Cleaning tool and method of manufacturing cleaning part thereof

A technology for cleaning parts and utensils, applied in the field of cleaning utensils, can solve the problems of inconvenient use and insufficient ability to remove dirt, and achieve the effect of excellent erasing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

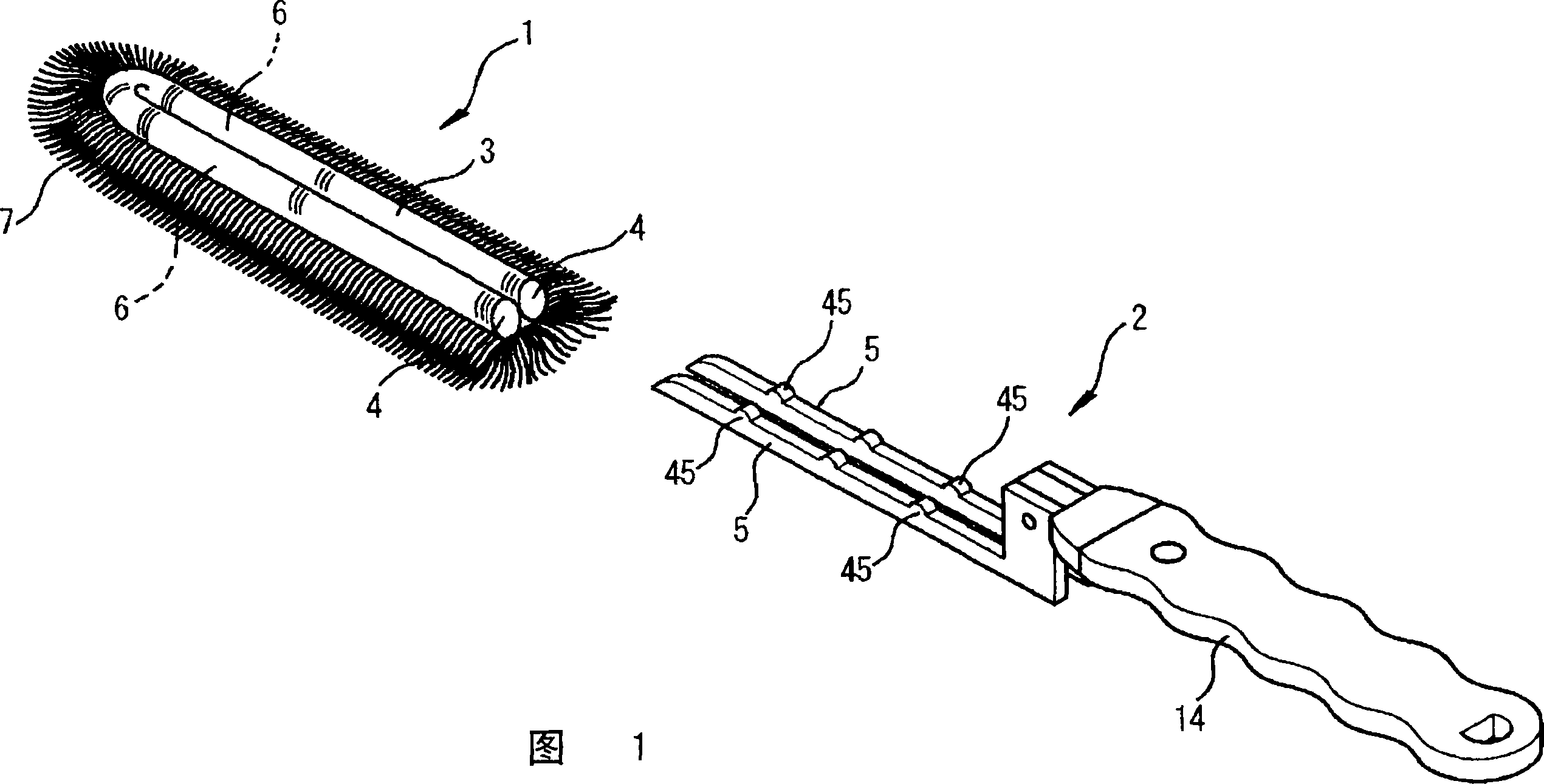

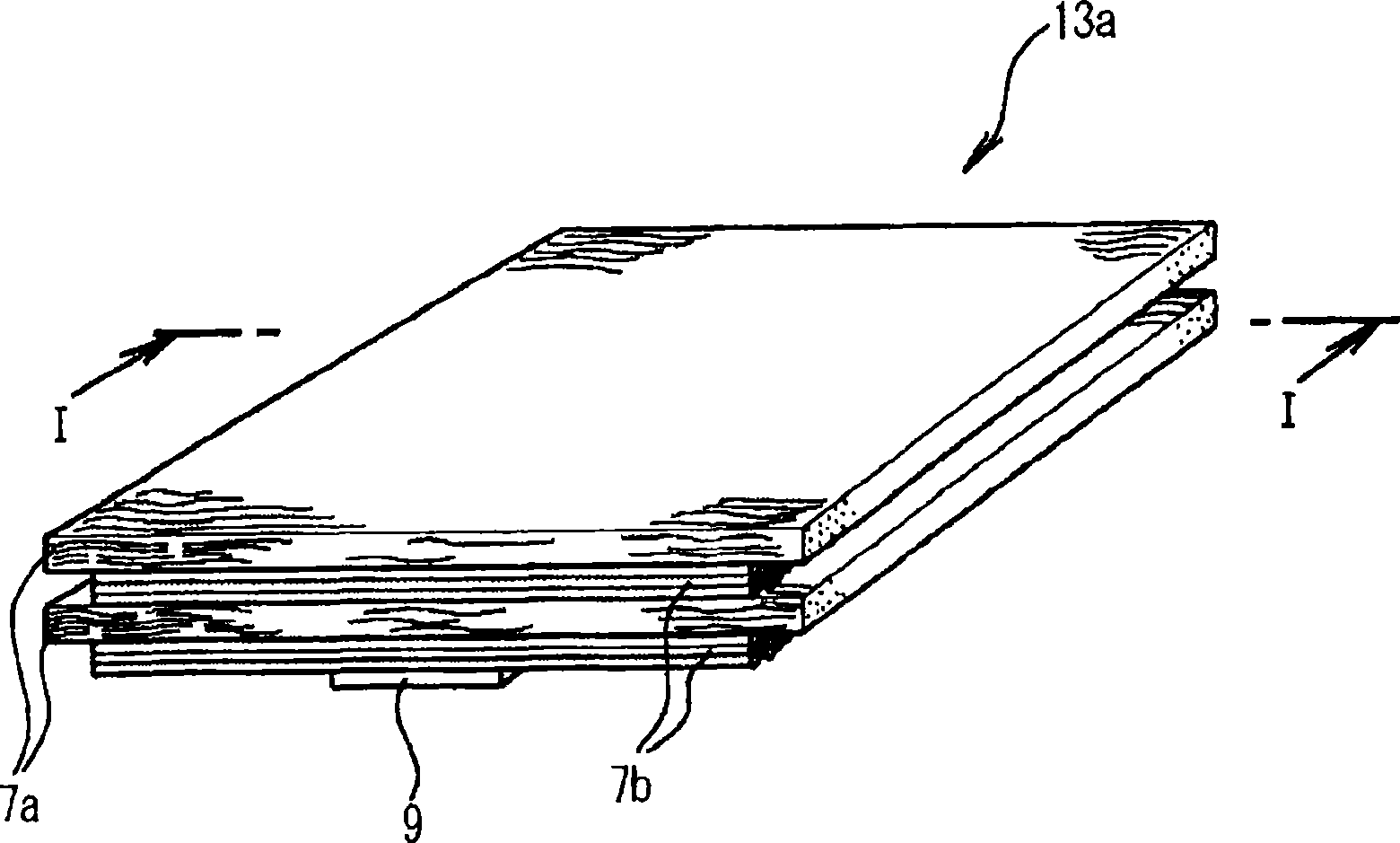

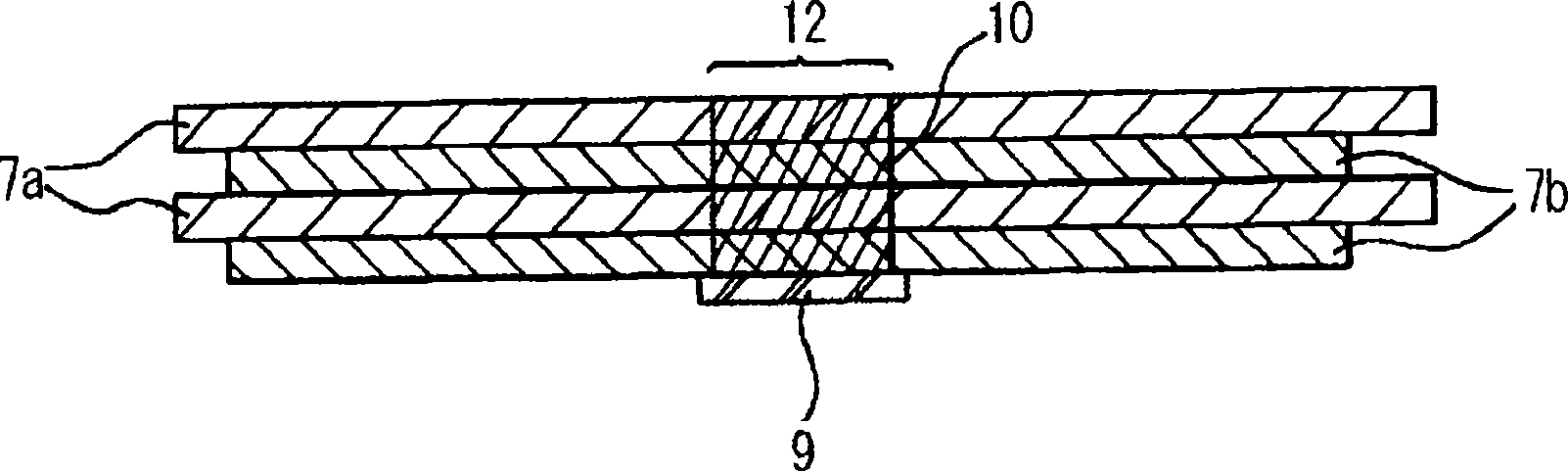

[0072] The cleaning tool of the present invention includes a cleaning part and a handle, and the cleaning part is formed integrally in the following manner: a bulky part forming part is formed by bending a stacked sheet body along a joint part, and the stacked sheet body The sheet-like fiber bundle and the sheet are bonded to form a junction, and the laminated sheet formed with the bulky portion forming portion is bent so that the bulky portion forming portion faces each other, and the facing sheet-like fiber bundles are mutually The abutting surface of the above-mentioned bulky part forming part is provided with a handle insertion opening opened at one end side of the bulky part forming part, and the support bar of the handle part is inserted into the handle inserting part formed inside the bulky part forming part.

[0073] As a sheet used for a cleaning part, paper, a synthetic resin sheet, a nonwoven fabric etc. are mentioned, Preferably it is a nonwoven fabric. As the non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com