Patents

Literature

58results about How to "Improved dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

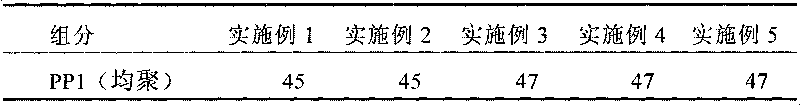

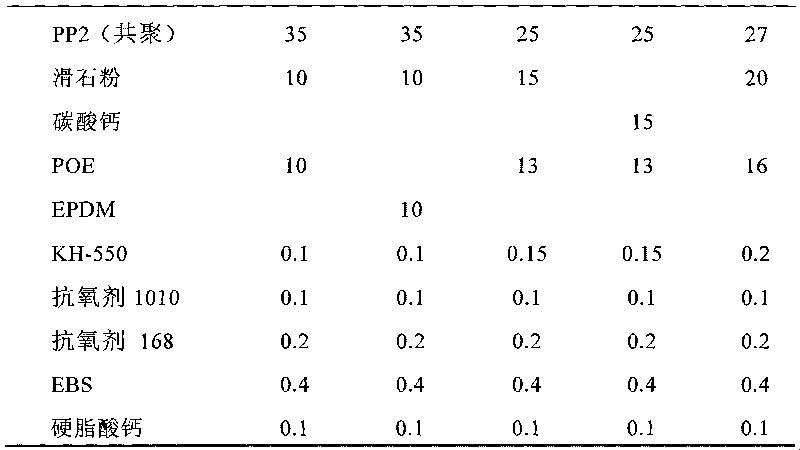

Polypropylene composition for automobile bumper and preparation method thereof

The invention relates to a polypropylene composition for a automobile bumper and a preparation method thereof; the composition comprises the following material by weight proportion: 50 to 80 percent of polypropylene resin, 10 to 25 percent of inorganic filler, 9 to 25 percent of toughener, 0 to 0.5 percent of coupling agent, 0.1 to 1 percent of antioxidant, and 0.1 to 1 percent of lubricant; and the preparation method comprises preparation, mixing, extrusion and other process steps. Compared with the prior art, the composition has the advantages of high toughness, high size stability and relatively modest cost, so that the prepared automobile bumper material meets the standards of cars, can well satisfy the needs of the customers, and has very good size matching property in the complete car assembly.

Owner:HEFEI GENIUS NEW MATERIALS

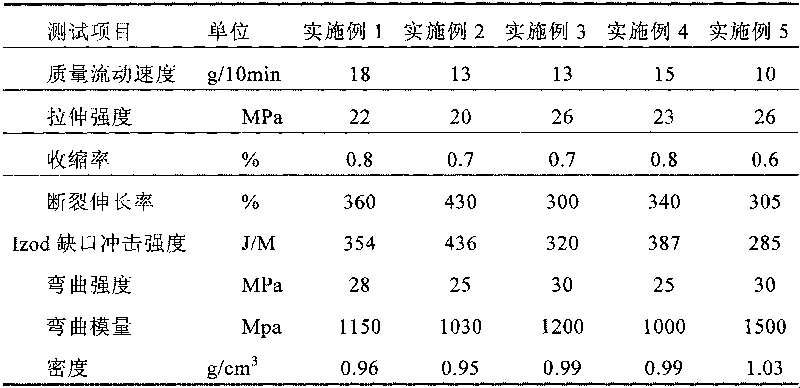

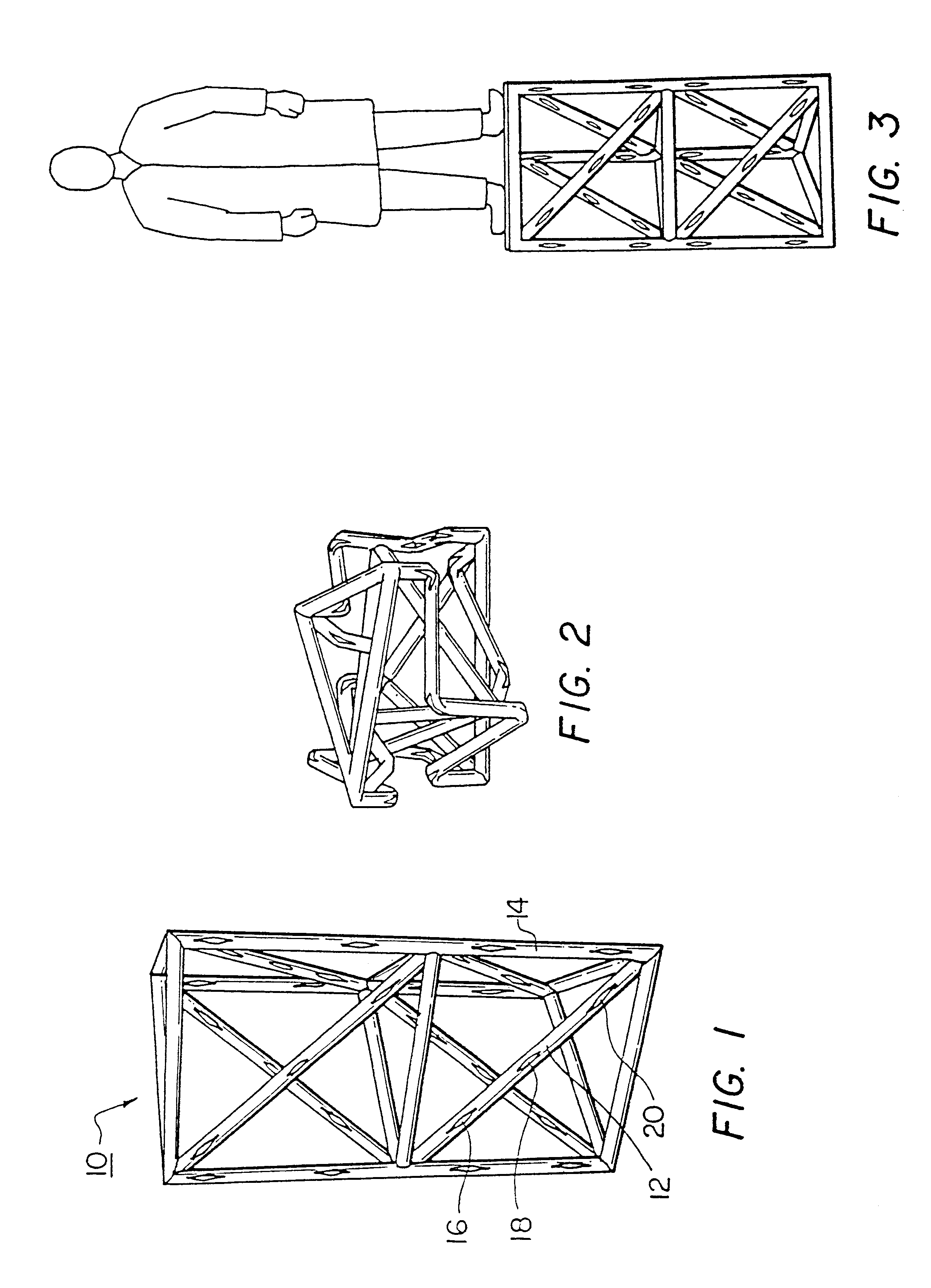

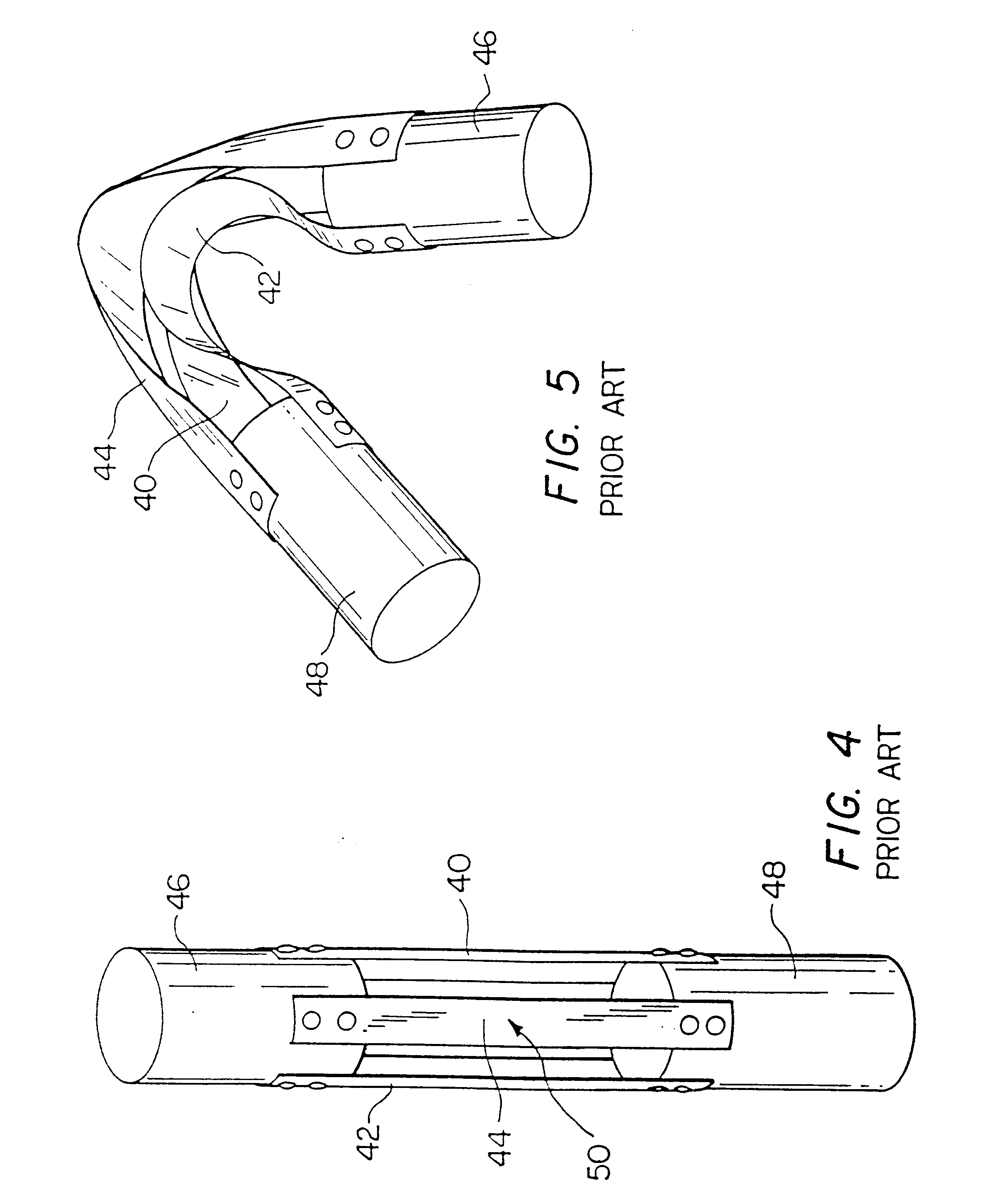

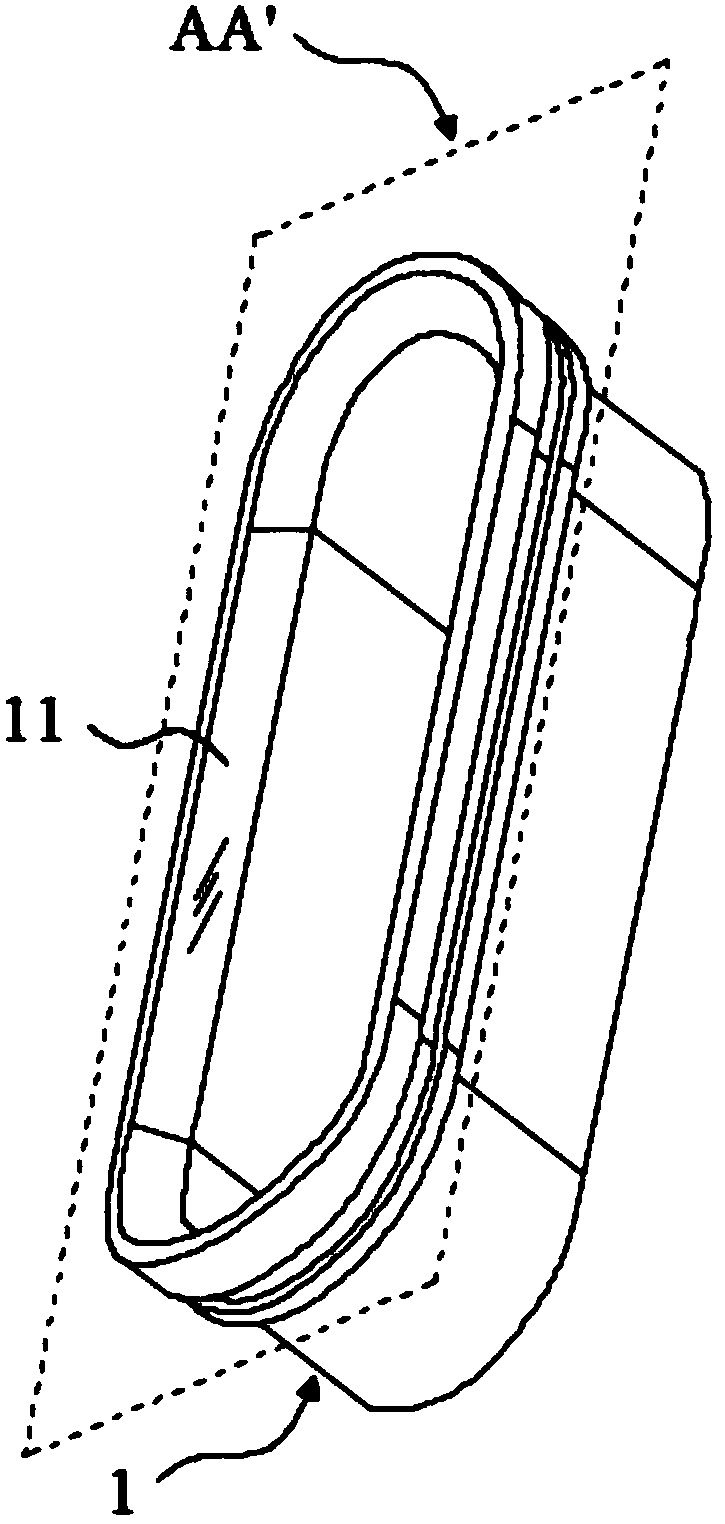

Foldable member

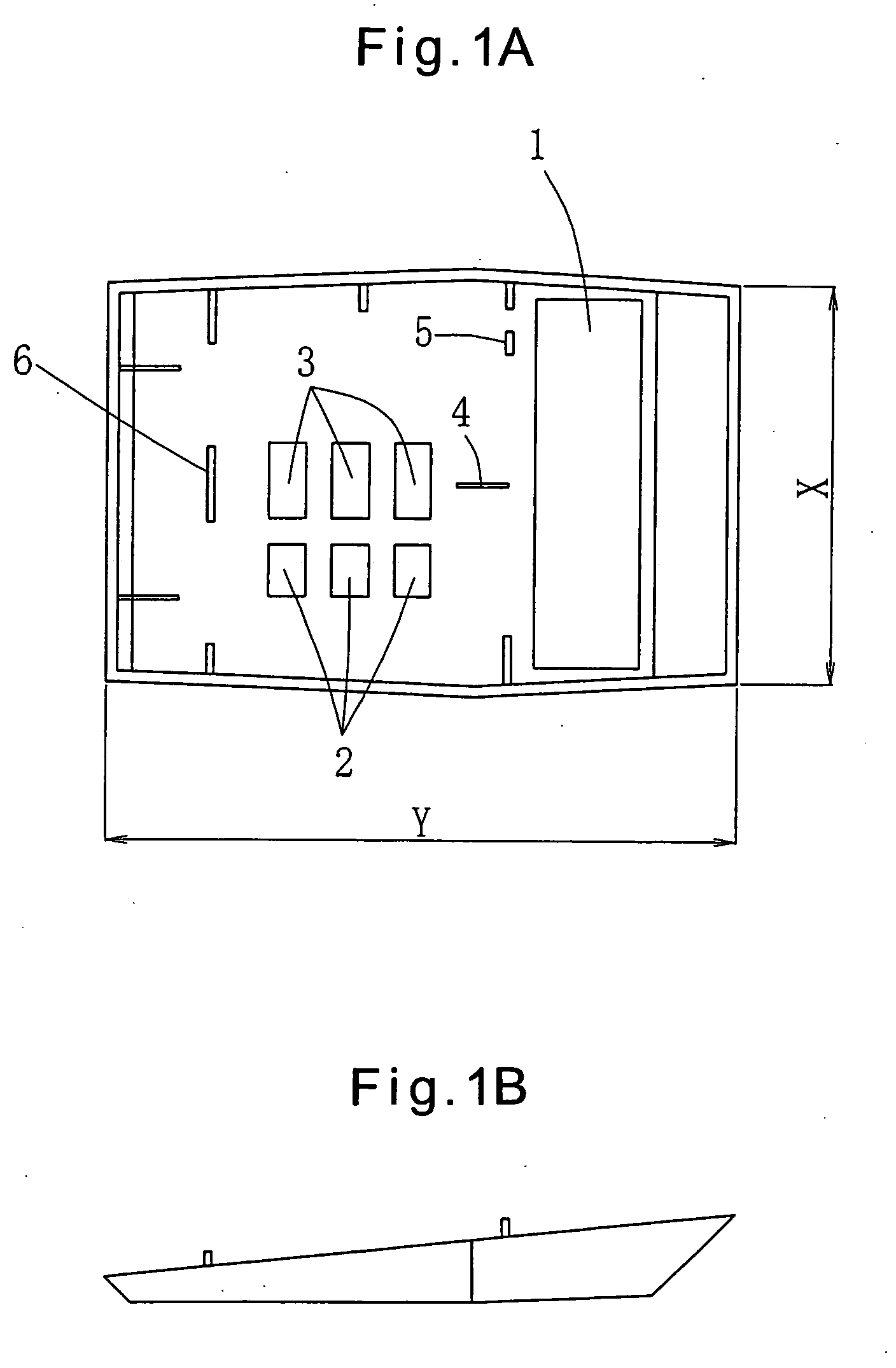

InactiveUS6321503B1Sharp weight reductionImproved dimensional stabilityCosmonautic vehiclesCosmonautic partsHinge angleEngineering

Owner:FOSTER-MILLER

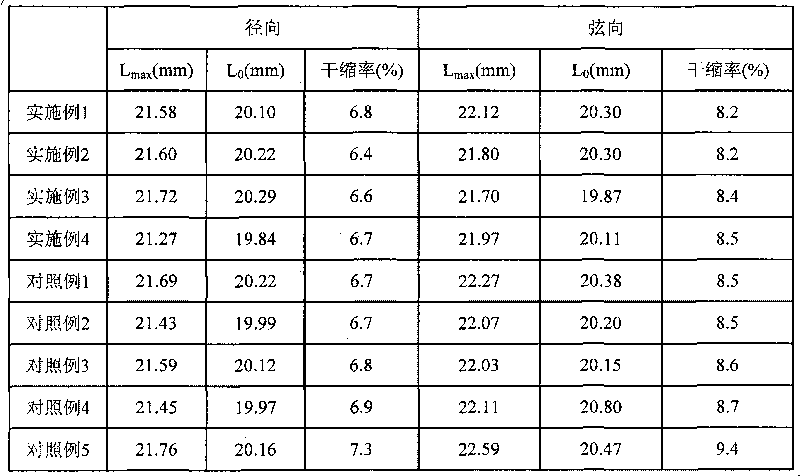

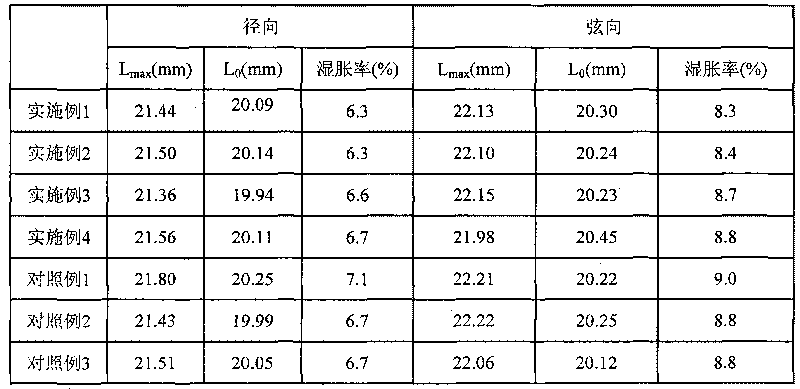

Modified planted forest timber and preparation method thereof

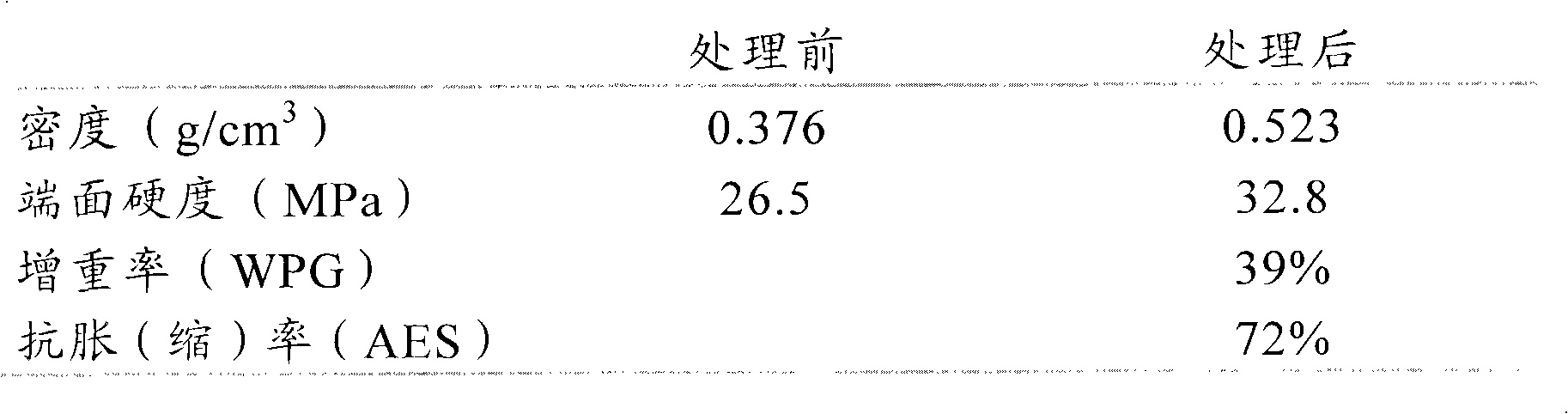

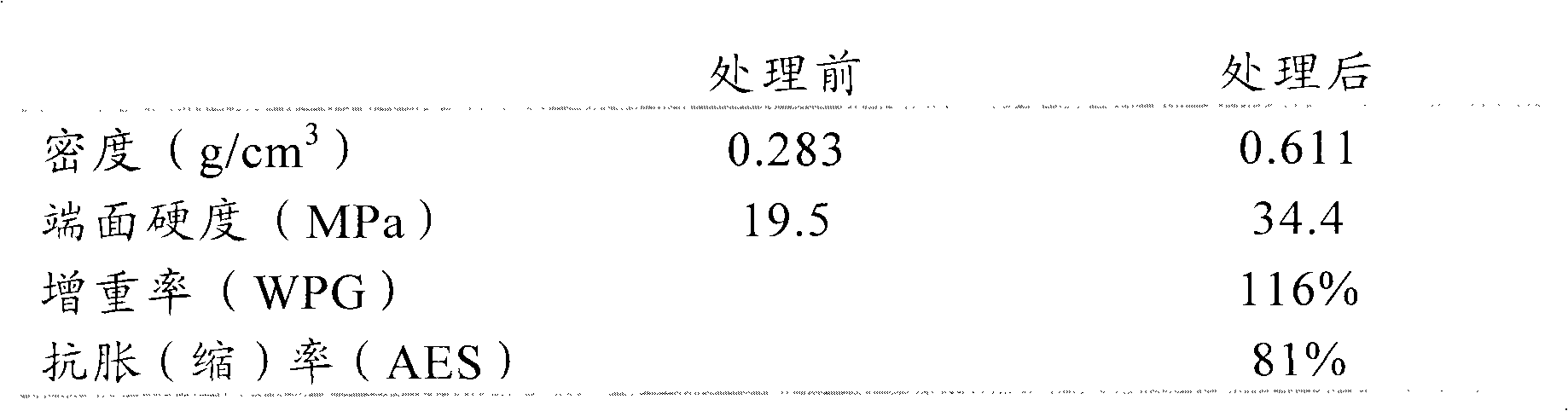

ActiveCN101745951AImproved dimensional stabilityIncreased dry shrinkage and corrosion resistancePressure impregnationWood dampingCorrosion resistantUrea

The invention discloses impregnation reinforcement-thermal treatment modifying technology for planted forest timber. The technology comprises the following steps in order: 1) impregnating the timber by adopting impregnation liquid which uses modified urea resin as a main agent of the impregnation liquid; and 2) thermally treating the impregnated timber in vacuum. The timber prepared by the method has high dimensional stability and high strength; the bulking resistance and the corrosion resistance of the timber are improved; the added value of the thermally-treated timber is improved; and the application range of the thermally-treated timber is expanded.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Ceramic exhaust gas sensor

InactiveUS20110139618A1Improved dimensional stabilityReduce occurrenceMaterial analysis by electric/magnetic meansAir quality improvementMetallurgyExhaust gas sensor

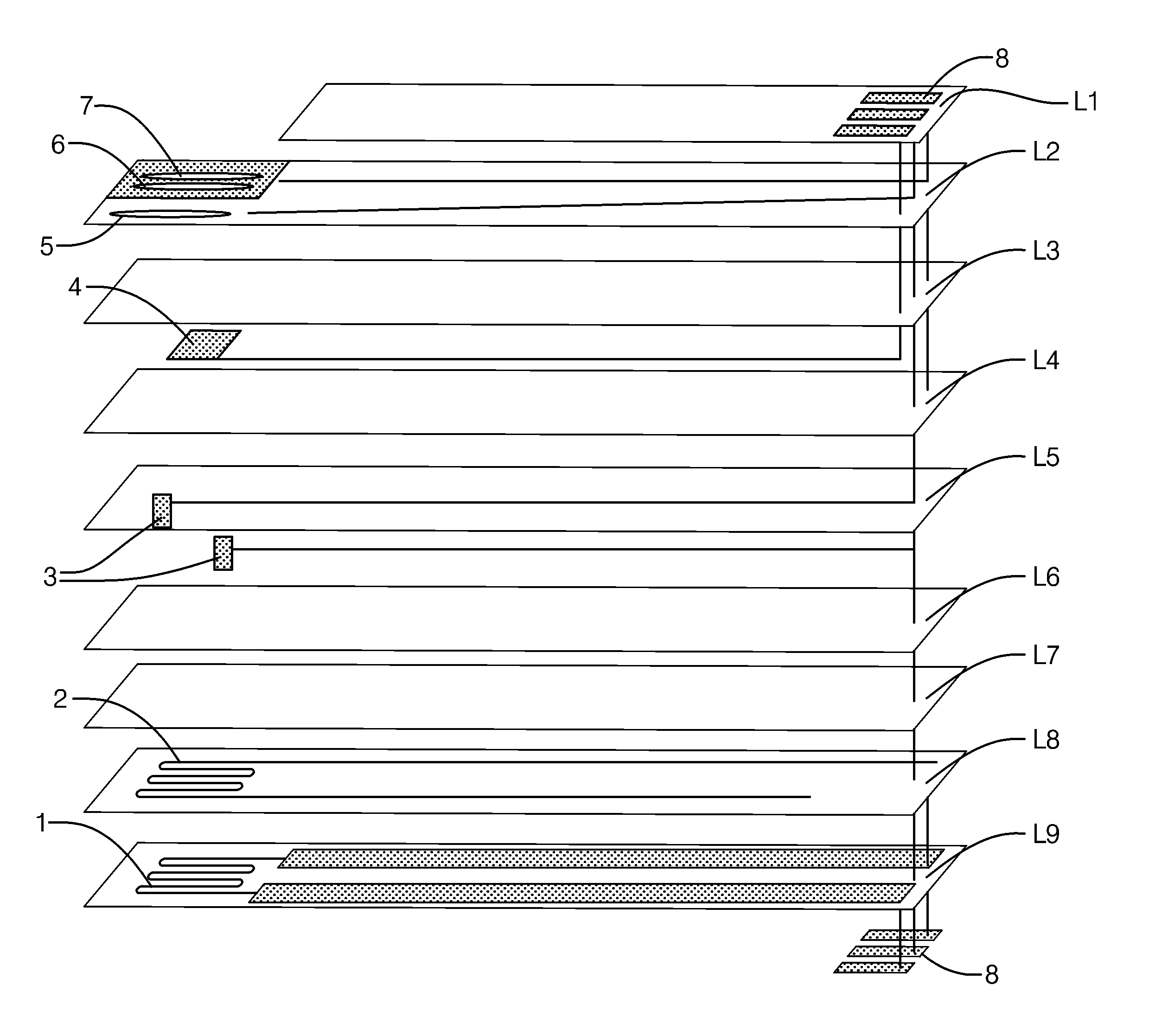

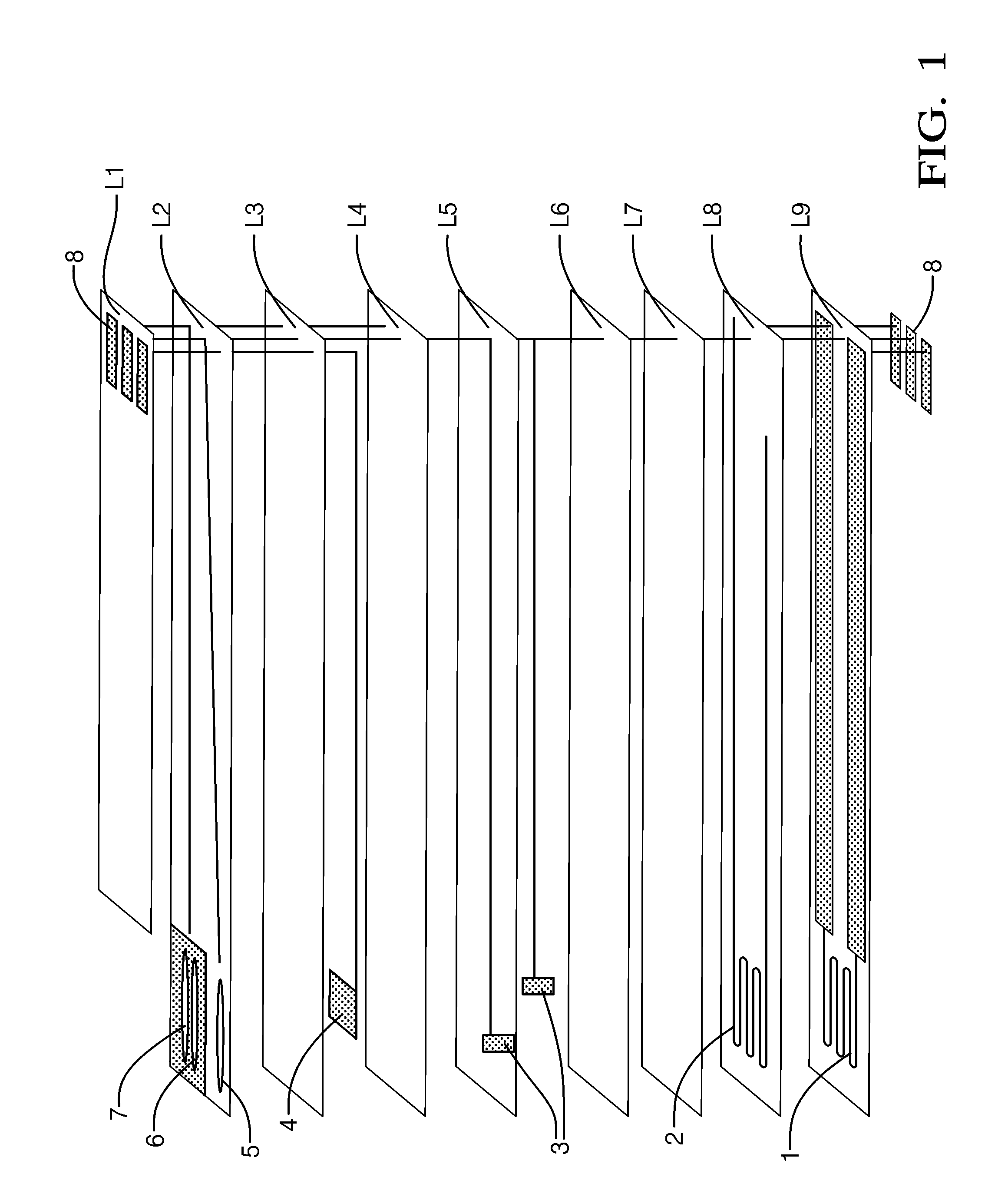

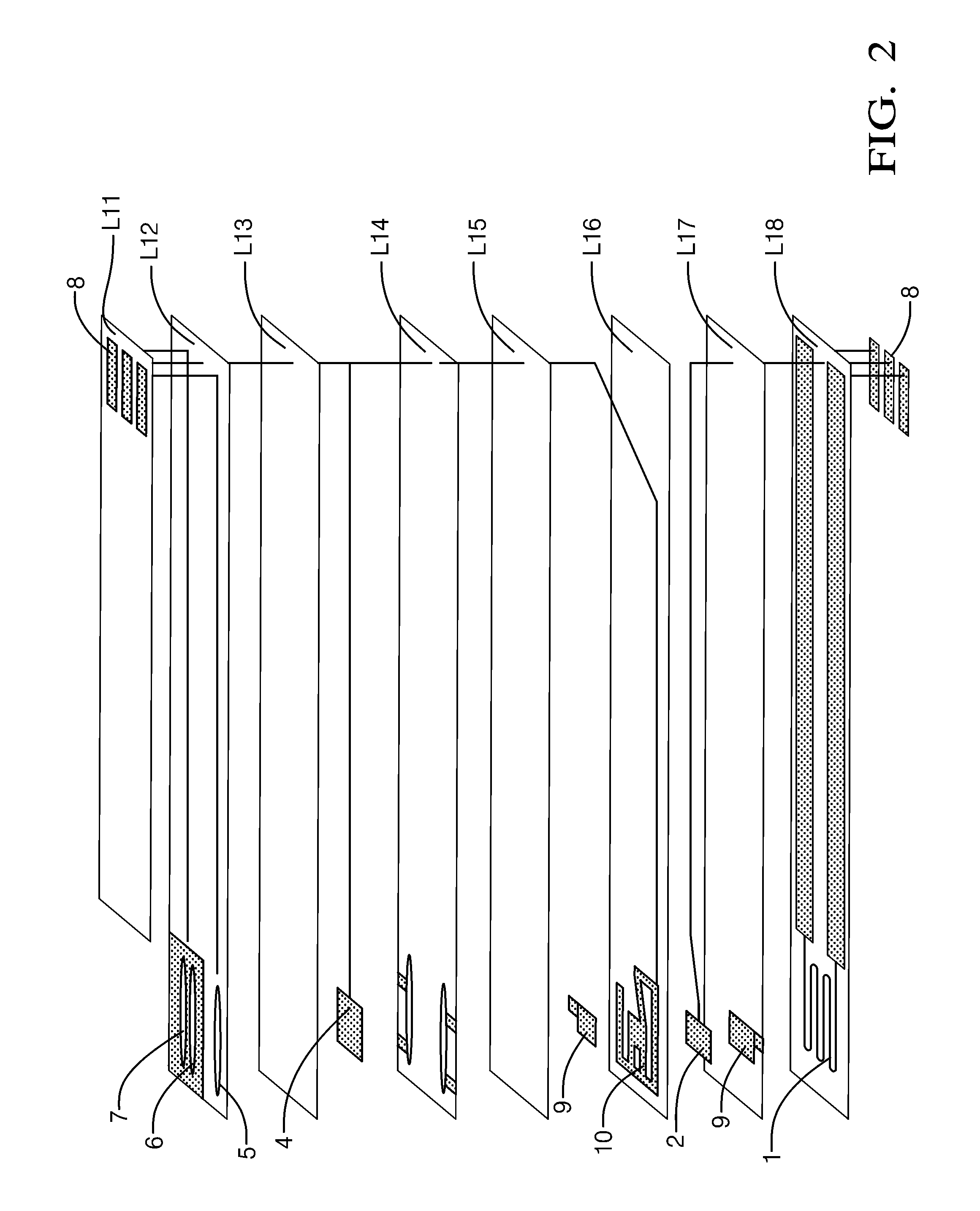

Ceramic exhaust gas sensors are disclosed that offer enhanced dimensional stability during curing, with reduced occurrence of deformations like bending or warping, and can be used in a variety of exhaust gas component sensing applications. The sensors of the invention utilize appropriate selection and orientation of the various layers of green ceramic tape that make up the sensor structure to provide enhanced dimensional stability.

Owner:DELPHI TECH INC

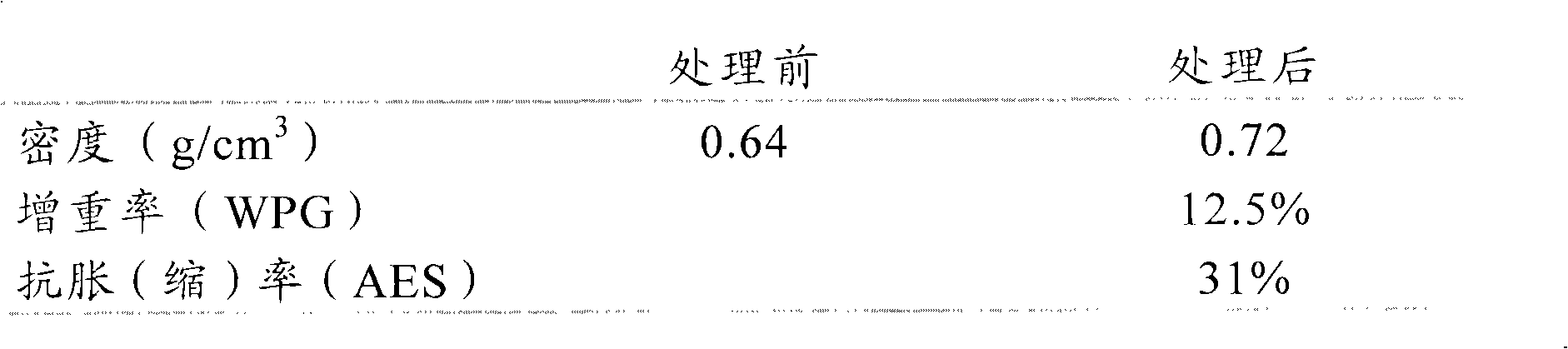

Method for processing polysaccharide material with polymer composition

The invention discloses a method for processing a polysaccharide material with a polymer composition. The method comprises the following steps of: (1) providing a polymer composition which contains at least one multi-hydroxyl compound and at least one compound containing more than one functional group with reaction activity with hydroxyls; (2) enabling the polymer composition to enter the polysaccharide material; and (3) processing the polysaccharide material so that the multi-hydroxyl compound and the compound containing more than one functional group with reaction activity with hydroxyls in the polymer composition are polymerized with the polysaccharide material to form a water-insoluble composite polymer product. The polysaccharide material obtained by using the method has greatly improved physical performance, moisture-proof and heat-resist performance and size stability.

Owner:吕品桦

Flame retardant resin composition and flame-retardant injection-molding

In order to provide a resin composition containing a lactic acid resin, and a molded article obtained from this resin composition which impart flame retardance to the resin composition and suppress a reduction in the molecular weight, use is made of a flame-retardant resin composition which contains a resin composition of which the major component is a lactic acid resin, and a surface-treated metallic hydroxide, wherein the surface-treated metallic hydroxide is added by 50-150 parts by mass per 100 parts by mass of the lactic acid resin.

Owner:SONY CORP

Bimodally-distributed glass fiber reinforced polypropylene composite material and preparation method thereof

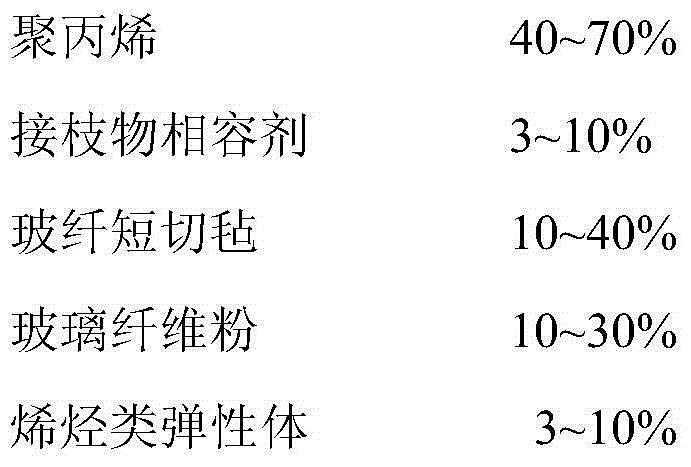

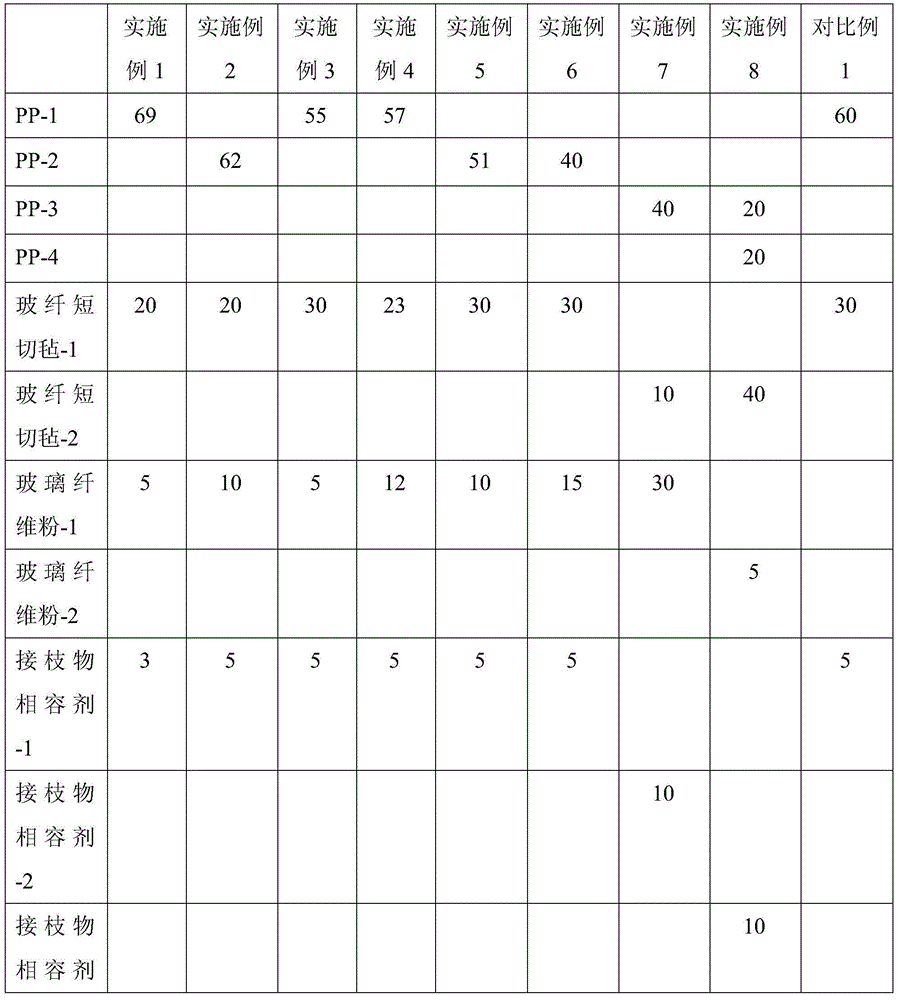

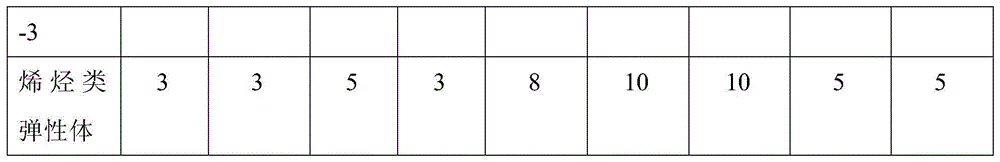

The invention relates to a bimodally-distributed glass fiber reinforced polypropylene composite material and a preparation method thereof, belonging to the technical field of high polymer materials. The bimodally-distributed glass fiber reinforced polypropylene composite material comprises the following raw materials in percentage by weight: 40%-70% of polypropylene, 3%-10% of a graft compatilizer, 20%-40% of a glass fiber chopped felt, 10%-30% of glass fiber powder and 3%-10% of an olefin elastomer. The bimodally-distributed glass fiber reinforced polypropylene composite material has the superiorities; by adding and compounding glass fiber reinforcement bodies of different lengths, a specific composite reinforcing system in which glass fiber lengths are of a bimodal distribution effect is built in polypropylene, the structural and performance differences of traditional glass fiber reinforced polypropylene in the longitudinal direction and the transverse direction are changed, the mechanical performance and thermal performance of the material in a vertical flow direction are remarkably improved.

Owner:SHANGHAI JUNER NEW MATERIALS

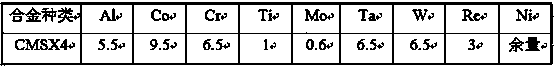

Method for reducing inner residual stress of nickel-based superalloy

InactiveCN103668022AReduce residual stressDimensionally stableHeat treatment process controlProcess efficiency improvementTemperingSuperalloy

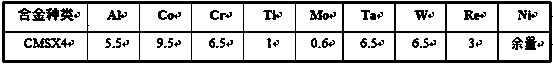

The invention relates to nickel-based superalloy, and particularly relates to a method for reducing the inner residual stress of the nickel-based superalloy. The method is characterized in that a corresponding thermal-cold cycling treatment technology is designed based on the variety of nickel-based alloy; by adjusting main parameters such as cooling rate during cold treatment, low-temperature treatment temperature, heat preserving time, tempering temperature, treatment time, cycle numbers and the like, the purpose of reducing the inner residual stress of the nickel-based superalloy is realized, and the dimensional stability of castings can be improved by 40-45%. The method has important significance for improving the service safety of the nickel-based superalloy.

Owner:JIANGSU UNIV

Method for manufacturing high-strength environmentally-friendly binderless particle board

InactiveCN102248572AImprove mechanical propertiesImproved dimensional stabilityWood working apparatusFlat articlesProcess engineeringManufacturing engineering

The invention provides a method for manufacturing a high-strength environmentally-friendly binderless particle board. In the method, paper-making black liquor is applied to a particle board preparation process, abundant lignin, hemicellulose and other chemical components in the paper-making black liquor are utilized to prepare the high-strength environmentally-friendly binderless particle board; in the particle board hot-pressing process, the lignin and the hemicellulose in the black liquor and a part of lignin and hemicellulose of wood shavings perform a chemical reaction under the action of thermal moisture to generate massive components similar to binders, therefore the mechanical performance of the particle board is remarkably increased, and the size stability of the particle board is improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Timber water-tight and anti shrinkage-and-swell processing method

InactiveCN1788952ALittle deformation of woodImproved dimensional stabilityPressure impregnationWood impregnation detailsSolid woodAcrylate

The present invention provides waterproof and swelling and shrinking preventing timber treating method, and the method is treating timber with waterproof and swelling and shrinking preventing timber treating solution. The timber treating solution consists of fatty dihydric alcohol or its polymer 10-70 wt%, alkyl acrylate 5-10 wt%, alcohol 5-10 wt%, and distilled water 10-80 wt%. The treating process includes soaking timber or timber product in the timber treating solution inside a sealed treating tank under the pressure one -0.1 to 0.5 MPa, pressurizing and heating for soaking treatment, and final drying treatment. Thus treated timber sample has shrinkage resisting coefficient up to 70 % and moisture absorption resisting coefficient up to 60 %, so that the present invention can prevent deformation and cracking of timber product and raise the size stability of timber product effectively.

Owner:北京市龙顺成中式家具有限公司

Mass acrylonitrile-butadiene-phenylethene and polyterephthalic acid butanediol fat compound and preparation method thereof

The present invention relates to a mass polymerization compound of an acrylonitrile- butadiene-cinnamene and poly-terephthalic acid butanediol lipid, which is characterized by consisting of the following weight percentage compositions of materials: 30-70 percent of mass polymerization acrylonitrile- butadiene-cinnamene (ABS) resin, 5-30 percent of poly-terephthalic acid butanediol lipid (PBT) resin, 2-8 percent of compatibilizer, 0.5-5 percent of heat resisting modifier and 10-35 percent of glass fibre, and the manufacturing method thereof is characterized in that under the high speed cut, milling and delivery of a screw, the material can be melted and compounded sufficiently, and the final product can be achieved after fusing, extruding a stray, cooling, pelleting and drying. The advantage of the present invention is to obtain the performance, such as high intension, fatigue resistance, shock resistance, of the mass polymerization acrylonitrile- butadiene-cinnamene (ABS), extending the application range of the mass polymerization acrylonitrile- butadiene-cinnamene (ABS).

Owner:SHANGHAI KINGFA SCI & TECH +1

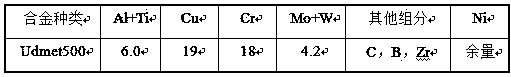

Glass fiber-enhanced montmorillonite-modified nylon composite material with low water absorption and high dimensional stability and preparation method thereof

The invention discloses a glass fiber-enhanced montmorillonite-modified nylon composite material with low water absorption and high dimensional stability and a preparation method thereof. Montmorillonite-modified nylon compound, lubricant and antioxidant are uniformly mixed and then added via the feed inlet of an extruder, glass fibers are added into the double-screw extruder via the side feed inlet, and after extrusion and pelleting, the glass fiber-enhanced montmorillonite-modified nylon composite material is obtained. With the organic montmorillonite-modified nylon prepared by a melt intercalation method as a matrix, the prepared glass fiber-enhanced montmorillonite-modified nylon composite material has higher degree of crystallinity, modulus and strength, higher dimensional stability and low water absorption in comparison with conventional glass fiber-enhanced nylon materials.

Owner:ORINKO NEW MATERIAL CO LTD

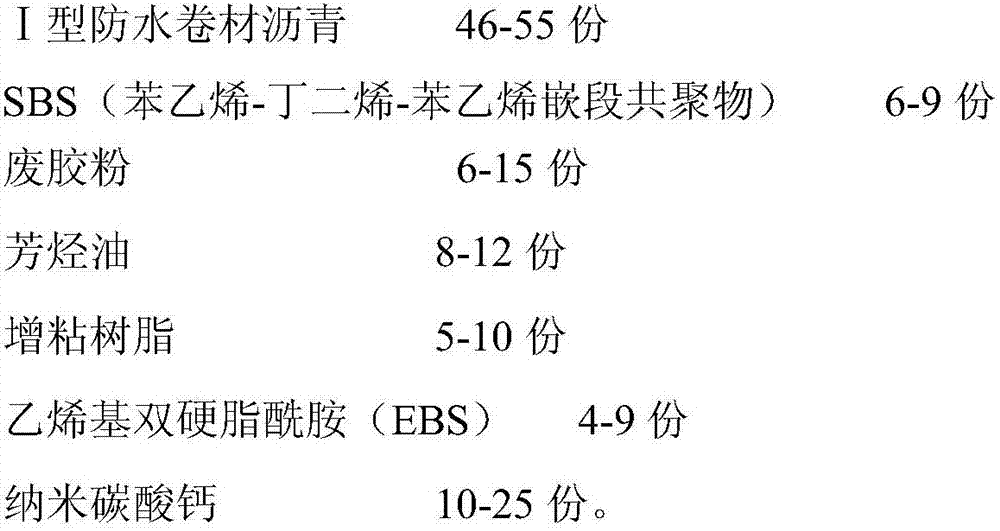

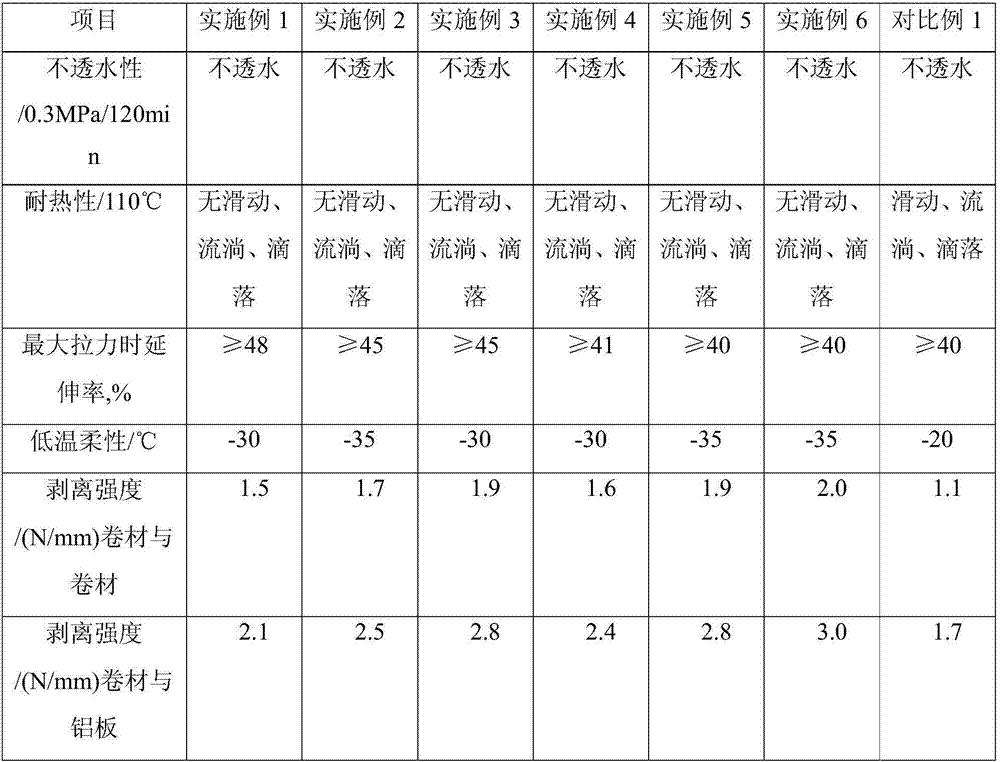

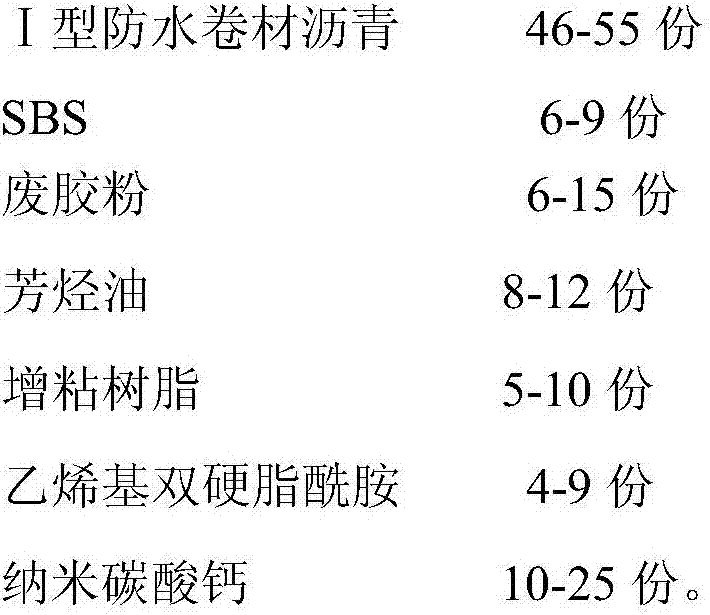

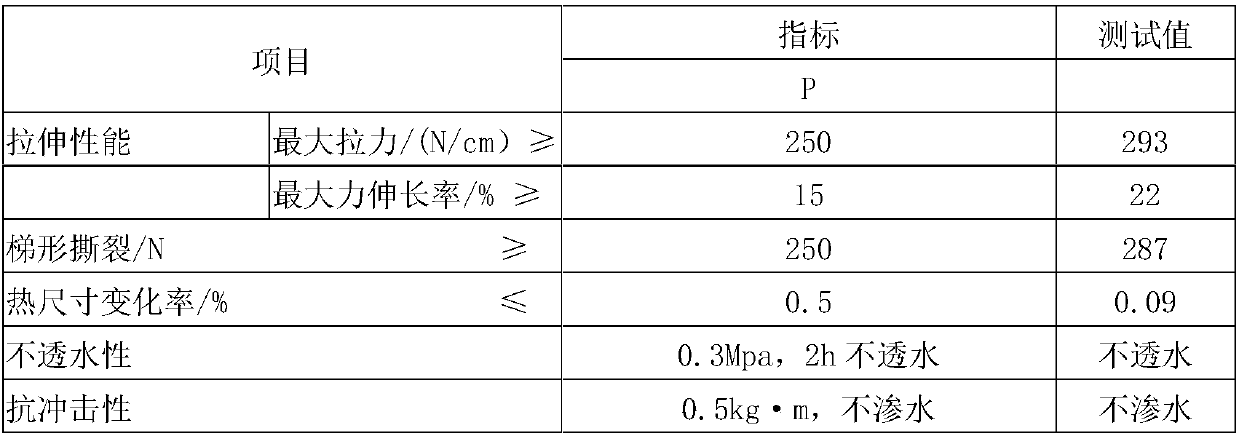

Self-adhesive waterproofing coiled material cementing material, its preparation method and waterproofing coiled material prepared from self-adhesive waterproofing coiled material cementing material

ActiveCN107474793AReduce manufacturing costImproved dimensional stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesEthylene bisCalcium carbonate

The invention belongs to the technical field of building waterproof engineering and particularly relates to a self-adhesive waterproofing coiled material cementing material and its preparation method and a waterproofing coiled material prepared from the self-adhesive waterproofing coiled material cementing material. The self-adhesive waterproofing coiled material cementing material is prepared from 46 to 55 parts by weight of type I waterproofing coiled material asphalt, 6 to 9 parts by weight of SBS, 6 to 15 parts by weight of waste rubber powder, 8 to 12 parts by weight of aromatic oil, 5 to 10 parts by weight of tackifying resin, 4 to 9 parts by weight of ethylene bis-stearamide and 10 to 25 parts by weight of nanometer calcium carbonate. The preparation method solves the problem that the traditional method for preparing a waterproofing coiled material from SBR butadiene styrene rubber powder easily produces clustering and blocks a pipe. The processing temperature is low so that the production time of the self-adhesive waterproofing coiled material is greatly reduced and a production cost is reduced. The self-adhesive waterproofing coiled material cementing material has good waterproofing properties, high tensile strength, good extensibility, excellent low-temperature flexibility and heat resistance.

Owner:CHINA PETROLEUM & CHEM CORP

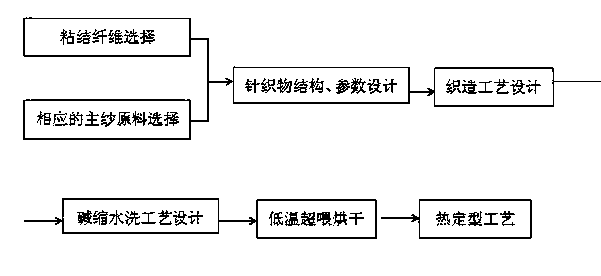

Processing process of stable-dimension knitted fabrics

ActiveCN103437050AImproved dimensional stabilityGood dimensional stabilityWeft knittingHeating/cooling textile fabricsYarnMachining process

The invention relates to a processing process of stable-dimension knitted fabrics, and belongs to the technical field of knitted fabric processing processes. The processing process comprises the steps of material selection, yarn steaming, knitting and afterfinish. Yarns with good elasticity, high intensity and low shrinkage rate are selected; the structure parameters of loops are determined so that the structure parameters are identical to the structure parameters in the full loosening state, a proper on-machine process is selected, the yarns adopts an interweaving mode for knitting the texture structures for effectively improving the dimension stability of the knitted fabrics; and a tensile force reduction and forced contraction mode is adopted for realizing the afterfinish on the fabrics, the surface layers of bonding fiber is molten, and molten nodes are formed inside the fabrics for improving the fabric dimension stability. The technical scheme is adopted, and the processing process has the advantages that the fabric dimension stability is good, the production process is green and environment-friendly, and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

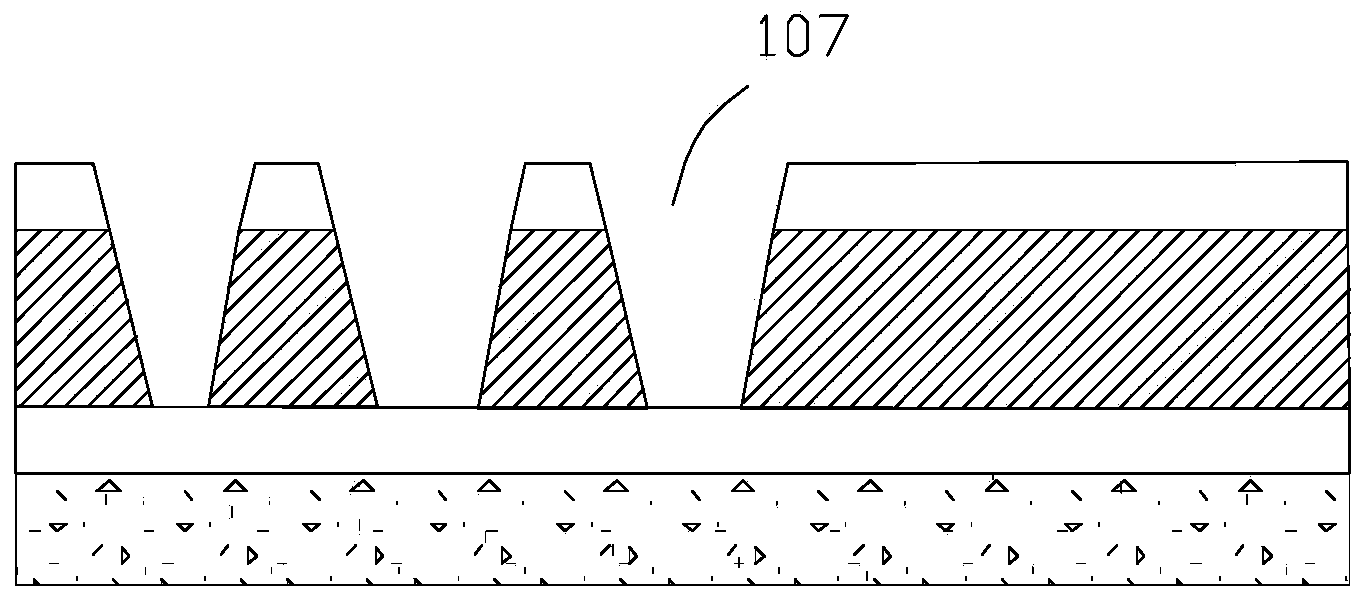

High-density package substrate on-hole disk product and preparation method thereof

ActiveCN104270888AImproved dimensional stabilityOptimizing the Laser Processing ProcessPrinted circuit aspectsElectrical connection printed elementsCopper foilEtching

The invention discloses a high-density package substrate on-hole disk product and a preparation method of the high-density package substrate on-hole disk product. The preparation method comprises the following steps of drying a substrate, manufacturing locating holes, conducting laser drilling, conducting micro-etching, conducting copper plating, conducting pattern transfer, conducting electroplating for hole filling and conducting film stripping and etching, and then the high-density package substrate on-hole disk product is obtained. According to the method, under the effect of protective film layers of the thin copper substrate, the problem that copper foil at the bottom is cut through in the thin copper processing process in the past is solved, and a complete half-through hole structure is made on the thin copper substrate; meanwhile, the direct laser processing technology is adopted, the thickness of the copper foil can not be influenced, and through good matching between the direct laser processing technology and the MSAP process, a high-density Flip-chip product with the high-flatness on-hole disk structure can be manufactured.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

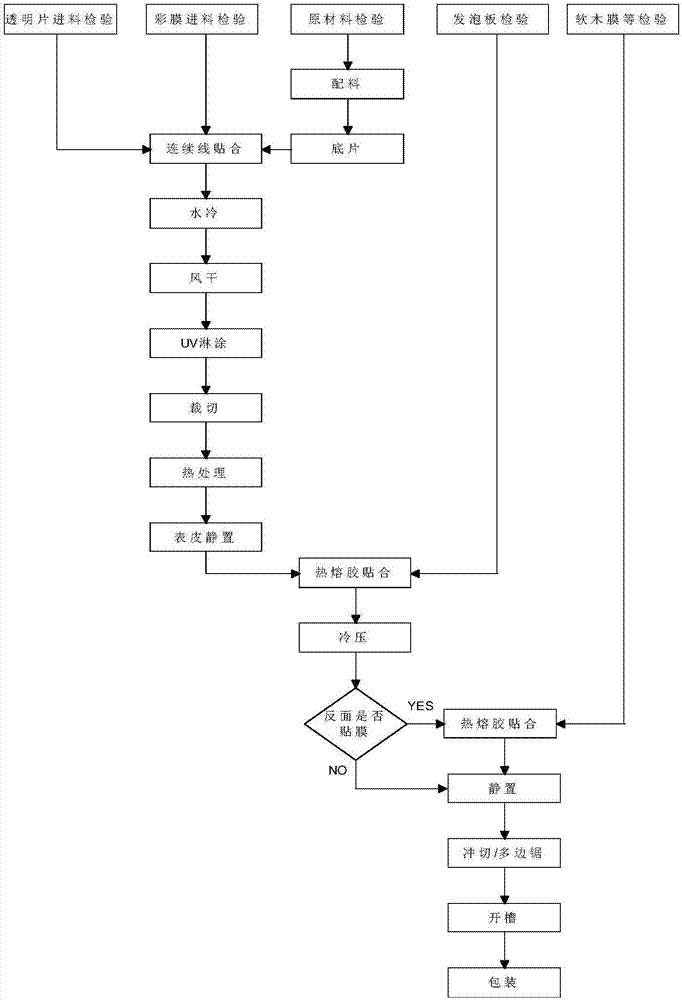

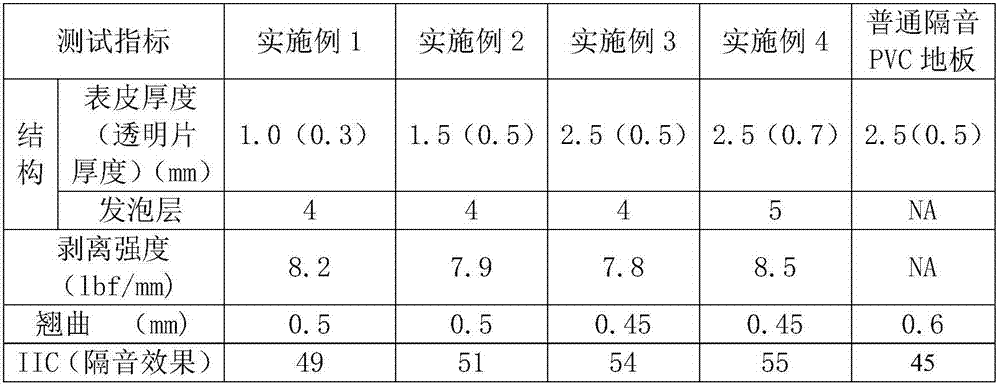

Preparation method for soundproof hard PVC floor

InactiveCN107119880AGood textureImproved dimensional stabilityLamination ancillary operationsLaminationEngineeringHot-melt adhesive

The invention discloses a preparation method for a soundproof hard PVC floor. Aiming at the poor soundproof effect of existing PVC floors and various defects existing in existing soundproof PVC floor preparation, preparation is conducted by adhering a foaming material to the back face of a common PVC floor; the floor is prepared through the technological processes of base piece production, continuous attachment, surface production, hot melt adhesive attachment, standing, punching, slotting, packing and product performance detection; the technological steps of all the processes of continuous attachment and hot melt adhesive attachment and the technological parameters including time, temperature and humidity, the speed, pressure and the like are intensively optimized; the prepared hard PVC floor is good in texture, soundproof effect and flatness, size stability of the floor is effectively improved, peeling strength and warping of the floor both accord with national or industrial standards; and additionally, the preparation method further effectively reduces the production cost.

Owner:DECORIA MATERIALS JIANGSU CO LTD

Method for carrying out reinforcing and sealing-protection on wood by using nano cellulose

ActiveCN110181632AImproved dimensional stabilityImprove wood quality and added valueWood treatment detailsPretreatment apparatusElastic modulusFiber

The invention belongs to a method for carrying out reinforcing and sealing-protection on wood by using nano cellulose. The method comprises the following steps: classifying the wood according to waterpermeability of the wood, and performing brushing or immersion treatment on the wood according to classification with a nano-cellulose sealing-protection liquid prepared by a carboxymethyl celluloseor hydroxypropyl cellulose or hydroxyethyl cellulose polymer solution with a concentration of 0.5-2.5%, a cellulose nano crystal with a concentration of 0.5-1.5%, a nano cellulose dispersion liquid ofTEMPO oxidized nano fibers with a concentration of 0.2-0.7%, and a modification liquid of a silica sol with a concentration of 0.5-1.5%. The method can improve dimensional stability, density, flexural modulus and compressive strength of the wood, and has the advantages of significantly improving quality and added values of the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

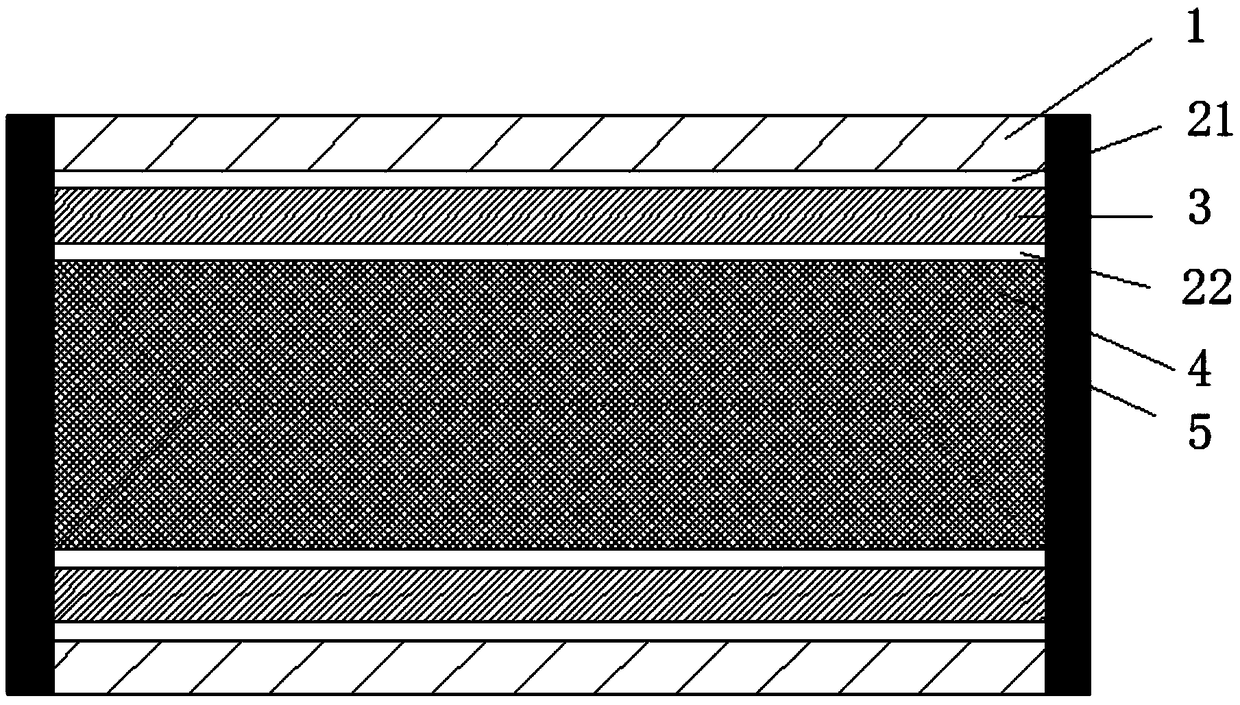

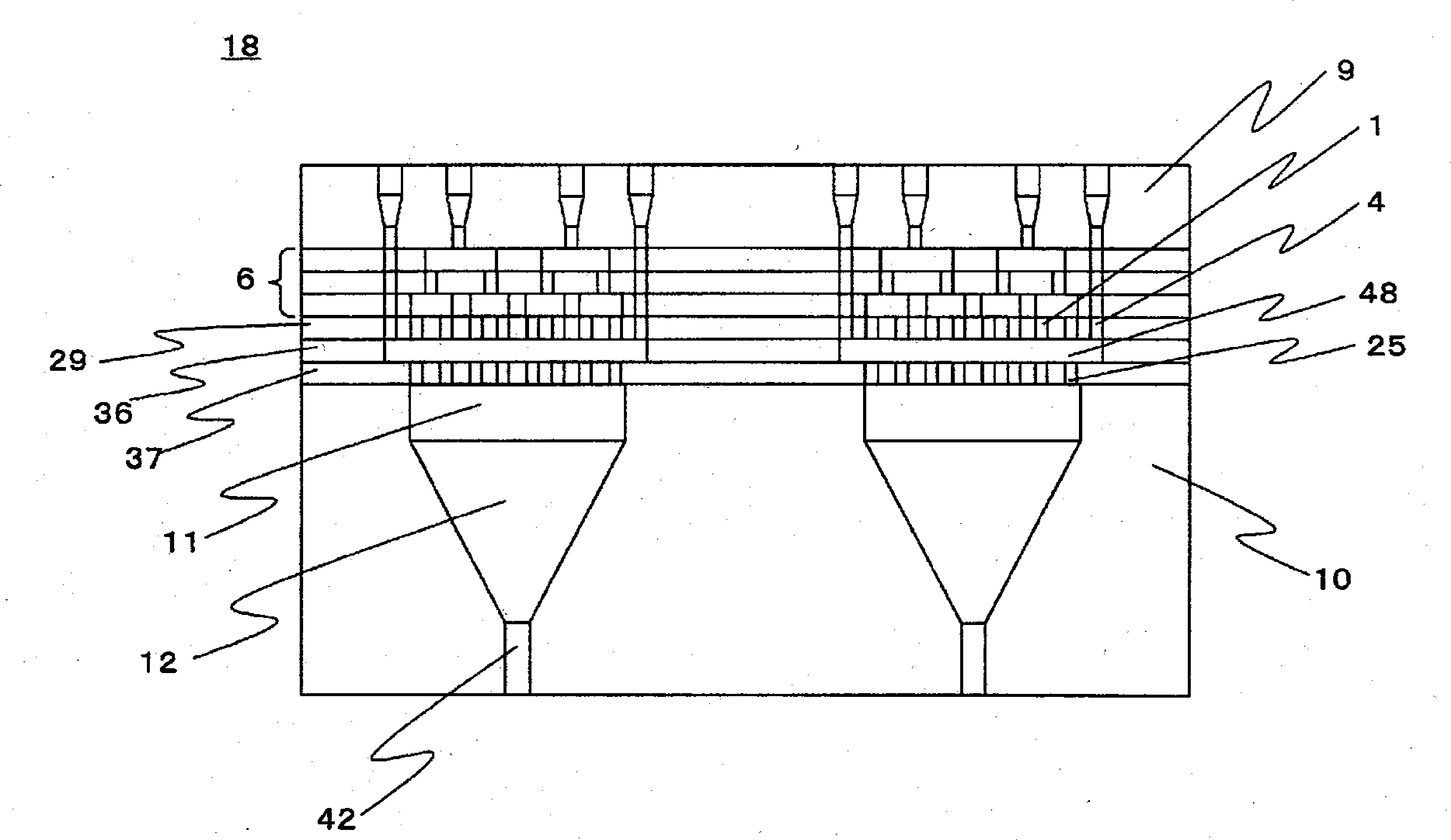

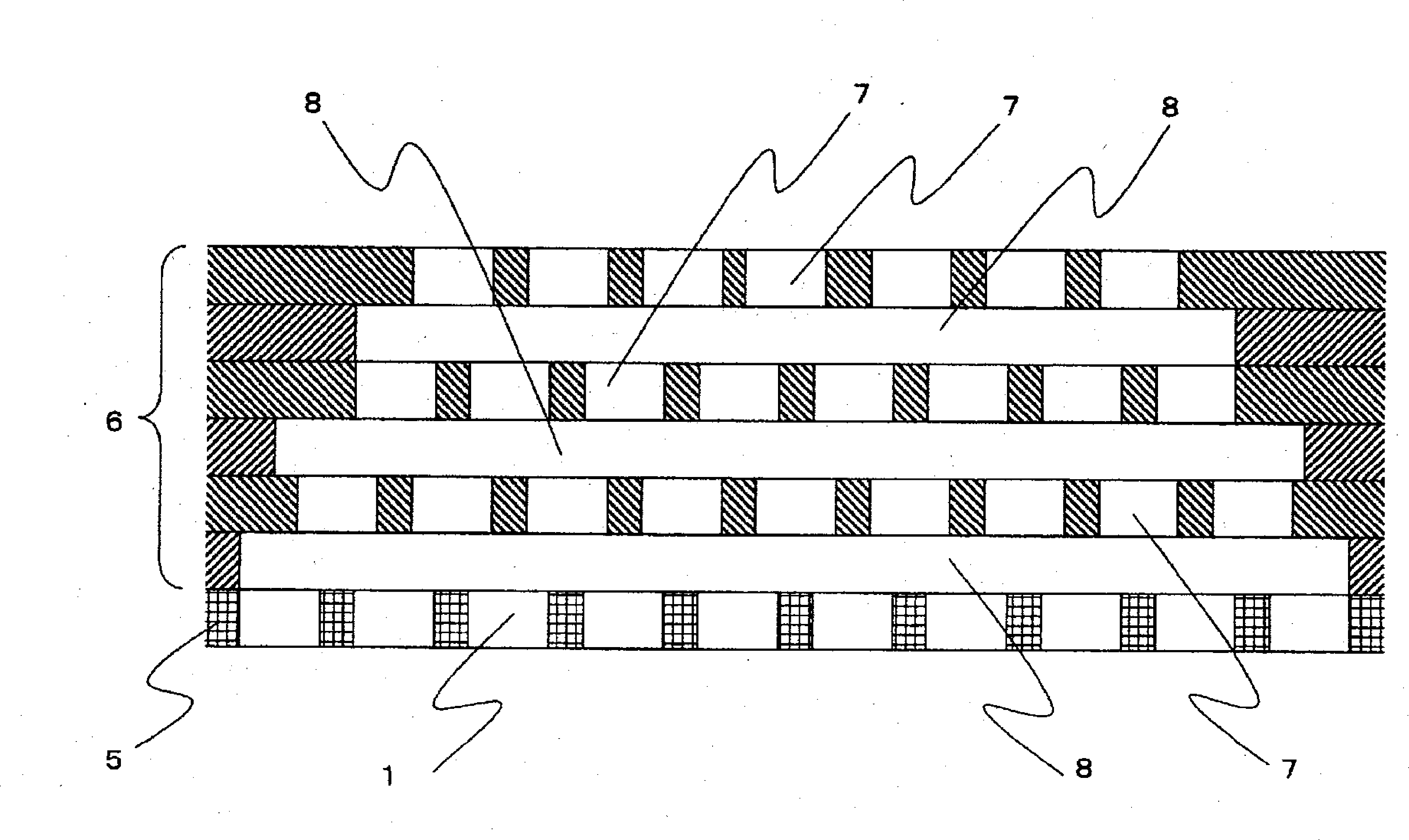

Heat conduction multifunctional composite artificial board for floor-heating floor substrate and manufacture method thereof

ActiveCN108406982AImprove thermal conductivityImproved dimensional stabilityOther plywood/veneer working apparatusSynthetic resin layered productsManufacturing efficiencyBonding strength

The invention provides a heat conduction multifunctional composite artificial board for a floor-heating floor substrate and a manufacture method thereof. The heat conduction multifunctional compositeartificial board comprises a surface layer substrate, a glue layer, a heating layer and an intermediate substrate. The heating layer is a carbon-based film, at least one carbon-based film is correspondingly arranged on the upper side and the lower side of the intermediate substrate, and heat-conducting layers are arranged on the side faces of the periphery of the heat conduction multifunctional composite artificial board for the floor-heating floor substrate. The heat-conducting layers are formed by coating heat-conducting paint. According to the heat conduction multifunctional composite artificial board, the heat-conducting layers can form rapid heat-conducting channels and enhance the heat-conducting performance; at the same time, after the implanted carbon-based film and bonding materials are fused and solidified, the mechanical and mechanical properties such as structural stability, bonding strength, bending strength and impact resistance can be effectively enhanced; and at the same time, because the implanted carbon-based film has good conductivity, the good antistatic and electromagnetic radiation shielding properties are achieved. The manufacture method can effectively improve the heat-conducting property and dimensional stability while improving the manufacture efficiency, and the large-scale production is facilitated.

Owner:GUANGXI UNIV

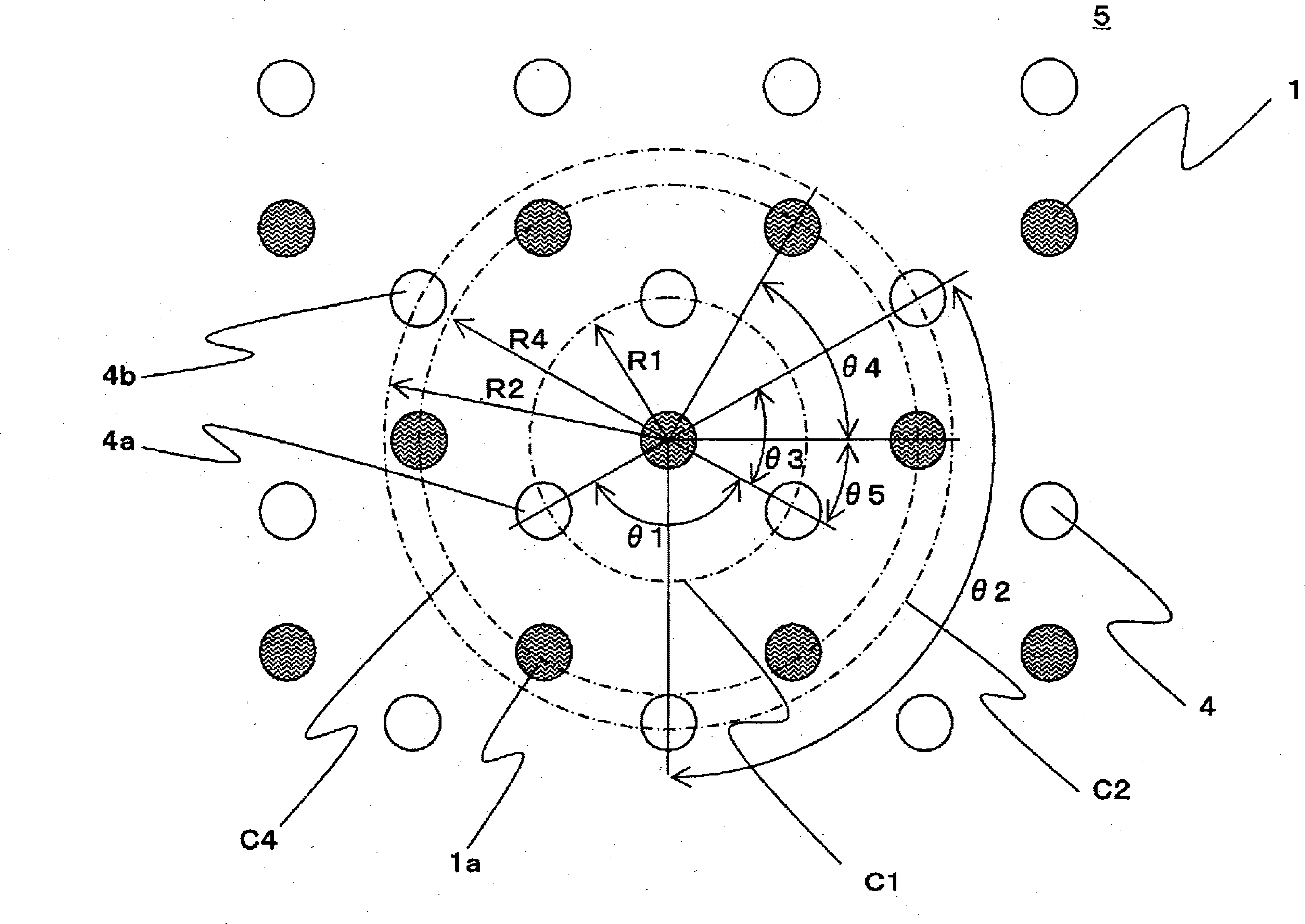

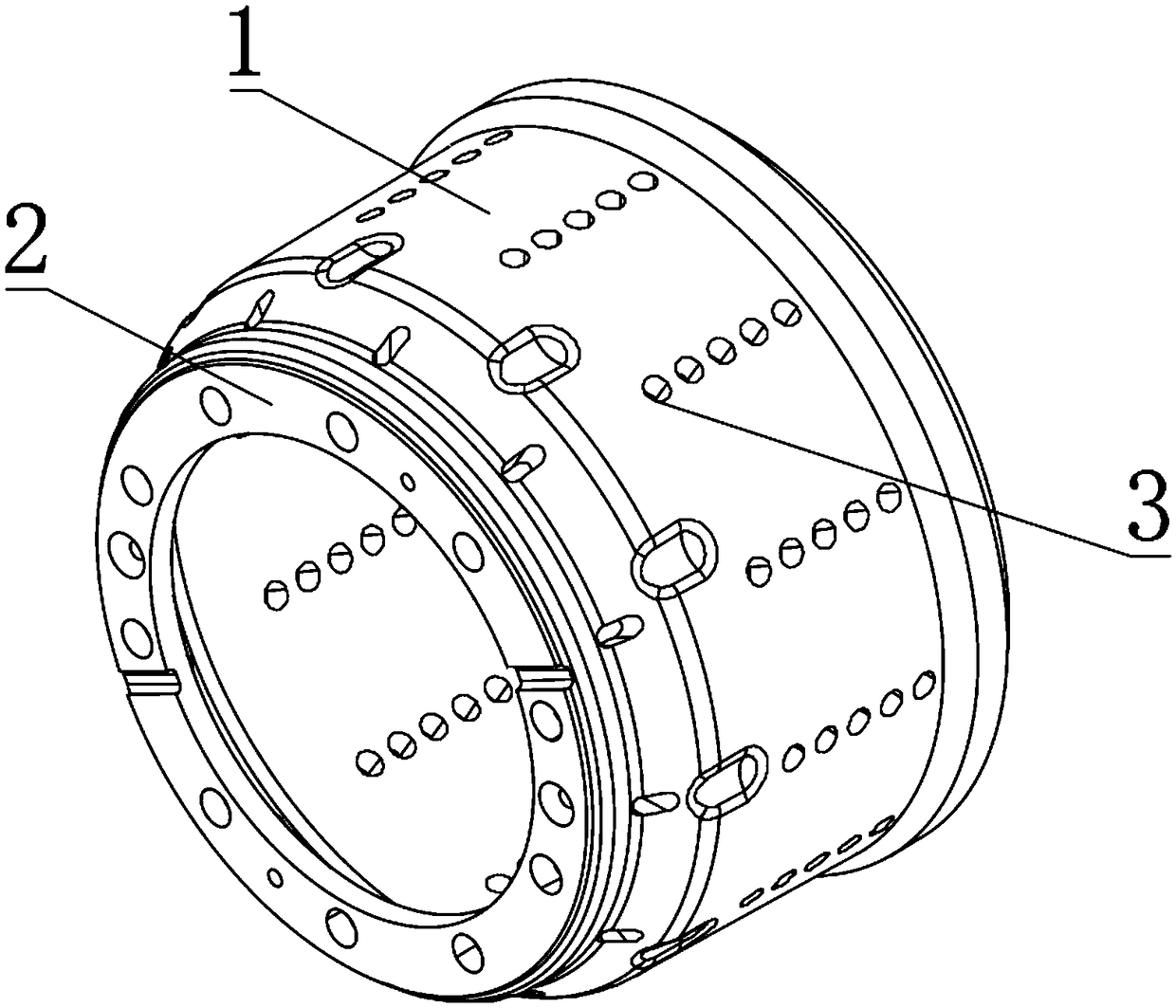

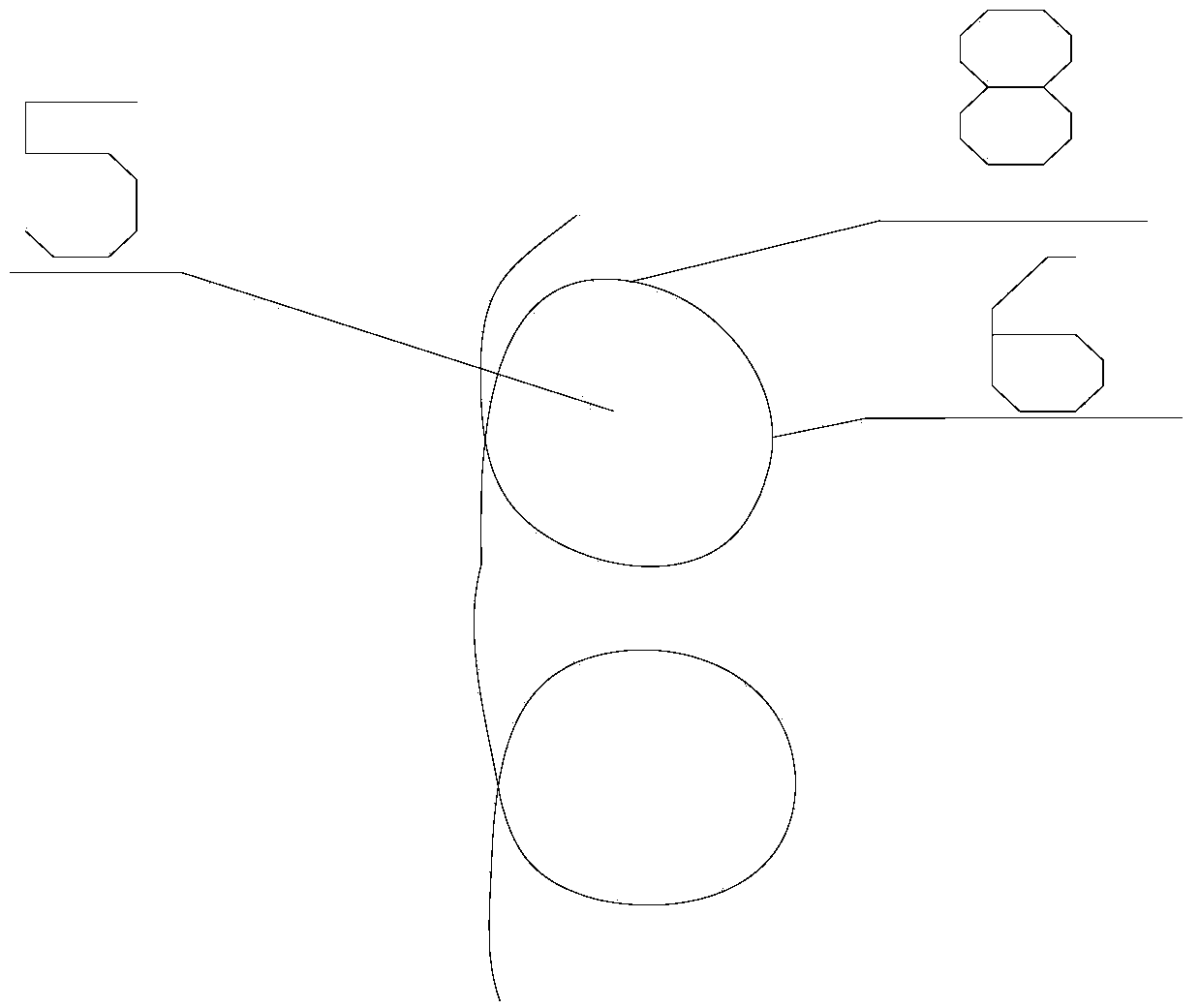

Composite spinneret and method of manufacturing composite fiber

ActiveCN103261494APrevent confluenceImproved dimensional stabilitySpinnerette packsFilament/thread formingComposite polymerFiber

Provided is a composite spinneret for the manufacture of islands-in-the-sea composite fibers, whereby the island component polymer streams can be prevented from converging while the hole packing density of the extrusion holes for the island component polymer is expanded, and whereby various fiber cross sections, and particularly heteromorphic cross sections, can be formed with high accuracy, while maintaining high dimensional stability of the cross section. The present invention provides a composite spinneret for extruding composite polymer streams composed of an island component polymer and a sea component polymer, the composite spinneret being characterized by being composed of one or more distribution plates in which are formed distribution holes and distribution grooves for distributing the polymer components; and a lowermost layer distribution plate positioned to the downstream side of the distribution plate in the direction of the polymer spinning path, and having formed therein a plurality of island component extrusion holes and a plurality of sea component extrusion holes. The present invention is also characterized in that some of the sea component extrusion holes are arranged on a virtual circular line (C1) of radius (R1) centered on the island component extrusion holes, some of the sea component extrusion holes are arranged on a virtual circular line (C2) of radius (R2), and some of the island component extrusion holes are arranged on a virtual circular line (C4) of radius (R4) according to a predetermined arrangement while satisfying the expression (1) R2>=R4>=3*R1.

Owner:TORAY IND INC

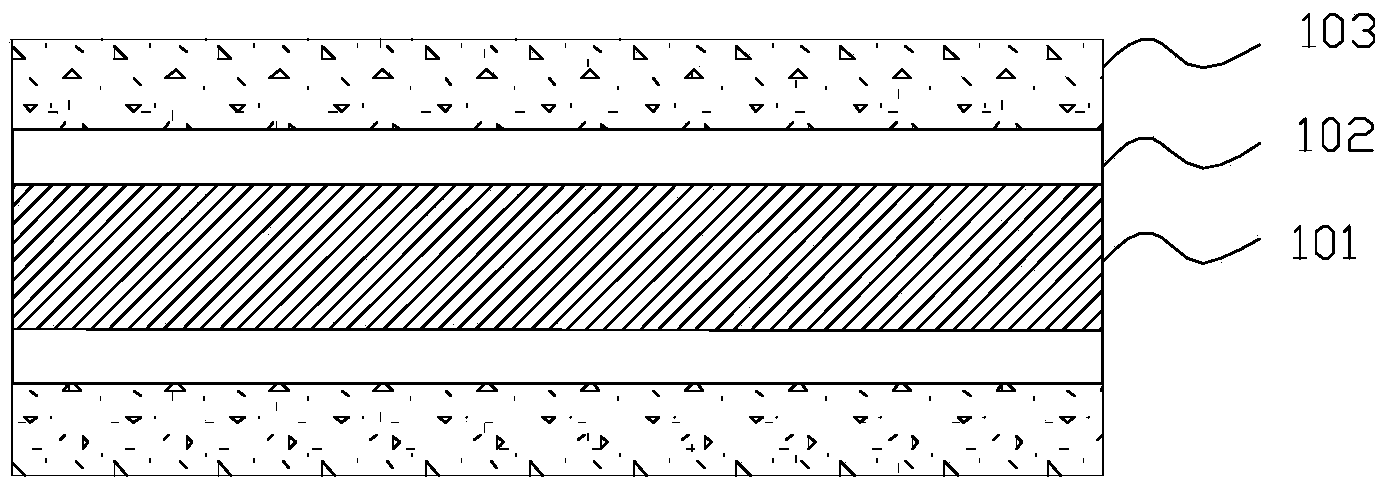

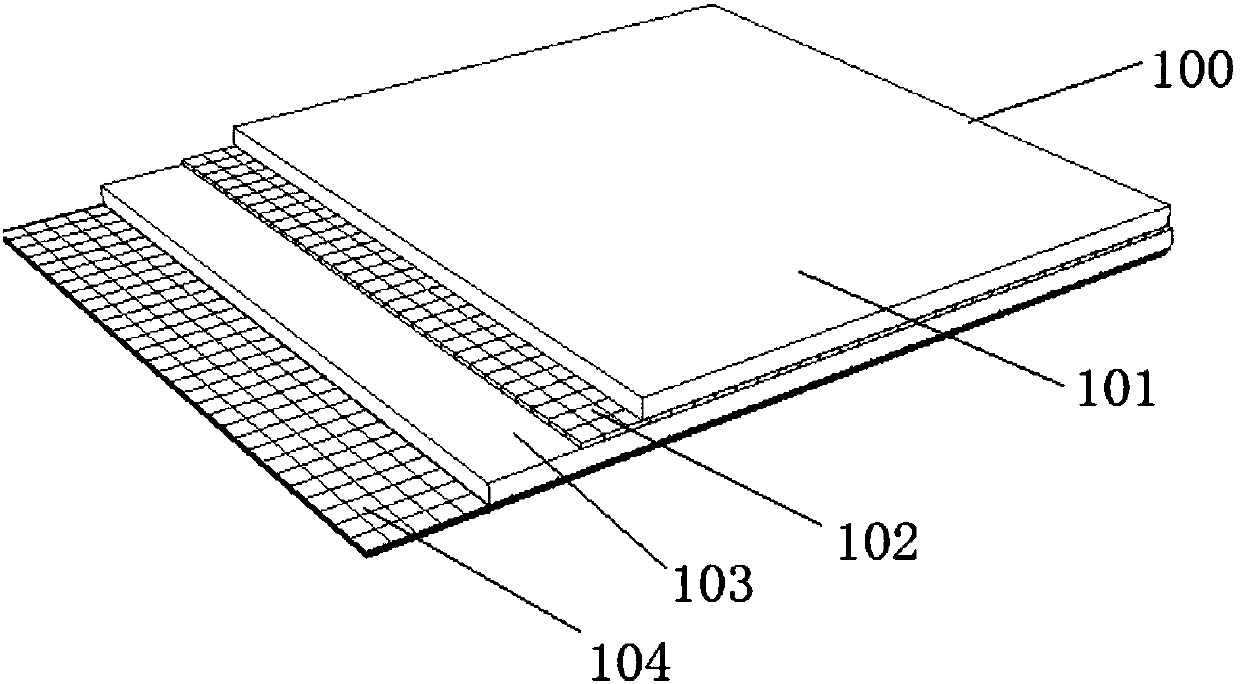

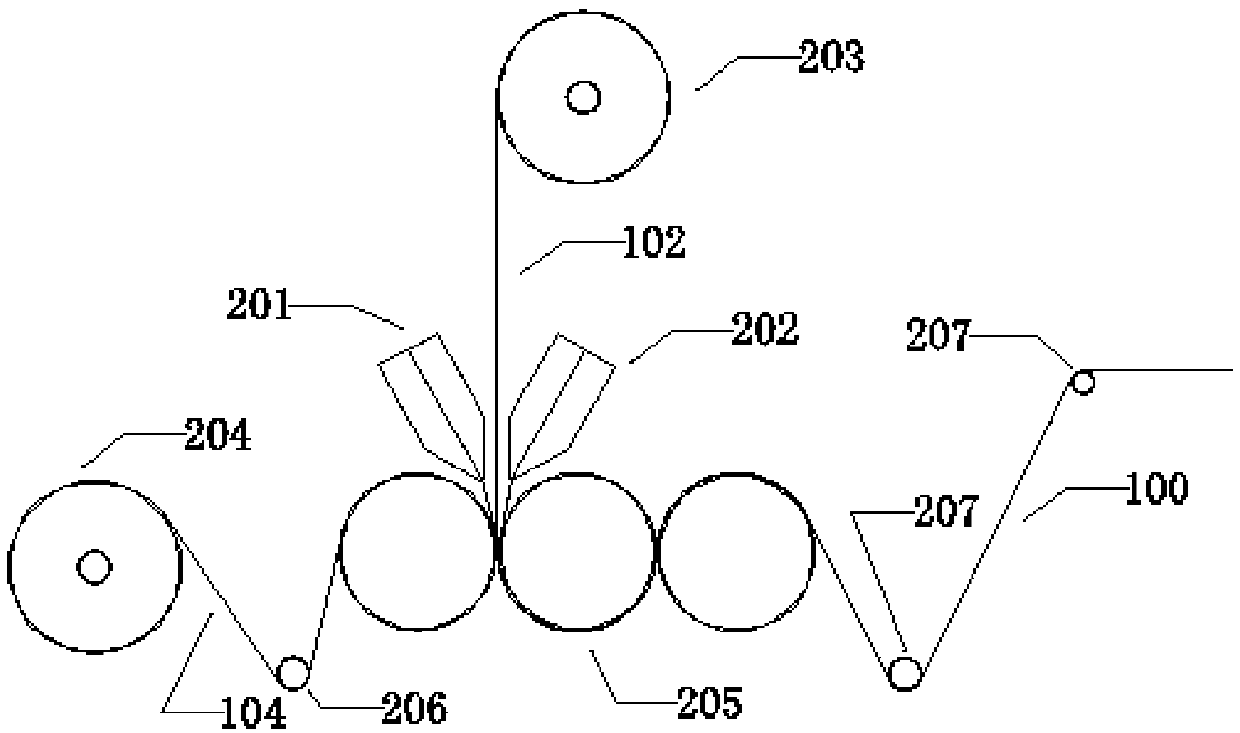

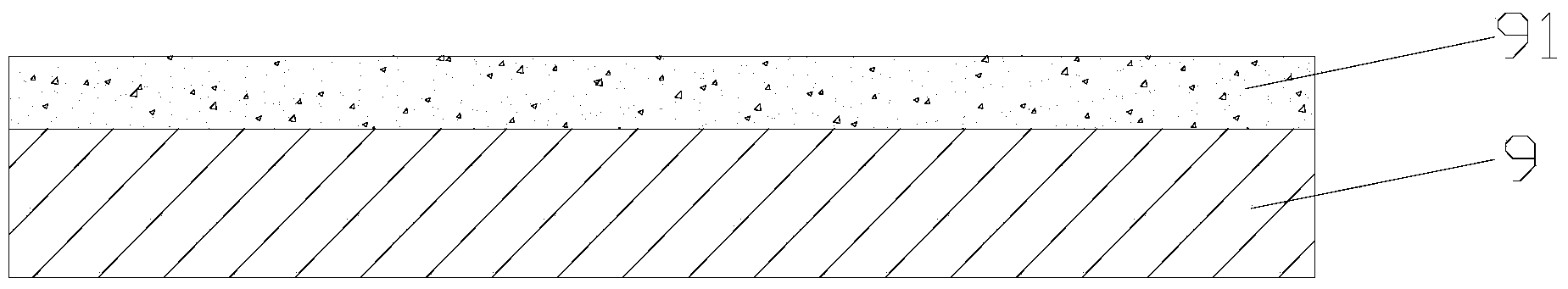

Multilayer waterproof roll for composite internal-enhancing fabric and production process thereof

InactiveCN107813568AImproved dimensional stabilityOverall smooth and not easy to shrinkRoof covering using flexible materialsSynthetic resin layered productsPolyesterMesh grid

The invention creates and provides a multilayer waterproof roll for a composite internal-enhancing fabric and a production process thereof. The multilayer waterproof roll comprises a surface layer, aninternal-enhancing fabric layer, a back layer and a back-lining layer which are sequentially adhered from top to bottom, wherein the surface layer and the back layer are high molecular material layers, the internal-enhancing fabric layer is polyester gridding cloth, and the back-lining layer is polyester fiber cloth. Multiple layers of the multilayer waterproof roll can be composited by virtue ofa three-roll calender through a synchronous composite process, so that the compositing strength among composite layers can be furthest guaranteed; and the strength of the multilayer waterproof roll is mainly supplied by the internal-enhancing polyester gridding cloth in the use process, and the applicability is supplied by the back-lining layer, so that the mutual complementation of the advantages and disadvantages of reinforcing ribs and back linings is realized.

Owner:天津滨海澳泰防水材料有限公司

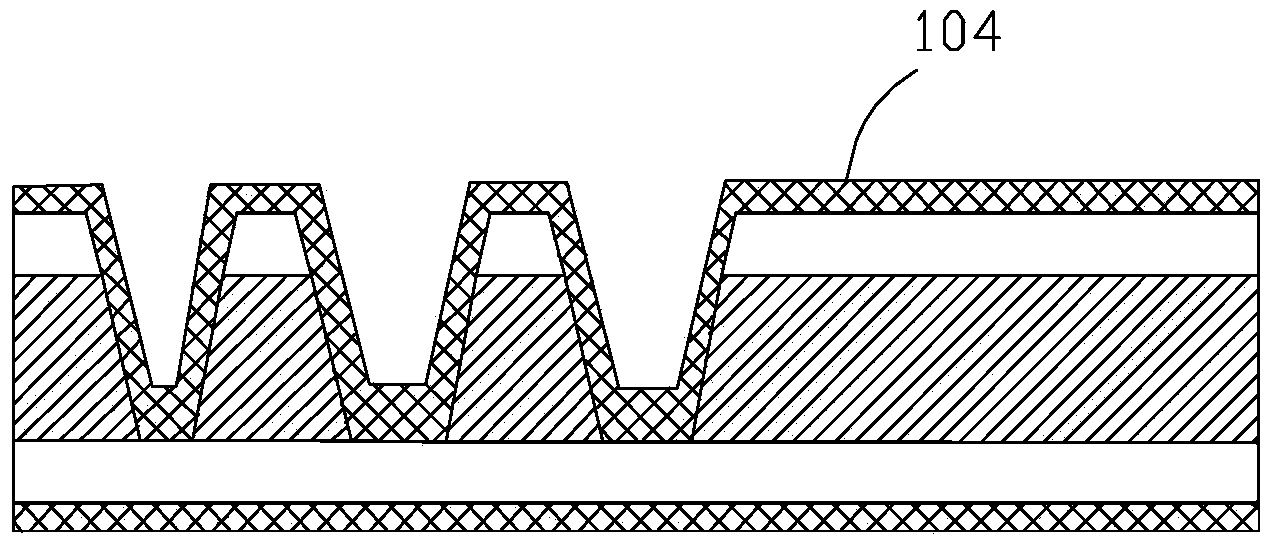

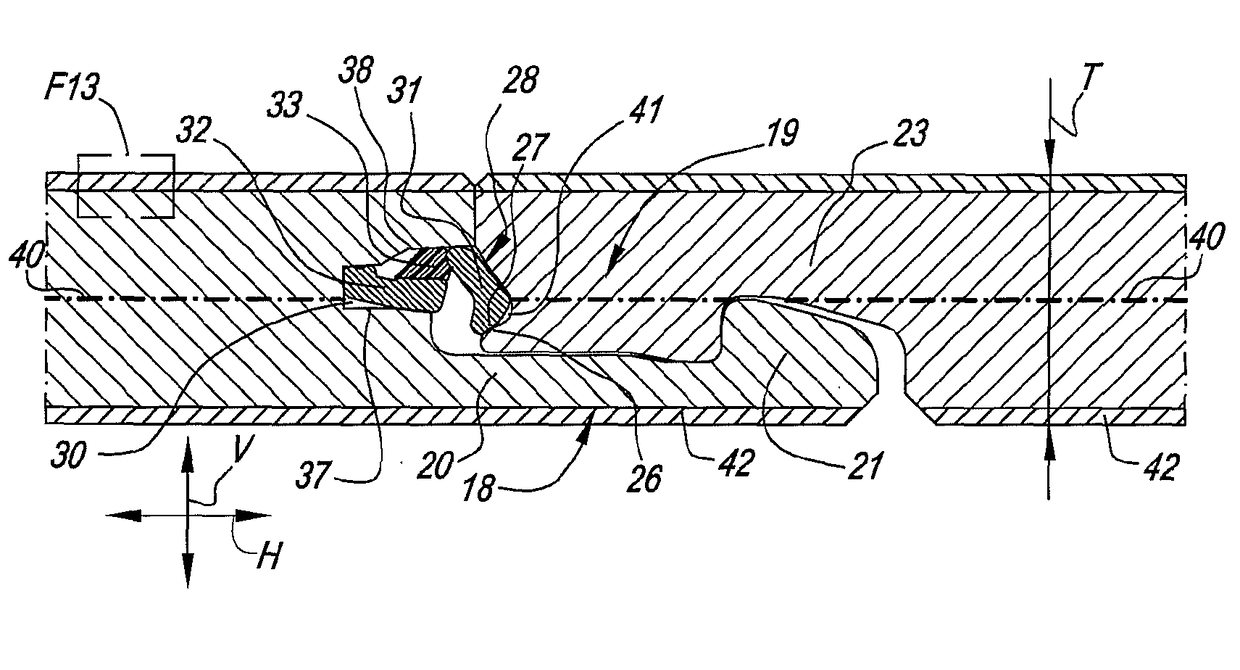

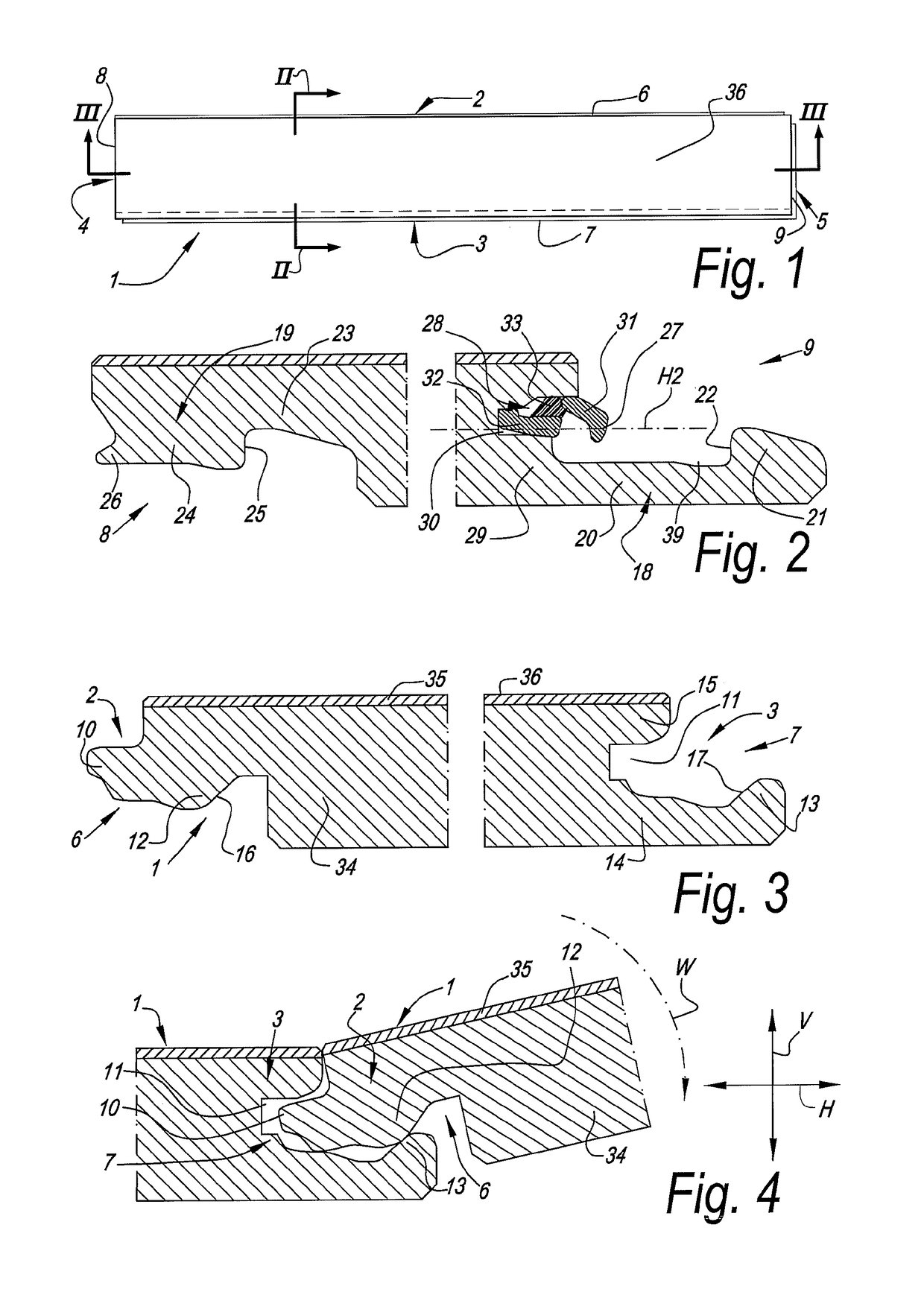

Floor panel for forming a floor covering, floor covering formed from such floor panels and method for manufacturing such floor panels

ActiveUS9771721B2Improved dimensional stabilityMinimize riskConstruction materialSynthetic resin layered productsEngineeringPanelling

A floor panel is arranged for forming a floor covering, and substantially consists of synthetic material and has a decorative upper side. The floor panel, on at least one pair of opposite edges, comprises coupling parts which allow coupling two of such floor panels to each other. The coupling parts effect a locking in a first direction perpendicular to the plane of the floor panels as well as in a second direction perpendicular to the respective edge and in the plane of the floor panels. The at least one of the coupling parts comprises a separate locking element, which, in coupled condition, provides for at least a locking in the first direction.

Owner:FLOORING IND LTD

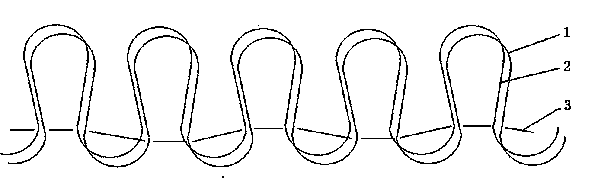

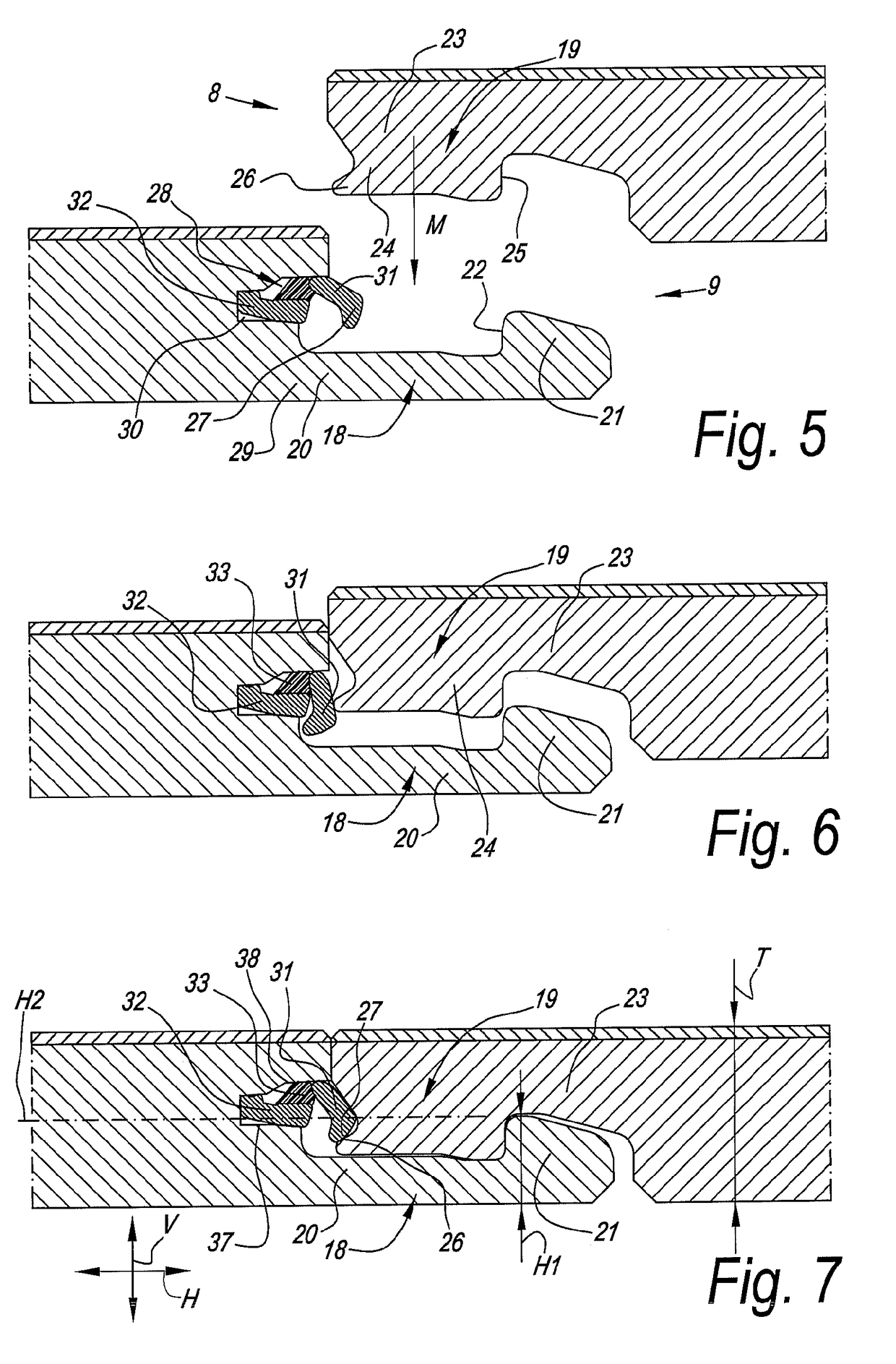

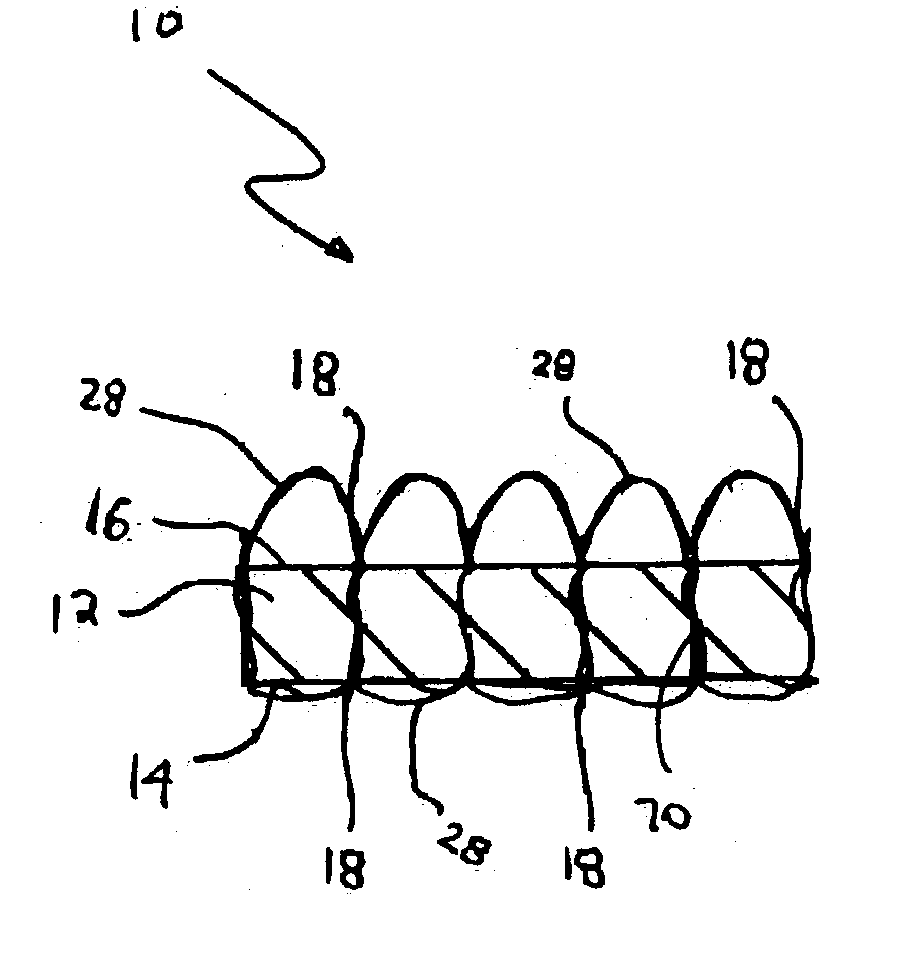

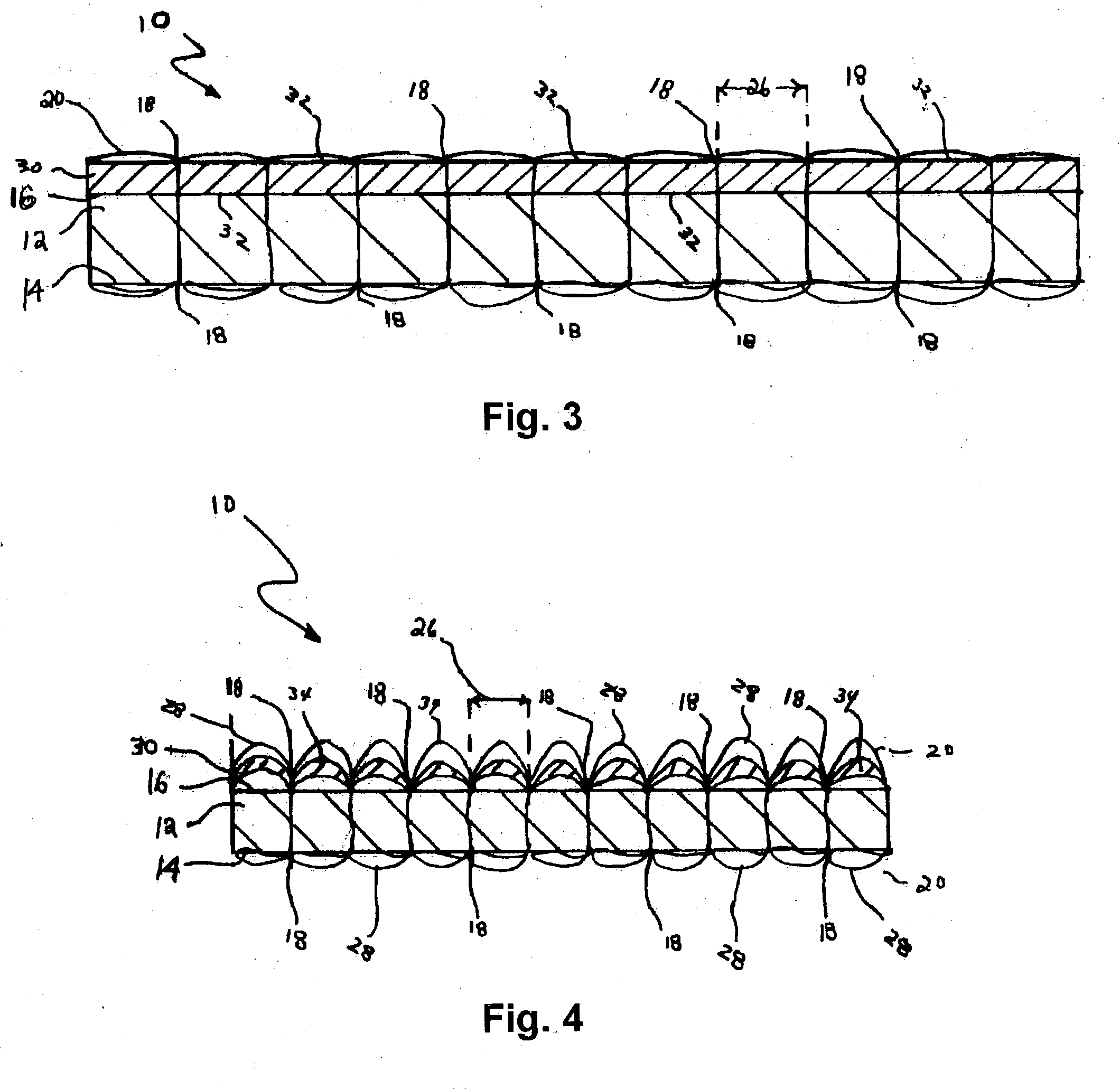

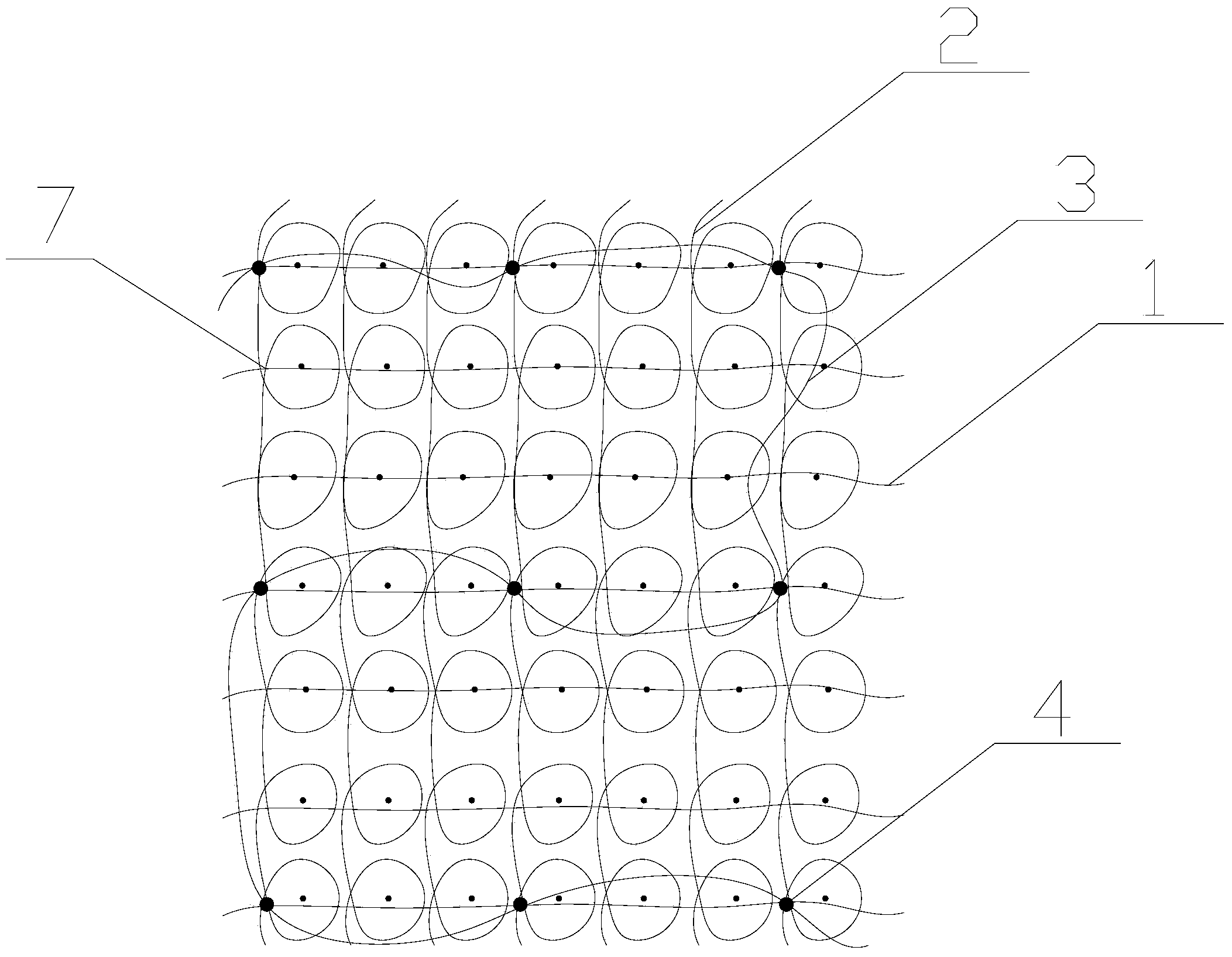

Stitch-bonded and gathered composites and methods for making same

ActiveUS20050003140A1Improved dimensional stabilityGood dimensional stabilityWarp knittingLaminationFibrous layerYarn

Disclosed herein is a composite comprising at least one heat shrinkable adhesive layer stitch-bonded with yarns, which shrink less than the adhesive layer or do not shrink, when the adhesive layer is exposed to heat. The stitch-bonded yarns form loops upstanding from the shrunk adhesive layer and the loops create a textured surface on the composite, and the composite is substantially inelastic after the adhesive layer is shrunk. The composite may further comprise at least one fibrous layer stitch-bonded to the shrinkable adhesive layer, and the fibrous layer is less shrinkable than the adhesive layer or is substantially non-shrinkable.

Owner:J&J FLOORING GRP LLC

High temperature resistant and solvent resistant phenolic resin glue sheet

ActiveCN108753220AImproved dimensional stabilityGood high temperature resistanceAldehyde/ketone condensation polymer adhesivesConjugated diene hydrocarbon adhesivesSolventTemperature resistance

The invention relates to the field of glue and particularly relates to a high temperature resistant and solvent resistant phenolic resin glue sheet. The glue sheet at least comprises, by weight, 25 to40 parts of nitrile rubber, 50 to 80 parts of phenolic resin, 2 to 10 parts of a curing agent, 0.2 to 1.5 parts of a curing accelerator and 0.2 to 0.4 parts of a vulcanizing agent. The phenolic resinglue sheet is modified by using monomers containing a polycyclic group and an unsaturated double bond group so that the curing mode of the phenolic resin is changed, the dimensional shrinkage of thephenolic resin glue sheet during curing is avoided and the dimensional stability of the glue sheet in use is improved. Through compounding of raw materials in different ratios and modification of thephenolic resin with different monomers, the phenolic resin glue sheet has high temperature resistance. Through high temperature heat treatment on the glue sheet, all performances can be kept in good levels, the application field of the phenolic resin glue sheet is broadened and the service life is prolonged.

Owner:长春峰泰科技有限公司

Alloy material, lightweight brake drum with alloy material applied, and lightweight brake drum preparation method

InactiveCN109371327AImproved dimensional stabilityImproves Strength and ToughnessBraking drumsFurnace typesQuenchingDriving safety

The invention relates to the technical field of brake materials, in particular to an alloy material, a lightweight brake drum with the alloy material applied, and a lightweight brake drum preparationmethod. The alloy material is prepared from, by weight, C: 0.23-0.28%, Si: 0.45-0.55%, Mn: 1.05-1.10%, S: no greater than 0.007%, P: no greater than 0.008%, Ni: 1.05-1.20%, Cr: 0.8-0.95%, Mo: 0.5-0.62%, Al: no greater than 0.04%, and the balance Fe. The alloy material has better mechanical properties and thermal fatigue resistance. The annealing and quenching and tempering processes are added in the casting process of the lightweight brake drum, so that the mechanical property of the lightweight brake drum is enhanced. In addition, the wall thickness can be thinned and the structure of the lightweight brake drum can be optimized so as to enhance the braking stability of the lightweight brake drum and increase the driving safety performance.

Owner:天宜上佳(天津)新材料有限公司

Energy-saving environment-friendly solar heat preservation building material

InactiveCN105778035AImproved dimensional stabilityHigh closed cell rateBuilding materialThermal conductivity

The invention discloses an energy-saving environment-friendly solar heat preservation building material. The heat preservation building material is obtained by foaming the following raw materials in parts by weight: 120-140 parts of dimer acid diisocyanate, 50-70 parts of polyether polyol I, 35-50 parts of polyether polyol II, 3-6 parts of expanded vermiculite, 5-8 parts of nanosilicon dioxide, 10-20 parts of chlorodifluoroethane, 5-6 parts of dimethyl methylphosphate, 1-5 parts of ethylene glycol monoisopropanolamine and 1-5 parts of organosilicone foam stabilizer. The energy-saving environment-friendly solar heat preservation building material is obviously improved in indexes such as thermal conductivity, compressive strength, tensile adhesive strength, dimensional stability and close pore ratio compared with an existing heat preservation building material and produces no phenomenon such as shrinkage, deformation, expansion and cracking under the freezing or high temperature condition, so that the heat preservation building material disclosed by the invention is excellent in performance.

Owner:毛文辉

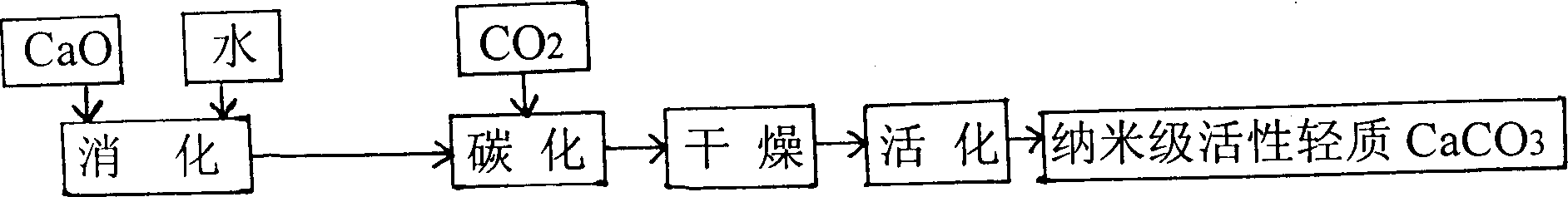

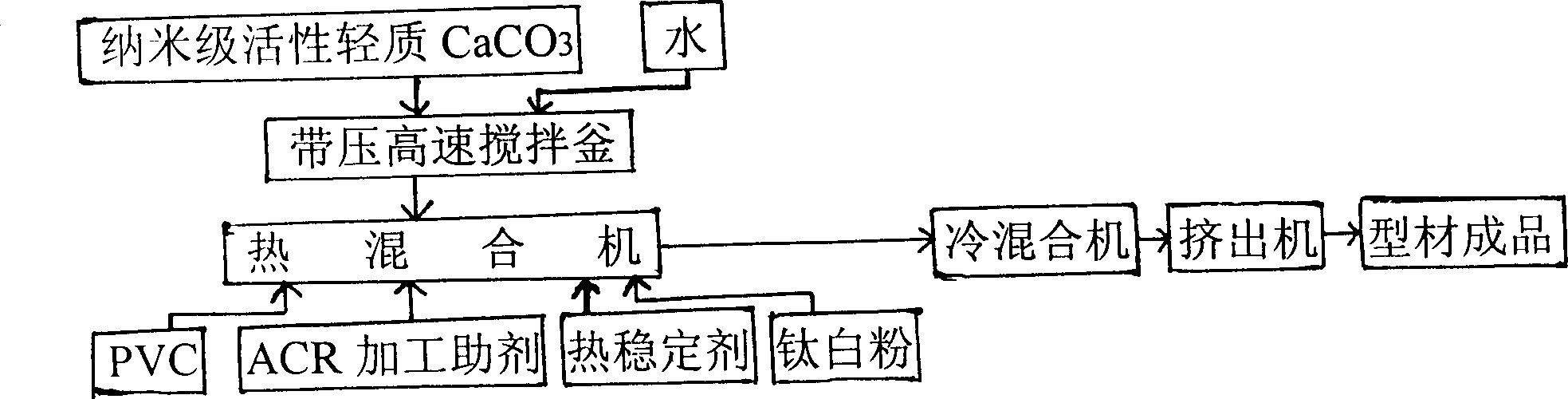

PVC section containing nano-class active light calcium carbonate for door or window and its preparing process and apparatus

A PVC section for door or window is characterized by that it conains nano-class active light calcium carbonate, instead of the polyvinylchloride or ACR as anti-impact modifier and ordinary active light calcium carbonate. Its advantages are low cost, and high size stability, low-temp anti-impact performance, hardness and flame-retarding nature.

Owner:赵玉杰

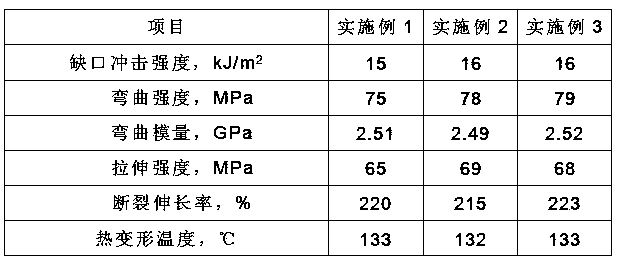

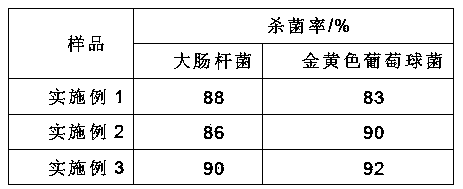

Antibacterial fluorescent PET/PC (Polyethylene Terephthalate/Polycarbonate) alloy and preparation method thereof

The invention relates to an antibacterial fluorescent PET / PC (Polyethylene Terephthalate / Polycarbonate) alloy and a preparation method thereof and belongs to the technical field of high polymers. The antibacterial fluorescent PET / PC alloy comprises the following components in parts by weight: 20-40 parts of PET, 80-100 parts of PC, 1-3 parts of a compatilizer, 0.5-1 part of antioxidant 1010, 0.2-0.5 part of antioxidant 168, 2-5 parts of rare earth aluminate noctilucent powder, 1-3 parts of ultraviolet absorber (UV) and 1-3 parts of a natural antibacterial agent. According to the product, the PET and PC are compounded, so that the prepared product has excellent performances of the PET and PC, is high in heat resistance and high in dimensional stability and has a sterilization function. According to the antibacterial fluorescent PET / PC alloy, light-induced energy storage noctilucent powder which is harmless to a human body is added, so that the product has the fluorescence characteristic, and normal use of a switch can be guaranteed when the light source is dark.

Owner:吴江市东泰电力特种开关有限公司

3C product charging connector shell highlight process

ActiveCN108312048AReduce damageImproved dimensional stabilityEdge grinding machinesPolishing machinesElectrical and Electronics engineeringFlow time

The invention discloses a 3C product charging connector shell highlight process. The 3C product charging connector shell highlight process comprises following steps that firstly, a CNC numerical control device is adopted to machine a charging connector shell; secondly, grinding stone I and the charging connector shell obtained in the first step are added into a grinding bucket of a rolling grinding machine according to the proportion to be subject to rolling grinding, and the ground charging connector shell is cleaned and dried; thirdly, the charging connector shell obtained in the second stepis subject to sand blasting treatment; fourthly, grinding stone II and the charging connector shell obtained in the third step are added into the grinding bucket of the rolling grinding machine according to the proportion to be ground. The 3C product charging connector shell highlight process has the good highlight effect, the product yield and the stability can be improved, the machining flow time can be shortened, manpower is saved, material losses are reduced, product production cost is reduced, and the product market competitiveness is improved.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Changing chain elastic lining and manufacturing process thereof

ActiveCN103710852AImproved dimensional stabilityGood follow-upGarmentsWarp knittingEngineeringHot-melt adhesive

The invention discloses an elastic lining and a manufacturing process of the elastic lining. The elastic lining comprises a base cloth layer formed by braiding weft, warp and laid yarn, the weft and the warp are interwoven with each other, the warp forms a plurality of coils in the longitudinal direction, the coils in the longitudinal direction form a chain, every two adjacent chains are connected through weft, the laid yarn penetrates through the coils and enables the chains to be connected, connection points between the laid yarn and the coils form first intersections, and the surface of the base cloth layer is coated with a hot melt adhesive layer. According to the elastic lining and the manufacturing process of the elastic lining, polyester filaments serve as the weft, the fabric which is stable in form, composed of the coils which are tangled with one another, and knitted through the changing chain warp knitting technology serves as the base cloth layer, and due to the reverse laid yarn, the intersections of the fabric are increased, the dimensional stability is greatly enhanced, the elastic lining can completely be freely and accordingly changed along with shrinkage or loosening of the fabric, the mobility is extremely good, the adhesive strength is extremely high, the original style of a garment can be kept in the use process, and the hand feeling, the drapability, the shape maintenance and the like of the garment can not be lowered after the garment is repeatedly washed.

Owner:CHANGXING SANJIN SPECIAL TEXTILE

More-than-once foaming type extrusion molding insulation board production process and equipment thereof

InactiveCN106182554AUniform foamingImproved dimensional stabilityStability indexManufacturing engineering

The invention discloses a more-than-once foaming type extrusion molding insulation board production process and equipment thereof. The production process comprises the steps of steaming and baking, foaming and traction re-foaming after primary foaming extrusion. The equipment comprises a first extruder, a second extruder, a clamping plate setting machine, a multi-roller tractor, a first steam foaming box, a second steam foaming box, a four-roller tractor and a third steam foaming box which are connected mutually. The more-than-once foaming type extrusion molding insulation board production process and the equipment thereof have the advantages that the size stability of an insulation board is improved substantially, the phenomenon that the insulation board is subjected to contraction deformation due to the fact that the size stability index of the insulation board cannot reach the code standard and the temperature is changed in spring, summer, autumn and winter, and consequently an outer wall insulation board cracks and falls is avoided, and the project quality is ensured.

Owner:北京首豪新型建材科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com