Patents

Literature

611results about How to "Avoid environmental problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

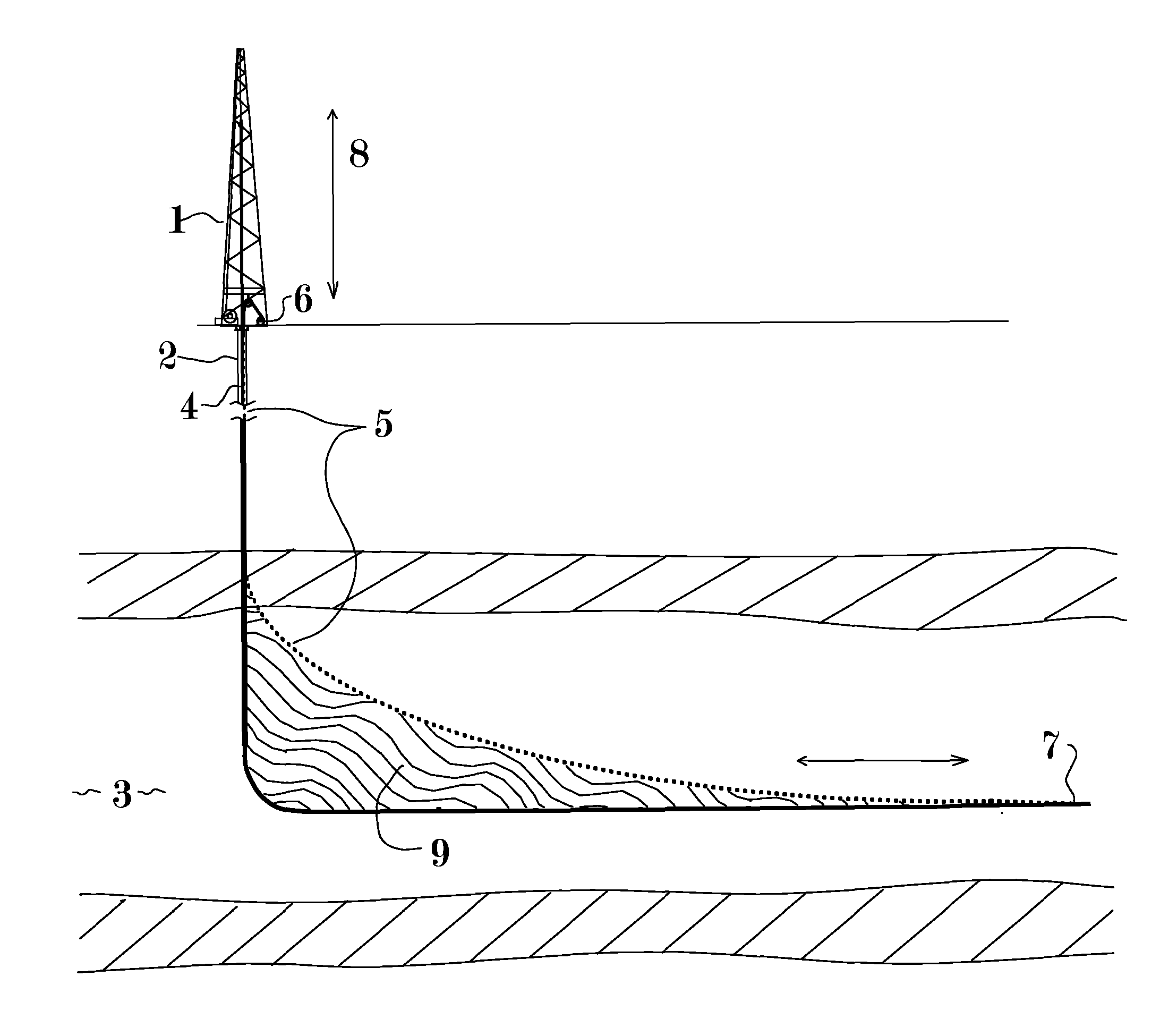

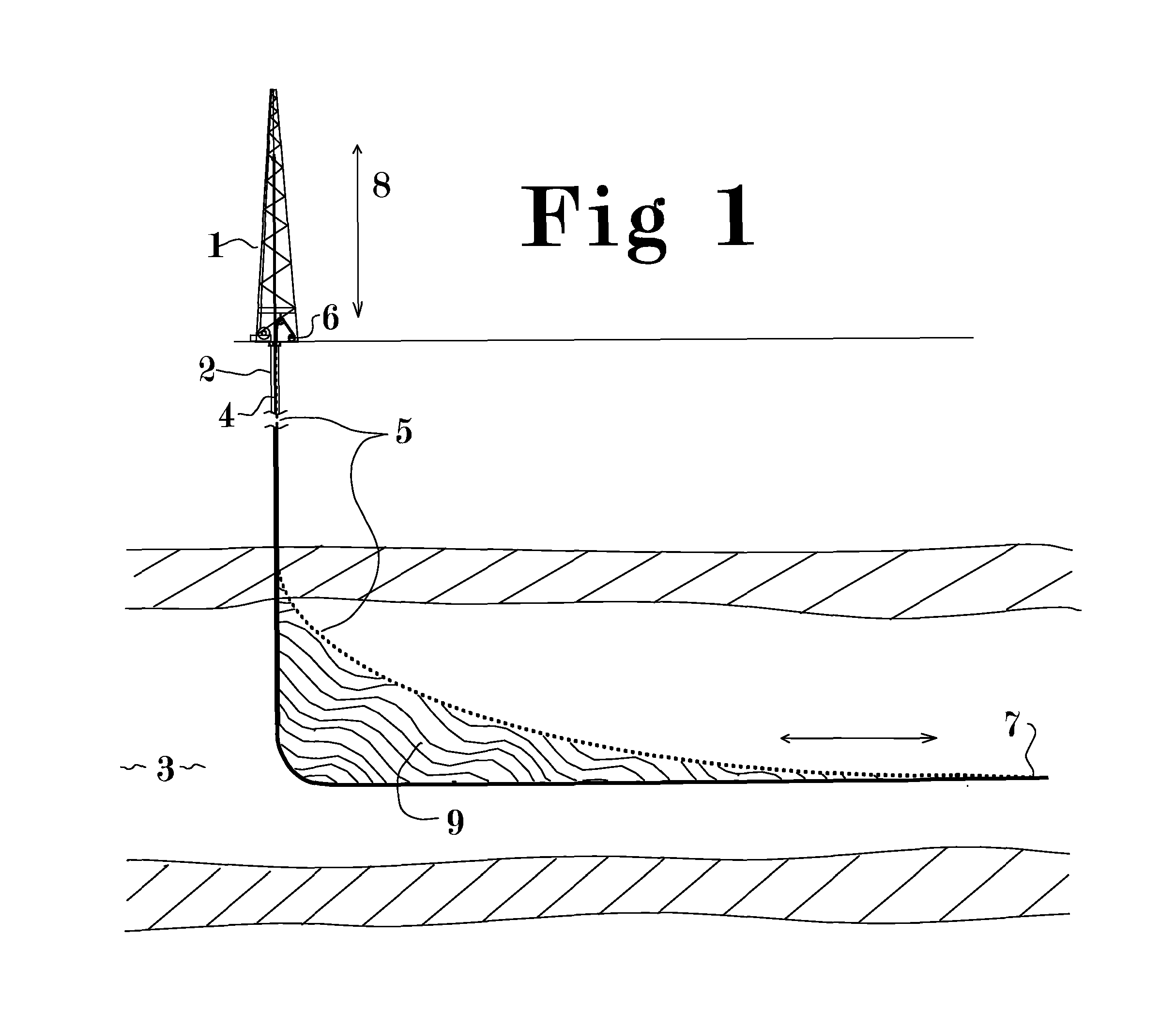

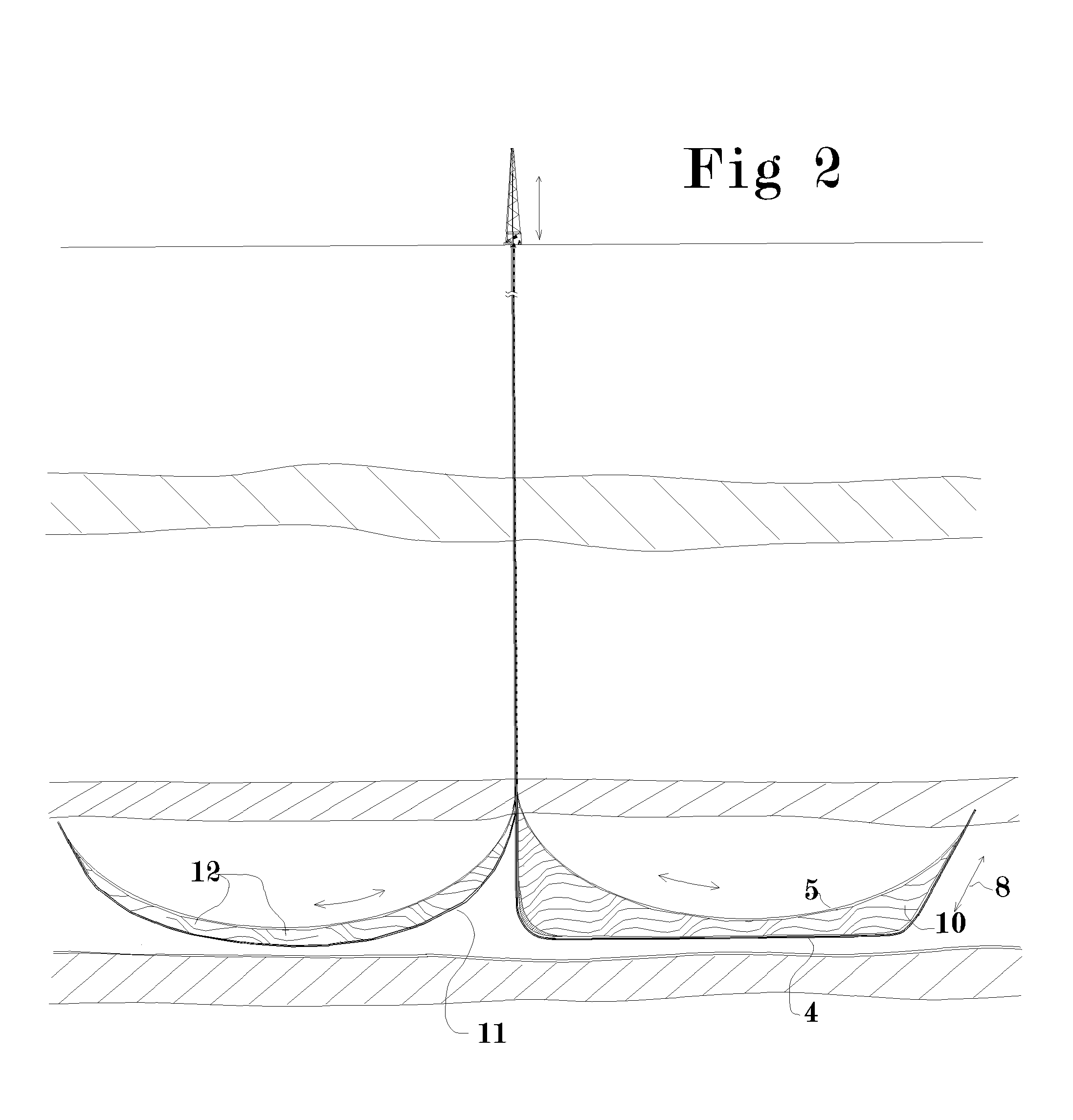

Method and Apparatus for Increasing Well Productivity

InactiveUS20110247816A1Increase productivityRate of flow of resources between the formation and the well is substantially increasedEarth drilling toolsFluid removalEnvironmental issueFlow limitation

This patent application discloses method and apparatus to cut an extended slot connecting a well to a substantial cross section of a desired producing formation whereby material can flow freely between the formation and the wellbore and at least partially overcome the flow limitations of low permeability formations without the environmental issues associated with hydraulic fracturing. It is further disclosed that the connection between said slot and the formation may be further enhanced by explosive or combustive processes that rapidly generate gas pressure within the large surface area of the slot, thereby changing its characteristics and forcing open additional fractures into the cross section of formation exposed to the slot. The method may significantly increase the recoverable percentage of natural gas from low permeability deposits such as shale and coal.

Owner:CARTER JR ERNEST E

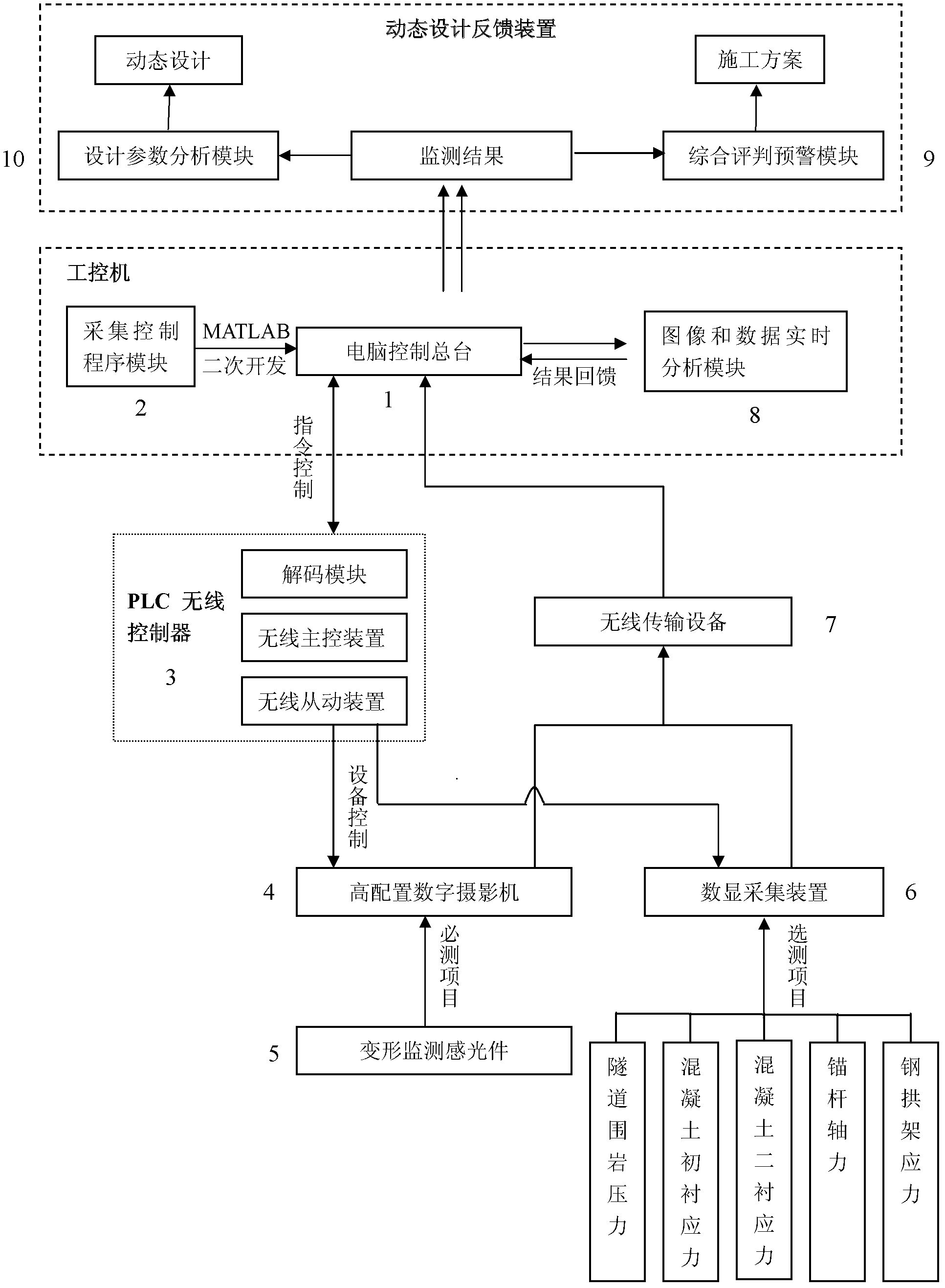

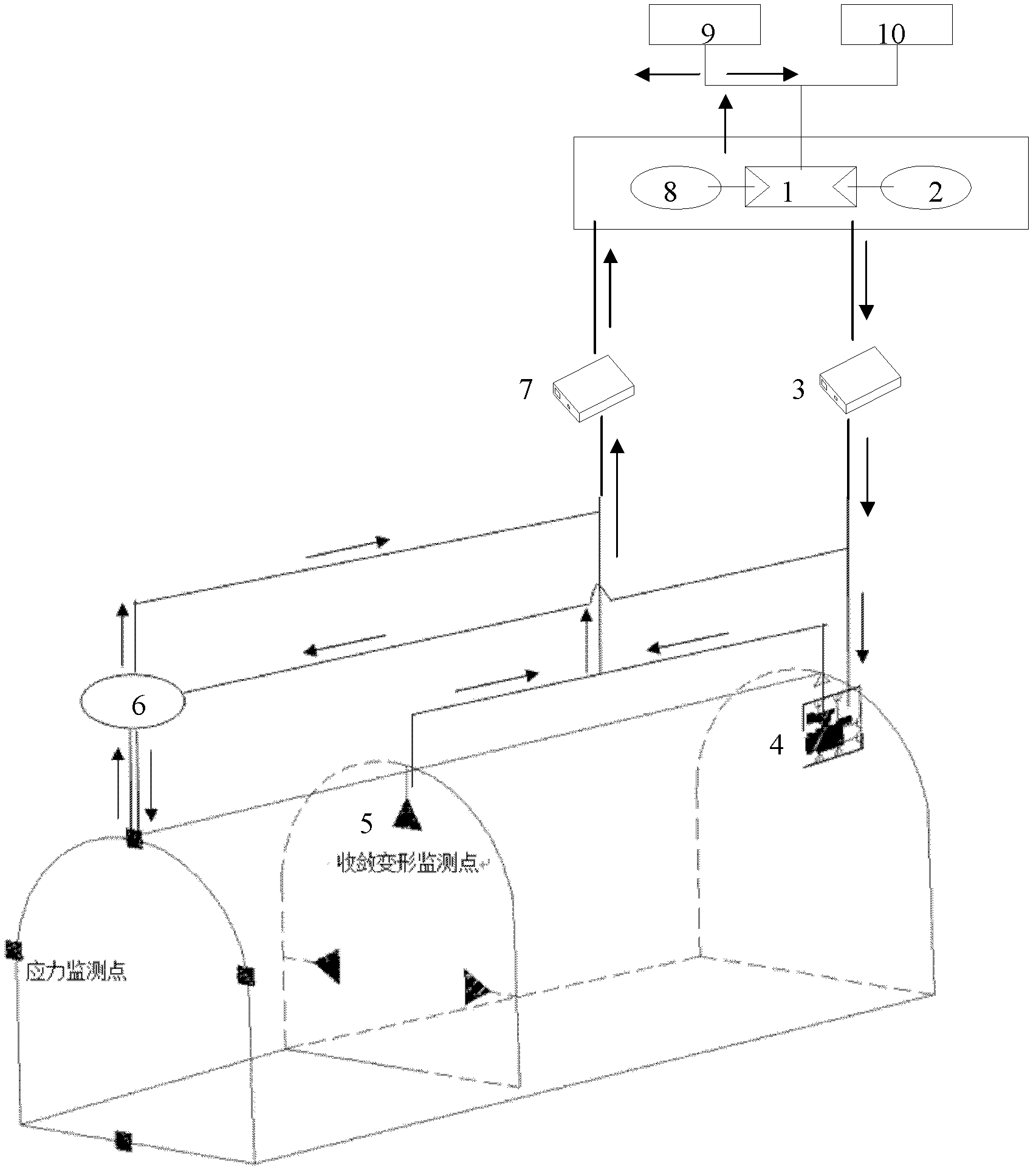

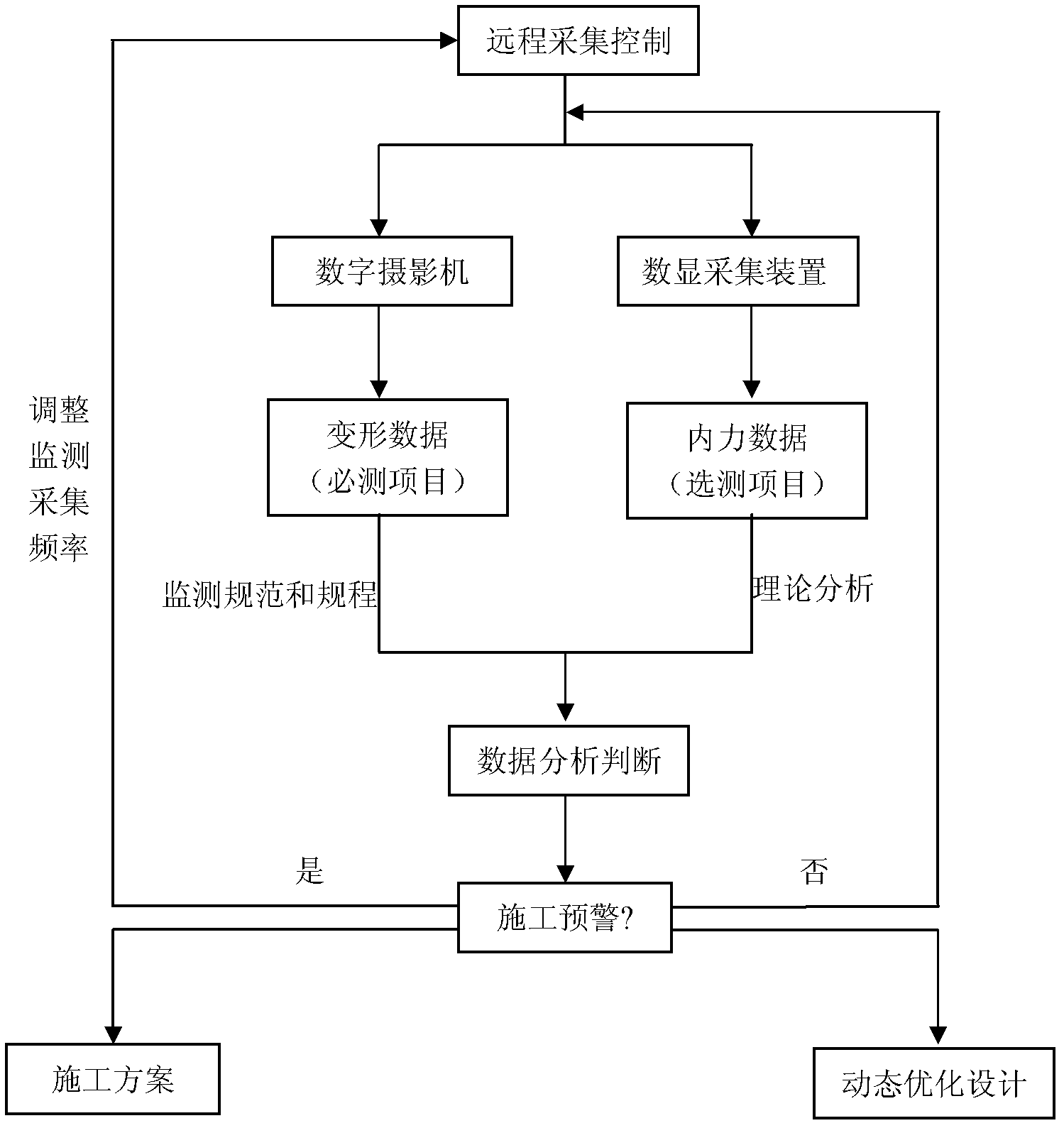

Tunnel construction informatization dynamic monitoring system and monitoring method thereof

InactiveCN102587986AHigh precisionAvoid error accumulationMining devicesTransmission systemsInformatizationReal time analysis

The invention discloses a tunnel construction informatization dynamic monitoring system and a monitoring method thereof. The system comprises an industrial personal computer, a PLC (programmable logic controller) wireless controller, a high-configuration digital camera, a deformation monitoring sensitization part, digital display acquisition equipment, wireless transmission equipment and a dynamic design feedback device. The method includes: 1), controlling commands to be transmitted to the PLC wireless controller by a computer control main station and controlling the digital camera and the digital display acquisition equipment; 2), acquiring internal force monitoring data by the aid of the digital display acquisition equipment; and acquiring a deformation monitoring image via the deformation monitoring sensitization part by the digital camera; 3), transmitting a monitored value to the computer control main station by the aid of the wireless transmission equipment; 4), analyzing results by the computer control main station via a real-time analysis module; and 5), transmitting the analyzed results to the dynamic design feedback device, analyzing relative difference of the really monitored value and a standard value, and early warming in real time by an early warning module. The tunnel construction informatization dynamic monitoring system is scientific, safe and practical, the method is convenient, instant, fast and effective, and safety problems in construction monitoring of tunnels are avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

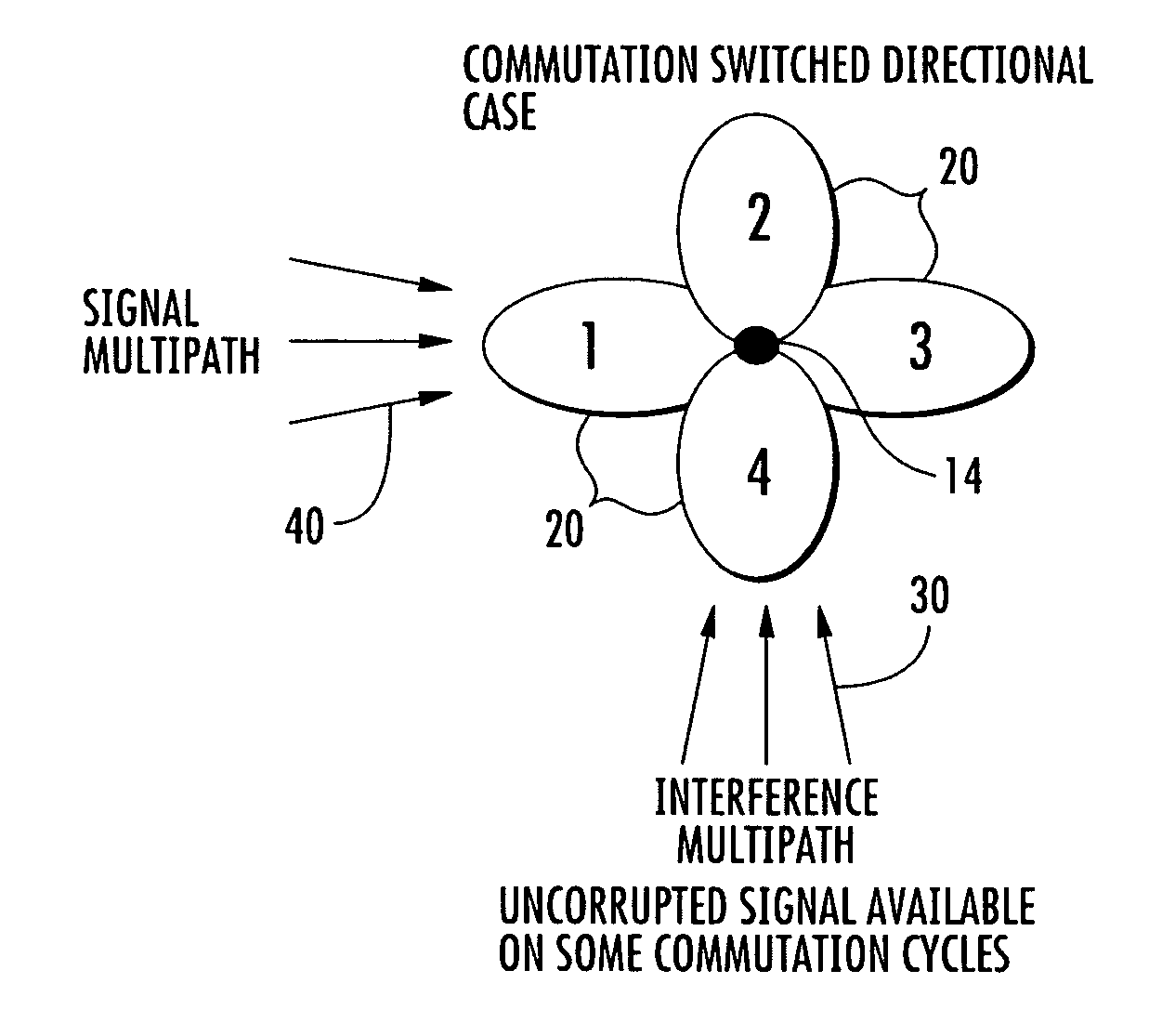

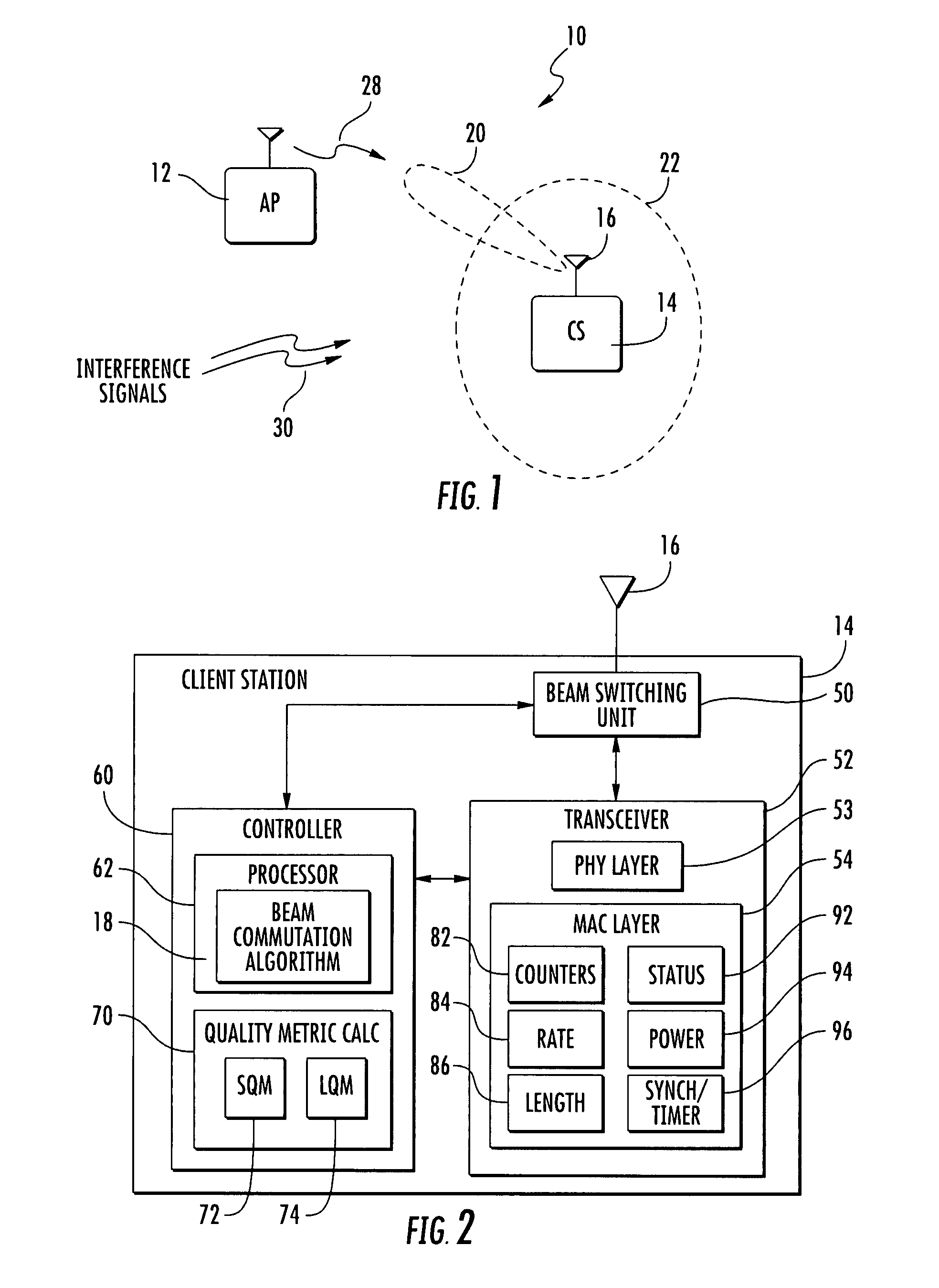

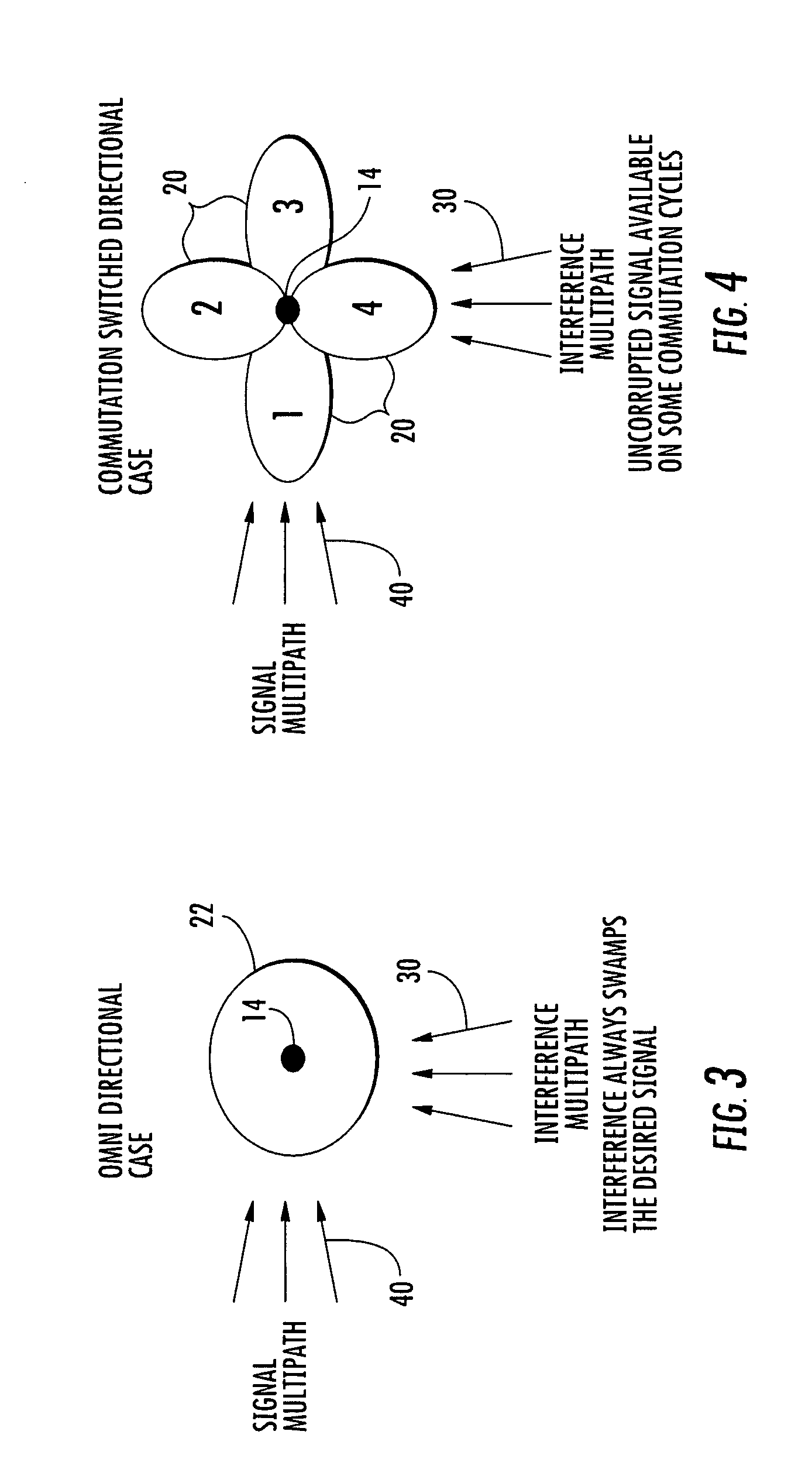

Methods for improving wireless communications when interference or signal loss is directional in nature

ActiveUS20080002627A1Increased link gainWell as to enableError preventionNetwork traffic/resource managementOmnidirectional antennaCommunications system

A client station in a wireless local area network (WLAN) communication system includes a beam commutation algorithm and a smart antenna responsive to the beam commutation algorithm for selecting one of a plurality of directional antenna beams. The smart antenna is configured as a virtual omni-directional antenna by using a commutation of switched directional antenna beams. A switched directional antenna system that performs a commutation sequencing can be blind to environmental conditions and changes.

Owner:INTERDIGITAL TECH CORP

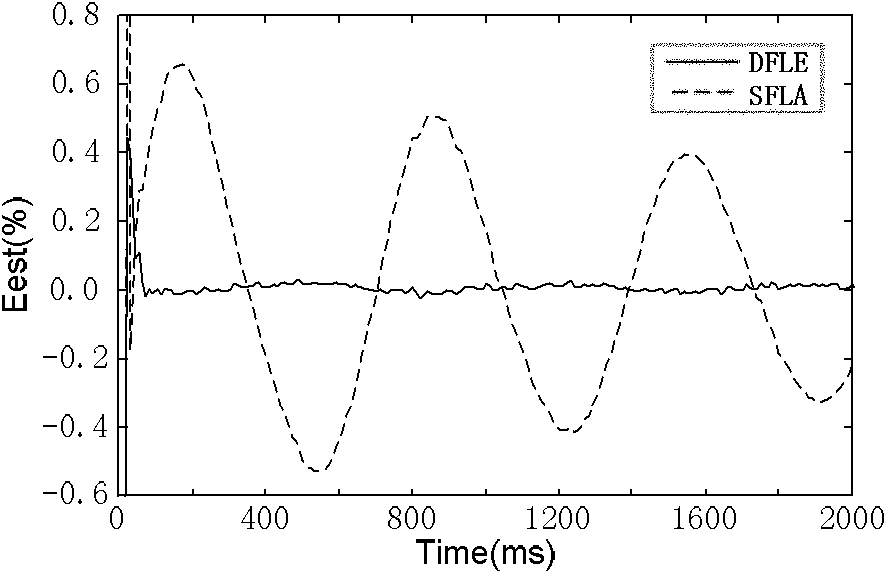

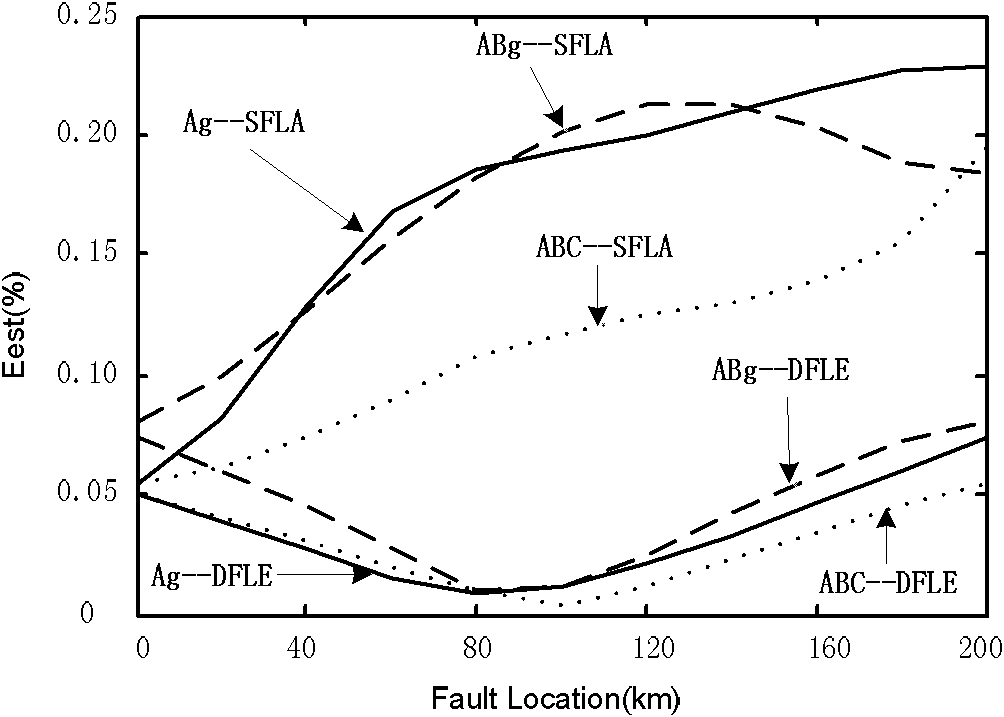

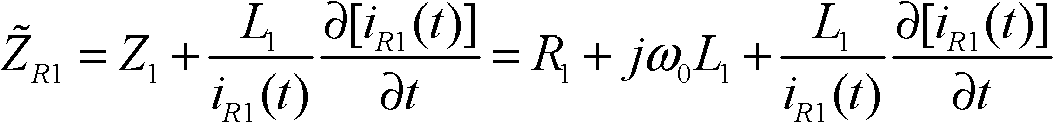

Two-end distance measuring method of transmission line fault under dynamic condition

ActiveCN102081132APrevent agingAvoid environmental problemsFault locationCable fault locationPhasor measurement unit

The invention relates to a two-end distance measuring method of transmission line fault under a dynamic condition, comprising the following steps of: acquiring two-end voltage and current signals through two-end phasor measurement units of the transmission line; then acquiring dynamic positive sequence impedance, admittance, wave impedance and propagation coefficients according to line parameter estimation and a dynamic line parameter method; and finally solving a nonlinear equation related to a fault distance according to the fact that positive sequence voltages derived from two ends to a fault point are equal by applying a Newton iteration method so as to obtain a dynamic distance measuring result of the transmission line fault. The two-end distance measuring method can more effectivelysolve the problem of line parameter and fault distance estimation under the dynamic condition and has accurate and reliable fault distance measuring result.

Owner:SOUTHWEST JIAOTONG UNIV

High-strength casted air-colled bainite wear-resisting steel and preparing method

InactiveCN1775983AImprove mechanical propertiesImprove toughnessMolten metal pouring equipmentsFoundryWear resistant

The invention relates to a high strength foundry air cooling bainite wear resistant steel that the chemical constituents is 0.32-0.65 C, 0.8-3.0 Si, 1.2-3.0 Mn, 0.5-0.8 Cr, 0.3-0.8 Cu, 0.001-0.008 B, 0.18-0.35 Al, 0.05-0.15 Y, 0.05-0.20 Ti, 0-0.12 Mg, 0-0.12 Ca, 0-0.15 Zn, and 0.10<Mg+Ca+Zn<0.25, the else is Fe and trace impurities. The process includes the following steps: smelting waste steel, pig iron, ferrochrome iron and copper board, adding ferrosilicon and ferromanganese preliminary deoxidation into melting down and alloying; heating to 1600-1660 degree centigrade after adjusting the constituents adding aluminum deoxidatioin and alloying and blast furnace tapping; putting the compounding modification particle of Yt, boron, titanium, magnesium, calcium, and zinc on the bottom of pouring ladle, taking modification process to the molten steel; molding the molten steel after modification process into normal matrix for casting. The invention could prolong the useful life of antifriction component, improve working efficiency, and have good economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Watch type non-invasive light sound blood sugar monitoring instrument

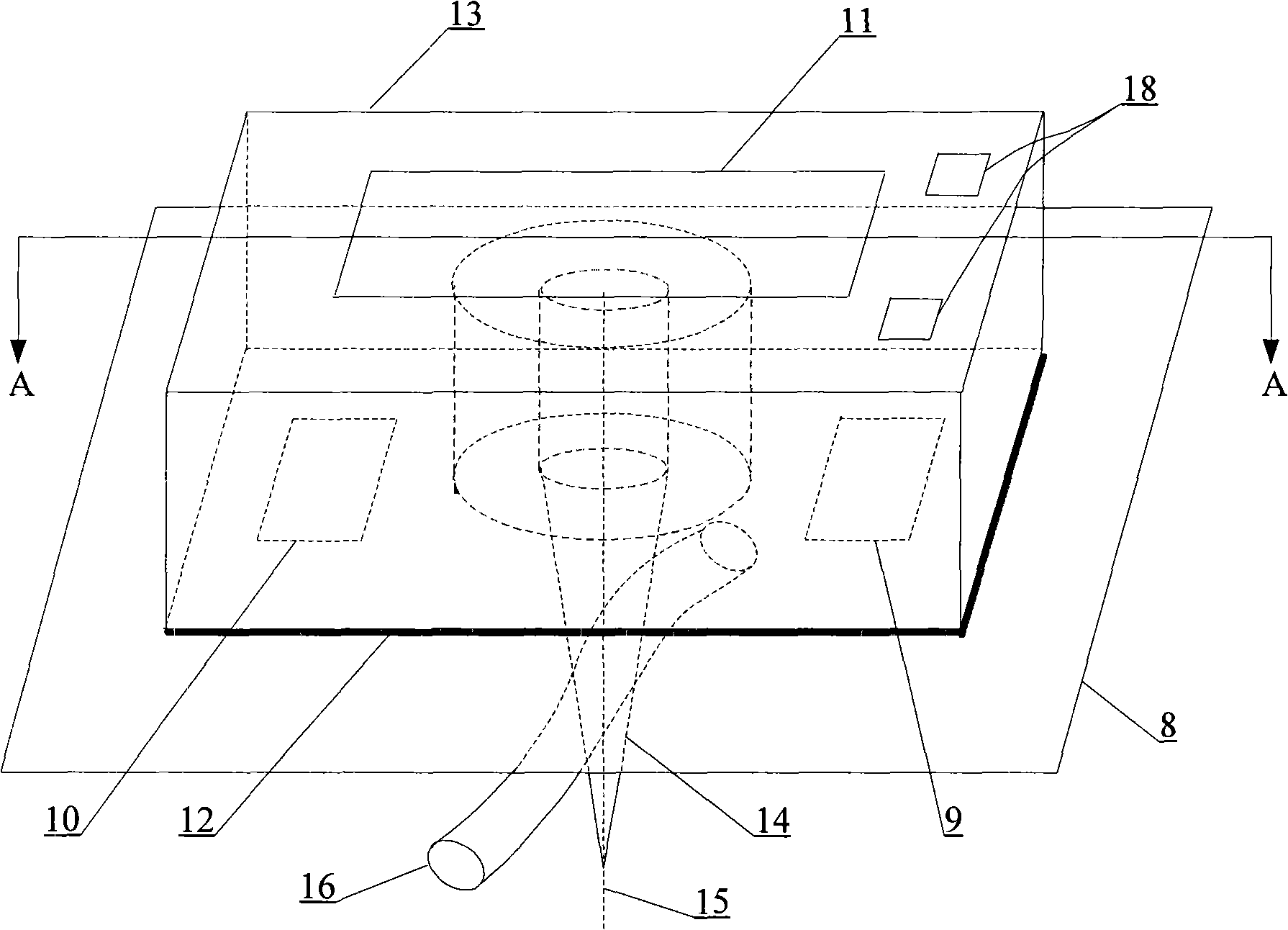

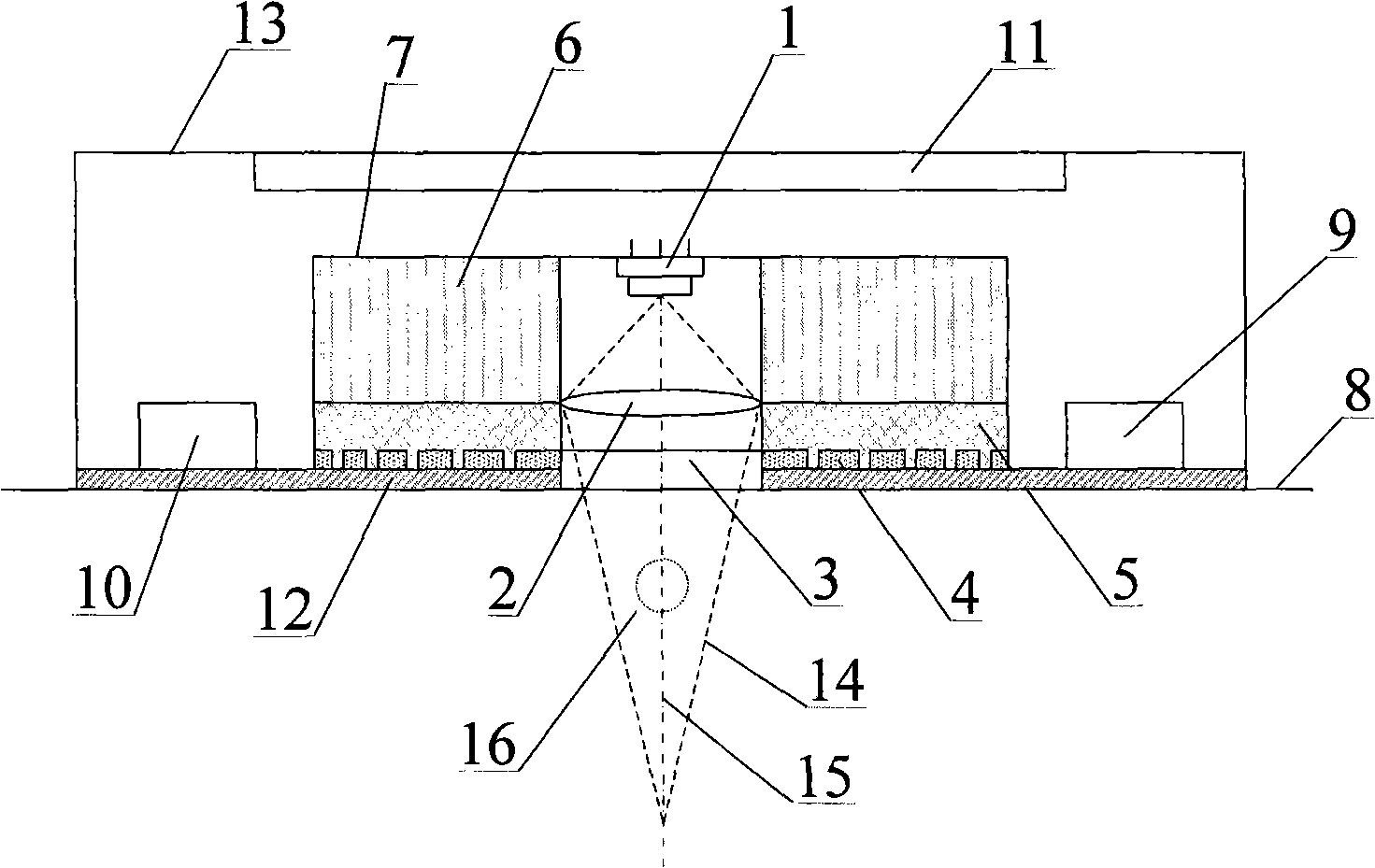

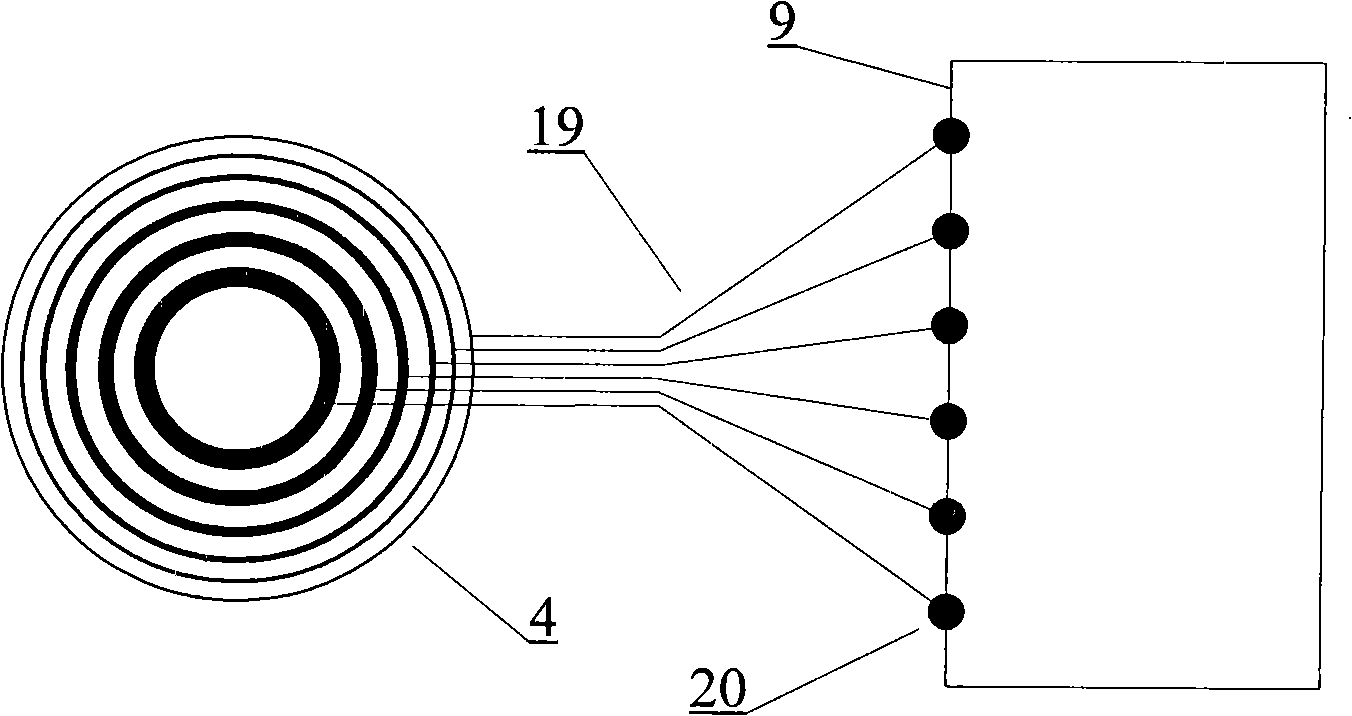

InactiveCN101301202ARealize real-time monitoringCompact structureDiagnostic recording/measuringSensorsBlood sugar monitoringNon invasive

The invention relates to a watch-type non-trauma optical acoustic blood sugar monitor. A display screen, a control button, a controller, a cell and a measurement box are arranged in watch-type casing, an acoustic insulating layer, a sound absorption pad, a semiconductor laser tube, a Fourier lens, a light-transparent protection film and a hollow multi-ring array sensor are packaged in the measurement box to form a integrated coaxial confocal structure. The watch-type casing is equipped with a watchband to be wore on wrist of detector, an optical acoustic excitation source and an optical path lens system generate focused laser beam which passes through the hollow multi-ring array sensor and radiates to blood vessel of wrist to realize optical acoustic blood sugar detection of continuous A-type dynamic focusing scan and provide optical acoustic blood sugar results of multiple sites along wrist depth direction. The monitor has advantages of having small structure and simple operation, realizing real-time monitoring of optical acoustic blood sugar, having no trauma when detecting, having no need of blood supply and test paper, and avoiding cross infection and environmental influence.

Owner:JIANGXI SCI & TECH NORMAL UNIV

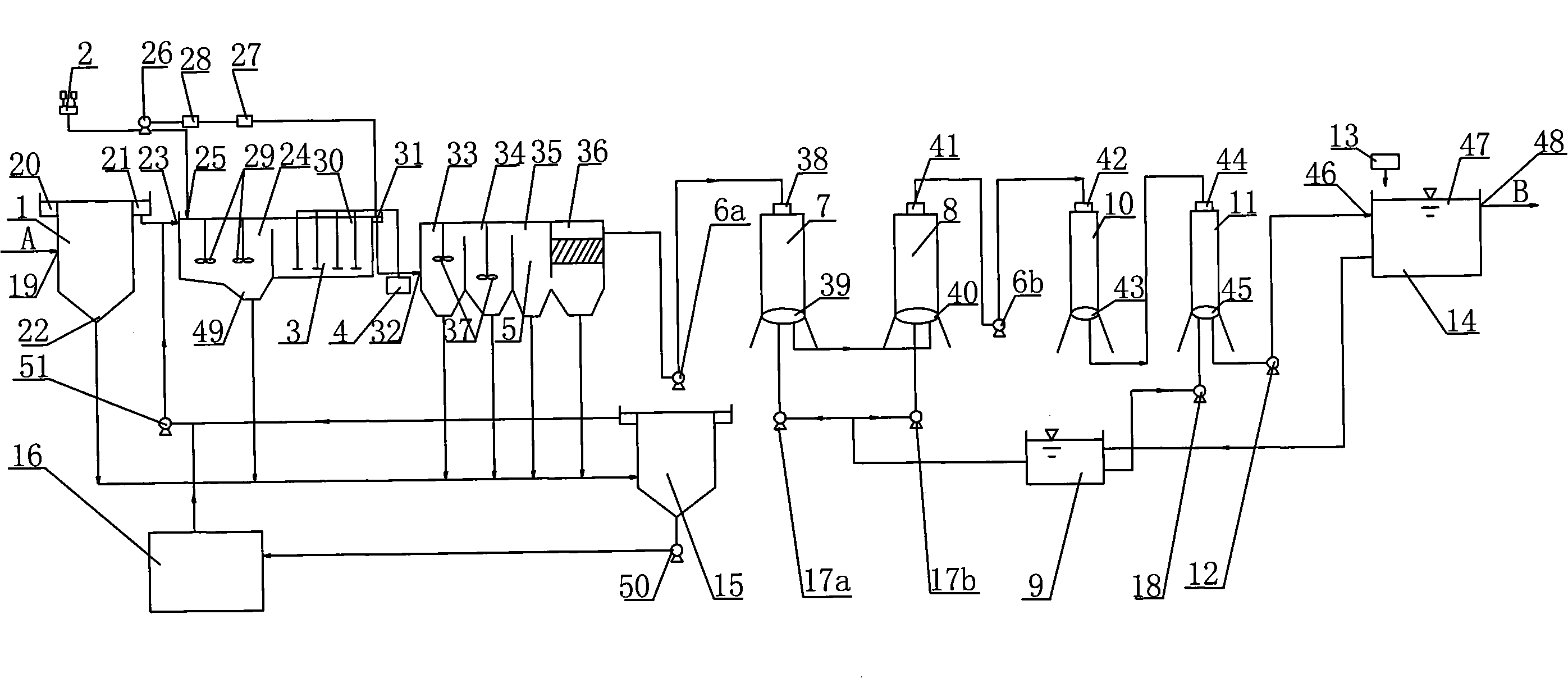

Acid mine water treatment system

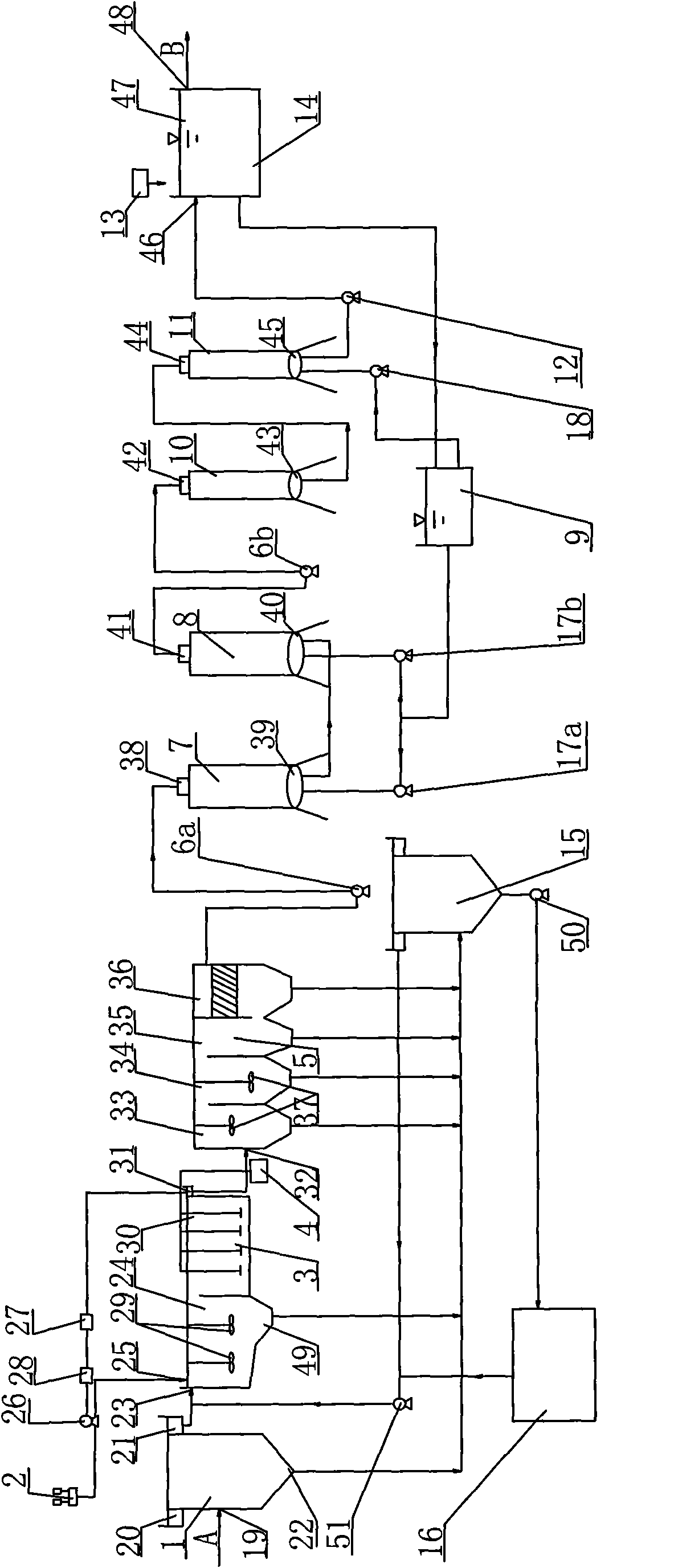

InactiveCN101830585ALarge specific surface areaImprove settlement performanceWaste water treatment from quariesMultistage water/sewage treatmentWater treatment systemManganese

The invention discloses an acid mine water treatment system and belongs to the field of water treatment. The system consists of a neutralization system, a coagulation sedimentation system, a filtration system, a reverse osmosis system and a sterilization system which are connected in turn, wherein the coagulation sedimentation system comprises a mixing region, a reaction region, a transition region and a settling region; the mixing region is communicated with the reaction region, the transition region and the settling region in turn; the water inlet of the mixing region is communicated with the water outlet of the neutralization system; the water outlet of the settling region is communicated with the water inlet of the filtration system; and the filtration system comprises a manganese sand filter in which a modified manganese sand filter material modified by 1 to 7 mass percent potassium permanganate solution is arranged. Four regions are arranged in the coagulation sedimentation system of the system, so coagulation treatment effect is enhanced; and the modified manganese sand filter material is adopted in the manganese sand filter, so the effect of removing ferro-manganese ions in the mine water is enhanced and the aim of treating and recycling the acid mine water with high turbidity, high ferro-manganese content and high mineralization is fulfilled.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

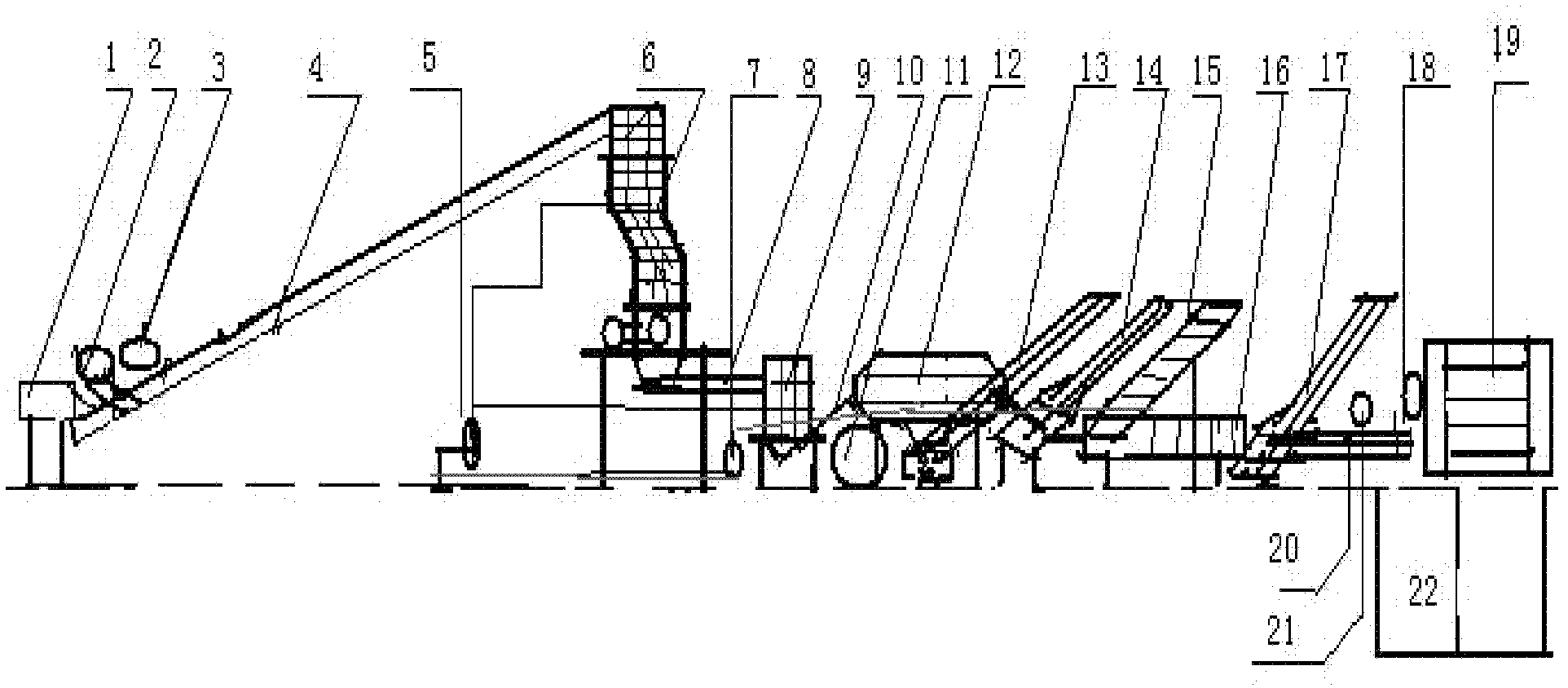

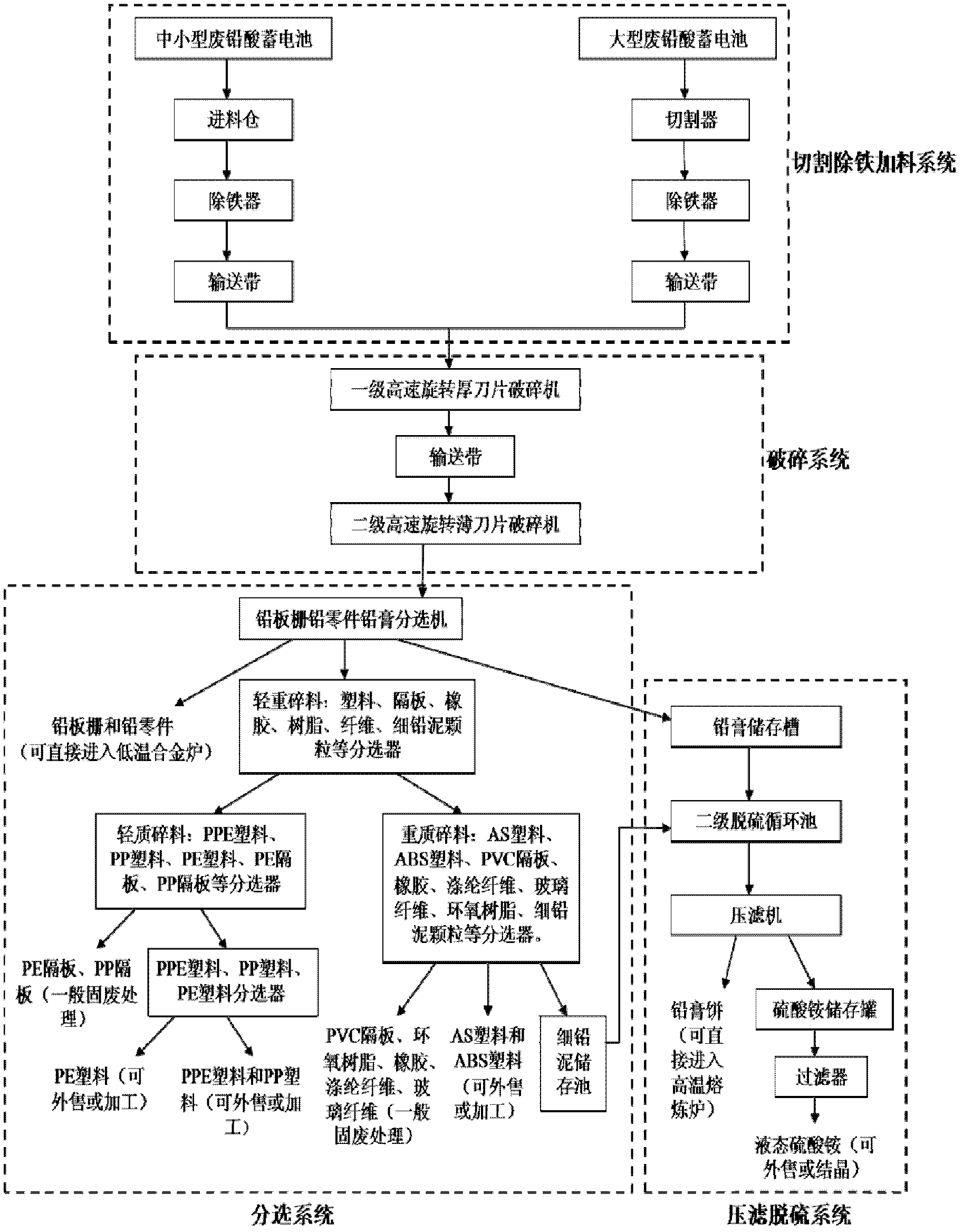

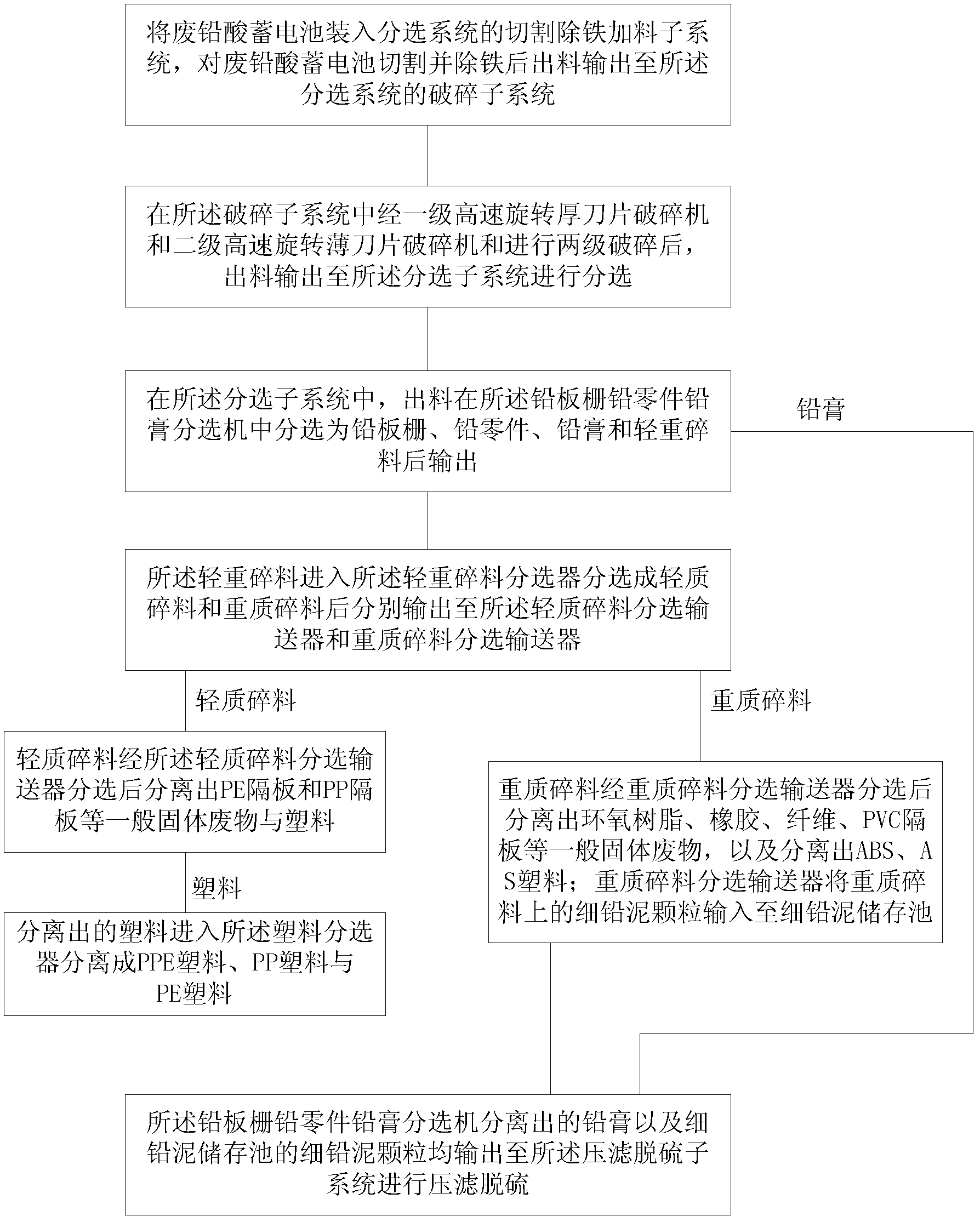

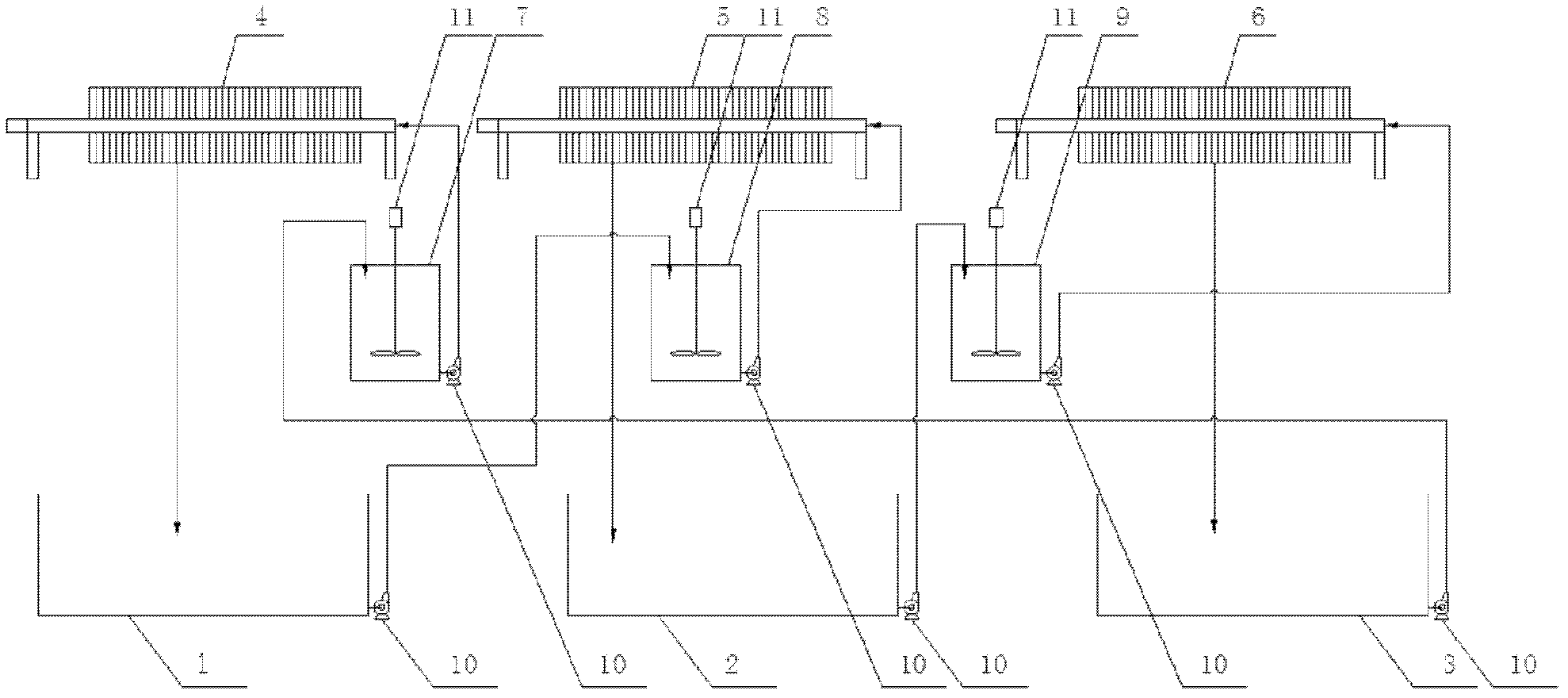

Automatic crushing and separation system and automatic crushing and separation method for waste lead-acid storage battery

ActiveCN102615095ASmall granularityAvoid energy consumptionSolid waste disposalBattery recyclingEnergy consumptionCrusher

The invention discloses an automatic crushing and separation system and automatic crushing and separation method for waste lead-acid storage battery and belongs to the recycling and processing field of the waste lead-acid storage battery. The system comprises a cutting and feeding subsystem, a crushing subsystem, a separation subsystem and a pressure filtration and desulphurization subsystem. A discharge end of the cutting and feeding subsystem is connected with the crushing subsystem, the separation subsystem and the pressure filtration and desulphurization subsystem sequentially. The crushing subsystem comprises a first-level crusher with high-speed rotating thick blades, a crusher water pump, a first-level conveyor, a second-level crusher with high-speed rotating thin blades and a second-level conveyor. By the cooperation of each system, accurate separation of the battery, partition plates on the battery and various light and heavy plastics is realized, and large energy consumption and environment pollution in subsequent processing are avoided.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

Processing method of salt-free dyeing through activated dye

InactiveCN102899929AIncrease the adsorption rateImprove adsorption capacityDyeing processInorganic saltsOrganic solvent

The invention relates to a processing method of salt-free dyeing through activated dye, which includes the steps of: (1), acid pickling and enzyme washing of cotton fabric after the pretreatment of scouring and bleaching; (2) mixing water with organic solvent at volume ratio of (1:4)-(1:9) to form a mixed solution, and then adjusting the pH value of the mixed solution; and (3)dyeing the pretreated cotton fabric in 20-30 DEG C activated dye by using the mixed solution, then carrying out water scrubbing, acid pickling, soaping, hot-water scrubbing, color fixing and softening on the dyed cotton fabric, and finally recovering the solvent. With the processing method, the adsorption rate and the equilibrium adsorption amount of the activated dye are improved, and environmental and ecological problems caused when large quantity of inorganic salt is used are completely solved. In the dyeing process, the input of inorganic salt is omitted, so the operational techniques and the labor intensity in the dyeing process are effectively simplified and the production cost is reduced. Through a solvent recovery system, the solvent contained in the dyeing residue of the hydrosolvent is recovered for cycle use. Therefore, the recovery and the recycling of the resource are realized, the production cost is saved and the pollution to the environment is alleviated.

Owner:DONGHUA UNIV +1

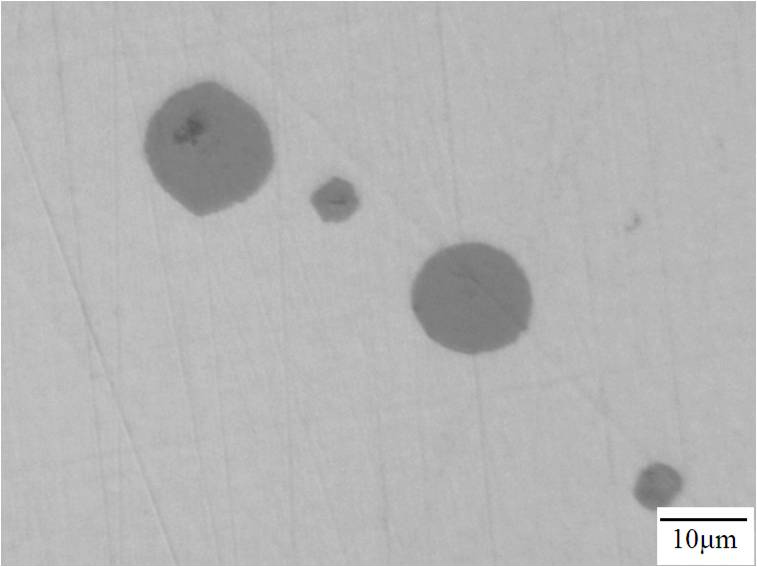

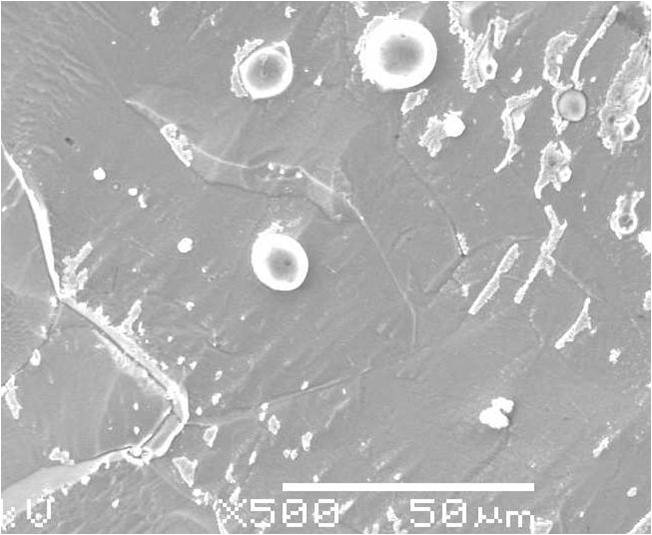

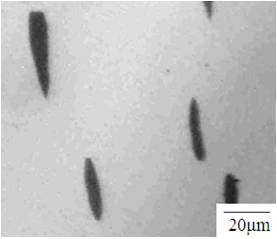

Low-carbon high-sulfur free-cutting steel with excellent cutting performance and manufacturing method thereof

The invention discloses low-carbon high-sulfur free-cutting steel with excellent cutting performance and a manufacturing method thereof, and belongs to the technical field of free-cutting steel. the free-cutting steel contains the following ingredients by mass percentage composition: 0.05 to 0.2 percent of C, 0.6 to 2.0 percent of Mn, 0.04 to 0.1 percent of P, 0.2 to 0.45 percent of S, 0.005 to 0.02 percent of O, less than or equal to 0.02 percent of N, less than or equal to 0.005 percent of Si and less than or equal to 0.001 percent of Al. Generated MnS impurities have the following characteristics: (1) over 95 percent of MnS impurities in as cast steel are Class I MnS, and the proportion of single-phase MnS impurities is equal to or larger than 80 percent; (2) the length of at least 70 percent of MnS impurities in the rolling direction is equal to or larger than 5 micron, and the length-width ratio is lower than or equal to 6; and (3) the average area of MnS impurities in 1 square mm in the rolling direction is no less than 50 square micron. C is adopted for deoxygenation, the cooling rate of ingoting is controlled to range from 2 to 4 mm / min, the roll opening temperature is controlled to range from 1200 to 1250 DEG C, and the roll closing temperature is controlled to be equal to or larger than 1050 DEG C. The low-carbon high-sulfur free-cutting steel has excellent cutting performance. After cutting, the surface fineness of parts is improved. The low-carbon high-sulfur free-cutting steel is generally close to or matches the lead-containing low-carbon free-cutting steel, and is suitable for high-speed cutting.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

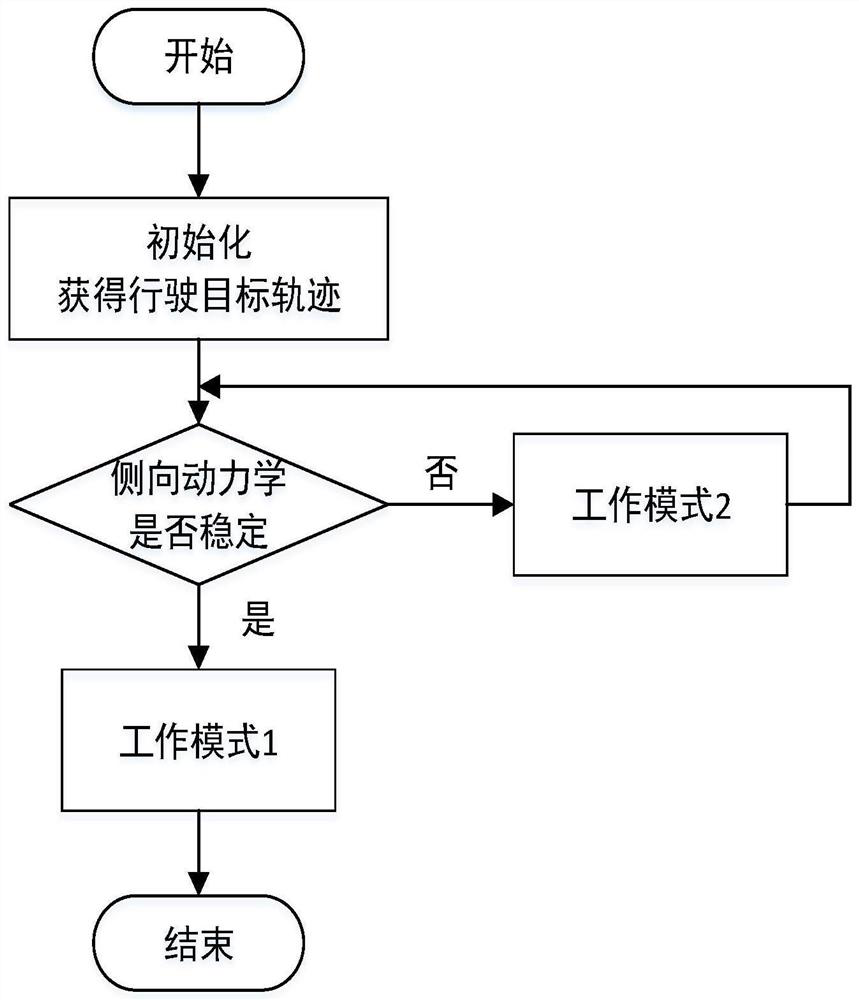

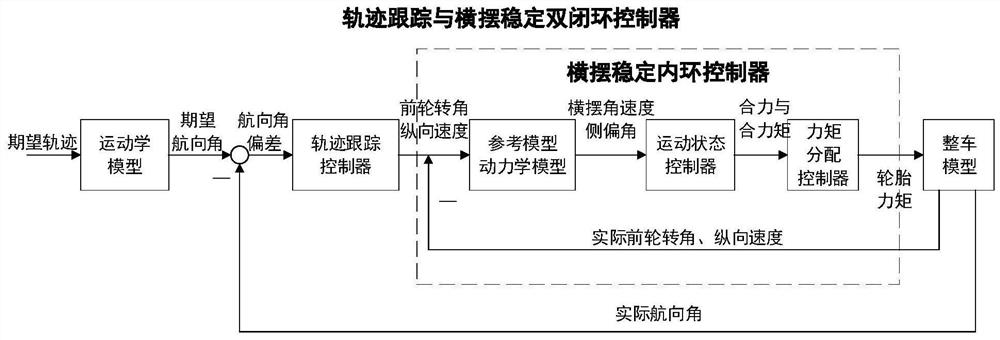

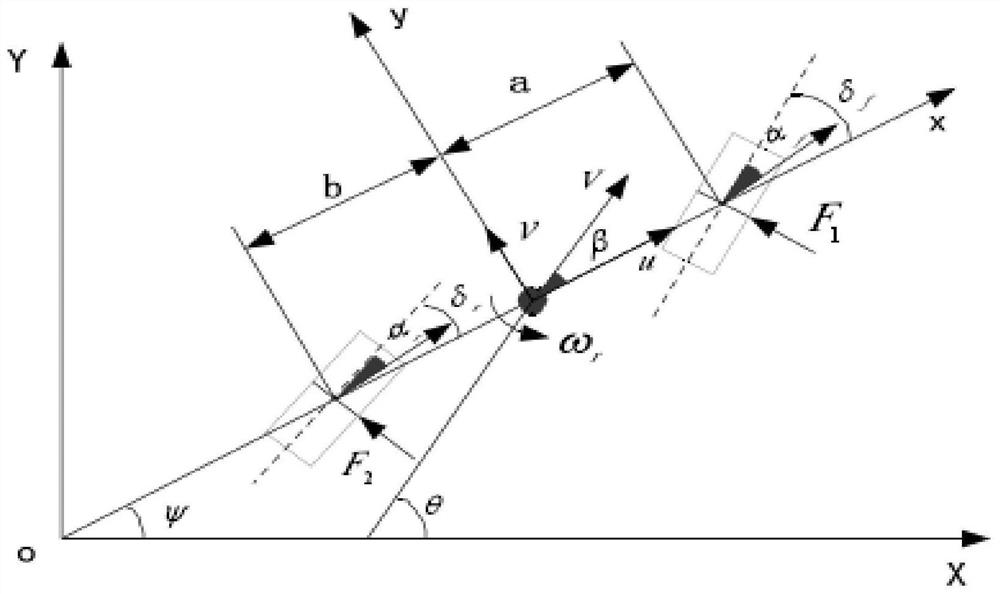

Intelligent electric vehicle trajectory tracking and motion control method

ActiveCN111890951AGuaranteed stabilityImprove stabilitySpeed controllerElectric energy managementVehicle dynamicsLoop control

The invention discloses an intelligent electric vehicle trajectory tracking and motion control method which comprises the following steps: judging whether a vehicle can work in a lateral stable rangeor not according to a given target trajectory and a current road condition; if the vehicle works in the stable area, executing the step 2; if the lateral stability range is exceeded, executing the step 3; 2, executing a working mode 1, and performing vehicle trajectory tracking and stability control by adopting vehicle trajectory tracking and yawing stability double closed-loop control: calculating an expected course angle of a vehicle according to an expected driving trajectory and a vehicle kinematics model; establishing a three-degree-of-freedom vehicle dynamic model, designing a trajectorytracking controller, inputting the difference between the expected course angle of the vehicle and the course angle of the previous moment into the trajectory tracking controller, and solving to obtain a front wheel rotation angle and a longitudinal speed; designing a yaw stability controller by adopting a model predictive control algorithm and then carrying out moment distribution; and 3, executing a working mode 2, and carrying out drifting control on vehicle trajectory tracking.

Owner:JILIN UNIV

Production method of recycled aggregates of building wastes

InactiveCN104671685ASolve the stacking areaSolve environmental pollutionSolid waste managementRoad engineeringPrimary screening

The invention discloses a production method of recycled aggregates of building wastes. The method comprises the following steps: (a) pre-screening; (b) impurity removal; (c) primary crushing; (d) primary screening; (e) secondary crushing; (f) secondary screening; (g) material division; (h) mixing of the recycled aggregates; (I) homogenization and entrance into warehouse. According to the production method of the recycled aggregates of the building wastes, based on a series of treatment processes, the building wastes are manufactured into engineering dinas (also named as aggregates), so that the problems of land occupation and environment pollution caused by stacking the building wastes are solved, a large quantity of dinas for building engineering can also be provided, and the method is energy-saving and environmentally friendly; meanwhile, the problems of energy sources and environment caused in a manual dinas exploitation process also can be solved. The recycled aggregates produced by using the production method is stable in performance, and can be widely applied to construction of various kinds of building engineering and road engineering.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

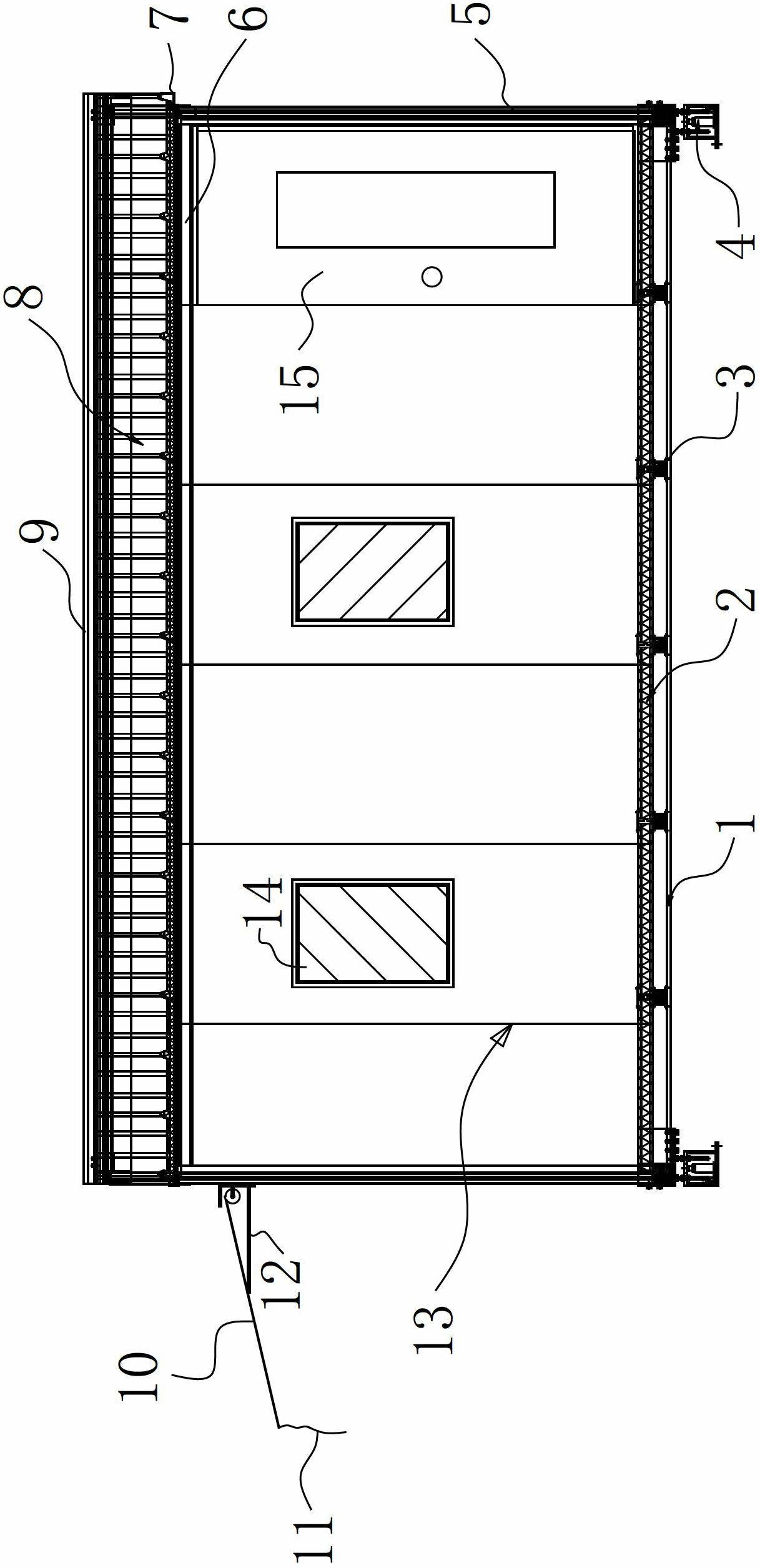

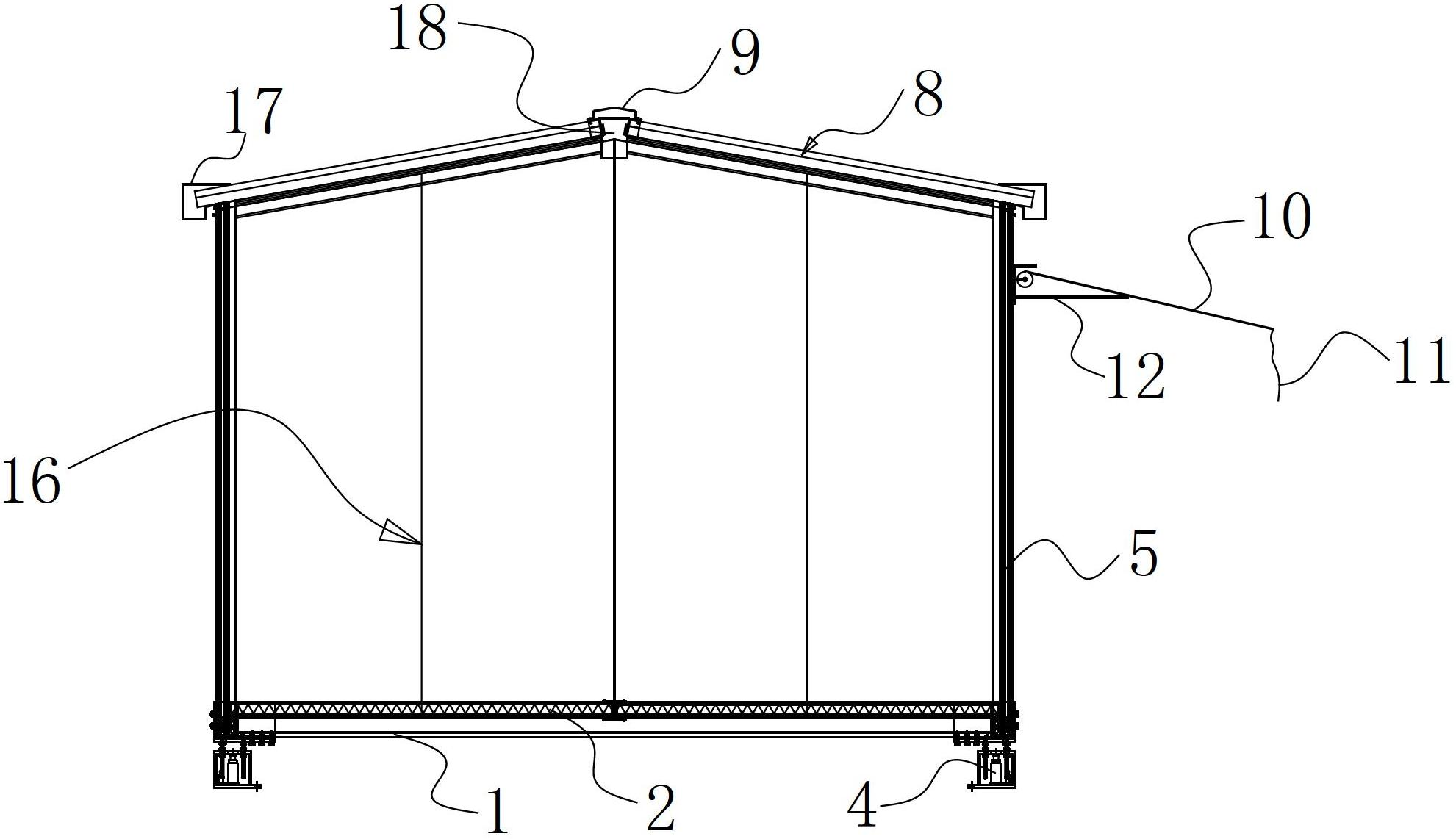

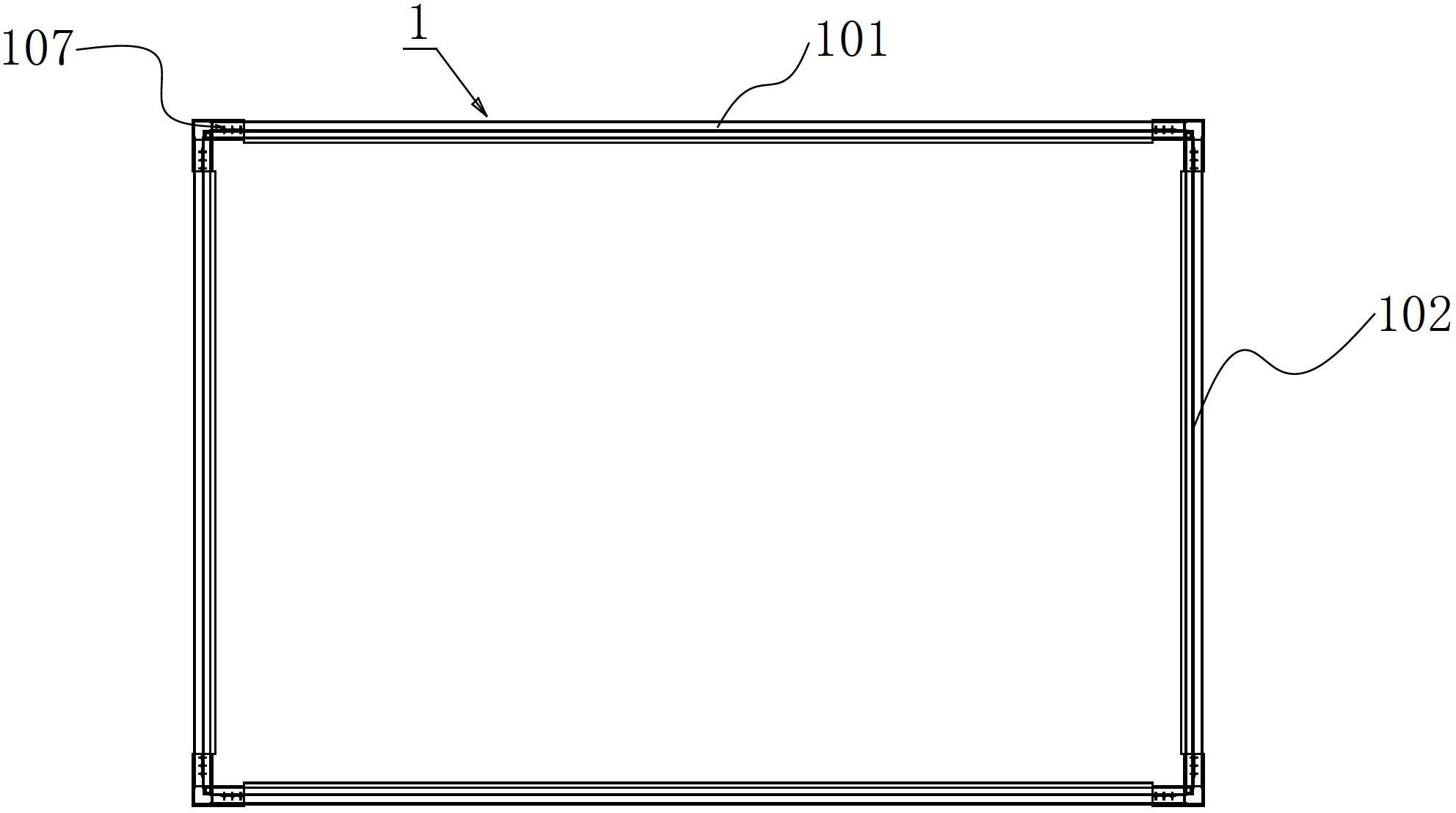

Modular integrated house

InactiveCN102691352AAvoid environmental problemsAvoid noise pollutionBuilding constructionsModularityBuilding construction

The invention discloses an industrialized, large-scale and factorized modular integrated house, which has the advantages of quick construction, firmness, durability, wind resistance, shock absorption, convenience in secondary disassembly and assembly and the like, is beneficial to warehousing and transportation, is not required to be installed by professionals and realizes industrialized and large-scale production and free house combination. The modular integrated house comprises ground beams which form a frame-type structure through connecting profiles; a plurality of floor units are detachably connected into a whole, and the integral edge of the floor units is lapped on a floor on the upper part of the inner side of the frame-type structure of the ground beams; a plurality of wall panels are detachably connected into transverse and longitudinal wall panels, an upright post is fixedly arranged on each corner of the ground beams, the lateral surfaces and the bottoms of the transverse and longitudinal wall panels are correspondingly detachably arranged on the upright posts and the ground beams to form an integral wall of the integrated house, and doors and windows are formed on the wall panels; and transverse and longitudinal collecting edges arranged on the tops of the wall panels and a ridge are positioned on the roof of the integrated house to form a roof slab.

Owner:CHONGQING QICHI TECH

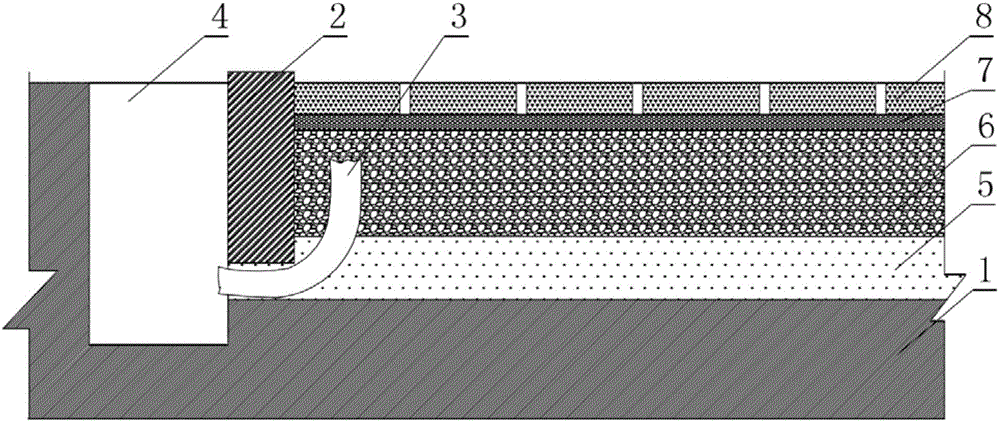

Construction method for water-permeable and water-retaining water-permeable pavement structure

InactiveCN104878678AResolve disposal issuesSolve energy problemsPaving gutters/kerbsRoads maintainenceSurface layerRoad surface

The invention discloses a construction method for a water-permeable and water-retaining water-permeable pavement structure. The method comprises the steps of carrying out roadbed excavation, carrying out cushion laying, carrying out base course laying, carrying out leveling layer laying, carrying out surface layer laying and carrying out joint sand laying. According to the method, the process is simple, and the water-permeable pavement structure with high water permeability and high water retention is obtained through processing construction waste into recycled aggregate and constructing, so that the problem of construction waste disposal is solved, a great deal of building materials can be provided, meanwhile, energy problem, environmental problem and social problem resulting from the exploitation of natural stone resources are avoided, and thus the method is a multipurpose measure; particularly, the water-permeable pavement structure plays an important role in adjusting the humiture of urban ground surface due to high water permeability and high water retention.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

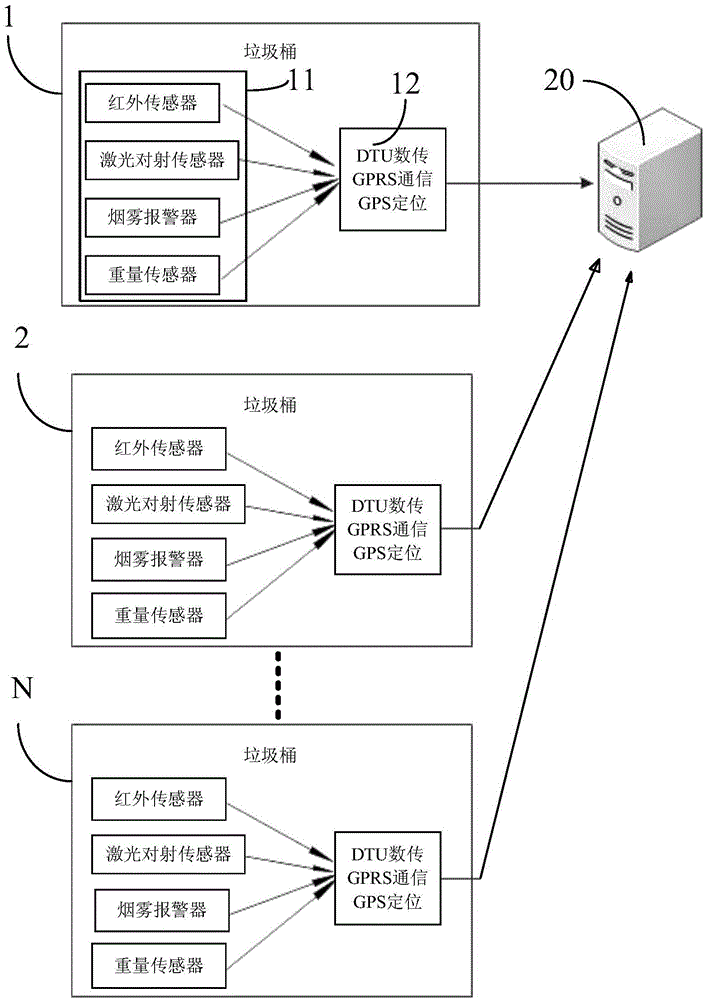

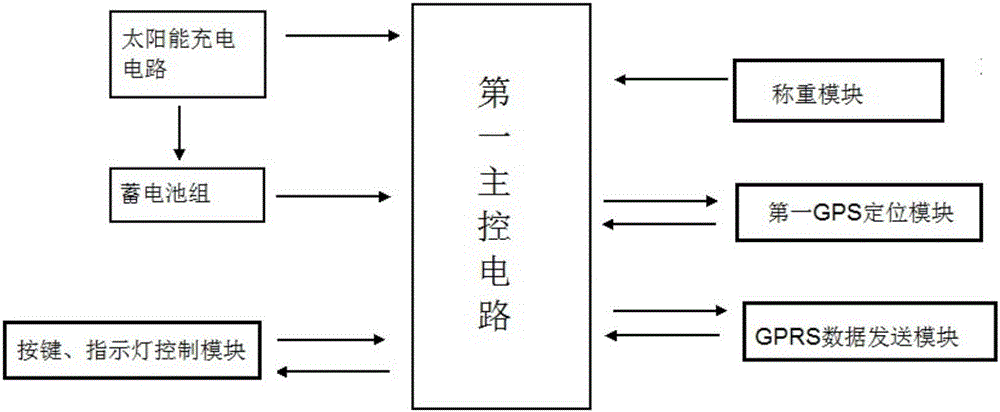

Internet of Things management system for district intelligent dustbins

InactiveCN105046403ATimely processingAvoid the problem of poor environment in the communityResourcesTransmissionComputer moduleManagement system

The invention discloses an Internet of Things (IOT) management system for district intelligent dustbins. The IOT management system comprises at least one dustbin and a management server. Each dustbin is provided with a sensor assembly and an information receiving transmission module. The sensor assembly is in communication connection with the information receiving transmission module and may acquire dustbin state information and sends the dustbin state information via the information receiving transmission module. The management server is provided with an information receiving module. The information receiving module is in communication connection with the information receiving transmission module of each dustbin, receives the dustbin state information sent by the information receiving transmission module of each dustbin, and gives prompt information about the real-time state of each dustbin according to the dustbin state information. The IOT management system may timely transmit the real-time states of the dustbins to the management server in order that a district property management worker timely and reasonably sends for a transfer station worker to clear the garbage, thereby achieving a purpose of saving environmental sanitation management cost to the utmost extent.

Owner:启迪城市环境服务集团有限公司

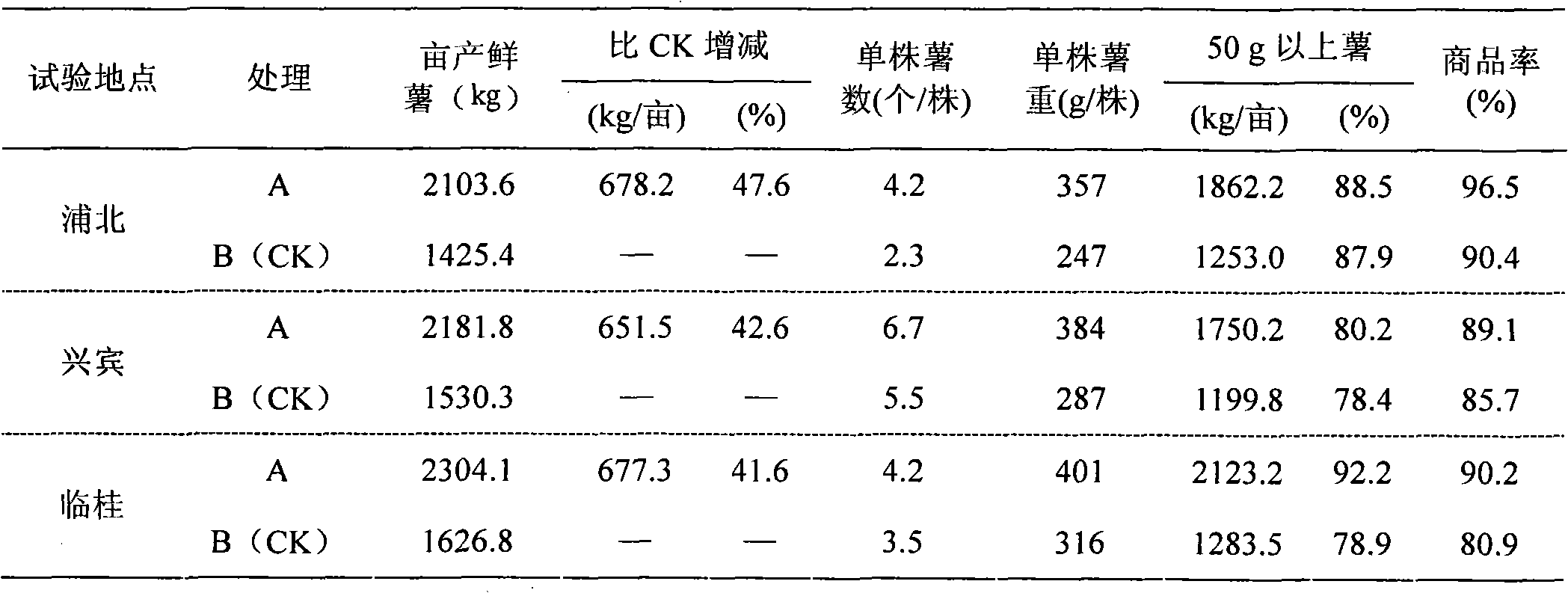

Planting method for improving production environment of potatoes

InactiveCN102150526AHighlight substantive featuresSignificant progressHorticultureEcological environmentPlastic mulch

The invention discloses a planting method for improving the production environment of potatoes, which comprises the following steps: regularly placing treated potato seeds on the surface of soil which is not ploughed or fallowed or slightly leveled, with the eyes of the seeds close to the soil downwards or sideways; applying high-quality thoroughly-decomposed farmyard manure or compound fertilizer beside the potato seeds, wherein the farmyard manure or fertilizer can not be in contact with the potato seeds; then covering 3-4 grass or thin soil layers on the surfaces of the potato seeds at intervals, or additionally covering one mulching film layer before covering the top layer; and then carrying out field management, and harvesting at the right time. By using the planting method, the production environment of potatoes can be improved, the yield and commodity rate can be increased, labor and time are saved, and the ecological environment is protected, thereby being beneficial to improving the soil structure and enhancing the soil productivity.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION AGRI TECH PROMOTION GENERAL STATION

Betel nut chewing gum and preparation method

The invention discloses betel nut chewing gum and a preparation method. The preparation method utilizes betel nut biotin and a chewing gum base as main raw material and also may utilize a proper amount of auxiliary ingredients according to demands. The preparation method comprises the following steps of sorting fresh betel nuts, carrying out cleaning, carrying out fragmentation, adding water into the fragmented betel nuts, adding 0.1-1% of cellulase into the mixture for biological pyrolysis, adjusting a pH value to 2-7, carrying out standing for 0.5-4h, carrying out plate filtration to obtain extract, carrying out high-speed centrifugation at a rate of 3000-20000rmin to obtain a solution, carrying out vacuum continuous dehydration on the solution at a temperature below 60 DEG C to obtain solids, crushing the solids into powder of 30-120 meshes, carrying out examination to obtain a powdery betel nut biotin, and adding the powdery betel nut biotin into the chewing gum base to obtain the betel nut chewing gum. The betel nut chewing gum retains active components of fresh betel nut, has a fresh betel nut chewing taste, causes a transitory intoxication feel and skin fever and redness, and avoids mucous membrane damage and environment problem caused by betel nuts.

Owner:许启太

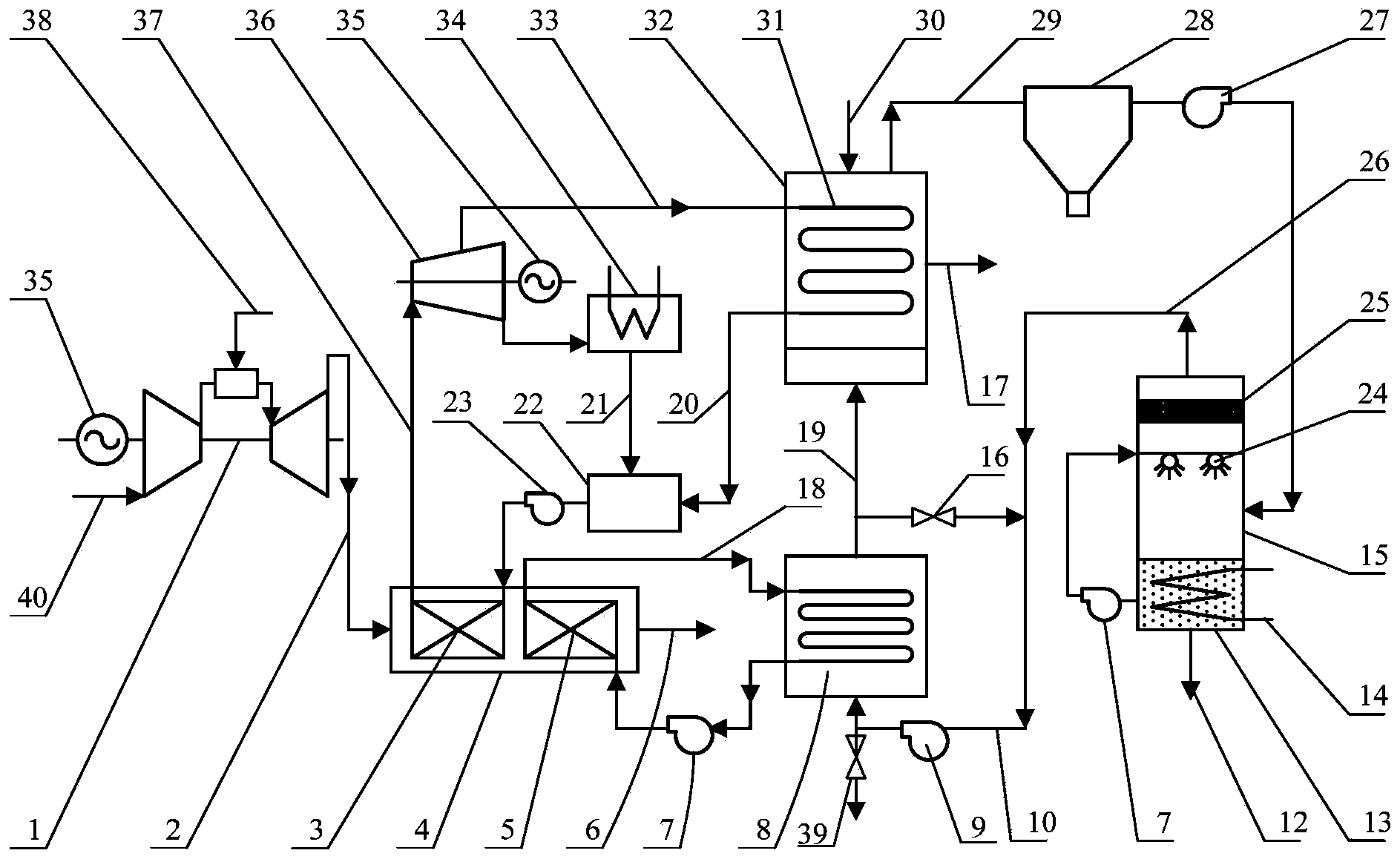

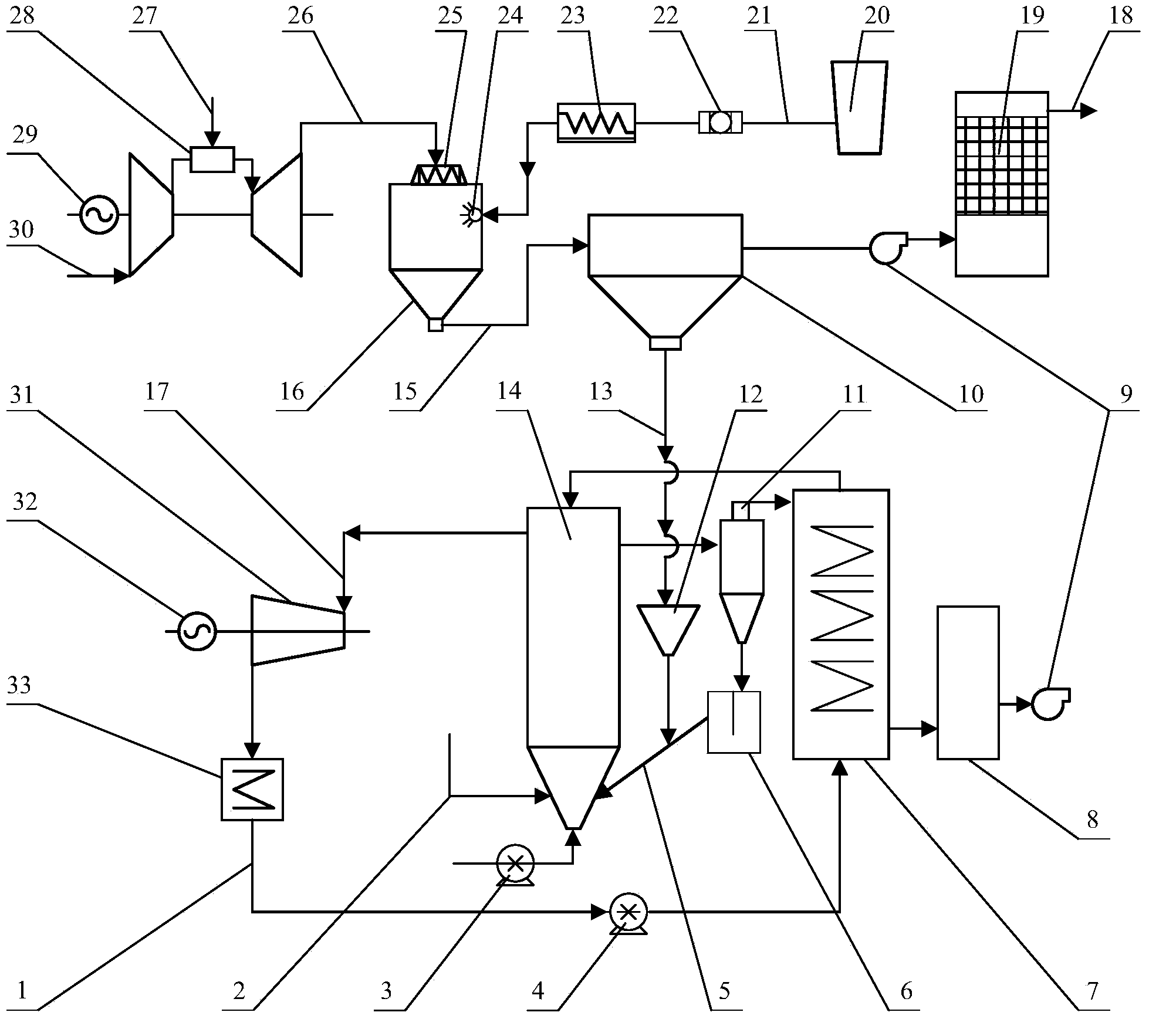

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

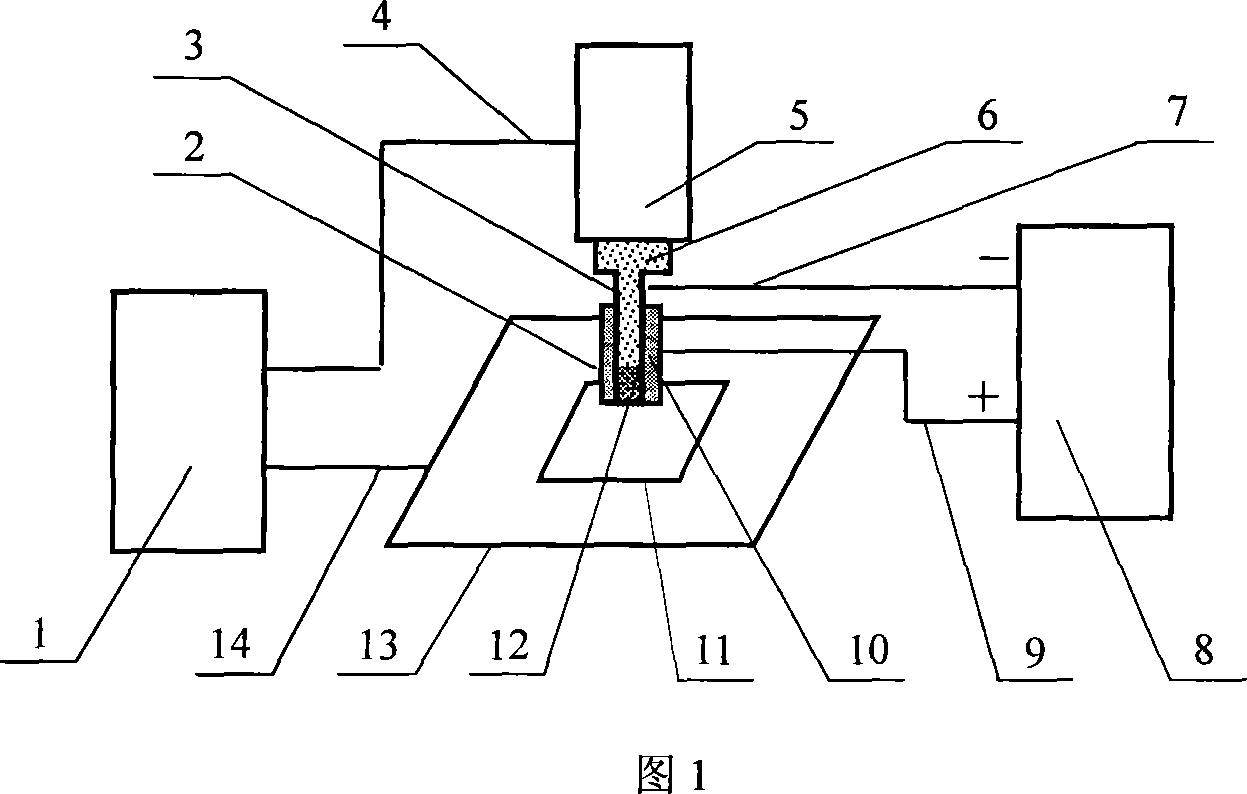

Non-conducting material electric spark milling method

ActiveCN101185983ARealize the processing effectSmall macro forceElectrical-based machining electrodesElectricityConductive materials

The invention relates to an EDM milling method used for nonconductive materials, belonging to a mechanical machining field. When machining, a tool anode and a tool cathode are respectively connected with the anode and the cathode of an impulse powder supply. The tool anode and the tool cathode are provided with tubular structures and are arranged on the same shaft, and are separated by an insulation medium layer. A conductive liquid flows from the central hole of internal tool electrodes to the surface of the nonconductive material, and triggers discharge when flowing through the ends of the tool anode and the tool cathode, and then the nonconductive material can be corrosion-removed and machined by effects of high temperatures and high voltages generated by the discharge instantaneously. A main shaft head can drive the tool anode and the tool cathode to revolve and do a Z-direction movement. A nonconductive material work piece to be machined is arranged on X and Y movable work tables, and an EDM milling to the nonconductive material work piece with a complicated shape is realized by a linkage between the main shaft head and the work tables. The EDM milling method used for nonconductive materials of the invention has the advantages that machining efficiency is high, surface quality is high and the environment is not polluted, etc.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

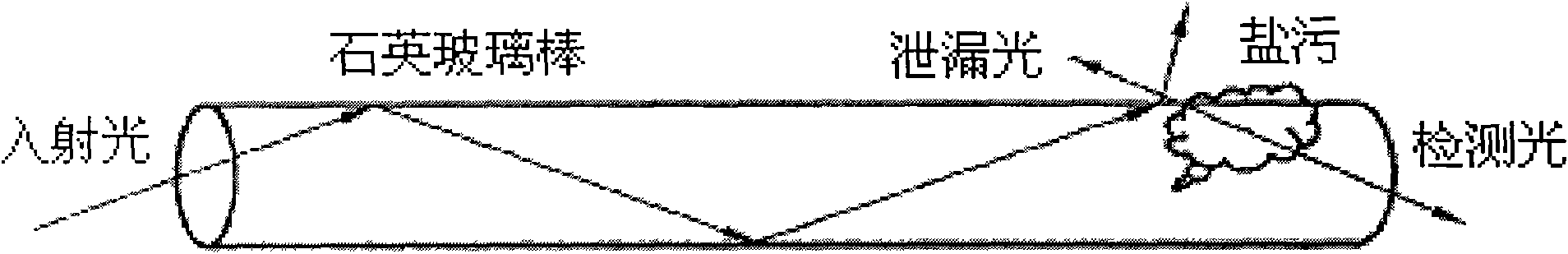

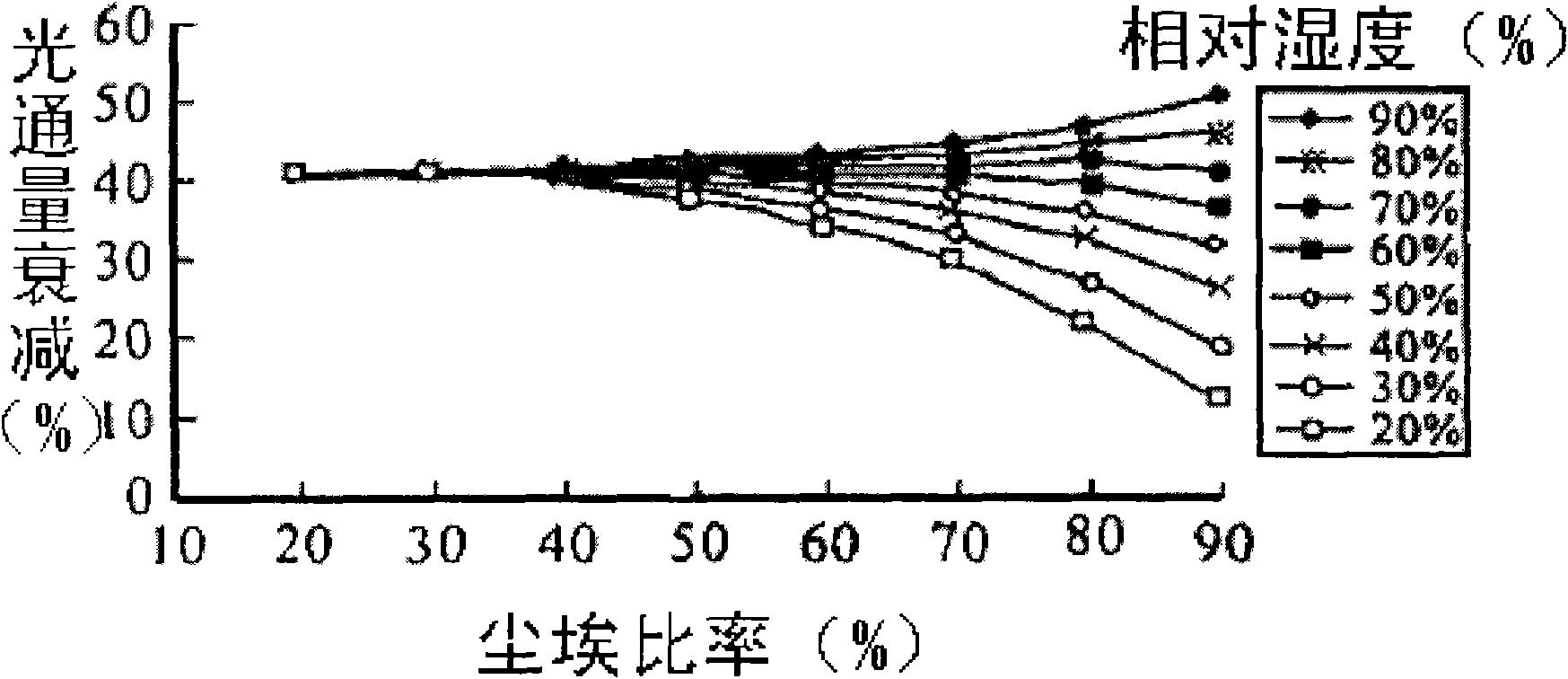

Insulator equivalent salt density optical fiber test method based on particle swarm support vector machine

InactiveCN101655456ASave manpower and material resourcesReduce pollution flashover accidentsTransmissivity measurementsNonlinear regressionComputational physics

The invention discloses a high voltage insulator equivalent salt density optical fiber test method based on a particle swarm support vector machine. In the method, firstly luminous flux attenuation and relative humidity are tested to be transmitted to a supervisory computer in a manner of wireless communication; then the luminous flux attenuation is subject to normalization pretreatment; referringto a standard relation curve graph of dust ratio with the luminous flux attenuation and the relative humidity, corresponding dust ratio is searched; and the particle swarm support vector machine is used for establishing a nonlinearity regression model among an insulator equivalent salt density value, the luminous flux attenuation, the relative humidity, and the dust ratio to obtain the insulatorequivalent salt density value. The high voltage insulator equivalent salt density optical fiber test method based on the particle swarm support vector machine in the invention realizes on-line test ofinsulator salt density with high precision, is suitable for various voltage levels, avoids the defects of the traditional salt density measurement such as time consuming, effort consuming and poor measurement effect, and improves reliability of power supply system.

Owner:XIAN UNIV OF TECH

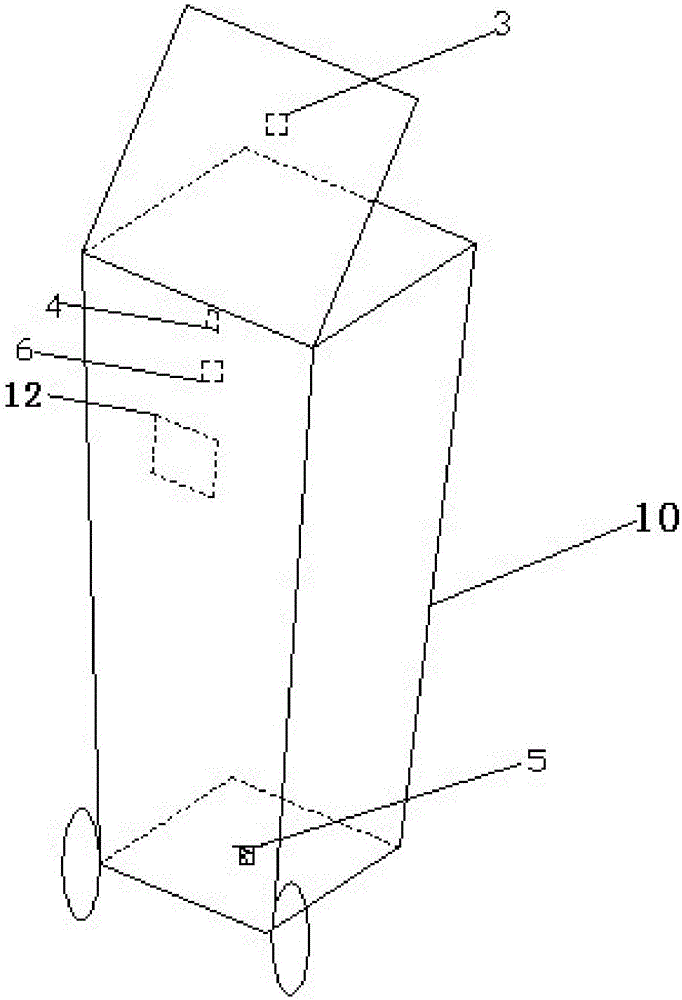

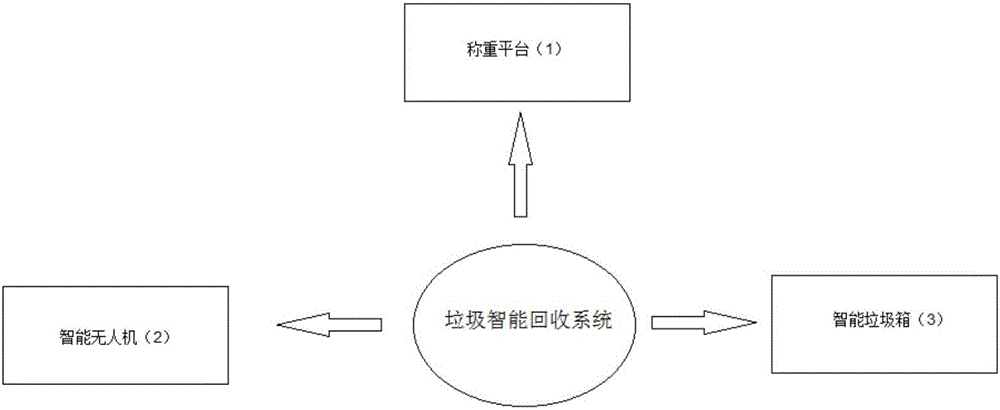

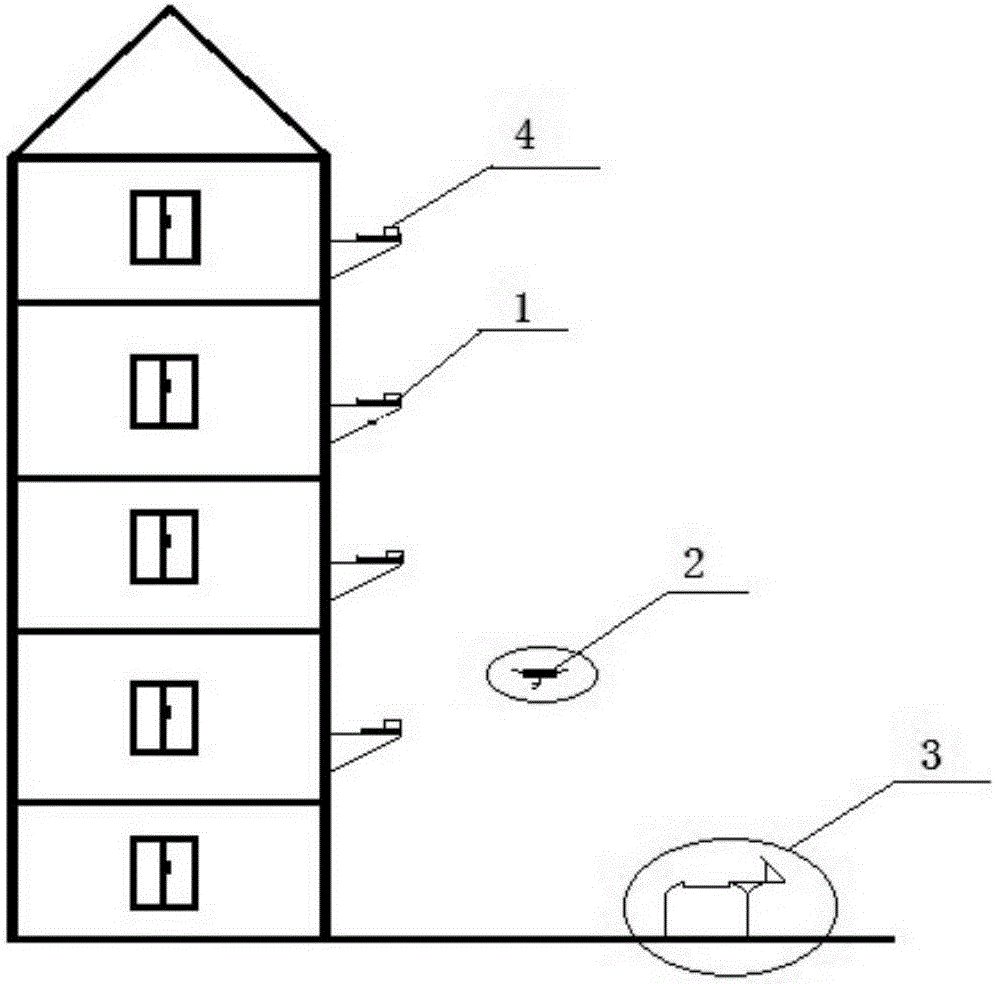

Intelligent community rubbish recovery system based on unmanned aerial vehicle and working method of intelligent community rubbish recovery system

ActiveCN106081426AEnvironmental AwarenessHigh precisionRefuse receptaclesRefuse cleaningRemote controlUncrewed vehicle

The invention discloses an intelligent community rubbish recovery system based on an unmanned aerial vehicle. The system comprises a weighing platform used for rubbish weighing, an intelligent unmanned aerial vehicle used for rubbish recovery, an intelligent rubbish can and a remote control device, wherein the intelligent rubbish weighing platform, the intelligent rubbish recovery unmanned aerial vehicle and the intelligent rubbish can are all connected through a wireless network to form the intelligent rubbish recovery system and are connected with the remote control device. The intelligent rubbish weighing platform is set by the aid of a user terminal, cooperates with the unmanned aerial vehicle and the intelligent rubbish can and cooperates with an altitude height sensor through a GPS positioning module, the intelligent community rubbish recovery system realizes route planning independently, rubbish from the user terminal is conveyed into the intelligent rubbish can through a manipulator, the rubbish treatment problem in a community is well solved, rubbish treatment is intelligent, the interest of a user in rubbish treatment is improved, and the environment-friendly awareness of the user is improved.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

Integrated system and method for generating electricity employing drying and burning of sludge

InactiveCN103539332ASolve the emission problemImprove thermal efficiencyFluidized bed combustionSludge treatment by de-watering/drying/thickeningSludgeNitric oxide

The invention provides an integrated system and method for generating electricity employing drying and burning of sludge. A gas turbine is connected with a generator; a smoke outlet of the gas turbine is communicated with a sludge drying device; an outlet of the sludge drying device is connected with a gas-solid separating device; a dry sludge outlet of the gas-solid separating device is communicated with a hopper; the hopper is communicated with a feed pipe of a fluidized bed boiler; the smoke outlet of the fluidized bed boiler is communicated with a separator; a solid outlet of the separator is communicated with a feeding hole of the fluidized bed boiler through a return feeder; smoke afterheat of the gas turbine is utilized as a heat source for drying the sludge; gradient utilization of an energy source and high thermal efficiency are achieved; the problem of emission of sulfur dioxide, nitric oxide, dust and the like generated by burning fire coal to dry the sludge is avoided; the problem of polluting underground water and the environment caused by sludge landfill and soil utilization is effectively avoided; the moisture content of the dried sludge is greatly reduced; stable combustion can be achieved inside the fluidized bed boiler; auxiliary fuel does not need to be added; a highly toxic pollutant dioxin is avoided.

Owner:HANGZHOU LANZHENG ENVIRONMENTAL ENG

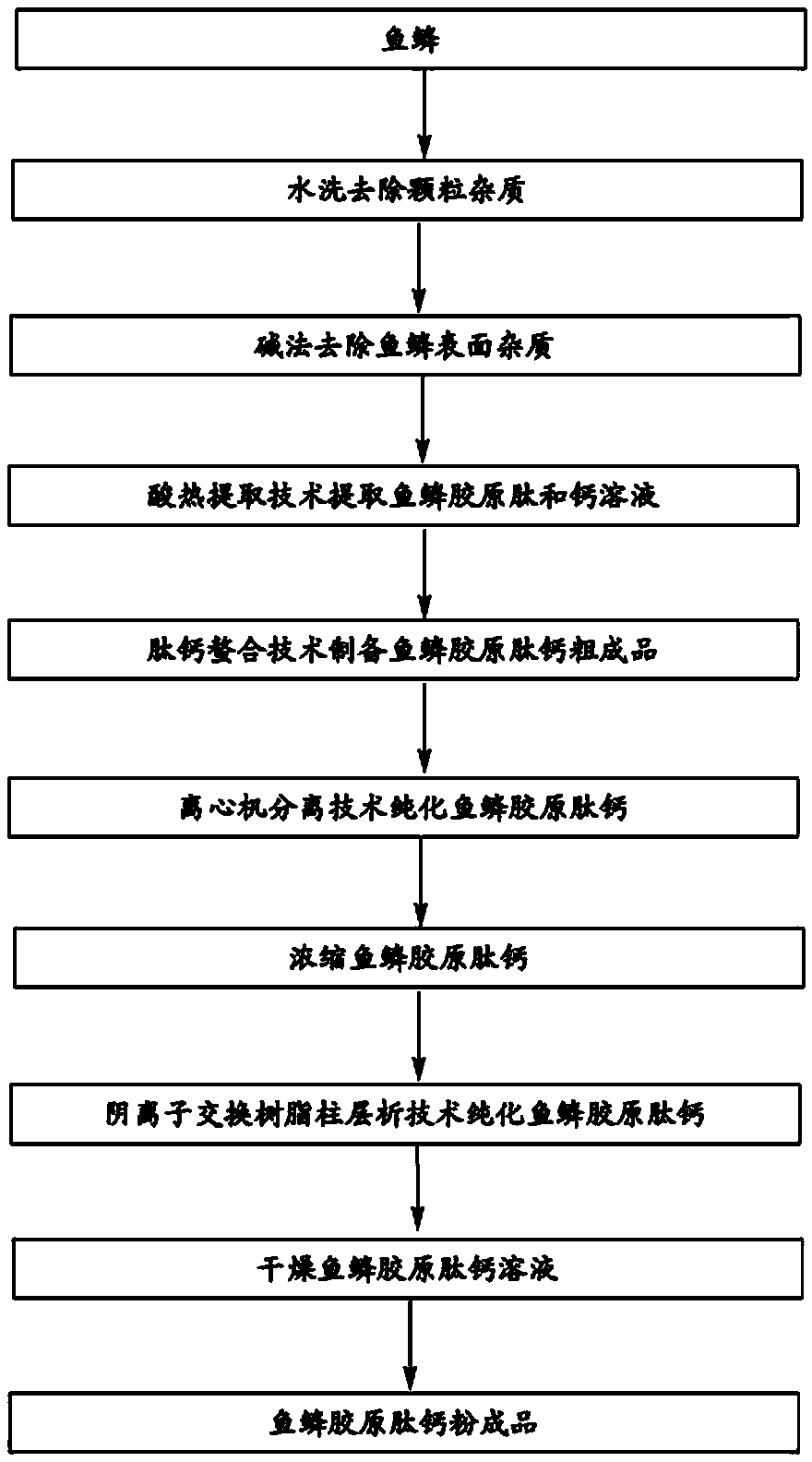

Production process for fish scale collagen peptide calcium

InactiveCN103462018AReduce manufacturing costImprove technical levelFood preparationPeptideColumn chromatography

The invention discloses a production process for fish scale collagen peptide calcium, and belongs to the technical field of biology. The production process comprises the following steps: (1) pretreating fish scale; (2) extracting fish scale collagen peptide and a calcium solution by an acid heat extraction technology; (3) preparing crude finished fish scale collagen peptide calcium by a peptide calcium chelating technology; (4) removing solid impurities by a centrifuge separation technology; (5) concentrating the fish scale collagen peptide calcium; (6) purifying the fish scale collagen peptide calcium by an anion exchange resin column chromatography technology to obtain a fish scale collagen peptide calcium solution; (7) drying the solution to obtain finished fish scale collagen peptide powder with the calcium content of greater than 1 percent and the protein content of greater than 85 percent. According to the process, fish scrap, namely fish scale, serves as a raw material; an exogenous calcium salt is not added; a separation and purification technology system integrated with the centrifuge separation technology and the anion exchange resin column chromatography technology is established, an organic solvent is not required to be used, the produced fish scale collagen peptide calcium product has high calcium content, high bioavailability and high safety; both the peptide and the calcium can be supplemented, so that the fish scale collagen peptide calcium has a great market prospect.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

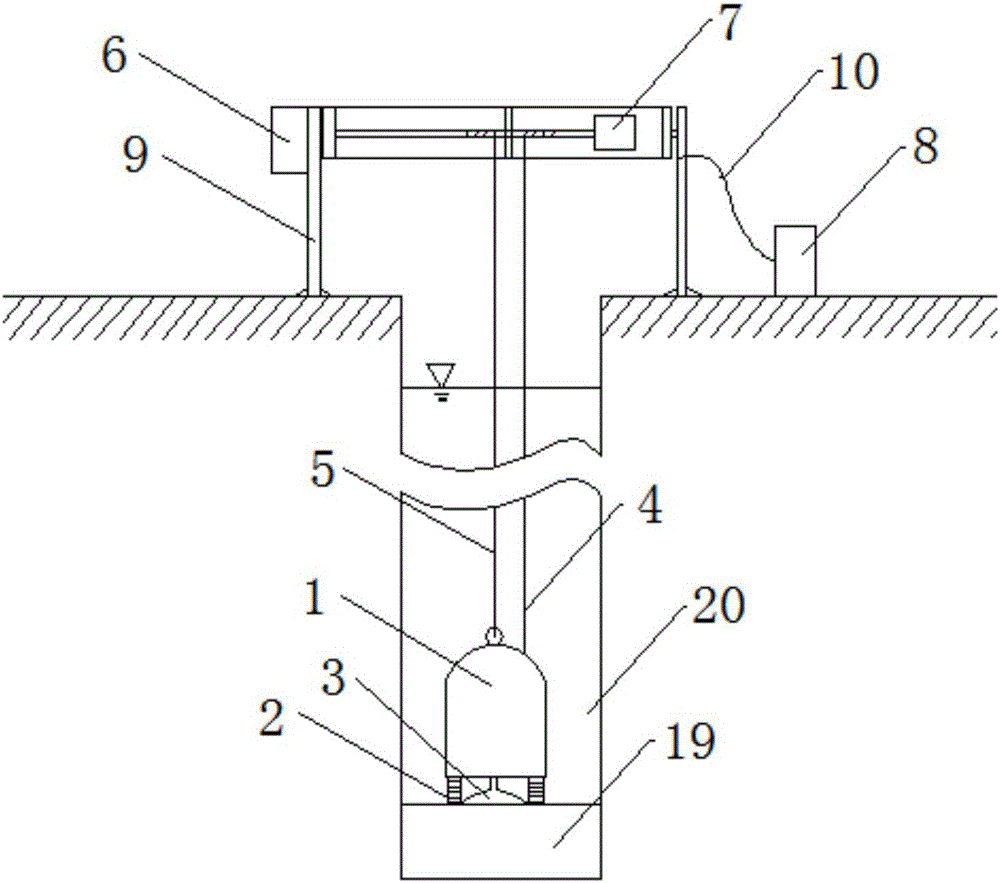

Sediment removal machine for removing sediment at bottom of pile and working method thereof

ActiveCN105821881AThorough slag removalAvoid the risk of hole collapseBulkheads/pilesSediment FilterDischarge return

The invention discloses a sediment removal machine for removing sediment at the bottom of a pile and a working method thereof. The sediment removal machine comprises a sediment removal device and a main controller for controlling work of the sediment removal device. The sediment removal device comprises an outer cover, a sediment suction tube for sucking the sediment is arranged in the outer cover, and the bottom end of the sediment suction tube extends out of the outer cover so that the sediment at the bottom of the pile can be sucked into the outer cover. At least one layer of sediment filter screen is arranged between the outer cover and the sediment suction tube. The positions where the sediment filter screens are located are lower than an outlet of the sediment suction tube. A water outlet is formed in the bottom surface of the outer cover so as to discharge return mud flowing down the sediment filter screens. A sediment amount sensor is arranged on the upper portion of the inner side face of the outer cover and connected with the main controller. Mud displacement does not exist, mud pouring is not needed, the automation degree is high, operability is high, the sediment removal efficiency and effect are improved, the hole collapse risk caused by mud displacement is avoided, and the problem that the environment is polluted because a large amount of mud is used is solved.

Owner:SHANDONG UNIV

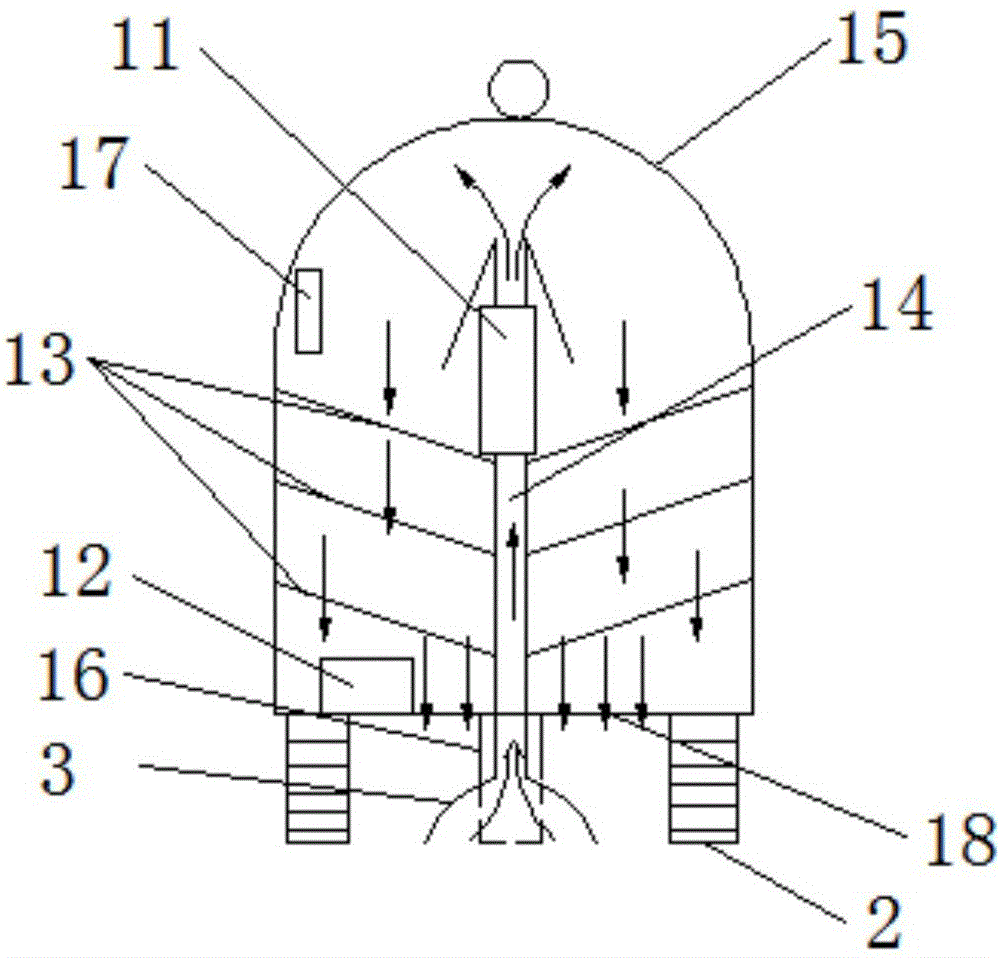

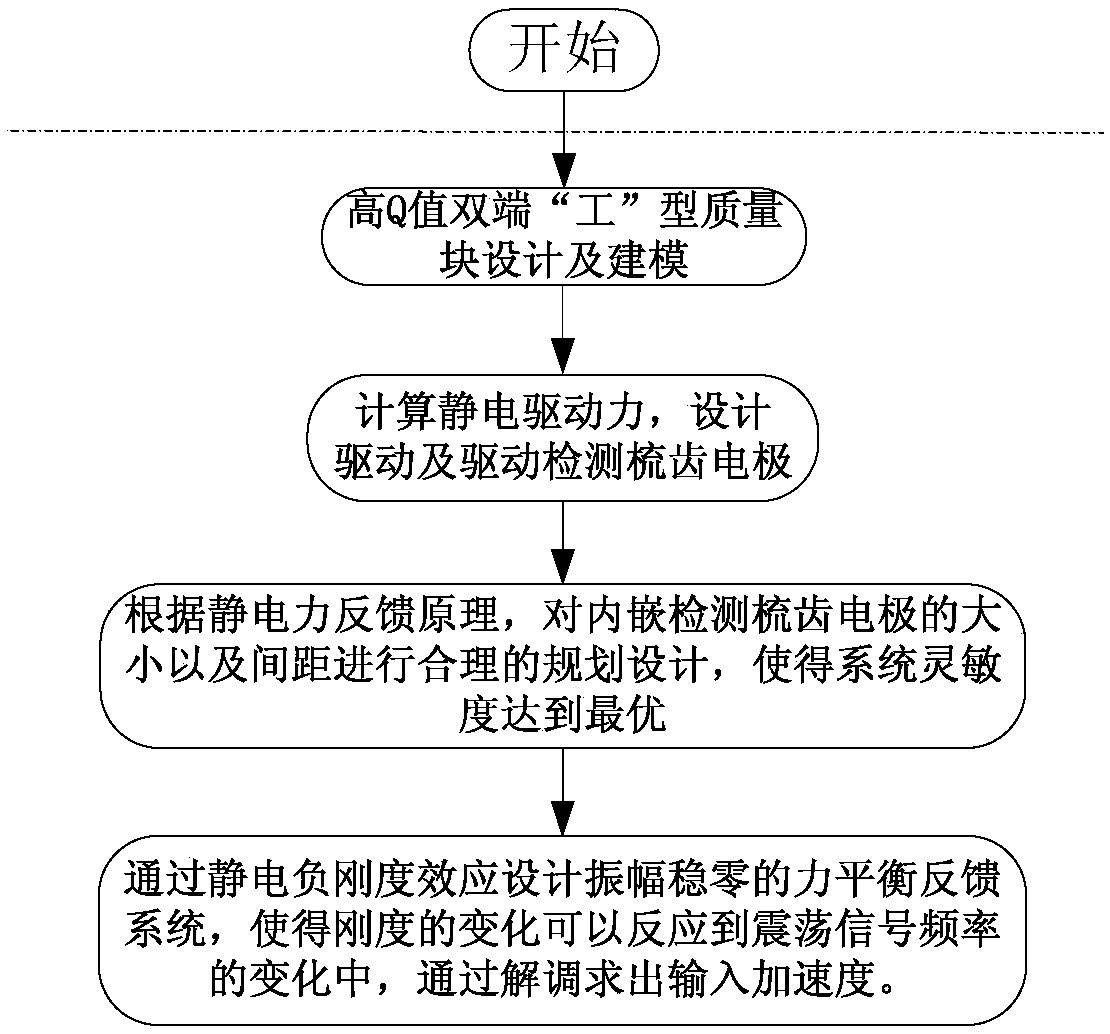

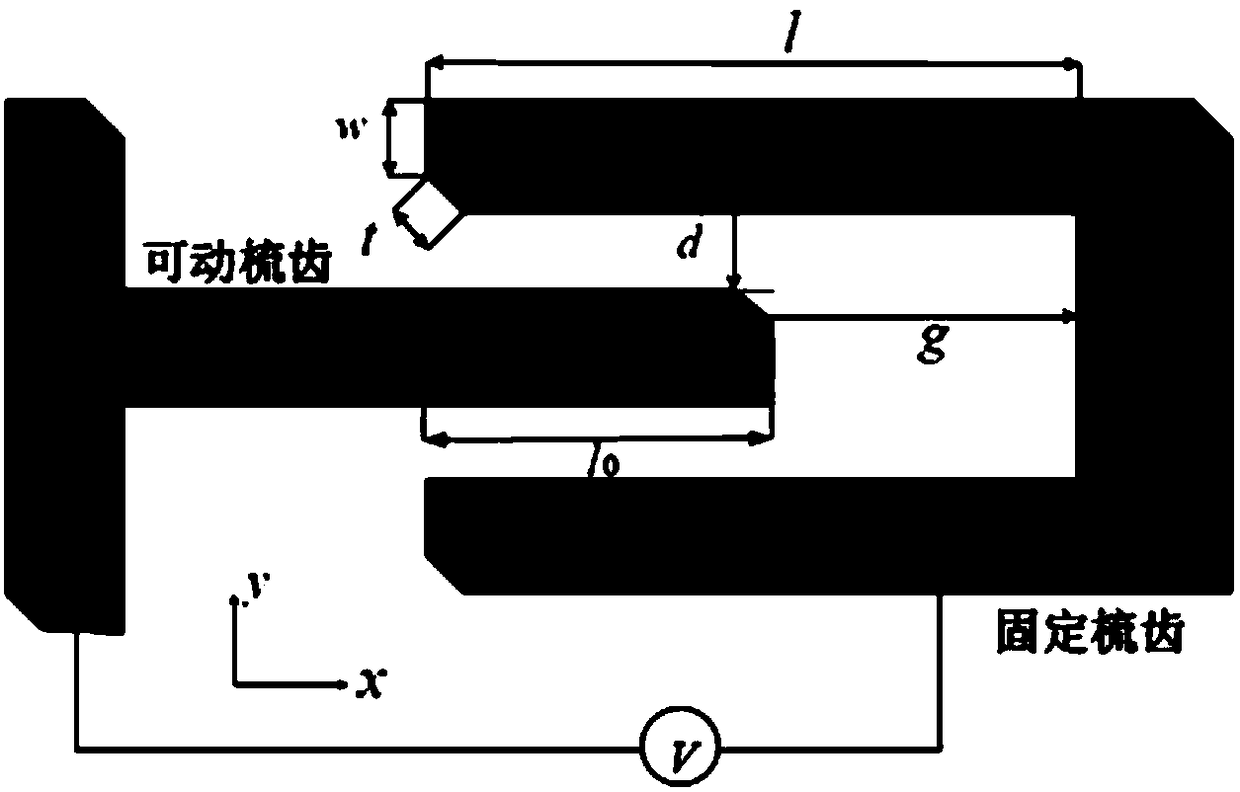

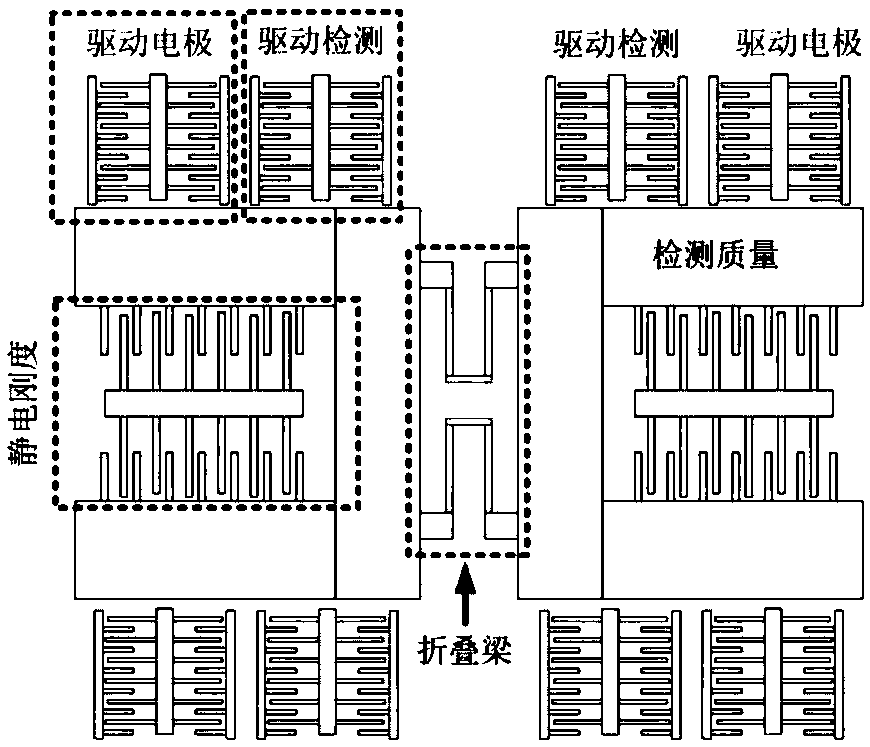

Design method of electrostatic negative stiffness accelerometer

ActiveCN109061226AAvoid temperatureAvoid environmental problemsAcceleration measurementSpecial data processing applicationsCapacitanceSymmetric design

The invention discloses a design method of an electrostatic negative stiffness accelerometer. The method is characterized by comprising the steps that S1, an interface electromechanical model of the electrostatic negative stiffness accelerometer is established, and the interface electromechanical model is converted into a coordinate system equation; S2, by calculating electrostatic force of a combtooth capacitor, the position length and symmetric design of a driver and driven detection comb teeth are determined; S3, according to the electrostatic force feedback principle, planning design is performed on the size and spacing of embedded detection comb tooth electrodes; and S4, according to the principle of the acceleration and electrostatic negative stiffness effect in the accelerometer based on electrostatic negative stiffness regulation, a relational expression influencing acceleration finally is obtained. The design method of the high-performance FM accelerometer based on electrostatic negative stiffness regulation is good in use effect and has quite high application and popularization value.

Owner:SUZHOU GST INFOMATION TECH CO LTD

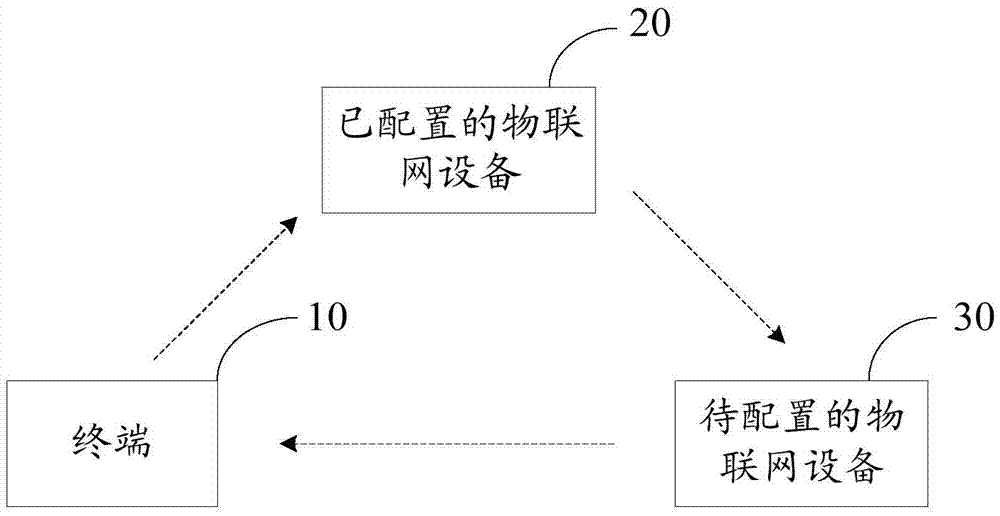

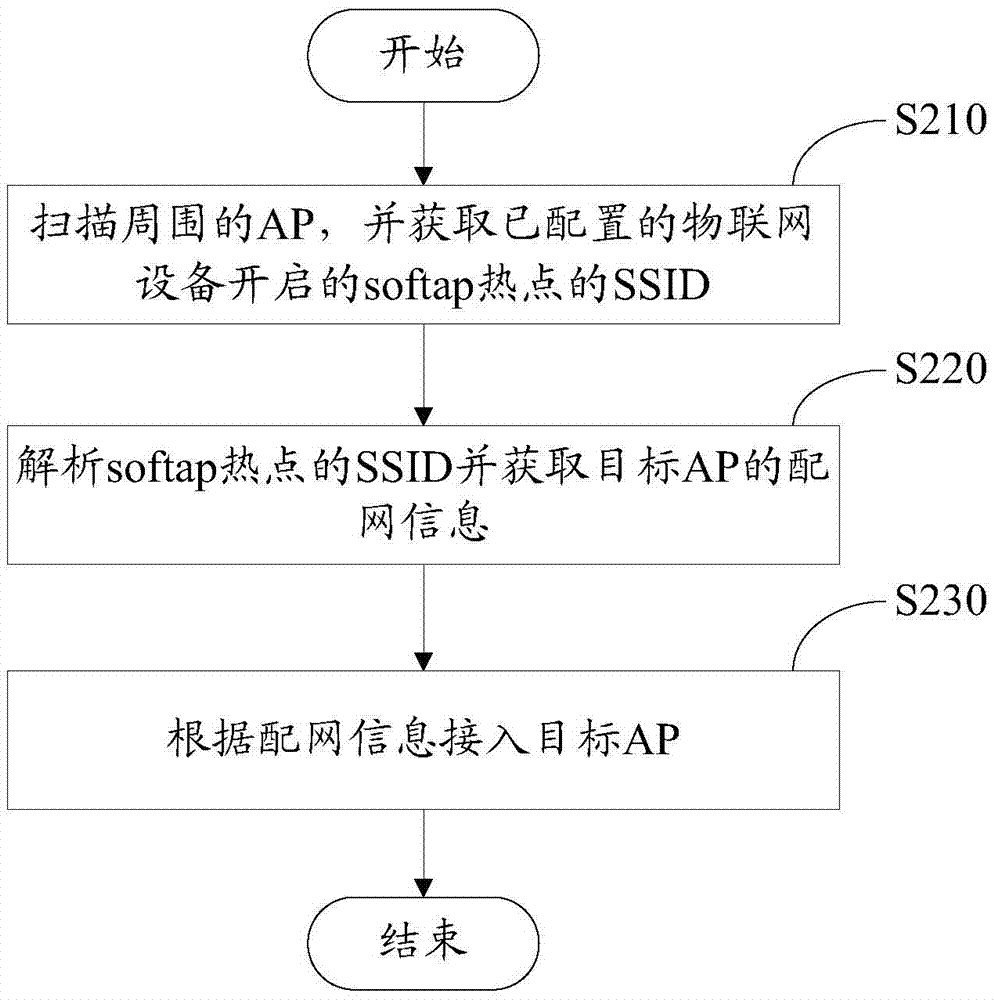

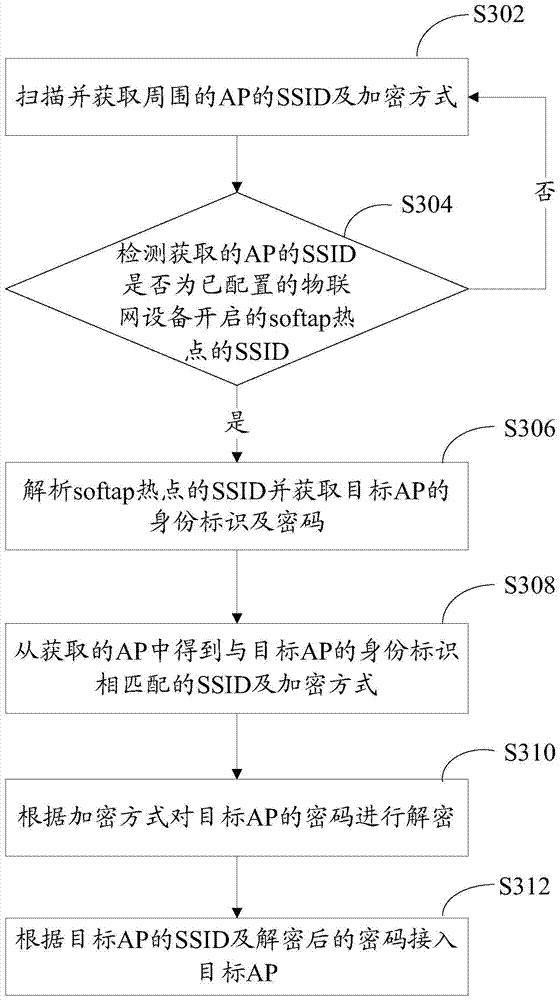

Internet-of-things device configuration method and Internet-of-things device configuration system

ActiveCN105451230AAvoid adverse effects caused by network accessImprove the success rate of distribution networkAssess restrictionSecurity arrangementComputer compatibilityEnvironmental factor

The invention relates to an Internet-of-things (IOT) device configuration method and an IOT device configuration system. The method comprises the following steps: scanning surrounding APs, and acquiring the SSID of a softap hotspot opened by a configured IOT device, wherein the configured IOT device opens the softap hotspot according to a message from a terminal; parsing the SSID of the softap hotspot and acquiring the network configuration information of a target AP; and accessing the target AP according to the network configuration information. By employing the IOT device configuration method and the IOT device configuration system, the adverse impacts of the compatibility of mobile terminals and routers and the environmental factors on IOT device networking can be avoided effectively, and the network configuration success rate of IOT devices can be improved.

Owner:深圳市白泽图腾科技有限公司

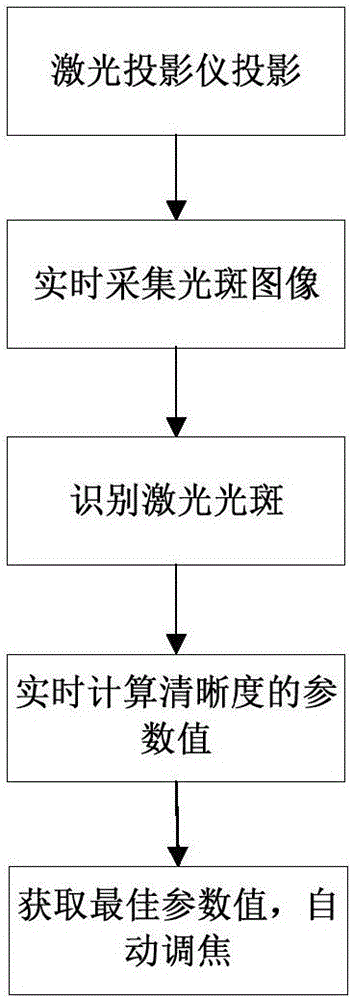

Method for recognizing laser light spots, method and system for automatic focusing of laser projector

The invention discloses a method and system for automatic focusing of a laser projector. The method includes S1, the laser projector projecting at least one light beam into space; S2, a collecting module collecting light spot images in real time; S3, a recognizing module recognizing the laser light spots according to second derivative of distribution of the light spot strength; S4, a computation module computing parameter values of definition of the light spot images; S5, a focusing module focusing relative relation of a light source constantly and repeating the step 1-4; S5, the focusing module comparing the parameter values acquired in real time to acquire the optimum parameter value, and focusing the light source to the optimum position according to the optimum parameter value. With the method and the system, automatic focusing of the laser projector can be realized, the problem of low precision brought by manual focusing in the prior art is solved, and meanwhile, focusing efficiency is greatly improved.

Owner:SHENZHEN ORBBEC CO LTD

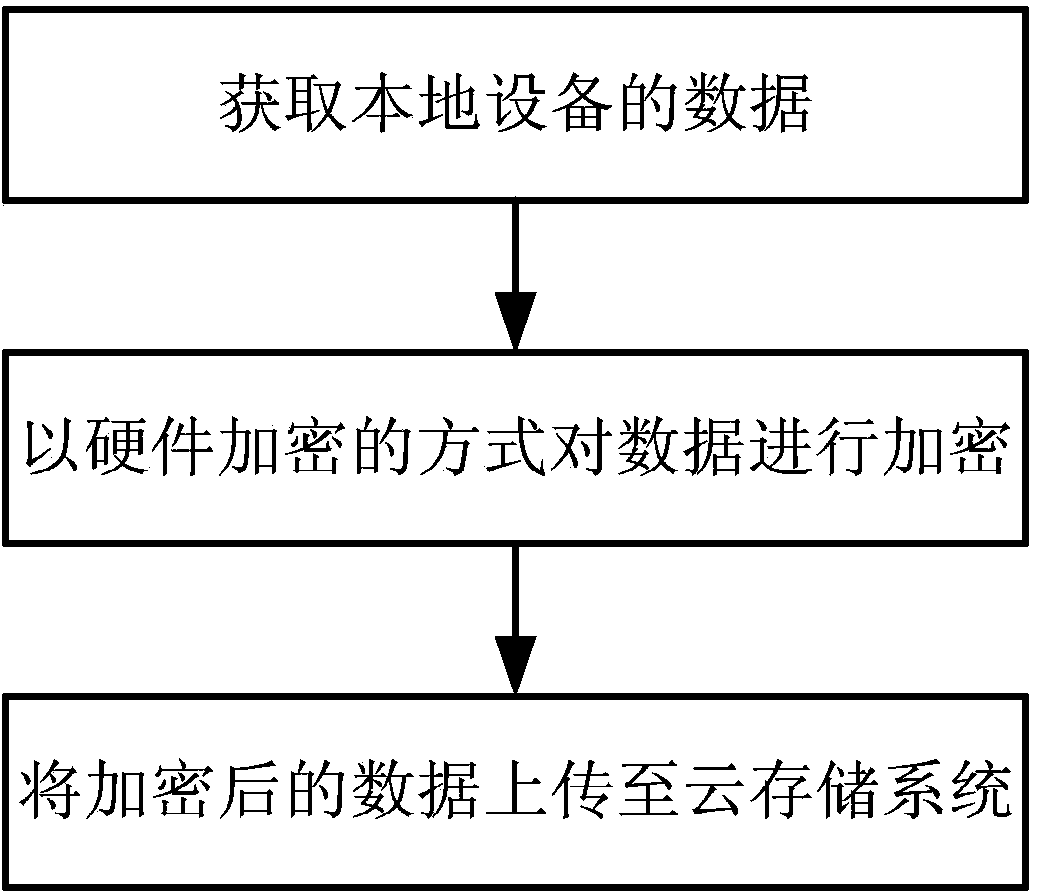

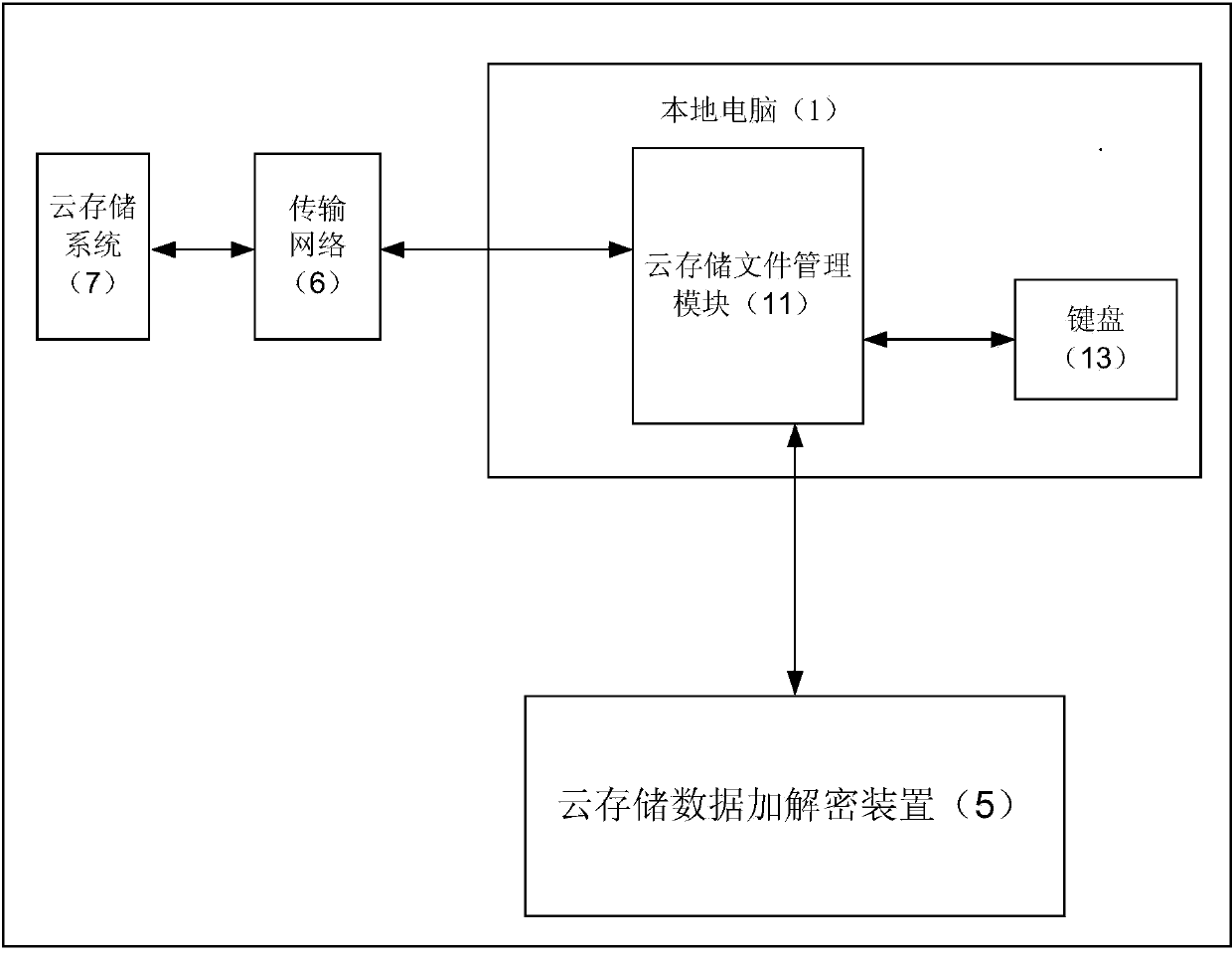

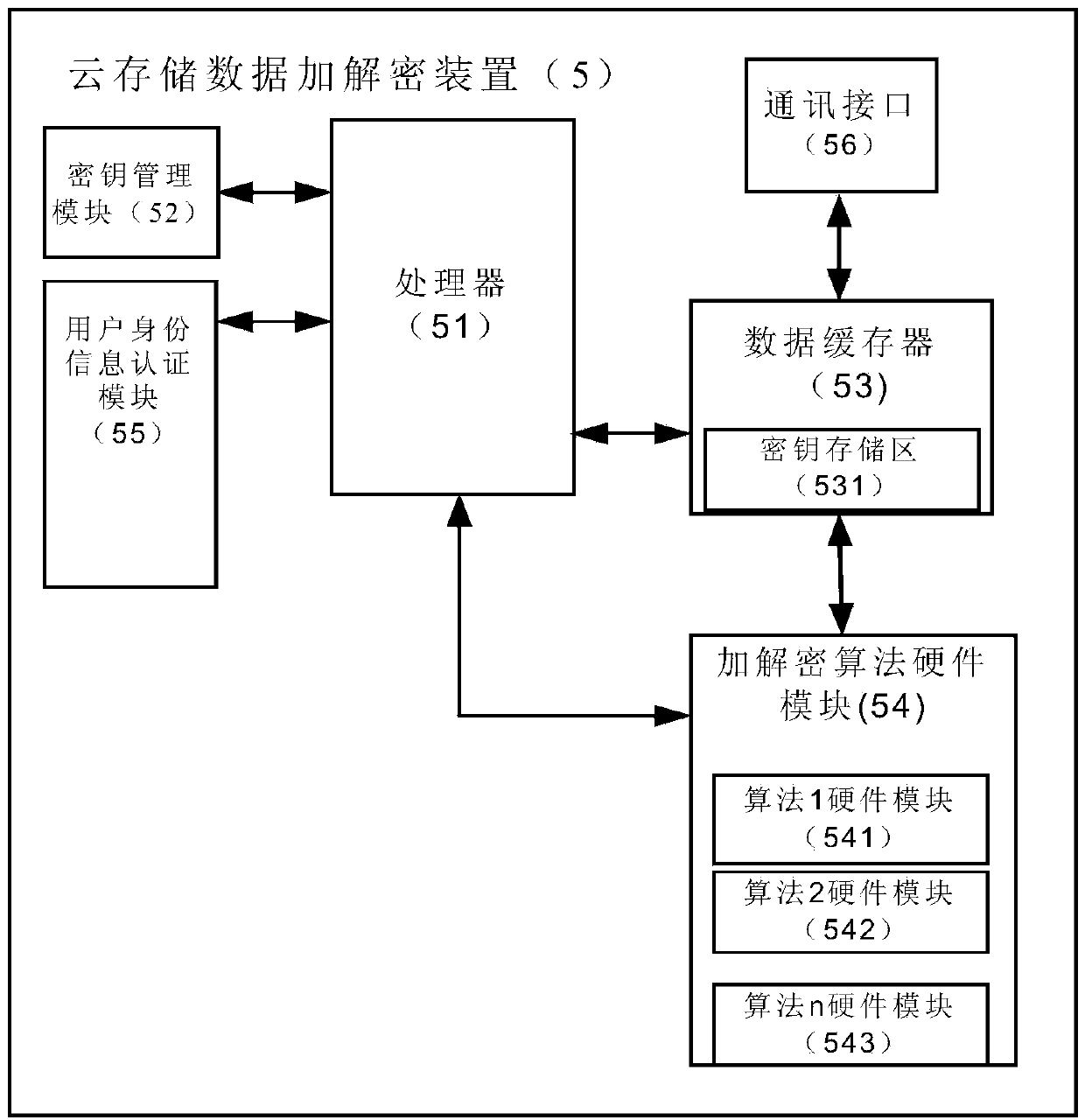

Security method of personal data in cloud storage

ActiveCN104219234AAvoid technical bottlenecks and complex application environmentsImprove securityTransmissionClient-sideData security

The invention provides a security method of personal data in cloud storage. The security method includes, in the process of uploading of local data, encrypting the data by means of hardware encryption and then uploading the same to a cloud storage system so as to keep the data stored in the cloud storage system encrypted; in the process of downloading the data to a local device from the cloud storage system, decrypting the data by means of hardware decryption and then storing the same to the local device. According to the technical scheme, encryption and decryption of client files in cloud disks are independent of network and cloud computing systems, all the operations of encryption and decryption are completed on the client side, technical bottleneck and complicated application environment to implementation of data security measures on the cloud side are avoided, and the security method has the advantages of high safety, reliability and usability and the like.

Owner:SAGE MICROELECTRONICS CORP

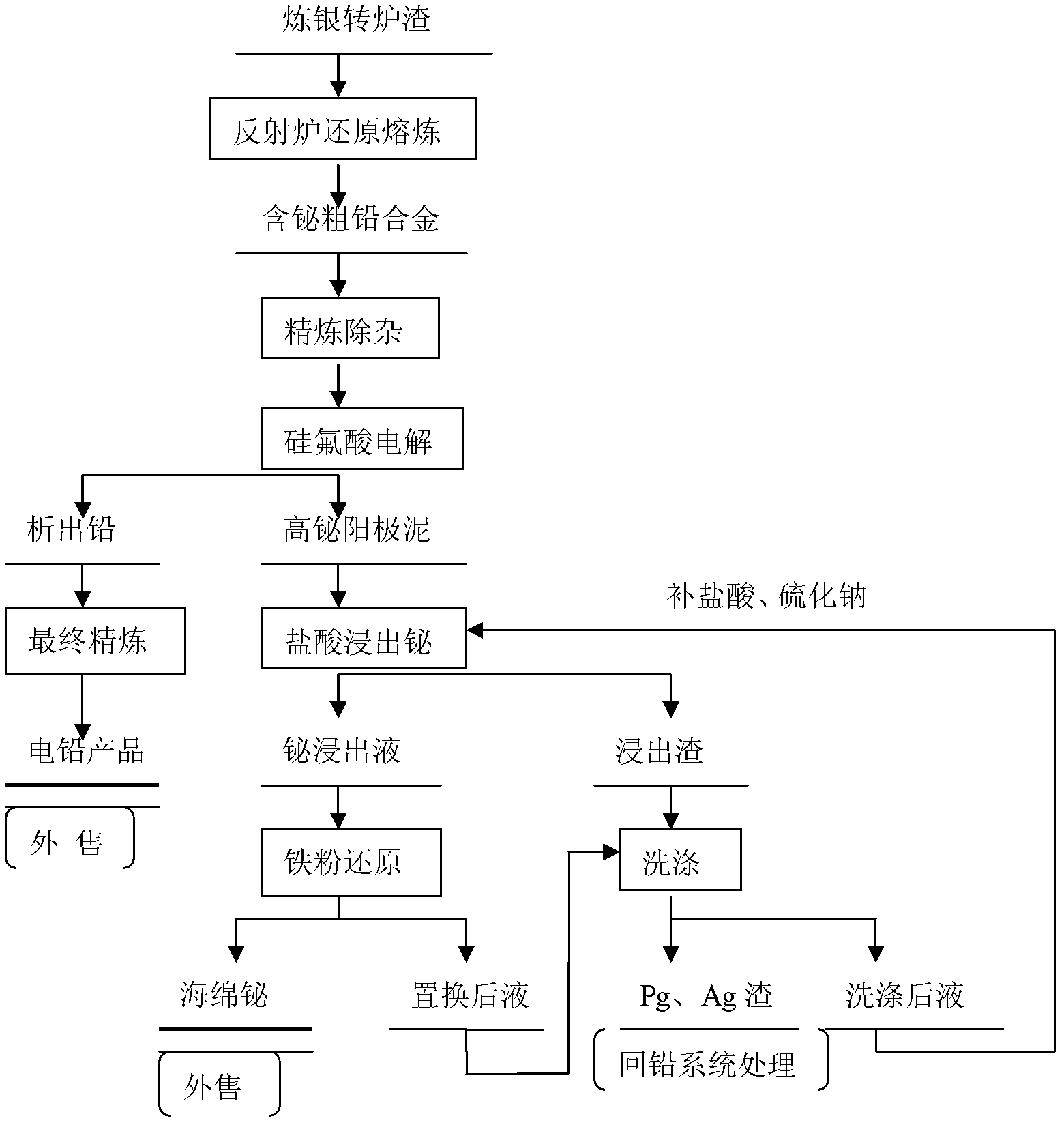

Method for recovering bismuth from bismuth slag

ActiveCN102586627AAvoid safety hazardsReduce labor intensityProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering bismuth from bismuth slag, which includes steps of: firstly, smelting silver-refining converter oxidizing slag in high-temperature restoring mode to obtain lead-bismuth alloy, performing silico-fluoric acid system lead-bismuth alloy electrolysis to obtain electric lead products and high-bismuth anode mud; secondly performing hydrochloric acid leaching on the high-bismuth anode mud, filtering to obtain bismuth-contained leaching liquid, wherein the leaching condition is that: liquid-solid ratio (weight ratio) is 3-6:1, process temperature is 40-70 DEG C, hydrochloric acid concentration is 150-200g / L, and reaction time is1.5-2.5h; and thirdly, replacing bismuth in the leaching liquid through reduced iron powder to obtain sponge bismuth and obtain refined bismuth with high purity in pyro-refining electrolysis. Sodium sulfide for sedimenting silver is added in the leaching process to obtain bismuth leaching liquid, silver can be prevented from immersing into the liquid as much as possible, when return washing liquid is used for leaching high-bismuth anode mud, a part of hydrochloric acid is refilled to maintain necessary potential of hydrogen (pH) value, concentration of Cl- is controlled to be 150-200g / L, and simultaneously bismuth ion hydrolysis can be avoided. Compared with the prior art, the method has no operations of water quenching, ball milling, hydrolysis, neutralization and the like of coarse bismuth alloy, has less procedures, is low in cost and free of pollution, simultaneously achieves double-metal electrolysis of the lead-bismuth alloy and does not influence the electric-lead main system.

Owner:蒙自矿冶有限责任公司

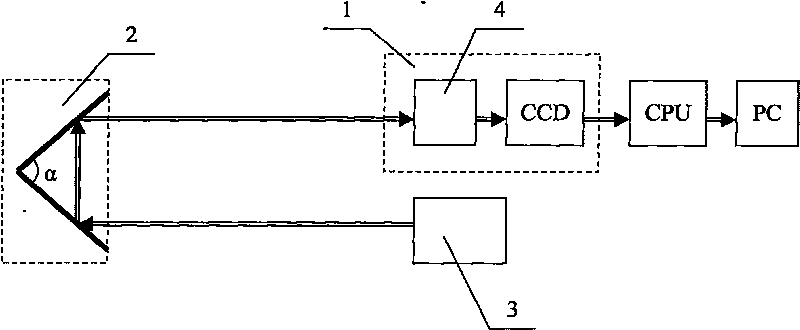

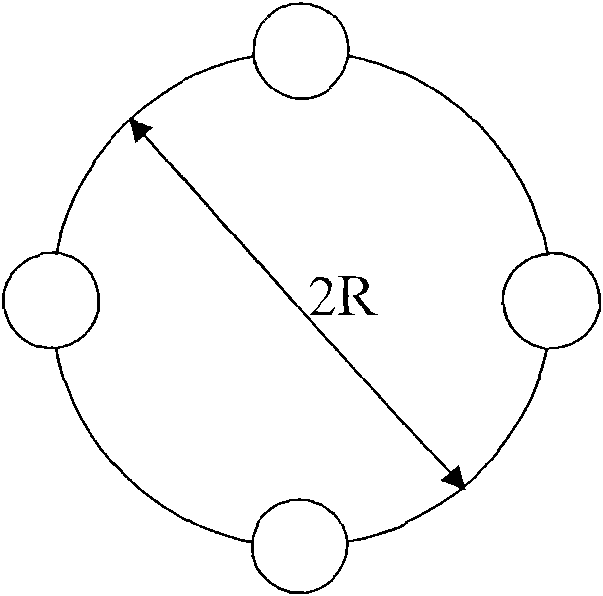

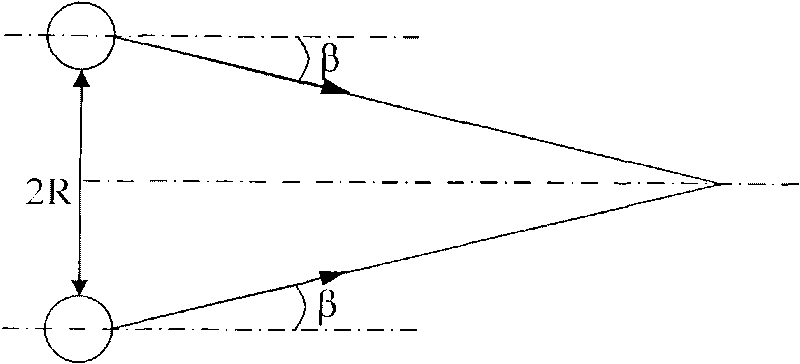

Multi-beam deformation detecting device and use method thereof

InactiveCN101718529ACorrection of deformationHigh precisionUsing optical meansDigital signal processingOffset distance

The invention relates to a multi-beam deformation detecting device which comprises a probe, a digital signal processor DSP, a personal computer PC, a laser group and a prism reflection target, wherein the prism reflection target is arranged on a point to be tested, the probe and the laser group are arranged on a measuring point, a laser beam group emitted from the laser group is reflected through the prism reflection target by adjusting the laser group and then forms an overlapped light spot on the probe, a barycenter of the overlapped light spot is determined by utilizing a photoelectronic tracing macro pixel iteration barycenter method, and the deformation of the point to be tested is further determined through the barycenter offset distance. The invention can effectively avoid the influences on environmental change, air turbulence and stray light, can realize long-term online monitoring, and has accurate measurement data, high detection precision, simple structure, low cost and convenient operation.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com