Oil fume purifying cover

A lampblack purification and cover technology, applied in the field of lampblack cover, can solve the problems of high noise, failure to achieve energy saving and environmental protection, high fan power, etc., and achieve the effect of solving noise pollution, low operating cost and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

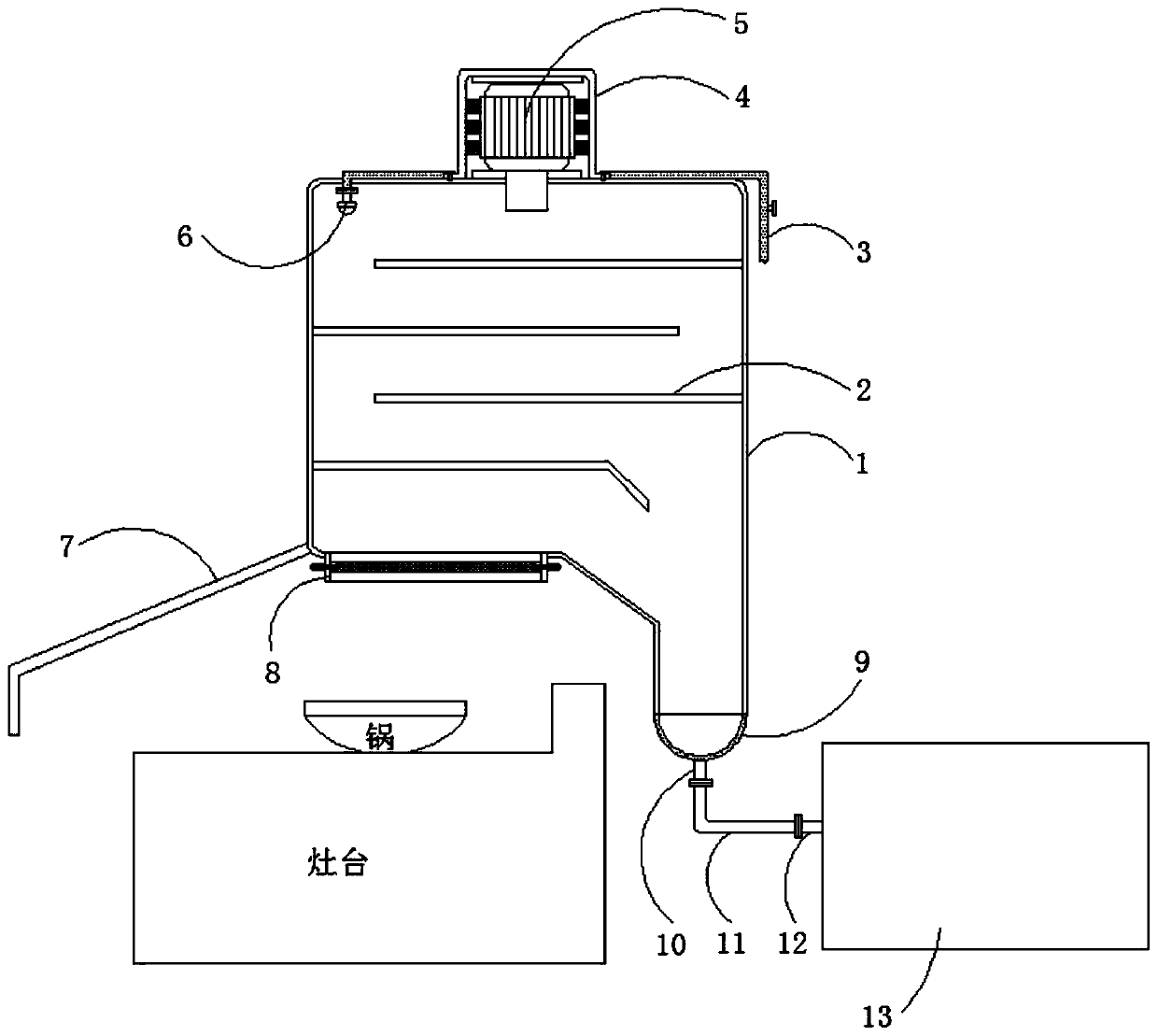

[0024] Embodiment one, with reference to figure 1 : A kind of oil fume purification cover, comprising cover body 1 and cleaning solution pool 13, is characterized in that: the inner surface wall of both sides of cover body 1 is equidistantly welded with two baffle plates 2, and baffle plate 2 can be used in use To achieve baffle flow, thereby reducing the oil fume circulation speed, a buffer plate 26 is fixed at the center of the top of the cover body 1, and the buffer plate 26 can buffer the vibration generated by the fan 5 when it is started. The fan 5 is installed on the top of the buffer plate 26, And the air inlet of the fan 5 extends to the inside of the cover body 1. The fan 5 adopts the model of RB-61D-3. The fan 5 is an existing technology. The fan 5 is given a high-strength negative pressure to extract the oil fume. A spray water supply pipe 3 is laid on the top of the cover body 1, and one end of the spray water supply pipe 3 extends to the inside of the cover body ...

Embodiment 2

[0025] Embodiment two, refer to Figure 4 : the outer surface of the blower fan 5 is covered with a protective shell 4, the protective shell 4 can protect the blower fan 5, the inner surface walls on both sides of the protective shell 4 are equidistantly welded with a plurality of buffer springs 24, and the plurality of buffer springs 24 are divided into Two groups, and a buffer pad 25 is fixed between one end of each group of a plurality of buffer springs 24, and one side outer surface of the buffer pad 25 is attached to the outer surface of the blower fan 5, and the position of the buffer pad 25 can be adjusted by the buffer spring 24. Fix the vibration generated when the blower fan 5 starts, the vibration can be buffered by the buffer pad 25, the buffer plate 26 and a plurality of buffer springs 24, thereby effectively reducing the noise. The inner top surface of the protective shell 4 is fixed with Noise-absorbing plate 22, the sound-absorbing plate 22 is existing technolo...

Embodiment 3

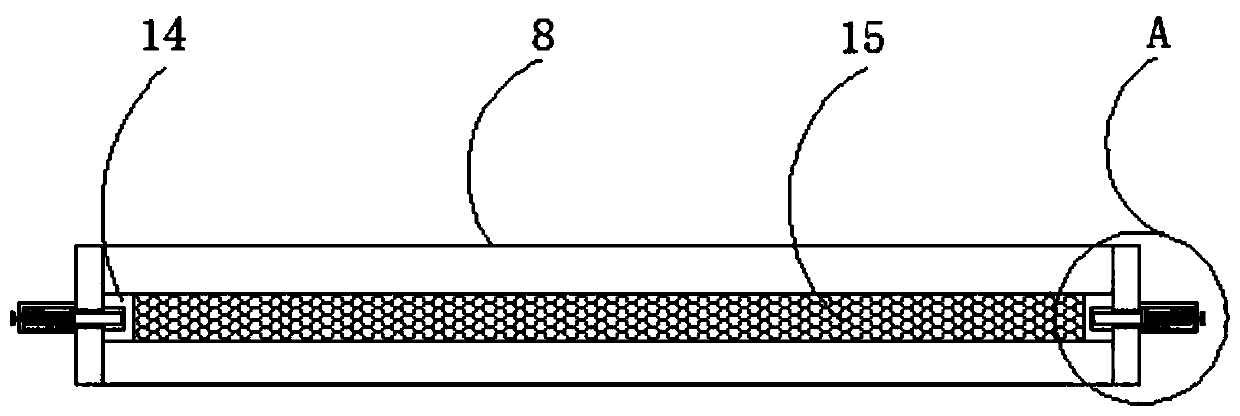

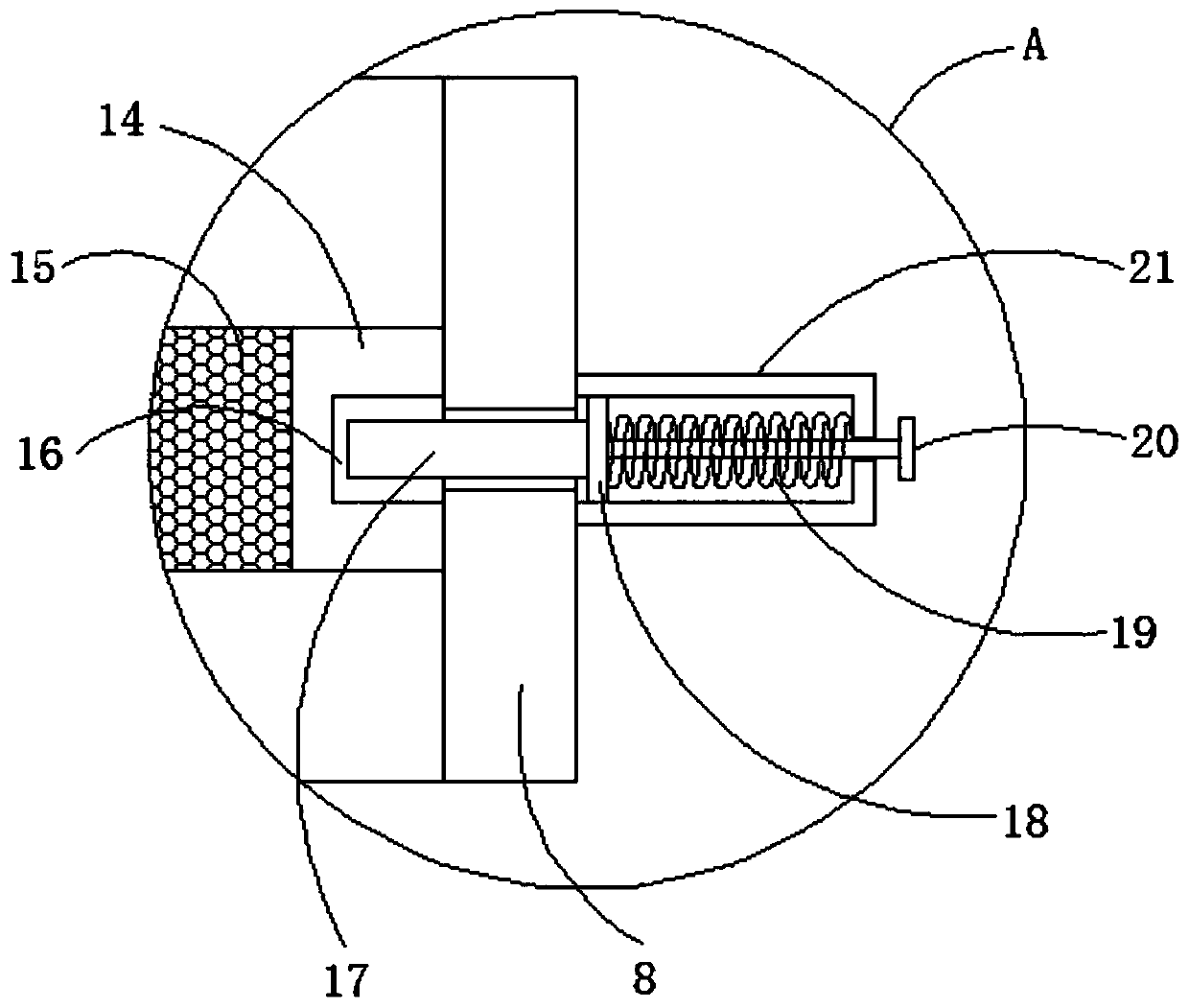

[0026] Embodiment three, refer to figure 2 , image 3 and Figure 5 : the inner surface wall of the ring plate 8 is slidably embedded with a ring block 14, the inner surface wall of the ring block 14 is fixed with a filter screen 15, the ring block 14 and the filter screen 15 are integrally structured, and the outer side of the ring block 14 There are four engaging grooves 16 equidistant along the circumferential direction, and the engaging grooves 16 are provided to facilitate engaging the engaging rods 17 in the engaging grooves 16, so that the position of the filter screen 15 can be installed and fixed. The outer side of the plate 8 is welded with four hollow tubes 21 equidistant along the circumferential direction. The hollow tubes 21 can fix the position of the return spring 19, so that the return spring 19 can be stably used inside the hollow tube 21. The four hollow tubes 21 The inner and outer walls of each are welded with return springs 19. After the ring block 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com