Patents

Literature

312results about How to "Correction of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

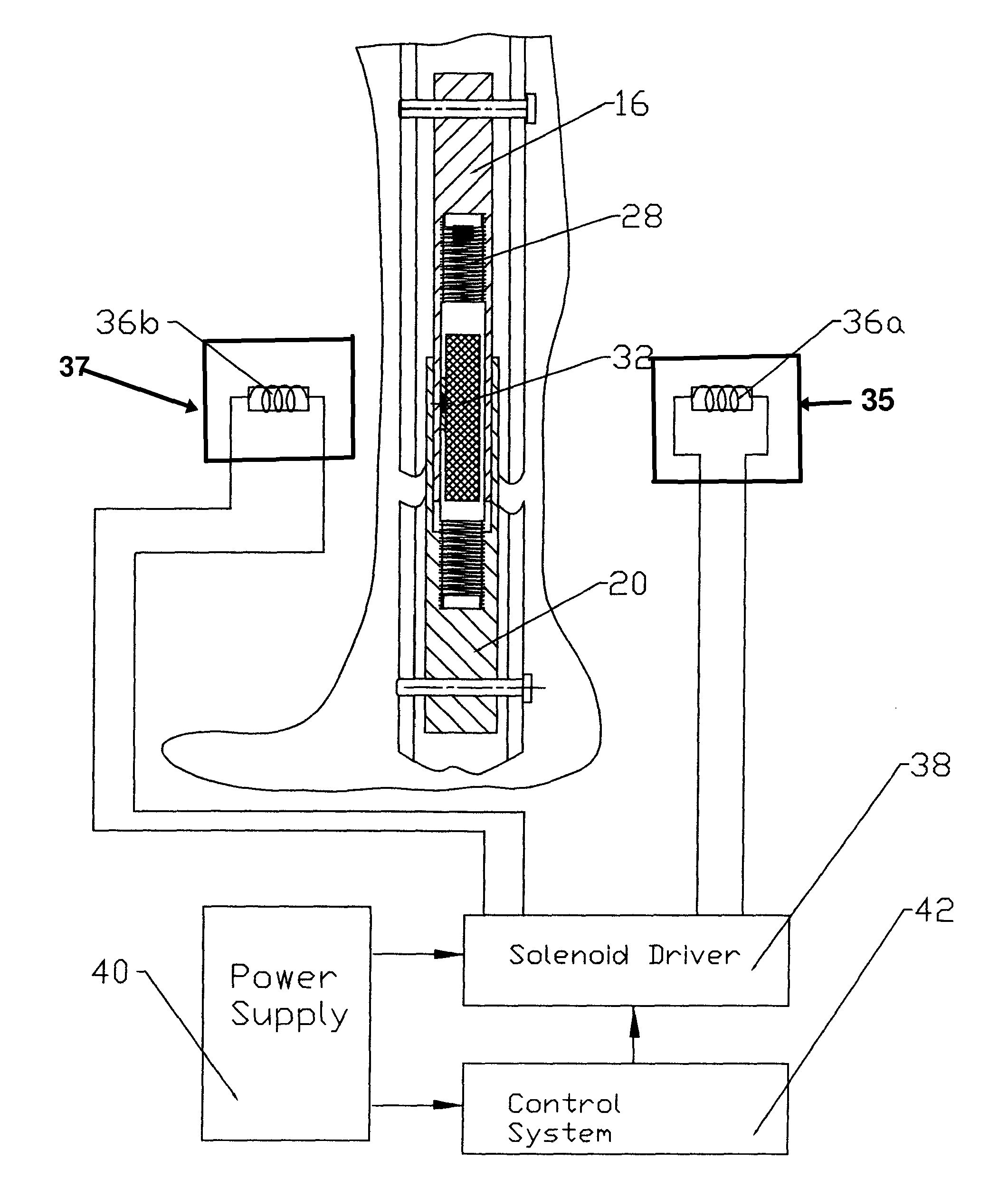

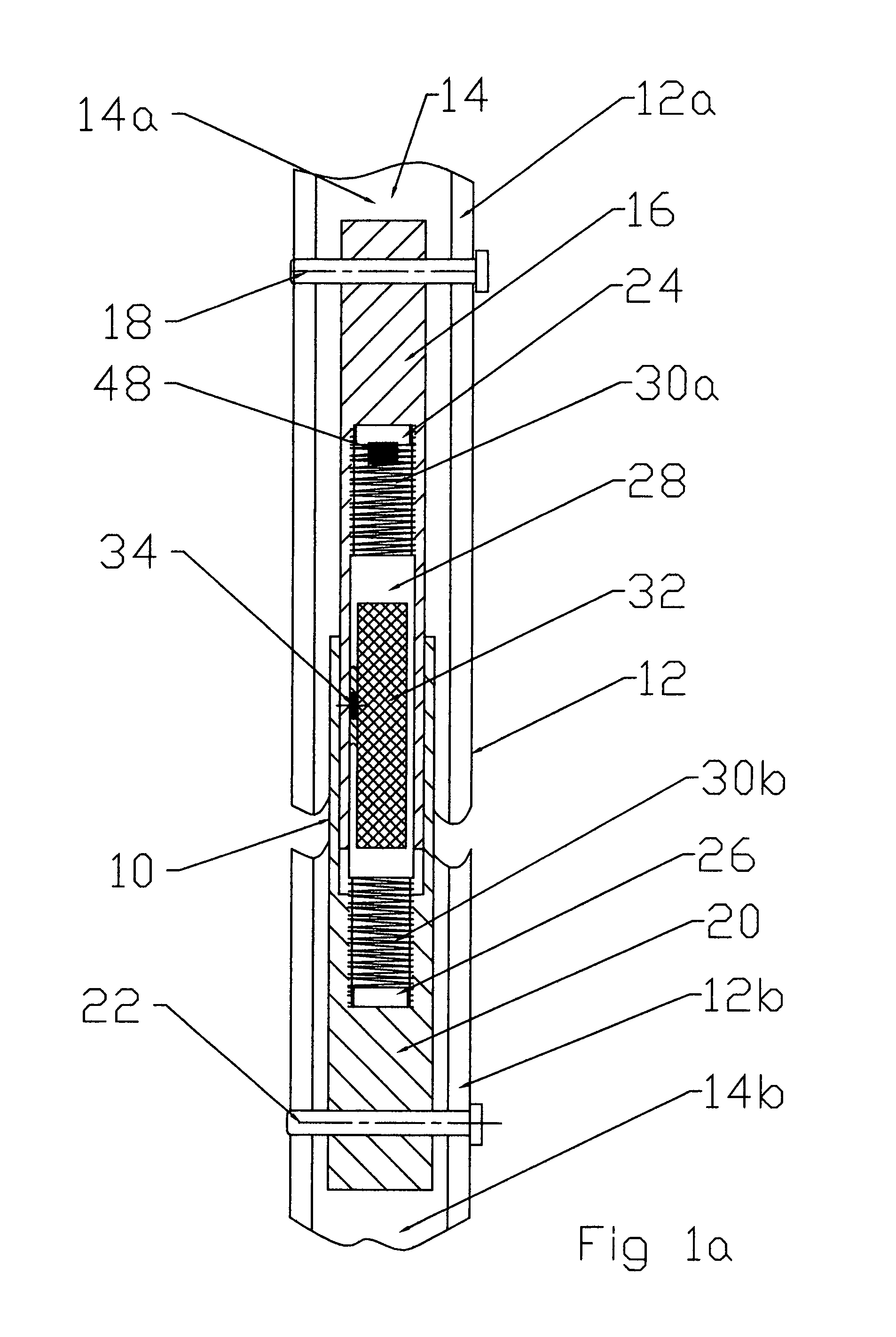

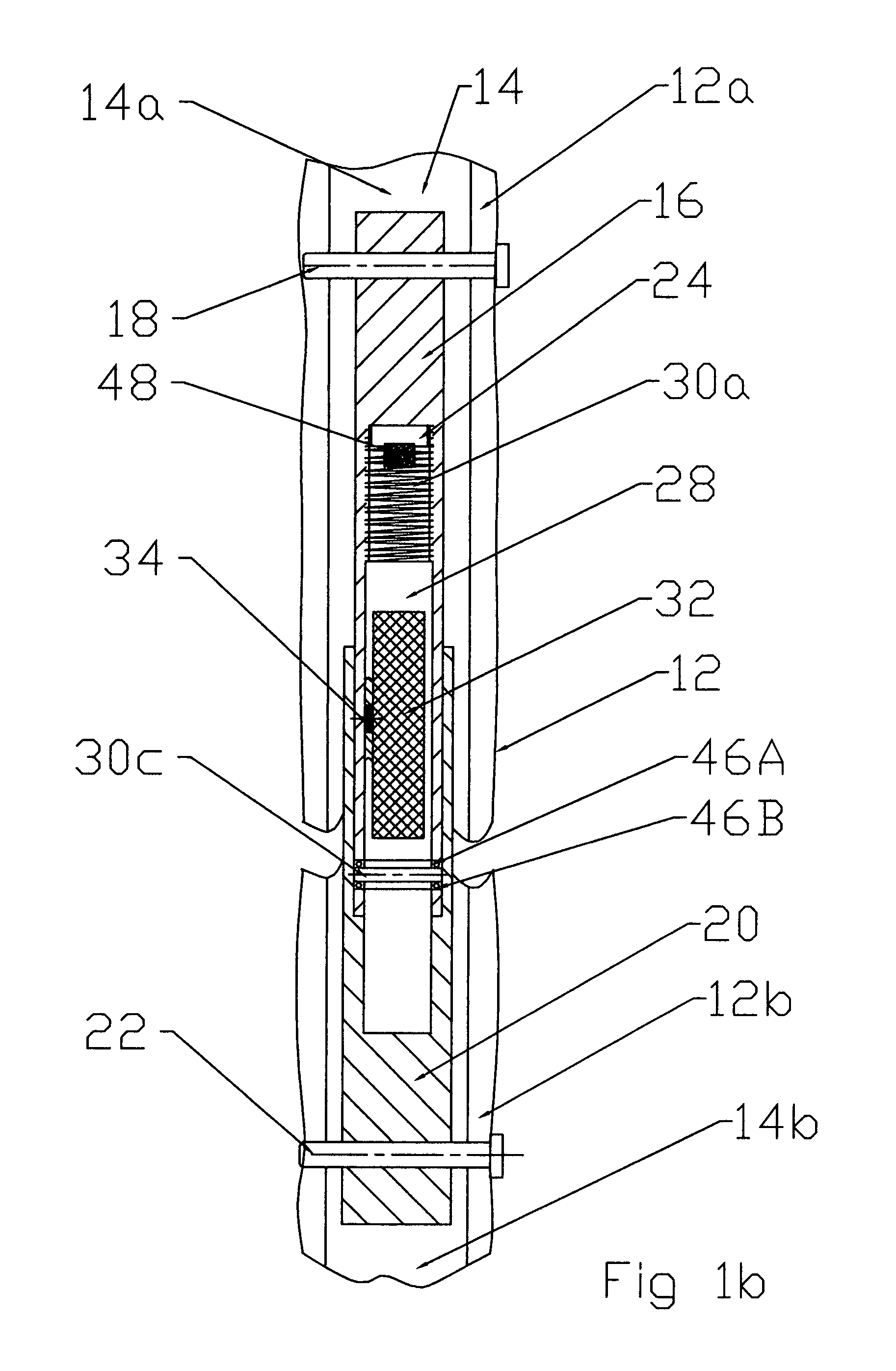

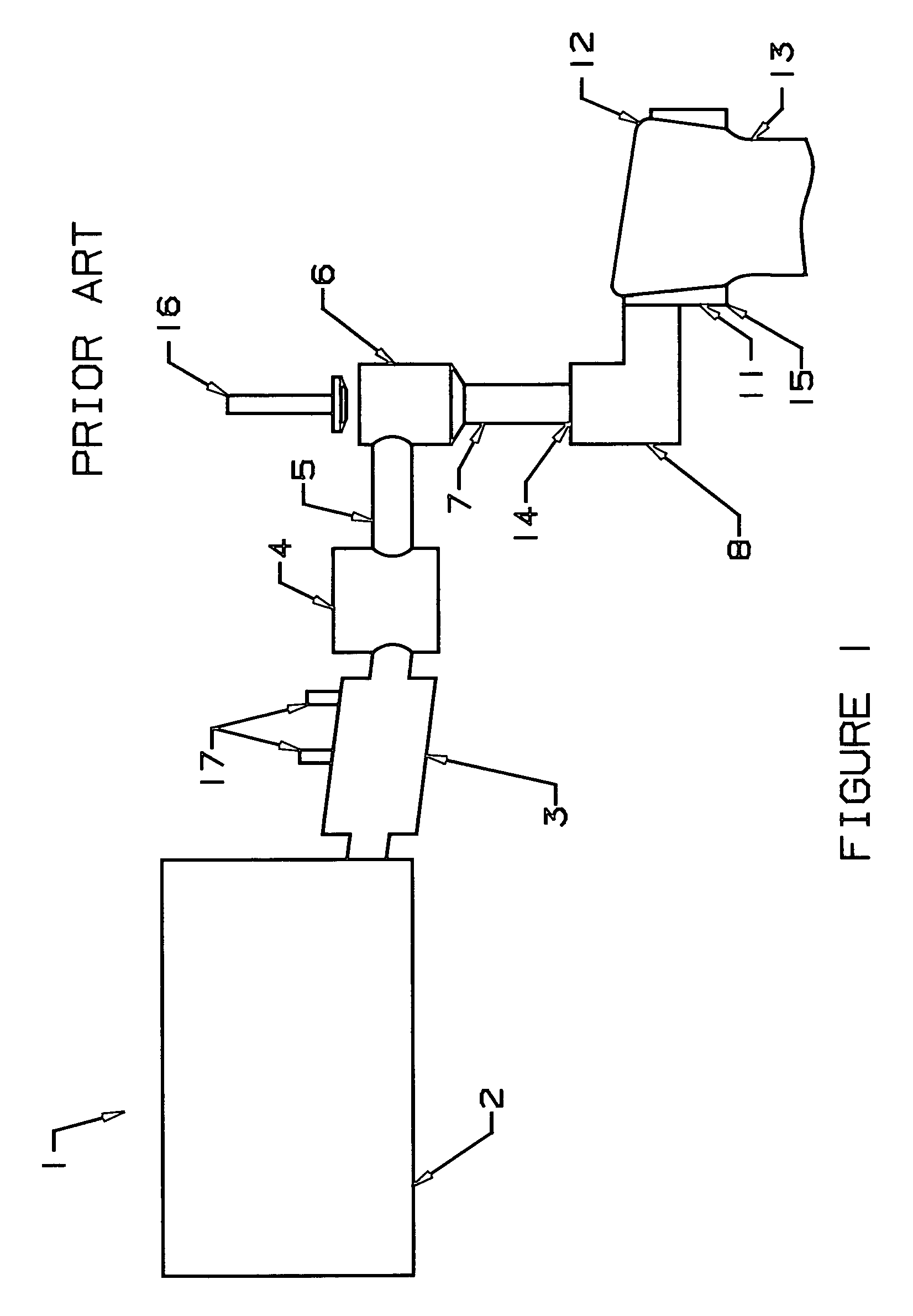

Bi-directional bone length adjustment system

InactiveUS7753915B1Correction of deformationSimplified and reliable implantableInternal osteosythesisJoint implantsEngineeringScrew thread

Bone length adjustment method and system includes a two-part telescopic device connected to bone parts whose length between the connection points is to be adjusted, with each part of the telescopic device being secured to the bone part, and a rod with an embedded permanent magnet which is in threaded engagement at one or both of its ends with one or both of the parts of the telescopic device. The permanent magnet in the rod is excited by an external solenoid arrangement to cause a radial force to develop at the rod thereby causing it to rotate. Rotation of the rod is converted via the threads at one or both of its ends to axial motion or movement of the telescopic parts relative to each other and thereby causes an increase or decrease in the bone length depending on the direction of axial movement between the telescopic parts.

Owner:EKSLER AUGUST +2

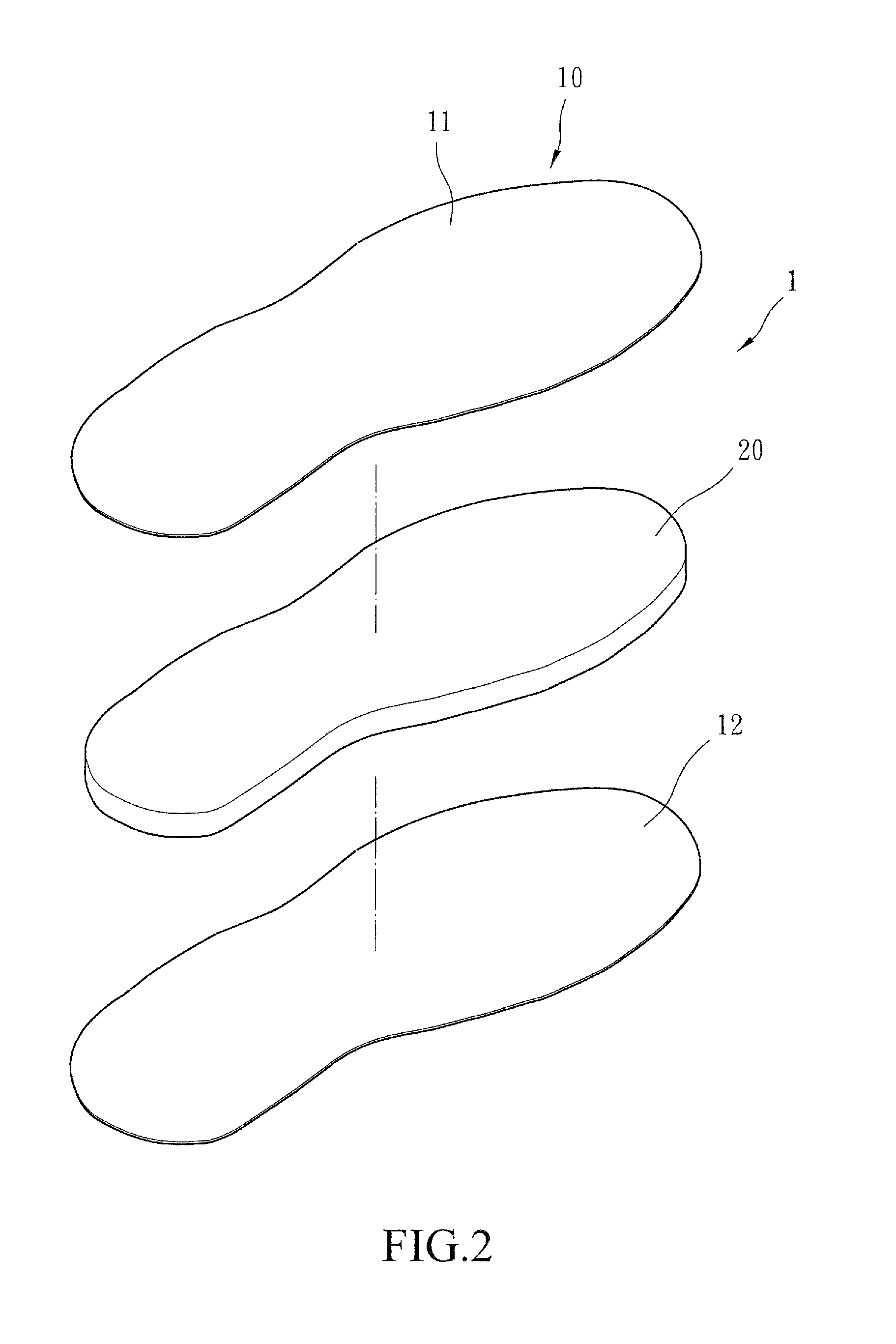

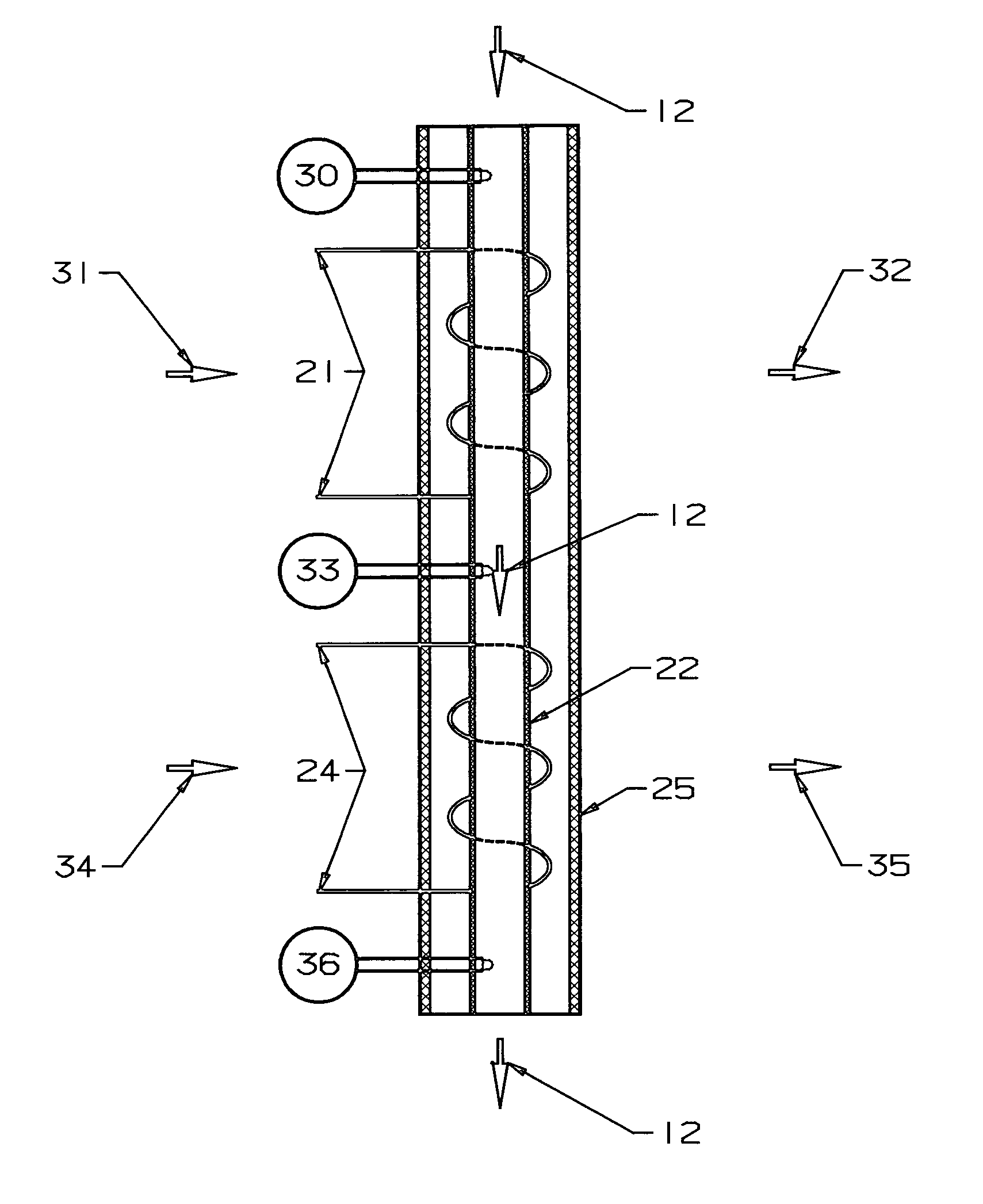

Structure of shoe sole

InactiveUS20100212186A1Add valueIncrease economic valueSolesInsolesComposite materialCustom made shoes

A structure of shoe sole is provided, which is a custom-made shoe sole that is formed according to a user's foot sole so as to improve the effects of support and wrapping of the shoe sole. The shoe sole includes an enclosure and a clay-like thermoplastic material. The enclosure includes upper and lower cover layers that are made of a material showing local stretchability and air permeability. The thermoplastic material is received between the upper and lower cover layers and is a thermoplastic mixture in the form of soft ceramic. With the shoe sole placed in a shoe and the shoe put on a user's foot, the thermoplastic material of the shoe sole may get deformed inside the enclosure according to the contour of the user's foot sole, making the shoe sole shaped to completely match the foot sole of the user.

Owner:CHENG FU YUAN +2

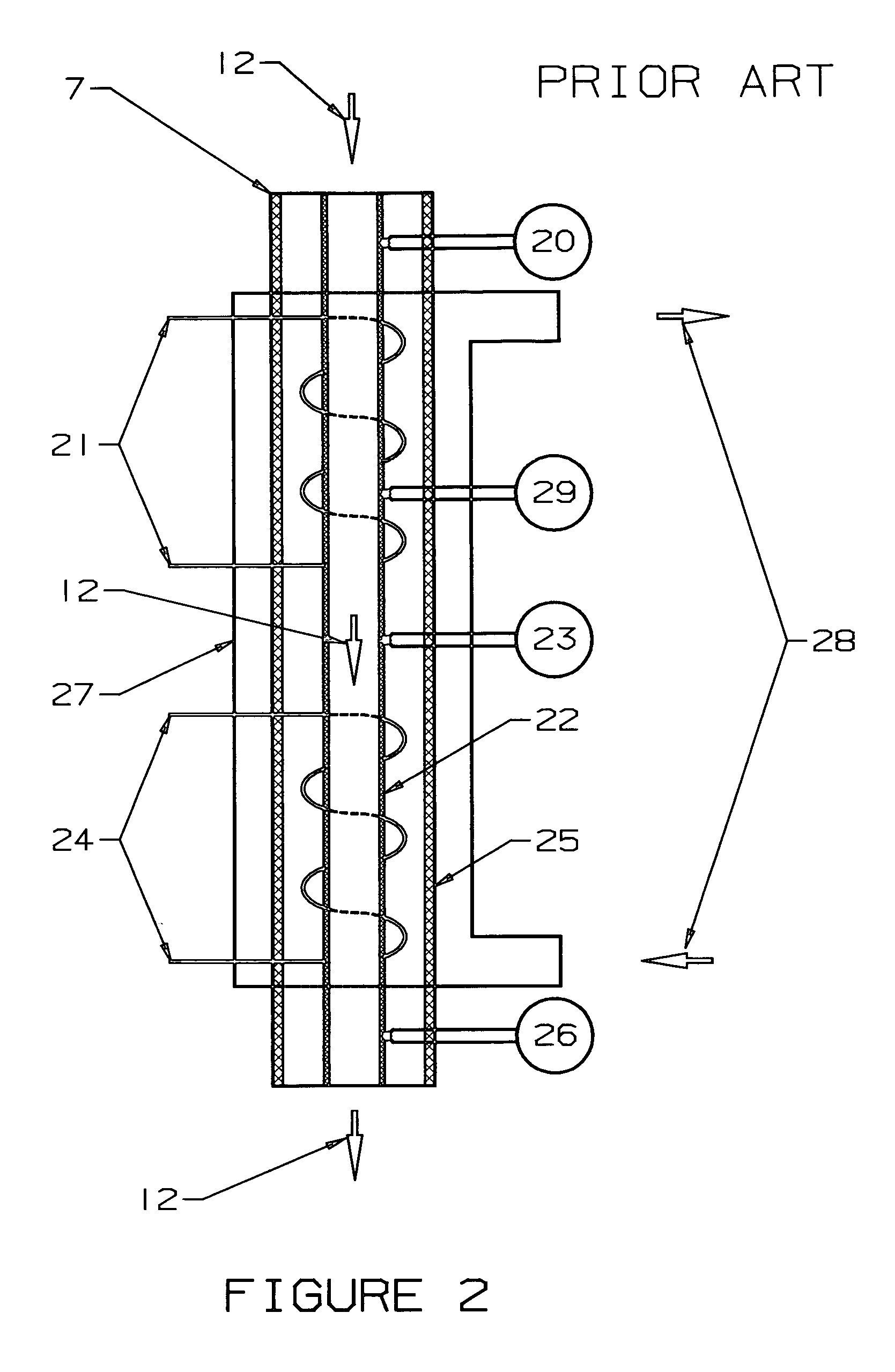

Overflow downdraw glass forming method and apparatus

ActiveUS20060016219A1Process can be modifiedMinimizing thickness variationGlass furnace apparatusVolume/mass flow measurementThermal creepEngineering

The present invention significantly modifies “The Overflow Process”. It includes a method and apparatus for measuring glass flow rate and maintaining a constant glass flow rate. It also embodies design features and methods that support and stress the forming apparatus in a manner such that the deformation that results from thermal creep is corrected, thus minimizing the effect of the thermal creep on the thickness variation of the glass sheet. The present invention also embodies design features that change the process from a single step (combined flow distribution and cooling) to a two step process; step one being flow distribution and step two being cooling.

Owner:CORNING INC

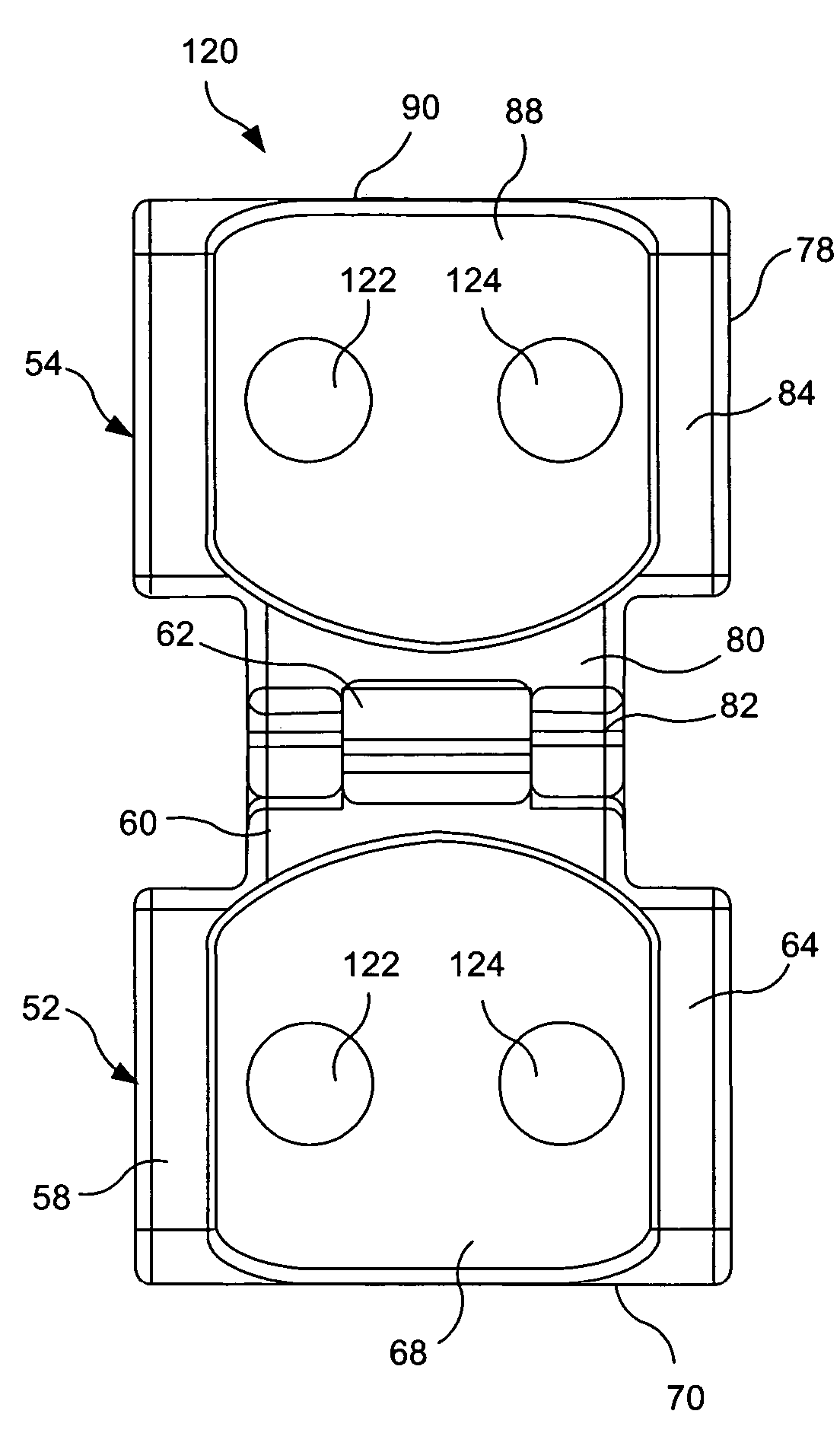

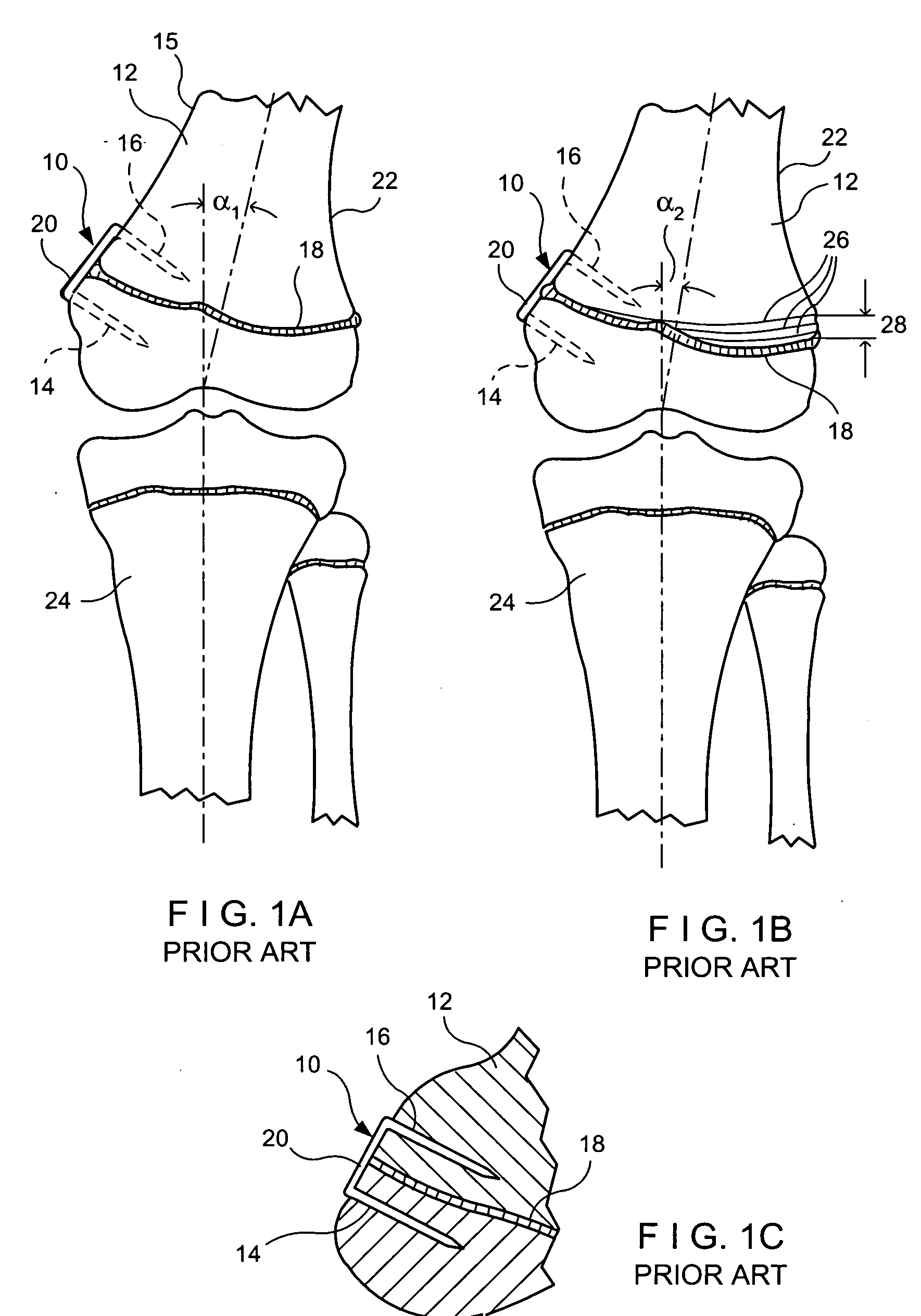

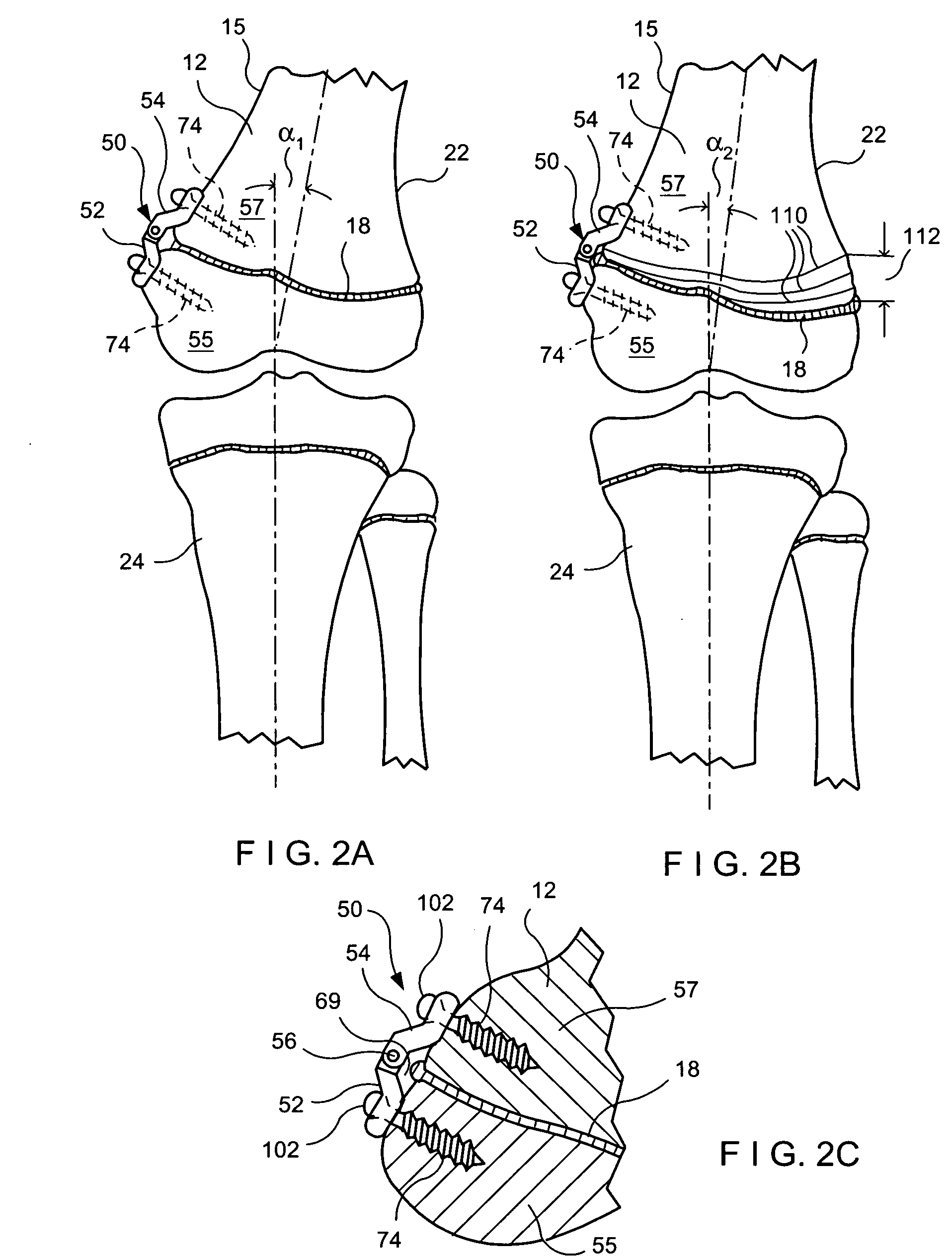

Orthopedic device and method for correcting angular bone deformity

InactiveUS20060142767A1Correct angular deformationPromote growthJoint implantsBone platesBone structureEngineering

An orthopedic device and method for correcting angular deformation of a bone structure having a growth plate. The device includes first and second hinge members connected together at a hinge joint. The device is adapted for mounting the orthopedic device to the bone structure with the pivot joint positioned over the growth plate. Alignment of the pivot joint with the growth plate promotes asymmetric growth of the growth plate to thereby correct the angular deformation.

Owner:GREEN DANIEL W +1

Method for manufacturing auxiliary gas-adding polyurethae/polyurethane-urea polishing pad

InactiveUS20040021243A1Improve accuracyImprove flatnessFlexible-parts wheelsLapping toolsHydrogenPolythiol resin

A method for manufacturing a PU (polyurethane) polishing pad is provided. Resins containing active hydrogen functional groups such as polyol resins, polyamine resins, and polythiol resins, and polyisocyanate resins containing -NCO functional groups are mixed to form a foamed PU polishing pad with excellent polishing properties by reaction injection-molding under high pressure, low temperature and auxiliary gas-adding. The PU polishing pad in accompany with an abrasive slurry can be widely used to polish high-level products such as wafers and optical glass.

Owner:IV TECH CO LTD

Heat exchanger and related exchange module

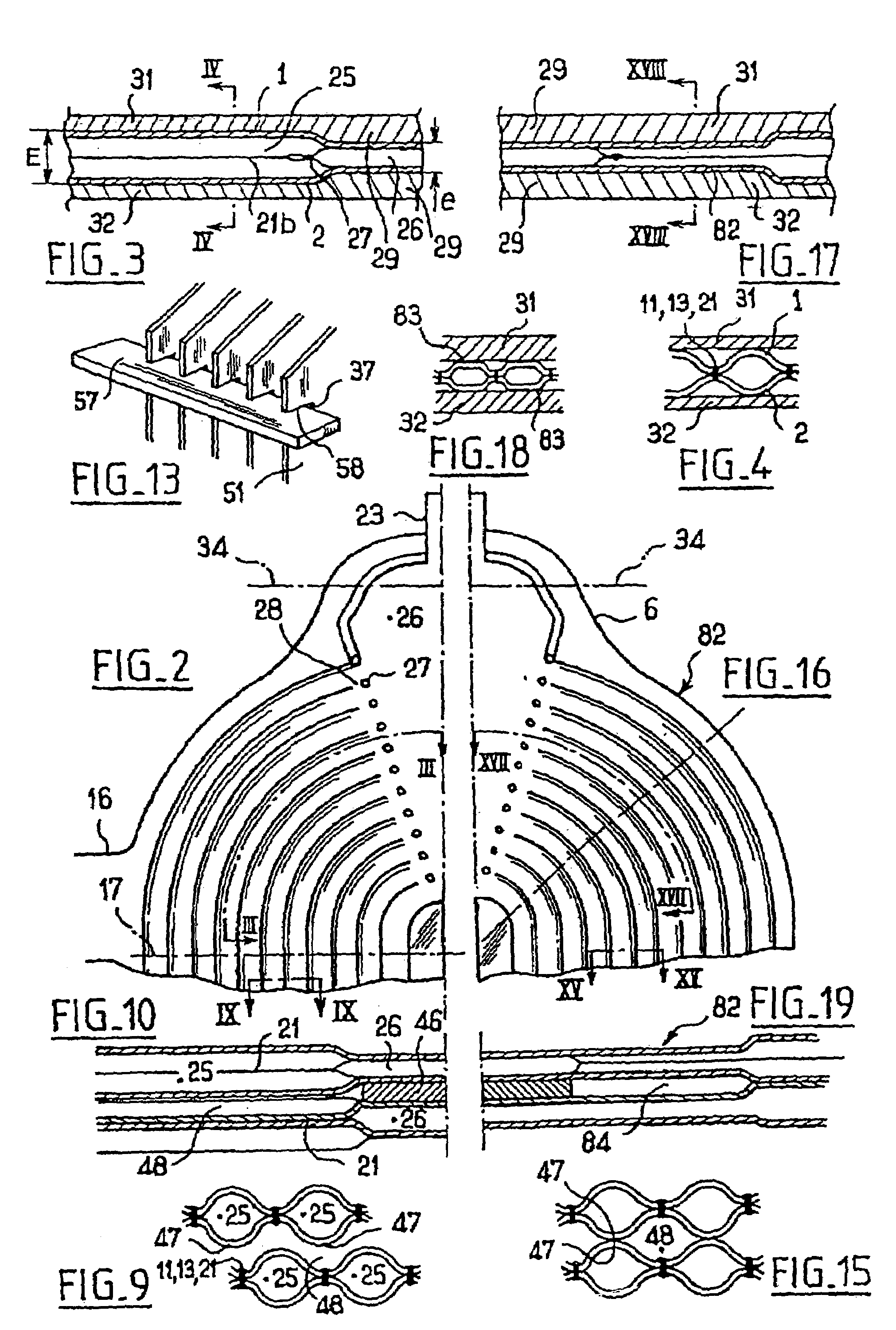

InactiveUS7044207B1Preserve cross sectionPrevent correct deformationHeat exchanger casingsLaminated elementsCoronal planeEngineering

A heat exchange module is disclosed comprising two metal sheets welded along weld lines defining between them a group of channels disposed side by side substantially in a common plane, intended to be passed through by an exchange fluid and, from the fluidic point of view, being in parallel with each other between two connection orifices of the module. The group of channels has a generally U-shape configuration, which connects together the said connection orifices that are laterally separated from each other.

Owner:ZIEPACK

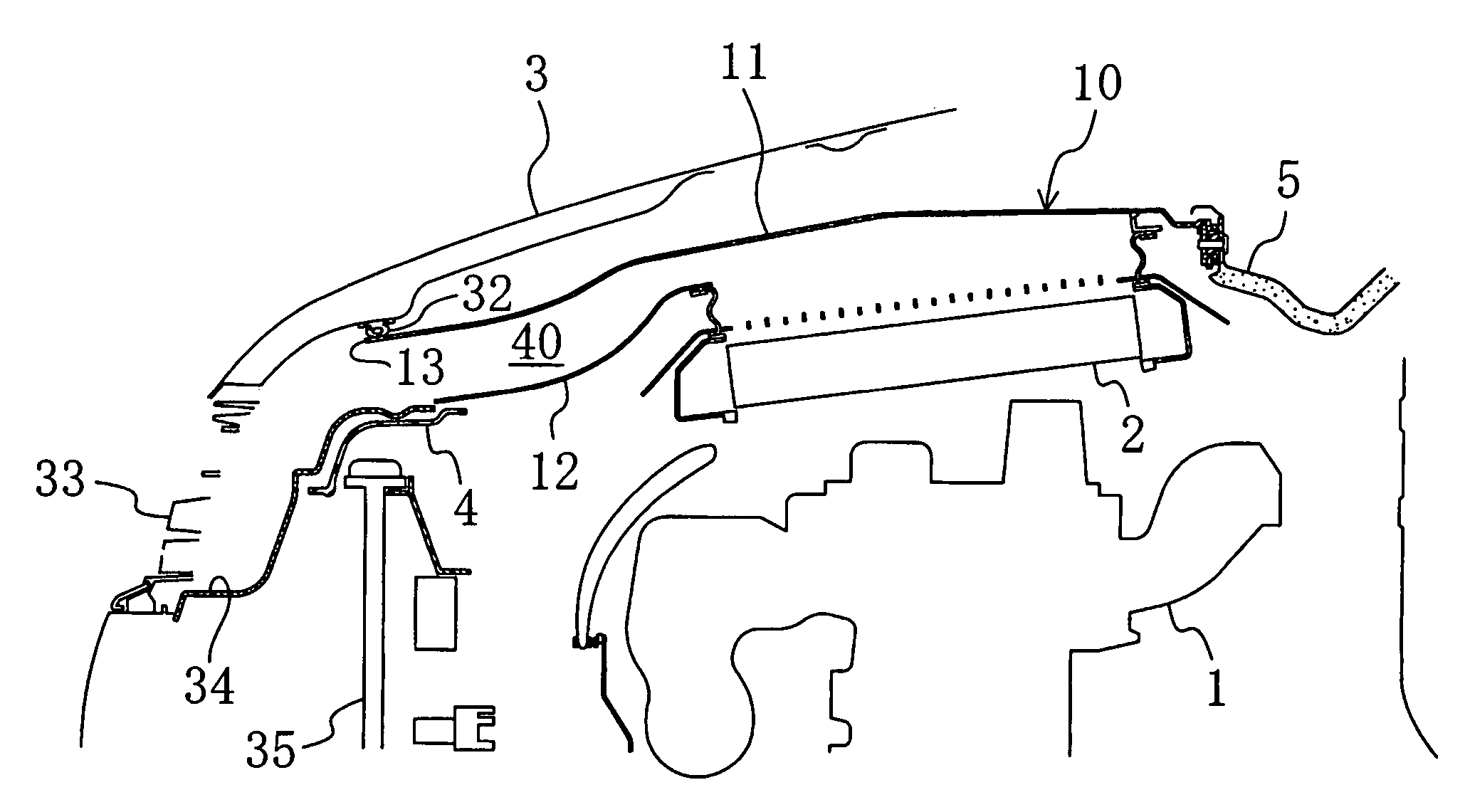

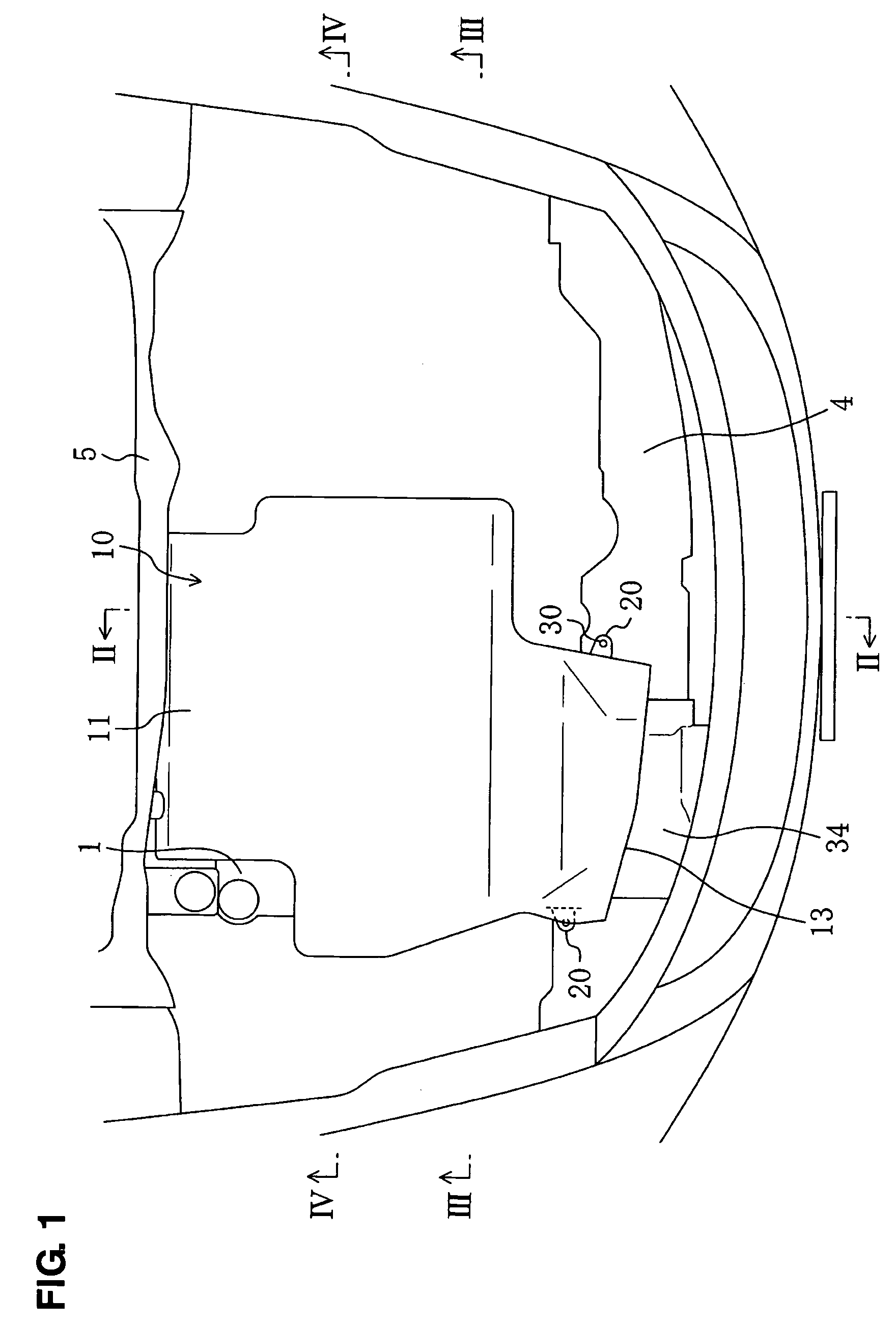

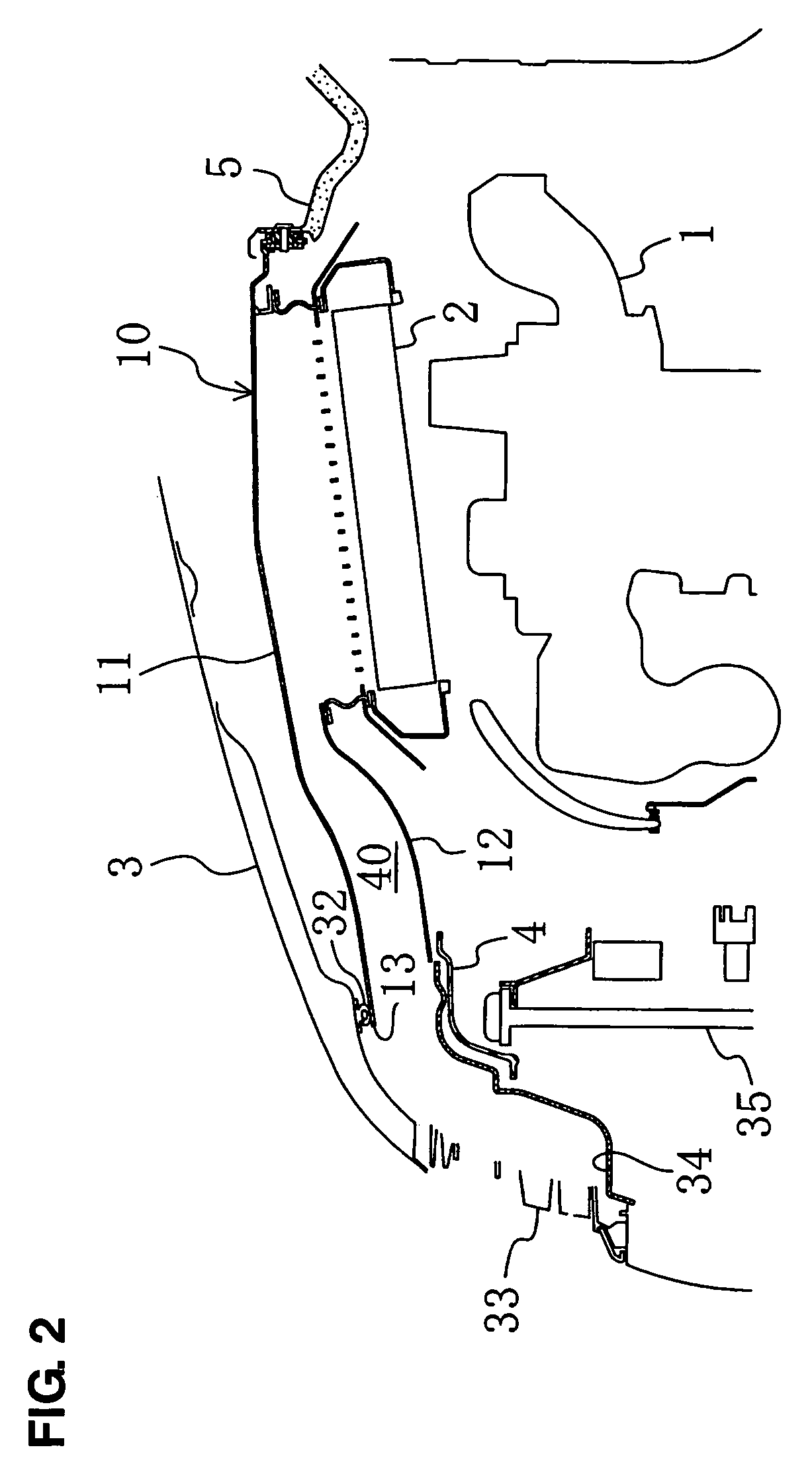

Support structure of cooling air intake duct for intercooler of vehicle

InactiveUS7523798B2Correction of deformationAccurate protectionInternal combustion piston enginesPedestrian/occupant safety arrangementEngineeringIntercooler

The duct comprises the upper member and the lower member, which are formed separately and assembled integrally by being attached to one another. There is provided the seal member to interconnect the opening at the lower member and the intercooler, which is pressed against the upper face of the intercooler. The front side of the lower member is supported at the shroud panel, and the rear side of the upper panel is supported at the cowl panel. Thus, the rear attachment portion is detached earlier than the front attachment portion at the pedestrian's hit. Accordingly, the duct can be split surely and the engine hood can be allowed to be properly deformed without being prevented, so that the protection of the head of pedestrians can be attained properly.

Owner:MAZDA MOTOR CORP

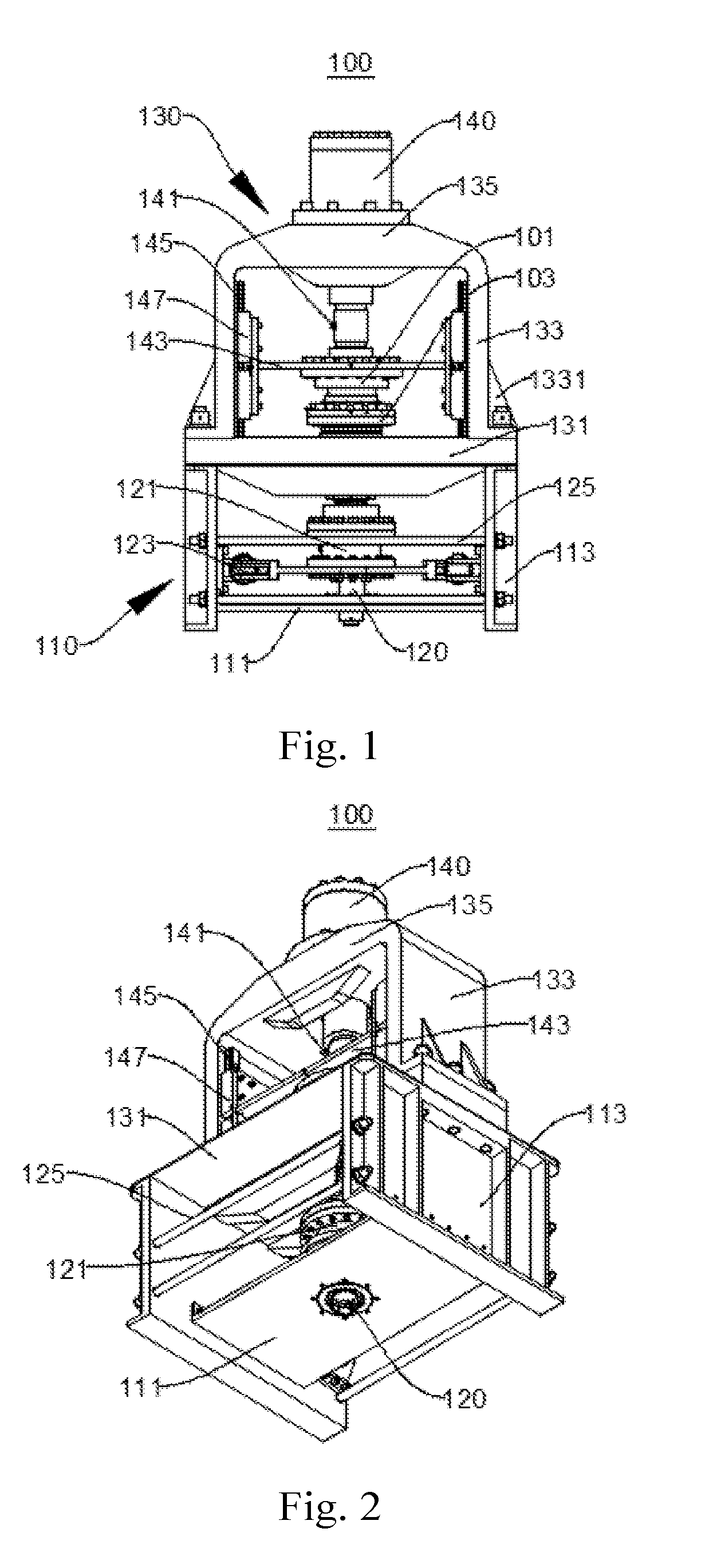

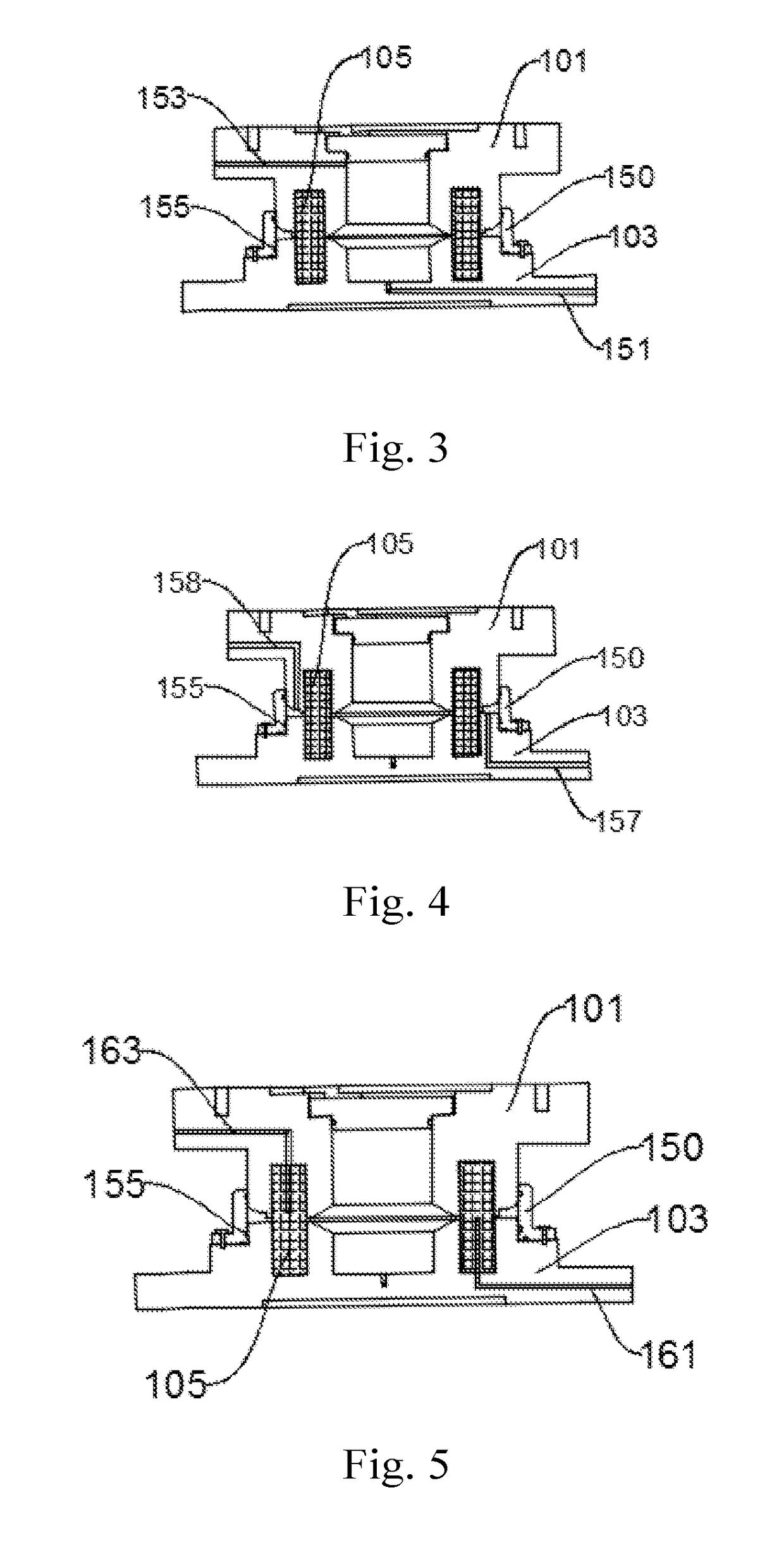

Ring Shear and Seepage-Coupled Apparatus and Ring Shear and Seepage-Coupled Test System for Rock and Rock Fracture under Tension or Compression Stress

ActiveUS20190011344A1Convenient operation and controlSimple structureLiquid dispersion analysisMaterial strength using tensile/compressive forcesTorque sensorEngineering

A ring shear and seepage-coupled apparatus and a ring shear and seepage-coupled test system for rock and rock fracture under tension or compression stress are provided, relating to the technical field of mechanical testing devices. As to the ring shear and seepage-coupled apparatus, an axial piston rod is connected with an upper shear box, a torque transferring shaft is connected with a lower shear box, an axial force transducer is provided on the axial piston rod, a torque transducer is provided on the torque transmitting shaft, and a force transferring plate is fixedly connected onto the upper shear box. The force transferring plate is able to transmit a counter force for exerting a torque. Radial and circumferential seepage tests can be achieved by providing a seepage structure. The ring shear and seepage-coupled test system comprises a servo pump and the ring shear and seepage-coupled apparatus as mentioned above.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

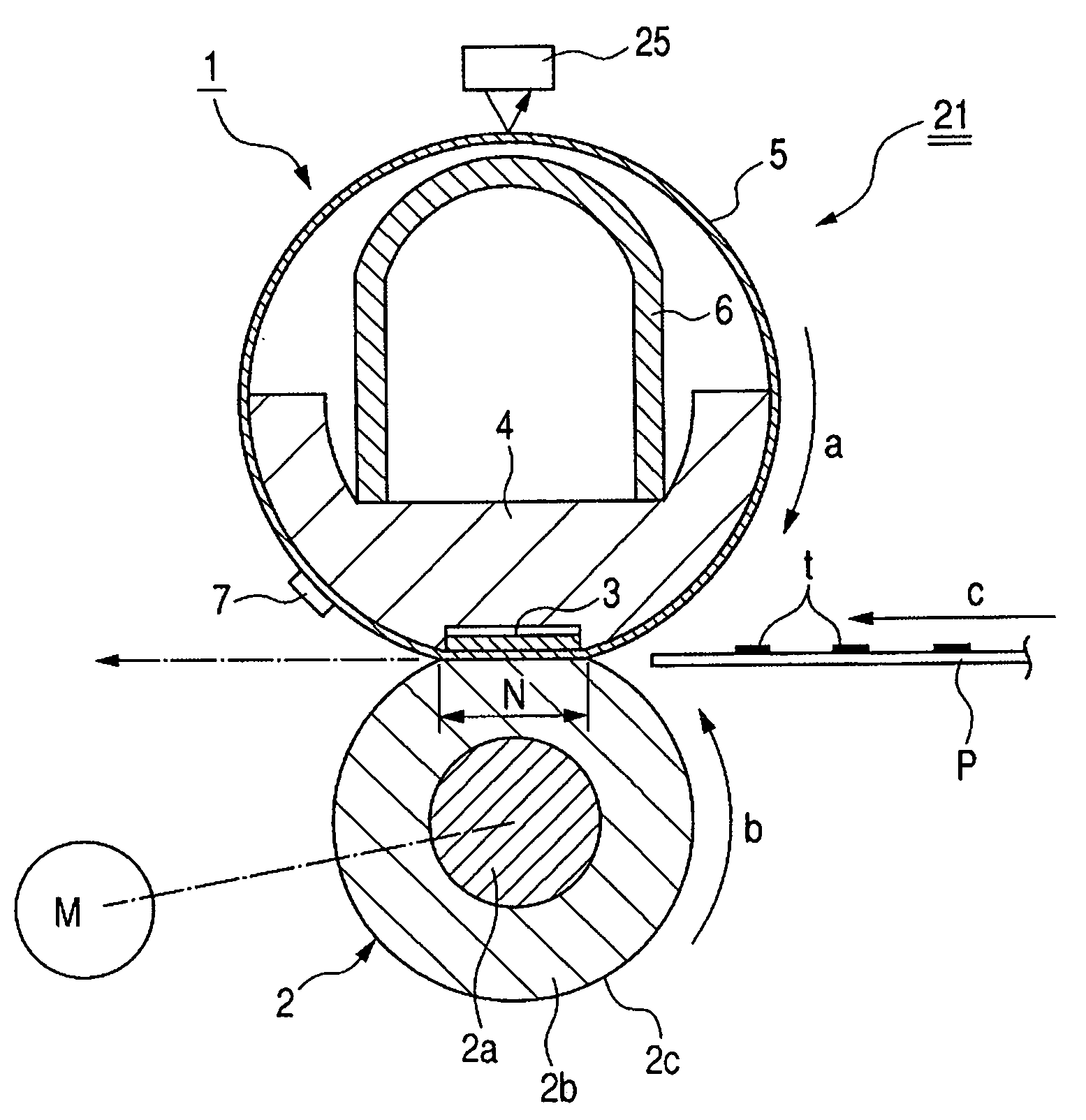

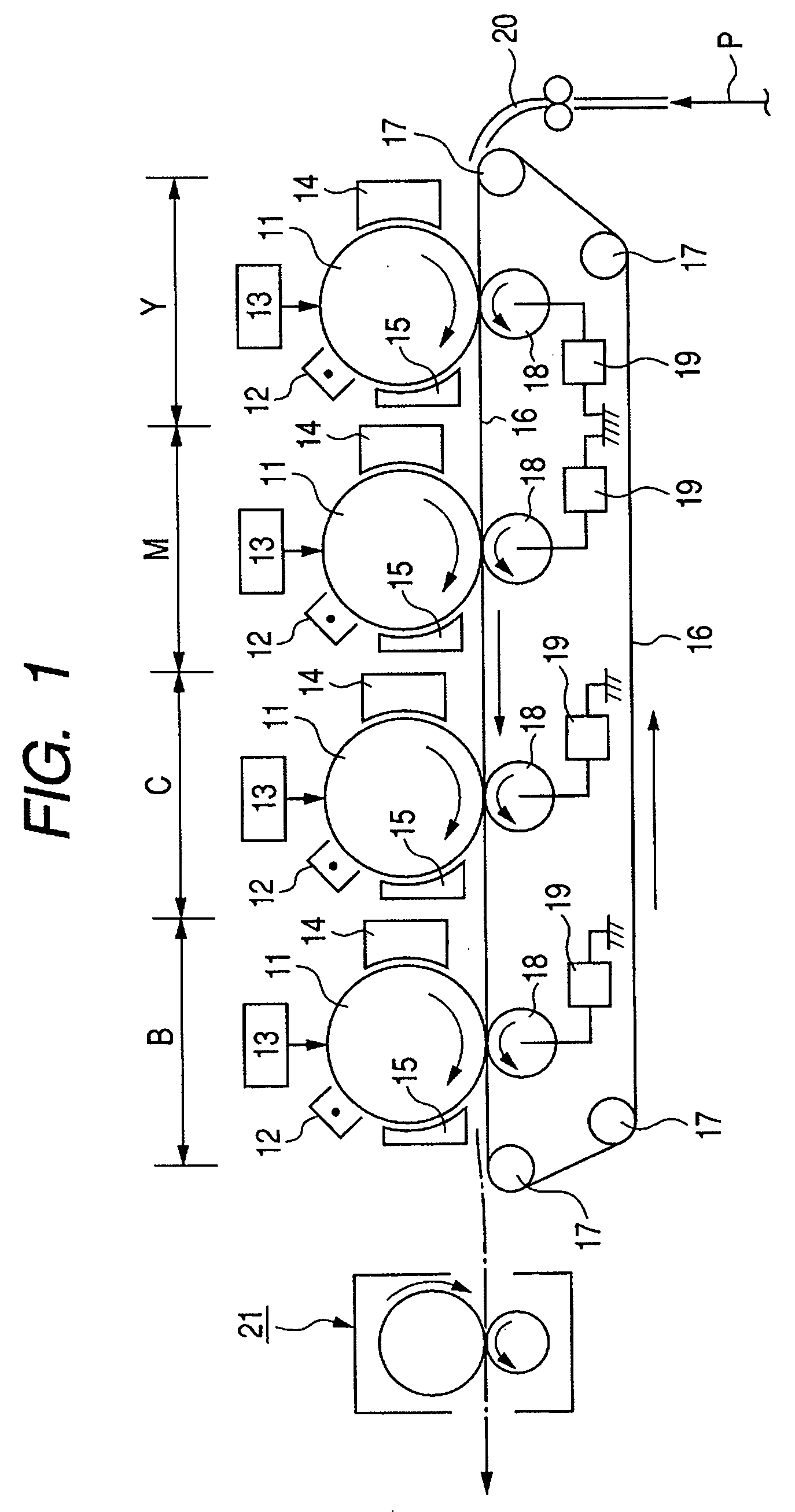

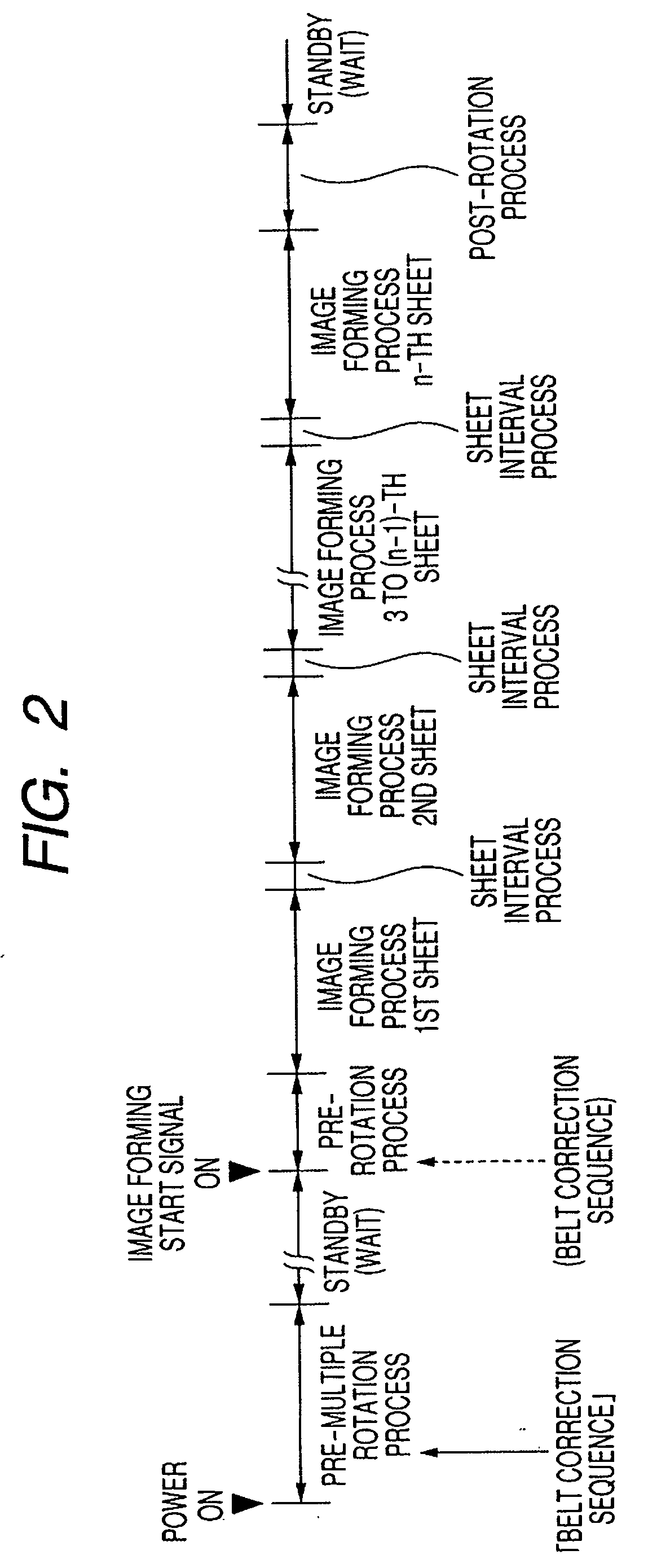

Image heating apparatus

InactiveUS20060127144A1Correct deformationCorrection of deformationElectrographic process apparatusEngineeringMechanical engineering

A fixing apparatus has a belt-shaped rotary member, a pressure member urged against the rotary member to form a nip portion, and a heater for the rotary member. A portion of the rotary member is maintained so that the belt portion has a radius of curvature smaller than an inner diameter of the rotary member, and after the apparatus is stopped, a predetermined time, when the rotary member is rotated again a control sequence in which the portion of the rotary member including the smaller radius of curvature is conveyed and positioned in the nip portion and the heating is performed in a condition that the rotation of the rotary member is stopped is carried out, or, after the apparatus is stopped more than a predetermined time, when the rotary member is rotated again a control sequence is carried out while conveying the portion of the rotary member including the smaller radius of curvature through the nip portion once at a speed smaller than a normal conveying speed.

Owner:CANON KK

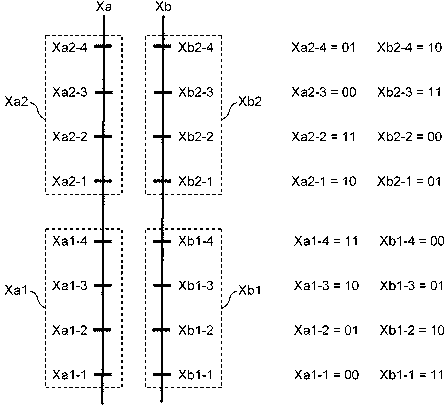

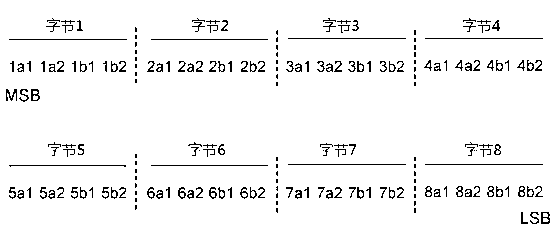

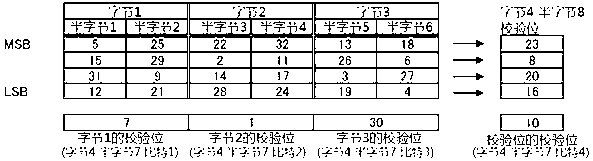

Information expression method, article formed with information expression pattern, information output device, and information expression device

ActiveCN102985934ACorrection of deformationData processing is simpleInput/output for user-computer interactionRecord carriers used with machinesEngineeringOutput device

Owner:西崎传生

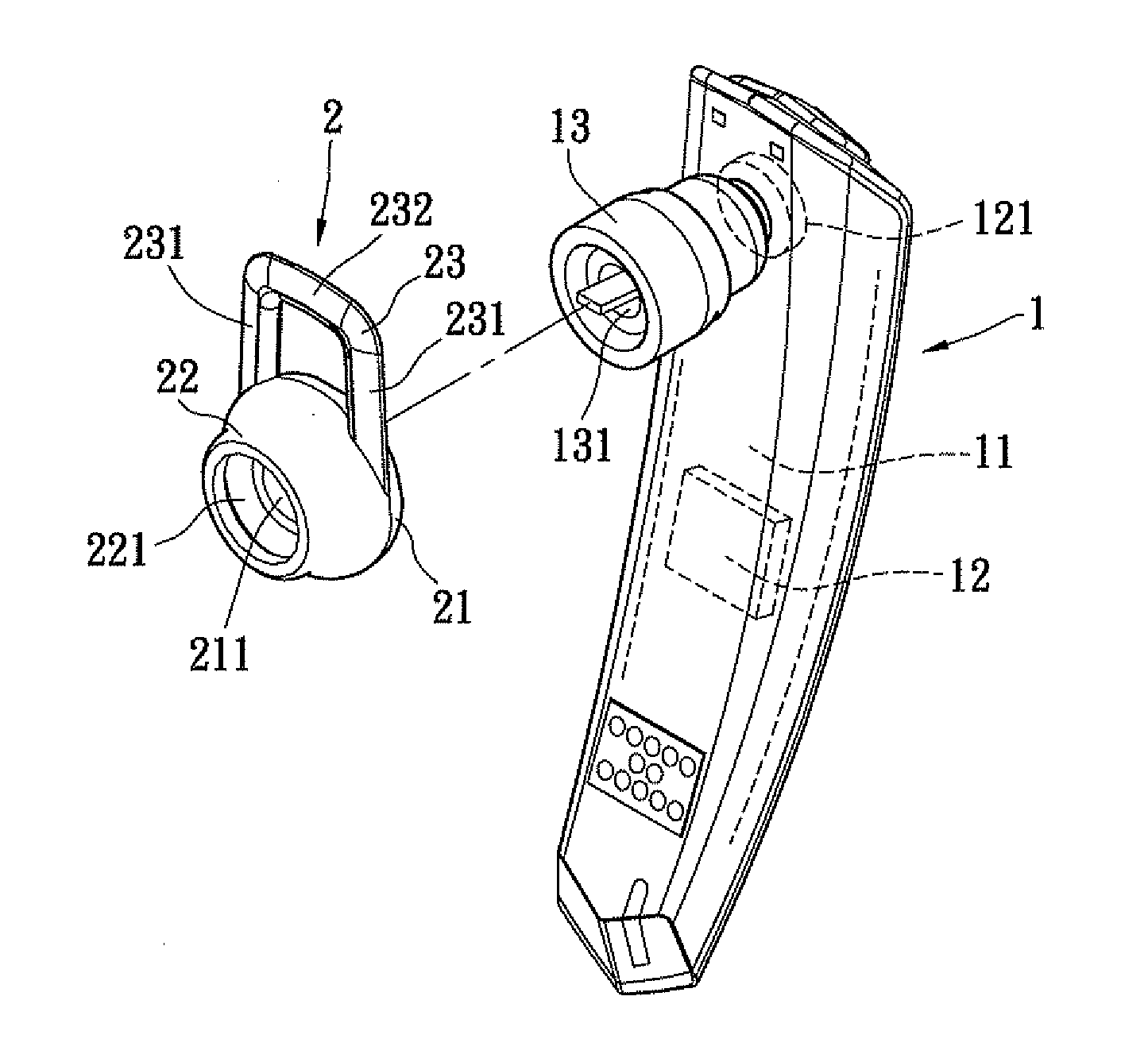

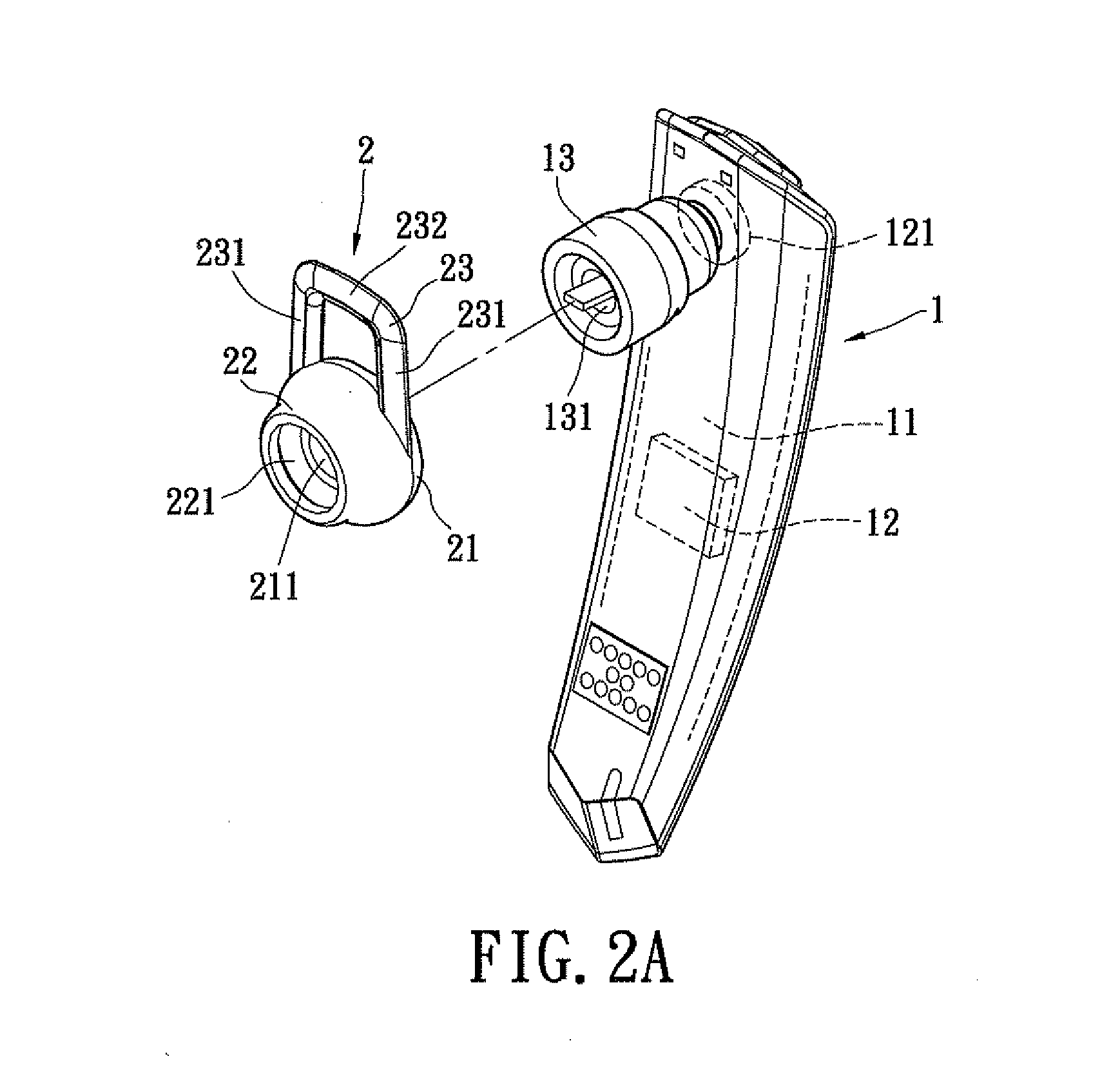

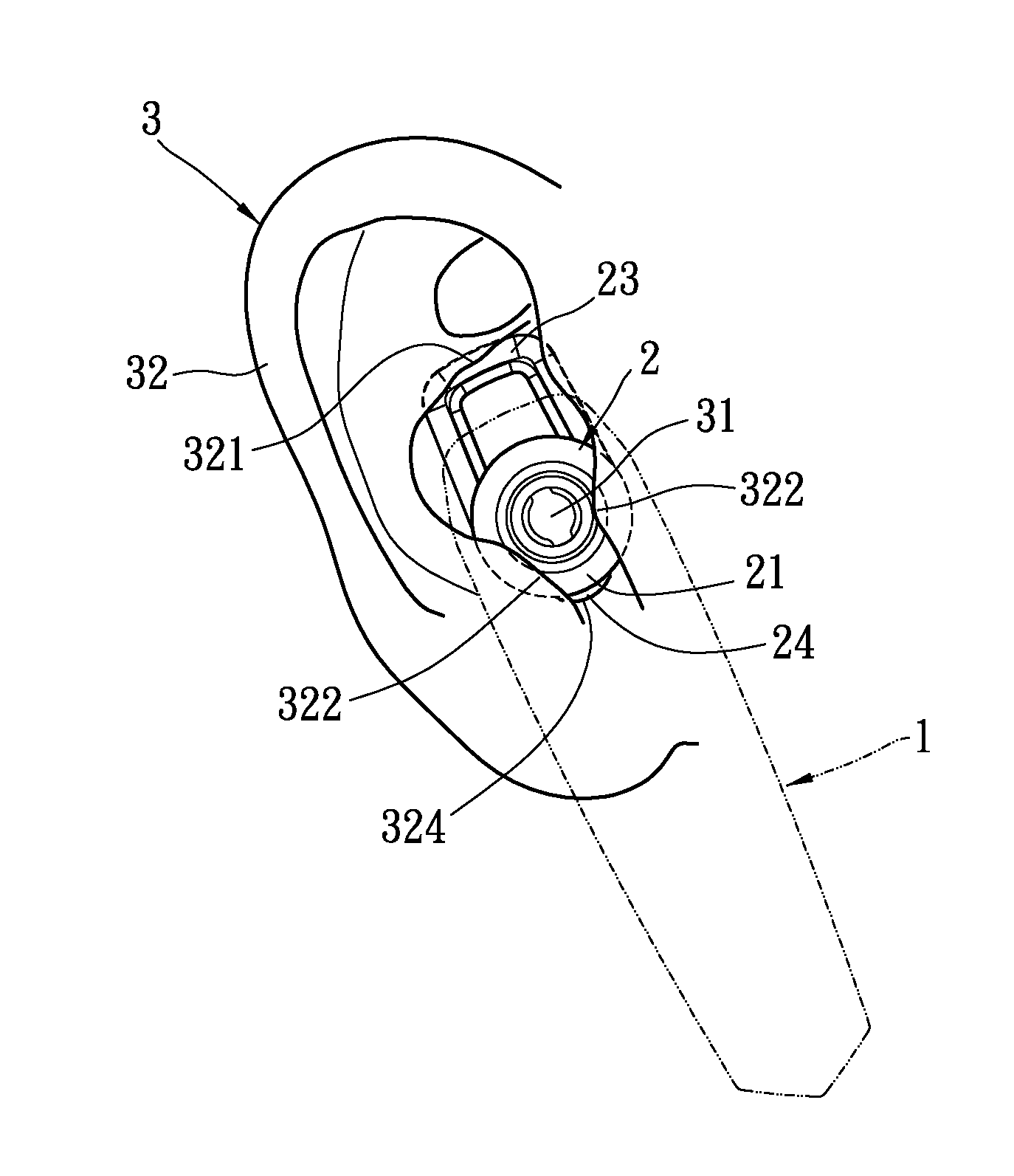

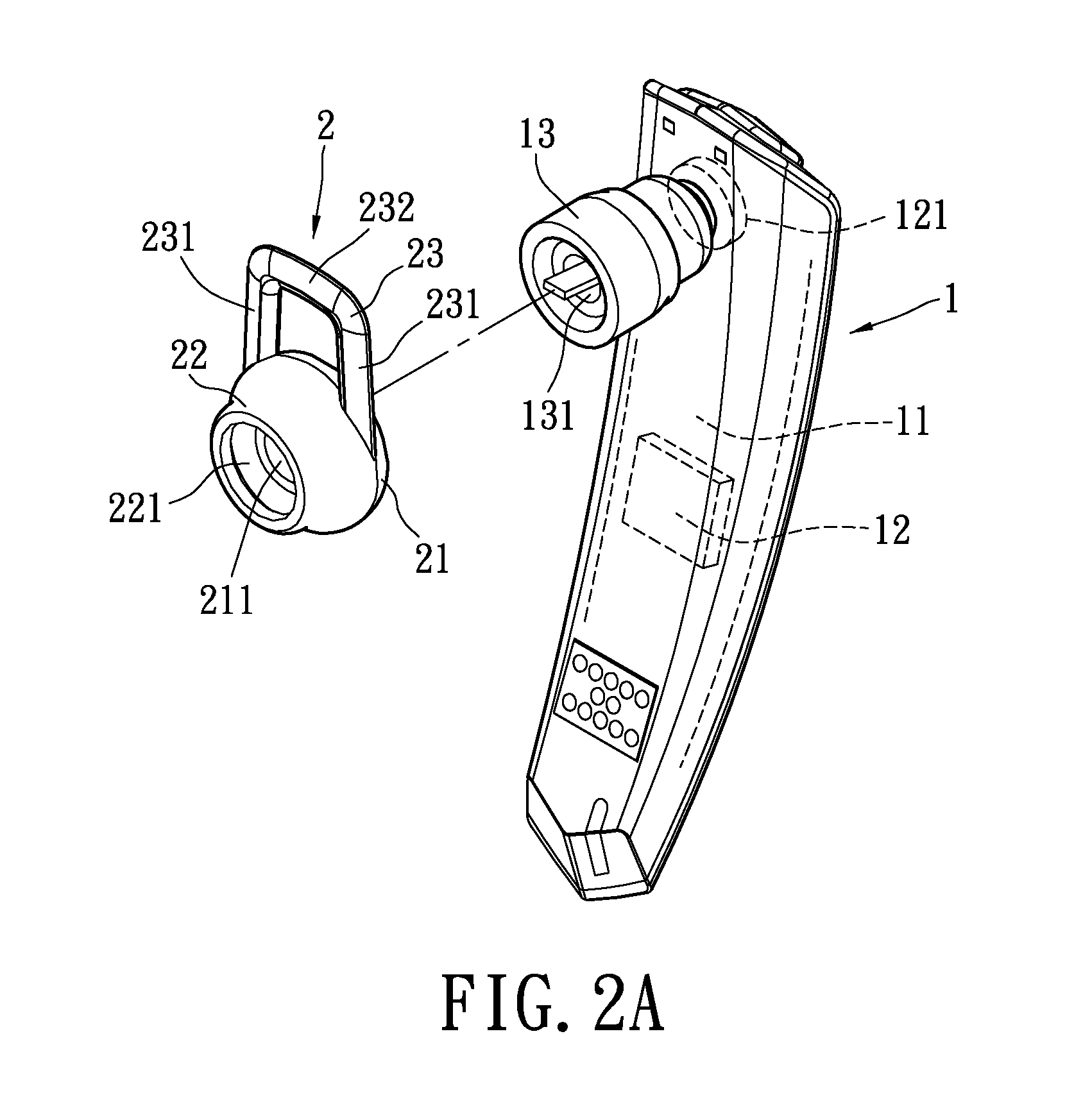

Earphone with a fixed function and earplug with a fixed function

InactiveUS20110176699A1Comfortably and stably secureImprove stereoIntra aural earpiecesDeaf-aid setsEngineering

An earphone with a fixed function includes an earphone housing having a holding portion and an earplug sleeved around the holding portion. The earplug has a sleeved portion, a fixed portion and an abutting portion. The fixed portion extended from a periphery of the sleeved portion has a bent portion and a jamming portion. One end of the bent portion is fixed on the sleeved portion and the other end of the bent portion is bent and extended to form the jamming portion.

Owner:SURE BEST

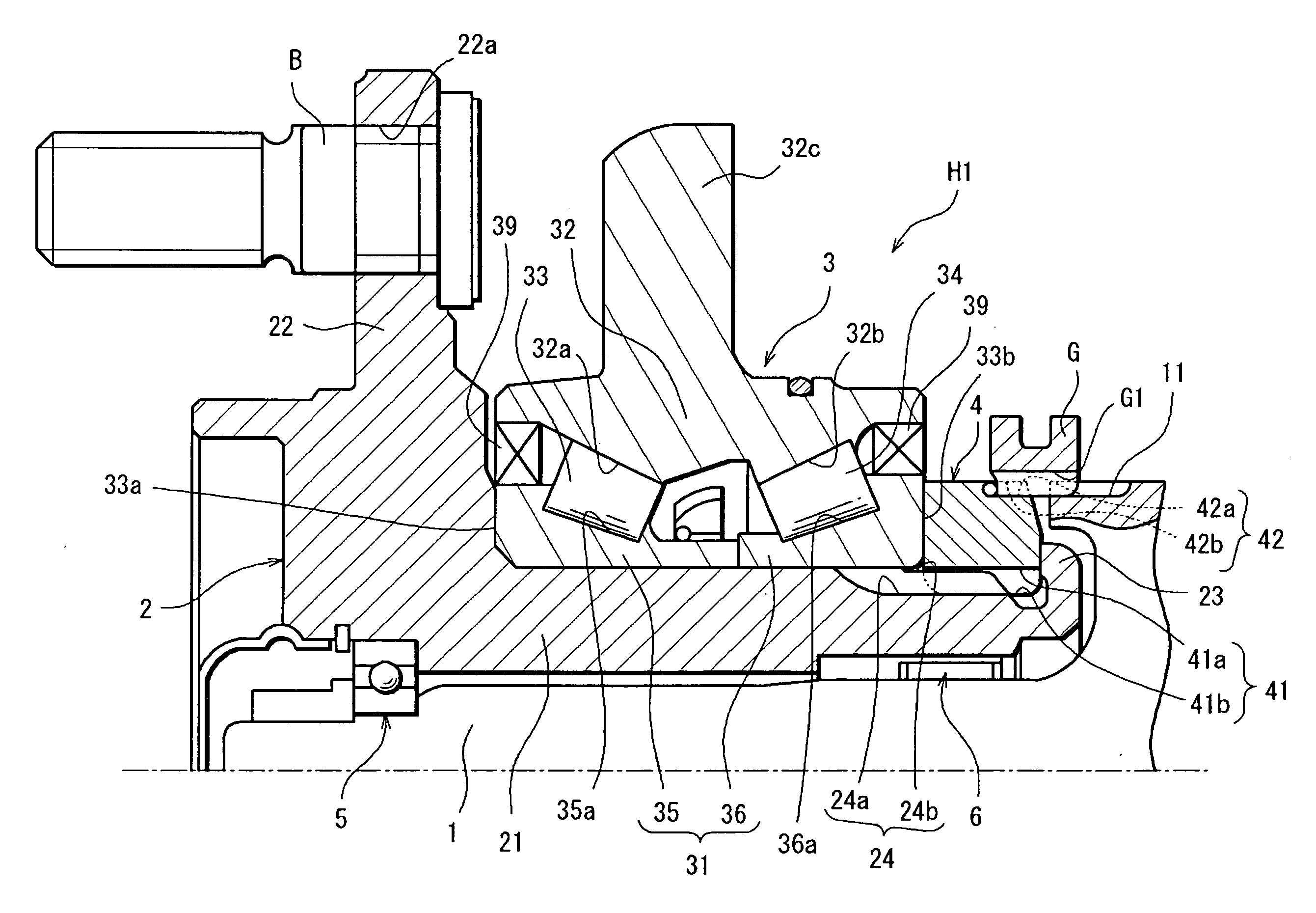

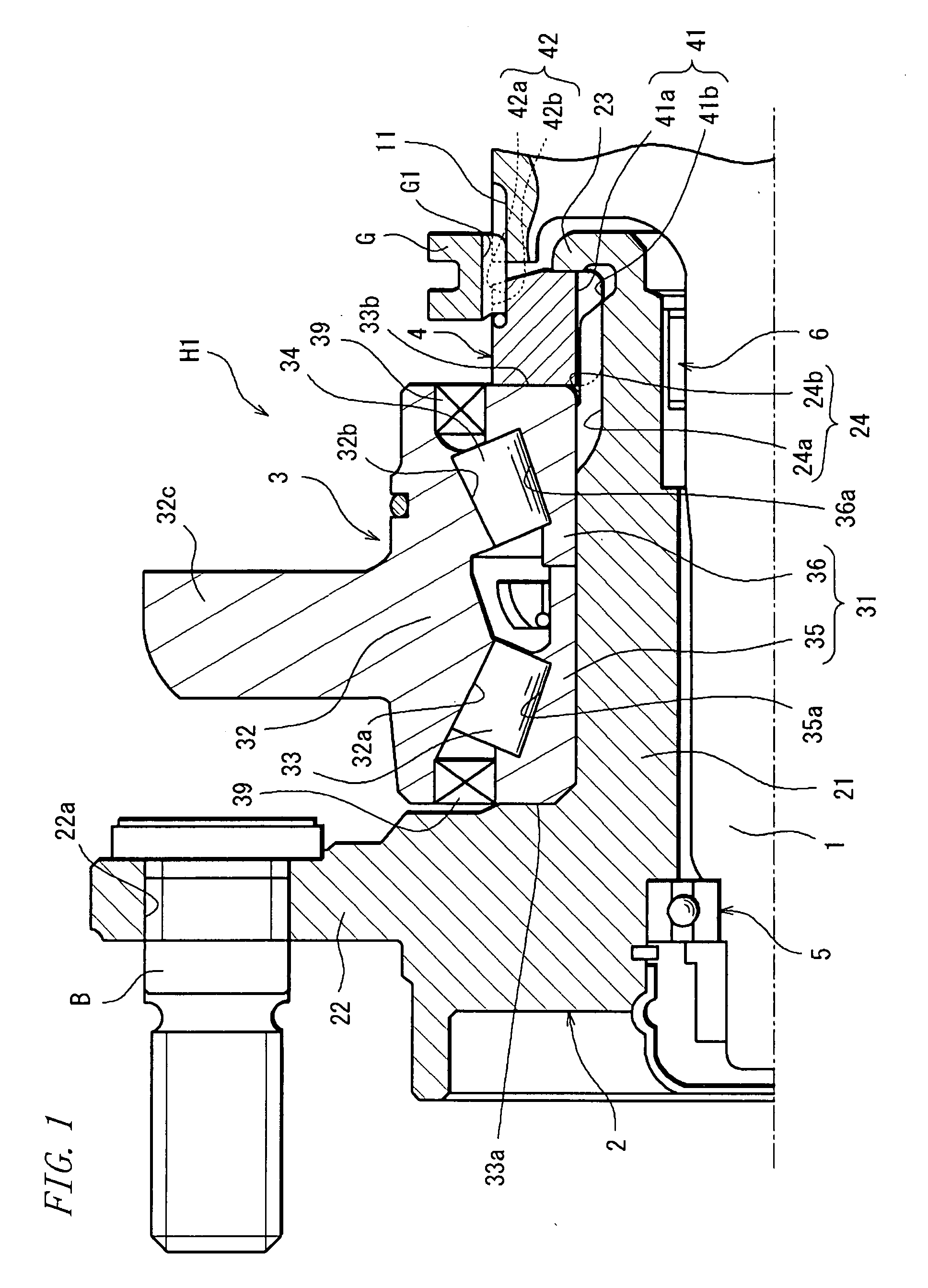

Hub Unit, Rolling Bearing Assembly and Manufacture Method Thereof, as Well as Assembling Apparatus for Rolling Bearing Assebly and Assebly Method Thereof

InactiveUS20070217728A1High-accuracy assembling operationAvoid crackingRolling contact bearingsHubsRolling-element bearingMechanical engineering

A rolling bearing adapted to prevent crack formation in a caulking portion is provided. A rolling bearing assembly includes: a hub shaft having the caulking portion at an axial end thereof, the caulking portion bendably deformed in a radially outward direction; the rolling bearing mounted on an outside surface of the hub shaft; and an annular member spline-engaged with the hub shaft and caulk-fixed to place by the caulking portion. An inner-side axial end of a second male spline formed on the hub shaft is shifted from an inner-side end of the hub shaft toward an outer side far enough to ensure that the second male spline is not susceptible to the plastic deformation of the caulked caulking portion.

Owner:JTEKT CORP

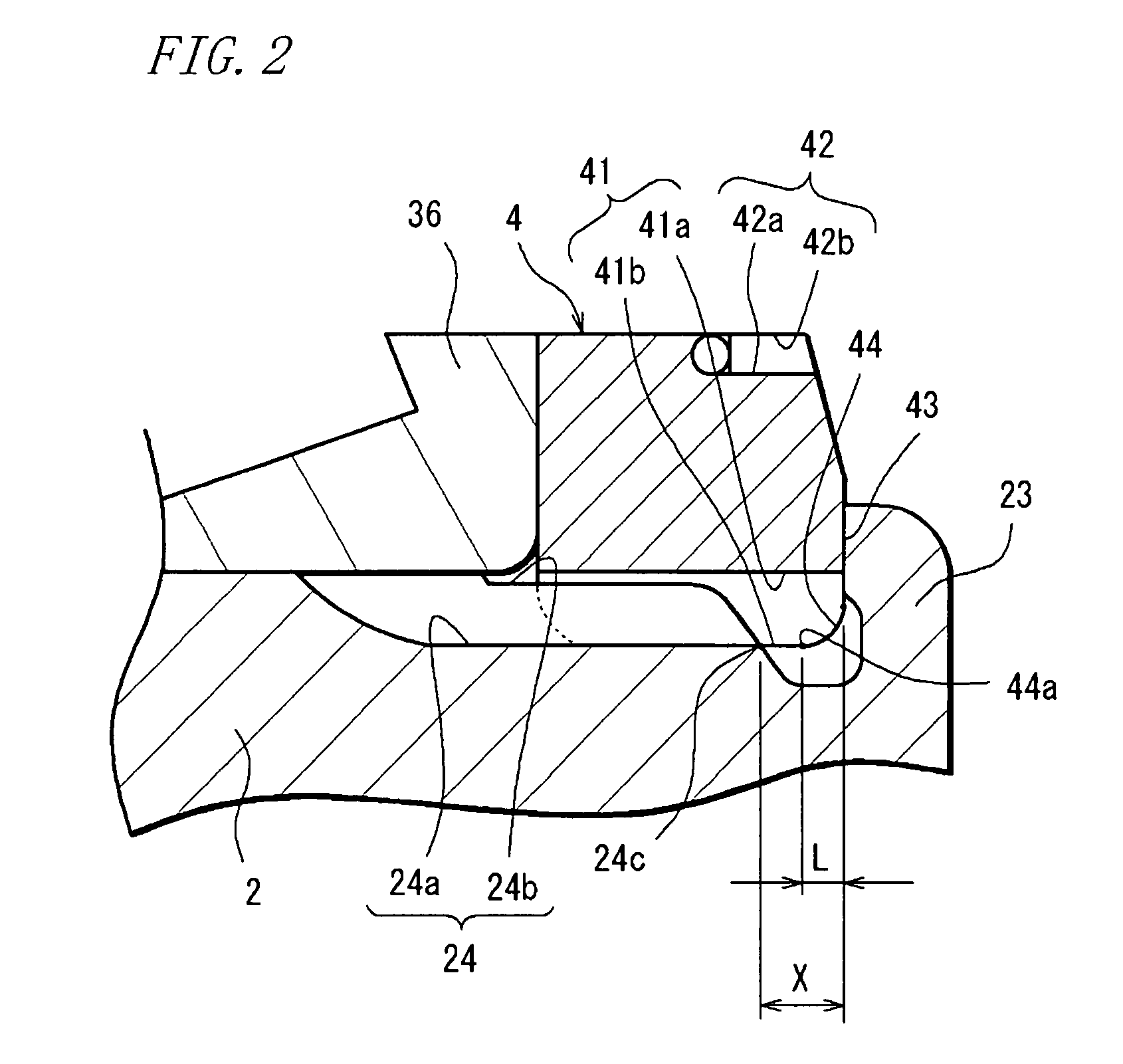

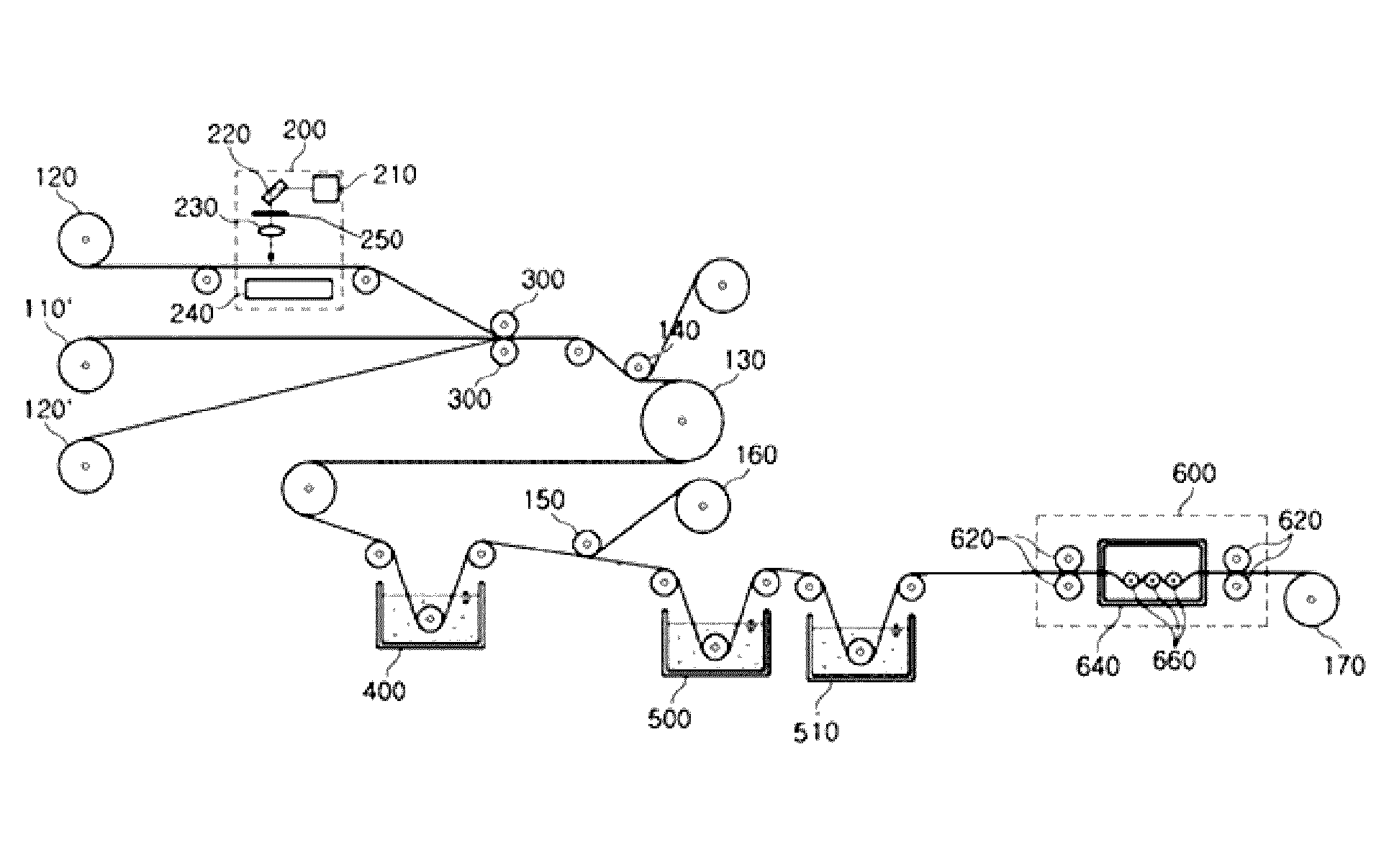

Methods for manufacturing polarizing element, polarizing element roll and single sheet type polarizing element having local bleaching areas (as amended)

ActiveUS20160299271A1Minimize damageImprove processing efficiencyOptical articlesPolarising elementsPolyvinyl alcoholEngineering

The present invention relates to a method for manufacturing a polarizing element including locally bleached areas including steps of providing a polarizing element including a polyvinyl alcohol-based polarizer in which at least one of iodine and dichroic dye is oriented in a certain direction; forming a mask layer including at least one punched area on one surface of the polarizing element; partially bleaching the polarizing element formed with the mask layer by immersing the polarizing element into a bleaching solution; and correcting an appearance of the partially bleached polarizing element.

Owner:LG CHEM LTD

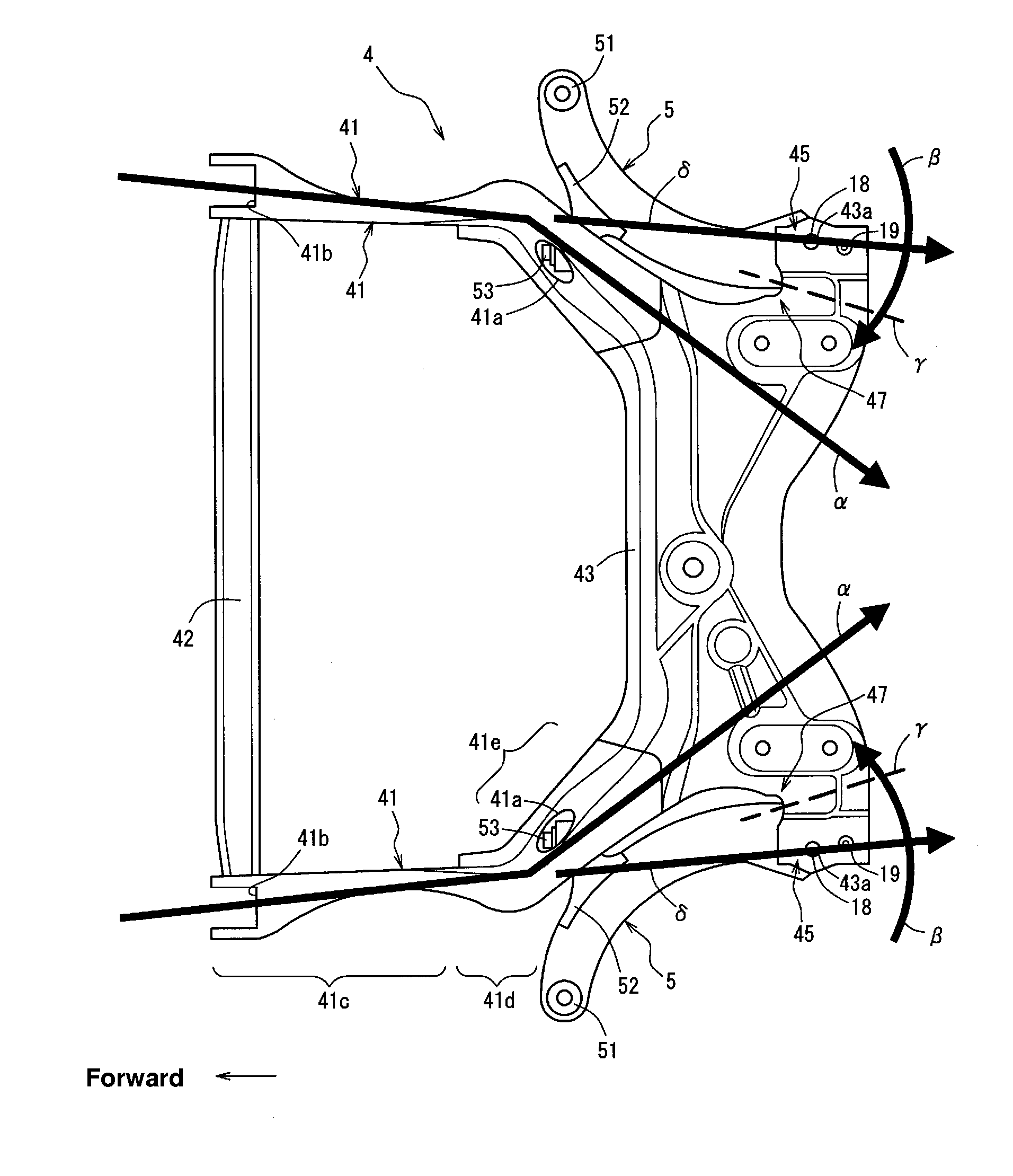

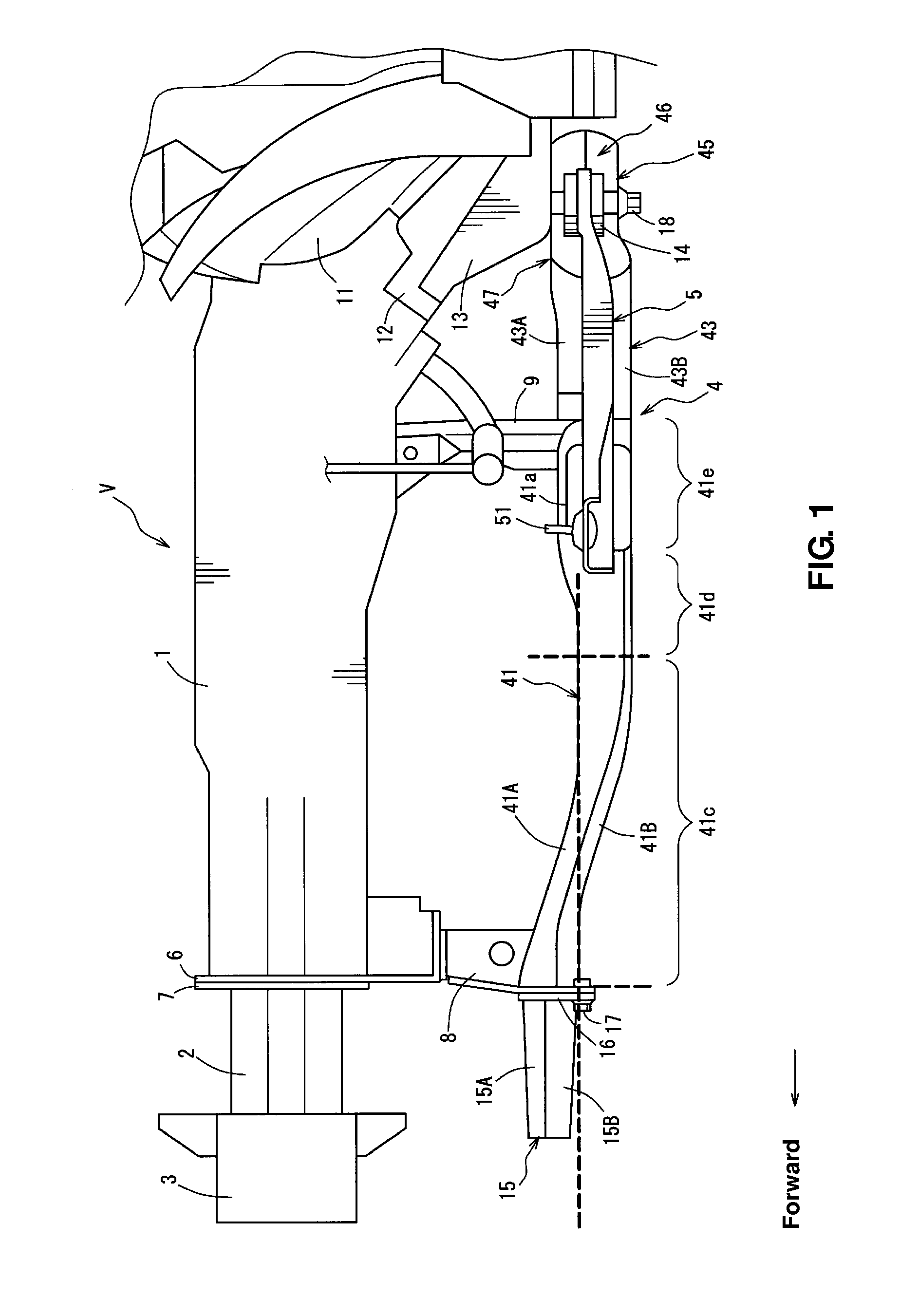

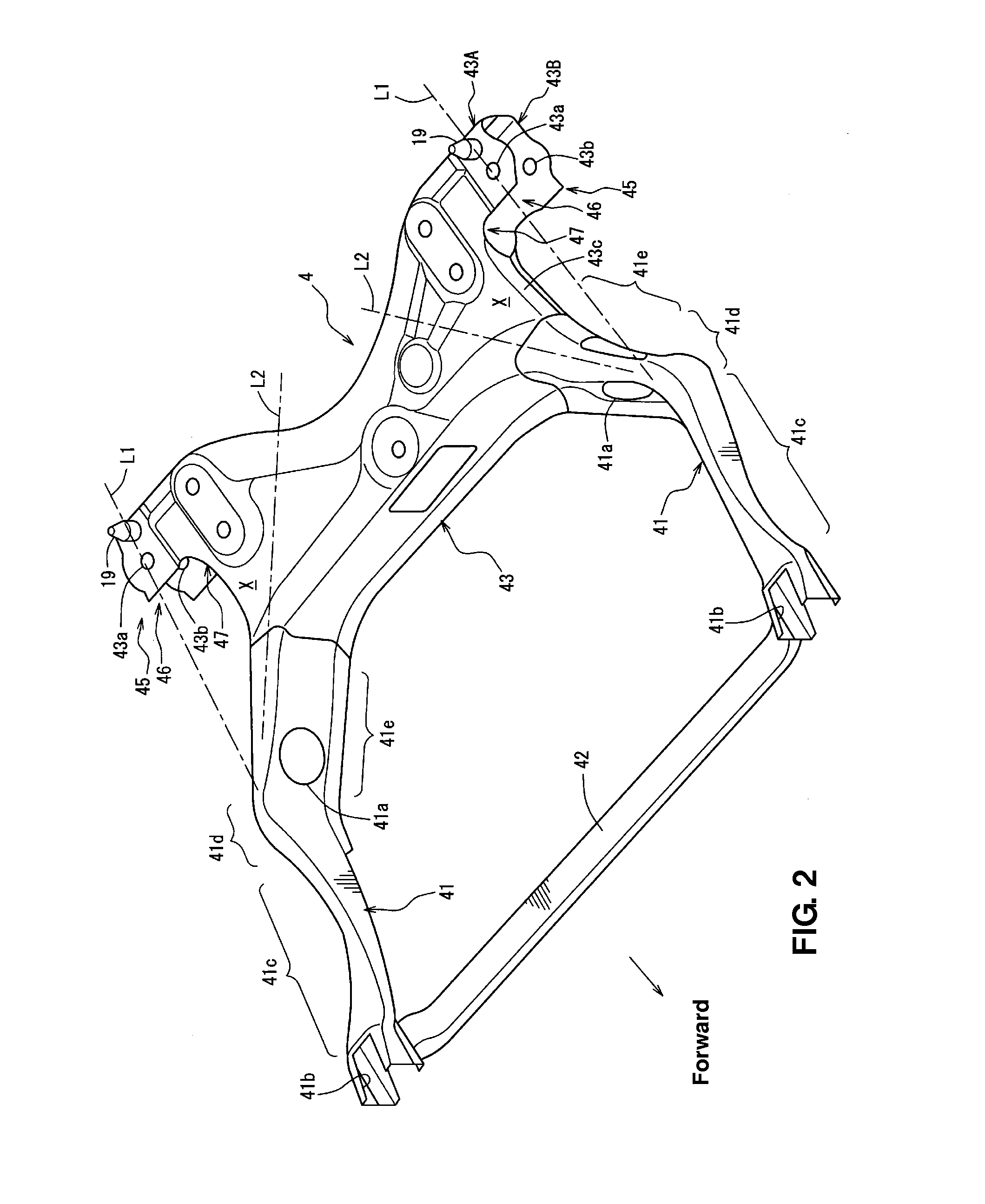

Front vehicle-body structure of vehicle

ActiveUS20140252739A1Correction of deformationEfficient executionUnderstructuresResilient suspensionsHead-on collisionEngineering

Owner:MAZDA MOTOR CORP

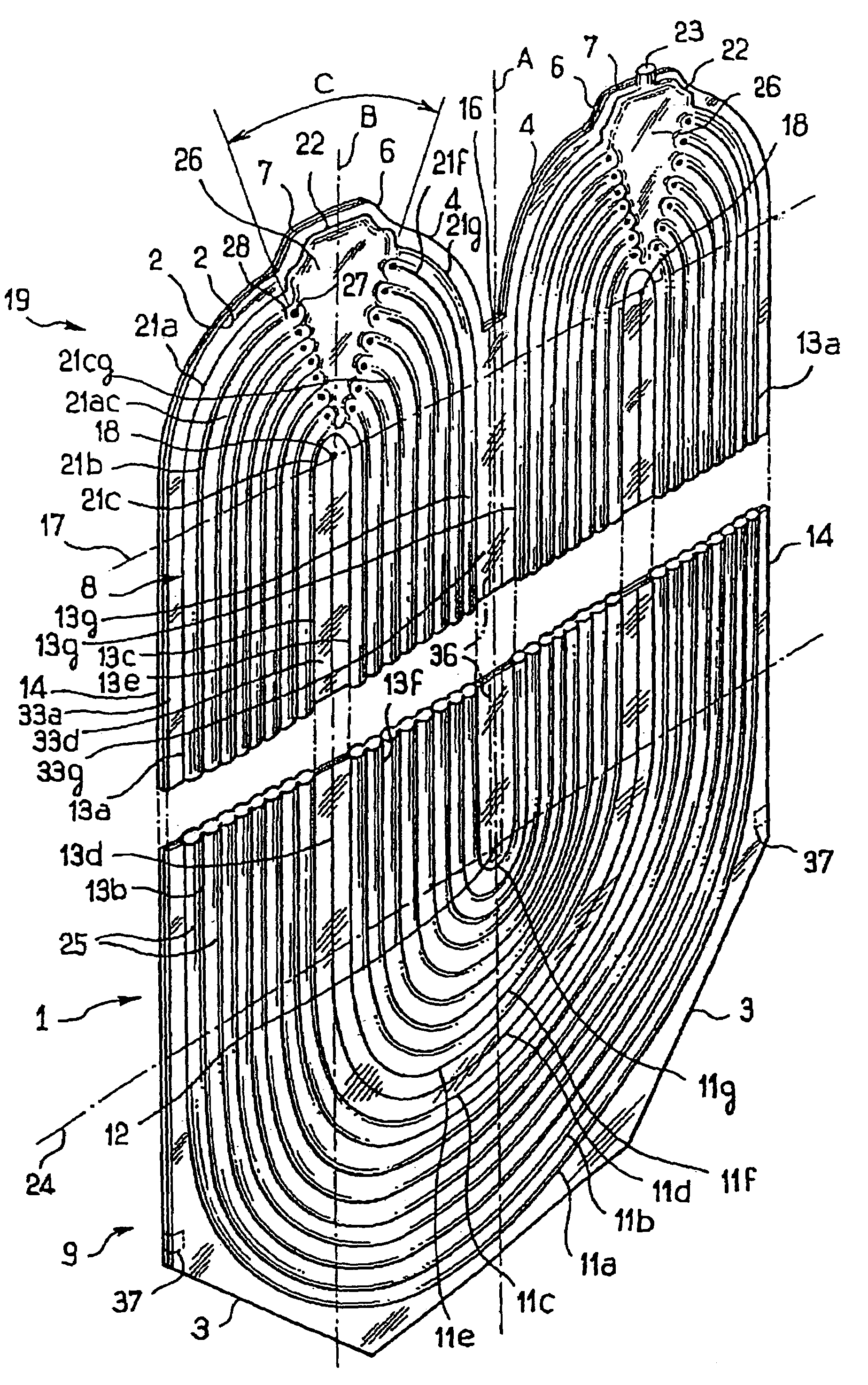

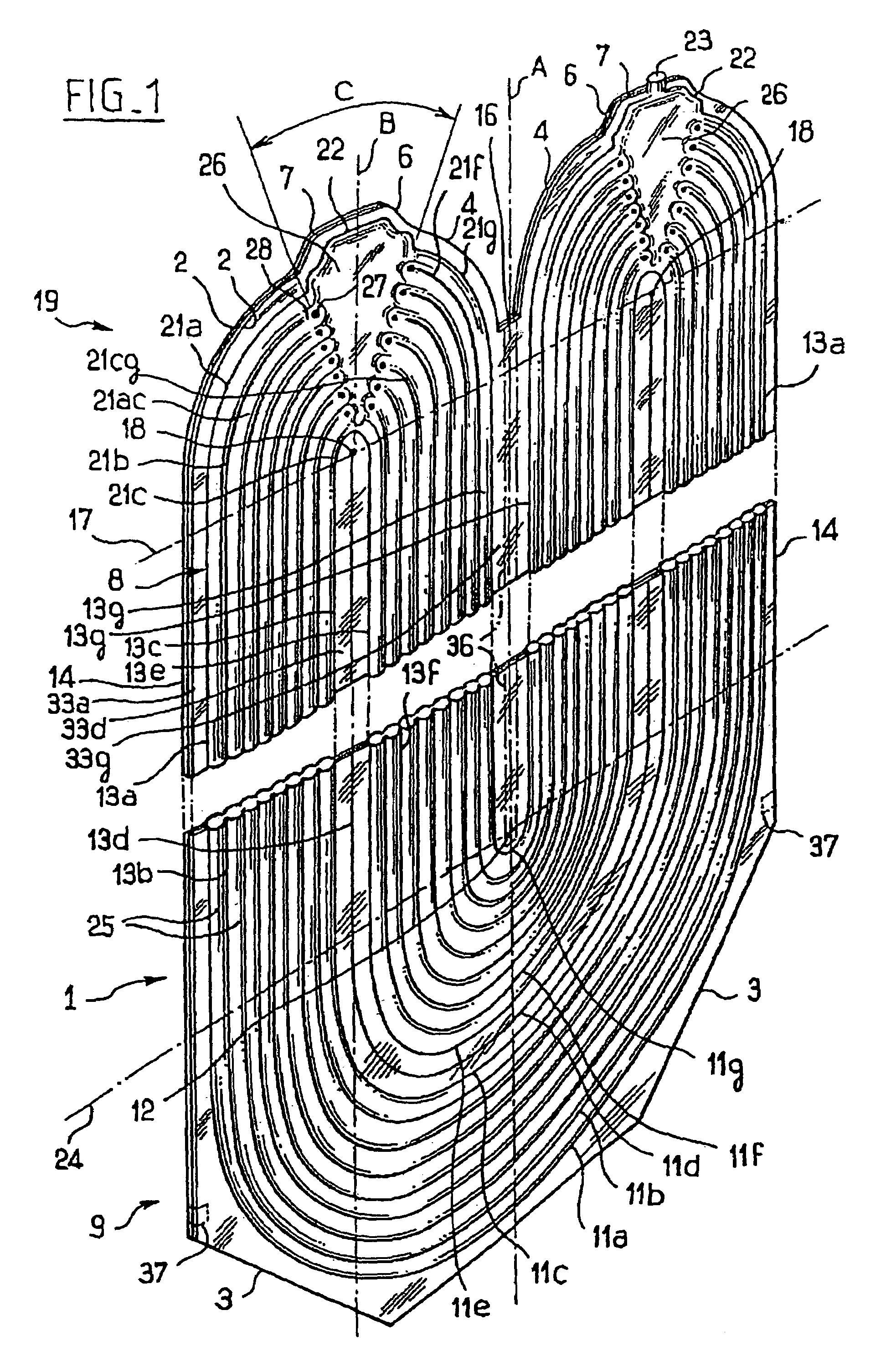

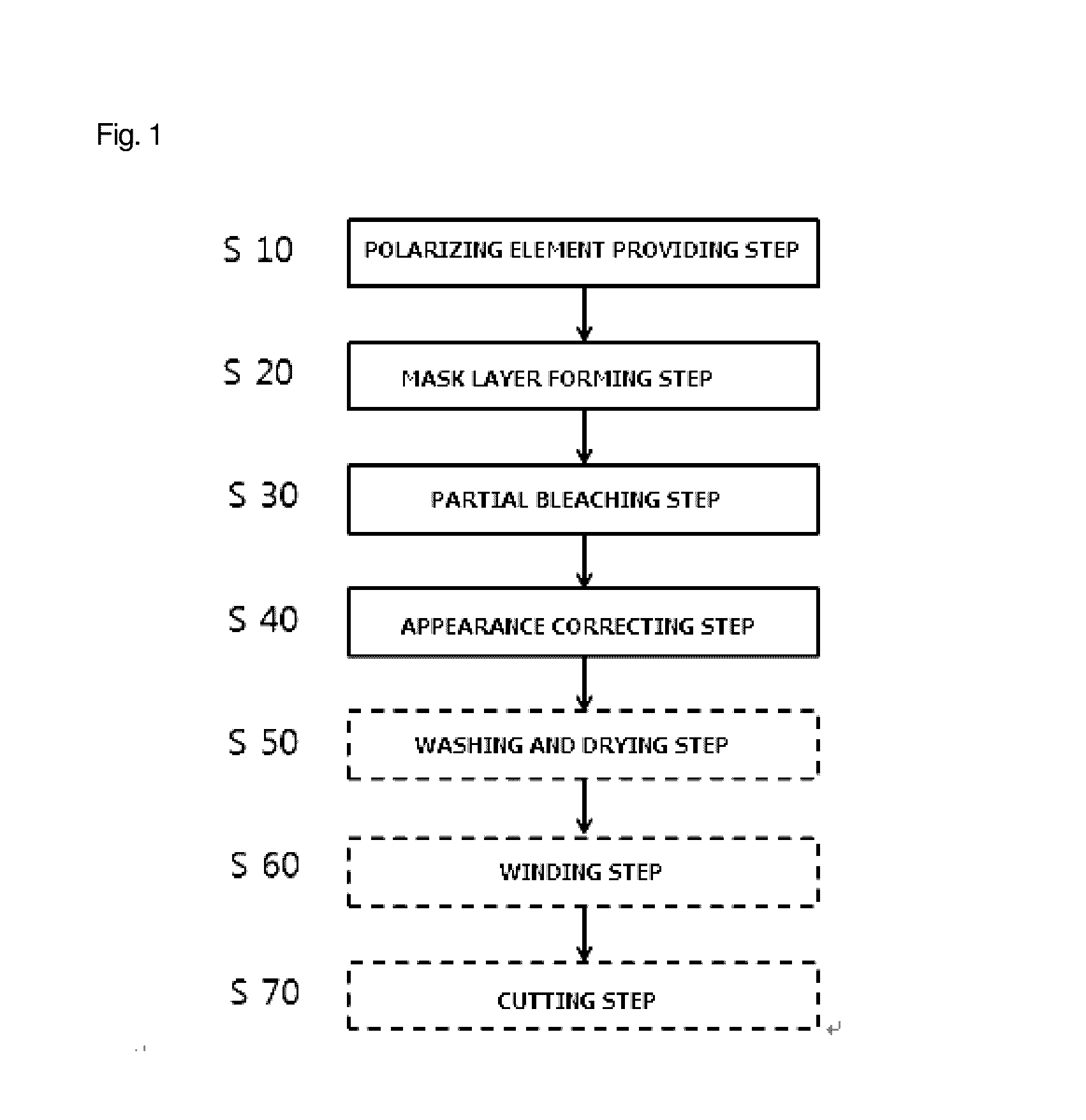

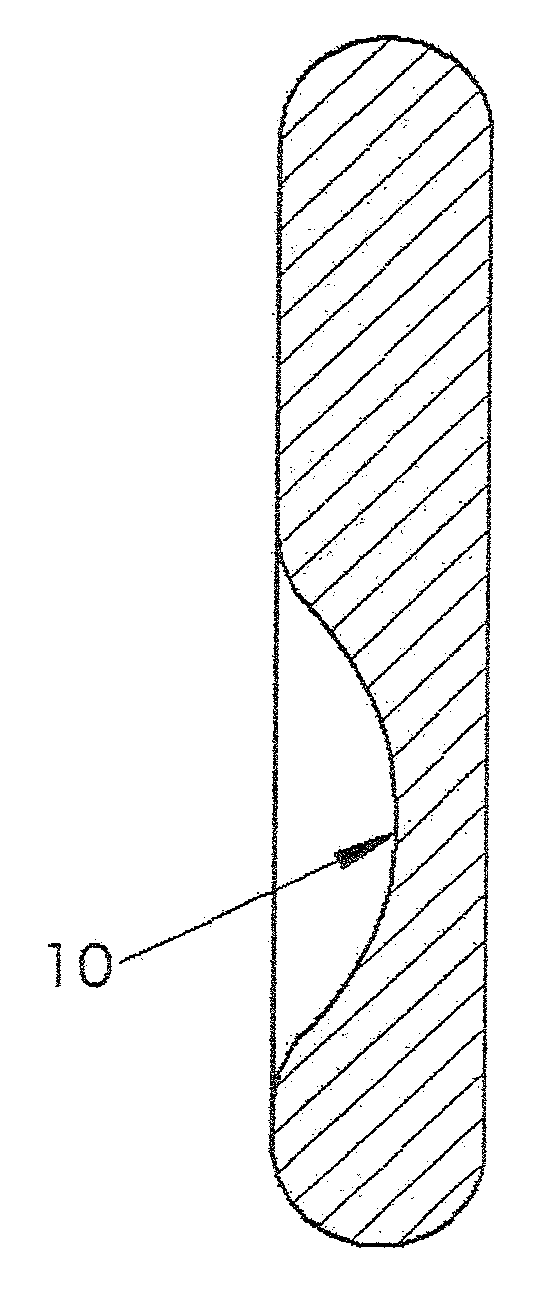

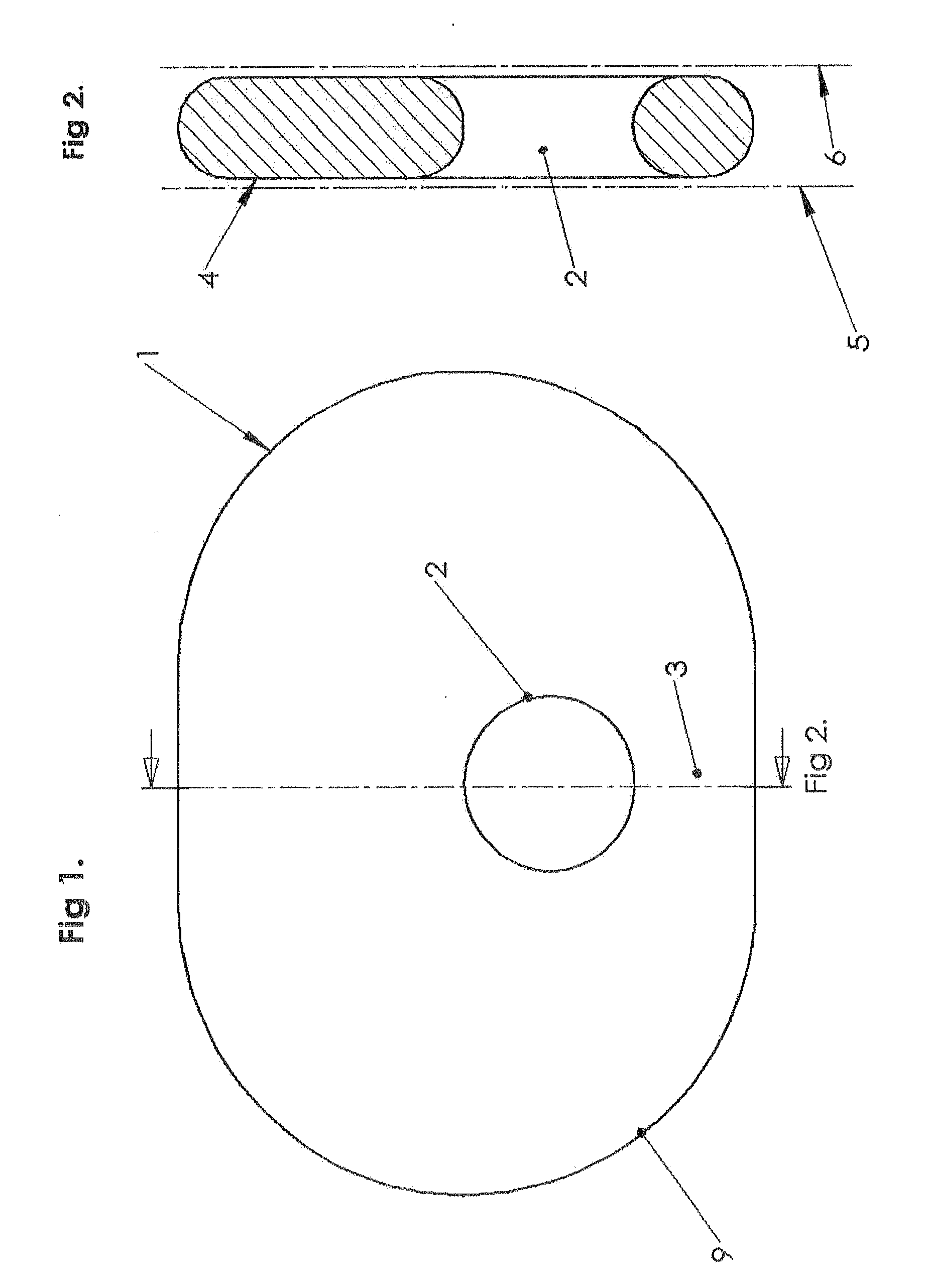

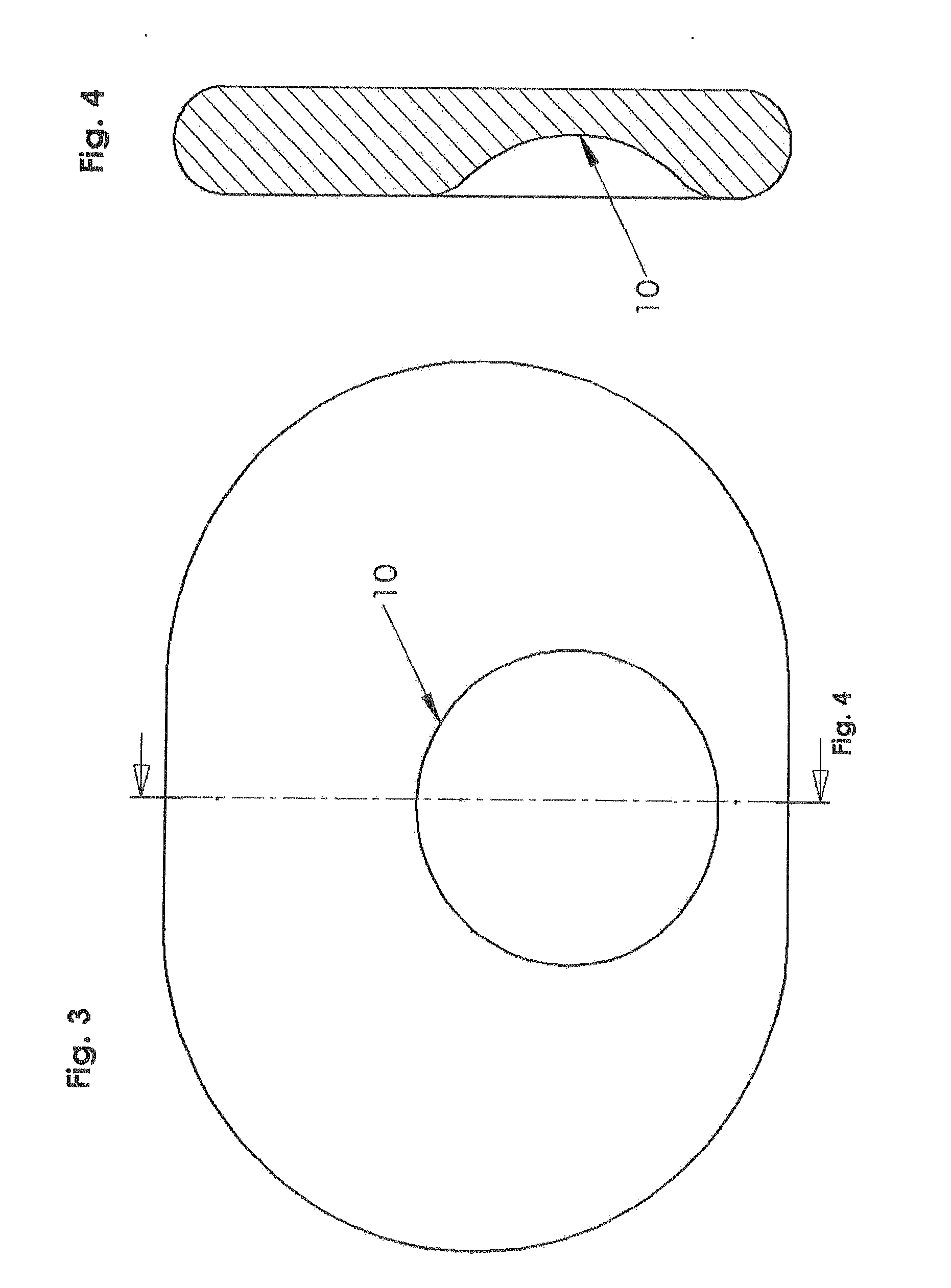

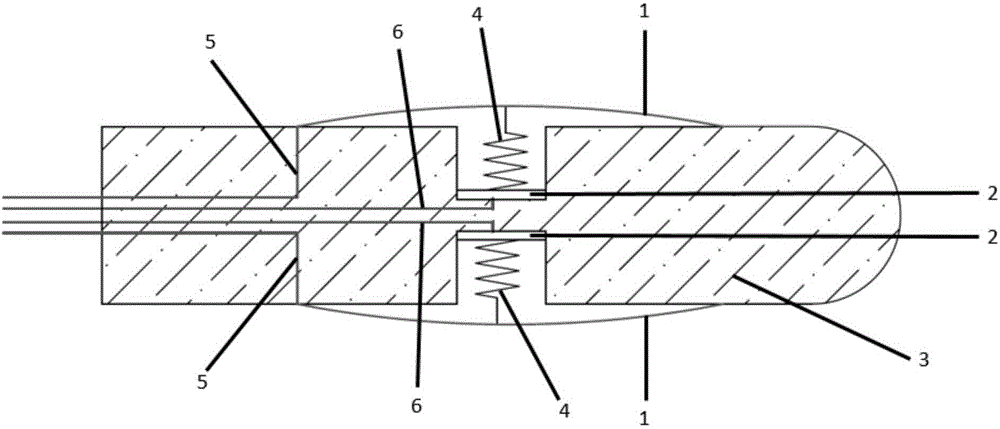

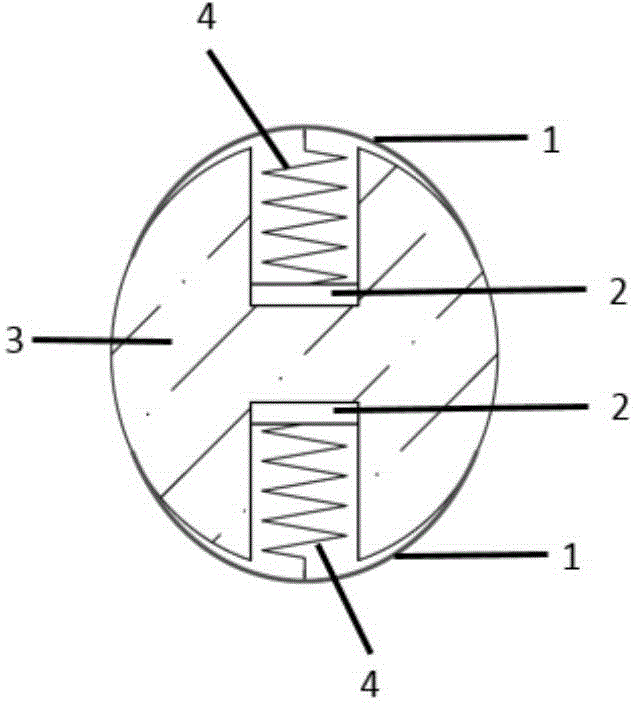

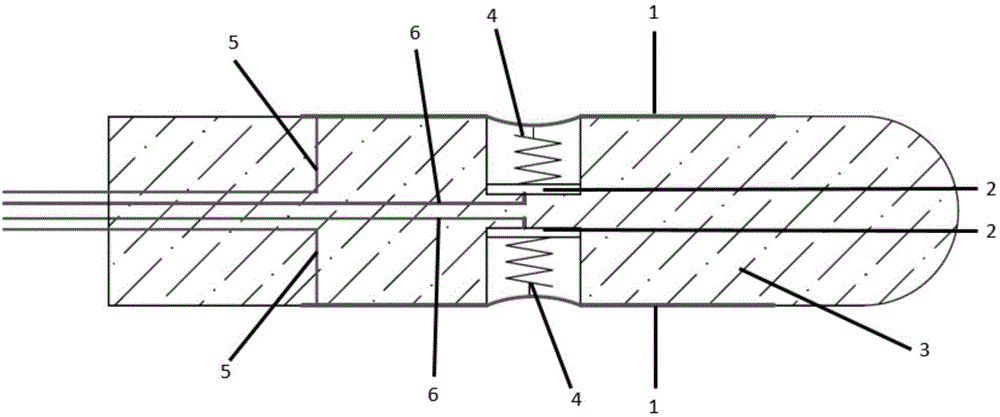

Device for osteosynthesis and for immobilization and stabilisation of tubular bones

ActiveUS20110106182A1Easy to useGreat fillet lengthSuture equipmentsInternal osteosythesisBiologyMechanical engineering

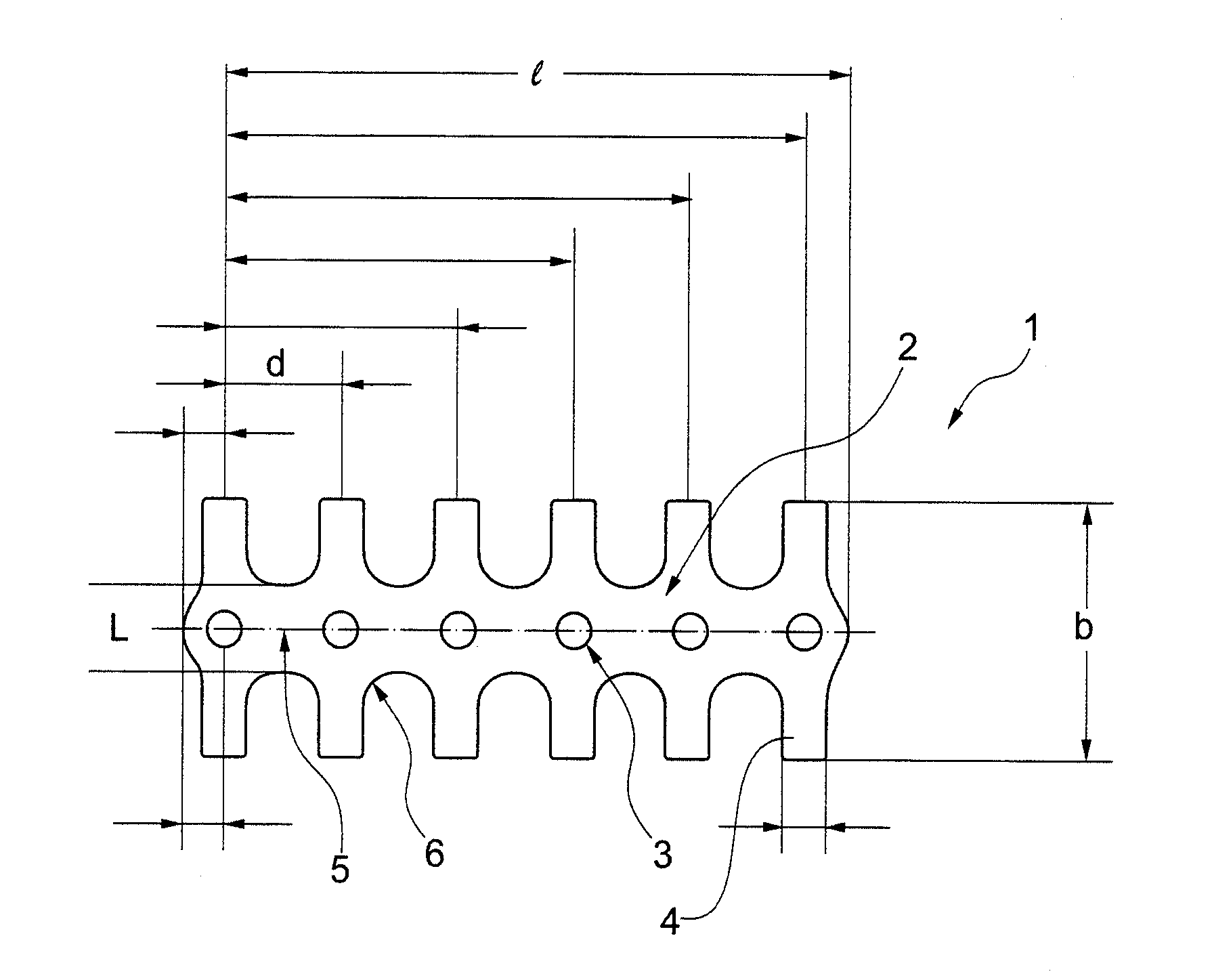

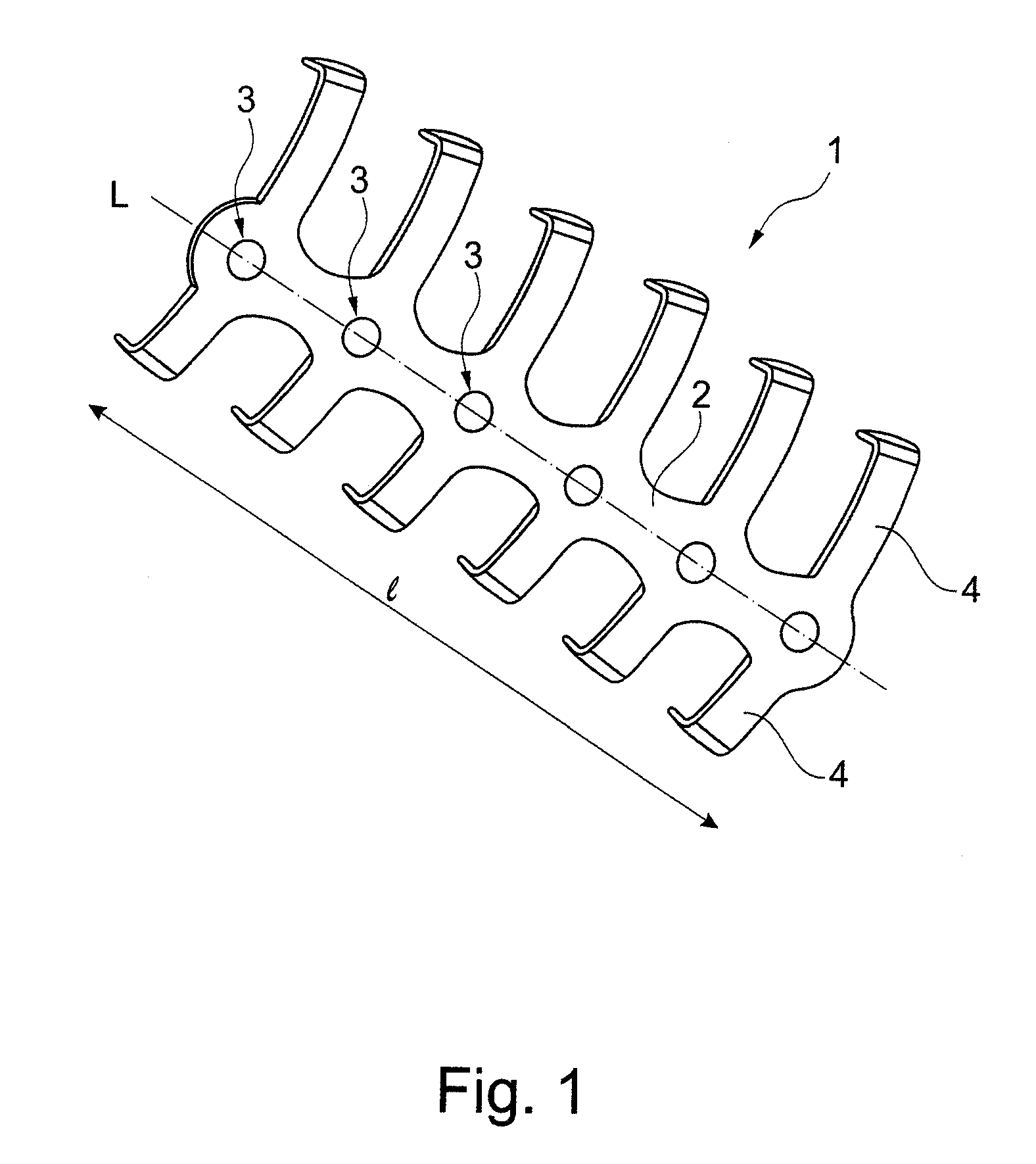

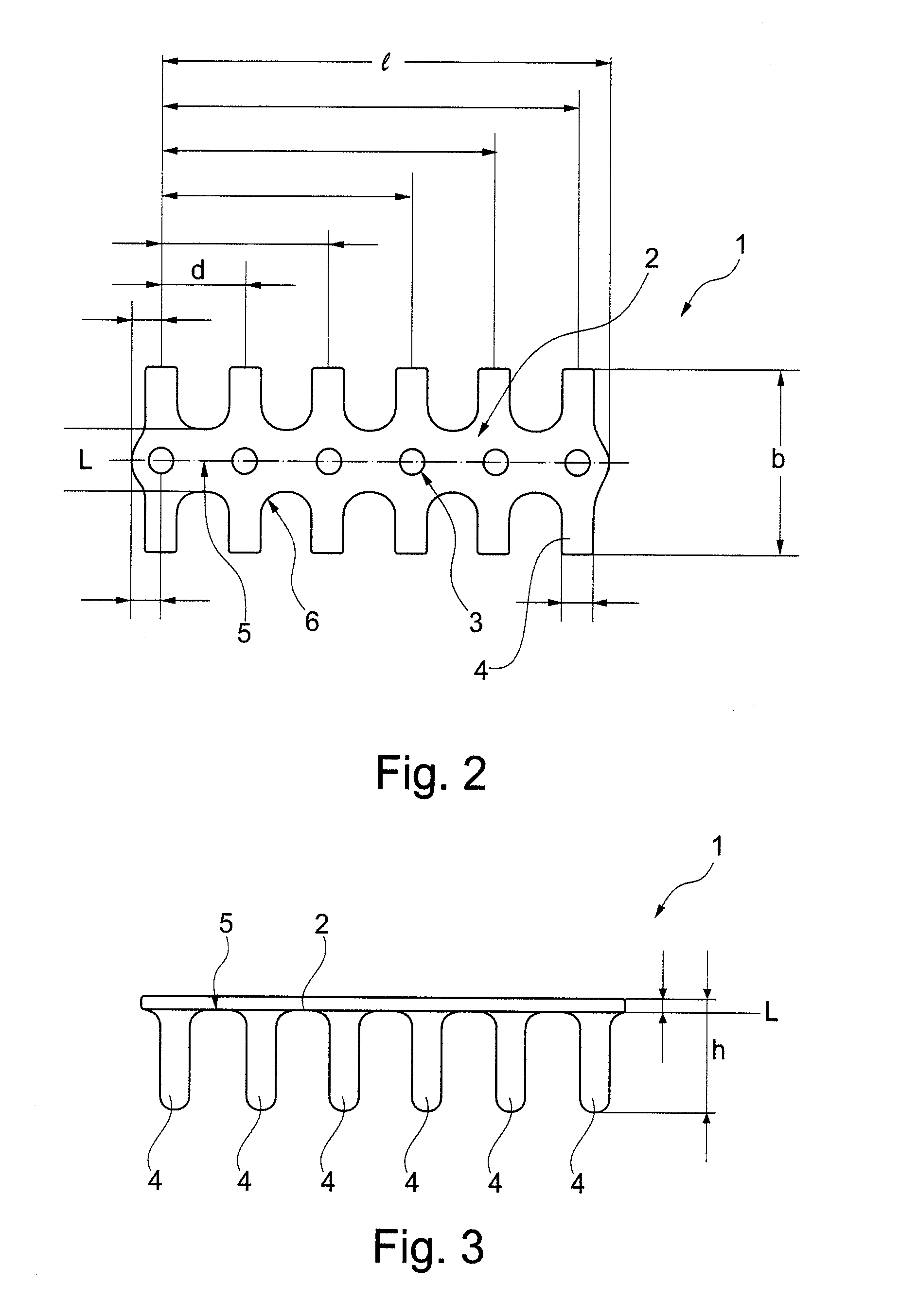

FIG. 1 shows an inventive implant 1. It has a central fillet 2 extending along a longitudinal axis L. The fillet 2 has openings 3 which are formed at regular intervals. At the level of the openings 3 and extending at right angles on both sides are clamps 4, which, when the implant is inserted, are brought into mutual engagement with a tubular bone and clamped to it. The fillet 2 is formed so as to be bendable in three-dimensions. It can be bent in two planes relative to the longitudinal axis L of the fillet 2 and torqued about the longitudinal axis L. Thus, a simple implant 1 with an overall regular structure is provided which can be cut with a cutting pliers to a desired length.

Owner:REISBERG ERHARD

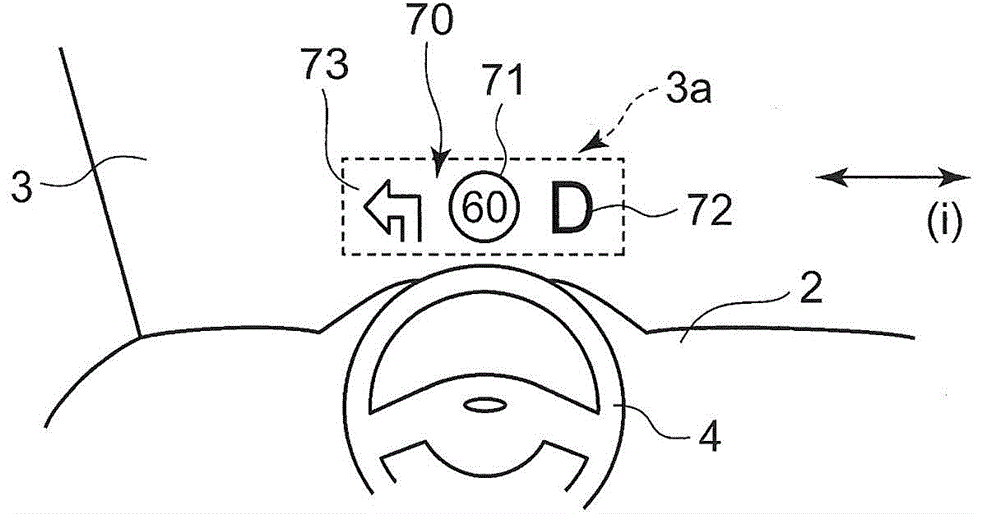

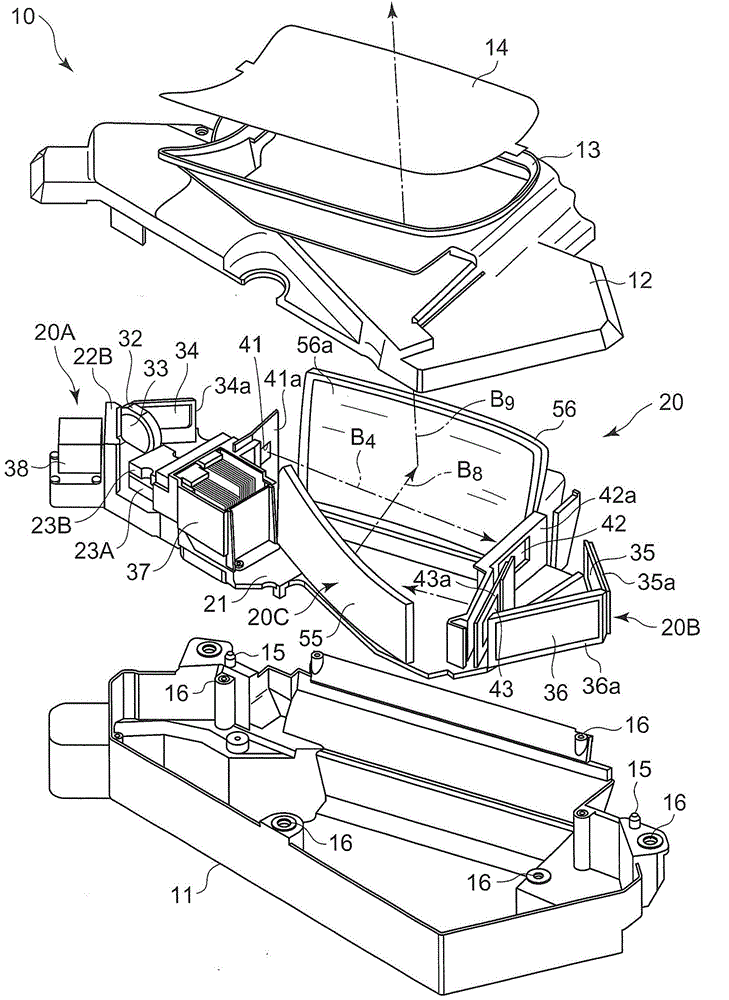

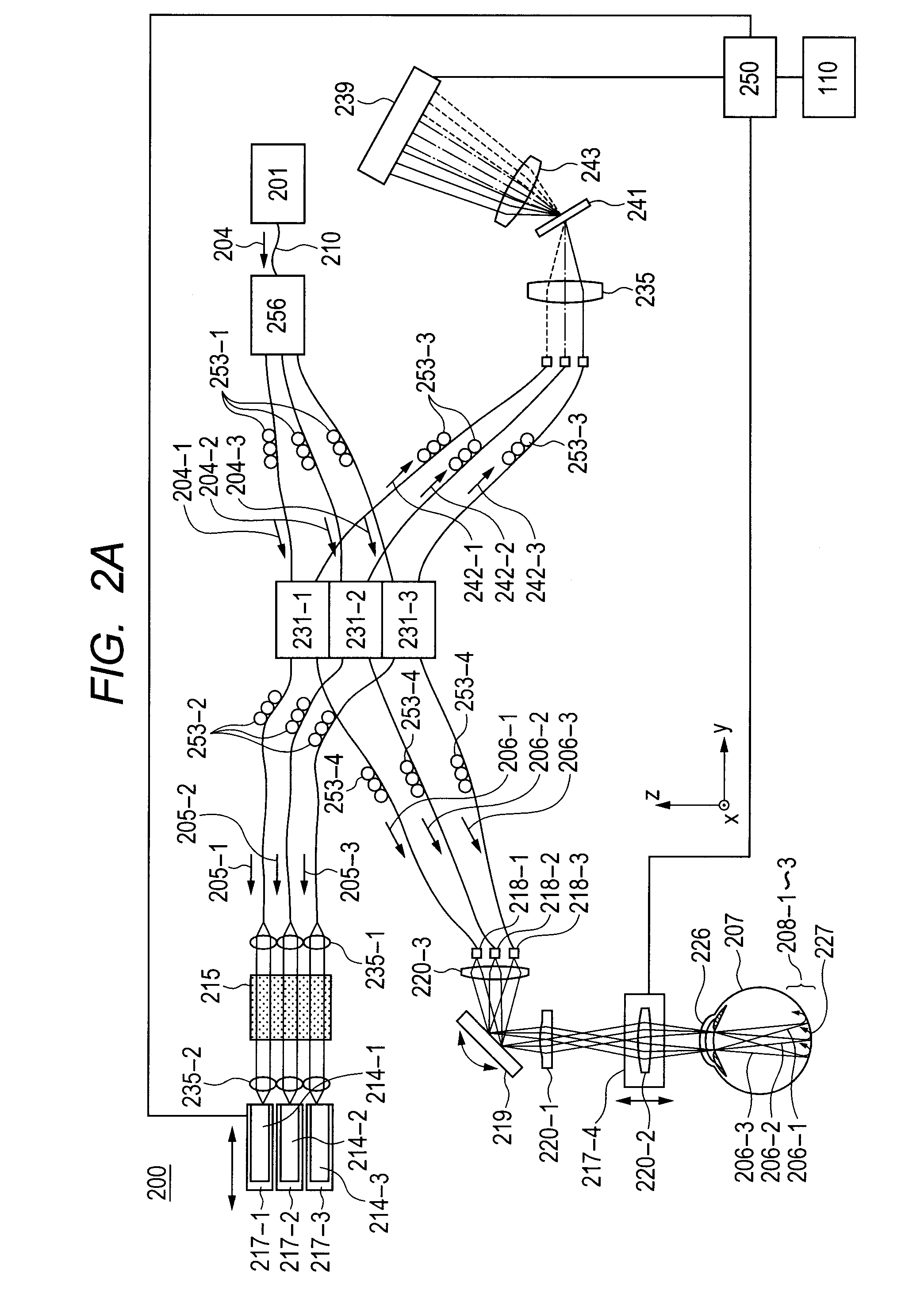

A vehicle-mounted projection device

ActiveCN104597601AAvoid deformationCorrection of deformationOptical viewingOptical elementsComputer sciencePhase modulation

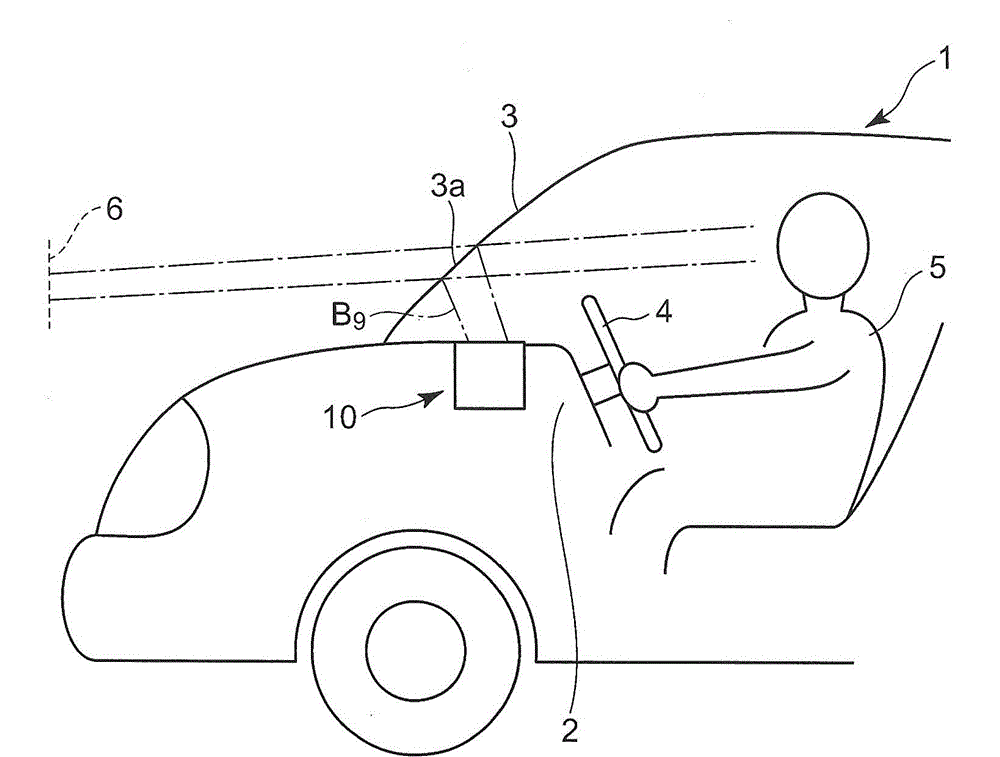

The invention provides a vehicle-mounted projection device. When the vehicle-mounted projection device projects a holographic image projected on a screen on a windshield, deformation of the image can be fully corrected even if the multiplying power is raised. According to the vehicle-mounted projection device, phase modulation is carried out on laser through utilization of a phase modulation array to enable the holographic image (70h) to form on the screen. The holographic image (70h) is reflected by a reflector (55a) of a first projection mirror (55) and a reflector (56a) of a second projection mirror (56) on the windshield. A projection ratio is set through utilization of the first projection mirror (55) and the second projection mirror (56), and deformation of the image due to inclination and bending of the windshield is corrected. Correction is realized through utilization of the two projection mirrors, so that deformation of the image can be suppressed even if the projection ratio is raised.

Owner:DUALITAS LTD

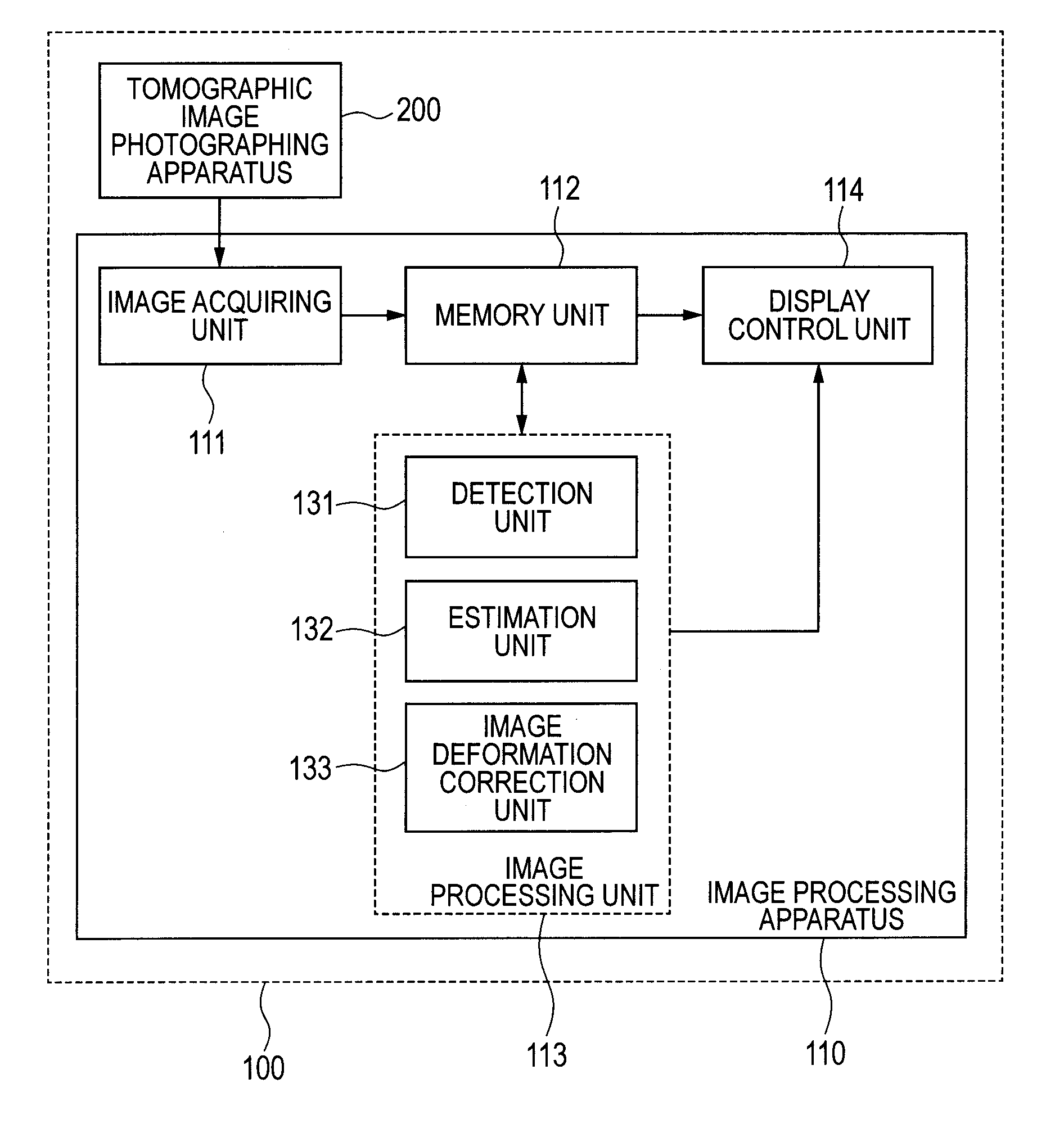

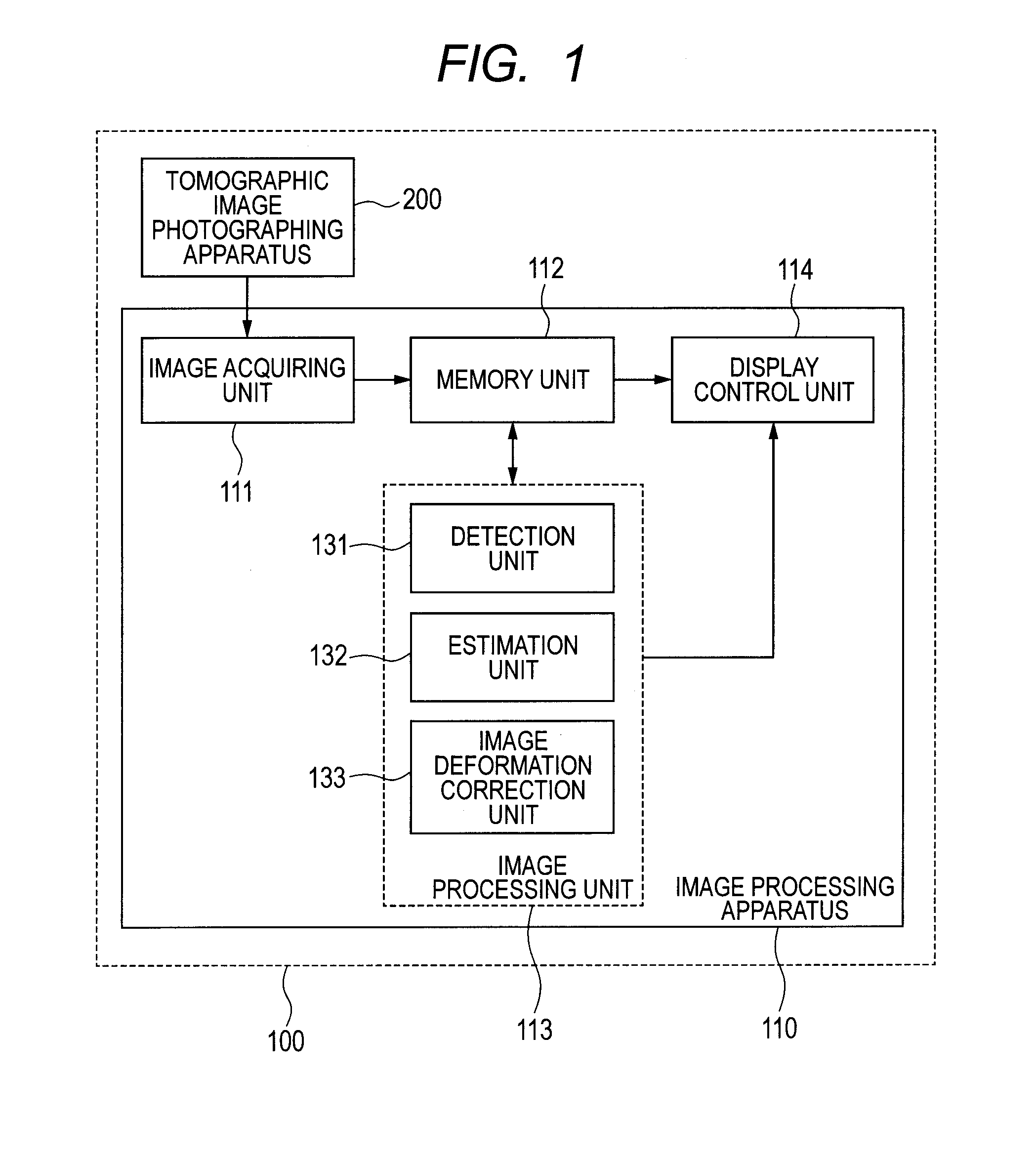

Image processing apparatus and method

InactiveUS20120288175A1Correction of deformationImage enhancementImage analysisImaging processingLight beam

In a tomographic image photographing apparatus, a deformation of a volume image is corrected accurately even if an object to be inspected moves when the volume image is acquired. An image processing apparatus acquires a tomographic image of the object to be inspected from combined light beams of return light beams, which is obtained by irradiating the object to be inspected with a plurality of measuring light beams, and corresponding reference light beams. In the image processing apparatus, a photographing unit obtains a tomographic image of a fundus with the plurality of measuring light beams, and a detection unit detects a retina layer from the tomographic image. Based on the detected retina layer, a fundus shape is estimated. Based on the estimated fundus shape, a positional deviation between tomographic images is corrected.

Owner:CANON KK

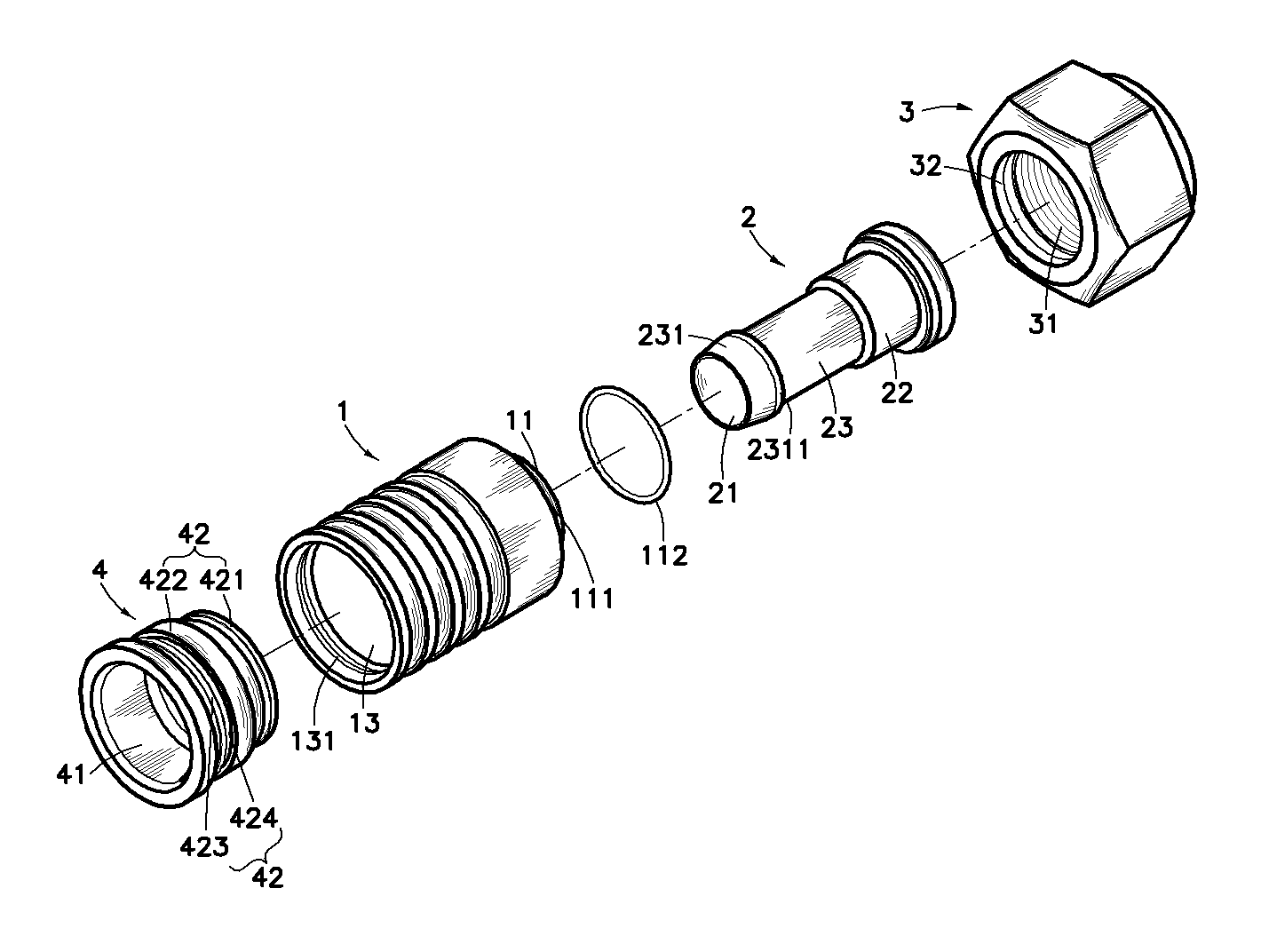

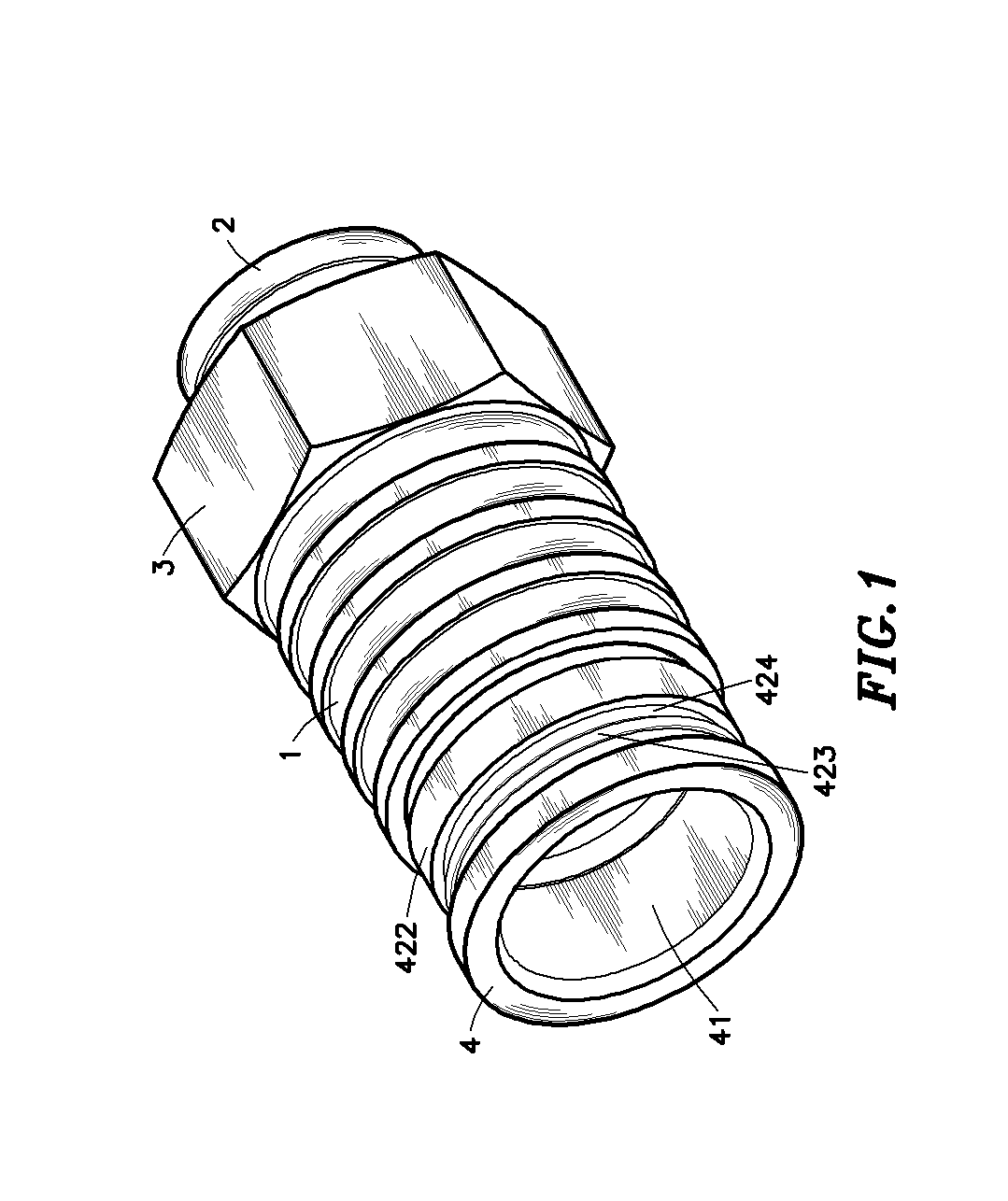

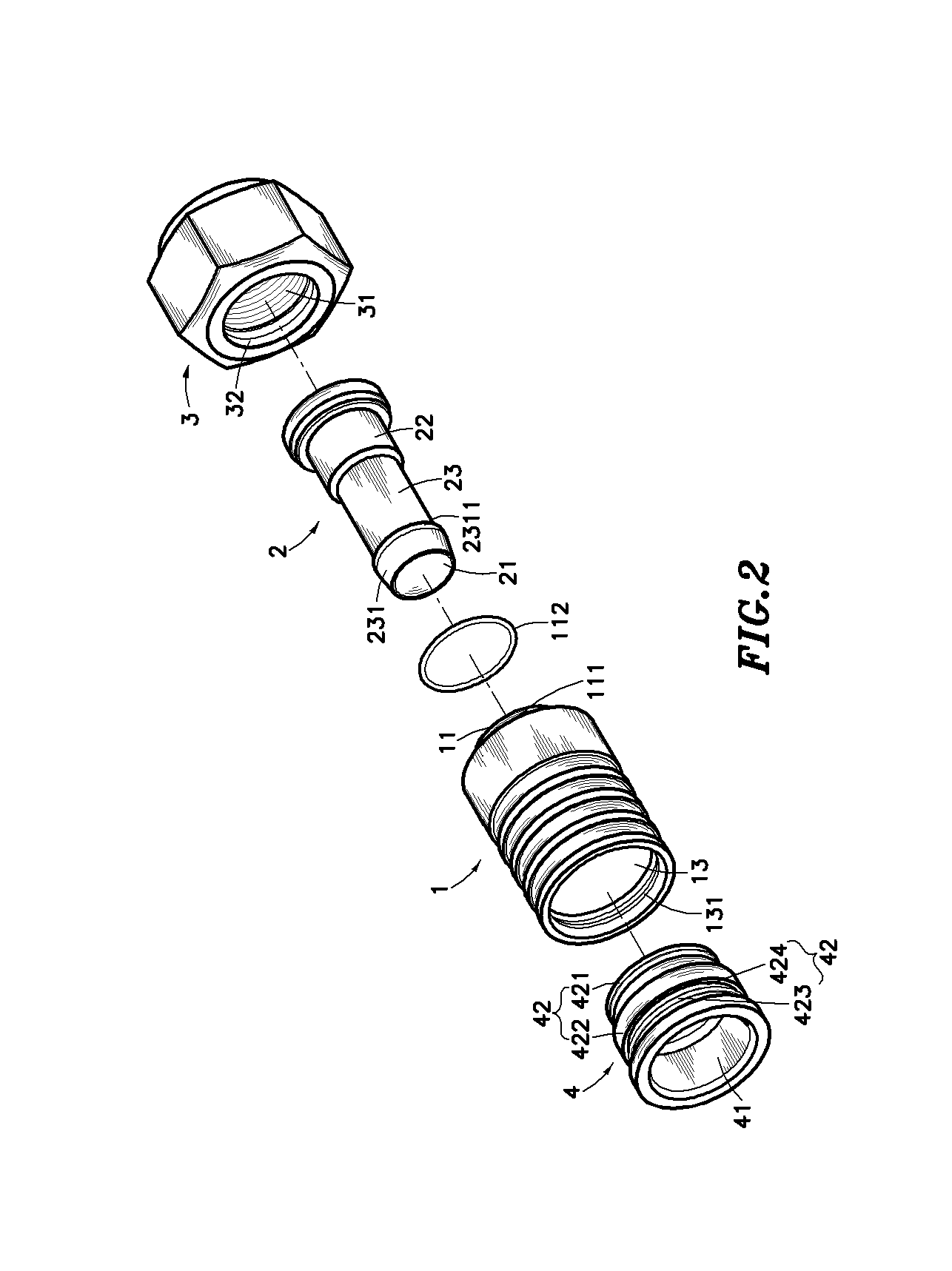

Structure of signal line connector

InactiveUS6960101B1Simple structureDrawback can be obviatedRelieving strain on wire connectionElectrically conductive connectionsElectrical conductorCoupling

A signal line connector includes a locknut, a hollow cylindrical casing, which has a coupling neck extended from one end thereof and fitted into the locknut, a locating barrel fitted into the other end of the casing, the locating barrel having a pressure collar and an outside annular flange extended around the periphery thereof for engaging into the hollow cylindrical casing to force the locating barrel to deform at an amount subject to the size of the signal line used, the pressure collar and the outside annular flange of the locating barrel having different outer diameters, and an outside annular groove defined between the pressure collar and the outside annular flange for buffering and compensating the deformation, and a center holding down tube mounted in the casing and secured to the locknut by the casing for holding down a tubular outer conductor and an outer insulative layer of a signal line against the inside wall of the locating barrel, keeping a center conductor of the signal line axially suspended in the locknut.

Owner:CABLENET

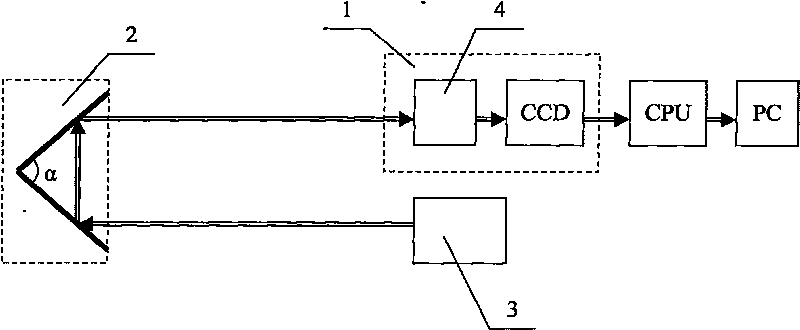

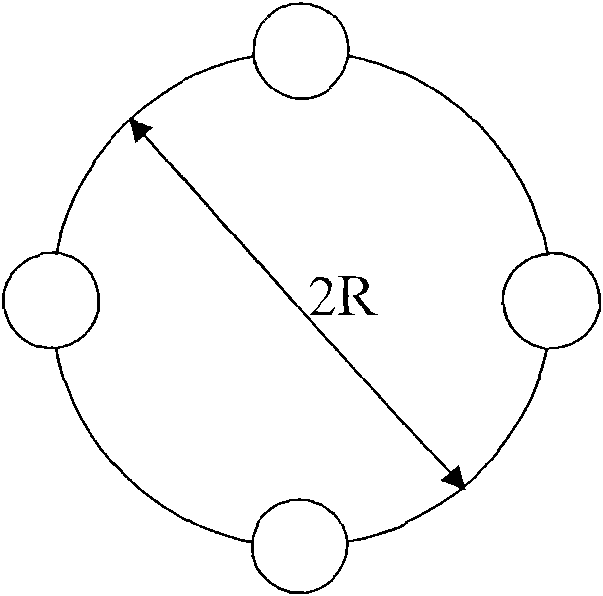

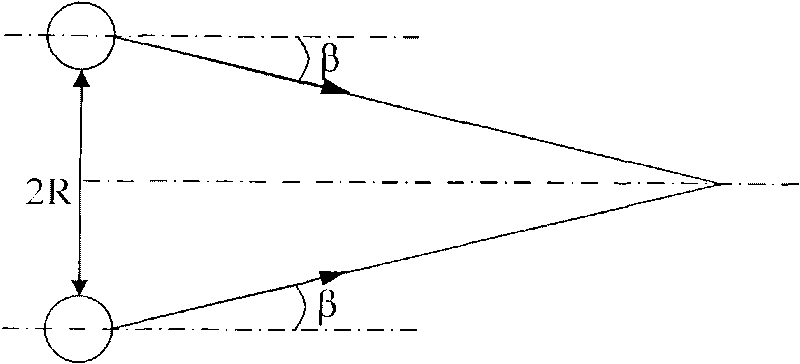

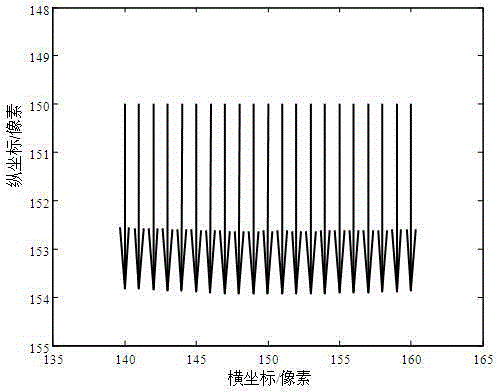

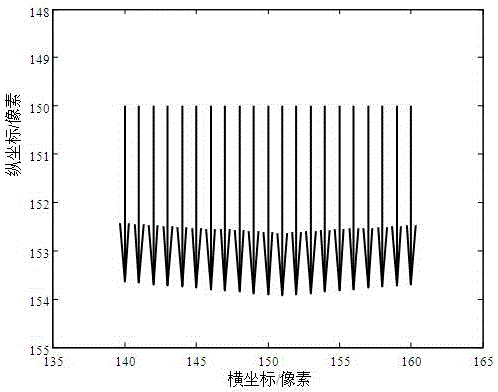

Multi-beam deformation detecting device and use method thereof

InactiveCN101718529ACorrection of deformationHigh precisionUsing optical meansDigital signal processingOffset distance

The invention relates to a multi-beam deformation detecting device which comprises a probe, a digital signal processor DSP, a personal computer PC, a laser group and a prism reflection target, wherein the prism reflection target is arranged on a point to be tested, the probe and the laser group are arranged on a measuring point, a laser beam group emitted from the laser group is reflected through the prism reflection target by adjusting the laser group and then forms an overlapped light spot on the probe, a barycenter of the overlapped light spot is determined by utilizing a photoelectronic tracing macro pixel iteration barycenter method, and the deformation of the point to be tested is further determined through the barycenter offset distance. The invention can effectively avoid the influences on environmental change, air turbulence and stray light, can realize long-term online monitoring, and has accurate measurement data, high detection precision, simple structure, low cost and convenient operation.

Owner:CHONGQING UNIV

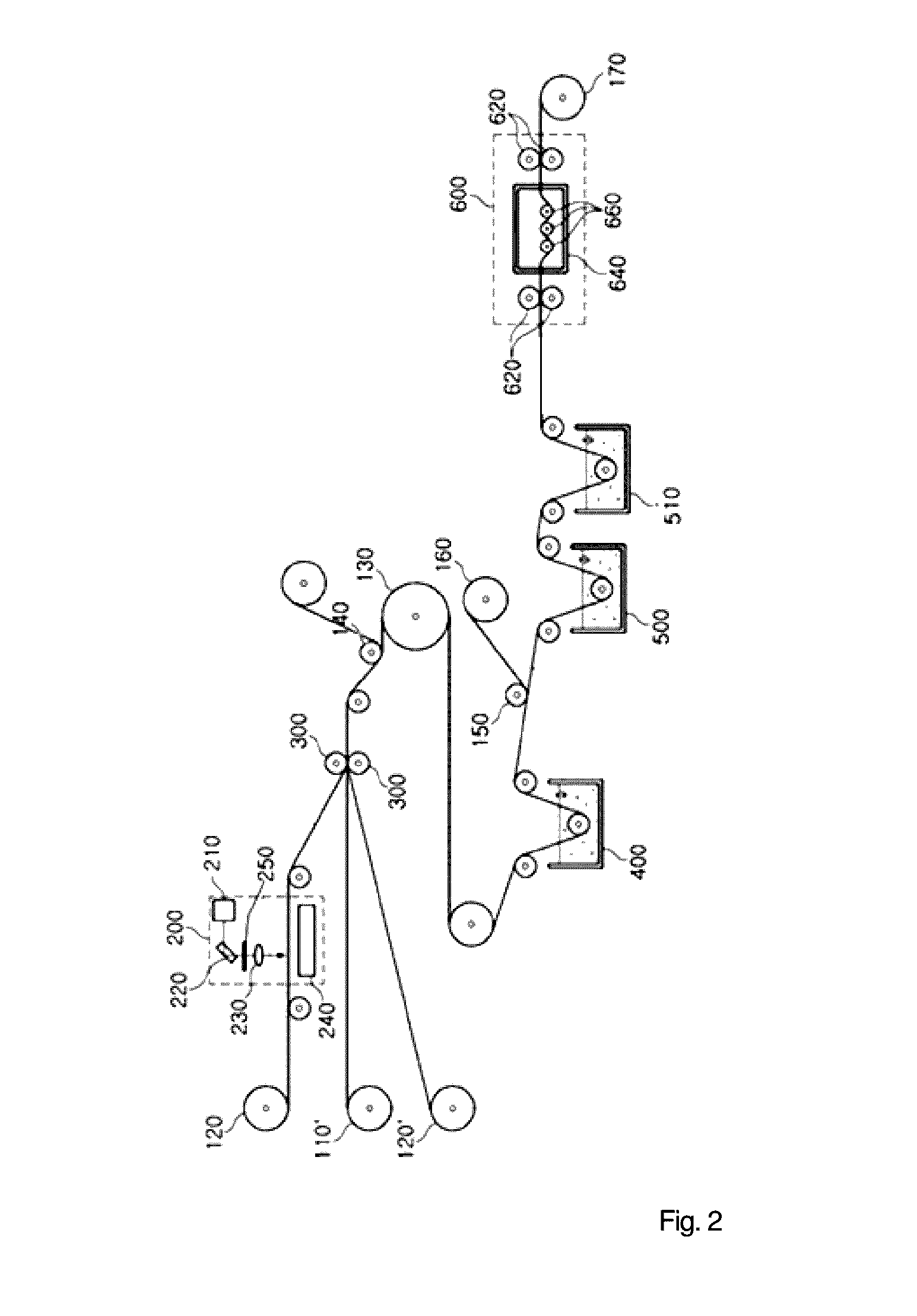

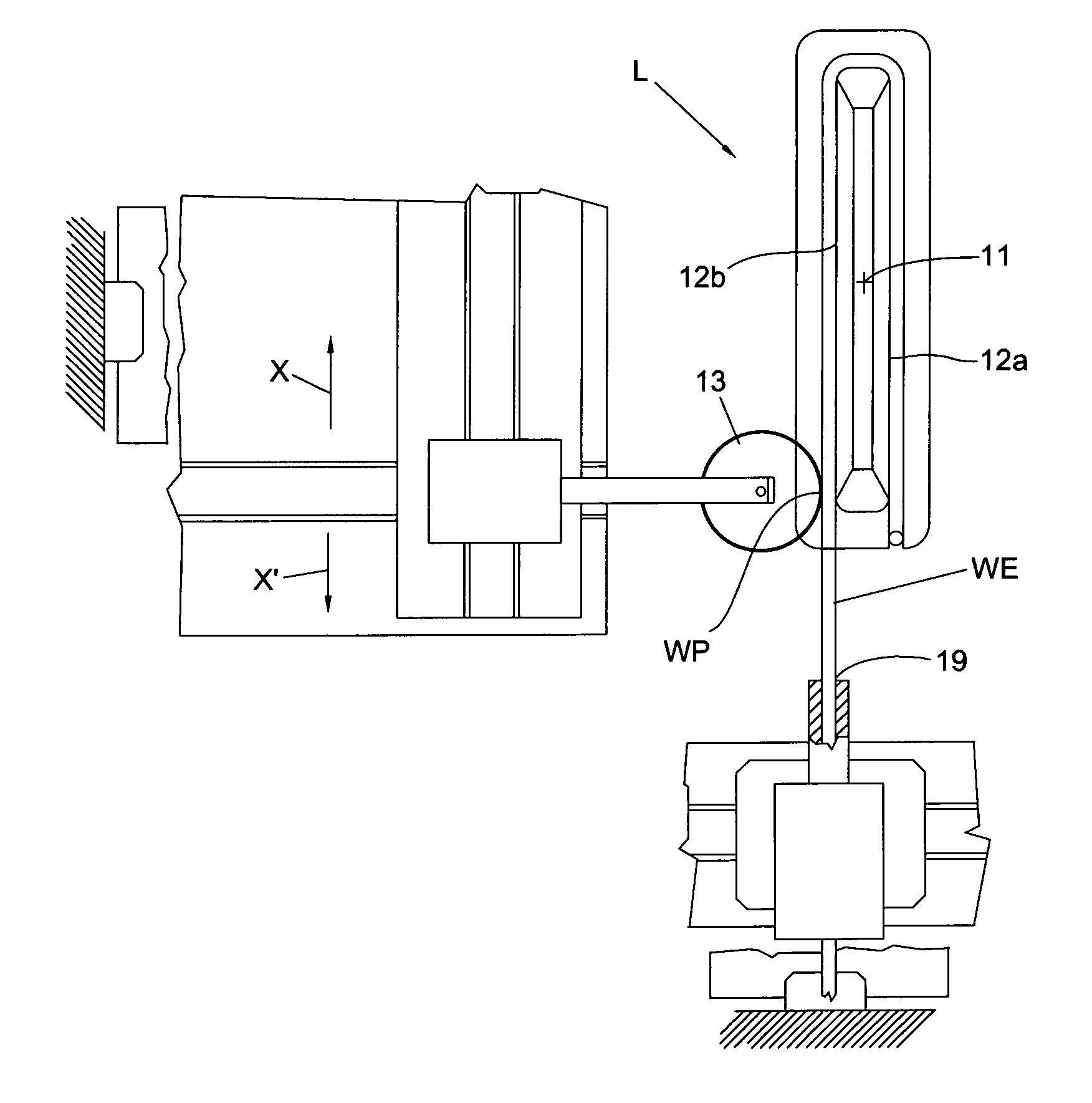

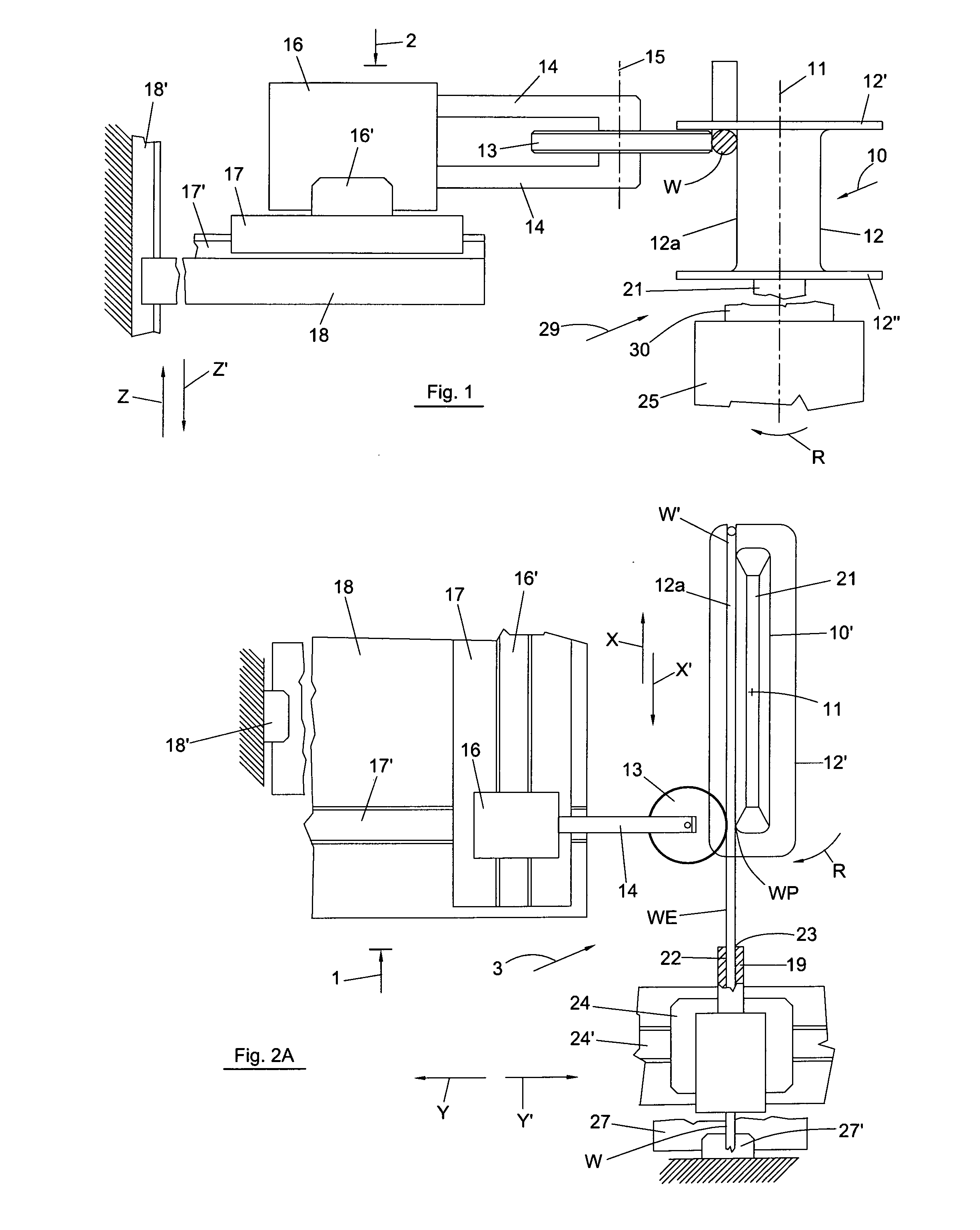

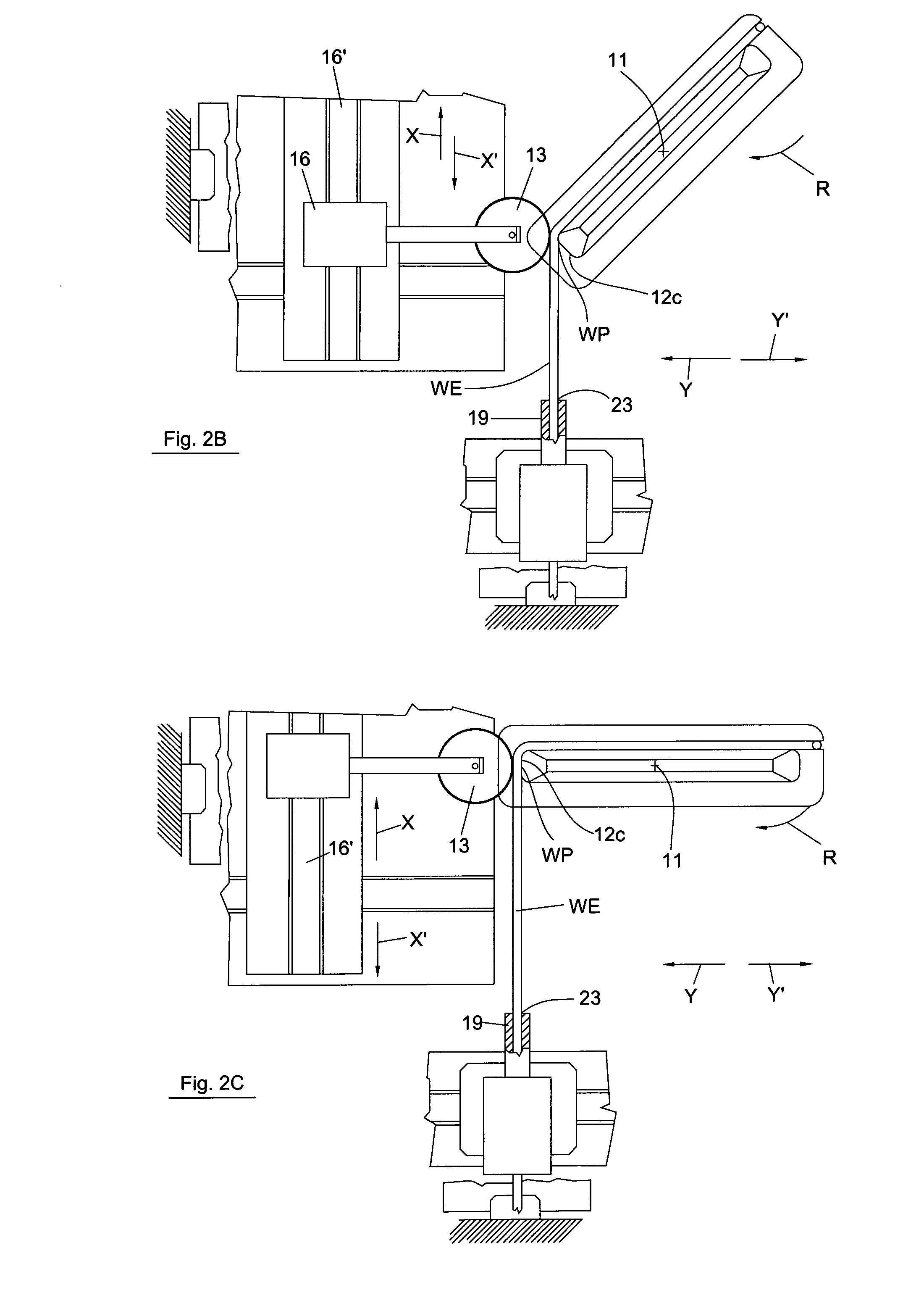

Apparatus and methods for winding supports for coils and single poles of cores of dynamo electric machines

ActiveUS20100325875A1Correction of deformationEasy to fillManufacturing dynamo-electric machinesInductances/transformers/magnets manufactureEngineeringAngular orientation

Apparatus and method for winding at least one electric wire W on a coil support (10) of a core of a dynamo electric by using a wire dispensing member (19) means (21, 25) for rotating the coil support with respect to the dispensing member (19). It is foreseen to provide a relative movement of the dispensing member (19) with respect to the coil support (10) to maintain the angular orientation constant during winding. Furthermore it is foreseen to press on a portion (WP) of wire wound on the coil support (10) where the portion of wire (WP) is located immediately adjacent to a portion of wire that still has to be wound on the coil support (10). Engaging occurs also of the wire portion (WP) wound on the coils support and that extends to the dispensing member (19) when passage from one turn to another occurs for the stratification; the engagement occurring in opposition to the direction (Z′) of stratification of the wire. Pressing on the wire (W) can be accomplished in a direction (K) having an angle (E) that is more than zero and not perpendicular to an axis of the coil support.

Owner:ATOP SPA

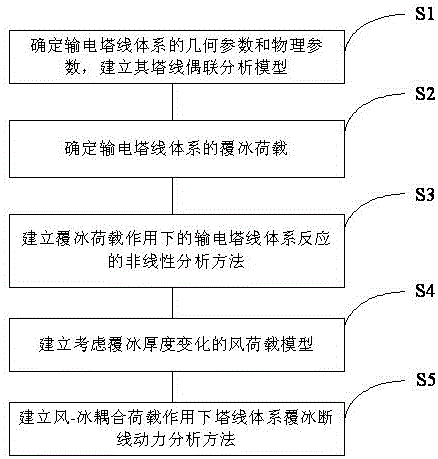

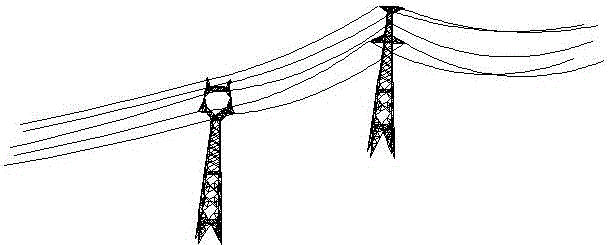

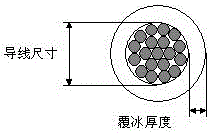

Analysis method of transmission line wind-ice coupling load line breakage effect

ActiveCN106326584APhysical concepts are clearFast and accurate analysis and calculationDesign optimisation/simulationSpecial data processing applicationsTransmission lineEngineering

The invention provides an analysis method of a transmission line wind-ice coupling load line breakage effect. The analysis method includes the following steps that 1, geometric parameters and physical parameters of a transmission tower line system are determined, and a transmission tower line system analysis model is established; 2, icing loads of the transmission tower line system are determined; 3, a non-linear analysis method of a transmission tower line system reaction under the effect of the icing loads is established; 4, a wind load model in which the wire icing thickness changes is established; 5, a dynamic analysis method that a transmission wire is broken under the effect of wind-ice coupling loads is established, and the dynamic effect of transmission line icing line breakage is analyzed and calculated. According to the method, the coupling effect of the icing loads and wind loads is considered at the same time, the analysis formula is displayed and expressed, the calculation speed is high, the calculation amount is small, and the defects of existing traditional methods can be effectively overcome. The method is suitable for analysis and calculation of the icing line breakage effect of various transmission tower line systems with different spans and sags under the effect of the ice-wind coupling loads.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +2

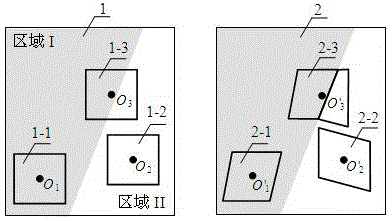

Half-subarea-segmentation-method-based digital image correlation method

InactiveCN105157594AEasy to solveSimplify the solution processUsing optical meansPattern recognitionComputer graphics (images)

Provided in the invention is a half-subarea-segmentation-method-based digital image correlation method. The correlation method comprises: a certain number of measurement points are distributed on a picture before deformation, a deformation field, containing two kinds of deformation modes, of a picture after deformation is obtained by using a sub-pixel digital image correlation method, and measuring points with poor results are selected; a square sample subarea is selected by using each measuring point with a poor result as a center, the subarea is segmented into two half subareas by using one line segment crossing the center point of the subarea, an optimum target subarea among all subareas at different segmentation angles is searched by using an overall-pixel digital image correlation method, and rough measurement displacement and a rough segmentation angle are obtained; and with the rough measurement displacement and rough segmentation angle as initial values, measurement displacement and a segmentation angle are searched precisely by using the sub-pixel digital image correlation method and a convex function extreme seeking method. Compared with the traditional digital image correlation method, the provided digital image correlation method enables displacement of measuring points near a boundary of two kinds of deformation modes to be searched and the application range is expanded.

Owner:LIAONING TECHNICAL UNIVERSITY

Earphone with fixing function and earplug thereof

InactiveUS20130195310A1Comfortably and stably secureImprove stereoIntra aural earpiecesDeaf-aid setsFixed-functionMechanical engineering

Owner:SURE BEST

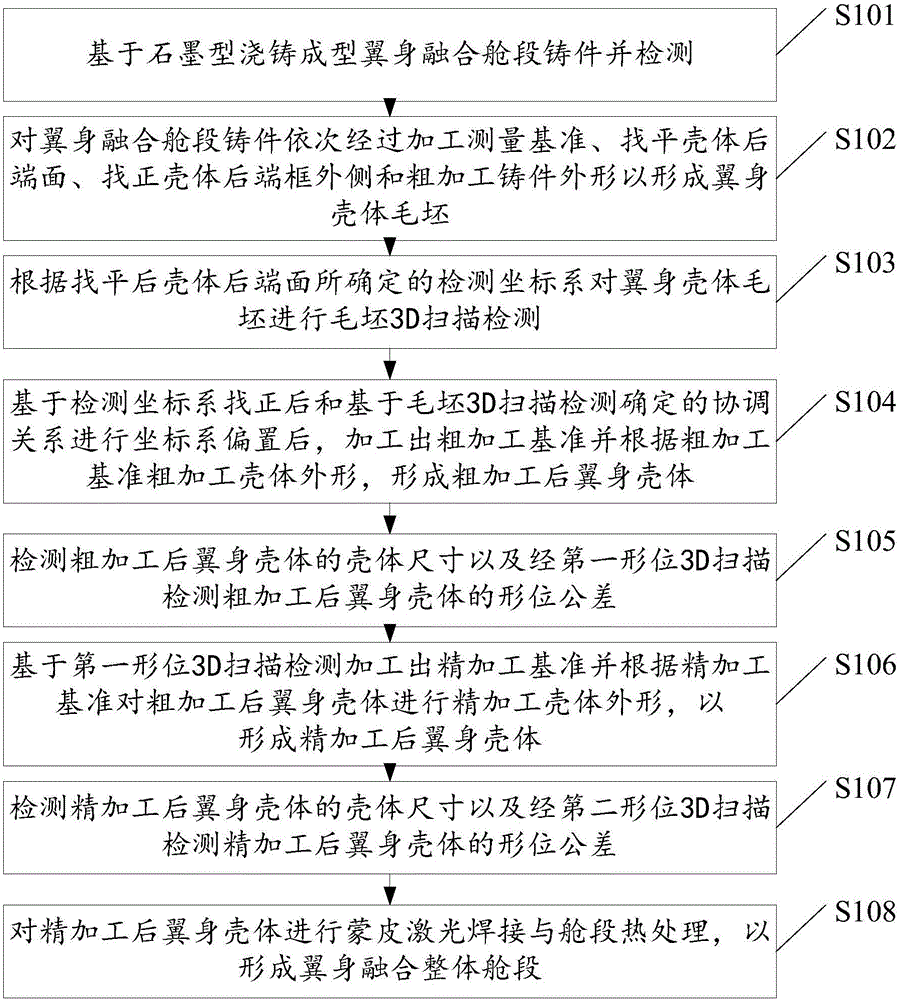

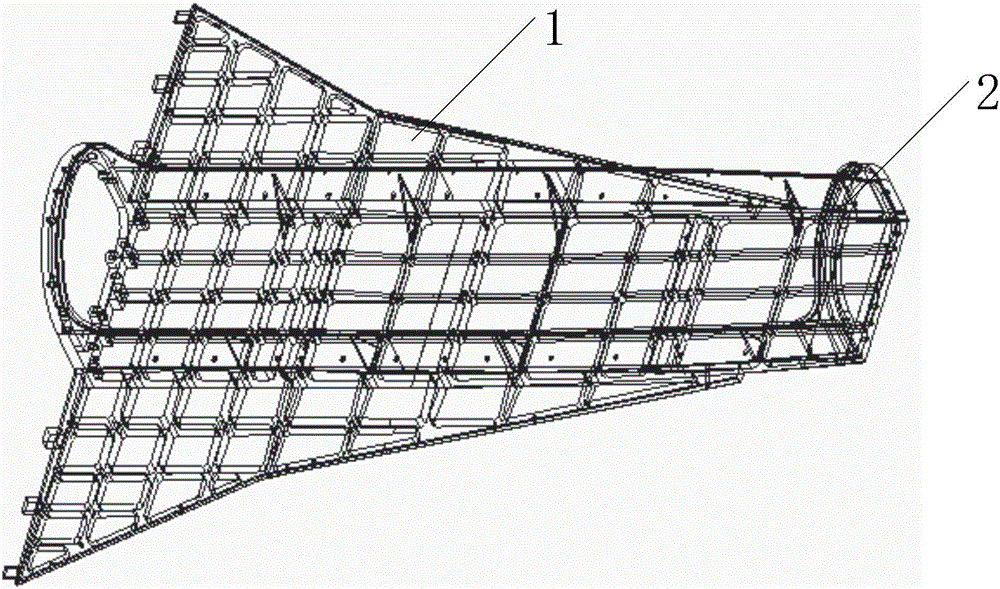

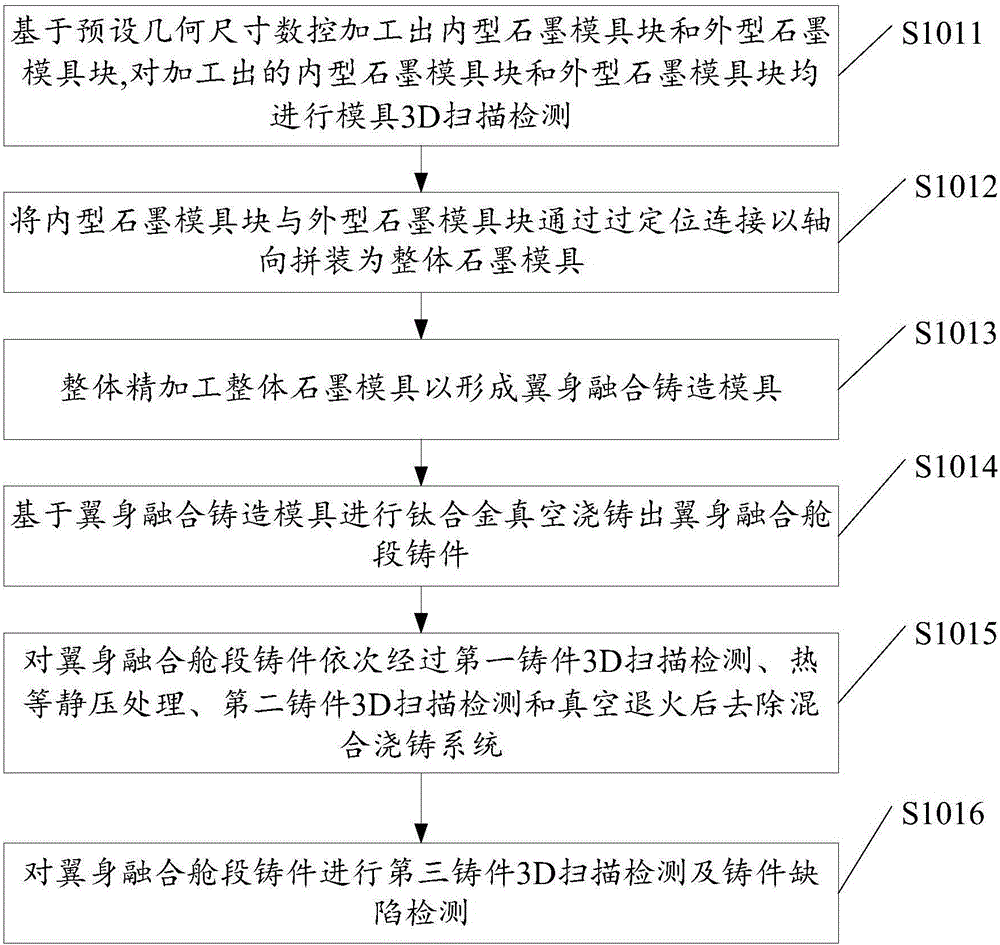

Manufacturing method for integral wing-body-fused cabin

ActiveCN106002088AQuality assuranceAvoid deformation accumulationAircraft componentsGraphite3d scanning

The invention discloses a manufacturing method for an integral wing-body-fused cabin. The manufacturing method comprises the steps that a wing-body-fused cabin casting is cast and formed based on the graphite type and detected; the wing-body-fused cabin casting is sequentially subjected to machining, datum measuring and the like, a wing body shell blank is formed, and blank 3D scanning detection is conducted; a rough machining datum is machined, and the shell appearance is roughly machined according to the rough machining datum; the shell size of the roughly-machined wing body shell is detected, and the form and location tolerance of the roughly-machined wing body shell is detected through first shape and location 3D scanning; a finish machining datum is machined based on the first shape and location 3D scanning, shell appearance finish machining is conducted on the roughly-machined wing body shell according to the finish machining datum, the shell size of the wing body shell subjected to finish machining is detected, and the form and location tolerance of the wing body shell subjected to finish machining is detected through second shape and location 3D scanning; and skin laser welding and cabin heat treatment are conducted on the wing body shell subjected to finish machining. The manufacturing method effectively solves the technical problem that machining of existing integral wing-body-fused cabin products is hard to control, and accordingly the overall quality of the integral wing-body-fused cabin is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

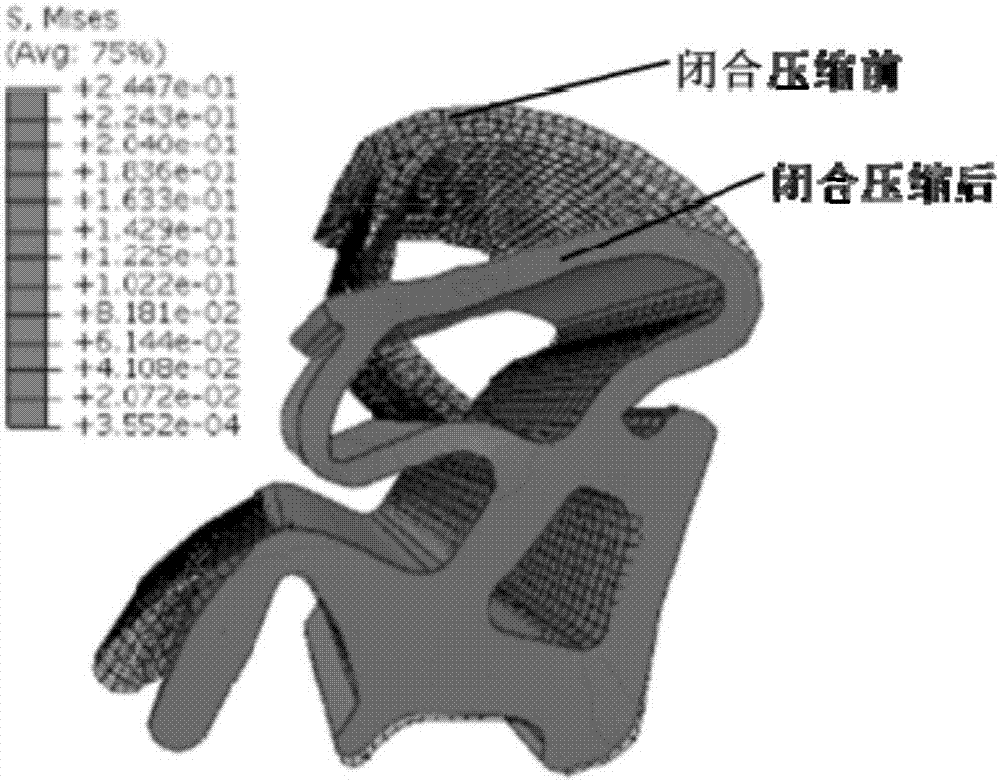

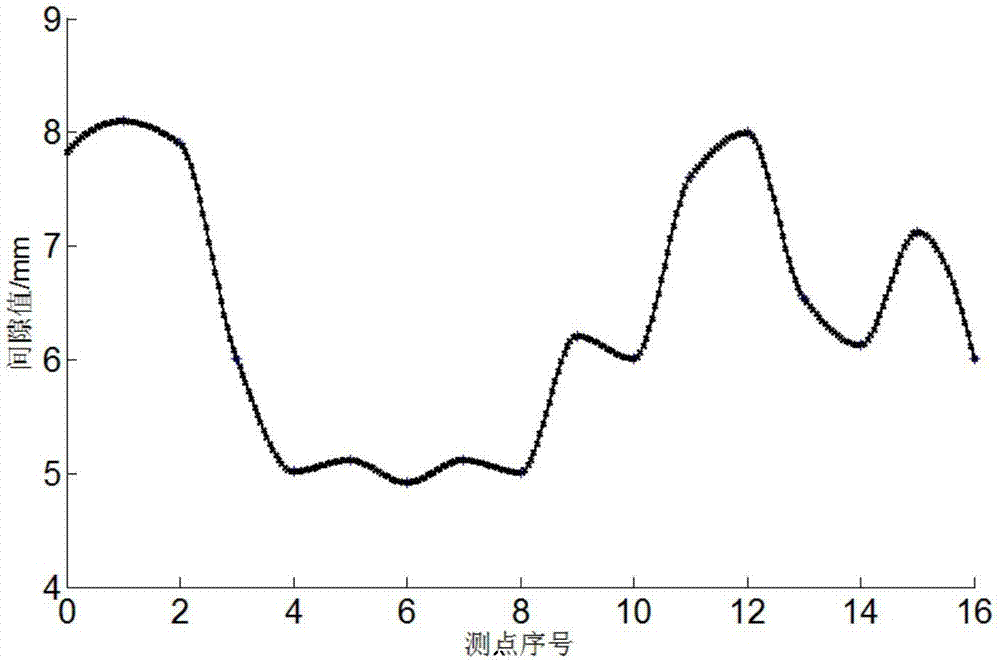

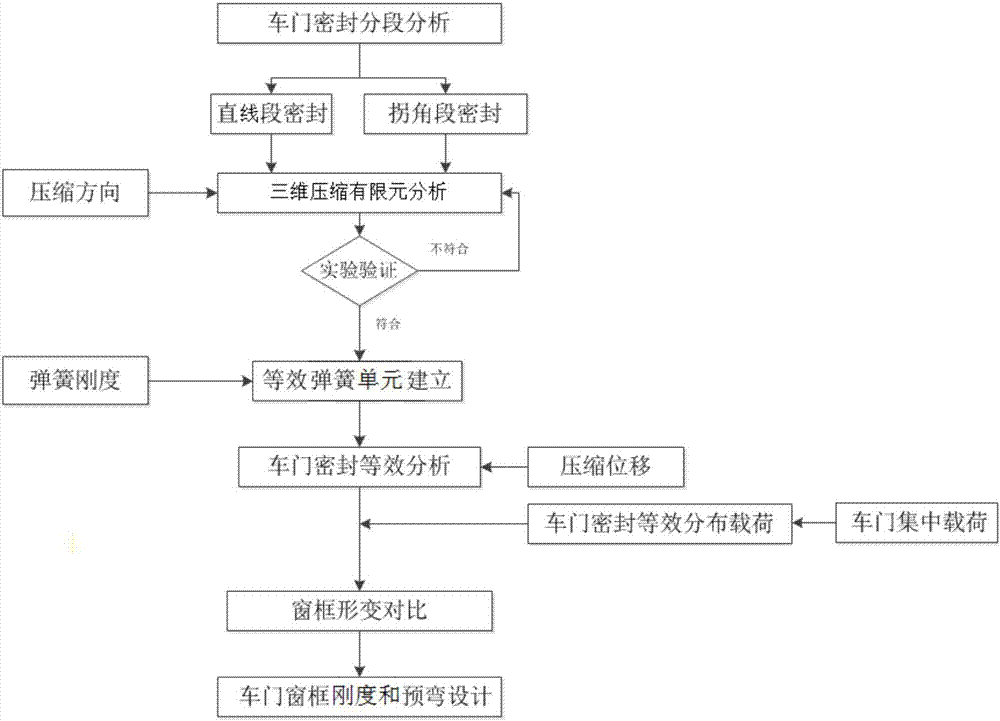

Window frame structure design method based on car door sealing fine equivalent model

ActiveCN107045567ASimulation force situationWindow frame improvementGeometric CADDesign optimisation/simulationStraight segmentOptimal design

The invention relates to a window frame structure design method based on a car door sealing fine equivalent model. The method is characterized by comprising the steps that S1, a window frame edge of a car door is segmented into a straight segment and a turning segment, and a compression-displacement curve and stiffness coefficients of all sealing strips are obtained; S2, the car door sealing fine equivalent model is established; S3, compression displacement of equivalent spring units is obtained according to clearance between a car door window frame and a door frame side wall, and the deformation amount of the window frame is obtained based on stiffness coefficients of all the equivalent spring units and the corresponding compression displacement; and S4, an optimal stiffness value and an optimal pre-bending amount value of the window frame are obtained according to the deformation amount of the window frame. Compared with the prior art, smaller stiffness meeting a sealing requirement can be obtained, redundant stiffness obtained through a concentrated load method can be remarkably compressed, a more reliable reference can be provided for design of the car window pre-bending amount including a sealing fine reaction, and light minimum car door stiffness optimal design is supported.

Owner:TONGJI UNIV

Pillow for the prevention of cranial deformities in newborns

InactiveUS20100180381A1Reduce pressure exertedReduce pressurePillowsSofasCRANIAL DEFORMITYEngineering

The pillow has an orifice of suitable dimensions, which decreases the local pressure exerted on the skull, which is formed by a body of foam or another material deformable under pressure and a fabric coating which protects the core and improves the hold of the head, whose coating has an upper layer and another lower one sewn together in the same orifice and followings its perimeter and at mid height of the foam core, although the fabric, due to its physical, elastic or contraction properties, offers sufficient support and said upper and lower layers do not require being joined together in the perimeter of the orifice. The cavity formed has dimensions which adapt to the natural shape of the newborn baby's head.

Owner:THINK PIPE LINE

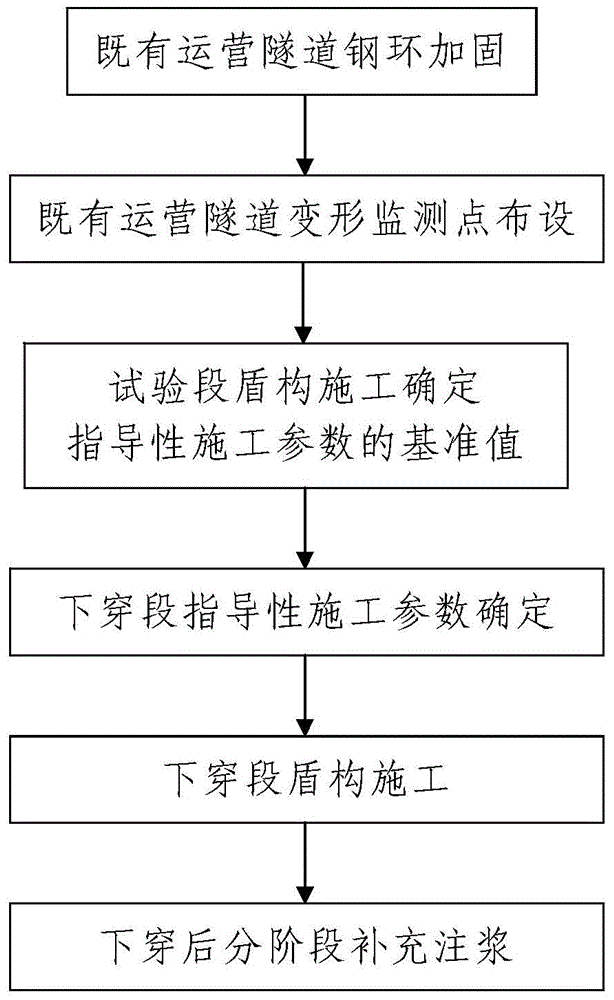

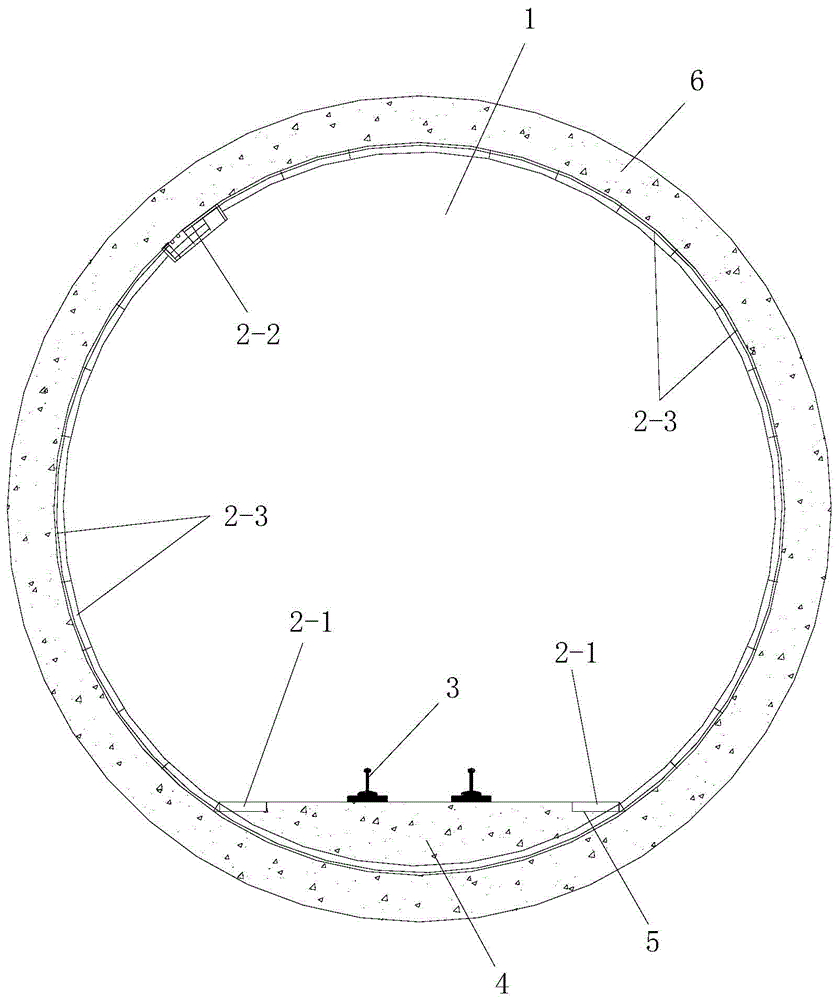

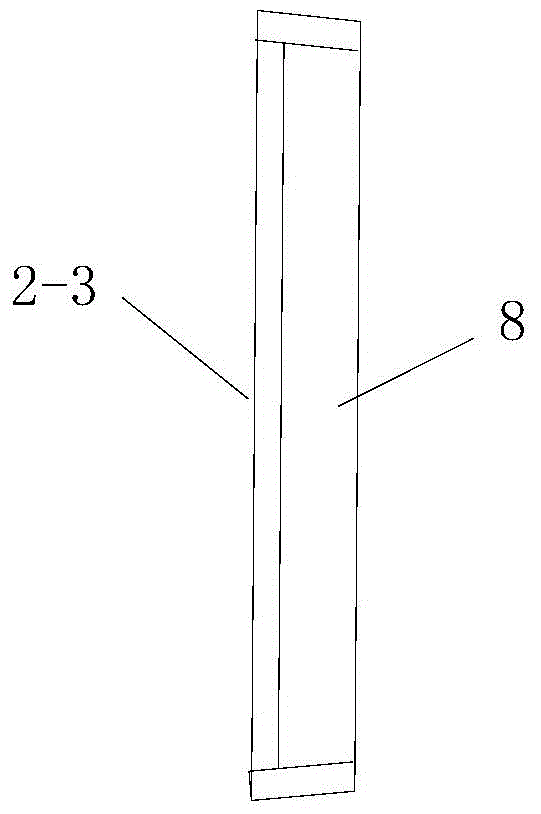

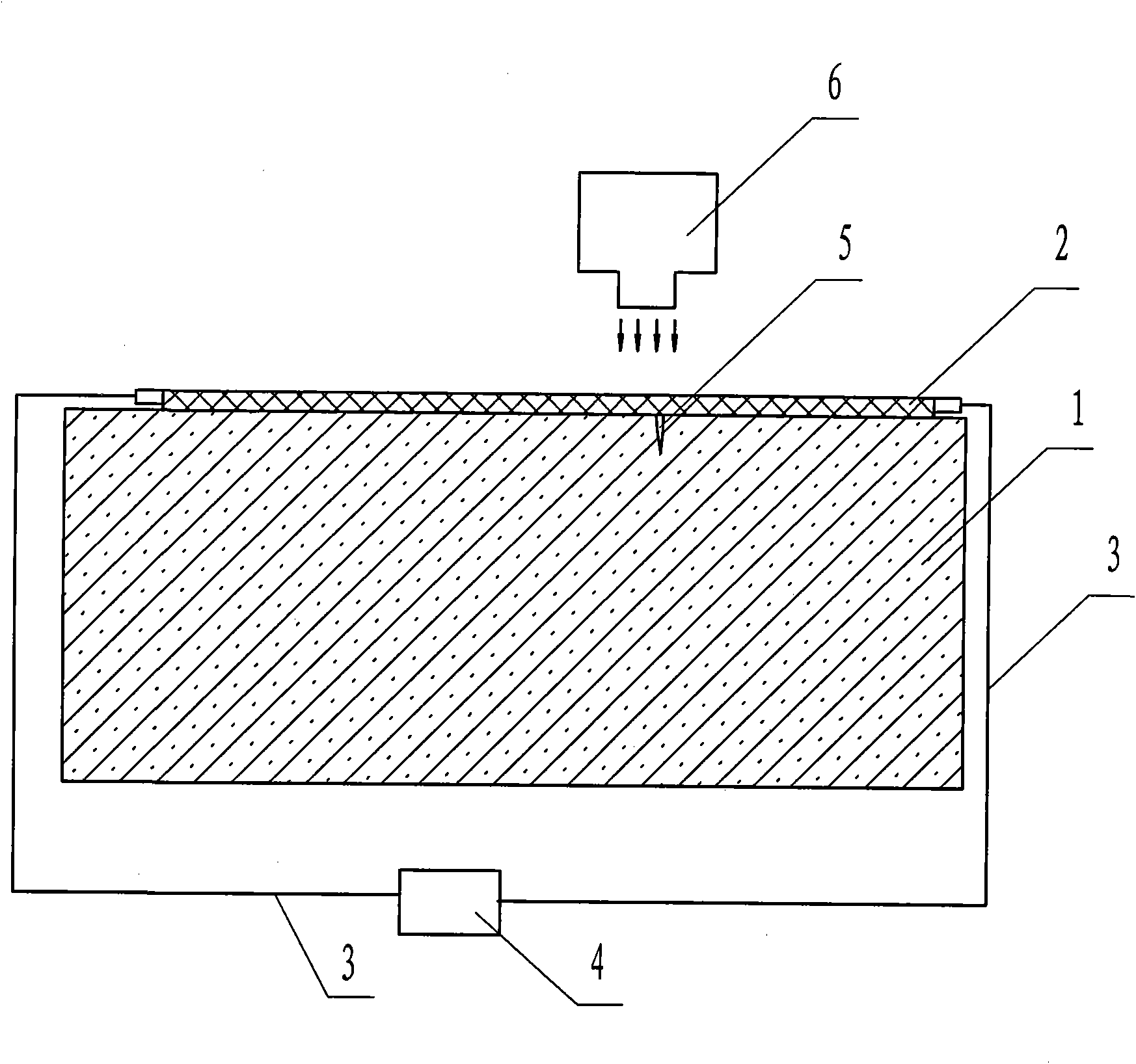

Construction method for deformation control over existing operation tunnel crossing under shield

ActiveCN104912562AThe method steps are simpleReasonable designUnderground chambersTunnel liningDeformation monitoringDeformation control

The invention discloses a construction method for deformation control over an existing operation tunnel crossing under a shield. A construction tunnel is a shield tunnel of an under-crossing existing operation tunnel. A tunnel segment of the under-crossing existing operation tunnel is an under-crossing segment. The process of constructing the under-crossing segment comprises following steps: 1, reinforcing a steel ring of the operation tunnel; 2, laying distortion monitoring points of the existing operation tunnel; 3, determining reference values of guiding construction parameters based on shield construction of a test section; 4, determining parameters for guiding construction of the under-crossing segment: determining parameters for guiding construction of the under-crossing segment based on reference values of guiding construction parameters; 5, carrying out shield construction of the under-crossing segment; 6, after under-crossing construction, supplementing and grouting in phases: supplementing and grouting the under-crossing segment based on a monitoring result and by means of grouting holes in shield tunnel segments.The construction method for deformation control over the existing operation tunnel crossing under the shield has following beneficial effects: the construction method has simple processes and is reasonably designed; construction is performed easily and conveniently; a fine construction effect is obtained; and effective control over distortion of the existing operation tunnel crossing under the shield is achieved in a short period at low cost.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for monitoring and positioning concrete cracks by using elastic conducting film sensor and infrared thermal imaging technique

InactiveCN101666766AAccurately determine the locationSmall thermal inertiaMaterial flaws investigationConductive coatingEngineering

The invention discloses a method for monitoring and positioning concrete cracks by using an elastic conducting film sensor and an infrared thermal imaging technique, comprising the following steps: 1)solidifying conductive coatings to form an elastic conducting film, laying the elastic conducting film on a concrete member and arranging leads at two ends of the elastic conducting film to form theelastic conducting film sensor; 2) when discovering cracks on the concrete member or carrying out routine inspection, connecting the leads at two ends of the elastic conducting film to a power supplyto be electrified to generate heat; 3) carrying out scan detection by using an infrared thermal imaging device; and 4) accurately determining the positions, quantity, trends, sizes and other information of the cracks according to the images obtained after scan detection by the infrared thermal imaging device. By the method, the resistivity of the elastic conducting film sensor on the positions ofthe cracks is increased, and the heat output on the positions of the cracks after electrifying is more than that on the common positions. The positions, quantity, trends, sizes and other information of the cracks can be accurately displayed by adopting the infrared thermal imaging device for scanning.

Owner:邓安仲

Novel probe used for pelvic floor muscle rehabilitation therapy apparatus and using method thereof

InactiveCN104436437ACorrection of deformationAccurate pressure signalDiagnostic recording/measuringSensorsHuman bodyPhysical medicine and rehabilitation

The invention discloses a novel probe used for pelvic floor muscle rehabilitation therapy apparatus. The novel probe comprises a carrier, two oval conductive pasting films, two elastic components, two pressure sensors, a pair of wires which are connected to the tail portions of the pasting films and used for receiving electrical stimulation and sending electromyographic signals and a pair of wires connected to the pressure sensors and used for transmitting pressure signals out of a human body, wherein the carrier is a cylinder made of electrical insulating materials in an injection molding mode, the section, perpendicular to the axis, of the carrier is an oval, and one end of the carrier is smooth and suitable for being arranged in a cavity; the two oval conductive pasting films are located at the two ends of the long axis of the oval section of the carrier and are soft and slack, and the edges of the two oval conductive pasting films are connected to the carrier in a seamless mode; the two elastic components are located in the carrier and connected with the middles of the pasting films; the two pressure sensors are located in the carrier and connected with the elastic components. The novel probe enables the rehabilitation therapy apparatus to carry out electrical stimulation on the pelvic floor muscle through the conductive pasting films and transmit out the collected electromyographic signals; meanwhile, the muscle will generate pressure on the elastic components through the pasting films along with contraction of the pelvic floor muscle, so that the elastic components deform, and the pressure sensors can transmit the pressure signals out of the human body.

Owner:SHANGHAI JIAO TONG UNIV

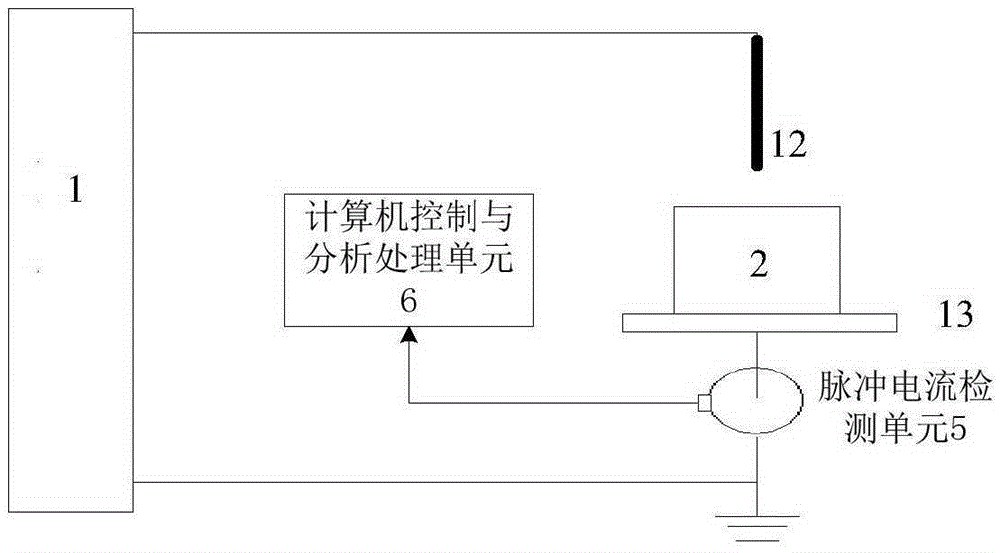

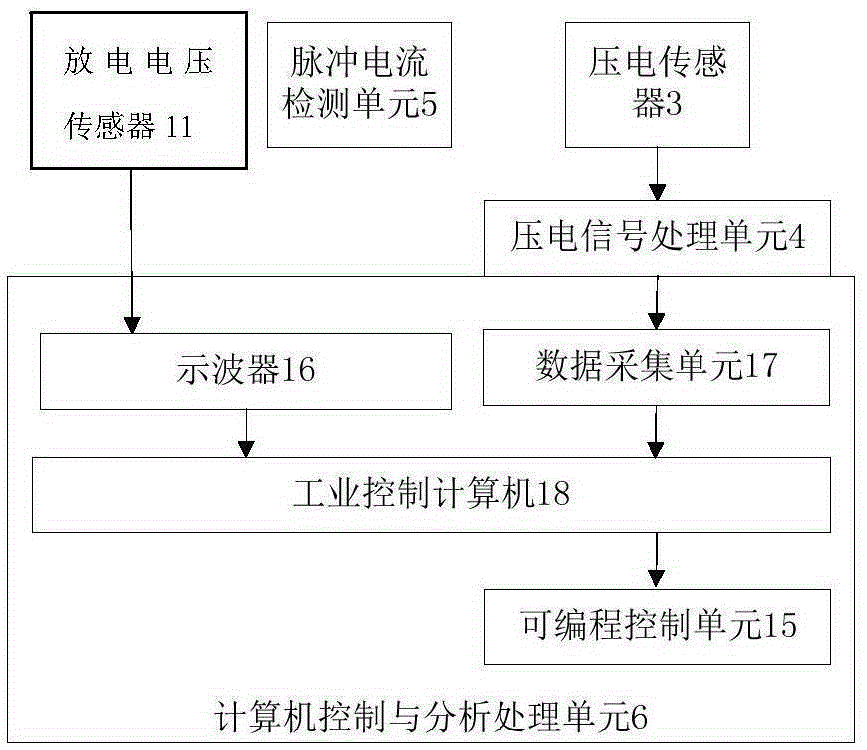

Carbon fiber composite material impact force measuring device and method

ActiveCN105300583ACorrection of deformationAccurate impactElectrical testingApparatus for force/torque/work measurementData acquisitionPulse power supply

The invention discloses a carbon fiber composite material impact force measuring device and method. According to the invention, the impact voltage or the impact intensity of a controllable intensity pulse power supply is controlled by an industrial control computer through a programmable controller (PLC); the impact voltage and pulse current flowing through a carbon fiber composite laminated plate are sampled by a voltage sensor and a pulse current detection unit, are acquired by an oscilloscope and are transmitted to a computer control and analysis processing unit. A piezoelectric signal which is processed by a piezoelectric signal processing unit is input into an A / D data acquisition system, and an analog digital conversion result is transmitted to the computer control and analysis processing unit. A computer processes and analyzes the received data to acquire the law of the relationship among the impact voltage borne by the carbon fiber composite laminated plate, the flowing impact current and the deformation or the impact force of the laminated plate.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com