More-than-once foaming type extrusion molding insulation board production process and equipment thereof

A technology of multiple foaming and production process, which is applied in the production of extruded thermal insulation board, the production process of multiple foamed extruded thermal insulation board and its equipment field, which can solve the problem that the dimensional stability of products exceeds the specification value and the dimensional stability of products is poor. , The overall board density is not uniform, etc., to achieve uniform foaming, uniform cells, and display obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

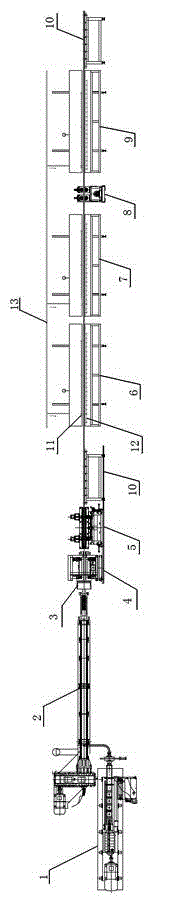

[0021] Such as figure 1 as shown,

[0022] The production process of multi-foaming extruded plastic insulation board includes the steps of steaming, foaming, traction and re-foaming after one-time foaming extrusion, wherein the specific operation of the foaming step is as follows:

[0023] First, control the steam pressure used in the first steam foaming box, and the control range is between 0.2 and 22.12 MPa. After the first foaming, the insulation board enters the first steam foaming box and connects to the second steam foaming box. box, the third steam foaming box (the number of times of steaming is different for different thickness insulation boards, and the final foaming shall prevail. In the initial stage of putting into use, adjust the pressure valve to control the temperature between 40 and 100 ℃, and then adjust the valve to control the temperature at 50 Between -150°C, at the same time, adjust the traction height and speed of the intermediate multi-roller tractor ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com