Scraping plate mechanism for filter

A filter and scraper technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problems of filter belt damage, poor scraping effect of filter belt, etc., and achieve fast scraping and good scraping effect , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

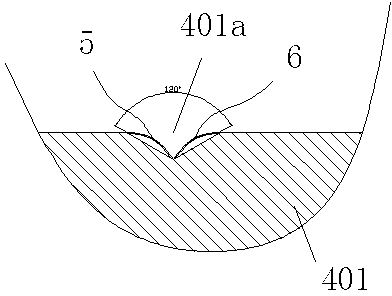

[0031] Embodiment 2, see attached image 3 The connecting rod 401 is axially fixed with a plurality of annular grooves 401a matched with the fastening screws 403, and the annular grooves 401a are inclined grooves gradually narrowing inward, which have a left side and a right side, The two sides of the left side and the right side form an angle of 120°, and the left side is provided with a left elastic piece 5, and the right side is provided with a right elastic piece 6, and the fastening screw 403 and the left elastic piece and the right elastic piece The pieces are in elastic contact, so that the gravity block 402 can move slightly elastically along the axial direction of the connecting rod 401, so that the force of the scraper on the filter belt is elastic, and a better scraping effect can be achieved.

Embodiment 3

[0032] Embodiment 3, see attached Figure 4 , in this embodiment, the gravity block 402 is not on the connecting rod 401 of the suit, but is screwed on the connecting rod 401, the connecting rod 401 is provided with external threads, and the gravity block 402 is provided with internal threads, and, on the connecting rod 401 is provided with fastening nuts 404 for fastening the gravity block 402 on the connecting rod 401 , two fastening nuts 404 are arranged on both sides of the gravity block 402 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com