Antibacterial fluorescent PET/PC (Polyethylene Terephthalate/Polycarbonate) alloy and preparation method thereof

A PET20 and alloy technology, applied in the polymer field, can solve the problems of limited use range, no light source, long molding cycle, etc., and achieve the effects of easy popularization and application, normal use, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

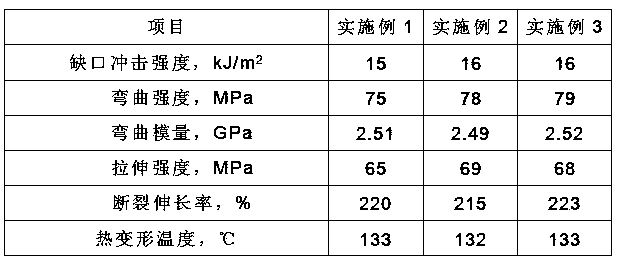

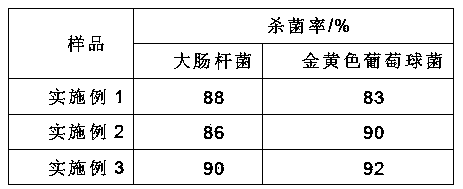

Examples

Embodiment 1

[0018] An antibacterial fluorescent PET / PC alloy, including the following components in parts by weight: 20 parts of PET, 80 parts of PC, 1 part of maleic anhydride graft compatibilizer, 0.5 part of antioxidant 1010, and 168 0.2 part of antioxidant , 2 parts of rare earth aluminate luminous powder, 1 part of ultraviolet absorber UV328, 1 part of chitin.

[0019] The preparation method of the antibacterial fluorescent PET / PC alloy of this embodiment includes the following steps:

[0020] Step (1): Vacuum dry PET and PC for 2h;

[0021] Step (2): Put the dried PET and PC in step (1) in a mixer, stir at low speed at 400r / min, and add maleic anhydride graft compatibilizer, antioxidant 1010, and antioxidant 168. Rare earth aluminate luminous powder, ultraviolet light absorber UV328 and chitin are stirred until they are uniformly mixed to obtain a mixture;

[0022] Step (3): The mixture material obtained in step (2) is melt-extruded and pelletized by a twin-screw extruder at an extrusion t...

Embodiment 2

[0024] An antibacterial fluorescent PET / PC alloy, comprising the following components in parts by weight: 40 parts of PET, 100 parts of PC, 3 parts of maleic anhydride graft compatibilizer, 1 part of antioxidant 1010, 1680.5 parts of antioxidant, 5 parts of rare earth aluminate luminous powder, 3 parts of ultraviolet absorber UV328, 3 parts of chitin.

[0025] The preparation method of the antibacterial fluorescent PET / PC alloy of this embodiment includes the following steps:

[0026] Step (1): Vacuum dry the PET and PC for 5 hours;

[0027] Step (2): Put the dried PET and PC in step (1) in a blender, stir at low speed at 600r / min, and add maleic anhydride graft compatibilizer, antioxidant 1010, and antioxidant 168. Rare earth aluminate luminous powder, ultraviolet light absorber UV328 and chitin are stirred until they are uniformly mixed to obtain a mixture;

[0028] Step (3): The mixture material obtained in step (2) is melt-extruded and pelletized by a twin-screw extruder at an ex...

Embodiment 3

[0030] An antibacterial fluorescent PET / PC alloy, including the following components in parts by weight: 30 parts of PET, 90 parts of PC, 2 parts of maleic anhydride graft compatibilizer, 1010 0.7 parts of antioxidant, and 168 0.3 parts of antioxidant , Rare earth aluminate luminous powder 4 parts, ultraviolet absorber UV328 1.8 parts, chitin 2 parts.

[0031] The preparation method of the antibacterial fluorescent PET / PC alloy of this embodiment includes the following steps:

[0032] Step (1): Vacuum dry PET and PC for 3.5h;

[0033] Step (2): Put the dried PET and PC in step (1) in a mixer, stir at low speed at 500r / min, and add maleic anhydride graft compatibilizer, antioxidant 1010, and antioxidant 168. Rare earth aluminate luminous powder, ultraviolet light absorber UV328 and chitin are stirred until they are uniformly mixed to obtain a mixture;

[0034] Step (3): The mixture material obtained in step (2) is melt-extruded and pelletized by a twin-screw extruder at an extrusion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com