An eddy current ramjet engine

A ramjet and vortex technology, applied in ramjet engines, machines/engines, rocket engine devices, etc., can solve the problems of insufficient fuel combustion, insufficient injection speed, and speed limit, etc., to achieve fast propulsion speed and avoid The effect of cylinder wall burning and high thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

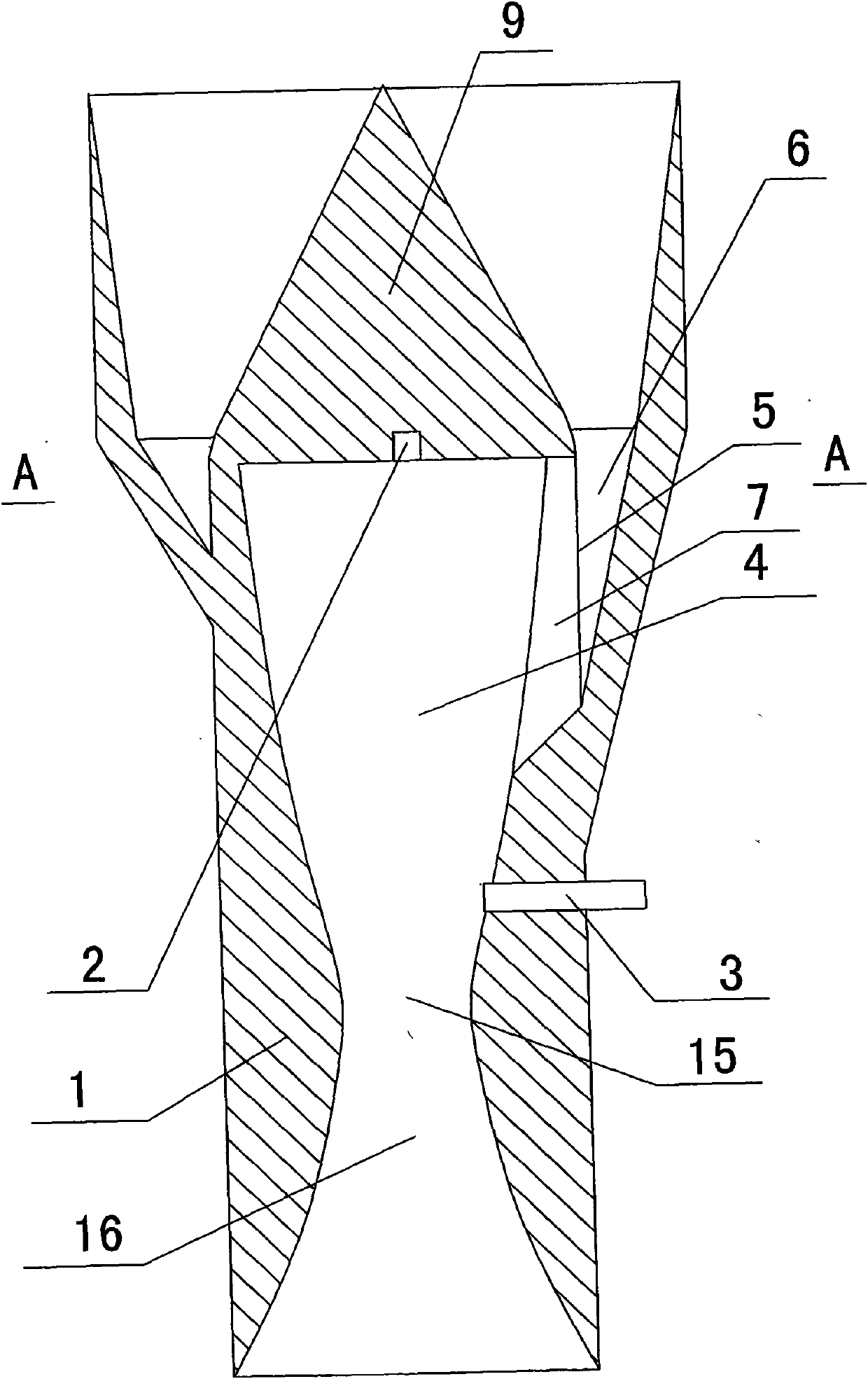

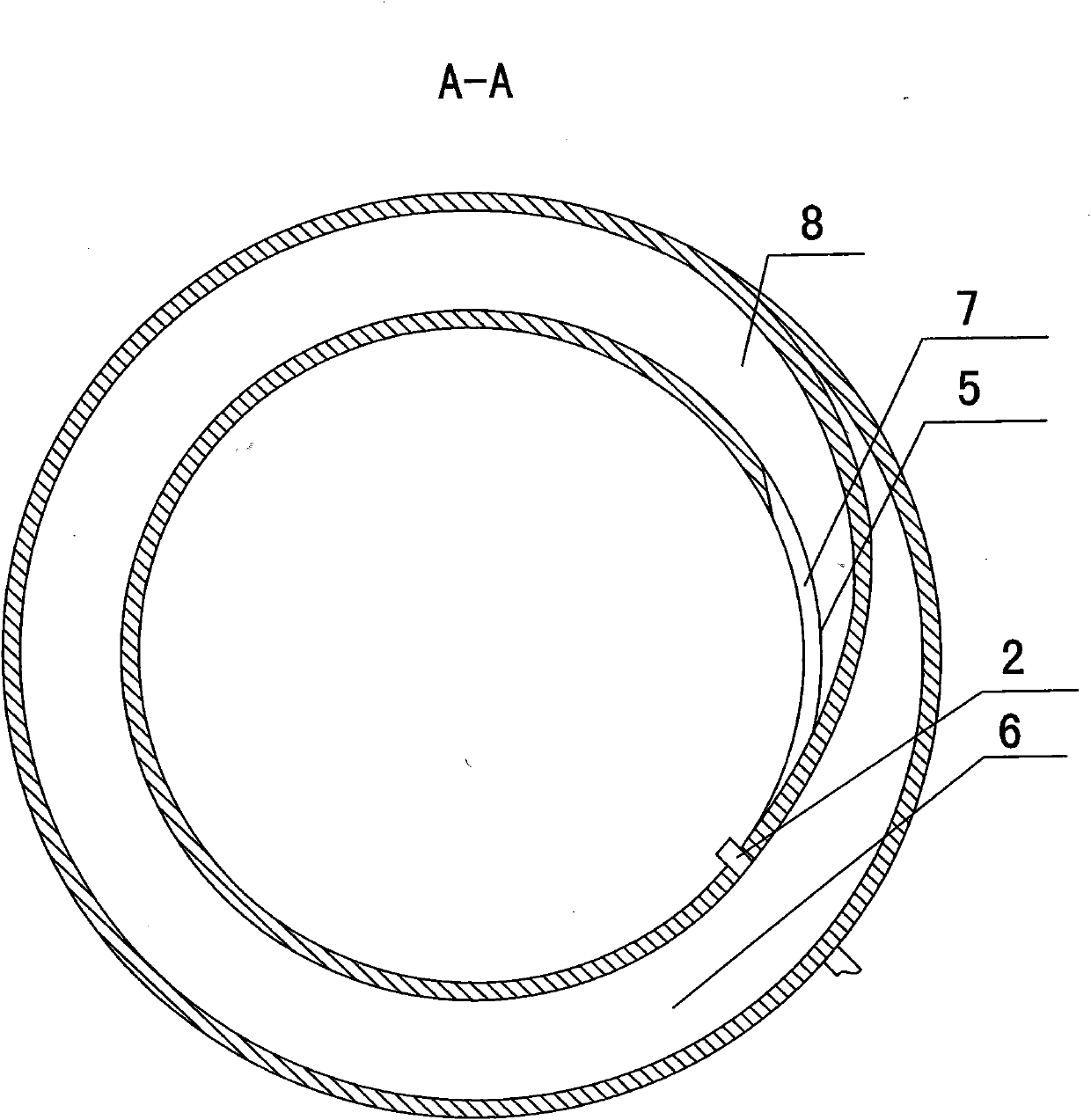

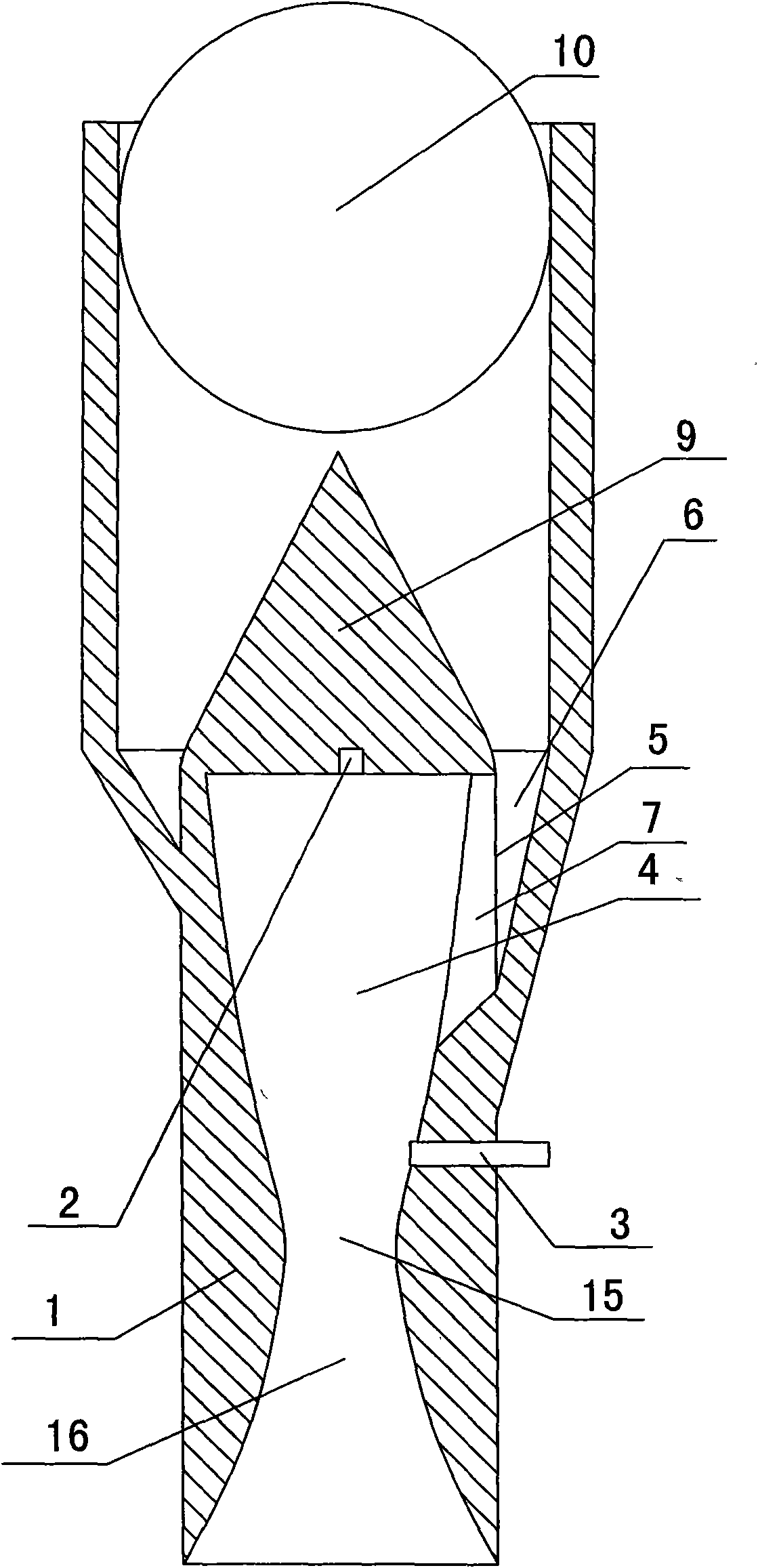

[0017] The main structure of the present invention is: a vortex ramjet engine, comprising a housing 1, a fuel system 2 and an ignition system 3, the inner chamber of the housing 1 has a circular cross-section, the housing 1 is provided with a combustion chamber 4 and an injection chamber 16, and the combustion chamber 4. The combustion chamber air inlet 5 and the combustion chamber gas outlet 15 are set, the combustion chamber gas outlet 15 is connected to the jet chamber 16, the cross-sectional area of the combustion chamber gas outlet 15 is smaller than the maximum cross-sectional area of the combustion chamber 4, and the inner cavity of the jet chamber 16 faces the jet direction The opening expands, the combustion chamber intake port 5 is connected to the intake chamber 6 , and the fuel system 2 and the ignition system 3 are arranged corresponding to the combustion chamber 4 .

[0018] The casing 1 is the main body of the vortex ramjet engine of the present invention, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com