Assembly type unit keel partition wall system

A prefabricated and keel technology, applied to walls, building components, buildings, etc., can solve problems such as low work efficiency, heavy construction, and non-environmental protection, and achieve the effects of quick installation, environmentally friendly installation process, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

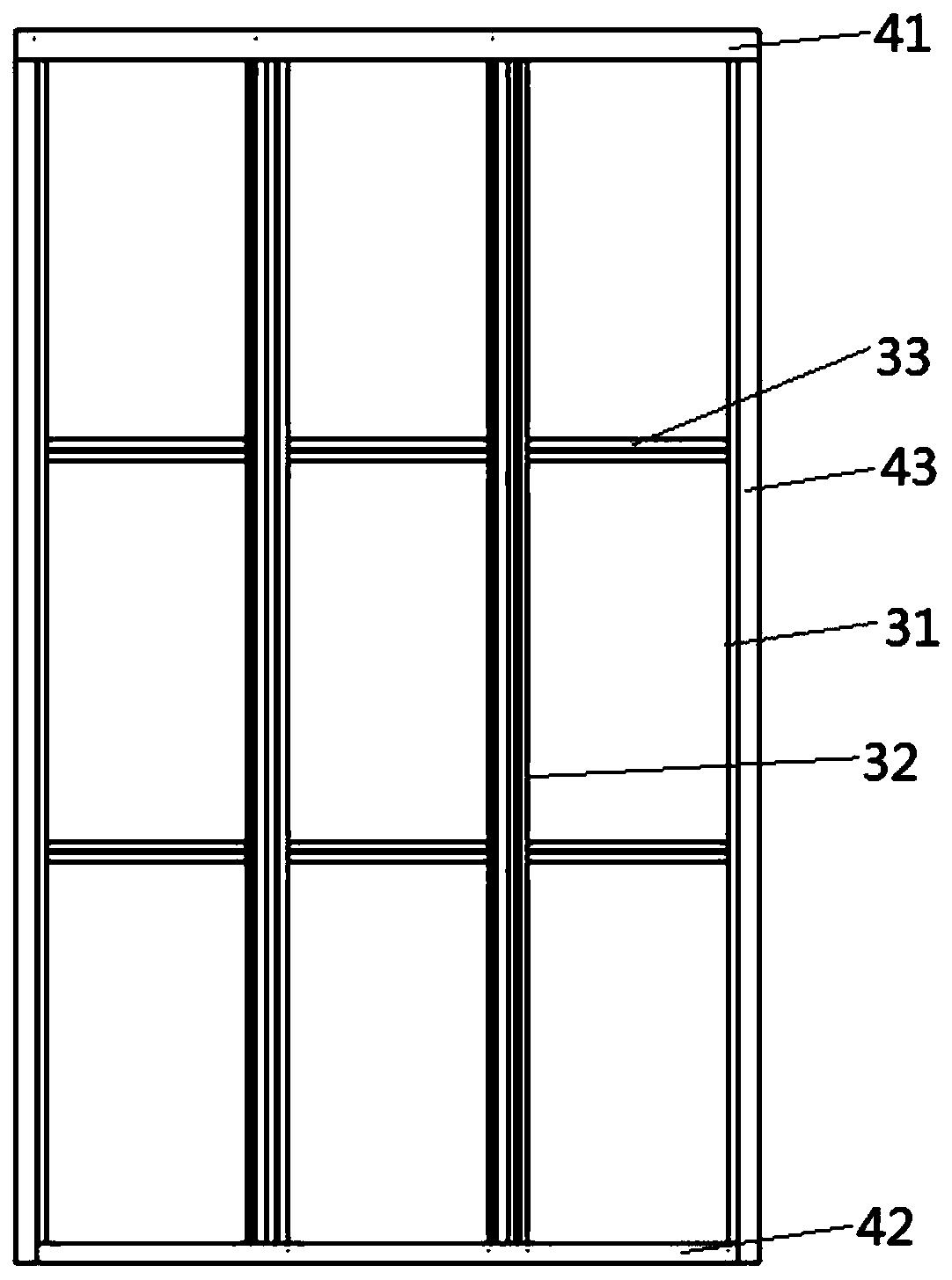

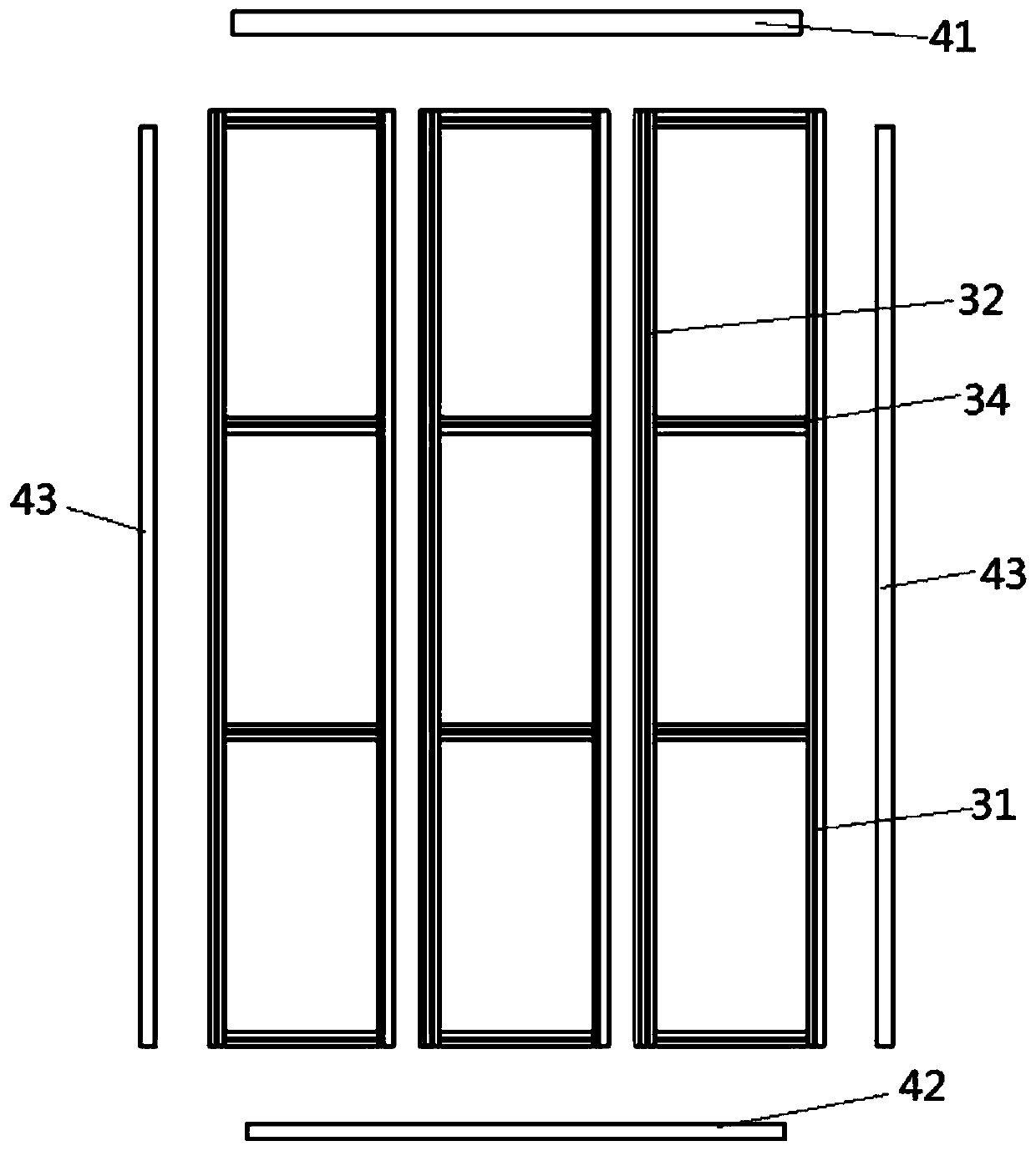

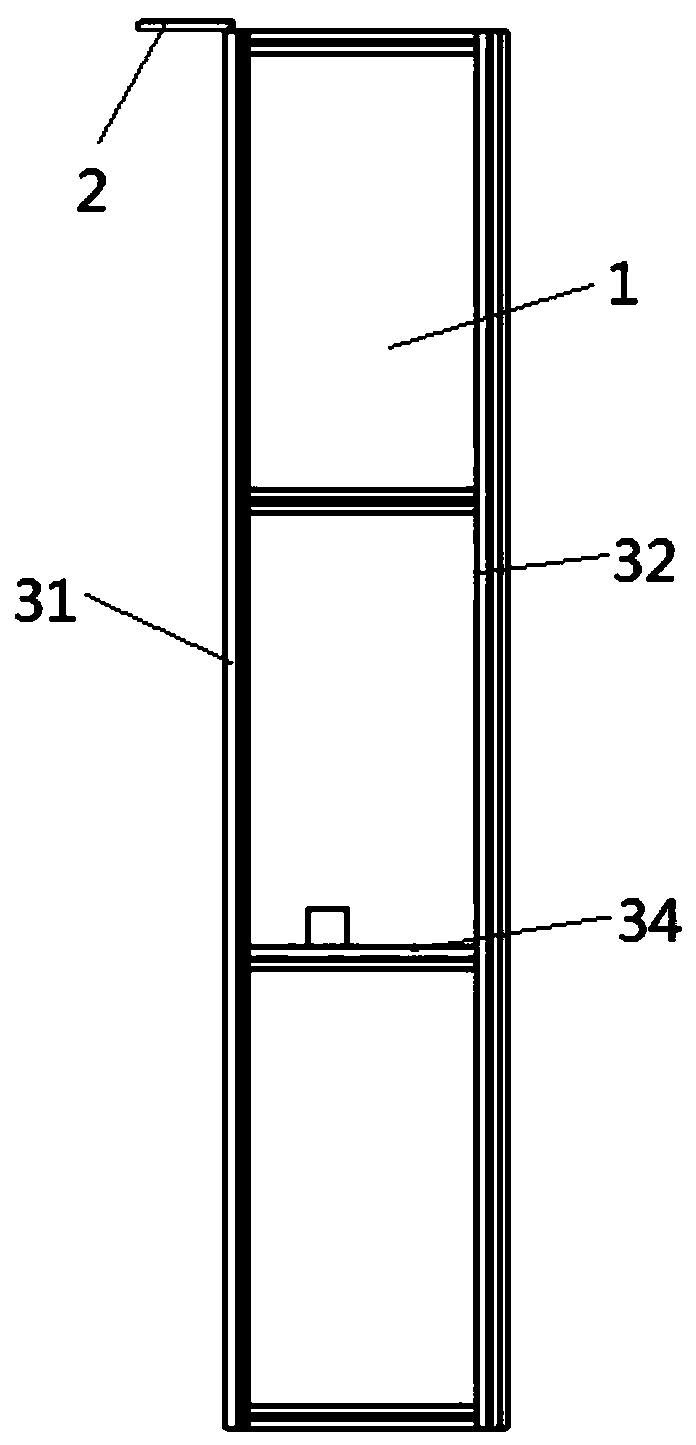

[0042] See Figure 1 to 9 , Picture 11 , The figure shows a prefabricated unit keel partition wall system provided in the first embodiment of the present invention, including: a keel partition wall, which includes a plurality of unit keel partition walls joined together, and the unit keel partition wall includes a unit keel frame, Sound insulation layer 1 and pipeline 2, the keel frame includes a female keel 31, a male keel 32, an adapter 33, and a middle keel 34. The female keel 31 and the convex keel 32 are located on the side of the middle keel, and the middle keel 34 is located in the middle position , The two ends of the middle keel 34 are respectively connected to the concave keel 31 and the convex keel 32 through the adapter 33; the sky keel includes the sky keel 41, the ground keel 42 and the side keel 43. The sky keel 41 is set on the top of the keel partition wall. The ground keel 42 is set at the bottom of the keel partition wall, and the side keel 43 is set at the s...

Embodiment 2

[0052] See Figure 6 to Figure 7 , Picture 10 , The figure shows a prefabricated unit keel partition wall system provided in the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following as an improved technical solution: concave keel 31 The connecting edge of the keel is provided with a connecting groove 311, and the connecting edge of the male keel 32 is provided with a connecting protrusion 321; the connecting groove 311 and the connecting protrusion 321 match; the female keel 31 and the male keel 32 of the adjacent two unit keel partition walls Phase card connection. Through the arrangement of the above structure, the clamping and installation work of two adjacent unit keel partition walls can be quickly realized, and the connection is firm and the installation effect is good.

Embodiment 3

[0054] See Figure 12 to Figure 14 , The figure shows a prefabricated unit keel partition wall system provided in the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as an improvement: Tianke 41 The ground keel 42 and the side keel 43 are all U-shaped light steel; the sky keel 41, the ground keel 42 and the side keel 43 are clamped to the four sides of the keel partition wall and fixedly connected by self-tapping screws 5. Through the arrangement of the above structure, a protective structure can be formed around the keel partition wall, strengthen the connection between the keel of the sky and the earth and the partition wall keel, and improve the overall quality of the keel partition wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com