Rotary dropwise adding and mixing device for phosphorous acid ingredient production

A mixing device and phosphorous acid technology, which is applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of unable to add, slowly add raw materials, and cannot assist in cleaning the inner wall of the container, so as to save labor and save The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

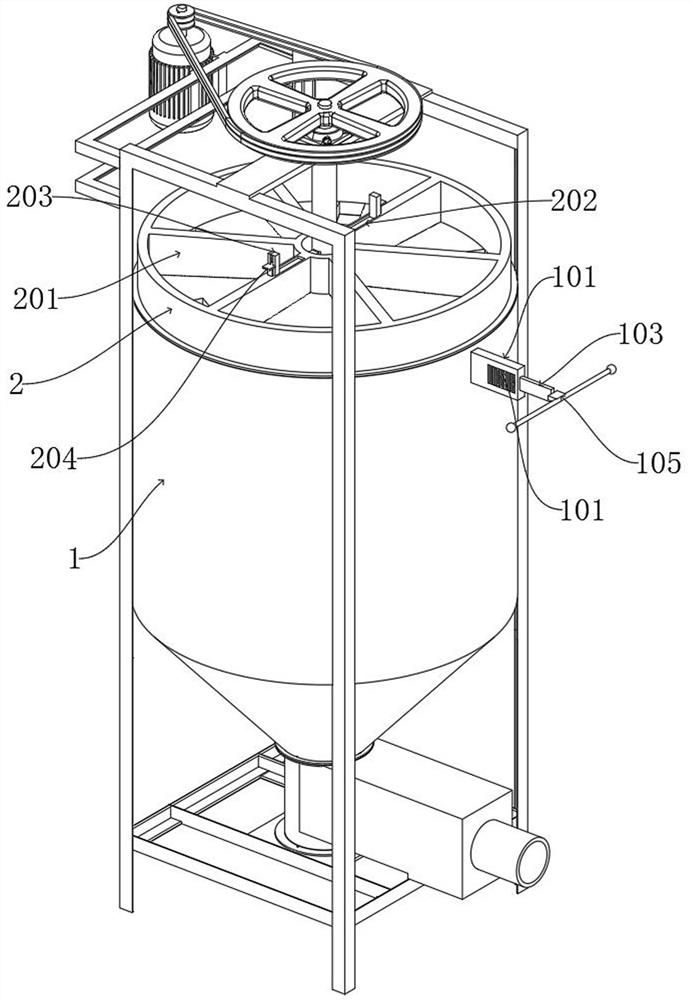

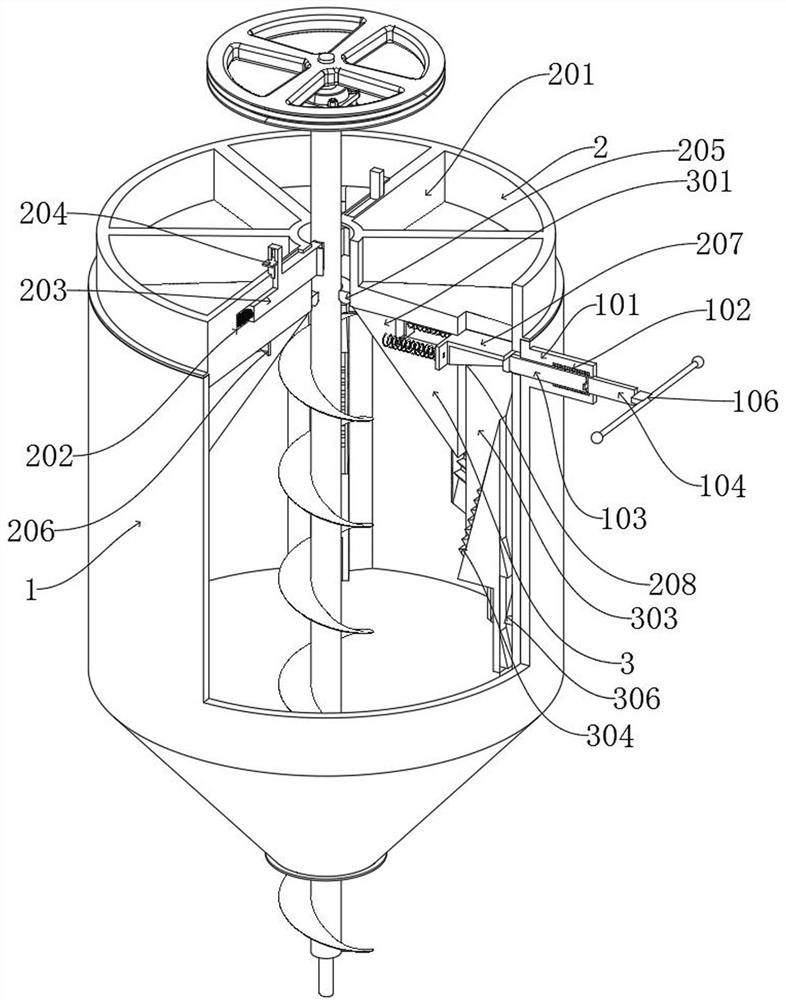

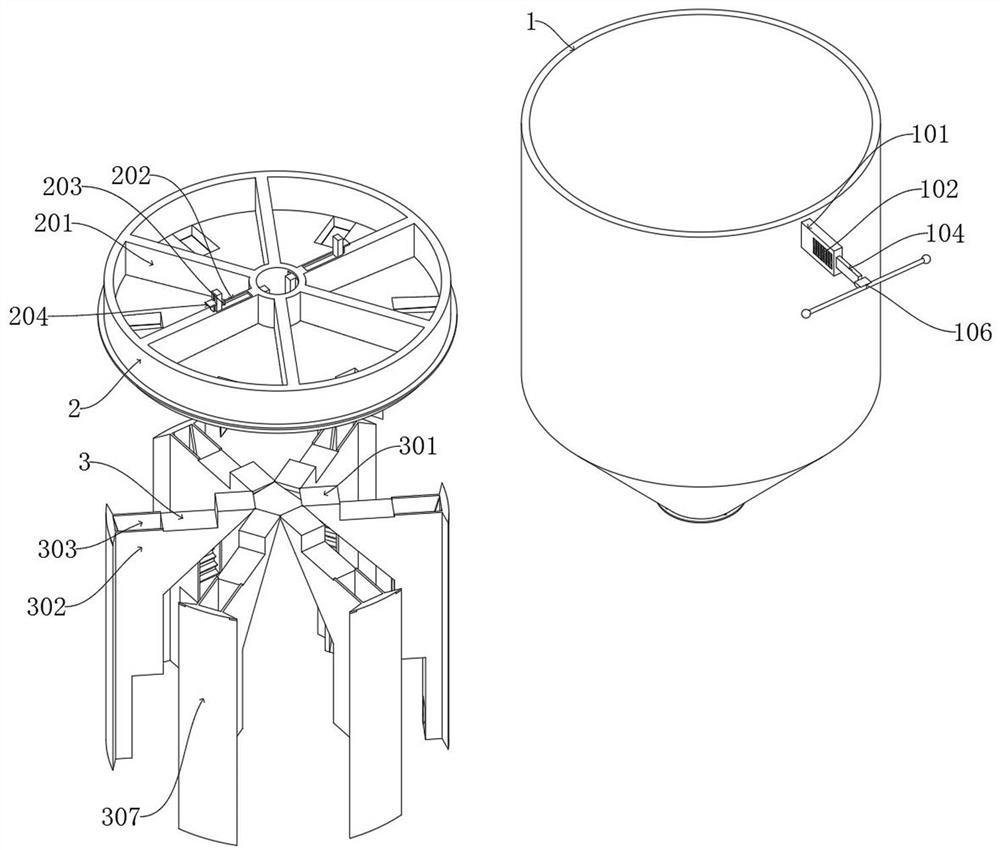

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028]The invention provides a rotary dripping and mixing device for the production of phosphorous acid ingredients, which includes a main body 1; the main body 1 is a mixing chamber, and the inside of the main body 1 is provided with a stirring rod, which is used to receive the power of the motor to rotate, so that the raw materials can be Stirred and mixed, the two sides of the top of the stirring rod are respectively provided with a rectangular groove, which is used to insert and install the inner end of the stopper 204, so that the fixing plate 203 can be connected with the stirring rod, and then rotate by force. The motor and the bracket, the top of the main body 1 is equipped with a rotating disk 2, the rotating disk 2 is a circular structure, and the inner middle of the rotating disk 2 is provided with a round tube, which is used to allow the top of the stirring rod to pass through, and the inside of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com