Construction method of long-service-life pass-through induced drainage pavement

A construction method and water-absorbing technology, applied to roads, roads, on-site paved condensing pavements, etc., can solve problems that affect the effective use of rainwater, difficulty in urban groundwater sources, and aggravate the pollution of natural water bodies. Property loss, strengthening insulation measures and high temperature construction, and improving the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1. A construction method for a long-life permeable induced drainage pavement, comprising the following steps:

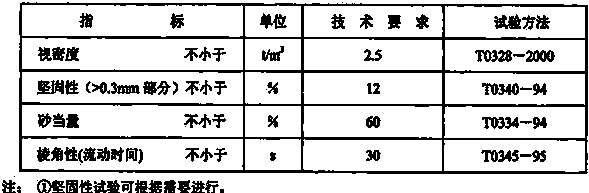

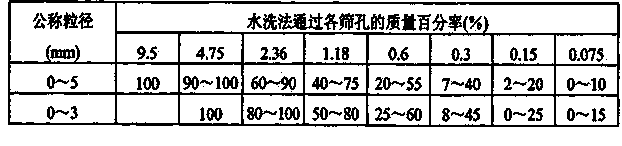

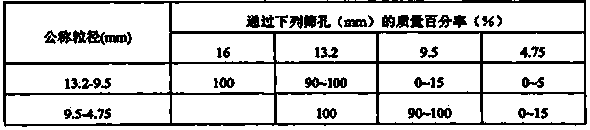

[0048]①Preparation of permeable water-inducing pavement filter material: the multi-void drainage and noise-reducing asphalt mixture composed of coarse aggregate, fine aggregate and modified asphalt mixture is used as the filter material for permeable water-inducing pavement The weight ratio of fine aggregate and modified asphalt mixture is 58.5:35.85:5.65, wherein: the modified asphalt mixture includes slaked lime, red mud and combined fiber, and the weight ratio of slaked lime, red mud and combined fiber is 32.1:64.2: 3.7; The weight ratio of wood fiber and basalt fiber in the combined fiber is 1:2, and the consumption of combined fiber should be 3.7%;

[0049] ② Base treatment of construction pavement: operate according to the base treatment of conventional construction methods;

[0050] ③A layer of adhesive layer or sealing layer is arranged at ...

Embodiment 2

[0057] Embodiment 2: The specific construction steps of a long-life permeable induced drainage pavement are as follows:

[0058] ①Mix ratio design: The production mix ratio of the test road is carried out in the construction site laboratory. Firstly, the raw materials of the hot bin were tested for indicators, and then the Marshall test was carried out according to the relevant steps, and finally the ratio of the coarse and fine aggregates of the hot bin to the modified asphalt mixture was determined to be: 58.5:35.85:5.65

[0059] ②Stirring process:

[0060] Before mixing in the asphalt mixing plant, adjust the gradation and asphalt-stone ratio of the mixing plant so that the gradation tends to the median value of the grading range. The mixer is equipped with air supply equipment, adding fibers, and the heating temperature of the asphalt is controlled at no more than 180°C , The mineral material heating temperature is 190~2lO℃, the asphalt mixture is normally 180~185...

Embodiment 3

[0068] Embodiment 3: Adopting the construction method of the present invention, the degree of compaction of the road surface is detected by the drilling method on the second day after the construction is completed, and the detection results of each section are shown in Table 6.1:

[0069]

[0070] From the results of the compaction test, the paving temperature has a great influence on the compaction effect of the mixture. For these two types of fiber mixtures, the paving temperature should be guaranteed to be around 170°C in the subsequent paving process. .

[0071] Half a year after the paving of the test road was completed and opened to traffic, we investigated the pavement use of the test road, and measured the water seepage coefficient and pendulum value of the test road (structural depth > 0.55mm). The results are shown in Table 6.2:

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Absolute viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com