Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

A technology for enhancing thermoplastic and composite materials, applied in the field of thermoplastic composite materials, can solve the problems of low mechanical properties, easy shrinkage, and difficult molding, etc., achieve the effect of interlayer performance, protect yarns, and avoid yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

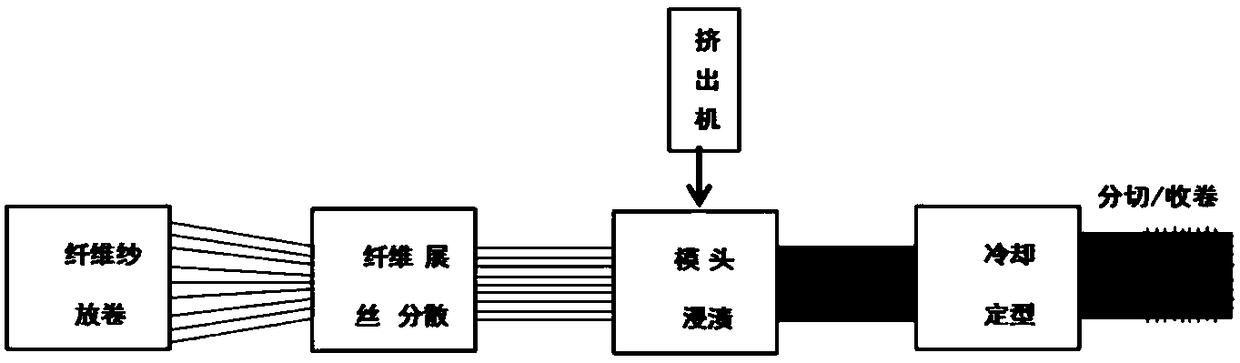

[0045] In another technical solution of the present invention, a method for preparing a molded preform of a discontinuous long fiber reinforced thermoplastic composite material is provided, the preparation method comprising the following steps:

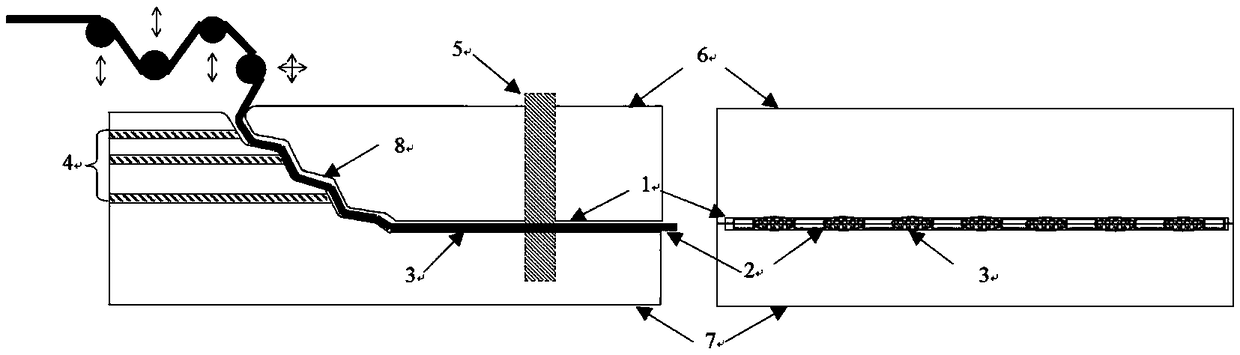

[0046] (1) Preparation of continuous fiber-reinforced thermoplastic composite material prepreg / prepreg yarn: the unidirectional continuous fiber / continuous fiber tow is passed through the extrusion die, fully impregnated with melt resin, and cooled to form a continuous fiber-reinforced prepreg. Dipped sheet / prepreg yarn;

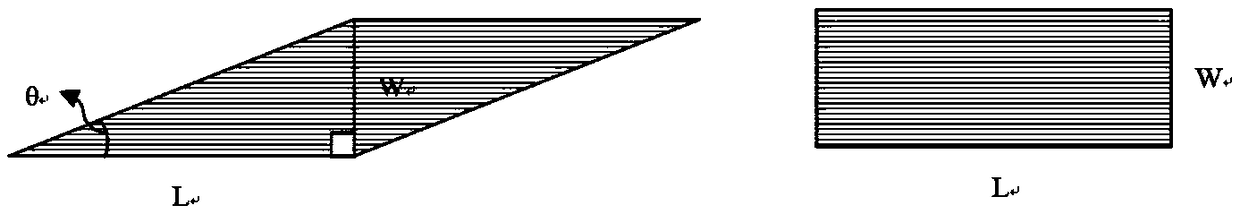

[0047] (2) Preparation of discontinuous long-fiber reinforced thermoplastic composite sheets: continuous fiber-reinforced prepregs / prepregs are slit / cut off-line or off-line, and made into slices of designed size and shape;

[0048] (3) Processing of discontinuous long-fiber-reinforced thermoplastic composite molded preforms: slices are conveyed, mixed, spread, hot-pressed, cooled, and cut to make molded preforms. ...

Embodiment 1

[0055] A discontinuous large-fiber-reinforced thermoplastic composite molded preform, which consists of equal-sized

[0056] CF / PA610 prepreg slices are hot-pressed into 5mm boards, the carbon fiber content in the slices is 40wt%, the slice length is 35mm, the width is 10mm, and the angle is 90°.

Embodiment 2

[0058] A non-continuous long fiber reinforced thermoplastic composite molded prefabricated body, made of GF / PP prepreg sheet and CF / PP prepreg yarn slices, hot-pressed into 5mm boards, wherein the fiber content is 60wt%, and the length of the slices is 5mm, 10mm , 15mm, 35mm, GF / PP prepreg slice width 12.7mm, angle 30°, CF / PP prepreg yarn slice width 3.2mm, 6.4mm, angle 90°, slices of various scales are mixed in equal proportions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com