High-toughness and ageing-resistant wood-plastic composite material and application thereof

A wood-plastic composite material and anti-aging technology, applied in the field of wood-plastic composite materials, can solve the problems of poor shielding and application limitations, and achieve the effects of high flame retardant grade, high mechanical strength and strong hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment relates to a high-toughness and aging-resistant wood-plastic composite material and its preparation method. The composite material is composed of the following raw materials in parts by weight:

[0052] Polyvinyl chloride resin powder SG-5 56 parts;

[0053] 35 parts of mallow stem bark fiber;

[0054] 5 parts of maleic anhydride grafted ABS resin;

[0055] 9 parts of perovskite tailings powder;

[0056] 8 parts fluff powder;

[0057] 2 parts of epoxy fatty acid methyl ester;

[0058] Glue Yisu T-78 1 part;

[0059] 1.5 parts of yangbuck powder;

[0060] 2.5 parts of compound coupling agent;

[0061] 0.8 part of compound antioxidant.

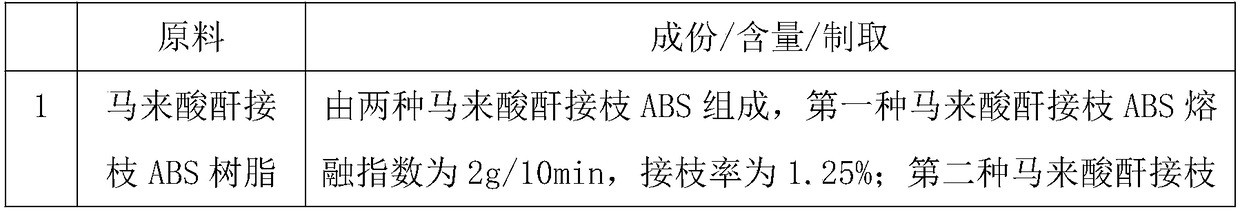

[0062] The selection and preparation of maleic anhydride grafted ABS resin, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 1 below:

[0063] Table 1

[0064]

[0065]

[0066] The preparation method of the wood-plastic composite material in this embodiment is ge...

Embodiment 2

[0072] This embodiment relates to a high-toughness and aging-resistant wood-plastic composite material and its preparation method. The composite material is composed of the following raw materials in parts by weight:

[0073] Polyvinyl chloride resin powder SG-5 62 parts;

[0074] 38 parts of mallow stem bark fiber;

[0075] 5.5 parts of maleic anhydride grafted ABS resin;

[0076] 10 parts of perovskite tailings powder;

[0077] 8.5 parts of fluff powder;

[0078] 2.3 parts of epoxy fatty acid methyl ester;

[0079] Glue Yisu T-78 1.4 parts;

[0080] 1.8 parts of yangbuck powder;

[0081] 3 parts of compound coupling agent;

[0082] 0.9 part of compound antioxidant.

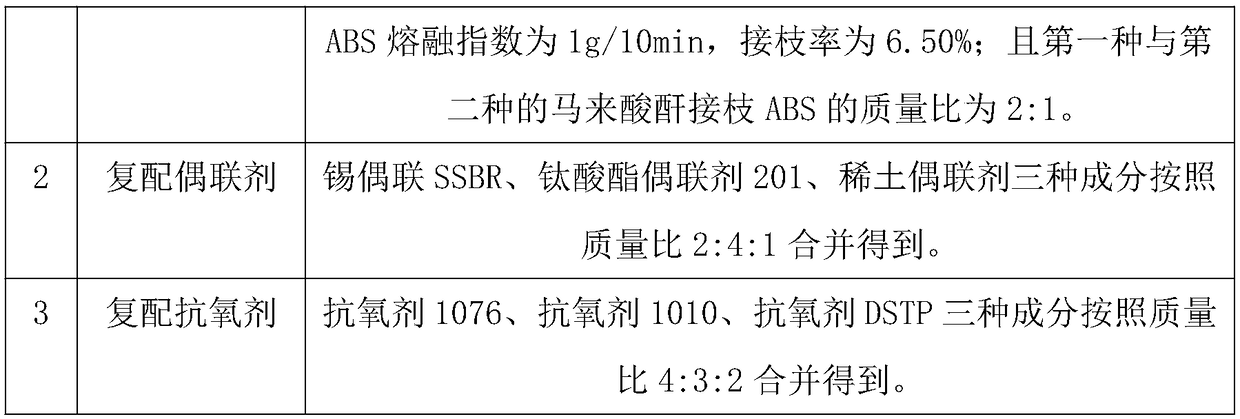

[0083] The selection and preparation of maleic anhydride grafted ABS resin, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 2 below:

[0084] Table 2

[0085]

[0086] The preparation method of the wood-plastic composite material in this embodiment is gen...

Embodiment 3

[0092] This embodiment relates to a high-toughness and aging-resistant wood-plastic composite material and its preparation method. The composite material is composed of the following raw materials in parts by weight:

[0093] Polyvinyl chloride resin powder SG-5 64 parts;

[0094] 40 parts of mallow stem bark fiber;

[0095] 6 parts of maleic anhydride grafted ABS resin;

[0096] 11 parts of perovskite tailings powder;

[0097] 9 parts fluff powder;

[0098] 2.5 parts of epoxy fatty acid methyl ester;

[0099] Glue Yisu T-78 1.5 parts;

[0100] 2 parts yangbuck powder;

[0101] 3.2 parts of compound coupling agent;

[0102] 1 part of compound antioxidant.

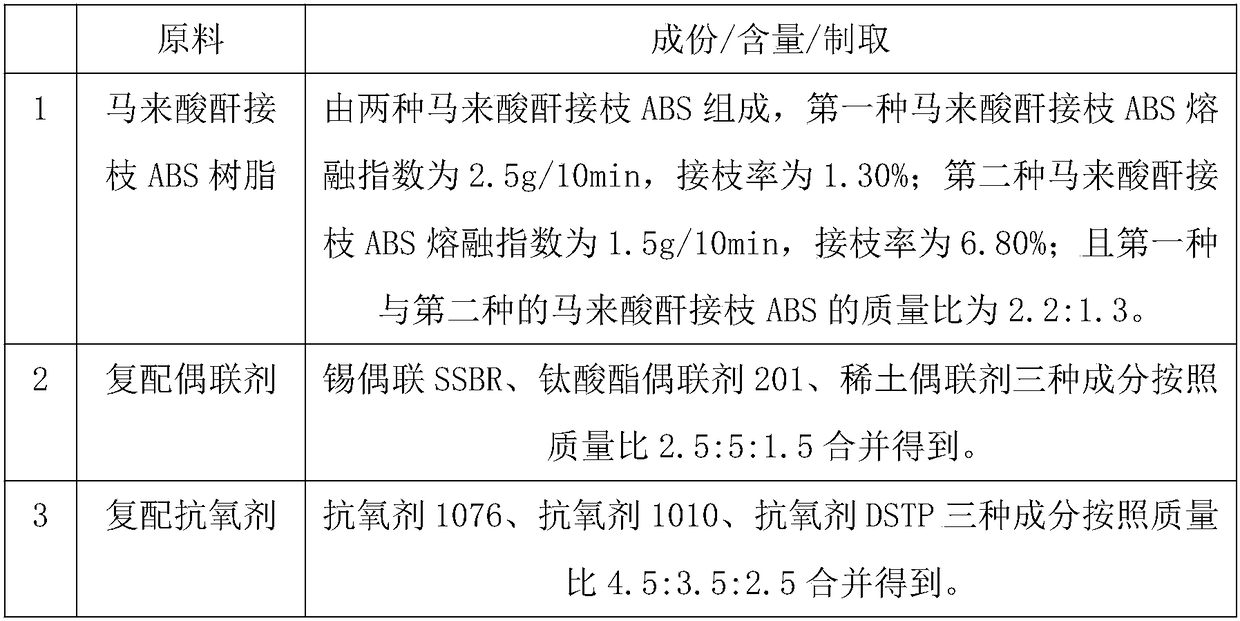

[0103] The selection and preparation of maleic anhydride grafted ABS resin, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 3 below:

[0104] table 3

[0105]

[0106] The preparation method of the wood-plastic composite material in this embodiment is generally carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com