Assembly structure, method and fixture of pulley and bearing

A technology of bearing assembly and pulley, applied in the direction of belt/chain/gear, rigid support of bearing components, bearing components, etc., can solve the problems that cannot meet the needs of batch and rapid production, complex processing and assembly, low efficiency, etc., and achieve the quality of finished products and Reliable precision, low loss of raw materials, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

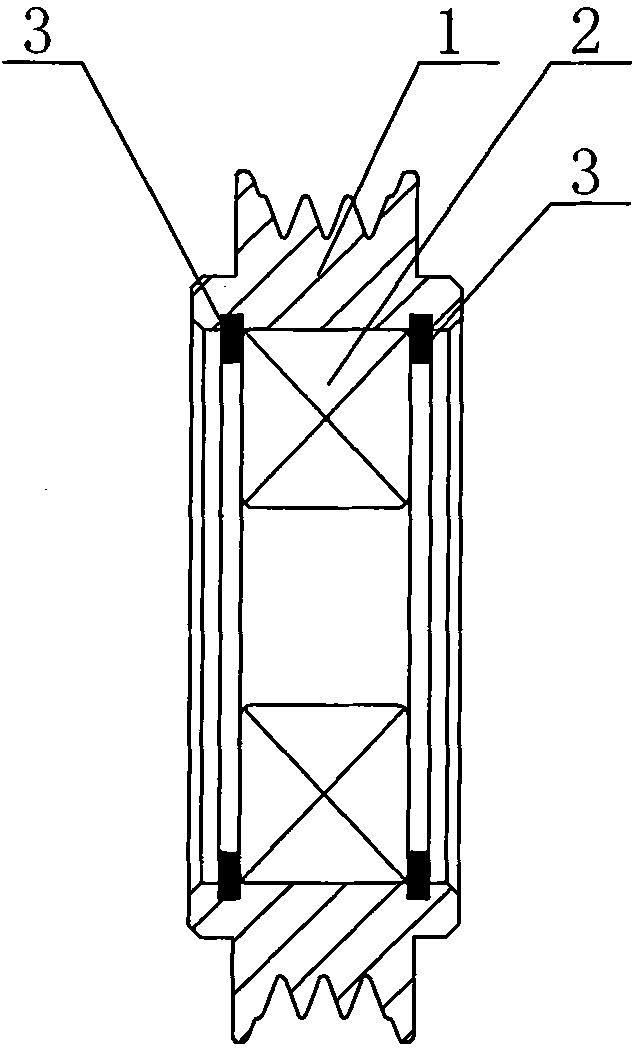

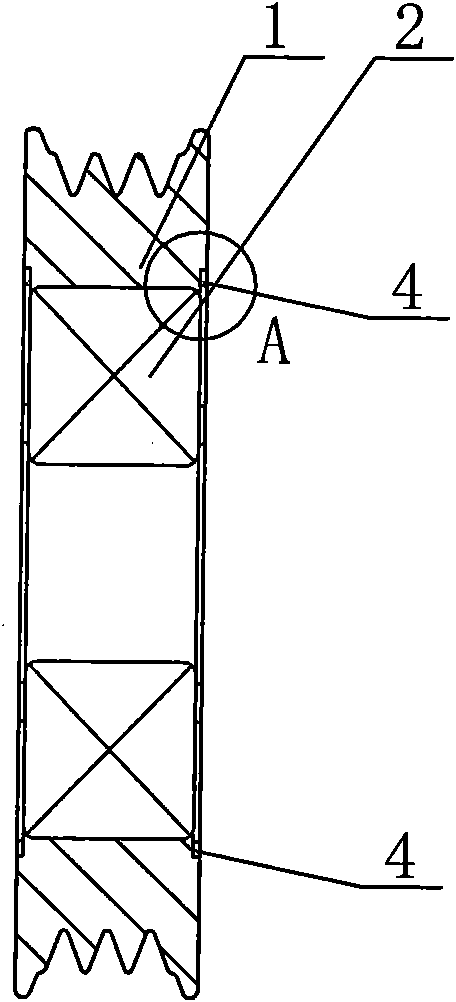

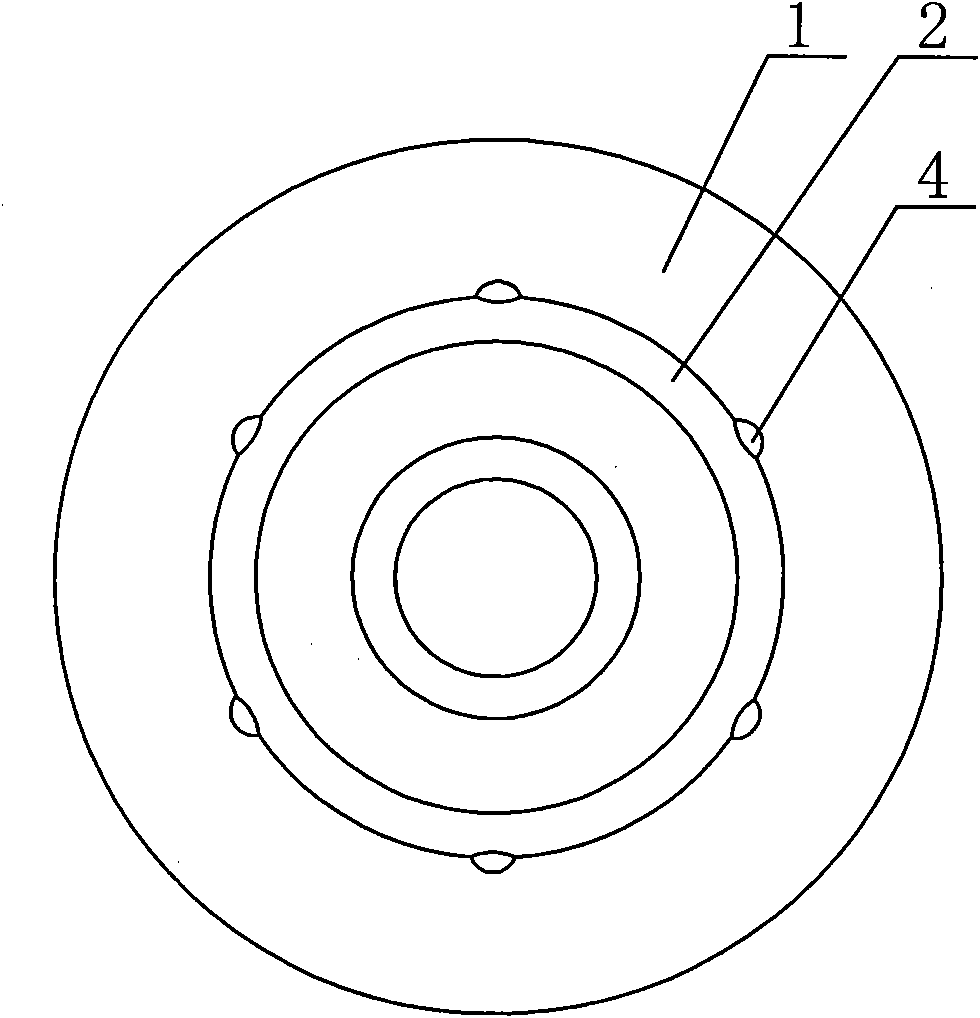

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0030] Such as figure 2 , image 3 , Figure 4 As shown, the outer circumference of the bearing 2 is in interference fit with the inner hole of the pulley 1, and a plurality of evenly distributed riveting points are pressure riveted on both sides of the inner hole circumference of the pulley 1, and the riveting points are partially squeezed into the rounding or The chamfered part can realize the axial positioning of the bearing and prevent the axial movement of the bearing.

[0031] Correspondingly, the assembly method of the pulley and the bearing of the present invention comprises the following steps:

[0032] The first step: interference fit the bearing on the inner wall of the inner hole of the pulley;

[0033] Step 2: Squeeze the end faces on both sides of the inner hole circumference of the pulley to form a number of riveting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com