Patents

Literature

78results about How to "Different strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

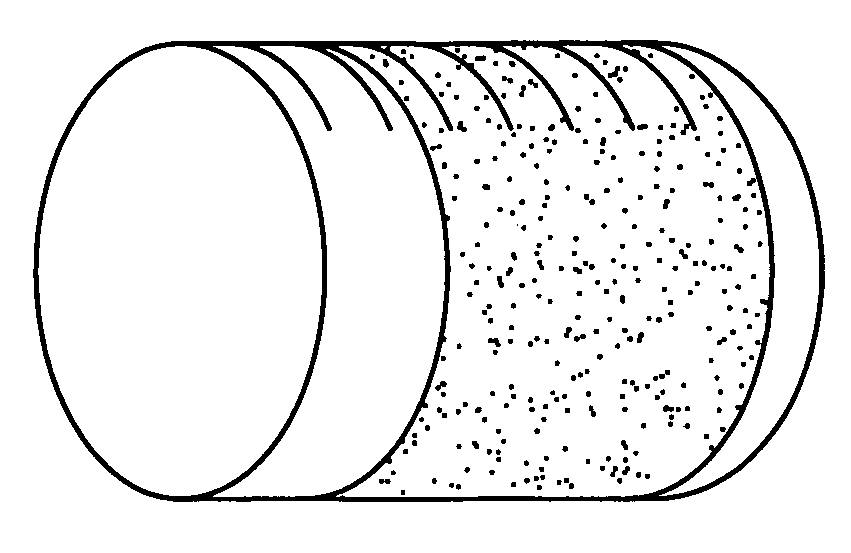

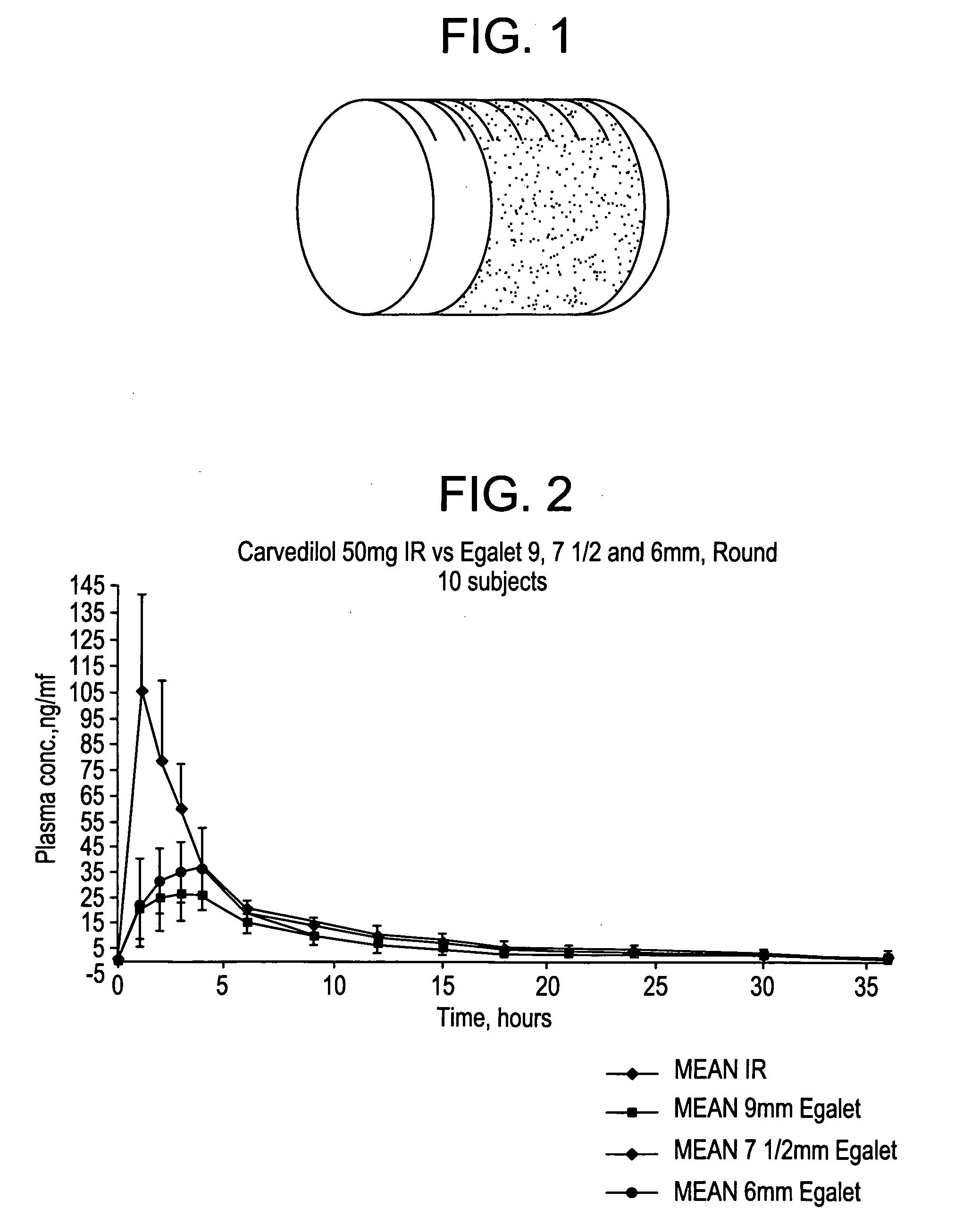

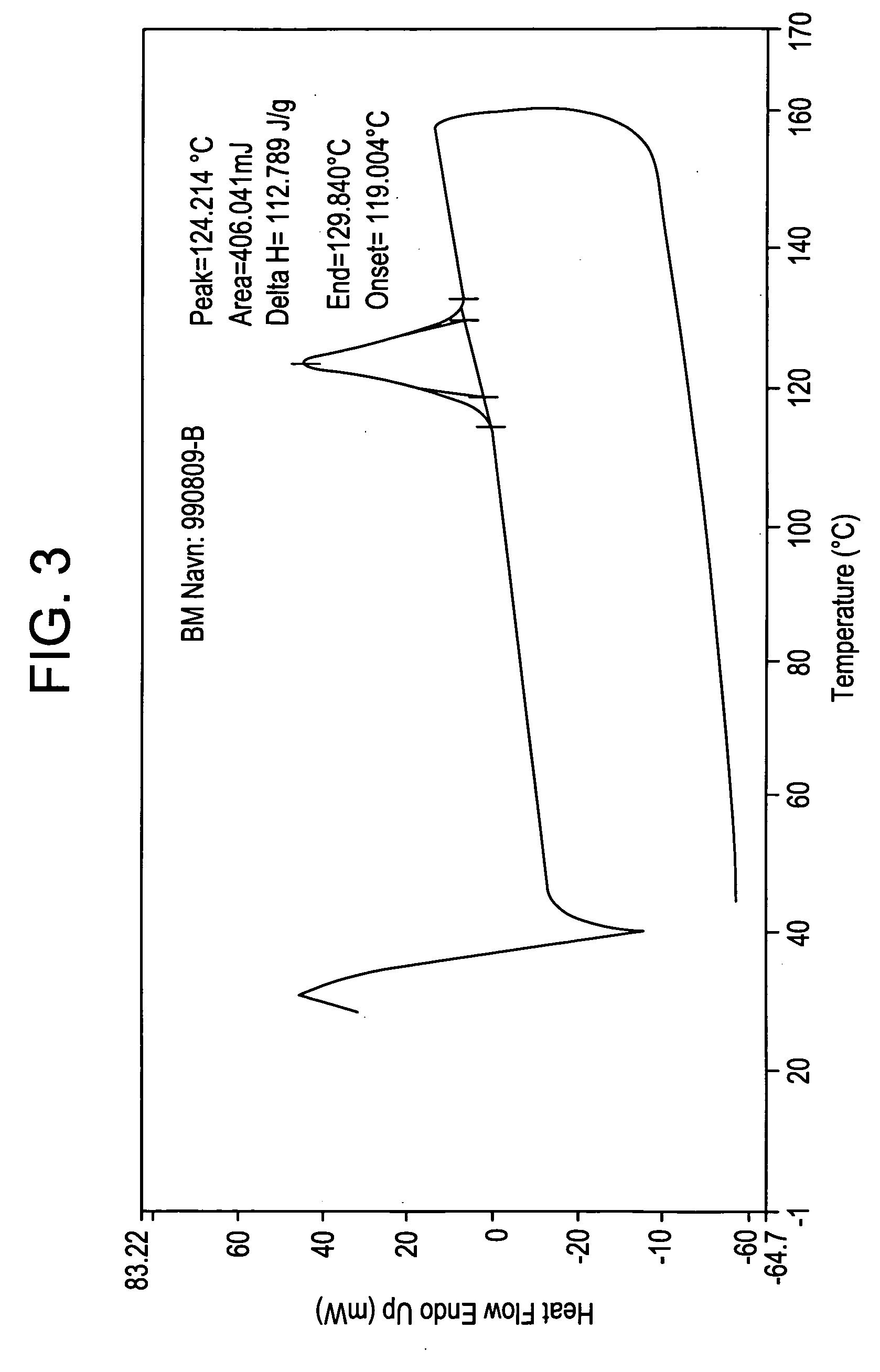

Controlled release solid dispersions

InactiveUS20080234352A1Different equipmentInhibition strengthBiocideAnimal repellantsSolubilityPolyethylene oxide

A controlled release pharmaceutical composition for oral use comprising a solid dispersion of i) at least one therapeutically, prophylactically and / or diagnostically active substance, which at least partially is in an amorphous form, ii) a pharmaceutically acceptable polymer that has plasticizing properties, and iii) optionally a stabilizing agent, the at least one active substance having a limited water solubility, and the composition being designed to release the active substance with a substantially zero order release. The polymer is typically a poly ethylene glycol and / or polyethylene oxide having a molecular weight of at least about 20,000 in crystalline and / or amorphous form or a mixture of such polymers, and the active substance is typically carvedilol. The composition may comprise a coated matrix, the coating comprising a first cellulose derivative which is substantially insoluble in the aqueous medium, and at least one of a) a second cellulose derivative which is soluble or dispersible in water, b) a plasticizer, and c) a filler.

Owner:EGALET LTD

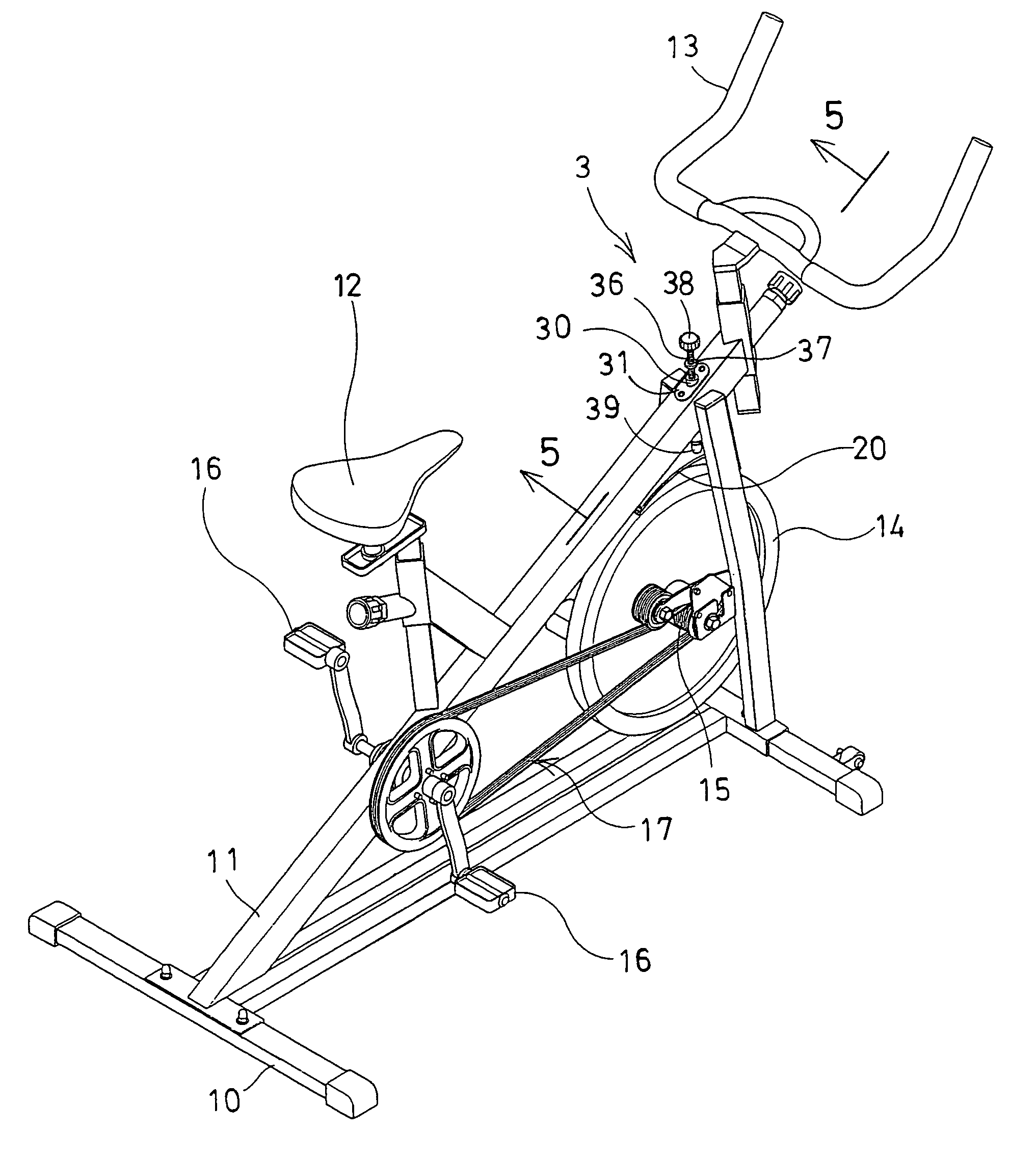

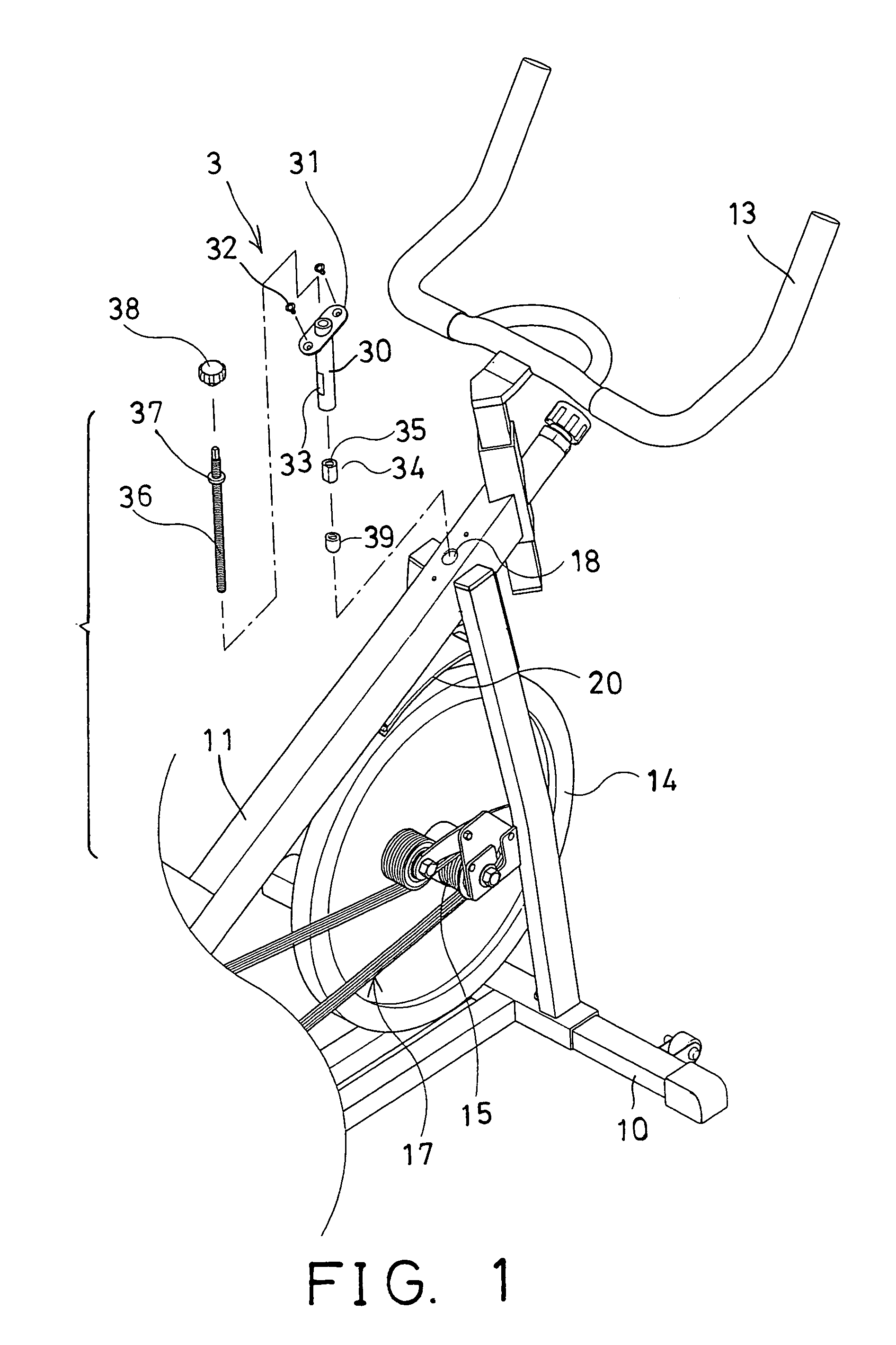

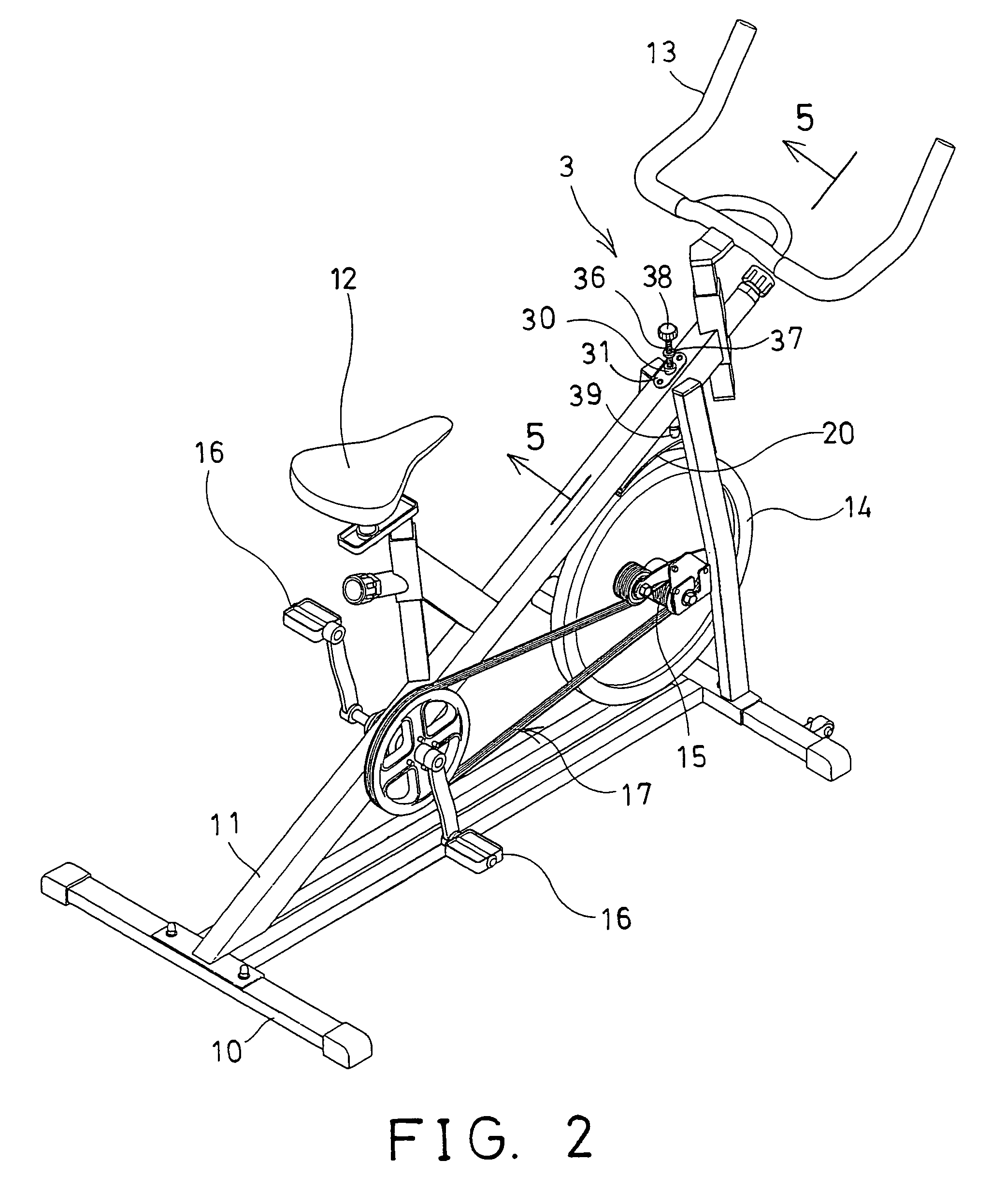

Exerciser having magnetic retarding device

InactiveUS7004888B1Different strengthSuitable for operationFrictional force resistorsMovement coordination devicesFlywheelBrake shoe

An exerciser includes a flywheel rotatably attached onto a frame and coupled to a pair of foot pedals with a transmission device, an arch having one end rotatably coupled to the frame, one or more magnetic members attached to the arch and moveable toward or away from the flywheel, to adjust the magnetic retarding force to the flywheel. A brake shoe is attached to the other end of the arch, and movable to engage with and to brake the flywheel. A spring may bias the arch and the brake shoe away from the flywheel, to allow the brake shoe to be moved toward and against the flywheel and to brake the flywheel selectively. An actuating device may force the brake shoe of the arch to engage with and to brake the flywheel.

Owner:LUNG TUNG HAI +2

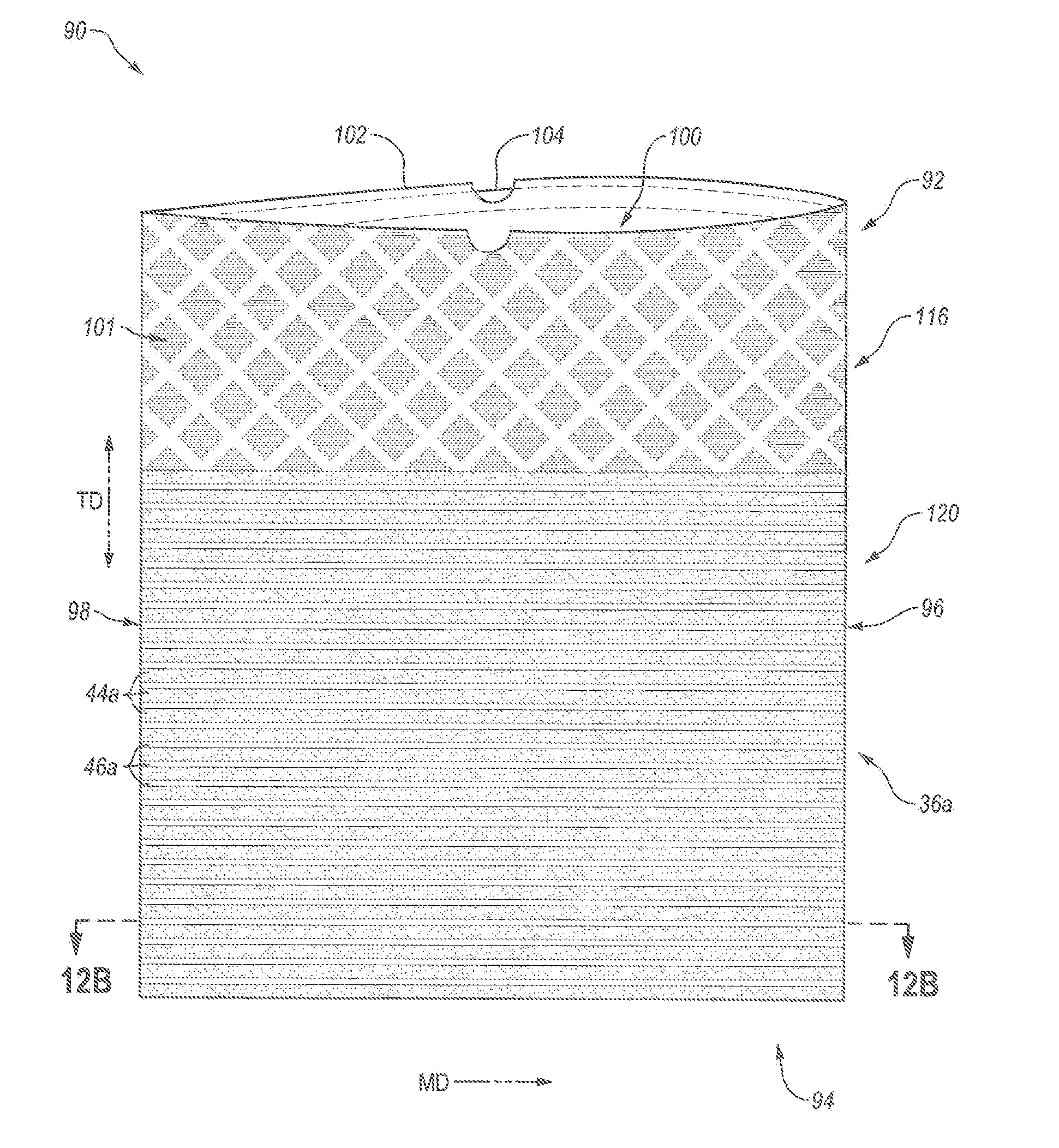

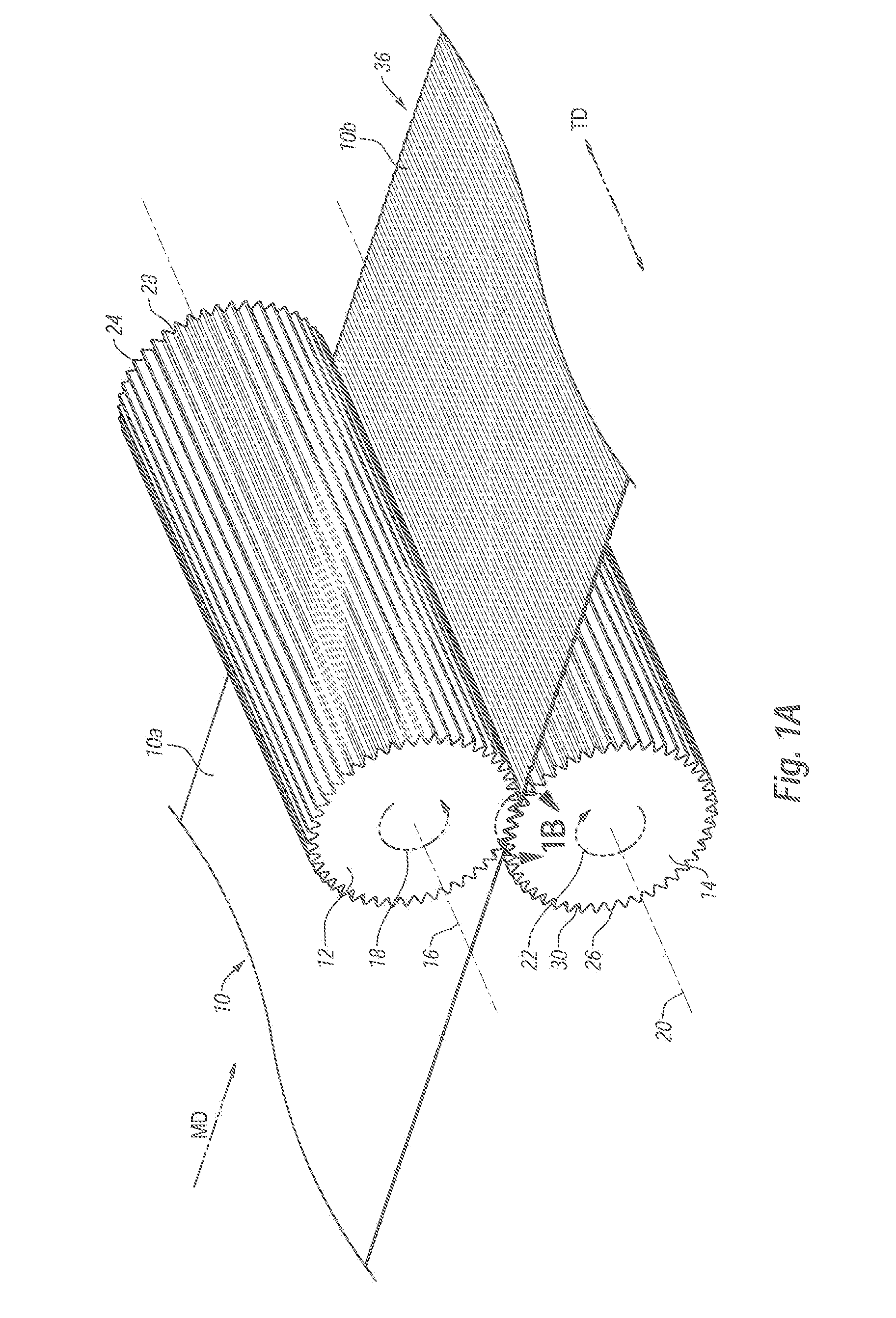

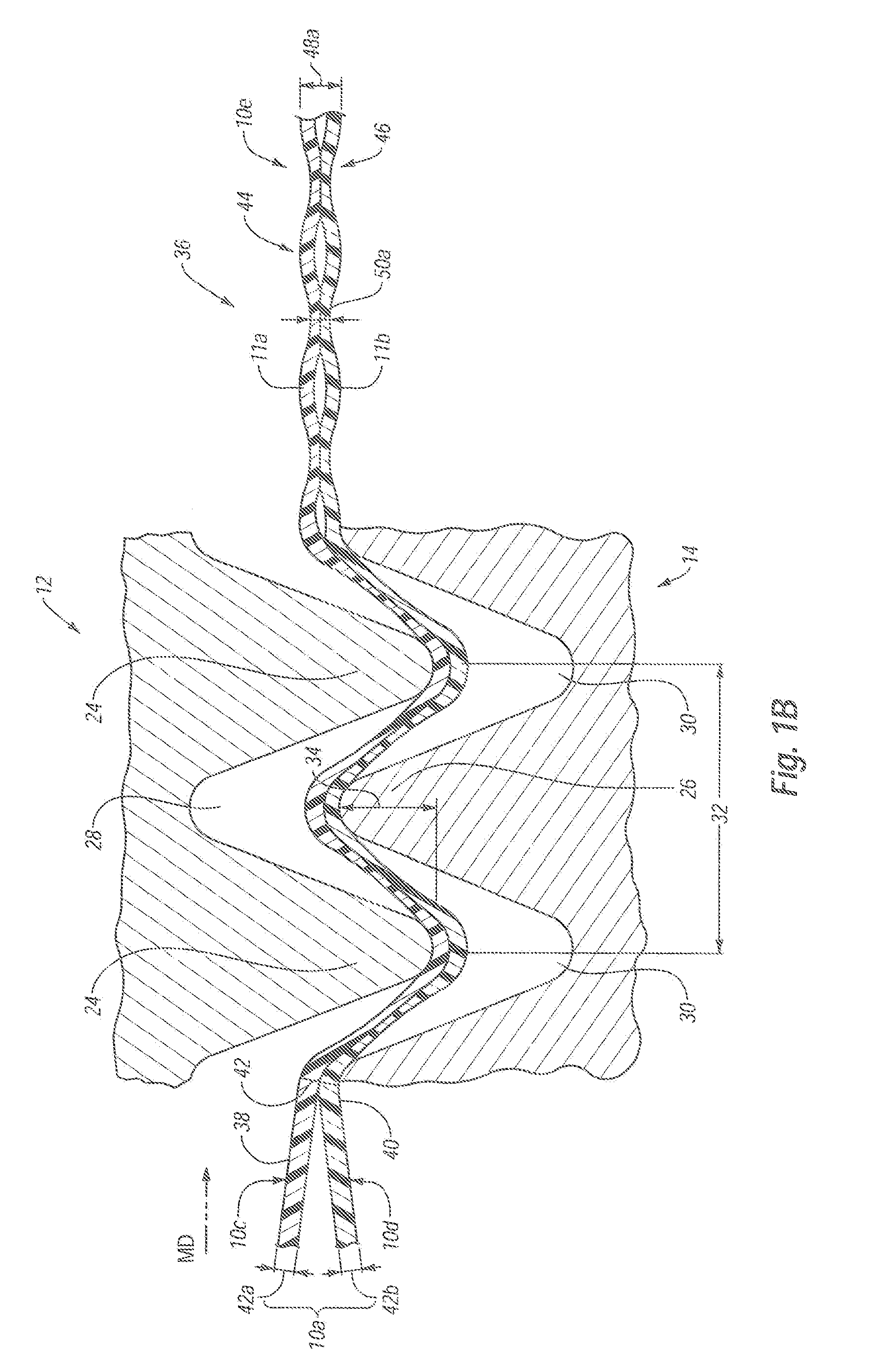

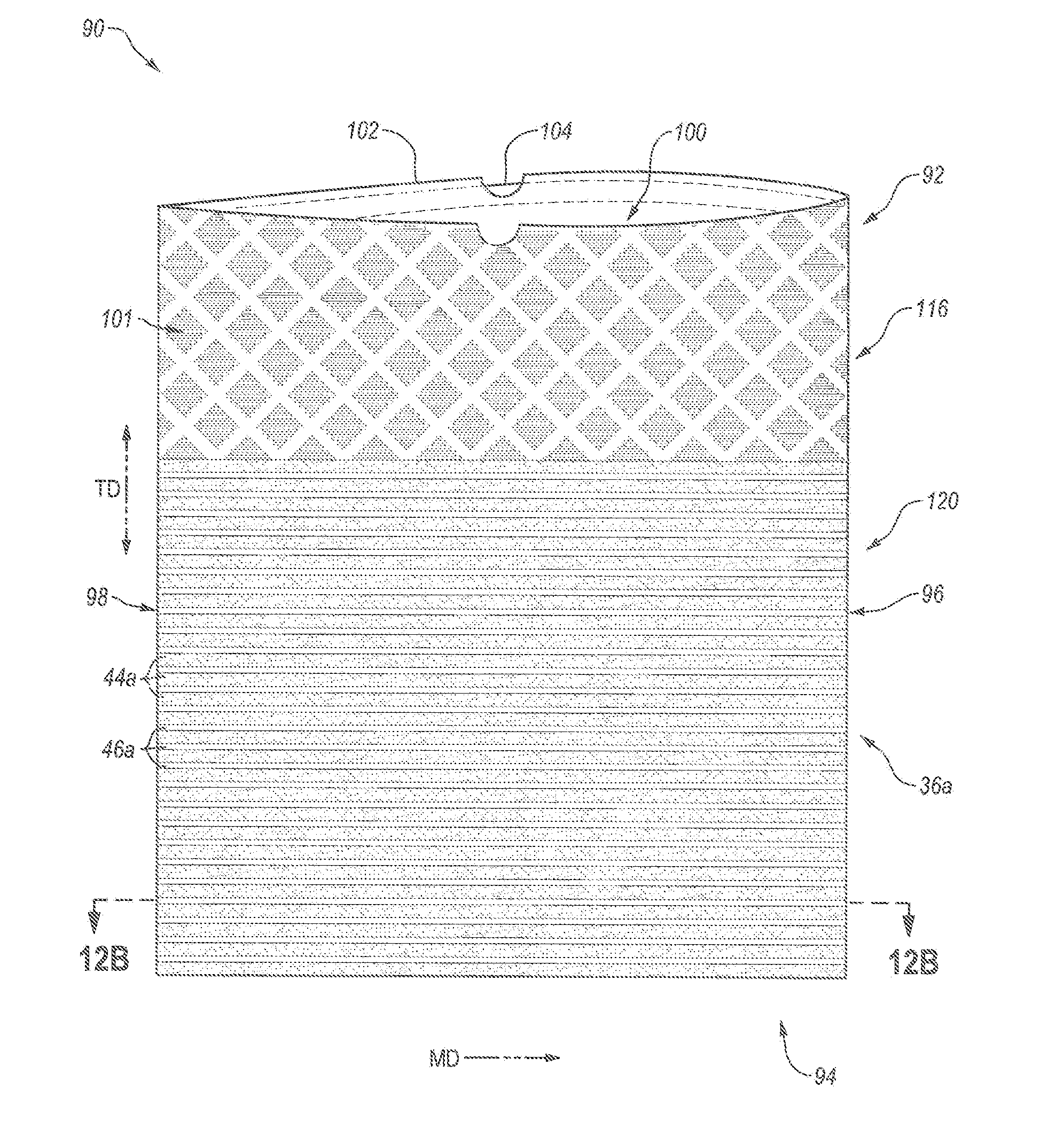

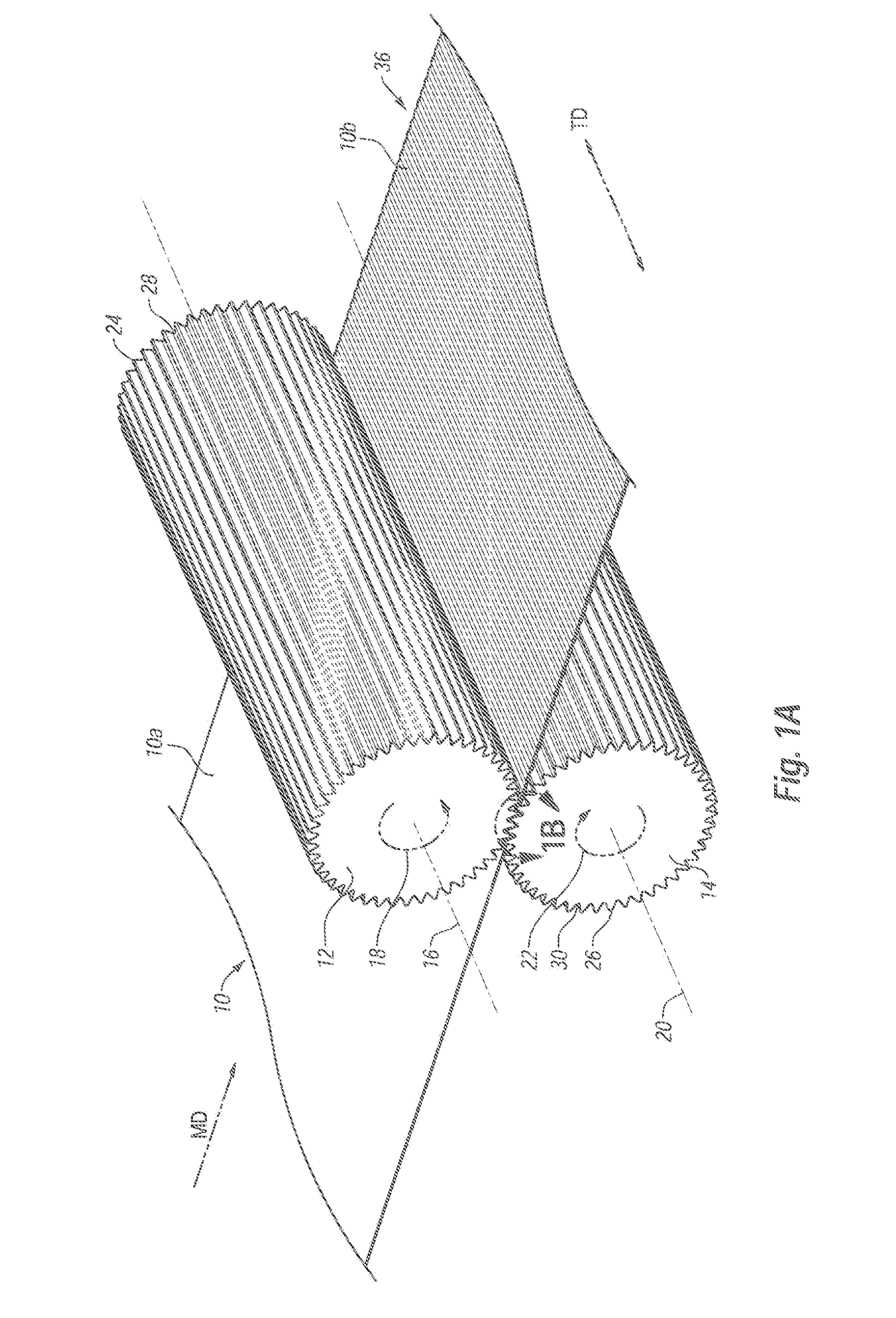

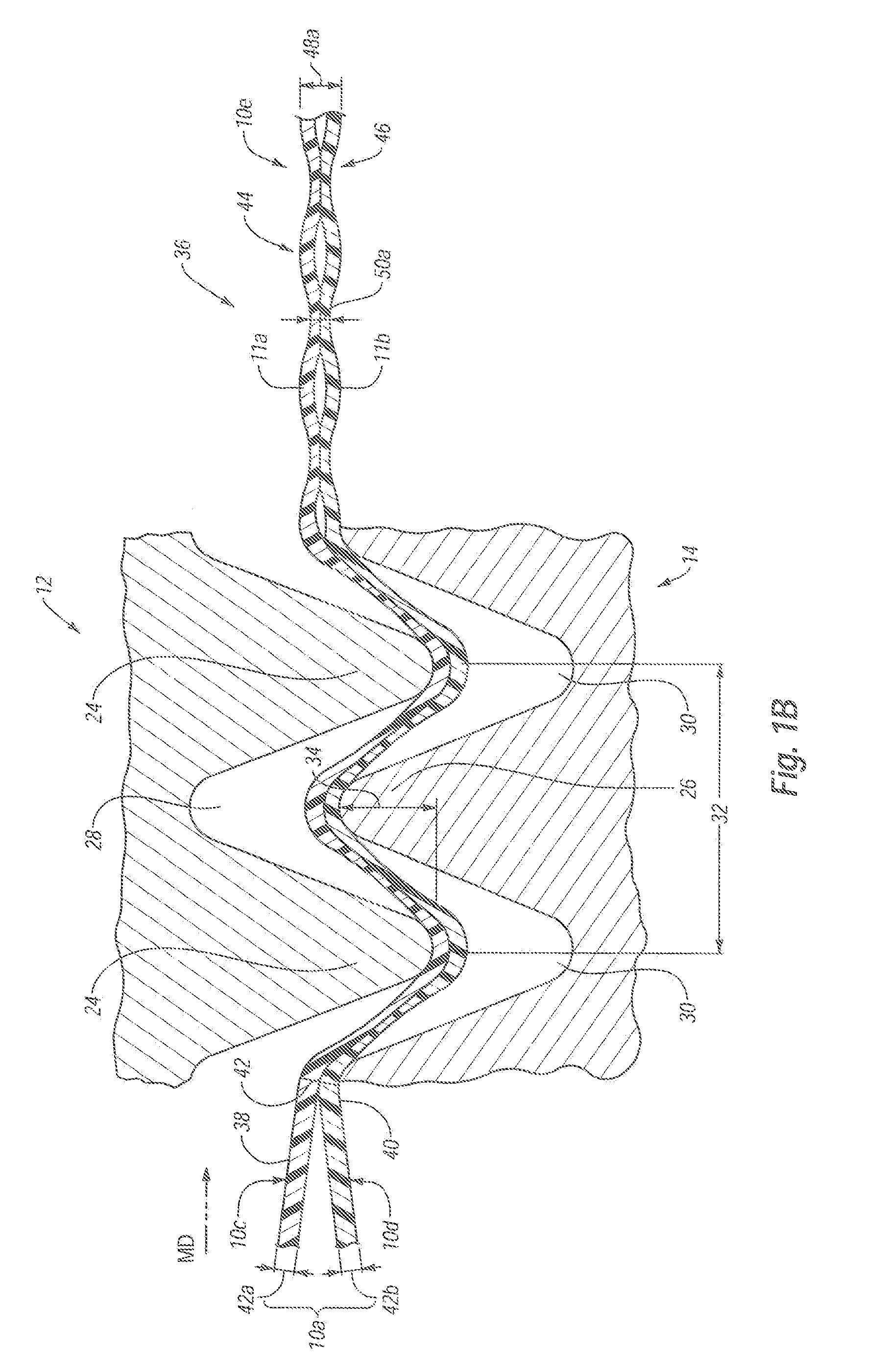

Multi-Layered Bags With Discrete Non-Continuous Lamination

ActiveUS20120063706A1Increased strength parameterReduce amountEnvelopes/bags making machineryMechanical working/deformationGround layerEngineering

Multi-layer bags may be formed to include first and second sidewalls joined along a first side edge, an opposite second side edge, and a closed bottom edge. The first and second layers may be non-continuously laminated together in discrete sections to include bonded regions in which the layers are bonded and unbonded regions in which the layers are not bonded. Such a bag may be described as a “bag-in-a-bag” type configuration in which the inner bag is non-continuously bonded to the outer bag. The inventors have surprisingly found that such configurations of non-continuous bonding provides increased and unexpected strength properties to the multi-layer films and bags.

Owner:THE GLAD PROD CO

Method for manufacturing auxiliary gas-adding polyurethae/polyurethane-urea polishing pad

InactiveUS20040021243A1Improve accuracyImprove flatnessFlexible-parts wheelsLapping toolsHydrogenPolythiol resin

A method for manufacturing a PU (polyurethane) polishing pad is provided. Resins containing active hydrogen functional groups such as polyol resins, polyamine resins, and polythiol resins, and polyisocyanate resins containing -NCO functional groups are mixed to form a foamed PU polishing pad with excellent polishing properties by reaction injection-molding under high pressure, low temperature and auxiliary gas-adding. The PU polishing pad in accompany with an abrasive slurry can be widely used to polish high-level products such as wafers and optical glass.

Owner:IV TECH CO LTD

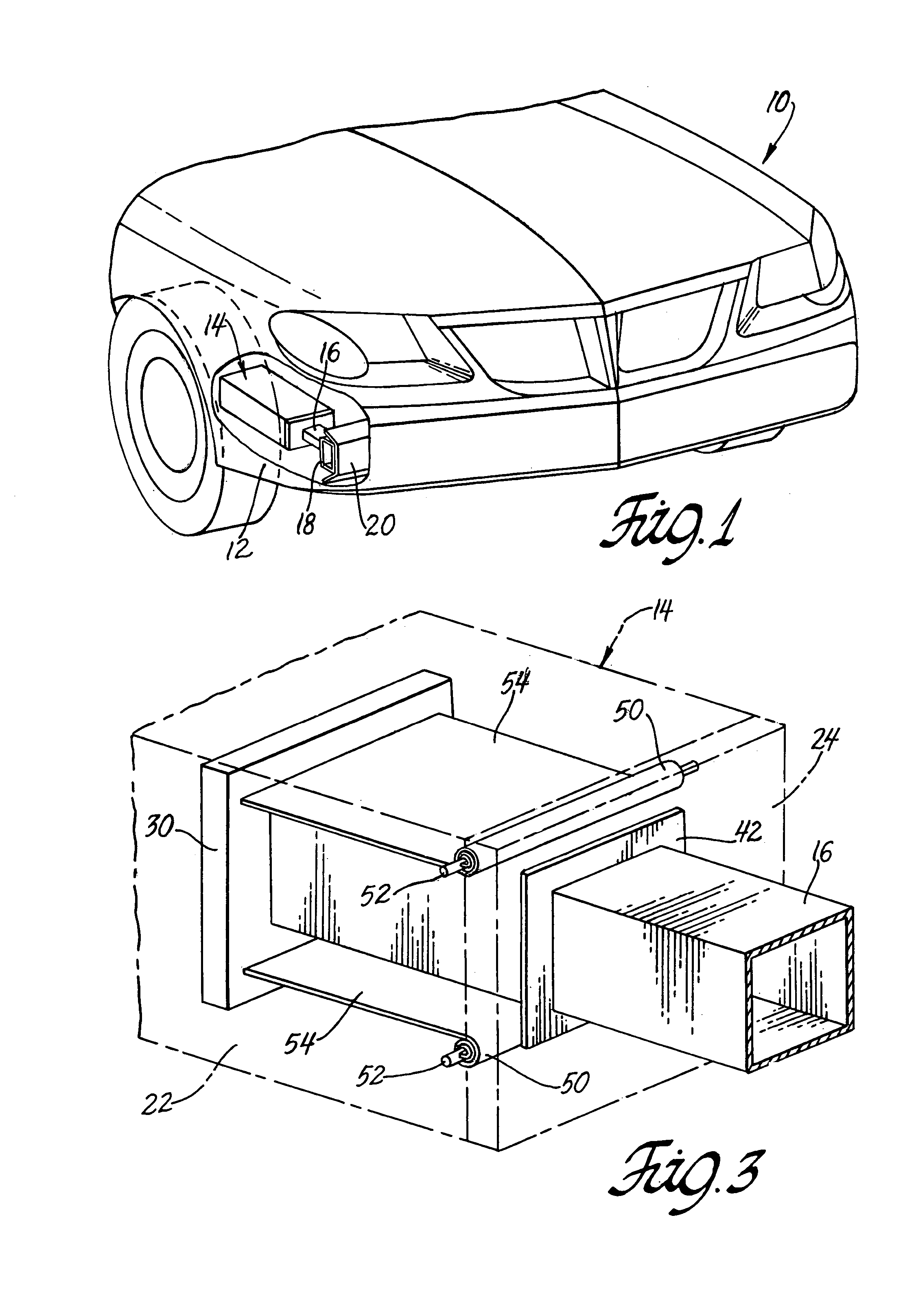

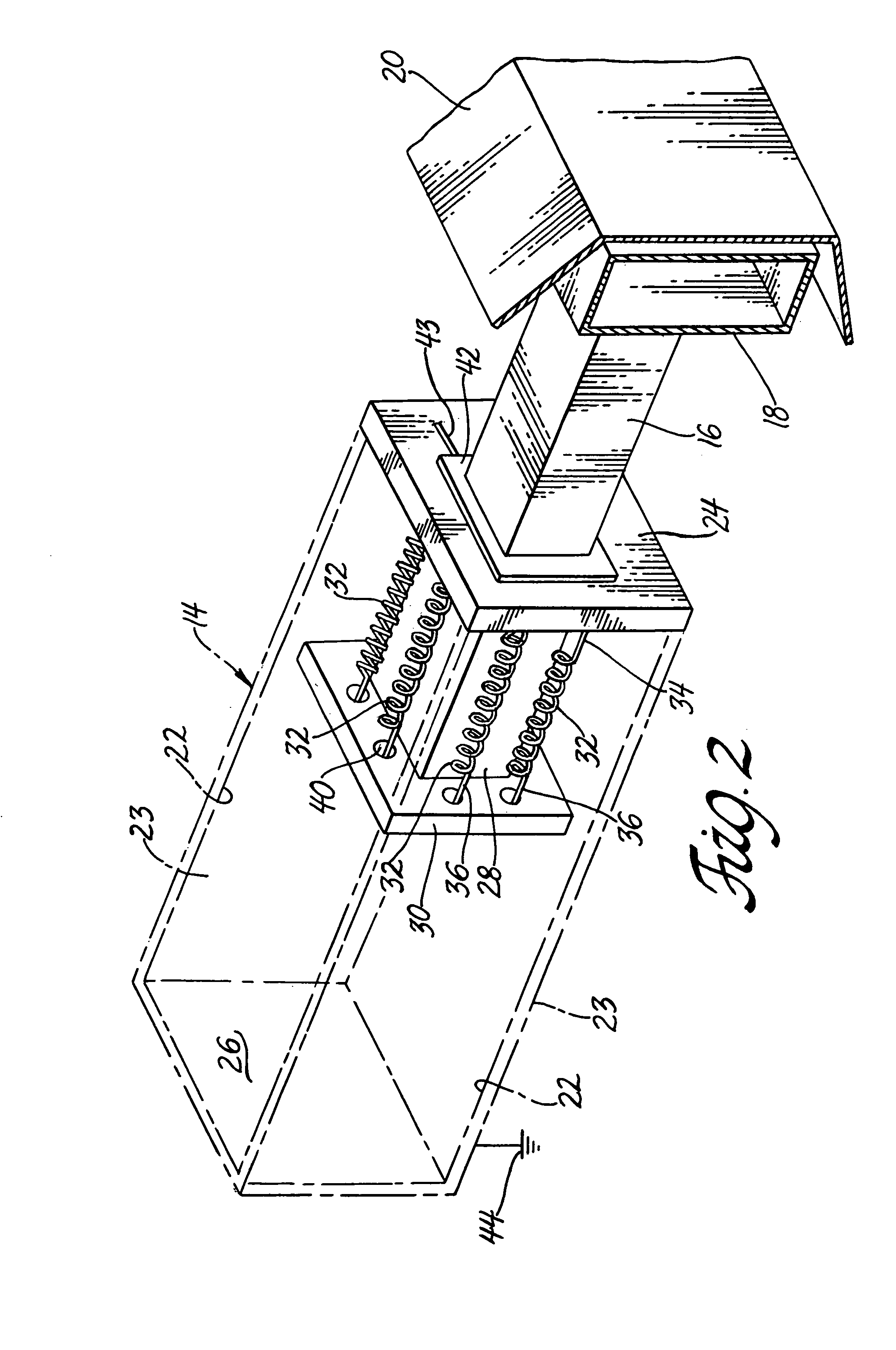

Tunable, healable vehicle impact devices

InactiveUS7029044B2Large energy absorption capacityImprove energy absorptionVehicle seatsPedestrian/occupant safety arrangementLow speedEnergy absorption

Owner:GM GLOBAL TECH OPERATIONS LLC

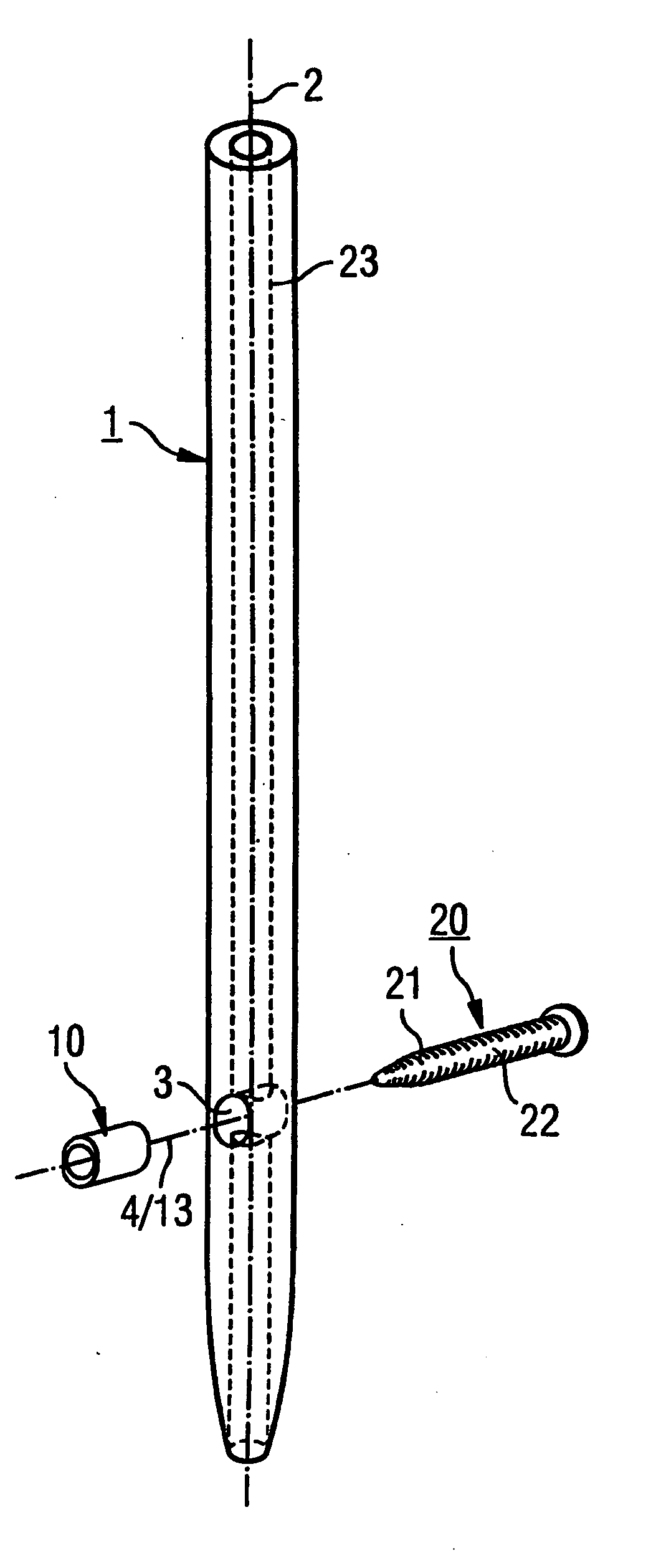

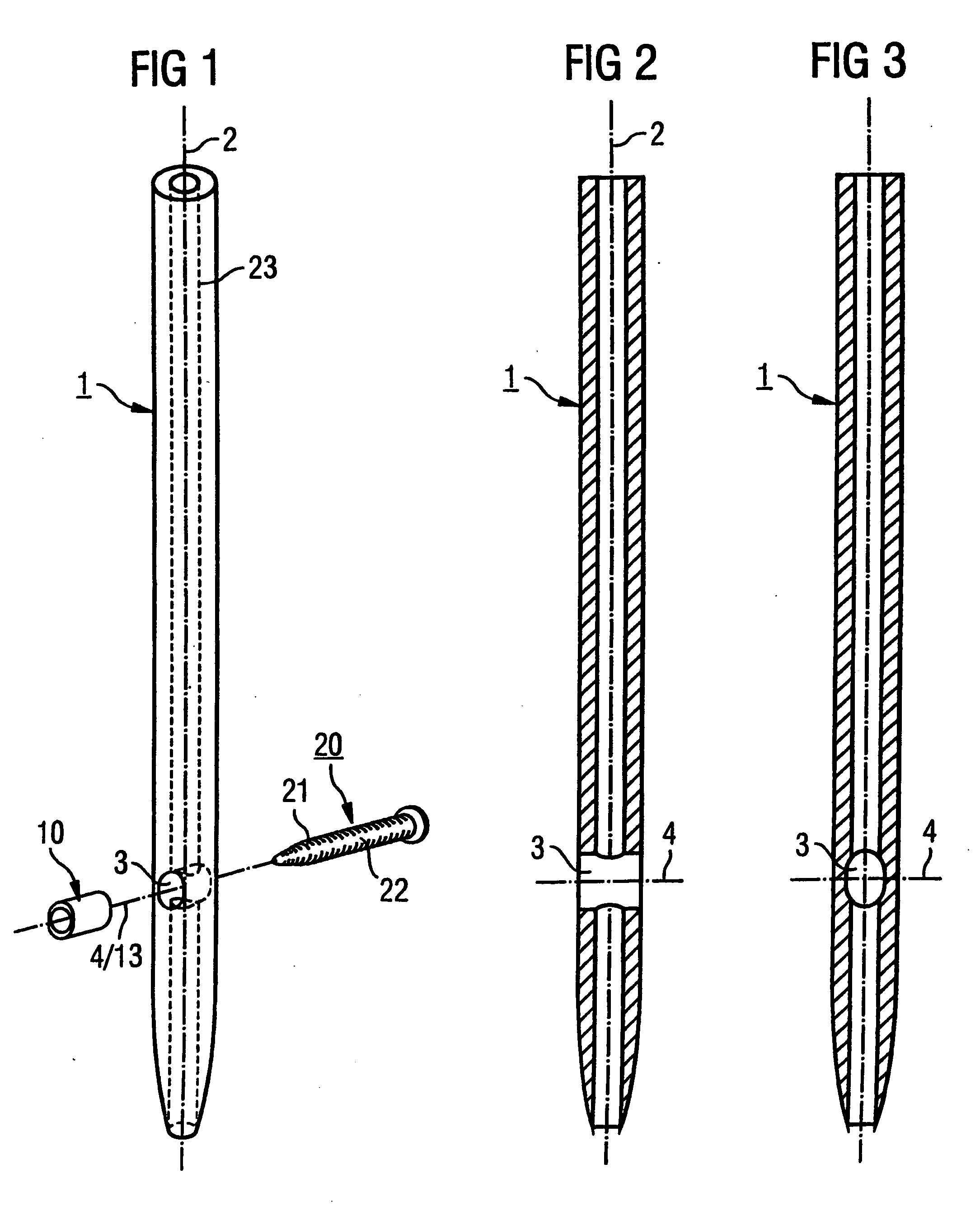

Surgical nail

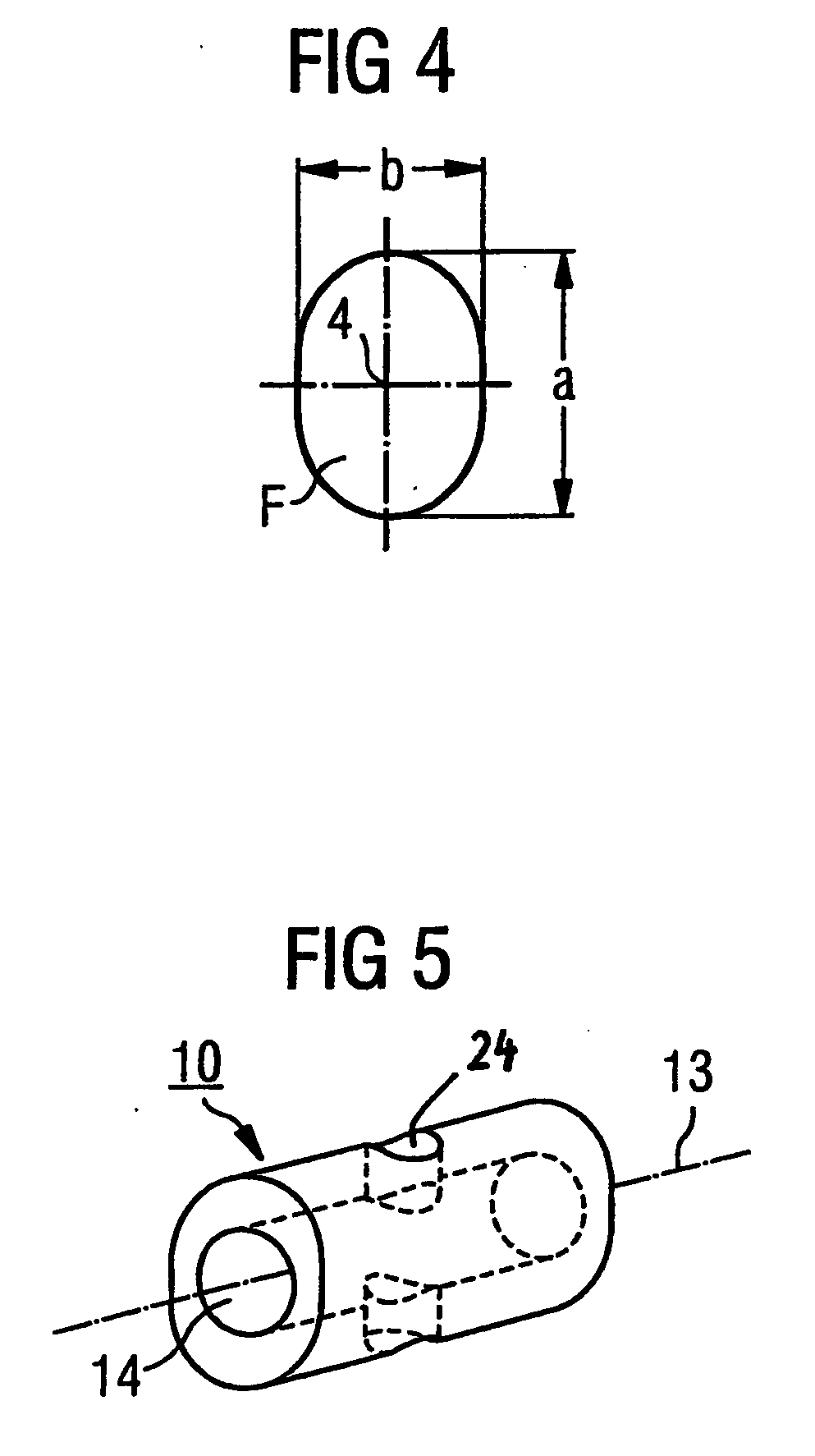

ActiveUS20060149248A1ClearanceImprove retentionInternal osteosythesisJoint implantsElastic modulusTransverse axis

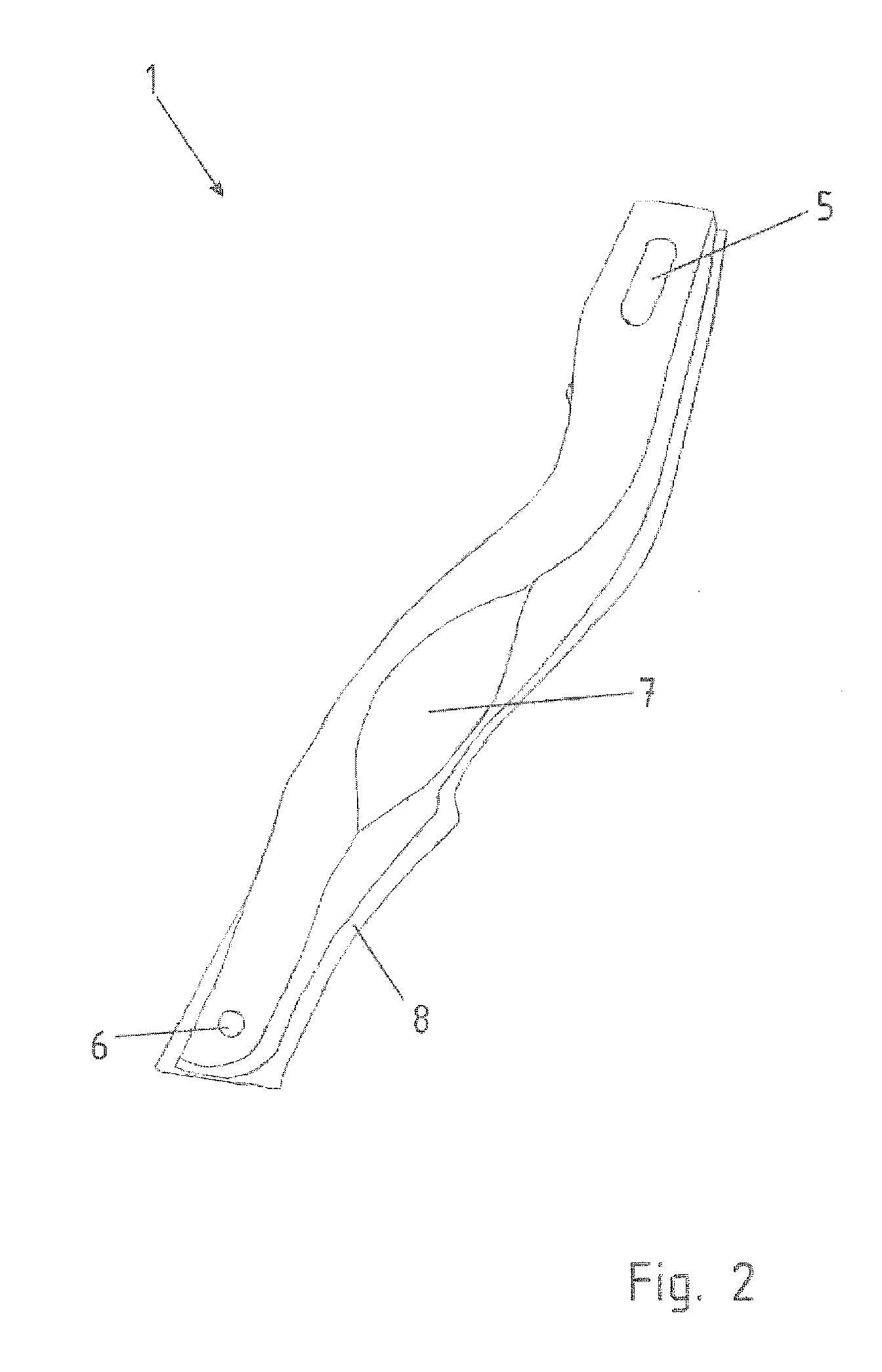

The invention relates to a surgical nail in the form of an intramedullary nail with a central axis made from a material M with a tensile strength Fz, compressive strength Fd, density ρ2 and modulus of elasticity E. Said nail has a transverse bore extending transversely to the central axis and having a cross-sectional profile F and a transverse axis, the cross-sectional profile F having a maximum length a that runs in the direction of the central axis and a maximum width b that runs perpendicular to the length. An insert with the longitudinal axis, made from material m and having a modulus of elasticity e that is smaller than the modulus of elasticity E of material M, can be introduced into the transverse bore. The insert also has a length L that runs in the direction of its longitudinal axis and satisfies the condition L>0.2 D.

Owner:DEPUY SYNTHES PROD INC

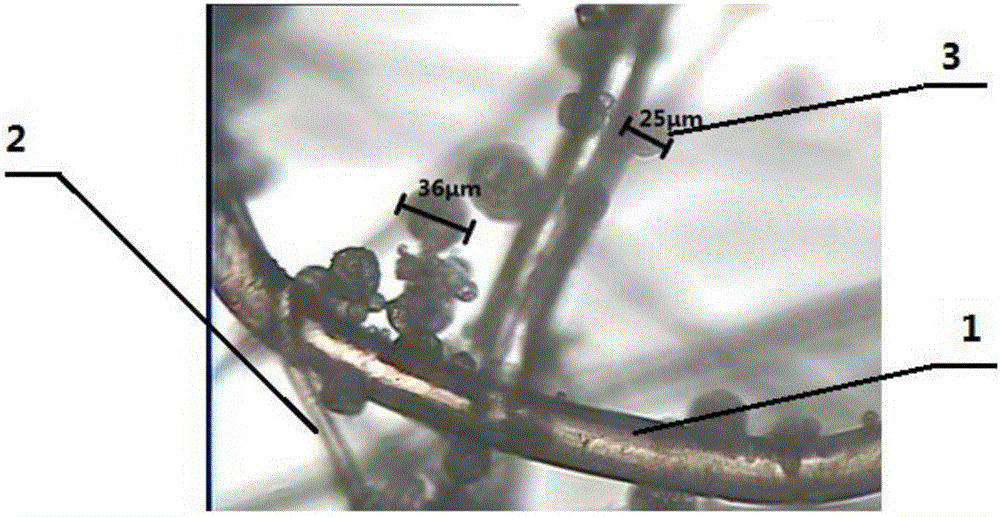

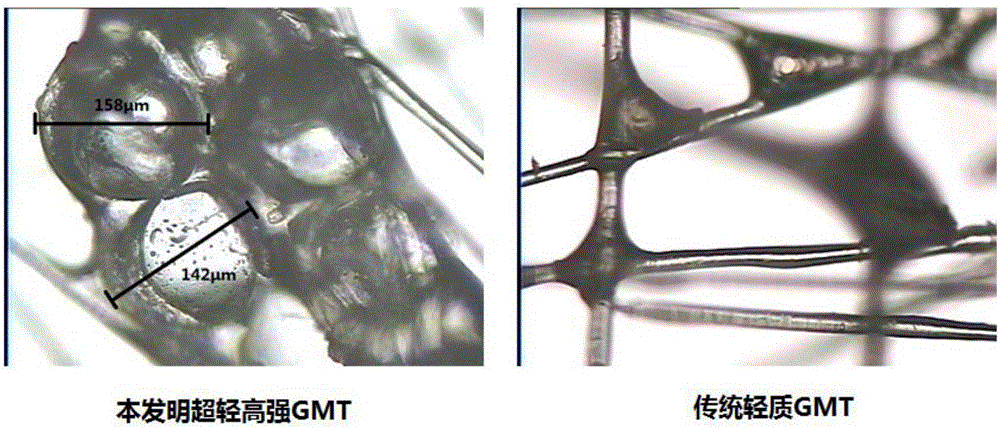

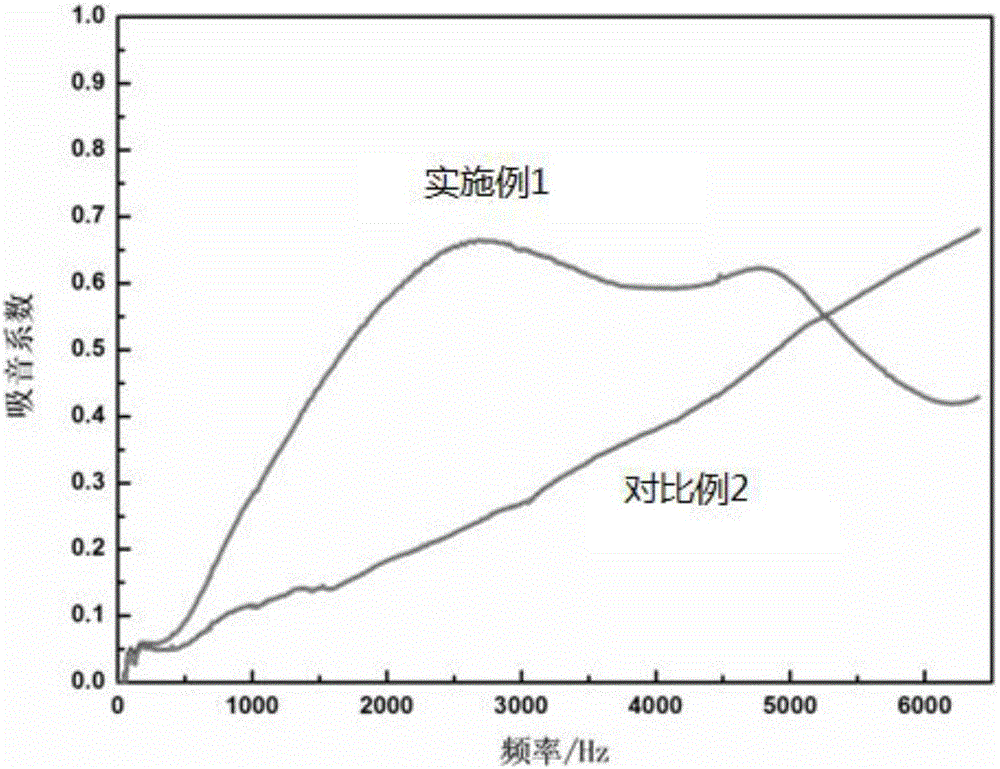

Preparation method of high-sound-absorption ultralight high-strength GMT composite board

ActiveCN106427163AIncrease freedomDifferent strengthLamination ancillary operationsLaminationFiberFoaming agent

The invention discloses a preparation method of a high-sound-absorption ultralight high-strength GMT composite board. According to the preparation method, a microsphere foaming agent is introduced into a GMT felt screen through an impregnation technology in the back pass of an existing light GMT dry combing felt forming technology, the expansibility of the board is adjusted by changing a supporting method of connection of lattice points among reinforced fibers and combining the expanding characteristic of the microsphere foaming agent, the obtained board can be expanded in secondary forming, and then the thickness reaches 5-10 times that of the original thickness; pressing fixing is conducted as needed by adjusting the expanded compression ratio according to the product performance requirements, and automotive internal and external ornament products with different strength, rigidity and sound resistance characteristics are obtained. Therefore, the problems that in a traditional light GMT product, further ultra-lightweight design is difficult, the impregnated air volume is insufficient, and the design freedom degree and the NVH performance of the product are far behind of those of foreign imported products are effectively solved.

Owner:浙江华江科技股份有限公司

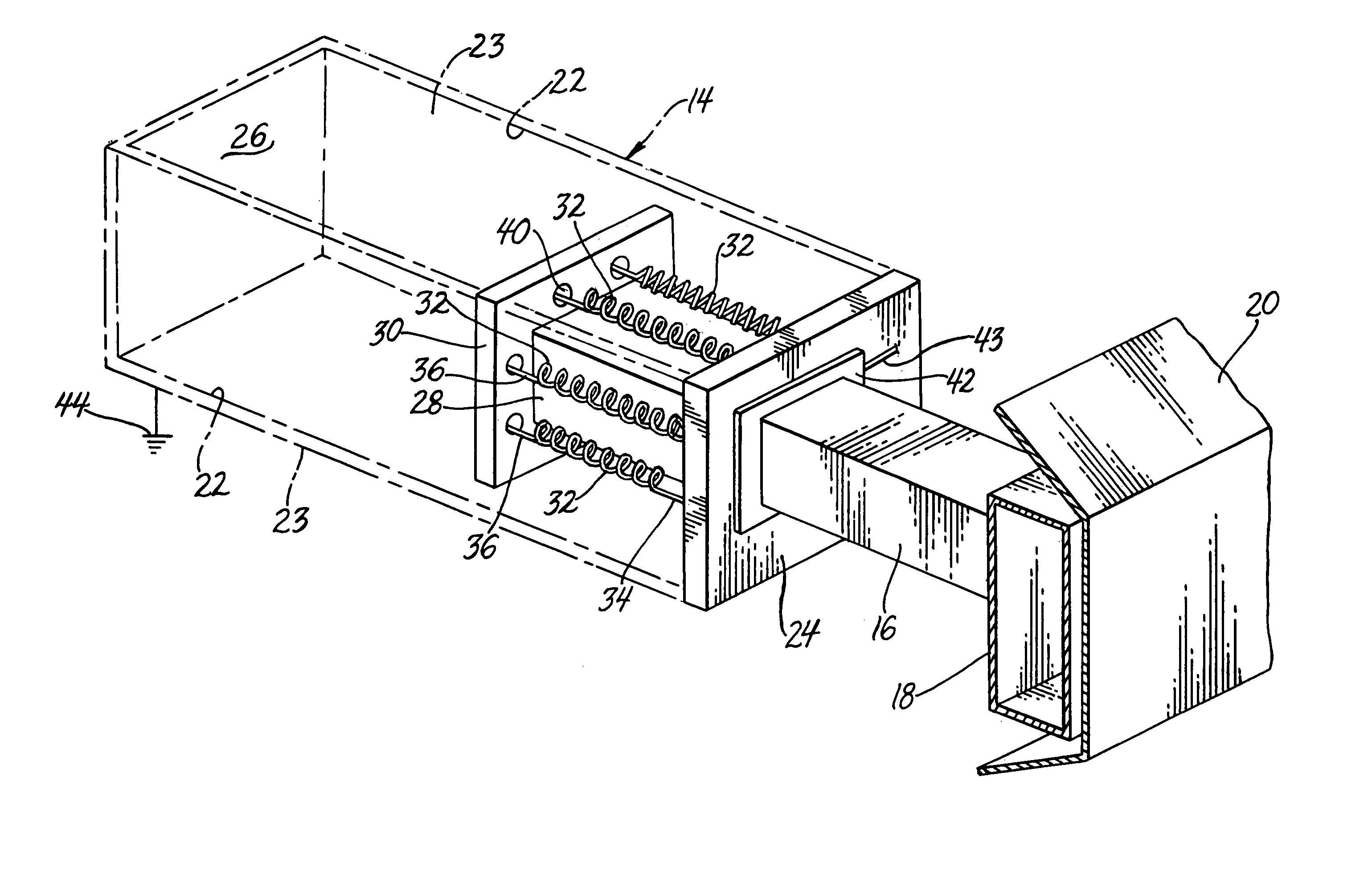

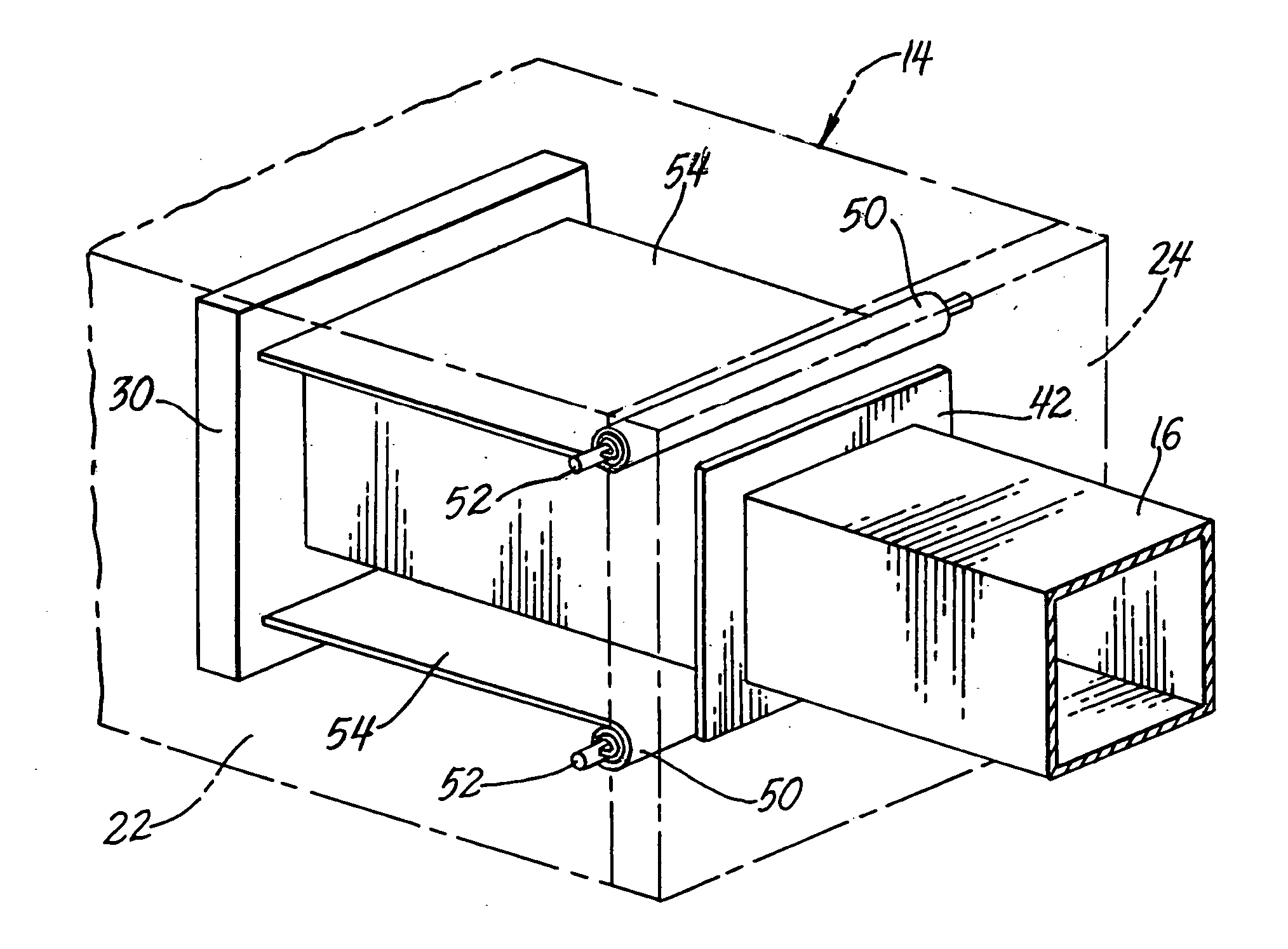

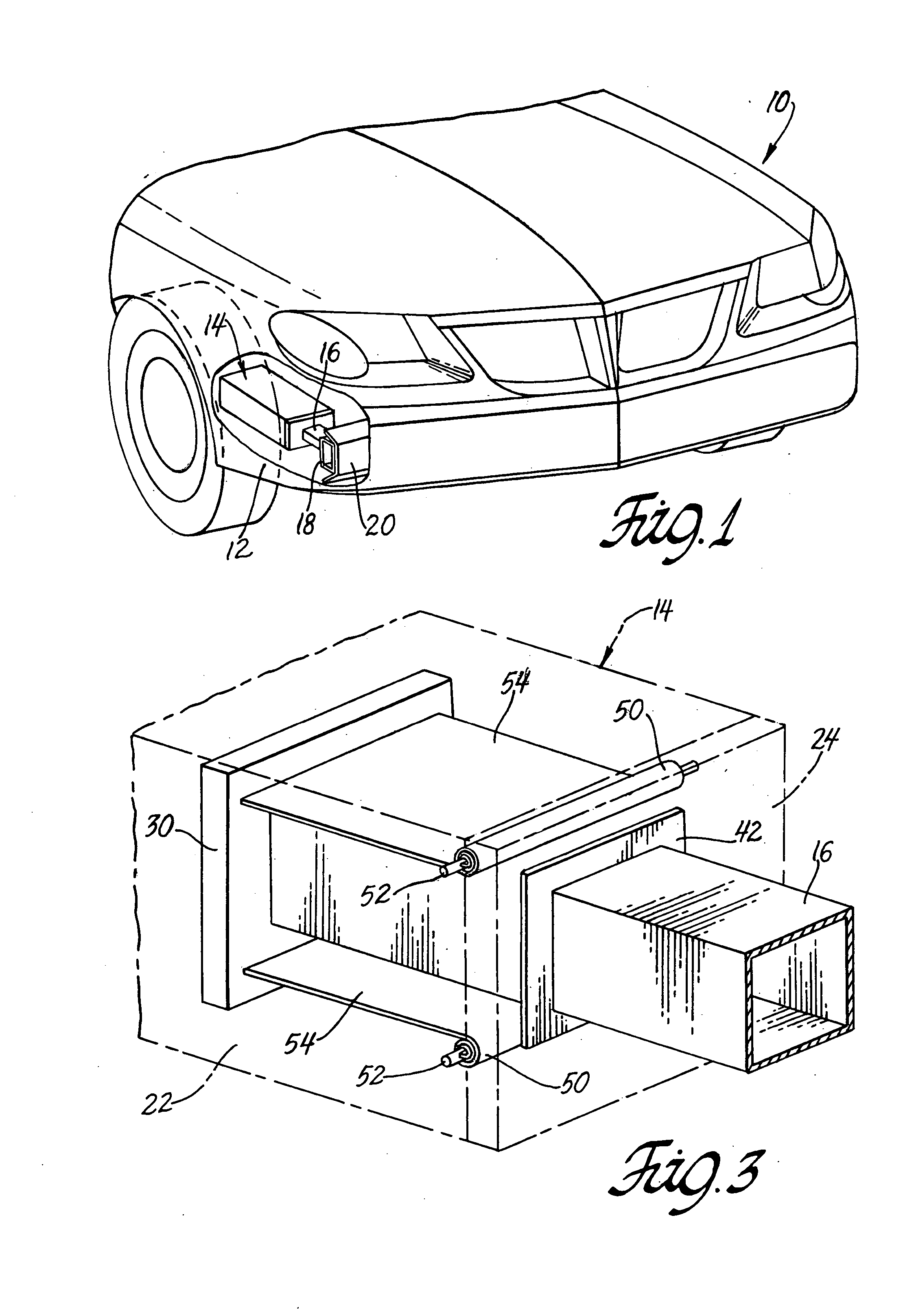

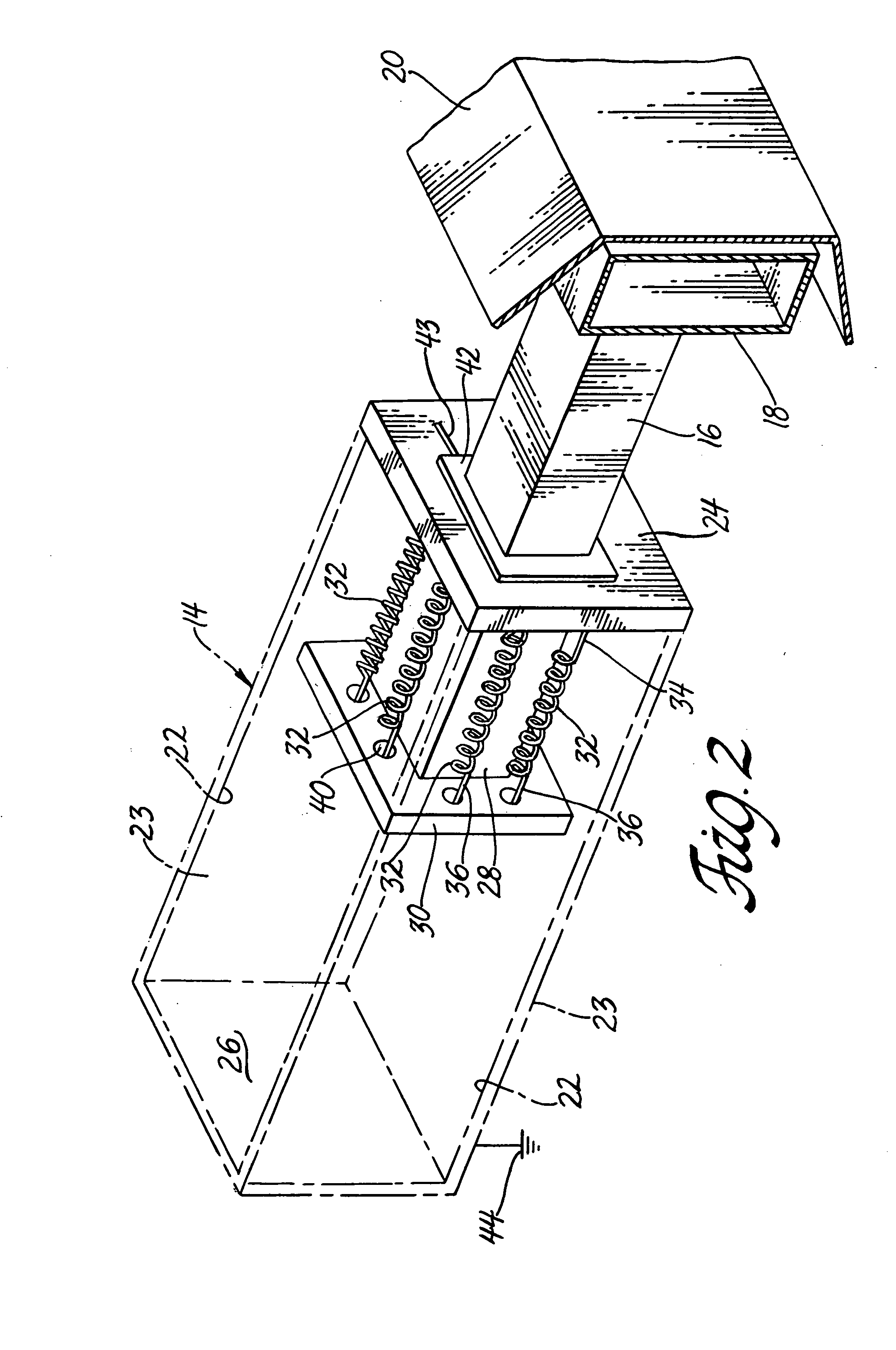

Tunable, healable vehicle impact devices

ActiveUS20050104391A1Low costLarge energy absorption capacityBumpersShock absorbersLow speedEnergy absorption

An impact absorbing device for a vehicle uses a shape memory material that can be heated to repair deformation from a relatively low speed, low energy impact and its stroking force and energy absorption can be tuned by heating. The shape memory material is suitably used in a crash box having an inserted impact absorbing ram, the box being placed, for example, between a bumper and strong body member. The shape memory material is attached to the box and ram for absorbing energy as the ram is driven into the box. Heating means is provided to repair or tune the shape memory material.

Owner:GM GLOBAL TECH OPERATIONS LLC

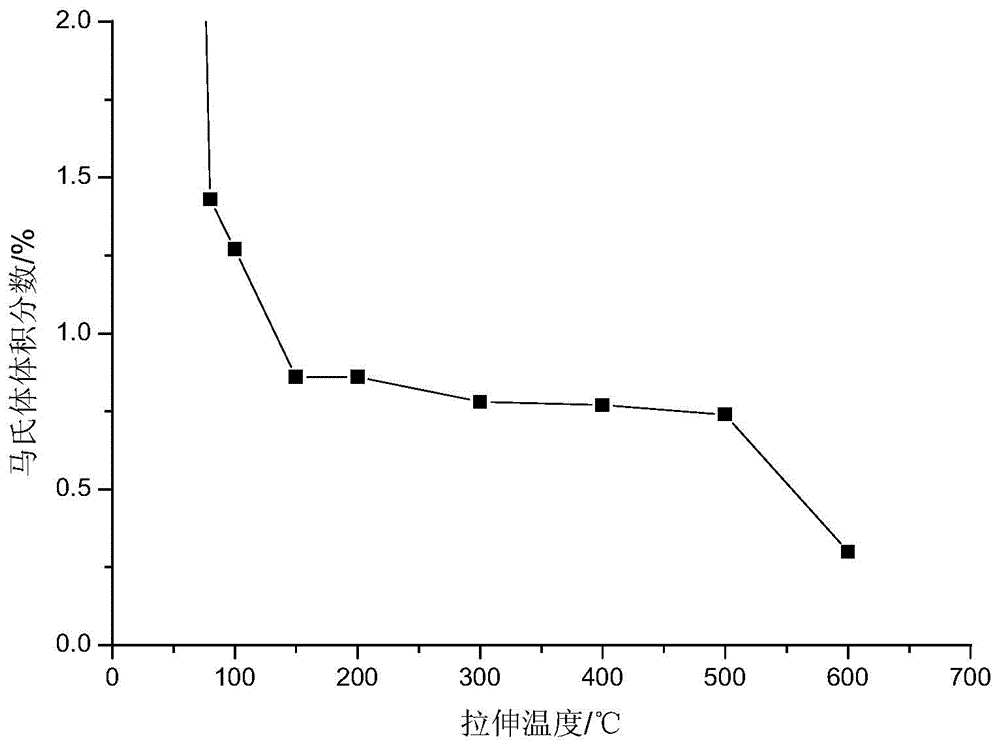

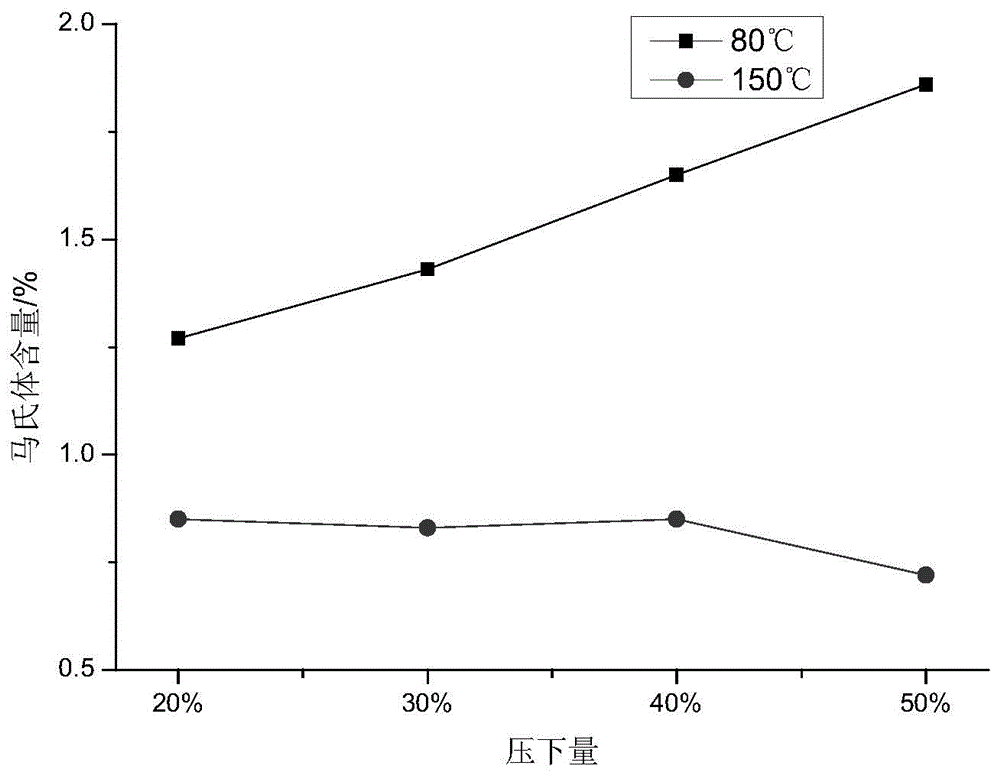

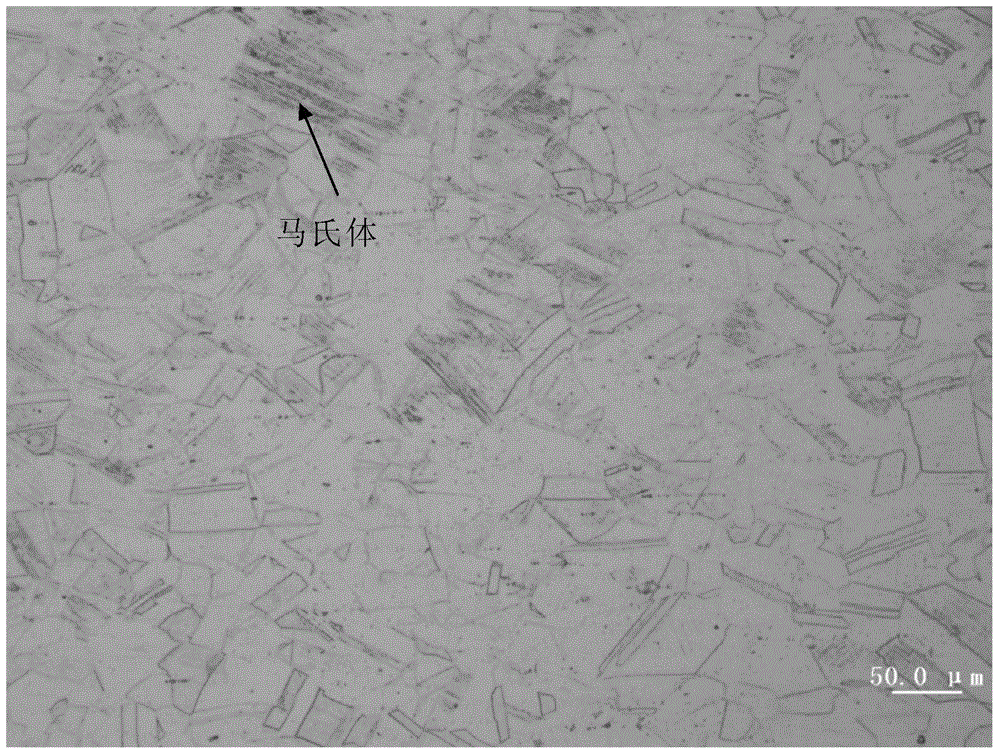

800-1,600 MPa grade high strength austenitic stainless steel, manufacturing method and warm forming method

The invention provides 800-1,600 MPa grade high strength austenitic stainless steel, manufacturing method and a warm forming method. The austenitic stainless steel comprises steel chemical components in weight of 0.04%-0.14% of C, 0.2%-0.6% of Si, 2%-12% of Mn, 12%-18% of Cr, 0.5%-6.5% of Ni, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 0.05%-0.25% of N, 0%-2% of Cu, one or more of Mo, Nb and Ti and the balance of Fe and inevitable impurities, and the condition that W(Ni)eq is larger than or equal to 20.5 and smaller than or equal to 25.5 is required to be met. The high strength austenitic stainless steel is obtained by controlling the rolling reduction to be 10%-40% in a rolling process, the tensile resistance is 800-1,600 MPa, and the extension is 13%-40%. At the same time, with the warm forming method, ultra-complex formed high strength stainless steel parts can be obtained, and the high strength austenitic stainless steel has excellent corrosion resistance, high strength and delayed cracking resistance.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

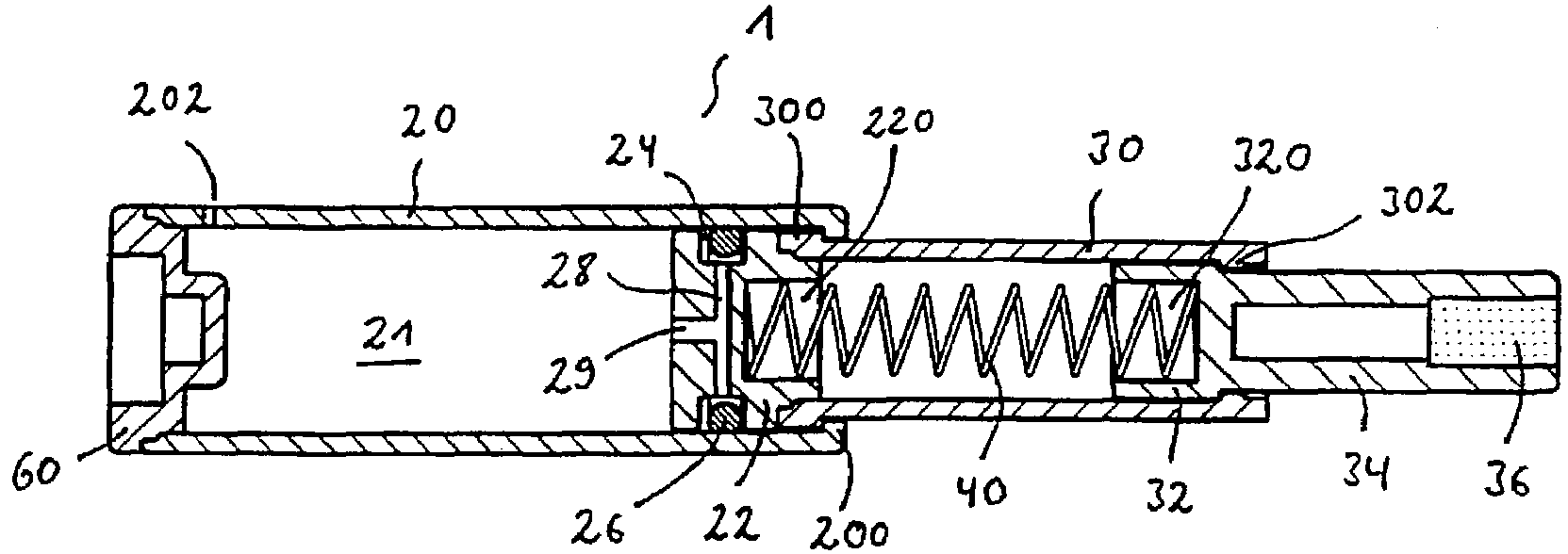

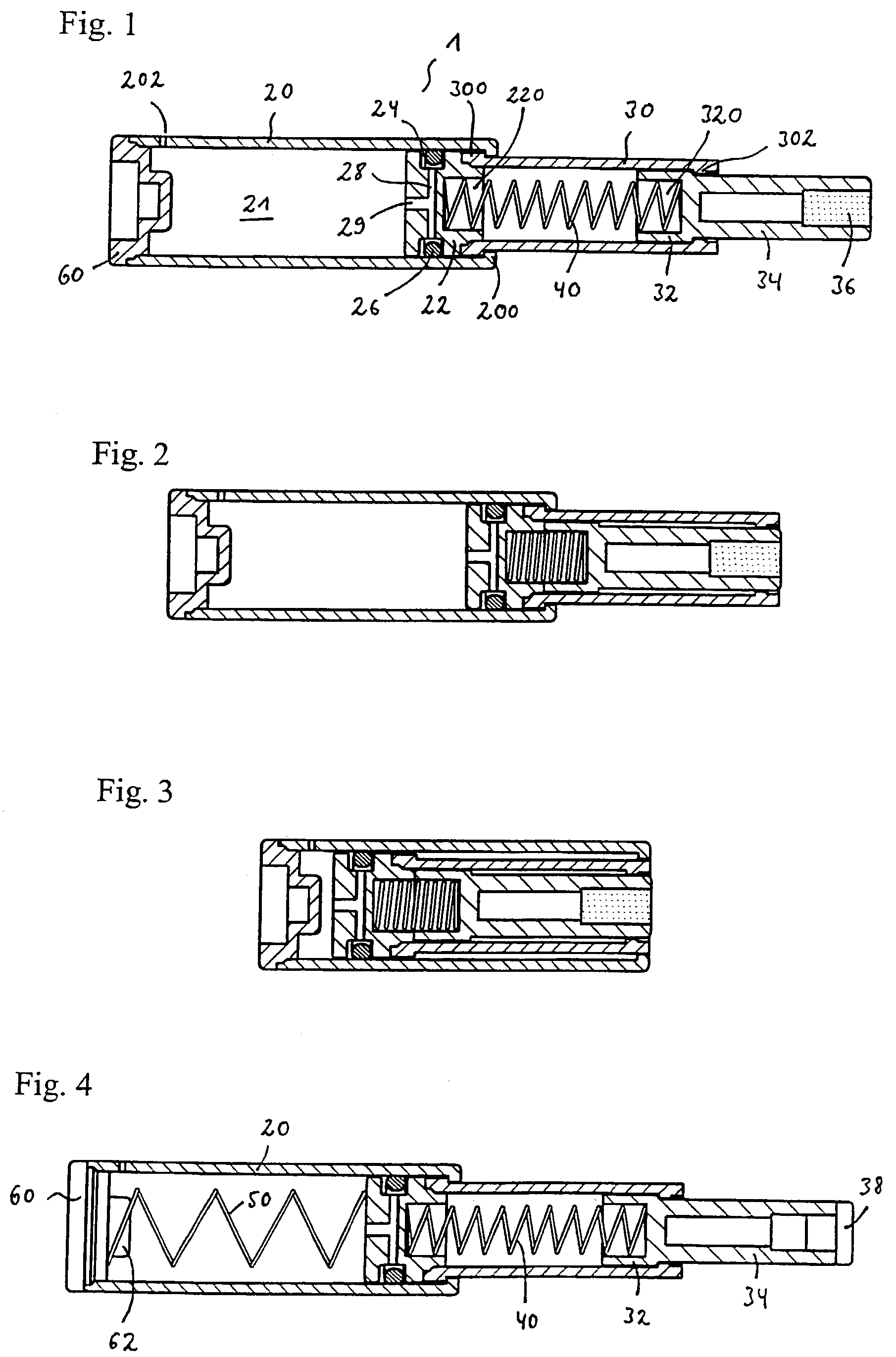

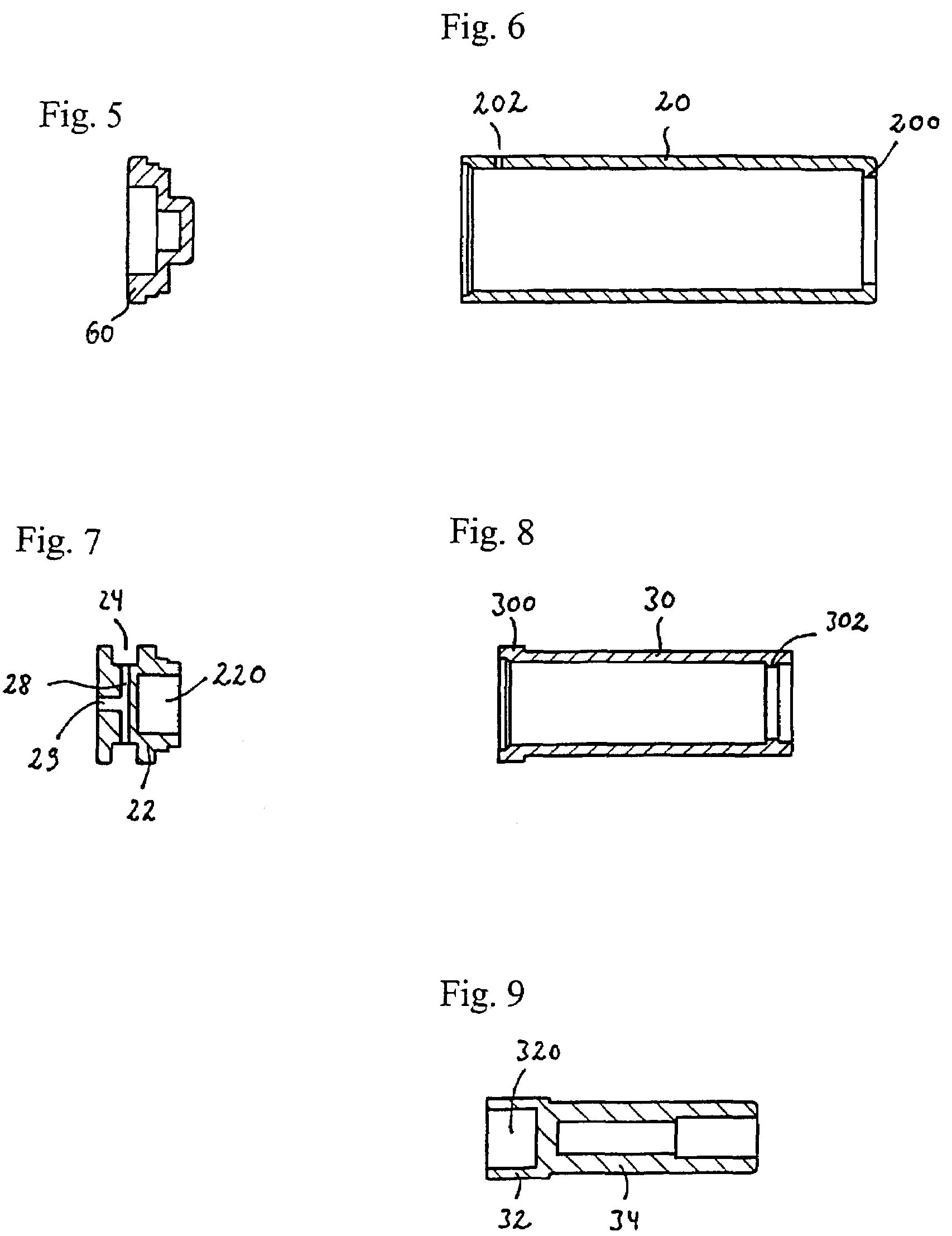

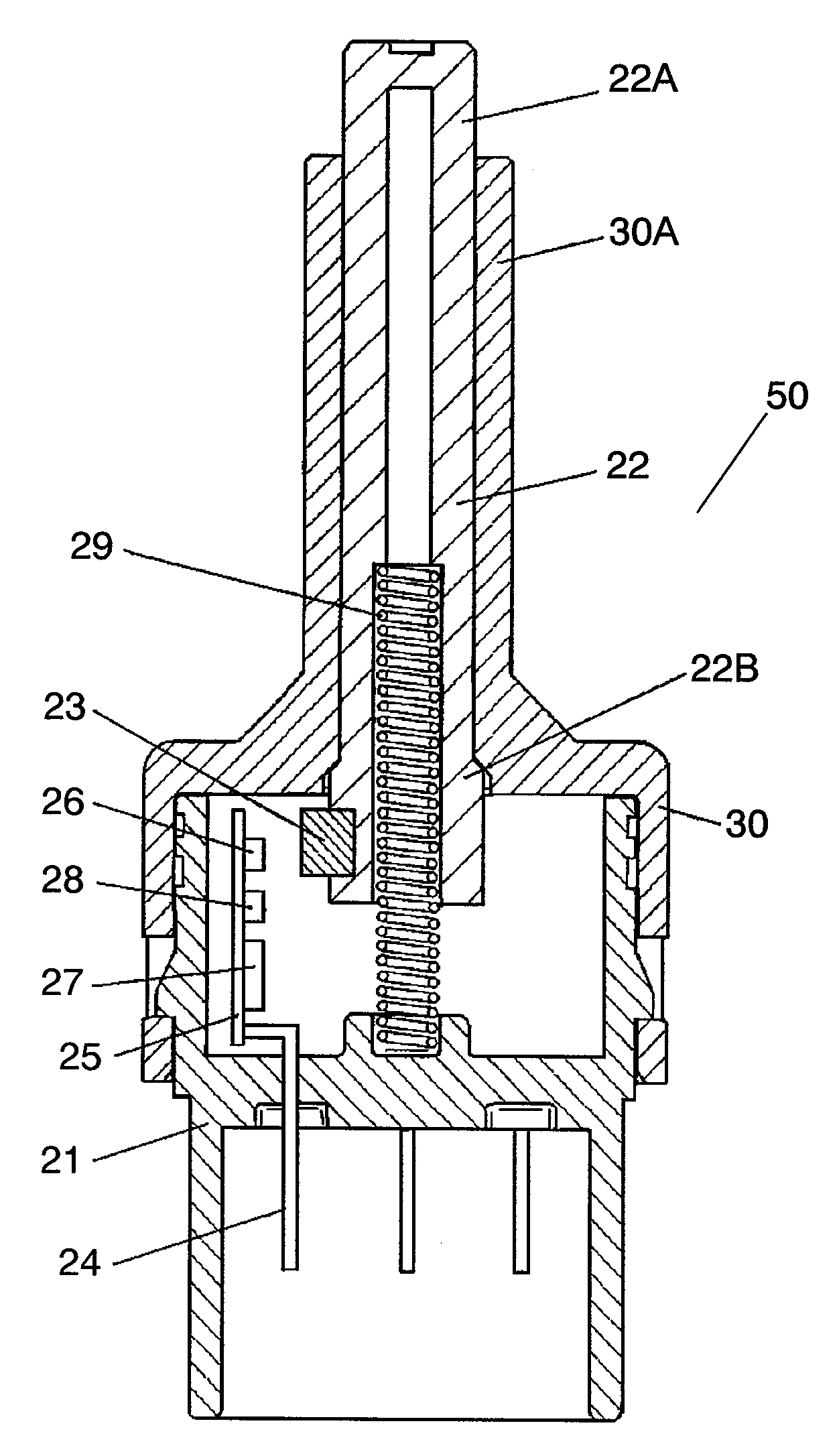

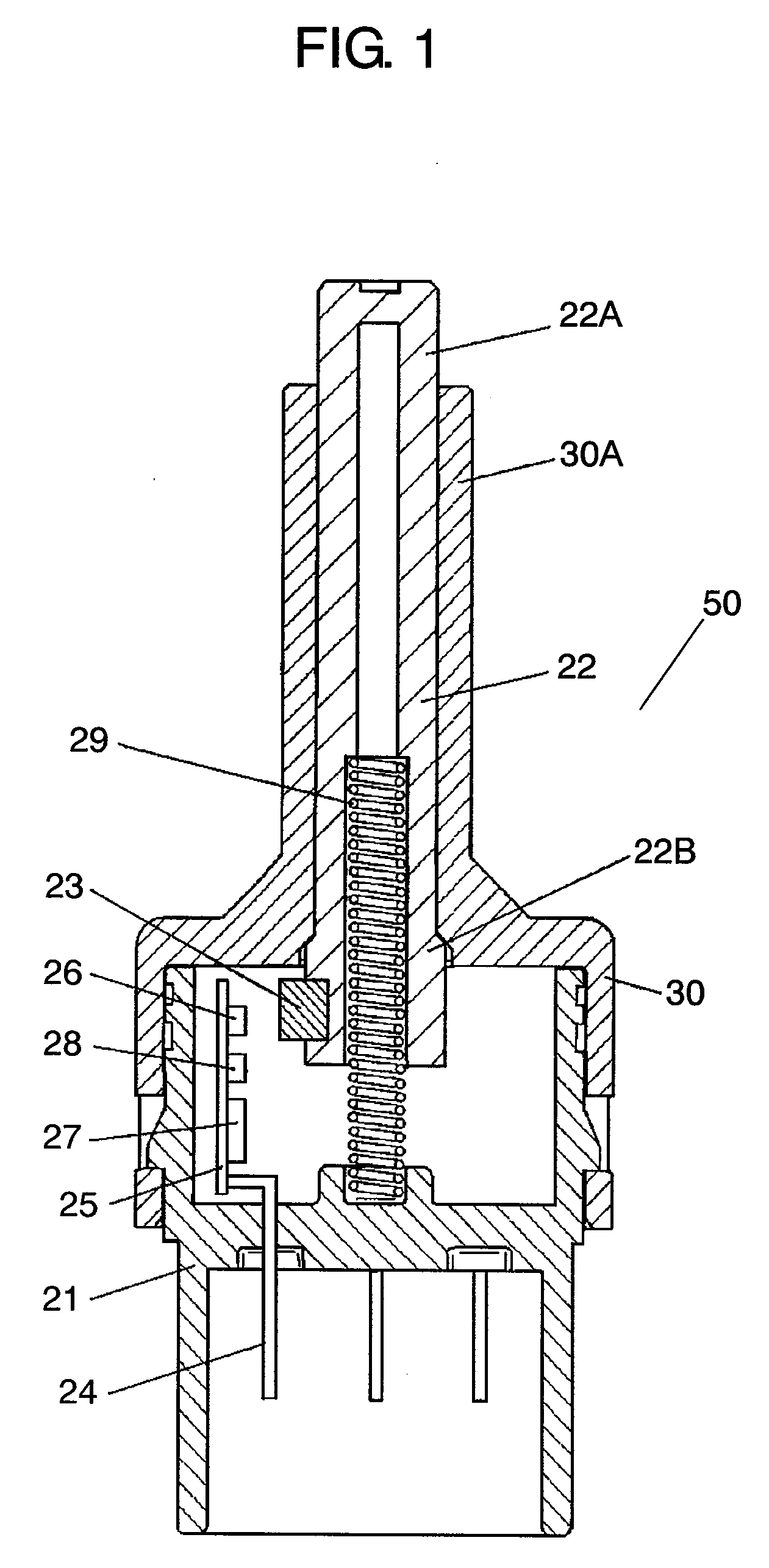

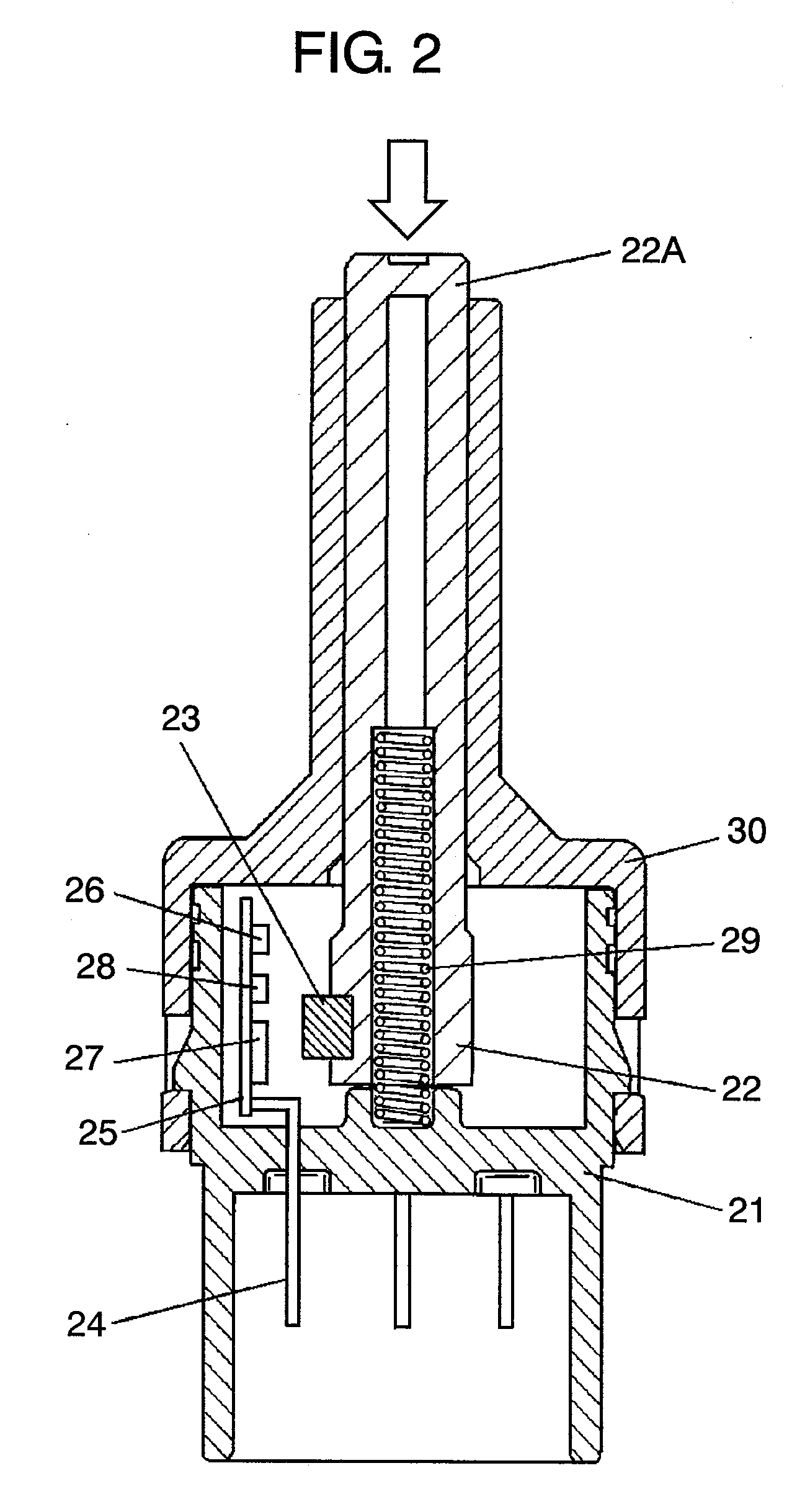

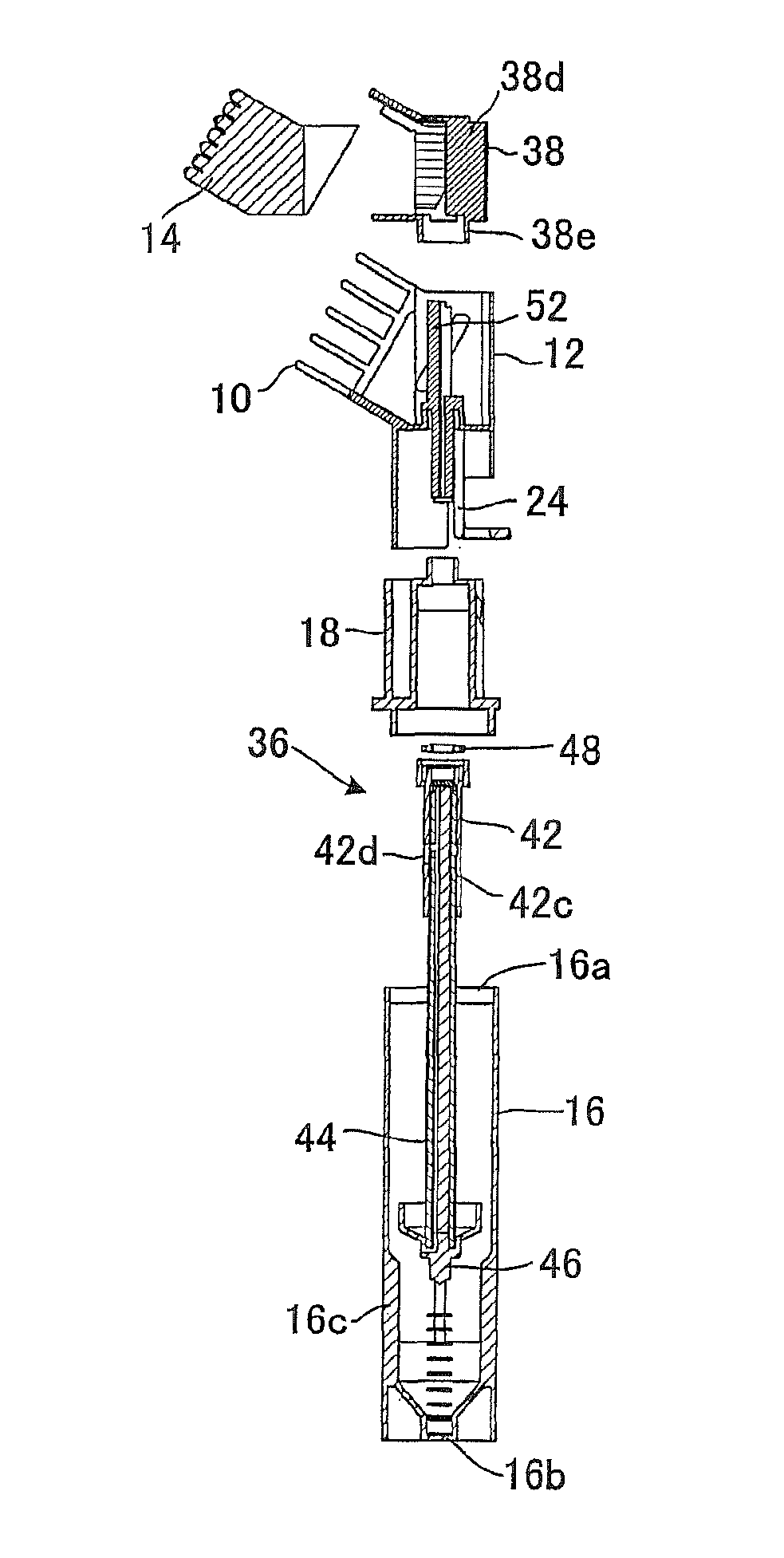

Damping apparatus for moving furniture parts

InactiveUS7281704B2Damping actionAvoid partialBuilding braking devicesWing accessoriesPistonEngineering

The present invention relates to a damping apparatus for moving furniture parts, for example doors, flaps or drawers. Such a damping apparatus of a compact construction which avoids a possible springing back movement of the furniture parts is provided in accordance with the invention in that the damping apparatus has at least two damping stages each having a cylinder having a piston longitudinally displaceable therein which exert a damping action of different strengths.

Owner:ARTURO SALICE

Mold and method for sectionally adjusting cooling efficiency of the mold

InactiveUS20130125603A1Adjusts the heat-dissipation rate or cooling efficiencyDifferent hardnessShaping toolsHeat exchange apparatusEngineeringCooling channel

The present invention provides a method for sectionally controlling a cooling efficiency of a mold. The method comprises steps of: (a) configuring at least a cooling passage including a first section having a first heat-dissipating inner surface area and a second section having a second heat-dissipating inner surface area in the mold; and (b) adjusting the first and the second heat-dissipating inner surface areas unequally by using a heat-dissipating element.

Owner:METAL INDS RES & DEV CENT

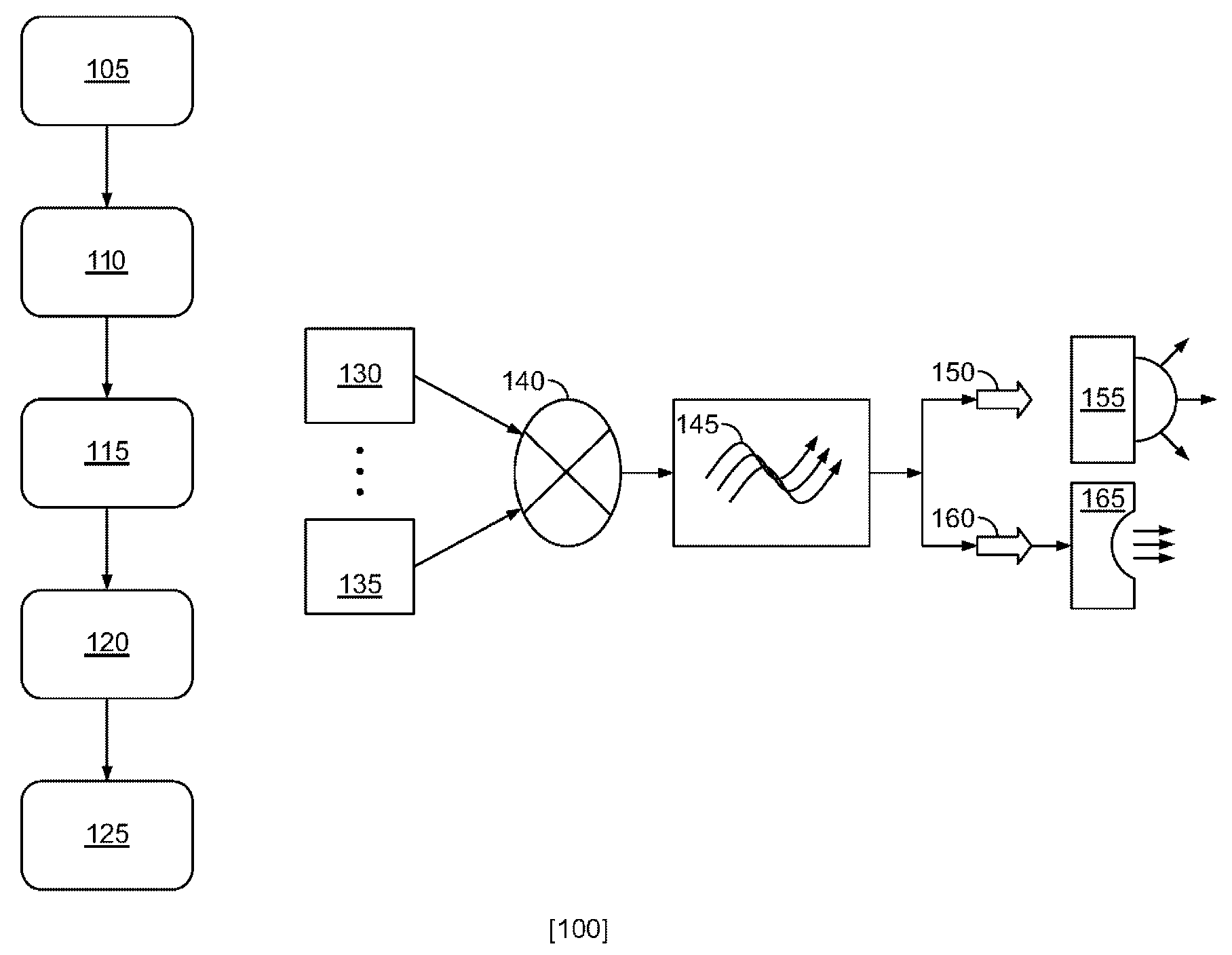

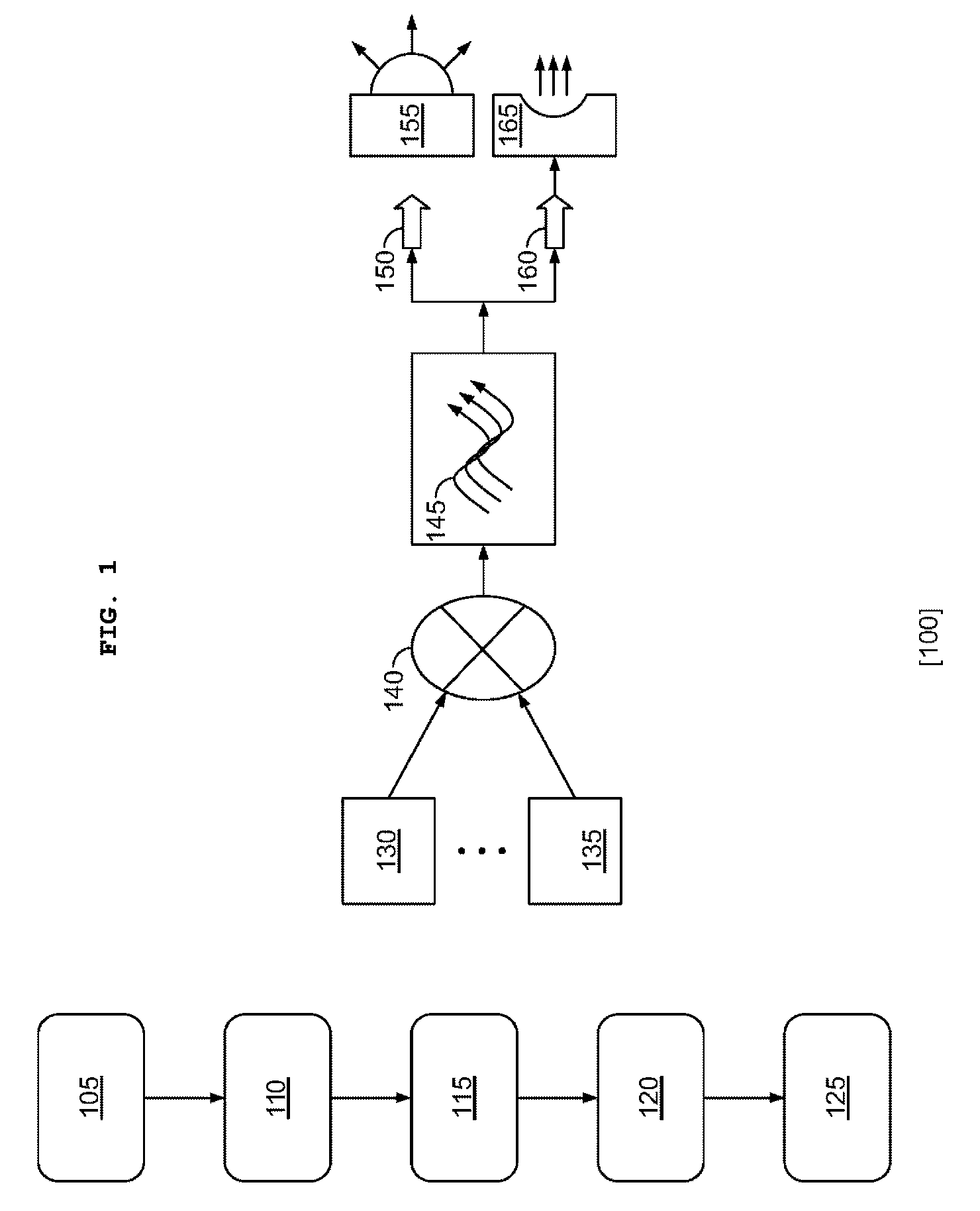

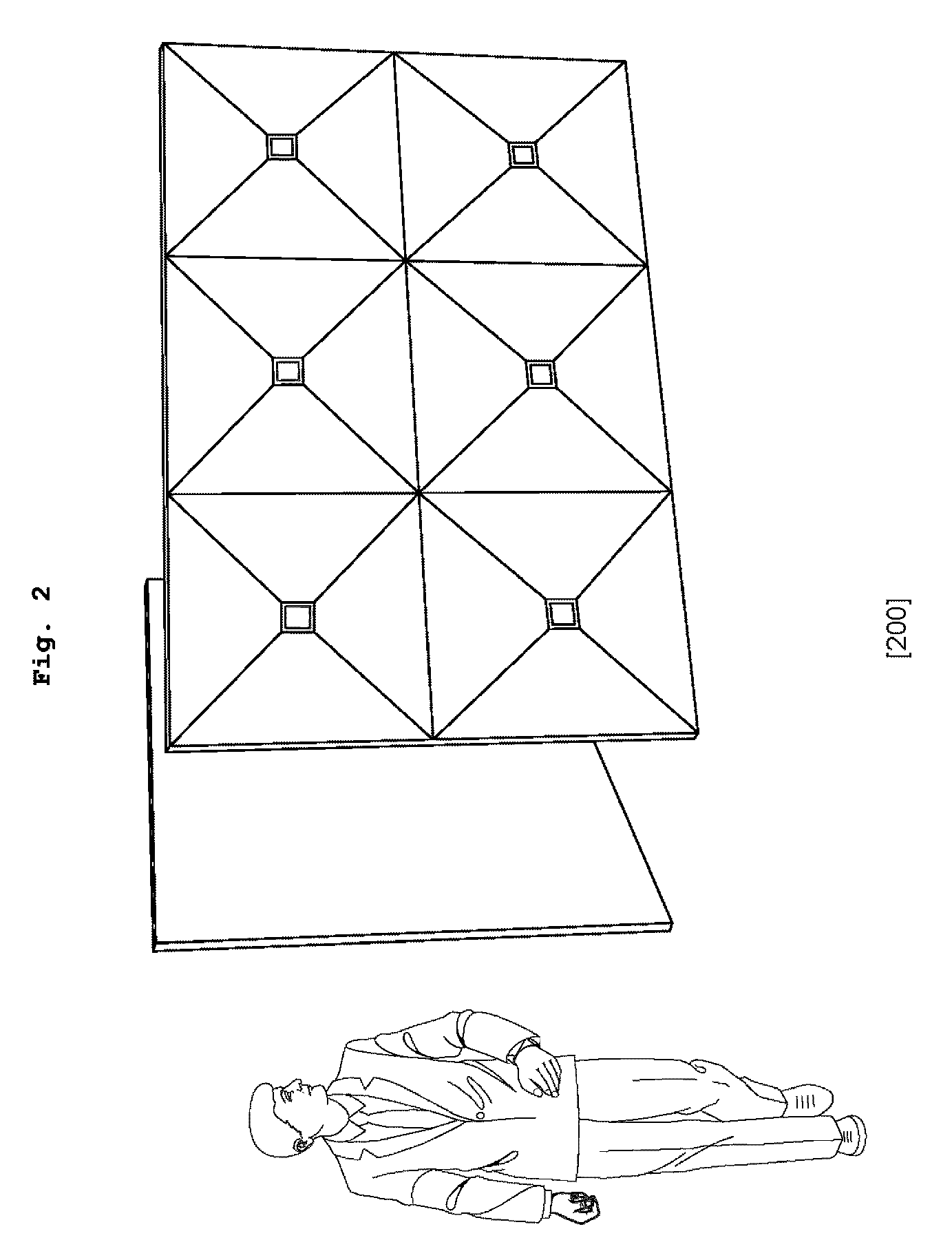

Hybrid Telecom Network-structured Architecture and System for Digital Image Distribution, Display and Projection

ActiveUS20090231358A1Improve bindingEfficient integrationTelevision system detailsProjectorsImage resolutionComputer graphics (images)

A hybrid and telecom-structured image display and projection system implementing a desired image display and projection solution that is fast, cheap to manufacture, low-power, light-weight, scalable in size and resolution, fast-switching and capable of a broad range of mode characteristics of light for implementing dimensional display and projection, flexible, rigid-flat, or rigid-conformal as needed.

Owner:PHOTONICA

Vehicle switch

ActiveUS20070290642A1Reduce troubleDifferent strengthDC motor speed/torque controlContact operating partsLower limitMagnetic detector

A vehicle switch includes a magnet mounted to an operating unit accommodated in an external packaging such that the operating unit can move linearly. A magnetic detector is placed so as to receive different strength of the magnetism from the magnet in the two cases that the operating unit is at the upper limit position and at the lower limit position. A control circuit coupled to the magnetic detector opens and closes a switching device in response to strength of the detected magnetism.

Owner:PANASONIC CORP

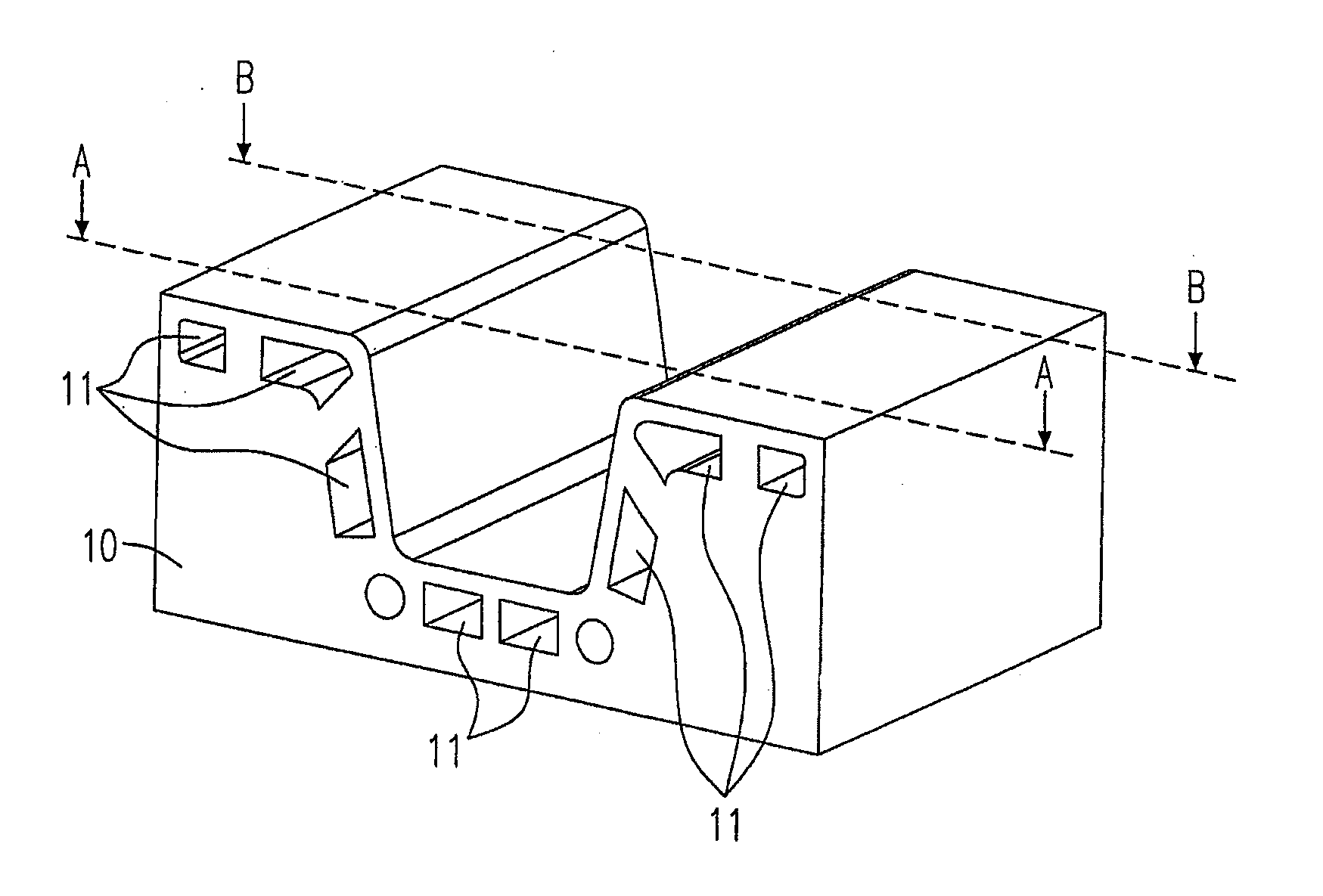

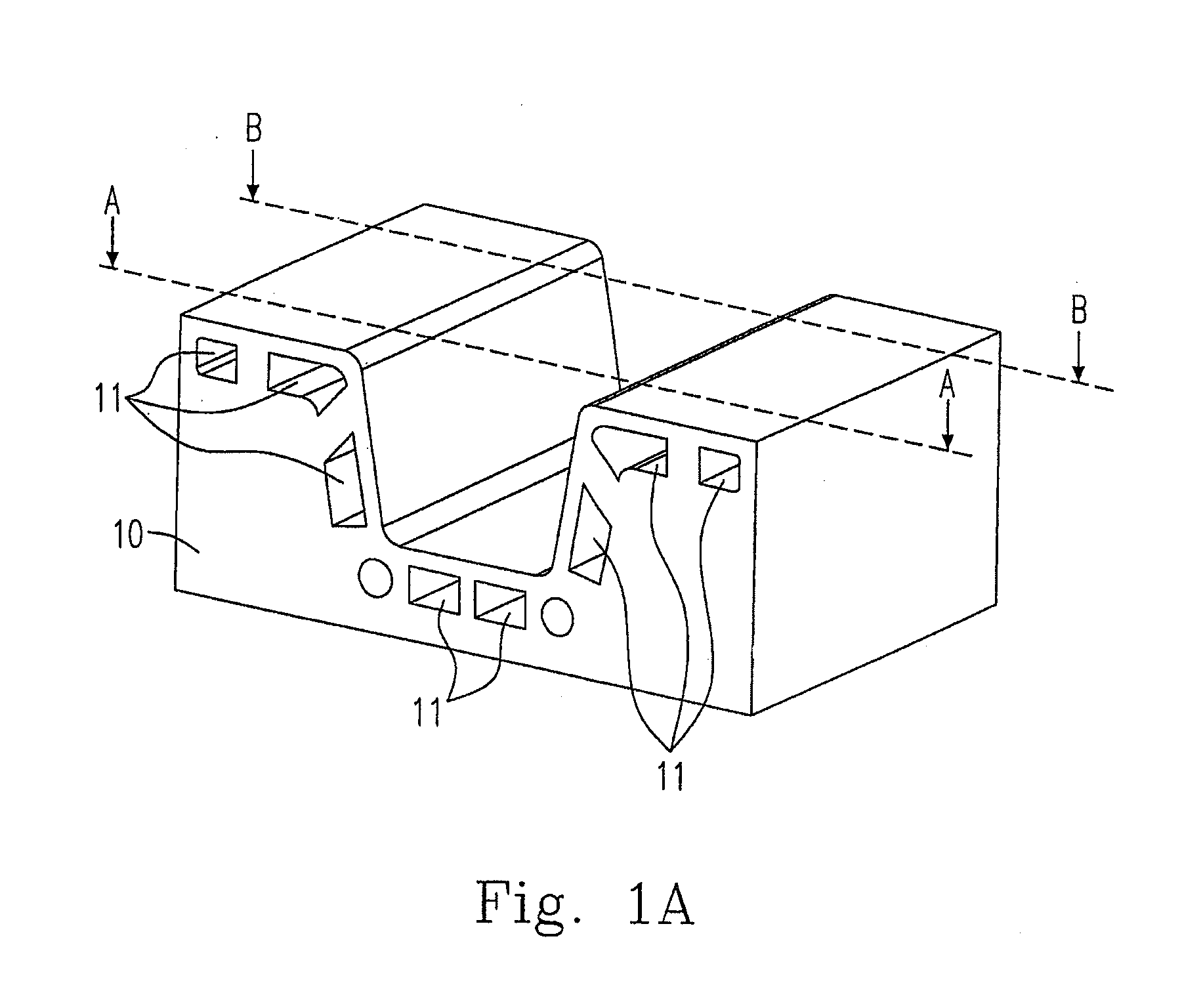

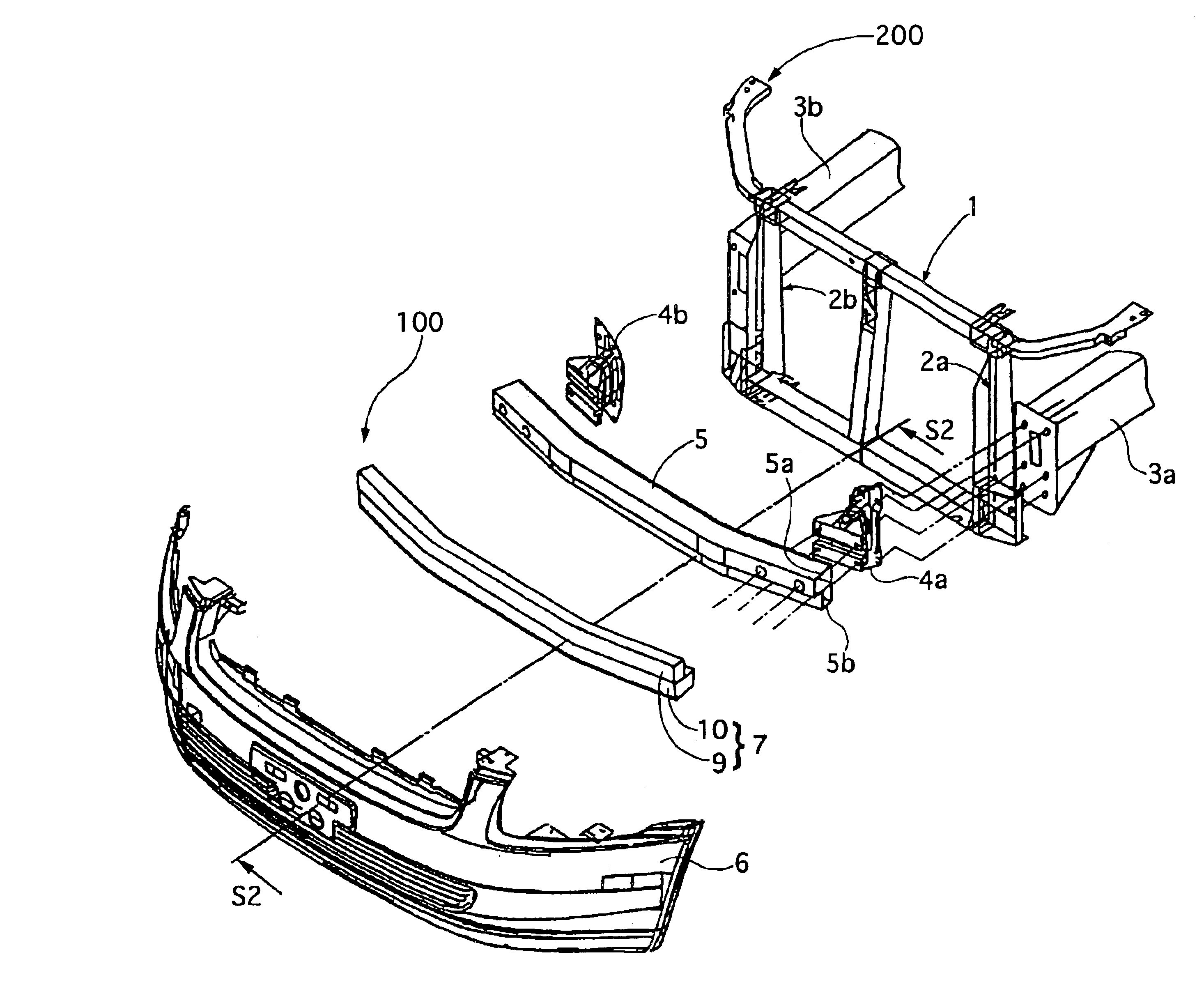

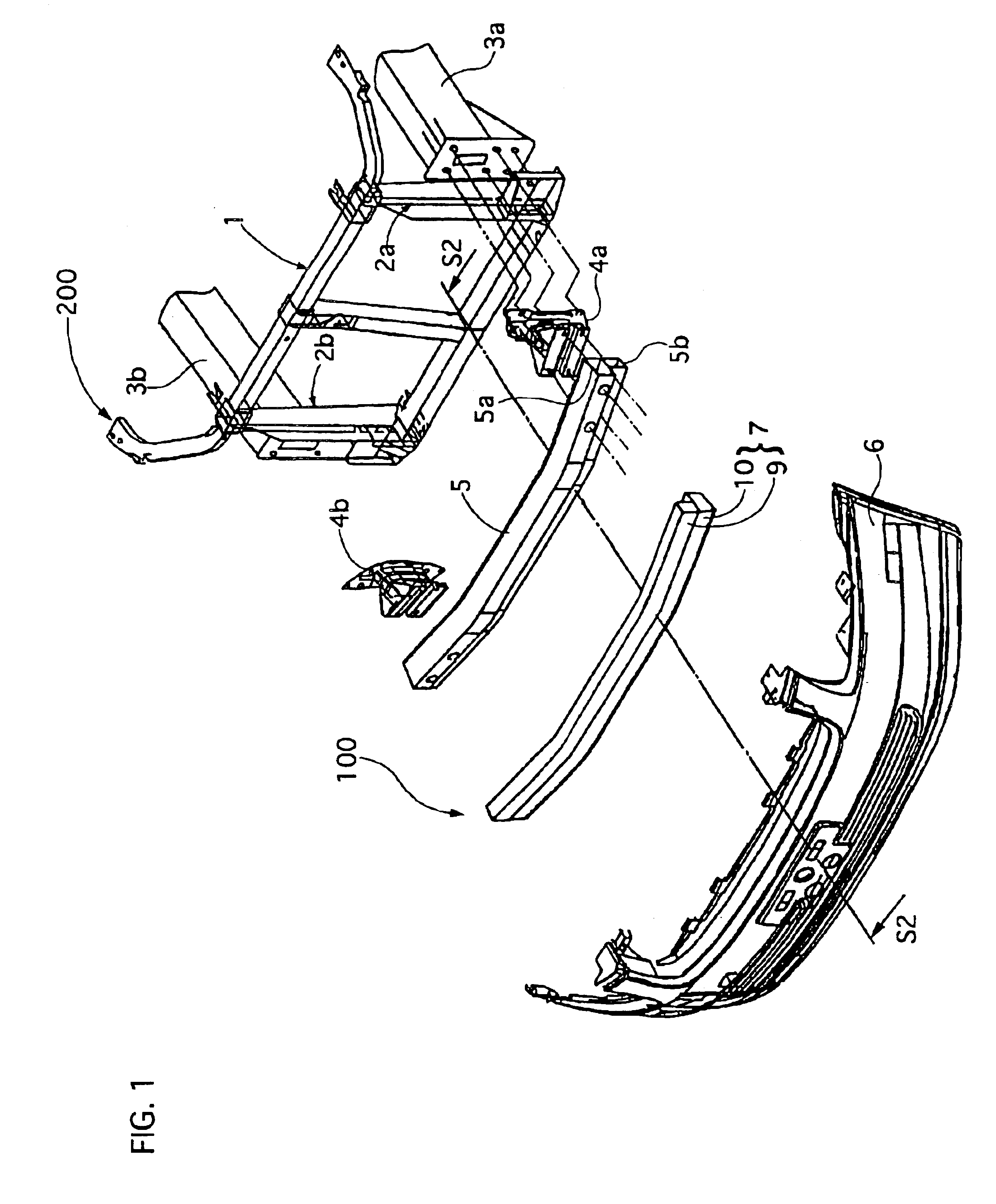

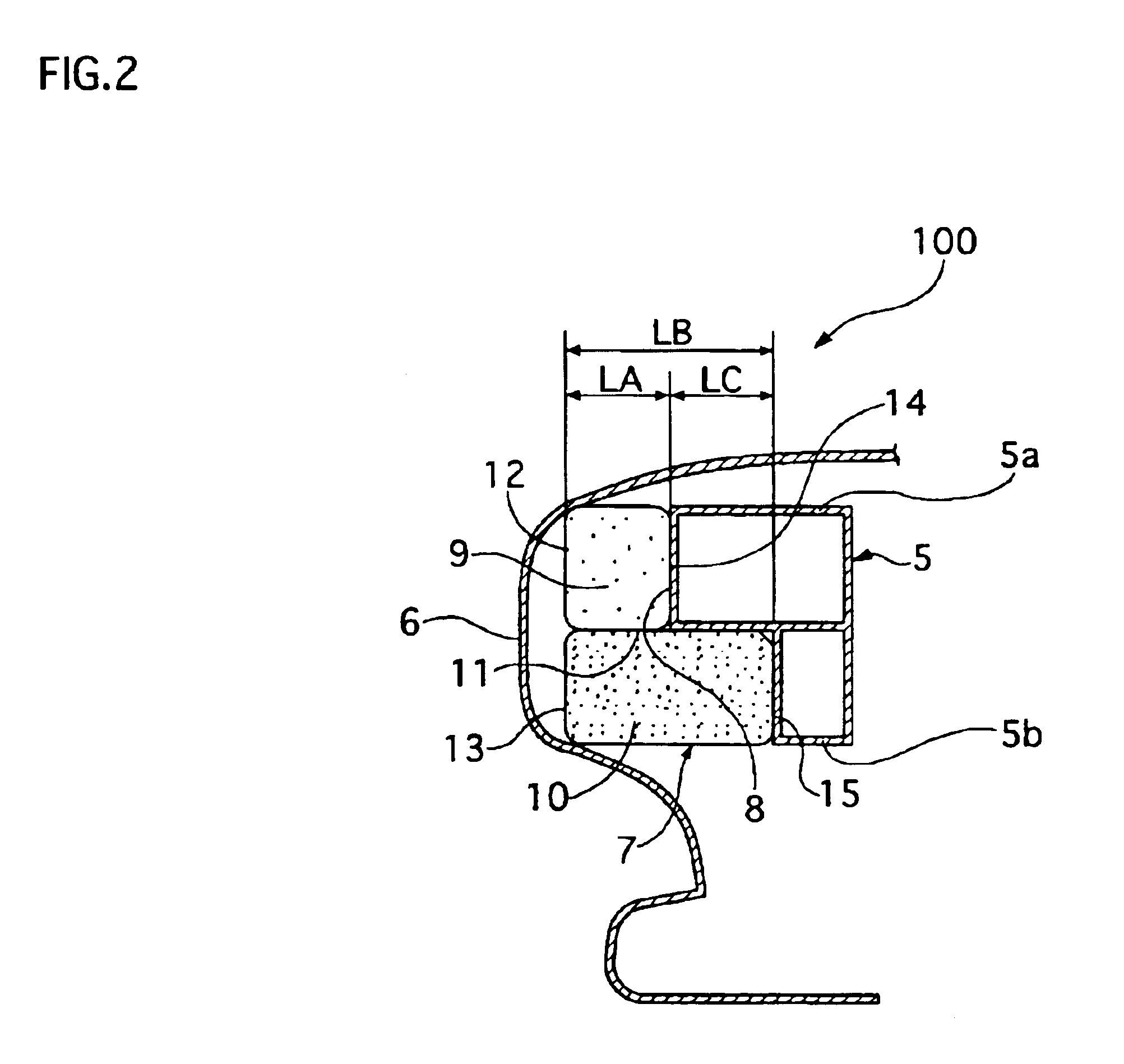

Bumper structure for a motor vehicle

InactiveUS6913300B2Reduce in quantityDifferent strengthPedestrian/occupant safety arrangementBumpersMobile vehicleEngineering

A bumper structure comprise a bumper reinforcement, a bumper fascia extending along and located in front of the bumper reinforcement, and an impact absorber arranged between the bumper reinforcement and the bumper fascia. The bumper reinforcement extends in a lateral direction of a vehicular body and attached to the vehicular body. The bumper reinforcement has a front surface, stepped or tapered in shape, so that the bumper reinforcement retreats at a lower portion thereof more than at an upper portion thereof. The impact absorber has upper and lower portions so that the lower portion thereof is longer and stronger than the upper portion thereof. The impact absorber has a rear surface, stepped or tapered in shape, such that the rear surface of the lower portion projects toward the bumper reinforcement with respect to the rear surface of the upper portion so as to face the front surface of the bumper reinforcement.

Owner:CALSONIC KANSEI CORP

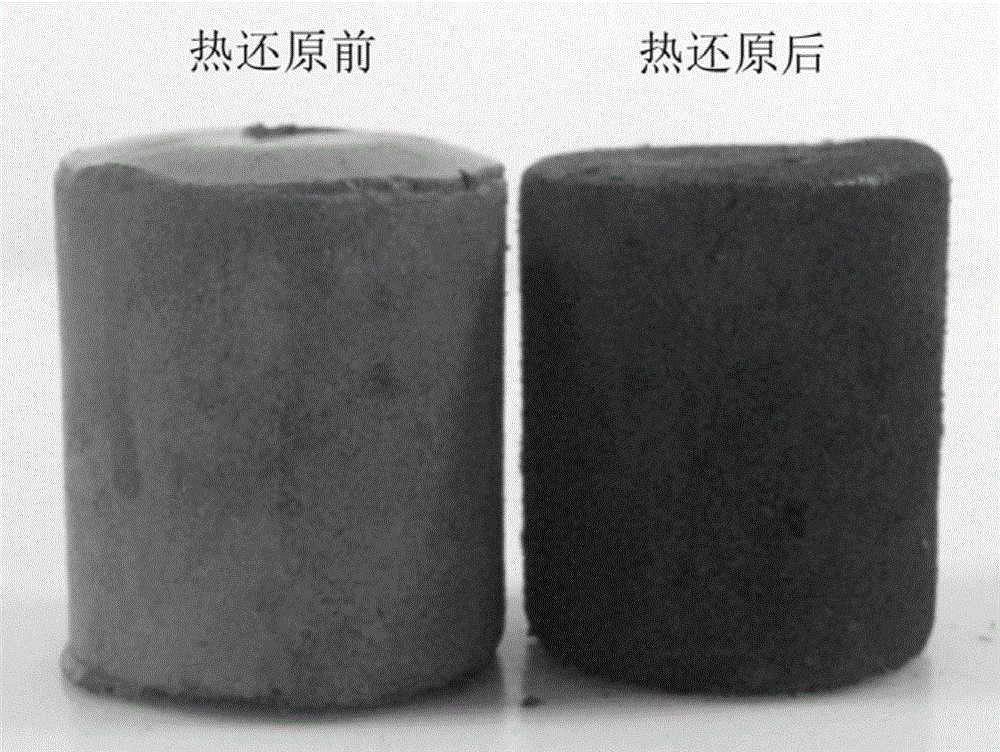

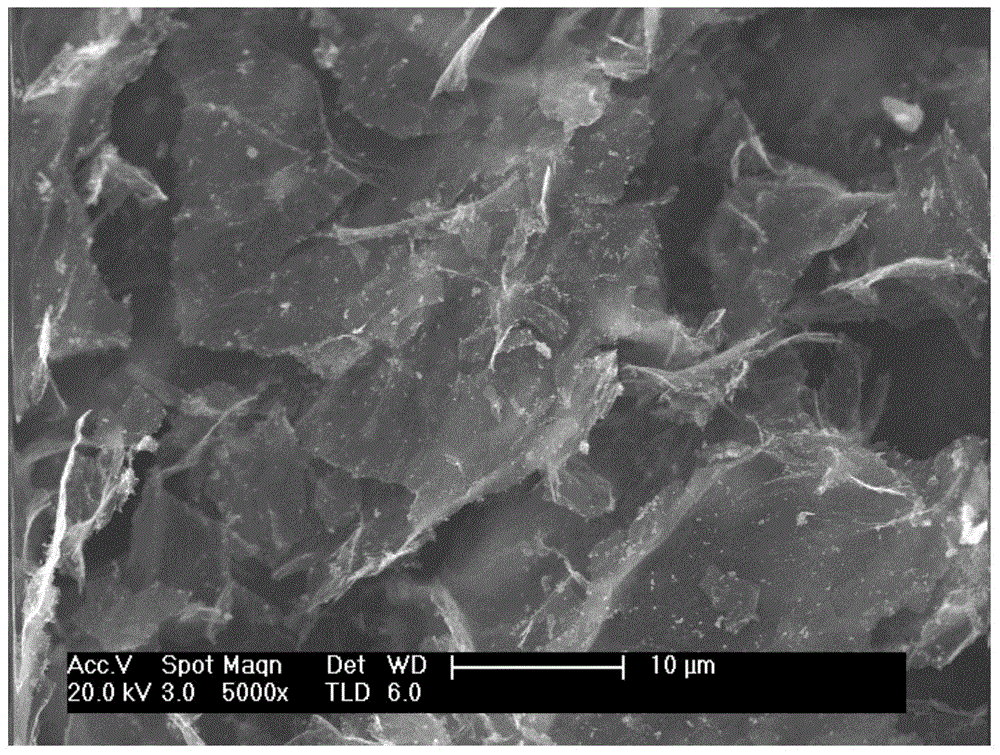

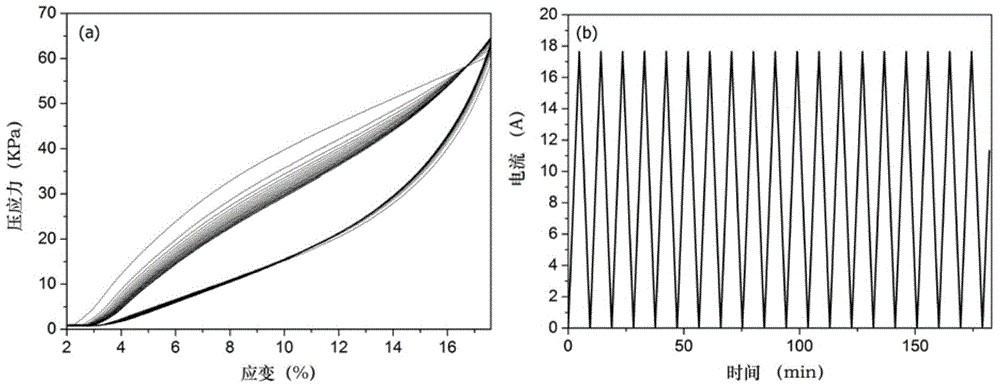

Three-dimensional porous lithium ion battery anode material of graphene composite material and preparation method of three-dimensional porous lithium ion battery anode material

InactiveCN105047890AGuaranteed uniformityThe reduction process is simpleCell electrodesSecondary cellsPorous grapheneFreeze-drying

The invention discloses a three-dimensional porous lithium ion battery anode material of a graphene composite material and a preparation method of the lithium ion battery anode material. The preparation method of the three-dimensional porous lithium ion battery anode material comprises the following steps: dissolving oxidized graphene, semiconductor nanoparticles and polyvinyl alcohol into water, and mixing the raw materials evenly; carrying out freeze drying on the mixture obtained from the previous step in a mold, and obtaining a solid oxidized graphene / semiconductor nanoparticle / polyvinyl alcohol three-dimensional porous nano-material; carrying out thermal treatment reduction on the product which is obtained from the previous step, restoring the electrical conductivity of the product, and obtaining a high-elasticity solid oxidized graphene / semiconductor nanoparticle / polyvinyl alcohol three-dimensional porous graphene composite material; and cutting the material obtained from the previous step into slices to serve as the anode material assembling battery of a lithium ion battery, and obtaining the three-dimensional porous lithium ion battery anode material of the graphene composite material. According to the three-dimensional porous lithium ion battery anode material disclosed by the invention, the electrical conductivity of the graphene material can be restored; the three-dimensional porous lithium ion battery anode material has a three-dimensional continuous conductive network and the cycling stability; and the mechanical property of the material can be adjusted.

Owner:SOUTHEAST UNIV

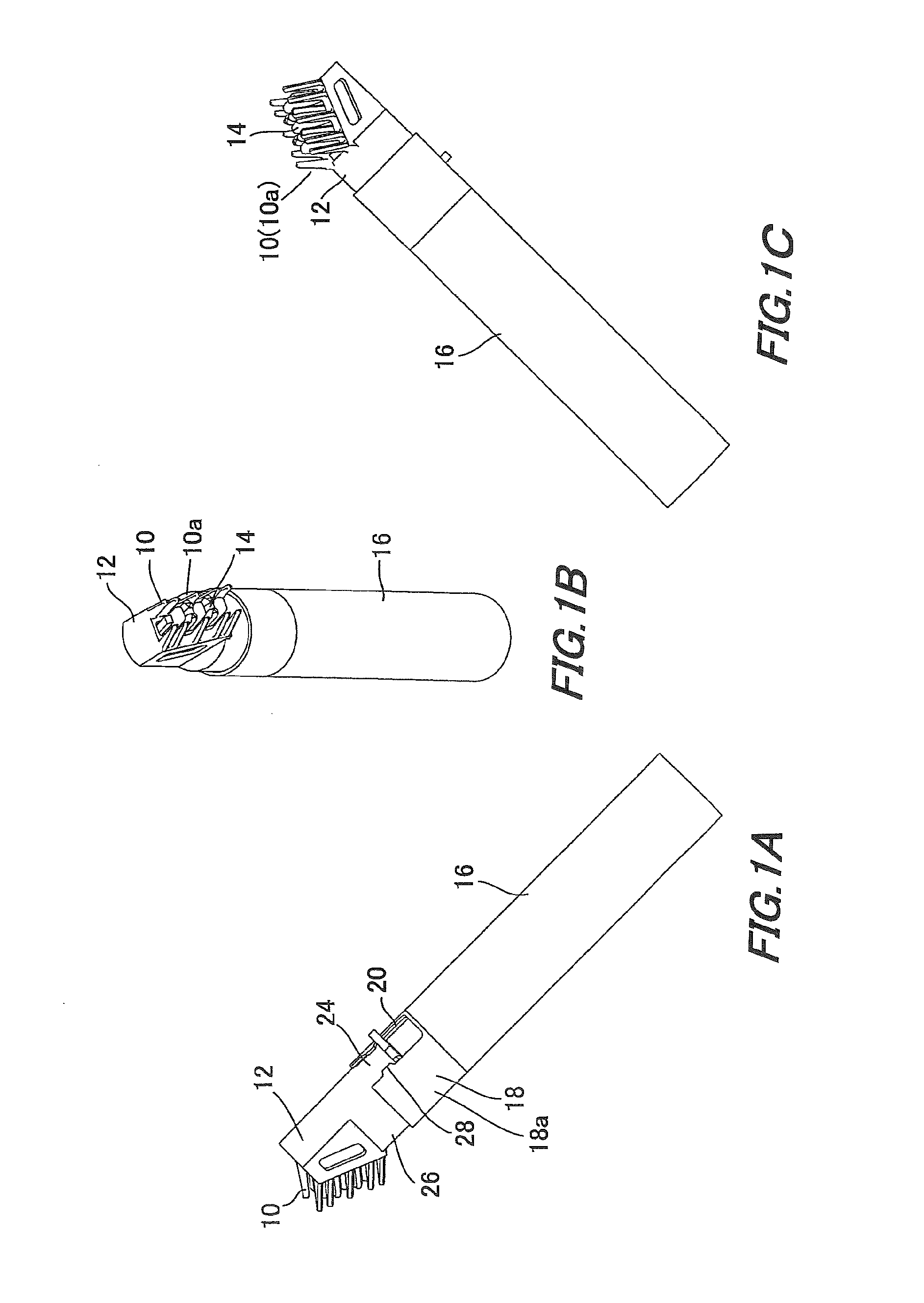

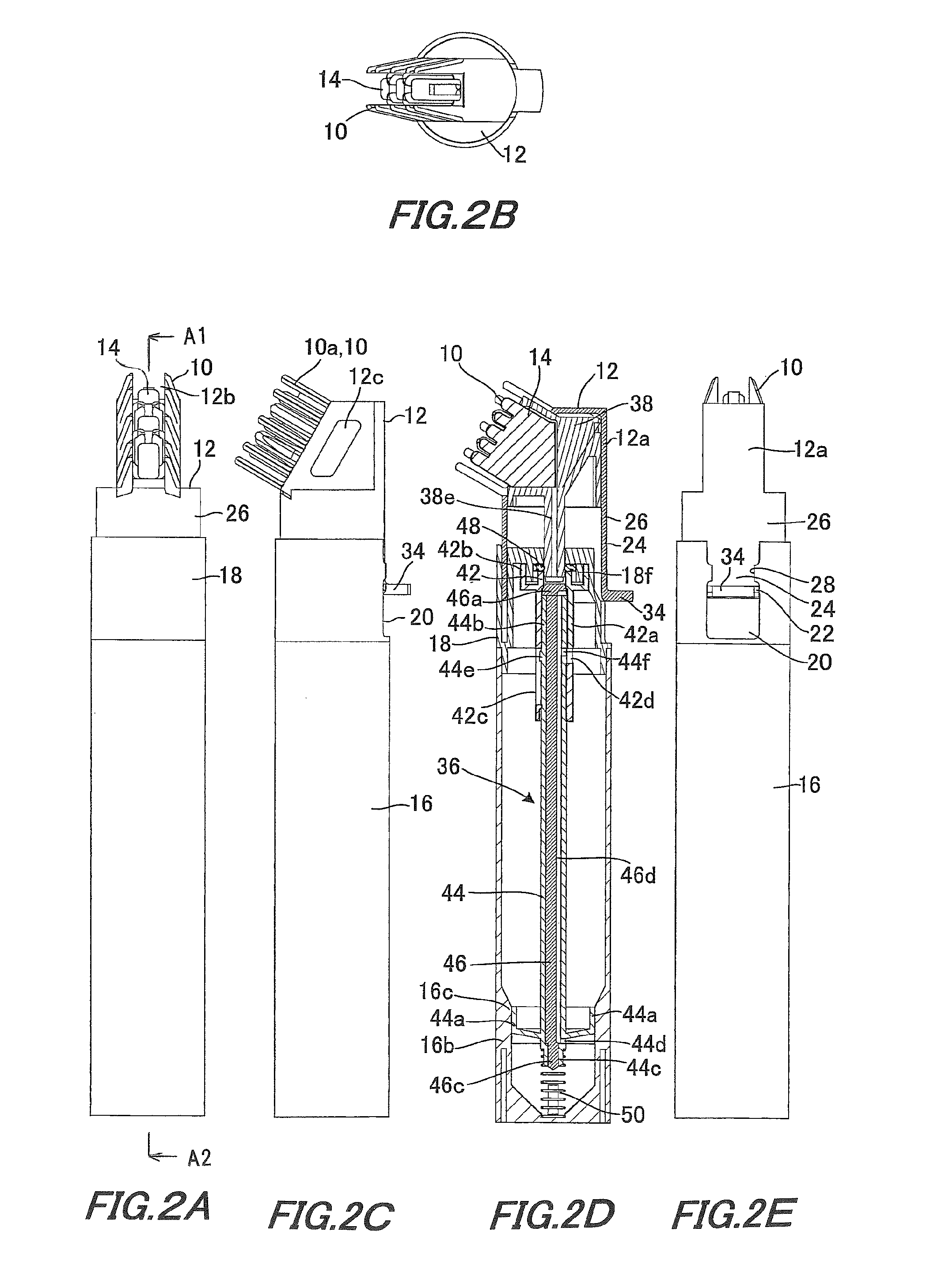

Applicator

InactiveUS9271554B2Easy to visually confirmImprove efficiencyLiquid surface applicatorsHair combsEngineeringReflectivity

Owner:MITSUBISHI PENCIL CO LTD

Multi-layered bags with discrete non-continuous lamination

ActiveUS8940377B2Increased strength parameterReduce the amount requiredEnvelopes/bags making machineryMechanical working/deformationEngineeringUltimate tensile strength

Multi-layer bags may be formed to include first and second sidewalls joined along a first side edge, an opposite second side edge, and a closed bottom edge. The first and second layers may be non-continuously laminated together in discrete sections to include bonded regions in which the layers are bonded and unbonded regions in which the layers are not bonded. Such a bag may be described as a “bag-in-a-bag” type configuration in which the inner bag is non-continuously bonded to the outer bag. The inventors have surprisingly found that such configurations of non-continuous bonding provides increased and unexpected strength properties to the multi-layer films and bags.

Owner:THE GLAD PROD CO

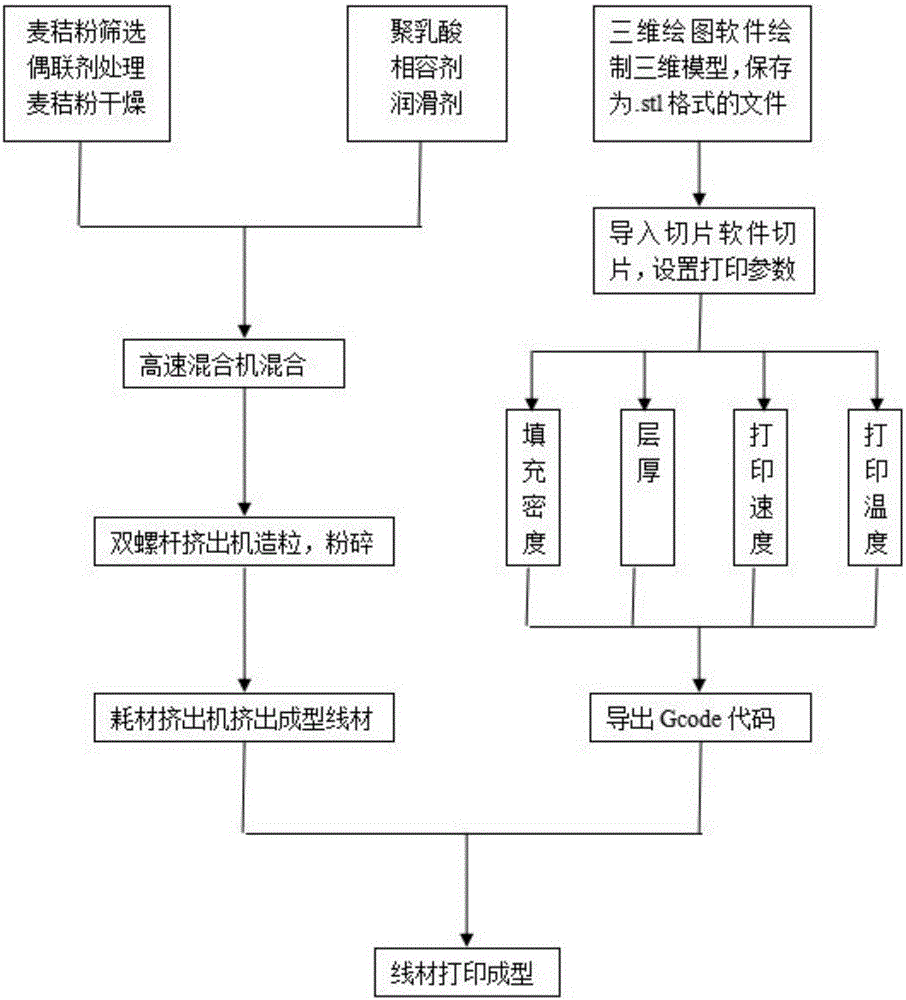

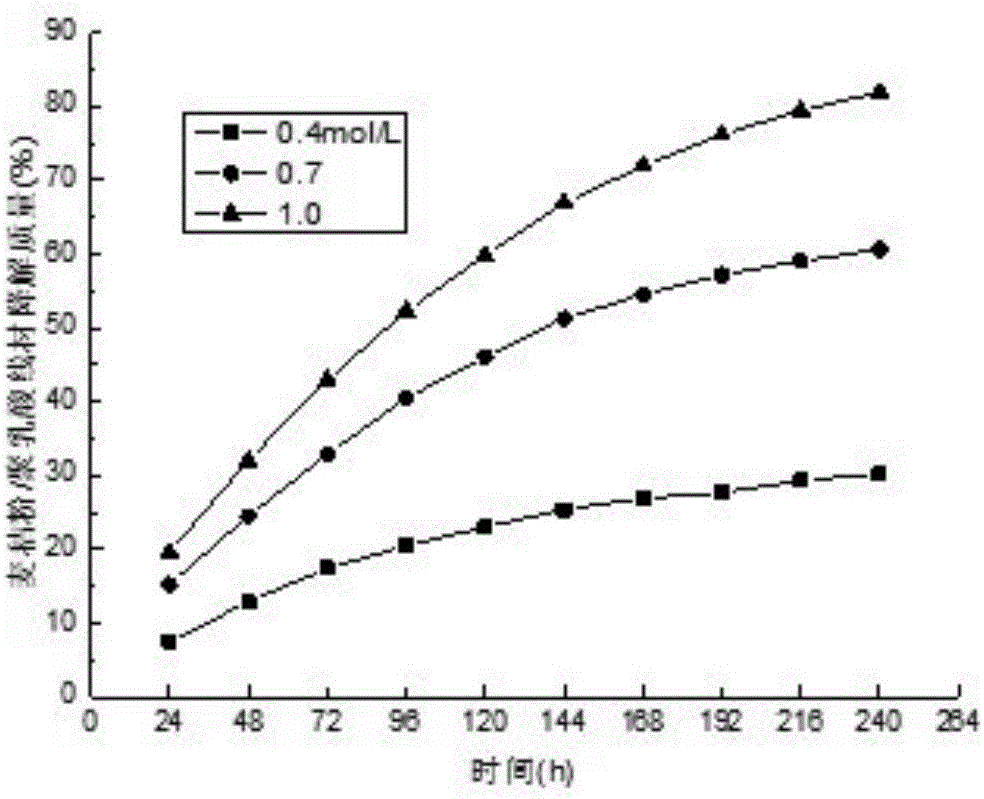

Wheat straw powder composite wire for fused deposition modeling and preparation method and 3D (Three-Dimensional) printing method thereof

InactiveCN106751626AIncreased degradation rateCreate pollutionManufacturing driving meansFused deposition modelingPollution

The invention discloses a wheat straw powder composite wire for fused deposition modeling and a preparation method and a 3D (Three-dimensional) printing method thereof, and belongs to the technical field of a preparation technology and application of composite materials. At present, a 3D printing technology is in rapid development, but materials suitable for 3D printing are in slow development. The wheat straw powder composite wire for the fused deposition modeling is prepared from the following raw materials in parts by weight: 1 to 5 parts of wheat straw powder, 95 to 99 parts of polylactic acid, 0.02 to 0.4 part of a coupler, 0.5 to 1.5 parts of a compatilizer and 0.2 to 1 part of a lubricant. A product printed by the wheat straw powder composite wire for the fused deposition modeling, disclosed by the invention, has a woodiness feeling, the raw materials of the wheat straw powder and the polylactic acid are completely biodegradable, and any pollution to an environment cannot be caused.

Owner:NORTHEAST FORESTRY UNIVERSITY

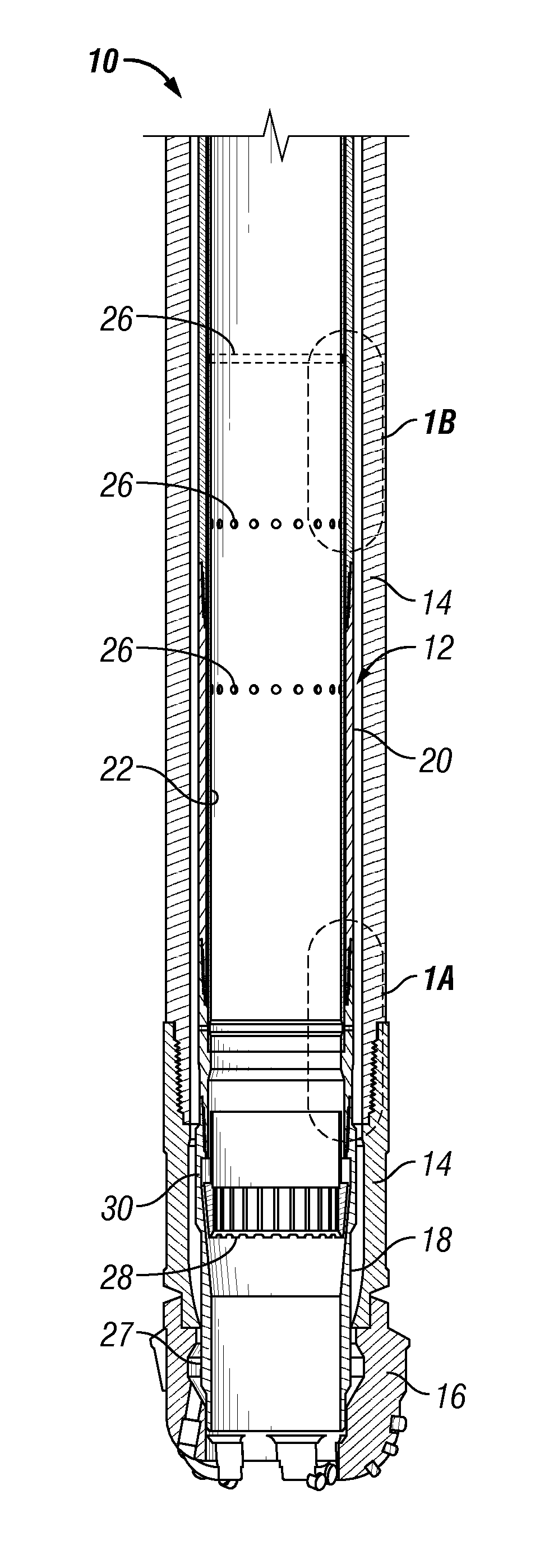

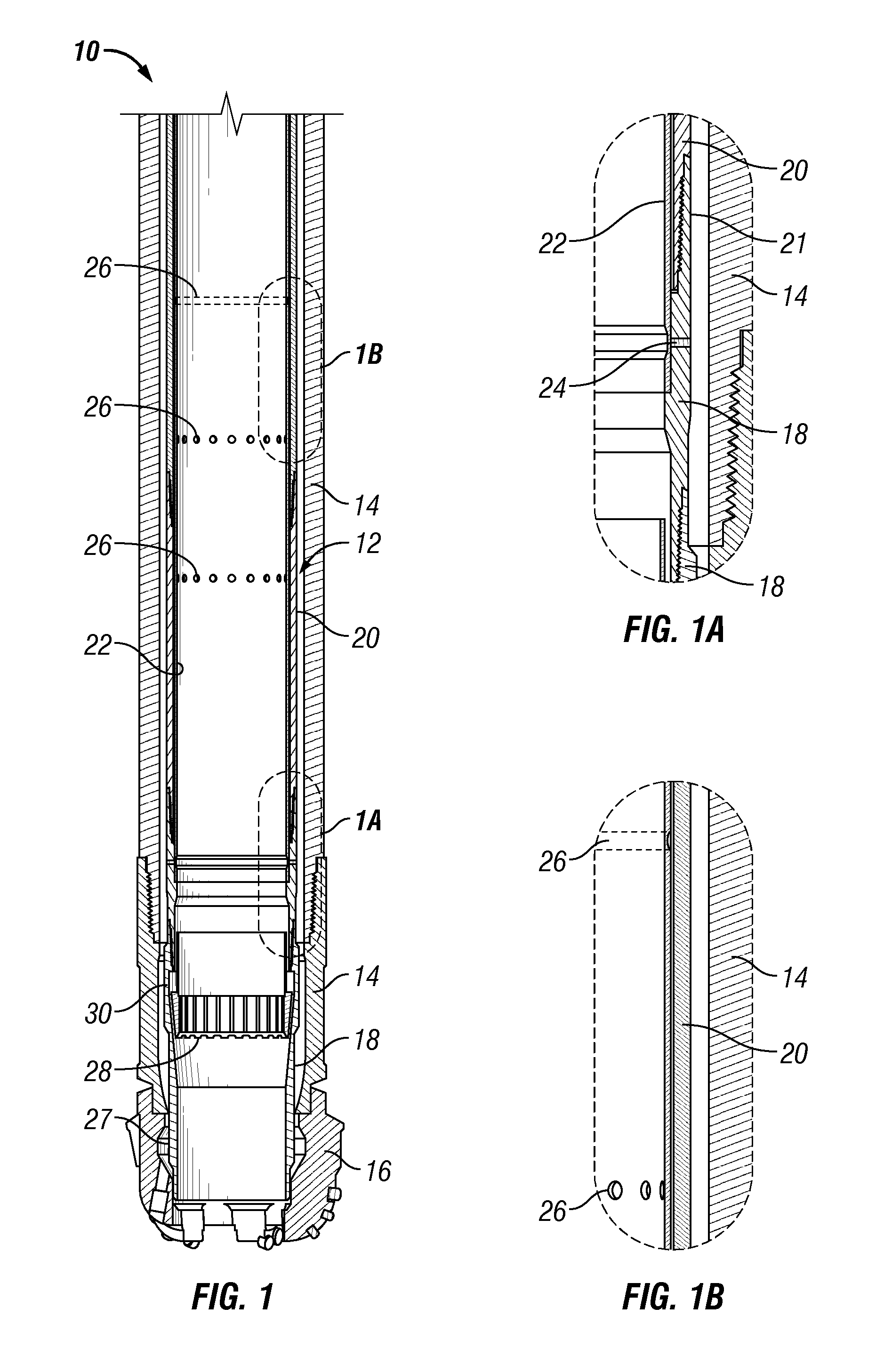

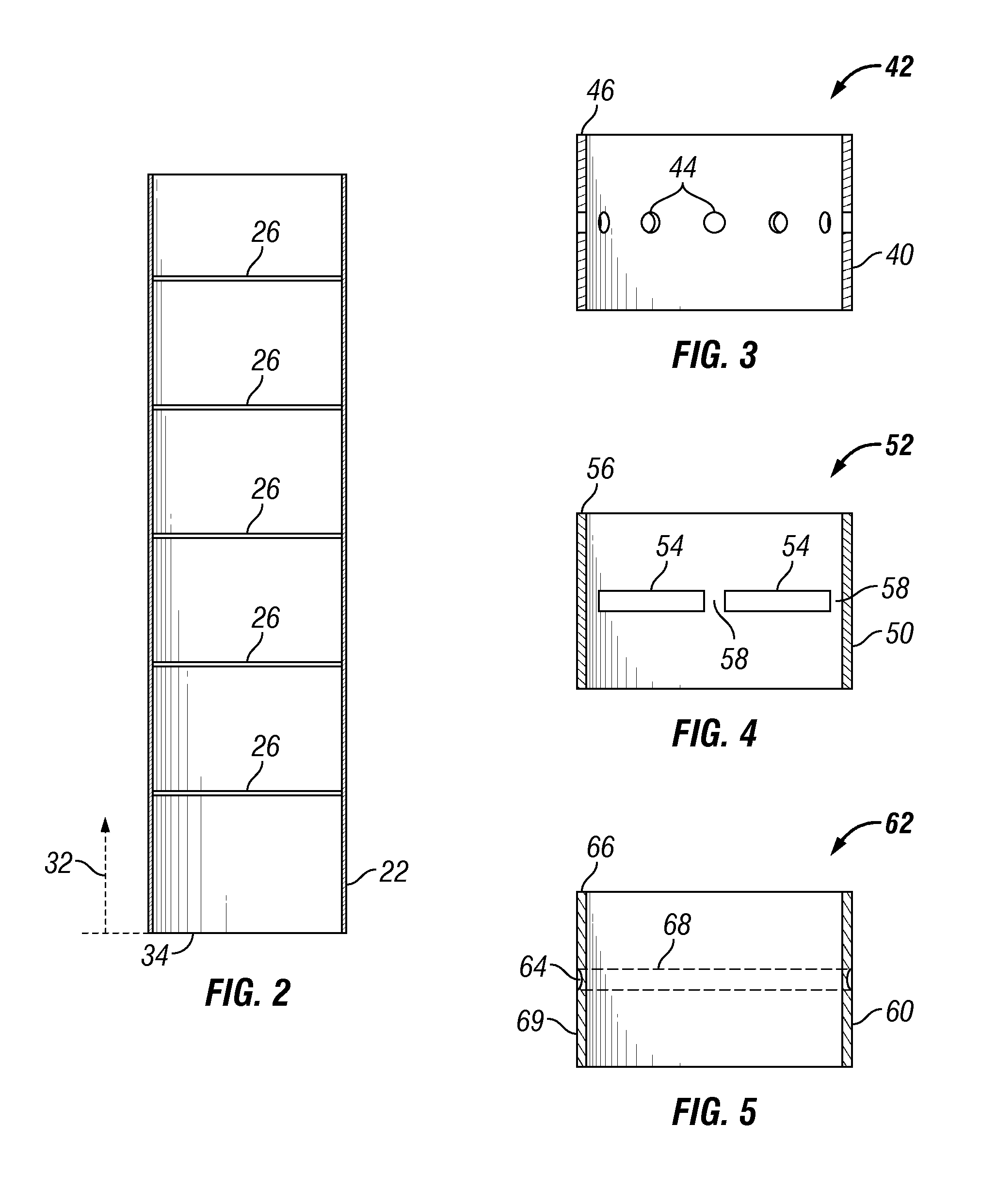

Frangible core barrel

ActiveUS20150275604A1Different strengthStrength be lowerDrill bitsBorehole/well accessoriesDrill bitEngineering

A coring assembly comprises an outer barrel coupled to a coring bit. An inner barrel is disposed within the outer barrel. An inner sleeve is disposed within the inner barrel and includes at least one frangible region that allows the inner sleeve to break so that coring operations can continue after the occurrence of a core jam.

Owner:NAT OILWELL VARCO LP

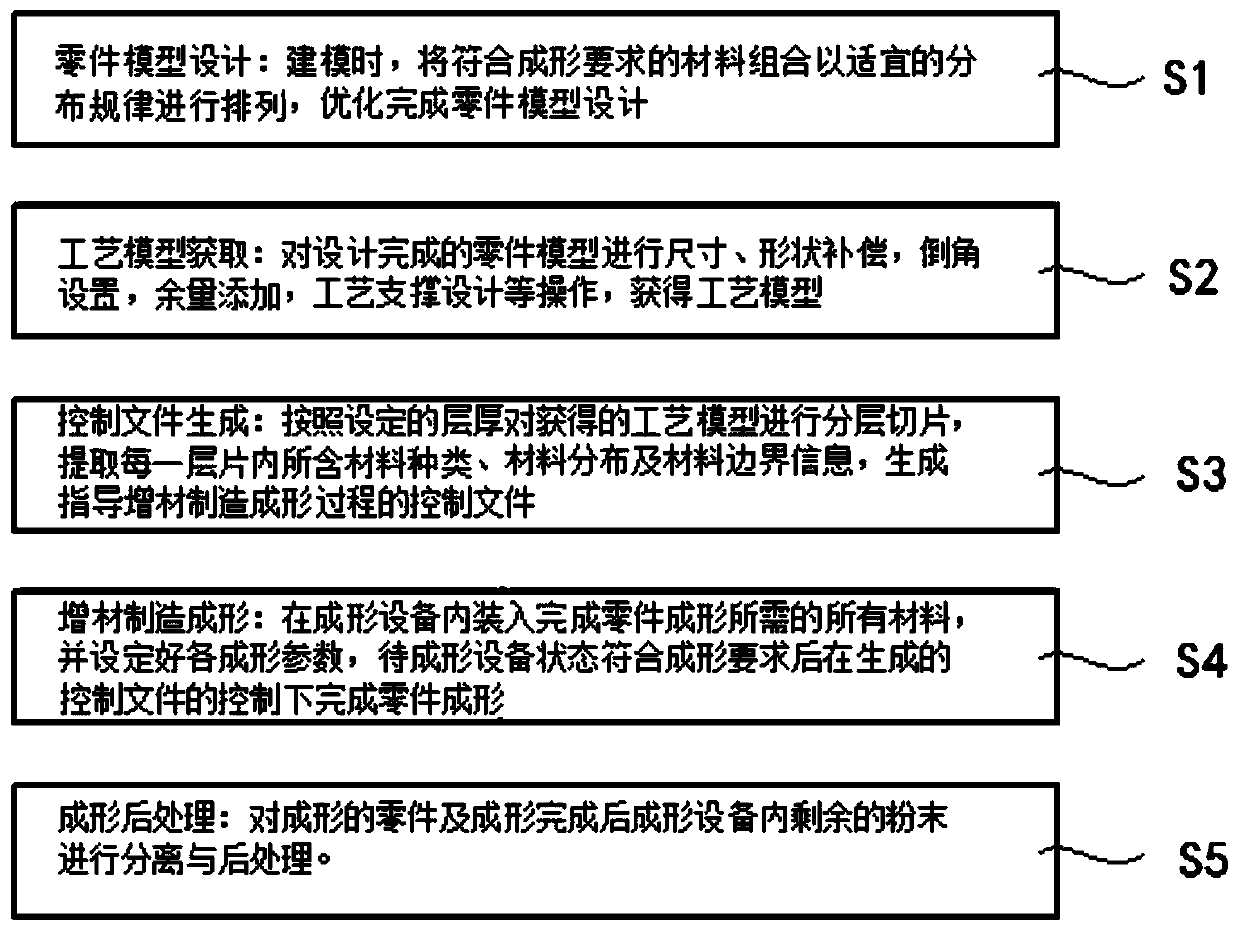

Selective laser melting forming method of multi-material part

InactiveCN111036901ASolve the problem of low bonding strengthQuality improvementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingProcess engineering

The invention relates to the field of a part forming process, and discloses a selective laser melting forming method of a multi-material part. The method comprises the following steps of S1, part model design, wherein during modeling, materials meeting forming needs are combined to be arranged according to the proper distribution rule, and part model design is finished in an optimized manner; S2,process model obtaining, wherein a designed part model is subjected to size and shape compensation, chamfering, remaining adding, process support design and the like, and a process model is obtained;S3, control file generation, wherein the obtained process model is subjected to layered slicing, the material kind, material distribution and material boundary information contained in each layer areextracted, and a control file guiding an additive manufacturing forming process is generated; S4, additive manufacturing forming; and S5, forming aftertreatment. According to the method, through the selective laser melting forming technology, the high-precision high-quality multi-material part can be formed.

Owner:XIAN SPACE ENGINE CO LTD

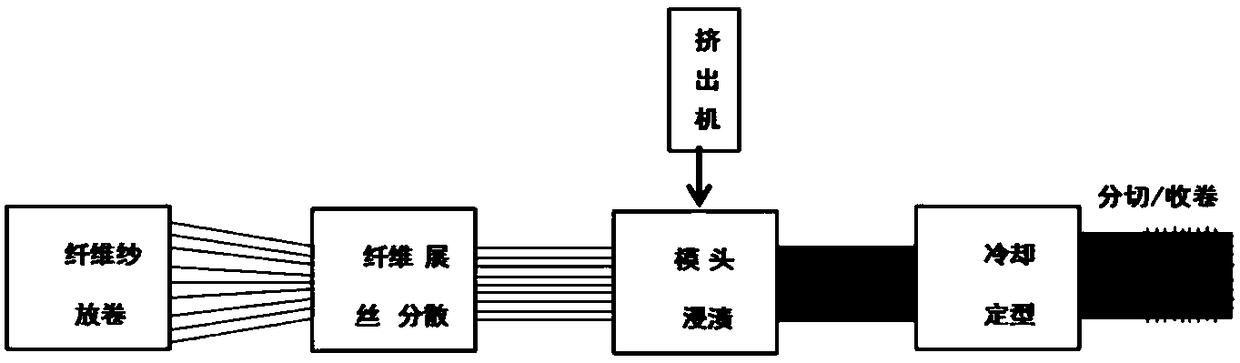

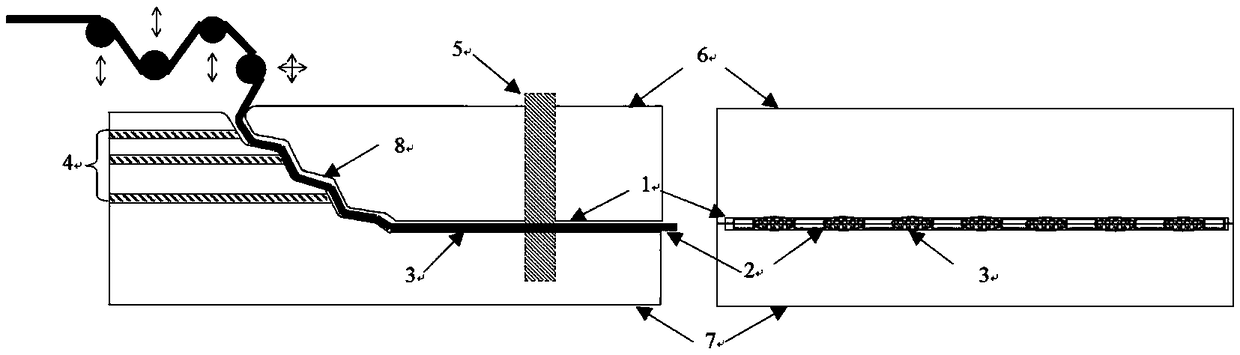

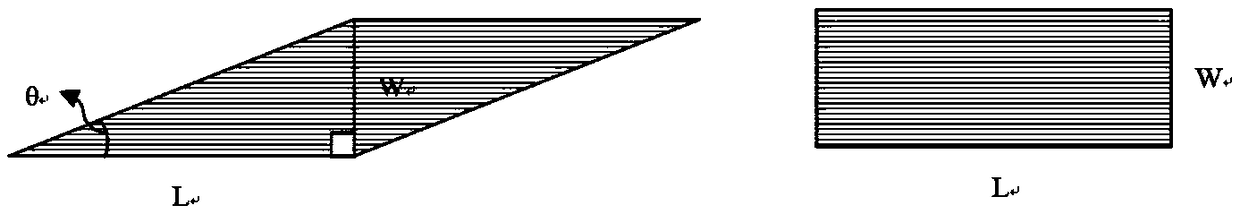

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

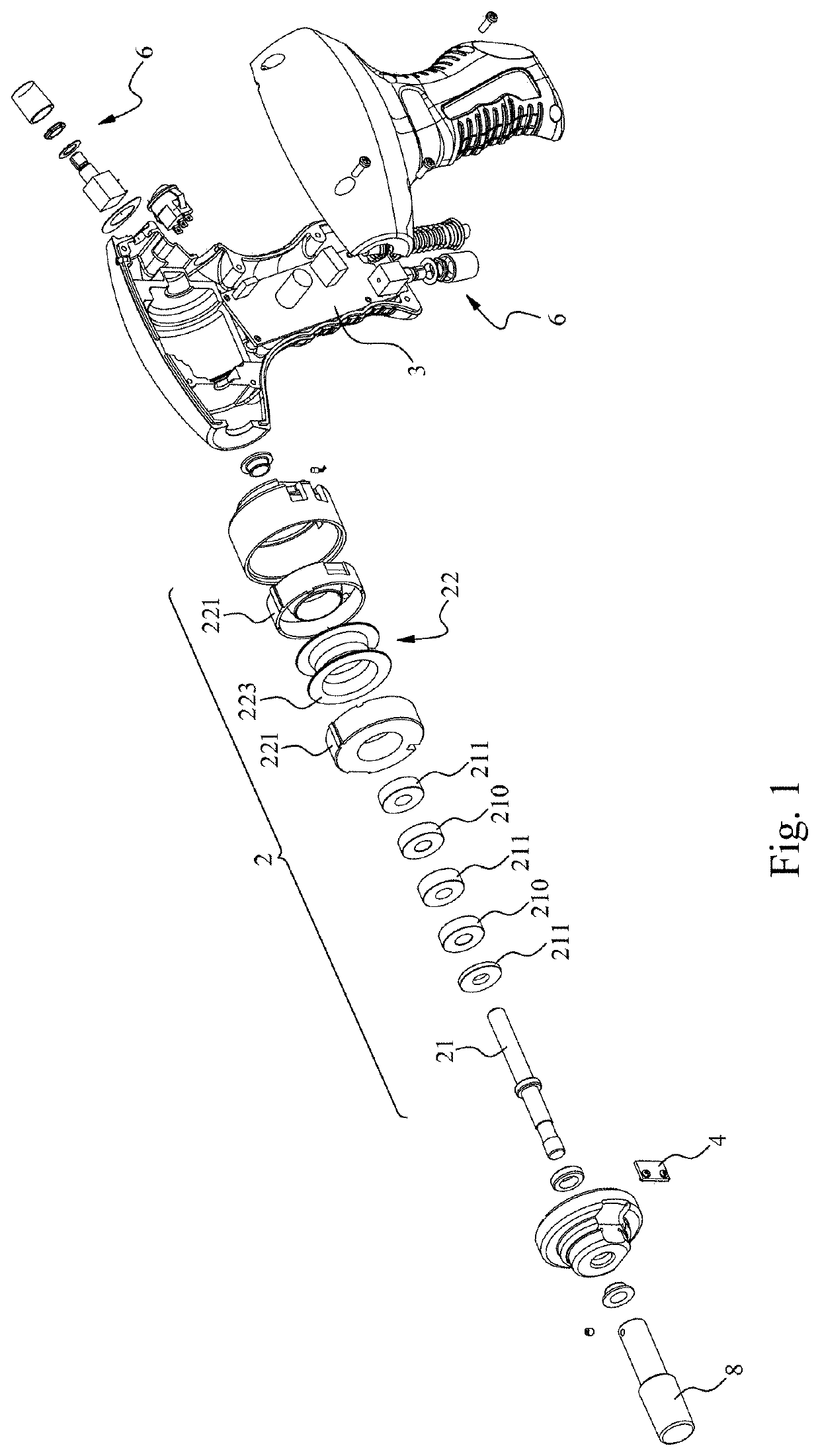

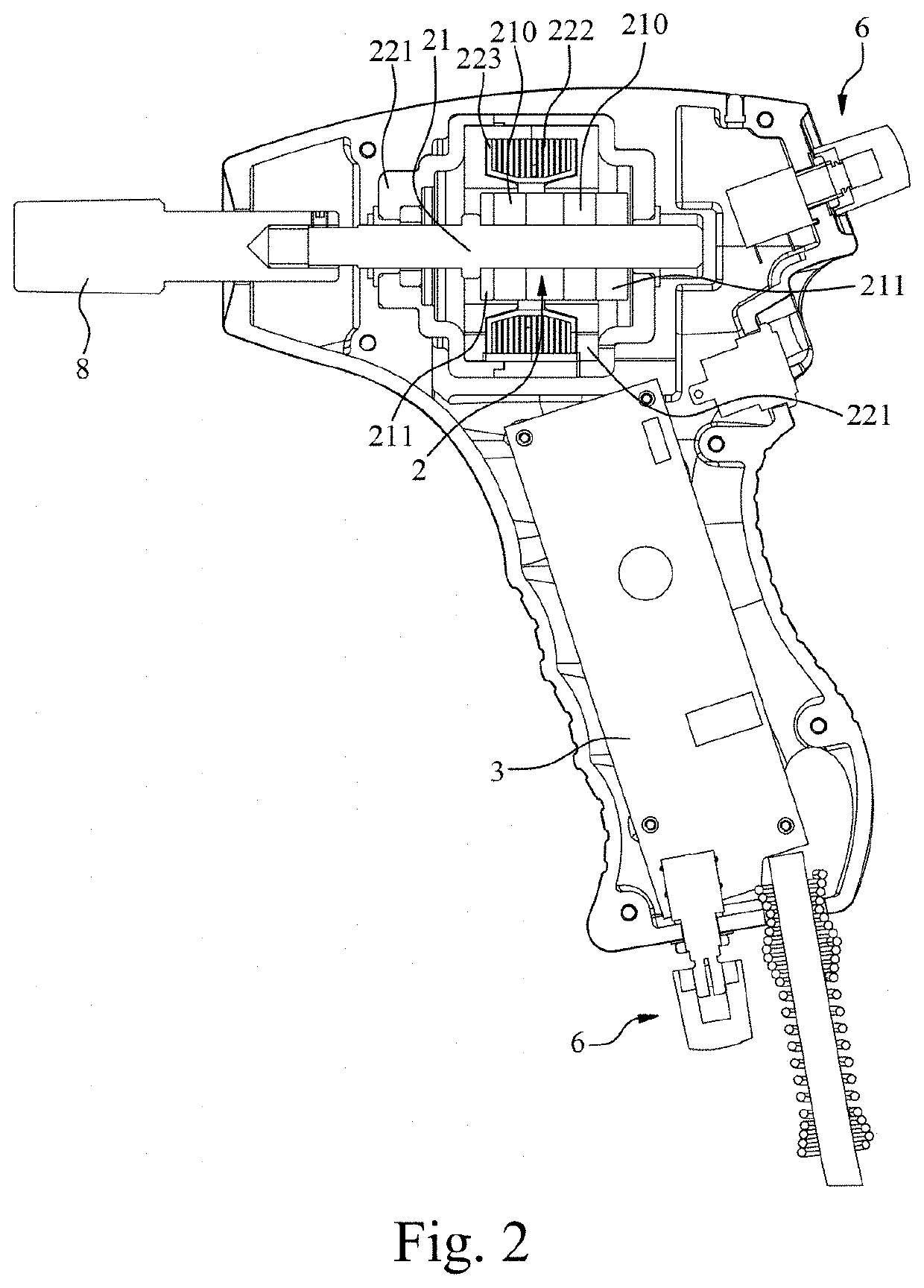

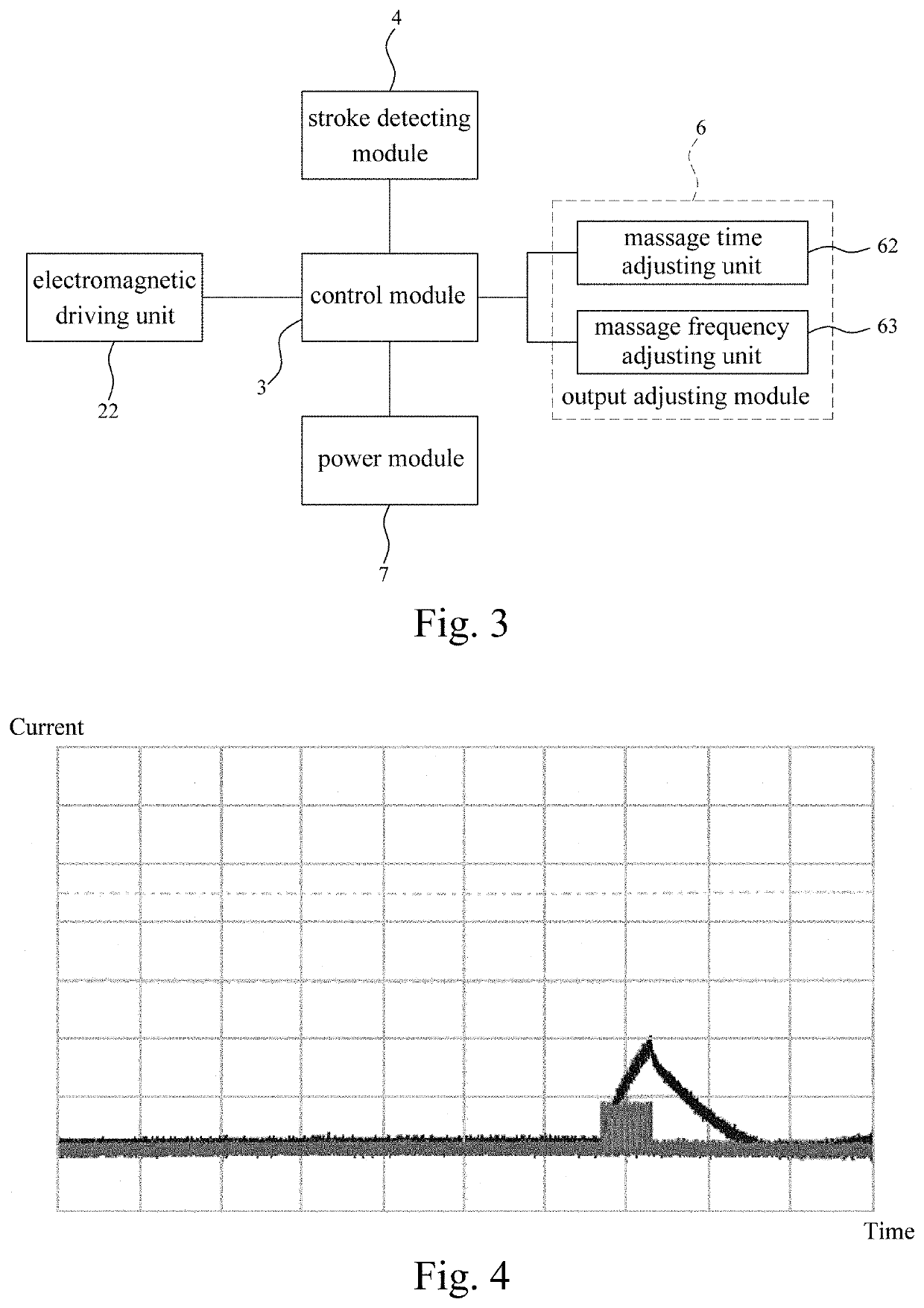

Massage device

PendingUS20210113421A1Large frequency bandwidthWell formedDiagnosticsDevices for pressing relfex pointsDriving currentPhysical medicine and rehabilitation

The present invention relates to an electric massage device capable of gradually increasing a massage force during an outward stroke, mainly comprising a massage module and a control module. In the outward stroke, the control module applies a driving current to the electromagnetic driving unit, and the driving current is gradually increased with an elapsed time or a stroke displacement of the output shaft. In a return stroke, the control module deenergizes the driving current or applies a weak reverse current less than one-fifth of the driving current. At the beginning of the outward stroke, the massage force is weak due to the smaller driving current and hence would not cause skin hurt. At the end of the outward stroke, the massage force is strong due to the greater driving current and hence produces a deep muscle massage effect.

Owner:JAGUAR PRECISION IND

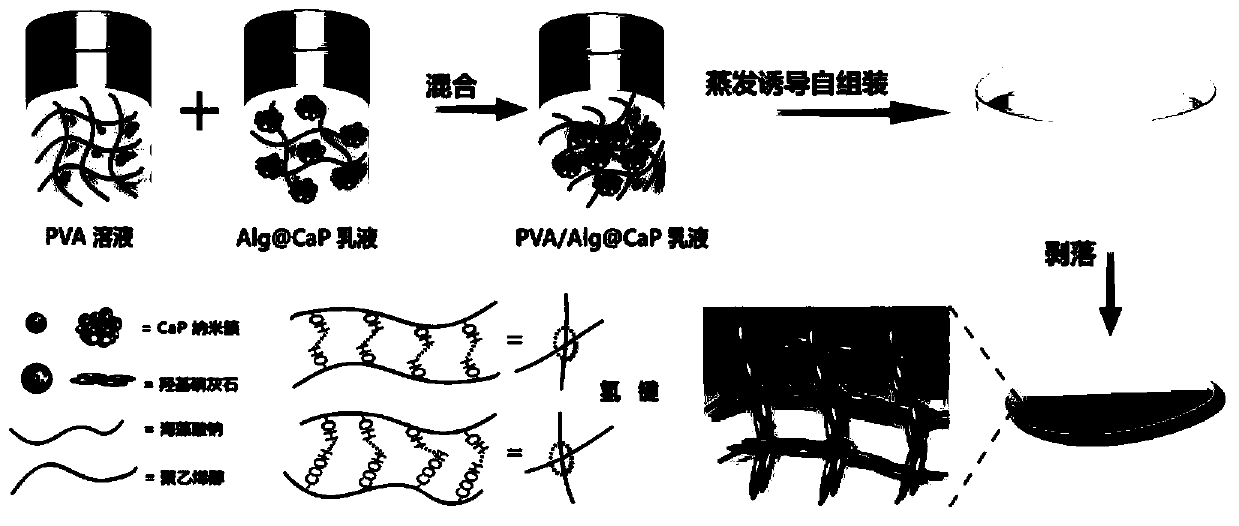

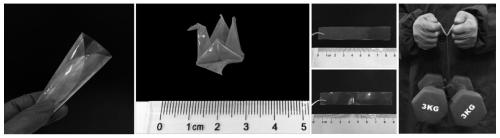

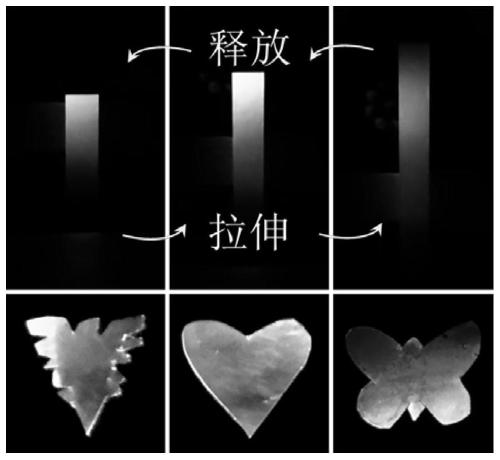

Stress-responsive multi-color-change composite film material as well as preparation method and application thereof

ActiveCN110183742ADifferent strengthDifferent toughnessNon-linear opticsComposite filmPolyvinyl alcohol

The invention discloses a stress-responsive multi-color-change composite film material. The composite film comprises 50-90 wt% of organic matter and 10-50 wt% of calcium phosphate nanoclusters; and the organic matter comprises polyvinyl alcohol and sodium alginate, wherein a mass ratio of the polyvinyl alcohol to the sodium alginate is (3-9):1. The invention also discloses a method for preparing the stress-responsive multi-color-change composite film material. The method comprises the following steps: (1) using the calcium phosphate nanoclusters as an inorganic unit precursor, sequentially adding the sodium alginate aqueous solution and the polyvinyl alcohol aqueous solution, and preparing the isotropic composite film by an emulsion evaporation induced self-assembly process. The compositefilm provided by the invention exhibits excellent toughness, can be crimped and folded, and has higher mechanical bearing capacity and excellent elasticity; and the composite film has reversible and highly-sensitive color change in an orthogonal polarized light system, and can be used in optical devices, sensors or information storage materials.

Owner:ZHEJIANG UNIV

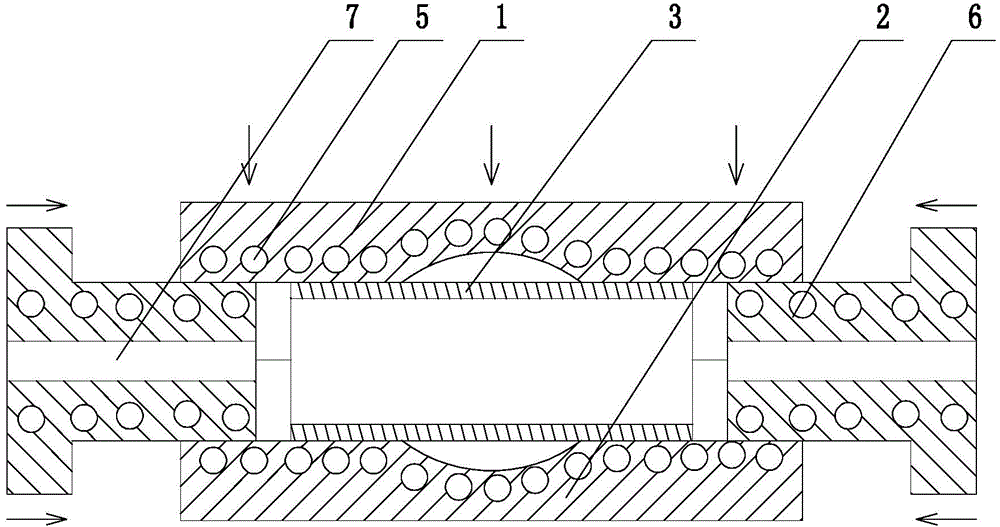

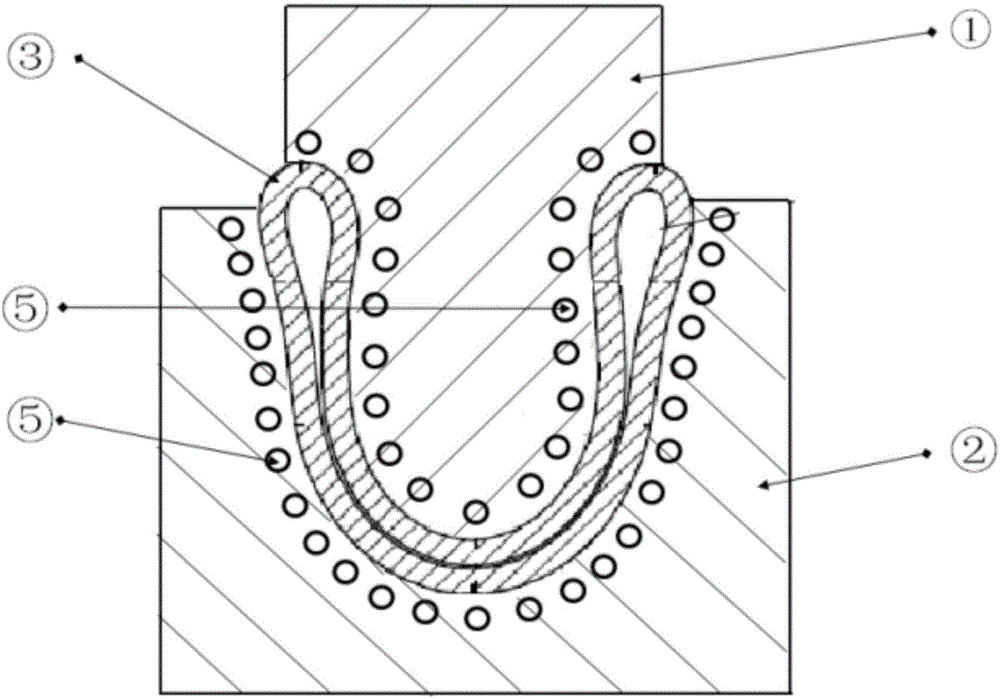

High-pressure gas bulging thermoforming die of boron steel pipe

InactiveCN104438878AHigh strengthBig spaceShaping toolsQuenching devicesHydraulic cylinderHigh pressure

The invention relates to a high-pressure gas bulging thermoforming die of a boron steel pipe. The die comprises an upper die base and a lower die base, and is characterized in that an upper die forming insert is mounted on the lower surface of the upper die base; a lower die forming insert is mounted on the upper surface of the lower die base; the lower surface of the upper die forming insert and the upper surface of the lower die forming insert are the forming surface of a workpiece of the boron steel pipe; seal heads are arranged at the two ends of the workpiece of the boron steel pipe respectively; the front ends of the seal heads are in contact with the pipe ends of the workpiece of the boron steel pipe; an axial hydraulic cylinder or an air cylinder is connected to the rear ends of the seal heads; vent holes are formed in the centers of the seal heads; the front ends of the vent holes are communicated with the interior of the workpiece of the boron steel pipe; a high-pressure gas station is connected to the rear ends of the vent holes; cooling passages are arranged at the lower part of the upper die forming insert and the upper part of the lower die forming insert respectively and directly connected with a water pipe or connected with the water pipe through the upper die base and the lower die base. According to the die, the workpiece which has the material mechanical strength of 1,500 MPa and is variable in cross-section shape and circumference can be produced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

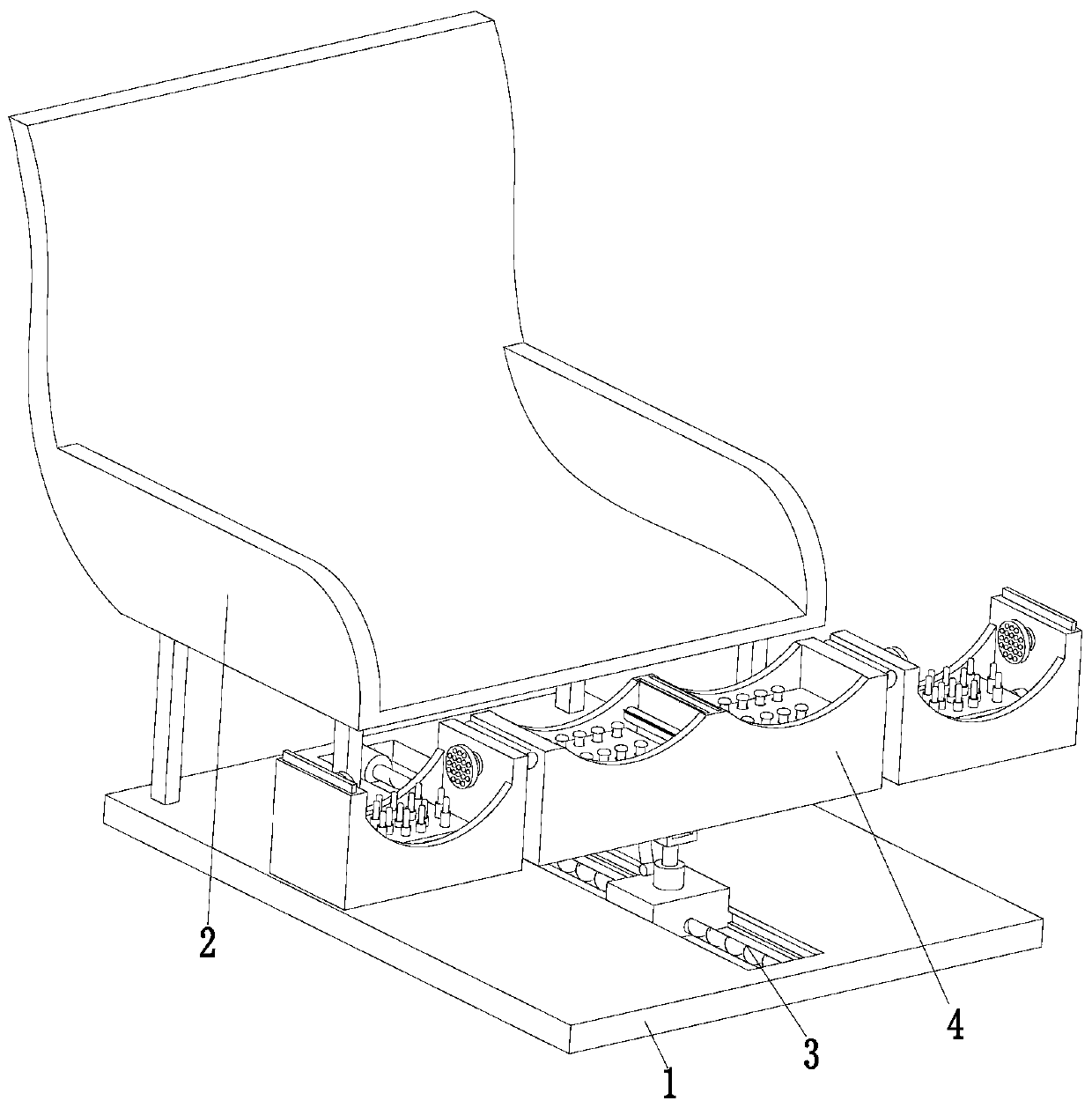

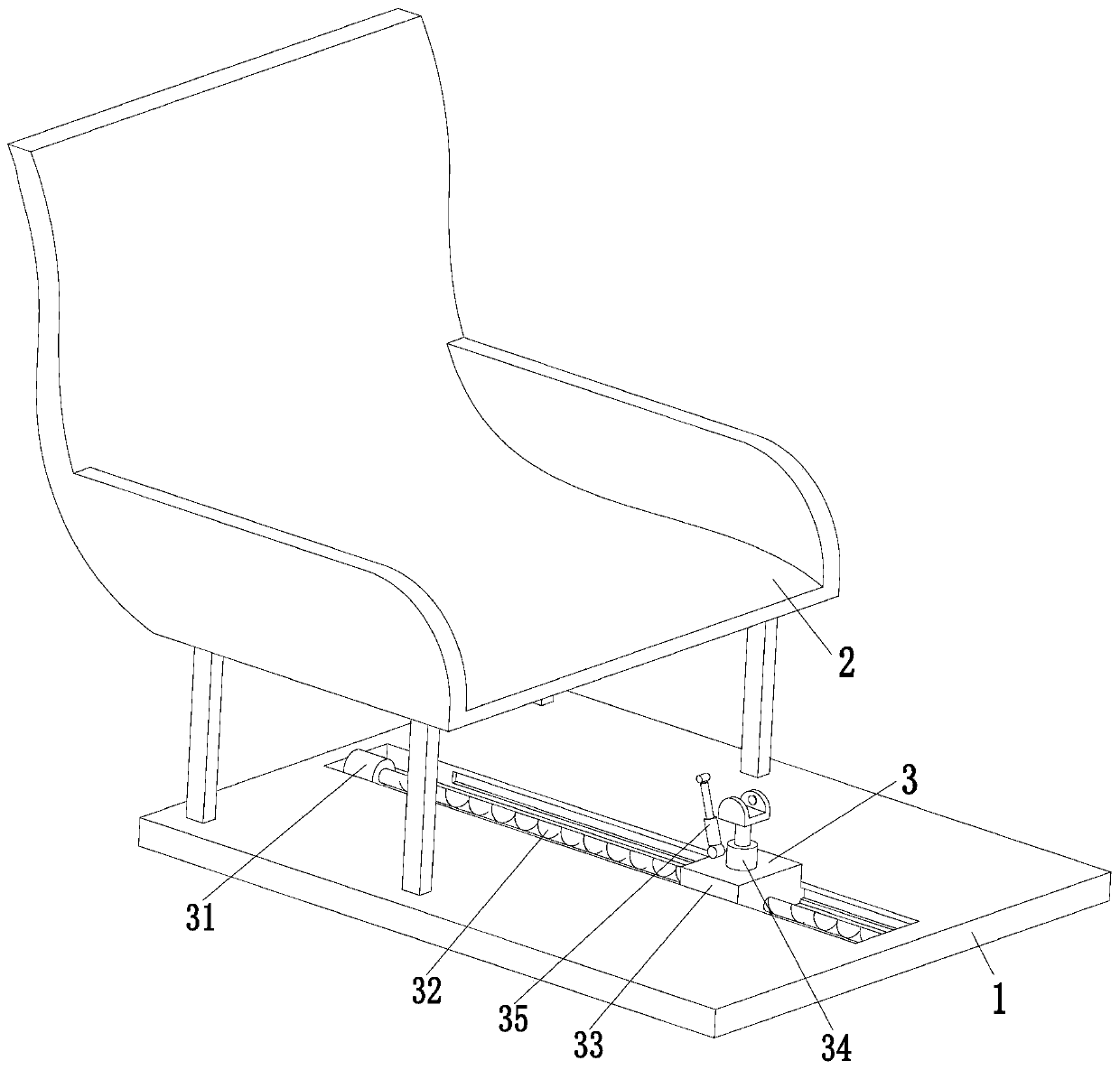

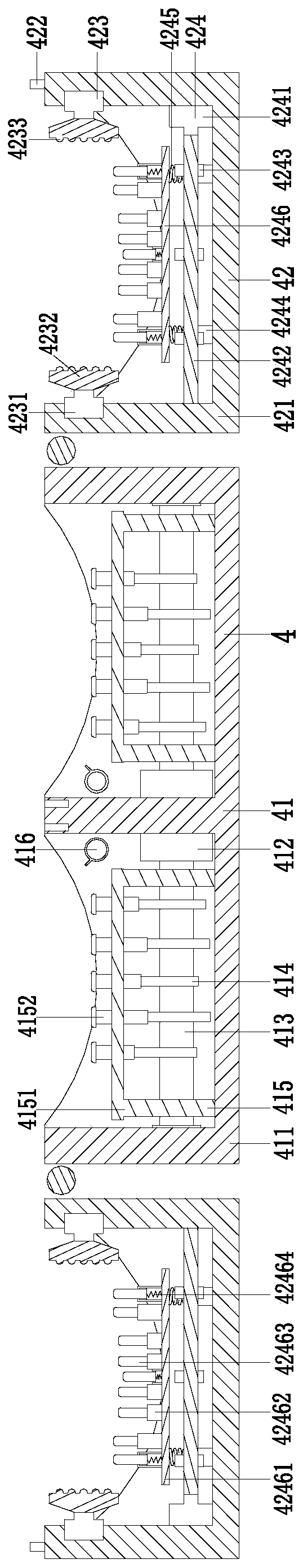

Rehabilitation chair with leg massage function

ActiveCN110353938AEasy to operateMassage evenlyChiropractic devicesVibration massagePhysical medicine and rehabilitationMassage

The invention provides a rehabilitation chair with a leg massage function. The rehabilitation chair comprises a bottom plate, a massage chair, an adjustment mechanism and a massage device. The rehabilitation chair can solve the problems of leg massage equipment on the market that leg massage instruments have uneven massage areas and can only massage the calves; the massage strength for different areas cannot be controlled according to the shapes of the legs; the massage instruments on the market have the same massage strength for different areas, so that massage injuries are easily caused whenthe strength is too large and the massage effect is not achieved when the strength is too small; the massage instruments have the problems that the structure is complicated, the operation is difficult, and especially it is difficult for the elderly to use the massage instruments. The functions of evenly massaging the legs on a large scale and eliminating the soreness of the legs can be achieved;the rehabilitation chair has the advantages that the operation is simple, massaging is uniform, the massage area is wide, and different massage strengths are provided for different parts.

Owner:上海丁阁仕电子商务有限公司

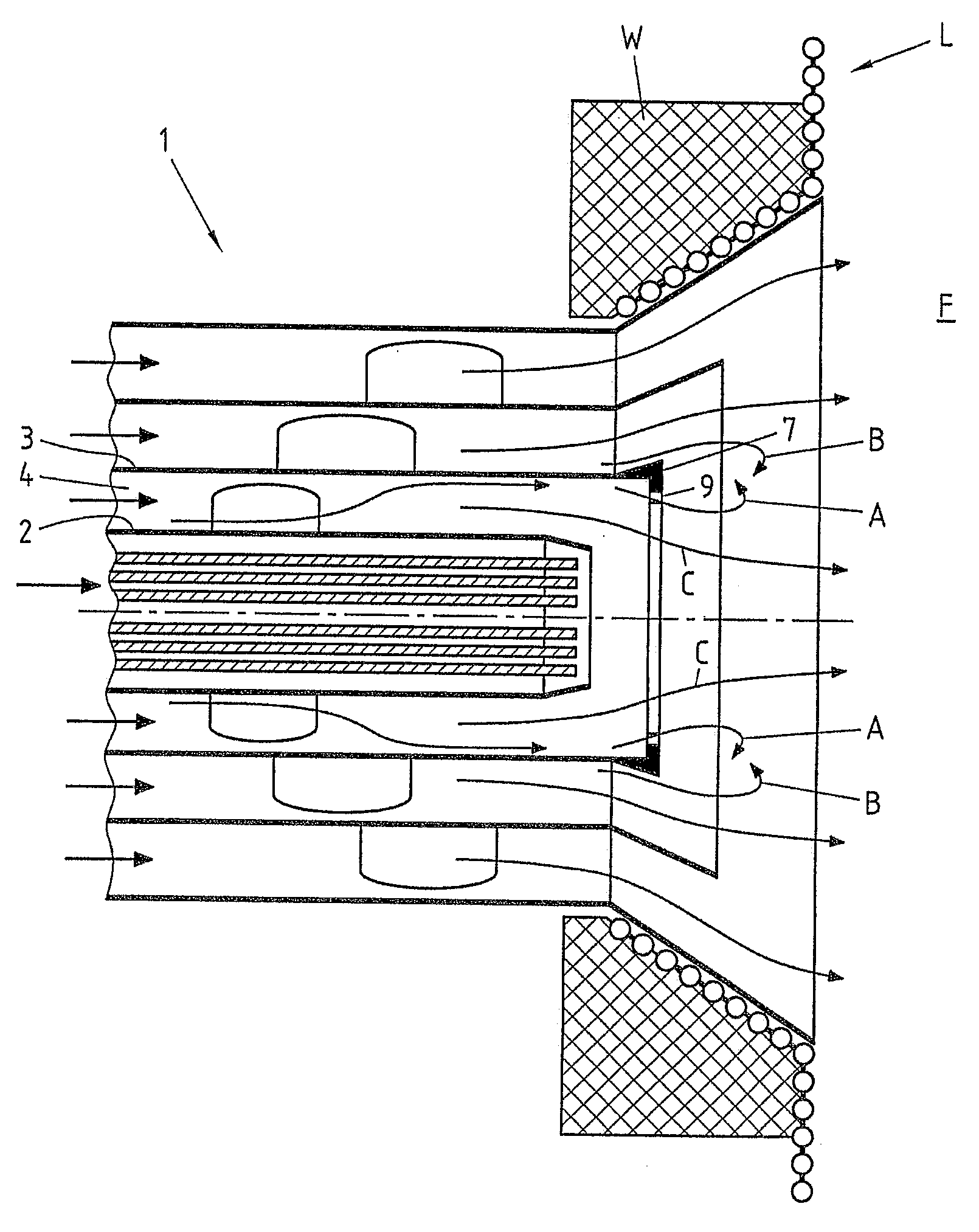

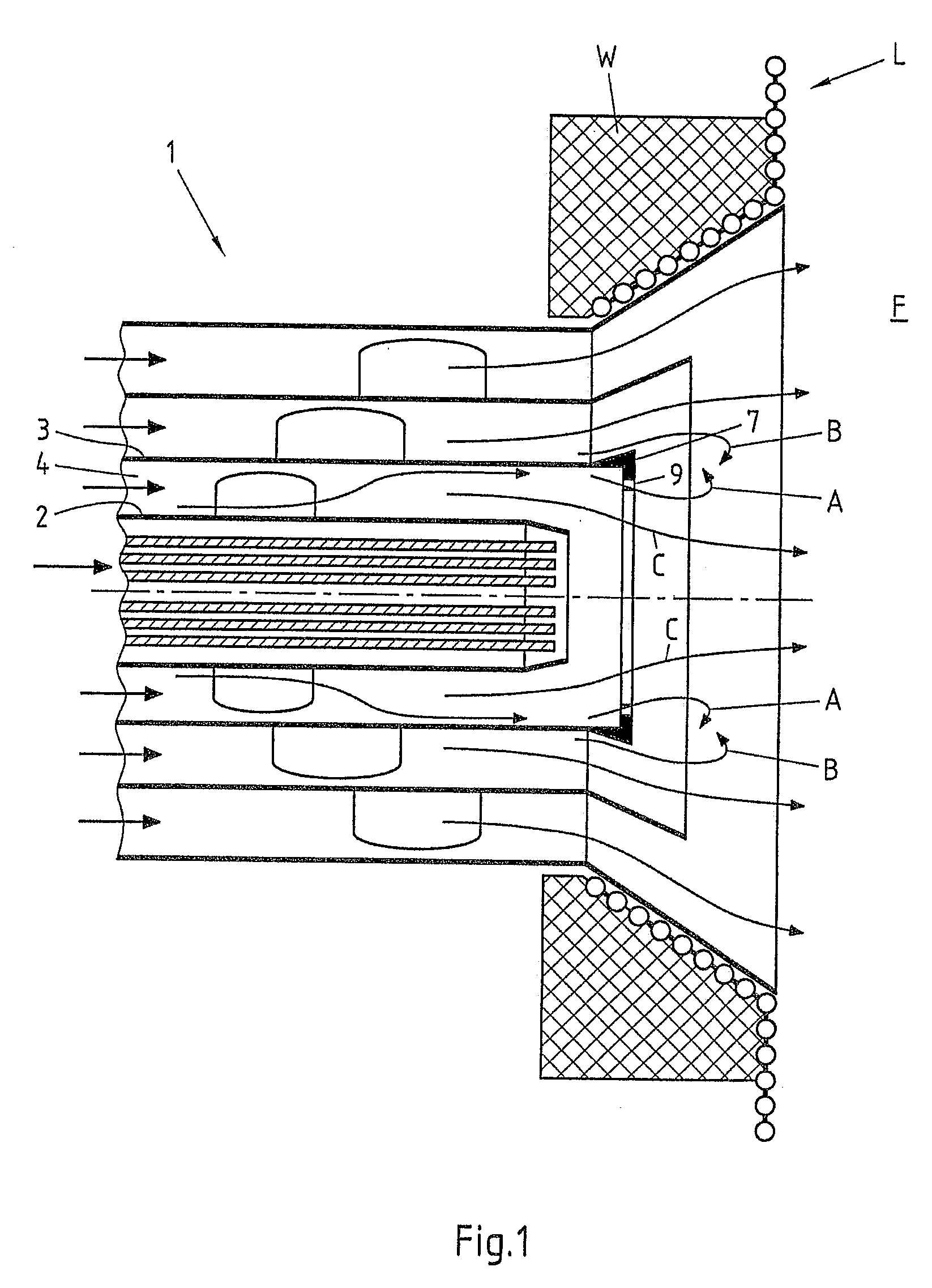

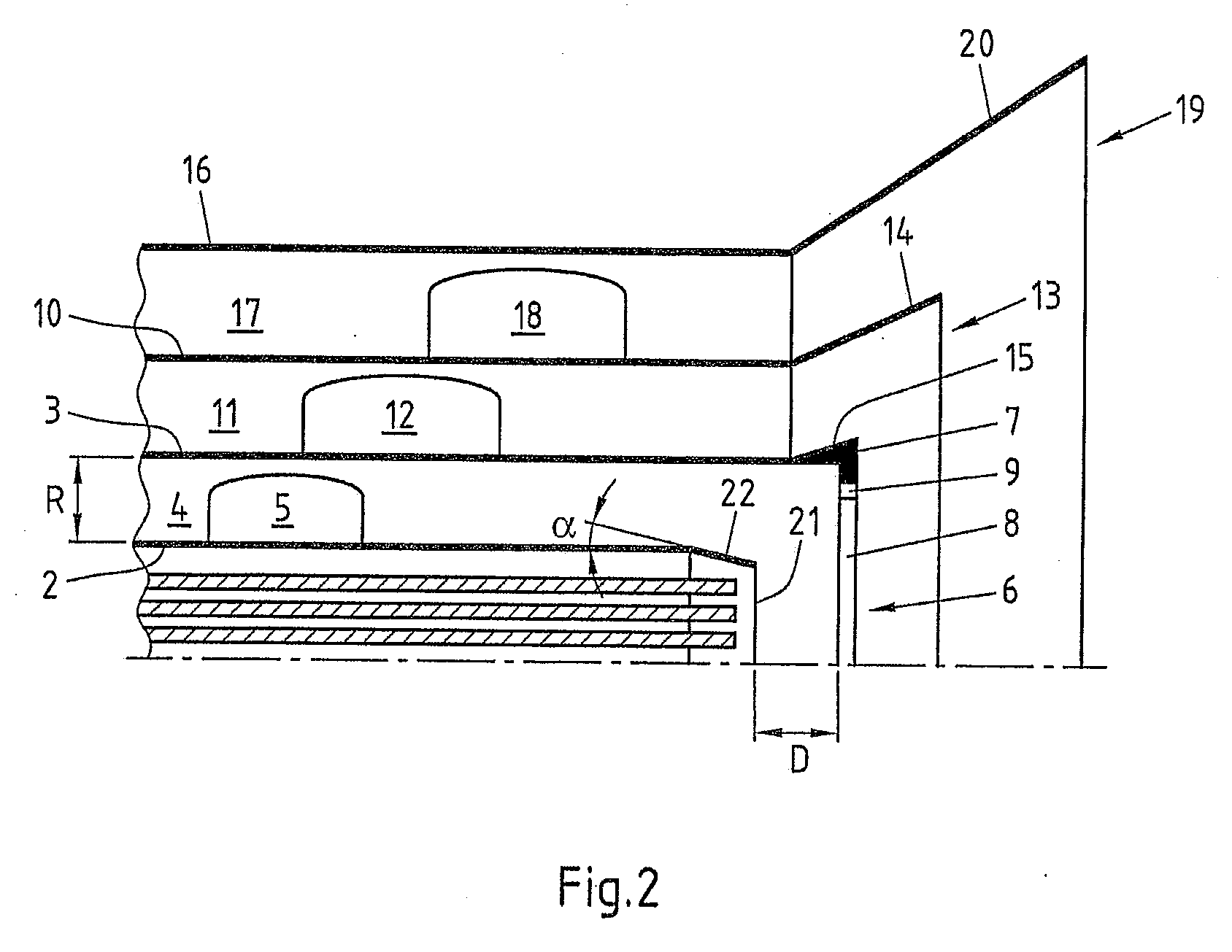

Burner for Particulate Fuel

InactiveUS20120272875A1Good effectReduce swirlPulverulent fuel combustion burnersCombustion apparatusParticulatesCombustor

Disclosed is a burner for particulate fuel, in particular made of biomass, with a primary tube and a core tube arranged in the primary tube. The primary tube and the core tube form a primary tube gap and the primary tube gap is configured to guide a flow of particulate fuel and gaseous combustion means from an inlet-side end to an outlet-side opening of the primary tube. In order to prevent the drawbacks occurring when using coarse-grain particles, preferably biomass, as a fuel for dust firing, or at least to reduce them without having to accept an increased outlay for equipment and / or additional energy losses, at least one device is provided for centring the flow within the primary tube in the region of the outlet-side end of the primary tube.

Owner:BABCOCK BORSIG STEINMUELLER GMBH

Corundum aggregate with micro-nano-pore structure and preparation method of corundum aggregate

The invention particularly relates to a corundum aggregate with a micro-nano-pore structure and a preparation method of the corundum aggregate. According to the technical scheme, the preparation method comprises the following steps of: with 60-82 wt% of alpha-Al2O3 fine powder, 6-15 wt% of alpha-Al2O3 micro powder, 3-15 wt% of rho-Al2O3 fine powder and 5-15 wt% of sillimanite as raw materials, adding 5-50 wt% of foam, 8-35 wt% of water and 0.5-2.5 wt% of burning accelerant in terms of the raw materials, and uniformly mixing to prepare a spherical biscuit; and naturally drying, roasting, heating to 1600-1780 DEG C, and insulating heat for 2-4 hours to obtain the corundum aggregate with the micro-nano-pore structure. The corundum aggregate with the micro-nano-pore structure and the preparation method disclosed by the invention have the advantages of being simple in production process, low in production cost, and energy-saving and environment-friendly; and the prepared corundum aggregate with the micro-nano-pore structure is good in thermal shock resistance, wide in application range, and capable of being used as a lining material for a kiln or a refractory castable for a heavy working layer during steel-making.

Owner:浙江自立新材料股份有限公司

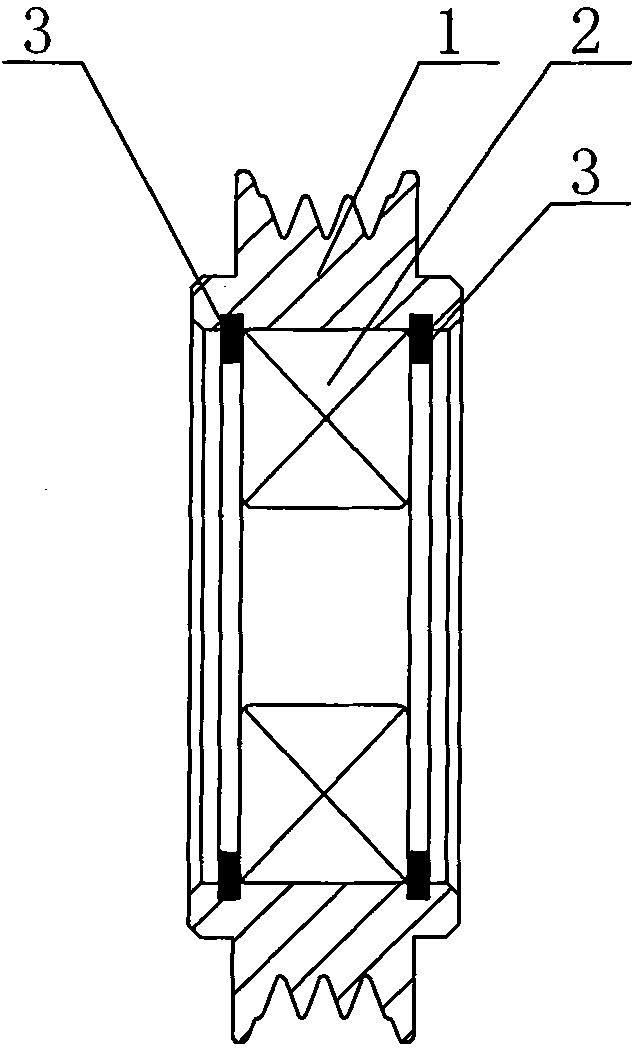

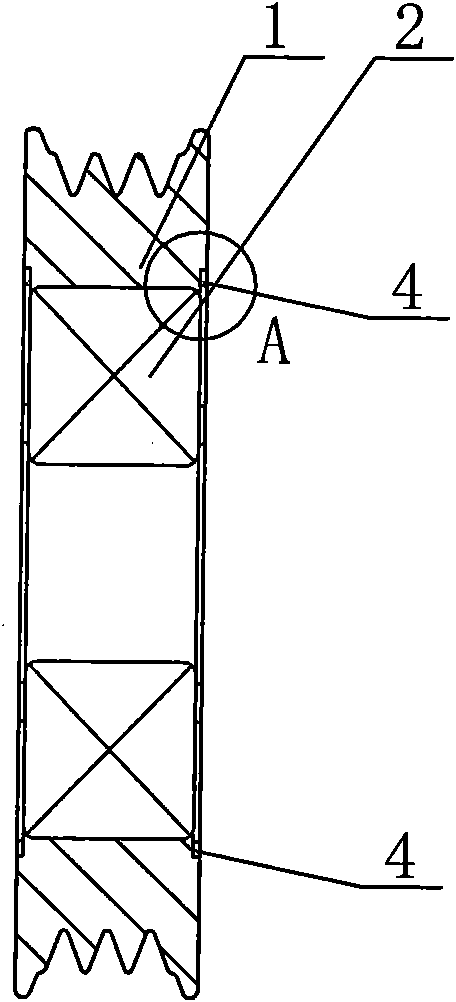

Assembly structure, method and fixture of pulley and bearing

ActiveCN101881304AReduce lossSimple processing technologyPortable liftingGearing elementsInterference fitHigh volume manufacturing

The invention relates to an assembly structure of a pulley and a bearing and a method and fixture for manufacturing the assembly structure. The outer ring periphery of the bearing is in interference fit with the inner bore of the pulley. The assembly structure is characterized in that riveted structures are distributed on the end surfaces at the two sides of the inner bore circumference of the pulley; and part of the pulley materials on the riveted structures is extruded into the rounding portion of the outer ring periphery of the bearing. The assembly structure and method radically change the processing and assembling modes of the conventional steel pulleys, the assembly fixture adopted by the invention can synchronously complete the bearing pressing process and double-sided press riveting process of the pulley conveniently, quickly and accurately, and the press rivet points at the two ends can effectively prevent the bearing from moving axially in the inner bore of the pulley, thus greatly lowering the production cost, saving the production time, improving the assembly efficiency, ensuring the product quality and reliability and meeting the requirement of volume production.

Owner:WUXI YONGKAIDA GEAR

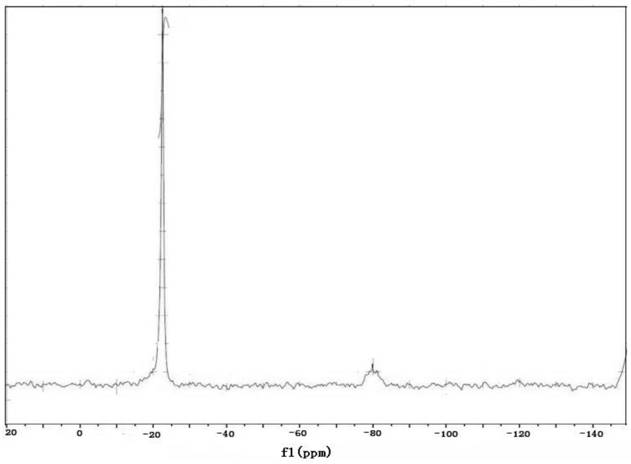

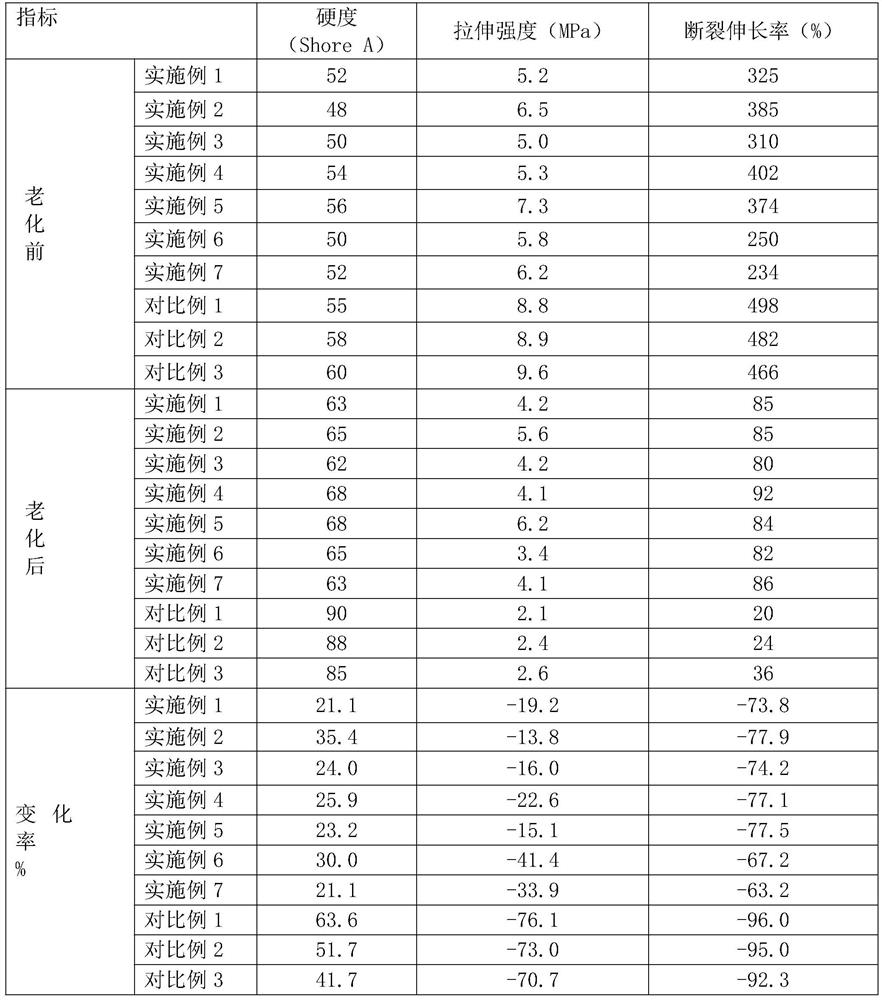

High-heat-resistance copolymerized silicon resin and preparation method thereof

The invention relates to a high-heat-resistance copolymerized silicon resin and a preparation method thereof. The preparation method comprises the following steps: catalyzing hydroxyl-terminated linear polysiloxane and organic trichlorosilane to be precondensed by using a weak base compound in an organic solvent medium, then carrying out cohydrolytic condensation under the action of a strong base to obtain a copolymer, and carrying out high-temperature curing on the copolymer to obtain a product with the structural formula of (R1R2ViSiO0.5)a(R1R2SiO)b(R3SiO1.5)c, wherein a+b+c=1, a:c=(3-20):1, b:c=(1-6):1, R1, R2 and R3 are the same or different and are selected from one or more of Me, Ph and Vi, and the number-average molecular weight is 5*10<4>-10<6>. The copolymerized silicon resin not only can keep good physical and mechanical properties, but also has high heat resistance, can be used for a long time at 300 DEG C, and still keeps high strength and high elasticity after being subjected to thermo-oxidative aging for 72 hours in an environment at 350 DEG C.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Side rail and method for producing a hot-formed and press-hardened side rail

InactiveUS20120318415A1Improve manufacturabilityReliable implementationSuperstructure subunitsQuenching devicesEngineeringUltimate tensile strength

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com