Electrocatalysis oxidation pulping method for purified cotton and production system equipment

A technology for electrocatalytic oxidation and cotton refining, which is applied in the fields of pulping with inorganic alkali, pulping of cellulose raw materials, textiles and papermaking, etc. It can solve the problems of large washing water consumption, low production efficiency and backward equipment, and achieve breakthrough technology. Bottleneck, solve the effect of energy saving and emission reduction, saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

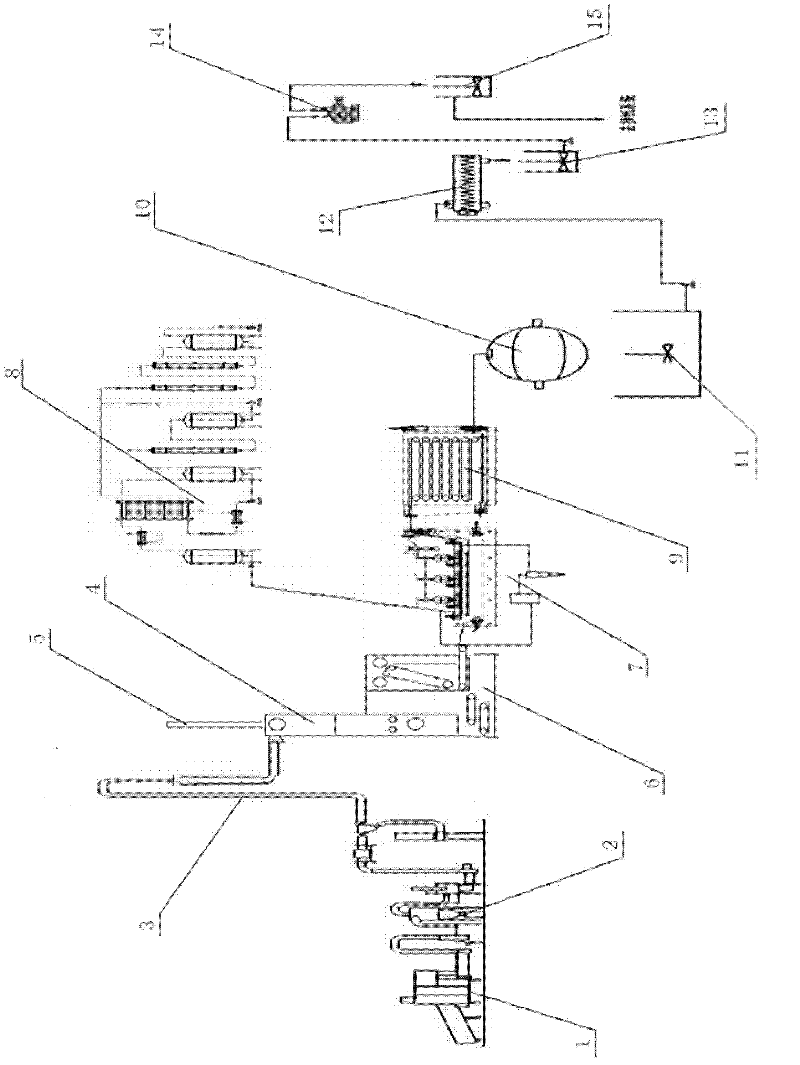

[0024] Such as figure 1 As shown, the refined cotton electrocatalytic oxidation pulping production system equipment mainly consists of a cotton opener 1, a cyclone dust collector 2, a double cheek sleeve conveying pipeline 3, a compound cotton feeder 6, an impregnation machine 7, and a catalytic oxidation reactor 9 , a retention reactor 10, a screw press pulp washer 12 and a beater 14 to form a pulping system equipment.

[0025] Cotton opener 1 is existing equipment, and it loosens the compressed cotton linters bag into smaller cotton blocks or cotton bundles, so as to facilitate the smooth progress of mixing and impurity removal. The impurity removal function in this step is a cotton opener with a rake, which opens the cotton linter bale and removes part of the cotton husk during the process of opening the cotton bale; the cotton mixing function of the cotton opener is to mix cotton with different components. The linters are fully and evenly mixed to stabilize the quality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com