Changing chain elastic lining and manufacturing process thereof

A preparation process and chain braiding technology, applied in the field of clothing fabrics and interlinings, can solve the problems of hand feel, drape, shape retention, stability, poor follow-up, and lack of good stretchability, etc., and achieve follow-up Excellent performance, soft hand feeling and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

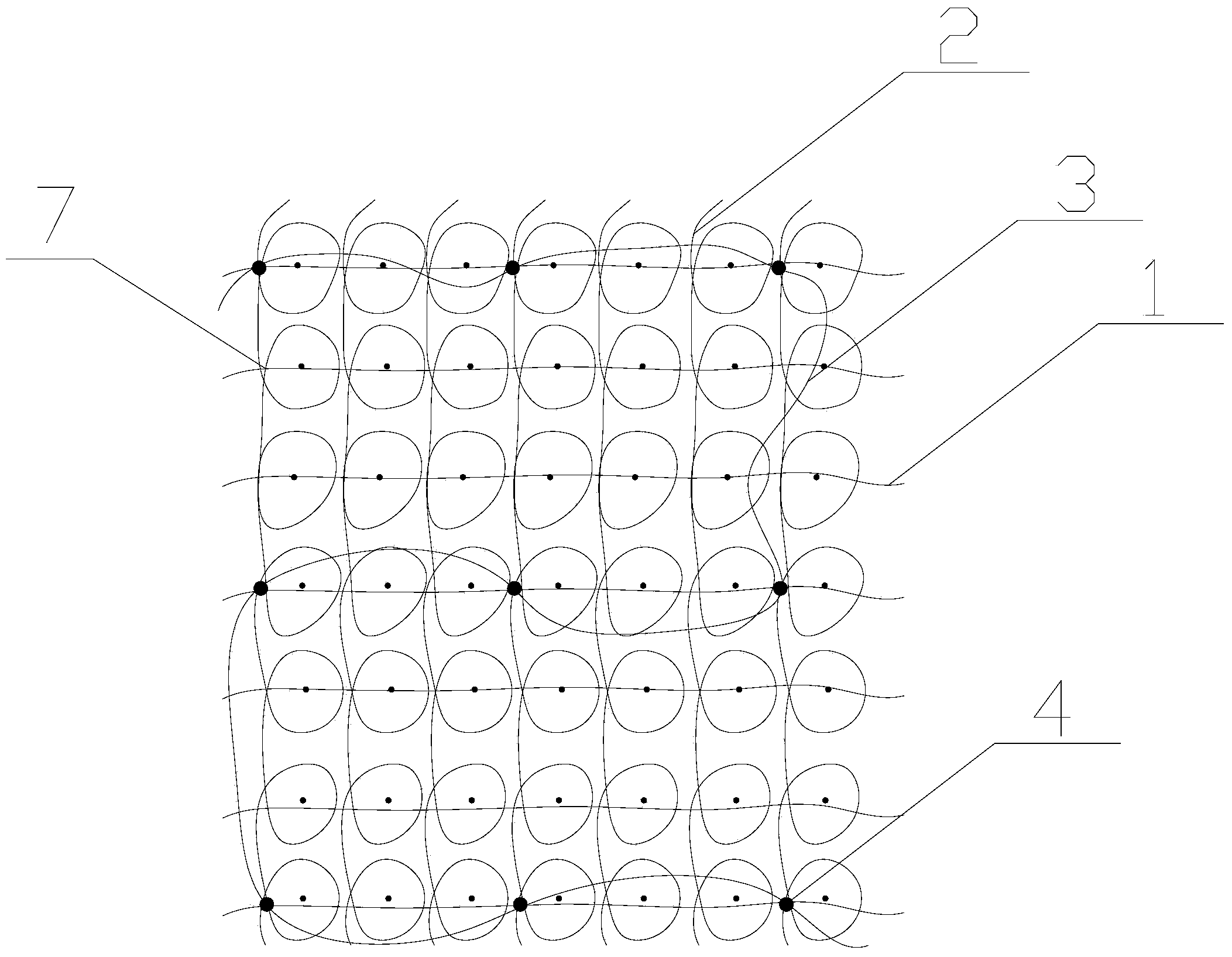

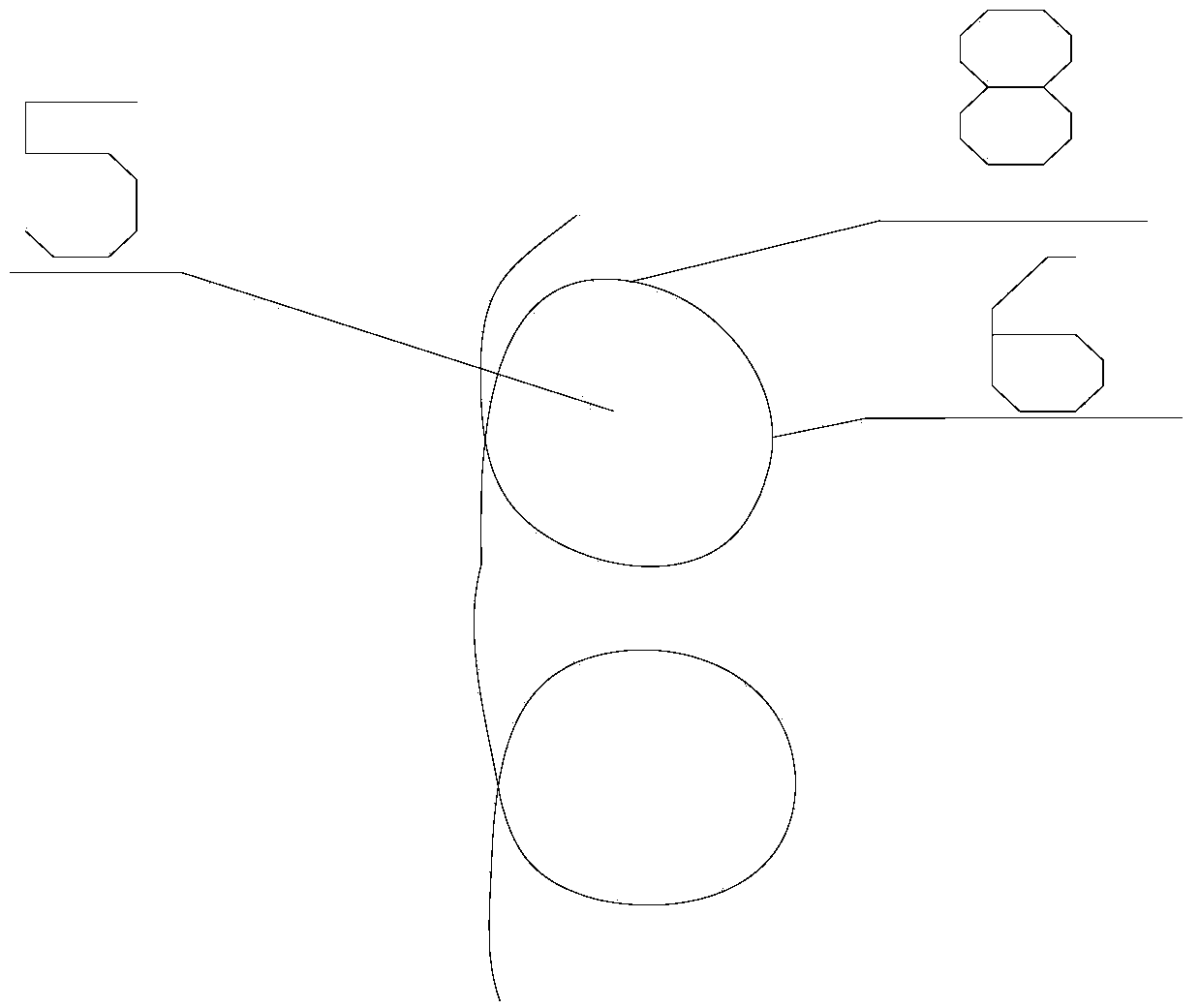

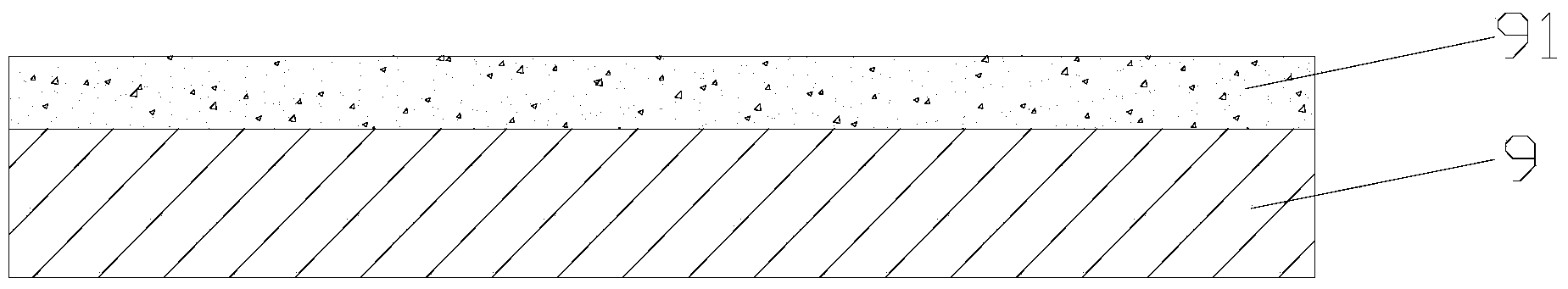

[0028] refer to figure 1 , figure 2 with image 3 , a variable knitting chain elastic interlining of the present invention, comprising a base fabric layer 9 woven from weft yarns 1, warp yarns 2 and lap yarns 3, the weft yarns 1 and warp yarns 2 interweave, and the warp yarns 2 form several warp yarns in the wale direction a plurality of coils 5 in the wale direction constitute a knitting chain, and two adjacent knitting chains are connected by a weft yarn 1; The connection point with the coil 5 forms the first intersection point 4, the surface of the base fabric layer 9 is coated with a hot melt adhesive layer 91, the cross section of the weft yarn 1 is an irregular polygon, and the several weft yarns 1 are made of composite polyester The ester filament forms a toothed structure on its surface, and the loop 5 includes a coil post 6 and a needle loop 8, the needle loop 8 is located at the top of the loop post 6, and the weft yarn 1 passes through the loop post 6 and the loo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com