PVC section containing nano-class active light calcium carbonate for door or window and its preparing process and apparatus

A technology of active light weight and manufacturing method, which is applied in the field of plastic profiles, can solve the problems of not being able to bring economic benefits to profile manufacturers, dimensional stability, poor hardness and flame retardancy, and no plastic door and window profiles, etc., to achieve hardness and retardation Good flammability, improved dimensional stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

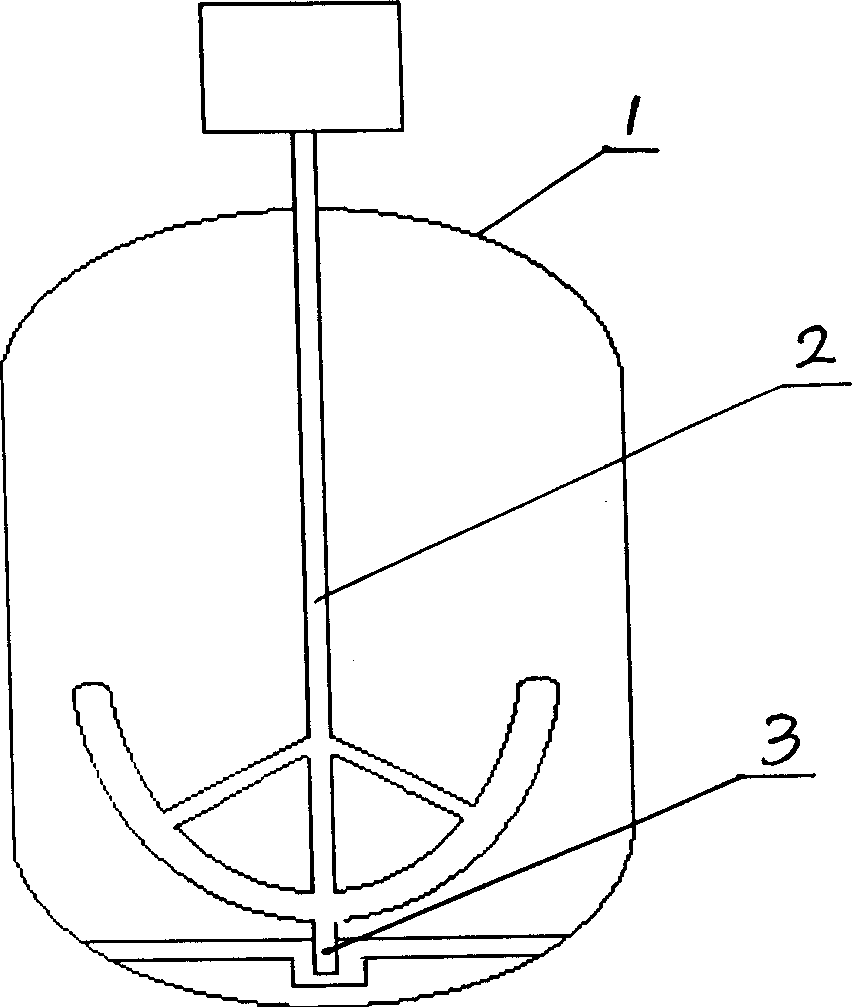

Image

Examples

Embodiment Construction

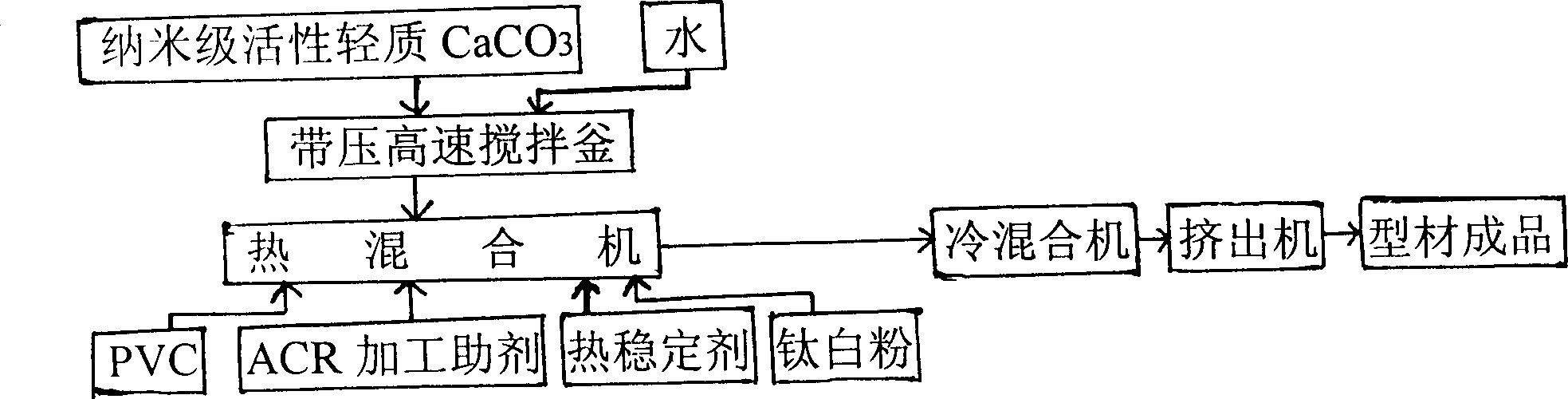

[0024] The present invention will be further described below in conjunction with specific examples. The present invention adds nano-scale active light calcium carbonate PVC door and window profiles, and replaces the impact modifier in ordinary PVC door and window profiled materials with nano-scale active light calcium carbonate: chlorine Polyethylene or ACR impact modifier and ordinary active light calcium carbonate, and PVC, ACR processing aids, heat stabilizers, titanium dioxide are added at the same time as the above calcium carbonate.

[0025] Its weight ratio is: PVC100, 100, 100, ACR processing aid 1, 1.5, 2.5, heat stabilizer (organic tin, compound salt, rare earth) 2, 3, 5.6, titanium dioxide 4, 4.5, 5, nano-scale Active light calcium carbonate 3, 14, 25.

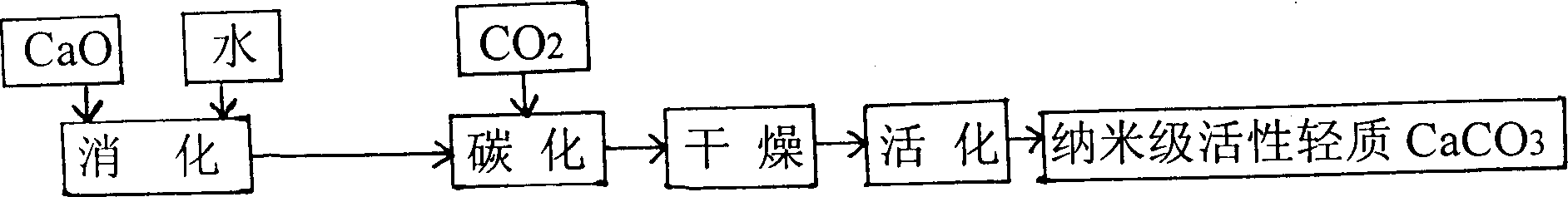

[0026] The nano-scale active light calcium carbonate is made by the following method: under the high-speed stirring of 400-800 rpm, the digestion reaction is carried out with water and calcium oxide, and then carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com