Energy saving fireproof paint and preparation method thereof

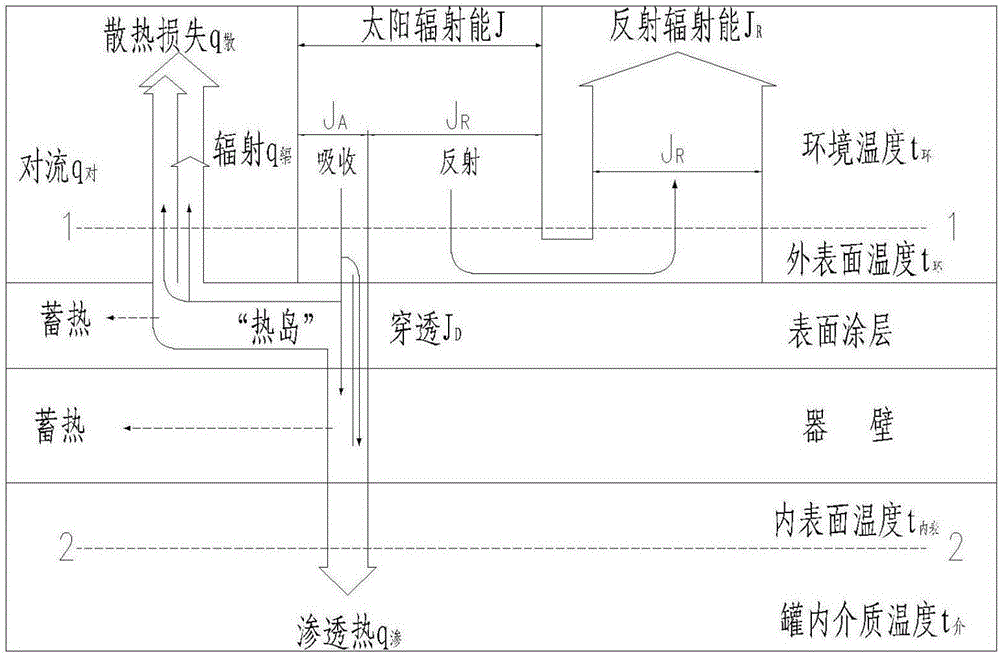

A technology of fire-resistant coatings and base materials, applied in fire-resistant coatings, coatings, etc., can solve the problems of not having energy-saving functions, not having fire-proof functions, etc., and achieve good oxygen insulation, improved flame-retardant and heat-insulating properties, and increased carbon layer strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An embodiment of the energy-saving fireproof coating of the present invention, the energy-saving fireproof coating of this embodiment is prepared by the following method:

[0060] (1) Accurately weigh 7 parts by weight of carbonizing agent, 7 parts by weight of foaming agent, 20 parts by weight of flame retardant, 5 parts by weight of titanium dioxide, 1 part by weight of magnesium hydroxide, and 2 parts by weight of diatomaceous earth, add to the homogeneous mixture Mix uniformly in a container to obtain a fireproof base material; wherein, the carbonizing agent is pentaerythritol, the foaming agent is melamine, and the flame retardant is ammonium polyphosphate.

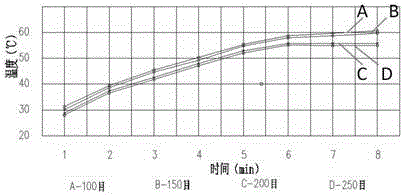

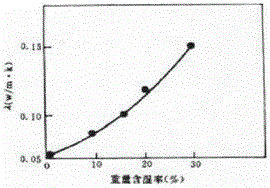

[0061] (2) Accurately weigh 9 parts by weight of inorganic hollow materials consisting of 20% of 200 meshes, 50% of 500 meshes and 30% of 800 meshes of inorganic hollow materials, and 1 weight part of magnesium hydroxide, carry out with organic silane coupling agent modified. Add 5 parts by weight of titanium...

Embodiment 2

[0068] An embodiment of the energy-saving fireproof coating of the present invention, the energy-saving fireproof coating of this embodiment is prepared by the following method

[0069] (1) Accurately weigh 10 parts by weight of carbonizing agent, 10 parts by weight of foaming agent, 25 parts by weight of flame retardant, 8 parts by weight of titanium dioxide, 2 parts by weight of magnesium hydroxide, and 3 parts by weight of diatomaceous earth, add to the homogeneous mixture Mix uniformly in a container to obtain a fireproof base material; wherein, the carbonizing agent is pentaerythritol, the foaming agent is melamine, and the flame retardant is ammonium polyphosphate.

[0070] (2) Accurately weigh 12 parts by weight of inorganic hollow materials consisting of 20% of 270 meshes, 50% of 500 meshes and 30% of 800 meshes of inorganic hollow materials, and 1 weight part of magnesium hydroxide, carry out with organic silane coupling agent modified. Add 8 parts by weight of titan...

Embodiment 3

[0077] An embodiment of the energy-saving fireproof coating of the present invention, the energy-saving fireproof coating of this embodiment is prepared by the following method

[0078] (1) Accurately weigh 12 parts by weight of carbonizing agent, 12 parts by weight of foaming agent, 30 parts by weight of flame retardant, 11 parts by weight of titanium dioxide, 2 parts by weight of magnesium hydroxide, and 5 parts by weight of diatomaceous earth, add to the homogeneous mixture Mix uniformly in a container to obtain a fireproof base material; wherein, the carbonizing agent is pentaerythritol, the foaming agent is melamine, and the flame retardant is ammonium polyphosphate.

[0079] (2) Accurately weigh 15 parts by weight of inorganic hollow materials consisting of 30% of 270 meshes, 40% of 500 meshes and 30% of 800 meshes of inorganic hollow materials, 3 parts by weight of magnesium hydroxide, carry out with organic silane coupling agent modified. Add 11 parts by weight of tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com