Patents

Literature

437results about How to "Stop burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

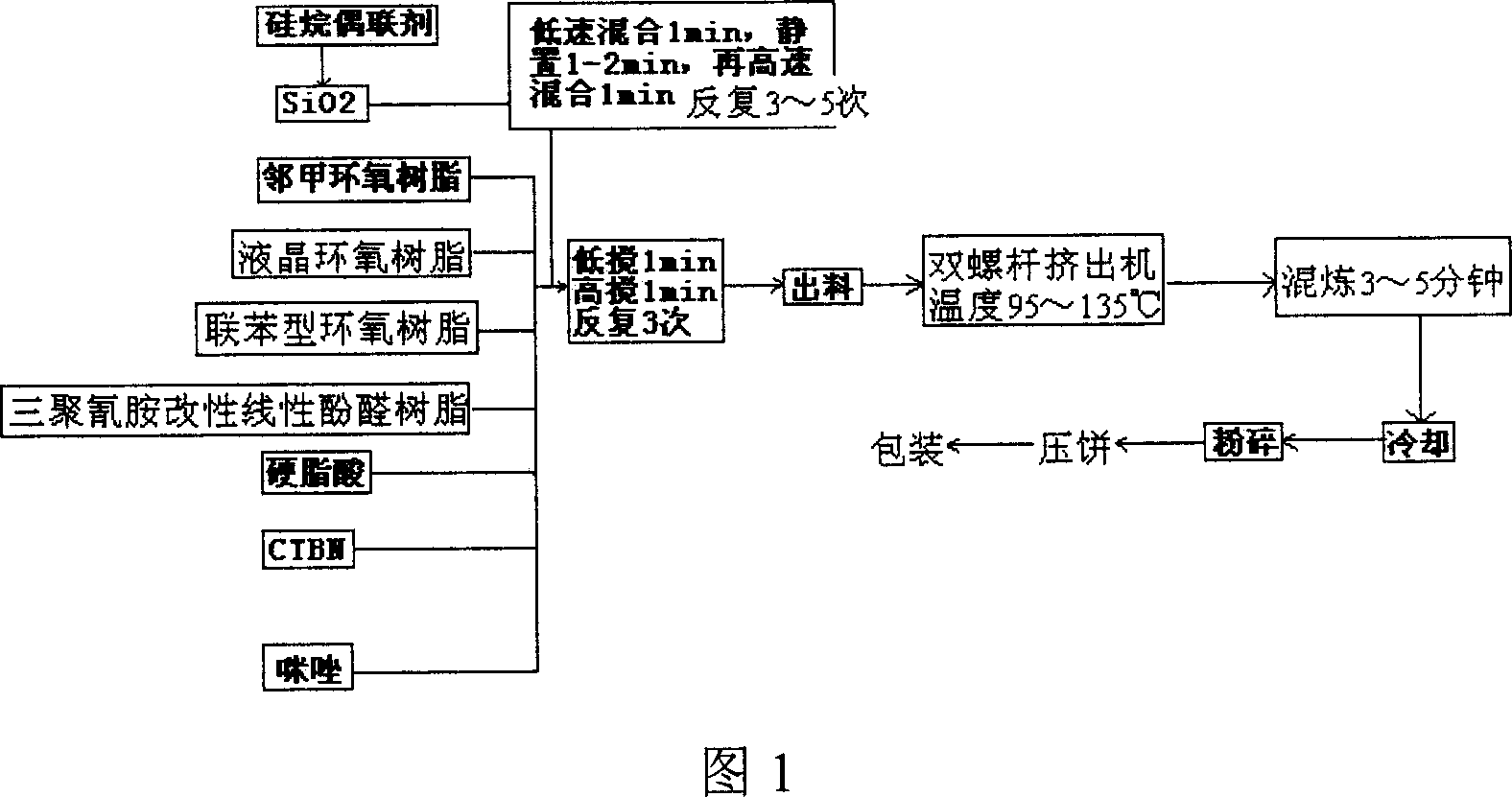

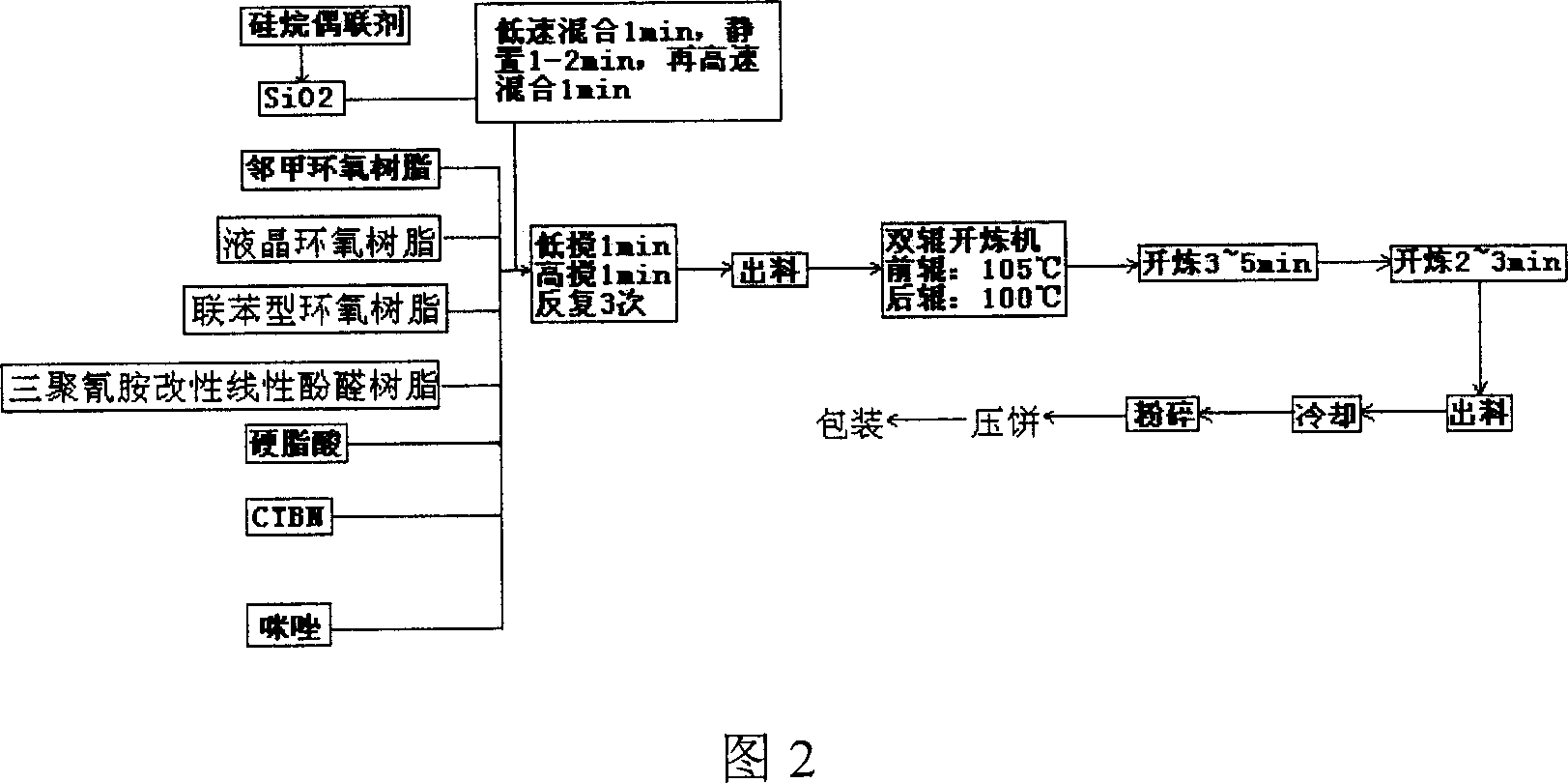

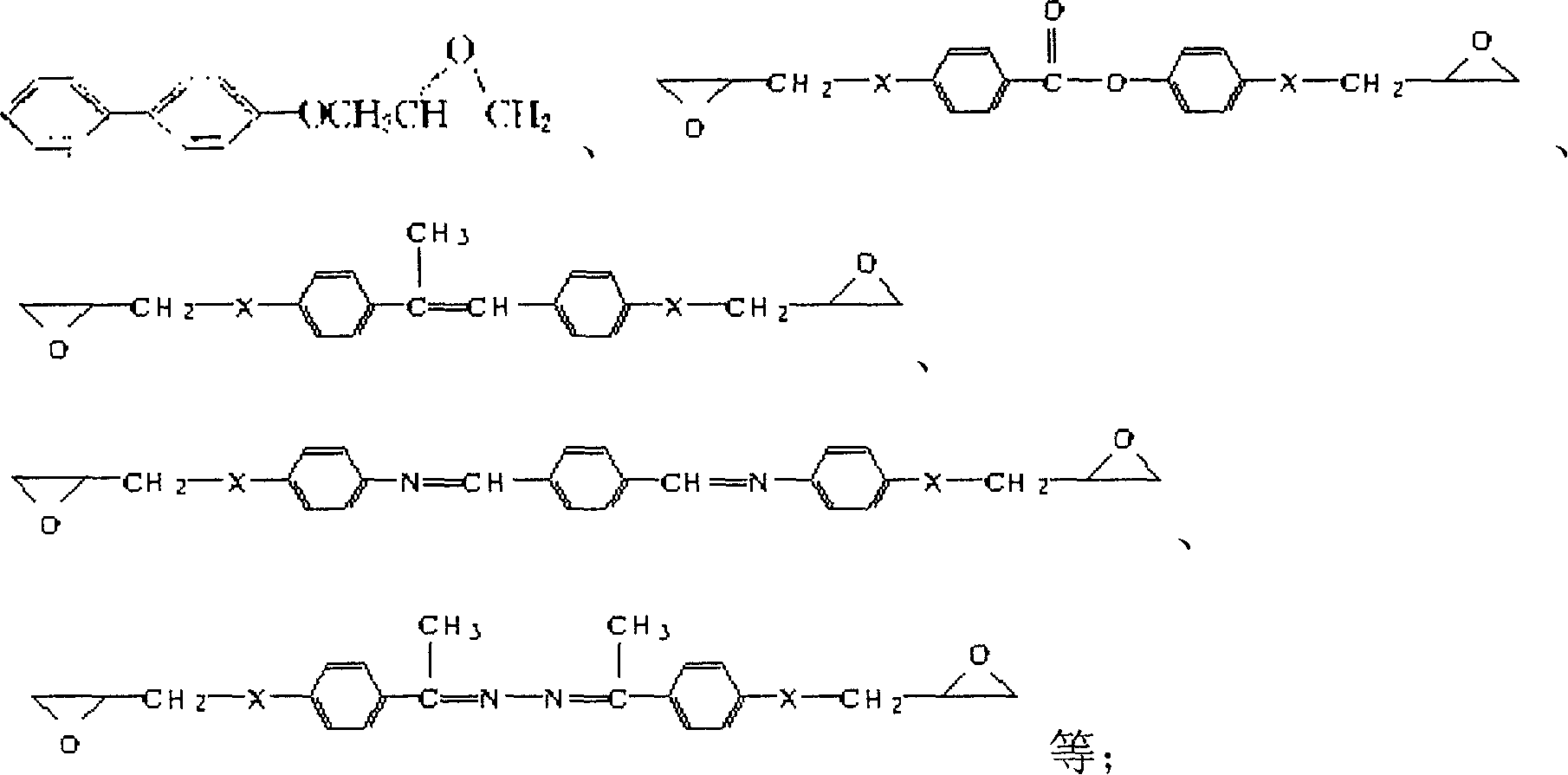

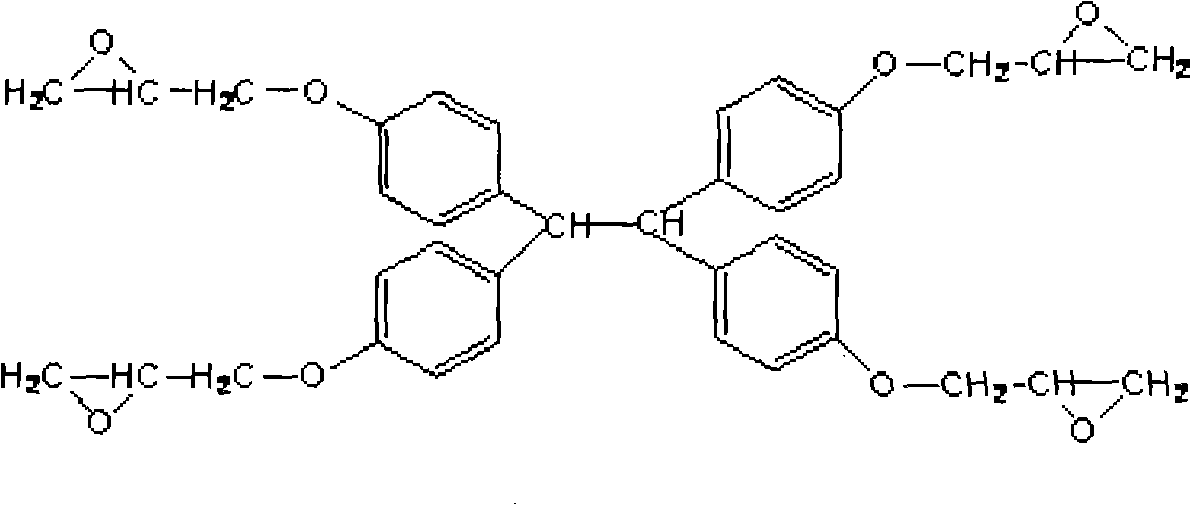

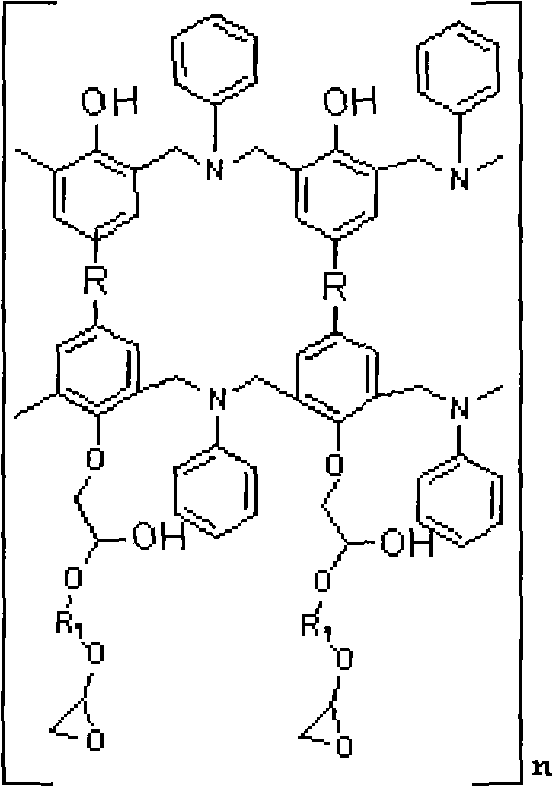

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

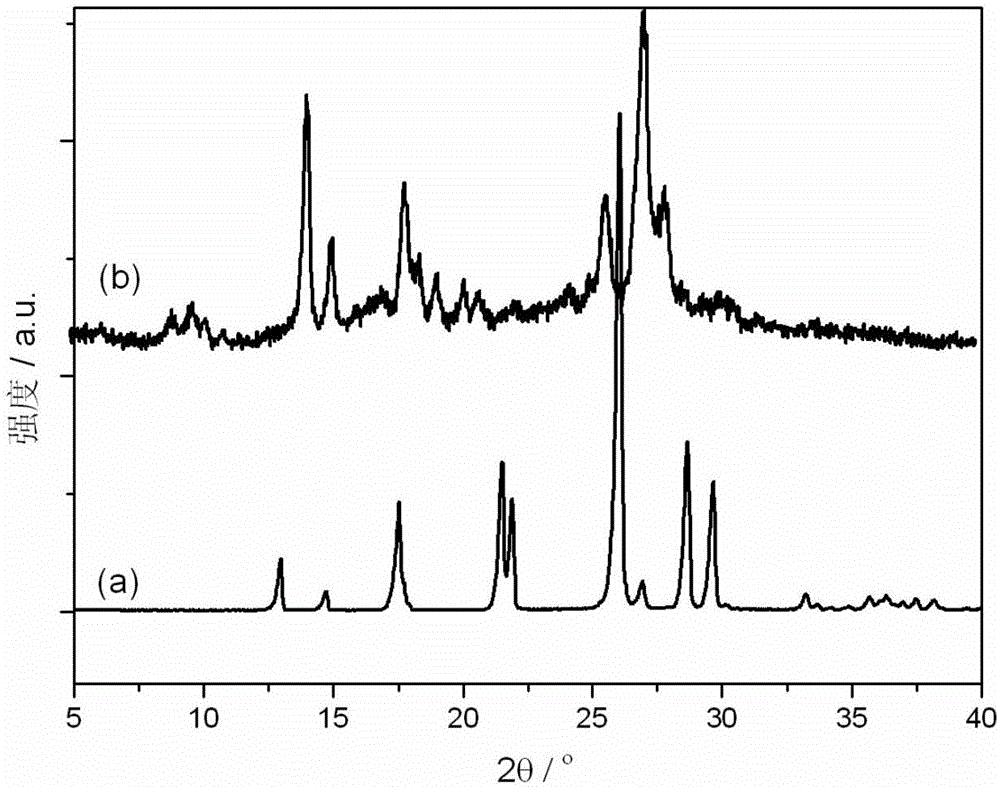

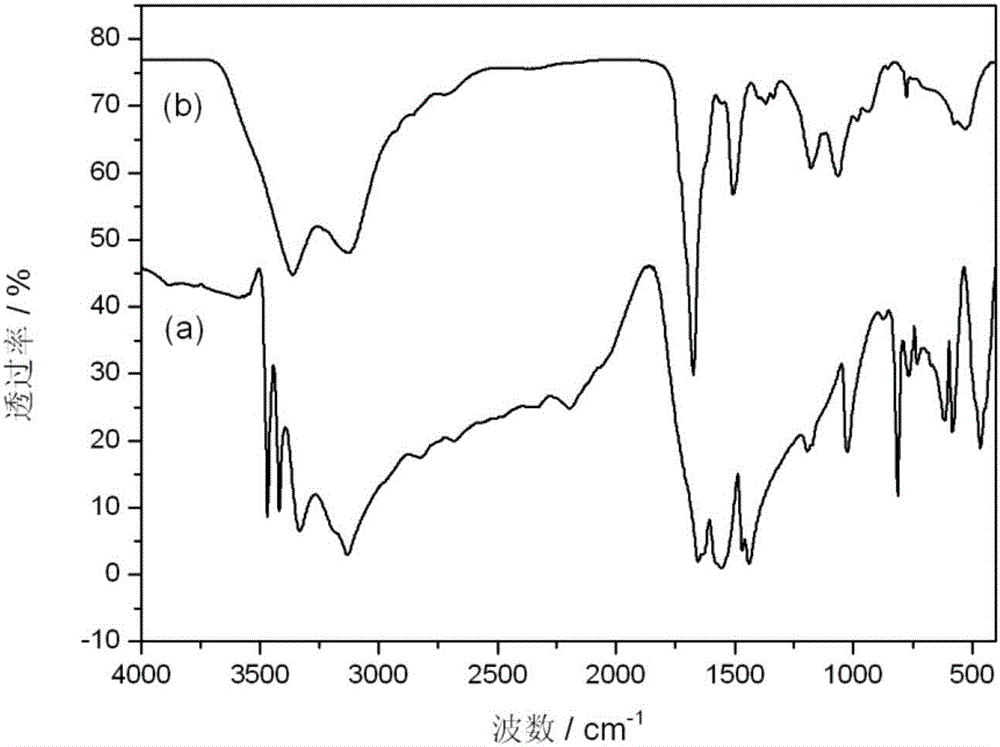

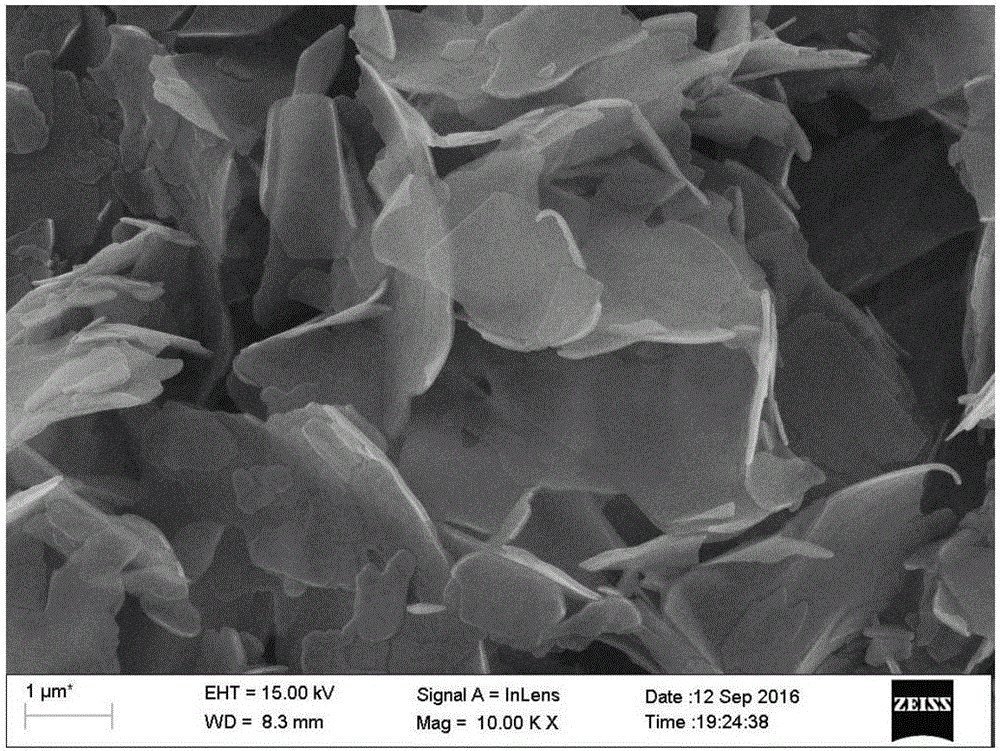

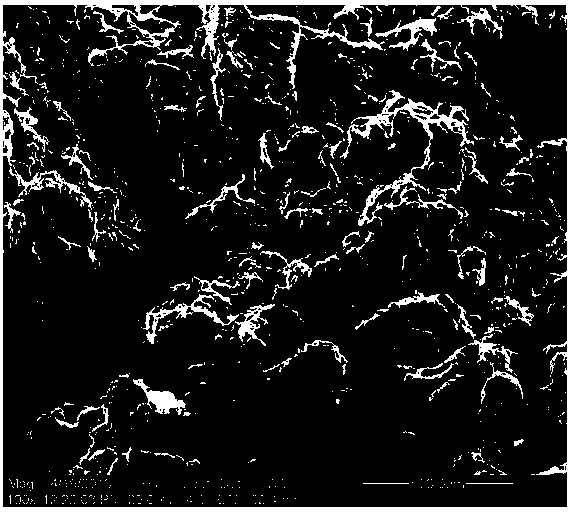

Preparation method and application of phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant

ActiveCN106519239AImprove thermal stabilityGive full play to the synergistic flame retardant effectFiltrationPhytic acid

The invention discloses a preparation method of a phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant of a nano-sheet structure. The preparation method is characterized in that phytic acid, melamine and a solvent are prepared, the substance amount ratio of the phytic acid to the melamine is 1: 3 to 1: 15, and 20-50 ml of the solvent is added into every 0.01 mol of the melamine; the melamine is added into a reaction container provided with a thermometer and a stirrer, the solvent is added with stirring, the phytic acid is added at the temperature of 20-40 DEG C, and a reaction is conducted with stirring for 20-50 minutes, so that reaction liquid is obtained; and the reaction liquid is poured into a reaction still to react for 24-56 h at the temperature of 70-120 DEG C, cooling and suction filtration are conducted, solid is washed with ethyl alcohol and then washed with water till the pH is 7, and the solid is dried, so that the flame retardant is obtained. The preparation method is simple and environmentally friendly, and the synthesized phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant of the nano-sheet structure has good compatibility with a polymer matrix and has good flame retardance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

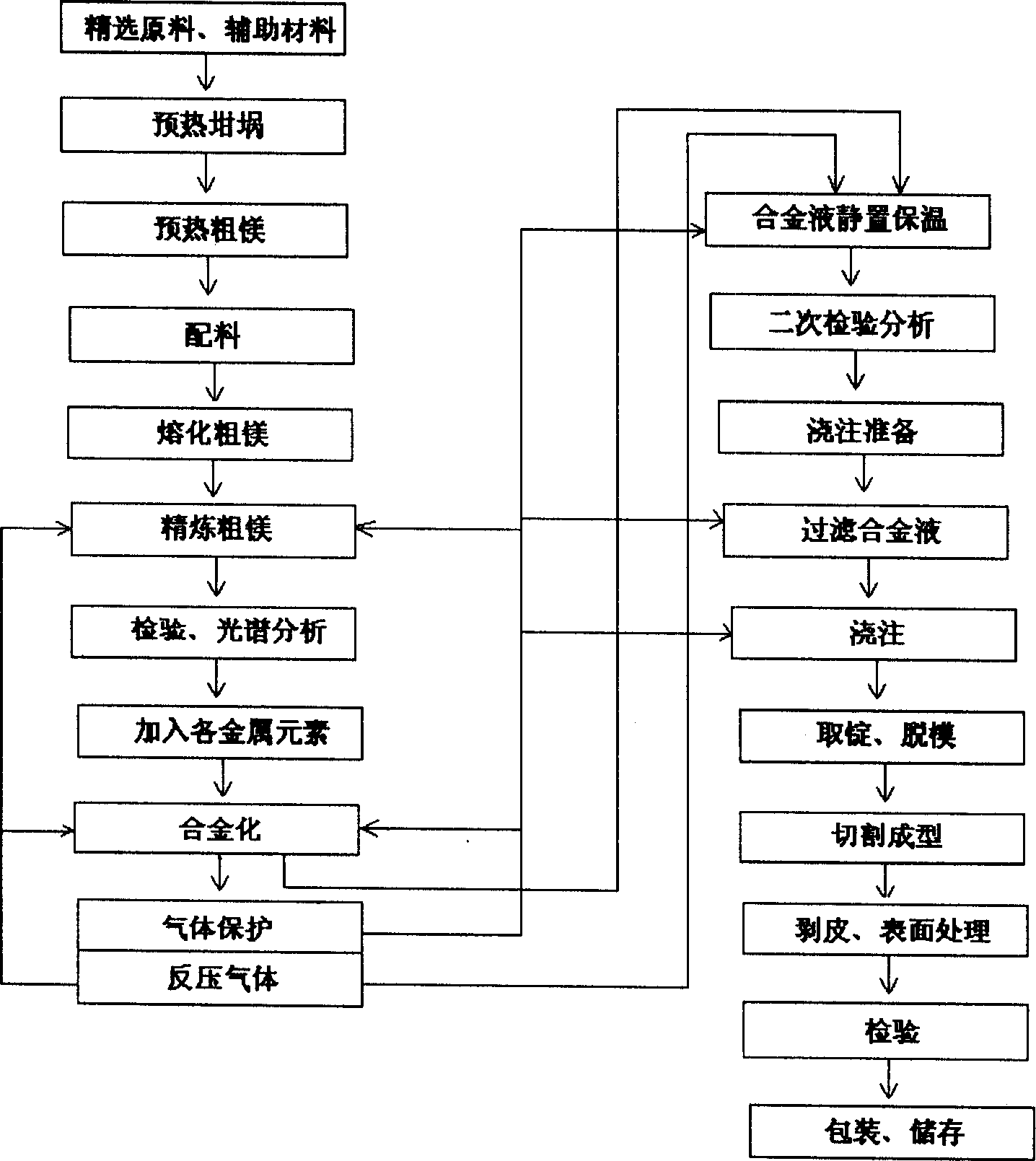

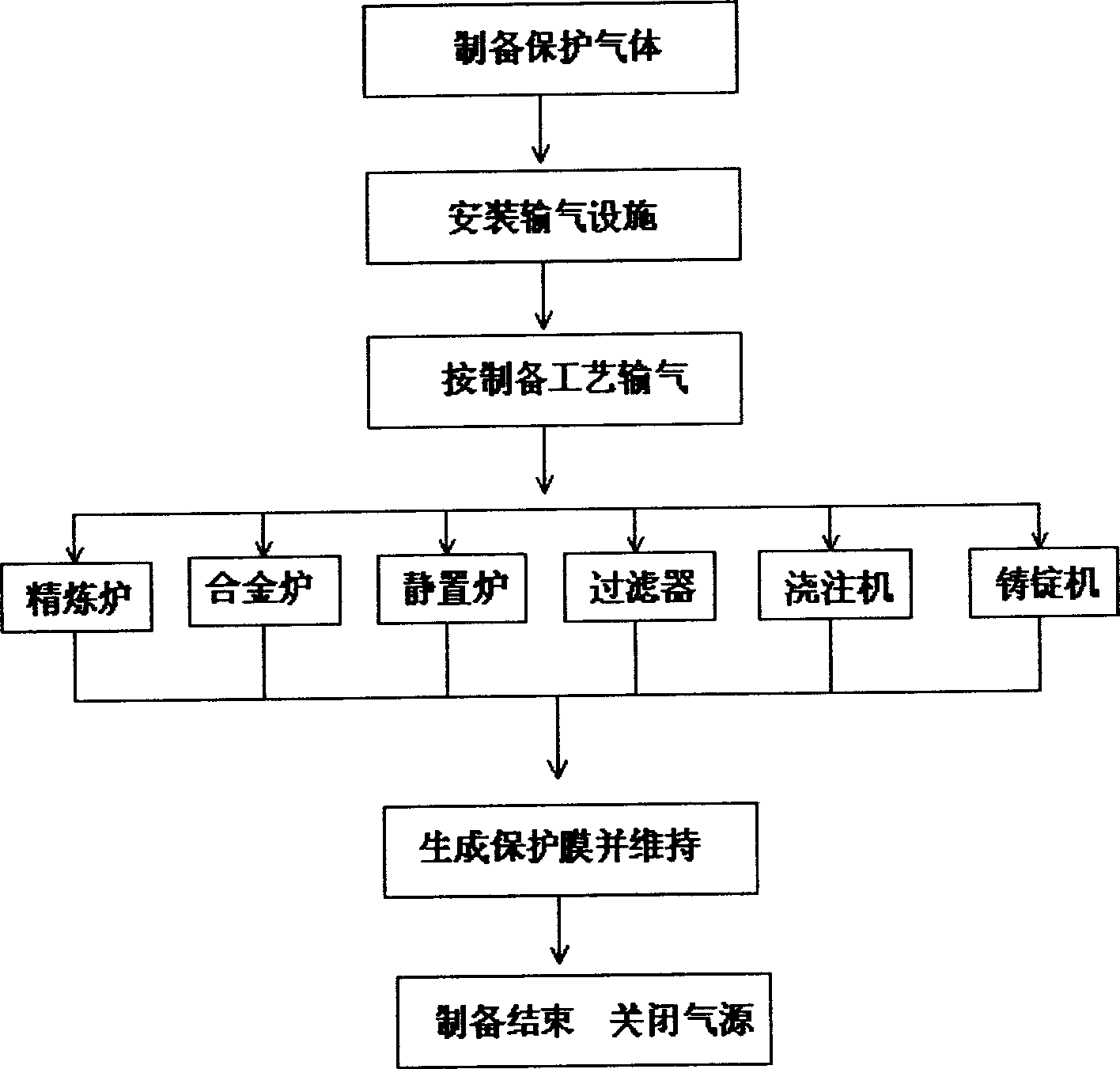

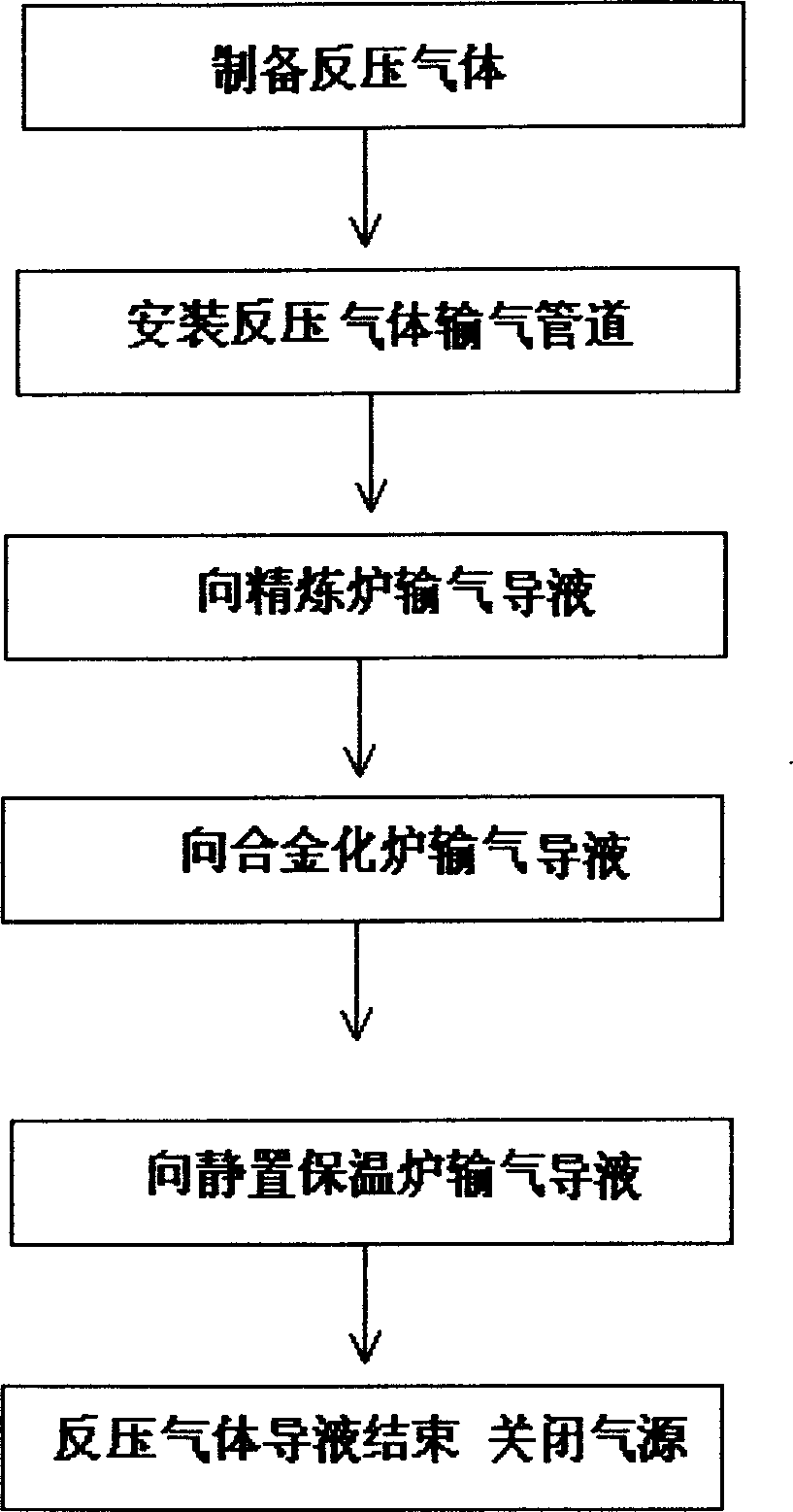

Preparation method of magnesium alloy

The preparation method of magnesium alloy is characterized by that it adopts optimum metal element mixing ratio, respectively implements magnesium-refining process, molten magnesium alloying process and alloy liquor standing still and heat-insulating process, and also adopts the following measures of gas protection, negative pressure gas liquid guide, semi-continuously pouring, water circulation cooling, dust-removing cleaning and exhausting and spectral analysis so as to to raise purity of magnesium alloy and its quality.

Owner:山西至诚科技有限公司

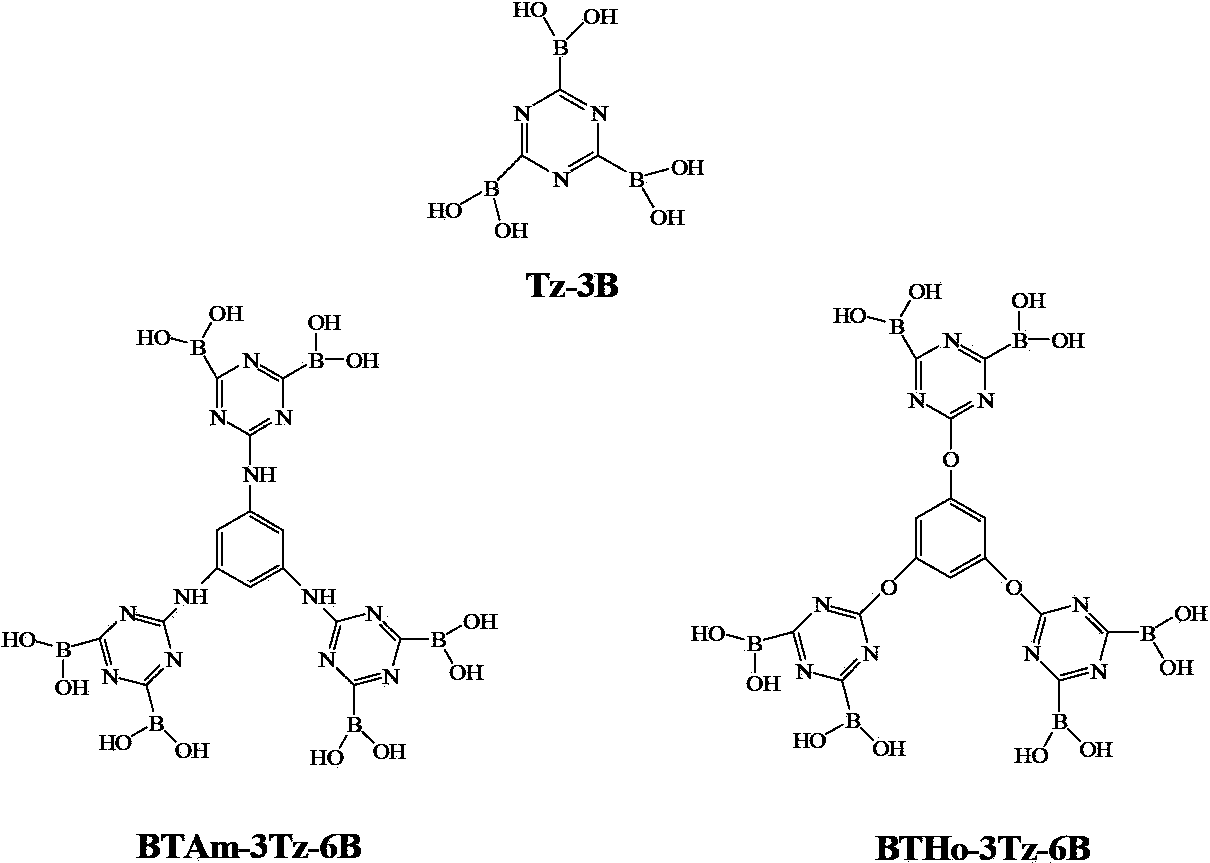

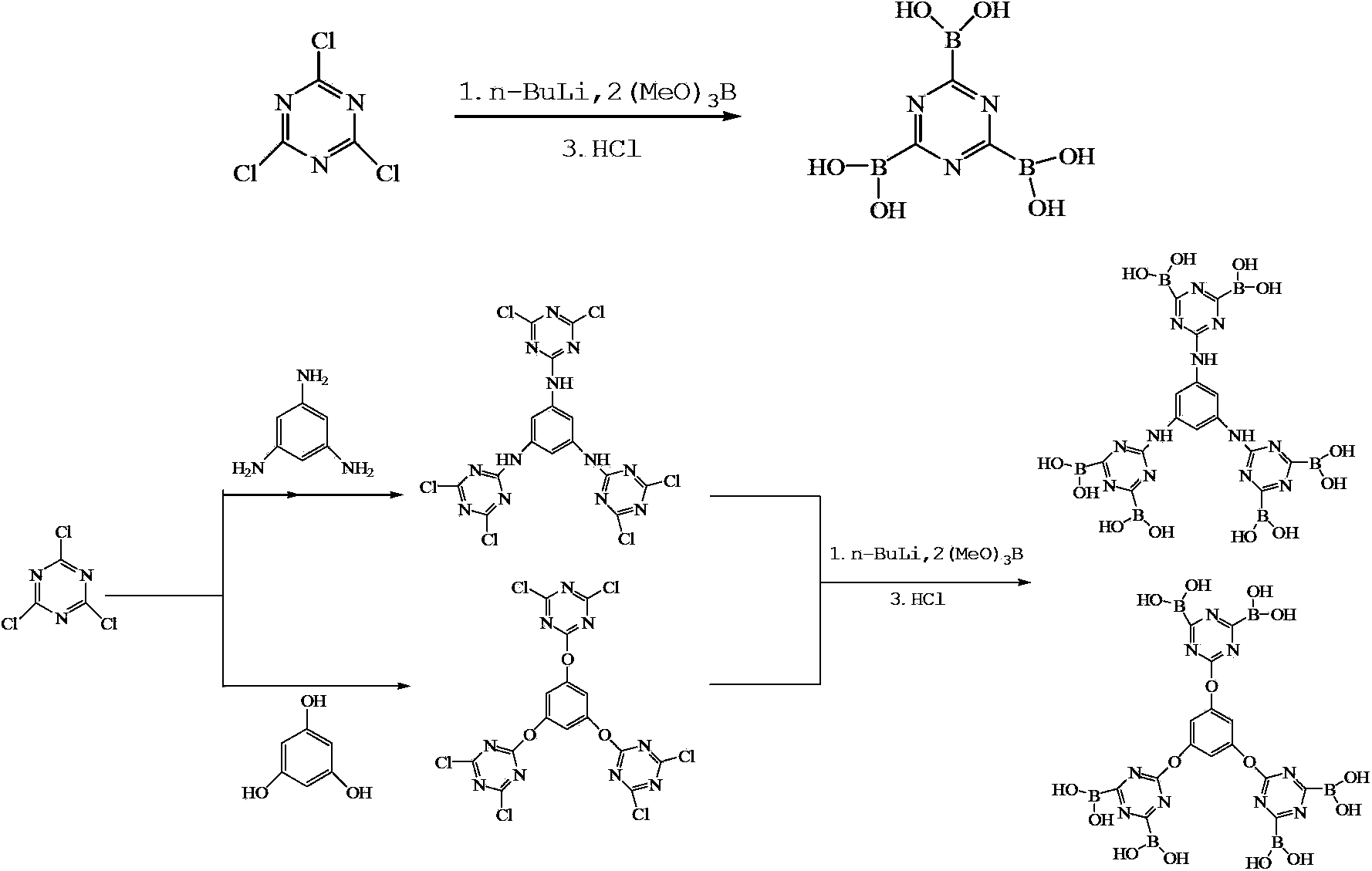

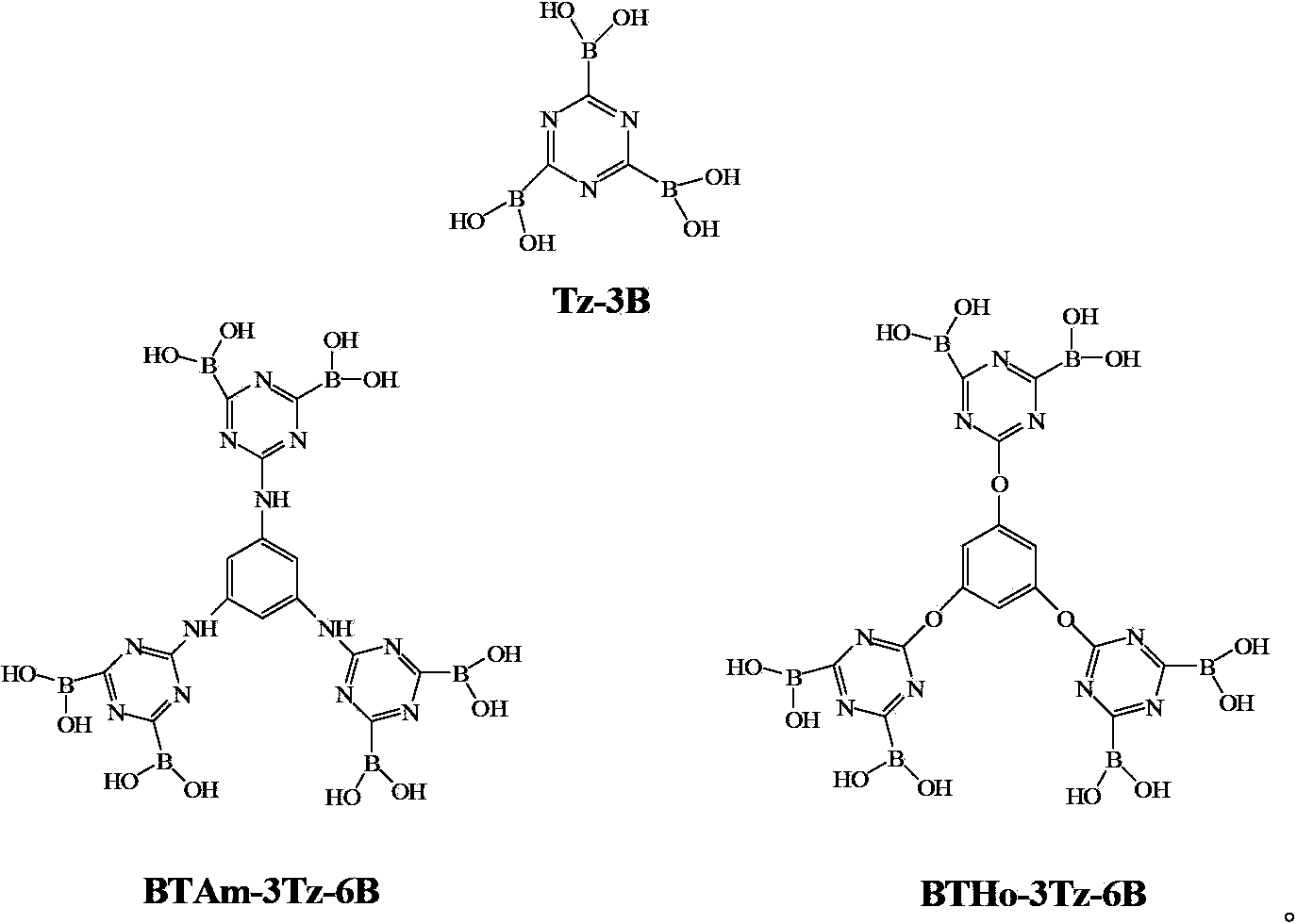

Triazine boric acid derivatives and preparation methods thereof

ActiveCN103374025ATo solve the toxicStop burningGroup 3/13 element organic compoundsButyl lithiumChemistry

The invention provides triazine boric acid derivatives and preparation methods thereof. The derivatives are Tz-3B, BTAm-3Tz-6B and BTHo-3Tz-6B. The Tz-3B is obtained by firstly enabling cyanuric chloride to react with n-butyl lithium, then performing nucleophilic substitution reaction with borate ester, and finally performing acid hydrolysis by using dilute hydrochloric acid; the BTAm-3Tz-6B is obtained by enabling the cyanuric chloride to react with 1, 3, 5-benzene triamine, then enabling an obtained product to react with the n-butyl lithium, further performing the nucleophilic substitution reaction with the borate ester, and finally performing acid hydrolysis by using dilute hydrochloric acid; and the BTHo-3Tz-6B is obtained by enabling the cyanuric chloride to react with 1, 3, 5-benzene triol, then enabling the obtained product to react with the n-butyl lithium, further performing the nucleophilic substitution reaction with the borate ester, and finally performing acid hydrolysis by using dilute hydrochloric acid. The obtained products are expected to become excellent environment-friendly organic flame retardants.

Owner:SOUTH CHINA UNIV OF TECH

Precoated sand material applicable to laser sintering of magnesium alloy, and preparation method thereof

InactiveCN103551492APreform Strength GuaranteeImprove curing rateFoundry mouldsIncreasing energy efficiencyFire retardantUltimate tensile strength

The invention discloses a preparation method for a precoated sand material applicable to the laser sintering of a magnesium alloy. The precoated sand material comprises evenly mixed crude sand, an organic binder, a coupling agent, a curing agent and a flame retardant, wherein the flame retardant is a mixture of any two or three of boric acid powder, carbon powder and pyrite powder. By adding the composite flame retardant, the defects of surface ablation and formed holes, micropores and the like when in pouring a magnesium alloy can be greatly reduced; in addition, the composite flame retardant added in the precoated sand solves the problem that a single flame retardant can greatly reduce the strength of an initial precoated sand laser-sintered part blank. According to the preparation method, not only can the magnesium alloy flame retardance problem of an SLS precoated sand mold sand core be solved, but also the strength of the initial laser-sintered molding part blanks can be guaranteed, the precoated sand material can be directly applied to pouring of a magnesium alloy, especially to high-temperature pouring of the magnesium alloy, and has great advantages on the fast integral precise forming aspects of especially complicated inner cavity, and integrated sand mold sand core.

Owner:NANCHANG HANGKONG UNIVERSITY

Flame-retarding paint for casting Mg-alloy and its preparing process

InactiveCN1381321AStrong coatingStrong thixotropyFoundry mouldsFoundry coresPorosityCarboxymethylcellulose Sodium

A fire-retarding paint for casting Mg-alloy with lost mould is prepared from magnesia sand powder, perlite powder, mica powder silica sol, white emulsoid, polyacrylamide, carboxymethylcellulose sodium, adsorbent and flame-retarding agent through preparing solution from adsorbent, carboxymethylcellulose sodium, polyacrylamide and water, and mixing with others. It can make the Mg-alloy casting havesmooth surface.

Owner:SHANGHAI AIERSI LIGHT ALLOY

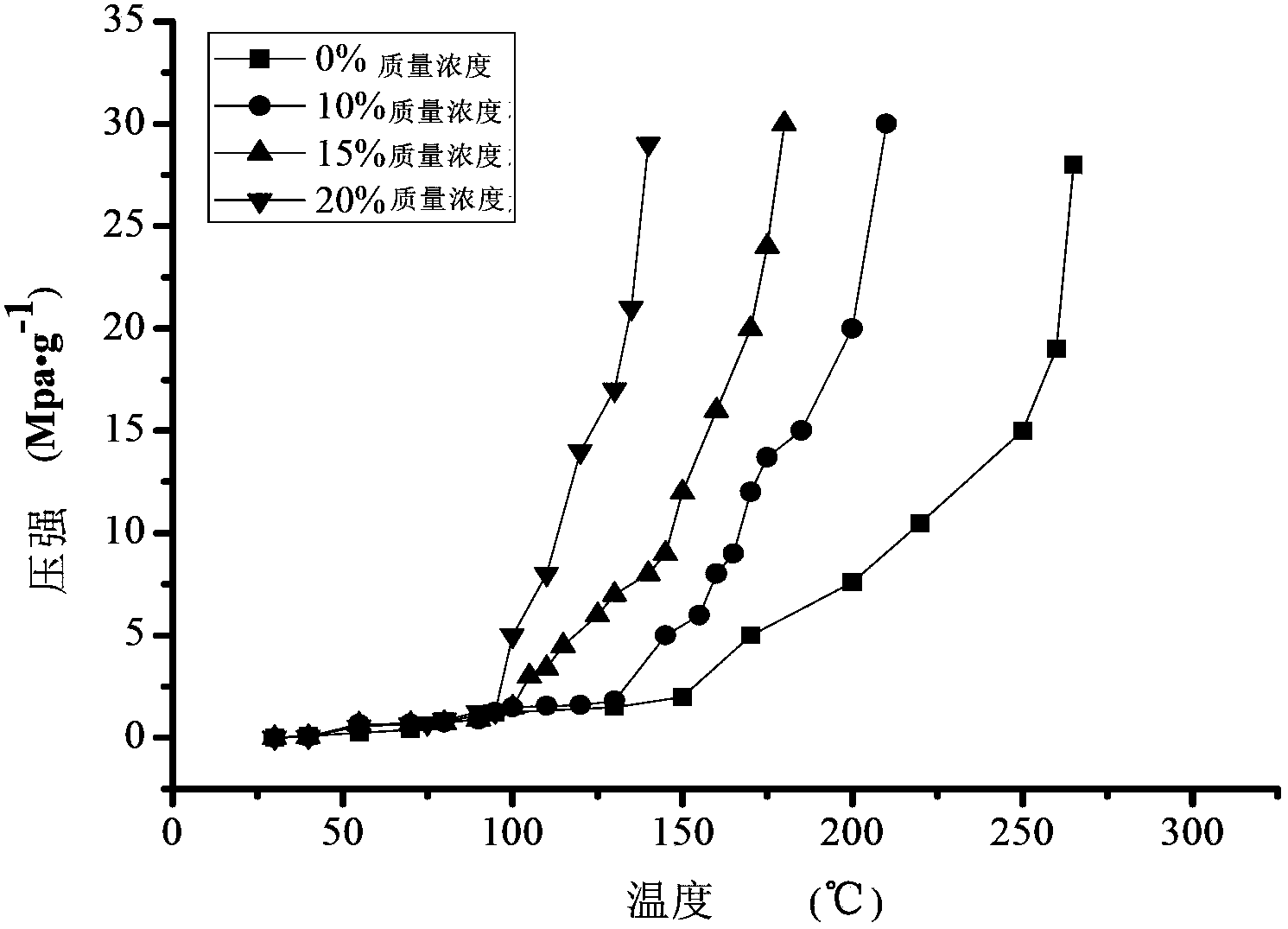

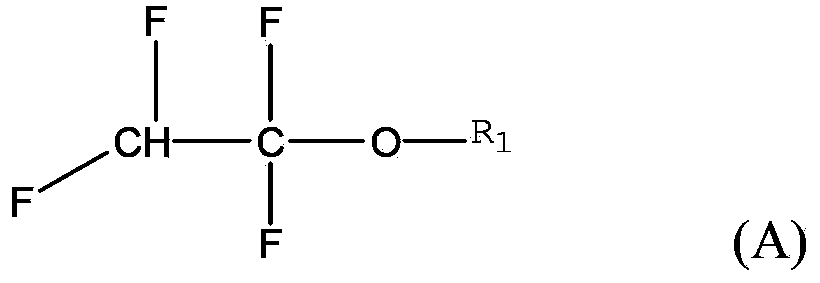

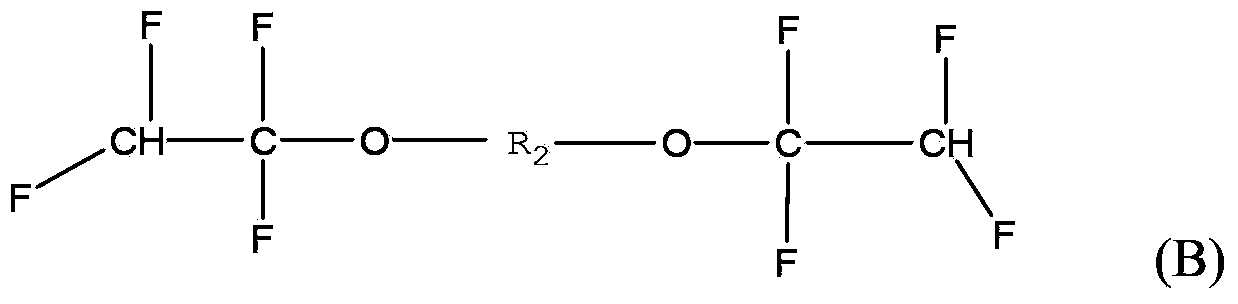

High safety battery electrolyte solution

ActiveCN104124470AImprove securityStop burningSecondary cellsElectrolytesElectrical batteryPhysical chemistry

The invention discloses a high safety battery electrolyte solution, which includes an electrolyte and a solvent. The solvent is a mixed solvent of carbonic ester and a fluoro-ether solvent. The electrolyte solution provided by the invention can significantly improve the safety performance of batteries, and effectively prevent electrolyte solution combustion or even explosion due to overheat of batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

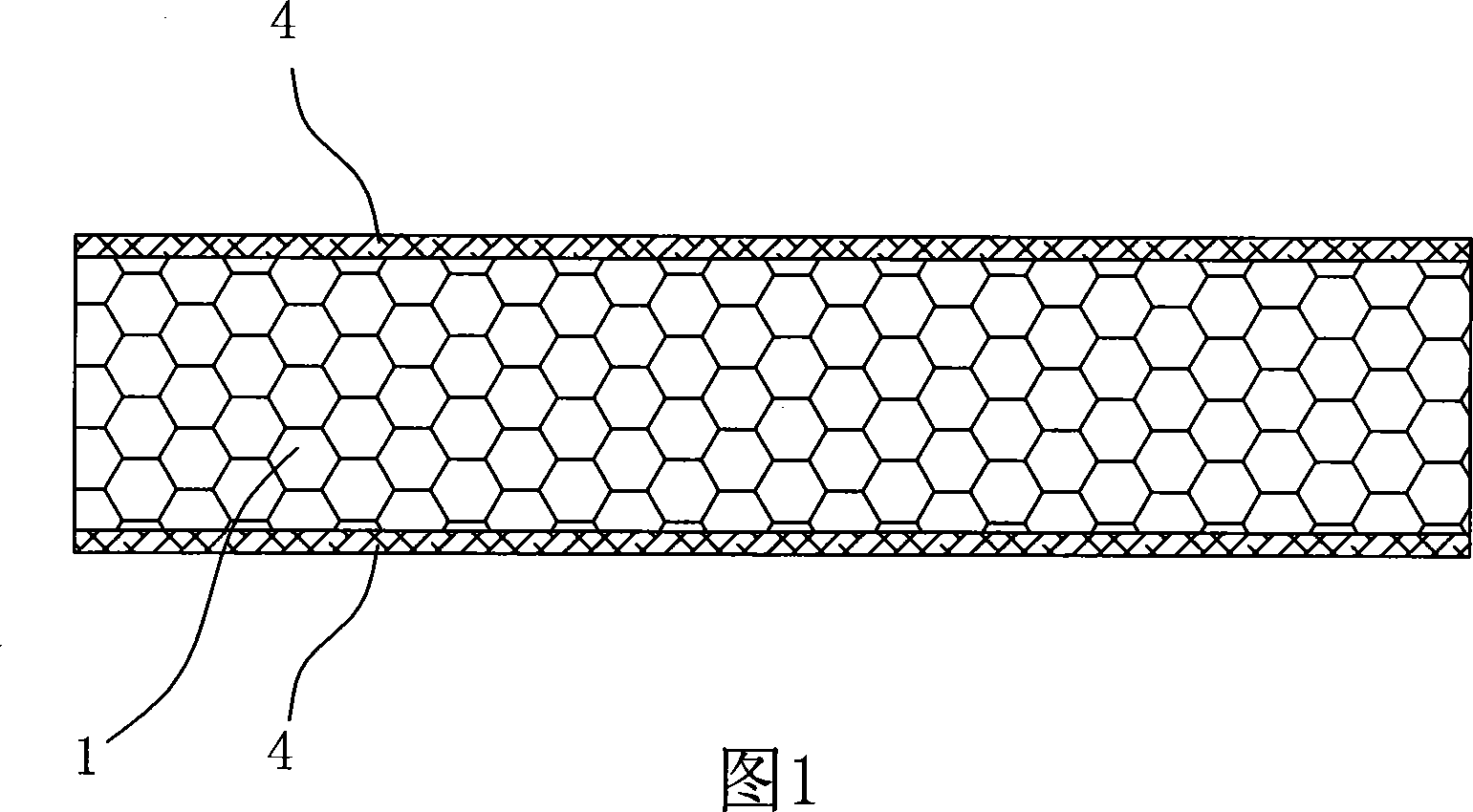

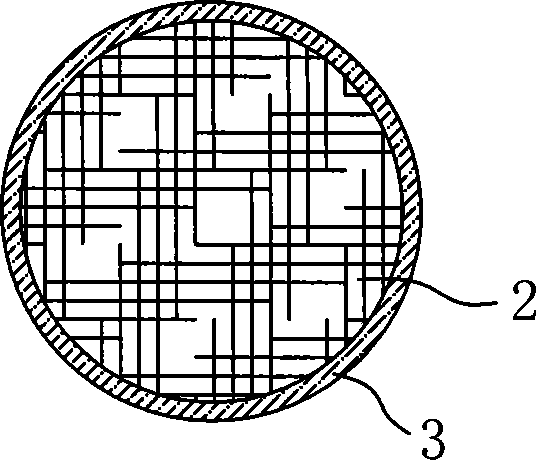

Direct current cable for subway

InactiveCN101714417AGood flexibilityHelp slipPlastic/resin/waxes insulatorsClimate change adaptationPolyesterYarn

The invention relates to a direct current cable for subway, which comprises a conductor, wherein the conductor adopts tin-plating copper wires; the strand is stranded by a plurality of tin-plating copper wires; water blocking yarns are clamped among the tin-plating copper wires; a power wire core is stranded by a plurality of strands horizontally coated with double-surface semi-conductive water blocking tapes and is coated with two layers of double-surface semi-conductive water blocking tapes outside which polyester film tapes are coated; the polyester film tapes is coated with 105 DEG C heat-resistant, high-strength and flame-retardant ethylene propylene terpolymer rubber outside which an expansion type semi-conductive water resistance tape is coated; aluminum plastic composite tapes are arranged outside the expansion type semi-conductive water resistance tapes and are overlapped, horizontally coated and welded in a lapping way; a high flame retardant oxygen-blocking layer is extruded and coated between the aluminum plastic composite tapes and a polyethylene inner sheath, wherein the high flame retardant oxygen-blocking layer is filled with a great amount of organic flame retardants, such as metal hydroxides of aluminum hydroxide, magnesium hydroxide and the like; a ratproof, termiteproof, ultraviolet-resistant, low-smoke, halogen-free and high flame retardant type polyolefine sheath is arranged outside the polyethylene inner sheath. The invention can be completely used under bad geological conditions.

Owner:兴乐电缆有限公司

Polystyrene foam plate and manufacturing method thereof

InactiveCN101244583AReduce consumptionStop burningCeramic shaping apparatusGlass/slag layered productsPolystyreneOxygen

The invention relates to a polystyrene cystosepiment with magnesium oxychloride cement covered on the surface of polystyrene foam particles and the making method. The making method comprises the following steps: foaming the polystyrene plastic particles into lightweight foam particles by means of steam; preparing magnesium oxychloride cement; well blending the polystyrene foam particles and the magnesium oxychloride cement, so as to cover the magnesium oxychloride cement on the surface of the foam particles; manufacturing the blended foam particles into the magnesium oxychloride cement polystyrene cystosepiment. Inorganic adhesive layers can be combined on the two surfaces of the magnesium oxychloride cement polystyrene cystosepiment. With substantial characteristics and remarkable progress, the making method has the advantages of simple process, easy operation and ability to reduce energy consumption. The polystyrene cystosepiment has the advantages that the foam particles are covered with magnesium oxychloride cement, thereby enabling flame retarding effect of the foam particles due to the obstructing effect of the magnesium oxychloride cement, and the incombustibility is up to grade A to meet the fire resistance requirements of buildings.

Owner:支亮

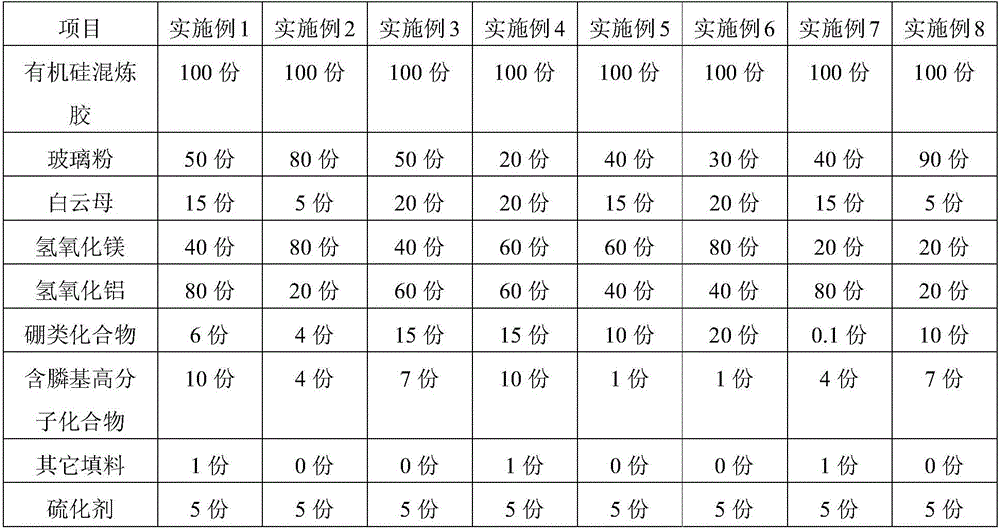

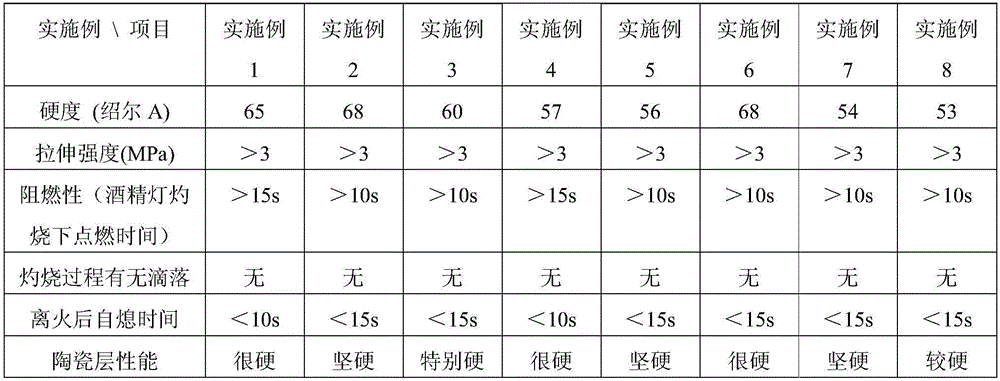

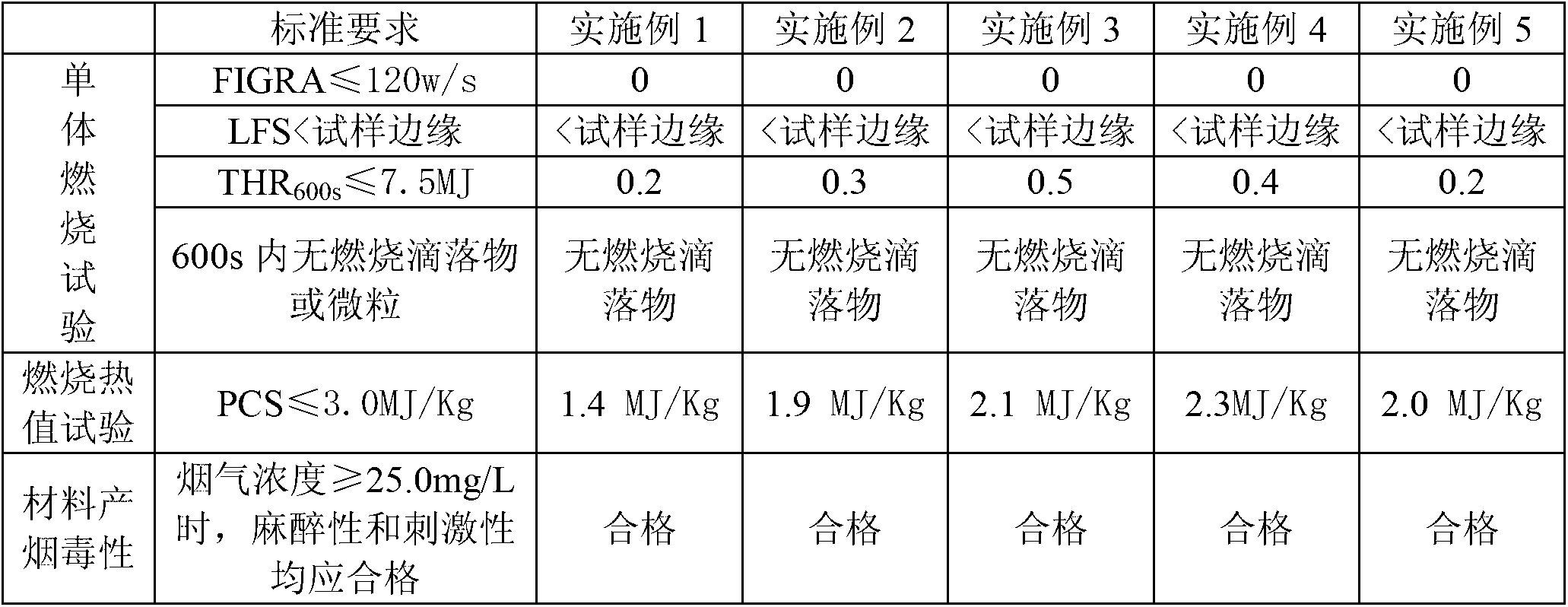

Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

ActiveCN105884267AGood physical and mechanical propertiesThe process is simple and easy to controlAluminium hydroxideEconomic benefits

The invention relates to flame-retardant and drippage-free ceramization silicon rubber and a preparation method thereof. The silicon rubber is prepared from components in parts by weight as follows: 100 parts of organic silicon rubber compounds, 1 part to 10 parts of a vulcanizing agent, 100 parts to 150 parts of ceramization powder and 0 to 100 parts of other filler or auxiliaries, wherein the ceramization powder is prepared from raw materials in parts by weight as follows: 1 part to 120 parts of glass powder, 1 part to 20 parts of muscovite, 1 part to 200 parts of magnesium hydroxide, 1 part to 200 parts of aluminum hydroxide, 0.1 parts to 50 parts of boron compounds and 0.1 parts to 20 parts of phosphono-containing polymer compounds. The ceramization silicon rubber prepared with the method has advantages of good flame retardance and self-extinguishment performance; a ceramic layer formed after firing has good compactness and insulativity, external force resistance and the like. The preparation process is simple, raw materials are cheap, and accordingly the silicon rubber is expected to be applied to fields such as wires and cables, the electronic and electrical technology, aerospace engineering and the like and has quite good economic benefits and popularization value.

Owner:SHANDONG UNIV

Flame-proof filling material special for tunnel sheet pavement

ActiveCN101173105AHigh flame retardant efficiencyImprove road performanceIn situ pavingsBuilding insulationsAluminium hydroxideFilling materials

The invention relates to flame retarding type fillings, in particular to flame retarding type fillings special for a tunnel asphalt road surface. The invention is characterized in that the fillings comprises limestone powder, flame retarding substance and modified substance with the weight ratio of 100:60 to 120:70 to 150, wherein, the flame retarding substance consists of aluminium hydroxides, magnesium hydrates, boron flame retardants and synergists with the weight ratio of 100:60 to 85:4 to 15:2 to 6. The synergist is Fe oxidant, Sb2O3, MgO or MoO3. The modified substance comprises lime hydrate, diatomite and natural zeolite powder with the weight ratio of 100:60 to 80:15 to 30. The invention has the advantages of high flame retarding efficiency, nontoxic operation, effective usage for improving the properties of asphalt mixed material, etc. when being used on roads.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Essential Element Management

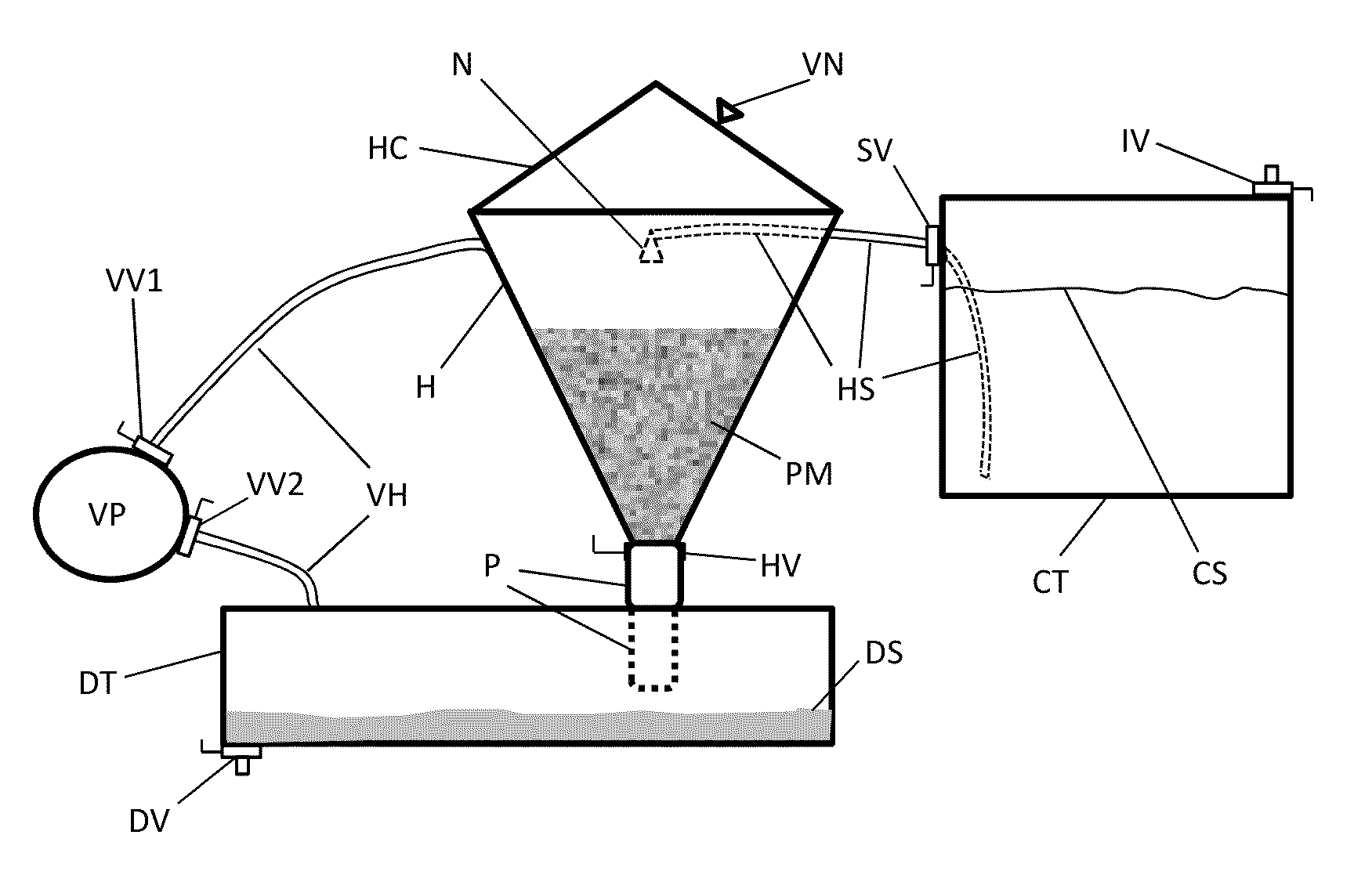

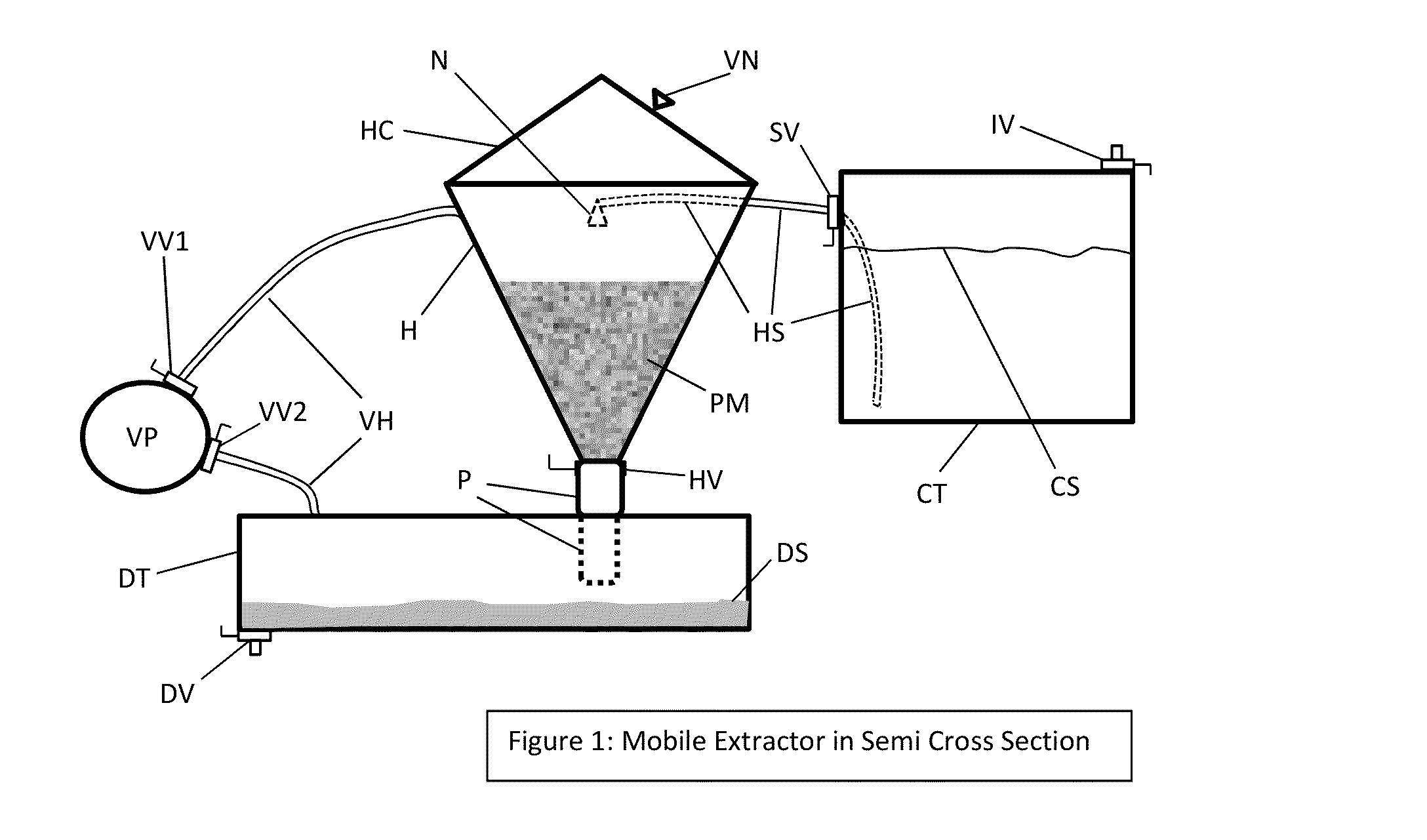

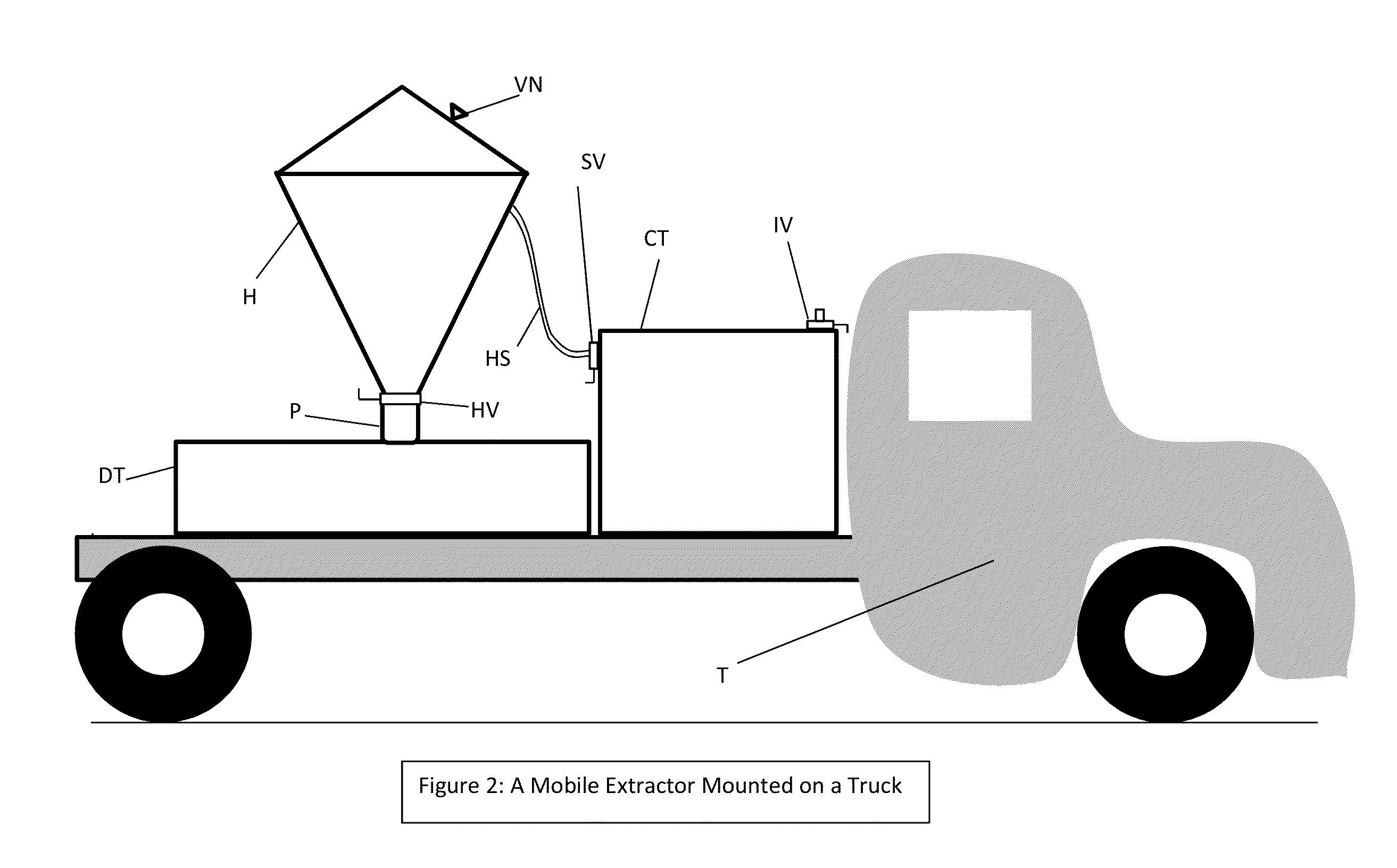

The invention extends the utility of apparatus used to extract medicinal cannabis compounds into an eluate by separating a portion of medicinal cannabis compounds contained within a portion of eluate at a first extraction target level providing enough clean solvent to continue extraction operations. A high efficiency concentrator such as a rotary evaporator or a wiped film evaporator processes eluate from one or more tanks or extraction vessels creating clean solvent when extraction targets are met or when clean solvent is exhausted. This manages eluate concentration levels and limits the quantity of concentrated medicinal cannabis compounds on site at any moment in time. The invention enables a business model for keeping medicinal cannabis compounds within a legal system, and reduces pollution because law enforcement would no longer have to burn large quantities of cannabis plant matter.

Owner:HOSPODOR ANDREW D +1

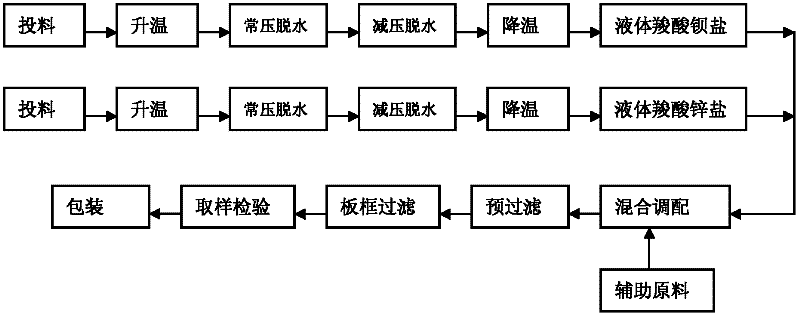

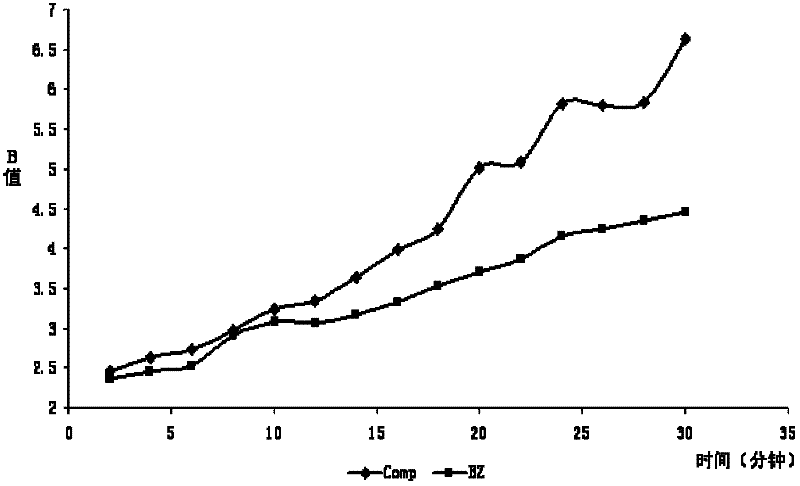

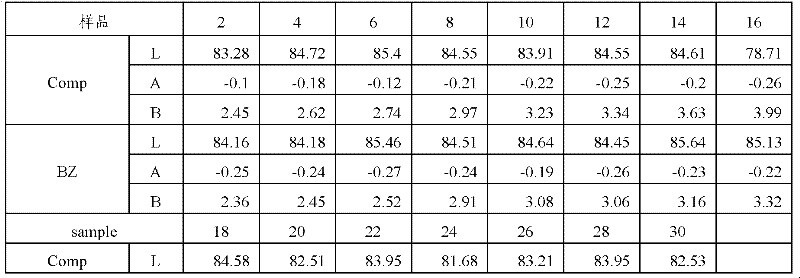

Heat stabilizer containing liquid barium and zinc, preparation method thereof and application thereof

The invention relates to a heat stabilizer containing liquid barium and zinc, a preparation method thereof, and application thereof. The heat stabilizer consists of the following components in percentage by weight: 10%-30% of liquid carboxylate with the percentage by weight of barium as 5%-20%, 5%-30% of liquid carboxylate with the percentage by weight of zinc as 2%-15%, 10%-40% of composite phosphite ester, 1.5%-5% of beta-diketone, 0.5%-3% of antioxygen1010, 10%-40% of DOP (dioctyl phthalate), and 1.0%-5% of odourless kerosene. Liquid carboxylic acid metallic soap and auxiliary stabilizer are adopted to exert the synergistic effect, excellent heat stability and excellent initial-stage dyeing property and transparency are achieved for PVC (polyvinyl chloride) soft products, the production process is simple, only two steps are required, the production cost is low, the investment is low, and the heat stabilizer containing liquid barium and zinc is applicable to large-scale industrial production.

Owner:湖北犇星新材料股份有限公司

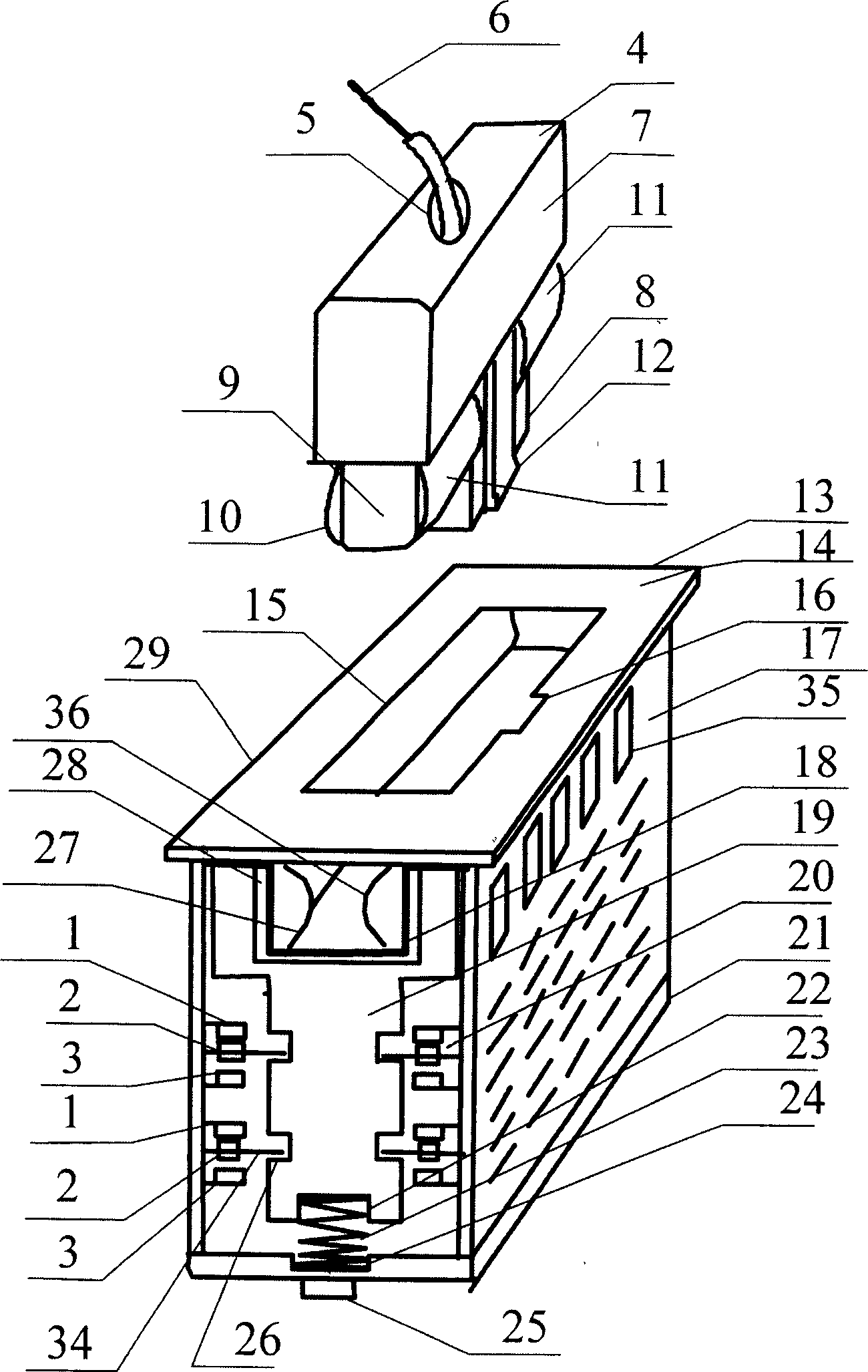

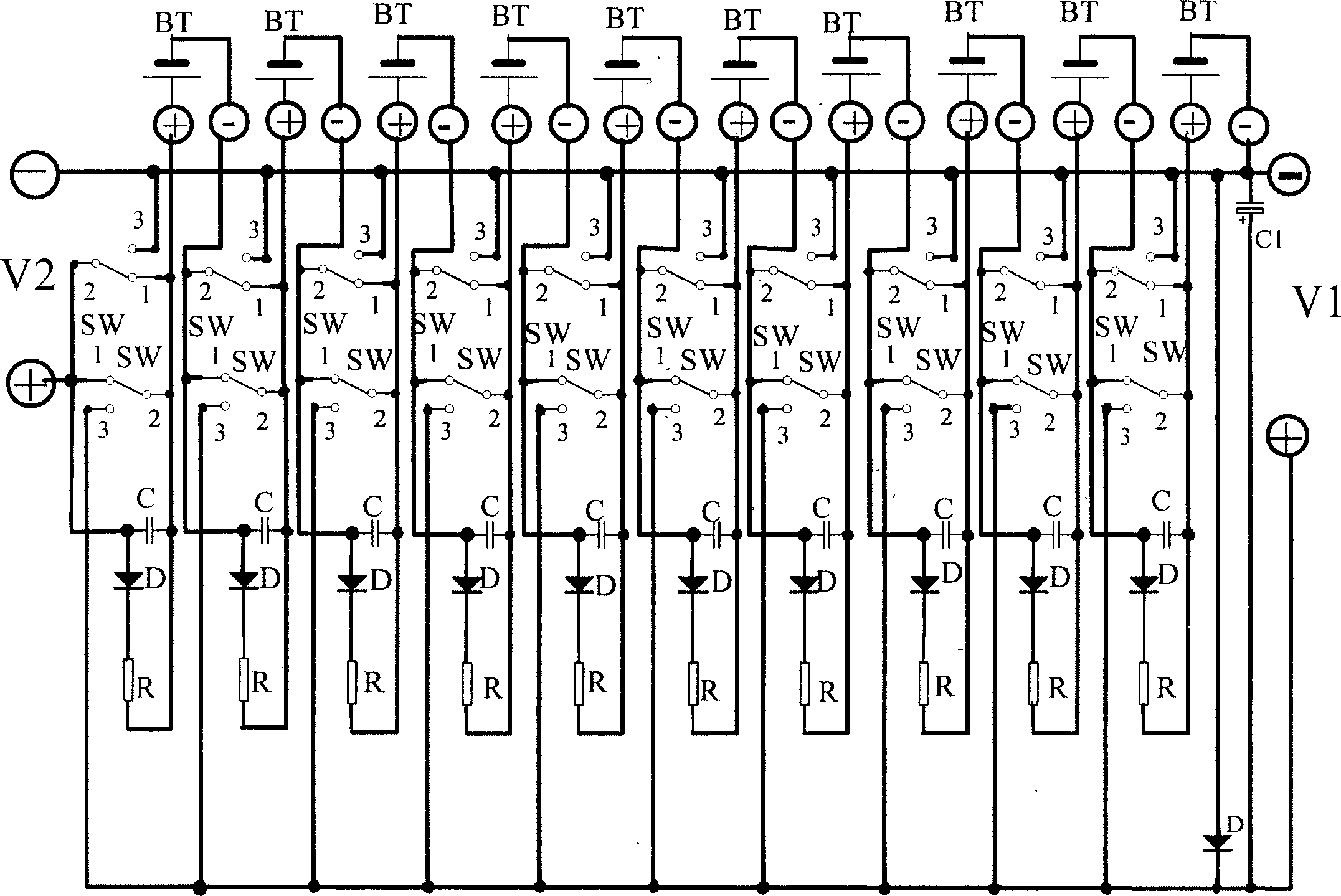

Series-parallel converting connector for lithium cell charging of electric bicycle

InactiveCN1905267AFully chargedSolve uneven partial pressureCoupling device connectionsElectric discharge tubesActive coreBattery cell

The invention relates to an electric bicycle Li-battery charging series-parallel conversion connector, characterized in comprising plug and socket, where the plug connected with a charging power supply is equipped with contact spring plate and raised head part, and the socket comprises main component, active core, two removable switch side plates and removable baseboard, the switch side plates are horizontally equipped with switches composed of normally closed static contact, active contact and normally opened static contact, vertically arranged in order; the top surface of the active core is made with plug socket and the two sides are equipped with contact drive grooves and the bottom is equipped with support spring; and inserting and pulling out the plug and driving switch contacts can change Li-battery connecting mode so as to implement a series-discharging and parallel- charging effect. And the invention provides a series-parallel converter for implementing series discharging and parallel charging of Li battery, and can assure Li-battery voltage reaches a desired value.

Owner:北京中润恒动电池有限公司

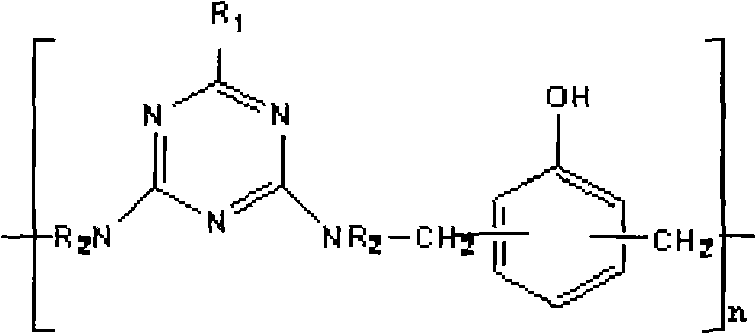

Halogen-phosphorus-free flame retardant epoxy resin composition and application thereof in bonding sheet and copper-clad plate

InactiveCN102093672AIncrease flame retardancySelf-extinguishingCircuit susbtrate materialsMetal layered productsEpoxyThermal expansion

The invention relates to a halogen-phosphorus-free flame retardant epoxy resin composition, which comprises inorganic fillers such as benzoxazine epoxy resin, a modified phenolic resin curing agent, imvite and the like, an inorganic auxiliary flame retardant material and the like, wherein the modified phenolic resin curing agent is nitrogen-containing phenolic resin; a resin condensate system has higher flame retardancy due to the self-extinguishment of the nitrogen-containing phenolic resin during combustion; and the glass-transition temperature of a condensate can be improved further by a unique structure formed by nano-level imvite and condensate molecules, and particularly the condensate has a lower thermal expansion coefficient. The resin composition does not contain halogen and phosphorus elements, and does not generate harmful substances, so a bonding sheet and a copper-clad foil layer, which are produced by the composition, for a printed circuit board have higher heat resistance and flame retardance, and are environmentally-friendly.

Owner:力森诺科电子材料(广州)有限公司

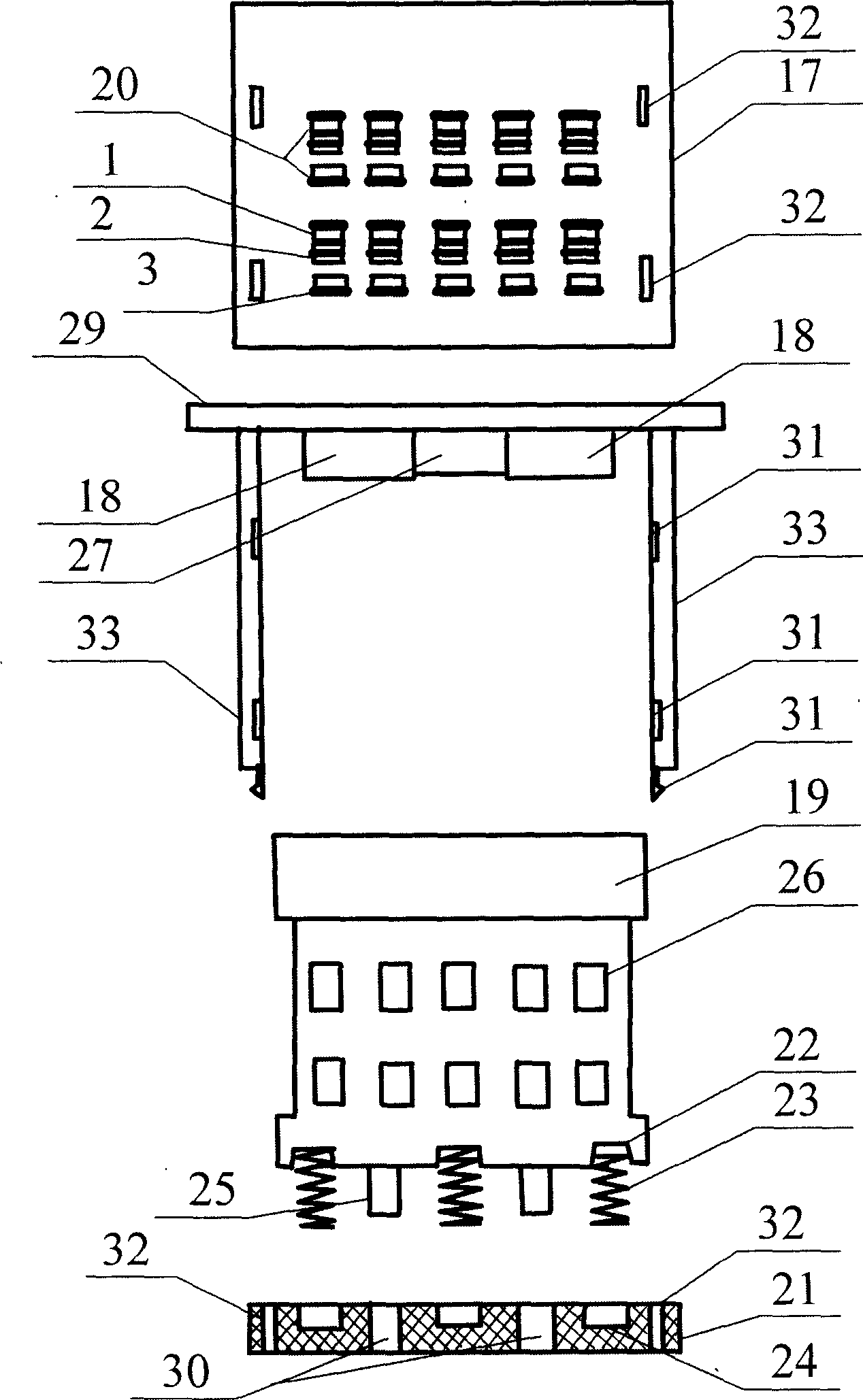

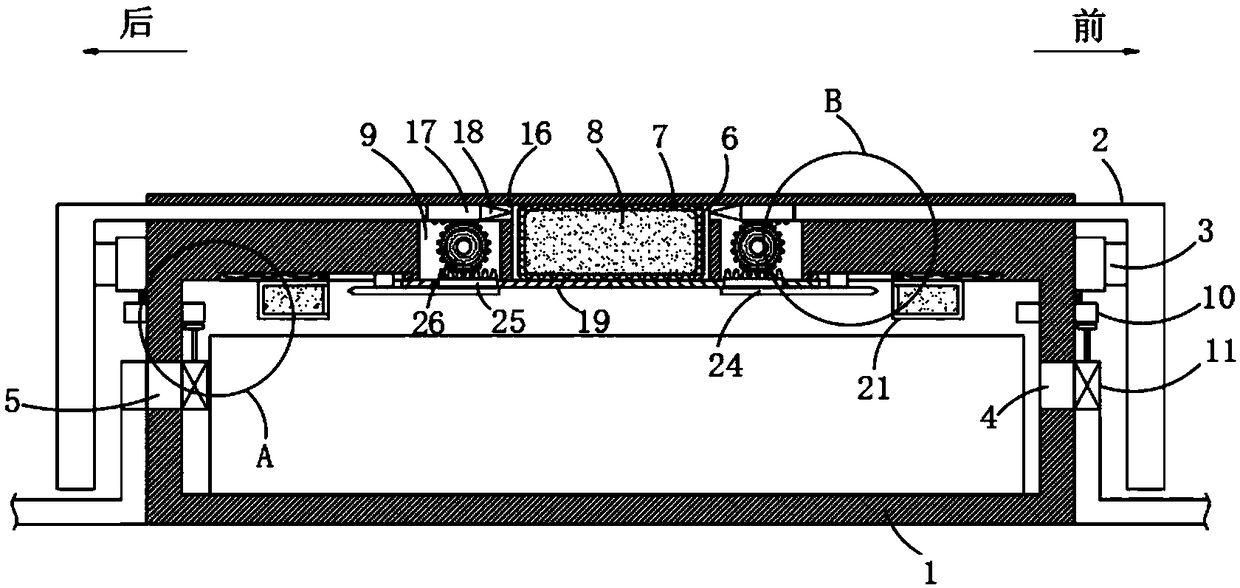

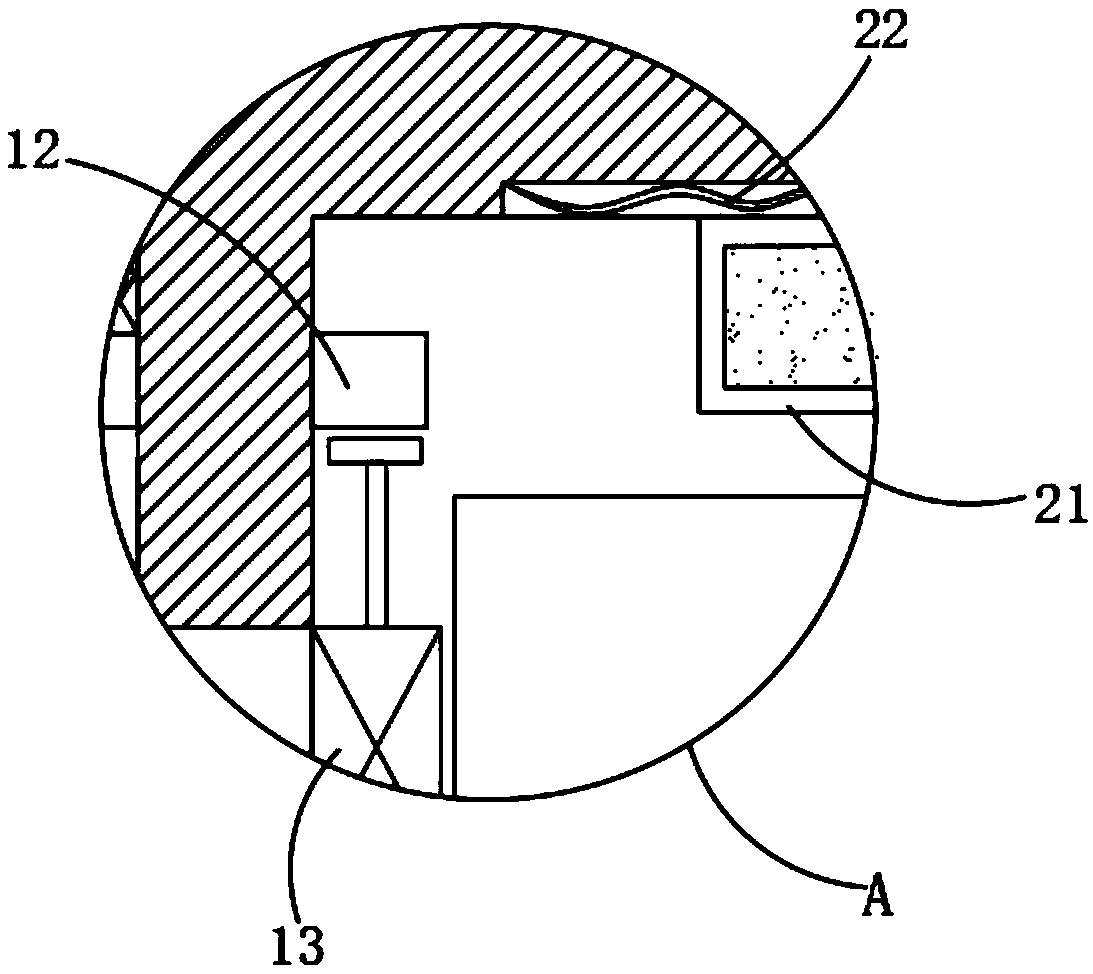

New energy automobile battery protective device

InactiveCN109378415AReduce air contentStop burningFire rescueCell component detailsNew energyElectrical battery

The invention discloses a new energy automobile battery protective device. The new energy automobile battery protective device comprises a battery holder for placing a battery and a protective mechanism located outside the battery holder, wherein the protective mechanism comprises two L-shaped plates which are respectively located at the front side and rear side of the battery holder; the verticalparts of the L-shaped plates are connected to the battery holder through buffering air cylinders; an air inlet and an air outlet are respectively formed in the front end and rear end of the battery holder; a front blocking mechanism for blocking the air inlet is arranged on the side wall of the battery holder; the buffering air cylinders drive the front blocking mechanism to move; a rear blockingmechanism for blocking the air outlet is arranged on the inner wall of the battery holder; and a storage tank is arranged on the inner top wall of the battery holder. When an automobile is collided,the new energy automobile battery protective device timely sprays dry powder into the battery holder; if the automobile meets the open fire, the new energy automobile battery protective device can generate carbon dioxide by decomposing to play a role in flame retardant, and further reduce the oxygen content in the battery holder, can seal and isolate the battery holder and further prevents a battery from burning.

Owner:赵鹏凯

Cable production process

InactiveCN104217818AAvoid scratchesReduce toughnessCable/conductor manufactureProcess engineeringElectric cables

The invention discloses a cable production process which includes the steps of firstly, single wire drawing; secondly, single wire annealing; thirdly, stranding; fourthly, cabling; fifthly, coating. The production process is reasonable and simple, and the produced cables are resistant to corrosion and oxidation, long in service life, suitable for various severe environments, free of electric leakage and high in safety performance.

Owner:安徽顺驰电缆股份有限公司

Inorganic flame retardant for wrapping polystyrene granules

The invention provides an inorganic flame retardant for wrapping polystyrene granules, solving the problem of the conventional flame retardant polystyrene plate that the environment is easily polluted due to the added brominated flame retardant. The inorganic flame retardant for wrapping the polystyrene granules is characterized by comprising the following components in parts by weight: 15 to 25 parts of aluminium hydroxide, 5 to 15 parts of iron oxide red, 2 to 4 parts of foaming agent, 10 to 20 parts of expanded graphite, 3 to 8 parts of inorganic glue, 1 to 3 parts of coupling reagent, and 1 to 3 parts of zirconium dioxide, which are loaded on a resin carrier. According to the inorganic flame retardant, all the components are inorganic components, and thus less pollution is brought to the environment; the addition amount of the inorganic flame retardant is small, and 1 to 10wt% of the inorganic flame retardant is always added and can efficiently retard the flame, and therefore the fireproof performance of the polystyrene plate can be increased to A2 level.

Owner:QINGDAO HEINOSKY TECH CO LTD

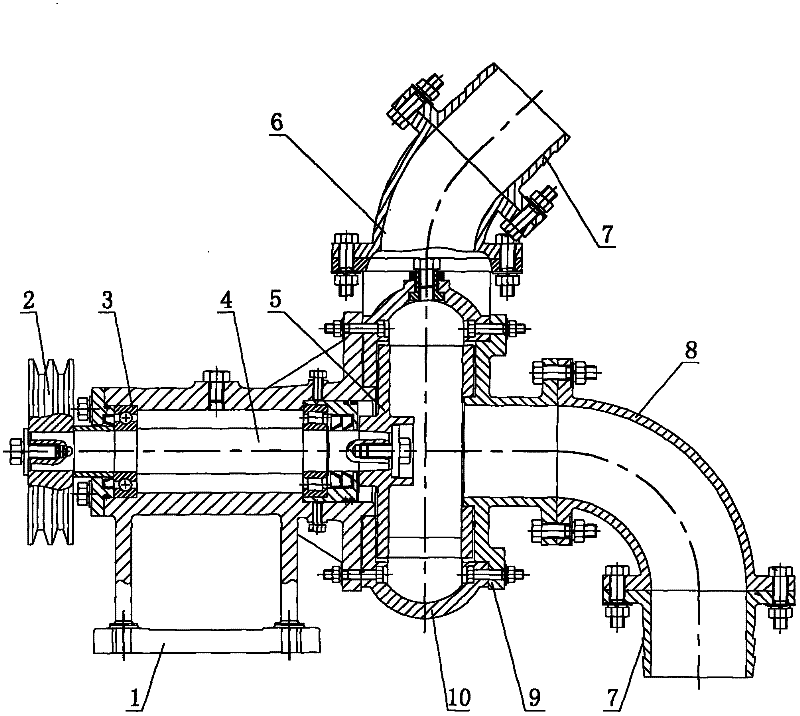

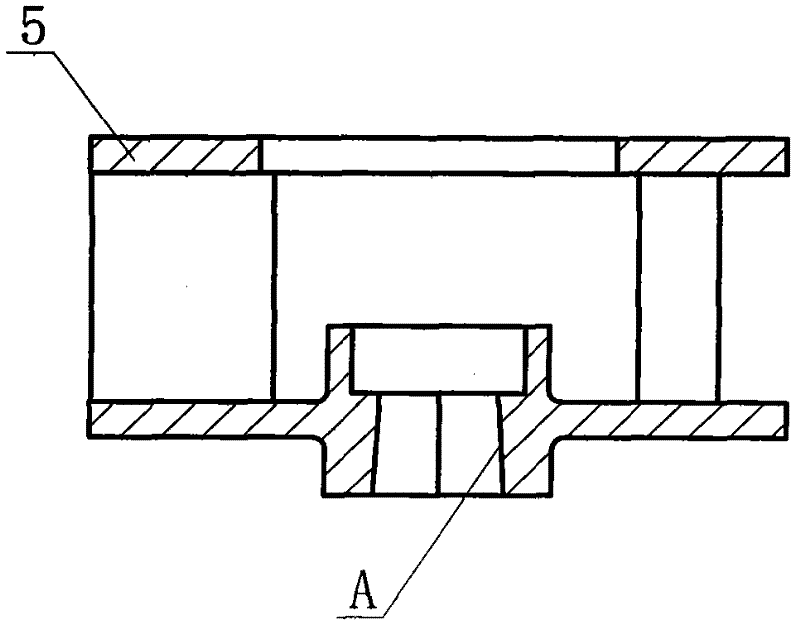

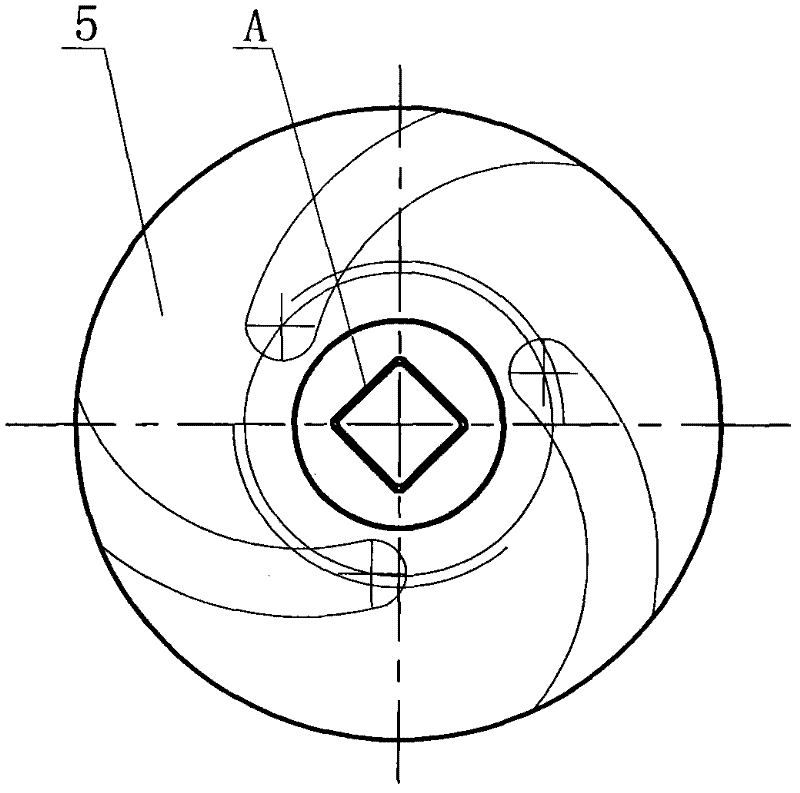

Wear-resisting sand pump and casting method thereof

InactiveCN102235365AQuality improvementGood surface accuracySpecific fluid pumpsFoundry mouldsImpellerDry sand

The invention discloses a method for casting a wear-resisting sand pump. In the wear-resisting sand pump, a pump impeller, a material inlet and a pump body are precisely cast by a vacuum lost mold; a shaft is connected with the pump impeller through an outer cone and an inner cone; and the outer cone and the inner cone are rectangular, prismatic or hexagonal and are fastened by screws. The precise casting method comprises the following process steps of: 1, partitioning a foam material to obtain main parts, and bonding by using an adhesion agent to obtain an integrated model of which the shape is consistent with the main shape of a casting; 2, coating a mica-based coating onto the outer surface of a foam model, and drying; 3, putting the dried foam model into a sand box, filling dry sand into the sand box, and performing three-dimensional oscillation compaction; 4, vacuumizing the sand box by using a vacuum system through negative pressure; 5, pouring molten metallic iron from the feeder head of the sand box to replace the position of a foam-molded model so as to obtain a corresponding main part of the sand pump; and 6, condensing. The wear-resisting sand pump has the characteristics of high casting quality, high surface precision, high rigidity, high wear-resisting property, environment friendliness and the like, and is sanitary, safe and reliable.

Owner:梁汉民

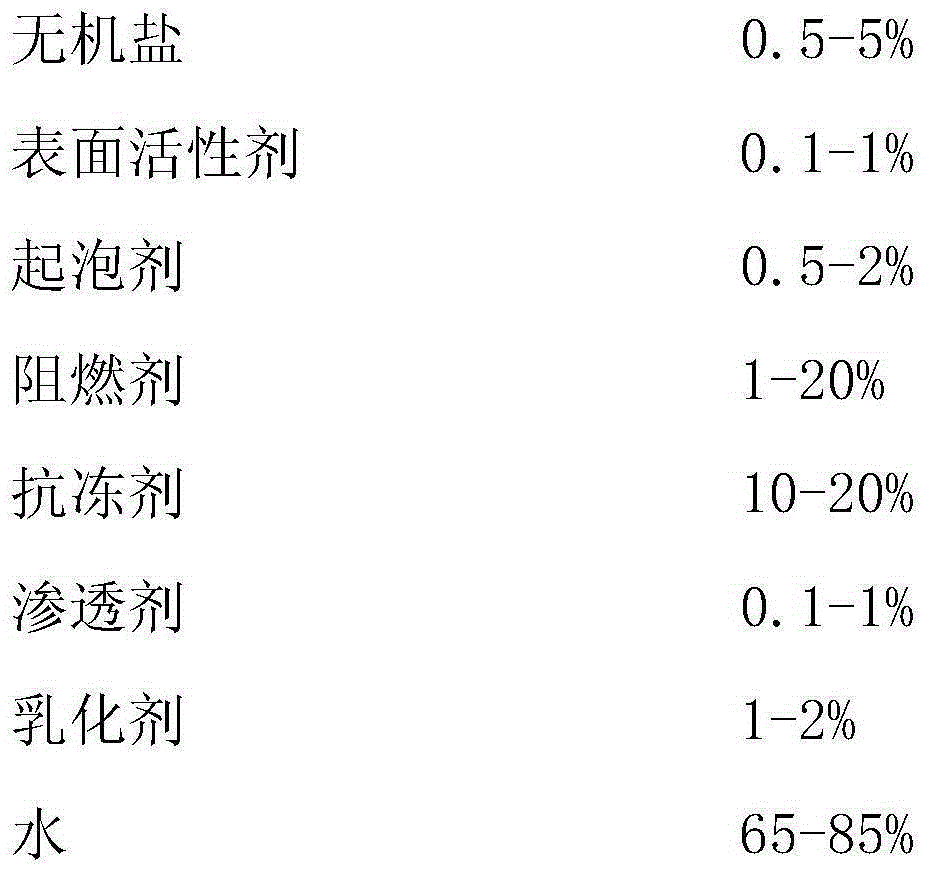

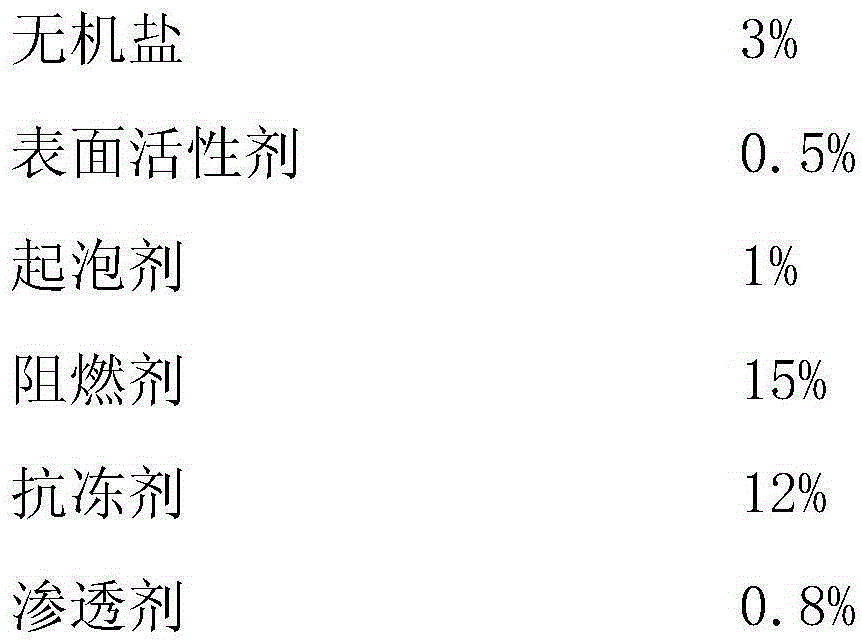

Water-series fire extinguishing agent

InactiveCN106693268AIncrease the proportionReduce the joining ratioFire extinguisherInorganic saltsFoaming agent

The invention relates to a water-series fire extinguishing agent and belongs to the technical field of firefighting. The water-series fire extinguishing agent comprises 0.5%-5% of inorganic salt, 0.1%-1% of surfactants, 0.5%-2% of foaming agents, 1%-20% of fire retardants, 10%-20% of antifreeze agents, 0.1%-1% of penetrating agents, 1%-2% of emulsifying agents and 65%-85% of water. The water-series fire extinguishing agent provided by the invention is low in cost, good in fire extinguishing performance, harmless to environment and people and wide in application range, and toxic and hazardous waste gas cannot be produced in the fire extinguishing process.

Owner:上海汇友精密化学品有限公司

Cable production technology

InactiveCN104795184AAvoid scratchesReduce toughnessCable/conductor manufactureElectric cablesIndustrial engineering

The invention discloses a cable production technology. The cable production technology includes the following steps of 1), monofilament drawing; 2), monofilament annealing; 3), stranding; 4), cabling; 5), wrapping. The cable production technology is reasonable and concise, cables are corrosion resistant, antioxidant, long in service life and applicable to various severe environments, electric leakage never occurs, and safety performance is high.

Owner:中山市鸿程科研技术服务有限公司

Pressure resistant, fire prevention and smoke abatement chlorinated polyvinyl chloride (CPVC) tube, fittings and valve composition for fire-fighting

InactiveCN101451009AIncrease temperaturePromote carbonizationPipe elementsRigid pipesMasterbatchChlorinated polyvinyl chloride

The invention relates to a pressure-proof, waterproof and smoke-removed chlorinated polyvinyl chloride (CPVC) pipeline for fire fighting, a fitting part and a valve composition. Manufacturing materials of the pipeline consists of a chlorinated polyvinyl chloride resin finished product material, a toughener and an inorganic flame retardant; and the chlorinated polyvinyl chloride resin finished product material, the toughener and the inorganic flame retardant (a master batch) are mixed to prepare a finished product according to proportion 1:0.05:0.05-0.1. The invention determines to use the chlorinated polyvinyl chloride (CPVC) resin as a main material and use the toughener and the organic flame retardant for assistance to prepare the product through corresponding processing equipment; and the product has good fireproof performance, low flame expansibility, low smog production, automatic extinguishment, no production of fire drops and the like.

Owner:上海佑利积水管业有限公司 +1

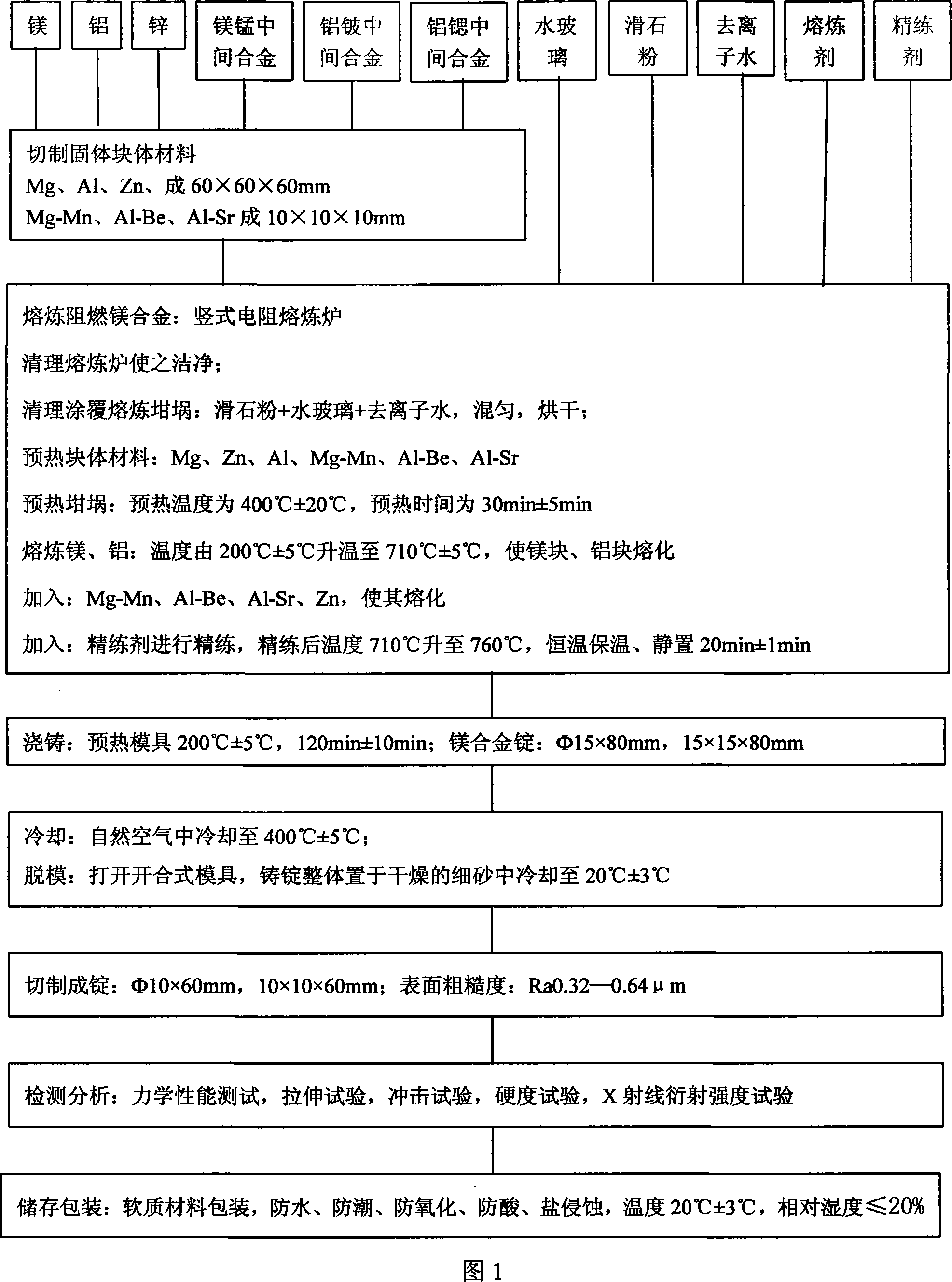

Flame-proof magnesium alloy added with beryllium and strontium and preparation method thereof

The invention relates to a flame-retardant Mg alloy doped with Gl and Sr and a preparation method thereof. The alloy is made from Mg, Al, Zn, and Mg-Mn intermediate alloy as raw materials, Al-Gl intermediate alloy and Al-Sr intermediate alloy as fire retardants and Al-Sr intermediate alloy as an agent for enhancing mechanical property of the alloy. The preparation method is carried out in a vertical smelting furnace, and comprises smelting at 710 plus or minus 5 DEG C, refining at 760 plus or minus 5 DEG C, standing, casting at 700 plus or minus 5 DEG C, adding smelting and refining agents, incubating at a constant temperature, standing to obtain a molten liquid of flame-retardant Mg alloy, casting in a die, cooling, cutting and shaping to obtain flame-retardant Mg alloy ingot. During the smelting process, the addition of Al-Gl intermediate alloy and Al-Sr intermediate alloy can efficiently prevent the combustion and oxidation of Mg alloy and simultaneously improve the mechanical property of Mg alloy. This method has the advantages of rigor process, reasonable formation, short process flow, less environmental pollution, and good compactness and uniformity of metallurgical structure of Mg alloy ingot product. The average crystal grain of the product is less than or equal to 90 micron, the tensile strength reaches 200 MPa, and the impact ductility reaches 15J / cm<2>.

Owner:TAIYUAN UNIV OF TECH

Preparation method of halogen-free composite flame retardant polypropylene/thermoplastic polyurethane elastomer composite material

The invention discloses a preparation method of a halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The method mainly consists of: A. mixing 80 parts by weight of polypropylene, 20 parts by weight of a thermoplastic polyurethane elastomer, 3 parts by weight of dry polypropylene grafted maleic anhydride and 0.2 part by weight of an antioxidant fully, then employing a double-screw extruder to perform mixing and granulating, and conducting drying to obtain a modified polypropylene masterbatch; B. then fully mixing 100 parts by weight of modified polypropylene masterbatches, 6.7-15 parts by weight of modified expandable graphite, and 4-13.3 parts by weight of red phosphorus flame retardant masterbatches to obtain a mixture; and then subjecting the mixture to mixing and granulating by the double-screw extruder, drying the extruded granules, and then carrying out injection molding by an injection molding machine, thus obtaining the halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The flame retardant polypropylene / thermoplastic polyurethane elastomer composite material prepared by the method has good flame retardance, and the flame retardant level can reach vertical burning UL-94V-0.

Owner:SOUTHWEST JIAOTONG UNIV

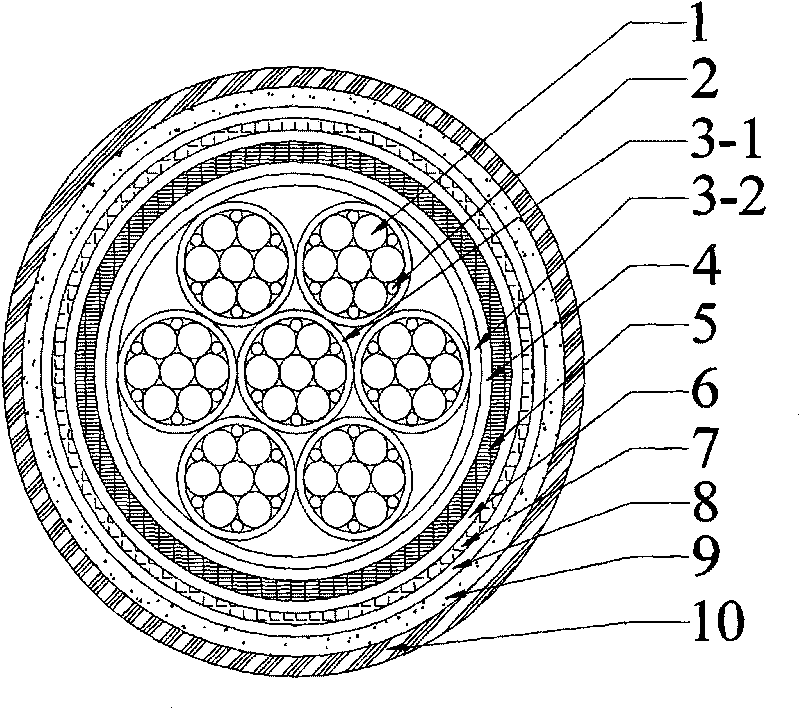

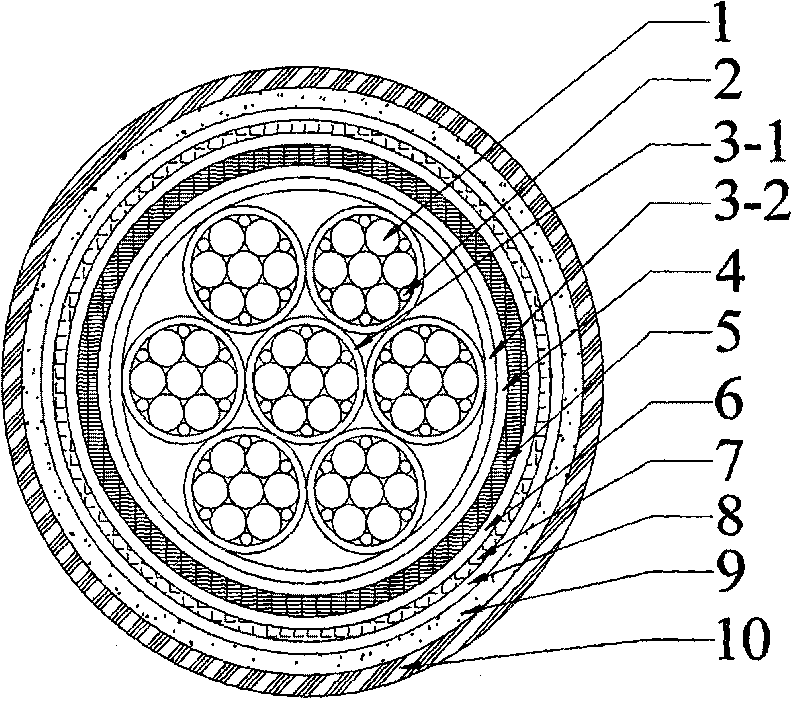

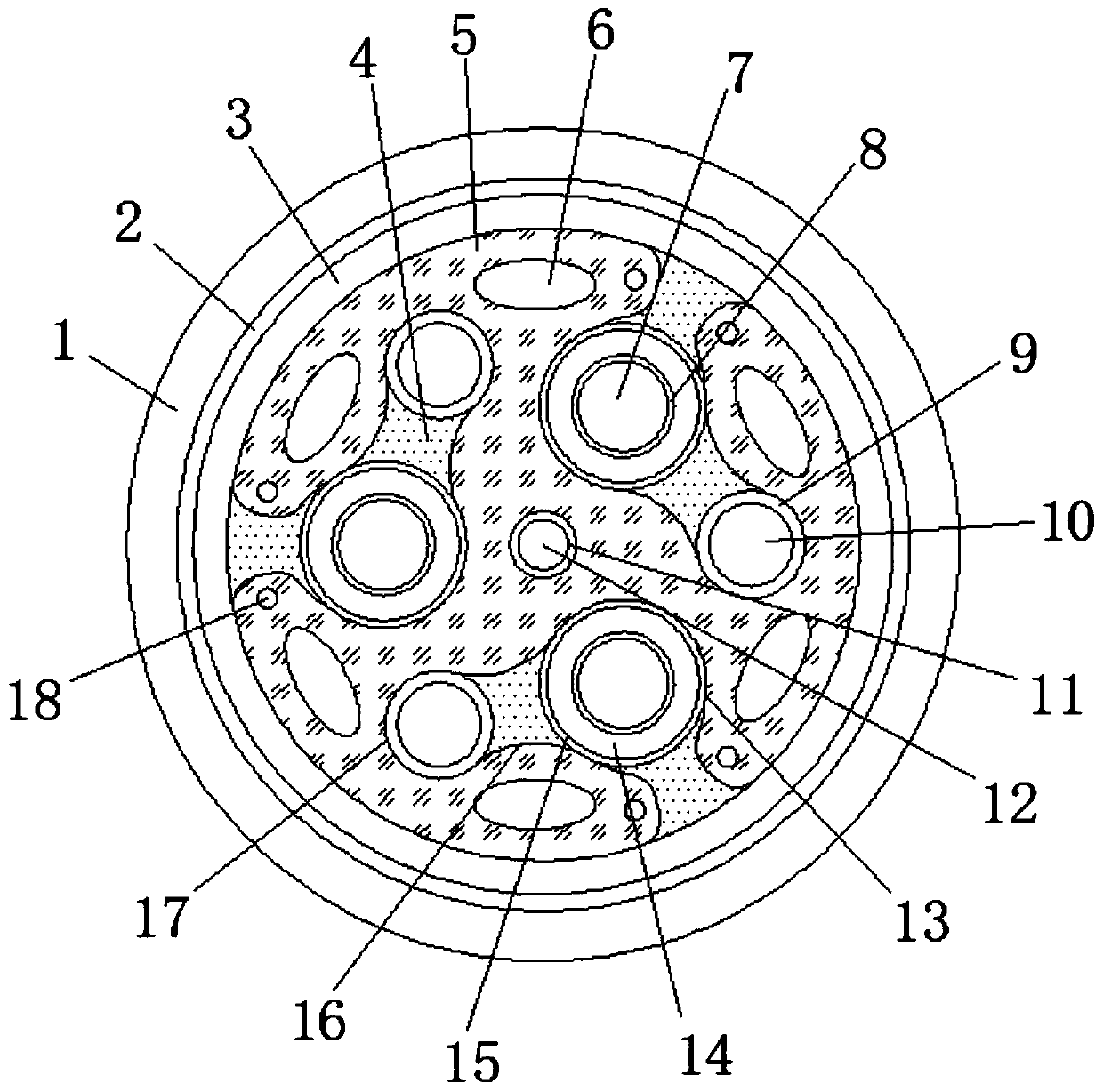

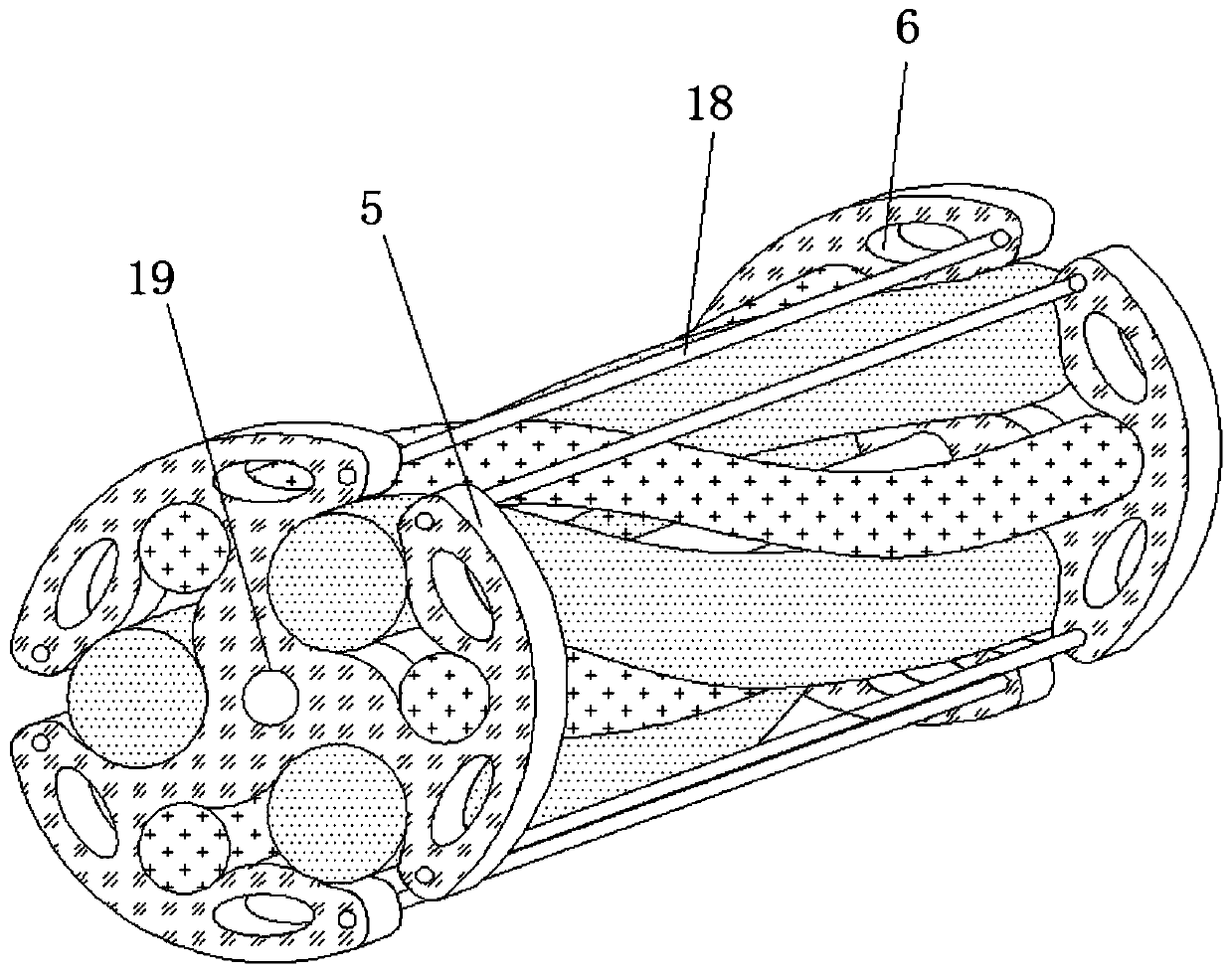

Intelligent anti-interference low-smoke halogen-free flame-retardant loadable monitoring type medium-voltage cable

ActiveCN110504066AIncrease loading capacityIncreased payload securityFlexible cablesFlexible conductorsToxic gasPower cable

The invention discloses an intelligent anti-interference low-smoke halogen-free flame-retardant loadable monitoring type medium-voltage cable. The intelligent anti-interference low-smoke halogen-freeflame-retardant loadable monitoring type medium-voltage cable comprises an outer sheath, a steel wire load layer, an inner sheath and a cable core, wherein the outer side of the cable core is extrudedwith the inner sheath, the steel wire load layer is wrapped on the outer side of the inner sheath, and the outer side of the steel wire load layer is extruded with the outer sheath; and the cable core comprises elastic fillers, a fixed support, 6 elastic guide belts, 3 power cable cores, 3 monitoring cable cores and an optical transmission cable core. According to the invention, the inner sheath,the steel wire load layer and the outer sheath are sequentially wrapped outside the cable core, and the fixed support arranged inside the cable core is used for improving the structural strength andthe bending performance of a cable, so that the cable can be conveniently laid and used in a complex mine, the real-time monitoring picture information of an underground production site is effectivelytransmitted, the loading force of the cable is improved, the safety of the load is ensured, the cable can be effectively prevented from burning when a fire disaster occurs, the cable is prevented from burning to generate toxic gas, and the pollution to the environment is reduced.

Owner:ANHUI LINGYU CABLE TECH

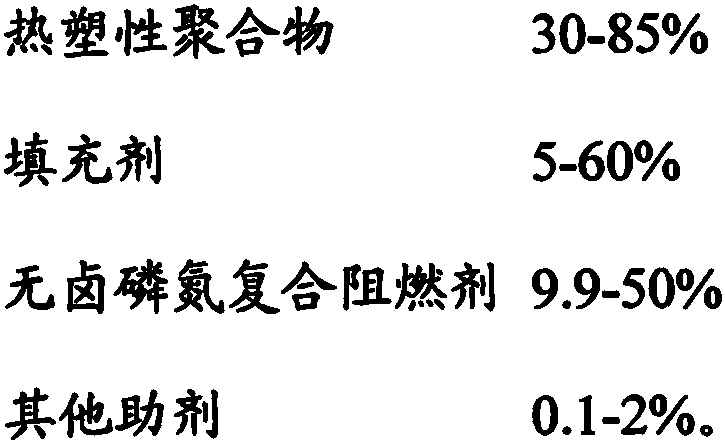

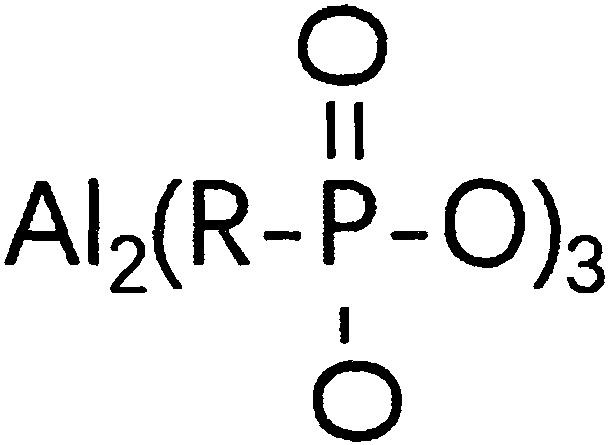

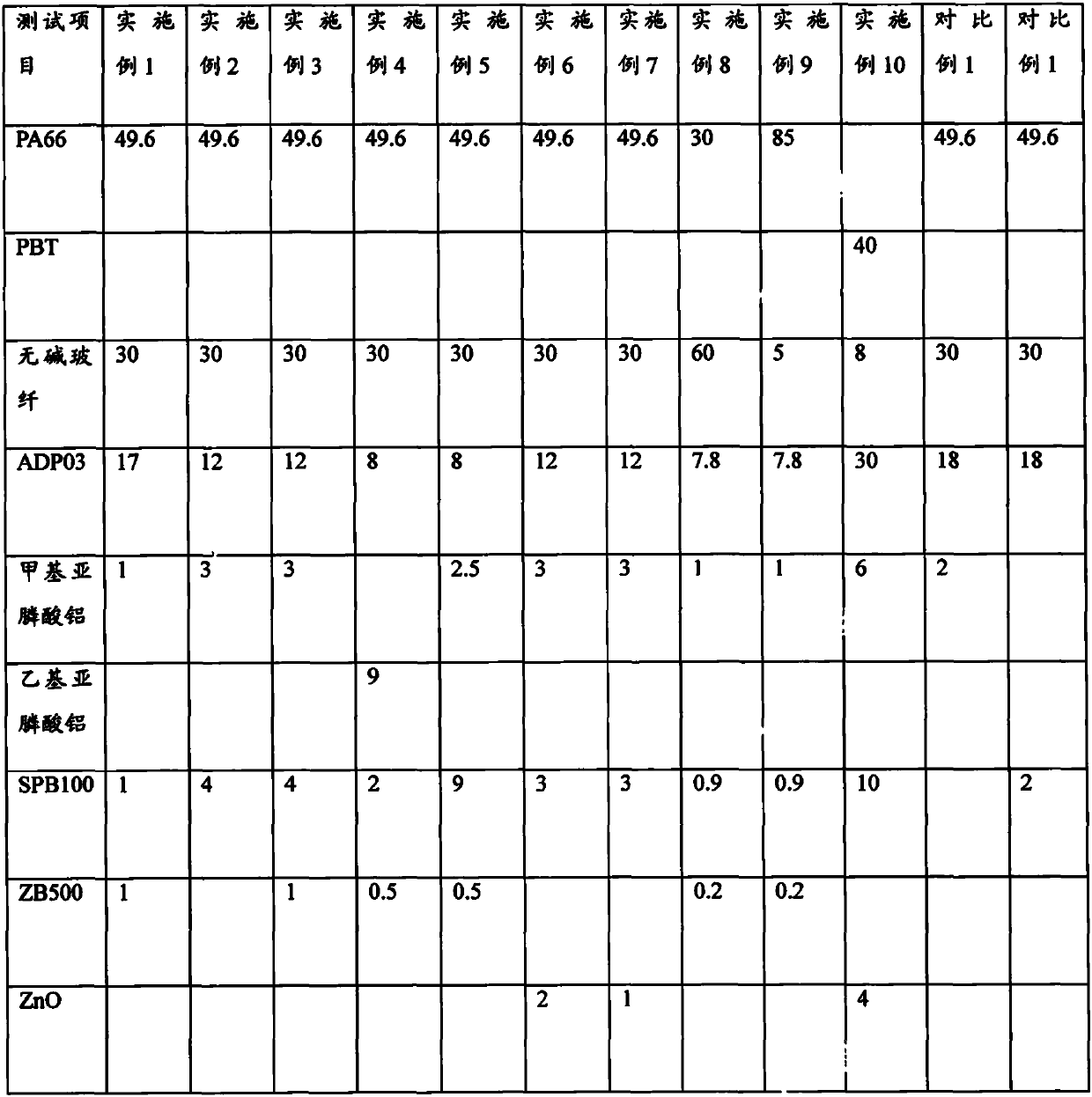

Halogen-free phosphorus-nitrogen composite flame retardant and halogen-free flame-retardant plastic polymer containing composite flame retardant

PendingCN109721768AGood environment friendlyImprove flame retardant performanceGlass fiberEngineering plastic

The invention discloses a halogen-free phosphorus-nitrogen composite flame retardant. The composite flame retardant is prepared from the following components in parts by weight: 40-89.5 parts of aluminum diethylphosphinate, 5-45 parts of organic aluminum phosphite, 5-45 parts of phosphonitrile and 0.5-10 parts of a heat stabilizer, wherein the organic aluminum phosphite is methyl or ethyl substituted aluminum phosphite, and the heat stabilizer is a zinc salt compound and / or cerium oxide. The invention aims to provide the halogen-free phosphorus-nitrogen composite flame retardant with high glowing filament performance and high flame retardancy. The flame retardant can be applied to non-filled or filled thermoplastic polymers, especially has excellent flame retardancy to glass fiber reinforced engineering plastic, and can be used to prepare parts or products in the field of electronic equipment.

Owner:广州市寅源新材料股份有限公司

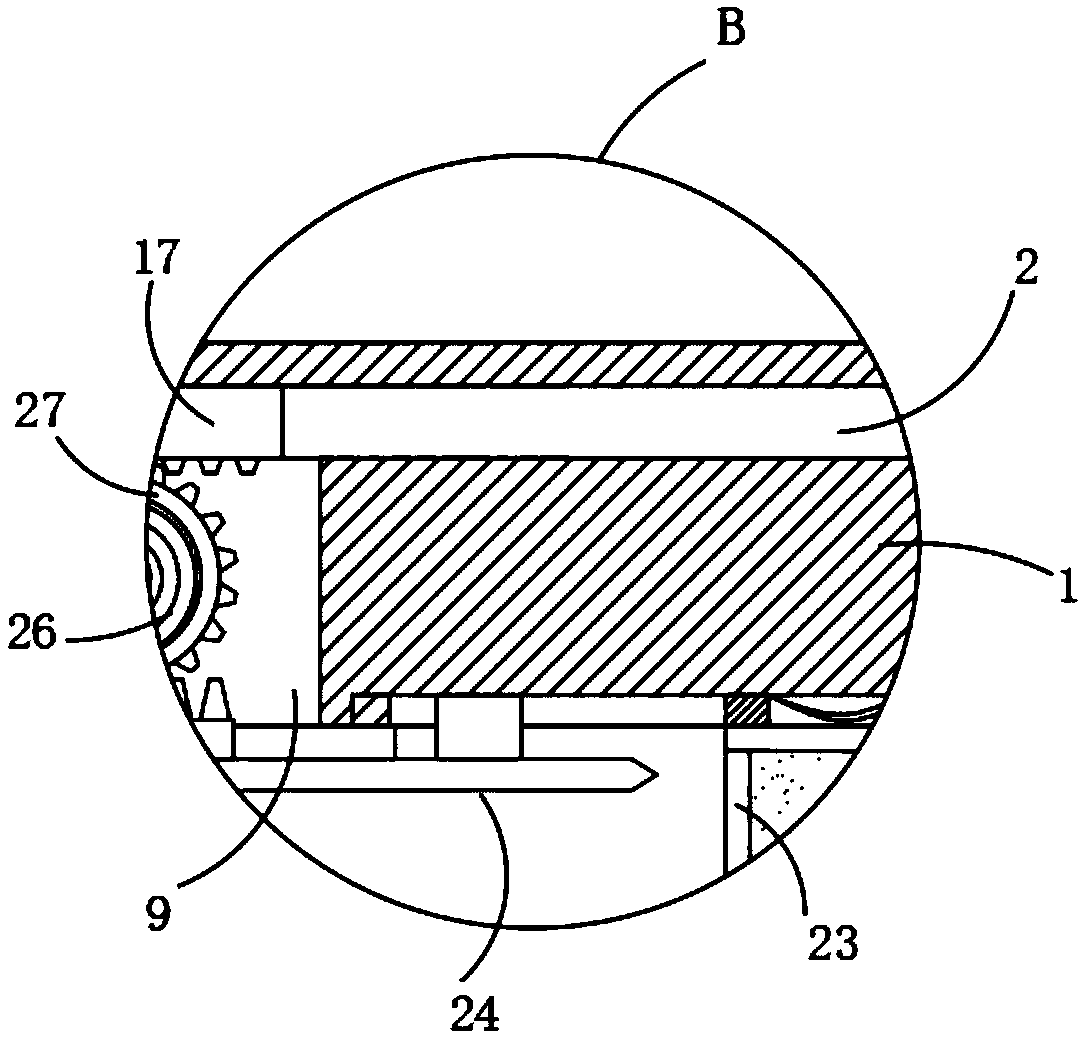

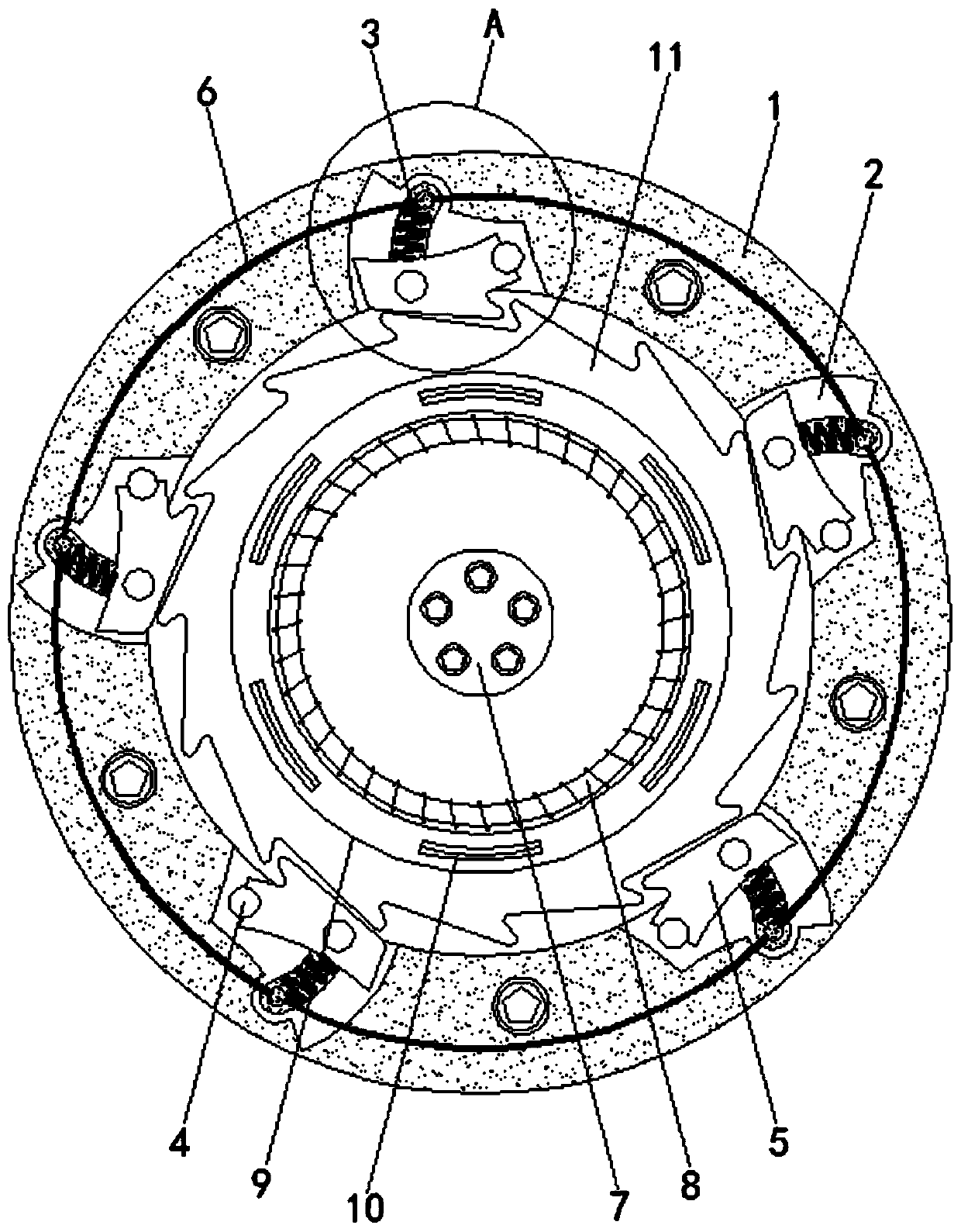

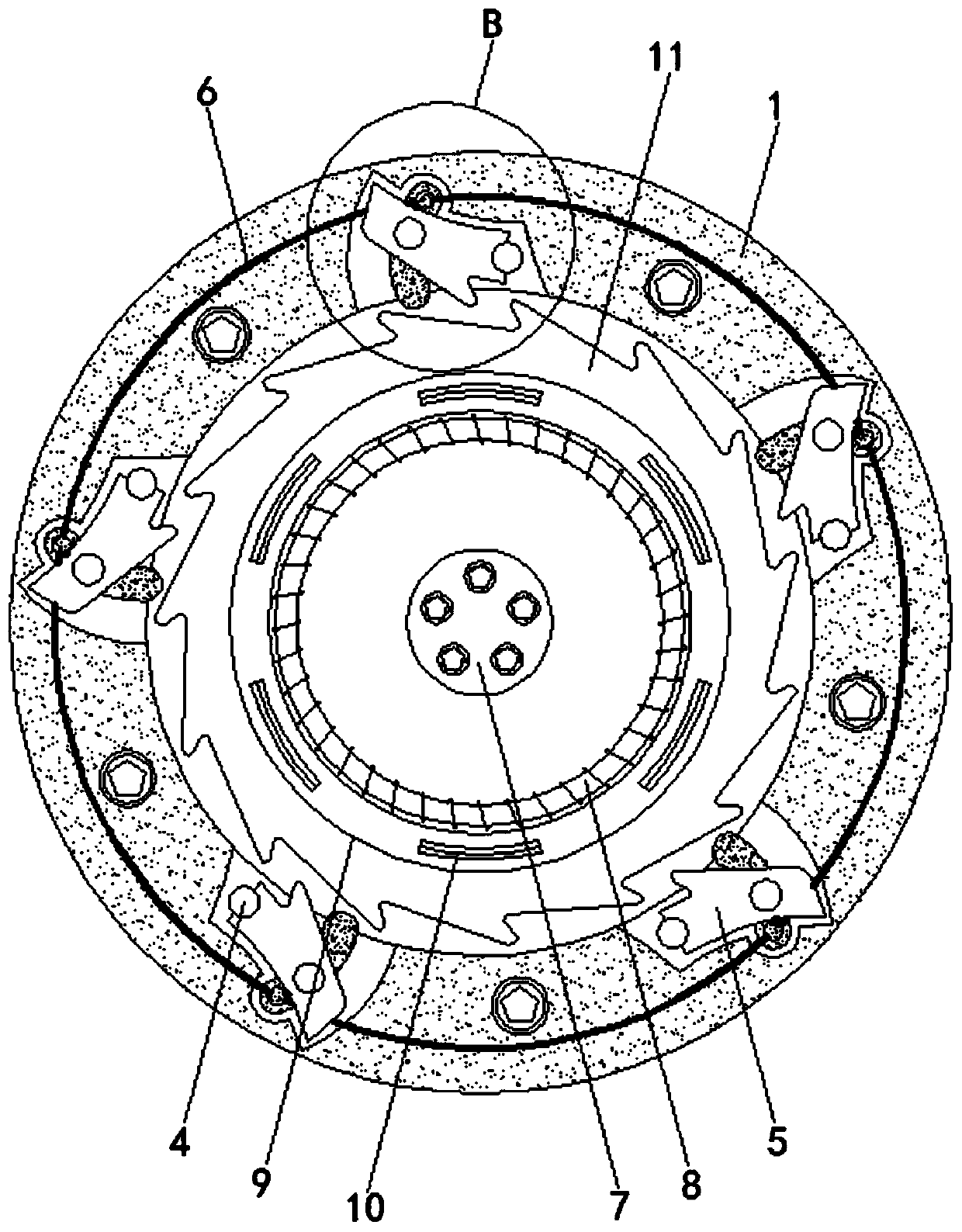

Stall self-locking mechanism for household wind driven generator transmission shaft in field of new energy

ActiveCN111550509AAvoid wastingIncrease speedLiquid resistance brakesSelf acting brakesEnergy technologyWind driven

The invention relates to the technical field of new energy, in particular to a stall self-locking mechanism for a household wind driven generator transmission shaft in the field of new energy. The stall self-locking mechanism comprises a mounting seat, movable cavities are formed inside the mounting seat, self-locking mechanism bodies are arranged inside the movable cavities, hinge columns are movably connected inside the movable cavities, and self-locking blocks are movably connected to the outer sides of the hinge columns. According to the stall self-locking mechanism for the household winddriven generator transmission shaft in the field of the new energy, automatic locking can be achieved so as to stop rotating of a generator set when the rotating speed of the generator set exceeds therated rotating speed, so that the problem of equipment damage caused by power overload of the generator set is effectively solved, meanwhile, the situation that the internal temperature of the generator set is too high or the generator set is burnt due to power overload is completely eradicated, the safety of wind power generation equipment is greatly protected, and the normal operation of the equipment is guaranteed. Meanwhile, various potential safety hazards possibly caused by power overload of the generator set are eliminated, and the requirements and use specifications of the nation forthe new energy technology are better met.

Owner:湖南驰兴工程建设有限公司

Preparation method of flame retardant paper

InactiveCN110130148ALow costHigh whiteness of paperPaper/cardboardIgnifugeants additionAmmonium polyphosphateChemistry

The invention relates to a preparation method of flame retardant paper, and belongs to the technical field of paper flame retardant materials. Through a sol-gel method, the surface of ammonium polyphosphate is modified by methyl triethoxysilane to prepare microcapsule wrapped ammonium polyphosphate; the waterproof performance and heat stability of ammonium polyphosphate are improved; the heat stability and char forming amount of flame retardant paper in a high temperature zone are enhanced; the heat release during the combustion process is effectively reduced, the flame retardant performance of flame retardant paper is obviously strengthened; the porosity and strong adsorbing performance of diatomite are utilized, diatomite, modified ammonium polyphosphate, antimony pentoxide, and aluminumhydroxide carry out in-situ polymerization to prepare a composite flame retardant having a good smog absorbing performance; diatomite is taken as the carrier, due to the porosity and strong absorbingperformance of diatomite, in-situ polymerization happens on the surface of diatomite and in the pores of diatomite; the prepared composite flame retardant has a strong flame retardant performance; due to the added composite flame retardant, paper has a good flame retardant effect, at the same time, the physical properties of paper are barely influenced, the paper quality is improved, and the application range is enlarged.

Owner:陈莉玲

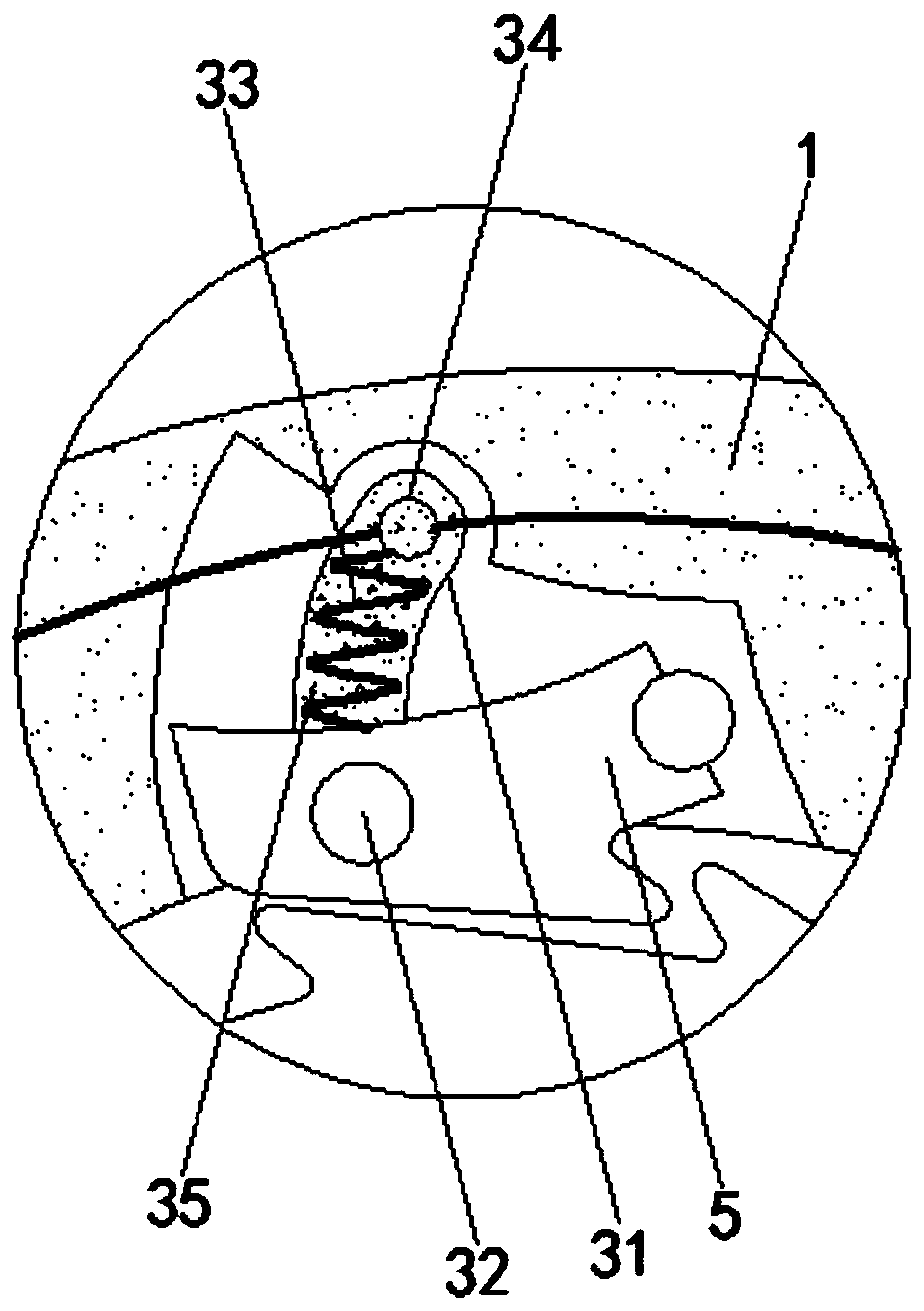

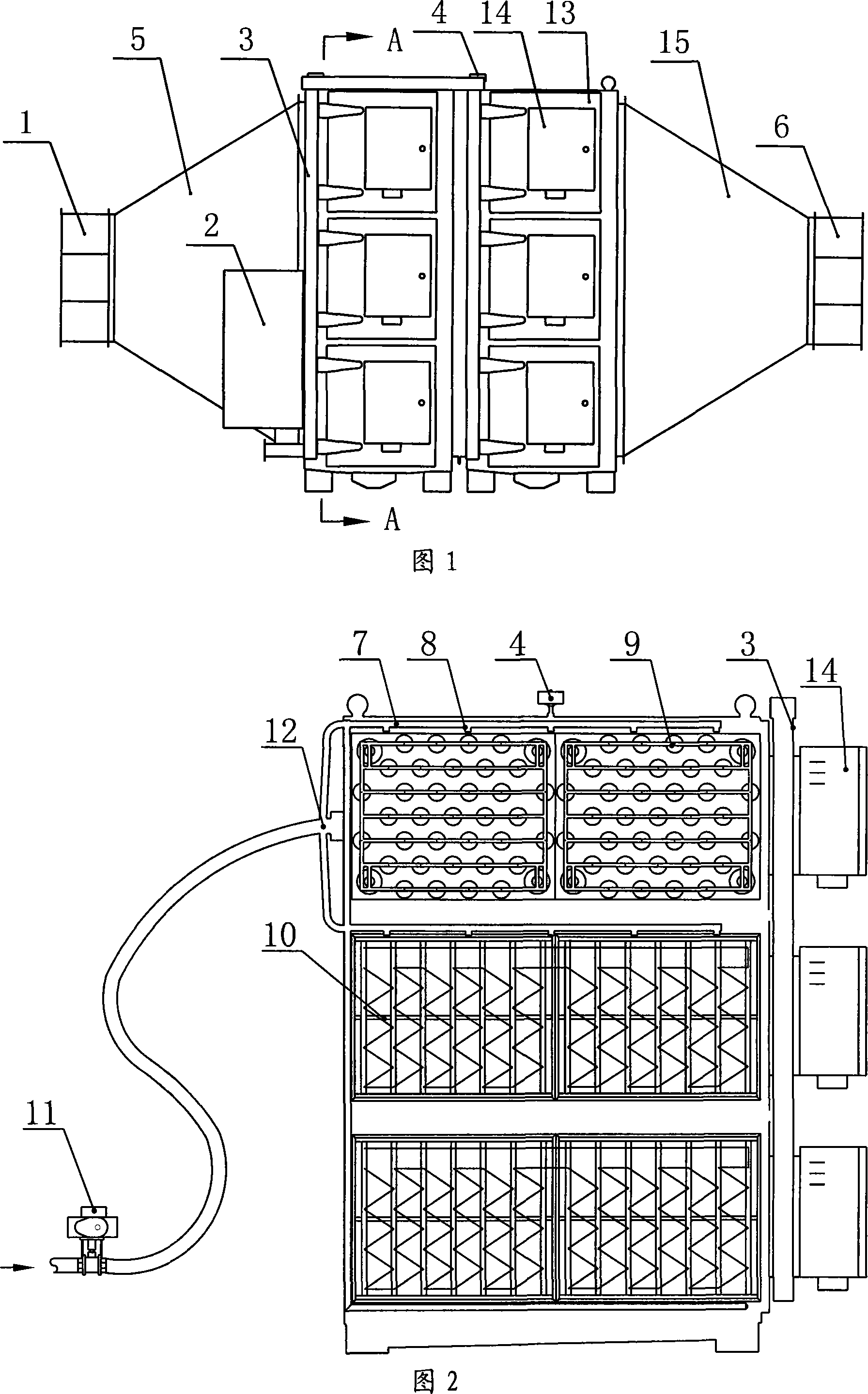

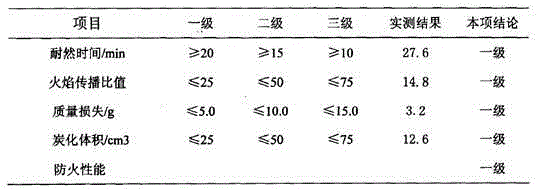

Electrostatic type fume cleaning equipment with fire-fighting mechanism

ActiveCN101108374AReduce the temperatureReduce damageExternal electric electrostatic seperatorEmergency control systemsChemical industryTemperature response

The invention discloses a static smoke purifying equipment with a fire-fighting structure, when fire disaster happening in the equipment, start autologous fire-fighting structure to extinguish to ensure the safety of the equipment. The invention comprises a shell, a main control case, a direct current high pressure power, a honeycomb cylindrical electric field, an overhauling wicket and a preposing electricity box. An air separation component is arranged at one side of the air inlet of the shell and one side of the air outlet respectively, and the inner of the shell and the outer air are separated by sealing; a temperature response net is also arranged in the shell, the signal output end are connected with a PLC control circuit input end arranged in the main control case, test if the inner of the equipment on fire in real time; a water spraying extinguish structure connected with the fire-fighting water is arranged at the middle on the shell. The invention is mainly suitable for the purifying process to the oil and smoke, oil fog and dust generated during the production process of dye and finishing, feather, heat process, metal process, food process and chemical industry.

Owner:KELAN TECHNICS ENVIRONMENTAL PROD CO LTD

Water-based intumescent fire-retardant coating for timber structure and preparation method of coating

InactiveCN104673036AImprove insulation performanceGood oxygen barrier effectFireproof paintsEpoxy resin coatingsPolymer sciencePtru catalyst

The invention discloses a water-based intumescent fire-retardant coating for a timber structure. The coating comprises a first component and a second component which are mixed in the ratio of (4-5):(1.2-1.5) in parts by weight, wherein the first component and the second component comprise components in parts by weight as follows: the first component comprises components in parts by weight as follows: a silicone-acrylate emulsion, a char-forming catalyst, a first component char-forming agent, a foaming agent, a pigment, a film-forming aid, a dispersing agent and an auxiliary material; the second component comprises components in parts by weight as follows: a composite emulsion, a second component char-forming agent, a flame retardant, a layered double hydroxide, filler, antimony trioxide, a film-forming agent, a thickening agent, an antifoaming agent and a curing agent. The coating has excellent physical and chemical properties, good fire retardance and a certain decoration property, is an efficient, environment-friendly and multifunctional fire-retardant coating and completely conforms to the development direction of the fire-retardant coating industry.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com