Patents

Literature

600results about How to "Avoid noise pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

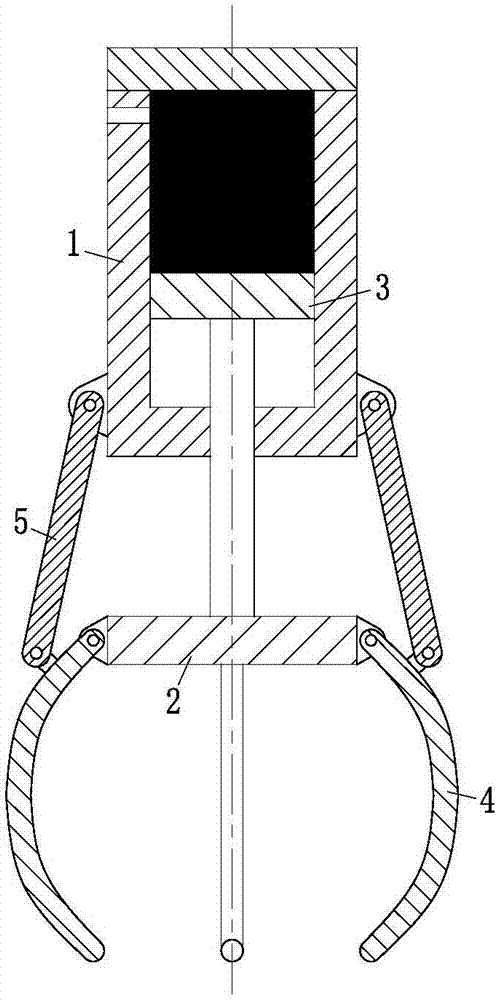

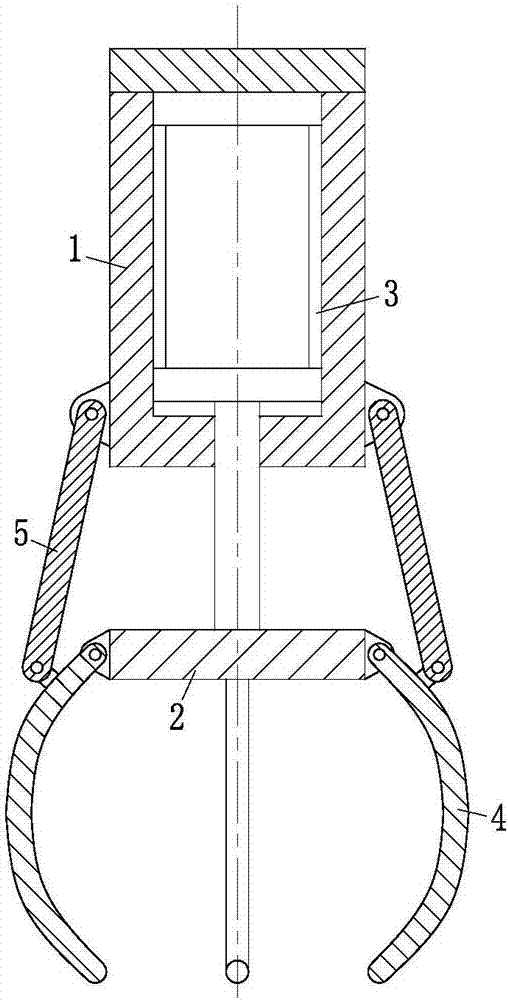

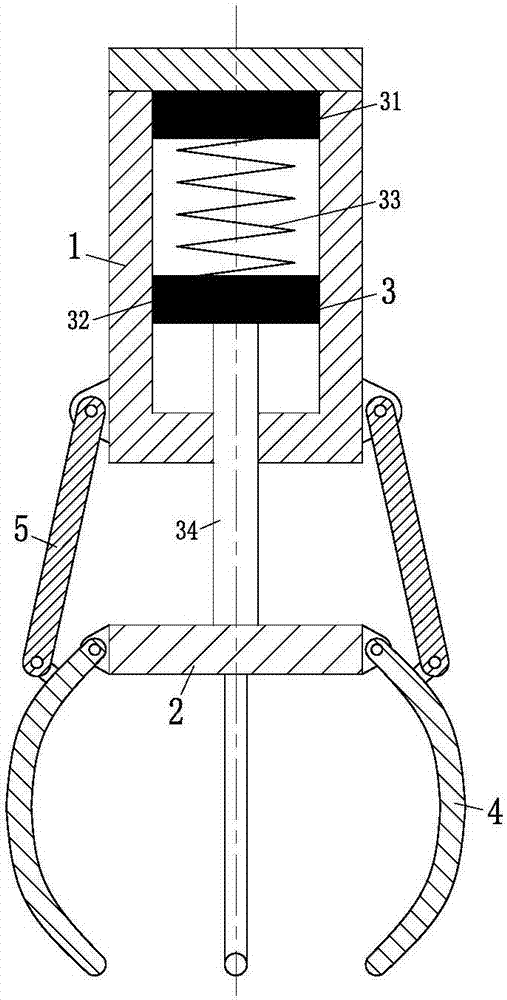

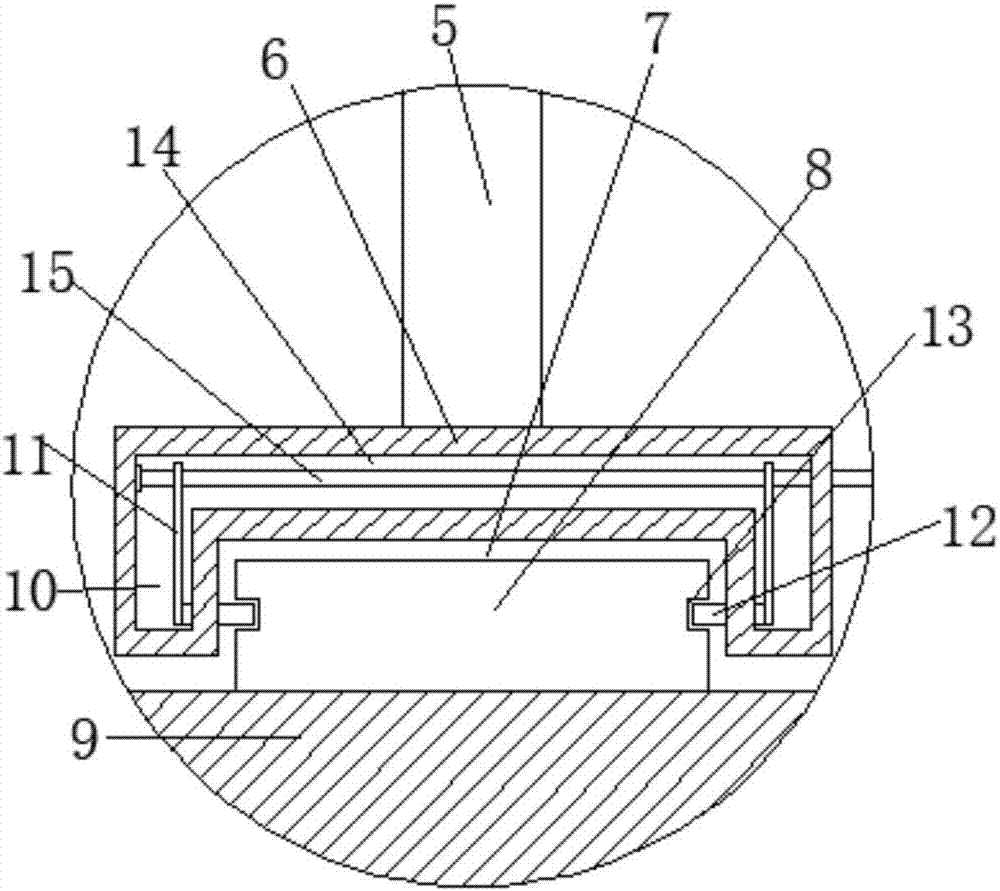

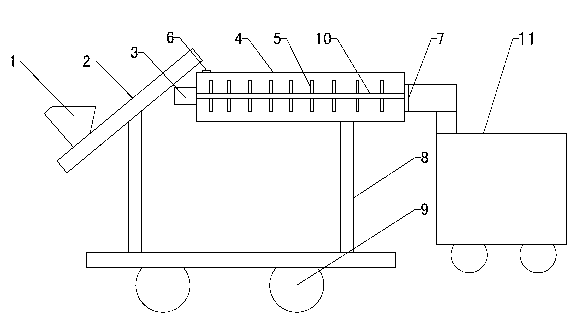

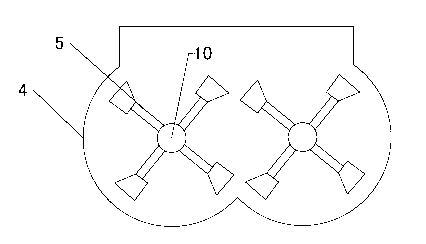

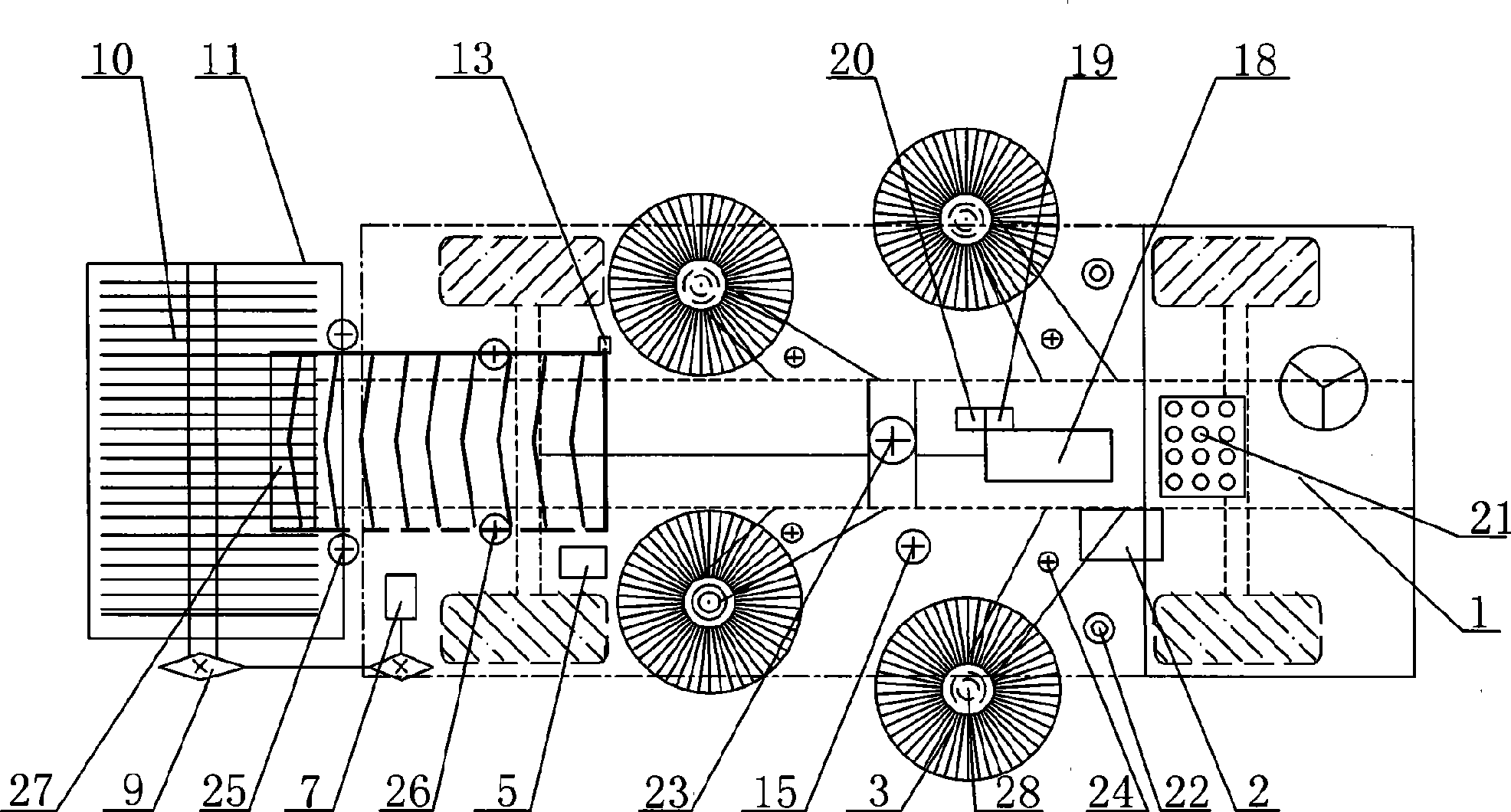

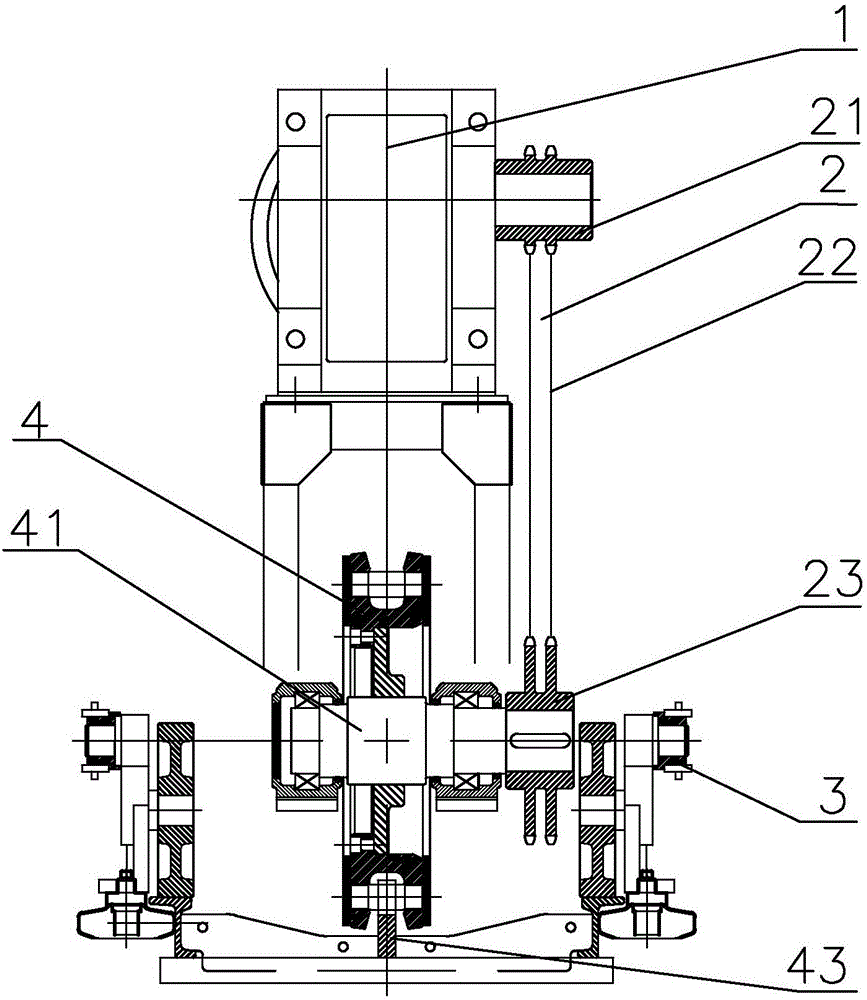

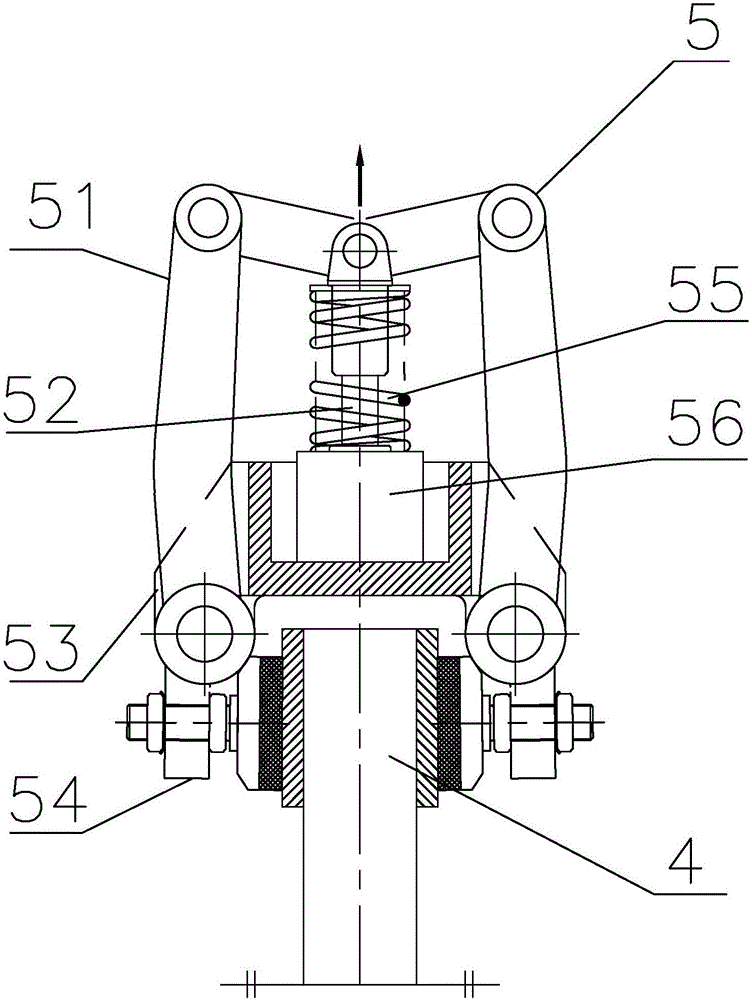

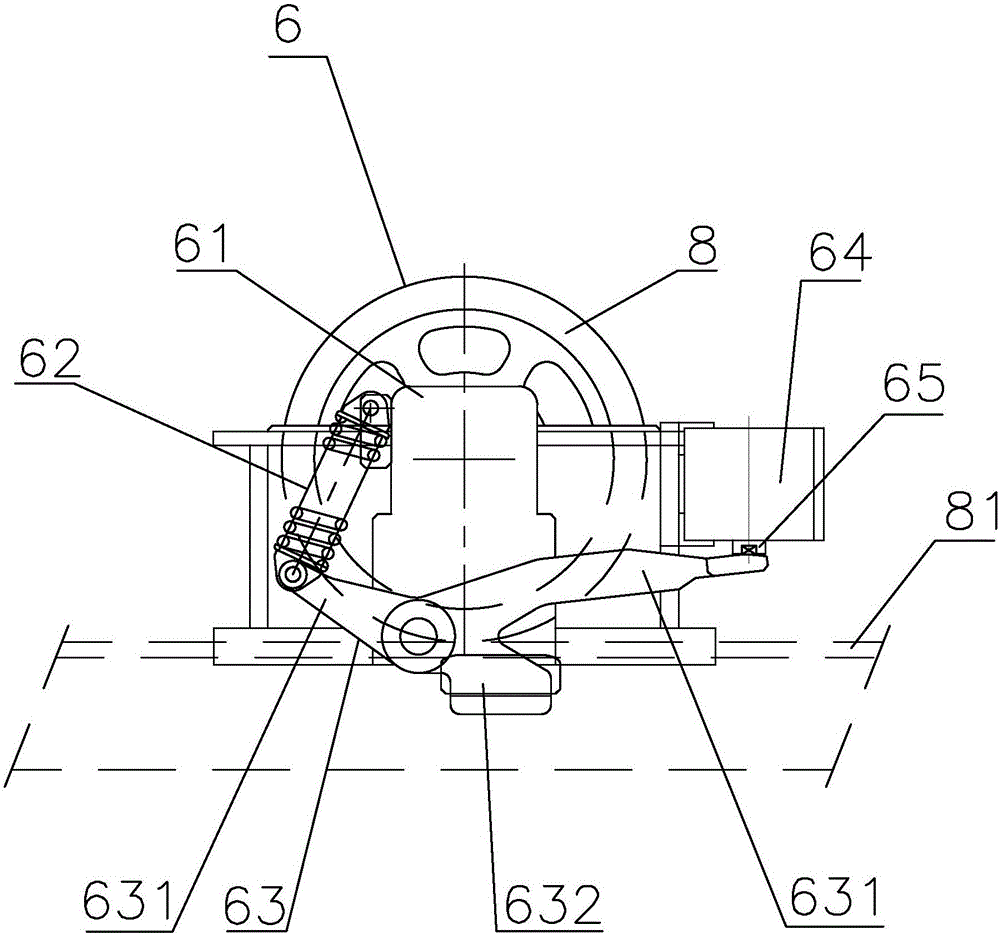

Three-claw manipulator for doll catcher

InactiveCN106861178ARealize clamping workAdapt to a wide rangeIndoor gamesGripping headsHydraulic cylinderEngineering

The invention relates to the field of toys for children, in particular to a three-claw manipulator for a doll catcher. The manipulator comprises a cylinder and further comprises a bottom plate, a pushing mechanism, clamping claws and connection rods. The pushing mechanism can be a micro hydraulic cylinder or a micro pneumatic cylinder or a pen type electric push rod or an electromagnetic element. The clamping claws can be rigid elastic clamping claws or air bag type elastic clamping claws. A layer of foaming cotton can be wound around each clamping claw, each clamping claw can be wrapped by a layer of pure cotton soft cloth, and clamping electromagnets can be installed on the clamping claws. The clamping claws can be various combinations of rigid clamping claws, elastic clamping claws and electromagnetic clamping claws. The three-claw manipulator for the doll catcher can be suitable for clamping toys made from one of or various materials such as common stuffing, hard plastic, soft plastic, wood and iron, and can greatly enrich the varieties of toys in the doll catcher.

Owner:张新

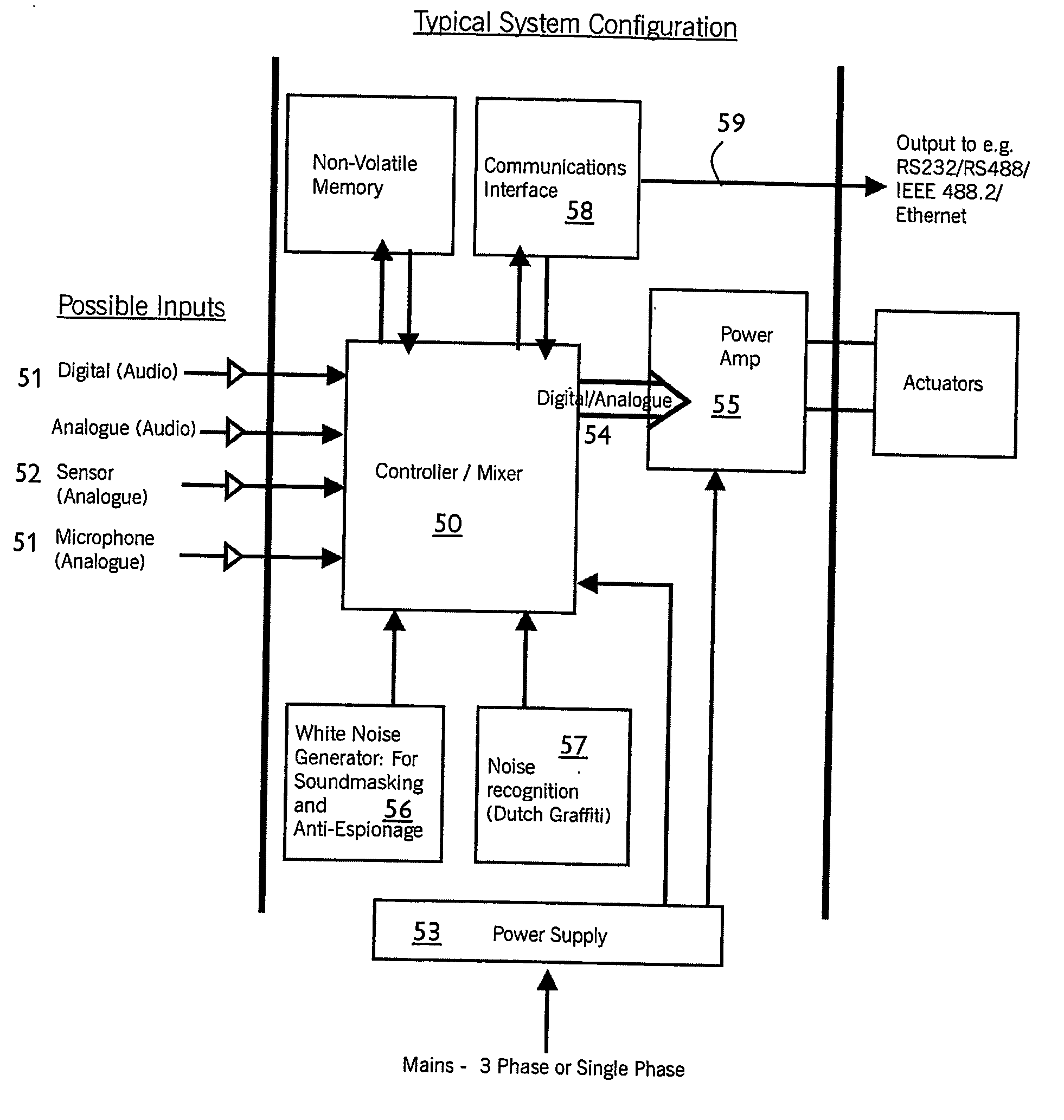

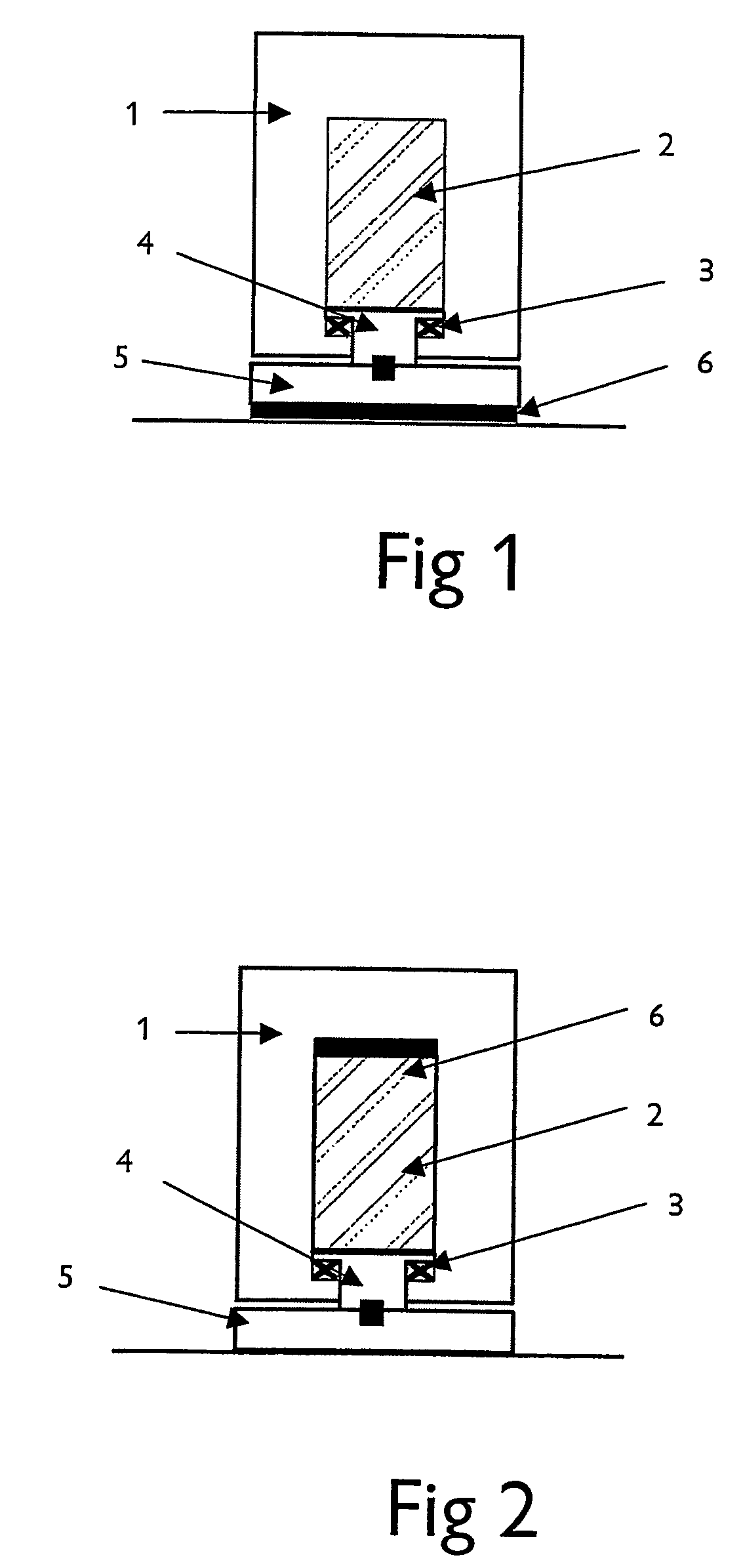

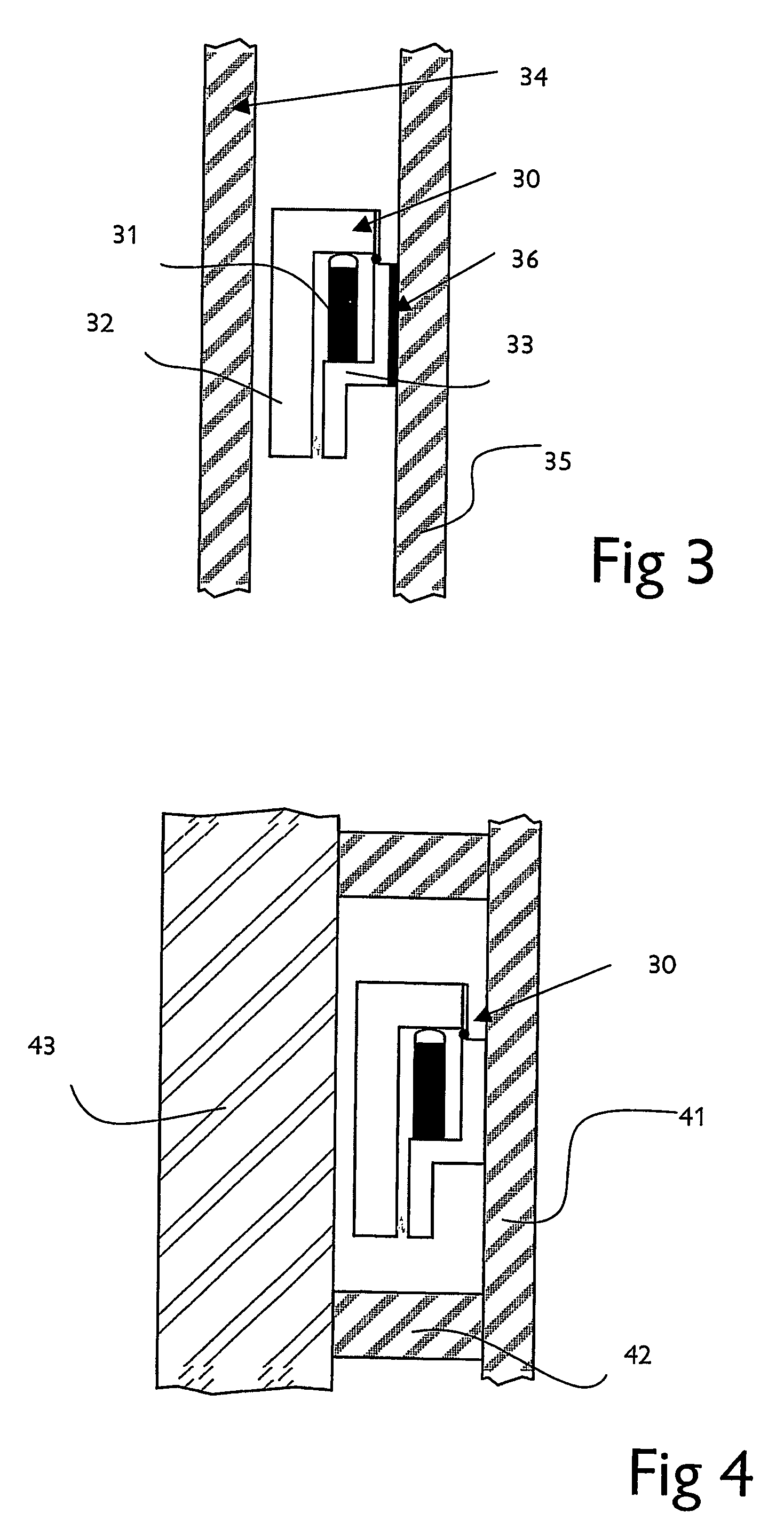

Audio system

InactiveUS20060147051A1Avoids unnecessary noise pollutionEffect ambient noiseMicrophonesEar treatmentEngineeringActuator

An audio system comprises, according to one aspect of the invention, an audio frequency actuator coupled to a body so as to cause the body to radiate sound when an audio signal is supplied to the actuator by a controller, and an acoustic sensor coupled to said body or to an adjacent body so as to sense acoustic vibrations in said body, the sensor being connected to the controller, whereby the controller is arranged to change the audio signal supplied to the actuator according to the vibrations sensed by the sensor. Another aspect provides an audio system comprising an audio frequency actuator coupled to a body so as to cause the body to radiate sound when an audio signal is supplied to the actuator by a controller, and an acoustic sensor coupled to said body or to an adjacent body so as to sense acoustic vibrations in said body, the sensor being connected to the controller, whereby the controller is arranged to detect predetermined characteristics of the sensed acoustic vibrations and to output an alerting signal in response thereto.

Owner:FEONIC

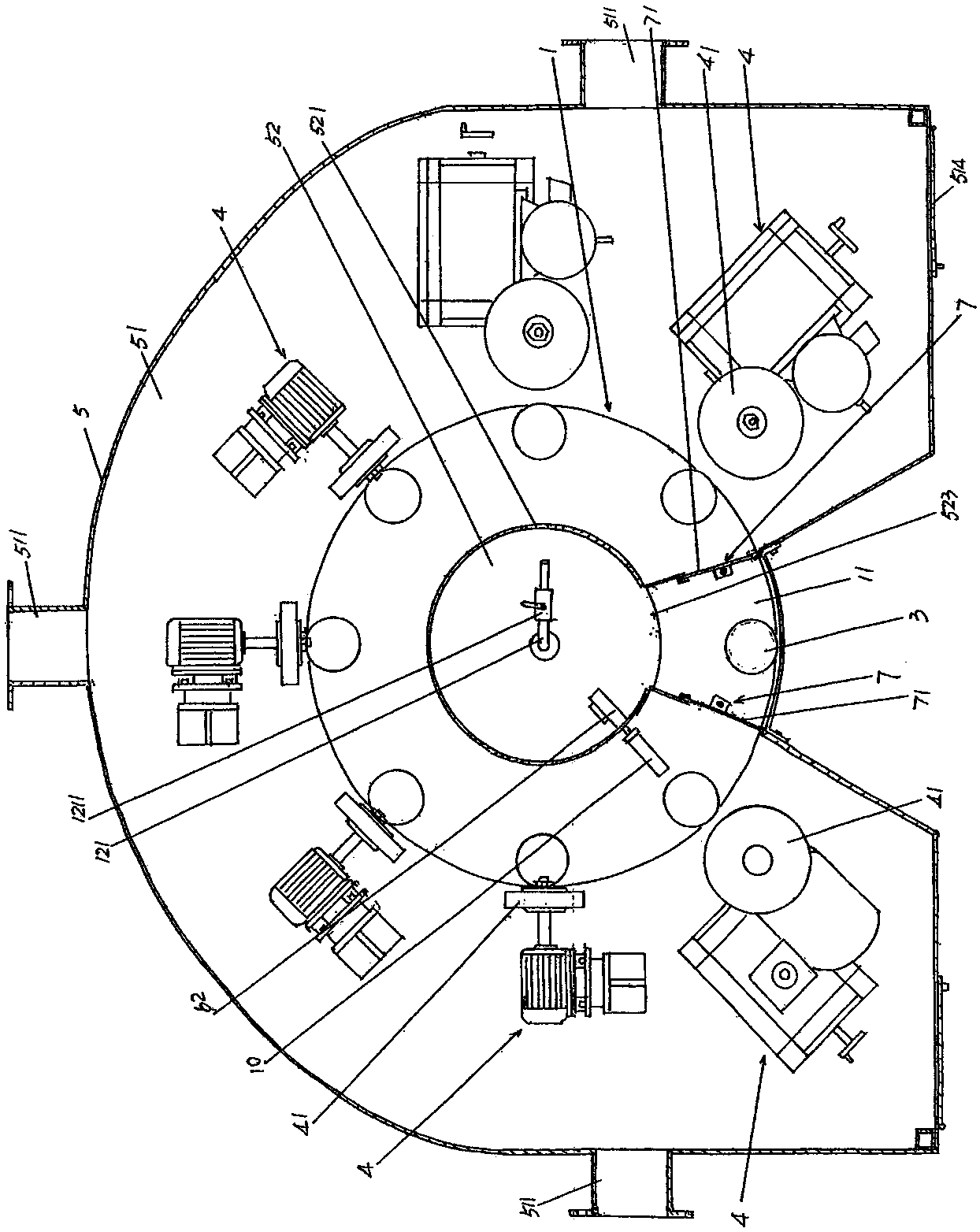

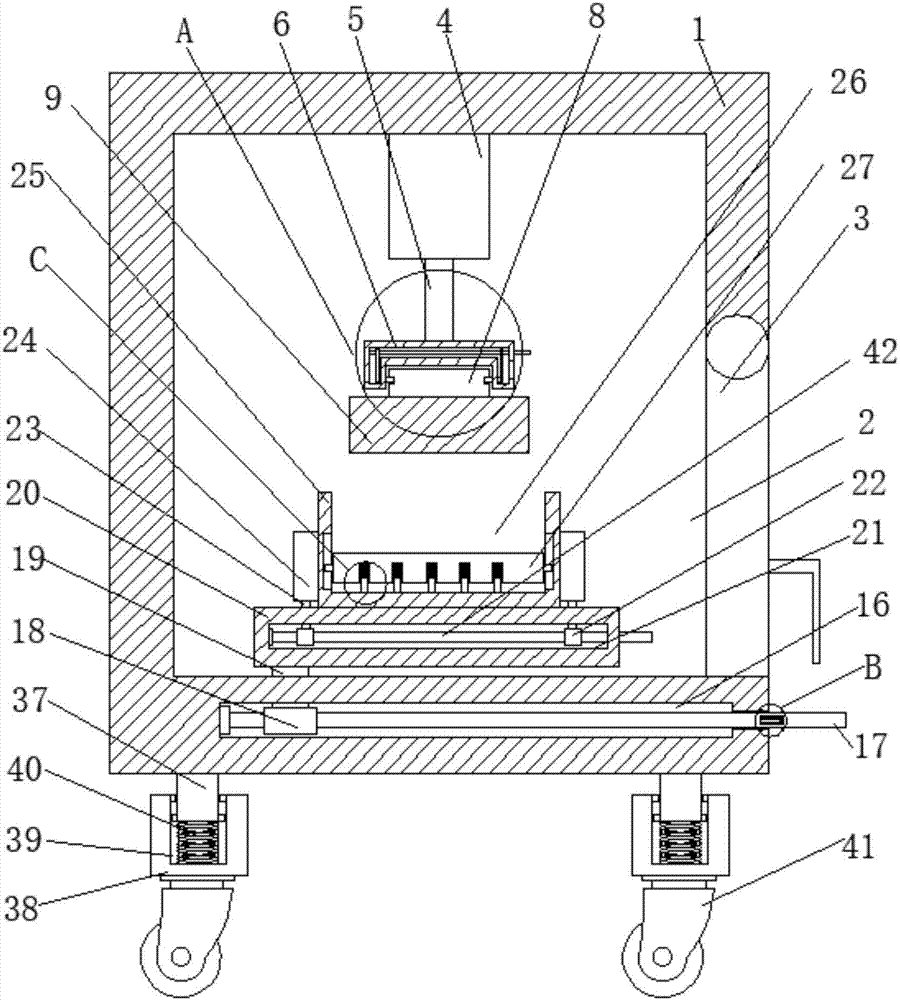

Sealed type dust removal polishing machine

InactiveCN103921202AInhibited DiffusionKeep healthyPolishing machinesGrinding/polishing safety devicesEngineeringNoise reduction

The invention provides a sealed type dust removal polishing machine, and belongs to the technical field of polishing machines and environment-friendly facilities. The sealed type dust removal polishing machine comprises a rotary polishing table, a set of cover die drive mechanism and a polishing machine body, wherein the upper portion of the cover die drive mechanism is provided with cover dies. The sealed type dust removal polishing machine is characterized in that a noise reduction dust removal room is further included, the noise reduction dust removal room is composed of a polishing dust collection chamber and a waxing work chamber, the polishing dust collection chamber is connected with one end of a dust discharge pipe in a matched mode, the other end of the dust discharge pipe is connected with a dust removal device, the waxing work chamber is arranged in the center of the polishing dust collection chamber in a spaced mode, the wall of the waxing work chamber is provided with a waxing window, an automatic waxing mechanism is arranged at the bottom of the waxing work chamber, the cover dies and the polishing machine body are located in the polishing dust collection chamber, the noise reduction dust removal room further comprises an operation room, the polishing dust collection chamber is provided with a cover die outlet and a cover die inlet, and the outer wall of the polishing dust collection chamber is provided with an inlet opening and closing mechanism. The sealed type dust removal polishing machine can meet the requirement of continuous polishing, is high in polishing efficiency, lowers noise, prevents dust from spreading and lightens labor intensity.

Owner:SUZHOU VOCATIONAL UNIV

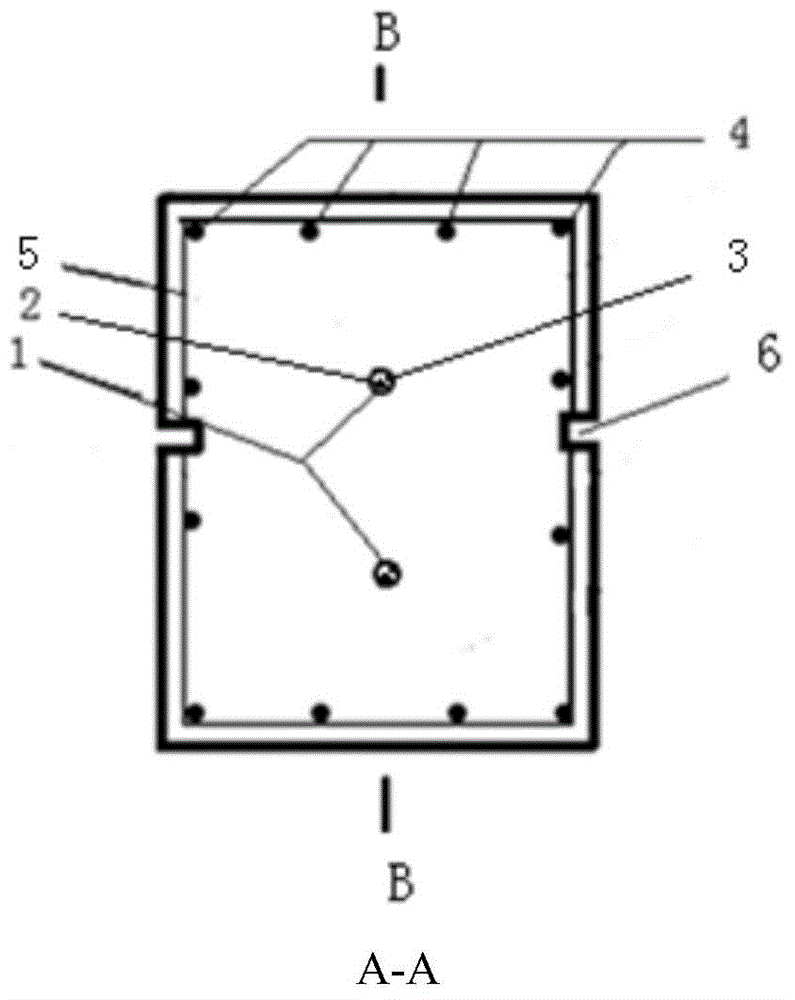

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

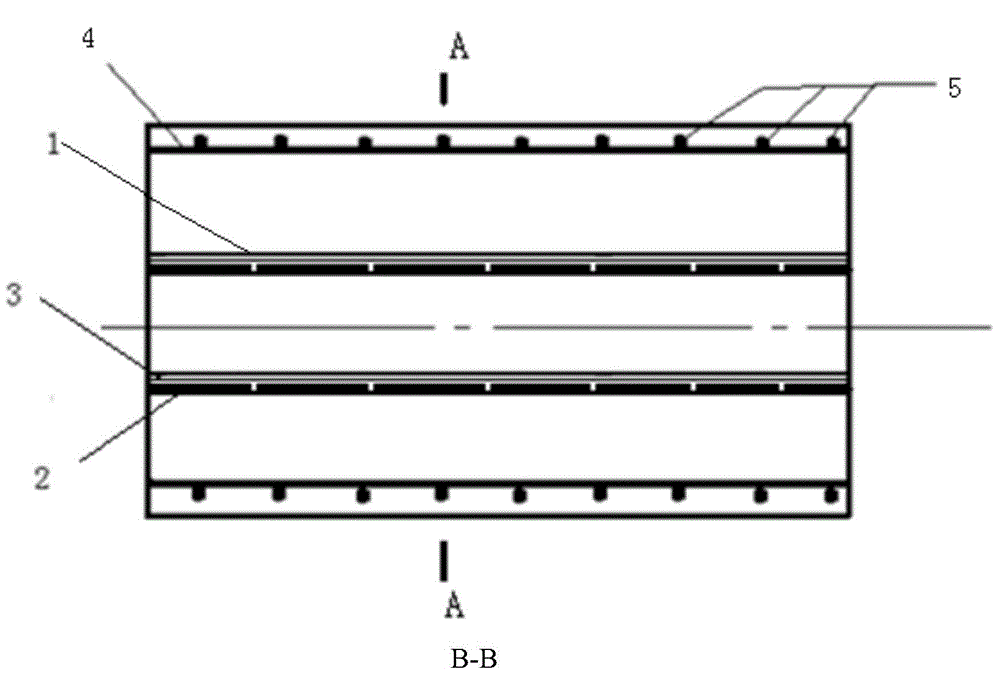

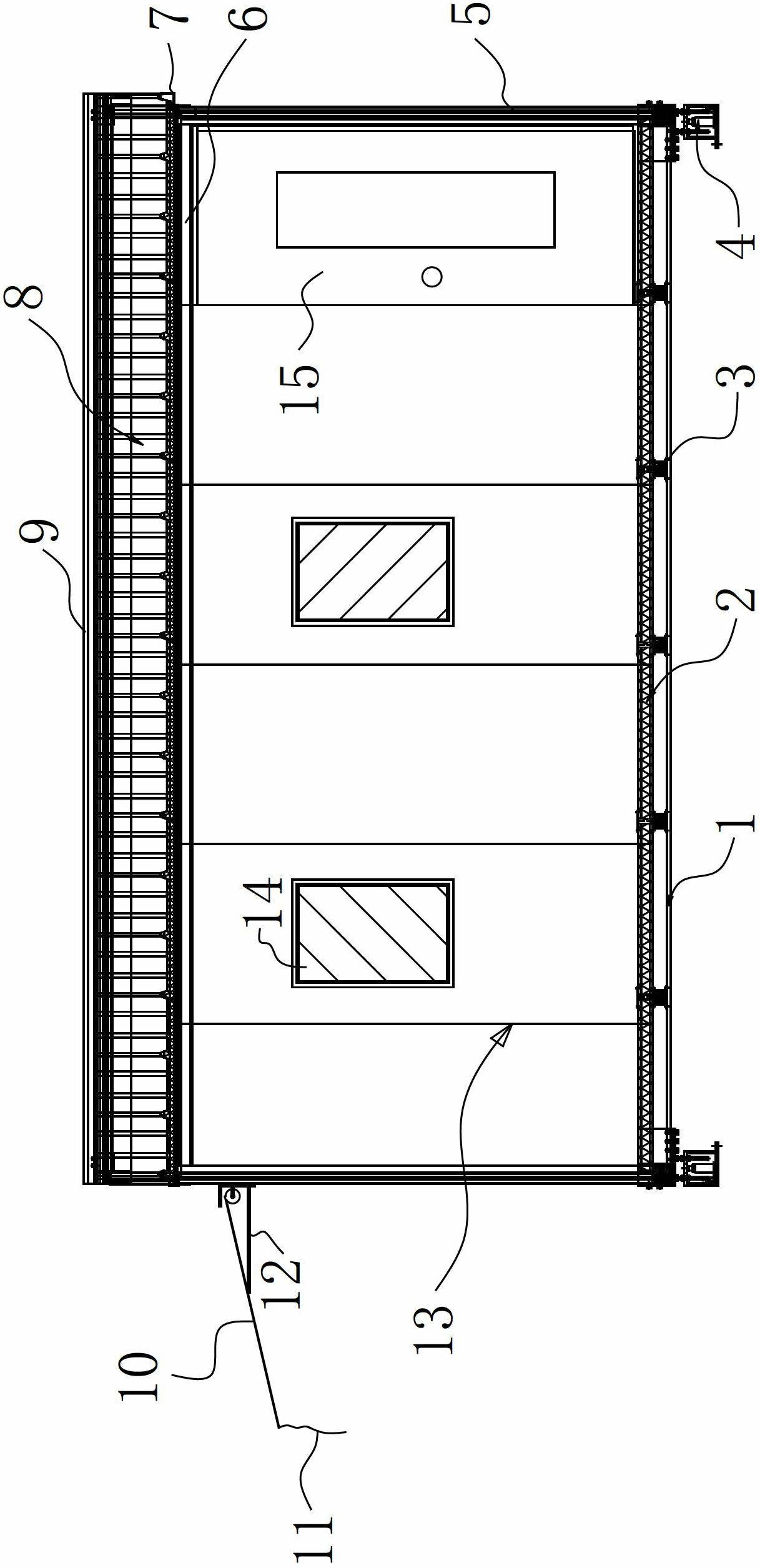

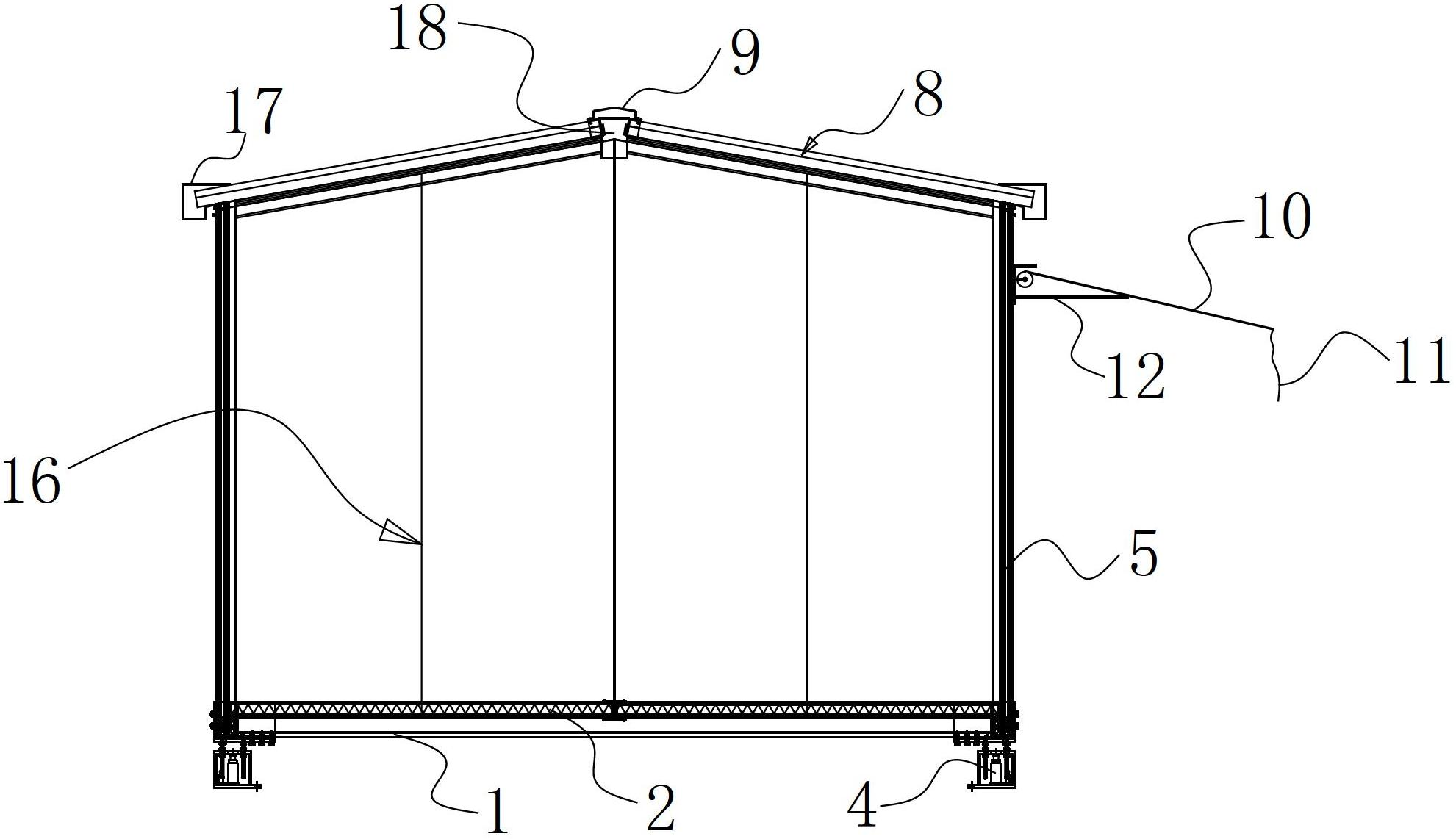

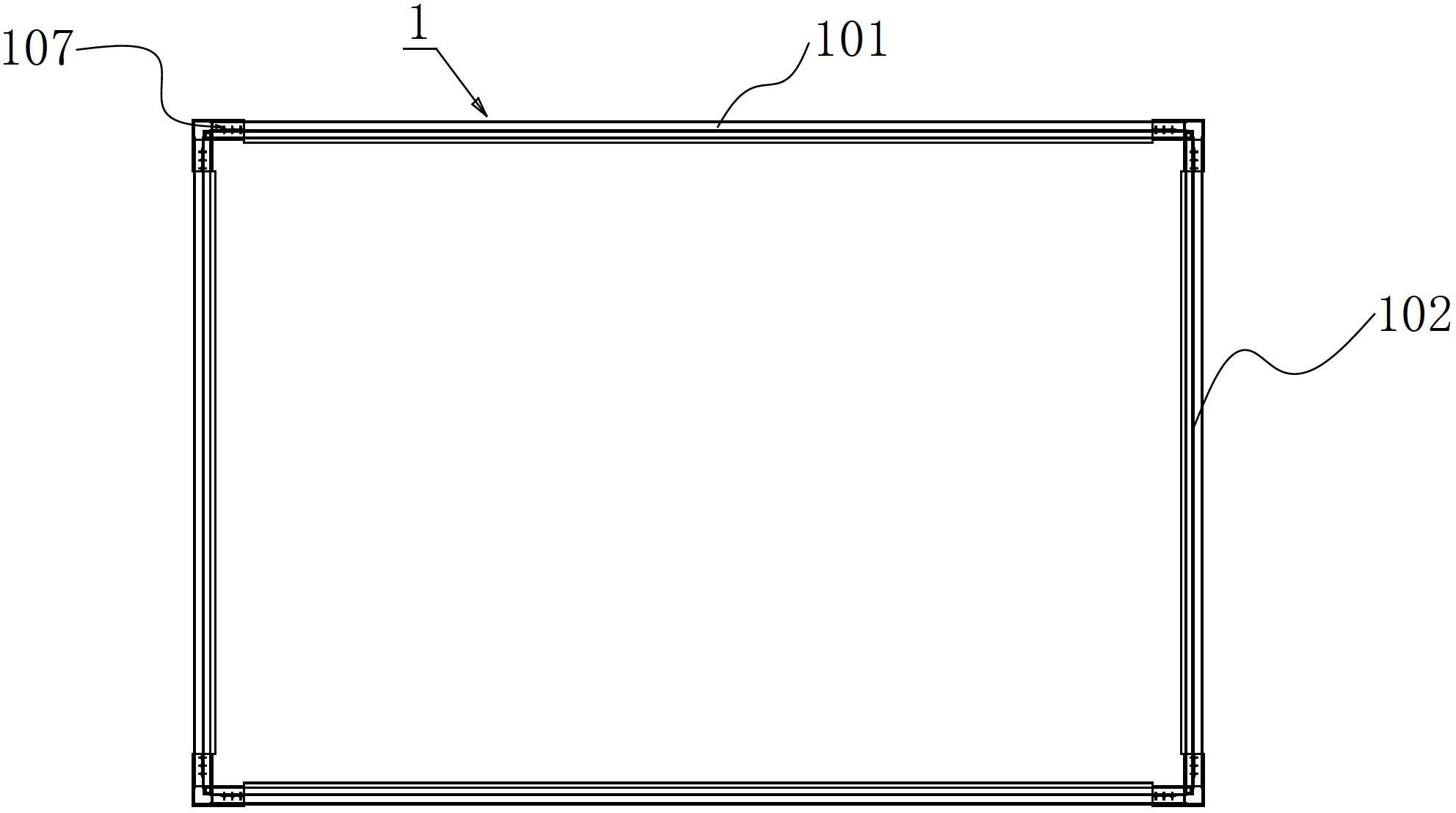

Modular integrated house

InactiveCN102691352AAvoid environmental problemsAvoid noise pollutionBuilding constructionsModularityBuilding construction

The invention discloses an industrialized, large-scale and factorized modular integrated house, which has the advantages of quick construction, firmness, durability, wind resistance, shock absorption, convenience in secondary disassembly and assembly and the like, is beneficial to warehousing and transportation, is not required to be installed by professionals and realizes industrialized and large-scale production and free house combination. The modular integrated house comprises ground beams which form a frame-type structure through connecting profiles; a plurality of floor units are detachably connected into a whole, and the integral edge of the floor units is lapped on a floor on the upper part of the inner side of the frame-type structure of the ground beams; a plurality of wall panels are detachably connected into transverse and longitudinal wall panels, an upright post is fixedly arranged on each corner of the ground beams, the lateral surfaces and the bottoms of the transverse and longitudinal wall panels are correspondingly detachably arranged on the upright posts and the ground beams to form an integral wall of the integrated house, and doors and windows are formed on the wall panels; and transverse and longitudinal collecting edges arranged on the tops of the wall panels and a ridge are positioned on the roof of the integrated house to form a roof slab.

Owner:CHONGQING QICHI TECH

Sand casting die assembly

ActiveCN107876709AAvoid disassembly and replacementEasy to disassemble and replaceMoulding machinesCompression moldingSand casting

The invention discloses a sand casting die assembly comprising a shell which is of a hollow structure. One side wall of the shell is further provided with a feed port of which the opening position isrotatably connected to a cover plate, and the inner wall of the upper side of the shell is fixedly connected to a cylinder; the output end of the cylinder is connected to a piston rod, and the end, far away from the cylinder, of the piston rod is connected to a mounting plate of which the lower end is further provided with a die; the upper end of the die is provided with a mounting block, and thelower side wall of the mounting plate is provided with a mounting groove matched with the mounting block; the mounting plate is internally provide with two cavities arranged symmetrically, and the cavities are internally provided with first slide bars arranged vertically; the opposite side walls of the two first slide bars are both provided with first clamping blocks which penetrate the cavities;and the side wall of the mounting block is provided with a first slot matched with the first clamping blocks. According to the sand casting die assembly disclosed by the invention, a clamping sand mould is simple and firm, and the die for compression molding is easy to remove and displace; and the die assembly is wide in application scope.

Owner:马鞍山市海华金属制品有限公司

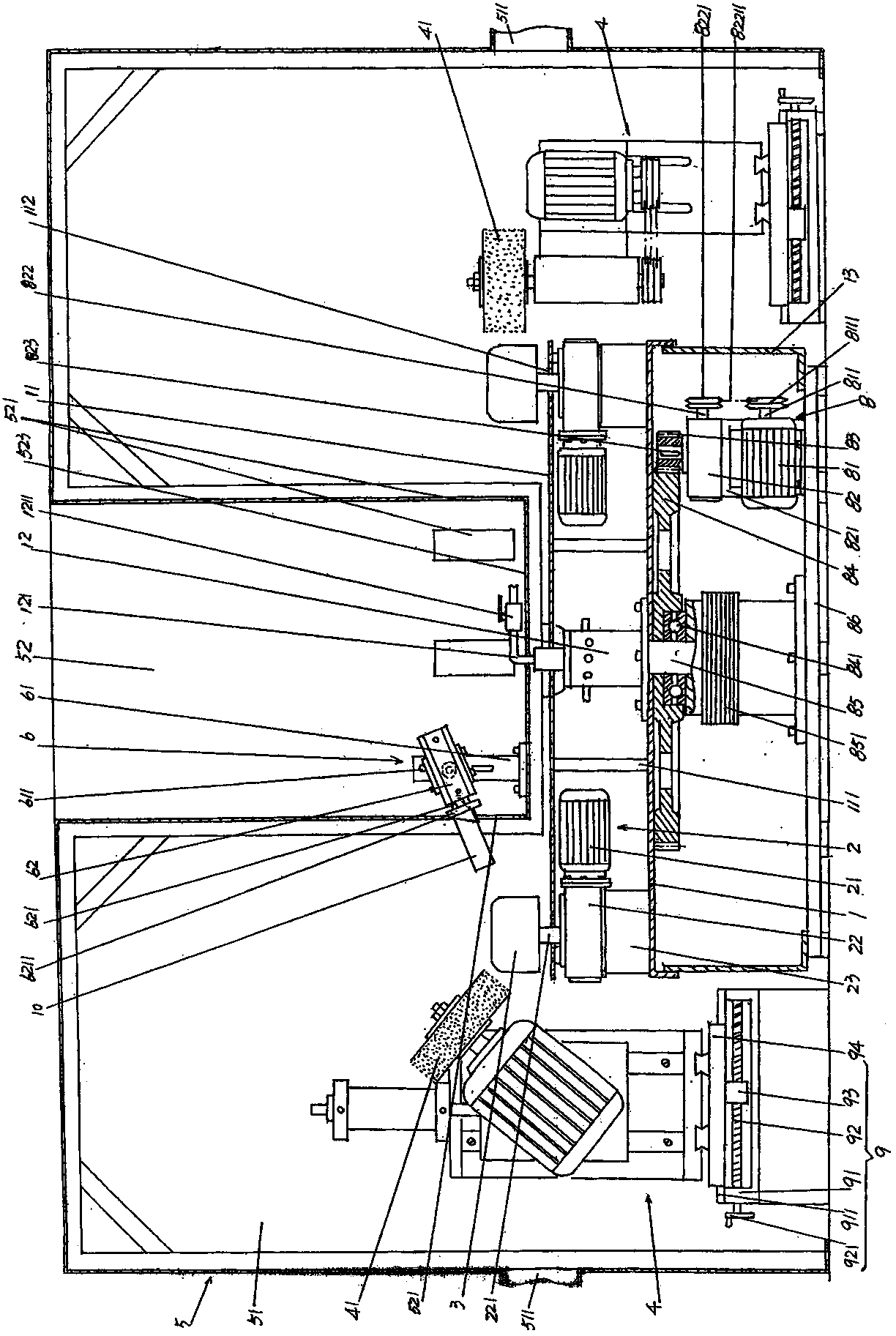

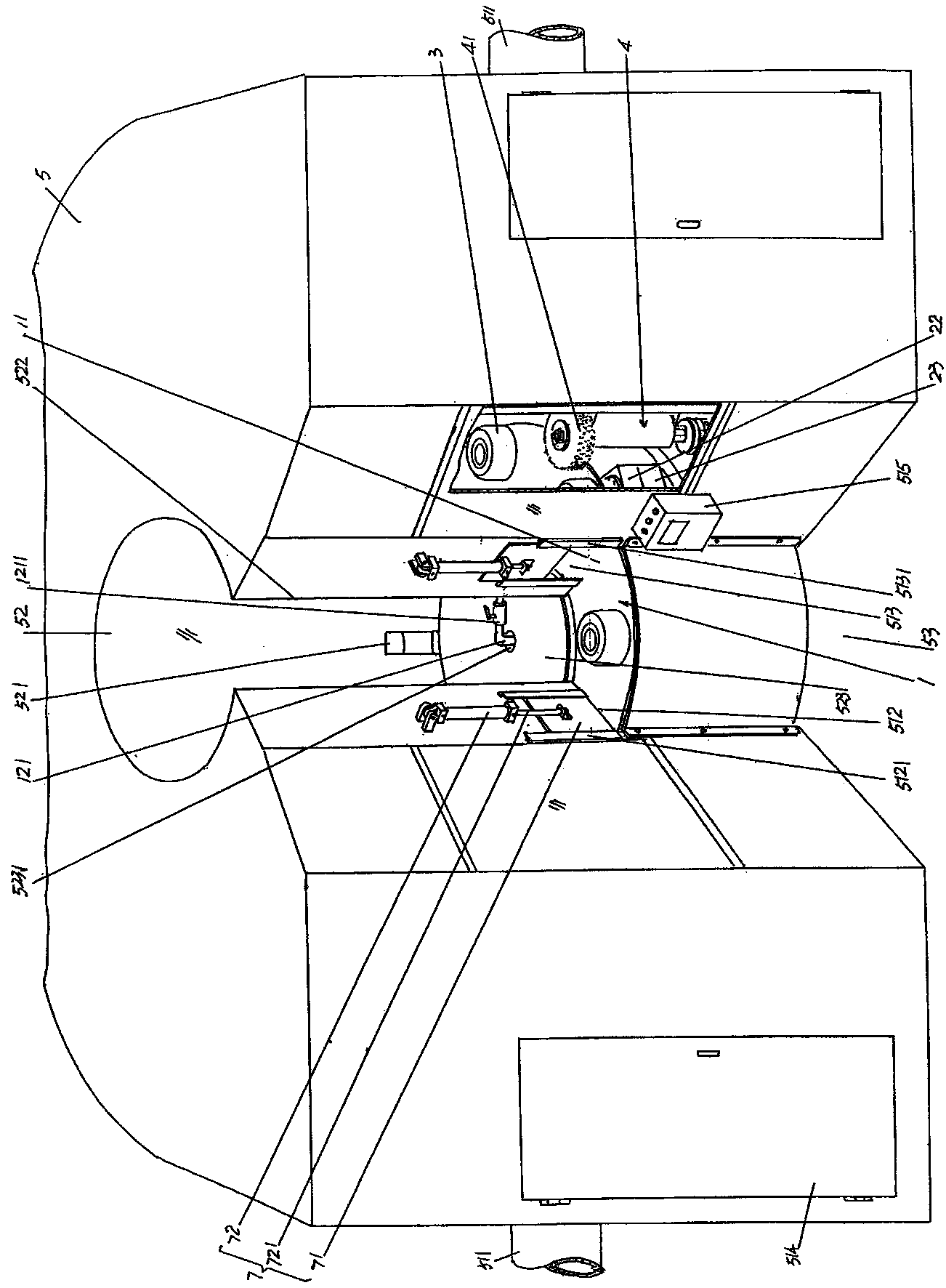

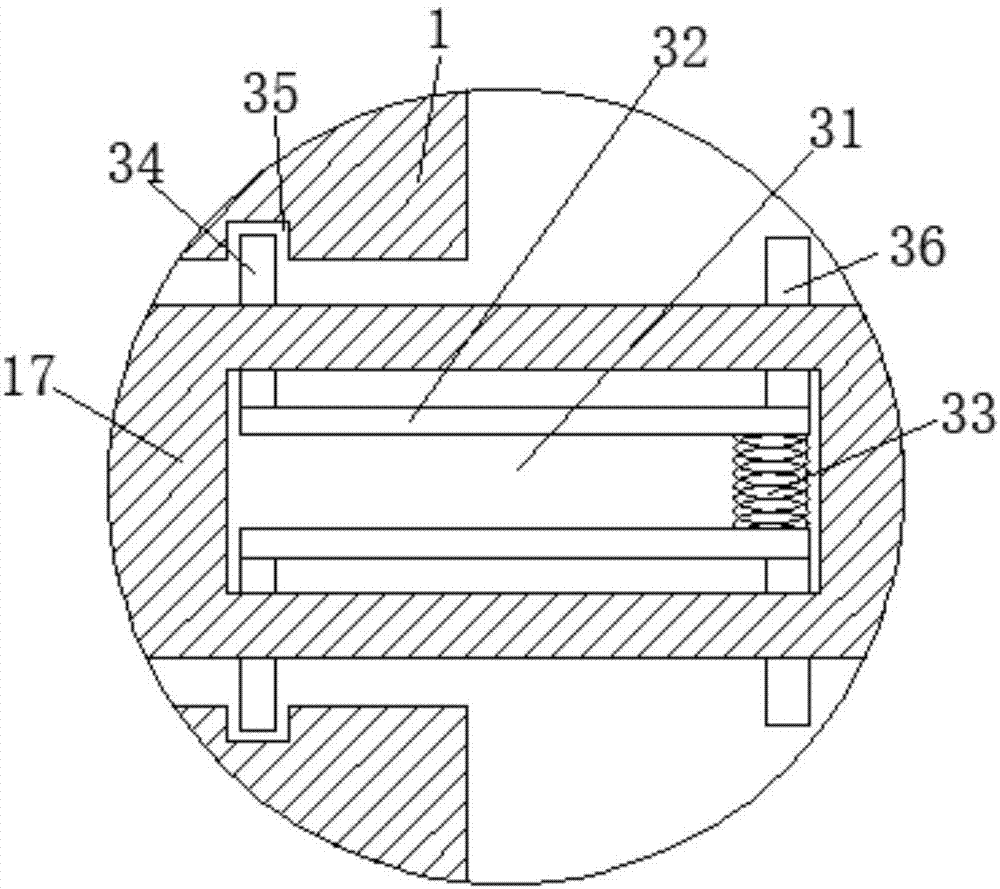

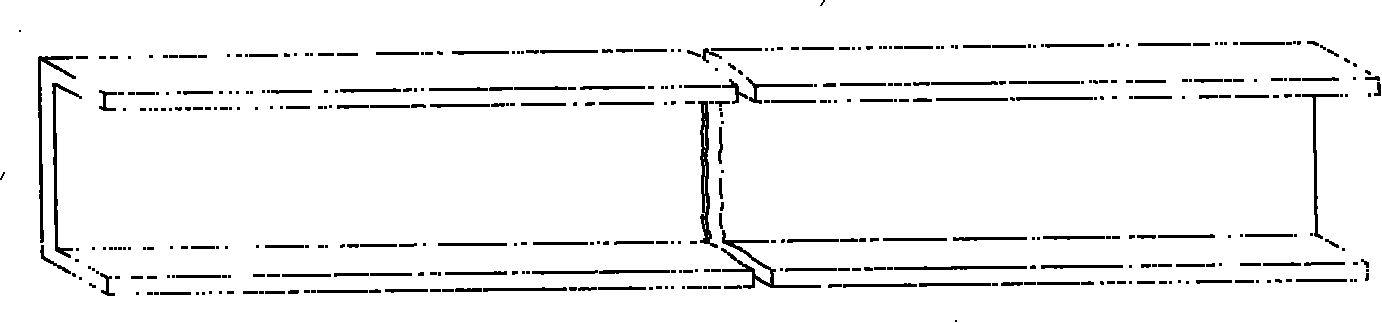

Method for shaping container bottom cross beam and preparing method

InactiveCN101176892AReduce labor intensityIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringUltimate tensile strength

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

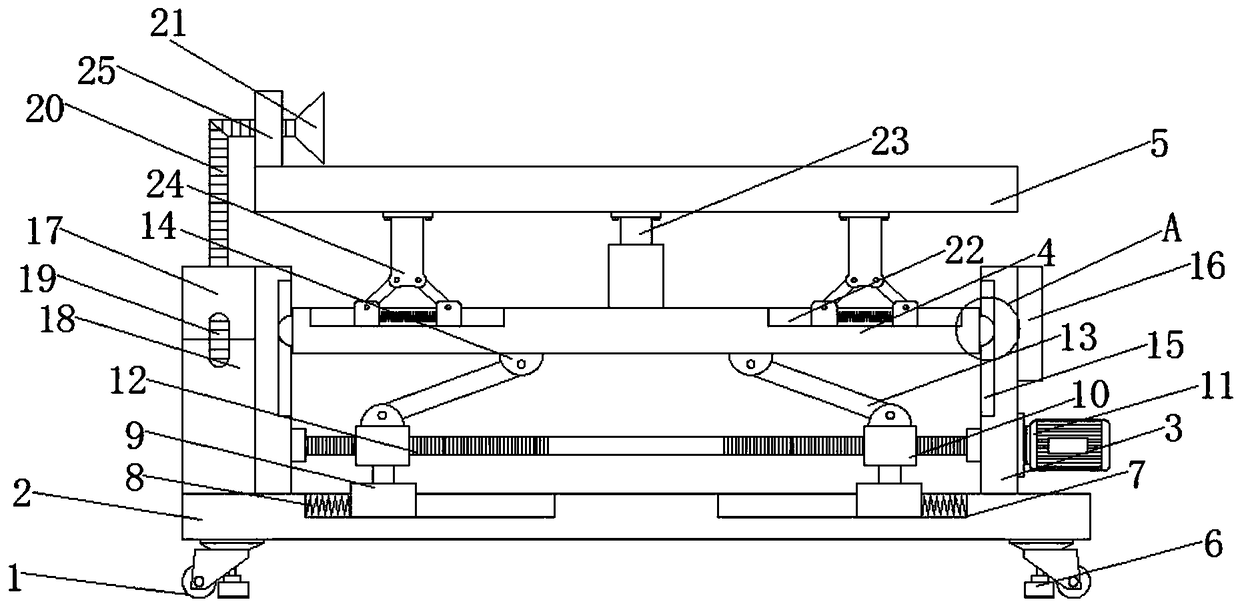

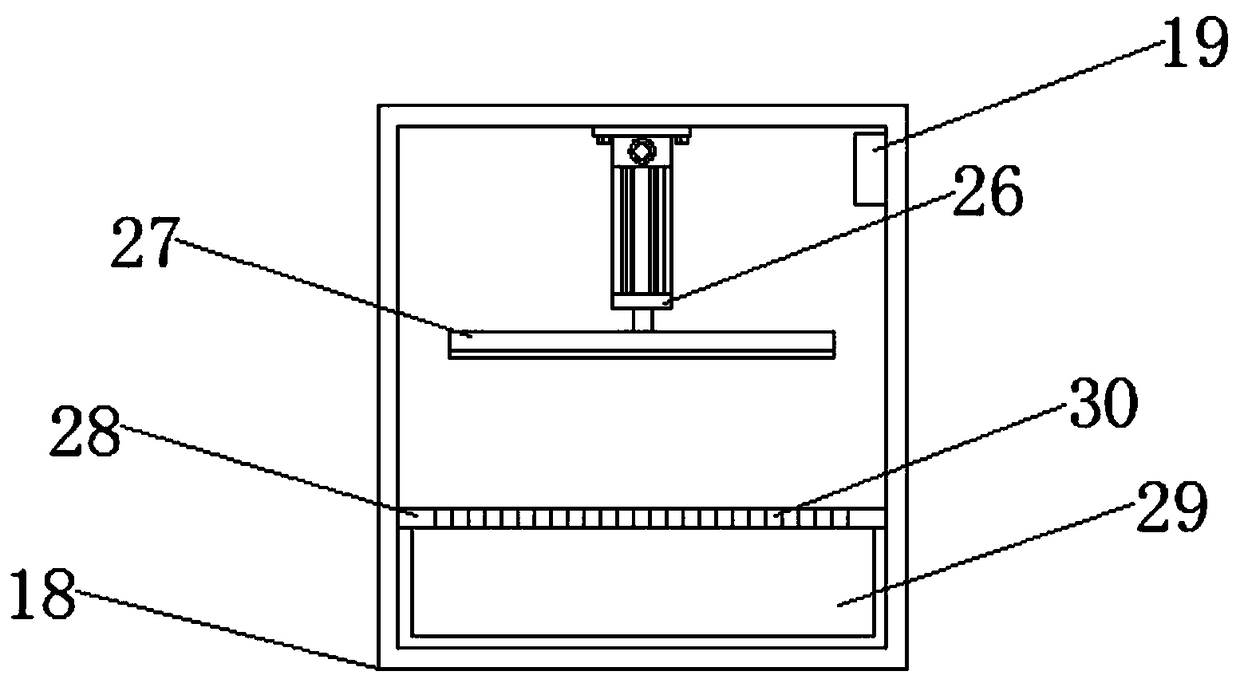

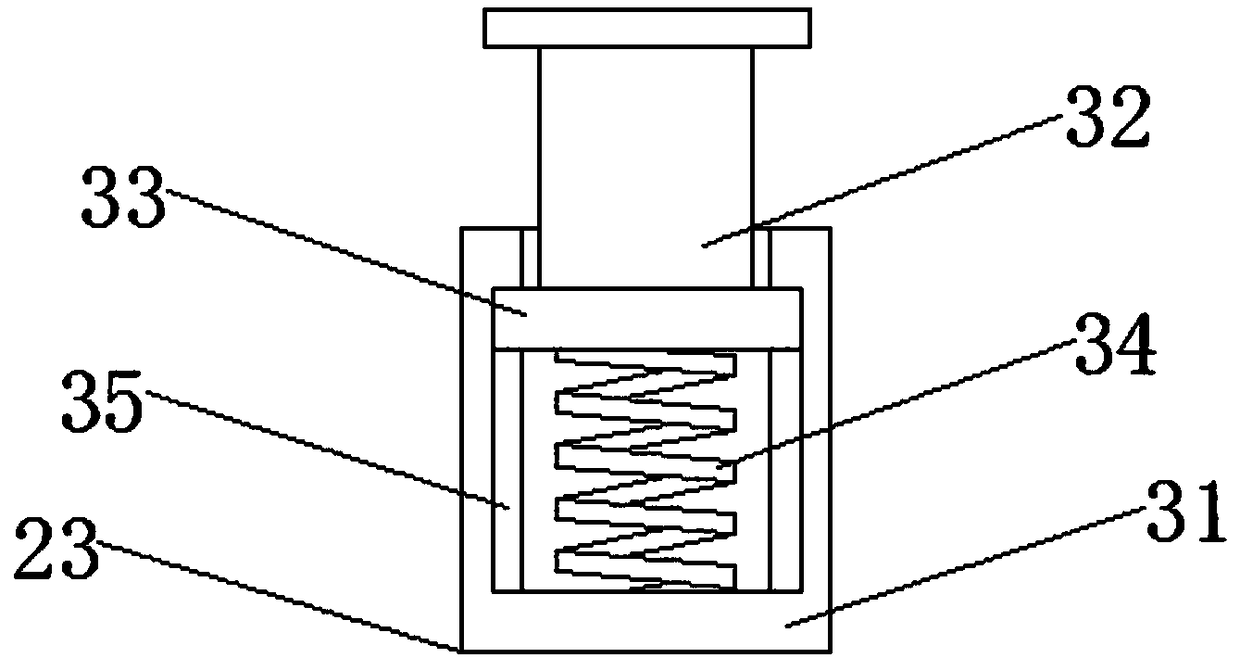

Vibration attenuation and dust collection rack special for fabric equipment

ActiveCN108916544AImprove shock absorptionExtended service lifePortable framesNon-rotating vibration suppressionVibration attenuationWorking environment

The invention discloses a vibration attenuation and dust collection rack special for fabric equipment. A base is arranged at the bottom of a rack body, first sliding grooves are formed in the two sides of the base, springs are installed at one ends of the first sliding grooves, one ends of the springs are electrically connected with sliding blocks, moving blocks are installed on the tops of the sliding blocks, first connecting rods are hinged to the top ends of the moving blocks, hinge bases are hinged to the top ends of the first connecting rods, a sliding plate is installed on the tops of the hinge bases, and a first damper is installed at the middle portion of the sliding plate; and second sliding grooves are formed in the two sides of the sliding plate, second dampers are installed inside the second sliding grooves, a working table is installed on the tops of the first damper and the second dampers, and castors are installed at the bottoms of the base. According to the vibration attenuation and dust collection rack, the first damper and the second dampers are used in cooperation to achieve mutual collaboration, the damping effect of the rack body is greatly strengthened, the service life of the fabric equipment is prolonged, the maintaining cost is saved, meanwhile, noise pollution is avoided, and a good working environment is conveniently created.

Owner:陈玉龙

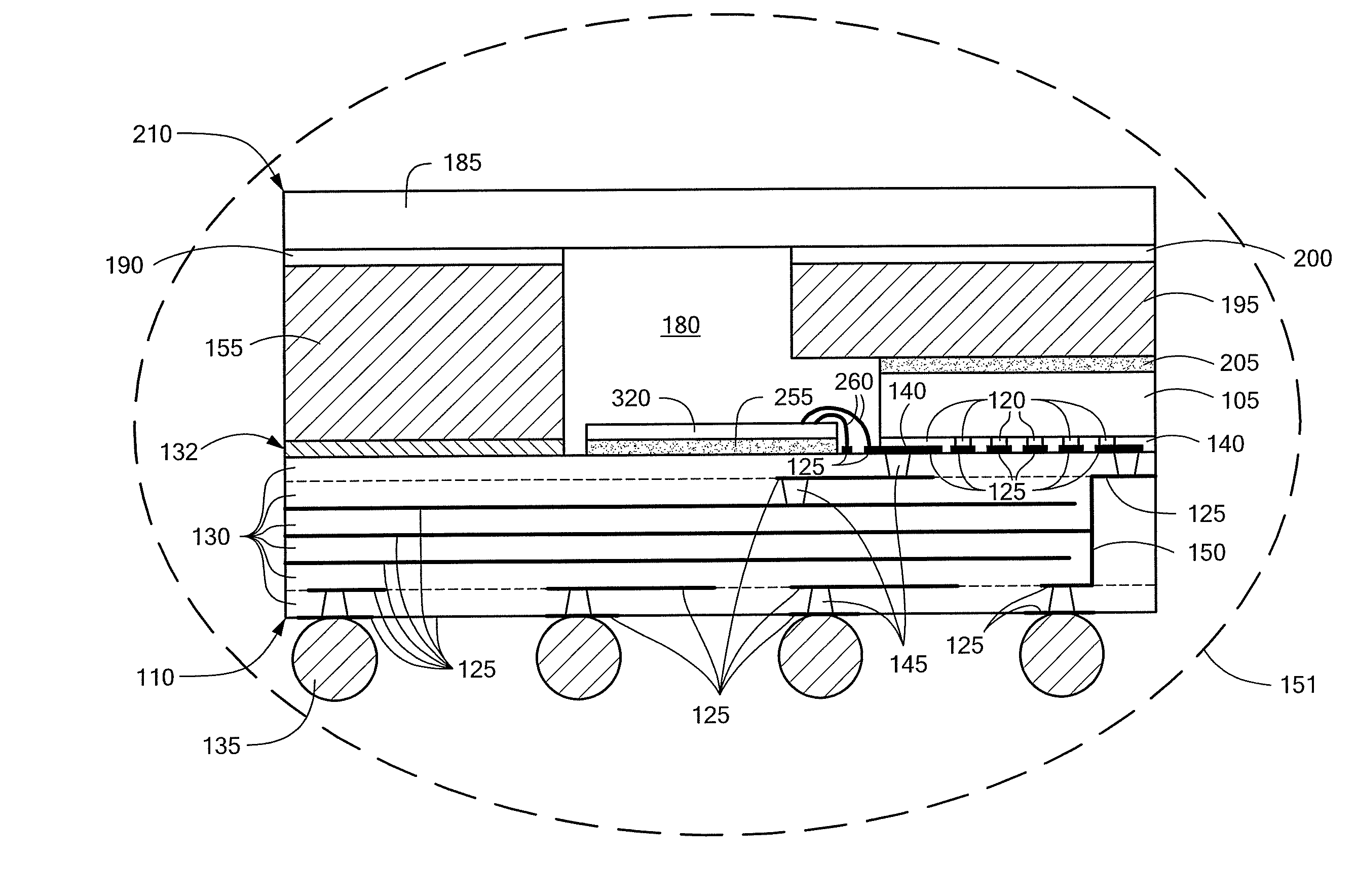

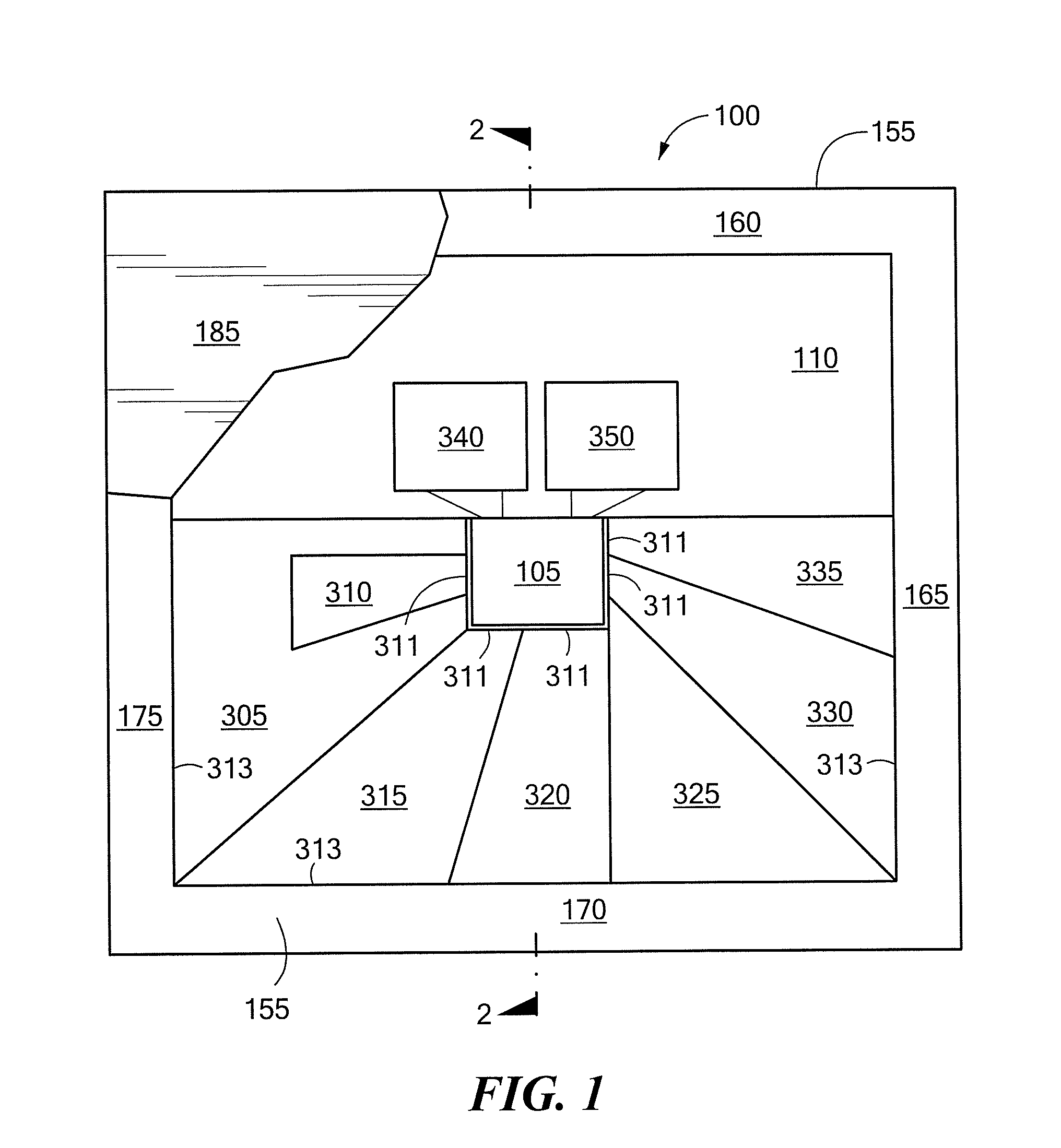

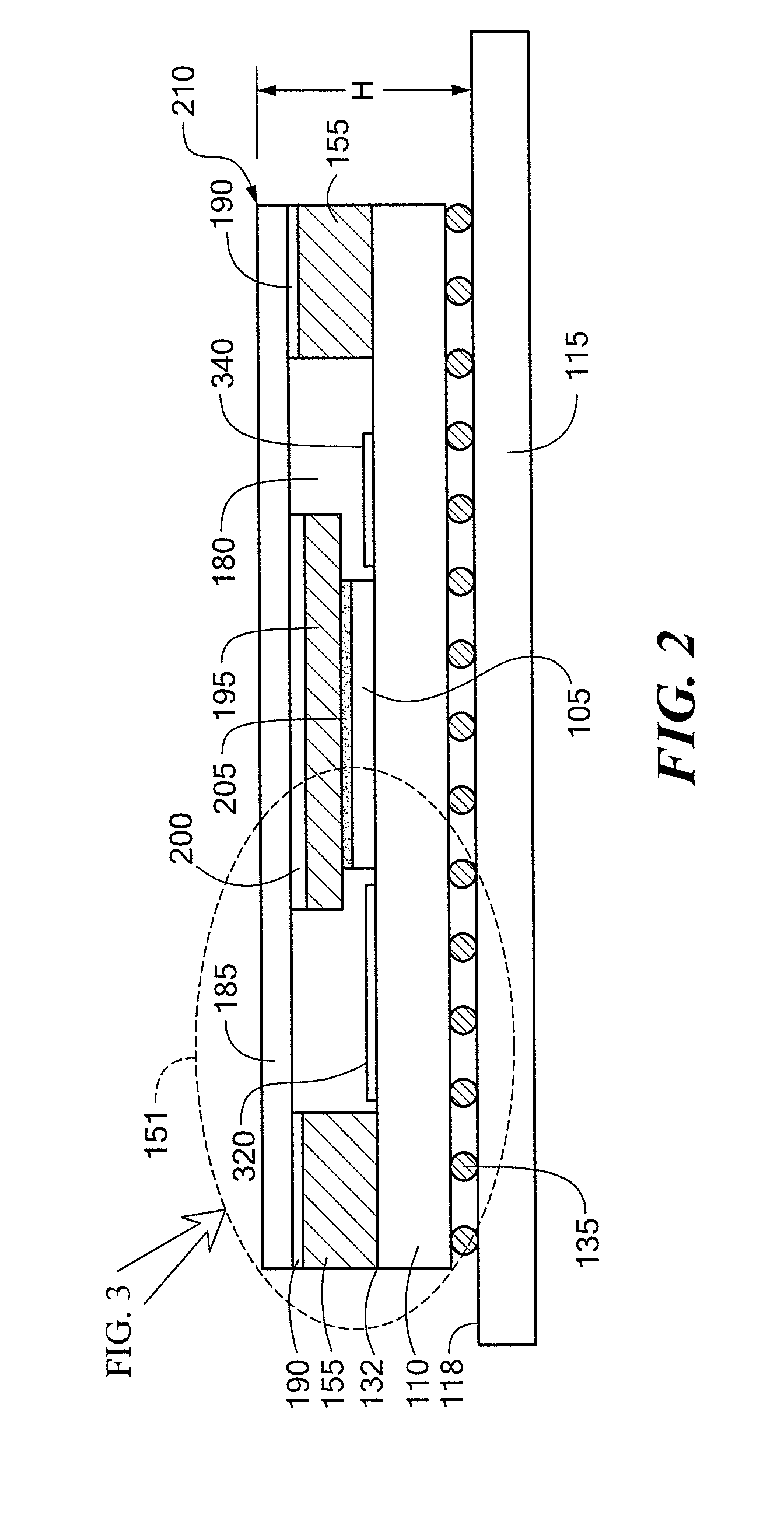

Low noise high thermal conductivity mixed signal package

ActiveUS20110018126A1Efficient thermal managementHigh thermal conductivity materialSemiconductor/solid-state device detailsSolid-state devicesLow noiseEngineering

An improved microelectronic assembly (100) and packaging method includes a device package for housing a semiconductor die or chip, (105), an array of passive electronic components (305-355) operating in cooperation with the flip chip semiconductor die (105) and housed inside the device package to decouple noise from input signals, and a heat spreader (195) disposed between a top surface of the semiconductor die (105) and a package cover (185). The semiconductor die (105) is configured as a flip chip die and the device package includes a package substrate (110) configured as a ball grid array. The improved microelectronic device (100) reduces parasitic inductance in electrical interconnections between the semiconductor die and an electrical system substrate (115) and reduces signal noise in mixed signal high frequency analog to digital converters operating at clock rates above 1 GHz.

Owner:RAYTHEON CO

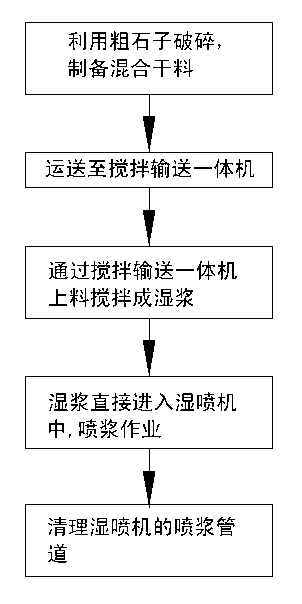

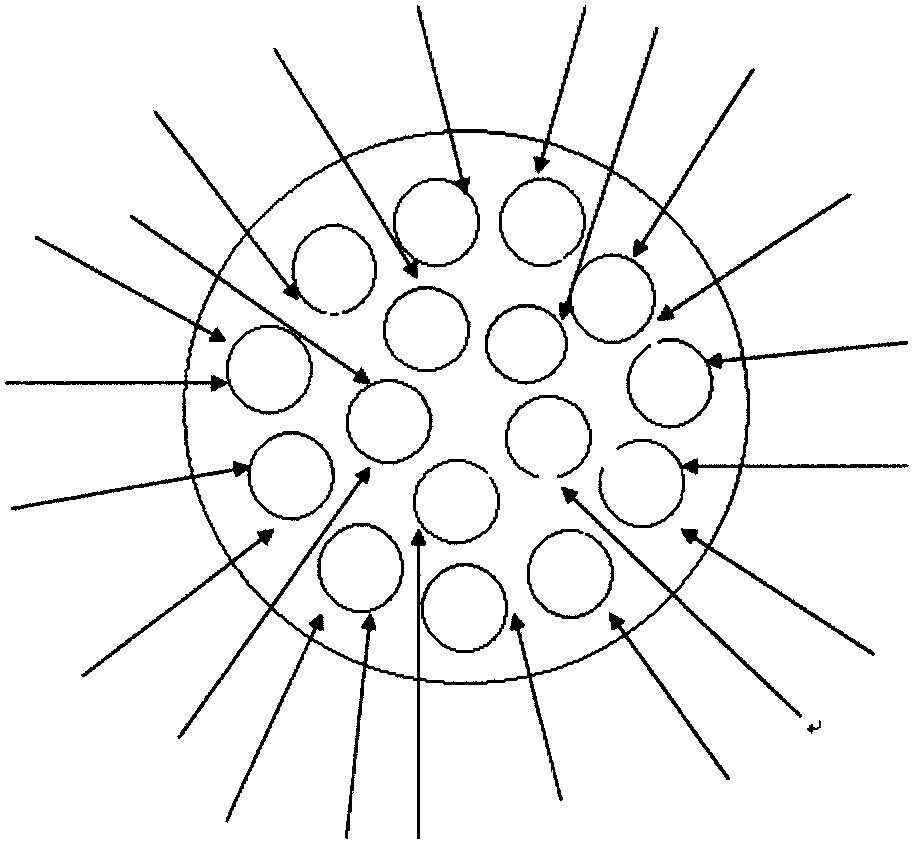

Coal mine wet method guniting process

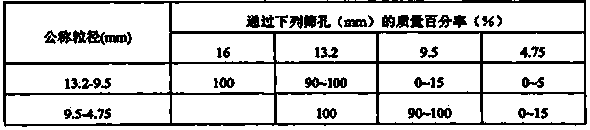

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

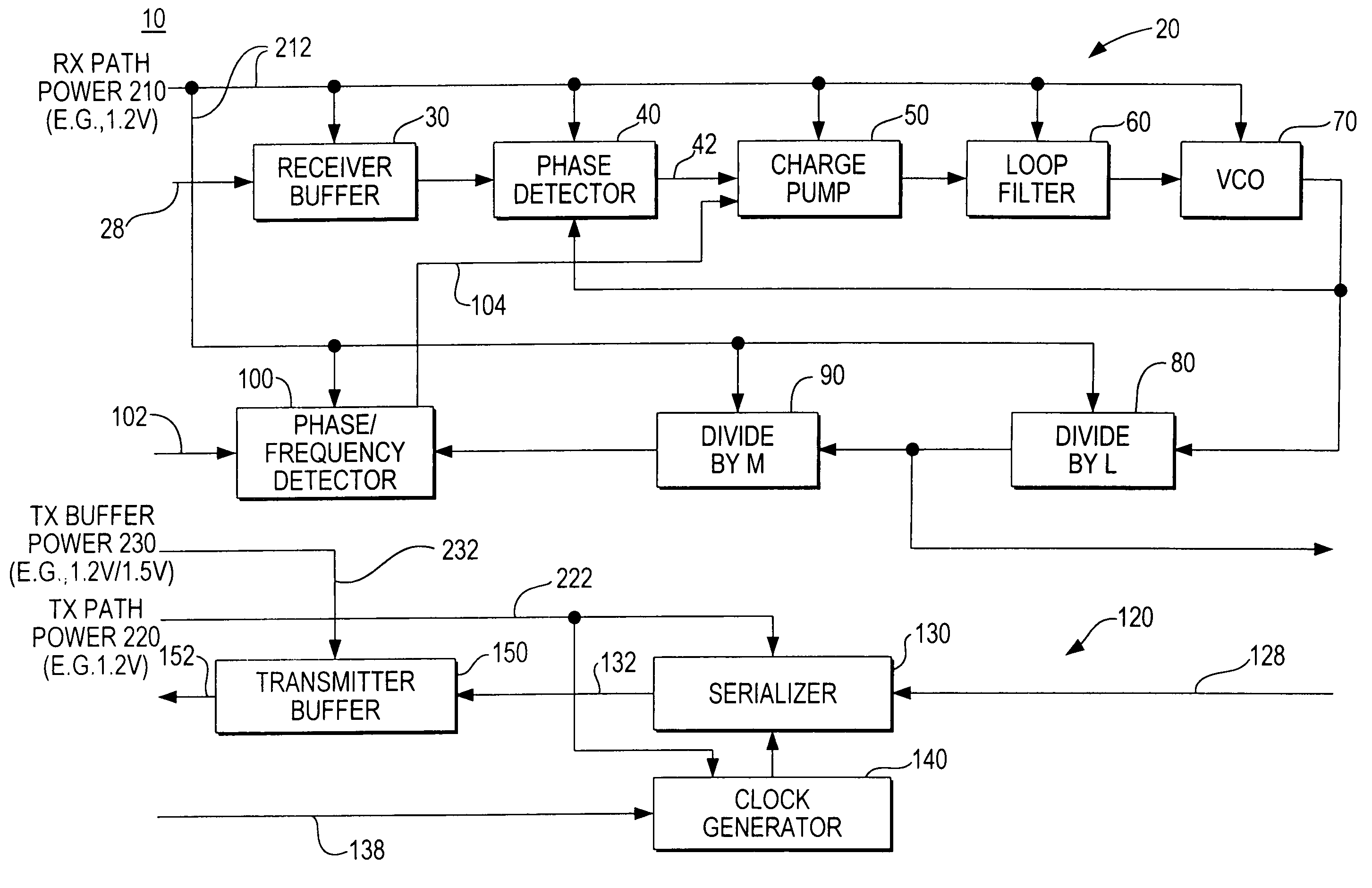

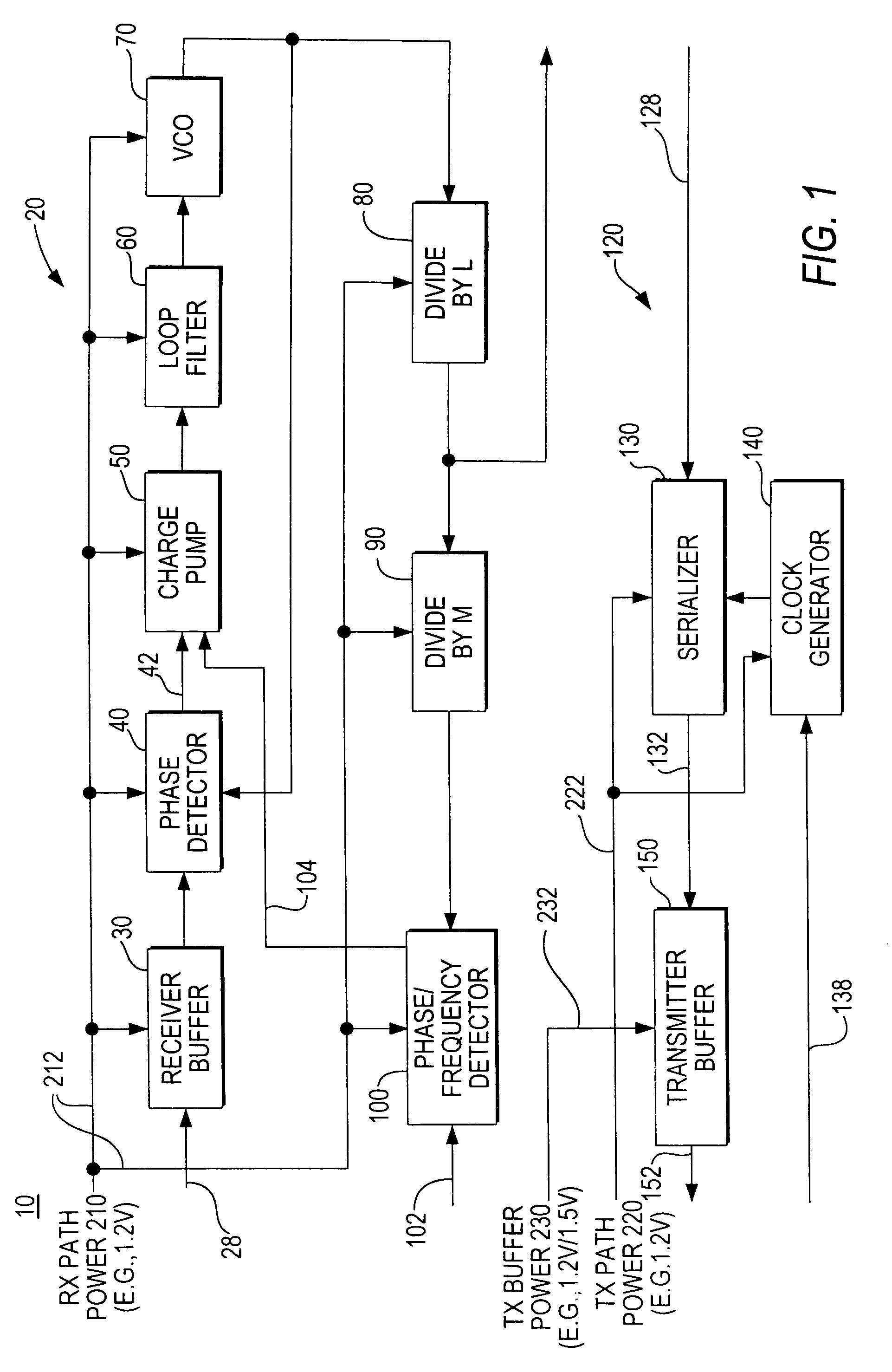

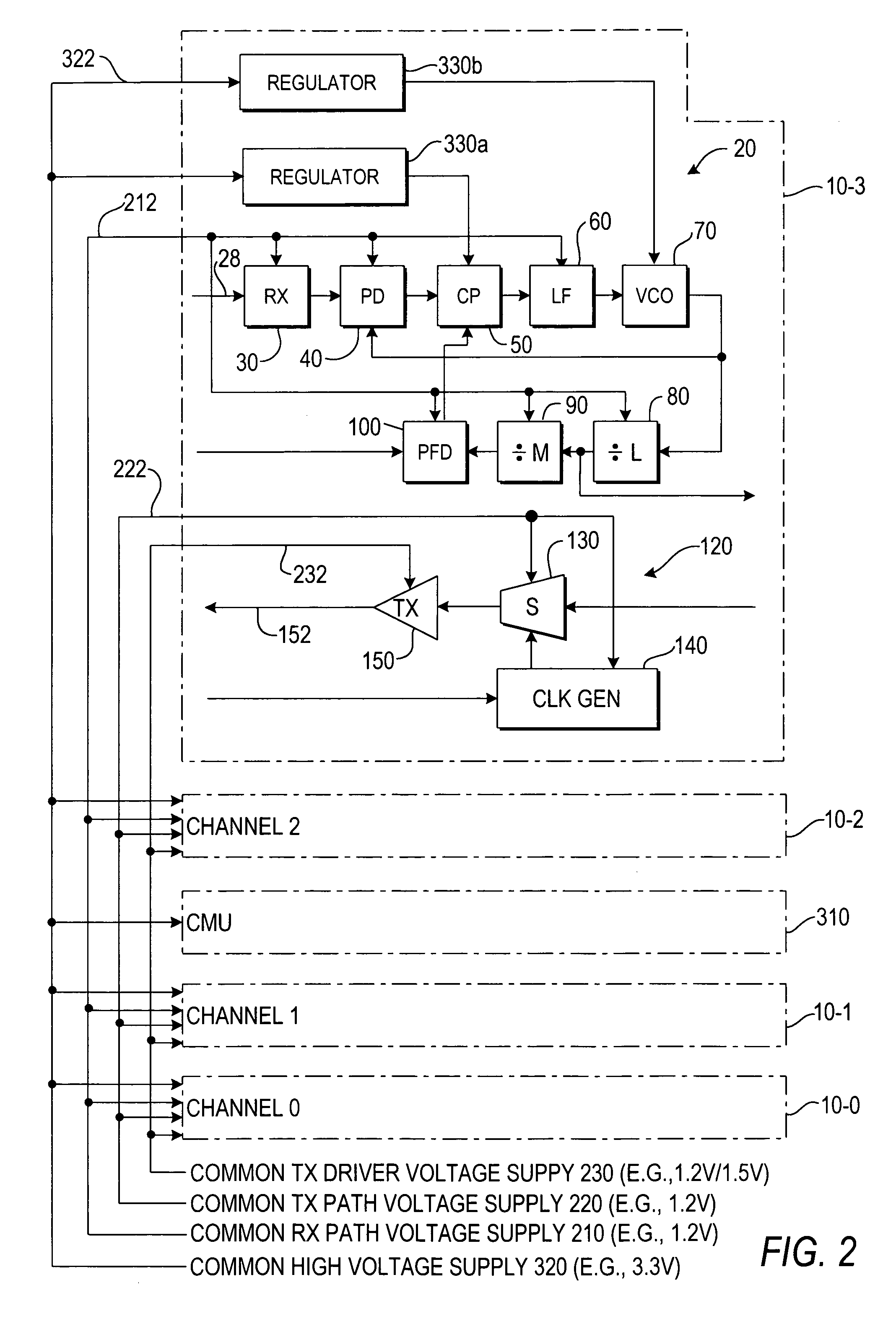

Power supply circuitry for data signal transceivers on integrated circuits

ActiveUS7639993B1Avoid noise contaminationAvoid noise pollutionResonant long antennasSubstation equipmentIntegrated circuitTransceiver

The various components of transceiver circuitry on an integrated circuit are put together in various ways for purposes of being supplied with power to help prevent noise propagation between the groups. In the case of multi-channel transceiver circuitry there can be various amounts of power supply sharing between similar groups in multiple channels.

Owner:ALTERA CORP

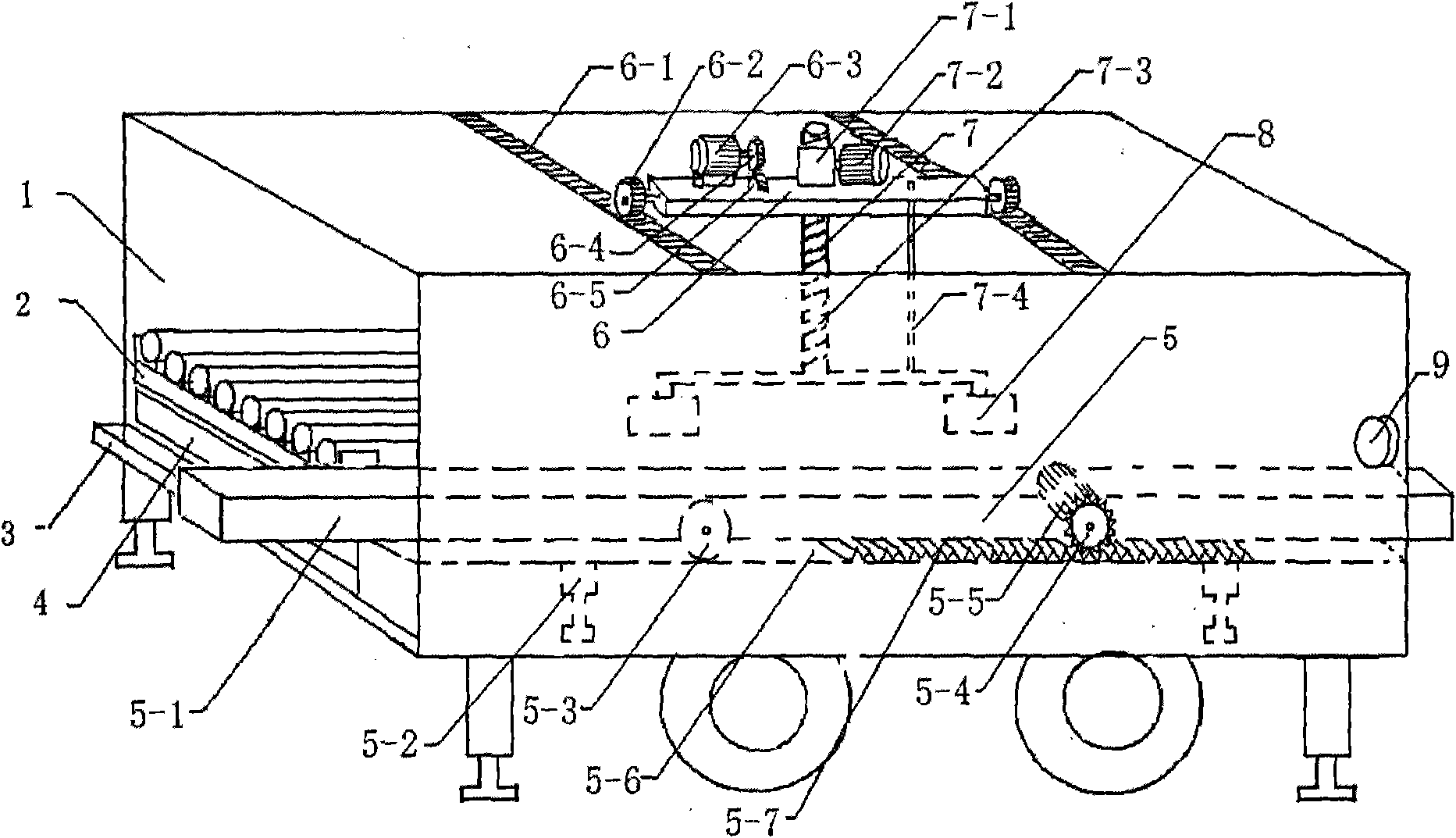

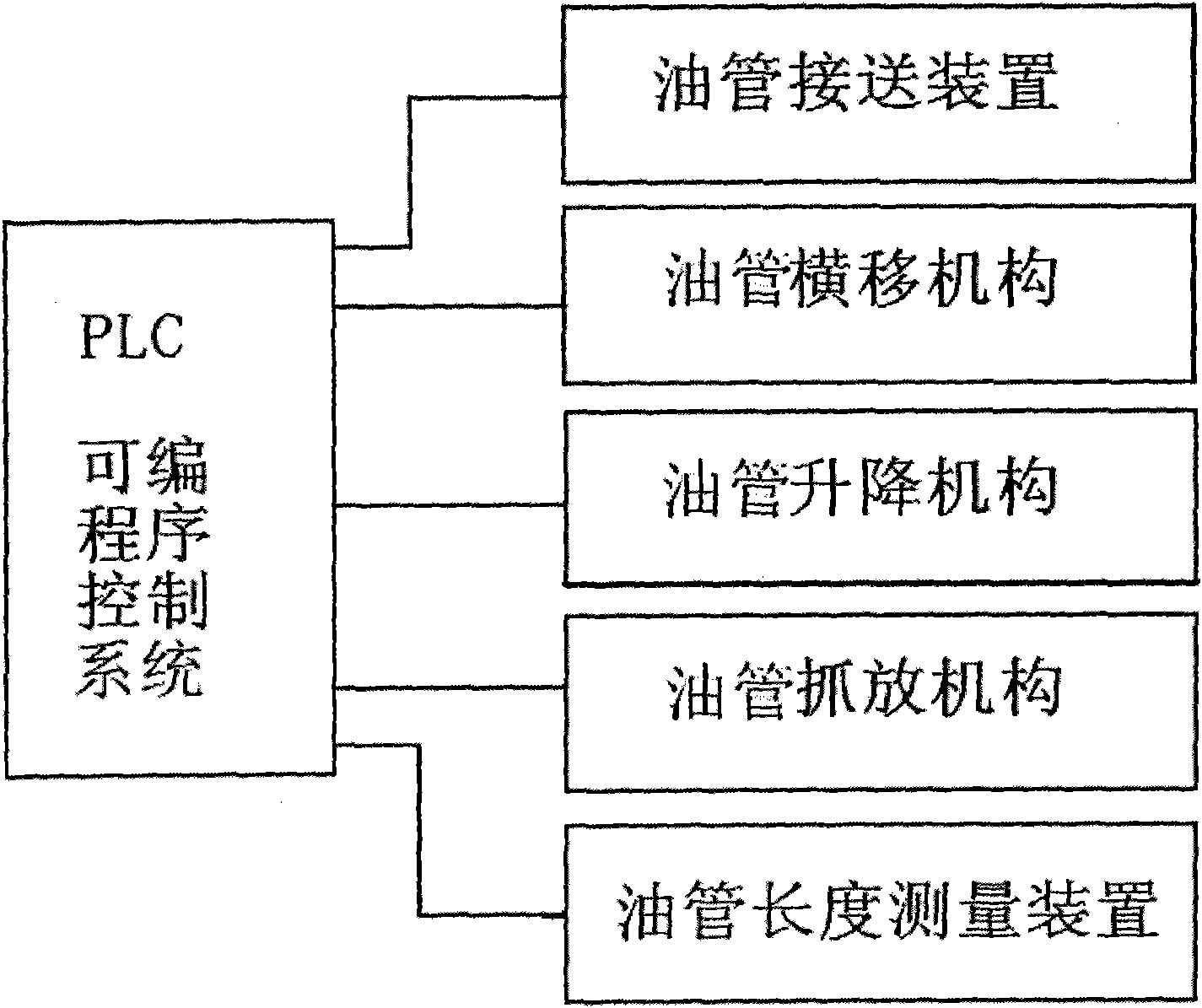

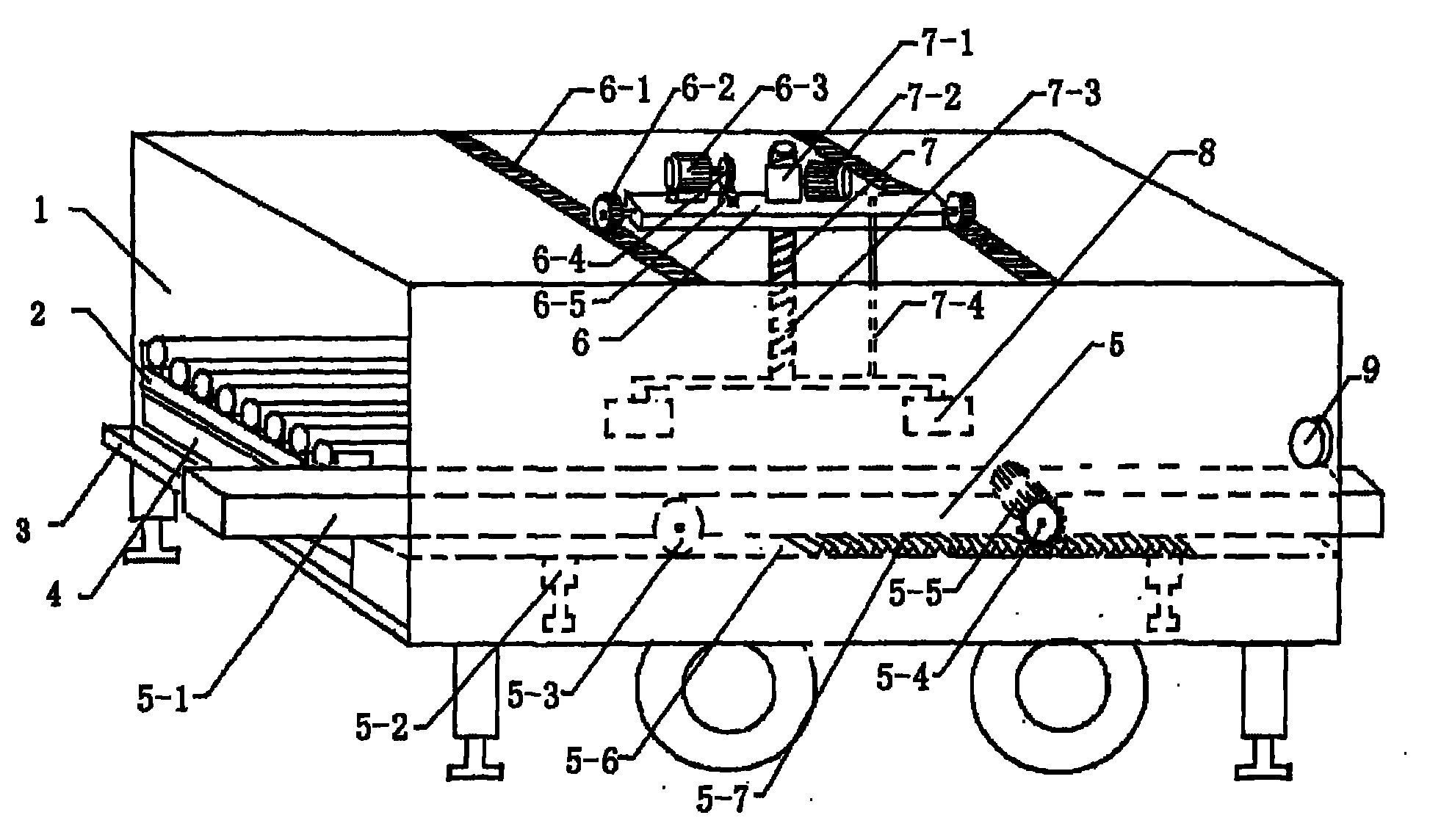

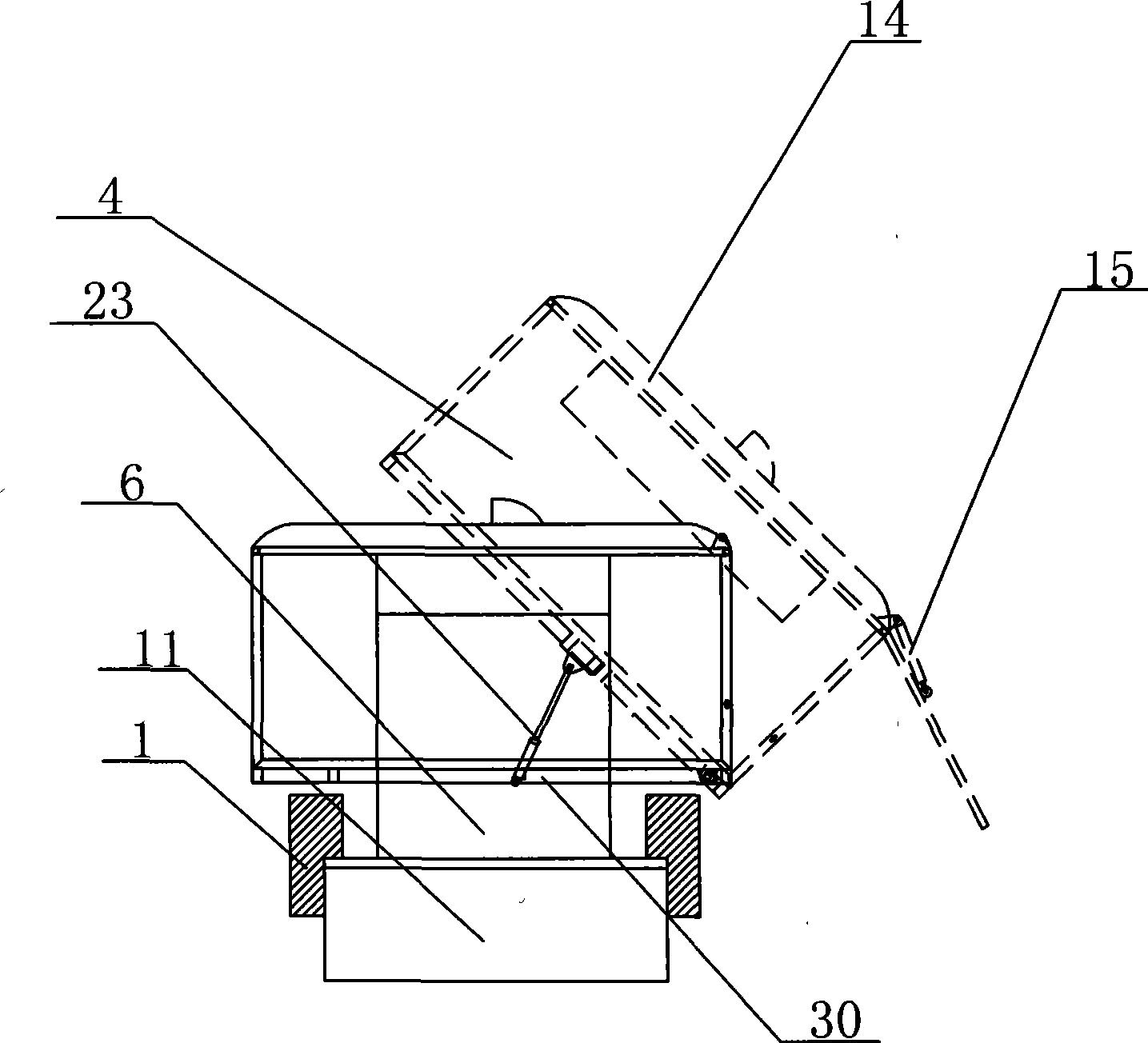

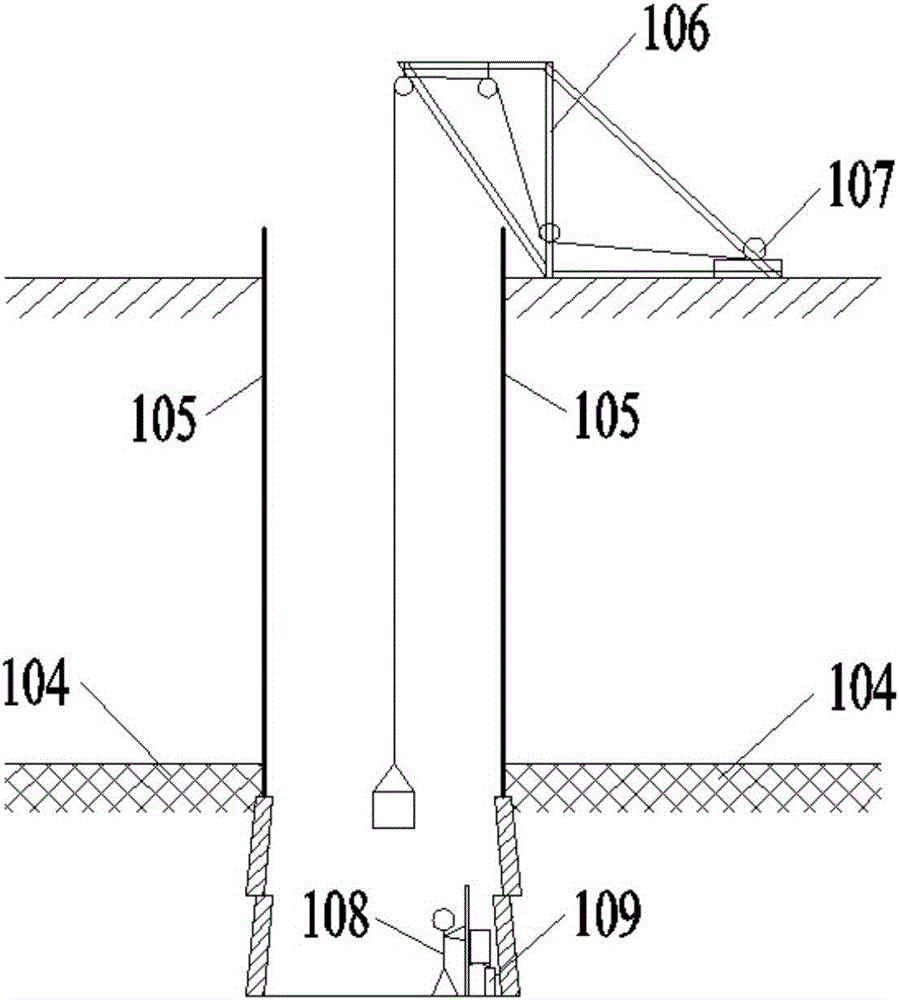

Movable oil pipe box for oil/water well operation

InactiveCN102146774AReduce labor intensityAvoid safety hazardsDrilling rodsDrilling casingsMeasuring instrumentProgrammable logic controller

The invention discloses a movable oil pipe box for oil / water well operation. The movable oil pipe box comprises a trailer chassis, an oil pipe box, an oil pipe bracket, a sewage accumulating pool, an oil pipe oscillating mechanism, an oil pipe elevating mechanism, an oil pipe gripping mechanism, an oil pipe receiving and conveying device, an oil pipe length measuring instrument and a PLC (Programmable Logic Controller) system and is characterized in that the oil pipe box is rectangular and consists of a left part and a right part; the oil pipe bracket is arranged at the middle lower part of the left part; the sewage accumulating pool is arranged at the lower part of the left part; the oil pipe receiving and conveying device capable of extending inwards and outwards is arranged at the lower part of the right part; the oil pipe length measuring instrument is arranged at an inwardly extending opening of the oil pipe or the upper part of the back end of the oil pipe receiving and conveying device; the top middle part of the oil pipe box is provided with an oil pipe traversing mechanism; the oil pipe traversing mechanism is provided with the oil pipe elevating mechanism; the oil pipe gripping mechanism is arranged at the lower end of the oil pipe elevating mechanism; the oil pipe box is arranged on the trailer chassis; and the oil pipe receiving and conveying device, the oil pipe traversing mechanism, the oil pipe elevating mechanism and the oil pipe gripping mechanism are controlled by using the PLC system.

Owner:胜利油田泰峰机电有限责任公司

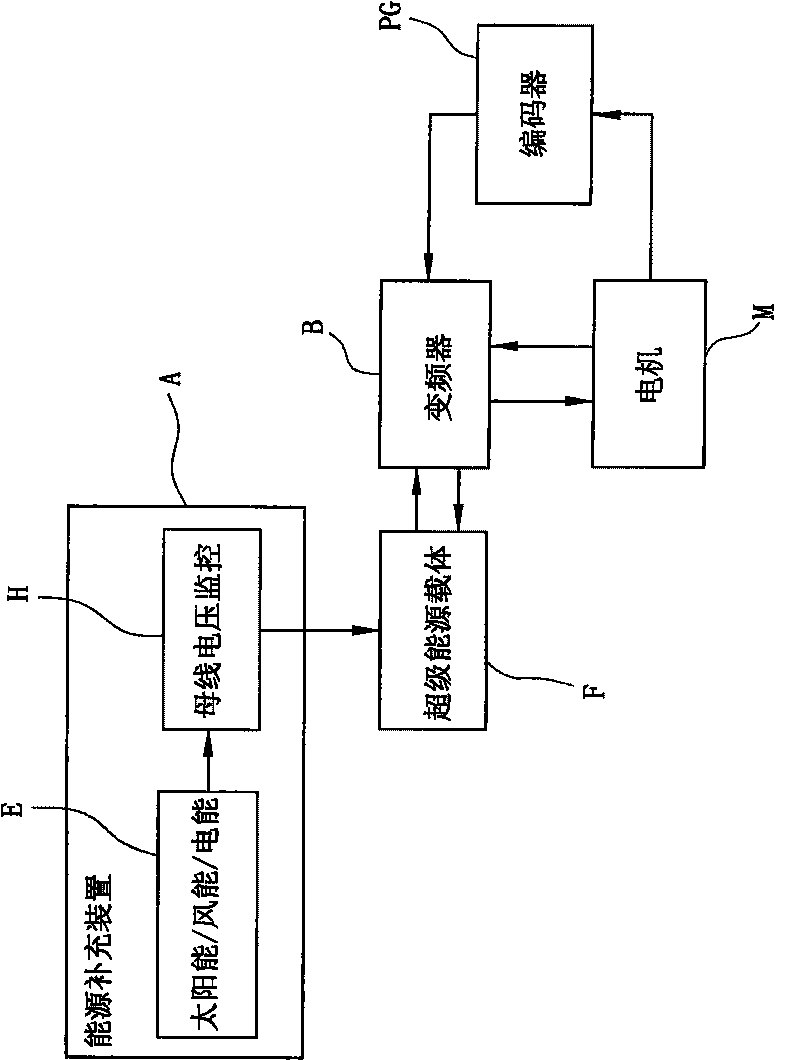

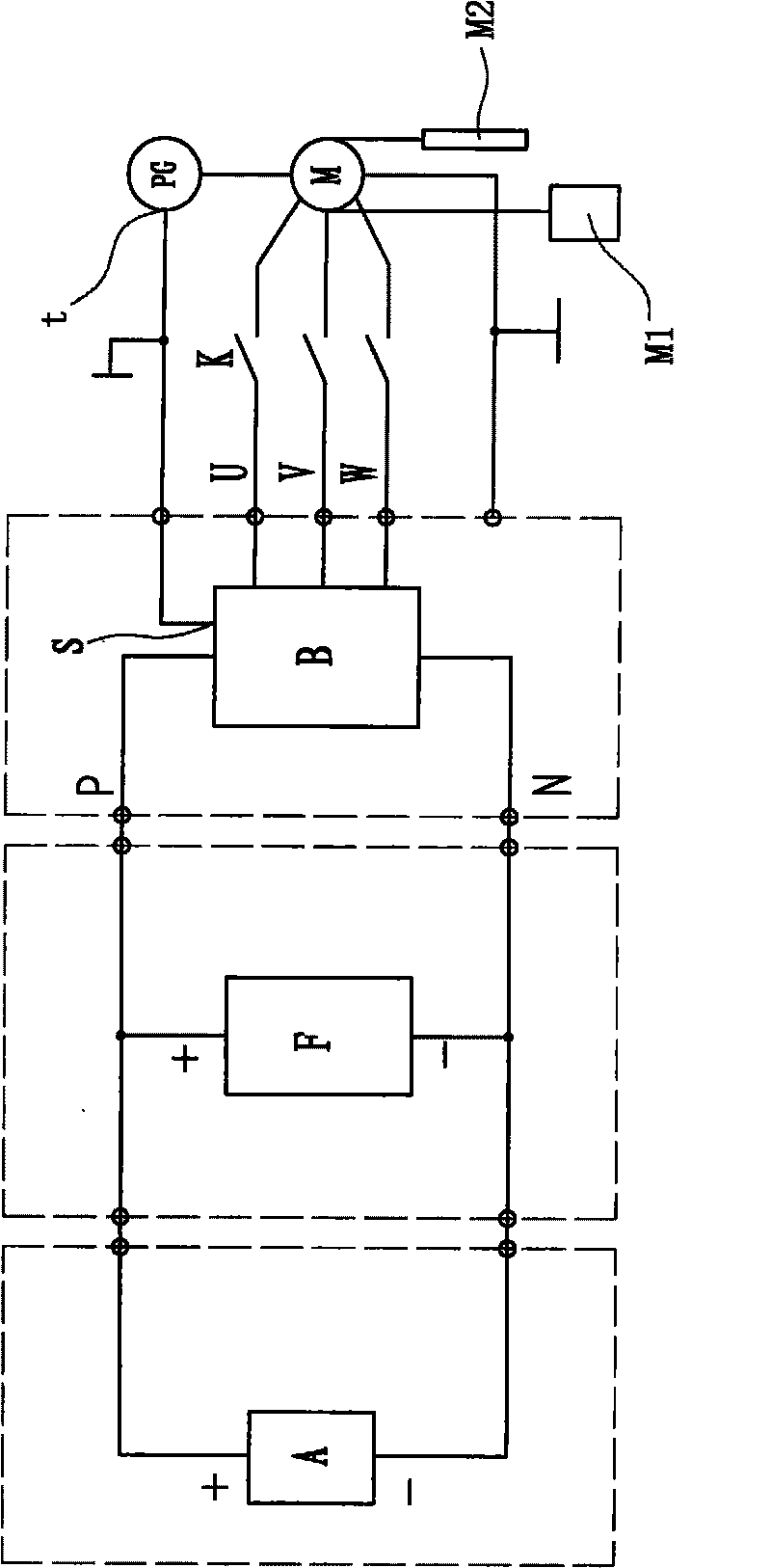

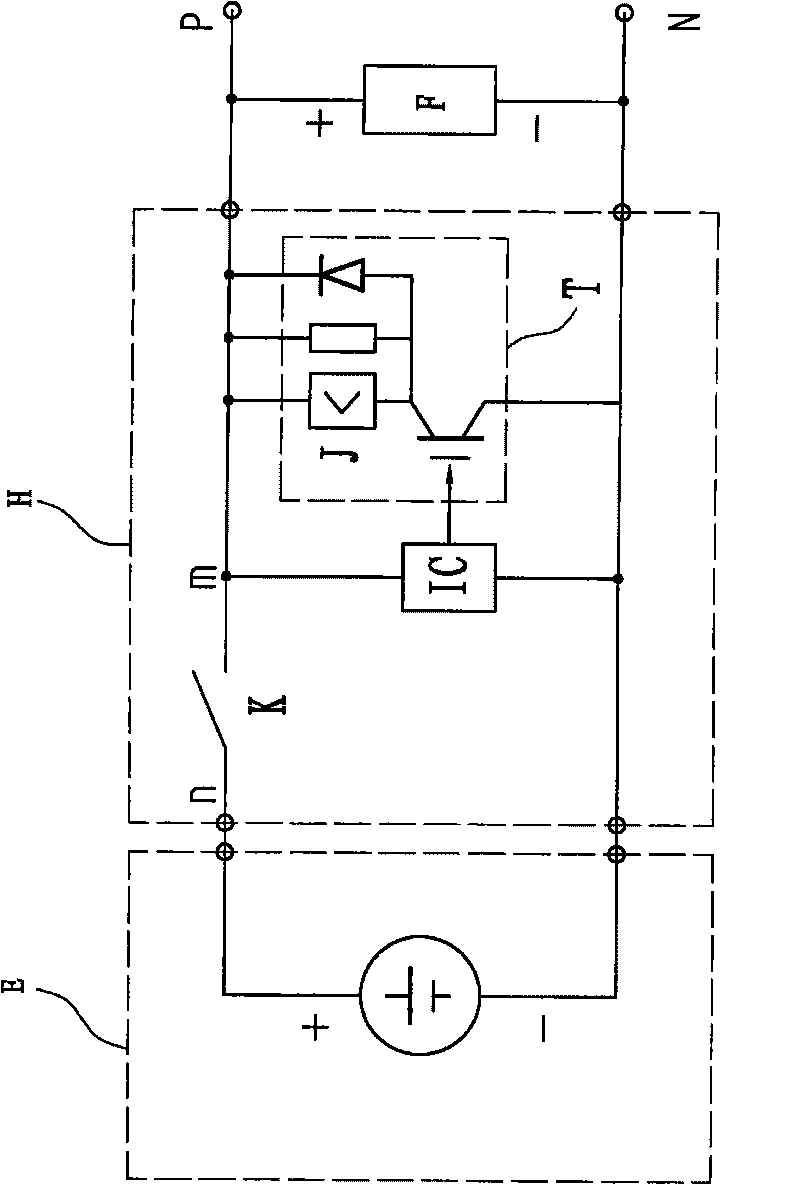

Micro power consumption elevator

InactiveCN101697429ALow costAvoid heat pollutionElectrical storage systemMotor/generator/converter stoppersFrequency changerElectrical battery

The invention relates to a micro power consumption elevator, which comprises a motor, a frequency converter and an encoder. The micro power consumption elevator is characterized by further comprising a super-capacitor component, wherein an positive electrode of the super-capacitor component is connected with a positive electrode input end of the frequency converter; an negative electrode of the super-capacitor component is connected with a positive electrode input end of the frequency converter; in a motor power generation state, the super-capacitor component stores the electric energy generated by the motor, and in a motor electro-motion state, the super-capacitor component supplies power to the motor for running; and an energy supplement device charges the super-capacitor component when the working voltage of the super-capacitor component is lower than a designed voltage lower limit value. The micro power consumption elevator has the advantages that the super-capacitor component is used as a main power supply carrier for continuously supplying power to the elevator and the super-capacitor component not only serves as an energy storage element but also serves as a battery and makes full use of the electric energy generated in the running process of the elevator so that a brake unit (or a brake resistor) is unnecessary to be arranged in the elevator, an inverter is also unnecessary to be arranged in the elevator, not only the equipment cost is saved, but also thermal pollutions and harmonic noise pollutions are avoided, and the micro power consumption elevator is more energy-saving and environment-friendly.

Owner:林肯电梯(中国)有限公司

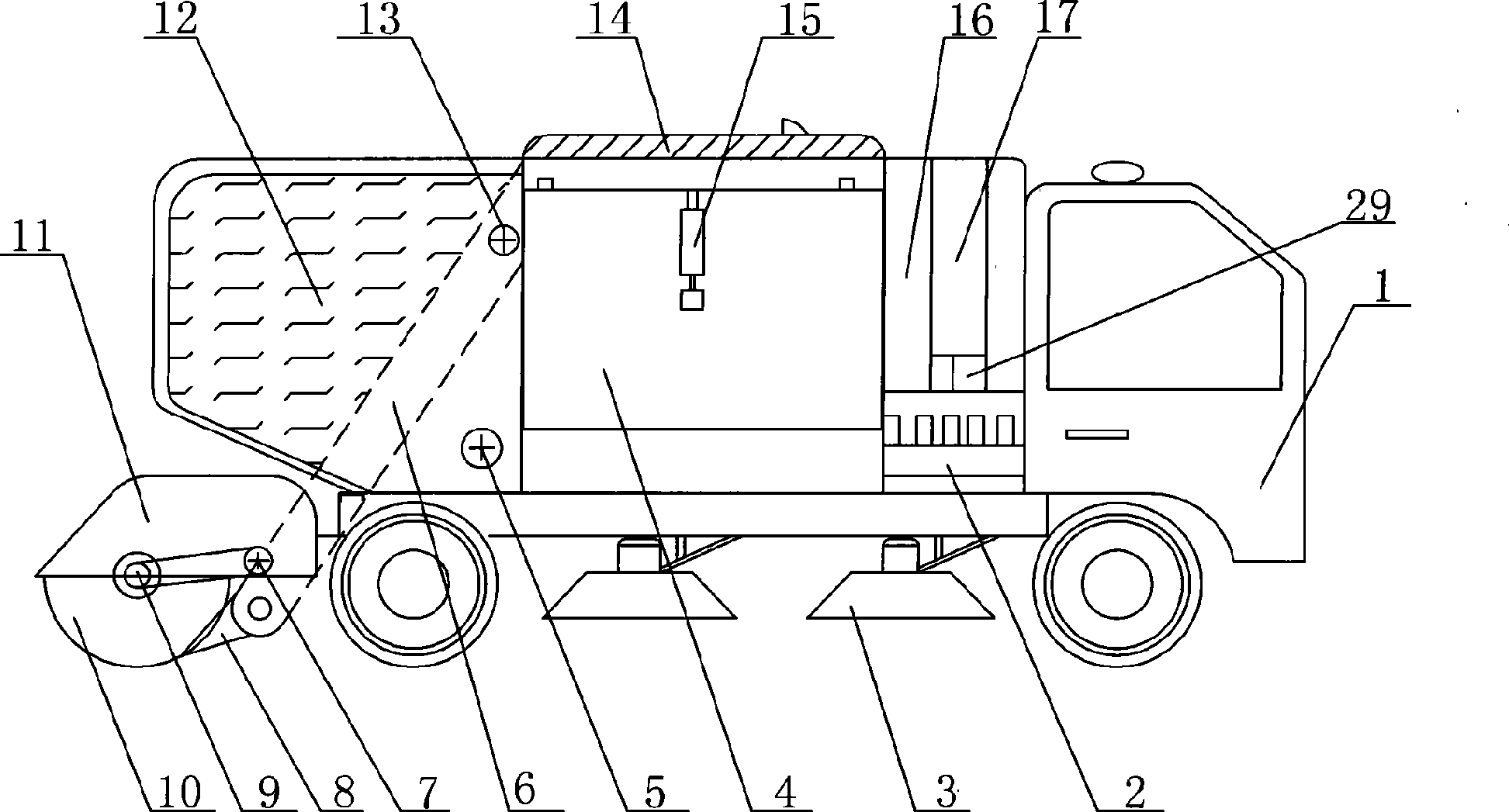

Purely sweeping type road sweeper

The invention belongs to the technical field of an environmental sanitation vehicle, in particular to a pure-sweeping typed cleaning vehicle. The cleaning vehicle comprises an automobile chassis, a middle sweeping device assembly, a garbage conveyer assembly, a garbage collecting box and a hydraulic system. The rear suspension position of the automobile chassis is fixedly provided with the middle sweeping device assembly; wherein, a roller brush is arranged on the shell of the middle sweeping device; the roller brush is connected with the hydraulic motor of the middle sweeping device by a chain wheel pair; the front part of the roller brush is provided with a feeding dustpan hole; the front part of the feeding dustpan hole is provided with a garbage feeding hole; and a lifting hydraulic cylinder of the middle sweeping device is arranged between the shell of the middle sweeping device and the automobile chassis. The pure-sweeping typed cleaning vehicle integrates collecting, sweeping and dust-pressing into a whole, has simple structure, little malfunction, is not restricted by reasons and provided with a spraying dust-pressing device, thus avoiding the secondary pollution due to dust flying during the operation process.

Owner:郑振华

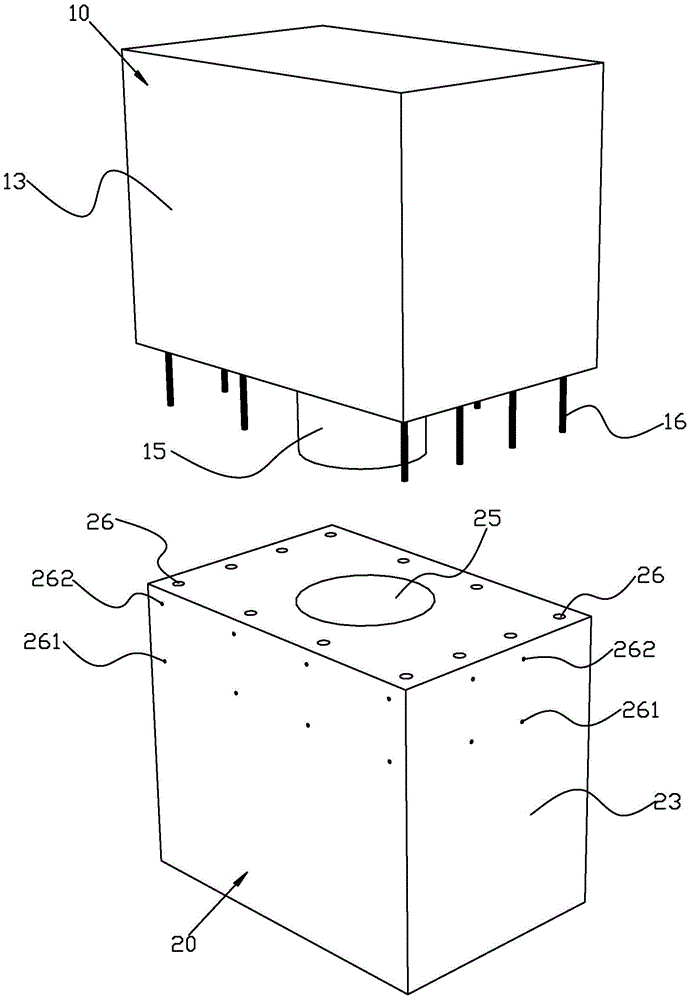

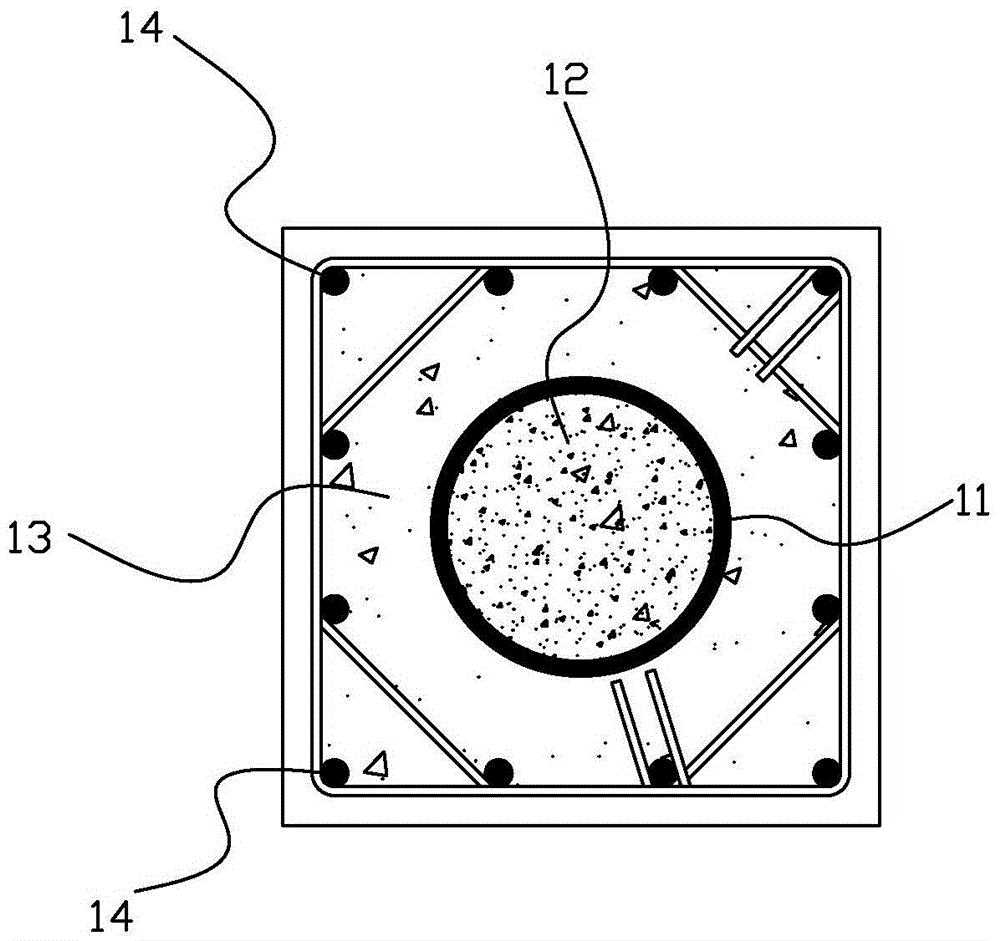

Assembling type steel tube concrete combination column

The invention discloses an assembling type steel tube concrete combination column which comprises two column segments. Each column segment comprises a steel tube and a steel reinforcement cage distributed outside the steel tube, wherein the steel tube is filled with concrete, the steel tube and the steel reinforcement cage are cast by concrete so as to form exterior concrete. The first steel tube is provided with a plugging portion stretching out of a first matching face of a first exterior concrete portion. A first longitudinal steel reinforcement bar is provided with a reserved segment stretching out of the first matching face. One end of the second steel tube is fixedly connected with a steel sleeve. A first slot is formed in the steel sleeve. One end of a second longitudinal steel reinforcement bar is fixedly connected with a steel sleeve. A second slot is formed in the steel sleeve. The first matching face of the first column segment is opposite to the second matching face of the second external concrete portion. The plugging portion is plugged into the first slot of the steel sleeve, the reserved segment is plugged into the second slot of the steel sleeve, and sizing materials are injected into a gap between the plugging portion and the steel sleeve and a gap between the reserved segment and the steel sleeve. The assembling type steel tube concrete combination column has the advantages that the two column segments can be prefabricated, the manufacturing precision can be improved, the construction period is shortened, and the mechanical performance is reliable.

Owner:HUAQIAO UNIVERSITY +1

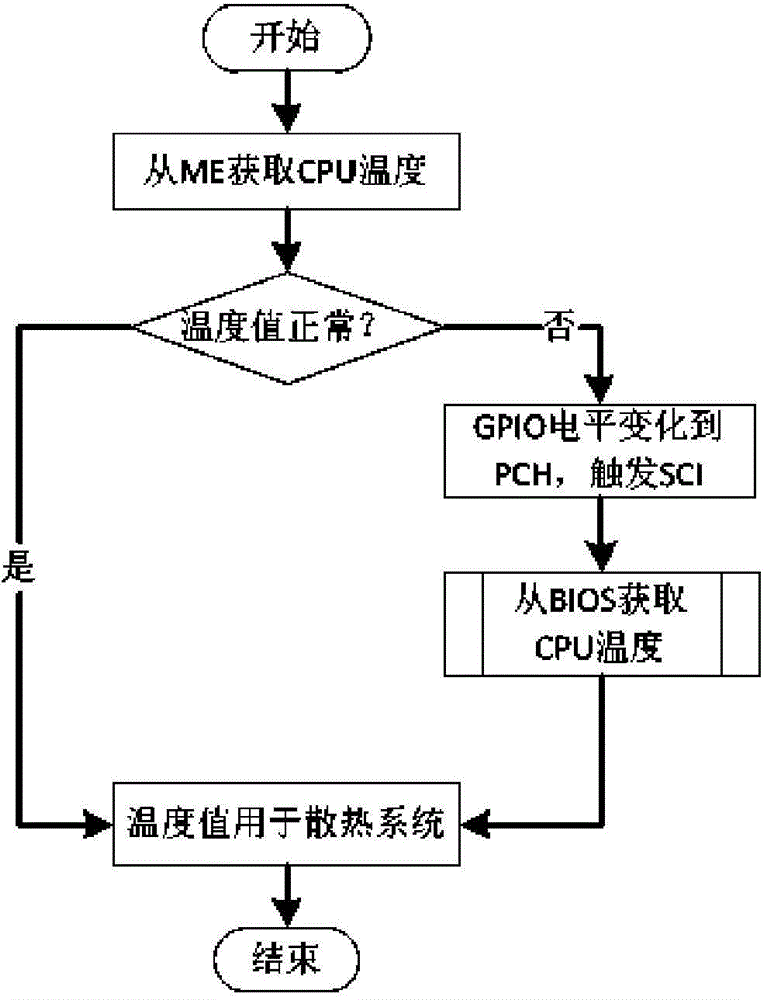

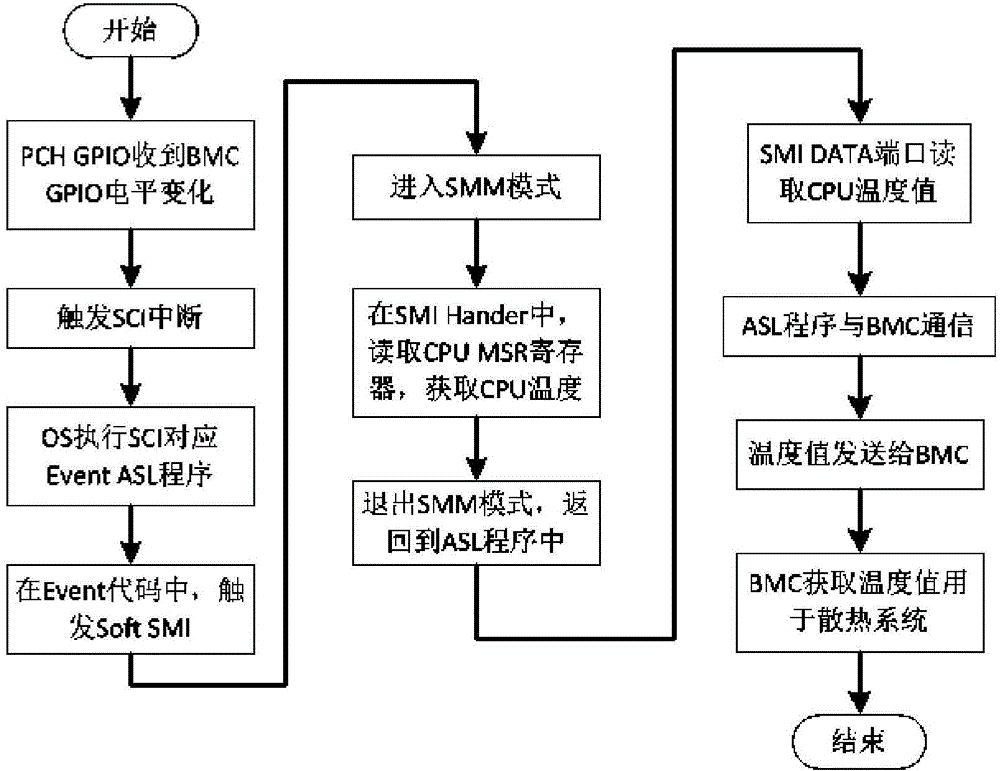

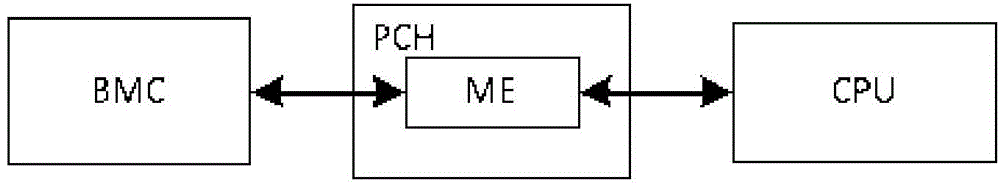

Operating system based CPU temperature obtaining system

ActiveCN104899109AImprove reliabilityGuaranteed accuracyFault responseOperational systemNormal functioning

The invention relates to the field of servers, and particularly to an operating system based CPU temperature obtaining method. The method comprises the following steps of: A) a BMC determining whether a CPU temperature obtained from the ME is correct; B) if the CPU temperature obtained from the ME is correct, applying the temperature to a heat dissipation system; C) if the CPU temperature obtained from the ME is not correct, the BMC obtaining the CPU temperature by using the BIOS; and D) applying the CPU temperature obtained in step C to the heat dissipation system. According to the method, for the problem in the existing scheme according to which the BMC obtains the temperature, improvement and optimization are performed: a candidate scheme is added, so that two schemes can be selected to obtain the CPU temperature, the correctness of the temperature can be determined and checked, and it is ensured that the temperature provided to the heat dissipation system is correct, thereby enabling the heat dissipation system to work normally, improving reliability of the heat dissipation system, and meanwhile avoiding fan noise pollution and wasting of power caused by an invalid temperature.

Owner:SHENZHEN TONGTAIYI INFORMATION TECH CO LTD

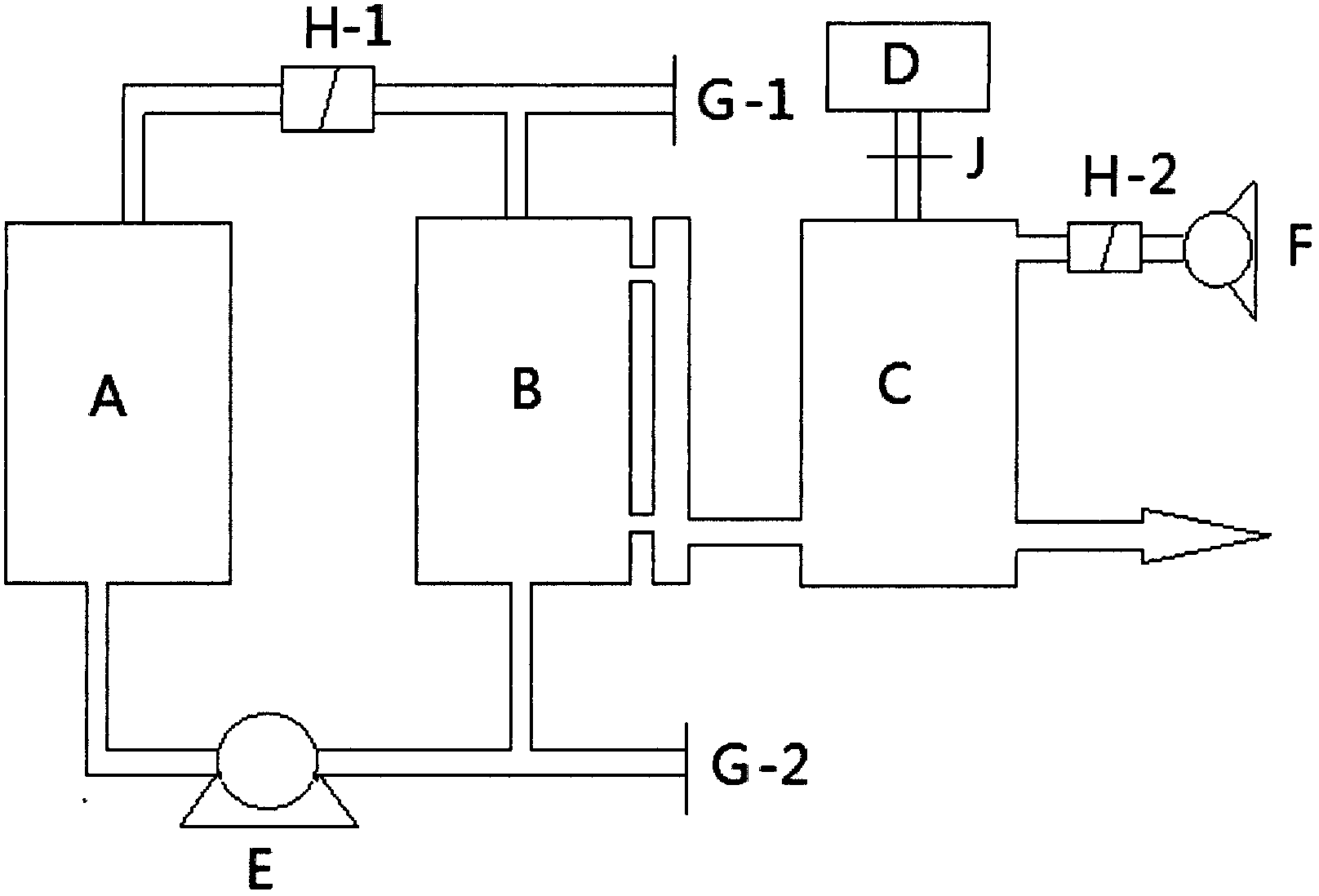

An eddy current ramjet engine

An eddy current ramjet engine comprises a case, a fuel system and an igniting system. The cross section of the inner chamber of the case is of circular shape. And a combustion chamber and a blowing chamber are installed inside the case. An air intake and an air outtake are installed in the combustion chamber of which the air outtake is connected with the blowing chamber. The cross section area of the combustion air outtake is smaller than the largest cross section area of the combustion chamber. The inner chamber of the blowing chamber is opened and extended towards the blowing direction. The air intake of the combustion chamber is connected to the air intake chamber and the fuel system and the igniting system are arranged correspondingly to the combustion chamber. The engine can be started in a static state by this brand new air admission method. The eddy current is formed by full utilization of circular motion and fluid motion and rotates with increasing speed from the periphery to the center. The eddy current enables fully combust fuel and prevents the combustion chamber from being burned. A spiral jet stream which rotates with increasing speed from the periphery to the center is also formed. The stream can unlimitedly increase the aircraft speed and can help the aircraft reach super speed which can not be reached by current jet engines; and the aircraft speed can be increased by hundreds, thousands or tens of thousands of times than the current aircraft speed.

Owner:陈久斌

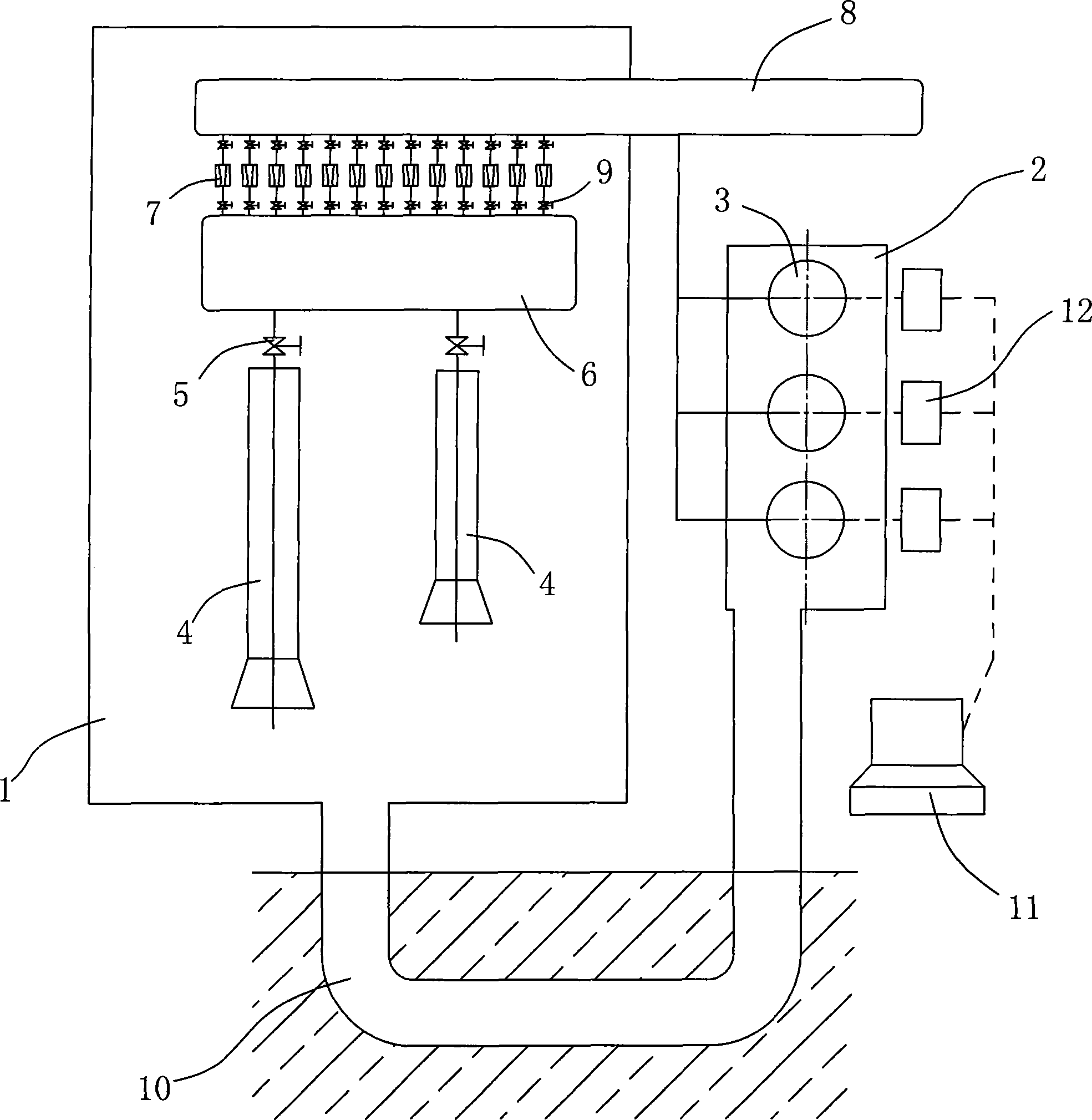

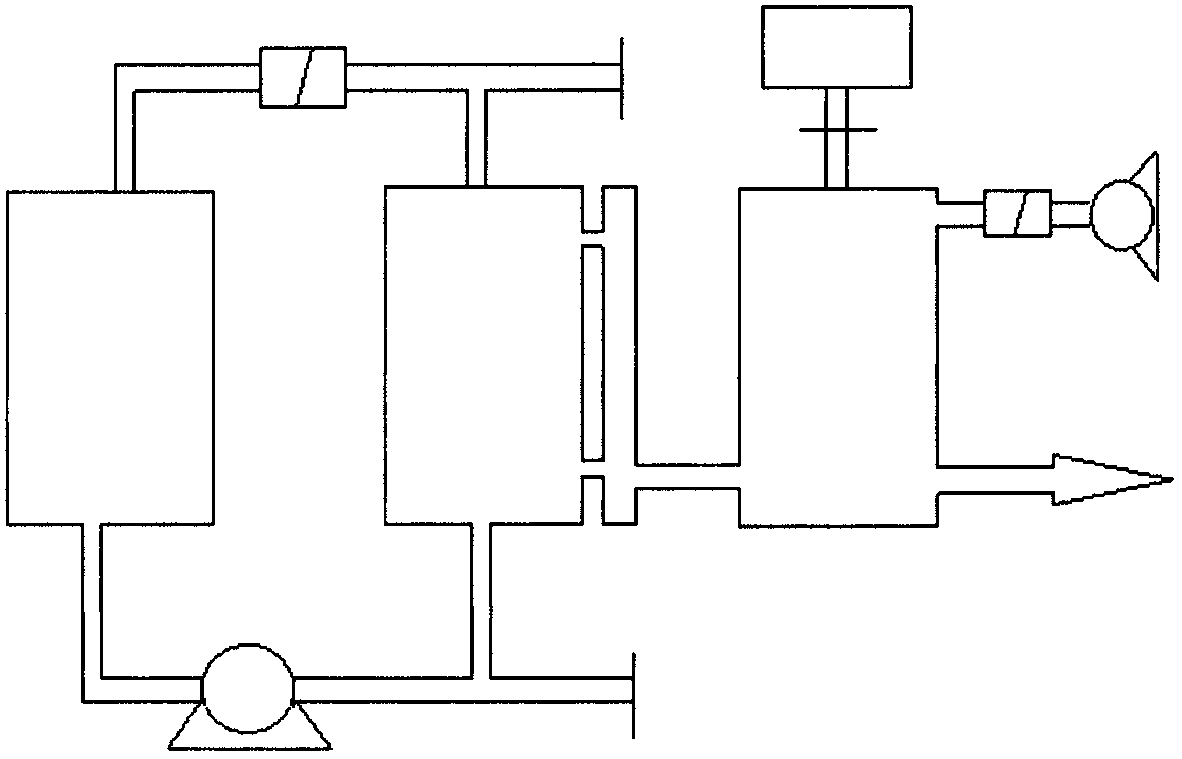

Apparatus for calibrating gas instrument

ActiveCN101251405AChange of pumping methodAvoid noise pollutionTesting/calibration apparatusLow noiseSonic nozzle

The invention discloses a gas instrument calibration device, which comprises a calibration platform for assembling a flowmeter to be tested. The calibration platform is at least connected with a stagnation container, a sonic nozzle, a negative pressure pipe and a Roots vacuum pump adopting the variable frequency control in turn. The calibration platform and the gas inlet of the calibration platform are arranged in a lockable calibration chamber, and the gas outlet of the vacuum pump is communicated with the calibration chamber through an underground duct. The gas instrument calibration device which has the advantages of low noise pollution, low energy consumption and small error is particularly suitable for the calibration of a gas flow measuring instrument.

Owner:YUYAO YINHUAN FLOWMETER

Audio system

InactiveCN1843054AAvoid noise pollutionSound producing devicesTransducer circuitsEngineeringActuator

An audio system comprises, according to one aspect of the invention, an audio frequency actuator coupled to a body so as to cause the body to radiate sound when an audio signal is supplied to the actuator by a controller, and an acoustic sensor coupled to said body or to an adjacent body so as to sense acoustic vibrations in said body, the sensor being connected to the controller, whereby the controller is arranged to change the audio signal supplied to the actuator according to the vibrations sensed by the sensor. Another aspect provides an audio system comprising an audio frequency actuator coupled to a body so as to cause the body to radiate sound when an audio signal is supplied to the actuator by a controller, and an acoustic sensor coupled to said body or to an adjacent body so as to sense acoustic vibrations in said body, the sensor being connected to the controller, whereby the controller is arranged to detect predetermined characteristics of the sensed acoustic vibrations and to output an alerting signal in response thereto.

Owner:FEONIC

Multi-power hybrid driving system

InactiveCN106627605AGuaranteed unobstructedAvoid strandedBraking element arrangementsRack railwaysHydraulic motorDrive wheel

The invention provides a multi-power hybrid driving system and relates to the field of hybrid power driving. The multi-power hybrid driving system adopts modularized hybrid driving, environmental pollution is low, and multi-power interconversion is facilitated. The multi-power hybrid driving system comprises power sources, driving modules and driving wheels; the power sources are connected with the driving modules which are connected with the driving wheels, the power sources comprise a storage battery power supplying system, a cable conveying power supplying system and a fuel oil power system; and the driving modules comprise a permanent magnet motor drive, a speed reducer drive and a hydraulic motor drive, hybrid power driving modes are formed by means of the method that any two of the power sources are connected with any one or two of the driving modules, and the multiple mixing power driving modes are integrated to form the multi-power mixing driving system of a rack rail vehicle or a trapped rail vehicle.

Owner:秦皇岛鸿鼎轨道交通设备有限公司

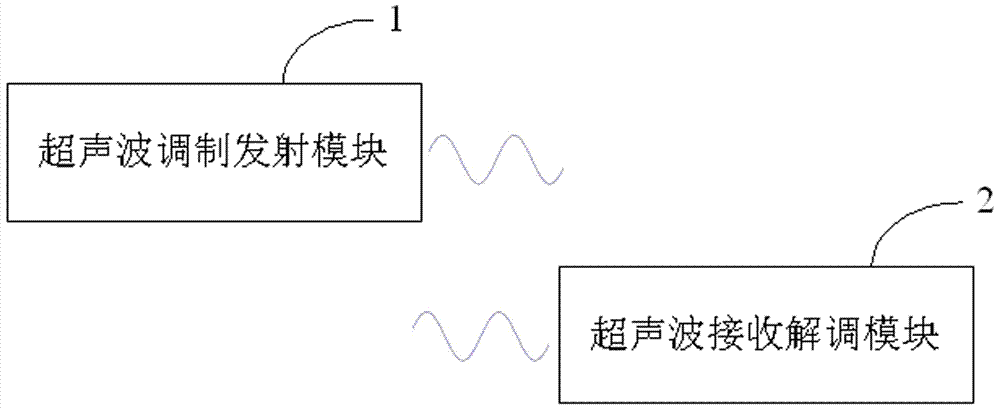

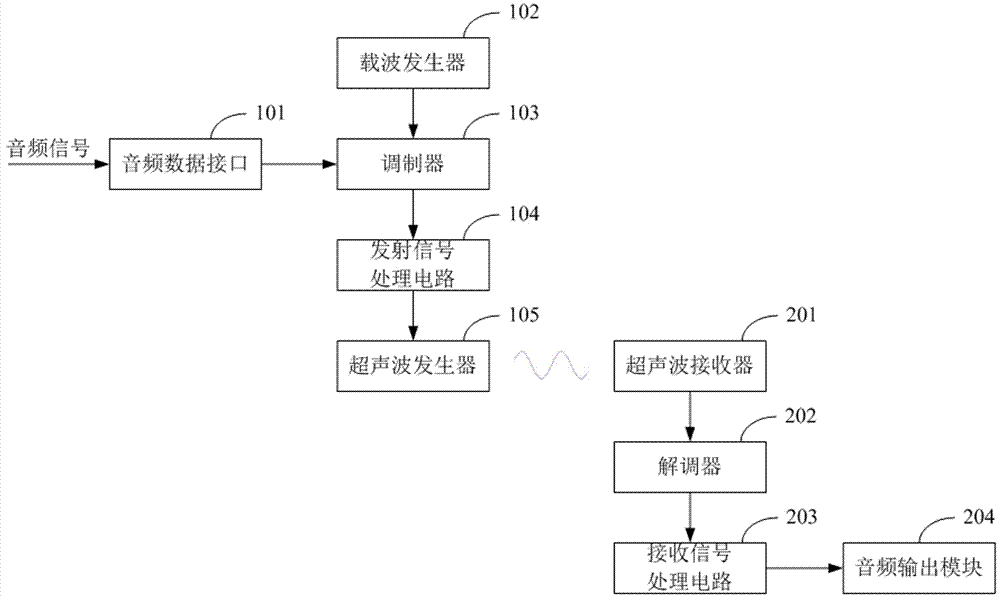

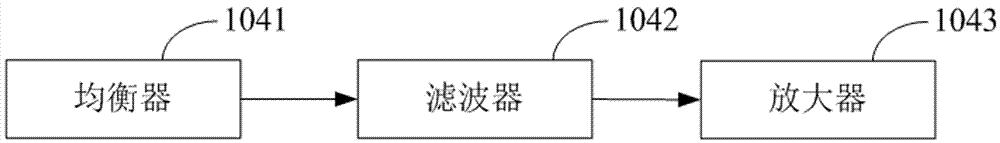

Device and method for ultrasonic transmission of audio

PendingCN107171738AAvoid noise pollutionSimple planSonic/ultrasonic/infrasonic transmissionMultiple carrier systemsSignal processing circuitsCarrier signal

A device and a method for ultrasonic transmission of audio are provided. A modulator modulates an audio signal extracted by an audio data interface to a high-frequency oscillation signal generated by a carrier generator. A transmitted signal processing circuit processes a signal output by the modulator. An ultrasonic generator generates an ultrasonic signal containing audio information under the drive of the high-frequency oscillation signal. An ultrasonic receiver receives the ultrasonic signal from the ultrasonic generator. A demodulator demodulates an audio signal from the ultrasonic signal. A received signal processing circuit processes the audio signal. An audio output module plays audio. Based on the characteristics of ultrasonic, an audio signal generated by audio generation equipment is loaded to an ultrasonic signal for transmission, and a user needing to receive the audio signal demodulates the ultrasonic signal to get the audio signal. Noise pollution to the environment in the process of transmission is avoided, and other people are not disturbed. The scheme is simple, easy to implement, highly practical, and wide in range of application.

Owner:SHENZHEN TRANSSION HLDG CO LTD

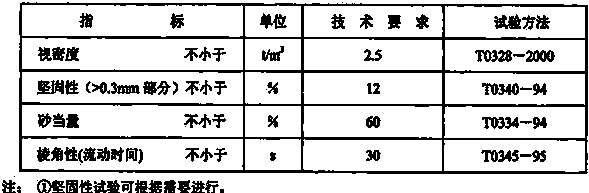

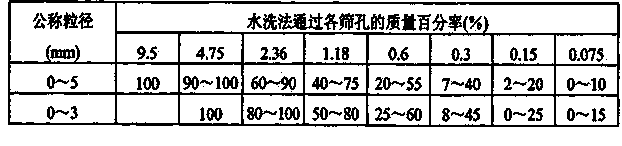

Construction method of long-service-life pass-through induced drainage pavement

ActiveCN103850164AReduce noiseImprove the quality of lifeIn situ pavingsSoil scienceGeotechnical engineering

The invention discloses a construction method of a long-service-life pass-through induced drainage pavement. The construction method comprises the following steps: 1, preparing filtering materials of the pass-through water-induced pavement, including coarse aggregate, fine aggregate and modified bituminous mixture according to the weight ratio of 58.5 to 35.85 to 5.65, wherein the modified bituminous mixture comprises slaked lime, red mud and conjugate fiber according to the weight ratio of 58.5 to 35.85 to 5.65, and the conjugate fiber comprises wood fiber and basalt fiber according to the weight ratio of 1 to 2; 2, processing a substrate of the construction pavement; 3, arranging an adhesive layer or sealing layer which has the thickness of 0.1-0.2mm and the porosity of 30%; 4, arranging a substrate filtering material layer which is 0.05-0.15mm thick between a soil layer and a gravel layer of the substrate; 5, mechanically paving; 6, treating joints; and 7, maintaining the pavement. The construction method can obviously improve the adhering force, anti-cracking performance, tensile and water-damage resistance performance and noise reducing performance of the pavement, enhance the rainstorm resistance of the pavement, and reduce the influence of long-term rain storage on stability performance of bituminous concrete.

Owner:郑州市公路工程公司

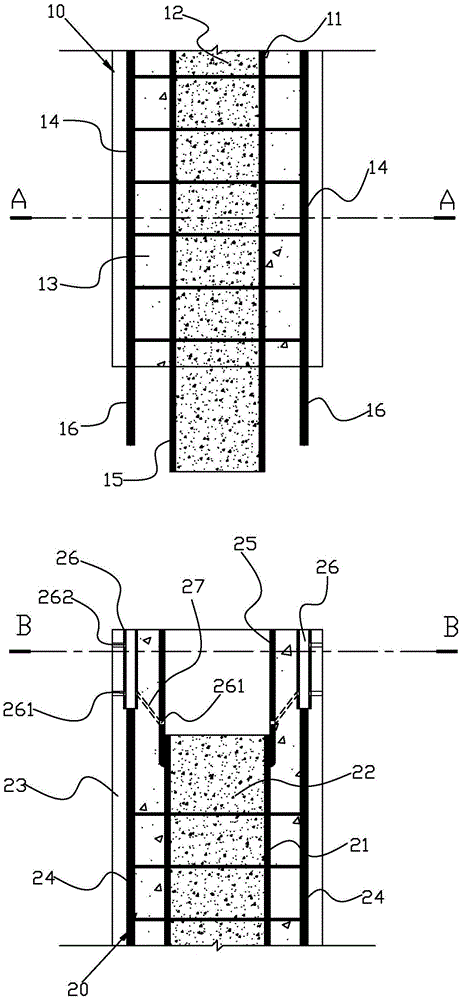

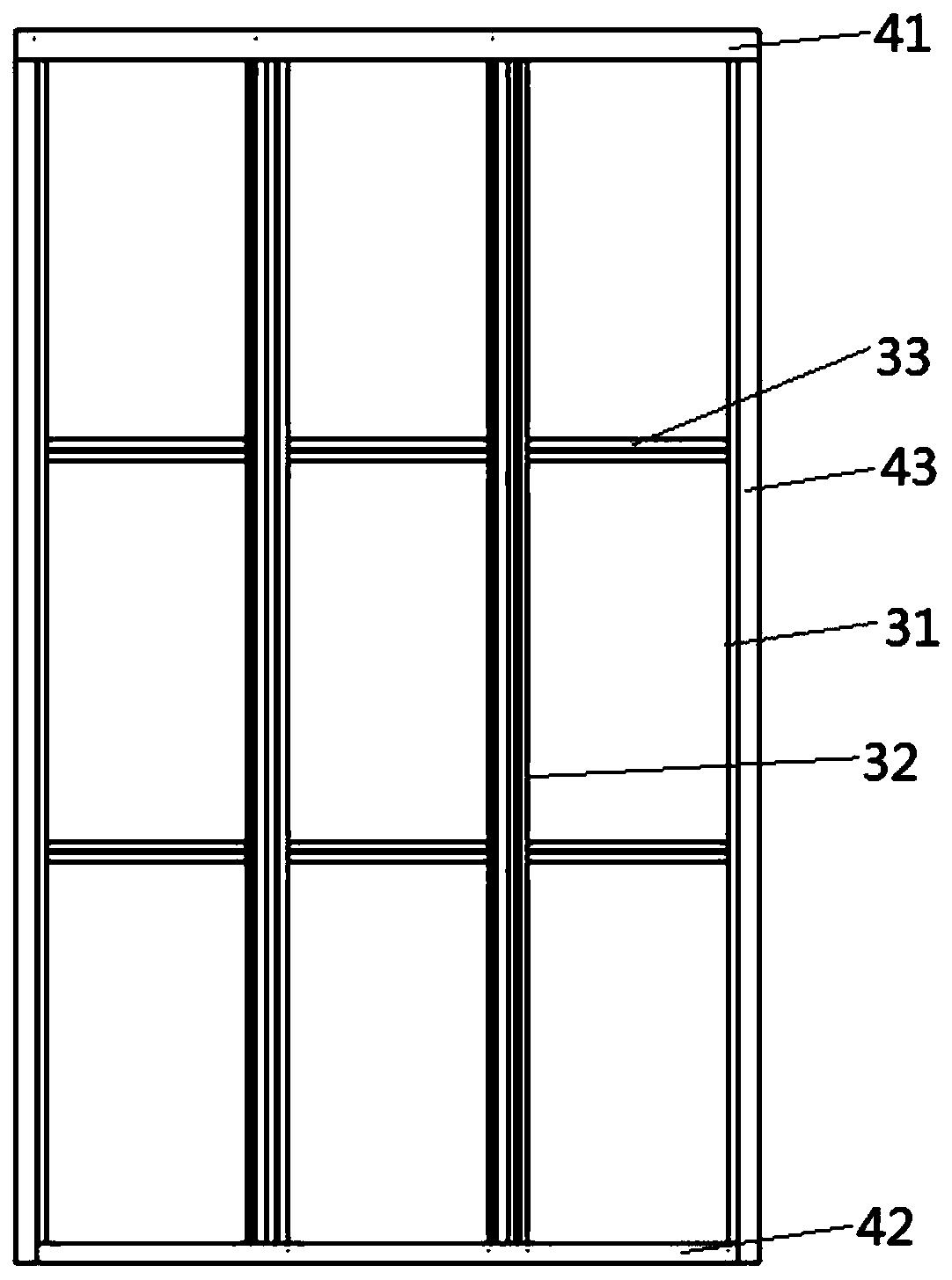

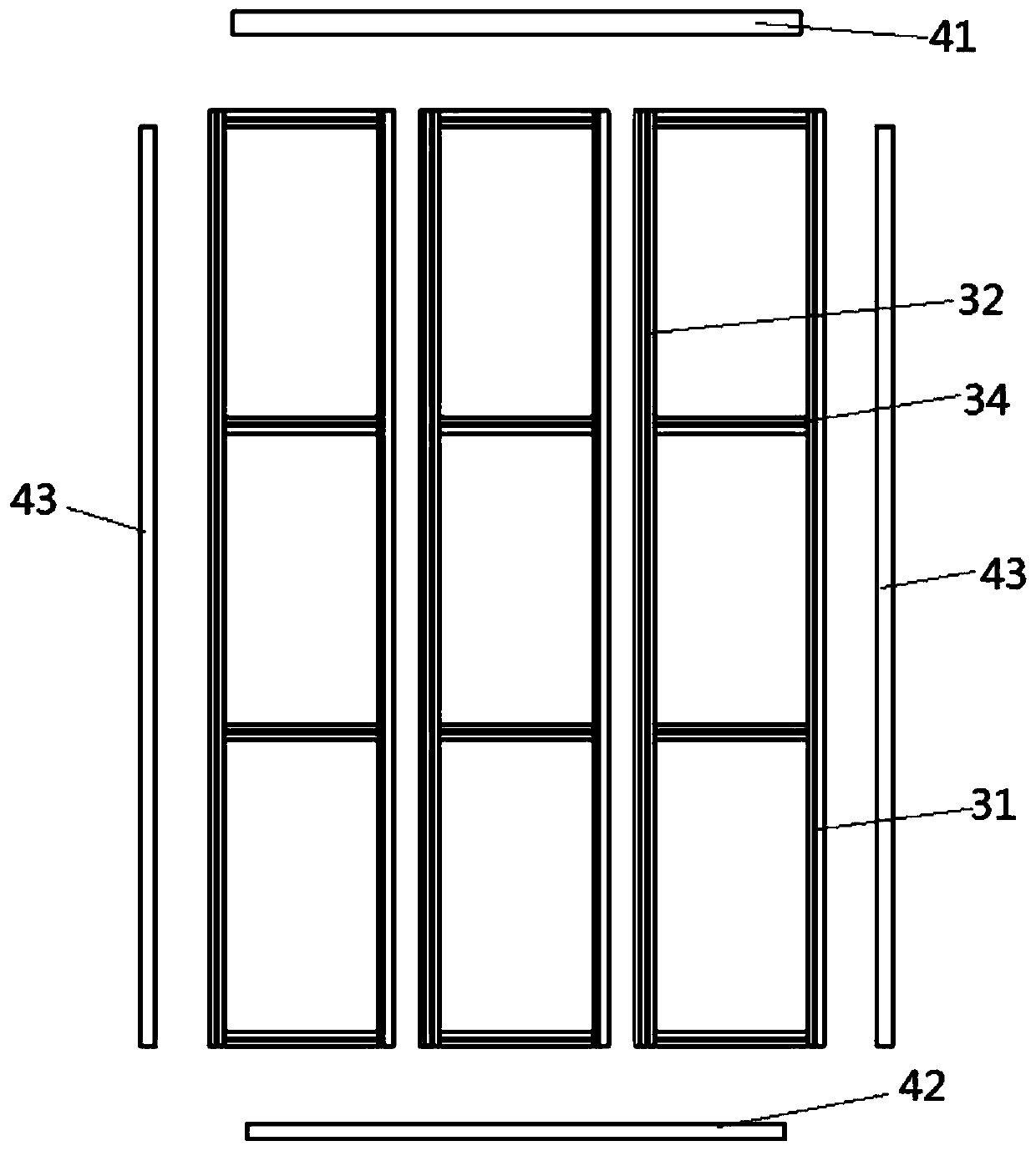

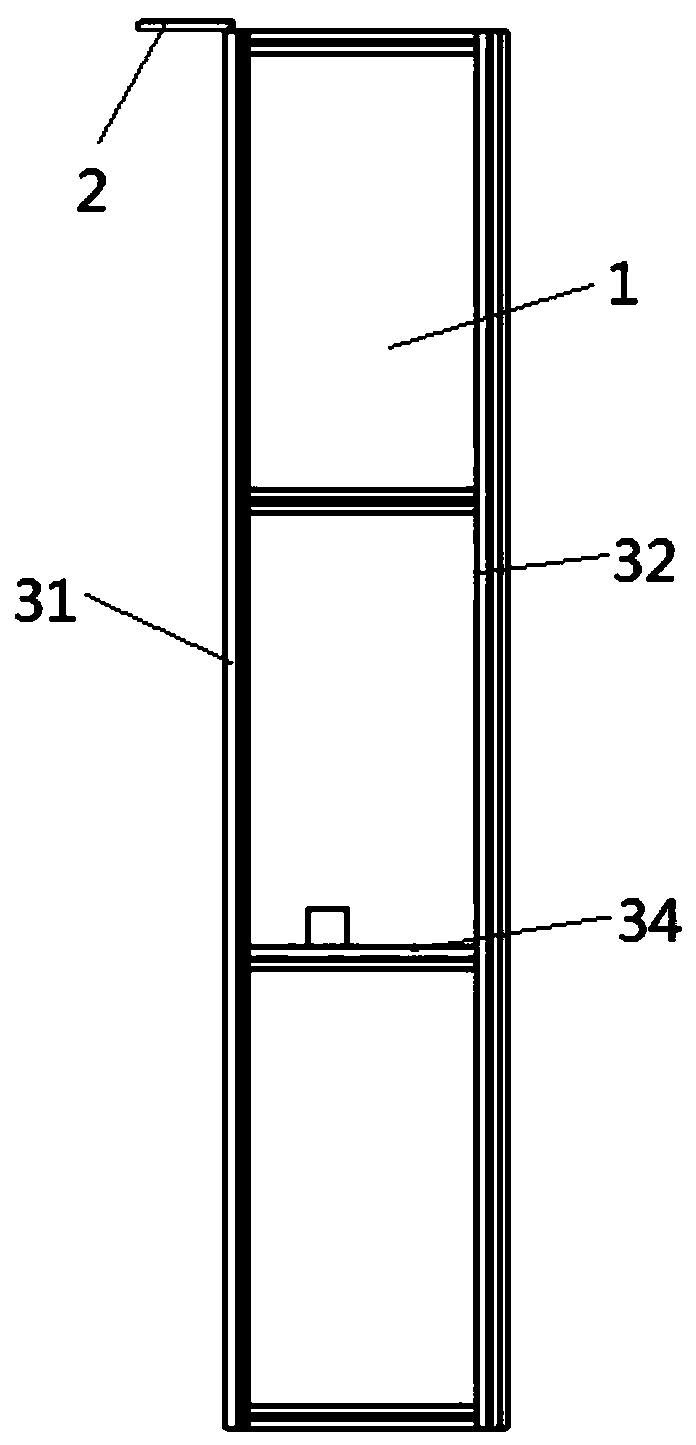

Assembly type unit keel partition wall system

The invention provides an assembly type unit keel partition wall system. The assembly type unit keel partition wall system comprises a keel partition wall and upper and lower side keels, wherein the keel partition wall comprises a plurality of unit keel partition walls which are connected, each unit keel partition wall comprises a unit keel framework, a soundproof thermal-insulation layer and a pipeline, the keel framework comprises a concave keel, a convex keel, adaptors and a middle keel, the concave keel and the convex keel are positioned at the side of the middle keel, the middle keel is positioned on the middle position, and the two ends of the middle keel are separately connected to the concave keel and the convex keel through the adaptors; the upper and lower side keels comprise upper keels, lower keels and side keels, the upper keels are arranged on the tops of the keel partition walls, the lower keels are arranged on the bottoms of the keel partition walls, and the side keelsare arranged on the sides of the keel partition walls. Compared with the prior art, the assembly type unit keel partition wall system has the advantages that prefabrication can be performed in a plant, direct splicing can be performed on the site, and mounting is convenient. The assembly type unit keel partition wall system avoids noise pollution caused by field cutting, and solves the problems that working efficiency is low, environment friendliness is bad, construction is heavy, and the like.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

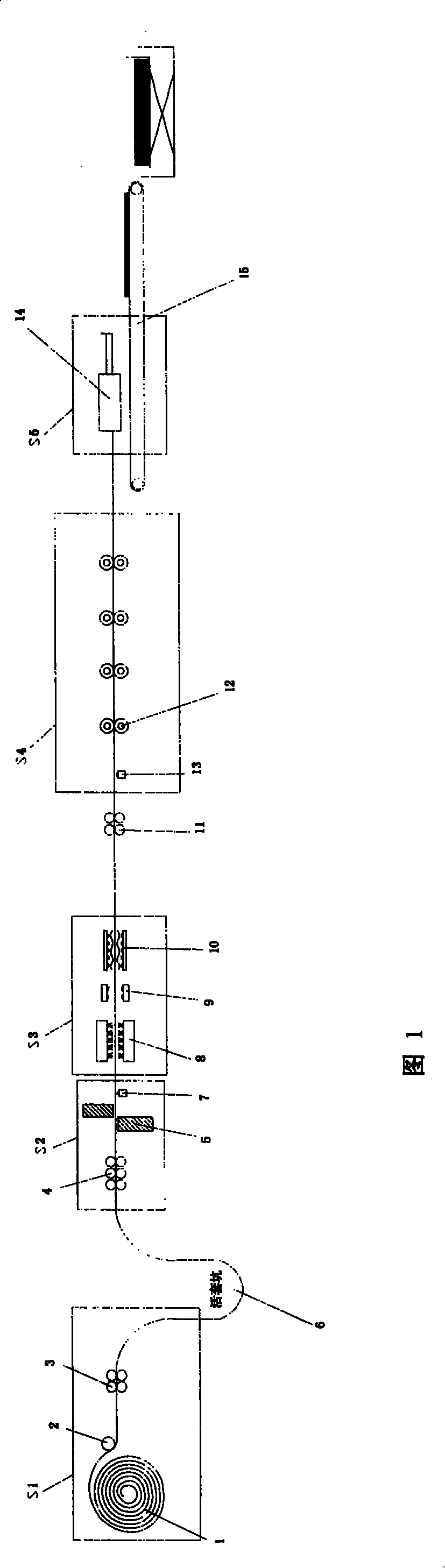

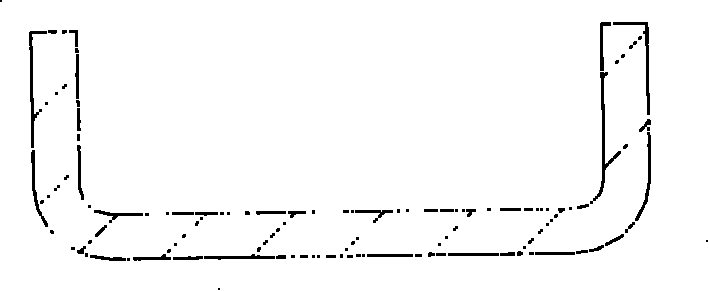

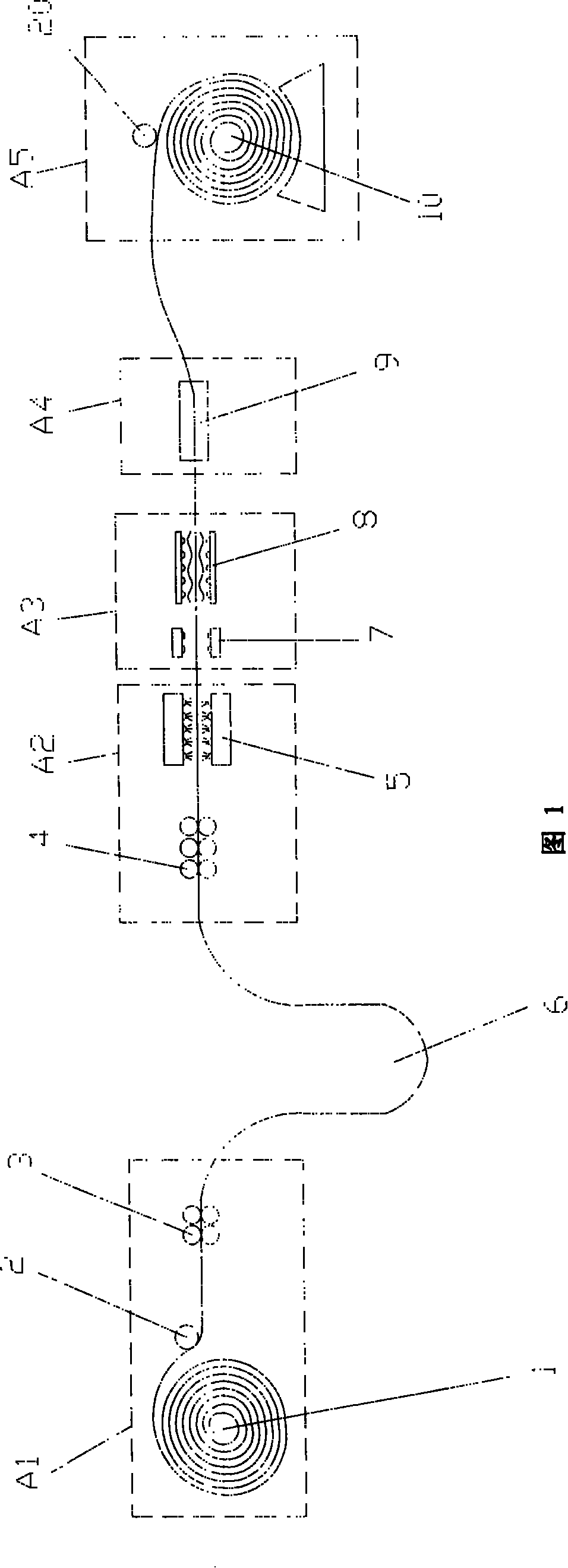

Method for producing container bottom cross beam

ActiveCN101176968AReduce labor intensityIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsLacquerStrip mill

The invention relates to a production method for the container bottom beam, which comprises a striping procedure and a molding procedure; wherein, the striping procedure comprises: A1: unreeling the wide roll material and extract the sheet metal continuously; A2: gripping blasting the sheet metal continuously; A3: spraying painting or roll painting and drying continuously; A4: strip coiling the dried sheet metal to get the narrow roll material. The molding procedure comprises: B1: unreeling the roll material and extract the sheet metal continuously; B2: sending the roll material to the mill continuously, cold roll to the continuous profile material of specified section with a plurality of rollers of the mill; B3: cutting off the continuous profile material to specified length. The invention has the advantages that: in the processing of molding, the working procedures, such as unreel, molding and shear are completed continuously, without stowing and swinging for the workpiece respectively, which greatly improves the productivity; furthermore, spray painting or roll painting is processed to the wide roll material, avoiding the paint waste and environmental pollution caused by processing more difficult spray painting working procedure to the striped narrow roll material and the molded profile material, making the environment more friendly.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

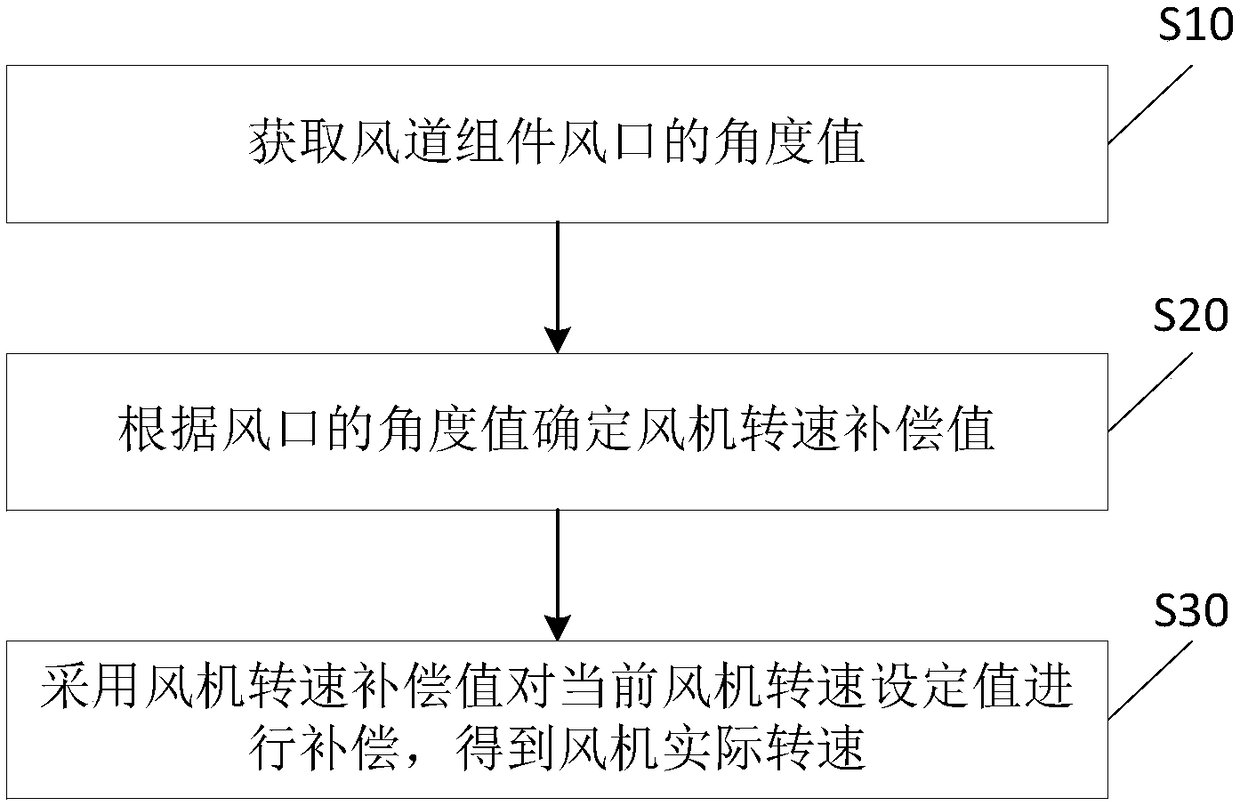

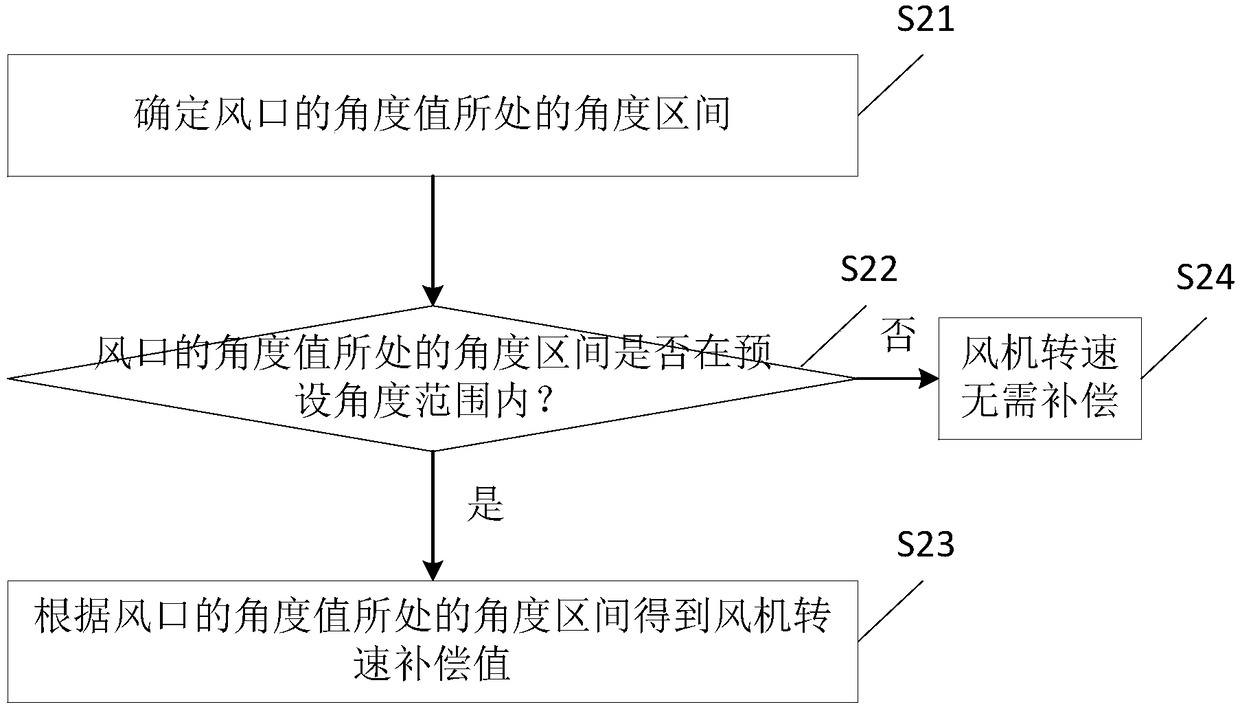

Rotate speed control method and rotate speed control device of fan and blowing equipment

InactiveCN108800475AStable output air volumeAvoid noise pollutionMechanical apparatusLighting and heating apparatusAir volumeEngineering

The invention discloses a rotate speed control method and a rotate speed control device of a fan and blowing equipment. The method comprises the following steps: acquiring an angle value of a tuyere of an air duct assembly; determining a rotate speed compensation value of the fan according to the angle value of the tuyere; and compensating the current rotate speed set value of the fan by adoptingthe rotate speed compensation value of the fan to obtain the actual rotate speed of the fan. The blowing equipment compensates the rotate speed of the fan when the size of an air inlet / an air outlet of the air duct assembly changes, so as to compensate the output air quantity, so that the output air quantity of the blowing equipment can be stable when the size of the air inlet / the air outlet of the air duct assembly changes, and therefore, noise pollution as a result of unstable air quantity of the blowing equipment which blows at multiple angles is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

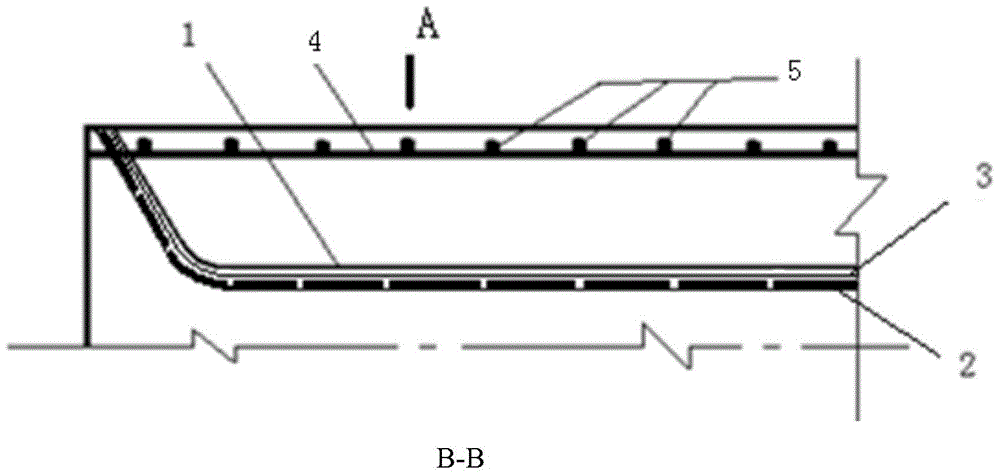

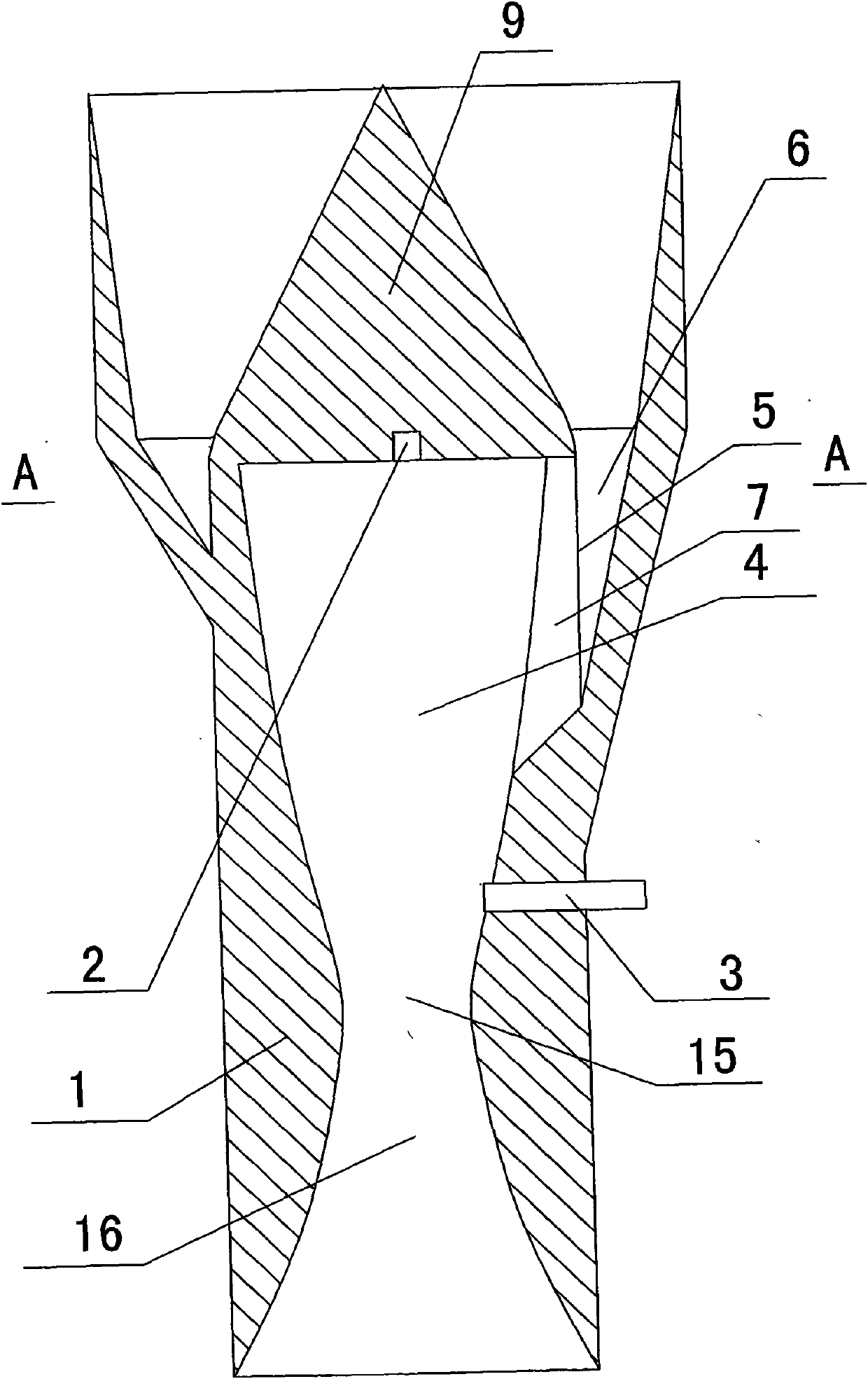

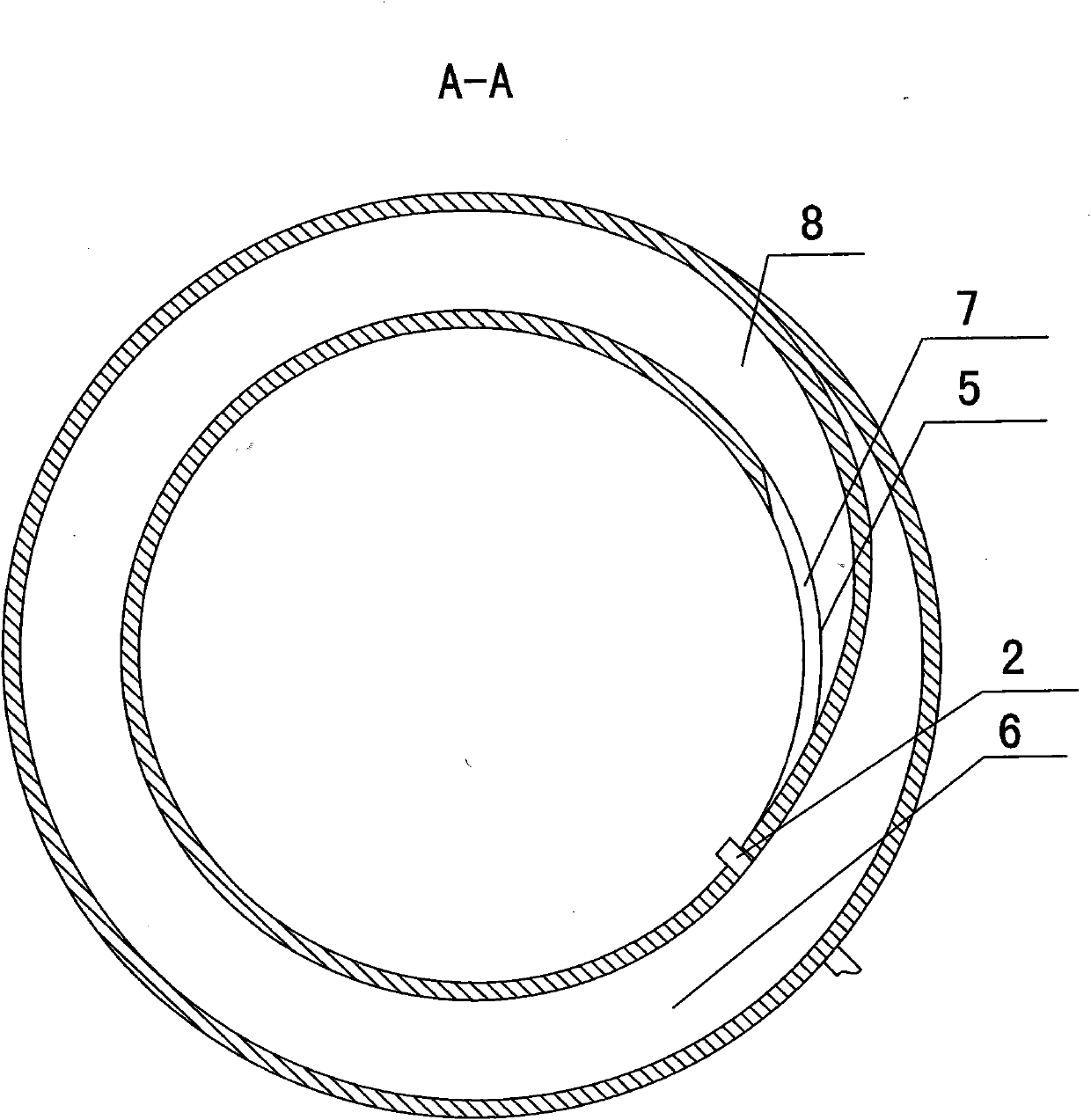

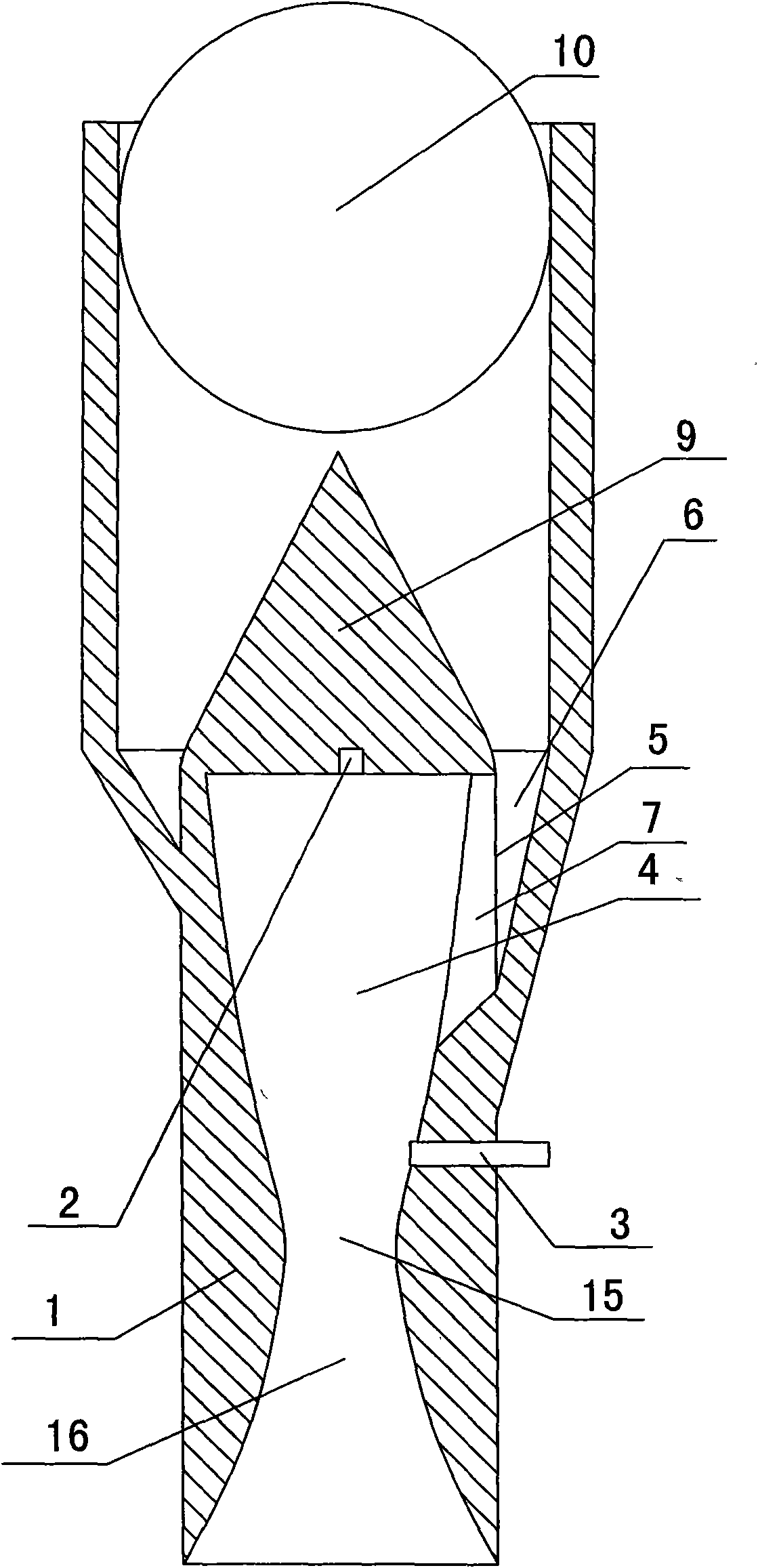

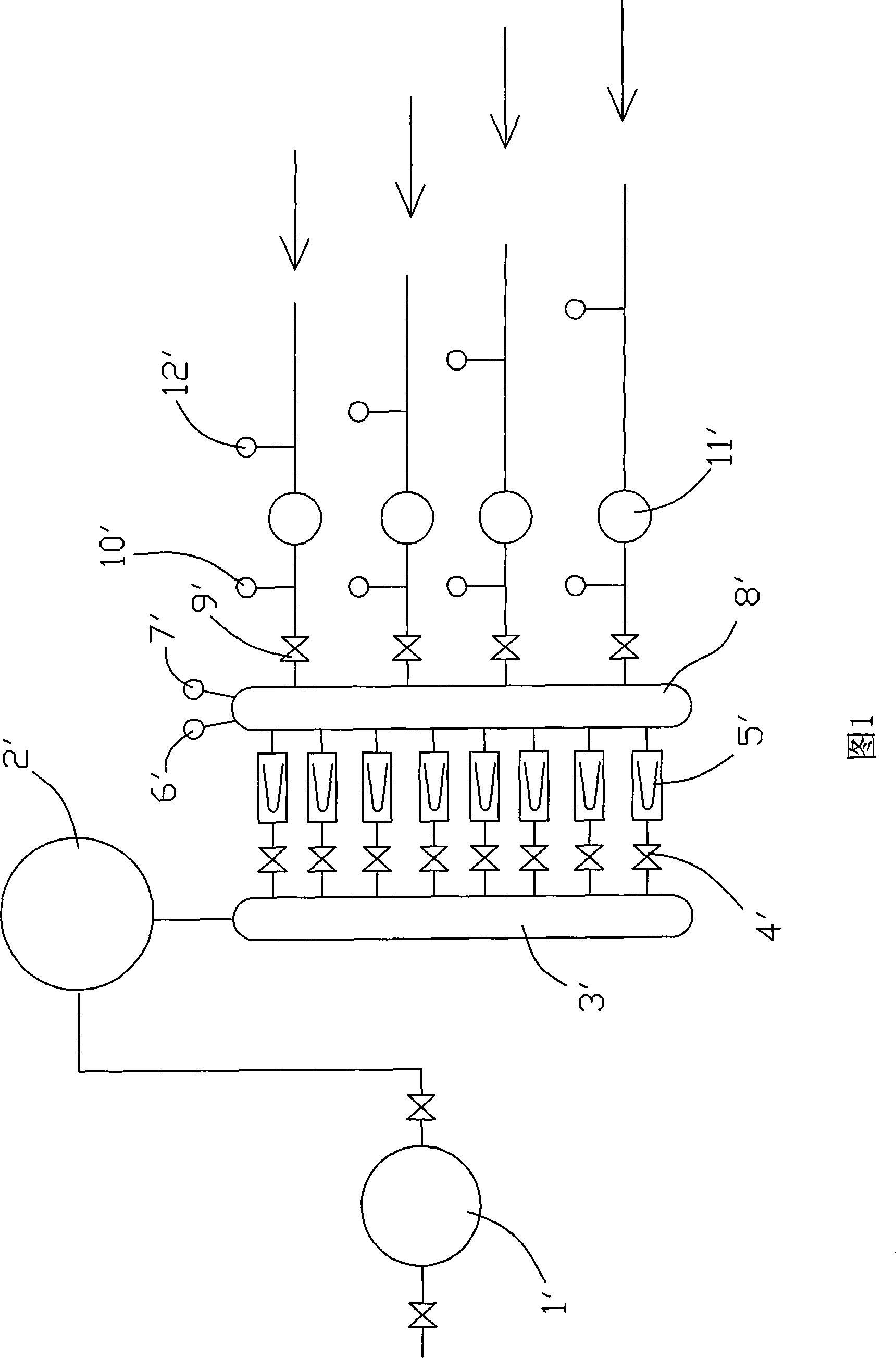

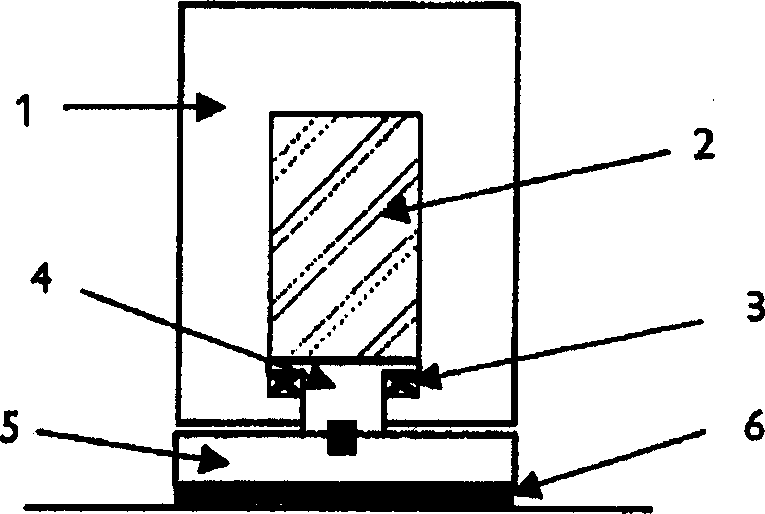

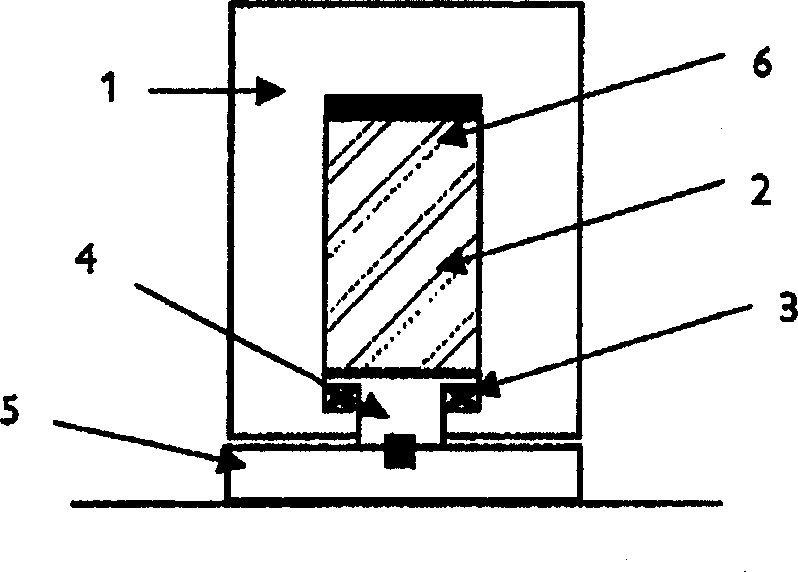

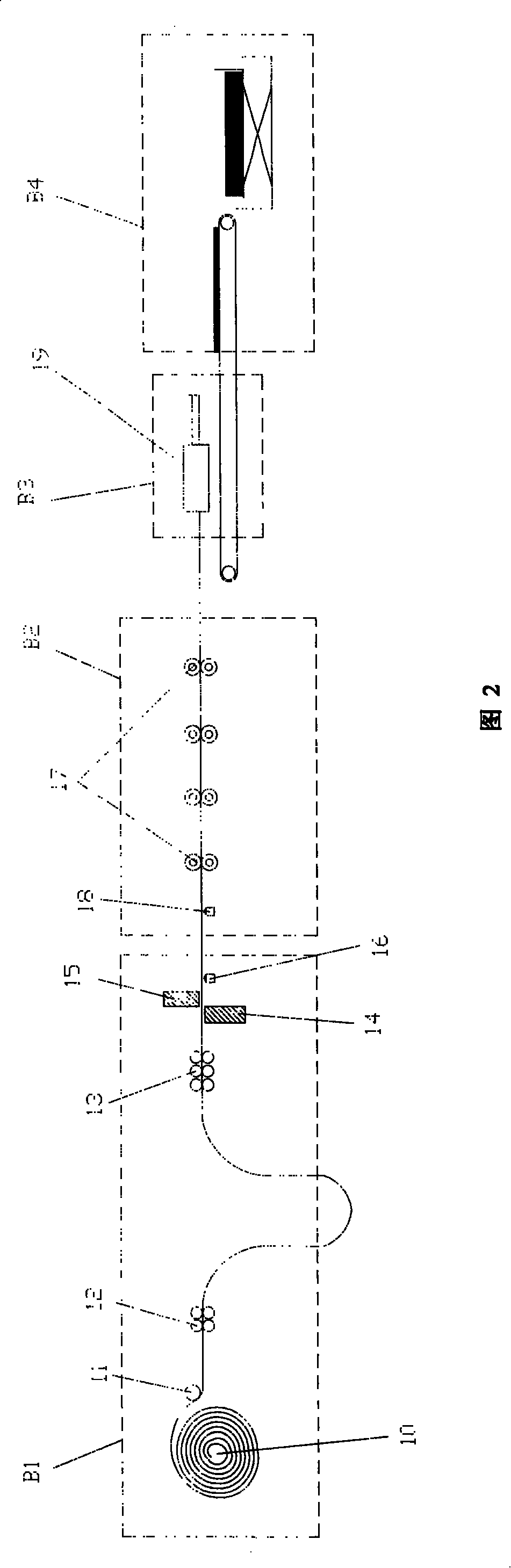

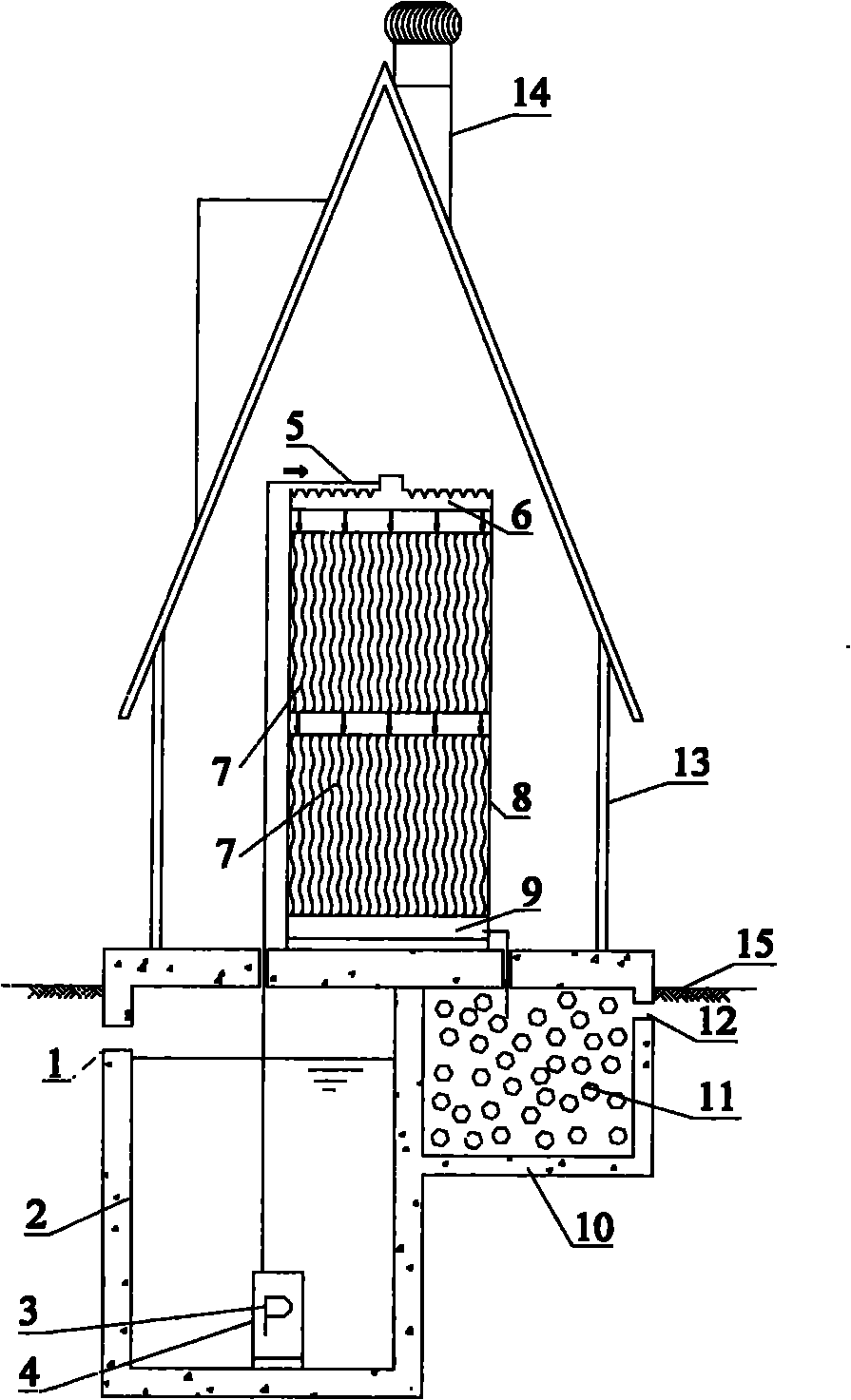

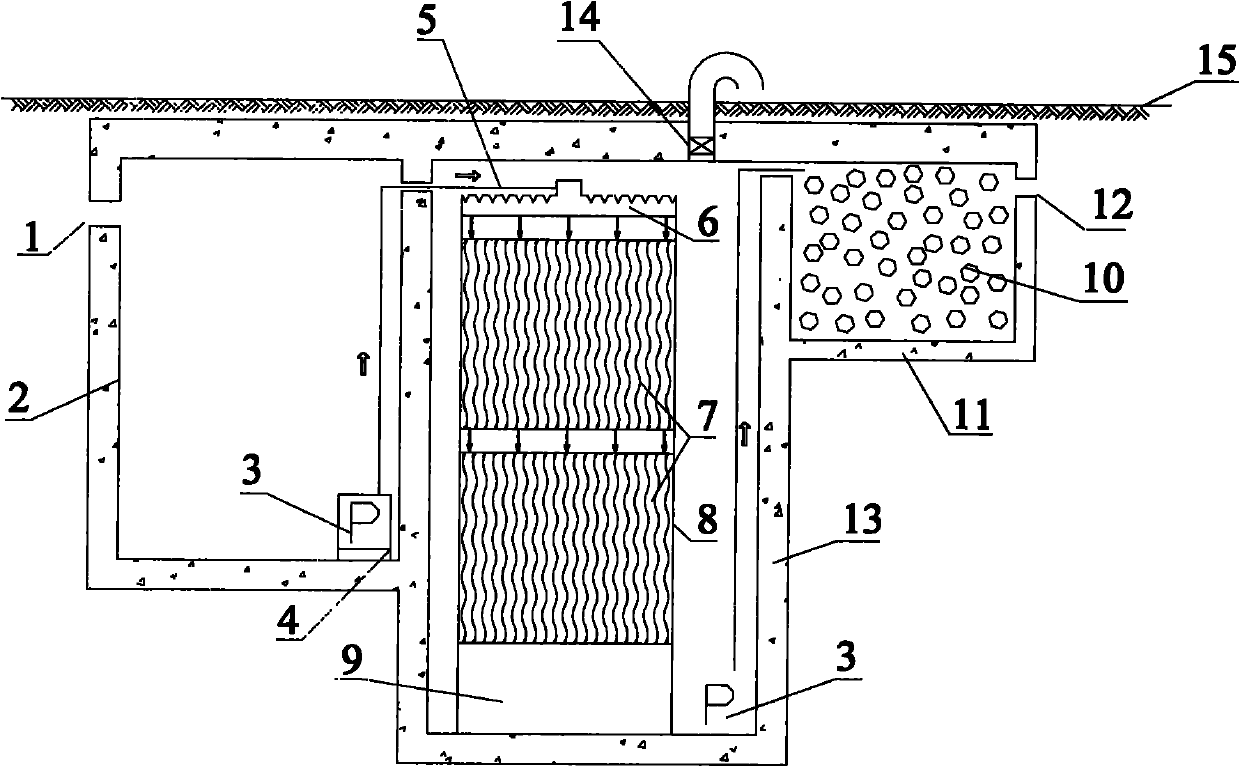

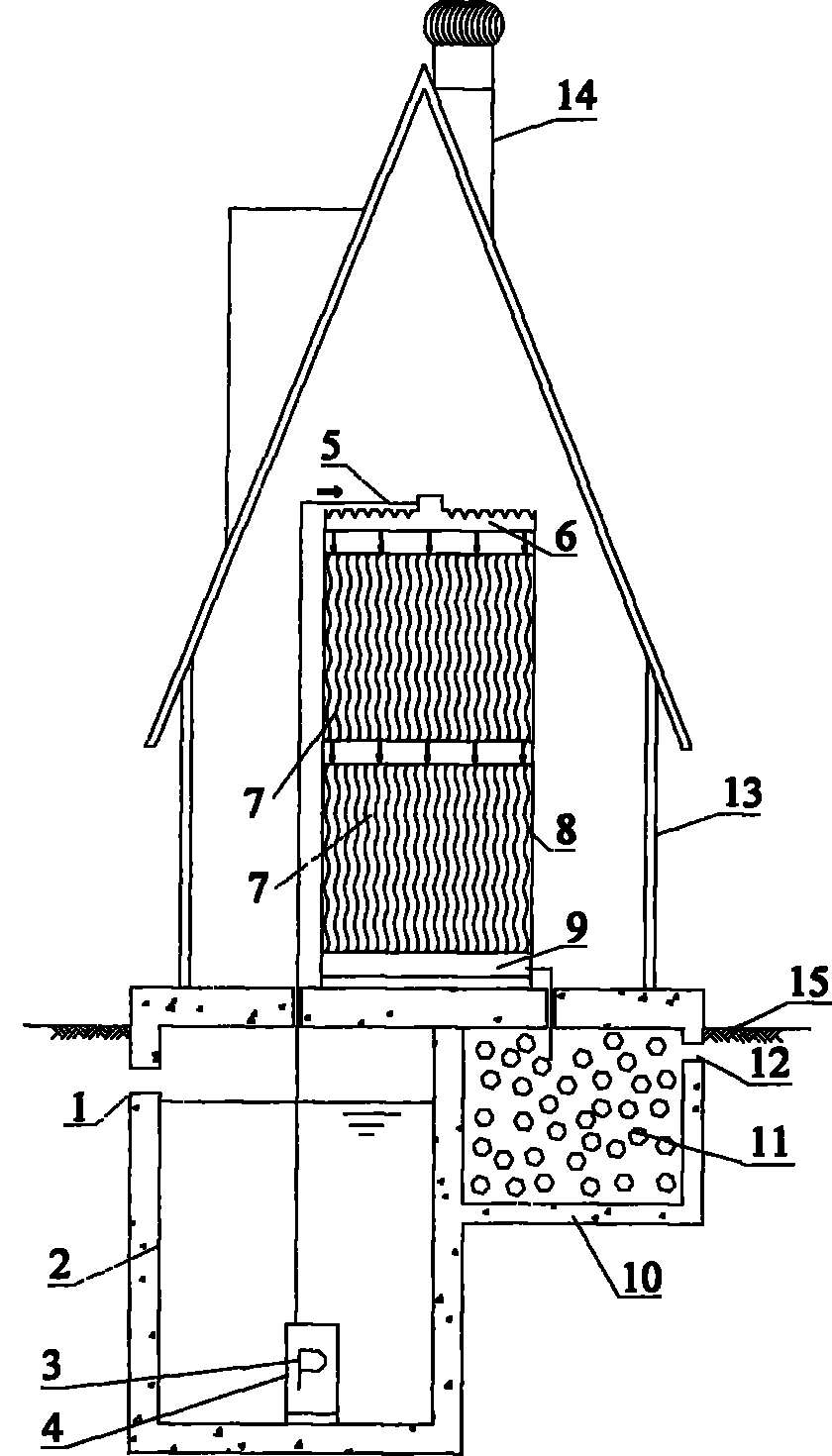

Decentralized sewage treatment method

InactiveCN102020395AEasy to handleSatisfy the need for oxygenTreatment using aerobic processesMultistage water/sewage treatmentMicroorganismNatural ventilation

The invention relates to a decentralized sewage treatment method, which comprises that: a sewage inlet pipe (1) is connected with a sewage collection pipe; sewage is carried to an adjusting tank (2); large impurities are separated by a pump gate cover (4); the sewage is lifted into a non-clogging biotrickling filter (5) by a sewage pump (3) and uniformly distributed on a filler module (7) arranged on a filler support frame (8), and fully contacts with biomembranes attached to and grown on the surfaces of fillers to be purified; trickled water drained from the non-clogging biotrickling filter (5) is collected by a biotrickling filter water outlet groove (9), enters a dephosphorization groove (10) and contacts with a dephosphorization medium (11) for dephosphorization; and the dephosphorized water is drained from a water outlet pipe (12). The decentralized sewage treatment method saves the links of a secondary sedimentation tank, sludge concentration, sludge treatment and the like in a conventional sewage treatment process, simplifies a treatment flow and satisfies the needs of microorganisms in oxygen by natural ventilation oxygen supply; and the main unit equipment is modularly designed and simple in control.

Owner:上海浩为环境工程有限公司

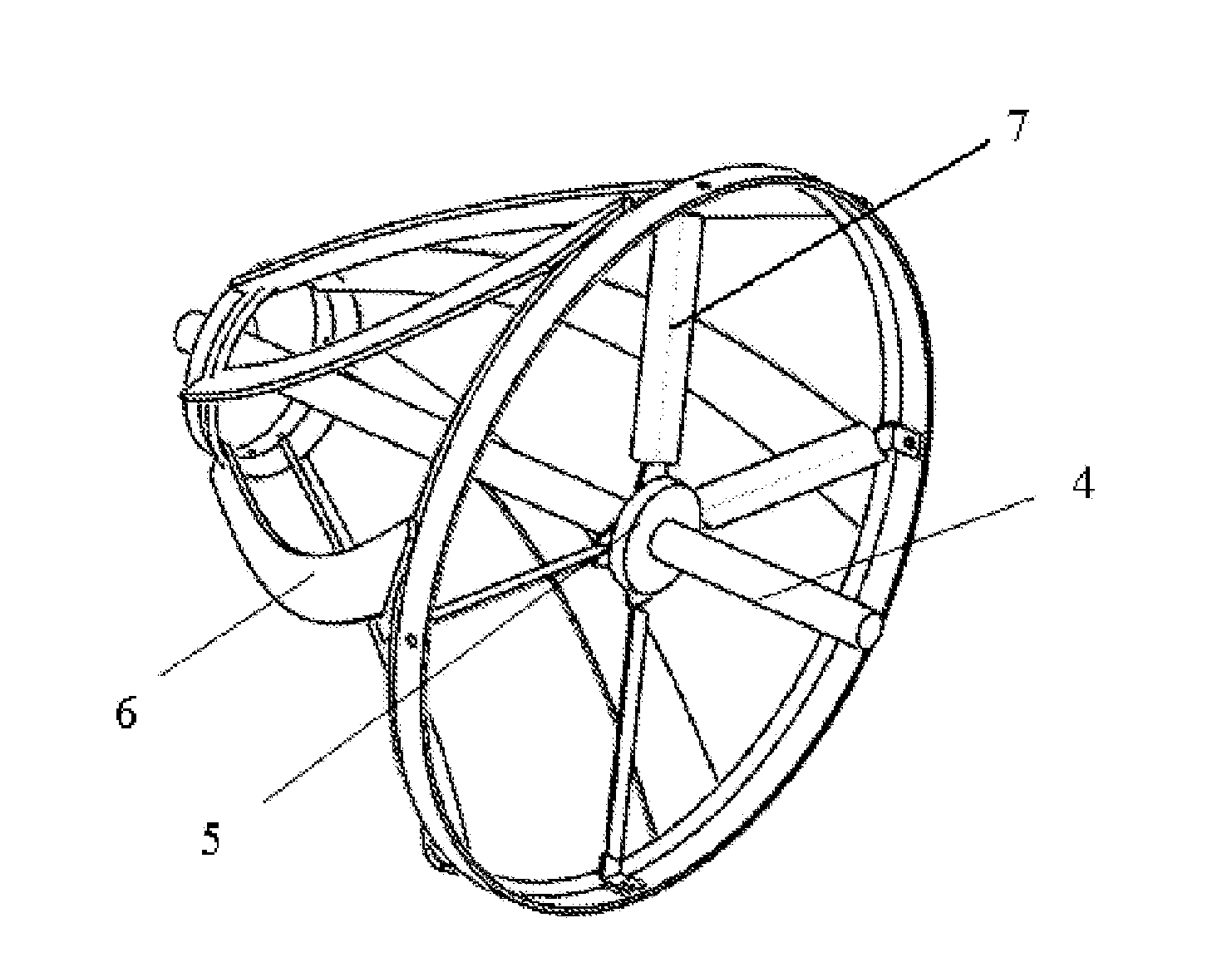

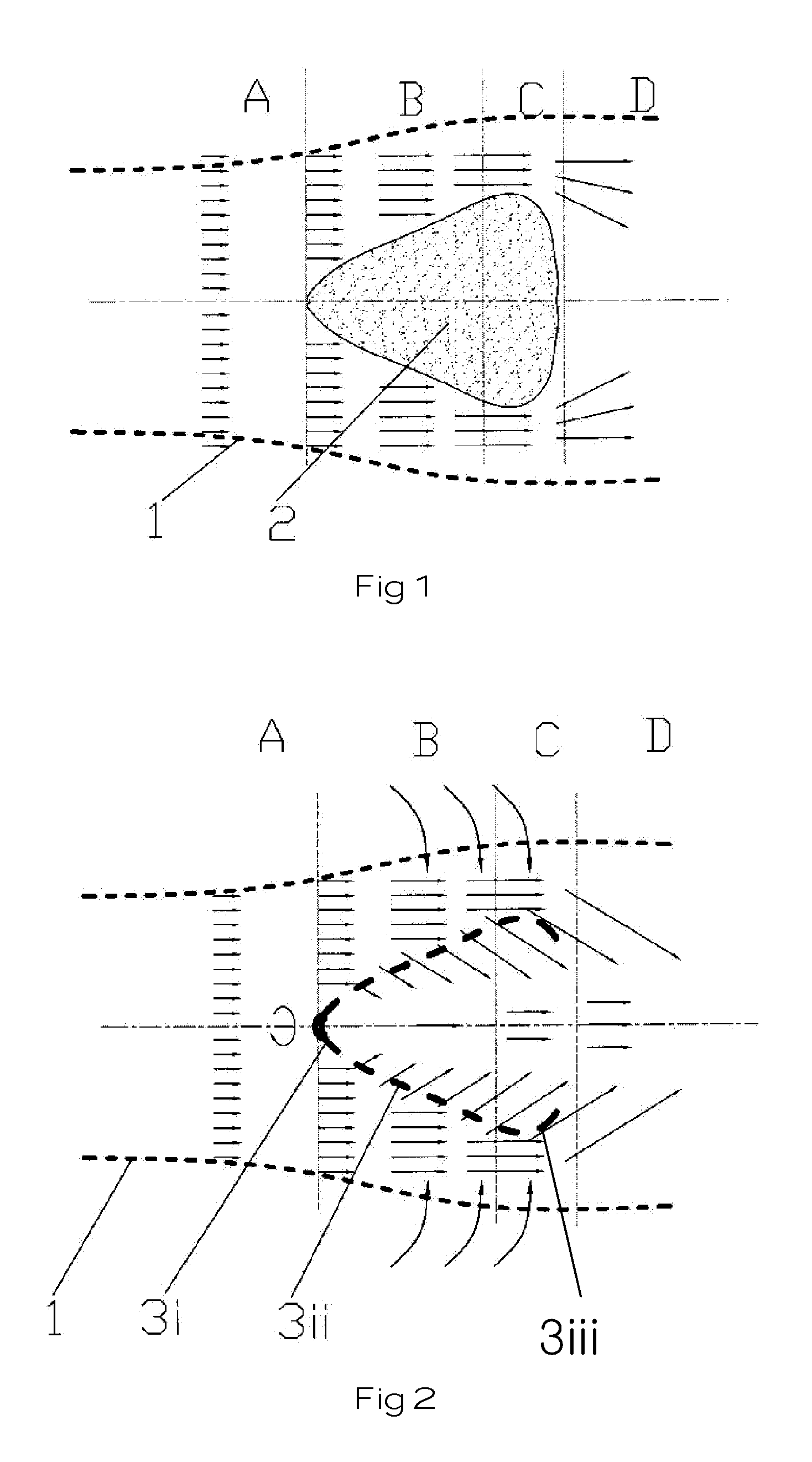

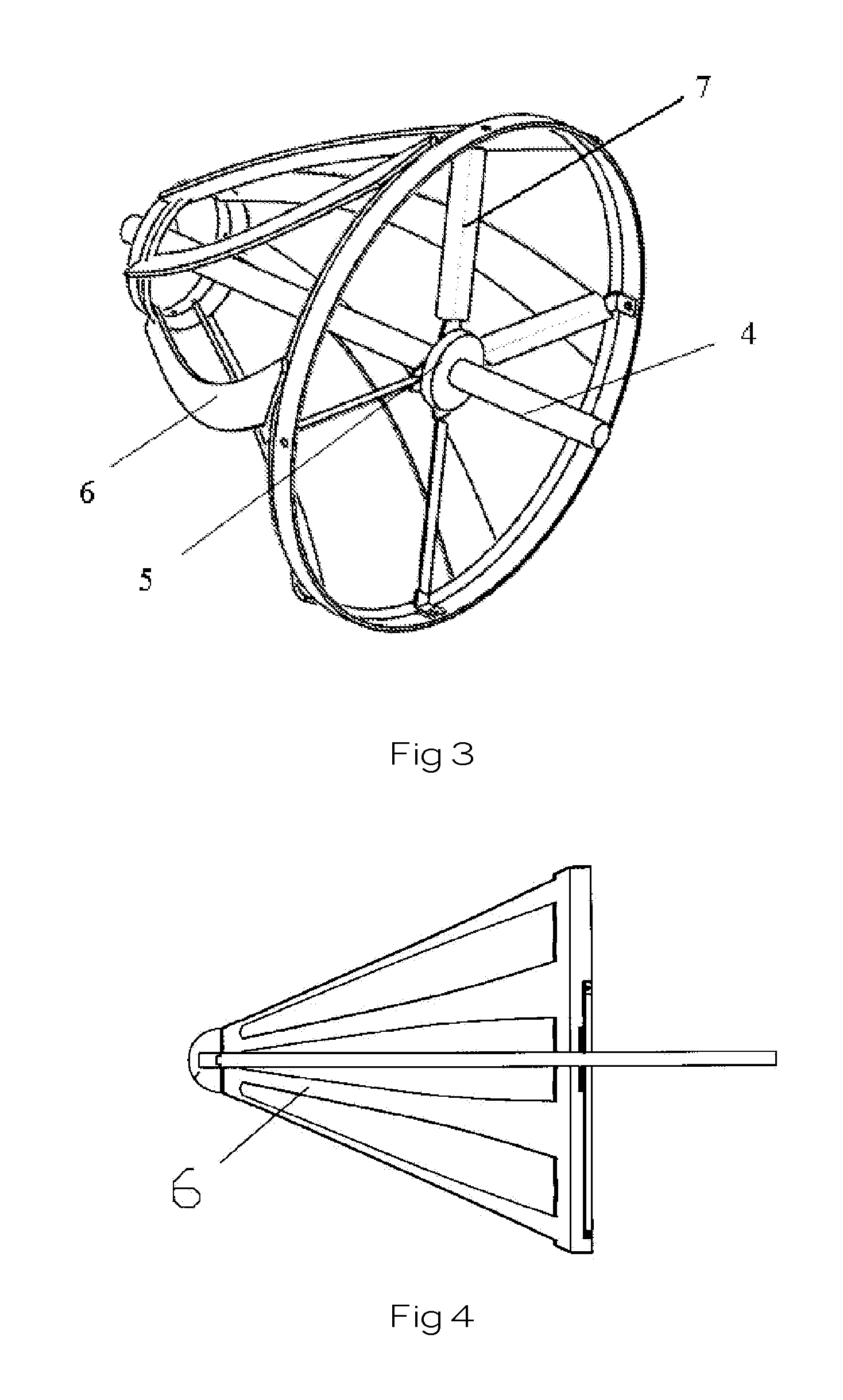

Wind turbine rotor with venturi tube effect

InactiveUS20110176920A1Simple and efficientImprove wind energy utilization efficiencyPropellersPump componentsEnergy transferWind energy conversion

The present invention discloses a rotor of wind energy conversion system (WECS) with the Venturi-tube effect. All the blades mounted on the blade-mounting seat envelop together to form a revolving-body cage turbine, which can be divided from structure into a head portion at the windward end, a tail portion at the wind exhaust end, and an airstream compression portion between the head portion and the tail portion and constituted by the enveloping blades. The revolution diameter of the airstream compression portion is gradually substantially increased from the head portion to the tail portion. The cage turbine forms a dynamic Venturi tube during the revolving process, with which the blade revolves to constitute its outline tube wall with the air permeability. The airstream passes through a window between the blades, and the incoming wind does work towards the blade during the process of permeating from the external space to the internal space of this outline tube wall, thus realizing the energy transfer.

Owner:SHANGHAI FOREVOO NEW ENERGY SYST +1

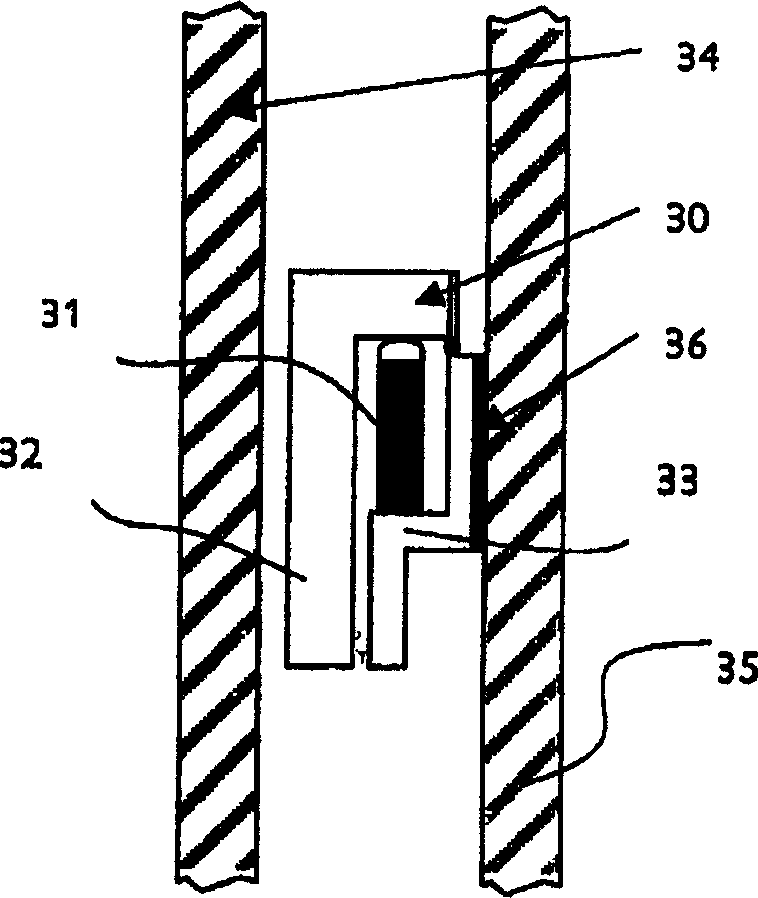

On-line back washing process system of porous ceramic film

ActiveCN102688694AAvoid secondary pollutionOvercome energy consumptionSemi-permeable membranesProcess systemsElectricity

The invention relates to an on-line back washing process system of a porous ceramic film. A cleaning liquid is extruded into a ceramic film assembly by adopting air pressure or a submersible pump, and a cleaning liquid discharge switch is arranged, and the pressure required by back washing can be lowered; a switch and a soundproofing device are installed above a cleaning tank, and the noise pollution caused by air in a cleaning liquid storage tank is solved; the opening and closing time and the pressure of an air pump are regulated through a time relay, thus the liquid in the cleaning liquid storage tank is always maintained to be 1 / 3 of the volume of the cleaning liquid storage tank; and through installing the cleaning liquid discharge switch at a material discharge end of a filtering device of the porous ceramic film, most of the cleaning liquid can be recycled, thus the cleaning liquid can be prevented from circulating and entering an original liquid storage tank, and the secondary pollution to the film is prevented. The system not only can improve the film flux recovery speed, the film flux recovery rate can reach 95% above, and water is saved and electricity is saved. The on-line back washing process system of the porous ceramic film provided by the invention is mainly applied to the back washing process of the application of the porous ceramic film in the liquid filtering process, can effectively recover the film flux, and is beneficial to popularization and application..

Owner:河南方周瓷业有限公司 +1

Preparing method for embedded expanding piece of car

Am embedded expandable plate for car is prepared through prepairng the foaming mother particles from resin, foaming agent, foaming assistant and disperser, proportionally mixing then with polyolefin resin and cross-linking agent, and injection moulding.

Owner:HENKEL CORP

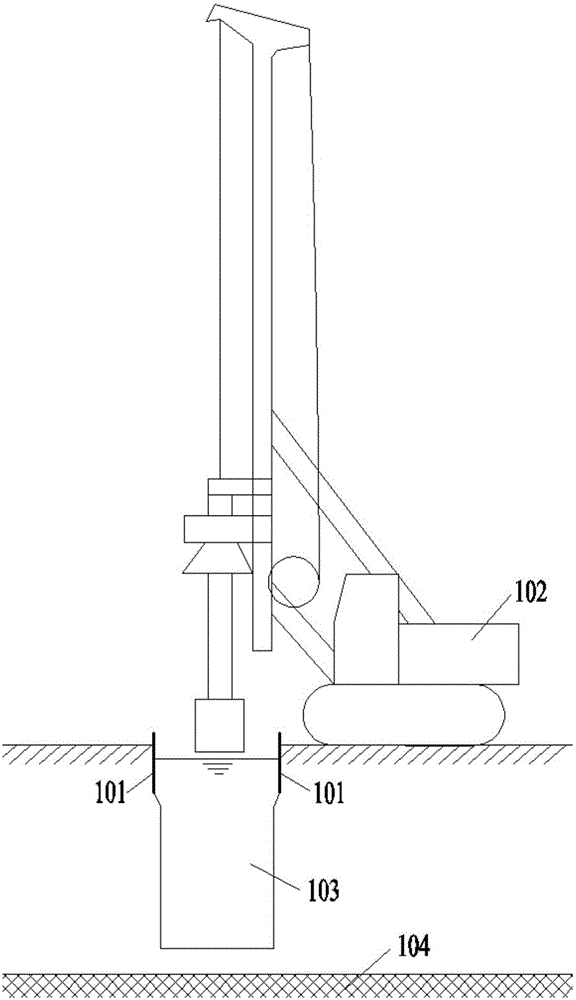

Method for forming pile in stratum with hard rock stratum in lower part

ActiveCN106545007AGuaranteed efficiencyGuarantee the construction qualityBulkheads/pilesGeomorphologySludge

The invention discloses a method for forming a pile in a stratum with a hard rock stratum in a lower part. The method comprises the following steps: drilling by adopting a rotary drilling rig, and stopping drilling construction when the rotary drilling rig reaches the hard rock stratum; continuing drilling to a designed elevation by adopting a water mill drilling rig; cleaning the bottom of a hole, placing a steel reinforcement cage into the drilled hole, and then filling pile body concrete. According to the method, vibration and noise pollution caused by hard rock impact and blasting are avoided; a secondary hole cleaning link after the hole is finished is also omitted; the problems of hole bottom sludge and difficulty in loosen soil cleaning are solved; respective advantages of the rotary drilling rig and a manual hole digging pile are fully played; the construction period can be effectively shortened; the construction cost can be reduced; the construction quality can be ensured; the method is not limited by ambient environment; the requirements of safe, civilized and green construction are met.

Owner:CCCC SECOND HARBOR ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com