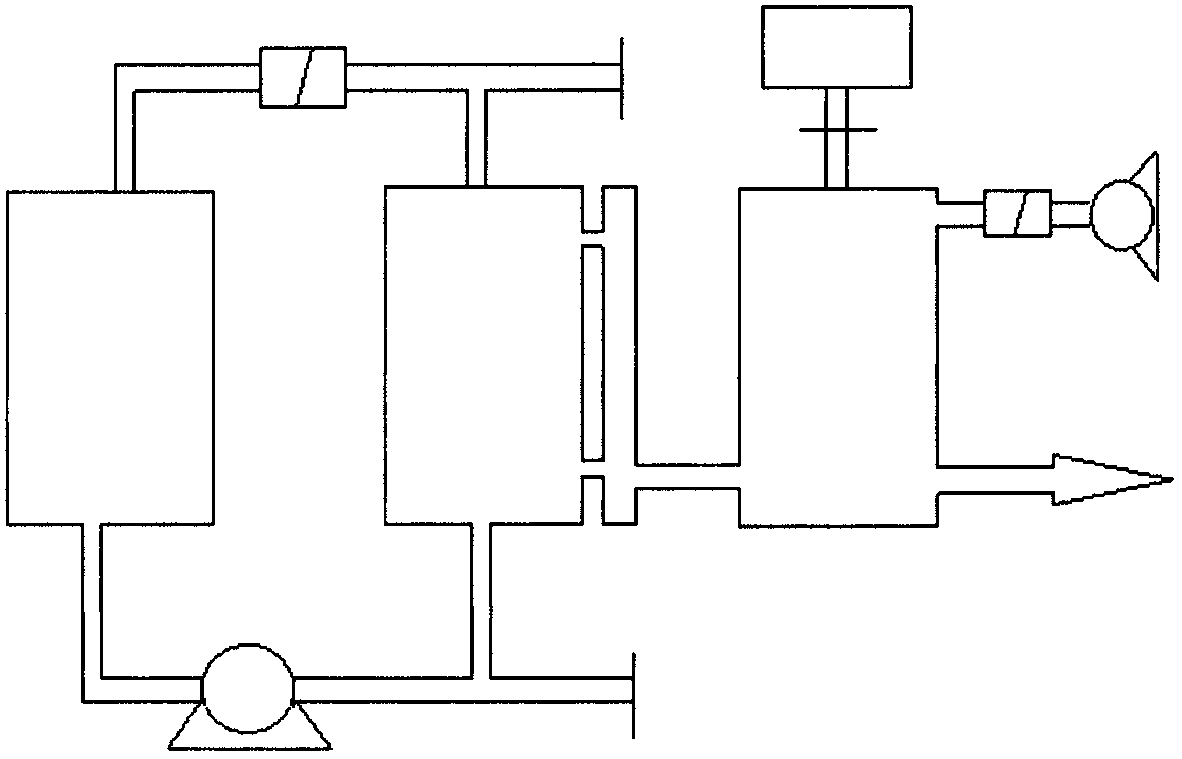

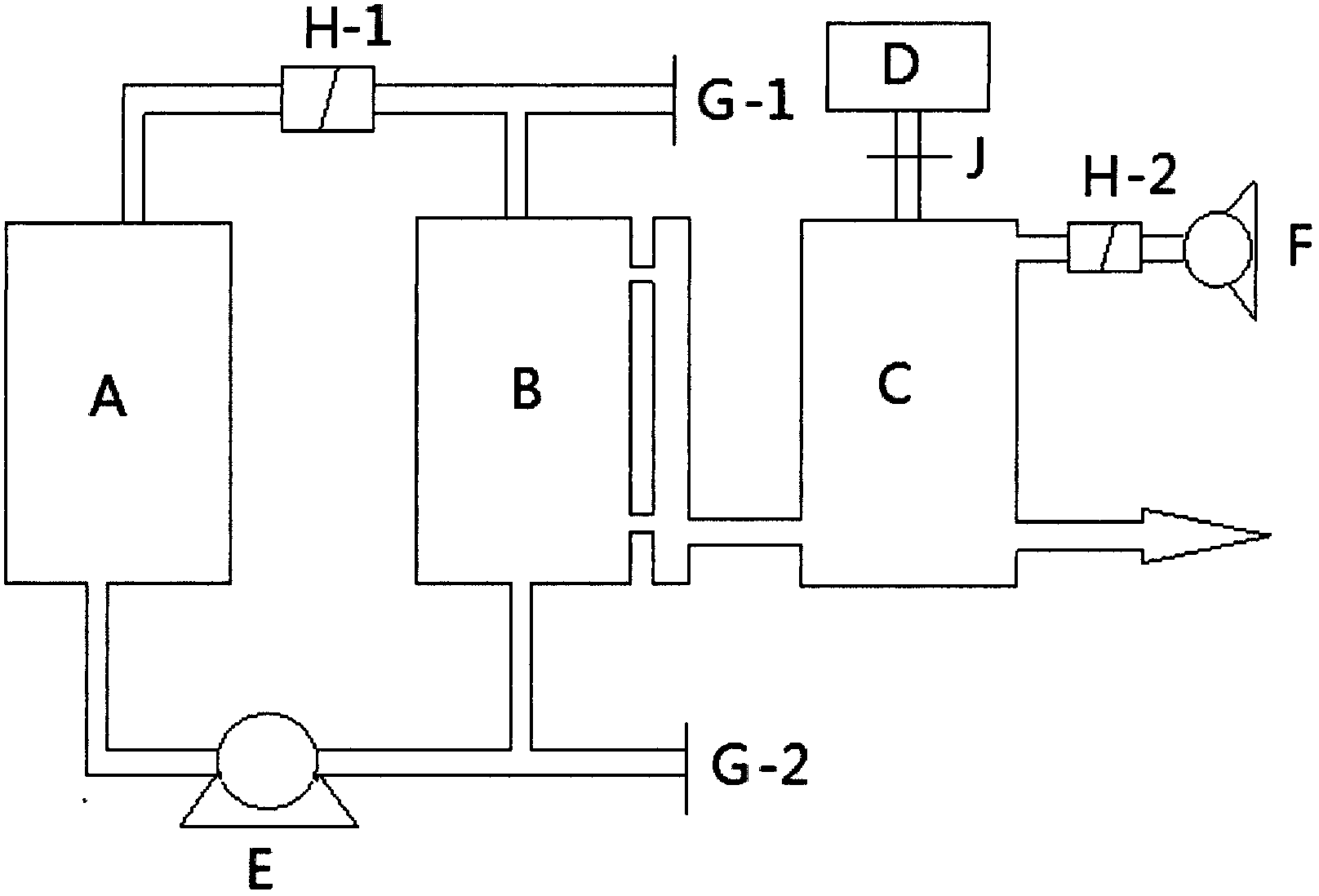

On-line back washing process system of porous ceramic film

A porous ceramic membrane and process system technology, which is applied in the field of dead end or micro-cross-flow porous ceramic membrane online backwash process system, can solve the problems of high energy consumption and slow recovery of flux, etc., to avoid secondary pollution and reduce pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

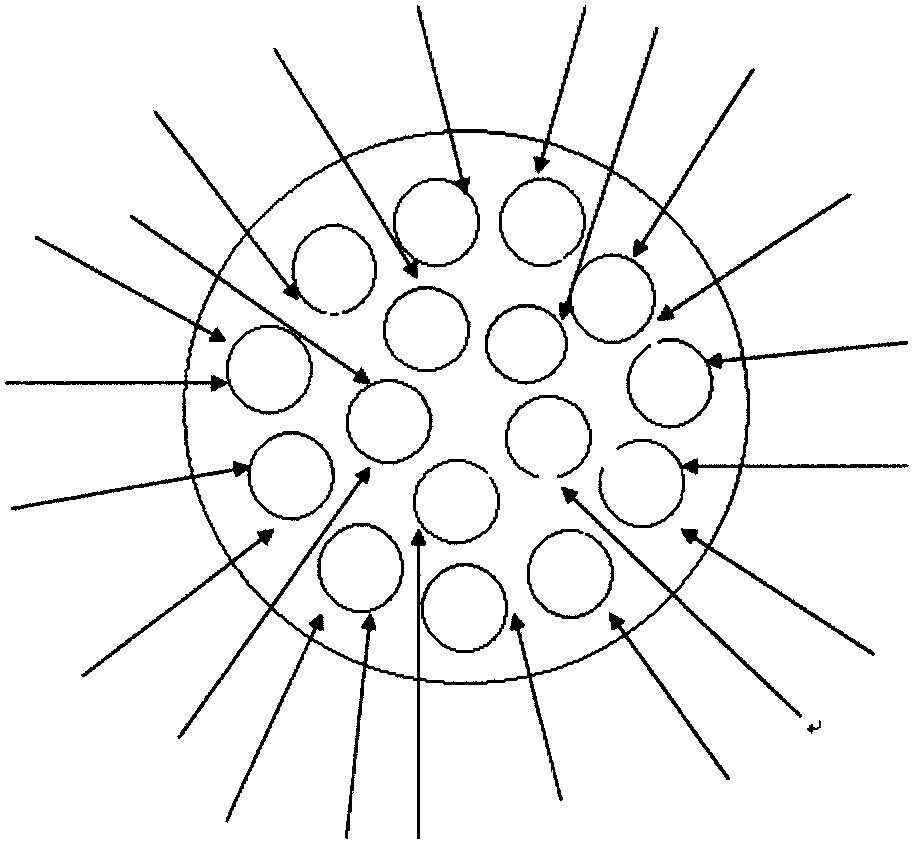

Method used

Image

Examples

Embodiment 1

[0020] ZrO 2 Porous ceramic membrane instead of hollow fiber membrane for seawater desalination process, without backwash, ZrO 2 The initial membrane flux of the porous ceramic membrane is 1 ton / m 2 h, the membrane flux decays to 0.5 tons / m after half an hour 2 h, after 24 hours, the membrane flux decays to 0.4 tons / m 2 h, then the membrane flux was restored to 100% after acid-base cleaning.

[0021] ZrO 2 Porous ceramic membranes instead of hollow fiber membranes for seawater desalination process, ZrO 2 The initial membrane flux of the porous ceramic membrane is 1 ton / m 2 h, the membrane flux decays to 0.5 tons / m after half an hour 2 h, followed by backwashing, the membrane flux is restored to 100%, and then backwashing every half an hour, the permeation separation efficiency can be increased by more than 25%.

Embodiment 2

[0023] ZrO 2 Porous ceramic membrane used in mine water treatment process, without backwash, ZrO 2 The initial membrane flux of the porous ceramic membrane is 0.5 tons / m 2 h, the membrane flux decays to 0.3 tons / m after half an hour 2 h, after 24 hours, the membrane flux decays to 0.2 tons / m 2 h, then the membrane flux was restored to 100% after acid-base cleaning.

[0024] ZrO 2 Porous ceramic membranes instead of hollow fiber membranes for seawater desalination process, ZrO 2 The initial membrane flux of the porous ceramic membrane is 0.5 tons / m 2 h, the membrane flux decays to 0.3 tons / m after half an hour 2 h, followed by backwashing, the membrane flux is restored to 100%, and then backwashing every half an hour, the osmotic separation efficiency can be increased by about 30%.

Embodiment 3

[0026] ZrO 2 Porous ceramic membrane used in the extraction process of erythromycin fermentation broth, when there is no backwash, ZrO 2 The initial membrane flux of the porous ceramic membrane is 400L / m 2 h, the membrane flux decays to 100L / m after 10min 2 h, the membrane flux decays to 40L / m after 2h 2 h, then the membrane flux was restored to 100% after acid-base cleaning.

[0027] ZrO 2 Porous ceramic membrane used in the extraction process of erythromycin fermentation broth, ZrO 2 The initial membrane flux of the porous ceramic membrane is 400L / m 2 h, the membrane flux decays to 100L / m after 10min 2 h, followed by backwashing, the membrane flux is restored to 100%, and then backwashing every 10 minutes, the permeation separation efficiency can be increased by more than 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com