Patents

Literature

93results about How to "Strong dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved microporous polymer film and preparation method thereof

The invention relates to an improved microporous polymer film and a preparation method thereof, and belongs to the field of chemistry. The improved microporous polymer film comprises the following compositions by weight percentage: 55% to 99.79% of polypropylene homopolymer, 0.01% to 5% of beta crystal nucleating agent, 0.1% to 20% of polymeric additive and 0.1% to 20% of inorganic modifier. The improved microporous polymer film is prepared by stretching a melt about 2 to 60 times at a speed of 1 m to 100 m / min in casting, calendering, extruding or film blowing process. Compared with the prior art, more beta crystals can be obtained within shorter time, the formed beta crystals have higher thermal stability, and have better film-forming stability and pore-forming properties, and the prepared microporous film has the characteristics of easiness in processing, higher permeability, excellent productivity, and strong mechanical properties and dimensional stability, and the porosity is further improved, and thereby the permeability of various media can be obviously improved.

Owner:CHENGDU WISEDONE TECH

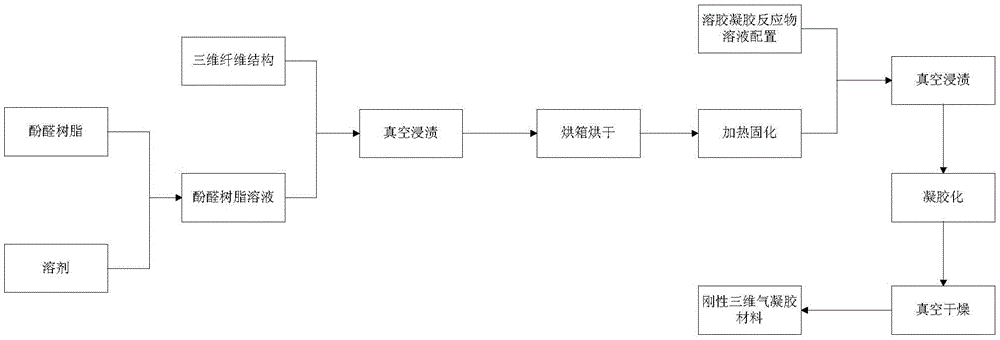

Preparation method of rigid structure reinforced phenolic aerogel heat shielding material

ActiveCN105601854ASolve problems that are difficult for large-scale engineering applicationsStrong dimensional stabilityEngineeringSolvent

The invention relates to a preparation method of a rigid structure reinforced phenolic aerogel heat shielding material. The method includes: firstly dissolving phenolic resin in a solvent in a vacuum impregnation container to form a phenolic solution, then pressing a three-dimensional fiber structure into the phenolic resin solution, and conducting vacuum pumping on the vacuum impregnation container, after a period of time, opening a seal cover to maintain smooth air pressure with the outside and conducting standing for a period of time, then taking out the three-dimensional fiber structure and putting it into an oven to perform drying, and conducting high temperature curing to form a rigid three-dimensional fiber structure, then mixing resorcinol, furfural, ethanol and sodium hydroxide uniformly in proportion in the vacuum impregnation container to form a reactant solution, then pressing the rigid three-dimensional fiber structure into the solution, conducting vacuum pumping on the vacuum impregnation container again, maintaining the state for a period of time, then placing the vacuum impregnation container into the oven to carry out sol-gel process, and finally taking out the gel-containing three-dimensional fiber structure and performing drying, thus obtaining the rigid structure reinforced phenolic aerogel product.

Owner:BEIJING SATELLITE MFG FACTORY

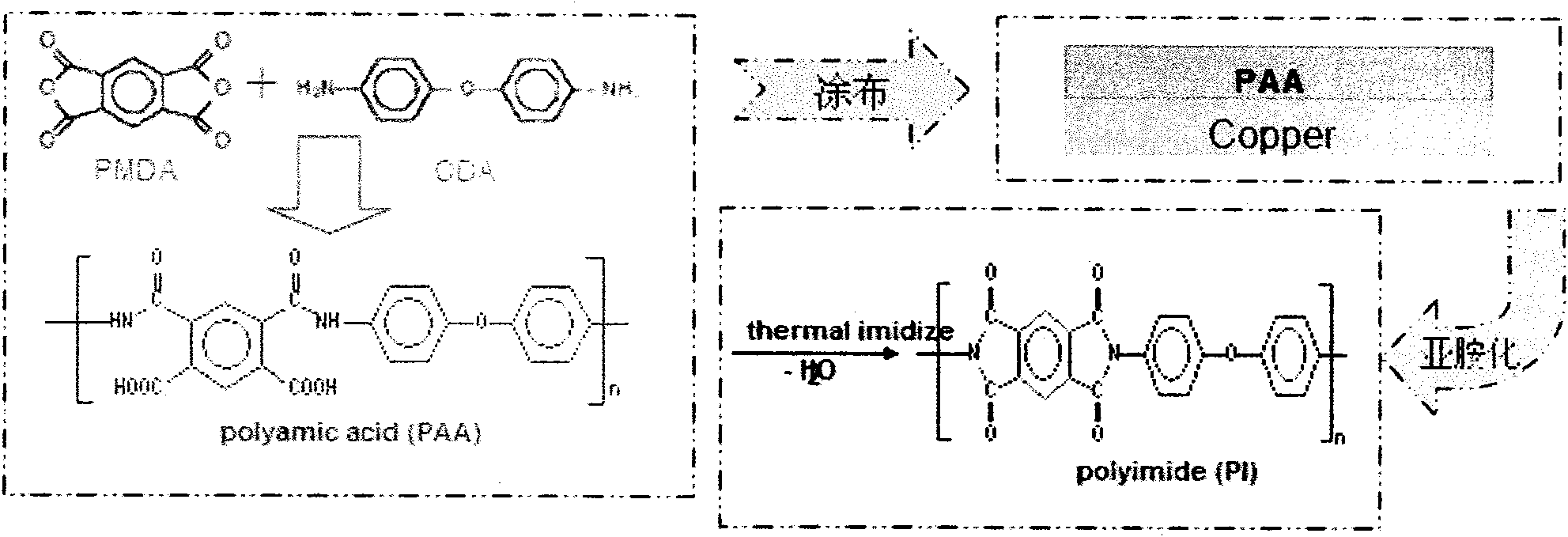

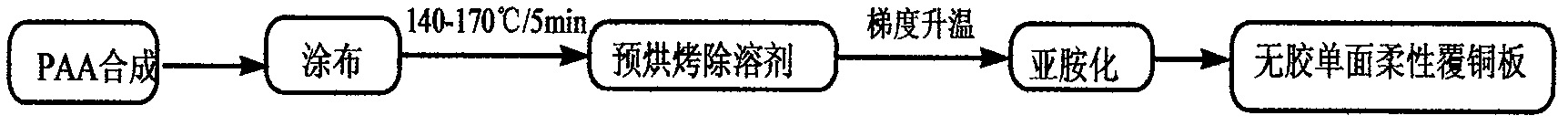

Method for synthesizing polyimide precursor polymer resin and method for manufacturing single-sided flexible copper-clad plates

ActiveCN101974155AImprove heat resistanceLittle change in tear strengthCircuit susbtrate materialsMetal layered productsEtchingInsulation layer

The invention relates to a method for synthesizing polyimide precursor polymer resin and a method for manufacturing single-sided flexible copper-clad plates, which are applied to the technical field of microelectronics. An adhesive-free single-sided flexible copper-clad plate is obtained by the steps of: dissolving a monomer aromatic diamine in a non-proton polar solvent, stirring for dissolution, adding a silane coupling agent, stirring, adding an aromatic dianhydride monomer for polymerization to generate a polyimide precursor polymer resin solution, reacting and standing for defoaming; andcoating resin on a copper foil, pre-baking in an oven, removing the solvent, and heating in a gradient way in the high-temperature non-oxidation over (importing with nitrogen) so as to carry out complete imidization. The single-sided flexible copper-clad plate has the advantages that the heat resistance is good, the dimensional stability is strong, a substrate is thin, the peel strength is not less than 1.1kgf / cm, the polyimide resin is smooth and level after total etching, the elongation percentage is not less than 35%, the tensile strength is not less than 250MPa, the heat resistant temperature Tg of a polyimide insulation layer is not less than 328DEG C, and meanwhile, the plate has lower heat expansion coefficient, dielectric constant and water absorption rate.

Owner:金华市磁盟知识产权服务有限公司

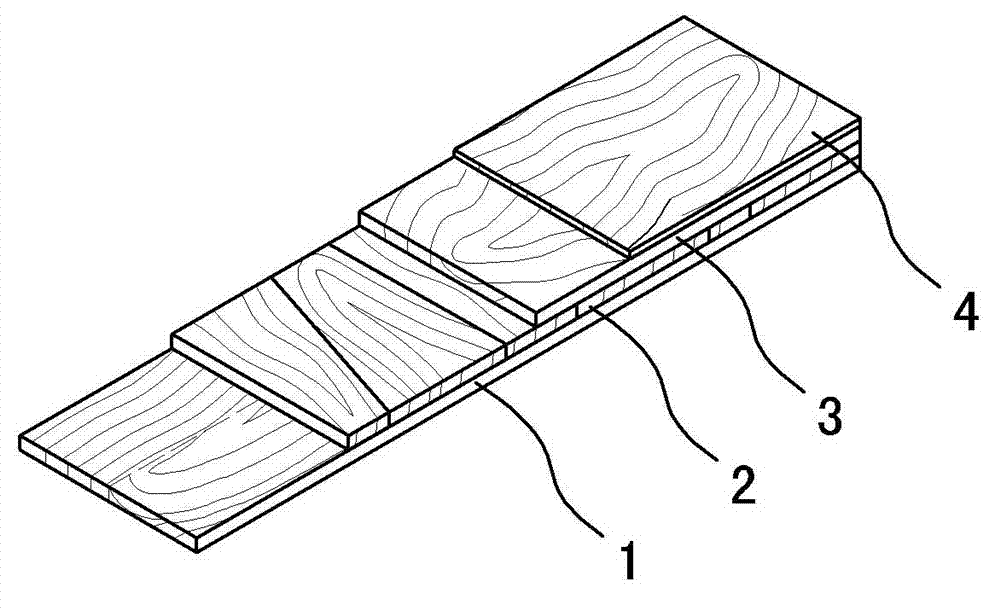

Composite carbon-based floor and production method thereof

InactiveCN102733579AStrong weather resistanceStrong dimensional stabilityLaminationWood working apparatusAdhesive cementCold area

The invention relates to a composite carbon-based floor and a production method of the floor; a raw wood is sliced by a vertical veneer slicer into a veneer for manufacturing a base plate, a core plate and a secondary surface veneer of a substrate and a veneer for manufacturing a surface veneer; the base plate, the core plate, the secondary surface veneer and the veneer to be carbonized are subjected to high temperature carbonization treatment, the carbonized base plate, veneer and secondary surface veneer are bonded with a surface wooden veneer or a surface carbonized veneer by glue, or the carbonized base plate, the carbonized core plate veneer and the surface carbonized veneer or the surface wooden veneer are bonded by glue, so as to obtain the floor. The composite carbon-based floor has very high weather resistance and size stability, is green, nontoxic, insect-resistant and anticorrosive, long in service life, and free from limit of amplitude width. The floor is suitable for terrestrial heat condition of cold areas and does not deform and crack. The composite carbon-based floor production method has the advantages of low material consumption, low energy consumption, low cost, and small pollution.

Owner:薜继武

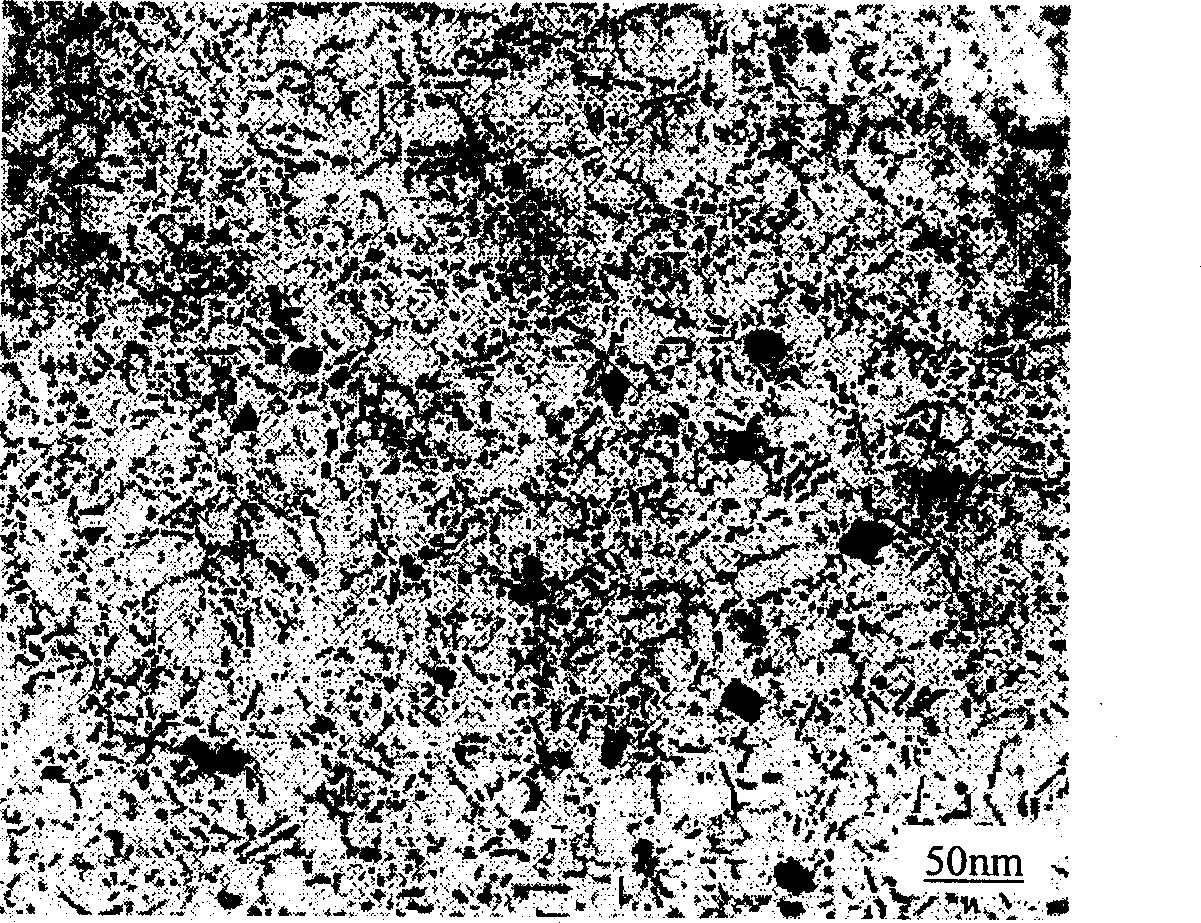

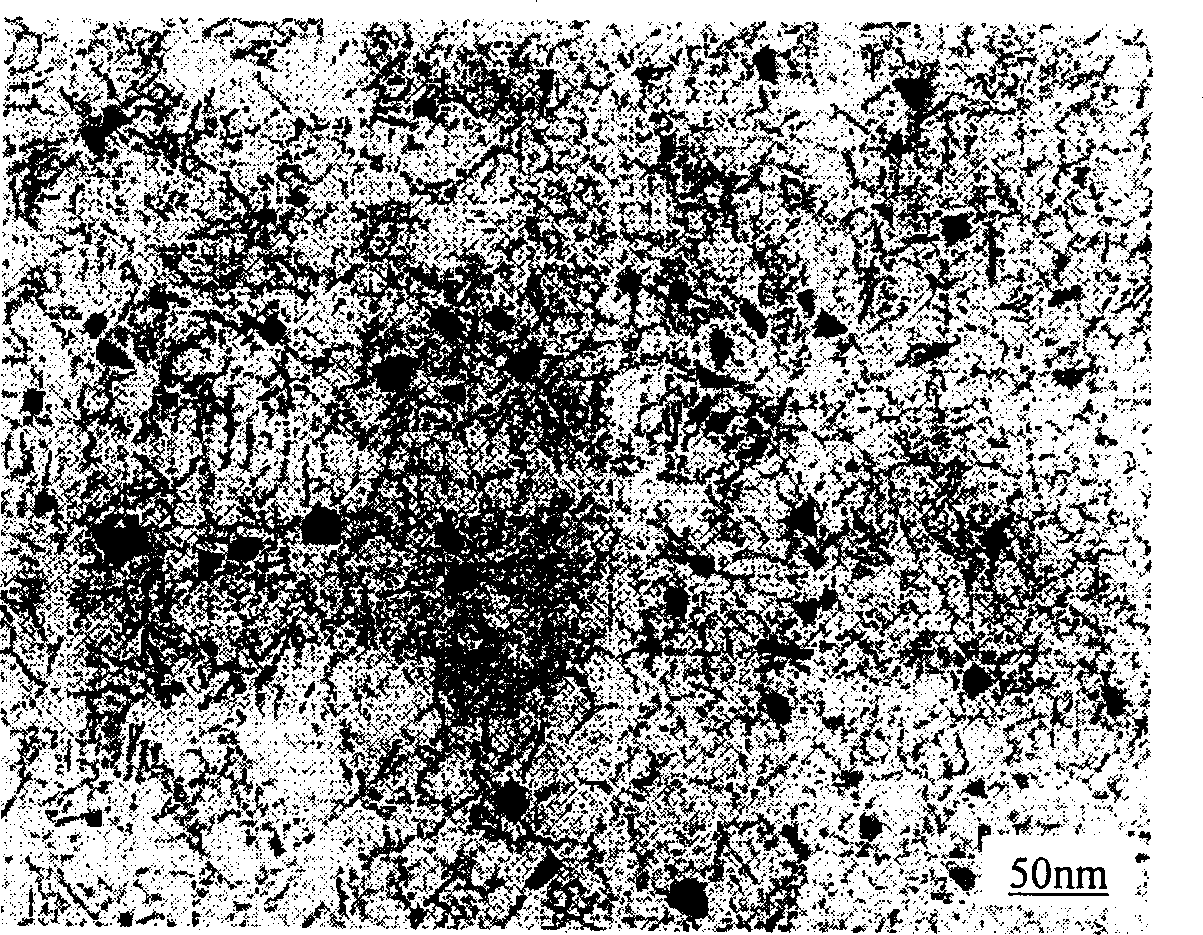

High strength heat resistant alloy

A high-strength refractory Al alloy with high strength, size stability and resistance to high temp (350-400 deg.C) and wearing contains proportionally Si, Cu, Ni, Mn, Mg, Ti, B, Zr, Cd, P and Al. It features that it contains the uniformly distributed Al3X particles with LI2 crystal structure and TiB2 particles with hcc crystal structure.

Owner:XIAN POLYTECHNIC COLLEGE

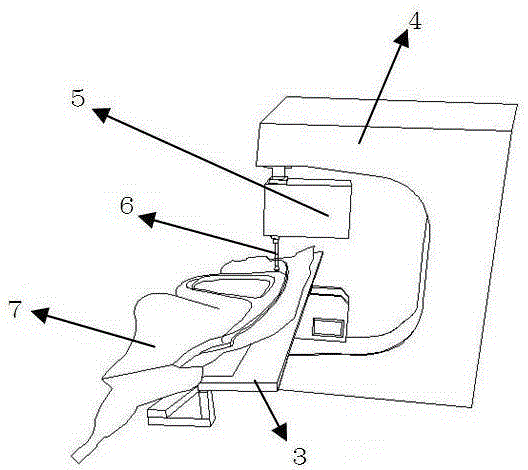

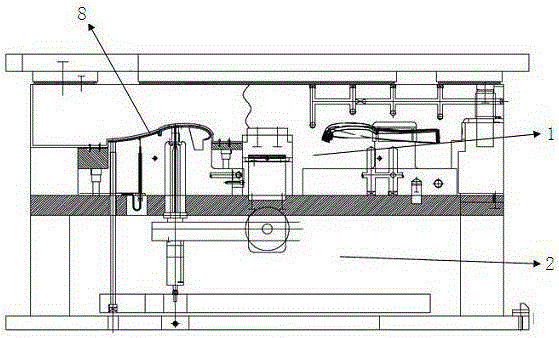

Injection molding method for soft surface and stitch lines of automotive door interior trimming panel

ActiveCN105196474AReduce processEasy to operateDomestic articlesCoatingsEngineeringInjection molding machine

The invention discloses an injection molding method for a soft surface and stitch lines of an automotive door interior trimming panel. The method comprises the following three steps: 1 surface premolding; 2 finishing adding of real stitch lines to complicated shapes of curved surfaces and the like through 3D stitching on the surface; and 3 carrying out injection molding through a low-pressure injection molding mold to finish the injected automotive interior with the surface with target grains and the stitch lines. Products produced by the injection molding method are uniform in size, can be seamlessly lapped with matched parts, and are high in size stability, relatively small in internal stress, and not easy to deform; the stitch lines can be added to the curved surfaces and complicated surfaces; and the model of the automotive door interior trimming panel is beautified.

Owner:QUANXING TOOLING EQUIP NANJING

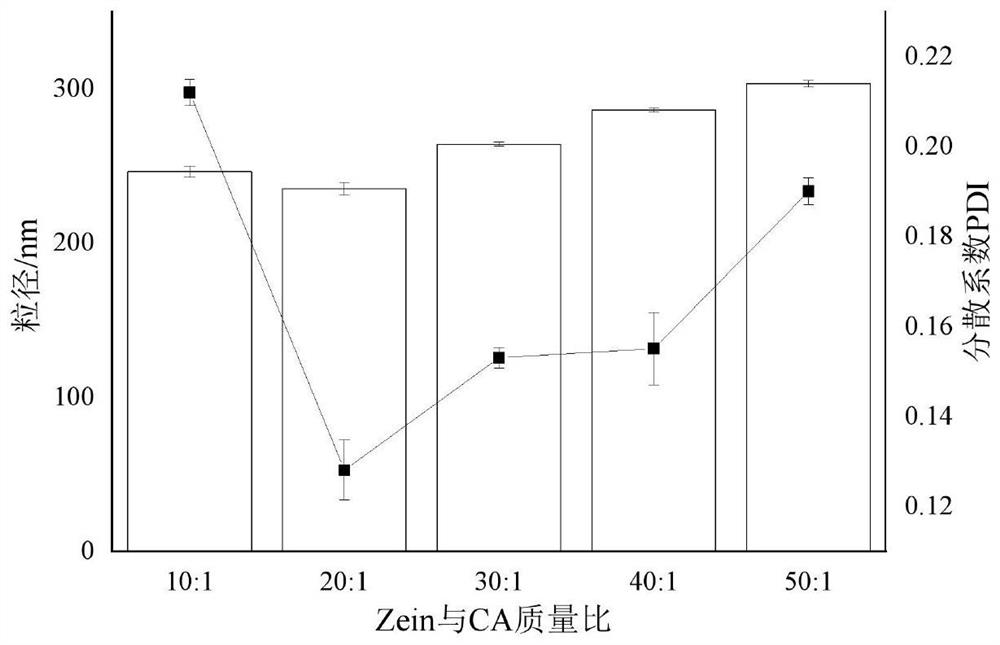

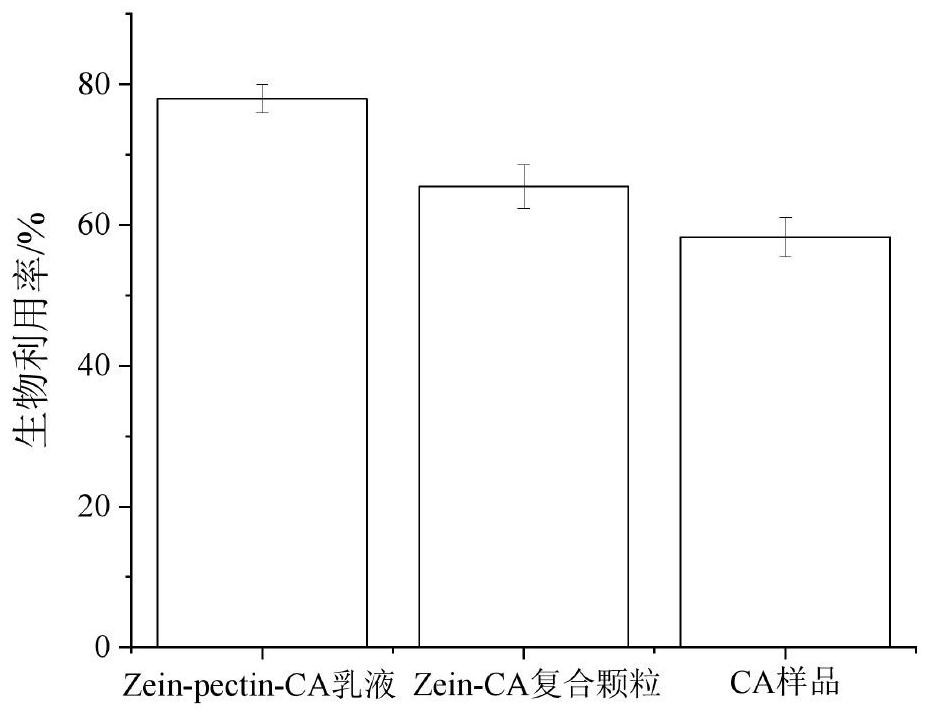

Preparation method and application of Pickering emulsion by utilizing prolamin loaded eucommia ulmoides chlorogenic acid

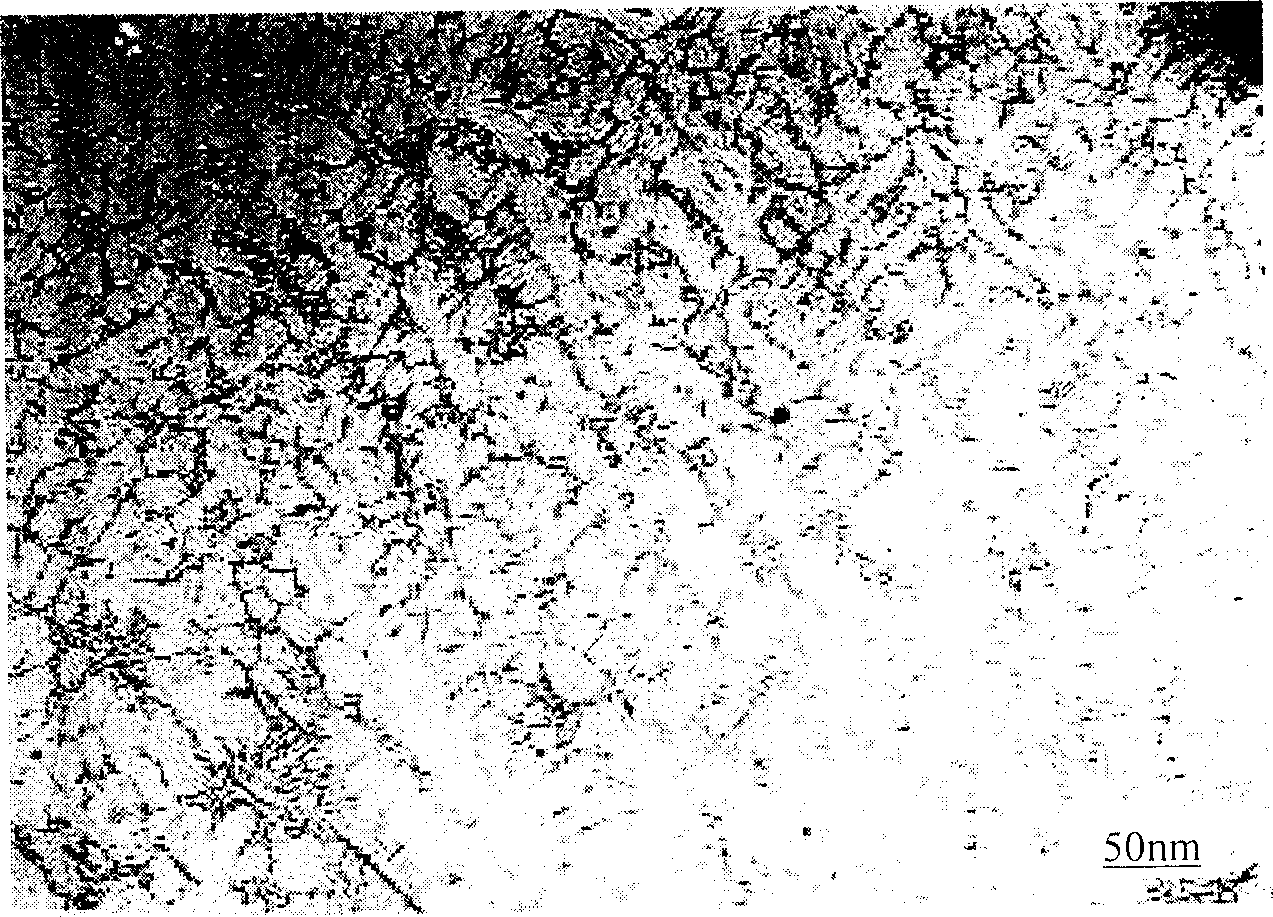

PendingCN112957324ASmall particle sizeEvenly distributedCosmetic preparationsOrganic active ingredientsSolubilityChlorogenic acid

The invention discloses a preparation method of Pickering emulsion by utilizing prolamin loaded eucommia ulmoides chlorogenic acid. The unique solubility and self-assembly characteristic of prolamin are utilized, composite nanoparticles of prolamin loaded chlorogenic acid are prepared by adopting an anti-solvent method, and the Pickering emulsion is further prepared. The preparation method is simple in operation, small in the dosage of an emulsifier, low in cost, and environment-friendly; the prepared Pickering emulsion is uniform in particle size distribution, free of surfactants, low in toxicity and obvious in biological activity; alcohol-soluble nano-particles form a compact interface layer on an oil-water interface, so that the Pickering emulsion is high in stability and biocompatibility and is degradable, and polysaccharide-based particles are high in spatial stability and can resist flocculation and coagulation phenomena, so that the stability of the Pickering emulsion can be further improved, the solubility and stability of chlorogenic acid can be obviously improved, and the bioavailability of chlorogenic acid can be improved.

Owner:INST OF ANALYSIS GUANGDONG ACAD OF SCI (CHINA NAT ANALYTICAL

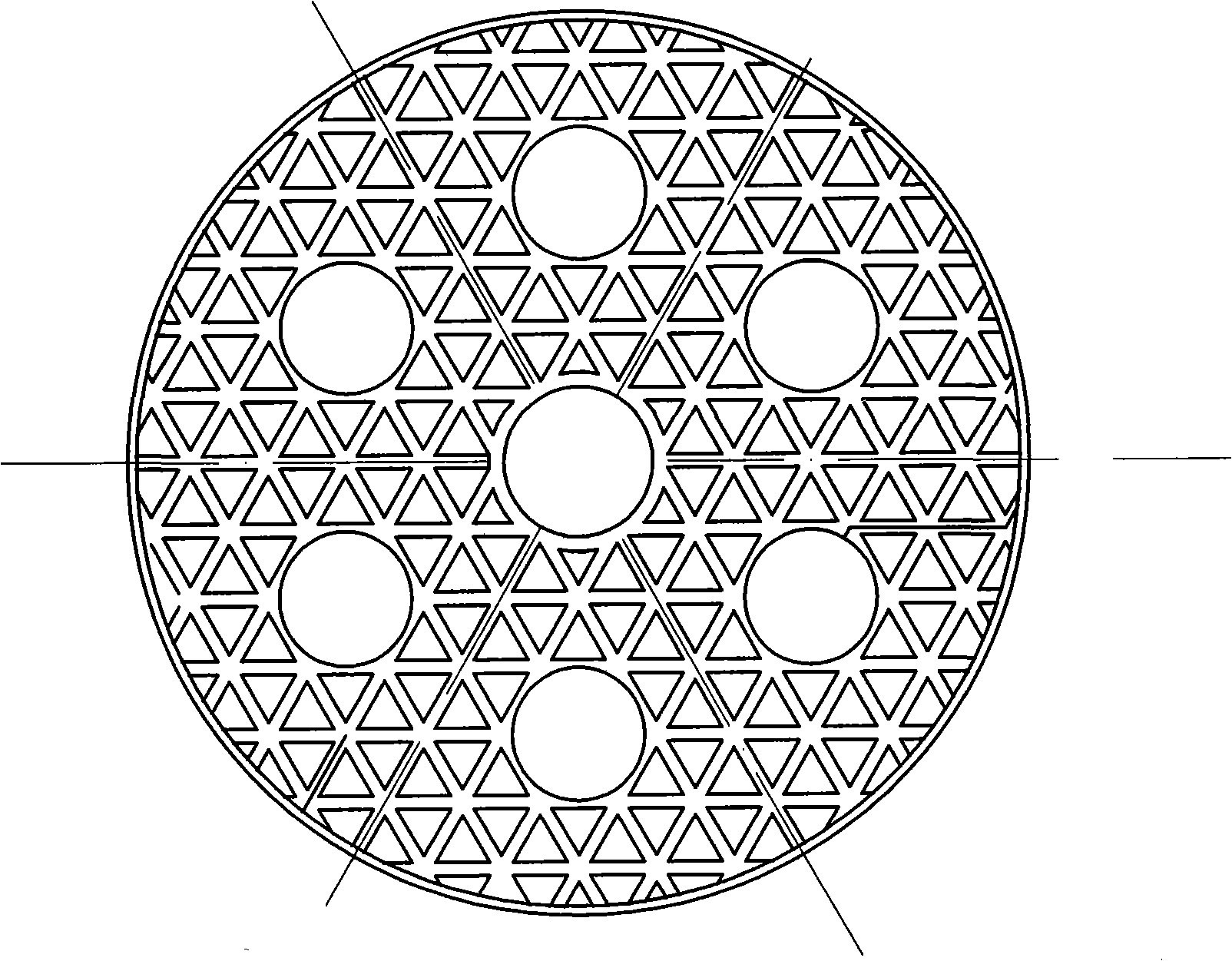

Production method of oversize silicon carbide spacing reflection mirror body

InactiveCN101315436AReduce washoutReduce deformation errorMirrorsMountingsNumerical controlSpace optics

The invention relates to a method for manufacturing the blank body of a silicon carbide space reflecting mirror with super large size, as well as the application thereof. In the prior art, in order to obtain sufficient specific rigidity, the weight is rapidly increased when traditional optical materials, for example, optical glass is adopted for producing a large-size optical element, and the imaging quality rapidly drops, thus traditional optical materials with the optical glass as the representative is no longer suitable for the requirement on the development of space optics, and a novel product is required to replace the traditional optical materials. The method adopts the following steps: the appearance and the size of the reflecting mirror are designed optimally; the reflecting mirror with super large size is divided into small-size blank drawings; dies are manufactured and pulp is prepared through a computer and a numerical control processing apparatus; casting is carried out; the blanks are manufactured through the reactive sintering method; the blanks are processed; and then all the blanks are connected together and trimmed by adopting the braze welding method. The method is used for manufacturing the blank body of the silicon carbide space reflecting mirror with super large size.

Owner:HARBIN INST OF TECH

Preparation method of cross-linked polyfluorene piperidine anion exchange membrane

The invention discloses a preparation method of a cross-linked polyfluorene piperidine anion exchange membrane. The method comprises the following steps: dissolving 9,9-dimethyl fluorene, N-methyl piperidone and trifluoroacetone in dichloromethane to obtain a homogeneous solution, adding trifluoroacetic acid and trifluoromethanesulfonic acid as catalysts, performing reacting for 24-36 hours at 0-10 DEG C in a nitrogen atmosphere, performing precipitating with a K2CO3 aqueous solution, and performing washing with deionized water to obtain light yellow solid polyfluorene piperidine polymer powder; dissolving the obtained polyfluorene piperidine and iodomethane in chloroform, performing heating and refluxing for 24-36 hours under a dark condition and a nitrogen atmosphere, then pouring a reaction solution into diethyl ether to precipitate, and performing washing with deionized water to obtain a quaternized polyfluorene piperidine polymer; and dissolving the obtained solution in dimethyl sulfoxide, adding a brominated amino siloxane cross-linking agent solution, performing reacting for 12-24 hours at 50-60 DEG C, adding iodomethane, performing reacting for 24-48 hours at 30-40 DEG C in a dark nitrogen atmosphere, adding ethanol, performing standing for 24-36 hours at room temperature, performing standing for 12-24 hours at 80 DEG C, standing for 3-6 hours at 100 DEG C, and performing standing for 1-3 hours at 120 DEG C to obtain the cross-linking type polyfluorene piperidine anion exchange membrane.

Owner:WUHAN UNIV OF TECH

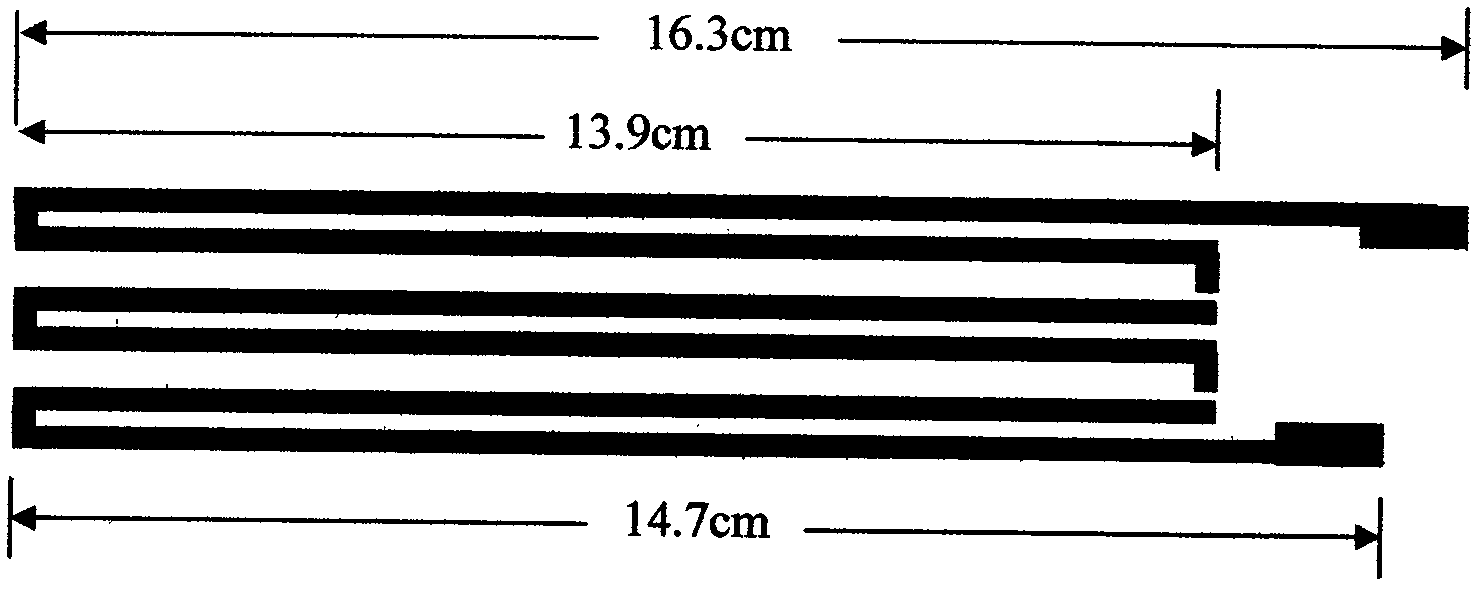

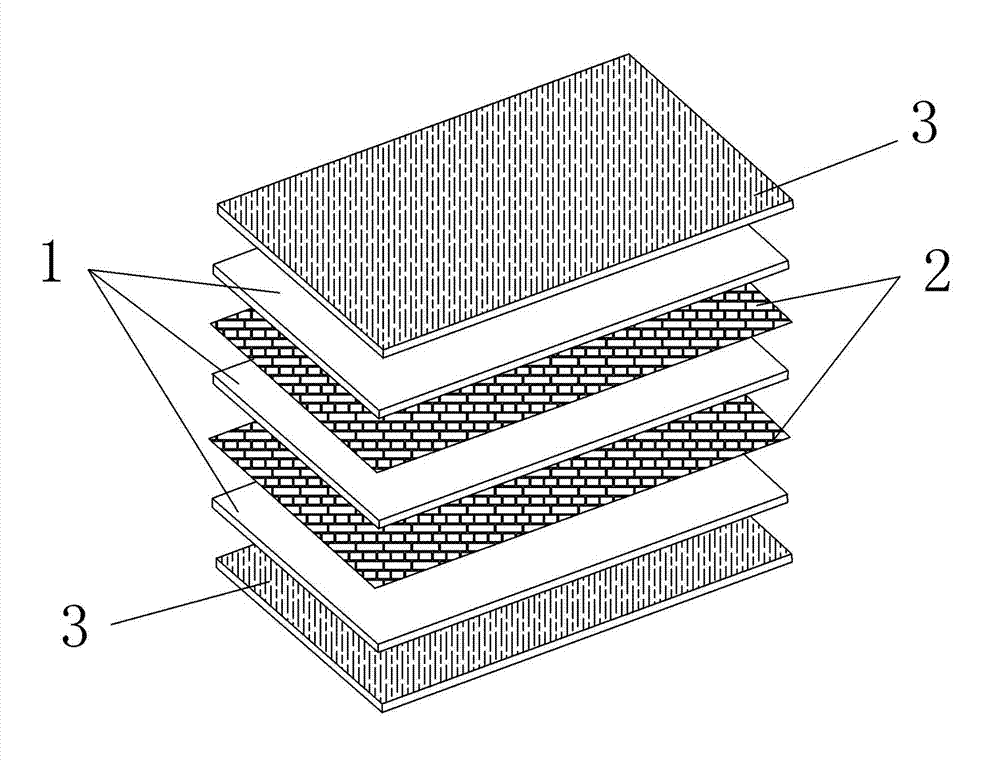

Processing method for laminated composite cutting die plate

InactiveCN103029412AFlame retardantCorrosion resistantLamination ancillary operationsLaminationGlass fiberWeather resistance

The invention discloses a laser cutting die processing method and particularly discloses a processing method for a laminated composite cutting die plate. The processing method comprises the steps of rotary cutting for obtaining a veneer, grinding the veneer in a beveled way, splicing the veneer in a beveled way, soaking the veneer, soaking a glass fiber cloth, drying, gluing onto PVC, assembling and thermally pressing, reconditioning and the like. Aiming at solving the problems of poor weather resistance, poor corrosion resistance, easy deformation at high temperature and the like existing in a wooden laser cutting die plate, a product obtained through the processing method disclosed by the invention comprises an upper surface layer and a lower surface layer which are both PVC thin layers, a secondary outer layer which is the bevel connection veneer, and other layers which are formed by laminating the glass fiber cloth and wooden layers in a staggered manner. The obtained product by adopting the method provided by the invention has the advantages of light weight, high strength, strong thermal stability, difficulty in deformation and the like and has significant economic benefit and market value.

Owner:郑州兴旺木业有限公司

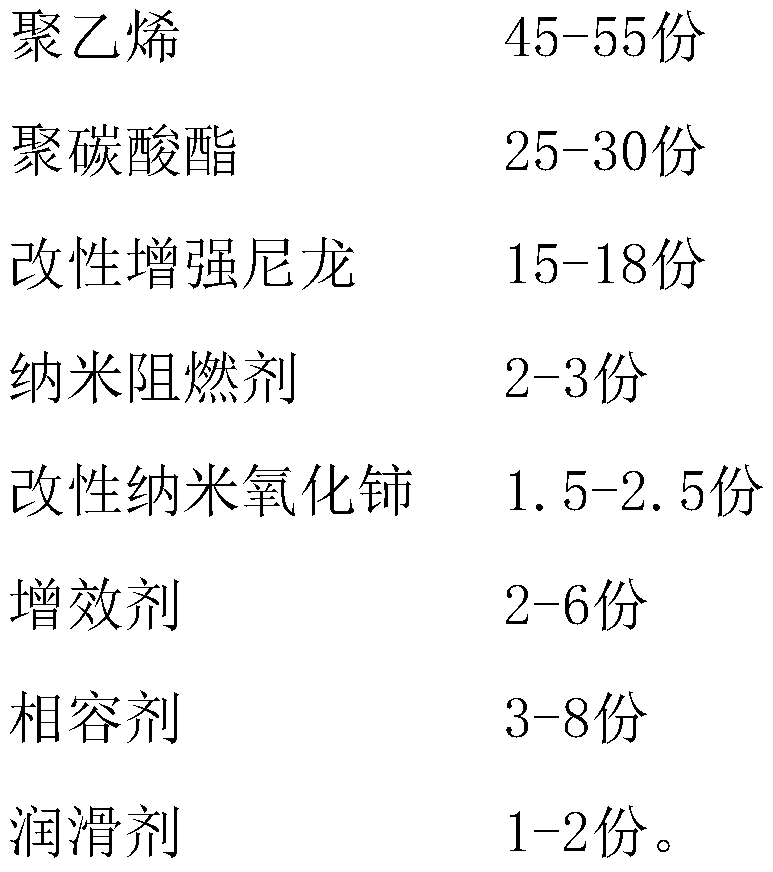

Fireproof aluminium-plastic panel containing nanometer flame retardant and core material special for fireproof aluminium-plastic panel containing nanometer flame retardant

InactiveCN110157072AGood compatibilityGood dispersionSynthetic resin layered productsMetal layered productsDispersityInjection moulding

The invention relates to the technical field of aluminium-plastic panels, in particular to a fireproof aluminium-plastic panel containing a nanometer flame retardant and a core material special for the fireproof aluminium-plastic panel containing the nanometer flame retardant. The core material comprises the following raw materials in parts by weight: 45-55 parts of polyethylene, 25-30 parts of polycarbonate, 15-18 parts of modified enhanced nylon, 2-3 parts of the nanometer flame retardant, 1.5-2.5 parts of modified nanometer cerium oxide, 2-6 parts of a synergist, 3-8 parts of a compatilizerand 1-2 parts of a lubricant. The core material has excellent flame-retardant and fireproof performance, the mobility is high, a core layer can be easily produced through extrusion molding and injection molding, and the core layer produced by using the core material is high in strength and excellent in hardness, resists bending, is not liable to deform, and is excellent in weather resistance; andby adopting the nanometer flame retardant, through combined action of the nanometer flame retardant and the synergist, the core material can have the excellent flame retardant and fireproof performance, and not only can the synergist have an flame-retardant effect, but also a powder state of the synergist can promote the dispersity of materials, so that the rheological property of the core material in the subsequent technologies is improved.

Owner:东莞华尔泰装饰材料有限公司

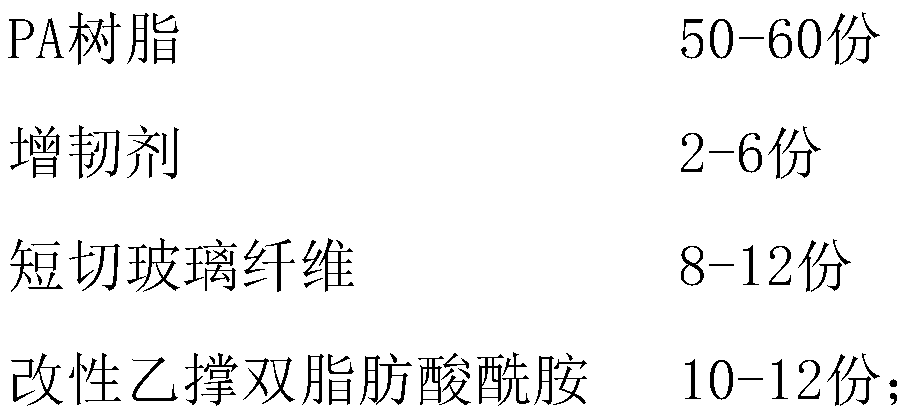

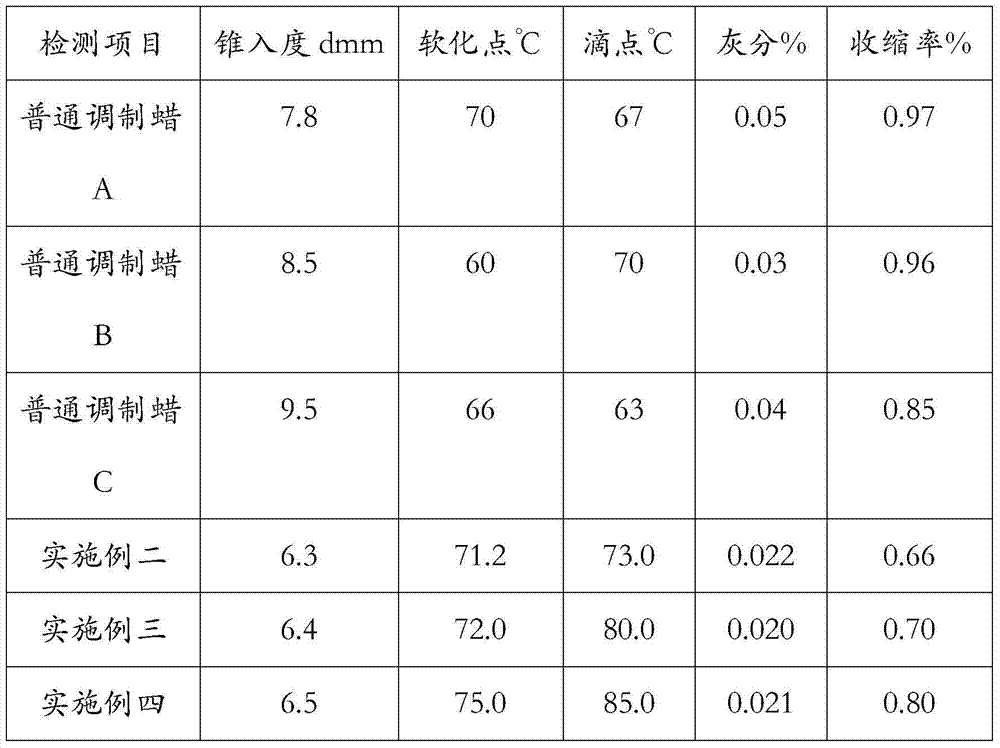

Precise casting medium temperature modulated wax and preparation method thereof

ActiveCN104841880AEvenly mixedReduce the probability of subsidenceFoundry mouldsFoundry coresMicrocrystalline waxGray level

The invention discloses a precise casting medium temperature modulated wax and a preparation method thereof. The precise casting medium temperature modulated wax is prepared from the following raw materials in part by mass: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of lignite wax, 34-36 parts of rosin resin, 3.5-4.5 parts of ethylene-vinyl acetate copolymer, and 12-14 parts of pure monomer resin. The modulated wax disclosed by the invention is applied to the precise casting industry, and has the advantages of being strong in stability, high in strength, hard to deform, low in gray level, capable of reducing the pollution to the metal casting, easy to demold and easy to melt along with a wax pattern while demolding so as to flow out of a molding shell, and capable of effectively improving the production efficiency in the precise casting process.

Owner:青岛新诺科新材料科技发展有限公司 +1

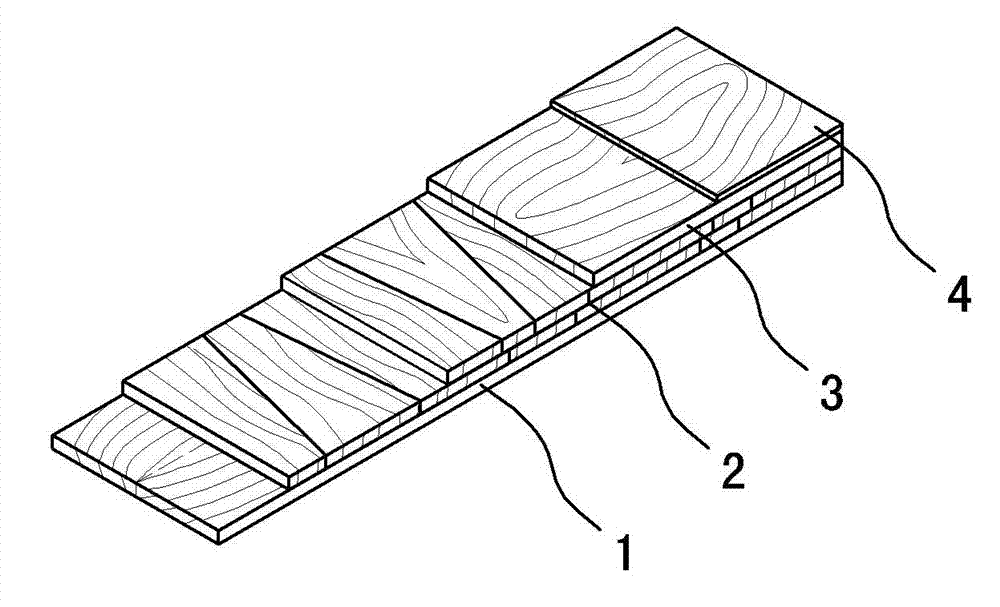

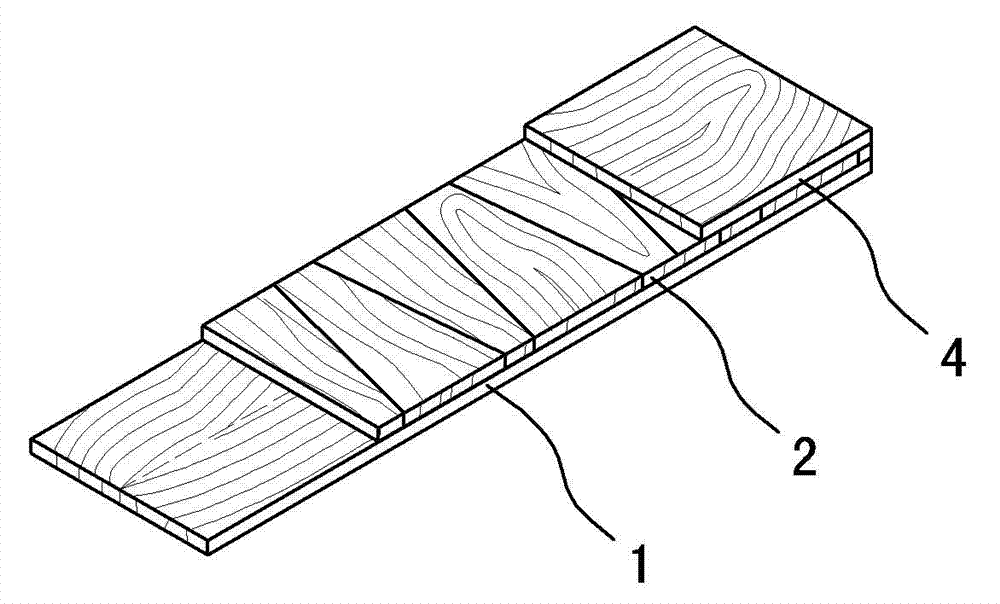

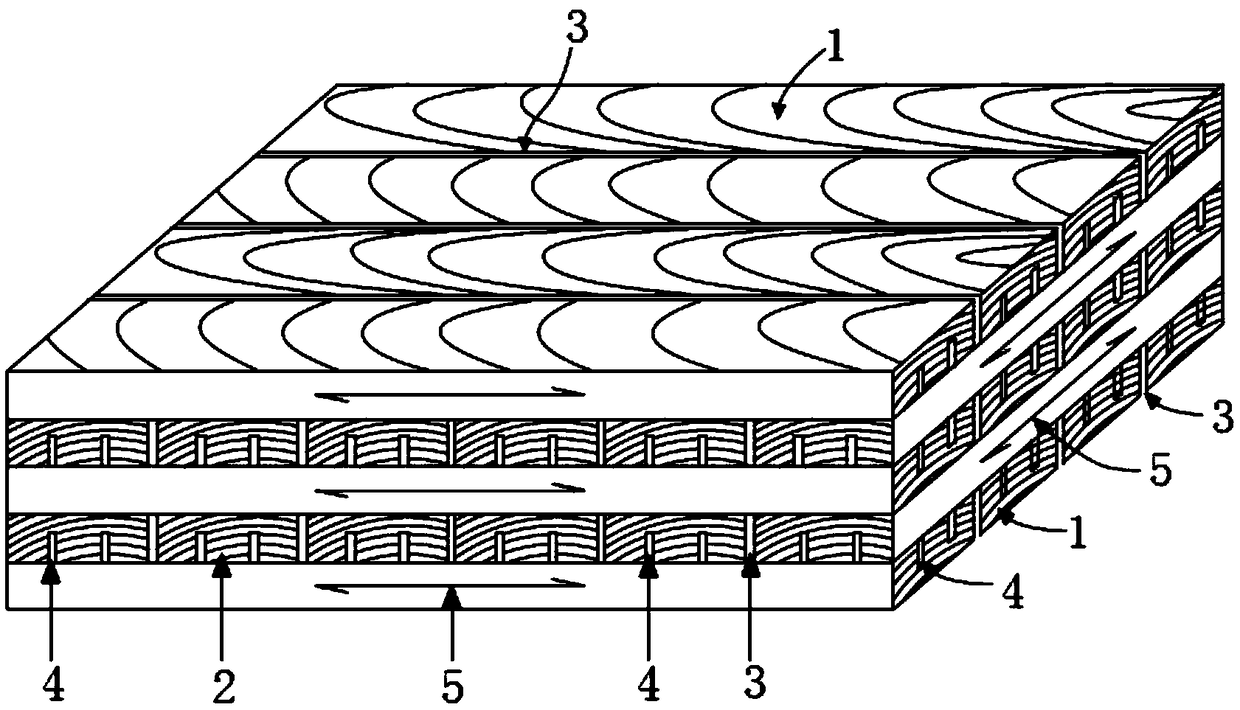

Woodiness function gradient laminate for high size-stability structure and manufacturing method of woodiness function gradient laminate for high size-stability structure

InactiveCN103802175AHigh strengthHigh gel contentWood veneer joiningWood layered productsSurface layerSingle plate

The invention discloses a woodiness function gradient laminate for a high size-stability structure and a manufacturing method of the woodiness function gradient laminate for the high size-stability structure. The woodiness function gradient laminate is characterized in that fast-growing woodiness recombination units serve as core layers, high-strength woodiness recombination units or bamboo recombination units serve as outer layers, inorganic solutions soaked by the units on the adjacent layers are in contact and are hot-pressed to produce gel, and the woodiness function gradient laminate is formed. The woodiness function gradient laminate has the advantages that use materials are structural woods or low-quality man-made forest small-diameter grade woods or branch woods or leftover materials or bamboo woods, the product structure is reasonable and designable, the material use rate is high, the product cost is low, the mechanical strength is high, the size stability is high, the service life is long, the product is anticorrosion and capable of preventing insects, and has the functionality such as inflaming retarding, and the woodiness function gradient laminate can be used as building wall materials, a floorboard or a roof board; the surfaces of the materials are covered with a whole chemical woodiness single plate to serve as the surface layer and the secondary surface layer, the attractive appearance decoration effect can be achieved, and the woodiness function gradient laminate can be completely used for replacing traditional woodiness laminate materials such as a plywood and laminated veneer lumber and can be used as furniture and home decoration materials.

Owner:NANJING UNIV OF TECH

Precision casting concocted wax and treatment process

InactiveCN105907107AEasy to prepareReasonable workmanshipFoundry mouldsFoundry coresRosinParaffin oils

The invention discloses precision casting concocted wax. The concocted wax is prepared from, by weight, 38-42 parts of microcrystalline wax, 18-25 parts of paraffin, 10-12 parts of candelilla wax, 20-24 parts of polystyrene, 16-25 parts of stearic acid, 25-32 parts of ethylene-ethyl acetate copolymer, 9-12 parts of 1,3-oxaazacyclohexane, 10-15 parts of octadecanoic acid, 14-22 parts of calcium stearate, 8-10 parts of sodium dodecyl benzene sulfonate, 12-20 parts of rosin resin, 20-32 parts of ethylene-vinyl acetate copolymer, 18-30 parts of pure monomer resin and 5-6 parts of compatilizer. Compared with the prior art, the precision casting concocted wax has the advantages that a preparing method is simple and reasonable in process, the softening point of the prepared casting concocted wax is within the ideal range so that the concocted wax can be easy to demold in the casting process, and production efficiency is high; the prepared casting concocted wax is low in linear shrinking percentage and subsidence rate, the size stability of the product is high, and a casting is high in surface smoothness and high in quality.

Owner:安徽宜安精密机械零部件有限公司

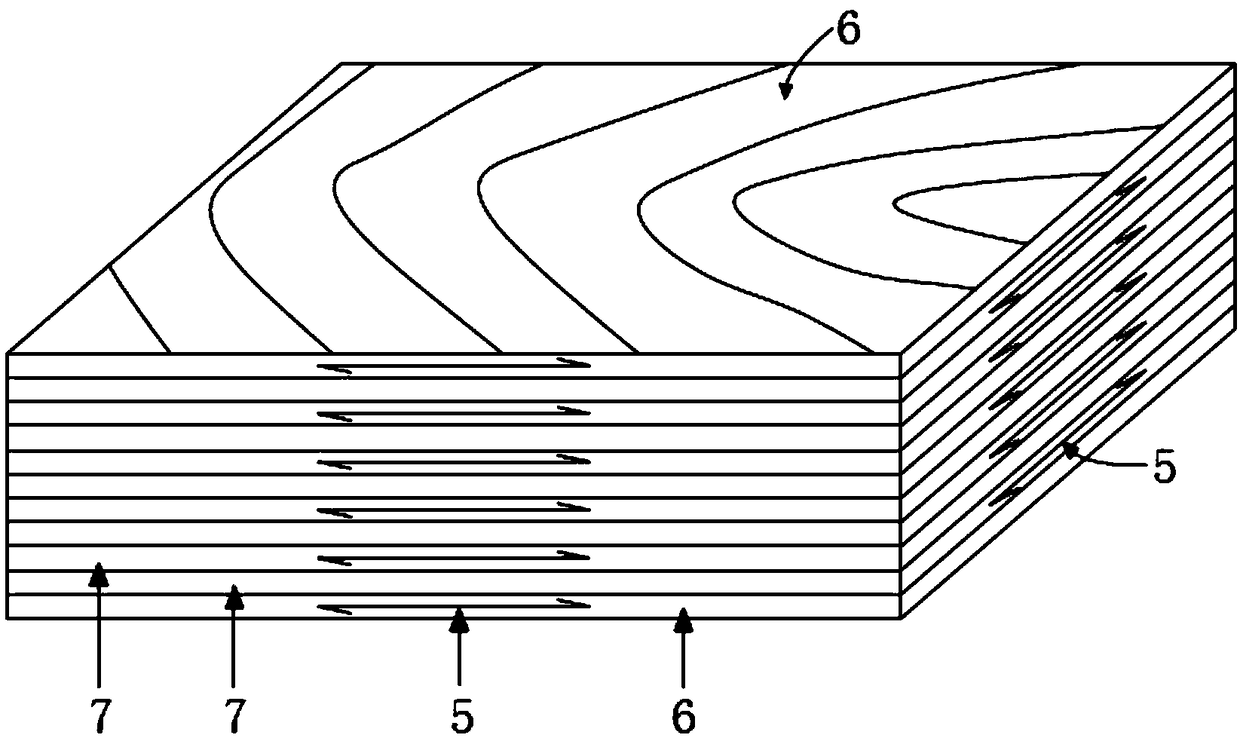

Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

PendingCN109434975AImprove mechanical propertiesImprove fire resistanceLaminationLamination apparatusMechanical propertyAdverse effect

The invention discloses cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and a preparation method thereof, and belongs to the field of timber structures. A laminated board of the cross laminated timber comprises a fast growing timber laminated board with cracks, the fast growing timber laminated board is a whole cracked board, and lengths of all laminated boards of the cross laminated timber are consistent in the horizontal direction. In the preparation method, adjacent layers formed by the fast growing timber laminated board or fast growing timber laminated board combination are assembled and configured in a manner that wood textures are perpendicular to each other in the thickness direction of laminated wood. According to the cross laminated timber combining the fast growing timber material characteristics and meeting the building structure requirements and the preparation method thereof, the material characteristics that the fast growing timber is soft in material and prone to be made into the laminated board with the cracks in a rotary cutting mode are fully utilized, structural stock lumber is replaced for preparing the cross laminated timber, the utilization of the fast growing timber in the field of building structures is expanded, the material cost of a conventional component is greatly reduced, the component preparation process is simplified, the production period is shortened, and the problem that adverse effects on the mechanical property, durability and fireproof performance of the component are caused through gaps in laminated boards of a structural material cross laminated timber component is solved.

Owner:NANJING UNIV OF TECH

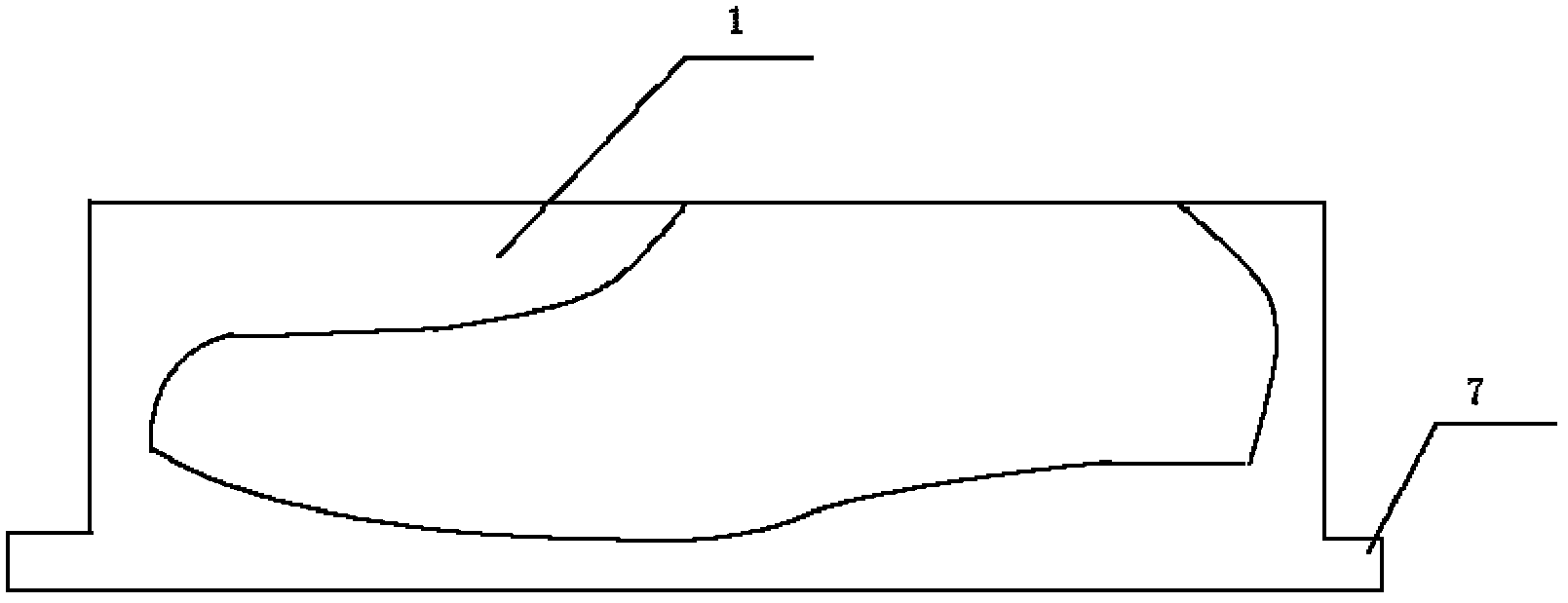

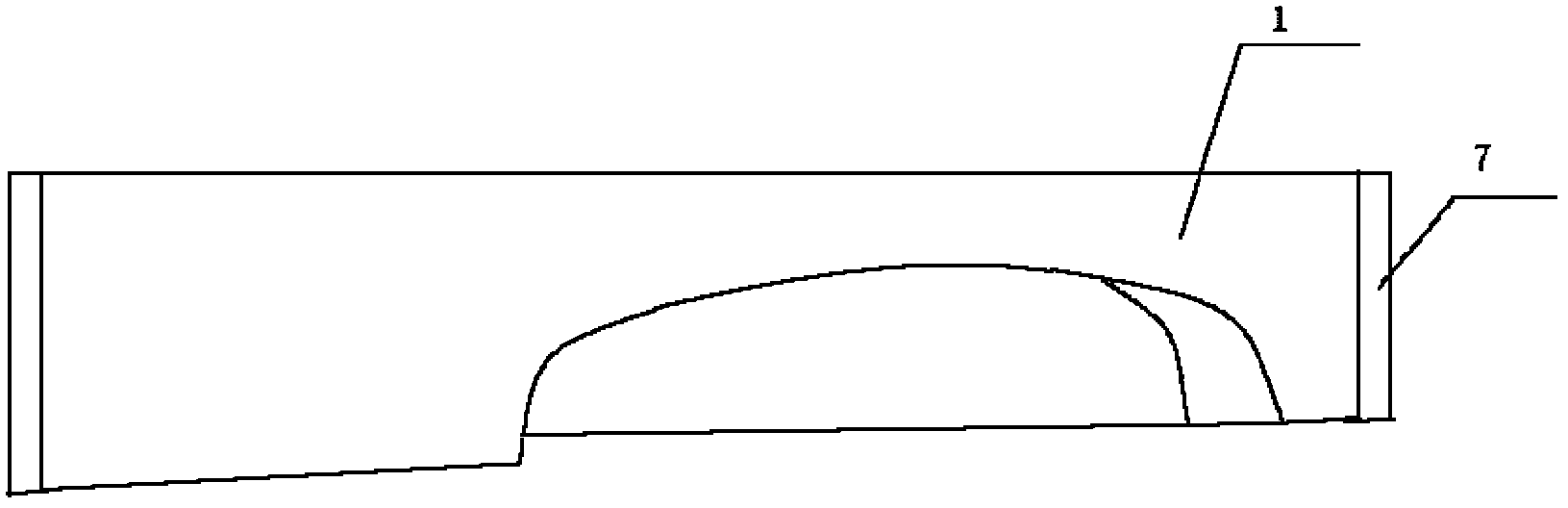

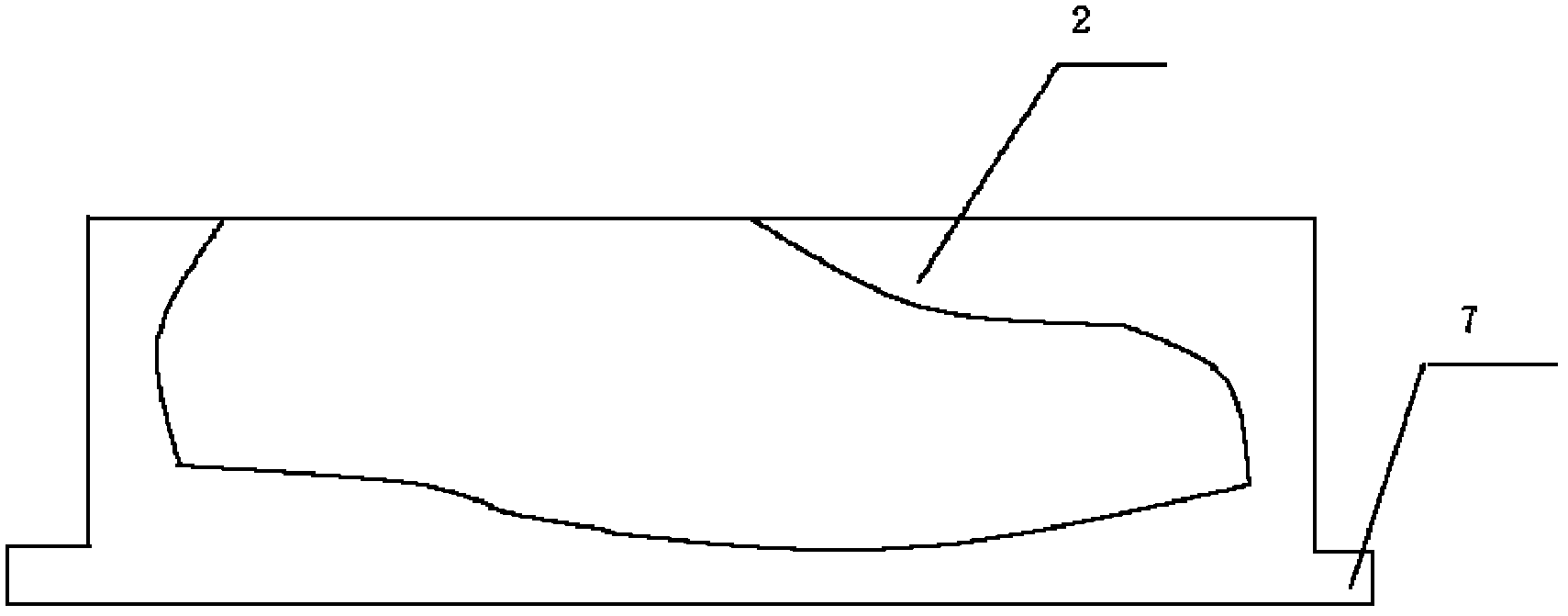

Tool and method for manufacturing foot mould

InactiveCN102601847AEasy to assembleEasy to measureCeramic shaping apparatusFoot typeUser satisfaction

The invention relates to a tool for manufacturing a foot mould, which is characterized in that the tool comprises a first mould (3) and a second mould (4), wherein the first mould (3) comprises a first cavity (1) and a second cavity (2), the second mould (4) comprises a third cavity (5) and a fourth cavity (6), and each of the first mould (3) and the second mould (4) is in a foot sole similar shape. Simultaneously, the invention further provides a method for manufacturing the foot mould by applying the tool for manufacturing the foot mould. The tool for manufacturing the foot mould is simple in assembly, simple and convenient in measurement method and capable of manufacturing one exclusive personal foot mould for a user according to the foot shape of the user, and further an exclusive shoe last for the user can be manufactured, and hand-made customized shoes consistent with the size of the feet of the user and human engineering can be manufactured, so that user satisfaction is improved.

Owner:WENZHOU HEYUAN SHOES

Wood impermeable flame retarding modification treatment agent for wood floor

ActiveCN104057512AImprove penetration resistanceStrong dimensional stabilityWood impregnation detailsSodium acetateCellulose

The invention relates to the field of wood modification treatment for wood floor, and in particular to a wood impermeable flame retarding modification treatment agent for wood floor. The modification agent is prepared from the following raw materials in parts by weight: 0.1-0.2 part of calcium sulfate, 0.01-0.02 parts of naphthalene sodium acetate, 4-5 parts of methylene binaphthalene sulfonic acid, 0.1-0.2 part of guaiacol, 10-12 parts of cellulose ether, 35-38 parts of diammonium hydrogen phosphate, 0.1-0.2 part of methyl sodium silicate, 350-400 parts of water and 6-8 parts of additives. The raw materials of the modification treatment agent are environment-friendly, easy to obtain, simple in production and low in cost; effective components including calcium sulfate, naphthalene sodium acetate, guaiacol and cellulose ether permeate into the wood, then are uniformly dispersed and adhered, and are filled into seams of the wood material, thus the compactness of tissue is improved, the impermeability of the wood material is greatly improved, the withstanding resistance to the ambient environment is relatively high, the size stability is good, the effective components are not easy to lose, and the modification effect is long-lasting; the wood floor made of the modified wood material is long-lasting, durable, waterproof, flame-retarding, good in security and high in market competitiveness.

Owner:定远县林能木业有限责任公司

Basalt fiber-enhanced wood-plastic composite material

The invention discloses a basalt fiber-enhanced wood-plastic composite material which is prepared from the following components: PVC resin, polyvinyl chloride resin particles, basalt fibers, sulfo-dipropionic acid dilaurate ester, zinc naphthenate, zinc stearate, aminopropyl triethyl silane, wood fibers, a vermiculite power, pentaerythritol and a plasticizer. Under the synergetic cooperation action of the basalt fibers, the vermiculite power, the wood fibers and the plasticizer, the mechanical property of the basalt fiber-enhanced wood-plastic composite material is greatly improved.

Owner:中汉新材料科技(浙江)有限公司

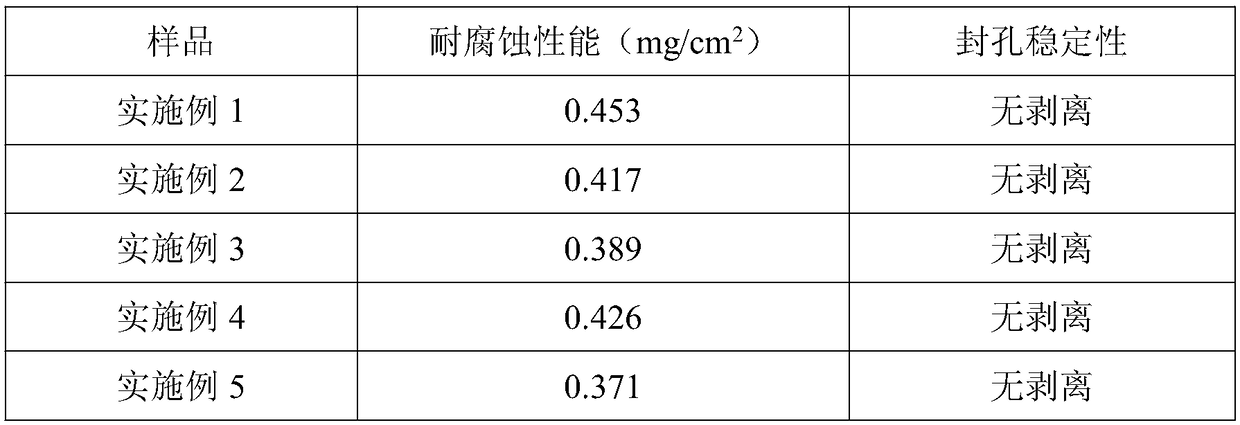

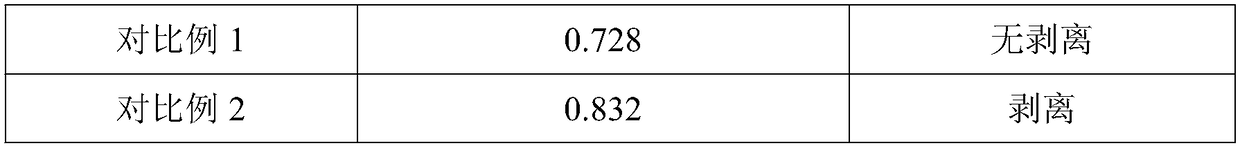

Hole sealing process for magnesium-aluminum alloy

InactiveCN108441923AGood adhesionImprove compactnessSurface reaction electrolytic coatingStearic acidMaterials science

The invention discloses a hole sealing process for magnesium-aluminum alloy. The hole sealing process comprises the following steps of: washing the magnesium-aluminum alloy by using water; degreasingthe magnesium-aluminum alloy by using alkaline liquid; polishing the magnesium-aluminum alloy by using an electrolyte and subsequently carrying out anodic oxidation; washing the magnesium-aluminum alloy by using deionized water and drying the magnesium-aluminum alloy by cold air to obtain film-coated magnesium-aluminum alloy for later use; by weight, adding 10-13 parts of tetraethoxysilane into 40parts of ethanol; subsequently adding acetic acid to regulate the pH value to be 4.6 to 5.3; continuously mixing for 30 min to 40 min to obtain sol A; adding 5-7 parts of butyl titanate into 60 partsof ethanol; mixing the butyl titanate with the ethanol uniformly; afterwards slowly adding the acetic acid to regulate the pH value to 3.5 to 4; continuously mixing for 30 min to 40 min to obtain solB; dissolving stearic acid by using isopropanol; adding the sol A and the soil B into the isopropanol to obtain hole sealing liquid; and carrying out hole sealing on the magnesium-aluminum alloy by using the hole sealing liquid. The hole sealing process disclosed by the invention has the characteristics of being free of fluorine, free of heavy metal pollution, stable in hole sealing effect and low in energy consumption.

Owner:长沙小新新能源科技有限公司

High-strength high-toughness modified PET/PTT alloy material

The invention discloses a high-strength high-toughness modified PET / PTT alloy material, which comprises the following components by mass: 37%-63% of PET, 20%-30% of PTT, 8%-15% of modified carbon fiber, 5%-10% of a plasticizer, 2%-4% of AS-g-GMA, 1%-3% of nano-silicon dioxide, 0.1%-0.5% of an antioxidant, and 0.1%-1% of a lubricant. The modified carbon fiber is short cut polyacrylonitrile carbon fiber with the surface subjected to oxidation pre-treatment and gamma-aminopropyl trimethoxy silane coupling agent activation treatment. The high-strength high-toughness modified PET / PTT alloy material provided by the invention integrates the respective advantages of PET and PTT, also has the advantages of high strength, high modulus, high toughness, good electrical conductivity, thermal conductivity and thermal stability, etc., and has the characteristics of good size stability, strong chemical resistance, low cost and wide adaptability.

Owner:王妮娜

Manufacturing process of IMD type automobile rolling door

ActiveCN110435173AIncrease diversityHigh transparencySynthetic resin layered productsVehicle componentsInjection mouldingInjection molding machine

The invention relates to the technical field of manufacturing processes of automobile rolling doors, in particular to a manufacturing process of an IMD type automobile rolling door. The process comprises the following steps of: 1. heating a glue film to soften the glue film; 2. carrying out plastic-suction forming treatment on the softened glue film by a plastic-suction forming method; 3. cuttingthe glue film into a preset shape after plastic-suction forming; 4. placing the glue film obtained in the step 3 into an injection mold; 5. closing the mold by an injection molding machine and injecting the molten hard glue into an injection mold, wherein the glue film and the hard glue are molded into a whole; and 6. and opening the mold of the injection molding machine and taking out the injection molded product. The manufacturing process of the IMD type automobile rolling door, provided by the application, replaces the flexible glue with the IMD glue film, and the pattern layer of the IMD glue film can be subjected to treatments such as pattern biting, pattern increasing, grain manufacturing and the like, and diversification of the IMD glue film is increased. The protective film layer of IMD glue film can prevent the pattern layer from being scraped flower, and makes IMD glue film's surface reach highlight effect simultaneously. The base layer of IMD glue film and hard glue are firmand the IMD glue film is difficult to take off from the hard glue.

Owner:DONGGUAN HIROCA AUTOMOTIVE TRIM TECH CO LTD

Preparation method of stereoscopic low-carbon fur spun wool

InactiveCN102808277ASuper three-dimensional senseUnique textureWeft knittingTextile treatment by pouringPre treatmentSizing

The invention discloses a preparation method of stereoscopic low-carbon fur spun wool. The preparation method comprises the following steps of: production of a finished color stripe, spinning of spun yarns, weaving and settling, wherein production of the finished color stripe comprises the following steps of: pre-treatment of wool and prolivon fiber Paster, respective dyeing of the wool and the prolivon fiber Paster, back washing, drying, silver mixing, first needle, second needle, recombing, can gilling and finisher gilling to obtain a finished stripe; spinning of the spun yarns comprises the following steps of: silver mixing, first needle, second needle, third needle, fourth needle, roving, combined spinning plus winding machines, doubling and two-for-one twisting; weaving comprises the following steps of production of a card, yarn drum placement and weaving with a circular knitting machine; and settling comprises the following steps of: wool washing with liquid flow, wet blank sizing, brushing and shearing, and burning and steaming. According to the method disclosed by the invention, the fur spun wool prepared by the method has the advantages of full bone feel, strong size stability, strong third dimension of a wool surface of a product, good glossiness, difficulty in deformation, strong recovery property, dual character of formal clothes and leisure fabric of the product, and wide application range.

Owner:JIANGSU LUGANG SCI & TECH

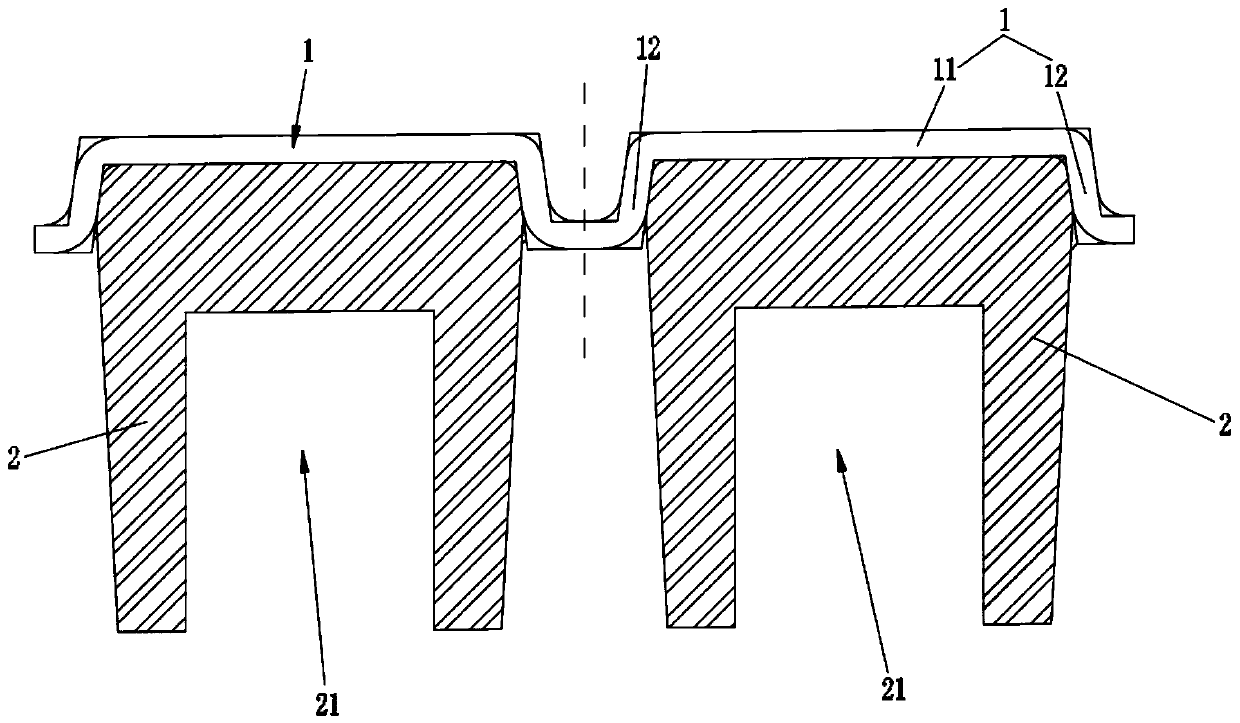

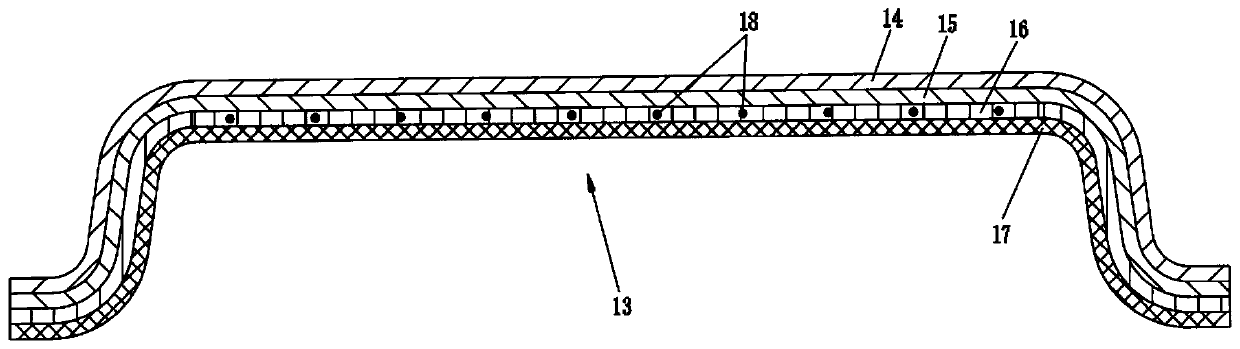

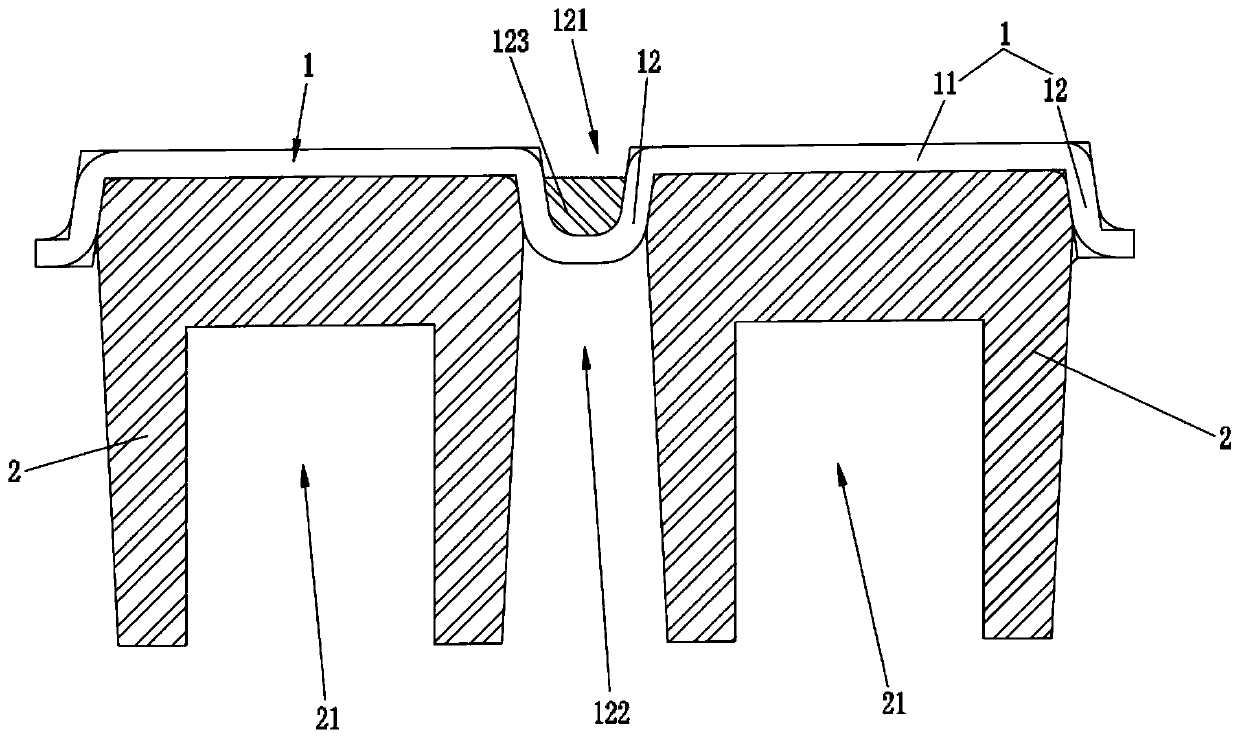

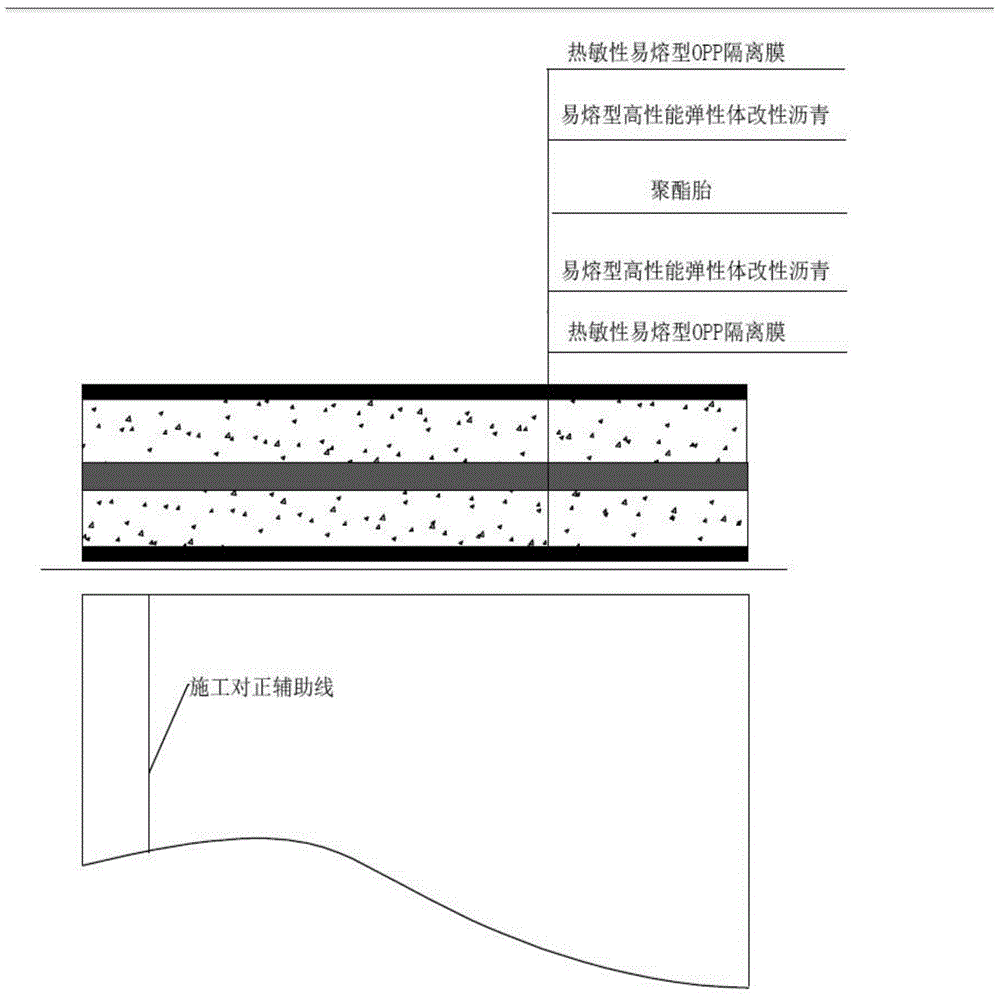

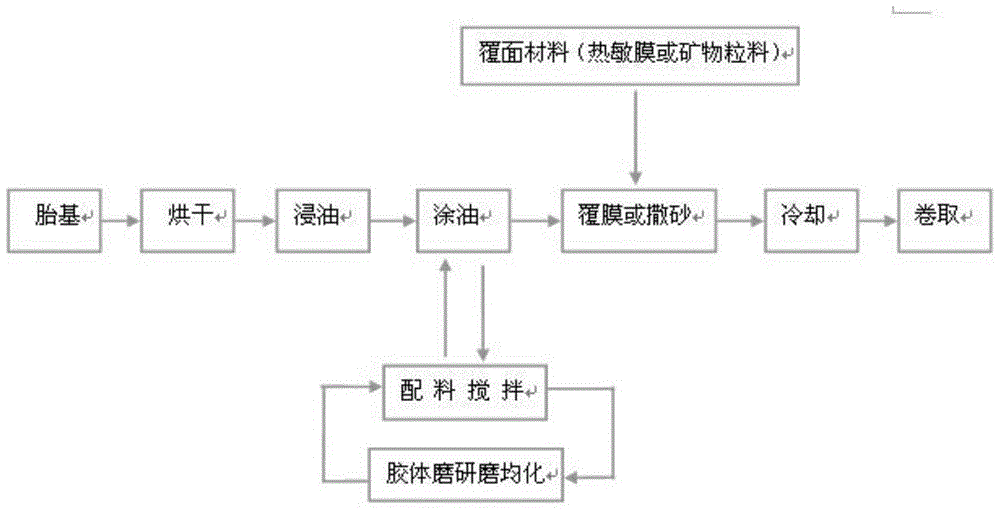

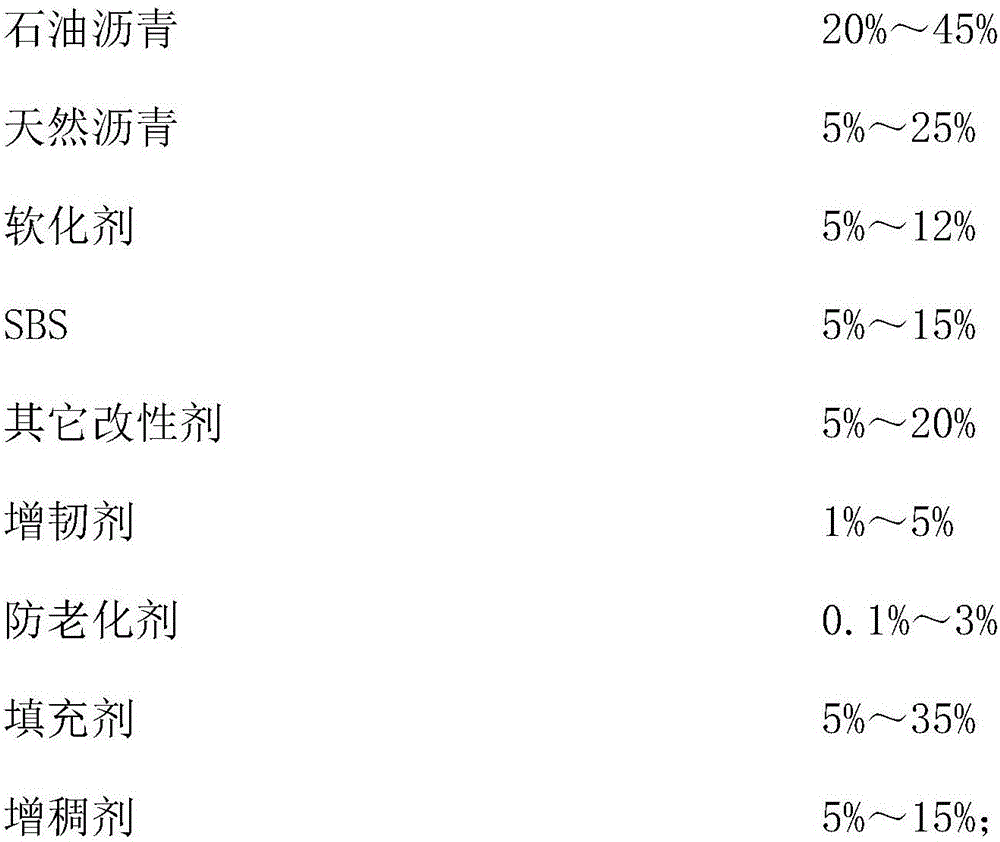

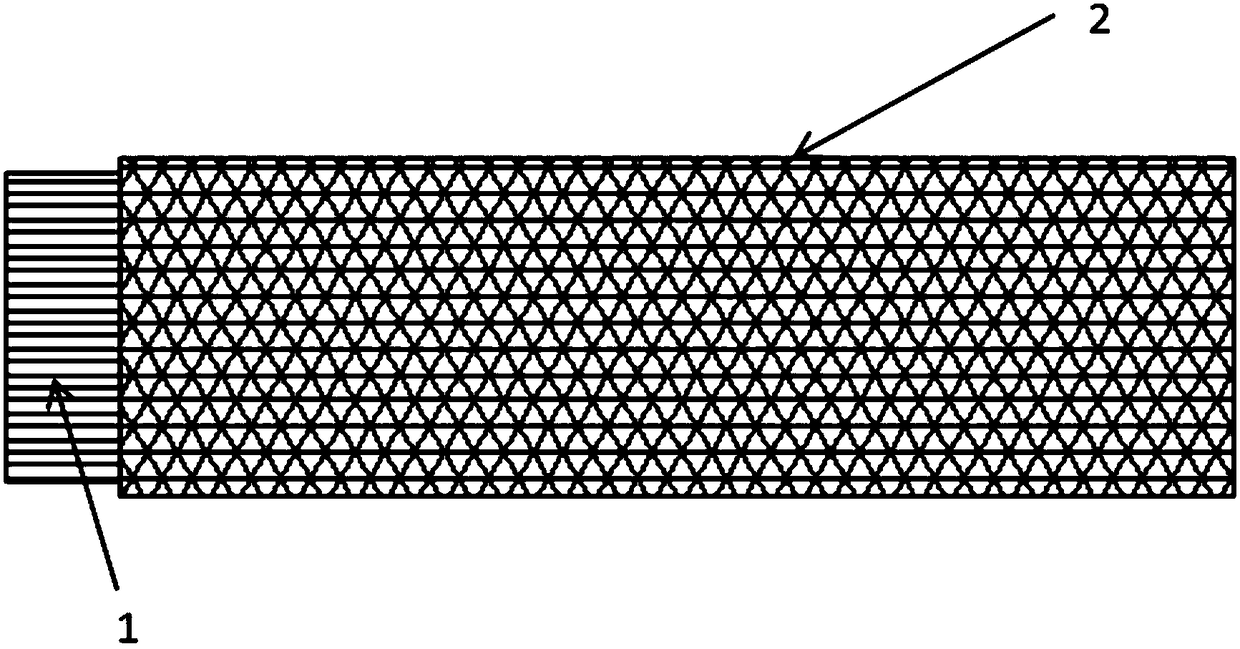

A Fusible Elastomer Modified Asphalt Waterproof Membrane

ActiveCN104553130BImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsPolyester

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

Filter cloth applied to non-ferrous metal high-purity extraction and weaving method thereof

ActiveCN104353285AAvoid slackHigh interception precisionFiltration separationPolymer scienceNonferrous metal

The invention discloses filter cloth applied to non-ferrous metal high-purity extraction. The multifilament of the filter cloth adopts superfine denier porous polypropylene multifilament, the filter cloth is manufactured in a high-temperature instantaneous polymerization surface treatment process after the weaving of warps and wefts, the texture of the filter cloth is plain, twill, satin weave or any one of all multilayer fabric structures, and the high temperature range is 120-220 DEG C. The filter cloth takes full advantages of the superfine denier porous polypropylene multifilament such as fine single fibers and porous single-beam multifilament, high-temperature instantaneous polymerization surface treatment process is adopted, and the woven filter cloth has the characteristics of high interception precision, good filter cake stripping capacity, excellent acid and alkali resistance and better hydrophobicity. Meanwhile, the invention discloses a weaving method of the filter cloth.

Owner:厦门厦迪亚斯环保过滤技术有限公司

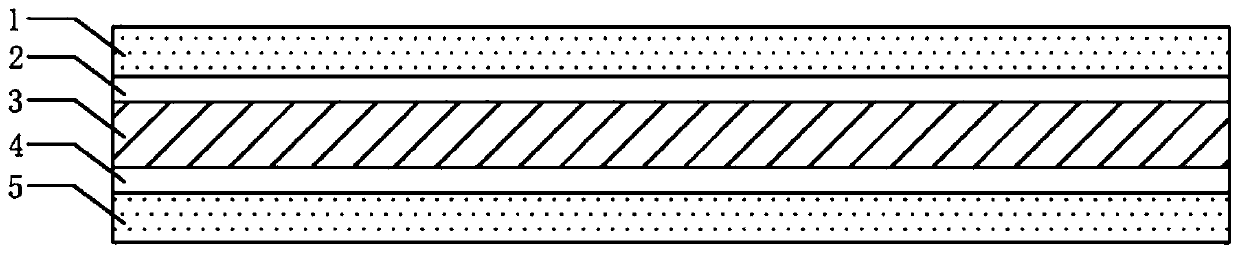

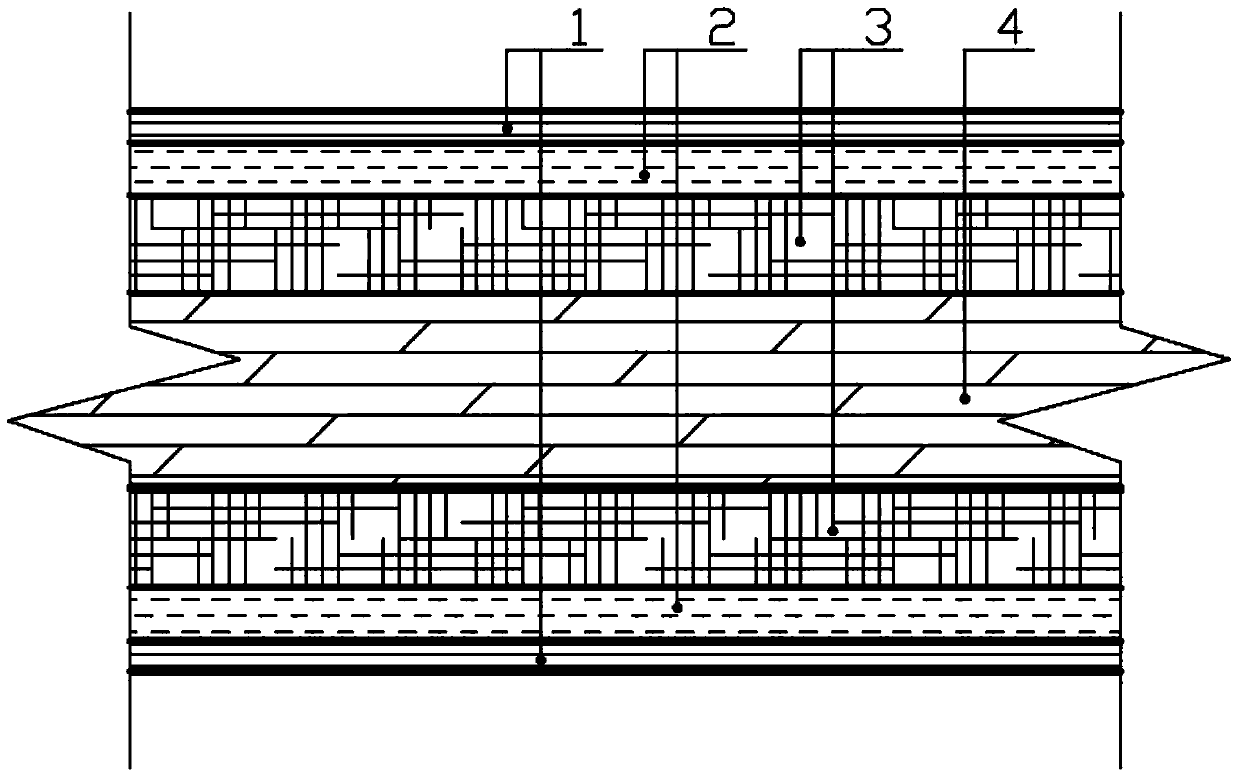

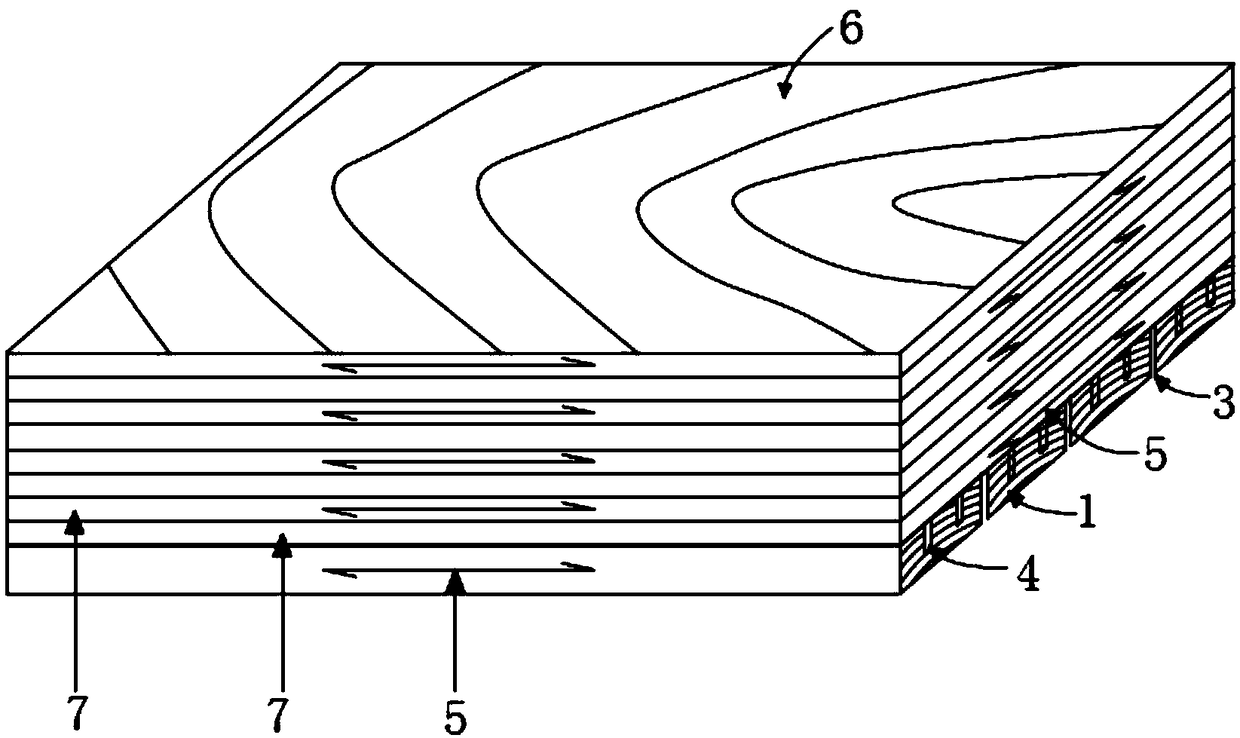

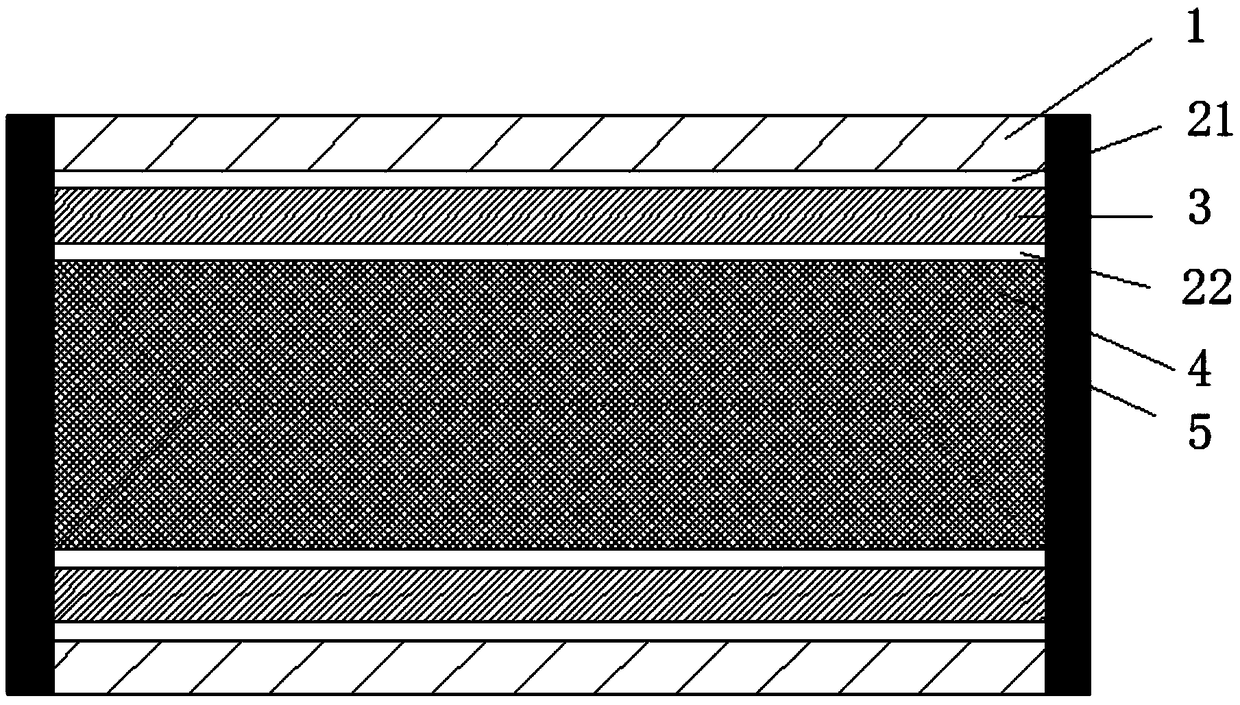

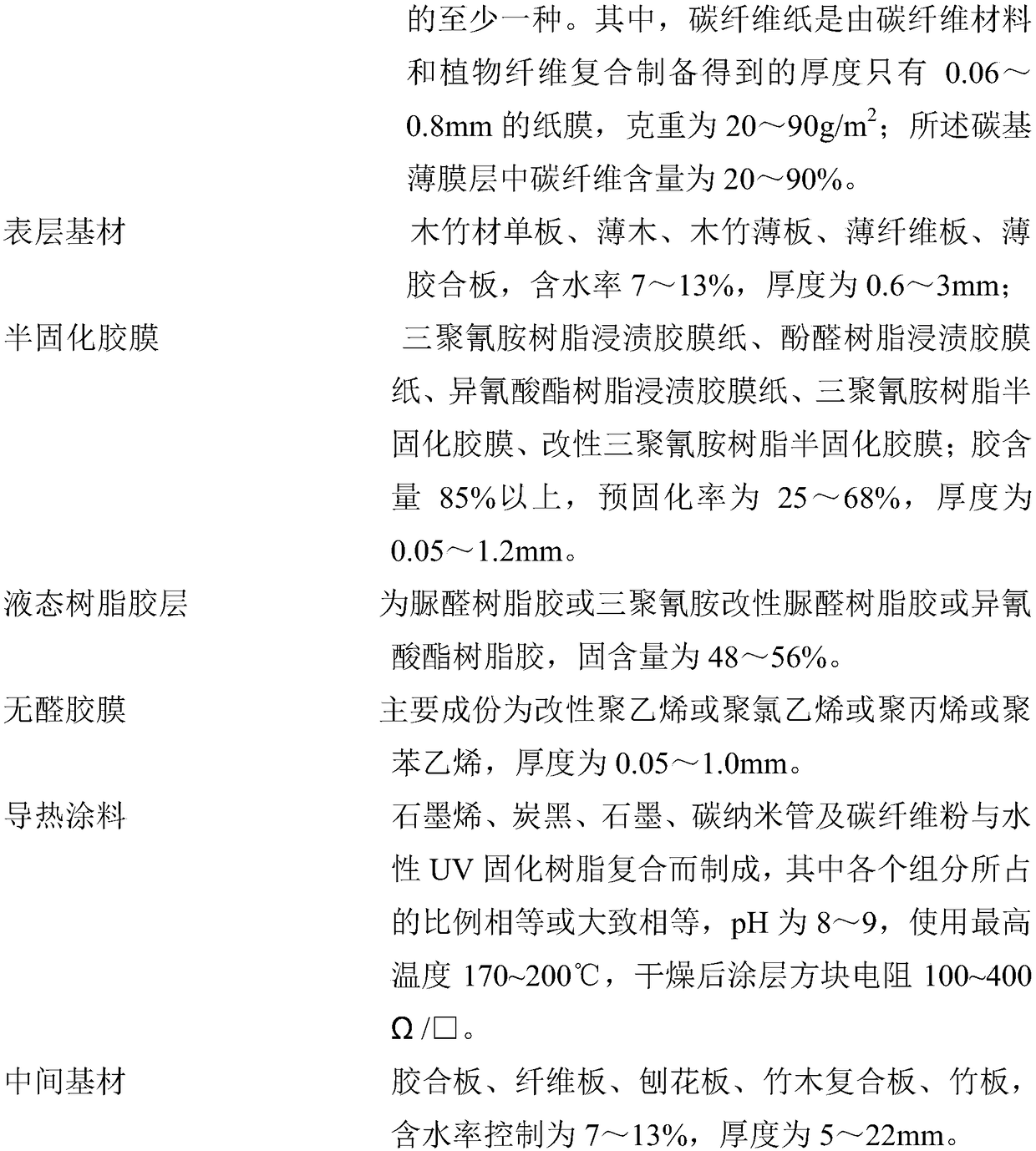

Heat conduction multifunctional composite artificial board for floor-heating floor substrate and manufacture method thereof

ActiveCN108406982AImprove thermal conductivityImproved dimensional stabilityOther plywood/veneer working apparatusSynthetic resin layered productsManufacturing efficiencyBonding strength

The invention provides a heat conduction multifunctional composite artificial board for a floor-heating floor substrate and a manufacture method thereof. The heat conduction multifunctional compositeartificial board comprises a surface layer substrate, a glue layer, a heating layer and an intermediate substrate. The heating layer is a carbon-based film, at least one carbon-based film is correspondingly arranged on the upper side and the lower side of the intermediate substrate, and heat-conducting layers are arranged on the side faces of the periphery of the heat conduction multifunctional composite artificial board for the floor-heating floor substrate. The heat-conducting layers are formed by coating heat-conducting paint. According to the heat conduction multifunctional composite artificial board, the heat-conducting layers can form rapid heat-conducting channels and enhance the heat-conducting performance; at the same time, after the implanted carbon-based film and bonding materials are fused and solidified, the mechanical and mechanical properties such as structural stability, bonding strength, bending strength and impact resistance can be effectively enhanced; and at the same time, because the implanted carbon-based film has good conductivity, the good antistatic and electromagnetic radiation shielding properties are achieved. The manufacture method can effectively improve the heat-conducting property and dimensional stability while improving the manufacture efficiency, and the large-scale production is facilitated.

Owner:GUANGXI UNIV

High-fatigue-resistance composite material automobile plate spring and manufacturing method thereof

InactiveCN108099317AStrong anti-fatigueStrong dimensional stabilitySynthetic resin layered productsLaminationMechanical engineeringShear resistance

The invention discloses a high-fatigue-resistance composite material automobile plate spring and a manufacturing method thereof. The high-fatigue-resistance composite material automobile plate springcomprises at least one layer of unidirectional fiber layer which is stacked and laid, and at least one layer of two-dimensional braided sleeve which sleeves the outer surface of the unidirectional fiber layer. The manufacturing method comprises the following steps: stacking and laying at least one layer of the unidirectional fiber layer; sleeving the at least one layer of the two-dimensional braided sleeve on at least one layer of the unidirectional fiber layer with the at least one layer of two-dimensional braided sleeve to prepare a fiber pre-molded body; putting the fiber pre-molded body into a molding mold, and adopting a molding technology for immersing, curing, de-molding and trimming to obtain the composite material automobile plate spring. According to the high-fatigue-resistance composite material automobile plate spring, the properties of continuous fibers, controllable angles and good mold adhering performance in the two-dimensional braided sleeve are utilized and the automobile plate spring with high fatigue resistance and excellent inter-laminar shearing resistance is prepared; the preparation technology is simple and the problems that a traditional pure unidirectionallaid fiber plate spring has no restriction in an annular direction and poor fatigue resistance and a three-dimensional pre-molded body braiding technology is complicated are effectively avoided.

Owner:WUHAN UNIV OF TECH

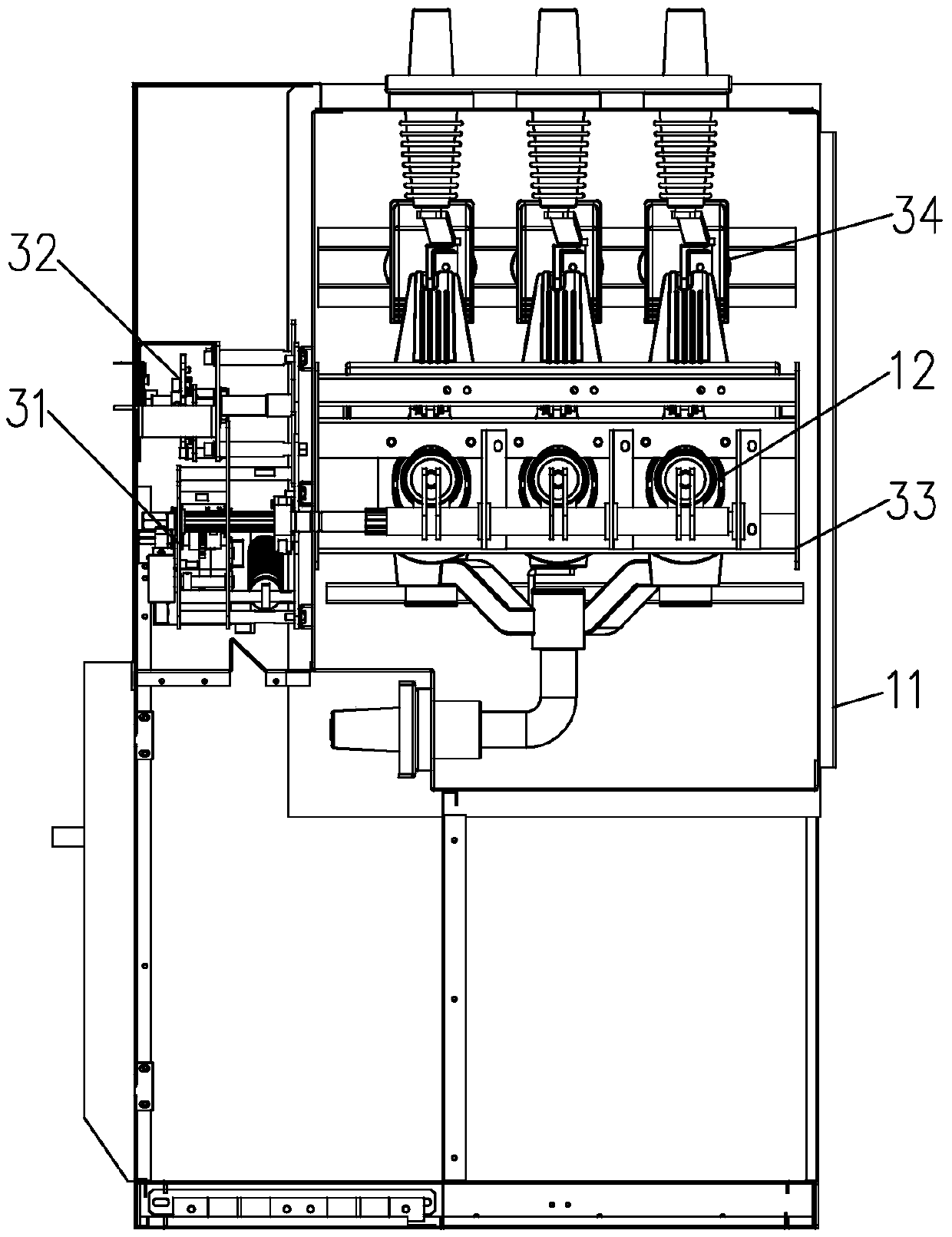

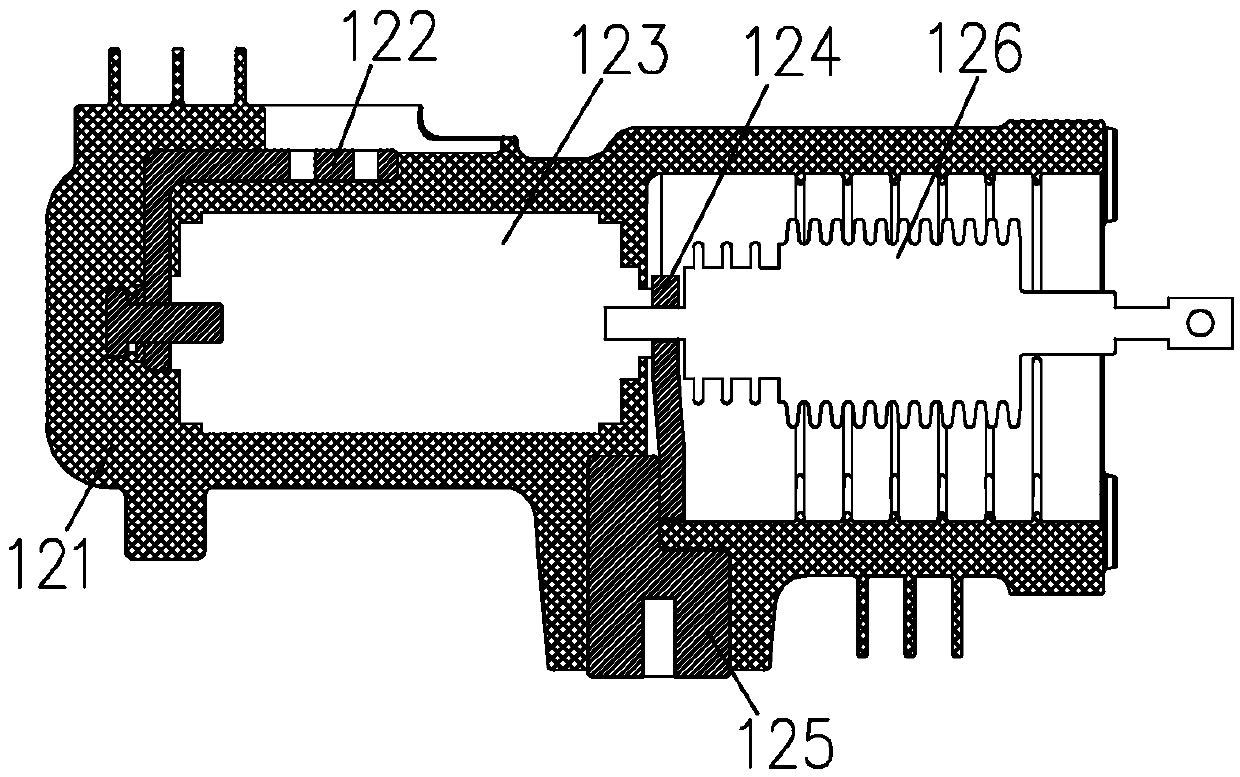

Air insulation ring main unit

An air insulation ring main unit comprises a housing and a breaker body arranged inside the housing, wherein the breaker body comprises a solid-sealed polar pole shell which is made of glass fiber reinforced nylon resin. The air insulation ring main unit provided by the invention has a relatively safe and reliable running process, is relatively low in manufacture and maintenance cost, is harmless to environment and a human body, can be recycled, has a reduced overall weight and is easy to carry, and is low in cost.

Owner:BEIJING HEROSAIL POWER SCI & TECH

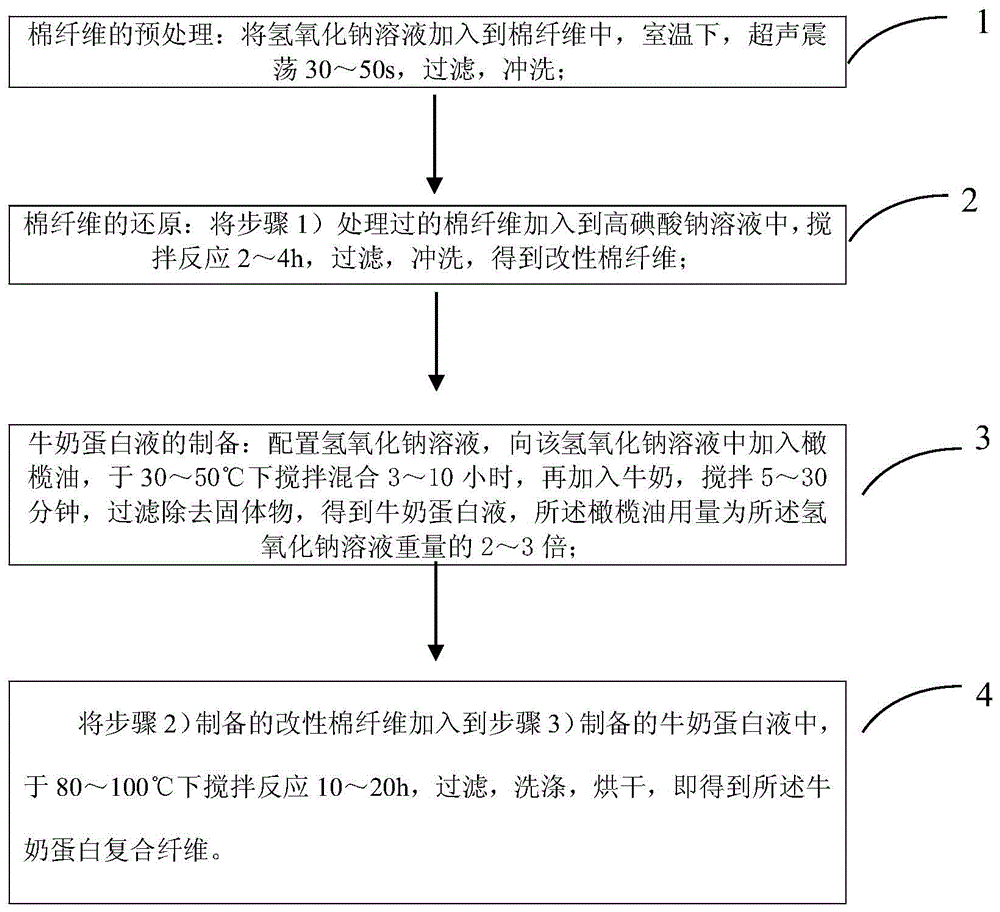

Preparation method for milk protein composite fiber, milk protein composite fiber and application

ActiveCN104005227ARaw materials are easy to getCompact reaction stepsVegetal fibresPre treatmentChemistry

A provided preparation method for milk protein composite fiber comprises the following steps: pre-treatment on cotton fiber, preparation of a reduction milk protein solution of cotton fiber, and preparation of milk protein composite fiber. The preparation method for the milk protein composite fiber is easily available in raw materials, compact in reaction steps, easily controllable in process and strong in technology maneuverability and repeatability. The invention also provides the milk protein composite fiber which comprises cotton fiber at the core and milk protein at the external surface of cotton fiber, and application of the milk protein composite fiber as a clothes material. When a garment made from the provided composite fiber is worn on a body, milk protein directly contacts skin, the skin-friendly property is better than that of conventional plant fiber, and also the garment has gloss of silk and is strong in sweat absorbing property, good in dimension stability and low in cost. According to the application of the milk protein composite fiber, the milk protein composite fiber is applicable to prepare intimate apparels, such as bras, underpants, small vests and summer clothes.

Owner:COSMO LADY (CHINA) HOLDINGS

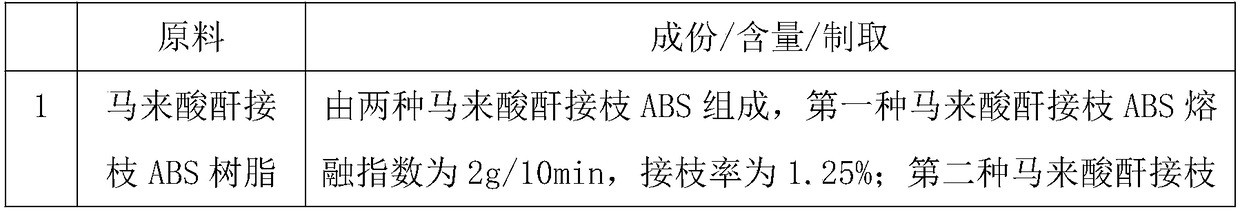

High-toughness and ageing-resistant wood-plastic composite material and application thereof

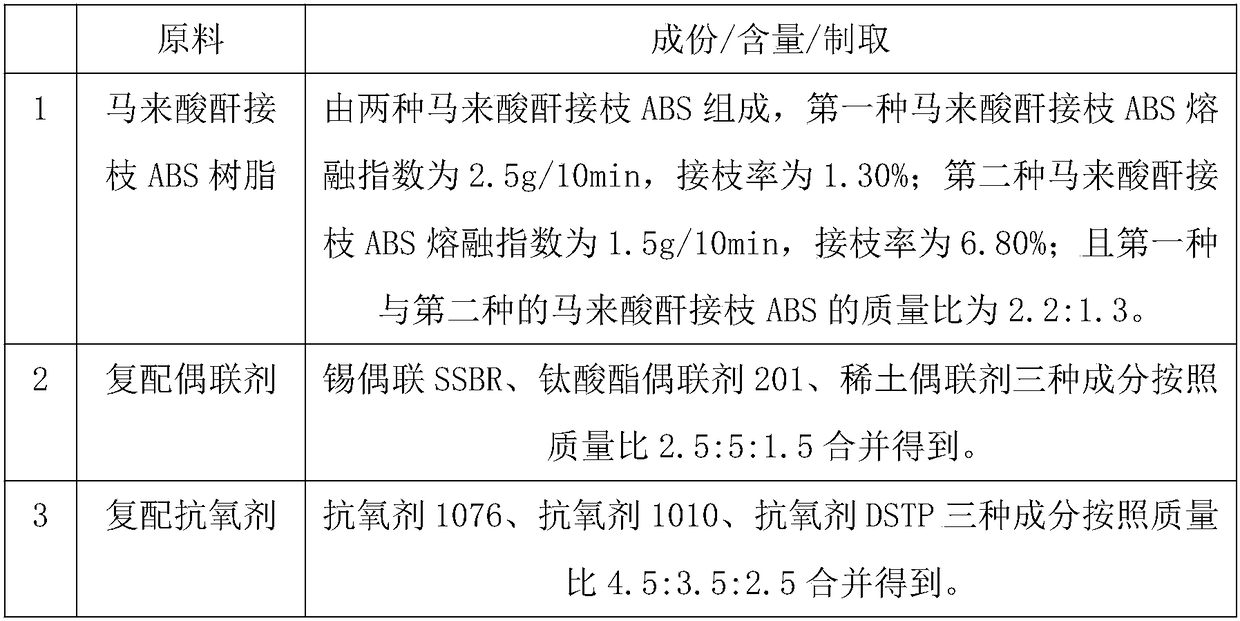

The invention discloses a high-toughness and ageing-resistant wood-plastic composite material and an application thereof and relates to the technical field of wood-plastic composite materials. The high-toughness and ageing-resistant wood-plastic composite material contains the following raw materials: polyvinyl chloride resin powder SG-5, mallow bark fiber, maleic anhydride grafted ABS (Acrylonitrile Butadiene Styrene) resin, calcium-titanium tailing powder, villus powder, epoxidized fatty acid methyl ester, gum easy T-78, yangba powder, compound coupling agent and compound antioxidant. The wood-plastic composite material disclosed by the invention has the beneficial effects that the properties in the aspects of mechanical strength, waterproof property, oxidation resistance, ageing resistance and shielding property and the like are obviously improved, the whole property of the wood-plastic composite material is improved, the application property is improved, the service life is betterensured and the promotion value is good.

Owner:合肥岑遥新材料科技有限公司

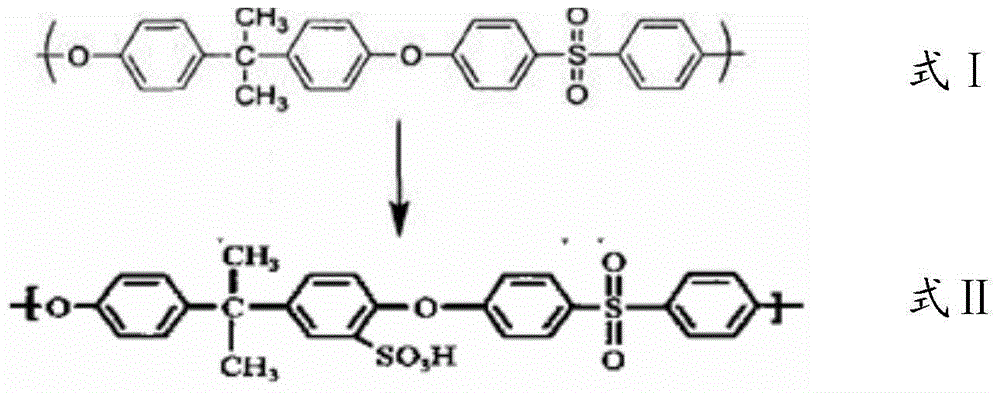

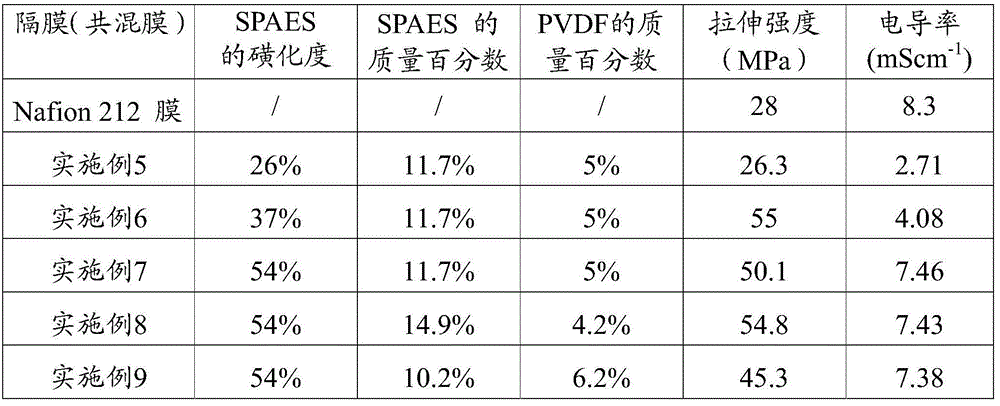

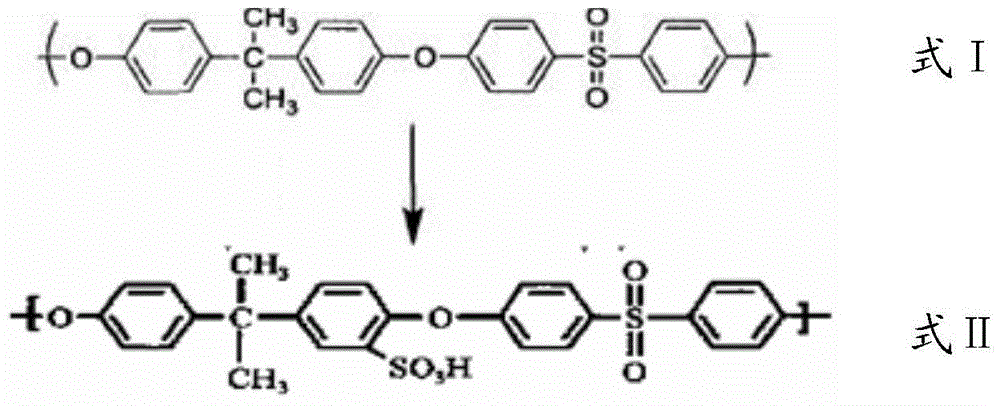

Sulfonated poly (arylene ether sulfone), blend film for all-vanadium flow battery and preparation methods thereof

ActiveCN103601888ALow priceLow costCell component detailsFuel cell detailsPolymer scienceElectrical battery

The invention discloses sulfonated poly (arylene ether sulfone), a blend film for an all-vanadium flow battery and preparation methods thereof. The preparation method of the sulfonated poly (arylene ether sulfone) is as follows: mixing poly (arylene ether sulfone) containing a type-I repeat unit with concentrated sulfuric acid in a ratio of 1:10-1:30w / v, reacting at 80-90 DEG C for 5-25h to obtain the sulfonated poly (arylene ether sulfone) containing a type-II repeat unit; the preparation method of the blend film is as follows: mixing the sulfonated poly (arylene ether sulfone) with polyvinylidene fluoride, adding an organic solvent to enable the mass fractions of the sulfonated poly (arylene ether sulfone) and the polyvinylidene fluoride respectively to be 10-35% and 1-12%, stirring for dissolving, filtering for defoaming, coating a glass plate, successively keeping warm at 50-80 DEG C and at 95-105 DEG C, and cooling to obtain the blend film. The preparation methods are low in price of used raw materials and simple in process, and greatly reduce the cost of the blend film. The prepared blend film has high mechanical strength and high dimensional stability and wear resistance, is suitable for long-term operation of the vanadium battery, and is conducive to commercialization.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com