Patents

Literature

107results about How to "Slow down circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

ActiveCN103253819AReduce maintenance workloadExtend the life cycleMultistage water/sewage treatmentAlkali metal sulfites/sulfatesThermodynamicsDistillation

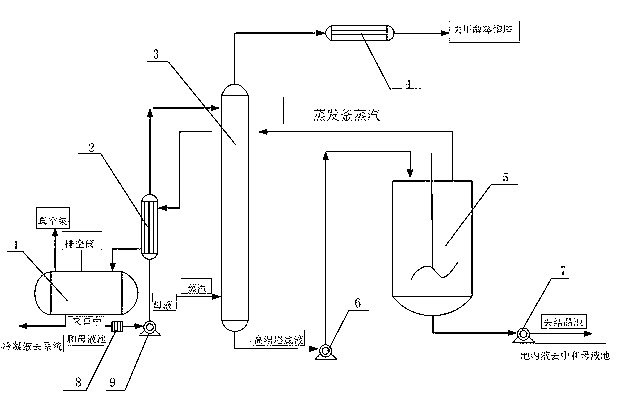

The invention discloses a device and a production technology for treating ternary-monomer wastewater and extracting sodium sulfate. The device comprises a plate-and-frame filter press, a mother liquid heat exchanger, a stripping tower and a condenser which are sequentially communicated through a pipeline, wherein the condenser is communicated with a methane distillation tower through the pipeline. The production technology comprises the following steps of: (1) pumping neutralized mother liquid into the plate-and-frame filter press, preheating the mother liquid through the mother liquid heat exchanger, and then pumping the mother liquid into the stripping tower from the top of the stripping tower; (2) pumping steam into the stripping tower from the bottom of the stripping tower, after methane in the mother liquid is brought out by the steam, condensing the steam through the condenser, then entering the methane distillation tower, and separating to obtain methane; (3) pumping liquid at the bottom of a high-temperature tower into an evaporation and concentration kettle to be concentrated, steaming out moisture, and using the steam generated by the evaporation and concentration kettle for heating the mother liquid heat exchanger; and (4) after concentrating a material in the evaporation and concentration kettle, placing the concentrated material in a crystallizing pond, and feeding the mother liquid, Na2SO4.10H2O in which is separated out in the crystallizing pond, into a mother liquid neutralization pond to be reused.

Owner:WEIFANG WORLD CHEM

Air purifying system

InactiveCN104197412AAchieve replacementAvoid Hazardous SituationsDucting arrangementsSpace heating and ventilation safety systemsSide effectAir pump

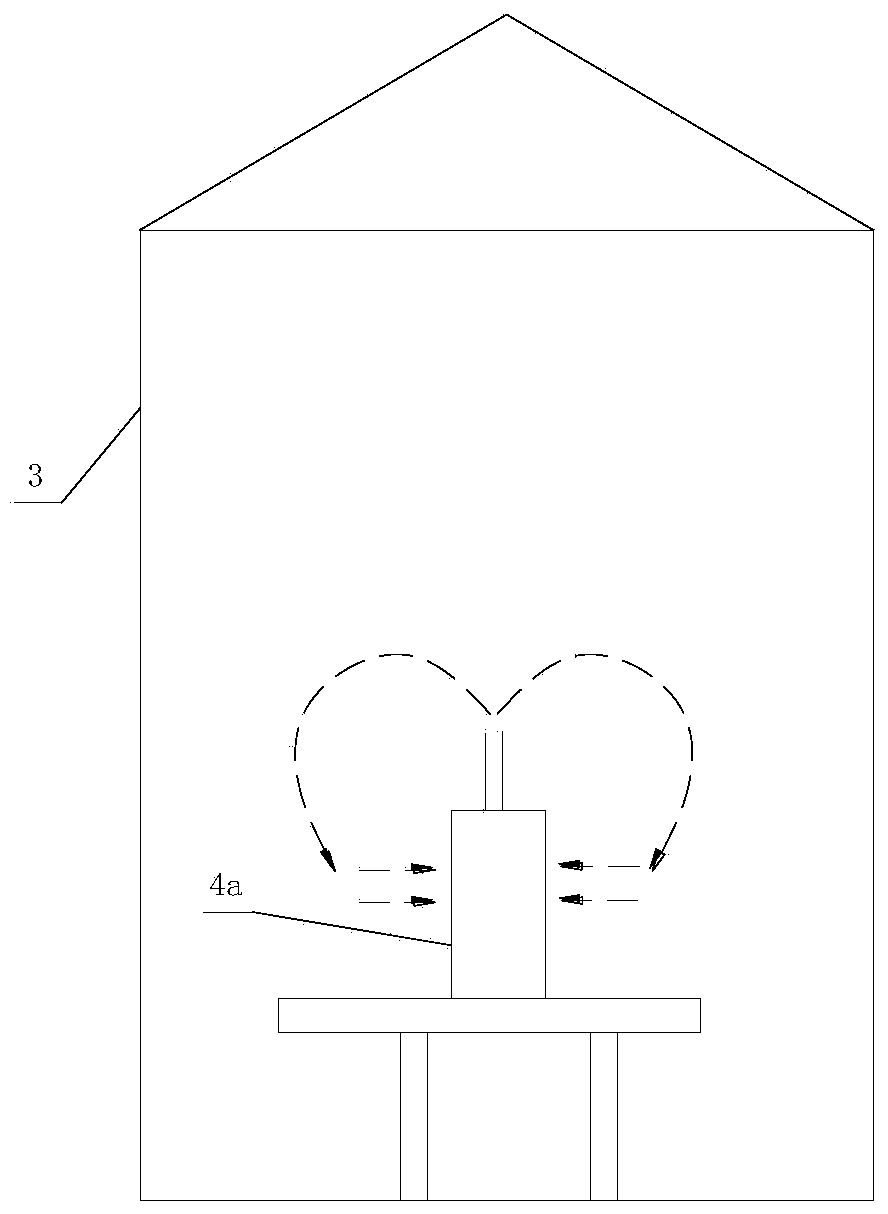

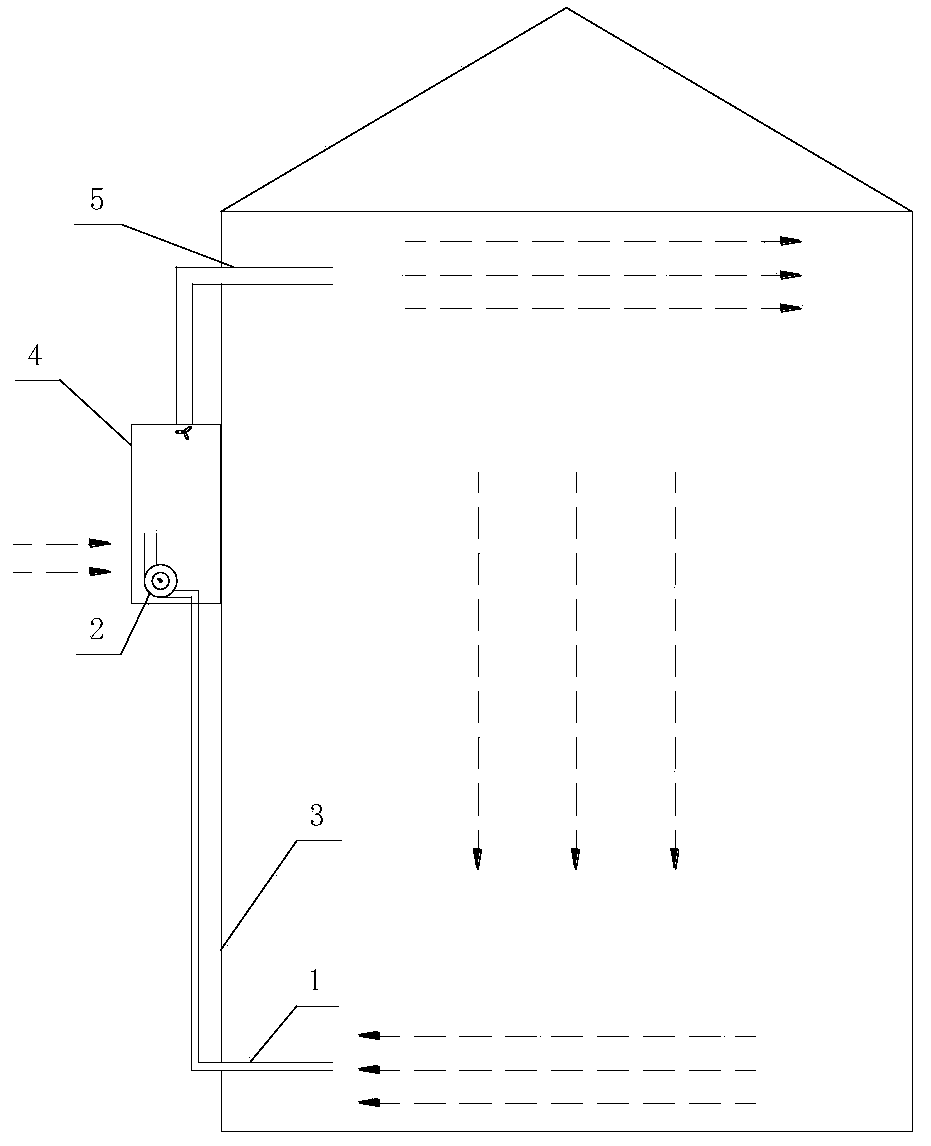

The invention relates to the technical field of air purifying and provides an air purifying system. The air purifying system overcomes the defects that an air purifying system in the prior art has the general defects of being poor in air purifying effect, high in side effect, low in intelligent degree, poor in use comfort of a user and the like. The air purifying system comprises an air purifier (4) fixedly arranged on the outer side of the wall of a room (3), an air supplying pipeline (5) communicated with an air outlet of the air purifier (4), an air pump (2) and an exhaust pipeline (1) communicated with an air sucking opening of the air pump (2). The air supplying pipeline (5) penetrates through and is fixed to the upper middle of the wall of the room (3), and the exhaust pipeline (1) penetrates through and is fixed to the lower portion of the wall of the room (3). Due to the structural layout arrangement of the air purifying system, all air in the room can be replaced within a short time when the air purifier and the air pump are started, and residual unpurified air cannot remain.

Owner:CHENGDU HANGHAO TECH

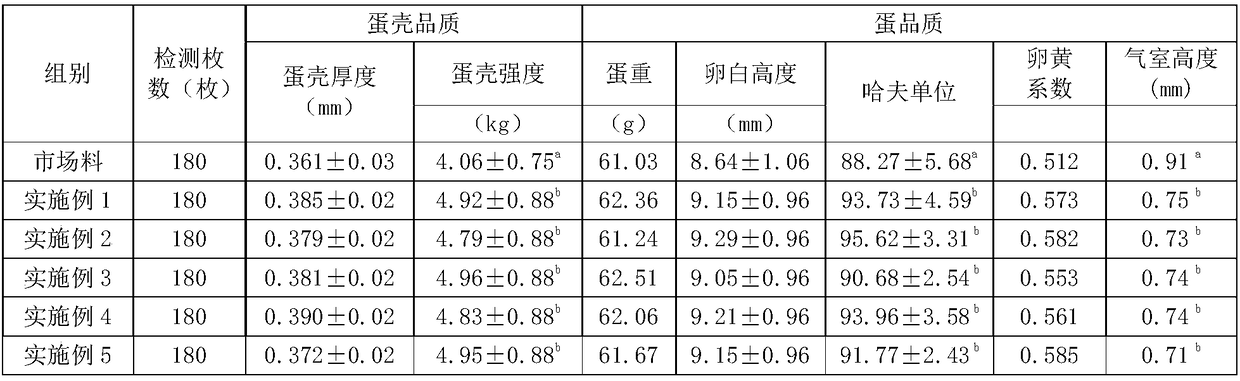

Disease resistance-promoting feed for egg producing period of hens and preparation method thereof

PendingCN107041483AAvoid damageReduce the use of pesticides in farmingFood processingAnimal feeding stuffDiseaseFiber

The invention relates to a disease resistance-promoting feed for an egg producing period of hens and a preparation method thereof. The feed is prepared from the following raw materials in parts by weight: 10-20 parts of oat, 8-20 parts of bean pulp, 2-6 parts of corn protein powder, 1-5 parts of sesame seed meal, 1-5 parts of chili slag, 0.5-1.5 parts of rice bran oil, 1-5 parts of gardenia fruit pomace, 0.03-0.1 part of hydrolysable tannins, 0.025-0.1 part of Perstorp SR130, 0.01-0.03 part of beta-carotene, 0.1-0.2 part of natural xanthophyll, 0.001-0.05 part of carnitine, 0.03-0.08 part of glycine betaine, 0.05-0.1 part of probiotics, 0.05-0.1 part of a complex enzyme preparation, 0.01-0.12 part of a mycotoxin adsorbent and 1-2 parts of mixed yeast of oat bran and wheat fibers. The disease resistance-promoting feed for the egg producing period of hens has the effects of obviously promoting the immunological functions of the hens, promoting the intestine health and enhancing the disease resistance.

Owner:公主岭禾丰牧业有限责任公司

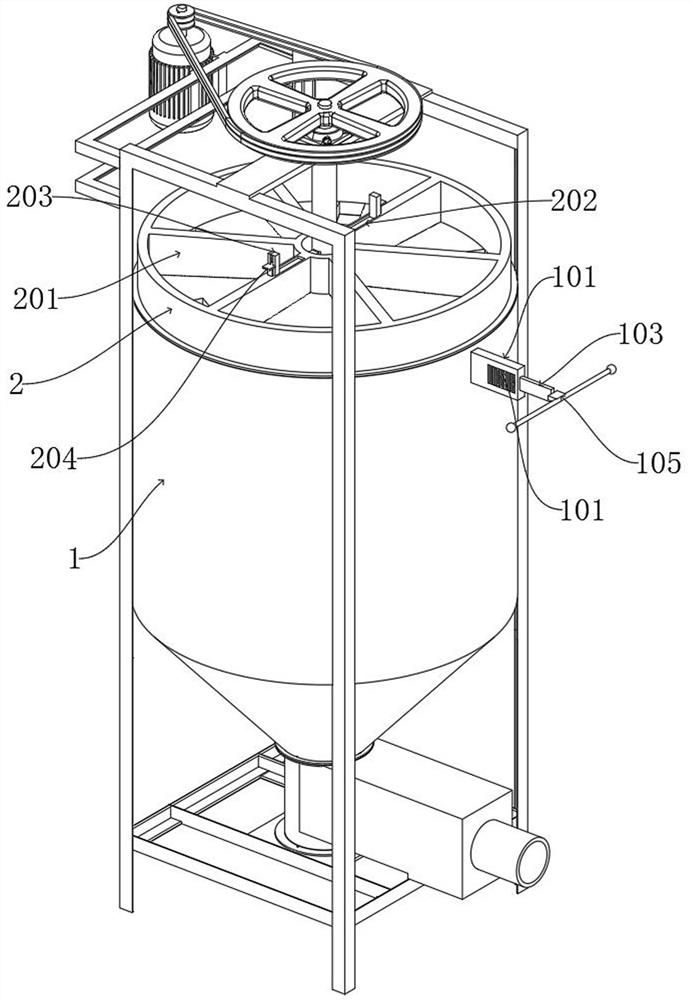

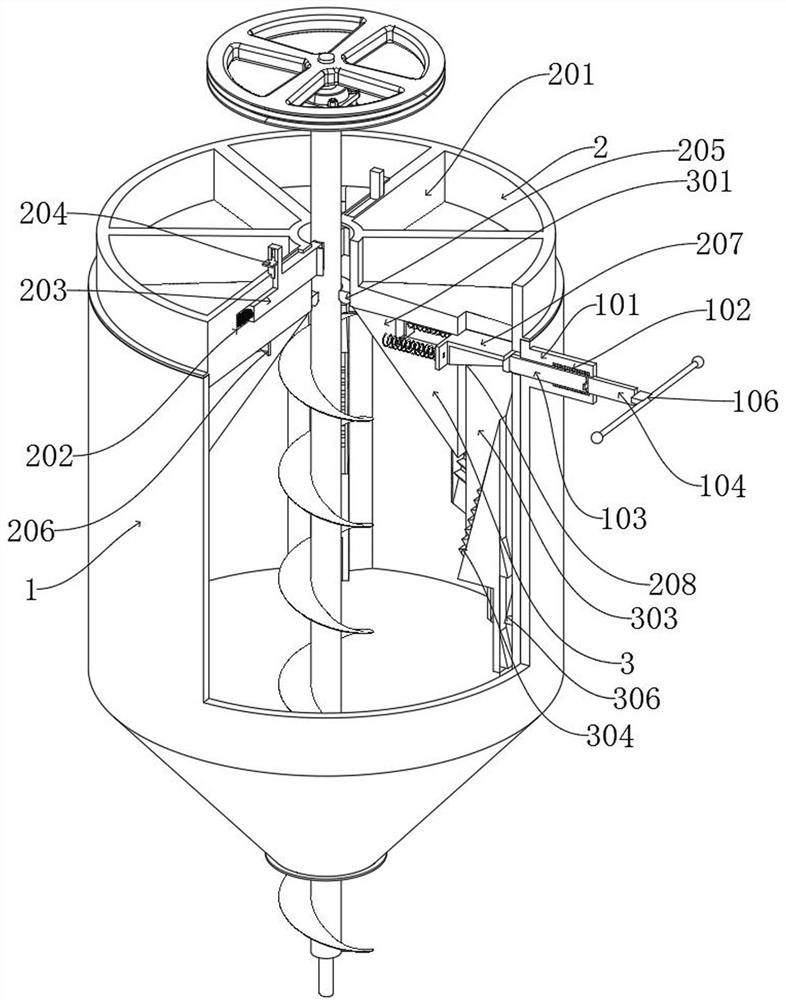

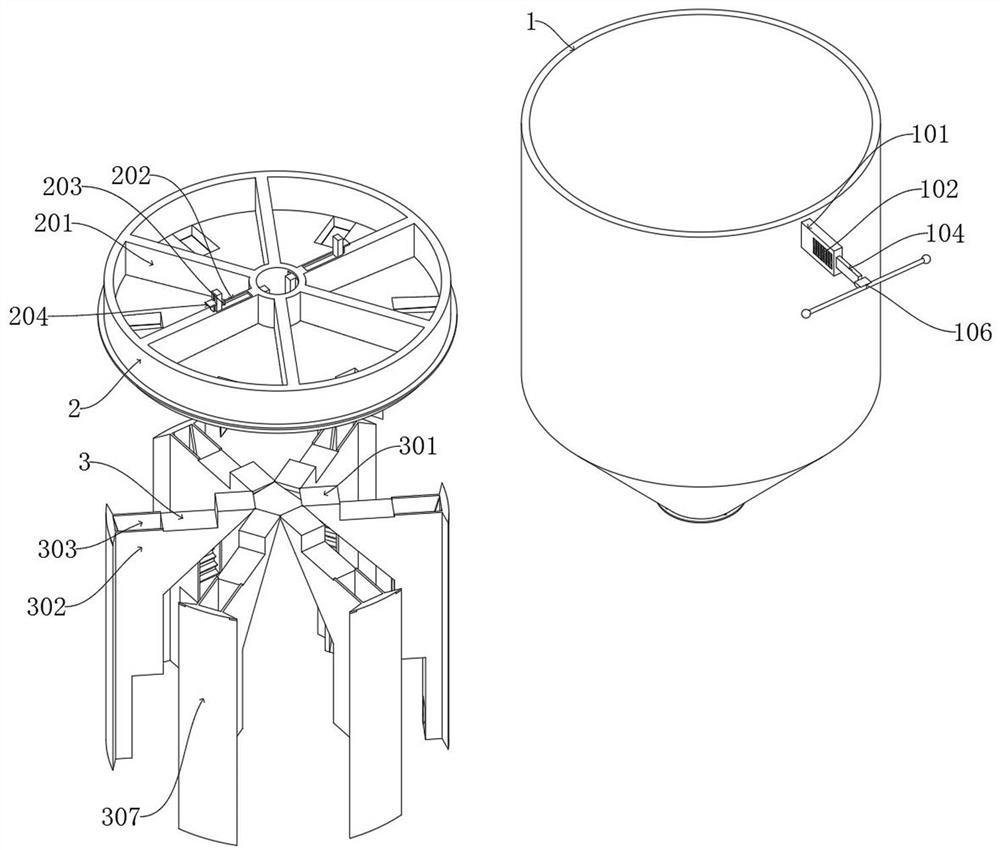

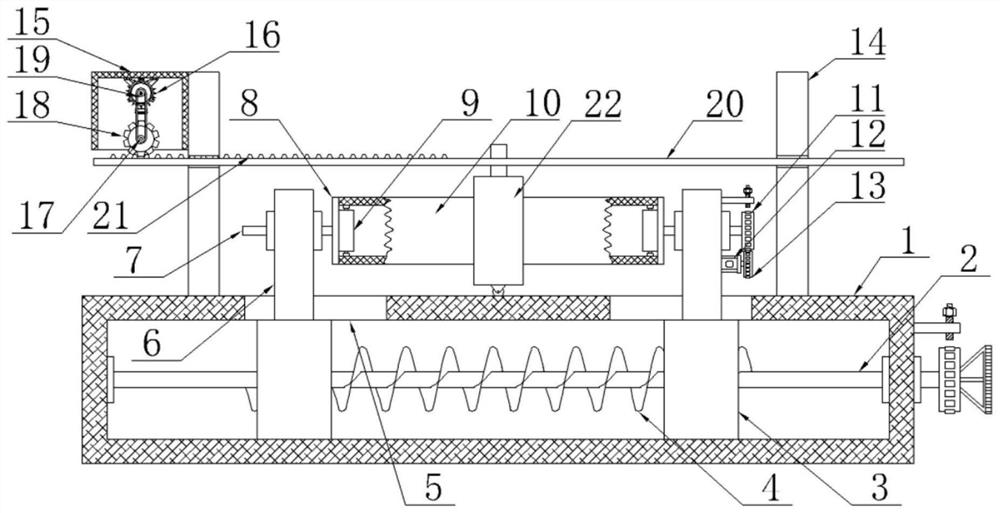

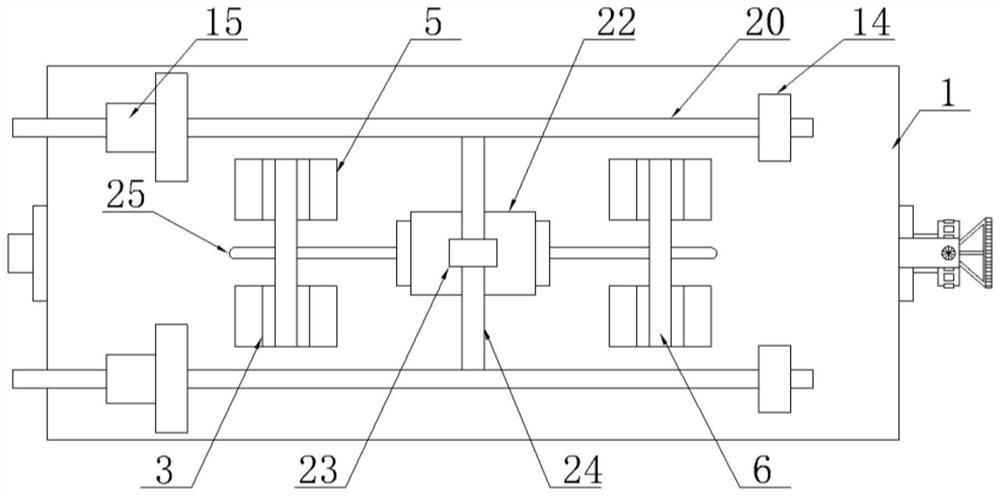

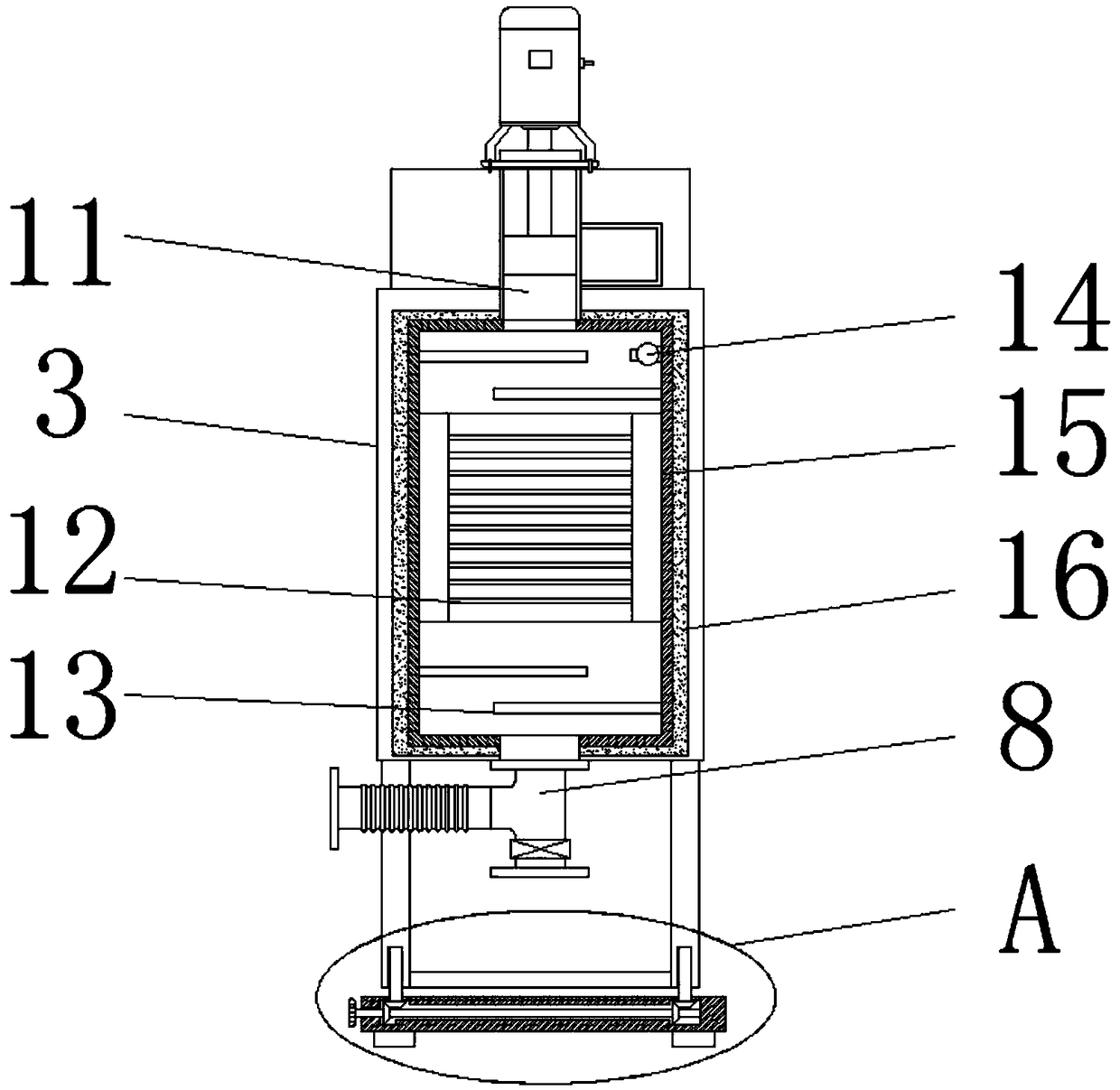

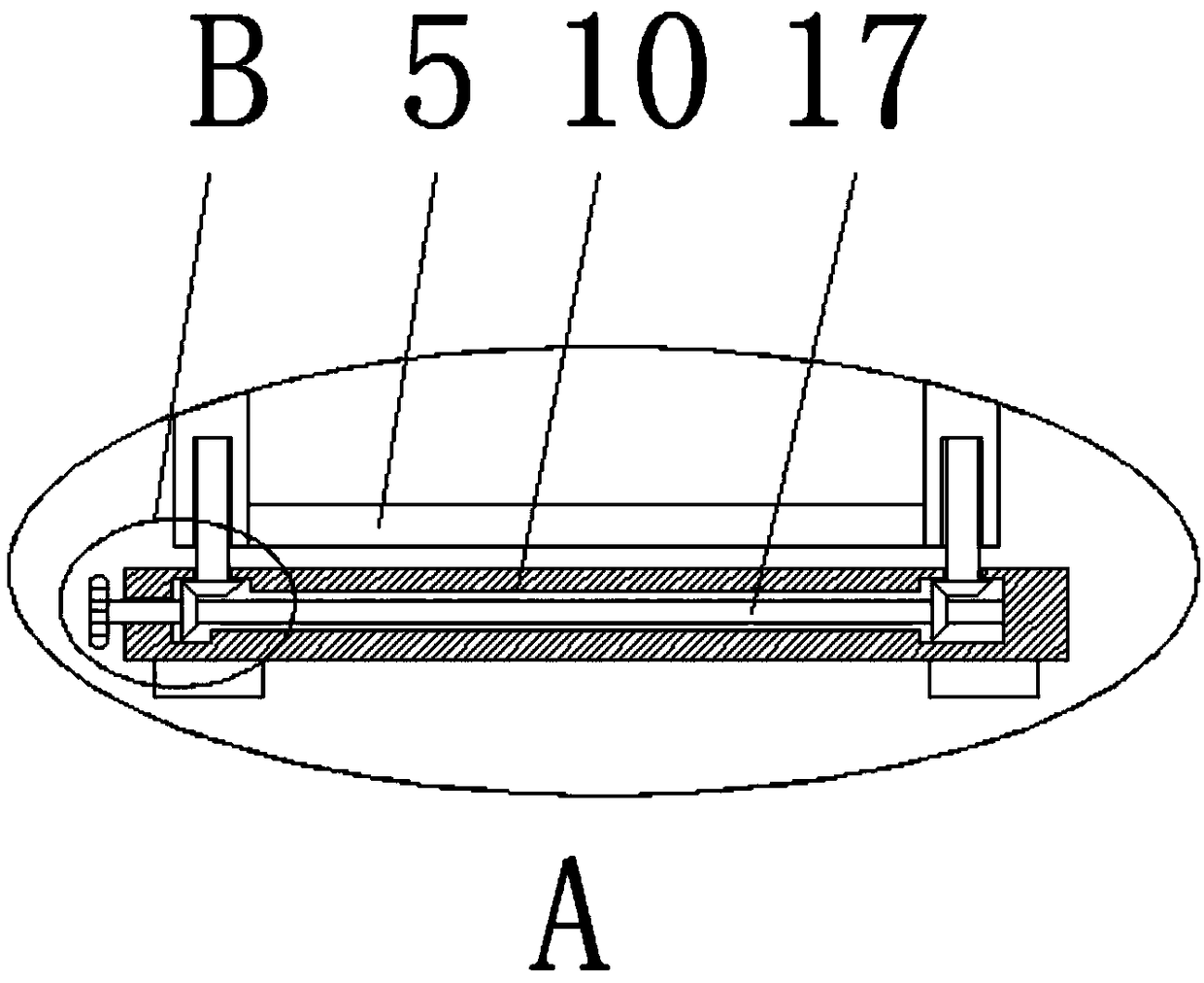

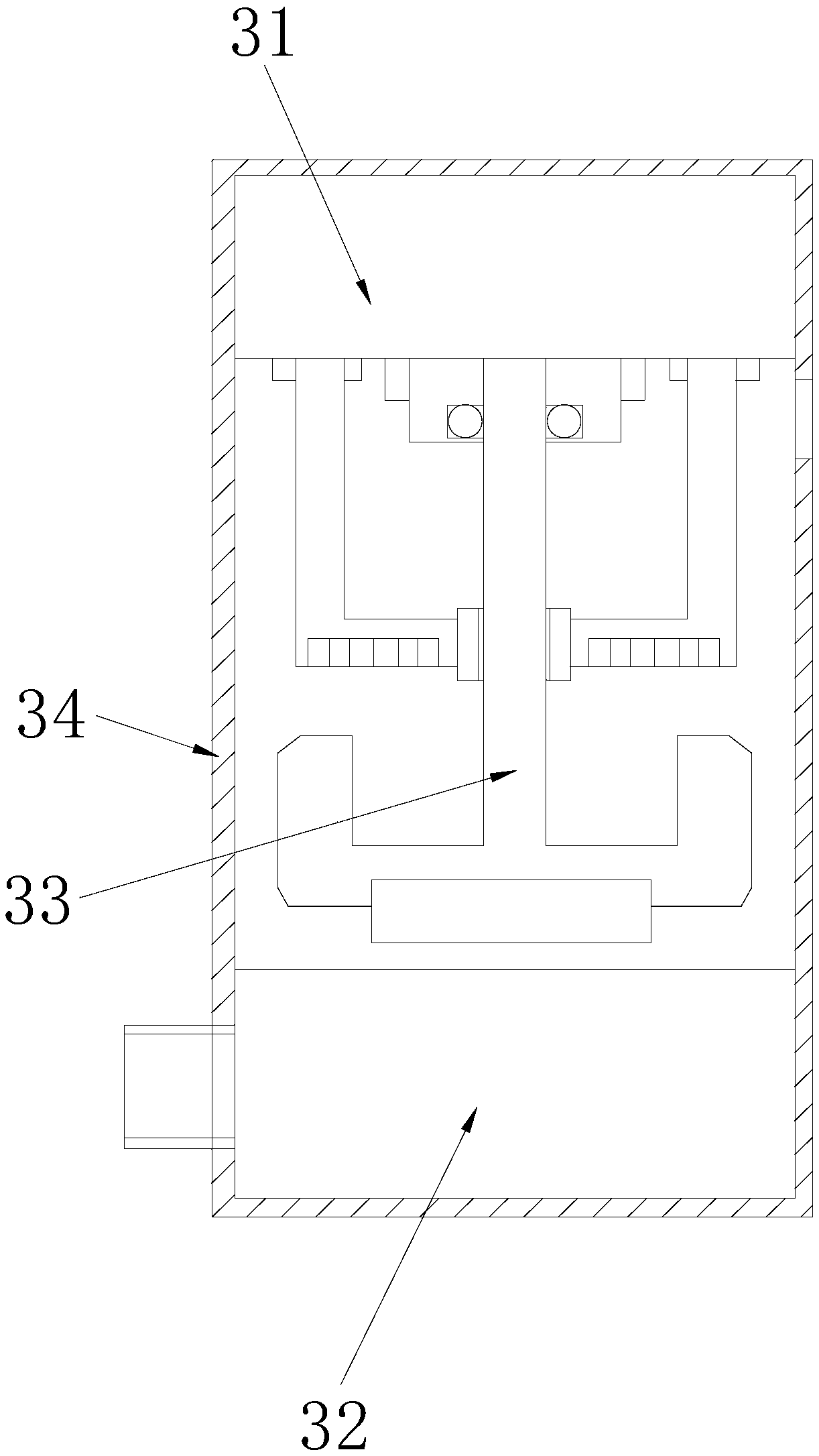

Rotary dropwise adding and mixing device for phosphorous acid ingredient production

InactiveCN113680246AReduce use costLow costRotary stirring mixersMixer accessoriesPhosphorous acidEngineering

The invention provides a rotary dropwise adding and mixing device for phosphorous acid ingredient production, and relates to the field of mixing devices. The invention aims to solve the problems that when an existing phosphorous acid raw material mixing device is used, raw materials need to be slowly added during raw material adding due to the characteristics of phosphorous acid, the inner wall of a container cannot be cleaned in an auxiliary mode during adding, and adhered raw materials cannot be cleaned. The device provided by the invention comprises a round pipe and auxiliary parts which are arranged in the middle of the interior of a rotating disc, wherein the auxiliary parts are annularly arranged, and the auxiliary parts are installed at the bottom of the rotating disc through connecting blocks. Each auxiliary part comprises a scraping plate, wherein the scraping plate is fixed to the outer end of an outer rod, and the outer side of the scraping plate makes contact with the inner wall of a main body; meanwhile, when the auxiliary part rotates along with the rotating disc, the scraping plate can be driven to rotate together, the outer side of the scraping plate makes contact with the inner wall of the main body, and the scraping plate can effectively scrape the inner wall of the main body; and thus, raw material residues are reduced, and the situation that raw materials adhere to the inner wall of the main body and cannot be cleaned is avoided.

Owner:南通汇顺化工有限公司

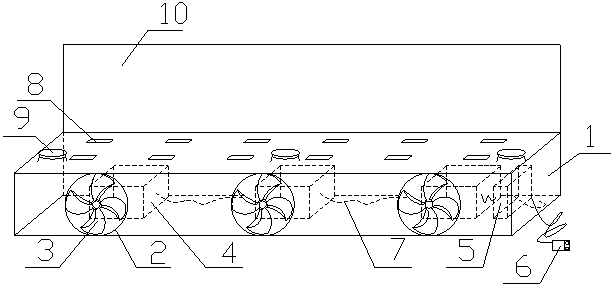

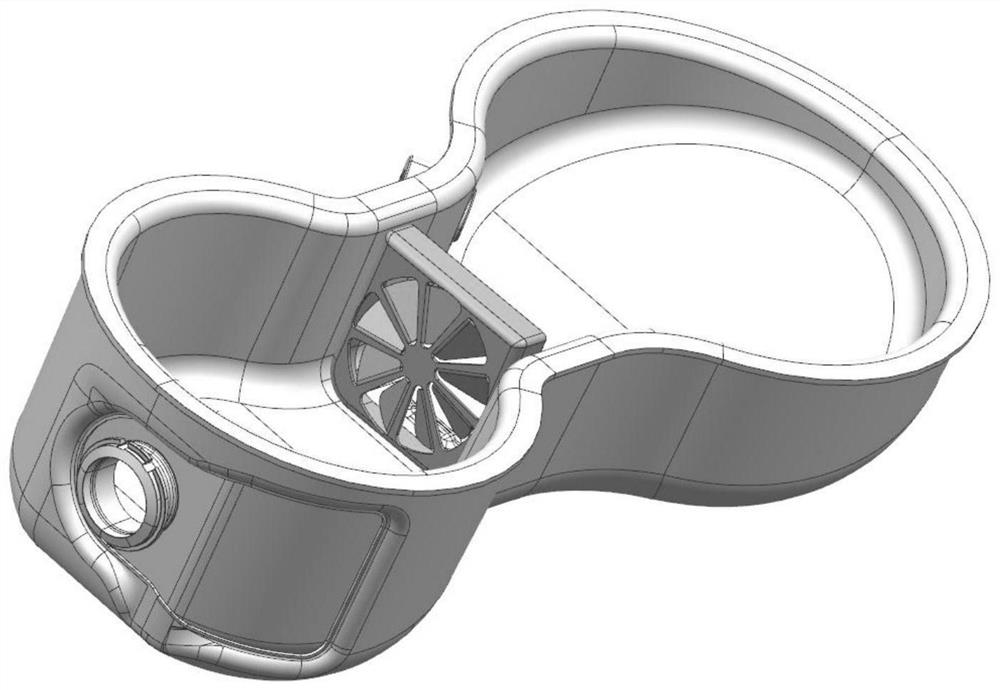

Radiator for notebook computer

The invention discloses a radiator for a notebook computer. The radiator for the notebook computer comprises a support (1), exhaust outlets (2), exhaust fans (3), motors (4), a storage battery (5) and a USB interface (6), wherein the exhaust outlets (2), the exhaust fans (3), the motors (4), the storage battery (5) and the USB interface (6) are located on the support (1), the support (1) is a cuboid shell, and the upper surface of the cuboid shell makes contact with the bottom face of the external computer. The exhaust outlets (2) are formed in the side wall of the cuboid shell. The exhaust fans (3) and the rotating shafts of the motors (4) are fixed and then the exhaust fans (3) stretch into the exhaust outlets (2). The motors (4) are connected with the storage battery (5) and the USB interface (6) in sequence through lead wires (7). The motors (4) are used for controlling the exhaust fans (3) to rotate to generate heat dissipating wind, and heat is dissipated after perpendicularity is formed between the heat dissipating wind and the heat emitted from the bottom face of the external computer. The radiator for the notebook computer effectively enables the heat dissipating area to be enlarged, and is small in size, light in structure, convenient to use, good in heat dissipating effect low in cost and capable of better achieving heat dissipation and carrying.

Owner:WUXI TONGMING TECH

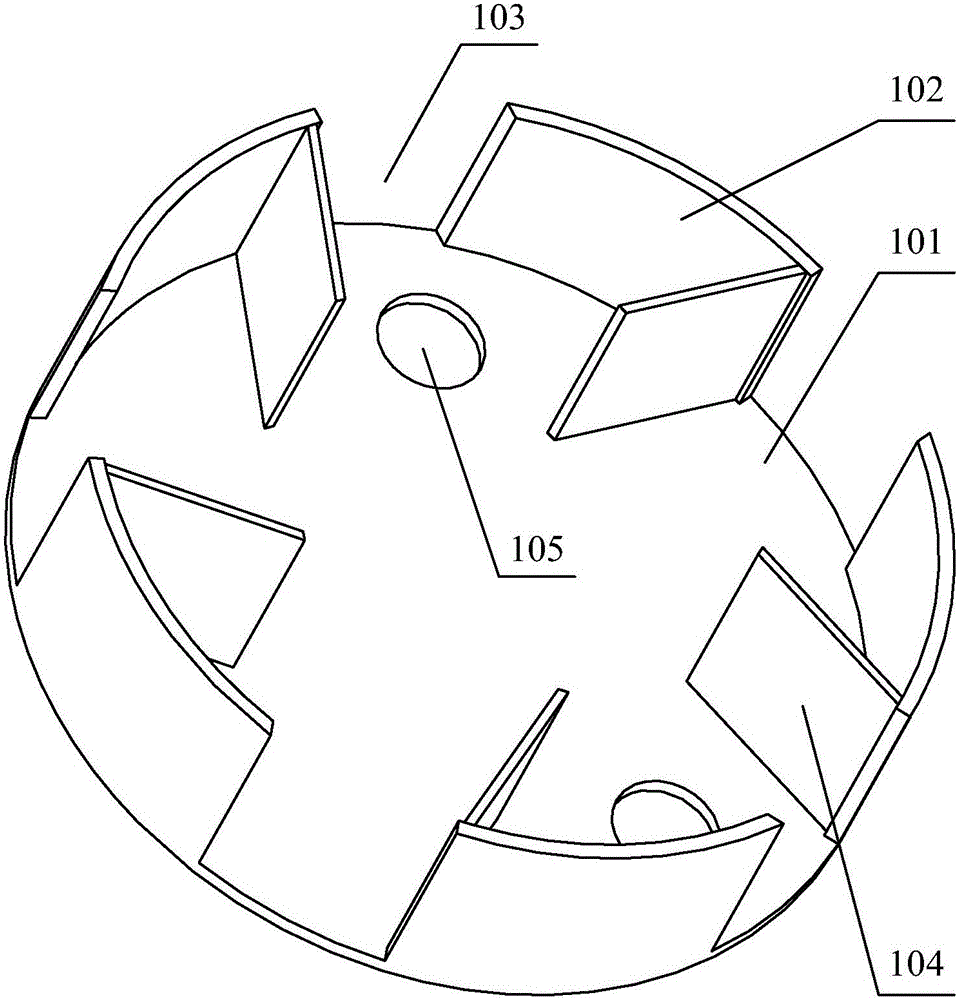

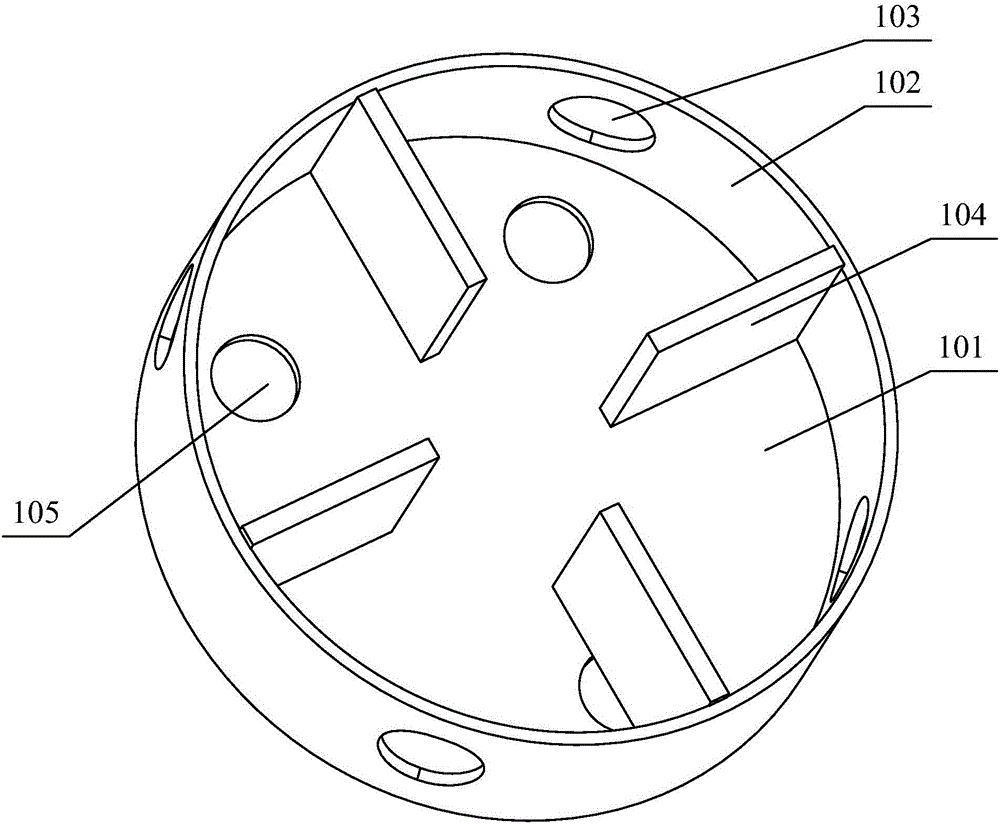

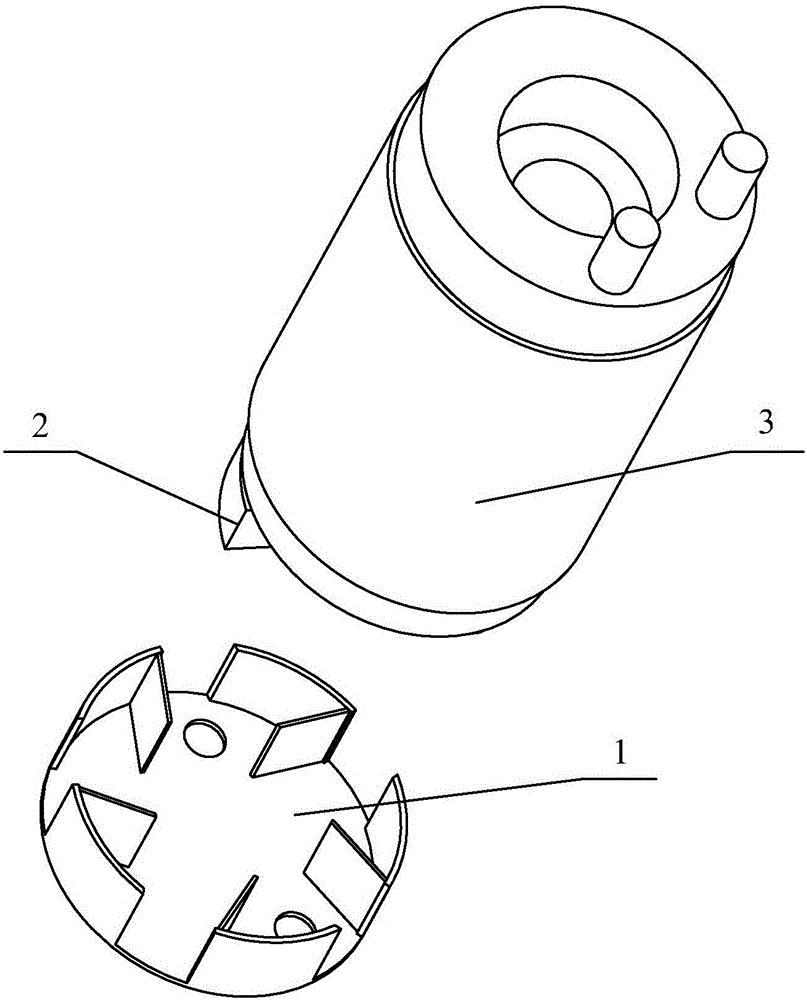

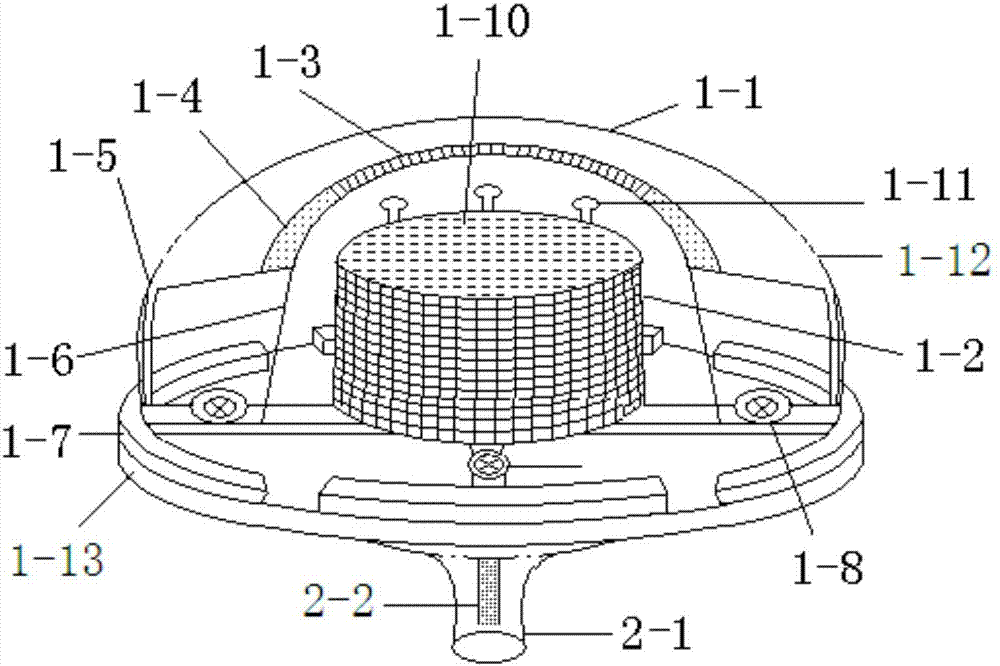

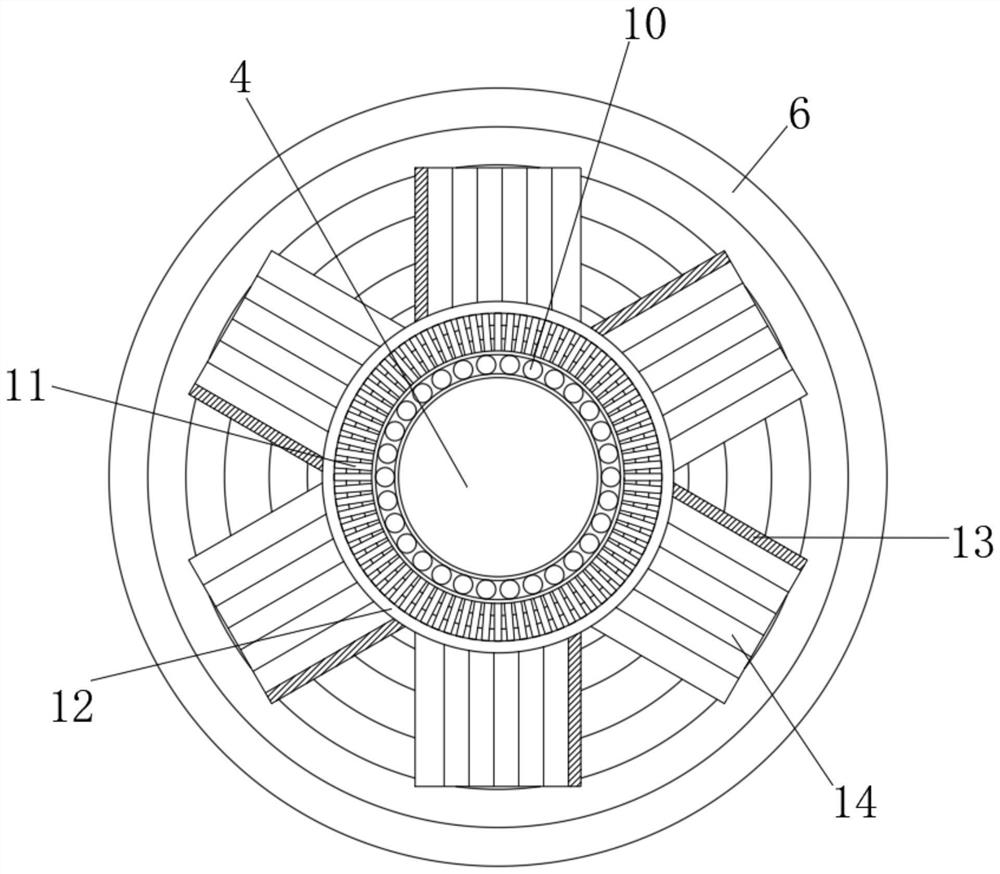

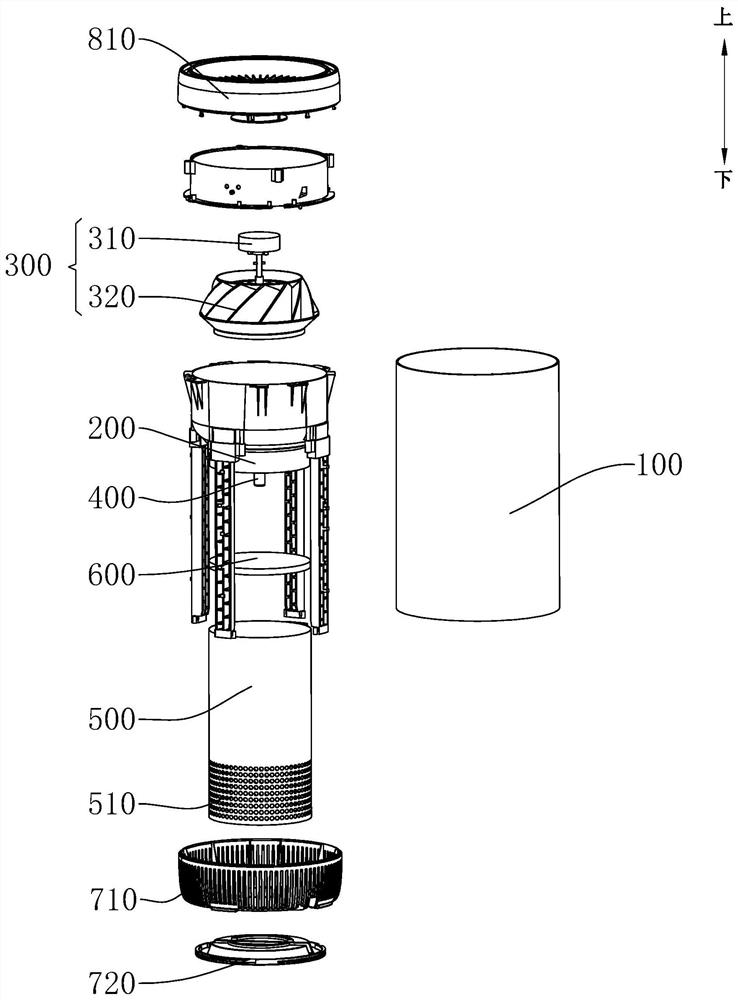

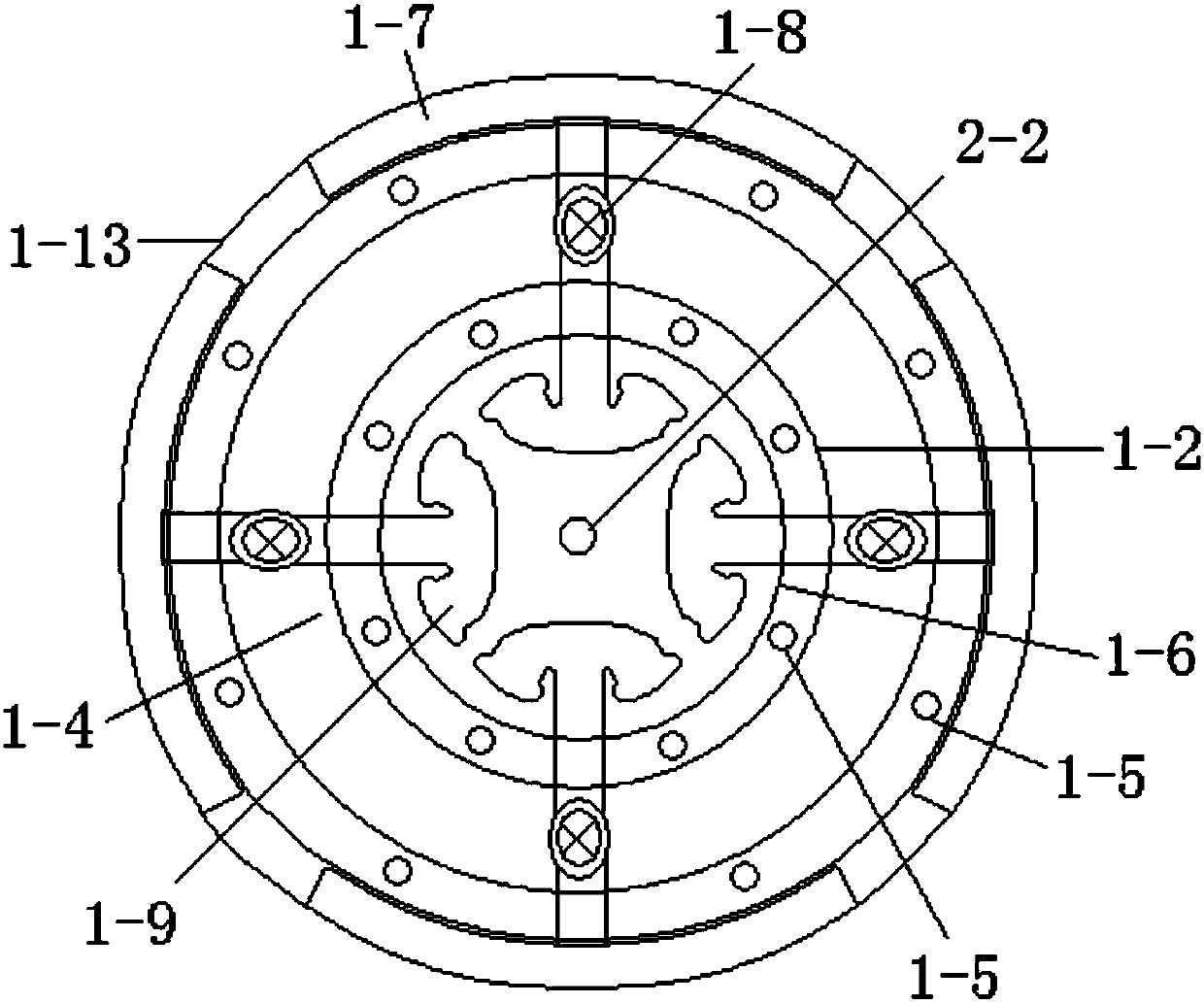

Oil baffle plate, compressor rotor assembly, compressor and air conditioner

InactiveCN106015007AHigh rotational strengthEasy to separateRotary/oscillating piston pump componentsLiquid fuel engine componentsPetroleum engineeringGas separation

An oil baffle disclosed in an embodiment of the present invention includes an oil baffle body, the surface of the oil baffle body facing the rotor is an oil-gas separation surface, and an oil-gas separation surface arranged on the oil baffle body side guide vanes. For the oil baffle provided by the present invention, when the oil baffle rotates together with the rotor, the guide vanes located on the oil-air separation surface of the oil baffle body will rotate together with the oil baffle body, because the turbulence caused by the rotation of the guide vanes The function enhances the rotation strength of the refrigerant flow field and assists the gas circulation, thereby enhancing the separation effect of the oil-gas mixture, reducing the oil discharge of the compressor, and improving the overall performance of the compressor. The invention also discloses a compressor rotor assembly, a compressor and an air conditioner.

Owner:ZHUHAI LANDA COMPRESSOR +1

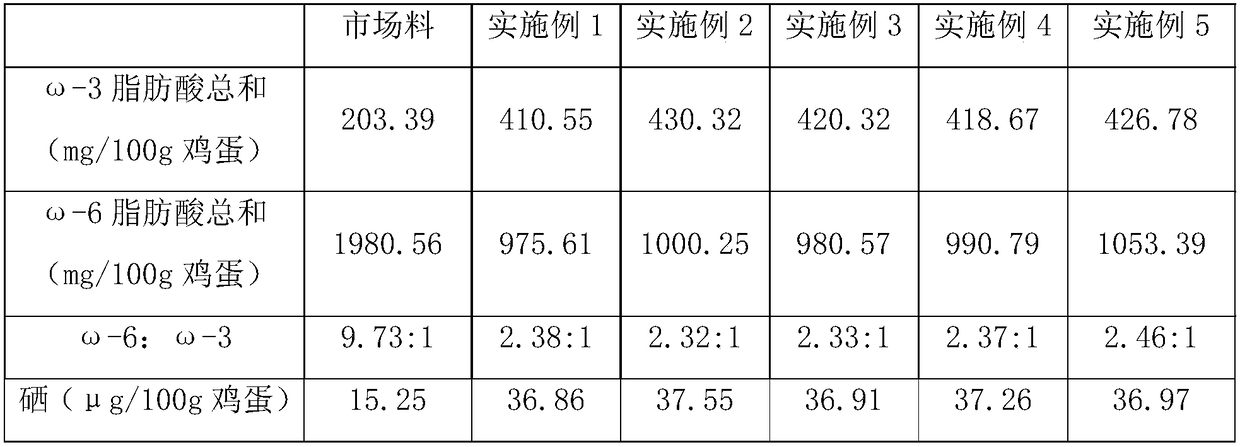

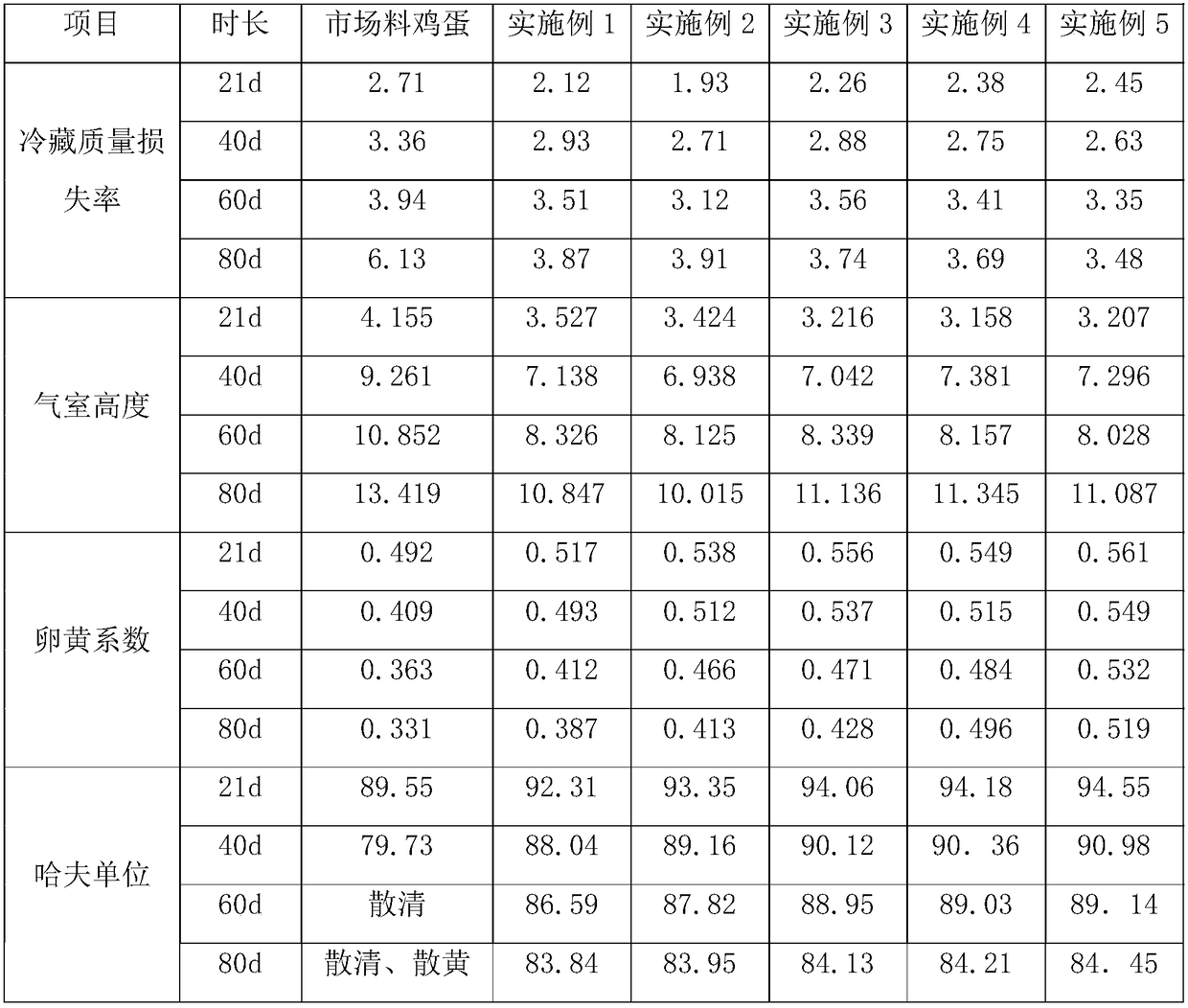

Feed for laying hens in hen laying period for extending shelf life of egg and preparation method

ActiveCN108850659AExtended shelf lifeImprove qualityFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention belongs to the technical field of feed compositions, particularly relates to a feed for laying hens in the hen laying period for extending the shelf life of an egg and a preparation method, and relates to a high-selenium egg with long shelf life by using the feed. The feed is prepared from the following raw materials of 20 to 35 parts of corn, 5 to 8 parts of soybean meal, 2 to 5 parts of extruded soybean, 3 to 8 parts of extruded flaxseed, 3 to 8 parts of corn protein powder, 2 to 4 parts of sesame meal, 3 to 8 parts of rice bran, 1 to 3 parts of pepper residue, 0.5 to 1.0 partof palm kernel oil, 1 to 5 parts of barley rootlet, 0.8 to 2 parts of biological fermenting feed, 0.03 to 0.05 part of Youkebao, 0.025 part of selenium yeast, and the like. The biological fermenting feed is prepared by mixing and fermenting coagulation bacillus, lactobacillus plantarum, lactobacillus lactobacillus and saccharomyces cerevisiae. The feed has the advantages that the feed is used forthe culturing of laying hens, the content of selenium in each is higher than 22.85mug, the shelf life is 80 days at the temperature of 4 to 8 DEG C, and the shelf life at normal temperature is 50 days.

Owner:LIAONING WELLHOPE AGRI TECH

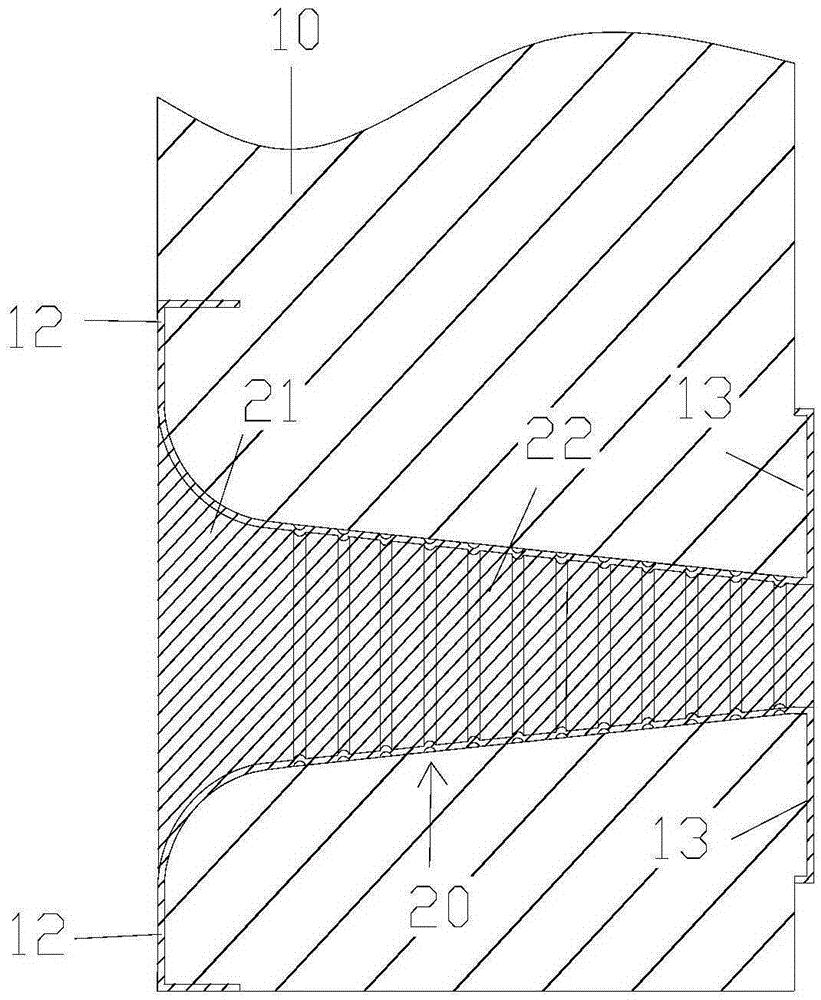

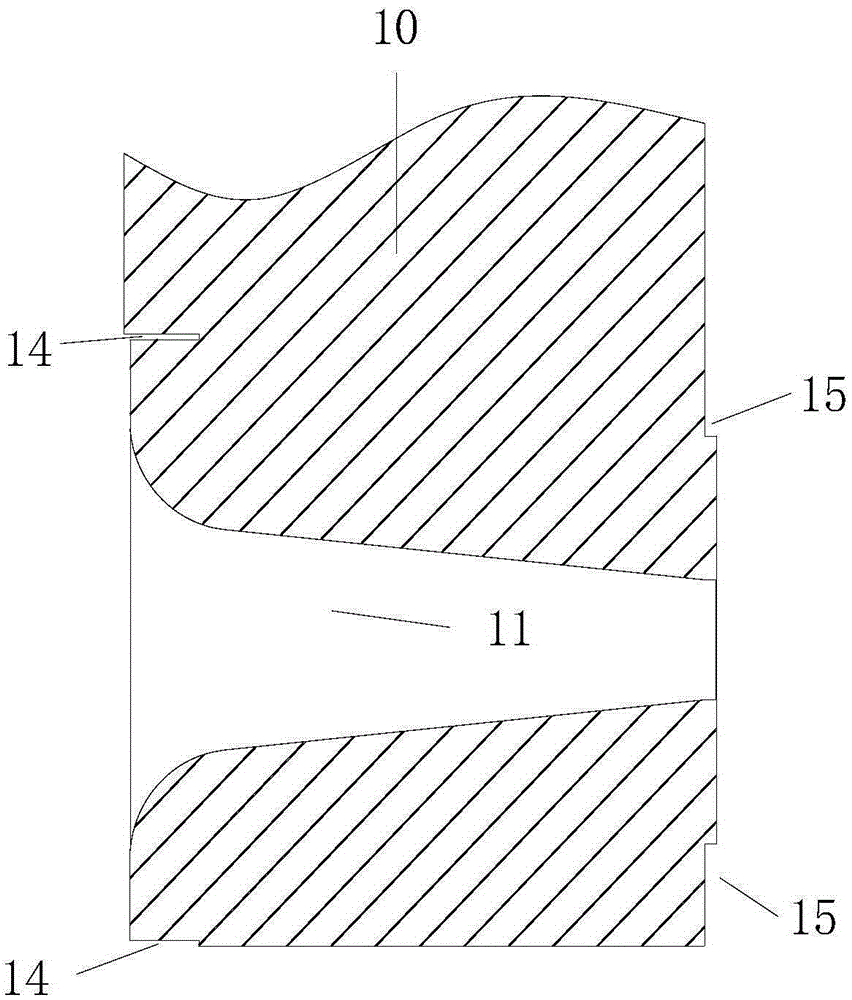

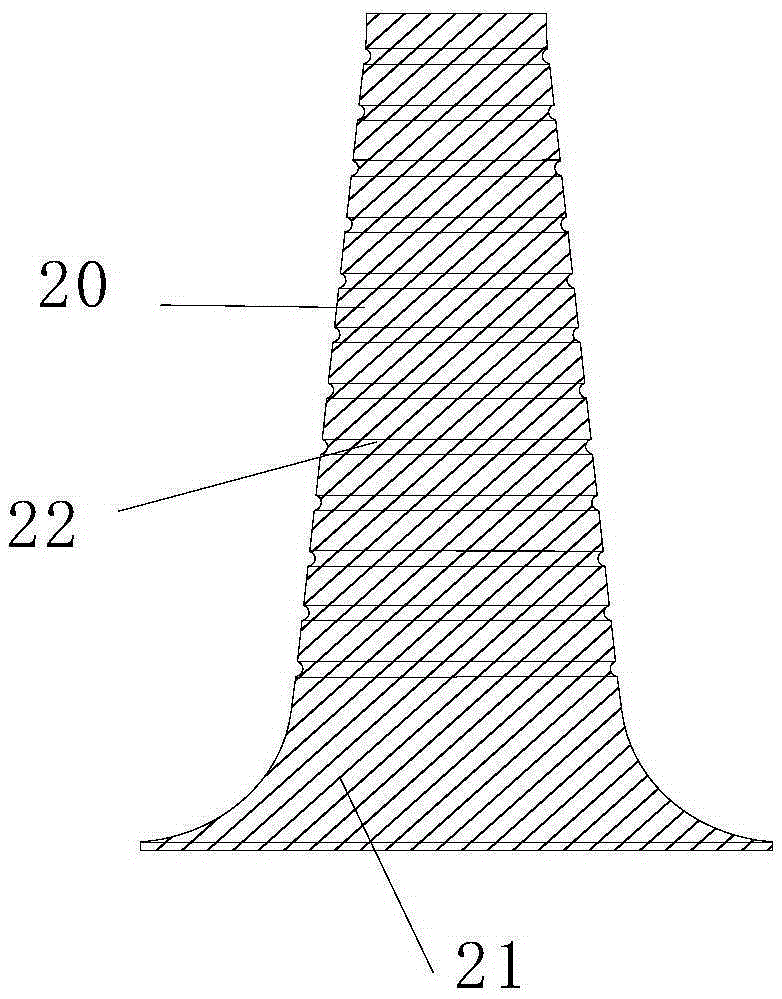

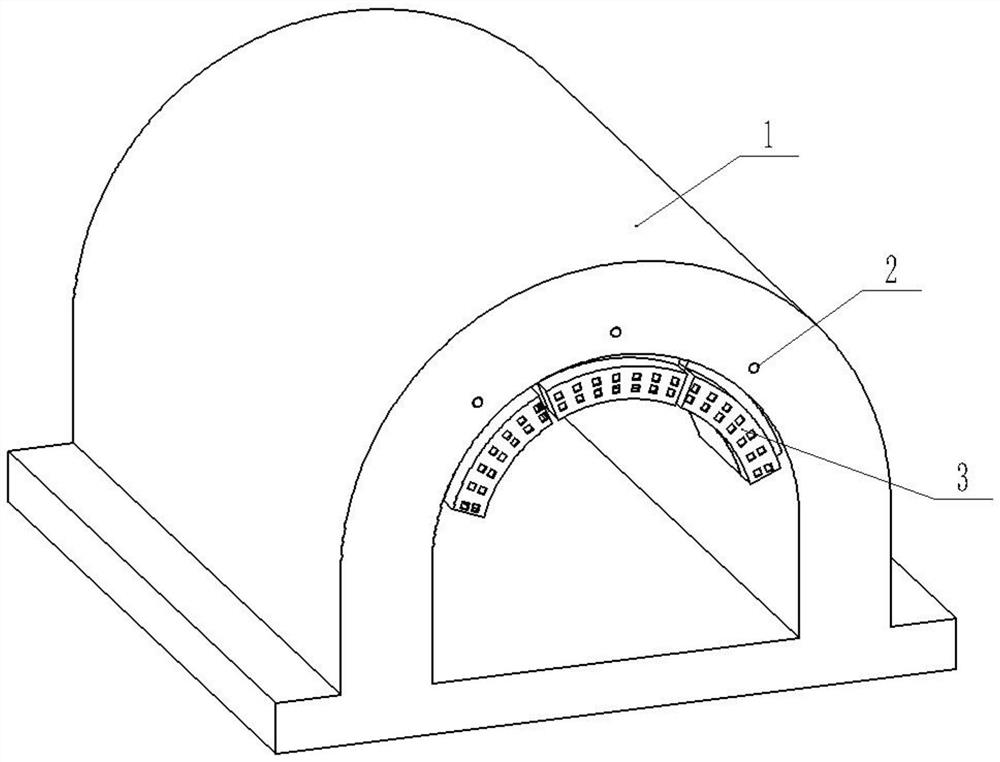

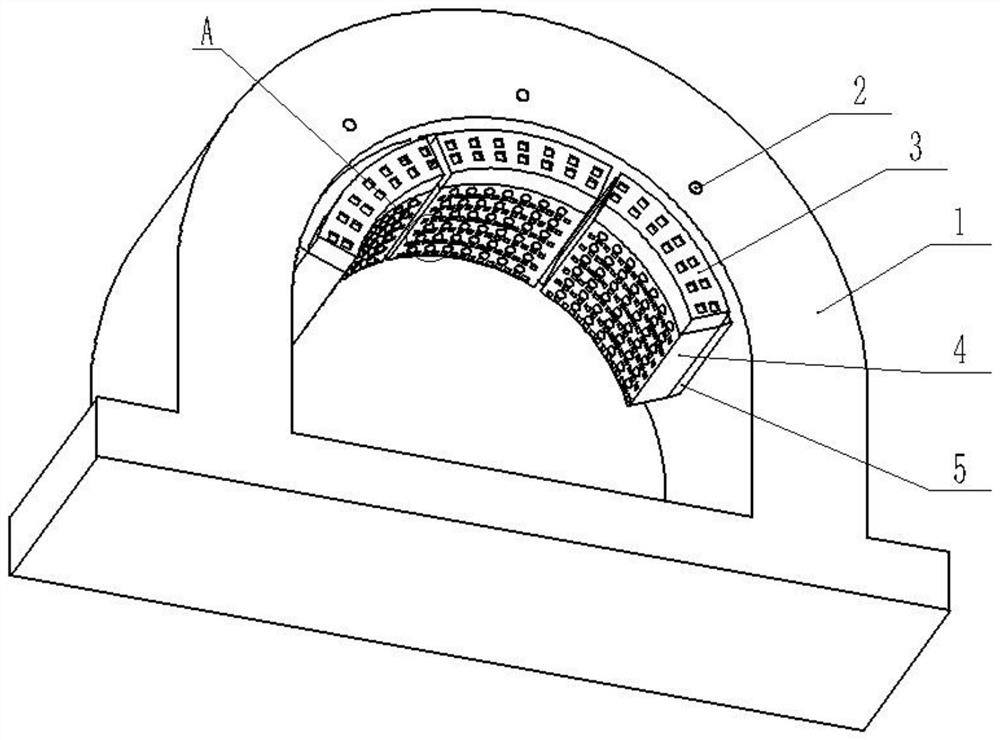

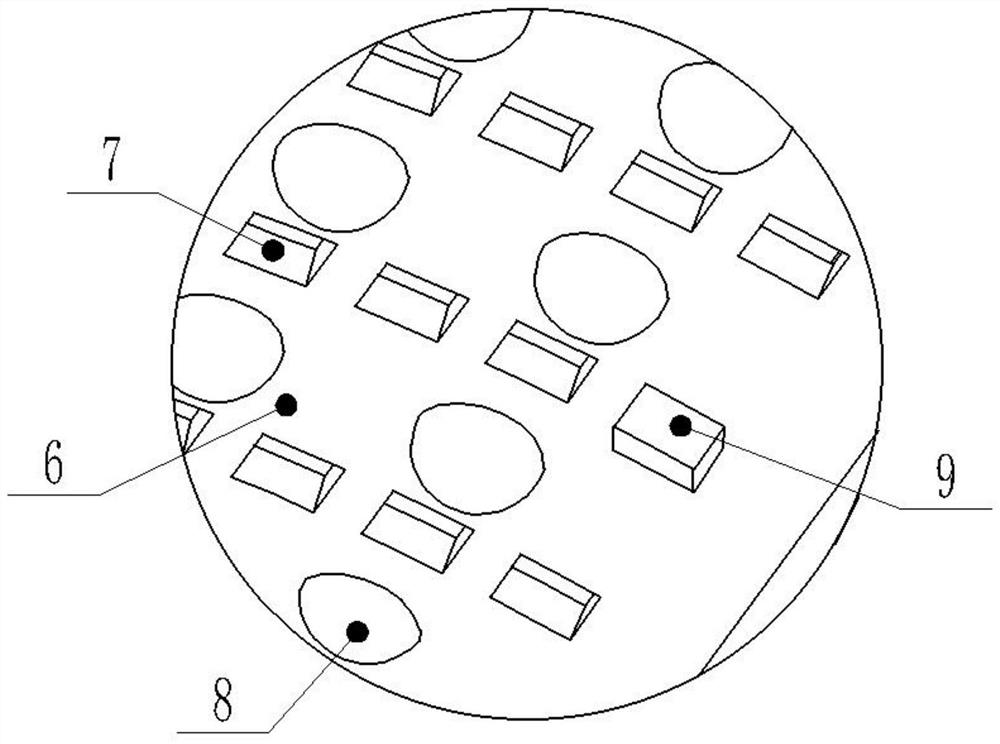

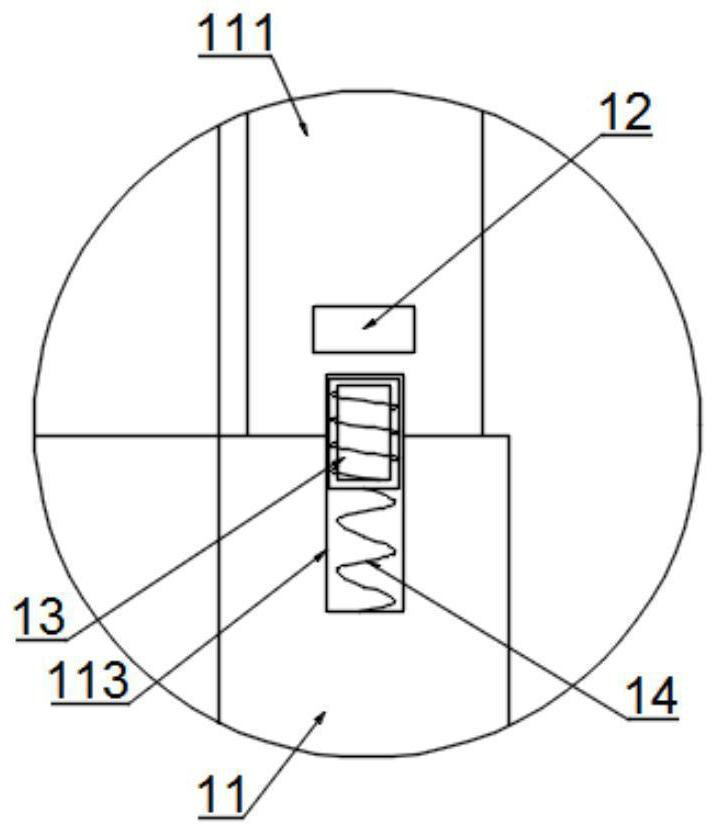

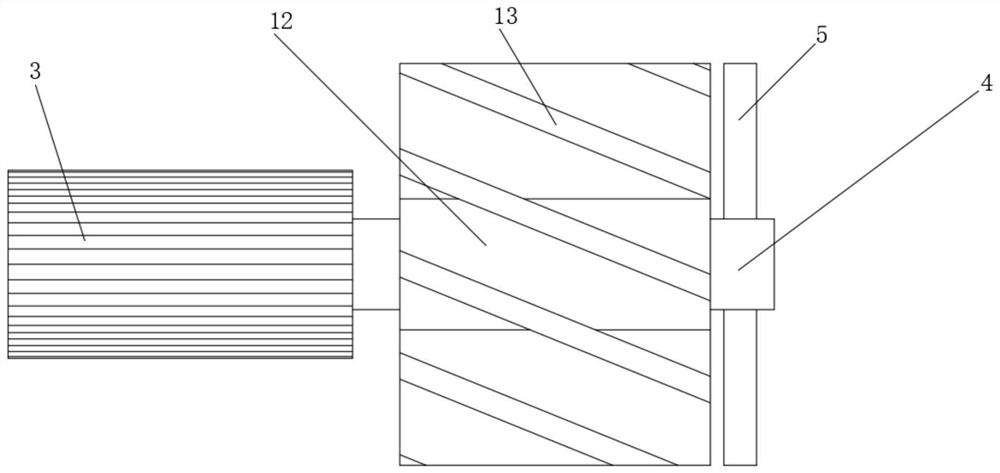

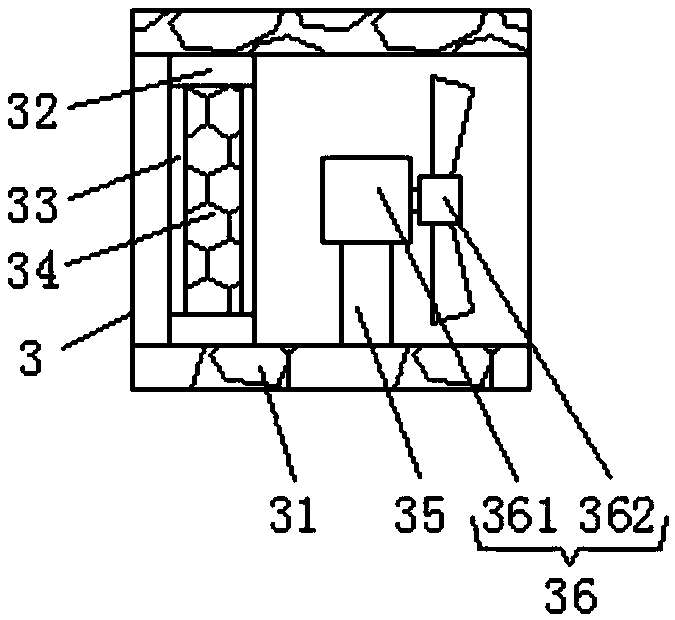

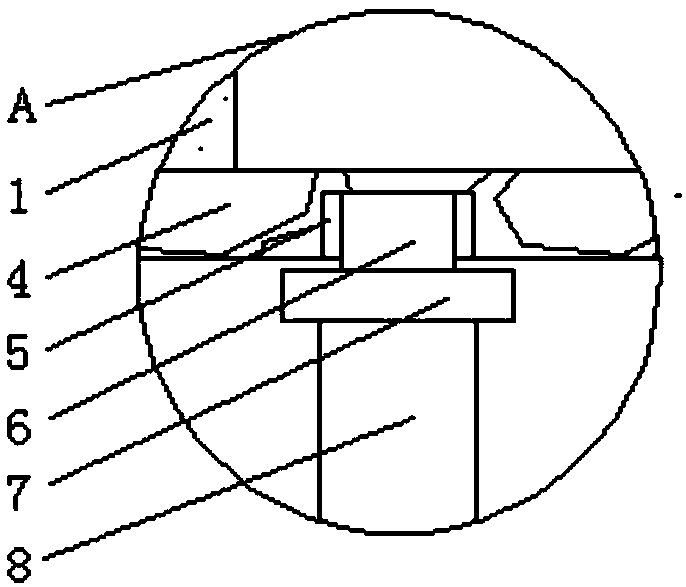

Glass substrate kiln brick provided with fluid flowing hole

ActiveCN105417932AImprove protectionSlow down circulationGlass furnace apparatusGlass productionBrickEngineering

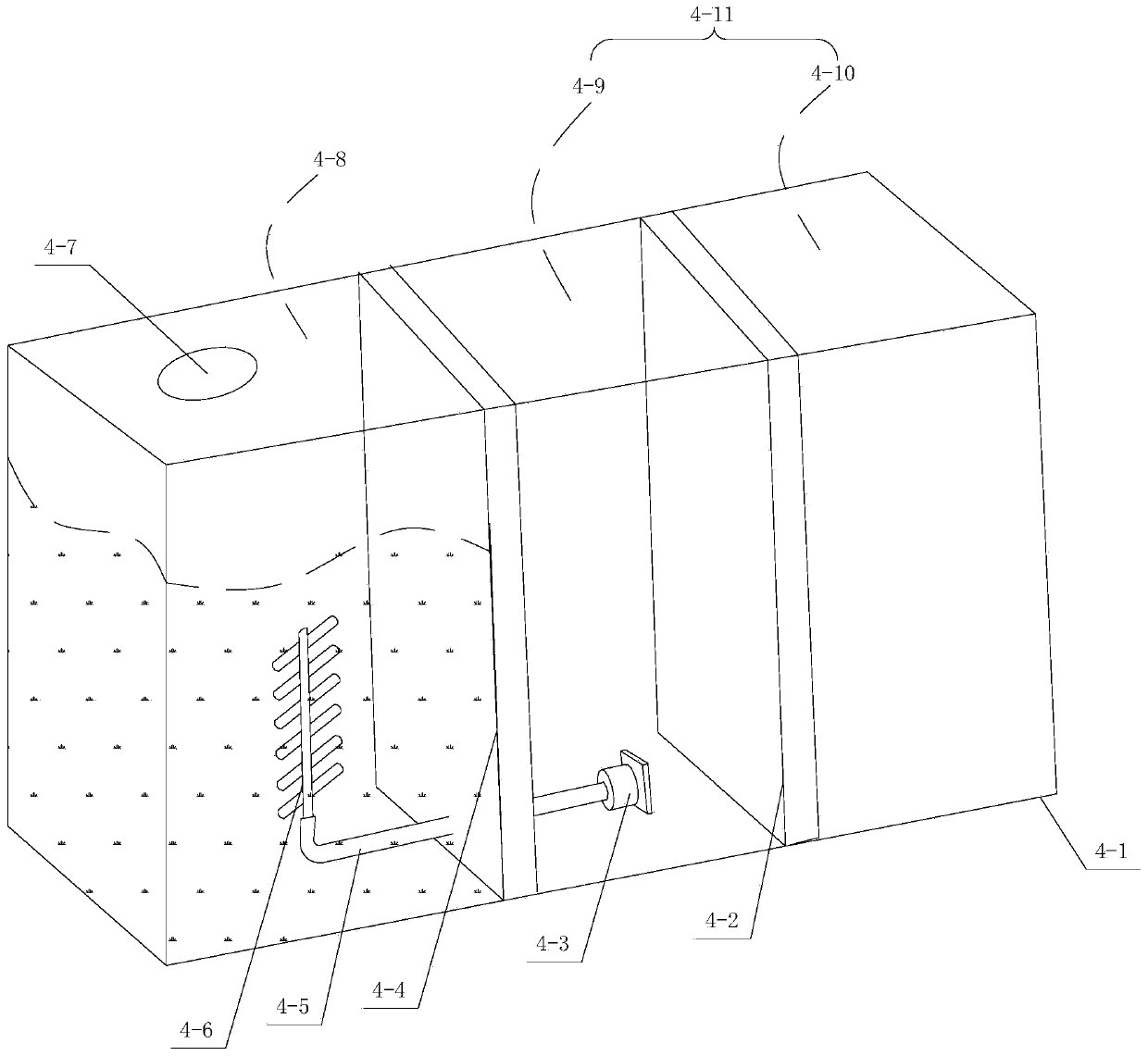

The invention provided with a glass substrate kiln brick provided with a fluid flowing hole. The brick comprises a brick body (10), a through fluid flowing hole (11) is formed in the brick body (10), a protective pipe (20) for preventing the brick body (10) from being corroded is arranged in the fluid flowing hole (11), the wall of the protective pipe (20) is attached to the wall of the fluid flowing hole (11), and a trumpet structure, whose larger opening faces the internal side, is formed in the inner end of the protective pipe (20). Compared with the conventional protective pipe with equal diameters, the provided protective pipe has the advantages that the circulating flow strength of molten glass in the inlet of the fluid flowing opening is reduced, the flowing state of molten glass is optimized, the washing of molten glass on the corner is reduced, the erosion of molten glass on the inlet of the fluid flowing hole is relieved, the service life of kiln is prolonged, the kiln cost is reduced, the phenomenon that the brick body falls in or is melt into molten glass is reduced, the pollution to the glass is reduced, the refractory stone on the surface of glass substrate is reduced, and the quality and output of glass substrate are both improved.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

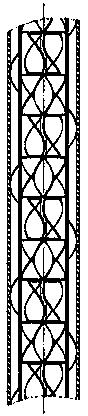

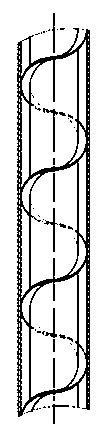

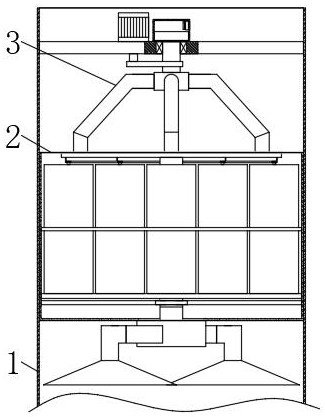

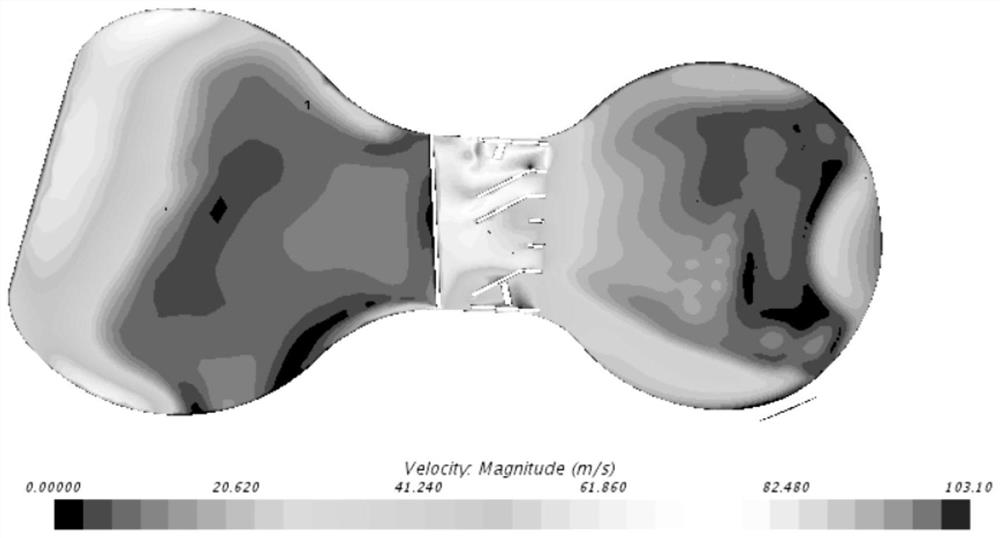

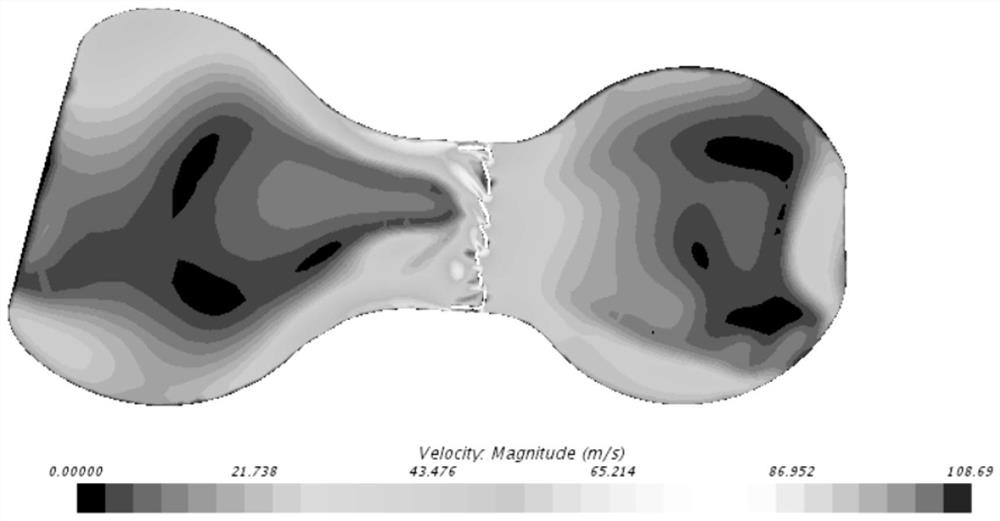

One group of double-turbulence loop reactor

InactiveCN103349958AReasonable design parametersReasonable matchChemical/physical/physico-chemical stationary reactorsEngineeringSurface shape

The invention provides one group of double-turbulence loop reactor and relates to chemical equipment. The group of double-turbulence loop reactor comprises a fluid inlet, an axial flow circulating pump, a fluid outlet, elbows and loop reactor pipe sections with jackets, and is characterized in that a static mixing turbulent flow component is arranged in an inner pipe of each reactor pipe section; a turbulent flow component is arranged in the jacket of each loop reactor pipe section; the turbulent flow component in the pipe is a column-shaped, sheet-shaped, curved surface-shaped, strip-shaped and spiral static mixing component with a turbulent flow effect; the turbulent flow component in the jacket has a spiral sheet type, a turbulent flow column type and a combined type of the spiral sheet type and the turbulent flow column type; the pipe length of the pipe section is 6 m, the inner diameter of the inner pipe is 600 mm, and the spiral sheet in the jacket has the thickness of 10 mm and the screw pitch of 100 mm; the loop reactor pipe sections (5) with the jackets are connected through the elbows (4); and two loop reactor pipe sections belong to one group. The group of unit reactor has reasonably matched design parameters and best benefits, can be used singly or in a combined mode, and has higher operating elasticity compared with the existing loop reactor.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

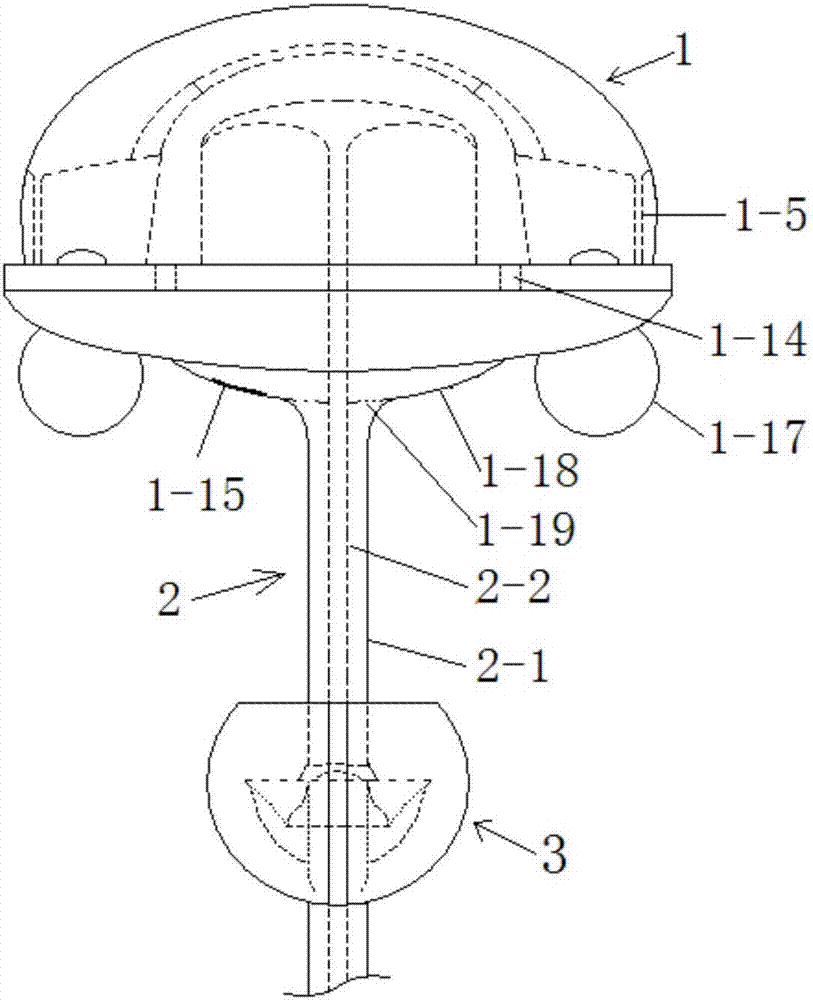

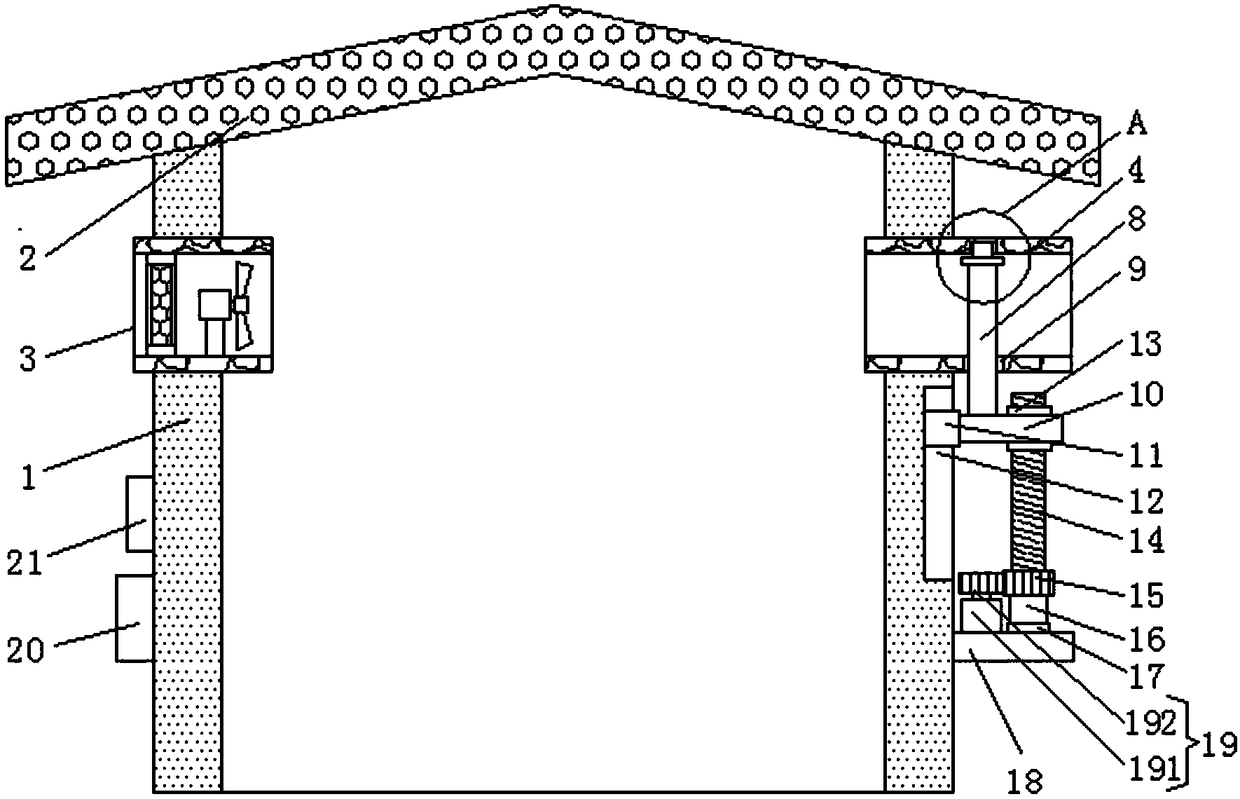

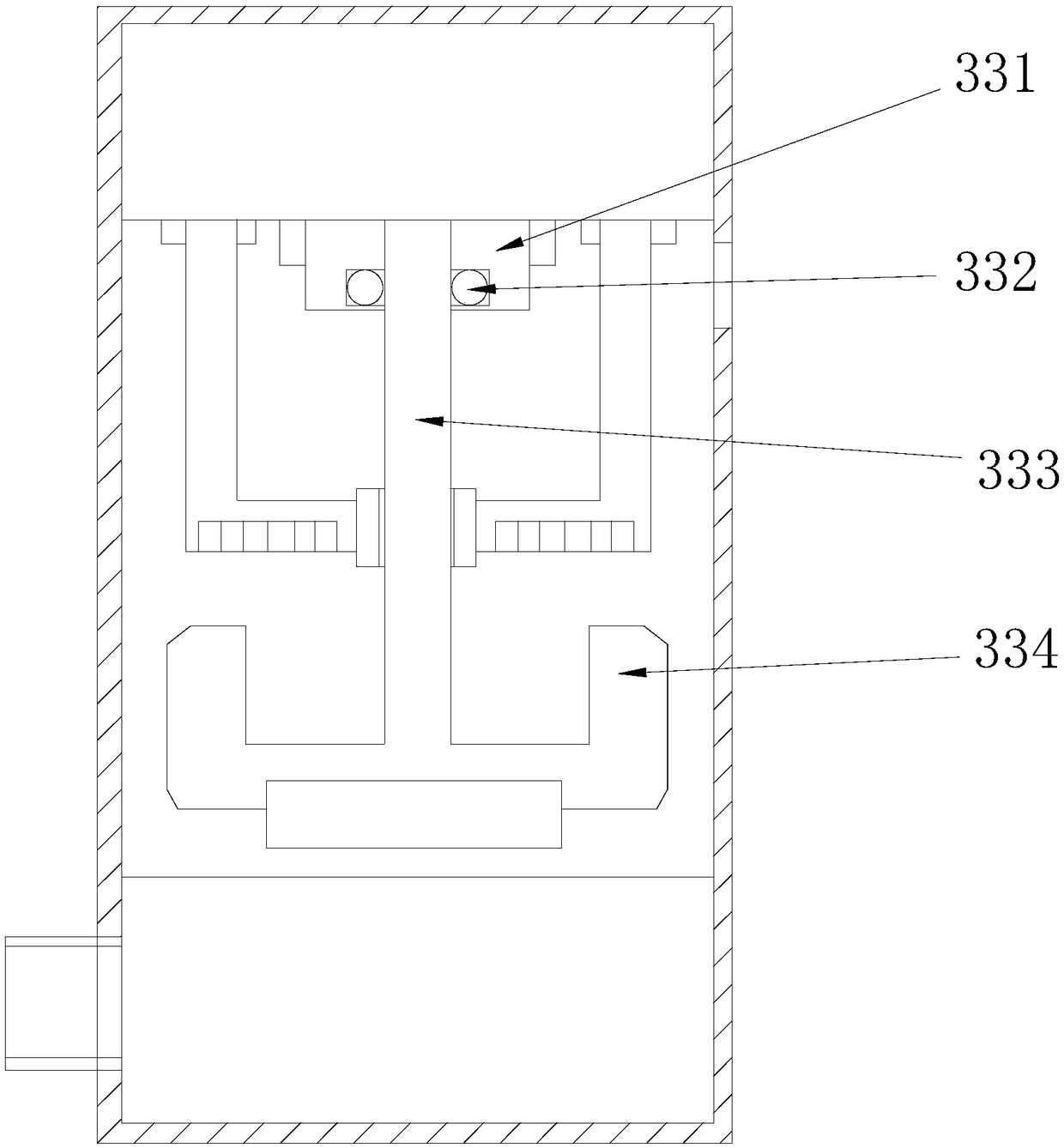

Railway tunnel air oscillation controller

The invention relates to the field of tunnels, and particularly discloses a railway tunnel air oscillation controller. The railway tunnel air oscillation controller comprises an arc-shaped control unit arranged on the inner wall of a tunnel; the control unit comprises an outer shell, a plurality of layers of partition plates are arranged in the outer shell, and a plurality of air inlet holes and aplurality of buffer mechanisms are arranged on each layer of partition plate; each buffer mechanism comprises a mounting groove, a first spring and buffer sheets; the mounting grooves are formed in the bottoms of the partition plates, the first springs are arranged in the mounting grooves, the buffer sheets are arranged on the first springs, the buffer sheets and the air inlet holes are alternately arranged, and the buffer sheets are partially spherical surfaces which are bent downwards; and a buffer cavity is formed between every two layers of partition plates, and a plurality of exhaust holes are formed in the two sides of the outer shell. The railway tunnel air oscillation controller aims to solve the technical problem of air oscillation caused when a train enters the tunnel.

Owner:温州泰乐维工程设计有限公司

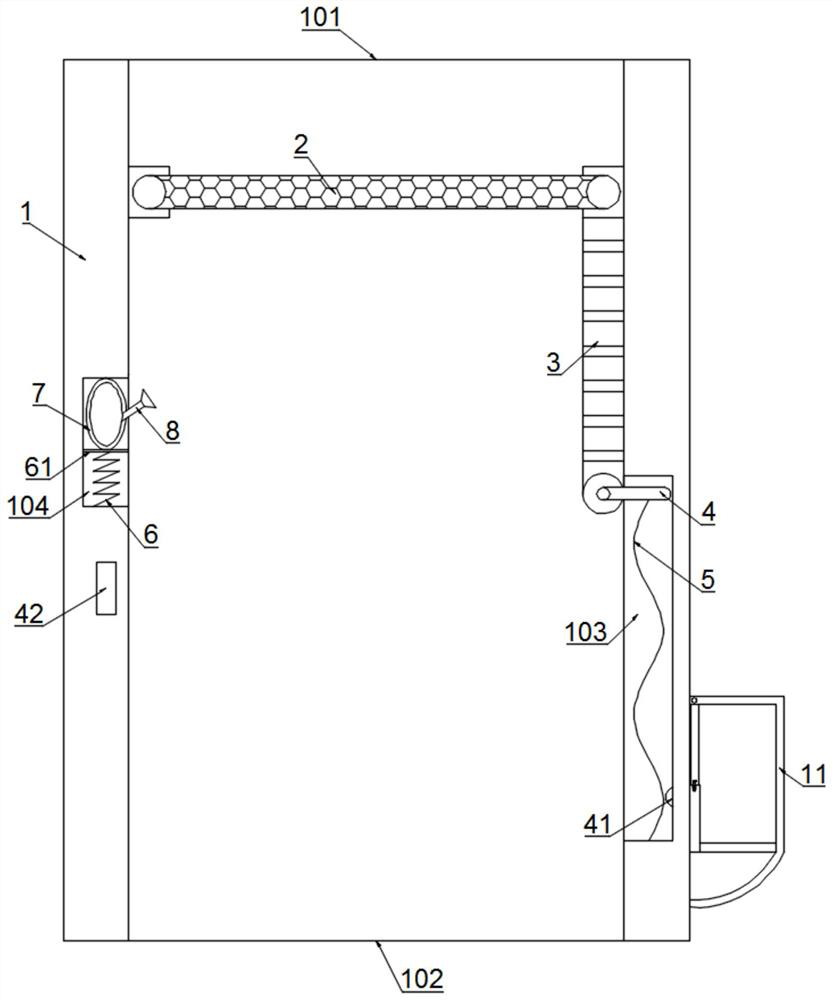

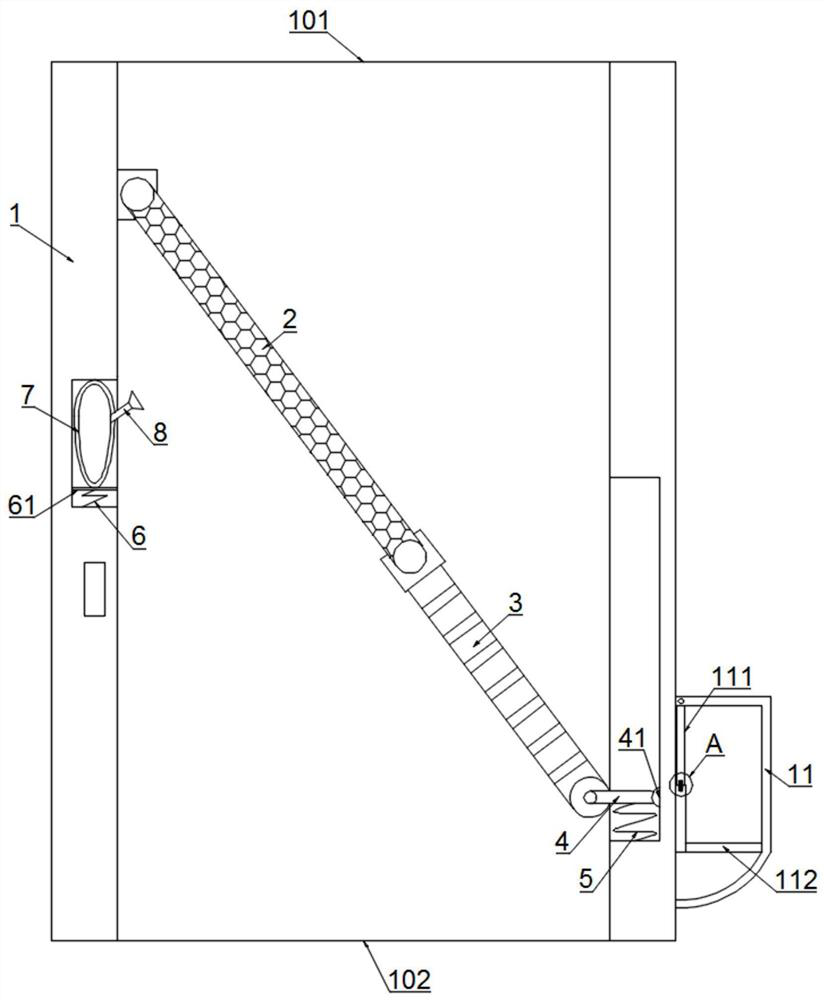

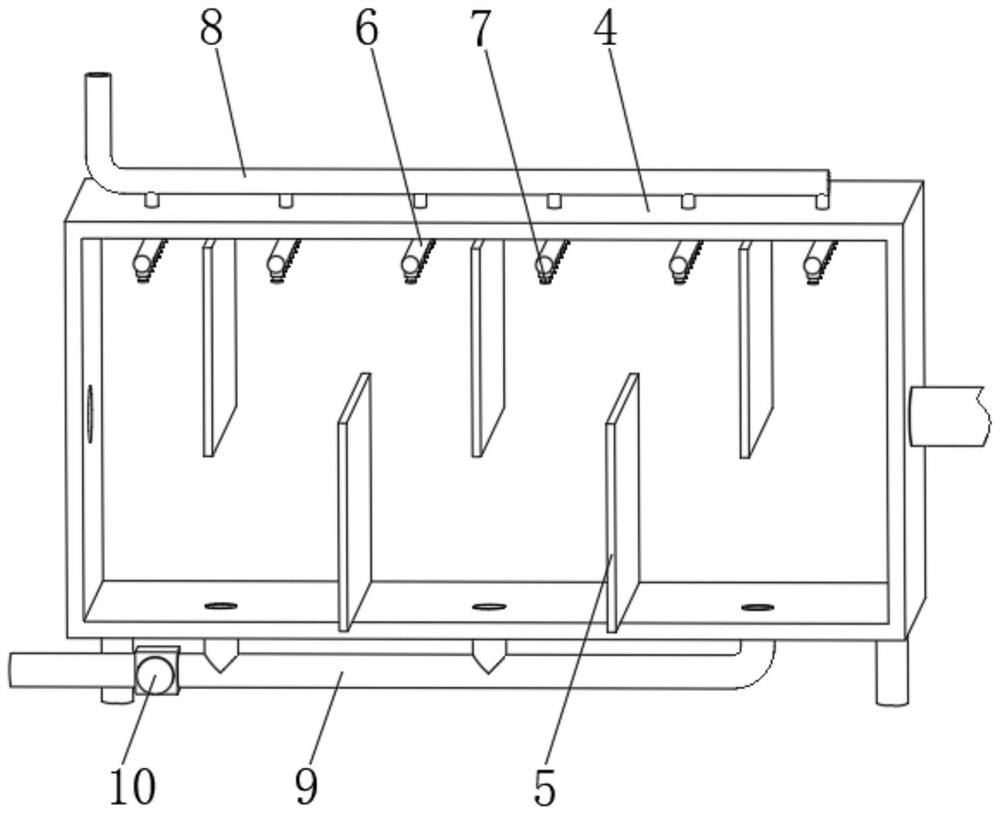

Method for carrying out water circulation air purification and plant water cultivation based on street lamp bodies

ActiveCN107990262APromote absorptionPromotes nutrient absorptionMechanical apparatusUsing liquid separation agentWater storageSprayer

The invention discloses a method for carrying out water circulation air purification and plant water cultivation based on street lamp bodies, and belongs to the field of air purification. The air purification and plant water cultivation process of the method comprises the steps that an air exchange mechanism is firstly started, and outside air is introduced; a large water mist sprayer is utilizedfor spraying water mist, air is firstly subjected to spraying of the large water mist sprayer, and pollutants in the air are adsorbed by water drops and are discharged together along with converged water; the water mist is discharged through drainage openings in a bottom disc to enter inner cavities of flowerpot inner containers in electrostatic water cultivation mechanisms to be used as a nutrient solution for plant growing; the water finally flows into a water storage pond of a heat storage and supply mechanism; and water is supplied to the large water mist sprayer through a water inlet pipe, and cyclic utilization of purified water is achieved. According to the method, arranged water mist sprayers are used for spraying the water mist to purify the air, dirt water is fed to the electrostatic water cultivation mechanisms for plant growing, meanwhile, the dirt water is purified, and cyclic utilization can be achieved; and the aims of air purification and environment beautifying are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

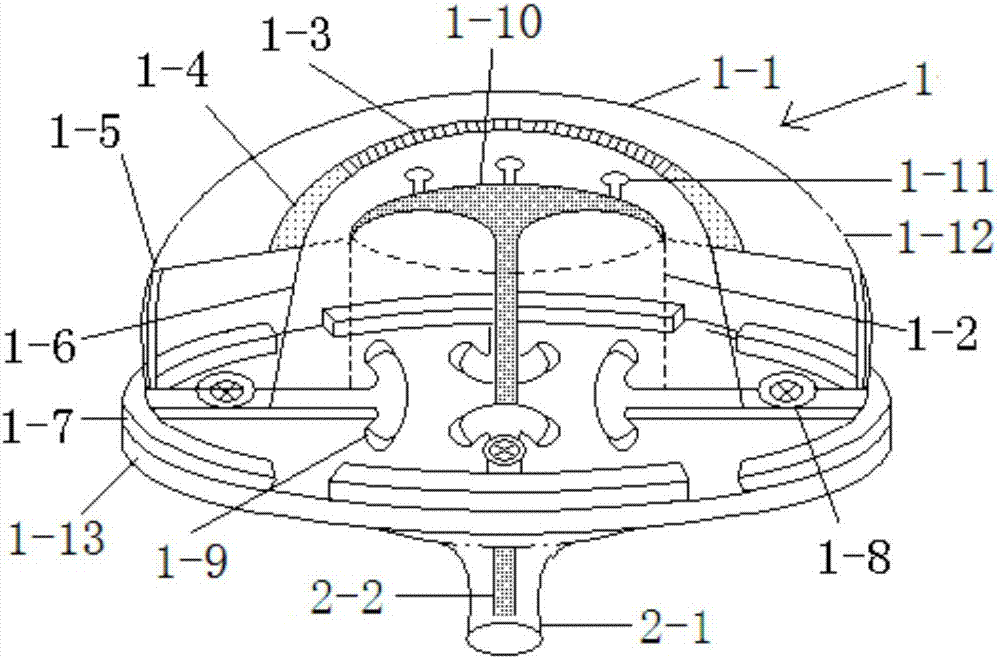

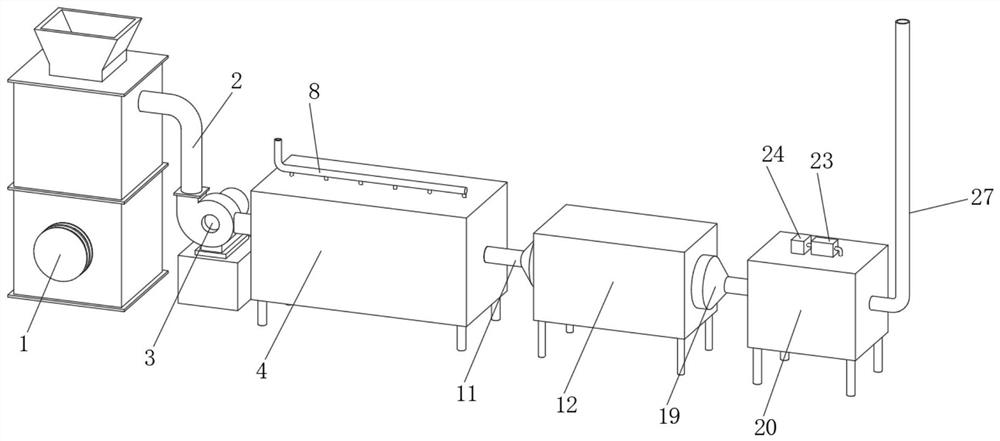

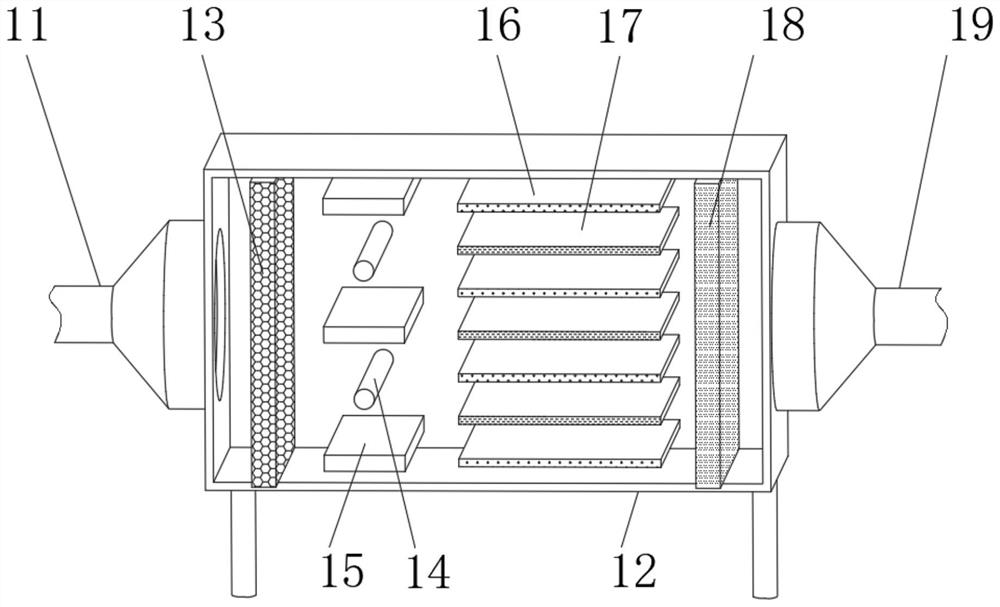

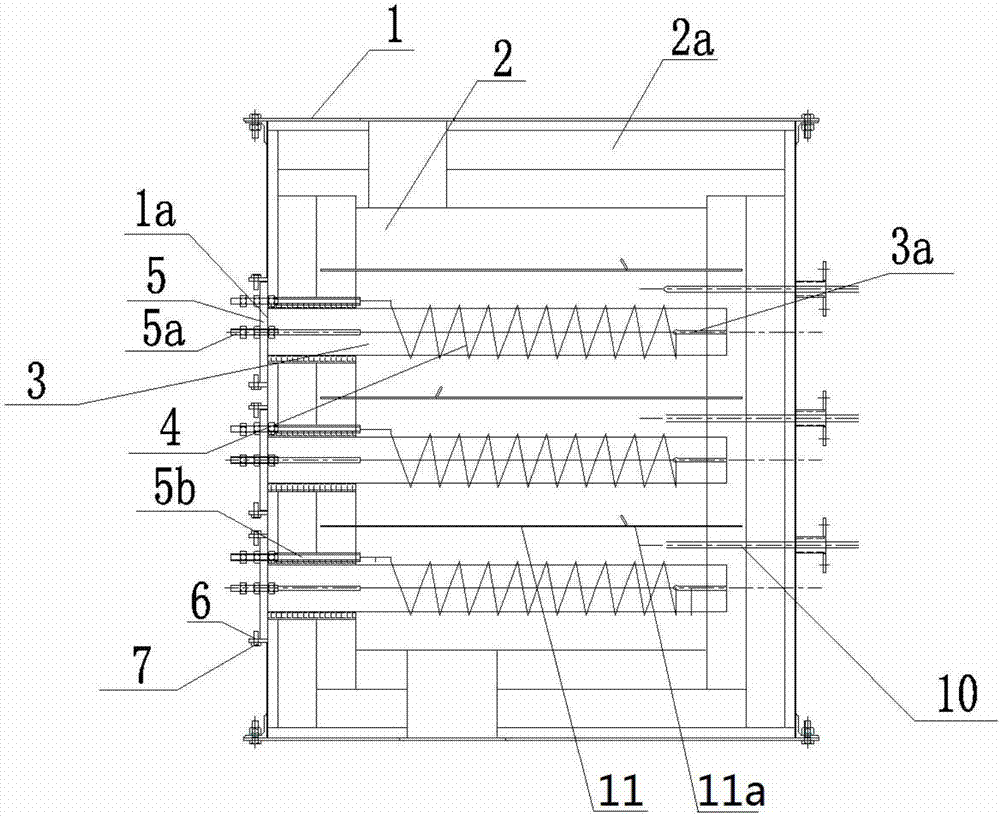

Flue gas dust removal, denitration and waste heat utilization integrated device and treatment method thereof

PendingCN109331647ASimple internal structureSimple structureGas treatmentDispersed particle filtrationAir preheaterFlue gas

The invention relates to the technical field of fuel gas purification, and discloses a flue gas dust removal, denitration and waste heat utilization integrated device and a treatment method thereof. The device is connected with a position between a boiler economizer and a desulfurizing tower, and comprises a casing, wherein the interior of the casing is divided into a dust removal zone and a comprehensive reaction zone which are horizontally arranged side by side and communicated with each other through a baffle; a denitration zone and an air preheating zone are sequentially arranged in the comprehensive reaction zone along the flue gas flowing direction; a fuel gas inlet is formed in the side wall of the casing of the dust removal zone; a fuel gas outlet is formed in the side wall of thecasing at the bottom of the comprehensive reaction zone; a high-temperature dust removal module which can directly perform dust removal and filtering on 350 to 400 DEG C fuel gas is arranged in the dust removal zone; the denitration zone is arranged at the upper part of the comprehensive reaction zone; the air preheating zone is positioned under the denitration zone; an air preheater is arranged inside the air preheating zone. The device is simple in structure, low in economic cost and operation cost, simple in structure, good in dust removal effect, high in denitration efficiency and small inequipment volume.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

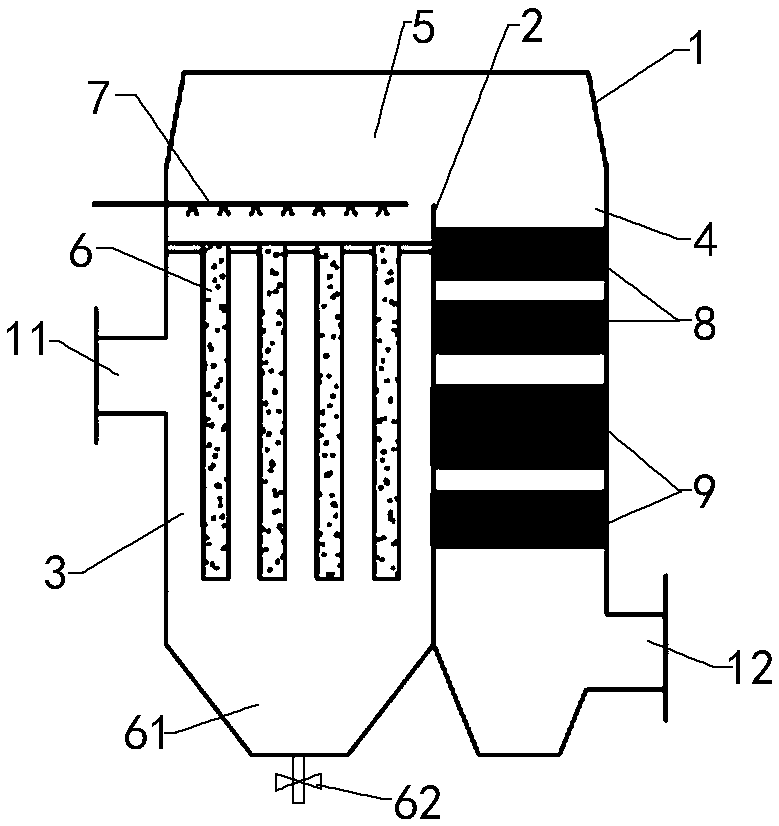

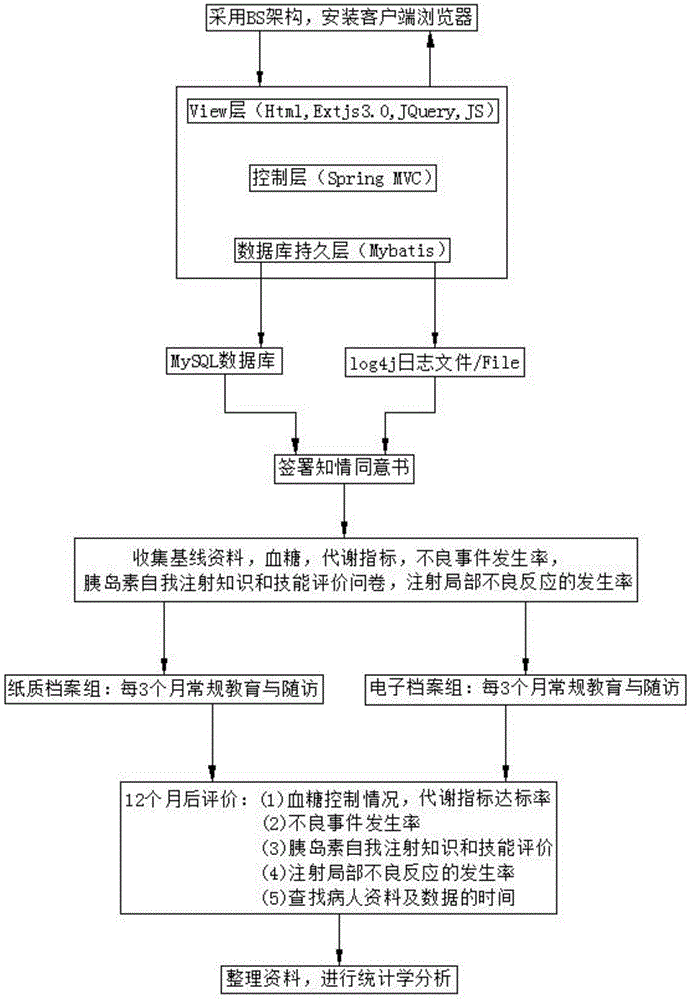

Insulin injection standardized management system

ActiveCN106503464AImprove work efficiencySpeed up circulationData processing applicationsTelemedicinePersonalizationHigh density

The invention discloses an insulin injection standardized management system, adopting a BS architecture and comprising a system client and a system server in both-way connection with the system client, wherein the system server comprises a view module, a control module in both-way connection with the view module, and a database persistence module connected with the control module, and the database persistence module is connected with a database. According to the insulin injection standardized management system provided by the invention, through using the characteristics of scientific design, convenient modification, high-density information storage, attention on long term, and capability of conveniently retrieving, extracting, transcribing, and counting by continuous monitoring of standardized management software, the limiting of time, region and space is broken through, one electronic file can be read by different persons simultaneously at different time and different sites, and the deficiency that a paper file cannot be exchanged and used through internet is overcome, a doctor can monitor and report in real time, and make a personalized diagnosis and treatment scheme for a patient, and adjust insulin dosage and use in time.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

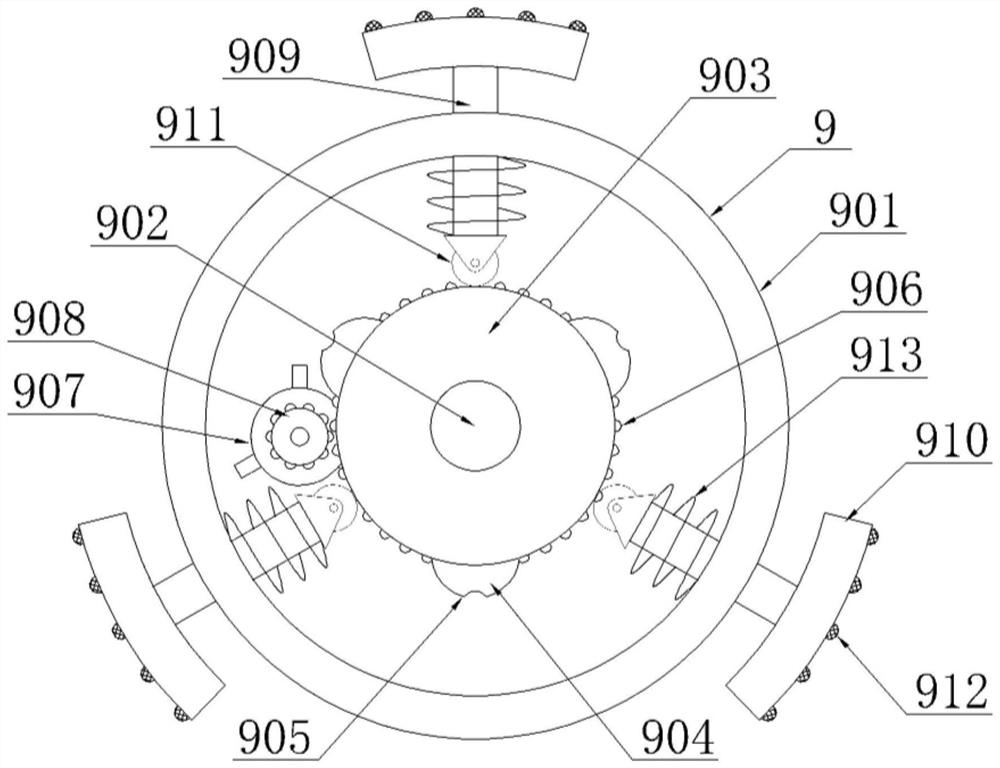

Round pipeline paint sprayer with quick drying function for round hollow pipe

ActiveCN112756167AAvoid drippingQuick paintPretreated surfacesCoatingsStructural engineeringManufacturing engineering

The invention discloses a round pipeline paint sprayer with a quick drying function for round hollow pipe in the technical field of pipe paint sprayers. The round pipeline paint sprayer comprises a case, wherein pipe fitting locking assemblies are mounted at the opposite ends of two rotating rods, and the outer walls of the two pipe fitting locking assemblies are sleeved with a pipeline; a paint sprayer for rapidly drying a paint layer is arranged in a sliding groove in a sliding mode, a pump body is started to suck external air into an air drying pipeline through an air inlet nozzle, air blocks in the air drying pipeline can slow down the air circulation speed, the air in the air drying pipeline is fully heated, then hot air is sprayed out through nozzles, and rapid paint spraying and drying operation of the pipeline is realized; and meanwhile, a rotating motor drives a swing arm to rotate, at the moment, a swing rod drives a sliding block to slide left and right on a sliding rod, a transmission rack drives an arc-shaped rack and a circular air pipe to rotate, the air sprayed out of the nozzles is evenly sprayed to the pipeline and is matched with the pipeline rotating in the reverse direction, and the paint layer on the outer wall of the pipeline is uniformly air-dried.

Owner:辽宁联通管业有限公司

Intelligent power plant carbon emission monitoring system and monitoring method thereof

InactiveCN114236052AReduce manufacturing costReduce use costPreparing sample for investigationGas analyser construction detailsFlue gasMonitoring system

The invention discloses an intelligent power plant carbon emission monitoring system and a monitoring method thereof.The intelligent power plant carbon emission monitoring system comprises a chimney, a flow equalizing structure is fixedly installed in the chimney, a monitoring structure is fixedly installed in the chimney and located above the flow equalizing structure, the flow equalizing structure comprises a flow equalizing box, and the top of the flow equalizing box is open; a partition plate is fixedly installed in the flow equalizing box, and a middle vertical pipe is installed at the circle center of the partition plate in a penetrating and inserting mode. According to the intelligent power plant carbon emission monitoring system and the monitoring method thereof, discharged flue gas is intensively guided in, disordered and then guided into the flow equalizing cylinder in a staggered manner, so that the flue gas at different positions can be staggered together and uniformly mixed, the concentration of carbon dioxide in the flue gas is more uniform, and the carbon emission of the power plant is more uniform. It is guaranteed that follow-up carbon dioxide concentration detection data is representative, detection errors are reduced, and a plurality of carbon dioxide concentration sensors do not need to be installed.

Owner:娄金洋

Tail gas treatment cracking device

PendingCN109099444AReduce difficulty of useIncrease flexibilityIncinerator apparatusExhaust gasCombustion chamber

The invention discloses a tail gas treatment cracking device. The tail gas treatment cracking device includes a fan, a shell, a corrugated pipe, a base, an exhaust pipe, a three-way pipe, a one-way valve, a base plate, an exhaust passage, a ceramic fiber heater, an exhaust gas combustion chamber and an insulating layer. According to the tail gas treatment cracking device, the height between the base and the base plate can be adjusted, so that the height of the corrugated pipe is adjusted, thus the connection between the corrugated pipe with an exhaust port of a degreasing furnace is facilitated, the using difficulty of the tail gas treatment cracking device is reduced, so that the corrugated pipe can be matched with different models of degreasing furnaces for use, the heights of exhaust ports of the different models of degreasing furnaces are different, the using flexibility of the tail gas treatment cracking device is higher, the tail gas treatment cracking device has a wide application range, and the practicality of the tail gas treatment cracking device is improved; and according to the tail gas treatment cracking device, the flow path of exhaust gas in the exhaust gas combustion chamber can be increased through baffle plates, the flow velocity of the exhaust gas in the exhaust combustion chamber can be reduced, so that the combustion of the exhaust gas in the exhaust gas combustion chamber is more fully, and thus the effect of exhaust gas treatment is improved.

Owner:合肥费舍罗热工装备有限公司

Household cleaning floor drain

ActiveCN111705897AImprove filtering effectMaintain liquidityFatty/oily/floating substances removal devicesSewerage structuresSewageMechanical engineering

The invention discloses a household cleaning floor drain, and relates to the technical field of floor drains. The household cleaning floor drain comprises a floor drain shell body, a water inlet is formed in the top of the floor drain shell body, a water outlet is formed in the bottom of the floor drain shell body, a filter screen is rotationally connected to one side in the floor drain shell body, a mesh plate is rotationally connected to one end, away from the floor drain shell body, of the filter screen, sliding blocks are rotationally connected to the two sides of one end, away from the filter screen, of the mesh plate correspondingly, sliding grooves are formed in the two sides of one face, away from the joint with the filter screen, in the floor drain shell body in the vertical direction correspondingly, the ends, away from the mesh plate, of the two sliding blocks are slidably connected into the sliding grooves, and reset springs are fixedly connected to the bottoms of the two sliding blocks. According to the household cleaning floor drain, after the flow and the flow speed of sewage flowing into the floor drain shell body are reduced, a spray head rushes out cleaning liquidto the filter screen to dredge blocked meshes in the filter screen, so that the filtering effect and the drainage speed of the filter screen are kept; and meanwhile, dredged and flushed-out impurities and originally intercepted impurities are collected in a collecting basket, so that the burden of the filter screen is reduced, and meanwhile centralized cleaning is facilitated.

Owner:浙江新颖铜业有限公司

Dust removal device for dry-mixed mortar production

InactiveCN113599940AEvenly dispersedAvoid clogging the filterCombination devicesAir pumpDust control

The invention discloses a dust removal device for dry-mixed mortar production, and relates to the field of dry-mixed mortar production. The dust removal device comprises a device main body, one side of the device main body is provided with an air pump, the air inlet end of the air pump is connected with an air inlet pipe, and the air outlet end of the air pump communicates with the device main body. When the air pump sucks air into the device main body, fan blades rotate under the influence of wind power, and the air can be uniformly dispersed under the action of an air dispersing plate and air dispersing holes, so that the air can be in uniform contact with a filter screen, the filtering effect is improved, when the fan blades rotate, a first rotating shaft rotates, the first rotating shaft rotates to enable a cleaning brush to rotate, the cleaning brush is in contact with the filter screen, and when the cleaning brush rotates, the outer surface of the filter screen is cleaned, so that the problem that the filter screen is blocked by dust is avoided, the dust removal efficiency is improved, and the frequency of manually cleaning the filter screen by workers is reduced.

Owner:怀化市昌顺建筑工程有限公司

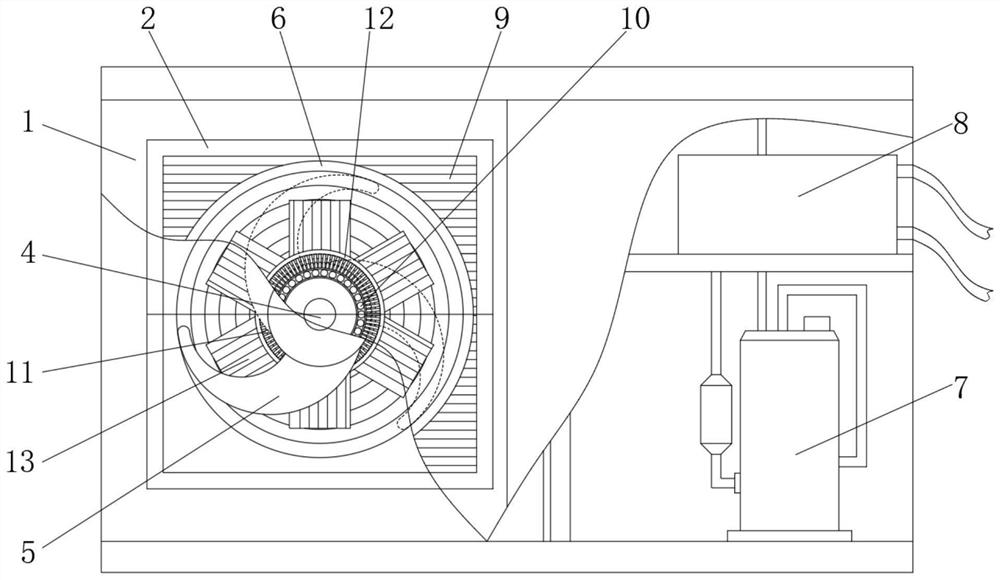

Air-energy heating pump

ActiveCN111637663ASufficient heat exchangeImprove heat transfer efficiencyHeat pumpsEvaporators/condensersElectric machineryRefrigerant

The invention relates to the technical field of heating equipment, and discloses an air-energy heating pump. The air-energy heating pump comprises a mainframe box body, wherein an air inlet hole is formed in one side of the front surface of the mainframe box body, a motor is fixedly installed on the portion, corresponding to the air inlet hole, of the back surface inside the mainframe box body, and a compressor is fixedly installed on the other side inside the mainframe box body. According to the air-energy heating pump, by means of an inclined guide fan matched with a fan, the air sucked in rotation of the fan makes contact and collides with the guide fan, so that the guide fan rotates, and the air circulation speed can be decreased; under the action of the centrifugal force of the rotating guide fan, the collision air flows around, the side contact heat exchange time between the air and an evaporator can be shortened, repeated heat exchange does not occur after the normal-temperatureair makes contact with the evaporator, and sufficient heat exchange between the flowing air and the evaporator is ensured; and meanwhile, the side heat exchange efficiency between the air and the evaporator is ensured, and a side refrigerant can be subjected to heat exchange to the highest temperature.

Owner:重庆鑫隆旭机械有限公司

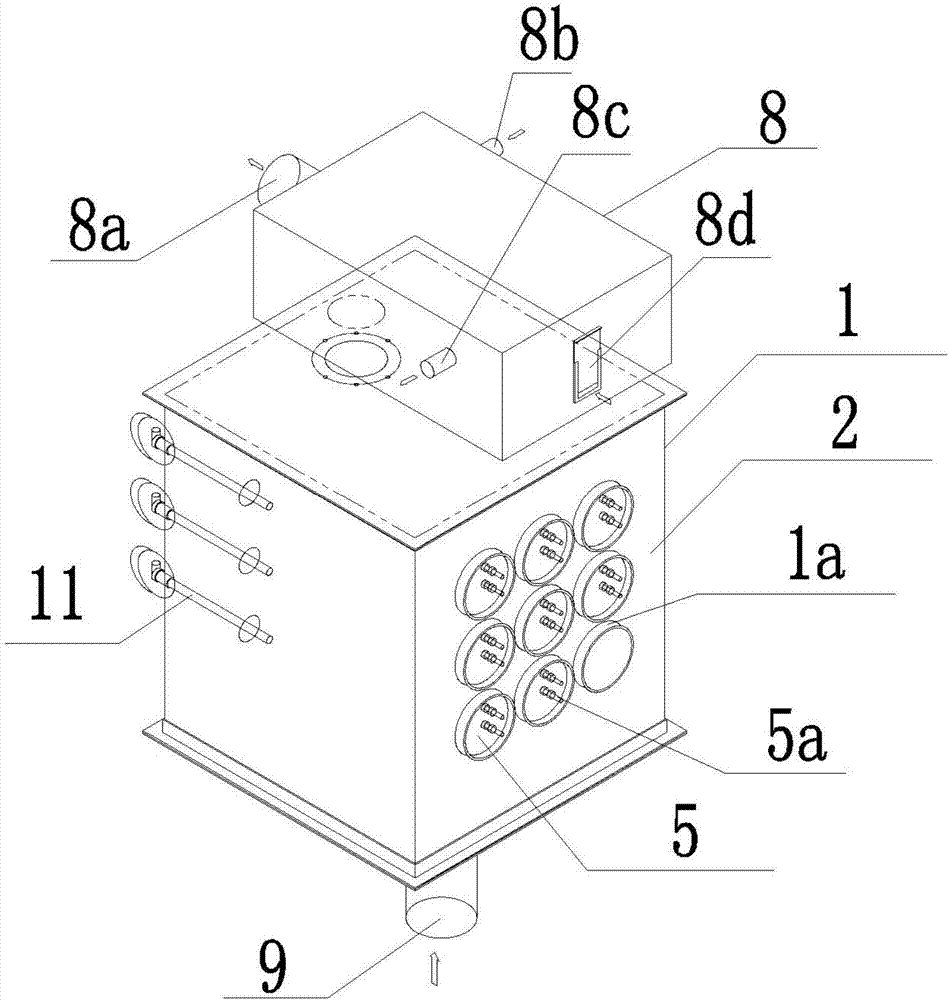

Dust removal device for ore crusher

PendingCN112620292AFully settledSlow down circulationCombination devicesUsing liquid separation agentMining engineeringCrusher

The invention discloses a dust removal device for an ore crusher, and relates to the technical field of ore processing, in particular to a dust removal device for an ore crusher. The device comprises a crusher; the right side of the crusher is fixedly connected with a dust suction pipe; the bottom of the dust suction pipe is fixedly connected with a conveying fan; the right side of the conveying fan is fixedly connected with a settling chamber; a flow baffle is fixedly mounted in the settling chamber; and a water spraying pipe is fixedly mounted at the top of the settling chamber. According to the dust removal device for the ore crusher, the water spray pipe is arranged in the settling chamber, dust generated during crushing is sucked into the settling chamber through a dust suction pipe, water mist is sprayed out through an atomizing spray head at the top of the water spray pipe, and small water drops adsorb dust in dusty gas, so that the dust in the dusty gas settles along with the water drops, and the dust is prevented from polluting air.

Owner:福建省大田县山友机械有限公司

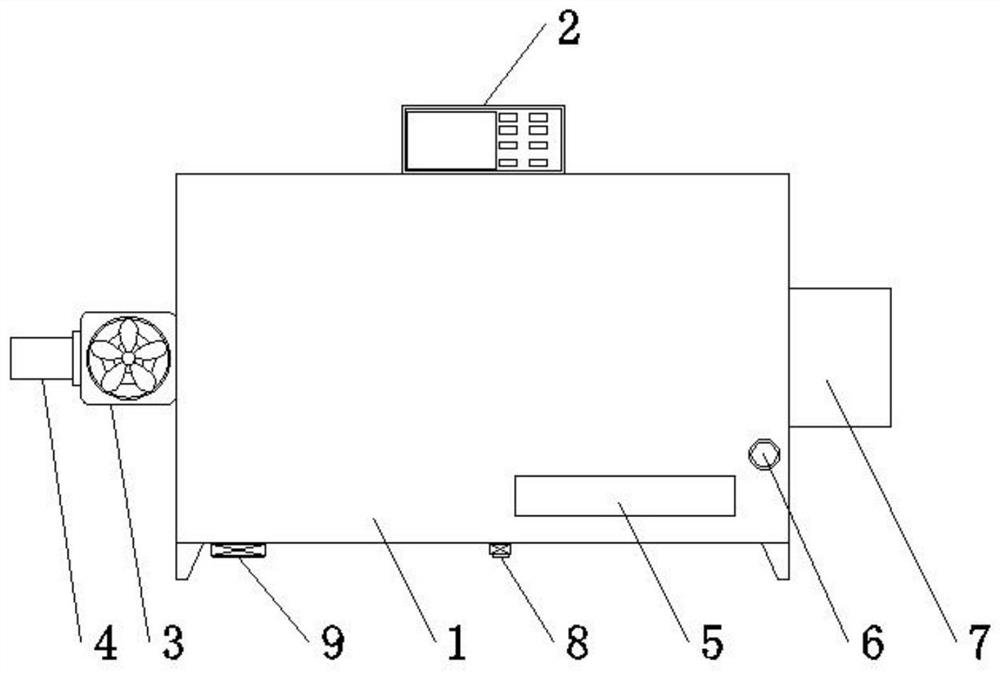

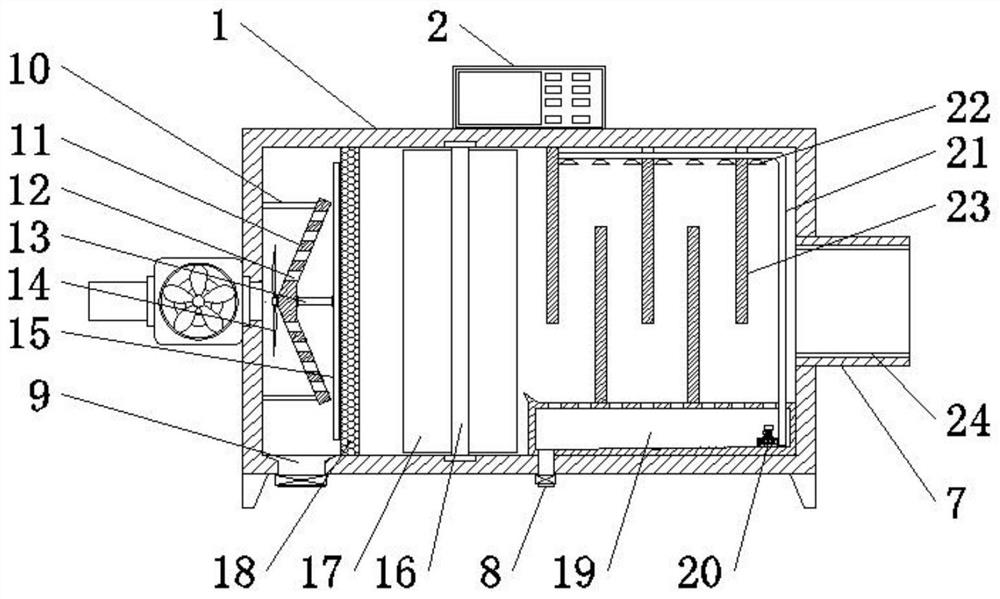

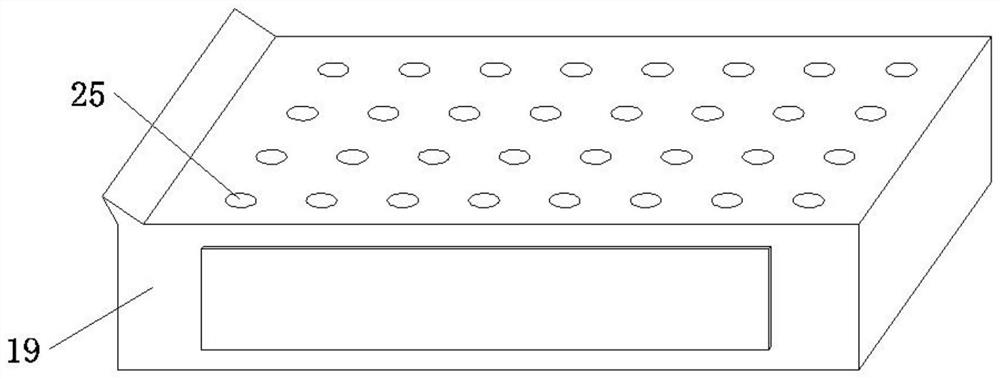

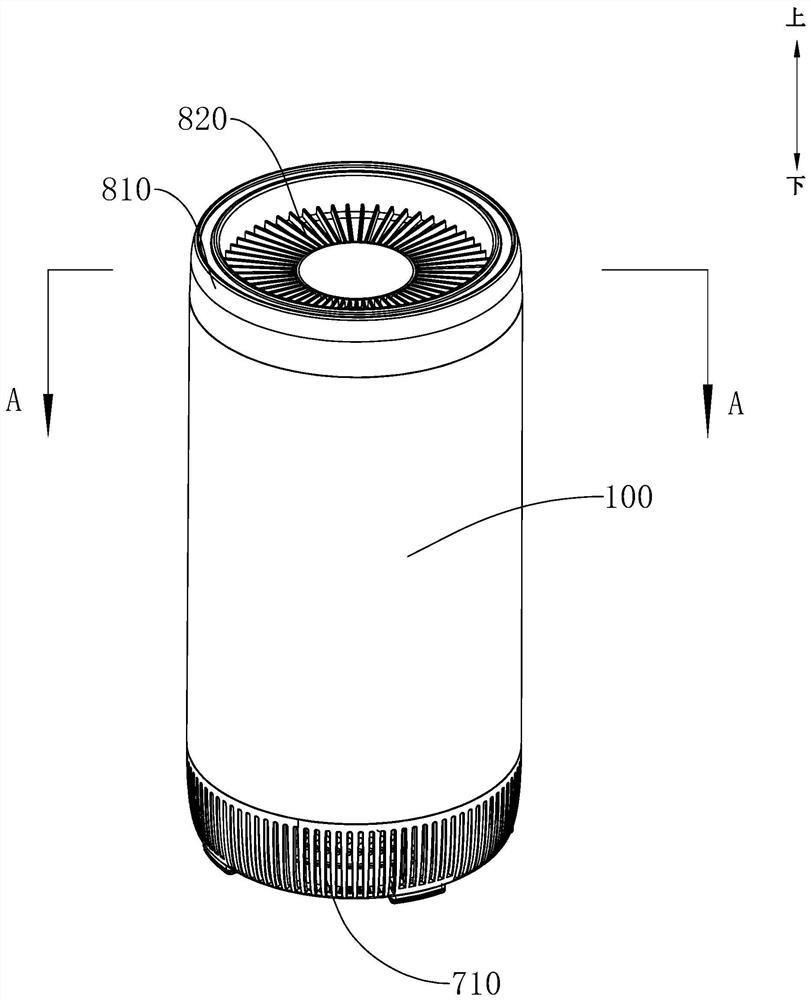

Intercepting and killing type air disinfection machine

PendingCN111829090ASlow down circulationImprove the bactericidal effectLighting and heating apparatusHeating and ventilation casings/coversSterilizing UnitsMechanical engineering

The invention discloses an intercepting and killing type air disinfection machine. The machine comprises a housing, a first filter part, an induced draft device and a disinfection device; the housingis provided with an accommodating cavity, an air outlet communicated with the accommodating cavity is arranged at the top of the housing, and an air inlet communicated with the accommodating cavity isarranged at the bottom of the housing; the first filter part is arranged on the housing, and the first filter part divides the accommodating cavity into an air outlet chamber and a chamber to be filtered; the induced draft device is arranged on the air outlet chamber; the disinfection device is arranged on the housing, and the disinfection device can disinfect the chamber to be filtered and the first filter part. According to the air disinfection machine, the residence time of air in a disinfection area can be increased, and the quality of sterilization and disinfection is improved.

Owner:中山市赛恩电器科技有限公司

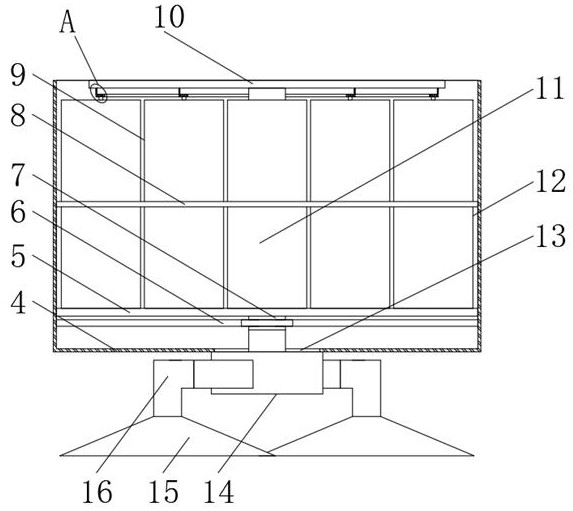

Temperature-variable indoor hot water heating radiator

ActiveCN113375219AReduce inflowSlow down circulationSpace heating and ventilation detailsStationary conduit assembliesThermodynamicsWater flow

The invention discloses a temperature-variable indoor hot water heating radiator, and belongs to the field of heating equipment. The temperature-variable indoor hot water heating radiator comprises a heat dissipation assembly, a water inlet end, a water outlet end, a water inlet control assembly and a water outlet control assembly, the water inlet control assembly comprises a water inlet air bag, the water inlet air bag is fixedly arranged on the periphery of a communicating opening of an upper back pipe and a heat dissipation pipe, and the water inlet air bag is made of a flexible material, a caliber of the communicating opening of the upper back pipe and the heat dissipation assembly is reduced after the water inlet air bag is heated, the water outlet control assembly comprises a water outlet air bag, the water outlet air bag is fixedly arranged on the periphery of the communicating opening of a lower back pipe and the heat dissipation pipe, and the water outlet air bag is made of the flexible material, so that the caliber of the communicating opening of the lower back pipe and the heat dissipation pipe is reduced after the water outlet air bag is heated; according to the temperature of hot water flowing in a pipe, the flowing speed of the hot water in the pipe can be automatically adjusted, heat energy of the hot water is fully released, the heat energy is effectively utilized, and energy consumption is reduced.

Owner:ZHEJIANG SUNLIGHT HEATING EQUIP

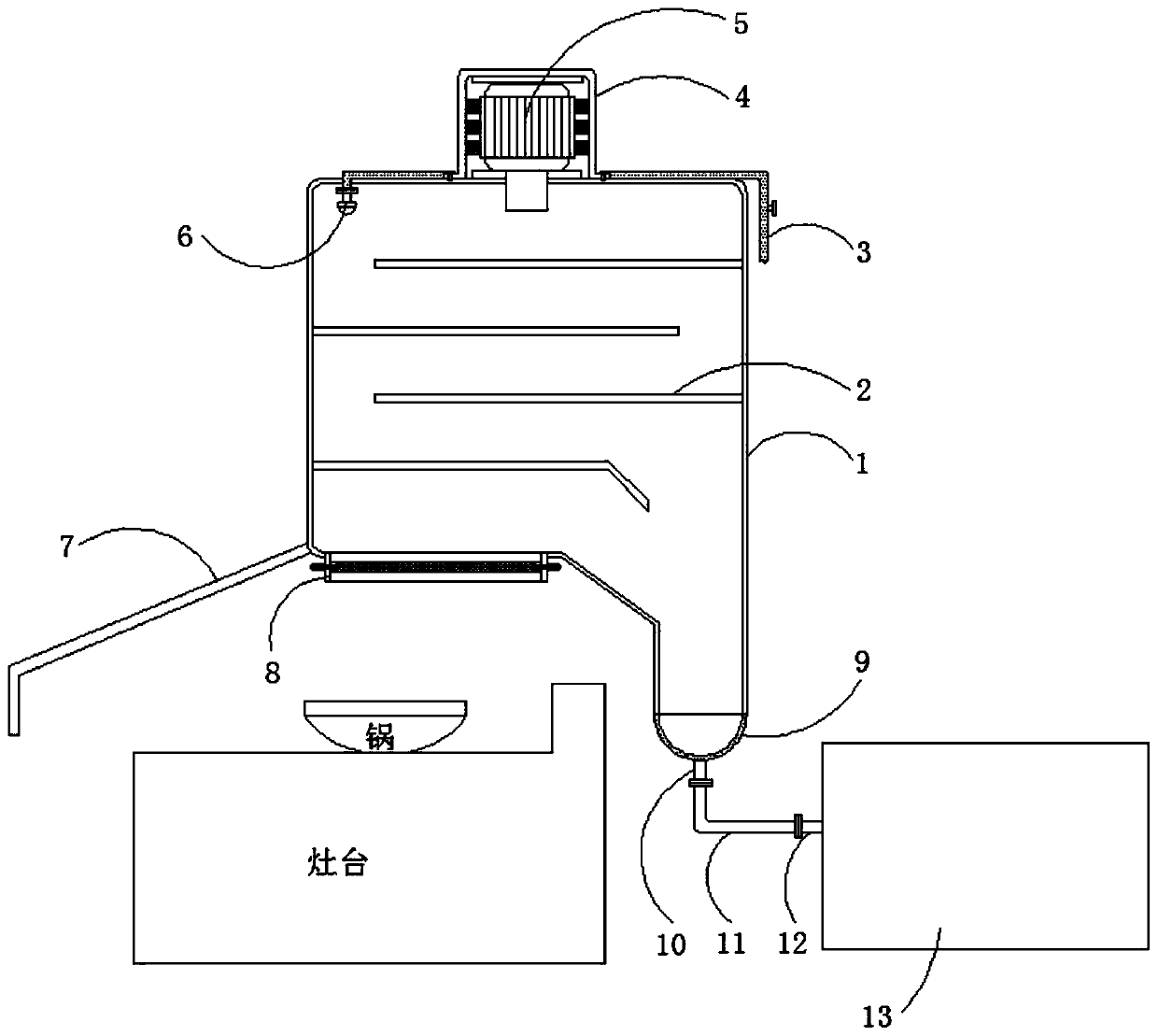

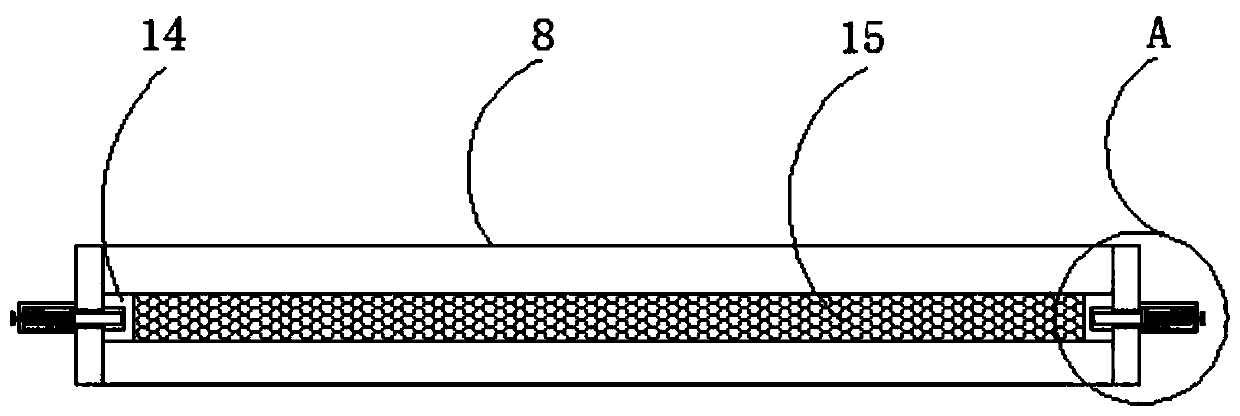

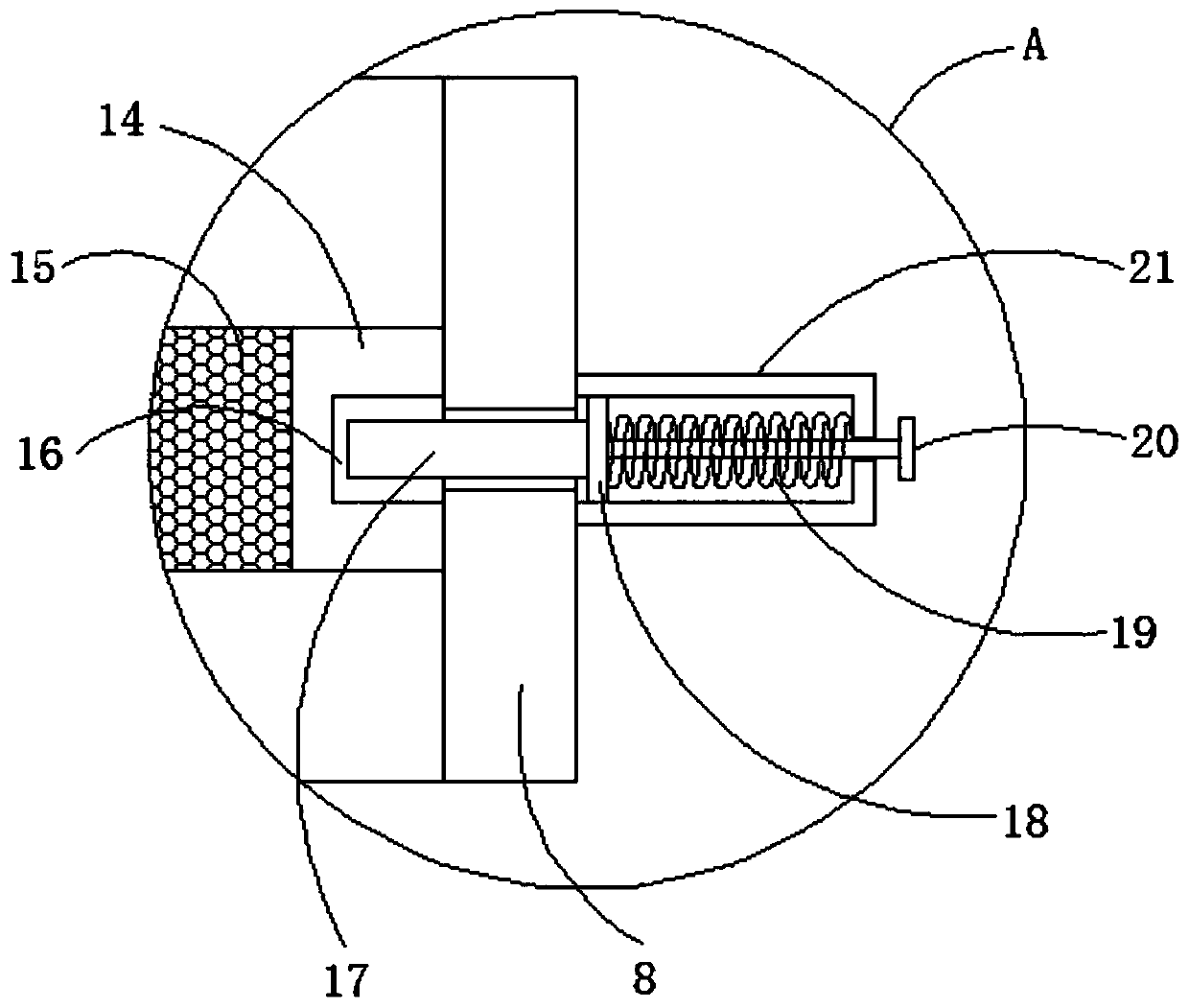

Oil fume purifying cover

PendingCN111473382AReduce operating costsReduce pollutionDomestic stoves or rangesPump componentsDust controlWater supply

The invention discloses an oil fume purifying cover. The oil fume purifying cover comprises a cover body and a washing solution pool, wherein two baffling plates are welded to the inner surface wallsof each of the two sides of the cover body at equal intervals, a buffering plate is fixed to the center of the top of the cover body, a draught fan is installed at the top of the buffering plate, an air inlet of the draught fan extends into the cover body, a spraying water supply pipe is laid at the top of the cover body, and one end of the spraying water supply pipe extends into the cover body. According to the oil fume purifying cover, oil fume passes through a route inside extending equipment, the oil fume circulation speed is reduced in a baffling mode, and then a cleaning medicine liquidsprayed by a high-pressure spray head makes full contact with oil fume gas to form rapid dust removal and cooling, so that the oil fume and the atomized medicine liquid flow in a cross direction, oilmolecules in the oil fume gas are decomposed and purified into a fluid, and then flow to the washing solution pool for curing, in use, the environment-friendly, energy-saving, fireproof and safe effects are achieved, a flue is free of oil and self-cleaning, and self-equipment and an oil fume exhausting pipeline are free of washing.

Owner:天津君盛宏达科技有限公司

Exhaust system mixer

ActiveCN113530649AImprove use valueSlow down circulationExhaust apparatusSilencing apparatusThermodynamicsMechanical engineering

The invention discloses an exhaust system mixer which comprises a shell. The inner walls of the two sides, located in the middle, of the shell are fixedly connected with the same mounting frame, the inner wall of the mounting frame is fixedly connected with a fan-shaped mixer body, and the outer wall, close to the fan-shaped mixer body, of the mounting frame is fixedly connected with a flow limiting frame. A square mixer is replaced by the fan-shaped mixer body, and gas entering the shell through a gas inlet pipe firstly passes through a flow guide assembly and then passes through a uniform distribution assembly, so that the gas flowing to the fan-shaped mixer body uniformly passes through each fan-shaped blade on the fan-shaped mixer body; and due to the existence of the fan-shaped blades, after the gas flows through the fan-shaped mixer body, the gas flows out at an inclined angle, so that staggered impact is generated between the gas and gas flow at the other end of the fan-shaped mixer body, the situation that the circulation speed is greatly reduced due to straight-face impact is avoided, the gas circulation speed is increased, and the use value of the fan-shaped mixer body is improved.

Owner:东风佛吉亚排气控制技术有限公司

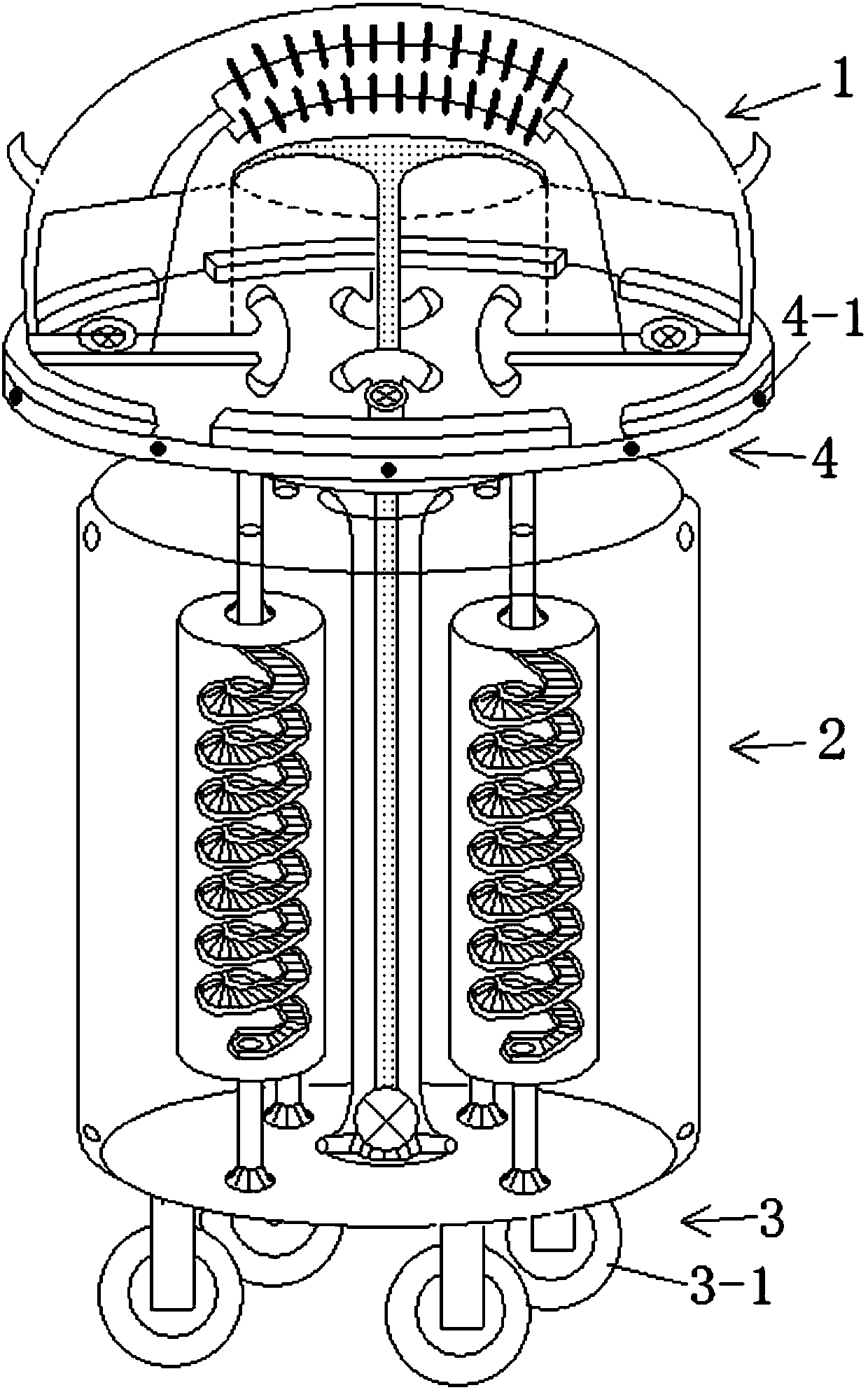

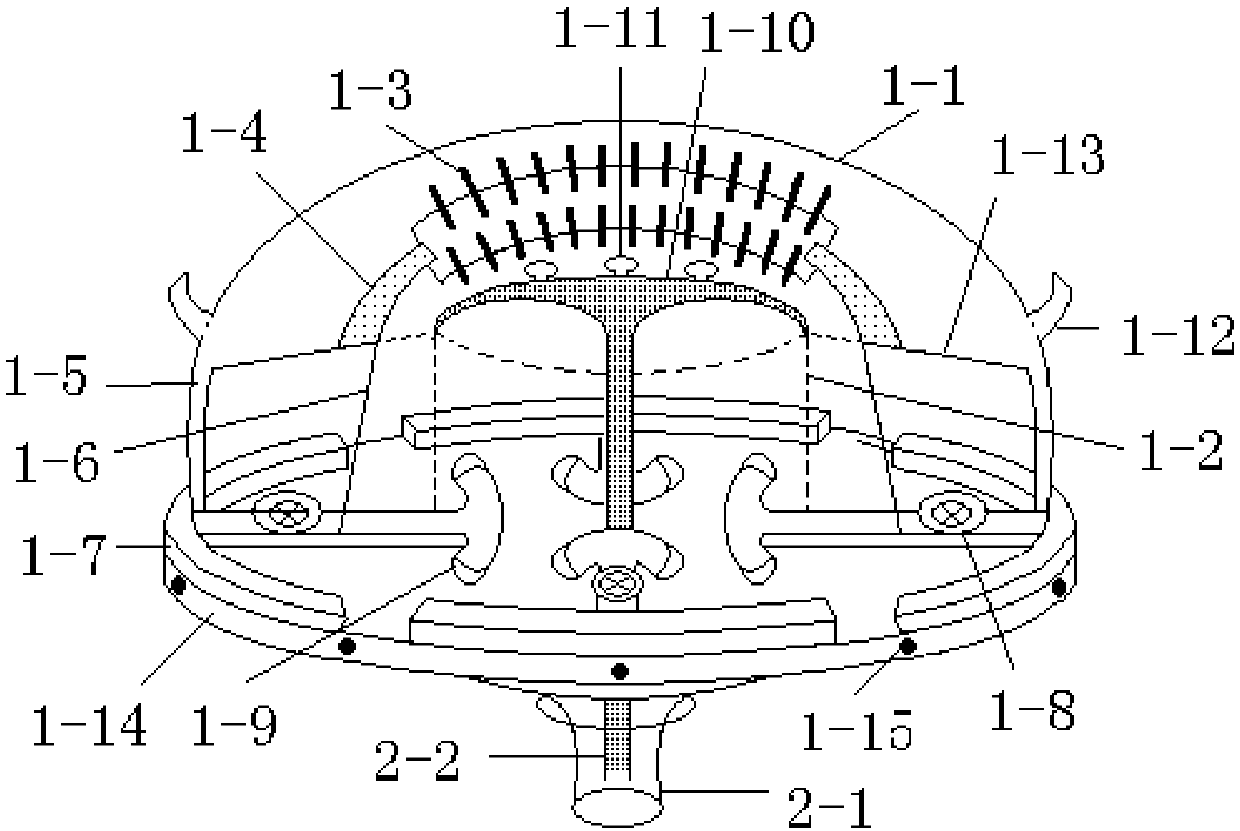

Air purification method based on air purification robot

ActiveCN107901047AImprove the degree of purificationImprove purification effectGas treatmentUsing liquid separation agentControl systemEngineering

The invention discloses an air purification method based on an air purification robot, and belongs to the field of air purification devices. According to the air purification method disclosed by the invention, air purification is achieved by using the air purification robot. The robot comprises a smaze purification mechanism, a sewage purification mechanism, a driving mechanism and a smaze detection mechanism, and a small water mist spraying device in the smaze purification mechanism is used for spraying water mist to a photocatalytic device; external air induced by a ventilation mechanism flows through the photocatalytic device and is purified, and sewage flowing out of the smaze purification mechanism is recycled after being purified by the spiral trapezoidal photocatalytic device; and the smaze detection mechanism is used for detecting the concentration of smaze in air, and a control system is used for controlling the movement of the driving mechanism according to received signals.According to the air purification method based on the air purification robot; the water mist and photocatalysis are used for haze removal, and sewage for haze removal is purified; the air purificationmethod is combined with the robot walking technology, so that high-smaze areas can be automatically identified indoors, and the air purification is performed; and the intelligent degree is high.

Owner:合肥市宗恩信息科技有限公司

Stem cell storage workshop with good ventilation effect

PendingCN108613321AImprove ventilationEasy to storeMechanical apparatusLighting and heating apparatusFresh airEngineering

The invention discloses a stem cell storage workshop with a good ventilation effect. The stem cell storage workshop comprises a workshop body. A ceiling is fixedly connected to the top of the workshopbody, and an air inlet device is arranged on the left side face of the workshop body. The air inlet device comprises a first pipeline. The first pipeline is clamped to the upper portion of the left side face of the workshop body, and a first fixing plate is arranged inside the first pipeline. According to the stem cell storage workshop with the good ventilation effect, by arranging an air blowingdevice and a driving device, an output shaft of a first motor in the air blowing device rotates to drive fan blades to rotate, the fan blades rotate and can blow fresh air into the workshop body, anoutput shaft of a second motor in the driving device rotates forward to drive a movable plate to descend, the movable plate drives a baffle to descend, and the baffle descends to open a second pipeline, so that the air inside the workshop body circulates with the outside, the ventilation effect of the workshop body is better, and convenience is brought to people in the process of storing stem cells.

Owner:湖州佳灏信息技术有限公司

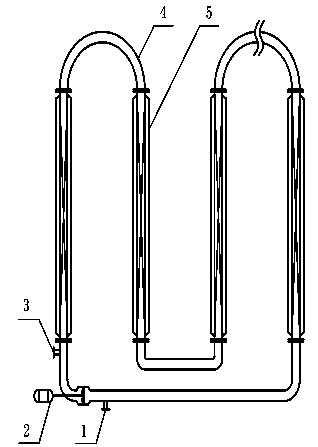

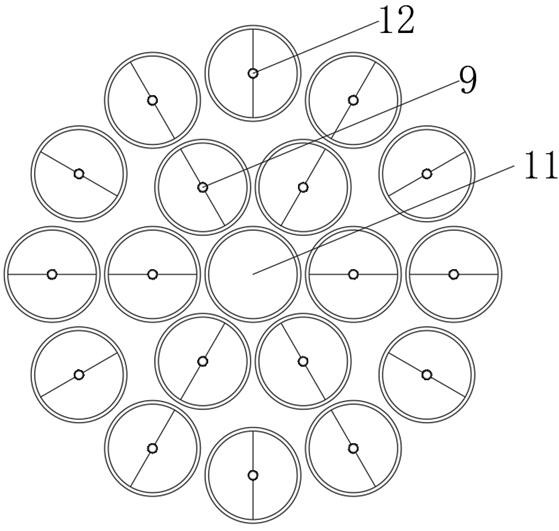

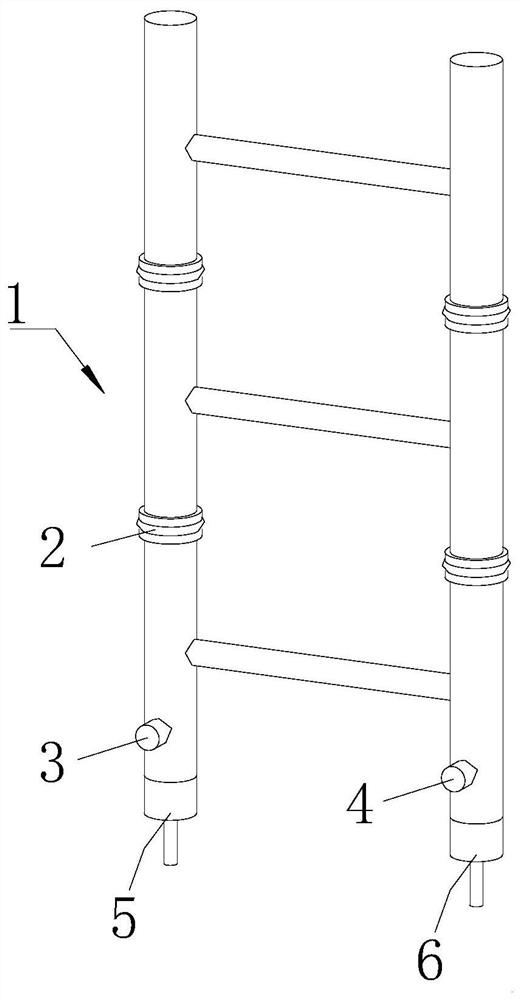

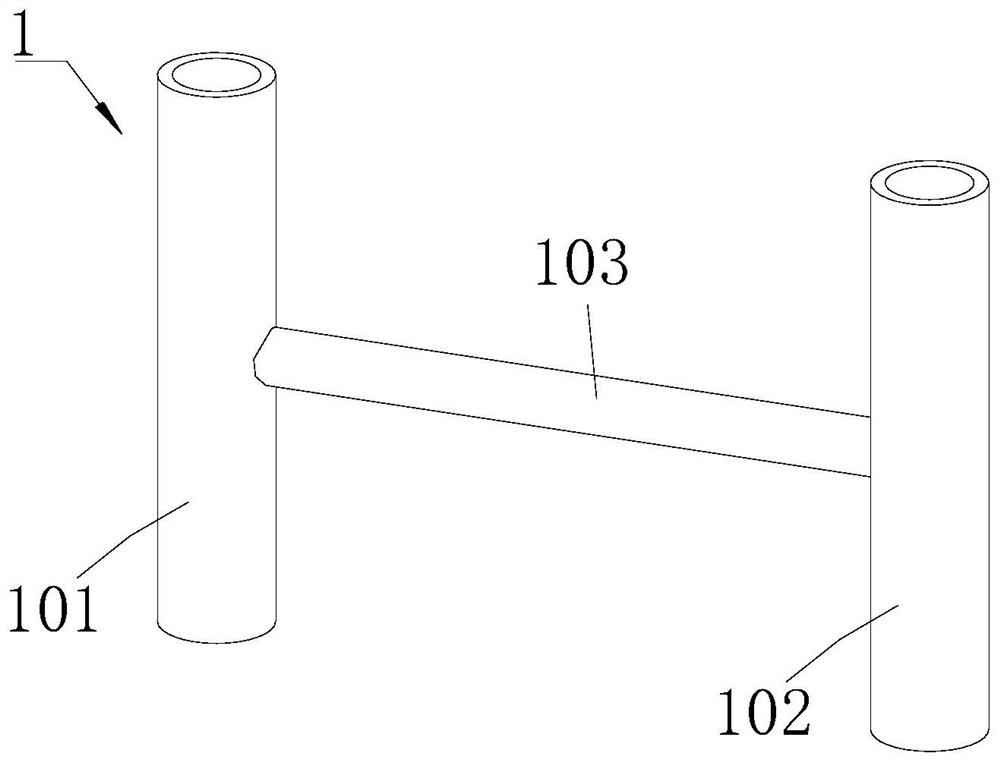

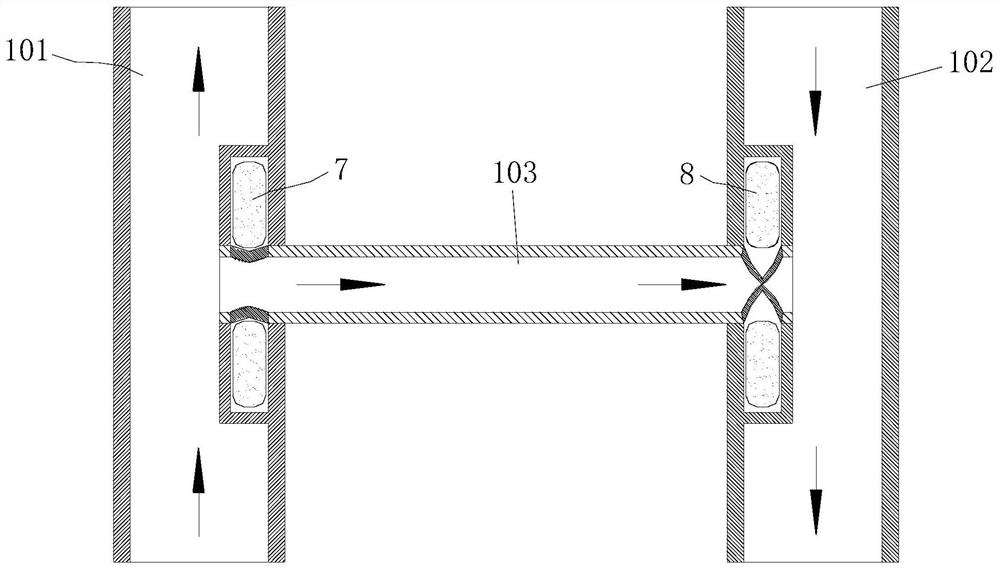

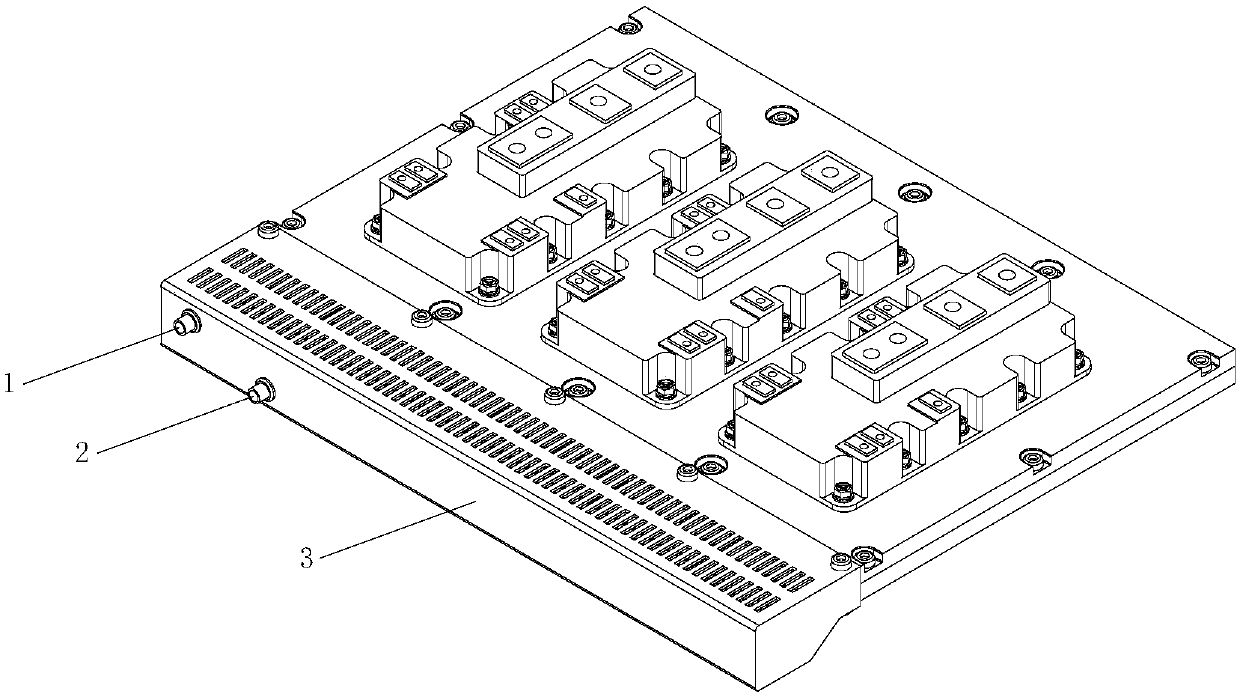

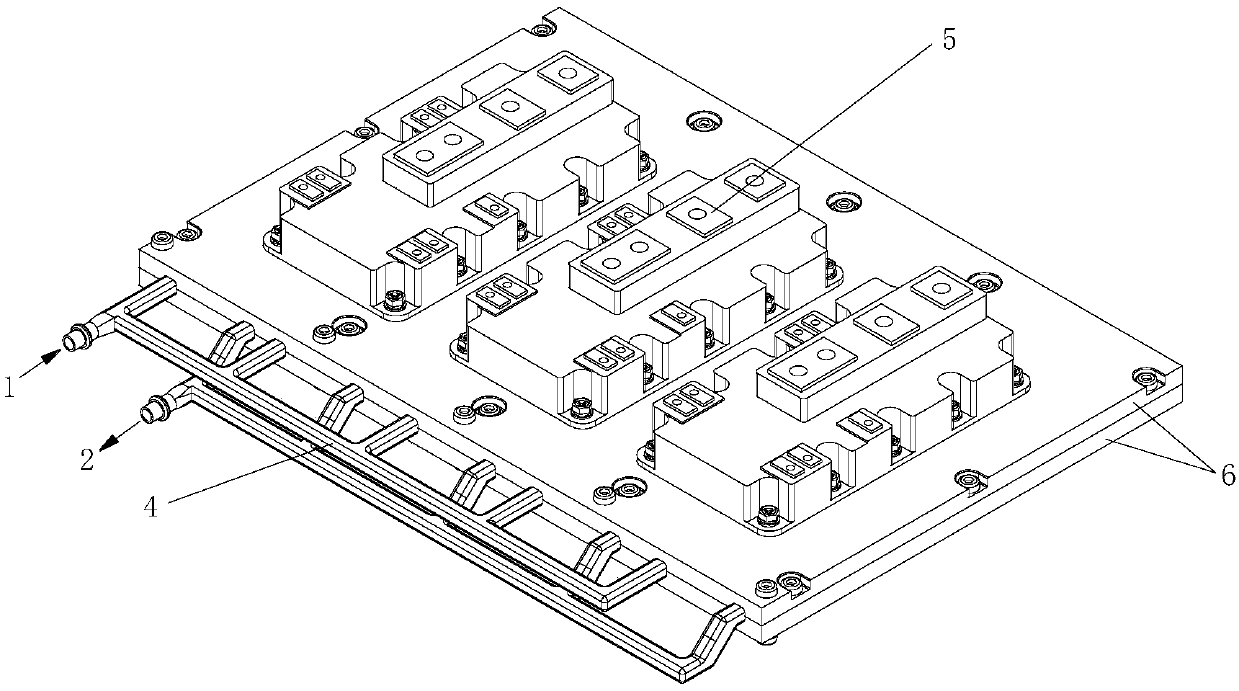

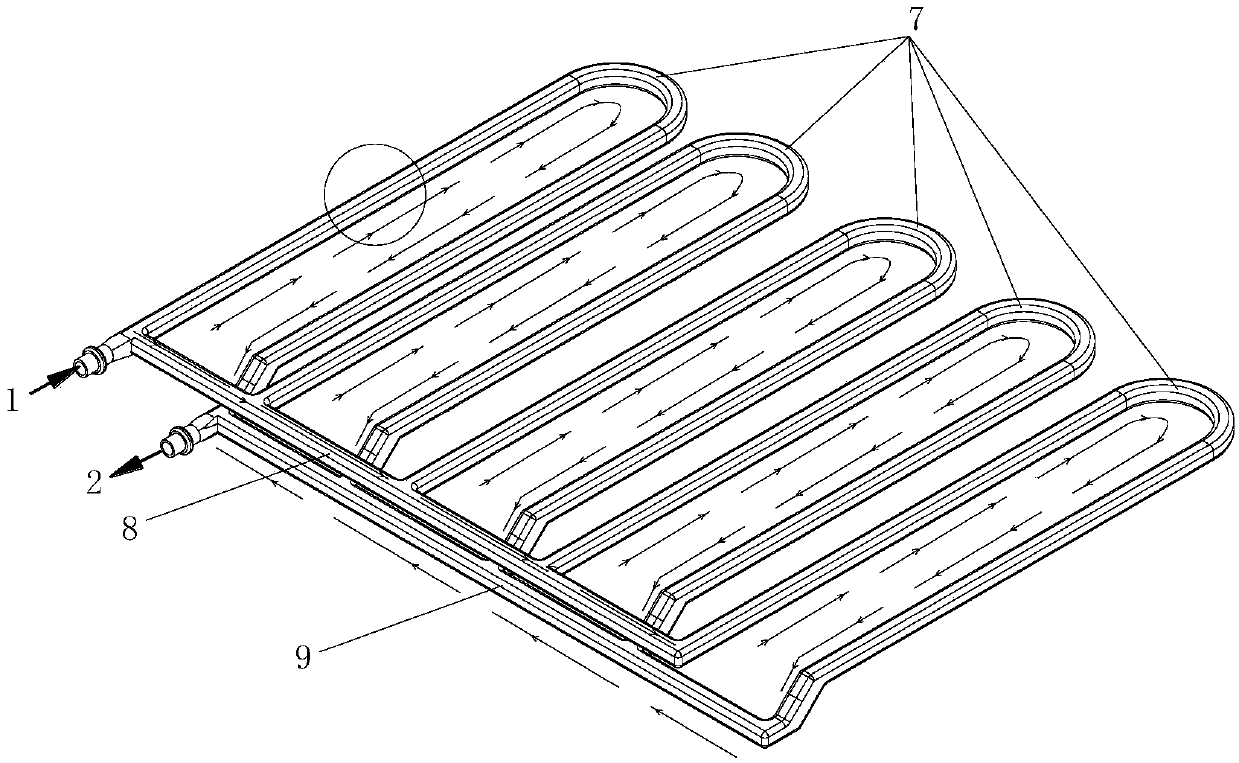

Parallel pipe liquid-cooling radiator for heat dissipation of high-power IGBT

ActiveCN109637989AShorten cycle strokeReduce volumeSemiconductor/solid-state device detailsSolid-state devicesBalance performancePower electronics

The invention relates to a parallel pipe liquid-cooling radiator used for the heat radiation of a high-power IGBT, and relates to the technical field of power electronics. The radiator comprises two aluminum plates and a composite copper pipe. The composite copper pipe is embedded between the two overlapped aluminum plates, and the aluminum plates are provided with grooves corresponding to the composite copper pipe. The composite copper pipe comprises a plurality of U-shaped loops connected in parallel, and a liquid inlet pipe and a liquid outlet pipe which are parallel to each other. One endof the liquid inlet pipe is communicated with one end of the liquid outlet pipe, and the other end of the liquid inlet pipe serves as a liquid inlet, and the other end of the liquid outlet pipe servesas a liquid outlet. One end of each U-shaped loop is communicated with the liquid inlet pipe, and the other end of each U-shaped loop is communicated with the liquid outlet pipe. The radiator is moreconvenient to install and maintain, the heat exchange balance performance of the radiator is improved, and meanwhile. the safety and reliability of the liquid cooling radiator are improved.

Owner:DAYU ELECTRIC

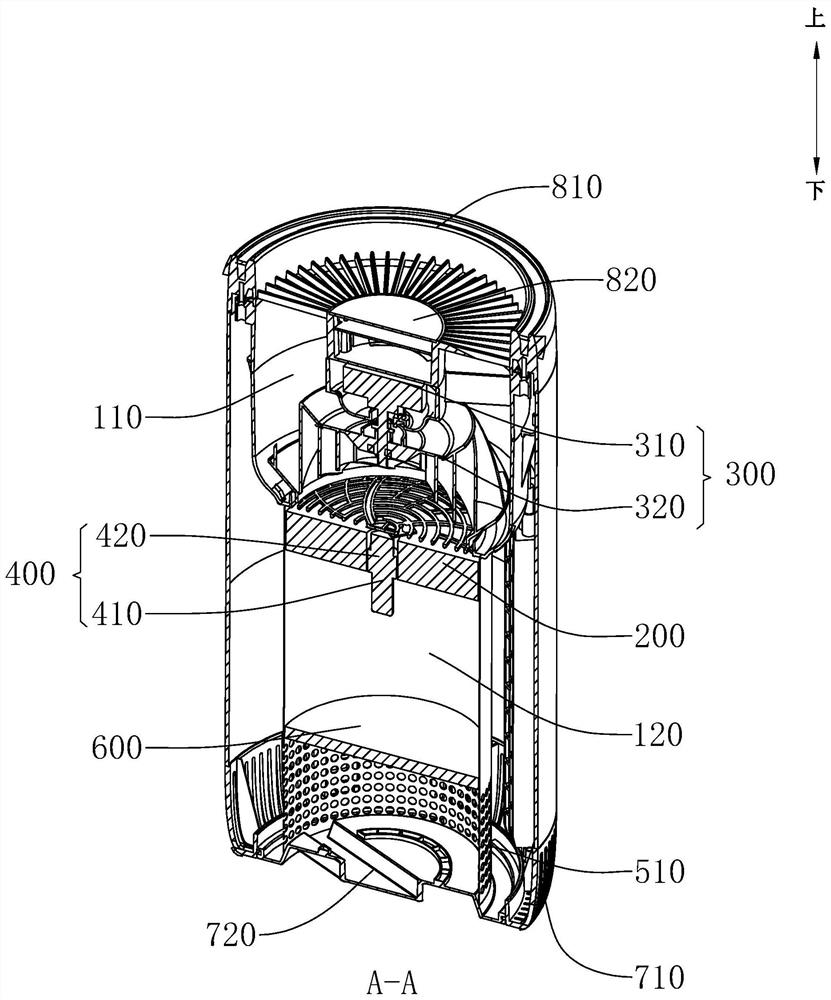

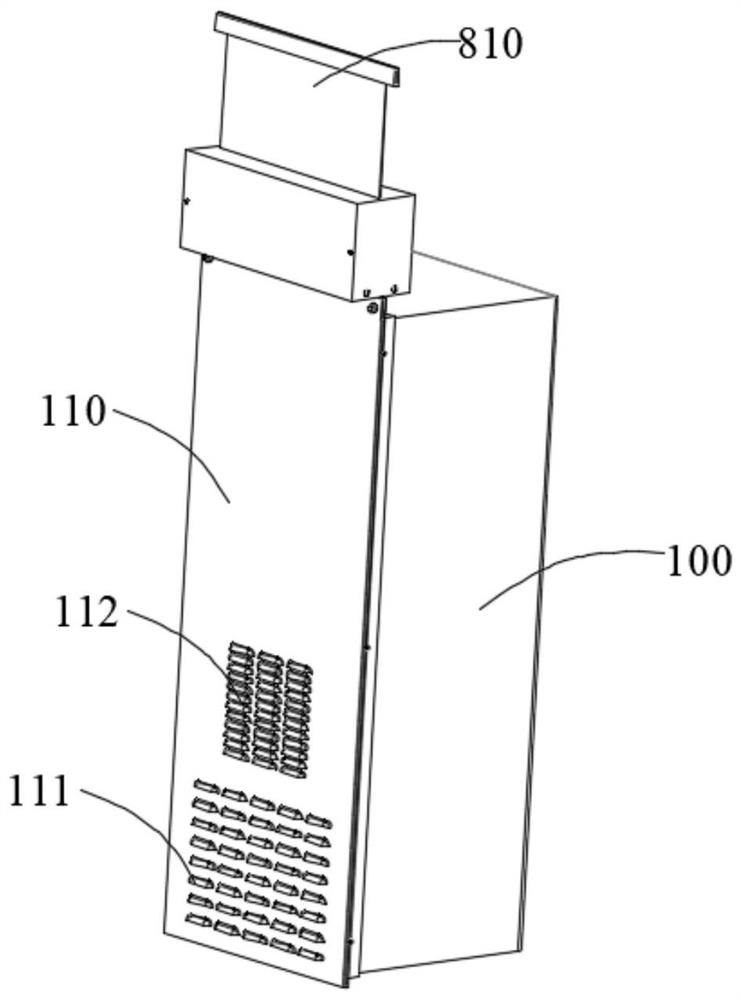

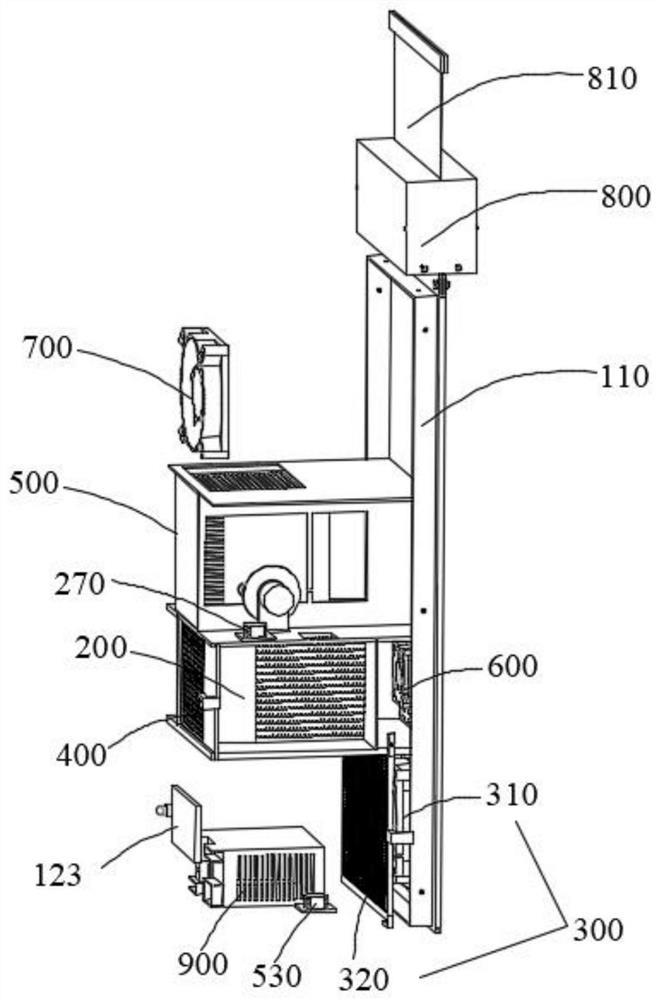

A window-type sensible heat exchange fresh air fan

ActiveCN110906461BExtended pathSlow down circulationEnergy recovery in ventilation and heatingMechanical apparatusAir filterFresh air

The invention discloses a window type sensible heat exchange fresh air ventilator, which comprises a body, a heat exchange part, a fresh air filtering device, an exhaust air filtering device, a freshair humidity adjusting device and a controller. The heat exchange part, the fresh air filtering device, the exhaust air filtering device, the fresh air humidity adjusting device and the controller arearranged in the body. The heat exchange part is used for carrying out heat exchange on indoor exhaust air and outdoor fresh air; the fresh air filtering device is used for filtering outdoor fresh air; the exhaust air filtering device is used for filtering indoor exhaust air; the fresh air humidity adjusting chamber is used for selecting whether to humidify or dehumidify the outdoor fresh air subjected to heat exchange. The window type sensible heat exchange fresh air ventilator is a two-way flow type fresh air ventilator, indoor exhaust air and outdoor fresh air can be subjected to heat exchange after being filtered, after heat exchange is finished, the outdoor fresh air is fed into a room, the indoor exhaust air is exhausted out of the room, the fresh air humidity adjusting chamber is arranged, and the outdoor fresh air can be humidified or dehumidified.

Owner:HUBEI UNIV OF TECH

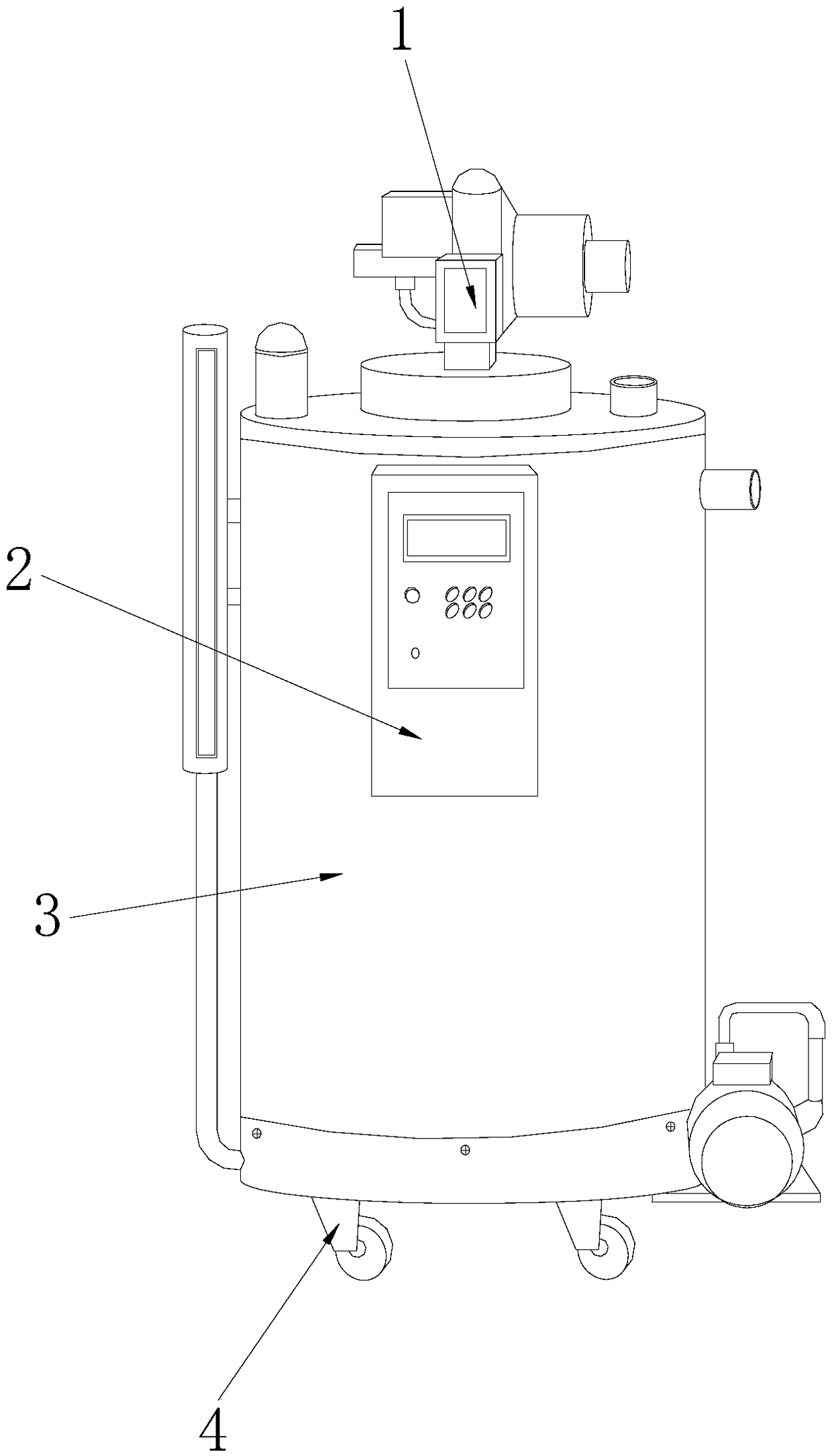

Vacuum emulsifying device for cosmetic production

InactiveCN108970481ASlow down circulationReduce impactRotary stirring mixersMixing methodsPulp and paper industryAtmospheric pressure

The invention discloses a vacuum emulsifying device for cosmetic production. The vacuum emulsifying device structurally comprises a motor, a controller, a tank body and rolling wheels; the bottom endof the motor is welded to the top end of the tank body; the controller is arranged at the front end of the tank body; the top ends of the rolling wheels are welded to the bottom end of the tank body,and the tank body comprises a liquid feeding mechanism, a liquid discharging mechanism, a stirring mechanism and a shell; and the top end of the liquid feeding mechanism is welded to the top end of the shell. According to the vacuum emulsifying device, part of the structure is improved, so that quantitative emulsifier is added into the raw materials according to the liquid level height of added liquid, so that the addition proportion is more accurate, and therefore the phenomenon that the specification of a same product is different due to the fact that the proportion is different by manuallyadding the emulsifier can be effectively avoided, meanwhile, in the discharging process, flow-dividing speed reduction is carried out on a discharging pipeline through a flow-dividing buffering method, and the phenomena that the emulsifier in a machine body is rapidly discharged at the moment when a discharge port is opened, and then strong impact force is generated to extrude and damage the machine body due to the fact that the air pressure generated in the machining process extrudes a finished product can be avoided.

Owner:沈旭源

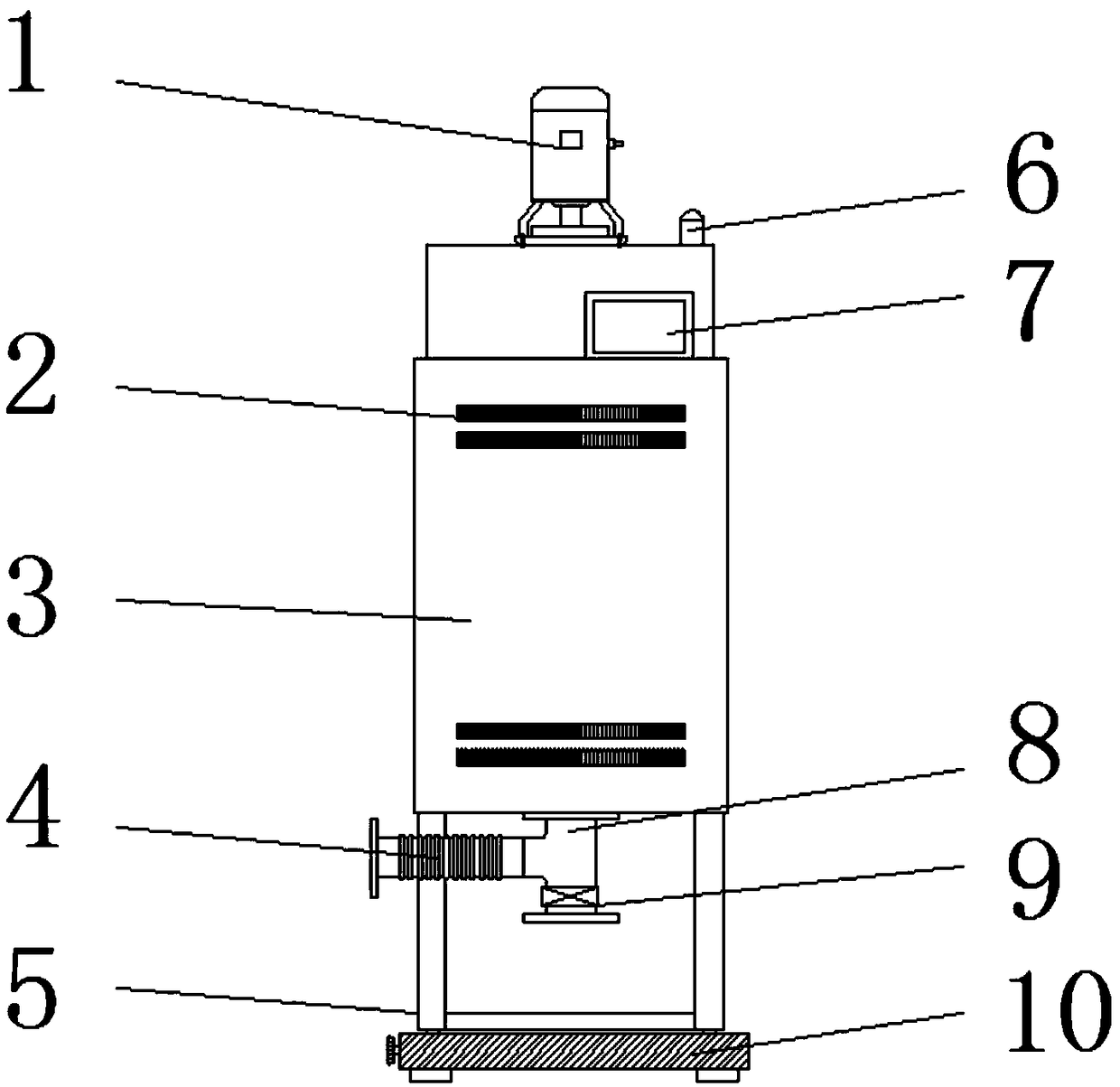

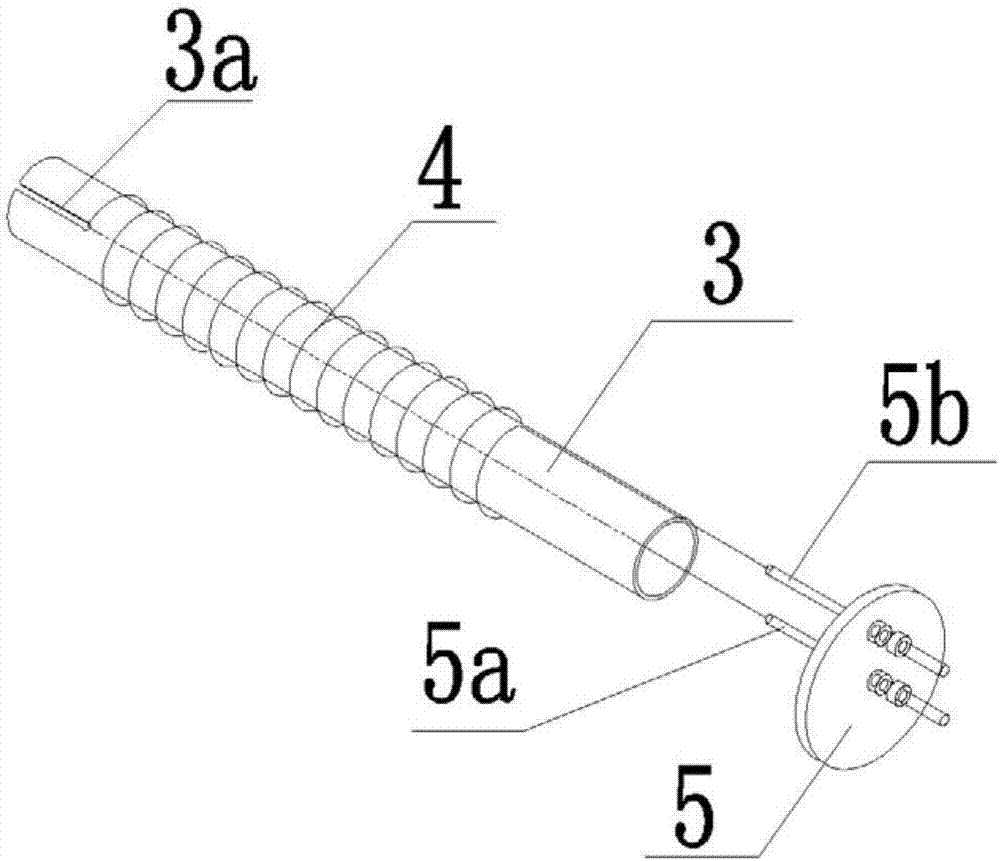

VOC waste gas efficient purifying furnace with electric heating wires conveniently replaced

PendingCN107448960AEasy to operateShort time spentIncinerator apparatusExhaust fumesElectric heating

The invention discloses a VOC waste gas efficient purifying furnace with electric heating wires conveniently replaced. The VOC waste gas efficient purifying furnace comprises a furnace shell, a hearth of the furnace shell, heating assemblies arranged in the hearth and a drive power source electrically connected with the heating assemblies. The VOC waste gas efficient purifying furnace is characterized in that multiple assembly holes are formed in the side wall of the furnace shell; each heating assembly comprises multiple ceramic pipes corresponding to the corresponding assembly hole, wherein the ceramic pipes are transversely inserted in the furnace shell through the corresponding assembly hole, penetrate the side wall of one face of the hearth and are then inserted in the side wall of the other opposite face to be fixed; and the electric heating wires are wound around the ceramic pipes, cover plates covering the assembly holes are fixed to the furnace shell, two electric heating wire leading-out bars are arranged on each cover plate in a penetrating manner, the two ends of each heating wire are welded to the corresponding two electric heating wire leading-out bars correspondingly, and the electric heating wire leading-out bars are connected with the drive power source through wires. By means of the VOC waste gas efficient purifying furnace with the electric heating wires conveniently replaced, the convenience degree of replacement of the electric heating wires can be improved, the input cost is reduced, meanwhile, stability and high efficiency of work of the purifying furnace are ensured, and the purifying effect is greatly improved.

Owner:ALCERA (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com