Window frame structure design method based on car door sealing fine equivalent model

An equivalent model and structure design technology, applied in design optimization/simulation, calculation, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

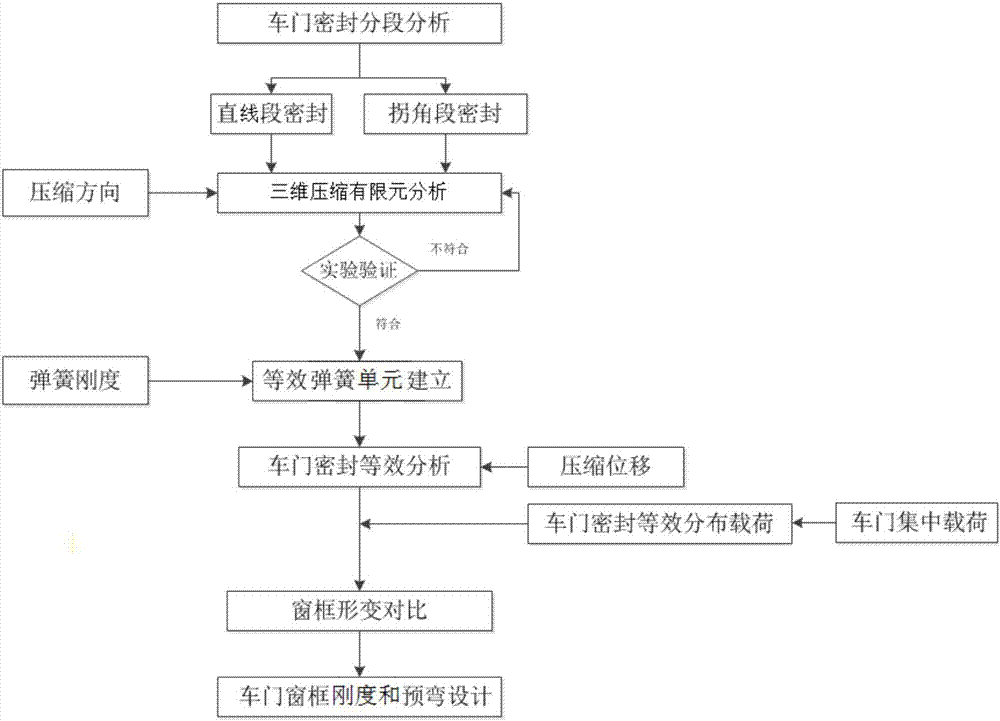

[0046] Such as figure 1 As shown, a window frame structure design method based on the fine equivalent model of the door seal includes the following steps:

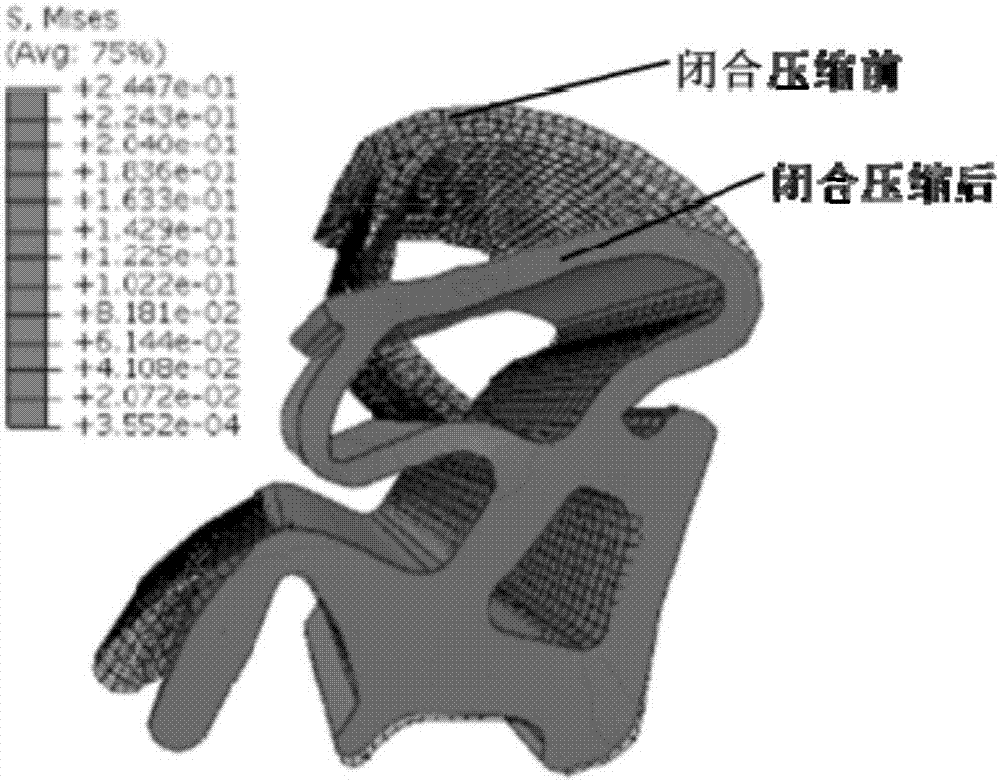

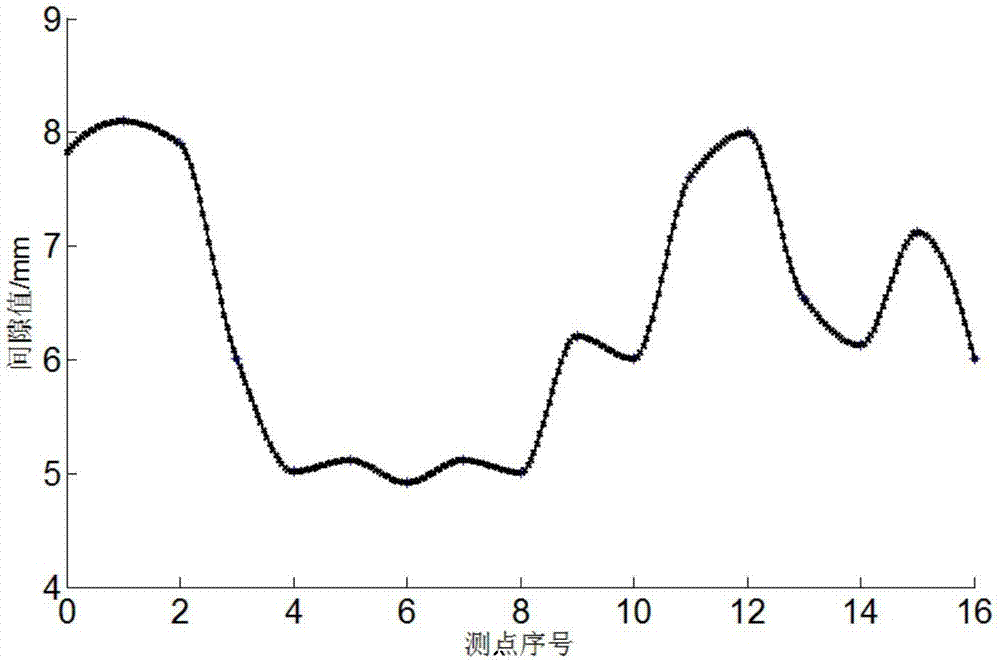

[0047] S1: Car door seal segmentation and CLD curve acquisition: Segment the edge of the window frame of the car door into a straight line segment and a corner segment, and perform three-dimensional compression finite element analysis on the sealing strips at the straight line segment and corner segment respectively, and obtain the sealing strip of each segment The compression-displacement curve and the stiffness coefficient of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com