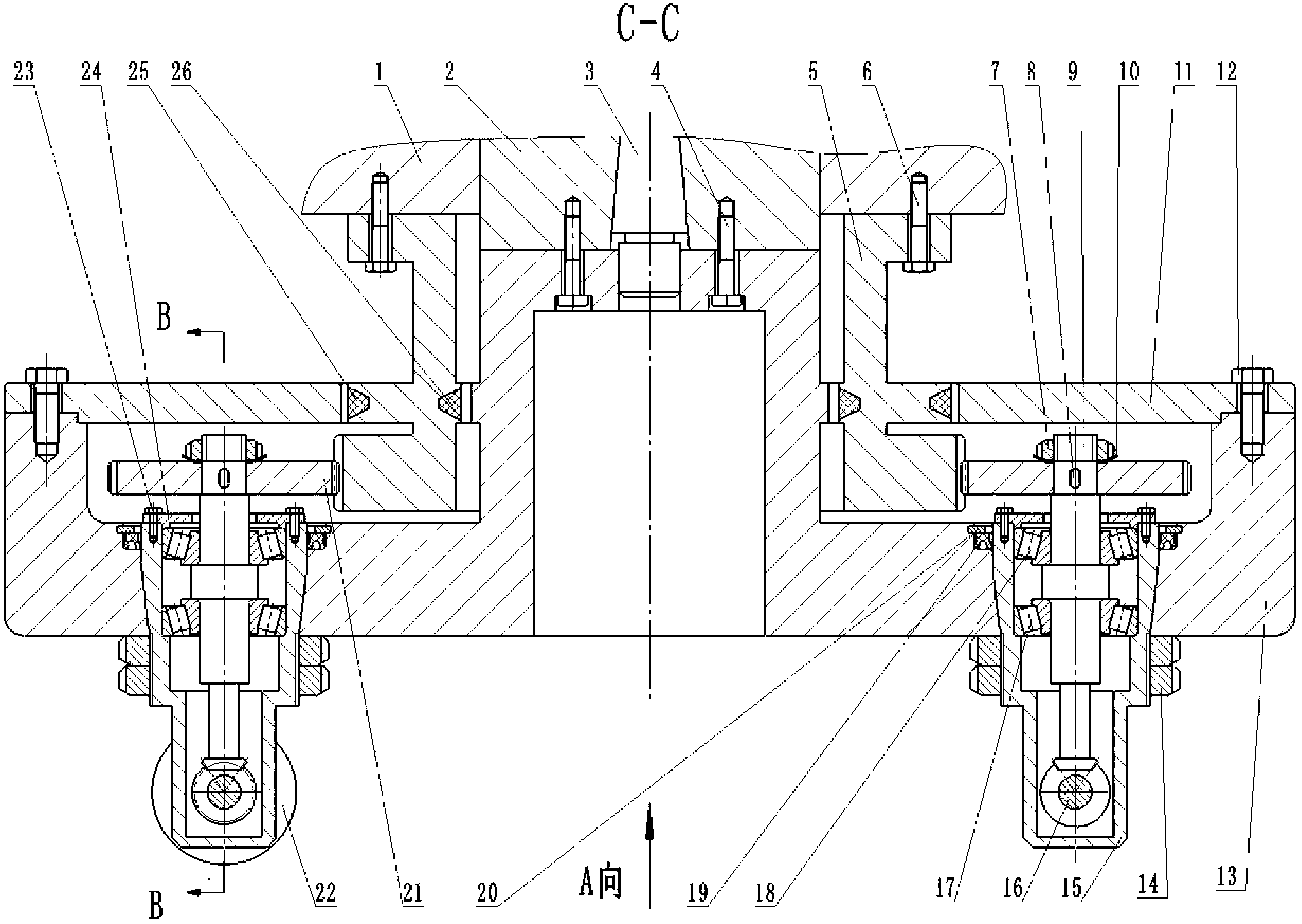

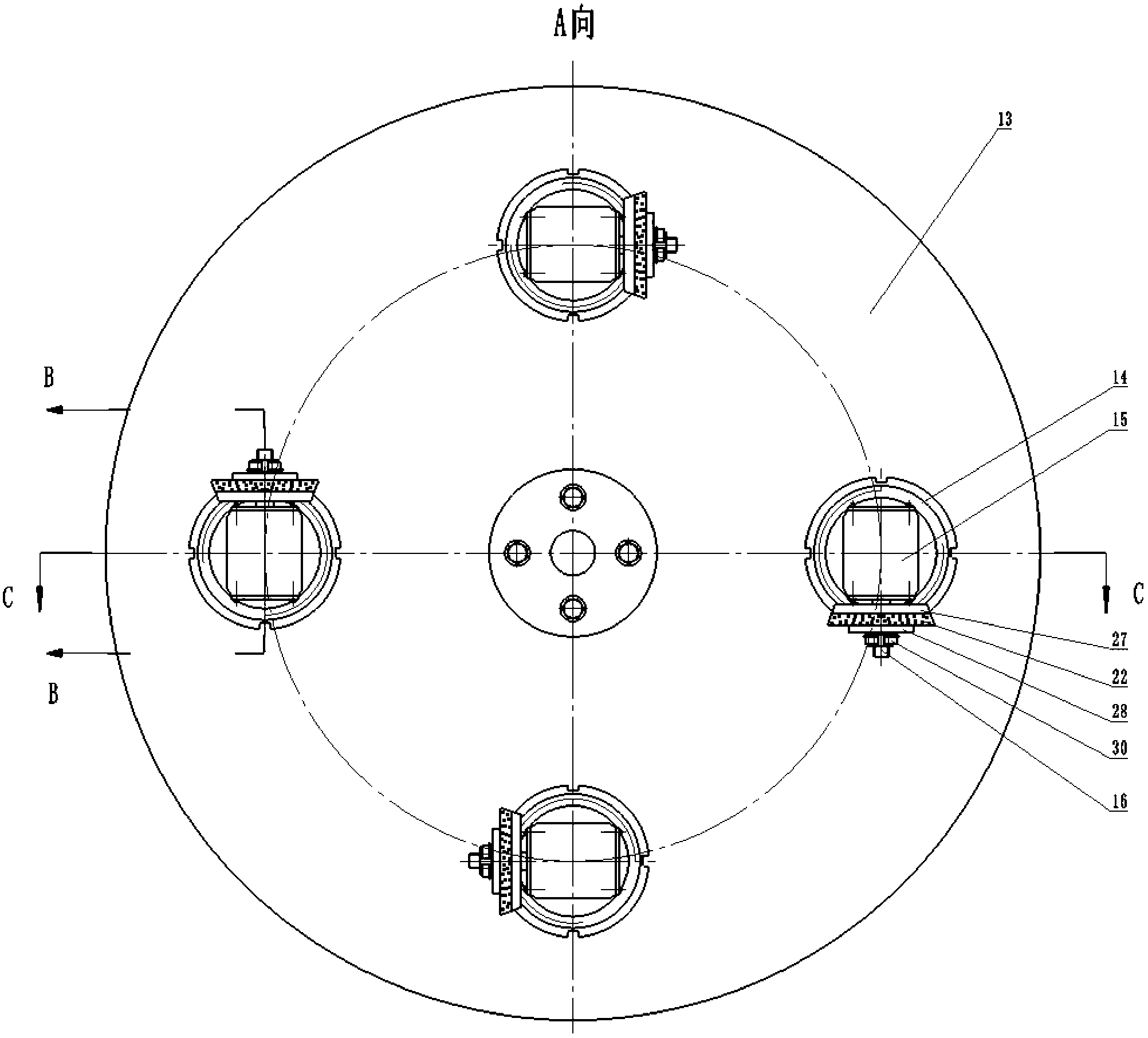

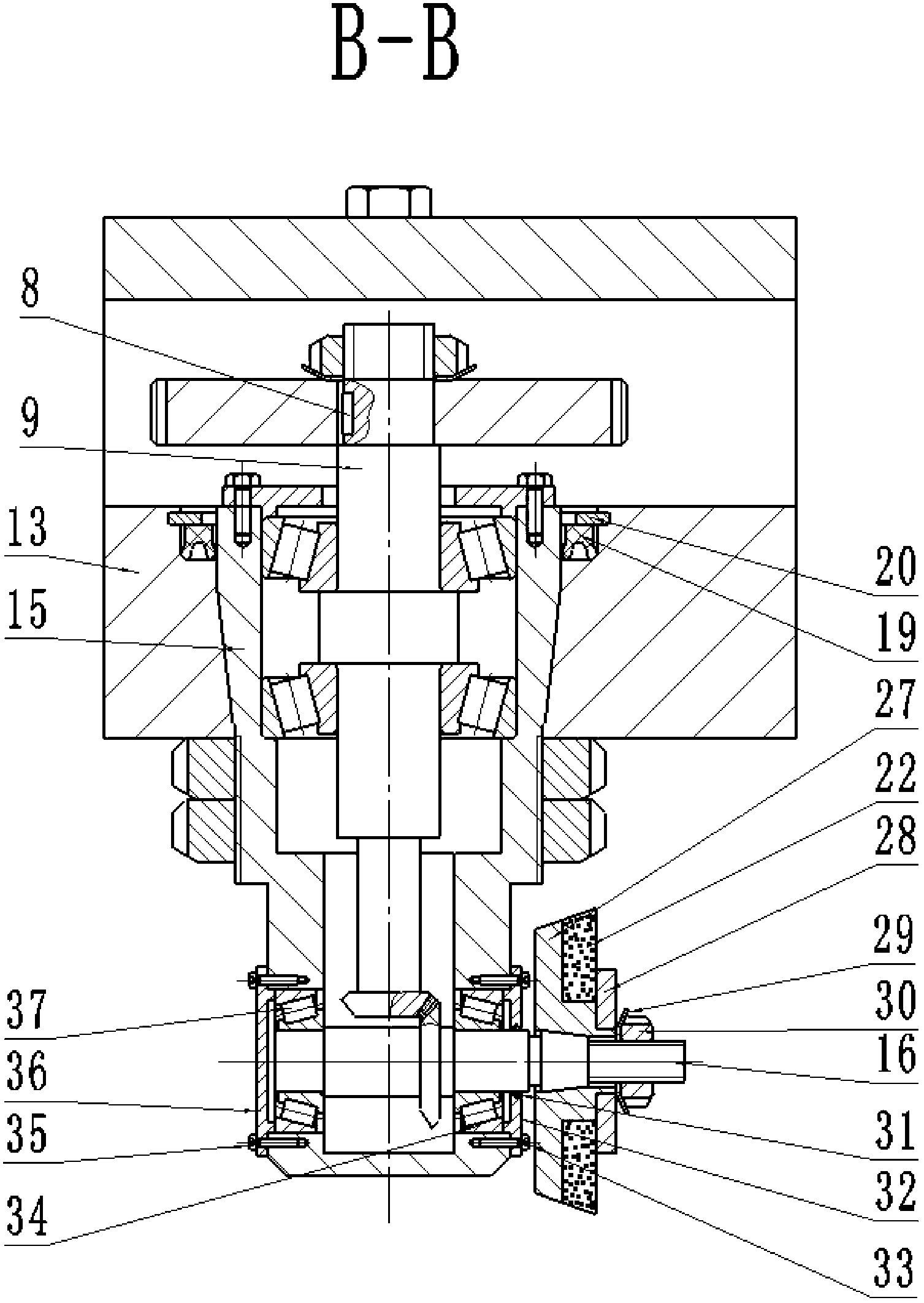

[0021] A special milling cutter for difficult-to-machine materials of the present invention such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes machine tool spindle box 1, machine tool rotating spindle 2, milling cutter positioning mandrel 3, fastening screw 4, center wheel frame 5, wheel frame bolt 6, upper round nut 7, flat key 8, planetary wheel shaft 9, upper Round nut stopper 10, upper cover plate 11, upper cover plate bolt 12, cutter head 13, lower round nut 14, planetary wheel sleeve cup 15, rotary cutter shaft 16, lower bearing 17, upper bearing 18, sealing ring 19, Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com