Preliminary dip material for wind-driven generator impeller vane

A technology of wind turbines and prepregs, applied in wind turbine components, wind engines, wind power generation, etc., can solve the problems of unstable resin content, high viscosity, harmful to human body, etc., and achieve the effect of superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

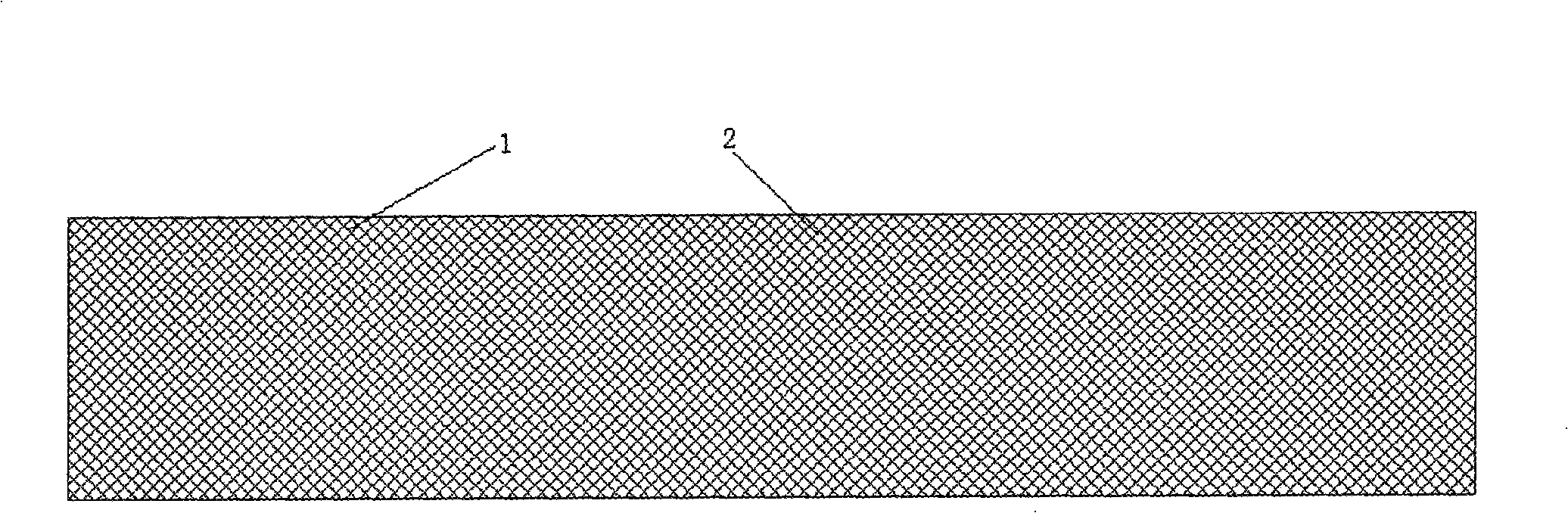

[0023] like figure 1 As shown, in this embodiment, the release paper is used as a carrier, and the epoxy resin matrix is coated. After the epoxy resin matrix is heated and melted, the fiber reinforcement material is impregnated to form a prepreg. The fiber reinforcement material is a biaxial warp knitted fabric, and the fiber reinforcement The mass per unit area of the material is greater than or equal to 400g / m 2 , less than or equal to 2000g / m 2 , the fiber reinforced material is +45 degree fiber 2 and -45 degree fiber 1 biaxial warp knitted fabric stitched by polyester yarn, and the fiber is one or more of glass fiber, carbon fiber, basalt fiber, aramid fiber Several kinds.

[0024] The mass per unit area of polyester yarn is greater than or equal to 5g / m 2 , less than or equal to 15g / m 2 , and does not contain any lubricants. The gel time of the epoxy resin matrix at 120°C is less than or equal to 25min, the viscosity of the lowest point of the epoxy resin mat...

Embodiment 2

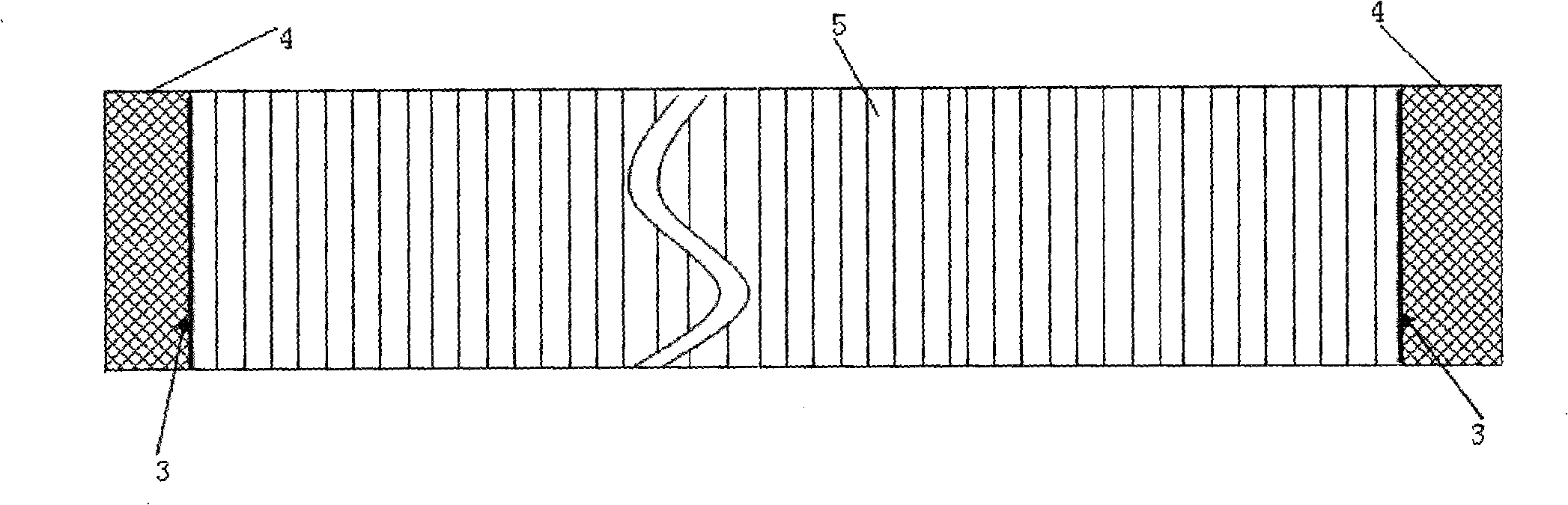

[0041] like image 3 As shown, in this embodiment, the release paper is used as the carrier, and the epoxy resin matrix is coated. After the epoxy resin matrix is heated and melted, the fiber reinforcement material is impregnated to form a prepreg. The fiber reinforcement material is a triaxial warp knitted fabric, and the fiber reinforcement The mass per unit area of the material is greater than or equal to 400g / m 2 , less than or equal to 2000g / m 2 , the inner 35mm area of the warp knitted fabric only has ±45° fibers, and the middle area contains 0° fibers in addition to +45° fiber 2 and -45° fiber 1. The triaxial warp stitched by polyester yarn For braided fabrics, polyester yarn with obvious color difference is used at the junction of triaxial area 5 and biaxial area 4 to form marking line 3 with obvious color difference. The fiber is one of glass fiber, carbon fiber, basalt fiber, and aramid fiber. species or several.

[0042] The mass per unit area of polyes...

Embodiment 3

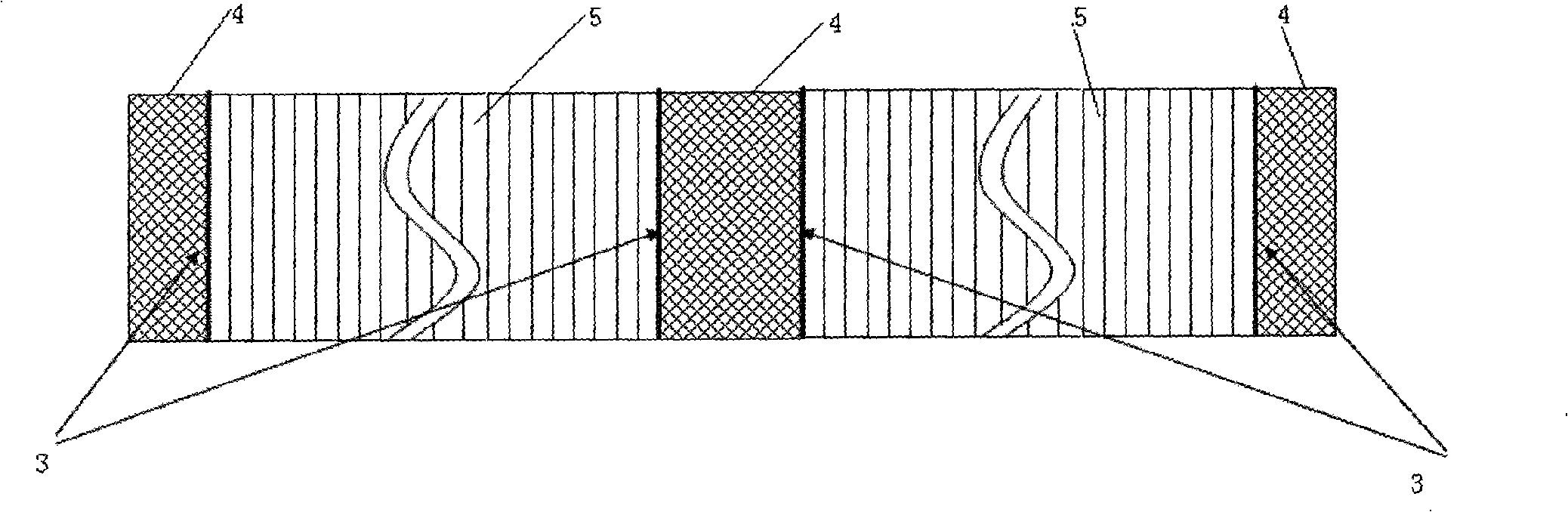

[0045] like figure 2 As shown, in this embodiment, the release paper is used as the carrier, and the epoxy resin matrix is coated. After the epoxy resin matrix is heated and melted, the fiber reinforcement material is impregnated to form a prepreg. The fiber reinforcement material is a triaxial warp knitted fabric, and the fiber reinforcement The mass per unit area of the material is greater than or equal to 400g / m 2 , less than or equal to 2000g / m 2, the 70mm area in the center of the warp knitted fabric and the inward 35mm area of the fabric edge only have ±45° fibers, and the other areas contain 0° fibers in addition to +45° fiber 2 and -45° fiber 1, which are stitched by polyester yarn The triaxial warp-knitted fabric, the polyester yarn with obvious color difference is used at the junction of the triaxial area 5 and the biaxial area 4 to form a marking line 3 with obvious color difference, and the fibers are glass fiber, carbon fiber, basalt fiber, One or sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com