Patents

Literature

108results about How to "Improve wear characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

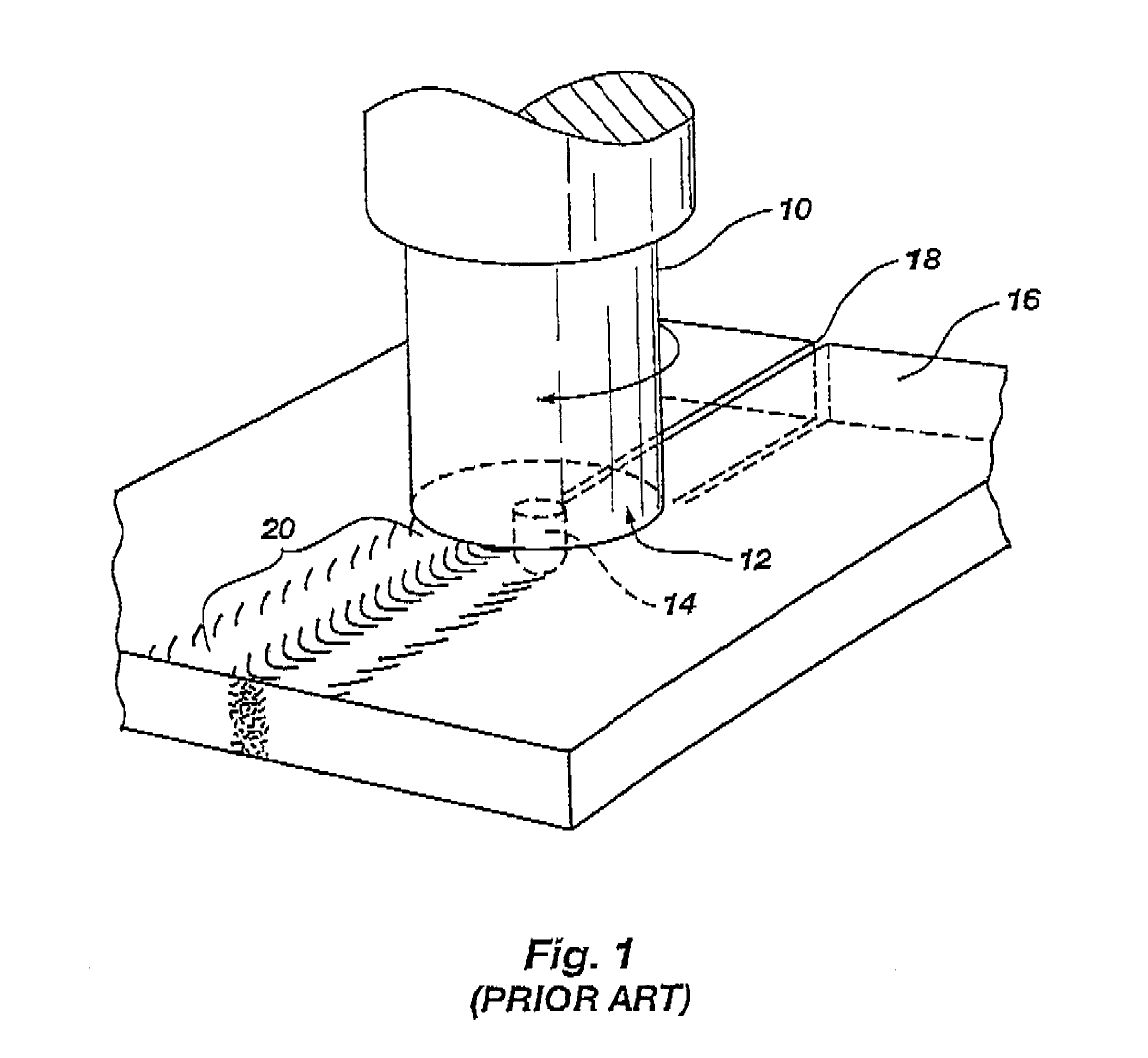

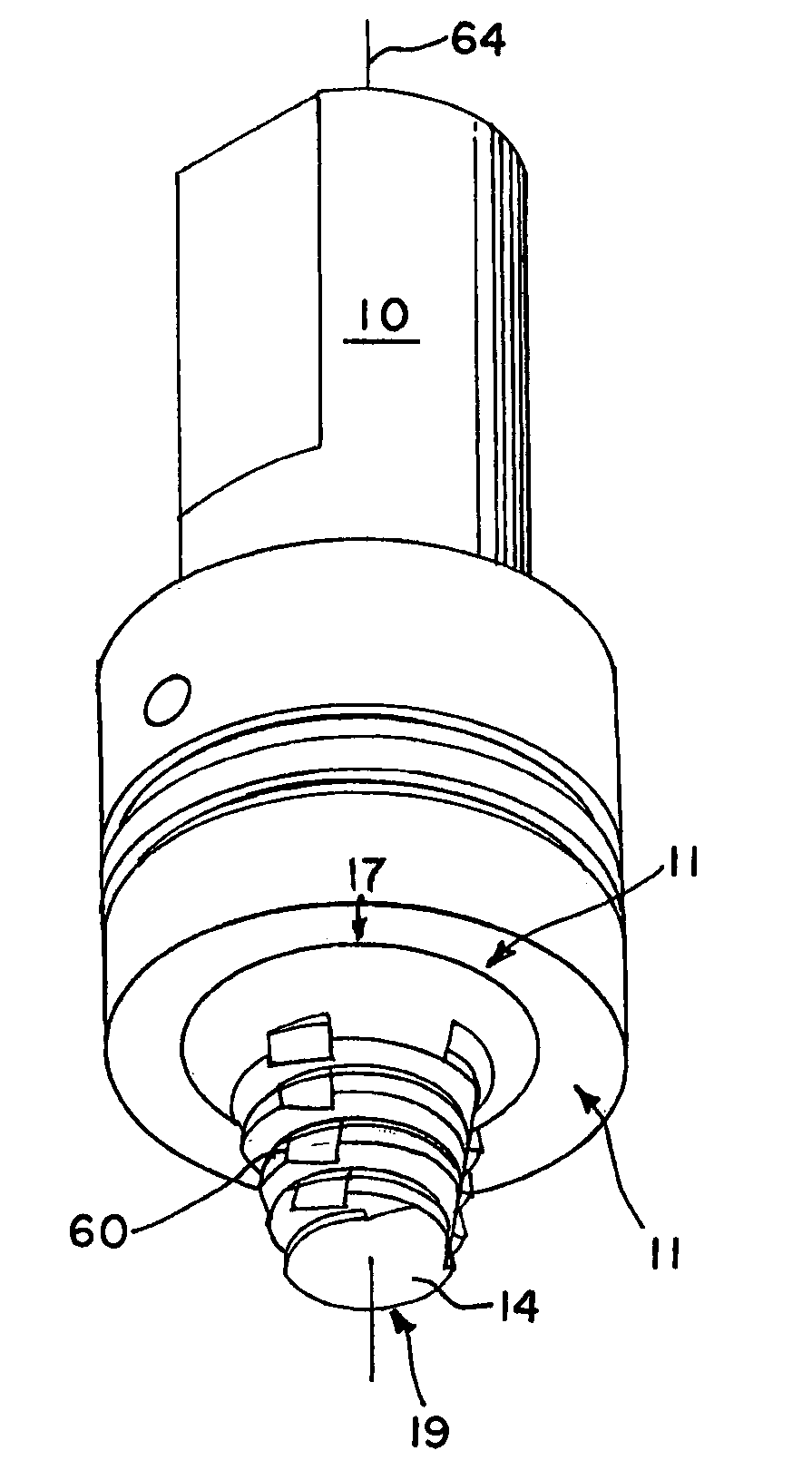

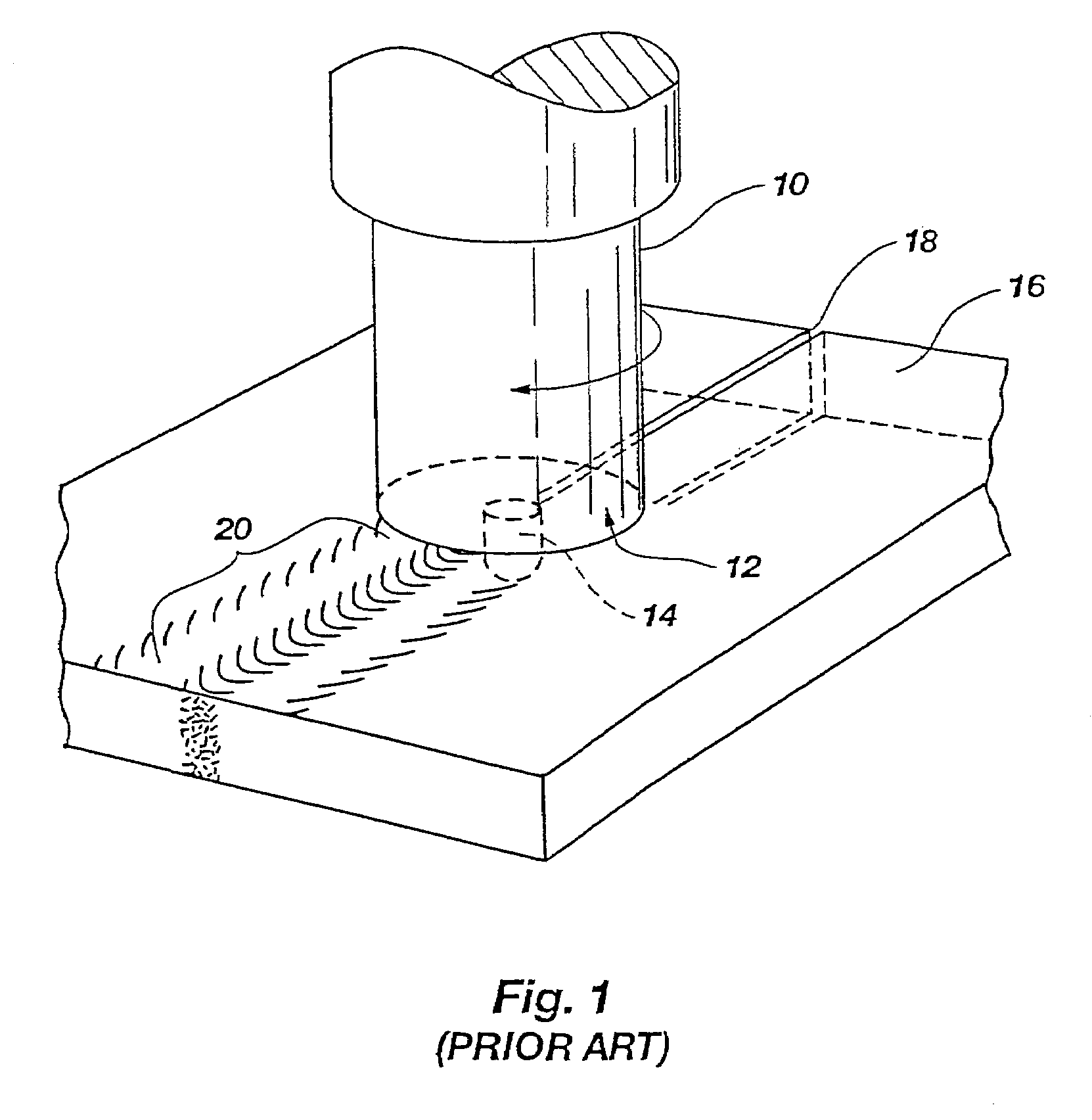

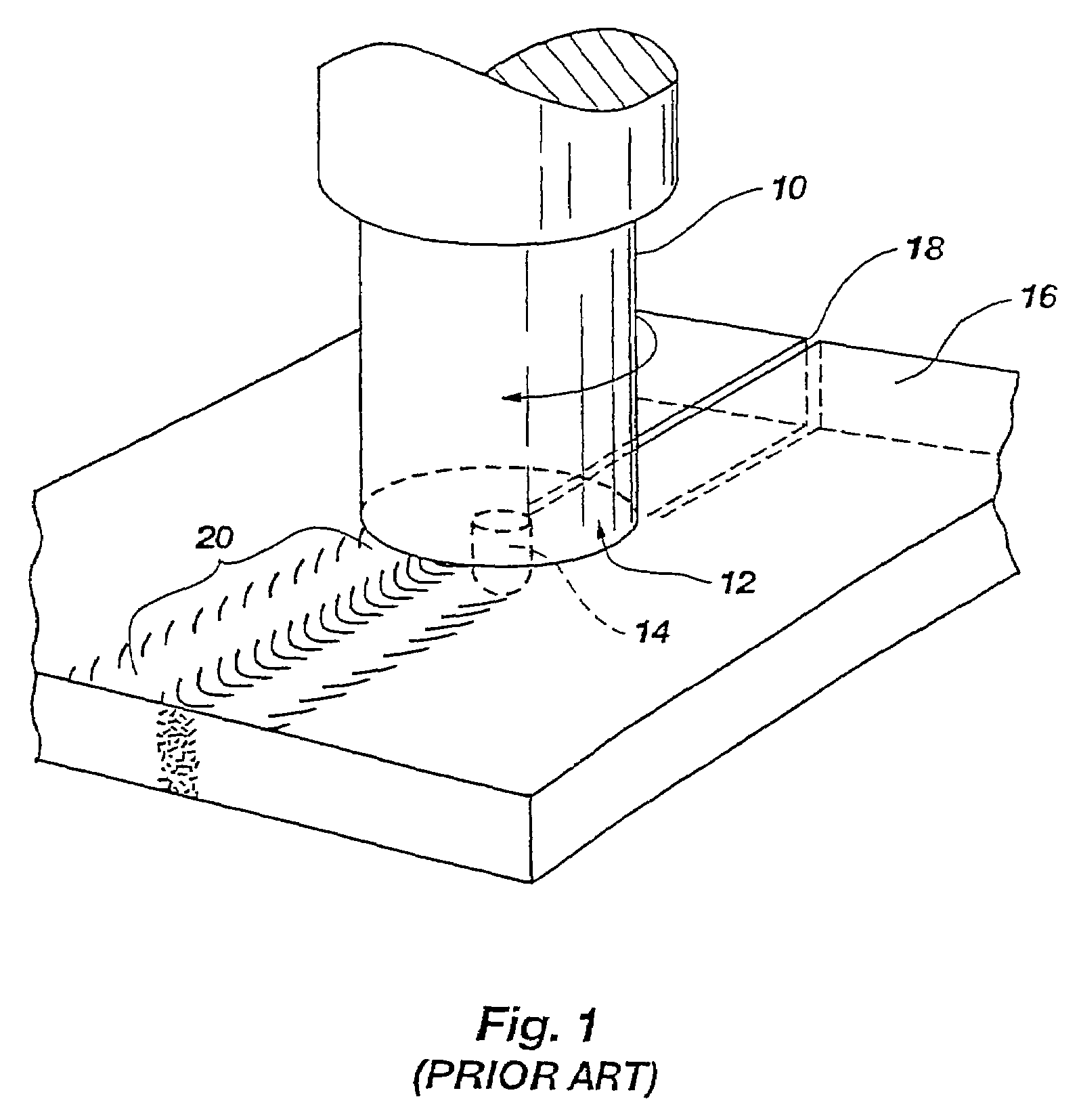

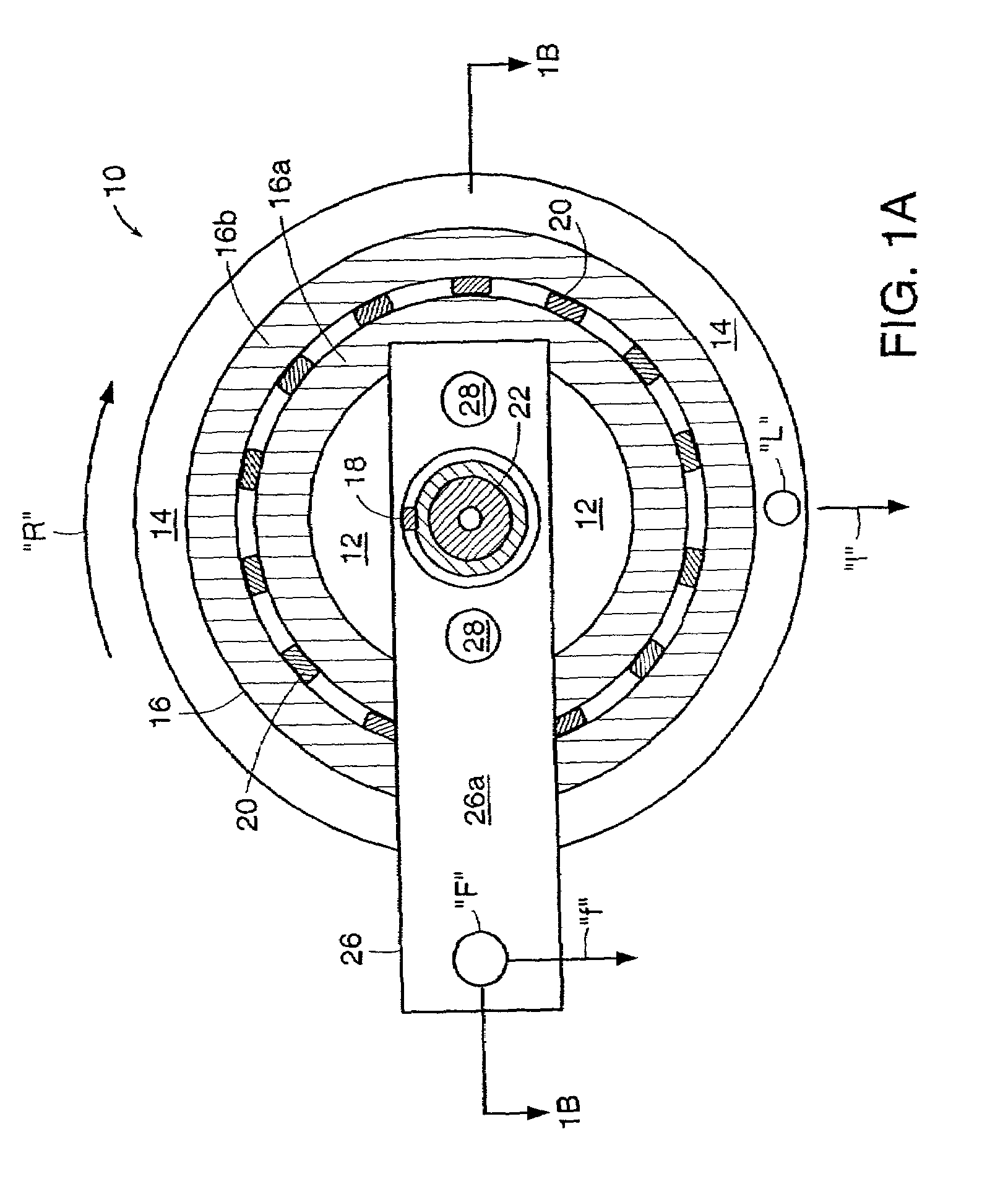

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

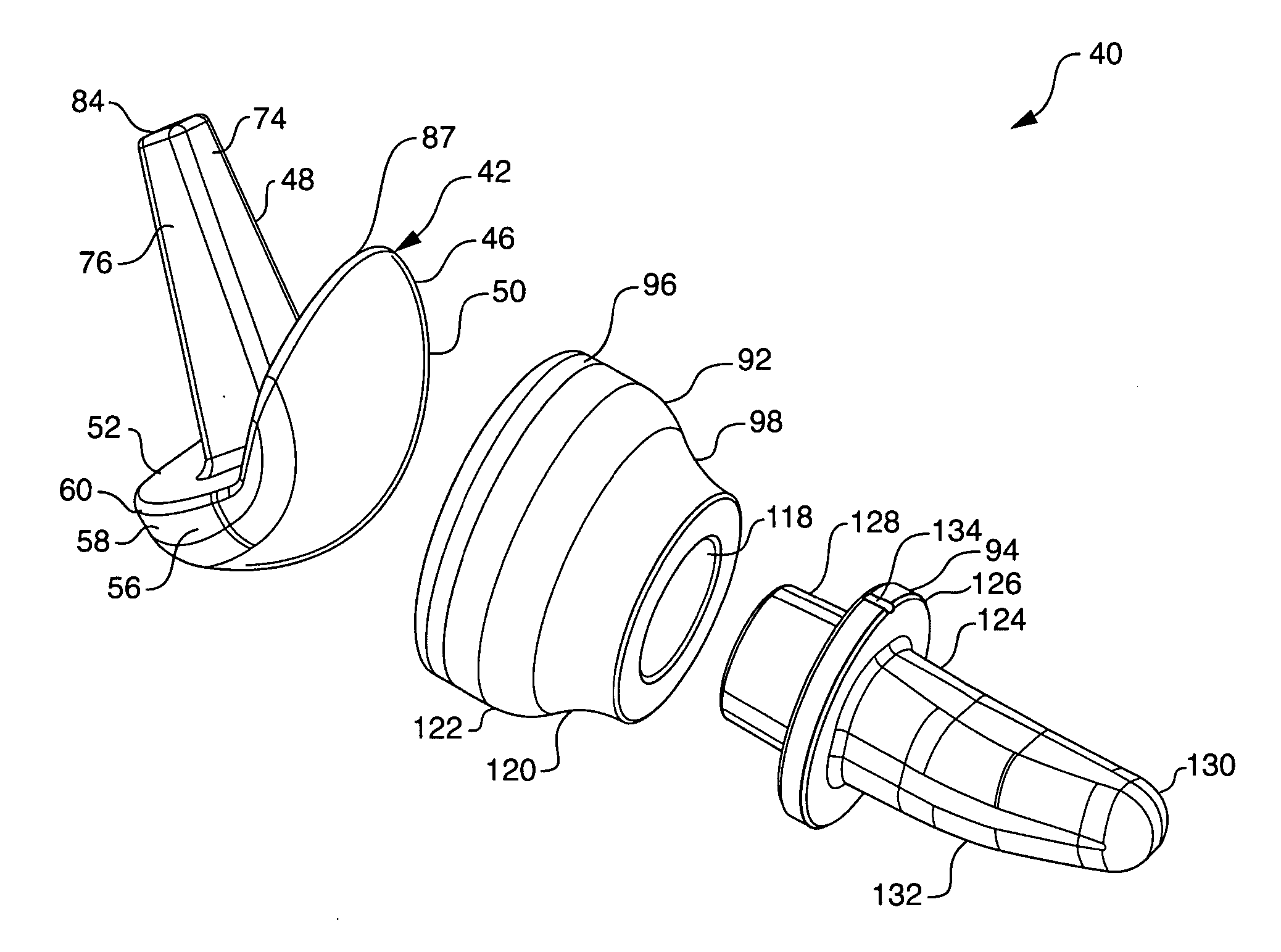

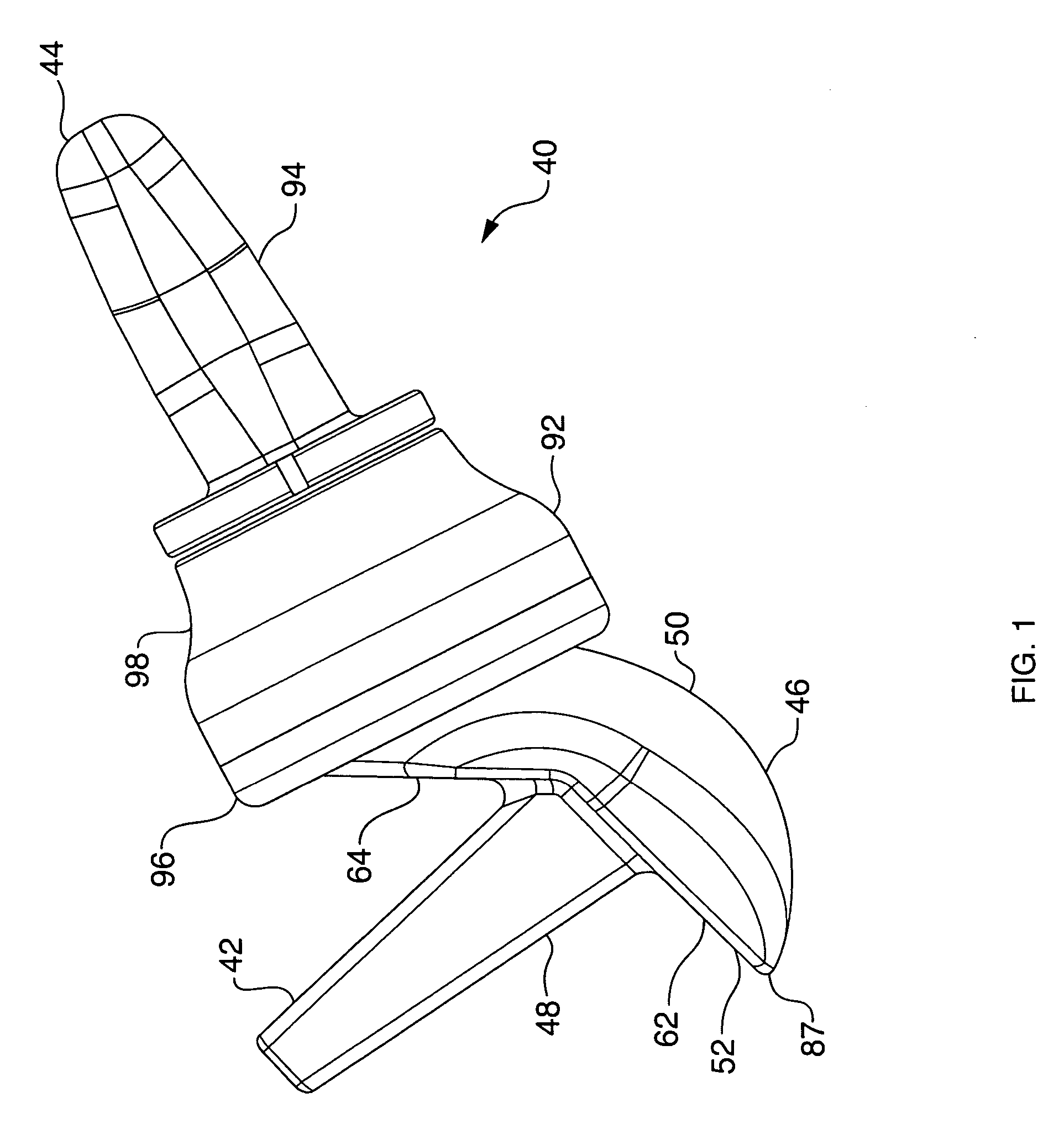

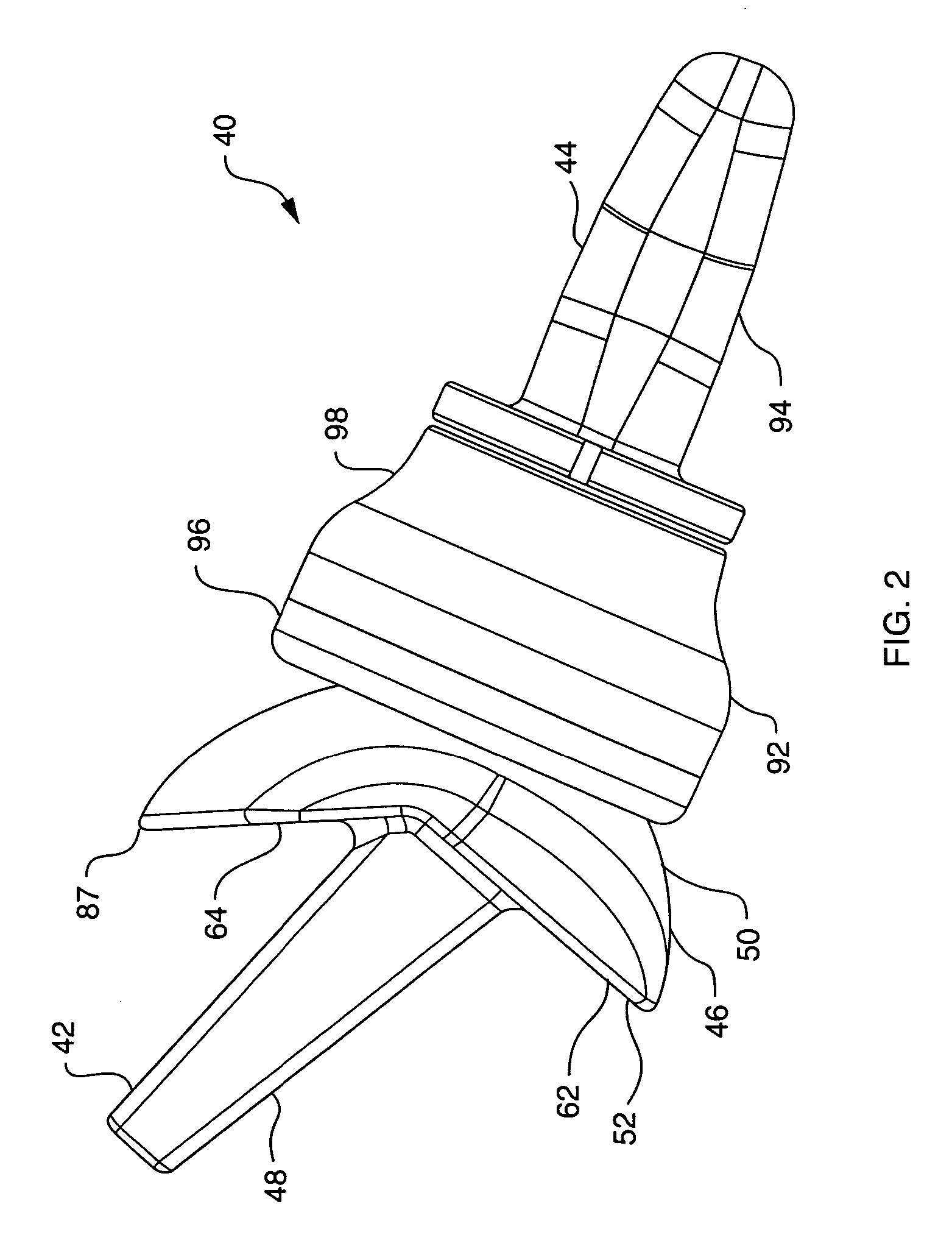

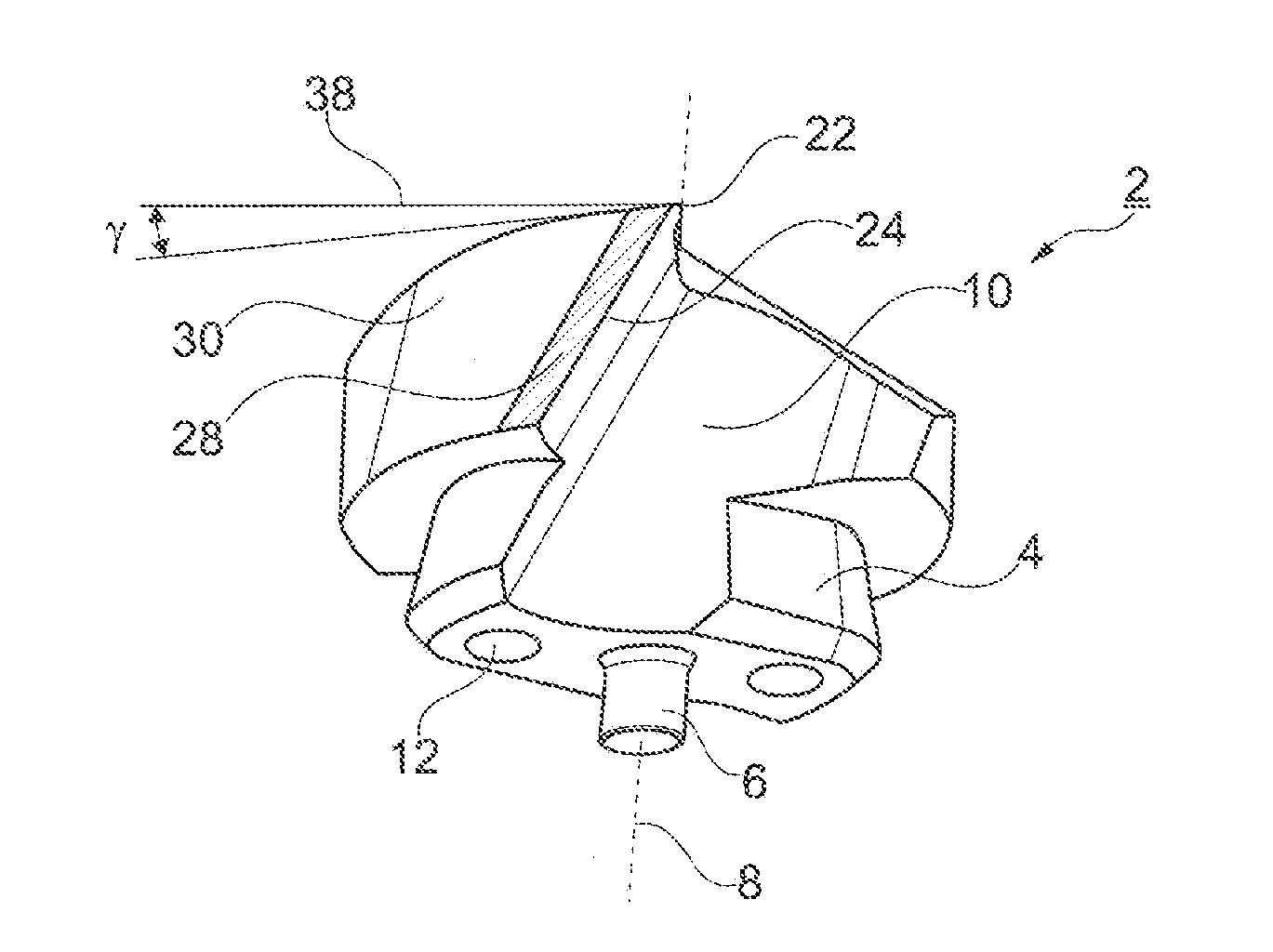

Radial-capitellar implant

ActiveUS20070073409A1Facilitates smooth glidingImprove wear characteristicsJoint implantsCoatingsArticular headHumerus

A radial-capitellar implant for surgical replacement of the capitellum of the humerus and, optionally, the head of the radius. The radial-capitellar implant includes a capitellar implant or surface replacement arthroplasty of the capitellum and a radial prosthesis for replacement of the head of the radius. In one embodiment the radial prosthesis includes an articular head which moveable articulates with a stem implantable in the radius.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

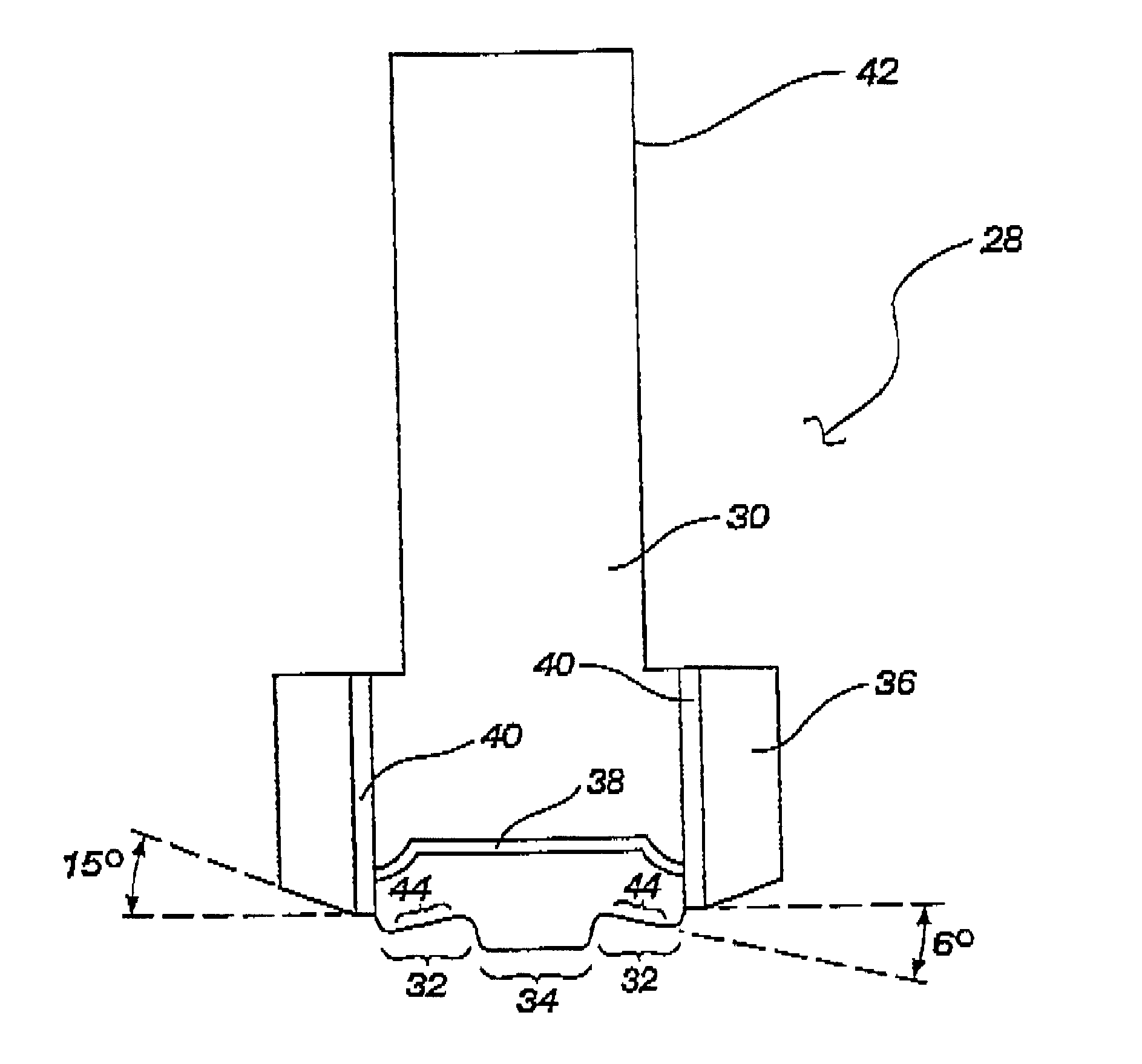

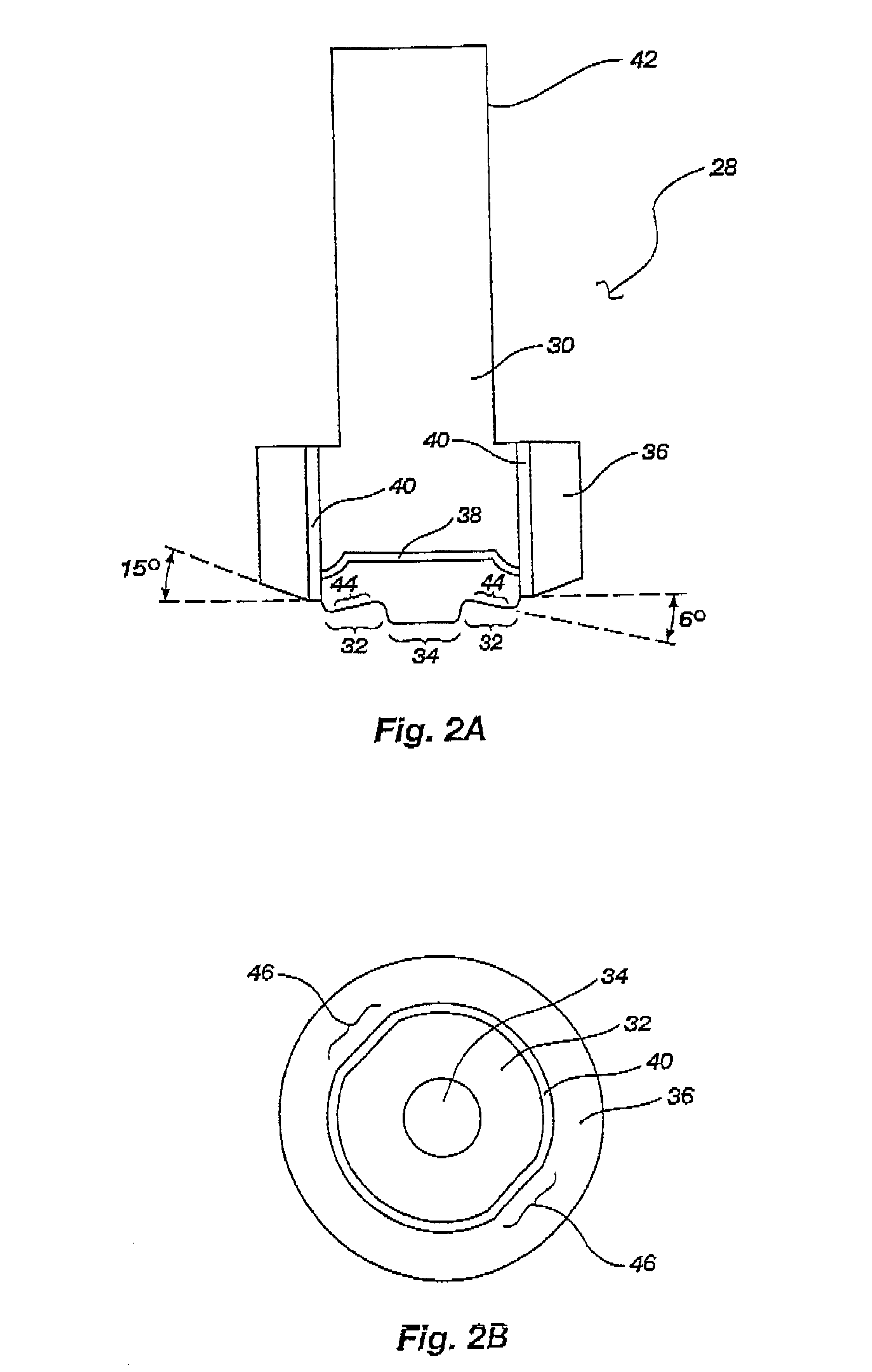

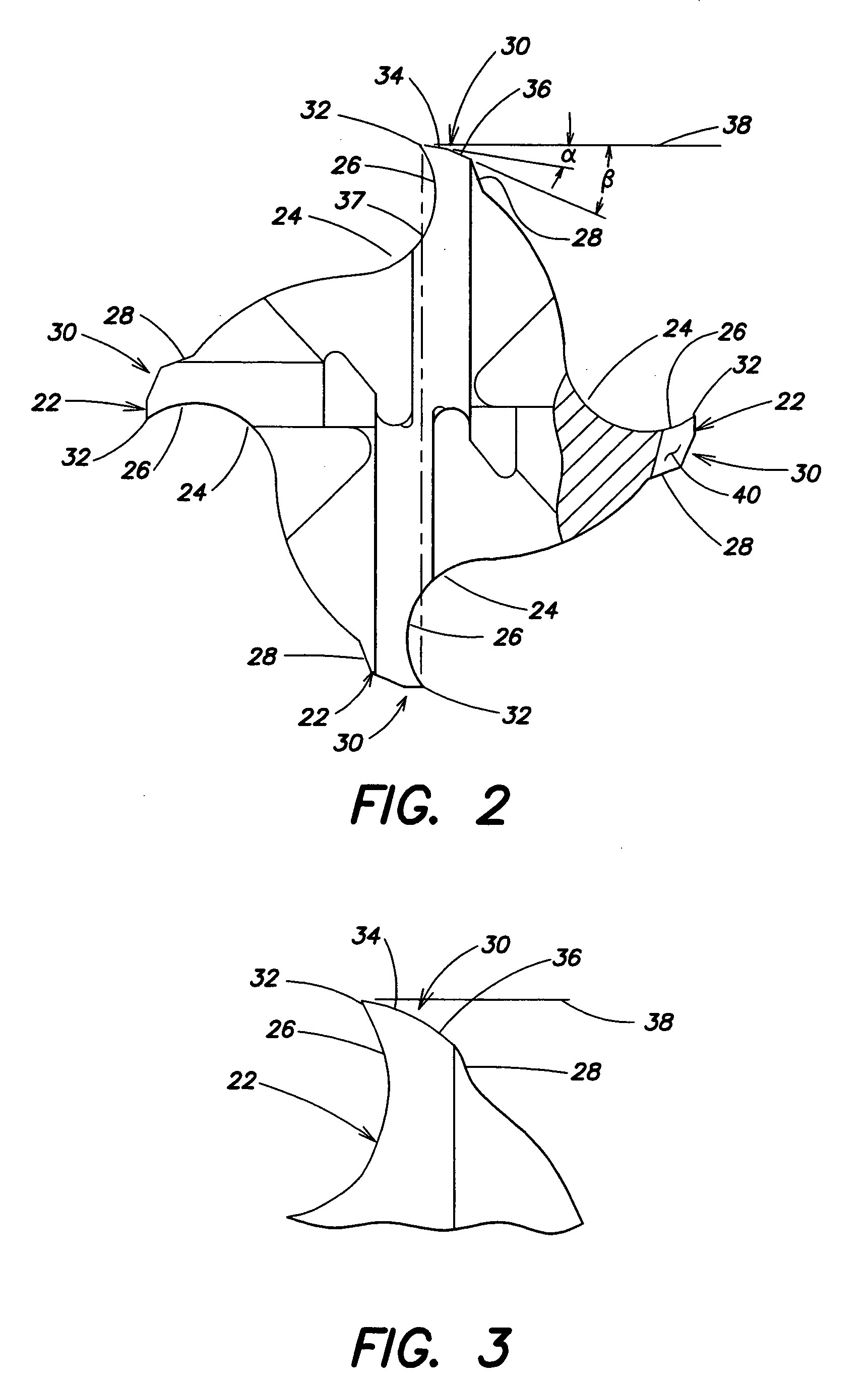

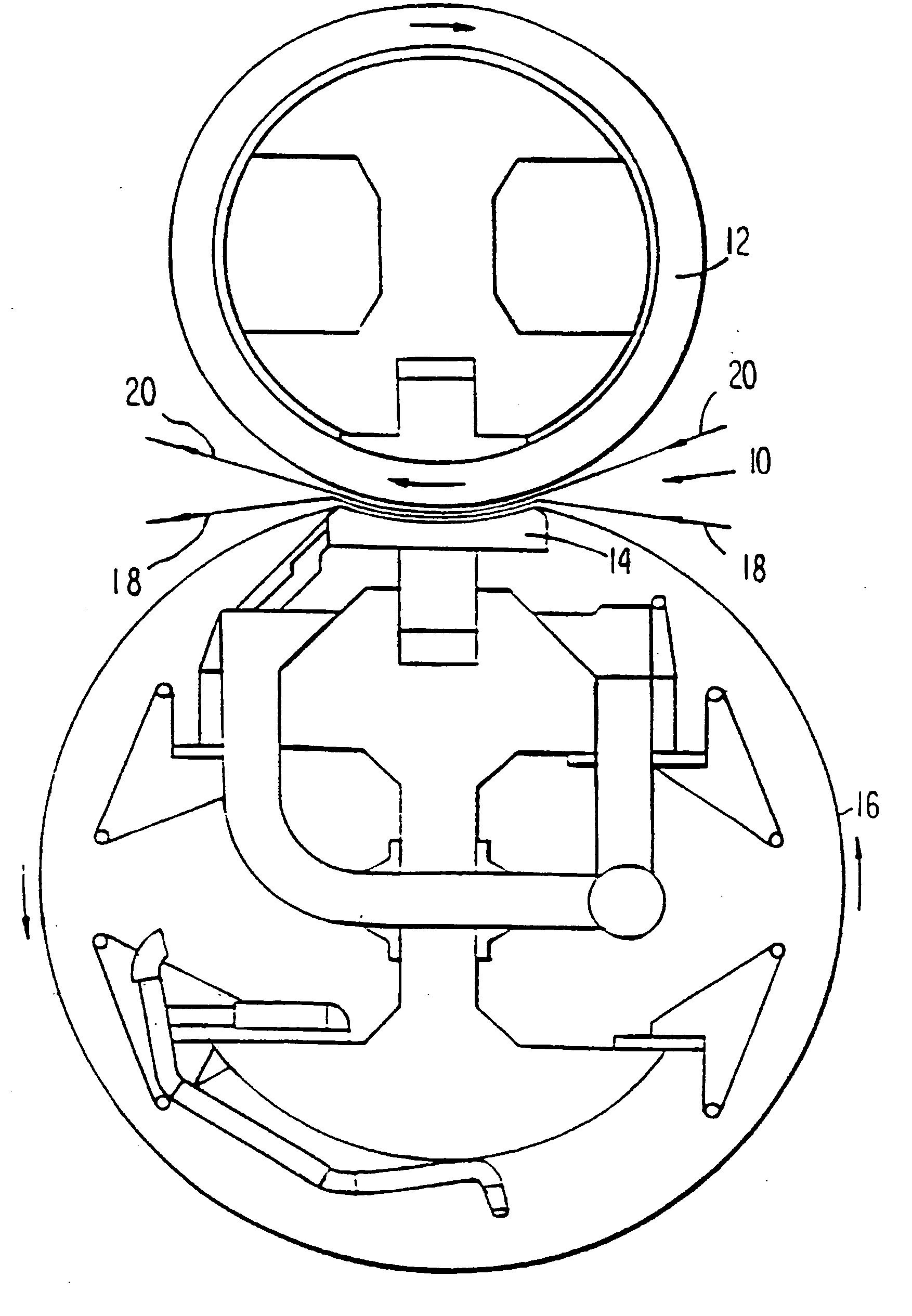

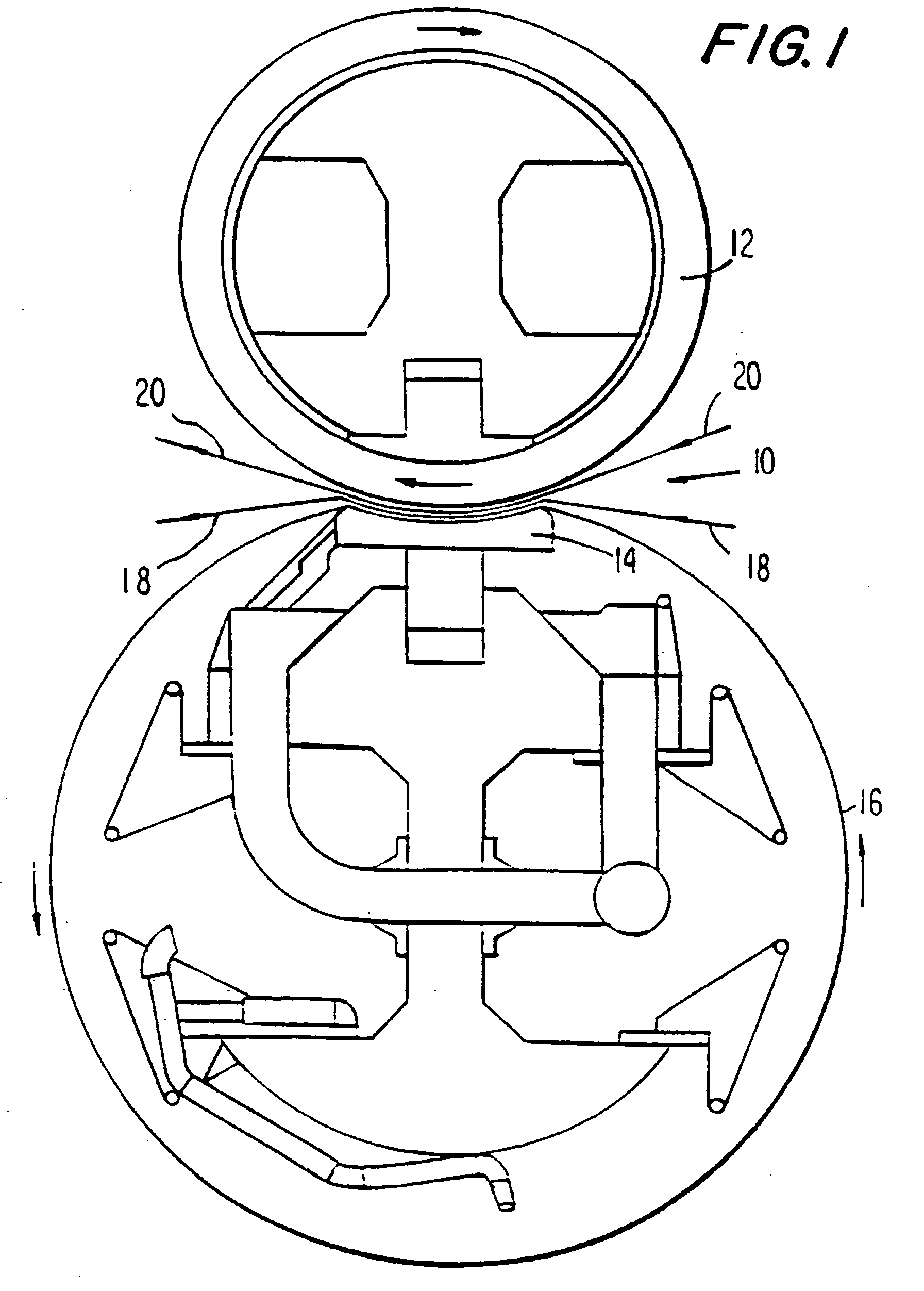

Friction stir weld tools

InactiveUS7275675B1Traverse speed is fastImprove tool lifeWelding/cutting auxillary devicesAuxillary welding devicesFluteToughness

A friction stir weld tool sleeve is supported by an underlying support pin. The pin material is preferably selected for toughness and fracture characteristics. The pin sleeve preferably has a geometry which employs the use of an interrupted thread, a plurality of flutes and / or eccentric path to provide greater flow through. Paddles have been found to assist in imparting friction and directing plastic metal during the welding process.

Owner:NASA

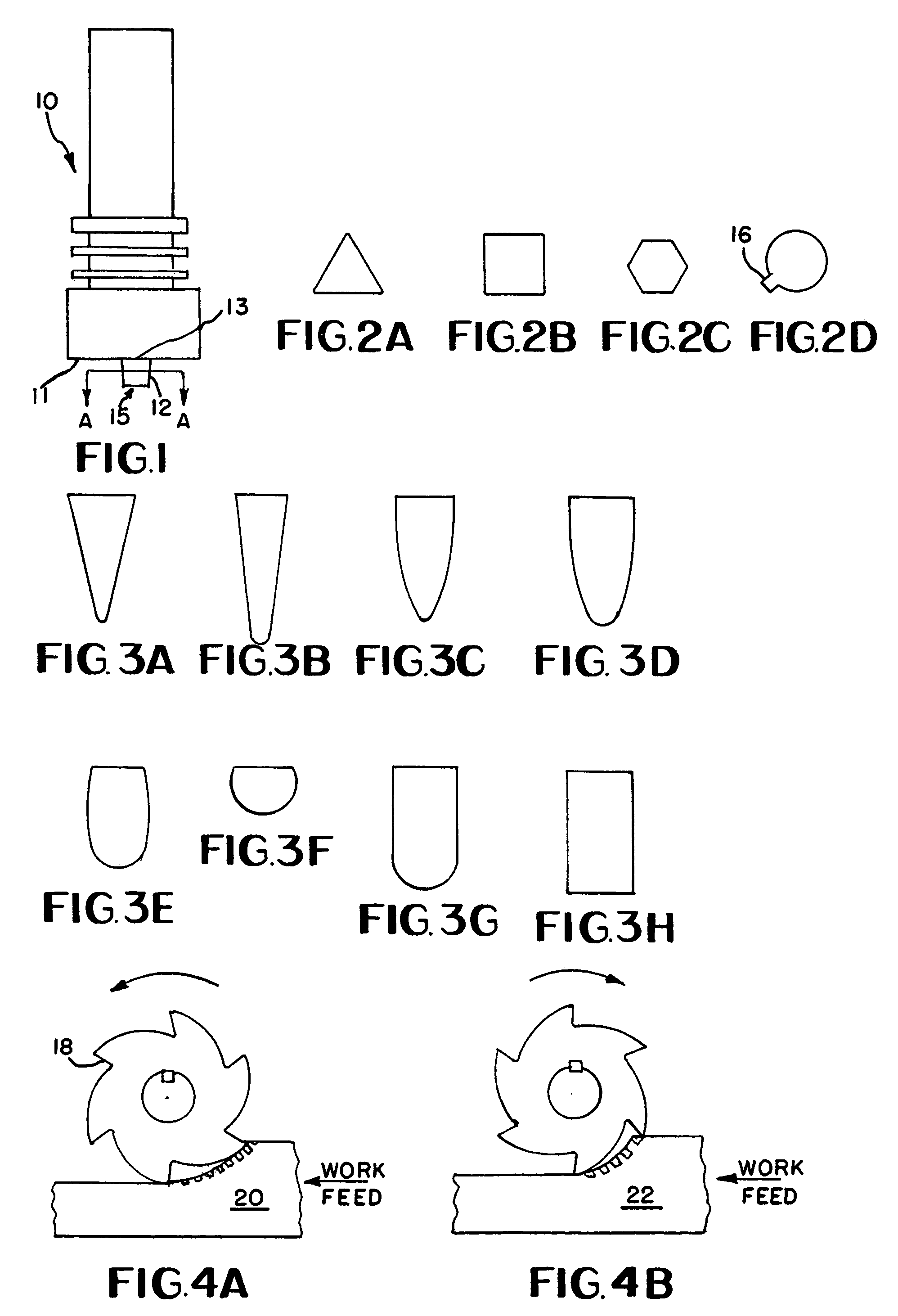

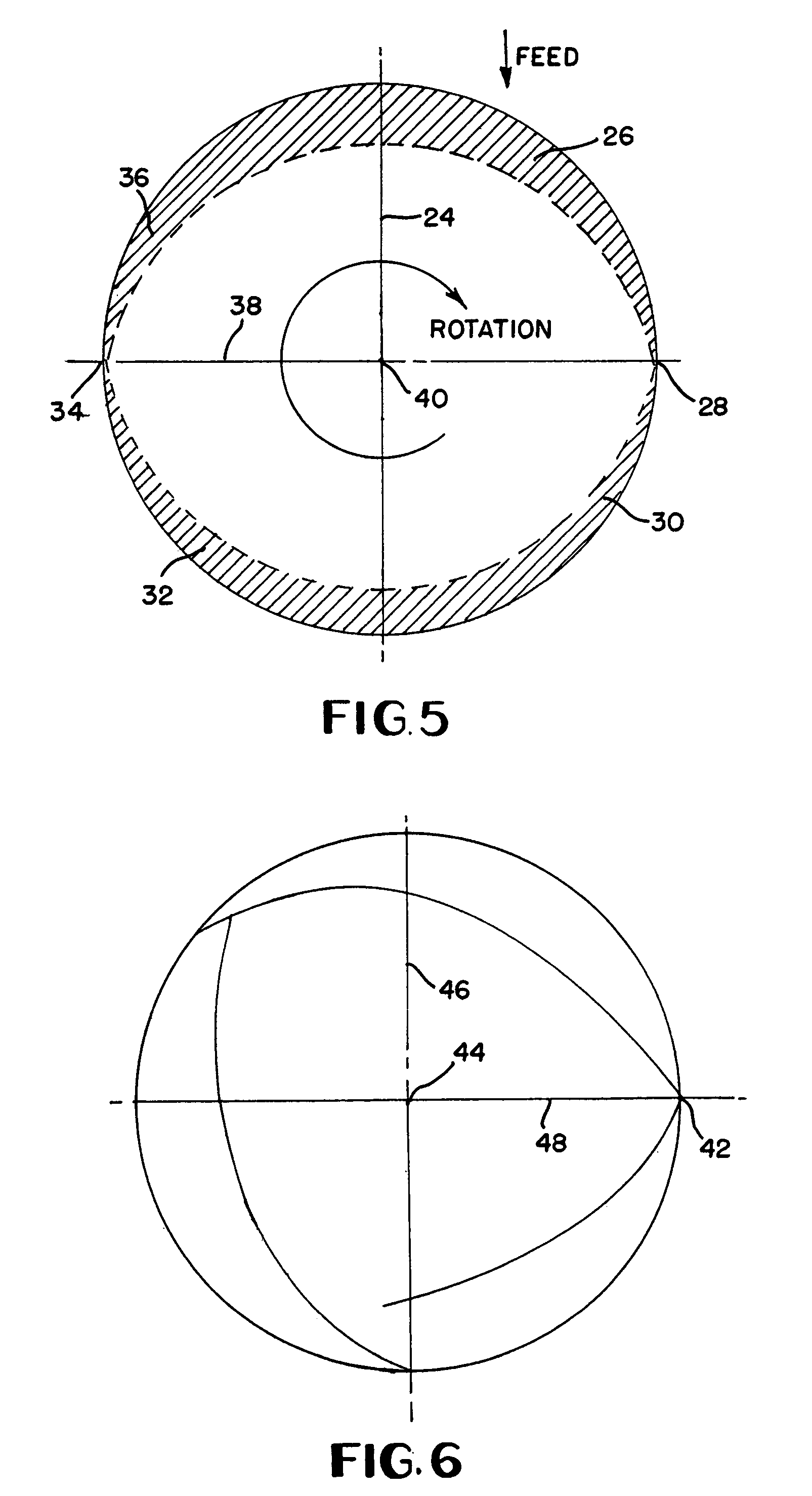

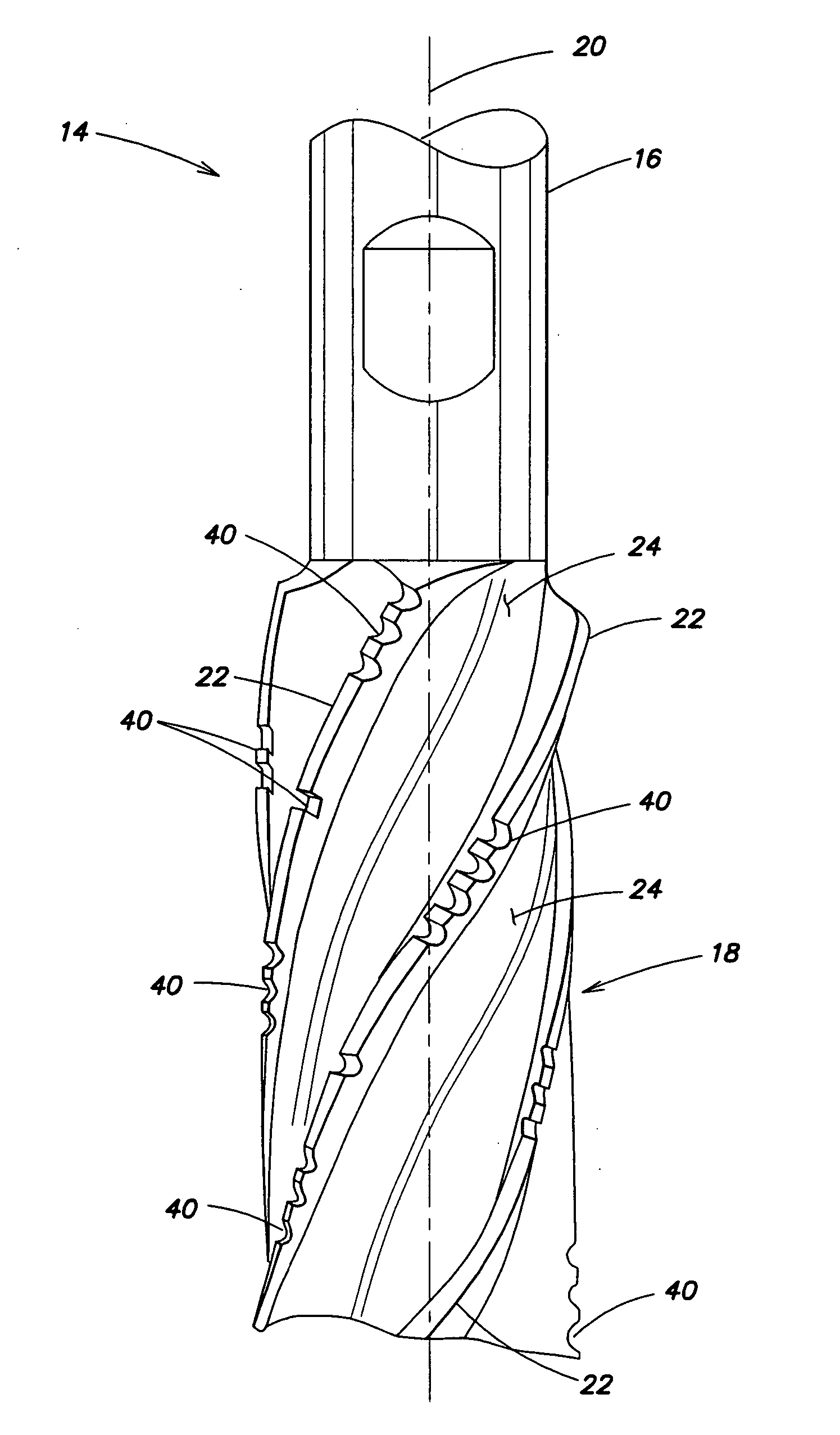

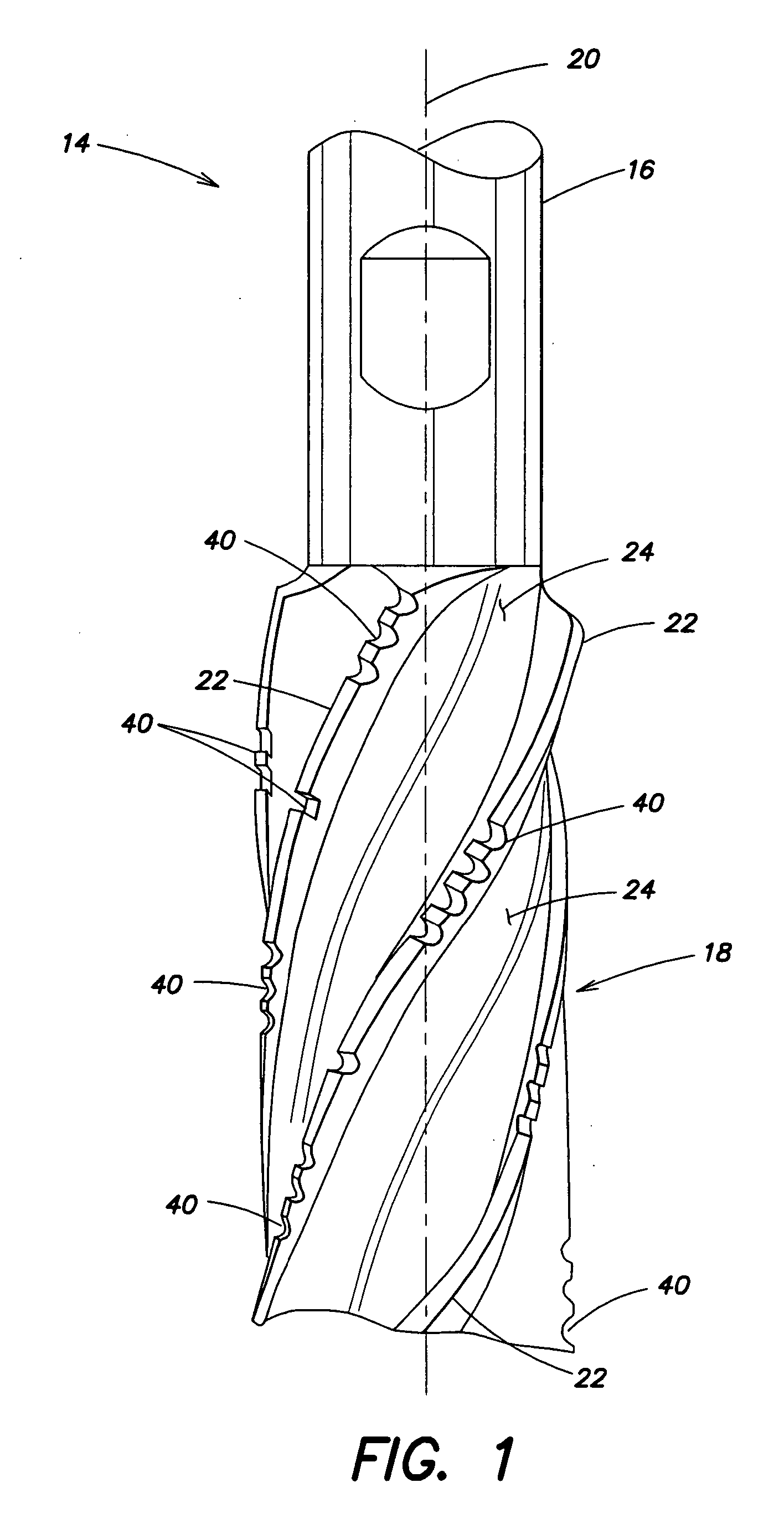

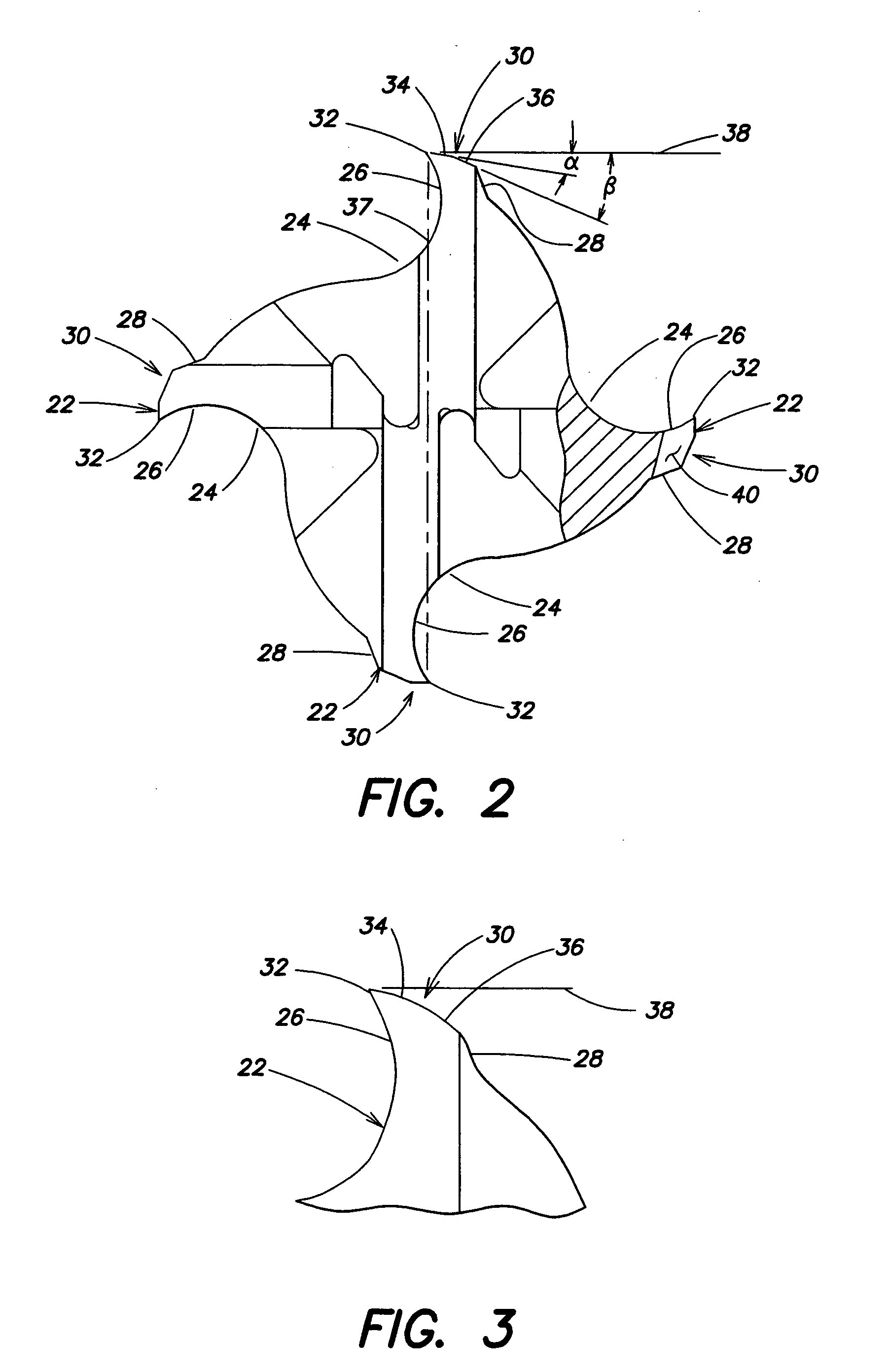

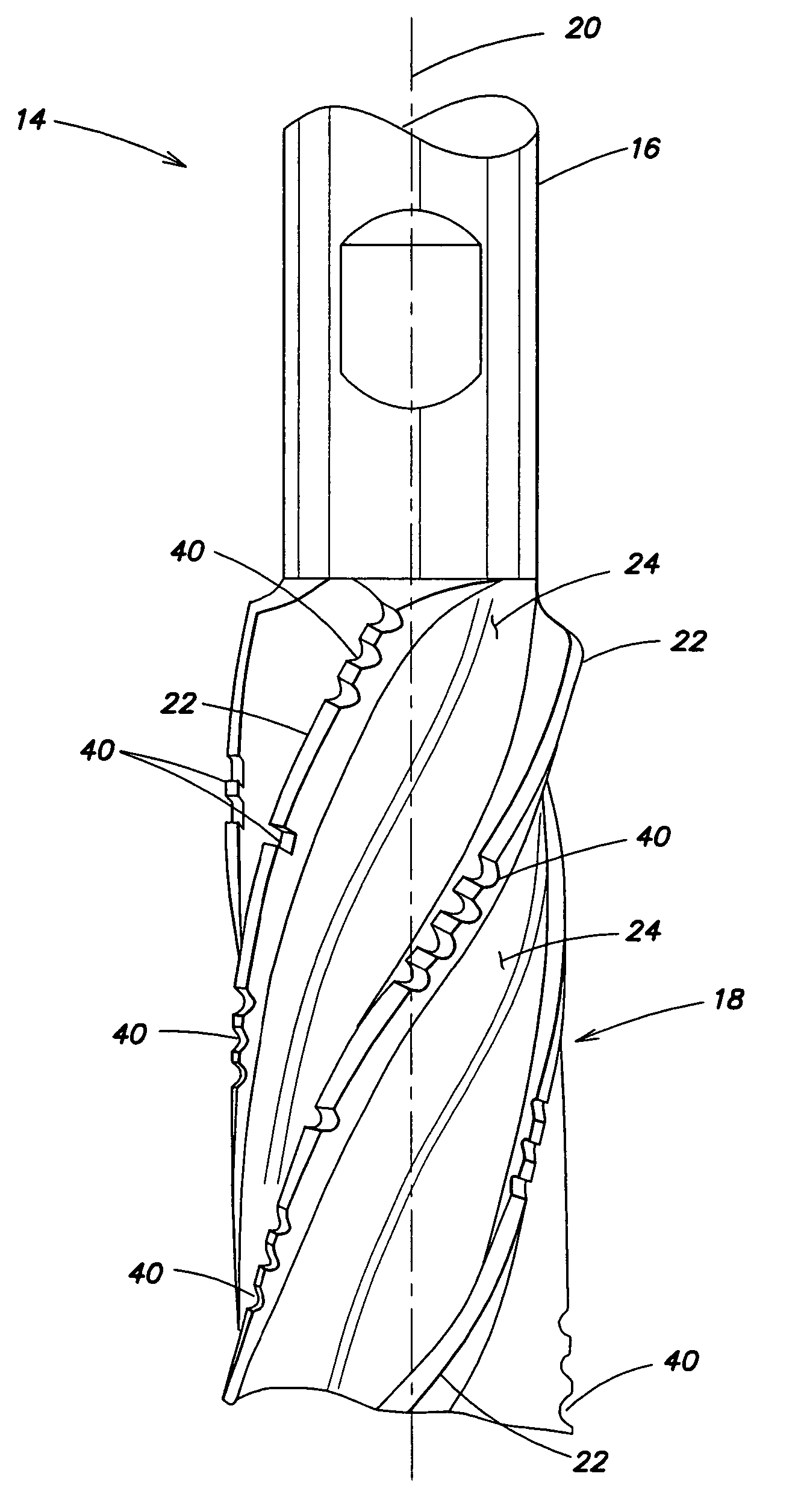

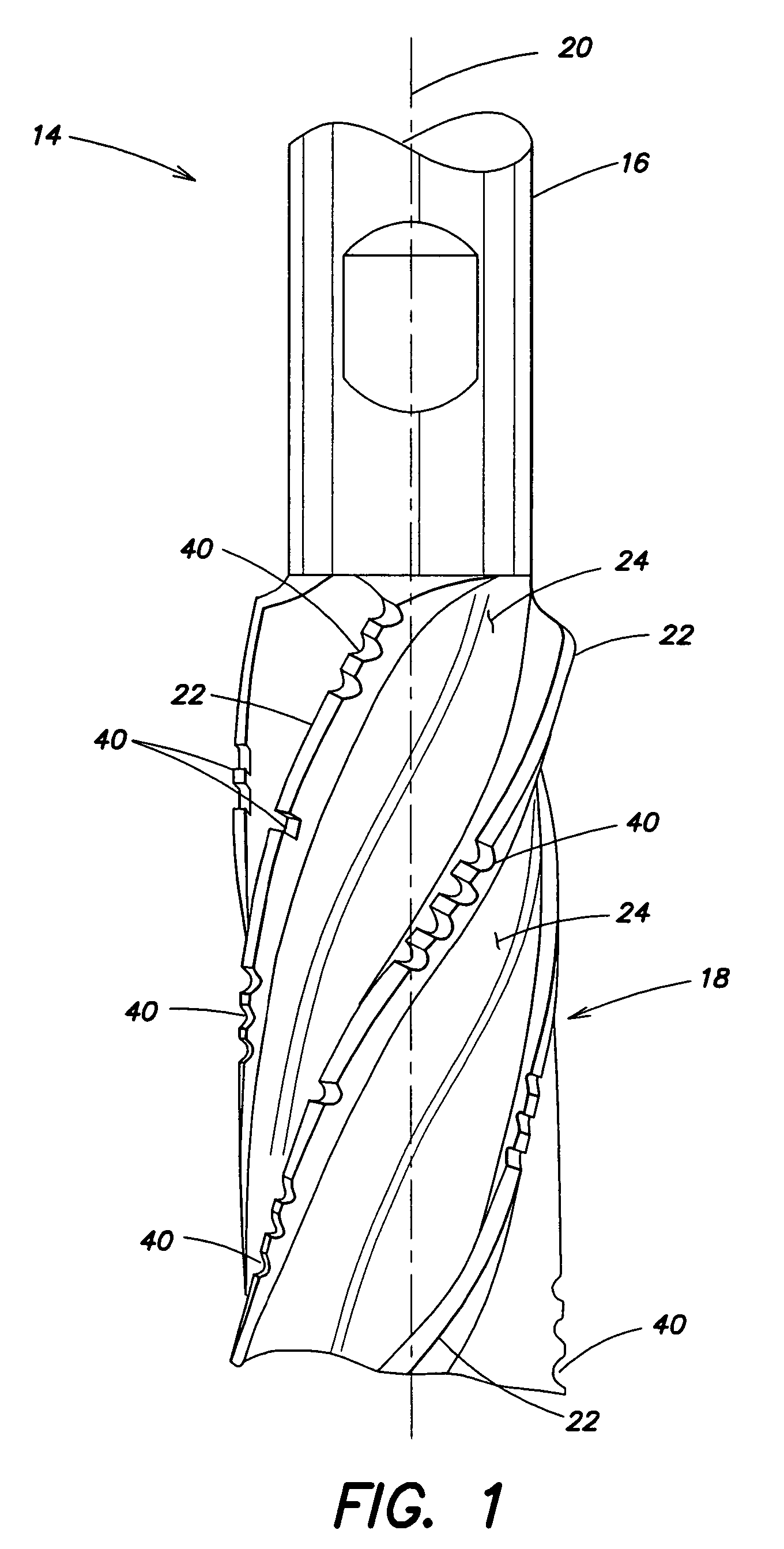

Rotary cutting tool with non-uniform distribution of chip-breaking features

ActiveUS20070098506A1Less materialCut performance be enhanceWood turning toolsTransportation and packagingFluteMechanical engineering

A rotary cutting tool with a longitudinal axis is provided that includes a shank portion, a cutting portion, and a plurality of chip-breaking features. The cutting portion, which extends out from the shank portion, includes a length, a plurality of blades and a plurality of flutes. The blades and flutes extend substantially all of the length of the cutting portion. Each blade includes a leading face side, a trailing face side, and a land surface that extends between the leading face side and the trailing face side. The plurality of chip-breaking features are disposed in the land surfaces of the blades, and non-uniformly distributed among the blades.

Owner:BERKSHIRE PRECISION TOOL

Radial-capitellar implant

ActiveUS7160329B2Facilitates smooth glidingImprove wear characteristicsJoint implantsCoatingsArticular headHumerus Head

A radial-capitellar implant for surgical replacement of the capitellum of the humerus and, optionally, the head of the radius. The radial-capitellar implant includes a capitellar implant or surface replacement arthroplasty of the capitellum and a radial prosthesis for replacement of the head of the radius. In one embodiment the radial prosthesis includes an articular head which moveable articulates with a stem implantable in the radius.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

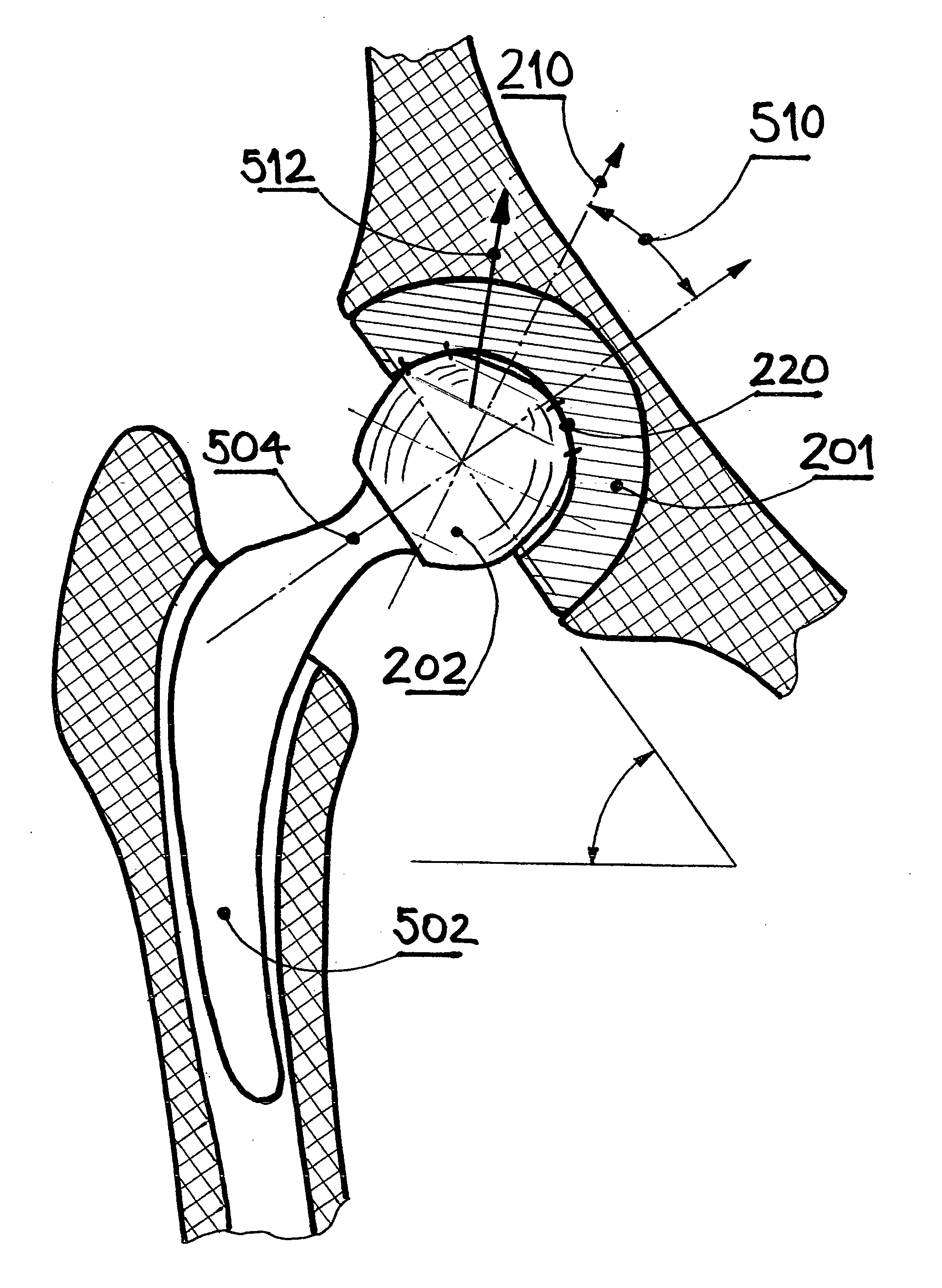

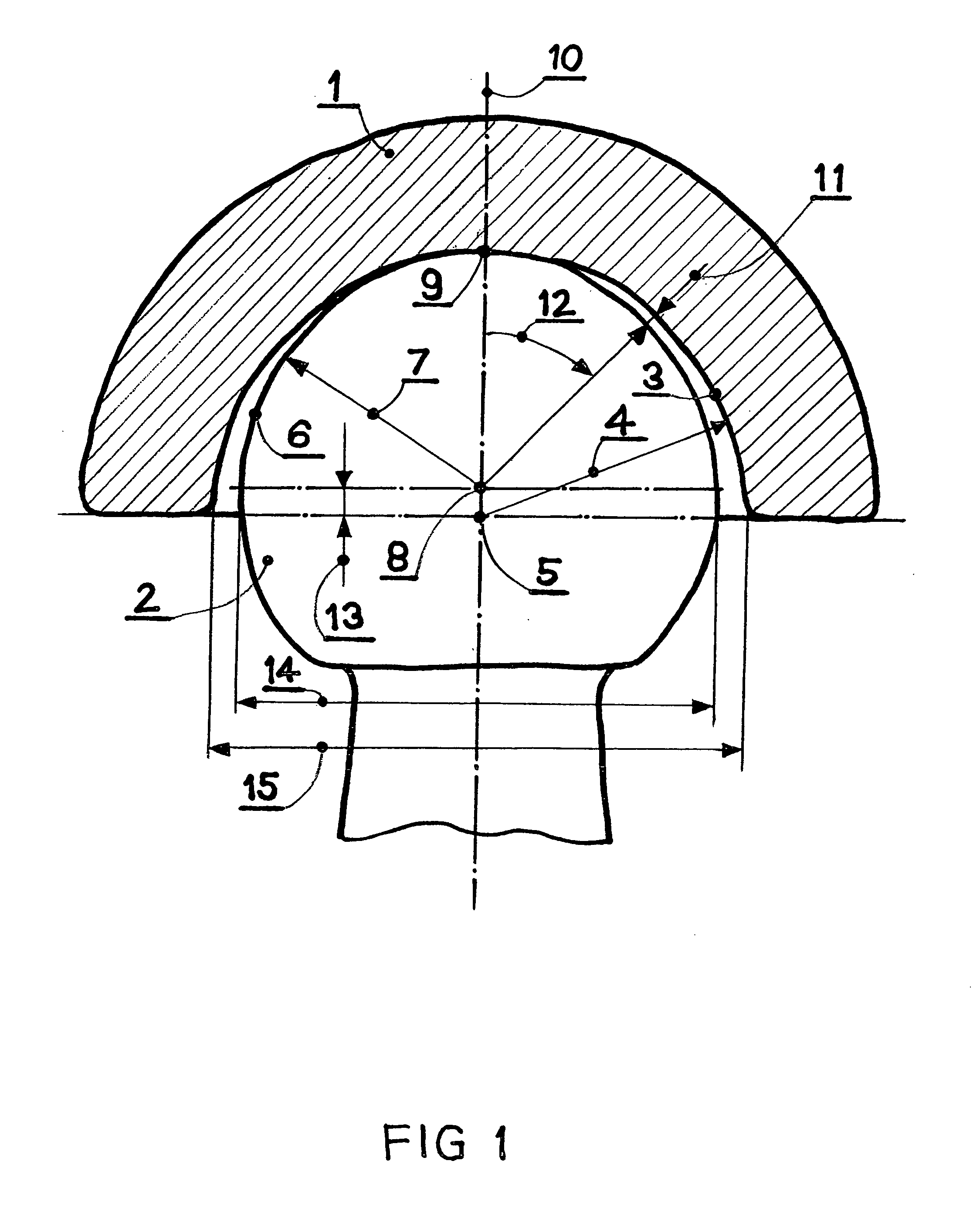

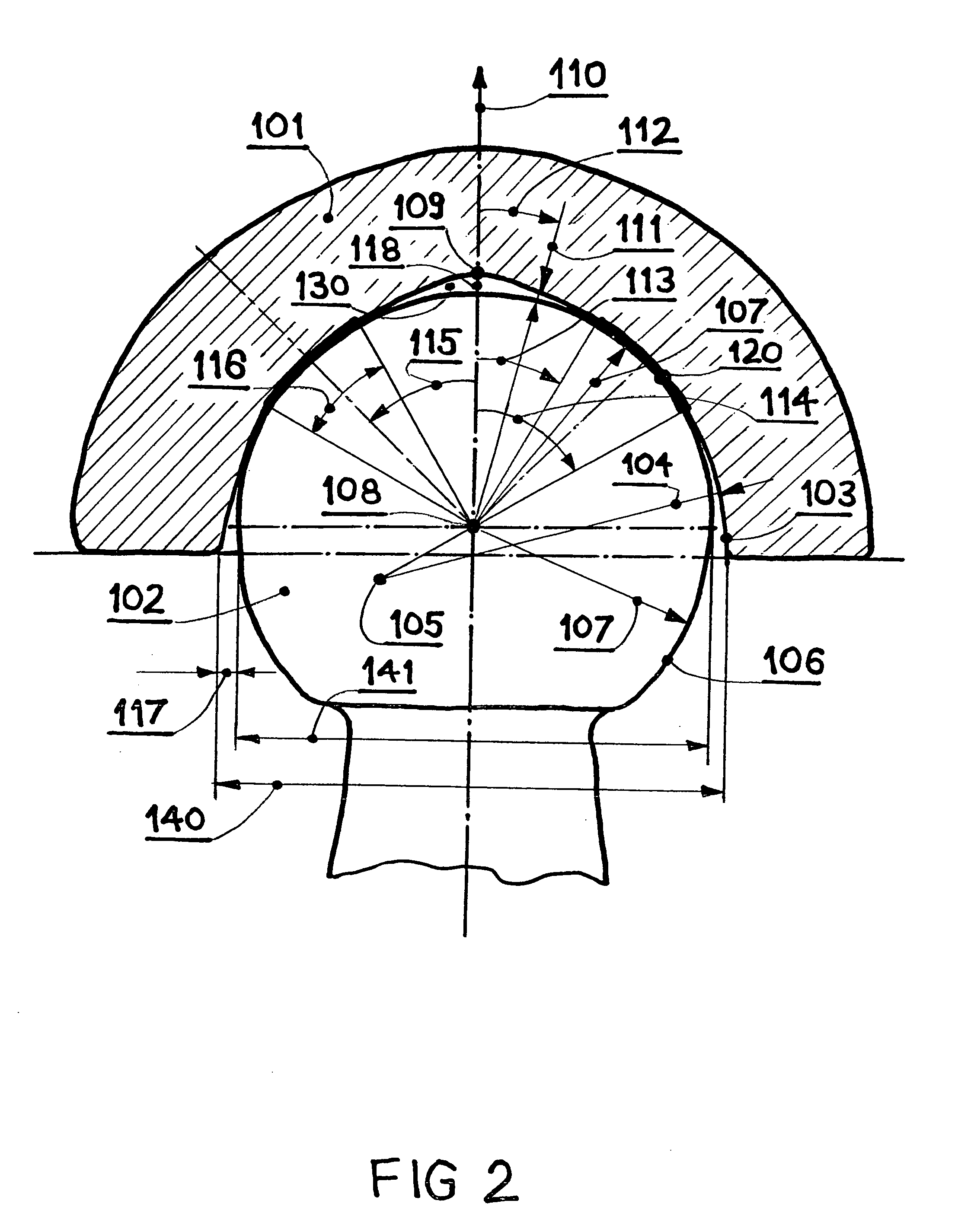

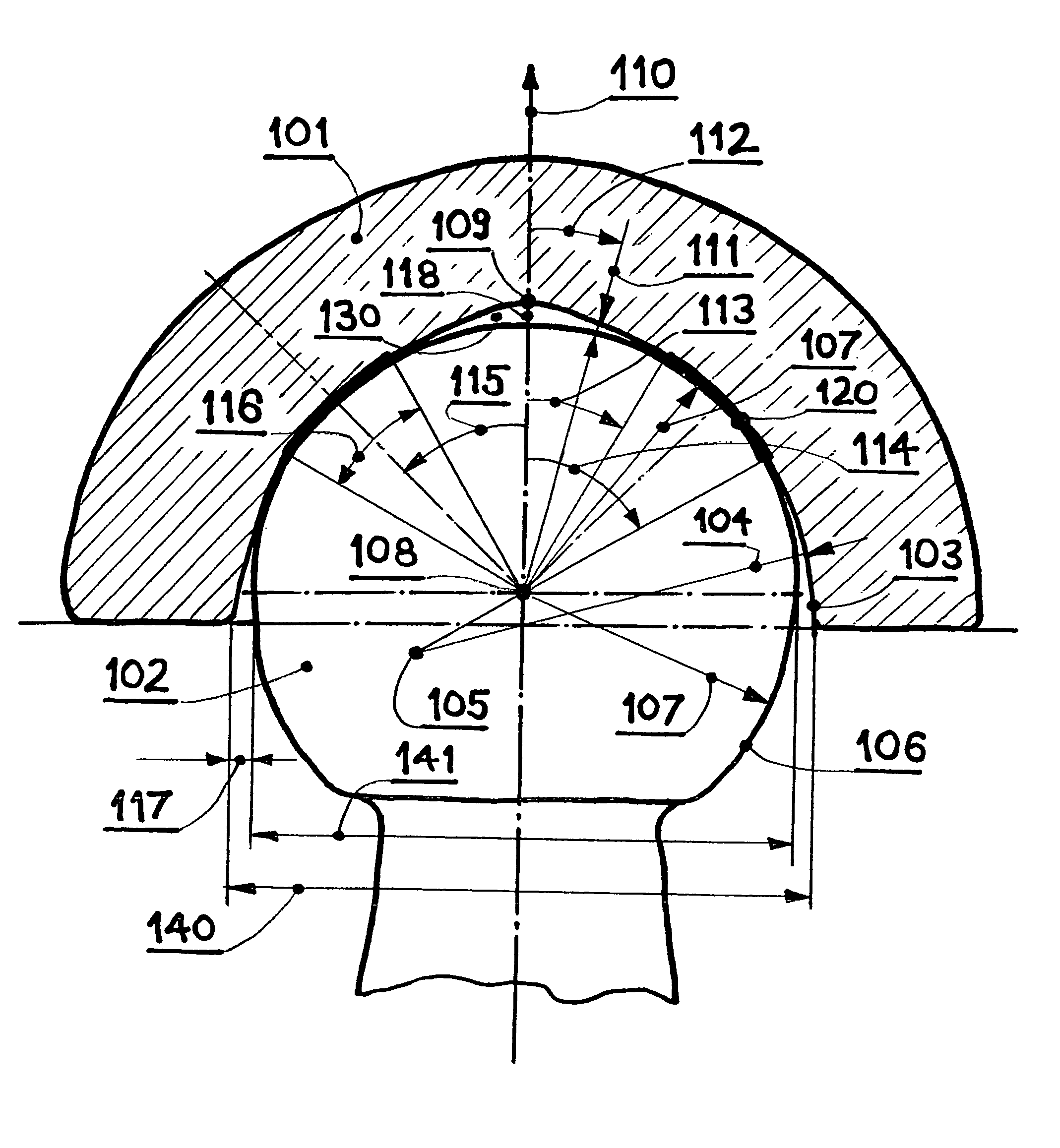

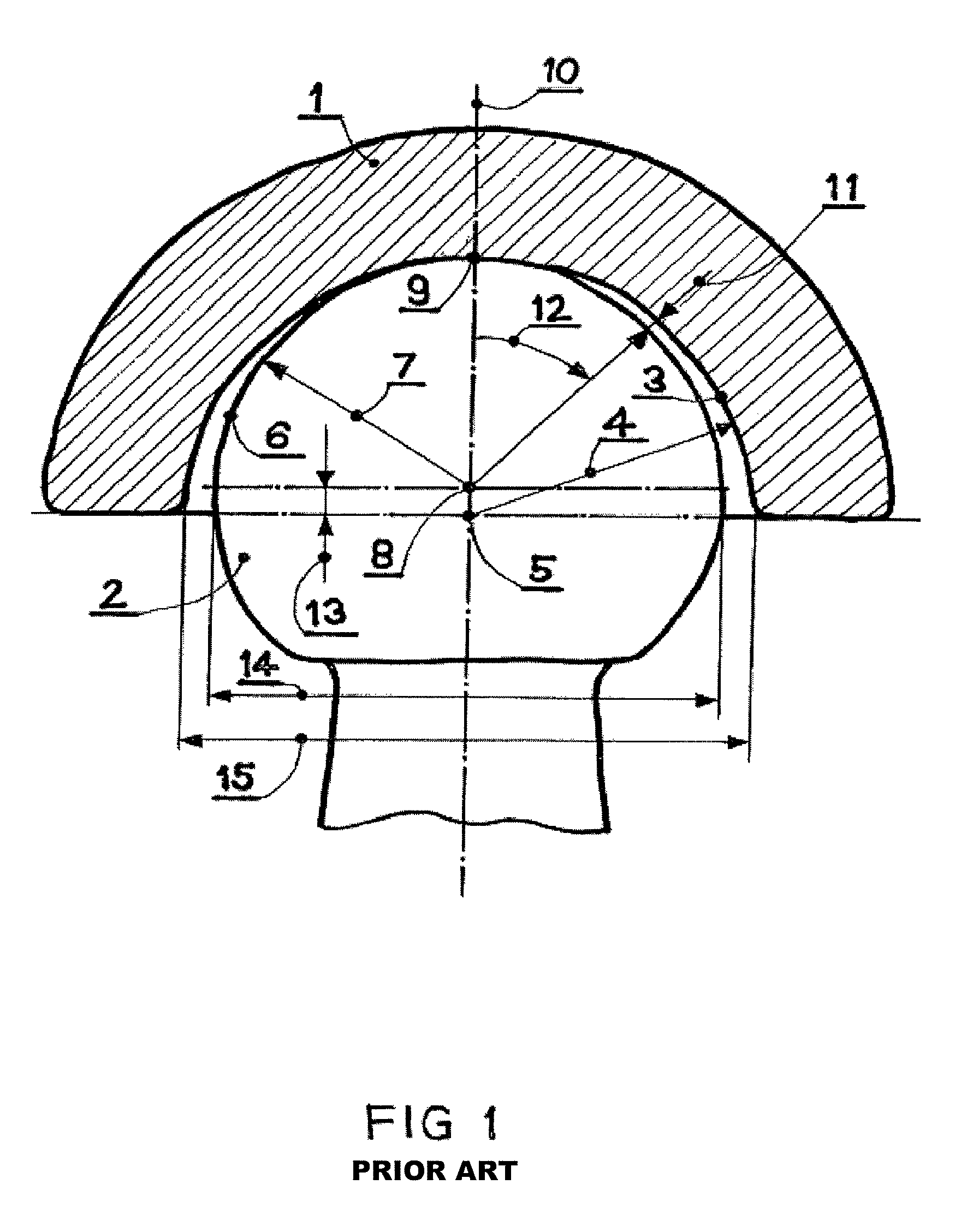

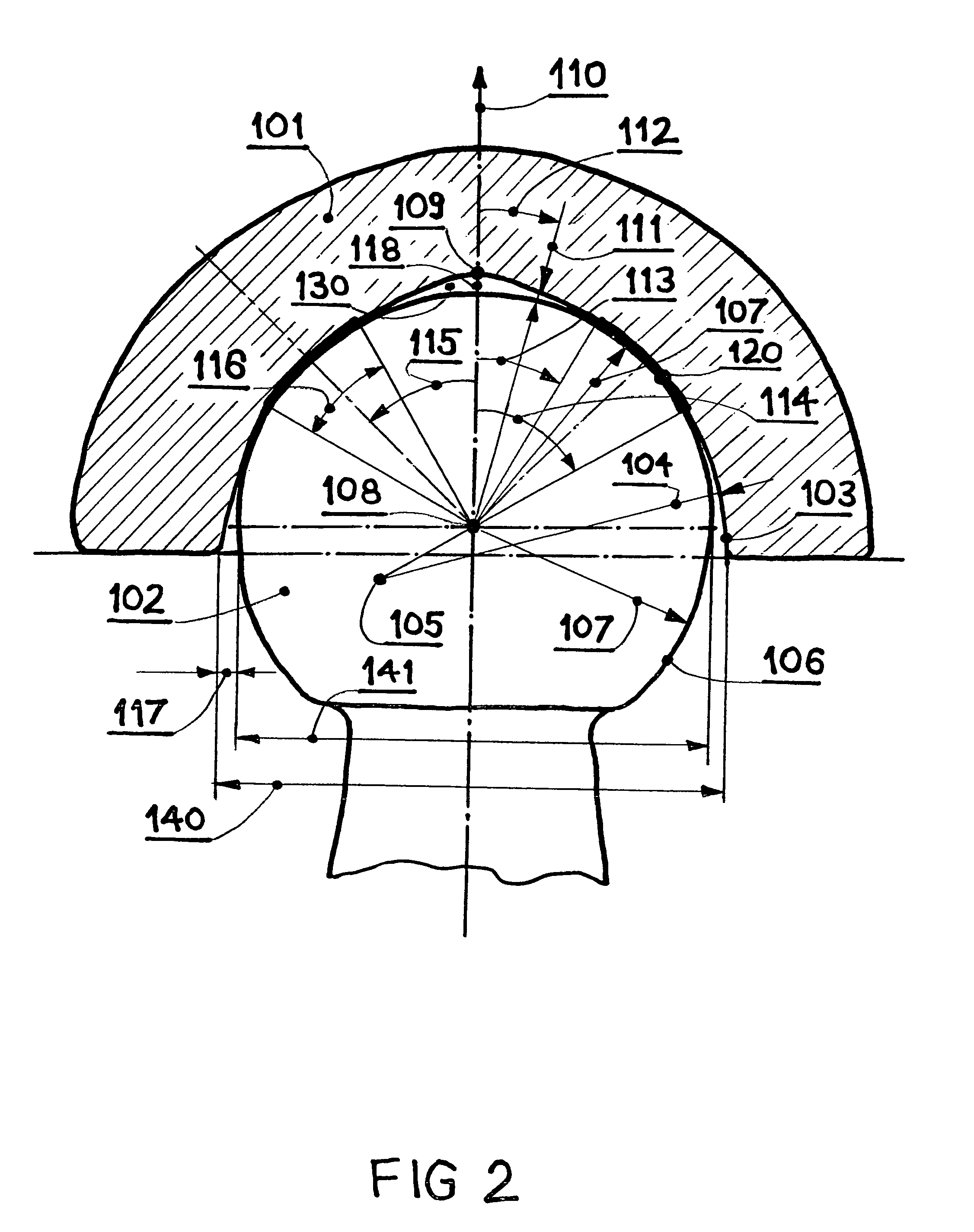

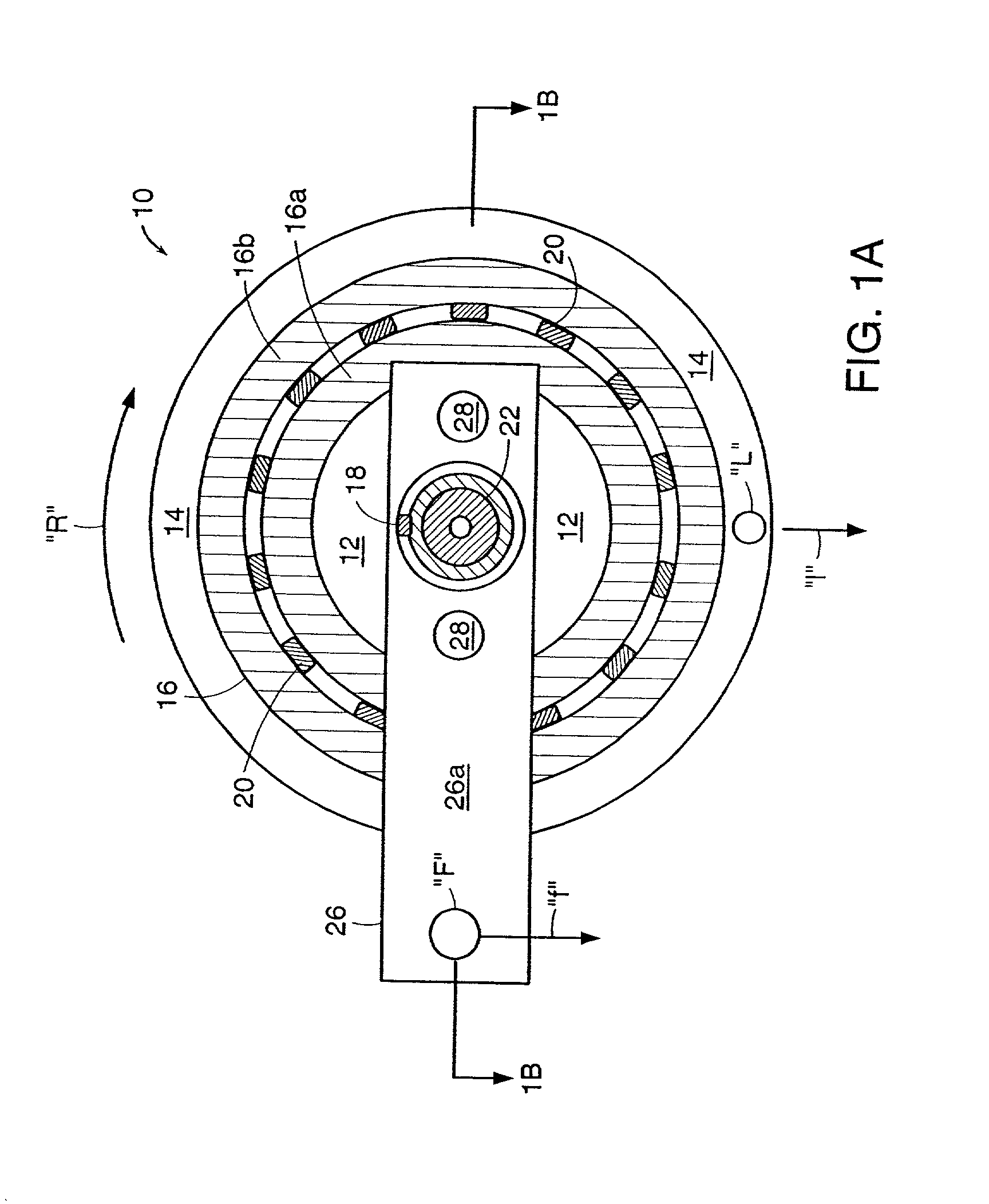

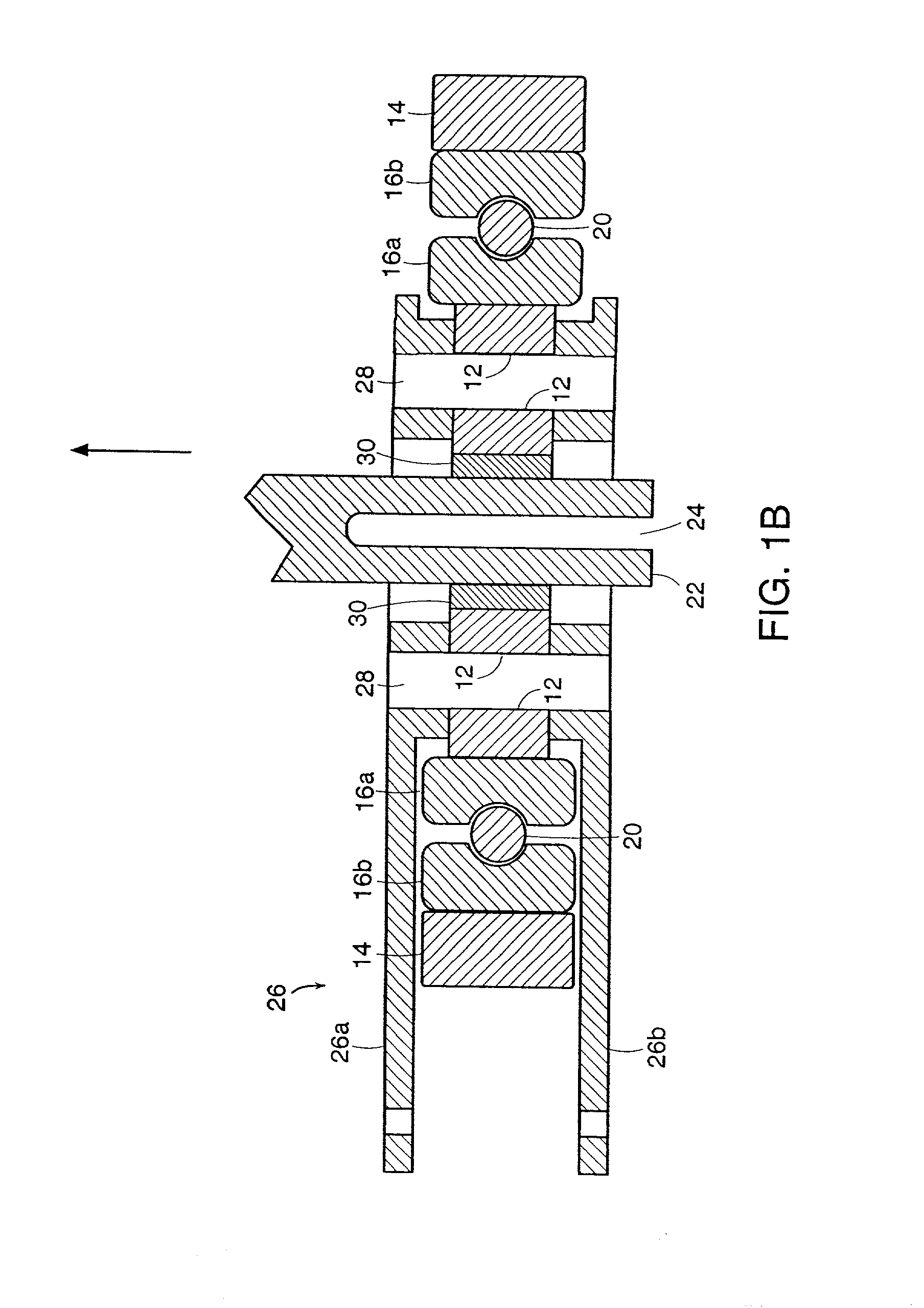

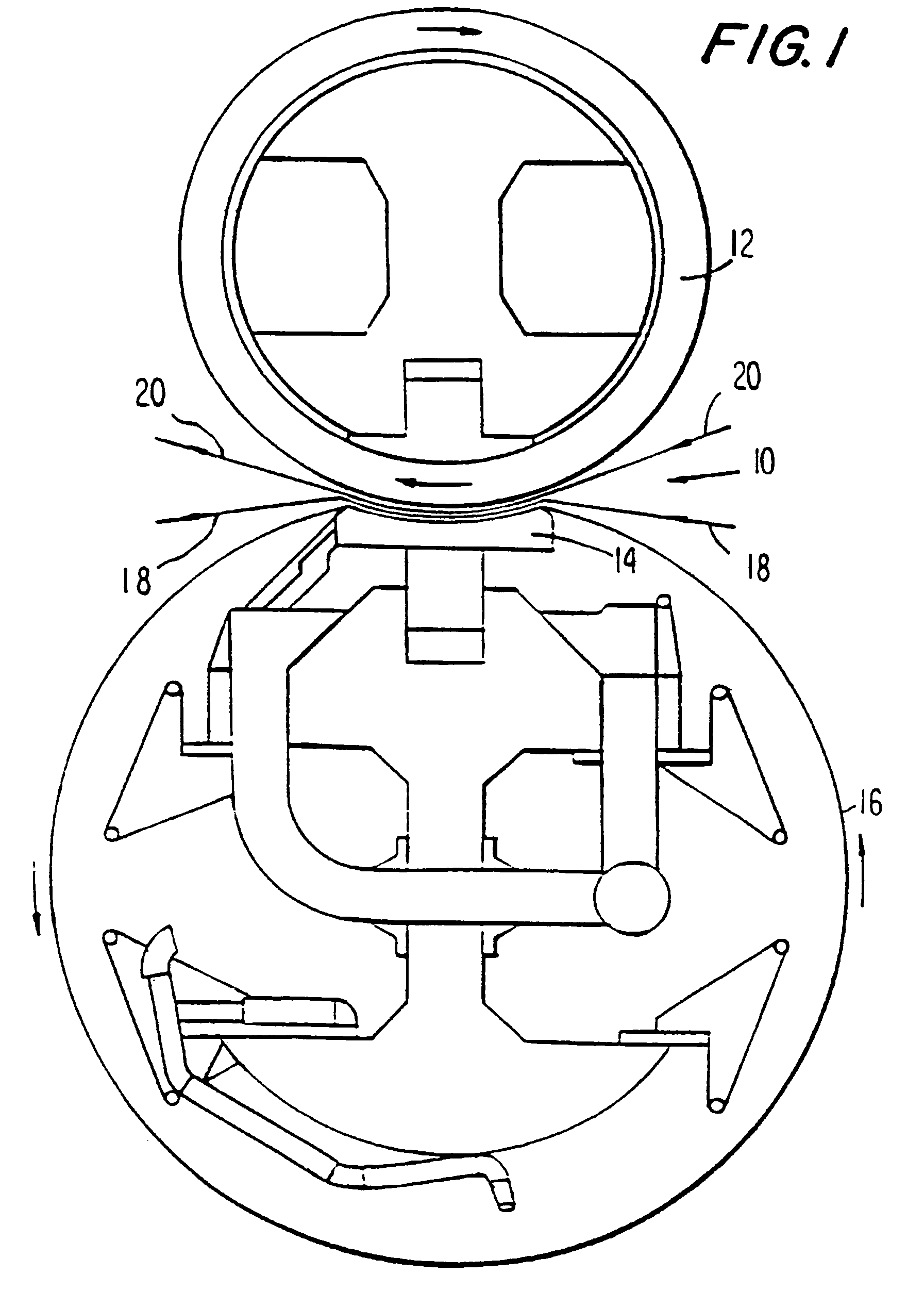

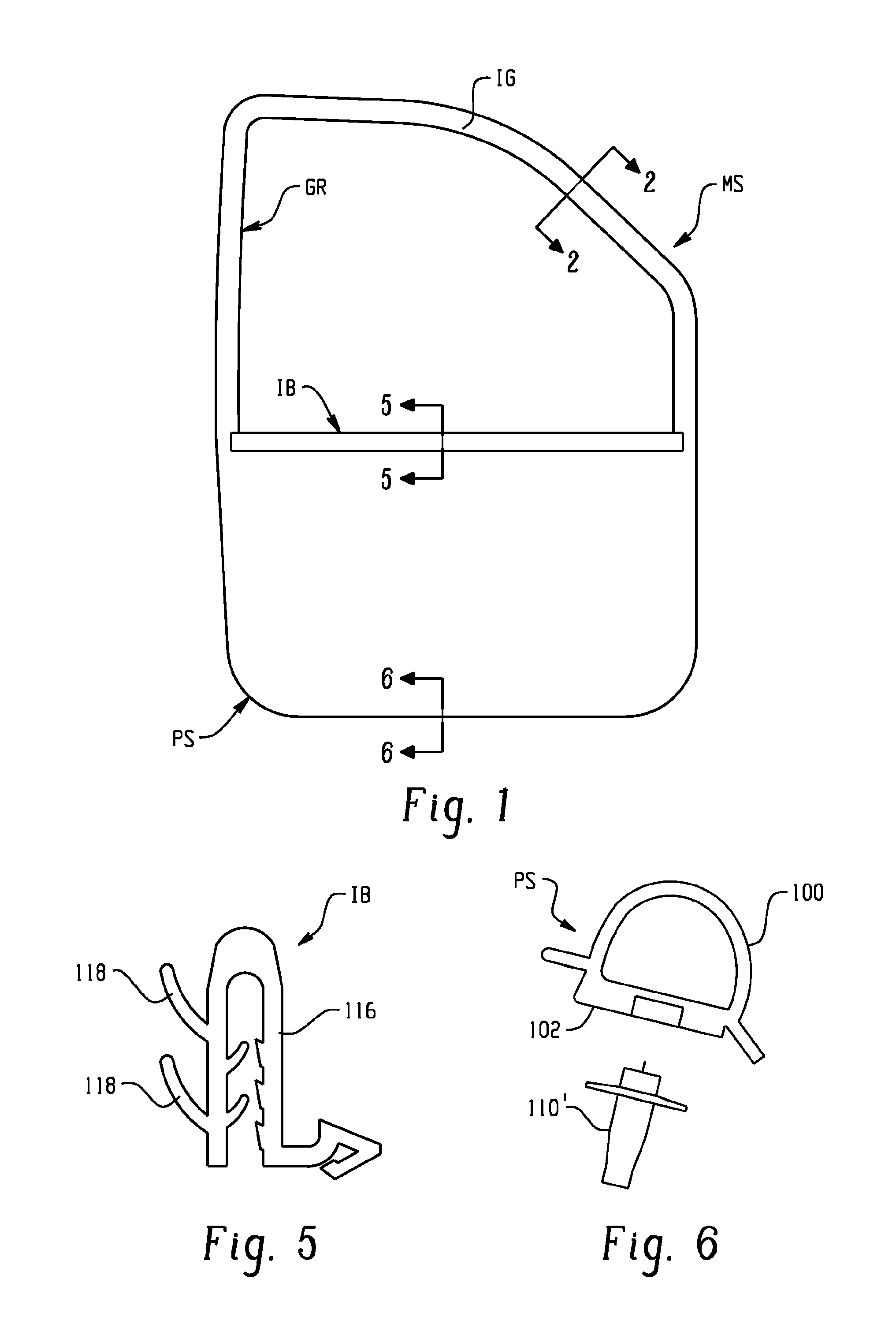

Wear-reducing geometry of articulations in total joint replacements

ActiveUS20100063589A1Improve stabilityImprove wearing rateFinger jointsWrist jointsHip joint simulatorClassical mechanics

The invention reduces wear in total joint articulations by modifications of the shape of either component of the kinematic pair, so as to result in an annular surface contact between the two components. Fluid trapped between the two components within the inner contour of the annular contact area is pressurized under load due to elastic deformation of the components and exuded out through inter-articular gap over the surface of contact, aiding in lubrication and reducing the wear. Reduced to practice for a total hip joint with UHMWPE-metal pair, the wear rate tested in a hip joint simulator up to five million cycles was reduced by factor seven to fifteen compared to conventionally shaped components.

Owner:SCYON ORTHOPAEDICS

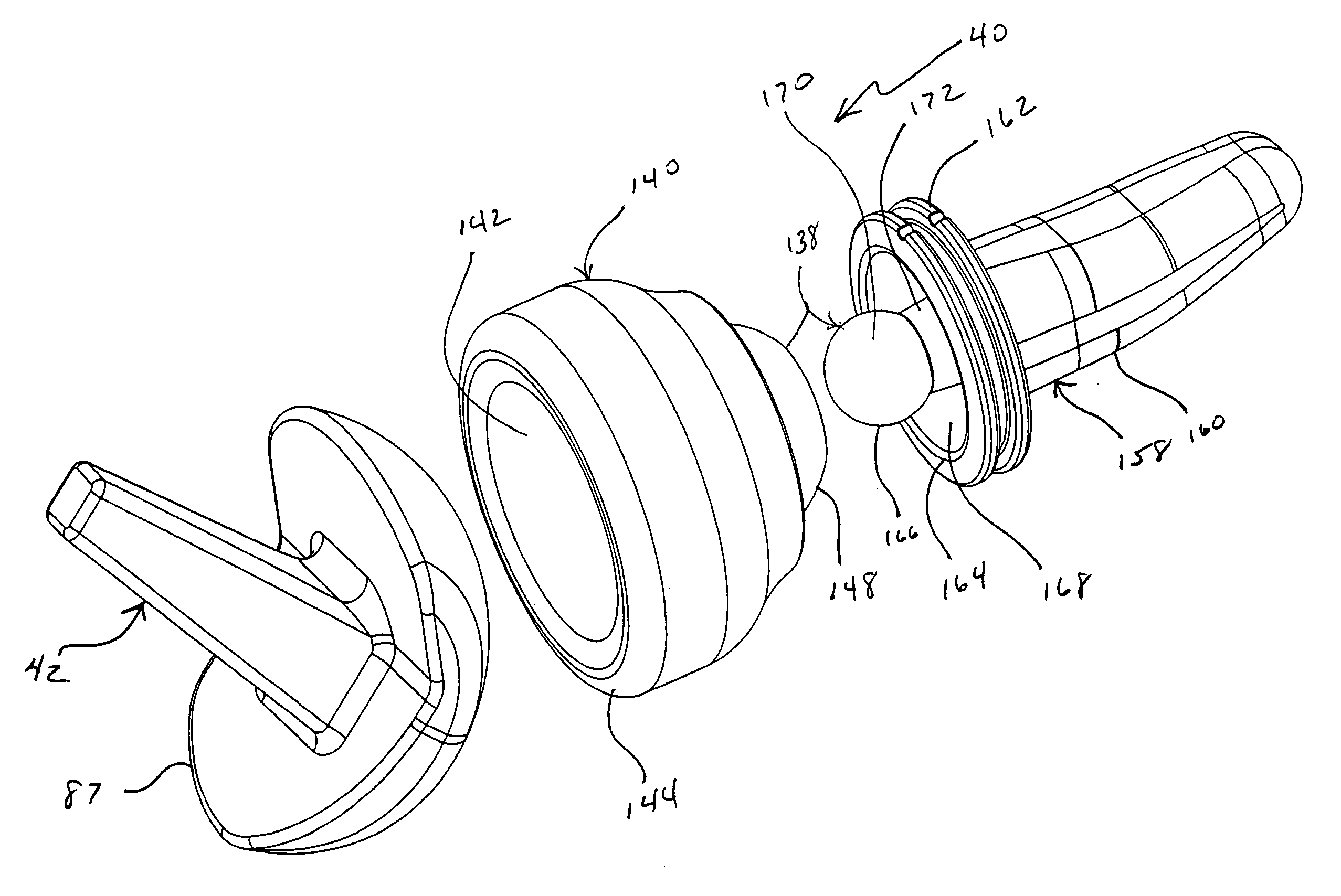

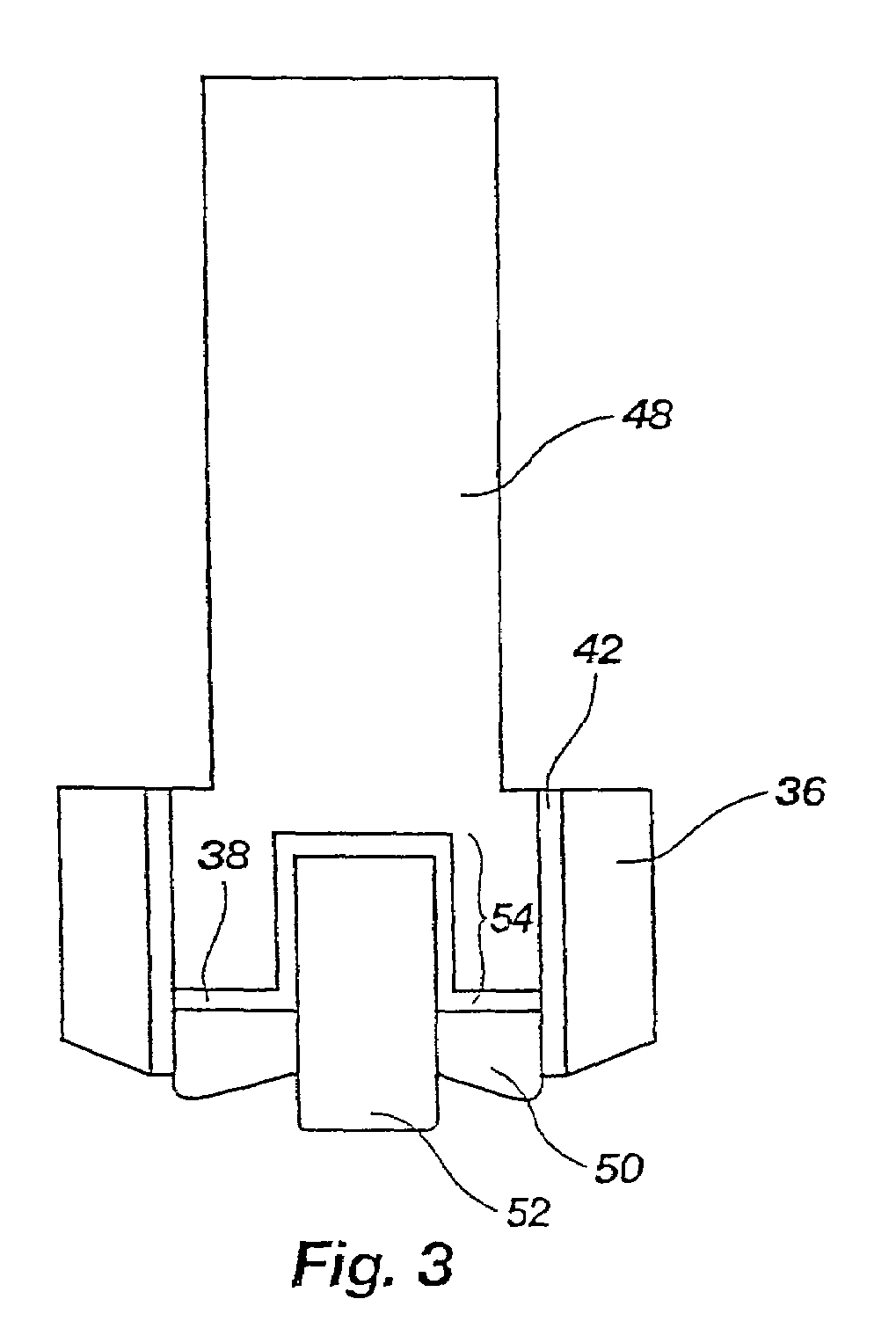

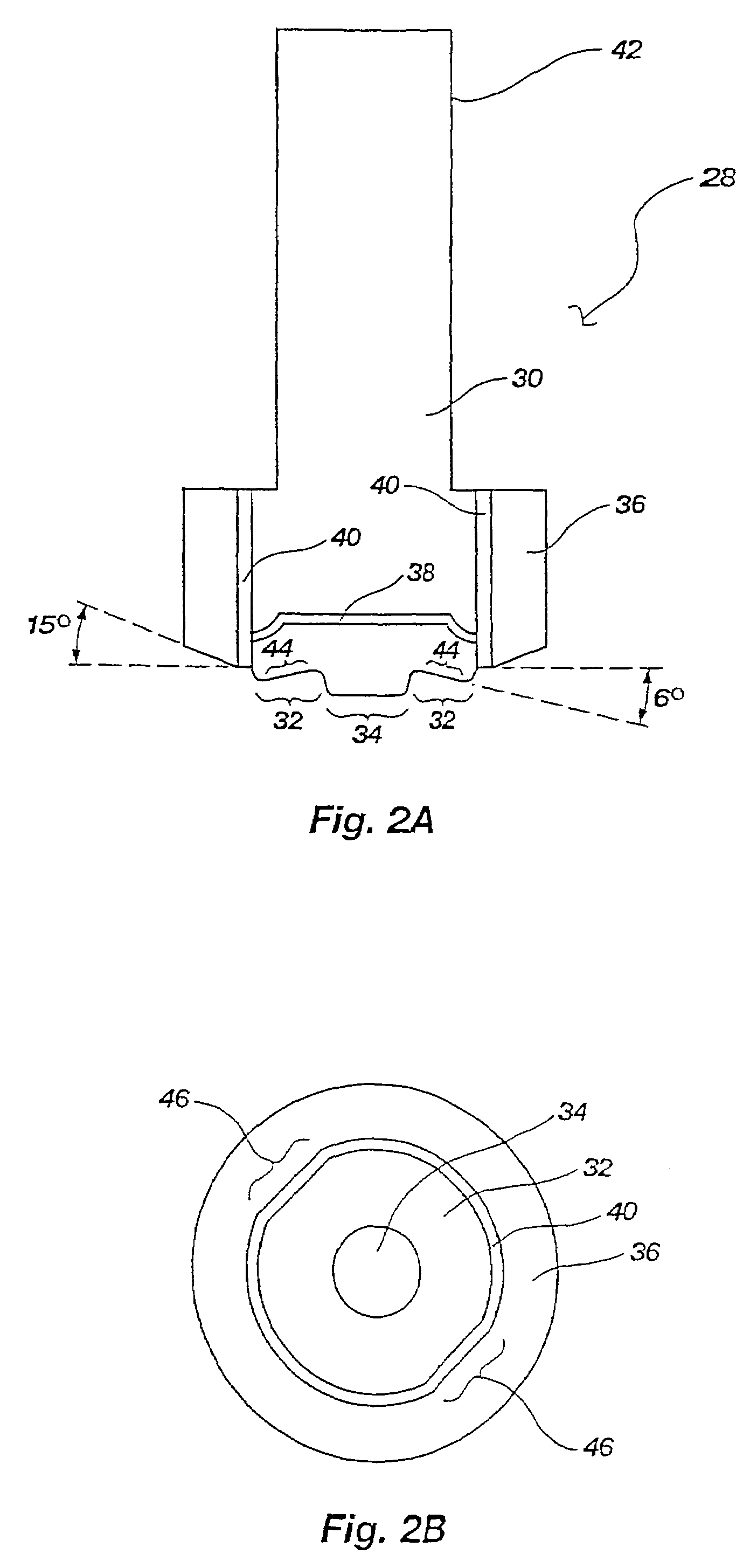

Friction stir welding using a superabrasive tool

InactiveUS7152776B2Improve wear characteristicsVacuum evaporation coatingSputtering coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:MAZAK CORP

Friction stir welding of metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys using a superabrasive tool

InactiveUS7124929B2Improve wear characteristicsWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowSuperalloy

Owner:MAZAK CORP

Wear-reducing geometry of articulations in total joint replacements

ActiveUS8323346B2Improve wear characteristicsFinger jointsWrist jointsFactor SevenHip joint simulator

The invention reduces wear in total joint articulations by modifications of the shape of either component of the kinematic pair, so as to result in an annular surface contact between the two components. Fluid trapped between the two components within the inner contour of the annular contact area is pressurized under load due to elastic deformation of the components and exuded out through inter-articular gap over the surface of contact, aiding in lubrication and reducing the wear. Reduced to practice for a total hip joint with UHMWPE-metal pair, the wear rate tested in a hip joint simulator up to five million cycles was reduced by factor seven to fifteen compared to conventionally shaped components.

Owner:SCYON ORTHOPAEDICS

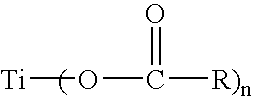

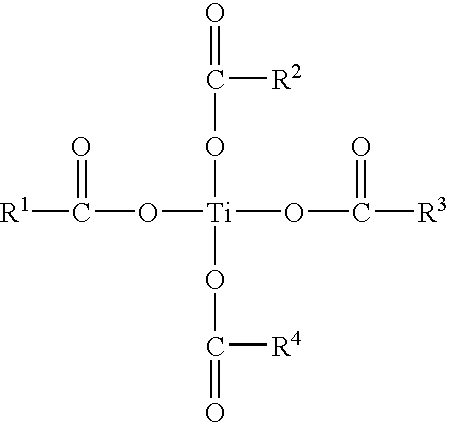

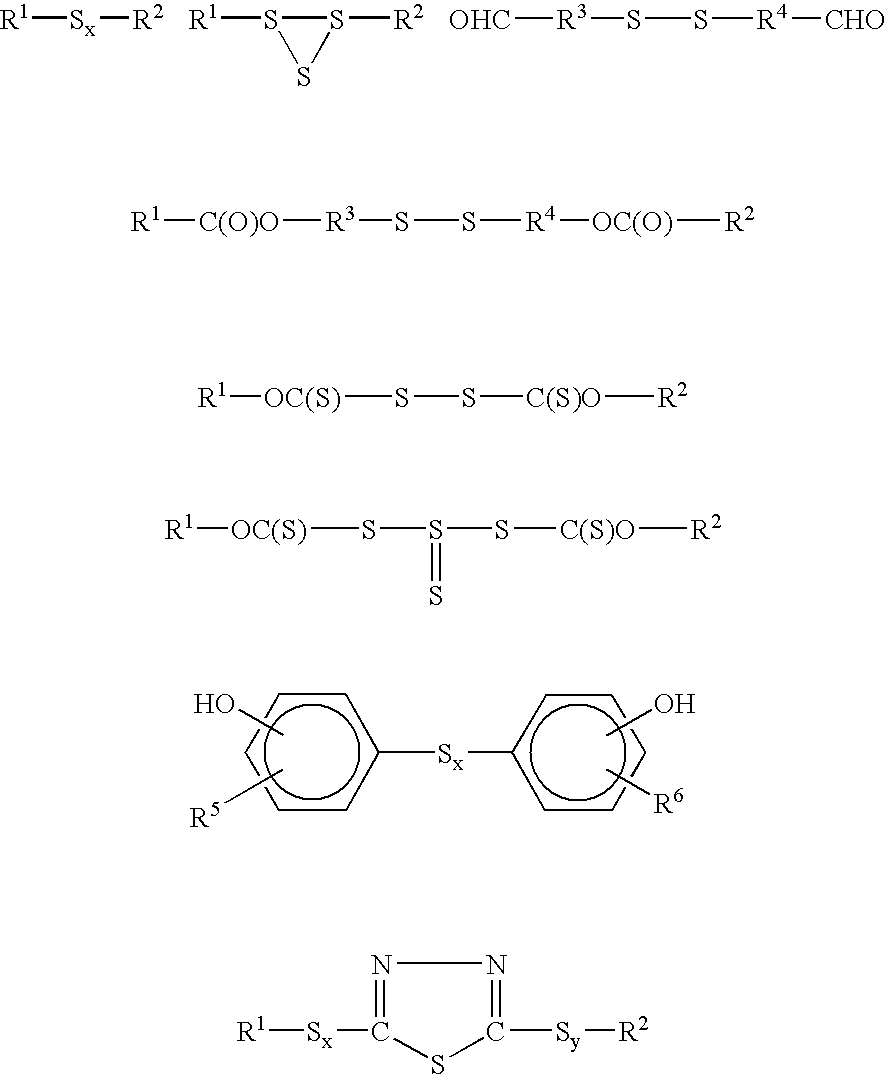

Titanium-containing lubricating oil composition

ActiveUS20070132274A1Improve fuel economyImprove wear characteristicsVehicle seatsWindowsTitanium metalPhysical chemistry

A lubricating oil composition comprising a) an oil of lubricating viscosity having a viscosity index of at least about 95; b) at least one calcium detergent; c) at least one oil soluble titanium compound; d) at least one friction modifier; and e) at least one metal dihydrocarbyldithiophosphate compound. The composition has a Noack volatility of about 15 wt. % or less, and contains from about 0.05 to about 0.6 wt. % calcium from the calcium detergent, titanium metal in an amount of at least about 10 ppm up to about 1500 ppm titanium from the titanium compound, and phosphorus from the metal dihydrocarbyldithiophosphate compound in an amount up to about 0.1 wt. %.

Owner:AFTON CHEMICAL

Rotary cutting tool with non-uniform distribution of chip-breaking features

ActiveUS7544021B2Less materialValuable machining timeWood turning toolsTransportation and packagingFluteMechanical engineering

A rotary cutting tool with a longitudinal axis is provided that includes a shank portion, a cutting portion, and a plurality of chip-breaking features. The cutting portion, which extends out from the shank portion, includes a length, a plurality of blades and a plurality of flutes. The blades and flutes extend substantially all of the length of the cutting portion. Each blade includes a leading face side, a trailing face side, and a land surface that extends between the leading face side and the trailing face side. The plurality of chip-breaking features are disposed in the land surfaces of the blades, and non-uniformly distributed among the blades.

Owner:BERKSHIRE PRECISION TOOL

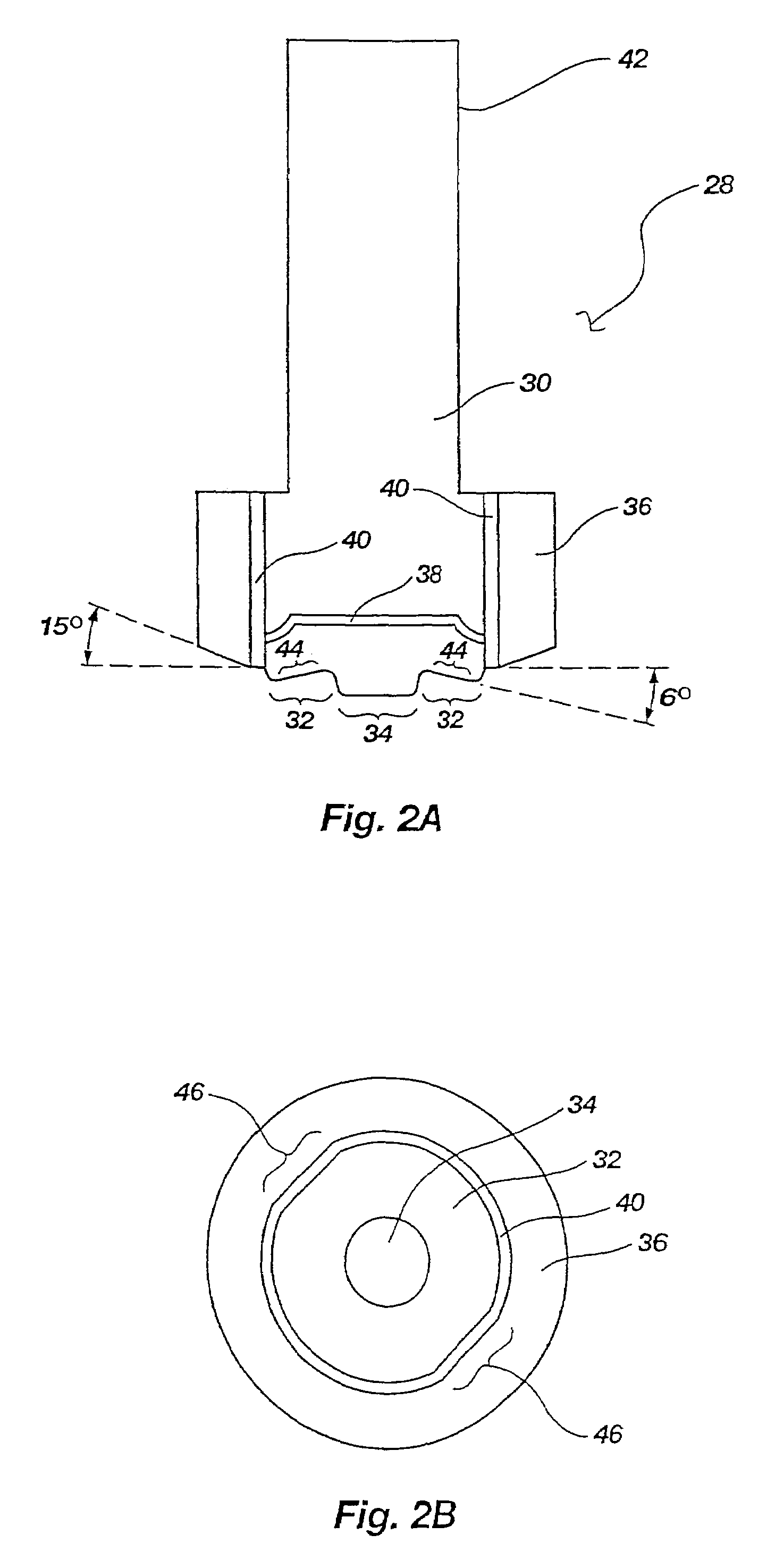

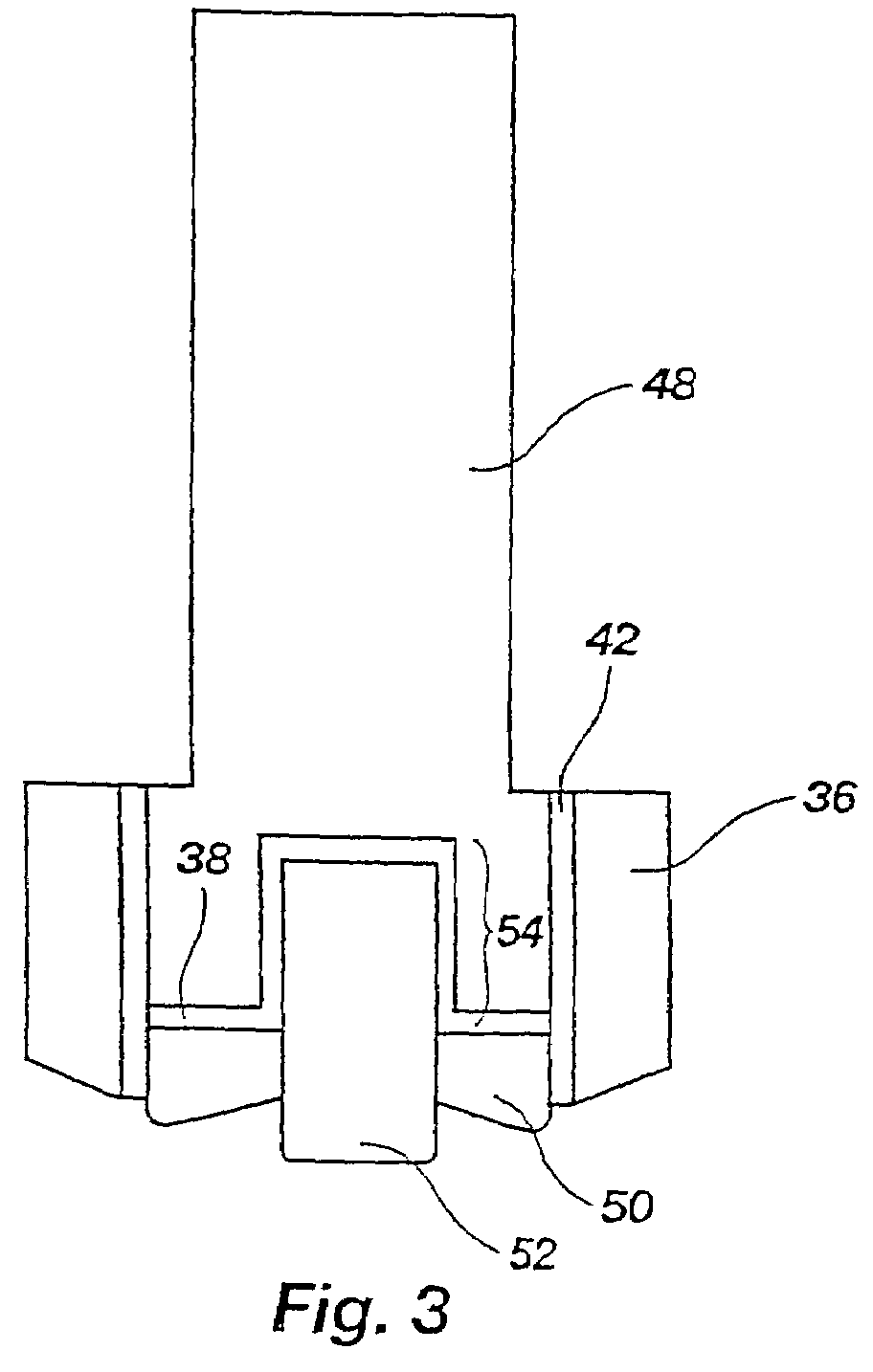

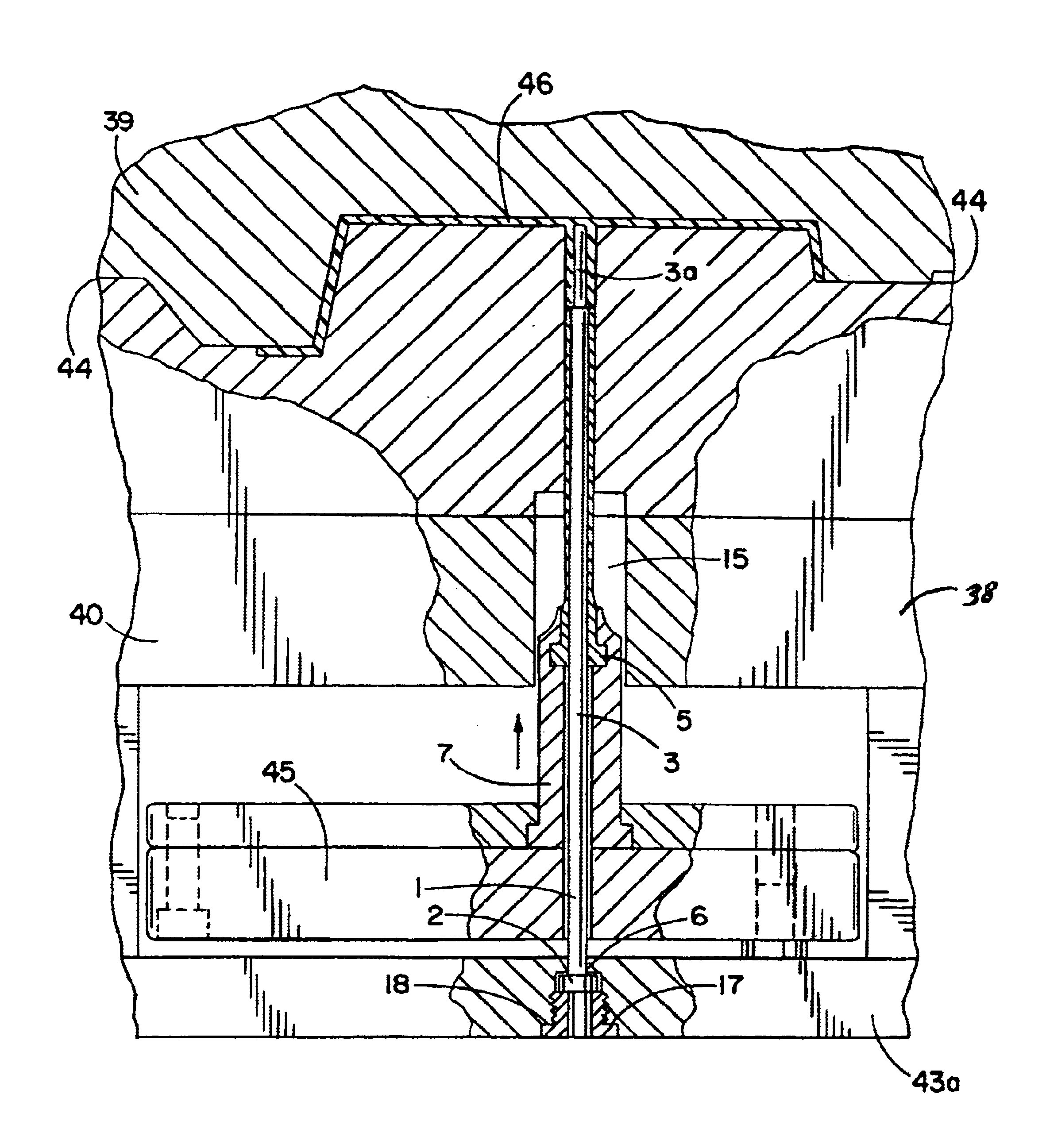

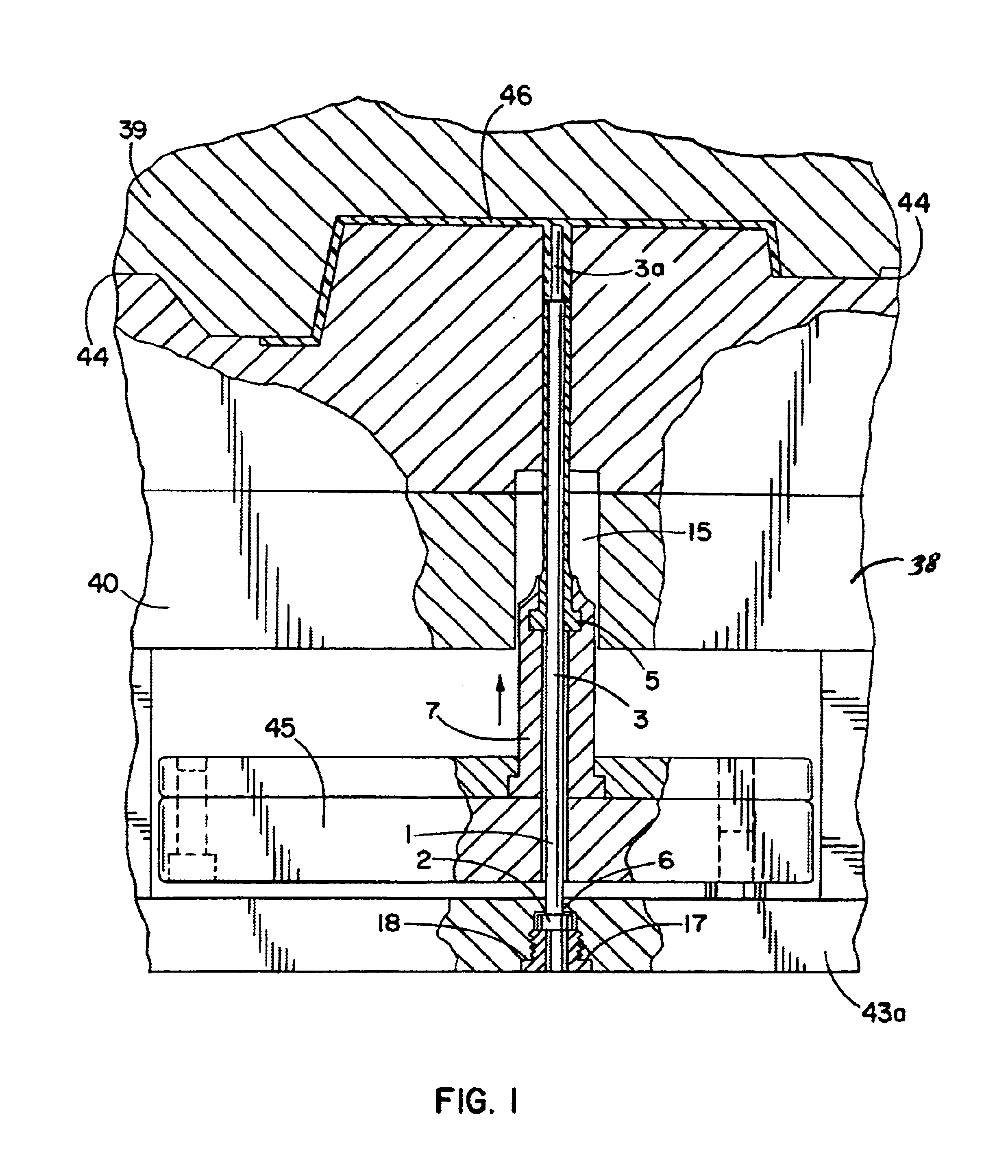

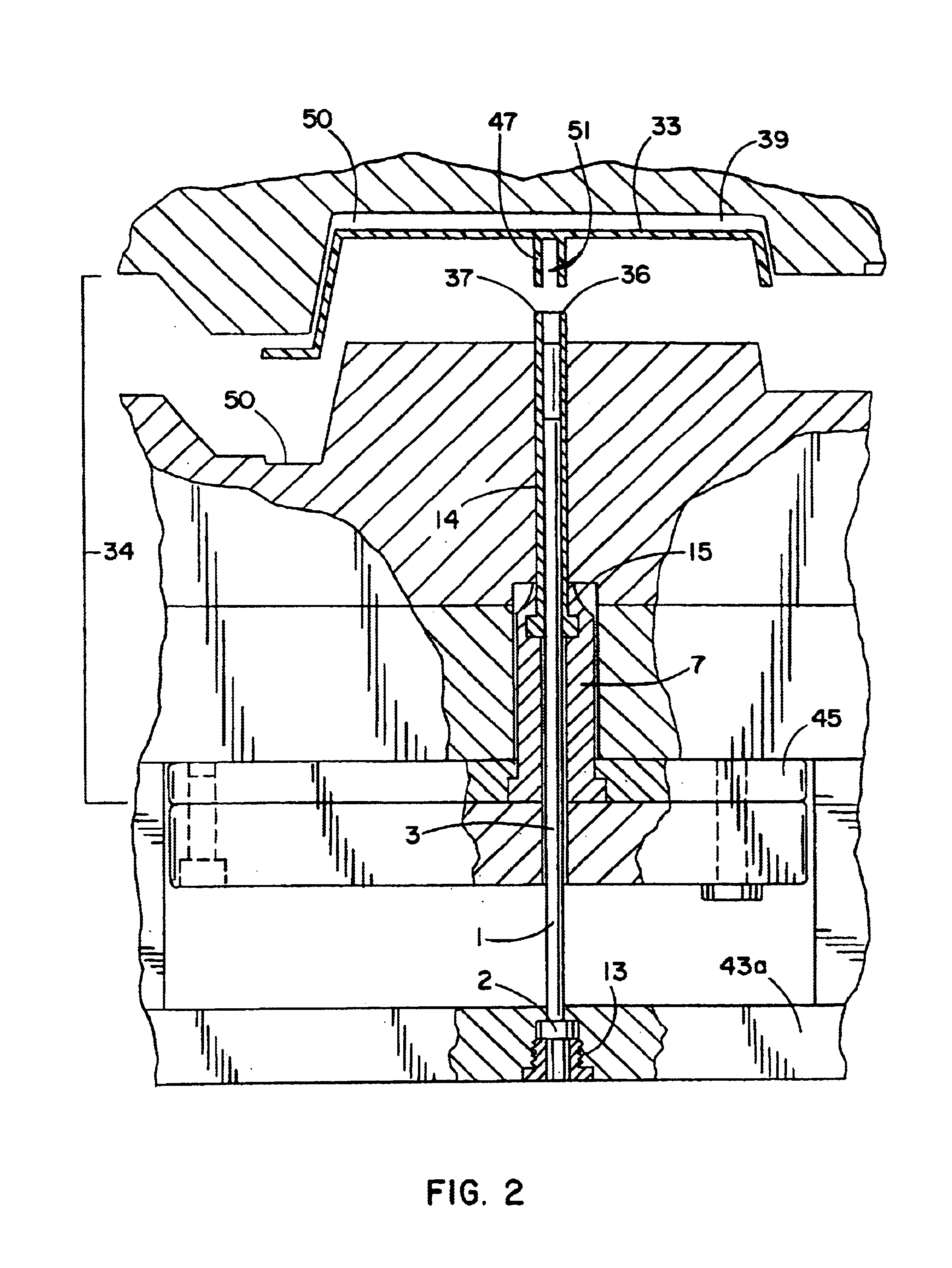

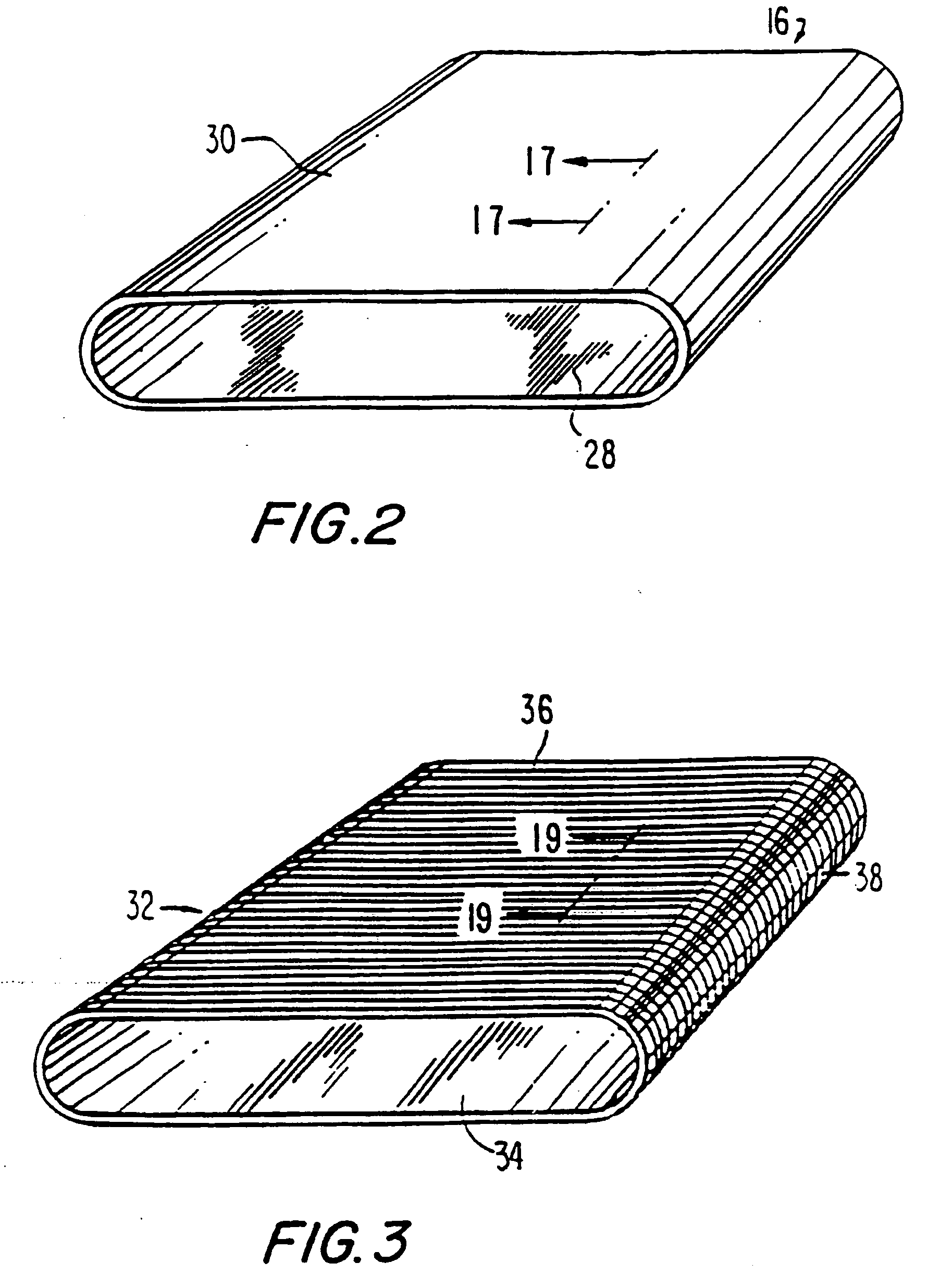

Ejector sleeve for molding a raised aperture in a molded article

The present invention includes an improved ejector sleeve (5) having thinner side-walls than prior sleeves. The sleeves generally include a ring (31) for mounting the sleeve, a central bore (42) for receiving a core pin (1), a tube portion extending from the ring to a tube end portion. The side-walls defining the tube end portion have a thickness of less than forty thousandths, and preferably thirty thousandths of an inch. Preferably, the coated ejector sleeve is provided in which a thin, lubricous coating of nickel, chromium or alloys of chromium or nickel is applied to at least a portion of the sleeve. The coating is applied in thickness of less than 0.0001 inch which improves the wear characteristics of the pins and sleeves as well as allowing the coated pins and sleeves to be stocked and used as nominal thickness parts.

Owner:PROGRESSIVE COMPONENTS INT CORP

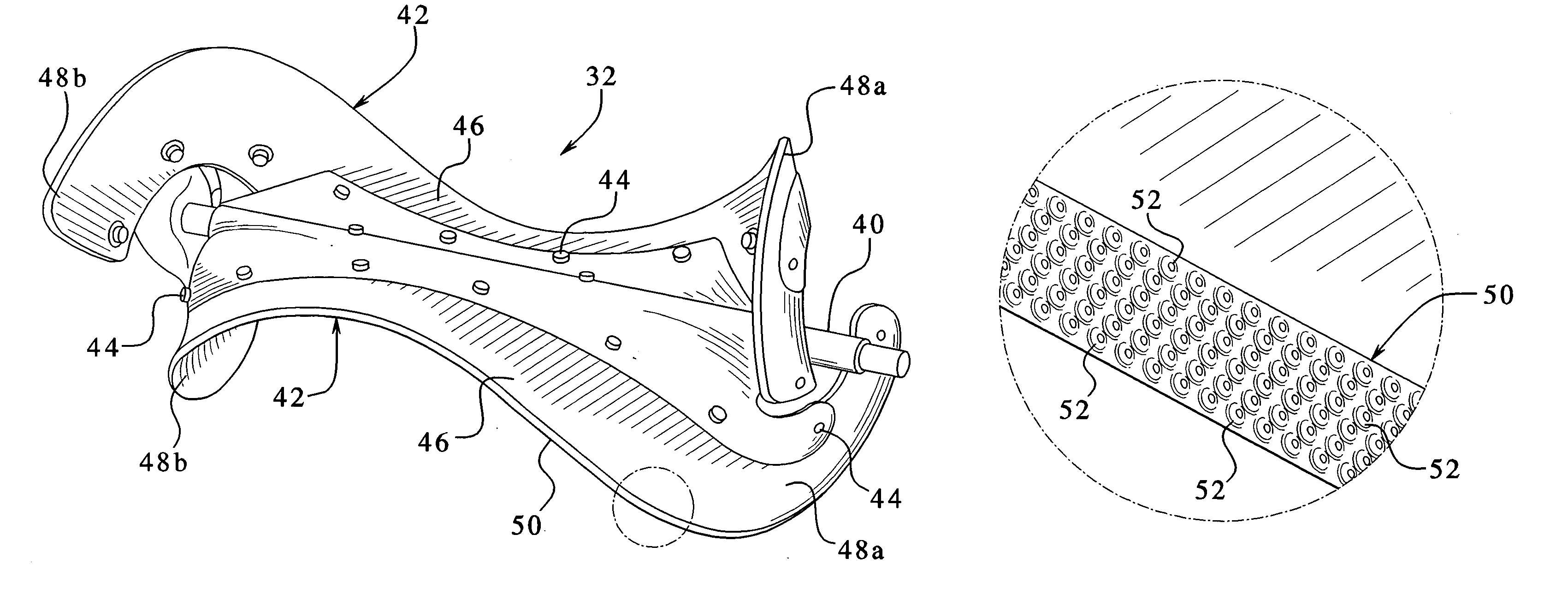

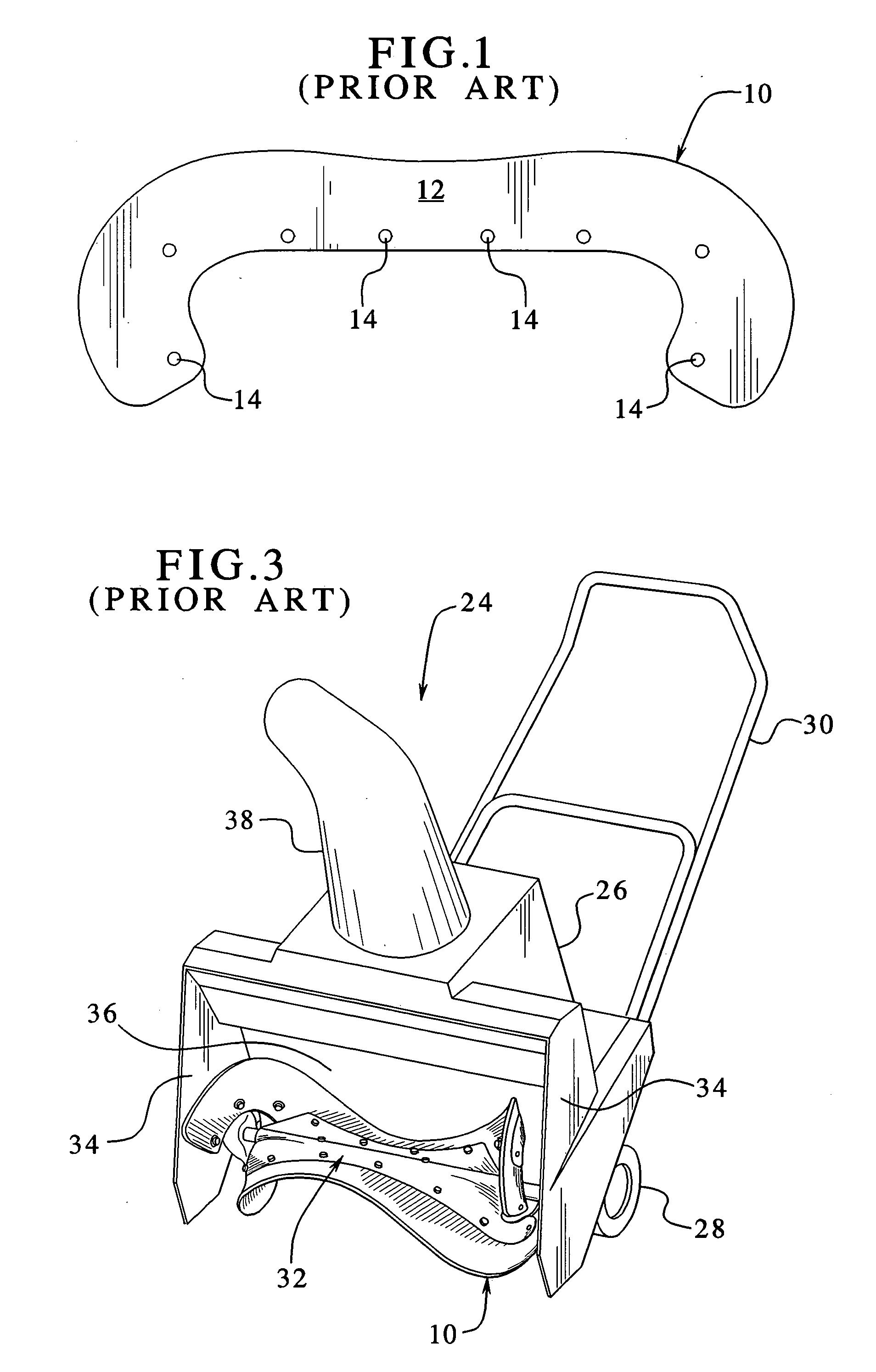

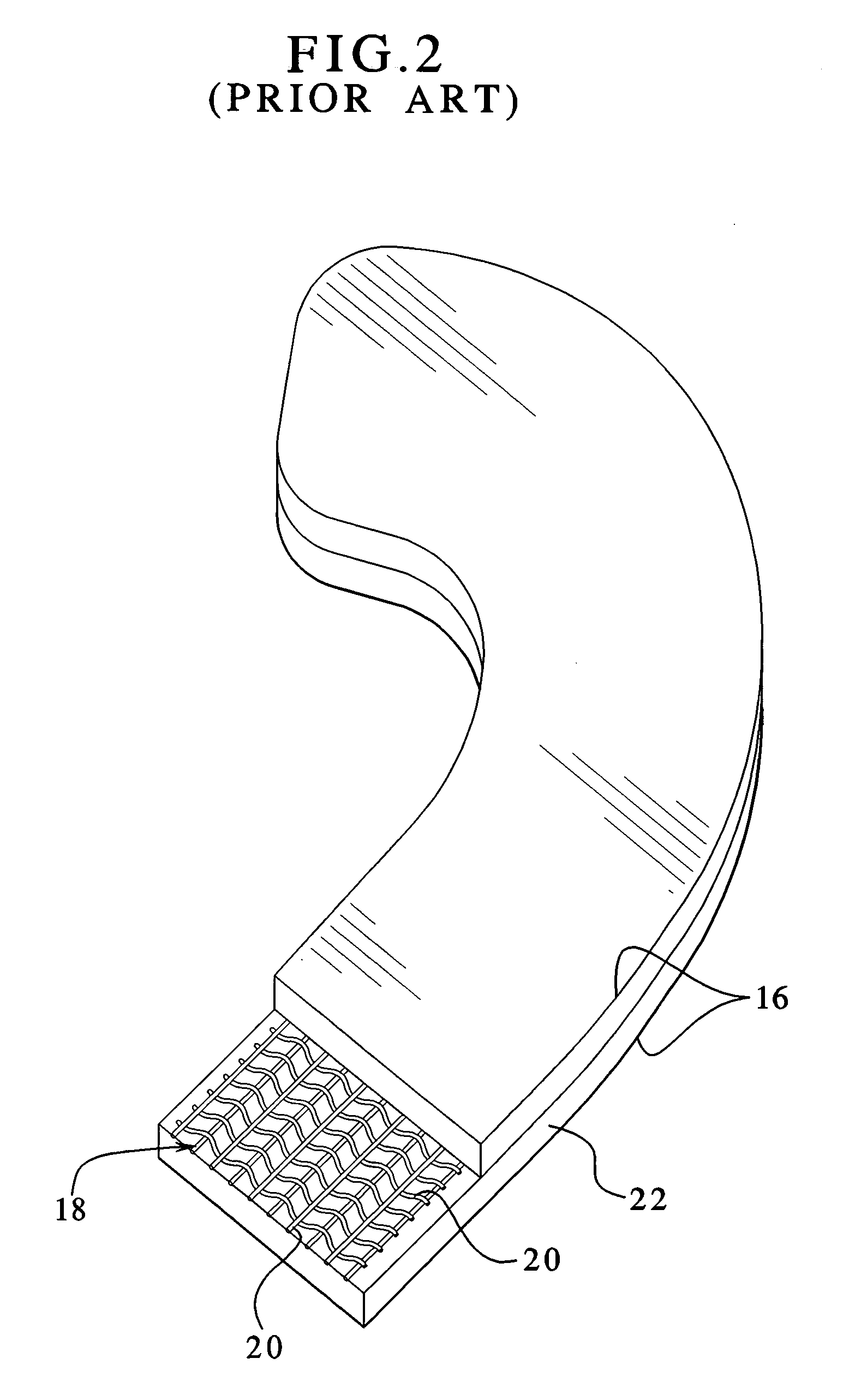

Impeller blade for snowblower

A blade or paddle for use with a snowblower impeller formed from a flexible material. The flexible material includes a plurality of layers of reinforcing material to reinforce the blade and provide greater tensile strength. The working edge of the blade includes a plurality or pattern of indentations, serrations or dimples that provide an improved engagement function of the blade or paddle and the surface of the ground.

Owner:LAKIN GENERAL CORP

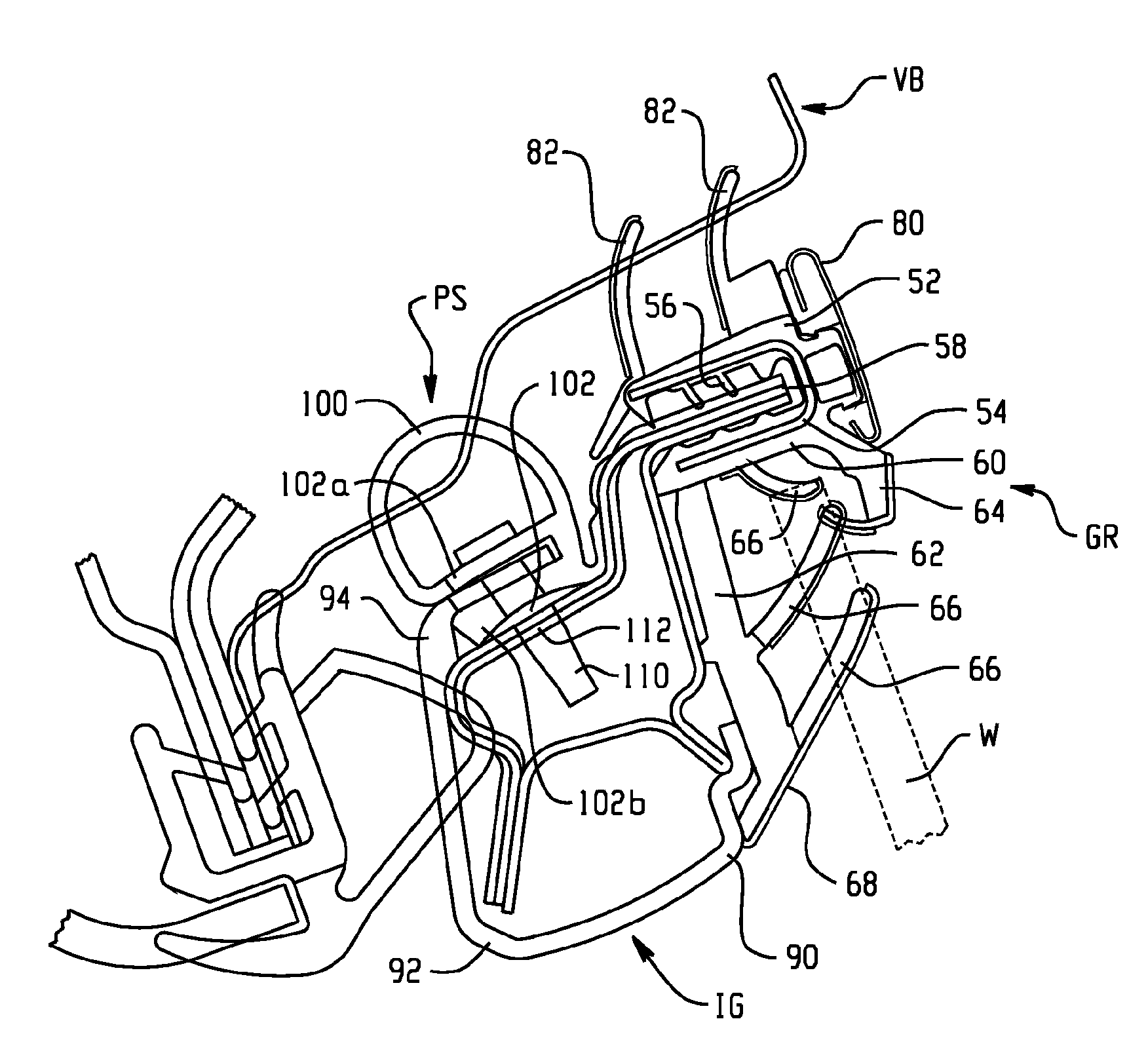

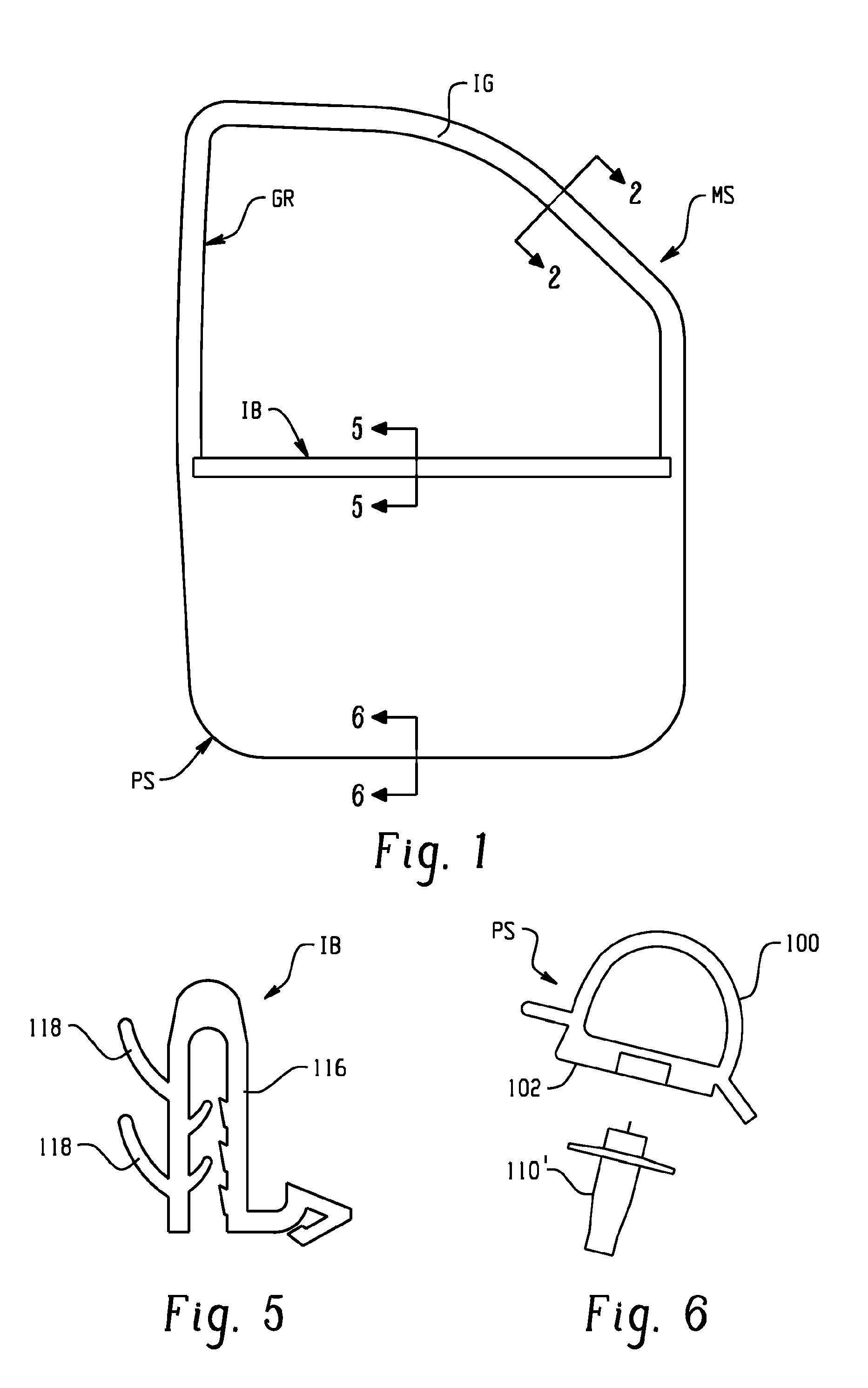

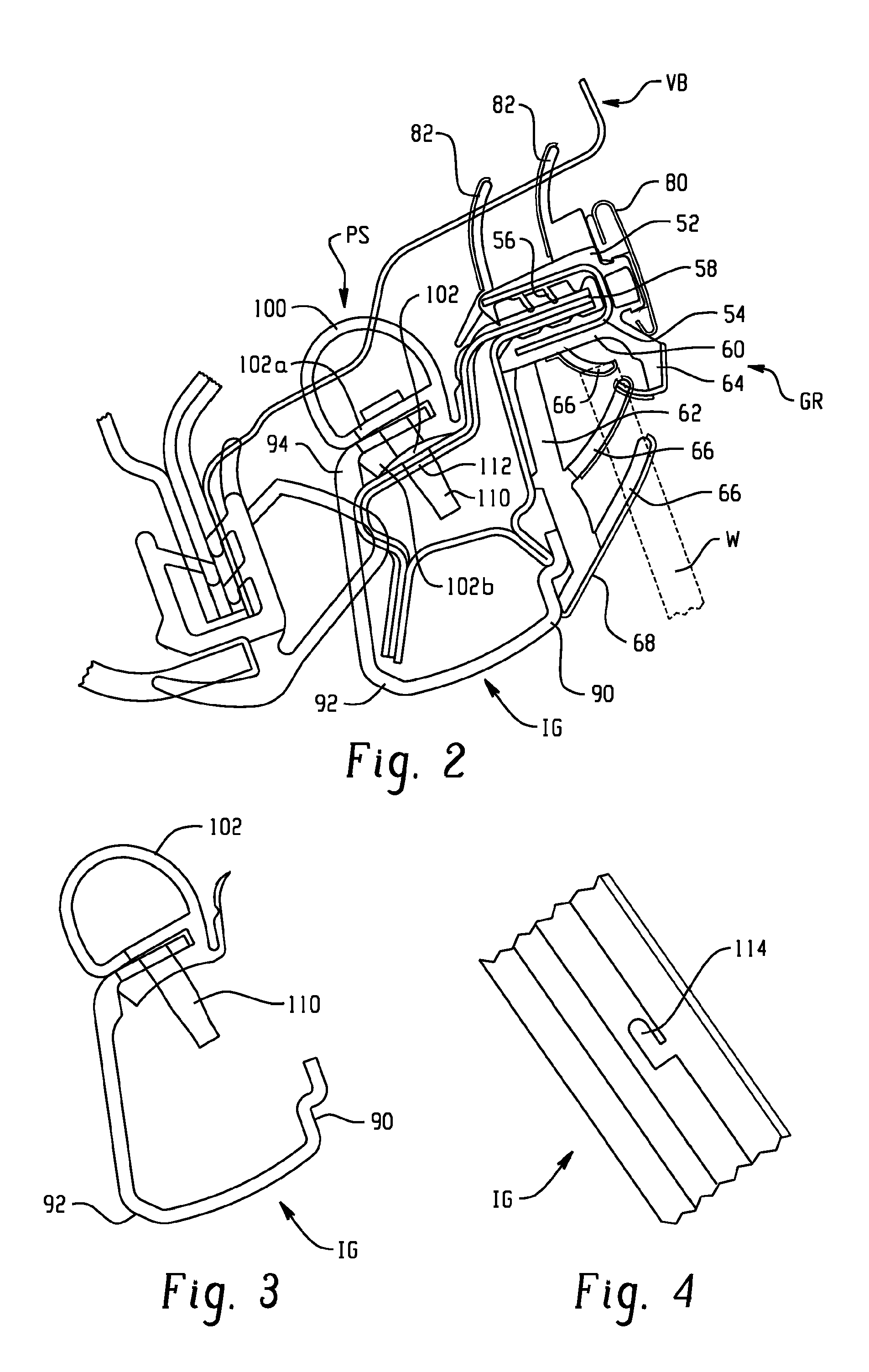

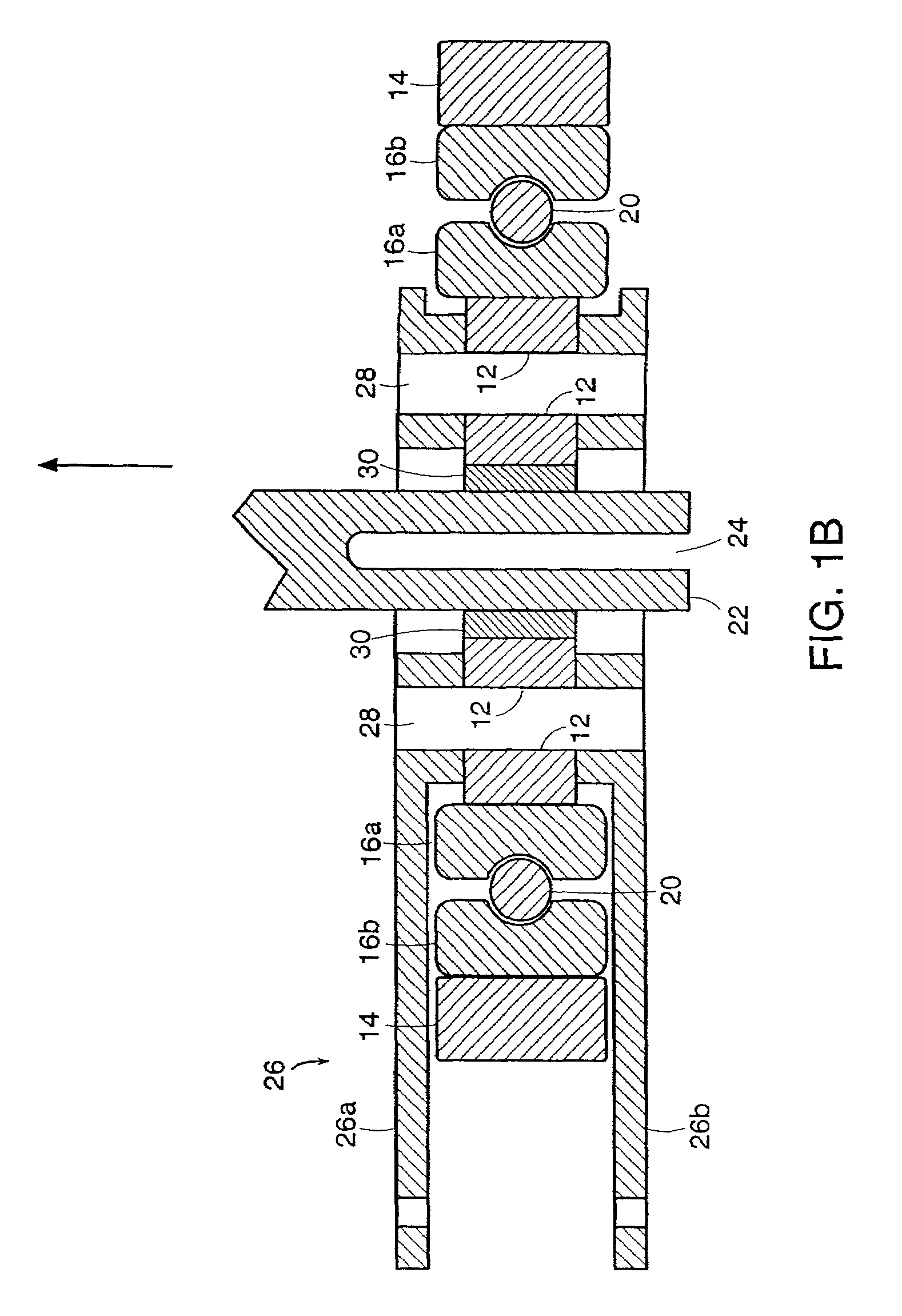

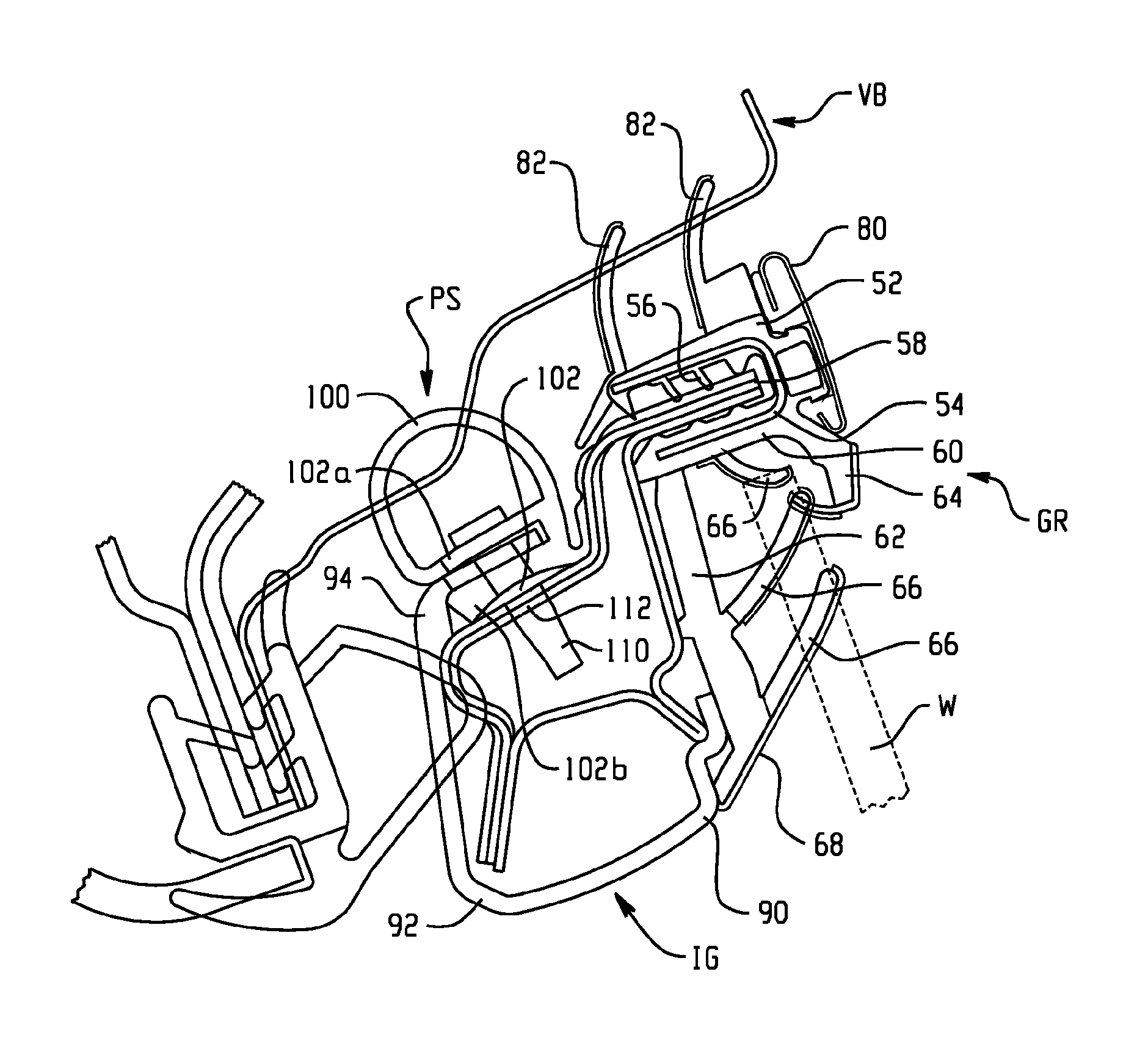

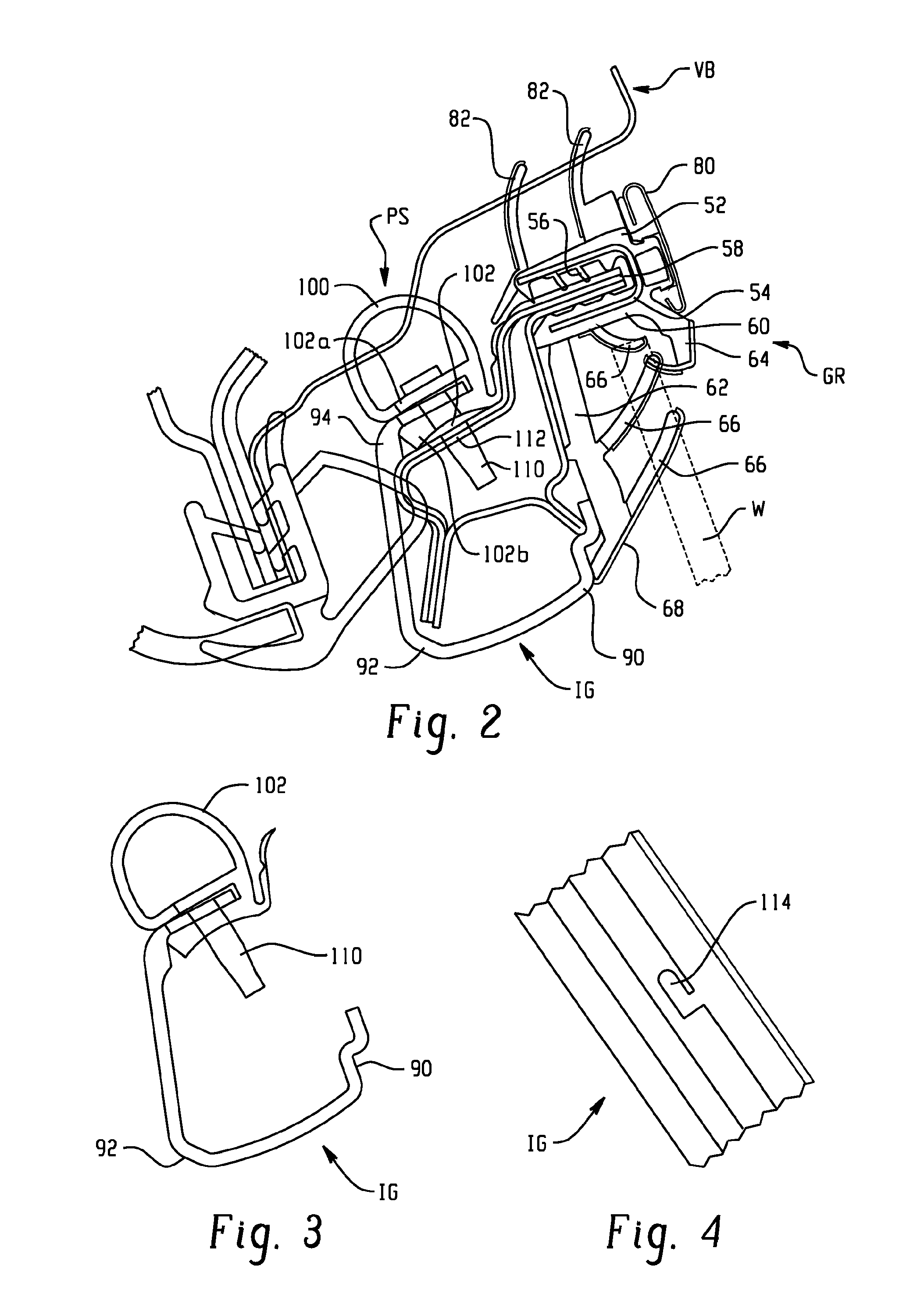

Inner garnish assembly module system

A one-piece inner garnish assembly module system (MS) joins an inner garnish molding (IG), primary seal (PS), glass run (GR), and inner beltline weatherstrip (IB) into a single component prior to installation of the module system on a vehicle. The garnish is secured to the glass run along the A and B pillars, and the interconnecting header portion of a vehicle door. In addition, the primary seal is operatively associated or secured to the garnish, and may be pin-mounted to the door, or mechanically connected, and / or adhesively secured to the door.

Owner:COOPER STANDARD AUTOMATIVE INC

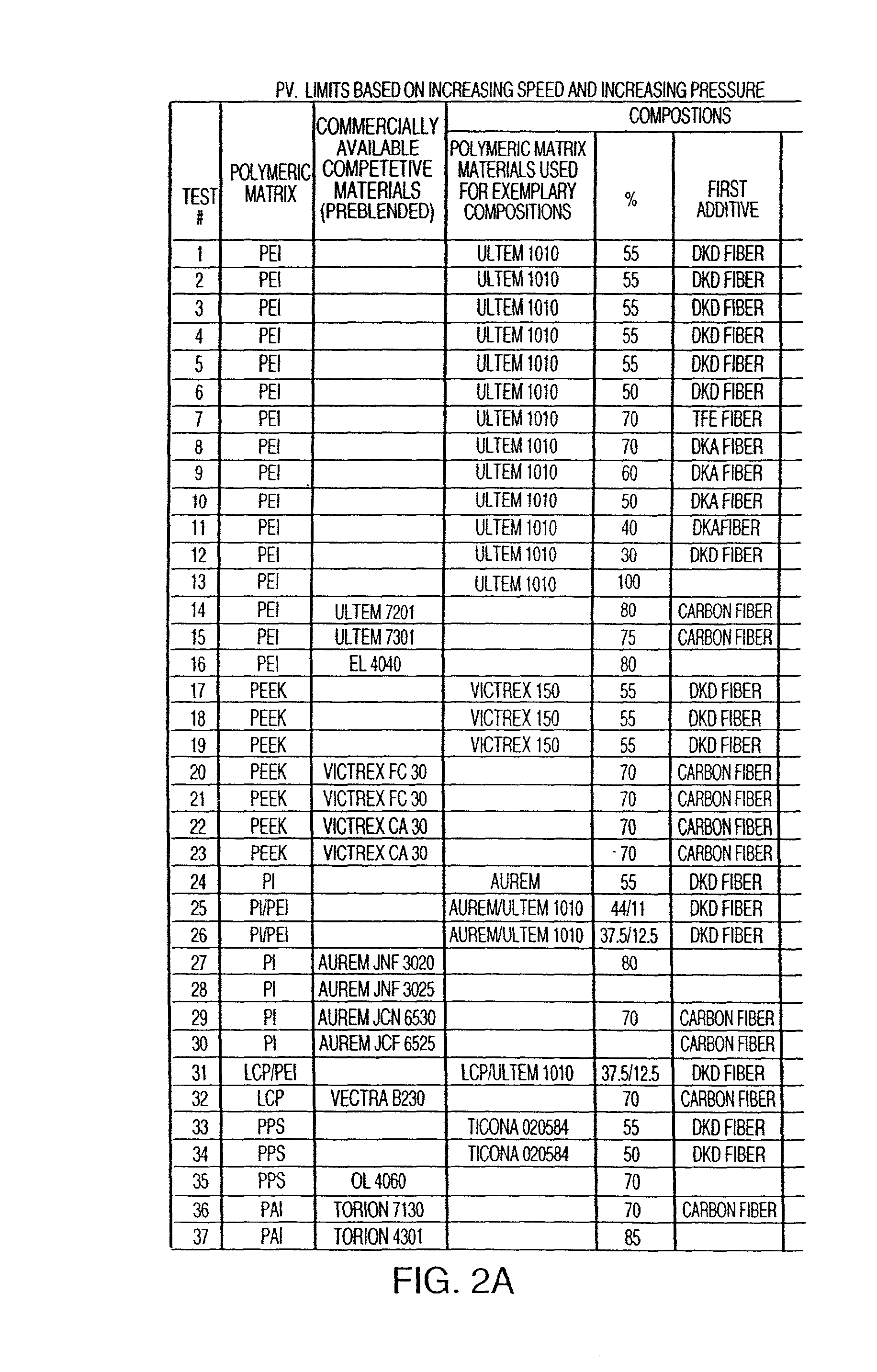

Tribological materials and structures and methods for making the same

InactiveUS20050096234A1Improve featuresImprove wear characteristicsBearing componentsBearing surfaceMaterials science

An article having a bearing surface with improved wear characteristics is provided. The article may be formed from a composition that includes a polymeric material, a lubricious and reinforcing additive, and a solid lubricant. Methods for forming the compositions and structures are also provided.

Owner:TRI MACK PLASTICS MFG

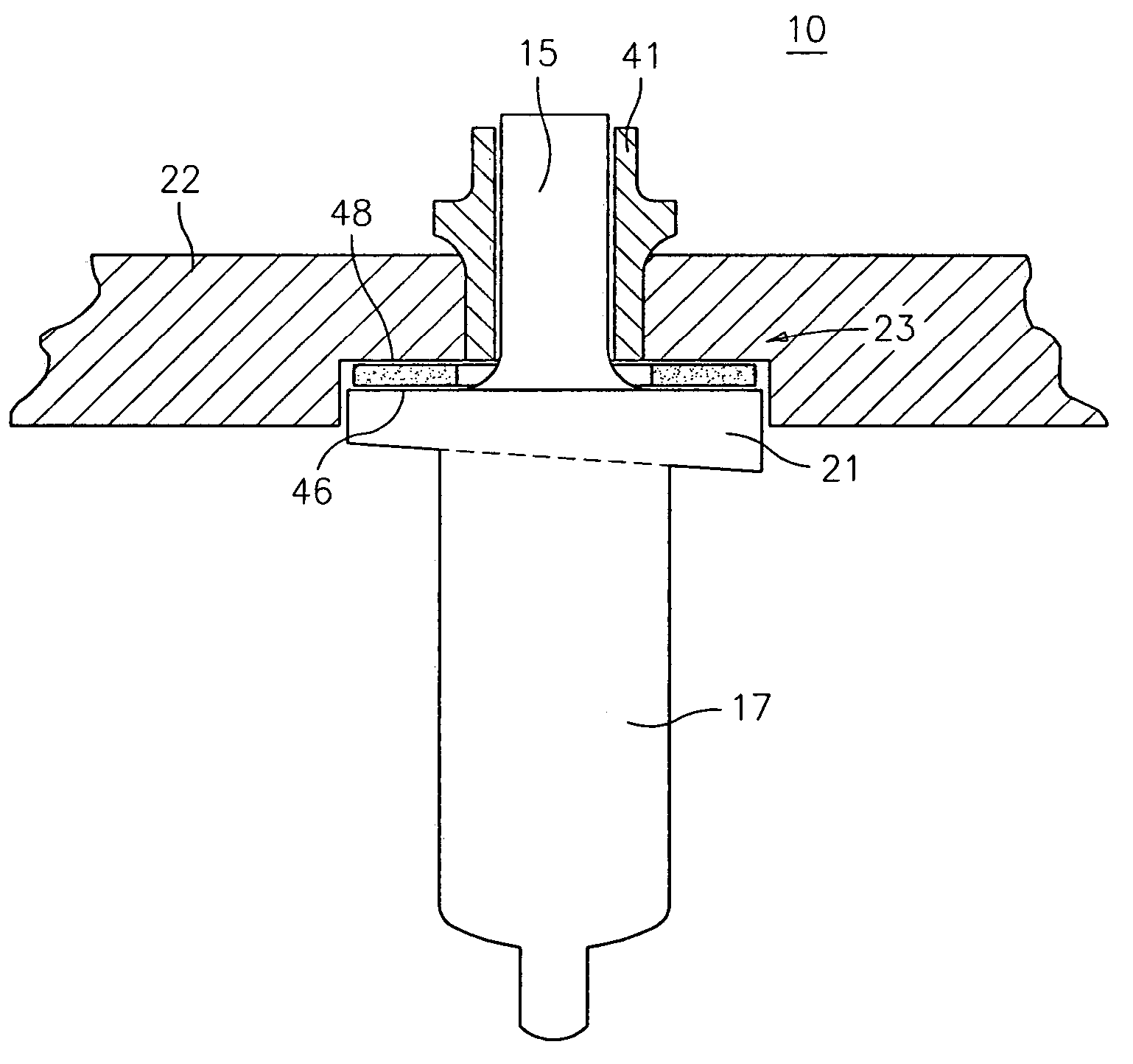

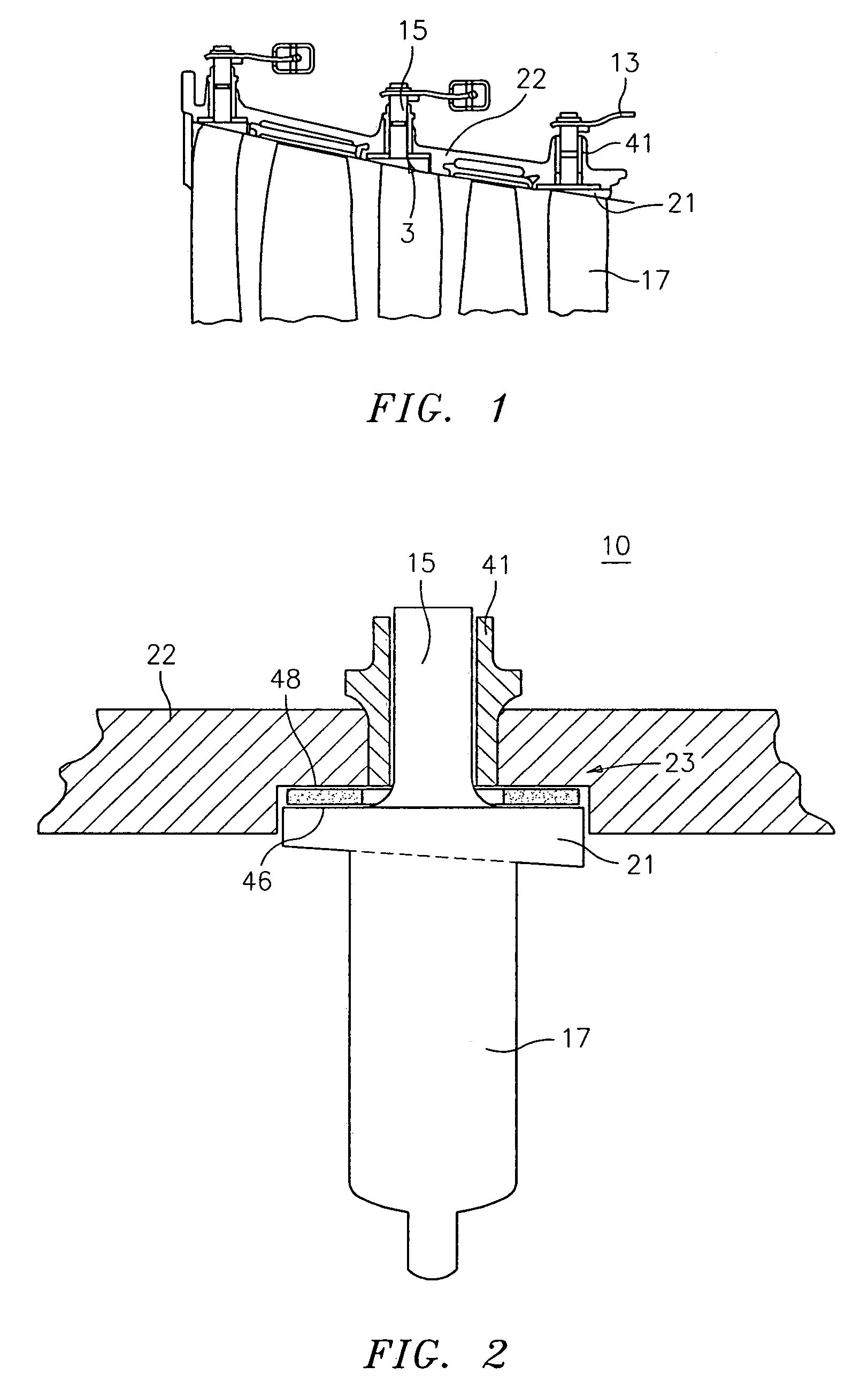

Variable vane electro-graphic thrust washer

ActiveUS7112039B2Improve wear characteristicsReduce wearWind motor controlPump componentsGraphicsEngineering

A method for improving the wear characteristics of a system for operating a variable vane comprising the steps of providing a trunnion connected to the variable vane via an vane platform and means for causing rotation of the trunnion, and positioning a thrust washer formed from a carbon material about a lower portion of the trunnion and in a space between the vane platform and an outer split case so that during operation of the system the space between the vane platform and the outer split case is maintained substantially constant and unwanted deflection of the vane is avoided.

Owner:RTX CORP

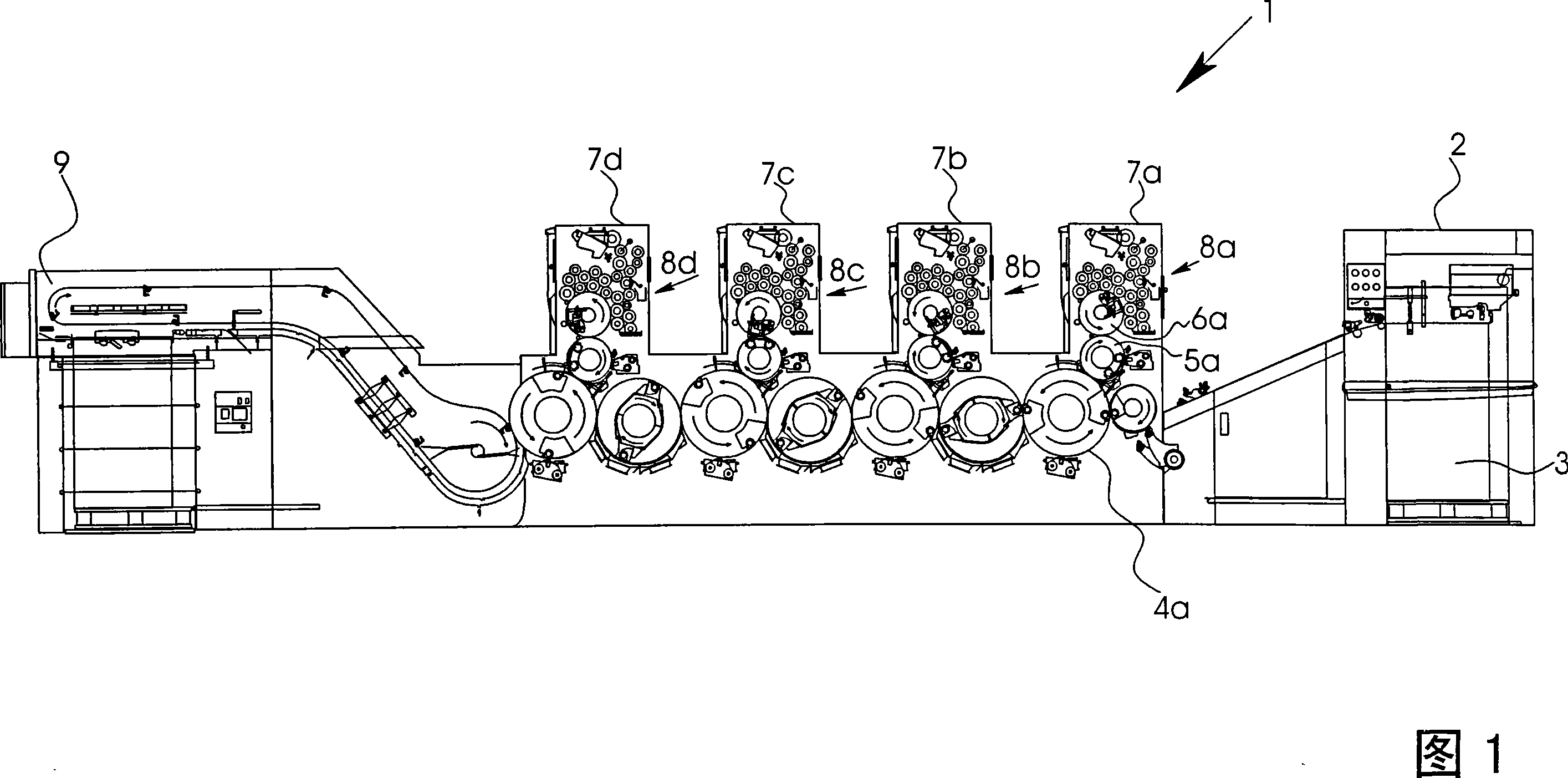

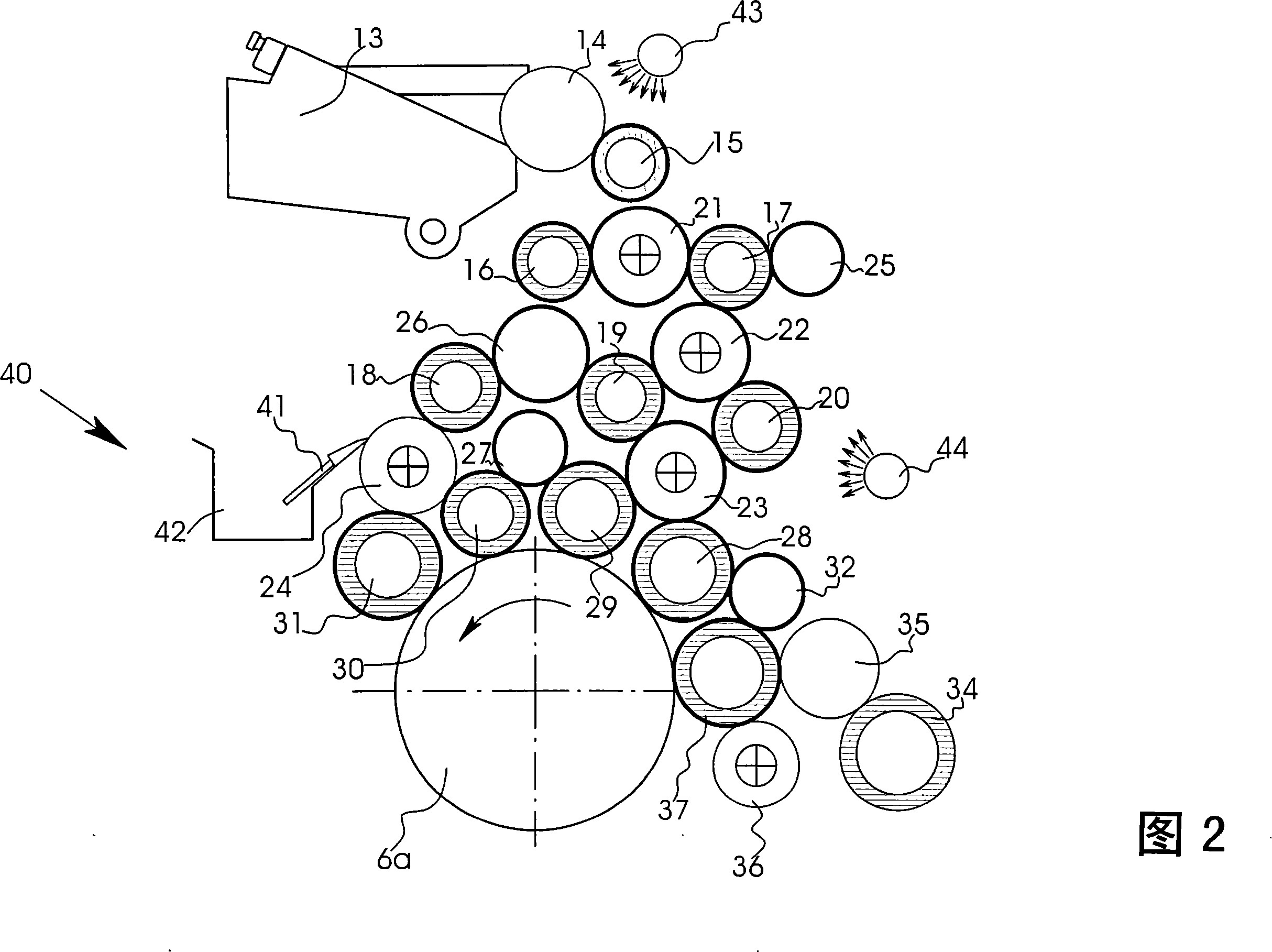

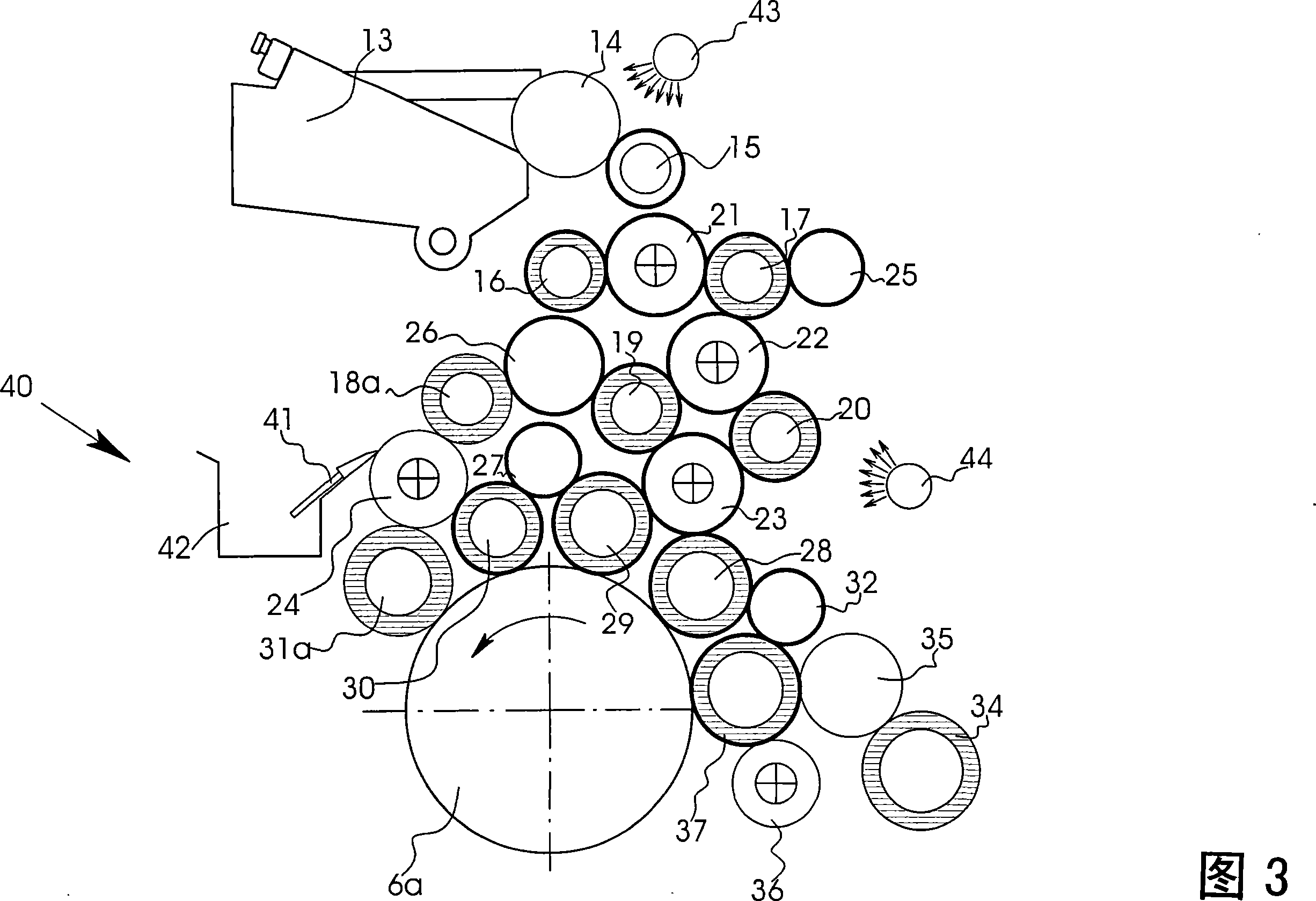

Printing press with a washing device for an inking unit

ActiveCN101195298AEfficient scrapingGood removal effectPrinting press partsEngineeringPrinting press

A printing press includes inking units having rollers provided with a phobic coating made of a material of low surface energy. At least one roller of the inking unit remains uncoated. Ink residues are stripped off the uncoated roller and removed by a blade during a cleaning operation.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

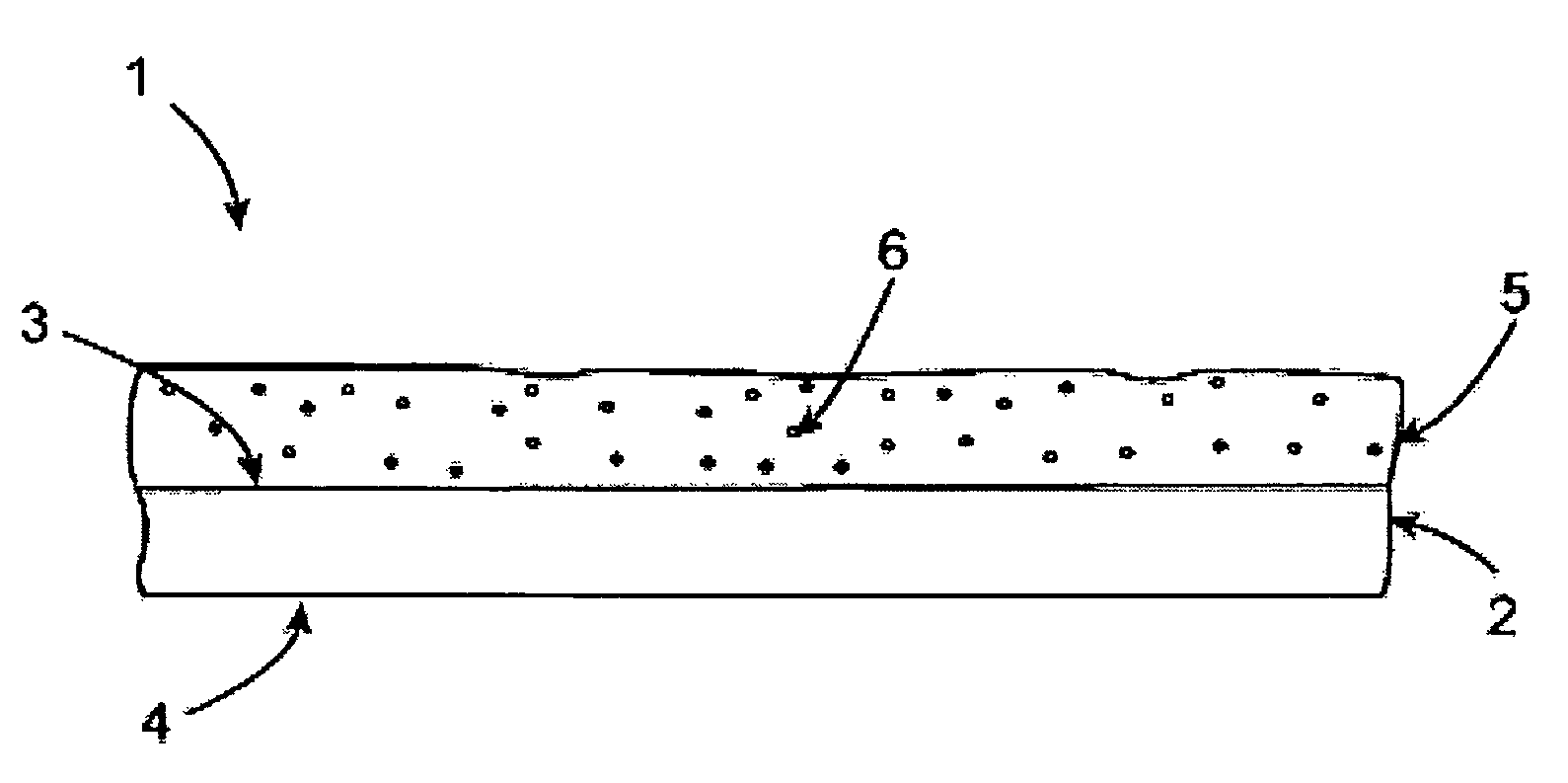

Belts and roll coverings having a nanocomposite coating

ActiveUS7736468B2Improve fatigueIncrease resistanceSynthetic resin layered productsPretreated surfacesNanoparticleNanocomposite coating

The present invention relates to a urethane-based coating having nanoparticles for improving the characteristics of a papermaking process belt, roll cover and belts used in textile applications. For example, the present invention improves resistance to flex fatigue, crack propagation, groove closure and wear characteristics of urethane coatings on such belts and roll coverings. The present invention also improves the resistance to water and oil permeation characteristics of urethane coated belts and roll coverings.

Owner:ALBANY INT CORP

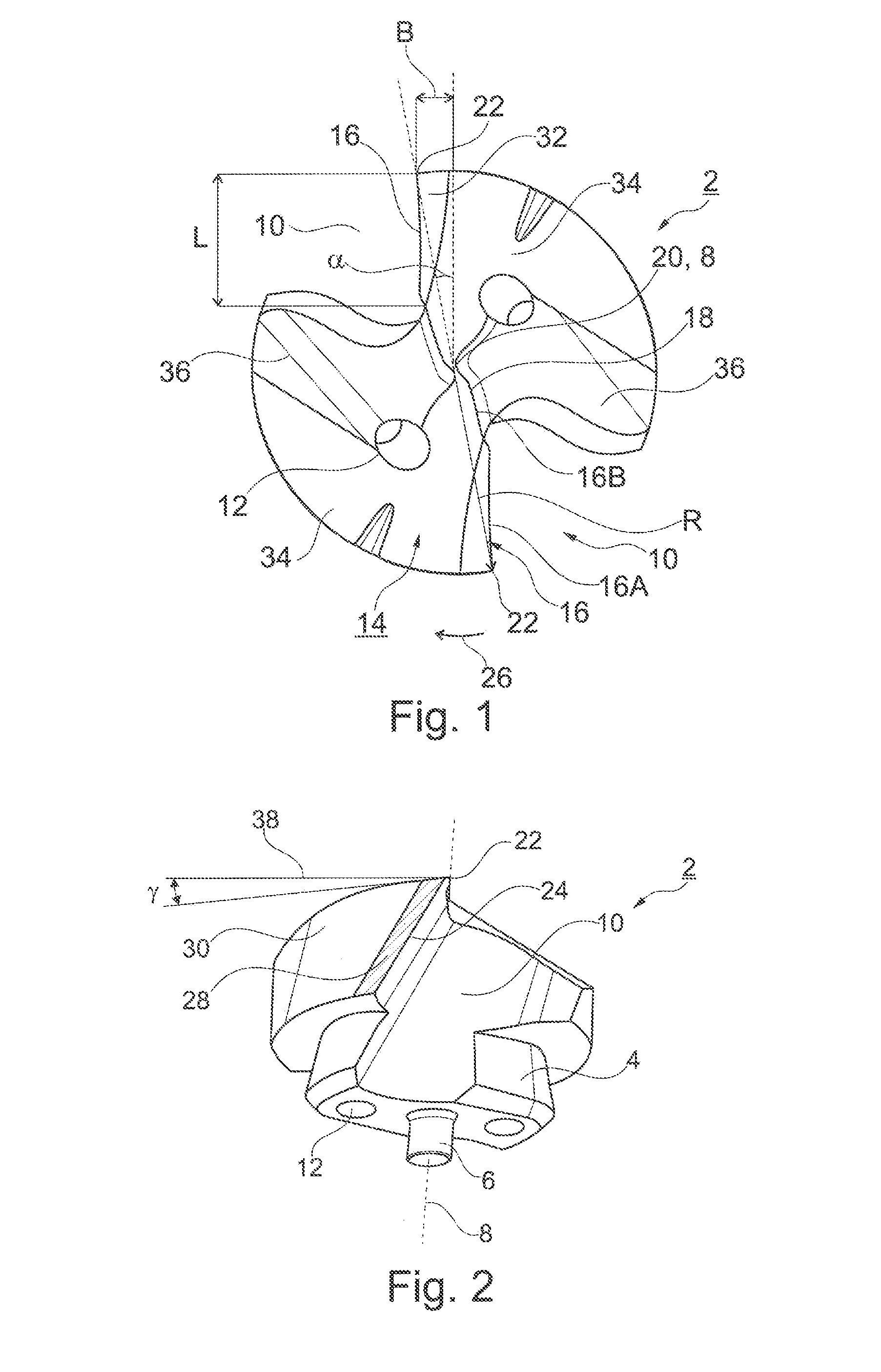

Rotary tool and method for manufacturing

ActiveUS20160263663A1Improve propertiesImprove wear characteristicsWorkpiecesTurning toolsEngineeringMechanical engineering

A rotary tool, in particular drilling tool, extends along a longitudinal axis and has an end surface; a brad point; and at least one major cutting edge extending outward up to an edge corner. A first free surface segment adjoins the major cutting edge, and a second free surface segment in turn adjoins said first free surface segment. To keep the stress, in particular the wear, low in the region of the end surface, the first free surface segment has a lower average abrasiveness than the second free surface segment.

Owner:KENNAMETAL INC

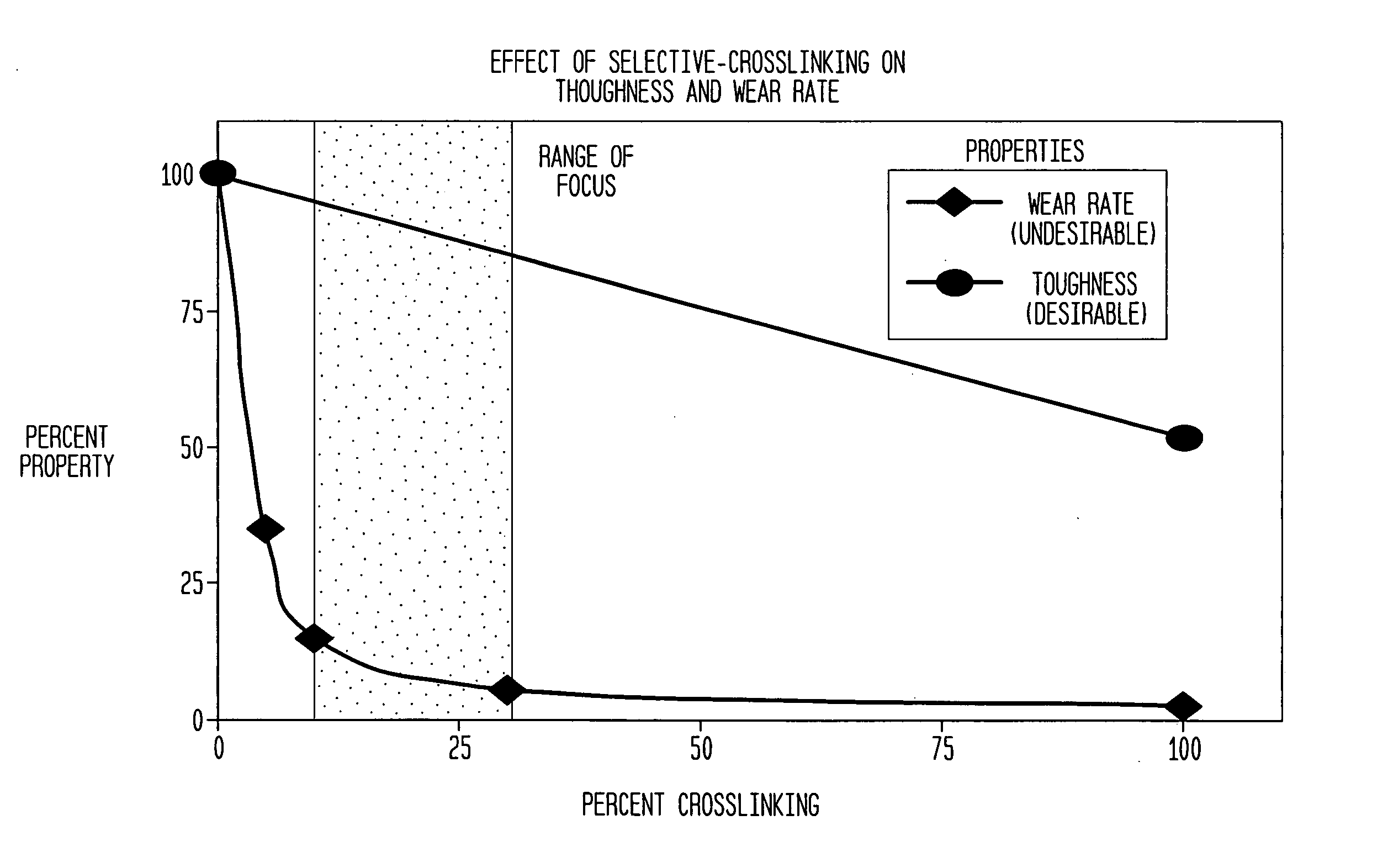

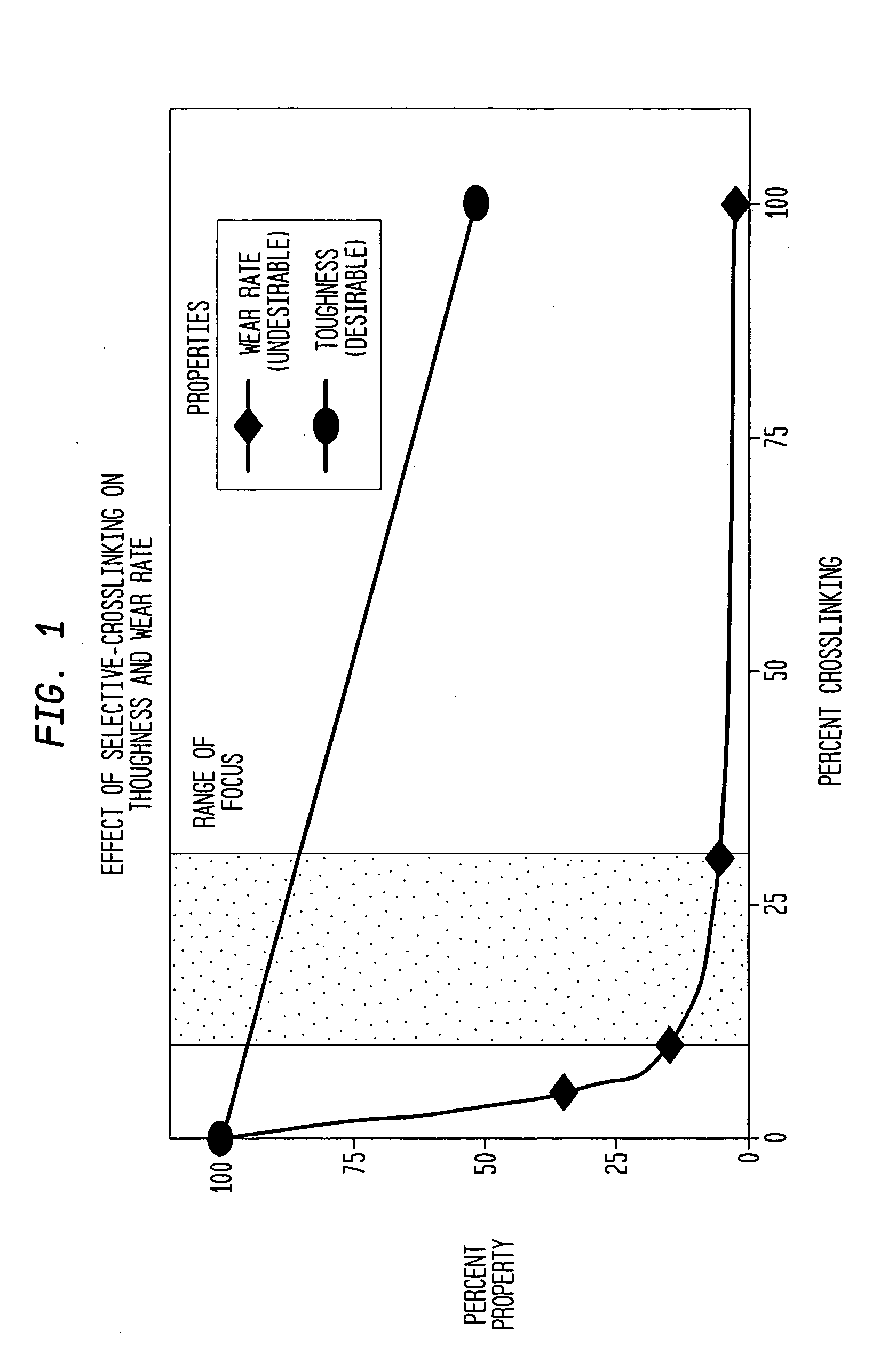

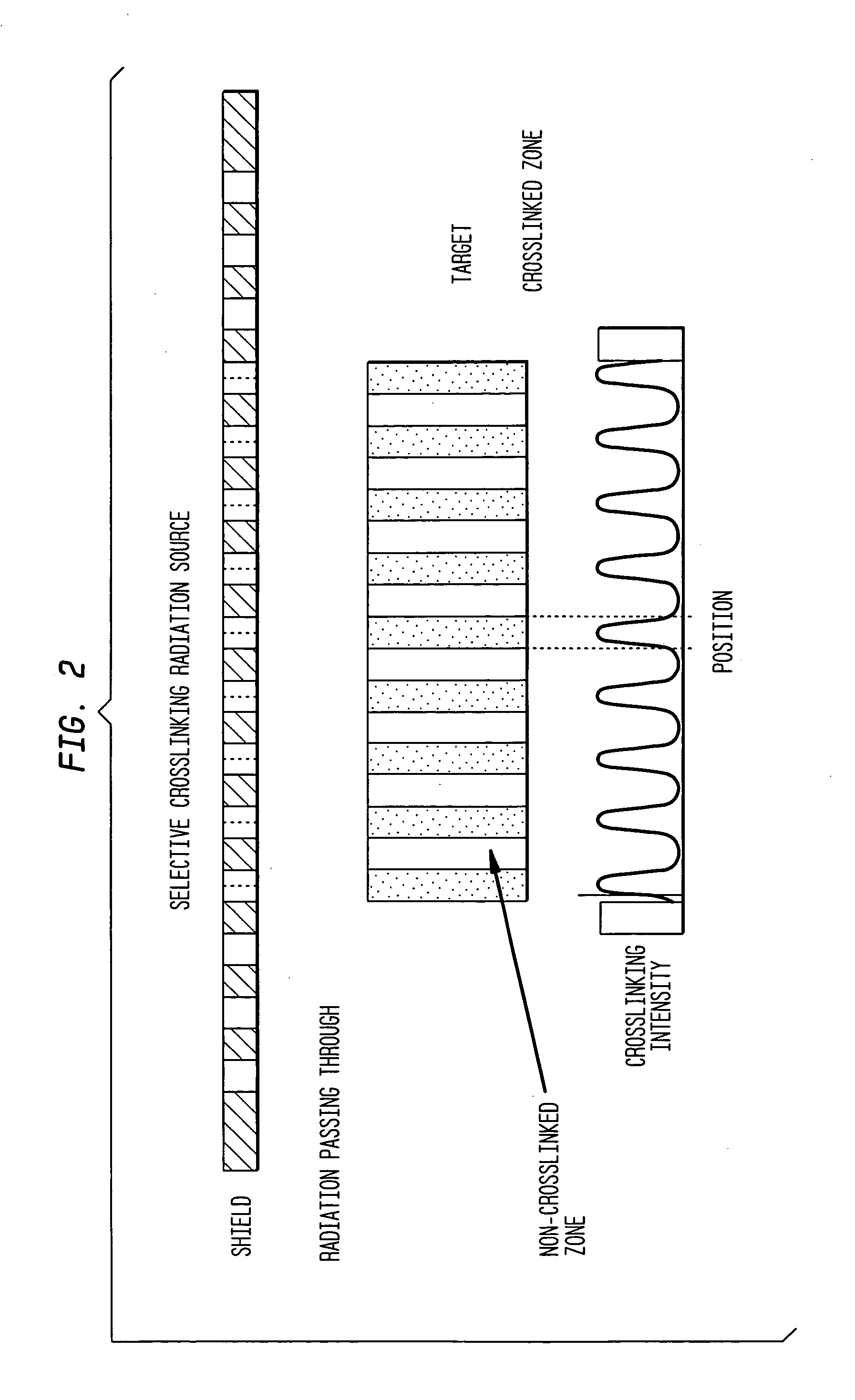

Selectively cross-linked polyethylene orthopedic devices

InactiveUS20050113935A1Improve wear characteristicsLimited amountBone implantJoint implantsCross-linkCross-linked polyethylene

An improved prosthetic medical device having improved wear resistance and toughness is provided in the present application. A method is provided to selectively cross-link the polymeric matrix comprising the medical device by employing an interrupting means such as a mask, wire mesh or chopper wheel placed in between the medical device and irradiation source. In addition, the medical device may be translated while being irradiated to further effect the selective cross-linking. The present invention also provides for an injection molding process wherein a prosthetic medical device is formed in a single step, then selectively cross-linked.

Owner:HOWMEDICA OSTEONICS CORP

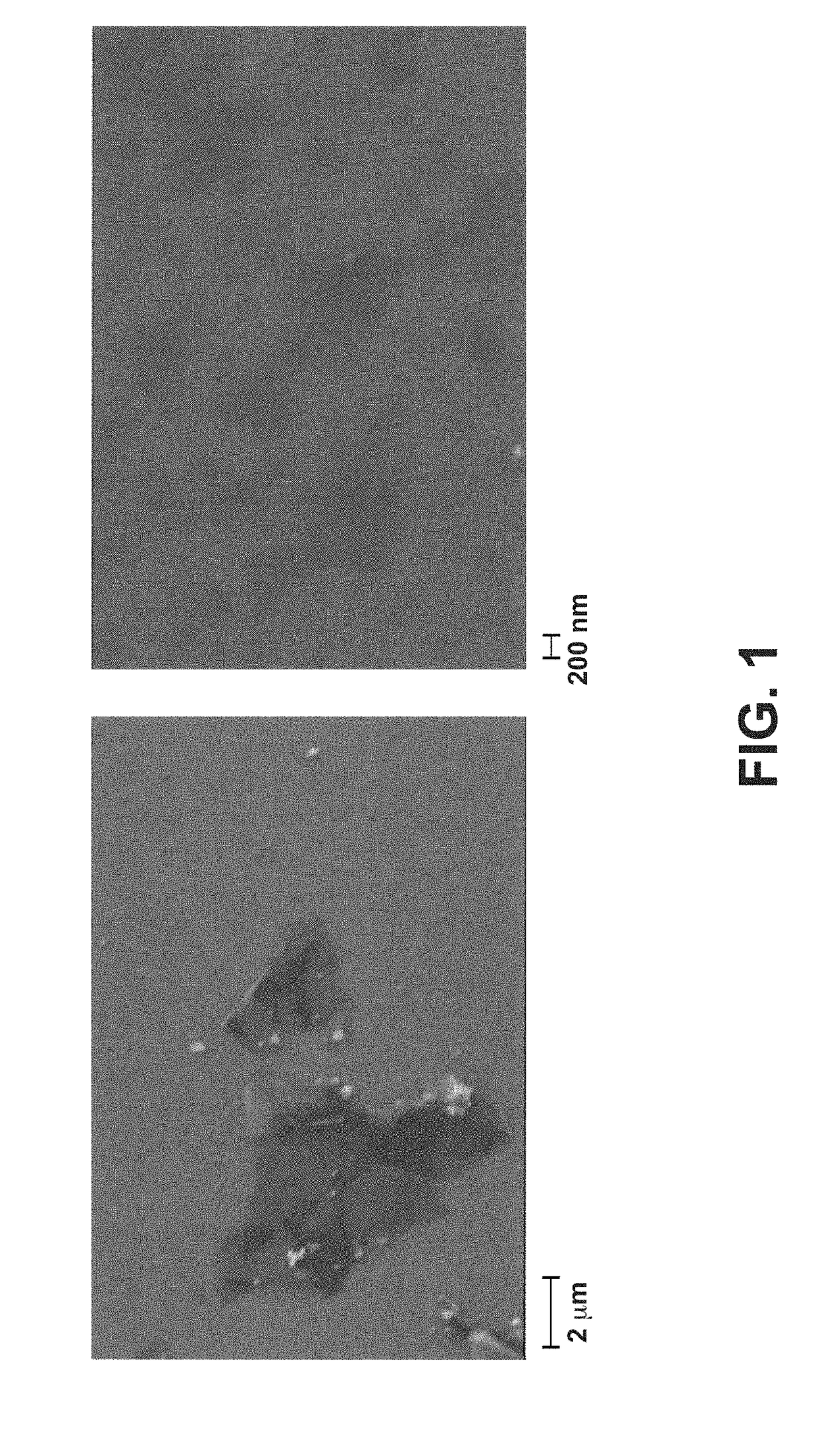

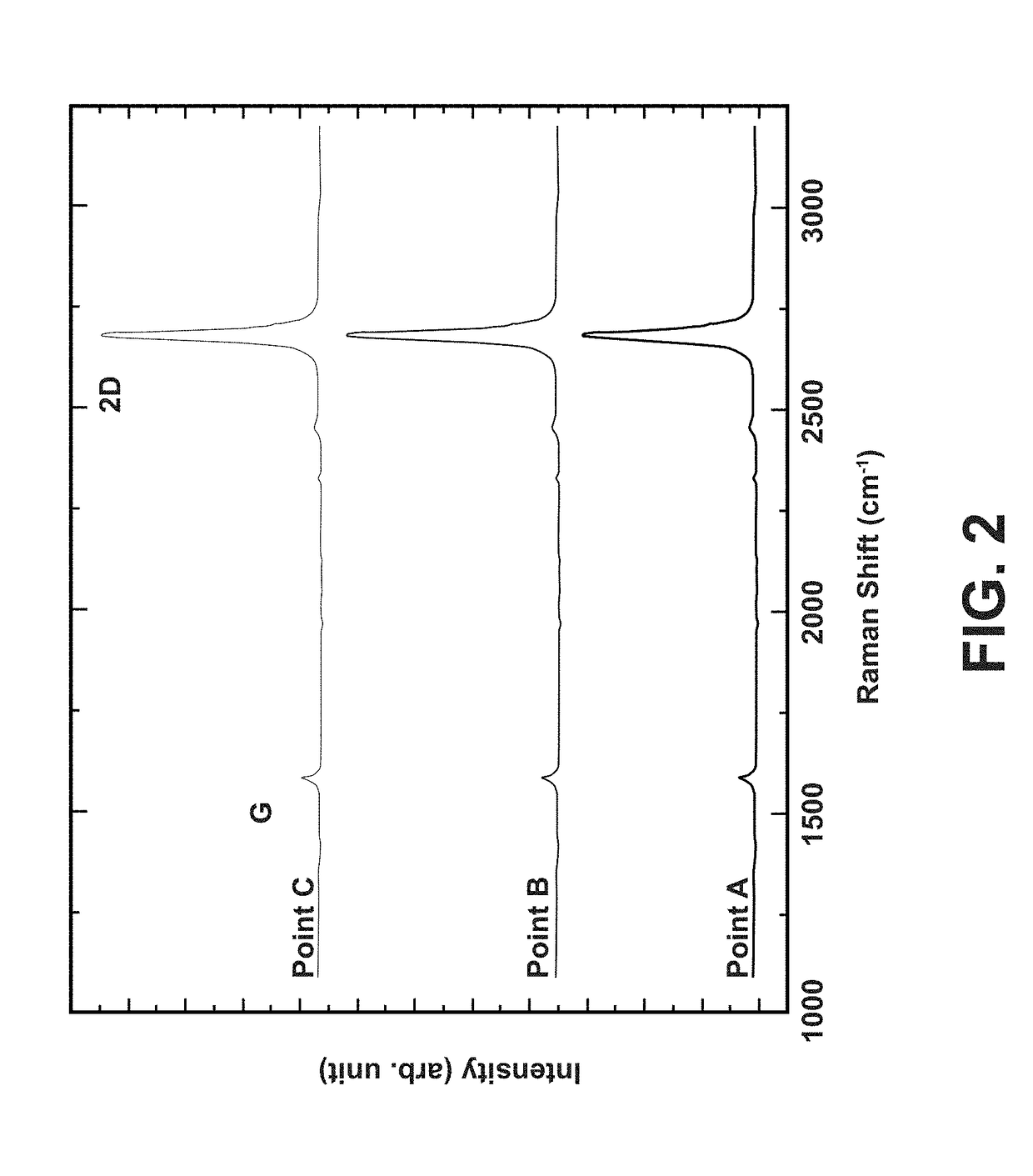

Nanocomposite Additives Based on Graphene Sheets and Silica Nanofibers

ActiveUS20180346684A1Reduction in hysteric lossesUniform temperature distributionInorganic material artificial filamentsElectro-spinningPolymer scienceNanofiber

A method for producing a composite polymeric article, an additive for a polymeric article, and a composite polymeric article are provided. The method generally includes providing a plurality of graphene nanoplatelets, providing a plurality of silica nanofibers, providing a polymeric material, and distributing the plurality of silica nanofibers and the plurality of graphene nanoplatelets within the polymeric material to achieve a composite article. The additive for a polymeric article includes a plurality of graphene nanoplatelets and a plurality of silica nanofibers. The composite polymeric article includes a plurality of graphene nanoplatelets, a plurality of silica nanofibers, and a polymeric matrix. The plurality of graphene nanoplatelets and the plurality of silica nanofibers are distributed within the polymeric matrix. The silica nanofibers have a mean cross sectional diameter of not more than 100 nm.

Owner:UT BATTELLE LLC

Belts and roll coverings having a nanocomposite coating

ActiveUS20080081179A1Improve fatigueIncrease resistanceSynthetic resin layered productsPretreated surfacesNanoparticleNanocomposite coating

The present invention relates to a urethane-based coating having nanoparticles for improving the characteristics of a papermaking process belt, roll cover and belts used in textile applications. For example, the present invention improves resistance to flex fatigue, crack propagation, groove closure and wear characteristics of urethane coatings on such belts and roll coverings. The present invention also improves the resistance to water and oil permeation characteristics of urethane coated belts and roll coverings.

Owner:ALBANY INT CORP

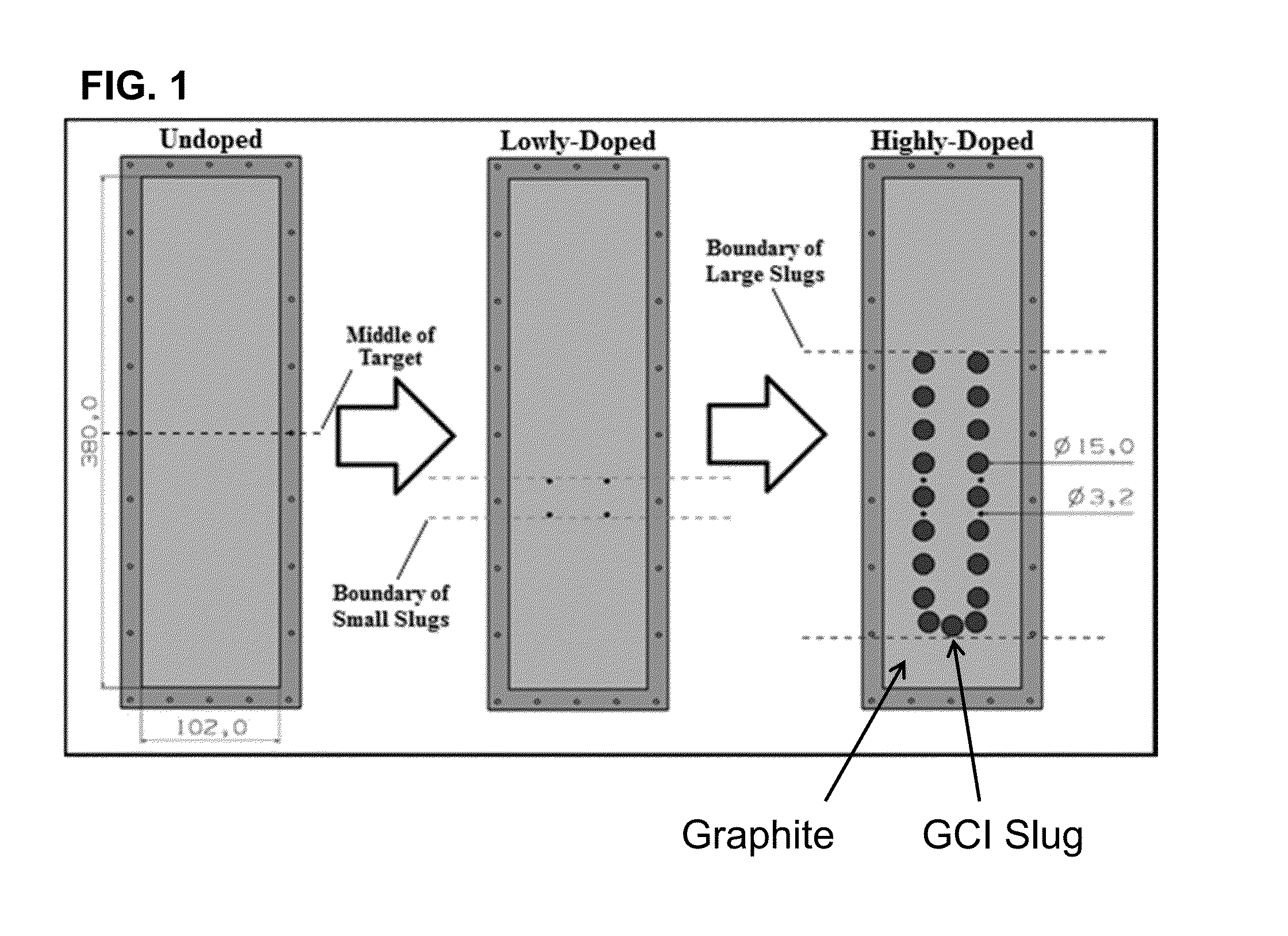

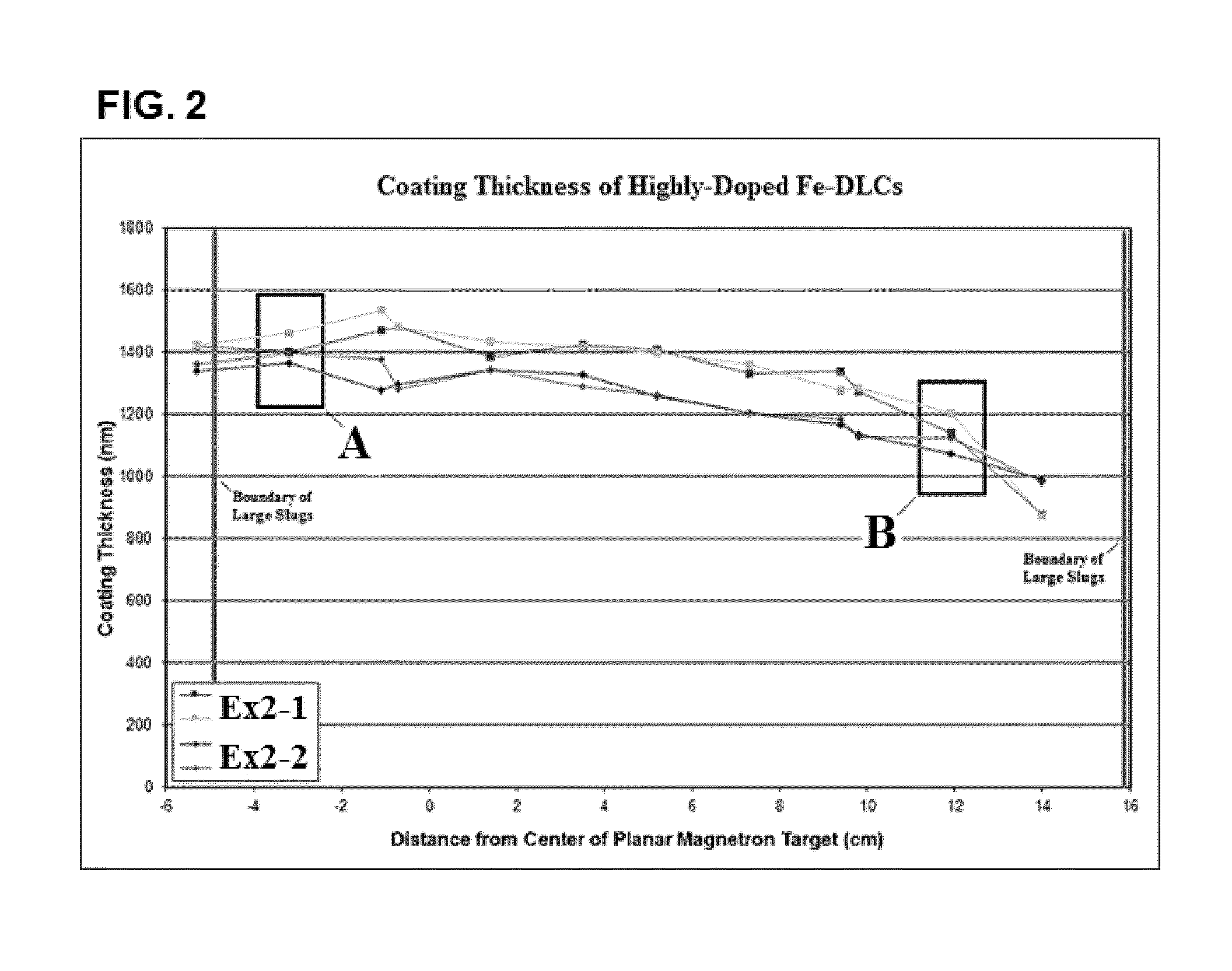

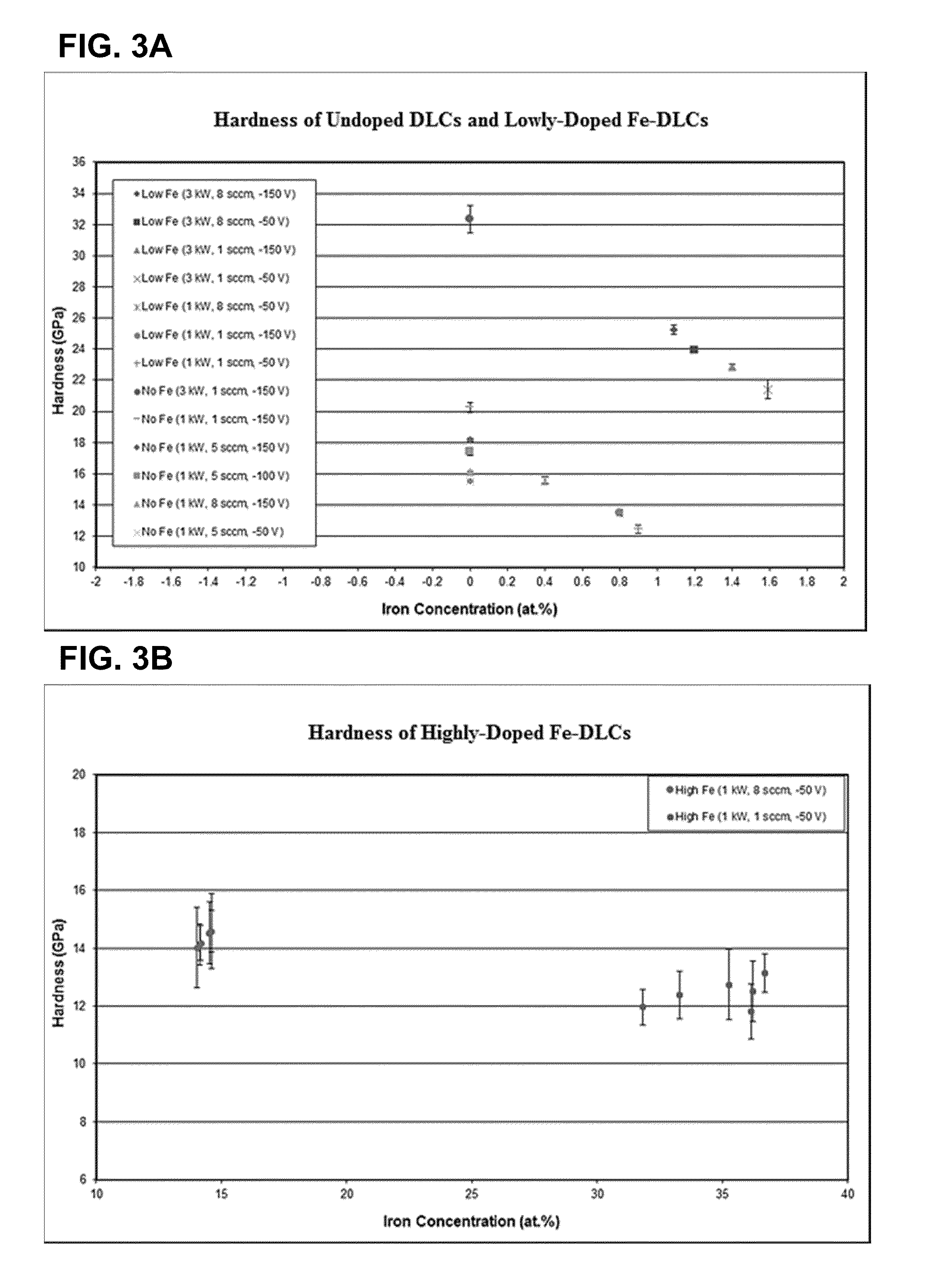

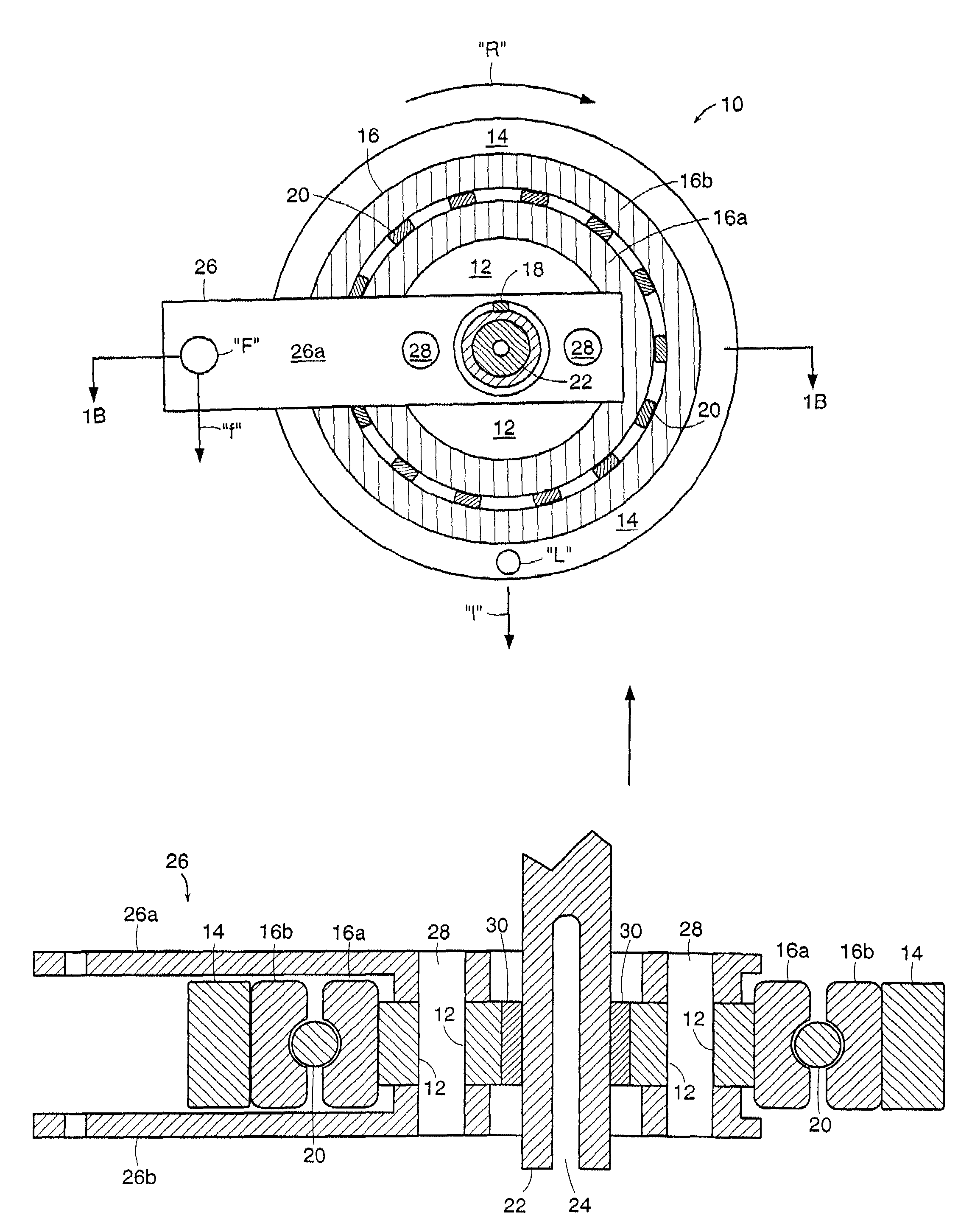

Grey cast iron-doped diamond-like carbon coatings and methods for depositing same

ActiveUS20160115417A1Low residual stressFacilitates adhesionEngine sealsVacuum evaporation coatingAdamiteMaterials science

The disclosure provides grey cast iron-doped diamond-like carbon coating compositions useful for reducing friction and wear in mechanical contact surfaces and methods for deposition of such compositions.

Owner:GUPTA PARAG

Tribological materials and structures and methods for making the same

InactiveUS7235514B2Improve featuresImprove wear characteristicsBearing componentsBearing surfaceLubricant

Owner:TRI MACK PLASTICS MFG

Inner garnish assembly module system

ActiveUS8840170B2Reduce decreaseImprove wear characteristicsWindowsEngine sealsEngineeringSingle component

A one-piece inner garnish assembly module system (MS) joins an inner garnish molding (IG), primary seal (PS), glass run (GR), and inner beltline weatherstrip (IB) into a single component prior to installation of the module system on a vehicle. The garnish is secured to the glass run along the A and B pillars, and the interconnecting header portion of a vehicle door. In addition, the primary seal is operatively associated or secured to the garnish, and may be pin-mounted to the door, or mechanically connected, and / or adhesively secured to the door.

Owner:COOPER STANDARD AUTOMATIVE INC

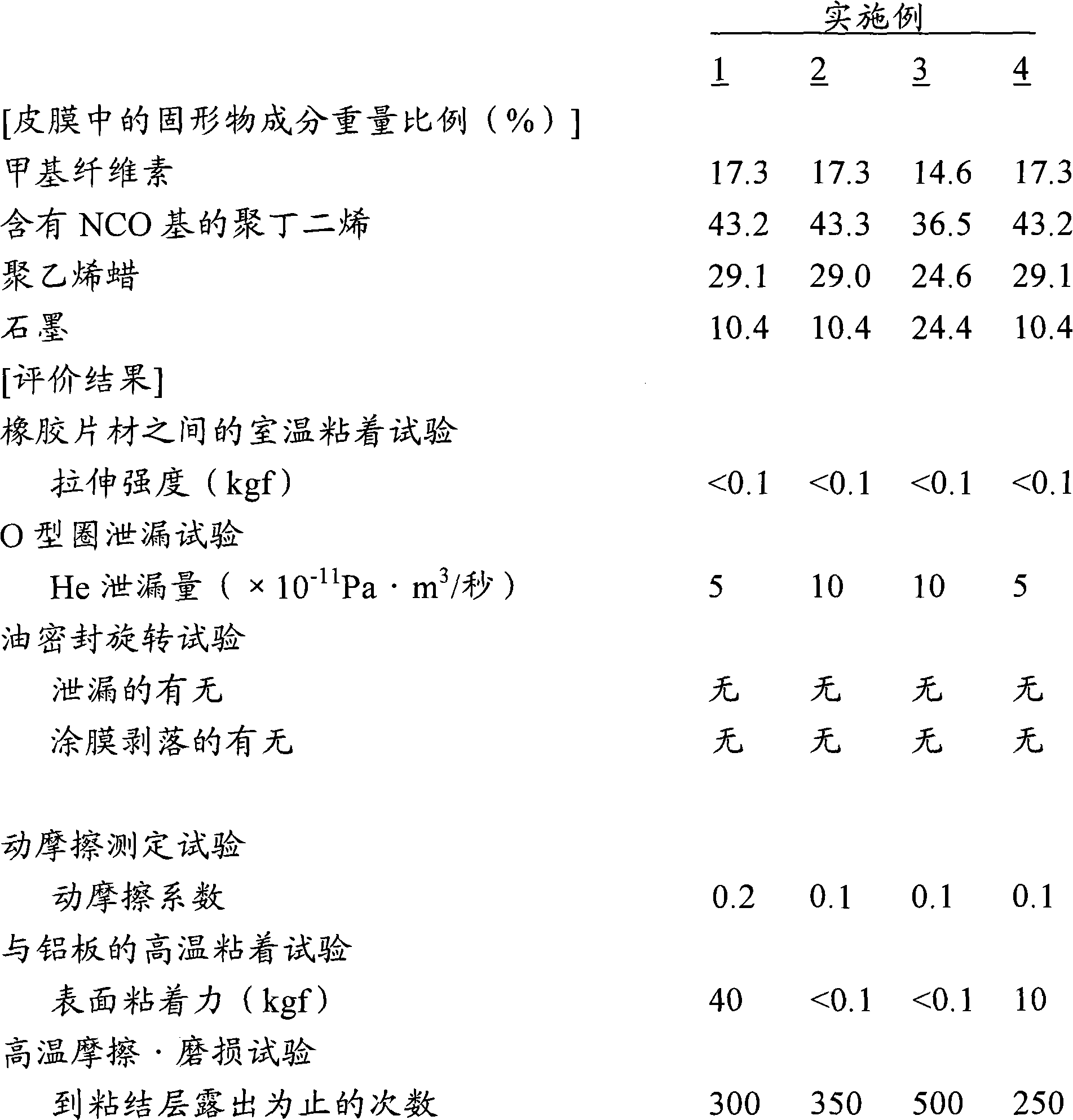

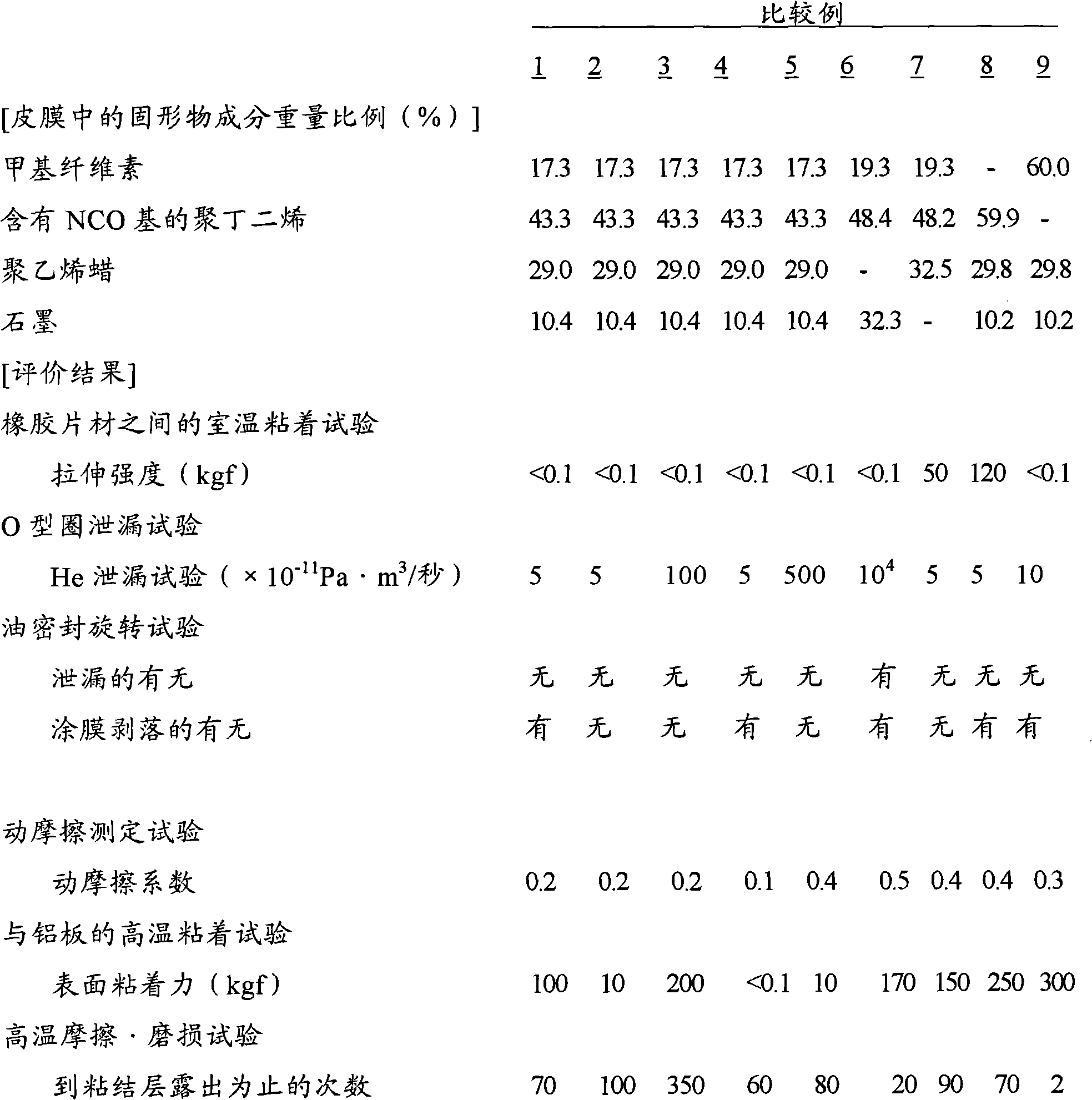

Coating agent

Disclosed is a coating agent comprising a cellulose derivative, a 1,2-polybutadiene having an isocyanate group, a synthetic wax having a softening point of 100 to 150 DEG C, an aliphatic amide having a softening point of 60 to 170 DEG C and graphite. The coating agent has satisfactory levels of properties required for a coating agent for a rubbery elastic material, such as a sticking-preventing property, an adhesion-preventing property, a blocking-preventing property, and improved abrasion resistance. The coating agent can be used as a surface treatment agent for a vulcanized rubber, which does not cause adhesion upon compression at a high temperature or detachment of a coating film by friction / abrasion under a high surface pressure.

Owner:NOK CORP

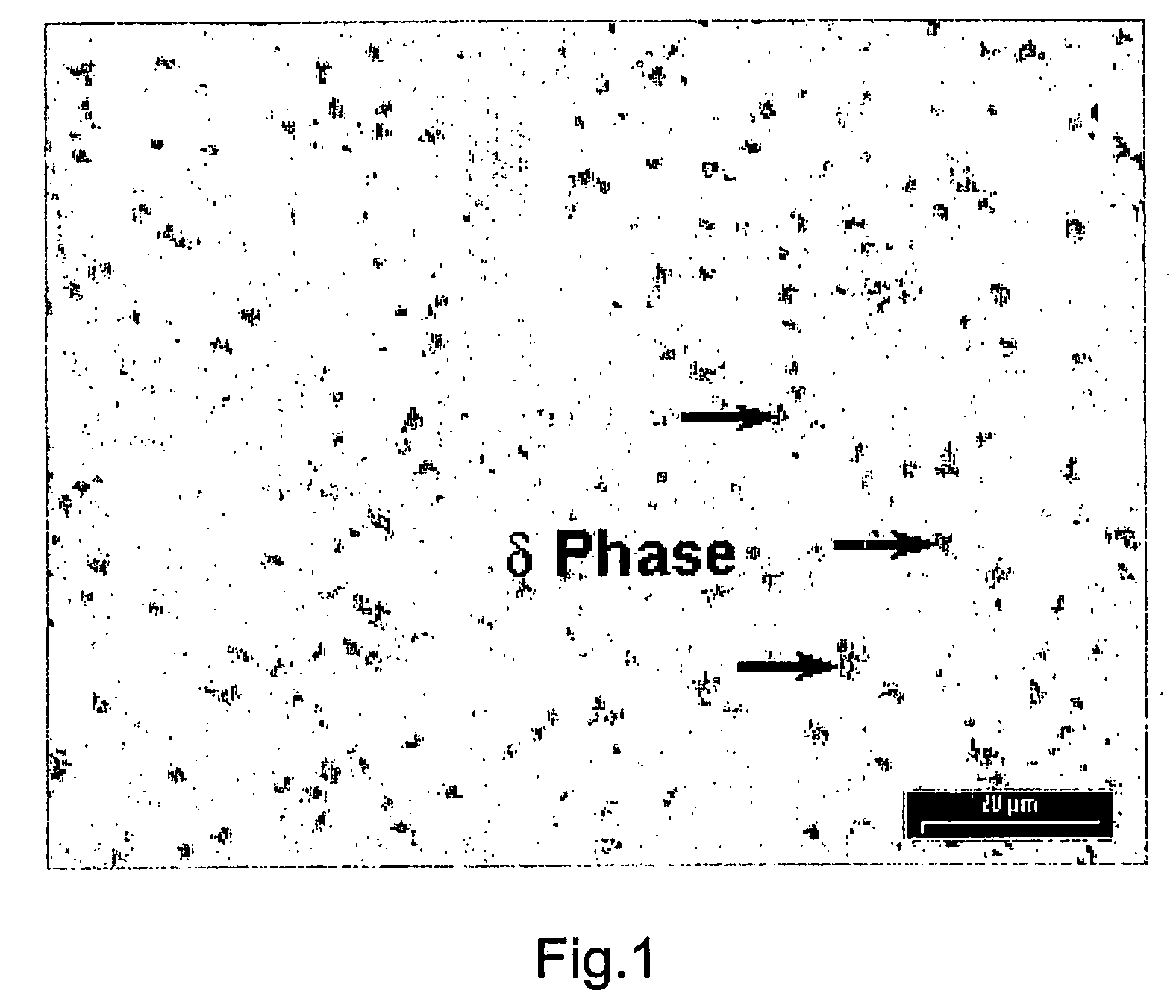

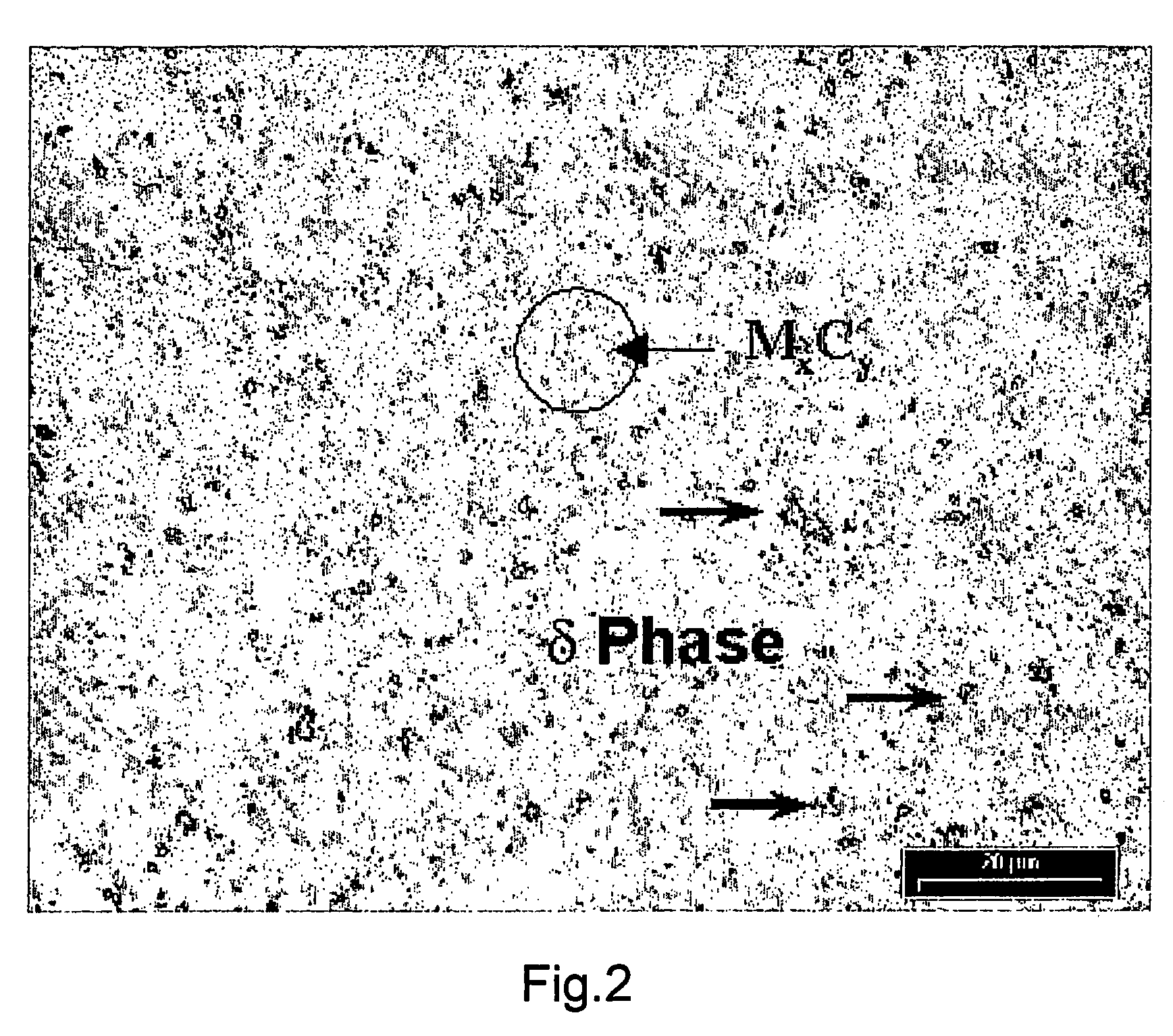

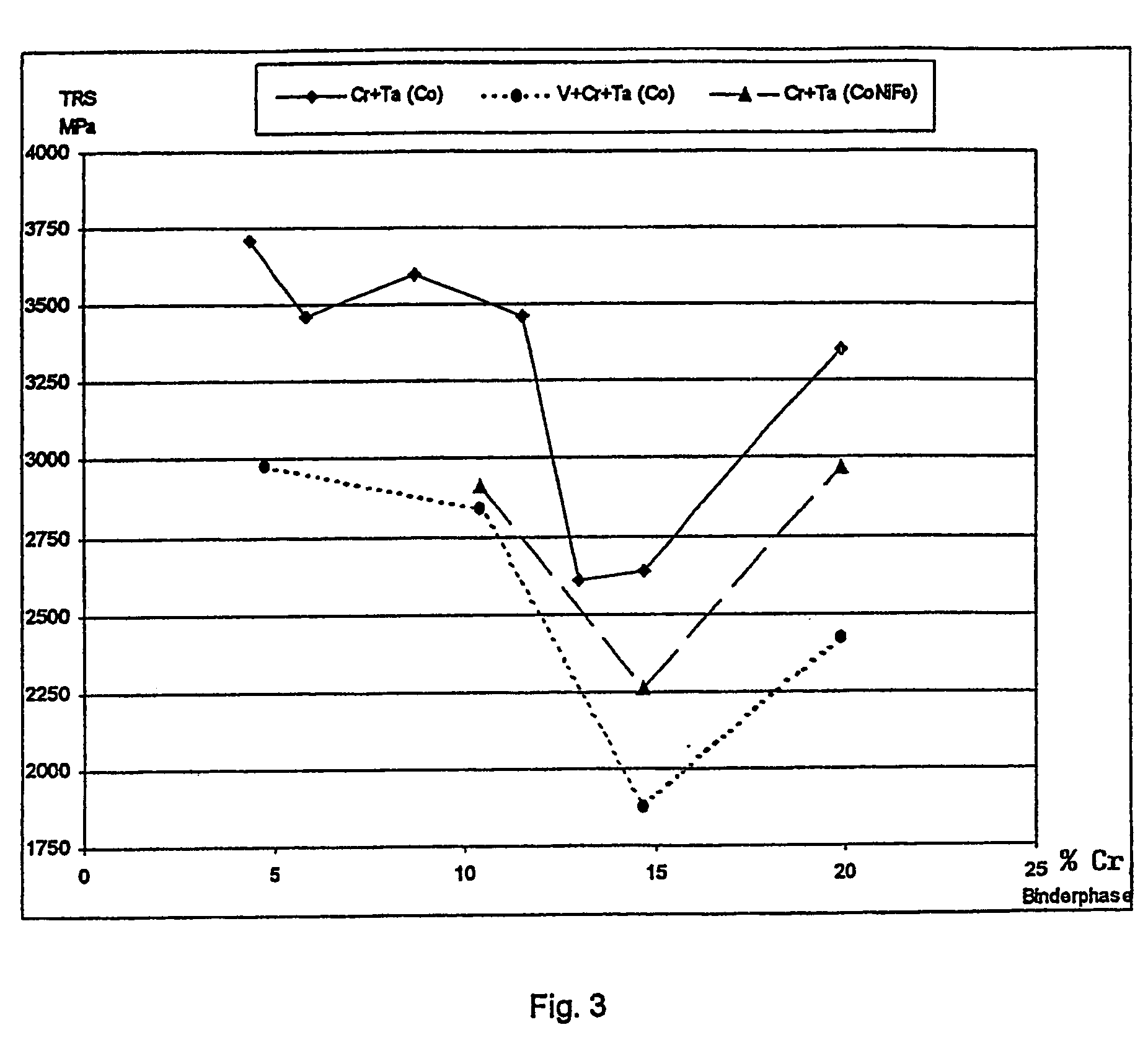

Fine grained sintered cemented carbide, process for manufacturing and use thereof

InactiveUS7179319B2Improve high temperature performanceImprove wear characteristicsPigmenting treatmentOther chemical processesCemented carbidePowder metallurgy

The invention proposes a fine grained sintered cemented carbide containing chromium and based on WC and a binder based on Co or CoNiFe, and having at least one additional phase comprising at least one carbide or mixed carbide of tantalum. For improving the high-temperature properties while simultaneously maintaining a good trade-off between hardness and bending strength, it is proposed that the sintered cemented carbide contains approximately 0.3 to 4% Ta, as related to the total mass of the sintered cemented carbide, that the WC has a grain size of between 0.1 and 1.3 μm, that the binder phase contains the metals W, Cr and Ta, dissolved in solid solution, and that the at least one additional phase comprises a TaC phase visible by optical microscopy. The invention further relates to a powder-metallurgical process for manufacturing the sintered cemented carbide and to the use of the sintered cemented carbide for manufacturing cutting tools having improved high-temperature properties.

Owner:KENNAMETAL INC

Reinforced brake lining and method of producing

A method of producing a brake lining assembly having a wear surface with increased wear characteristics comprises the steps of winding a metal strip, placing the wound metal strip into a brake lining cup, filling the brake lining cup with a brake lining material of powdered metal and then sintering the powdered metal thus embedding the wound metal strip into the brake lining material, forming a brake lining assembly. The metal strip has a width approximately equal to that of the brake lining assembly desired depth, and is wound into a shape and size which will fit into the brake lining cup. The wound metal strip is then placed into the brake lining cup such that the metal strip width is approximately perpendicular to the brake lining wear surface. Alternatively the wound metal strip may be produced by extrusion. The result is a brake lining assembly which is reinforced by a metallic winding structure.

Owner:THE BF GOODRICH CO

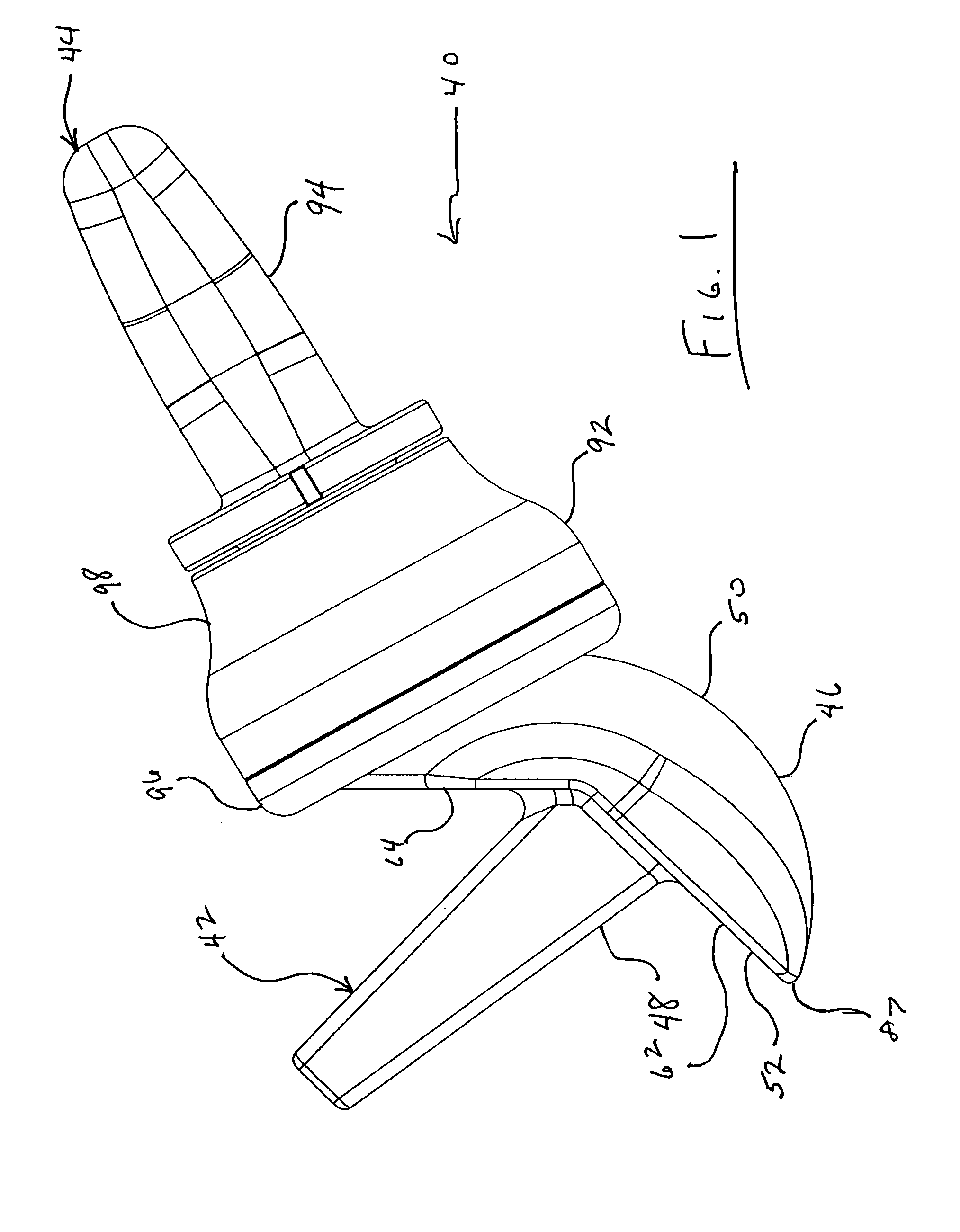

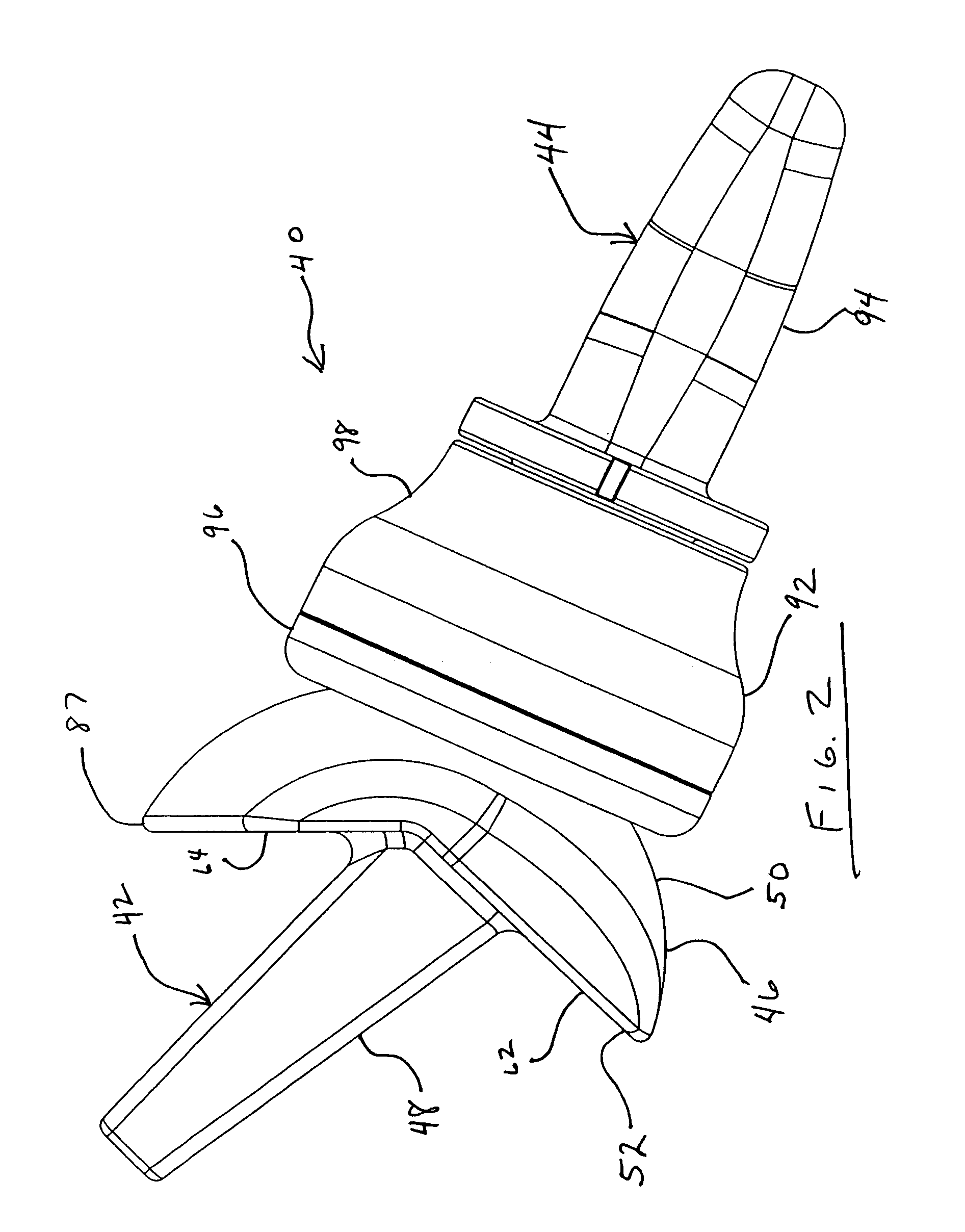

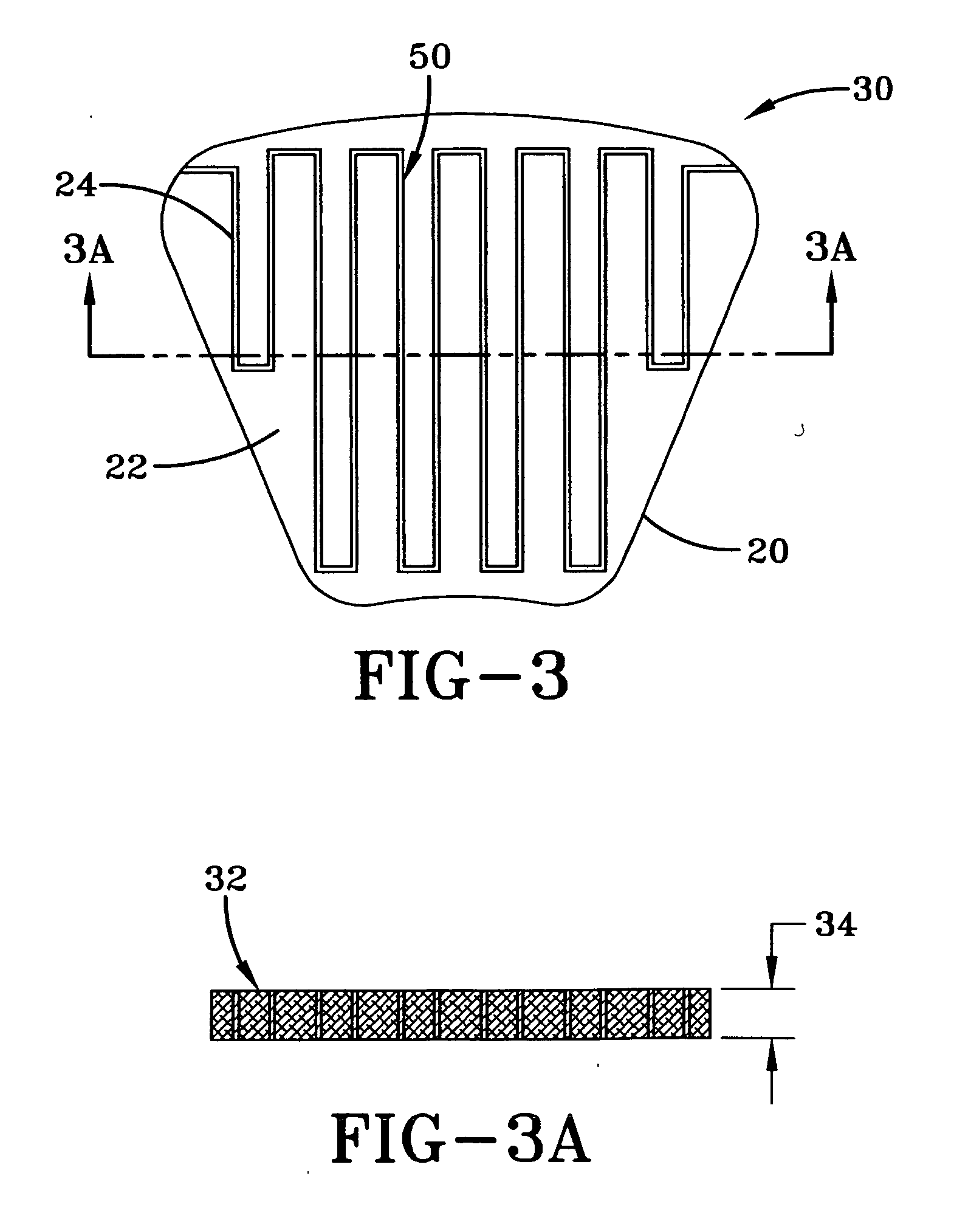

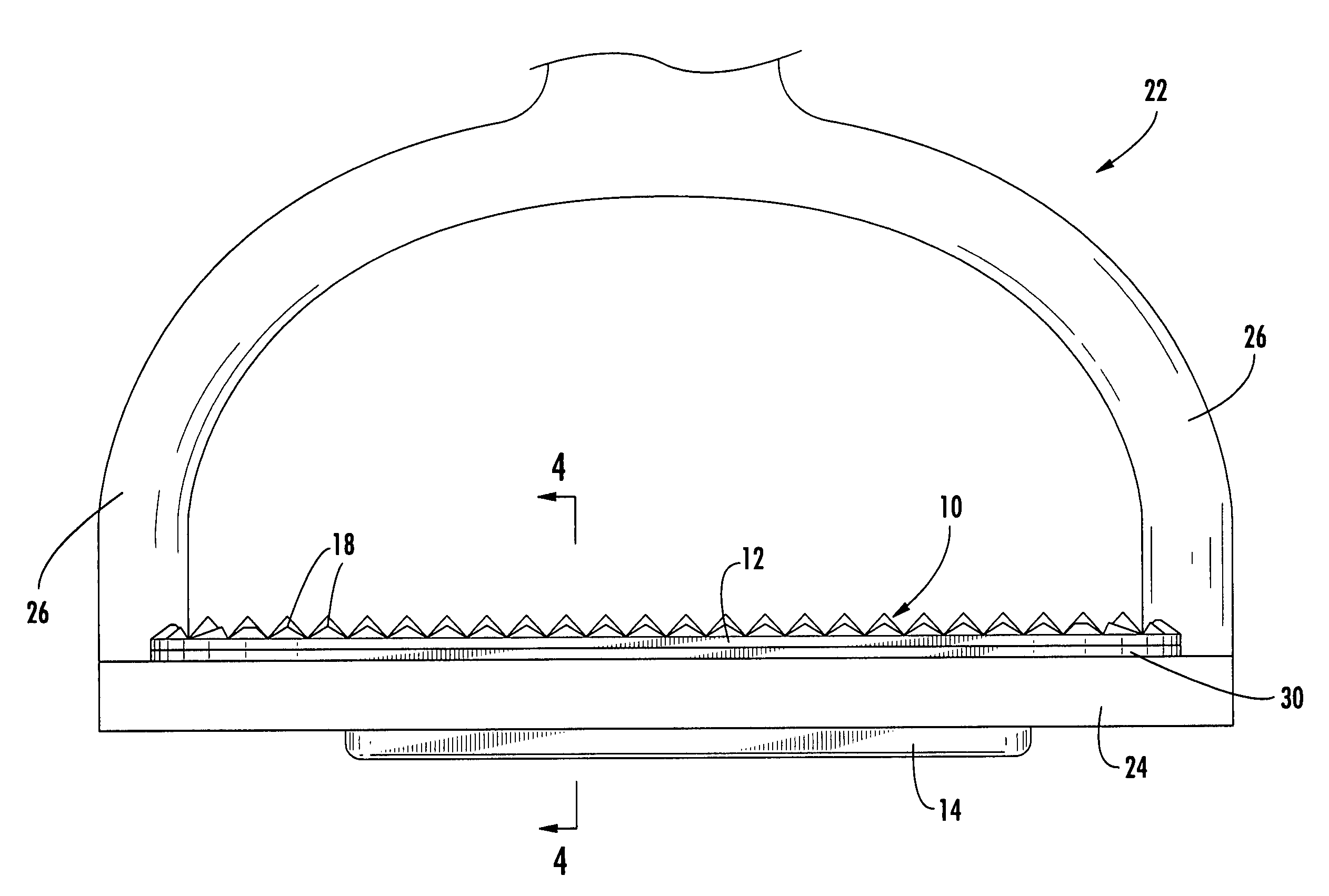

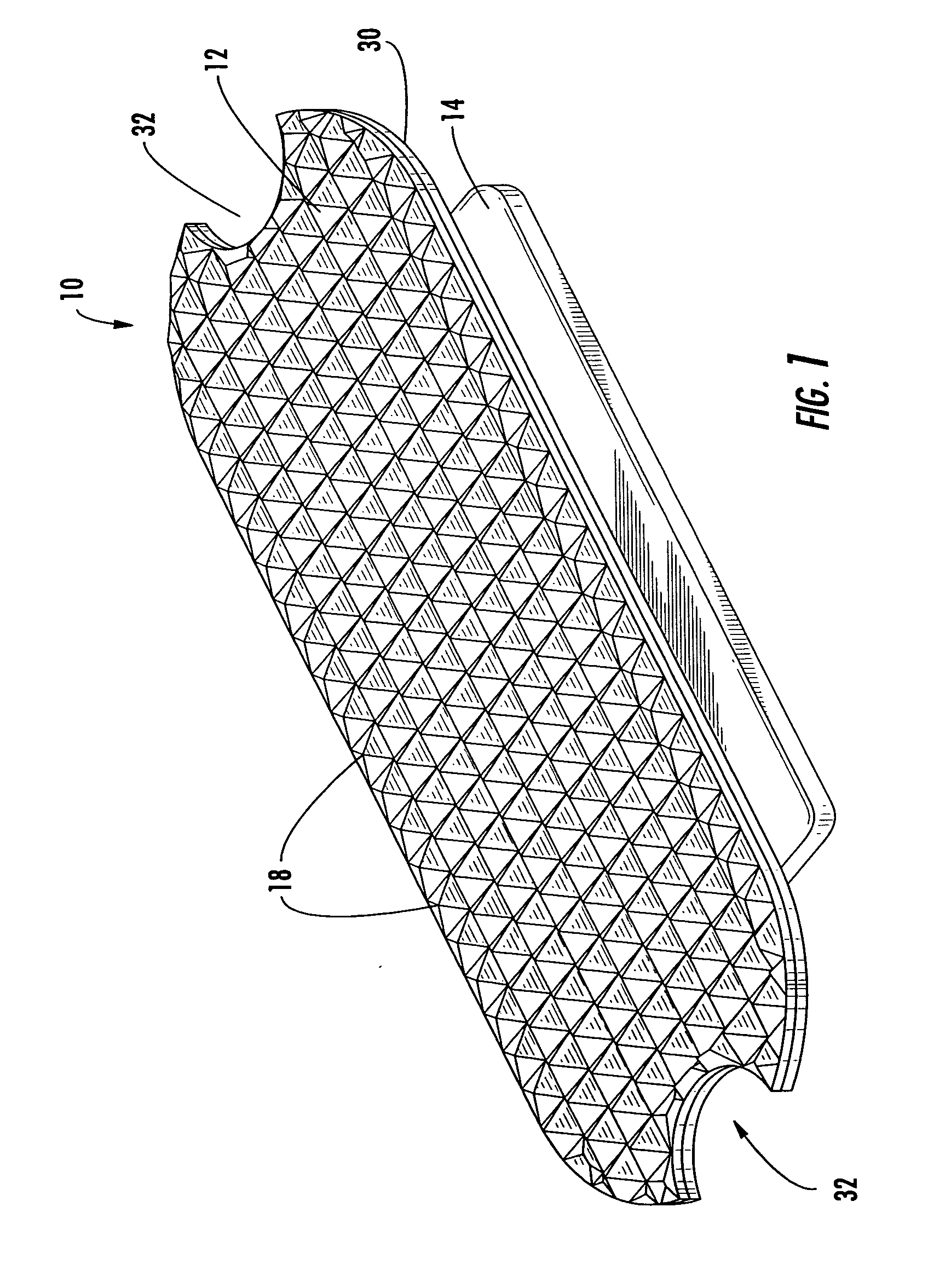

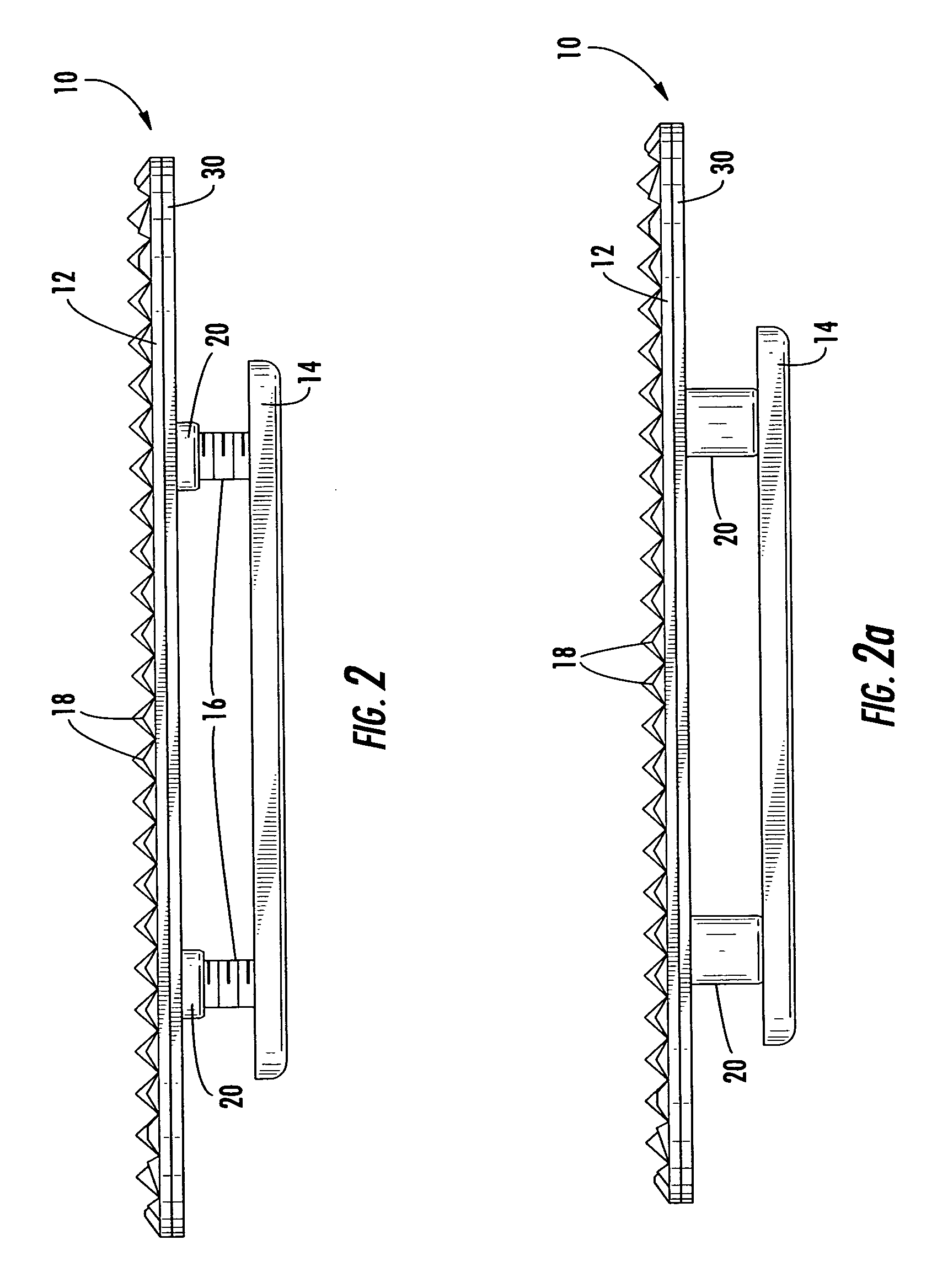

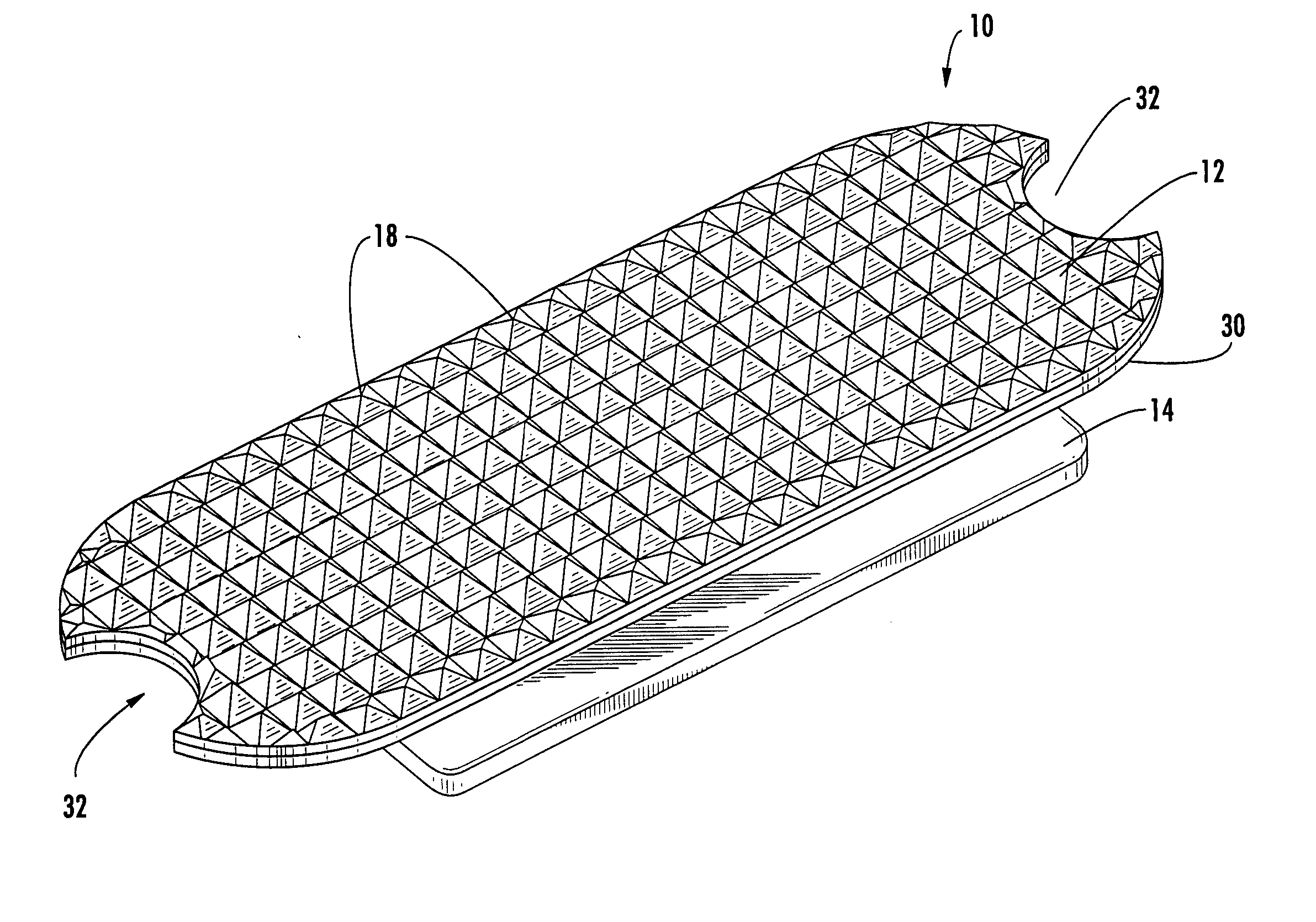

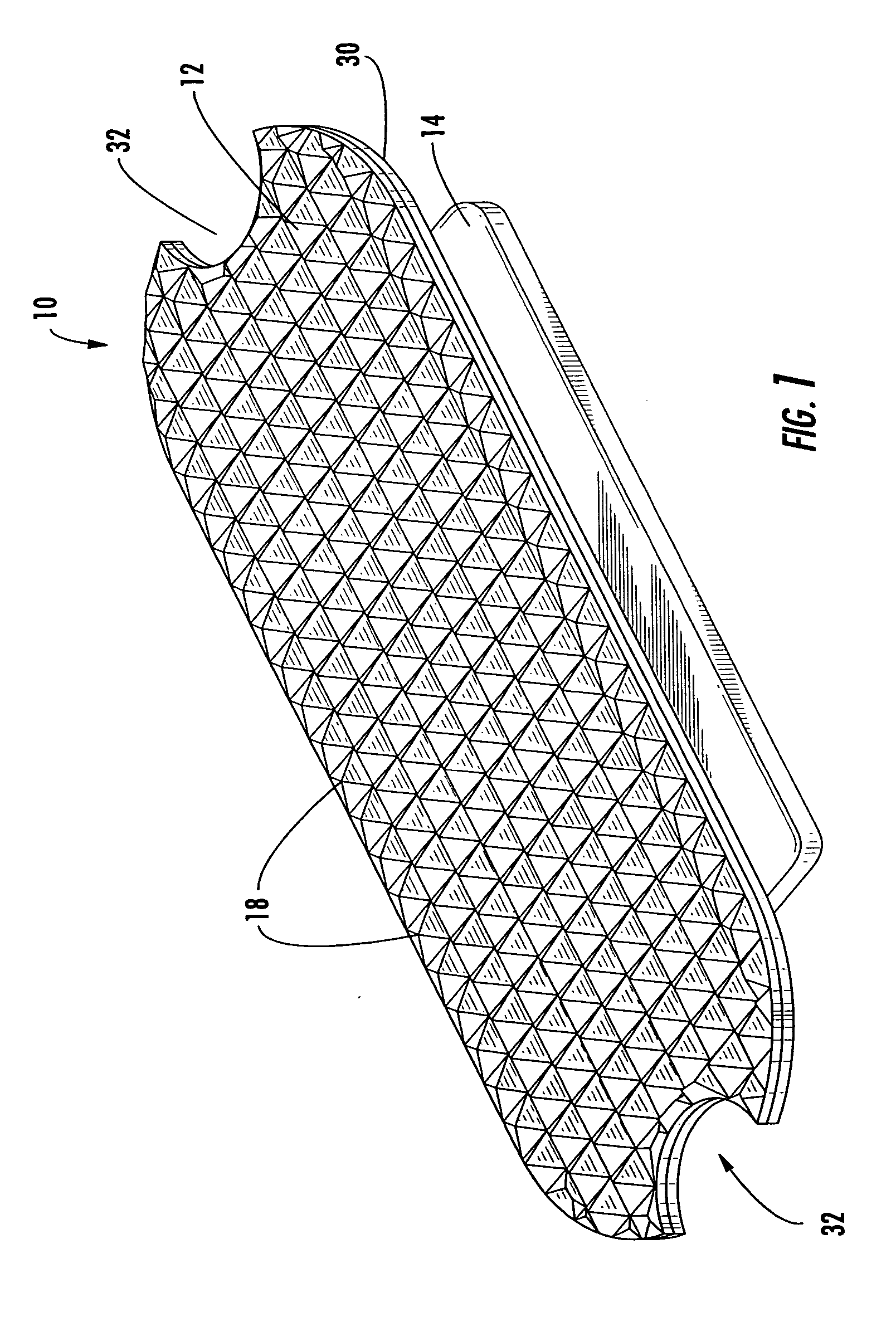

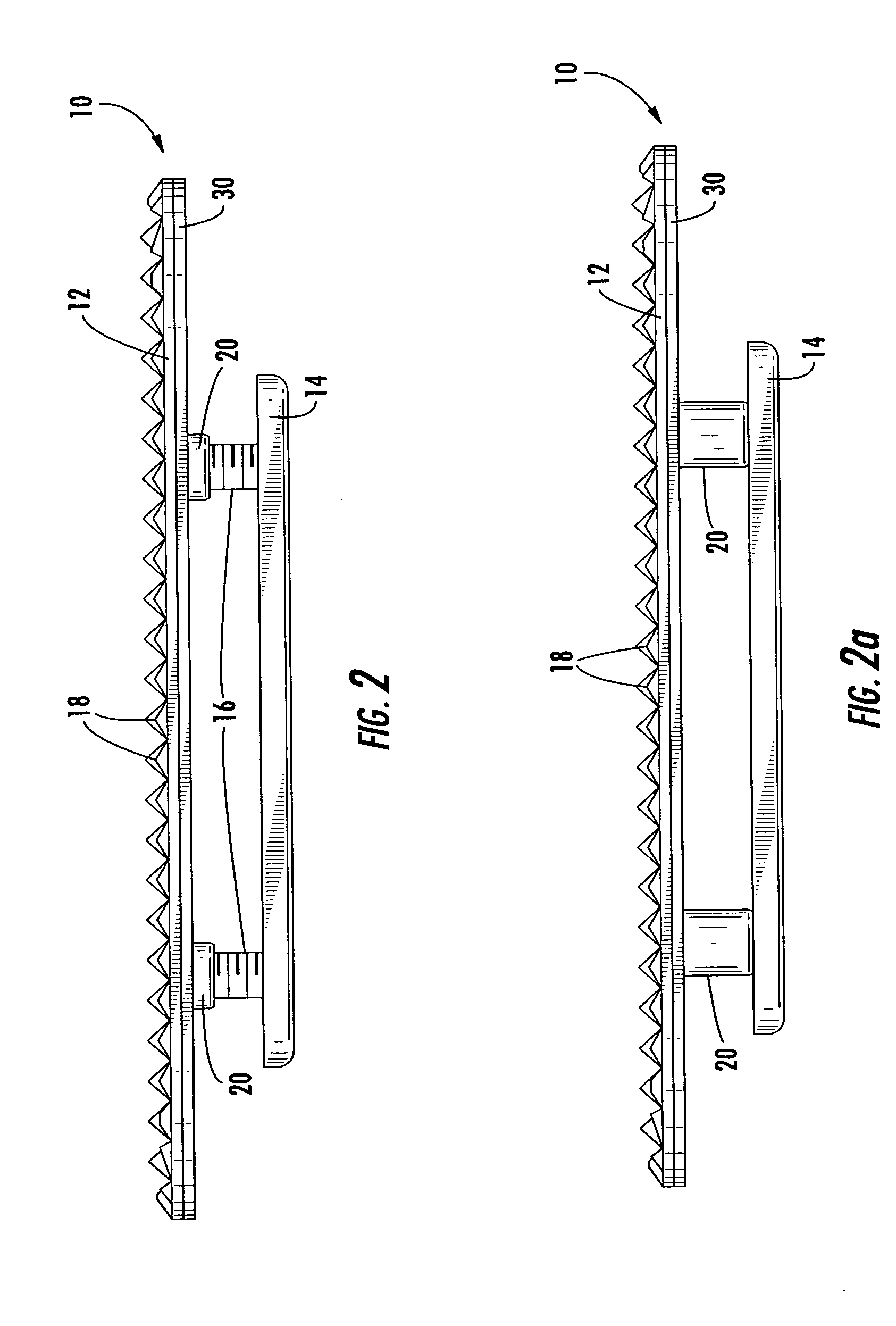

Traction stirrup insert

InactiveUS6865867B1Improve wear characteristicsPrevent slidingFastening devicesStirrupsEngineeringStirrup

An equestrian stirrup insert for enhancing the stability and traction of the stirrup foot plate. In this regard, the present invention provides for a traction enhancing insert assembly that is installed into the foot plate of stirrups. The insert is formed from milled aluminum. The milled aluminum plate provides a durable surface that has greatly improved wear characteristics. The assembly includes a top traction surface that is placed onto the foot plate of the stirrup. A mounting plate is placed beneath the stirrup and connected to the underside of the traction surface using fasteners. Since the insert is rigidly fixed to the stirrup using fasteners, the insert is prevented sliding in the stirrup. In this manner, the rigid relation ship between the insert and the foot plate of the stirrup allows for enhanced force transfer from the rider's foot into the stirrup with a greatly reduced potential for the insert to slip relative to the stirrup.

Owner:ZUCCHINI MICHAEL R

Traction stirrup insert

InactiveUS20050039424A1Improve wear characteristicsPrevent slidingFastening devicesStirrupsStirrupFastener

An equestrian stirrup insert for enhancing the stability and traction of the stirrup foot plate. In this regard, the present invention provides for a traction enhancing insert assembly that is installed into the foot plate of stirrups. The insert is formed from milled aluminum. The milled aluminum plate provides a durable surface that has greatly improved wear characteristics. The assembly includes a top traction surface that is placed onto the foot plate of the stirrup. A mounting plate is placed beneath the stirrup and connected to the underside of the traction surface using fasteners. Since the insert is rigidly fixed to the stirrup using fasteners, the insert is prevented sliding in the stirrup. In this manner, the rigid relation ship between the insert and the foot plate of the stirrup allows for enhanced force transfer from the rider's foot into the stirrup with a greatly reduced potential for the insert to slip relative to the stirrup.

Owner:ZUCCHINI MICHAEL R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com