Automatic scraping plate type air bubble removing mechanism

A scraper-type, bubble technology, applied in electrical components, climate sustainability, batteries, etc., can solve problems such as breakage, wrinkles, bubbles, etc., to achieve the effect of simple structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

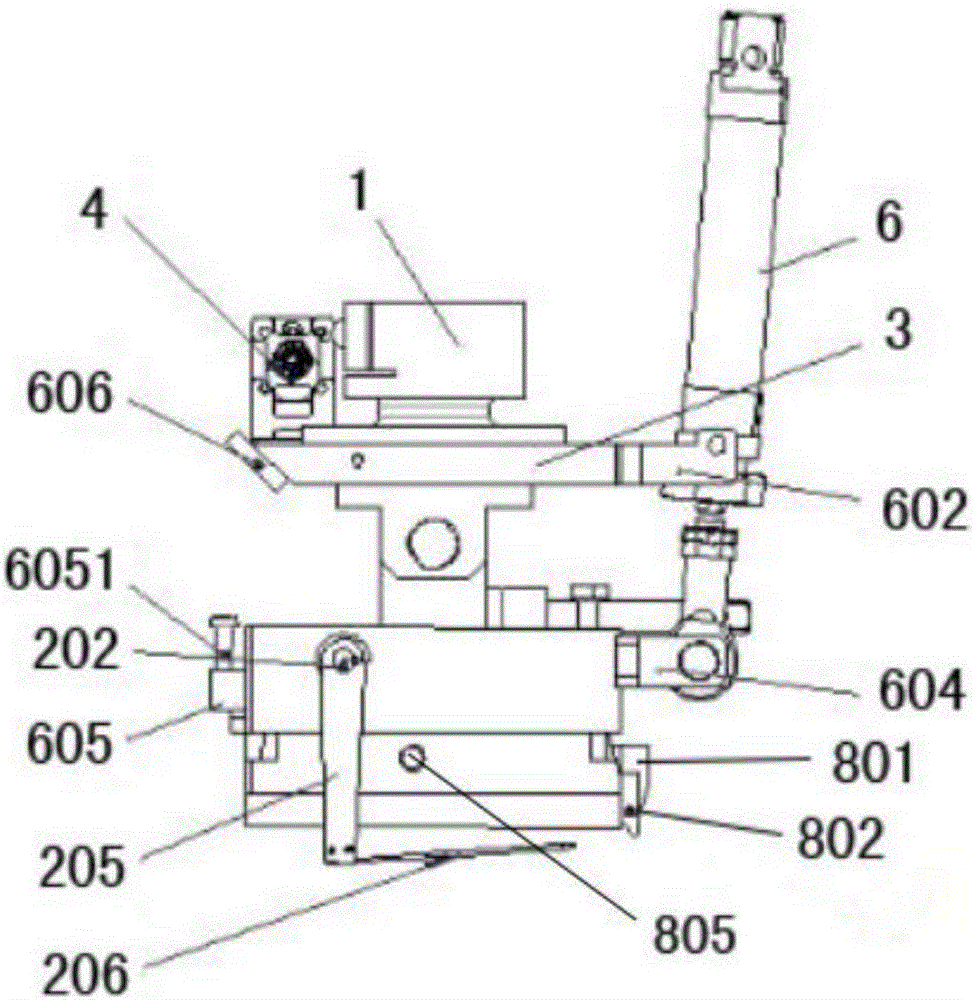

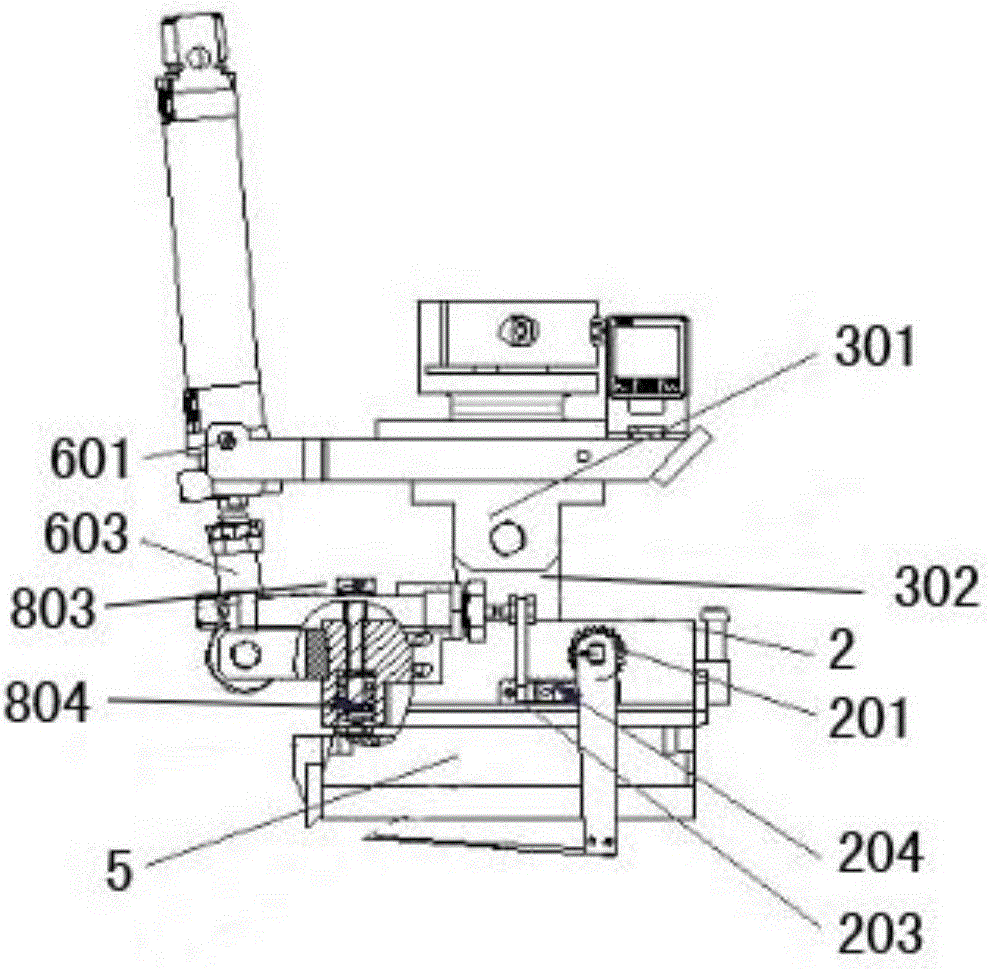

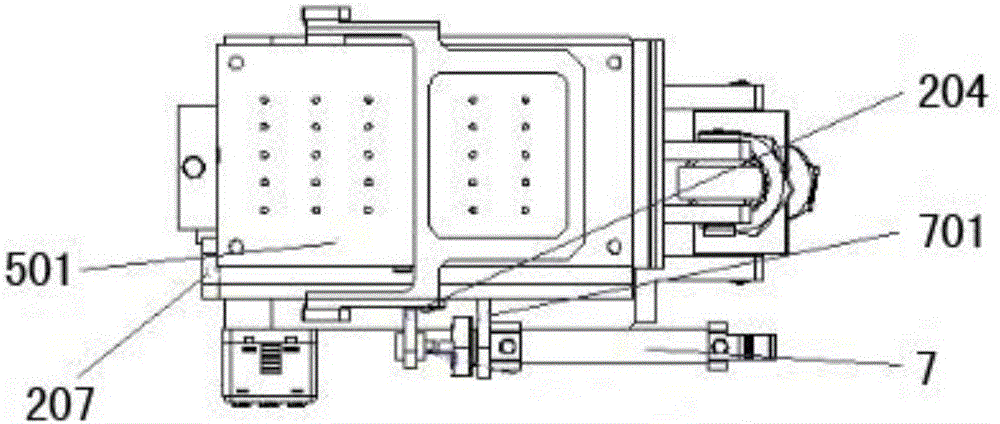

[0019] An automatic scraper type air bubble removal mechanism, comprising a double-sided adhesive assembly and an air bubble removal assembly, the double-sided adhesive assembly includes a glue main board 2, the lower end of the glue main board 2 is connected to a vacuum suction cup main board 5, the The lower end surface of the vacuum chuck main board 5 is provided with a vacuum chuck 501; the air bubble removal assembly includes a floating platen 801 connected to the vacuum chuck main board 5 through a rotating shaft 805 and a scraper 802 fixed below the floating platen 801. The front end of the plate 802 protrudes from the lower end surface of the vacuum chuck 501 .

[0020] The height of the floating platen 801 is adjusted by the limit bolt 803 and the adjustment spring 804 arranged above it, and then the length of the scraper 802 protruding from the lower end surface of the vacuum chuck 501 is adjusted.

[0021] The described double-sided adhesive assembly is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com