Patents

Literature

531results about How to "Efficient scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

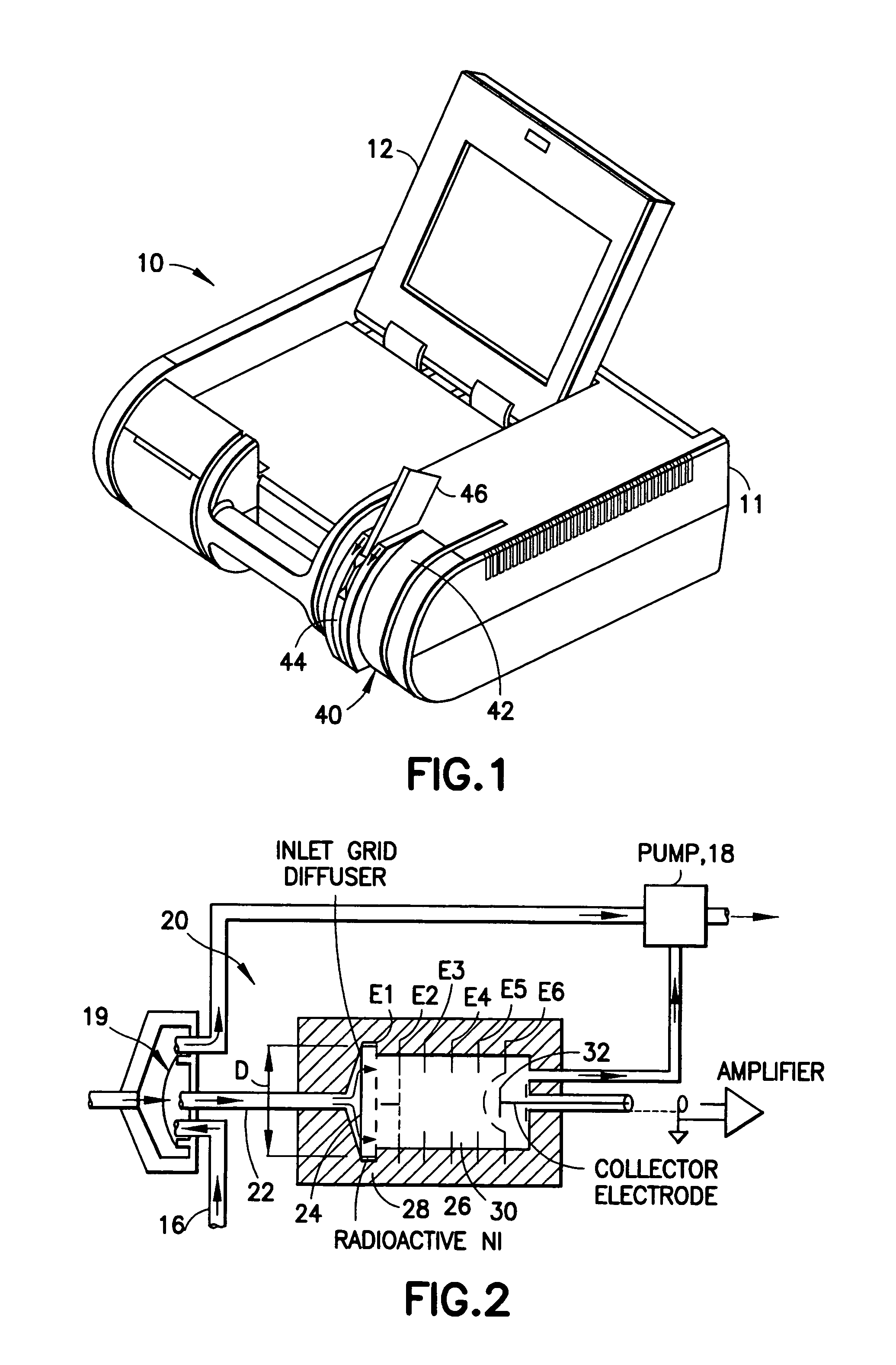

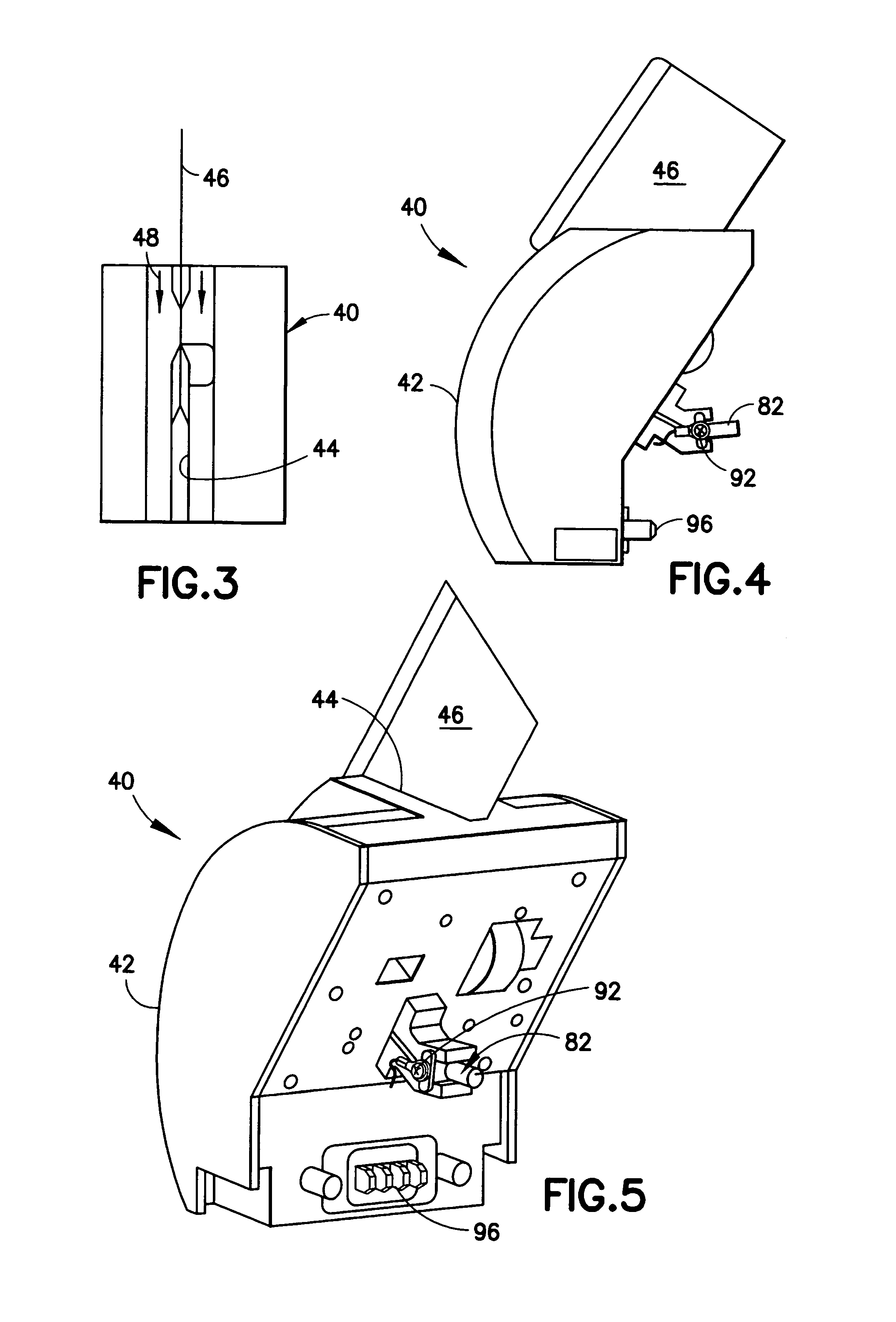

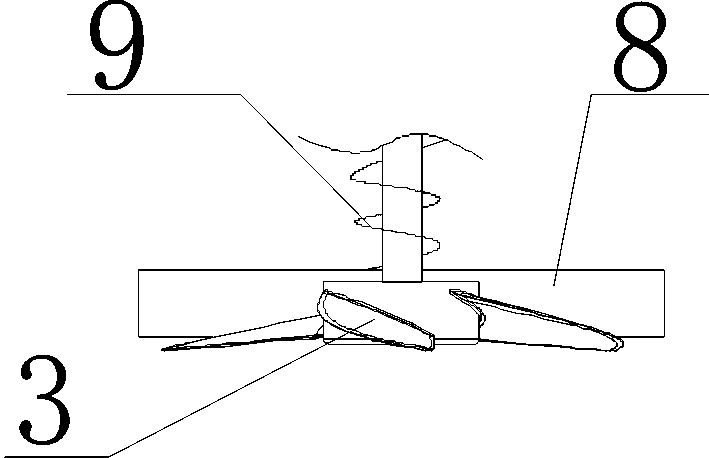

Device for testing surfaces of articles for traces of explosives and/or drugs

InactiveUS20050019220A1Laborious and time-consumingHeating fastMaterial analysis using wave/particle radiationTime-of-flight spectrometersExplosive materialMetal

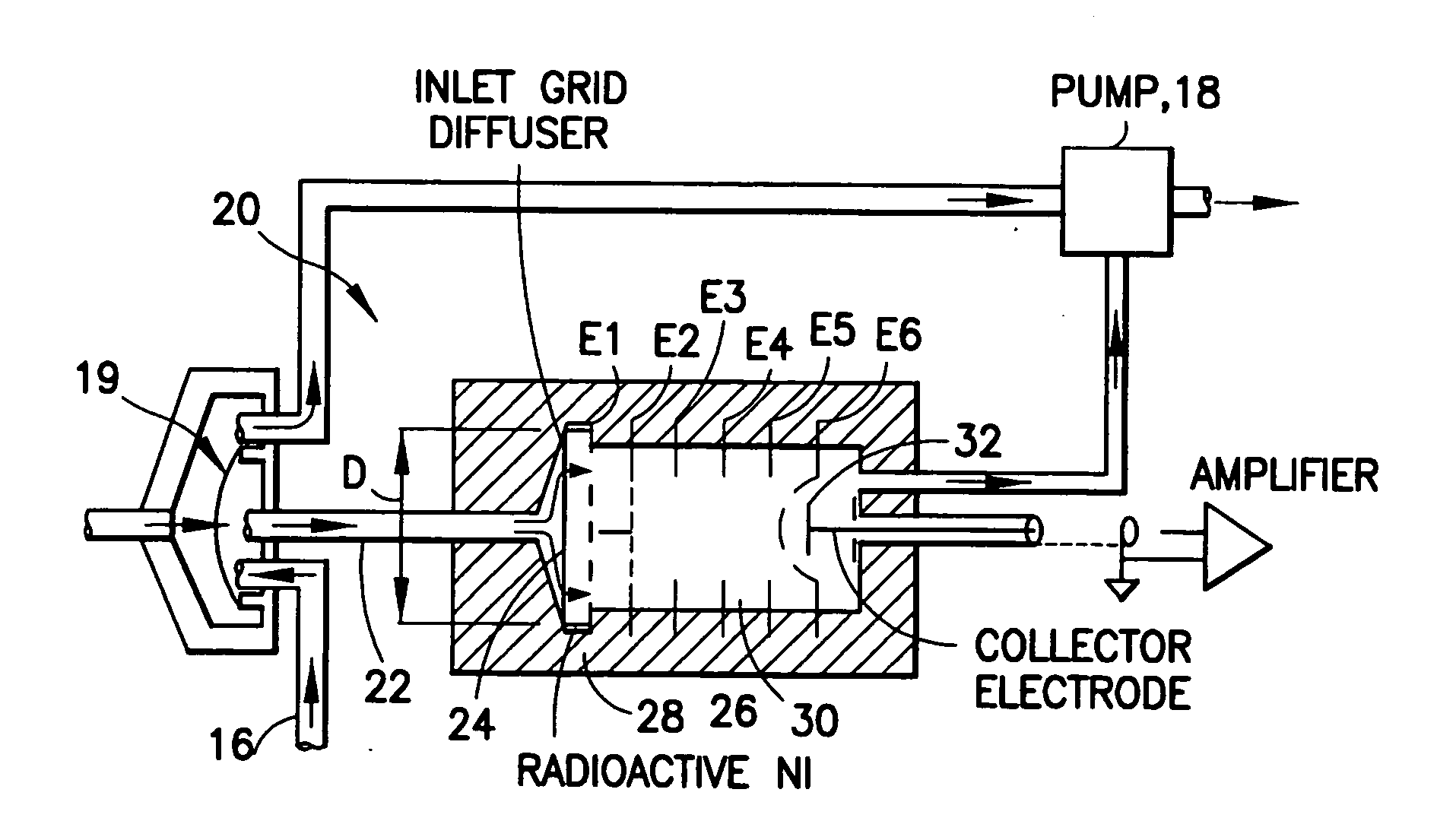

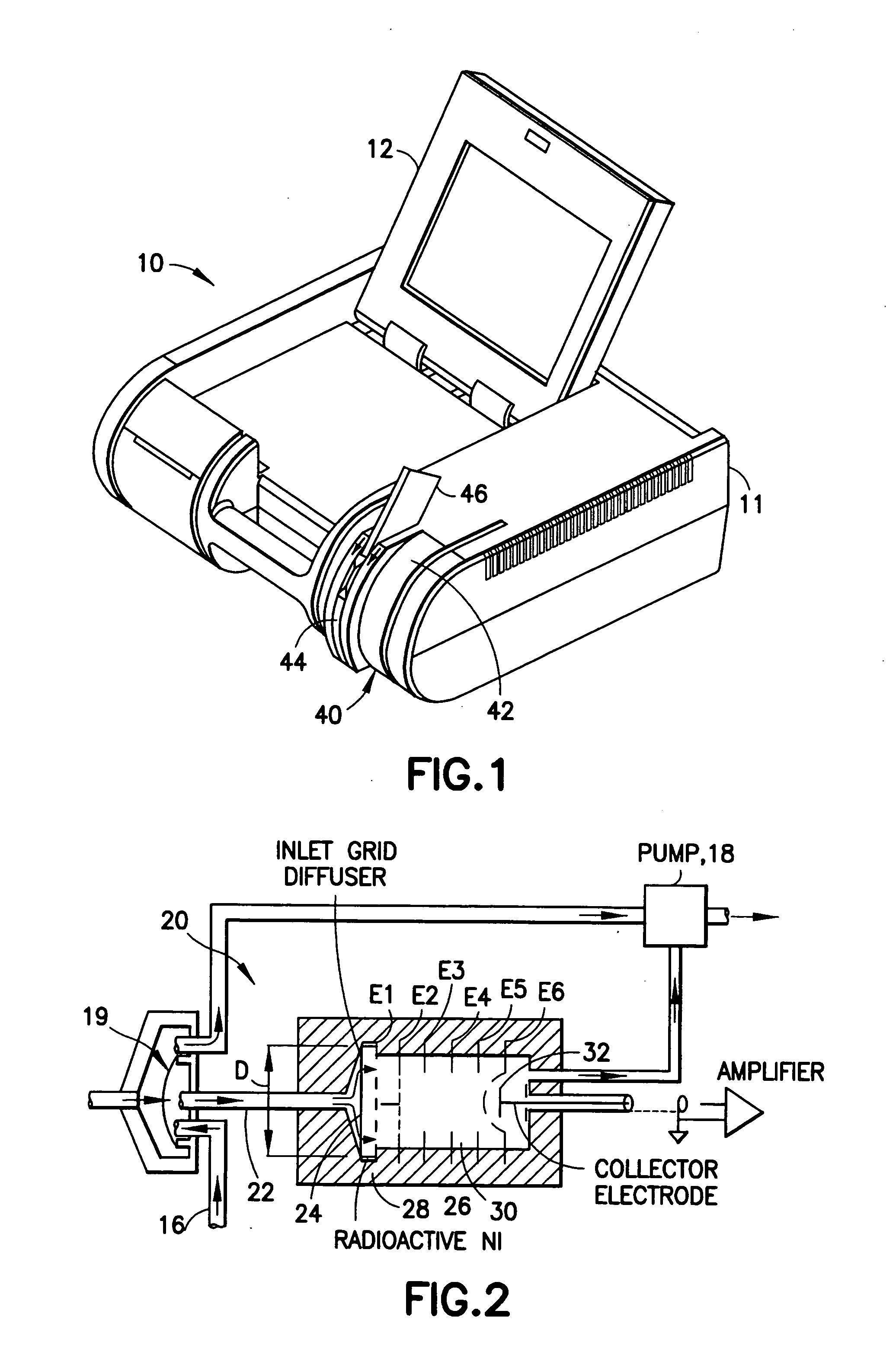

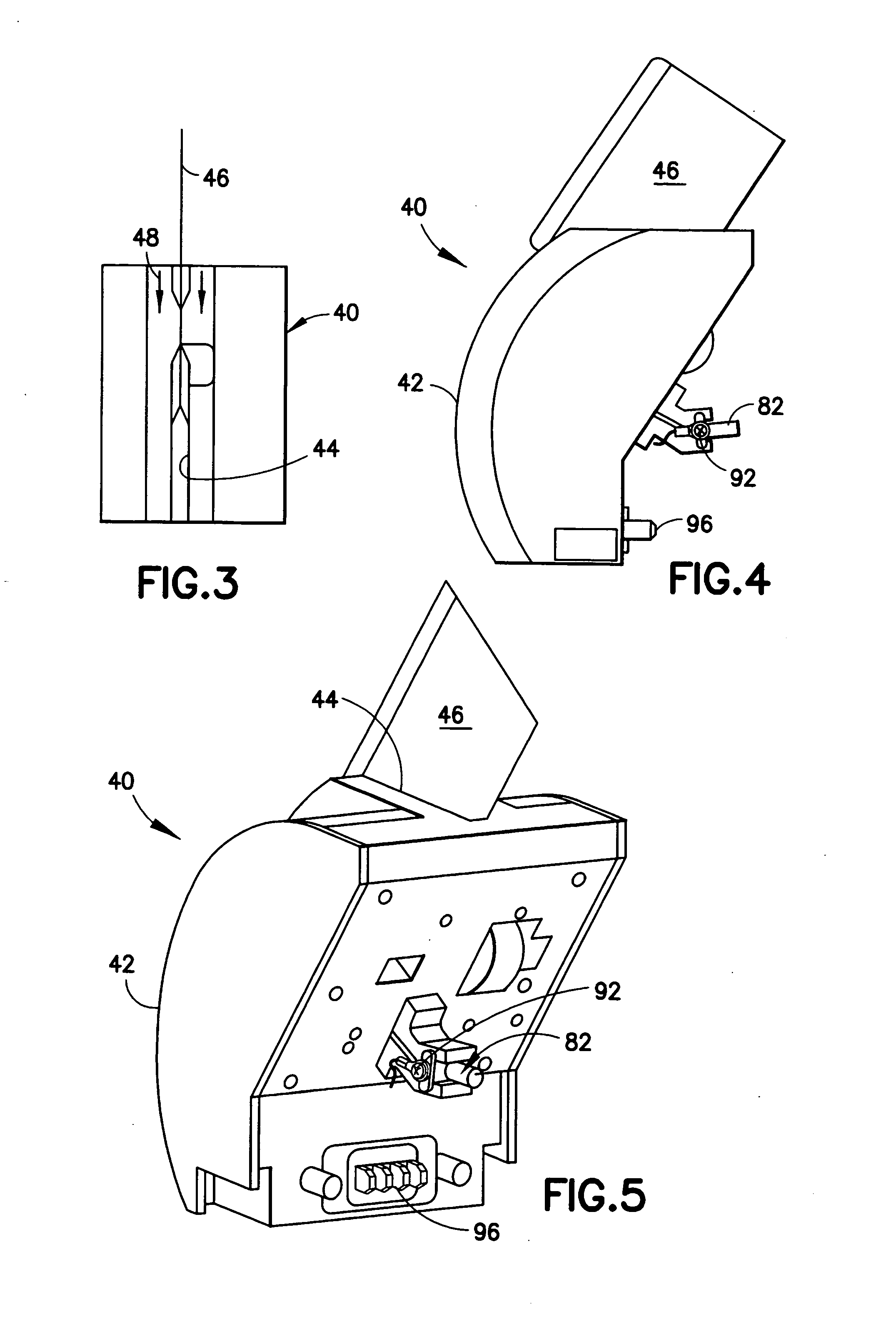

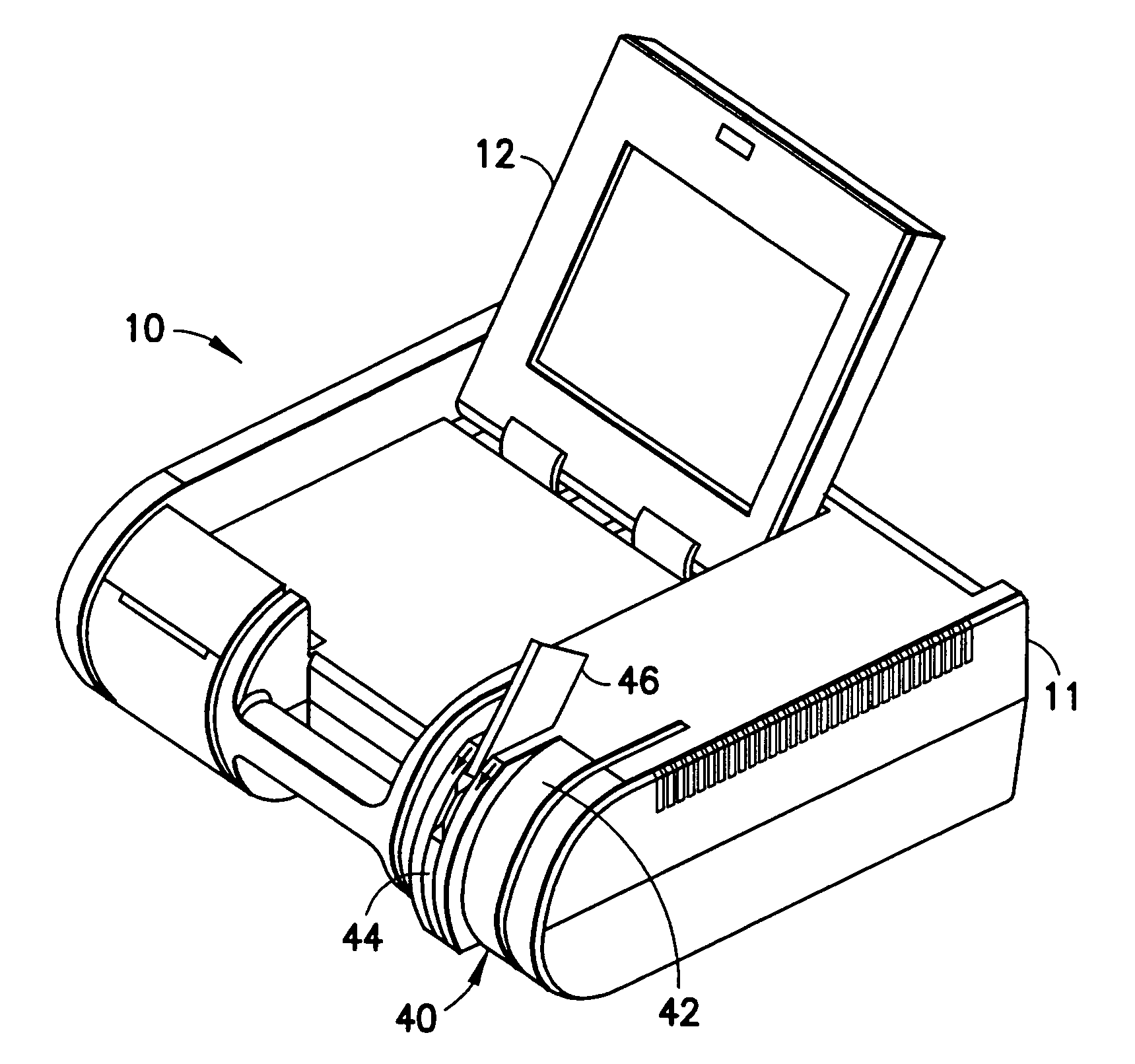

A device is provided for testing surfaces of a card for the presence of explosives, drugs or other substances of interest. The device includes a slot for receiving the card. Thin metallic wiper blades are dispose in alignment with the slot and wipe over surfaces of the card as the card is passed through the slot. Thus, substances on the surface of the card are transferred to the wiper blade. The wiper blade then is enclosed and rapidly heated to desorb the material retrieved from the card. The enclosure then is placed in communication with a detector to test for the presence of substances of interest.

Owner:RAPISCAN SYST INC (US)

Device for testing surfaces of articles for traces of explosives and/or drugs

InactiveUS7456393B2Efficient scrapingEffectively wipedMaterial analysis using wave/particle radiationTime-of-flight spectrometersExplosive materialMetal

A device is provided for testing surfaces of a card for the presence of explosives, drugs or other substances of interest. The device includes a slot for receiving the card. Thin metallic wiper blades are dispose in alignment with the slot and wipe over surfaces of the card as the card is passed through the slot. Thus, substances on the surface of the card are transferred to the wiper blade. The wiper blade then is enclosed and rapidly heated to desorb the material retrieved from the card. The enclosure then is placed in communication with a detector to test for the presence of substances of interest.

Owner:RAPISCAN SYST INC (US)

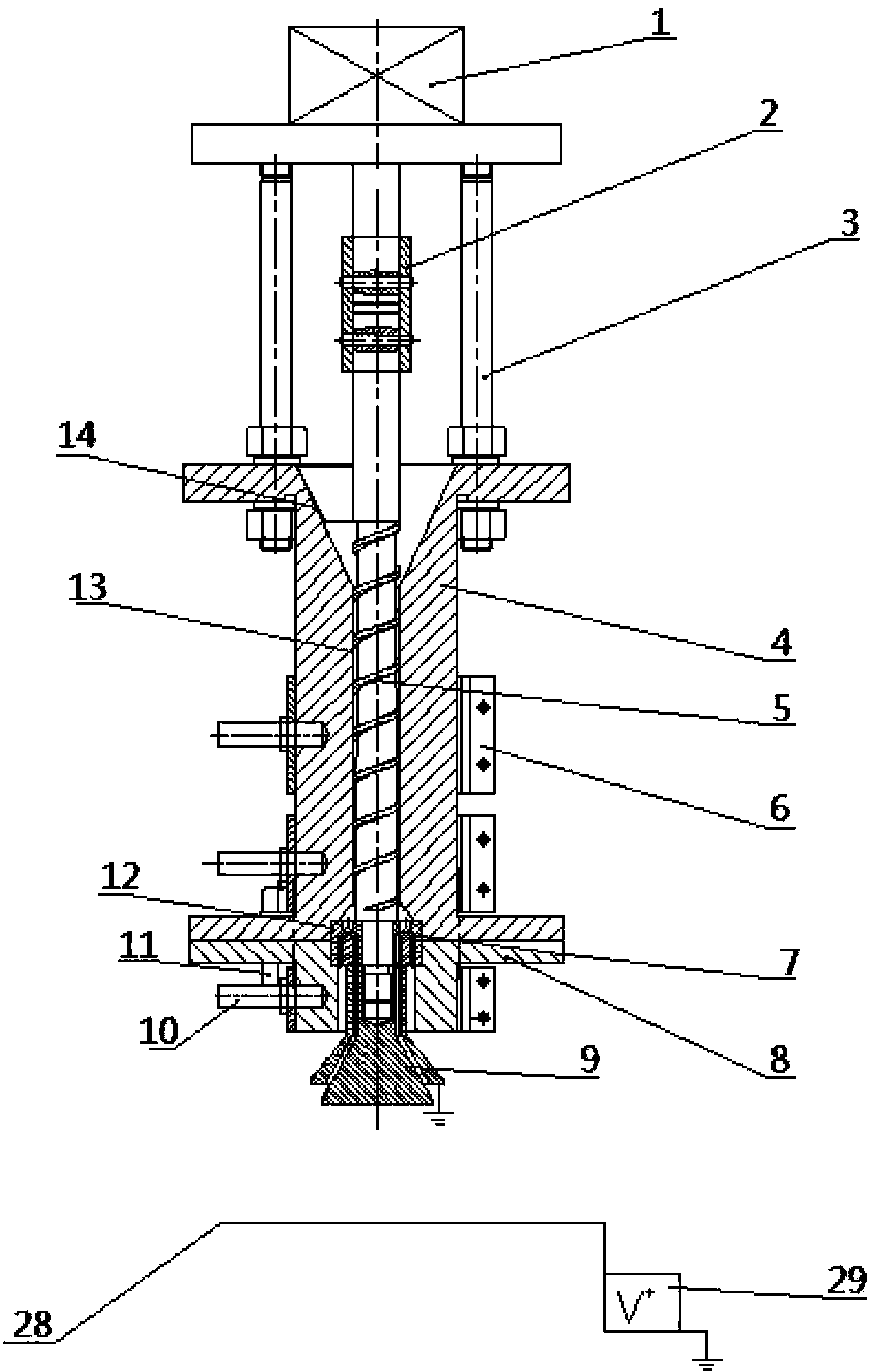

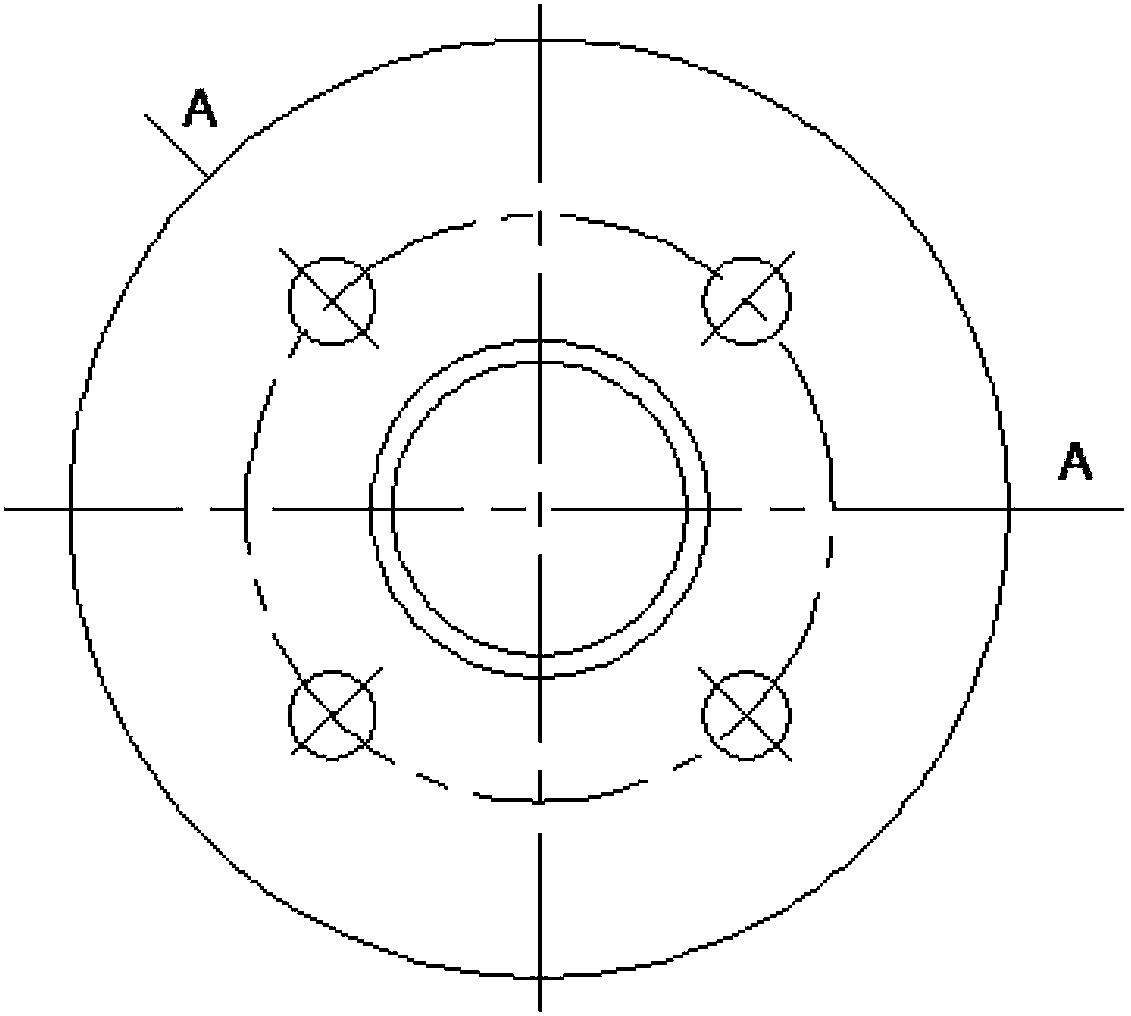

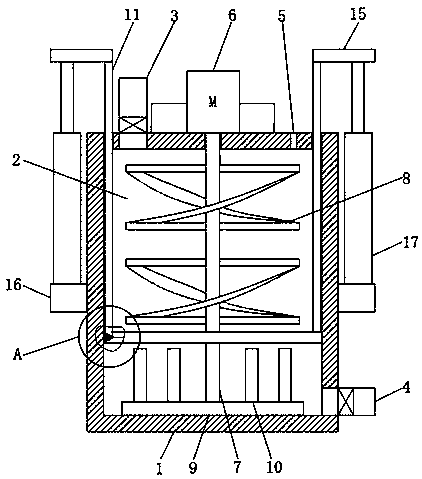

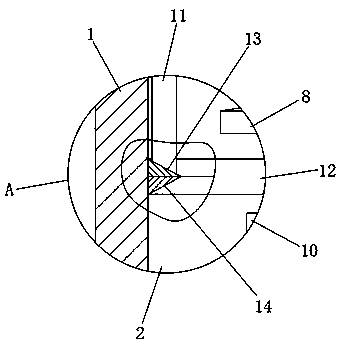

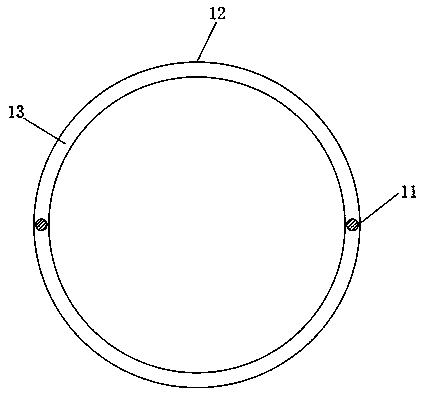

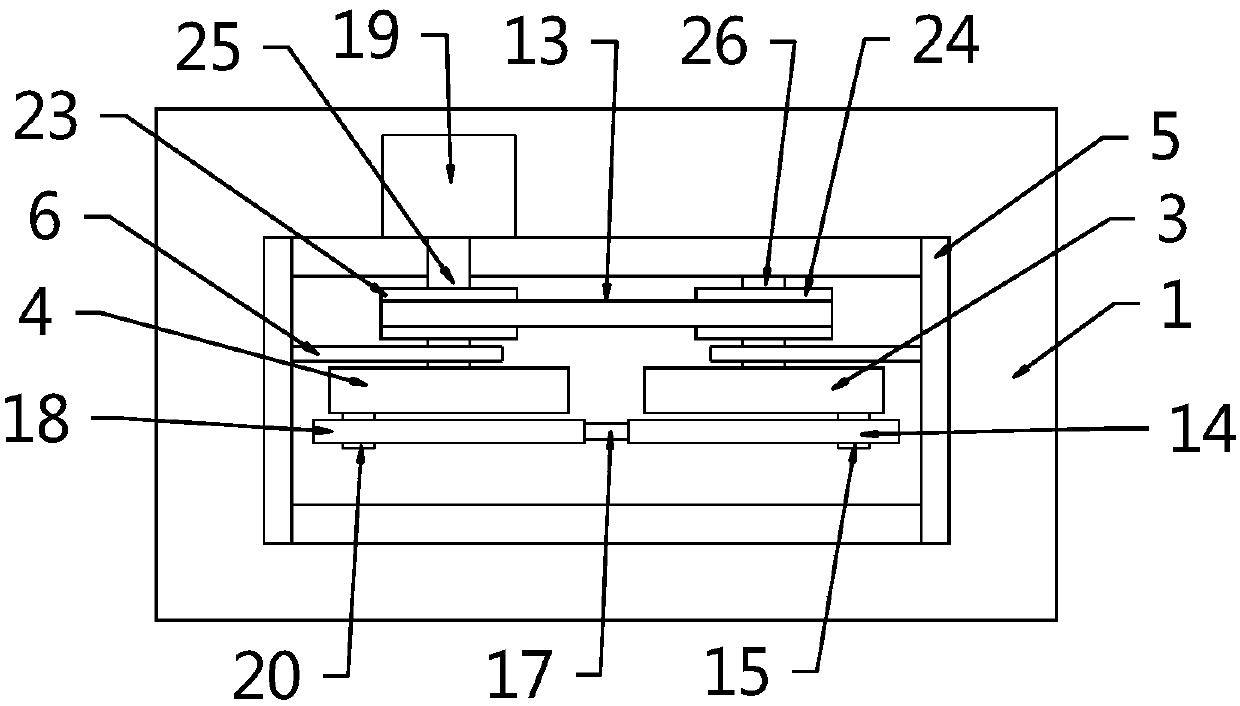

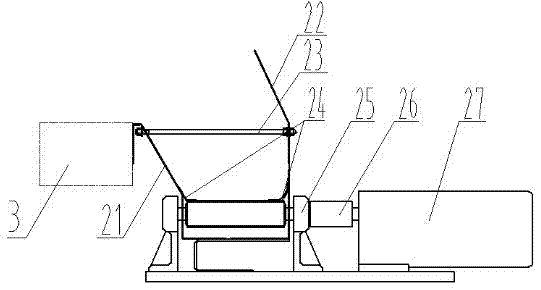

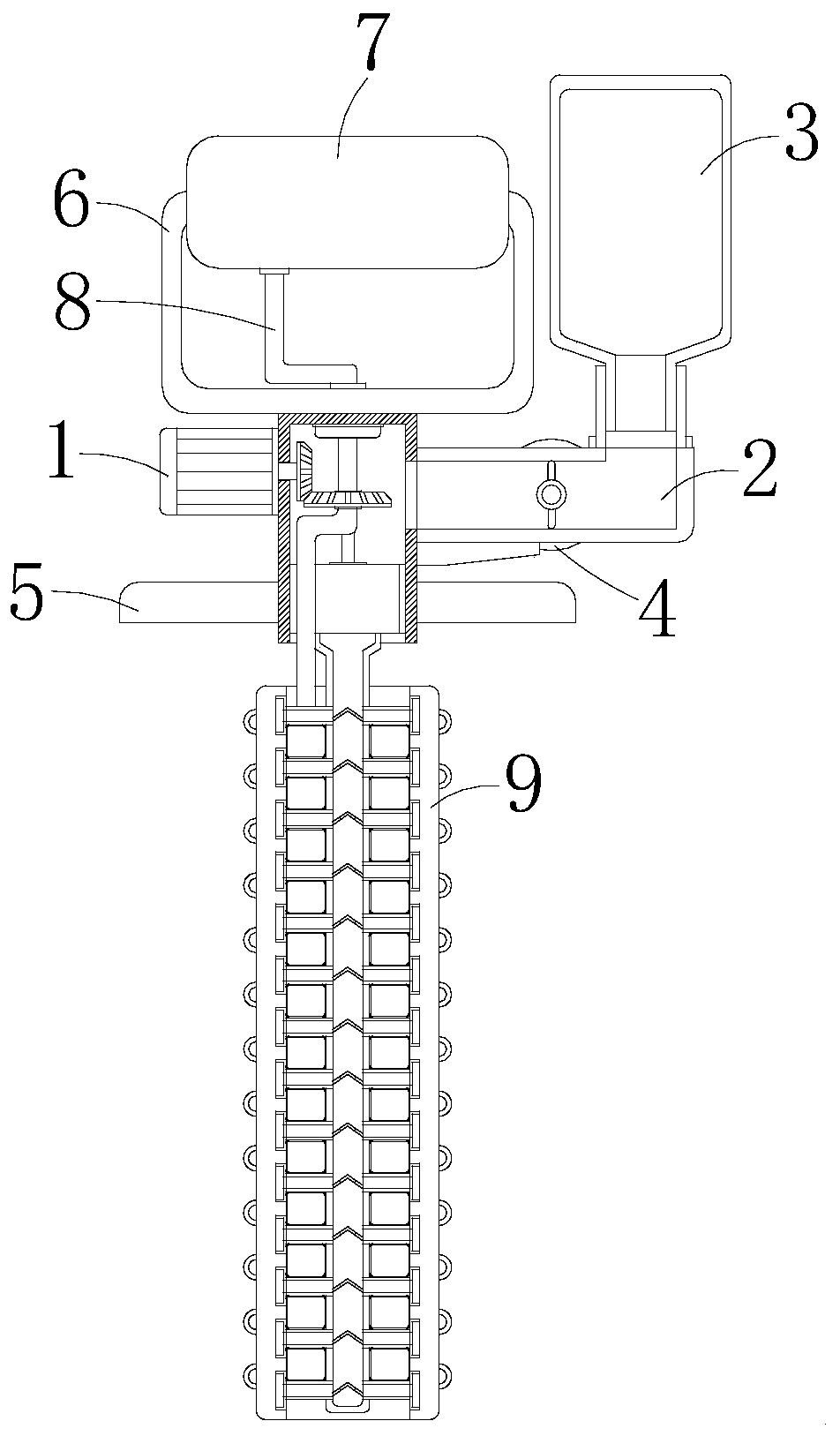

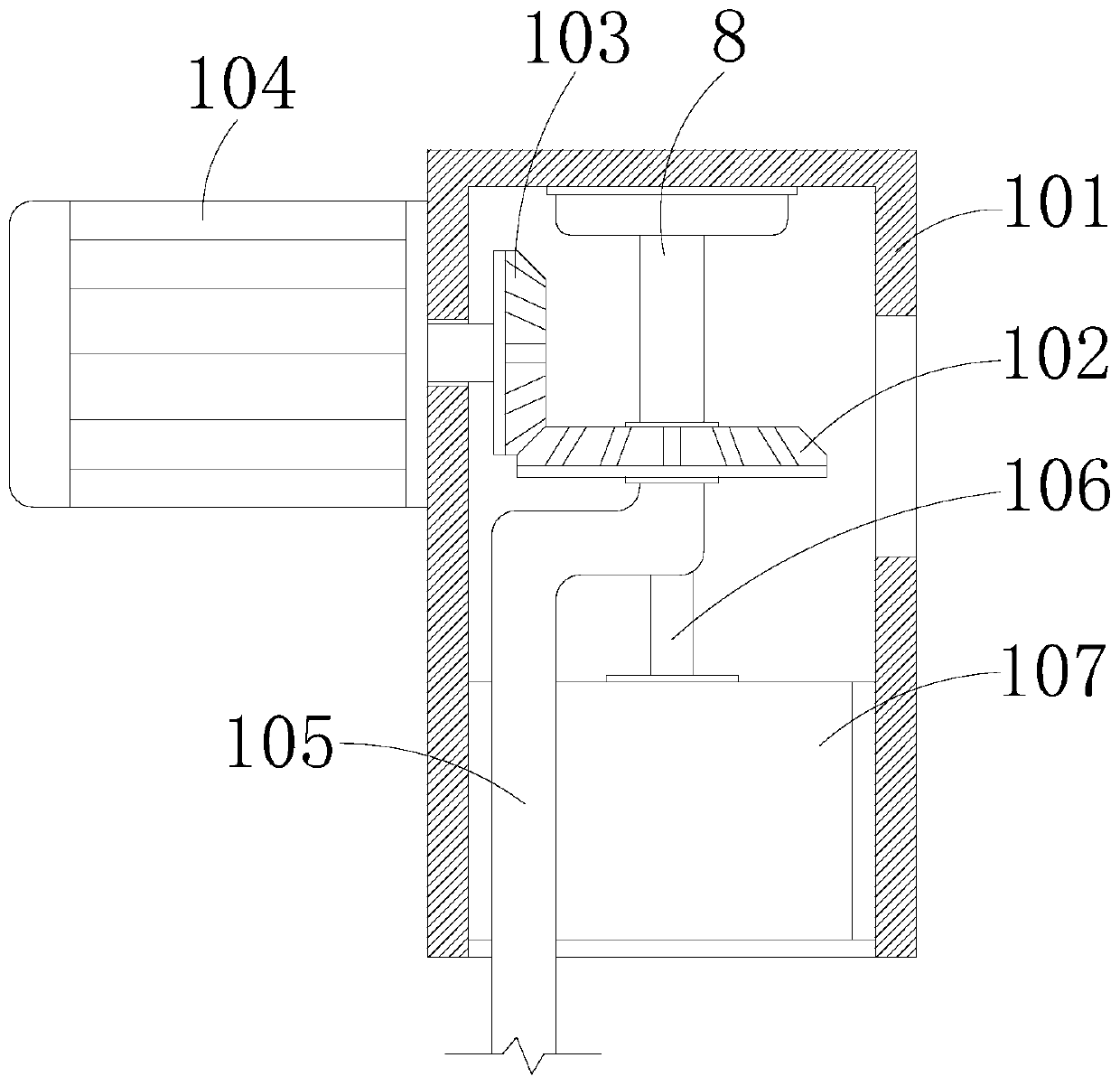

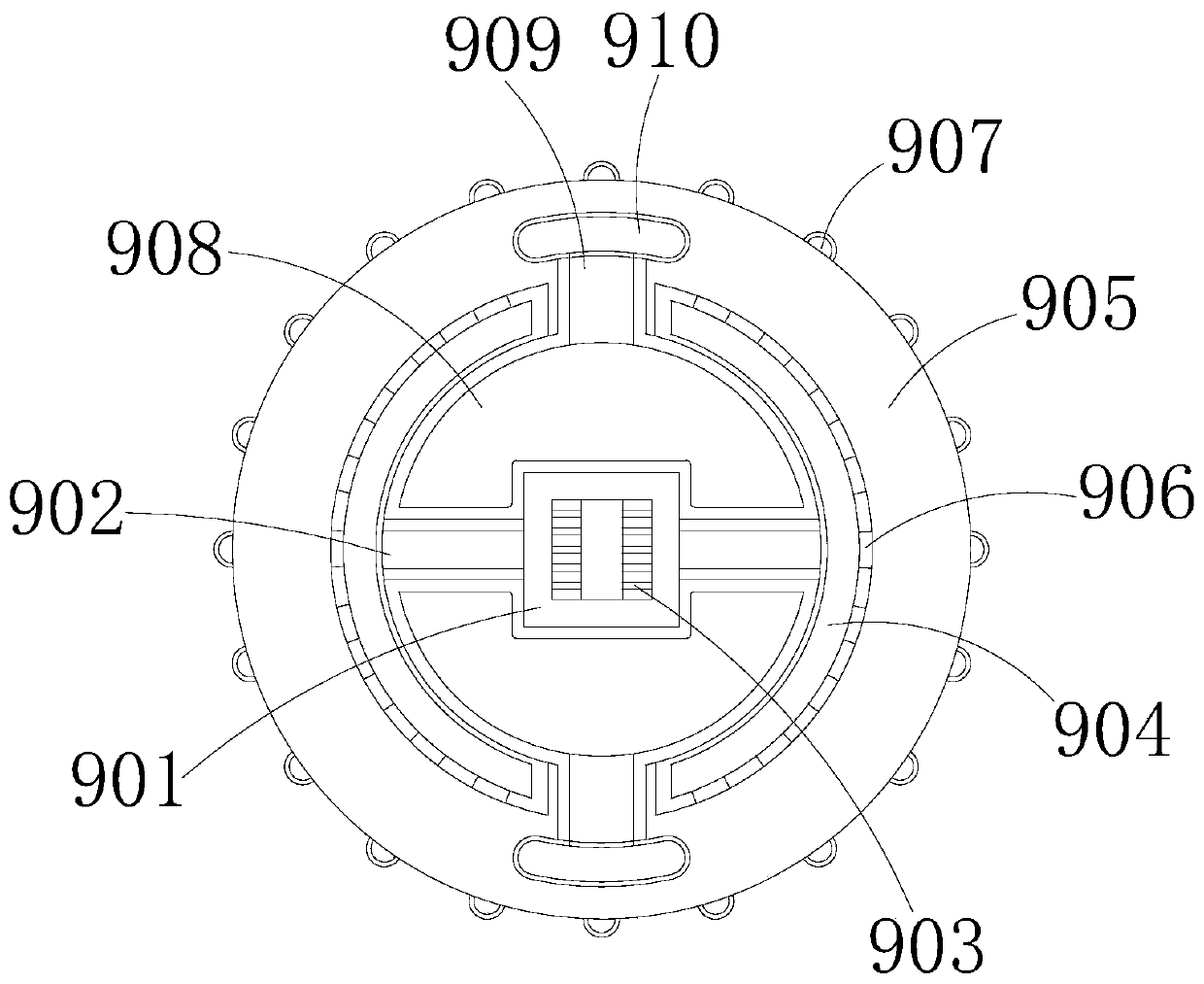

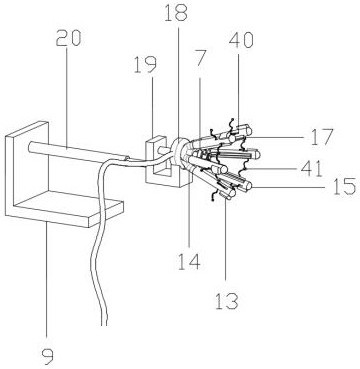

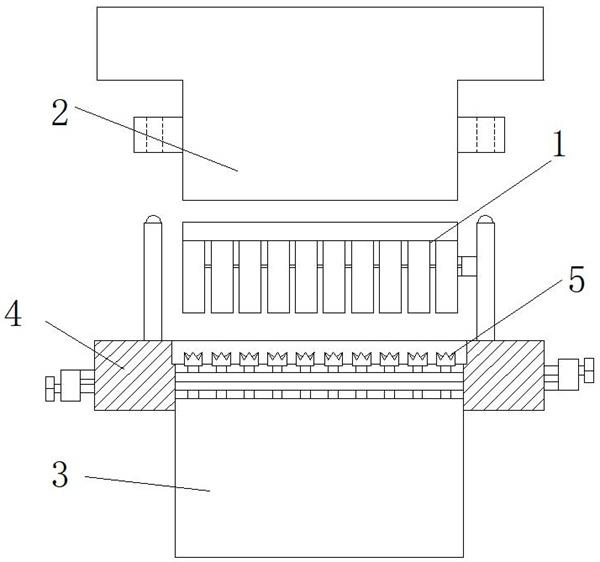

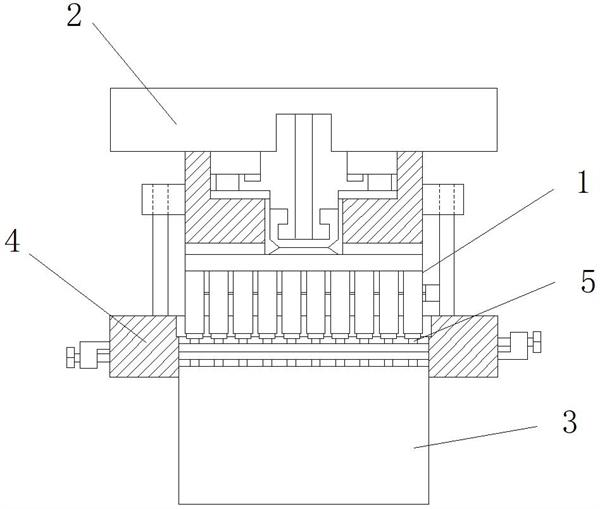

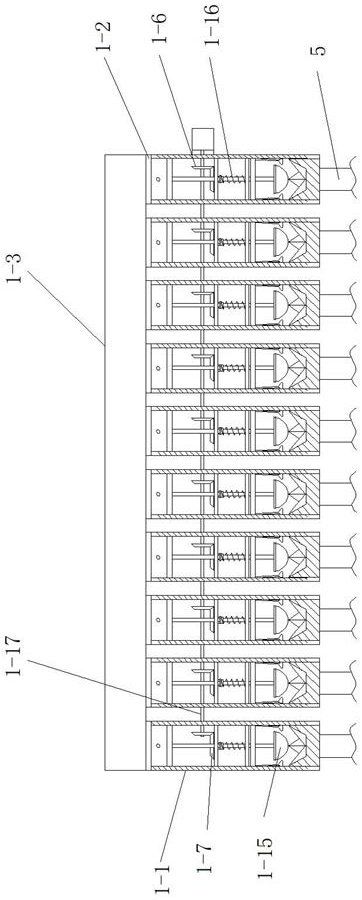

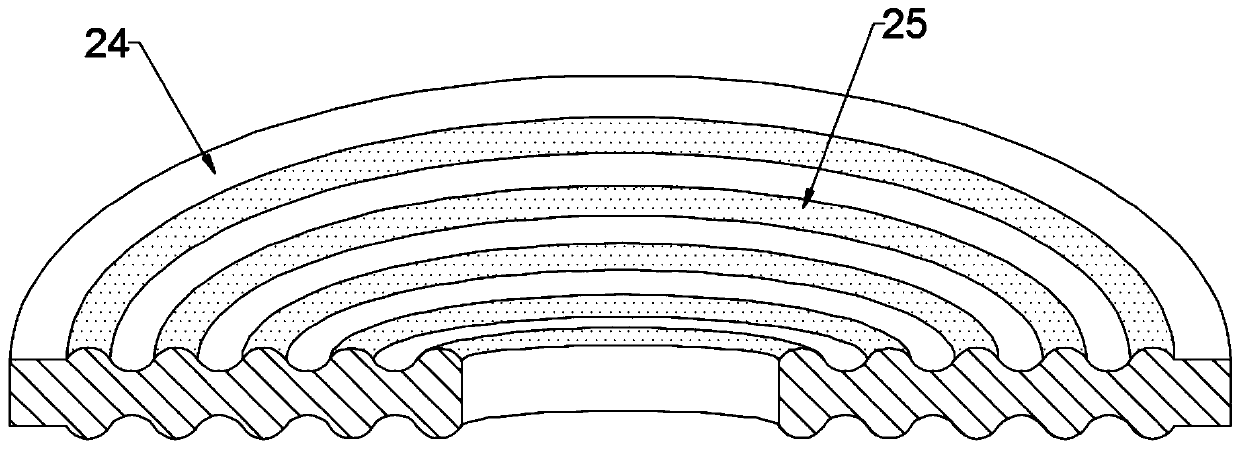

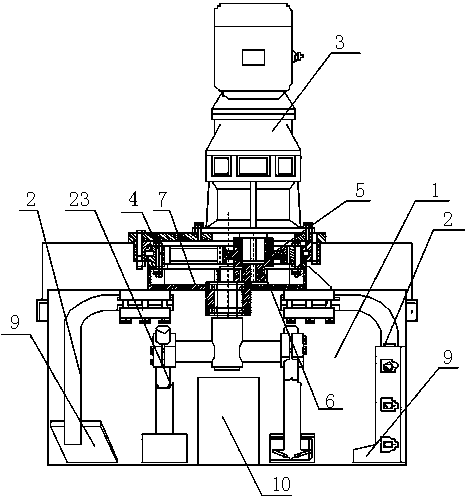

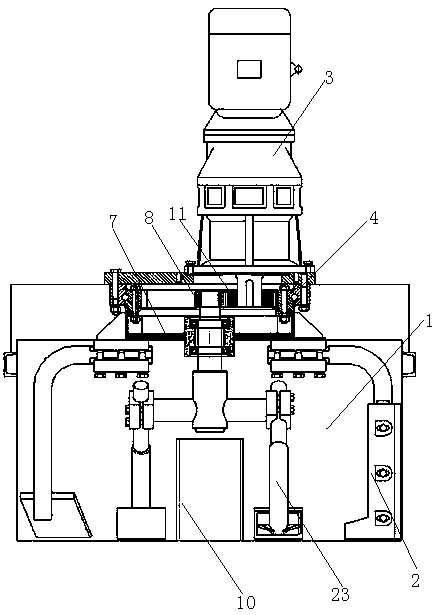

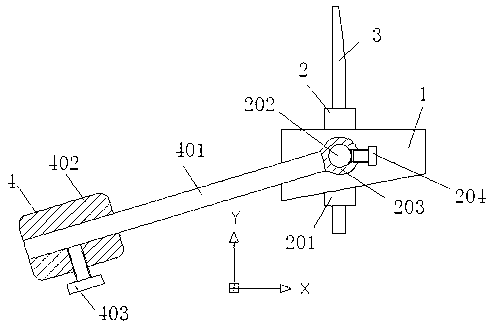

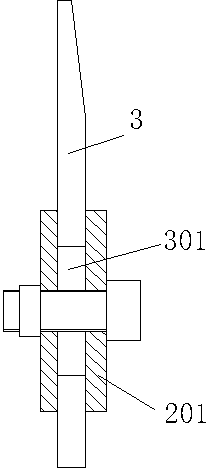

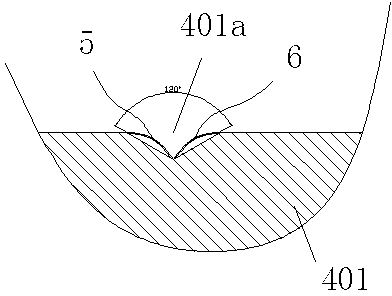

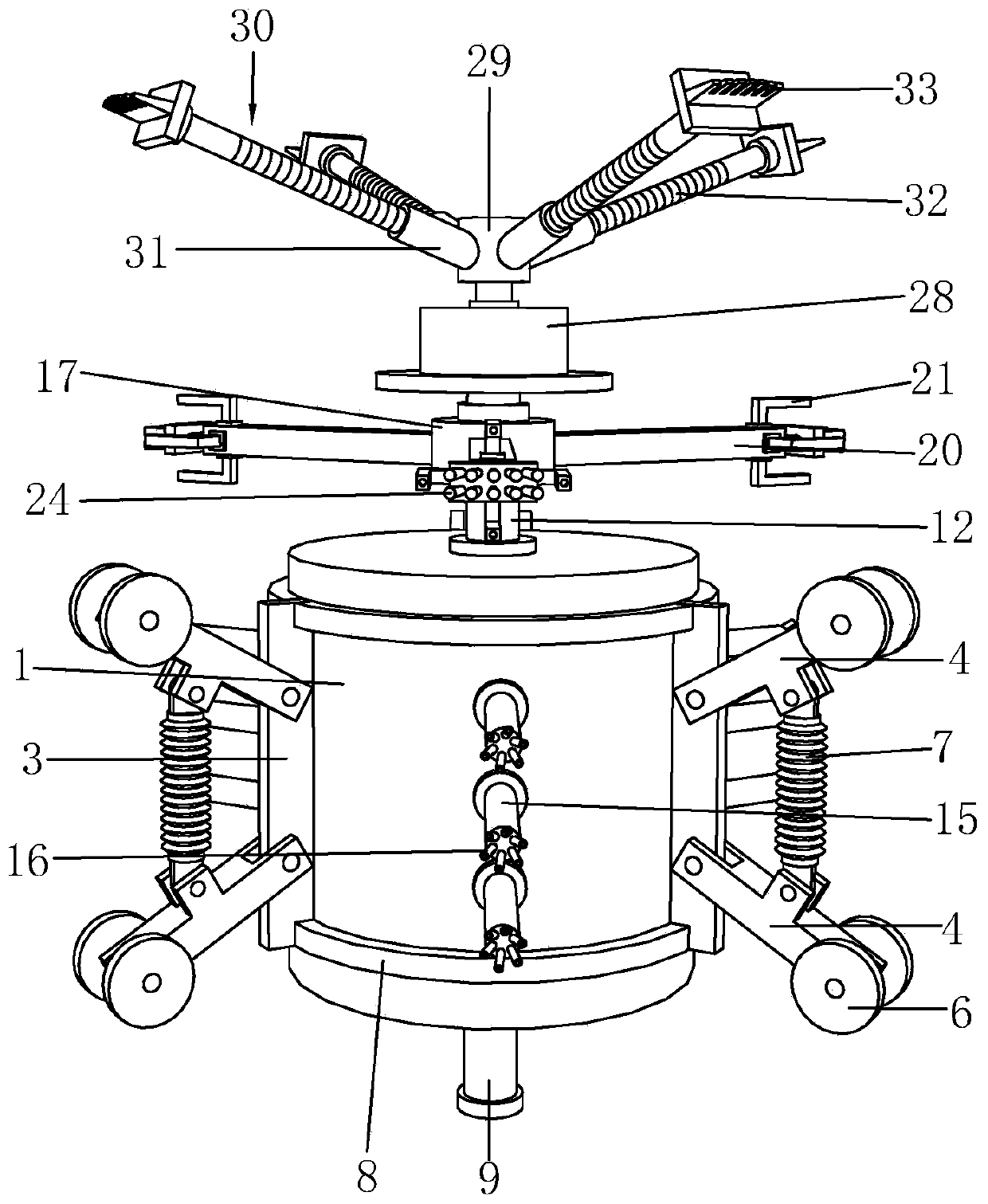

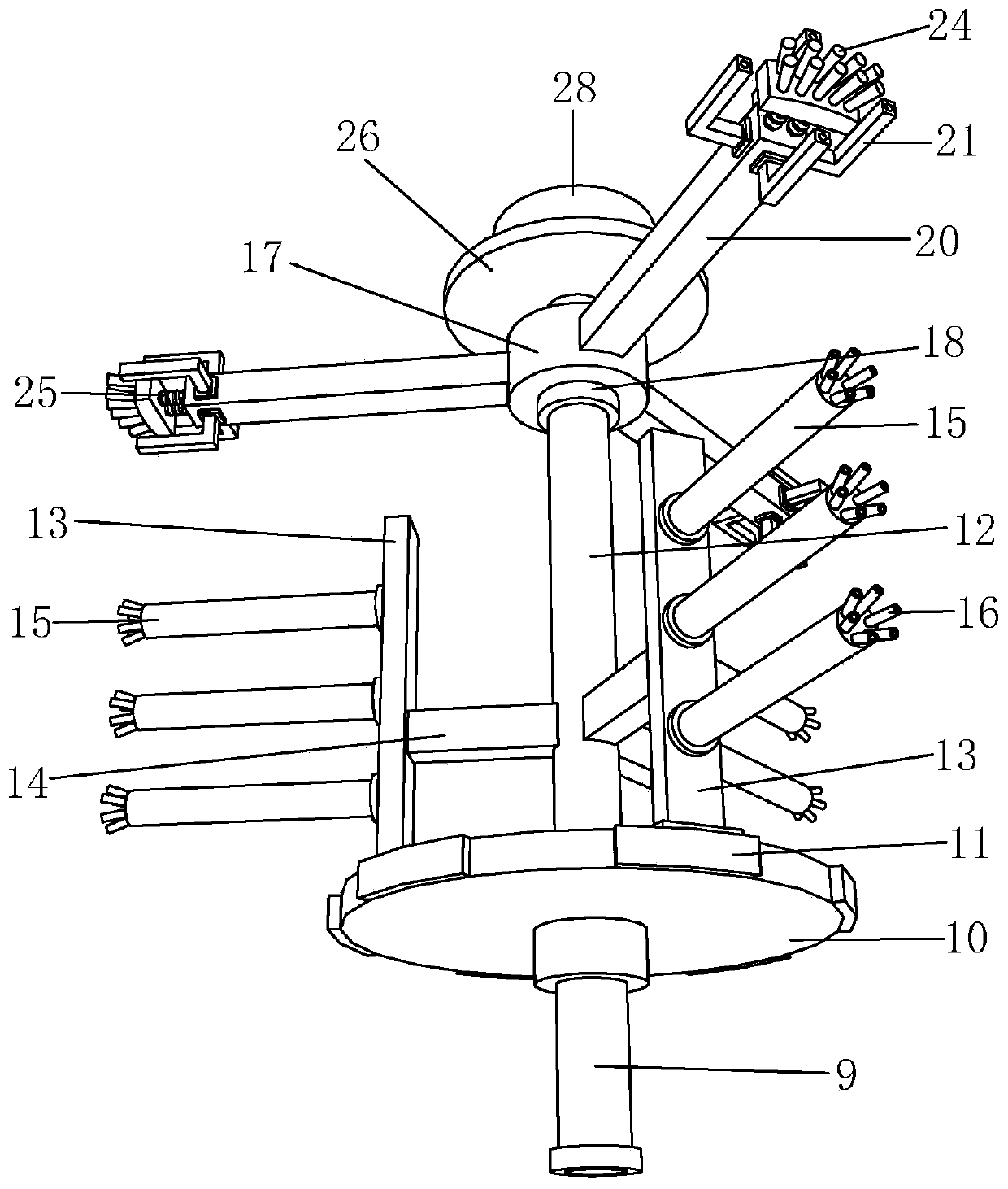

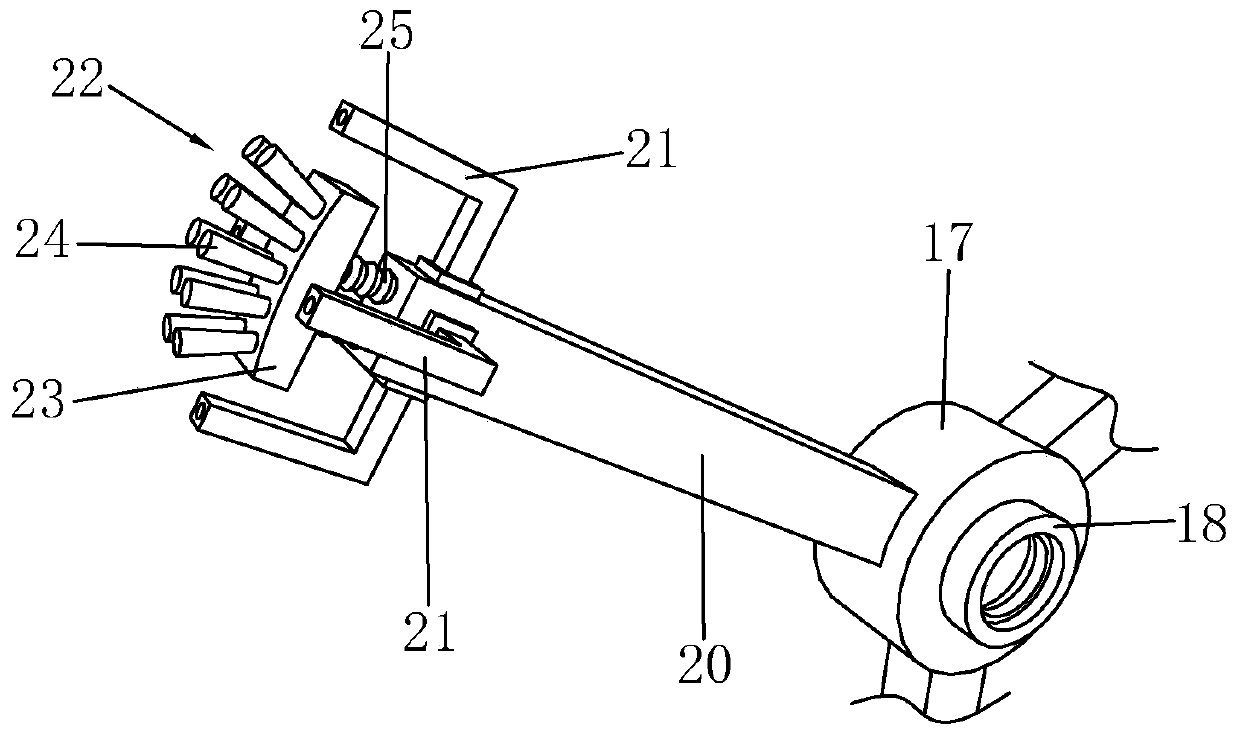

Electrospinning device with bi-layer petal-shaped nozzle

ActiveCN103451751APrevents reduction in spinning efficiencyImprove spinning efficiencySpinnerette packsFilament/thread formingFiberMotor drive

The invention discloses an electrospinning device with a bi-layer petal-shaped nozzle, and belongs to the field of electrospinning. The electrospinning device comprises a motor, a coupling, a feeding barrel, a discharging barrel, a receiving device, a high-voltage electrostatic generator, the nozzle, a heating unit, a screw, a copper-ring sliding bearing and a temperature sensor. The motor and the feeding barrel are supported by long bolts, the feeding barrel is connected with the discharging barrel through short bolts, the copper-ring sliding bearing is arranged between the feeding barrel and the discharging barrel in a matched manner, distribution flow passages are formed in the copper-ring sliding bearing and matched with the bi-layer petal-shaped nozzle to form bi-layer jet, the motor drives the screw to rotate through the coupling, the screw is matched with the feeding barrel and the discharging barrel through the copper-ring sliding bearing, and the lower end of the screw is connected with the nozzle in a threaded manner and drives the nozzle to rotate. The motor drives the screw to rotate, and thereby spinning feed delivery amount can be effectively controlled; due to multi-stage distribution and nozzle rotation, finer and evener fibers can be obtained; through the petal-shaped nozzle, spinning efficiency can be improved.

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

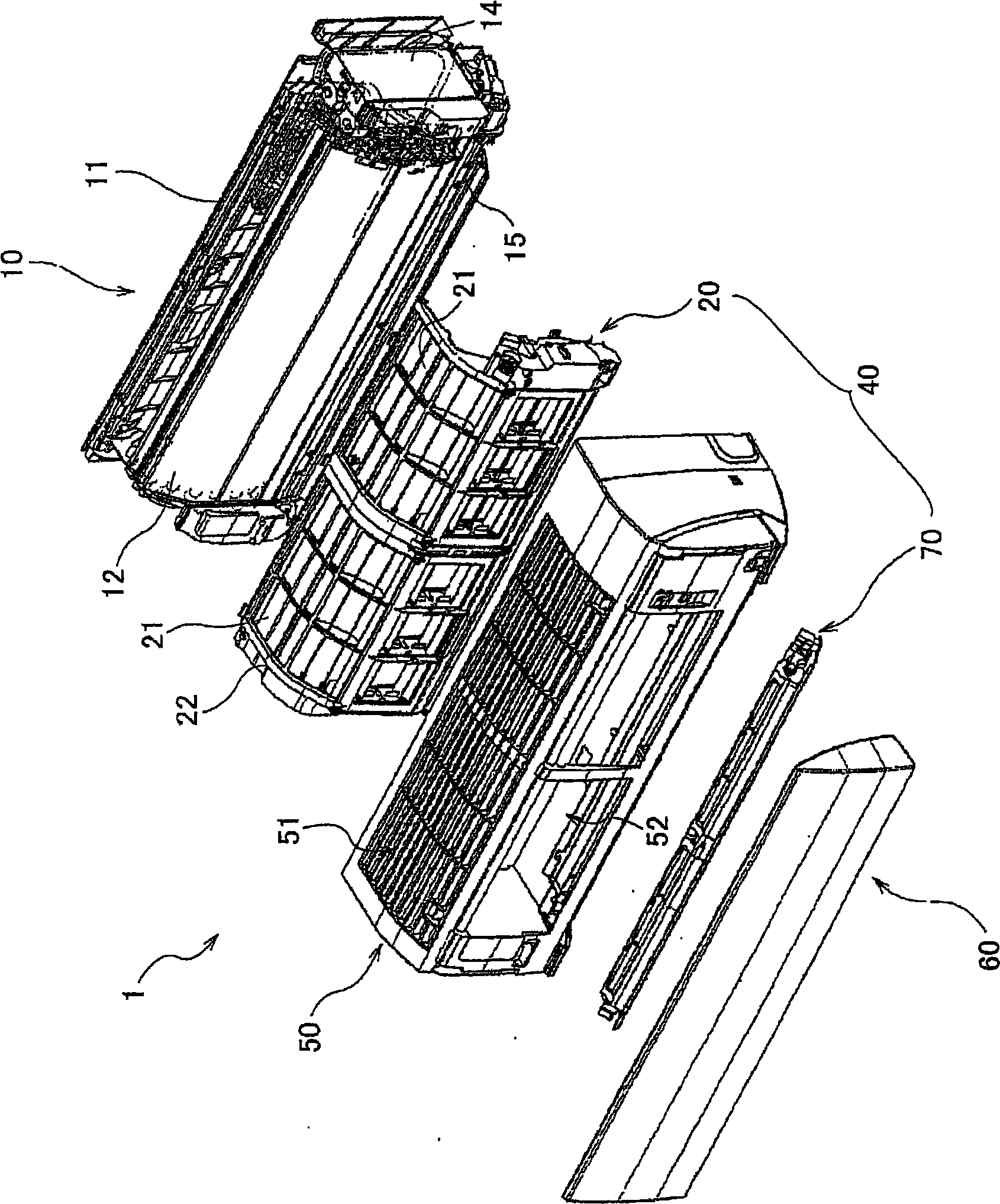

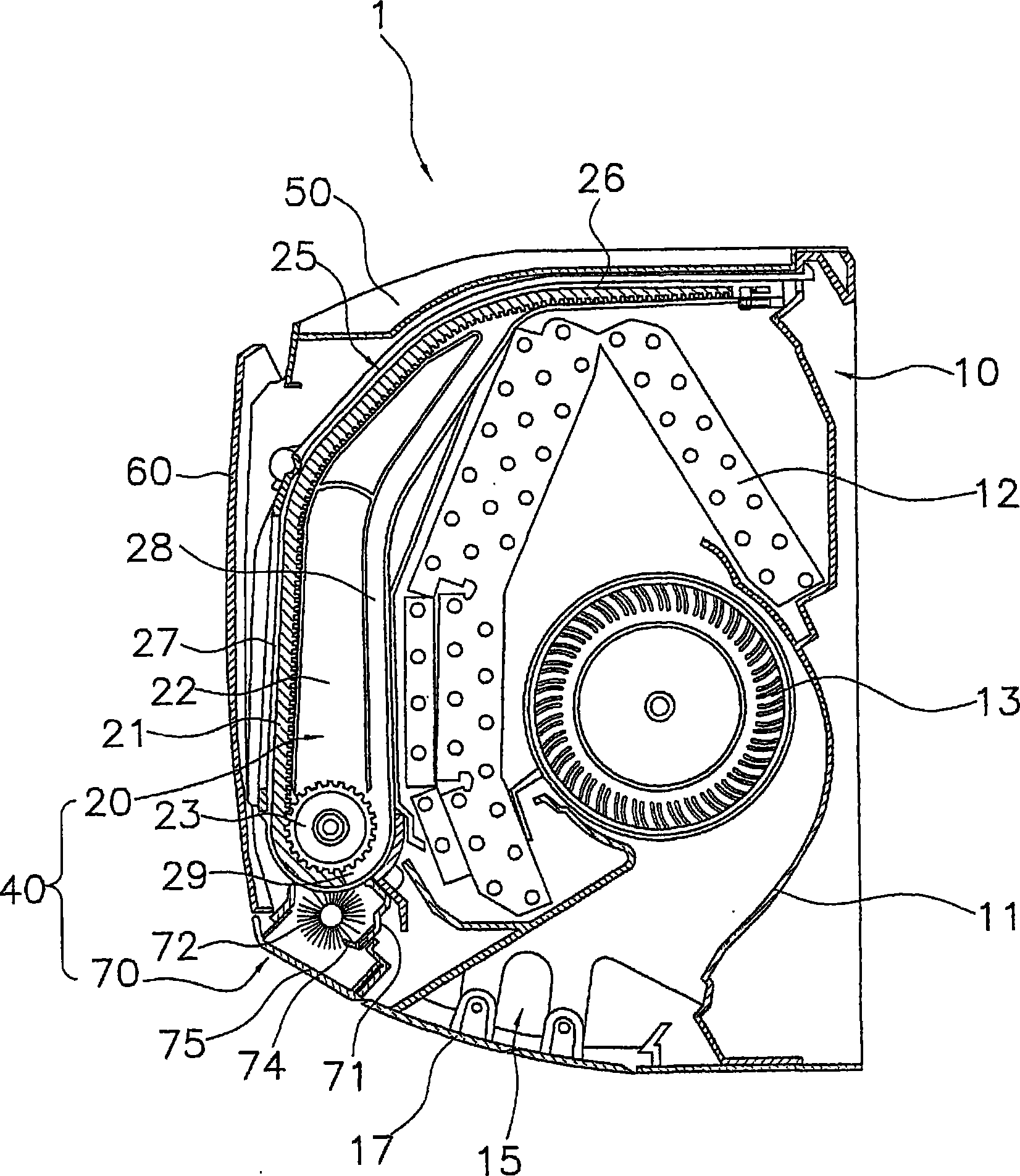

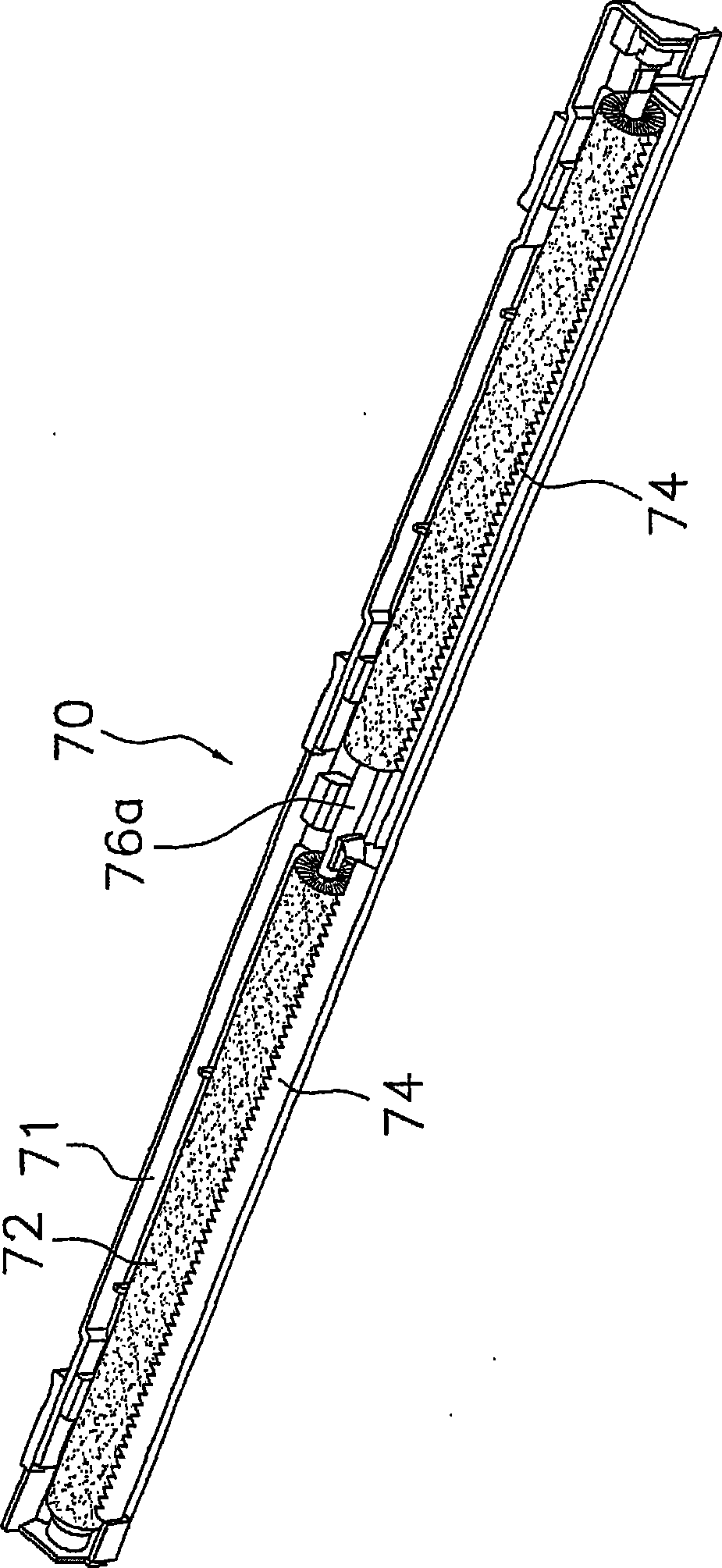

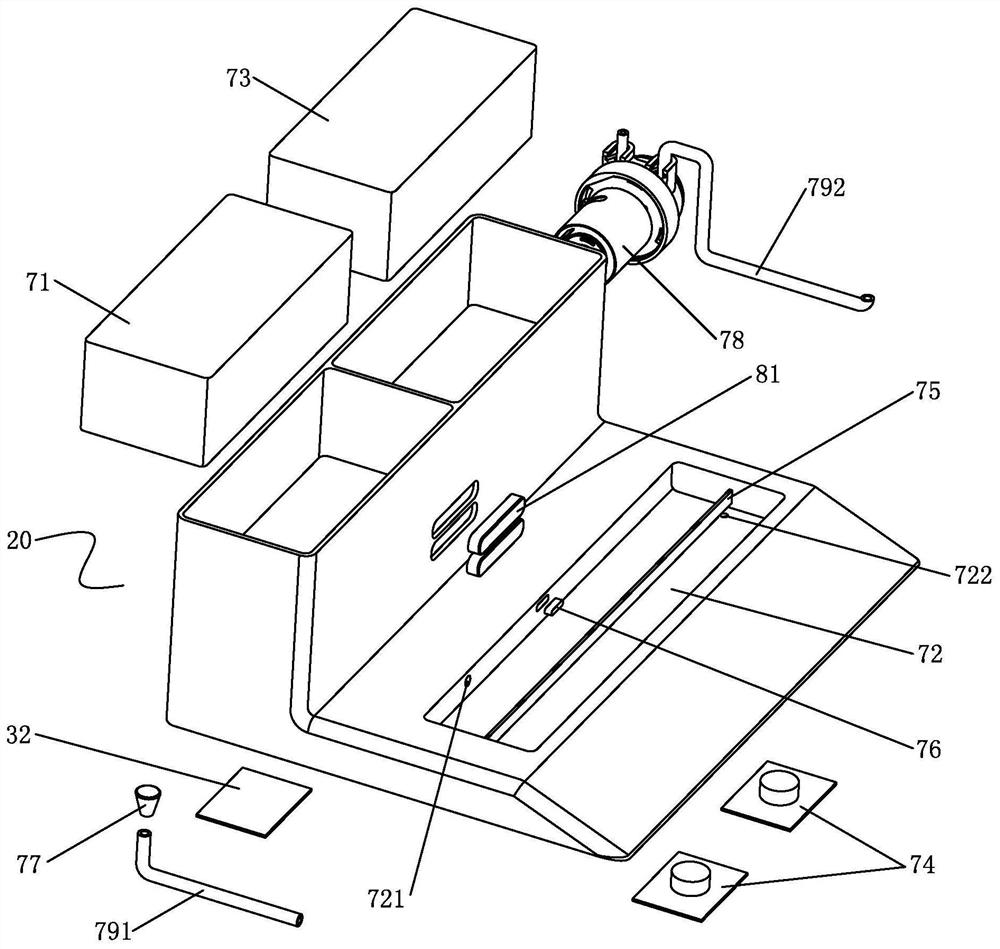

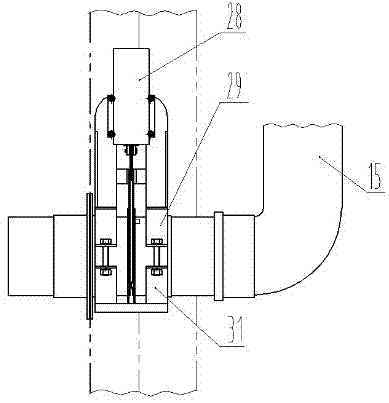

Filter cleaning mechanism for air conditioning apparatus

ActiveCN101548138AHigh densityEasy to handleMechanical apparatusLighting and heating apparatusEngineeringWire rod

Provided are a filter cleaning mechanism by which deterioration of filter cleaning performance can be suppressed, and an air conditioning apparatus. A filter cleaning mechanism (40) for an air conditioning apparatus is provided with a filter (21) for removing dusts from air passing through, a brush section (72), a brush driving section (73), and a brush cleaning section (74). The brush section (72) is provided with a core material (76), and a plurality of wire rods (77) arranged on the circumference of the core material (76), and dusts are removed from the filter (21) by bringing the wire rods (77) into contact with the filter (21). The brush driving section (73) rotates the brush section (72). The brush cleaning section (74) is arranged along the rotating shaft direction of the brush section (72) and has a comb-like shape that makes contact with the brush section (72). The brush cleaning section scrapes out dusts from the brush section (72) by rotating the brush section (72).

Owner:DAIKIN IND LTD

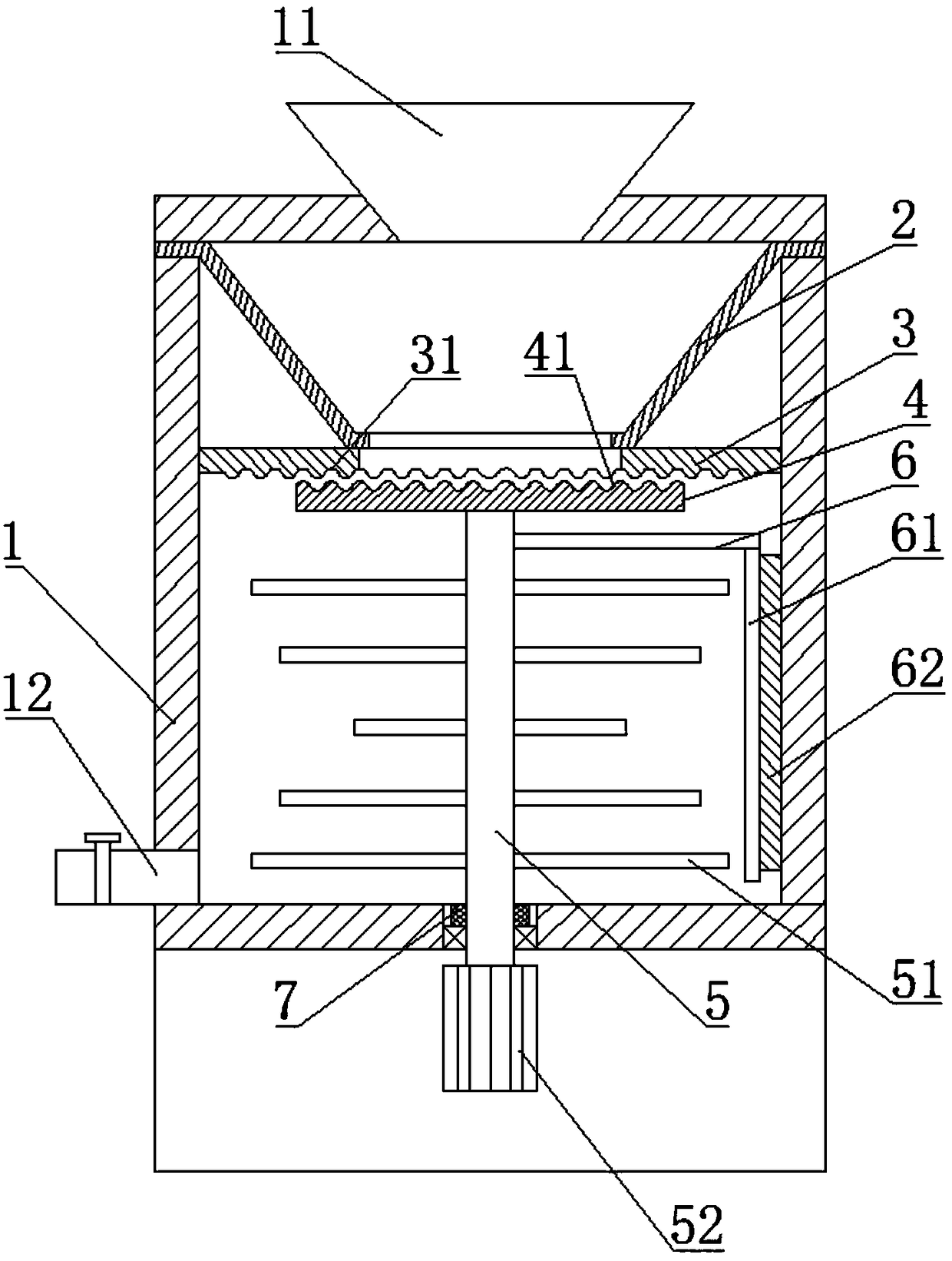

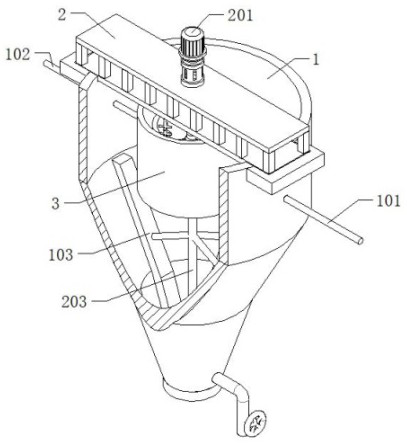

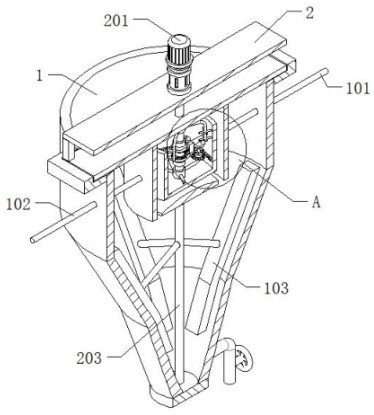

Grinding and mixing device for coating

InactiveCN108187572APromote fragmentationEfficient scrapingRotary stirring mixersTransportation and packagingCoatingFunnel shape

The invention discloses a grinding and mixing device for a coating. A material collecting hopper, a static grinding pan, a dynamic grinding pan and a rotating shaft are arranged in a material barrel;the material collecting hopper is fixedly arranged at the upper part of the interior of the material barrel; the material collecting hopper is in a funnel shape with a large upper opening and a smalllower opening; the static grinding pan is arranged below the material collecting hopper, and is further fixedly connected with the side wall of the material barrel; the middle of the static grinding pan is provided with an orifice; the lower surface of the static grinding pan is provided with a grinding layer I; the orifice of the static grinding pan is in tight fit with a lower opening of the material collecting hopper; the dynamic grinding pan is arranged below the static grinding pan; the upper surface of the dynamic grinding pan is provided with a grinding layer II; the rotating shaft is arranged at the lower part of the dynamic grinding pan; the rotating shaft is rotationally connected with the bottom part of the material barrel; the top end of the rotating shaft is fixedly connectedwith the dynamic grinding pan; the rotating shaft is provided with vanes for agitating the coating. The grinding and mixing device adopts the mutual rotational grinding way of the dynamic grinding panand the static grinding pan, can be used for promoting to crush the agglomerated coating, is used for guaranteeing the coating to be further uniformly agitated and mixed, meanwhile, is provided witha scraping plate, can be used for scraping the coating adhered to the inner wall of the material barrel, and is used for reducing the waste of the coating.

Owner:SUZHOU WUZHONG DISTRICT SHUANGLONG PAINT CO LTD

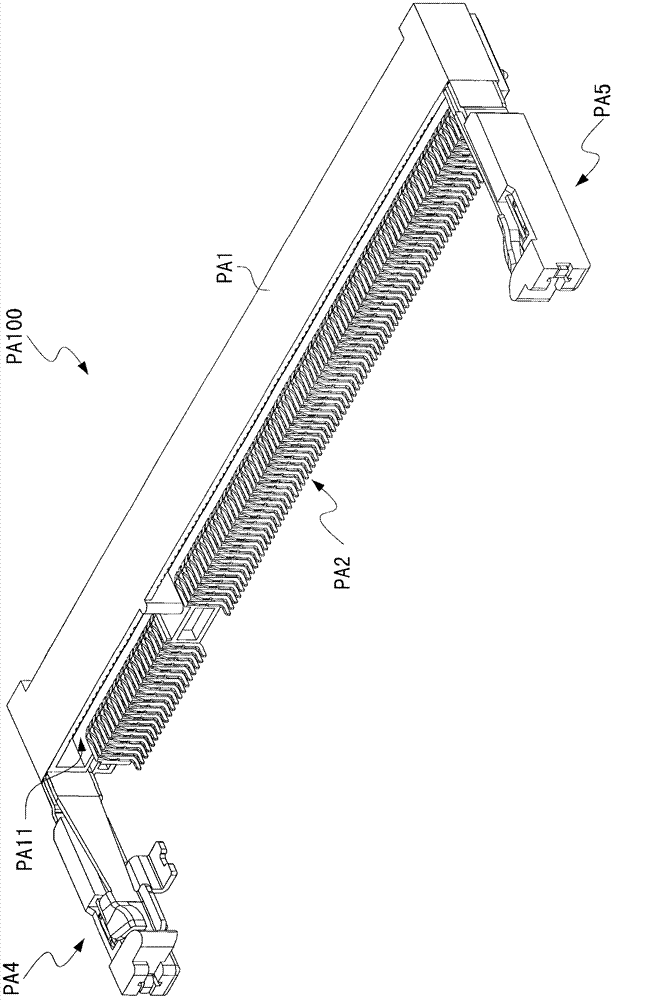

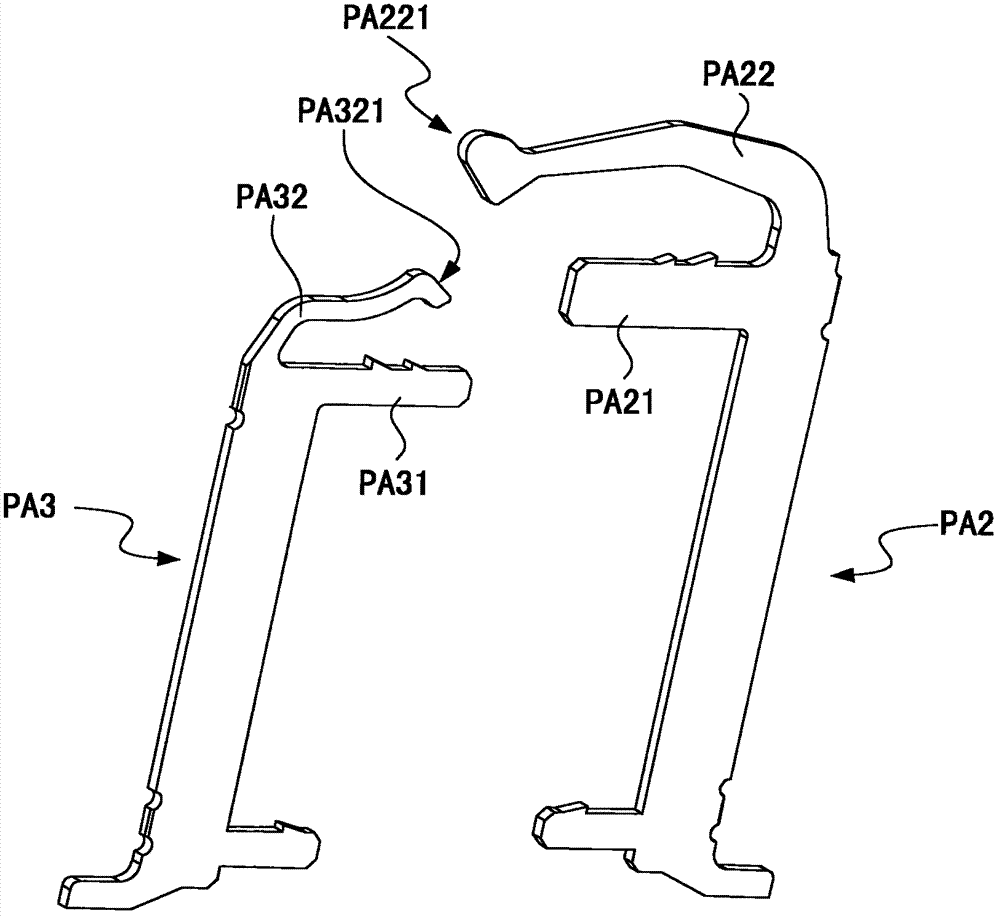

Card edge connector and manufacturing method thereof

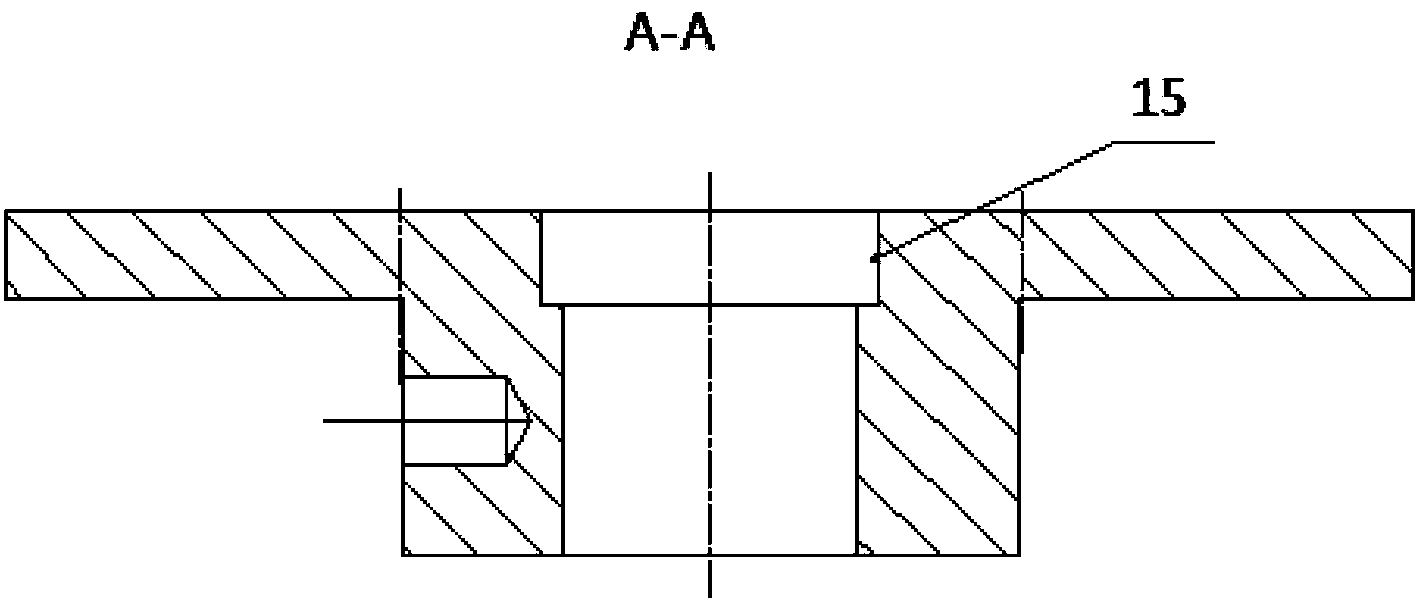

InactiveCN103199357AEfficient scrapingEfficient exclusionContact member manufacturingCoupling contact membersMechanical engineeringEdge connector

The invention discloses a card edge connector and a manufacturing method thereof. The card edge connector comprises an insulating body, a plurality of first terminals and a plurality of second terminals. The insulating body is provided with an inserting connection groove. Each first terminal comprises a first fixing part and a first transmission part. Each fixing part is fixedly installed on the insulating body. Each first transmission part is buckled and extends to the inserting connection groove from each first fixing part in an integrally formed mode, and is provided with a scratch side corner. Each second terminal comprises a second fixing part and a second transmission part. Each second fixing part is fixedly arranged on the insulating body. Each second transmission part is buckled and extends to the inserting connection groove from each second fixing part in an integrally formed mode, an inserting connection space is formed by each second transmission part and each first transmission part, and each scratch side corner protrudes towards each inserting connection space. The invention further provides the manufacturing method of the card edge connector, wherein the manufacturing method is used for manufacturing the card clamp connector.

Owner:GOLDEN TRANSMART INT

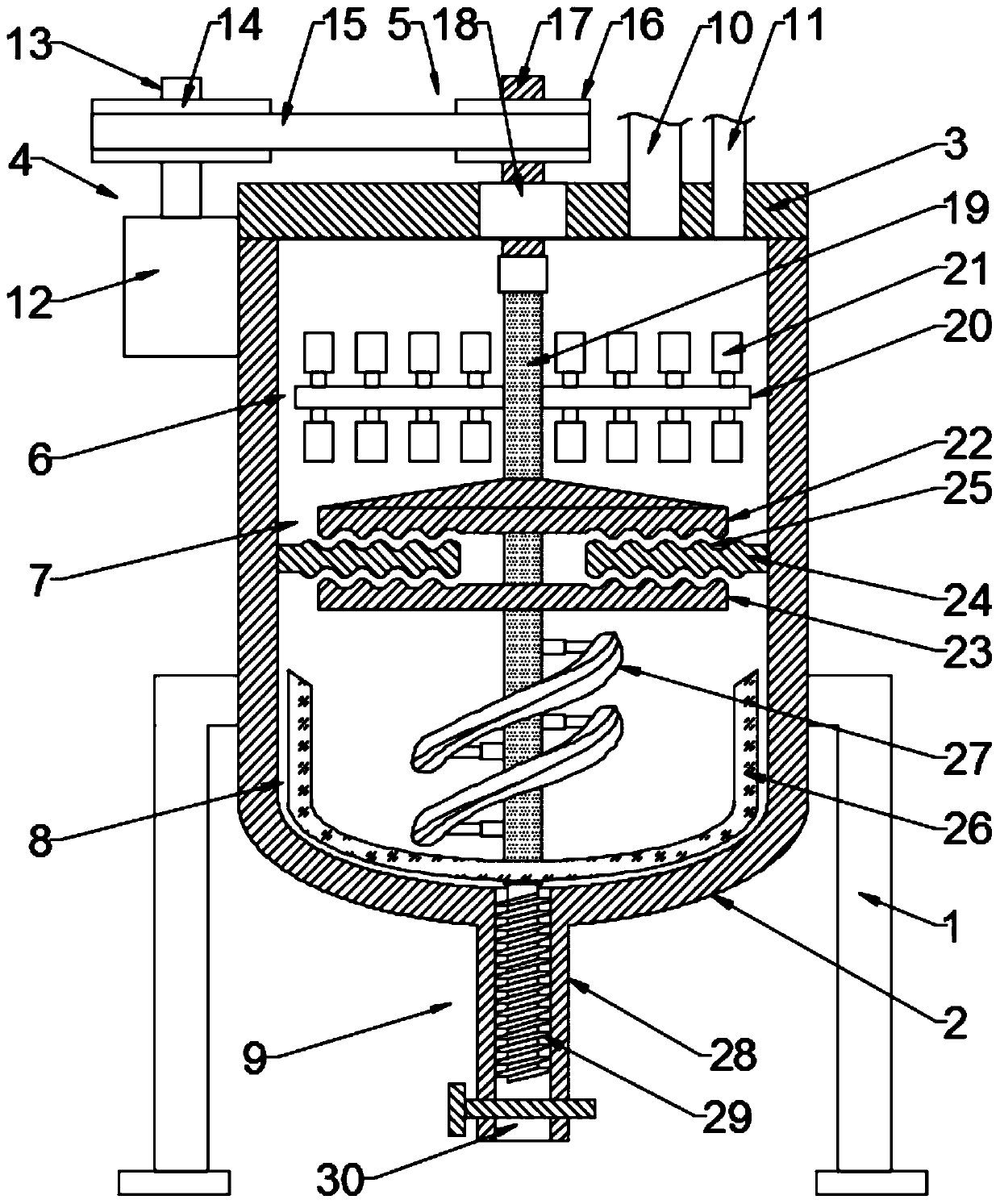

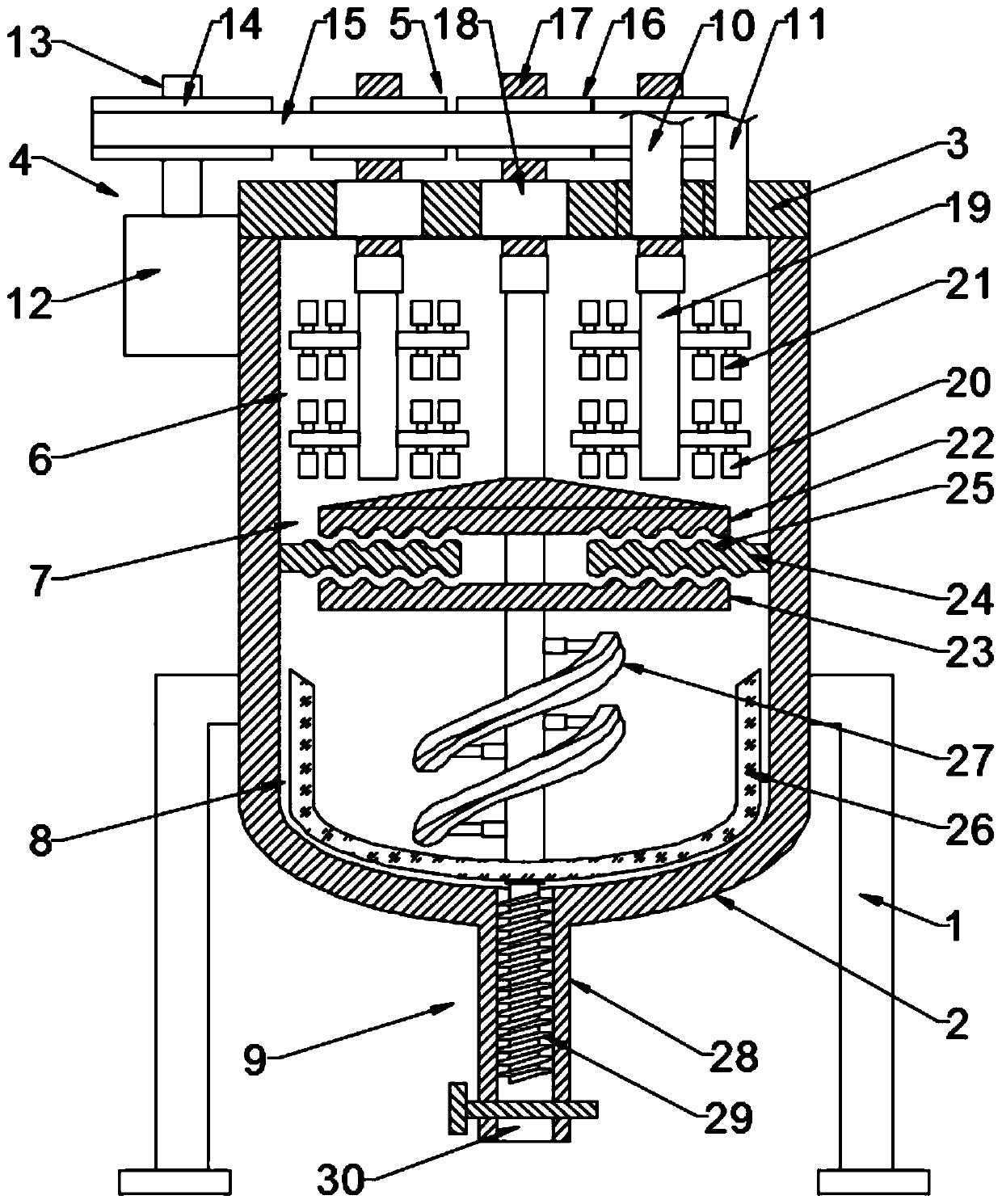

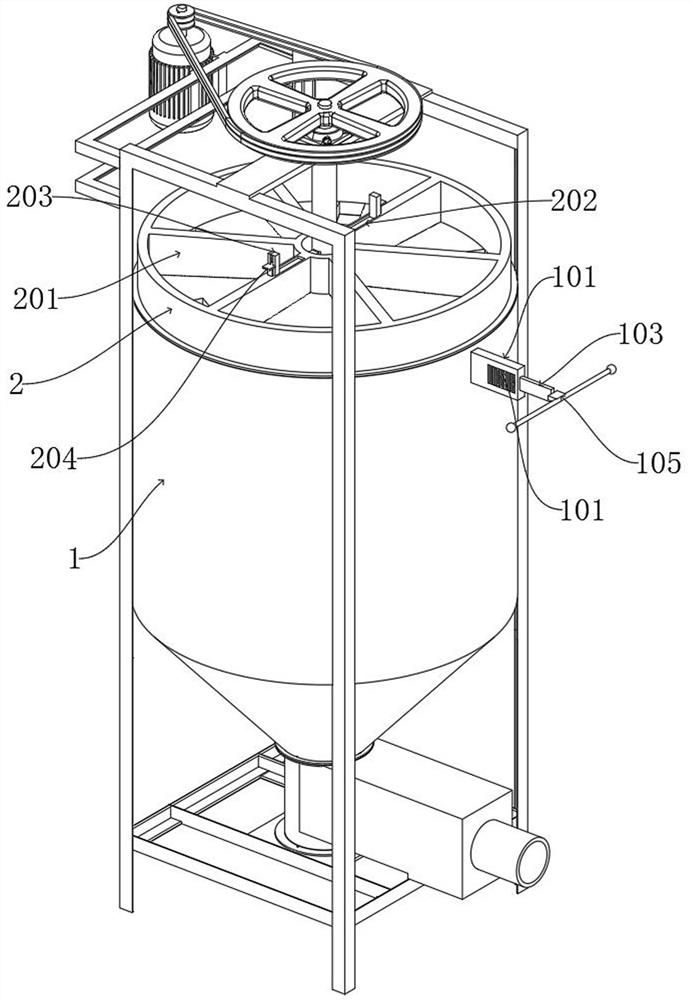

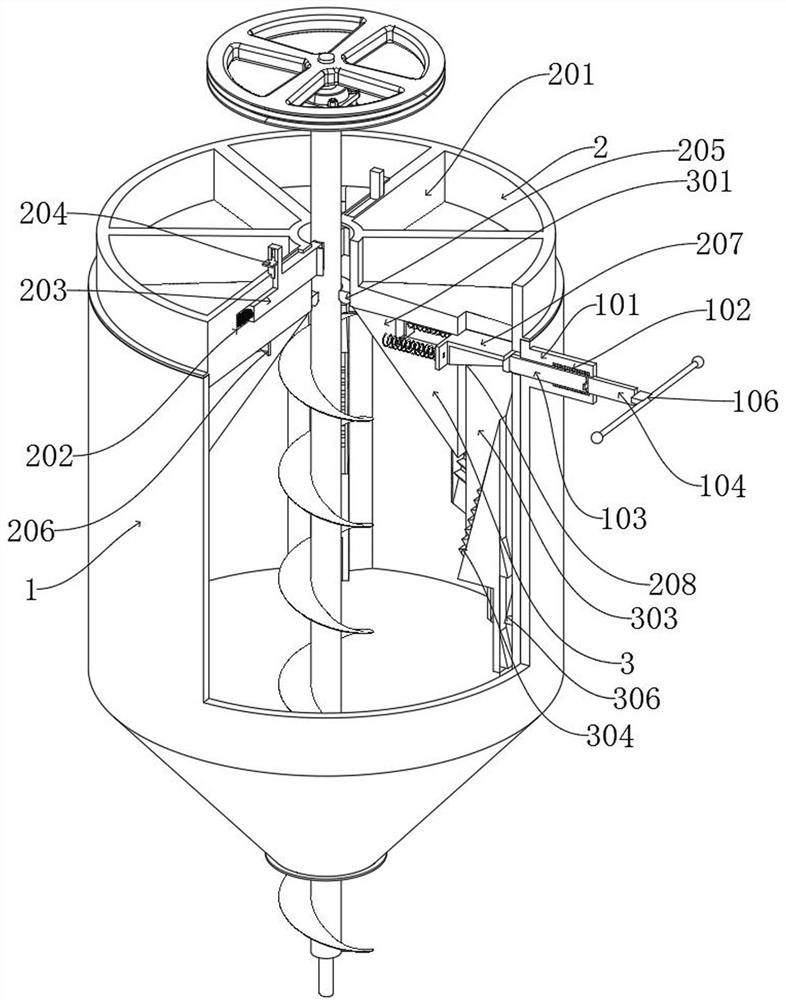

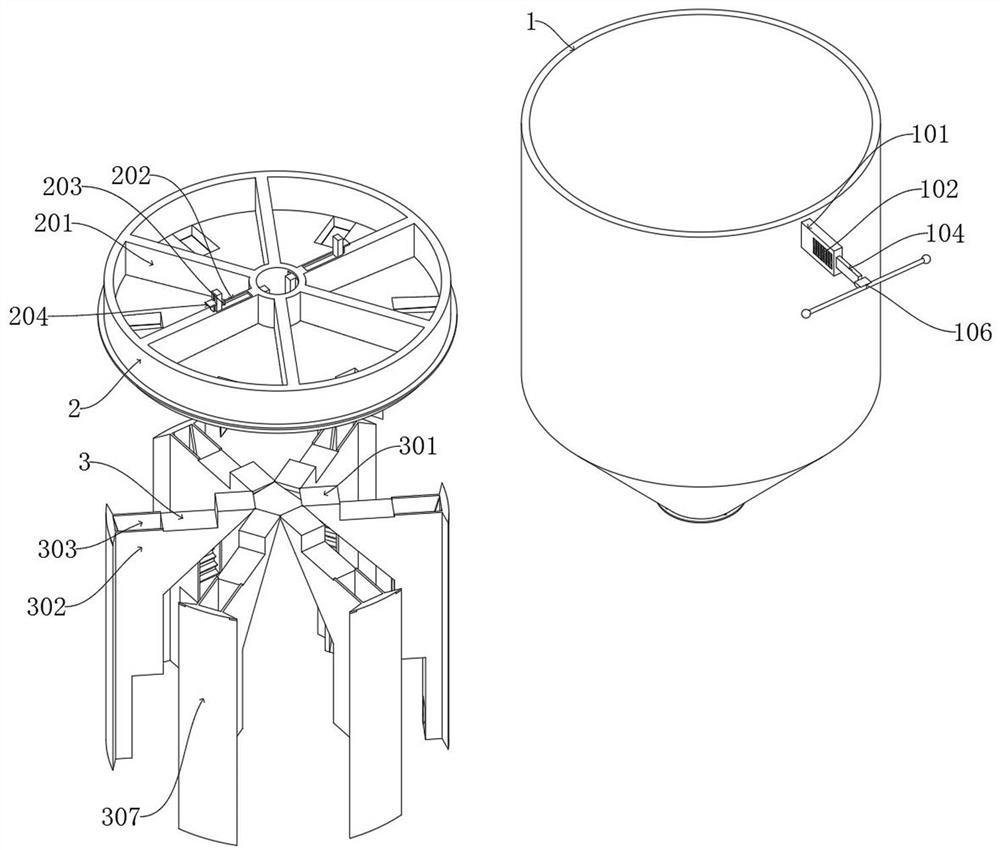

Vertical stirring tank for production of modified asphalt waterproof coiled material

InactiveCN109289643AEffectively break upFacilitates flow mixingShaking/oscillating/vibrating mixersRotary stirring mixersImpellerBituminous waterproofing

The invention discloses a vertical stirring tank for production of a modified asphalt waterproof coiled material. The vertical stirring tank comprises a tank body, the tank body is internally providedwith a stirring chamber, a feed pipe runs through the top side wall of the tank body, a discharge pipe runs through the lower side wall of the tan body, and an air vent runs through the top side wallof the tank body. Through the following two different stirring modes, i.e. double-helix belt impellers and stirring blades, the stirring can be fuller, the double-helix belt impellers can effectivelyscatter the produced agglomerates, promote the flow mixing of materials, roll and stir materials, and achieve a good stirring effect, not only can scrape the materials off the bottom of the stirringchamber, but also can scrape the materials off the inner side wall of the stirring chamber, thus effectively avoiding the high temperature ignition phenomenon caused by accumulation of a large numberof solid or powder modifiers on the stirring chamber inner wall around an asphalt liquid level.

Owner:江苏贝施特防水科技有限公司

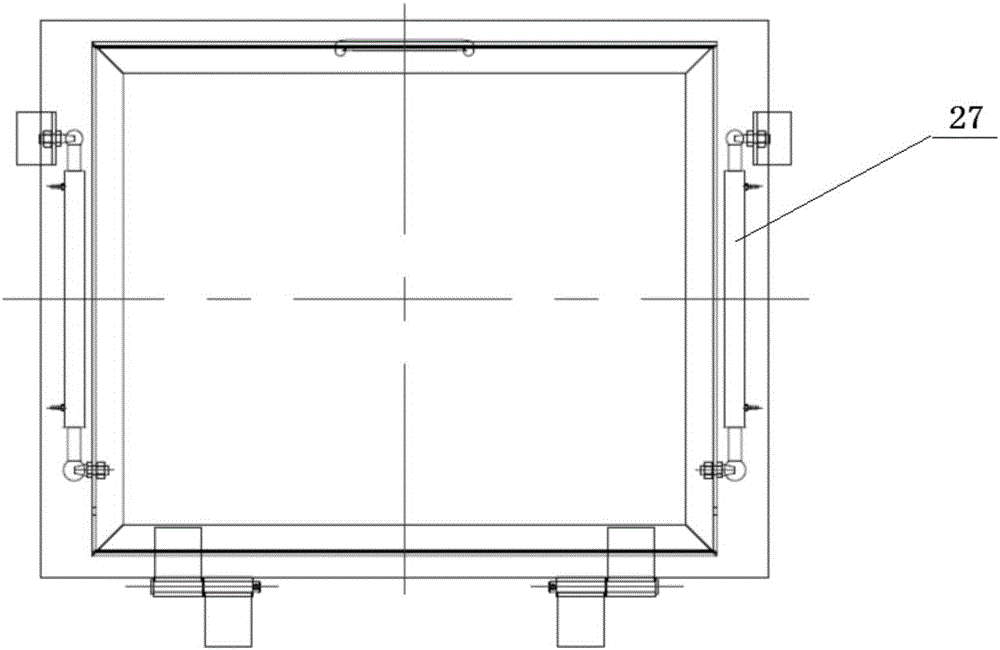

Boiler with pipeline impurity cleaning function based on Internet of Things

InactiveCN108548170AImprove filtering effectImprove heat transfer efficiencyBoiler cleaning apparatusCleaning using toolsThe InternetHearth

The invention relates to a boiler with a pipeline impurity cleaning function based on the Internet of Things. The boiler comprises a hearth, a first air outlet pipe, a second air outlet pipe, a descaling mechanism, a filter mechanism and a center control mechanism. The descaling mechanism comprises a first drive assembly, a lifting assembly, at least two drive rods and at least two scraper blades;the filter mechanism comprises two filter assemblies; and each filter assembly comprises a second motor, a cleaning port, a steam pipe, a baffle plate, a filter screen, a limiting block, a torsion spring, an anti-wind plate, a cleaning unit and two air cylinders. In the boiler with the pipeline impurity cleaning function based on the Internet of Things, through the descaling mechanism, water scale on an inner wall of the hearth can be effectively scraped, so that the adhesion amount of the water scale on the inner wall of the hearth is reduced, the heat conduction efficiency of the boiler isimproved, and the practicability of the boiler is improved; and through the filter mechanism, the impurities in the steam pipelines in the boiler can be filtered, so that the steam quality is improved, and the practicability of the boiler is further improved.

Owner:SHENZHEN LEILING GUANGTONG TECH DEV CO LTD

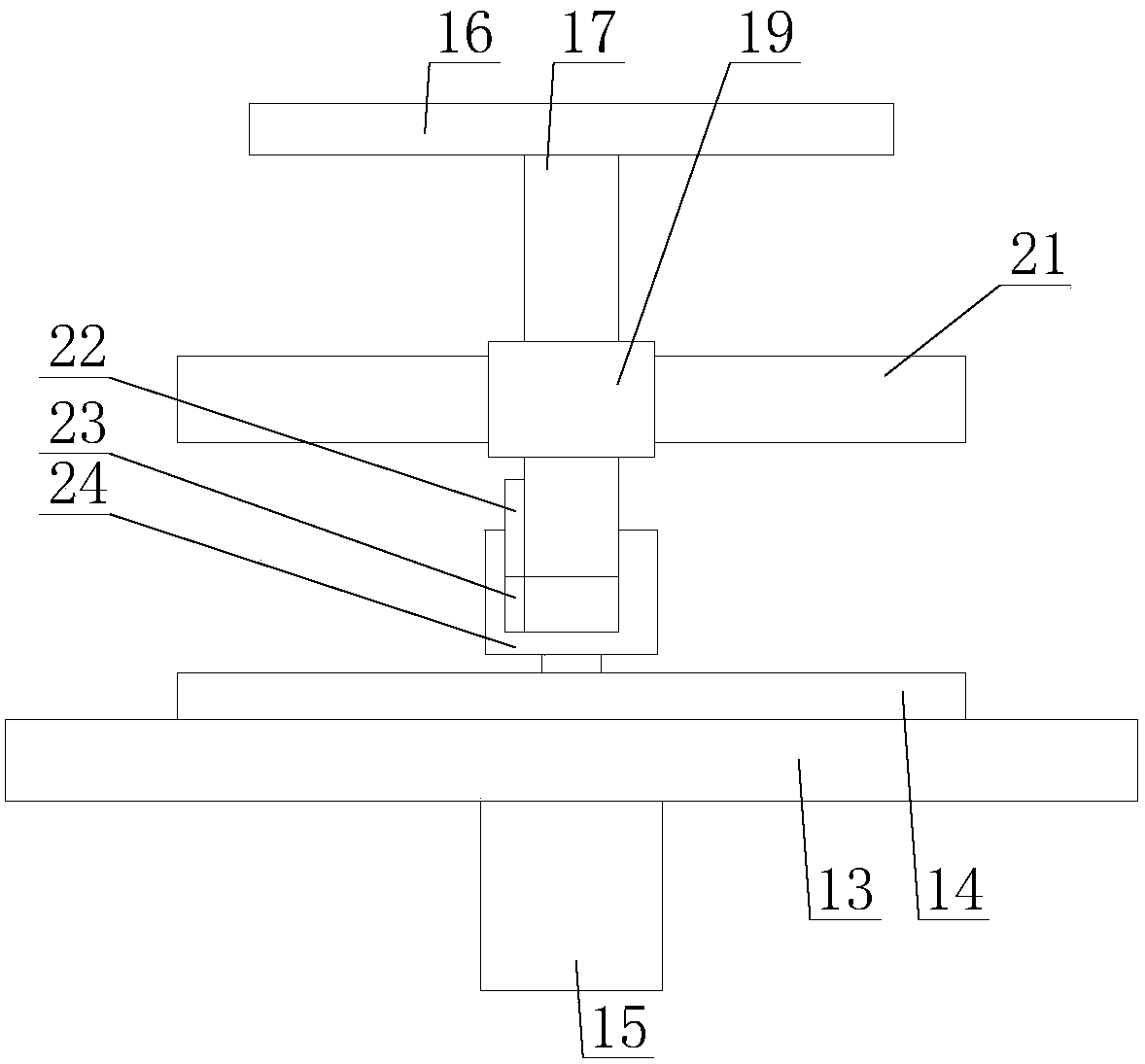

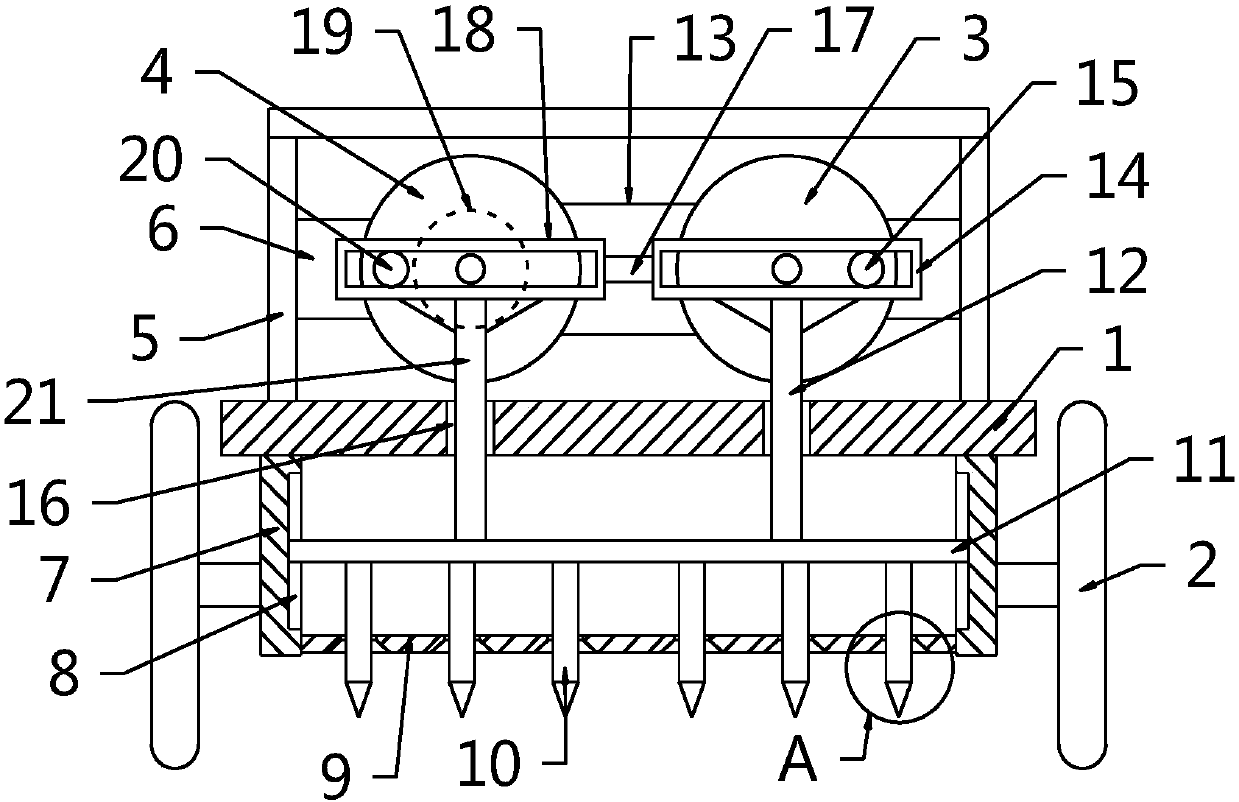

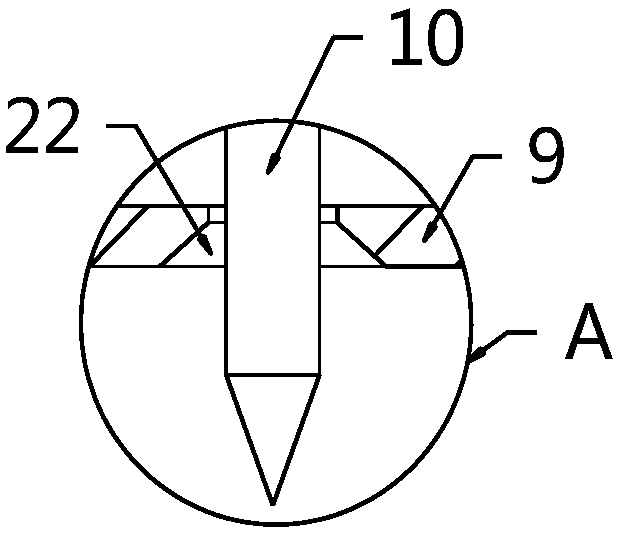

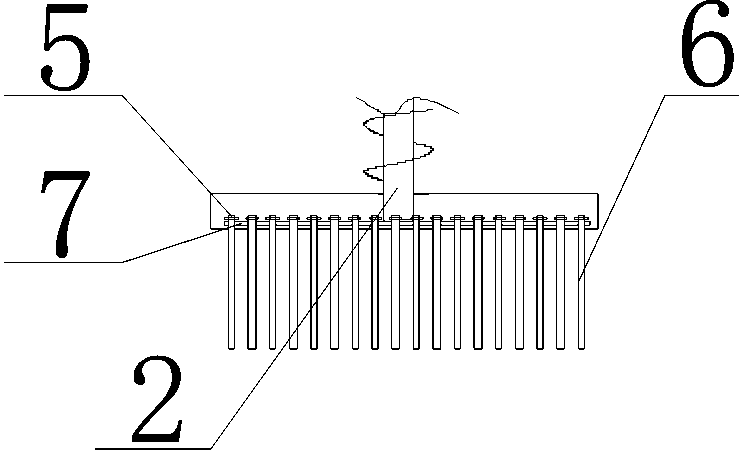

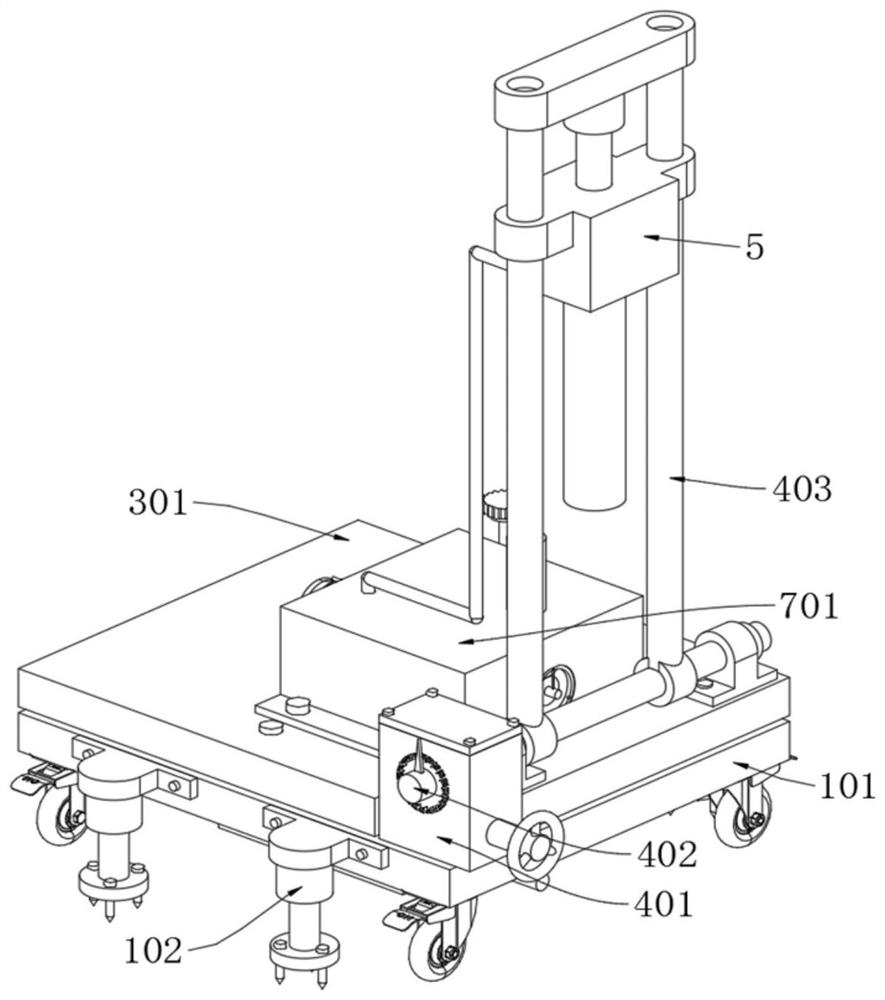

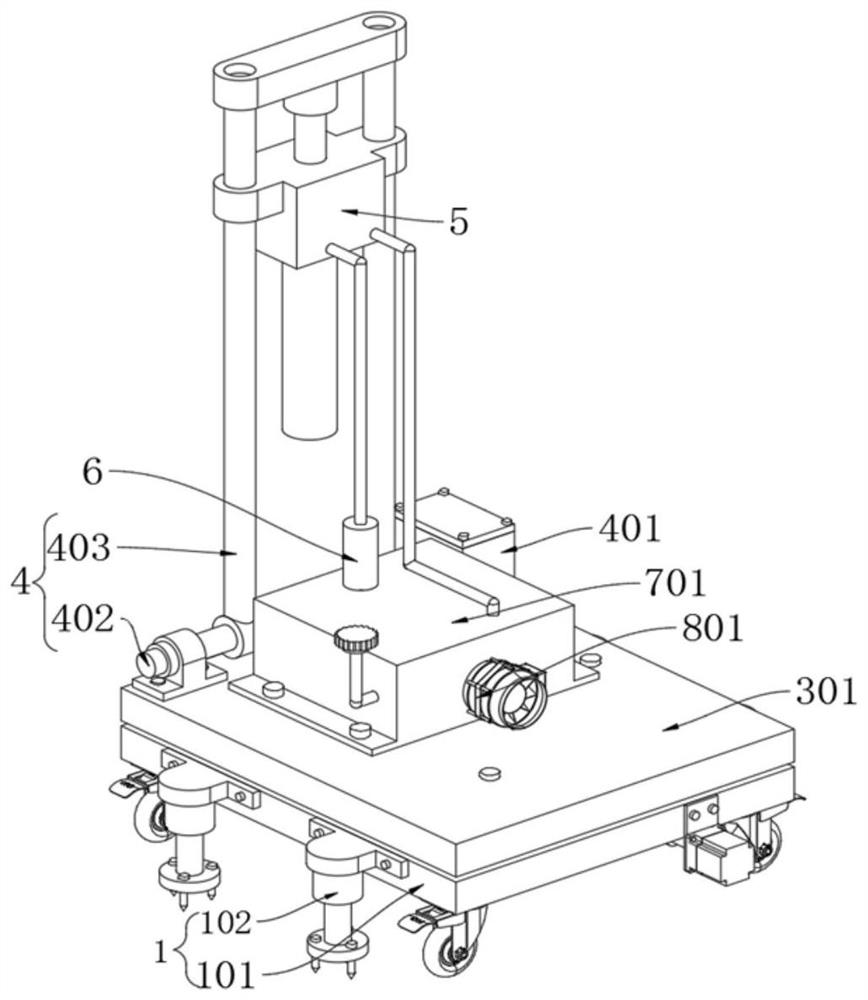

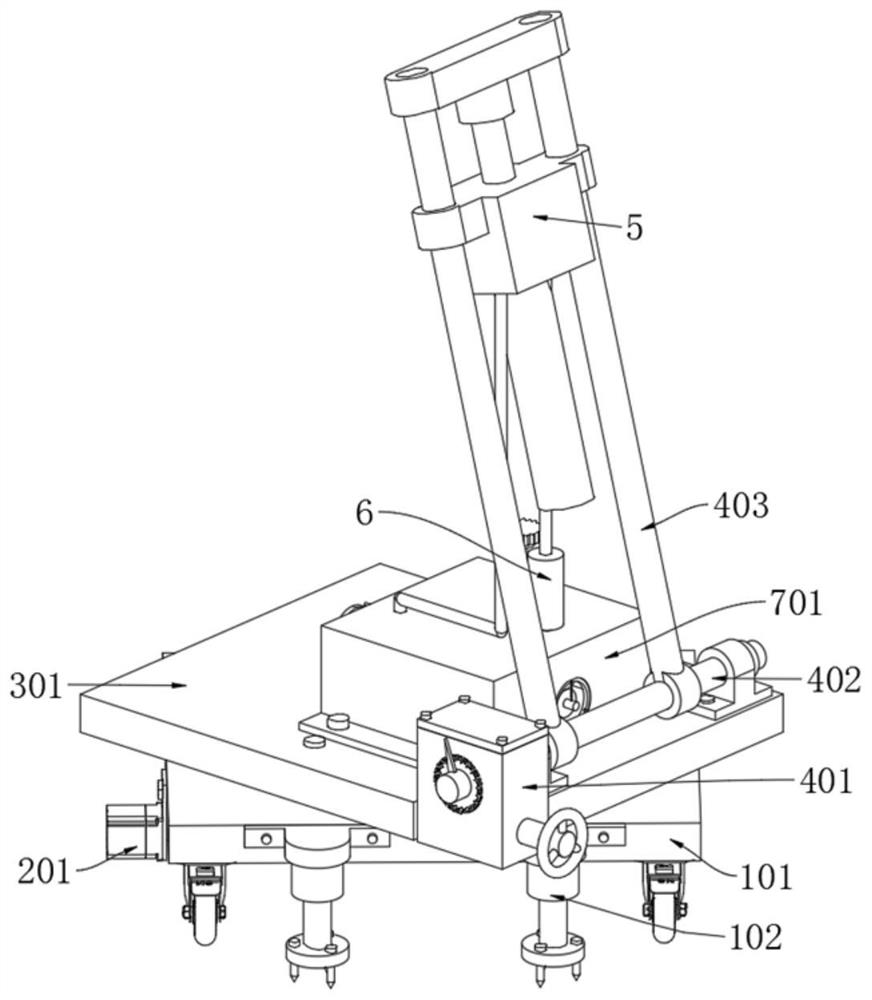

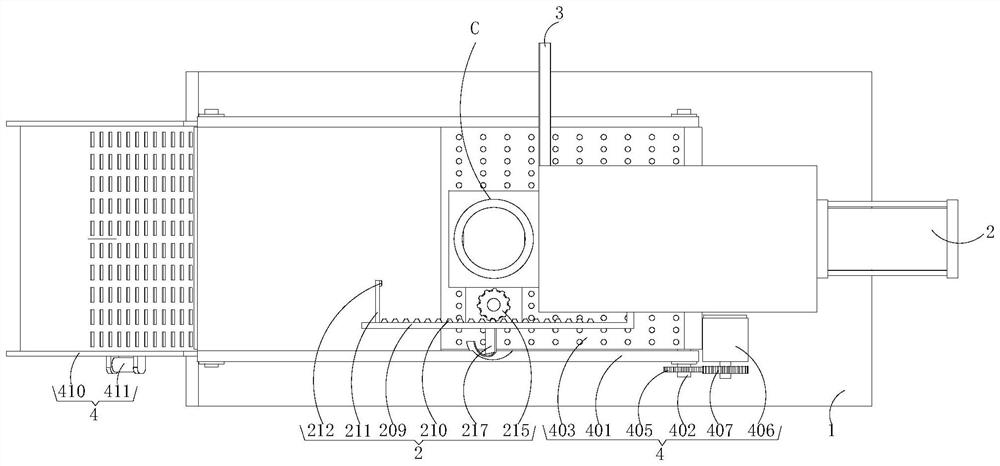

Lawn aeration device for landscape landscaping engineering

InactiveCN107896528AEfficient scrapingEasy to cleanLawn machinesLandscapingArchitectural engineering

The invention discloses a lawn aeration device for landscape landscaping engineering. The lawn aeration device comprises a frame; walking wheels, a right rotating disc, a left rotating disc, a drivingbox, a supporting box body, aeration nails, a lifting plate, a right sleeve plate and a left sleeve plate; a right guide column is fixedly arranged on the outer ring surface of the right rotary disc;a left guide column is fixedly arranged on the outer ring surface of the left rotary disc; the right sleeve plate sleeves the right guide column; the left sleeve plate sleeves the left guide column;the top end of a right pressing rod is fixedly connected with the bottom of the right sleeve plate; the top end of a left pressing rod is fixedly connected with the bottom of the left sleeve plate; the lifting plate is vertically arranged in an inner cavity of the supporting box body in a sliding mode; a plurality of aeration nails are uniformly and fixedly arranged at the bottom of the lifting plate; the left side of the lifting plate is fixedly arranged at the bottom end of the left pressing rod; and the right side of the lifting plate is fixedly arranged at the bottom end of the right pressing rod. The device provided by the invention is convenient in use, low in labor intensity, uniform and continuous in aeration and high in working efficiency, and is suitable for popularization and application.

Owner:贾杨博

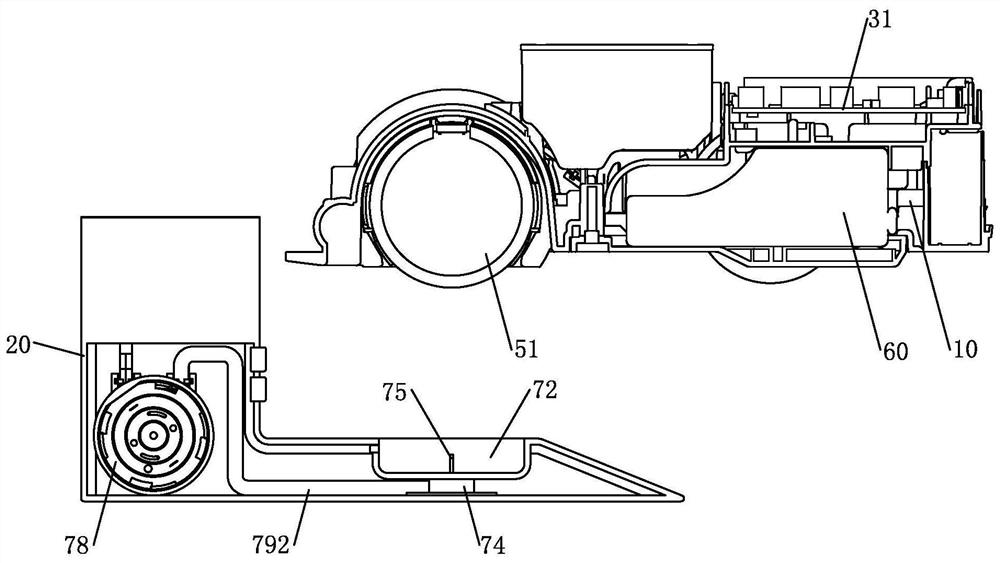

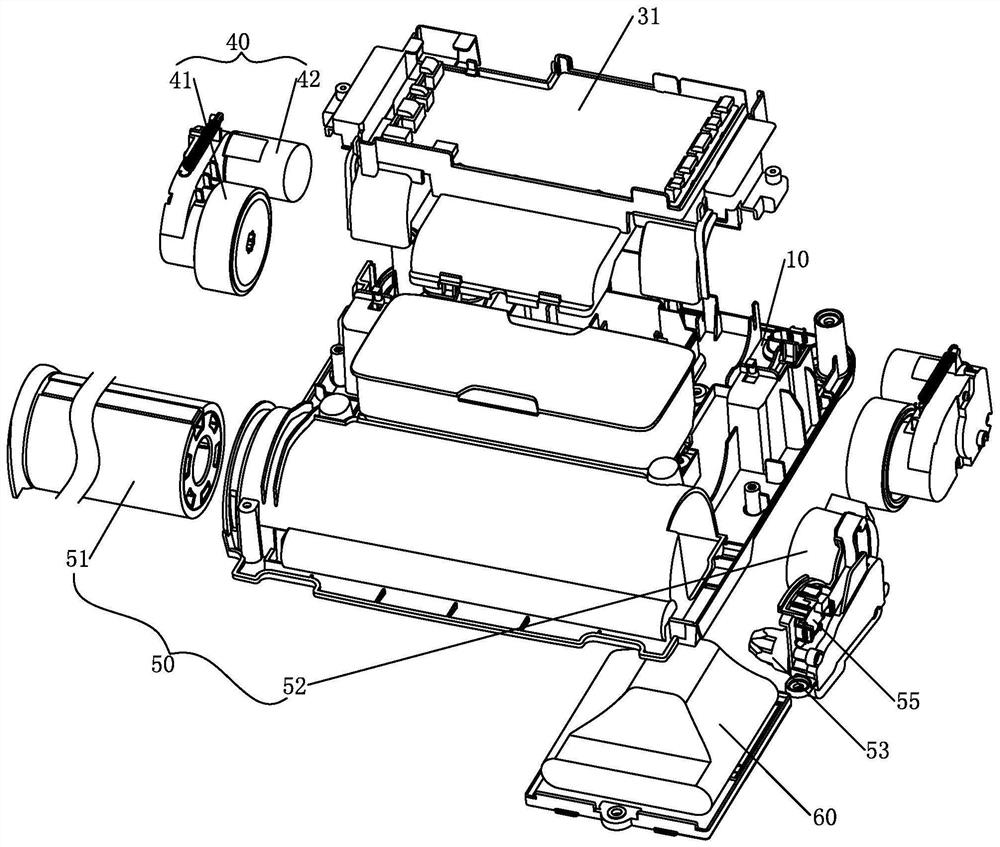

Working method of floor mopping robot

ActiveCN111820824AHigh degree of intelligenceTo achieve the purpose of dryingCarpet cleanersFloor cleanersProcess engineeringIndustrial engineering

The invention discloses a working method of a floor mopping robot, which belongs to the technical field of cleaning equipment working methods. The floor mopping robot enters a self-cleaning program under the condition that the starting condition of a self-cleaning program is met. In the self-cleaning procedure, the floor mopping robot returns to a base station firstly, then the floor mopping robotcompletes cleaning of a to-be-cleaned wiping surface on a wiping piece on the premise that the electric quantity meets the preset requirement, and the floor mopping robot enables the wiping piece torotate for a period of time to complete dehydration after the wiping piece is cleaned. The purpose of automatic cleaning of the wiping piece can be achieved through the self-cleaning program, a user does not need to manually detach or replace the wiping piece, the use cost of the whole floor mopping robot can be reasonably reduced on the premise that the intelligent degree of the floor mopping robot is improved, and the use experience of the user is improved.

Owner:PANASONIC APPLIANCES CHINA CO LTD

Concentrated cotton removal device of roving frame

InactiveCN105442117ASimple structureGood cotton removal effectTextiles and paperAgricultural engineeringWaste management

The invention discloses a concentrated cotton removal device of a roving frame. The concentrated cotton removal device comprises a cotton removal groove, an annular belt arranged in the cotton removal groove, a cleaning scraper located at one end of the annular belt, a waste cotton discharge port formed in the tail end of the cotton removal groove and located below the cleaning scraper, and an air pipe with one end connected with the waste cotton discharge port and the other end connected with a draught fan. The edge of the cleaning scraper makes contact with the surface of the annular belt to conduct scraping. Waste cotton is conveyed through the annular belt, waste cotton on the belt is scraped into the air pipe through the cleaning scraper at the tail end of the cotton removal groove, waste cotton in the air pipe is removed through wind power of the draught fan instead of manual operation, the structure is simple, the cotton removal effect is good, labor is saved, and efficiency is improved.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

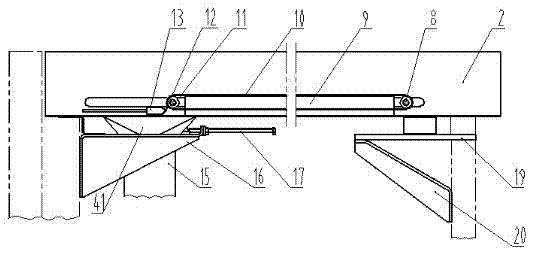

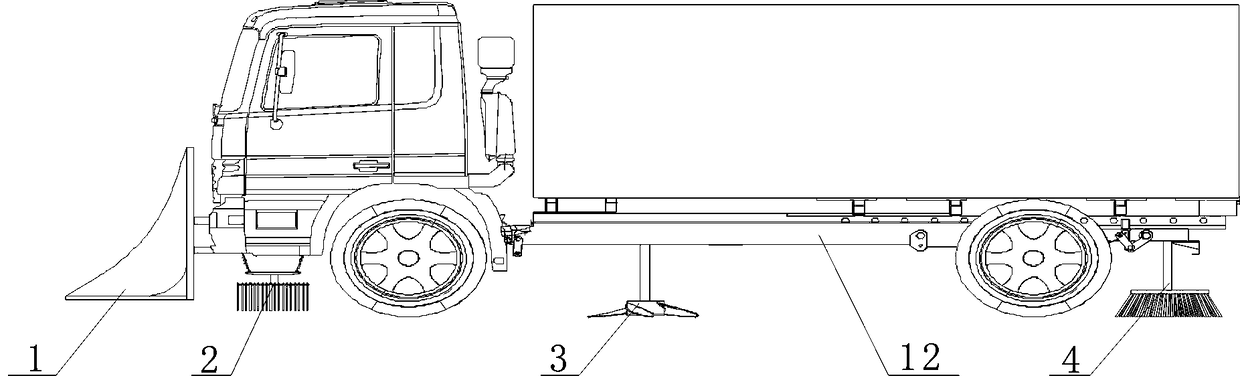

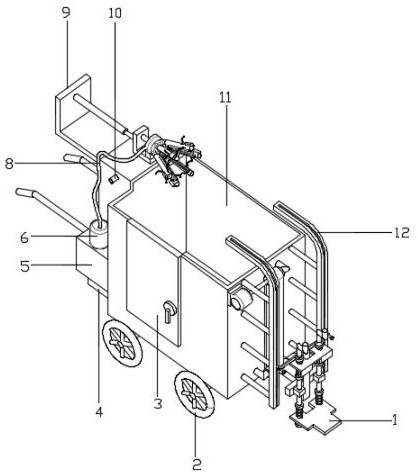

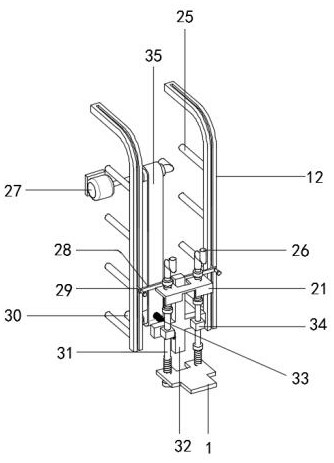

Road surface sweeping snow removal and ice breaking cart

PendingCN108824334AClean up thoroughlyClean up in timeRoad cleaningSnow cleaningSnow removalDrive shaft

The invention relates to a road surface sweeping snow removal and ice breaking cart in the technical field of road sweeping mechanical equipment. The cart comprises a snow removal shovel, ice breakingrotating discs, spiral ice scrapers, sweeping rotating discs and a cart body; the snow removal shovel is arranged at the lower portion of the front end of the cart body, at least two ice breaking rotating discs are arranged at the lower face of the head of the cart body in parallel, at least two spiral ice scraper are arranged at the lower portion of a cart body chassis in parallel, at least twosweeping rotating discs are arranged at the rear end of the lower portion of the cart body chassis, the whole widths of the ice breaking rotating discs, the spiral ice scrapers and the sweeping rotating discs are all not smaller than the width of the cart body, the ice breaking rotating discs, the spiral ice scrapers and the sweeping rotating discs are connected with corresponding driving devicesthrough transmission shafts respectively, and the transmission shafts and the cart body chassis are corresponding in a perpendicular state; the problems that a traditional road sweeping device has a single function, and the ice removal effect is not ideal are effectively solved.

Owner:刘福祥

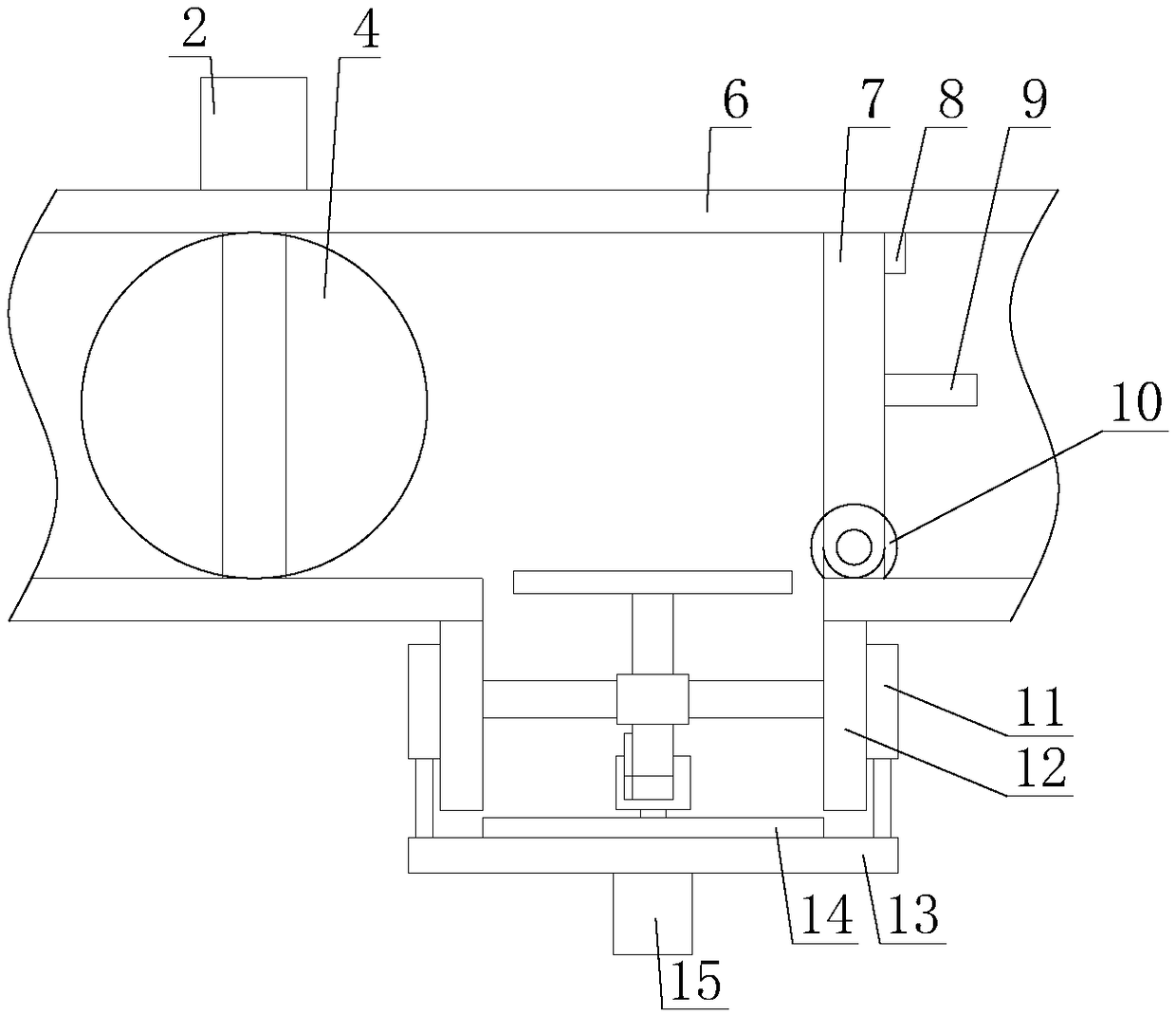

Fuel cylinder block cleaning device

The invention discloses a fuel cylinder block cleaning device, and relates to the technical field of fuel cylinder cleaning. The fuel cylinder block cleaning device comprises a driving mechanism, a holding handle, an inflation bag, a gas transmission pipe and a cleaning mechanism; the middle part of the bottom of the holding handle is fixedly connected to the top of the driving mechanism; the inflation bag is fixedly mounted in the middle part of the top of the holding handle; an exhaust port of the inflation bag is connected with and communicates with the top end of the gas transmission pipe;the bottom end of the gas transmission pipe penetrates through the top of the driving mechanism, and extends into the driving mechanism; and the cleaning mechanism is fixedly mounted under the driving mechanism. The fuel cylinder block cleaning device discharges cleaning liquid into the cleaning mechanism through the driving mechanism, drives the cleaning mechanism to rotate through the driving mechanism to discharge the cleaning liquid, can perform rotary brushing when the cleaning liquid is uniformly coated on the walls of intake manifolds, effectively removes accumulated cartons attached in the intake manifolds, and guarantees normal use of fuel cylinders.

Owner:王治军

Crude-fiber nylon yarn carpet and production mode thereof

InactiveCN108677353AImprove wear resistanceNo hair lossFilament forming substance formingWoven fabricsYarnSingle fiber

The invention discloses a crude-fiber nylon yarn carpet using nylon 6 / nylon 66 as a material. The crude-fiber nylon yarn carpet is prepared by a whole bunch of a crude-fiber nylon yarn of which a single-fiber fineness is 200-3000 dtex, or blending with a whole bunch of a carpet yarn of which the single-fiber fineness is less than or equal to 35 dtex. The crude-fiber nylon yarn carpet has the beneficial effects of no unhairing, strong recovery capability, skid resistance, static resistance, excellent flame retardant property, convenient cleaning and the like.

Owner:青岛百花旺塑料科技有限公司

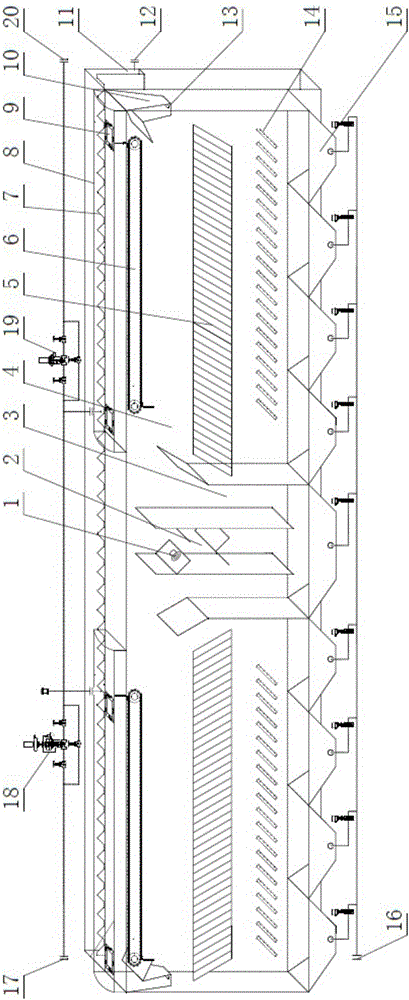

Micro-positive pressure fully-closed large air floatation apparatus and sewage treatment method

InactiveCN106365236AImprove flotation separation efficiencyAvoid slag backmixingWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusPositive airway pressureEngineering

The invention relates to a micro-positive pressure fully-closed large air floatation apparatus. The apparatus comprises an air dissolving system and an air floatation device body, a coagulation chamber is provided with a sewage inlet, an air dissolving system release opening is arranged beside the sewage inlet in the coagulation chamber, the coagulation chamber is formed by coagulation spacing boards, micro-bubble releasing chambers formed by spacing boards are arranged beside the coagulation chamber, separation areas are arranged beside the micro-bubble releasing chambers, the separation areas are provided with inclined board groups, the upper portion of the air floatation device body is provided with an arc-shaped top cover, the arc-shaped top cover and the air floatation device body are sealed, the air floatation device body is connected with a gas supply device, a pressure release device and a pressure control device, and the pressure control device controls the gas supply device and the pressure release device to make the pressure in the air floatation device body always be a micro-positive pressure. The air flotation device is symmetric separation structure, improves the flotation separating efficiency and avoids return mixing of falling residues; and trapezoid water collecting weirs are arranged along the length direction of the tank to realize effective residue scraping and prevent overflow of residue collecting tanks, so the adjustment of a water outlet weir is not needed when the water flow greatly fluctuates.

Owner:青岛海晏环境技术工程有限公司

Cleaning device for inner wall of industrial waste barrel in industrial park

InactiveCN111790706AEfficient scrapingImprove cleaning efficiencyHollow article cleaningTruckElectric machinery

The invention discloses a cleaning device for the inner wall of an industrial waste barrel in an industrial park. In view of the problems that after the waste barrel is dumped, the cleaning efficiencyof the inner wall is low, the effect is poor, manpower is consumed, and residual or wall-hanging residues cannot be cleaned to influence the environment, the following scheme is proposed that the cleaning device comprises a water delivery pipe, a garbage truck and an air cylinder, wherein a fixed shaft is fixed to the outer wall of one side of the garbage truck through screws, the outer wall of the fixed shaft is sleeved with a transmission chain through a roller, the outer wall of one side of the roller is connected with a motor through bolts, fixing rods are welded to the outer wall of oneside of the transmission chain, one ends of the fixing rods are connected with a lifting frame through hinges, and a sliding mechanism is arranged on one side of the lifting frame; and supporting rodsare fixed to the outer wall of one side of the garbage truck through bolts, and one ends of the supporting rods are fixed with sliding rails through bolts. Through mutual cooperation of the components, the inner wall of the waste barrel is thoroughly cleaned, adhesion stains on the inner wall can be effectively scraped, the cleaning efficiency is improved, and manpower is saved.

Owner:徐卫

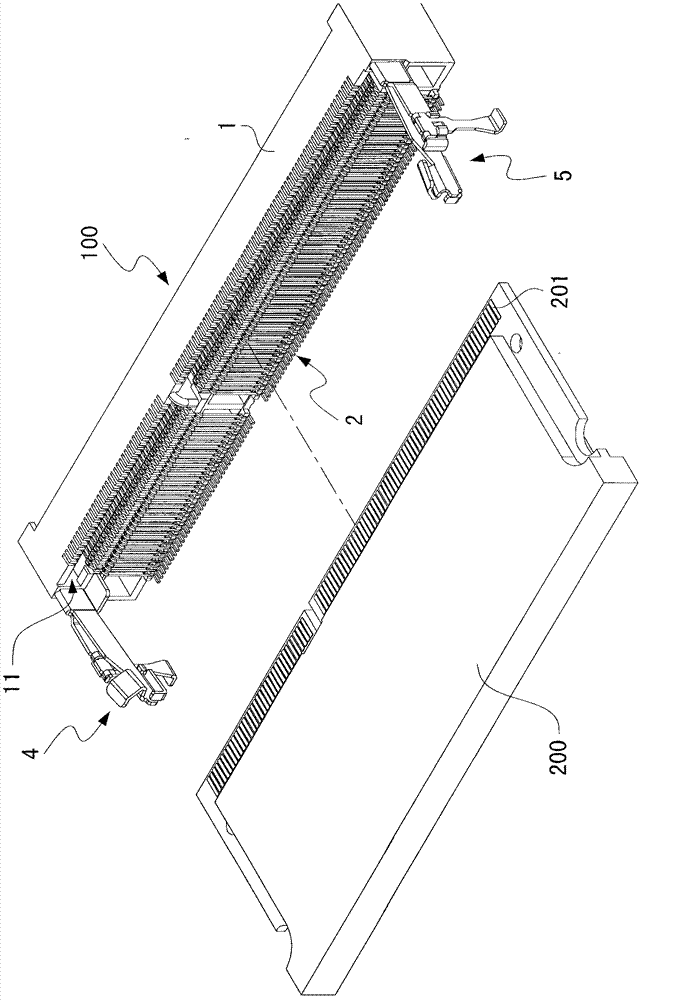

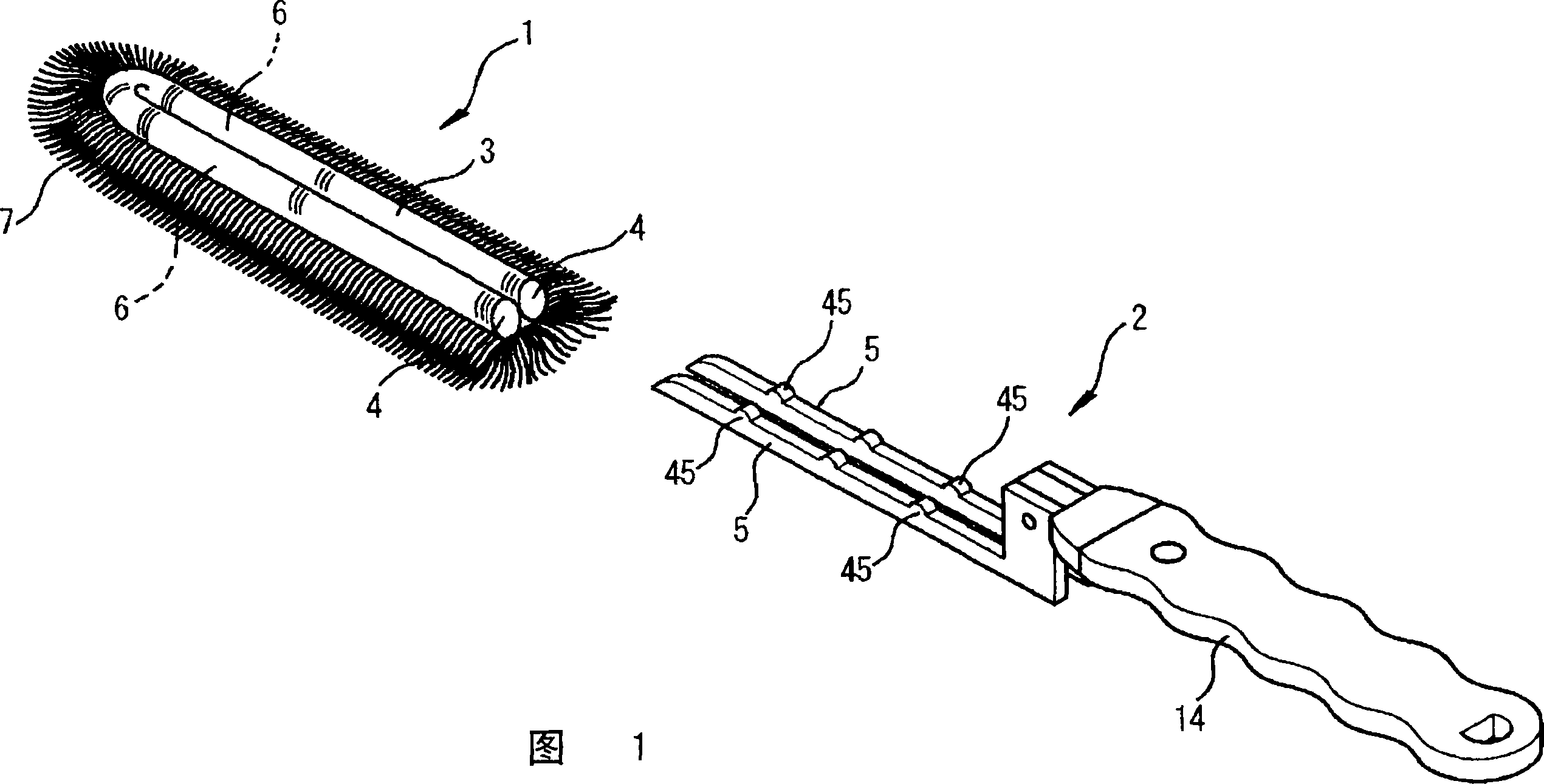

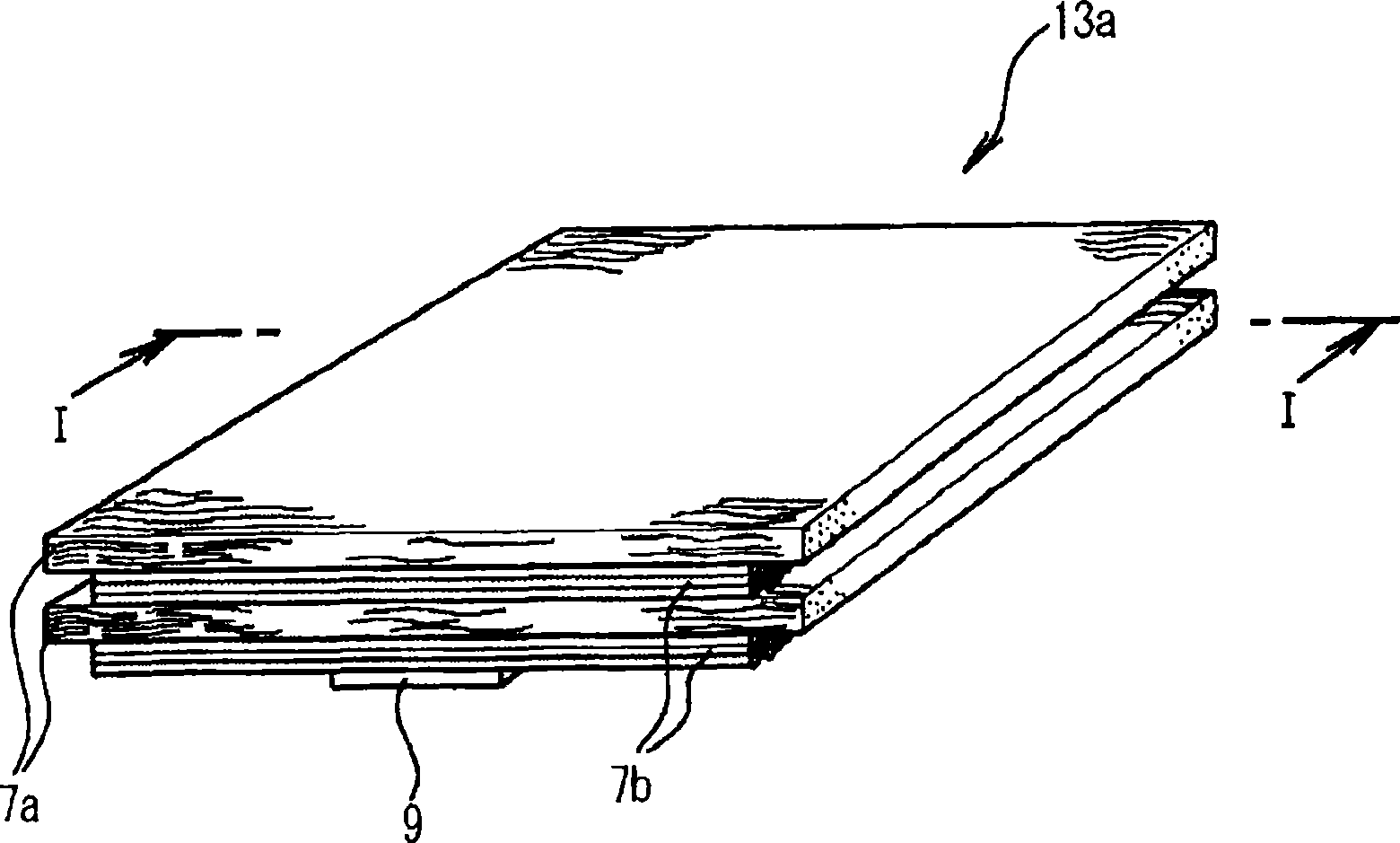

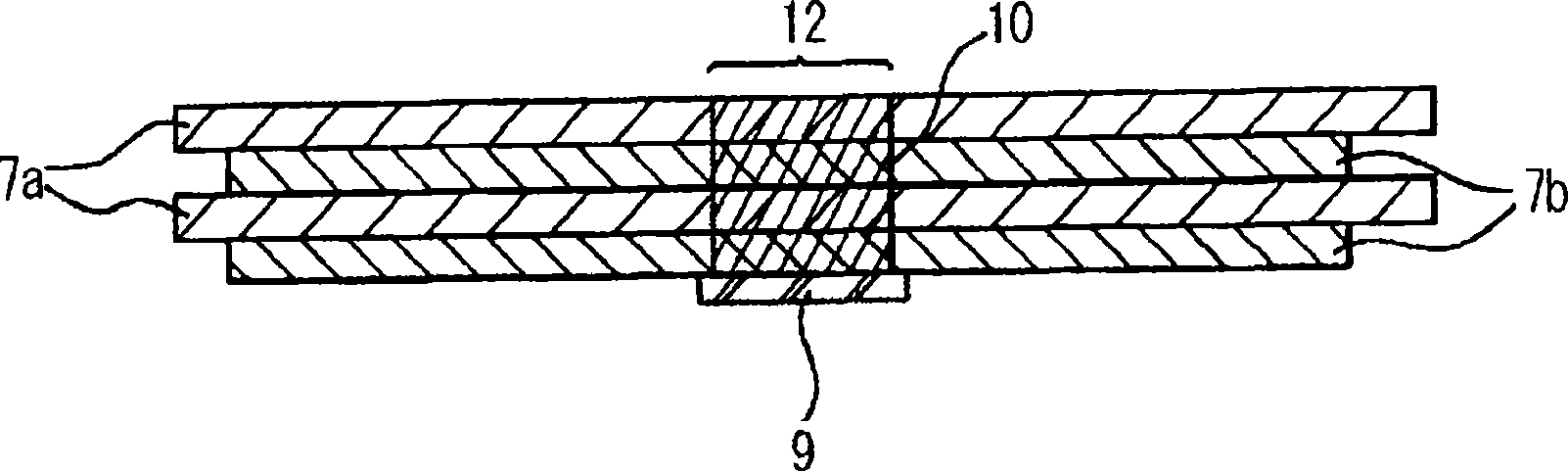

Cleaning tool and method of manufacturing cleaning part thereof

InactiveCN1909821AEfficient scrapingImprove erase effectCarpet cleanersFloor cleanersFiber bundleEngineering

A cleaning tool and a method of manufacturing the cleaning part of the cleaning tool. The cleaning tool capable of sufficiently developing cleaning capacity even for cleaning in a small space comprises the cleaning part (1) and a grip part (2). The method of manufacturing the cleaning part (1) comprises the steps of forming a bulky section forming part (3) by bending a sheet stacked body having an adhered part formed by adhering a sheet-like fiber bundle (7) to a sheet along the adhered part, bending the sheet stacked body having the bulky section forming part (3) formed thereon to face the bulky section forming part (3), and forming the contact surfaces of the opposed sheet-like fiber bundles (7) integrally with each other so that these contact surfaces are adhered to each other. Opened grip insert ports (4) are formed at one end of the bulky section forming part (3), and the support bars (5) of the grip part (2) are inserted into grip insert parts (6) formed in the bulky section forming part (3).

Owner:山田千代惠

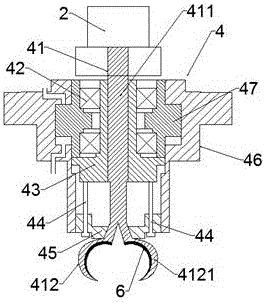

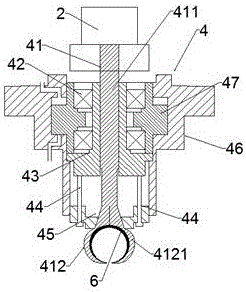

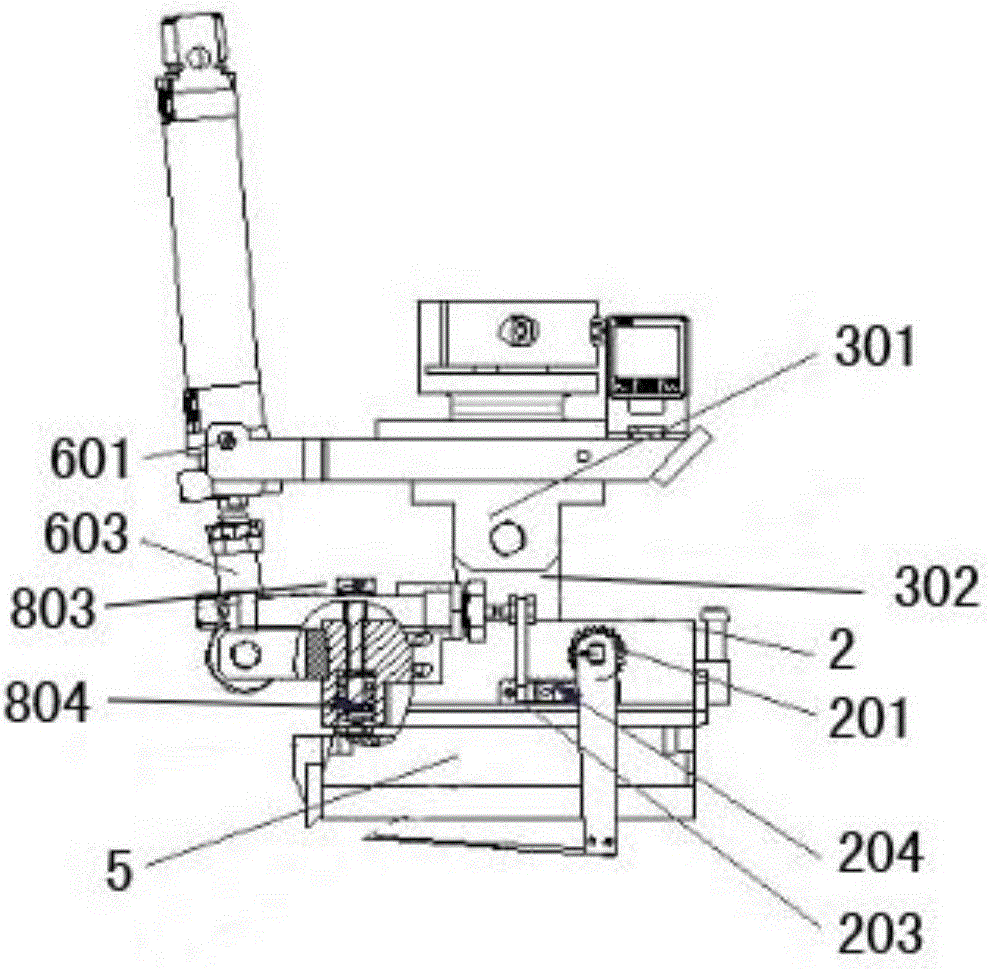

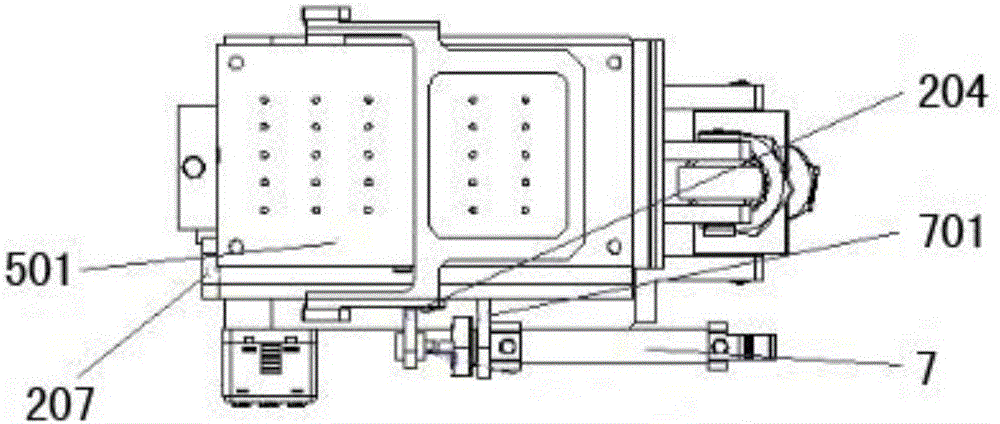

Test probe cleaning device and clamping member and test base thereof

ActiveCN112462109AEfficient scrapingEffective and thorough scrapingElectrical measurement instrument detailsElectrical testingTest efficiencyMechanical engineering

The invention discloses a test probe cleaning device and a clamping component and a test base thereof, relates to the technical field of semiconductors, and aims to solve the problems of how to effectively replace manual cleaning and how to thoroughly clean a probe in the prior art. The test probe cleaning device comprises a cleaning component, a clamping component, a test socket, a test base anda test probe. The clamping component is arranged above the cleaning component, a test socket is arranged below the cleaning component, the test socket is installed on the test base, and the clamping component can move and control the cleaning component above the test socket through a transmission mechanical arm so that the cleaning component can move into the test socket, and is abutted against the probe head of the test probe in the test socket. The problems of how to effectively replace manual cleaning and how to thoroughly clean the probe in the prior art are solved, so that manual cleaningis effectively replaced, and meanwhile, the cleaning quality and the testing efficiency are ensured.

Owner:FTDEVICE TECH (SUZHOU) CO LTD

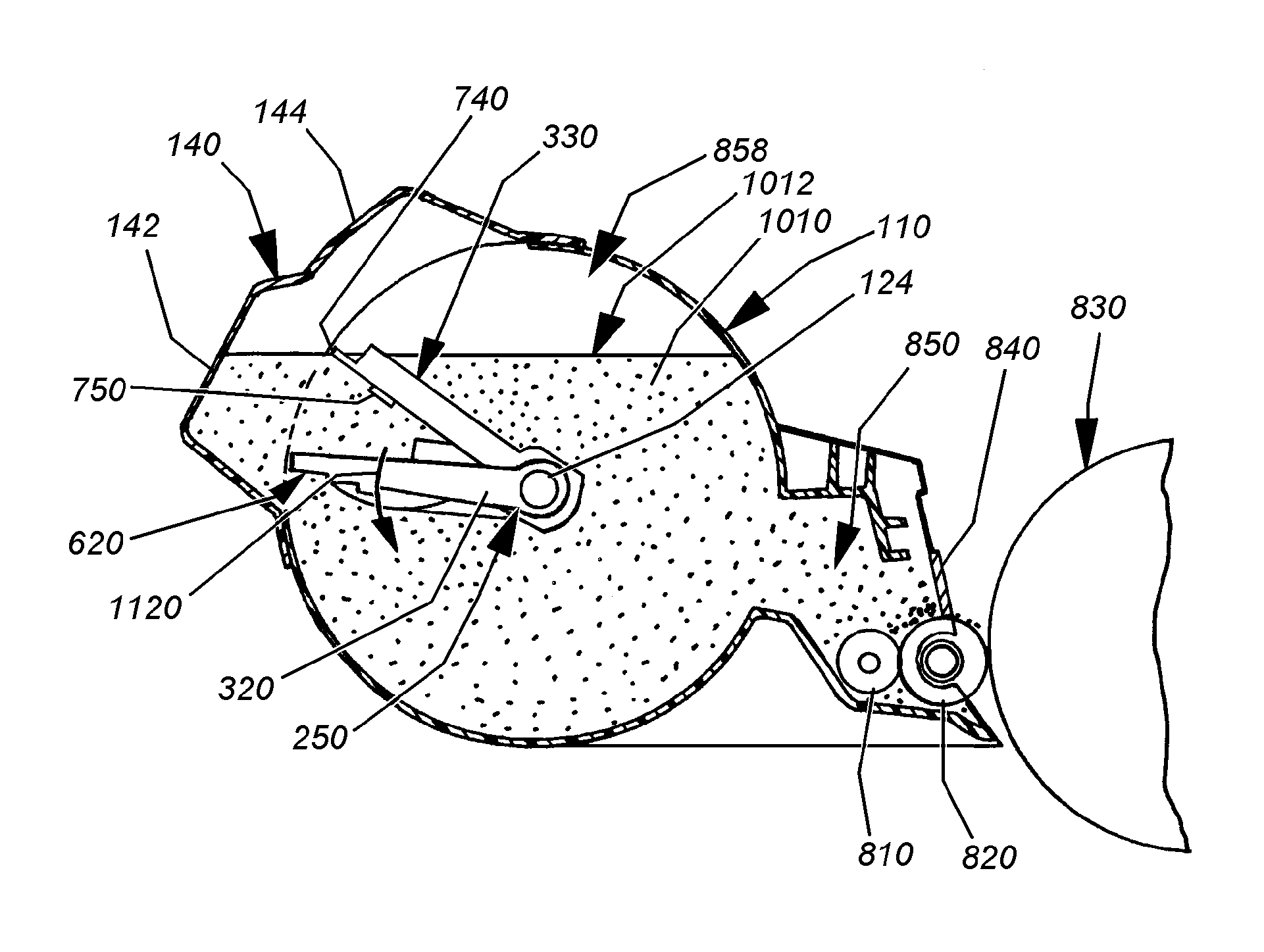

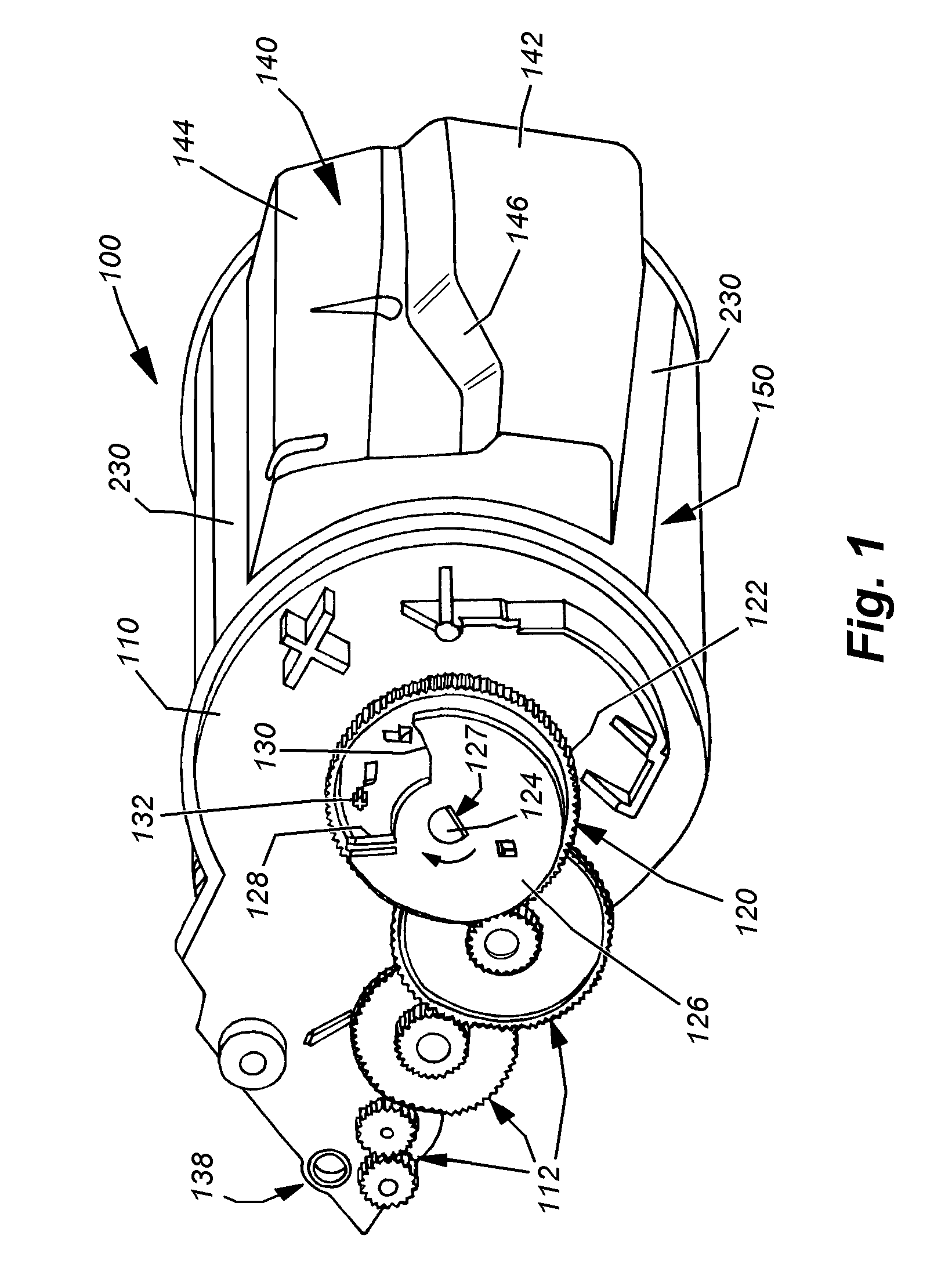

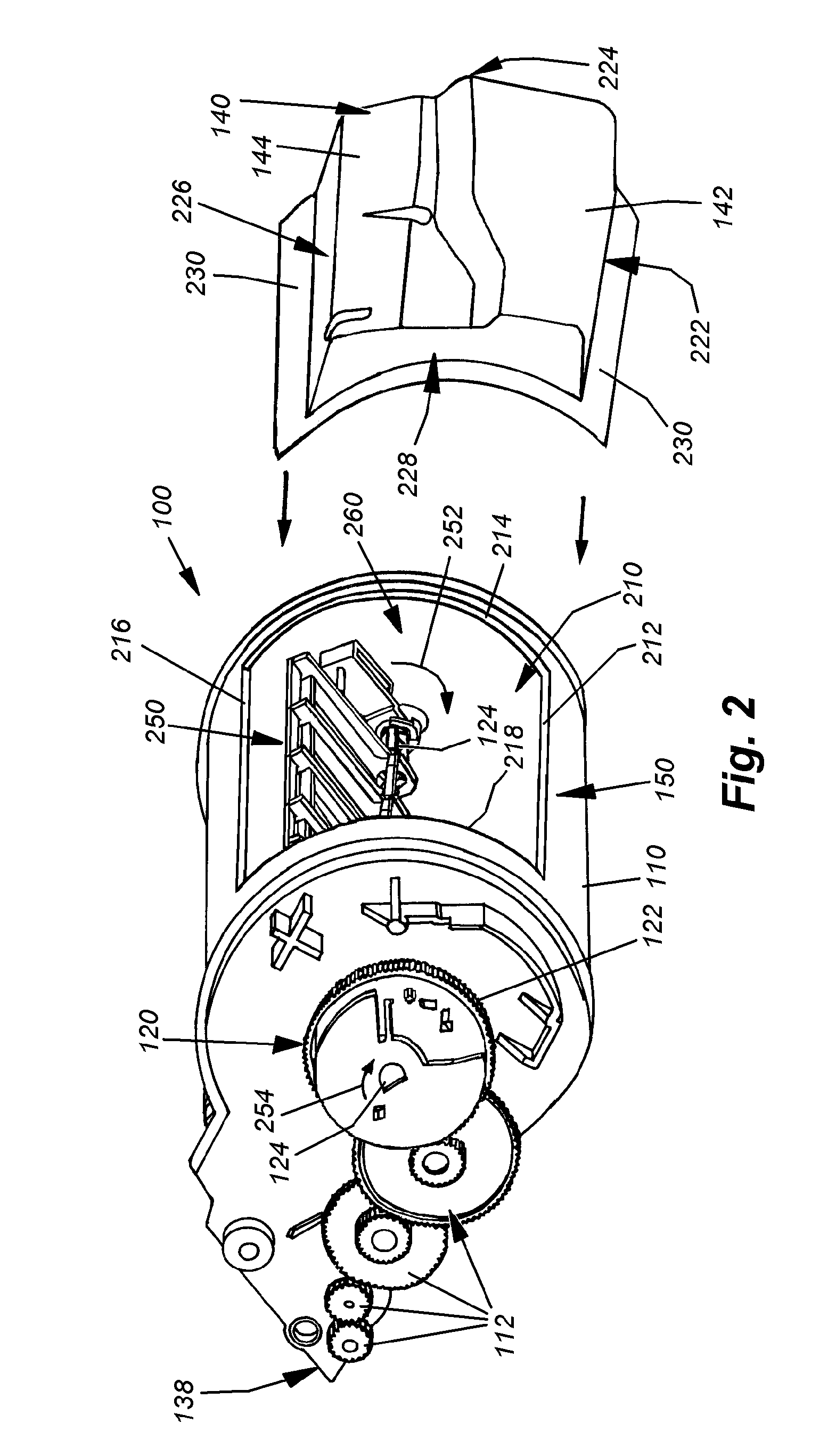

High-capacity toner cartridge and toner agitator

InactiveUS20080145112A1Increase capacityReduce loadElectrographic process apparatusEngineeringMechanical engineering

This invention provides an agitator blade and toner cartridge employing such an agitator blade that enables a higher capacity of toner while lowering the load exerted by the print engine motor as toner is agitated. This blade and cartridge also allows for greater efficiency at low toner levels as the blade is brought closer to the inner wall of the cartridge toner tank. The blade consists of an axially directed axle shaft having a plurality of rigid, radially directed ribs that extend to a location proximate to the inner wall of the tank. A plurality of cross bar members are mounted between each pair of ribs. Each cross bar includes axially extended, rib-engaging wings. The wings are mounted so that the cross bars are generally prevented from passing between the ribs when the cross bars are driven by the ribs in the normal direction of agitator rotation. However, the wings are sufficiently resilient so that a predetermined level of toner resistance at high fill levels causes the wings and cross bars to elastically deform and pass through the ribs, leaving only the thinner ribs to traverse the toner in that cycle. The toner cartridge can include a volume extension member that is sized to fit within the empty space of a corresponding print engine. The cartridge can also include a compound angle doctor blade for better toner distribution.

Owner:TURBON AMERICA

Angle-adjustable engineering geological drilling machine

InactiveCN112065273AOptimize heat dissipation structureSpeed up heat dissipationEarth drilling toolsDrilling rodsEnvironmental geologyStructural engineering

The invention provides an angle-adjustable engineering geological drilling machine, and relates to the technical field of geological exploration. The angle-adjustable engineering geological drilling machine comprises a supporting mechanism, wherein a connecting seat for supporting a rotating mechanism is mounted on the supporting mechanism; a shell for protecting the rotating mechanism is mountedat the bottom of the supporting mechanism; four universal wheels convenient to move are mounted at the bottom of the supporting mechanism; a connecting mechanism which is rotatably connected is mounted on the supporting mechanism; and a rectangular limiting groove is formed in the middle of the connecting mechanism. A worm gear A is arranged at the bottom of a base, a rotating shaft B of a worm gear is fixedly connected with a connecting plate, when the worm gear rotates, the connecting plate can be driven to rotate, thus, the rotating shaft B drives the connecting plate to rotate to adjust the circumferential rotating angle of a drilling mechanism, and the drilling mechanism can conveniently sample different positions; and a worm gear B is arranged on one side of a connecting rod of a polished rod, thus, the connecting rod rotates to drive the polished rod to swing, and the swinging angle of the drilling mechanism is adjusted.

Owner:戴兴

Stirring device for building decoration paint

PendingCN111068567AAvoid problemsFully scrape and drainRotary stirring mixersTransportation and packagingMechanical engineeringIndustrial engineering

The invention discloses a stirring device for building decoration paint, which belongs to the technical field of paint stirring devices. The paint is fully mixed for a long time when the building decoration paint is mixed, the problem that large-particle paint cannot mixed with large particles exists; according to the technical key points, the stirring device comprises a stirring barrel, a stirring mechanism, a grinding mechanism, a scraping assembly and an extrusion mechanism from top to bottom, the stirring mechanism is connected with the grinding mechanism, the scraping assembly and the extrusion mechanism are sequentially installed in the stirring barrel, the stirring mechanism is connected with a transmission mechanism, and the transmission mechanism is connected with a driving mechanism; the interior of the stirring barrel is divided into an upper part and a lower part by the grinding mechanism, large-particle or undissolved paint is avoided after the upper part of paint is stirred and ground by the grinding mechanism, the lower part of the paint can be fully scraped and discharged after being mixed, and convenience and quickness are achieved.

Owner:季红专

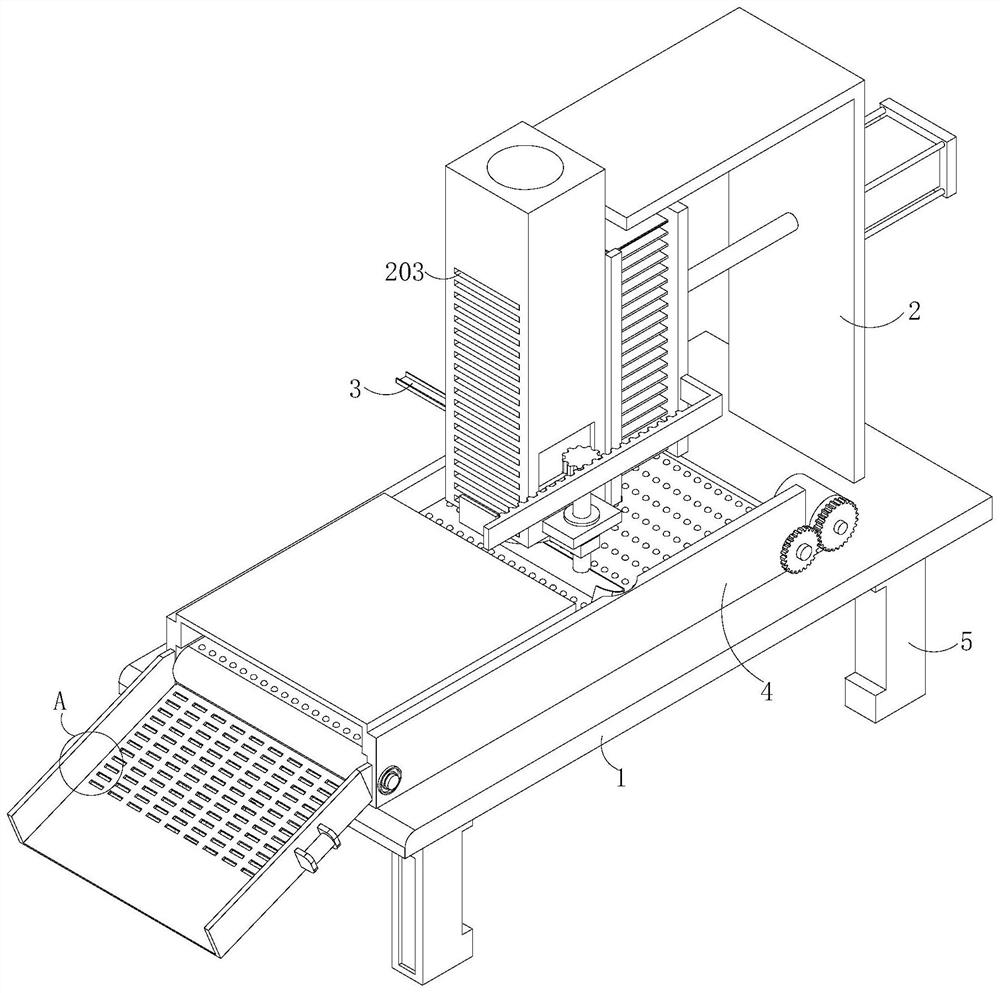

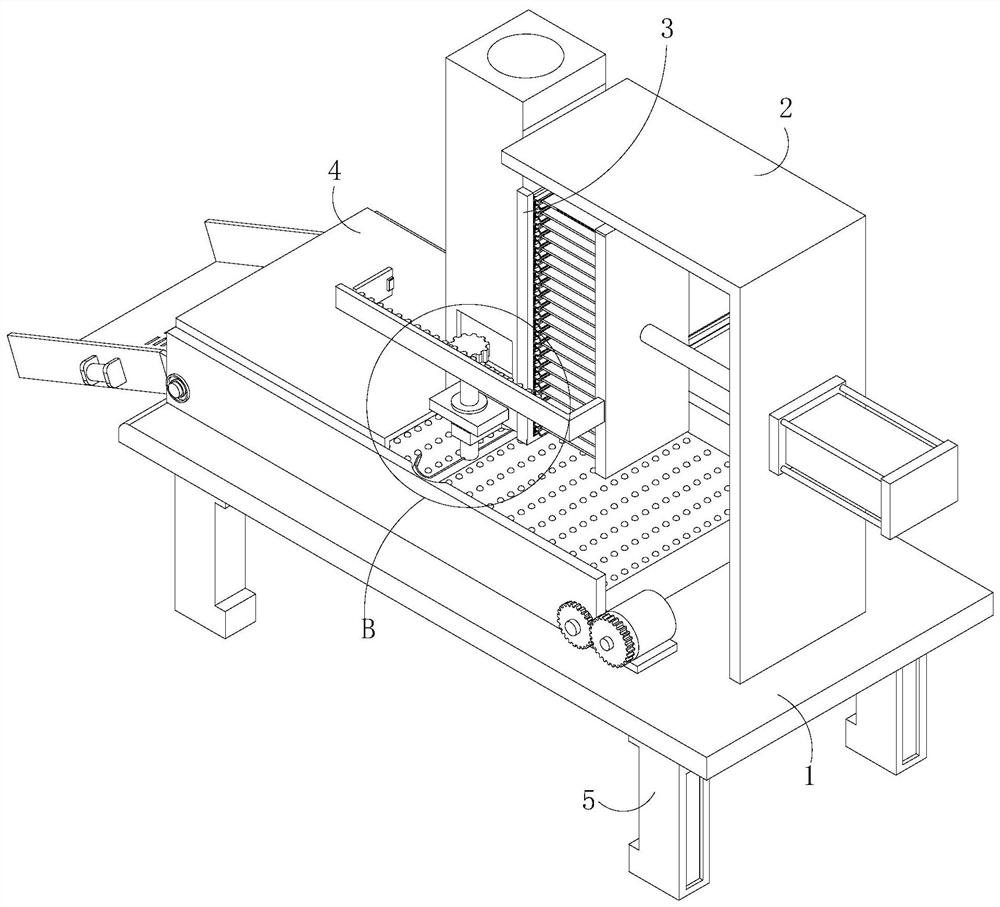

Slicing device for angelica sinensis processing

ActiveCN113370278AImprove product qualityEasy for slicing workSievingScreeningAngelica Sinensis RootKnife blades

The invention provides a slicing device for angelica sinensis processing, and relates to the field of traditional Chinese medicinal material processing. The slicing device for angelica sinensis processing comprises a carrying table, a slicing mechanism, a cleaning mechanism, a material guiding mechanism and supporting legs; the bottom of the right end of the slicing mechanism is fixedly connected with the top face of the right end of the carrying table; the left end of the cleaning mechanism is fixedly connected with the right side face of the left end of the slicing mechanism; the bottom of the material guiding mechanism is fixedly connected with the top face of the left end of the carrying table; and the top ends of the supporting legs are connected with the four corners of the bottom face of the carrying table respectively. According to the slicing device for angelica sinensis processing, through an arranged cleaning piece, firstly, the shape of the cleaning piece can prevent a blade from damaging the cleaning piece; then, cutter teeth on the cleaning piece can prevent sliced angelica sinensis pieces from adhering to the surface of the cleaning piece; impurities on the blade can be effectively scraped, and juice in angelica sinensis is prevented from adhering to the surface of the blade; and therefore, the service life of the blade is prolonged to a great extent.

Owner:JILIN AODONG SHIHANG PHARMA

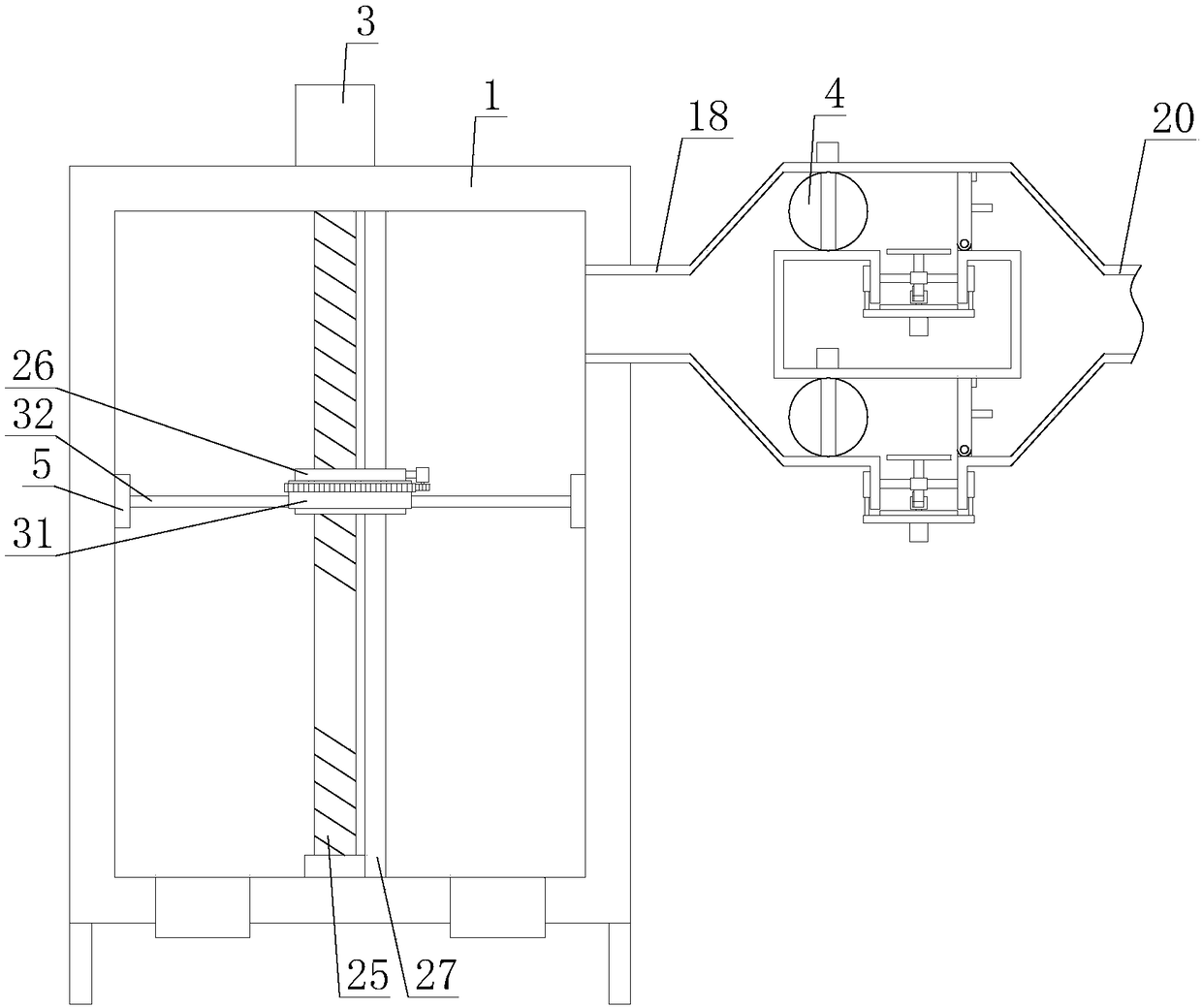

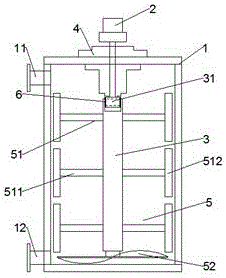

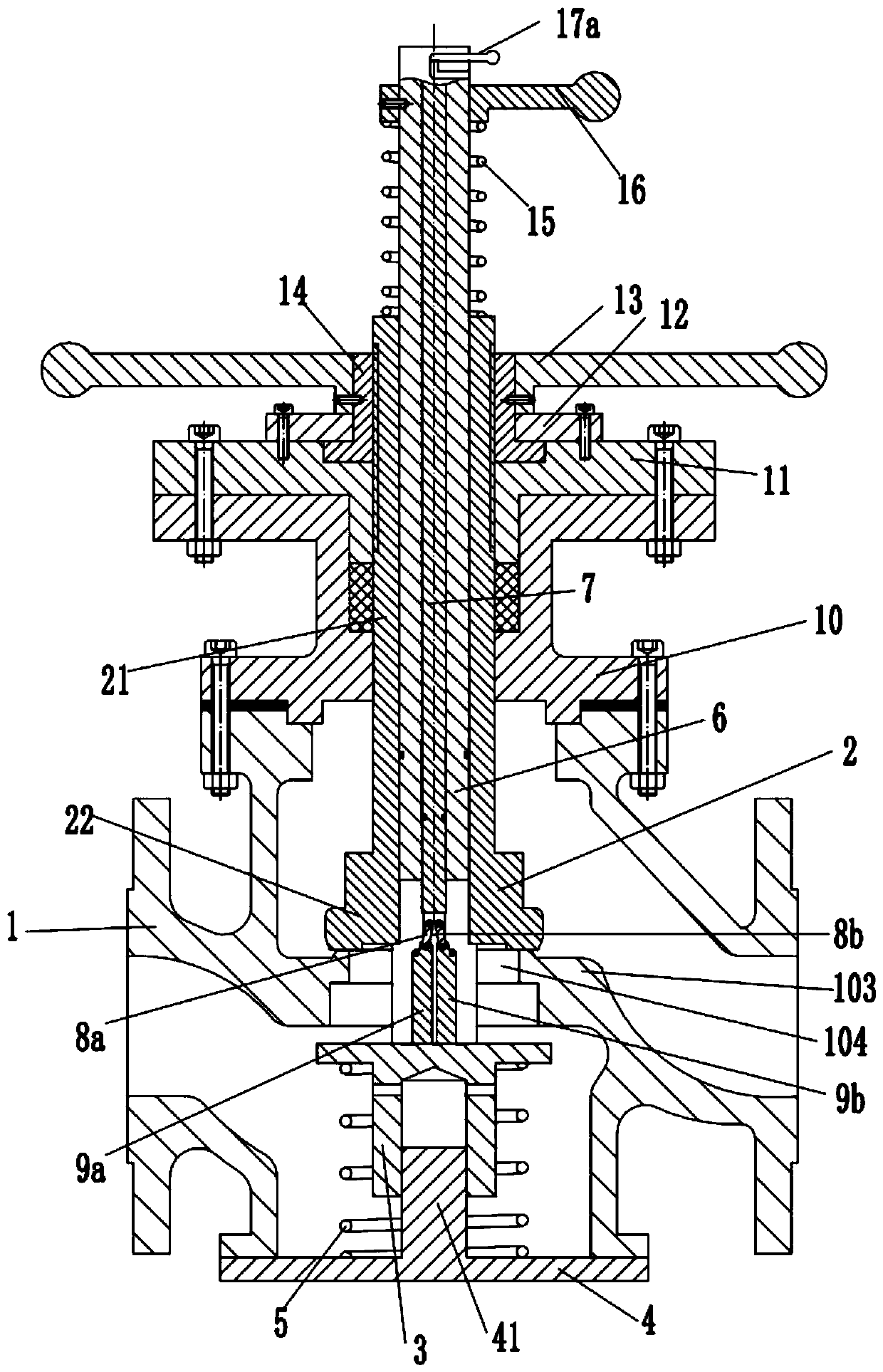

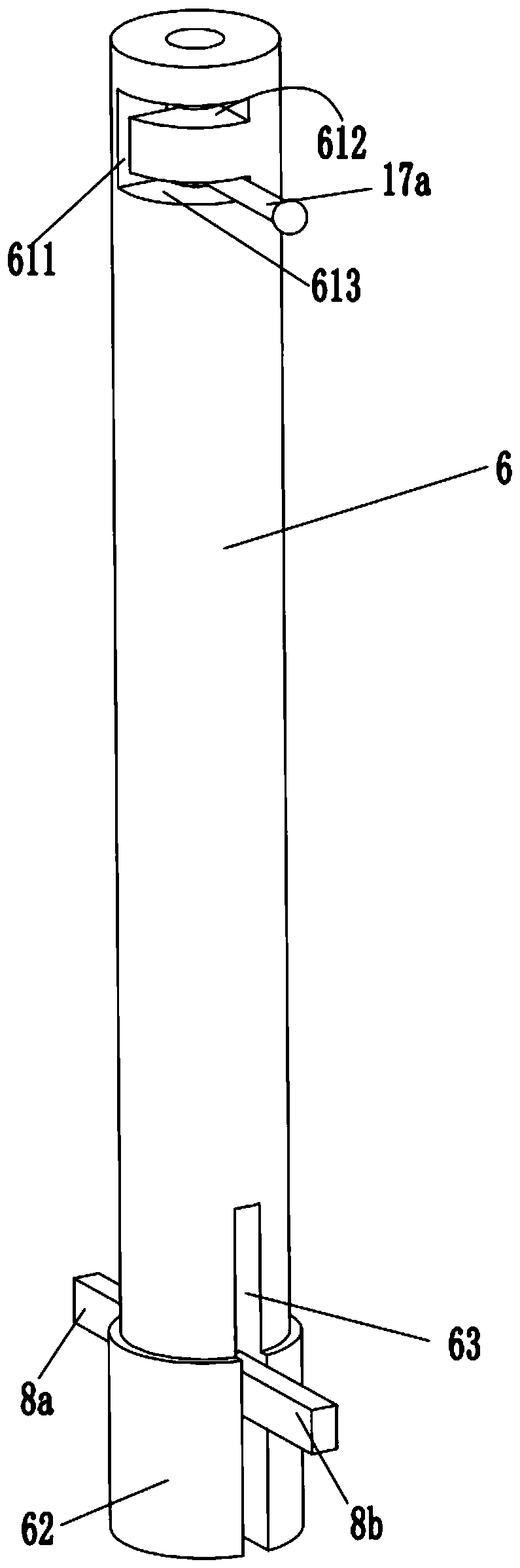

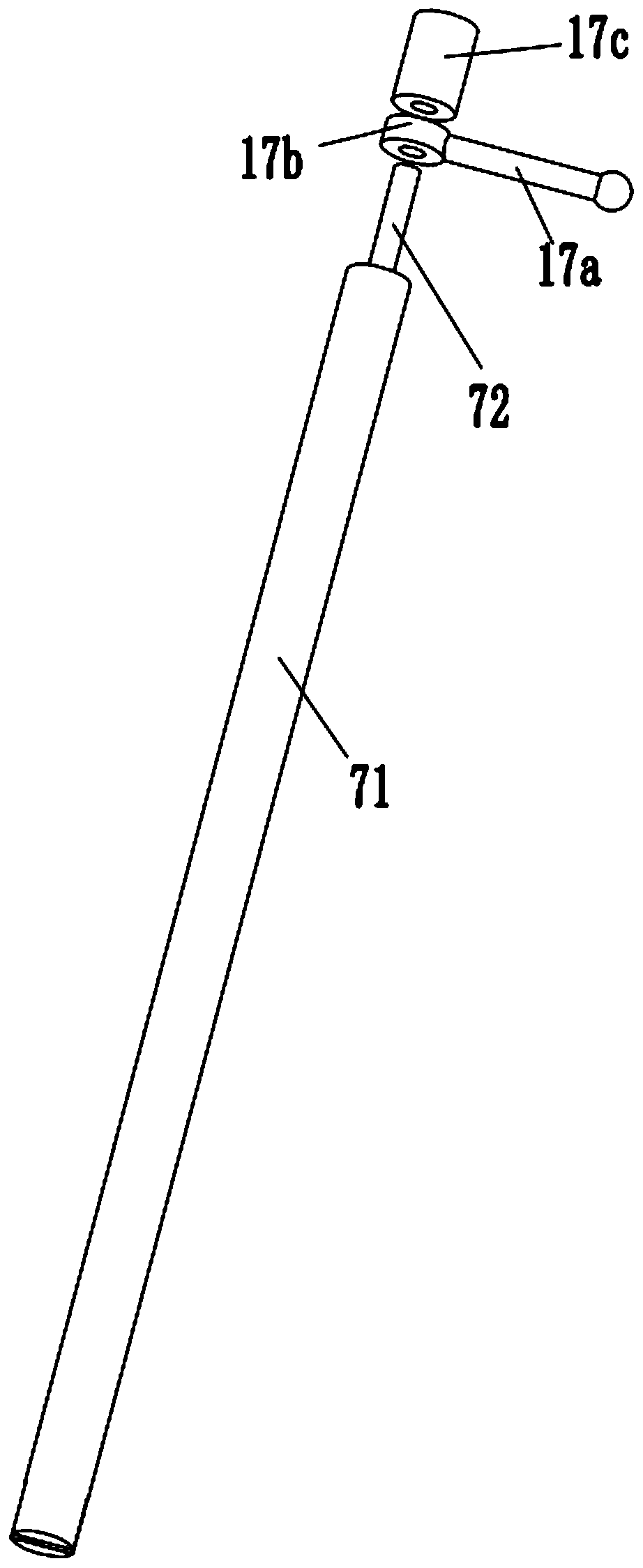

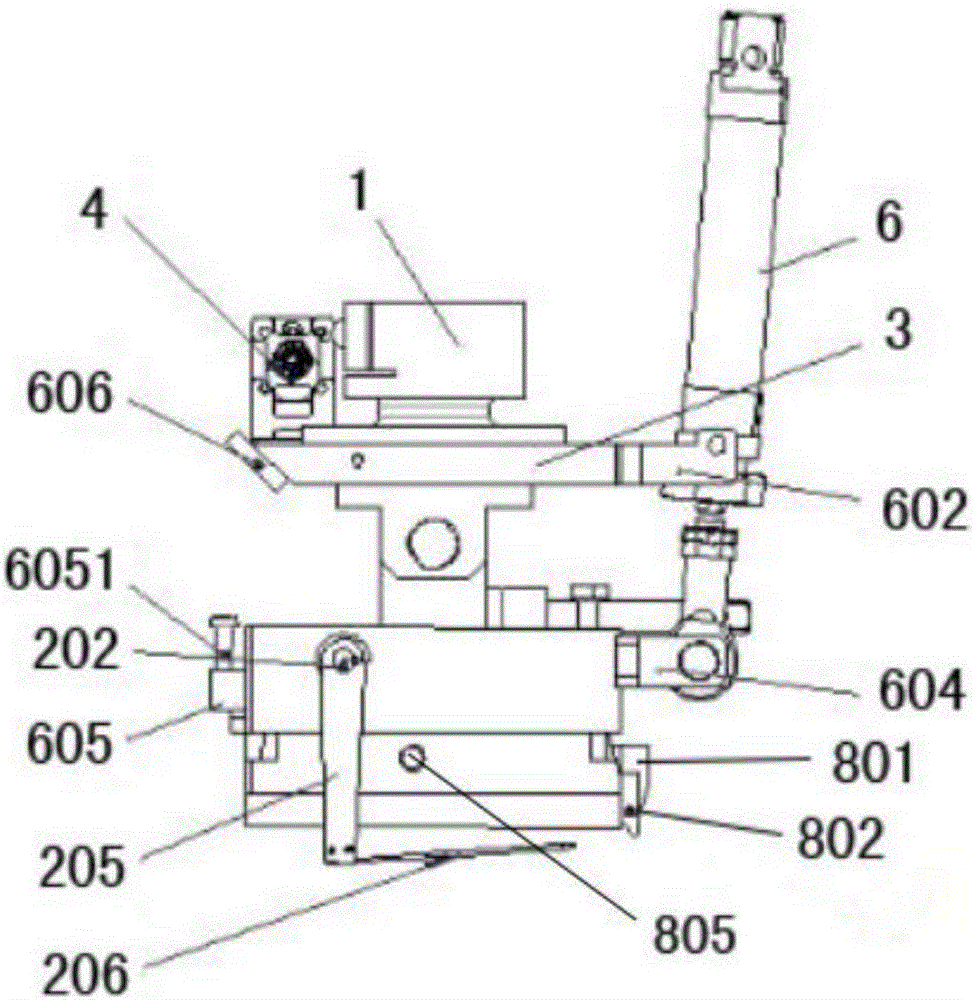

Novel stirring kettle with stirring shaft capable of being conveniently replaced

InactiveCN106422874ASimple structureSolve needsRotary stirring mixersTransportation and packagingPistonConvection

The invention provides a novel stirring kettle with a stirring shaft capable of being conveniently replaced. The novel stirring kettle comprises a stirring kettle body, wherein the stirring shaft is arranged in the center of the stirring kettle body; the top end is tightly clamped by a clamping device; in addition, a stirring paddle is arranged on the stirring shaft; the clamping device comprises a clamp head, a bearing, a push sleeve, a guide rod, a locking plate, an air cylinder and a piston; the clamp head comprises a clamping part formed by a rotating rod and two clamp heads; each clamping head is a circular arc plate with the semicircular cross section; the outer side of the end part connected with the rotating rod is a conical surface; a through hole matched with the rotating rod is formed in the push sleeve; inner cone holes matched with the outer conical surfaces of the clamping heads are formed in the locking plate; the rotating rod is connected into the through hole of the push sleeve in a penetrating way; the clamping part is arranged in the inner cone hole of the locking plate; the guide rod is arranged on the push sleeve. The novel stirring kettle has the advantages that the problem of high replacing difficulty of the stirring shaft is solved; the problem that whether the stirring shaft and a motor are concentric or not does not need to be considered; the stirring paddle realizes the vertical convection of the materials; the materials attached onto the inner wall of the stirring kettle can be effectively stirred and scraped; the stirring efficiency is improved.

Owner:南京途酷信息科技有限公司

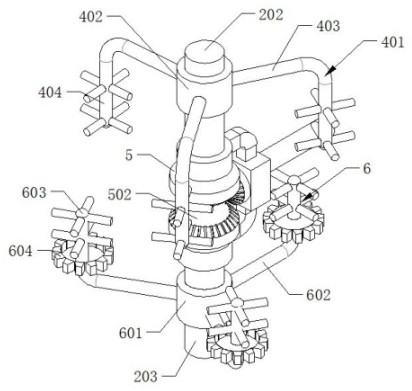

Dehydration device of efficient deep cone thickener

InactiveCN111620421AEasy to handleIncrease the degree of agitation and mixingSedimentation separationWater/sewage treatment by flocculation/precipitationPulp treatmentEngineering

The invention provides a dehydration device of an efficient deep cone thickener. The dehydration device comprises a tank body and a driving mechanism; the top wall of the tank body is connected with abridge frame; the driving mechanism is connected to the top wall of the bridge frame; the bottom wall of the bridge frame is connected with a flow stabilizing barrel; a barrel body is connected intothe flow stabilizing barrel; a stirring device is connected inside the barrel body; the stirring device comprises a first stirring mechanism and a second stirring mechanism; the first stirring mechanism is connected to the outer wall of the output end of the driving mechanism through a first connecting sleeve; the outer wall of the output end of the driving mechanism is also connected with a reverse transmission mechanism; the output end of the reverse transmission mechanism is connected with a second rotating shaft, the second stirring mechanism is connected to the outer wall of the second rotating shaft through a second connecting sleeve, an ore pulp feeding pipe and a flocculating agent feeding pipe are arranged on the outer wall of the tank body, and the ore pulp feeding pipe and the flocculating agent feeding pipe penetrate through the tank body and the flow stabilizing barrel and are communicated with the barrel body. The dehydration device is simple in structure and convenient to use, the mixing degree of ore pulp and a flocculating agent can be effectively increased, and the ore pulp treatment effect is improved.

Owner:HUAIBEI KUANGHUAN WASHES EQUIP

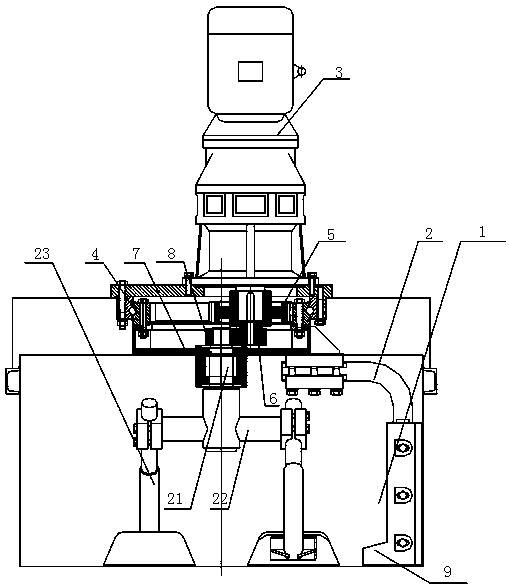

Vertical shaft stirrer

ActiveCN103624877AEfficient scrapingAdequate exerciseCement mixing apparatusSlewing bearingMechanical engineering

Owner:四川宏劲机械有限公司

Scraping plate mechanism for filter

InactiveCN103316528ASimple structureLow priceMoving filtering element filtersMechanical engineeringEngineering

The invention discloses a scraping plate mechanism for a filter. The scraping plate mechanism comprises an installation support, a scraping plate frame rotationally installed on the installation support, a scraping plate fixed on the scraping plate frame, and a gravity pressure-applying device fixedly connected with the installation support, and enables the scraping plate frame to rotate under the action of gravity so as to apply a pressure on the filter cloth of the filter. According to the scraping plate mechanism disclosed by the invention, the scraping plate is acted by the gravity pressure-applying device, so as to scrap the filter cloth; according to the scraping plate mechanism, the structure is simple, the price is low, the scraping effect on the filter cloth is good, and damage is slight.

Owner:HUZHOU HEHONG MACHINERY

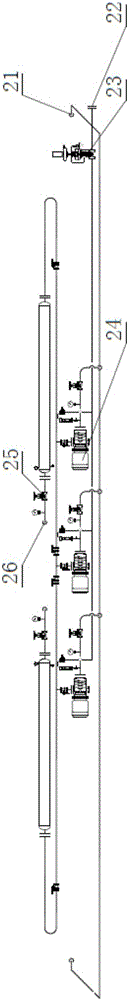

Cleaning device and method for chemical grouting pipeline

ActiveCN111530856AChange the expansion rangeAffectHollow article cleaningChemical groutingElectric machinery

The invention discloses a cleaning device and method for a chemical grouting pipeline. The cleaning device comprises a barrel body, traveling mechanisms are circumferentially distributed on the outerwall of the barrel body, a main pipe penetrates through one side of the barrel body, the main pipe is connected with a liquid separating disc, a central pipe and a liquid separating pipe are respectively arranged on the liquid separating disc, a liquid spraying pipe is arranged on the liquid separating pipe, the liquid spraying pipe penetrates out of the barrel body, spray heads are circumferentially distributed at one end of the liquid spraying pipe, and a fixed disc is arranged at one end of the central pipe. The fixed disc is positioned outside the barrel body, the fixed disc is provided with a driving motor, the output end of the driving motor is connected with a driving seat, and scraper assemblies are circumferentially distributed on the driving seat. The cleaning method comprises the following steps of (a) pipe feeding adjustment, (b) initial scraping, (c) primary cleaning and (d) fine cleaning. The cleaning device is novel in structure, high in cleaning efficiency, large in cleaning range, good in effect and convenient and fast to use, the cleaning method is sectioned in order and complemented with each other, the cleaning effect is improved, cleaning is comprehensive and thorough, and dirt is effectively removed.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

Stop valve

ActiveCN110332317AEfficient scrapingEffectively scrape off adhesionOperating means/releasing devices for valvesCleaning using toolsVALVE PORTValve seat

The invention relates to a stop valve. The stop valve comprises a valve body, a valve cover, a valve clack, a valve rod, a pull rod, a left connecting rod, a right connecting rod, a left scraper, a right scraper, a lifting component, a first handle, a first spring, a blocking component and an adjusting component, wherein the valve body is internally provided with an inlet flow channel, an outlet flow channel and a valve seat; the valve seat is provided with a throughflow hole and a stopping hole; and the valve cover is fixedly arranged at the upper end of the valve body. The stop valve disclosed by the invention is simple and reasonable in structure and has the advantages of good sealing property and long service life; and by use of the stop valve, mediums attached to the valve clack and the valve seat can be effectively scraped, and the sealing property of the valve clack during closing is improved; and the service life of the valve clack during closing is prolonged.

Owner:凯瑞特阀业集团有限公司

Automatic scraping plate type air bubble removing mechanism

ActiveCN106450480ASimple structureEfficient scrapingAdhesive processesFinal product manufactureAdhesivePulp and paper industry

The invention discloses an automatic scraping plate type air bubble removing mechanism. The automatic scraping plate type air bubble removing mechanism comprises a double-sided adhesive sticking assembly and an air bubble removing assembly, wherein the double-sided adhesive sticking assembly comprises an adhesive sticking main plate; a lower end face of the adhesive sticking main plate is connected with a vacuum suction disc main plate; a vacuum suction disc is arranged on the lower end face of the vacuum suction disc main plate; the air bubble removing assembly comprises a floating pressing plate which is connected with the vacuum suction disc main plate through a rotary shaft and a scraping plate which is fixed below the floating pressing plate; and a front end of the scraping plate stretches out of the lower end face of the vacuum suction disc. The automatic scraping plate type air bubble removing mechanism is simple in structure; the air bubble removing assembly can be used for effectively scraping air bubbles generated in a double-sided adhesive sticking process; and the automatic scraping plate type air bubble removing mechanism can be finely adjusted according to actual requirements and has high applicability.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

Rotary dropwise adding and mixing device for phosphorous acid ingredient production

InactiveCN113680246AReduce use costLow costRotary stirring mixersMixer accessoriesPhosphorous acidEngineering

The invention provides a rotary dropwise adding and mixing device for phosphorous acid ingredient production, and relates to the field of mixing devices. The invention aims to solve the problems that when an existing phosphorous acid raw material mixing device is used, raw materials need to be slowly added during raw material adding due to the characteristics of phosphorous acid, the inner wall of a container cannot be cleaned in an auxiliary mode during adding, and adhered raw materials cannot be cleaned. The device provided by the invention comprises a round pipe and auxiliary parts which are arranged in the middle of the interior of a rotating disc, wherein the auxiliary parts are annularly arranged, and the auxiliary parts are installed at the bottom of the rotating disc through connecting blocks. Each auxiliary part comprises a scraping plate, wherein the scraping plate is fixed to the outer end of an outer rod, and the outer side of the scraping plate makes contact with the inner wall of a main body; meanwhile, when the auxiliary part rotates along with the rotating disc, the scraping plate can be driven to rotate together, the outer side of the scraping plate makes contact with the inner wall of the main body, and the scraping plate can effectively scrape the inner wall of the main body; and thus, raw material residues are reduced, and the situation that raw materials adhere to the inner wall of the main body and cannot be cleaned is avoided.

Owner:南通汇顺化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com