Patents

Literature

247results about How to "Fully impregnated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal element improved biochar-based nitrate radical adsorbent and preparation method thereof

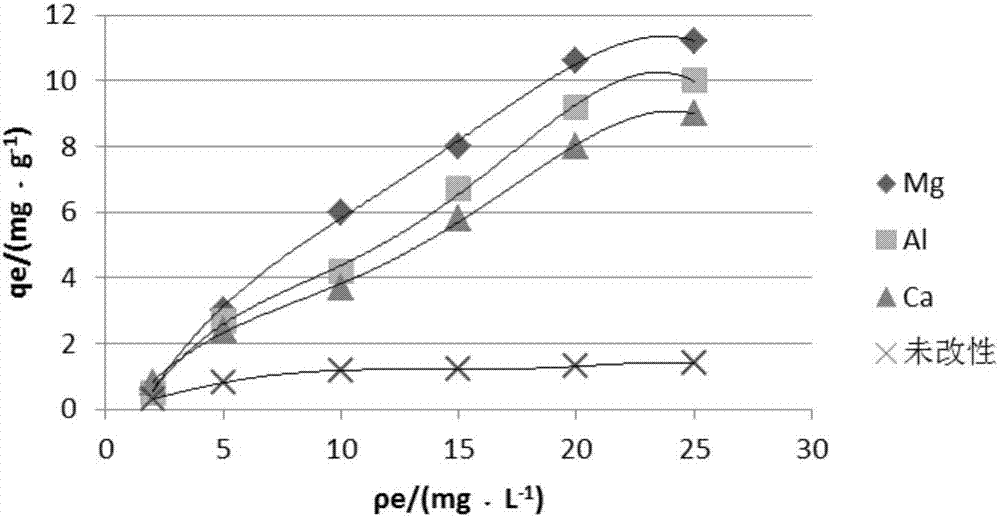

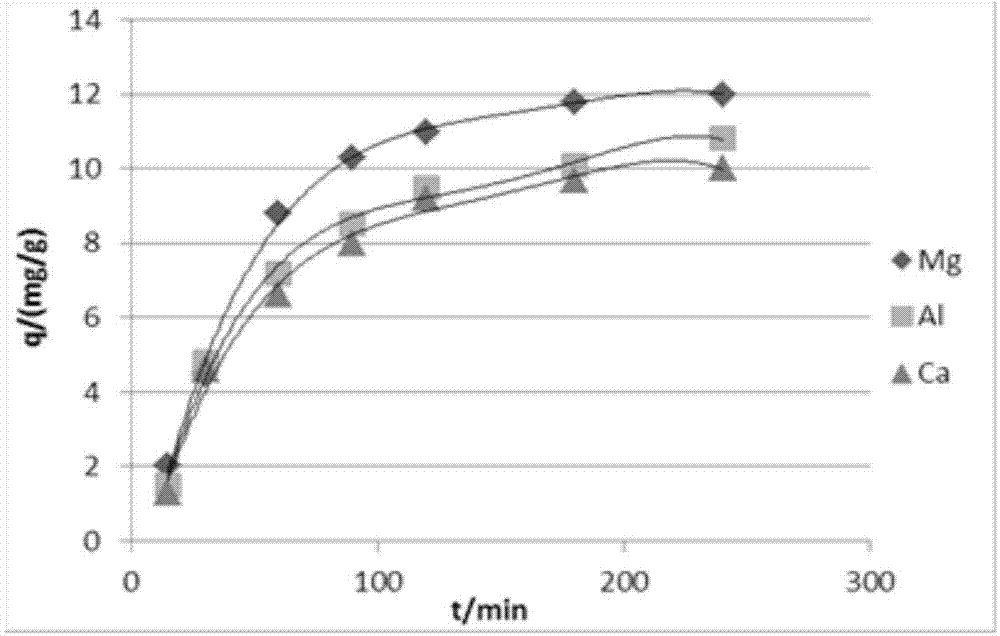

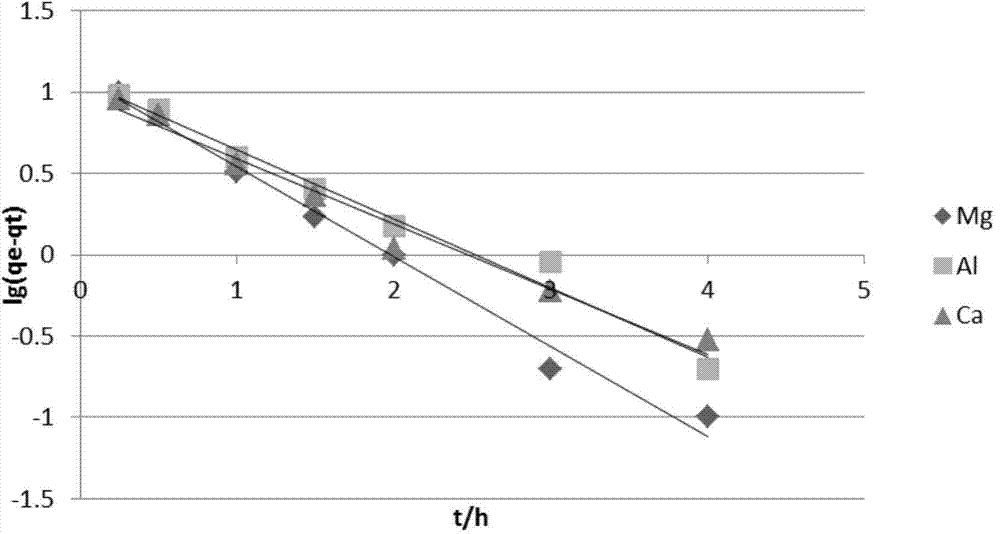

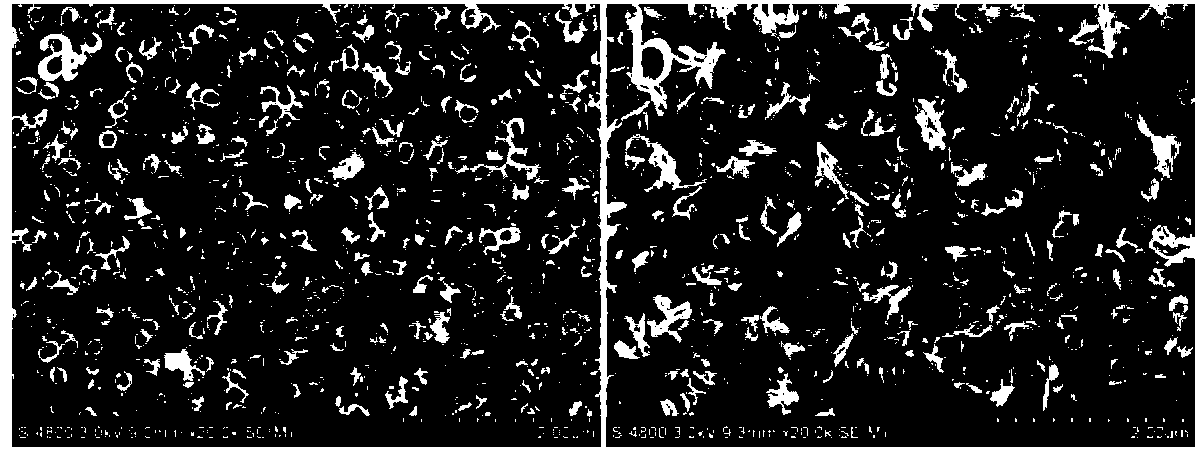

InactiveCN104258812AEfficient removalReduce pollutionOther chemical processesWater contaminantsAdsorption equilibriumSorbent

The invention discloses a metal element improved biochar-based nitrate radical adsorbent and a preparation method thereof. Straws are used as raw materials, and metal ions are impregnated, pyrolyzed and washed under certain conditions, so a metal ion improved cbiochar is prepared. According to the metal element improved biochar-based nitrate radical adsorbent and the preparation method thereof disclosed by the invention, by using adsorption research on nitrate radical waste water and comparing the adsorption effect of the biochar before and after improvement, the improved biochar prepared by the preparation method disclosed by the invention has good adsorption effect for potassium nitrate, wherein Mg<2+> improved wheat straw biochar has optimal adsorption effect for nitrate nitrogen; compared with the unmodified biochar, the Mg<2+> improved biochar prepared under the optimizing conditions has the advantages that the adsorption performance is improved by 10 times, and the adsorption equilibrium can be realized in a shorter time. The modified biochar adsorbent is a green adsorbent with application potential and can be used for effectively removing the nitrate nitrogen in a water body; besides, the effects of fixing carbon, reducing discharge and relieving the non-point source pollution are achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

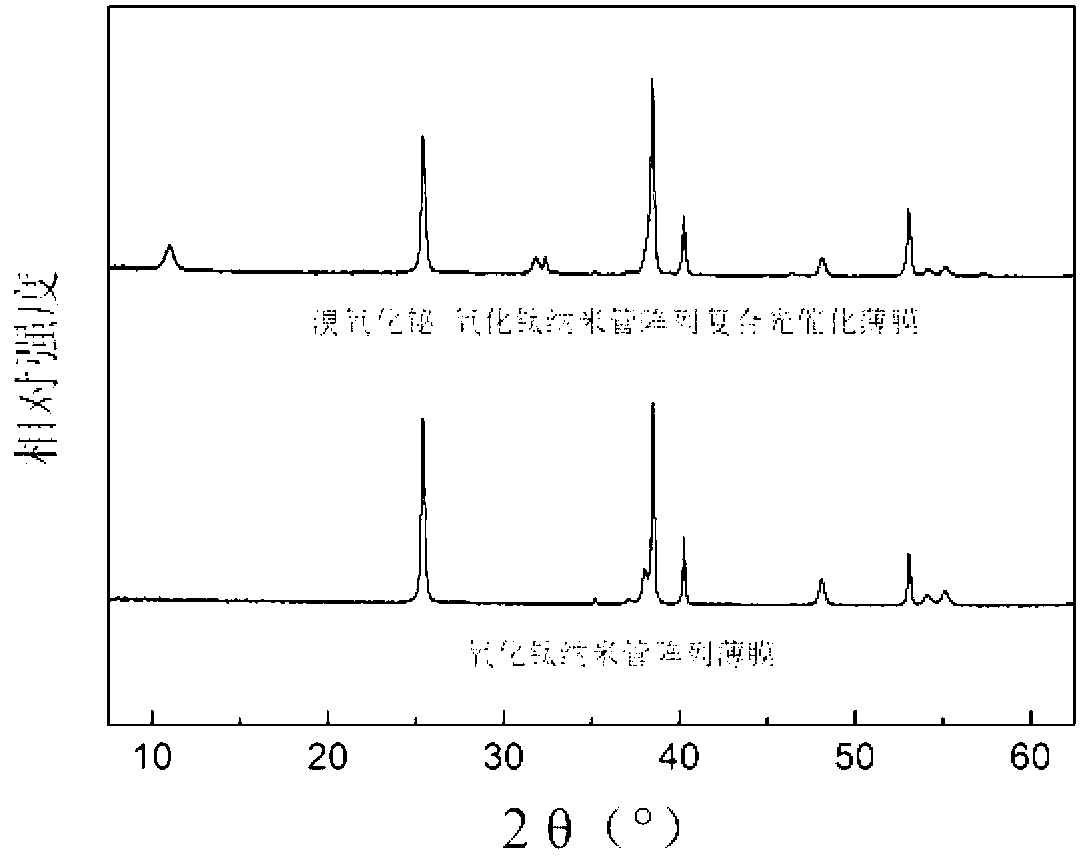

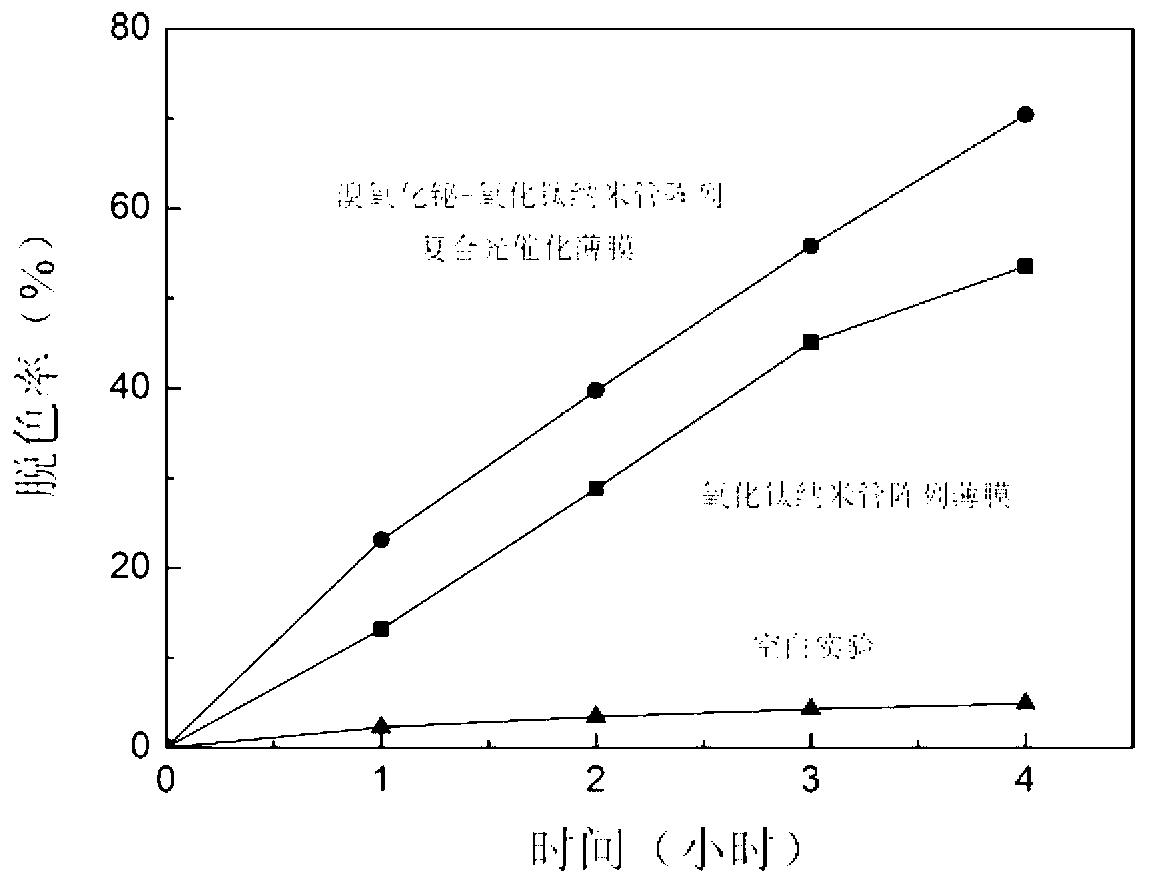

Preparation method of bismuth oxide halide-titanium oxide nanotube array composite photo-catalytic membrane

InactiveCN103285891AEasy to useImprove photocatalytic performancePhysical/chemical process catalystsSurface reaction electrolytic coatingTio2 nanotubeControllability

The invention belongs to the field of photo-catalysis, and in particular relates to a preparation method of a bismuth oxide halide-titanium oxide nanotube array composite photo-catalytic membrane. The method comprises the steps of: first, preparing a titanium dioxide nanotube array membrane by adopting an anode oxidization method; then, enabling bismuth ions to enter nanotubes by vacuum impregnation; and at last, with a solution containing halide ions as a precipitator, enabling the halide ions to react with the bismuth ions to generate bismuth oxide halide, wherein the bismuth oxide halide is deposited in the nanotubes and on the surface of the nanotube of the titanium dioxide nanotube array so as to obtain the bismuth oxide halide-titanium oxide nanotube array composite photo-catalytic membrane. The preparation method disclosed by the invention combines the advantages of the titanium dioxide nanotube array and the advantages of the bismuth oxide halide, is convenient to use, and can be used for preparing composite photo-catalytic membranes with different bismuth oxide halide load capacities by changing the concentration of bismuth ions, etc; and the prepared composite photo-catalytic membrane has good photo-catalysis performance, large adjustability and high controllability,.

Owner:HEBEI UNIV OF TECH

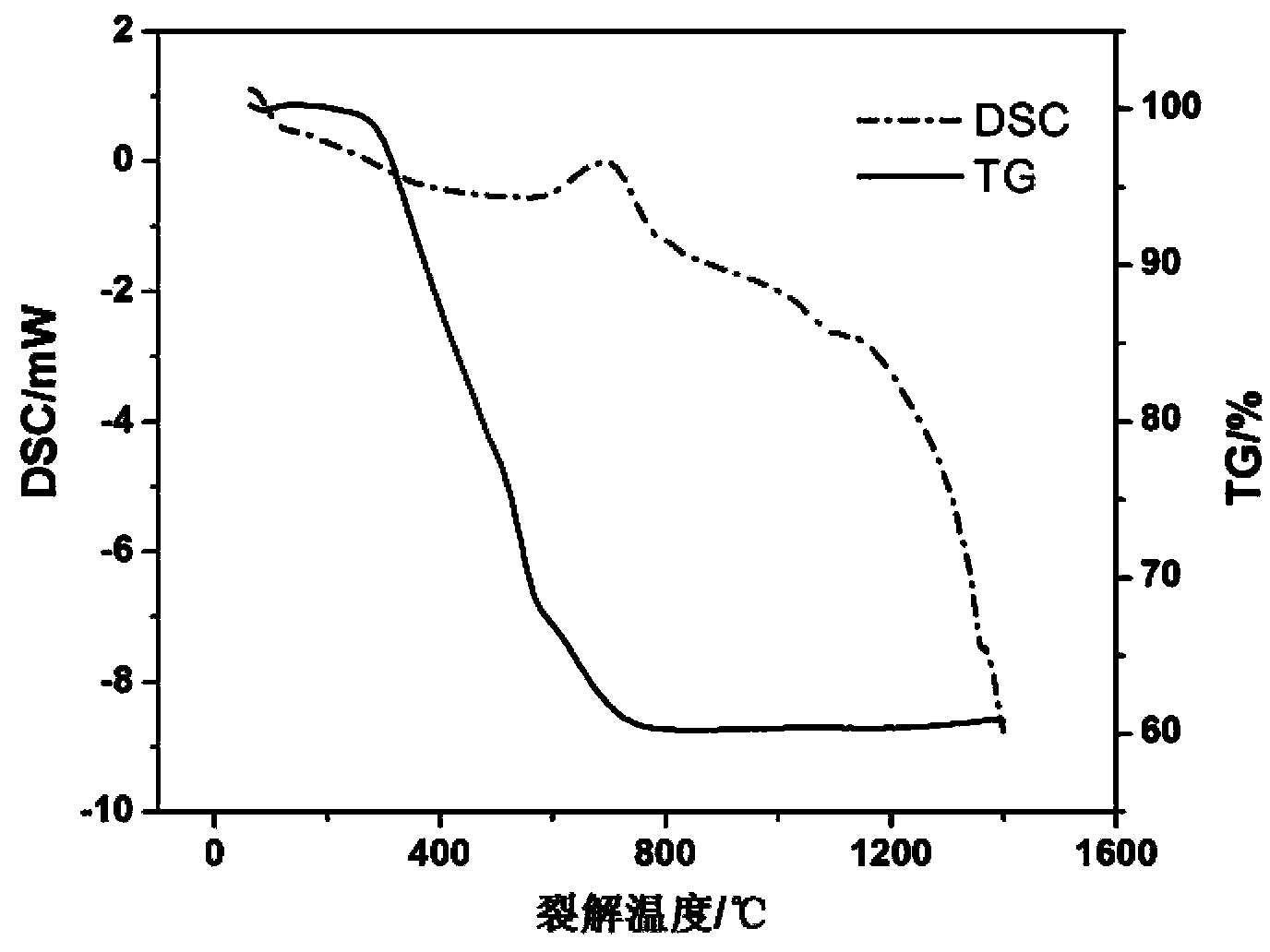

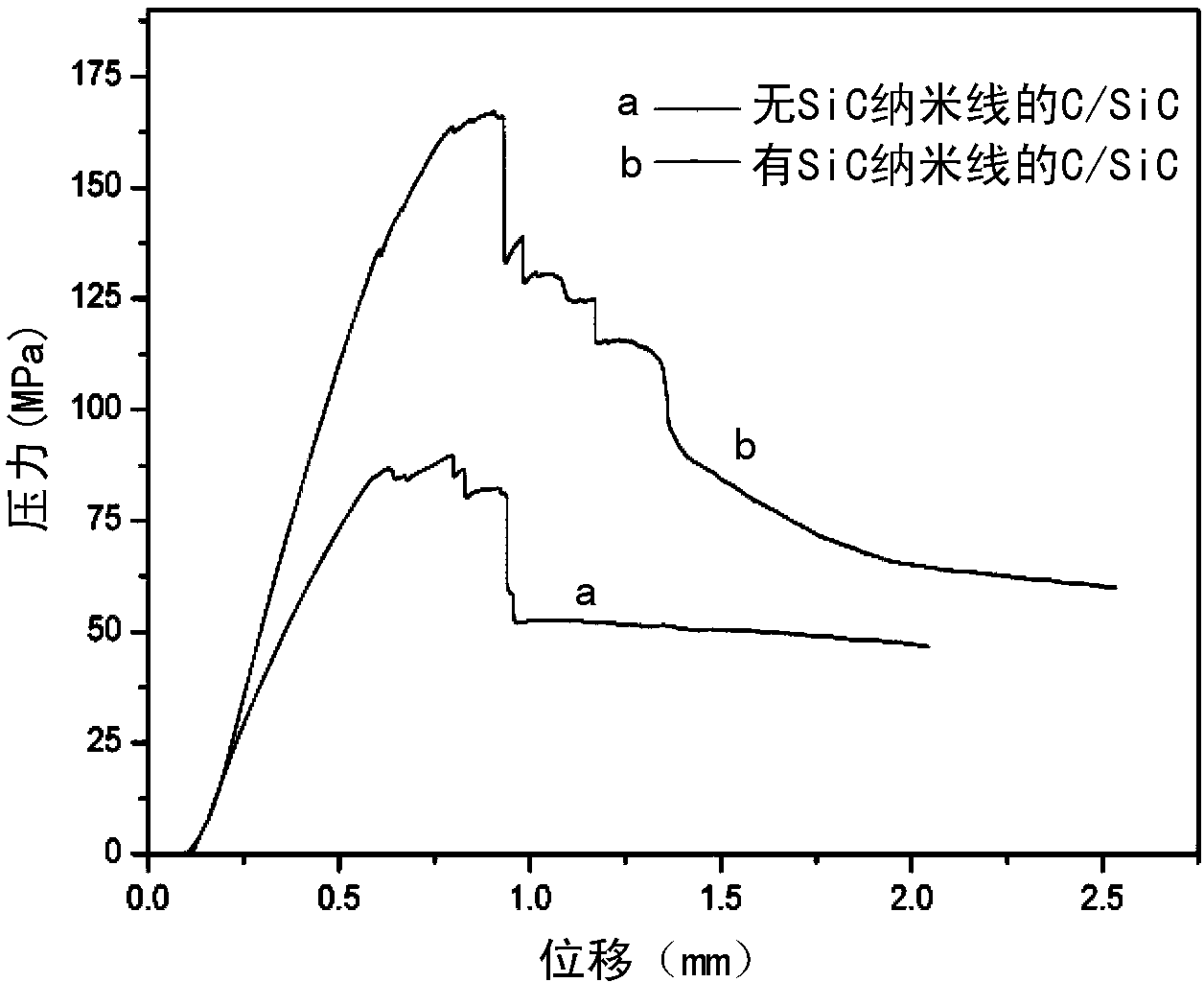

In-situ growth SiC nanowire enhanced C/SiC composite material and preparation method thereof

The invention relates to an in-situ growth SiC nanowire enhanced C / SiC composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing size, namely mixing and ball milling polycarbosilane, a catalyst and a solvent to prepare the size, wherein the catalyst is iron, nickel and / or ferrocene; (2) performing vacuum high pressure impregnation, namely immersing a C fiber preform in the size, keeping in a vacuum state for 0.1-1 hour, introducing high-pressure inert gases to 1-10MPa, and maintaining the pressure for 1-4 hours; (3) cross-linking and curing, namely performing cross-linking and curing on the impregnated C fiber preform in air for over 6 hours to prepare a preform; and (4) performing high-temperature pyrolysis, namely raising the temperature of the preform to be 1000-1300 DEG C at a temperature rise rate of 2-10 DEG C per minute in a protective atmosphere, keeping the temperature for 1-4 hours, and growing SiC nanowires in situ under the action of a metal catalyst in the polycarbosilane pyrolysis process, so that the in-situ growth SiC nanowire enhanced C / SiC composite material is prepared.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

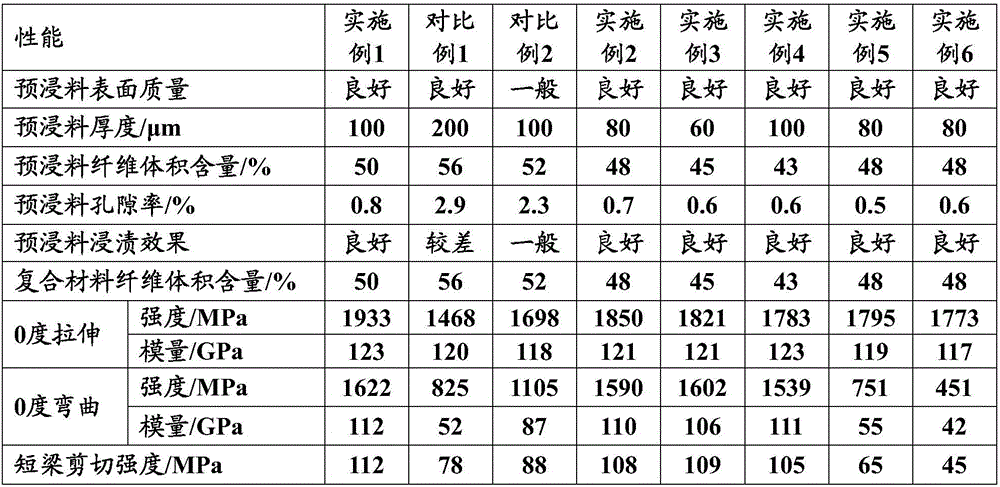

Toughened epoxy resin/glass fiber prepreg and preparation method

InactiveCN103146147AImprove mechanical propertiesImprove impact performanceLayered product treatmentPhysical treatmentEpoxyFiber

The invention relates to the field of high polymer materials, in particular to a toughened epoxy resin / glass fiber prepreg and a preparation method thereof. In a vacuum apparatus, a glass fiber cloth treated by plasmas is impregnated by toughened epoxy resin so as to form the prepreg with reinforced fiber fully impregnated by the matrix resin, wherein the resin content is greater than or equal to 15% and is less than or equal to 30%. A vacuum infusion process employed in the invention solves the problems of complex preparation process, high cost, difficult control of resin content and the like in current glass fiber prepregs. In addition, the toughened epoxy resin used in the prepreg adopts a mixed amine curing agent and a nano-toughening agent, the toughening effect is obvious, a resin cast body can have excellent properties. Under a vacuum condition, the resin cast body and the glass fiber woven cloth can be impregnated to prepare a prepreg, and after curing, the composite material obtained has excellent impact resistance.

Owner:CHANGZHOU LOONG TOP NEW MATERIALS TECH

Epoxy resin composition for fiber reinforced composite material, prepreg, and fiber reinforced composite material

ActiveUS20130217283A1Reduced trapped airMinimize amount of water vaporLaminationLamination apparatusEpoxyPolymer science

An epoxy resin composition having components (A), (B), (C), and (D), wherein the epoxy resin composition has a viscosity at 40° C. of about 1×103 to about 1×104 Pa·s, a curing start temperature of about 90 to about 110° C., and a minimum viscosity at the curing start temperature of about 2 to about 20 Pa·s, wherein the components (A), (B), (C), and (D) are as follows: (A) About 60 weight parts or more of a tetraglycidyl amine type epoxy resin per 100 weight parts of the epoxy resin blend; (B) Dicyandiamide; (C) Diaminodiphenyl sulfone and (D) Urea compound.

Owner:TORAY IND INC

Paper-making-stage bamboo wood pulp plate denaturalization producing technique

ActiveCN101148836ADip evenlyFully impregnatedPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making bamboo pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making bamboo pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Catalyst loading CoCr(Mn/Al)FeNi high-entropy alloy nano particles and preparation method and application of catalyst

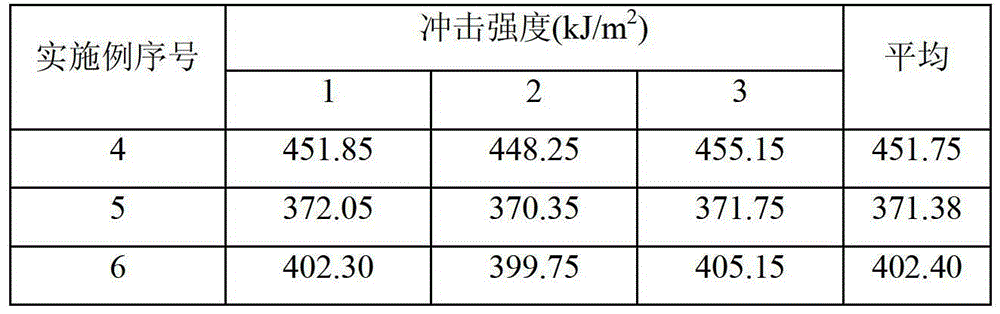

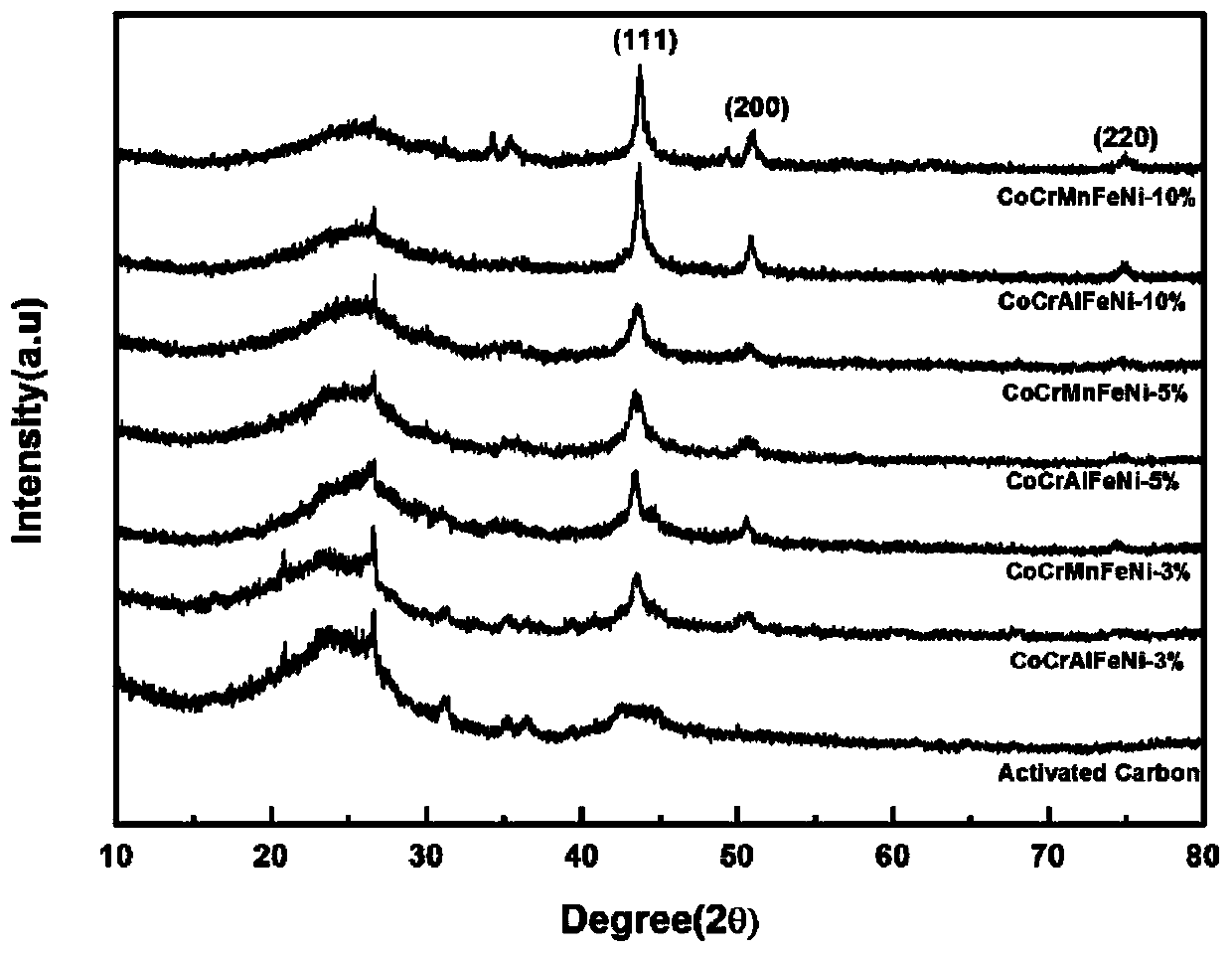

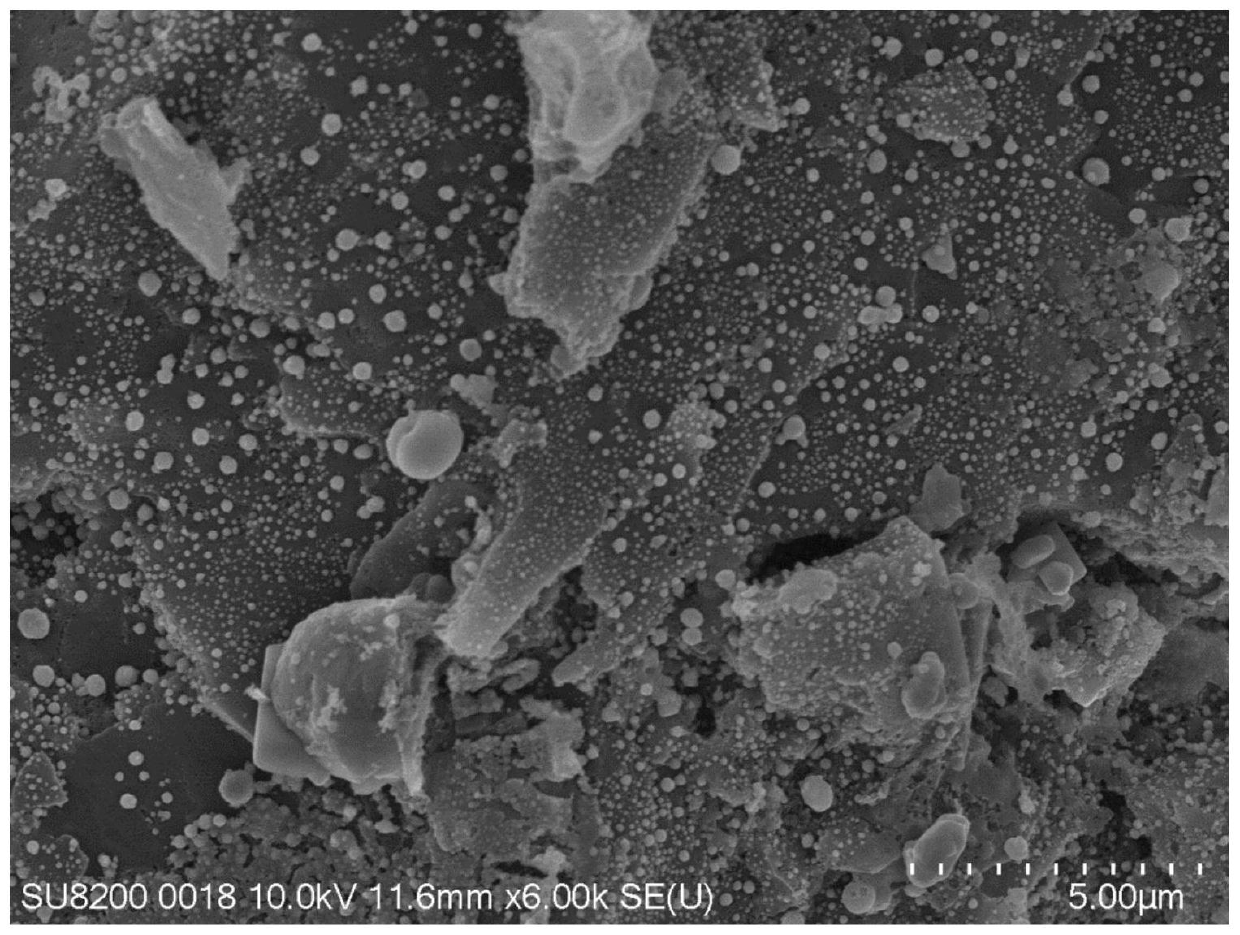

ActiveCN109999830AIncrease mixing entropyGood fade effectMaterial nanotechnologyWater contaminantsActivated carbonHigh entropy alloys

The invention discloses a catalyst loading CoCr(Mn / Al)FeNi high-entropy alloy nano particles and a preparation method and application of the catalyst. Activated carbon or a mineral material is adoptedas the matrix of the catalyst, the CoCr(Mn / Al)FeNi high-entropy alloy nano particles are loaded on the surface of the matrix, wherein the mass content of the matrix is 90-97% by weight. The CoCr(Mn / Al)FeNi high-entropy alloy nano particles loaded on the carrier are uniformly distributed, the loading capacity is controllable, the catalytic performance is excellent, and a galvanic effect can be achieved by the high-entropy alloy particles and the matrix at a nanometer scale, so that the catalytic degradation performance on azo dye is improved greatly.

Owner:CHINA UNIV OF MINING & TECH

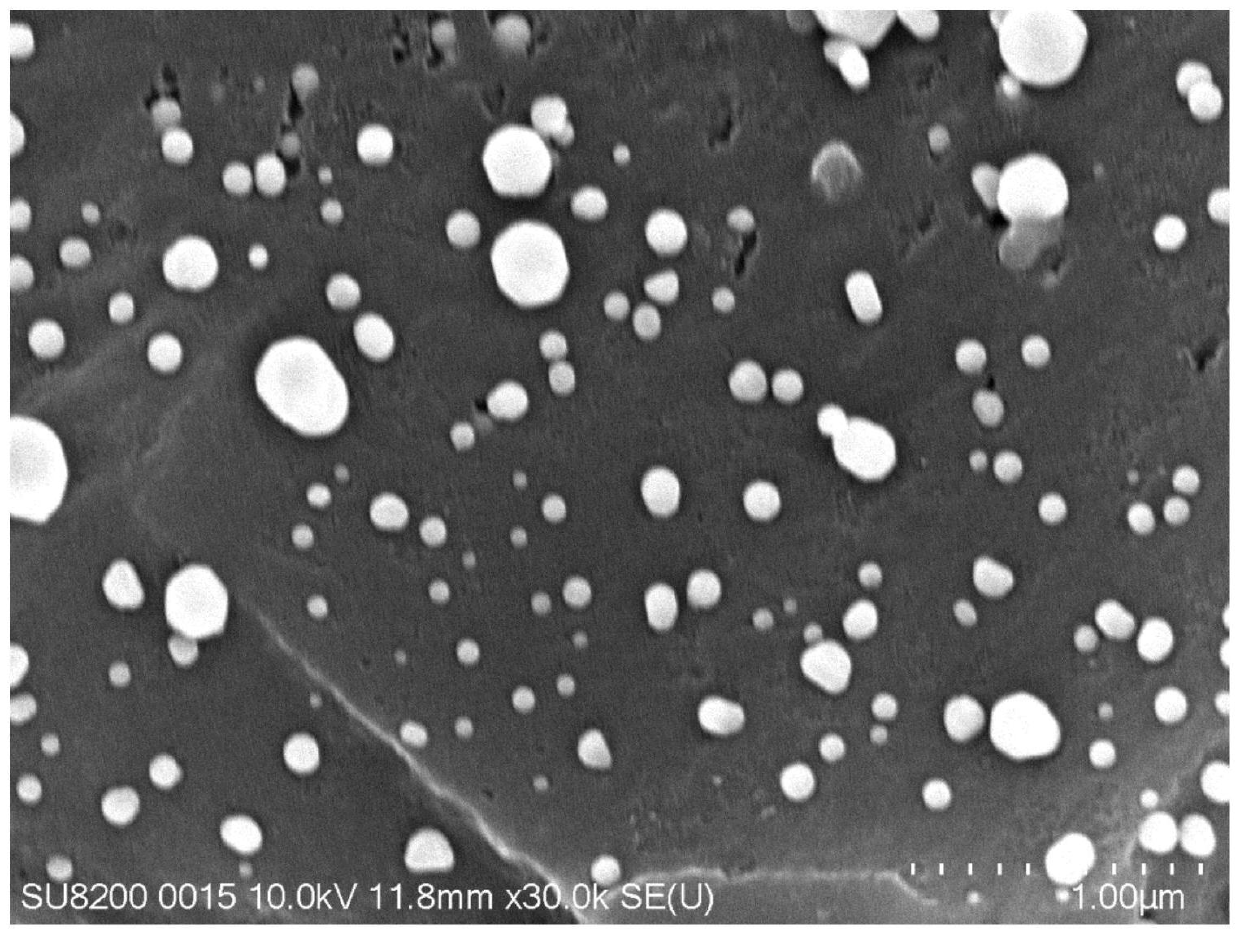

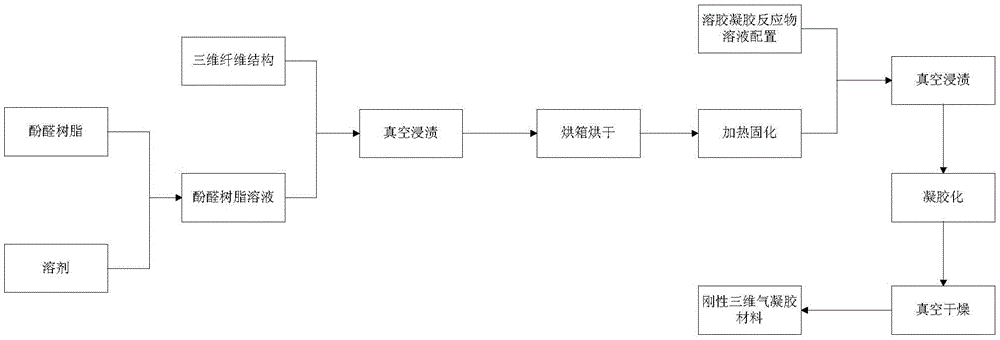

Preparation method of rigid structure reinforced phenolic aerogel heat shielding material

ActiveCN105601854ASolve problems that are difficult for large-scale engineering applicationsStrong dimensional stabilityEngineeringSolvent

The invention relates to a preparation method of a rigid structure reinforced phenolic aerogel heat shielding material. The method includes: firstly dissolving phenolic resin in a solvent in a vacuum impregnation container to form a phenolic solution, then pressing a three-dimensional fiber structure into the phenolic resin solution, and conducting vacuum pumping on the vacuum impregnation container, after a period of time, opening a seal cover to maintain smooth air pressure with the outside and conducting standing for a period of time, then taking out the three-dimensional fiber structure and putting it into an oven to perform drying, and conducting high temperature curing to form a rigid three-dimensional fiber structure, then mixing resorcinol, furfural, ethanol and sodium hydroxide uniformly in proportion in the vacuum impregnation container to form a reactant solution, then pressing the rigid three-dimensional fiber structure into the solution, conducting vacuum pumping on the vacuum impregnation container again, maintaining the state for a period of time, then placing the vacuum impregnation container into the oven to carry out sol-gel process, and finally taking out the gel-containing three-dimensional fiber structure and performing drying, thus obtaining the rigid structure reinforced phenolic aerogel product.

Owner:BEIJING SATELLITE MFG FACTORY

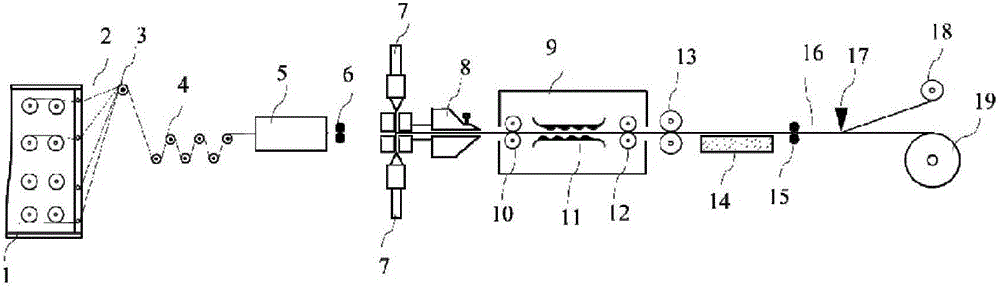

Ultrathin continuous fiber reinforced thermoplastic resin prepreg and preparation method thereof

The invention discloses a preparation method of a continuous fiber reinforced thermoplastic resin prepreg. The method comprises the steps of: (1) thinning continuous fiber; and (2) impregnating the thinned fiber prepared in step (1) with thermoplastic resin melt. The method provided by the invention particularly can realize impregnation of fiber in high temperature and high viscosity PEEK resin so as to obtain high performance continuous fiber reinforced thermoplastic prepreg.

Owner:BEIHANG UNIV

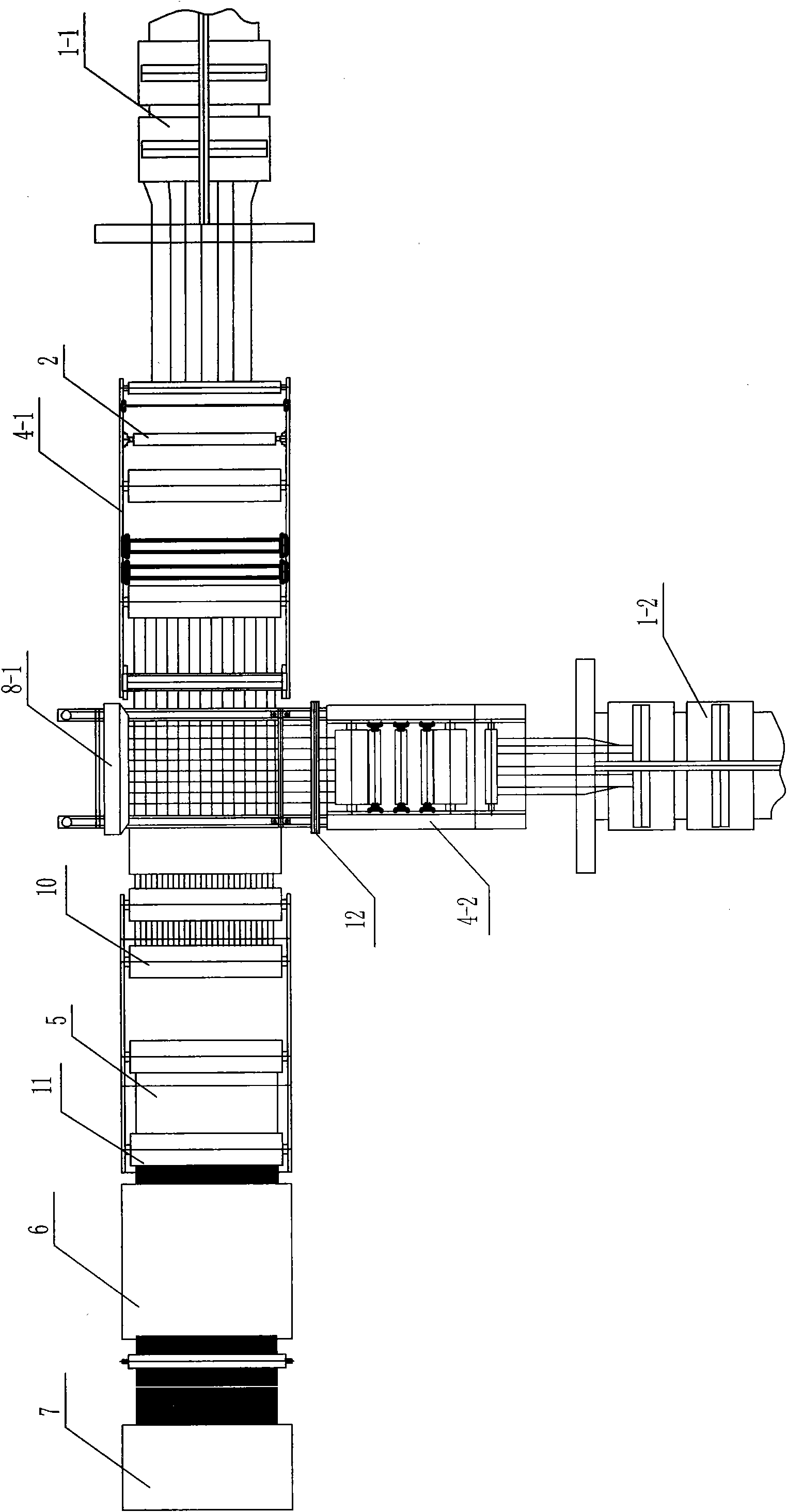

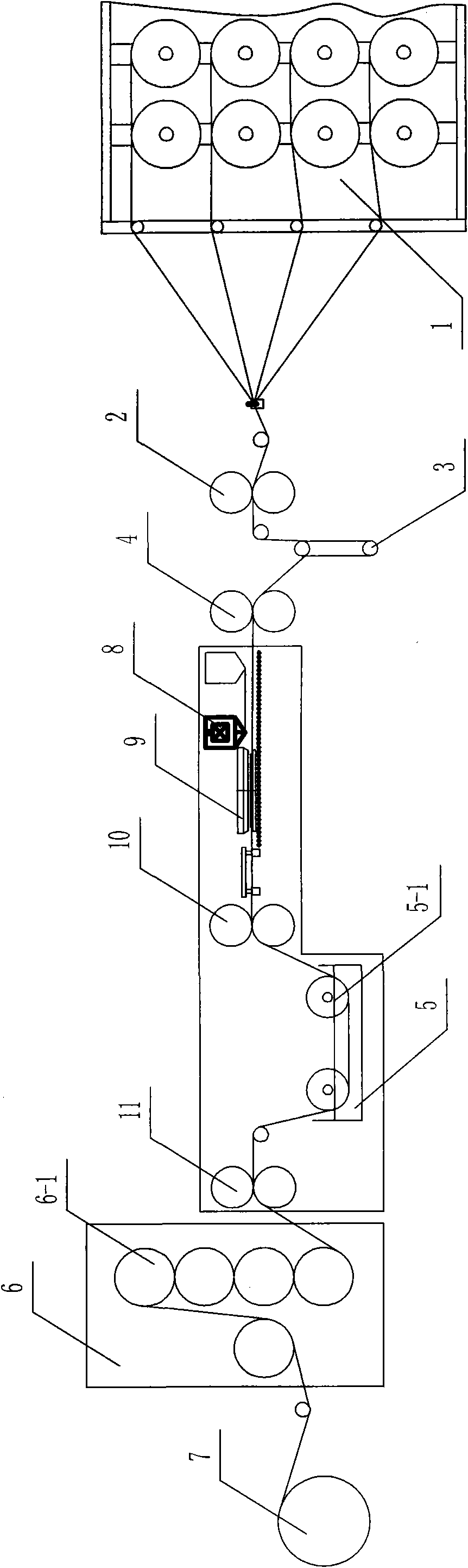

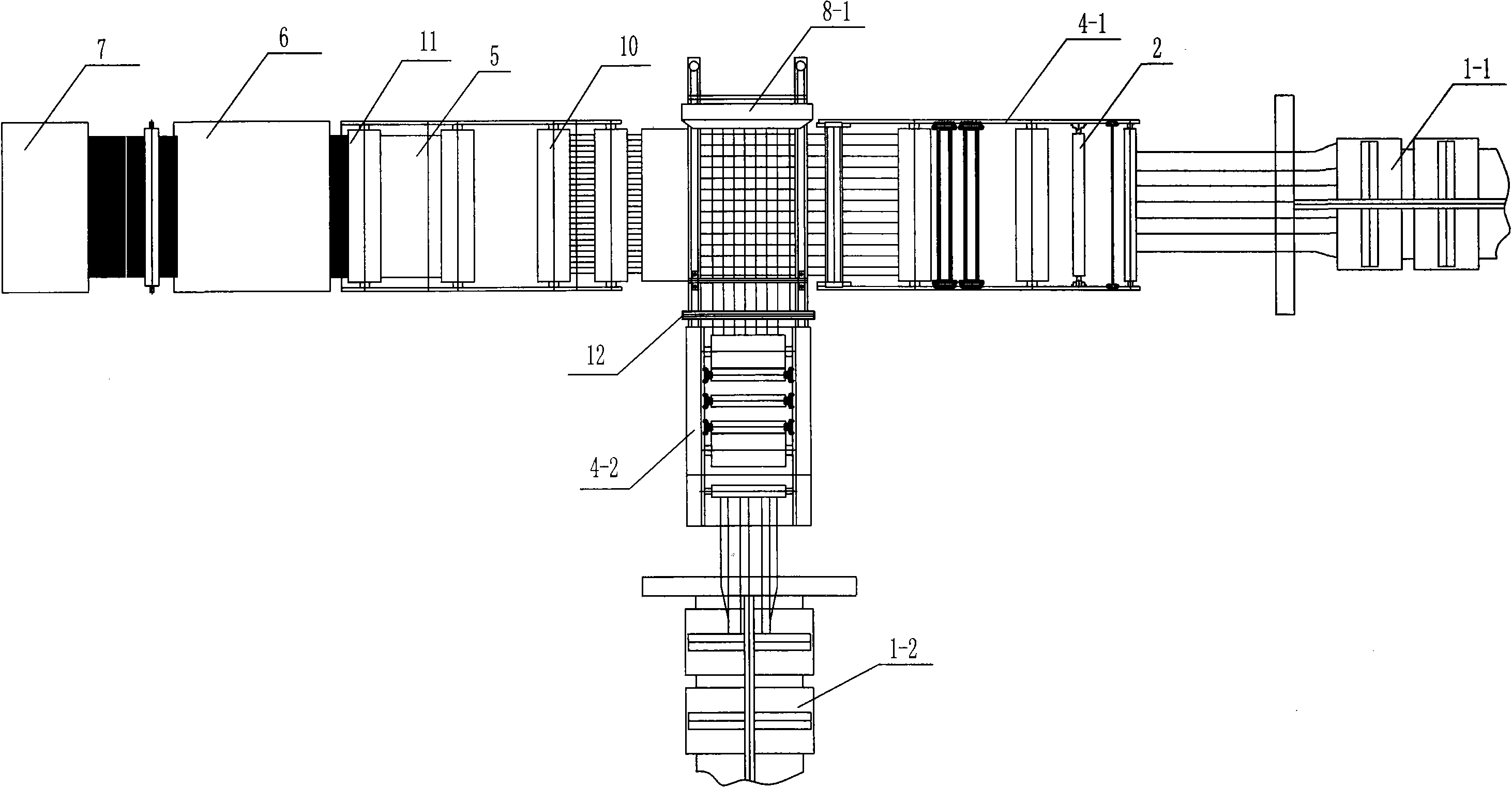

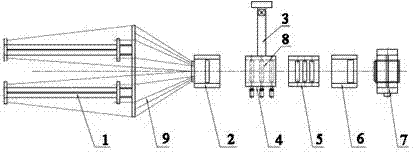

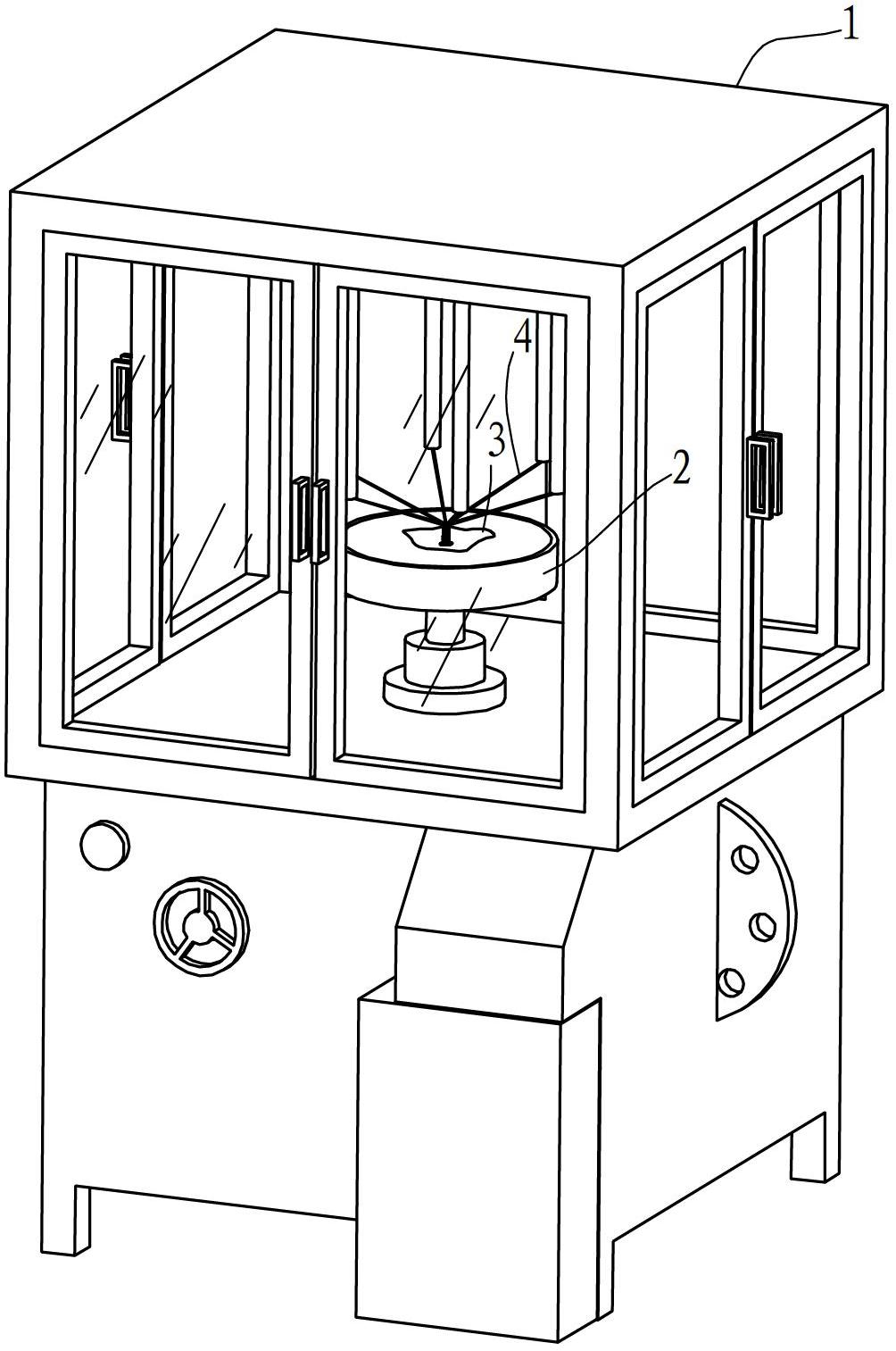

Processing equipment of longitude and latitude overlapping non-weaving composite material

InactiveCN101831813AImprove physical and mechanical propertiesImprove mechanical and physical propertiesTextiles and paperFlexural strengthEngineering

The invention relates to a longitude and latitude overlapping non-weaving composite material, in particular to processing equipment of the longitude and latitude overlapping non-weaving composite material. The processing equipment comprises a creel, a dragging silk distribution device, a tension regulator, a wire feeder, a glue spraying device, an immersion device, a drier, an anti-static device and a winder which are successively connected in order. The product produced by the bidirectional equipment at 0-90 degrees adopted by the invention can solve the problem that fiber can not be completely immersed in thermoplastic resin to ensure that fiber is fully immersed in an immersion groove; thus mechanical properties and certain physical properties, such as tensile strength, flexural strength and the like of the product can be greatly improved; particularly, the bidirectional product at 0-90 degrees has same mechanical property and physical property in lateral direction and longitudinal direction so as to meet the high property requirement of various products.

Owner:江苏安格特新材料科技有限公司 +1

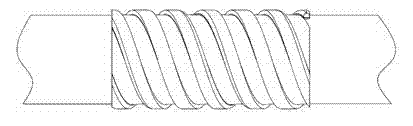

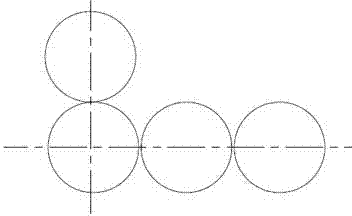

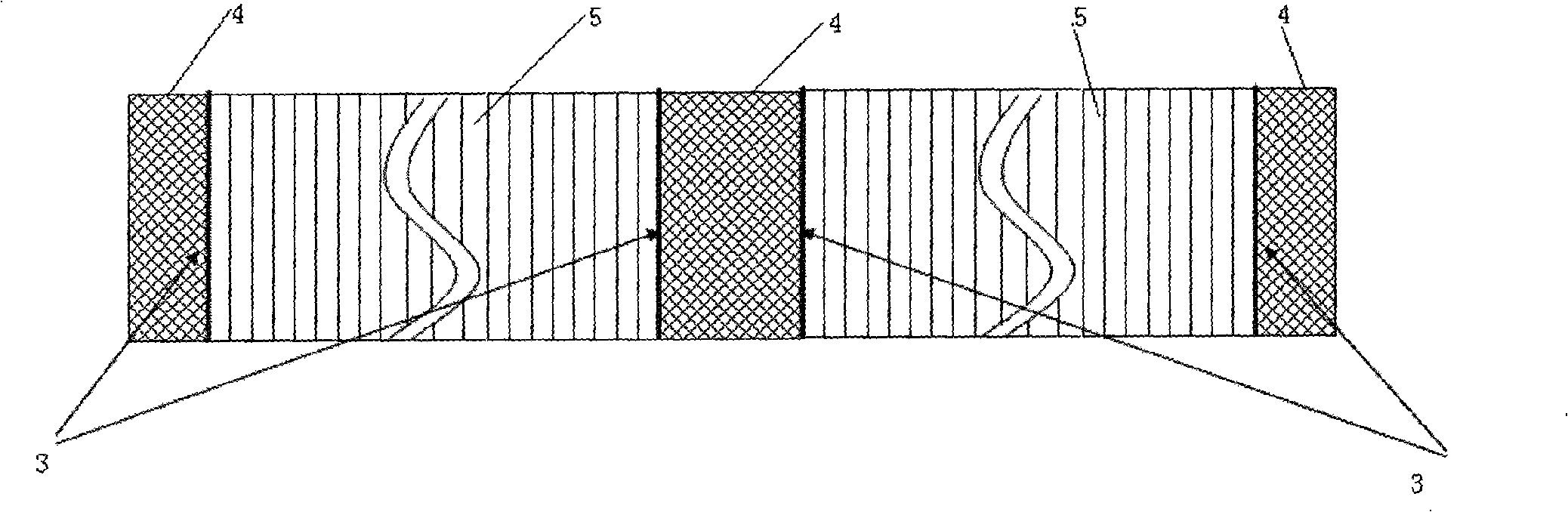

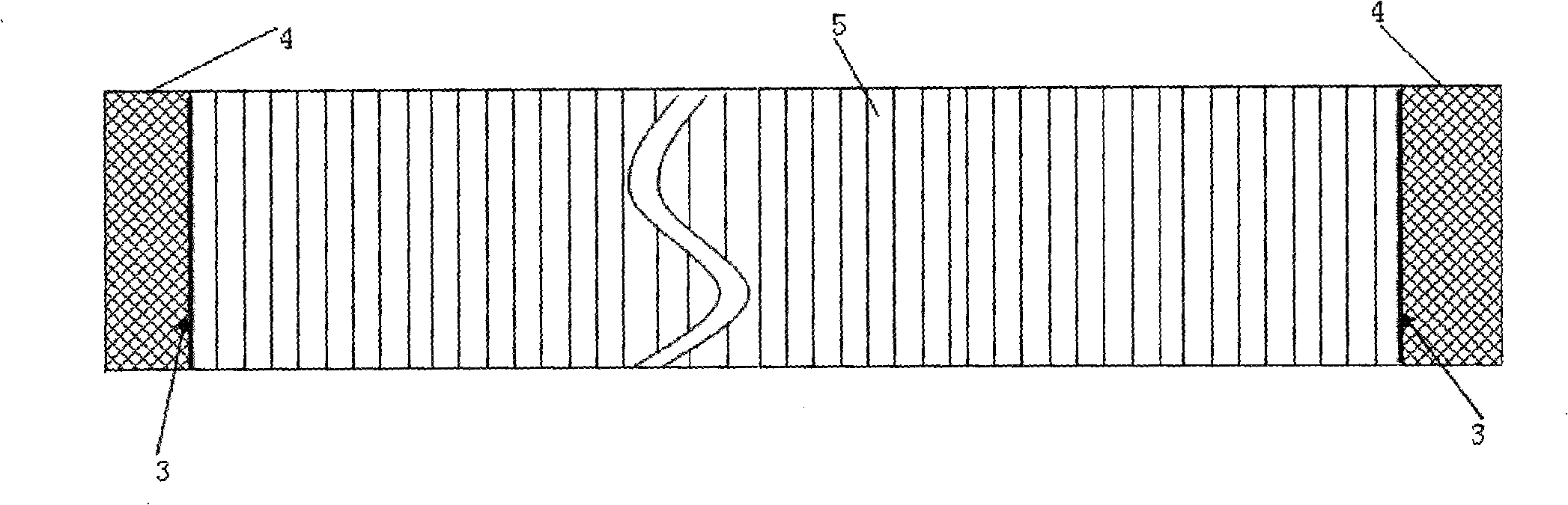

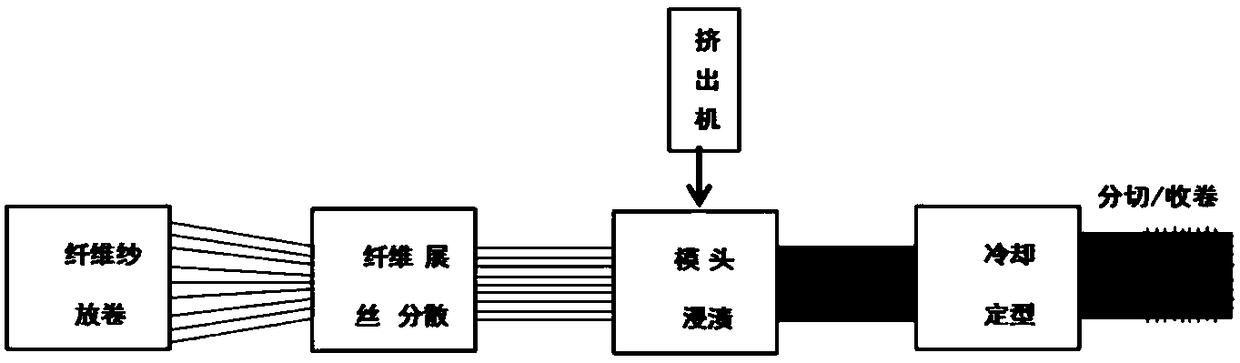

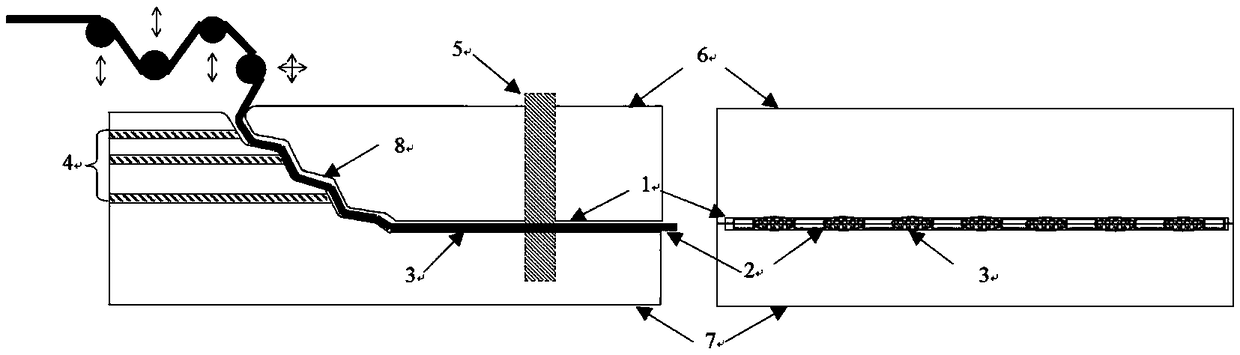

Forming device and forming method of continuous fiber reinforced thermoplastic resin preimpregnation sheet material

The invention discloses a forming device and a forming method of a continuous fiber reinforced thermoplastic resin preimpregnation sheet material. The forming device comprises a creel, a fiber pre-dispersing device, a single-screw extruder, a screw-type smelting immersing mold, a secondary rolling device, a cooling traction machine and a coiling machine; 1 to 3 screw immersing rolls are arranged in the screw-type smelting immersing mold, a screw groove is formed in the outer surface of each screw immersing roll, and each screw immersing roll is driven by a motor to rotate in the screw-type smelting immersing mold. When the screw immersing rolls rotate, resin flows along the screw groove so as to immerse the fiber in the longitudinal direction, due to the extrusion effect, melt can flow along the direction perpendicular to the fiber, and the transverse immersion can be realized. The continuous fiber reinforced thermoplastic resin preimpregnation sheet material prepared by utilizing the forming device is good in impregnation effect, high in impregnation efficiency and good in production stability, so that a product excellent in performance can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

Paper-making-stage wood pulp plate denaturalization producing technique

ActiveCN101148835AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making wood pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-8 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

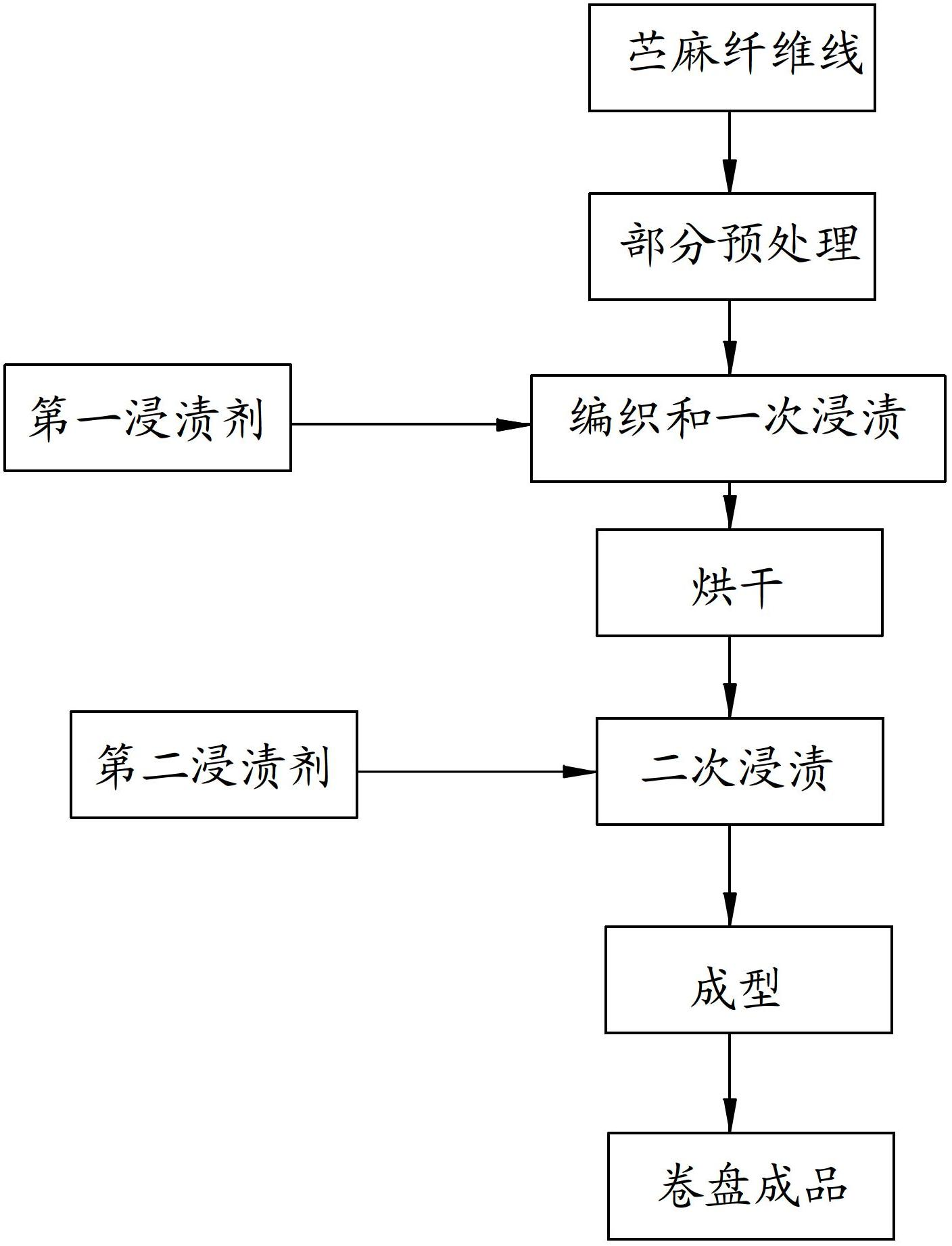

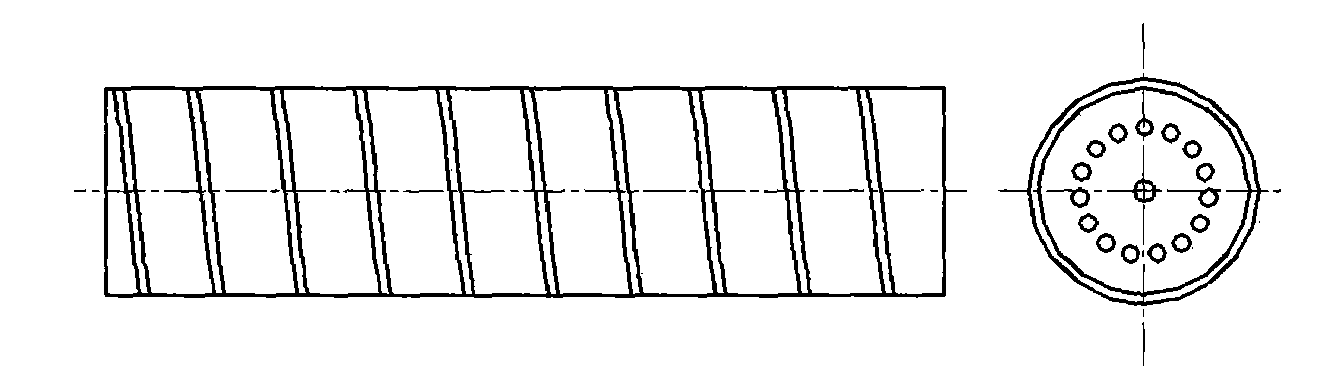

Fiber packing preparation method

ActiveCN102678922AFully impregnatedImprove compactnessEngine sealsVegetal fibresLubricationParaffin oils

A fiber packing preparation method is characterized by comprising the following steps: firstly, on a knitting machine, primary impregnation for fiber threads is preformed through first impregnant on weaving edges, so that the weight of the fiber threads gains 30% to 40%; secondly, the fiber threads after impregnation are taken out, and dried for 4 to 6 hours at the temperature of 90 to 110 DEG C; thirdly, the secondary impregnation is performed through adopting second impregnant for 10 to 20 minutes, and the second impregnant includes paraffin oil; and finally, the forming is carried. Compared with the prior art, the fiber packing preparation method provided by the invention has the advantages as follows: the impregnant is divided into two parts for the twice independent impregnation from start to finish, so that the impregnation is completer, and the improvement on the inner compactness of the packing is facilitated; meanwhile, the paraffin oil is separated out from the lower part at the ordinary temperature, and can be unceasingly separated out for lubrication when the temperature rise reaches to a certain extent during the practical application of the packing, so that the separated out paraffin oil is increased unceasingly to improve the lubrication under the condition that plenty of friction heat is generated, and the service life of the packing is greatly prolonged.

Owner:慈溪博格曼密封材料有限公司

High-performance aerogel composite material, preparation method and equipment thereof

The invention provides a high-performance aerogel composite material, and a preparation method and equipment of the high-performance aerogel composite. The aerogel composite material comprises a silicon dioxide aerogel and a fiber material, wherein the silicon dioxide aerogel uses tetramethyl orthosilicate and water as raw materials and an alcohol solvent as a solvent to prepare a silica sol, and no gel catalyst is added in the silica sol. The equipment comprises a reaction part and a circulated cooling part. The method comprises the steps of preparing the sol, dipping glue, standing, gelatinizing, aging gel, dewatering, drying and the like. With the adoption of the method, materials with planar or abnormal shapes and multiple sizes can be conveniently and selectively prepared, the gelation time is controllable, no catalyst is needed, the kinds of raw materials are few, the operation is simple and convenient, and the environmental pollution is low. The material is excellent in heat-insulating property and has a wide application prospect in the fields of the civil industry, the space flight and aviation industry and the military industry.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Paper-making-stage broad-leaved wood pulp plate denaturalization producing technique

ActiveCN101148834AReduce manufacturing costReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHardwoodViscose fiber

The present invention provides denaturating production process of paper-making hardwood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making hardwood wood pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5.5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

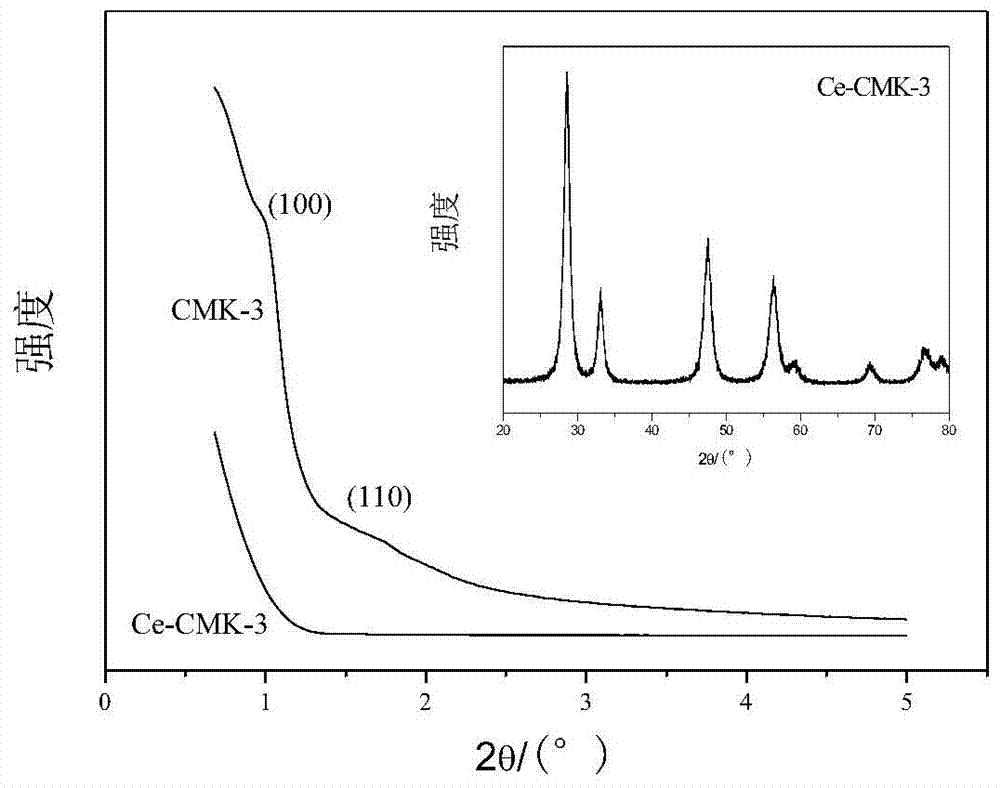

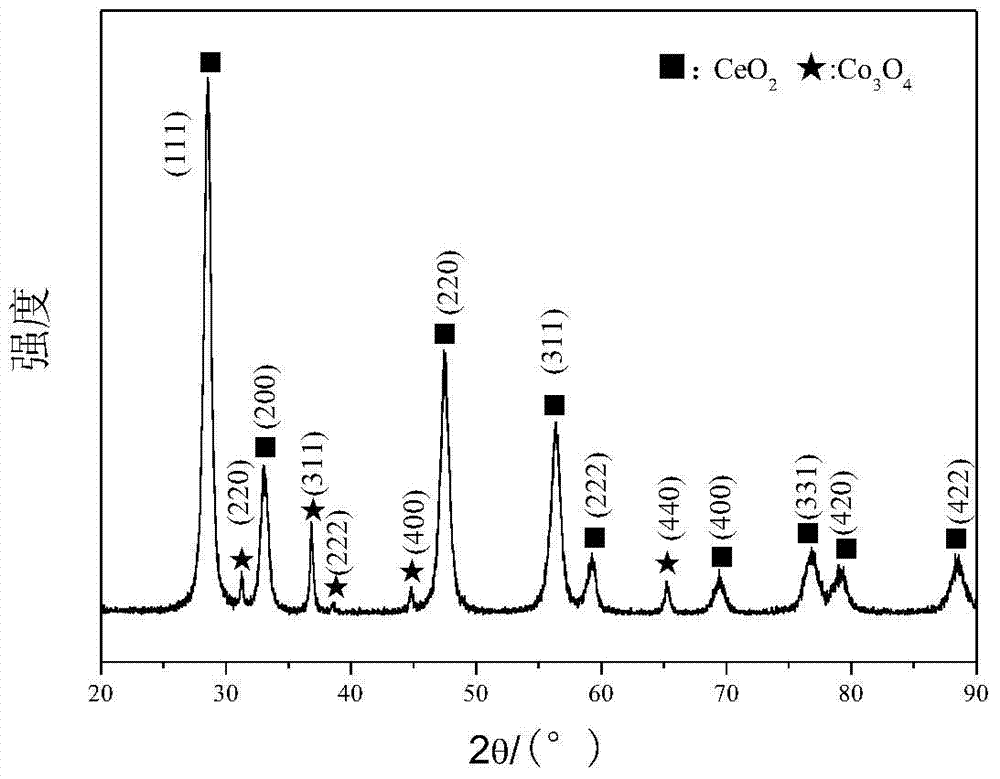

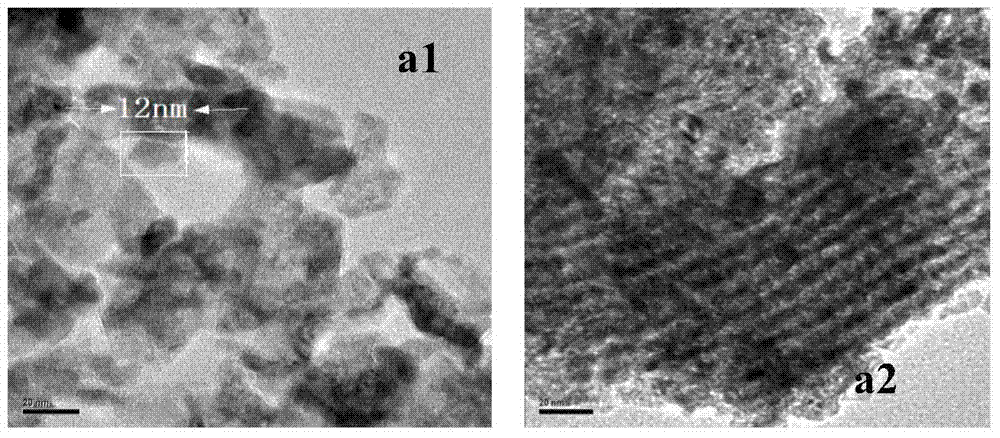

Mesoporous Co/CeO2 catalyst for hydrogen preparation reaction by reforming ethanol vapor and preparation method thereof

InactiveCN103752318AStrong ability to resist carbon depositionLarge specific surface areaMaterial nanotechnologyHydrogenHydrogenHigh energy

The invention relates to a mesoporous Co / CeO2 catalyst for a hydrogen preparation reaction by reforming an ethanol vapor and a preparation method thereof. The size of the particle diameter of a mesoporous CeO2 carrier is 12nm or so; the specific surface area of the mesoporous CeO2 carrier can reach up 177m<2> / g; the pore structures of the mesoporous CeO2 carrier are sequentially arranged in a short range; the bore diameters of the mesoporous CeO2 carrier are mainly distributed within 3nm or so; cobalt (Co) taken as an active component is carried on the mesoporous CeO2 carrier; the carrying quantity of CoO2 is 5% to 20% of the mass of the catalyst. The mesoporous CeO2 prepared by using a hard template method has the large specific surface area, the short-range and sequential pore structures and the uniformly distributed bore diameters. The mesoporous CeO2 prepared from mesoporous carbon CMK-3 is mainly used for exposing a high-energy crystal face (110) and has a better oxygen storing / releasing capacity.

Owner:INNER MONGOLIA UNIV OF TECH

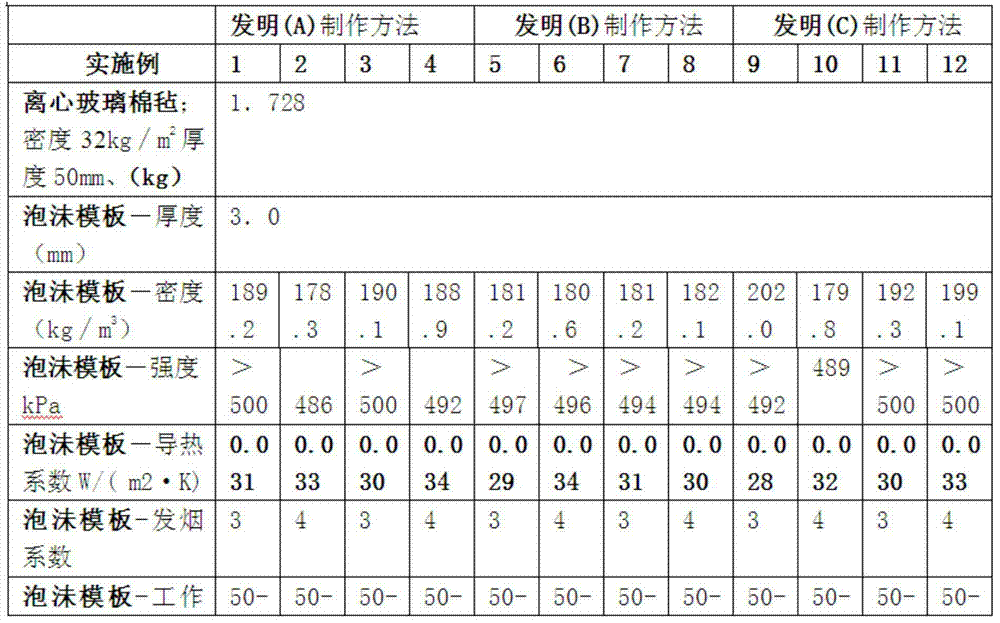

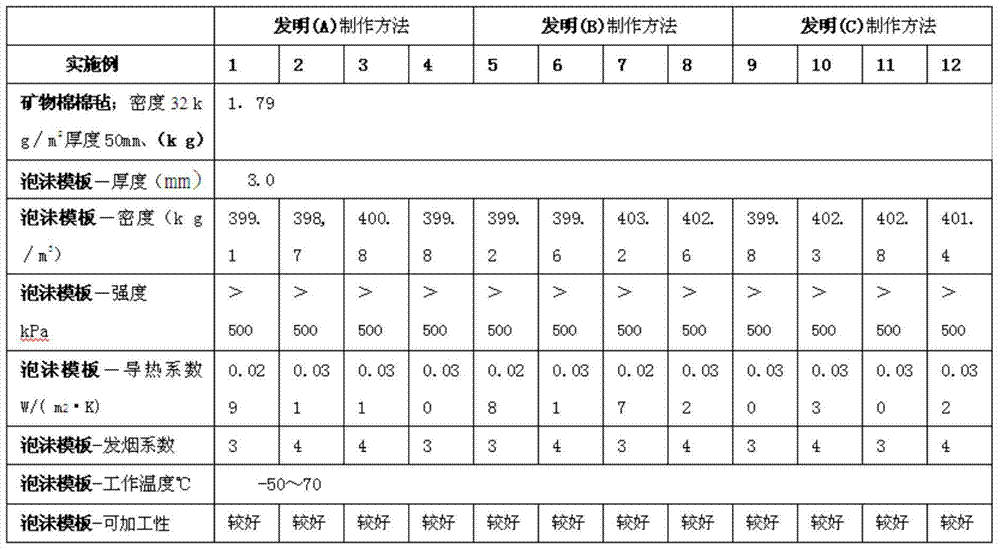

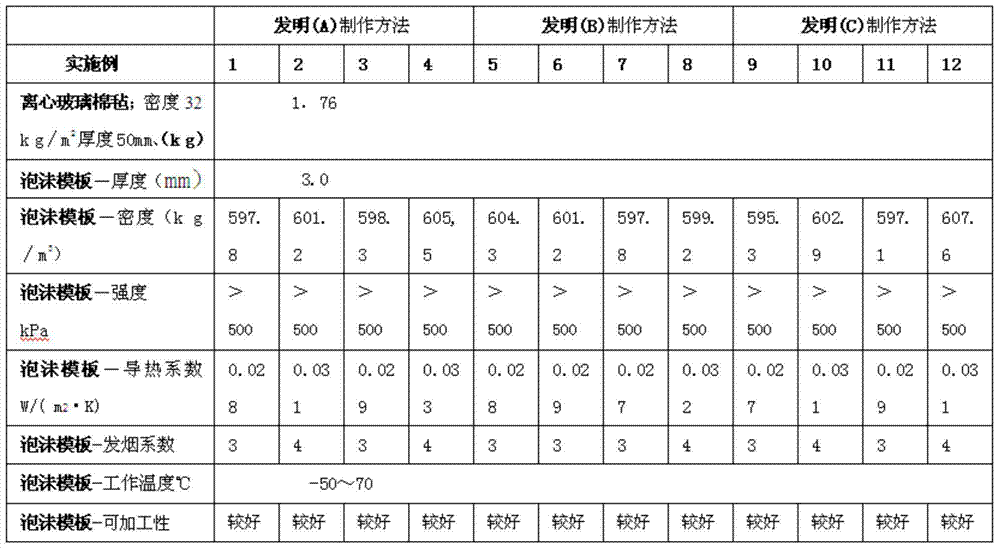

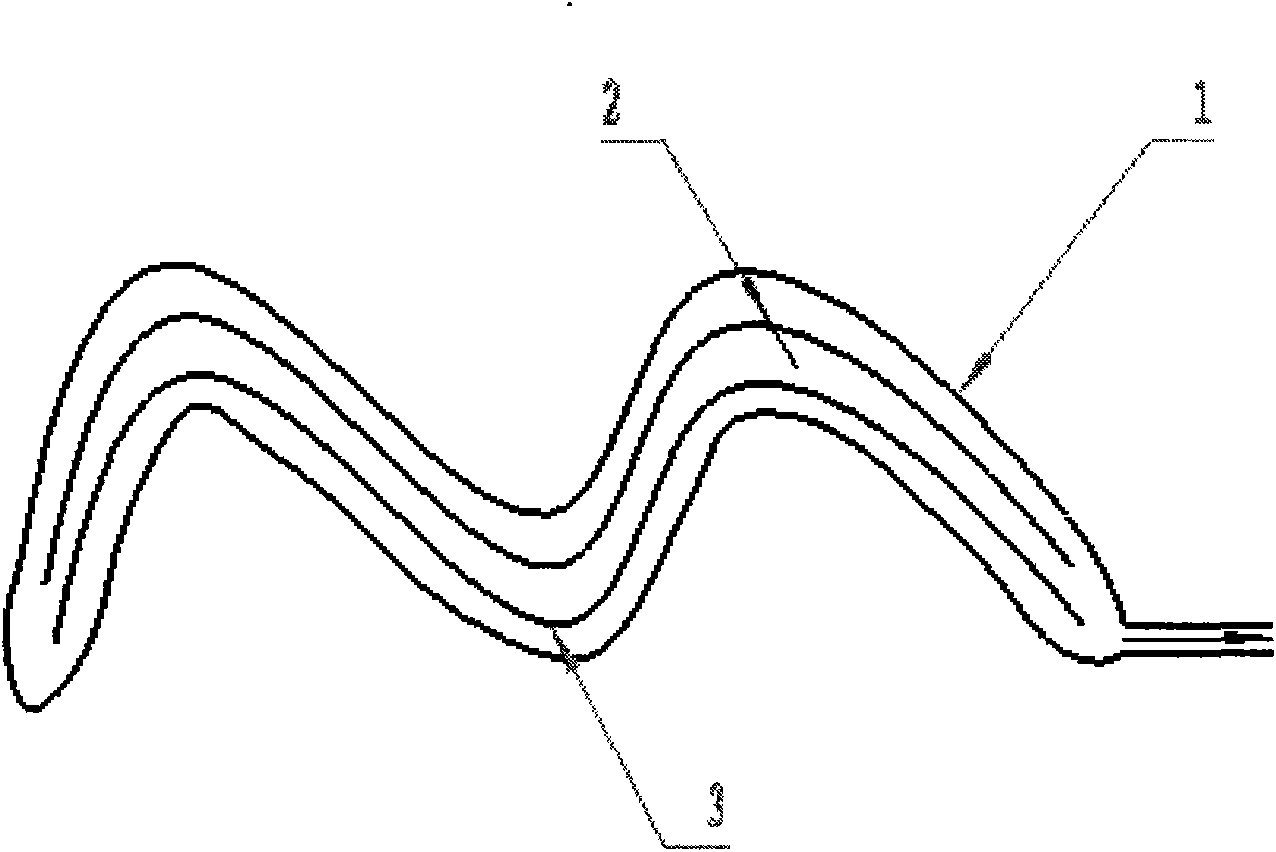

Enhanced foam stay-in-place building concrete template and manufacturing method thereof

ActiveCN104744886AFully impregnatedDip evenlyForming/stuttering elementsSustainable buildingsThermal insulationSurface-active agents

The invention relates to an enhanced foam stay-in-place building concrete template and a manufacturing method thereof. The enhanced foam stay-in-place building concrete template is an enhanced hard phenolic aldehyde foam template which is foamed and formed by taking phenolic resin and a glass wool or mineral wool blanket as the basic materials under the action of various additives including a glass wool or mineral wool fibre surface treatment agent, a foaming agent, a surface active agent, a curing agent, a modifying agent and a penetrating agent uniformly blended into the phenolic resin in advance. The enhanced foam stay-in-place building concrete template has a micro-porous structure of independent bubbles having uniformity, compactness and high closed pore rate; furthermore, because of the enhancement effect due to the fact that the micro-porous structure is bond to glass wool or mineral wool fibre in foam compactly and uniformly, the foam template not only has the excellent characteristics of phenolic aldehyde foam, such as fire resistance and heat insulation property, but also has higher compressive strength and impact resistance; therefore, the strength requirements of the building template can be satisfied; the construction processes of dismantling a poured concrete template and installing a thermal insulation layer in the construction process are avoided; the construction period and the cost are effectively saved; and the environment-friendly purposes of saving energy and reducing emission are achieved.

Owner:宁波与翼新材料科技有限公司

Vacuum rush gum forming method of fiber-reinforced resin matrix compound material

The invention relates to a resin flowing compound material forming method which is aided by vacuum. A fiber-reinforced material is tailored and then paved in a mould cavity according to the design of layer quantity and structure of a product. Resin and firming agent are prepared into dipping glue solution which is evenly coated in the mould cavity and ensured to permeate the fiber-reinforced material. A mould is sent into a vacuum bag which is sealed and then vacuumized till a vacuum bag film closely clings to the surface of the reinforced material supported by the mould. A panel with elastic planes is used for expel foams and surplus glue solution in the vacuum bag to the edges outside the mould cavity. Then, in the conditions of normal temperature or heating and vacuum, the product gradually undergoes solidification and demoulding. The method can improve the mechanical properties and the surface quality of the compound material product, reduce the cost on production apparatuses and auxiliary materials and simplify the method operation.

Owner:SHENZHEN OYA CARBON TECH +1

Paper-making-stage high viscosity wood pulp plate denaturalization producing technique

ActiveCN101148832AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscosity

The present invention provides denaturating production process of paper-making high viscosity wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making high viscosity wood pulp sheet in a paging device, alkali dipping in 8-18 % concentration alkali solution in a dip vat to form 2.5-4.5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Preliminary dip material for wind-driven generator impeller vane

ActiveCN101293970AFully impregnatedLow viscosityMachines/enginesWind energy generationWind drivenPolyester

The invention relates to the field of polymer materials and particularly relates to a prepreg used for blades of a wind power generator. The prepreg is formed by using release paper as a carrier, applying an epoxy resin matrix to the carrier, heating and melting the epoxy resin matrix, and impregnating the same with a fiber reinforcement material. The weight content of the epoxy resin matrix in the prepreg is more than or equal to 25% but less than or equal to 60%. The fiber reinforcement material is multi-axial warp-knitted fabric. The mass per unit area of the fiber reinforcement material is more than or equal to 400 g / m<2> but less than or equal to 2000 g / m<2>. The fiber reinforcement material is the warp-knitted fabric formed by knitting fiber of plus or minus 45 DEG with polyester yarns or covering one surface of the warp-knitted fabric with a fibrofelt before knitting. Alternatively, the fiber reinforcement material is the warp-knitted fabric formed by knitting fiber of plus or minus 45 DEG and 0 DEG with polyester yarns, and optionally one surface of the warp-knitted fabric is covered with a fibrofelt before knitting.

Owner:WEIHAI GUANGWEI COMPOSITES

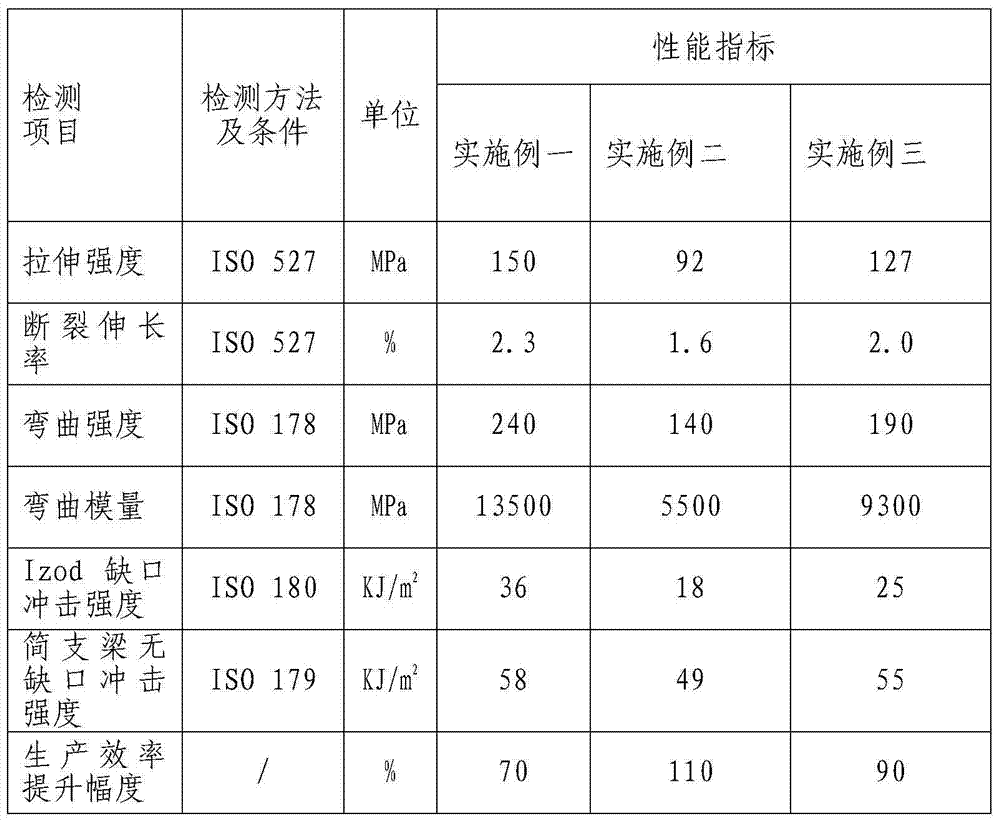

Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

The invention relates to a material and a preparation method thereof, and particularly relates to a long glass fiber reinforced polypropylene material adopting a foaming technique and a preparation method thereof, belonging to the technical field of materials. The long glass fiber reinforced polypropylene material comprises the following components by mass percent: 30-75wt% of polypropylene, 20-60wt% of long glass fiber, 0.5-5wt% of chemical foaming agent and 1-5wt% of compatibilizer. The viscosity of the resin is further reduced by adopting a micro-foaming technology, meanwhile, the chance that a glass fiber strong dispersing device reduces or avoids direct contact of a glass fiber bundle and a roller or a convex part is reduced, the damage to the glass fiber is reduced, and the traction resistance of a material bar is reduced. The long glass fiber reinforced polypropylene material has the beneficial effects that the product performance, quality stability and production efficiency are improved when the impregnation effect on the glass fiber caused by polypropylene resin is ensured.

Owner:NANJING JULONG SCI&TECH CO LTD

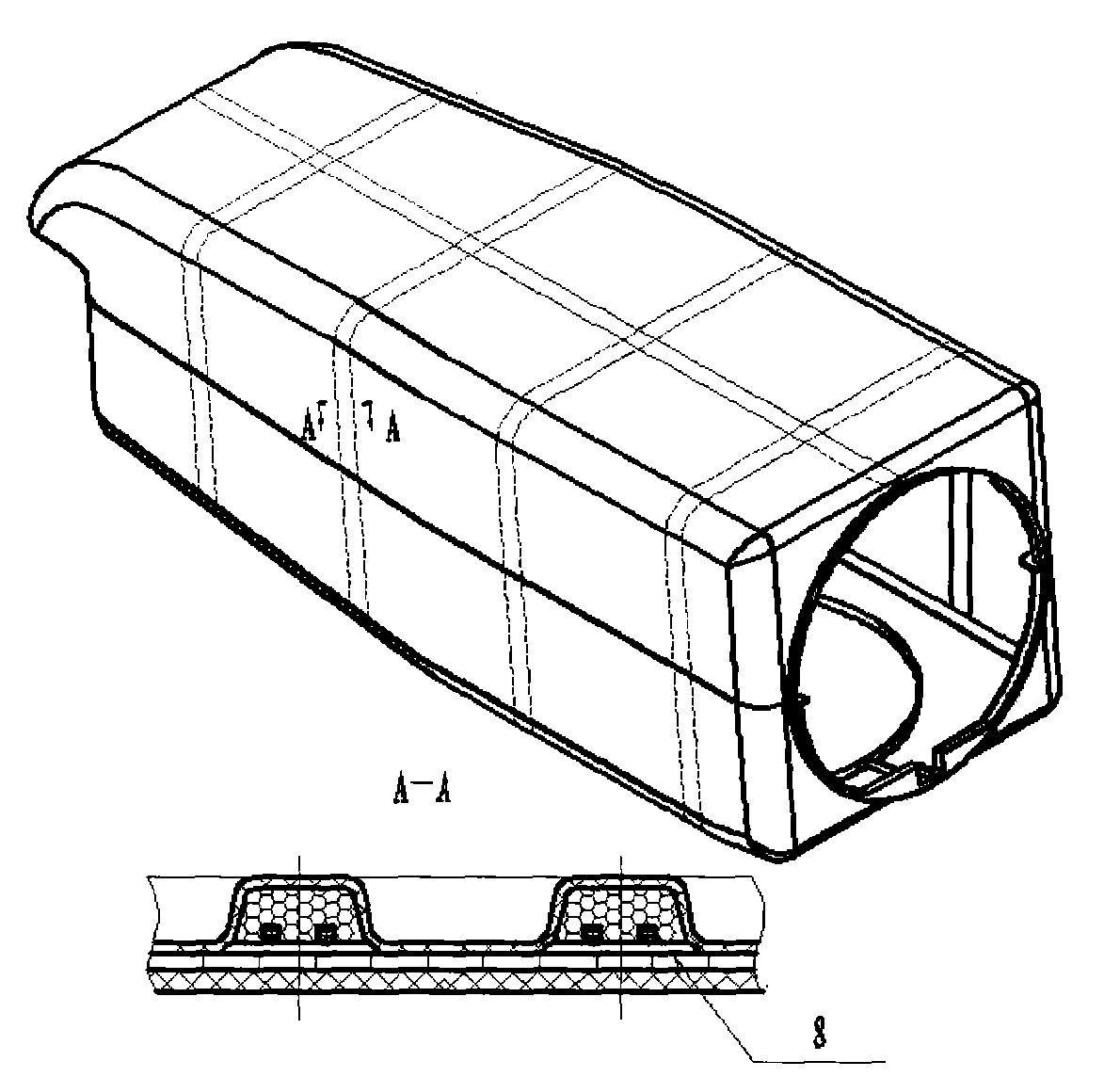

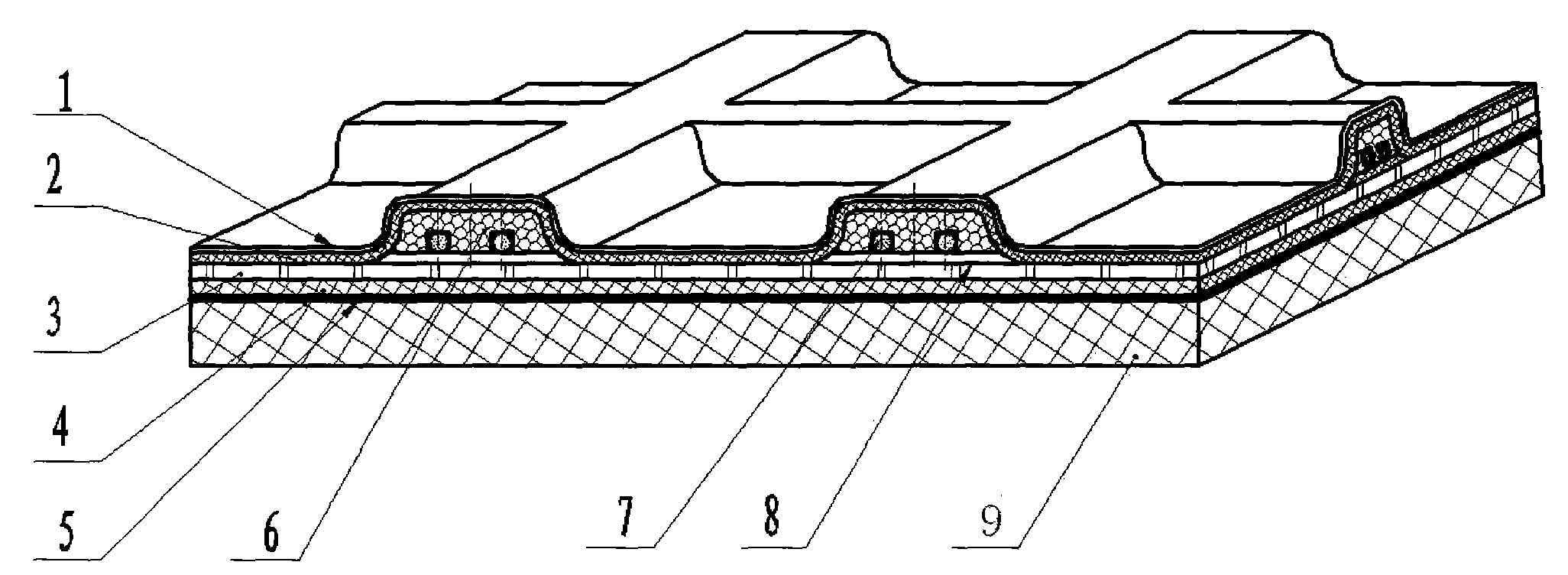

Grid type reinforcing structure

InactiveCN101649817AIncrease stiffnessReduce vibrationFinal product manufactureMachines/enginesThin shellsCross connection

The invention relates to a grid type reinforcing structure of a cabin cover of a large wind power generator set, comprising a shell plate of the cabin cover, an inner core of a reinforcing rib, a cross connection block, resin guiding tubes and a diversion band. A light sandwich layer is arranged between an outer plate and an inner plate; a grid-shaped diversion layer, the inner core of the reinforcing rib and the cross connection block are arranged on the upper surface of the light sandwich layer; cutting bottoms are provided with square slots; the resin guiding tubes are arranged in the square slots; and a surface coating is coated on the surface of the outer plate. The outer plate and a reinforcing frame are simultaneously formed by a vacuum assistant forming (AVRI) technology, thereby largely simplifying the production technology. The cabin cover with the structure has the characteristics of high integrity, thorough immersion, dense structure, high strength, good rigidity, one-stepformation and the like. The grid type reinforcing structure can be widely used for the cabin cover of the large wind power generator set and similar large thin shell products.

Owner:秦皇岛耀华装备集团股份有限公司

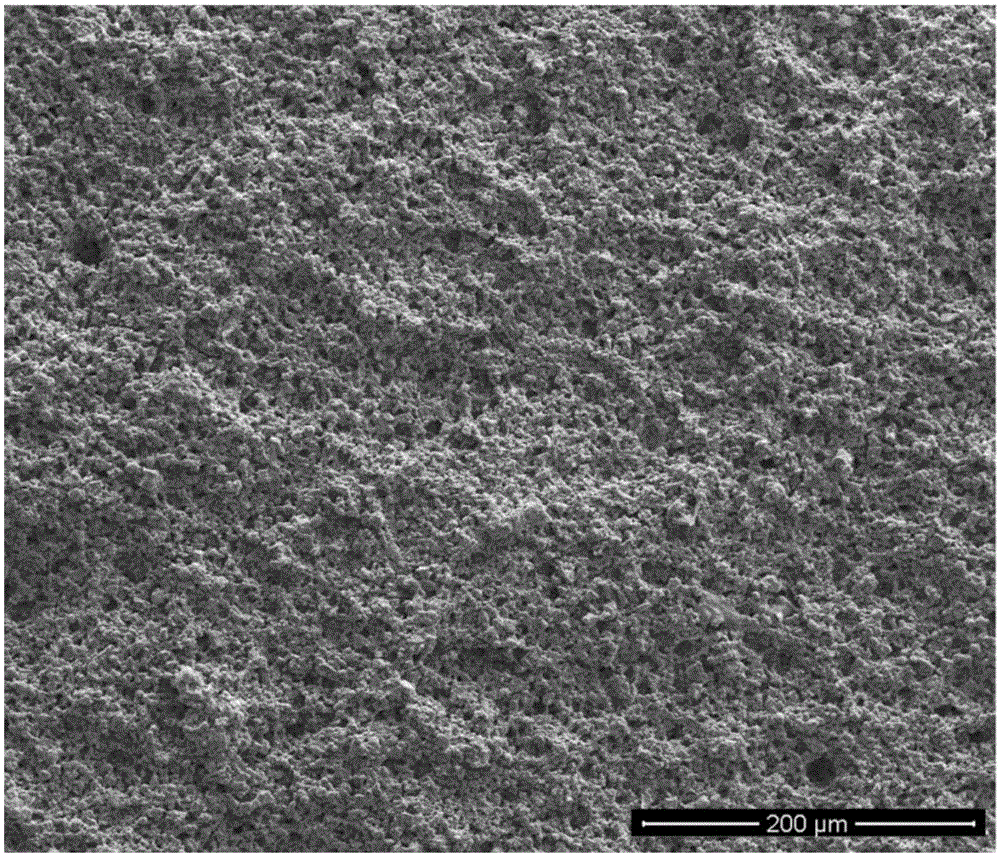

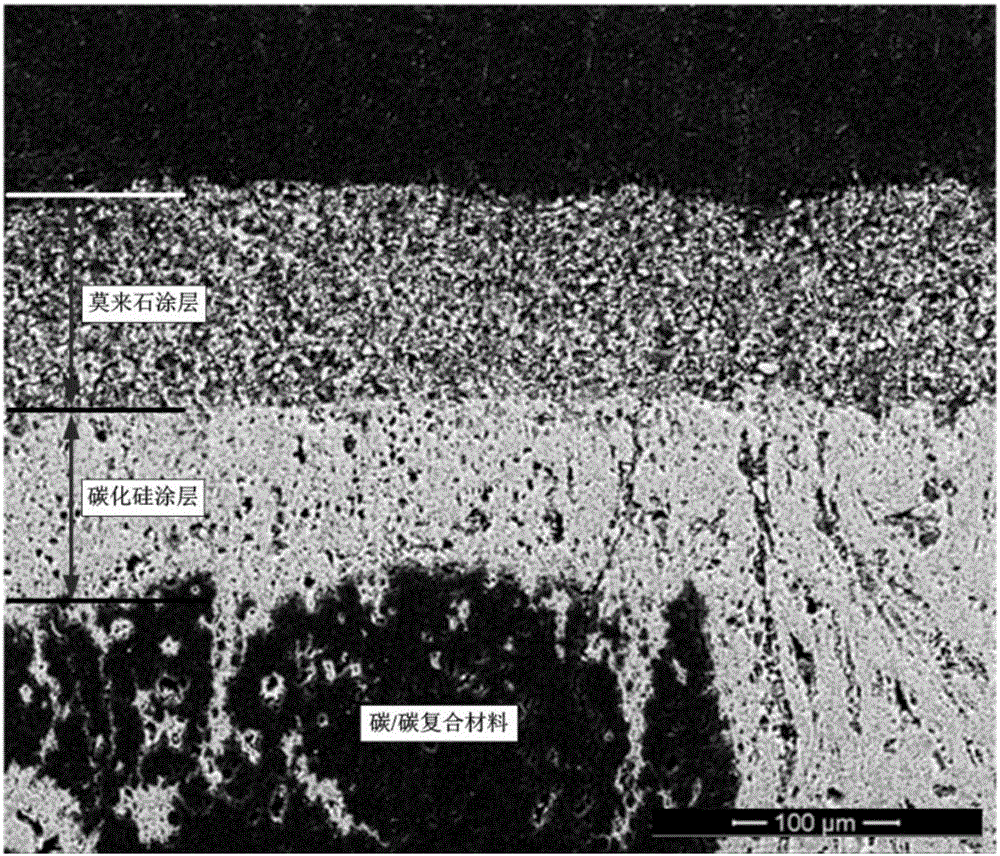

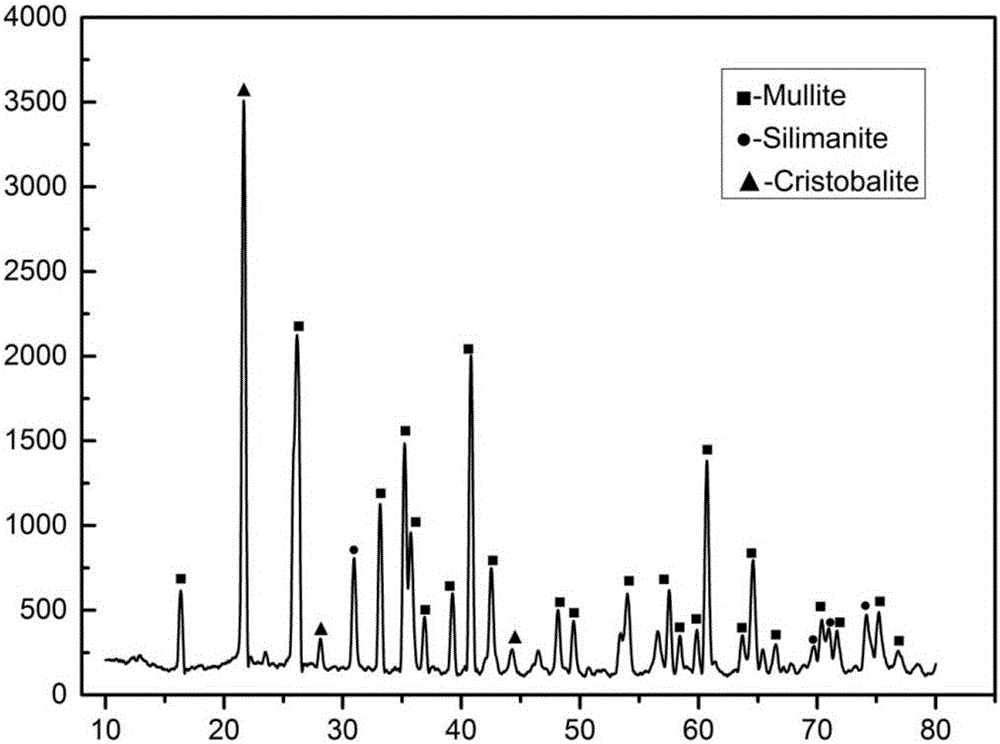

Preparation method of mullite oxidation resistant coating

The invention relates to a preparation method of a mullite oxidation resistant coating, particularly to a method for preparing a mullite / SiC bilayer-structure oxidation resistant coating on the surface of a carbon / carbon composite material. The preparation method comprises the following steps: pre-calcining mullite powder A and mullite precursor powder B according to the mass ratio of (4-6):1 to prepare pre-calcined mullite powder A and mullite precursor powder B, preparing a coalescing agent and a drying inhibitor according to certain ratio, uniformly mixing the pre-calcined mullite powder A, the pre-calcined mullite precursor powder B, the coalescing agent and the drying inhibitor to obtain a sizing agent, dipping a matrix in the sizing agent, performing sizing agent coating by adopting the dip-coating technology, and after the sizing agent coating, calcining at 1480-1515 DEG C to obtain the mullite oxidation resistant coating. According to the invention, the technology is simple, the raw material is cheap and available, the industrial production is facilitated, and the obtained coating has the advantages of high uniformity and compactness, excellent binding property, and high high-temperature oxidation resistant capacity.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Preparation method for preparing surface SiC coating of silicon carbide-based composite material

The present invention relates to a preparation method for preparing the surface SiC coating of a silicon carbide-based composite material and belongs to the technical field of oxidation protection. According to the method, silicon powders are embedded in the surface of the silicon carbide-based composite material. After the high-temperature vacuum infiltration process, the composite material is embedded in a melt. After that, the composite material embedded in the melt is placed in an excess carbon source, and is subjected to the high-temperature heat treatment again. After residues on the surface of the composite material are removed, the composite material with the SiC coating can be obtained. According to the technical scheme of the invention, the coating is prepared through the reactive infiltration process. Therefore, during the preparation of the coating, the density of the base material can be further improved at the same time. the excess melt is removed by the carbon source, so that the formed SiC coating is uniform and smooth.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

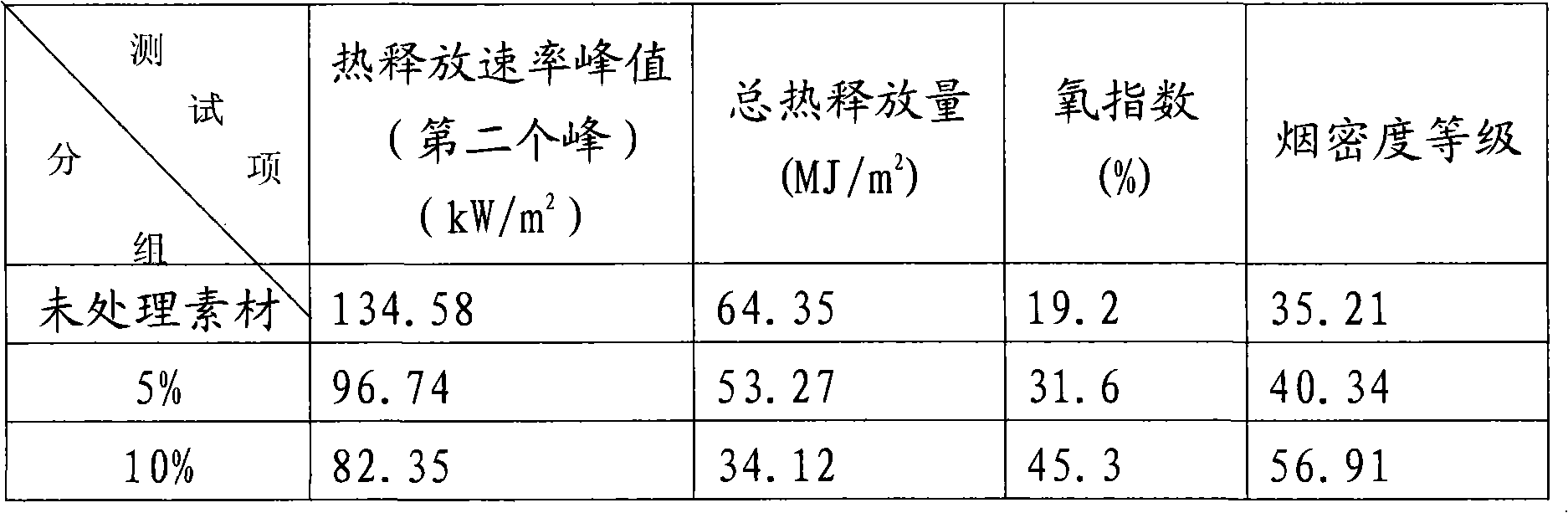

Preparation method of phosphate timber fire retardant and method for processing timber by using fire retardant

ActiveCN101982305AImprove flame retardant performancePromote expansionPressure impregnationOpen tank impregnationCarbon layerOrganic solvent

The invention provides a preparation method of phosphate timber fire retardant and a method for processing timber by using the fire retardant. The fire retardant prepared by the invention is expansible annular phosphate timber fire retardant which contains an acid source, a carbon source and a gas resource, has the advantages of good expansiveness, compact carbon layer and certain intensity, and has good antiflaming effect proved by the measurement of an oxygen index and smoke density and the analysis of a dual cone calorimeter. The fire retardant is insoluble in water but soluble in organic solvent. The method for processing timber by fire retardant has the advantages of complete dipping, large dipping depth and lasting antiflaming effect, the dipping time is shorter than common dipping time, and time is saved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

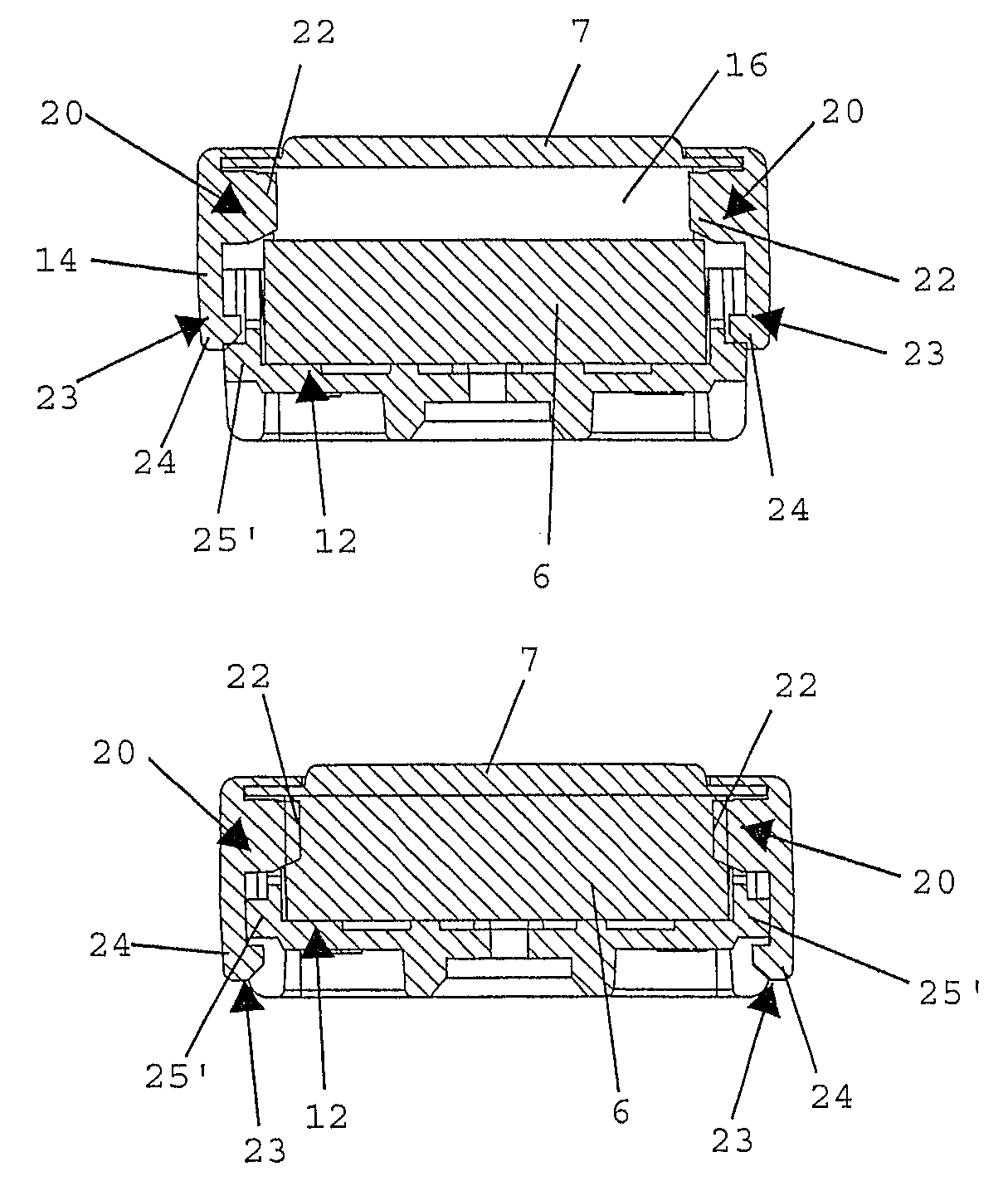

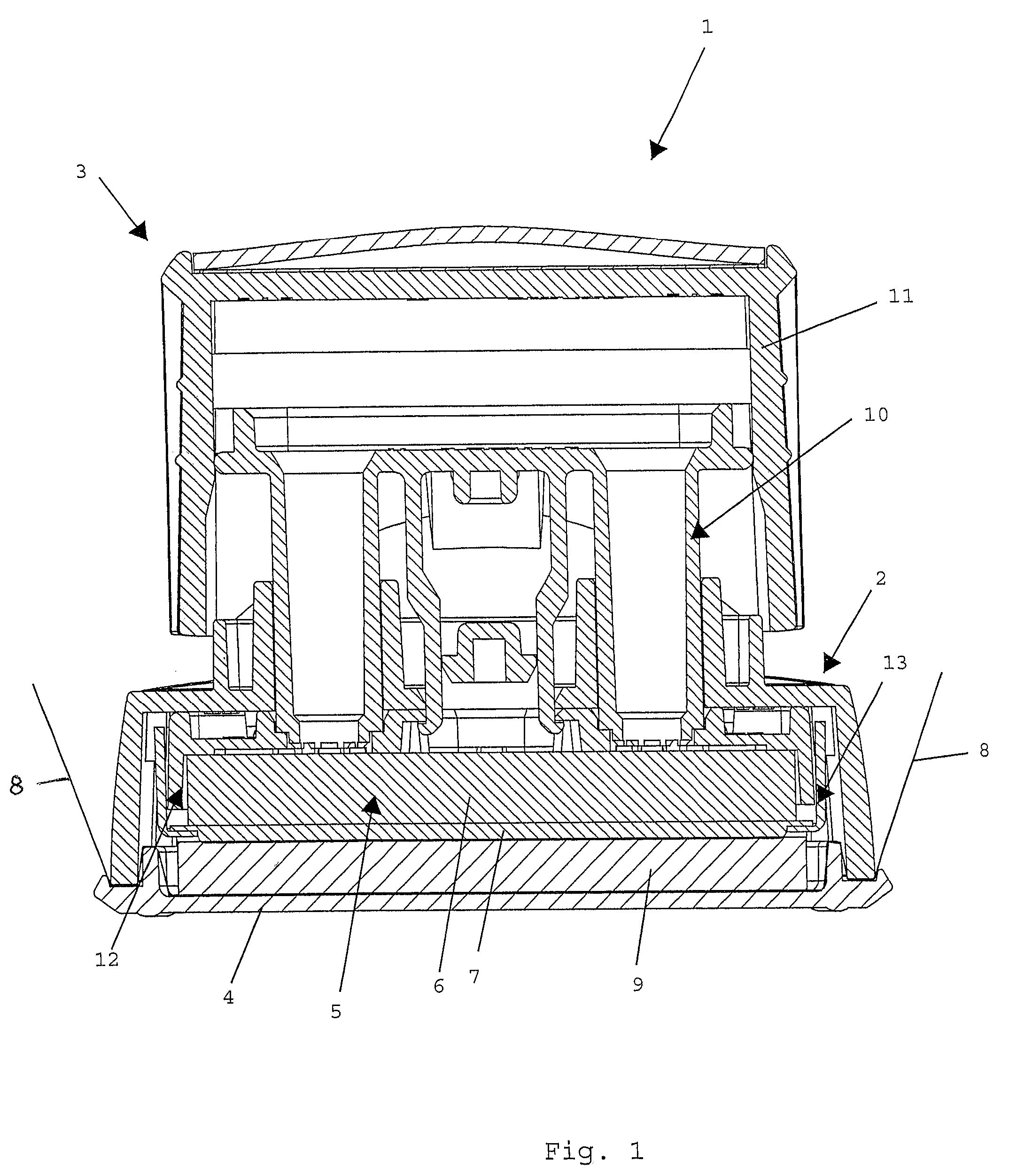

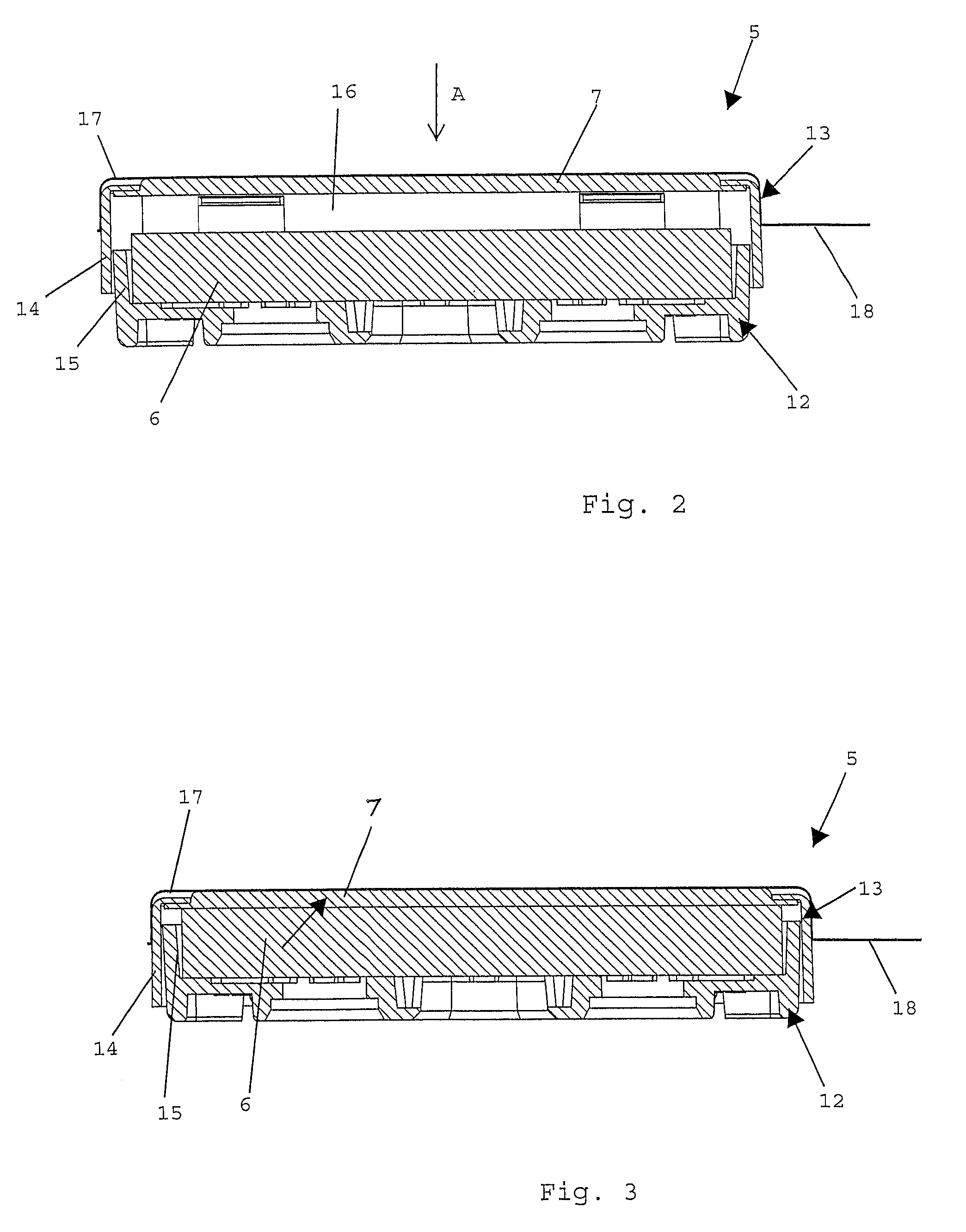

Ink storing unit for a hand-operated stamp

ActiveUS8925454B2Permanently reliable fixation of the storage body within the retainerAvoid damageCylinder pressesStampingMechanical engineeringEngineering

Owner:COLOP STEMPELERZEUGUNG SKOPEK GMBH & CO KG

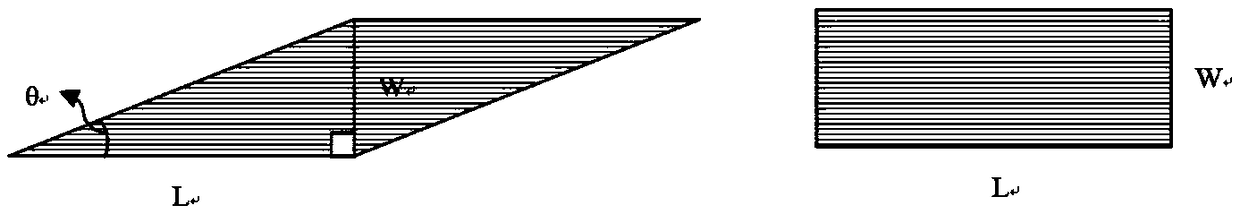

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

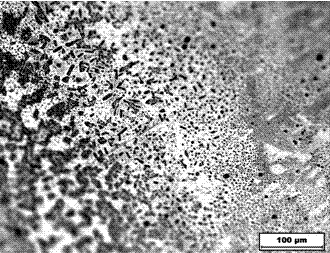

Method for preparing iron-based surface composite material by virtue of in-situ synthesis

The invention relates to a metal-based composite material and specifically relates to a method for preparing an iron-based surface composite material by virtue of in-situ synthesis. The method disclosed by the invention comprises the following steps: uniformly mixing reactant Al and Fe2O3 (or Fe2O3 plus Cr2O3) powder, forming and pre-sintering to form particles, and then preparing a pre-formed body to ensure the penetration of molten iron or molten steel in the reactant pre-formed body, so that the flexible design of a composite layer is realized, the in-situ chemical reaction among reactants is initiated through the heating action of the molten iron, a high-hardness reinforcement phase is obtained, the molten iron at the higher temperature can be ensured by reaction heat release, and material densification can be realized by continuous infiltration of the molten iron or the molten steel into the reactant pre-formed body and among reaction products.

Owner:JIANGSU UNIV

Electrocatalysis oxidation pulping method for purified cotton and production system equipment

InactiveCN102392377AReduce processing costsReduce energy consumptionPulping with inorganic basesBlack liquorPulp and paper industry

An electrocatalysis oxidation pulping method for purified cotton and production system equipment belong to the technical field of purified cotton production. The method adopts the technology that bales of cotton linter are opened by an opener and then are made into a linter quilt through a combined cotton feeding device, the linter quilt enters into an impregnating machine through double clamp belts, an on-site hydroxyl free radical active oxygen and oxygen preparing method is adopted to continuously supply a pulping agent, the linter quilt and a pulping assistant are fully impregnated and then enter into an electrocatalysis oxidized still, pulp enters into a retention reactor that is filled with steam with a certain pressure, produced half stuff enters into a replacement and washing section and an extrusion and drying stage, and purified cotton cellulose products are obtained after the drying operation. Through the adoption of the method and the production system equipment, the effects of no black liquor, resource economy and energy consumption reduction can be achieved in the pulping process; and the pulping yield is high while clean and continuous pulping can be realized.

Owner:扬州市江都区明月机械有限公司

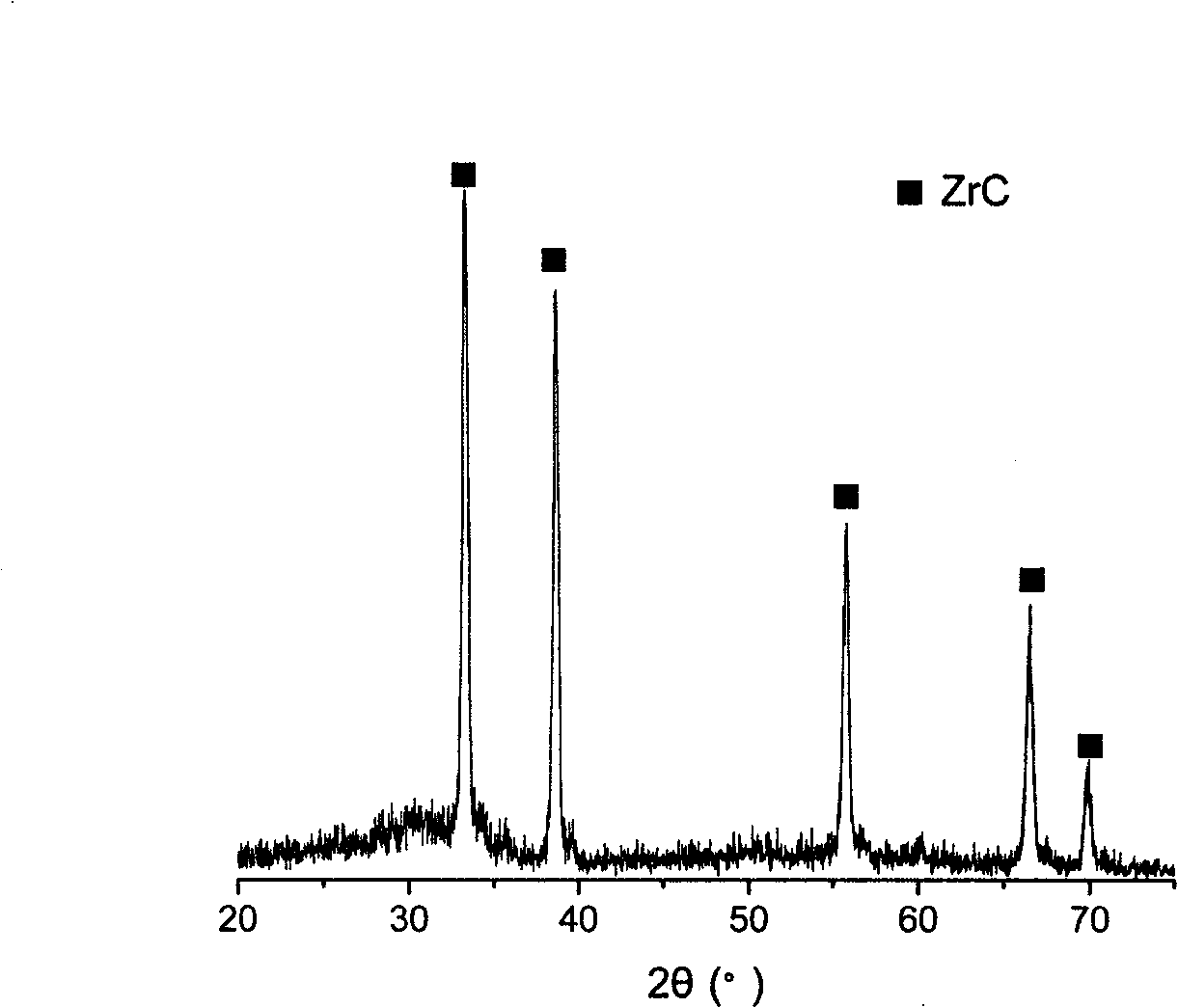

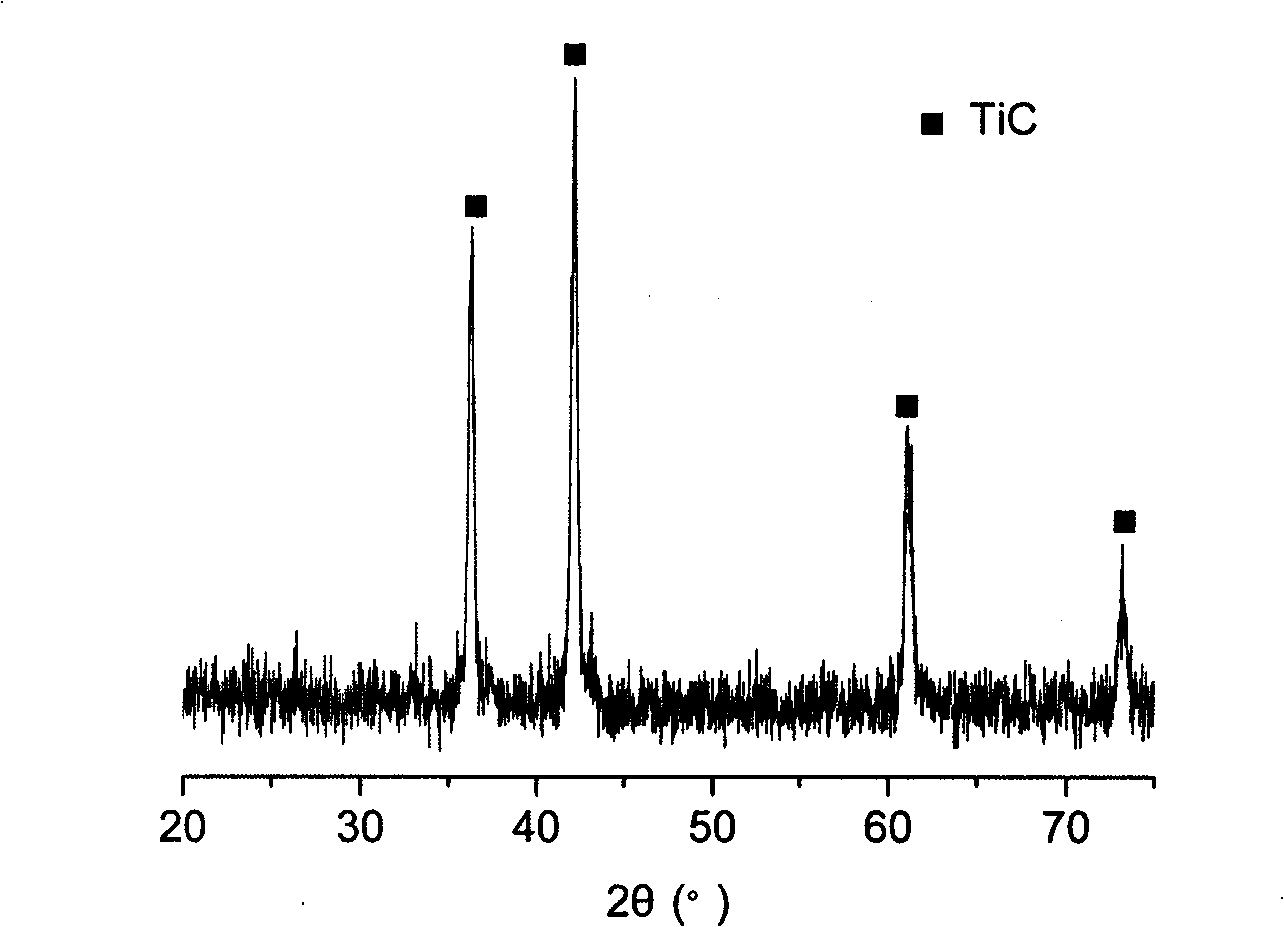

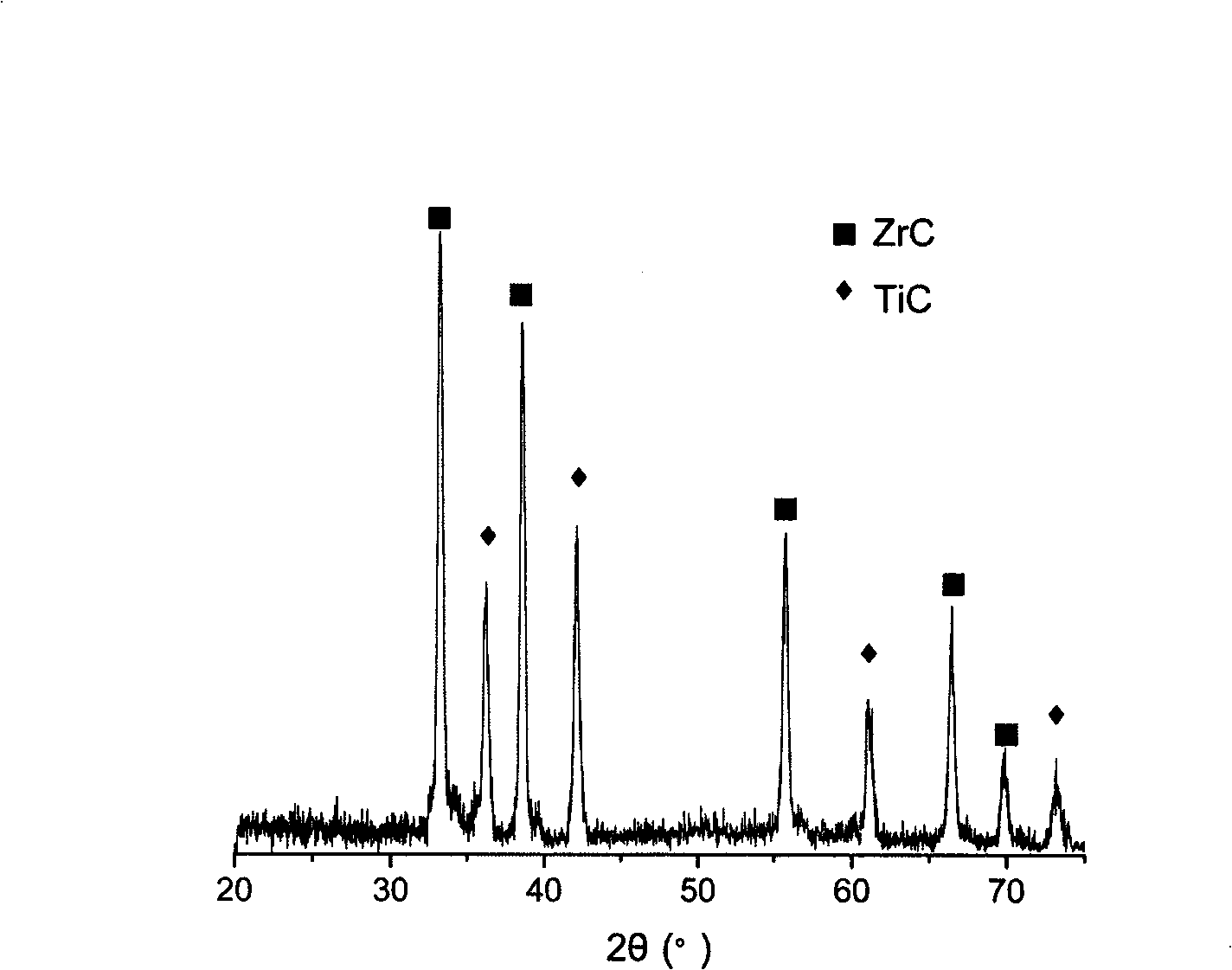

Precursor solution of carbide ceramic, carbide ceramic and preparation thereof

The invention discloses precursor solution for carbide ceramics. The precursor solution uses an alkoxy compound of more than one refractory metal as solute, and uses divinylbenzene, vinyl group acetylenyl benzene or diacetylene-benzene as solvent, and the molar ratio of the solute to the solvent is 1 to between 0.2 and 2. The invention also discloses carbide ceramics and a preparation method thereof. The method comprises the following preparation steps: the precursor solution of the invention is evenly mixed and heated to between 150 and 300 DEG C, and then is insulated for 0.5 to 4 hours; the precursor after low temperature crosslinking treatment is heated to between 1, 200 and 1, 800 DEG C in an inert atmosphere or under a vacuum condition, and then is insulated for 0.5 to 2 hours for high temperature pyrolysis; and the carbide ceramics is obtained after temperature reduction. The precursor solution has the advantages of low viscosity, good stability, simple preparation process, and so on. The method for preparing the carbide ceramics has the advantages of high impregnation efficiency, simple crosslinking process, high ceramics yield, and so on.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com